High Frequency Switch Mode

BATA

BATB

VCC

DRV

EOC

CS–

CS+

ISET

BATA

ADJ

GND

RESET

V

IN

VL

ADP3801/ADP3802

SD

BATB

3.3V

40mV

A/B

COMP

PROG

68mH

a

FEATURES

Stand-Alone Li-Ion Battery Chargers

High End-of-Charge Voltage Accuracy

ⴞ0.4% @ +25ⴗC

ⴞ0.75% @ –10ⴗC to +70ⴗC

Intelligent End-of-Charge Output Signal

Pin Programmable Cell Number Select

On Chip 3.3 V LDO Regulator

Programmable Charge Current with High Side Sense

Softstart Charge Current

Undervoltage Lockout

Drives External PMOS

ⴞ10% Adjustable End-of-Charge Voltage

Charges NiCad, NiMH (with External Controller)

PWM Oscillator Frequency:

ADP3801: 200 kHz

ADP3802: 500 kHz

APPLICATIONS

Fast Chargers

Universal Chargers

Cellular Phones

Portable Computers

Portable Instrumentation

Desktop Chargers

Personal Digital Assistants

Dual Li-Ion Battery Chargers

ADP3801/ADP3802

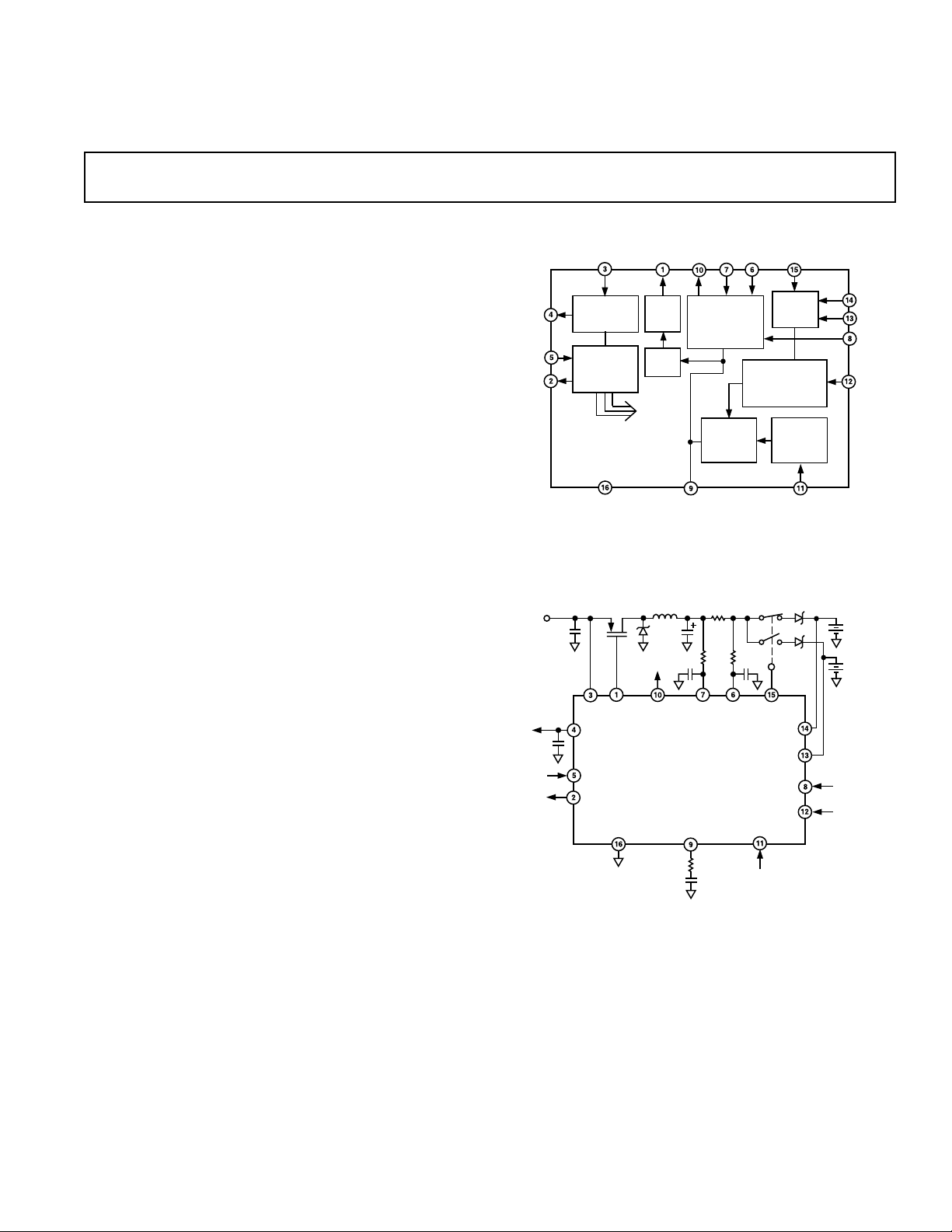

FUNCTIONAL BLOCK DIAGRAM

RESET

VL

SD

LDO +

REFERENCE

SHUTDOWN

RESET

ADP3801/ADP3802

UVLO

+

GND

DRVVCC

GATE

DRIVE

PWM

SD\UVLO

EOC

CURRENT

LOOP

AMP + EOC

COMPARATOR

VOLTAGE

LOOP

COMP

CS+

CS–

FINAL BATTERY

AMP

A/B

A/B

SELECT

MUX

VOLTAGE

PROGRAM

(4.2, 8.4, 12.6)

BATTERY

VOLTAGE

ADJUST

610%

ADJ

BATA

BATB

ISET

PROG

GENERAL DESCRIPTION

The ADP3801 and ADP3802 are complete battery charging

ICs. The devices combine a high accuracy final battery voltage

control with a constant charge current control and an on-board

Low Drop-Out Regulator (LDO). The accuracy of the final

battery voltage control is guaranteed to ±0.75% to safely charge

Li-Ion batteries. An internal multiplexer allows the alternate

charging of two separate battery stacks. The final voltage is pin

programmable to one of three Li-Ion options: 4.2 V (one Li-Ion

cell), 8.4 V (two Li-Ion cells), or 12.6 V (three Li-Ion cells).

Paired with an external microcontroller for charge termination,

the ADP3801/ADP3802 works as a fast charger for NiCad/

NiMH batteries or as a universal charger for all three battery

chemistries. In addition, a pin is provided for changing the final

battery voltage by up to ±10% to adjust for variations in battery

chemistry from different Li-Ion manufacturers without loss of

accuracy in the final battery voltage.

REV. 0

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 World Wide Web Site: http://www.analog.com

Fax: 781/326-8703 © Analog Devices, Inc., 1998

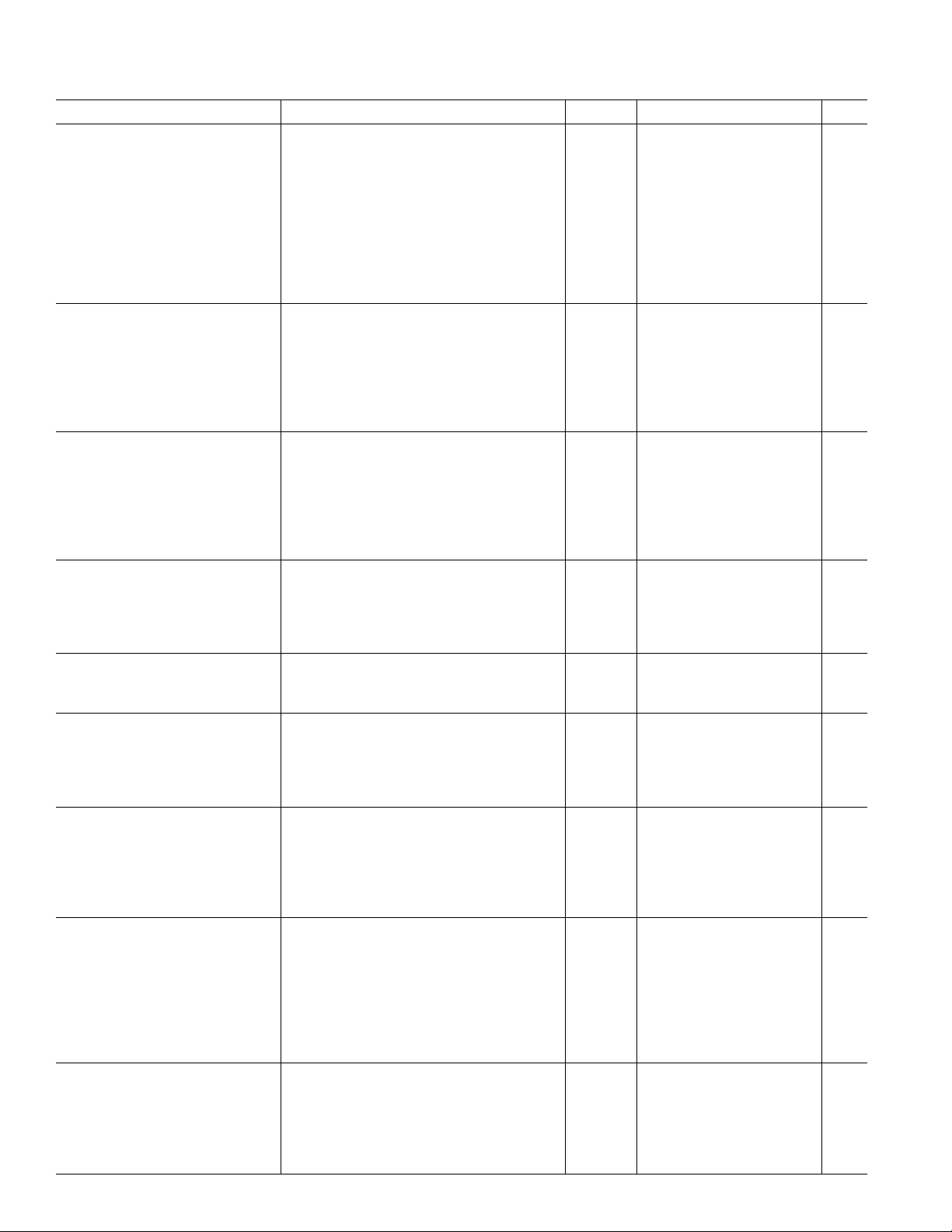

Figure 1. 4 Amp Dual Battery Charger

ADP3801/ADP3802–SPECIFICATIONS

(@ –40ⴗC ≤ TA ≤ +85ⴗC, VCC = 10.0 V, unless otherwise noted)

