Digital Power Factor Correction Controller

R

Data Sheet

FEATURES

Flexible digital power factor correction (PFC) controller

Single phase operation (ADP1047); interleaved and

bridgeless operation (ADP1048)

True rms ac power metering

Enhanced dynamic response

Optimized light load efficiency performance

Output voltage adjustment

Frequency reduction

Inrush current control

Switching frequency spread spectrum for improved EMI

External frequency synchronization

PMBus compliant

Programmable ac line fault detection and protection

Programmable output fault detection and protection

Extensive fault protection for high reliability systems

Frequency range from 30 kHz to 400 kHz

8 kB EEPROM

Programming via easy-to-use graphical user interface (GUI)

APPLICATIONS

AC/DC power supplies for applications

Computing server and storage

Network and communication infrastructure

Industrial and medical

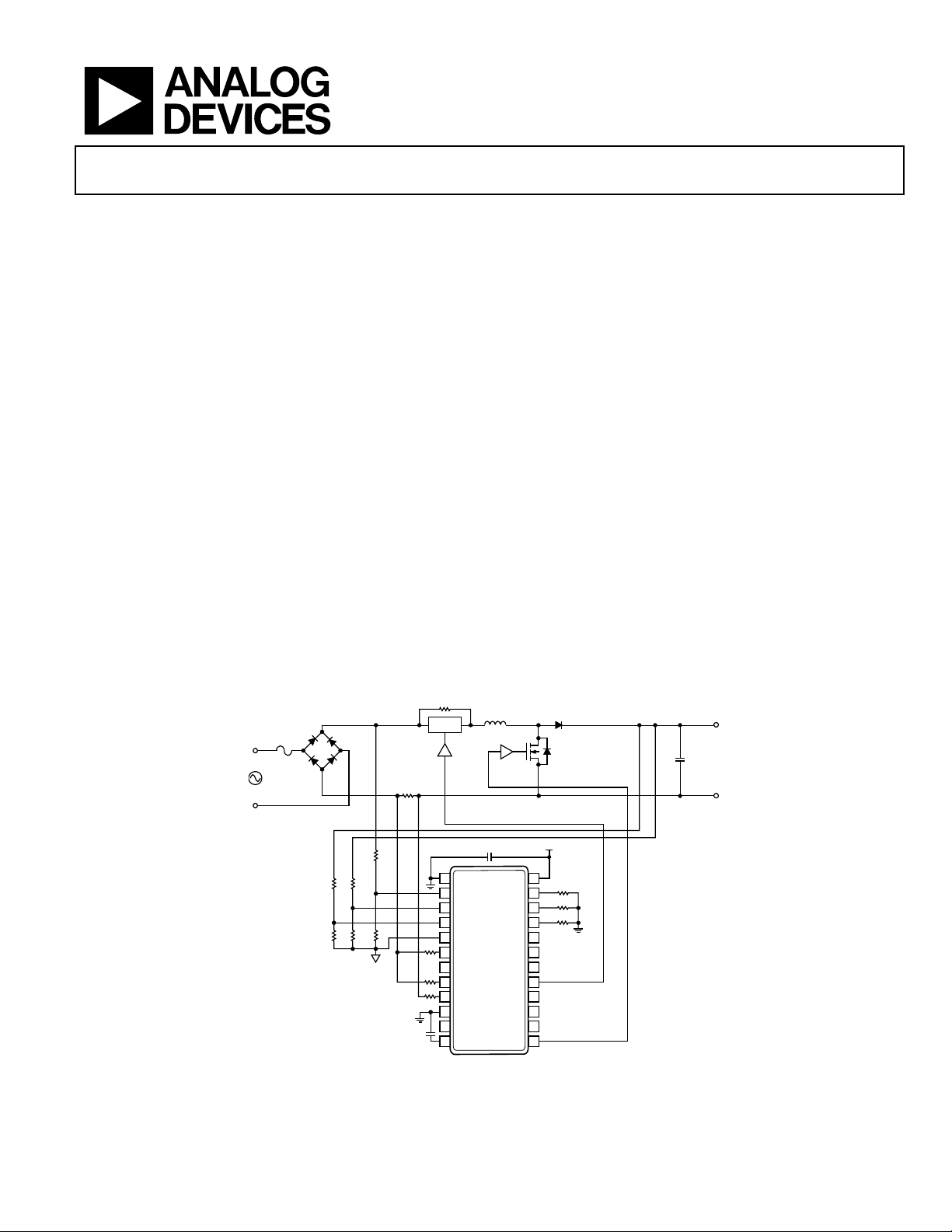

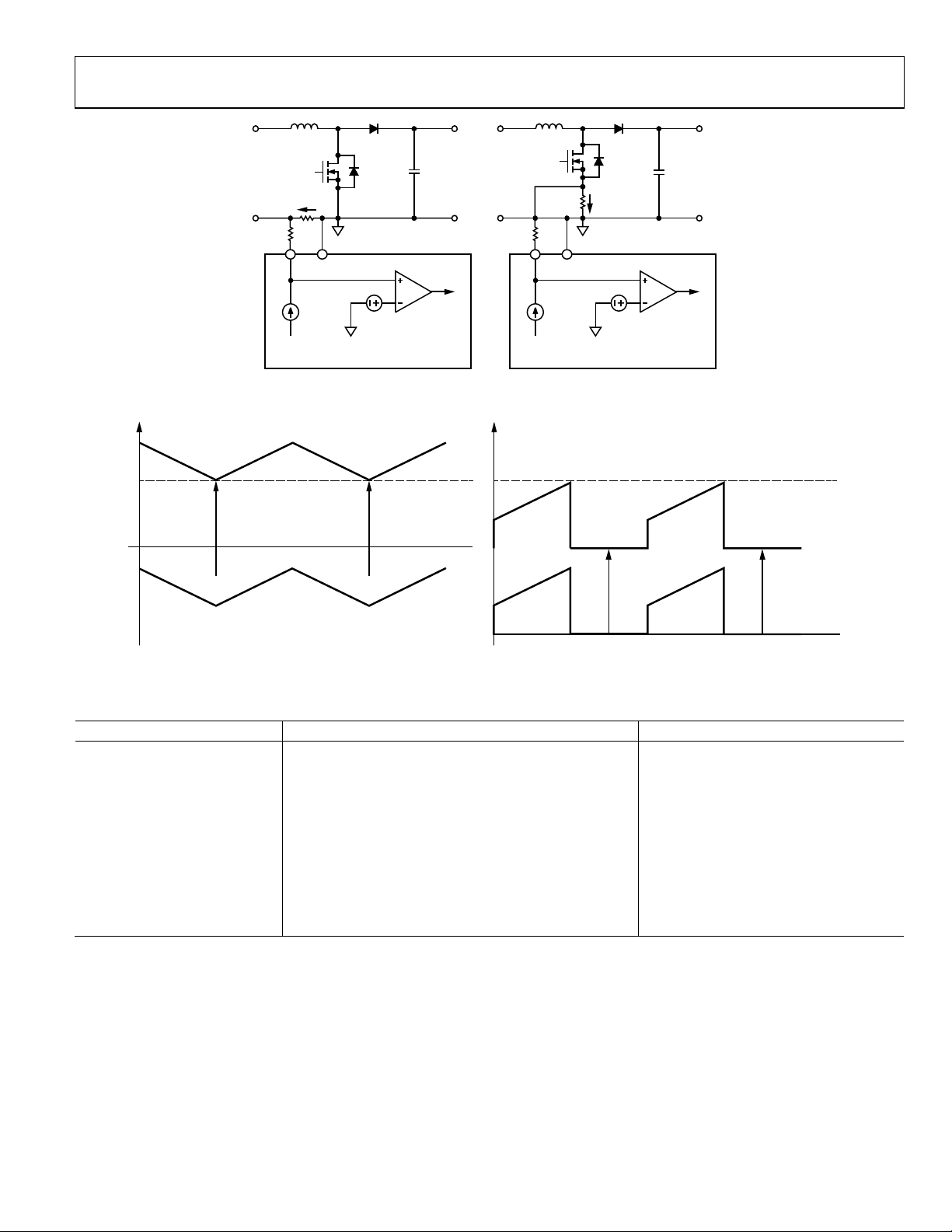

TYPICAL APPLICATIONS CIRCUIT

V

REC

RELAY

with Accurate AC Power Metering

ADP1047/ADP1048

GENERAL DESCRIPTION

The ADP1047/ADP1048 are digital power factor correction

(PFC) controllers that provide accurate input power metering

capability and inrush current control for ac/dc systems. The

ADP1047 is designed for single phase PFC applications; the

ADP1048 is designed especially for interleaved and bridgeless

PFC applications.

The digital PFC function is based on a conventional boost PFC

with multiplication of the output voltage feedback combined with

the input current and voltage to provide optimum harmonic

correction and power factor for ac/dc systems. All signals are

converted into the digital domain to provide maximum flexibility;

all key parameters can be reported and adjusted via the PMBus™

interface. The ADP1047/ADP1048 allow users to optimize system

performance, maximize efficiency across the load range, and

reduce design time to market.

The ADP1047/ADP1048 provide accurate rms measurement

of input voltage, current, and power. This information can be

reported to the microcontroller of the power supply via the

PMBus interface.

V

OUT

AC

INPUT

1

AGND

2

VAC

3

VFB

4

OVP

5

PGND

6

ILIM

7

NC

8

CS–

9

CS+

10

DGND

11

PSON

12

VCORE

Rev. 0

Information furnished by Analog Devices is believed to be accurate and reliable. However, no

responsibility is assumed by Analog Devices for its use, nor for any infringements of patents or other

rights of third parties that may result from its use. Specifications subject to change without notice. No

license is granted by implication or otherwise under any patent or patent rights of Analog Devices.

Trademarks and registered trademarks are the property of their respective owners.

BULK

CAPACITO

3.3V

24

VDD

23

RES

22

RTD

21

ADD

20

SDA

PMBus

19

SCL

18

SYNC

17

INRUSH

16

PGOOD

15

AC_OK

14

PWM2

13

PWM

ADP1047

09696-101

Figure 1.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700 www.analog.com

Fax: 781.461.3113 ©2011 Analog Devices, Inc. All rights reserved.

ADP1047/ADP1048 Data Sheet

TABLE OF CONTENTS

Features .............................................................................................. 1

Applications ....................................................................................... 1

General Description ......................................................................... 1

Typical Applications Circuit ............................................................ 1

Revision History ............................................................................... 4

Specifications ..................................................................................... 6

Absolute Maximum Ratings ............................................................ 9

Thermal Resistance ...................................................................... 9

ESD Caution .................................................................................. 9

