Precision Analog Microcontroller

www.BDTIC.com/ADI

Preliminary Technical Data

FEATURES

Analog I/O

Multi-Channel, 12-bit, 1MSPS ADC

- Up to 16 ADC channels *

Fully differential and single-ended modes

0 to V

12-bit Voltage Output DACs

- Up to 4 DAC outputs available*

On-Chip 20ppm/°C Voltage Reference

On-Chip Temperature Sensor (±3°C)

Uncommitted Voltage Comparator

Microcontroller

ARM7TDMI Core, 16/32-bit RISC architecture

JTAG Port supports code download and debug

Clocking options: - Trimmed On-Chip Oscillator (± 3%)

45MHz PLL with Programmable Divider

Memory

62k Bytes Flash/EE Memory, 8k Bytes SRAM

In-Circuit Download, JTAG based Debug

Software triggered in-circuit re-programmability

On-Chip Peripherals

UART, 2 I

Up to 40-Pin GPIO Port*

Analog Input Range

REF

- External Watch crystal

- External clock source

2

C and SPI Serial I/O

12-bit Analog I/O,

ARM7TDMI® MCU

ADuC702x Series

2 X General Purpose Timers

Wake-up and Watchdog Timers

Power Supply Monitor

Three-phase 16-bit PWM generator*

PLA – Programmable Logic (Array)

Power

Specified for 3V operation

Active Mode: 3mA (@1MHz)

50mA (@45MHz)

Packages and Temperature Range

From 40 lead 6x6mm LFCSP to 80 pin LQFP*

Fully specified for –40°C to 85°C operation

Tools

Low-Cost QuickStart Development System

Full Third-Party Support

* Package, PWM, GPIO availability and number of Analog I/O

depend on part model. See page 9.

APPLICATIONS

Industrial Control and Automation Systems

Smart Sensors, Precision Instrumentation

Base Station Systems, Optical Networking

(See general description on page 11)

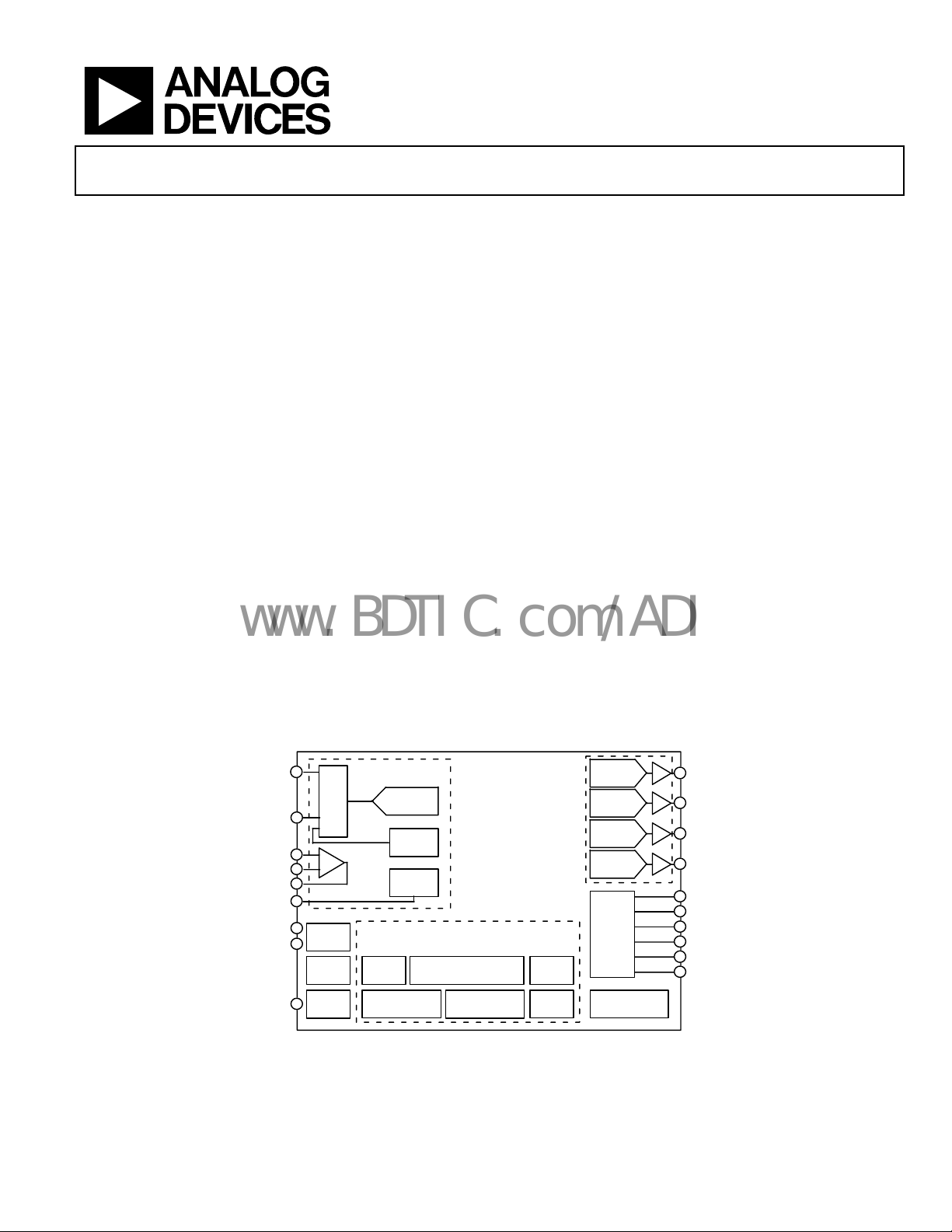

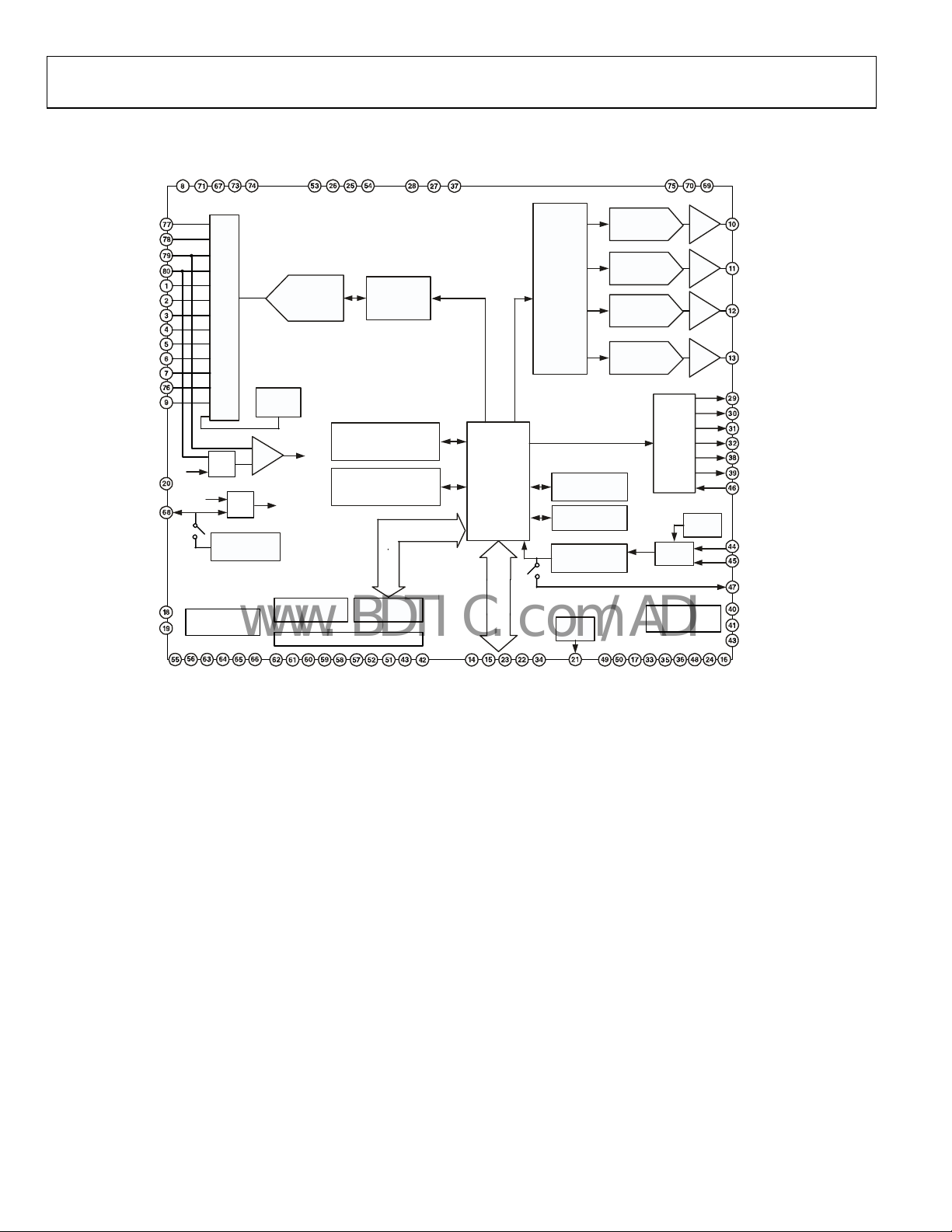

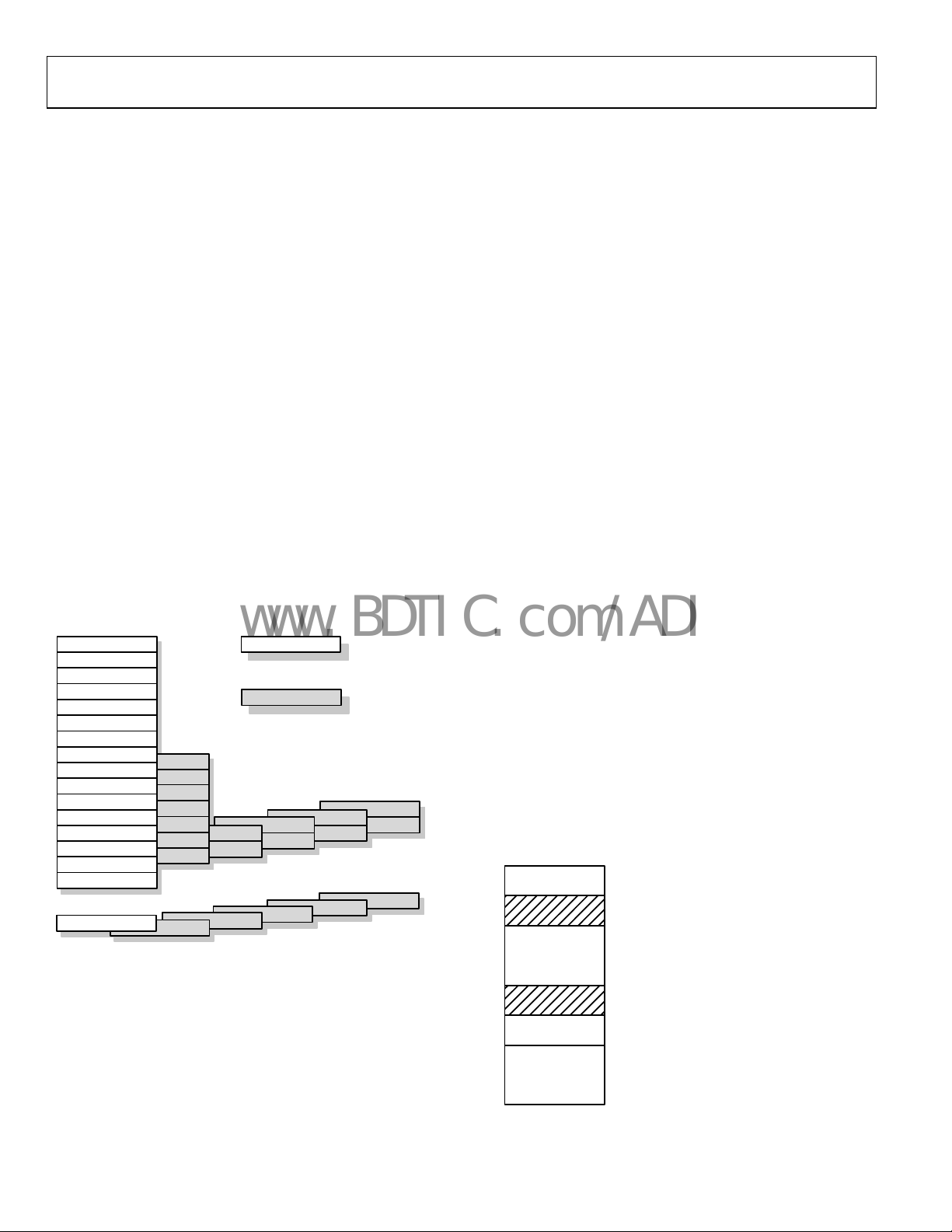

FUNCTIONAL BLOCK DIAGRAM

ADC0

...

...

MUX

ADC11

CMP0

CMP1

CMP

OUT

V

REF

XCLKI

XCLKO

RST

Rev. PrA

Information furnished by Analog Devices is believed to be accurate and reliable.

However, no responsibility is assumed by Analog Devices for its use, nor for any

infringements of patents or other rights of third parties that may result from its use.

Specifications subject to change without notice. No license is granted by implication

or otherwise under any patent or patent rights of Analog Devices. Trademarks and

registered trademarks are the property of their respective companies.

+

-

OSC

&PLL

PSM

POR

1MSPS

12-BIT ADC

TEMP

SENSOR

BANDGAP

REF

ARM7TDMI-BASED MCU WITH

ADDITIONAL PERIPHERALS

PLA

4 GEN. PUR-

POSE TIMERS

2kX32 SRAM

31kX16 FLASH/EEPROM

UART, SPI, I2C

SERIAL I/O

Figure 1

DAC012-BIT DAC

ADuC7026*

GPIO

JTAG

Threephase

PWM

EXT. MEMORY

INTERFACE

DAC112-BIT DAC

DAC212-BIT DAC

DAC312-BIT DAC

PWM0H

PWM0L

PWM1H

PWM1L

PWM2H

PWM2L

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700

Fax: 781.326.8703 © 2004 Analog Devices, Inc. All rights reserved.

www.analog.com

ADuC702x Series Preliminary Technical Data

www.BDTIC.com/ADI

TABLE OF CONTENTS

ADuC702x—Specifications ............................................................ 3

Reset and Remap........................................................................ 35

Terminology ...................................................................................... 6

Absolute Maximum Ratings............................................................ 7

Ordering Guide............................................................................. 9

Pin function descriptions ..............................................................10

General Description ....................................................................... 19

Overview of the ARM7TDMI core.......................................... 19

Memory organisation................................................................. 20

ADC circuit information............................................................... 25

General Overview....................................................................... 25

ADC Transfer Function............................................................. 25

Typical Operation....................................................................... 26

Converter operation................................................................... 28

Driving the analog inputs.......................................................... 29

ADC Calibration ........................................................................ 29

Temperature Sensor ...................................................................29

Other analog peripherals............................................................... 36

DAC.............................................................................................. 36

Power Supply Monitor............................................................... 38

Comparator................................................................................. 38

Oscillator and PLL - Power control ......................................... 39

Digital peripherals.......................................................................... 41

Three-phase PWM..................................................................... 41

General Purpose I/O.................................................................. 48

Serial Port Mux........................................................................... 50

Programmable Logic Array (PLA)........................................... 60

Processor reference peripherals.................................................... 63

Interrupt System ......................................................................... 63

Timers.......................................................................................... 65

ADuC702x Hardware Design considerations ............................ 73

Power supplies ............................................................................ 73

Bandgap Reference..................................................................... 29

Nonvolatile Flash/EE Memory ..................................................... 31

Flash/EE memory overview ...................................................... 31

Flash/EE Memory and the ADuC702x.................................... 31

Flash/EE memory security ........................................................ 31

Flash/EE Control Interface........................................................ 32

Execution time from SRAM and FLASH/EE .........................33

Grounding and Board Layout Recommendations................. 73

Clock Oscillator.......................................................................... 74

Power-on reset operation .......................................................... 74

Typical sysem configuration ..................................................... 75

Development Tools ........................................................................ 76

In-Circuit Serial Downloader................................................... 76

Outline Dimensions....................................................................... 77

Rev. PrA | Page 2 of 78

Preliminary Technical Data ADuC702x Series

www.BDTIC.com/ADI

ADUC702X—SPECIFICATIONS

Table 1. (AV

unless otherwise noted.)

