查询ADP3088供应商

PRELIMINARY TECHNICAL DATA

a

1 MHz, 750 mA Buck Regulator

Preliminary Technical Data ADP3088

FEATURES

1 MHz PWM Frequency

Automatic PWM to Power Saving Mode at Light Load

Fully Integrated 1 A Power Switch

3% Output Regulation Accuracy over Temperature,

Line, and Load

100% Duty Cycle Operation

Simple Compensation

Output Voltage: 1.25 V to 10.5 V

Small Inductor and MLC Capacitors

Low Quiescent Current while Pulse Skipping

Thermal Shutdown

Fully Integrated Soft Start

Cycle-by-cycle Current Limit

APPLICATONS

PDAs and Palmtop Computers

Notebook Computers

PCMCIA Cards

Bus Products

Portable Instruments

IN

IN

COMP

GND

GND

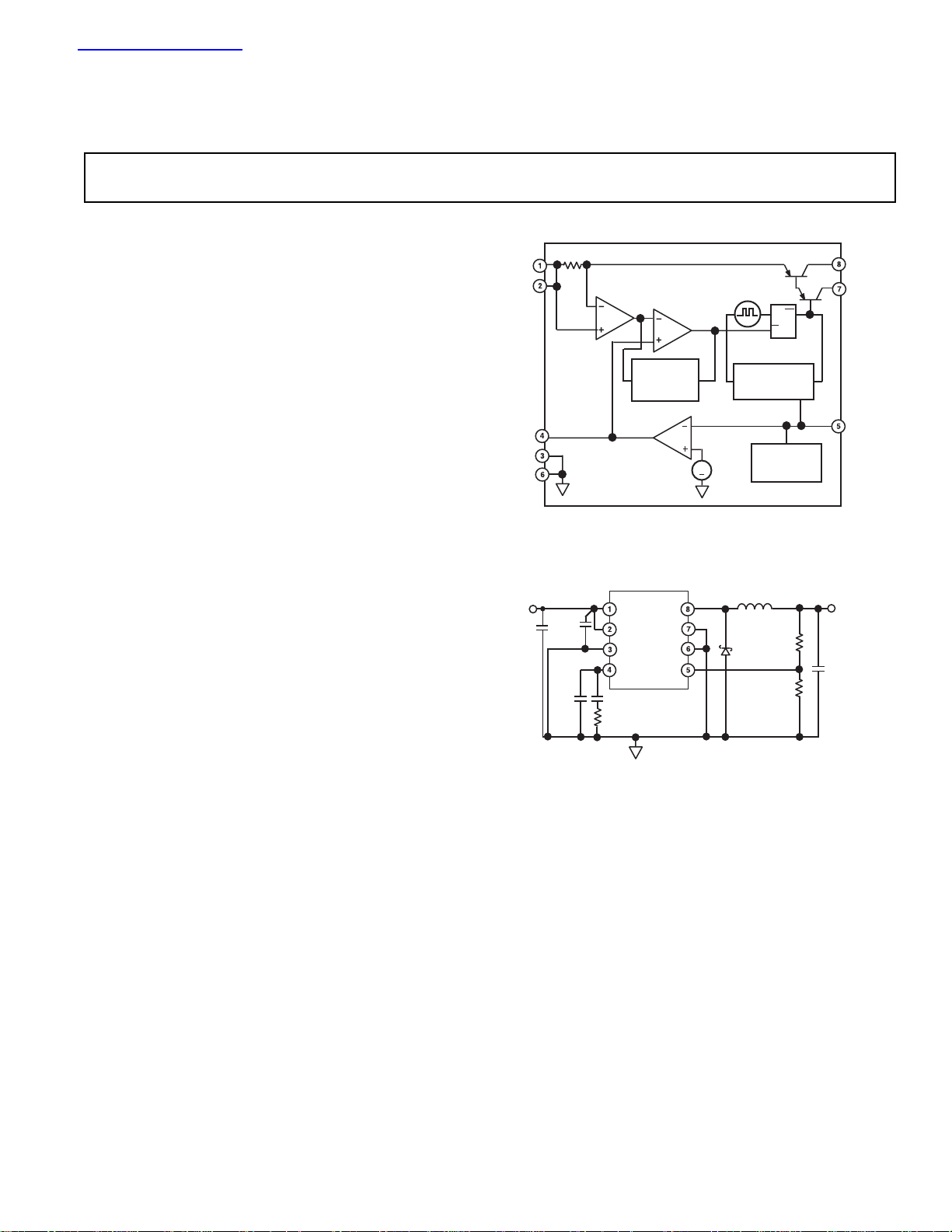

FUNCTIONAL BLOCK DIAGRAM

CURRENT

SENSE

AMP

PWM

COMPARATOR

PROTECTION

LOGIC

(ILIM, OT)

ERROR

AMP

g

m

+

REF

1.245V

1MHz

SQ

R

RUN/STOP

COMPARATORS

SOFT-START

TIMER

SW

DRV

FB

GENERAL DESCRIPTION

The ADP3088 is a high frequency, non-synchronous PWM

step-down DC-DC regulator with an integrated 1A power

switch in a space-saving MSOP8 package. It provides high

efficiency, excellent dynamic response, and is very simple

to use.

The ADP3088’s 1 MHz switching frequency allows for

small, inexpensive external components, and the current

mode control loop is simple to compensate and eases noise

filtering. It operates in PWM current mode under heavy

loads and saves energy at lighter loads by switching automatically into Power Saving mode. Soft start is integrated

completely on chip, as is the cycle-by-cycle current limit.

Capable of operating from 2.5 V to 11 V input, it is ideal for

many applications, including portable, battery power applications, where local point-of-use power regulation is required. Supporting output voltages down to 1.25 V, the

ADP3088 is ideal to generate low voltage rails, providing

the optimal solution in its class for delivering power efficiently, responsively, and simply with minimal printed circuit board area.

The device is specified over the industrial temperature

range of -40 °C to +85°C.

