Charge Pump, 7-Channel

V

R

Smart LED Driver with I2C Interface

FEATURES

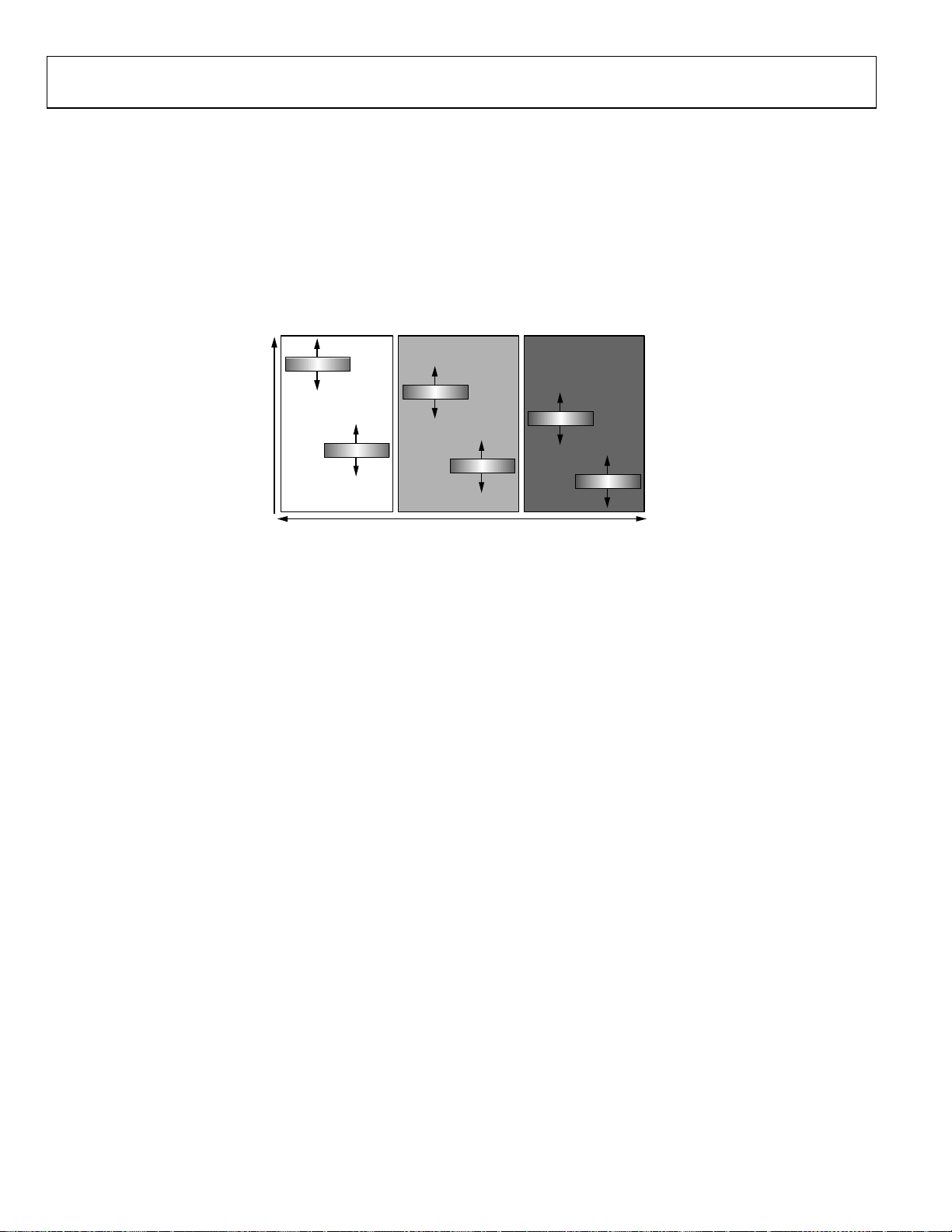

Charge pump with automatic gain selection of 1×, 1.5×, and

2× for maximum efficiency

Up to two built-in comparator inputs with programmable

modes for ambient light sensing

Outdoor, office, and dark modes for maximum backlight

power savings

7 independent and programmable LED drivers

6 drivers capable of 30 mA (typical)

1 driver capable of 60 mA (typical)

Programmable maximum current limit (128 levels)

Standby mode for <1 μA current consumption

16 programmable fade in and fade out times

0.1 sec to 5.5 sec

Choose from linear, square, or cubic rates

Fading override

2

I

C-compatible interface for all programming

Dedicated reset pin and built-in power-on reset (POR)

Short-circuit, overvoltage, and overtemperature protection

Internal soft start to limit inrush currents

Input-to-output isolation during faults or shutdown

Operation down to V

(UVLO) at V

IN

Small wafer level chip scale package (WLCSP) or lead frame

chip scale package (LFCSP)

APPLICATIONS

Mobile display backlighting

Mobile phone keypad backlighting

Dual RGB backlighting

LED indication

General backlighting of small format displays

GENERAL DESCRIPTION

The ADP8860 combines a programmable backlight LED charge

pump driver with automatic phototransistor control. This combination allows for significant power savings because it changes the

current intensity in office and dark ambient light conditions. By

performing this function automatically, it eliminates the need for

a processor to monitor the phototransistor.

The light intensity thresholds are fully programmable via the

2

I

C® interface. A second phototransistor input, with dedicated

comparators, improves the ambient light detection levels for

various user operating conditions.

= 2.5 V with undervoltage lockout

IN

= 2.0 V

ADP8860

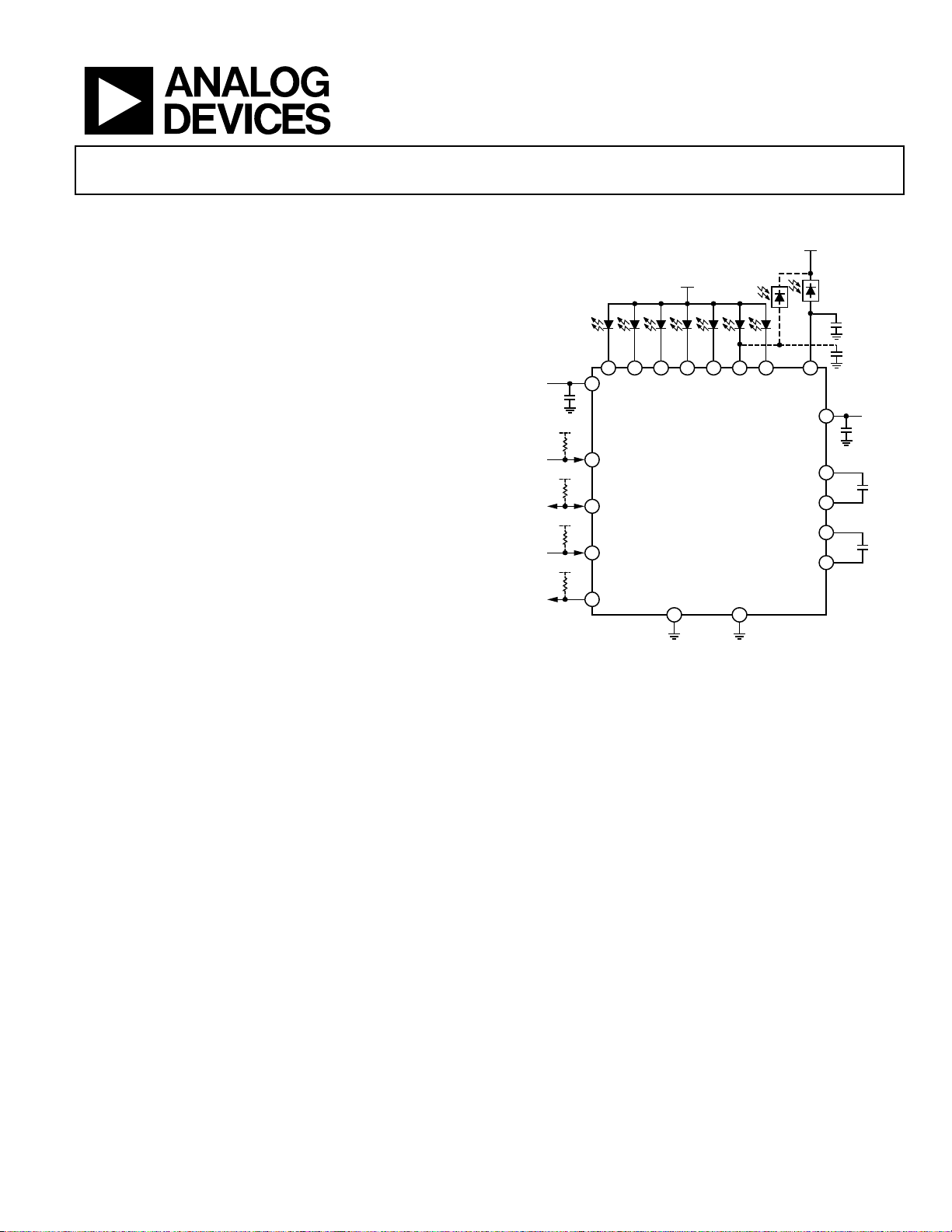

TYPICAL OPERATING CIRCUIT

OPTIONAL

OUT

CMP_IN2

ADP8860

GND1

PHOTOSENSOR

D7

D6/

D1

GND2

V

nRST

SDA

SCL

nINT

IN

V

D3D1E3D2E4D3D4D4C4D5B4

A3

1µF

VDDIO

E1

VDDIO

C2

VDDIO

E2

VDDIO

D2

A4

Figure 1.

The ADP8860 allows as many as six LEDs to be independently

driven up to 30 mA (typical). A seventh LED can be driven to

60 mA (typical). All LEDs are programmable for minimum/maximum current and fade in/out times via the I

LEDs can also be combined into groups to reduce the processor

instructions during fade in/out.

Driving this entire configuration is a two-capacitor charge pump

with gains of 1×, 1.5×, and 2×. This setup is capable of driving a

maximum I

of 240 mA from a supply of 2.5 V to 5.5 V. The

OUT

device includes a variety of safety features including short-circuit,

overvoltage, and overtemperature protection. These features

allow easy implementation of a safe and robust design. Additionally, input inrush currents are limited via an integrated soft

start combined with controlled input-to-output isolation.

The ADP8860 is available in two package types, either a compact

2 mm × 2.4 mm × 0.6 mm WLCSP (wafer level chip scale package)

or a small LFCSP (lead frame chip scale package).

ALS

PHOTOSENSO

CMP_IN

B3

C3

A2

A1

C1

B1

B2

2

C interface. These

C1+

C1–

C2+

C2–

0.1µF

0.1µF

1µF

V

OUT

C1

1µF

C2

1µF

07967-001

Rev. 0

Information furnished by Analog Devices is believed to be accurate and reliable. However, no

responsibility is assumed by Analog Devices for its use, nor for any infrin gements of patents or other

rights of third parties that may result from its use. Specifications subject to change without notice. No

license is granted by implication or otherwise under any patent or patent rights of Analog Devices.

Trademarks and registered trademarks are the property of their respective owners.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700 www.analog.com

Fax: 781.461.3113 ©2009 Analog Devices, Inc. All rights reserved.

ADP8860

TABLE OF CONTENTS

Features .............................................................................................. 1

Applications ....................................................................................... 1

General Description ......................................................................... 1

Typical Operating Circuit ................................................................ 1

Revision History ............................................................................... 2

Specifications ..................................................................................... 3

I2C Timing Diagram ..................................................................... 5

Absolute Maximum Ratings ............................................................ 6

Maximum Temperature Ranges ................................................. 6

Thermal Resistance ...................................................................... 6

ESD Caution .................................................................................. 6

Pin Configurations and Function Descriptions ........................... 7

Typical Performance Characteristics ............................................. 8

Theory of Operation ...................................................................... 12

Power Stage.................................................................................. 13

Operating Modes ........................................................................ 14

Backlight Operating Levels ....................................................... 16

Backlight Maximum and Dim Settings ................................... 17

Automated Fade In and Fade Out ............................................ 17

Backlight Turn On/Turn Off/Dim ........................................... 17

Automatic Dim and Turn Off Timers ..................................... 18

Fade Override ............................................................................. 19

Ambient Light Sensing .............................................................. 19

Automatic Backlight Adjustment ............................................. 20

Independent Sink Control ........................................................ 20

Short-Circuit Protection Mode ................................................ 21

Overvoltage Protection .............................................................. 21

Thermal Shutdown/Overtemperature Protection ................. 21

Interrupts ..................................................................................... 23

Applications Information .............................................................. 24

Layout Guidelines....................................................................... 24

Example Circuits ........................................................................ 25

I2C Programming and Digital Control ........................................ 26

Backlight Register Descriptions ............................................... 30

Independent Sink Register Descriptions ................................. 37

Comparator Register Descriptions .......................................... 45

Outline Dimensions ....................................................................... 49

Ordering Guide .......................................................................... 50

REVISION HISTORY

5/09—Revision 0: Initial Version

Rev. 0 | Page 2 of 52

ADP8860

SPECIFICATIONS

VIN = 3.6 V, SCL = 2.7 V, SDA = 2.7 V, nINT = open, nRST = 2.7 V, CMP_IN = 0 V, V

typical values are at T

= 25°C and are not guaranteed, minimum and maximum limits are guaranteed from TA = −40°C to +85°C, unless

A

= 0.4 V, C1 = 1 F, C2 = 1 F, C

D1:D7

OUT

= 1 F,

otherwise noted.

Table 1.

