Dual Bootstrapped 12 V MOSFET

FEATURES

All-in-one synchronous buck driver

Bootstrapped high-side drive

1 PWM signal generates both drives

Anticross-conduction protection circuitry

Output disable control turns off both MOSFETs to float the

output per Intel® VRM 10 and AMD Opteron specifications

APPLICATIONS

Multiphase desktop CPU supplies

Single-supply synchronous buck converters

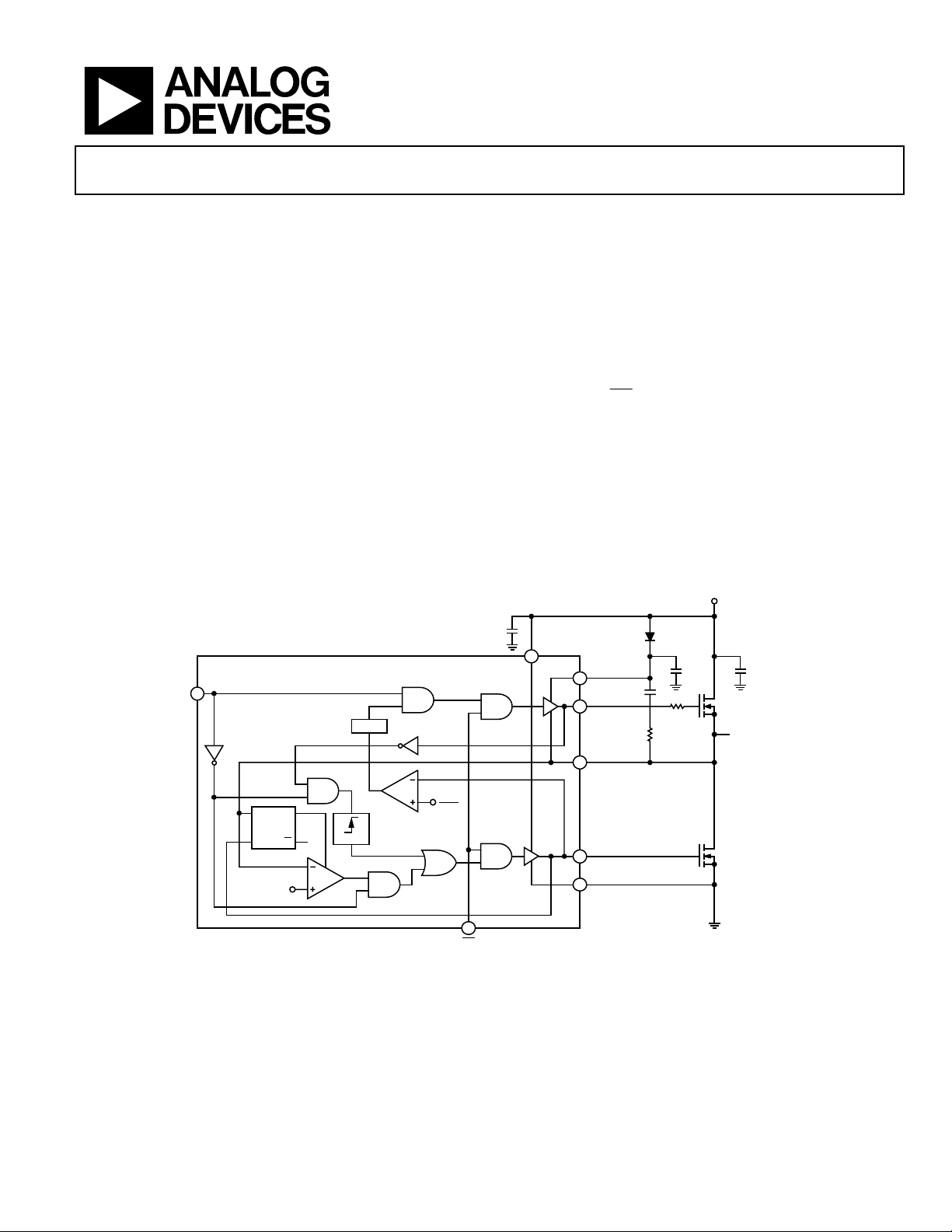

FUNCTIONAL BLOCK DIAGRAM

Driver with Output Disable

ADP3418

GENERAL DESCRIPTION

The ADP3418 is a dual, high voltage MOSFET driver optimized

for driving two N-channel MOSFETs, the two switches in a

nonisolated, synchronous, buck power converter. Each of the

drivers is capable of driving a 3000 pF load with a 30 ns transition

time. One of the drivers can be bootstrapped, and is designed to

handle the high voltage slew rate associated with floating highside gate drivers. The ADP3418 includes overlapping drive

protection to prevent shoot-through current in the external

OD

MOSFETs. The

low-side MOSFETs to prevent rapid output capacitor discharge

during system shutdowns.

The ADP3418 is specified over the commercial temperature

range of 0°C to 85°C, and is available in an 8-lead SOIC

package.

pin shuts off both the high-side and the

12V

C

IN

ADP3418

2

SQ

R

Q

1V

CMP

DELAY

DELAY

CMP

VCC

6

OD

VCC

3

VCC

4

1

8

7

5

6

BST

DRVH

SW

DRVL

PGND

C

R

BST1

BST1

D1

C

BST2

R

Q1

G

TO

INDUCTOR

Q2

03229-B-001

Figure 1.

Rev. B

Information furnished by Analog Devices is believed to be accurate and reliable.