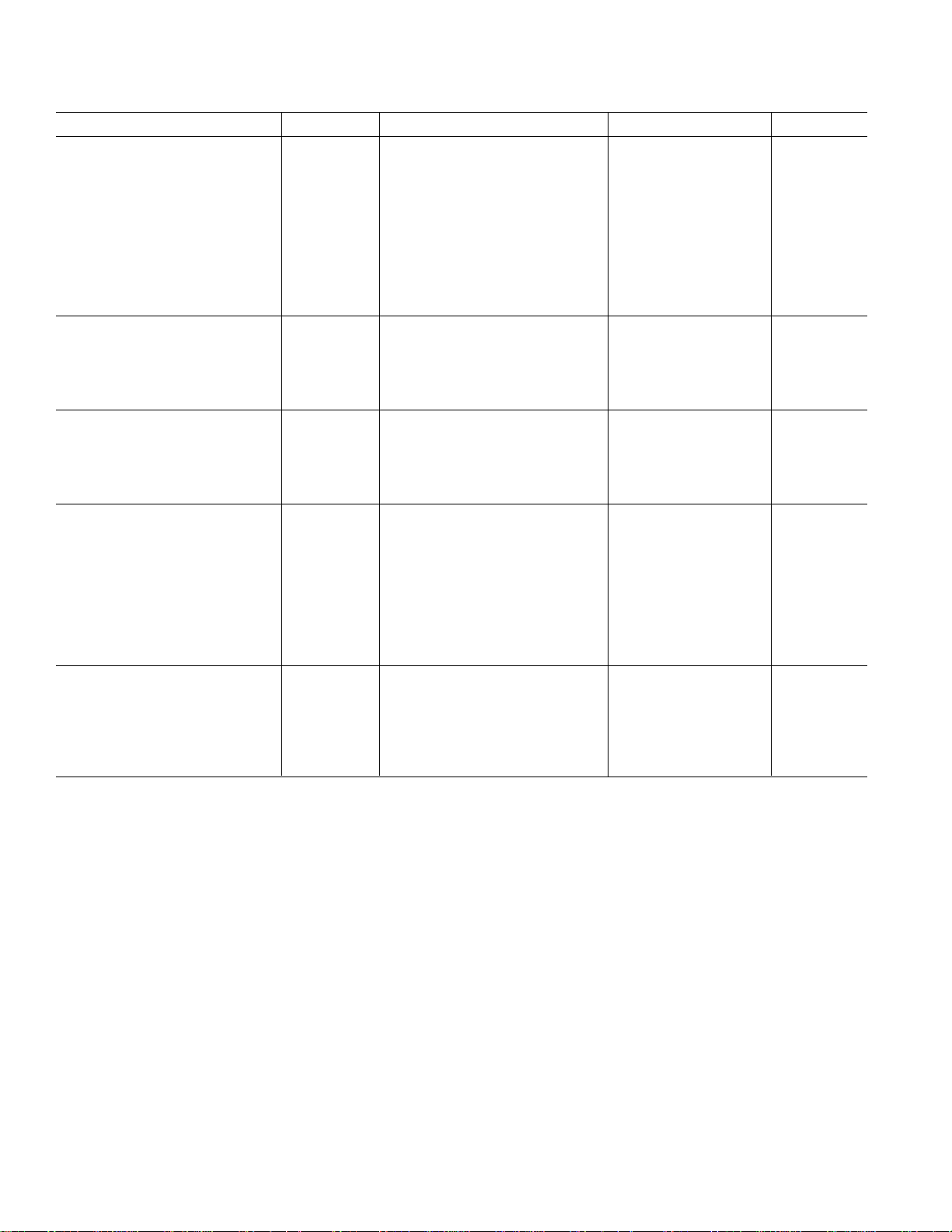

VIN

3.3V

10µF

0.1µF

4.7pF

220pF

20kΩ

ADP3088

IN

IN

GND

COMP

SW

DRV

GND

FB

3.3µH

1N5817

10.0kΩ

22.4kΩ

Figure 1. Typical Application

10µF

VOUT

1.8V

REV. PrK 3/28/02

Information furnished by Analog Devices is believed to be accurate and reliable. However, no responsibility is assumed by Analog Devices for its use, nor

for any infringements of patents or other rights of third parties which may

result from its use. No license is granted by implication or otherwise under any

patent or patent rights of Analog Devices.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 World Wide Web Site: http://www.analog.com

Fax: 781/326-8703 Analog Devices, Inc., 2002

PRELIMINARY TECHNICAL DATA

1

ADP3088–SPECIFICATIONS

Parameter Symbol Conditions Min Typ Max Units

SUPPLY

Input Voltage Range V

Quiescent Current Operating I

Quiescent Current Operating I

Shutdown I

Ground Current I

Normal Operation VIN = 11 V, IL = 500 mA, 2.5 3.6 mA

Thermal Shutdown Threshold T

OSCILLATOR

Oscillator Frequency f

Minimum Sleep Duty Cycle D

Maximum Duty Cycle D

Wake up Hysteresis V

OUTPUT SWITCH

Switch On Voltage V

Current Limit Threshold I

Leakage Current VIN = 12 V 0.5 µA

ERROR AMPLIFIER

Reference Voltage Accuracy V

Reference Voltage Line FB = COMP, .02 %/V

Regulation V

Feedback Input Bias Current I

Sink/Source Current I

Short Circuit Current I

Transconductance gm,

MODULATOR

Transconductance gm,

Control Offset Voltage V

Soft Start Time t

Shutdown Threshold Voltage V

Slope Compensation m

NOTES

1 All limits at temperature extremes are guaranteed via correlation using standard Statistical Quality Control (SQC).

2 For higher efficiency operation, tie the DRV pin to the output for IL < 250 mA, and VIN > 3 V.

3 V(IN) - V(SW), includes voltage drop across internal current sensor.

Specifications subject to change without notice.

IN

Q

Q

SD

2

GND

SD

SW

PSM

MAX

HYST

3

IO

LIM

REF

FB

COMP

COMP, SD

EA

MOD

PWM, OS

SS

COMP, SD

SC

(VIN = +3.3 V, TA = -40°C to +85°C, unless otherwise noted)

DRV = GND 2.5 11 V

VIN = 10 V, IL = 500 mA, 6 mA

DRV = GND

No load 150 250 µA

V

= 0 V 15 40

COMP

DRV = 2 V

160 °C

0.75 1 1.25 MHz

IL = 500 mA 14 %

100 %

FB voltage drops below V

REF

20 30 40 mV

IL = 500 mA, FB and DRV = 0.25 0.4 V

GND

1.0 1.2 1.4 A

FB = COMP 1.222 1.245 1.265 V

= 3 V to 12 V

IN

soft start expired -50 1 50 nA

35 60 85 µA

V

= 0 V, activating 20 40 µA

COMP

shutdown

FB = COMP 480 µA/V

V

COMP

to I

L

1 A/V

0.90 V

250 600 µs

340 750 mV

Effectively summed to I

SW

0.7 A/µs

–2– REV. PrK

PRELIMINARY TECHNICAL DATA

PRELIMINARY TECHNICAL DATA

ADP3088

ABSOLUTE MAXIMUM RATINGS*

Input Supply Voltage ............................... –0.3 V to +12 V

Voltage on any pin with respect to GND .. –0.3 V to +12 V

(voltage on any pin may not exceed V

)

IN

Operating Ambient Temperature Range .. –40°C to +85°C

Operating Junction Temperature ......................... +125°C

(4-layer board)........................................... +116°C/W

θ

JA

θ

(2-layer board)........................................... +159°C/W

JA

Storage Temperature Range .................. –65°C to +150°C

Lead Temperature Range (Soldering, 10 sec.) ..... +300°C

Vapor Phase (60 sec) ........................................ +215°C

Infrared (15 sec) ............................................... +220°C

*This is a stress rating only; operation beyond these limits can cause the device

to be permanently damaged. Unless otherwise specified, all voltages are

referenced to GND.

