3 MHz, 600 mA, Low Quiescent Current

V

V

V

V

FEATURES

Input voltage range: 2.3 V to 5.5 V

LDO input (VIN2) 1.65 V to 5.5 V

Buck output voltage range: 1.0 V to 3.3 V

LDO output voltage range: 0.8 V to 3.3 V

Buck output current: 600 mA

LDO output current: 300 mA

LDO quiescent current: 22 μA with zero load

Buck quiescent current: 20 μA in PSM mode

Low shutdown current: <0.3 μA

Low LDO dropout 110 mV @ 300 mA load

High LDO PSRR

65 dB @ 10 kHz at V

55 dB @ 100 kHz at V

Low noise LDO: 40 μV rms at V

Initial accuracy: ±1%

Current-limit and thermal overload protection

Power-good indicator

Optional enable sequencing

10-lead 0.75 mm × 3 mm × 3 mm LFCSP package

APPLICATIONS

Mobile phones

Personal media players

Digital camera and audio devices

Portable and battery-powered equipment

GENERAL DESCRIPTION

The ADP2140 includes a high efficiency, low quiescent 600 mA

stepdown dc-to-dc converter and a 300 mA LDO packaged in a

small 10-lead 3 mm × 3 mm LFCSP. The total solution requires

only four tiny external components.

The buck regulator uses a proprietary high speed current-mode,

constant frequency, pulse-width modulation (PWM) control

scheme for excellent stability and transient response. To ensure

the longest battery life in portable applications, the ADP2140 has

a power saving variable frequency mode to reduce switching frequency under light loads.

The LDO is a low quiescent current, low dropout linear regulator

designed to operate in a split supply mode with V

1.65 V. The low input voltage minimum allows the LDO to be

powered from the output of the buck regulator increasing efficiency and reducing power dissipation. The ADP2140 runs from

input voltages of 2.3 V to 5.5 V allowing single Li+/Li− polymer

OUT2

OUT2

= 1.2 V

= 1.2 V

OUT2

= 1.2 V

as low as

IN2

Buck with 300 mA LDO Regulator

ADP2140

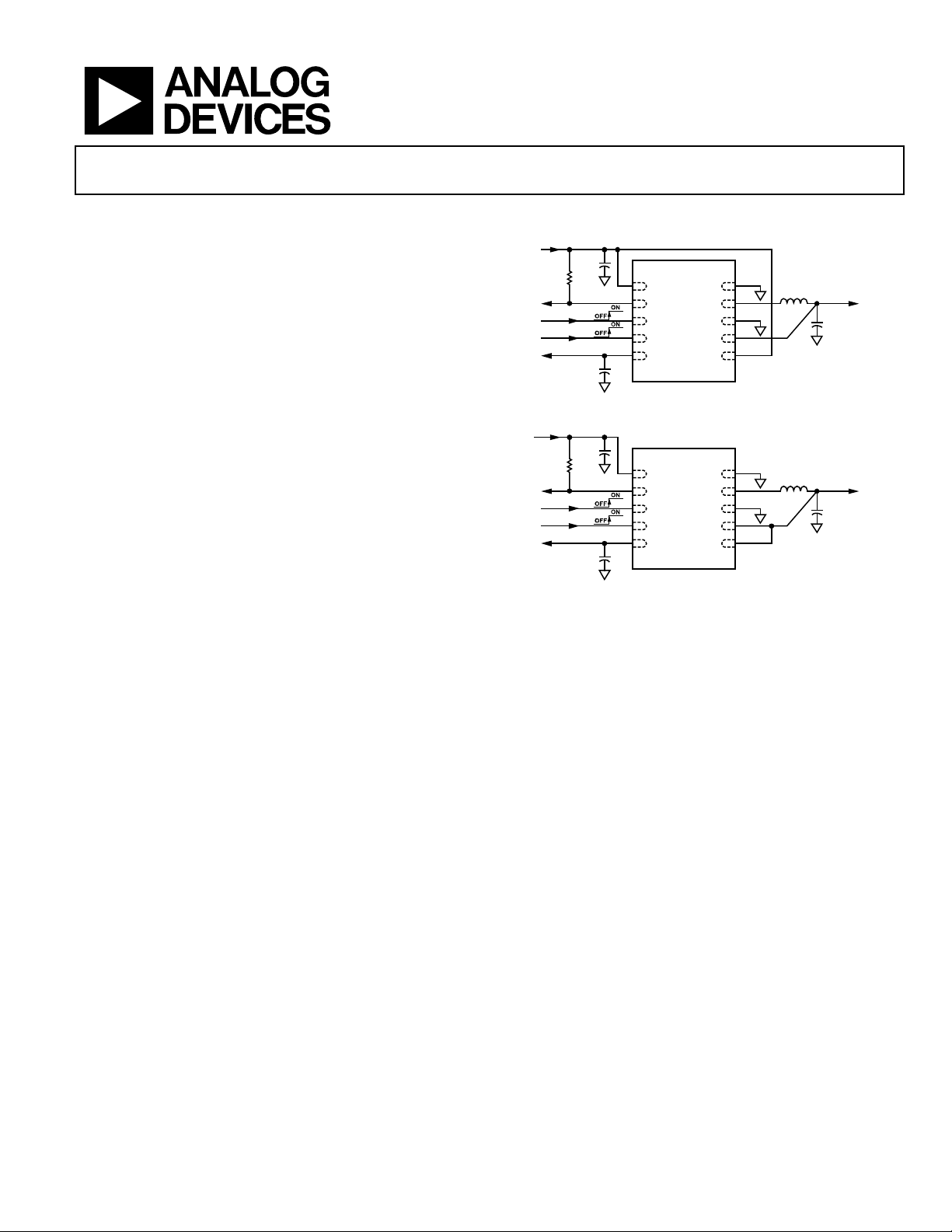

TYPICAL APPLICATION CIRCUITS

= 3.6

IN1

+

C

IN

10µF

100kΩ

PG

EN1

EN2 FB

V

= 1.8V

OUT2

+

C

OUT2

1µF

Figure 1. ADP2140 with LDO Connected to V

= 3.3

IN1

+

C

IN

10µF

100kΩ

PG

EN1

EN2 FB

V

= 1.2V

OUT2

+

C

OUT2

1µF

Figure 2. ADP2140 with LDO Connected to Buck Output

cell, multiple alkaline/NiMH cell, PCMCIA, and other standard

power sources.

ADP2140 includes a power-good pin, soft start, and internal

compensation. Numerous power sequencing options are userselectable through two enable inputs. In autosequencing mode,

the highest voltage output enables on the rising edge of EN1.

During logic controlled shutdown, the input disconnects from

the output and draws less than 300 nA from the input source.

Other key features include: undervoltage lockout to prevent deep

battery discharge, soft start to prevent input current overshoot

at startup, and both short-circuit protection and thermal overload

protection circuits to prevent damage in adverse conditions.

When the ADP2140 is used with two 0603 capacitors, one 0402

capacitor, one 0402 resistor, and one 0805 chip inductor, the total

solution size is approximately 90 mm

print solution to meet a variety of portable applications.

10

9

8

7

6

10

9

8

7

6

ADP2140

VIN1 PGND

PG SW

EN1 AGND

EN2

VOUT2

VIN2

ADP2140

VIN1 PGND

PG SW

EN1 AGND

EN2

VOUT2

VIN2

1

2

3

4

5

1

2

3

4

5

2

resulting in the smallest foot-

1µH

1µH

V

= 1.2V

OUT

+

C

OUT

10µF

IN1

V

= 1.8V

OUT

+

C

OUT

10µF

07932-001

07932-002

Rev. 0

Information furnished by Analog Devices is believed to be accurate and reliable. However, no

responsibility is assumed by Analog Devices for its use, nor for any infringements of patents or other

rights of third parties that may result from its use. Specifications subject to change without notice. No

license is granted by implication or otherwise under any patent or patent rights of Analog Devices.

Trademarks and registered trademarks are the property of their respective owners.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700 www.analog.com

Fax: 781.461.3113 ©2010 Analog Devices, Inc. All rights reserved.

ADP2140

TABLE OF CONTENTS

Features .............................................................................................. 1

Applications ....................................................................................... 1

General Description ......................................................................... 1

Typical Application Circuits ............................................................ 1

Revision History ............................................................................... 2

Specifications ..................................................................................... 3

Recommended Specifications: Capacitors and Inductor ........ 4

Absolute Maximum Ratings ............................................................ 5

Thermal Data ................................................................................ 5

Thermal Resistance ...................................................................... 5

ESD Caution .................................................................................. 5

Pin Configuration and Function Descriptions ............................. 6

Typical Performance Characteristics ............................................. 7

Buck Output .................................................................................. 7

LDO Output ................................................................................ 14

Theory of Operation ...................................................................... 19

Buck Section ................................................................................ 19

Control Scheme .......................................................................... 19

PWM Operation ......................................................................... 19

PSM Operation ........................................................................... 19

Pulse Skipping Threshold .......................................................... 19

Selected Features ............................................................................. 20

Short-Circuit Protection ............................................................ 20

Undervoltage Lockout ............................................................... 20

Thermal Protection .................................................................... 20

Soft Start ...................................................................................... 20

Current Limit .............................................................................. 20

Power-Good Pin ......................................................................... 20

LDO Section ............................................................................... 20

Applications Information .............................................................. 21

Power Sequencing ...................................................................... 21

Power-Good Function ............................................................... 24

External Component Selection ................................................ 24

Selecting the Inductor ................................................................ 24

Output Capacitor ........................................................................ 24

Input Capacitor ........................................................................... 24

Efficiency ..................................................................................... 25

Recommended Buck External Components .......................... 25

LDO Capacitor Selection .......................................................... 26

LDO as a Postregulator to Reduce Buck Output Noise ........ 26

Thermal Considerations ................................................................ 28

PCB Layout Considerations ...................................................... 29

Outline Dimensions ....................................................................... 30

Ordering Guide .......................................................................... 30

REVISION HISTORY

6/10—Revision 0: Initial Version

Rev. 0 | Page 2 of 32

ADP2140

SPECIFICATIONS

V

= 3.6 V, V

IN1

C

= 10 µF, C

OUT

specifications, unless otherwise noted.

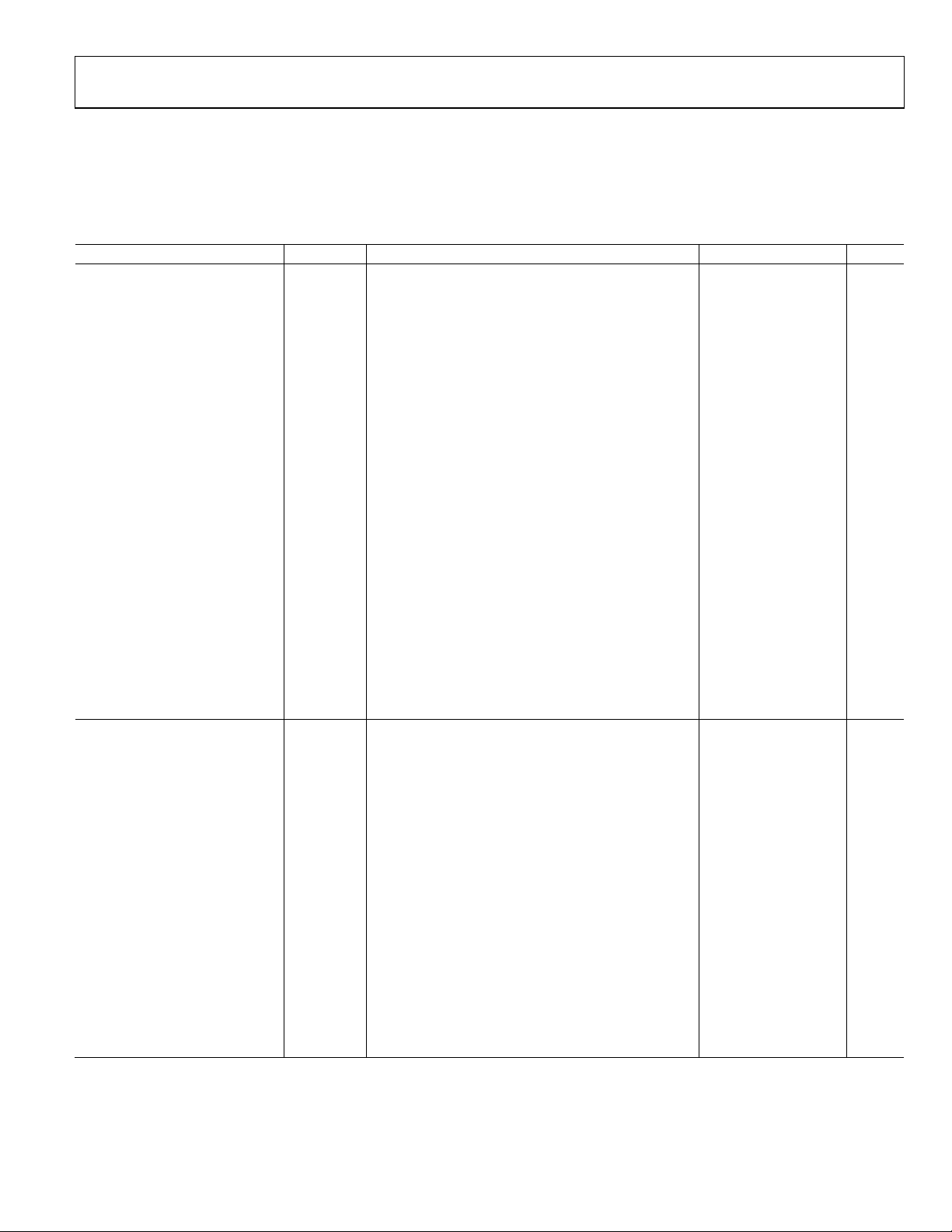

Table 1.

