查询ADP3167供应商

5-Bit Programmable 2-Phase

a

FEATURES

ADOPT™ Optimal Positioning Technology for Superior

Load Transient Response and Fewest Output Capacitors

Complies with VRM 9.0 with Lowest System Cost

Active Current Balancing between Both Output Phases

5-Bit Digitally Programmable 1.1 V to 1.85 V Output

Dual Logic-Level PWM Outputs for Interface to External

High Power Drivers

Total Output Accuracy ⴞ0.8% over Temperature

Current-Mode Operation

Short Circuit Protection

Power Good Output

Overvoltage Protection Crowbar Protects

Microprocessors with No Additional

External Components

APPLICATIONS

Desktop PC Power Supplies for:

Intel Pentium

AMD Athlon™ Processors

VRM Modules

®

4 Processors

Synchronous Buck Controller

ADP3160/ADP3167

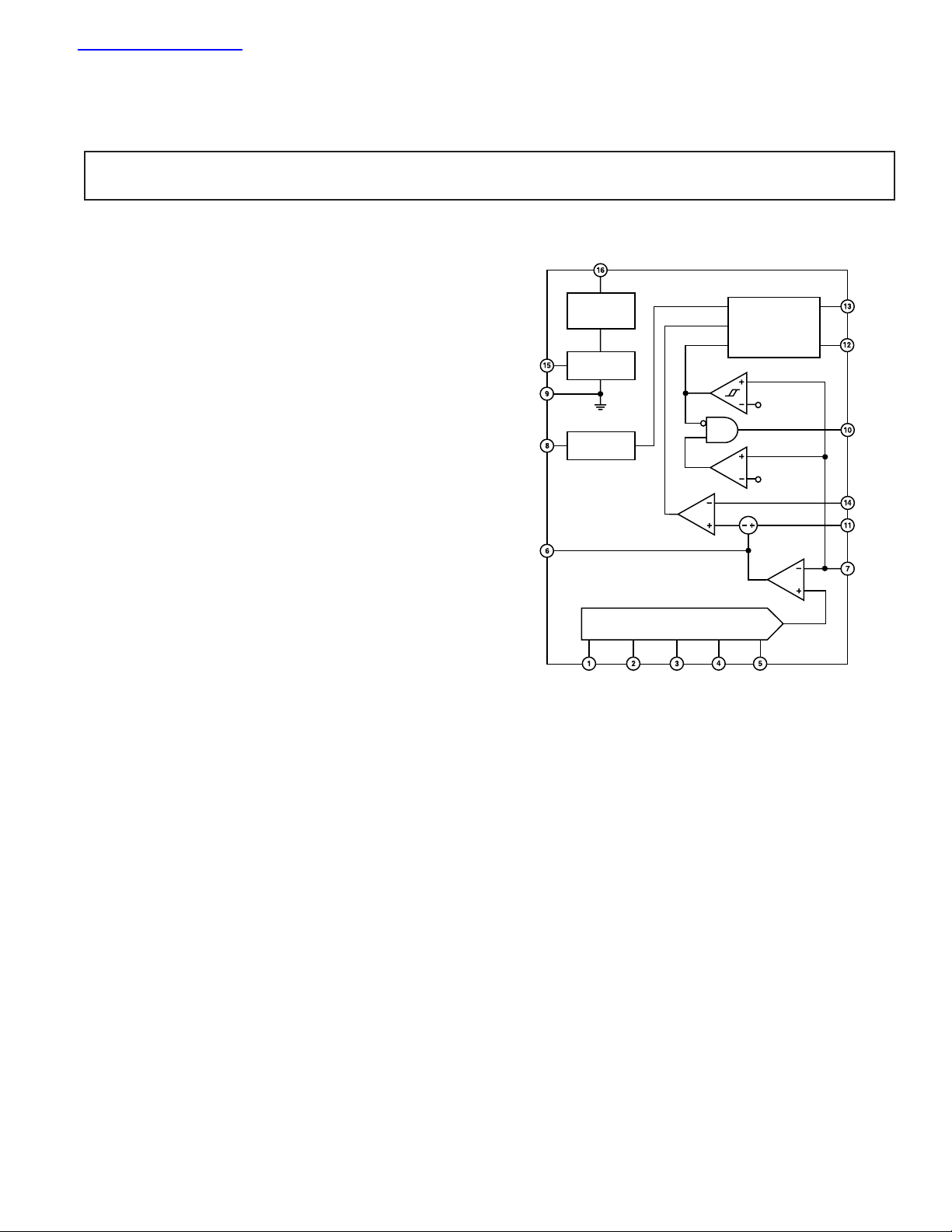

FUNCTIONAL BLOCK DIAGRAM

VCC

CROWBAR

CMP1

SET

RESET

CMP3

CMP2

CMP

CMP

2-PHASE

DRIVER

LOGIC

DAC+24%

DAC–18%

g

m

REF

GND

CT

COMP

UVLO

AND

BIAS

3.0V

REFERENCE

OSCILLATOR

ADP3160/ADP3167

PWM1

PWM2

PWRGD

CS–

CS+

FB

GENERAL DESCRIPTION

The ADP3160 and ADP3167 are highly efficient, dual output,

synchronous buck switching regulator controllers optimized for

converting a 5 V or 12 V main supply into the core supply voltage

required by high-performance processors, such as Pentium 4 and

Athlon. The ADP3160 uses an internal 5-bit DAC to read a voltage identification (VID) code directly from the processor that is

used to set the output voltage between 1.1 V and 1.85 V. The

devices use a current-mode PWM architecture to drive two logiclevel outputs at a programmable switching frequency that can be

optimized for VRM size and efficiency. The output signals are

180 degrees out of phase, allowing for the construction of two

complementary buck switching stages. These two stages share the

dc output current to reduce overall output voltage ripple. An

active current balancing function ensures that both phases carry

equal portions of the total load current, even under large transient

loads, to minimize the size of the inductors. The ADP3160 control

ADOPT is a trademark of Analog Devices, Inc.

Athlon is a trademark of Advanced Micro Devices, Inc.

Pentium is a registered trademark of Intel Corporation.

VID

DAC

VID4 VID3 VID2 VID1 VID0

loop has been optimized for conversion from 12 V, while the

ADP3167 is designed for conversion from a 5 V supply.

The ADP3160 and ADP3167 also use a unique supplemental

regulation technique called active voltage positioning to enhance

load transient performance. Active voltage positioning results

in a dc/dc converter that meets the stringent output voltage

specifications for high-performance processors, with the minimum

number of output capacitors and smallest footprint. Unlike

voltage-mode and standard current-mode architectures, active

voltage positioning adjusts the output voltage as a function of

the load current so that it is always optimally positioned for a

system transient. They also provide accurate and reliable short

circuit protection and adjustable current limiting.

The ADP3160 is specified over the commercial temperature

range of 0∞C to 70∞C and is available in a 16-lead narrow body

SOIC package.

REV.B

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties that

may result from its use. No license is granted by implication or otherwise

under any patent or patent rights of Analog Devices.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700www.analog.com