Parameter Symbol Test Conditions/Comments Min Typ Max Unit

SUPPLY

Input Voltage

Operating Range VIN 2.5 5.5 V

Startup Level V

Low Level V

V

Hysteresis V

IN(START)

UVLO Noise Filter t

VIN increasing 2.05 2.30 V

IN(START)

VIN decreasing 1.75 1.97 V

IN(STOP)

After startup 80 mV

IN(HYS)

10 μs

UVLO

Quiescent Current IQ

Prior to V

During Standby I

After Startup and Switching I

I

IN(START)

Q(START)

VIN = 3.6 V, Bit nSTBY = 0, SCL = SDA = 0 V 0.3 1.0 μA

Q(STBY)

Q(ACTIVE)

VIN = V

− 100 mV 10 μA

IN(START)

VIN = 3.6 V, Bit nSTBY = 1, I

= 0 mA,

OUT

4.5 7.2 mA

gain = 2×

OSCILLATOR

Switching Frequency fSW 0.8 1 1.32 MHz

Duty Cycle D 50 %

OUPUT CURRENT CONTROL

Maximum Drive Current I

D1:D7(MAX)

V

D1:D7

= 0.4 V

D1 to D7 Bit SCR = 0 in the ISC7 register

TJ = 25°C 26.2 30 34.1 mA

TJ = −40°C to +85°C 24.4 34.1 mA

D7 Only (60 mA Setting) I

VD7 = 0.4 V, Bit SCR = 1 in the ISC7 register

D7(60 mA)

TJ = 25°C 52.5 60 67 mA

TJ = −40°C to +85°C 48.8 67 mA

LED Current Source Matching

All Current Sinks I

D2 to D7 Current Sinks I

Leakage Current on LED Pins I

Equivalent Output Resistance R

Gain = 1× VIN = 3.6 V, I

Gain = 1.5× VIN = 3.1 V, I

Gain = 2× VIN = 2.5 V, I

Regulated Output Voltage V

1

I

MATCH

V

MATCH7

V

MATCH6

VIN = 5.5 V, V

D1:D7(LKG)

OUT

VIN = 3 V, gain = 2×, I

OUT(REG)

= 0.4 V 2.0 %

D1:D7

= 0.4 V 1.5 %

D2:D7

= 2.5 V, Bit nSTBY = 1 0.5 μA

D1:D7

= 100 mA 0.5 Ω

OUT

= 100 mA 3.0 Ω

OUT

= 100 mA 3.8 Ω

OUT

= 10 mA 4.3 4.9 5.5 V

OUT

AUTOMATIC GAIN SELECTION

Minimum Voltage

Gain Increases V

Minimum Current Sink Headroom

Decrease V

HR(UP)

V

IDX = I

HR(MIN)

until the gain switches up 162 200 276 mV

D1:D7

× 95% 180 mV

DX(MAX )

Voltage

Gain Delay t

The delay after gain has changed and

GAIN

100 μs

before gain is allowed to change again

Rev. 0 | Page 3 of 52

ADP8860

Parameter Symbol Test Conditions/Comments Min Typ Max Unit

AMBIENT LIGHT SENSING

COMPARATORS

Ambient Light Sensor Current I

DAC Bit Step

Threshold L2 Level I

Threshold L3 Level I

FAULT PROTECTION

Startup Charging Current Source ISS V

Output Voltage Threshold V

Exit Soft Start V

Short-Circuit Protection V

Output Overvoltage Protection V

Activation Level 5.8 V

OVP Recovery Hysteresis 500 mV

Thermal Shutdown

Threshold TSD 150 °C

Hysteresis TSD

Isolation from Input to Output

During Fault

Time to Validate a Fault t

I2C INTERFACE

V

Voltage Operating Range V

DDIO

Logic Low Input2 VIL V

Logic High Input3 VIH V

I2C TIMING SPECIFICATIONS Guaranteed by design

Delay from Reset Deassertion to

I2C access

SCL Clock Frequency f

SCL High Time t

SCL Low Time t

Setup Time

Data t

Repeated Start t

Stop Condition t

Hold Time

Data t

Start/Repeated Start t

Bus Free Time (Stop and Start

Conditions)

Rise Time (SCL and SDA) tR 20 + 0.1 CB 300 ns

Fall Time (SCL and SDA) tF 20 + 0.1 CB 300 ns

Pulse Width of Suppressed Spike tSP 0 50 ns

Capacitive Load Per Bus Line C

1

Current source matching is calculated by dividing the difference between the maximum and minimum current from the sum of the maximum and minimum.

2

VIL is a function of the input voltage. See in the section for typical values over operating ranges. Figure 16

3

VIH is a function of the input voltage. See in the section for typical values over operating ranges.

CMP_IN = VD6 = 2.8 V, Bit CMP2_SEL = 1 0.70 1.08 1.33 mA

ALS

I

L2BIT

I

L3BIT

OUT

OUT(START)

V

OUT(SC)

OVP

20 °C

(HYS)

I

VIN = 5.5 V, V

OUTLKG

2 μs

FAULT

5.5 V

DDIO

t

20 μs

RESET

400 KHz

SCL

0.6 μs

HIGH

1.3 μs

LOW

100 ns

SU, DAT

0.6 μs

SU, STA

0.6 μs

SU, STO

0 0.9 μs

HD, DAT

0.6 μs

HD, STA

t

1.3 μs

BUF

B

Figure 16

= I

L2BIT

L3BIT

V

/250 4.3 μA

ALS

= I

/2000 0.54 μA

ALS

= 3.6 V, V

IN

rising 0.92 × VIN V

OUT

falling 0.55 × VIN V

OUT

= 3.6 V 0.6 V

IN

= 3.6 V 1.30 V

IN

= 0.8 × VIN 2.5 3.75 5.5 mA

OUT

= 0 V, Bit nSTBY = 0 1.5 μA

OUT

400 pF

Typical Performance Characteristics

Typical Performance Characteristics

Rev. 0 | Page 4 of 52

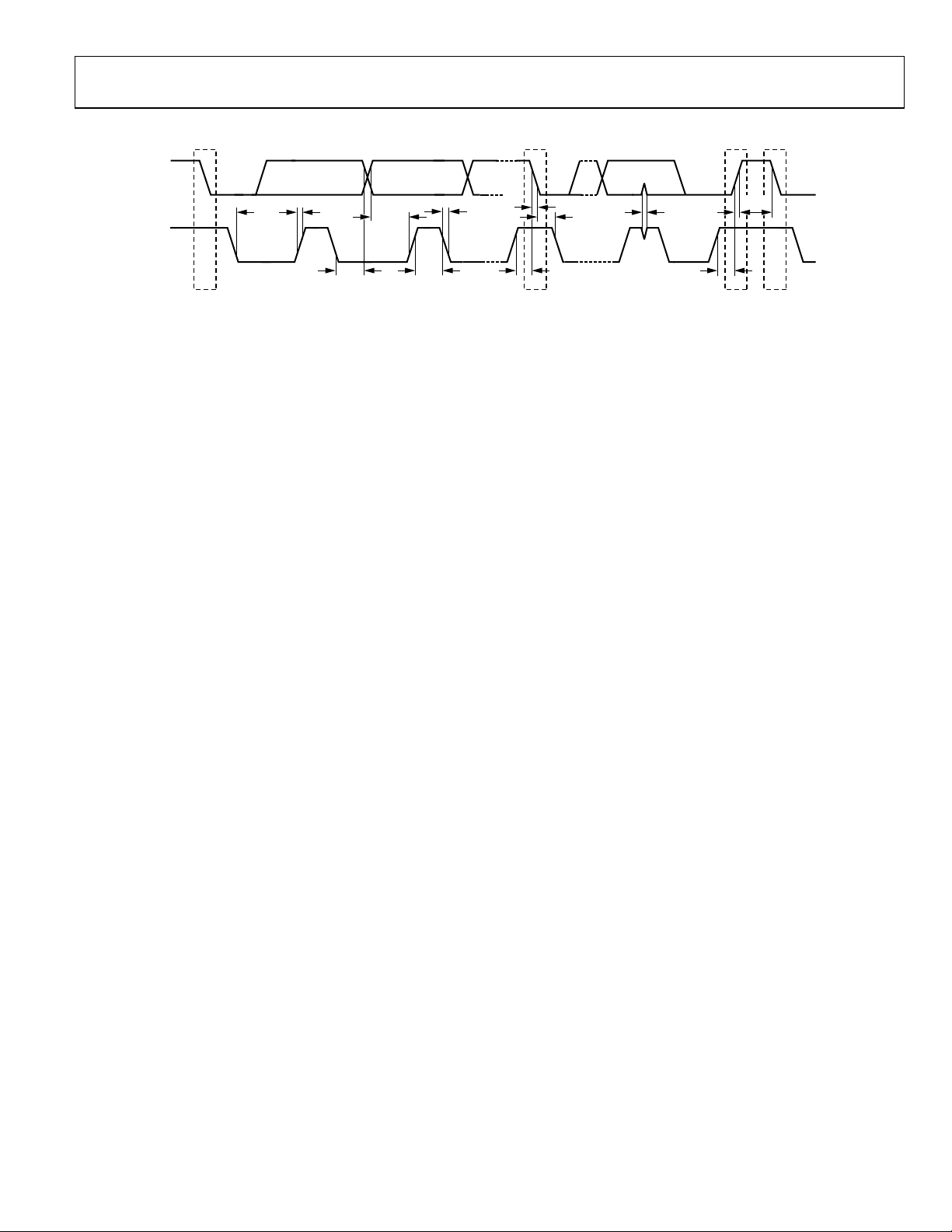

ADP8860

SDA

I2C TIMING DIAGRAM

t

t

LOW

SCL

S

S = START CONDITION

Sr = REPEATED ST ART CONDITI ON

P = STOP CONDITION

t

R

t

HD, DAT

t

SU, DAT

t

HIGH

Figure 2. I

t

F

t

F

t

SU, STA

2

C Interface Timing Diagram

Sr

t

HD, STA

t

SP

t

SU, STO

t

R

BUF

P S

07967-002

Rev. 0 | Page 5 of 52

ADP8860

ABSOLUTE MAXIMUM RATINGS

Table 2.

Parameter Rating

VIN, VOUT −0.3 V to +6 V

D1, D2, D3, D4, D5, D6, and D7 −0.3 V to +6 V

CMP_IN −0.3 V to +6 V

nINT, nRST, SCL, and SDA −0.3 V to +6 V

Output Short-Circuit Duration Indefinite

Operating Ambient Temperature Range –40°C to +85°C1

Operating Junction Temperature Range –40°C to +125°C

Storage Temperature Range –65°C to +150°C

Soldering Conditions JEDEC J-STD-020

ESD (Electrostatic Discharge)

Human Body Model (HBM) ±2 kV

Charged Device Model (CDM) ±2 kV

1

The maximum operating junction temperature (T

maximum operating ambient temperature (T

Temperature Ranges section for more information.

) supersedes the

J(MAX)

). See the Maximum

A(MAX)

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

Absolute maximum ratings apply individually only, not in

combination. Unless otherwise specified, all voltages are

referenced to GND.

THERMAL RESISTANCE

θJA (junction to air) is specified for the worst-case conditions,

that is, a device soldered in a circuit board for surface-mount

packages. The θ

case) are determined according to JESD51-9 on a 4-layer

printed circuit board (PCB) with natural convection cooling.

For the LFCSP package, the exposed pad must be soldered to

the GND1 and/or GND2 terminal(s) on the board.

Table 3. Thermal Resistance

Package Type θJA θ

WLCSP 48 9 N/A °C/W

LFCSP_VQ 49.5 N/A 5.3 °C/W

1

N/A means not applicable.

ESD CAUTION

, θJB (junction to board), and θJC (junction to

JA

1

θ

JB

Unit

JC

MAXIMUM TEMPERATURE RANGES

The maximum operating junction temperature (T

supersedes the maximum operating ambient temperature

(T

). Therefore, in situations where the ADP8860 is

A(MAX)

exposed to poor thermal resistance and a high power

dissipation (P

), the maximum ambient temperature may need

D

to be derated. In these cases, the ambient temperature

maximum can be calculated with the following equation:

T

A(MAX)

= T

J(MAX)

− (θJA × P

D(MAX)

)

J(MAX)

)