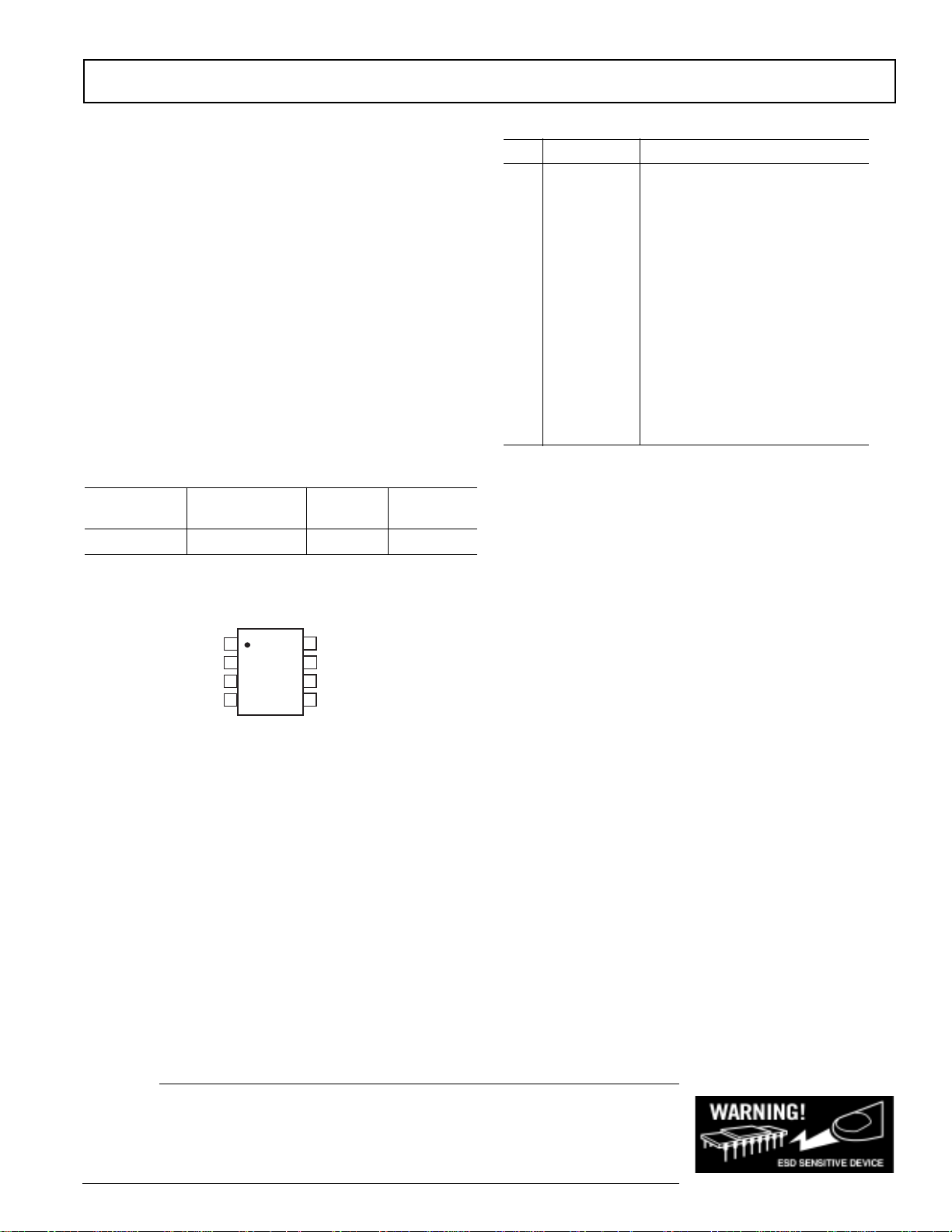

ORDERING GUIDE

Temperature Package Branding

Model Range Option Information

ADP3088ARM -40°C to +85°C MSOP-8 P0A

PIN FUNCTION DESCRIPTIONS

Pin Mnemonic Function

1, 2 IN Power Supply Input. Both pins

must be connected.

3,6 GND Ground. Both pins must be con-

nected.

4 COMP Feedback Loop Compensation

and Shutdown Input. An open

drain or collector used to pull

the pin to ground will shutdown

the device.

5 FB Feedback Voltage Sense Input.

This pin senses the voltage via

an external resistor divider.

7 DRV This pin provides a separate

path for drive current to be connected to ground.

8 SW Switching Output.

PIN CONFIGURATION

GND

COMP

1

IN

2

IN

ADP3088

3

4

8

SW

7

DRV

6

GND

5

FB

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection.

Although the device features proprietary ESD protection circuitry, permanent damage may occur on devices subjected to high energy electrostatic discharges. Therefore, proper ESD

precautions are recommended to avoid performance degradation or loss of functionality.

–3–REV. PrK

ADP3088

PRELIMINARY TECHNICAL DATA

THEORY OF OPERATION

The ADP3088 is a fixed frequency buck switching regulator in an MSOP-8 package using an external Schottky rectifier. It features an integrated 1A power switch and switches

at 1MHz. ADP3088 utilizes PWM operation and incorporates soft-start for controlled start-up sequence and over

temperature switch protection. The ADP3088 draws low

current while running in power saving mode, and even

lower current in shutdown.

Refer to the functional block diagram on page 1. The system shown is configured for a 1.8 V output using a 10 µH

inductor. At the beginning of a cycle the 1 MHz oscillator

enables an SR latch, enabling the internal 1 A power

switch. The current sense amplifier and the protection logic

block monitor the current flowing between the IN and SW

pins. The switch is turned off when the current reaches a

level determined by the protection logic block or PWM

comparator, whichever is lower. The error amplifier measures the output voltage through an external resistor divider

tied to the FB pin. This amplifier servos the switch current

to regulate the FB pin voltage to 1.245 V. An internal regulator provides power to the control circuitry. The COMP

pin can be used to shutdown the ADP3088. When pulled

low it turns off the internal regulator, thus biasing down the

chip, reducing the input current and disconnecting the

output from the input. Anti-saturation circuitry is used to

drive the switch to the edge of saturation. This allows the

driver to quickly switch at 1 MHz and maintain good efficiency. And for improved efficiency, the DRV pin may be

connected to the output provided that the input voltage is

at least 1 V greater than the output.

