1.2 A, 20 V, 700 kHz/1.4 MHz,

C

Nonsynchronous Step-Down Regulator

FEATURES

1.2 A maximum load current

±2% output accuracy over temperature range

Wide input voltage range: 3.0 V to 20 V

700 kHz (ADP2300) or 1.4 MHz (ADP2301)

switching frequency options

High efficiency up to 91%

Current-mode control architecture

Output voltage from 0.8 V to 0.85 × V

Automatic PFM/PWM mode switching

Precision enable pin with hysteresis

Integrated high-side MOSFET

Integrated bootstrap diode

Internal compensation and soft start

Minimum external components

Undervoltage lockout (UVLO)

Overcurrent protection (OCP) and thermal shutdown (TSD)

ADIsimPower™ online design tool

Available in ultrasmall, 6-lead TSOT package

APPLICATIONS

LDO replacement for digital load applications

Intermediate power rail conversion

Communications and networking

Industrial and instrumentation

Healthcare and medical

Consumer

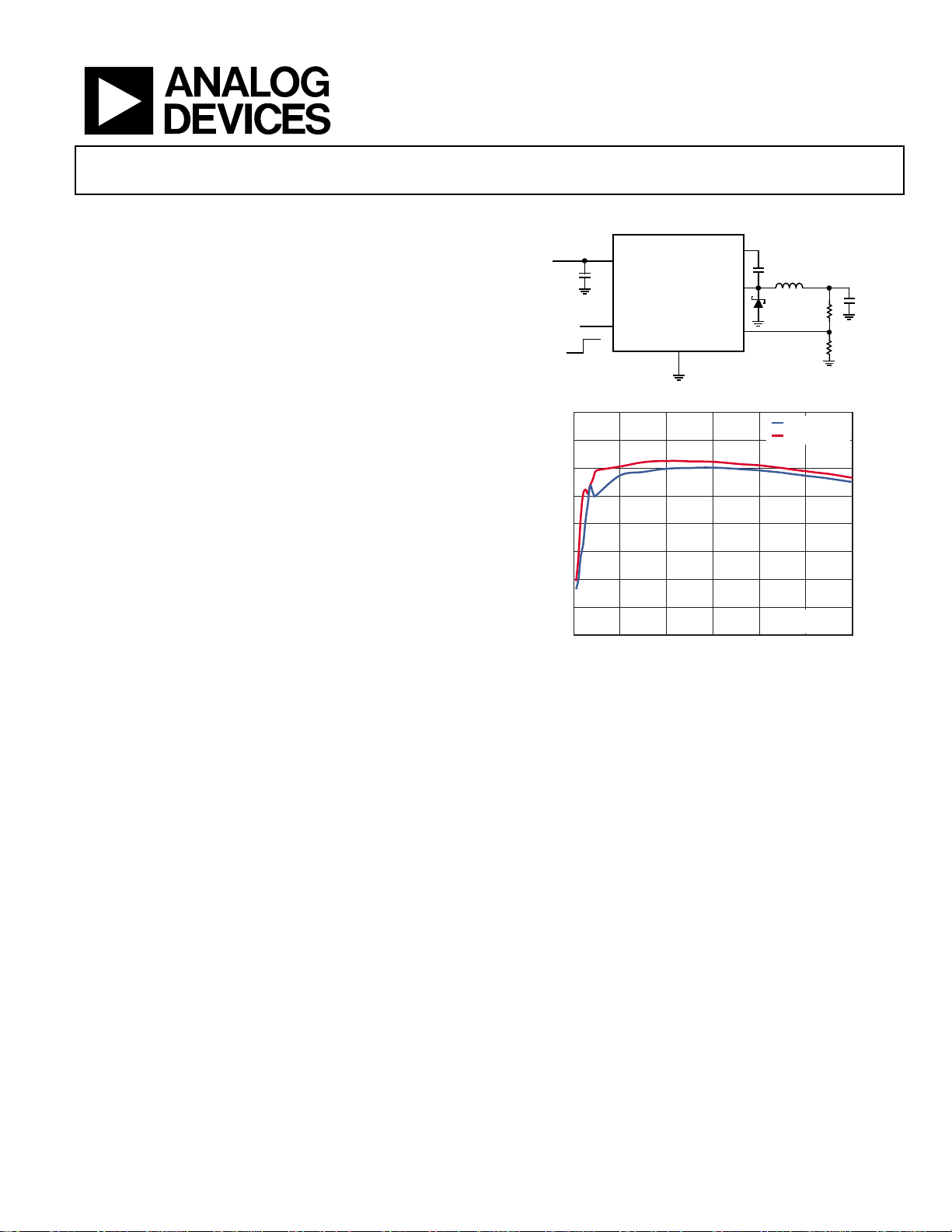

IN

ADP2300/ADP2301

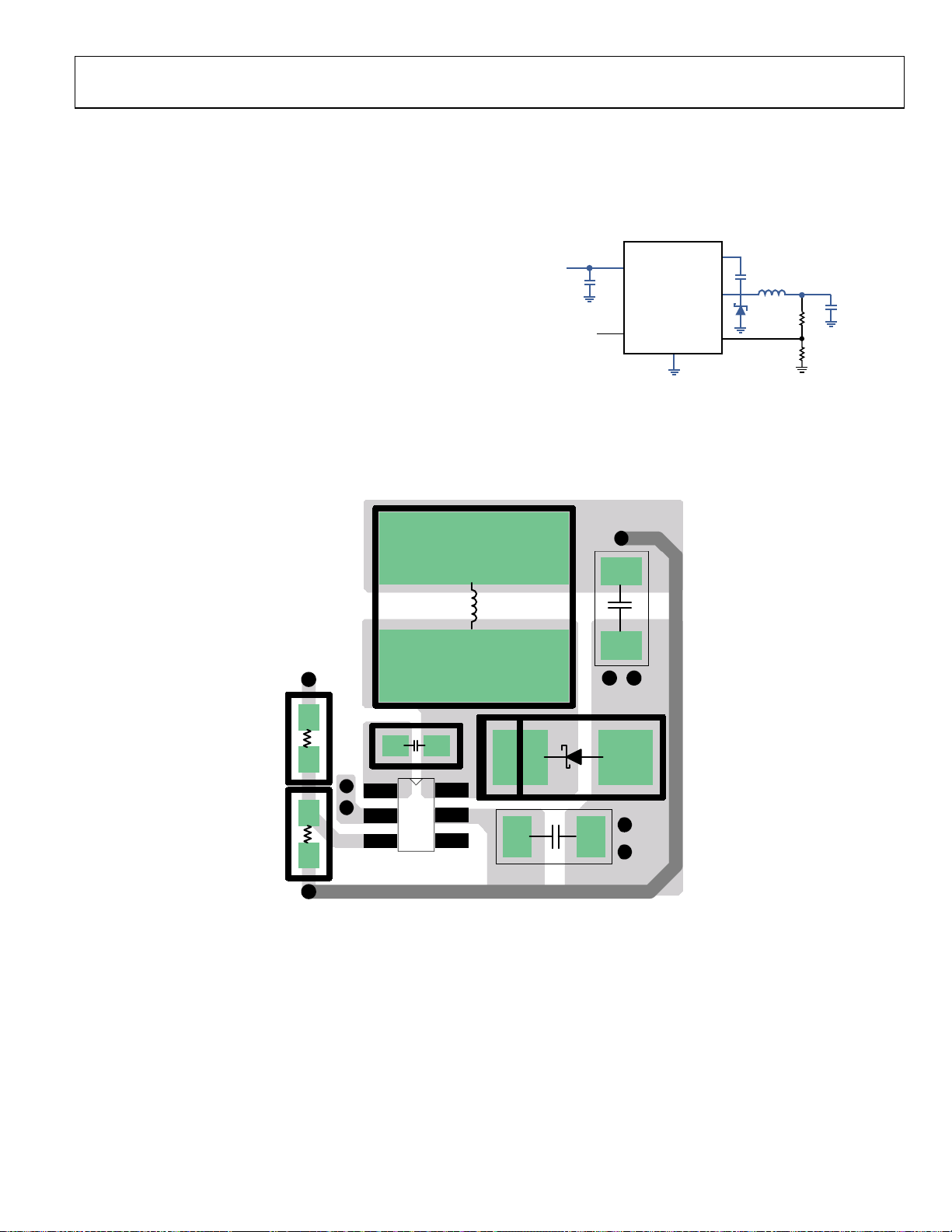

TYPICAL APPLICATIONS CIRCUIT

Figure 1.

I

(A)

OUT

BST

SW

FB

f

SW

f

SW

3.0V TO 20V

OFF

100

95

90

85

Y (%)

80

75

EFFICIEN

70

65

60

0 0.2 0.4 0.6 0.8 1.0 1.2

VIN

ADP2300/

ADP2301

EN

ON

Figure 2. Efficiency vs. Output Current

GND

= 1.4MHz

= 700kHz

V

= 12V

IN

V

OUT

V

= 5.0V

OUT

08342-001

08342-069

GENERAL DESCRIPTION

The ADP2300/ADP2301 are compact, constant-frequency,

current-mode, step-down dc-to-dc regulators with integrated

power MOSFET. The ADP2300/ADP2301 devices run from

input voltages of 3.0 V to 20 V, making them suitable for a wide

range of applications. A precise, low voltage internal reference

makes these devices ideal for generating a regulated output

voltage as low as 0.8 V, with ±2% accuracy, for up to 1.2 A load

current.

There are two frequency options: the ADP2300 runs at 700 kHz,

and the ADP2301 runs at 1.4 MHz. These options allow users to

make decisions based on the trade-off between efficiency and

Rev. A

Information furnished by Analog Devices is believed to be accurate and reliable. However, no

responsibility is assumed by Analog Devices for its use, nor for any infringem ents of patents or other

rights of third parties that may result from its use. Specifications subject to change without notice. No

license is granted by implication or otherwise under any patent or patent rights of Analog Devices.

Trademarks and registered trademarks are the property of their respective owners.

total solution size. Current-mode control provides fast and stable

line and load transient performance. The ADP2300/ADP2301

devices include internal soft start to prevent inrush current at

power-up. Other key safety features include short-circuit protection, thermal shutdown (TSD), and input undervoltage lockout

(UVLO). The precision enable pin threshold voltage allows the

ADP2300/ADP2301 to be easily sequenced from other input/

output supplies. It can also be used as a programmable UVLO

input by using a resistive divider.

The ADP2300/ADP2301 are available in a 6-lead TSOT package

and are rated for the −40°C to +125°C junction temperature range.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700 www.analog.com

Fax: 781.461.3113 ©2010 Analog Devices, Inc. All rights reserved.