Rev. 0 | Page 6 of 52

ADP8860

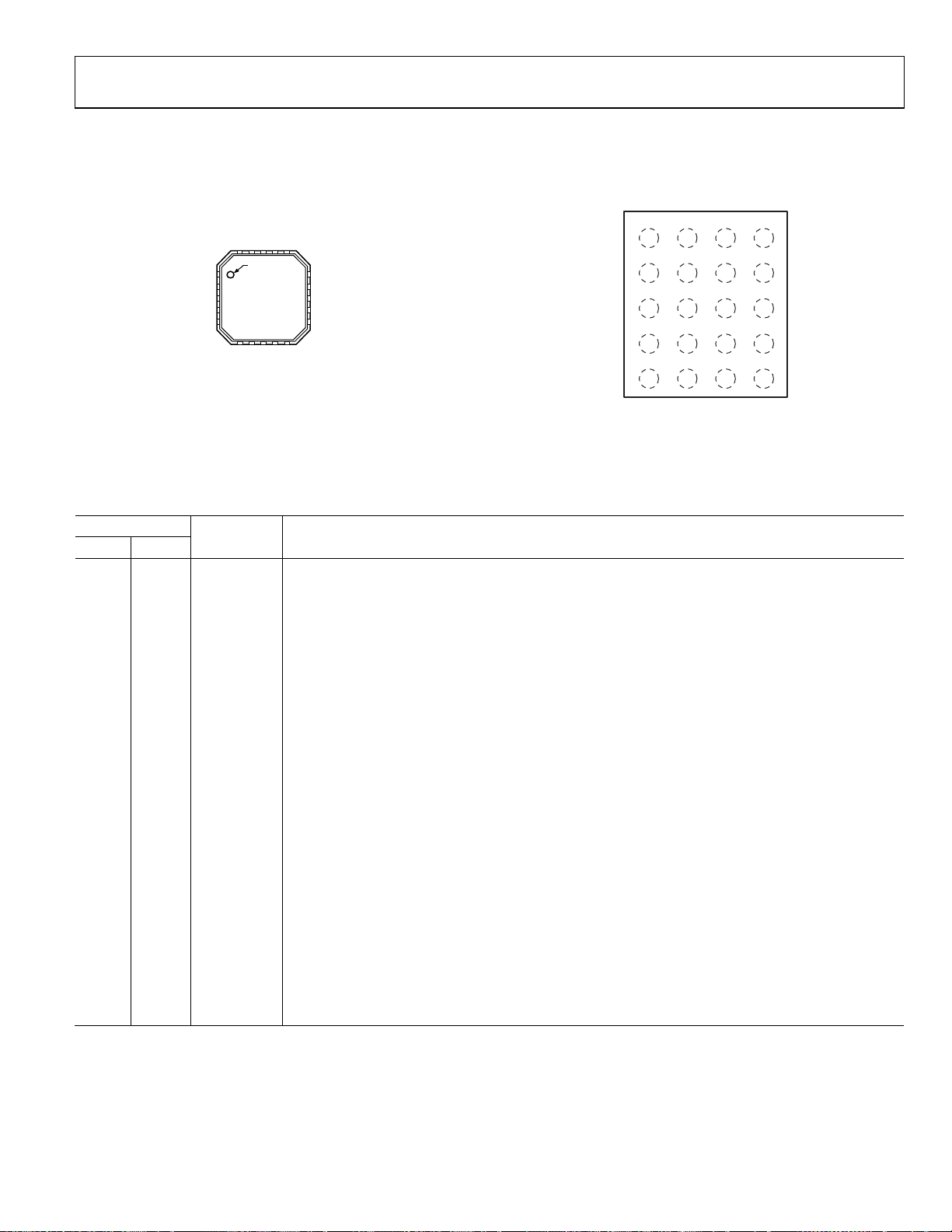

PIN CONFIGURATIONS AND FUNCTION DESCRIPTIONS

ADP8860

234

1

CMP_IN

D5

D4

D6/CMP_IN2

D7

17

16

18

19

20

PIN 1

INDICATO R

1D3

2D2

ADP8860

3D1

TOP VIEW

4SCL

(Not to Scale)

5nRST

8

6

7

ND2

SDA

nINT

NOTES

1. CONNECT THE EXPOSED PADDLE

TO GND1 AND/O R GND2.

G

15 GND1

14 VIN

13 VOUT

12 C2+

11 C1+

9

10

C2–

C1–

Figure 3. LFCSP Pin Configuration

7967-003

C1+

A

C2+

B

C1–

C

GND2

D

nRST

E

(BALL SIDE DOW N)

Figure 4. WLCSP Pin Configuration

Table 4. Pin Function Descriptions

Pin No.

Mnemonic Description LFCSP WLCSP

14 A3 VIN Input Voltage 2.5 V to 5.5 V.

3 D3 D1 LED Sink 1.

2 E3 D2 LED Sink 2.

1 E4 D3 LED Sink 3.

20 D4 D4 LED Sink 4.

19 C4 D5 LED Sink 5.

17 B4 D6/CMP_IN2 LED Sink 6/Comparator Input for Second Phototransistor. When using this pin as a second

phototransistor input, a capacitor (0.1 μF recommended) must be connected from this pin to ground.

16 B3 D7 LED Sink 7.

18 C3 CMP_IN Comparator Input for Phototransistor. When using this function, a capacitor (0.1 μF recommended) must

be connected from this pin to ground.

13 A2 VOUT Charge Pump Output.

11 A1 C1+ Charge Pump C1+.

9 C1 C1−

Charge Pump C1−.

12 B1 C2+ Charge Pump C2+.

10 B2 C2− Charge Pump C2−.

15 A4 GND1 Ground. Connect the exposed pad to GND1 and/or GND2.

8 D1 GND2 Ground. Connect the exposed pad to GND1 and/or GND2.

6 D2 nINT Processor Interrupt (Active Low). Requires an external pull-up resistor. If this pin is not used, it can be left

floating.

5 E1 nRST Hardware Reset (Active Low). This bit resets the device to the default conditions. If not used, this pin

must be tied above V

IH(MIN)

.

7 C2 SDA I2C Serial Data. Requires an external pull-up resistor.

4 E2 SCL I2C Clock. Requires an external pull-up resistor.

VIN

GND1VOUT

D7

C2–

SDA

nINT D4

TOP VIEW

Not to Scale

CMP_IN2

CMP_IN

D1

D2

D6/

D5

D3SCL

07967-004

Rev. 0 | Page 7 of 52

ADP8860

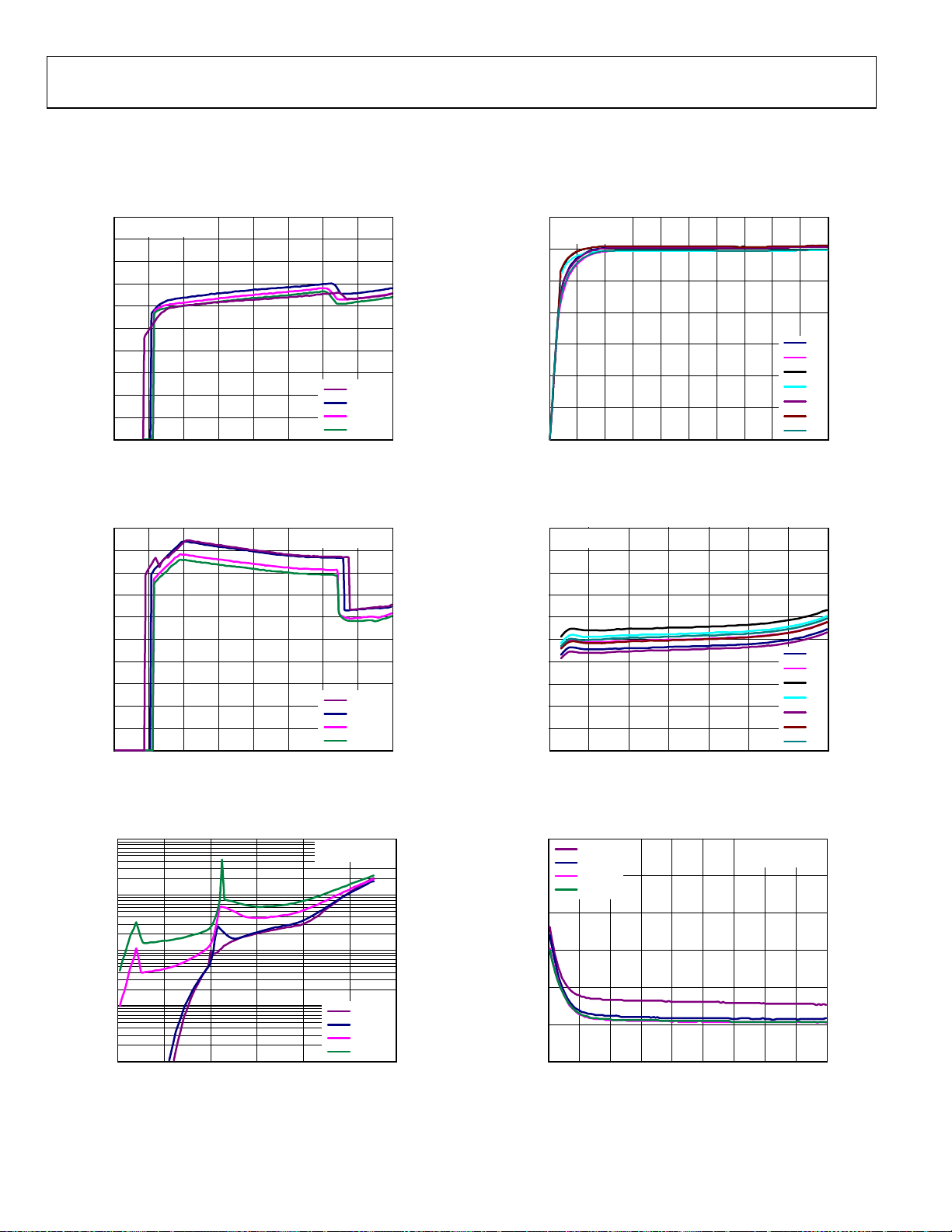

TYPICAL PERFORMANCE CHARACTERISTICS

VIN = 3.6 V, SCL = 2.7 V, SDA = 2.7 V, nRST = 2.7 V, V

otherwise noted.

2.0

I

= NO LOAD

OUT

1.8

1.6

1.4

1.2

1.0

(mA)

Q

I

0.8

0.6

0.4

0.2

0

1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0 5.5

VIN (V)

Figure 5. Typical Operating Current, G = 1×

5.0

4.5

4.0

3.5

3.0

2.5

(mA)

Q

I

2.0

1.5

1.0

0.5

0

1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0 5.5

VIN (V)

Figure 6. Typical Operating Current, G = 2×, I

10

1

–40°C

+25°C

+85°C

+105°C

I

= NO LOAD

OUT

–40°C

+25°C

+85°C

+105°C

Q(ACTIVE)

SCL = SDA = 0V

nRST = 2. 7V

= 0.4 V, CIN = 1 μF, C1 = 1 μF, C2 = 1 μF, C

D1:D7

35

VIN = 3.6V

I

D1:D7

30

25

20

(mA)

OUT

15

I

10

5

0

0 0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8 2.0

07967-100

Figure 8. Typical Diode Current vs. Current Sink Headroom Voltage (VHR)

35

V

D1:D7

34

33

32

31

(mA)

30

OUT

I

29

28

27

26

25

2.0 5.52.5 3.0 3.5 4.0 4.5 5.0

07967-101

6

5

4

= 1 μF, TA= 25°C, unless

OUT

= 30mA

VHR (V)

= 0.4V

VIN (V)

Figure 9. Typical Diode Matching vs. VIN

–40°C

+25°C

+85°C

+105°C

VIN = 3.6V

I

D1:D7

D1

D2

D3

D4

D5

D6

D7

07967-103

D1

D2

D3

D4

D5

D6

D7

07967-104

= 30mA

(µA)

Q

I

0.01

0.001

0.1

–40°C

+25°C

+85°C

+105°C

10 23456

VIN (V)

07967-102

Figure 7. Typical Standby IQ

Rev. 0 | Page 8 of 52

3

MISMATCH (%)

2

1

0

0.2 2.01.81.61.41.21.00.80.60.4

VHR (V)

07967-105

Figure 10. Typical Diode Matching vs. Current Sink Headroom Voltage (VHR)

ADP8860

35

VIN = 3.6V

= 30mA

I

D1:D7

30

25

20

(mA)

OUT

15

I

10

5

0

00.2 2.01.81.61.41.21.00. 80. 60. 4

(V)

V

HR

–40°C

+25°C

+85°C

+105°C

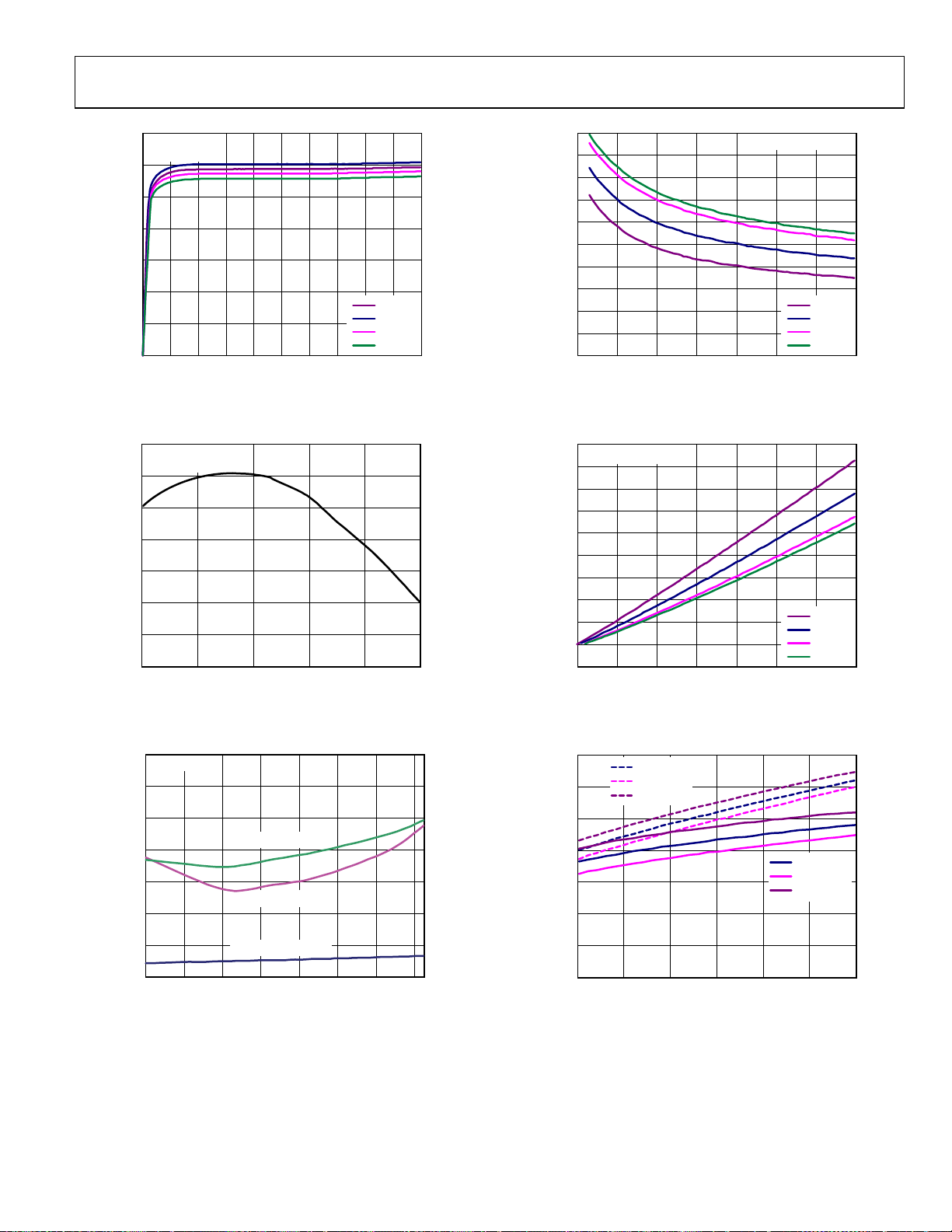

Figure 11. Typical Diode Current vs. Current Sink Headroom Voltage (VHR)