Fax: 781/326-8703 © Analog Devices, Inc., 2002

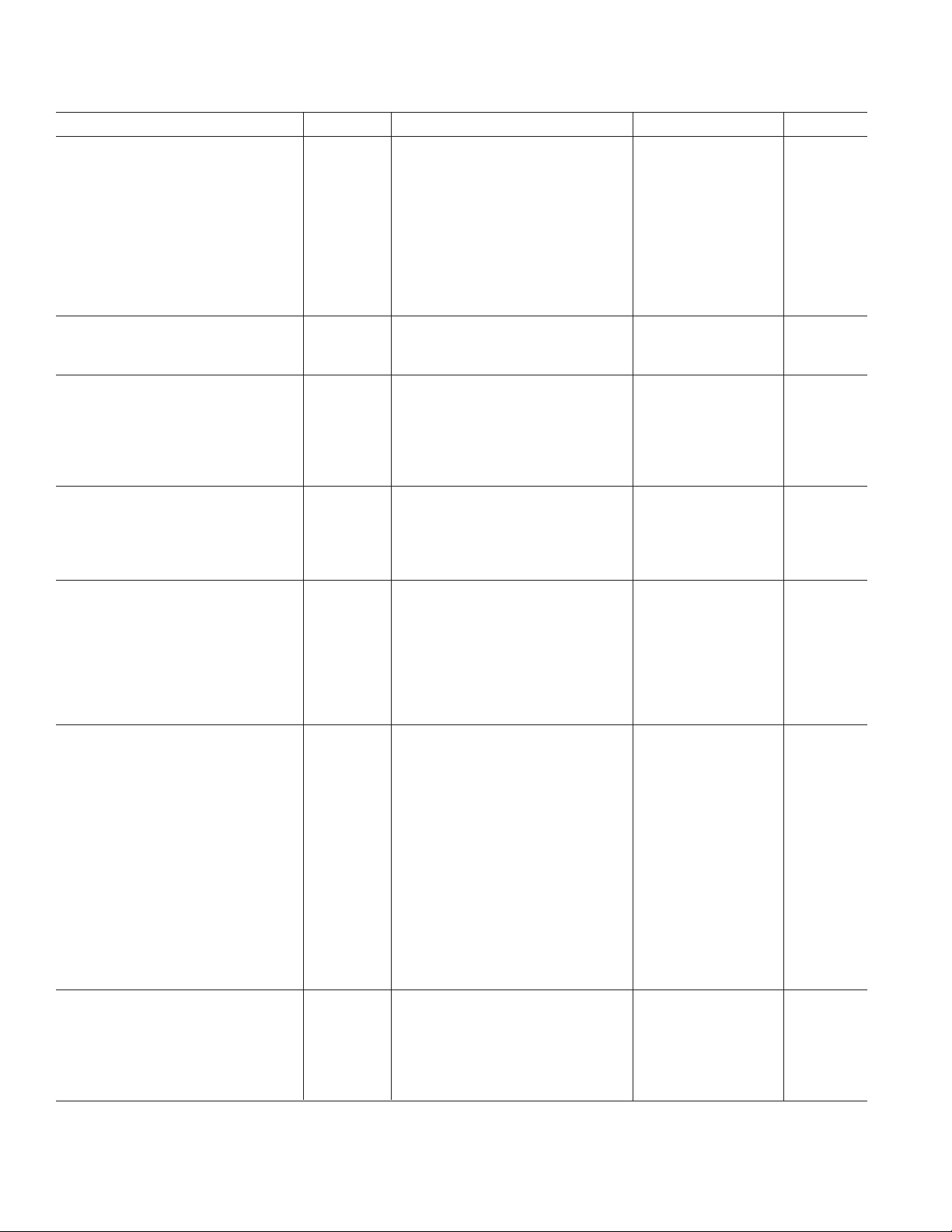

ADP3160/ADP3167–SPECIFICATIONS

(VCC = 12 V, I

1

unless otherwise noted.)

= 150 A, TA = 0ⴗC to 70ⴗC,

REF

Parameter Symbol Conditions Min Typ Max Unit

FEEDBACK INPUT

Accuracy V

FB

1.1 V Output See Figure 1 1.091 1.1 1.109 V

1.475 V Output See Figure 1 1.463 1.475 1.487 V

1.85 V Output See Figure 1 1.835 1.85 1.865 V

Line Regulation ⌬V

Input Bias Current I

FB

Crowbar Trip Threshold V

FB

CROWBAR

VCC = 10 V to 14 V 0.05 %

550 nA

Percent of Nominal Output 114 124 134 %

Crowbar Reset Threshold Percent of Nominal Output 50 60 70 %

Crowbar Response Time t

CROWBAR

Overvoltage to PWM Going Low 300 ns

REFERENCE

Output Voltage V

Output Current I

REF

REF

2.952 3.0 3.048 V

300 mA

VID INPUTS

Input Low Voltage V

Input High Voltage V

Input Current I

Pull-Up Resistance R

IL(VID)

IH(VID)

VID

VID

2.2 V

VID(X) = 0 V 180 250 mA

20 28 kW

0.6 V

Internal Pull-Up Voltage 4.5 5.0 5.5 V

OSCILLATOR

Maximum Frequency

Frequency Variation ⌬f

CT Charge Current I

2

f

CT(MAX)

CT

CT

2000 kHz

TA = 25∞C, CT = 91 pF 430 500 570 kHz

TA = 25∞C, VFB in Regulation 130 150 170 mA

TA = 25∞C, VFB = 0 V 263646 mA

ERROR AMPLIFIER

Output Resistance R

Transconductance g

Output Current I

Maximum Output Voltage V

Output Disable Threshold V

O(ERR)

m(ERR)

O(ERR)

COMP(MAX)

COMP(OFF)

2.0 2.2 2.45 mmho

VFB = 0 V 1 mA

FB Forced to V

– 3% 3.0 V

OUT

ADP3160 560 720 800 mV

200 kW

ADP3167 640 800 880 mV

–3 dB Bandwidth BW

ERR

COMP = Open 500 kHz

CURRENT SENSE

Current Limit Threshold Voltage V

CS(CL)

ADP3160, CS+ = VCC 142 157 172 mV

FB Forced to V

OUT

– 3%

ADP3167, CS+ = VCC 69 79 89 mV

FB Forced to V

OUT

– 3%

0.8 V £ COMP £ 1 V 0 15 mV

Current Limit Foldback Voltage V

CS(FOLD)

ADP3160, FB £ 375 mV 75 95 115 mV

ADP3167, FB £ 750 mV 37 47 58 mV

COMP

/DV

CS

DV

Input Bias Current I

Response Time t

n

I

CS+

CS

, I

CS–

ADP3160, 1 V £ V

ADP3167, 1 V £ V

£ 3 V 12.5 V/V

COMP

£ 3 V 25 V/V

COMP

CS+ = CS– = VCC 0.5 5 mA

ADP3160, CS+ – (CS–) ≥ 172 mV 50 ns

to PWM Going Low

ADP3167, CS+ – (CS–) ≥ 89 mV 50 ns

to PWM Going Low

POWER GOOD COMPARATOR

Undervoltage Threshold V

Overvoltage Threshold V

Output Voltage Low V

PWRGD(UV)

PWRGD(OV)

OL(PWRGD)IPWRGD(SINK)

% Nominal Output 76 82 88 %

% Nominal Output 114 124 134 %

= 100 mA30200 mV

Response Time FB Going High 2 ms

FB Going Low 200 ns

REV. B–2–

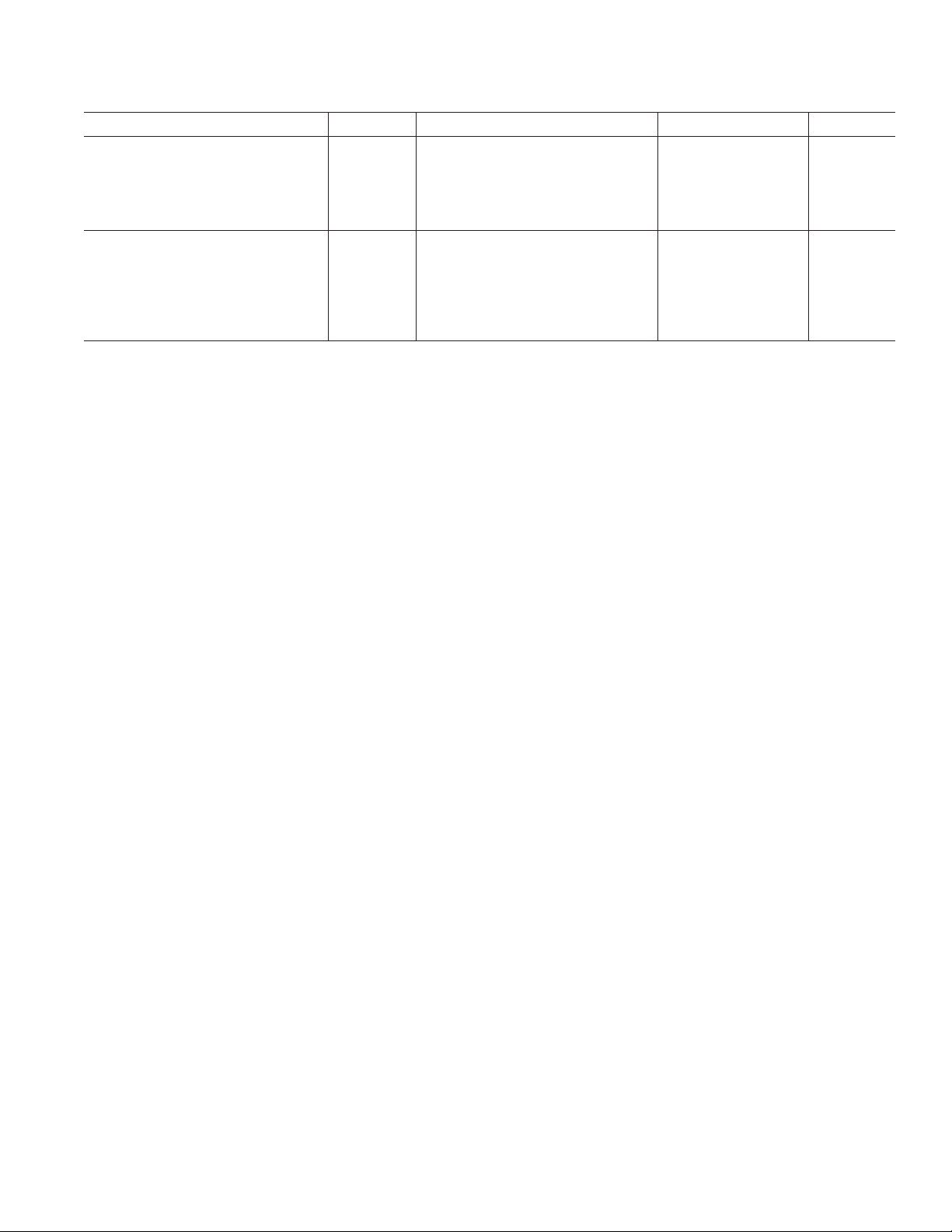

ADP3160/ADP3167

Parameter Symbol Conditions Min Typ Max Unit

PWM OUTPUTS

Output Voltage Low V

Output Voltage High V

Output Current I

Duty Cycle Limit

2

OL(PWM)

OH(PWM)

PWM

D

MAX

SUPPLY

DC Supply Current

Normal Mode I

UVLO Mode I

UVLO Threshold Voltage V

CC

CC(UVLO)

UVLO

UVLO Hysteresis 0.1 0.4 0.6 V

NOTES

1

All limits at temperature extremes are guaranteed via correlation using standard Statistical Quality Control (SQC) methods.