Parameter Symbol Test Conditions/Comments Min Typ Max Unit

BUCK SECTION

Input Voltage Range V

Buck Output Accuracy V

V

Transient Load Regulation V

Load = 50 mA to 250 mA, rise/fall time = 200 ns 75 mV

Load = 200 mA to 600 mA, rise/fall time = 200 ns 75 mV

Transient Line Regulation V

V

V

V

PWM To PSM Threshold V

Output Current I

Current Limit I

Switch On Resistance

PFET R

NFET R

Switch Leakage Current I

Quiescent Current IQ No load, device not switching 20 30 A

Minimum On Time ON-TIME

Oscillator Frequency FREQ 2.55 3.0 3.15 MHz

Frequency Foldback Threshold V

Start-Up Time1 t

Soft Start Time2 SS

LDO SECTION

Input Voltage Range V

LDO Output Accuracy V

1 mA < I

Line Regulation

Load Regulation3

Dropout Voltage4 V

I

Ground Current I

I

I

Power Supply Rejection Ratio PSRR V

PSRR on V

100 kHz, V

100 kHz, V

100 kHz, V

IN2

= V

OUT2

+ 0.3 V or 1.65 V, whichever is greater; 5 V EN1 = EN2 = V

OUT2

= 1 µF, L

= 1 H; TJ = −40°C to +125°C for minimum/maximum specifications, and TA = 25°C for typical

OUT

2.3 5.5 V

IN1

I

OUT

TR-LOAD

Line transient = 4 V to 5 V, 4 s rise time

TR-LINE

600 mA

OUT

V

LIM

V

PFET

V

NFET

EN1 = GND, VIN1 = 5.5 V, and SW = 0 V −1 A

LEAK-SW

Output voltage where fSW ≤ 50% of nominal frequency 50 %

FOLD

START-UP

V

TIME

1.65 5.5 V

IN2

I

OUT2

OUT

IN1

V

V

OUT

OUT

OUT

OUT

IN1

IN1

IN1

IN1

70 ns

MIN

OUT

OUT

OUT2

1 mA < I

= 25°C

V

/V

OUT2

V

/I

OUT2

DROPOUT

No load, buck disabled 22 35 A

AGND

10 kHz, V

IN2

V

IN2

IN2

I

OUT2

OUT2

I

OUT2

OUT2

OUT2

OUT2

IN2

; I

IN1

= 200 mA, I

OUT

= 10 mA, CIN = 10 F,

OUT2

= 10 mA −1.5 +1.5 %

= 2.3 V or (V

+ 0.5 V) to 5.5 V, I

OUT

= 1 mA to 600 mA −2.5 +2.5 %

OUT

= 1.8 V

= 1.0 V 40 mV

= 1.8 V 25 mV

= 3.3 V 25 mV

= 2.3 V or (V

= 2.3 V or (V

+ 0.5 V) to 5.5 V 100 mA

OUT

+ 0.5 V) to 5.5 V 1100 1300 mA

OUT

= 2.3 V to 5.5 V 250 mΩ

= 2.3 V to 5.5 V 250 mΩ

= 1.8 V, 600 mA load 70 µs

= 1.8 V, 600 mA load 150 s

= 10 mA, TJ = 25°C −1 +1 %

−1.5 +1.5 %

= (V

< 300 mA, V

OUT2

< 300 mA, V

OUT2

+ 0.3 V) to 5.5 V, I

OUT2

IN2

IN2

= (V

= (V

+ 0.3 V) to 5.5 V, TJ

OUT2

+ 0.3 V) to 5.5 V −3 +3 %

OUT2

= 10 mA −0.05 +0.05 %/V

OUT2

= 1 mA to 300 mA 0.001 0.005 %/mA

= 10 mA, V

= 300 mA, V

= 1.8 V 4 7 mV

OUT2

= 1.8 V 110 200 mV

OUT2

= 10 mA 65 90 A

= 300 mA 150 220 A

= V

OUT2

OUT2

+ 1 V, V

OUT2

OUT2

OUT2

= 5 V, I

IN1

= 10 mA

OUT2

= 1.2 V, 1.8 V, 3.3 V 65 dB

= 3.3 V 53 dB

= 1.8 V 54 dB

= 1.2 V 55 dB

Rev. 0 | Page 3 of 32

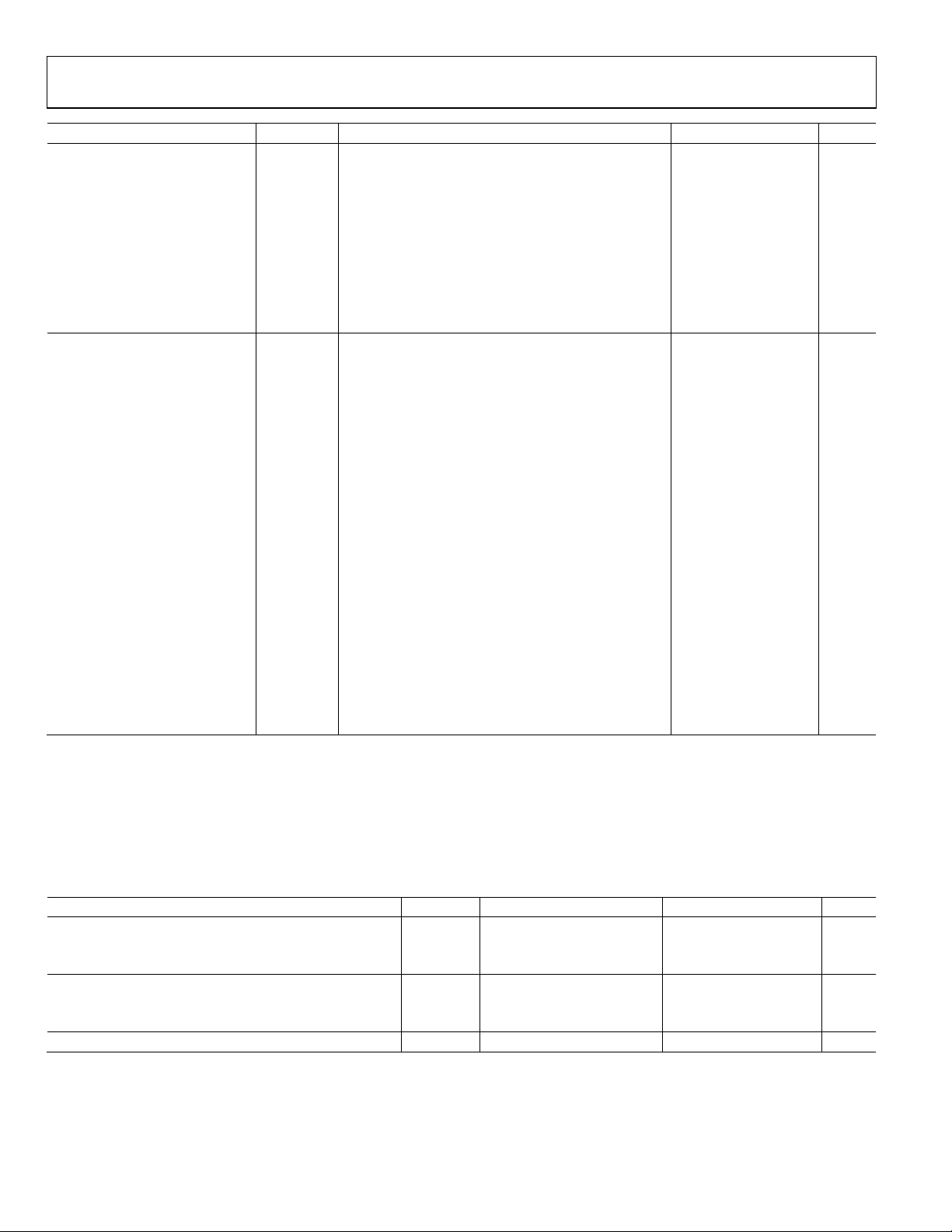

ADP2140

Parameter Symbol Test Conditions/Comments Min Typ Max Unit

Output Noise OUT

10 Hz to 100 kHz, V

10 Hz to 100 kHz, V

10 Hz to 100 kHz, V

10 Hz to 100 kHz, V

10 Hz to 100 kHz, V

Current Limit I

Input Leakage Current I

Start-Up Time1 t

Soft Start Time2 SS

ADDITIONAL FUNCTIONS

Undervoltage Lockout UVLO

Input Voltage Rising UVLO

Input Voltage Falling UVLO

EN Input

EN1, EN2 Input Logic High VIH 2.3 V ≤ V

EN1, EN2 Input Logic Low VIL 2.3 V ≤ V

EN1, EN2 Input Leakage I

EN1, EN2 = V

Shutdown Current I

Thermal Shutdown

Threshold TSSD T

Hysteresis TS

Power Good

Rising Threshold PG

Falling Threshold PG

Power-Good Hysteresis PG

Output Low VOL I

Leakage Current IOH Power-good pin pull-up voltage = 5.5 V 1 A

Buck to LDO Delay t

Power-Good Delay t

1

Start-up time is defined as the time between the rising edge of ENx to V

2

Soft start time is defined as the time between V

3

Based on an endpoint calculation using 1 mA and 300 mA loads.

4

Dropout voltage is defined as the input-to-output voltage differential when the input voltage is set to the nominal output voltage. This applies only for output

voltages above 2.3 V.

V

NOISE

T

LIM

EN2 = GND, V

LEAK-LDO

V

START-UP

V

TIME

2.23 2.3 V

RISE

2.05 2.16 V

FAL L

EN1, EN2 = V

EN-LKG

V

SHUT

20

SD-HYS

92 %V

RISE

86 %V

FAL L

6 %V

HYS

PWM mode only 5 ms

DELAY

PWM mode only 5 ms

RESET

being at 10% to V

OUTx

= V

= 5 V, I

IN2

IN1

= 25°C 360 500 760 mA

J

= 3.3 V, 300 mA load 70 µs

OUT2

= 3.3 V, 300 mA load 130 s

OUT2

≤ 5.5 V 1.0 V

IN1

≤ 5.5 V 0.27 V

IN1

= 5.5 V, EN1, EN2 = GND, TJ = −40°C to +85°C 0.3 1.2 A

IN1

rising 150

J

= 4 mA 0.2 V

SINK

OUTx

being at 90% of the V

OUTx

= 10 mA

OUT2

= 0.8 V 29 µV rms

OUT2

= 1.2 V 40 µV rms

OUT2

= 1.8 V 50 µV rms

OUT2

= 2.5 V 66 µV rms

OUT2

= 3.3 V 88 µV rms

OUT2

= 5.5 V and V

IN2

or GND 0.05 µA

IN1

or GND 1 µA

IN1

being at 10% of the V

= 0 V 1 A

OUT2

nominal value.

OUTx

nominal value.

OUTx

°C

°C

OUT

OUT

OUT

RECOMMENDED SPECIFICATIONS: CAPACITORS AND INDUCTOR

Table 2.

Parameter Symbol Test Conditions/Comments Min Typ Max Unit

MINIMUM INPUT AND OUTPUT CAPACITANCE1

Buck C

LDO C

MIN

MIN

CAPACITOR ESR

Buck R

LDO R

MINIMUM INDUCTOR IND

1

The minimum input and output capacitance should be greater than 0.70 F over the full range of operating conditions. The full range of operating conditions in the

application must be considered during device selection to ensure that the minimum capacitance specification is met. X7R- and X5R-type capacitors are recommended,

Y5V and Z5U capacitors are not recommended for use with any LDO.

ESR

ESR

MIN

Rev. 0 | Page 4 of 32

TA = −40°C to +125°C

TA = −40°C to +125°C

7.5 10 µF

0.7 1.0 µF

Ω

0.001 0.01 Ω

0.001 1 Ω

0.7 1 H

ADP2140

ABSOLUTE MAXIMUM RATINGS

Table 3.

Parameter Rating

VIN1, VIN2 to PGND, AGND −0.3 V to +6.5 V

VOUT2 to PGND, AGND −0.3 V to V

SW to PGND, AGND −0.3 V to V

IN2

IN1

FB to PGND, AGND −0.3 V to +6.5 V

PG to PGND, AGND −0.3 V to +6.5 V

EN1, EN2 to PGND, AGND −0.3 V to +6.5 V

Storage Temperature Range −65°C to +150°C

Operating Ambient Temperature Range −40°C to +85°C

Operating Junction Temperature Range −40°C to +125°C

Soldering Conditions JEDEC J-STD-020

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

THERMAL DATA

Absolute maximum ratings apply individually only, not in com-

bination. The ADP2140 can be damaged when the junction

temperature limits are exceeded. Monitoring ambient temperature

does not guarantee that T

limits. In applications with high power dissipation and poor

thermal resistance, the maximum ambient temperature may

need to be derated.

In applications with moderate power dissipation and low

is within the specified temperature

J

Junction-to-ambient thermal resistance (θ

based on modeling and calculation using a 4-layer board. The

junction-to-ambient thermal resistance is highly dependent on

the application and board layout. In applications where high

maximum power dissipation exists, close attention to thermal

board design is required. The value of θ

on PCB material, layout, and environmental conditions. The

specified values of θ

board. Refer to JESD 51-7 for detailed information on the board

construction.