1

VIN = 3.6V

V

= 0.40V

D1:D7

0

–1

–2

–3

DEVIATION (%)

OUT

I

–4

–5

–6

–40 –10 20 50 80 110

JUNCTION TEM PERATURE (°C)

Figure 12. Typical Change In Diode Current vs. Temperature

7

I

= 100mA

OUT

6

5

4

(Ω)

OUT

3

R

2

G = 2× @ V

G = 1.5× @ V

= 2.5V

IN

IN

= 3V

07967-106

07967-107

1.0

0.9

0.8

0.7

0.6

(Ω)

0.5

OUT

R

0.4

0.3

0.2

0.1

0

2.0 2.5 3.0 3.5 4. 0 4.5 5.0 5.5

VIN (V)

I

OUT

Figure 14. Typical ROUT (G = 1×) vs. VIN

10

V

= 80% OF V

OUT

9

8

7

6

(mA)

5

OUT

I

4

3

2

1

0

2.0 2.5 3.0 3.5 4. 0 4.5 5.0 5.5

IN

VIN (V)

Figure 15. Typical Soft Start Current, ISS

1.4

1.2

1.0

0.8

0.6

THRESHOLD (V)

0.4

VIH = +25°C

VIH = +85°C

VIH = –40°C

= 100mA

–40°C

+25°C

+85°C

+105°C

07967-109

–40°C

+25°C

+85°C

+105°C

07967-110

VIL = +25°C

VIL = +85°C

VIL = –40°C

1

0

–40 –20 0 20 40 60 80 100

G = 1× @ V = 3.6V

TEMPERATURE (°C)

Figure 13. R

IN

vs. Temperature

OUT

07967-108

Rev. 0 | Page 9 of 52

0.2

0

2.5 3.0 3.5 4.0 4.5 5.0 5.5

VIN (V)

Figure 16. Typical I2C Thresholds, VIH and VIL

07967-111

ADP8860

1.4

1.3

1.2

1.1

(mA)

ALS

1.0

I

0.9

0.8

0.7

5.5

VIN = 3V

GAIN = 2×

5.4

I

OUT

5.3

5.2

5.1

(V)

5.0

OUT

V

4.9

4.8

4.7

4.6

4.5

Figure 18. Typical Regulated Output Voltage (V

6.0

5.8

(V)

5.6

OUT

V

–40°C

+25°C

+85°C

+105°C

3.02.5 3.5 4.0 4.5 5. 0 5.5

Figure 17. Typical ALS Current, I

V

(V)

IN

ALS

= 10mA

–10–40 20 50 80 110

JUNCTION TEMPERATURE (°C)

OUT(REG)

OVP THRESHOLD

0.9

0.8

0.7

0.6

0.5

0.4

EFFICIENCY (%)

0.3

0.2

I

0.1

0

2.5 5.55.04. 54. 03. 53. 0

07967-112

= 140mA, Vf = 3. 1V

OUT

I

= 210mA, Vf = 3. 2V

OUT

VIN (V)

450

400

350

300

250

200

150

100

50

0

(mA)

IN

I

07967-115

Figure 20. Typical Efficiency (Low Vf Diode)

1.0

0.9

0.8

0.7

0.6

0.5

0.4

EFFICIENCY (%)

0.3

0.2

I

= 140mA, Vf = 3. 85V

OUT

0.1

I

= 210mA, Vf = 4. 25V

OUT

0

2.5 5.55.04.54.03.53.0

07967-113

)

Figure 21. Typical Efficiency (High Vf Diode)

VIN (V)

450

400

350

300

250

200

150

100

50

0

(mA)

IN

I

07967-116

T

1

2

VIN (AC-COUPLED) 50mV/DIV

V

(AC-COUPLED) 50mV/DIV

OUT

5.4

OVP RECOVERY

5.2

–10–40 20 50 80 110

JUNCTION TEMPERATURE (°C)

Figure 19. Typical Overvoltage Protection (OVP) Threshold

07967-114

Rev. 0 | Page 10 of 52

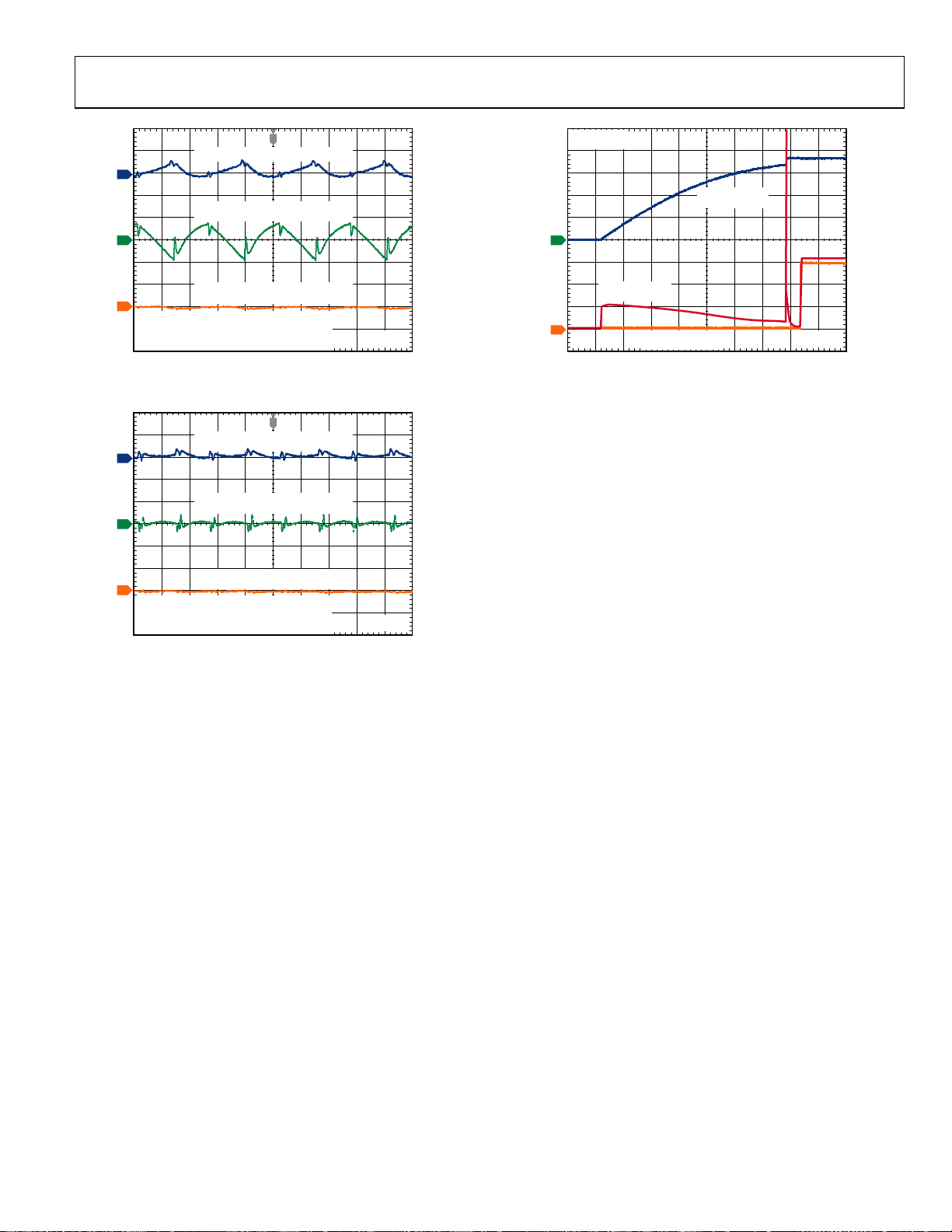

3

CIN = 1µF, C

V

I

OUT

IN

= 3.6V

= 120mA

IIN (AC-COUPLED) 10mA/ DIV

= 1µF, C1 = 1µF, C2 = 1µF

OUT

Figure 22. Typical Operating Waveforms, G = 1×

500ns/DIV

07967-117

ADP8860

2

VIN = 3.7V

V

(1V/DIV)

OUT

T

VIN (AC-COUPLED) 50mV /DIV

1

V

(AC-COUPLED) 50mV/DIV

OUT

2

3

C

= 1µF, C

IN

= 3.0V

V

IN

= 120mA

I

OUT

IIN (AC-COUPLED) 10mA/ DIV

= 1µF, C1 = 1µF, C2 = 1µF

OUT

Figure 23. Typical Operating Waveforms, G = 1.5×

T

VIN (AC-COUPLED) 50mV /DIV

1

V

(AC-COUPLED) 50mV/DIV

OUT

2

3

CIN = 1µF, C

= 2.5V

V

IN

= 120mA

I

OUT

IIN (AC-COUPLED) 10mA/ DIV

= 1µF, C1 = 1µF, C2 = 1µF

OUT

Figure 24. Typical Operating Waveforms, G = 2×

500ns/DIV

500ns/DIV

IIN (10mA/DIV)

4

07967-118

I

OUT

(10mA/DIV)

100µs/DIV

07967-120

Figure 25. Typical Start-Up Waveform

07967-119

Rev. 0 | Page 11 of 52

ADP8860

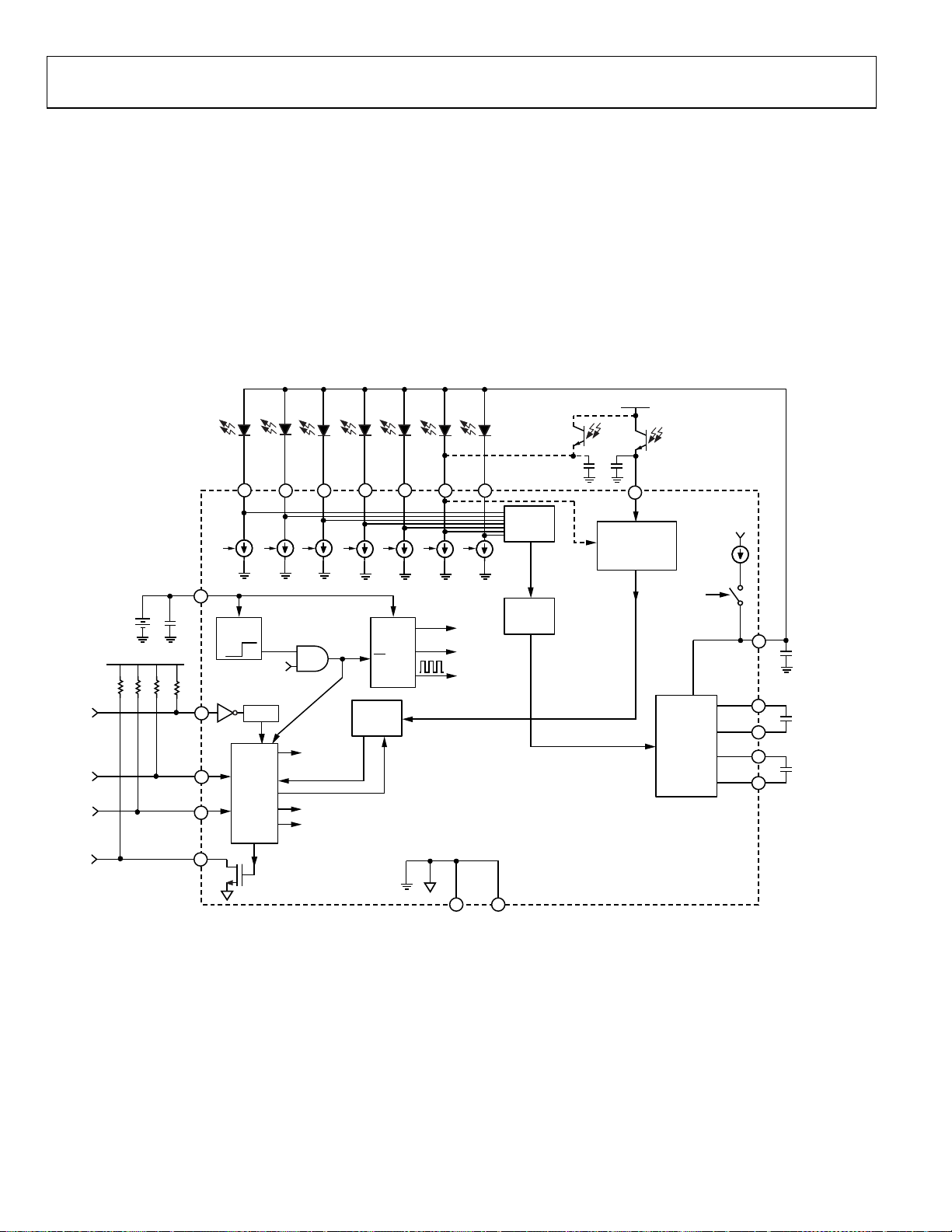

THEORY OF OPERATION

The ADP8860 combines a programmable backlight LED charge

pump driver with automatic phototransistor control. This combination allows for significant power savings because it is able to

change the current intensity based on the lighting conditions. It

performs this function automatically thereby removing the

need for a processor to monitor the phototransistor. The light

intensity levels are fully programmable via the I

second phototransistor input, with dedicated comparators,

improves the ambient light detection abilities for various useroperating conditions.