Parameter Conditions Symbol Min Typ Max Units

FINAL BATTERY VOLTAGE

One Li-Ion Cell PROG = VT1, ADJ = VL, T

Two Li-Ion Cells

1

Three Li-Ion Cells

PROG = V

PROG = V

PROG = VT2, ADJ = VL, T

PROG = V

1

PROG = V

PROG = VT3, ADJ = VL, T

PROG = V

PROG = V

, ADJ = VL, –10°C ≤ TA ≤ +70°CV

T1

, ADJ = VL, –40°C ≤ TA ≤ +85°CV

T1

, ADJ = VL, –10°C ≤ TA ≤ +70°CV

T2

, ADJ = VL, –40°C ≤ TA ≤ +85°CV

T2

, ADJ = VL, –10°C ≤ TA ≤ +70°CV

T3

, ADJ = VL, –40°C ≤ TA ≤ +85°CV

T3

= +25°CV

A

= +25°CV

A

= +25°CV

A

BAT

BAT

BAT

BAT

BAT

BAT

BAT

BAT

BAT

4.180 4.200 4.220 V

4.168 4.232 V

4.150 4.250 V

8.366 8.400 8.434 V

8.337 8.463 V

8.300 8.500 V

12.550 12.600 12.650 V

12.505 12.695 V

12.450 12.750 V

BATTERY PROGRAMMING

INPUT (PROG)

One Li-Ion Cell (4.2 V) V

Two Li-Ion Cells (8.4 V) V

Three Li-Ion Cells (12.6 V) V

T1

T2

T3

0.00 0.20 V

1.00 1.20 V

2.05 2.30 V

Fail Safe Voltage (4.2 V) Defaults to 1 Li-Ion Cell 3.10 3.30 V

PROG Input Current I

B

1.5 5 µA

A/B SELECT MUX

Select Battery BATB V

Select Battery BATA V

A/B Input Current I

BATA or BATB Input Resistance Channel Selected R

BATA or BATB Input Current Channel Not Selected I

BATA or BATB Shutdown Current Part in Shutdown IBA, I

2

BATTERY ADJUST INPUT

% of Final Battery Voltage ADJ = 1.0 V, –10°C ≤ T

% of Final Battery Voltage ADJ = 2.3 V, –10°C ≤ T

(ADJ)

≤ +70°C 899091 %

A

≤ +70°C 109 110 111 %

A

IN

BA

IH

IL

IN

, I

2.0 V

0.02 1 µA

185 265 kΩ

BB

BB

0.2 1 µA

0.2 1 µA

0.8 V

ADJ Disable Voltage Threshold 0% Change 2.475 2.6 V

ADJ Bias Current 1.0 V ≤ ADJ ≤ 2.3 V I

B

10 100 nA

OVERVOLTAGE COMPARATOR

Trip Point Percent Above V

BAT

8%

Response Time DRV Goes High tr 2 µs

OSCILLATOR

200 kHz Option (ADP3801) f

500 kHz Option (ADP3802) f

OSC

OSC

150 200 250 kHz

375 500 625 kHz

0% Duty Cycle Threshold @ COMP Pin 1.0 V

100% Duty Cycle Threshold @ COMP Pin 2.0 V

GATE DRIVE

Rise Time CL = 1 nF, VCC – 4 V to 90% t

Fall Time C

Output High Saturation Voltage VCC – V

= 1 nF, 90% to VCC – 4 V t

L

DRV

Output Low Voltage VCC = 8 V V

VCC > 8 V V

r

f

V

OH

OL

OL

1.0 2.0 V

VCC – 7 VCC – 6 V

35 ns

75 ns

275 mV

CURRENT SENSE AMPLIFIER

Input Common-mode Range V

Input Differential Mode Range V

Input Offset Voltage

4

Input Bias Current 0.0 V ≤ V

Input Offset Current 0.0 V ≤ V

Over Current Trip Point V

and V

CS+

3

CS

0.0 V ≤ V

3

CS

CS–

≤ VCC – 2 V V

CSCM

≤ VCC – 2 V V

CSCM

≤ VCC – 2 V V

CSCM

V

CSCM

V

CSDM

CSVOS

CSIB

CSIOS

0.0 VCC – 2 V

0.0 185 mV

1mV

0.3 1 µA

0.01 0.15 µA

185 mV

Response Time DRV Goes High tr 2 µs

ISET INPUT

Charge Current Programming

Function 0.0 V ≤ V

Programming Function Accuracy V

= 1.65 V, –10°C ≤ TA ≤ +70°C–5±1.0 +5 %

ISET

V

= 0.10 V, –10°C ≤ TA ≤ +70°C –25 ±10 +25 %

ISET

ISET Bias Current 0.0 V ≤ V

≤ 1.65 V V

ISET

≤ 1.65 V I

ISET

CS/VISET

B

3

0.1 V/V

15 100 nA

–2–

REV. 0

ADP3801/ADP3802

Parameter Conditions Symbol Min Typ Max Units

BAT

CS+

+ 2 V.

) – (V

5

CS–

3

CS

3

CS

H

L

6

).

0 mA ≤ I

4.1 V ≤ VCC ≤ 20 V, –10°C ≤ T

0 mA ≤ I

4.1 V ≤ VCC ≤ 20 V, –40°C ≤ T

= 10 mA V

LOAD

LOAD

LOAD

≤ 10 mA,

≤ 10 mA,

≤ +70°C VL 3.267 3.3 3.333 V

A

≤ +85°C VL 3.250 3.350 V

A

≥ 95% of the final battery voltage.

BAT

DO

VL

SYON

SYOFF

2.0 V

10 20 mA

10 mV

0.2 mV

0.8 V

0.4 0.8 V

5.0 7.0 mA

115 180 µA

EOC OUTPUT

Trip Point 100 kΩ to VL V

Hysteresis 100 kΩ to VL V

SHUTDOWN (SD)

ON SD

OFF SD

SD Input Current 0.2 1 µA

LOW DROPOUT REGULATOR

Output Voltage

Dropout Voltage (VCC – VL) I

Output Current Drive I

RESET OUTPUT

VL Rising Threshold RESET High 2.5 2.7 2.9 V

VL Falling Threshold RESET Low 2.4 2.55 2.8 V

Output High Logic Level 1 MΩ to Ground External 2.4 2.9 V

POWER SUPPLY

ON Supply Current No External Loads I

OFF Supply Current No External Loads I

6, 7

UVLO

VCC Rising Threshold Turn On 3.8 3.9 4.0 V

VCC Falling Threshold Turn Off, IVL = 1 mA 3.4 V

NOTES

1

VCC = V

2

See Figure 5.

3

VCS = (V

4

Accuracy guaranteed by ISET INPUT, Programming Function Accuracy specification.

5

EOC Output Comparator monitors charge current, and it is enabled when V

6

LDO is active during SD and UVLO.

7

Turn-off threshold depends on LDO dropout.

All limits at temperature extremes are guaranteed via correlation using standard Statistical Quality Control (SQC) methods.

Specifications subject to change without notice.

–3–REV. 0

ADP3801/ADP3802

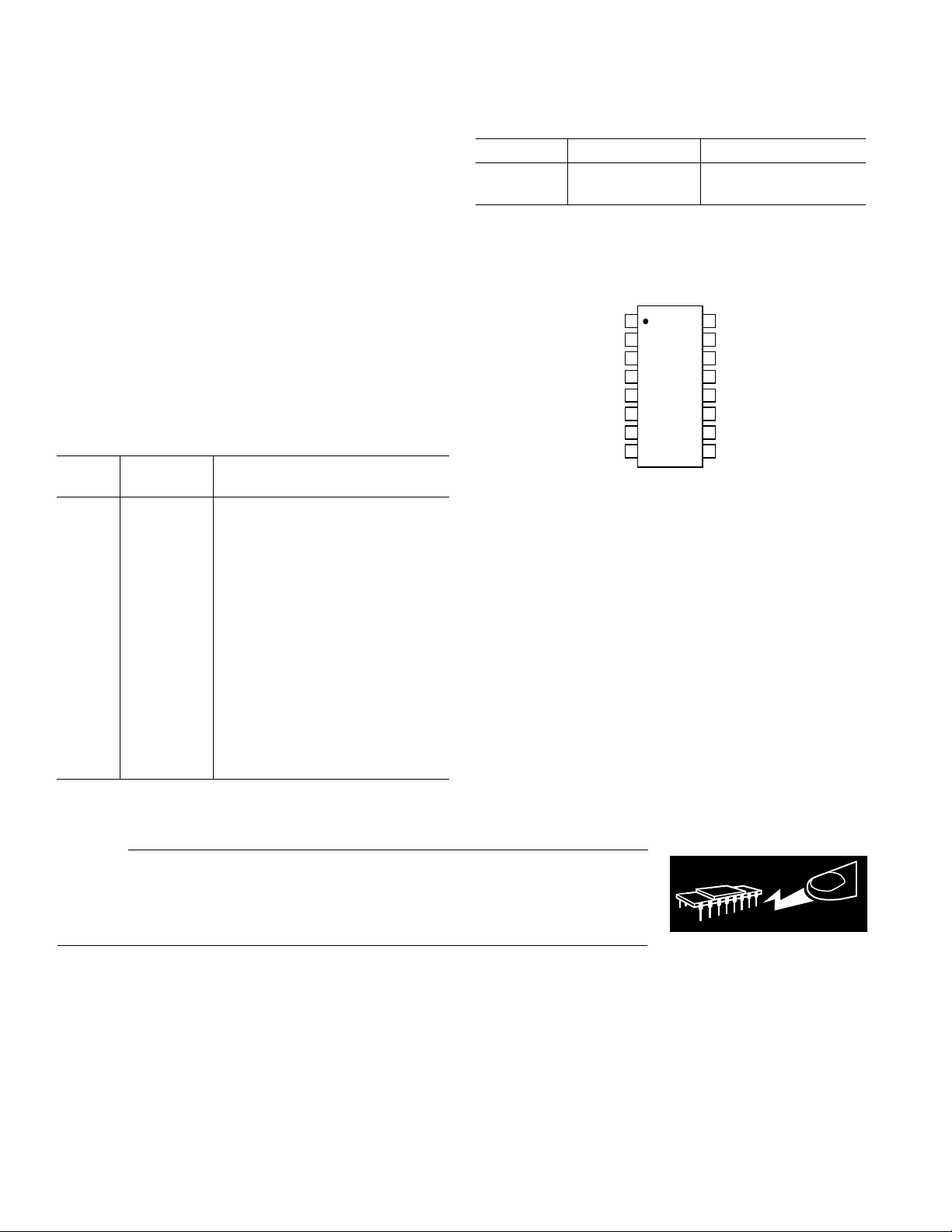

TOP VIEW

(Not to Scale)

16

15

14

13

12

11

10

9

1

2

3

4

5

6

7

8

DRV

VL

SD

CS–

CS+

ISET

GND

A/B

BATA

BATB

PROG

ADJ

EOC

COMP

ADP3801

ADP3802

VCC

RESET

WARNING!

