500 mA, 6 MHz, Synchronous

www.BDTIC.com/ADI

Preliminary Technical Data

FEATURES

92 % peak efficiency

6 MHz operating frequency

38 µA (typical) no load quiescent current in PFM mode

1.80 V, 1.82 V, 1.85V, 1.875V fixed output voltage

500 mA continuous output current

Input voltage :2.3 V to 5.5 V

0.28 µA (typical) shutdown supply current

Automatic power-saving mode

Compatible with tiny multilayer inductors

Internal synchronous rectifier

Internal compensation

Internal soft start

Output to ground short circuit protection

Current-limit protection

Enable/shutdown logic input

Undervoltage lockout

Thermal shutdown

Ultra small 6-ball 1.17 mm

APPLICATIONS

Mobile phones

Digital cameras

Digital audio

Portable equipment

1-cell Li+/Li-polymer and 3-cell alkaline/nickel

2

WLCSP

Step-Down, DC-to-DC Converter

ADP2121

GENERAL DESCRIPTION

The ADP2121 is a high frequency, low quiescent current, stepdown, dc-to-dc converter optimized for portable applications in

which board area and battery life are critical constraints. Fixed

frequency operation at 6 MHz enables the use of tiny ceramic

inductors and capacitors. Additionally the synchronous rectification

improves efficiency and results in fewer external components. At

high load currents, the device uses a voltage regulating pulse-width

modulation (PWM) mode that maintains a constant frequency

with excellent stability and transient response. At light load

conditions, the ADP2121 can automatically enter a power saving

mode that utilizes pulse-frequency modulation (PFM) to reduce

the effective switching frequency and ensure the longest battery

life in portable applications. During logic controlled shutdown

(EN = 0), the input is disconnected from the output and draws less

than 0.28 A (typical) from the source.

The ADP2121 has an input voltage range of 2.3 V to 5.5 V allowing the

use of a single Li+/Li-polymer cell, multiple alkaline/Ni-MH cell,

PCMCIA, and other standard power sources. The converter is

internally compensated to minimize external components, and its 1.80

V, 1.82 V, 1.85 V, or 1.875 V fixed output can source up to 500 mA.

Other key features include undervoltage lockout (UVLO) to prevent

deep-battery discharge and soft start to prevent input current

overshoot at startup.

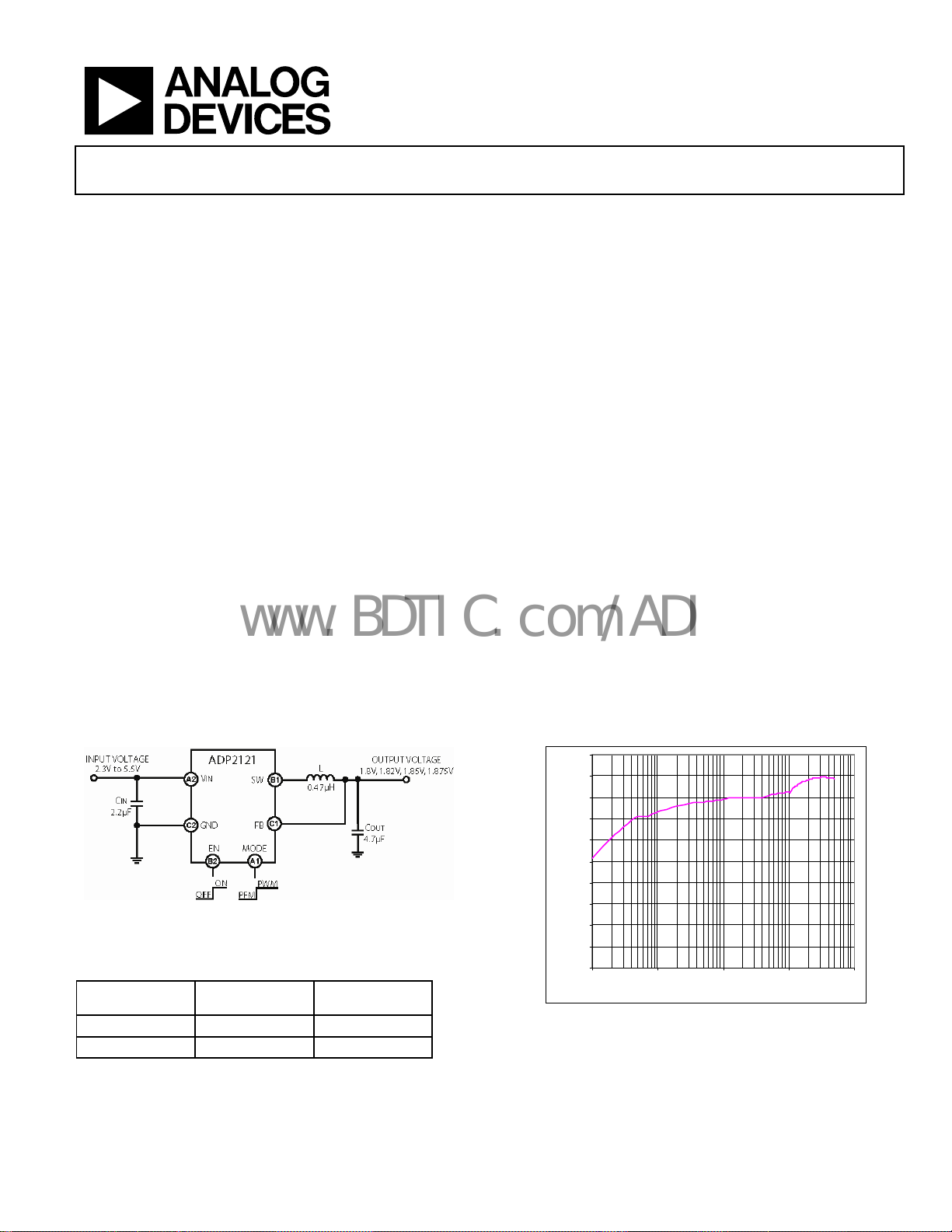

TYPICAL APPLICATION CIRCUIT

Figure 1. Circuit Configuration of ADP2121

OUTPUT VOLTAGE OPTIONS

Table 1.

