Analog Devices ADP3412 a Datasheet

Dual MOSFET Driver

a

FEATURES

All-In-One Synchronous Buck Driver

Bootstrapped High Side Drive

One PWM Signal Generates Both Drives

Programmable Transition Delay

Anticross-Conduction Protection Circuitry

APPLICATIONS

Multiphase Desktop CPU Supplies

Mobile Computing CPU Core Power Converters

Single-Supply Synchronous Buck Converters

Standard-to-Synchronous Converter Adaptations

GENERAL DESCRIPTION

The ADP3412 is a dual MOSFET driver optimized for driving

two N-channel MOSFETs which are the two switches in a

nonisolated synchronous buck power converter. Each of the

drivers is capable of driving a 3000 pF load with a 20 ns propagation delay and a 30 ns transition time. One of the drivers can

be bootstrapped and is designed to handle the high voltage

slew rate associated with “floating” high side gate drivers. The

ADP3412 includes overlapping drive protection (ODP) to prevent shoot-through current in the external MOSFETs.

with Bootstrapping

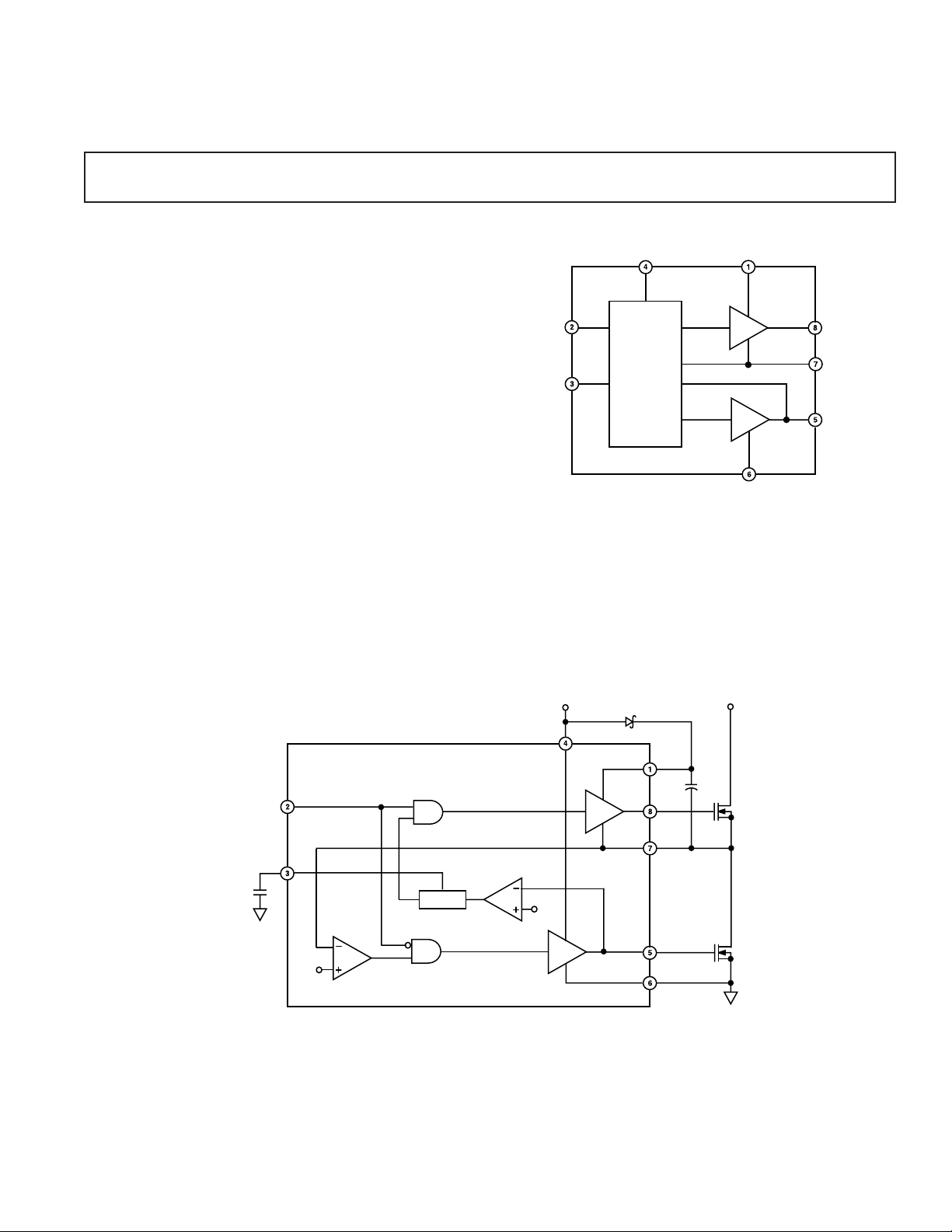

FUNCTIONAL BLOCK DIAGRAM

VCC

ADP3412

IN

OVERLAP

DLY

PROTECTION

CIRCUIT

ADP3412

BST

DRVH

SW

DRVL

PGND

ADP3412

IN

DLY

C

DLY

1V

DELAY

Figure 1. General Application Circuit

REV. A

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties that

may result from its use. No license is granted by implication or otherwise

under any patent or patent rights of Analog Devices.