2

Guaranteed by design, not tested in production.

Specifications subject to change without notice.

I

PWM(SINK)

I

PWM(SOURCE)

= 400 mA 100 500 mV

= 400 mA 4.0 V

Per Phase, Relative to f

VCC £ V

, VCC Rising 220 400 mA

UVLO

CT

0.4 1 mA

50 %

3.8 5.5 mA

5.9 6.4 6.9 V

REV. B

–3–

ADP3160/ADP3167

WARNING!

ESD SENSITIVE DEVICE

ABSOLUTE MAXIMUM RATINGS*

VCC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . –0.3 V to +15 V

CS+, CS– . . . . . . . . . . . . . . . . . . . . . . –0.3 V to VCC + 0.3 V

All Other Inputs and Outputs . . . . . . . . . . . . –0.3 V to +10 V

Operating Ambient Temperature Range . . . . . . . 0∞C to 70∞C

Operating Junction Temperature . . . . . . . . . . . . . . . . . . 125∞C

Storage Temperature Range . . . . . . . . . . . . –65∞C to +150∞C

JA

Two-Layer Board . . . . . . . . . . . . . . . . . . . . . . . . . . 125∞C/W

Four-Layer Board . . . . . . . . . . . . . . . . . . . . . . . . . . 81∞C/W

Lead Temperature (Soldering, 10 sec) . . . . . . . . . . . . . 300∞C

Vapor Phase (60 sec) . . . . . . . . . . . . . . . . . . . . . . . . . . . 215∞C

Infrared (15 sec) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220∞C

*This is a stress rating only; operation beyond these limits can cause the device to

be permanently damaged. Unless otherwise specified, all voltages are referenced

to GND.

PIN CONFIGURATION

VID4

VID3

VID2

VID1

VID0

COMP

FB

CT

1

2

3

ADP3160/

ADP3167

4

TOP VIEW

5

(Not to Scale)

6

7

8

16

15

14

13

12

11

10

9

VCC

REF

CS–

PWM1

PWM2

CS+

PWRGD

GND

PIN FUNCTION DESCRIPTIONS

Pin Mnemonic Function

1–5 VID4– Voltage Identification DAC Inputs.

VID0 These pins are pulled up to an internal

reference, providing a Logic 1 if left open.

The DAC output programs the FB regulation voltage from 1.1 V to 1.85 V. Leaving

all five DAC inputs open results in the

ADP3160/ADP3167 going into a “No

CPU” mode, shutting off its PWM outputs.

6 COMP Error Amplifier Output and Compensation

Point. The voltage at this output programs

the output current control level between

CS+ and CS–.

7FB Feedback Input. Error amplifier input for

remote sensing of the output voltage.

8CT External Capacitor CT Connection to

ground sets the frequency of the device.

9GND Ground. All internal signals of the ADP3160/

ADP3167 are referenced to this ground.

10 PWRGD Open-Drain Output that signals when the

output voltage is in the proper operating range.

11 CS+ Current Sense Positive Node. Positive input

for the current comparator. The output

current is sensed as a voltage at this pin with

respect to CS–.

12 PWM2 Logic-Level Output for Phase 2 Driver

13 PWM1 Logic-Level Output for Phase 1 Driver

14 CS– Current Sense Negative Node. Negative

input for the current comparator.

15 REF 3.0 V Reference Output

16 VCC Supply Voltage for the ADP3160/ADP3167.

ORDERING GUIDE

Temperature Package

Model Range Description Package Option

ADP3160JR 0∞C to 70∞CNarrow Body SOIC R-16A (SO-16)

ADP3167JR 0∞C to 70∞CNarrow Body SOIC R-16A (SO-16)

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection. Although the

ADP3160/ADP3167 features proprietary ESD protection circuitry, permanent damage may occur on

devices subjected to high-energy electrostatic discharges. Therefore, proper ESD precautions are

recommended to avoid performance degradation or loss of functionality.

REV. B–4–

ADP3160/ADP3167

ADP3160/ADP3167

VCC

REF

CS–

PWM1

PWM2

CS+

PWRGD

GND

16

15

14

13

12

11

10

1.2V

+

1F

20k⍀

9

5-BIT CODE

100⍀

100nF

1

2

3

4

5

6

7

8

AD820

VID4

VID3

VID2

VID1

VID0

COMP

FB

CT

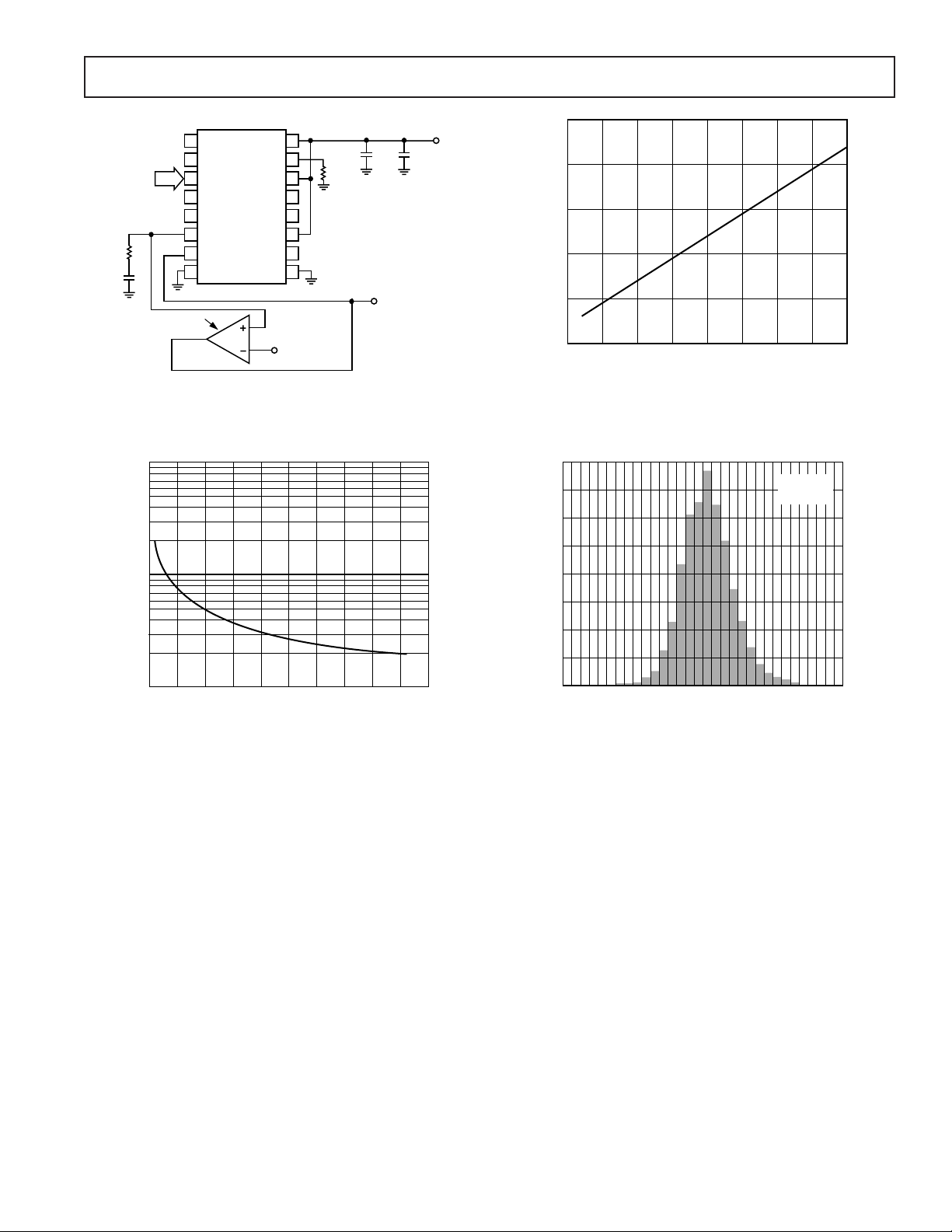

Figure 1. Closed-Loop Output Voltage Accuracy

Test Circuit

10000

4.10

12V

100nF

V

FB

4.05

4.00

3.95

SUPPLY CURRENT – mA

3.90

3.85

0 2000

250 500 750 1250 1500 1750

OSCILLATOR FREQUENCY – kHz

1000

Figure 3. Supply Current vs. Oscillator Frequency

16

TA = 25ⴗC

= 1.6V

V

OUT

12

1000

OSCILLATOR FREQUENCY – kHz

100

0

100

200 300 400 500

CT CAPACITOR – pF

Figure 2. Oscillator Frequency vs. Timing Capacitor

8

NUMBER OF PARTS – %

4

0

–1 1

OUTPUT ACCURACY – % of Nominal

0

Figure 4. Output Accuracy Distribution

REV. B

–5–

ADP3160/ADP3167

THEORY OF OPERATION

The ADP3160 and ADP3167 combine a current-mode, fixed

frequency PWM controller with antiphase logic outputs in a

controller for a 2-phase synchronous buck power converter.