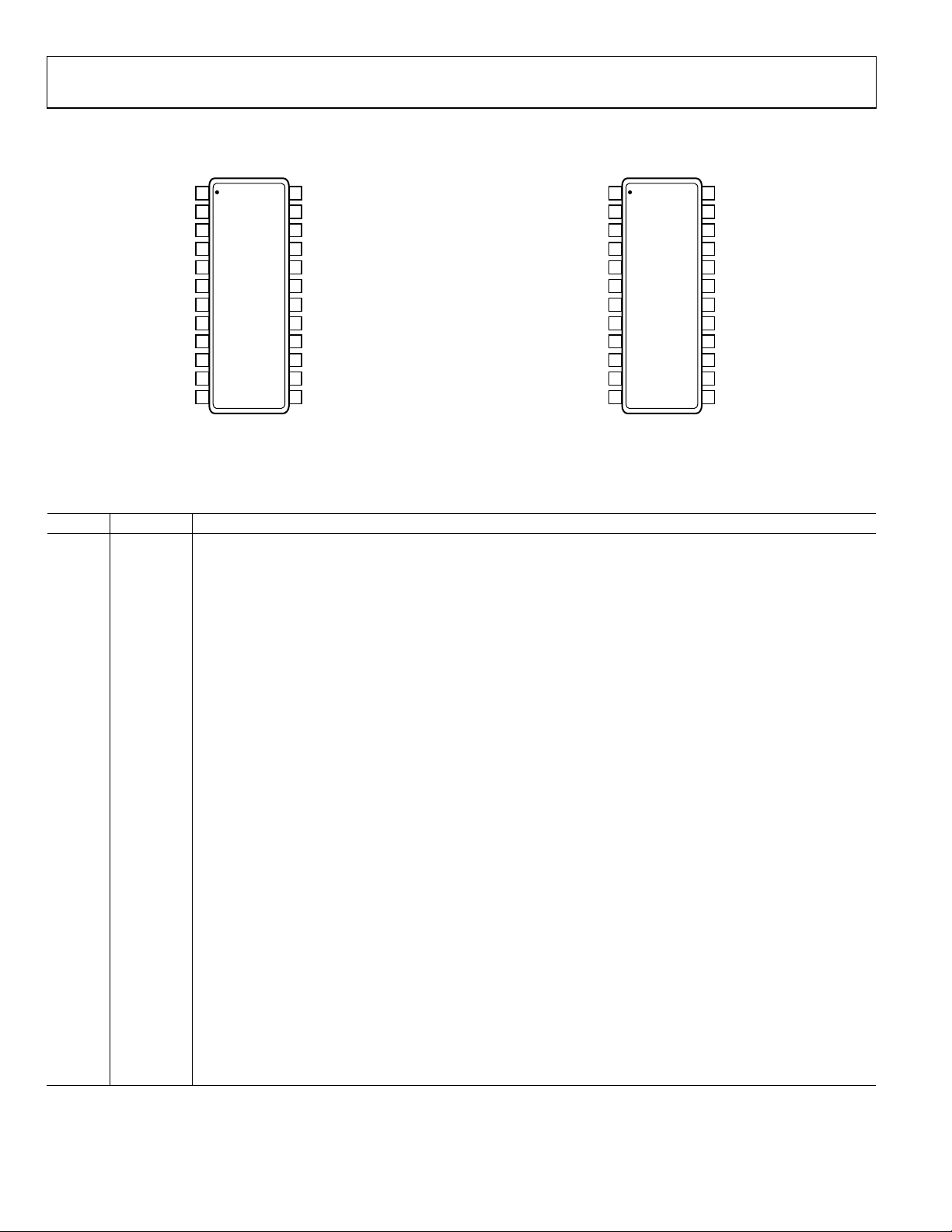

Pin Configurations and Function Descriptions ......................... 10

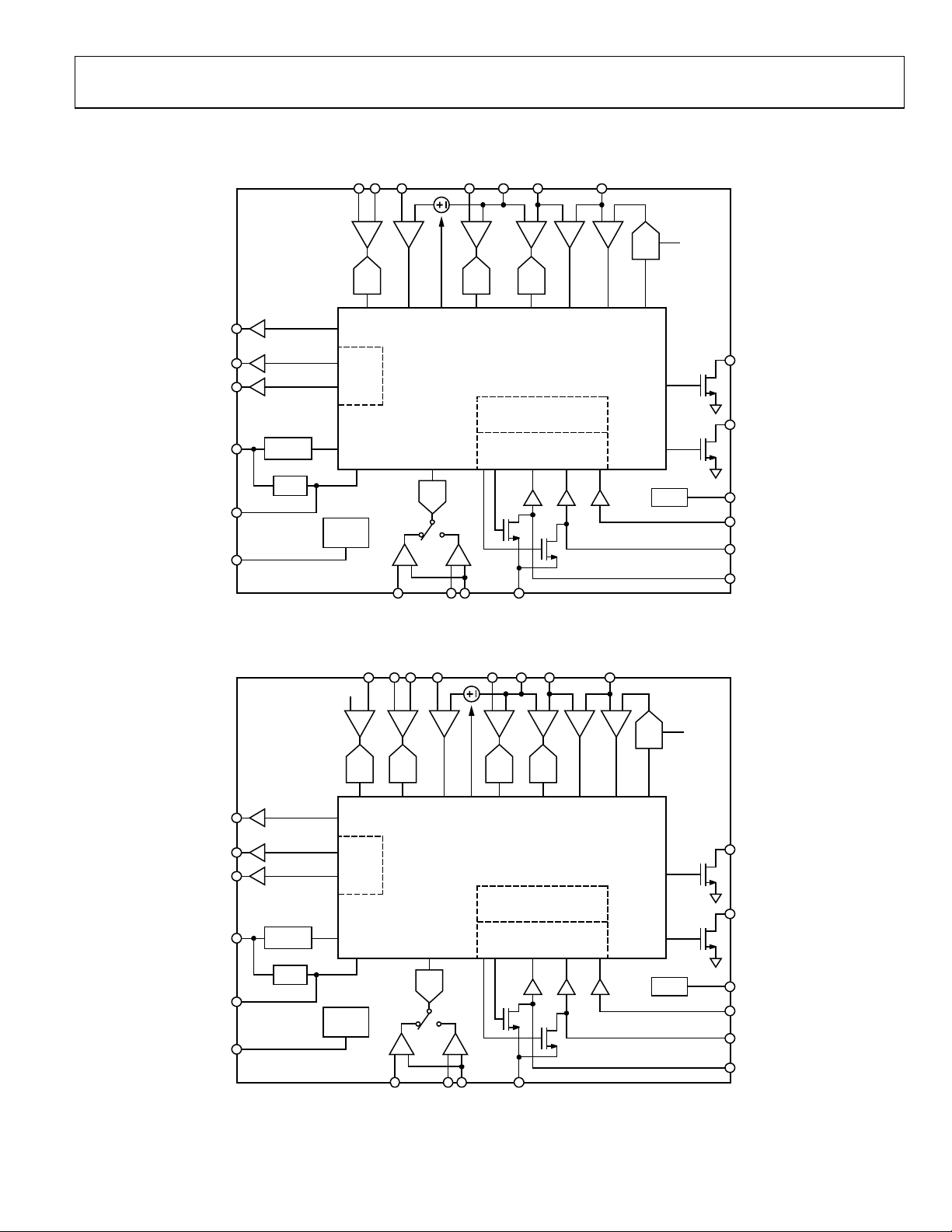

Functional Block Diagrams ........................................................... 11

Controller Architecture ................................................................. 12

Current Sense .............................................................................. 12

RMS Input Overcurrent Protection ......................................... 12

Fast Overcurrent Protection (ILIM Pin) ................................. 12

Current Balancing (IBAL Pin, ADP1048 Only) ..................... 14

Voltage Sense ............................................................................... 14

Overvoltage Protection .............................................................. 15

Power Factor Correction Control Loop ...................................... 17

Digital Compensation Filters .................................................... 17

Pulse-Width Modulation ........................................................... 18

Duty Cycle Minimum/Maximum Limits ................................ 18

Auxiliary PWM Output (ADP1047 Only) .............................. 18

Switching Frequency Programming ........................................ 19

Line Fault Protections and Soft Start Sequencing ...................... 20

PSON Operation ........................................................................ 20

AC Line Detection ...................................................................... 20

Soft Start Procedure ................................................................... 22

Line Fault Protections ................................................................ 22

Advanced Input Power Metering.................................................. 24

Power Supply System and Fault Monitoring ............................... 25

Flag Conventions ........................................................................ 25

Manufacturer-Specific Flags ..................................................... 25

Standard PMBus Flags ............................................................... 26

PMBus Fault Flag Response ...................................................... 27

Manufacturer-Specific Flag Response ..................................... 28

Monitoring Functions ................................................................ 29

First Error Fault .......................................................................... 29

Overtemperature Protection (OTP) ........................................ 29

AC_OK and PGOOD Signals ................................................... 29

Advanced Features ......................................................................... 30

Frequency Dithering (Spread Spectrum) ................................ 30

PWM Frequency Synchronization ........................................... 30

Smart Output Voltage (Load Line) .......................................... 30

Smart Switching Frequency ...................................................... 31

Current Loop Filter for Light Load .......................................... 31

Phase Shedding (ADP1048 Only) ............................................ 31

Current Loop Feedforward ....................................................... 31

Bridgeless Boost Operation (ADP1048 Only)........................ 32

Power Supply System Calibration and Trim ............................... 33

Output Voltage (VFB) Calibration and Trim ......................... 33

Input Voltage (VAC) Gain and Offset Trim ............................ 33

Current Sense Gain and Offset Trim ....................................... 33

Input Power Gain and Offset Trim .......................................... 33

PMBus Digital Communication ................................................... 34

Features ........................................................................................ 34

Overview ..................................................................................... 34

PMBus Address .......................................................................... 34

Data Transfer............................................................................... 35

General Call Support ................................................................. 36

Fast Mode .................................................................................... 36

Fault Conditions ......................................................................... 36

Timeout Condition .................................................................... 36

Data Transmission Faults .......................................................... 37

Data Content Faults ................................................................... 37

EEPROM ......................................................................................... 38

Overview ..................................................................................... 38

Page Erase Operation ................................................................. 38

Read Operation (Byte Read and Block Read) ........................ 38

Write Operation (Byte Write and Block Write) ..................... 39

EEPROM Password .................................................................... 39

Downloading EEPROM Settings to Internal Registers ......... 39

Saving Register Settings into EEPROM .................................. 40

EEPROM CRC Checksum ........................................................ 40

Software GUI .................................................................................. 41

Standard PMBus Commands Supported by the

ADP1047/ADP1048 ....................................................................... 42

Manufacturer-Specific PMBus Commands ................................ 43

Detailed Register Descriptions ..................................................... 45

OPERATION Register ............................................................... 45

Rev. 0 | Page 2 of 84

Data Sheet ADP1047/ADP1048

ON_OFF_CONFIG Register ..................................................... 45

CLEAR_FAULTS Command ..................................................... 45

WRITE_PROTECT Register ..................................................... 45

RESTORE_DEFAULT_ALL Command .................................. 45

STORE_USER_ALL Command ................................................ 45

RESTORE_USER_ALL Command .......................................... 46

CAPABILITY Register ............................................................... 46

VOUT_MODE Register ............................................................. 46

VOUT_COMMAND Register .................................................. 46

VOUT_SCALE_LOOP Register ............................................... 46

VOUT_SCALE_MONITOR Register ...................................... 47

VIN_ON Register........................................................................ 47

VIN_OFF Register ...................................................................... 47

VOUT_OV_FAULT_LIMIT Register ...................................... 47

VOUT_OV_FAULT_RESPONSE Register ............................. 47

VOUT_OV_WARN_LIMIT Register ...................................... 48

VOUT_UV_WARN_LIMIT Register ...................................... 48

VOUT_UV_FAULT_LIMIT Register ...................................... 48

VOUT_UV_FAULT_RESPONSE Register ............................. 49

OT_FAULT_RESPONSE Register ............................................ 49

VIN_OV_FAULT_LIMIT Register........................................... 50

VIN_OV_FAULT_RESPONSE Register .................................. 50

VIN_UV_WARN_LIMIT Register ........................................... 51

VIN_UV_FAULT_LIMIT Register .......................................... 51

VIN_UV_FAULT_RESPONSE Register .................................. 52

IIN_OC_FAULT_LIMIT Register ............................................ 52

IIN_OC_FAULT_RESPONSE Register ................................... 53

IIN_OC_WARN_LIMIT Register ............................................ 53

PIN_OP_WARN_LIMIT Register ............................................ 54

STATUS_BYTE Register ............................................................ 54

STATUS_WORD Register ......................................................... 54

STATUS_VOUT Register ........................................................... 55

STATUS_INPUT Register ......................................................... 55

STATUS_TEMPERATURE Register ........................................ 55

READ_VIN Register ................................................................... 55

READ_IIN Register .................................................................... 55

READ_VOUT Register .............................................................. 56

READ_PIN Register ................................................................... 56

PMBUS_REVISION Register .................................................... 56

MFR_ID Register ........................................................................ 56

MFR_MODEL Register .............................................................. 56

MFR_REVISION Register ......................................................... 56

EEPROM_DATA_00 Through EEPROM_DATA_15

Commands ................................................................................... 56

EEPROM_CRC_CHKSUM Register ....................................... 57

EEPROM_NUM_RD_BYTES Register ................................... 57

EEPROM_ADDR_OFFSET Register ....................................... 57

EEPROM_PAGE_ERASE Register ........................................... 57

EEPROM_PASSWORD Register .............................................. 57

TRIM_PASSWORD Register .................................................... 57

EEPROM_INFO Command ..................................................... 57

CS_FAST_OCP_RESPONSE Register ..................................... 58

OVP_FAST_OVP_RESPONSE Register ................................. 58

OLP_RESPONSE Register ......................................................... 58

VDD3P3_RESPONSE Register ................................................. 59

VCORE_RESPONSE Register ................................................... 59

PGOOD_AC_OK_DEBOUNCE_SET Register ..................... 59

PSON_SET Register ................................................................... 60

FLAG_FAULT_ID Register ....................................................... 60

SOFTSTART_FLAGS_BLANK1 Register ............................... 61

SOFTSTART_FLAGS_BLANK2 Register ............................... 61

PGOOD_FLAGS_LIST Register ............................................... 61

AC_OK_FLAGS_LIST Register ................................................ 61

PWM and PWM2 Timing Registers ........................................ 62

PWM_SET Register .................................................................... 63

PWM_LIMIT Register ............................................................... 63

RTD ADC Offset Trim Setting (MSB) Register ...................... 63

RTD ADC Offset Trim Setting (LSB) Register ....................... 63

RTD ADC Gain Trim Setting Register .................................... 64

OT_FAULT_LIMIT Register ..................................................... 64

OT_WARN_LIMIT Register ..................................................... 64

Switching Frequency Setting Register ...................................... 65

Low Power Switching Frequency Setting Register ................. 66

Frequency Dithering Set Register ............................................. 67

Frequency Synchronization Set Register ................................. 68

Voltage Loop Filter Gain Register ............................................. 68

Voltage Loop Filter Zero Register ............................................. 68

Fast Voltage Loop Filter Gain Register ..................................... 68

Fast Voltage Loop Filter Zero Register ..................................... 68

Fast Voltage Loop Enable Register ............................................ 68

VAC_THRESHOLD_SET Register .......................................... 69

VAC_THRESHOLD_READ Register ...................................... 69

Rev. 0 | Page 3 of 84

ADP1047/ADP1048 Data Sheet

MIN_AC_PERIOD_SET Register ........................................... 69

MAX_AC_PERIOD_SET Register .......................................... 69

Current Loop Filter Gain for Low Line Input Register ......... 70

Current Loop Filter Zero for Low Line Input Register ......... 70

Current Loop Filter Gain for High Line Input Register ........ 70

Current Loop Filter Zero for High Line Input Register ........ 70

Soft Start Set Register ................................................................. 70

Inrush Set Register ..................................................................... 71

FAST_OVP_FAULT_RISE Register ......................................... 71

FAST_OVP_FAULT_FALL Register ........................................ 71

FAST OVP Debounce Time Setting Register ......................... 71

Low Power Mode Operation Threshold Register .................. 72

Power Metering Offset Trim for Low Line Input Register .... 72

Power Metering Gain Trim for Low Line Input Register ...... 72

High Line Limit Register ........................................................... 72

Low Line Limit Register ............................................................ 72

ILIM_TRIM Register ................................................................. 72

Voltage Loop Output Register .................................................. 72

Exponent Register ...................................................................... 73

Read Update Rate Register ........................................................ 73

VIN Scale Monitor Register ...................................................... 73

IIN_GSENSE Register ............................................................... 73

CS Fast OCP Blank Register ..................................................... 74

CS Fast OCP Setting Register ................................................... 74

Temperature Hysteresis Register .............................................. 74

VAC ADC Gain Trim Register ................................................. 75

VFB ADC Gain Trim Register .................................................. 75

CS ADC Gain Trim for 500 mV Range Register .................... 75

IBAL Gain Register (ADP1048 Only) ..................................... 75

Smart VOUT Low Power Threshold (P1) Register ............... 75

Smart VOUT High Power Threshold (P2) Register .............. 75

Smart VOUT Low Line (VOL1) Register ................................ 76

Smart VOUT Low Line (VOL2) Register ................................ 76

Smart VOUT High Line (VOH1) Register ............................. 76

Smart VOUT High Line (VOH2) Register ............................. 76

Smart VOUT Upper Limit (VOH) Register ........................... 76

Smart VOUT Super High Line Register .................................. 76

SYNC Delay Register ................................................................. 76

SMART_VOUT_SUPER_HIGH_LINE_HYS Register ........ 77

POWER_HYS Register .............................................................. 77

Advanced Feature Enable Register ........................................... 77

VOUT_OV_FAULT_HYS Register ......................................... 77

VIN_UV_FAULT_HYS Register .............................................. 77

VAC ADC Offset Trim Register ............................................... 78

CS ADC Offset Trim for 500 mV Range Register ................. 78

CS ADC Gain Trim for High (750 mV) Range Register....... 78

CS ADC Offset Trim for High (750 mV) Range Register .... 78

Latched Flag Registers ............................................................... 78

PWM Value Register .................................................................. 79

VAC_LINE_PERIOD Register ................................................. 79

Read Temperature ADC Register ............................................. 79

Power Metering Offset Trim for High Line Input Register .. 79

Power Metering Gain Trim for High Line Input Register .... 80

Current Loop Filter Gain for Low Line Input and Light

Load Register .............................................................................. 80

Current Loop Filter Zero for Low Line Input and Light

Load Register .............................................................................. 80

Current Loop Filter Gain for High Line Input and Light

Load Register .............................................................................. 80

Current Loop Filter Zero for High Line Input and Light

Load Register .............................................................................. 80

Smart VOUT Power Reading Register .................................... 80

IBAL Configuration Register (ADP1048 Only) ..................... 81

Debug Flag Registers .................................................................. 81

Outline Dimensions ....................................................................... 83

Ordering Guide .......................................................................... 83

REVISION HISTORY

9/11—Revision 0: Initial Version

Rev. 0 | Page 4 of 84

Data Sheet ADP1047/ADP1048

R

The combination of a flexible, digitally controlled PFC engine

and accurate input power metering facilitates the adoption

of intelligent power management systems that are capable of

making decisions to improve end-user system efficiency. The

device supports additional efficiency improvements through

programmable frequency reduction at light load and the

capability to reduce the output voltage at light load.

The ADP1047/ADP1048 provide enhanced integrated features

and functions; the inrush current and soft start control functions

provide significant component count reduction with easy design

optimization.

The devices are designed for high reliability, redundant power

supply applications and have extensive and robust protection

circuitry: independent overvoltage protection (OVP) and

overcurrent protection (OCP), ground continuity monitoring,

and ac sensing. Internal overtemperature protection (OTP)

is provided whereby the external temperature can be recorded

via an external sensing device.