ADP2300/ADP2301

TABLE OF CONTENTS

Features .............................................................................................. 1

Applications ....................................................................................... 1

Typical Applications Circuit ............................................................ 1

General Description ......................................................................... 1

Revision History ............................................................................... 2

Specifications ..................................................................................... 3

Absolute Maximum Ratings ............................................................ 4

Thermal Resistance ...................................................................... 4

ESD Caution .................................................................................. 4

Pin Configuration and Function Descriptions ............................. 5

Typical Performance Characteristics ............................................. 6

Functional Block Diagram ............................................................ 13

Theory of Operation ...................................................................... 14

Basic Operation .......................................................................... 14

PWM Mode ................................................................................. 14

Power Saving Mode .................................................................... 14

Bootstrap Circuitry .................................................................... 14

Precision Enable ......................................................................... 14

Integrated Soft Start ................................................................... 14

Current Limit .............................................................................. 14

Short-Circuit Protection ............................................................ 15

Undervoltage Lockout (UVLO) ............................................... 15

Thermal Shutdown .................................................................... 15

Control Loop ............................................................................... 15

Applications Information .............................................................. 16

Programming the Output Voltage ........................................... 16

Voltage Conversion Limitations ............................................... 16

Low Input Voltage Considerations .......................................... 17

Programming the Precision Enable ......................................... 17

Inductor ....................................................................................... 18

Catch Diode ................................................................................ 19

Input Capacitor ........................................................................... 19

Output Capacitor........................................................................ 19

Thermal Considerations ............................................................ 20

Design Example .............................................................................. 21

Switching Frequency Selection ................................................. 21

Catch Diode Selection ............................................................... 21

Inductor Selection ...................................................................... 21

Output Capacitor Selection....................................................... 21

Resistive Voltage Divider Selection .......................................... 22

Circuit Board Layout Recommendations ................................... 23

Typical Application Circuits ......................................................... 24

Outline Dimensions ....................................................................... 26

Ordering Guide .......................................................................... 26

REVISION HISTORY

6/10—Rev. 0 to Rev. A

Changes to Figure 54 ...................................................................... 25

Changes to Ordering Guide .......................................................... 26

2/10—Revision 0: Initial Version

Rev. A | Page 2 of 28

ADP2300/ADP2301

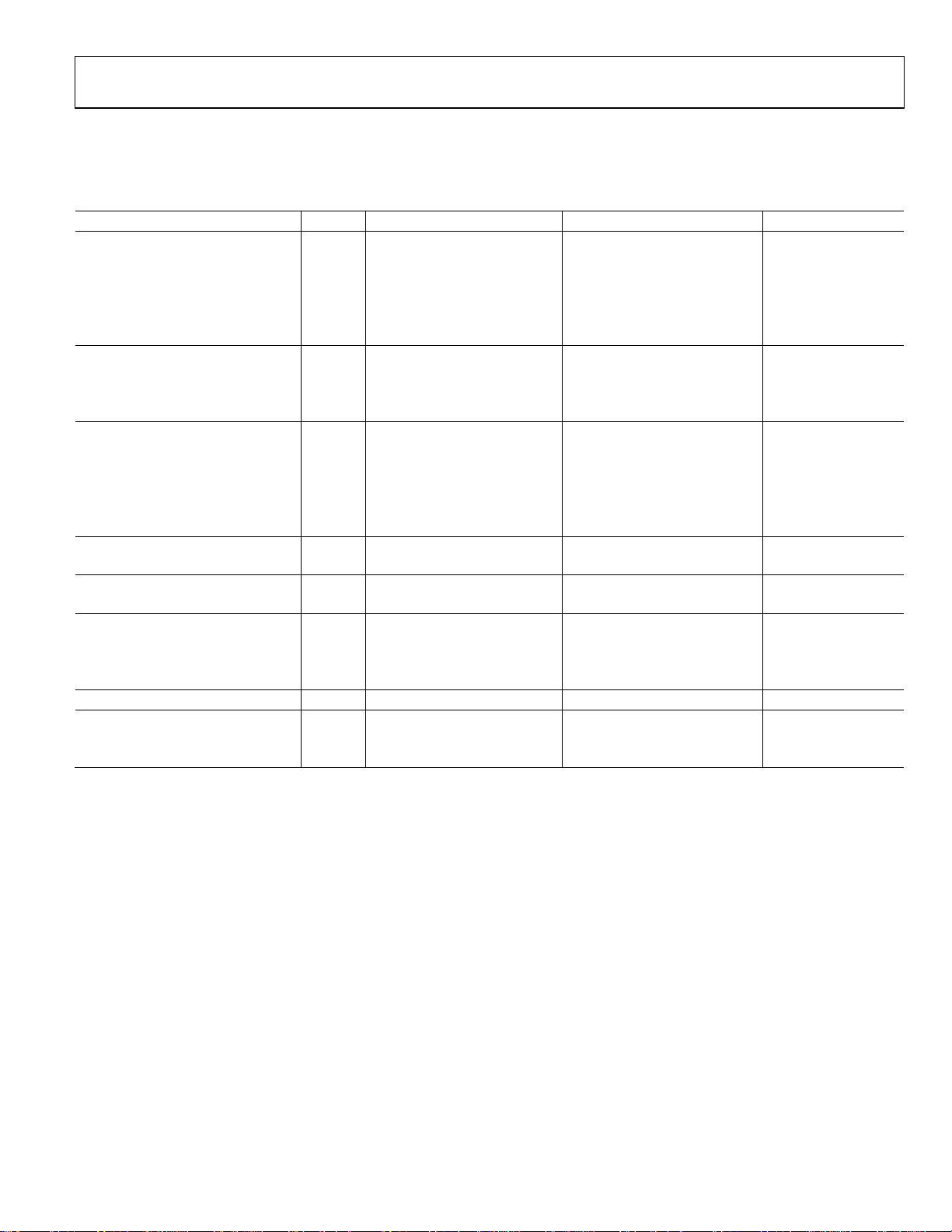

SPECIFICATIONS

VIN = 3.3 V, TJ = −40°C to +125°C for minimum/maximum specifications, and TA = 25°C for typical specifications, unless otherwise noted.

Table 1.

Parameter Symbol Test Conditions Min Typ Max Unit

VIN

Voltage Range VIN 3 20 V

Supply Current I

Shutdown Current I

Undervoltage Lockout Threshold UVLO VIN rising 2.80 2.95 V

V

FB

Regulation Voltage VFB T

T

Bias Current IFB 0.01 0.1 μA

SW

On Resistance1 V

Peak Current Limit2 V

Minimum On Time 100 135 ns

Minimum Off Time ADP2300 145 190 ns

ADP2301 70 120 ns

OSCILLATOR FREQUENCY ADP2300 0.5 0.7 0.9 MHz

ADP2301 1.0 1.4 1.75 MHz

SOFT START TIME ADP2300 1460 μs

ADP2301 730 μs

EN

Input Threshold VEN 1.13 1.2 1.27 V

Input Hysteresis 100 mV

Pull-Down Current 1.2 μA

BOOTSTRAP VOLTAGE V

THERMAL SHUTDOWN

Threshold 140 °C

Hysteresis 15 °C

1

Pin-to-pin measurements.

2

Guaranteed by design.

No switching, VIN = 12 V 640 800 μA

VIN

VEN = 0 V, VIN = 12 V 18 35 μA

SHDN

falling 2.15 2.40 V

IN

= 0°C to +125°C 0.788 0.800 0.812 V

J

= −40°C to +125°C 0.784 0.800 0.816 V

J

− VSW = 5 V, ISW = 150 mA 440 700 mΩ

BST

− VSW = 5 V, VIN = 12 V 1.5 1.9 2.5 A

BST

No switching, VIN = 12 V 5.0 V

BOOT

Rev. A | Page 3 of 28

ADP2300/ADP2301

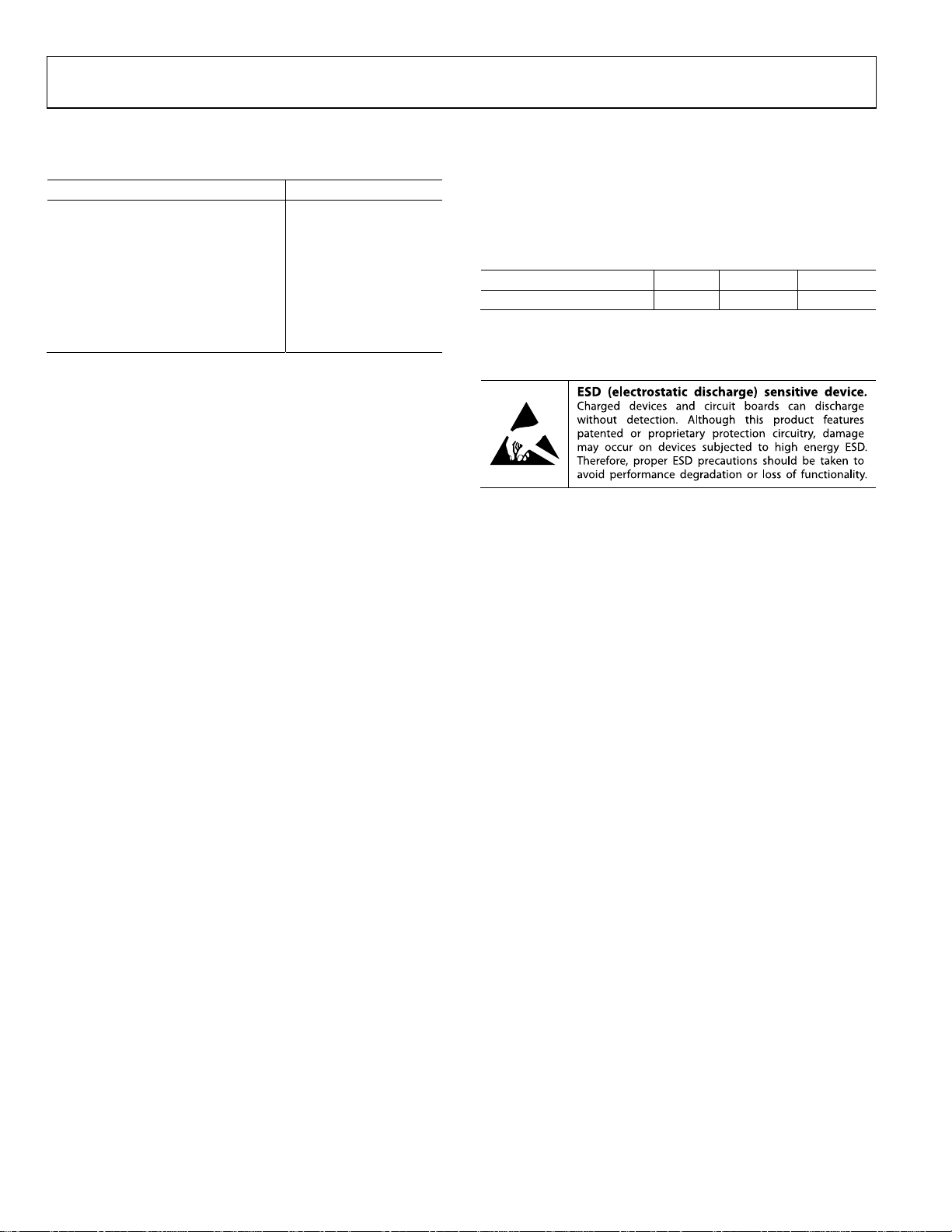

ABSOLUTE MAXIMUM RATINGS

Table 2.

Parameter Rating

VIN, EN −0.3 V to +28 V

SW −1.0 V to +28 V

BST to SW −0.6 V to +6 V

BST −0.3 V to +28 V

FB −0.3 V to +3.3 V

Operating Junction Temperature Range −40°C to +125°C

Storage Temperature Range −65°C to +150°C

Soldering Conditions JEDEC J-STD-020

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

Absolute maximum ratings apply individually only, not in

combination. Unless otherwise specified, all voltages are

referenced to GND.

THERMAL RESISTANCE

θJA is specified for the worst-case conditions, that is, a device

soldered in a circuit board for surface-mount packages.

Table 3. Thermal Resistance

Package Type θJA θ

6-Lead TSOT 186.02 66.34 °C/W

1

θJA and θJC are measured using natural convection on a JEDEC 4-layer board.