For more information, see

and Manufacturing Guide for the Lead Frame Chip Scale Package

(LFCSP).

Ψ

is the junction-to-board thermal characterization parameter

JB

with units of °C/W. Ψ

calculation using a 4-layer board. The JESD51-12, Guidelines for

Reporting and Using Package Thermal Information, states that

thermal characterization parameters are not the same as thermal

resistances. Ψ

multiple thermal paths rather than a single path, as in thermal

resistance, θ

from the top of the package as well as radiation from the package,

factors that make Ψ

Maximum junction temperature (T

board temperature (T

formula

T

= TB + (PD × ΨJB)

J

Refer to JESD51-8 and JESD51-12 for more detailed

information about Ψ

printed circuit board (PCB) thermal resistance, the maximum

ambient temperature can exceed the maximum limit as long as

the junction temperature is within specification limits. The

junction temperature (T

ambient temperature (T

(P

), and the junction-to-ambient thermal resistance of the

D

package (θ

).

JA

Maximum junction temperature (T

ambient temperature (T

) of the device is dependent on the

J

), the power dissipation of the device

A

) is calculated from the

J

) and power dissipation (PD) using the

A

formula

T

= TA + (PD × θJA)

J

THERMAL RESISTANCE

θJA and ΨJB are specified for the worst-case conditions, that is, a

device soldered in a circuit board for surface-mount packages.

Table 4. Thermal Resistance

Package Type θJA ΨJB Unit

10-Lead 3 mm × 3 mm LFCSP 35.3 16.9 °C/W

ESD CAUTION

are based on a 4-layer, 4 in. × 3 in. circuit

JA

AN-772 Application Note, A Design

of the package is based on modeling and

JB

measures the component power flowing through

JB

. Therefore, ΨJB thermal paths include convection

JB

more useful in real-world applications.

JB

J

) and power dissipation (PD) using the

B

.

JB

) of the package is

JA

may vary, depending

JA

) is calculated from the

Rev. 0 | Page 5 of 32

ADP2140

PIN CONFIGURATION AND FUNCTION DESCRIPTIONS

PGND

AGND

NOTES

1. THE EXPOSED PAD ON THE BOTTOM OF T HE LFCSP PACKAGE E NHANCES

THERMAL PERF ORMANCE AND IS EL ECTRICALLY CONNECTED TO G ROUND

INSIDE THE PACKAGE. IT IS RECOMMENDE D T HAT THE EXPO SED PAD BE

CONNECTED TO THE GROUND PL ANE ON THE CIRCUIT BOARD.

SW

VIN2

FB

1

2

ADP2140

TOP VIEW

3

(Not to S cale)

4

5

VIN1

10

PG

9

EN1

8

EN2

7

VOUT2

6

Figure 3. Pin Configuration

Table 5. Pin Function Descriptions

Pin Mnemonic Description

1 PGND Power Ground.

2 SW Connection from Power MOSFETs to Inductor.

3 AGND Analog Ground.

4 FB Feedback from Buck Output.

5 VIN2 LDO Input Voltage.

6 VOUT2 LDO Output Voltage.

7 EN2 Logic 1 to Enable LDO or No Connect for Autosequencing.

8 EN1

Logic 1 to Enable Buck or Initiate Sequencing. This is a dual function pin and the state of EN2 determines

which function is operational.

9 PG

Power Good. Open-drain output. PG is held low until both output voltages (which includes the external

inductor and capacitor sensed by the FB pin) rise above 92% of nominal value. PG is held high until both

outputs fall below 85% of nominal value.

10 VIN1 Analog Power Input.

EP

Exposed Pad. The exposed pad on the bottom of the LFCSP package enhances thermal performance and is

electrically connected to ground inside the package. It is recommended that the exposed pad be connected

to the ground plane on the circuit board.

07932-003

Rev. 0 | Page 6 of 32

ADP2140

TYPICAL PERFORMANCE CHARACTERISTICS

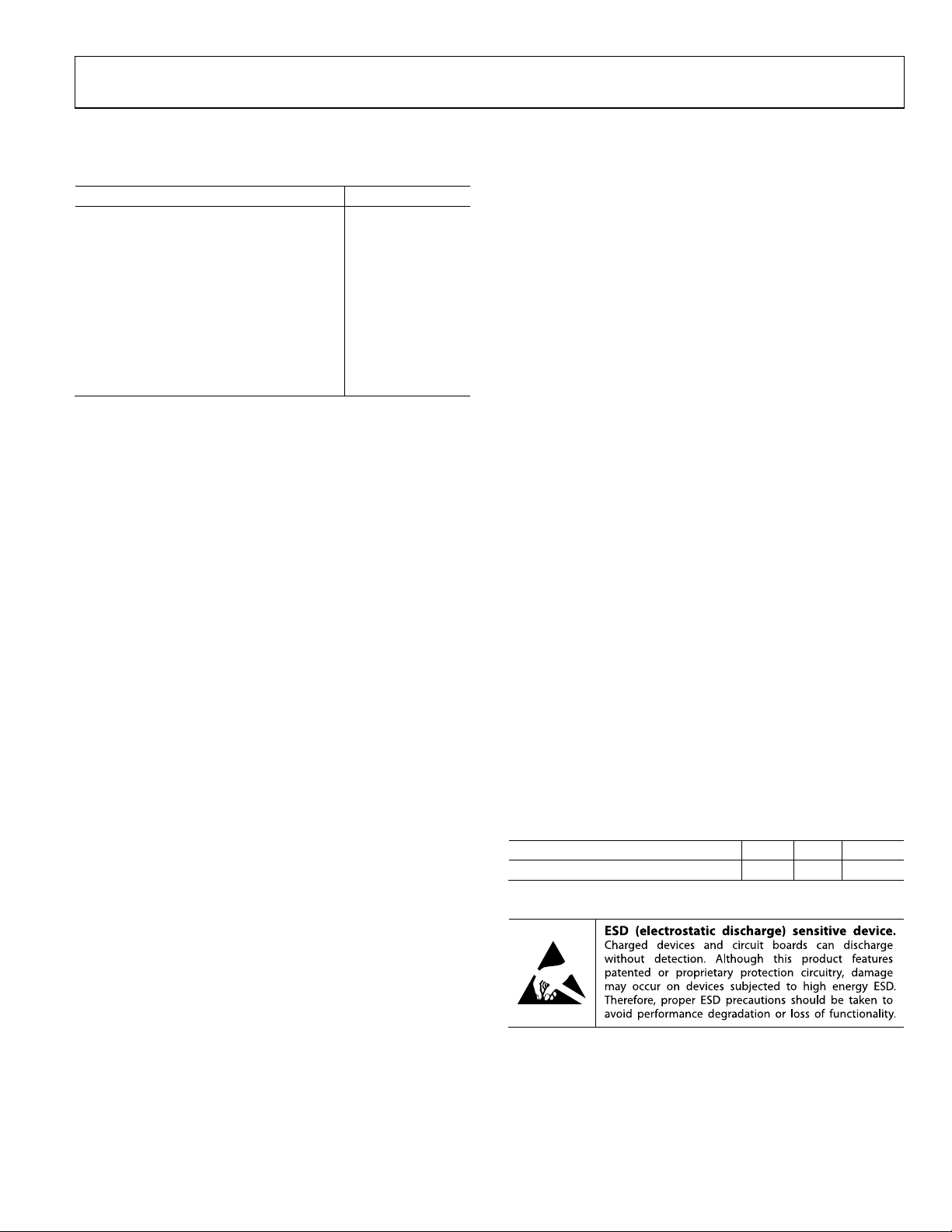

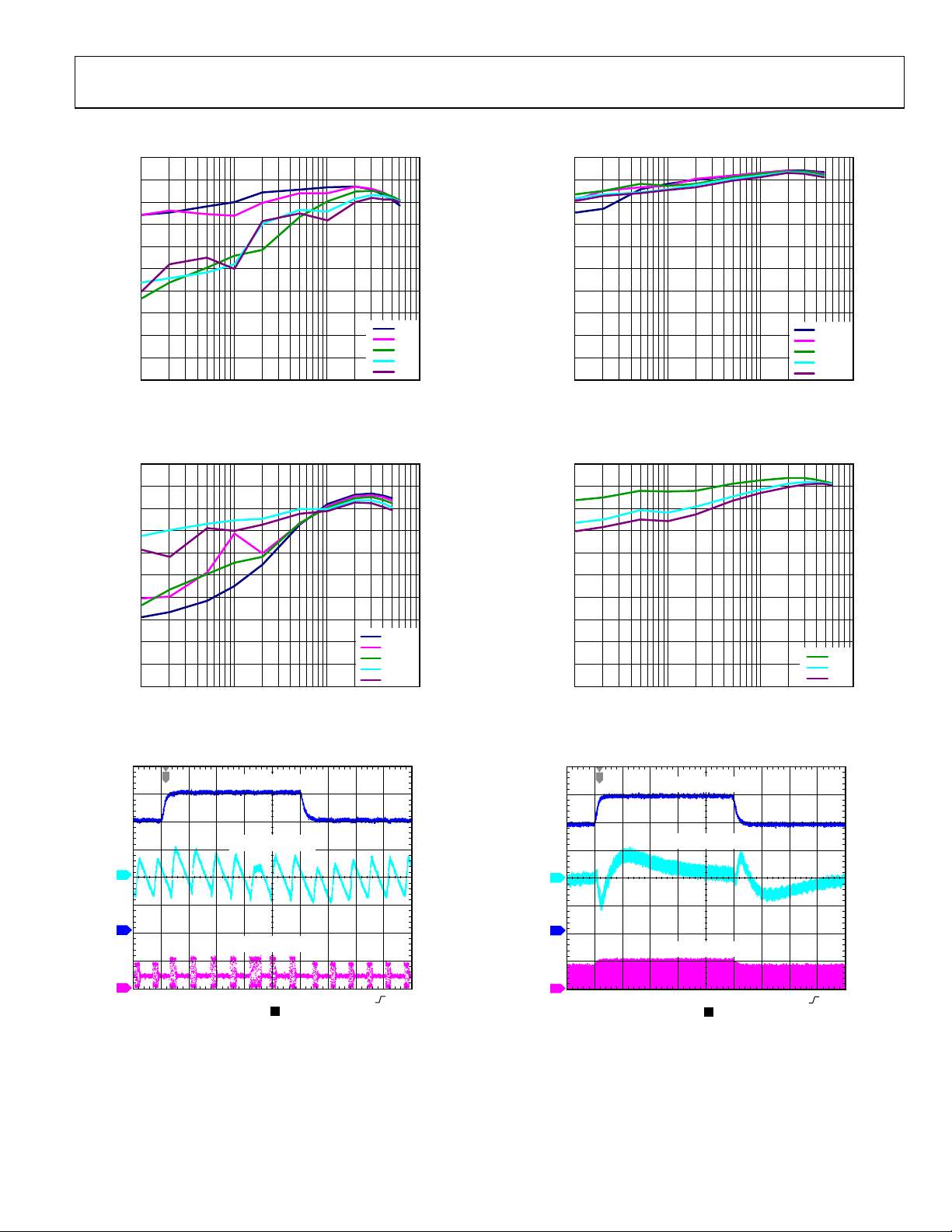

BUCK OUTPUT

V

= 4 V, V

IN1

= 1.8 V, I

OUT

30

= 10 mA, CIN = C

OUT

= 10 µF, TA = 25°C, unless otherwise noted.

