Constant-Frequency, Current-Mode

www.BDTIC.com/ADI

FEATURES

92% efficiency (no sense resistor required)

±1.0% initial accuracy

IC supply voltage range: 2.9 V to 5.5 V

Power-input voltage as low as 1.0 V

Capable of high supply input voltage (>5.5 V)

with an e

UVLO and 35 mA shunt regulator

V

IN

External slope compensation with 1 resistor

Programmable operating frequency

(100 k

Lossless current sensing for switch-node voltage <30 V

Resistor current sensing for switch-node voltage >30 V

Synchronizable to external clock

Current-mode operation for excellent line and load transient

r

esponses

10 μA shutdown current

Current limit and thermal overload protection

Soft start in 2048 clock cycles

APPLICATIONS

APD bias

Portable electronic equipment

Isolated dc/dc converter

Step-up/step-down dc/dc converter

LED driver for laptop computer and navigation system

LCD backlighting

GENERAL DESCRIPTION

The ADP1621 is a fixed-frequency, pulse-width modulation

(PWM), current-mode, step-up converter controller. It drives an

external n-channel MOSFET to convert the input voltage to a

higher output voltage. The ADP1621 can also be used to drive

flyback, SEPIC, and forward converter topologies, either isolated

or nonisolated.

The ADP1621 eliminates the use of a current-sense power

sistor by measuring the voltage drop across the on resistance

re

of the n-channel MOSFET. This technique, allowed up to a

maximum voltage of 30 V at the switch node, maximizes

efficiency and reduces cost. For switch-node voltages higher than

30 V or for more accurate current limiting, the CS pin can be

connected to a current-sense resistor in the source of the MOSFET.

The slope compensation is implemented by an external resistor,

allowing a wide range of external components (inductors and

MOSFETs), and can be chosen for various switching frequencies

and input and output voltages.

The ADP1621 supply input voltage range is 2.9 V to 5.5 V, although

hig

her input voltages are possible with the use of a small-signal

Rev. A

Information furnished by Analog Devices is believed to be accurate and reliable. However, no

responsibility is assumed by Anal og Devices for its use, nor for any infringements of patents or ot her

rights of third parties that may result from its use. Specifications subject to change without notice. No

license is granted by implication or otherwise under any patent or patent rights of Analog Devices.

Trademarks and registered trademarks are the property of their respective owners.

xternal NPN or a resistor

Hz to 1.5 MHz) with 1 resistor

Step-Up DC/DC Controller

ADP1621

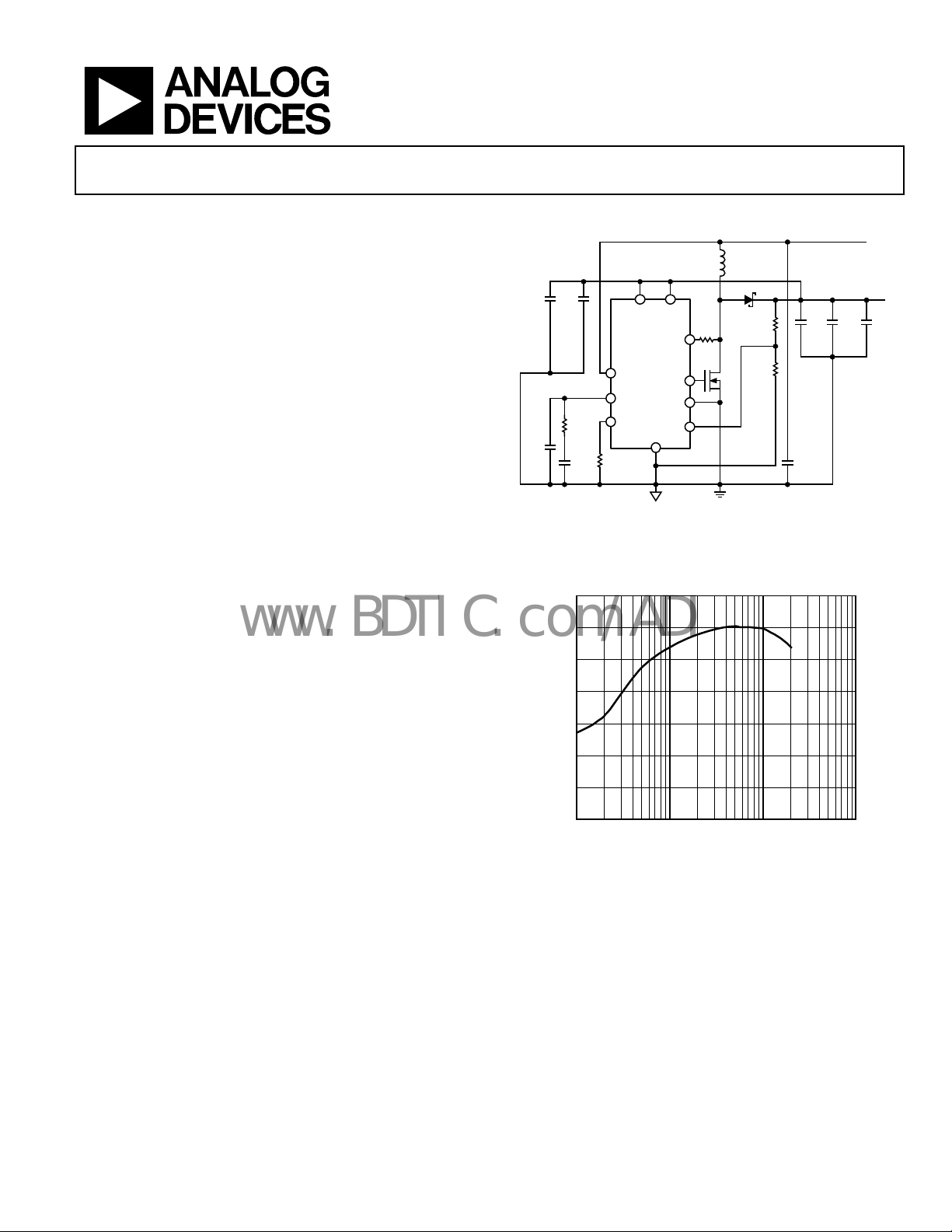

TYPICAL APPLICATION CIRCUIT

L1

4.7µH

D1

C3

C4

1µF

0.1µF

10V

10V

SDSN

COMP

R

COMP

COMP

R

FREQ

31.6kΩ

1%

FREQ

9.09kΩ

C2

120pF

C

1.8nF

f

= 600kHz

OSC

C1 = MURATA GRM31CR60J476M

C

= SANYO POSCAP 6TPE150M

OUT3

L1 = TOKO FDV0630-4R7M

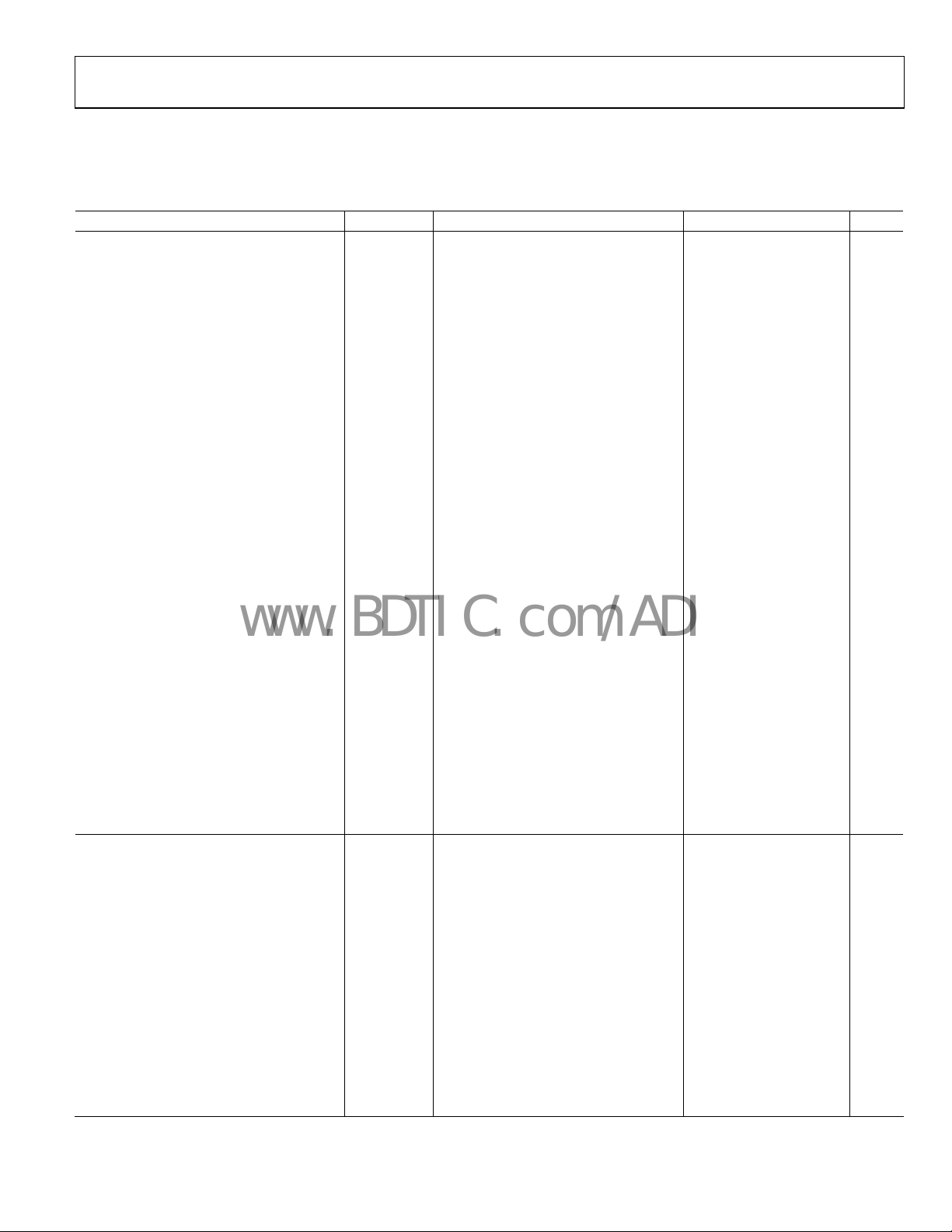

Figure 1. High Efficiency Output Bo

3.3 V Input, 5 V Output (Bootstrapped)

100

90

80

70

60

EFFICIENCY (%)

50

40

30

0.01 10

Figure 2. Efficiency of Circuit Shown in Figure 1

NPN pass transistor or a single resistor. The voltage of the

power input can be as low as 1 V for fuel cell applications. The

switching frequency is set by an external resistor over a range of

100 kHz to 1.5 MHz and can be synchronized to an external

clock by using the SDSN pin. The shutdown quiescent current is

less than 10 μA. The ADP1621 has a thermal shutdown feature

that shuts down the gate driver when the junction temperature

reaches approximately 150°C. The internal soft start circuit limits

inrush current at startup. The ADP1621 is available in the 10-lead

MSOP lead-free package and is specified over the −40°C to +125°C

junction temperature range.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700 www.analog.com

Fax: 781.461.3113 ©2006 Analog Devices, Inc. All rights reserved.