Two-phase operation is important for switching the high currents

required by high-performance microprocessors. Handling the

high current in a single-phase converter would place difficult

requirements on the power components such as inductor wire

size, MOSFET ON resistance, and thermal dissipation. Their

high-side current sensing topology ensures that the load currents

are balanced in each phase, such that neither phase has to carry

more than half of the power. An additional benefit of high-

side

current sensing over output current sensing is that the average

current through the sense resistor is reduced by the duty cycle

of the converter, allowing the use of a lower power, lower cost

resistor. The outputs of the ADP3160/ADP3167 are logic

drivers only and are not intended to drive external power

MOSFETs directly. Instead, the ADP3160/ADP3167

be paired with drivers such as the ADP3414 or ADP3417.

should

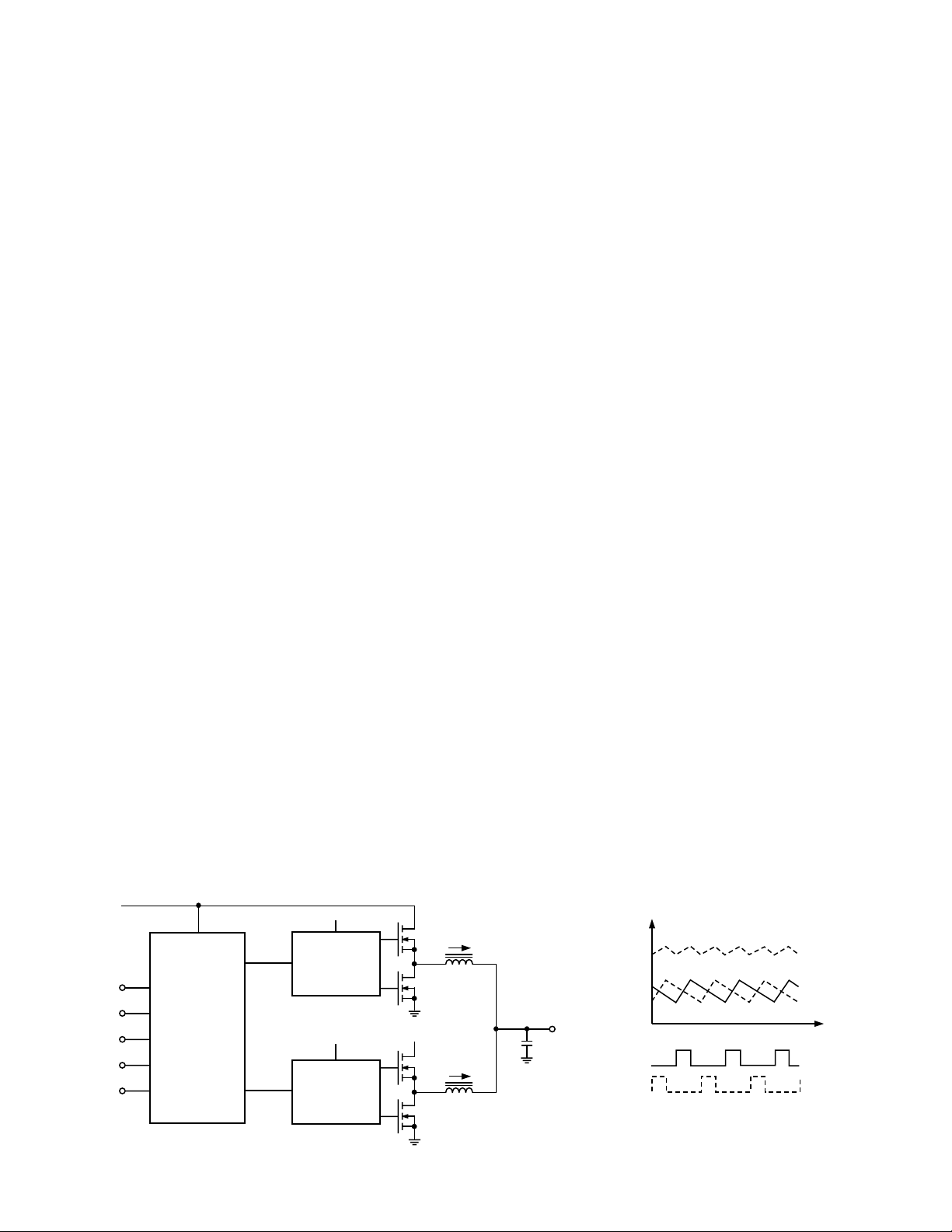

A

system level block diagram of a 2-phase power supply for high

current CPUs is shown in Figure 5.

The frequency of the device is set by an external capacitor

connected to the CT pin. Each output phase operates at half of

the frequency set by the CT pin. The error amplifier and

current sense comparator control the duty cycle of the PWM

outputs to maintain regulation. The maximum duty cycle per

phase is inherently limited to 50% because the PWM outputs

toggle in 2-phase operation. While one phase is on, the other

phase is off. In no case can both outputs be high at the same time.

Output Voltage Sensing

The output voltage is sensed at the FB pin allowing for remote

sensing. To maintain the accuracy of the remote sensing, the

GND pin should also be connected close to the load. A voltage

error amplifier (g

) amplifies the difference between the output

m

voltage and a programmable reference voltage. The reference voltage is programmed between 1.1 V and 1.85 V by an internal 5-bit

DAC that reads the code at the voltage identification (VID) pins.

Refer to Table I for the output voltage versus VID pin code

information.

Active Voltage Positioning

The ADP3160 and ADP3167 use Analog Devices Optimal

Positioning Technology (ADOPT), a unique supplemental

regulation technique that uses active voltage positioning and

provides optimal compensation for load transients. When implemented, ADOPT adjusts the output voltage as a function of the

load current, so that it is always optimally positioned for a load

transient. Standard (passive) voltage positioning has poor dynamic

performance, rendering it ineffective under the stringent repetitive

transient conditions required by high-performance processors.

ADOPT, however, provides optimal bandwidth for transient

response that yields optimal load transient response with the

minimum number of output capacitors.

Reference Output

A 3.0 V reference is available and is commonly used to set the

voltage positioning accurately using a resistor divider to the

COMP pin. In addition, the reference can be used for other

functions such as generating a regulated voltage with an external

amplifier. The reference is bypassed with a 1 nF capacitor to

ground. It is not intended to supply current to large capacitive

loads, and it should not be used to provide more than 1 mA of

output current.

Cycle-by-Cycle Operation

During normal operation (when the output voltage is regulated), the

voltage-error amplifier and the current comparator are the main

control elements. The voltage at the CT pin of the oscillator ramps

between 0 V and 3 V. When that voltage reaches 3 V, the oscillator

sets the driver logic, which sets PWM1 high. During the ON time

of Phase 1, the driver IC turns on the high-side MOSFET. The CS+

and CS– pins monitor the current through the sense resistor that

feeds both high-side MOSFETs. When the voltage between the

two pins exceeds the threshold level set by the voltage error ampli-

), the driver logic is reset and the PWM output goes low.

fier (g

m

This signals the driver IC to turn off the high-side MOSFET and

turn on the low-side MOSFET. On the next cycle of the oscillator,

the driver logic toggles and sets PWM2 high. On each following

cycle of the oscillator, the outputs toggle between PWM1 and

PWM2. In each case, the current comparator resets the PWM

output low when the current comparator threshold is reached. As

the load current increases, the output voltage starts to decrease.

This causes an increase in the output of the g

amplifier, which in

m

turn leads to an increase in the current comparator threshold,

thus programming more current to be delivered to the output so

that voltage regulation is maintained.

5V

OR

12V

VID INPUTS

ADP3160/

ADP3167

2-PHASE

SYNCHRONOUS

BUCK

CONTROLLER

5V

I

PWM1

PWM2

ADP3412

SYNCHRONOUS

DRIVER

5V

ADP3412

SYNCHRONOUS

DRIVER

5V OR 12V

L1

OUT

+

I

L2

I

PWM2

PWM1

OUT

I

L2

Figure 5. 2-Phase CPU Supply System Level Block Diagram

I

L1

REV. B–6–

ADP3160/ADP3167

Active Current Sharing

The ADP3160 and ADP3167 ensure current balance in the two

phases by actively sensing the current through a single sense resistor.

During one phase’s ON time, the current through the respective

high-side MOSFET and inductor is measured through

resistor (R4 in Figure 6). When the comparator (CMP1

Functional Block Diagram) threshold programmed by the g

the sense

in the

ampli-

m

fier is reached, the high-side MOSFET turns off. In the next cycle,

the device switches to the second phase. The current is

measured

with the same sense resistor and the same internal comparator,

ensuring accurate matching. This scheme is immune to imbalances

in the MOSFETs’ R

and inductors’ parasitic resistances.

DS(ON)

If for some reason one of the phases fails, the other phase will

still be limited to its maximum output current (one-half of the

short circuit current limit). If this is not sufficient to supply the

load, the output voltage will droop and cause the PWRGD

output to signal that the output voltage has fallen out of its

specified range.

Short Circuit Protection

The ADP3160 and ADP3167 have multiple levels of short

circuit protection to ensure fail-safe operation. The sense resistor and the maximum current sense threshold voltage given in

the specifications set the peak current limit.

When the load current exceeds the current limit, the excess current

discharges the output capacitor. When the output voltage is

below the foldback threshold V

output current is cut by reducing the current sense threshold

from the current limit threshold, V

old, V

oscillator frequency is reduced by a factor of 5 when the output is

0 V. This further reduces the average current in short circuit.

Power Good Monitoring

The Power Good comparator monitors the output voltage of the

supply via the FB pin. The PWRGD pin is an open-drain output

whose high level (when connected to a pull-up resistor) indicates

that the output voltage is within the specified range of the nominal output voltage requested by the VID DAC. PWRGD will go

low if the output is outside this range.