2

C interface. A

The ADP8860 allows up to seven LEDs to be independently

driven up to 30 mA (typical). The seventh LED can also be

driven to 60 mA (typical). All LEDs can be individually programmed or combined into a group to operate backlight LEDs.

A full set of safety features including short-circuit, overvoltage,

and overtemperature protection with input-to-output isolation

allow for a robust and safe design. The integrated soft start

limits inrush currents at startup, restart attempts, and gain

transitions.

V

ALS

OPTIONAL

PHOTOSENSOR

VBAT

VDDIO

nRST

SCL

SDA

nINT

D1

50µs

ID2

UVLO

D2E3D3

E4

ID3

STNDBY

SWITCH CONTROL

ILED CONTROL

D3

ID1

A3

C

VIN

IN

STNDBY

NOISE FILTER

E1

RESET

E2

C2

D2

I2C

LOGIC

D4D4D5

ID4 ID5

EN

LIGHT

SENSOR

LOGIC

VIN

ID6

V

I

REFS

REFS

D6B4D7

ID7

CLK

A4

GND1

B3

GND2

D1

GAIN

SELECT

LOGIC

CHARGE

PUMP

LOGIC

C4

CMP_IN

C3

PHOTOSENSOR

CONVERSION

SOFT START

(1×, 1.5×, 2×)

CHARGE

PUMP

V

IN

I

SS

VOUT

A2

C

OUT

C1+

A1

C1

1µF

C1

C1–

C2+

B1

C2

1µF

B2

C2–

07967-011

Figure 26. Detailed Block Diagram

Rev. 0 | Page 12 of 52

ADP8860

POWER STAGE

Because typical white LEDs require up to 4 V to drive them,

some form of boosting is required over the typical variation in

battery voltage. The ADP8860 accomplishes this with a high

efficiency charge pump capable of producing a maximum I

of 240 mA over the entire input voltage range (2.5 V to 5.5 V).

Charge pumps use the basic principle that a capacitor stores

charge based on the voltage applied to it, as shown in the

following equation:

Q = C × V (1)

By charging the capacitors in different configurations, the

charge, and therefore the gain, can be optimized to deliver

the voltage required to power the LEDs. Because a fixed

charging and discharging combination must be used, only

certain multiples of gain are available. The ADP8860 is capable

of automatically optimizing the gain (G) from 1×, 1.5×, and 2×.

These gains are accomplished with two capacitors (labeled C1

and C2 in Figure 26) and an internal switching network.

In G = 1× mode, the switches are configured to pass VIN

directly to VOUT. In this mode, several switches are connected

in parallel to minimize the resistive drop from input to output.

In G = 1.5× and 2× modes, the switches alternatively charge

from the battery and discharge into the output. For G = 1.5×,

the capacitors are charged from VIN in series and are discharged

to VOUT in parallel. For G = 2×, the capacitors are charged

OUT

from VIN in parallel and are discharged to VOUT in parallel. In

certain fault modes, the switches are opened and the output is

physically isolated from the input.

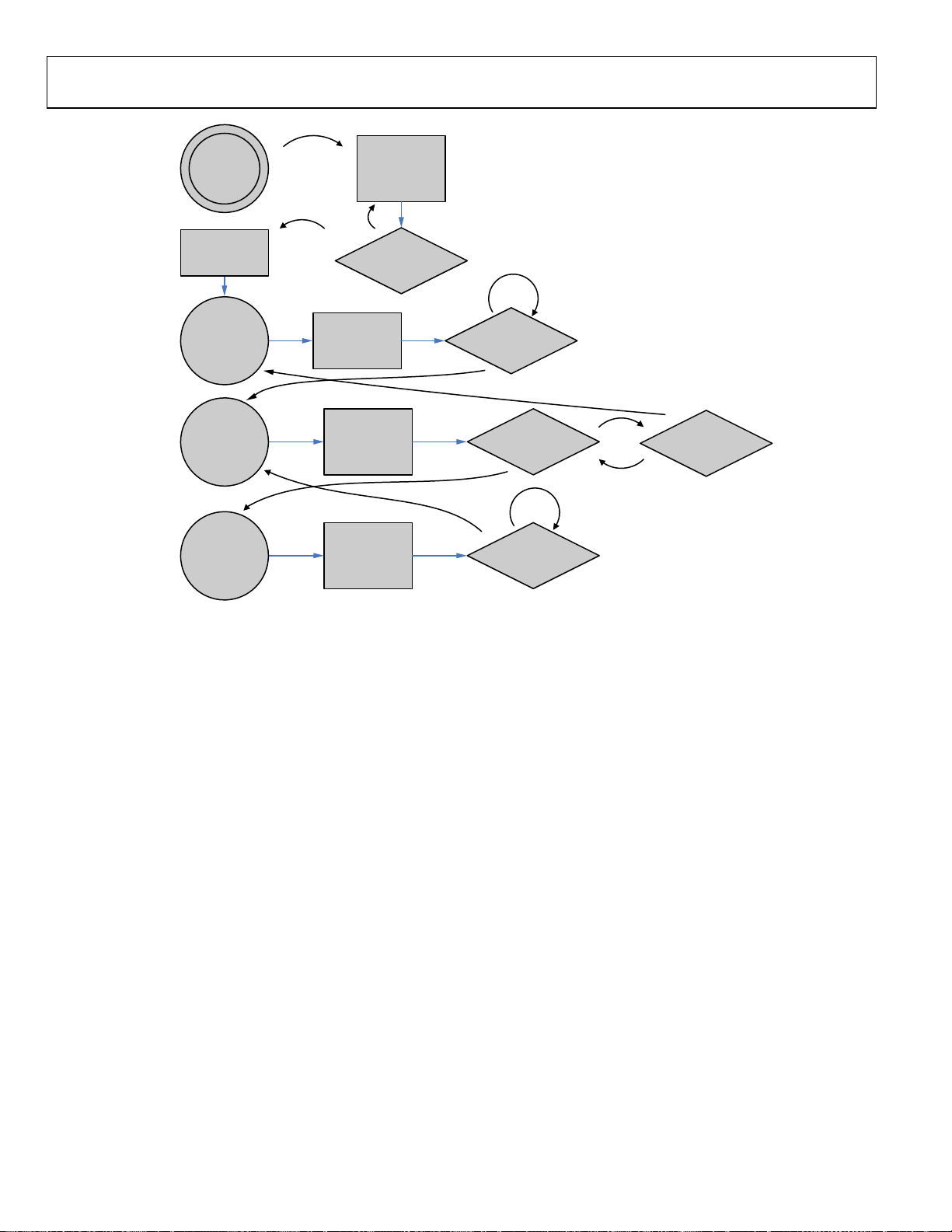

Automatic Gain Selection

Each LED that is driven requires a current source. The voltage

on this current source must be greater than a minimum headroom voltage (200 mV typical) to maintain accurate current

regulation. The gain is automatically selected based on the

minimum voltage (V

) at all of the current sources. At startup,

Dx

the device is placed into G = 1× mode and the output charges

to V

. If any VDx level is less than the required headroom

IN

(200 mV), the gain is increased to the next step (G = 1.5×).

A 100 s delay is allowed for the output to stabilize prior to

the next gain switching decision. If there remains insufficient

current sink headroom, then the gain is increased again to 2×.

Conversely, to optimize efficiency, it is not desirable for the

output voltage to be too high. Therefore, the gain reduces when

the headroom voltage is great enough. This point (labeled

V

in Figure 27) is internally calculated to ensure that the

DMAX

lower gain still results in ample headroom for all the current

sinks. The entire cycle is illustrated in Figure 27.

Note that the gain selection criteria apply only to active current

sources. If current sources have been deactivated through an

2

I

C command (for example, only five LEDs are used), then the

voltages on the deactivated current sources are ignored.

Rev. 0 | Page 13 of 52

ADP8860

V

V

0

VOUT > V

WAIT

WAIT

100µs (TYP)

WAIT

100µs (TYP)

STATUP:

CHARGE

TO V

IN

OUT(START)

OUT

STBY

EXIT

STARTUP

G = 1

G = 3/2

G = 2

NOTES

1.

IS THE CALCULATED GAIN DOWN TRANSITI ON POINT.

DMAX

EXIT STBY

1

100µs (TYP)

1

Figure 27. State Diagram for Automatic Gain Selection

Soft Start Feature

At startup (either from UVLO activation or fault/standby

recovery), the output is first charged by I

until it reaches about 92% of V

. This soft start feature reduces

IN

(3.75 mA typical)

SS

the inrush current that is otherwise present when the output

capacitance is initially charged to V

. When this point is

IN

reached, the controller enters 1× mode. If the output voltage is

not sufficient, then the automatic gain selection determines the

optimal point as defined in the Automatic Gain Selection section.

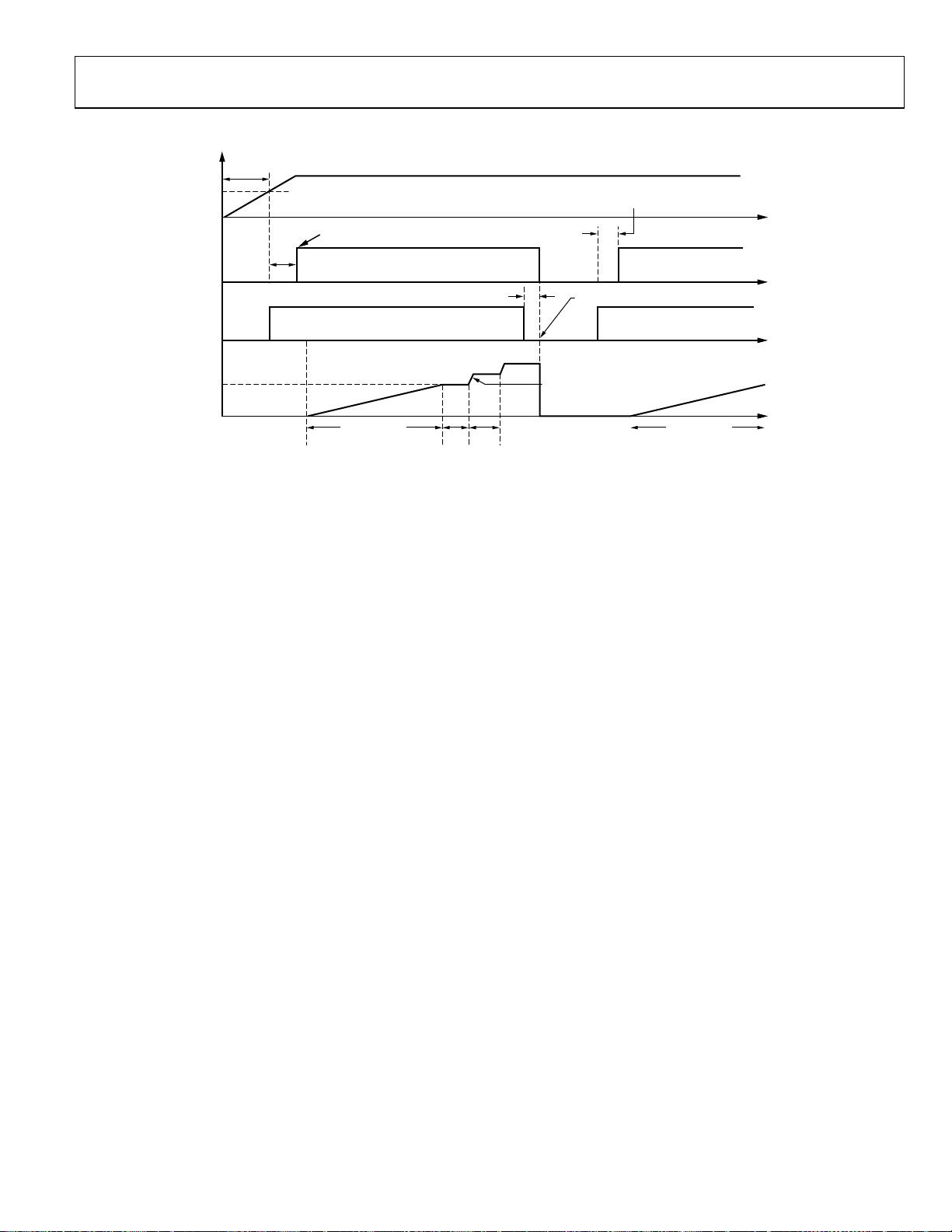

OPERATING MODES

There are four different operating modes: active, standby,

shutdown, and reset.

Active Mode

In active mode, all circuits are powered up and in a fully

operational state. This mode is entered when nSTBY (in

Register MDCR) is set to 1.

Standby Mode

Standby mode disables all circuitry except for the I2C receivers.

Current consumption is reduced to less than 1 A. This mode is

entered when nSTBY is set to 0 or when the nRST pin is held

low for more than 100 s (maximum). When standby is exited,

a soft start sequence is performed.

0

MIN (V

1

1

1

D1:D7

MIN (V

MIN (V

) < V

D1:D7

D1:D7

HR(UP)

) < V

0

) < V

HR(UP)

DMAX

0

MIN (V

0

D1:D7

) > V

DMAX

07967-012

Shutdown Mode

Shutdown mode disables all circuitry, including the I2C receivers.