Input Voltage

Range (V)

2.3 - 5.5 100 1.800, 1.850, 1.875

2.3 - 5.5 300 1.820

Rev. PrA

Information furnished by Analog Devices is believed to be accurate and reliable. However, no

responsibility is assumed by Analog Devices for its use, nor for any infringements of patents or other

rights of third parties that may result from its use. Specifications subject to change without notice. No

license is granted by implication or otherwise under any patent or patent rights of Analog Devices.

Trademarks and registered trademarks are the property of their respective owners.

Maximum Start-

up Time (s)

Fixed Output

Voltage (V)

TYPICAL PERFORMANCE

10 0 %

90%

80%

70%

60%

50%

40%

Efficiency

30%

20%

10 %

0%

0 .1 1 10 10 0 10 0 0

Figure 2. Efficiency vs. Load Current (V

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700 www.analog.com

Fax: 781.461.3113 ©2008 Analog Devices, Inc. All rights reserved.

Load C urre nt ( mA )

= 3.6 V, V

IN

= 1.82 V, Auto Mode)

OUT

ADP2121 Preliminary Technical Data

www.BDTIC.com/ADI

TABLE OF CONTENTS

Features.............................................................................................. 1

Applications....................................................................................... 1

General Description ......................................................................... 1

Typical Application Circuit ............................................................. 1

Typical Performance......................................................................... 1

Revision History ............................................................................... 2

Specifications..................................................................................... 3

Absolute Maximum Ratings............................................................ 4

Thermal Resistance ...................................................................... 4

ESD Caution.................................................................................. 4

Pin Configuration and Function Descriptions............................. 5

Typical Performance Characteristics ............................................. 6

REVISION HISTORY

11/08—Revision PrA: Preliminary Version

Theory of Operation .........................................................................8

Overview ........................................................................................8

Mode Selection ..............................................................................8

Enable/Shutdown..........................................................................9

Internal Control Features.............................................................9

Applications Information.............................................................. 11

Inductor Selection...................................................................... 11

Input Capacitor Selection.......................................................... 11

Output Capacitor Selection ...................................................... 11

PCB Layout Guide.......................................................................... 13

Outline Dimensions....................................................................... 14

Ordering Guide .......................................................................... 14

Rev. PrA | Page 2 of 14

Preliminary Technical Data ADP2121

www.BDTIC.com/ADI

SPECIFICATIONS1

VIN = EN = 3.6 V, all values are at TA = 25°C.

Table 2.

Parameters Conditions Min Typ Max Unit

SUPPLY

Input Voltage Range I

I

Quiescent Current VIN = 3.6 V (PFM mode), no load, TA = 85°C 38 55 µA

V

Shutdown Current VEN = 0 V 0.28 0.5 µA

UNDERVOLTAGE LOCKOUT

Undervoltage Lockout Threshold VIN rising 2.2 V

V

OUTPUT

Continuous Output Current VIN = 2.3 V 400 mA

V

2

Feedback Bias Current VFB = 1.8 V 3.8 µA

SWITCHING CHARACTERISTICS

)

DSon

SW Leakage Current VIN = 5.5 V, V

SW Current Limit P-channel switch 850 1000 1150 mA

Oscillator Frequency 5.4 6 6.6 MHz

EFFICIENCY (VIN = 3.6 V, V

= 1.82 V) L = 0.47 H, C

OUT

I

I

I

I

I

EN/MODE INPUT LOGIC

High Threshold Voltage 1.2 V

Low Threshold Voltage 0.4 V

Leakage Current VEN = V

SOFT START

3

C

Soft Start Period V

THERMAL SHUTDOWN

Thermal Shutdown Threshold 150 °C

Thermal Shutdown Hysteresis 30 °C

= 0 mA to 400 mA 2.3 5.5 V

LOAD

= 0 mA to 500 mA 2.5 5.5

LOAD

= 3.6 V (PWM mode), no load 10 mA

IN

falling 1.8 V

IN

= 2.5 V to 5.5V 500 mA

IN

Auto mode - 2% V

PWM mode - 2% V

+ 3% V Output Accuracy (1.82 V, VIN = 3.6)

NOM

+ 3% V

NOM

P-channel switch 225 440 m SW On Resistance (R

N-channel synchronous rectifier 290 810 m

= 0 V, 5.5 V 1 µA

SW

= 4.7 F

OUT

= 10 mA (PFM mode) 79 %

LOAD

= 50 mA (PFM mode) 81 %

LOAD

= 150 mA (PWM mode) 87 %

LOAD

= 250 mA (PWM mode) 89 %

LOAD

= 500 mA (PWM mode) 89 %

LOAD

= 0.5 V, 5.5 V 0.01 1 µA

MODE

= 4.7 F, VIN = 3.6 V (time from EN = 0 to stable

OUT

V

)

OUT

= 1.82 V

OUT

V

= 1.8 V, 1.85 V, 1.875 V

OUT

270

80

300

100

µs

µs

1

All limits are subject to change upon final temperature characterization and release.

2

Transients not included in voltage accuracy specifications. For PFM mode, the V

3

Guaranteed by design.

accuracy specification is for the lower point of the ripple.

OUT

Rev. PrA | Page 3 of 14

ADP2121 Preliminary Technical Data

www.BDTIC.com/ADI

ABSOLUTE MAXIMUM RATINGS

Table 3.