OUT

1.82

25

20

15

10

QUIESCENT CURRENT (µA)

5

0

2.3 2.8 3.3 3.8 4.3 4.8 5.3

INPUT VOLTAGE ( V)

–40°C

–5°C

+25°C

+85°C

+125°C

07932-004

Figure 4. Quiescent Supply Current vs. Input Voltage, Different Temperatures

3.1

3.0

2.9

2.8

2.7

FREQUENCY (MHz )

+25°C

2.6

2.5

2.3 2.8 3.3 3.8 4.3 4.8 5.3

INPUT VOLTAGE ( V)

–40°C

–5°C

+85°C

+125°C

07932-005

Figure 5. Switching Frequency vs. Input Voltage, Different Temperatures

3.10

3.05

3.00

2.95

2.90

2.85

2.80

FREQUENCY (MHz )

2.75

2.70

2.65

2.60

–60 –40 –20 0 20 40 60 80 100 120 140

TEMPERATURE ( °C)

5.5V

4.6V

3.1V

2.3V

07932-006

Figure 6. Switching Frequency vs. Temperature, Different Input Voltages

1.81

1.80

1.79

1.78

OUTPUT VOLTAGE (V)

1.77

1.76

–40 1258525–5

Figure 7. Output Voltage vs. Temperature, V

LOAD CURRENT = 1mA

LOAD CURRENT = 10mA

LOAD CURRENT = 50mA

LOAD CURRENT = 100mA

LOAD CURRENT = 300mA

LOAD CURRENT = 600mA

JUNCTION TEM PERATURE (°C)

= 2.3 V, Different Loads

IN1

1200

1150

1100

1050

1000

950

900

850

CURRENT LIMI T (mA)

800

750

700

–60 –40 –20 0 20 40 60 80 100 120 140

JUNCTION TEMPERATURE (° C)

2.3V

3.0V

4.0V

5.0V

5.5V

Figure 8. Current Limit vs. Temperature, Different Input Voltages

140

120

100

80

60

CURRENT (mA)

40

20

0

3.50 5.505.255.004.754.504.254.003.75

INPUT VOLTAGE (V)

–40°C

–5°C

+25°C

+85°C

+125°C

Figure 9. PSM to PWM Mode Transition vs. Input Voltage, Different

Temperatures

07932-007

07932-008

07932-009

Rev. 0 | Page 7 of 32

ADP2140

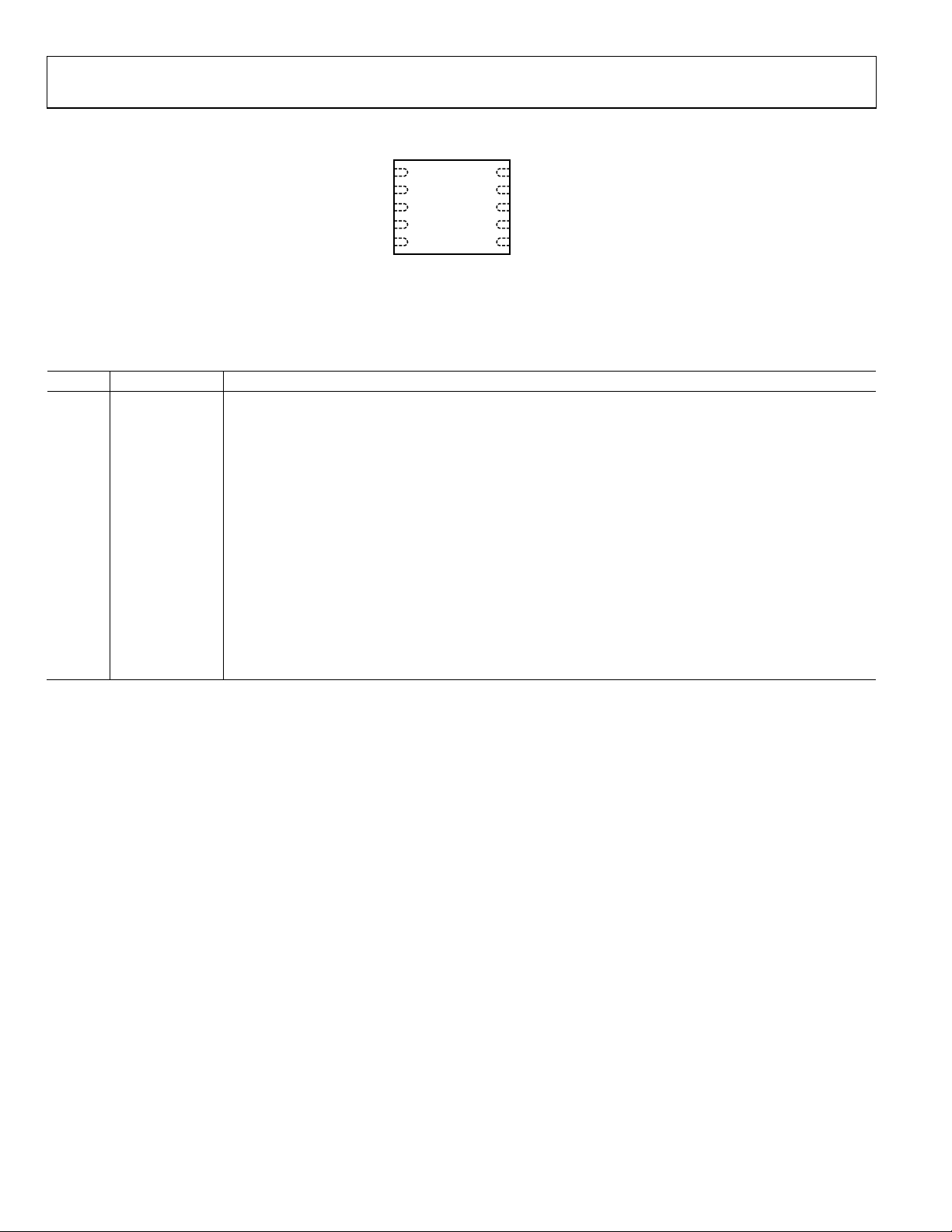

V

= 4 V, V

IN1

OUT

1.82

1.81

1.80

= 1.8 V, I

= 10 mA, CIN = C

OUT

= 10 µF, TA = 25°C, unless otherwise noted.

OUT

3.350

3.325

1.79

1.78

OUTPUT VOLTAGE (V)

1.77

1.76

2.3 5.55.14.74.33.93.53.12.7

Figure 10. Line Regulation, V

LOAD CURRENT = 1mA

LOAD CURRENT = 10mA

LOAD CURRENT = 50mA

LOAD CURRENT = 100mA

LOAD CURRENT = 300mA

LOAD CURRENT = 600mA

INPUT VOLTAG E ( V)

= 1.8 V, Different Loads

OUT

1.82

1.81

1.80

1.79

1.78

OUTPUT VOLTAGE (V)

1.77

1.76

1 10 100 1000

Figure 11. Load Regulation, V

LOAD CURRENT (mA)

= 1.8 V, V

OUT

IN1

1.22

1.21

1.20

1.19

OUTPUT VOLTAGE (V)

1.18

1.17

1 10 100 1000

Figure 12. Load Regulation, V

LOAD CURRENT (mA)

= 1.2 V, V

OUT

IN1

07932-010

07932-011

= 2.3 V

07932-012

= 2.3 V

3.300

OUTPUT VOLTAGE (V)

3.275

3.250

1 10 100 1000

LOAD CURRENT (mA)

Figure 13. Load Regulation, V

100

90

80

70

60

50

40

EFFICIENCY (%)

30

20

10

0

1 10 100 1000

LOAD CURRENT (mA)

Figure 14. Efficiency vs. Load Current, V

100

90

80

70

60

50

40

EFFICIENCY (%)

30

20

10

0

1 10 100 1000

LOAD CURRENT (mA)

Figure 15. Efficiency vs. Load Current, V

= 3.3 V

OUT

2.5V

3.0V

4.0V

5.0V

5.5V

= 1.8 V, Different Input Voltages

OUT

–40°C

–5°C

+25°C

+85°C

+125°C

= 1.8 V, Different Temperatures

OUT

07932-013

07932-014

07932-015

Rev. 0 | Page 8 of 32

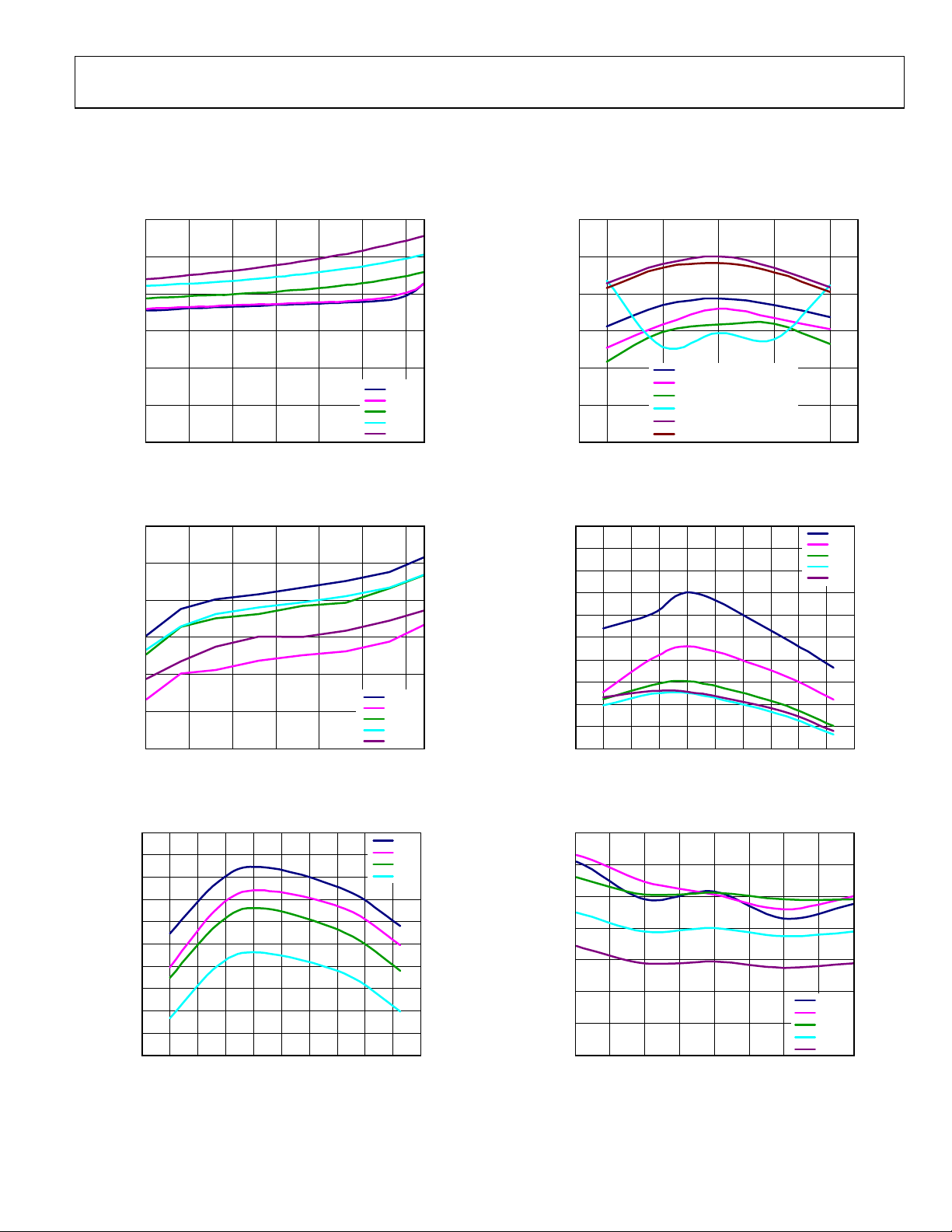

ADP2140

V

= 4 V, V

IN1

100

90

80

70

60

50

40

EFFICIENCY (%)

30

20

10

Figure 16. Efficiency vs. Load Current, V

100

90

80

70

60

50

40

EFFICIENCY (%)

30

20

10

Figure 17. Efficiency vs. Load Current, V

= 1.8 V, I

OUT

0

1 10 100 1000

= 10 mA, CIN = C

OUT

LOAD CURRENT (mA)

= 1.2 V, Different Input Voltages

OUT

= 10 μF, TA = 25°C, unless otherwise noted.

OUT

2.5V

3.0V

4.0V

5.0V

5.5V

–40°C

–5°C

+25°C

+85°C

0

1 10 100 1000

LOAD CURRENT (mA)

= 1.2 V, Different Temperatures

OUT

+125°C

100

90

80

70

60

50

40

EFFICIENCY (%)

30

20

10

0

1 10 100 1000

07932-016

Figure 19. Efficiency vs. Load Current, V

LOAD CURRENT (mA)

= 3.3 V, Different Temperatures

OUT

–40°C

–5°C

+25°C

+85°C

+125°C

07932-019

100

90

80

70

60

50

40

EFFICIENCY (%)

30

20

10

0

1 10 100 1000

07932-017

Figure 20. Efficiency vs. Load Current, V

LOAD CURRENT (mA)