Output Crowbar

The ADP3160 and ADP3167 include a crowbar comparator that

senses when the output voltage rises higher than the specified trip

threshold, V

and sets both PWM outputs low. The driver ICs turn off the

high-side MOSFETs and turn on the low-side MOSFETs, thus

pulling the output down as the reversed current builds up in the

inductors. If the output overvoltage is due to a short of the highside MOSFET, this action will current limit the input supply or

Table I. Output Voltage vs. VID Code

VID4 VID3 VID2 VID1 VID0 V

OUT(NOM)

11111No CPU

111101.100 V

111011.125 V

111001.150 V

110111.175 V

110101.200 V

110011.225 V

110001.250 V

101111.275 V

101101.300 V

101011.325 V

101001.350 V

100111.375 V

100101.400 V

100011.425 V

100001.450 V

011111.475 V

blow its fuse, protecting the microprocessor from destruction.

The crowbar comparator releases when the output drops below the

specified reset threshold, and the controller returns to normal

operation if the cause of the overvoltage failure does not persist.

Output Disable

The ADP3160 and ADP3167 include an output disable function

that turns off the control loop to bring the output voltage to 0 V.

Because an extra pin is not available, the disable feature is accomplished by pulling the COMP pin to ground. When the COMP pin

drops below 0.56 V for the ADP3160 and 0.64 V for the ADP3167,

the oscillator stops and both PWM signals are driven low. This

function does not place the part in a low quiescent current shutdown state, and the reference voltage is still available. The COMP

pin should be pulled down with an open collector or open-drain

type of output capable of sinking at least 2 mA.

APPLICATION INFORMATION

A VRM 9.0-Compliant Design Example

The design parameters for a typical high-performance Intel CPU

application (see Figure 6) are as follows:

011101.500 V

011011.525 V

011001.550 V

010111.575 V

010101.600 V

010011.625 V

010001.650 V

001111.675 V

001101.700 V

001011.725 V

001001.750 V

000111.775 V

000101.800 V

000011.825 V

000001.850 V

, the maximum deliverable

FB(LOW)

, to the foldback thresh-

CS(FOLD)

Input Voltage (V

. Along with the resulting current foldback, the

CROWBAR

. This comparator overrides the control loop

) = 12 V

IN

Nominal Output Voltage (V

Static Output Tolerance (V

CS(CL)

) = 1.7 V

OUT

) = (V+) – (V–) =

⌬

0 mV – (–130 mV) = 130 mV

Average Output Tolerance (V =

OUT

+

(V+) + (V–)

2

= . V

1 635

V

AVG

)

Maximum Output Current (IO) = 53.4 A

Output Current di/di < 50 A/s

REV. B

–7–

ADP3160/ADP3167

270F ⴛ 4

1

2

3

4

5

6

7

8

C1

150pF

C12

ADP3160

VID4

VID3

VID2

VID1

VID0

COMP

FB

CT

OS-CON 16V

U1

PWM1

PWM2

PWRGD

V

IN

12V

V

RTN

IN

R

A

26.1k⍀

C

OC

3.3nF

R

B

11.0k⍀

C2

100pF

NC = NO CONNECT

FROM

CPU

C11

R1

1k⍀

R7

20⍀

R4

4m⍀

1F

U2

DRVH

SW

PGND

DRVL

RUBYCON MBZ 6.3V

C15 C16

C9

VCC

REF

CS–

CS+

GND

C13

C26

R6

1F

C6

C23

15nF

D2

MBR052LTI

4.7F

Z1

ZMM5236BCT

ADP3414

BST

1

IN

2

NC

3

4

VCC

U3

R5

2.4k⍀

DRVH

SW

PGND

DRVL

C10

1F

8

7

6

5

Q5

2N3904

C14

10⍀

C4

4.7F

16

C25 1nF

15

14

13

12

11

10

9

1F

C5

D1

MBR052LTI

Q3

FDB7030L

Q4

FDB8030L

1

2

3

4

600nH

BST

IN

NC

VCC

ADP3414

L2

Figure 6. 53.4 A Intel CPU Supply Circuit, VRM 9.0 FMB Design

2200F ⴛ 9

C18

C17

Q1

FDB7030L

Q2

FDB8030L

C19

C20 C21

8

7

6

5

13m⍀ ESR (EACH)

L1

600nH

C22

C23

V

CC(CORE)

1.1V – 1.85V

53.4A

V

CC(CORE)

RTN

CT Selection—Choosing the Clock Frequency

The ADP3160 and ADP3167 use a fixed-frequency control architecture. The frequency is set by an external timing capacitor, C

The value of C

for a given clock frequency can be selected using

T

the graph in Figure 2.

The clock frequency determines the switching frequency, which

.

T

For 12.5 A peak-to-peak ripple current, which corresponds to

just under 50% of the 26.7 A full-load dc current in an inductor, Equation 1 yields an inductance of:

relates directly to switching losses and the sizes of the inductors

and input and output capacitors. A clock frequency of 400 kHz

sets the switching frequency of each phase, fSW, to 200 kHz, which

represents a practical trade-off between the switching losses and

the sizes of the output filter components. From Figure 2, for 400 kHz

the required timing capacitor value is 150 pF. For good frequency

stability and initial accuracy, it is recommended to use a capacitor

with a low temperature coefficient and tight tolerance, e.g., an

MLC capacitor with NPO dielectric and with 5% or less tolerance.

Inductance Selection

The choice of inductance determines the ripple current in the

A 600 nH inductor can be used, which gives a calculated ripple

current of 12.2 A at no load. The inductor should not saturate

at the peak current of 32.8 A and should be able to handle the

sum of the power dissipation caused by the average current of

26.7 A in the winding and the core loss.

The output ripple current is smaller than the inductor ripple

current due to the two phases partially canceling. This can be

calculated as follows:

inductor. Less inductance leads to more ripple current, which

increases the output ripple voltage and the conduction losses in

the MOSFETs, but allows using smaller size inductors and, for

a specified peak-to-peak transient deviation, output capacitors

with less total capacitance. Conversely, a higher inductance

means lower ripple current and reduced conduction losses,

but requires larger size inductors and more output capacitance

for the same peak-to-peak transient deviation. In a 2-phase

converter a practical value for the peak-to-peak inductor ripple

current is under 50% of the dc current in the same inductor.

A choice of 46% for this particular design example yields a total

peak-to-peak output ripple current of 23% of the total dc output

current. The following equation shows the relationship between

the inductance, oscillator frequency, peak-to-peak ripple current

in an inductor, and input and output voltages.

Designing an Inductor

Once the inductance is known, the next step is either to design

an inductor or find a standard inductor that comes as close as

possible to meeting the overall design goals. The first decision in

designing the inductor is to choose the core material. There are

several possibilities for providing low core loss at high frequencies. Two examples are the powder cores (e.g., Kool-Mm

Magnetics) and the gapped soft ferrite cores (e.g., 3F3 or 3F4

from Philips). Low-frequency powdered iron cores should be

avoided due to their high core loss, especially when the inductor

value is relatively low and the ripple current is high.

VV V

(– )

IN AVG AVG

L

=

Vf I

¥¥

IN SW L RIPPLE

VV V

(–. ).

12 1 635 1 635

L

V kHz A

¥¥

12 400 2 12 5

¥¥

22

I

=

O

D

¥¥

21635 12 2 1 635

.(–.)

VnHkHz

¥¥

12 600 400

¥

()

¥

/.

VV V

(– )

AVG IN AVG

VLf

¥¥

IN OSC

VV V

=

=

565

=

99

.

(1)

nH=

(2)

A

®

from

REV. B–8–

ADP3160/ADP3167

Two main core types can be used in this application. Open

magnetic loop types, such as beads, beads on leads, and rods and

slugs, provide lower cost but do not have a focused magnetic field

in the core. The radiated EMI from the distributed magnetic

field may create problems with noise interference in the circuitry

surrounding the inductor. Closed-loop types, such as pot cores,

PQ, U, and E cores, or toroids, cost more, but have much

better EMI/RFI performance. A good compromise between

price and performance are cores with a toroidal shape.

There are many useful references for quickly designing a power

inductor. Table II gives some examples.

Table II. Magnetics Design References

Magnetic Designer Software

Intusoft (www.intusoft.com)

Designing Magnetic Components for High-Frequency DC-DC

Converters

McLyman, Kg Magnetics

ISBN 1-883107-00-08

Selecting a Standard Inductor

The companies listed in Table III can provide design consultation and deliver power inductors optimized for high power

applications upon request.

Table III. Power Inductor Manufacturers

Coilcraft

(847) 639-6400

www.coilcraft.com

Coiltronics

(561) 752-5000

www.coiltronics.com

Sumida Electric Company

(510) 668-0660

www.sumida.com

C

Selection—Determining the ESR

OUT

The required equivalent series resistance (ESR) and capacitance

drive the selection of the type and quantity of the output capacitors.

The ESR must be small enough to contain the voltage deviation caused by a maximum allowable CPU transient current

within the specified voltage limits, giving consideration also to the

output ripple and the regulation tolerance. The capacitance must

be large enough that the voltage across the capacitor, which is the

sum of the resistive and capacitive voltage deviations, does not

deviate beyond the initial resistive deviation while the inductor

current ramps up or down to the value corresponding to the new

load current. The maximum allowed ESR also represents the

maximum allowed output resistance, R

OUT

.

