Dual LED Flash Driver with

http://www.BDTIC.com/ADI

FEATURES

Ultracompact solution

Small 2 mm × 1.5 mm 12-ball WLCSP package

Tiny, low profile 2.2 H power inductor

LED current source for local LED grounding and low EMI

Synchronous 2 MHz PWM boost convertor, no external diode

High efficiency: 88% peak

Reduces high levels of input battery current during flash

Limits battery current drain in torch mode

2

I

C programmable

Currents up to 400 mA in flash mode for two LEDs

Currents up to 500 mA in flash mode for one LED with

5% accuracy

Currents up to 160 mA in torch mode with 10% accuracy

Peak inductor current limit

Flash timer

Control

2

I

C-compatible control registers

External STROBE pin

External direct TORCH pin

TX_MASK input to prevent high input battery current levels

Safety

Thermal overload protection

Flash timeout

Inductor fault detection

Output overvoltage

Short circuit protection

Soft start reduces inrush input current

I2C-Compatible Interface

ADP1655

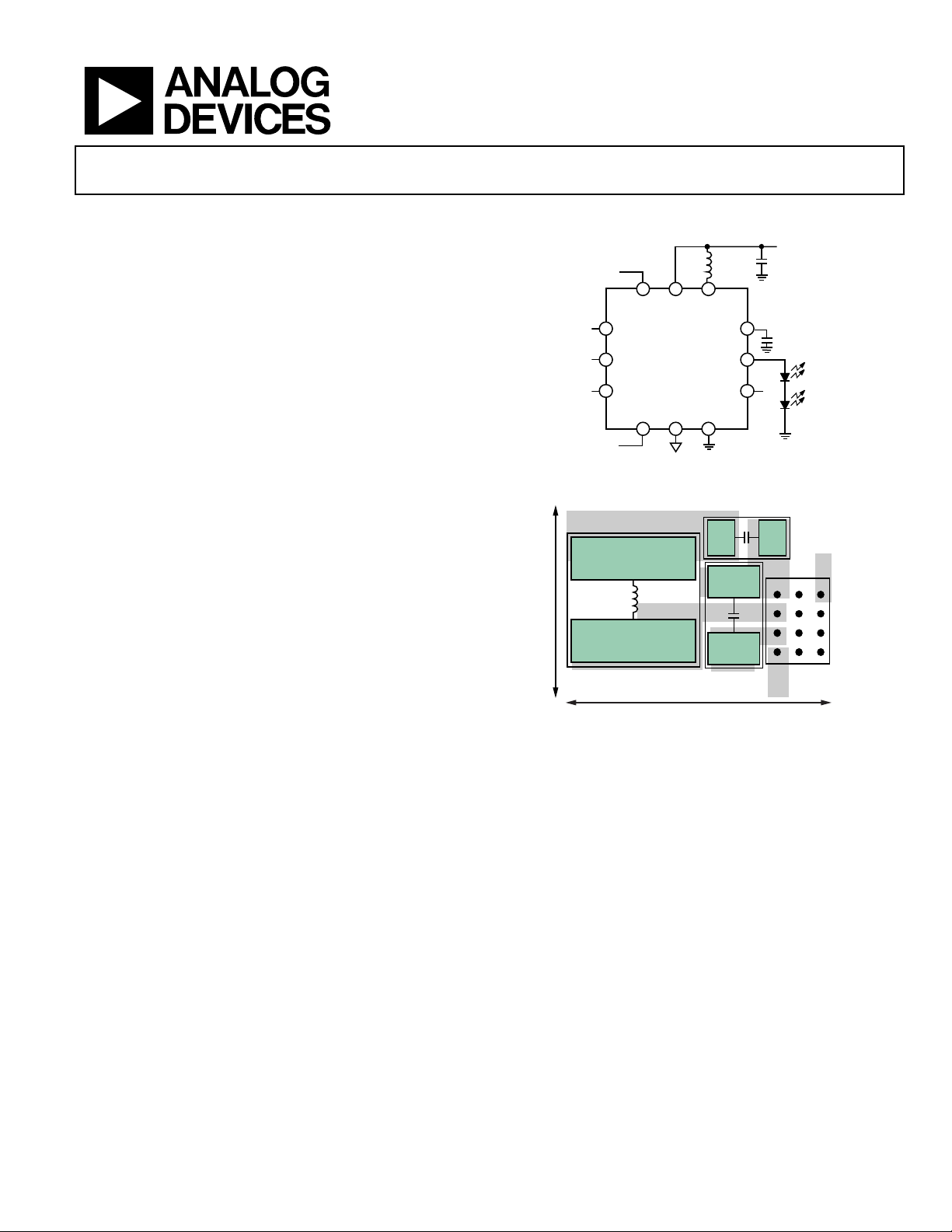

FUNCTIONAL BLOCK DIAGRAM

INPUT VOLTAGE = 2.5V TO 5.5V

2.2µH

STROBE VIN SW

TORCH

ADP1655

SCL/EN1

SDA/EN2

I2C/EN SGND PGND

VOUT

LED_OUT

TX_MASK

Figure 1.