Parameter Rating

VIN −0.3 V to +6 V

VEN/V

VFB/VSW −0.3 V to VIN + 0.2 V

Operating Ambient Temperature –40°C to +85°C

Operating Junction Temperature –40°C to + 125°C @ 500 mA

Storage Temperature –45°C to +150°C

Soldering (10 sec) 300°C

Vapor Phase (60 sec) 215°C

Infrared (15 sec) 220°C

ESD (electrostatic discharge)

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

−0.3 V to +6 V

MODE

Machine Model −100 V to +100 V

Human Body Model −2000 V to +2000 V

Charged Device Model −500 V to +500 V

THERMAL RESISTANCE

The thermal resistance of the system, θJA, is specified for the

worst-case conditions, that is, a device soldered in a circuit

board for surface-mount packages. The junction-to-ambient

thermal resistance is highly dependent on the application and

board layout. In applications where high maximum power

dissipation exists, attention to thermal board design is required.

The value of θ

and environmental conditions.

Table 4.

Package Type θ

6-Ball WLCSP

2-Layer Board 105 °C/W

4-Layer Board 198 °C/W

Maximum Power Dissipation

2-Layer Board 380 mW

4-Layer Board 202 mW

may vary, depending on PCB material, layout,

JA

Unit

JA

ESD CAUTION

Rev. PrA | Page 4 of 14

Preliminary Technical Data ADP2121

www.BDTIC.com/ADI

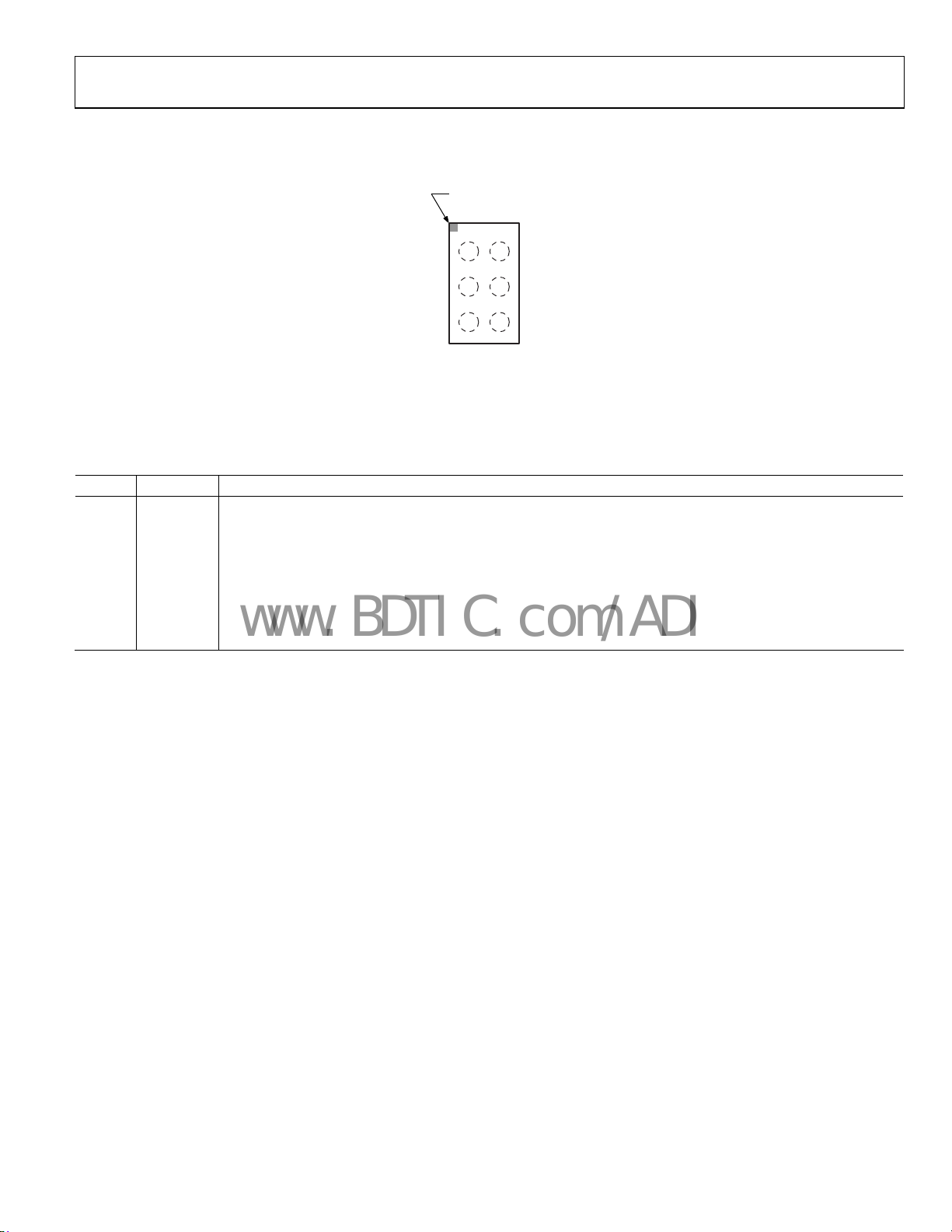

PIN CONFIGURATION AND FUNCTION DESCRIPTIONS

BALLA1

INDICATOR

1

2

MODE VIN

A

SW

B

C

(BALL SIDE DOW N)

(BUMPS ON OPPOSITE SIDE)

Figure 3. Pin Configuration

Table 5. Pin Function Descriptions

Pin No. Mnemonic Description

A1 MODE Mode Select. This pin toggles between auto (PFM and PWM switching) and PWM modes. Set MODE low to allow

the part to operate in auto mode. Pull MODE high to force the part to operate in PWM mode.

B1 SW Switch Node.

C1 FB Feedback Divider Input. Connect the output capacitor from FB to GND to set the output voltage ripple and to

complete the control loop.