The cumulative errors in the output voltage regulations cut into

the available regulation window, V

. When considering dynamic

WIN

load regulation this relates directly to the ESR. When considering dc load regulation, this relates directly to the programmed

output resistance of the power converter.

Some error sources, such as initial voltage accuracy and ripple

voltage, can be directly deducted from the available regulation

window. Other error sources scale proportionally to the

amount of voltage positioning used, which, for an optimal design,

should use the maximum that the regulation window will allow.

The error determination is a closed-loop calculation, but it can

be closely approximated. To maintain a conservative design while

avoiding an impractical design, various error sources should

be considered and summed statistically.

The output ripple voltage can be factored into the calculation by

summing the output ripple current with the maximum output

current to determine an effective maximum dynamic current

change. The remaining errors are summed separately according

to the formula:

VVV k

Ê

Á

Á

Ë

where k

I

O

–

1

II

+

OO

D

= 0.7% is the initial programmed voltage tolerance

VID

from the graph of Figure 4, k

current sense resistor, k

current sense filter components, k

two termination resistors added at the COMP pin, and k

accounts for the IC current loop gain tolerance including the g

(–( ))

=¥¥

WIN VID VID

D

Ê

k

2

k

RCS

CSF

+

Á

2

Ë

RCS

= 20% is the summed tolerance of the

CSF

2

2

ˆ

˜

¯

22

kk mV

++

RT EA

= 2% is the tolerance of the

= 2% is the tolerance of the

RT

ˆ

˜

=

˜

¯

94

EA

(3)

= 8%

m

tolerance.

The remaining window is then divided by the maximum output

current plus the ripple to determine the maximum allowed ESR

and output resistance:

V

RR

E MAX OUT MAX

R

E MAX

==

() ()

mV

94

=

()

AA

53 4 9 9

..

+

WIN

II

+

OO

D

15

.

=

(4)

m

W

The output filter capacitor bank must have an ESR of less than

1.5 mW. One can, for example, use nine MBZ-type capacitors

from Rubycon, with 2.2 mF capacitance, a 6.3 V voltage rating,

and 13 mW ESR. The nine capacitors have a maximum total ESR

of 1.44 mW when connected in parallel. Without ADOPT voltage

positioning, the ESR would need to be less than 0.9 mW, yielding

a 50% increase to 14 MBZ-type output capacitors.

C

—Checking the Capacitance

OUT

As long as the capacitance of the output capacitor is above a

critical value and the regulating loop is compensated with

ADOPT, the actual value has no influence on the peak-to-peak

deviation of the output voltage to a full step change in the load

current. The critical capacitance can be calculated as follows:

C

OUT CRIT

C

OUT CRIT

=

()

=

()

I

O

¥

RV

E OUT

53 4

..

144 17

m

.

W¥

L

¥

2

A

600

nH

¥=

2

.

65

(5)

mF

The critical capacitance for the nine Rubycon capacitors with

an equivalent ESR of 1.44 mW is 6.5 mF, while the equivalent

capacitance of those nine capacitors is 9 ¥ 2.2 mF = 19.8 mF.

Therefore, the capacitance is safely above the critical value.

REV. B

–9–

ADP3160/ADP3167

R

SENSE

The value of R

is based on the maximum required output

SENSE

current. The current comparator of the ADP3160 has a minimum current limit threshold of 142 mV. Note that the 142 mV

value cannot be used for the maximum specified nominal current,

as headroom is needed for ripple current and tolerances.

The current comparator threshold sets the peak of the inductor

current yielding a maximum output current, IO, which equals

twice the peak inductor current value less half of the peak-topeak inductor ripple current. From this the maximum value of

is calculated as:

R

SENSE

R

SENSE

V

CS CL MIN

()( )

£

I

I

LRIPPLE

()

O

+

22

=

mV

142

AA

+

..

26 7 6 1

m

=W

.

43

(6)

In this case, 4 mW was chosen as the closest standard value.

Once R

where current limit is reached, I

has been chosen, the output current at the point

SENSE

, can be calculated using

OUT(CL)

the maximum current sense threshold of 172 mV:

V

CS CL MAX

I

OUT CL

172

¥

2

=¥ =

mV

W

4

m

()( )

2

R

SENSE

–. .

12 2 73 8

=

AA

–

I

L RIPPLE()

()

(7)

At output voltages below 425 mV, the current sense threshold is

reduced to 95 mV, and the ripple current is negligible. Therefore, at dead short the output current is reduced to:

I

OUT SC()

95

.=¥ =2

A

47 5

m

4

W

(8)

mV

To safely carry the current under maximum load conditions, the

sense resistor must have a power rating of at least:

PI R

=¥

R SENSE RMS SENSE

SENSE

2

()

(9)

where:

2

I

I

SENSE RMS

2

()

=¥

V

O OUT

n

V

¥h

IN

(10)

In this formula, n is the number of phases, and is the converter

efficiency, in this case assumed to be 85%. Combining Equations 9

and 10 yields:

2

..

AV

P

R

53 4

=¥¥¥W=

SENSE

2

17

.

085 12

mmW

4 950

V

Power MOSFETs

In the standard 2-phase application, two pairs of N-channel

power MOSFETs must be used with the ADP3160 and

ADP3412, one pair as the main (control) switches and the

other pair as the synchronous rectifier switches. The main

selection parameters for the power MOSFETs are V

and R

. The minimum gate drive voltage (the supply volt-

DS(ON)

GS(TH)

age to the ADP3412) dictates whether standard threshold or

logic-level threshold MOSFETs must be used. Since V

logic-level threshold MOSFETs (V

< 2.5 V) are strongly

GS(TH)

GATE

< 8 V,

recommended.

The maximum output current I

determines the R

O

DS(ON)

requirement for the power MOSFETs. When the ADP3160 is operating

in continuous mode, the simplifying assumption can be made

that in each phase one of the two MOSFETs is always conducting the average inductor current. For V

V

= 1.6 V, the duty ratio of the high-side MOSFET is:

OUT

V

D

OUT

==13 3.%

HSF

V

IN

= 12 V and

IN

(11)

The duty ratio of the low-side (synchronous rectifier) MOSFET is:

DD

==1867–.%

LSF HSF

(12)

The maximum rms current of the high-side MOSFET during

normal operation is:

I

HSF MAX

()

Ê

I

O

D

HSF

2

I

()

LRIPPLE

1

Á

Ë

¥

3

ˆ

=

98

˜

2

I

¯

O

(13)

A

.=¥+

2

The maximum rms current of the low-side MOSFET during

normal operation is:

II

LSF MAX HSF MAX

==25

() ()

The R

for each MOSFET can be derived from the allowable

DS(ON)

LSF

D

HSF

A

(14)

D

dissipation. If 10% of the maximum output power is allowed for

MOSFET dissipation, the total dissipation in the four MOSFETs

of the 2-phase converter will be:

PVI

MOSFET TOTAL MIN O

PVAW

MOSFET TOTAL

()

()

.

=¥ ¥

01

.. . .

=¥ ¥ =

01 157 534 84

(15)

Allocating half of the total dissipation for the pair of high-side

MOSFETs and half for the pair of low-side MOSFETs, and

assuming that the resistive and switching losses of the high-side

MOSFET are equal, the required maximum MOSFET resistances will be:

R

()( )

DS ON HS MAX

R

()( )

DS ON HS MAX

R

()( )

DS ON LS MAX

R

()( )

DS ON LS MAX

P

MOSFET TOTAL

=

8

=

898

P

MOSFET TOTAL

=

4

=

425

()

2

¥

I

HSF MAX

.

84

W

(. )

¥

A

()

2

¥

I

LSF MAX

.

84

W

()

¥

A

()

=W

11

m

2

()

.

=W

34

2

m

(16)

(17)

Note that there is a trade-off between converter efficiency and

cost. Larger MOSFETs reduce the conduction losses and allow

higher efficiency, but increase the system cost. If efficiency is

not a major concern, a Fairchild FDB7030L (R

DS(ON)

= 7 mW

nominal, 10 mW worst case) for the high-side and a Fairchild

FDB8030L (R

= 3.1 mW nominal, 5.6 mW worst case)

DS(ON)

for the low-side are good choices. The high-side MOSFET

dissipation is:

PR I

=¥

()

HSF DS ON HS

VI Qf

¥¥¥

IN L PK G

()

()

I

¥

2

G

2

HFS MAX

()

SW

VQ f

+¥¥

()

+

(18)

IN RR SW

where the second term represents the turn-off loss of the

MOSFET and the third term represents the turn-on loss due to

the stored charge in the body diode of the low-side MOSFET.

(In the second term, Q

the gate for turn-off and I

is the gate charge to be removed from

G

is the gate turn-off current. From

G

REV. B–10–

ADP3160/ADP3167

the data sheet for the FDB7030L, the value of QG is about 35 nC

and the peak gate drive current provided by the ADP3412 is

about 1 A. In the third term, Q

is the charge stored in the

RR

body diode of the low-side MOSFET at the valley of the inductor

current. The data sheet of the FDB8030L does not give that

information, so an estimated value of 150 nC is used. The estimate is based on information found on the data sheet of a

similar device, the IRF7809. In both terms, f

switching frequency of the MOSFETs, or 200 kHz. I

is the actual

SW

L(PK)

is the

peak current in the inductor, or 32.8 A.