Li-ION +

C1

L1

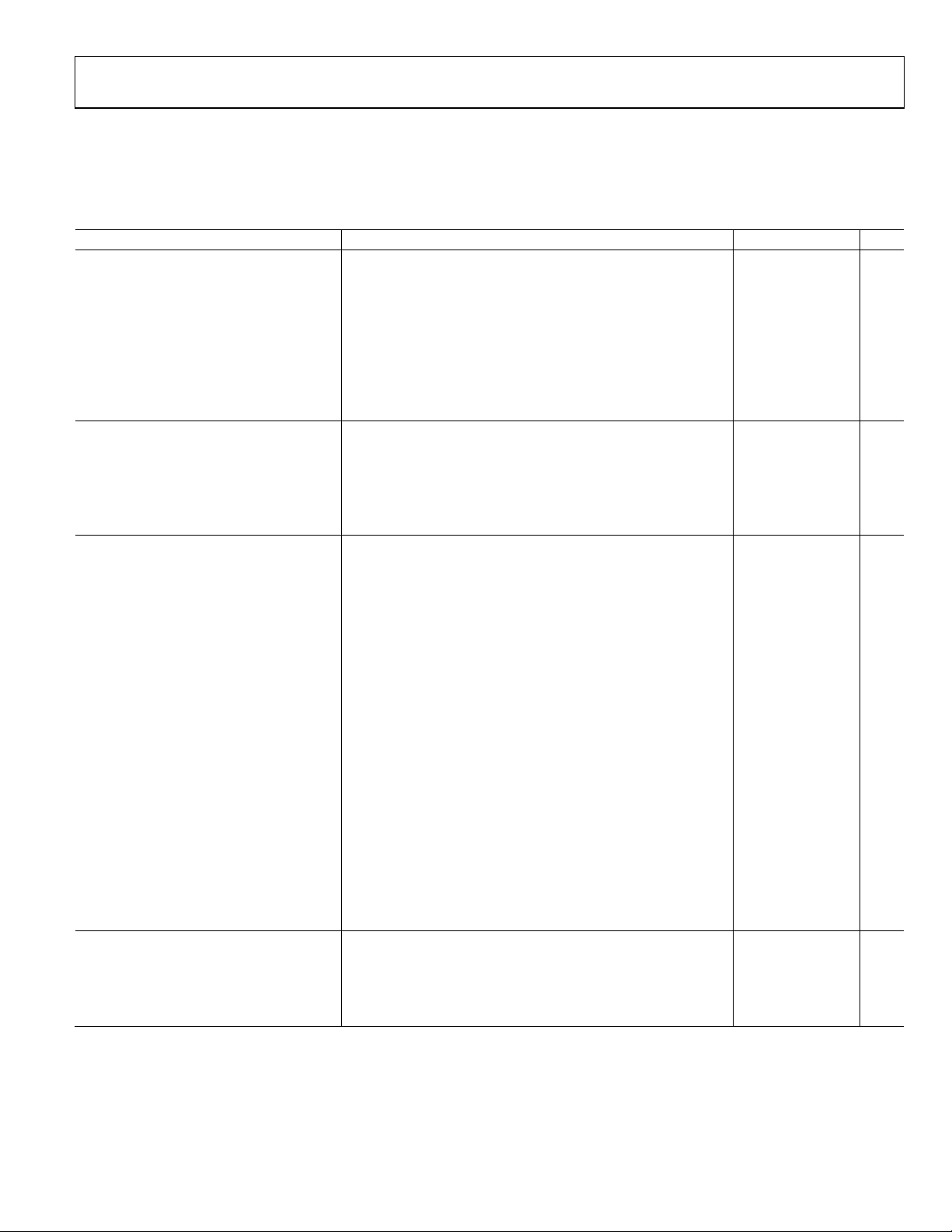

3mm

INDUCTOR

6.5mm

Figure 2. PCB Layout

10µF

10µF

8028-001

PGND

C2

LED

ANODE

Li-ION +

DIGITAL

INPUT/

OUTPUT

08028-002

APPLICATIONS

Camera-enabled cellular phones and smart phones

Digital still cameras, camcorders, and PDAs

GENERAL DESCRIPTION

The ADP1655 is a very compact, highly efficient, dual white

LED flash driver for high resolution camera phones, which

improves picture and video quality in low light environments.

The device integrates a 2 MHz synchronous inductive boost

convertor, an I

source. The high switching frequency enables the use of a tiny,

low profile 2.2 µH power inductor, and the current source

permits LED cathode grounding for thermally enhanced,

low EMI and compact layouts.

The efficiency is high over the entire battery voltage range to

maximize the input power to LED power conversion and

Rev. 0

Information furnished by Analog Devices is believed to be accurate and reliable. However, no

responsibility is assumed by Analog Devices for its use, nor for any infringements of patents or other

rights of third parties that may result from its use. Specifications subject to change without notice. No

license is granted by implication or otherwise under any patent or patent rights of Analog Devices.

Trademarks and registered trademarks are the property of their respective owners.

2

C-compatible interface and a 500 mA current

minimize battery current draw during flash events. In addition,

a Tx-mask input permits the flash LED current to reduce quickly

and, therefore, the battery current reduces quickly, during a

GSM power amplifier current burst.

2

The I

C-compatible interface enables the programmability

of timers, currents, and status bit readback for operation

monitoring and safety control.

The ADP1655 comes in a compact 12-ball 0.5 mm pitch

WLCSP package and is specified over the full −40°C to

+125°C junction temperature range.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700 www.analog.com

Fax: 781.461.3113 ©2009 Analog Devices, Inc. All rights reserved.

ADP1655

http://www.BDTIC.com/ADI

TABLE OF CONTENTS

Features .............................................................................................. 1

Applications ....................................................................................... 1

Functional Block Diagram .............................................................. 1

General Description ......................................................................... 1

Revision History ............................................................................... 2

Specifications ..................................................................................... 3

Recommended Specifications: Input and Output Capacitance

and Inductance ............................................................................. 4

I2C-Compatible Interface Timing Specifications ..................... 5

Absolute Maximum Ratings ............................................................ 6

Thermal Data ................................................................................ 6

Thermal Resistance ...................................................................... 6

ESD Caution .................................................................................. 6

Pin Configuration and Function Descriptions ............................. 7

Typical Performance Characteristics ............................................. 8

Theory of Operation ...................................................................... 12

White LED Driver ...................................................................... 12

Assist Light and Torch Modes .................................................. 12

2-Bit Logic Interface Mode (I2C/EN = 0) ............................... 13

I2C Interface Mode (I2C/EN = 1) ............................................. 13

State Transitions ......................................................................... 15