Parameter ADuC702x Unit Test Conditions/Comments

ADC CHANNEL SPECIFICATIONS

ADC Powerup Time 500 uS

DC Accuracy

Resolution 12 Bits

Integral Nonlinearity

Integral Nonlinearity

Differential Nonlinearity

Differential Nonlinearity

DC Code Distribution

CALIBRATED ENDPOINT ERRORS

Offset Error

Offset Error Match

Gain Error

Gain Error Match

DYNAMIC PERFORMANCE Fin = 10kHz Sine Wave, f

Signal-to-Noise Ratio (SNR)

Total Harmonic Distortion (THD) -78 dB typ

Peak Harmonic or Spurious Noise

Channel-to-Channel Crosstalk

ANALOG INPUT

Input Voltage Ranges

Differential mode V

Single-ended mode 0 to V

Leakage Current ±5 µA max

Input Capacitance 20 pF typ During ADC Acquisition

ON-CHIP VOLTAGE REFERENCE

Output Voltage

Accuracy ±10 mV max Measured at TA = 25°C

Reference Temperature Coefficient

Power Supply Rejection Ratio

Output Impedance

Internal V

EXTERNAL REFERENCE INPUT9

Input Voltage Range

Input Impedance

DAC CHANNEL SPECIFICATIONS

DC ACCURACY

Resolution 12 Bits

Relative Accuracy ±2 LSB typ

Differential Nonlinearity ±1 LSB max Guaranteed Monotonic

Offset Error

Gain Error

Gain Error Mismatch

= IOVDD = 2.7 V to 3.6 V, V

DD

2, 3

4

4

5

6

7

Power-On Time

REF

1

= 2.5 V Internal Reference, f

REF

f

±1.5

±0.5

±2.0

+1/-0.9

±0.5

+1/-0.9

1

±5

±1

±5

±1

LSB max

LSB typ

LSB max

LSB max

LSB typ

LSB max

LSB typ

LSB max

LSB typ

LSB max

LSB typ

71 dB typ

-78

-80

8

±V

/2 Volts

CM

REF

Volts

REF

2.5

±10

80

10

1

0.625

AV

DD

TBD

dB typ

dB typ

V

ppm/°C typ

dB typ

Ω typ

ms typ

V min

V max

KΩ typ

±2

±5

±0.5

TBD

mV max

mV max

% max

% typ

= 45MHz, All specifications TA = T

CORE

= 1MSPS

SAMPLE

2.5V internal reference

2.5V internal reference

1.0V external reference

2.5V internal reference

2.5V internal reference

1.0V external reference

ADC input is a dc voltage

SAMPLE

0.47µF from V

to AGND

REF

= 5kΩ, CL = 100pF

R

L

DAC output unbuffered

DAC output buffered

% of fullscale on DAC0

MAX

= 1MSPS

to T

MIN

,

Rev. PrA | Page 3 of 78

ADuC702x Series Preliminary Technical Data

www.BDTIC.com/ADI

Parameter ADuC702x Unit Test Conditions/Comments

ANALOG OUTPUTS

Output Voltage Range_0

Ouput Voltage Range_1

Output Voltage Range_2

Output Impedance 10

DAC AC CHARACTERISTICS

Voltage Output Settling Time

Voltage Output Settling Time

Digital to Analog Glitch Energy

COMPARATOR

Input Offset Voltage

Input Bias Current

Input Voltage Range

Input Capacitance

Hysteresis

Response Time

TEMPERATURE SENSOR

Voltage Output at 25°C

Voltage TC

Accuracy ±3 °C typ

POWER SUPPLY MONITOR (PSM)

IOVDD Trip Point Selection 2.79 V Two selectable Trip Points

3.07 V

Power Supply Trip Point Accuracy ±2.5 % max Of the selected nominal Trip Point Voltage

Watchdog Timer (WDT)

Timeout Period

Flash/EE MEMORY

Endurance10 10,000 Cycles min

Data Retention11 30 Years min TJ = 55°C

Digital Inputs

Input Leakage Current

Input Capacitance

Logic Inputs4

VINL, Input Low Voltage

VINH, Input High Voltage

Logic Outputs

VOH, Output High Voltage IOVDD – 400mV V min I

VOL, Output Low Voltage12 0.4 V max I

MCU CLOCK RATE 355.5

STARTUP TIME

At Power-On

From Idle Mode

From Power-Down Mode

Programmable Logic Array (PLA)

Propagation Delay

4

0 to DACREF

0 to 2.5V

0 to DACV

10

15

TBD

±10

5

AGND to AV

7

5

10

1

10

TBD

-2.0

0

TBD

±10

±1

10

0.4

2.0

45.5

TBD

TBD

TBD

TBD

DD

DD

-1.2

V typ

V typ

V typ

Ω typ

µs typ

µs typ

nV-sec typ

mV

nA typ

Vmin/Vmax

pF typ

mV min

mv max

µs min

µs max

mV typ

mV/°C typ

ms min

ms max

µA max

µA typ

pF typ

V max

V min

kHz min

MHz max

ns typ

DACREF range: DACGND to DACV

DD

DAC Output buffered

DAC Output unbuffered

I LSB change at major carry

Hysteresis can be turned on or off via the

CMPHYST bit in the CMPCON register

Response time may be modified via the CMPRES

bits in the CMPCON register

All digital inputs including XTAL1 and XTAL2

All Logic inputs including XTAL1 and XTAL2

= 1.6mA

SOURCE

= 1.6mA

SINK

8 programmable core clock selections within this

range

Core Clock = TBD MHz

From input pin to output pin

Rev. PrA | Page 4 of 78

Preliminary Technical Data ADuC702x Series

www.BDTIC.com/ADI

Parameter ADuC702x Unit Test Conditions/Comments

POWER REQUIREMENTS 13, 14

Power Supply Voltage Range

AVDD – AGND and IOVDD - IOGND 2.7 V min

3.6 V max

Power Supply Current Normal Mode 3mA

Power Supply Current Idle Mode

Power Supply Current Power Down

Mode

1

Temperature Range -40° to +85°C

2

All ADC Channel Specifications are guaranteed during normal MicroConverter core operation.

3

These specification apply to all ADC input channels.

4

These numbers are not production tested but are supported by design and/or characterization data on production release.

5

Based on external ADC system components, the user may need to execute a system calibration to remove external endpoint and achieve these specifications..

6

SNR calculation includes distortion and noise components.

7

Channel-to-channel crosstalk is measured on adjacent channels.

8

The input signal can be centered on any dc common-mode voltage (VCM) as long as this value is within the ADC voltage input range specified.

9

When using an external reference input pin, the internal reference must be disabled by setting the lsb in the REFCON Memeory Mapped Register to 0.

10

Endurance is qualified to 50,000 cycles as per JEDEC Std. 22 method A117 and measured at -40°C, +25°C and +85°C. Typical endurance at 25°C is 70,000 cycles.

11

Retention lifetime equivalent at junction temperature (Tj) = 55°C as per JEDEC Std. 22 method A117. Retention lifetime will derate with junction temperature.

12

Test carried out with a maximum of 20 I/O set to a low output level.

13

Power supply current consumption is measured in normal, idle and power-down modes under the following conditions:

Normal Mode: TBD

Idle Mode: TBD

Power-Down: TBD

14

DVDD power supply current increases typically by TBD mA during a Flash/EE memory program or erase cycle.

1MHz clock

1MHz clock

45MHz clock

5

50

mA typ

mA max

mA typ

60 mA max 45MHz clock

1

30

100

mA max

µA typ

µA max

External Crystal or Internal Osc ON

External Crystal or Internal Osc ON

Rev. PrA | Page 5 of 78

ADuC702x Series Preliminary Technical Data

www.BDTIC.com/ADI

TERMINOLOGY

ADC Specifications

Integral Nonlinearity

This is the maximum deviation of any code from a straight line

passing through the endpoints of the ADC transfer function.

The endpoints of the transfer function are zero scale, a point 1/2

LSB below the first code transition and full scale, a point 1/2

LSB above the last code transition.

fundamental. Noise is the rms sum of all nonfundamental

signals up to half the sampling frequency (fS/2), excluding dc.

The ratio is dependent upon the number of quantization levels

in the digitisation process; the more levels, the smaller the

quantization noise. The theoretical signal to (noise + distortion)

ratio for an ideal N-bit converter with a sine wave input is given

by:

Signal to (Noise + Distortion) = (6.02N + 1.76) dB

Differential Nonlinearity

This is the difference between the measured and the ideal 1 LSB

change between any two adjacent codes in the ADC.

Offset Error

This is the deviation of the first code transition (0000 . . . 000) to

(0000 . . . 001) from the ideal, i.e., +1/2 LSB.

Gain Error

This is the deviation of the last code transition from the ideal

AIN voltage (Full Scale – 1.5 LSB) after the offset error has been

adjusted out.

Signal to (Noise + Distortion) Ratio

This is the measured ratio of signal to (noise + distortion) at the

output of the ADC. The signal is the rms amplitude of the

Thus for a 12-bit converter, this is 74 dB.

Total Harmonic Distortion

Total Harmonic Distortion is the ratio of the rms sum of the

harmonics to the fundamental.

DAC SPECIFICATIONS

Relative Accuracy

Relative accuracy or endpoint linearity is a measure of the

maximum deviation from a straight line passing through the

endpoints of the DAC transfer function. It is measured after

adjusting for zero error and full-scale error.

Voltage Output Settling Time

This is the amount of time it takes for the output to settle to

within a 1 LSB level for a full-scale input change..

Rev. PrA | Page 6 of 78

Preliminary Technical Data ADuC702x Series

www.BDTIC.com/ADI

ABSOLUTE MAXIMUM RATINGS

Table 2. Absolute Maximum Ratings (TA = 25°C unless otherwise noted)

Parameter Rating

AVDD to DVDD TBD

AGND to DGND TBD

DVDD to DGND, AVDD to AGND TBD

Digital Input Voltage to DGND TBD

Digital Output Voltage to DGND TBD

VREF to AGND TBD

Analog Inputs to AGND TBD

Operating Temperature Range

Industrial ADuC702x

Storage Temperature Range TBD

Junction Temperature TBD

θJA Thermal Impedance (CSP)

θJA Thermal Impedance (LQFP)

Lead Temperature, Soldering

Vapor Phase (60 sec) TBD

Infrared (15 sec) TBD

Stresses above those listed under Absolute Maximum Ratings may cause permanent damage to the device. This is a stress rating only;

functional operation of the device at these or any other conditions above those listed in the operational sections of this specification is not

implied. Exposure to absolute maximum rating conditions for extended periods may affect device reliability.

–40°C to +85°C

TBD

TBD

ESD Caution

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily accumulate on the

human body and test equipment and can discharge without detection. Although this product features

proprietary ESD protection circuitry, permanent damage may occur on devices subjected to high-energy

electrostatic discharges. Therefore, proper ESD precautions are recommended to avoid performance

degradation or loss of functionality.