If the output load increases, the error amplifier will detect a

lower voltage on the FB pin, via the resistor divider on the

output, and send a signal to the PWM comparator to increase the on time of the switch. This in effect increases the

duty cycle and provides more current to drive the increased

load during the transient event, until a new operating point

is established.

Reference

The ADP3088 incorporates an internal bandgap reference,

it includes curvature correction for extremely low temperature coefficient. The reference can be disabled by grounding the COMP pin which also turns off the bias for the rest

of the chip.

Error Amplifier

The error amplifier provides a control voltage to the PWM

stage to set the peak inductor current which sets the output

current of the regulator. It is a g

is a current to the COMP pin.

Protection Logic

The protection logic block provides current limit and overtemperature protection. The over temperature protection is

enabled when the temperature of the chip exceeds a specified preset temperature; the switch will be disabled until the

temperature drops below a specified level, then normal

operation will resume. The thermal shutdown only stops

switching, but does not put the chip to power saving mode,

nor does it re-initiate soft start. As the chip cools slightly, it

will cycle in and out of thermal shutdown rapidly, maintaining the die temp at 150°C, but allowing the output voltage

amplifier in that its output

m

and current to swing up and down. The current limit protection overrides the PWM comparator; if this occurs then

the switch pulse will be terminated and the soft start mode

will be reset.

Current Sense Amplifier

The voltage on the internal current sense resistor is sensed

and passed to the ramp input of the PWM comparator.

This current sense signal is also passed to the current limit

comparator for peak current limit shutdown . At current

limit the soft-start capacitor is reset and soft-start is reinitiated. The current limit is normally 1.2 peak switch

current. Slope compensation is added to ADP3088 to stabilize the loop. A generated ramped signal is summed with

the current sense signal to provide slope compensation.

Slope compensation is needed to close the inner loop so

subharmonic oscillation is avoided. The ramp is reset with

each clock cycle so that the ADP3088 is capable of true

100% duty cycle.

Run/Stop Comparators

This block creates the 1 MHz signal sent to the SR latch

which is used for the switching frequency. It also takes the

FB voltage and decides when to go into and wake up from

power saving mode. The decision to induce power saving

mode is based upon duty ratio. During steady-state continuous operation, the duty ratio of a PWM buck regulator

is simply a function of input/output voltage ratio, with second order effects including the voltage drop of the internal

switch and the external diode. Once the load drops to a

certain point, discontinuous operation occurs, and the duty

ratio begins to modulate to maintain regulation. In the

ADP3088, the regulator goes to sleep when the integrated

duty ratio measurements drops to less than half of the minimum expected integrated duty ratio. The minimum expected duty ratio occurs at max input voltage, min output

voltage in continuous mode operation.

PWM Comparator

The PWM comparator looks at the signal from the current

sense amplifier and the error amplifier to determine the

correct switch on time to regulate the output voltage under

a given load.

Soft-Start Timer

Soft start will prevent saturating the inductor which could

cause uncontrolled overshoot of the output voltage and

electrical stress to the system at start up. When first powered up, an internal soft start capacitor is discharged and

the soft start circuitry provides a gradually decaying offset

to the error amplifier to prevent it from saturating and from

commanding maximum switch current to charge the output

capacitor. The output voltage approaches the final regulation voltage with a smooth exponential decay. This will

reduce electrical stress to the system.

Output

The output stage contains the bipolar power switch, and

the circuits necessary to switch it on and off quickly. The

pass switch is driven to the edge of saturation and the result

is a fast switching response and low switch resistance. For

improved efficiency, the DRV pin may be connected to the

output provided that the input voltage is at least 1 V higher

than the output. This will send the current needed to drive

the bipolar switch to the output load instead of routing it to

–4– REV. PrK

PRELIMINARY TECHNICAL DATA

X

ADP3088

ground. For some VIN and I

configurations, the DRV

LOAD

pin must be grounded for reliable operation.

APPLICATION INFORMATION

Output Voltage Setting

In its standard usage, the output voltage of the ADP3088 is

programmed to a desired fixed value by a resistor divider

from the output voltage into the feedback node, the pin FB,

at which node the control loop ensures regulation at the

reference level, V

. The divider should be designed to

REF

satisfy the formula:

(1)

VV

=×+

OUT REF

R

B

1

R

A

where RA is the upper divider resistor (between the output

and FB) and R

and RB are recommended to have values in the range of

R

A

is the lower one (between FB and ground).

B

2~200 kΩ and are likely to require a 1% tolerance or better

to attain acceptable output voltage tolerance.

In less conventional applications described separately, the

resistor feedback configuration can be modified or tapped

with other resistors to affect current flow into the FB node

that, in turn, influences the output voltage. Even a switched

voltage can be summed into the FB node as long as it is

sufficiently integrated and does not intolerably compromise

the transient response. This latter application is considered

further below in an application for powering a DSP.

Input Voltage, Power Dissipation Considerations, and

Power Savings Mode

The input voltage range is not typically considered a critical

parameter for electrical functionality, but there are several

considerations, upon which there is further elaboration

below:

must never exceed the maximum rated voltage

1. V

IN

2. V

must be within the specified operating range when

IN

normal operation is expected

3. V

must be greater than V

IN

by at least the specified

OUT

headroom when DC regulation is expected

4. V

, if not sufficiently greater than V

IN

, may limit the

OUT

large signal transient response of a buck converter

5. V

, if much greater than V

IN

, may give rise to such a

OUT

low duty ratio that it activates power savings mode even

at static higher load conditions or upon dynamic load

changes when it is not desired.

6. V

affects the device power dissipation (a lower value

IN

causes higher dissipation), which in turn affects die

temperature that must be kept below a maximum rating.

The lowest input voltage together with the maximum output voltage and maximum current create the conditions for

maximum power dissipation in the device, which determine

maximum temperature rise that should be checked against

the maximum junction temperature rating. The formula for

maximum power dissipation in the device is given by:

VV

+

@,

PIV

DMAX O MAX SW IO MA

OFIOMAX

=××

V

IN

,@,

(2)

where VF is the diode forward voltage drop and VSW is the

drop across the internal switch and current sensing resistor

that appears between the VIN and SW pins of the

ADP3088 during the on state of the switch. Both of these

variables can be approximated from a combination of

worst-case specs and typical graphs. Multiply the power

dissipation by the thermal resistance from junction to case

or ambient, as desired, to determine internal temperature

rise.