1

Unit

JC

ESD CAUTION

Rev. A | Page 4 of 28

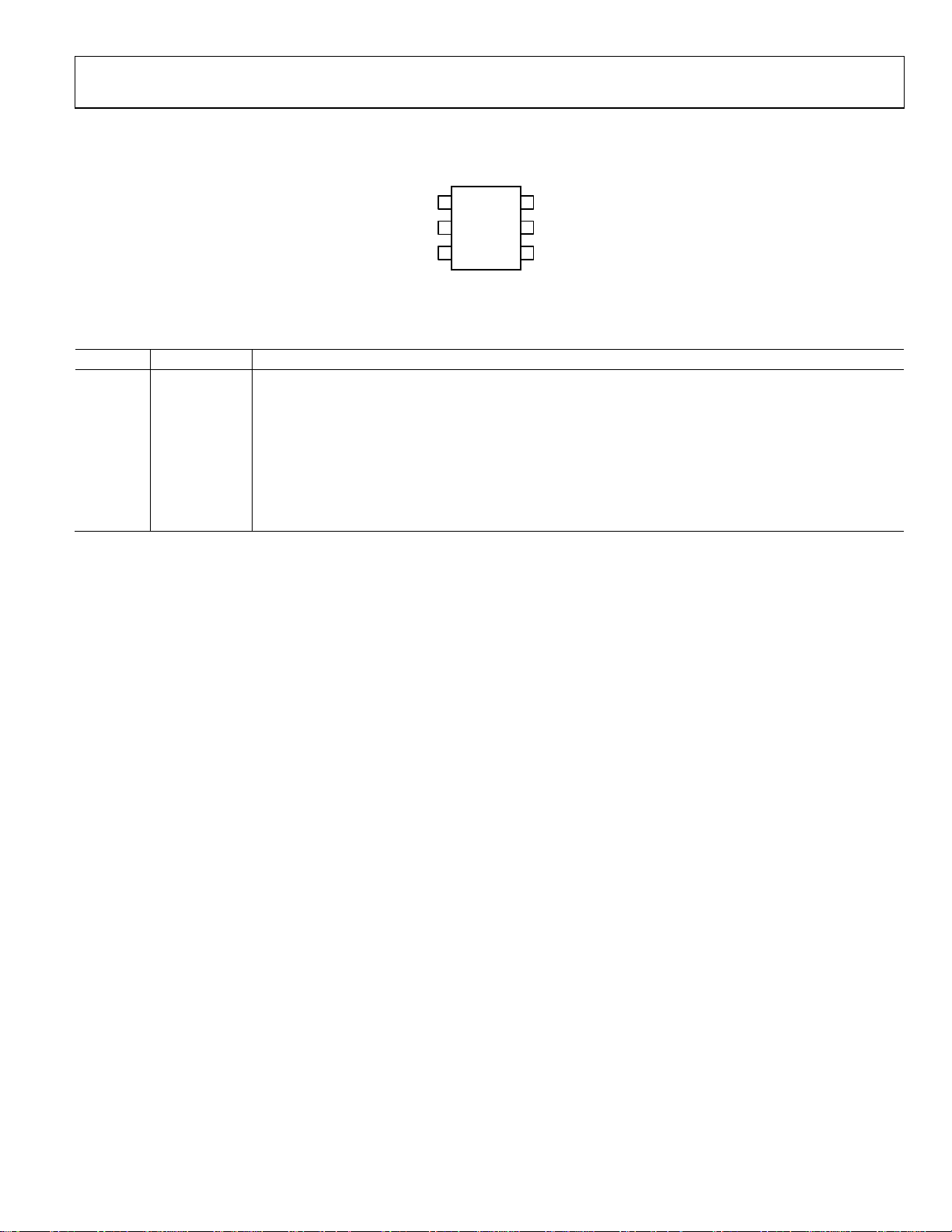

ADP2300/ADP2301

PIN CONFIGURATION AND FUNCTION DESCRIPTIONS

BST

GND

FB

1

ADP2300/

ADP2301

2

TOP VIEW

(Not to Scale)

3

6

SW

5

VIN

4

EN

08342-002

Figure 3. Pin Configuration

Table 4. Pin Function Descriptions

Pin No. Mnemonic Description

1 BST

Boost Supply for the High-Side MOSFET Driver. A 0.1 μF capacitor is connected between the SW and BST pins

to form a floating supply to drive the gate of the MOSFET switch above the VIN supply voltage.

2 GND Ground. Connect this pin to the ground plane.

3 FB

4 EN

Feedback Voltage Sense Input. Connect this pin to a resistive divider from V

desired V

OUT

.

Output Enable. Pull this pin high to enable the output. Pull this pin low to disable the output. This pin can

. Set the voltage to 0.8 V for a

OUT

also be used as a programmable UVLO input. This pin has a 1.2 μA pull-down current to GND.

5 VIN Power Input. Connect to the input power source with a ceramic bypass capacitor to GND directly from this pin.

6 SW Switch Node Output. Connect an inductor to V

and a catch diode to GND from this pin.

OUT

Rev. A | Page 5 of 28

ADP2300/ADP2301

C

C

C

C

TYPICAL PERFORMANCE CHARACTERISTICS

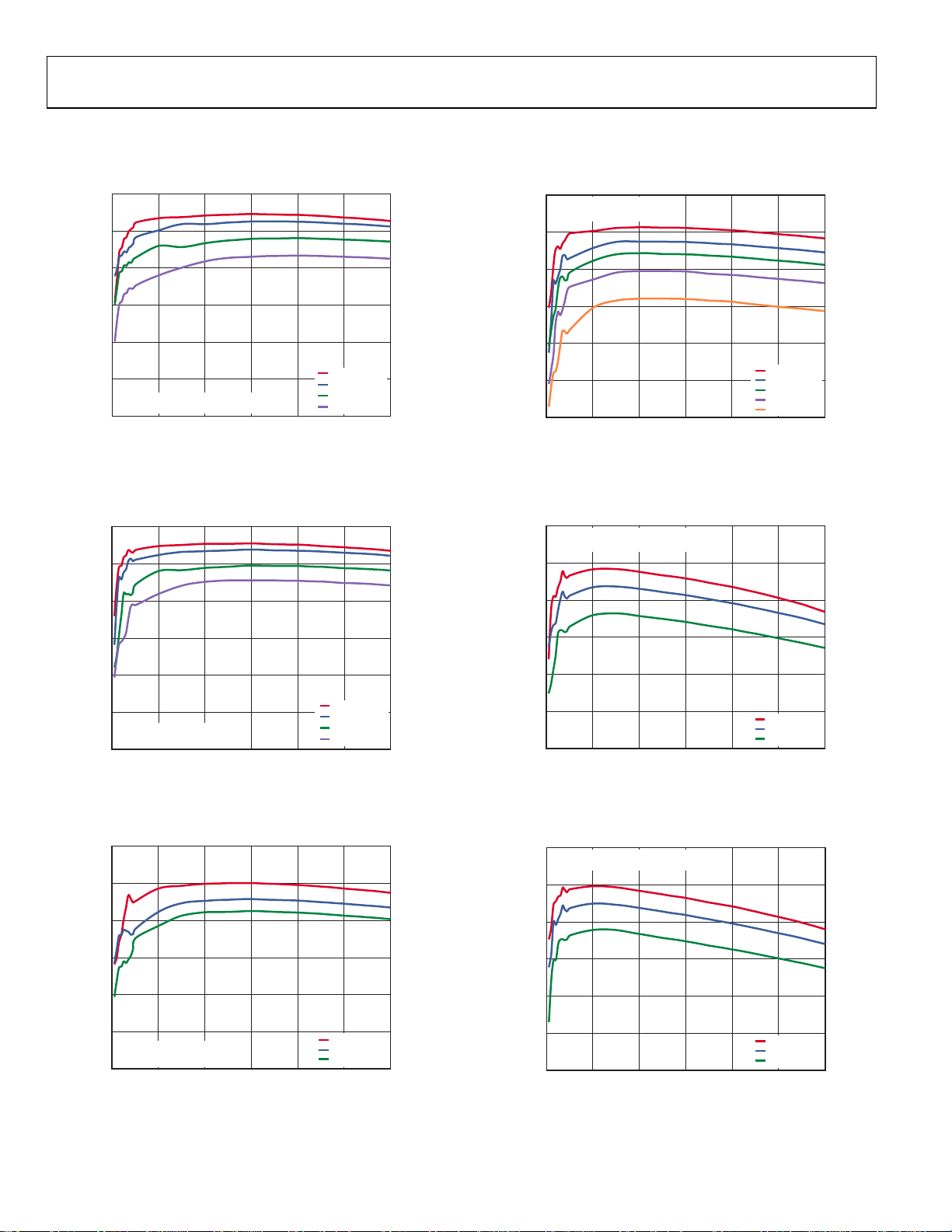

VIN = 3.3 V, TA = 25°C, VEN = VIN, unless otherwise noted.

100

90

100

INDUCTOR: LPS6225-103MLC

DIODE: B230A

90

80

70

EFFICIENCY (%)

60

50

INDUCTOR: L PS6225-472MLC

DIODE: B230A

40

0 0.2 0.4 0.6 0.8 1.0 1.2

I

(A)

OUT

V

V

V

V

Figure 4. Efficiency Curve, VIN = 18 V, fSW = 1.4 MHz

100

90

80

Y (%)

70

EFFICIEN

60

50

INDUCTOR: L PS6225-103MLC

DIODE: B230A

40

0 0.2 0.4 0.6 0.8 1.0 1.2

I

(A)

OUT

Figure 5. Efficiency Curve, VIN = 18 V, fSW = 700 kHz

80

Y (%)

70

EFFICIEN

60

V

= 5.0V

OUT

OUT

OUT

OUT

= 12V

= 9V

= 5.0V

= 3.3V

50

40

0 0.2 0.4 0.6 0.8 1.0 1.2

I

08342-070

OUT

(A)

OUT

V

= 3.3V

OUT

V

= 2.5V

OUT

V

= 1.8V

OUT

V

= 1.2V

OUT

8342-073

Figure 7. Efficiency Curve, VIN = 12 V, fSW = 700 kHz

100

INDUCTOR: L PS6225-472MLC

DIODE: B230A

90

80

Y (%)

70

EFFICIEN

60

V

= 12V

OUT

V

= 9V

OUT

V

= 5.0V

OUT

V

= 3.3V

OUT

08342-071

50

40

0 0.2 0.4 0.6 0.8 1.0 1.2

I

(A)

OUT

V

= 2.5V

OUT

V

= 1.8V

OUT

V

= 1.2V

OUT

08342-074

Figure 8. Efficiency Curve, VIN = 5.0 V, fSW = 1.4 MHz

100

90

80

Y (%)

70

EFFICIEN

60

50

INDUCTOR: LPS6225-472MLC

DIODE: B230A

40

0 0.2 0.4 0.6 0.8 1.0 1.2

I

(A)

OUT

Figure 6. Efficiency Curve, VIN = 12 V, fSW = 1.4 MHz

V

= 5.0V

OUT

V

= 3.3V

OUT

V

= 2.5V

OUT

08342-072

100

INDUCTOR: L PS6225-103MLC

DIODE: B230A

90

80

70

EFFICIENCY (%)

60

50

40

0 0.2 0.4 0.6 0.8 1.0 1.2

I

(A)