ESD SENSITIVE DEVICE

ABSOLUTE MAXIMUM RATINGS*

Input Voltage (VCC to GND) . . . . . . . . . . . . . . –0.3 V to 20 V

DRV, V

CS+

, V

to GND . . . . . . . . . . . . . . . . –0.3 V to VCC

CS–

BATA, BATB to GND . . . . . . . . . . . . . . . . . –0.3 V to 14.0 V

A/B, ISET, PROG, ADJ to GND . . . . . . . . . . . –0.3 V to VL

SD, RESET, COMP, EOC to GND . . . . . . . . . . –0.3 V to VL

Power Dissipation . . . . . . . . . . . . . . . . . . . . Internally Limited

θJA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75°C/W

Ambient Temperature Range . . . . . . . . . . . . –40°C to +85°C

Storage Temperature Range . . . . . . . . . . . . –65°C to +150°C

Lead Temperature Range (Soldering 10 sec) . . . . . . . +300°C

NOTES

*This is a stress rating only and functional operation of the device at these or any

other conditions above those indicated in the operation section of this specification

is not implied. Exposure to absolute maximum rating conditions for extended

periods may affect device reliability.

θ

is specified for worst case conditions with device soldered on a circuit board.

JA

PIN FUNCTION DESCRIPTIONS

Pin

Number Mnemonic Function

1 DRV External Transistor Drive

2 RESET Power on RESET Output

3 VCC Supply Voltage

4 VL LDO Output

5 SD Shutdown Control Input

6 CS– Negative Current Sense Input

7 CS+ Positive Current Sense Input

8 ISET Charge Current Program Input

9 COMP External Compensation Node

10 EOC End-of-Charge Output Signal

11 ADJ Adjust Battery Voltage ±

10%

12 PROG Program Final Battery Voltage Input

13 BATB Battery “B” Voltage Sense

14 BATA Battery “A” Voltage Sense

15 A/B

1

“A” or “B” Battery Select Input

16 GND Ground

NOTE

1

“L” = Battery “A.”

ORDERING GUIDE

Model Package Option Oscillator Frequency

ADP3801AR R-16A 200 kHz

ADP3802AR R-16A 500 kHz

PIN CONFIGURATION

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection. Although

the ADP3801/ADP3802 features proprietary ESD protection circuitry, permanent damage may

occur on devices subjected to high energy electrostatic discharges. Therefore, proper ESD precautions are recommended to avoid performance degradation or loss of functionality.

–4–

REV. 0

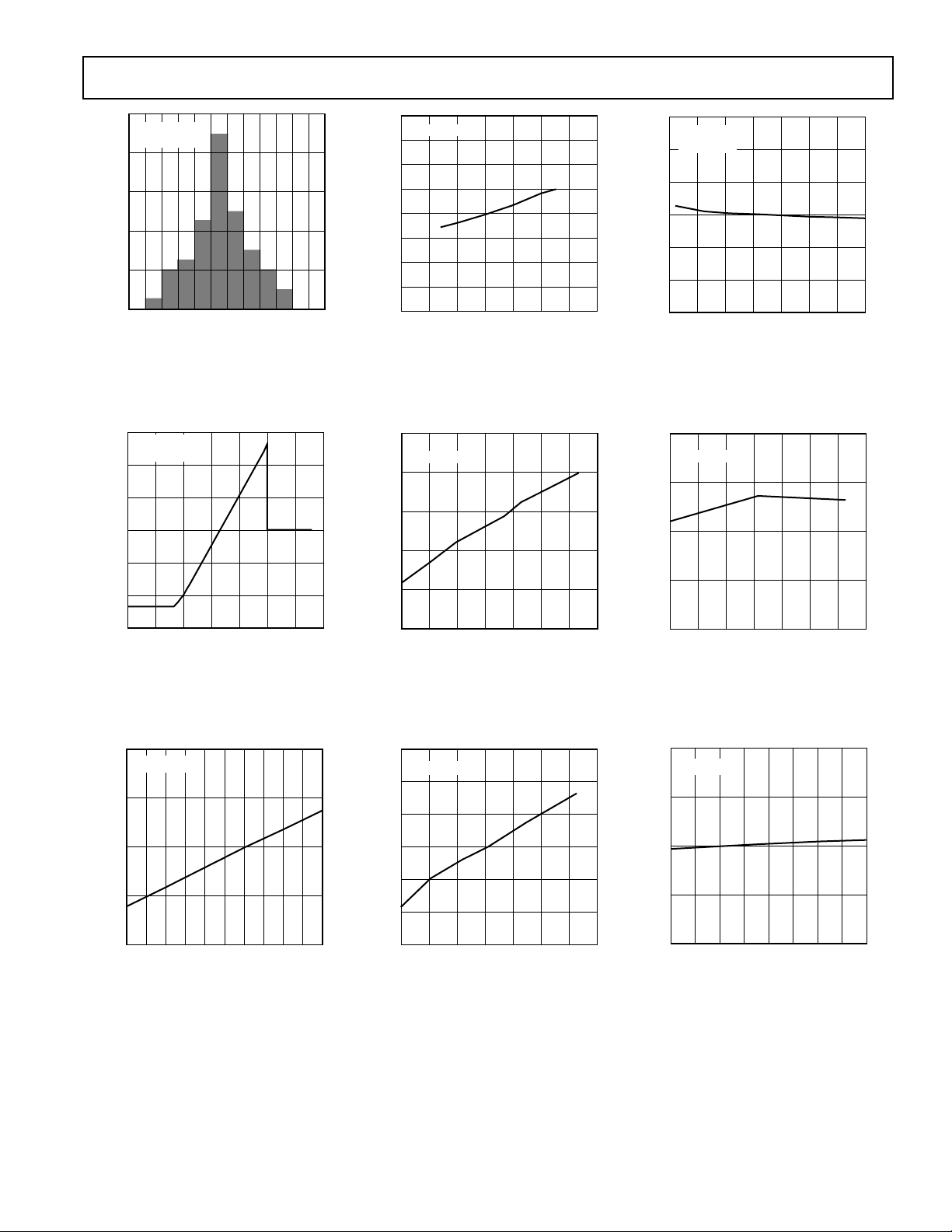

Typical Performance Characteristics–ADP3801/ADP3802

SUPPLY VOLTAGE – Volts

LDO ACCURACY – %

4681012 1618

0

0.1

0.2

14 20

TA = +258C

–0.2

–0.1

100

VCC = 10V

= +258C

T

A

80

60

40

20

TOTAL NUMBEROF PARTS

0

–0.3

–0.5

–0.4

–0.2 0 0.2 0.4 0.6

V

Figure 2. V

15

10

5

0

–5

PERCENT CHANGE – %

BAT

V

–10

BAT

VCC = 10V

T

= +258C

A

–0.1

0.1 0.3 0.5

ACCURACY – %

BAT

Accuracy Distribution

0.4

VCC = 10V

0.3

0.2

0.1

0

ACCURACY – %

–0.1

BAT

V

–0.2

–0.3

–0.4

–40

Figure 3. V

Temperature

10

9

8

7

THRESHOLD – %

6

–20 0 20 40 60 80 100

TEMPERATURE – 8C

Accuracy vs.

BAT

VCC = 10V

0.3

TA = +258C

V

= 4.2V

BAT

0.2

0.1

0

ACCURACY – %

–0.1

BAT

V

–0.2

–0.3

6 8 10 12 14 18 20

SUPPLY VOLTAGE – Volts

Figure 4. V

Accuracy vs. Supply

BAT

16

Voltage

200

VCC = 10V

195

190

THRESHOLD – mV

185

–15

0 0.5 1.0 1.5 2.0 3.0 3.5

Figure 5. V

3.7

TA = +258C

3.6

3.5

3.4

UVLO TRIP POINT – Votts

3.3

01234 67

V

ADJ

Percent Change vs. V

BAT

LDO LOAD CURRENT – mA

2.5

– Volts

58910

Figure 8. UVLO Trip Point-Off vs.

LDO Load Current

ADJ

5

–40 –20 0 20 40 80 100

TEMPERATURE – 8C

60

Figure 6. Overvoltage Comparator

Threshold vs. Temperature

0.3

VCC = 10V

0.2

0.1

0

–0.1

LDO ACCURACY – %

–0.2

–0.3

–40

–20 0 20 40 60 80 100

TEMPERATURE – 8C

Figure 9. LDO Accuracy vs.