Substituting the above data in Equation 19, and using the worstcase value for the MOSFET resistance yields a conduction loss

of 0.96 W, a turn-off loss of 2.75 W, and a turn-on loss of 0.72 W.

Thus the worst-case total loss in a high-side MOSFET is 4.43 W.

The worst-case low-side MOSFET dissipation is:

PR I

=¥

LSF DS ON LS

PmAW

LSF

()

.().

56 25 35

=W¥ =

2

LSF MAX

()

2

(19)

(Note that there are no switching losses in the low-side MOSFET.)

CIN Selection and Input Current di/dt Reduction

In continuous inductor-current mode, the source current of the

high-side MOSFET is approximately a square wave with a duty

ratio equal to V

OUT/VIN

and an amplitude of one-half of the

maximum output current. To prevent large voltage transients, a

low ESR input capacitor sized for the maximum rms current

must be used. The maximum rms capacitor current is given by:

I

C RMS

()

I

C RMS

()

I

O

=¥-¥

53 4

=¥¥=

DD

22

2

A

.

2

()

HSF HSF

.–( .) .

20133 20133 11 9

2

(20)

2

A

Note that the capacitor manufacturer’s ripple current ratings are

often based on only 2000 hours of life. This makes it advisable

to further derate the capacitor, or to choose a capacitor rated at

a higher temperature than required. Several capacitors may be

placed in parallel to meet size or height requirements in the

design. In this example, the input capacitor bank is formed by

four 270 mF, 16 V OS-CON capacitors.

The ripple voltage across the three paralleled capacitors is:

V

C RIPPLE

()

V

C RIPPLE

()

Ê

InESR

OCCHSF

=¥ +

Á

nDnC f

Ë

Am

.

53 4218

=¥W+

CINSW

Ê

Á

4

Ë

¥¥

4 270 200

ˆ

˜

¯

0 133

.

F kHz

¥m¥

(21)

ˆ

mV

=

137

˜

¯

To reduce the input current di/dt to below the recommended

maximum of 0.1 A/ms, an additional small inductor (L > 1 mH@

15 A) should be inserted between the converter and the supply

bus. That inductor also acts as a filter between the converter and

the primary power source.

Feedback Loop Compensation Design for ADOPT

Optimized compensation of the ADP3160 and ADP3167 allow

the best possible containment of the peak-to-peak output voltage

deviation. Any practical switching power converter is inherently

limited by the inductor in its output current slew rate to a value

much less than the slew rate of the load. Therefore, any sudden

change of load current will initially flow through the output capacitors, and assuming that the capacitance of the output capacitor

is larger than the critical value defined by Equation 5, this will

produce a peak output voltage deviation equal to the ESR of the

output capacitor times the load current change.

The optimal implementation of voltage positioning, ADOPT,

will create an output impedance of the power converter that is

entirely resistive over the widest possible frequency range, including dc, and equal to the maximum acceptable ESR of the output

capacitor array. With the resistive output impedance, the output

voltage will droop in proportion with the load current at any

load current slew rate; this ensures the optimal positioning and

allows the minimization of the output capacitor.

With an ideal current-mode controlled converter, where the

average inductor current would respond without delay to the

command signal, the resistive output impedance could be

achieved by having a single-pole roll-off of the voltage gain of

the voltage-error amplifier. The pole frequency must coincide

with the ESR zero of the output capacitor. The devices use constant

frequency current-mode control, which is known to have a

nonideal, frequency dependent command signal to inductor current

transfer function. The frequency dependence manifests in the

form of a pair of complex conjugate poles at one-half of the switching frequency. A purely resistive output impedance could be

achieved by canceling the complex conjugate poles with zeros at

the same complex frequencies and adding a third pole equal to

the ESR zero of the output capacitor. Such a compensating network

would be quite complicated. Fortunately, in practice it is

sufficient to cancel the pair of complex conjugate poles with a

single real zero placed at one-half of the switching frequency.

Although the end result is not a perfectly resistive output impedance, the remaining frequency dependence causes only a small

percentage of deviation from the ideal resistive response. The

single-pole and single-zero compensation can be easily implemented

by terminating the g

error amplifier with the parallel combina-

m

tion of a resistor and a series RC network.

The first step in the design of the feedback loop compensation is to determine the targeted output resistance, R

E(MAX)

, of the

power converter using Equation 4. The compensation can then

be tailored to create that output impedance for the power

converter, and the quantity of output capacitors can be chosen

to create a net ESR that is less than or equal to R

E(MAX)

.

The next step is to determine the total termination resistance of

the g

amplifier that will yield the correct output resistance:

m

nR

¥

R

T

R

T

I SENSE

=

gR

¥¥

mEMAX

()

.

12 5 4

=

..

22 15 2

mmho m

2

m

¥W

¥W¥

.

757

k

=W

(22)

where nI is the division ratio from the output voltage signal of

the g

amplifier to the PWM comparator (CMP1), gm is the

m

transconductance of the g

amplifier itself, and the factor of 2 is

m

the result of the 2-phase configuration. Note that the internal

current multiplier (n

) is 12.5 for the ADP3160, but is 25 for

I

the ADP3167. For this example, assume that we use the

Rubycon capacitors at the output with their ESR of 1.44 mW.

Once R

from the REF pin to output of the g

is known, the two resistors that make up the divider

T

amplifier (COMP pin)

m

must be calculated. The resistive divider introduces an offset to

the output of the g

the gain of the g

amplifier that, when reflected back through

m

stage, accurately positions the output voltage

m

near its allowed maximum at light load. Furthermore, the output

of the g

amplifier sets the current sense threshold voltage. At no

m

load, the current sense threshold is increased by the peak of the

ripple current in the inductor and reduced by the delay between

REV. B

–11–

ADP3160/ADP3167

sensing when the current threshold has been reached and when

the high-side MOSFET actually turns off. These two factors are

combined with the inherent voltage at the output of g

that commands a current sense threshold of 0 mV (V

IRn

L RIPPLE SENSE I

VV

=+

GNL GNL

VV

-

IN AVG

L

VV+

=

1

GNL

V– . V

12 1 635

nH

600

()

0

¥¥¥ ¥

2

tR n

()

D SENSE I

.A m .

12 2 4 12 5

¥¥ ¥ ¥

260 4 1251201

The output voltage at no load (V

¥¥

2

¥¥

W

2

ns m . = . V

–

W

) can be calculated by

ONL

-

amplifier

m

):

GNL0

(23)

starting with the VID setting, adding in the positive offset (V+),

subtracting half the ripple voltage, and then subtracting the

dominant error terms:

RI

VVV

=+- -¥

ONL VID

2

kk

+¥

VID RT

VVV

17 0007 002

17 0

=+-

ONL

.(.).

.

V

¥+¥

+

Ê

V

Á

Ë

WIN

V

2

With these two terms calculated, the divider resistors (R

D

EO

V

2

ˆ

˜

¯

VID

138 99

..

VID

2

mA

W¥

2

Ê

Á

Ë

94

17

.

mV

V

(24)

–

2

ˆ

1 681

=

˜

¯

V

.

A

for the upper and RB for the lower) can be calculated.

Assuming that the internal resistance of the g

(R

) is 200 kW:

OGM

amplifier

m

Choosing the nearest 1% resistor value gives RB = 11.0 kW.

Finally, R

is calculated:

A

R

=

A

111

--

RR R

T OGM B

=

R

A

1

757

..

kk k

1

(26)

1

1

-

200

W

W

-

1

11 3

25 86

.

=W

k

W

Again, choosing the nearest 1% resistor value gives RA= 26.1 kW.

The compensating capacitor can be calculated from the equation:

CR

¥

C

C

p

OUT E MAX

=

OC

19 8 1 5

..

=

OC

kHz k

¥¥W

400 7 57

()

RfR

T OSC T

mF m

757

.

2

-

¥W

k

W

.

=

2

¥¥

p

-

nF

35

.

(27)

The closest standard value for COC is 3.3 nF.

The resistance of the zero-setting resistor in series with the

compensating capacitor is:

R

=

Z

R

=

Z

2

Cf

¥¥

p

OC OSC

2

nF kHz

¥¥

33 400

p.

=W

482

(28)

The nearest standard 5% resistor value is 470 W. Note that this

resistor is only required when C

25% or less). In this example, C

OUT

OUT

approaches C

> C

, and RZ can there-

CRIT

CRIT

(within

fore be omitted.

R

=

B

VV

R

=

B

–

REF GNL

R

T

VV

-

312

.

-¥

k

W

757

.

V

REF

-¥ -

()

gV V

m ONL VID

V

3

mmho V V

22 1681 17

.(.–.)

10 73

.

k

=W

(25)

REV. B–12–

1

2

Ch1

500mV 20mV 700mVCh1M 200sCh2

Figure 7. Transient Response of the 53.4 A

Design Example of Figure 6

AMD Athlon Design Example

The design parameters for a typical high-performance AMD

CPU application (see Figure 8) are as follows:

Input Voltage (V

Nominal Output Voltage (V

Static Output Tolerance (V

) = 5 V

IN

) = 1.7 V

OUT

) = (V+) – (V–) =

⌬

50 mV – (–50 mV) = 100 mV

Average Output Voltage (V ) =

(V+) + (V–)

+

V

OUT

2

AVG

= 1.7 V

Maximum Output Current (IO) = 45 A

Output Current di/dt < 50 A/s

Using the design procedure previously shown, the final values

for this application were calculated, and are shown in Figure 8.