A2 VIN Power Supply Input.

B2 EN Enable. Pull this pin high to enable the part. Set this pin low to disable the part. Do not leave this pin floating.

C2 GND Ground Pin.

EN

FB GND

TOP VIEW

Not to Scale

07407-003

Rev. PrA | Page 5 of 14

ADP2121 Preliminary Technical Data

(

)

www.BDTIC.com/ADI

TYPICAL PERFORMANCE CHARACTERISTICS

10 0 %

90%

80%

70%

60%

50%

40%

Efficiency

30%

20%

10 %

0%

0 .1 1 10 10 0 10 0 0

VIN = 3.6 V

VIN = 2.3 V

Load C urre nt ( mA )

VIN = 4.2 V

Figure 4. Efficiency vs. Load Current (Auto Mode, V

1.9 0 0

1.8 9 0

1.8 8 0

1.8 70

1.8 6 0

1.8 50

1.8 4 0

VIN = 2.3 V

1.8 3 0

Output Voltage (V)

1.8 2 0

1.8 10

1.8 0 0

0.1 1 10 100 1000

VIN = 3.6 V

Load C urre nt ( mA)

VIN = 5.5 V

Figure 5. Output Voltage Accuracy (Auto Mode, V

VIN = 5.5 V

= 1.82 V)

OUT

VIN = 4.2 V

= 1.82 V)

OUT

10 0 %

90%

VIN = 2.3 V

80%

70%

60%

50%

40%

Efficiency

30%

20%

10 %

0%

1 10 100 1000

Load C urre nt ( mA)

VIN = 5.5 V

VIN = 3.6 V

VIN = 4.2 V

Figure 7. Efficiency vs. Load Current (PWM Mode, V

1.9 0 0

1.8 9 0

1.8 8 0

1.8 70

1.8 6 0

1.8 50

1.8 4 0

1.8 3 0

VIN = 4.2 V

1.8 2 0

Output Voltage (V)

1.8 10

VIN = 2.3 V

1.8 0 0

1 10 100 1000

VIN = 5.5 V

= 1.82 V)

OUT

VIN = 3.6 V

Load C urrent ( mA )

Figure 8. Output Voltage Accuracy (PWM Mode, V

= 1.82 V)

OUT

V

(20m V/DIV, 1.82 V Offs et)

OUT

SW

(2V/DIV)

= 3.6 V

V

IN

= 1.82 V

V

OUT

I

= 25 mA

OUT

I

L

(200m A/DIV)

t (1.0µs/DIV)

Figure 6. PFM Mode Operation

Rev. PrA | Page 6 of 14

VIN = 3.6 V, V

V

(20m V /DIV, 1.82 V DC Offs e t)

OUT

SW (5V/DIV)

I

(200m A/DIV)

L

t

100ns /DIV

Figure 9. PWM Mode Operation

= 1.82 V, I

OUT

= 200 mA

OUT

Preliminary Technical Data ADP2121

www.BDTIC.com/ADI

= 1.82 V

V

OUT

V

OUT

(1V/DIV)

EN

(2V/DIV)

I

L

(200m A/DIV)

= 3.6 V

V

IN

= 1.82 V

V

OUT

No L o ad

V

(100m V/DIV)

OUT

(1A/DIV)

I

L

t (40µs/DIV)