Temperature

180

–40 –20 0 20 40 80 100

TEMPERATURE – 8C

60

Figure 7. Overcurrent Comparator

Threshold vs. Temperature

Figure 10. LDO Accuracy vs. Supply

Voltage

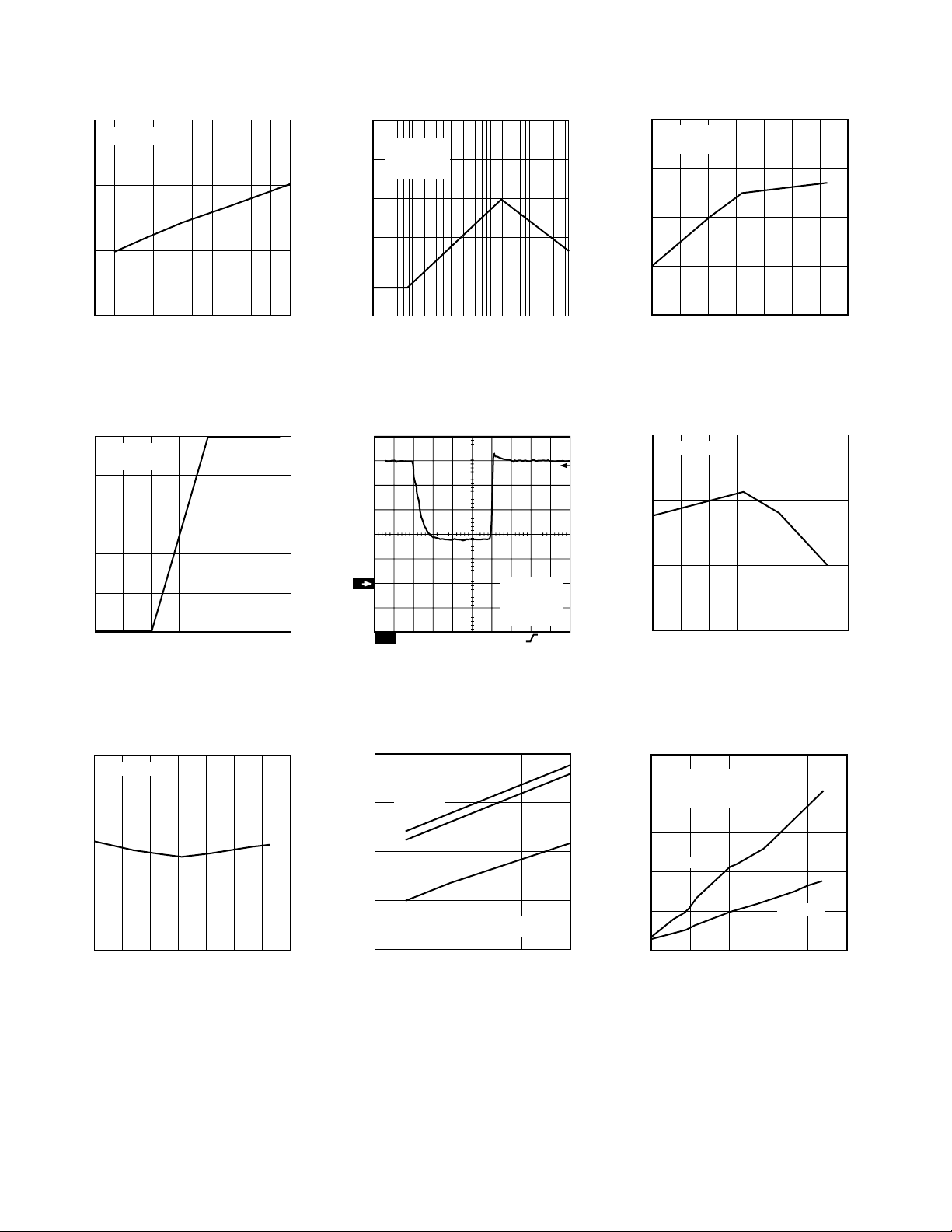

–5–REV. 0

ADP3801/ADP3802

SATURATION VOLTAGE – Volts

–40 –20

40 60 80

0

0.2

100

VCC = 10V

200

0.4

0.3

TEMPERATURE – 8C

0.4

TA = +258C

0.3

0.2

DROPOUT VOLTAGE – Volts

0.1

01234 6758

LOAD CURRENT – mA

910

Figure 11. LDO Dropout Voltage vs.

Load Current

100

VCC = 10V

TA = +258C

80

60

40

DUTY CYCLE – %

20

0

0

0.5 2.0 2.5 3.0

V

1.51.0

COMP

– Volts

3.5

Figure 14. Duty Cycle vs. COMP Pin

Voltage

0

VCC = 10V

= +258C

T

A

–20

–40

–60

PSRR – dB

–80

–100

1.0E+01

= 1mF

C

LDO

1.0E+03 1.0E+04 1.0E+05 1.0E+06

1.0E+02

FREQUENCY – Hz

Figure 12. LDO PSRR vs. Frequency

12

10

8

6

4

DRV – Volts

2

0

1

2.00V

CH1

TIME – ns

VCC = 10V

= 1nF

C

L

T

= +258C

A

250ns/DIV

Figure 15. DRV Rise and Fall Times

215

ADP3801

VCC = 10V

205

195

FREQUENCY – kHz

185

175

–40 –20

0 20 40 80 10060

TEMPERATURE – 8C

Figure 13. Oscillator Frequency vs.

Temperature

9.40VCH1M 250ns

Figure 16. DRV High Saturation Voltage vs. Temperature

3.9

VCC = 10V

3.8

3.7

3.6

CLAMP VOLTAGE – Volts

3.5

–40 –20

Figure 17. DRV Output Low Voltage

with VCC = 10 V vs. Temperature

40 60 80

200

TEMPERATURE – 8C

5.5

TA = +858C

5.0

TA = +258C

4.5

TA = –408C

NOT SWITCHING

SD = ON

12

100

4.0

POWER SUPPLY CURRENT – mA

3.5

48 16

SUPPLY VOLTAGE – Volts

Figure 18. Power Supply Current vs.

Supply Voltage @ Three Temperatures

–6–

15

VCC = 10V

= +258C

T

A

13

50% DUTY CYCLE

11

ADP3802

9

7

POWER SUPPLY CURRENT – mA

20

5

0 0.5 1.5

CAPACITIVE LOAD – nF

ADP3801

2.01.0

2.5

Figure 19. Power Supply Current vs.

Capacitive Load on DRV

REV. 0

ADP3801/ADP3802

APPLICATIONS SECTION

PRODUCT DESCRIPTION

The ADP3801 and ADP3802 are complete Li-Ion battery charging ICs. Combined with a microcontroller, they also function as

voltage limited, µC programmable constant current source chargers

for NiCad and NiMH chemistries. Utilizing an external PMOS

pass transistor, the devices realize a buck type constant current,

constant voltage (CCCV) charger controller that is capable of

charging two separate battery packs for such applications as

portable computer chargers and cellular phone chargers. The

Functional Block Diagram shows the ICs’ functional blocks,

which are detailed below:

• A/B SELECT MUX—Two-channel multiplexer for charging

two battery stacks.

• FINAL BATTERY VOLTAGE PROGRAM—Multiplexer to

program 4.2 V, 8.4 V, or 12.6 V final battery voltage.

• VOLTAGE LOOP AMP—GM-type amplifier to control

the final battery voltage. It includes a built-in overvoltage

comparator.

• EOC COMPARATOR—End-of-charge detection output to

signal when the battery is fully charged.

• BATTERY VOLTAGE ADJUST—Amplifier to adjust the

final battery voltage up to ±10%.

• CURRENT LOOP AMP—High-side-current-sense amplifier

to sense and control the charge current at a programmable

level. It includes an overcurrent comparator.

• PWM—Pulsewidth modulator and oscillator (ADP3801200 kHz, ADP3802-500 kHz).

• GATE DRIVE—Gate drive to control an external pass transistor. It includes a clamp to limit the drive voltage to protect

the external PMOS.

• LDO + REFERENCE—3.3 V low dropout regulator to supply an external microcrontroller and for on-chip supply. Includes an internal precision reference (VREF = VL/ 2).

• SHUTDOWN—Logic input to shut down the charger. The

LDO remains on.

• UVLO—Undervoltage lockout circuit to shut down the charger

for low supply voltages.

• RESET—Active LOW output to reset external logic on powerup.

During charging, the ADP3801/ADP3802 maintains a constant,

programmable charge current. The high side current sense

amplifier has low offset allowing the use of a low voltage drop

for current sensing: 165 mV for the maximum charge current.

The input common-mode range extends from ground to

VCC – 2 V ensuring current control over the full charging voltage of the battery, including a short circuit condition. A high

impedance dc voltage input (ISET) is provided for programming the charge current over a wide range. When the battery

voltage approaches its final limit, the part automatically transfers to voltage control mode. Both the current control loop and

the voltage control loop share the same compensation pin minimizing the number of external components. An internal comparator monitors the charge current to detect the end-of-charge

(EOC). When the current decreases such that V

EOC output pulls low.

≤ 8 mV, the

CS

A 3.3 V LDO is used to generate a regulated supply for internal

circuitry. Additionally, the LDO can deliver up to 10 mA of

current to power external circuitry such as a microcontroller. An

Undervoltage Lockout (UVLO) circuit is included to safely shut

down the charging circuitry when the input voltage drops below

its minimum rating. A shutdown pin is also provided to turn off

the charger when, for example, the battery has been fully charged.

The LDO remains active during shutdown or UVLO and has a

quiescent current of 110 µA.

Battery Charging Overview

Figure 20 shows a simplified Buck type battery charger application circuit for the ADP3801/ADP3802. When a discharged

battery is first placed in the charger, the battery voltage is well

below the final charge voltage, so the current sense amplifier

controls the charge loop in constant current mode. The charge

current creates a voltage drop across the sense resistor R

voltage drop is buffered and amplified by amplifier GM1. Amplifier GM2 compares the output of GM1 to an external current

control voltage provided at the ISET pin and servos the charger

loop to make these voltages equal. Thus, the charge current is

programmed using the ISET input voltage.

The output of GM2 is analog “OR’ed” with the output of GM3,

the voltage loop amplifier. Only one or the other amplifier controls the charge loop at any given time. As the battery voltage

approaches its final voltage, GM3 comes into balance. As this

occurs, the charge current decreases, unbalancing GM2, and

control of the feedback loop naturally transfers to GM3.

The ADP3801/ADP3802 can control the charging of two independent battery stacks or a single battery stack. The A/B SELECT

MUX has a logic input to choose between the two batteries. See

Figure 31 for more information on dual battery charging. The

output of the multiplexer is applied to a precision thin-film

resistor string to divide down the battery voltage. The final

battery voltage is chosen by selecting the proper resistor divider

tap with the PROG multiplexer. The output of this mux goes

directly to the input of GM3, comparing the divided down

battery voltage to the internal reference. To guarantee ±0.75%

accuracy, a high precision internal reference and high accuracy

thin film resistors are used. Including these components onchip saves the significant cost and design effort of adding them

externally.

CS

. This

–7–REV. 0

ADP3801/ADP3802

3.3V

VL

(TO mC)

RESET

(TO mC)

SD

(FROM mC)

V

N

I

POWER-

ON

RESET

ADP3801/ADP3802

VCC

LDO

V

REF

BIAS

L

C

N

I

EOC

DRV

V

REF

UVLO

GATE

DRIVE

Q

FF

S

R

OSCILLATOR

GND

COUT

D1

COMP

CS+

VT

R

CS

Rf2Rf1

CS–

GM1

V

REF

GM2

GM3

R

V

REF

RB

FINAL

VBAT

PROG

3R

MUX

2.475V

A/B

D2

BATA

BATA

BATB

PROG

(FROM mC)

ISET

100kV

1mF

ADJ

1mF

(FROM mC)

100kV

Figure 20. Simplified Application Diagram

Setting the Final Battery Voltage

The final battery voltage is determined by the voltage on the

Battery Programming (PROG) pin. This pin controls the state

of the PROG multiplexer, which selects the appropriate tap

from the internal battery voltage resistor divider. The specification table details the PROG voltages for each final battery voltage. A resistor divider from the LDO can be used to set the

PROG voltage as shown in Figure 21. To provide fail safe operation, a PROG voltage equal to 0.0 V or 3.3 V results in the

minimum final battery voltage of 4.2 V. The PROG input is

high impedance, so the voltage can be set with a high impedance resistor divider from VL. Alternatively, a PWM output

from a microcontroller can be used with an RC filter to generate

the desired threshold voltage.