If the input voltage were so much higher than the output

voltage that it required an average duty ratio less than an

internally preset threshold, then power savings mode

(“PSM”) – that is characterized by periodic shutdown and

wakeup of the device that reduces average quiescent current – would be active for all load conditions rather than

only at lighter loads, for which it is intended. PSM operation is characterized by low-frequency ripple on the output

that appears similar to the behavior of a hysteretic regulator. This is usually not a factor for consideration and may

be ignored if PSM operation is acceptable for all load conditions, but in case it is relevant, the following recommendation is offered:

IN

D

PSM MAX

()

(3)

+

VV

OF

<

V

It is not possible to prevent the duty ratio from tending

towards zero in non-synchronous buck converters below a

certain minimum load current level called "borderline current" or "critical current" for the power converter. That

corresponds to the inductor ripple current reaching zero at

its bottom peak - sometimes called the "valley current". If

PSM activation strains the lower regulation limit due to the

hysteretic ripple, the output voltage can be offset slightly

upward by readjusting the nominal voltage setpoint with the

resistor divider.

Even though a buck converter may have a low dropout

voltage that allows the static regulation to be maintained as

the input voltage drops near to the output voltage, in buck

converters the slew rate limitation of inductor current can

compromise the dynamic regulation in response to load

current step increases. That is because the maximum rate

that current can be increased in the inductor is proportional

to the voltage available to impress across it, which is compromised as the input voltage reduces toward the output

voltage. This is not a limitation of the device but of buck

converters in general. The limitation is considered as part

of the output filter design, although it could also be considered in terms of a minimum acceptable input voltage for a

given output filter that will ensure that the dynamic response is acceptably maintained.

Output Filter Components

In most applications it is desirable to use the smallest inductor value that does not introduce practical problems, as this

tends to yield the lowest cost inductor. One reason for using

an even larger inductor than the minimum tolerable might

be to reduce output ripple voltage further, but cost being

–5–REV. PrK

ADP3088

PRELIMINARY TECHNICAL DATA

equal, this is generally better accomplished with a better

quality or proportionally larger output capacitor instead,

since a larger inductor degrades the large-signal transient

performance capability.

A conservative nominal design target value for the inductor

of a typical application circuit is that which creates a peakto-peak ripple current, ∆I

, for the nominal input voltage

L

that is approximately a third of the nominal 500mA rating

of the ADP3088. The reason for not suggesting to base the

ripple current on the maximum load current is for concern

of overload protection. Scaling of the ripple currents with

lower load currents would yield higher inductor values that

might give satisfactory operation, but in order for overload

operation up to the current limit level of the ADP3088 to

be satisfactory, it would be necessary to choose an inductor

rated up to that higher current, which would likely yield an

unsatisfactory inductor size and cost. In any case, having

chosen a target level for ∆I

, the recommended inductor

L

value is given by:

−× +

1

DVV

()

L

=

()

OF

×∆

fI

SW L

(4)

where D is the duty ratio - the suffix indicating continuous

inductor current - and is given by:

VV

+

D

=

OF

VVV

+−

IN F SW

(5)

and VSW and VF are assessed at full load, and fSW is the fixed

switching frequency of the ADP3088. The formula suggests the calculation of L using a nominal input voltage, and

for applications requiring a large ranges of V

tions of transient response at V

ripple at V

may warrant deeper consideration of how

IN(MAX)

versus the higher

IN(MIN)

the limita-

IN

to optimize the design. In applications where load transients are not severe, this conservative design for L is recommended. A more aggressive minimization of L is

outlined below, but a few restrictions are noted.

As inductance becomes smaller the ripple current becomes

larger. If the ripple becomes particularly large or, as an

additional factor, if the load is particularly dynamic, then

there is an increasing possibility that the peak inductor current will undesirably reach the current limit shutdown

threshold, ICL. This should be avoided by restricting the

minimum inductor value to keep the ripple current moderated. An alternate way to prevent excessive dynamic overshoot of inductor current during a load transient is to

reduce the DC gain of the error amplifier by adding resistive feedback; this idea is discussed below.

Another important restriction of the minimum inductor

value may apply. The design should ensure against possible

subharmonic oscillation that can occur in all fixed-frequency current-controlled switching power supplies when

switching at high duty ratios. The subharmonic oscillation

phenomenon will not be explained here - there are plenty

of papers written on the subject - except to say that it is

characterized by alternating high and low duty ratios - i.e.,

every other cycle - that produces additional ripple on the

output. To prevent subharmonic oscillation the following

restriction for the minimum inductor value is recommended:

VV

H

2

µ

LVV

> ×+×

VV

The value used for V

()

OF

should be only the minimum

IN(MIN)

+

OF

IN MIN

()

−

0.35

(6)

input voltage for which normal high performance operation

must be assured. Note the value returned for L may be

negative in which case the restriction does not apply. If the

preceding formula yields a lower inductor value than the

conservative recommendation given previously, as is likely

for most applications, then it is time to consider further

limitations to see how low the value can be minimized.

For a given inductor selection, the earlier formula is rearranged for convenience and skewed to the worst case input

voltage to determine the maximum inductor ripple current,

∆I

:

L

VVV

∆= ×

I

LMAX

()

IN MAX

VVVfL

IN MAX

−−

()

()

OSW

+− ×

FSWSW

VV

+

F

O

(7)

Performance degradation of the inductor - consisting of

some loss of inductance or excessive power loss - may be

encountered at higher ripple currents, so the ripple current

figure, together with knowledge of the expected DC current should be checked against specifications of the inductor.

If the ESR of the output capacitor is substantial - as it is

likely to be if a MLC capacitor is not used - then the ripple

voltage on the output, dominated by the ESR, may be

substantial and of concern for regulation specifications.

The resistive component of the output voltage ripple is

simply the ripple current times the ESR, and if it is more

than a few millivolts it will dominate the output capacitance

in contributing to output ripple voltage.