I2C Register Map ............................................................................. 16

Safety Features ................................................................................. 19

Overvoltage Fault ....................................................................... 19

Output Capacitor Fault .............................................................. 19

Timeout Fault .............................................................................. 19

Overtemperature Fault .............................................................. 19

Short-Circuit Fault ..................................................................... 19

Current Limit .............................................................................. 19

Amount of LED Detection ........................................................ 19

Input Undervoltage .................................................................... 19

Applications Information .............................................................. 20

External Component Selection ................................................ 20

PCB Layout ...................................................................................... 22

Outline Dimensions ....................................................................... 23

Ordering Guide .......................................................................... 23

REVISION HISTORY

5/09—Revison 0: Initial Version

Rev. 0 | Page 2 of 24

ADP1655

http://www.BDTIC.com/ADI

SPECIFICATIONS

VIN = 3.6 V, TJ = −40°C to +125°C for minimum/maximum specifications and TA = 25°C for typical specifications, unless

otherwise noted.

Table 1.

Parameter1 Conditions Min Typ Max Unit

SUPPLY

Input Voltage Range 2.7 5.5 V

Undervoltage Lockout Threshold VIN falling 2.3 2.4 2.5 V

Hysteresis 50 100 150 mV

Shutdown Current TJ = −40°C to +85°C, current into VIN pin, VIN = 2.7 V to 4.5 V 0.3 1 μA

Standby Current TJ = −40°C to +85°C, current into VIN pin, VIN = 2.7 V to 4.5 V 3 10 μA

I2C/EN = SCL/EN1 = SDA/EN2 = 1.8 V

Operating Quiescent Current Torch mode, two LEDs, LED current = 40 mA 5.3 mA

SW Switch Leakage TJ = −40°C to +85°C 1 μA

INPUTS

Input Logic Low Voltage 0.54 V

Input Logic High Voltage 1.26 V

TORCH, STROBE, TX_MASK Pull-Down 350 kΩ

SCL/EN1, SDA/EN2 Pull-Down I2C/EN = 0 V 350 kΩ

TORCH Glitch Filtering Delay From TORCH rising edge to device start 6.3 9 11.7 ms

LED DRIVER

LED Current

Assist Light, Torch I2C/EN = 0, one LED 80 mA

I2C/EN = 0, two LEDs 40 mA

I2C/EN = 1, assist light value setting = 0 (000 binary) 20 mA

I2C/EN = 1, assist light value setting = 7 (111 binary) 160 mA

Flash I2C/EN = 0, one LED 500 mA

I2C/EN = 0, two LEDs 320 mA

I2C/EN = 1, flash value setting = 0 (0000 binary) 200 mA

I2C/EN = 1, one LED, flash value setting = 15 (1111 binary) 500 mA

LED Current Accuracy I

I

I

LED Current Source Headroom2 Flash typical, 400 mA LED current 290 mV

Torch 160 mA 190

LED_OUT Ramp-Up Time 1 ms

LED_OUT Ramp-Down Time 0.5 ms

Maximum Timeout For Flash 850 ms

Timer Accuracy −7.5 +7.5 %

SWITCHING REGULATOR

Switching Frequency 1.85 2 2.15 MHz

Minimum Duty Cycle 9.0 %

N-FET Resistance 135 mΩ

P-FET Resistance 290 mΩ

I2C/EN = 1, two LEDs, flash value setting = 10 to 15 (1010 to

1111 binary)

= 320 mA to 500 mA −5 +5 %

LED

= 60 mA to 320 mA −5 +10 %

LED

= 20 mA to 60 mA −5 +20 %

LED

400 mA

Rev. 0 | Page 3 of 24

ADP1655

http://www.BDTIC.com/ADI

Parameter1 Conditions Min Typ Max Unit

SAFETY FEATURES

Thermal Shutdown Threshold

TJ Rising 150 °C

TJ Falling 140 °C

Overvoltage Threshold 9.0 9.5 10.1 V

Coil Peak Current Limit Peak current value setting = 0 (00 binary) 1.13 1.25 1.38 A