V

SETTING R1 (5%) R2 (5%)

BAT

4.2 V

8.4 V

12.6 V

*CONNECT PROG TO

GND FOR V

= 0.0V 0*

T1

= 1.1V 200kV 100kV

T2

= 2.2V 100kV 200kV

T3

= 4.2V

BAT

PROG

VL

R1

R2

Figure 21. Resistor Divider Sets the Final Battery Voltage

–8–

REV. 0

ADP3801/ADP3802

Adjusting the Final Battery Voltage

In addition to the PROG input, the ADP3801/ADP3802 provides an input (ADJ) for fine adjustment of the final battery

voltage. For example, the ADJ amplifier allows the nominal

4.2 V per cell setting for Li-Ion battery cells to be adjusted to

4.1 V for certain chemistries. An internal amplifier buffers the

ADJ pin and adjusts the internal reference voltage on the input

to GM3. Figure 5 shows a graph of the percent change in final

battery voltage vs. the ADJ voltage. The linear portion between

0.6 V

and 1.4 V

REF

follows the formula below:

REF

VV

−

J

∆V

BAT

AD REF

%

=

()

V

4

REF

×

100

The factor of four in the denominator is due to internal scaling.

When V

the ADJ amplifier, giving a 0% change in V

is above 2.5 V, an internal comparator switches off

ADJ

. Whenever the

BAT

ADJ function is not used it should be connected to VL.

The total range of adjustment is ±10%. For example, the 4.2 V

final battery voltage setting can be adjusted from 3.78 V to

4.62 V. Of course, care must be taken not to adjust the final

battery voltage to an unsafe charging level for Li-Ion batteries.

Follow the battery manufacturers specifications for the appropriate final battery voltage. Never charge a Li-Ion battery above

the manufacturers rated maximum!

Voltage Loop Accuracy

The ADP3801/ADP3802 guarantees that the battery voltage be

within ±0.75% of the setpoint over the specified temperature

range and the specified charge current range. This inclusive

specification saves the designer the time and expense of having

to design-in additional high accuracy components such as a

reference and precision resistors.

To maintain the ±0.75% specification, the layout and design of

the external circuitry must be considered. The input impedance

of BATA and BATB is typically 265 kΩ, so any additional im-

pedance on these inputs will cause an error. As a result, do not

add external resistors to the battery inputs. Furthermore, if the

output voltage is being used for other purposes, such as to supply additional circuitry, the current to this circuitry should be

routed separately from the sense lines to prevent voltage drops

due to impedance of the PC-board traces. In general, route the

sense lines as Kelvin connections as close to the positive terminals of the battery as possible.

The same care must be given to the ground connection for the

ADP3801/ADP3802. Any voltage difference between the battery ground and the GND pin will cause an error in the charge

voltage. This error includes the voltage drop due to the ground

current of the part. Thus, the GND pin should have a thick

trace or ground plane connected as close as possible to the

battery’s negative terminal. Any current from additional circuitry should be routed separately to the supply return and not

share a trace with the GND pin.

Dual Battery Operation

The ADP3801/ADP3802 is designed to charge two separate

battery packs. These batteries can be of different chemistries

and have a different number of cells. At any given time, only

one of the two batteries is being charged. To select which battery is being monitored, and therefore which battery is being

charged, the ADP3801/ADP3802 includes a battery selector

mux. This two-channel mux is designed to be “break-beforemake” to ensure that the two batteries are not shorted together

momentarily when switching from one to the other. The A/B

input is a standard logic input, with a logic low selecting BATA

and a logic high selecting BATB. See the application in Figure

31 for more information.

Overvoltage Comparator

GM3 includes an overvoltage comparator. Its output bypasses

the COMP node to quickly reduce the duty cycle of the PWM

to 0% when an overvoltage event occurs. A second output is

connected to the COMP node and, with slower response, reduces the voltage on the COMP cap to provide a soft start recovery. The threshold of the comparator is typically 8% above

the final battery voltage. This comparator protects external

circuitry from any condition that causes the output voltage to

quickly increase. The most likely reason is if the battery is

suddenly removed while it is being charged with high current.

Figure 27 shows the transient response when the battery is

removed. Notice that the output voltage increases to the comparator trip point, but it is quickly brought under control and

held at the final battery voltage.

–9–REV. 0

ADP3801/ADP3802

Current Sense Amplifier

A differential, high side current sense amplifier (GM1 in Figure

20) amplifies the voltage drop across a current sense resistor

. The input common-mode range of GM1 extends from

R

CS

ground to VCC – 2 V. Sensing to ground ensures current regulation even in short circuit conditions. To stay within the common-mode range of GM1, VCC must be at least 2 V greater

than the final battery voltage or a circuit such as shown in Figure 32 must be used. RC filters are included to filter out high

frequency transients, which could saturate the internal circuitry.

The filter’s cutoff is typically set at half the switching frequency

of the oscillator.

The charge current is controlled by the voltage on the ISET pin

according to the following formula:

V

I

CHARGE

ISET

=

R

×10

CS

The factor of 10 is due the GM1’s gain of 10 V/V. To set a charge

current of 1.5 A with R

= 0.1 Ω, V

CS

must be 1.5 V. Figure

ISET

22 shows the linearity of the charge current control as the voltage is increased from 0 V to the programmed final battery voltage (12.6 V in this case). It is important to state that this curve

is taken with an ideal, zero impedance load. An actual Li-Ion

battery will exhibit a more gradual drop in charge current due to

the internal impedance of the battery as shown in Figure 25.

3.5

3.0

2.5

2.0

– Amps

1.5

CHARGE

I

1.0

0.5

0

23

45678910

V

– Volts

OUT

11 12 13

Figure 22. CCCV Characteristic with Ideal Load

Overcurrent Comparator

Similar to the voltage loop, the current loop includes a comparator to protect the external circuitry from an overcurrent

event. This comparator trips when GM1’s differential input

voltage exceeds 185 mV. Like the overvoltage comparator, it has

two outputs to quickly reduce the duty cycle to 0% and to provide a soft-start recovery. The response time of the internal

comparator is approximately 1 µs; however, the filter on the

input of GM1 may slow down the total response time of the

loop.

End-of-Charge Output

The ADP3801/ADP3802 provides an active low, end-of-charge

(EOC) logic output to signal when the battery has completed

charging. The typical Li-Ion charging characteristic in Figure 25

shows that when the battery reaches its final voltage the current

decreases. To determine EOC, an internal comparator senses

when the current falls below 6% of full scale, ensuring that the

battery has been fully charged. The comparator has hysteresis to

prevent oscillation around the trip point.

To prevent false triggering (such as during soft-start), the comparator is only enabled when the battery voltage is within 5% of

its final voltage. As the battery is charging up, the comparator

will not go low even if the current falls below 6% as long as the

battery voltage is below 95% of full scale. Once the battery has

risen above 95%, the comparator is enabled.

There are two important reasons for this functionality. First,

when the circuit is initially powered on, the charge current is

zero because of the soft start. If the comparator is not gated by

the battery voltage, then EOC would go low erroneously. Second, a provision must be made for battery discharge. Assume

that a battery has been fully charged. EOC goes low, and the

charger is gated off. When the battery voltage falls to 95%, due

to self-discharge for example, EOC will return high. Then the

charger can start up and top off the battery, preventing the

battery from “floating” at the end-of-charge voltage.

The EOC output has many possible uses as shown in Figure 23.

One simple function is to terminate the charging to prevent

floating (Figure 23a). It can be used as a logic signal to a

microcontroller to indicate that the battery has finished charging. The microcontroller can then switch to the next battery if

appropriate or shutdown the ADP3801/ADP3802. It can also be

used to turn on an LED to signal charge completion (Figure

23b). Using a flip-flop, EOC can control the switching from

BATA to BATB (Figure 23d). The RC filter delays switching

between the two batteries to ensure that the output capacitor is

discharged.

–10–

REV. 0

ADP3800

EOC

(b)

COMP

(a)

EOC

Output Terminates Charge

ADP3800

EOC

EOC

Turns on LED to Signal Charge Completion

VL

100kV

0.1mF

2N3906

Terminates Charge and Turns on LED

ADP3800

COMP

20kV

2N3904 3 2

100kV

(c)

100kV

0.1mF

100kV

EOC

EOC

10kV

2N3906

VL

0.1mF

ADP3800

10kV

20kV

100kV

VL

100kV

1mF

EOC

100kV

270V

20kV

RESET

74H73A

JKQ

*LEVEL SHIFTED TO

TO DRIVE PMOS

270V

2N3906

COMP

2N3904 3 2

Q

BATSELB*

A/B + BATSELA*

(d) Flip-Flop Switches Between Batteries on

Figure 23.

EOC

Output Circuits

EOC

Signal

ADP3801/ADP3802

COMP Node

Both the current loop and the voltage loop share a common,

high impedance compensation node, labeled COMP. A series

capacitor and resistor on this node help to compensate both

loops. The resistor is included to provide a zero in the loop

response and boost phase margin.

The voltage at the COMP node determines the duty cycle of the

PWM. The threshold levels are typically 1.0 V for 0% duty cycle

and 2.0 V for 100% duty cycle, resulting in a total range of

1.0 V. When the ADP3801/ADP3802 first turns on, the COMP

capacitor is at 0.0 V. It has to charge up to at least 1.0 V before

the duty cycle rises above 0% and the pass transistor turns on.

This “soft-start” behavior is desirable to avoid undue stress on

the external components. In addition, whenever the part is

placed in Shutdown or in UVLO, the COMP capacitor is discharged to ensure soft start upon recovery.

The current available to charge and discharge the COMP ca-

pacitor during normal operation is 100 µA. Thus, the slew rate

at this node is equal to 100 µA divided by the capacitor. For a

typical capacitance of 1 µF, the slew rate is 0.1 V/ms. Thus, it

takes about 10 ms before the ADP3801/ADP3802 starts to

operate from a soft-start state. This is regardless of the internal

oscillator frequency. One important note is that the COMP

node is a high impedance point. Any external resistance or leakage current on this node will cause an error in both the charge

current control and the final battery voltage.

Gate Drive

The ADP3801/ADP3802 gate drive is designed to provide high

transient currents to drive the pass transistor. The rise and fall

times are typically 20 ns and 200 ns respectively when driving

a 1 nF load, which is typical for a PMOSFET with R

60 mΩ. Figure 15 shows the typical transient response of the

output stage driving this load from a 10 V supply.

A voltage clamp is added to limit the pull-down voltage to 7 V

below VCC. For example, if VCC is 10 V then the output will

pull down to 3 V minimum, limiting the V

voltage applied to

GS

the external FET.

Low Dropout Regulator and Reference

A 3.3 V LDO is used to generate a regulated supply for internal

circuitry. Additionally, the LDO can deliver up to 10 mA of

current to power external circuitry such as a microcontroller. A

1.0 µF capacitor must be placed close to the VL pin to ensure

stability of the regulator. Due to the design of the regulator,

stability is not contingent on the ESR for the output capacitor.