IN

PIN

CS

ADP1621

GATE

PGND

FB

GND

AGND

M1 = VISHAY Si7882DP

D1 = VISHAY SSA33L

0.1 1

LOAD CURRENT (A)

R

35.7kΩ

S

80Ω

11.5kΩ

M1

ost Converter in Lossless Mode,

V

= 3.3V

IN

R1

1%

C

OUT1

1µF

10V

R2

1%

C1

47µF

6.3V

C

10µF

10V

OUT2

V

= 5V

OUT

1A

C

OUT3

150µF

6.3V

×2

06090-001

06090-042

ADP1621

www.BDTIC.com/ADI

TABLE OF CONTENTS

Features.............................................................................................. 1

Applications....................................................................................... 1

General Description ......................................................................... 1

Typical Application Circuit ............................................................. 1

Revision History ............................................................................... 2

Specifications..................................................................................... 3

Absolute Maximum Ratings............................................................ 5

Thermal Resistance ...................................................................... 5

ESD Caution.................................................................................. 5

Simplified Block Diagram ............................................................... 6

Pin Configuration and Function Descriptions............................. 7

Typical Performance Characteristics ............................................. 8

Theory of Operation ...................................................................... 12

Control Loop............................................................................... 12

Current-Sense Configurations.................................................. 12

Current Limit.............................................................................. 13

Undervoltage Lockout ............................................................... 13

Shutdown..................................................................................... 13

Soft Start ...................................................................................... 13

Internal Shunt Regulators.......................................................... 13

Setting the Oscillator Frequency and Synchronization

Frequency .................................................................................... 13

Application Information: Boost Converter................................. 14

Duty Cycle................................................................................... 14

Setting the Output Voltage........................................................ 14

Inductor Current Ripple............................................................ 14

Inductor Selection...................................................................... 14

Input Capacitor Selection.......................................................... 15

Output Capacitor Selection....................................................... 15

Diode Selection........................................................................... 15

MOSFET Selection..................................................................... 16

Loop Compensation .................................................................. 16

Slope Compensation.................................................................. 17

Current Limit.............................................................................. 18

Light Load Operation ................................................................ 18

Recommended Component Manufacturers........................... 19

Layout Considerations................................................................... 20

Efficiency Considerations ............................................................. 21

Examples of Application Circuits................................................. 22

Standard Boost Converter—Design Example........................ 22

Bootstrapped Boost Converter................................................. 23

SEPIC Converter Circuit........................................................... 27

Low Voltage Power-Input Circuit ............................................ 27

LED Driver Application Circuits ............................................. 28

Related Parts.................................................................................... 30

Outline Dimensions....................................................................... 31

Ordering Guide .......................................................................... 31

REVISION HISTORY

12/06—Rev. 0 to Rev. A

Changes to Table 1............................................................................ 3

Changes to Table 2............................................................................ 5

Added Table 3.................................................................................... 5

Changes to Table 5.......................................................................... 19

Changes to Ordering Guide.......................................................... 31

7/06—Revision 0: Initial Version

Rev. A | Page 2 of 32

ADP1621

www.BDTIC.com/ADI

SPECIFICATIONS

VIN = 5 V, R

Table 1.

Parameter Symbol Conditions Min Typ Max Unit

MAIN CONTROL LOOP

Internal Soft Start Time tSS 2048 Cycles

PIN Supply Voltage

IN Supply Voltage

Shunt Regulation Voltage V

I

Shunt Resistance R

Current into PIN = 8 mA to 12 mA 7 Ω

IN Quiescent Current IIN V

IN Shutdown Current VIN = 2.9 V to 5.5 V, SDSN = GND 1 10 μA

PIN Supply Current I

Static Mode, No Switching VFB = 1.3 V, V

Shutdown Mode SDSN = GND 1 10 μA

Undervoltage Lockout Threshold at

IN Pin

FB Regulation Voltage VFB T

1.197 1.215 1.233 V

FB Input Current IFB V

Line Regulation

2.9 V ≤ VIN ≤ 5 V, TJ = −40°C to +125°C 0.02 0.072 %/V

Load Regulation

Error Amplifier Transconductance gm 300 μS

COMP Zero-Current Threshold V

COMP Clamp High Voltage V

T

Current-Sense Amplifier Gain n 7.5 9.5 11.5 V/V

Peak Slope-Compensation Current at

CS Pin

CS Pin Leakage Current I

Shutdown Time tSD SDSN pin from high to low or left floating 50 μs

Thermal Shutdown Threshold

Thermal Shutdown Hysteresis

OSCILLATOR

Oscillator Frequency Range

Oscillator Frequency f

Oscillator Frequency Tempco f

SDSN Input Level Threshold V

SDSN Threshold Hysteresis −0.19 V

SDSN Internal Pull-Down Resistor R

Synchronization Minimum Pulse Width t

Synchronization Maximum Pulse Width t

Synchronization Frequency f

GATE Minimum On Time t

GATE Minimum Off Time t

Maximum Duty Cycle

Recommended Maximum

Synchronized Frequency Ratio

= 100 kΩ, f

FREQ

4

= 200 kHz, TJ = −40°C to 125°C, unless otherwise noted.

OSC

1

1

2

3

5

5

6

6, 7

6, 8

V

2.9 V

PIN

VIN 2.9 V

I

SHUNT

Current into IN = 8 mA to 12 mA 13 Ω

SHUNT

PIN

V

V

UVLO

V

= 3 mA, I

IN

= 3 mA, I

IN

= 2.9 V to 5.5 V, VFB = 1.215 V 1.8 3 mA

IN

rising 2.2 2.5 2.8 V

UVLO

hysteresis −80 mV

UVLO

= 25°C 1.203 1.215 1.227 V

A

= 1.215 V, TA = 25°C −75 +25 +75 nA

FB

= 3 mA, TA = 25°C 5.4 5.6 5.7 V

PIN

= 3 mA 5.2 5.6 6.0 V

PIN

COMP

< V

, GATE = 0 V 1 10 μA

COMP,ZCT

SHUNT

SHUNT

V

V

∆VFB/∆VIN 2.9 V ≤ VIN ≤ 5 V, TJ = −40°C to +85°C 0.02 0.06 %/V

∆VFB/∆V

COMP,ZCT

COMP,CLAMP

I

SC,PK

CS,LEAK

T

TMSD

COMP

V

= 1.4 V to 1.5 V −1 −0.1 %

COMP

0.85 1.0 1.15 V

TJ = −40°C to +85°C 1.9 2.0 2.1 V

= −40°C to +125°C 1.9 2.0 2.2 V

J

= 0 V to 100 mV maximum

V

CS

across R

V

= 30 V (GATE low) 5 μA

CS

(GATE high)

S

55 70 85 μA

150 °C

−10 °C

f

100 1500 kHz

OSC

R

OSC

±0.06 %/°C

OSC,TC

SDSN,THRESH

SDSN

SYNC,MIN

SYNC,MAX

SYNC

ON,MIN

OFF,MIN

D

MAX

f

SYNC/fOSC

VIN = V

100 kΩ

V

V

110 1800 kHz

V

V

f

f

= 65 kΩ, TA = 25°C 255 325 395 kHz

FREQ

= 5 V 1.5 1.7 1.9 V

PIN

= 0 V to VIN 45 100 ns

SDSN

= 0 V to VIN 0.8/f

SDSN

= 1.215 V, V

FB

= 1.215 V, V

FB

= 200 kHz, R

SW

= 200 kHz, R

OSC

= 1.0 V 180 215 ns

COMP

= 2.0 V 190 230 ns

COMP

= 100 kΩ 93 97 %

FREQ

= 100 kΩ, f

FREQ

= fSW 1.1 1.2 1.4

SYNC

ns

SYNC

Rev. A | Page 3 of 32

ADP1621

www.BDTIC.com/ADI

Parameter Symbol Conditions Min Typ Max Unit

GATE DRIVER

GATE Rise Time

GATE Fall Time

1

The maximum input voltage is the shunt regulation voltage, which is typically 5.5 V and can range from 5.3 V to 6.0 V over the specified temperature range.

2

The ADP1621 is tested in a feedback servo loop, which servos VFB to the internal reference voltage. The voltage change in FB is measured while VIN is changed from

2.9 V to 5 V. The line regulation is calculated by (∆VFB/VFB) × 100%/∆VIN.

3

The ADP1621 is tested in a feedback servo loop, which servos VFB to the internal reference voltage, and V

(1.0 V ≤ V

4

The peak slope-compensation current at the CS pin is typically 70 μA, and effectively clamped at 116 mV. Thus, RS should not exceed 1.6 kΩ (116 mV/70 μA).

5

Guaranteed by design for thermal shutdown. When the thermal junction temperature of the ADP1621 reaches approximately 150°C, the ADP1621 goes into thermal

COMP

shutdown and the GATE voltage is pulled low. When the junction temperature drops below about 140°C, the soft start sequence is initiated and the ADP1621 resumes

normal operation.

6

f

is the natural oscillation frequency, f

OSC

7

Guaranteed by design and bench characterization.

8

To ensure proper synchronization operation, set the synchronization frequency, f

be synchronized to as high as 1.8 MHz, the peak slope-compensation current decreases at higher synchronization frequencies. It is recommended that the maximum

f

be less than 1.4× of f

SYNC

Compensation section in the Application Information: Boost Converter section).

9

GATE rise and fall times are measured from 10% to 90% levels.

9

≤ 2.0 V).

9

is the synchronization frequency, and fSW is the switching frequency. If synchronization is used, then fSW = f

SYNC

and should not exceed 1.8 MHz. The slope-compensation resistor, RS, should be chosen for the synchronization frequency (see the Slope

OSC

tR C

tF C

= 3.3 nF 17 ns

GATE

= 3.3 nF 13 ns

GATE

, to 1.2× of the free-running frequency, f

SYNC

is forced from 1.4 V to 1.5 V. The V

COMP

. Although the switching frequency can

OSC

range is

COMP

; otherwise, fSW = f

SYNC

OSC

.

Rev. A | Page 4 of 32

ADP1621

www.BDTIC.com/ADI

ABSOLUTE MAXIMUM RATINGS

Table 2.

Parameter Rating

IN to GND −0.3 V to V

FB, COMP, SDSN, FREQ, GATE to GND −0.3 V to (VIN + 0.3 V)

CS to GND −5 V to +33 V

PIN to PGND −0.3 V to V

Supply Current into IN 25 mA

Supply Current into PIN 35 mA

Storage Temperature Range −55°C to +150°C

Junction Operating Temperature Range1 −55°C to +150°C

Junction Storage Temperature Range −55°C to +150°C

Lead Temperature (Soldering, 10 sec) 300°C

Package Power Dissipation1 (T

1

In applications where high power dissipation and poor package thermal

resistance are present, the maximum ambient temperature may need to be

derated. Maximum ambient temperature (TA,MAX) is dependent on the

maximum operating junction temperature (TJ,MAX = 150oC), the maximum

power dissipation of the device in the application (PD,MAX), and the junctionto-ambient thermal resistance of the package in the application (θ

by the following equation: T

A,MAX = TJ,MAX --- (θJA x PD,MAX).

J,MAX

− TA)/θJA

SHUNT

SHUNT

JA), is given

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

Absolute maximum ratings apply individually only, not in

mbination. Unless otherwise specified, all other voltages are

co

referenced to GND.

THERMAL RESISTANCE

θJA is specified for the worst-case conditions, that is, a device

soldered in a circuit board for surface-mount packages.

Table 3. Thermal Resistance

Package Type θJA Unit

10-lead MSOP on a 2-layer PCB 200 °C/W

10-lead MSOP on a 4-layer PCB 172 °C/W

Junction-to-ambient thermal resistance of the package is based

on modeling and calculation using 2-layer and 4-layer boards,

and natural convection. The junction-to-ambient thermal

resistance is application- and board-layout dependent. In

applications where high maximum power dissipation exists,

attention to thermal dissipation issues in board design is

required.