5V

VCC

1V

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 www.analog.com

Fax: 781/326-8703 © Analog Devices, Inc., 2002

D1

BST

DRVH

SW

DRVL

PGND

12V

C

BST

Q1

Q2

1

ADP3412–SPECIFICATIONS

Parameter Symbol Conditions Min Typ Max Unit

SUPPLY

Supply Voltage Range VCC 4.15 5.0 7.5 V

Quiescent Current ICC

PWM INPUT

Input Voltage High

Input Voltage Low

2

2

HIGH SIDE DRIVER

Output Resistance, Sourcing Current V

Output Resistance, Sinking Current V

Transition Times

Propagation Delay

3

(See Figure 2) tr

3, 4

(See Figure 2) tpdh

LOW SIDE DRIVER

Output Resistance, Sourcing Current VCC = 4.6 V 2.5 5 Ω

Output Resistance, Sinking Current VCC = 4.6 V 2.5 5 Ω

Transition Times

Propagation Delay

NOTES

1

All limits at temperature extremes are guaranteed via correlation using standard Statistical Quality Control (SQC) methods.

2

Logic inputs meet typical CMOS I/O conditions for source/sink current (~1 µA).

3

AC specifications are guaranteed by characterization but not production tested.

4

For propagation delays, “tpdh” refers to the specified signal going high; “tpdl” refers to it going low.

5

Maximum propagation delay = 40 ns + (1 ns/pF C

Specifications subject to change without notice.

3

(See Figure 2) tr

3, 4

(See Figure 2) tpdh

DRVH

tpdl

DRVL

tpdl

DLY

Q

, tf

DRVH

DRVH

, tf

DRVL

DRVL

).

(TA = 0ⴗC to 70ⴗC, VCC = 5 V, BST = 4 V to 26 V, unless otherwise noted.)

12 mA

2.0 V

– VSW = 4.6 V 2.5 5 Ω

BST

– VSW = 4.6 V 2.5 5 Ω

BST

V

– V

DRVH

DRVL

= 4.6 V, C

SW

– V

= 4.6 V 10 20 Note 5 ns

SW

– V

= 4.6 V 25 ns

SW

V

V

BST

BST

BST

VCC = 4.6 V, C

LOAD

= 3 nF 20 35 ns

LOAD

= 3 nF 20 35 ns

VCC = 4.6 V 30 ns

VCC = 4.6 V 25 ns

0.8 V

ABSOLUTE MAXIMUM RATINGS*

VCC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . –0.3 V to +8 V

BST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . –0.3 V to +30 V

BST to SW . . . . . . . . . . . . . . . . . . . . . . . . . . . –0.3 V to +8 V

SW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . –5.0 V to +25 V

IN . . . . . . . . . . . . . . . . . . . . . . . . . . . . –0.3 V to VCC + 0.3 V

Operating Ambient Temperature Range . . . . . . . 0°C to 70°C

Operating Junction Temperature Range . . . . . . 0°C to 125°C

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155°C/W

θ

JA

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40°C/W

θ

JC

Storage Temperature Range . . . . . . . . . . . . –65°C to +150°C

Lead Temperature (Soldering, 10 sec) . . . . . . . . . . . . . 300°C

*This is a stress rating only; operation beyond these limits can cause the device to

be permanently damaged. Unless otherwise specified, all voltages are referenced

to PGND.