OUT

Figure 9. Efficiency Curve, VIN = 5.0 V, fSW = 700 kHz

V

= 2.5V

OUT

= 1.8V

V

OUT

= 1.2V

V

OUT

08342-075

Rev. A | Page 6 of 28

ADP2300/ADP2301

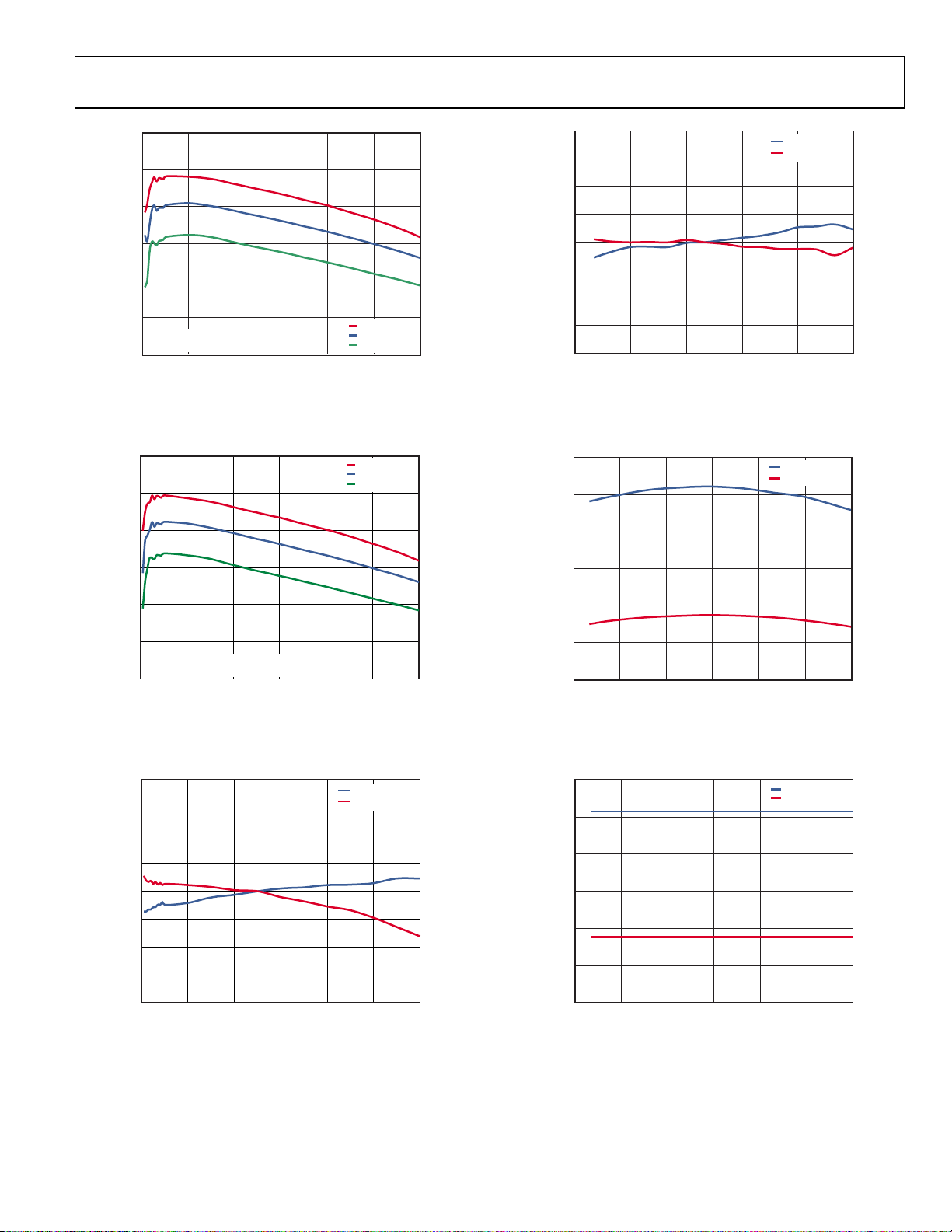

A

A

C

C

100

90

80

70

EFFICIENCY (%)

60

50

INDUCTOR: L PS6225-472MLC

DIODE: B230A

40

0 0.2 0.4 0.6 0.8 1.0 1.2

I

(A)

OUT

V

= 1.8V

OUT

V

= 1.2V

OUT

V

= 0.8V

OUT

Figure 10. Efficiency Curve, VIN = 3.3 V with External 5.0 V Bootstrap Bias

Voltage, f

= 1.4 MHz

SW

08342-089

0.20

0.15

0.10

0.05

TION (%)

0

–0.05

LINE REGUL

–0.10

–0.15

–0.20

5 8 11 14 17 20

VIN (V)

Figure 13. Line Regulation, V

= 3.3 V, I

OUT

f

SW

f

SW

= 500 mA

OUT

= 1.4MHz

= 700kHz

8342-068

100

90

80

70

EFFICIENCY (%)

60

50

INDUCTOR: LPS6225-103MLC

DIODE: B230A

40

0 0.2 0.4 0.6 0.8 1.0 1.2

(A)

I

OUT

V

= 1.8V

OUT

V

= 1.2V

OUT

V

= 0.8V

OUT

Figure 11. Efficiency Curve, VIN = 3.3 V with External 5.0 V Bootstrap Bias

Voltage, f

0.20

0.15

0.10

0.05

TION (%)

0

= 700 kHz

SW

FSW = 1.4MHz

F

= 700kHz

SW

1600

1400

1200

Y (kHz)

1000

800

FREQUEN

600

400

–50 –20 10 40 70 100 130

08342-066

TEMPERATURE (°C)

f

SW

f

SW

= 1.4MHz

= 700kHz

08342-076

Figure 14. Frequency vs. Temperature

1600

1400

1200

Y (kHz)

1000

f

SW

f

SW

= 1.4MHz

= 700kHz

–0.05

LOAD REGUL

–0.10

–0.15

–0.20

0.20 0.4 0.6 0.8 1.0 1.2

Figure 12. Load Regulation, V

I

OUT

(A)

OUT

8342-067

= 3.3 V, VIN = 12 V

800

FREQUEN

600

400

2 5 8 11 14 17 20

V

(V)

IN

Figure 15. Frequency vs. VIN

08342-077

Rev. A | Page 7 of 28

ADP2300/ADP2301

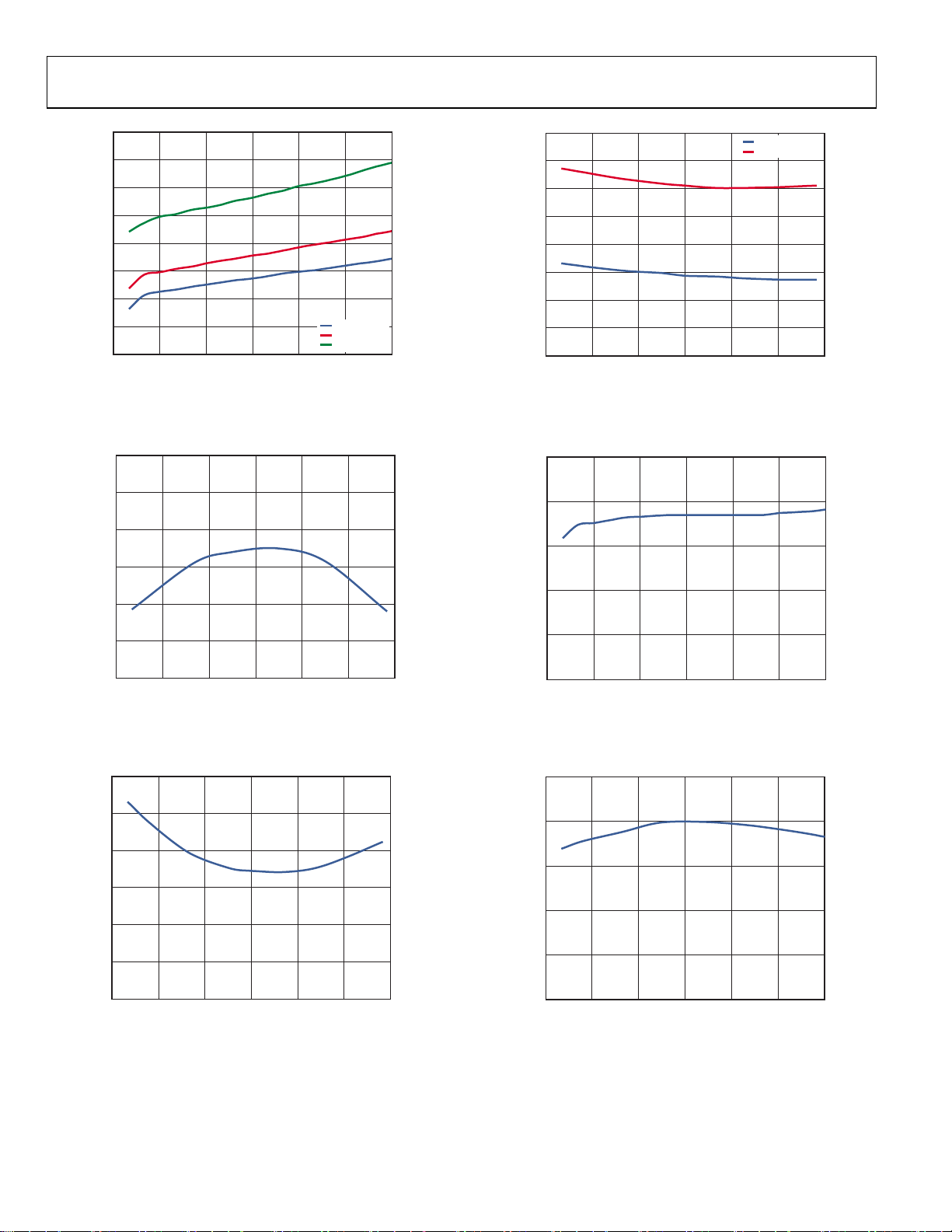

40

35

160

140

f

SW

f

SW

= 1.4MHz

= 700kHz

30

25

20

15

10

SHUTDOWN CURRENT (µA)

5

0

2 5 8 11 14 17 20

VIN (V)

Figure 16. Shutdown Current vs. VIN

0.804

0.802

0.800

0.798

0.796

0.8V FEEDBACK VO LTAGE (V)

0.794

T

= −40°C

J

T

= +25°C

J

T

= +125°C

J

120

100

80

60

MINIMUM OFF TIME (ns)

40

20

0

–50 –20 10 40 70 100 130

8342-078

TEMPERATURE (°C)

08342-081

Figure 19. Minimum Off Time vs. Temperature

2.5

2.0

1.5

1.0

CURRENT LIMIT (A)

0.5

0.792

–50 –20 10 40 70 100 130

TEMPERATURE (°C)

Figure 17. 0.8 V Feedback Voltage vs. Temperature

110

105

100

95

90

MINIMUM ON TIME (ns)

85

80

–50 –20 10 40 70 100 130

TEMPERATURE (°C)

Figure 18. Minimum On Time vs. Temperature

0

2 5 8 11 14 17 20

08342-079

Figure 20. Current-Limit Threshold vs. VIN, V

2.5

2.0

1.5

1.0

CURRENT LIMIT (A)

0.5

0

–50 –20 10 40 70 100 130

08342-080

VIN (V)

TEMPERATURE (°C)