= 3.3 V, Different Input Voltages

OUT

4.0V

5.0V

5.5V

07932-018

T

2

1

3

CH1 1.00V CH2 50.0mV M20.0µs A CH1 4.68V

Figure 18. Line Transient, V

INPUT VOLTAGE

OUTPUT VOLTAGE

SWITCH NO DE

T 11.60%CH3 5.00V

= 1.8 V, Power Save Mode, 50 mA,

OUT

= 4 V to 5 V, 4 μs Rise Time

V

IN1

07932-020

Rev. 0 | Page 9 of 32

T

2

1

3

CH1 1.00V CH2 20.0mV M20. 0µ s A CH1 4.68V

Figure 21. Line Transient, V

INPUT VOLTAGE

OUTPUT VOLTAGE

SWITCH NO DE

T 11.60%CH3 5.00V

= 1.8 V, PWM Mode, 600 mA, V

OUT

4 μs Rise Time

= 4 V to 5 V,

IN1

07932-021

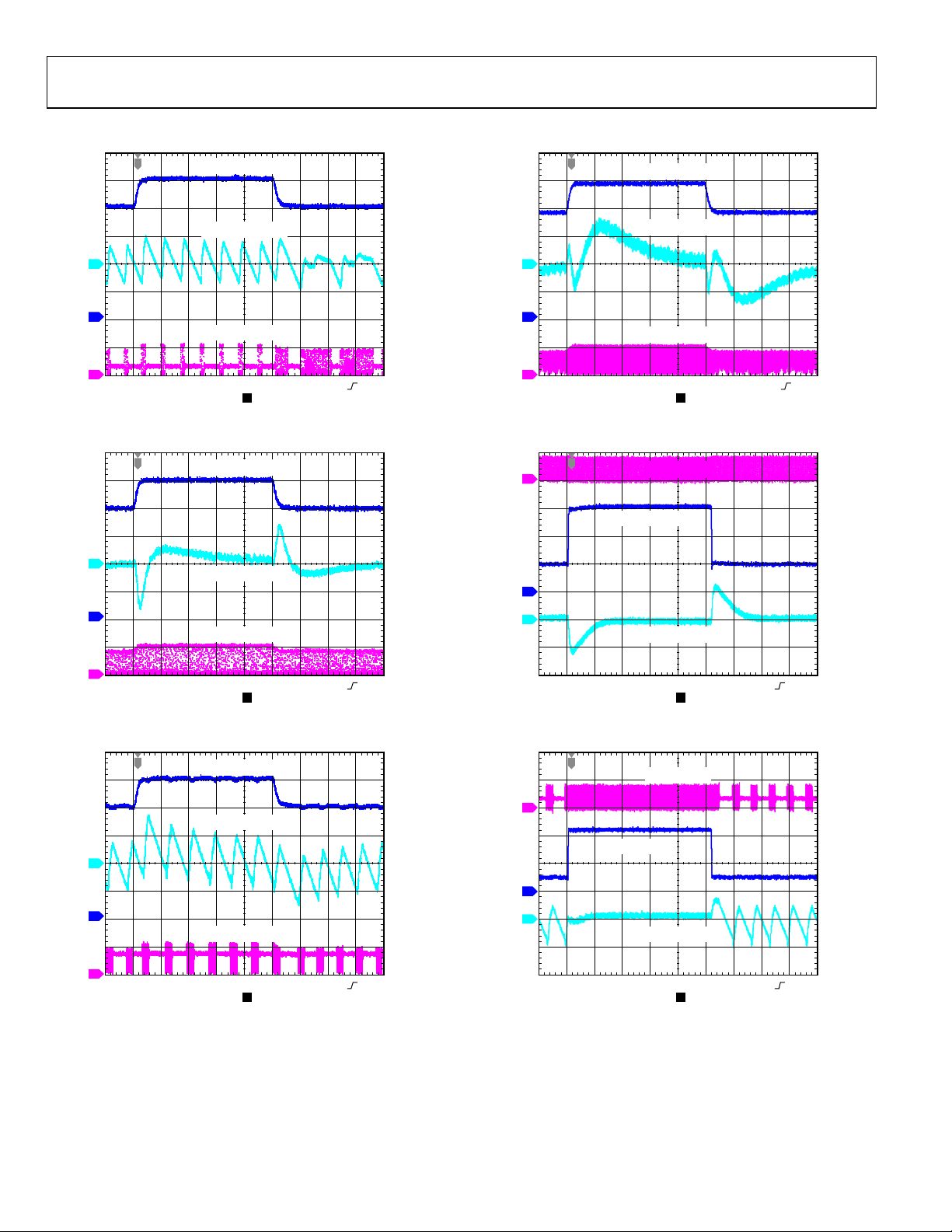

ADP2140

V

= 4 V, V

IN1

OUT

= 1.8 V, I

= 10 mA, CIN = C

OUT

= 10 µF, TA = 25°C, unless otherwise noted.

OUT

T

2

1

3

CH1 1.00V CH2 50.0mV M20.0µs A CH1 4.68V

Figure 22. Line Transient, V

INPUT VOLTAGE

OUTPUT VOLTAGE

SWITCH NO DE

T 11.60%CH3 5.00V

= 1.2 V, PSM Mode, 50 mA, V

OUT

4 s Rise Time

T

2

1

INPUT VOLTAGE

OUTPUT VOLTAGE

SWITCH NO DE

= 4 V to 5 V,

IN1

T

2

1

3

CH1 1.00V CH2 20.0mV M20. 0µ s A CH1 4.68V

07932-022

Figure 25. Line Transient, V

INPUT VOLTAGE

OUTPUT VOLTAGE

SWITCH NO DE

T 11.60%CH3 5.00V

= 3.3 V, PWM Mode, 600 mA, V

OUT

07932-025

= 4 V to 5 V,

IN1

4 s Rise Time

T

3

1

2

SWITCH NO DE

LOAD CURRENT

OUTPUT VOLTAGE

3

CH1 1.00V CH2 20.0mV M20. 0µ s A CH1 4.32V

Figure 23. Line Transient, V

T

2

1

3

CH1 1.00V CH2 50.0mV M20. 0µ s A CH1 4.68V

Figure 24. Line Transient, V

T 10.80%CH3 5.00V

= 1.2 V, PWM Mode, 600 mA, V

OUT

4 s Rise Time

INPUT VOLTAGE

OUTPUT VOLTAGE

SWITCH NO DE

T 11.60%CH3 5.00V

= 3.3 V, PSM Mode, 50 mA, V

OUT

4 s Rise Time

= 4 V to 5 V,

IN1

= 4 V to 5 V,

IN1

CH1 200mA CH2 50.0mV M20.0µs A CH1 288mA

07932-023

Figure 26. Load Transient, V

OUT

T 10.40%CH3 5.00V

07932-026

= 1.8 V, 200 mA to 600 mA, Load Current Rise

Time = 200 ns

T

3

1

2

CH1 100mA CH2 50.0mV M20.0µs A CH1 136mA

07932-024

Figure 27. Load Transient, V

SWITCH NO DE

LOAD OUTPUT

OUTPUT VOLTAGE

T 10.40%CH3 5.00V

= 1.8 V, 50 mA to 250 mA, Load Current Rise

OUT

07932-027

Time = 200 ns

Rev. 0 | Page 10 of 32

ADP2140

V

= 4 V, V

IN1

= 1.8 V, I

OUT

= 10 mA, CIN = C

OUT

= 10 µF, TA = 25°C, unless otherwise noted.

OUT

T

3

LOAD CURRENT

1

2

CH1 50.0mA CH2 50.0mV M20.0µs A CH1 51.0mA

Figure 28. Load Transient, V

SWITCH NO DE

OUTPUT VOLTAGE

T 10.40%CH3 5.00V

= 1.8 V,10 mA to 110 mA, Load Current Rise

OUT

Time = 200 ns

T

3

LOAD CURRENT

1

SWITCH NO DE

T

3

LOAD CURRENT

1

2

CH1 50.0mA CH2 100.0mV M20.0µs A CH1 50. 0 mA

07932-028

Figure 31. Load Transient, V

SWITCH NO DE

OUTPUT VO LTAGE

T 10.40%CH3 5.00V

= 3.3 V,10 mA to 110 mA, Load Current Rise

OUT

07932-031

Time = 200 ns

T

SWITCH NO DE

3

1

LOAD CURRENT

2

CH1 200mA CH2 100.0mV M20.0µs A CH1 292mA

Figure 29. Load Transient, V

T

3

LOAD CURRENT

1

2

CH1 100mA CH2 100.0mV M20.0µs A CH1 80.0mA

Figure 30. Load Transient, V

OUTPUT VOLTAGE

T 10.40%CH3 5.00V

= 3.3 V, 200 mA to 600 mA, Load Current Rise

OUT

Time = 200 ns

SWITCH NO DE

OUTPUT VOLTAGE

T 10.40%CH3 5.00V

= 3.3 V, 50 mA to 250 mA, Load Current Rise

OUT

Time = 200 ns

2

CH1 200.0mA CH2 50.0mV M20.0µ s A CH1 376mA

07932-029

Figure 32. Load Transient, V

OUTPUT VO LTAGE

T 10.40%CH3 5.00V

= 1.2 V, 200 mA to 600 mA, Load Current Rise

OUT

07932-032

Time = 200 ns

T

3

LOAD CURRENT

1

2

CH1 100.0mA CH2 50.0mV M20.0µ s A CH1 154mA

07932-030

Figure 33. Load Transient, V

SWITCH NO DE

OUTPUT VO LTAGE

T 10.40%CH3 5.00V

= 1.2 V, 50 mA to 250 mA, Load Current Rise

OUT

07932-033

Time = 200 ns

Rev. 0 | Page 11 of 32

ADP2140

V

= 4 V, V

IN1

OUT

= 1.8 V, I

= 10 mA, CIN = C

OUT

= 10 µF, TA = 25°C, unless otherwise noted.

OUT

T

3

LOAD CURRENT

1

2

CH1 50.0mA CH2 50.0mV M20.0µs A CH1 48.0mA

Figure 34. Load Transient, V

SWITCH NO DE

OUTPUT VOLTAGE

T 10.40%CH3 5.00V

= 1.2 V,10 mA to 110 mA, Load Current Rise

OUT

Time = 200 ns

T

3

1

SWITCH NO DE

INDUCTOR CURRENT

OUTPUT VOLTAGE

T

3

1

2

4

CH1 500mA CH2 2.00V

07932-034

CH4 5.00V

M40.0µs A CH4 2.70V

T 10.40%CH3 5.00V

Figure 37. Startup, V

T

3

1

SWITCH NO DE

INDUCTOR CURRENT

OUTPUT VO LTAGE

ENABLE 1

= 3.3 V, 10 mA

OUT

SWITCH NO DE

INDUCTOR CURRENT

OUTPUT VO LTAGE

07932-037

2

4

CH1 500mA CH2 1.00V

CH4 5.00V

Figure 35. Startup, V

ENABLE 1

M100µs A CH4 2.70V

T 10.40%CH3 5.00V

= 1.8 V, 10 mA

OUT

2

4

07932-035

CH1 500mA CH2 2.00V

CH4 5.00V

Figure 38. Startup, V

M40.0µs A CH4 2.70V

T 10.40%CH3 5.00V

OUT

ENABLE 1

07932-100

= 3.3 V, 600 mA

T

3

1

2

4

CH1 500mA CH2 1.00V

CH4 5.00V

Figure 36. Startup, V

SWITCH NO DE

INDUCTOR CURRENT

ENABLE 1

M40.0µs A CH4 2.70V

T 10.40%CH3 5.00V

= 1.8 V, 600 mA

OUT

OUTPUT VO LTAGE

07932-036

T

3

1

2

4

CH1 200mA CH2 1.00V

CH4 5.00V

Figure 39. Startup, V

SWITCH NO DE

INDUCTOR CURRENT

OUTPUT VO LTAGE

ENABLE 1

M100µs A CH4 2.30V

T 10.40%CH3 5.00V

= 1.2 V, 10 mA

OUT

07932-039

Rev. 0 | Page 12 of 32

ADP2140

V

= 4 V, V

IN1

= 1.8 V, I

OUT

= 10 mA, CIN = C

OUT

= 10 µF, TA = 25°C, unless otherwise noted.

OUT

T

3

1

2

4

CH1 500mA CH2 1.00V

CH4 5.00V

Figure 40. Startup, V

SWIT C H NODE

INDUCTOR CURRENT

OUTPUT VOLTAGE

ENABLE 1

M40.0µs A CH4 2.30V

T 10.00%CH3 5.00V

= 1.2 V, 600 mA

OUT

T

1

2

3

4

CH1 1.00V CH2 1.00V

07932-040

Figure 41. Startup, Autosequence Mode, V

CH4 5.00V

BUCK OUTPUT

LDO OUTPUT

PG SIGNAL

ENABLE 1

M2.00ms A CH4 2.30V

T 10.00%CH3 5.00V

= 1.8 V, V

OUT

OUT2

07932-041

= 1.2 V

Rev. 0 | Page 13 of 32

ADP2140

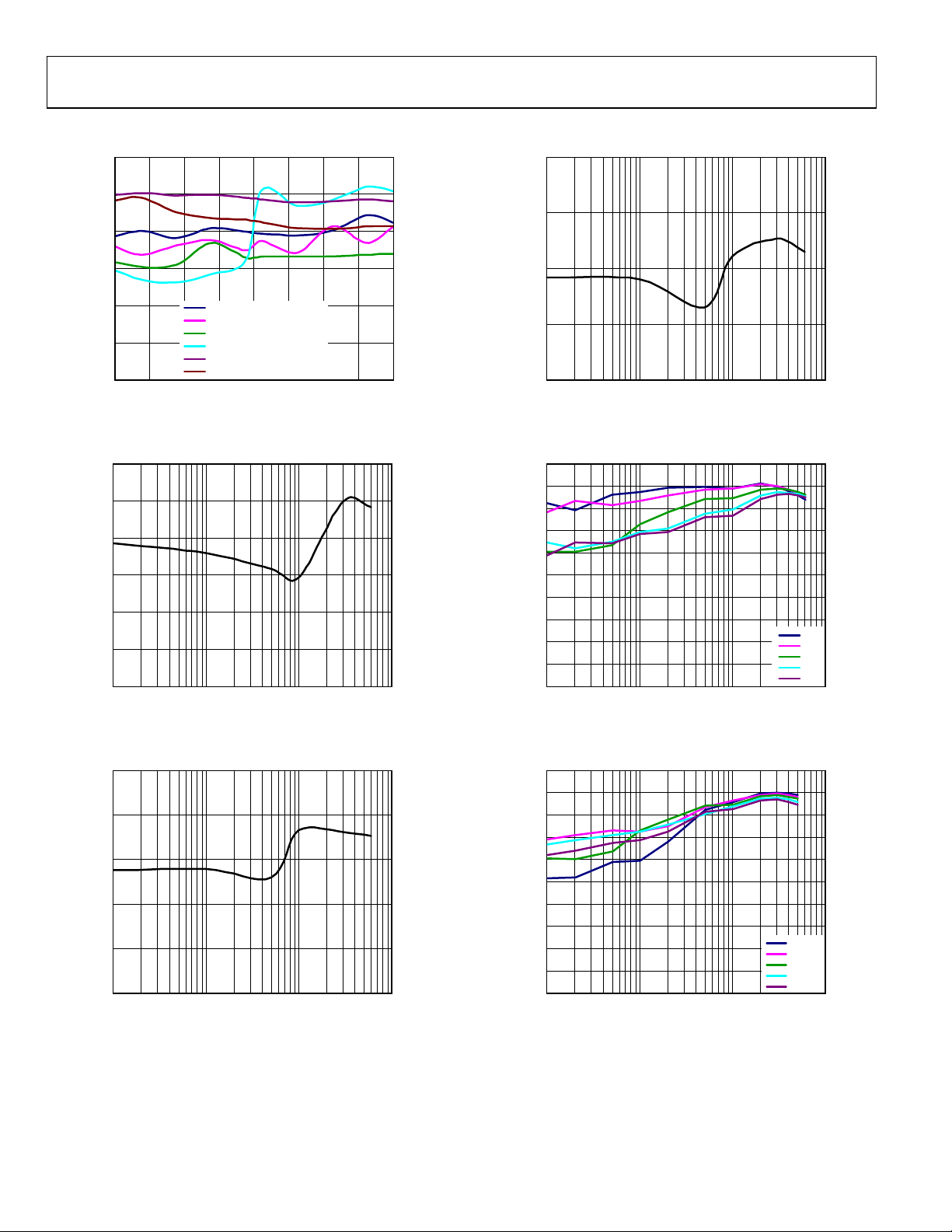

LDO OUTPUT

V

= 5 V, V

IN1

1.83

1.82

1.81

1.80

1.79

OUTPUT VOLTAGE (V)

1.78

1.77

Figure 42. Output Voltage vs. Junction Temperature, Different Loads

1.820

= 2.3 V, V

IN2

–40 1258525–5

= 1.8 V, I

OUT2

LOAD CURRENT = 1mA

LOAD CURRENT = 5mA

LOAD CURRENT = 10mA

LOAD CURRENT = 50mA

LOAD CURRENT = 100mA

LOAD CURRENT = 300mA

JUNCTION TEMPERATURE (°C)

= 10 mA, C

OUT2

IN2

= C

= 1 µF, TA = 25°C, unless otherwise noted.