Peak current value setting = 1 (01 binary) 1.35 1.5 1.65 A

Peak current value setting = 2 (10 binary) 1.58 1.75 1.93 A

Peak current value setting = 3 (11 binary) 1.8 2.0 2.2 A

LED_OUT Short-Circuit Detection

Comparator Reference Voltage

LED Counting Comparator

Threshold Voltage

LED value setting = 0 (00 binary) 4.3 V

LED value setting = 1 (01 binary) 4.6 V

LED value setting = 2 (10 binary) 4.0 V

LED value setting = 3 (11 binary) 4.9 V

1

All limits at temperature extremes are guaranteed via correlation using standard statistical quality control (SQC).

2

Two LEDs are used for this parameter.

RECOMMENDED SPECIFICATIONS: INPUT AND OUTPUT CAPACITANCE AND INDUCTANCE

1.2 1.3 V

Table 2.

Parameter Symbol Conditions Min Typ Max Unit

CAPACITANCE C

Input TA = −40°C to +125°C 4.0 μF

Output TA = −40°C to +125°C 4.0 20 μF

MINIMUM AND MAXIMUM INDUCTANCE L TA = −40°C to +125°C 1.5 2.8 μH

MIN

Rev. 0 | Page 4 of 24

ADP1655

A

http://www.BDTIC.com/ADI

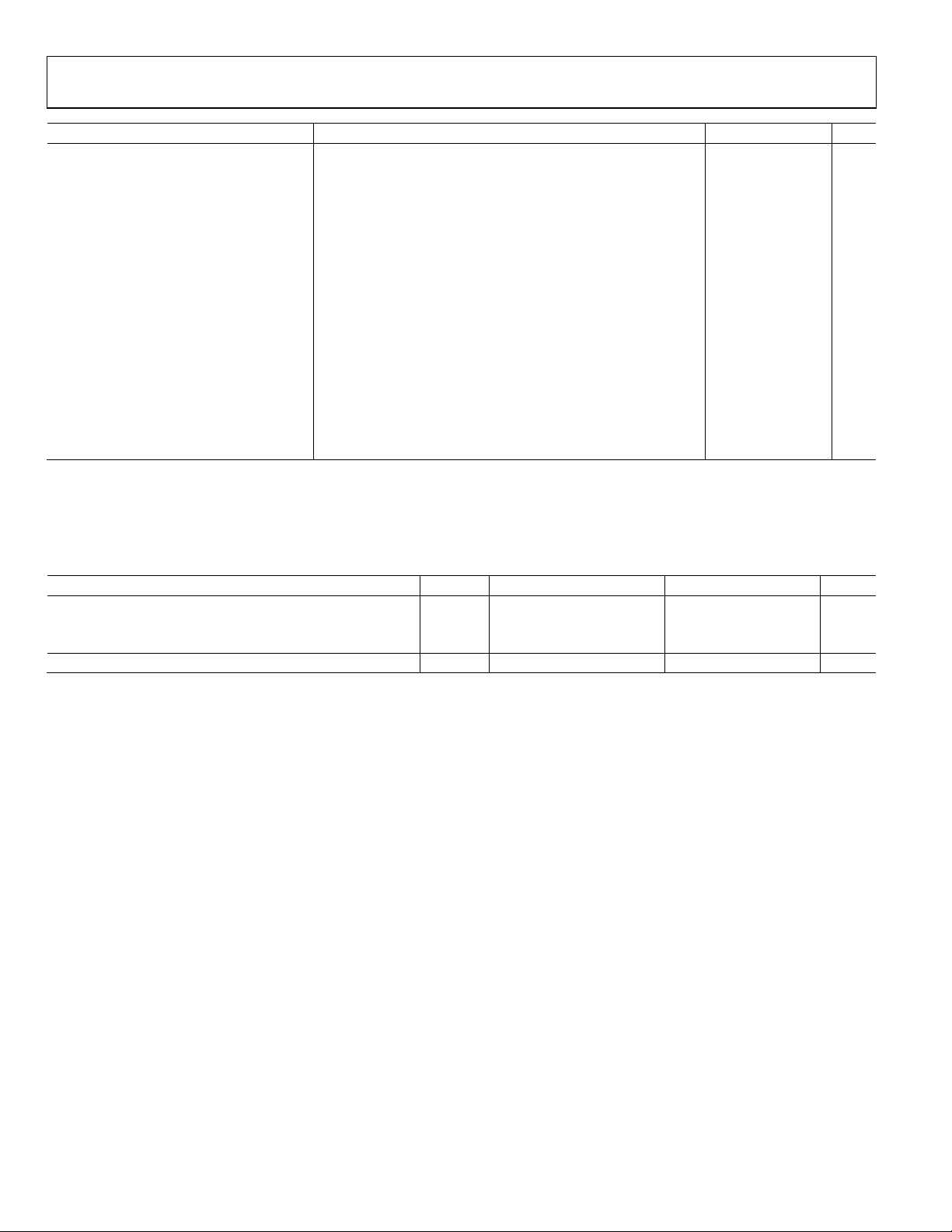

I2C-COMPATIBLE INTERFACE TIMING SPECIFICATIONS

Table 3.

Parameter1 Min Max Unit Description

f

SCL

t

HIGH

t

LOW

t

SU, DAT

t

0 0.9 μs Data hold time

HD, DAT

t

SU, STA

t

HD, STA

t

BUF

t

SU, STO

tR 20 + 0.1 C

tF 20 + 0.1 C

t

SP

CB 400 pF Capacitive load for each bus line

1

Guaranteed by design.

2

CB is the total capacitance of one bus line in picofarads.

400 kHz SCL clock frequency

0.6 μs SCL high time

1.3 μs SCL low time

100 ns Data setup time

0.6 μs Setup time for repeated start

0.6 μs Hold time for start/repeated start

1.3 μs Bus free time between a stop and a start condition