However, no responsibility is assumed by Analog Devices for its use, nor for any

infringements of patents or other rights of third parties that may result from its use.

Specifications subject to change without notice. No license is granted by implication

or otherwise under any patent or patent rights of Analog Devices. Trademarks and

registered trademarks are the property of their respective owners.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700

Fax: 781.326.8703 © 2004 Analog Devices, Inc. All rights reserved.

www.analog.com

ADP3418

TABLE OF CONTENTS

Specifications..................................................................................... 3

Overlap Protection Circuit...........................................................9

Absolute Maximum Ratings............................................................ 4

ESD Caution.................................................................................. 4

Pin Configuration and Function Descriptions............................. 5

Timing Characteristics..................................................................... 6

Typical Performance Characteristics ............................................. 7

Theory of Operation ........................................................................ 9

Low-Side Driver............................................................................ 9

High-Side Driver .......................................................................... 9

REVISION HISTORY

8/04—Data Sheet Changed from Rev. A to Rev. B

Updated Figure 1; Deleted Figure 2.....................................................1

Updated Specifications Table...............................................................3

Updated Pin Description......................................................................5

Updated Theory of Operation .............................................................9

Updated Applications Section............................................................10

Change to Ordering Guide.................................................................14

Application Information................................................................ 10

Supply Capacitor Selection ....................................................... 10

Bootstrap Circuit........................................................................ 10

MOSFET Selection..................................................................... 10

PC Board Layout Considerations................................................. 12

Outline Dimensions....................................................................... 14

Ordering Guide .......................................................................... 14

4/04—Data Sheet Changed from Rev. 0 to Rev. A

Updated Format...................................................................... Universal

Change to General Description...........................................................1

Change to Figure 13 ..............................................................................8

Change to Ordering Guide.................................................................12

3/03—Revision 0: Initial Version

Rev. B | Page 2 of 16

ADP3418

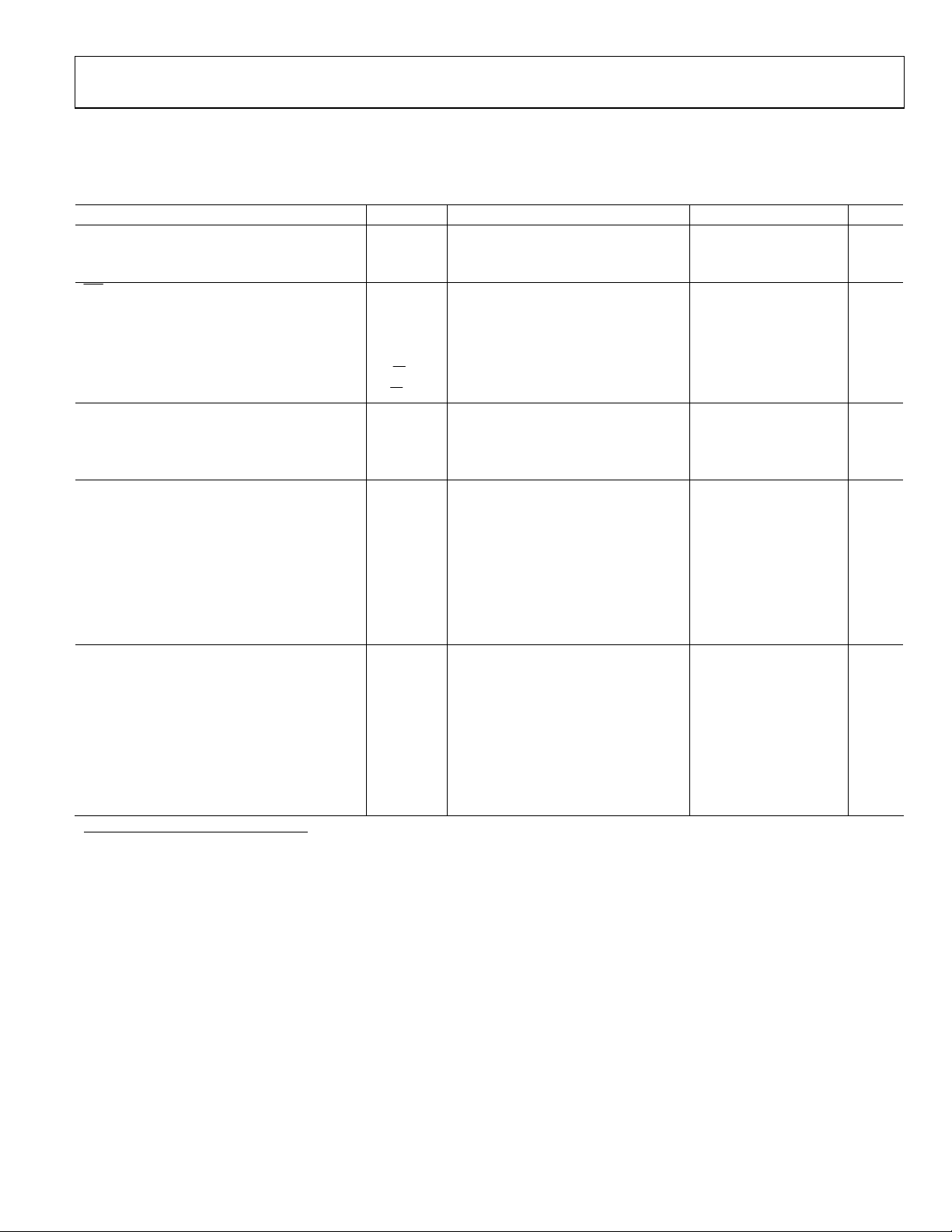

SPECIFICATIONS

VCC = 12 V, BST = 4 V to 26 V, TA = 0°C to 85°C, unless otherwise noted.