BST − VSW

= 5.0 V

08342-082

08342-083

Figure 21. Current-Limit Threshold vs. Temperature

Rev. A | Page 8 of 28

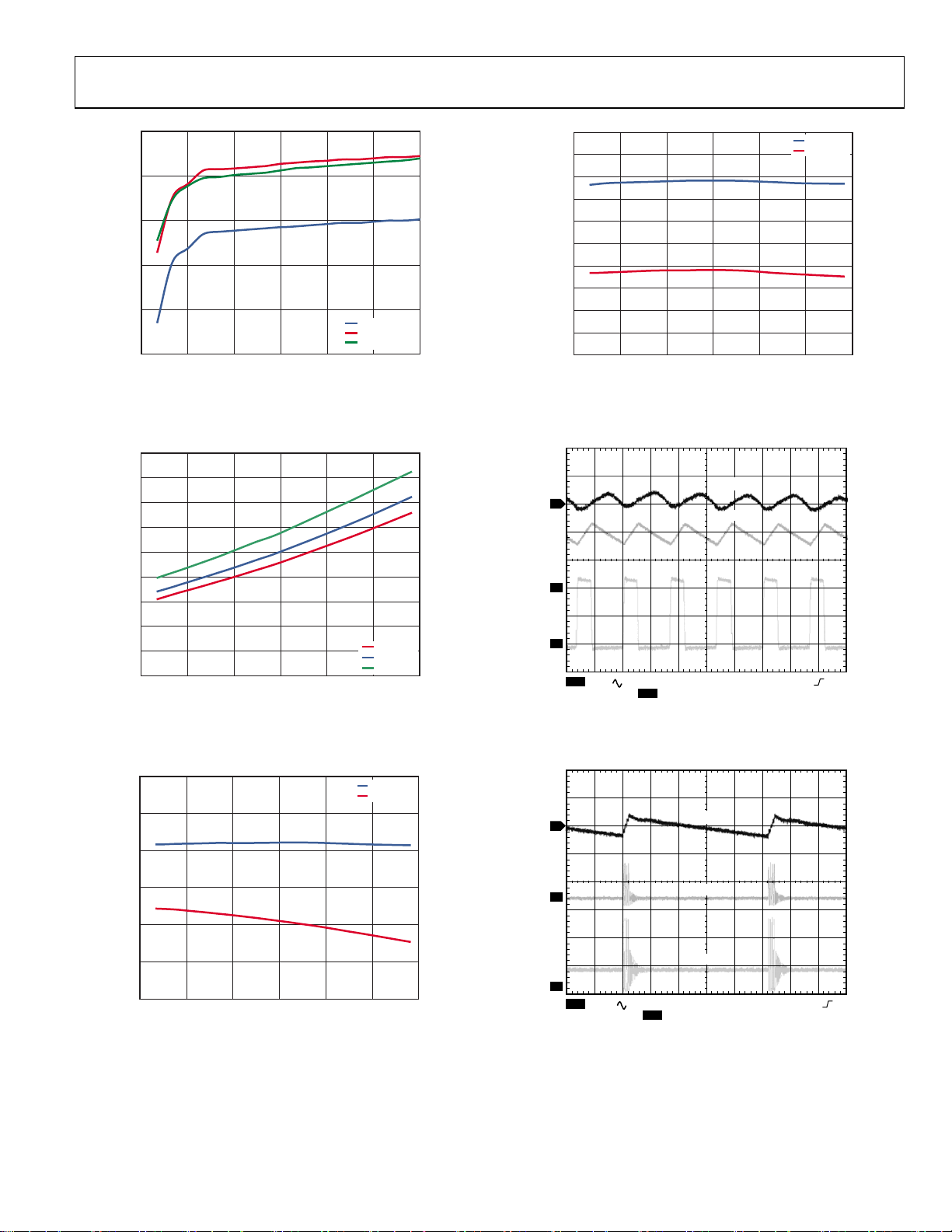

ADP2300/ADP2301

m

700

660

620

580

QUIESCENT CURRENT (µA)

540

500

25811141720

V

(V)

IN

TJ = −40°C

T

= +25°C

J

T

= +125°C

J

Figure 22. Quiescent Current vs. VIN

900

800

700

Ω)

600

(

500

DS (ON)

400

300

MOSFET R

200

100

0

–50 –20 10 40 70 100 130

TEMPERATURE (°C)

Figure 23. MOSFET R

vs. Temperature (Pin-to-Pin Measurements)

DS(ON)

VGS = 5V

V

GS

V

GS

= 4V

= 3V

08342-084

08342-085

3.0

2.9

2.8

2.7

2.6

2.5

2.4

2.3

UVLO THRESHO LD (V)

2.2

2.1

2.0

–50 –20 10 40 70 100 130

TEMPERATURE (°C)

Figure 25. UVLO Threshold vs. Temperature

V

OUT

1

4

2

CH1 5mV

B

CH2 5V M400ns A CH2 7.4V

W

CH4 500mA Ω

Figure 26. Steady State at Heavy Load, f

IL

SW

B

W

B

W

= 1.4 MHz, I

SW

RISING

FALLING

= 1 A

OUT

08342-087

08342-024

1.30

1.25

RISING

FALLING

V

1

OUT

1.20

1.15

4

IL

1.10

ENABLE THRESHOLD (V)

1.05

1.00

–50 –20 10 40 70 100 130

TEMPERATURE (°C)

Figure 24. Enable Threshold vs. Temperature

2

CH1 20mV

08342-086

B

CH2 5V M10µs A CH2 8V

W

CH4 200mA Ω

Figure 27. Steady State at Light Load, fSW = 1.4 MHz, I

SW

B

W

B

W

OUT

= 40 mA

8342-025

Rev. A | Page 9 of 28

ADP2300/ADP2301

V

OUT

IL

1

4

EN

SW

3

2

CH1 1V

CH3 10V

B

CH2 10V M100µ s A CH3 8V

W

B

CH4 500mA Ω

W

B

W

B

W

Figure 28. Soft Start with 1 A Resistance Load, fSW = 1.4 MHz

V

OUT

1

4

IL

EN

SW

3

2

CH1 1V

CH3 10V

B

CH2 10V M100µ s A CH3 8V

W

B

CH4 500mA Ω

W

B

W

B

W

Figure 29. Soft Start with No Load, fSW = 1.4 MHz

V

1

4

2

08342-026

CH1 50mV

B

CH2 10V M100 µs A CH4 630mA

W

CH4 500mA Ω

B

W

B

W

Figure 31. ADP2301 Load Transient, 0.2 A to 1.0 A, V

= 1.4 MHz, L = 4.7 μH, C

(f

SW

1

4

2

08342-027

CH1 200mV

B

CH2 10V M100 µs A CH4 630mA

W

CH4 500mA Ω

= 22 μF)

OUT

B

W

B

W

Figure 32. ADP2300 Load Transient, 0.2 A to 1.0 A, V

= 700 kHz, L = 10 μH, C

(f

SW

= 22 μF)

OUT

OUT

I

OUT

SW

= 3.3 V, VIN = 12 V

OUT

V

OUT

I

OUT

SW

= 5.0 V, VIN = 12 V

OUT

08342-058

08342-059

V

1

4

2

CH1 100mV

OUT

I

OUT

SW

B

CH2 10V M100µs A CH4 580mA

W

CH4 500mA Ω

B

W

B

W

Figure 30. ADP2301 Load Transient, 0.2 A to 1.0 A, V

= 1.4 MHz, L = 4.7 μH, C

(f

SW

= 10 μF)

OUT

= 5.0 V, VIN = 12 V

OUT

08342-057

Rev. A | Page 10 of 28

1

4

2

CH1 100mV

B

CH2 10V M100µ s A CH4 630mA

W

CH4 500mA Ω

B

W

B

W

Figure 33. ADP2300 Load Transient, 0.2 A to 1.0 A, V

= 700 kHz, L = 10 μH, C

(f

SW

= 22 μF)

OUT

V

OUT

I

OUT

SW

= 3.3 V, VIN = 12 V

OUT

08342-060

ADP2300/ADP2301

200

160

120

80

40

0

–40

–80

–120

–160

–200

PHASE [B/A] (Degrees)

1

3

2

CH1 5mV

CH3 5V

B

CH2 10V M1ms A CH3 11.4V

W

B

W

Figure 34. ADP2301 Line Transient,

7 V to 15 V, V

= 3.3 V, I

OUT

OUT

V

OUT

V

IN

SW

= 1.2 A, fSW = 1.4 MHz

100

80

60

40

20

0

–20

–40

MAGNITUDE [B/A] (dB)

–60

–80

CROSS FREQ UENCY: 127kHz

PHASE MARGIN: 53 °

–100

08342-061

1k 10k 100k

FREQUENCY (Hz)

Figure 37. ADP2301 Bode Plot, V

= 1.4 MHz, L = 4.7 μH, C

(f

SW

12

= 5.0 V, VIN = 12 V

OUT

OUT

1M

= 10 μF)

08342-062

V

OUT

1

IL

4

2

CH1 1V

B

CH2 10V M10µs A CH1 2.56V

W

CH4 1A Ω

SW

B

W

B

W

Figure 35. ADP2301 Short-Circuit Entry, V

= 1.4 MHz)

(f

SW

1

V

OUT

IL

4

2

CH1 1V

B

W

SW

CH2 10V M100 µs A CH1 1.2V

CH4 1A Ω

B

W

B

W

Figure 36. ADP2301 Short-Circuit Recovery, V

= 1.4 MHz)

(f

SW

= 3.3 V

OUT

OUT

= 3.3 V

100

80

60

40

20

0

–20

–40

MAGNITUDE [B/ A] (dB)

–60

–80

CROSS FREQ UENCY: 80kHz

PHASE MARGIN: 68°

–100

8342-033

1k 10k 100k

FREQUENCY (Hz)

Figure 38. ADP2301 Bode Plot, V

= 1.4 MHz, L = 4.7 μH, C

(f

SW

1

OUT

2

1M

= 3.3 V, VIN = 12 V

= 22 μF)

OUT

100

80

60

40

20

0

–20

–40

MAGNITUDE [B/A] (dB)

–60

–80

CROSS FREQ UENCY: 27kHz

PHASE MARGIN: 76°

–100

08342-034

1k 10k 100k

Figure 39. ADP2300 Bode Plot, V

(f

SW

12

1M

FREQUENCY (Hz)

= 5.0 V, VIN = 12 V

= 700 kHz, L = 10 μH, C

OUT

OUT

= 22 μF)

200

160

120

80

40

0

–40

–80

–120

–160

–200

200

160

120

80

40

0

–40

–80

–120

–160

–200

PHASE [B/A] ( Degrees)

08342-063

PHASE [B/A] (Degrees)

08342-064

Rev. A | Page 11 of 28

ADP2300/ADP2301

100

80

60

40

20

0

–20

–40

MAGNITUDE [B/A] (dB)

–60

–80

CROSS FREQUENCY: 47kHz

PHASE MARGIN: 77°

–100

1k 10k 100k

Figure 40. ADP2300 Bode Plot, V

= 700 kHz, L = 10 μH, C

(f

SW

12

FREQUENCY (Hz)

= 3.3 V, VIN = 12 V

OUT

OUT

1M

= 22 μF)

200

160

120

80

40

0

–40

–80

–120

–160

–200

PHASE [B/A] (Degrees)

08342-065

Rev. A | Page 12 of 28

ADP2300/ADP2301

V

FUNCTIONAL BLOCK DIAGRAM

IN

VIN

5

OFF

ON

EN

FB

SHUTDOWN

4

3

THERMAL

1.20V

1.2µA

0.90V

0.8V

SHUTDOWN

OVP

220kΩ

90pF

LOGIC

SHUTDOWN IC

0.5V

V

= 1.1V

BIAS

0.7pF

UVLO

OCP

250mV/A

RAMP

GENERATOR

V

FB

BOOT

REGULATOR

RSQ

CLK

GENERATOR

FREQUENCY F OLDBACK

(

f

, ½

f

, ¼

f

SW

)

SW

SW

BST

1

V

OUT

SW

6

GND

2

ADP2300/ADP2301

08342-038

Figure 41. ADP2300/ADP2301 Functional Block Diagram

Rev. A | Page 13 of 28

ADP2300/ADP2301

THEORY OF OPERATION

The ADP2300/ADP2301 are nonsynchronous, step-down

dc-to-dc regulators, each with an integrated high-side power

MOSFET. A high switching frequency and ultrasmall, 6-lead

TSOT package allow small step-down dc-to-dc regulator

solutions.

The ADP2300/ADP2301 can operate with an input voltage from

3.0 V to 20 V while regulating an output voltage down to 0.8 V.

The ADP2300/ADP2301 are available in two fixed-frequency

options: 700 kHz (ADP2300) and 1.4 MHz (ADP2301).

BASIC OPERATION

The ADP2300/ADP2301 use the fixed-frequency, peak currentmode PWM control architecture at medium to high loads, but

shift to a pulse-skip mode control scheme at light loads to reduce

the switching power losses and improve efficiency. When the

devices operate in fixed-frequency PWM mode, output regulation

is achieved by controlling the duty cycle of the integrated MOSFET.

When the devices operate in pulse-skip mode at light loads, the

output voltage is controlled in a hysteretic manner with higher

output ripple. In this mode of operation, the regulator periodically

stops switching for a few cycles, thus keeping the conversion

losses minimal to improve efficiency.

Since the pulse-skip mode comparator monitors the internal

compensation node, which represents the peak inductor current

information, the average pulse-skip load current threshold depends

on the input voltage (V

and the output capacitor.

Because the output voltage occasionally dips below regulation

and then recovers, the output voltage ripple in the power saving

mode is larger than the ripple in the PWM mode of operation.