ESD CAUTION

Rev. A | Page 5 of 32

ADP1621

www.BDTIC.com/ADI

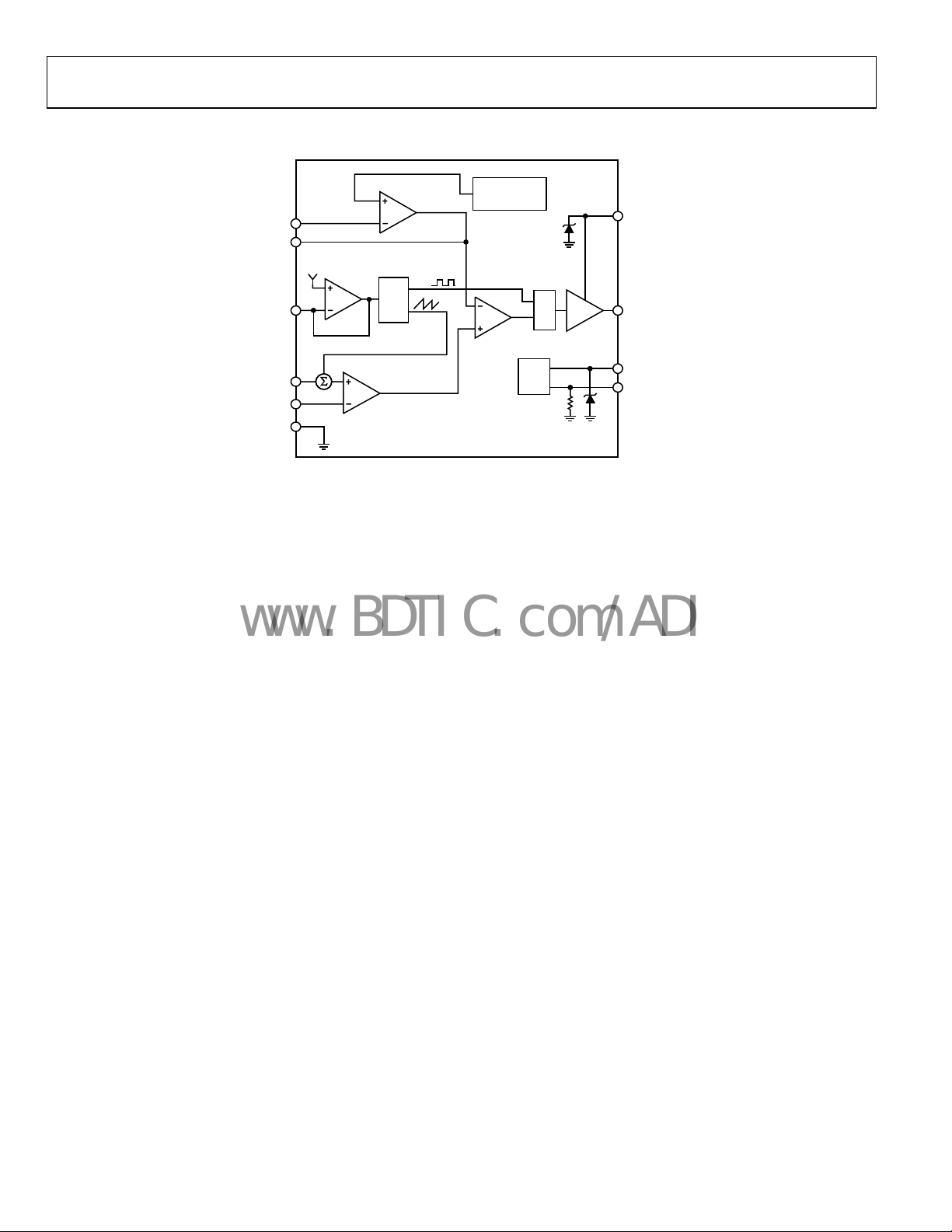

SIMPLIFIED BLOCK DIAGRAM

FB

COMP

V

OSC

1.4V

FREQ

+

+

CS

PGND

GND

V

REF

1.215V

ERROR

AMPLIFIER

g

m

SET

OSC

SLOPE

COMP

n

SOFT START

(2048 CYCLES)

PWM

COMPARATOR

Figure 3. ADP1621 Simplified Block Diagram

UVLO

5.5V

S

R

100kΩ

ADP1621

GATE

DRIVER

5.5V

PIN

GATE

IN

SDSN

06090-002

Rev. A | Page 6 of 32

ADP1621

C

www.BDTIC.com/ADI

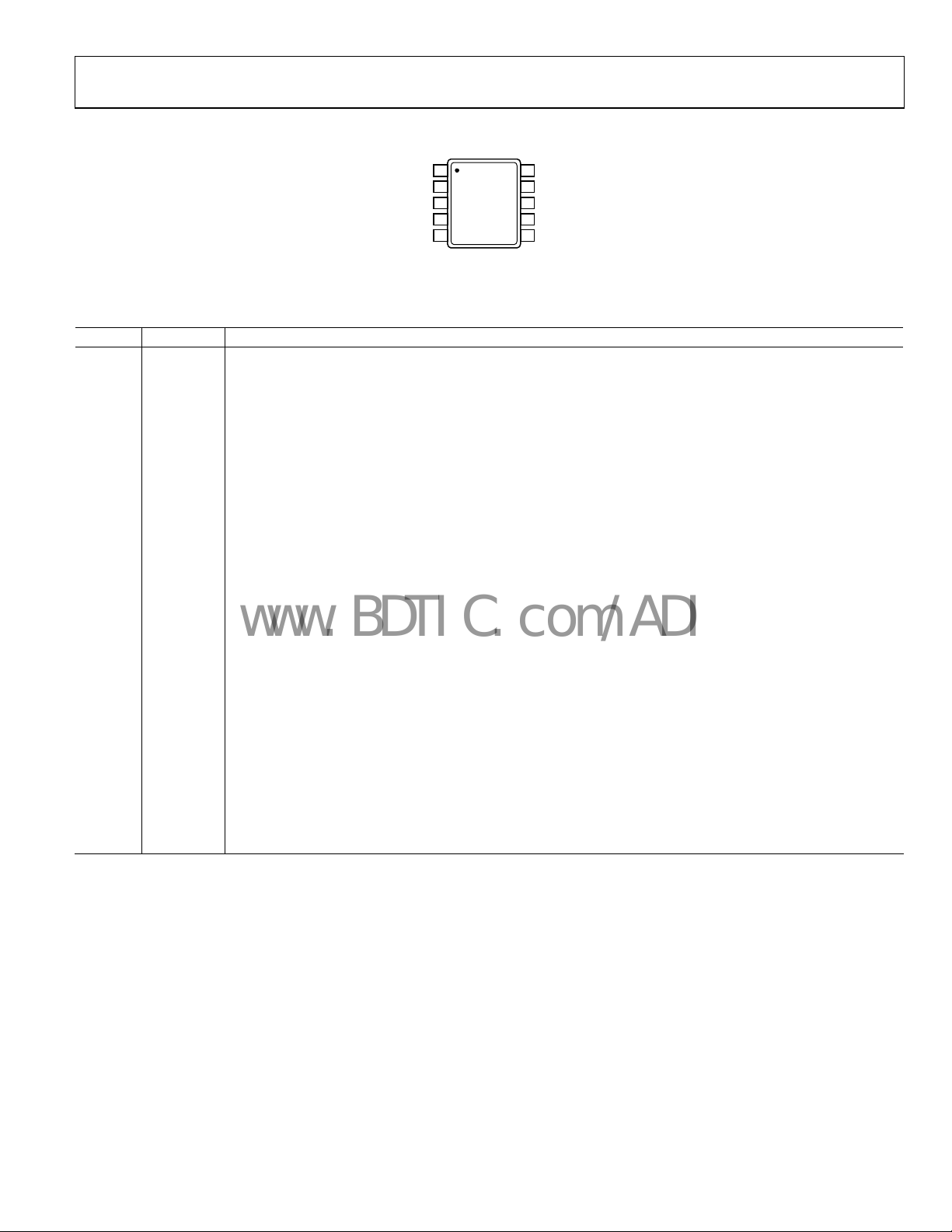

PIN CONFIGURATION AND FUNCTION DESCRIPTIONS

Table 4. Pin Function Descriptions

Pin No. Mnemonic Description

1 SDSN

Shutdown and Synchronization Input. Tur

If SDSN is left floating or when the SDSN is pulled low, the ADP1621 goes into shutdown after 50 μs. If synchronization is

needed, synchronize the switching frequency to an external clock by connecting the external clock to the SDSN

pin. An internal 100 kΩ pull-down resistor is connected from SDSN to GND.

2 GND Ground.

3 COMP

Regulation Control Compensation Node. COMP is the output of

Connect a series RC from COMP to GND to compensate the regulator. The nominal voltage range for this pin is

1.0 V to 2.0 V.

4 FB

Feedback Input. FB is the input to the in

through a resistive voltage divider. The ratio of the voltage divider sets the output voltage. The regulation voltage

at FB is nominally 1.215 V.

5 FREQ

Frequency Control Input. Connect a resistor from FREQ t

between 100 kHz and 1.5 MHz. The nominal voltage of this pin is 1.4 V.

6 PGND

Power Ground Input. PGND is the ground return for the inter

current-sense amplifier. Connect PGND to GND as close to the ADP1621 as possible.

7 GATE

Gate Driver Output. The maximum gate driver output is equal t

external n-channel power MOSFET. Connect GATE to the gate of the MOSFET.

8 PIN

Power Input. PIN powers the gate driver output. An internal 5.5 V shunt regulat

PIN to PGND with a 0.1 μF or greater capacitor.

9 CS

Current-Sense Input. CS is the positive input of the current-se

the CS pin increases linearly from 0 V to a maximum of 116 mV, and the nominal peak slope-compensation output

current is 70 μA. When GATE is off, the CS function is disabled. For current sensing in lossless mode, connect CS to

the drain of the power MOSFET. The absolute maximum voltage at CS is 33 V. For higher accuracy current sensing

or higher switch-node voltages, connect CS to a current-sense power resistor in the source of the power MOSFET.

In both sensing methods, it is required to add a slope-compensation resistor, R

in the inductor current for duty cycles greater than 50%. However, it is recommended to add R

because load transients can momentarily cause the duty cycle to be greater than 50%, even when the steady-

state duty cycle is less than 50%.

10 IN

Input Voltage. IN powers the ADP1621 internal circuitry. An in

Bypass IN to GND with a 0.1 μF or greater capacitor.