OUT2

180

160

140

120

100

GROUND CURRENT (µA)

07932-242

LOAD CURRENT = 1mA

LOAD CURRENT = 5mA

LOAD CURRENT = 10mA

80

60

40

20

0

–40 1258525–5

JUNCTION TEM PERATURE (°C)

Figure 45. Ground Current vs. Junction Temperature, Different Loads

160

LOAD CURRENT = 50mA

LOAD CURRENT = 100mA

LOAD CURRENT = 300mA

07932-245

1.815

1.810

1.805

1.800

1.795

OUTPUT VOLTAGE (V)

1.790

1.785

1.780

1 10 100 1000

LOAD CURRENT (mA)

Figure 43. Output Voltage vs. Load Current

1.820

1.815

1.810

1.805

1.800

1.795

OUTPUT VOLTAGE (V)

1.790

1.785

1.780

2.2 2.6 3.0 3.4 3.8 4.2 4.6 5.0 5.4

LOAD CURRENT = 1mA

LOAD CURRENT = 5mA

LOAD CURRENT = 10mA

LOAD CURRENT = 50mA

LOAD CURRENT = 100mA

LOAD CURRENT = 300mA

INPUT VOLTAGE ( V)

Figure 44. Output Voltage vs. Input Voltage, Different Loads

140

120

100

80

60

GROUND CURRENT (µA)

40

20

0

1 10 100 1000

07932-243

LOAD CURRENT (mA)

07932-246

Figure 46. Ground Current vs. Load Current

160

140

120

100

80

60

GROUND CURRENT (µA)

40

20

0

2.2 2.6 3.0 3.4 3.8 4.2 4.6 5.0 5.4

07932-244

LOAD CURRENT = 1mA

LOAD CURRENT = 5mA

LOAD CURRENT = 10mA

LOAD CURRENT = 50mA

LOAD CURRENT = 100mA

LOAD CURRENT = 300mA

INPUT VOLTAGE ( V)

07932-247

Figure 47. Ground Current vs. Input Voltage, Different Loads

Rev. 0 | Page 14 of 32

ADP2140

V

= 5 V, V

IN1

SHUTDOWN CURRENT ( µA)

Figure 48. Shutdown Current vs. Temperature at Various Input Voltages

150

125

100

DROPOUT VOLTAGE (mV)

1.85

1.80

1.75

1.70

1.65

1.60

OUTPUT VOLTAGE (V)

1.55

1.50

1.45

= 2.3 V, V

IN2

1.0

2.2V

2.6V

0.9

3.4V

3.8V

0.8

4.6V

5.5V

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0

–50 –25 0 25 50 75 100 125

= 1.8 V, I

OUT2

TEMPERATURE (°C)

= 10 mA, C

OUT2

75

50

25

0

1 10 100 1000

LOAD CURRENT (mA)

Figure 49. Dropout Voltage vs. Load Current

V

= 1mA

DROP

V

= 5mA

DROP

V

= 10mA

DROP

V

= 50mA

DROP

V

= 100mA

DROP

V

= 300mA

DROP

1.60 2.001.951.901.851.801.751.701.65

INPUT VOLTAGE (V)

Figure 50. Output Voltage vs. Input Voltage (in Dropout)

IN2

= C

= 1 μF, TA = 25°C, unless otherwise noted.

OUT2

200

180

160

140

120

100

80

60

I

= 1mA

GROUND CURRENT (µA)

07932-048

GND

I

= 5mA

GND

40

I

= 10mA

GND

I

= 50mA

GND

20

I

= 100mA

GND

I

= 300mA

GND

0

1.6 1.7 1.8 1.9 2.0

Figure 51. Ground Current vs. Input Voltage (in Dropout)

0

300mA

–10

–20

–30

–40

–50

PSRR (dB)

–60

–70

–80

–90

–100

07932-249

100mA

10mA

1mA

10 100 1k 10k 100k 1M 10M

Figure 52. Power Supply Rejection Ratio vs. Frequency V

0

300mA

–10

–20

–30

–40

–50

PSRR (dB)

–60

–70

–80

–90

–100

07932-250

200mA

100mA

10mA

1mA

10 100 1k 10k 100k 1M 10M

Figure 53. Power Supply Rejection Ratio vs. Frequency V

INPUT VOLTAGE (V)

FREQUENCY (Hz)

= 2.2 V

V

IN2

FREQUENCY (Hz)

= 1.7 V

V

IN2

OUT2

OUT2

= 1.2 V, V

= 1.2 V, V

IN1

IN1

07932-251

07932-252

= 5 V,

07932-253

= 5 V,

Rev. 0 | Page 15 of 32

ADP2140

V

= 5 V, V

IN1

–10

–20

–30

–40

–50

PSRR (dB)

–60

–70

–80

–90

–100

Figure 54. Power Supply Rejection Ratio vs. Frequency, V

–10

–20

–30

–40

–50

PSRR (dB)

–60

–70

–80

–90

–100

Figure 55. Power Supply Rejection Ratio vs. Frequency, V

(µV/ Hz)

0.1

0.01

Figure 56. Output Noise Spectrum, V

= 2.3 V, V

IN2

0

300mA

100mA

10mA

1mA

10 100 1k 10k 100k 1M 10M

0

300mA

100mA

10mA

1mA

10 100 1k 10k 100k 1M 10M

10

1

10 100 1k 10k 100k

= 1.8 V, I

OUT2

FREQUENCY (Hz)

= 5 V, V

V

IN1

FREQUENCY (Hz)

= 5 V, V

V

IN1

FREQUENCY (Hz)

OUT2

= 4.3 V

IN2

= 2.8 V

IN2

= 5 V, Load Current = 10 mA

IN2

= 10 mA, C

OUT2

OUT2

= C

IN2

= 3.3 V,

= 1.8 V,

1.2V

1.8V

2.5V

3.3V

= 1 µF, TA = 25°C, unless otherwise noted.

OUT2

0

300mA

–10

–20

–30

–40

–50

PSRR (dB)

–60

–70

–80

–90

–100

07932-254

200mA

100mA

10mA

1mA

10 100 1k 10k 100k 1M 10M

Figure 57. Power Supply Rejection Ratio vs. Frequency, V

V

0

300mA

–10

–20

–30

–40

–50

PSRR (dB)

–60

–70

–80

–90

–100

07932-255

200mA

100mA

10mA

1mA

10 100 1k 10k 100k 1M 10M

Figure 58. Power Supply Rejection Ratio vs. Frequency V

V

100

NOISE (µV rms)

07932-055

1.2V

1.8V

90

2.5V

3.3V

80

70

60

50

40

30

20

10

0

100n 1µ 10µ 100µ 1m 10m 1100m

Figure 59. Output Noise vs. Load Current and Output Voltage

FREQUENCY (Hz)

= 5 V, V

IN1

= 5 V, V

IN1

LOAD CURRENT (A)

= 3.8 V

IN2

FREQUENCY (Hz)

= 2.3 V

IN2

V

= 5 V

IN2

OUT2

OUT2

07932-256

= 3.3 V,

07932-257

= 1.8 V,

07932-261

Rev. 0 | Page 16 of 32

ADP2140

V

= 5 V, V

IN1

= 2.3 V, V

IN2

OUT2

= 1.8 V, I

= 10 mA, C

OUT2

IN2

= C

= 1 µF, TA = 25°C, unless otherwise noted.

OUT2

T

1

2

CH1 100mA CH2 100mV M 40.0µs A CH1 68mA

Figure 60. Load Transient Response, V

LOAD CURRENT

V

OUT2

T 10.40%

= 4 V, V

IN2

OUT2

1 mA to 300 mA, Load Current Rise Time = 200 ns

T

1

2

LOAD CURRENT

V

OUT2

= 1.2 V,

T

2

1

CH1 1.00V CH2 5.00mV M2.00µs A CH4 12mV

07932-259

Figure 63. Line Transient Response, V

= 4 V to 5 V, 1 s Rise Time

V

IN2

T

2

1

V

IN2

V

OUT2

T 10.20%

= 1.8 V, Load Current = 1 mA,

OUT2

V

IN2

V

OUT2

07932-263

CH1 100mA CH2 100mV M 40.0µs A CH1 68mA

Figure 61. Load Transient Response, V

1 mA to 300 mA, Load Current Rise Time = 200 ns

T

1

2

CH1 100mA CH2 100mV M 40.0µs A CH1 68mA

Figure 62. Load Transient Response, V

1 mA to 300 mA, Load Current Rise Time = 200 ns

T 10.40%

LOAD CURRENT

V

OUT2

T 10.40%

= 4 V, V

IN2

= 4 V, V

IN2

OUT2

OUT2

= 1.8 V,

= 3.3 V,

CH1 1.00V CH2 5.00mV M2.00µs A CH4 12mV

07932-260

Figure 64. Line Transient Response, V

= 4 V to 5 V, 1 s Rise Time

V

IN2

T

2

1

CH1 1.00V CH2 5.00mV M2.00µs A CH4 12mV

07932-262

Figure 65. Line Transient Response, V

V

= 4 V to 5 V, 1 s Rise Time

IN2

T 10.20%

= 1.2 V, Load Current = 1 mA,

OUT2

V

IN2

V

OUT2

T 10.20%

= 3.3 V, Load Current = 1 mA,

OUT2

07932-264

07932-265

Rev. 0 | Page 17 of 32

ADP2140

V

= 5 V, V

IN1

IN2

= 2.3 V, V

OUT2

= 1.8 V, I

= 10 mA, C

OUT2

IN2

= C

= 1 µF, TA = 25°C, unless otherwise noted.

OUT2

T

2

1

CH1 1.00V CH2 5.00mV M2.00µs A CH4 12mV

Figure 66. Line Transient Response, V

= 4 V to 5 V, 1 s Rise Time

V

IN2

T

2

V

IN2

V

OUT2

T 10.20%

= 1.8 V, Load Current = 300 mA,

OUT2

V

IN2

V

OUT2

T

2

1

CH1 1.00V CH2 5.00mV M2.00µs A CH4 12mV

07932-266

Figure 68. Line Transient Response, V

V

IN2

V

IN2

V

OUT2

T 10.20%

= 3.3 V, Load Current = 300 mA,

OUT2

= 4 V to 5 V, 1 s Rise Time

07932-268

1

CH1 1.00V CH2 5.00mV M2.00µs A CH4 12mV

Figure 67. Line Transient Response, V

= 4 V to 5 V, 1 s Rise Time

V

IN2

T 10.20%

= 1.2 V, Load Current = 300 mA,

OUT2

07932-267

Rev. 0 | Page 18 of 32

ADP2140

A

THEORY OF OPERATION

FB

VIN2

GND

EN1

EN2

R1

R2

REFERENCE

0.5V

ENABLE/

SEQUENCING

SOFT

START

OSCILLATOR

SHUTDOWN

UVLO

Gm ERROR

AMP

3MHz

THERMAL

Figure 69. Internal Block Diagram

BUCK SECTION

The ADP2140 contains a step-down dc-to-dc converter that

uses a fixed frequency, high speed current-mode architecture. The

high 3 MHz switching frequency and tiny 10-lead, 3 mm × 3 mm

LFCSP package allow for a small step-down dc-to-dc converter

solution.

The ADP2140 operates with an input voltage from 2.3 V to 5.5 V.

Output voltage options are 1.0 V, 1.1 V, 1.2 V, 1.5 V, 1.8 V, 1.875 V,

2.5 V, and 3.3 V.

CONTROL SCHEME

The ADP2140 operates with a fixed frequency, current-mode

PWM control architecture at medium to high loads for high

efficiency, but shifts to a variable frequency control scheme at

light loads for lower quiescent current. When operating in fixed

frequency PWM mode, the duty cycle of the integrated switches

adjust to regulate the output voltage, but when operating in power

saving mode (PSM) at light loads, the switching frequency adjusts

to regulate the output voltage.