–2–

REV. A

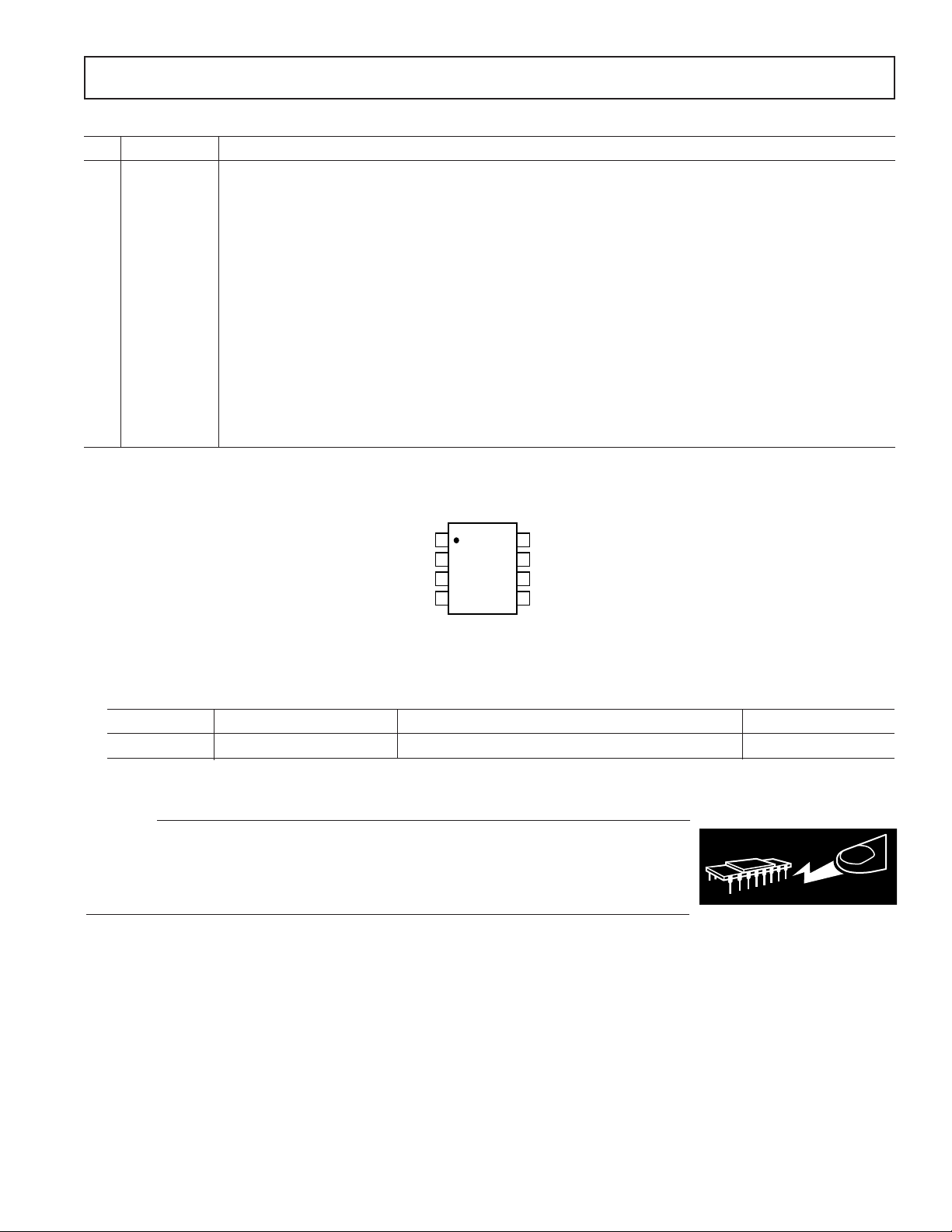

ADP3412

PIN FUNCTION DESCRIPTIONS

Pin Mnemonic Function

1 BST Floating Bootstrap Supply for the Upper MOSFET. A capacitor connected between BST and SW Pins

holds this bootstrapped voltage for the high side MOSFET as it is switched. The capacitor should be

chosen between 100 nF and 1 F.

2IN TTL-level input signal that has primary control of the drive outputs.

3 DLY Low High Transition Delay. A capacitor from this pin to ground programs the propagation delay from

turn-off of the lower FET to turn-on of the upper FET. The formula for the low high transition delay

is DLY = C

4 VCC Input Supply. This pin should be bypassed to PGND with ~1 µF ceramic capacitor.

5 DRVL Synchronous Rectifier Drive. Output drive for the lower (synchronous rectifier) MOSFET.

6 PGND Power Ground. Should be closely connected to the source of the lower MOSFET.

7SW This pin is connected to the buck-switching node, close to the upper MOSFET’s source. It is the floating

return for the upper MOSFET drive signal. It is also used to monitor the switched voltage to prevent turn-

on of the lower MOSFET until the voltage is below ~1 V. Thus, according to operating conditions, the

high low transition delay is determined at this pin.

8 DRVH Buck Drive. Output drive for the upper (buck) MOSFET.

× (1 ns/pF) + 20 ns. The rise time for turn-on of the upper FET is not included in the formula.