Many different types of capacitors can be used providing flexibility and ease of design. The LDO also includes a high accuracy, low drift internal reference equal to half of VL to set levels

within the part. During shutdown and UVLO, both the reference and the LDO remain active.

Shutdown

The IC may be placed in shutdown at any time to stop charging

of the batteries and to conserve power. For example, to safely

switch from one battery to the next, the part should be shut

down to momentarily interrupt charging. Also, if the batteries

have completed charging or no batteries are present, then the

part may be placed in shutdown to save power. A logic low on

DS(ON)

=

–11–REV. 0

ADP3801/ADP3802

SD results in shutdown. All internal circuitry is shut off except

for the LDO and the reference, and the supply current is typically 110 µA. When SD returns high, the part resumes full op-

eration. The compensation capacitor at the COMP node is

discharged during shutdown, so the part will resume operation

in soft-start mode.

Undervoltage Lockout—UVLO

The internal Undervoltage Lockout (UVLO) circuit monitors

the input voltage and keeps the part in shut-down mode until

VCC rises above 3.9 V. During UVLO, the LDO and reference

are still active, but the analog front end, the oscillator, and the

gate drive are off. UVLO helps to prevent the circuitry from

entering an unknown state that could incorrectly charge a battery.

To prevent oscillation around VCC = 3.9 V, the UVLO circuitry has built-in hysteresis. Once the part is on, the UVLO

circuitry does not shut it off until the LDO enters dropout.

Because the dropout voltage depends on the LDO’s load, the

UVLO trip point-off also depends on the load. Refer to Figure 8

for a graph of the UVLO trip point-off versus LDO load.

RESET

When the power is first applied to the ADP3801/ADP3802, the

RESET pin is held at ground by an external 1 MΩ resistor. It

remains low until the LDO output voltage rises to above 80% of

its final value. When this threshold is reached, the RESET pin is

pulled high. The internal RESET comparator includes about

150 mV of hysteresis to avoid oscillation around the threshold.

Supply Considerations

The guaranteed operating supply voltage range of the ADP3801/

ADP3802 is from 4 V to 20 V, and it typically consumes 5.0 mA

of quiescent current when not switching. However, the part

needs at least 2 V of headroom between VCC and the voltage

on the CS+ and CS– pins. This is for the common-mode range

on the current sense amplifier. In applications where the input

supply does not offer enough headroom, the circuits in Figures

32 and 33 can be used as explained in the section on low overhead charging.

Overtemperature Shutdown

The ADP3801/ADP3802 has an on-chip temperature detector

to shut the part down when the die temperature reaches typi-

cally +160°C. Such a condition could occur with a short-circuit

on the LDO or a short on the DRV pin. In either case, the operation of the charger will stop and the DRV pin will be pulled

high. With approximately +10°C hysteresis, the overtemperature

shutdown releases at typically +150°C. These temperatures are

higher than the absolute maximum ratings for the die, and are

included as a safety feature only.

Li-Ion Battery Charger

The ADP3801 and ADP3802 are ideally suited for a single or

dual Li-Ion batterypack charger. They combine 200 kHz or

500 kHz switching with a PMOS pass transistor drive to realize

a Buck topology CCCV charger. The following discussion goes

through the complete design of a charger using the ADP3801.

This information also applies to the ADP3802.

Charger Specifications

Battery: 3 Series Cell Li-Ion Pack.

Input Voltage: V

Final Battery Voltage: V

Charge Current: I

= 15 V dc to 20 V dc.

IN

CHARGE

= 12.6 V.

BAT

= 4.0 A (for VO = 0 V to 12.6 V)

Circuit Topology

The complete Buck charger circuit is shown in Figure 24. The

dc-source voltage can be supplied from an ac/dc adaptor or an

external dc/dc supply.

(+15V TO +20V)

V

RESET

SD

VL = +3.3V

1.0mF

EOC

R

C7

56V

40mV

4.3kV

CS

MBRD835

4.3kV

100kV

200kV

100kV

C9

2.2nF

BATA

12.6V

MAX

DRV

RESET

VCC

VL

SD

CS–

CS+

ISET

33mH

MBRD835

ADP3801/

ADP3802

TOP VIEW

(Not to Scale)

1kV

140mF

25V

2.2nF

GND

A/B

BATA

BATB

PROG

ADJ

EOC

COMP

4.7mF

N

I

0.1mF

1MV

100kV

24kV

20kV

210mF

25V

Si4463

Figure 24. Li-Ion Battery Charger

–12–

REV. 0

ADP3801/ADP3802

Current Sense

The maximum charging current is specified by the battery

manufacturer as 4.0 A. To avoid losing excessive power on the

current-sense resistor, it is advisable to keep the voltage drop

across the resistor at maximum current to 160 mV or below.

Thus, R

= 0.16 V/4 A = 40 mΩ. The resistor’s maximum

CS

power rating can be calculated using the data sheet specification

for the Overcurrent Comparator. The overcurrent protection is

specified at 4.9 A when using a 40 mΩ resistor; therefore, the

resistor has to be rated at P

= (4.9)

R

2

× 0.04 = 0.96 W. Thus a

1.0 W or higher power rated resistor should be used. Two

2.2 nF capacitors are connected from the CS+ and CS– inputs

to ground to filter out high frequency switching noise.

ISET Programming Voltage

This voltage programs the charge current based on the above

calculated R

. Using the data sheet specification for the current

CS

programming at the ISET input of 0.1 V/V, we need:

V

ISET

RI

×

CS CHARGE

=

01

./

VV

004 40

..

=

01

./

Ω

VV

A

×

=

16

.

V

The 1.6 V can be obtained from the 3.3 V LDO by a resistor

divider of 20 kΩ and 22 kΩ.

PROG Voltage

Next, the PROG voltage has to be determined to set the proper

final battery voltage. From the data sheet, V

for two Li-Ion

PROG

batteries in series (12.6 V) is between 2.05 V and 2.3 V. A 2.2 V

input can be obtained from the 3.3 V LDO by a resistor divider

of 66.5 kΩ and 33.2 kΩ.

ADJ Voltage

Since no further adjustment of the final battery voltage is required, this pin is tied to the VL pin, which disables the internal

amplifier.

Output Voltage and Duty Cycle

A Buck type of converter’s output voltage VO can be calculated

as follows:

VDVT

IN IN ON

V

=

O

×

×

=

T

×100 100

In the above equation, D is the maximum duty cycle of the

converter in percentage, and T

total period respectively. Setting V

and T are the ON time and

ON

= 15 V provides margin

INMIN

for external voltage drops and the common-mode input range of

the current sense amplifier.

For VIN = 11 V: D

= 20 V: D

For V

IN

MAX

MAX

= V

× 100 / VIN = 12.6 × 100 / 15 = 84%

O

= V

× 100 / VIN = 12.6 × 100 / 20 = 63%

O

Buck Inductor

The inductor value can be calculated after determining the

allowable amount of inductor ripple current. For continuous

buck operation, and considering low cost inductor core materials and acceptable core losses at 200 kHz, the usual peak-topeak inductor ripple current (I

maximum dc current. Using 25% of 4.0 A

) used is 20%-40% of the

RPP

gives I

DC

RPP

= 1.0 APP.

The maximum off-time of the Buck switch (T

OFFMAX

) occurs at

the maximum input voltage of 20 V:

T

OFFMAX

−

=

100

MAX

×

=

100

f kHz

OSC

200 100

−

100 63

×

=

19. µ

s

D

This gives an inductor value of:

VT

×

OMAX OFFMAX

L

>

I

RPP

Vs

12 6 1 9

..

=

10

.

×

µ

H

=

24

µ

A

The max inductor peak current is calculated as follows:

I

LPEAK

= IDC + I

/2 = 4.0 + 1.0/2 = 4.5 A

RPP

PEAK

The max inductor rms current is calculated (where 0.577 is the

conversion factor for a peak to RMS value):

I

LRMS

VT

×××

0 577 0 5 0 577 0 5 12 6 1 9

.. ....

=

L

O OFF

=

×× ×

H

24

µ

s

µ

A

=

03

.

An appropriate inductor is the Coiltronix UP4B330, which is

specified at 33 µH and can carry the 4.5 A current with about a

20°C temperature rise. For the ADP3802, the above formulas

give: T

= 0.74 µs and L = 10 µH.

OFFMAX

PFET Selection and Thermal Design

We have to consult the available P-channel MOSFET (PFET)

transistor selection charts for switch-mode power supply applications to find a PFET in the desired package whose Safe

Operation Area (SOA) would meet the maximum V

and I

IN

O

requirements with acceptable margin. For this application, the

Temic Si4463 was selected in an SO-8 package. This transistor

is specified at V

(for V

4.0 A

= 4.5 V), and I

GS

, and 4.5 A

DC

= –20 V, V

DSS

DMAX

application requirements with adequate

PEAK

= 12 V, R

GSMAX

DS(ON)

= 10 A. Its SOA covers the 20 V,

= 0.013 Ω

margin.

Since the switching losses are negligible for properly driven

PFETs compared to conduction losses, the worst-case conduction losses can be estimated from the worst case ON resistance

(R

) of the selected PFET when subjected to short circuit

DS(ON)

current at the minimum input voltage and close to 100% duty

cycle. R

increases about 50% at T

DS(ON)

= 150°C. Thus the

J

worst case value we can use is 0.023 Ω. The maximum PFET

dissipation is calculated as follows:

P

DMAX

= I

PEAK

2

× R

DS(ON)

= 4.5 A

Next the maximum junction temperature T

2

× 0.023 Ω = 0.47W

of the transistor

JMAX

can be calculated:

T

JMAX

where T

= TA + (R

= 50°C and R

A

θ

JA

) × P

θ

= 50 + (50) × 0.47 = 74°C

DMAX

= 50°C/W, as specified on the

JA

transistor’s data sheet for a 1 inch square PCB-pad. The calculated T

should be below the maximum allowed junction

JMAX

temperature of the transistor with adequate margin. The

Si4463 specifies a T

of 150°C, which we meet with more

JMAX

than adequate margin.

–13–REV. 0

ADP3801/ADP3802

Gate Drive

The ADP3801 and ADP3802 are designed to directly drive the

gate of a PFET with no additional circuitry as shown on the

circuit diagram. The DRV pin pulls the gate up to within

250 mV of VCC, which is more than enough to ensure that the

transistor turns off. To turn the PFET on, the DRV pin pulls

down to a clamped voltage that is at most 7 V below VCC. Check

the specified PFET’s maximum Gate-Source rating to see if this

voltage does not exceed its breakdown. The Si4463 is rated at

= 12 V, which is well above the maximum gate drive for

V

GSMAX

the ADP3801/ADP3802.