Table 1.

Parameter Symbol Conditions Min Typ Max Unit

SUPPLY

Supply Voltage Range V

Supply Current I

OD INPUT

Input Voltage High 2.6 V

Input Voltage Low 0.8 V

Input Current –1 +1 µA

Propagation Delay Time

t

PWM INPUT

Input Voltage High 3.0 V

Input Voltage Low 0.8 V

Input Current –1 +1 µA

HIGH-SIDE DRIVER

Output Resistance, Sourcing Current V

Output Resistance, Sinking Current V

Transition Times t

t

Propagation Delay

t

LOW-SIDE DRIVER

Output Resistance, Sourcing Current 1.8 3.0 Ω

Output Resistance, Sinking Current 1.0 2.5 Ω

Transition Times t

t

Propagation Delay2 t

t

Timeout Delay SW = 5 V 240 ns

SW = PGND 90 120 ns

1

All limits at temperature extremes are guaranteed via correlation using standard Statistical Quality Control (SQC).

2

For propagation delays, t

1

CC

SYS

2

refers to the specified signal going high, and t

pdh

t

pdh

OD

pdl

OD

rDRVH

fDRVH

t

pdhDRVH

pdlDRVH

rDRVL

See Figure 4, C

fDRVL

pdhDRVL

pdlDRVL

4.15 13.2 V

BST = 12 V, IN = 0 V 3 6 mA

See Figure 3 25 40 ns

See Figure 3 20 40 ns

− VSW = 12 V 1.8 3.0 Ω

BST

− VSW = 12 V 1.0 2.5 Ω

BST

See Figure 4, V

= 3 nF

C

LOAD

See Figure 4, V

= 3 nF

C

LOAD

See Figure 4, V

V

− VSW = 12 V 20 35 ns

BST

See Figure 4, C

− VSW = 12 V,

BST

− VSW = 12 V,

BST

− VSW = 12 V 40 65 ns

BST

= 3 nF 25 35 ns

LOAD

= 3 nF 21 30 ns

LOAD

35 45 ns

20 30 ns

See Figure 4 30 60 ns

See Figure 4 10 20 ns

refers to it going low.

pdl

Rev. B | Page 3 of 16

ADP3418

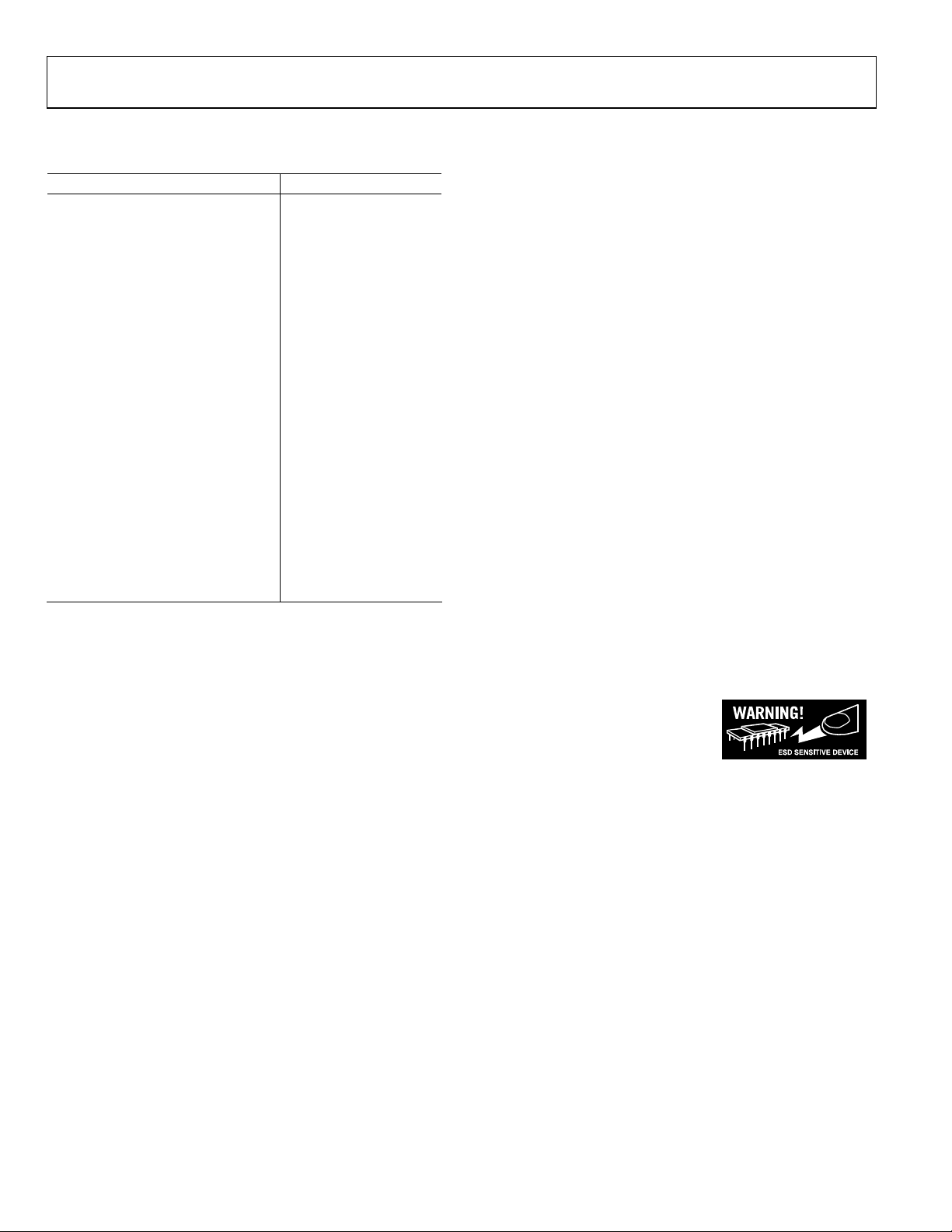

ABSOLUTE MAXIMUM RATINGS

Table 2.