0.6 μs Setup time for stop condition

2

300 ns Rise time of SCL and SDA

B

B

300 ns Fall time of SCL and SDA

0 50 ns Pulse width of suppressed spike

SD

t

LOW

SCL

S

S = START CONDITION

Sr = REPEATED ST ART CONDITI ON

P = STOP CO NDITION

t

R

t

HD, DAT

t

SU, DAT

Figure 3. I

t

F

t

F

t

HIGH

2

C-Compatible Interface Timing Diagram

t

SU, STA

t

HD, STA

Sr P S

t

SP

t

SU, STO

t

BUF

t

R

08028-003

Rev. 0 | Page 5 of 24

ADP1655

http://www.BDTIC.com/ADI

ABSOLUTE MAXIMUM RATINGS

Table 4.

Parameter Rating

VIN, SDA/EN2, SCL/EN1, I2C/EN,

STROBE, TORCH, TX_MASK to SGND

LED_OUT, SW, VOUT to SGND −0.3 V to +12 V

PGND to SGND −0.3 V to +0.3 V

VOUT to LED_OUT −0.3 V to +6 V

Ambient Temperature Range (TA) −40°C to +85°C

Junction Temperature Range (TJ) −40°C to +125°C

Storage Temperature JEDEC J-STD-020

ESD Human Body Model ±2000 V

ESD Charged Device Model ±1000 V

ESD Machine Model ±200 V

−0.3 V to +6 V

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

THERMAL DATA

The ADP1655 may be damaged if the junction temperature

limits are exceeded. Monitoring T

is within the specified temperature limits. In applications with

high power dissipation and poor thermal resistance, the maximum

T

may have to be derated. In applications with moderate power

A

dissipation and low PCB thermal resistance, the maximum T

can exceed the maximum limit as long as the T

fication limits. T

of the device is dependent on the TA, the power

J

dissipation (PD) of the device, and the junction-to-ambient

thermal resistance (θ

calculated from the T

= TA + (PD × θJA)