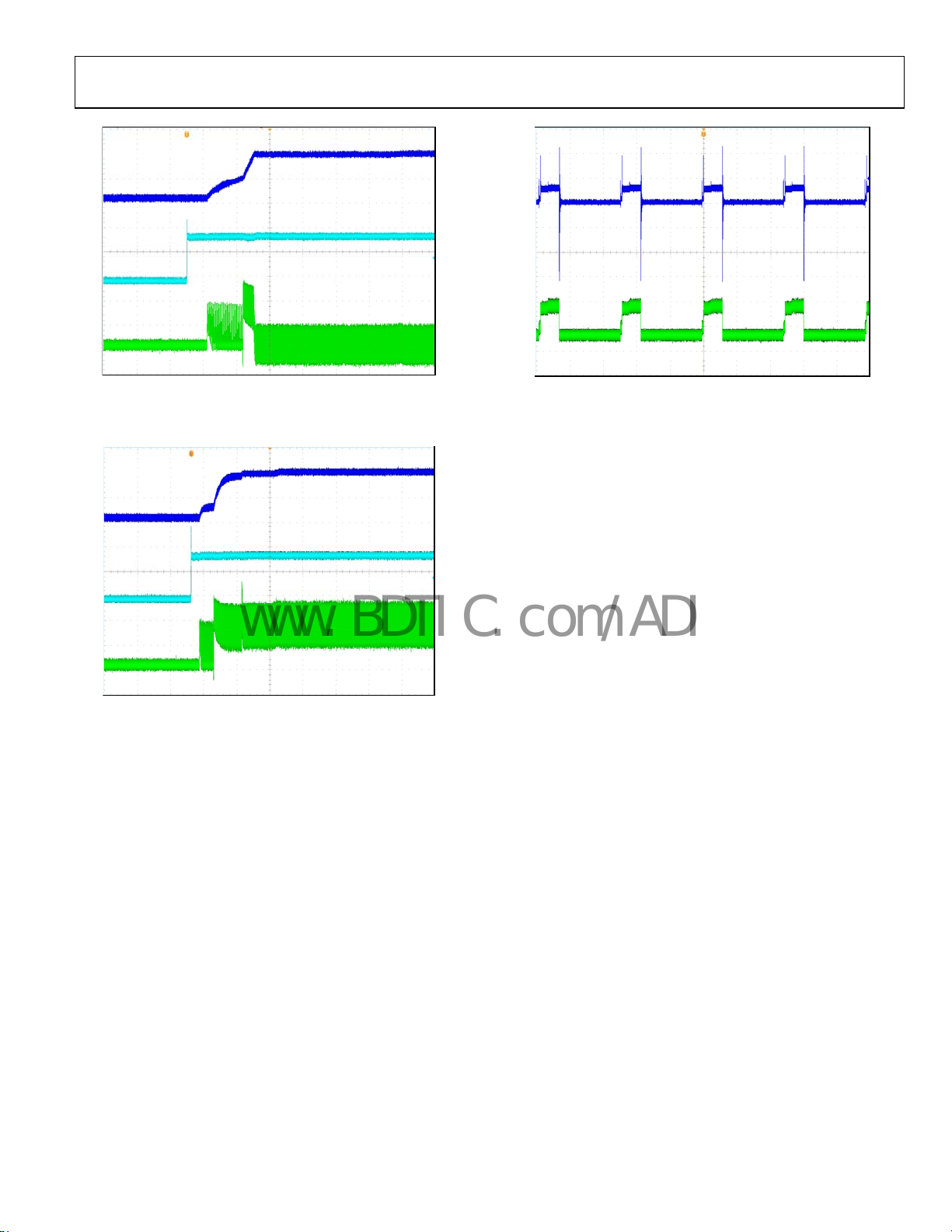

Figure 10. Start-Up Waveform (No Load, VIN = 3.6 V, V

V

OUT

(1V/DIV)

EN

(2V/DIV)

I

L

(200m A/DIV)

t (100µs/DIV)

Figure 11. Start-Up Waveform (R

= 5.1 Ω, VIN = 3.6 V, V

LOAD

V

V

R

IN

OUT

LOAD

= 1.82 V)

OUT

= 3.6 V

= 1.82 V

= 5.1 Ω

= 1.82 V)

OUT

t (1.0ms/DIV)

Figure 12. Output Short Circuit Response

Rev. PrA | Page 7 of 14

ADP2121 Preliminary Technical Data

V

V

www.BDTIC.com/ADI

THEORY OF OPERATION

BAT

OUT

FB

C1

R1

R2

AGND

REF

BANDGAP

EAMP

BG

COMPENSATION

PFM

COMPARATOR

BG

B2

PFM

EN

ANGD

6MHz

OSCILLATOR

THRESHOLD

DETECT

RAMP

V(V

SHUTDOWN

SOFT ST ART

A1

MODE

PWM

COMP

EAMP

IN)

THERMAL

THRESHOLD

DETECT

2.3 TO 5. 5V

SHOOTTHROUG H

CONTROL

LOGIC

AND

PWM/PFM

CONTROL

PLLIM

ZXCOMP

DETECT

2.2µF

X5R

6V3

PDRIVE

NDRIVE

PFM

AV

PV

IN

IN

PREF

NREF

VIN

V

FB

A2

SW

470nH

B1

PGND

GND

C2

AGND

IN

4.7µF

X5R

6V3

V

OUT

Figure 13. Internal Block Diagram

OVERVIEW

The ADP2121 is a high efficiency, synchronous, step-down, dcto-dc converter that operates from a 2.3 V to 5.5 V input voltage.

It provides up to 500 mA of continuous output current at a fixed

1.80 V, 1.82 V, 1.85 V, or 1.875 V (typical) output voltage. The 6

MHz operating frequency enables the use of tiny external

components. The internal control schemes of the ADP2121 give

excellent stability and transient response. External control for

mode selection and part enabling provides power-saving options

that are aided by internal features such as synchronous

rectification and compensation. Other internal features such as

current limit, soft start, undervoltage lockout, output-to-ground

short circuit protection, and thermal shutdown provide

protection for internal and external circuit components.

MODE SELECTION

The ADP2121 has two modes of operation, determined by the

state of the MODE pin: auto and PWM.

Pull the MODE pin high to force the converter to operate in

PWM mode, regardless of the output current. Otherwise, set

MODE low to allow the converter to automatically enter the

power saving PFM mode at light load currents. Do not leave this

pin floating.

07407-034

Pulse-Width Modulation (PWM) Mode

The PWM mode forces the part to maintain a fixed frequency

of 6 MHz (typical) over all load conditions. The converter

controls the amount of power delivered to the load by varying

the duty cycle of the internal oscillator. This control provides

excellent stability, transient response, and output regulation,

but results in lower efficiencies at light load currents.

= 3.6 V, V

V

IN

V

(20m V /DIV, 1.82 V DC Offs e t)

OUT

SW (5V/DIV)

I

(200m A/DIV)

L

t (100ns /DIV)

Figure 14. Typical PWM Operation (V

= 1.82 V, I

OUT

= 3.6 V, V

IN

= 1.82V, I

OUT

= 200 mA

OUT

LOAD

= 150 mA)

Rev. PrA | Page 8 of 14

Preliminary Technical Data ADP2121

www.BDTIC.com/ADI

Auto Mode (PFM-PWM Switching)

Auto mode is a power saving feature that enables the converter to

switch between PWM and PFM in response to the output load.

The ADP2121 operates in PFM mode for light load currents and

switches to PWM mode for medium and heavy load currents

(Figure 15).

V

(20m V/DIV, 1.82 V Offs et)

OUT

SW

(2V/DIV)

I

L

(200m A/DIV)

= 3.6 V

V

IN

V

OUT

I

= 25 mA

OUT

= 1.82 V

Figure 15. PFM-to-PWM Transition Point

Pulse-Frequency Modulation

When the converter is operating under light load conditions, the

effective switching frequency and supply current are decreased

and varied using PFM to regulate the output voltage. This results

in improved efficiencies and lower quiescent currents. In PFM

mode, as shown in Figure 16, the converter only switches when

necessary to keep the output voltage within the PFM limits set by

an internal comparator. Switching stops when the upper limit is

reached and resumes when the lower limit is reached.