Parameter Rating

VCC –0.3 V to +15 V

BST

DC –0.3 V to VCC + 15 V

<200 ns –0.3 V to 36 V

BST to SW –0.3 V to +15 V

SW

DC –5 V to +15 V

< 200 ns –10 V to +25 V

DRVH SW – 0.3 V to BST + 0.3 V

DRVL (< 200 ns) –2 V to VCC + 0.3 V

All Other Inputs and Outputs –0.3 V to VCC + 0.3 V

Operating Ambient Temperature

Range

Operating Junction Temperature

Range

Storage Temperature Range –65°C to +150°C

Junction-to-Air Thermal Resistance

)

(θ

JA

2-Layer Board 123°C/W

4-Layer Board 90°C/W

Lead Temperature (Soldering, 10 s) 300°C

Infrared (15 s) 260°C

0°C to 85°C

0°C to 150°C

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability. Absolute maximum ratings apply individually

only, not in combination. Unless otherwise specified, all voltages

are referenced to PGND.

ESD CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily accumulate on

the human body and test equipment and can discharge without detection. Although this product features

proprietary ESD protection circuitry, permanent damage may occur on devices subjected to high energy

electrostatic discharges. Therefore, proper ESD precautions are recommended to avoid performance

degradation or loss of functionality.

Rev. B | Page 4 of 16

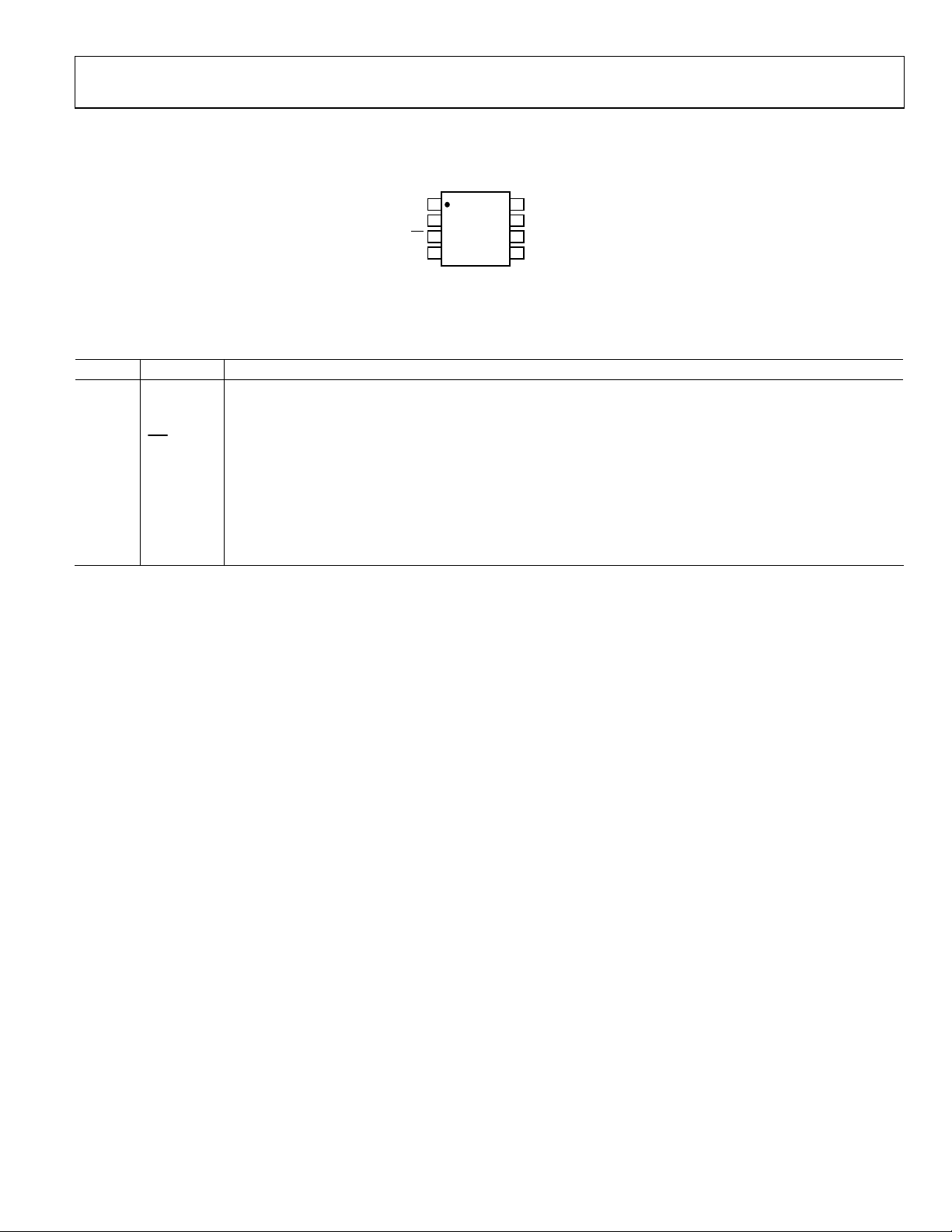

ADP3418

V

PIN CONFIGURATION AND FUNCTION DESCRIPTIONS

DRVH

BST

1

AD3418

IN

2

TOP VIEW

3

OD

(Not to Scale)