), the output voltage (V

IN

), the inductor,

OUT

BOOTSTRAP CIRCUITRY

The ADP2300/ADP2301 each have an integrated boot regulator,

which requires that a 0.1 µF ceramic capacitor (X5R or X7R) be

placed between the BST and SW pins to provide the gate drive

voltage for the high-side MOSFET. There must be at least a 1.2 V

difference between the BST and SW pins to turn on the high-side

MOSFET. This voltage should not exceed 5.5 V in case the BST

pin is supplied with an external voltage source through a diode.

The ADP2300/ADP2301 generate a typical 5.0 V bootstrap voltage

for a gate drive circuit by differentially sensing and regulating the

voltage between the BST and SW pins. A diode integrated on the

chip blocks the reverse voltage between the VIN and BST pins

when the MOSFET switch is turned on.

PWM MODE

In PWM mode, the ADP2300/ADP2301 operate at a fixed

frequency, set by an internal oscillator. At the start of each

oscillator cycle, the MOSFET switch is turned on, sending a

positive voltage across the inductor. The inductor current

increases until the current-sense signal crosses the peak

inductor current threshold that turns off the MOSFET switch;

this threshold is set by the error amplifier output. During the

MOSFET off time, the inductor current declines through the

external diode until the next oscillator clock pulse starts a new

cycle. The ADP2300/ADP2301 regulate the output voltage by

adjusting the peak inductor current threshold.

POWER SAVING MODE

To achieve higher efficiency, the ADP2300/ADP2301 smoothly

transition to the pulse-skip mode when the output load decreases

below the pulse-skip current threshold. When the output voltage

dips below regulation, the ADP2300/ADP2301 enter PWM mode

for a few oscillator cycles until the voltage increases to within

regulation. During the idle time between bursts, the MOSFET

switch is turned off, and the output capacitor supplies all the

output current.

PRECISION ENABLE

The ADP2300/ADP2301 feature a precision enable circuit that

has a 1.2 V reference voltage with 100 mV hysteresis. When the

voltage at the EN pin is greater than 1.2 V, the part is enabled. If the

EN voltage falls below 1.1 V, the chip is disabled. The precision

enable threshold voltage allows the ADP2300/ADP2301 to be

easily sequenced from other input/output supplies. It can also be

used as programmable UVLO input by using a resistive divider.

An internal 1.2 µA pull-down current prevents errors if the EN pin

is floating.

INTEGRATED SOFT START

The ADP2300/ADP2301 include internal soft start circuitry

that ramps the output voltage in a controlled manner during

startup, thereby limiting the inrush current. The soft start time is

typically fixed at 1460 µs for the ADP2300 and at 730 µs for the

ADP2301.

CURRENT LIMIT

The ADP2300/ADP2301 include current-limit protection circuitry

to limit the amount of positive current flowing through the highside MOSFET switch. The positive current limit on the power

switch limits the amount of current that can flow from the input

to the output.

Rev. A | Page 14 of 28

ADP2300/ADP2301

SHORT-CIRCUIT PROTECTION

The ADP2300/ADP2301 include frequency foldback to prevent

output current runaway when there is a hard short on the output.

The switching frequency is reduced when the voltage at the FB pin

drops below a certain value, which allows more time for the

inductor current to decline, but increases the ripple current while

regulating the peak current. This results in a reduction in average

output current and prevents output current runaway. The correlation between the switching frequency and the FB pin voltage

is shown in Tabl e 5 .

Table 5. Correlation Between the Switching Frequency

and the FB Pin Voltage

FB Pin Voltage Switching Frequency

VFB ≥ 0.6 V fSW

0.6 V > VFB > 0.2 V ½ fSW

VFB ≤ 0.2 V ¼ fSW

When a hard short (VFB ≤ 0.2 V) is removed, a soft start cycle

is initiated to regulate the output back to its level during normal

operation, which helps to limit the inrush current and prevent

possible overshoot on the output voltage.

UNDERVOLTAGE LOCKOUT (UVLO)

The ADP2300/ADP2301 have fixed, internally set undervoltage

lockout circuitry. If the input voltage drops below 2.4 V, the

ADP2300/ADP2301 shut down and the MOSFET switch turns

off. After the voltage rises again above 2.8 V, the soft start

period is initiated, and the part is enabled.

THERMAL SHUTDOWN

If the ADP2300/ADP2301 junction temperature rises above 140°C,

the thermal shutdown circuit disables the chip. Extreme junction

temperature can be the result of high current operation, poor

circuit board design, or high ambient temperature. A 15°C

hysteresis is included so that when thermal shutdown occurs,

the ADP2300/ADP2301 do not return to operation until the onchip temperature drops below 125°C. After the devices recover

from thermal shutdown, a soft start is initiated.

CONTROL LOOP

The ADP2300/ADP2301 are internally compensated to minimize

external component count and cost. In addition, the built-in

slope compensation helps to prevent subharmonic oscillations

when the ADP2300/ADP2301 operate at a duty cycle greater

than or close to 50%.

Rev. A | Page 15 of 28

ADP2300/ADP2301

−+××

=

−+××−=

APPLICATIONS INFORMATION

PROGRAMMING THE OUTPUT VOLTAGE

The output voltage of the ADP2300/ADP2301 is externally set by

a resistive voltage divider from the output voltage to the FB pin,

as shown in Figure 42. Suggested resistor values for the typical

output voltage setting are listed in Ta bl e 6. The equation for the

output voltage setting is

⎛

V

OUT

⎜

1V800.0

⎜

⎝

where:

V

is the output voltage.

OUT

R

is the feedback resistor from V

FB1

R

is the feedback resistor from FB to GND.

FB2

ADP2300/

ADP2301

FB

Figure 42. Programming the Output Voltage Using a Resistive Voltage Divider

Table 6. Suggested Values for Resistive Voltage Divider

V

(V) R

OUT

(kΩ), ±1% R

FB1

1.2 4.99 10

1.8 12.7 10.2

2.5 21.5 10.2

3.3 31.6 10.2

5.0 52.3 10

⎞

R

1

FB

⎟

+×=

⎟

R

2

FB

⎠

to FB.

OUT

V

OUT

R

FB1

R

FB2

08342-039

(kΩ), ±1%

FB2

VOLTAGE CONVERSION LIMITATIONS

There are both lower and upper output voltage limitations for a

given input voltage due to the minimum on time, the minimum

off time, and the bootstrap dropout voltage.

The lower limit of the output voltage is constrained by the finite,

controllable minimum on time, which can be as high as 135 ns for

the worst case. By considering the variation of both the switching

frequency and the input voltage, the equation for the lower limit

of the output voltage is

VVVftV

)(

OUT

(min)

-

INSW

(max)(max)

ONMIN

where:

V

is the maximum input voltage.

IN(max)

f

is the maximum switching frequency for the worst case.

SW(max)

is the minimum controllable on time.

t

MIN-ON

V

is the diode forward drop.

D

The upper limit of the output voltage is constrained by the minimum controllable off time, which can be as high as 120 ns in

the ADP2301 for the worst case. By considering the variation of

both the switching frequency and the input voltage, the equation

for the upper limit of the output voltage is

OUT

(max)

OFFMIN

(min)(max)

INSW

-

where:

is the minimum input voltage.

V

IN(min)

is the maximum switching frequency for the worst case.

f

SW(max)

V

is the diode forward drop.

D

is the minimum controllable off time.

t

MIN-OFF

In addition, the bootstrap circuit limits the minimum input

voltage for the desired output due to internal dropout voltage.

To attain stable operation at light loads and ensure proper startup

for the prebias condition, the ADP2300/ADP2301 require the

voltage difference between the input voltage and the regulated

output voltage (or between the input voltage and the prebias

voltage) to be greater than 2.1 V for the worst case. If the voltage

difference is smaller, the bootstrap circuit relies on some minimum

load current to charge the boost capacitor for startup. Figure 43

shows the typical required minimum input voltage vs. load current

for the 3.3 V output voltage.

DD

VVVftV

)()1(

DD

Rev. A | Page 16 of 28

ADP2300/ADP2301

V

5.5

5.3

5.1

4.9

4.7

(V)

4.5

IN

4.3

4.1

MINIMUM

3.9

3.7

3.5

1 10 100 1k

FOR STARTUP

FOR RUNNING

LOAD CURRENT (mA)

V

OUT

f

SW

= 3.3V

= 1.4MHz

Figure 43. Minimum Input Voltage vs. Load Current

Based on three conversion limitations (the minimum on time,

the minimum off time, and the bootstrap dropout

voltage), Figure 44 shows the voltage conversion limitations.

22

17

(V)

12

IN

V

7

MAXIMUM INPUT FOR ADP2300

MAXIMUM INPUT FOR ADP2301

2

2 4 6 8 10 12 14 160

MINIMUM INPUT FOR ADP2300/ADP2301

V

(V)

OUT

08342-055

Figure 44. Voltage Conversion Limitations

LOW INPUT VOLTAGE CONSIDERATIONS

For low input voltage between 3 V and 5 V, the internal boot

regulator cannot provide enough 5.0 V bootstrap voltage due to

the internal dropout voltage. As a result, the increased MOSFET

R

reduces the available load current. To prevent this, add

DS(ON)

an external small-signal Schottky diode from a 5.0 V external

bootstrap bias voltage. Because the absolute maximum rating

between the BST and SW pins is 6.0 V, the bias voltage should

be less than 5.5 V. Figure 45 shows the application diagram for

the external bootstrap circuit.

3V ~ 5V

VIN

ADP2300/

ADP2301

BST

SW

SCHOTTKY DIO DE

5V BIAS

VOLTAGE

PROGRAMMING THE PRECISION ENABLE

Generally, the EN pin can be easily tied to the VIN pin so that the

device automatically starts up when the input power is applied.

However, the precision enable feature allows the ADP2300/

ADP2301 to be used as a programmable UVLO by connecting

a resistive voltage divider to V

configuration prevents the start-up problems that can occur

when V

ramps up slowly in soft start with a relatively high

IN

load current.

V

IN

R

EN1

R

EN2

Figure 46. Precision Enable Used as a Programmable UVLO

The precision enable feature also allows the ADP2300/ADP2301 to

be sequenced precisely by using a resistive voltage divider with

another dc-to-dc output supply, as shown in Figure 47.

OTHER DC-TO-DC

OUTPUT

Figure 47. Precision Enable Used as a Sequencing Control

from Another DC-to-DC Output

With a 1.2 µA pull-down current on the EN pin, the equation for

the start-up voltage in Figure 46 and Figure 47 is

V2.1

⎛

V

STARTUP

⎜

⎜

R

2

EN

⎝

where:

is the start-up voltage to enable the chip.

V

STARTUP

is the resistor from the dc source to EN.

R

EN1

R

is the resistor from EN to GND.

EN2

, as shown in Figure 46. This

IN

VIN

ADP2300/

ADP2301

EN

ADP2300/

ADP2301

R

EN1

⎞

+=

⎟

⎟

⎠

EN

R

EN2

+×

R

1

EN

8342-043

08342-044

V2.1A2.1

OFF

ON

EN

GND

FB

08342-042

Figure 45. External Bootstrap Circuit for Low Input Voltage Application

Rev. A | Page 17 of 28

ADP2300/ADP2301

Δ

INDUCTOR

The high switching frequency of the ADP2300/ADP2301 allows

the use of small inductors. For best performance, use inductor

values between 2 H and 10 H for ADP2301, and use inductor

values between 2 H and 22 H for ADP2300.

The peak-to-peak inductor current ripple is calculated using the

following equation:

I

RIPPLE

−

VV

IN

=Δ

×

fL

sw

OUT

⎛

)(

OUT

⎜

×

⎜

⎝

where:

is the switching frequency.

f

SW

L is the inductor value.

is the diode forward drop.

V

D

is the input voltage.

V

IN

V

is the output voltage.

OUT

Inductors of smaller values are usually smaller in size and less

expensive, but increase the ripple current and the output voltage

ripple. As a guideline, the inductor peak-to-peak current ripple

should typically be set to 30% of the maximum load current for

optimal transient response and efficiency. Therefore, the inductor

value is calculated using the following equation:

L

where I

()

−

VV

IN

=

3.0

LOAD(max)

OUT

LOAD

(max)

is the maximum load current.