Once the upper level is reached, the output stage and oscillator

turn off to reduce the quiescent current. During this stage, the

output capacitor supplies the current to the load. As the output

capacitor discharges and the output voltage reaches the lower

PFM comparator threshold, switching resumes and the process

repeats. The output voltage, switching node voltage, and inductor

current during this process are shown in Figure 16.

t (1.0µs/DIV)

Figure 16. Typical PFM Operation (V

= 3.6 V, V

IN

= 1.82V, I

OUT

LOAD

= 25 mA)

Mode Transition

The converter switches between PFM and PWM automatically

to maintain optimal transient response and efficiency. The

mode transition point depends on input voltage. Hysteresis

exists in the transition point to prevent instability and

decreased efficiencies that could result if the converter were

able to oscillate between PFM and PWM for a fixed input

voltage and load current.

A switch from PFM to PWM occurs when the output voltage

dips below the lower PFM comparator threshold. Switching to

PWM allows the converter to maintain efficiency and supply a

heavier current to the load.

A switch from PWM to PFM occurs when the converter

outputs a decreased peak current for multiple consecutive

switching cycles. Switching to PFM allows the converter to

save power and supply a lighter load current with fewer

switching cycles.

Figure 16 shows the threshold voltage in PFM mode is slightly

higher to ensure that the converter is able to supply enough

current when transitioning into PWM mode.

ENABLE/SHUTDOWN

The EN input turns the ADP2121 on or off. Connect EN to

PGND or logic low to shut down the part and reduce the

current consumption to 0.1 µA (typical). Connect EN to VIN

or logic high to enable the part. Do not leave this pin floating.

INTERNAL CONTROL FEATURES

Overcurrent Protection

To ensure that excessively high currents do not damage the

inductor, the ADP2121 incorporates cycle-by-cycle overcurrent

protection. This function is accomplished by monitoring the

instantaneous peak current on the power PMOS switch. If this

current exceeds the maximum level (1 A typical), then the

PMOS is immediately turned off. This minimizes the potential

Rev. PrA | Page 9 of 14

ADP2121 Preliminary Technical Data

www.BDTIC.com/ADI

for damage to power components during certain faults and

transient events.

Soft Start

To prevent excessive input inrush current at startup, the

ADP2121 operates with an internal soft start. When EN goes

high, or when the part recovers from a fault (UVLO, TSD, or

short-circuit protection), a soft start timer begins. The soft start

timer corresponds to the maximum soft start period for the given

fixed output voltage. During this time, the peak current limit is

gradually increased to its maximum. As seen in the start-up

waveforms in the Typical Performance Characteristics, the output

voltage passes through several stages to ensure that each stages of

the converter is able to startup effectively and in proper sequence.

After the soft start period has expired, the peak current limit

remains at 1 A (typical) and the part enters the operating mode

determined by the MODE pin.

Synchronous Rectification

In addition to the P-channel MOSFET switch, the ADP2121

includes an N-channel MOSFET synchronous rectifier. The

synchronous rectifier improves efficiency, especially for small

load currents, and reduces cost and board space by eliminating

the need for an external rectifier.

erratic operation at low input voltages. The UVLO levels have

approximately 100 mV of hysteresis to ensure glitch-free

startup.

Output Short Circuit Protection

If the output voltage is inadvertently shorted to GND, a

standard dc-to-dc controller would deliver maximum power

into that short. This could result in a potentially catastrophic

failure. To prevent this, the ADP2121 senses when the output

voltage is below the SCP threshold (typically 1.2 V). At this

point, the controller turns off for approximately 1.8 ms and

then automatically initiates a soft start sequence. This cycle

repeats until the short is removed or the part is disabled. This

dramatically reduces the power delivered into the short circuit,

yet still allows the converter to recover if the fault is removed.

= 1.82 V

V

(100m V/DIV)

OUT

V

OUT

Compensation

The control loop is internally compensated to deliver maximum

performance with no additional external components. The error

amplifier compares the regulated output voltage on the feedback

pin (FB) to an internal reference voltage. The ADP2121 has been

designed to work with 0.47 H chip inductors and 4.7 F

capacitors (see

performance and/or stability.

Table 6 and Ta b le 7.) Other values may reduce

Undervoltage Lockout (UVLO)

If the input voltage is below the UVLO threshold, the ADP2121

automatically turns off the power switches and places the part

into a low power consumption mode. This prevents potentially

(1A/DIV)

I

L

t (1.0ms/DIV)

Figure 17. Output Short Circuit Protection

Thermal Shutdown (TSD) Protection

The ADP2121 also includes TSD protection. If the die

temperature exceeds 150°C (typical), the TSD protection

activates and turn off the power devices. They remain off until

the die temperature falls below 120°C (typical), at which point

Rev. PrA | Page 10 of 14

Preliminary Technical Data ADP2121

(

)

−

www.BDTIC.com/ADI

APPLICATIONS INFORMATION

The external component selection for the ADP2121

applications circuit is driven by the load requirement and

begins with the selection of Inductor L (see ). Once

the inductor is chosen, C

and C

IN

can be selected.

OUT

INDUCTOR SELECTION

The high switching frequency of the ADP2121 allows for minimal

output voltage ripple, even with small inductors. Inductor sizing

is a trade-off between efficiency and transient response. A small

inductor leads to a larger inductor current ripple that provides

excellent transient response, but degrades efficiency. Due to the

high switching frequency of the ADP2121, multilayer ceramic

inductors can be used for an overall smaller solution size. Shielded

ferrite core inductors are recommended for their low core losses

and low electromagnetic interference (EMI).

As a guideline, the inductor peak-to-peak current ripple is

typically set to

I

= 0.45 × I

L

where I

LOAD

current, I

L

IDEAL

where f

SW

is the maximum output current. The largest ripple

, occurs at the maximum input voltage.

L

=

is the switching frequency.