CC

4

Figure 2. Pin Configuration

Table 3. Pin Function Descriptions

Pin No. Mnemonic Description

1 BST

Upper MOSFET Floating Bootstrap Supply. A capacitor connected between the BST and SW pins holds this

bootstrapped voltage for the high-side MOSFET as it is switched. The capacitor should be between 100 nF and 1 µF.

2 IN Logic Level Input. This pin has primary control of the drive outputs.

3

OD

Output Disable. When low, this pin disables normal operation, forcing DRVH and DRVL low.

4 VCC Input Supply. This pin should be bypassed to PGND with ~1 µF ceramic capacitor.

5 DRVL Synchronous Rectifier Drive. Output drive for the lower (synchronous rectifier) MOSFET.

6 PGND Power Ground. Should be closely connected to the source of the lower MOSFET.

7 SW

This pin is connected to the buck switching node, close to the upper MOSFET’s source. It is the floating return for

the upper MOSFET drive signal.

8 DRVH Buck Drive. Output drive for the upper (buck) MOSFET.

8

SW

7

PGND

6

DRVL

5

03229-B-002

Rev. B | Page 5 of 16

ADP3418

O

TIMING CHARACTERISTICS

OD

DRVH

R DRVL

t

pdlOD

90%

t

pdhOD

10%

03229-B-003

Figure 3. Output Disable Timing Diagram

IN

t

rDRVL

03229-B-004

DRVL

DRVH-SW

SW

t

pdlDRVLtfDRVL

t

pdhDRVH

t

rDRVH

V

TH

t

pdlDRVH

V

t

fDRVH

TH

t

pdhDRVL

1V

Figure 4. Timing Diagram. Timing is referenced to the 90% and 10% points, unless otherwise noted.

Rev. B | Page 6 of 16

ADP3418

TYPICAL PERFORMANCE CHARACTERISTICS

26

= 12V

V

1

IN

CC

= 3nF

C

LOAD

24

DRVL

2

3

DRVH

DRVL

03229-B-005

Figure 5. DRVH Rise and DRVL Fall Times

22

20

FALL TIME (ns)

18

16

JUNCTION TEMPERATURE (°C)

Figure 8. DRVH and DRVL Fall Times vs. Temperature

DRVH

1250 25 50 75 100

03229-B-008

IN

1

DRVH

2

DRVL

3

60

TA=25°C

V

= 12V

CC

50

40

30

RISE TIME (ns)

20

DRVH

DRVL

Figure 6. DRVH Fall and DRVL Rise Times

40

VCC = 12V

= 3nF

C

LOAD

35

30

RISE TIME (ns)

25

20

JUNCTION TEMPERATURE (°C)

Figure 7. DRVH and DRVL Rise Times vs. Temperature

DRVH

DRVL

03229-B-006

1250 25 50 75 100

03229-B-007

Rev. B | Page 7 of 16

10

LOAD CAPACITANCE (nF)

Figure 9. DRVH and DRVL Rise Times vs. Load Capacitance

35

TA=25°C

= 12V

V

CC

30

25

20

FALL TIME (ns)

15

10

LOAD CAPACITANCE (nF)

Figure 10. DRVH and DRVL Fall Times vs. Load Capacitance

DRVL

DRVH

51234

03229-B-009

51234

03229-B-010

ADP3418

60

TA=25°C

= 12V

V

CC

= 3nF

C

LOAD

5

4

TA = 25°C

C

= 3nF

LOAD

40

20

SUPPLY CURRENT (mA)

0

16

15

14

13

SUPPLY CURRENT (mA)

IN FREQUENCY (kHz)

Figure 11. Supply Current vs. Frequency

VCC = 12V

= 3nF

C

LOAD

f

= 250kHz

IN

3

2

1

DRVL OUTPUT VOLTAGE (V)

12000 200 400 600 800 1000

03229-B-011

0

VCC VOLTAGE (V)

501234

03229-B-013

Figure 13. DRVL Output Voltage vs. Supply Voltage

12

JUNCTION TEMPERATURE (°C)

1250 25 50 75 100

03229-B-012

Figure 12. Supply Current vs. Temperature

Rev. B | Page 8 of 16

ADP3418

THEORY OF OPERATION

The ADP3418 is a dual MOSFET driver optimized for driving

two N-channel MOSFETs in a synchronous buck converter

topology. A single PWM input signal is all that is required to

properly drive the high-side and the low-side MOSFETs. Each

driver is capable of driving a 3 nF load at speeds up to 500 kHz.

A more detailed description of the ADP3418 and its features

follows. Refer to Figure 1.

LOW-SIDE DRIVER

The low-side driver is designed to drive a ground-referenced

N-channel MOSFET. The bias to the low-side driver is internally

connected to the VCC supply and PGND.

When the driver is enabled, the driver’s output is 180 degrees

out of phase with the PWM input. When the ADP3418 is disabled, the low-side gate is held low.