Rev. PrA | Page 7 of 78

ADuC702x Series Preliminary Technical Data

www.BDTIC.com/ADI

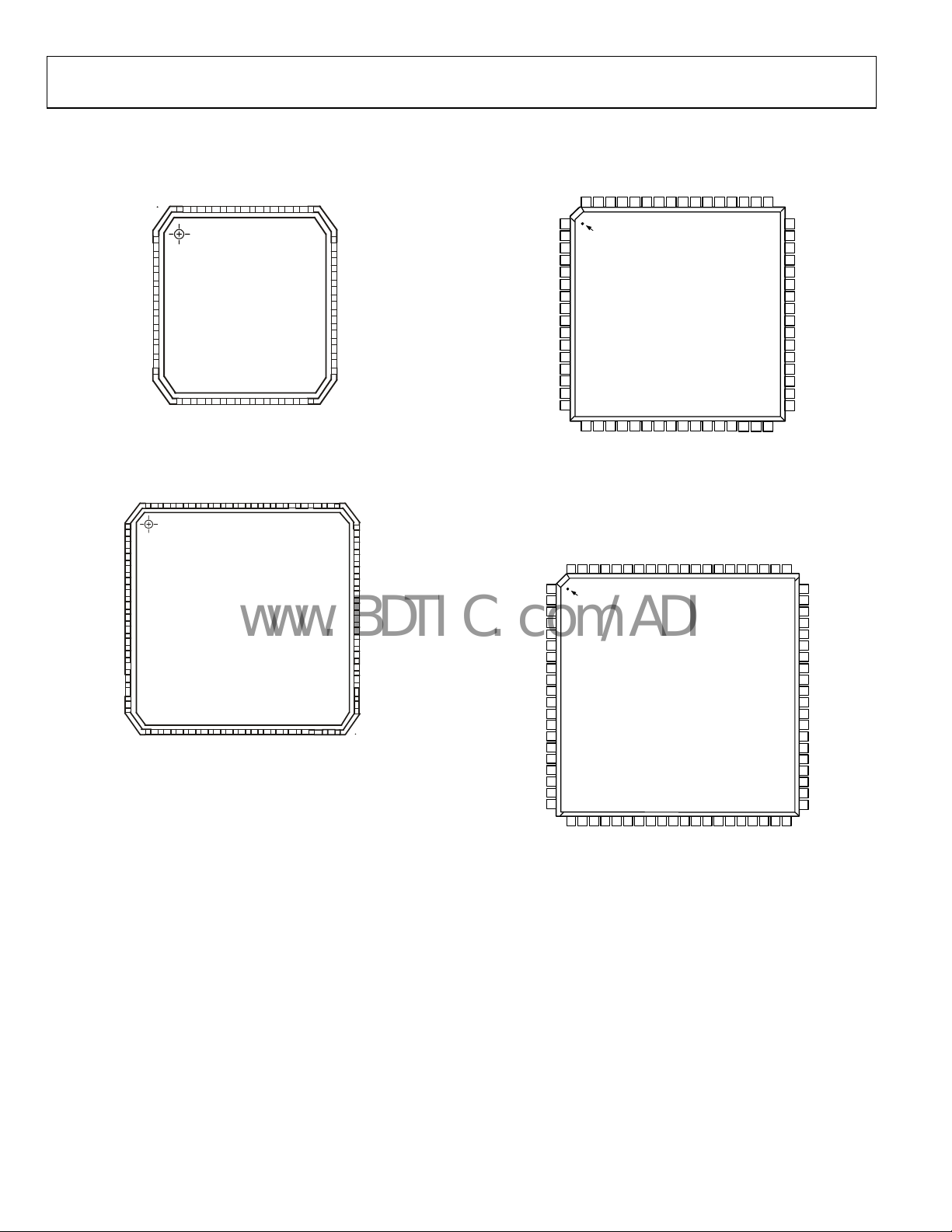

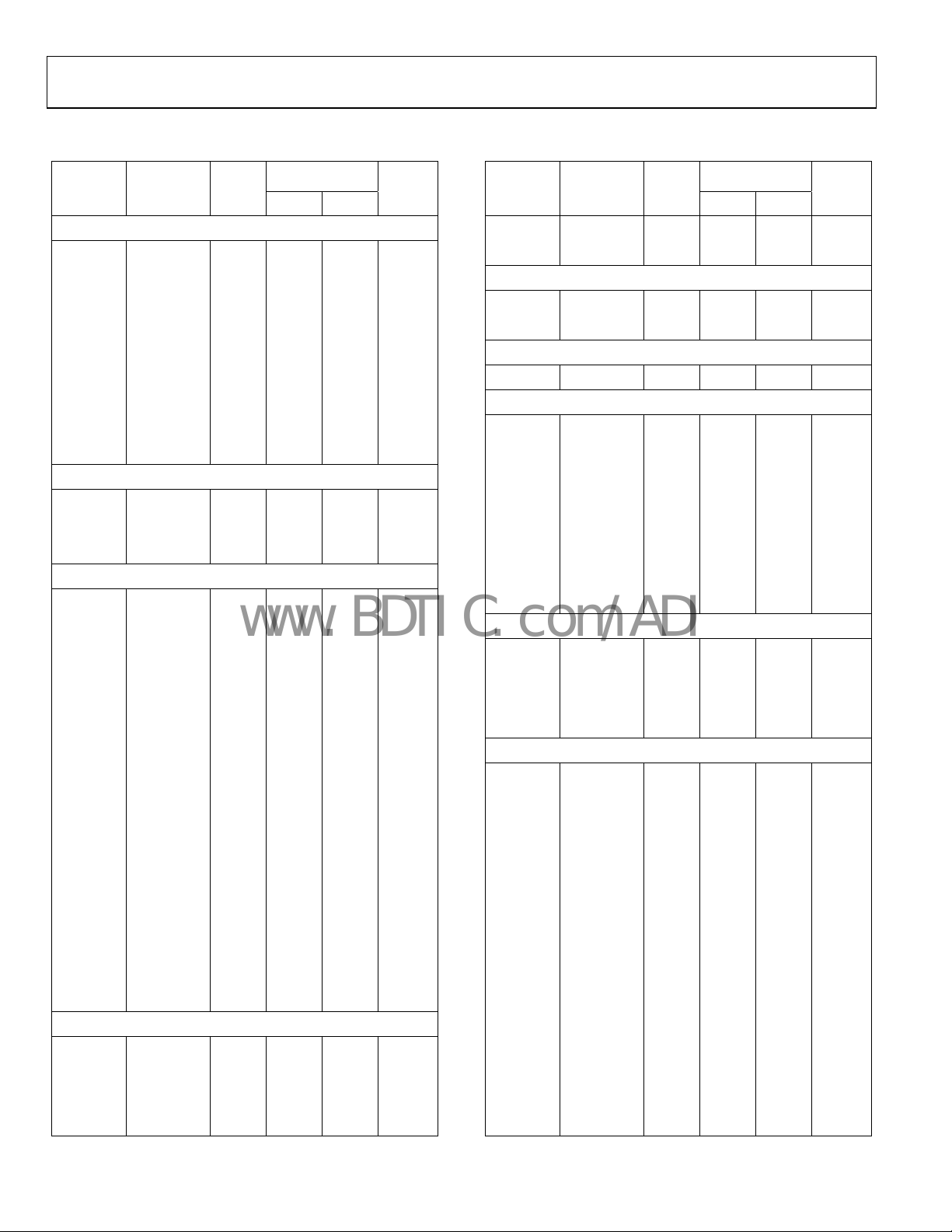

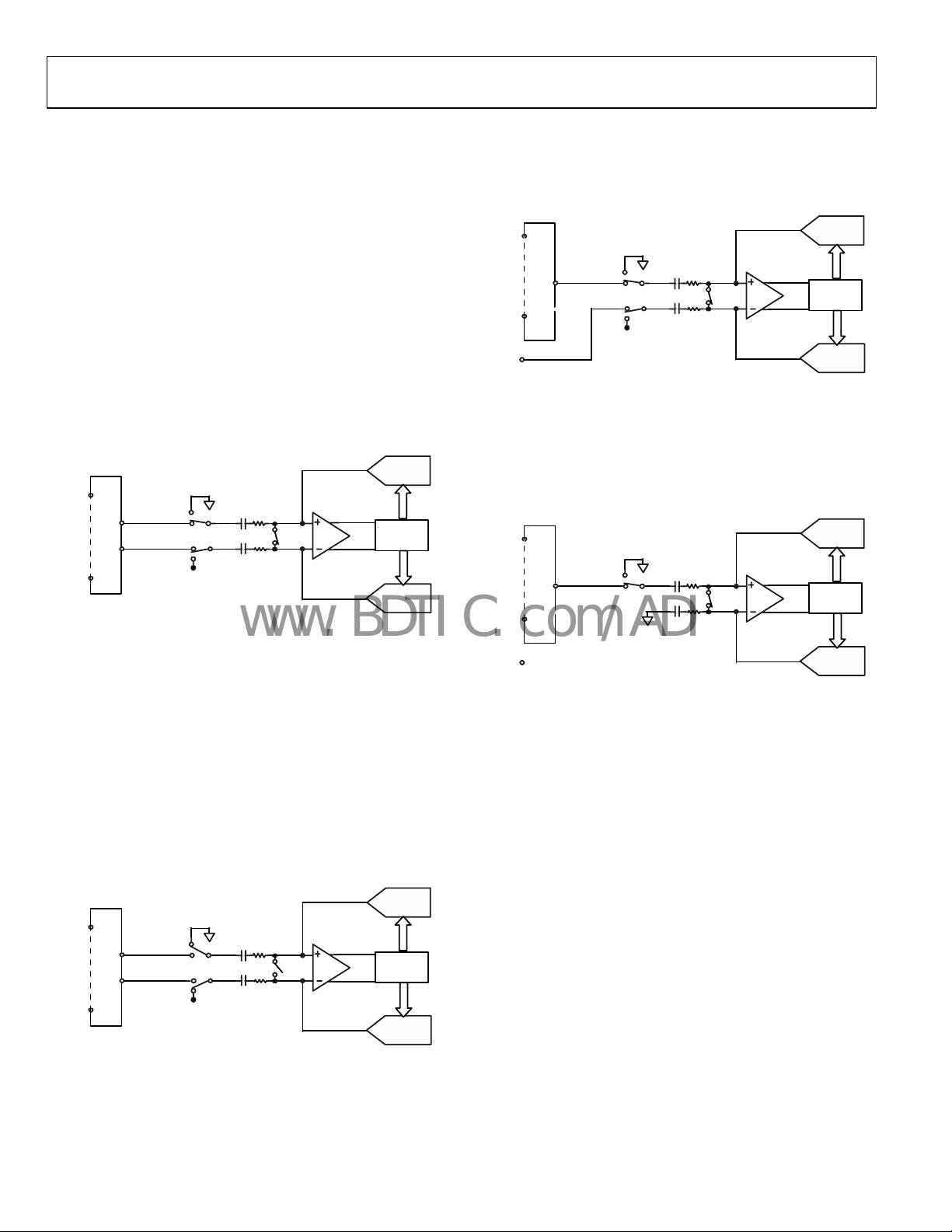

PIN CONFIGURATION

40-Lead CSP

40

1

PIN 1

IDENTIFIER

31

30

64

1

64-Lead LQFP

PIN 1

IDENTIFIER

49

48

TOP VIE W

(Not to Scale)

10

11

21

20

16

64-Lead CSP

64

IDENTIFIER

17

PIN 1

ADuC7024/A D u C7025

TOP V IEW

(Not to Scale)

1

16

49

48

33

32

80

1

ADuC7024/ADuC7025

64-LEAD L QFP

17

80-Lead LQFP

PIN 1

IDENTIFIER

ADuC7026 80-LEAD LQFP

TOP VIEW

(Not to Scale)

TOP VIEW

(No t to S cale )

33

32

61

60

20

21

41

40

Rev. PrA | Page 8 of 78

Preliminary Technical Data ADuC702x Series

www.BDTIC.com/ADI

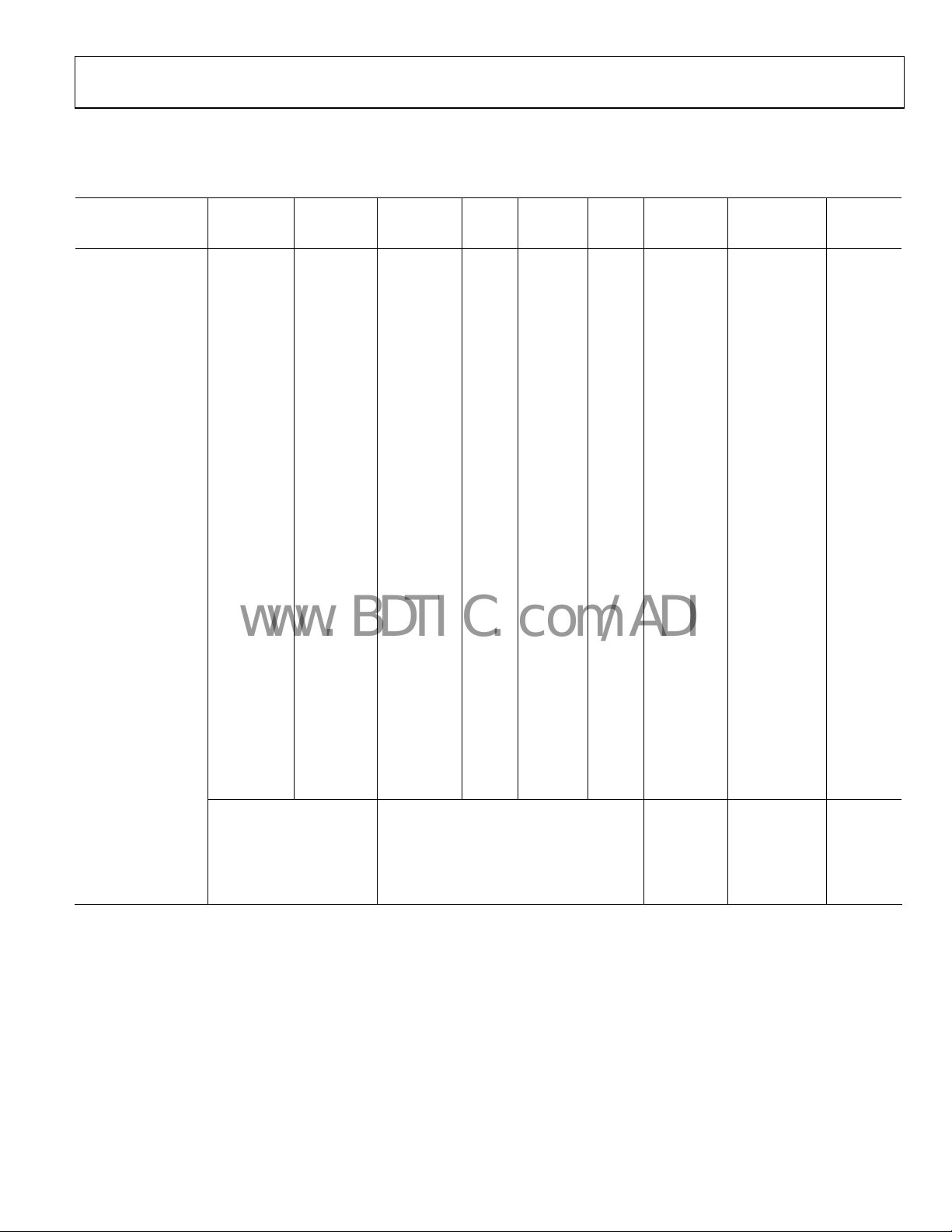

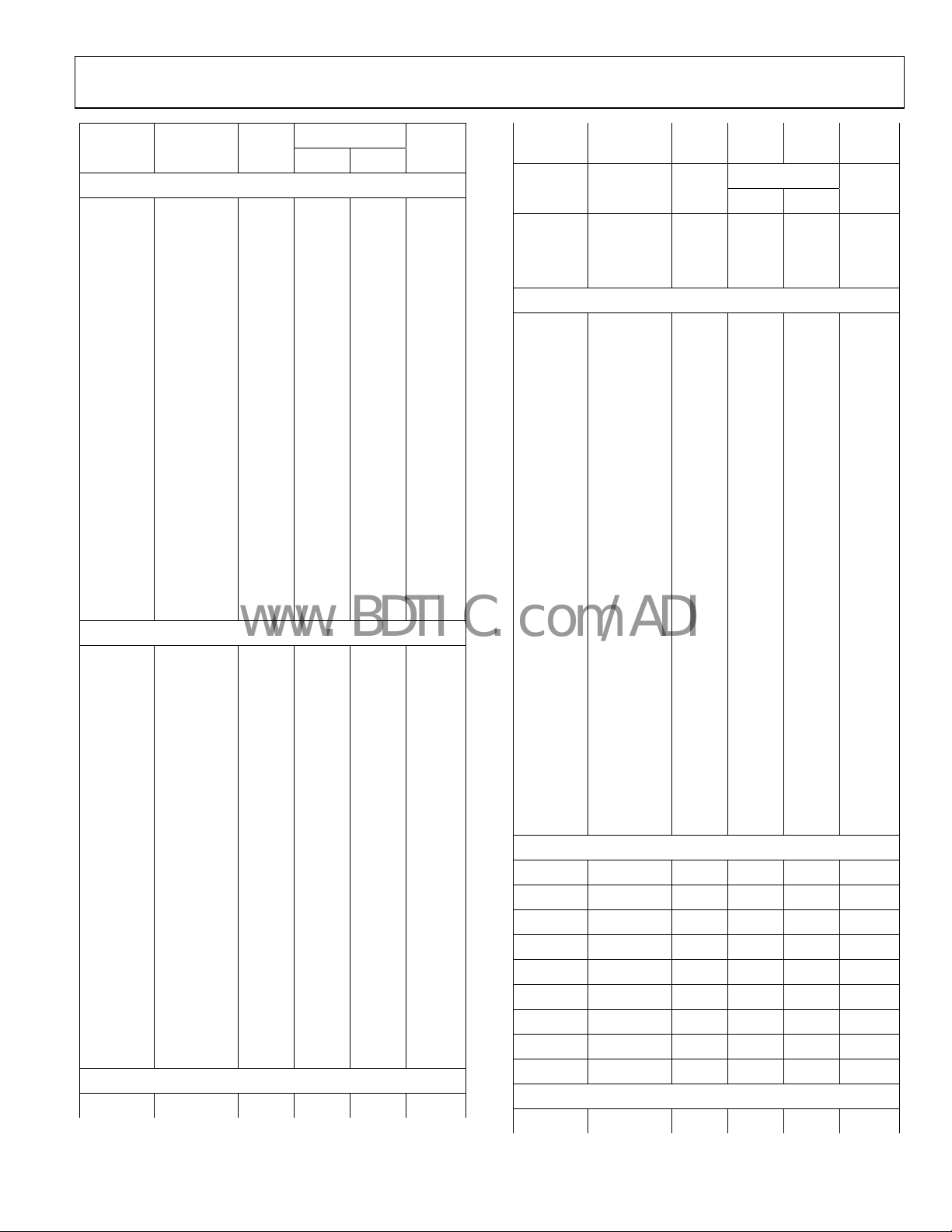

ORDERING GUIDE

Model ADC

Channels

DAC

Channels

FLASH /

RAM

PWM Ext

Memory

GPIO Temp

Range

Package

Description

Package

Option

ADuC7020BCP62 5 4 62kB/8kB 14

ADuC7021BCP62 8 2 62kB/8kB 13

ADuC7021BCP32 8 2 32kB/4kB 13

ADuC7021ACP32

ADuC7022BCP62 10 62kB/8kB 13

ADuC7022BCP32 10 32kB/4kB 13

ADuC7022ACP32

ADuC7024BCP62 10 2 62kB/8kB Yes 30

ADuC7024BST62 10 2 62kB/8kB Yes 30

ADuC7025BCP62 12 62kB/8kB Yes 30

ADuC7025BCP32 12 32kB/4kB Yes 30

ADuC7026BST62 12 4 62kB/8kB Yes Yes 40

ADuC7027BST62 16 62kB/8kB Yes Yes 40

ADuC7027AST62

EVAL-ADuC7020QS

EVAL-ADuC7024QS

EVAL-ADuC7026QS

8 (10 Bit

NMC)

10 (10 Bit

NMC)

16 (10 Bit

NMC)

2 32kB/4kB 13

62kB/8kB 13

62kB/8kB Yes Yes 40

–40°C to +

85°C

–40°C to +

85°C

–40°C to +

85°C

–40°C to +

85°C

–40°C to +

85°C

–40°C to +

85°C

–40°C to +

85°C

–40°C to +

85°C

–40°C to +

85°C

–40°C to +

85°C

–40°C to +

85°C

–40°C to +

85°C

–40°C to +

85°C

–40°C to +

85°C

Contact the factory for chip availability.