Schottky Rectifier Selection and Thermal Design

The Schottky diode’s peak current and average power dissipation must not exceed the diode ratings. The most stressful condition for the output diode is under short circuit (V

where the diode duty cycle D

dition, the diode must safely handle I

is at least 95%. Under this con-

D

at close to 100% duty

PK

= 0 V),

O

cycle.

The diode power dissipation (P

the forward voltage drop (V

) is calculated by multiplying

D

) times the Schottky diode duty

F

cycle multiplied by the short circuit current. The worst-case

forward voltage drop of MBRD835 diode is 0.41 V at I

PK

=

4.5 A, thus:

P

= I

× DD × VF = 4.5 × 0.95 × 0.41 = 1.8W

D

PK

From the diode’s worst-case dissipation, the maximum junction

temperature T

T

JMAX

R

is the junction to ambient thermal impedance of the diode.

θJA

The calculated T

junction temperature of the diode with adequate margin. T

of the diode can be calculated:

JMAX

= TA + R

JMAX

× PD = 25 + (40) × 1.8 = 97°C

θJA

should be below the maximum allowed

JMAX

of the MBRD835 is 125°C, which is met with adequate margin.

Input Capacitor Selection

In continuous mode, the source current of the PMOS is a square

wave of duty cycle V

OUT/VIN

. To prevent large voltage transients, a low ESR input capacitor sized for the maximum rms

current must be used. The maximum rms capacitor current is

given by:

I

I

RMS

This formula has a maximum at VIN = 2 V

I

/2 = 2.0 A.

OUT

OUT

≈× −

V

VVV

IN

()

OUT IN OUT

, where I

OUT

RMS

=

This simple worst case condition is commonly used for design

because even significant deviations do not offer much relief.

Note that capacitor manufacturers’ ripple current ratings are

often based on only 2000 hours of life. This makes it advisable

to further derate the capacitor, or to choose a capacitor rated at

a higher temperature than required. Several capacitors may also

be paralleled to meet size or height requirements in the design.

As a first choice, three 68 µF/20 V Sprague type 593D tantalum

capacitors are used in parallel. Each is specified as follows:

ESR = 0.2 Ω, maximum ripple current of 0.91A

. In addition

RMS

to C

, a 0.1 µF decoupling capacitor is required as close as

IN

possible to the VCC pin.

Once the capacitor is chosen, the input ripple voltage should be

checked:

V I ESR

INRIPPLE O

=× +

D

/

ON

fC

×

OSC IN

A

=× +

..

40 007

200 210

84 100

kHz F

/100

×

µ

mV

=

360Ω

PP

This is low enough for most applications. For cost reduction,

one of the 68 µF capacitors could be removed, or a cheaper

electrolytic could be used instead.

Output Capacitor Selection

As a first choice, we’ll use two of the same type of 68 µF

Sprague capacitors for the output. The inductor rms ripple current

was calculated as 0.3 A, which is far below the specification for

these capacitors. The other consideration is the allowable output

ripple voltage. Assuming high battery internal resistance, all of

the worst case inductor ripple current may flow through the

output capacitor. This results in a ripple voltage of:

V I ESR

OUTRIPPLE LPP

=× +

D

/

ON

fC

×

OSC OUT

A

=× +

..

10 01

84 100

kHz F

200 140

/100

×

mV

=

130Ω

PP

µ

This ripple is low enough for most applications. Again, one of

the capacitors could be removed or lower cost electrolytic capacitors could be used to reduce cost.

Charger Performance Summary

The circuit properly executes the charging algorithm, exhibiting

stable operation regardless of battery conditions, including an

open circuit load in which the battery is removed.

Li-Ion charging characteristics are given in Figure 25. The

charge current is maintained at its programmed level until the

battery reaches its final voltage. Then the current begins to

decrease. The shape of the current decrease is dependent on the

internal impedance of the battery. When the current drops below

240 mA, the EOC comparator signals the end-of-charge of the

battery.

4.5

4.0

3.5

– Volts

3.0

BAT

V

2.5

4.0

– Amps

2.7

1.3

CHARGE

I

0

0 0.5 1.0 1.5 2.0 3.0

V

BAT

I

CHARGE

TIME – Hours

EOC

2.5

Figure 25. Li-Ion Charging Characteristic

–14–

REV. 0

The efficiency of this circuit is shown in Figure 26 for a charge

current of 4 Amps. As expected, the efficiency increases with the

output voltage, up to a maximum of 92% at 12.6 V.

100

VCC = 15V

I

= 4 AMP

CHARGE

90

80

EFFICIENCY – %

70

60

67

Figure 26. Efficiency for I

FREQ = 200kHz

FREQ = 500kHz

910 1211

8

OUTPUT – Volts

CHARGE

13

= 4.0 Amp

14

Figure 27 shows the output voltage transient when a battery

load is snapped off. The output is charging a battery (which is

currently discharged to 5 V) at 4.0 A when the battery is removed. The high charge current causes the output voltage to

quickly increase and exceed the final battery voltage. However,

the overvoltage comparator quickly controls the output and only

a small overshoot results. When the battery is returned to the

circuit, VBAT is pulled back down to the battery’s voltage.

14V

12V

10V

8V

6V

OUTPUT VOLTAGE – Volts

CH1

2.00V

V

BAT

I

CHARGE

VCC = 15V

50ms/DIV

M50.0ms CH 1

TIME – ms

= 12.6V

= 4 AMP

10.0V

Figure 27. Output Voltage Transient Due to Battery Snap

Off

The behavior of the circuit when it is powered on with a dead

battery inserted is important to check to make sure that the

charger does not exhibit irregular behavior during power-up. In

this case, the ADP3801 needs to regulate the output current to

4.0 A. Figure 28 shows the average Si4463 source current

under such a condition. When the input power is applied to the

charger, the source current ramps up in a controlled manner

due to the ADP3801’s soft start.

ADP3801/ADP3802

15V

10V

– Volts

CC

V

5V

0A

– Amps

4A

CHARGE

I

Figure 28. Source Current Due to Input Turn-On

Feedback Loop Compensation Design

The ADP3801 and ADP3802 have two separate feedback loops,

the current control loop and the voltage control loop. Each loop

must be compensated properly so that the circuit is stable during the entire charging cycle of a battery including the case where

no battery is present. A series RC from the COMP pin to ground

provides pole/zero compensation for both loops. The circuit in

Figure 24 is properly compensated for the ADP3801 and

ADP3802 and can be used as is.

Figure 29 shows a typical ac model of the ADP3801/ADP3802.

The current loop and voltage loop are comprised of voltage

controlled current sources (GM stages). The gains given in the

schematic and the impedance at the COMP node are typical

values for both the ADP3801 and ADP3802. This model can be

used to simulate the small signal ac behavior of the part using a

SPICE-based simulator when paired with an ac model of a buck

regulator. However, transient and dc behavior is not modeled

with this model. The GM stages are actually modeled using the

“Table” component in PSpice, which limits the dc levels to ease

dc convergence. The coefficients on the schematic give the table

coefficients. The input resistors (R1 and R2) are currently set

for a 4.2 V final battery voltage. Use the accompanying table to

adjust R1 and R2 for the other voltage options. Doing so is

important to properly set the voltage loop gain.

CS+

CS–

ISET

V

BAT

GM1

gm = 1E – 4

(0,0) (0.2, 20E – 6)

100kV

R1

173kV

VCC

I

(AVERAGE)

CHARGE

V

BAT

4.2V 173kV 112kV

8.4V 229kV 56kV

12.6V 247.7kV 37.3kV

R3

(–12.5m, –200E – 6) (12.5m,0)

V1

1.65V

R2

112kV

(–62.5m, –200E – 6) (62.5m,0)

VCC = 15V

T

I

20ms/DIV

R1 R2

GM2

gm = 8E – 3

GM3

gm = 1.6E – 3

= +258C

A

CHARGE

100mA

= 4 Amps

I1

R4

4MV

E4

OUT

GAIN = 1V/V

Figure 29. AC Behavioral SPICE Model for the ADP3801

and ADP3802

–15–REV. 0

ADP3801/ADP3802

NiCad/NiMH Charging

When paired with a low cost, 8-bit microcontroller, the

ADP3801/ADP3802 charges NiCad and NiMH batteries. The

ADP3801/ADP3802 is used to provide a programmable charge

current limit with a fail-safe voltage limit, and the microcontroller

monitors the battery and determines the charge termination.

Common methods for termination are “negative delta V” and

“delta T.” Both methods require that the present value of either

the voltage or temperature be compared to a previous value.

Such functionality is performed by an µC with an on-board

ADC.

The µC and the ADP3801/ADP3802 are configured as shown

in Figure 30 for the universal charger. The voltage setting on the

ADP3801/ADP3802 should not interfere with normal charging,

but still provide a fail safe voltage if the battery is removed. For

example, if a 6-cell NiCad battery is being charged, the output

voltage of the ADP3801/ADP3802 should be programmed to

12.6 V. The 6-cell battery has a peak voltage of approximately

1.7 V–1.8 V per cell, giving a total voltage of 9.6 V–10.8 V.

Thus, the 12.6 V setting provides enough headroom for normal

charging.

Universal Battery Charger

The combination of a µC and the ADP3801/ADP3802 can be

extended to a low cost universal charger for Li-Ion and NiCad/

NiMH as shown in Figure 30. The µC with on-board A/D con-

verter monitors the battery’s voltage and temperature to determine the end-of-charge for either NiCad or NiMH batteries.

The ADP3801/ADP3802 also monitors the battery voltage to

determine the end-of-charge for Li-Ion. The EOC output is

connected to a digital input on the µC for signaling. The µC can

shutdown the charger circuitry when it is not required. The µC

shown operates from 3.3 V, so it can be powered directly from

the LDO of the ADP3801/ADP3802. The LDO voltage also

serves as a 1% reference for the µC’s ADC.

VIN

VDD

AN0

AN1

PA0

MICRO-

CONTROLLER

PA1

PA2PA3

R1

R4

ISET

C1

R2

PROG

R5

C2

VCC

ADP3801/

ADP3802

CHARGER CIRCUIT

SD

EOC

BATA

GND

VL

R3

C3

T

T = BATTERY

THERMISTOR

Figure 30. Universal Battery Charger Block Diagram

Both the charge current and the final battery voltage can be

dynamically set by using a PWM output from the µC. The PWM

inputs to ISET and PROG are filtered by an RC combination to

generate a dc voltage on the pins. This functionality allows

multiple battery types and chemistries to be accommodated in a

single charger circuit.

Dual Li-Ion Battery Charger

Some applications such as certain desktop chargers for cellular

phones or laptops with two batteries require that two separate

battery stacks be charged independently. The ADP3801/ADP3802

is designed to handle these applications with two battery sense

inputs and a multiplexer to select between the two. The application circuit is essentially the same as Figure 24 except that external FETs must be added to direct the charge current to the

proper battery stack. Figure 31 shows the additional circuitry

needed.