HIGH-SIDE DRIVER

The high-side driver is designed to drive a floating N-channel

MOSFET. The bias voltage for the high-side driver is developed

by an external bootstrap supply circuit, which is connected

between the BST and SW pins.

The bootstrap circuit comprises a diode, D1, and bootstrap

. C

capacitor, C

BST1

BST2

and R

side gate drive voltage and limit the switch node slew-rate

(referred to as a Boot-Snap™ circuit, see the Application

Information section for more details). When the ADP3418 is

starting up, the SW pin is at ground, so the bootstrap capacitor

will charge up to VCC through D1. When the PWM input goes

high, the high-side driver will begin to turn on the high-side

MOSFET, Q1, by pulling charge out of C

turns on, the SW pin will rise up to V

+ V

V

IN

, which is enough gate-to-source voltage to hold Q1

C(BST)

on. To complete the cycle, Q1 is switched off by pulling the gate

down to the voltage at the SW pin. When the low-side MOSFET,

Q2, turns on, the SW pin is pulled to ground. This allows the

bootstrap capacitor to charge up to VCC again.

are included to reduce the high-

BST

and C

BST1

, forcing the BST pin to

IN

BST2

. As Q1

OVERLAP PROTECTION CIRCUIT

The overlap protection circuit prevents both of the main power

switches, Q1 and Q2, from being on at the same time. This is

done to prevent shoot-through currents from flowing through

both power switches and the associated losses that can occur

during their on/off transitions. The overlap protection circuit

accomplishes this by adaptively controlling the delay from the

Q1 turn off to the Q2 turn on, and by internally setting the

delay from the Q2 turn off to the Q1 turn on.

To prevent the overlap of the gate drives during the Q1 turn off

and the Q2 turn on, the overlap circuit monitors the voltage at

the SW pin. When the PWM input signal goes low, Q1 will

begin to turn off (after propagation delay). Before Q2 can turn

on, the overlap protection circuit makes sure that SW has first

gone high and then waits for the voltage at the SW pin to fall

from V

1 V, Q2 begins turn on. If the SW pin had not gone high first,

then the Q2 turn on is delayed by a fixed 120 ns. By waiting for

the voltage on the SW pin to reach 1 V or for the fixed delay

time, the overlap protection circuit ensures that Q1 is off before

Q2 turns on, regardless of variations in temperature, supply

voltage, input pulse width, gate charge, and drive current. If SW

does not go below 1 V after 240 ns, DRVL will turn on. This can

occur if the current flowing in the output inductor is negative

and is flowing through the high-side MOSFET body diode.

To prevent the overlap of the gate drives during the Q2 turn off

and the Q1 turn on, the overlap circuit provides an internal

delay that is set to 40 ns. When the PWM input signal goes high,

Q2 will begin to turn off (after a propagation delay), but before

Q1 can turn on, the overlap protection circuit waits for the

voltage at DRVL to drop to approximately one sixth of V

Once the voltage at DRVL has reached this point, the overlap

protection circuit will wait for the 40 ns internal delay time.

Once the delay period has expired, Q1 will begin turn on.

to 1 V. Once the voltage on the SW pin has fallen to

IN

.

CC

The high-side driver’s output is in phase with the PWM input.

When the driver is disabled, the high-side gate is held low.

Rev. B | Page 9 of 16

ADP3418

×

=

−

APPLICATION INFORMATION

SUPPLY CAPACITOR SELECTION

For the supply input (VCC) of the ADP3418, a local bypass

capacitor is recommended to reduce the noise and to supply

some of the peak currents drawn. Use a 4.7 µF, low ESR

capacitor. Multilayer ceramic chip (MLCC) capacitors provide

the best combination of low ESR and small size. Keep the

ceramic capacitor as close as possible to the ADP3418.

BOOTSTRAP CIRCUIT

The bootstrap circuit uses a charge storage capacitor (C

a diode, as shown in Figure 1. These components can be

selected after the high-side MOSFET has been chosen. The

bootstrap capacitor must have a voltage rating that is able to

handle twice the maximum supply voltage. A minimum 50 V

rating is recommended. The capacitor values are determined

using the following equations:

Q

where Q

V

GATE

CC ×=+ 10

BST2BST1

C

BST1

CC

+

BST2BST1

is the total gate charge of the high-side MOSFET at

GATE

, V

is the desired gate drive voltage (usually in the

GATE

range of 5-10 V, 7 V being typical), and V

GATE

(1)

V

GATE

V

GATE

=

(2)

VVCC

−

D

is the voltage drop

D

across D1. Rearranging Equations 1 and 2 to solve for C

yields

Q

C

BST1

can then be found by rearranging Equation 1:

C

BST2

C −×=

BST2

GATE

×=10

Q

GATE

V

GATE

−

VVCC

D

C

110BST

For example, an NTD60N02 has a total gate charge of about

12 nC at V

C

= 12 nF and C

BST1

= 7 V. Using VCC = 12 V and VD = 1 V, we find

GATE

= 6.8 nF. Good quality ceramic

BST2

capacitors should be used.

is used for slew-rate limiting to minimize the ringing at the

R

BST

switch node. It also provides peak current limiting through D1.

value of 1.5 Ω to 2.2 Ω is a good choice. The resistor

An R

BST

needs to be able to handle at least 250 mW due to the peak

currents that flow through it.