40-Lead Chip

Scale Package

40-Lead Chip

Scale Package

40-Lead Chip

Scale Package

40-Lead Chip

Scale Package

40-Lead Chip

Scale Package

40-Lead Chip

Scale Package

40-Lead Chip

Scale Package

64-Lead Chip

Scale Package

64 Lead

Plastic Quad

Flatpack

64-Lead Chip

Scale Package

64-Lead Chip

Scale Package

80 Lead

Plastic Quad

Flatpack

80 Lead

Plastic Quad

Flatpack

80 Lead

Plastic Quad

Flatpack

Development

System

Development

System

Development

System

CP-40

CP-40

CP-40

CP-40

CP-40

CP-40

CP-40

CP-64-1

ST-64

CP-64-1

CP-64-1

ST-80

ST-80

ST-80

Rev. PrA | Page 9 of 78

ADuC702x Series Preliminary Technical Data

www.BDTIC.com/ADI

PIN FUNCTION DESCRIPTIONS – ADUC7020/ADUC7021/ADUC7022

Table 3. Pin Function Descriptions

Pin# ADuC702X

7020 7021 7022

38 37 36 ADC0 I Single-ended or differential Analog input 0

39 38 37 ADC1 I Single-ended or differential Analog input 1

40 39 38 ADC2/CMP0 I Single-ended or differential Analog input 2 / Comparator Positive Input

1 40 39 ADC3/CMP1 I Single-ended or differential Analog input 3 / Comparator Negative Input

2 1 40 ADC4 I Single-ended or differential Analog input 4

- 2 1 ADC5 I Single-ended or differential Analog input 5

- 3 2 ADC6 I Single-ended or differential Analog input 6

- 4 3 ADC7 I Single-ended or differential Analog input 7

- - 4 ADC8 I Single-ended or differential Analog input 8

- - 5 ADC9 I Single-ended or differential Analog input 9

3 5 6 GND

4 6 - DAC0/ADC12 I/O DAC0 Voltage Output / Single-ended or differential Analog input 12

5 7 - DAC1/ADC13 I/O DAC1 Voltage Output / Single-ended or differential Analog input 13

6 - - DAC2/ADC14 I/O DAC2 Voltage Output / Single-ended or differential Analog input 14

7 - - DAC3/ADC15 I/O DAC3 Voltage Output / Single-ended or differential Analog input 15

8 8 7 TMS I JTAG Test Port Input - Test Mode Select. Debug and download access

9 9 8 TDI I JTAG Test Port Input – Test Data In. Debug and download access

10 10 9

11 11 10

12 12 11 TCK/XCLK I

13 13 12 TDO O JTAG Test Port Output - Test Data Out. Debug and download access

14 14 13 IOGND S Ground for GPIO. Typically connected to DGND

15 15 14 IOVDD S 3.3V Supply for GPIO and input of the on-chip voltage regulator.

16 16 15 LVDD S

17 17 16 DGND S Ground for core logic.

18 18 17 TRST I JTAG Test Port Output - Test Reset. Debug and download access

19 19 18 RST I Reset Input. (active low)

20 20 19

21 21 20

22 22 21

23 23 22

Mnemonic Type* Function

S

REF

BM/P0.0/CMP

LAI[7]

P0.6/T1/MRST/PLA

O[3]

IRQ0/P0.4/CONV

/PLAO[1]

ART

IRQ1/P0.5/ADC

/PLAO[2]

P2.0/SPM9/PLAO[

5]/CONV

P0.7/ECLK/SPM8/P

LAO[4]

START

/P

OUT

ST

BUSY

Ground voltage reference for the ADC. For optimal performance the

analog power supply should be separated from IOGND and DGND

Multifunction I/O pin:

Boot Mode. The ADuC702X will enter UART serial download mode if BM

I/O

is low at reset and will execute code if BM is pulled high at reset through

a 1kOhm resistor/ General Purpose Input-Output Port 0.0 / Voltage

Comparator Output/ Programmable Logic Array Input Element 7

Multifunction pin: driven low after reset

O

General Purpose Output Port 0.6 / Timer 1 Input / Power on reset output

/ Programmable Logic Array Output Element 3

JTAG Test Port Input - Test Clock. Debug and download access / Input to

the internal clock generator circuits

2.5V. Output of the on-chip voltage regulator. Must be connected to a

0.47µF capacitor to DGND

Multifunction I/O pin:

External Interrupt Request 0, active high / General Purpose Input-Output

I/O

Port 0.4 / Start conversion input signal for ADC / Programmable Logic

Array Output Element 1

Multifunction I/O pin:

I/O

External Interrupt Request 1, active high / General Purpose Input-Output

Port 0.5 / ADC

Serial Port Multiplexed:

I/O

General Purpose Input-Output Port 2.0 / UART / Programmable Logic

Array Output Element 5/ Start conversion input signal for ADC

Serial Port Multiplexed:

I/O

General Purpose Input-Output Port 0.7 / Output for External Clock signal

/ UART / Programmable Logic Array Output Element 4

signal / Programmable Logic Array Output Element 2

BUSY

Rev. PrA | Page 10 of 78

Preliminary Technical Data ADuC702x Series

www.BDTIC.com/ADI

Pin# ADuC702X

7020 7021 7022

24 24 23 XCLKO O Output to the crystal oscillator inverter

25 24 24 XCLKI I

26 26 25

27 27 26 P1.6/SPM6/PLAI[6] I/O

28 28 27 P1.5/SPM5/PLAI[5] I/O

29 29 28 P1.4/SPM4/PLAI[4] I/O

30 30 29 P1.3/SPM3/PLAI[3] I/O

31 31 30 P1.2/SPM2/PLAI[2] I/O

32 32 31 P1.1/SPM1/PLAI[1] I/O

33 33 32

34 - - P4.2/PLAO[10] I/O

35 34 33 V

36 35 34 AGND S Analog Ground. Ground reference point for the analog circuitry

37 36 35 AVDD S 3.3V Analog Power

*

I = Input, O = Output, S = Supply.

- No pin assigned.

Mnemonic Type* Function

Input to the crystal oscillator inverter and input to the internal clock

generator circuits

P1.7/SPM7/PLAO[

0]

P1.0/T1/SPM0/PLA

I[0]

I/O

REF

Serial Port Multiplexed:

I/O

General Purpose Input-Output Port 1.7 / UART / SPI / Programmable

Logic Array Output Element 0

Serial Port Multiplexed:

General Purpose Input-Output Port 1.6 / UART / SPI / Programmable

Logic Array Input Element 6

Serial Port Multiplexed:

General Purpose Input-Output Port 1.5 / UART / SPI / Programmable

Logic Array Input Element 5

Serial Port Multiplexed:

General Purpose Input-Output Port 1.4 / UART / SPI / Programmable

Logic Array Input Element 4

Serial Port Multiplexed:

General Purpose Input-Output Port 1.3/ UART / I2C1 /Programmable

Logic Array Input Element 3

Serial Port Multiplexed:

General Purpose Input-Output Port 1.2 / UART / I2C1 /Programmable

Logic Array Input Element 2

Serial Port Multiplexed:

General Purpose Input-Output Port 1.1 / UART / I2C0 / Programmable

Logic Array Input Element 1

Serial Port Multiplexed:

I/O

General Purpose Input-Output Port 1.0/ Timer 1 Input / UART / I2C0 /

Programmable Logic Array Input Element 0

General Purpose Input-Output Port 4.2 / Programmable Logic Array

Output Element 10

2.5V internal Voltage Reference. Must be connected to a 0.47uF capacitor

when using the internal reference.

Rev. PrA | Page 11 of 78

ADuC702x Series Preliminary Technical Data

www.BDTIC.com/ADI

PIN FUNCTION DESCRIPTIONS – ADUC7024/ADUC7025

Table 4. Pin Function Descriptions

Pin# Mnemonic Type* Function

1 ADC4 I Single-ended or differential Analog input 4

2 ADC5 I Single-ended or differential Analog input 5

3 ADC6 I Single-ended or differential Analog input 6

4 ADC7 I Single-ended or differential Analog input 7

5 ADC8 I Single-ended or differential Analog input 8

6 ADC9 I Single-ended or differential Analog input 9

7 GND

8 ADCNEG I

9 DAC0**/ADC12 I/O DAC0 Voltage Output / Single-ended or differential Analog input 12

10 DAC1**/ADC13 I/O DAC1 Voltage Output / Single-ended or differential Analog input 13

11 TMS I JTAG Test Port Input - Test Mode Select. Debug and download access

12 TDI I JTAG Test Port Input – Test Data In. Debug and download access

13 P4.6/PLAO[14] I/O

14 P4.7/PLAO[15] I/O

15 BM/P0.0/CMP

16 P0.6/T1/MRST/PLAO[3] O

17 TCK I JTAG Test Port Input - Test Clock. Debug and download access

18 TDO O JTAG Test Port Output - Test Data Out. Debug and download access

19 IOGND S Ground for GPIO. Typically connected to DGND

20 IOVDD S 3.3V Supply for GPIO and input of the on-chip voltage regulator.

21 LVDD S

22 DGND S Ground for core logic.

23 P3.0/PWM0H/PLAI[8] I/O

24 P3.1/PWM0L/PLAI[9] I/O

25 P3.2/PWM1H/PLAI[10] I/O

26 P3.3/PWM1L/PLAI[11] I/O

27 P0.3/TRST/ADC

28 RST I Reset Input. (active low)

29 P3.4/PWM2H/PLAI[12] I/O

30 P3.5/PWM2L/PLAI[13] I/O

S

REF

/PLAI[7] I/O

OUT

I/O

BUSY

Ground voltage reference for the ADC. For optimal performance the analog

power supply should be separated from IOGND and DGND

Bias point or Negative Analog Input of the ADC in pseudo differential mode.

Must be connected to the ground of the signal to convert. This bias point

must be between 0V and 1V

General Purpose Input-Output Port 4.6/ Programmable Logic Array Output

Element 14

General Purpose Input-Output Port 4.7/ Programmable Logic Array Output

Element 15

Multifunction I/O pin:

Boot Mode. The ADuC7024/ADuC7025 will enter UART serial download mode

if BM is low at reset and will execute code if BM is pulled high at reset through

a 1kOhm resistor/ General Purpose Input-Output Port 0.0 / Voltage

Comparator Output/ Programmable Logic Array Input Element 7

Multifunction pin: driven low after reset

General Purpose Output Port 0.6 / Timer 1 Input / Power on reset output /

Programmable Logic Array Output Element 3

2.5V. Output of the on-chip voltage regulator. Must be connected to a 0.47µF

capacitor to DGND

General Purpose Input-Output Port 3.0/ PWM phase 0 high side output /

Programmable Logic Array Input Element 8

General Purpose Input-Output Port 3.1/ PWM phase 0 low side output /

Programmable Logic Array Input Element 9

General Purpose Input-Output Port 3.2/ PWM phase 1 high side output /

Programmable Logic Array Input Element 10

General Purpose Input-Output Port 3.3/ PWM phase 1 low side output /

Programmable Logic Array Input Element 11

General Purpose Input-Output Port 0.3 / JTAG Test Port Input – Test Reset.

Debug and download access / ADC

General Purpose Input-Output Port 3.4 / PWM phase 2 high side output /

Programmable Logic Array Input 12

General Purpose Input-Output Port 3.5 / PWM phase 2 low side output /

Programmable Logic Array Input Element 13

signal output

BUSY

Rev. PrA | Page 12 of 78

Preliminary Technical Data ADuC702x Series

www.BDTIC.com/ADI

Pin# Mnemonic Type* Function

Multifunction I/O pin:

31 IRQ0/P0.4/CONV

32 IRQ1/P0.5/ADC

33 P2.0/PWM

34 P0.7/ECLK/SPM8/PLAO[4] I/O

35 XCLKO O Output to the crystal oscillator inverter

36 XCLKI I

37 P3.6/PWM

38 P3.7/PWMSYNC/PLAI[15] I/O

39 P1.7/SPM7/PLAO[0] I/O

40 P1.6/SPM6/PLAI[6] I/O

41 IOGND S Ground for GPIO. Typically connected to DGND

42 IOVDD S 3.3V Supply for GPIO and input of the on-chip voltage regulator.

43 P4.0/PLAO[8] I/O

44 P4.1/PLAO[9] I/O

45 P1.5/SPM5/PLAI[5] I/O

46 P1.4/SPM4/PLAI[4] I/O

47 P1.3/SPM3/PLAI[3] I/O

48 P1.2/SPM2/PLAI[2] I/O

49 P1.1/SPM1/PLAI[1] I/O

50 P1.0/T1/SPM0/PLAI[0] I/O

51 P4.2/PLAO[10] I/O

TRIP

TRIP

/PLAO[1] I/O

START

/PLAO[2] I/O

BUSY

/SPM9/PLAO[5]/CONV

/PLAI[14] I/O

I/O

START

External Interrupt Request 0, active high / General Purpose Input-Output Port

0.4 / Start conversion input signal for ADC / Programmable Logic Array

Output Element 1

Multifunction I/O pin:

External Interrupt Request 1, active high / General Purpose Input-Output Port

0.5 / ADC

Serial Port Multiplexed:

General Purpose Input-Output Port 2.0 / PWM safety cut off / UART /

Programmable Logic Array Output Element 5/ Start conversion input signal

for ADC

Serial Port Multiplexed:

General Purpose Input-Output Port 0.7 / Output for External Clock signal /

UART / Programmable Logic Array Output Element 4

Input to the crystal oscillator inverter and input to the internal clock

generator circuits

General Purpose Input-Output Port 3.6/ PWM safety cut off / Programmable

Logic Array Input Element 14

General Purpose Input-Output Port 3.7/ PWM synchronisation input output

/Programmable Logic Array Input Element 15

Serial Port Multiplexed:

General Purpose Input-Output Port 1.7 / UART / SPI / Programmable Logic

Array Output Element 0

Serial Port Multiplexed:

General Purpose Input-Output Port 1.6 / UART / SPI / Programmable Logic

Array Input Element 6

General Purpose Input-Output Port 4.0 / Programmable Logic Array Output

Element 8

General Purpose Input-Output Port 4.1 / Programmable Logic Array Output

Element 9

Serial Port Multiplexed:

General Purpose Input-Output Port 1.5 / UART / SPI / Programmable Logic

Array Input Element 5

Serial Port Multiplexed:

General Purpose Input-Output Port 1.4 / UART / SPI / Programmable Logic

Array Input Element 4

Serial Port Multiplexed:

General Purpose Input-Output Port 1.3/ UART / I2C1 /Programmable Logic

Array Input Element 3

Serial Port Multiplexed:

General Purpose Input-Output Port 1.2 / UART / I2C1 /Programmable Logic

Array Input Element 2

Serial Port Multiplexed:

General Purpose Input-Output Port 1.1 / UART / I2C0 / Programmable Logic

Array Input Element 1

Serial Port Multiplexed:

General Purpose Input-Output Port 1.0/ Timer 1 Input / UART / I

Programmable Logic Array Input Element 0

General Purpose Input-Output Port 4.2 / Programmable Logic Array Output

Element 10

signal / Programmable Logic Array Output Element 2

BUSY

2

C0 /

Rev. PrA | Page 13 of 78

ADuC702x Series Preliminary Technical Data

www.BDTIC.com/ADI

Pin# Mnemonic Type* Function

52 P4.3/PLAO[11] I/O

53 P4.4/PLAO[12] I/O

54 P4.5/PLAO[13] I/O

55 V

56 DAC

57 DACGND S Ground for the DAC. Typically connected to AGND

58 AGND S Analog Ground. Ground reference point for the analog circuitry

59 AVDD S 3.3V Analog Power

60 DACVDD S 3.3V Power Supply for the DACs. Typically connected to AVDD

61 ADC0 I Single-ended or differential Analog input 0

62 ADC1 I Single-ended or differential Analog input 1

63 ADC2/CMP0 I Single-ended or differential Analog input 2/ Comparator positive input

64 ADC3/CMP1 I Single-ended or differential Analog input 3/ Comparator negative input

*

I = Input, O = Output, S = Supply.

** DAC outputs not present on ADuC7025

I/O

REF

I External Voltage Reference for the DACs. Range: DACGND to DACVDD

REF

General Purpose Input-Output Port 4.3 / Programmable Logic Array Output

Element 11

General Purpose Input-Output Port 4.4 / Programmable Logic Array Output

Element 12

General Purpose Input-Output Port 4.5 / Programmable Logic Array Output

Element 13

2.5V internal Voltage Reference. Must be connected to a 0.47uF capacitor

when using the internal reference.

Rev. PrA | Page 14 of 78

Preliminary Technical Data ADuC702x Series

www.BDTIC.com/ADI

PIN FUNCTION DESCRIPTIONS – ADUC7026/ADUC7027

Table 5. Pin Function Descriptions

Pin# Mnemonic Type* Function

1 ADC4 I Single-ended or differential Analog input 4

2 ADC5 I Single-ended or differential Analog input 5

3 ADC6 I Single-ended or differential Analog input 6

4 ADC7 I Single-ended or differential Analog input 7

5 ADC8 I Single-ended or differential Analog input 8

6 ADC9 I Single-ended or differential Analog input 9

7 ADC10 I Single-ended or differential Analog input 10

8 GND

9 ADCNEG I

10 DAC0/ADC12 I/O DAC0 Voltage Output / Single-ended or differential Analog input 12

11 DAC1/ADC13 I/O DAC1 Voltage Output / Single-ended or differential Analog input 13

12 DAC1/ADC14 I/O DAC2 Voltage Output / Single-ended or differential Analog input 14

13 DAC1/ADC15 I/O DAC3 Voltage Output / Single-ended or differential Analog input 15

14 TMS I JTAG Test Port Input - Test Mode Select. Debug and download access

15 TDI I JTAG Test Port Input – Test Data In. Debug and download access

16

17 P2.3/AE

18 P4.6/AD14/PLAO[14] I/O

19 P4.7/AD15/PLAO[15] I/O

20 BM/P0.0/CMP

21 P0.6/T1/MRST/PLAO[3]/AE O

22 TCK I JTAG Test Port Input - Test Clock. Debug and download access

23 TDO O JTAG Test Port Output - Test Data Out. Debug and download access

24

25 IOGND S Ground for GPIO. Typically connected to DGND

26 IOVDD S 3.3V Supply for GPIO and input of the on-chip voltage regulator.

27 LVDD S

28 DGND S Ground for core logic.

29 P3.0/AD0/PWM0H/PLAI[8] I/O

30 P3.1/AD1/PWM0L/PLAI[9] I/O

31 P3.2/AD2/PWM1H/PLAI[10] I/O

32 P3.3/AD3/PWM1L/PLAI[11] I/O

33 P2.4/MS0 I/O General Purpose Input-Output Port 2.4 / External Memory select 0

S

REF

BLE

P0.1/

P0.2/

BHE

/PLAI[7] I/O

OUT

Ground voltage reference for the ADC. For optimal performance the analog

power supply should be separated from IOGND and DGND

Bias point or Negative Analog Input of the ADC in pseudo differential mode.

Must be connected to the ground of the signal to convert. This bias point

must be between 0V and 1V

I/O General Purpose Input-Output Port 0.1

General Purpose Input-Output Port 4.6/ External Memory

Interface/Programmable Logic Array Output Element 14

General Purpose Input-Output Port 4.7/ External Memory Interface /

Programmable Logic Array Output Element 15

Multifunction I/O pin:

Boot Mode. The ADuC7026 will enter UART serial download mode if BM is low

at reset and will execute code if BM is pulled high at reset through a 1kOhm

resistor/ General Purpose Input-Output Port 0.0 / Voltage Comparator

Output/ Programmable Logic Array Input Element 7

Multifunction pin: driven low after reset

General Purpose Output Port 0.6 / Timer 1 Input / Power on reset output /

Programmable Logic Array Output Element 3

I/O General Purpose Input-Output Port 0.2

2.5V. Output of the on-chip voltage regulator. Must be connected to a 0.47µF

capacitor to DGND

General Purpose Input-Output Port 3.0 / External Memory Interface/ PWM

phase 0 high side output / Programmable Logic Array Input Element 8

General Purpose Input-Output Port 3.1 / External Memory Interface / PWM

phase 0 low side output / Programmable Logic Array Input Element 9

General Purpose Input-Output Port 3.2 / External Memory Interface / PWM

phase 1 high side output / Programmable Logic Array Input Element 10

General Purpose Input-Output Port 3.3 / External Memory Interface / PWM

phase 1 low side output / Programmable Logic Array Input Element 11

Rev. PrA | Page 15 of 78

ADuC702x Series Preliminary Technical Data

www.BDTIC.com/ADI

Pin# Mnemonic Type* Function

34 P0.3/TRST/A16/ADC

35 P2.5/MS1 I/O General Purpose Input-Output Port 2.5 / External Memory select 1

36 P2.6/MS2 I/O General Purpose Input-Output Port 2.6 / External Memory select 2

37 RST I Reset Input. (active low)

38 P3.4/AD4/PWM2H/PLAI[12] I/O

39 P3.5/AD5/PWM2L/PLAI[13] I/O

40 IRQ0/P0.4/CONV

41 IRQ1/P0.5/ADC

42 P2.0/PWM

43 P0.7/ECLK/SPM8/PLAO[4] I/O

44 XCLKO O Output to the crystal oscillator inverter

45 XCLKI I

46 P3.6/AD6/PWM

47 P3.7/AD7/ECLK/PLAI[15] I/O

48 P2.7/MS3 I/O General Purpose Input-Output Port 2.7 / External Memory select 3

49 P2.1/WS I/O General Purpose Input-Output Port 2.1 / External Memory Write Strobe

50 P2.2/RS I/O General Purpose Input-Output Port 2.2 / External Memory Read Strobe

51 P1.7/SPM7/PLAO[0] I/O

52 P1.6/SPM6/PLAI[6] I/O

53 IOGND S Ground for GPIO. Typically connected to DGND

54 IOVDD S 3.3V Supply for GPIO and input of the on-chip voltage regulator.

55 P4.0/AD8/PLAO[8] I/O

56 P4.1/AD9/PLAO[9] I/O

57 P1.5/SPM5/PLAI[5] I/O

58 P1.4/SPM4/PLAI[4] I/O

59 P1.3/SPM3/PLAI[3] I/O Serial Port Multiplexed:

BUSY

/SPM9/PLAO[5]/CONV

TRIP

I/O

BUSY

/PLAO[1] I/O

START

/PLAO[2] I/O

I/O

START

/PLAI[14] I/O

TRIP

General Purpose Input-Output Port 0.3 / JTAG Test Port Input – Test Reset.

Debug and download access / ADC

General Purpose Input-Output Port 3.4 / External Memory Interface / PWM

phase 2 high side output / Programmable Logic Array Input 12

General Purpose Input-Output Port 3.5 / External Memory Interface /PWM

phase 2 low side output / Programmable Logic Array Input Element 13

Multifunction I/O pin:

External Interrupt Request 0, active high / General Purpose Input-Output Port

0.4 / Start conversion input signal for ADC / Programmable Logic Array

Output Element 1

Multifunction I/O pin:

External Interrupt Request 1, active high / General Purpose Input-Output Port

0.5 / ADC

Serial Port Multiplexed:

General Purpose Input-Output Port 2.0 / PWM safety cut off / UART /

Programmable Logic Array Output Element 5/ Start conversion input signal

for ADC

Serial Port Multiplexed:

General Purpose Input-Output Port 0.7 / Output for External Clock signal /

UART / Programmable Logic Array Output Element 4

Input to the crystal oscillator inverter and input to the internal clock

generator circuits

General Purpose Input-Output Port 3.6 / External Memory Interface / PWM

safety cut off / Programmable Logic Array Input Element 14

General Purpose Input-Output Port 3.7/ / External Memory Interface / Output

for External Clock signal /Programmable Logic Array Input Element 15

Serial Port Multiplexed:

General Purpose Input-Output Port 1.7 / UART / SPI / Programmable Logic

Array Output Element 0

Serial Port Multiplexed:

General Purpose Input-Output Port 1.6 / UART / SPI / Programmable Logic

Array Input Element 6

General Purpose Input-Output Port 4.0 / External Memory Interface /

Programmable Logic Array Output Element 8

General Purpose Input-Output Port 4.1 / External Memory Interface

/Programmable Logic Array Output Element 9

Serial Port Multiplexed:

General Purpose Input-Output Port 1.5 / UART / SPI / Programmable Logic

Array Input Element 5

Serial Port Multiplexed:

General Purpose Input-Output Port 1.4 / UART / SPI / Programmable Logic

Array Input Element 4

signal / Programmable Logic Array Output Element 2

BUSY

signal output

BUSY

Rev. PrA | Page 16 of 78

Preliminary Technical Data ADuC702x Series

www.BDTIC.com/ADI

Pin# Mnemonic Type* Function

General Purpose Input-Output Port 1.3/ UART / I2C1 /Programmable Logic

Array Input Element 3

Serial Port Multiplexed:

60 P1.2/SPM2/PLAI[2] I/O

61 P1.1/SPM1/PLAI[1] I/O

62 P1.0/T1/SPM0/PLAI[0] I/O

63 P4.2/AD10/PLAO[10] I/O

64 P4.3/AD11/PLAO[11] I/O

65 P4.4/AD12/PLAO[12] I/O

66 P4.5/AD13/PLAO[13] I/O

67 REFGND S Ground for the reference. Typically connected to AGND

68 V

69 DAC

70 DACGND S Ground for the DAC. Typically connected to AGND

71 AGND S Analog Ground. Ground reference point for the analog circuitry

72 AGND S Analog Ground. Ground reference point for the analog circuitry

73 AVDD S 3.3V Analog Power

74 AVDD S 3.3V Analog Power

75 DACVDD S 3.3V Power Supply for the DACs. Typically connected to AVDD

76 ADC11 I Single-ended or differential Analog input 11

77 ADC0 I Single-ended or differential Analog input 0

78 ADC1 I Single-ended or differential Analog input 1

79 ADC2/CMP0 I Single-ended or differential Analog input 2/ Comparator positive input

80 ADC3/CMP1 I Single-ended or differential Analog input 3/ Comparator negative input

*

I = Input, O = Output, S = Supply.

I/O

REF

I External Voltage Reference for the DACs. Range: DACGND to DACVDD

REF

General Purpose Input-Output Port 1.2 / UART / I

Array Input Element 2

Serial Port Multiplexed:

General Purpose Input-Output Port 1.1 / UART / I2C0 / Programmable Logic

Array Input Element 1

Serial Port Multiplexed:

General Purpose Input-Output Port 1.0/ Timer 1 Input / UART / I

Programmable Logic Array Input Element 0

General Purpose Input-Output Port 4.2 / External Memory Interface /

Programmable Logic Array Output Element 10

General Purpose Input-Output Port 4.3 / External Memory Interface

/Programmable Logic Array Output Element 11

General Purpose Input-Output Port 4.4 / External Memory Interface

/Programmable Logic Array Output Element 12

General Purpose Input-Output Port 4.5 / External Memory Interface

/Programmable Logic Array Output Element 13

2.5V internal Voltage Reference. Must be connected to a 0.47uF capacitor

when using the internal reference.