ADP3160/ADP3167

LAYOUT AND COMPONENT PLACEMENT GUIDELINES

The following guidelines are recommended for optimal performance of a switching regulator in a PC system.

General Recommendations

1. For good results, at least a four-layer PCB is recommended.

This should allow the needed versatility for control circuitry

interconnections with optimal placement, a signal ground

plane, power planes for both power ground and the input

power (e.g., 5 V), and wide interconnection traces in the

rest of the power delivery current paths. Keep in mind that

each square unit of 1 ounce copper trace has a resistance of

~0.53 mW at room temperature.

2. Whenever high currents must be routed between PCB layers,

vias should be used liberally to create several parallel current

paths so that the resistance and inductance introduced by

these current paths is minimized and the via current rating is

not exceeded.

3. If critical signal lines (including the voltage and current

sense lines of the ADP3160) must cross through power

circuitry, it is best if a signal ground plane can be interposed

between those signal lines and the traces of the power

circuitry. This serves as a shield to minimize noise injection into the signals at the expense of making signal ground

a bit noisier.

4. The power ground plane should not extend under signal

components, including the ADP3160 itself. If necessary,

follow the preceding guideline to use the signal ground

plane as a shield between the power ground plane and the

signal circuitry.

5. The GND pin of the ADP3160 should be connected first to

the timing capacitor (on the CT pin), and then into the

signal ground plane. In cases where no signal ground plane

can be used, short interconnections to other signal ground

circuitry in the power converter should be used.

12V V

12V V

R2

20.6k⍀

C

OC

1.8nF

100pF

REV. B

V

IN

CC

V

IN

5V

RTN

CC

RTN

FROM

R3

16.5k⍀

C2

CPU

R1

1k⍀

1800F ⴛ 4

RUBYCON MBZ SERIES

C14C13C12

U1

ADP3167

1

2

3

4

5

6

7

8

C1

150pF

VID4

VID3

VID2

VID1

VID0

COMP

FB

CT

VCC

REF

CS–

PWM1

PWM2

CS+

PWRGD

GND

Z1

U3

R5

2.4k⍀

DRVH

SW

PGND

DRVL

R7

20⍀

C10

1F

8

7

6

5

Q5

2N3904

C5

1F

D1

MBR052LTI

C7

15pF

Q3

FDB7030L

600nH

Q4

FDB7035L

R4

4m⍀

U2

ADP3412

BST

1

DRVH

IN

2

3

4

L2

SW

DLY

PGND

DRVL

VCC

RUBYCON 6.3V MBZ SERIES

13m

C11 C16

C17

C9

1F

8

7

6

5

2200F ⴛ 10

ESR (EACH)

C19

C18

Q1

FDB7030L

Q2

FDB7035L

C20

C24

C25

L1

600nH

C27

C28

V

CC(CORE)

1.1V – 1.85V

45A

V

CC(CORE)

RTN

C15

C26

C21

4.7F

15nF

R6

10⍀

C4

4.7F

16

C22 1nF

15

14

13

12

1F

C6

MBR052LTI

15pF

11

10

9

D2

C8

ZMM5236BCT

ADP3412

BST

1

IN

2

DLY

3

4

VCC

Figure 8. 45 A Athlon Duron CPU Supply Circuit

–13–

ADP3160/ADP3167

6. The output capacitors of the power converter should be

connected to the signal ground plane even though power

current flows in the ground of these capacitors. For this

reason, it is advisable to avoid critical ground connections

(e.g., the signal circuitry of the power converter) in the

signal ground plane between the input and output capacitors.

It is also advisable to keep the planar interconnection path

short (i.e., have input and output capacitors close together).

7. The output capacitors should also be connected as closely

as possible to the load (or connector) that receives the power

(e.g., a microprocessor core). If the load is distributed, the

capacitors should also be distributed, and generally in

proportion to where the load tends to be more dynamic.

8. Absolutely avoid crossing any signal lines over the switching

power path loop, described next.

Power Circuitry

9. The switching power path should be routed on the PCB to

encompass the smallest possible area to minimize radiated

switching noise energy (i.e., EMI). Failure to take proper

precautions often results in EMI problems for the entire PC

system as well as noise-related operational problems in the

power converter control circuitry. The switching power path

is the loop formed by the current path through the input

capacitors, the power MOSFETs, and the power Schottky

diode, if used (see next), including all interconnecting PCB

traces and planes. The use of short and wide interconnection traces is especially critical in this path for two reasons:

it minimizes the inductance in the switching loop, which can

cause high-energy ringing, and it accommodates the high

current demand with minimal voltage loss.

10. An optional power Schottky diode (3 A–5 A dc rating) from

each lower MOSFET’s source (anode) to drain (cathode) will

help to minimize switching power dissipation in the upper

MOSFETs. In the absence of an effective Schottky diode, this

dissipation occurs through the following sequence of switching

events. The lower MOSFET turns off in advance of the upper

MOSFET turning on (necessary to prevent cross-conduction).

The circulating current in the power converter, no longer

finding a path for current through the channel of the lower

MOSFET, draws current through the inherent body diode of

the MOSFET. The upper MOSFET turns on, and the reverse

recovery characteristic of the lower MOSFET’s body diode

prevents the drain voltage from being pulled high quickly. The

upper MOSFET then conducts very large current while it

momentarily has a high voltage forced across it, which translates

into added power dissipation in the upper MOSFET. The

Schottky diode minimizes this problem by carrying a majority of

the circulating current when the lower MOSFET is turned off,

and by virtue of its essentially nonexistent reverse recovery

time. The Schottky diode has to be connected with very short

copper traces to the MOSFET to be effective.

11. A small ferrite bead inductor placed in series with the drain

of the lower MOSFET can also help to reduce this previously

described source of switching power loss.

12. Whenever a power dissipating component (e.g., a power

MOSFET) is soldered to a PCB, the liberal use of vias, both

directly on the mounting pad and immediately surrounding

it, is recommended. Two important reasons for this are:

improved current rating through the vias, and improved

thermal performance from vias extended to the opposite side

of the PCB where a plane can more readily transfer the heat

to the air.

13. The output power path, though not as critical as the switching power path, should also be routed to encompass a small

area. The output power path is formed by the current path

through the inductor, the current sensing resistor, the output capacitors, and back to the input capacitors.

14. For best EMI containment, the power ground plane should

extend fully under all the power components except the

output capacitors. These components are: the input capacitors,

the power MOSFETs and Schottky diodes, the inductors, the

current sense resistor, and any snubbing element that might

be added to dampen ringing. Avoid extending the power

ground under any other circuitry or signal lines, including the

voltage and current sense lines.

Signal Circuitry

15. The output voltage is sensed and regulated between the FB

pin and the GND pin (which connects to the signal ground

plane). The output current is sensed (as a voltage) by the

CS+ and CS– pins. In order to avoid differential mode noise

pickup in the sensed signal, the loop area should be small.

Thus the FB trace should be routed atop the signal ground

plane and the CS+ and CS– pins (the CS+ pin should be

over the signal ground plane as well).

16. The CS+ and CS– traces should be Kelvin-connected to the

current sense resistor, so that the additional voltage drop

due to current flow on the PCB at the current sense resistor

connections does not affect the sensed voltage.

REV. B–14–

OUTLINE DIMENSIONS

Dimensions shown in millimeters and (inches)

16-Lead Standard Small Outline Package [SOIC]

Narrow Body

(R-16A/SO-16)

10.00 (0.3937)

9.80 (0.3858)

4.00 (0.1575)

3.80 (0.1496)

16

1

9

6.20 (0.2441)

5.80 (0.2283)

8

ADP3160/ADP3167

PIN 1

1.27 (0.0500)

COPLANARITY

0.25 (0.0098)

0.10 (0.0039)

CONTROLLING DIMENSIONS ARE IN MILLIMETERS; INCH DIMENSIONS

(IN PARENTHESES) ARE ROUNDED-OFF MILLIMETER EQUIVALENTS FOR

REFERENCE ONLY AND ARE NOT APPROPRIATE FOR USE IN DESIGN

BSC

1.75 (0.0689)

1.35 (0.0531)

0.51 (0.0201)

0.33 (0.0130)

SEATING

PLANE

0.25 (0.0098)

0.19 (0.0075)

0.50 (0.0197)

0.25 (0.0098)

8ⴗ

0ⴗ

1.27 (0.0500)

0.40 (0.0157)

ⴛ 45ⴗ

REV. B

–15–

ADP3160/ADP3167

Revision History

Location Page

05/02—Data Sheet changed from REV. A to REV. B.

Addition of ADP3167 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Universal

2/01—Data Sheet changed from REV. 0 to REV. A.

Changes to Reference section of SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Edits to Figure 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Replacement of Figure 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Edits to C

Edits to Figure 6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Changes to Equations 4, 6, and 24–28 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9, 10, 12

Edits to C

Edits to Power MOSFETs Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Changes to Figure 8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Selection—Choosing the Clock Frequency section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

T

—Checking the Capacitance section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

OUT

C02806–0–5/02(B)

–16–

PRINTED IN U.S.A.

REV. B

Loading...

Loading...