Shutdown occurs when V

When V

rises above V

IN

is below the undervoltage thresholds.

IN

(2.05 V typical), all registers are

IN(START)

reset and the part is placed into standby mode.

Reset Mode

In reset mode, all registers are set to their default values and the

part is placed into standby. There are two ways to reset the part:

power-on reset (POR) and the nRST pin. POR is activated anytime that the part exits shutdown mode. After a POR sequence

is complete, the part automatically enters standby mode.

After startup, the part can be reset by pulling the nRST pin low.

As long as the nRST pin is low, the part is held in a standby state

2

but no I

C commands are acknowledged (all registers are kept

at their default values). After releasing the nRST pin, all registers

remain at their default values, and the part remains in standby;

however, the part does accept I

2

C commands.

The nRST pin has a 50 s (typical) noise filter to prevent inadvertent activation of the reset function. The nRST pin must be

held low for this entire time to activate reset.

The operating modes function according to the timing diagram

in Figure 28.

Rev. 0 | Page 14 of 52

ADP8860

SHUTDOWN

V

nSTBY

nRST

IN

VIN CROSSES ~2.05V AND TRIGG ERS POWER O N RESET

BIT nSTBY IN REGISTER

MDCR GOES HIGH

~100µs DELAY BET WEEN POWER UP AND

2

C COMMANDS CAN BE RECEIV ED

WHEN I

25µs TO 100µ s NOISE F ILTE R

nRST MUST BE HIGH FO R 20µs (MAX)

BEFORE SENDING I

nRST IS LOW, WHICH FORCES nSTBY LOW

AND RESETS ALL I

2

C COMMANDS

2

C REGISTERS

V

OUT

V

IN

~3.75mA CHARGES

V

TO VIN LEVEL

OUT

1×

10µs 100µs

1.5×

2×

GAIN CHANGES ONLY OCCUR WHEN NECESSARY,

BUT HAVE A MIN TI ME BEFORE CHANGING

SOFT STARTSOFT START

7967-013

Figure 28. Typical Timing Diagram

Rev. 0 | Page 15 of 52

ADP8860

BACKLIGHT OPERATING LEVELS

Backlight brightness control operates in three distinct levels:

daylight (L1), office (L2), and dark (L3). The BLV bits in

Register 0x04 control the specific level in which the backlight

operates. These bits can be changed manually, or if in automatic

mode (CMP_AUTOEN is set high in Register 0x01), by the

ambient light sensor (see the Ambient Light Sensing section).

DAYLIGHT (L1) O FFICE ( L2) DARK (L 3)

30mA

DAYLIGHT_M AX

OFFICE _MAX

HT CURRENT

DAYLIGHT_DIM

BACKLIG

0

BACKLIGHT O PERATING LEVEL S

Figure 29. Backlight Operating Levels

By default, the backlight operates at daylight level (BLV = 00),

where the maximum brightness is set using Register 0x09

(BLMX1). A daylight dim setting can also be set using

Register 0x0A (BLDM1). When operating at office level (BLV =

01), the backlight maximum and dim brightness settings are set

by Register 0x0B (BLMX2) and Register 0x0C (BLDM2). When

operating at the dark level (BLV = 10), the backlight maximum

and dim brightness settings are set by Register 0x0D (BLMX3)

and Register 0x0E (BLDM3).

DARK_MAX

OFFICE_DIM

DARK_DIM

07967-014

Rev. 0 | Page 16 of 52

ADP8860

BACKLIGHT MAXIMUM AND DIM SETTINGS

The backlight maximum and dim current settings are determined by a 7-bit code programmed by the user into the

registers previously listed in the Backlight Operating Levels

section. The 7-bit resolution allows the user to set the backlight

to one of 128 different levels between 0 mA and 30 mA. The

ADP8860 can implement two distinct algorithms to achieve a

linear and a nonlinear relationship between input code and

backlight current. The law bits in Register 0x04 are used to

change between these algorithms.

By default, the ADP8860 uses a linear algorithm (law = 00),

where the backlight current increases linearly for a

corresponding increase of input code. Backlight current (in

millamperes) is determined by the following equation:

Backlight Current (mA) = Code × (Full-Scale Current/127) (2)

where:

Code is the input code programmed by the user.

Full-Scale Current is the maximum sink current allowed per

LED (typically 30 mA).

The ADP8860 can also implement a nonlinear (square approximation) relationship between input code and backlight current

level. In this case (law = 01), the backlight current (in

milliamperes) is determined by the following equation:

2

⎛

⎜

)mA(

×=

CodeCurrentBacklight

⎜

−

CurrentScaleFull

127

Figure 30 shows the backlight current level vs. input code for

both the linear and square law algorithms.

30

⎞

⎟

⎟

⎠⎝

(3)

Table 5. Available Fade In and Fade Out Rates

Code Fade Rate (in sec per Full-Scale Current)

0000 0.1 (disabled)

0001 0.3

0010 0.6

0011 0.9

0100 1.2

0101 1.5

0110 1.8

0111 2.1

1000 2.4

1001 2.7

1010 3.0

1011 3.5

1100 4.0

1101 4.5

1110 5.0

1111 5 . 5

The fade profile is based on the transfer law selected (linear,

square, Cubic 10, or Cubic 11) and the delta between the actual

current and the target current. Smaller changes in current

reduce the fade time. For linear and square law fades, the fade

time is given by

Fade Time = Fade Rate × (Code/127) (4)

where the Fade Rate is shown in Tabl e 5 .

The Cubic 10 and Cubic 11 laws also use the square backlight

currents in Equation 3; however, the time between each step is

varied to produce a steeper slope at higher currents and a

shallower slope at lighter currents (see Figure 31).

30

25

20

15

10

BACKLIGHT CURRENT (mA)

5

0

0 32 64 96 128

LINEAR

SQUARE

SINK CODE

Figure 30. Backlight Current vs. Input Code

07967-015

AUTOMATED FADE IN AND FADE OUT

The LED drivers are easily configured for automated fade in

and fade out. Sixteen fade in and fade out rates can be selected

via the I

0.1 sec to 5.5 sec (per full-scale current, either 30 mA or 60 mA).

2

C interface. Fade in and fade out rates range from

Rev. 0 | Page 17 of 52

25

LINEAR

20

15

CURRENT (mA)

10

5

0

010.750.500.25

Figure 31. Comparison of the Dimming Transfers Laws

SQUARE

UNIT FADE TIME

CUBIC 11

CUBIC 10

.00

07967-016

BACKLIGHT TURN ON/TURN OFF/DIM

With the device in active mode (nSTBY = 1), the backlight can

be turned on using the BL_EN bit in Register 0x01. Before

turning on the backlight, the user chooses which level (daylight

(L1), office (L2), or dark (L3)) in which to operate, and ensures

that maximum and dim settings are programmed for that level.

ADP8860

The backlight turns on when BL_EN = 1. The backlight turns

off when BL_EN = 0.

BACKLIGHT

CURRENT

MAX

BL_EN = 1 BL_EN = 0

7967-017

Figure 32. Backlight Turn On/Off

While the backlight is on (BL_EN = 1), the user can change to

the dim setting by programming DIM_EN = 1 in Register 0x01.

If DIM_EN = 0, the backlight reverts to its maximum setting.

BACKLIGHT

CURRENT

MAX

DIM

BL_EN = 1

DIM_EN = 1 DIM_EN = 0 BL_EN = 0

7967-018

Figure 33. Backlight Turn On/Dim/Turn Off

The maximum and dim settings can be set between 0 mA and

30 mA; therefore, it is possible to program a dim setting that is

greater than a maximum setting. For normal expected operation, ensure that the dim setting is programmed to be less than

the maximum setting.

BACKLIGHT

CURRENT

MAX

DIM

DIM TIMER

RUNNING

BL_EN = 1 BL_EN = 0DIM_EN = 1 DIM_EN = 0 DIM_EN = 1

SET BY USER

SET BY INTERNAL STATEMACHINE

DIM TIMER

RUNNING

Figure 34. Dim Timer

If the user clears the DIM_EN bit, the backlight reverts to its

maximum setting and the dim timer begins counting again.

When the dim timer expires, the internal state machine again

sets DIM_EN = 1, and the backlight enters its dim setting. The

backlight can be turned off at any point during the dim timer

countdown by clearing BL_EN.

The user can also program the backlight to turn off automatically by using the OFFT timer in Register 0x06. The off timer

has 127 settings ranging from 1 sec to 127 sec. Program the off

timer (OFFT) before turning on the backlight. If BL_EN = 1,

the backlight turns on to its maximum setting and the off timer

starts counting. When the off timer expires, the internal state

machine clears the BL_EN bit, and the backlight turns off.

BACKLIGHT

CURRENT

MAX

OFF TIMER

RUNNING

7967-019

AUTOMATIC DIM AND TURN OFF TIMERS

The user can program the backlight to dim automatically by

using the DIMT timer in Register 0x07. The dim timer has 127

settings ranging from 1 sec to 127 sec. Program the dim timer

(DIMT) before turning on the backlight. If BL_EN = 1, the

backlight turns on to its maximum setting and the dim timer

starts counting. When the dim timer expires, the internal state

machine sets DIM_EN = 1, and the backlight enters its dim

setting.

Rev. 0 | Page 18 of 52

SET BY USER

SET BY INTERNAL STATE MACHINE

BL_EN = 1 BL _EN = 0

07967-020

Figure 35. Off Timer

The backlight can be turned off at any point during the off

timer countdown by clearing BL_EN.

The dim timer and off timer can be used together for sequential

maximum-to-dim-to-off functionality. With both the dim and

off timers programmed, if BL_EN is asserted, the backlight

turns on to its maximum setting, and when the dim timer

expires, the backlight changes to its dim setting. When the off

timer expires, the backlight turns off.

ADP8860

BACKLIGHT

CURRENT

MAX

DIM

SET BY USER

SET BY INTERNAL STATE MACHINE

DIM TIMER

RUNNING

OFF TIMER

RUNNING

BL_EN = 1 BL_EN = 0DIM_EN = 1

Figure 36. Dim and Off Timers Used Together

FADE OVERRIDE

A fade override feature (FOVR in Register CFGR (0x04)) enables

the host to override the preprogrammed fade in or fade out

settings. If FOVR is set and the backlight is enabled in the

middle of a fade out process, the backlight instantly (within

approximately 100 ms) returns to its maximum setting. Alternatively, if the backlight is fading in, reasserting BL_EN overrides

the programmed fade in time and the backlight instantly goes

to its final fade value. This is useful for situations where a key

is pressed during a fade sequence. However, if FOVR is cleared

and the backlight is enabled in the middle of a fade process, the

backlight gradually brightens from where it was interrupted (it

does not go down to 0 and then come back on).

BACKLIGHT

CURRENT

MAX

FADE-IN

OVER-RIDDEN

FADE-OUT

OVER-RIDDEN

07967-021

These comparators have two programmable trip points (L2 and

L3) that select among three of the backlight operation modes

(daylight, office, and dark) based on the ambient lighting

conditions.

The L3 comparator controls the dark-to-office mode transition.

The L2 comparator controls the office-to-daylight transition

(see Figure 38). The currents for the different lighting modes

are defined in the BLMXx and BLDMx registers (see the

Backlight Operating Levels section).

L2_OUT = 1

L3_OUT = 1

0 LUX

0A

DARK OFFICE DAYLIGHT

Figure 38. Light Sensor Modes Based on the Detected Ambient Light Level

L2_OUT = 1

L3_OUT = 0

L3 L2

BRIGHTNESS

L2_OUT = 0

L3_OUT = 0

07967-023

Each light sensor comparator uses an external capacitor together

with an internal reference current source to form an analog-todigital converter (ADC) that samples the output of the external

photosensor. The ADC result is fed into two programmable trip

comparators. The ADC has an input range of 0 µA to 1080 µA

(typical).

L2_EN

L2_TRIP

L2_HYS

L2_OUT

BL_EN = 1 BL_EN = 0 BL_EN = 1 BL_ EN = 0BL_EN = 1

(RE-ASSERTED)

Figure 37. Fade Override Function (FOVR is High)

AMBIENT LIGHT SENSING

The ADP8860 integrates two ambient light sensing comparators.

One of the ambient light sensing comparator pins (CMP_IN)

is always available. The second pin (D6/CMP_IN2) can be

activated rather than connecting an LED to D6. Activating

the CMP_IN2 function of the pin is accomplished through

Bit CMP2_SEL in Register CFGR. Therefore, when Bit CMP2_SEL

is set to 0, Pin D6/CMP_IN2 is programmed as a current sink.

When Bit CMP2_SEL is set to 1, Pin D6/CMP_IN2 becomes

the input for a second phototransistor.

Rev. 0 | Page 19 of 52

FILTER

PHOTO

SENSOR

OUTPUT

07967-022

ADC

Figure 39. Ambient Light Sensing and Trip Comparators

SETTINGS

L3_TRIP

L3_HYS

L3_EN

L3_OUT

07967-024

The L2_CMPR detects when the photosensor output has dropped

below the programmable L2_TRP point (Register 0x1D). If this

event occurs, then the L2_OUT status signal is set. L2_CMPR

contains programmable hysteresis, meaning that the photosensor output must rise above L2_TRP + L2_HYS before

L2_OUT clears. L2_CMPR is enabled via the L2_EN bit. The

L2_TRP and L2_HYS values of L2_CMPR can be set between

0 µA and 1080 µA (typical) in steps of 4.3 µA (typical).

The L3_CMPR detects when the photosensor output has

dropped below the programmable L3_TRP point (Register 0x1F).