2

C1 /Programmable Logic

2

C0 /

Rev. PrA | Page 17 of 78

ADuC702x Series Preliminary Technical Data

www.BDTIC.com/ADI

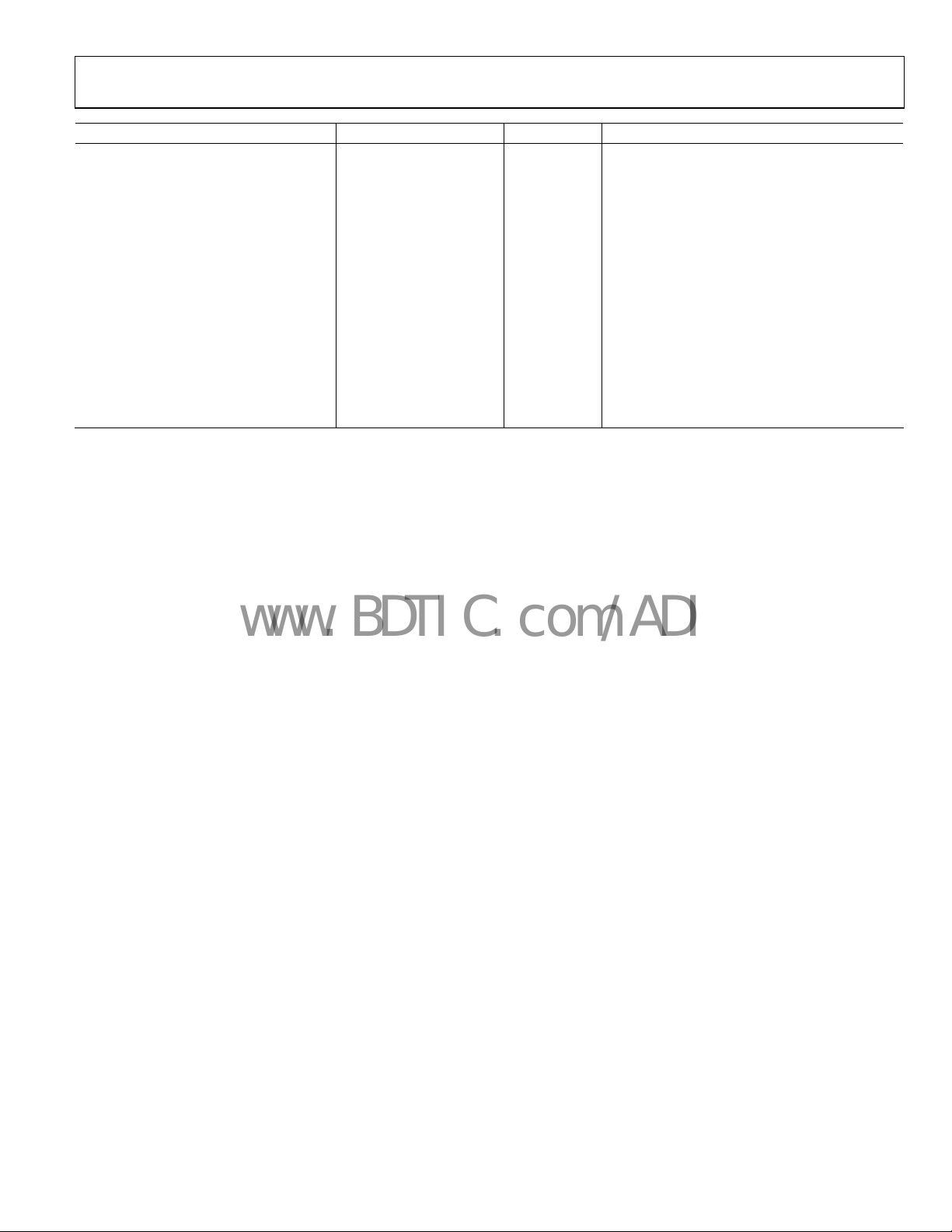

D

F

E

N

R

D

D

D

G

N

D

D

N

G

G

A

D

F

V

V

E

A

A

R

D

D

D

N

G

O

I

D

N

D

D

V

V

G

O

O

O

I

I

I

T

D

E

D

N

S

D

E

V

G

R

L

D

D

D

F

N

D

E

R

V

G

C

C

C

A

A

A

D

D

D

BM/P0.0/CMP

P4.6/PLAO/AD14

P4.7/PLAO/AD15

ADC0

ADC1

ADC2/CMP0

ADC3/CMP1

ADC4

ADC5

ADC6

ADC7

ADC8

ADC9

ADC10

ADC11

ADC

NEG

/PLAO

OUT

V

REF

DAC

DAC

PROG. LOGIC

MUX

MUX

MUX

BAND GAP

REFERENCE

ARRAY

12-BIT SAR

ADC 1MSPS

TEMP

SENSOR

62 KBYTES FLASH/EE

/IRQ

CMP

OUT

V

REF

SPI/I2CSERIAL

INTERFACE

SERIAL PORT MULTIPLEXER

8192 BYTES USER RAM

ADC

CONTROL

(31k X 16 bits)

(2k X 32 bits)

DOWNLOADER

UART

SERIAL PORT

ADuC7026*

ARM7TDMI

MCU

CORE

R

O

T

G

A

A

L

T

U

J

M

E

DAC

CONTROL

WAKEUP/

RTC TIMER

POWER SUPPLY

MONITOR

PROG. CLOCK

DIVIDER

POR

12-BIT

VOLTAGE

OUTPUT DAC

12-BIT

VOLTAGE

OUTPUT DAC

12-BIT

VOLTAGE

OUTPUT DAC

12-BIT

VOLTAGE

OUTPUT DAC

CONTROLLER

BUF

BUF

BUF

BUF

Three-

phase

PWM

OSC

PLL

INTERRUPT

DAC0*/ADC12

DAC1*/ADC13

DAC2*/ADC14

DAC3*/ADC15

P3.0/PWM0H/PLAI/AD0

P3.1/PWM0L/PLAI/AD1

P3.2/PWM1H/PLAI/AD2

P3.3/PWM1H/PLAI/AD3

P3.4/PWM2H/PLAI/AD4

P3.5/PWM2H/PLAI/AD5

P3.6/PWM

XCLKO

XCLKI

P3.7/ECLK/PLAI/AD7

IRQ0/P0.4/CONV

IRQ1/P0.5/ADC

P0.0

TRIP

/PLAI/AD6

START

/PLAO

BUSY

/PLAO

0

8

D

A

/

O

A

L

P

/

0

.

4

P

1

9

1

1

D

D

D

A

/

A

A

/

/

O

O

O

A

A

A

L

L

L

P

/

P

P

/

/

1

.

2

3

.

.

4

4

4

P

P

P

I

3

2

A

1

1

L

D

D

A

A

/P

/

/

0

O

O

M

A

A

P

L

L

S

P

P

/

/

/

0

.

5

4

.

.

1

4

4

P

P

P

I

I

I

I

A

A

A

A

L

L

L

L

P

P

P

P

/

/

/

/

3

2

1

4

M

M

M

M

P

P

P

P

S

S

S

S

/

/

/

/

3

2

1

4

.

.

.

.

1

1

1

1

P

P

P

P

I

I

I

A

A

L

L

P

P

/

/

6

5

M

M

P

P

S

S

/

/

6

5

.

.

1

1

P

P

T

O

A

R

A

L

A

L

T

P

/

P

S

/

7

V

8

M

M

M

P

O

P

S

/

S

C

/

/

7

.

K

O

1

L

A

P

C

L

E

P

/

/

7

9

.

0

M

P

P

/S

P

I

R

T

M

W

P

/

0

.

2

P

I

S

D

M

T

T

Y

O

K

L

D

T

C

X

/

K

C

T

E

S

A

U

/

B

O

C

A

D

L

A

P

/

/

6

T

1

S

A

R

/

T

M

/

S

6

.

R

0

T

/

P

3

.

0

P

E

S

S

A

R

W

/

/

/

3

2

1

.

.

.

2

2

2

P

P

P

3

0

1

2

E

S

S

M

M

/

/

4

5

.

.

2

2

P

P

* See selection table for

feature availabilityon

different models.

E

S

S

L

H

B

B

M

M

/

/

/

/

1

2

6

7

.

.

.

.

0

0

2

2

P

P

P

P

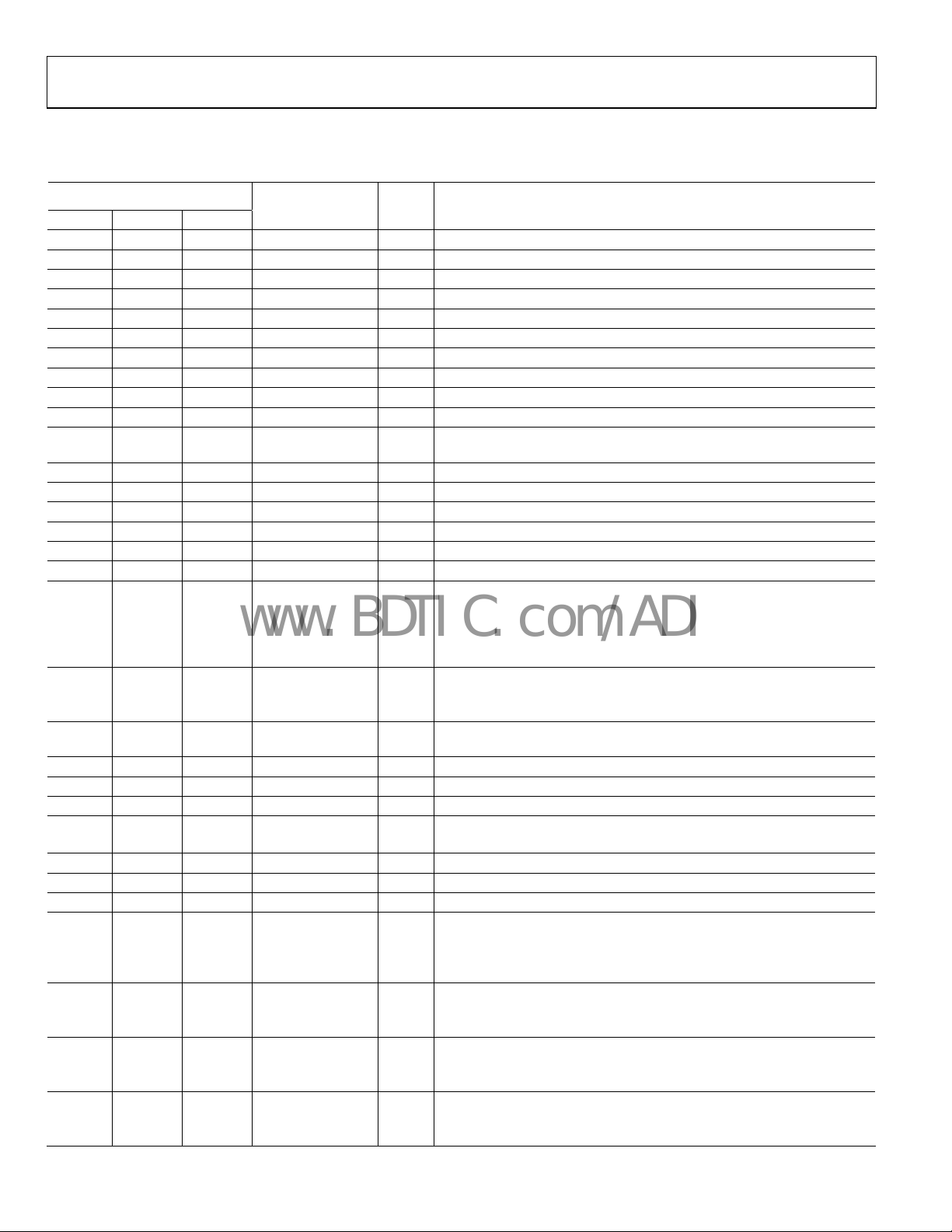

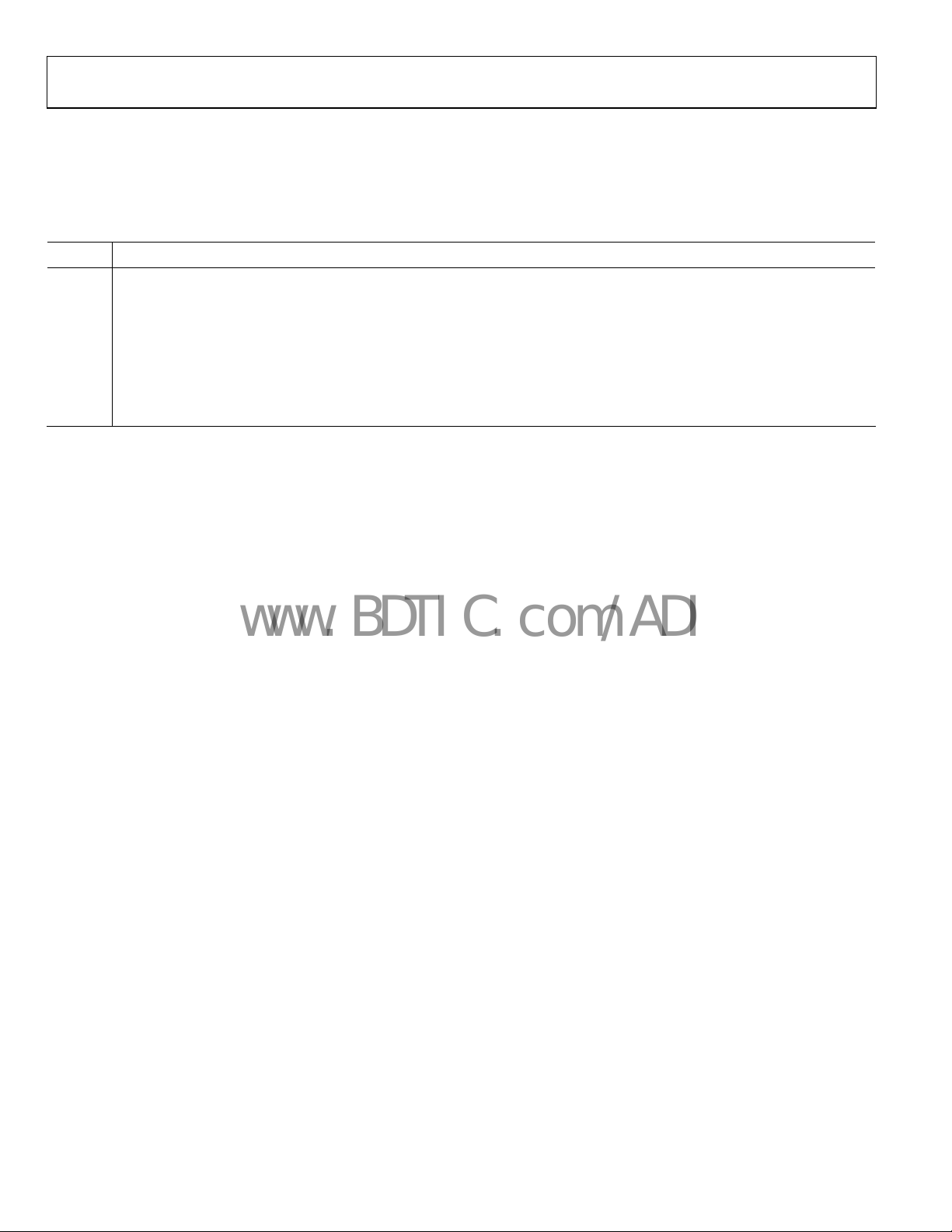

Figure 2: Detailed Block Diagram

Rev. PrA | Page 18 of 78

Preliminary Technical Data ADuC702x Series

www.BDTIC.com/ADI

GENERAL DESCRIPTION

The ADuC702x is fully integrated, 1MSPS, 12-bit data

acquisition system incorporating a high performance multichannel ADC, a 16/32-bit MCU and Flash/EE Memory on a

single chip.

The ADC consists of up to 12 single-ended inputs. An

additional 4 inputs are available but are multiplexed with the 4

DAC output pins. The 4 DAC outputs are only available on

certain models of the ADuC702x, though in many cases where

the DAC is not present this pin can still be used as an additional

ADC input, giving a maximum of 16 ADC input channels. The

ADC can operate in single-ended or differential input modes.

The ADC input voltage is 0 to V

reference, temperature sensor and voltage comparator complete

the ADC peripheral set.

The ADuC702x also integrates 4 buffered voltage output DACs

on-chip. The DAC output range is programmable to one of

three voltage ranges.

The device operates from an on-chip oscillator and PLL

generating an internal high-frequency clock of 45 MHz. This

clock is routed through a programmable clock divider from

which the MCU core clock operating frequency is generated.

The microcontroller core is an ARM7TDMI, 16/32-bit RISC

machine, offering up to 45 MIPS peak performance. 62k Bytes

of non-volatile Flash/EE are provided on-chip as well as 8k

Bytes of SRAM. Both the Flash/EE and SRAM memory arrays

are mapped into a single linear array.

. Low drift bandgap

REF

system debugging.

Thumb mode (T)

An ARM instruction is 32-bits long. The ARM7TDMI

processor supports a second instruction set that has been

compressed into 16-bits, the Thumb instruction set. Faster

execution from 16-bit memory and greater code density can

usually be achieved by using the Thumb instruction set instead

of the ARM instruction set, which makes the ARM7TDMI core

particularly suitable for embedded applications.