BST

BST1

) and

A small-signal diode can be used for the bootstrap diode due to

the ample gate drive voltage supplied by V

. The bo otstrap

CC

diode must have a minimum 15 V rating to withstand the

maximum supply voltage. The average forward current can be

estimated by

fQI

where f

GATE

)(

AVGF

is the maximum switching frequency of the

MAX

(3)

MAX

controller. The peak surge current rating should be calculated

using:

VVCC

D

I

=

PEAKF

)(

R

(4)

BST

MOSFET SELECTION

When interfacing the ADP3418 to external MOSFETs, there are

a few considerations that the designer should be aware of. These

will help to make a more robust design that will minimize

stresses on both the driver and MOSFETs. These stresses

include exceeding the short-time duration voltage ratings on

the driver pins as well as the external MOSFET.

It is also highly recommended to use the Boot-Snap circuit to

improve the interaction of the driver with the characteristics of

the MOSFETs. If a simple bootstrap arrangement is used, make

sure to then include a proper snubber network on the SW node.

High-Side (Control) MOSFETs

The high-side MOSFET is usually selected to be high speed to

minimize switching losses (see any ADI Flex-mode™ controller

datasheet for more details on MOSFET losses). This usually

implies a low gate resistance and low input capacitance/charge

device. Yet, there is also a significant source lead inductance that

can exist (this depends mainly on the MOSFET package; it is

best to contact the MOSFET vendor for this information).

The ADP3418 DRVH output impedance and the input

resistance of the MOSFETs determine the rate of charge

delivery to the gate’s internal capacitance, which determines the

speed at which the MOSFETs turn on and off. However, due to

potentially large currents flowing in the MOSFETs at the on and

off times (this current is usually larger at turn off due to

ramping up of the output current in the output inductor), the

source lead inductance will generate a significant voltage across

it when the high-side MOSFETs switch off. This will create a

significant drain-source voltage spike across the internal die of

the MOSFETs and can lead to catastrophic avalanche. The

mechanisms involved in this avalanche condition can be

referenced in literature from the MOSFET suppliers.

Rev. B | Page 10 of 16

ADP3418

The MOSFET vendor should provide a maximum voltage slew

rate at drain current rating such that this can be designed

around. Once you have this specification, the next step is to

determine the maximum current you expect to see in the

MOSFET. This can be done with the following equation:

Here, D

()

DCMAX

is determined for the VR controller being used with

MAX

)(

VVCCphaseperII

OUT

MAX

×−+=

MAX

(5)

Lf

×

OUT

D

the driver. Please note this current gets divided roughly equally

between MOSFETs if more than one is used (assume a worstcase mismatch of 30% for design margin). L

is the output

OUT

inductor value.

When producing your design, there is no exact method for

calculating the dV/dt due to the parasitic effects in the external

MOSFETs as well as the PCB. However, it can be measured to

determine if it is safe. If it appears the dV/dt is too fast, an

optional gate resistor can be added between DRVH and the

high-side MOSFETs. This resistor will slow down the dV/dt, but

it will also increase the switching losses in the high-side

MOSFETs. The ADP3418 has been optimally designed with an

internal drive impedance that will work with most MOSFETs to

switch them efficiently yet minimize dV/dt. However, some

high-speed MOSFETs may require this external gate resistor

depending on the currents being switched in the MOSFET.

Low-Side (Synchronous) MOSFETs

The low-side MOSFETs are usually selected to have a low onresistance to minimize conduction losses. This usually implies a

large input gate capacitance and gate charge. The first concern is

to make sure the power delivery from the ADP3418’s DRVL

does not exceed the thermal rating of the driver (see the Flexmode controller data sheet for details).

The next concern for the low-side MOSFETs is based on

preventing them from inadvertently being switched on when

the high-side MOSFET turns on. This occurs due to the draingate (Miller, also specified as C

) capacitance of the MOSFET.

rss

When the drain of the low-side MOSFET is switched to VCC by

the high-side turning on (at a rate dV/dt), the internal gate of

the low-side MOSFET will be pulled up by an amount roughly

equal to VCC × (C

). It is important to make sure this does

rss/Ciss

not put the MOSFET into conduction.

Another consideration is the non-overlap circuitry of the

ADP3418 which attempts to minimize the non-overlap period.

During the state of the high-side turning off to low-side turning

on, the SW pin is monitored (as well as the conditions of SW

prior to switching) to adequately prevent overlap.

However, during the low-side turn off to high-side turn on, the

SW pin does not contain information for determining the

proper switching time, so the state of the DRVL pin is

monitored to go below one sixth of VCC and then a delay is

added. But due to the Miller capacitance and internal delays of

the low-side MOSFET gate, one must ensure the Miller to input

capacitance ratio is low enough and the low-side MOSFET

internal delays are not large enough to allow accidental turn on

of the low-side when the high-side turns on.

A spreadsheet is available from ADI that will assist the designer

in the proper selection of low-side MOSFETs.

Rev. B | Page 11 of 16

ADP3418

PC BOARD LAYOUT CONSIDERATIONS

Use the following general guidelines when designing printed

circuit boards.

• Trace out the high current paths and use short, wide

(>20 mil) traces to make these connections.

• Connect the PGND pin of the ADP3418 as closely as

possible to the source of the lower MOSFET.

• The V

possible to the VCC and PGND pins.

• Use vias to other layers when possible to maximize thermal

conduction away from the IC.

The circuit in Figure 15 shows how four drivers can be

combined with the ADP3188 to form a total power conversion

solution for generating V

10.x compliant.