If this event occurs, the L3_OUT status signal is set. L3_CMPR

ADP8860

contains programmable hysteresis, meaning that the photosensor output must rise above L3_TRP + L3_HYS before

L3_OUT clears. L3_CMPR is enabled via the L3_EN bit. The

L3_TRP and L3_HYS values of L3_CMPR can be set between

0 µA and 137.7 µA (typical) in steps of 0.54 µA (typical).

L2_TRP

L2_HYS

L3_TRP

L3_HYS

1 10 100 1000

ADC RANGE (µA)

Figure 40. Comparator Ranges

Note that the full-scale value of the L2_TRP and L2_HYS

registers is 250 (decimal). Therefore, if the value of L2_TRP +

L2_HYS exceeds 250, the comparator output is unable to

deassert. For example, if L2_TRP is set at 204 (80% of the fullscale value, or approximately 0.80 × 1080 A = 864 A), then

L2_HYS must be set at less than 46 (250 − 204 = 46). If it is not,

then the L2_HYS + L2_TRP exceeds 250 and the L2_CMPR

comparator is never allowed to go low.

When both phototransistors are enabled and programmed

in automatic mode (through Bit L3_EN and Bit L2_EN in

Register 0x1B and Register 0x1C), the user application needs

to determine which of the comparator outputs to use, selecting

Bit SEL_AB in Register 0x04 for automatic light sensing

transitions. For example, the user’s software may select the

comparator of the phototransistor exposed to higher light

intensity to control the transition between the programmed

backlight intensity levels.

The L2_CMPR and L3_CMPR comparators can be enabled

independently of each other, or can operate simultaneously. A

single conversion from each ADC takes 80 ms (typical). When

CMP_AUTOEN is set for automatic backlight adjustment (see

the Automatic Backlight Adjustment section), the ADC and

comparators run continuously. If the backlight is disabled and

at least one independent sink is enabled, it is possible to use the

light sensor comparators in a single shot mode. A single shot

read of the photocomparators is performed by setting the

FORCE_RD bit. After the single shot measurement is completed,

the internal state machine clears the FORCE_RD bit.

The interrupt flags (CMP_INT and CMP_INT2) can be used to

notify the system when either L2 or L3 changes state. Refer to

the Interrupts section for more information.

07967-025

AUTOMATIC BACKLIGHT ADJUSTMENT

The ambient light sensor comparators can automatically

transition the backlight between one of its three operating

levels. To enable this mode, set the CMP_AUTOEN bit in

Register 0x01.

When enabled, the internal state machine takes control of the

BLV bits and changes them based on the L2_OUT and L3_OUT

status bits. When L2_OUT is set high, it indicates that the

ambient light conditions have dropped below the L2_TRP point

and the backlight should move to its office (L2) level. When

L3_OUT is set high, it indicates that ambient light conditions

have dropped below the L3_TRP point and the backlight should

move to its dark (L3) level. Tabl e 6 shows the relationship

between backlight operation and the ambient light sensor

comparator outputs.

The L3_OUT status bit has greater priority; therefore, the

backlight operates at L3 (dark) even if L2_OUT is set.

Filter times of between 80 ms and 10 sec can be programmed

for the comparators (Register 0x1B and Register 0x1C) before

they change state.

Table 6. Comparator Output Truth Table

CMP_AUTOEN L3_OUT L2_OUT Backlight Operation

0 X1 X

1 0 0 BLV = 00, backlight

1 0 1 BLV = 01, backlight

1 1 X1 BLV = 10, backlight

1

X is the don’t care bit.

1

BLV can be manually set

by the user

operates at L1 (daylight)

operates at L2 (office)

operates at L3 (dark)

INDEPENDENT SINK CONTROL

Each of the seven LEDs can be configured (in Register 0x05) to

operate as either part of the backlight or to operate as an independent sink current (ISC). Each ISC can be enabled independently

and has its own current level. All ISCs share the same fade in

rates, fade out rates, and fade law.

The ISCs have additional timers to facilitate blinking functions.

A shared on timer (SCON) used in conjunction with the off

timers of each ISC (SC1OFF, SC2OFF, SC3OFF, SC4OFF,

SC5OFF, SC6OFF, and SC7OFF) allow the LED current sinks to

be configured in various blinking modes. The on timer can be

set to four different settings: 0.2 sec, 0.6 sec, 0.8 sec, and 1.2 sec.

The off timers have four different settings: disabled, 0.6 sec,

1.2 sec, and 1.8 sec. Blink mode is activated by setting the off

timers to any setting other than disabled.

Rev. 0 | Page 20 of 52

ADP8860

Program all fade, on, and off timers before enabling any of the

LED current sinks. If ISCx is on during a blink cycle and

SCx_EN is cleared, it turns off (or fades to off if fade out is

enabled). If ISCx is off during a blink cycle and SCx_EN is

cleared, it stays off.

SCx

CURRENT

ON TIME ON TIME

FADE-IN FADE-O UT FADE-IN FADE-OUT

MAX

OFF

TIME

SCx_EN

SET BY USER

Figure 41. Independent Sink Blink Mode with Fading

OFF

TIME

07967-026

SHORT-CIRCUIT PROTECTION MODE

The ADP8860 can protect against short circuits on the output

(VOUT). Short-circuit protection (SCP) is activated at the point

when VOUT < 55% of V

. Note that this SCP sensing is disabled

IN

during both start-up and restart attempts (fault recovery). SCP

sensing reenables 4 ms (typical) after activation. During a shortcircuit fault, the device enters a low current consumption state

and an interrupt flag is set. The device can be restarted at any

time after receiving a short-circuit fault by simply rewriting

nSTBY = 1. It then repeats another complete soft start sequence.

Note that the value of the output capacitance (C

) should be

OUT

small enough to allow VOUT to reach approximately 55%

(typical) of V

within the 4 ms (typical) time. If C

IN

OUT

is too

large, the device inadvertently enters short-circuit protection.

OVERVOLTAGE PROTECTION

Overvoltage protection (OVP) is implemented on the output.

There are two types of overvoltage events: normal (no fault) and

abnormal (from a fault or sudden load change).

Normal Overvoltage

In a normal (no fault) overvoltage, the output voltage approaches

V

caused by a fault or load change, but it is simply a consequence

of the input voltage times the gain reaching the same level as the

clamped output voltage (V

(4.9 V typical) during normal operation. This is not

OUT(REG)

). To prevent this type of over-

OUT(REG)

voltage, the ADP8860 detects when the output voltage rises to

V

. It then increases the effective R

OUT(REG)

of the gain stage to

OUT

reduce the voltage that is delivered. This effectively regulates

V

to V

OUT

system can have on regulating V

; however, there is a limit to the effect that this

OUT(REG)

. It is designed only for normal

OUT

operation and it is not intended to protect against faults or sudden

load changes. When the output voltage is regulated to V

OUT(REG)

no interrupt is set and the operation is transparent to the LEDs

and the overall application.

Abnormal Overvoltage

Because of the open-loop behavior of the charge pump as well

as how the gain transitions are computed, a sudden load change

or fault can abnormally force V

beyond 6 V. This causes an

OUT

abnormal overvoltage situation. If the event happens slowly

enough, the system first tries to regulate the output to 4.9 V as

in a normal overvoltage scenario. However, if this is not

sufficient, or if the event happens too quickly, then the

ADP8860 enters overvoltage protection (OVP) mode when

V

exceeds the OVP threshold (typically 5.8 V). In the OVP

OUT

mode, only the charge pump is disabled to prevent V

OUT

from

rising too high. The current sources and all other device

functionality remain intact. When the output voltage falls by

about 500 mV (to 5.3 V typical), the charge pump resumes

operation. If the fault or load step recurs, the process may

repeat. An interrupt flag is set at each OVP instance.

THERMAL SHUTDOWN/OVERTEMPERATURE PROTECTION

If the die temperature of the ADP8860 rises above a safe limit

(150°C typical), the controllers enter thermal shutdown (TSD)

protection mode. In this mode, most of the internal functions

shut down, the part enters standby, and the TSD_INT interrupt

is set. When the die temperature decreases below ~130°C, the

part can be restarted. To restart the part, simply remove it from

standby. No interrupt is generated when the die temperature

falls below 130°C. However, if the software clears the pending

TSD_INT interrupt and the temperature remains above 130°C,

another interrupt is generated.

The complete state machine for these faults (SCP, OVP, and

TSD) is shown in Figure 42.

Rev. 0 | Page 21 of 52

ADP8860

VOUT < V

V

OVP(HYS)

OVP FAULT

OVP

STBY

EXIT STBY

0

1

TSD FAUL T

0

(HYS)

EXIT STBY

STARTUP:

CHARGE

TO V

V

IN

OUT

SCP FAUL T

DIE TEMP > TSD

1

DIE TEMP <

TSD – TSD

0

V

> V

OUT

OUT(START )

1

0

EXIT

STARTUP

VOUT < V

OUT(SC)

0

–

0

1

VOUT > V

OVP

0

G = 1

WAIT

100µs (TYP)

1

MIN (V

< V

1

D1:D7

HR(UP)

)

1

VOUT < V

V

OVP

OVP FAULT

1

VOUT > V

VOUT < V

V

OVP (HYS)

OVP FAULT

1

VOUT > V

OVP

(HYS)

OVP

OVP

OVP

1

> V

0

OUT(REG)

–

0

V

OUT

G = 3/2

WAIT

100µs (TYP)

MIN (V

< V

D1:D7

HR(UP)

)

0

0

MIN (V

> V

D1:D7

DMAX

)

1

0

TRY TO

REGULAT E

VOUT TO

V

OUT(REG)

1

1

0

–

0

1

0

V

> V

OUT

OUT(REG)

G = 2

WAIT

100µs (TYP)

MIN (V

> V

D1:D7

DMAX

)

1

0

TRY TO

REGULATE

VOUT TO

V

OUT(REG)

NOTES

IS THE CALCULAT ED GAIN DO WN TRANS ITIO N POI NT.

1. V

DMAX

Figure 42. Fault State Machine

07967-027

Rev. 0 | Page 22 of 52

ADP8860

INTERRUPTS

There are five interrupt sources available on the ADP8860.

• Main light sensor comparator: CMP_INT sets every time

the main light sensor comparator detects a threshold (L2

or L3) transition (rising or falling conditions).

• Sensor Comparator 2: CMP2_INT interrupt works the

same way as CMP_INT, except the sensing input derives

from the second light sensor. The programmable thresholds

are the same as the main light sensor comparator.

• Overvoltage protection: OVP_INT is generated when the

output voltage exceeds 5.8 V (typical).

• Thermal shutdown circuit: An interrupt (TSD_INT) is

generated when entering overtemperature protection.

• Short-circuit detection: SHORT_INT is generated when

the device enters short-circuit protection mode.

The interrupt (if any) that appears on the nINT pin is determined by the bits mapped in Register INTR_EN. To clear an

interrupt, write a 1 to the interrupt in the MDCR2 register or

reset the part. Reading the interrupt, or writing a 0, has no effect.

Rev. 0 | Page 23 of 52

ADP8860

V

APPLICATIONS INFORMATION

The ADP8860 allows the charge pump to operate efficiently

with a minimum of external components. Specifically, the user

must select an input capacitor (C

and two charge pump fly capacitors (C1 and C2). C

1 F or greater. The value must be high enough to produce a

stable input voltage signal at the minimum input voltage and

maximum output load. A 1 F capacitor for C

Larger values are permissible, but care must be exercised to

ensure that VOUT charges above 55% (typical) of V

4 ms (typical). See the Short-Circuit Protection Mode section

for more details.

For best practice, it is recommended that the two charge pump

fly capacitors be 1 F; larger values are not recommended and

smaller values may reduce the ability of the charge pump to

deliver maximum current. For optimal efficiency, the charge

pump fly capacitors should have low equivalent series resistance

(ESR). Low ESR X5R or X7R capacitors are recommended for

all four components. Use voltage ratings of 10 V or greater for

these capacitors.

If one or both ambient light sensor comparator inputs (CMP_IN

and D6/CMP_IN2) are used, a small capacitor (0.1 F is

recommended) must be connected from the input to ground.

Any color of LED can be used if the Vf (forward voltage) is less

than 4.1 V. However, using lower Vf LEDs reduces the input

power consumption by allowing the charge pump to operate at

lower gain states.

The equivalent circuit model for a charge pump is shown in

Figure 43.

OUT

R

OUT

G × V

Figure 43. Charge Pump Equivalent Circuit Model

I

OUT

C

OUT

IN

The input voltage is multiplied by the gain (G) and delivered to

the output through an effective resistance (R

current flows through R

= G ×VIN − I

V

OUT

The R

term is a combination of the R

OUT

OUT

OUT

× R

switches used in the charge pump and a small resistance that

accounts for the effective dynamic charge pump resistance. The

R

level changes based upon the gain (the configuration of the

OUT

switches). Typical R

values are given in Tab le 1 and Figure 13

OUT

and Figure 14.

), output capacitor (C

IN

V

DX

is recommended.

OUT

). The output

OUT

OUT

should be

IN

within

IN

0

07967-14

),

and produces an IR drop to yield

(G) (5)

OUT

resistance for the

DSON

V

is also equal to the largest Vf of the LEDs that are used

OUT

plus the voltage drop across the regulating current source. This

gives

V

OUT

= Vf

+ VDx (6)

(MAX)

Combining Equation 5 and Equation 6 gives

V

= (Vf

IN

(MAX)

+ VDx + I

OUT

× R

(G))/G (7)

OUT

This equation is useful for calculating approximate bounds for

the charge pump design.