1

SDSN

GND

2

OMP

FREQ

ADP1621

3

TOP VIEW

(Not to Scale)

FB

4

5

Figure 4. Pin Configuration

n the ADP1621 on by driving SDSN high; turn it off by driving SDSN low.

ternal transconductance error amplifier. Drive FB from the output voltage

10

IN

CS

9

PIN

8

GATE

7

6

PGND

06090-003

the internal transconductance error amplifier.

o GND to set the free-running switching frequency

nal gate driver and the negative input of the internal

o the PIN voltage. GATE drives the gate of the

or is connected to this pin. Bypass

nse amplifier. When GATE is turned on, the voltage at

, to the CS pin to achieve stability

S

ternal 5.5 V shunt regulator is connected to this pin.

for all duty cycles

S

Rev. A | Page 7 of 32

ADP1621

www.BDTIC.com/ADI

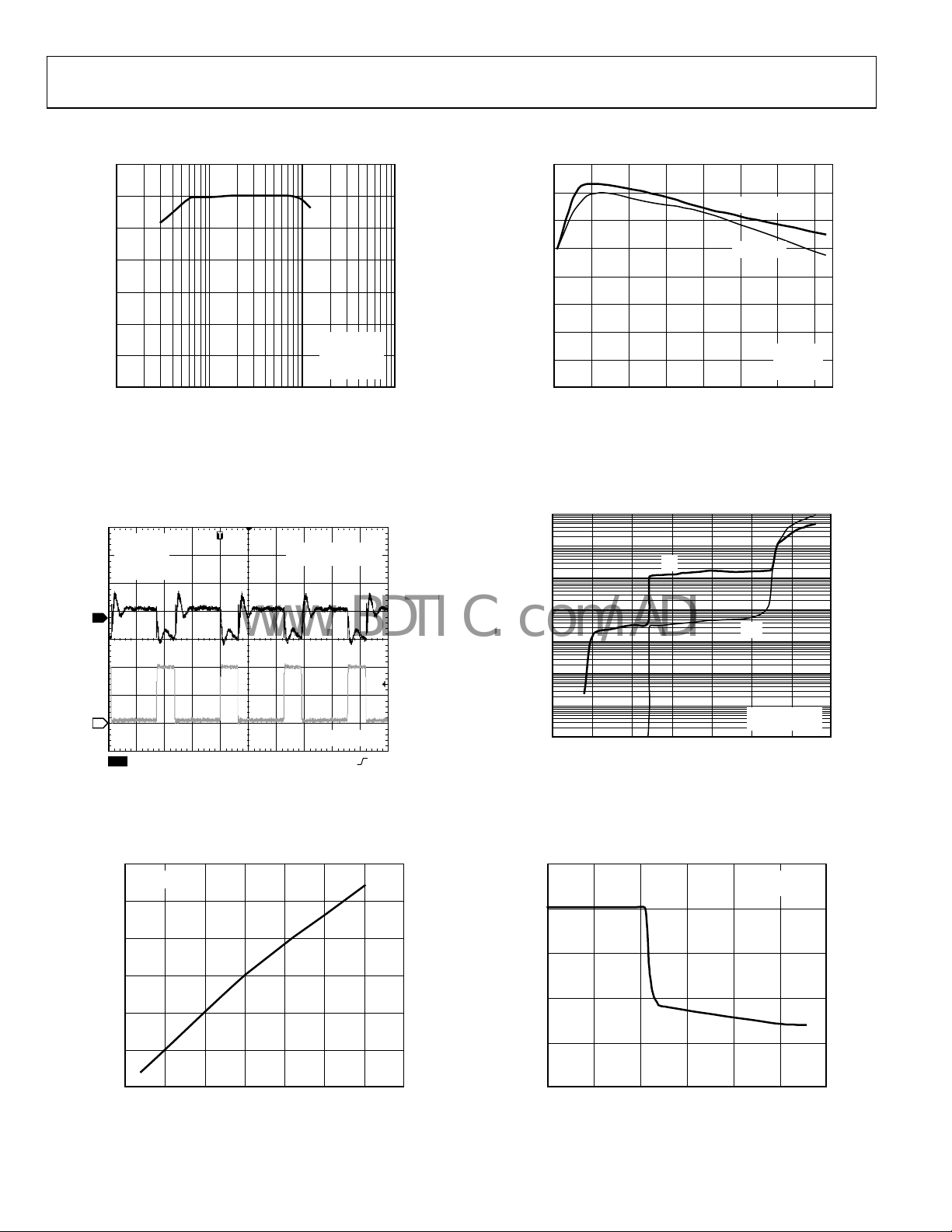

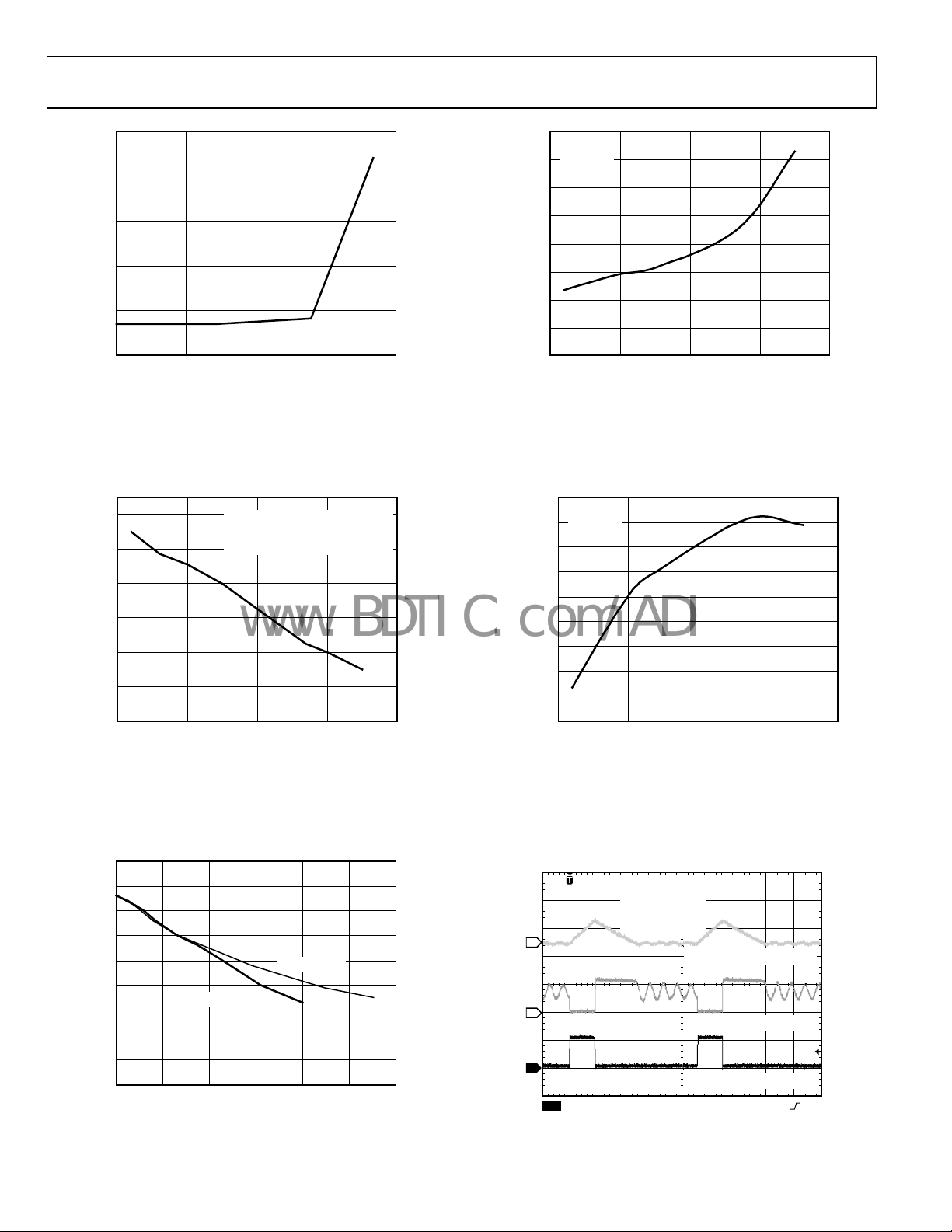

TYPICAL PERFORMANCE CHARACTERISTICS

100

92

90

80

70

60

EFFICIENCY (%)

50

40

30

0.01 10

0.1 1

LOAD CURRENT (A)

TA = 25°C

f

= 220kHz

SW

V

= 3.3V

IN

V

= 5V

OUT

Figure 5. Efficiency vs. Load Current

1

TA = 25°C

= 3.3V

V

IN

= 5V

V

OUT

LOAD = 1A

V

RIPPLES @ 5V

OUT

AC-COUPLED

91

90

89

88

87

EFFICIENCY (%)

86

85

84

100

300 500 700 900 1100 1300 1500

06090-004

SWITCHING FREQUENCY (kHz)

LOAD = 0.5A

LOAD = 1A

TA = 25°C

V

V

= 3.3V

IN

OUT

= 5V

06090-007

Figure 8. Efficiency vs. Switching Frequency

100

10

1

0.1

0.01

I

IN

I

PIN

2

CH1 20mV CH2 2V M 2µs A CH2 2.6V

CH2 = GATE

Figure 6. Output Voltage Ripple of the Circuit Shown in Figure 1

1.21605

TA=25°C

1.21600

1.21595

(V)

1.21590

FB

V

1.21585

1.21580

1.21575

2.5 6.0

3.0 3 .5 4.0 4.5 5.0 5.5

V

(V)

IN

Figure 7. V

vs. VIN

FB

0.001

SUPPLY CURRENT (mA)

0.0001

0.00001

07

123456

6090-005

SUPPLY VOLTAGE (V)

TA = 25°C

NO SWITCHING

06090-008

Figure 9. Supply Current vs. Supply Voltage

2.5

2.0

1.5

(V)

COMP

V

1.0

0.5

0

1.17 1.29

1.19 1. 21 1.23 1.25 1.27

V

06090-006

Figure 10. V

FB

(V)

COMP

vs. VFB

TA = 25°C

V

= 5V

IN

06090-009

Rev. A | Page 8 of 32

ADP1621

www.BDTIC.com/ADI

45

40

35

30

25

20

15

PIN SUPPLY CURRENT (mA)

10

5

0

0 1800

200 400 600 800 1000 1200 1400 1600

SWITCHING FREQUENCY (kHz)