The boundary condition of the inductor reaching the borderline current, I

VVV VV

+−−

OF INOSW

=×

I

OBL

()

2

fLV V V

SW IN F SW

can be determined by the formula:

O(BL)

+−

(8)

Below this output current level, the inductor current will be

discontinuous and the duty ratio will be modulated to lower

values, by factors substantially more than thus the losses

that cause only a small amount of modulation in continuous

inductor current operation. PSM is initiated automatically

by a proprietary technique comprising a duty ratio amplifier

with an internal time constant. As load current drops well

into the low current region and the duty ratio passes below

the threshold of D

for a sufficient time, PSM is acti-

PSM

vated. The corresponding level of output current is given

by:

VVV VVV

1

ID

=× ×

OPSM

()

PSM

2

+− −−

2

IN F SW IN SW

VV f L

+×

OF SW

0

(9)

It can be seen in the formula that this current threshold is

inversely proportional to inductance, so although it is usually not a relevant concern, it is noted that an aggressively

–6– REV. PrK

PRELIMINARY TECHNICAL DATA

ADP3088

low output inductance should be avoided to keep the PSM

threshold current at a desirably low level.

For the user's reference, when current is below the borderline level, the duty ratio is modulated according to the formula:

VV f L

+×

DI

2

=×× ×

DO

OF SW

VVV

+−

IN F SW

−−

VVV

IN O SW

(10)

where the suffix indicates that the inductor current is discontinuous.

For controlling the capacitive component of the output

ripple voltage, the following constraint on the minimum

output capacitance should be applied:

I

∆

>

fV

8

SW R

L

∆

(11)

C

O

where ∆VR is the tolerable ripple voltage. However, this

constraint is rarely relevant, as the typical capacitance requirement is driven more by dynamic response requirements than by ripple concerns. In a typical application

circuit, a 10 µF capacitor produces a capacitive output

voltage ripple component of only about 2 mV. 10 µF is

usually sufficient for applications that do not impose particularly HF load transients, which imposes additional constraints that are elaborated upon in the next section.

Load Characterization

Optimization of the compensation, as well as the output

filter, requires some knowledge of a fundamental characteristic of the load. Qualitatively, there are two types of

loads with which we are concerned: fast-slew-rate and

slow-slew-rate. These slew rates are assessed with respect

to the minimum [absolute] inductor [current] slew rate as

given by:

VVV

IN MIN

MIN and

,

dt L L

=<

−−

()

SW O

MAX MAX

VVdI

+

OFL

(12)

where the "<" sign indicates a selection of whichever of the

bracketed terms is the lesser.

If the slew rate of the load is fast compared to the minimum

inductor slew rate, then the ability of the power converter

to contain the output voltage deviation following a load

change is limited not only by the response of the control

loop - i.e., by its speed to demand zero or maximum duty

ratio from the modulator - but by the power stage as well.

In such a case, beginning with the recognition that output

voltage deviation would be substantial even if the loop response were instantaneous, it can be shown that one can

achieve better overall voltage containment by degenerating

the DC loop gain. As a technical matter, it should be noted

that there will always be some minimum output voltage

deviation downward due to a load step even if the inductor

slew is as fast as the load slew rate, because, during a

switching cycle, the modulator latches its "decision" to turn

off the switch and it cannot rescind that decision but must

wait for the next clock cycle to turn on the switch again and

begin slewing the inductor current upward. This is only a

second order consideration.

Slow slew rate loads may be referred to simply as conventional loads, since these have been the more prevalent type

of load. Optimally compensating a conventional load is

synonymous with small signal AC considerations: the objective is to maximize the AC gain up to the crossover frequency, ensure sufficient phase margin at the unity gain

crossover frequency, and keep the gain rolling off at higher

frequencies to avoid gain margin problems.

Fast slew rate loads may be referred to as digital loads

since, from the perspective of the power converter, they

have a digital characteristic when changing between two

extremes, and also because such fast slew rates tends to

characterize modern digital circuits, which often feature

power management interrupts - i.e., interrupt signals used

to turn on and off circuitry on an as-needed basis during

normal system operation. Optimally compensating a digital

load is more a task of impedance matching and DC gain

determination than a task of AC loop optimization.

Returning to constraints for choosing the output capacitor,

for digital loads another criteria for ensuring sufficient output capacitance applies:

2

∆

I

C

>

O

2

O

dI

∆

L

VMIN

O

dt

(13)

where ∆IO is the maximum HF load step. It should be

noted that the formula results strictly from the physical

limitation of the output filter; the compensation must also

be optimized to maximize the response of the control loop

to avoid substantial additional output voltage deviation.

The formula might be also written in to describe a maximum inductance for a given capacitance, but it is generally

better practice to choose the inductor first and add capacitance as needed.

The he impedance of the output capacitor together with a

digital load creates some limiting considerations, also. Series resistance (ESR) rather than capacitance can be a

dominant design consideration with non-MLC capacitors.

If the load is essentially digital, then the dynamic deviation

of the output voltage cannot be limited to any better than

the dynamic load current step times the ESR. In a formula:

VIESR

∆≥∆×

OO

(14)

In such a case, it is often important to choose a capacitor

that controls the ESR to a sufficiently small value, and

MLC capacitors are often chosen to practically eliminate

the consideration of ESR entirely.

Closing the Loop - Compensation

The factors determining the response of the power converter are noted: the feedback input resistor divider, a lead

network if applicable, the transconductance of the error

–7–REV. PrK

ADP3088

PRELIMINARY TECHNICAL DATA

amplifier, its frequency response limitation (i.e., as adequately modeled by a capacitance from output to ground)

its external termination impedance (i.e., the compensation,

that may or may not include DC feedback), the modulator

transconductance, and the power converter's termination

impedance (i.e., the output capacitor and load resistance).

Since the ADP3088 has a current controlled loop, the particular inductor value does not by first order consideration

affect small signal stability. However, slew rate limitations

as discussed earlier - a large signal limitation consideration set boundaries that are often relevant for optimizing compensation of the feedback loop. If the compensation of the

current control signal, i.e., the COMP pin, is designed to

promote a current response that is faster than the inductor

current can slew, then when a step load is applied the control signal will tend to initially respond in excess (of the

actual current change that is occurring) and then allow an

overshoot of the current and output voltage as it is delayed

in correcting its excess.

For conventional loads, the following describes how the

frequency corners (poles and zeroes) are positioned or

should be chosen to optimize the loop gain, beginning in

the low frequency spectrum:

1. The DC loop gain is limited by the applied load resistance and the output resistance of the error amplifier,

but it is not important to determine how high the DC

gain is.

2. Two poles in the LF spectrum begin to roll off the gain,

one determined by the load resistance and output capacitor, C

, and the other by the error amplifier's out-

O

put resistance and its termination capacitance - the

equivalent feedback capacitance and the added compensation capacitance C

; determining the location of

HF

these poles is not relevant to compensation design - it

suffices to know that both are decades below the crossover frequency.