The ADP2140 operates in the PWM mode only when the load

current is greater than the pulse skipping threshold current. At

load currents below this value, the converter smoothly transitions

to the PSM mode of operation.

PWM OPERATION

In PWM mode, the ADP2140 operates at a fixed frequency of

3 MHz set by an internal oscillator. At the start of each oscillator

cycle, the P-channel MOSFET switch is turned on, putting a

PWM/

PSM

CONTROL

FB

VIN1

CURRENT

SENSE AMP

CURRENT

LIMIT

DRIVER

AND

ANTISHOOT

POWER

GOOD

THROUGH

ZERO-CROSS

COMPARATOR

SW

PGND

PG

EPAD

7932-068

positive voltage across the inductor. Current in the inductor

increases until the current sense signal crosses the peak inductor

current level that turns off the P-channel MOSFET switch and

turns on the N-channel MOSFET synchronous rectifier. This

puts a negative voltage across the inductor, causing the inductor

current to decrease. The synchronous rectifier stays on for the

remainder of the cycle, unless the inductor current reaches zero,

which causes the zero-crossing comparator to turn off the

N-channel MOSFET.

PSM OPERATION

The ADP2140 has a smooth transition to the variable frequency

PSM mode of operation when the load current decreases below

the pulse skipping threshold current, switching only as necessary to

maintain the output voltage within regulation. When the output

voltage dips below regulation, the ADP2140 enters PWM mode

for a few oscillator cycles to increase the output voltage back to

regulation. During the wait time between bursts, both power

switches are off, and the output capacitor supplies the entire

load current. Because the output voltage occasionally dips and

recovers, the output voltage ripple in this mode is larger than the

ripple in the PWM mode of operation.

PULSE SKIPPING THRESHOLD

The output current at which the ADP2140 transitions from

variable frequency PSM control to fixed frequency PWM control

is called the pulse skipping threshold. The pulse skipping threshold

has been optimized for excellent efficiency over all load currents.

Rev. 0 | Page 19 of 32

ADP2140

SELECTED FEATURES

SHORT-CIRCUIT PROTECTION

The ADP2140 includes frequency foldback to prevent output

current runaway on a hard short. When the voltage at the feedback pin falls below 50% of the nominal output voltage, indicating

the possibility of a hard short at the output, the switching frequency

is reduced to 1/2 of the internal oscillator frequency. The reduction in the switching frequency gives more time for the inductor

to discharge, preventing a runaway of output current.

UNDERVOLTAGE LOCKOUT

To protect against battery discharge, undervoltage lockout

circuitry is integrated on the ADP2140. If the input voltage

drops below the 2.15 V UVLO threshold, the ADP2140 shuts

down and both the power switch and synchronous rectifier turn

off. When the voltage rises again above the UVLO threshold,

the soft start period initiates and the part is enabled.

THERMAL PROTECTION

In the event that the ADP2140 junction temperatures rises above

150°C, the thermal shutdown circuit turns off the converter.

Extreme junction temperatures can be the result of high current

operation, poor circuit board design, and/or high ambient temperature. A 20°C hysteresis is included; thus, when thermal

shutdown occurs, the ADP2140 does not return to operation

until the on-chip temperature drops below 130°C. When

emerging from a thermal shutdown, soft start initiates.

SOFT START

The ADP2140 has an internal soft start function that ramps the

output voltage in a controlled manner upon startup, thereby

limiting the inrush current. This prevents possible input voltage

drops when a battery or a high impedance power source is connected to the input of the converter.

CURRENT LIMIT

The ADP2140 has protection circuitry to limit the direction and

amount of current to 1000 mA flowing through the power switch

and synchronous rectifier. The positive current limit on the power

switch limits the amount of current that can flow from the input

to the output, and the negative current limit on the synchronous

rectifier prevents the inductor current from reversing direction

and flowing out of the load.

The ADP2140 also provides a negative current limit to prevent

an excessive reverse inductor current when the switching section

sinks current from the load in forced continuous conduction

mode. Under negative current limit conditions, both the highside and low-side switches are disabled.

POWER-GOOD PIN

The ADP2140 has a dedicated pin (PG) to signal the state of the

monitored output voltages. The voltage monitor circuit has an

active high, open-drain output requiring an external pull-up

resistor typically supplied from the I/O supply rail, as shown

in Figure 1. The voltage monitor circuit has a small amount

of hysteresis and is deglitched to ensure that noise or external

perturbations do not trigger the PG line.

LDO SECTION

The ADP2140 low dropout linear regulator uses an advanced

proprietary architecture to achieve low quiescent current, and

high efficiency regulation. It also provides high power supply

rejection ratio (PSRR), low output noise, and excellent line and

load transient response with just a small 1 F ceramic output capacitor. The wide input voltage range of 1.65 V to 5.5 V allows it to

operate from either the input or output of the buck. Supply current

in shutdown mode is typically 0.3 µA.

Internally, the LDO consists of a reference, an error amplifier, a

feedback voltage divider, and a pass device. The output current

is delivered via the pass device, which is controlled by the error

amplifier, forming a negative feedback system ideally driving

the feedback voltage to be equal to the reference voltage. If the

feedback voltage is lower than the reference voltage, the negative

feedback drives more current, increasing the output voltage. If

the feedback voltage is higher than the reference voltage, the

negative feedback drives less current, decreasing the output

voltage. The positive supply for all circuitry, except the pass

device, is the VIN1 pin.

The LDO has an internal soft start that limits the output voltage

ramp period to approximately 130 µs.

The LDO is available in 0.8 V, 1.0 V, 1.1 V, 1.2 V, 1.3 V, 1.5 V, 2.5 V,

2.8 V, 3.0 V, and 3.3 V output voltage options.

Rev. 0 | Page 20 of 32

ADP2140

V

APPLICATIONS INFORMATION

POWER SEQUENCING

The ADP2140 has a flexible power sequencing system

supporting two distinct activation modes:

• Individual activation control is where EN1 controls only

the buck regulator and EN2 controls only the LDO. A high

level on Pin EN1 turns on the buck and a high level on

Pin EN2 turns on the LDO. A logic low level turns off the

respective regulator.

• Autosequencing is where the two regulators turn on in a

specified order and delay after a low-to-high transition on

the EN1 pin.

Select the activation mode (individual or autosequence) by

decoding the state of Pin EN2. The individual activation mode

is selected when the EN2 pin is driven externally or hardwired

to a voltage level (VIN1 or PGND). The autosequencing mode

is selected when the EN2 pin remains unconnected (floating).

To minimize quiescent current consumption, the mode selection

executes one time only during the rising edge of VIN1. The

detection circuit then activates for the time needed to assess the

EN2 state, after which time the circuit is disabled until VIN1 falls

below 0.5 V.

When EN2 is unconnected, the internal control circuit provides

a termination resistance to ground. The 100 k termination

resistance is low enough to guarantee insensitivity to noise and

transients. The termination resistor is disabled in the event that

the EN2 pin is driven externally to a logic level high (individual

activation mode assumed) to reduce the quiescent current consumption.

When the autosequencing mode is selected, the EN1 pin is used to

start the on/off sequence of the regulators. A logic high sequences

the regulators on whereas a logic low sequences the regulators

off. The regulator activation order is associated with the voltage

selected for the buck regulator and the LDO.

When the turn on or turn off autosequence starts, the start-up

delay between the first and the second regulator is fixed to 5 ms

in PWM mode (t

When the application requires activating and deactivating the

regulators at the same time, use the individual activation mode,

which connects the EN1 and EN2 pins together, as shown in

Figure 75.

, as shown in Figure 71 and Figure 72).

REG12

Table 6. Power Sequencing Modes

EN21 EN1 Description

0 0 Individual mode: both regulators are off.

0 1 Individual mode: buck regulator is on.

1 0 Individual mode: LDO regulator is on.

1 1 Individual mode: both regulators are on.

NC Rising edge

Autosequence: Buck regulator turns on,

then the LDO regulator turns on. The LDO

voltage is less than the buck voltage.

NC Rising edge

Autosequence: LDO regulator turns on,

then the buck regulator turns on. The LDO

voltage is greater than the buck voltage.

NC Rising edge

Autosequence: If the buck voltage is 1.875 V,

then the LDO regulator always turns on first.

NC Falling edge

Autosequence: The LDO and buck regulators turn off at the same time.

1

NC means not connected.

Figure 70 to Figure 75 use the following symbols, as described in

Tabl e 7.

Table 7. Timing Symbols

Typ ic al

Symbol Description

t

START

Time needed for the internal circuitry

Value

60 s

to activate the first regulator

tSS Regulator soft start time 330 s

t

RESET

Time delay from power-good

5 ms

condition to the release of PG

t

REG12

Delay time between buck and LDO

5 ms

activation

EN1

92% V

BUCK

V

BUCK

t

SS

EN2

92% V

V

PG

LDO

LDO

t

SS

t

RESET

Figure 70. Individual Activation Mode

85% V

LDO

TIME

7932-069

Rev. 0 | Page 21 of 32

ADP2140

V

V

EN2 = UNCONNECTED

EN1

92% V

BUCK

V

BUCK

t

START

t

t

REG12

SS

V

PG

LDO

Figure 71. Autosequencing Mode, Buck First Then LDO

EN2 = UNCONNECTED

EN1

V

LDO

t

START

t

t

REG12

SS

V

PG

BUCK

Figure 72. Autosequencing Mode, LDO First Then Buck

The PG responds to the last activated regulator. As described in

the Power Sequencing section, the regulator order in the autosequencing mode is defined by the voltage option combination.

Therefore, if the sequence is buck first, the LDO and the PG

signal are active low for t

output voltage, at which time PG goes high and remains high

for as long as V

LDO

When the sequencing is LDO first then buck, V

PG. This control scheme also applies when the individual

activation mode is selected.

As soon as either regulator output voltage drops below 86% of

the respective nominal level, the PG pin is forced low.

EN1

92% V

V

BUCK

EN2

V

LDO

PG

Figure 73. Individual Activation Mode, Both Regulators Sensed

BUCK

92% V

LDO

85% V

LDO

t

SS

t

RESET

92% V

LDO

92% V

RESET

t

SS

t

RESET

after V

BUCK

reaches 92% of the rated

LDO

85% V

BUCK

is above 86% of the rated output voltage.

controls

BUCK

95%

V

BUCK

85% V

V

85%

BUCK

LDO

t

RESET

92% V

LDO

85% V

BUCK

t

RESET

TIME

TIME

Rev. 0 | Page 22 of 32

EN1

92% V

V

EN2

V

PG

BUCK

LDO

t

RESET

BUCK

92% V

LDO

85% V

85% V

BUCK

LDO

07932-073

Figure 74. Individual Activation Mode, One Regulator Only (Buck) Sensed

07932-111

EN1

EN2

V

BUCK

V

LDO

PG

92% V

92% V

t

RESET

BUCK

LDO

85% V

85% V

BUCK

LDO

7932-075

Figure 75. Individual Activation Mode, No Activation/Deactivation Delay

Between Regulators, EN1 and EN2 Pins Tied Together

T

7932-112

1

2

3

CH1 500mV CH2 500mV M1.00ms A CH3 1.16V

BUCK OUTPUT

LDO OUTPUT

EN1

T 10.00%CH3 2.00V

07932-101

Figure 76. Autosequence Mode Turn On Behavior, Buck Voltage = 1.8 V,

LDO Voltage = 1.2 V, Buck Load = 500 mA, LDO Load = 100 mA

T

BUCK OUTPUT

1

2

7932-072

3

CH1 500mV CH2 500mV M40.0µs A CH3 1.16V

LDO OUTPUT

EN1

T 10.00%CH3 2.00V

07932-102

Figure 77. Autosequence Mode Turn On Behavior, Buck Voltage = 1.8 V,

LDO Voltage = 1.2 V, Buck Load = 500 mA, LDO Load = 100 mA

ADP2140

T

BUCK OUTPUT

T

LDO OUTPUT

1

2

3

CH1 500mV CH2 500mV M40.0µs A CH3 1.16V

LDO OUTPUT

EN1

T 10.00%CH3 2.00V

07932-103

Figure 78. Autosequence Mode Turn On Behavior, Buck Voltage = 1.8 V,

LDO Voltage = 1.2 V, Buck Load = 500 mA, LDO Load = 100 mA

BUCK OUTPUT

1

2

3

CH1 1.00V CH2 1.0 0V M100ms A CH3 3.04V

CH3 2.00V

LDO OUTPUT

EN1

07932-104

Figure 79. Autosequence Mode Turn On Behavior, Buck Voltage =1.8 V,

LDO Voltage = 1.2 V, Buck Load = 1 mA, LDO Load = 100 mA

2

1

3

CH1 500mV CH2 1.00V M 40.0µs A CH3 2.04V

BUCK OUTPUT

EN1

T 10.00%CH3 2.00V

07932-106

Figure 81. Autosequence Mode Turn On Behavior, Buck Voltage = 1.0 V,

LDO Voltage = 3.3 V, Buck Load = 500 mA, LDO Load = 100 mA

(Expanded Version of Figure 80)

T

LDO OUTPUT

2

1

3

CH1 500mV CH2 1.00V M 40.0µs A CH3 2.04V

BUCK OUTPUT

EN1

T 10.00%CH3 2.00V

07932-107

Figure 82. Autosequence Mode Turn Off Behavior, Buck Voltage = 1.0 V,

LDO Voltage = 3.3 V, Buck Load = 500 mA, LDO Load = 100 mA

T

2

1

3

CH1 500mV CH2 1.00V M 2 .00ms A CH3 2.04V

LDO OUTPUT

BUCK OUTPUT

EN1

T 10.00%CH3 2.00V

Figure 80. Autosequence Mode Turn On Behavior, Buck Voltage = 1.0 V,

LDO Voltage = 3.3 V, Buck Load = 500 mA, LDO Load = 100 mA

07932-105

Rev. 0 | Page 23 of 32

T

2

1

3

CH1 500mV CH2 1.00V M 2 .00ms A CH3 3.04V

LDO OUTPUT

BUCK OUTPUT

EN1

T 10.00%CH3 2.00V

07932-108

Figure 83. Autosequence Mode Turn On Behavior, Buck Voltage = 1.0 V,

LDO Voltage = 3.3 V, Buck Load = 1 mA, LDO Load = 100 mA

ADP2140

−

×

T

1

2

3

CH1 500mV CH2 500mV M40.0µs A CH3 1.16V

Figure 84. Individual Activation Mode, EN1 and EN2 Pins Tied Together

POWER-GOOD FUNCTION

The ADP2140 power-good (PG) pin indicates the state of the

monitored output voltages. The PG function is the logical AND

of the state of both outputs. The PG function is an active high,

open-drain output, requiring an external pull-up resistor typically

supplied from the I/O supply rail, as shown in Figure 1. When the

sensed output voltages are below 92% of their nominal value, the

PG pin is held low. When the sensed output voltages rise above

92% of the nominal levels, the PG line is pulled high after t

The PG pin remains high as long as the sensed output voltages

are above 86% of the nominal output voltage levels.