MOSFET QG = 25nC

MOSFET QG = 15nC

MOSFET QG = 7nC

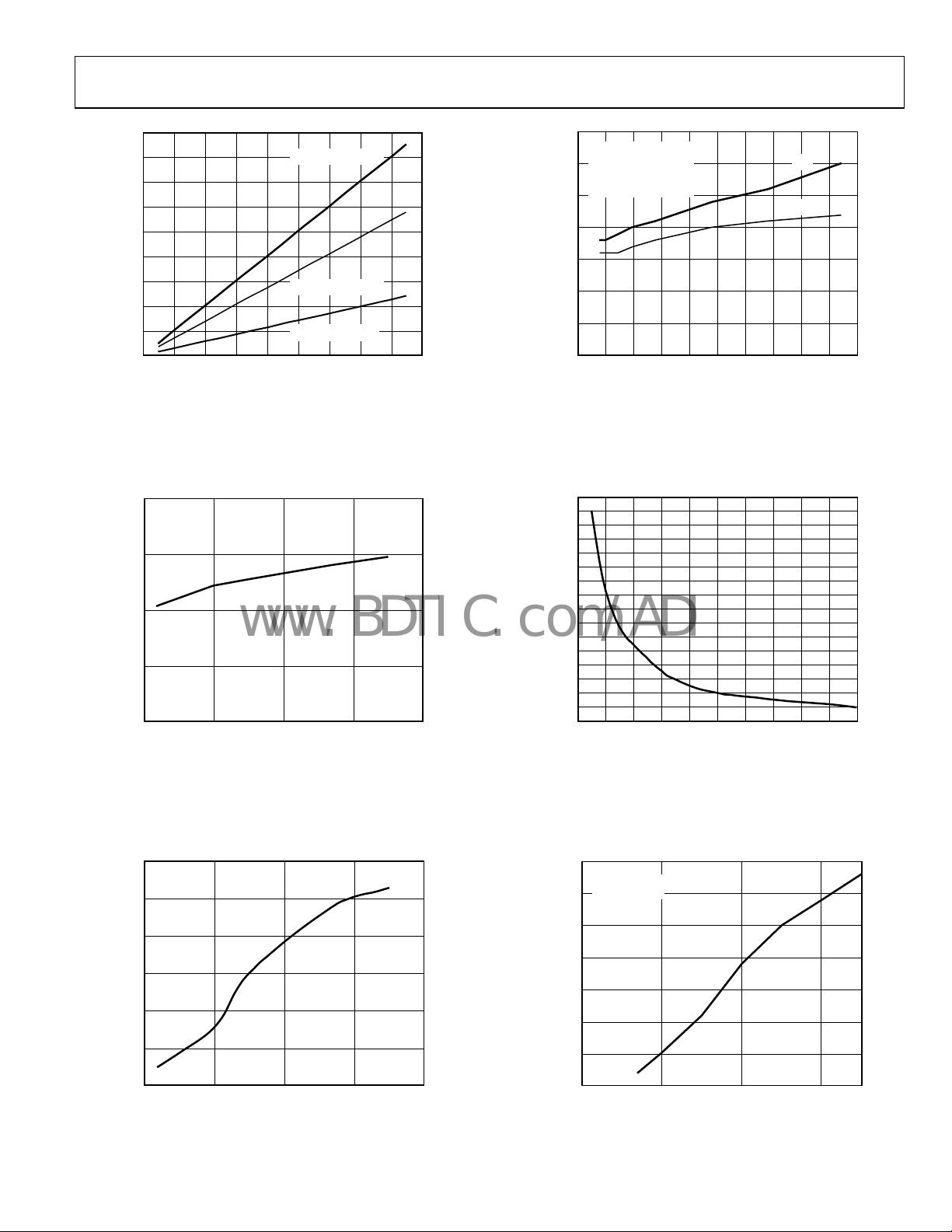

Figure 11. PIN Supply Current vs. Switching Frequency

06090-010

35

TA = 25°C

V

= V

= 5V

IN

30

25

20

15

10

GATE RISE AND FALL TI MES (ns)

5

0

PIN

t

OR

t

IS FROM

R

F

10% TO 90% O F

THE GATE VOLTAGE

05

5 1015202530354045

GATE CAPACITANCE (nF)

Figure 14. GATE Rise and

Fall Times vs. C

t

R

t

GATE

F

0

06090-013

2.60

SDSN = 5V

2.55

(V)

2.50

UVLO

V

2.45

2.40

–50 150

1.03

)

VIN = 5V

1.02

OSC,25°C

f

/

OSC

1.01

f

1.00

0.99

0.98

NORMALIZE D FREQUENCY (

0.97

–50 150

0 50 100

TEMPERATURE (° C)

Figure 12. V

Threshold vs. Temperature

UVLO

0 50 100

TEMPERATURE (° C)

Figure 13. Frequency vs. Temperature

1600

1500

1400

1300

1200

1100

1000

900

(kHz)

800

700

OSC

f

600

500

400

300

200

100

0

0 200

20 40 60 80 100 120 140 160 180

R

06090-011

Figure 15. Oscillator Freq

198

TA = 25°C

R

= 100kΩ

FREQ

197

196

195

(kHz)

OSC

194

f

193

192

191

2

06090-012

345

Figure 16. Oscillator Freq

(kΩ)

FREQ

uency vs. Resistance

V

(V)

IN

uency vs. V

06090-014

06090-015

IN

Rev. A | Page 9 of 32

ADP1621

www.BDTIC.com/ADI

250

VIN = 5V

CS = 30V

200

1.6

1.4

1.2

VIN = 5V

SDSN = 0V

150

100

TEMPERATURE ( °C)

50

0

–40 160

10 60 110

CS LEAKAGE (n A)

Figure 17. Temperature vs. CS Leakage

8

4

0

–4

–8

FB BIAS CURRENT (n A)

–12

–16

–50 150

VFB = 1.2113V AT 25° C

FB BIAS CURRENT I S MEASURED

BY FORCING A CONSTANT 1. 2113V

OVER THE T EMPERATURE RANGE .

0 50 100

TEMPERATURE (° C)

Figure 18. FB Bias Current vs. Temperature

1.0

0.8

0.6

0.4

SHUTDOWN IN CURRENT (µA)

0.2

0

–50 150

06090-016

0 50 100

TEMPERATURE (° C)

06090-019

Figure 20. Shutdown IN Current vs. Temperature

1.2165

VIN = 5V

1.2160

SDSN = 0V

1.2155

1.2150

1.2145

(V)

FB

V

1.2140

1.2135

1.2130

1.2125

1.2120

–50 150

06090-017

050100

TEMPERATURE ( °C)

Figure 21. FB Volta

ge vs. Temperature

06090-020

90

80

70

60

50

40

30

20

10

PEAK SLOPE CO MPENSATIO N CURRENT (µA)

0

1.0

1.2 1.4 1.6 1.8 2. 0

f

OSC

= 550kHz

Figure 19. Slope-Compensation Current vs. f

f

SYNC/fOSC

f

OSC

= 200kHz

SYNC/fOSC

2.2

06090-018

Rev. A | Page 10 of 32

4

2

1

CH1 5V CH2 5V

Figure 22. DCM Switching Waveform

TA = 25°C

V

= 3.3V

IN

V

= 5V

OUT

LOAD = 0.1A

DCM OPERATIO N

CH4 500mAΩ

CH4 = INDUCTOR CURRENT

CH2 = DRAIN VOLT AGE

CH1 = GATE

M2µs A CH1 2.9V

06090-021

ADP1621

www.BDTIC.com/ADI

TA = 25°C

V

IN

V

OUT

4

= 3.3V

= 5V

LOAD = 0.3A

CCM OPERATIO N

CH4 = INDUCTOR CURRENT

LOAD CURRENT

FROM 0.2A TO 1.2A

4

2

1

CH1 5V CH2 5V

TA = 25°C

= 3.3V

V

IN

= 5V

V

OUT

f

= 220kHz

SW

SOFT-START = 9.3ms

2

1

3

CH1 1V

CH3 5V

1

CH1 50mV

CH4 1AΩ

M200µs A CH4 700V

CH4 500mAΩ

CH2 = DRAIN VOLT AGE

CH1 = GATE

M2µs A CH1 2.9V

06090-022

Figure 23. CCM Switching Waveform Figure 26. Load Transient Response o

TA = 25°C

= 5V

V

CH1 = V

OUT

CH2 = SDSN

CH3 = GATE

CH2 5V M2ms A CH1 4.5V

Figure 24. Soft Start Waveform

06090-023

Figure 27. Line Transient Response of

OUT

NO LOAD AT V

1

2

CH1 50mV CH2 2V M400µs A CH2 3.8V

OUT

the Configuration Shown in Figure 1

wit

h No Load

OUTPUT, AC-COUPLED

TA = 25°C

= 3.3V

V

IN

= 5V

V

OUT

f the Circuit Shown in Figure 1

CH1 = V

CH2 = VIN FROM 3V TO 4V

, AC-COUPLED

OUT

06090-025

6090-026

TA = 25°C

= 5V

V

OUT

LOAD AT V

1

2

CH1 50mV CH2 2V M400µs A CH2 3.8V

Figure 25. Line Transient Response of

OUT

= 1A

CH1 = V

CH2 = VIN FROM 3V TO 4V

, AC-COUPLED

OUT

the Configuration Shown in Figure 1

wit

h a 1 A Load

6090-024

Rev. A | Page 11 of 32

ADP1621

V

www.BDTIC.com/ADI

THEORY OF OPERATION

The ADP1621 is a fixed-frequency, current-mode, step-up dc/dc

converter controller. It drives an external n-channel MOSFET

to step the input voltage up to a higher output voltage. It can be

used for SEPIC, flyback, boost, buck-boost, forward, and other

converter topologies. It operates at a fixed switching frequency that

is set by an external resistor over a range of 100 kHz to 1.5 MHz,

and it can be synchronized to an external clock by connecting

the SDSN pin to the clock.

The input supply current to the ADP1621 is less than 3 mA

d

uring normal operation and less than 10 μA during shutdown.

The ADP1621 can drive large external MOSFETs, allowing it to

support load currents in excess of 10 A.

CONTROL LOOP

The ADP1621 uses a current-mode architecture to regulate the

output voltage. The output voltage is monitored at FB through

a resistive voltage divider. The voltage at FB is compared to the

internal 1.215 V reference voltage by the internal transconductance

error amplifier to create an error current at COMP. A resistorcapacitor compensation impedance connected from COMP to

GND converts the error current to an error voltage.

At the beginning of the switching cycle, the MOSFET is turned

n and the inductor current ramps up. The MOSFET current is

o

measured and converted to a voltage using R

added to the stabilizing slope-compensation ramp. The resulting

voltage sum passes through the current-sense amplifier to generate

the current-sense voltage. When the current-sense voltage is

greater than the COMP error voltage, the MOSFET is turned off

and the inductor current ramps down until the internal clock

initiates the next switching cycle. The duty-cycle of the PWM

modulator is thus adjusted to provide the necessary load current

at the desired output voltage. Because the output voltage ultimately

controls the peak inductor current through the COMP error

voltage, this scheme is referred to as peak current-mode control.

With light loads, the converter can also operate under discon-

nuous conduction mode and pulse-skipping modulation to

ti

maintain output-voltage regulation. These two forms of operation

are discussed in detail in the

ote that the converter can also be designed to operate in

N

Light Load Operation section.

discontinuous conduction mode at full load if desired.

Overall, the current-mode regulation system of the ADP1621

lows fast transient responses while maintaining a stable output

al

voltage. By selecting the proper resistor-capacitor network from

COMP to GND, the regulator response can be optimized for a

wide range of input voltages, output voltages, and load currents.

CS

or R

DSON

and is

CURRENT-SENSE CONFIGURATIONS

The ADP1621 can sense the current across the on resistance of

the MOSFET to minimize external component count and improve

efficiency by eliminating the power that would be lost in a currentsense resistor. This lossless technique eliminates the need for an

expensive current-sense resistor. In the lossless mode configuration,

the voltage at the CS pin (or the switch-node voltage at the drain of

the MOSFET) must not exceed 30 V (see

zes efficiency and reduces cost. In practice, when the

maximi

calculated V

measure the actual V

approaches 30 V, one should build the board and

SW

before committing to the lossless mode

SW

design. Because of the parasitic inductance in the diode, output

capacitor, and PCB traces, V

typically has narrow peaks that

SW

exceed the theoretical maximum voltage at V

V

and the forward-voltage drop of Diode D1. If the measured

OUT

peak voltage exceeds 30 V, or if a more accurate current limit is

desired, then the CS pin can be connected to an external currentsense resistor in the source of the MOSFET (

imum power output is limited by the selection of the

max

external components.