The internal 8 kB EEPROM stores all programmed values

and allows standalone control without a microcontroller. All

parametric reporting and adjustments can be programmed via

an easy-to-use GUI. No complex programming is required.

The ADP1047/ADP1048 operate from a single 3.3 V supply. The

devices are available in a 24-lead QSOP package that is specified

over an ambient temperature range of −40°C to +85°C.

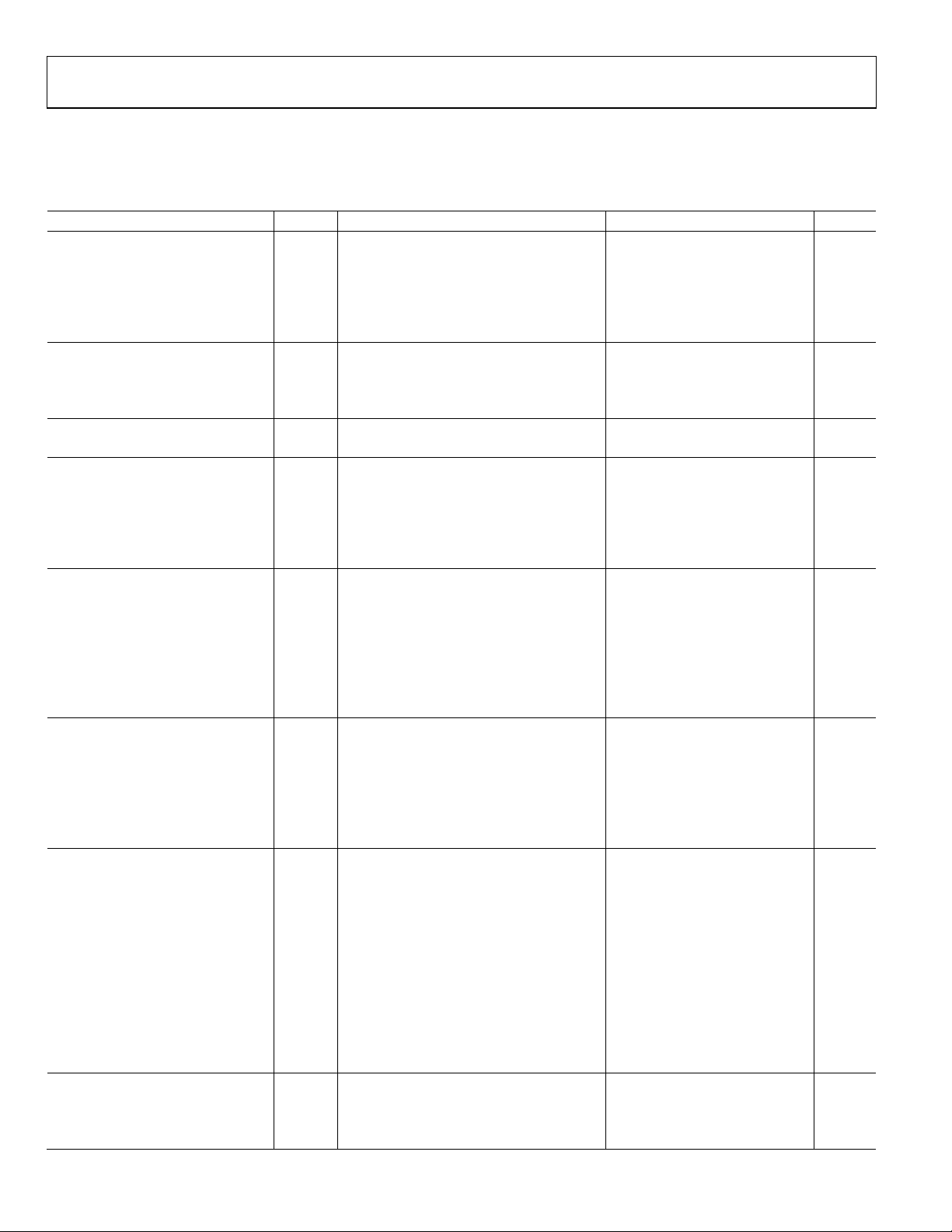

V

OUT

BULK

CAPACITO

09696-102

AC

INPUT

V

REC

RELAY

1

2

3

4

5

6

7

8

9

10

11

12

AGND

VAC

VFB

OVP

PGND

ILIM

IBAL

CS–

CS+

DGND

PSON

VCORE

VDD

RES

RTD

ADD

SDA

SCL

SYNC

INRUSH

PGOOD

AC_OK

PWM2

PWM

24

23

22

21

20

19

18

17

16

15

14

13

3.3V

PMBus

ADP1048

Figure 2. Typical Interleaved Application, ADP1048

Rev. 0 | Page 5 of 84

ADP1047/ADP1048 Data Sheet

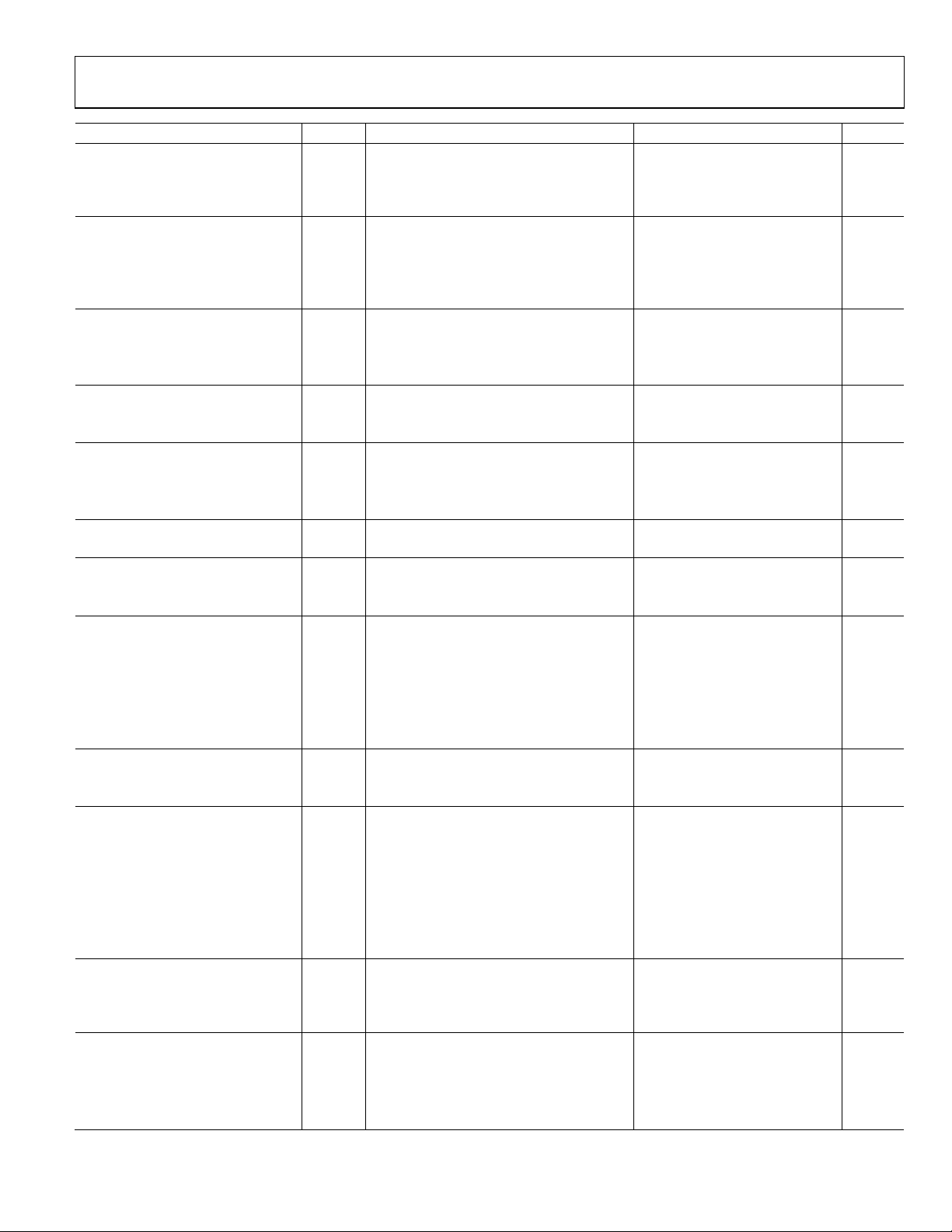

SPECIFICATIONS

VDD = 3.3 V, TA = −40°C to +85°C, unless otherwise noted.

Table 1.