However the Thumb mode has two limitations:

- Thumb code usually uses more instructions for the same job,

so ARM code is usually best for maximising the performance

of the time-critical code.

- The Thumb instruction set does not include some

instructions that are needed for exception handling, so ARM

code needs to be used for exception handling.

See ARM7TDMI User Guide for details on the core

architecture, the programming model and both the ARM and

ARM Thumb instruction sets.

Long Multiply (M)

The ARM7TDMI instruction set includes four extra

instructions which perform 32-bit by 32-bit multiplication with

64-bit result and 32-bit by 32-bit multiplication-accumulation

(MAC) with 64-bit result.

On-chip factory firmware supports in-circuit serial download

via the UART and JTAG serial interface ports while nonintrusive emulation is also supported via the JTAG interface.

These features are incorporated into a low-cost QuickStart

Development System supporting this MicroConverter family.

The parts operate from 2.7V to 3.6V and are specified over an

industrial temperature range of -40°C to 85°C. When operating

at 45MHz the power dissipation is 300mW. The ADuC702x is

available in a variety of memory models and packages. These

are detailed on page 9.

OVERVIEW OF THE ARM7TDMI CORE

The ARM7 core is a 32-bit Reduced Instruction Set Computer

(RISC). It uses a single 32-bit bus for instruction and data. The

length of the data can be 8, 16 or 32 bits and the length of the

instruction word is 32 bits.

The ARM7TDMI is an ARM7 core with 4 additional features:

- T support for the Thumb (16 bit) instruction set.

- D support for debug

- M support for long multiplies

- I include the EmbeddedICE module to support embedded

EmbeddedICE (I)

EmbeddedICE provides integrated on-chip support for the core.

The EmbeddedICE module contains the breakpoint and

watchpoint registers which allow code to be halted for

debugging purposes. These registers are controlled through the

JTAG test port.

When a breakpoint or watchpoint is encountered, the processor

halts and enters debug state. Once in a debug state, the

processor registers may be inspected as well as the Flash/EE, the

SRAM and the Memory Mapped Registers.

Exceptions

ARM supports five types of exceptions, and a privileged

processing mode for each type. The five type of exceptions are:

- Normal interrupt or IRQ. It is provided to service general-

purpose interrupt handling of internal and external events

- Fast interrupt or FIQ. It is provided to service data transfer or

communication channel with low latency. FIQ has priority

over IRQ

- Memory abort

- Attempted execution of an undefined instruction

Rev. PrA | Page 19 of 78

ADuC702x Series Preliminary Technical Data

www.BDTIC.com/ADI

- Software interrupt (SWI) instruction which can be used to

make a call to an operating system.

Typically the programmer will define interrupts as IRQ but for

higher priority interrupt, i.e. faster response time, the

programmer can define interrupt as FIQ.

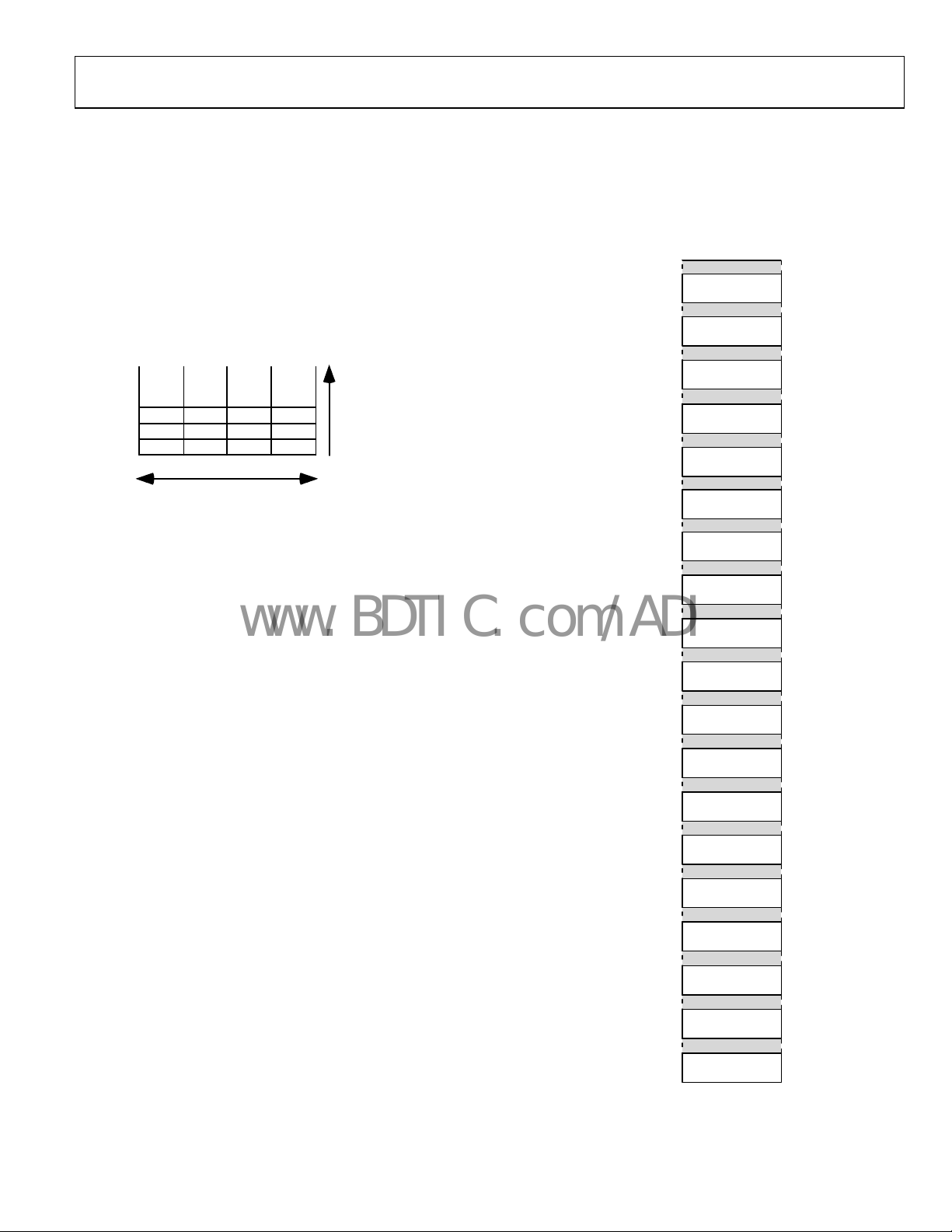

ARM Registers

ARM7TDMI has a total of 37 registers, of which 31 are general

purpose registers and six are status registers. Each operating

mode has dedicated banked registers.

When writing user-level programs, 15 general purpose 32-bit

registers (r0 to r14), the program counter (r15) and the current

program status register (CPSR) are usable. The remaining

registers are used only for system-level programming and for

exception handling.

When an exception occurs, some of the standard register are

replaced with registers specific to the exception mode. All

exception modes have replacement banked registers for the

stack pointer (r13) and the link register (r14) as represented in

Figure 3. The fast interrupt mode has more registers (8 to 12)

for fast interrupt processing, so that the interrupt processing

can begin without the need to save or restore these registers and

thus save critical time in the interrupt handling process.

r0

r1

r2

r3

r4

r5

r6

r7

r8

r9

r10

r11

r12

r13

r14

r15 (PC)

CPSR

r8_fiq

r9_fiq

r10_fiq

r11_fiq

r12_fiq

r13_fiq

r14_fiq

SPSR_fiq

r13_svc

r14_svc

SPSR_svc

r13_abt

r14_abt

SPSR_abt

usable in user mode

system modes only

r13_irq

r14_irq

SPSR_irq

r13_und

r14_und

SPSR_und

Interrupt latency

The worst case latency for an FIQ consists of the longest time

the request can take to pass through the synchronizer, plus the

time for the longest instruction to complete (the longest

instruction is an LDM) which loads all the registers including

the PC, plus the time for the data abort entry, plus the time for

FIQ entry. At the end of this time, the ARM7TDMI will be

executing the instruction at 0x1C (FIQ interrupt vector

address). The maximum total time is 41 processor cycles, which

is just over 909 nanoseconds in a system using a continuous 45

MHz processor clock. The maximum IRQ latency calculation is

similar, but must allow for the fact that FIQ has higher priority

and could delay entry into the IRQ handling routine for an

arbitrary length of time.

The minimum latency for FIQ or IRQ interrupts is five cycles in

total which consists of the shortest time the request can take

through the synchronizer plus the time to enter the exception

mode.

Note that the ARM7TDMI will always be run in ARM (32-bit)

mode when in privileged modes, i.e. when executing interrupt

service routines.

MEMORY ORGANISATION

The part incorporates two separate blocks of memory, 8kByte of

SRAM and 64kByte of On-Chip Flash/EE memory. 62kByte of

On-Chip Flash/EE memory are available to the user, and the

remaining 2kBytes are reserved for the factory configured boot

page. These two blocks are mapped as shown in

Figure 4

.

Note that by default, after a reset, the Flash/EE memory is

mirrored at address 0x00000000. It is possible to remap the

SRAM at address 0x00000000 by clearing bit 0 of the REMAP

MMR. This remap function is described in more details in the

Flash/EE memory chapter.

FFFFFFFFh

FFFF0000h

0008FFFFh

MMRs

Reserved

user mode fiq

mode

svc

mode

abord

mode

irq

mode

undefined

mode

Figure 3: register organisation

More information relative to the programmer’s model and the

ARM7TDMI core architecture can be found in the following

documents from ARM:

- DDI0029G, ARM7TDMI Technical Reference Manual.

- DDI0100E, ARM Architecture Reference Manual.

Rev. PrA | Page 20 of 78

00080000h

00010000h

00000000h

Flash/EE

Reserved

00011FFFh

0000FFFFh

SRAM

Re-mappableMemory Space

(Flash/EE or SRAM)

Figure 4: Physical memory map

Preliminary Technical Data ADuC702x Series

www.BDTIC.com/ADI

Memory Access

The ARM7 core sees memory as a linear array of 232 byte

location where the different blocks of memory are mapped as

outlined in

Figure 4

.

The ADuC702x memory organisation is configured in little

endian format: the least significant byte is located in the lowest

byte address and the most significant byte in the highest byte

address.

Byte0

...

89AB

4567

01

bit0

0xFFFFFFFFh

0x00000004h

0x00000000h

bit31

Byte3

...

Byte1Byte2

...

...

23

32 bits

Figure 5: little endian format

Flash/EE Memory

The total 64kBytes of Flash/EE are organised as 32k X 16 bits.

31k X 16 bits are user space and 1k X 16 bits is reserved for boot

loader. The page size of this Flash/EE memory is 256Bytes.

62kBytes of Flash/EE are available to the user as code and nonvolatile data memory. There is no distinction between data and

program as ARM code shares the same space. The real width of

the Flash/EE memory is 16 bits, which means that in ARM

mode (32-bit instruction), two accesses to the Flash/EE are

necessary for each instruction fetch. It is therefore

recommended to use Thumb mode when executing from

Flash/EE memory for optimum access speed. The maximum

access speed for the Flash/EE memory is 45MHz in Thumb

mode and 22.5MHz in full ARM mode. More details on

Flash/EE access time are outlined later in ‘Execution from

SRAM and Flash/EE’ section of this datasheet.

SRAM

8kBytes of SRAM are available to the user, organized as 2k X 32

bits, i.e. 2kWords. ARM code can run directly from SRAM at

45MHz , given that the SRAM array is configured as a 32-bit

wide memory array. More details on SRAM access time are

outlined later in ‘Execution from SRAM and Flash/EE’ section

of this datasheet.

Memory Mapped Registers

The Memory Mapped Register (MMR) space is mapped into

the upper 2 pages of the Flash/EE space and accessed by

indirect addressing through the ARM7 banked registers.

The MMR space provides an interface between the CPU and all

on-chip peripherals. All registers except the core registers

reside in the MMR area. All shaded locations shown in Figure 6

are unoccupied or reserved locations and should not be

accessed by user software. Table 6 shows a full MMR memory

map.