V

IN

PIN

IN

ADP1621

SDSN

PGND

Figure 28. CS Pin Connection for V

Figure 29. CS Pin Connection for V

(No Current-Sense Resistor Needed)

V

IN

PIN

ADP1621

SDSN

PGND

with a Current-Sense Resistor, R

CS

GATE

GND

IN

GATE

CS

GND

Figure 28). This technique

—the sum of

SW

Figure 29). The

D1

L

R

S

< 30 V, Lossless Mode

SW

L

R

S

> 30 V, Resistor Sense Mode

SW

V

OUT

V

SW

C

O

06090-027

D1

SW

V

OUT

C

O

R

CS

06090-028

CS

Rev. A | Page 12 of 32

ADP1621

www.BDTIC.com/ADI

CURRENT LIMIT SETTING THE OSCILLATOR FREQUENCY AND

The current limit is achieved by the COMP voltage clamp, owing

to the current-mode operation of the ADP1621. A detailed

explanation of how the current limit is determined can be found

in the

Current Limit section of the Application Information:

ost Converter section.

Bo

UNDERVOLTAGE LOCKOUT

An internal undervoltage lockout (UVLO) circuit at the IN pin

holds the GATE voltage low when the IN voltage is below the

UVLO voltage, which is typically 2.5 V.

SHUTDOWN

The ADP1621 goes into shutdown approximately 50 μs after the

SDSN pin is pulled low or left floating. There is an internal 100 kΩ

resistor connected between SDSN and GND.

When the junction temperature of the ADP1621 reaches about

150°C, t

he ADP1621 goes into thermal shutdown and the GATE

voltage is pulled low. When the junction temperature drops below

about 140°C, the ADP1621 resumes normal operation after the

soft start sequence.

SOFT START

The ADP1621 has an internal soft start circuit that ramps

the FB regulation voltage from 0 V to 1.215 V in 64 steps over

2048 clock oscillator cycles. This soft start ramp allows the

output voltage to slowly rise to the steady-state output voltage,

preventing input inrush current at startup.

INTERNAL SHUNT REGULATORS

The IN and PIN pins each have an internal shunt regulator that

allows the ADP1621 to operate over a wide input voltage range.

The shunt regulators limit the voltages at IN and PIN to about

5.5 V, allowing the use of logic-level MOSFETs independent of

the input and/or output voltage. The shunt regulator voltage can

reach 5.7 V at 10 mA. See

t

hese shunt regulators.

The internal power is derived from the IN pin, whereas the

MOS

FET gate driver (GATE) current comes from the power

input, PIN. By separating the two inputs, PIN can be driven

with an external small-signal NPN transistor to limit the power

loss in the PIN shunt regulator when the input voltage is higher

than 5.5 V. See

oing into PIN and IN should not exceed 35 mA and 25 mA,

g

Figure 37 for an example. The maximum currents

respectively.

Figure 9 for the I-V characteristics of

SYNCHRONIZATION FREQUENCY

The free-running oscillator frequency, f

from FREQ to GND. A 100 kΩ resistor sets the typical oscillator

frequency to 200 kHz, a 65 kΩ resistor sets it to 325 kHz, a 32 kΩ

resistor sets it to 600 kHz, and a 10 kΩ resistor sets it to 1.5 MHz.

Figure 30 shows a typical relationship between f

1600

1500

1400

1300

1200

1100

1000

900

(kHz)

800

700

OSC

f

600

500

400

300

200

100

0

20 40 60 80 100 120 140 160 180

0 200

(kΩ)

R

FREQ

Figure 30. f

OSC

vs. R

The switching frequency can be synchronized to an external clock

b

y driving the SDSN pin with that clock signal. The SDSN pin

serves the two functions of shutdown control and frequency

synchronization input. If the SDSN input detects a low-to-high

transition within 10 μs of a high-to-low transition, it resets the

oscillator to synchronize to the frequency of the signal at SDSN.

The ADP1621 only synchronizes to frequencies greater than the

free-running switching frequency. To ensure proper synchronization

operation, set the synchronization frequency, f

running frequency, f

f

. Although the switching frequency can be synchronized to as

SYNC

. The switching frequency, fSW, is equal to

OSC

high as 1.8 MHz, the peak slope-compensation current decreases at

higher f

1.4× of f

. It is recommended that the maximum f

SYNC

. The slope-compensation resistor, RS, should be chosen

OSC

for the synchronization frequency (see the Slope Compensation

s

ection). For SDSN to detect a high input, the high state must

remain high for at least 100 ns.

, is set by a resistor

OSC

and R

OSC

FREQ

, to 1.2× the free-

SYNC

SYNC

.

FREQ

06090-029

be less than

Rev. A | Page 13 of 32

ADP1621

VVV

×

I

I

Δ

(

)

−××

www.BDTIC.com/ADI

APPLICATION INFORMATION: BOOST CONVERTER

In this section, an analysis of a boost converter is presented,

along with guidelines for component selection. A typical boostconverter application circuit is shown in

Figure 1.

DUTY CYCLE

To determine the worst-case inductor current ripple, output voltage

ripple, and slope-compensation factor, it is first necessary to

determine the system duty cycle. The duty cycle in continuous

conduction mode (CCM) is calculated by the equation

−+

OUT

D

=

where V

is the desired output voltage, VIN is the input

OUT

voltage, and V

OUT

is the forward-voltage drop of the diode. A

D

IND

(1)

VV

+

D

typical Schottky diode has a forward-voltage drop of 0.5 V.

The GATE minimum on and off times determine the minimum

a

nd maximum duty cycles, respectively. The minimum on and

off times are typically 180 ns and 190 ns, respectively. The

minimum and maximum duty cycles are given by

D ×==

D ×−=−=

where D

cycle, t

time, t

MIN

MAX

MIN

ON,MIN

is the switching period, and fSW is the switching frequency.

SW

,

t

SW

t

,

MINOFF

t

SW

is the minimum duty cycle, D

is the minimum on time, t

ft

(2)

SWMINON

,

)(11

ft

,

(3)

SWMINOFF

is the maximum duty

MAX

is the minimum off

OFF,MIN

t

MINON

Note that when the converter tries to operate at a duty cycle

lo

wer than D

, pulse-skipping modulation occurs to maintain

MIN

the output voltage regulation (see the Light Load Operation

secti

on).

SETTING THE OUTPUT VOLTAGE

The output voltage is set through a voltage divider from the

output voltage to the FB input. The feedback resistor ratio sets

the output voltage of the system. The regulation voltage at FB is

1.215 V. The output voltage is given by (see

R1

V

OUT

⎛

⎜

⎝

⎞

+×=

1V215.1 (4)

⎟

R2

⎠

Figure 1)

The input bias current into FB is 25 nA typical, 70 nA

imum. For a 0.1% degradation in regulation voltage and

max

with 70 nA bias current, R2 must be less than 18 kΩ, which

results in 68 μA of divider current. Choose the value of R1 to set

the output voltage. Using higher values for R2 results in reduced

output voltage accuracy due to the input bias current at the FB

pin, whereas lower values cause increased quiescent current

consumption.

INDUCTOR CURRENT RIPPLE

Choose a peak-to-peak inductor ripple current between 20%

and 40% of the average inductor current. A good starting point

Rev. A | Page 14 of 32

for a design is to choose the peak-to-peak ripple current to be

30% of 1/(1 − D) times the maximum load current:

where ΔI

is the maximum load current required by the application.

INDUCTOR SELECTION

The inductor value choice is important because it dictates

the inductor current ripple and therefore the voltage ripple

at the output.

The average inductor current, I

and the peak-to-peak inductor ripple current is inversely

prop

where f

Assuming continuous conduction mode (CCM) operation, the

peak

Smaller inductor values are typically smaller in size and usually

les

also increases the power loss in the inductor core. Too large an

inductor value results in added expense and may impede load

transient responses because it reduces the effect of slope

compensation.

Assuming the ripple current is 30% of 1/(1 − D) times the maxi

mum load current, a reasonable choice for the inductor value is

From this starting point, modify the inductance to obtain the

r

ight balance of size, cost, and output voltage ripple while

maintaining the inductor ripple current between 20% and 40%

of 1/(1 − D) times the maximum load current. Keep in mind

that the inductor saturation current must be greater than the

peak inductor current. Magnetically shielded inductors are

generally recommended, although they cost slightly more than

unshielded inductors.

Also, losses due to the inductor winding resistance reduce the

ef

where P

inductor, and R

I

MAXLOAD

I

3.0

L

is the peak-to-peak inductor ripple current, and I

L

I

I

AVEL

,

,

×=Δ

LOAD

−=1

1

D

(5)

D

−

LOAD,MAX

, is given by

L,AVE

(6)

ortional to the inductor value:

DV

IN

=Δ

I

L

is the switching frequency, and L is the inductor value.

SW

(7)

Lf

×

SW

inductor current is given by

DV

I

LOAD

=

PKL

,

−

I

L

=

+

D

D

−

×

INLOAD

+

2121

(8)

Lf

××

SW

s expensive, but increase the ripple current. Larger ripple current

DDV

IN

L

=

3.0

1

If

××

(9)

MAXLOADSW

,

ficiency of the boost converter. This power loss is given by

2

I

⎞

⎛

P ×

LOAD

=

⎜

WL

,

L,W

D

−

1

⎝

is the power dissipation in the winding of the

is the winding resistance.

W

(10)

R

⎟

W

⎠

ADP1621

Δ

=

×

=

www.BDTIC.com/ADI

INPUT CAPACITOR SELECTION

The bulk input capacitor provides a low impedance path for the

inductor ripple current. Capacitor C1 in Figure 1 represents a

b

ulk input capacitor. Choose a bulk input capacitor whose

impedance at the switching frequency is lower than the

impedance of the voltage source V

.

IN

The preferred bulk input capacitor is a 10 μF to 100 μF ceramic

pacitor because it has low equivalent series resistance (ESR) and

ca

low impedance. Aluminum electrolytic and aluminum polymer

capacitors can also be used as the bulk input capacitors. The bulk

input capacitor does not need to be placed very close to the IN

and PIN pins. Aluminum electrolytic capacitors are the cheapest

and generally have high ESR values, which increase dramatically at

temperatures less than 0°C. Some aluminum electrolytic capacitors

have ESR less than 20 mΩ, but their capacitances are generally

greater than 800 μF. Aluminum polymer capacitors are more

expensive than the aluminum electrolytic ones, but are generally

cheaper than the ceramic capacitors for the same amount of

capacitance. Polymer capacitors have relatively low ESR, with

some models having less than 10 mΩ.

Regardless of the type of capacitor used, make sure the ripple

c

urrent rating of the bulk input capacitor, I

IIΔ

1

×=

(11)

2

where ΔI

,LRMSCIN

L

3

is the peak-to-peak inductor ripple current.

, is greater than

CIN,RMS

In addition to the bulk input capacitor, a bypass input capacitor is

equired. The function of the bypass capacitor is to locally filter the

r

input voltage to the ADP1621 and maintain the input voltage at a

steady value during switching transitions. The bypass capacitor is

typically a 0.1 μF or greater ceramic capacitor and should be placed

as close as possible to the IN and PIN pins of the ADP1621.

Capacitors C3 and C4 in

Figure 1 represent the bypass capacitors.

OUTPUT CAPACITOR SELECTION

The output capacitor maintains the output voltage and supplies

current to the load while the external MOSFET is on.

The value and characteristics of the output capacitor greatly

ffect the output voltage ripple and stability of the converter.

a

The amount of peak-to-peak output voltage ripple, ΔV

be approximated by

V

where ΔI

⎜

OUT

is the peak-to-peak inductor ripple current, fSW is the

L

−

⎝

⎛

⎜

⎜

2

SW

⎝

I

⎛

LOAD

≈Δ

switching frequency, C

effective ESR of C

inductance of C

OUT

OUT

I

⎞

L

+

D

1

Cf

××π

OUT

×

⎟

21

⎠

2

⎞

OUT

⎟

⎟

⎠

()

2

SW

is the output capacitance, ESR is the

, and ESL is the effective equivalent series

.