T

J

) of the package. Maximum TJ is

JA

and PD using the following formula:

A

does not guarantee that TJ

A

is within speci-

J

A

THERMAL RESISTANCE

θJA of the package is based on modeling and calculation using

a 4-layer board. θ

is highly dependent on the application and

JA

board layout. In applications where high maximum power dissipation exists, attention to thermal board design is required. The

value of θ

environmental conditions. The specified value of θ

may vary, depending on PCB material, layout, and

JA

is based

JA

on a 4-layer, 4 in × 3 in, 2 1/2 oz copper board, per JEDEC

standards. For more information, see the AN-617 Application

Note, MicroCSP

θ

is specified for a device mounted on a JEDEC 2S2P PCB.

JA

TM

Wafer Level Chip Scale Package.

Table 3. Thermal Resistance

Package Type θJA Unit

12-Ball WLCSP 75 °C/W

ESD CAUTION

Rev. 0 | Page 6 of 24

ADP1655

http://www.BDTIC.com/ADI

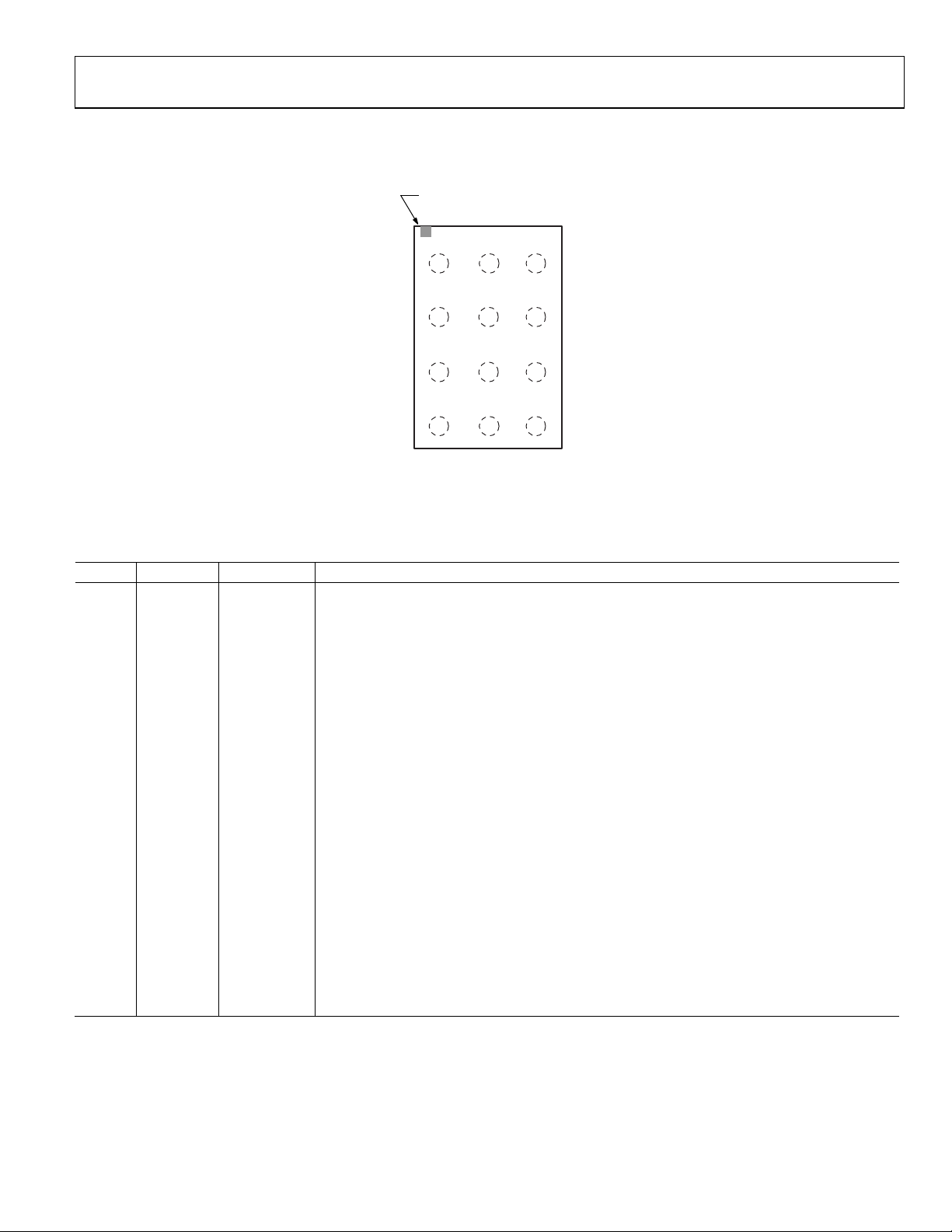

PIN CONFIGURATION AND FUNCTION DESCRIPTIONS

BALLA1

INDICATOR

1

PGND SGND VIN

A

23

SW

B

VOUT STROBE I2C/EN

C

LED_OUT SDA/EN2 SCL/EN1

D

(BALL SIDE DO WN)

Not to Scale

Figure 4. Pin Configuration

TORCH

TOP VIEW

TX_MASK

08028-004

Table 5. Pin Function Descriptions

Pin No. Mnemonic Type Description

A1 PGND Ground Ground for Internal Switching FET.

A2 SGND Ground Connect this pin at a single point to the power ground.

A3 VIN Supply

Connect the battery between VIN and PGND. Bypass VIN with a 10 μF, 6.3 V or greater X5R/X7R

capacitor.

B1 SW Output Connect a 2.2 μH inductor between SW and the battery.

B2 TORCH Digital Input This pin enables the torch, provided that the device is not in flash or assist light mode.

B3 TX_MASK Digital Input