(1)

LOAD

()

VVV

−×

IN

OUT

() ()

SW

MAXIN

OUT

IfV

×××

45.0

(2)

MAXLOAD

It is important that the inductor be capable of handling the

maximum peak inductor current, I

, determined by the

PK

following equation:

I

PK

= I

LOAD(MAX)

+ IL/2 (3)

The dc current rating of the inductor should be at least equal

to the maximum load current plus half the ripple current to

prevent core saturation.

Table 6 shows some typical surface

mount inductors that work well in ADP2121 applications.

INPUT CAPACITOR SELECTION

The input capacitor must be able to support the maximum

input operating voltage and the maximum rms input current.

The maximum rms input current flowing through the input

capacitor is at maximum I

capable of withstanding the rms input current for the maximum

load current in the application using the following equation:

IrmsI

OUTMAX

The input capacitor reduces the input voltage ripple caused by

the switch currents on the VIN pin. Place the input capacitor as

close as possible to the VIN pin.

/2. Select an input capacitor

OUT

()

VVV

−×

OUT

×=

IN

V

IN

OUT

(4)

In principle, different types of capacitors can be considered,

but for battery-powered applications, the best choice is the

multilayer ceramic capacitor, due to its small size and

equivalent series resistance (ESR).

Table 7 offers input capacitor

suggestions.

It is recommended that the VIN pin be bypassed with a 2.2 µF

or larger ceramic input capacitor if the supply line has a

distributed capacitance of at least 10 F. If not, at least a 10 F

capacitor is recommended on the input supply pin. The input

capacitor can be increased without any limit for better input

voltage filtering. X5R or X7R dielectrics are recommended, with a

voltage rating of 6.3 V or 10 V. Y5U and Z5U dielectrics are not

recommended, due to their poor temperature and dc bias

characteristics.

OUTPUT CAPACITOR SELECTION

The output capacitor selection affects both the output voltage

ripple and the loop dynamics of the converter. For a given loop

crossover frequency (the frequency at which the loop gain

drops to 0 dB), the maximum voltage transient excursion

(overshoot) is inversely proportional to the value of the output

capacitor. The ADP2121 has been designed to operate with

small ceramic capacitors in the 4.7 µF to 10 µF range that have

low ESR and equivalent series inductance (ESL) and are able,

therefore, to meet tight output voltage ripple specifications. X5R

or X7R dielectrics are recommended with a voltage rating of 6.3

Table 7 shows a list of input and output MLCC capacitors

V.

recommended for ADP2121 applications.

When choosing output capacitors, it is also important to

account for the loss of capacitance due to output voltage dc bias.

This may result in using a capacitor with a higher rated voltage

to achieve the desired capacitance value. Additionally, if

ceramic output capacitors are used, the capacitor rms ripple

current rating should always meet the application requirements.

The rms ripple current is calculated as:

rmsI

()

COUT

1

32

×

OUT

×= (5)

SW

At nominal load currents, the converter operates in forced

frequency (PWM) mode, and the overall output voltage ripple is

the sum of the voltage spike caused by the output capacitor ESR

plus the voltage ripple caused by charging and discharging the

output capacitor.

= IL × (ESR + 1/(8 × C

V

OUT

OUT

The largest voltage ripple occurs at the highest input voltage,

V

. At light load currents, if MODE is set low, then the

IN

converter operates in power save (PFM) mode and the output

voltage ripple increases.

VVV

OUT

)(

MAXIN

××

VfL

)(

MAXIN

× fSW)) (6)

Rev. PrA | Page 11 of 14

ADP2121 Preliminary Technical Data

www.BDTIC.com/ADI

Table 6. Recommended Inductor Selection

Manufacturer Series Inductance (µH) DCR (Ω) Current Rating (mA) Size (L × W × H) (mm) Package

Murata LQM2HP_G0 0.47 ± 20% 0.040 ± 25% 1800 2.5 × 2.0 × 0.90 1008

LQM21PNR47MC0D 0.47 ± 20% 0.120 ± 25% 1100 2.0 × 1.25 × 0.50 0805

Taiyo Yuden

Table 7. Recommended Input and Output Capacitor Selection

Manufacturer Capacitance (F) Voltage Rating (V)

Input

Murata 2.2 6.3 X5R GRM155R60J225M 1.0 × 0.5 × 0.5 0402

Taiyo Yuden 2.2 6.3 X5R JMK105BJ225MV-F 1.0 × 0.5 × 0.5 0402

Panasonic 2.2 6.3 X5R ECJ-0EB0J225M 1.0 × 0.5 × 0.5 0402

Output

Murata 4.7 6.3 X5R GRM188R60J475K 1.6 × 0.8 × 0.8 0603

Taiyo Yuden 4.7 4 X5R AMK105BJ475MV-F 1.0 × 0.5 × 0.5 0402

Panasonic 4.7 6.3 5R

BRC1608TR45M

0.45 ± 20% 0.117 ± 30% 800 1.6 × 0.8 × 0.8 0603

Temperature

Coefficient Part Number Size (L × W × H) (mm) Package

ECJ-0EB0J475M

1.0 × 0.5 × 0.5 0402

Rev. PrA | Page 12 of 14

Preliminary Technical Data ADP2121

www.BDTIC.com/ADI

PCB LAYOUT GUIDE

MODE

ADP2121

2.0mm

Figure 18. Example Layout for an ADP2121 Application

SW

L1

VOUT

C2

2.65mm

VIN

GND

C1EN

07407-039

For high efficiency, good regulation, and stability with the

ADP2121, a well-designed printed circuit board layout is

required.

Use the following guidelines when designing printed

circuit boards:

• Keep the low ESR input capacitor, C

, close to VIN and GND.

IN

• Keep high current traces as short and as wide as possible.

• Avoid routing high impedance traces near any node

connected to SW or near the inductor to prevent radiated

noise injection.