The typical PG delay when the buck is in PWM mode is 5 ms.

When the part is in PSM mode, the PG delay is load dependent

because the internal clock is disabled to reduce quiescent current

during the sleep stage. PG delay varies from hundreds of microseconds at 10 mA, up to seconds at current loads of less than 10 A.

T

1

2

3

4

CH1 2.00V CH2 2.00V

EXTERNAL COMPONENT SELECTION

The external component selection for the ADP2140 application

circuit that is shown in Tabl e 8 , Ta bl e 9, and Figure 86 is dependent

on input voltage, output voltage, and load current requirements.

Additionally, trade-offs between performance parameters such

as efficiency and transient response can be made by varying the

choice of external components.

BUCK OUTPUT

LDO OUTPUT

EN1

T 10.00%CH3 2.00V

EN1

BUCK

LDO

PG

CH4 2.00V

Figure 85. Typical PG Timing

M2.00ms A CH1 2.20V

T 10.20%CH3 2.00V

07932-109

RESET

07932-285

.

SELECTING THE INDUCTOR

The high frequency switching of the ADP2140 allows the selection

of small chip inductors. The inductor value affects the transition between CFM to PSM, efficiency, output ripple, and current

limit values. Use the following equation to calculate the inductor

ripple current:

)(

VVV

IN

OUT

=

I

L

IN

OUT

LfV

××

sw

where:

f

is the switching frequency (3 MHz typical).

SW

L is the inductor value.

The dc resistance (DCR) value of the selected inductor affects

efficiency, but a decrease in this value typically means an increase

in root mean square (rms) losses in the core and skin. As a

minimum requirement, the dc current rating of the inductor

should be equal to the maximum load current plus half of the

inductor current ripple, as shown by the following equation:

I

II +=

PK

)(LMAXLOAD

)

(

2

OUTPUT CAPACITOR

Output capacitance is required to minimize the voltage overshoot and ripple present on the output. Capacitors with low

equivalent series resistance (ESR) values produce the lowest

output ripple; therefore, use capacitors such as the X5R dielectric.

Do not use the Y5V and Z5U capacitors; they are not suitable

for this application because of their large variation in capacitance

over temperature and dc bias voltage. Because ESR is important,

select the capacitor using the following equation:

V

ESR≤

COUT

RIPPLE

I

L

where:

ESR

V

is the ESR of the chosen capacitor.

COUT

is the peak-to-peak output voltage ripple.

RIPPLE

Use the following equations to determine the output

capacitance:

V

SW

IN

×××

2)2(

SW

I

L

Vf

8

××

OUT

VLfπ

RIPPLE

C

≥

OUT

C

≥

OUT

Increasing the output capacitor has no effect on stability and

increasing the output capacitance may further reduce output

ripple and enhance load transient response. When choosing this

value, it is also important to account for the loss of capacitance

due to output voltage dc bias.

INPUT CAPACITOR

Input capacitance is required to reduce input voltage ripple; therefore, place the input capacitor as close as possible to the VINx

pins. As with the output capacitor, a low ESR X7R- or X5R-type

Rev. 0 | Page 24 of 32

ADP2140

V

V

V

capacitor is recommended to help minimize the input voltage

ripple. Use the following equation to determine the minimum

input capacitance:

−

VVV

CIN

IN

≥

II

OUT

)(

MAXLOAD

V

IN

OUT

)(

EFFICIENCY

Efficiency is defined as the ratio of output power to input power.

The high efficiency of the ADP2140 has two distinct advantages.

First, only a small amount of power is lost in the dc-to-dc converter package, which in turn, reduces thermal constraints. In

addition, high efficiency delivers the maximum output power

for the given input power, thereby extending battery life in

portable applications.

Power Switch Conduction Losses

Power switch dc conduction losses are caused by the flow of

output current through the P-channel power switch and the

N-channel synchronous rectifier, which have internal resistances (

R

) associated with them. The amount of power

DS(ON)

loss can be approximated by

2

))1((

CONDSW

where

_

D

=

V

OUT

V

IN

NONDSPONDS

_)(_)(

The internal resistance of the power switches increases with

temperature but decreases with higher input voltage.

Inductor Losses

Inductor conduction losses are caused by the flow of current

through the inductor, which has an internal resistance (DCR)

associated with it. Larger size inductors have smaller DCR,

which can decrease inductor conduction losses. Inductor core

losses relate to the magnetic permeability of the core material.

Because the ADP2140 is a high switching frequency dc-to-dc

converter, shielded ferrite core material is recommended for its

low core losses and low EMI.

To estimate the total amount of power lost in the inductor, use

the following equation:

P

= DCR × I

L

2

+ Core Losses

OUT

IDRDRP ×−×+×=

OUT

Switching Losses

Switching losses are associated with the current drawn by the

driver to turn on and turn off the power devices at the switching

frequency. Each time a power device gate is turned on and

turned off, the driver transfers a charge, Q, from the input

supply to the gate, and then from the gate to ground.

Estimate switching losses using the following equation:

P

SW

= (C

GATE_P

+ C

GATE_N

) × V

2

IN

× fSW

where:

C

is the gate capacitance of the internal high-side switch.

GATE_P

C

is the gate capacitance of the internal low-side switch.

GATE_N

f

is the switching frequency.

SW

Transition Losses

Transition losses occur because the P-channel switch cannot

turn on or turn off instantaneously. In the middle of an SW

node transition, the power switch provides all of the inductor

current. The source-to-drain voltage of the power switch is half

the input voltage, resulting in power loss. Transition losses

increase with both load current and input voltage and occur

twice for each switching cycle.

Use the following equation to estimate transition losses:

P

= VIN/2 × I

TRAN

× (tr + tf) × fSW

OUT

where:

tr is the rise time of the SW node.

is the fall time of the SW node.

t

f

RECOMMENDED BUCK EXTERNAL COMPONENTS

The recommended buck external components for use with the

ADP2140 are listed in Tabl e 8 (inductors) and Tab l e 9 (capacitors).

= 3.6

IN1

+

CIN

10µF

100kΩ

PG

EN1

EN2 FB

V

= 1.8V

OUT2

+

COUT2

1µF

Figure 86. Typical Application Circuit with LDO Connected to Input Voltage

10

VIN1 PGND

9

PG SW

8

EN1 AGND

7

EN2

6

VOUT2

ADP2140

VIN2

1

1µH

V

= 1.2

+

OUT

COUT

10µF

2

3

4

5

07932-076

Table 8. 1.0 μH Inductors

Vendor Model Case Size Dimensions ISAT (mA) DCR (mΩ)

Murata LQM21PN1R0MC0D 0805 2.0 mm × 1.25 mm × 0.5 mm 800 190

Murata LQM31PN1R0M00L 1206 3.2 mm × 1.6 mm × 0.95 mm 1200 120

Murata LQM2HPN1R0MJ0 1008 2.5 mm × 2.0 mm × 0.95 mm 1500 90

FDK MIPSA2520D1R0 2.5 mm × 2.0 mm × 1.0 mm 1200 90

Table 9. 10 μF Capacitors

Vendor Type Model Case Size Voltage Rating

Murata X5R GRM219R60J106 0805 6.3 V

Taiyo Yuden X5R JMK212BJ106 0805 6.3 V

TDK X5R C1608X5R0J106 0603 6.3 V

Rev. 0 | Page 25 of 32

ADP2140

LDO CAPACITOR SELECTION

Output Capacitor

The ADP2140 LDO is designed for operation with small, spacesaving ceramic capacitors, but functions with most commonly

used capacitors as long as care is taken about the effective series

resistance (ESR) value. The ESR of the output capacitor affects

stability of the LDO control loop. A minimum of 0.70 µF capacitance with an ESR of 1 Ω or less is recommended to ensure

stability of the ADP2140. Transient response to changes in load

current is also affected by output capacitance. Using a larger

value of output capacitance improves the transient response of

the ADP2140 to large changes in load current. Figure 87 shows

the transient response for an output capacitance value of 1 µF.

T

1

2

CH1 100mA CH2 100mV M 40.0µs A CH1 68mA

Figure 87. Output Transient Response, V

1 mA to 300 mA, Load Current Rise Time = 200 ns

Input Bypass Capacitor

Connecting a 1 µF capacitor from VIN to GND reduces the circuit sensitivity to the PCB layout, especially when long input

traces or high source impedance are encountered. If greater than

1 µF of output capacitance is required, increase the input

capacitor to match it.

Input and Output Capacitor Properties

Use any good quality ceramic capacitors with the ADP2140, as

long as they meet the minimum capacitance and maximum ESR

requirements. Ceramic capacitors are manufactured with a variety

of dielectrics, each with different behavior over temperature and

applied voltage. Capacitors must have a dielectric adequate to

ensure the minimum capacitance over the necessary temperature

range and dc bias conditions. X5R or X7R dielectrics with a voltage

rating of 6.3 V or 10 V are recommended for best performance.

Y5V and Z5U dielectrics are not recommended for use with any

LDO because of their poor temperature and dc bias characteristics.

Figure 88 depicts the capacitance vs. voltage bias characteristic

of a 0402 1 µF, 10 V, X5R capacitor. The voltage stability of a

capacitor is strongly influenced by the capacitor size and voltage

rating. In general, a capacitor in a larger package or higher voltage

LOAD CURRENT

V

OUT2

T 10.40%

= 1.8 V, C

OUT2

OUT

= 1 µF,

07932-286

rating exhibits better stability. The temperature variation of the

X5R dielectric is about ±15% over the −40°C to +85°C temperature range and is not a function of package or voltage rating.

1.2

1.0

0.8

0.6

0.4

CAPACITANCE (µF)

0.2

0

024681

Figure 88. Capacitance vs. Voltage Characteristic

MURATA PART NUMBER:

GRM155R61A105KE15

VOLTAGE (V)

0

07932-077

Use Equation 1 to determine the worst-case capacitance accounting

for capacitor variation over temperature, component tolerance, and

voltage.

C

= C

EFF

× (1 − TEMPCO) × (1 − TOL) (1)

BIAS

where:

C

is the effective capacitance at the operating voltage.

BIAS

TEMPCO is the worst-case capacitor temperature coefficient.

TOL is the worst-case component tolerance.

In this example, the worst-case temperature coefficient

(TEMPCO) over −40°C to +85°C is assumed to be 15% for an

X5R dielectric. The tolerance of the capacitor (TOL) is assumed

to be 10%, and C

is 0.94 F at 1.8 V as shown in Figure 88.

BIAS

Substituting these values in Equation 1 yields

C

= 0.94 F × (1 − 0.15) × (1 − 0.1) = 0.719 F

EFF

Therefore, the capacitor chosen in this example meets the

minimum capacitance requirement of the LDO over temperature and tolerance at the chosen output voltage.

To guarantee the performance of the ADP2140, it is imperative

that the effects of dc bias, temperature, and tolerances on the

behavior of the capacitors are evaluated for each application.

LDO AS A POSTREGULATOR TO REDUCE BUCK OUTPUT NOISE

The output of the buck regulator may not be suitable for many

noise sensitive applications because of its inherent switching

noise. This is particularly true when the buck is operating in

PSM mode because the switching noise may be in the audio

range. The ADP2140 LDO can greatly reduce the noise at the

output of the buck at high efficiency because of the load dropout

voltage of the LDO and the high PSRR of the LDO. Figure 89

and Figure 90 show the noise reduction that is possible when

the LDO is used as a post regulator.

Rev. 0 | Page 26 of 32

ADP2140

T

BUCK OUTPUT VOL T AG E

BUCK OUTPUT VOL T AG E

1

1

T

2

CH1 50.0mV CH2 10.0mV M40.0µs A CH1 –27.0 mV