Figure 14 shows an example of the typical land patterns based

on the guidelines given previously. For more detailed layout

guidelines for a complete CPU voltage regulator subsystem,

refer to the ADP3188 data sheet.

bypass capacitor should be located as close as

CC

for an Intel CPU that is VRD

CC(CORE)

C

BST1

BST2

R

BST

03229-B-014

C

D1

C

VCC

Figure 14. External Component Placement Example for the ADP3418 Driver

Rev. B | Page 12 of 16

ADP3418

CC (CORE)

CC (CORE) RTN

V

0.8375 V – 1.6V

95A TDC, 119A PK

V

LI

C8

R3

12nF

2.2Ω

2700MF/16V/3.3A × 2

18A

370nH

+

5mΩ EACH

560µF/4V × 8

C24 C31

+

SANYO SEPC SERIES

L4

320nH/1.4mΩ

F

µ

C7

4.7

Q1

NTD60N02

C6

876

6.8nF

DRVH

U2

ADP3418

BST1IN

D2

1N4148

++

C1 C2

SANYO MV-WX SERIES

IN

V

12V

RTN

IN

V

Q4

NTD110N02

5

SW

DRVL

PGND

VCC

OD

2

3

4

C5

4.7µF

MLCC IN

SOCKET

10µF× 18

RTH1

100kΩ, 5%

NTC

F

µ

C15

4.7

C14

6.8nF

U4

ADP3418

D4

1N4148

2827262524

VCC

PWM1

VID4

VID3

12345

1%

L4

Q9

NTD60N02

876

DRVH

BST1IN

PWM2

VID2

FROM

320nH/1.4mΩ

SW

2

PWM3

VID1

CPU

PGND

OD

3

PWM4

VID0

Q12

NTD110N02

Q11

NTD110N02

5

C20

DRVL

R6

VCC

4

F

µ

C13

4.7

R

2322212019

SW1

SW2

SW3

SW4

VID5

FBRTNFBCOMP

678

9

CFB22pF

B

C

470pF

1nF

C21

POWER

12nF

2.2Ω

PH1

R

158kΩ,

1%

PH2

158kΩ,

PH3

R

158kΩ,

PH4

R

158kΩ, 1%

181716

GND

CSCOMP

PWRGDENDELAYRTRAMPADJ

10

111213

A

R

12.1kΩ

A

C

470pF

B

R

1.21kΩ

GOOD

ENABLE

L3

320nH/1.4mΩ

F

µ

C11

4.7

Q5

NTD60N02

Q3

NTD110N02

C10

876

12nF

2.2Ω

U3

6.8nF

ADP3418

D3

DRVH

BST1IN

1N4148

C12

R4

Q8

NTD110N02

Q7

NTD110N02

5

C16

DRVL

VCC

4

C9

12nF

R5

2.2Ω

F

µ

4.7

SW

PGND

OD

2

3

U1

ADP3188

R2

137kΩ

D1

1N4148

C4

1µF

+

C3

100µF

C19

1%

1%

CS2

R

CS1

R

CS2

C

CS1

C

CSSUM

F

µ

4.7

C16

U5

84.5kΩ

35.7kΩ

1.5nF

560pF

6.8nF

ADP3418

D5

1N4148

C22

CSREF

T

R

LDY

R

LDY

C

L5

Q13

NTD60N02

876

DRVH

BST1IN

1nF

15

ILIMIT

14

137kΩ

470kΩ

39nF

320nH/1.4mΩ

Q16

NTD110N02

Q15

NTD110N02

5

SW

DRVL

PGND

VCC

OD

2

3

4

F

µ

C17

4.7

LIM

150kΩ

1%

R

1nF

C23

1%

3229-B-015

Figure 15. VRD 10.x Compliant Intel CPU Supply Circuit

Rev. B | Page 13 of 16

ADP3418

Y

OUTLINE DIMENSIONS

4.00 (0.1574)

3.80 (0.1497)

5.00 (0.1968)

4.80 (0.1890)

85

6.20 (0.2440)

5.80 (0.2284)

41

1.27 (0.0500)

BSC

0.25 (0.0098)

0.10 (0.0040)

COPLANARIT

0.10

CONTROLLING DIMENSIONS ARE IN MILLIMETERS; INCH DIMENSIONS

(IN PARENTHESES) ARE ROUNDED-OFF MILLIMETER EQUIVALENTS FOR

REFERENCE ONLY AND ARE NOT APPROPRIATE FOR USE IN DESIGN

SEATING

PLANE

COMPLIANT TO JEDEC STANDARDS MS-012AA

1.75 (0.0688)

1.35 (0.0532)

0.51 (0.0201)

0.31 (0.0122)

0.25 (0.0098)

0.17 (0.0067)

0.50 (0.0196)

0.25 (0.0099)

8°

1.27 (0.0500)

0°

0.40 (0.0157)

× 45°

Figure 16. 8-Lead Standard Small Outline Package [SOIC]

Narrow Body (R-8)

Dimensions shown in millimeters and (inches)

ORDERING GUIDE

Model Temperature Range Package Description Package Option

ADP3418KRZ

ADP3418KRZ–REEL

1

Z = Pb-free part.

1

1

0°C to 85°C SOIC RN-8

0°C to 85°C SOIC RN-8

Rev. B | Page 14 of 16

ADP3418

NOTES

Rev. B | Page 15 of 16

ADP3418

NOTES

© 2004 Analog Devices, Inc. All rights reserved. Trademarks

and

registered trademarks are the property of their respective owners.

C03229–0–8/04(B)

Rev. B | Page 16 of 16

Loading...

Loading...