Parameter Symbol Test Conditions/Comments Min Typ Max Unit

POWER SUPPLY

Operating Supply Voltage VDD 3.0 3.3 3.6 V

Supply Current IDD

Normal operation (PSON high) and no load

on PWM output

Supply Current for Programming I

Shutdown Current I

During EEPROM programming (50 ms) IDD + 8 mA

DD_PK

100 µA

DD_SD

POWER-ON RESET

Power-On Reset VDD rising 1.8 3 V

Undervoltage Lockout UVLO VDD falling 2.75 2.85 2.95 V

Overvoltage Lockout OVLO 3.7 3.9 4.1 V

VCORE PIN

Output Voltage Range Temperature = 25°C 2.26 2.45 2.65 V

PWM OUTPUTS PWM, PWM2 pins

Output Low Voltage V

Output High Voltage V

Rise Time C

Fall Time C

Sink current = 10 mA 0.4 V

PWMOL

Source current = 10 mA

PWMOH

= 50 pF 4 ns

LOAD

= 50 pF 4 ns

LOAD

VAC ADC

Input Voltage Range 0 1.6 V

Leakage Current 5 A

Equivalent Resolution 11 Bits

Voltage Sense Measurement

From 2.5% to 97.5% of input voltage range

Accuracy

VDD = 3.3 V −1.3 +1.3 % FSR

VDD varies from 3.0 V to 3.6 V −1.99 +1.99 % FSR

VFB ADC

Input Voltage Range 0 1.6 V

Equivalent Resolution 11 Bits

Voltage Sense Measurement

From 2.5% to 97.5% of input voltage range

Accuracy

VDD = 3.3 V −1.2 +1.2 % FSR

VDD varies from 3.0 V to 3.6 V −1.72 +1.72 % FSR

CURRENT SENSE ADC

High Input Voltage Range 0 750 mV

Low Input Voltage Range 0 500 mV

Equivalent Resolution 11 Bits

Current Sense Measurement

From 0% to 97.5% of input voltage range

Accuracy

VDD = 3.3 V −1.7 +1.7 % FSR

VDD varies from 3.0 V to 3.6 V −2.06 +2.06 % FSR

Current Source 10 kΩ level shifting resistor, V

CS+

− V

= 0 V

CS−

High Input 74 A

Low Input 84 A

Current Source Resolution ±0.03 %

RTD PIN

Input Voltage Range 0 0.8 V

Current Source Accuracy 9 10 11 A

Equivalent Resolution 14 Bits

17 40 mA

VDD −

V

0.4

Rev. 0 | Page 6 of 84

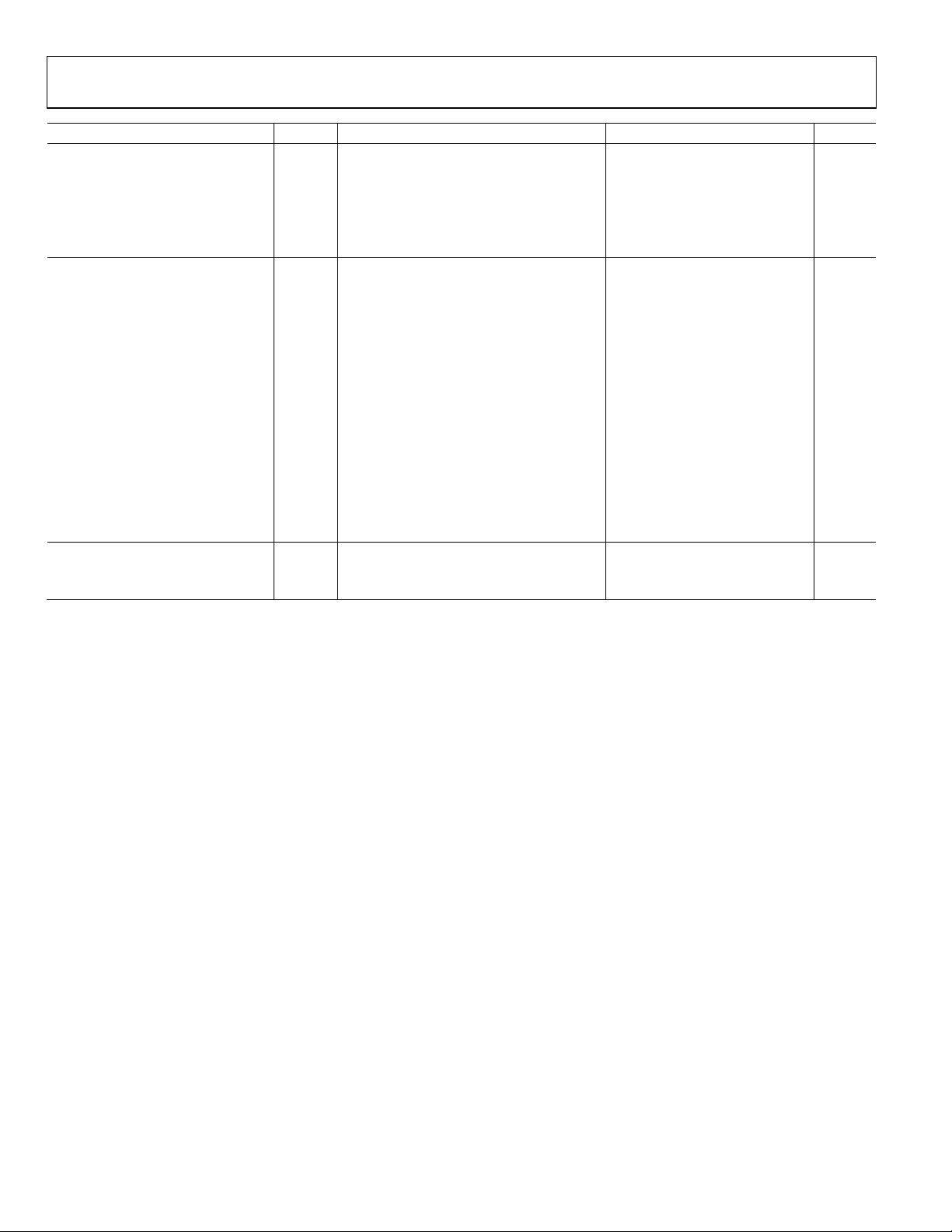

Data Sheet ADP1047/ADP1048

Parameter Symbol Test Conditions/Comments Min Typ Max Unit

Voltage Sense Measurement

Accuracy

VDD = 3.3 V −1.52 +1.52 % FSR

VDD varies from 3.0 V to 3.6 V −1.97 +1.97 % FSR

IBAL PIN (ADP1048 ONLY) Interleaved operation mode

Input Voltage Range 0 0.8 V

Equivalent Resolution 11 Bits

Channel Mismatch

POWER METER

Measurement Accuracy From 2.5% to 97.5% of input voltage range

VDD = 3.3 V −2.3 +2.3 % FSR

VDD varies from 3.0 V to 3.6 V −2.75 +2.75 % FSR

SWITCHING FREQUENCY

Frequency Range Programmable 30 400 kHz

Accuracy −3.85 +3.85 %

OSCILLATOR, CLOCK, AND PLL

Oscillator Frequency 1.516 1.56 1.62 MHz

Digital Clock Frequency 200 MHz

PLL Frequency 200 MHz

RES PIN

Temperature Stability −120 0 +120 ppm/°C

PGOOD, AC_OK PINS

Output Low Voltage 0.8 V

Output High Voltage 2.0 V

FAST OVERCURRENT PROTECTION

Fast OCP Threshold

Positive Signal 1455 1500 1550 mV

Negative Signal 452 500 523 mV

Current Source Accuracy ±4.4 %

Current Source Resolution ±3.2 %

Propagation Delay From threshold trip to PWM disabled 140 ns

RMS OVERCURRENT PROTECTION

RMS Accuracy VDD = 3.3 V −1.7 +1.7 %

Propagation Delay AC line frequency = 50 Hz 12 ms

FAST OVERVOLTAGE PROTECTION

Fast OVP Threshold Fully programmable from 1 V to 1.5 V

Rising Register 0xFE2F, Bits[6:0] 1 1.5 V

Falling Register 0xFE30, Bits[6:0] 1 1.5 V

OVP Threshold Minimum Step 3.9 mV

Accuracy −4 +4 LSB

Propagation Delay (Latency) Does not include blanking/debounce 120 ns

Blanking Time Blanking after threshold reprogramming 10 µs

ACCURATE OVERVOLTAGE

PROTECTION

Accuracy VDD = 3.3 V −1.2 +1.2 %

Propagation Delay AC line frequency = 50 Hz 12 ms

OPEN-LOOP PROTECTION

VFB Error Threshold

Propagation Delay 200 ns

Debounce Time 10 µs

Common-Mode Input Range −0.2 +1.6 V

From 2.5% to 97.5% of input voltage range

DC input and acquiring time window on

each channel is 526 µs

ΔVFB

±33 ±111 ±242 mV

−5 +5 % FSR

Rev. 0 | Page 7 of 84

ADP1047/ADP1048 Data Sheet

Parameter Symbol Test Conditions/Comments Min Typ Max Unit

SDA, SCL PINS VDD = 3.3 V

Input Low Voltage 0.8 V

Input High Voltage 2.2 V

Output Low Voltage 0.4 V

Pull-Up Current 100 350 µA

Leakage Current −5 +5 µA

SERIAL BUS TIMING

Clock Frequency 10 100 400 kHz

Glitch Immunity tSW 50 ns

Bus Free Time t

Start Condition Hold Time t

Start Condition Setup Time t

Stop Condition Setup Time t

Data Hold Time t

Data Setup Time t

SCL Low Timeout t

SCL Low Time t

SCL High Time t

Clock Low Extend Time t

SCL, SDA Rise Time tR 20 300 ns

SCL, SDA Fall Time tF 20 300 ns

EEPROM RELIABILITY

Endurance 10,000 Cycles

Data Retention Temperature = 85°C 20 Years

1.3 µs

BUF

0.6 µs

HD;STA

0.6 µs

SU;STA

0.6 µs

SU;STO

300 ns

HD;DAT

100 ns

SU;DAT

25 35 ms

TIMEOUT

1.3 µs

LOW

0.6 µs

HIGH

25 ms

LOW; SEXT

Rev. 0 | Page 8 of 84

Data Sheet ADP1047/ADP1048

ABSOLUTE MAXIMUM RATINGS

Table 2.

Parameter Rating

Supply Voltage (Continuous), VDD 3.8 V

Digital Core Supply Voltage, VCORE 2.7 V

Digital Pins −0.3 V to VDD + 0.3 V

Analog Pins −0.3 V to VDD + 0.3 V

AGND to DGND −0.3 V to +0.3 V

Operating Temperature Range −40°C to +85°C

Storage Temperature Range −65°C to +150°C

Maximum Junction Temperature 150°C

Peak Solder Reflow Temperature

SnPb Assemblies (10 sec to 30 sec) 240°C

RoHS-Compliant Assemblies

(20 sec to 40 sec)

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

260°C

THERMAL RESISTANCE

θJA is specified for the worst-case conditions, that is, a device

soldered in a circuit board for surface-mount packages.

Table 3. Thermal Resistance

Package Type θJA θJC Unit

24-Lead QSOP (RQ-24) 44.4 6.4 °C/W

ESD CAUTION

Rev. 0 | Page 9 of 84

ADP1047/ADP1048 Data Sheet

PIN CONFIGURATIONS AND FUNCTION DESCRIPTIONS

1

AGND

2

VAC

3

VFB

4

OVP

5

PGND

ILIM

CS–

CS+

DGND

PSON PWM2

VCORE PWM

NC = NO CONNECT. DO NOT CO NNECT TO THIS PIN.

NC

ADP1047

6

(Not to Scal e)

7

8

9

10

11

12

TOP VIEW

24

23

22

21

20

19

18

17

16

15

14

13

VDD

RES

RTD

ADD

SDA

SCL

SYNC

INRUSH

PGOOD

AC_OK

1

AGND

2

VAC

3

VFB

4

OVP

5

PGND

ILIM

IBAL

CS–

CS+

DGND

PSON

VCORE PWM

09696-003

ADP1048

6

(Not to Scale)

7

8

9

10

11

12

TOP VIEW

24

23

22

21

20

19

18

17

16

15

14

13

VDD

RES

RTD

ADD

SDA

SCL

SYNC

INRUSH

PGOOD

AC_OK

PWM2

09696-004

Figure 3. ADP1047 Pin Configuration Figure 4. ADP1048 Pin Configuration

Table 4. Pin Function Descriptions

Pin No. Mnemonic Description

1 AGND Analog Ground. AGND should be connected directly to DGND.

2 VAC Input Line Voltage Sense. The VAC signal is referred to PGND.

3 VFB

Feedback Voltage Sense. The VFB signal is referred to PGND. VFB is the feedback signal for PFC power circuit

regulation. It is used as the analog voltage input to the VFB ADC.

4 OVP Overvoltage Protection. The OVP signal is referred to PGND. This signal is used for redundant overvoltage protection.

5 PGND

Power Ground. PGND is the connection for the ground line of the power rail. There should be a low impedance

path between PGND and AGND.

6 ILIM Fast Current Limiting. This pin is referred to PGND.

7 NC/IBAL ADP1047: No Connect. Do not connect to this pin.

ADP1048: Current Balancing Input for Interleaved Operation. The IBAL input is referred to PGND.

8 CS−

Differential Current Sense Negative Input. The CS− signal is used for current measurement, monitoring, and

protection. A 0.1%, 10 kΩ resistor must be used to connect to this circuit.

9 CS+

Differential Current Sense Positive Input. The CS+ signal is used for current measurement, monitoring, and

protection. A 0.1%, 10 kΩ resistor must be used to connect to this circuit.

10 DGND Digital Ground. DGND should be connected directly to AGND.

11 PSON

Power Supply Enable Signal. The PSON signal is used to enable/disable the PFC controller. The PSON signal is

referred to DGND.

12 VCORE Output of 2.5 V Regulator. Connect a 100 nF capacitor from VCORE to DGND.

13 PWM PWM Output for PFC Regulation. The PWM signal is referred to AGND.

14 PWM2 Auxiliary PWM Output (ADP1047) or Interleaved PWM Output (ADP1048). The PWM2 signal is referred to AGND.

15 AC_OK Open-Drain Output. User-configurable signal from a combination of flags. The AC_OK signal is referred to AGND.

16 PGOOD Open-Drain Output. User-configurable signal from a combination of flags. The PGOOD signal is referred to AGND.

17 INRUSH Inrush Current Control Signal to an External Inrush Driver. This open-drain output is referred to AGND.

18 SYNC Allows parallel PFC controllers to synchronize to reduce interference. This pin is referred to DGND.

19 SCL I2C Serial Clock Input. The SCL signal is referred to DGND.

20 SDA I2C Serial Data Input and Output (Open-Drain). The SDA signal is referred to DGND.

21 ADD Address Select Input. Connect a resistor from ADD to AGND (see the PMBus Address section).

22 RTD Thermistor Input. A thermistor is placed from RTD to AGND. The RTD signal is referred to AGND.

23 RES Internal Voltage Reference. Connect a 0.1%, 50 kΩ resistor from RES to AGND.

24 VDD Positive Supply Input. The range is from 3.0 V to 3.6 V. The VDD signal is referred to AGND.

Rev. 0 | Page 10 of 84

Data Sheet ADP1047/ADP1048

V

V

A

V

V

A

A

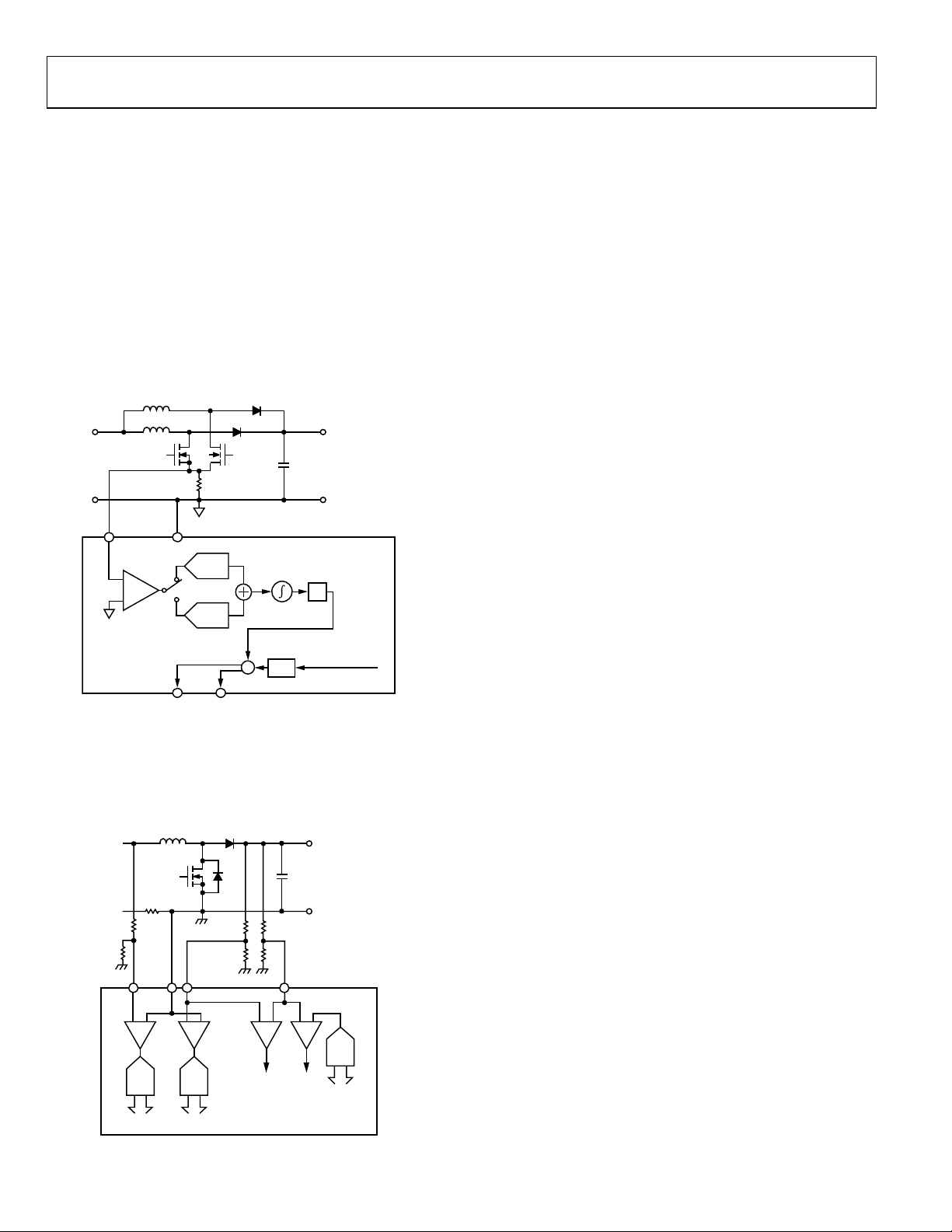

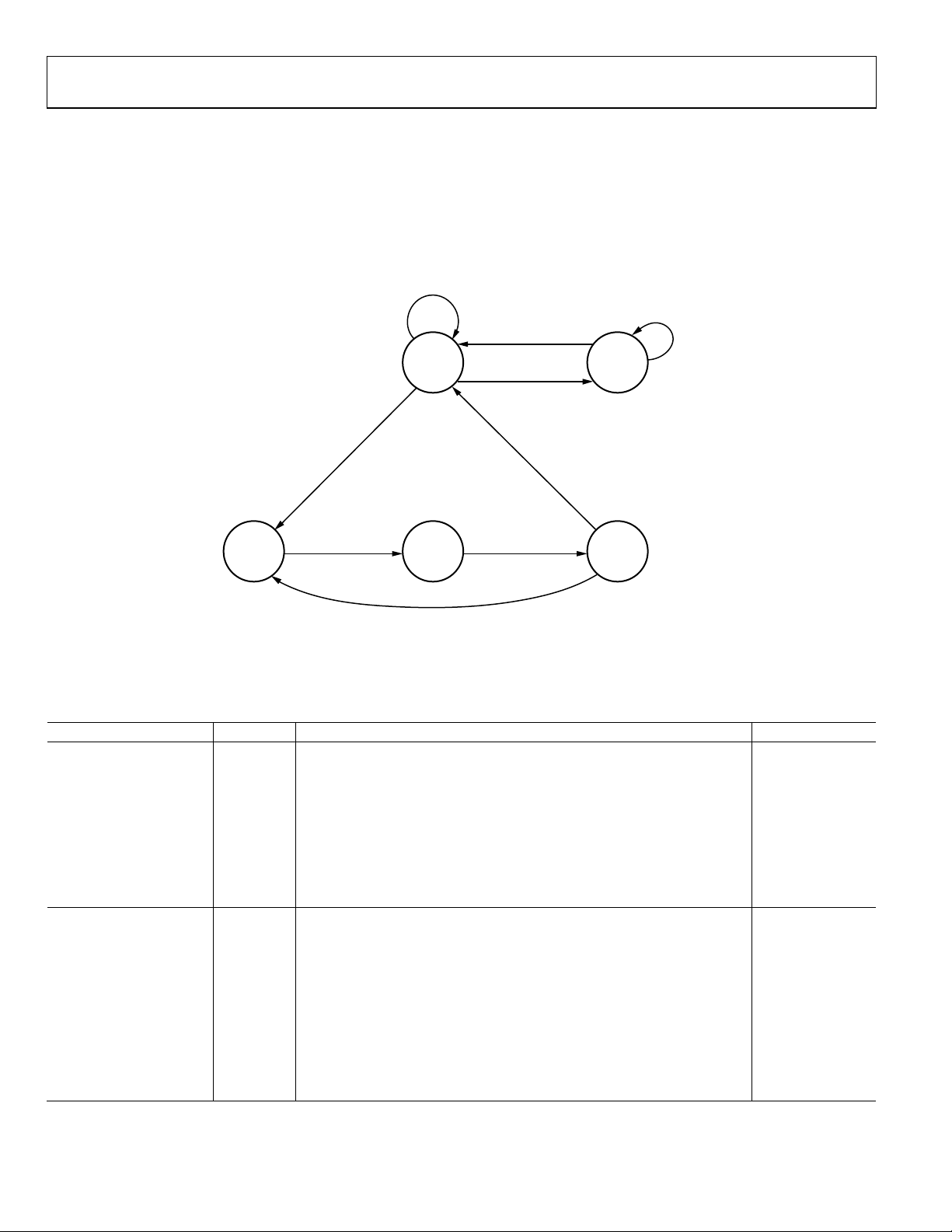

FUNCTIONAL BLOCK DIAGRAMS

CS+CS–

CILIM

FBPGND

OVP

ADP1047

–

INRUSH

PWM

PWM2

VDD

VCORE

RES

UVLO

LDO

ADC

CS OCP VAC VFB OLP OVP

PWM

ENGINE

VREF

ADC

ADC ADC

DIGITAL CORE

8kB EEPROM

INTERFACE

DGNDAGNDRTDADD

2

C

I

+

DAC

OSC

PGND

PGOOD

AC_OK

SYNC

PSON

SCL

SDA

09696-001

Figure 5. ADP1047 Functional Block Diagram

OVP

–

+

DAC

PGND

ADP1048

PGND

L

CS–

IB

CILIMCS+

FBPGND

INRUSH

PWM

PWM2

VDD

VCORE

RES

UVLO

LDO

PWM

ENGINE

VREF

ADC

ADC

CS OCP VAC VFB OLP OVP

CS

ADC

ADC ADC

DIGITAL CORE

8kB EEPROM

AGNDRTDADD

DGND

2

C

I

INTERFACE

OSC

PGOOD

AC_OK

SYNC

PSON

SCL

SDA

09696-002

Figure 6. ADP1048 Functional Block Diagram

Rev. 0 | Page 11 of 84

ADP1047/ADP1048 Data Sheet

CONTROLLER ARCHITECTURE

The ADP1047/ADP1048 integrate the following functions: The output of the Σ-Δ ADC is used for the following purposes:

• Power factor correction control loop (see the Power Factor

Correction Control Loop section)

• Advanced input power metering (see the Advanced Input

Power Metering section)

• PMBus digital communication (see the PMBus Digital

Communication section)

This section describes the internal architecture of the chip.

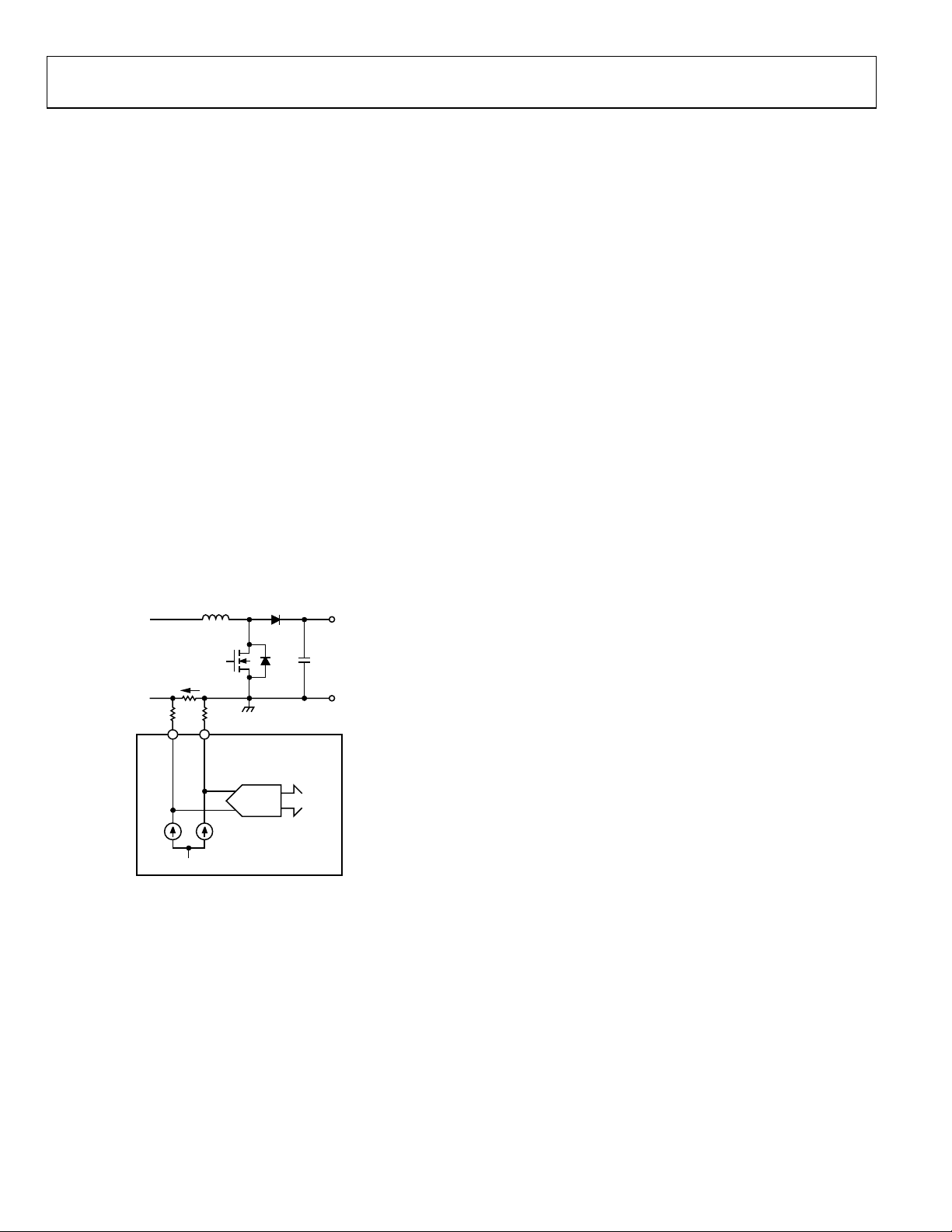

CURRENT SENSE

Current sensing is used for the control, protection, and monitoring of the PFC stage. For normal operation, the power factor

correction control loop requires inductor current information.

The typical implementation uses a sense resistor on the input

bus. A combination of two current transformers in series with

the power switch and the boost diode can be used to reconstruct

the inductor current and minimize losses in the resistive shunt,

but, in general, a good quality shunt resistor provides much

better accuracy in measuring input current and input power.

The inputs to the current sense ADC are differential. A pair of

matched current sources is provided to level shift the negative

signal across the current sense element in the input range of the

current sense ADC (see Figure 7).

• The output is decimated at the switching frequency for the

control loop. The effective number of bits (ENOB) is >7

when the current loop bandwidth is 10 kHz; the ENOB

is >10 when the current loop bandwidth is 1 kHz.

• The 11-bit result is calculated and updated at each half line

cycle for high accuracy ac line current and input power

monitoring and for overcurrent protection (accurate OCP).

RMS INPUT OVERCURRENT PROTECTION

The ADP1047/ADP1048 provide rms overcurrent protection

(OCP). RMS OCP (or accurate OCP) is distinct from the instantaneous pulse-by-pulse fast overcurrent protection and is based

on the rms value of the input ac current.

The measured value is compared to the limit set in the

IIN_OC_FAULT_LIMIT register (Register 0x5B) at the

end of each half cycle of the ac line. If the limit is exceeded,

the action programmed in the IIN_OC_FAULT_RESPONSE

register (Register 0x5C) is triggered.

In addition, an input current warning limit can be programmed

in the IIN_OC_WARN_LIMIT register (Register 0x5D). This

warning limit has no action attached to it, but it sets flags in the

STATUS_BYTE register (Register 0x78, Bit 0), the STATUS_WORD

register (Register 0x79, Bit 13), and the STATUS_INPUT register

(Register 0x7C, Bit 1).

I

L

10kΩ10kΩ

CS– CS+

+

–

ADP1047/ADP1048

VDD

Figure 7. Current Sense Configuration

11-B ITADC

09696-005

The current sense can be calibrated digitally to remove any

errors due to external components (see the Current Sense Gain

and Offset Trim section). This calibration can be performed in

the production environment; the settings are saved in the

EEPROM of the ADP1047/ADP1048.

FAST OVERCURRENT PROTECTION (ILIM PIN)

A dedicated current limiting pin (ILIM) is provided to protect

the part from pulse-by-pulse overcurrent events. When the

threshold is crossed, the PWM pulse is terminated. This action

is independent of any programming of the fast OCP flag. The

next switching cycle resumes normally. Additional actions can

be programmed (see Tabl e 5).

The OCP comparator on the ILIM pin can accept positive or

negative signals; the pin is referred to PGND (power ground) and

has programmable level shifting current sources (see Tab l e 5 ).

These sources can be changed during normal operation to adapt

to the level at which the overcurrent protection is triggered.

The OCP comparator also features programmable blanking and

debounce times (see Tabl e 5). If OCP is triggered, the PWM

signal is terminated and operation resumes at the next switching cycle unless a different action is specified for the fast OCP

response in Register 0xFE00.

Rev. 0 | Page 12 of 84

Data Sheet ADP1047/ADP1048

I

L

I

M

ILIM PGND

60µA TO

120µA

VDD

OCP

500mV

ADP1047/ADP1048

ILIM PGND

20µA TO

80µA

VDD

OCP

1500mV

ADP1047/ADP1048

9696-006

Figure 8. Fast Overcurrent Protection Schemes

500mV

0mV

LEVEL SHIFTING

10k × 120µA = 1.2V

Figure 9. Level Shifting and Threshold for OCP

1500mV

0mV

LEVEL SHIFTING

10k × 80µA = 0.8V

09696-007

Table 5. Programmable Options for Fast Overcurrent Protection

Parameter Values or Options Comments

Debounce Time 40 ns, 80 ns, 120 ns, 240 ns Register 0xFE3D, Bits[4:3]

Blanking Time 40 ns, 80 ns, 120 ns, 160 ns, 200 ns, 400 ns, 600 ns, 800 ns

Blanking from the leading edge;

Register 0xFE3D, Bits[2:0]

Propagation Delay 140 ns typical

Fixed value; does not include blanking or

debounce

Threshold Value and Polarity 500 mV (negative); 1500 mV (positive) Fixed values

Level Shifting Current Sources 60 A, 80 A, 100 A, 120 A (negative)

Register 0xFE3E, Bits[7:5]

20 A, 40 A, 60 A, 80 A (positive)

Actions for Fast OCP

Ignore (still terminates the PWM pulse); allow n switching

n = 1, 2, 4, 8; Register 0xFE00, Bits[7:6]

cycles, then shut down and soft start; allow n switching

cycles, then shut down and wait for PSON signal

Rev. 0 | Page 13 of 84

ADP1047/ADP1048 Data Sheet

V

V

CURRENT BALANCING (IBAL PIN, ADP1048 ONLY)

The ADP1048 has a dedicated circuit to maintain current balance

in each interleaved phase when operating in interleaved PFC

topology. This ensures that each interleaved phase provides equal

power regardless of the tolerance of the inductor and the boost

switch driving circuitry.

The input is through the IBAL pin specifically provided for the

ADP1048. The current balancing circuit monitors the current

flowing in both switches of the interleaved PFC topology and

stores this information. It compensates the PWM signals,

ensuring equal current flow to balance the current between

interleaved phases. Several switching cycles are required for

the circuit to operate effectively. The current balance settings

are programmed in Register 0xFE43 and Register 0xFE95.

The voltage sense can be calibrated digitally to remove any

errors due to external components (see the Output Voltage

(VFB) Calibration and Trim section). This calibration can

be performed in the production environment; the settings

are saved in the EEPROM of the ADP1047/ADP1048.

Input Voltage Sensing (VAC Pin)

The VAC pin is used for the monitoring and protection of the

rectified power supply input voltage. The sense point on the

power rail requires an external resistor divider to bring the signal

within the operating input range of the ADC (0 V to 1.6 V).

This scaled-down signal is fed into a high speed Σ-Δ ADC.

The output of the Σ-Δ ADC goes to the digital filter and is used

for the following purposes:

• The output is decimated at the switching frequency for the

control loop. The effective number of bits (ENOB) is >7

when the current loop bandwidth is 10 kHz; the ENOB

is >10 when the current loop bandwidth is 1 kHz.

• The 11-bit result is calculated and updated at each half line

cycle for high accuracy input voltage and power monitoring.

IBAL

ADP1048

PGND

0° TO 180°

ADC

+

–

ADC

180° TO 360°

PWM PWM2

Figure 10. Current Balancing (IBAL) for the ADP1048

PWM

K

OUTPUT OF PFC

CURRENT LOOP

09696-008

VOLTAGE SENSE

Voltage sensing is used for the control, protection, and monitoring of the PFC stage. Input and output voltages are sensed using

dedicated ADCs and references (see Figure 11).

REC

VAC P GND VF B

–

+

ADC

11-BIT

Figure 11. Typical Voltage Sense Configuration

+

ADC

11-BIT

–

OUT

OVP

–

+

DAC

OVPOLP

7-BIT

ADP1047/ADP1048

09696-009

Rev. 0 | Page 14 of 84

Output Voltage Sensing (VFB Pin)

The VFB pin is used for the control, monitoring, and protection

of the output voltage. This voltage is the main feedback loop for

the power supply control loop. The sense point on the power rail

requires an external resistor divider to bring the signal within the

operating input range of the ADC (0 V to 1.6 V). This scaleddown signal is fed into a high speed Σ-Δ ADC.

The output of the Σ-Δ ADC goes to the digital filter and is used

for the following purposes:

• The 11-bit result is used at each half line cycle for the

normal control loop to control the value of the output

voltage.

• The 10-bit, 1.5 kHz update rate is used for the fast voltage

control loop to control the value of the output voltage

during large transients.

To reduce the current distortion from the output voltage feedback, a prefilter is implemented before the voltage loop filter.

The prefilter detects the zero-crossing point of the input voltage

to identify the half input line cycle. The prefilter then performs

an averaging function for the sampled VFB signal during this

half line cycle. In this way, the fundamental frequency of the

output bulk voltage ripple and its harmonics are significantly

attenuated.

Data Sheet ADP1047/ADP1048

OVERVOLTAGE PROTECTION

The ADP1047/ADP1048 have two OVP circuits: an ADC-based

comparator and a fast comparator.

Accurate Overvoltage Protection (VFB Pin)

Overvoltage protection (OVP) is implemented using the information available on the output of the VFB ADC. The information

from the VFB ADC is averaged over one half the ac line frequency;

therefore, the response of this OVP is relatively slow.

The threshold for the accurate OVP is fully programmable

using the VOUT_OV_FAULT_LIMIT register (Register 0x40).

The programmed value is the dc average voltage.

When the accurate OVP threshold is crossed, the accurate OVP

flag is set. The response to this flag can be programmed for one

of several actions using the VOUT_OV_FAULT_RESPONSE

register (Register 0x41). If the disable PWM option is selected,

a voltage hysteresis can be programmed for the accurate OVP

threshold using Register 0xFE50.