⎛

OUT

⎜

×

⎜

××

fI

sw

⎝

⎞

+

VV

D

⎟

⎟

+

VV

DIN

⎠

⎞

+

VV

D

⎟

⎟

+

VV

DIN

⎠

The inductor peak current is calculated using the following

equation:

I

RIPPLE

PEAK

II

LOAD

+=

(max)

2

The minimum current rating of the inductor must be greater

than the inductor peak current. For ferrite core inductors with a

quick saturation characteristic, the inductor saturation current

rating should be higher than the switch current-limit threshold

to prevent the inductor from reaching its saturation point. Be

sure to validate the worst-case condition, in which there is a

shorted output, over the intended temperature range.

Inductor conduction losses are caused by the flow of current

through the inductor, which is associated with the internal dc

resistance (DCR). Larger sized inductors have smaller DCR and,

therefore, may reduce inductor conduction losses. However,

inductor core losses are also related to the core material and the

ac flux swing, which are affected by the peak-to-peak inductor ripple current. Because the ADP2300/ADP2301 are high

switching frequency regulators, shielded ferrite core materials

are recommended for their low core losses and low EMI. Some

recommended inductors are shown in Tab le 7 .

Table 7. Recommended Inductors

Dimensions

Vendor Value (μH) Part No. DCR (mΩ) I

SAT

(A)

L × W × H (mm)

Coilcraft 4.7 LPS6225-472MLC 65 3.1 6.0 × 6.0 × 2.4

6.8 LPS6225-682MLC 95 2.7 6.0 × 6.0 × 2.4

10 LPS6225-103MLC 105 2.1 6.0 × 6.0 × 2.4

Sumida 4.7 CDRH5D28RHPNP-4R7N 43 3.7 6.2 × 6.2 × 3.0

4.7 CDRH5D16NP-4R7N 64 2.15 5.8 × 5.8 × 1.8

6.8 CDRH5D28RHPNP-6R8N 61 3.1 6.2 × 6.2 × 3.0

6.8 CDRH5D16NP-6R8N 84 1.8 5.8 × 5.8 × 1.8

10 CDRH5D28RHPNP-100M 93 2.45 6.2 × 6.2 × 3.0

Cooper Bussmann 4.7 SD53-4R7-R 39 2.1 5.2 × 5.2 × 3.0

6.8 SD53-6R8-R 59 1.85 5.2 × 5.2 × 3.0

10 DR73-100-R 65 2.47 7.6 × 7.6 × 3.5

Toko 4.7 B1077AS-4R7N 34 2.6 7.6 × 7.6 × 4.0

6.8 B1077AS-6R8N 40 2.3 7.6 × 7.6 × 4.0

10 B1077AS-100M 58 1.8 7.6 × 7.6 × 4.0

TDK 4.7 VLC5045T-4R7M 34 3.3 5.0 × 5.0 × 4.5

6.8 VLC5045T-6R8M 46 2.7 5.0 × 5.0 × 4.5

10 VLC5045T-100M 66 2.1 5.0 × 5.0 × 4.5

Rev. A | Page 18 of 28

ADP2300/ADP2301

Δ

CATCH DIODE

The catch diode conducts the inductor current during the off

time of the internal MOSFET. The average current of the diode

in normal operation is, therefore, dependent on the duty cycle

of the regulator as well as the output load current.

I

where V

⎛

OUT

⎜

−=

1

AVGDIODE

⎜

⎝

is the diode forward drop.

D

⎞

+

VV

D

⎟

I

×

LOAD

⎟

+

VV

DIN

⎠

(max))(

The only reason to select a diode with a higher current rating than

necessary in normal operation is for the worst-case condition, in

which there is a shorted output. In this case, the diode current

increases up to the typical peak current-limit threshold. Be sure to

consult the diode data sheet to ensure that the diode can operate

well within the thermal and electrical limits.

The reverse breakdown voltage rating of the diode must be higher

than the highest input voltage and allow an appropriate margin

for the ringing that may be present on the SW node. A Schottky

diode is recommended for best efficiency because it has a low

forward voltage drop and fast switching speed. Tab l e 8 provides

a list of recommended Schottky diodes.

Table 8. Recommended Schottky Diodes

V

I

Vendor Part No.

RRM

(V)

AVG

(A)

ON Semiconductor MBRS230LT3 30 2

MBRS240LT3 40 2

Diodes Inc. B230A 30 2

B240A 40 2

Vishay SL23 30 2

SS24 40 2

INPUT CAPACITOR

The input capacitor must be able to support the maximum input

operating voltage and the maximum rms input current. The

maximum rms input current flowing through the input

capacitor is I

withstanding the rms input current for an application’s maximum load current using the following equation:

/2. Select an input capacitor capable of

LOAD(max)

OUTPUT CAPACITOR

The output capacitor selection affects both the output voltage ripple

and the loop dynamics of the regulator. The ADP2300/ADP2301

are designed to operate with small ceramic capacitors that have low

equivalent series resistance (ESR) and equivalent series inductance

(ESL) and are, therefore, easily able to meet stringent output voltage

ripple specifications.

When the regulator operates in forced continuous conduction

mode, the overall output voltage ripple is the sum of the voltage

spike caused by the output capacitor ESR plus the voltage ripple

caused by charging and discharging the output capacitor.

⎛

⎜

×Δ=Δ

RIPPLERIPPLE

⎜

⎝

1

sw

+

××

CfIV8

ESR

OUT

Capacitors with lower ESR are preferable to guarantee low

output voltage ripple, as shown in the following equation:

V

RIPPLE

ESR

≤

C

OUT

Δ

I

RIPPLE

Ceramic capacitors are manufactured with a variety of dielectrics,

each with different behavior over temperature and applied voltage.

X5R or X7R dielectrics are recommended for best performance,

due to their low ESR and small temperature coefficients. Y5V

and Z5U dielectrics are not recommended because of their poor

temperature and dc bias characteristics.

In general, most applications using the ADP2301 (1.4 MHz

switching frequency) require a minimum output capacitor value

of 10 µF, whereas most applications using the ADP2300 (700 kHz

switching frequency) require a minimum output capacitor value

of 20 µF. Some recommended output capacitors for V

are listed in Ta ble 9 .

Table 9. Recommended Capacitors for V

Vendor Value Part No.

Murata 10 μF, 6.3 V GRM31MR60J106KE19 3.2 × 1.6 × 1.15

22 μF, 6.3 V GRM31CR60J226KE19 3.2 × 1.6 × 1.6

TDK 10 μF, 6.3 V C3216X5R0J106K 3.2 × 1.6 × 1.6

22 μF, 6.3 V C3216X5R0J226M 3.2 × 1.6 × 0.85

OUT

⎞

⎟

C

OUT

⎟

⎠

≤ 5.0 V

OUT

≤ 5.0 V

Dimensions

L × W × H (mm)

)1(

DDII

(max))(

LOADRMSIN

−××=

where D is the duty cycle and is equal to

VV

+

D

OUT

D

=

VV

+

DIN

The recommended input capacitor is ceramic with X5R or X7R

dielectrics due to its low ESR and small temperature coefficients.

A capacitance of 10 µF should be adequate for most applications.

To minimize supply noise, place the input capacitor as close to

the VIN pin of the ADP2300/ADP2301 as possible.

Rev. A | Page 19 of 28

ADP2300/ADP2301

THERMAL CONSIDERATIONS

The ADP2300/ADP2301 store the value of the inductor current

only during the on time of the internal MOSFET. Therefore, a small

amount of power is dissipated inside the ADP2300/ADP2301

package, which reduces thermal constraints.

However, when the application is operating under maximum

load with high ambient temperature and high duty cycle, the

heat dissipated within the package may cause the junction

temperature of the die to exceed the maximum junction

temperature of 125°C. If the junction temperature exceeds

140°C, the regulator goes into thermal shutdown and recovers

when the junction temperature drops below 125°C.

The junction temperature of the die is the sum of the ambient

temperature of the environment and the temperature rise of the

package due to power dissipation, as indicated in the following

equation:

= TA + TR

T

J

where:

is the junction temperature.

T

J

is the ambient temperature.

T

A

is the rise in temperature of the package due to power

T

R

dissipation.

The rise in temperature of the package is directly proportional

to the power dissipation in the package. The proportionality

constant for this relationship is the thermal resistance from the

junction of the die to the ambient temperature, as shown in the

following equation:

= θJA × PD

T

R

where:

is the rise in temperature of the package.

T

R

is the thermal resistance from the junction of the die to the

θ

JA

ambient temperature of the package.

is the power dissipation in the package.

P

D

Rev. A | Page 20 of 28

ADP2300/ADP2301

(

DESIGN EXAMPLE

This section provides the procedures to select the external components, based on the example specifications listed in Tab le 1 0 .

The schematic for this design example is shown in Figure 48.

Table 10. Step-Down DC-to-DC Regulator Requirements

Additional

Parameter Specification

Requirements

Input Voltage, VIN 12.0 V ± 10% None

Output Voltage, V

3.3 V, 1.2 A, 1% V

OUT

OUT

None

ripple at CCM mode

Programmable

UVLO Voltage

VIN start-up voltage

approximately 7.8 V

None

SWITCHING FREQUENCY SELECTION

Select the switching frequency—700 kHz (ADP2300) or 1.4 MHz

(ADP2301)—using the conversion limitation curve shown

in Figure 44 to assess the conversion limitations (the minimum o

n

time, the minimum off time, and the bootstrap dropout voltage).

For example, in Figure 44 V

= 12 V ± 10% is within the conver-

IN

sion limitation for both the 700 kHz and 1.4 MHz switching

frequencies for an output voltage of 3.3 V, but choosing the 1.4 MHz

switching frequency provides the smallest sized solution. If higher

efficiency is required, choose the 700 kHz option; however, the

PCB footprint area of the regulator will be larger because of the

bigger inductor and output capacitors.

CATCH DIODE SELECTION

Select the catch diode. A Schottky diode is recommended for best

efficiency because it has a low forward voltage drop and faster

switching speed. The average current of the catch diode in

normal operation, with a typical Schottky diode forward

voltage, can be calculated using the following equation:

VV⎞⎛+

D

OUT

⎜

I ×

1

AVGDIODE

−=

⎜

⎝

where:

= 3.3 V.

V

OUT

= 12 V.

V

IN

LOAD(max)

= 0.4 V.

D

= 1.2 A.

DIODE(AVG)

= 0.85 A.

I

V

Therefore, I

However, for the worst-case condition, in which there is a shorted

output, the diode current would be increased to 2 A typical, determined by the peak switch current limit (see Tabl e 1). In this case,

selecting a B230A, 2.0 A/30 V surface-mount Schottky diode

would result in more reliable operation.

⎟

I

LOAD

⎟

VV

+

DIN

⎠

(max))(

INDUCTOR SELECTION

Select the inductor by using the following equation:

⎛

)

−

VV

IN

LOAD

OUT

(max)

××

fI

=

L

3.0

OUT

⎜

×

⎜

sw

⎝

⎞

+

VV

D

⎟

⎟

+

VV

DIN

⎠

where:

V

= 3.3 V.

OUT

= 12 V.

V

IN

I

V

f

= 1.2 A.

LOAD(max)

= 0.4 V.

D

= 1.4 MHz.

SW

This results in L = 5.15 µH. The closest standard value is 4.7 µH;

therefore, I

RIPPLE

= 0.394 A.

The inductor peak current is calculated using the following

equation:

PEAK

LOAD

(max)

+=

2

IIIΔ

RIPPLE

where:

LOAD(max)

RIPPLE

= 1.2 A.

= 0.394 A.

I

I

Therefore, the calculated peak current for the inductor is 1.397 A.

However, to protect the inductor from reaching its saturation

point in the current-limit condition, the inductor should be rated

for at least a 2.0 A saturation current for reliable operation.