0xFFFFFFFF

0xFFFFFC3C

0xFFFFFC00

0xFFFFF820

0xFFFFF800

0xFFFFF46C

0xFFFFF400

0xFFFF0B54

0xFFFF0B00

0xFFFF0A14

0xFFFF0A00

0xFFFF0948

0xFFFF0900

0xFFFF0848

0xFFFF0800

0xFFFF0730

0xFFFF0700

0xFFFF0620

0xFFFF0600

0xFFFF0538

0xFFFF0500

0xFFFF0490

0xFFFF048C

0xFFFF0448

0xFFFF0440

0xFFFF0420

0xFFFF0404

0xFFFF0370

0xFFFF0360

0xFFFF0350

0xFFFF0340

0xFFFF0334

0xFFFF0320

0xFFFF0310

0xFFFF0300

0xFFFF0238

0xFFFF0220

0xFFFF0110

0xFFFF0000

PWM

Flash Control

Interface

GPIO

PLA

SPI

I2C1

I2C0

UART

DAC

ADC

Bandgap

Reference

Power Supply

Monitor

PLL &

Oscillator Control

Watchdog

Timer

Wake Up

Timer

General Purpose

Timer

Timer 0

Remap &

System Control

Interrupt

Controller

Figure 6: Memory Mapped

Rev. PrA | Page 21 of 78

ADuC702x Series Preliminary Technical Data

www.BDTIC.com/ADI

Table 6. Complete MMRs list

Access Address Name Byte

Type Cycle

IRQ address base = 0xFFFF0000

0x0000 IRQSTA 4 R 1 63

0x0004 IRQSIG 4 R 1 63

0x0008 IRQEN 4 RW 1 63

0x000C IRQCLR 4 W 1 63

0x0010 SWICFG 4 W 1 64

0x0100 FIQSTA 4 R 1 63

0x0104 FIQSIG 4 R 1 63

0x0108 FIQEN 4 RW 1 63

0x010C FIQCLR 4 W 1 63

System Control address base = 0xFFFF0200

0x0220 REMAP 1 RW 1 35

0x0230 RSTSTA 1 R 1 35

0x0234 RSTCLR 1 W 1 35

Timer address base = 0xFFFF0300

0x0300 T0LD 2 RW 2 65

0x0304 T0VAL 2 R 2 65

0x0308 T0CON 2 RW 2 65

0x030C T0CLRI 1 W 2 65

0x0320 T1LD 4 RW 2 66

0x0324 T1VAL 4 R 2 66

0x0328 T1CON 2 RW 2 66

0x032C T1CLRI 1 W 2 66

0x0330 T1CAP 4 RW 2 66

0x0340 T2LD 4 RW 2 67

0x0344 T2VAL 4 R 2 67

0x0348 T2CON 2 RW 2 67

0x034C T2CLRI 1 W 2 67

0x0360 T3LD 2 RW 2 68

0x0364 T3VAL 2 R 2 68

0x0368 T3CON 2 RW 2 68

0x036C T3CLRI 1 W 2 68

PLL base address = 0xFFFF0400

0x0404 POWKY1 1 W 2 40

0x0408 POWCON 1 RW 2 40

0x040C POWKY2 1 W 2 40

0x0410 PLLKY1 1 W 2 40

Page

Address Name Byte

0x0414 PLLCON 1 RW 2 40

0x0418 PLLKY2 1 W 2 40

PSM address base = 0xFFFF0440

0x0440 PSMCON 2 RW 2 38

0x0444 CMPCON 2 RW 2 38

Reference address base = 0xFFFF0480

0x048C REFCON 1 RW 2 30

ADC address base = 0xFFFF0500

0x0500 ADCCON 1 RW 2 26

0x0504 ADCCP 1 RW 2 27

0x0508 ADCCN 1 RW 2 27

0x050C ADCSTA 1 RW 2 26

0x0510 ADCDAT 4 R 2 26

0x0514 ADCRST 1 RW 2 26

0x0530 ADCGN 2 RW 2 29

0x0534 ADCOF 2 RW 2 29

DAC address base = 0xFFFF0600

0x0600 DAC0CON 1 RW 2 36

0x0604 DAC0DAT 4 RW 2 36

0x0608 DAC1CON 1 RW 2 36

0x060C DAC1DAT 4 RW 2 36

UART base address = 0xFFFF0700

0x0700 COMTX 1 RW 2 51

COMRX 1 R 2 51

COMDIV0 1 RW 2 51

0x0704 COMIEN0 1 RW 2 52

COMDIV1 1 R/W 2 51

0x0708 COMIID0 1 R 2 52

0x070C COMCON0 1 RW 2 51

0x0710 COMCON1 1 RW 2 53

0x0714 COMSTA0 1 R 2 52

0x0718 COMSTA1 1 R 2 53

0x071C COMSCR 1 RW 2 51

0x0720 COMIEN1 1 RW 2 54

0x0724 COMIID1 1 R 2 54

0x0728 COMADR 1 RW 2 51

0X072C COMDIV2 2 RW 2 53

Access

Type Cycle

Page

Rev. PrA | Page 22 of 78

Preliminary Technical Data ADuC702x Series

www.BDTIC.com/ADI

Access Address Name Byte

Type Cycle

I2C0 base address = 0xFFFF0800

0x0800 I2C0MSTA 1 R 2 58

0x0804 I2C0SSTA 1 R 2 58

0x0808 I2C0SRX 1 R 2 57

0x080C I2C0STX 1 W 2 57

0x0810 I2C0MRX 1 R 2 57

0x0814 I2C0MTX 1 W 2 57

0x0818 I2C0CNT 1 RW 2 57

0x081C I2C0ADR 1 RW 2 57

0x0824 I2C0BYTE 1 RW 2 57

0x0828 I2C0ALT 1 RW 2 57

0x082C I2C0CFG 1 RW 2 57

0x0830 I2C0DIVH 1 RW 2 57

0x0834 I2C0DIVL 1 RW 2 57

0x0838 I2C0ID0 1 RW 2 57

0x083C I2C0ID1 1 RW 2 57

0x0840 I2C0ID2 1 RW 2 57

0x0844 I2C0ID3 1 RW 2 57

I2C1 base address = 0xFFFF0900

0x0900 I2C1MSTA 1 R 2 58

0x0904 I2C1SSTA 1 R 2 58

0x0908 I2C1SRX 1 R 2 57

0x090C I2C1STX 1 W 2 57

0x0910 I2C1MRX 1 R 2 57

0x0914 I2C1MTX 1 W 2 57

0x0918 I2C1CNT 1 RW 2 57

0x091C I2C1ADR 1 RW 2 57

0x0924 I2C1BYTE 1 RW 2 57

0x0928 I2C1ALT 1 RW 2 57

0x092C I2C1CFG 1 RW 2 57

0x0930 I2C1DIVH 1 RW 2 57

0x0934 I2C1DIVL 1 RW 2 57

0x0938 I2C1ID0 1 RW 2 57

0x093C I2C1ID1 1 RW 2 57

0x0940 I2C1ID2 1 RW 2 57

0x0944 I2C1ID3 1 RW 2 57

SPI base address = 0xFFFF0A00

0x0A00 SPISTA 1 R 2 55

Page

0x0A04 SPIRX 1 R 2 55

Access Address Name Byte

Type Cycle

0x0A08 SPITX 1 W 2 55

0x0A0C SPIDIV 1 RW 2 55

0x0A10 SPICON 2 RW 2 55

PLA base address = 0xFFFF0B00

0x0B00 PLAELM0 2 RW 2 60

0x0B04 PLAELM1 2 RW 2 60

0x0B08 PLAELM2 2 RW 2 60

0x0B0C PLAELM3 2 RW 2 60

0x0B10 PLAELM4 2 RW 2 60

0x0B14 PLAELM5 2 RW 2 60

0x0B18 PLAELM6 2 RW 2 60

0x0B1C PLAELM7 2 RW 2 60

0x0B20 PLAELM8 2 RW 2 60

0x0B24 PLAELM9 2 RW 2 60

0x0B28 PLAELM10 2 RW 2 60

0x0B2C PLAELM11 2 RW 2 60

0x0B30 PLAELM12 2 RW 2 60

0x0B34 PLAELM13 2 RW 2 60

0x0B38 PLAELM14 2 RW 2 60

0x0B3C PLAELM15 2 RW 2 60

0x0B40 PLACLK 1 RW 2 61

0x0B44 PLAIRQ 4 RW 2 61

0x0B48 PLAADC 4 RW 2 62

0x0B4C PLADIN 4 R 2 62

0x0B50 PLADOUT 4 RW 2 62

External Memory base address = 0xFFFFF000

0xF000 XMCFG 1 RW 2

0xF010 XM0CON 1 RW 2

0xF014 XM1CON 1 RW 2

0xF018 XM2CON 1 RW 2

0xF01C XM3CON 1 RW 2

0xF020 XM0PAR 2 RW 2

0xF024 XM1PAR 2 RW 2

0xF028 XM2PAR 2 RW 2

0xF02C XM3PAR 2 RW 2

GPIO base address = 0xFFFFF400

0xF400 GP0CON 4 RW 1 48

Page

Rev. PrA | Page 23 of 78

ADuC702x Series Preliminary Technical Data

www.BDTIC.com/ADI

0xF404 GP1CON 4 RW 1 48

0xF408 GP2CON 4 RW 1 48

0xF40C GP3CON 4 RW 1 48

0xF410 GP4CON 4 RW 1 48

0xF420 GP0DAT 4 RW 1 49

0xF424 GP0SET 1 W 1 49

0xF428 GP0CLR 1 W 1 49

0xF430 GP1DAT 4 RW 1 49

0xF434 GP1SET 1 W 1 49

0xF438 GP1CLR 1 W 1 49

0xF440 GP2DAT 4 RW 1 49

0xF444 GP2SET 1 W 1 49

0xFC24 PWMDAT2 2 RW 1

The ‘Access’ column corresponds to the access time reading or

writing a MMR. It depends on the AMBA (Advanced

Microcontroller Bus Architecture) bus used to access the

peripheral. The processor has two AMBA busses, AHB

(Advanced High-performance Bus) used for system modules

and APB (Advanced Peripheral Bus) used for lower

performance peripheral.

Access Address Name Byte

Type Cycle

0xF448 GP2CLR 1 W 1 49

0xF450 GP3DAT 4 RW 1 49

0xF454 GP3SET 1 W 1 49

0xF458 GP3CLR 1 W 1 49

0xF460 GP4DAT 4 RW 1 49

0xF464 GP4SET 1 W 1 49

0xF468 GP4CLR 1 W 1 49

Flash/EE base address = 0xFFFFF800

0xF800 FEESTA 1 R 1 32

0xF804 FEEMOD 1 RW 1 32

0xF808 FEECON 1 RW 1 32

0xF80C FEEDAT 2 RW 1 32

0xF810 FEEADR 2 RW 1 32

0xF818 FEESIGN 3 R 1 32

0xF81C FEEPRO 4 RW 1 33

0xF820 FEEHIDE 4 RW 1 33

PWM base address= 0xFFFFFC00

0xFC00 PWMCON 2 RW 1 46

0xFC04 PWMSTA 2 RW 1

0xFC08 PWMDAT0 2 RW 1

0xFC0C PWMDAT1 2 RW 1

0xFC10 PWMCFG 2 RW 1

0xFC14 PWMCH0 2 RW 1 46

0xFC18 PWMCH1 2 RW 1 46

0xFC1C PWMCH2 2 RW 1 46

0xFC20 PWMEN 2 RW 1 47

Page

Rev. PrA | Page 24 of 78

Preliminary Technical Data ADuC702x Series

A

www.BDTIC.com/ADI

ADC CIRCUIT INFORMATION

GENERAL OVERVIEW

ADC TRANSFER FUNCTION

The Analog Digital Converter (ADC) incorporates a fast, multichannel, 12-bit ADC. It can operate from 2.7V to 3.6V supplies

and is capable of providing a throughput of up to 1MSPS when

the clock source is 45MHz. This block provides the user with

multi-channel multiplexer, differential track-and-hold, on-chip

reference and ADC.

The ADC consists of a 12-bit successive-approximation

converter based around two capacitor DACs. It can operate in

one of three different modes, depending on the input signal

configuration :

• fully differential mode, for small and balanced signals

• single-ended mode, for any single-ended signals

• pseudo-differential mode, for any single-ended signals,

taking advantage of the common mode rejection

offered by the pseudo differential input.

The converter accepts an analog input range of 0 to V

REF

when

operating in single-ended mode or pseudo-differential mode. In

fully differential mode, the input signal must be balanced

around a common mode voltage V

and with a maximum amplitude of 2 V

V

DD

V

Figure 7: examples of balanced signals for fully differential mode

CM

V

CM

0

, in the range 0V to AVDD

CM

(see Figure 7).

REF

V

CM

2V

REF

2V

REF

2V

REF

A high precision, low drift, and factory calibrated 2.5 V

reference is provided on-chip. An external reference can also be

connected as described later.

Single or continuous conversion modes can be initiated in

software. An external CONV

pin, an output generated from

START

the on-chip PLA or a Timer1 or a Timer2 overflow can also be

used to generate a repetitive trigger for ADC conversions.

A voltage output from an on-chip bandgap reference

proportional to absolute temperature can also be routed

through the front end ADC multiplexer (effectively an

additional ADC channel input) facilitating an internal

temperature sensor channel, measuring die temperature to an

accuracy of ±3°C.

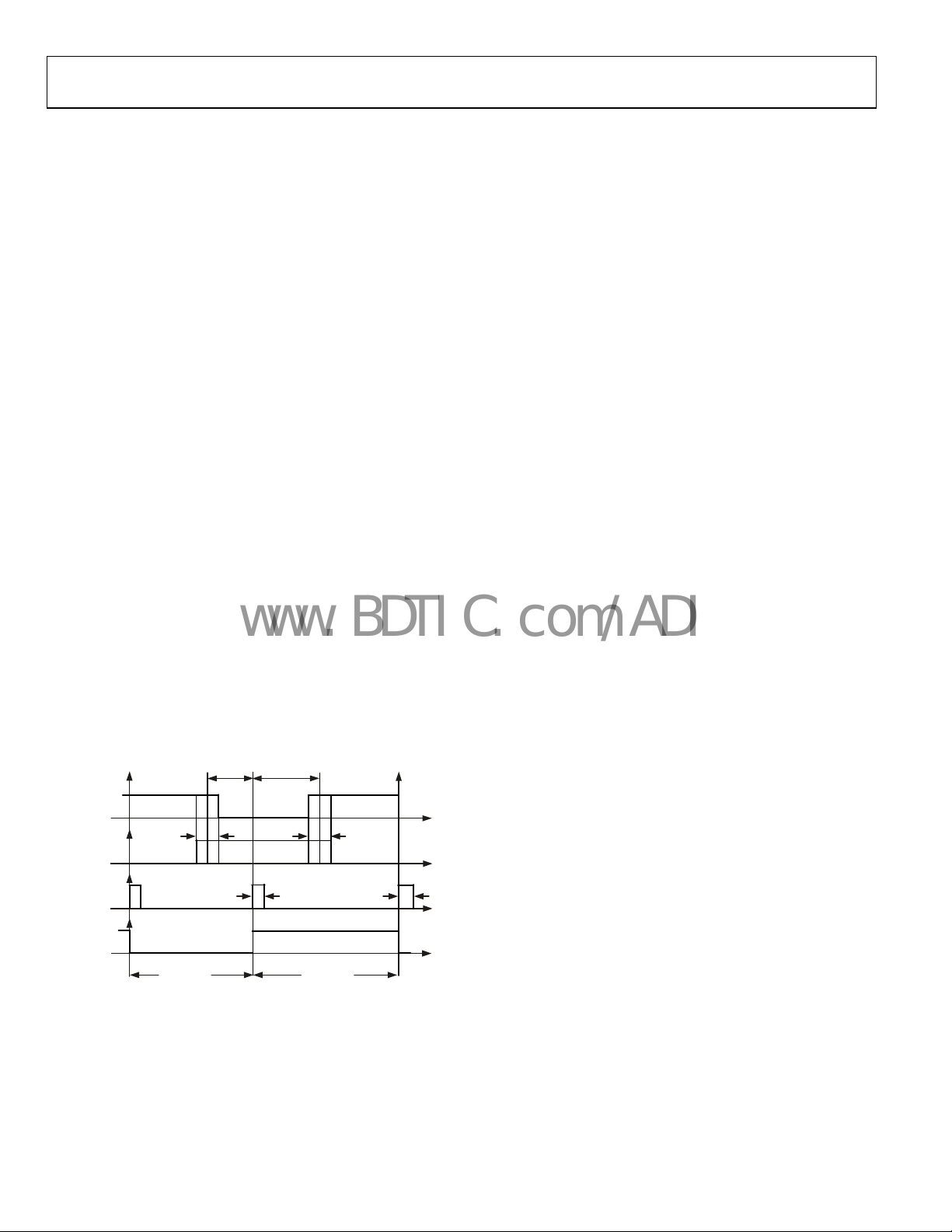

Pseudo-differential and single-ended modes

In pseudo-differential or single-ended mode, the input range is

0 V to V

REF. The output coding is straight binary in pseudo

differential and single-ended modes with 1 LSB = FS/4096 or

2.5 V/4096 = 0.61 mV or 610 µV when V

REF = 2.5 V. The ideal

code transitions occur midway between successive integer LSB

values (i.e. 1/2 LSB, 3/2 LSBs, 5/2 LSBs, . . ., FS –3/2 LSBs). The

ideal input/output transfer characteristic is shown in Figure 8.

OUTPUT

CODE

1111 1111 1111

1111 1111 1110

1111 1111 1101

1111 1111 1100

0000 0000 0011

0000 0000 0010

0000 0000 0001

0000 0000 0000

Figure 8: ADC transfer function in pseudo differential mode or single-ended

0V

1LSB

1LSB =

FS

4096

VOLTAGE INPUT

mode

+FS - 1LSB

Fully differential mode

The amplitude of the differential signal is the difference

between the signals applied to the V

V

IN–). The maximum amplitude of the differential signal is

therefore –V

REF to +VREF p-p (i.e. 2 X VREF). This is regardless of

the common mode (CM). The common mode is the average of

the two signals, i.e. (V

IN+ + VIN–)/2 and is therefore the voltage

that the two inputs are centred on. This results in the span of

each input being CM ± V

REF/2. This voltage has to be set up

externally and its range varies with V

The output coding is two’s complement in fully differential

mode with 1 LSB = 2V

when V

REF = 2.5 V. The designed code transitions occur midway

REF/4096 or 2x2.5 V/4096 = 1.22 mV

between successive integer LSB values (i.e., 1/2 LSB, 3/2 LSBs,

5/2 LSBs, . . ., FS –3/2 LSBs). The ideal input/output transfer

characteristic is shown in Figure 9.