Because the output capacitor is typically greater than 40 μF, the

ES

R dominates the output capacitance impedance and thus the

output voltage ripple. The use of low ESR, ceramic dielectric

capacitors is preferred, although aluminum electrolytic,

tantalum, OS-CON™ (from Sanyo), and aluminum polymer

capacitors can be used. At higher switching frequencies, the ESL

of the output capacitor may also be a factor in determining the

output voltage ripple. Multiple capacitors can be connected in

parallel to reduce the effective ESR and ESL. Keep in mind that

the capacitance of a given capacitor typically degrades with

increased temperature and bias voltage. Consult the capacitor

manufacturer’s data sheet when determining the actual

capacitance of a capacitor under certain conditions.

Ensure that the output capacitor ripple current rating, I

is greater than

D

×=

II

LOAD

RMSCOUT

,

(13)

D

−

1

DIODE SELECTION

The diode conducts the inductor current to the output capacitor

and load while the MOSFET is off. The average diode current is

the load current:

II

(14)

LOADAVEDIODE

,

The rms diode current in continuous conduction mode is given by

I

I

where D is t

LOAD

= 1

,

RMSDIODE

D

−

1

he duty cycle.

The power dissipated in the diode is

IVP

D

LOAD

where V

DIODE

is the forward-voltage drop of the diode.

D

(15)

D

−×

(16)

, can

OUT

22

(12)

ESLfESR

××π++

COUT,RMS

,

Rev. A | Page 15 of 32

ADP1621

(

I

+

=

+

=

www.BDTIC.com/ADI

The total power dissipation determines the diode junction

temperature, which is given by

θPTT ×+=

(17)

,

where T

perature, and θ

is the junction temperature, TA is the ambient tem-

J,DIODE

is the junction-to-ambient thermal resistance

JA

of the diode package. The diode junction temperature must not

exceed its maximum rating at the given power dissipation level.

For high efficiency, Schottky diodes are recommended. The low

rward-voltage drop of a Schottky diode reduces the power losses

fo

during the MOSFET off time, and the fast switching speed reduces

the switching losses during the MOSFET transitions. However,

for high voltage, high temperature applications where the reverse

leakage current of the Schottky diode can become significant

and degrade efficiency, use an ultrafast-recovery junction diode.

Make sure that the diode is rated to handle the average output

lo

ad current. Many diode manufacturers derate the current

capability of the diode as a function of the duty cycle. Verify

that the diode is rated to handle the average output load current

with the minimum duty cycle. Also, ensure that the peak inductor

current is less than the maximum rated current of the diode.

MOSFET SELECTION

When turned on, the external n-channel MOSFET allows

energy to be stored in the magnetic field of the inductor. When

the MOSFET is turned off, this energy is delivered to the load to

boost the output voltage.

The choice of the external power MOSFET directly affects the

oost converter performance. Choose the MOSFET based on

b

the following: threshold voltage (V

maximum voltage and current ratings, and gate charge.

The minimum operating voltage of the ADP1621 is 2.9 V.

hoose a MOSFET with a V

C

minimum input supply voltage at PIN used in the application.

Ensure that the maximum V

a few volts greater than the maximum voltage that is applied to

PIN. Ensure that the maximum V

exceeds the maximum V

on parasitics, the MOSFET may be exposed to voltage spikes that

exceed the sum of V

Estimate the rms current in the MOSFET under continuous

co

nduction mode by

I

,

RMSMOSFET

where D is t

he duty cycle. Derate the MOSFET current at least

20% to account for inductor ripple and changes in the forwardvoltage drop of the diode.

and the forward-voltage drop of the diode.

OUT

I

LOAD

=

1

−

JADIODEADIODEJ

), on resistance (R

T

that is at least 0.3 V less than the

T

rating of the MOSFET is at least

GS

rating of the MOSFET

DS

by at least 5 V to 10 V. Depending

OUT

(18)

D

×

D

DSON

),

The MOSFET power dissipation due to conduction is thus

2

I

⎞

⎛

P

where P

LOAD

= 1

C

is the conduction power loss, and R

C

⎟

⎜

D

−

1

⎠

⎝

DSON

(19)

(

KRD

+×××

)

is the MOSFET

DSON

on resistance. The variable K is a factor that models the increase

with temperature:

of R

DSON

oo

(20)

)

C25C/005.0

−×=

where T

TK

J,MOSFET

is the MOSFET junction temperature. Note that

J,MOSFE T

multiple n-channel MOSFETs can be placed in parallel to reduce

the effective R

DSON

.

The power dissipation due to switching transition loss is

a

pproximated by

LOAD

VV

×+

D

()

D

−

1

2

ftt

×+×

FR

SW

(21)

P

SW

where P

SW

time, and t

()

OUT

=

is the switching power loss, tR is the MOSFET rise

is the MOSFET fall time. The MOSFET rise and fall

F

times are functions of both the gate drive circuitry and the

MOSFET used in the application.

The total power dissipation of the MOSFET is the sum of the

nduction and transition losses:

co

PPP

(22)

SWC

where P

MOSFET

is the total MOSFET power dissipation. Ensure

MOSFET

that the maximum power dissipation is significantly less than

the maximum power rating of the MOSFET.

The total power dissipation also determines the MOSFET

unction temperature, which is given by

j

θPTT ×

(23)

MOSFETJ

,

where T

is the junction temperature, TA is the ambient

J,MOSFE T

temperature, and θ

A

MOSFET

is the junction-to-ambient thermal

JA

JA

resistance of the MOSFET package. The MOSFET junction

temperature must not exceed its maximum rating at the given

power dissipation level.

If lossless current sensing is not used, there will also be power

ssipation in the external current-sense resistor, R

di

dissipation, P

, in the external resistor due to conduction losses

CS

. The power

CS

is given by

2

I

⎛

⎞

LOAD

=

P ××

⎜

CS

⎟

−

D

1

⎝

⎠

(24)

RD

CS

LOOP COMPENSATION

The ADP1621 uses external components to compensate the

regulator loop, allowing optimization of the loop dynamics for

a given application.

The step-up converter produces an undesirable right-half plane

RHP) zero in the regulation feedback loop. This RHP zero

(

requires compensating the regulator such that the crossover

Rev. A | Page 16 of 32

ADP1621

V

V

×

×

www.BDTIC.com/ADI

frequency occurs well below the frequency of the RHP zero. The

location of the RHP zero is determined by the following equation:

R

2

LOAD

(25)

L

×π

2

is the equivalent

LOAD

where f

()

1

Df

RHPZ

,

is the RHP zero frequency, and R

Z,RHP

×−=

load resistance or the output voltage divided by the load current.

To stabilize the regulator, ensure that the regulator crossover

requency is less than or equal to one-fifth of the RHP zero

f

frequency and less than or equal to one-fifteenth of the switching

frequency. For an initial practical design, choose the crossover

frequency f

to be the lower of

C

f

SW

f =

C

15

(26)

Once the compensation resistor, R

formed by the resistor and compensation capacitor, C

one-fourth of the crossover frequency, or

COMP

=

2

(31)

RfC××π

COMPC

Capacitor C2 is chosen to cancel the zero introduced by the output

ca

pacitance ESR. Thus, C2 should be set to (see

CESR

OUT

=2

C

where ESR r

R

COMP

epresents the ESR of C

(32)

For low ESR output capacitors, such as ceramic capacitors, C2

is s

mall, generally in the range of 10 pF to 400 pF. Because of the

parasitic inductance, resistance, and capacitance of the PCB layout,

and

f

,RHPZ

f = (27)

C

5

where f

is the crossover frequency, and fSW is the switching

C

frequency.

the R

observing the load transient response of the ADP1621 to establish a

stable operating system and achieve optimal transient performance.

For most applications, R

and C

The regulator loop gain is

FB

A ×

VL

where A

()

V

OUT

is the loop gain, VFB is the feedback regulation

VL

voltage (typically 1.215 V), V

D is the duty cycle, g

m

gain (typically 300 μS), Z

ZgD

m

COMP

is the regulated output voltage,

OUT

is the error amplifier transconductance

is the impedance of the RC network

COMP

from COMP to GND, n is the current-sense amplifier gain

(typically 9.5), R

is the current-sense resistance, and Z

CS

the impedance of the load and output capacitor. In the case of

lossless current sensing, as shown in Figure 28, R

on resistance, R

represents the external current-sense resistor, as shown in

R

CS

, of the external power MOSFET. Otherwise,

DSON

Figure 29.

To determine the crossover frequency, it is important to note

th

at at that frequency the compensation impedance, Z

dominated by Resistor R

, and the output impedance, Z

COMP

is dominated by the impedance of the output capacitor, C

When solving for the crossover frequency, the equation is

simplified to

=||VLA

FB

V

OUT

()

1

RgD

COMP

×××−×

×

m

1

||1

×××−×=

Rn

×

CS

Z

OUT

(28)

||

SLOPE COMPENSATION

The ADP1621 includes a circuit that allows adjustable slope

compensation. Slope compensation is required by current-

is

OUT

is equal to the

CS

, is

COMP

,

OUT

.

OUT

×

11

CfRn

××π

2

CCS

OUT

1

=

mode regulators to stabilize the current-control loop when

operating in continuous conduction and the switching duty

cycle is greater than 50%.

Slope compensation is achieved by internally forcing a ramping

c

urrent source out of the CS current-sense pin. By placing a resistor

between the CS pin and the current sensing device (the drain of

the external MOSFET in the case of lossless current sensing or

the source of the MOSFET if a current-sense resistor is used), a

voltage is developed across the resistor that is proportional to

the slope-compensation current.

To ensure stability of the current-mode control loop, use a

co

half of the current-sense representation of the inductor current

downslope. Therefore, it follows that

(29)

where fC is the crossover frequency, R

resistor, and C

Solving for R

R

COMP

is the output capacitance.

OUT

gives

COMP

2

C

=

OUT

()

1

FB

×−×

is the compensation

COMP

VRnCf

×××××π

CS

OUT

gDV

m

(30)

where R

compensation current, f

current-sense resistor, V

forward-voltage drop of the diode, V

the minimum off time, and L is the power-stage inductor. In the

case of lossless current sensing, R

, C

COMP

COMP

, and C2 values might need to be adjusted by

COMP

is in the range of 5 kΩ to 100 kΩ,

COMP

is in the range of 100 pF to 30 nF.

REF

2

Figure 31. Compensation Components

COMP

g

m

mpensation voltage slope that is equal to or greater than one-

fI

R

××12

S

is the slope-compensation resistor, I

S

SWSC,PK

×−

ft

SWMINOFF,

is the switching frequency, RCS is the

SW

is the regulated output voltage, VD is the

OUT

, is known, set the zero

COMP

COMP

Figure 31)

.

OUT

3

R

COMP

COMP

OUT

C2

06090-030

−+

VVV

IND

L

is the peak slope-

SC,PK

(33)

C

×>

R

CS

is the input voltage, t

IN

is equal to the on resistance,

CS

, to

OFF,MIN

is

Rev. A | Page 17 of 32

ADP1621

(

)

(

)

(

×−=

(

−××

www.BDTIC.com/ADI

R

, of the external power MOSFET. Otherwise, RCS

DSON

represents the external current-sense resistor.

Solving for R

R

Keep in mind that the above inequality is a function of both

AD

P1621 parameters and off-chip components, the values of

which vary from part to part and with temperature. Select R

ensure current-loop stability for all possible variations.