OUTPUT CAPACITOR SELECTION

Select the output capacitor based on the output voltage ripple

requirement, according to the following equation:

⎛

⎜

×Δ=Δ

RIPPLERIPPLE

⎜

⎝

1

sw

+

××

CfIV8

ESR

OUT

where:

= 0.394 A.

ΔI

RIPPLE

= 1.4 MHz.

f

SW

= 33 mV.

V

RIPPLE

If the ESR of the ceramic capacitor is 3 m, then C

Because the output capacitor is one of the two external components

that control the loop stability, most applications using the ADP2301

(1.4 MHz switching frequency) require a minimum 10 µF capacitance to ensure stability. According to the recommended external

components in Table 1 1, choose 22 µF with a 6.3 V voltage rating

for this example.

C

OUT

⎞

⎟

⎟

⎠

= 1.2 µF.

OUT

Rev. A | Page 21 of 28

ADP2300/ADP2301

RESISTIVE VOLTAGE DIVIDER SELECTION

To select the appropriate resistive voltage divider, first calculate the

output feedback resistive voltage divider, and then calculate the

resistive voltage divider for the programmable V

The output feedback resistive voltage divider is

⎛

V

OUT

⎜

1V800.0

⎜

⎝

For the 3.3 V output voltage, choose R

⎞

R

1

FB

⎟

+×=

⎟

R

2

FB

⎠

FB1

= 10.2 k as the feedback resistive voltage divider, according to

the recommended values in Tab le 1 1 .

start-up voltage.

IN

= 31.6 k and R

FB2

The resistive voltage divider for the programmable V

voltage is

V2.1

⎛

⎜

V

STARTUP

If V

R

EN1

= 7.8 V, choose R

STARTUP

, which in this case is 56 k.

+=

⎜

R

2

EN

⎝

⎞

⎟

⎟

⎠

= 10.2 k, and then calculate

EN2

+×

R

1

EN

start-up

IN

V2.1A2.1

VIN = 12V

C1

10µF

25V

56kΩ

1%

10.2kΩ

1%

VIN

ADP2301

R3

R4

(1.4MHz)

EN

GND

BST

SW

FB

C3

0.1µF

6.3V

D1

B230A

L1

4.7µH

2.0A

31.6kΩ

1%

10.2kΩ

1%

V

= 3.3V

OUT

1.2A

C2

22µF

R1

R2

6.3V

08342-045

Figure 48. Schematic for the Design Example

Table 11. Recommended External Components for Typical Applications at 1.2 A Output Load

Part Number VIN (V) V

(V) I

OUT

(A) L (μH) C

OUT

(μF) R

OUT

(kΩ), ±1% R

FB1

(kΩ), ±1%

FB2

ADP2300 (700 kHz) 18 3.3 1.2 10 22 31.6 10.2

18 5.0 1.2 15 22 52.3 10

12 1.2 1.2 6.8 2 × 22 4.99 10

12 1.8 1.2 6.8 2 × 22 12.7 10.2

12 2.5 1.2 10 22 21.5 10.2

12 3.3 1.2 10 22 31.6 10.2

12 5.0 1.2 10 22 52.3 10

9 3.3 1.2 10 22 31.6 10.2

9 5.0 1.2 10 22 52.3 10

5 1.8 1.2 4.7 2 × 22 12.7 10.2

5 2.5 1.2 4.7 22 21.5 10.2

ADP2301 (1.4 MHz) 18 3.3 1.2 4.7 22 31.6 10.2

18 5.0 1.2 6.8 10 52.3 10

12 2.5 1.2 4.7 22 21.5 10.2

12 3.3 1.2 4.7 22 31.6 10.2

12 5.0 1.2 4.7 10 52.3 10

9 3.3 1.2 4.7 22 31.6 10.2

9 5.0 1.2 4.7 10 52.3 10

5 1.8 1.2 2.2 2 × 22 12.7 10.2

5 2.5 1.2 2.2 22 21.5 10.2

Rev. A | Page 22 of 28

ADP2300/ADP2301

CIRCUIT BOARD LAYOUT RECOMMENDATIONS

Good circuit board layout is essential to obtain the best

performance from the ADP2300/ADP2301. Poor layout can

affect the regulation and stability, as well as the electromagnetic

interface (EMI) and electromagnetic compatibility (EMC)

performance. A PCB layout example is shown in Figure 50.

Refer to the following guidelines for a good PCB layout:

• Place the input capacitor, inductor, catch diode, output

capacitor, and bootstrap capacitor close to the IC using

short traces.

• Ensure that the high current loop traces are as short and wide

as possible. The high current path is shown in Figure 49.

• Maximize the size of ground metal on the component side

to improve thermal dissipation.

• Use a ground plane with several vias connecting to the

component side ground to further reduce noise interference on sensitive circuit nodes.

INDUC TOR

L1

• Minimize the length of the FB trace connecting the top of the

feedback resistive voltage divider to the output. In addition,

keep these traces away from the high current traces and the

switch node to avoid noise pickup.

GND

BST

SW

FB

08342-046

VIN

ADP2300/

ADP2301

EN

Figure 49. Typical Application Circuit with High Current Traces Shown in Blue

C3

OUTPUT CAP

R

FB2

BST CAP

CATCH DIODE

D1

C1

C2

R

FB1

ADP2300/ADP2301

Figure 50. Recommended PCB Layout for the ADP2300/ADP2301

INPUT CAP

08342-056

Rev. A | Page 23 of 28

ADP2300/ADP2301

TYPICAL APPLICATION CIRCUITS

VIN = 12V

C1

10µF

25V

OFF

100kΩ

5%

ON

R3

VIN

EN

ADP2300

(700kHz)

GND

Figure 51. ADP2300—700 kHz Typical Application, V

BST

SW

FB

= 12 V, V

IN

C4

0.1µF

L1

6.3V

6.8µH

2.0A

D1

B230A

OUT

R1

4.99kΩ

1%

R2

10kΩ

1%

= 1.2 V/1.2 A with External Enabling

V

OUT

C2

22µF

6.3V

= 1.2V

1.2A

C3

22µF

6.3V

8342-052

VIN = 12V

C1

10µF

25V

OFF

R3

100kΩ

5%

ON

VIN

EN

ADP2300

(700kHz)

GND

Figure 52. ADP2300—700 kHz Typical Application, V

BST

SW

FB

= 12 V, V

IN

C4

0.1µF

L1

6.3V

6.8µH

2.0A

D1

B230A

12.7kΩ

10.2kΩ

= 1.8 V/1.2 A with External Enabling

OUT

1%

1%

R2

V

OUT

1.2A

C2

22µF

6.3V

R1

= 1.8V

C3

22µF

6.3V

8342-051

VIN = 12V

C1

10µF

25V

OFF

R3

100kΩ

5%

ON

VIN

EN

ADP2300

(700kHz)

GND

Figure 53. ADP2300—700 kHz Typical Application, V

BST

SW

FB

= 12 V, V

IN

C3

L1

0.1µF

10µH

6.3V

2.0A

D1

B230A

21.5kΩ

10.2kΩ

= 2.5 V/1.2 A with External Enabling

OUT

R1

1%

R2

1%

= 2.5V

V

OUT

1.2A

C2

22µF

6.3V

8342-050

Rev. A | Page 24 of 28

ADP2300/ADP2301

VIN= 12V

C1

10µF

25V

56kΩ

1%

10.2kΩ

1%

R3

R4

VIN

EN

ADP2301

(1.4MHz)

GND

Figure 54. ADP2301—1.4 MHz Typical Application, V

(with Programmable 7.8 V Start-Up Input Voltage)

BST

SW

FB

C3

0.1µF

6.3V

D1

B230A

L1

4.7µH

2.0A

= 12 V, V

IN

31.6kΩ

1%

10.2kΩ

1%

OUT

R1

R2

V

= 3.3V

OUT

1.2A

= 3.3 V/1.2 A

C2

22µF

6.3V

08342-049

VIN = 12V

C1

10µF

25V

OFF

100kΩ

5%

ON

R3

VIN

EN

ADP2301

(1.4MHz)

GND

Figure 55. ADP2301—1.4 MHz Typical Application, V

VIN = 18V

C1

10µF

25V

OFF

100kΩ

5%

ON

R3

VIN

EN

ADP2301

(1.4MHz)

GND

Figure 56. ADP2301—1.4 MHz Typical Application, V

VIN = 9V

C1

10µF

25V

OFF

100kΩ

5%

ON

R3

VIN

EN

ADP2301

(1.4MHz)

GND

Figure 57. ADP2301—1.4 MHz Typical Application, V

BST

SW

FB

IN

BST

SW

FB

IN

BST

SW

FB

IN

C3

0.1µF

6.3V

= 12 V, V

= 18 V, V

= 9 V, V

L1

4.7µH

2.0A

D1

B230A

52.3kΩ

= 5.0 V/1.2 A with External Enabling

OUT

C3

L1

0.1µF

6.8µH

6.3V

2.0A

D1

B230A

= 5.0 V/1.2 A with External Enabling

OUT

C3

L1

0.1µF

4.7µH

6.3V

2.0A

D1

B230A

= 3.3 V/1.2 A with External Enabling

OUT

R1

1%

R2

10kΩ

1%

52.3kΩ

1%

10.2kΩ

1%

31.6kΩ

1%

10.2kΩ

1%

V

= 5V

OUT

1.2A

C2

10µF

6.3V

V

= 5.0V

OUT

1.2A

C2

R1

R2

R1

R2

10µF

6.3V

= 3.3V

V

OUT

1.2A

C2

22µF

6.3V

8342-048

08342-090

08342-091

VIN = 5V

C1

10µF

25V

R3

100kΩ

5%

ON

OFF

Figure 58. ADP2301—1.4 MHz Typical Application, V

VIN

EN

ADP2301

(1.4MHz)

GND

BST

SW

FB

= 5 V, V

IN

C4

0.1µF

6.3V

D1

B230A

Rev. A | Page 25 of 28

L1

2.2µH

2.0A

12.7kΩ

10.2kΩ

= 1.8 V/1.2 A with External Enabling

OUT

1%

1%

= 1.8V

V

OUT

1.2A

R1

R2

C2

22µF

6.3V

C3

22µF

6.3V

8342-092

ADP2300/ADP2301

C

C

OUTLINE DIMENSIONS

2.90 BS

1.90

BSC

45

2.80 BSC

2

0.95 BSC

*

1.00 MAX

SEATING

PLANE

0.20

0.08

8°

4°

0°

0.60

0.45

0.30

102808-A

1.60 BSC

INDI

*

0.87

0.84

0.10 MAX

PIN 1

ATO R

0.90

6

13

0.50

0.30

*

COMPLIANT TO JEDEC ST ANDARDS MO-193-AA WI TH

THE EXCEPTI ON OF PACKAG E HEIGHT AND T HICKNESS.

Figure 59. 6-Lead Thin Small Outline Transistor Package [TSOT]

(UJ-6)

Dimensions shown in millimeters

ORDERING GUIDE

Switching

Model1

Frequency

Temperature Range Package Description

ADP2300AUJZ-R7 700 kHz −40°C to +125°C 6-Lead Thin Small Outline Transistor Package [TSOT] UJ-6 L87

ADP2300-EVALZ Evaluation Board

ADP2301AUJZ-R7 1.4 MHz −40°C to +125°C 6-Lead Thin Small Outline Transistor Package [TSOT] UJ-6 L86

ADP2301-EVALZ Evaluation Board

1

Z = RoHS Compliant Part.

Package

Option

Branding

Rev. A | Page 26 of 28

ADP2300/ADP2301

NOTES

Rev. A | Page 27 of 28

ADP2300/ADP2301

NOTES

©2010 Analog Devices, Inc. All rights reserved. Trademarks and

registered trademarks are the property of their respective owners.

D08342-0-6/10(A)

Rev. A | Page 28 of 28

Loading...

Loading...