DLY

PIN CONFIGURATION

BST

DLY

VCC

1

2

IN

3

4

ADP3412

TOP VIEW

(Not to Scale)

8

7

6

5

DRVH

SW

PGND

DRVL

ORDERING GUIDE

Model Temperature Range Package Description Package Option

ADP3412JR 0°C to 70°C 8-Lead Standard Small Outline Package (SOIC) SOIC-8

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection. Although

WARNING!

the ADP3412 features proprietary ESD protection circuitry, permanent damage may occur on

devices subjected to high energy electrostatic discharges. Therefore, proper ESD precautions are

recommended to avoid performance degradation or loss of functionality.

ESD SENSITIVE DEVICE

REV. A

–3–

ADP3412

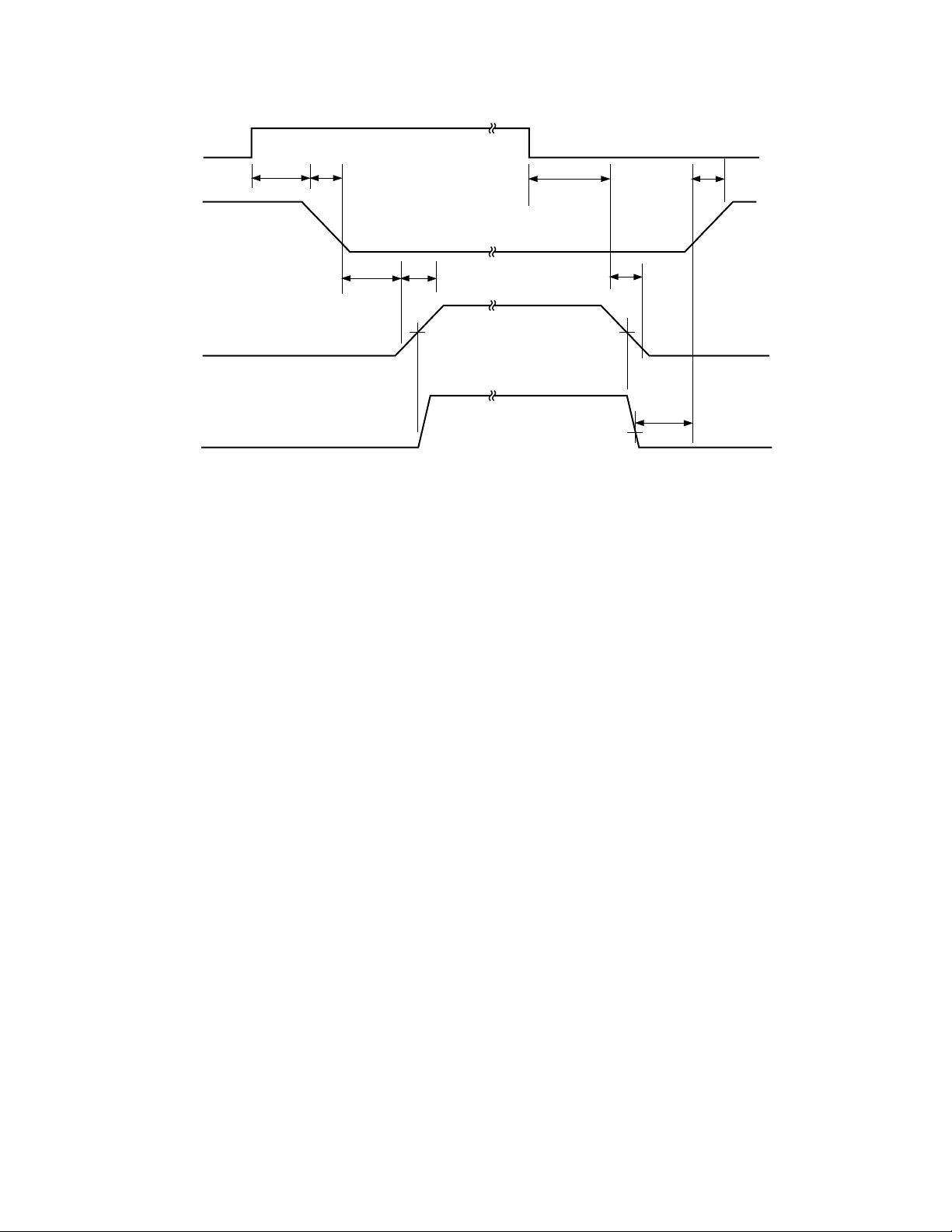

DRVL

IN

DRVL

tf

DRVL

tpdl

DRVH

tr

DRVL

tpdl

DRVH-SW

SW

tpdh

DRVH

tr

DRVH

V

TH

tf

DRVH

V

TH

tpdh

DRVL

1V

Figure 2. Nonoverlap Timing Diagram

(Timing Is Referenced to the 90% and 10% Points Unless Otherwise Noted)

–4–

REV. A

Loading...

Loading...