Table 6. Programmable Options for Fast Overvoltage Protection (Fast OVP)

Parameter Values or Options Comments

Debounce Time 120 ns, 240 ns, 480 ns, 640 ns

Blanking Time 10 s (fixed)

Propagation Delay 120 ns max (fixed) Does not include blanking or debounce

Threshold Rising 1 V to 1.5 V Programmable using Register 0xFE2F, Bits[6:0]

Threshold Falling 1 V to 1.5 V Programmable using Register 0xFE30, Bits[6:0]

Actions for Fast OVP

Immediate shutdown and wait for PSON;

disable PWM until the flag is cleared;

shut down and soft start; ignore (do nothing)

Fast Overvoltage Protection (OVP Pin)

A fast OVP mode is implemented using a programmable

comparator on the OVP pin. Fast OVP is used for overvoltage

protection of the bulk capacitors and to provide open-loop

protection. The sense point on the power rail requires an

external resistor divider to match the divider applied to VFB.

This separate divider introduces a level of redundancy in

sensing the output voltage to improve system reliability.

If the voltage divider on the VFB pin is damaged or drifts in

value, the OVP pin can still detect an overvoltage condition

and take the appropriate programmed action.

The fast OVP signal is fed into a comparator with a programmable threshold to set the trip point for overvoltage. The

threshold is set using a DAC.

Minimum duration of pulse to be considered;

programmable using Register 0xFE31, Bits[1:0]

Duration of time while the comparator is blanked

and the threshold changes from rising to falling

Register 0xFE01, Bits[7:6]

Rev. 0 | Page 15 of 84

ADP1047/ADP1048 Data Sheet

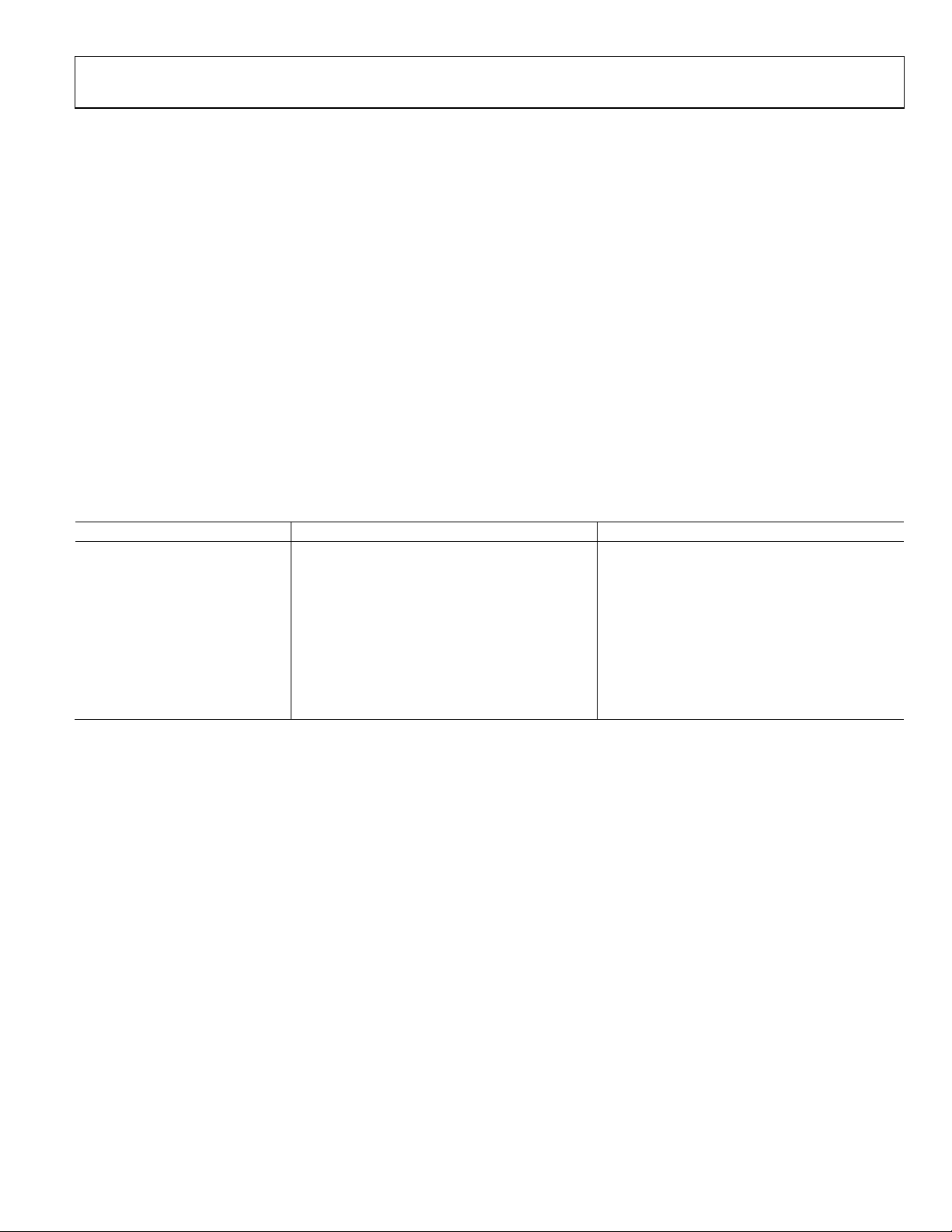

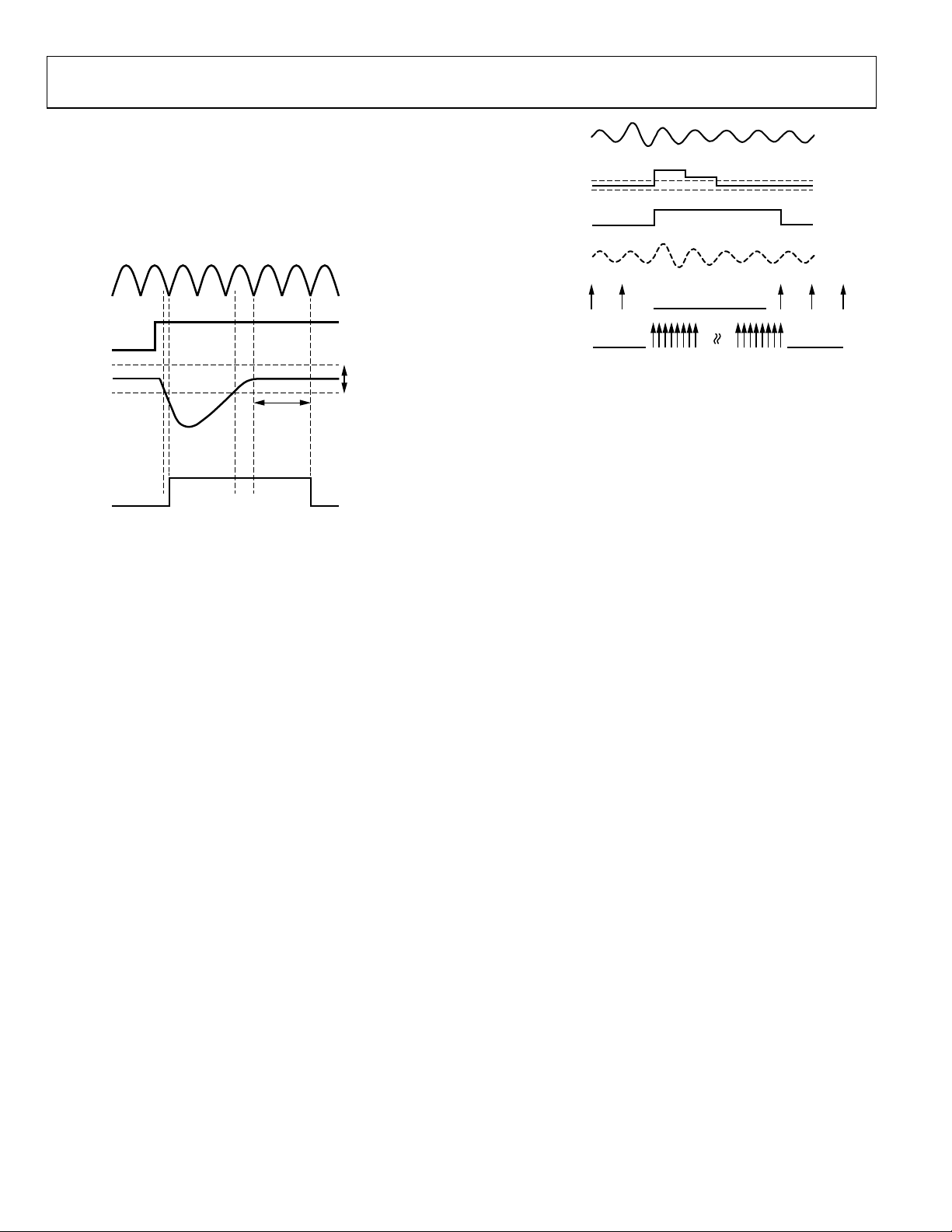

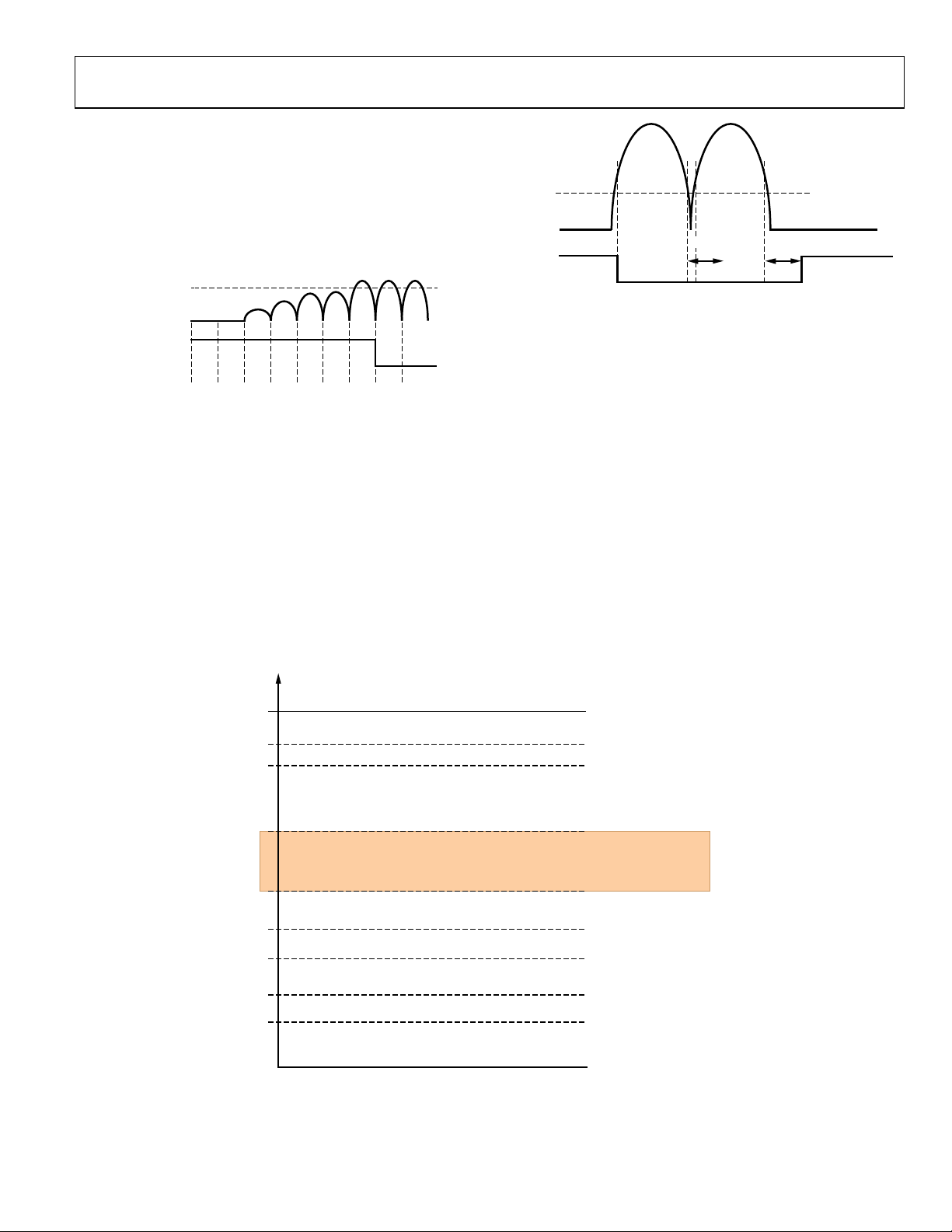

Figure 12 shows an example of the output voltage and the OVP

thresholds set. The rising and falling thresholds, FAST_OVP_

FAULT_RISE and FAST_OVP_FAULT_FALL, respectively, are

used for fast OVP protection. FAST_OVP_FAULT_RISE

corresponds to OVP

, which is the trip point for overvoltage

UP

protection (see Figure 13). FAST_OVP_FAULT_FALL corresponds to OVP

, which is the reset point for the fast OVP.

DOWN

When the rising threshold is triggered, the programmed action

is applied and the threshold is switched to the programmed falling threshold (if the programmed falling threshold is different

from the rising threshold).

A blanking time is applied when the thresholds are switched to

avoid spurious signals (see the timing diagram in Figure 13). A

programmable debounce time is applied to the OVP signal as

well to avoid false triggering.

The rising and falling thresholds are programmable from 1 V

to 1.5 V (at the OVP pin) using Register 0xFE2F and Register

0xFE30, respectively.

Open-Loop Protection

Open-loop protection detects differences between the OVP and

VFB pins. Identical resistor dividers are applied to these pins;

therefore, if a voltage difference is present, it means that one or

more resistors in the dividers have the wrong values or are not

connected. In this case, it is usually recommended that the user

shut down the system to prevent damage.

The open-loop protection detects a difference in voltage in

excess of ~100 mV, which equates to approximately 6.6% of

the full-scale range.

A debounce time of 10 μs is added to avoid false triggering. If

filtering capacitors are applied to the OVP and VFB pins, care

must be taken to make sure that the time constant difference

does not exceed 10 μs.

Table 7. Programmable Options for Open-Loop Protection (OLP)

Parameter Values or Options Comments

Debounce Time 10 s (fixed) Minimum duration of pulse to be considered

Propagation Delay 200 ns (fixed) Does not include debounce

Actions for OLP

Immediate shutdown and wait for PSON;

disable PWM until the flag is cleared;

shut down and soft start; ignore (do nothing)

ADC INPUT RANGE = 1.6V

1.6V

1.0V

0.5V

VOUT_OV_FAULT_LIMIT = 450V (REG 0x40)

FAST_OVP_FAULT_RISE = 435 V (REG 0xFE 2F)

VOUT_OV _WARN_LIMIT = 420V (REG 0x42)

FAST_OVP_FAULT_FALL = 400V (REG 0xFE30)

VOUT_COM MAND = 385V (REG 0x21)

VOUT_UV_FAULT_LIMIT = 200V (REG 0x44)

Figure 12. Output Voltage Levels

OUTPUT

VOLTAGE

DOWN

FLAG

OVP PIN

UP

DEBOUNCE

10µs

Figure 13. OVP Thresholds and Timing

OVP

OVP

OVP

Register 0xFE02, Bits[7:6]

FAST OVP

PROGRAMMING

RANGE

TIME

ADC

FULL

RANGE

09696-020

09696-021

Rev. 0 | Page 16 of 84

Data Sheet ADP1047/ADP1048

V

POWER FACTOR CORRECTION CONTROL LOOP

The ADP1047/ADP1048 implement the average current mode

power factor correction control loop using a traditional multiplier approach. The implementation of the loop is digital, and

all the signals are converted from analog to digital before they

are processed by the control loop. Σ-Δ ADCs are used to achieve

high performance, cost-effective implementation. Each ADC

has its own dedicated voltage reference.