MBRD835

Si4463

C

O

R

CS

40mV

4.3kV

CS–CS+

BATA

BATB

ADP3801/

ADP3802

4.3kV

A/B

100kV

Si4463

R

B

100kV

**

OPEN-COLLECTOR OUTPUTS

*

MBRD835

BATA

BATB

A/B

SELECTOR

Figure 31. Dual Li-Ion Battery Charger

To provide alternate or sequential charging, the two separate

batteries are alternately connected to the output of the charger

by two Si4463 PFETs. The control of these FETs is accom-

plished by open-collector logic outputs and 100 kΩ pull-up

resistors. The programming of the A/B terminal should come

from a 0 V to 3.3 V logic output. Most likely a dedicated logic

circuit or a microcontroller would control the system. The

BATB sense input is enabled by connecting a >2 V potential to

the A/B input (or <0.8 V to select BATA). The A and B battery

voltages are directly sensed by the BATA and BATB inputs.

Two Schottky diodes are also included to prevent one battery

stack from shorting to the other through the body diodes of the

FETs. When the charger has finished charging one battery (signaled by the EOC output), the MUX and external FETs can be

switched to charge the second battery. When switching from

one battery to the next the following procedure is recommended

to minimize transient currents:

1. Turn off the ADP3801/ADP3802 PWM by bringing the SD

pin low.

2. Turn off the FET to the battery being charged.

3. Wait approximately 60 seconds for C

R

.

B

to discharge through

O

4. Turn on the FET to the second battery.

5. Change the A/B SELECT MUX to the second battery.

6. Turn on the ADP3801/ADP3802 by bringing the SD pin

high.

–16–

REV. 0

ADP3801/ADP3802

Si4463

VCC

DRV

EOC

CS–

CS+

ISET

BATA

BATB

A/B

PROGADJ

COMPGND

SD

RESET

V

ISET

R

CS

40mV

4.3kV

4.3kV

2.2nF

GND

V

IN

VL

0.1mF

0.1mF

VL

V

BATPROG

210mF

ADP3801/ADP3802

2.2nF

The 60 second wait period allows the output capacitor to discharge before switching from one battery to the next. Without

this wait period, the capacitor would be fully charged when

switched to an uncharged battery. The current under this condition is only limited by the ESR of the capacitor, the ON resistance of the FET and diode, and the series resistance of the

battery. These values are typically very small, so current in

excess of 5 amps can flow for a short time period. In most

practical circuits the wait period is not required, but it is good

practice to have it in µC controlled systems. The duration of the

wait period is determined by the RC time constant of C

and R

O

B

and can be adjusted by changing these components.

The two Si4463 switches are turned on by connecting their

gates to ground. In a short circuit or overdischarged battery

condition, the switches could be operated in their linear region.

This may result in high power dissipation and excessive die

temperature rise. In µC controlled chargers a simple monitor

routine can reduce the charge current if the battery voltage is

lower than about 2 V. This should not happen under normal

circumstances as the Li-Ion cells are not discharged below

2.5 V/cell.

Low Overhead Charging

For applications where the input supply is less than 2 V higher

than the final battery voltage, the circuit of Figure 32 can be

used. This circuit adds a resistor divider to the input of the

current sense amplifier to increase its common-mode input

voltage range. The value of this resistor divider should divide

down the battery voltage such that the common-mode voltage at

CS+ and CS– is at least 2 V less than the chip’s VCC. The

formula for the ratio is:

Because the current sense voltage is divided down by these

input resistors, the current sense programming function also

changes. Remember to adjust the programming function by the

same ratio. In this example, the programming function would

become 0.125 V/V. Also, the EOC current detection point changes

by the same factor.

An alternative to adding the resistor divider is to use a low side

current sense. The CS+ and CS– inputs have a common-mode

range that extends approximately 300 mV below ground. The

circuit in Figure 33 shows how a low side current sense would

be configured. The current programming function, EOC detection point, and ac performance do not change from the normal

configuration.

RR

For example, if VCC

R

12

+

MIN

VCC V

2

≤

MIN

VBAT

−

MAX

= 9 V and VBAT

2

= 8.4 V, then the

MAX

Figure 33. Low Side Current Sensing For Low Overhead

Charging

ratio would be 0.833. To provide some headroom for resistor

tolerances and line drops, the actual ratio should be lowered to

0.8. The resistors should be reasonably large to keep the current

drain low. Values of R1 = 20 kΩ (0.1%) and R2 = 80 kΩ (0.1%)

work well. A diode is added between the current sense resistor

and the battery to prevent discharging the battery through these

resistors.

R

CS

0.1V

R1

20kV

R2

80kV

Figure 32. Low Overhead Charging

430pF

CS+ CS–

ADP3801/

ADP3802

430pF

R1

20kV

R2

80kV

–17–REV. 0

ADP3801/ADP3802

VCC Greater Than 20 V Operation

Some ac/dc adapters have a poorly regulated output voltage

that can rise above the 20 V maximum operating voltage of the

ADP3801/ADP3802. The circuit in Figure 34 uses a Zener

diode and an NPN transistor to extend the ADP3801/ADP3802’s

maximum input voltage. The Zener should be at least 3 V higher

than the final battery voltage to meet the minimum headroom

requirements. 3 V is used to account for the V

2N3904 transistor and additional losses in the circuit. If V

drop of the

BE

IN

drops below the value of the Zener diode, VCC is no longer

regulated and it tracks V

. If the 2 V of headroom on the cur-

IN

rent sense pins is not maintained, then the circuits of Figures 32

and 33 can also be used in conjunction with the circuit of Figure

34.

V

IN

10kV

3.3V

33mH

100kV

2N3904

9V

0.1mF

VL

SD

RESET

9V

VCC

DRV

ADP3801/ADP3802

140mF

0.1mF

EOC

CS+

40mV

CS–

BAT

A/B

BATA

BATB

ISET

system current and dynamically control the ADP3801/ADP3802’s

charge current.

The current setting voltage is produced by R3 and R4 according

to the following formula:

I

SET

1

≈×

10

R

CS

RR

3

R

34

VL

+

This equation is approximate because the impedance of R2 and

R1 does effect the resistor divider of R3 and R4, but the impact

is small. As the system current increases, the voltage across R

also increases. This voltage is subtracted from V

with a gain

ISET

SS

set by R1 and R2. As the graph in Figure 35 shows, the charge

current reduces as the system current increases, and eventually

the charge current becomes zero (I

). The system current at

ZERO

which this occurs can be set by selecting R1 and R2 according

to the following formula:

I

ZERO

≈×

R

R

1210

R

CS

ISET

×

R

SS

Because the AD8531 is a single supply amplifier with its negative rail at ground, its output does not go below 0.0 V, so any

further increase in system current does not change V

signing a charger with a maximum charge current of 3A (R

ISET

. De-

CS

=

0.05 Ω) which reduces to zero when the system current reaches

7A (R

= 0.025 Ω) results in the following resistor values: R1 =

SS

100 kΩ, R2 = 820 kΩ, R3 = 8.3 kΩ, R4 = 10 kΩ.

PROG

COMP

ADJGND

Figure 34. VCC Greater Than 20 V Operation

The gate drive of the PFET is capacitively coupled to the DRV

pin with a 0.1 µF capacitor. While the DRV pin is switching, the

voltage swing on the DRV pin is coupled to the gate, but the dc

voltage is blocked. This allows the gate of the PFET to be at a

voltage that is higher than the absolute maximum rating of the

DRV pin. The 9 V Zener diode limits the gate drive voltage and

the 100 kΩ resistor provides a dc pull-up to turn the PFET off

when the DRV pin is not switching.

System Current Sense Reduces Charge Current

In many applications the power required for the system and the

battery charger exceeds the total power available from the ac/dc

adapter. A design where battery charger current is decreased as

the system current increases helps to keep a constant power

demand on the brick. Dynamically adjusting the charge current

keeps the total power output of the brick constant. The circuit

in Figure 35 uses an external low cost amplifier to sense the

I

AC/DC

BRICK

VCC

100kV

R4

10kV

DRV

VCC

VL

I

BAT

ADP3801/ADP3802

(I

SET

0

0

SYSTEM

R1

R

SS

R1

R2

820kV

) = MAXIMUM CHARGE CURRENT

I

ZERO

R3

8.3kV

100kV

CS+

I

SYSTEM

I

BAT

R

820kV

OP193

CS

CS–

R2

V

BAT

ISET

SYSTEM

BAT

100kV

0.1mF

Figure 35. System Current Sense Reduces Charge Current

–18–

REV. 0

ADP3801/ADP3802

Board Layout Suggestions

When laying out the printed circuit board, the following checklist should be used to ensure proper operation of the ADP3801

and ADP3802. These items are also illustrated graphically in

the layout diagram on the evaluation board application note.

Check the following in your layout:

1) The IC ground must return to a) the power and b) the signal

grounds with as short of leads as possible. If a double layer

PCB board is used and a ground plane is available, connect

all grounded parts directly to the ground plane. The ground

returns to the anode of the Schottky diode and the minus

terminal of C

2) Connect the IC’s current sense pins (CS+ and CS–) to R

should have as short of lead lengths as possible.

IN

CS

with as short of leads (<0.5 inch) as possible.

3) Route the CS+ and CS– traces together with minimum spacing. The filter capacitors should be close to the IC.

4) Connect the positive side of C

as close as possible to the

IN

source of the P-channel MOSFET (or the emitter of the

PNP). This capacitor provides the ac current to the pass

transistor.

5) Connect the input decoupling capacitor (0.l µF) close to the

VCC input of the IC. This capacitor carries the DRV peak

currents.

6) Connect the 0.1 µF LDO decoupling capacitor as close as

possible to the VL pin.

7) The RESET pin has an internal pull-up, and should be pulled

low with an external resistor. The RESET pin is high impedance and should not be allowed to float.

–19–REV. 0

ADP3801/ADP3802

0.1574 (4.00)

0.1497 (3.80)

0.0098 (0.25)

0.0040 (0.10)

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

16-Lead Narrow Body (SOIC)

(R-16A)

0.3937 (10.00)

0.3859 (9.80)

16 9

PIN 1

0.2440 (6.20)

81

0.2284 (5.80)

0.0688 (1.75)

0.0532 (1.35)

0.0196 (0.50)

0.0099 (0.25)

C3351–8–10/98

x 45°

SEATING

PLANE

0.0500

(1.27)

BSC

0.0192 (0.49)

0.0138 (0.35)

0.0099 (0.25)

0.0075 (0.19)

8°

0°

0.0500 (1.27)

0.0160 (0.41)

–20–

PRINTED IN U.S.A.

REV. 0

Loading...

Loading...