After accounting for parameter variations, use values of R

are as close to the calculated limit as possible because excessive

slope compensation reduces the benefits of current-mode control

and increases the “softness” of the current limit, as discussed in the

Current Limit section. Given a typical peak slope-compensation

urrent of 70 μA, R

c

at the CS pin is typically clamped at 116 mV. It is also recommended that R

than 1.6 kΩ, the parameters in Equation 34, such as R

can be adjusted such that R

In conclusion, the value of R

CURRENT LIMIT

The current limit in the ADP1621 limits the peak inductor

current and is achieved by the COMP voltage clamp. The peak

inductor current, I

I

PKL

,

where V

V

COMP,ZCT

n is the current-sense amplifier gain (typically 9.5), I

peak slope-compensation current (typically 70 μA), R

slope-compensation resistor, D is the duty cycle, f

switching frequency, t

190 ns), and R

lossless current sensing, R

of the external power MOSFET. Otherwise, R

external current-sense resistor.

The current limit in the ADP1621 is a “soft” current limit.

hen the inductor current reaches the I

W

Equation 35, the duty cycle decreases, and the output voltage

drops below the desired voltage. The I

then increases in response to the smaller duty cycle, D. The

larger the slope-compensation resistor, R

on I

L,PK

in a “soft” current limit for the ADP1621. Use values of R

as close as possible to the calculated limit derived from

Equation 34. If high-precision current limiting is required,

consider inserting a fuse in series with the inductor.

Also, keep in mind that the current limit is a function of both

AD

P1621 parameters and off-chip components, the values of

gives the slope-compensation criterion:

S

ftVVVR

CS

>

S

=

COMP,CLAMP

1

OUT

be greater than 20 Ω. If the calculated RS is greater

S

IND

2

should not exceed 1.6 kΩ because the voltage

S

L,PK

SWPKSC

,

is less than 1.6 kΩ.

S

should be 20 Ω ≤ RS ≤ 1.6 kΩ.

S

, is given by

VV

−

n

R

CS

is the COMP clamp voltage (typically 2.0 V),

×−×−+×

SWMINOFF

,

LfI

×××

−

1

(34)

that

S

, fSW, and L,

CS

DRI

××

SPKSCZCTCOMPCLAMPCOMP

,,,

ft

×−

SWMINOFF

,

(35)

is the COMP zero-current threshold (typically 1.0 V),

is the

SC,PK

is the

S

is the

SW

is the minimum off time (typically

OFF,MIN

is the current-sense resistor. In the case of

CS

is equal to the on resistance, R

CS

represents the

CS

limit given in

L,PK

limit in Equation 35

L,PK

, the larger the effect

S

DSON

for an incremental decrease in D. This behavior results

that are

S

to

S

,

Rev. A | Page 18 of 32

which vary from part to part and with temperature. If lossless

current sensing is used, consider that the on resistance of a

MOSFET typically increases with increasing junction temperature.

The peak inductor current limit also limits the maximum load

current at a given output voltage. The maximum load current,

assuming CCM operation, is given by

)

DI

MAXLOAD1,

⎛

⎜

⎜

−

n

⎜

⎜

⎜

⎝

××

VV

R

CS

,,,

−

1

DRI

SPKSCZCTCOMPCLAMPCOMP

×−

ft

SWMINOFF

,

−

2

⎞

⎟

×

DV

⎟

IN

⎟

××

Lf

SW

⎟

⎟

⎠

(36)

If the load current exceeds I

, the output voltage drops

LOAD,MAX

below the desired voltage.

LIGHT LOAD OPERATION

Discontinuous Conduction Mode

With light loads, the average inductor current is small, and,

depending on the converter design, the instantaneous inductor

current may reach 0 during the time when the MOSFET is off.

This mode of operation is termed discontinuous conduction

mode. The condition for entering discontinuous conduction

mode in a boost converter is

1

)

LOAD

2

IN

<

I

When the instantaneous inductor current reaches 0 during the

c

ycle, the inductor ceases to be a current source, and ringing

can be observed in the waveforms of the MOSFET drain voltage

and the inductor current. The frequency of the ringing is the

resonant frequency of the inductor and the total capacitance

from the SW node to GND, which includes the capacitances of

the MOSFET and diode, and any parasitic capacitances from

the PCB. While adding a resistive element, such as a snubber, to

the system further dampens the resonance, it also decreases the

efficiency of the regulator.

Pulse-Skipping Modulation

The ADP1621 features circuitry that improves the converter

efficiency and minimizes power consumption with no load or

very light loads. When the COMP voltage drops below V

(typically 1.0 V), which can occur at sufficiently light loads, the

MOSFET is powered off until the FB voltage drops below 1.215 V.

Then, the error amplifier drives the COMP voltage higher, and

the converter resumes switching when the COMP voltage rises

above the V

COMP,ZCT

the output capacitor supplies current to the load.

With light loads, the COMP voltage hovers around 1.0 V, and

s

hort periods of switching are followed by long periods of the

MOSFET being powered off. This pulse-skipping modulation

operation improves converter efficiency by reducing the number of

switching cycles and therefore reducing the gate drive current and

the switching transition power loss.

DDV

(37)

fL

××

SW

COMP,ZCT

voltage. While the MOSFET is powered off,

ADP1621

www.BDTIC.com/ADI

Given the minimum on time of the ADP1621, pulse-skipping

modulation is also a requirement to maintain output voltage

regulation with light loads. During the short switching periods

of pulse-skipping modulation, the MOSFET is turned on for the

RECOMMENDED COMPONENT MANUFACTURERS

Table 5.

Vendor Components

AVX Corporation Capacitors

Central Semiconductor Corp. Diodes

Coilcraft, Inc. Inductors

Diodes, Inc. Diodes

International Rectifier Diodes, MOSFETs

Murata Manufacturing Co., Ltd. Capacitors, inductors

ON Semiconductor Diodes, MOSFETs

Rubycon Corporation Capacitors

Sanyo Capacitors

Sumida Inductors

Taiyo Yuden, Inc. Capacitors, inductors

Toko America, Inc. Inductors

United Chemi-Con, Inc. Capacitors

Vishay Siliconix Diodes, MOSFETs, resistors, capacitors

minimum on time each cycle, storing just enough energy in the

inductor to charge the output capacitor. During the long period

when the MOSFET is off, no current flows through the inductor,

and the light load current is supplied by the output capacitor.

Rev. A | Page 19 of 32

ADP1621

www.BDTIC.com/ADI

LAYOUT CONSIDERATIONS

Layout is important for all switching regulators, but is particularly important for regulators with high switching frequencies.

To achieve high efficiency, good regulation, and stability, a welldesigned printed circuit board layout is required. A sample PCB

layout for the standard boost converter circuit shown in Figure 33

Figure 32.

iven in

is g

Follow these guidelines when designing printed circuit boards:

• Keep the low ESR bypass input capacitor of 0.1 μF or higher

close to IN/PIN and GND.

• Keep the high current path from Bulk Input Capacitor C1

through Inductor L1 and MOSFET M1 to PGND as short

as possible.

• Keep the high current path from Bulk Input Capacitor C1

through Inductor L1, Diode D1, and Output Capacitor C

to PGND as short as possible. Place C

as close to PGND

OUT

as possible to reduce ground bouncing.

• Keep high current traces as short and wide as possible to

minimize parasitic series inductance, which causes spiking

and electromagnetic interference (EMI).

• To minimize switching noise, the drain of the power MOSFET

should be placed very close to the inductor, and the source

of the MOSFET (or the bottom side of the sense resistor)

should be connected directly to the power GND plane. Use

wide copper traces on the drain and on the source of the

MOSFET to minimize parasitic inductance and resistance.

Parasitic inductance can lead to excessive ringing during

switching transitions, and parasitic resistance reduces the

converter efficiency. Make sure that the MOSFET selected

is capable of handling the total power loss (conduction plus

transition losses) in the application circuit.

OUT

• Avoid routing high impedance traces near any node con-

nected to the switch node (the MOSFET drain) or near

Inductor L1 to prevent radiated switching-noise injection.

• Add an extra copper plane at the connection of the MOSFET

drain and the anode of the diode to help dissipate the heat

generated by losses in those components.

• Avoid ground loops by having one central ground node on the

PCB. If this is impractical, place the power ground with high

current levels physically closer to the PCB ground terminal.

The analog, low current-level ground should be placed farther

from the PCB ground terminal.

• Minimize the length of the PCB trace between the GATE

pin and the MOSFET gate. The parasitic inductance in this

PCB trace can give rise to excessive voltage ringing at the

MOSFET gate and drain, as well as the regulator output. It

is recommended to add 5 Ω of resistance for every inch of

PCB trace. This helps to reduce the overshoot and ringing at

the drain and the output. However, this added resistance

increases the rise and fall times of the MOSFET; thus, the

switching loss in the MOSFET is increased.

• Place the feedback resistors as close to FB as possible to

prevent high frequency switching-noise injection.

• Place the top of the upper feedback resistor, R1, as close

as possible to the top of C

for optimum output voltage

OUT

sensing.

• If a current-sense resistor is connected between the source

of the MOSFET and PGND, ensure that the capacitance from

CS to PGND is minimized.

• Place the compensation components as close as possible

to COMP.

V

IN

L1

SDSN

VIAS TO G ND PLANE

VIAS TO 2ND L AYER

Figure 32. PCB Layout of the Circuit Shown in Figure 33 (2-layer PCB)

C1

M1

GND

C3

C4

ADP1621

C2R1R2

GATE

R

FREQ

COMP

COMP

R

C

S

R

Rev. A | Page 20 of 32

GND

D1

C

OUT1

C

OUT2

C

OUT3

REMOTE OUTPUT

SENSING

V

OUT

6090-031

ADP1621

P

××=

(

)

×+=

(

)

(

)

×

=

www.BDTIC.com/ADI

EFFICIENCY CONSIDERATIONS

The efficiency, η, of a dc/dc converter is given by

η

where P

OUT

P

IN

is the output power, and PIN is the input power to the

OUT

(38)

%100×=

converter. While switching regulators are ideally lossless converters

of power, the nonideal characteristics of regulator components

degrade the efficiency of the regulator.

The primary sources of power dissipation in the regulator include

• The power dissipation in the external power MOSFET due

to conduction and switching losses.

PPP +=

(39)

MOSFET

=

SWC

I

⎡

⎛

⎞

LOAD

⎜

⎢

⎣

⎡

⎢

⎟

−

D

⎝

⎠

VV

OUT

⎢

⎢

⎢

⎣

DSON

I

LOAD

×+

)(

D

D

1

−

2

⎤

+×××

+

)1(1KRD

⎥

⎦

⎤

×+×

ftt

)(

FR

SW

⎥

⎥

⎥

⎥

⎦

• The power dissipation in the external current-sense

resistor if lossless current sensing is not used.

2

I

⎛

⎞

LOAD

=

P ××

⎜

CS

⎟

−

D

1

⎝

⎠

(40)

RD

CS

• The power dissipation in the external diode.

IVP ×=

DIODE

D

(41)

LOAD

• The power dissipation in the winding resistance of the

power stage inductor.

2

I

⎛

⎞

LOAD

=

P ×

⎜

,

WL

−

1

⎝

R

⎟

D

⎠

(42)

W

• The supply current to the ADP1621 IC, which includes the

quiescent current and the gate driver charging current. The

power dissipation due to gate charging loss is approximated by

fQVP

PIN

G

where P

is the gate charging power loss, V

G

the PIN pin, Q