DIGITAL COMPENSATION FILTERS

The ADP1047/ADP1048 are digital PFC controllers with ac power

monitoring. They are implemented in the digital domain using

a dedicated state machine, which allows the user to program the

loop response specifically, with no need for external loop

compensation.

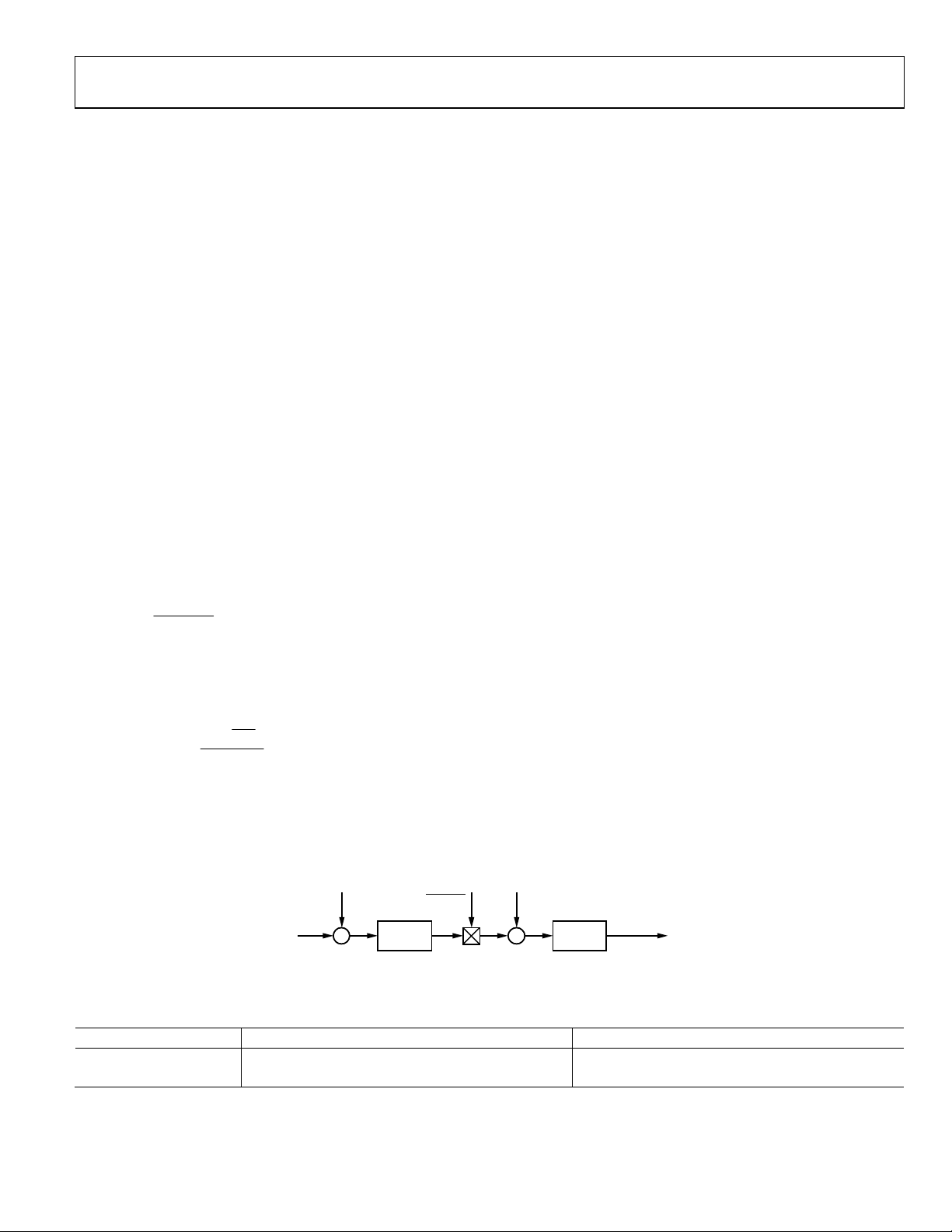

The detailed control loop configuration is illustrated in Figure 14.

V

is the digital reference voltage setting; VFB is the sensed feed-

REF

back voltage of the output. The difference between V

is processed first by the voltage loop filter (H

). Its output, VEA,

V

is then multiplied by the instantaneous rectified input voltage,

V

, and divided by the square of the rms value of VAC. The result,

AC

I

, is used as the reference signal for the current. The output of

REF

the current loop filter (H

) is the duty cycle command. The

I

mathematical expression is

VVI×

REF

=

ACEA

2

V

_ RMSAC

Both the voltage loop and current loop digital compensating

filters, H

(z) and HI(z), are programmable. The filter transfer

V

function in the digital domain is

a

⎛

z

⎜

⎝

××=

bkH(z)

⎞

−

⎟

256

⎠

()

1

−

z

where:

a is the filter zero.

b is the filter gain.

k is related to the switching frequency.

V

FB

–

V

+

REF

and VFB

REF

AC

2

V

AC_RMS

HV(z)

V

EA

Figure 14. Control Loop Digital Filters

The frequency gains and zero locations can all be programmed

individually to tailor the loop response to the application. It is

recommended that the Analog Devices, Inc., GUI software be

used to program the filter (see the Software GUI section). The

GUI displays the filter response in Bode plot format and can be

used to calculate all stability criteria for the power supply.

Optimized Compensation Filters

Instead of a single programmable compensation filter, the

ADP1047/ADP1048 offer the following filter presets so that

the dynamic response of the control loop can be tailored to

optimize different operating conditions.

•

Low line current filter

High line current filter

•

Fast voltage compensation filter

•

The ADP1047/ADP1048 can be configured to switch automatically between the high and low line filters when the rms

value of the ac line crosses the programmed threshold between

the high and low lines. (The high line threshold is programmed

in Register 0xFE35; the low line threshold is programmed in

Register 0xFE36.)

The ADP1047/ADP1048 check for the value of the rms input

voltage at each half line cycle. When a transition between the

high and low line threshold is detected, the part waits for four

full line cycles before switching to the correct filter at the zero

crossing of the input line cycle. This is done to avoid spurious

transitions due to a missing or distorted voltage line cycle.

During soft start, one of four combinations of filters can be

used, depending on whether the fast loop mode is enabled

and whether the high line or low line is detected for soft start

(see Tabl e 8).

I

L

–

I

REF

+

HI(z)

DUTY CYCLE

09696-010

Table 8. Summary of the PFC Digital Compensation Filters for Soft Start

Line Filter Normal Compensation Filter Fast Voltage Compensation Filter

High Line High line current filter, normal voltage filter High line current filter, fast voltage filter

Low Line Low line current filter, normal voltage filter Low line current filter, fast voltage filter

Rev. 0 | Page 17 of 84

ADP1047/ADP1048 Data Sheet

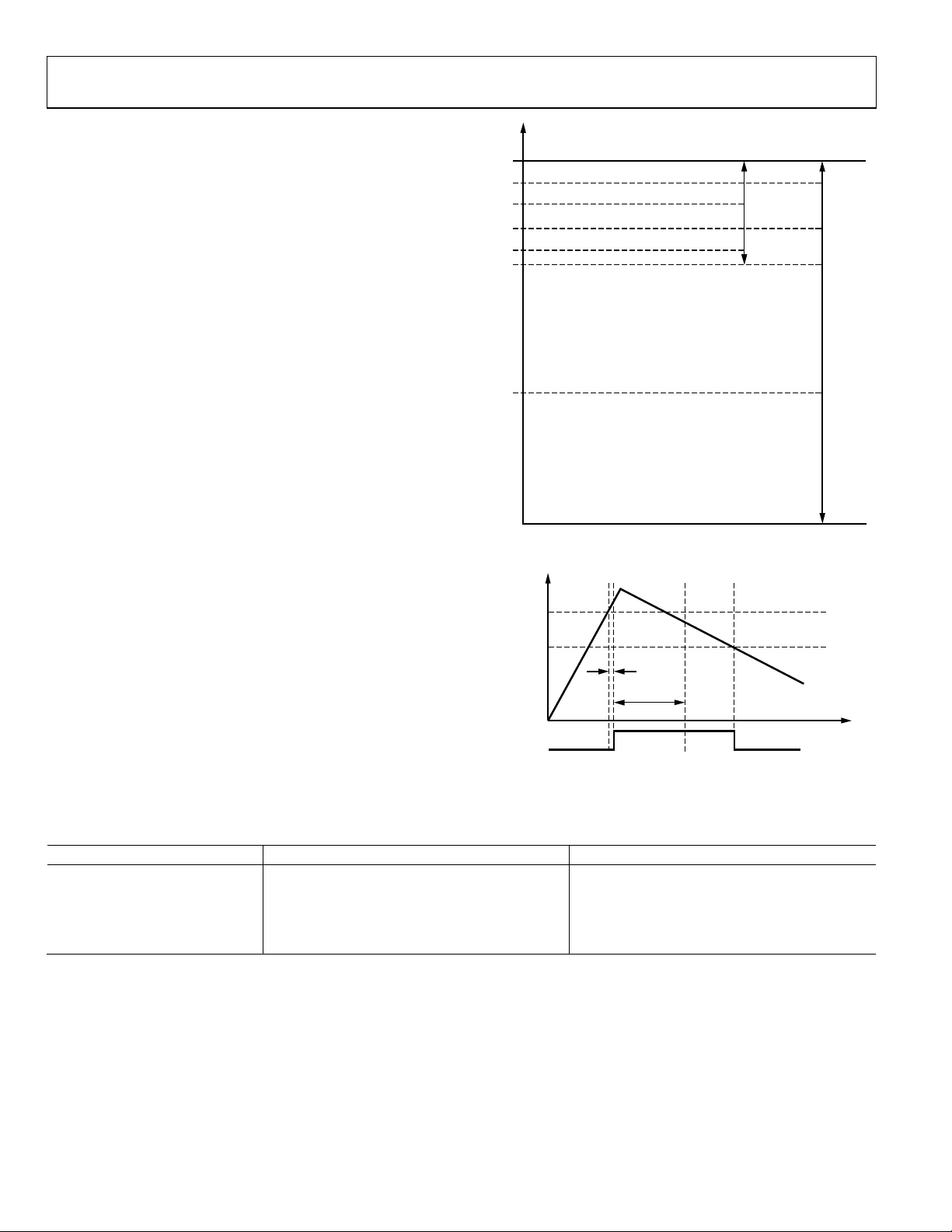

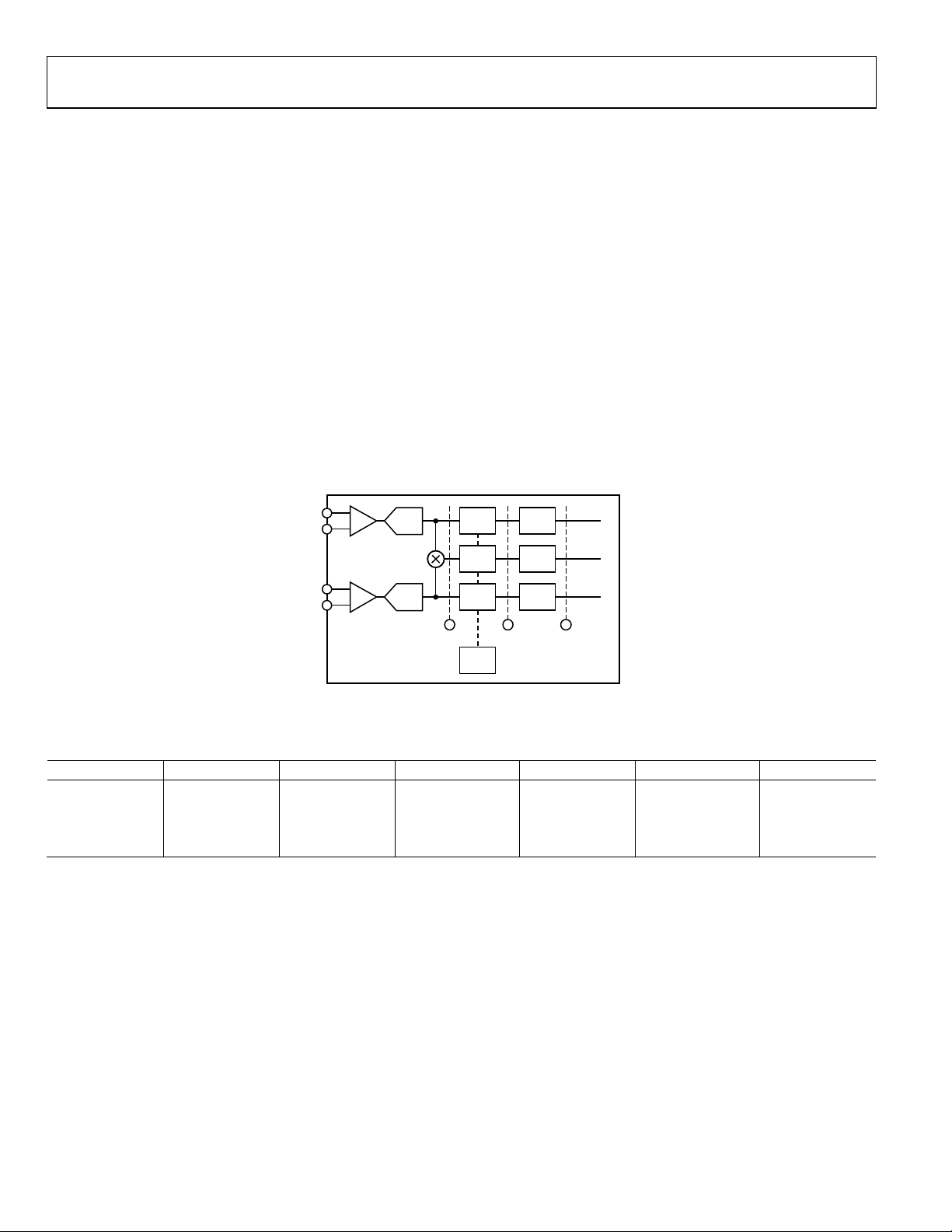

Fast Loop Mode

During transients, a fast loop mode is enabled to allow for faster

loop responses. Typical timing can be seen in Figure 15. The

fast loop mode has separate settings and can be programmed to

respond quickly to load transients. The user can disable the fast

loop mode if it is not required by the application.

V

REC

I

LOAD

PROGRAMMABLE

RANGE

V

OUT

FAST L OO P

Figure 15. Fast Loop for Transient Response Improvement

PROGRAM-

MABLE

DELAY

(0 TO 7

HALF LINE

CYCLES)

When fast loop mode is enabled and the feedback output voltage

is out of range from the desired reference value (programmable

band of 1.5%, 3%, 6%, or 12%, set in Register 0xFE24), the

ADP1047/ADP1048 enter fast loop mode.