3. A lead network is especially desirable for a variable output voltage application in order to keep a fairly constant

crossover frequency and phase margin for all output

voltages; if used, this lead network consists of simply a

capacitor, C

vider resistor, R

, in parallel with the upper feedback di-

FF

; this creates a closely spaced zero/pole

A

pair that provides a gain boost before crossover so that,

above the pole frequency, the loop gain and phase are

similar for all output voltages; if the lead network is used

for a fixed voltage application, the pole should be chosen to align with the following described zero; for variable voltage applications, the maximum frequency of

the pole should be placed as high as is comfortable without substantially degrading phase margin (e.g., not

within an octave or, more conservatively, a half decade

of the crossover frequency).

4. A zero turns the gain rolloff back to 1-pole sufficiently in

advance of the crossover frequency to create ample

phase margin, e.g., half a decade; the zero could feasibly be that of the output capacitor itself - i.e., the zero

formed by the ESR and the capacitance C

- but that is

O

both unlikely (since the zero frequency will likely be

higher than where the loop zero is desired) and generally imprudent (since the loop performance would de-

pend on the stability of the ESR, which often is poor or

unknown); as recommended, the zero, f

an R

circuit terminating the COMP pin (a resistor, RC,

C

in series with a capacitor, C

terminating the error amplifier, C

with R

to cancel the zero of the output capacitor, or, if

C

), while the capacitance

C

HF

, is created by

Z

, forms a pole, fP,

the zero is well above the crossover frequency, as may

be the case when using an MLC output capacitor, that

pole is set high enough above the crossover frequency,

again e.g., half a decade, so that it doesn't cut substantially into the phase margin at crossover, but still ensures

continued gain rolloff so that the gain margin is acceptably high; note that the previous guidelines suggest that

≥ 10 × CHF.

C

C

5. The gain crosses 0 dB (unity) at a crossover frequency

that is typically a tenth and advisably not greater than a

fourth of the switching frequency - one primary reason

for this approximate upper limit being the extra phase

margin loss due to the switching interval that is not predicted by the linear model.

Assuming no lead network is used, the open loop gain is

given by:

V

where V

600

µ× ×

A

≈

OL

is the nominal DC level. This equation to-

OUT

ZZ

COMP O

2

Ω

V

OUT

(15)

gether with the preceding recommendations should suffice

to determine compensation component selection for users

familiar with loop design. This begins with deciding the

crossover frequency, f

frequency, and setting the open loop gain, A

By example, f

= 125 kHz is chosen.

C

Assuming a well chosen C

, evaluating the impedances at that

C

as described previously - i.e.,

HF

, to unity.

OL

such that it creates a pole well above crossover or approximately matches the zero of the output capacitor, the following equation approximates the calculation of the

crossover frequency:

=+

1

f

C

where k1 = CO×V

()

Ω×

21 /

kAk

()

OUT/RC

and fZ = 1/2πRCCC - the zero

1

Z

(16)

1

+Ω××

150 /

kAfk

frequency set by the compensation - and the units are

shown with the constants in the equation for clarification.

The preceding equation cannot readily be solved in terms

of k

, but it can be solved closely enough by a few iterations

1

beginning with values for k

example below, set the zero about a half decade below f

previously advised, that is, choose f

Using the previously stated values for f

= 800 p(FA) satisfies the equation. RA and RB are pre-

k

1

around 1×109 (FA). For the

1

~ fC /√10 = 40 kHz.

Z

and fC, the value of

Z

C

sumed to be already chosen per earlier guidelines to set the

output voltage. As an example, R

= RB = 10 kΩ (imply-

A

ing an output voltage of 2.5 V). Similarly it is presumed

that C

then also C

simple formulas previously given. The example yields R

47 kΩ and C

was chosen; let CO = 15 µF. Then, finally, RC and

O

can be determined by rearrangement of

C

~ 82 pF. Assuming an MLC output capaci-

C

C

as

~

–8– REV. PrK

PRELIMINARY TECHNICAL DATA

ADP3088

tor of reasonable quality, the pole setting capacitor could

be chosen to be C

= 4.7 pF.

HF

A general purpose application circuit is shown in Figure 2.

6.8µH

1A

SCHOTTKY

10µF

MLCC

VOUT

1.5V

R

A

10kΩ

R

B

48.7kΩ

5V

MLCC

C

4.7pF

1µF

HF

C

C

470pF

R

C

10kΩ

ADP3088

IN

IN

GND

COMP

SW

DRV

GND

FB

Figure 2. +5 V to 1.5 V, General Purpose Application

Another application circuit features a voltage inversion and

regulation design such that the output voltage is negative,

see Figure 3. Negative output voltages are allowed in the

case that the input plus the output voltage does not exceed

the rating of the device. In the voltage inverting configuration, the ground reference of the ADP3088 is the negative

output voltage and the conventional output voltage point is

tied to ground. Operation is bootstrapped: the power converter behaves as if the input voltage were equal to the

actual input voltage plus the magnitude of the output voltage and as if the output voltage were not inverted. This

implies that it is possible to have the input voltage be less

than the magnitude of the output voltage - provided that

the input voltage alone is sufficient to start the operation of

the IC - i.e., before the negative output voltage has been

developed. (The circuit below with a -3.3V output works

fine over an input range from 2.5 V to 7.5 V.) Since the

ADP3088 features a current controlled loop, the feedback

effect of essentially boosting the input voltage atop the output (with respect to the ground connection of the

ADP3088) is reduced to a negligible second-order effect.

just enough so that the static load regulation allows a similar

voltage deviation with current as would be the peak voltage

deviation, ∆V

, that could not be avoided in the event that

O

a step change of current were to occur even if the loop

response were instantaneous. The reason for even an instantaneous response in the control loop allowing an output

voltage deviation is that the slew-rate of current in the output is limited by to the inductor, and a corresponding dynamic burden is placed on the output capacitor to maintain

the output voltage. Therefore, inductor value minimization

is desired both for concern of its size and cost, and also to

maximize the slew rate of current to the output so that a

smaller output capacitor is needed.

To implement voltage positioning, a resistor, R

, should

FB

be placed between the COMP and FB pins according to the

formula:

IR

∆

OA

=

R

where g

FB

gV

×∆

MOD O

is the modulator gain and ∆IO must be assessed

MOD

(17)

over the entire operating load range as the difference between maximum and minimum load. C

least large enough to support the targeted ∆V

must be chosen at

O

according to

O

the earlier stated formula governing the relationship between minimum output capacitance, voltage deviation, and

load current. In order to ensure that the output voltage will

be constrained within the limitations of ∆V

, the limitations

O

noted earlier for PSM hysteretic ripple if applicable in the

operating load range and ESR. Also an experimental adjustment downward to the value of R

may be needed, as

B

the DC bias point of the COMP node is usually a little

higher than V

, which would result in a slight downward

REF

shift of the nominal output voltage.