Connect a digital signal to the TX_MASK pin. When the logic level is driven high during a flash

event the current is reduced to the torch level.

C1 VOUT Output

VOUT senses the output voltage of the boost converter and provides the input voltage to the LED

current source. The VOUT pin features a comparator to detect an overvoltage condition if the LED

string is open circuited. Connect a 10.0 μF capacitor between VOUT and PGND.

C2 STROBE

Digital Input/

Output

The STROBE input is used to synchronize the timing of the camera module to the LED driver in

2

I

C-compatible interface mode. In 2-bit logic interface mode, this acts as an output, indicating the

number of LEDs attached. STROBE = high indicates two LEDs, whereas STROBE = low indicates

one LED.

C3 I2C/EN Digital Input

A logic low selects the 2-bit logic interface, whereas logic high selects I

2

C-compatible interface. If

I2C/EN is low and SDA/EN2 and SCL/EN1 are low, the driver enters shutdown mode with

consumption < 1 μA.

D1 LED_OUT Output

White LED Anode Connection. Connect LED_OUT to the anode of the white LED. LED_OUT is

internally connected to a programmable PMOS current source, which regulates the LED current.

D2 SDA/EN2

D3 SCL/EN1 Digital Input

Digital Input/

Output

Data Input/Output (SDA). In 2-bit logic interface mode, SDA/EN2 is the second input bit of the

digital interface.

Second Input Bit (EN2). In I

Clock Input (SCL). In 2-bit logic interface mode, SCL/EN1 is the first input bit of the digital interface.

First Input Bit (EN1). In I

2

C mode, SDA is the data input/output of the I2C-compatible interface.

2

C mode, SCL is the clock input of the I2C-compatible interface.

Rev. 0 | Page 7 of 24

Loading...

Loading...