Rev. 0 | Page 13 of 14

www.BDTIC.com/ADI

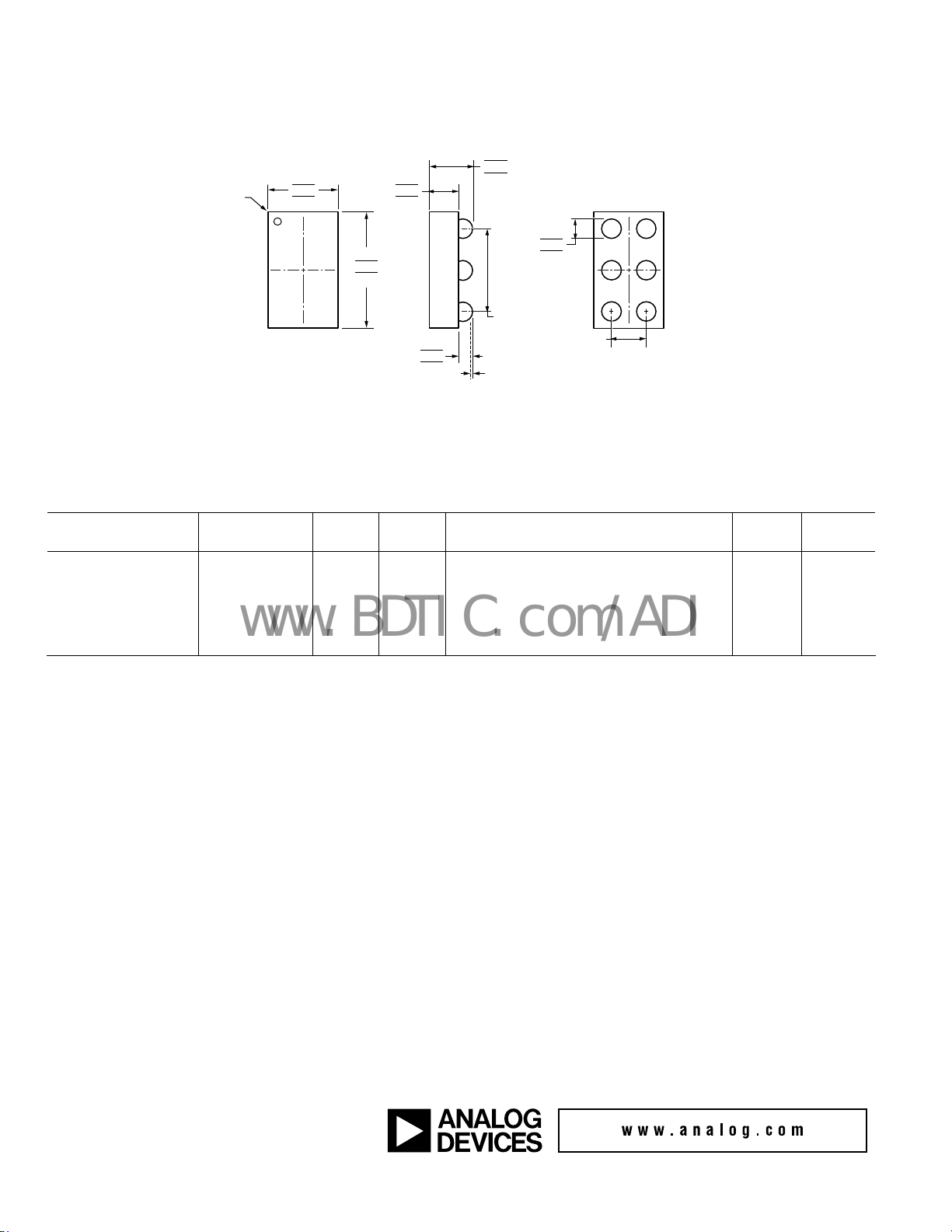

OUTLINE DIMENSIONS

A1 BALL

CORNER

0.940

0.900

0.860

1.340

1.300

1.260

0.430

0.400

0.370

0.660

0.600

0.540

0.280

0.260

0.240

12

A

B

C

021908-A

TOP VIEW

(BALL SI DE DOWN)

0.230

0.200

0.170

0.800

BSC

0.075 NOM

COPLANARITY

0.400 BSC

BALL PITCH

BOTTOM VIEW

(BALL SIDE UP)

Figure 19. 6-Ball Wafer Level Chip Scale Package (WLCSP)

(CB-6-4)

Dimensions shown in millimeters

ORDERING GUIDE

Te mp e ra tu r e

Model

ADP2121YCBZ-1.80R7

ADP2121YCBZ-1.82R7

ADP2121YCBZ-1.85R7

ADP2121YCBZ- −40 °C to +85 °C 1.875 V 80 s 6-Ball Wafer Level Chip Scale Package [WLCSP] CB-6-4 L95

4

1.875R7

Range

1

−40 °C to +85 °C 1.800 V 80 s 6-Ball Wafer Level Chip Scale Package [WLCSP] CB-6-4 L92

2

−40 °C to +85 °C 1.820 V 270 s 6-Ball Wafer Level Chip Scale Package [WLCSP] CB-6-4 L93

3

−40 °C to +85 °C 1.850 V 80 s 6-Ball Wafer Level Chip Scale Package [WLCSP] CB-6-4 L94

1

Z = RoHS Compliant Part.

2

Z = RoHS Compliant Part.

3

Z = RoHS Compliant Part.

4

Z = RoHS Compliant Part.

Output

Voltage

Startup

Time Package Description

Package

Option Branding

©2008 Analog Devices, Inc. All rights reserved. Trademarks and

registered trademarks are the property of their respective owners.

PR07407-0-11/08(PrA)

Rev. PrA | Page 14 of 14

Loading...

Loading...