Having chosen this design approach, the series RC of the

compensation network can be removed and the single remaining capacitor, C

, should be increased to approxi-

HF

mately:

4.7µH

1A

SCHOTTKY

10µF

MLCC

+

R

A

10kΩ

+

R

B

3.04kΩ

-3.3V

5V

MLCC

C

4.7pF

1µF

HF

C

C

220pF

R

C

20kΩ

ADP3088

IN

IN

GND

COMP

SW

DRV

GND

FB

Figure 3. +5V to -3.3V, General Purpose Inverting

Application

Voltage Positioning Designs

For digital loads a different compensation technique is recommended that involves implementing "voltage positioning", that is now commonly used on CPUs but is equally

applicable to any dynamic device. Voltage positioning is the

intentional and controlled variation of output voltage with

load current, such that the power supply appears to have a

substantial output resistance. The key to voltage positioning

optimization for a digital load is to degenerate the loop gain

CESR

×

O

=

C

HF

R

FB

(18)

If an MLC capacitor is used for CO, the value of CHF might

be calculated to be less than a few picofarads, in which case

it is recommended to use a 4.7~10 pF capacitor. The formula is derived from a patented design technique called

ADOPT

TM

- Analog Devices' Optimal Positioning Technology. This creates AC and DC impedance matching,

and the increased complexity of the DC regulation design is

moderated by the simplicity of the frequency compensation.

In this design approach, at higher currents the output voltage will be appreciably lower than at low currents. This is

equivalent to saying that the load regulation appears to be

poor. But, paradoxically perhaps to the user unfamiliar with

voltage positioning, the overall containment of voltage

within a given window will be improved, and that tends to

be of particularly importance in many highly dynamic

loads.

The application circuit in Figure 4 features a 3.3 V input

and a 2.5 V output at 100~400 mA which constrains the

–9–REV. PrK

ADP3088

PRELIMINARY TECHNICAL DATA

output voltage within a ~100 mV range with only a 4.7 µF

output capacitor, even when the load slew rate is extremely

fast. This does not include the initial tolerance of the voltage setting that is separately accounted with voltage positioning designs. Note that the lower resistor, R

, of the

B

feedback divider is reduced from the 10 kΩ value that one

would use for a standard (non-voltage-positioned) design

that had no voltage positioning resistor R

3.3µH

1A

SCHOTTKY

3.3V

C

HF

4.7pF

1µF

MLCC

ADP3088

IN

IN

GND

COMP

R

VP

51kΩ

SW

DRV

GND

FB

VP

4.7µF

MLCC

.

-2.5V

100-400 mA

R

A

10kΩ

R

B

8.75kΩ

Figure 4. Application Circuit using Voltage Positioning,

Allowing Small Output Capacitance

Extra-Low-Voltage Outputs

Some newer power management applications require voltage levels below the normal adjustable voltage range of the

ADP3088, i.e., below 1.25 V. Such applications can be

accommodated using the ADP3088 by modifying the application circuit to sum in a resistor-weighted portion of another regulated system voltage, e.g., 3.3 V, to the feedback

node (FB). The tolerance of the ADP3088's output voltage

will increase by an amount proportional to the tolerance of

the summed in system voltage times the ratio of the conductance from that node to that of the output voltage. The

below example in Figure 5 shows an implementation of this

technique together with another special implementation

described below. The resistor R

sums from a 2.5 V sys-

TT

tem voltage to the FB node that will reduce the output voltage according to the formula:

feature in the ADP3088, it can readily be accommodated

with a few components. Dynamic voltage control can be

implemented either by parallel bus control or by PWM. In

both cases, the output voltage is modified by summing

either switched bits with, presumably binary, weighting

resistors or a switched PWM node via a single resistor into

the FB pin. (The switched PWM node refers to an external

PWM control signal, not the switched node of the power

converter itself.) Since the PWM technique modulates a

current into the FB node, it is necessary both to integrate

that signal and to avoid slowing down the response of the

power converter to output voltage transitions. This can be

accomplished by placing a capacitor between the output

voltage and the feedback node, which serves to provide a

zero/pole pair in the main regulation loop, and appears as

an integration pole to the PWM signal.

The design of either parallel bit or PWM type of voltage

control must consider whether the interface node(s) - from

parallel switched bits or a single PWM signal - has an active

pullup state (in which case it must be to a known voltage)

or a passive pullup (open drain) that floats up to the FB

node voltage, 1.25 V, in its high state. If at least the lower

extreme of the desired output voltage range must be lower

than 1.25 V, either technique can be combined with the

technique for lowering the output voltage below 1.25 V.

Such an example of an application having this requirement

is the BlackFin™ DSP. Figure 5 shows an implementation

of this technique.

Input Voltage: 4.75 V ~ 7.5 V

Output Voltage: 0.9 V ~ 1.5 V

Dynamic voltage control interface technique: PWM,

active high to V

IO

System voltage used for lowering output voltage below

1.25 V: V

= VIO = 2.5 V

TT

Maximum output current: 700 mA

R

VV

∆=−×

OUT TT

A

R

TT

(19)

Dynamic Voltage Control

Some newer power management applications also require

an ability to adjust the voltage being delivered to a load

during operation. Although there is no integration of this

C

C

470pF

R

C

20kΩ

ADP3088

IN

IN

GND

COMP

SW

DRV

GND

FB

5V - 8V

C

HF

10pF

V

IN

MLCC

2.2µF

Figure 5. BlackFin DSP Application

10µH @ 1A

1N5817

C

FF

2.2nF

3×10µF

MLCC

R

A

10.0kΩ

R

TT

287kΩ

R

PWM

41.2kΩ

V

OUT

0.9V-1.5V

@700 mA

V

2.5V

TT

PWM 0-2.5V

–10– REV. PrK

PRELIMINARY TECHNICAL DATA

RM-8

8-Lead Mini/micro SOIC Package [Mini_SO]

0.122 (3.10)

0.114 (2.90)

ADP3088

0.122 (3.10)

0.114 (2.90)

0.006 (0.15)

0.002 (0.05)

SEATING

PLANE

85

1

PIN 1

0.0256 (0.65) BSC

0.120 (3.05)

0.112 (2.84)

0.018 (0.46)

0.008 (0.20)

0.199 (5.05)

0.187 (4.75)

4

0.043 (1.09)

0.037 (0.94)

0.011 (0.28)

0.003 (0.08)

0.120 (3.05)

0.112 (2.84)

33ⴗ

27ⴗ

0.028 (0.71)

0.016 (0.41)

–11–REV. PrK

Loading...

Loading...