Determining the Transition Point of the Charge Pump

Consider the following design example where:

Vf

= 3.7 V

(MAX)

I

= 140 mA (7 LEDs at 20 mA each)

OUT

R

(G = 1.5×) = 3 Ω (obtained from Figure 13)

OUT

At the point of a gain transition, V

typical value of V

as 0.2 V. Therefore, the input voltage

HR(UP)

Dx

= V

, Tabl e 1 gives the

HR(UP)

level when the gain transitions from 1.5× to 2× is

= (3.7 V + 0.2 V + 140 mA × 3 Ω)/1.5 = 2.88 V

V

IN

LAYOUT GUIDELINES

• For optimal noise immunity, place the C

capacitors as close as possible to their respective pins.

These capacitors should share a short ground trace. If the

LEDs are a significant distance from the VOUT pin, another

capacitor on VOUT, placed closer to the LEDs, is advisable.

• For optimal efficiency, place the charge pump fly capacitors

as close to the part as possible.

• The ADP8860 does not distinguish between power ground

and analog ground. Therefore, both ground pins can be

connected directly together. It is recommended that these

ground pins be connected at the ground for the input and

output capacitors.

• If using the LFCSP package, the exposed pad must be

soldered at the board to the GND1 and/or GND2 pin(s).

• Unused diode pins (Pin D1 to Pin D7) can be connected to

ground, VOUT, or remain floating. However, the unused

diode current sinks must be disabled by setting them as

independent sinks in Register 0x05 and then disabling

them in Register 0x10. If they are not disabled, the charge

pump efficiency may suffer.

• If the CMP_IN phototransistor input is not used, it can be

connected to ground or remain floating.

• If the interrupt pin (nINT) is not used, connect it to

ground or leave it floating. Never connect it to a voltage

supply, except through a ≥1 k series resistor.

and C

IN

OUT

Rev. 0 | Page 24 of 52

ADP8860

V

• The ADP8860 has an integrated noise filter on the nRST

pin. Under normal conditions, it is not necessary to filter

the reset line. However, if exposed to an unusually noisy

signal, then it is beneficial to add a small RC filter or

EXAMPLE CIRCUITS

V

OUT

bypass capacitor on this pin. If the nRST pin is not used, it must

be pulled well above the V

level (see Table 1). Do not allow

IH(MIN)

the nRST pin to float.

OPTIONAL

PHOTOSENSOR

ALS

PHOTOSENSOR

0.1µF

V

IN

1µF

VDDIO

nRST

VDDIO

SDA

VDDIO

SCL

VDDIO

nINT

DISPLAY BACKLI GHT

D3D1E3D2E4D3D4D4C4D5B4D6B3

A3

E1

D7C3CMP_IN

ADP8860

C2

E2

D2

A4

GND1

D1

GND2

Figure 44. Generic Application Schematic

UP TO 10 LEDs (6mA EACH)

60mA MAX TOTAL CURRENT

DL7R5DL8

ACCESSORY

LIGHTS OR

SUB-DISPLAY BL

A2

A1

C1

B1

B2

KEYPAD LIGHT

R6

C1+

C1–

C2+

C2–

DL17

R15

0.1µF

1µF

V

OUT

C1

1µF

C2

1µF

07967-028

2.8V

VDDIO

I

CONTRO L

SIGNALS

V

IN

R1 R2 R3 R4

nRST

2

C

nINT

1µF

DL1

A3

A4

D1

E1

C2

E2

D2

D3

D1

VIN

GND1

GND2

nRST

SDA

SCL

nINT

DL2

PH2

OPTIO NAL

DL3

DL4

E3

E4

D2

D3

D4

D4

DL5

C4

D5

CMP_IN2

ADP8860

DL6

B4

D6/

B3

D7C3CMP_IN

VOUT

C1+

C1–

C2+

C2–

A2

A1

C1

B1

B2

PHOTOSENSOR

0.1µF

1µF

C1

1µF

C2

1µF

PH1

MAIN

PHOTOSENSOR

0.1µF

7967-029

Figure 45. Application Schematic with Keypad Light Control

Rev. 0 | Page 25 of 52

ADP8860

I2C PROGRAMMING AND DIGITAL CONTROL

The ADP8860 provides full software programmability to

facilitate its adoption in various product architectures. The

default I

read). Therefore, the default write address is 0x54 and the read

address is 0x55.

Note the following general behavior of registers:

• All registers are set to their default values during reset or

2

C address is 0101010x (x = 0 during write, x = 1 during

after a UVLO event.

0 = WRITE

1 = READ

ST SP

0 1 0 1 0 1 0

R/W

0 0 0

• All registers are read/write unless otherwise specified.

• Unused bits are read as zero.

The following tables provide register and bit descriptions. The

reset value for all bits in the bit map tables is all 0s, except in

Tabl e 9 (see Ta b le 9 for its unique reset value). Wherever the

acronym N/A appears in the tables, it means not applicable.

CHIP ADDRESS REG ADDRESS DATA

ACK

Figure 46. I

2

C Command Sequence

ACK

Table 7. Register Set Definitions

Address Register Name Description

0x00 MFDVID Manufacturer and device ID

0x01 MDCR Device mode and status

0x02 MDCR2 Device mode and Status Register 2

0x03 INTR_EN Interrupts enable

0x04 CFGR Configuration register

0x05 BLSEN Sink enable backlight or independent

0x06 BLOFF Backlight off timeout

0x07 BLDIM Backlight dim timeout

0x08 BLFR Backlight fade in and out rates

0x09 BLMX1 Backlight (Brightness Level 1—daylight) maximum current

0x0A BLDM1 Backlight (Brightness Level 1—daylight) dim current

0x0B BLMX2 Backlight (Brightness Level 2—office) maximum current

0x0C BLDM2 Backlight (Brightness Level 2—office) dim current

0x0D BLMX3 Backlight (Brightness Level 3—dark) maximum current

0x0E BLDM3 Backlight (Brightness Level 3—dark) dim current

0x0F ISCFR Independent sink current fade control register

0x10 ISCC Independent sink current control register

0x11 ISCT1 Independent Sink Current Timer Register LED[7:5]

0x12 ISCT2 Independent Sink Current Timer Register LED[4:1]

0x13 ISCF Independent sink current fade register

0x14 ISC7 Independent Sink Current LED7

0x15 ISC6 Independent Sink Current LED6

0x16 ISC5 Independent Sink Current LED5

0x17 ISC4 Independent Sink Current LED4

0x18 ISC3 Independent Sink Current LED3

0x19 ISC2 Independent Sink Current LED2

0x1A ISC1 Independent Sink Current LED1

0x1B CCFG Comparator configuration

0x1C CCFG2 Second comparator configuration

0x1D L2_TRP L2 comparator reference

0x1E L2_HYS L2 hysteresis

0x1F L3_TRP L3 comparator reference

ACK

07967-030

Rev. 0 | Page 26 of 52

ADP8860

Address Register Name Description

0x20 L3_HYS L3 hysteresis

0x21 PH1LEVL First phototransistor ambient light level—low byte register

0x22 PH1LEVH First phototransistor ambient light level—high byte register

0x23 PH2LEVL Second phototransistor ambient light level—low byte register

0x24 PH2LEVH Second phototransistor ambient light level—high byte register

Table 8. Register Map

Addr Reg. Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0x00 MFDVID Manufacture ID Device ID

0x01 MDCR Reserved INT_CFG NSTBY DIM_EN Reserved SIS_EN CMP_AUTOEN BLEN

0x02 MDCR2 Reserved SHORT_INT TSD_INT OVP_INT CMP2_INT CMP_INT

0x03 INTR_EN Reserved SHORT_IEN TSD_IEN OVP_IEN CMP2_IEN CMP_IEN

0x04 CFGR Reserved SEL_AB CMP2_SEL BLV Law FOVR

0x05 BLSEN Reserved D7EN D6EN D5EN D4EN D3EN D2EN D1EN

0x06 BLOFF Reserved OFFT

0x07 BLDIM Reserved DIMT

0x08 BLFR BL_FO BL_FI

0x09 BLMX1 Reserved BL1_MC

0x0A BLDM1 Reserved BL1_DC

0x0B BLMX2 Reserved BL2_MC

0x0C BLDM2 Reserved BL2_DC

0x0D BLMX3 Reserved BL3_MC

0x0E BLDM3 Reserved BL3_DC

0x0F ISCFR Reserved SC_LAW

0x10 ISCC Reserved SC7_EN SC6_EN SC5_EN SC4_EN SC3_EN SC2_EN SC1_EN

0x11 ISCT1 SCON SC7OFF SC6OFF SC5OFF

0x12 ISCT2 SC4OFF SC3OFF SC2OFF SC1OFF

0x13 ISCF SCFO SCFI

0x14 ISC7 SCR SCD7

0x15 ISC6 Reserved SCD6

0x16 ISC5 Reserved SCD5

0x17 ISC4 Reserved SCD4

0x18 ISC3 Reserved SCD3

0x19 ISC2 Reserved SCD2

0x1A ISC1 Reserved SCD1

0x1B CCFG FILT FORCE_RD L3_OUT L2_OUT L3_EN L2_EN

0x1C CCFG2 FILT2 FORCE_RD2 L3_OUT2 L2_OUT2 L3_EN2 L2_EN2

0x1D L2_TRP L2_TRP

0x1E L2_HYS L2_HYS

0x1F L3_TRP L3_TRP

0x20 L3_HYS L3_HYS

0x21 PH1LEVL PH1LEV_LOW

0x22 PH1LEVH Reserved PH1LEV_HIGH

0x23 PH2LEVL PH2LEV_LOW

0x24 PH2LEVH Reserved PH2LEV_HIGH

Rev. 0 | Page 27 of 52

ADP8860

Manufacturer and Device ID (MFDVID)—Register 0x00

This is a read-only register.

Table 9. MFDVID Manufacturer and Device ID Bit Map

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Manufacture ID Device ID

0 0 0 0 0 1 1 1

Mode Control Register (MDCR)—Register 0x01

Table 10. MDCR Mode Control Bit Map

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Reserved INT_CFG nSTBY DIM_EN Reserved SIS_EN CMP_AUTOEN BL_EN

Table 11. Bit Descriptions for the MDCR Register

Bit Name Bit No. Description

N/A 7 Reserved.

INT_CFG 6 Interrupt configuration.

1 = processor interrupt deasserts for 50 μs and reasserts with pending events.

0 = processor interrupt remains asserted if the host tries to clear the interrupt while there is a pending event.

nSTBY 5 1 = device is in active mode.

0 = device is in standby mode, only the I2C interface is enabled.

DIM_EN 4 DIM_EN is set by the hardware after a DIM timeout. The user may also force the backlight into DIM mode by

asserting this bit. DIM mode can only be entered if BL_EN is also enabled.

1 = backlight is operating at the DIM current level (BL_EN must also be asserted).

0 = backlight is not in DIM mode.

N/A 3 Reserved.

SIS_EN 2 Synchronous independent sinks enable.

1 = enables all LED current sinks designated as independent sinks. All of the ISC enable bits must be cleared; if

any of the SC_EN bits in Register 0x10 are set, this bit has no effect.

0 = disables all sinks designated as independent sinks. All of the ISC enable bits must be cleared; if any of the

SC_EN bits are set in Register 0x10, this bit has no effect.

CMP_AUTOEN 1 1 = backlight automatically responds to the comparator outputs (L2_OUT and L3_OUT). L2_EN and/or L3_EN

must be set for this to function. BLV values in Register 0x04 are overridden.

0 = backlight does not autorespond to comparator level changes. The user can manually select backlight

operating levels using Bit BLV in Register 0x04.

BL_EN 0 1 = backlight is enabled (nSTBY must also be asserted).

0 = backlight is disabled.

Rev. 0 | Page 28 of 52

ADP8860

Mode Control Register 2 (MDCR2)—Register 0x02

Table 12. MDCR2 Bit Map

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Reserved SHORT_INT TSD_INT OVP_INT CMP2_INT CMP_INT

Table 13. Bit Descriptions for the MDCR2 Register

Bit Name Bit No. Description

N/A 7:5 Reserved.

SHORT_INT 4 Short-circuit error.

1 = a short-circuit or overload condition on VOUT was detected.

0 = no short-circuit or overload condition has been detected.

TSD_INT 3 Thermal shutdown.

1 = the device temperature has exceeded 150°C (typical).

0 = no overtemperature condition has been detected.

OVP_INT 2 Overvoltage interrupt.

1 = VOUT has exceeded V

0 = VOUT has not exceeded V

CMP2_INT 1 1 = indicates that the second ALS comparator (CMP_IN2) has changed state.

0 = the second sensor comparator has not triggered.

CMP_INT 0 1 = indicates that the main ALS comparator (CMP_IN) has changed state.

0 = the main sensor comparator has not triggered.

1

Interrupt bits are cleared by writing a 1 to the flag; writing a 0 or reading the flag has no effect.

1

.

OVP

.

OVP

Interrupt Enable (INTR_EN)—Register 0x03

Table 14. INTR_EN Bit Map

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Reserved SHORT_IEN TSD_IEN OVP_IEN CMP2_IEN CMP_IEN

Table 15. Bit Descriptions for the INTR_EN Register

Bit Name Bit No. Description

N/A 7:5 Reserved.

SHORT_IEN 4 Short-circuit interrupt is enabled. When the SHORT_INT status bit is set after an error condition, an interrupt is

raised to the host if the SHORT_IEN flag is enabled.

1 = the short-circuit interrupt is enabled.

0 = the short-circuit interrupt is disabled (the SHORT_INT flag continues to assert).

TSD_IEN 3 Thermal shutdown interrupt is enabled. When the TSD_INT status bit is set after an error condition, an interrupt is

raised to the host if the TSD_IEN flag is enabled.

1 = the thermal shutdown interrupt is enabled.