To ensure a smooth transition, the ADP1047/ADP1048 switch

from the regular filter to the fast loop filter at the zero crossing

of the rectified input voltage. When the output voltage returns

to regulation within the programmed band, the controller

switches back (after a programmable delay of 0 to 7 half line

cycles) to the normal loop at the next zero crossing of the

rectified input voltage.

If the output voltage does not return to regulation within the

programmed band after a fixed time of 630 ms, the control loop

automatically switches back to the normal loop.

In the normal compensation loop, the sampling frequency of

the output voltage is the same as the ripple oscillation frequency

(which is commonly 100 Hz or 120 Hz).

During fast loop operation, the feedback voltage is sampled

at 1.5 kHz, and the fast filter is applied to regulate the output

voltage. The output voltage is averaged and decimated at

1.5 kHz (see Figure 16).

Rev. 0 | Page 18 of 84

VFB

VFB ERROR

FAST LO OP

VFB FAST ERROR

NORMAL FILTER

@ 100Hz

FAST FI LTER

@ 1.5kHz

Figure 16. Fast Loop Operation

09696-012

Based on the requirements of the application, the user can enable

or disable the fast loop mode by programming Register 0xFE24.

It is recommended that fast loop mode be enabled for the

ADP1047/ADP1048 during large load transients. The fast loop

mode settings are also used during soft start, even when the fast

loop is disabled.

09696-011

PULSE-WIDTH MODULATION

The ADP1047/ADP1048 can implement either leading edge or

trailing edge modulation. Trailing edge modulation is the more

popular modulation scheme. Using trailing edge modulation,

the rms ripple current in the bulk capacitors can be reduced

when used with downstream converter synchronization. It is

recommended that the Analog Devices, Inc., GUI software be

used to program PWM (see the Software GUI section).

DUTY CYCLE MINIMUM/MAXIMUM LIMITS

The ADP1047/ADP1048 allow the user to program the mini-

mum off time and the minimum on time for the PWM outputs

separately, thereby allowing the minimum and maximum duty

cycles to be set.

The minimum off time represents the minimum time that the

PWM is low during each switching cycle. It can be programmed

from 40 ns to 1.2 μs in steps of 80 ns using Register 0xFE15,

Bits[3:0]. In this way, the maximum duty cycle can be clamped

between 96% and 99.8% at the minimum frequency and

between 48.8% and 96.8% at the maximum frequency.

The minimum on time is the smallest PWM pulse that the modulator generates on the PWM output. It can be programmed

from 0 ns to 1200 ns in steps of 80 ns using Register 0xFE15,

Bits[7:4].

AUXILIARY PWM OUTPUT (ADP1047 ONLY)

For the ADP1047, the PWM2 pin is the output for the auxiliary

PWM, which can be independent of the main PWM output.

PWM2 can be used as the control signal for auxiliary switching

in the zero-voltage transition soft-switched PFC boost circuit.

Data Sheet ADP1047/ADP1048

SWITCHING FREQUENCY PROGRAMMING

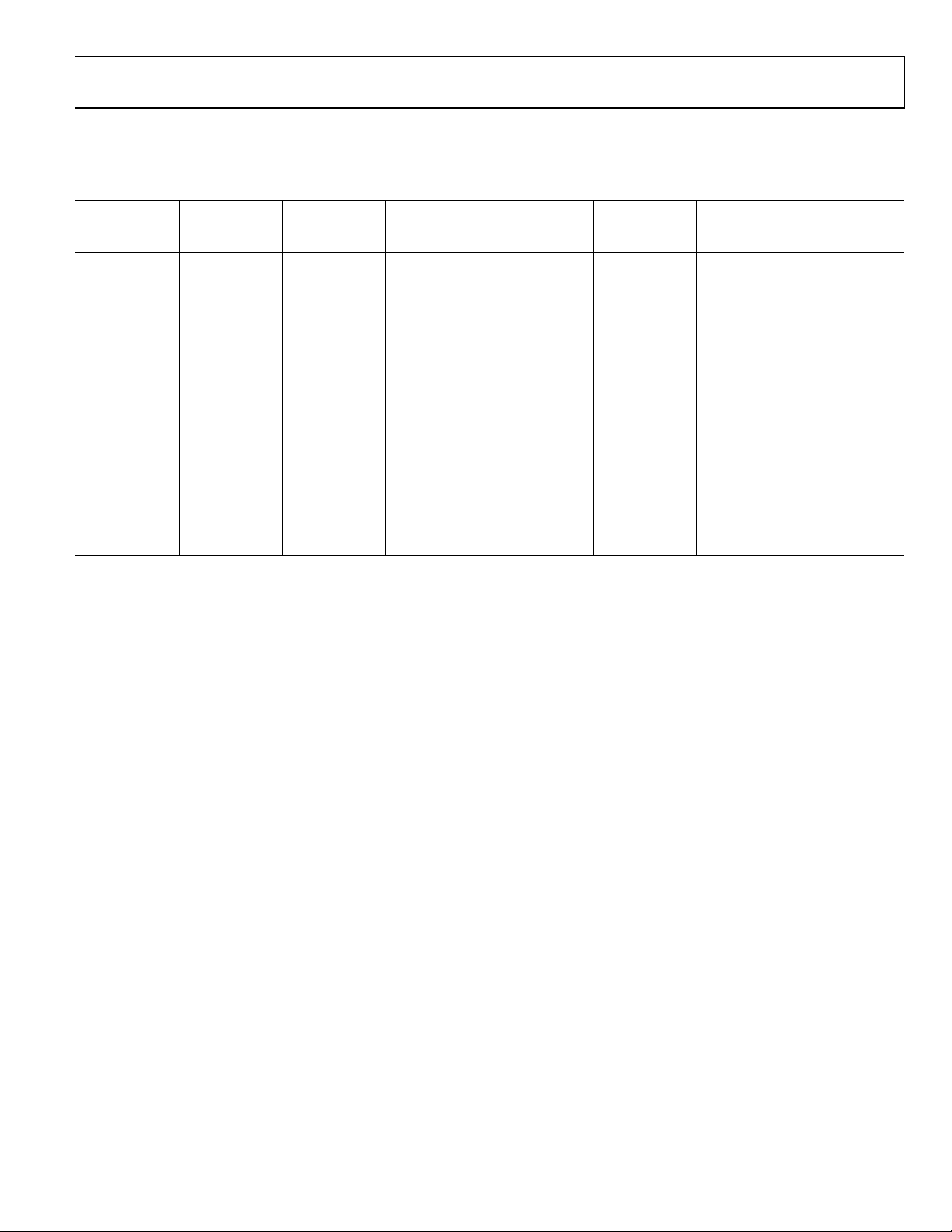

The switching frequency of the PWM outputs can be programmed from 30 kHz to 400 kHz using Register 0xFE1B, Bits[5:0] (see Tab l e 9).

Table 9. Switching Frequency Settings from 30 kHz to 400 kHz (Register 0xFE1B, Bits[5:0])

Frequency

Setting

(Decimal)

0 30.05 16 107.76 32 204.92 48 277.78

1 32.55 17 111.61 33 208.33 49 284.09

2 35.51 18 115.74 34 211.86 50 290.70

3 39.06 19 120.19 35 215.52 51 297.62

4 43.40 20 125.00 36 219.30 52 304.88

5 48.83 21 130.21 37 223.21 53 312.50

6 52.06 22 135.87 38 227.27 54 320.51

7 55.80 23 142.05 39 231.48 55 328.95

8 60.10 24 148.81 40 235.85 56 337.84

9 65.10 25 156.25 41 240.38 57 347.22

10 71.02 26 164.47 42 245.10 58 357.14

11 78.13 27 173.61 43 250.00 59 367.65

12 86.81 28 183.82 44 255.10 60 378.79

13 97.66 29 195.31 45 260.42 61 390.63

14 100.81 30 198.41 46 265.96 62 403.23

15 104.17 31 201.61 47 271.74 63 403.23

Frequency

(kHz)

Frequency

Setting

(Decimal)

Frequency

(kHz)

Frequency

Setting

(Decimal)

Frequency

(kHz)

Frequency

Setting

(Decimal)

Frequency

(kHz)

Rev. 0 | Page 19 of 84

ADP1047/ADP1048 Data Sheet

LINE FAULT PROTECTIONS AND SOFT START SEQUENCING

PSON OPERATION

To comply with PMBus standards, the PFC circuit controlled

by the ADP1047/ADP1048 can be turned on and off by the

hardware PSON pin and/or the software PSON command. The

setting of Bit 2 in Register 0x02 determines whether the PSON

pin and/or the PSON command is used. If the PSON pin is used,

the pin can be configured to be either active high or active low

(see Tabl e 18).

AC LINE DETECTION

The ADP1047/ADP1048 are capable of detecting several

parameters of the ac line input voltage and taking the appropriate programmed actions when necessary. The detection is

a combination of time and voltage measurements and is

implemented via the VAC pin, which detects the rectified ac

input voltage. This allows early detection of ac line faults and

early warning for the host system, thereby increasing reliability.

Five main parameters are related to ac line detection.

•

VAC_LINE_PERIOD (Register 0xFE85)

VAC_THRESHOLD_SET (Register 0xFE25)

•

VAC_THRESHOLD_READ (Register 0xFE26)

•

MIN_AC_PERIOD_SET (Register 0xFE27)

•

MAX_AC_PERIOD_SET (Register 0xFE28)

•

AC Line Period and Zero Crossing

The input ac line period is measured every half period of the ac

line cycle and is reported in the VAC_LINE_PERIOD register

(Register 0xFE85).

During the first 40 ms, the ac line period is measured between

two consecutive falling crossings of the threshold value, which

is set in the VAC_THRESHOLD_SET register (Register 0xFE25,

Bits[6:0]). The ac line period is then measured between two

consecutive falling crossings and compared to the average value

of the input line voltage, which is calculated during each half line

period. The VAC average reading can be found in the VAC_

THRESHOLD_READ register (Register 0xFE26, Bits[6:0]).

If the measured period is larger than MAX_AC_PERIOD_SET

or smaller than MIN_AC_PERIOD_SET, the default, MAX_AC_

PERIOD_SET, is used as the value of the period.

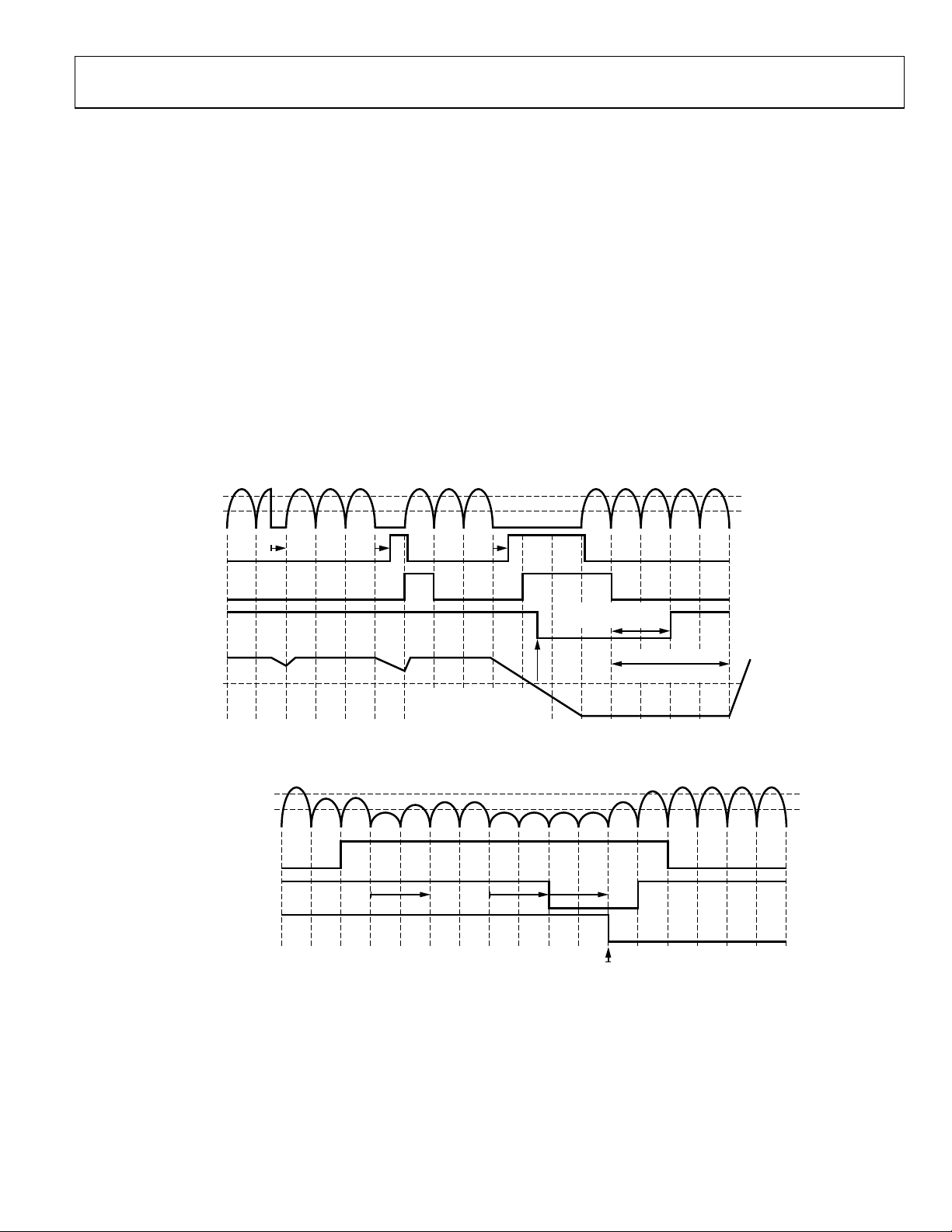

As shown in Figure 17, the two consecutive crossing points,

B and C, are used to determine the zero-crossing point of the

ac line. The middle point between B and C is calculated as the

zero-crossing point.

This information is used by the control loop, as well as the

power metering block.

THRESHOLD

(REG 0xFE2 5)

VAC

ABC

HALF AC

LINE PERIO D

Figure 17. AC Line Period Detection

VAC AVERAGE

(REG 0xFE 26)

09696-013

Rev. 0 | Page 20 of 84

Data Sheet ADP1047/ADP1048

V

AC Line Value Detection

To operate, the controller must detect the ac line value. At

startup, the controller waits for the PSON signal (hardware

PSON, software PSON, or both, depending on how the part

is programmed).

When the PSON signal is present, the controller looks for the

ac line period and value (see Figure 18).

IN_ON (REG 0x35)

VAC

BROWN_OUT F LAG

(REG 0xFE 80[2])

09696-014

Figure 18. VAC Detection for Startup

The start-up value for the ac line used by the controller to

initiate the start-up procedure is stored in the VIN_ON register

(Register 0x35). This value is the minimum rms value of the ac

line required for the system to start up. The controller measures

the value of VAC at every half line cycle and compares it with

VIN_ON. If VAC is larger than the value in the VIN_ON register,

the soft start procedure is initiated and the BROWN_OUT flag

is reset.

AC Line Early Fault Detection

After the VIN_ON limit is crossed and the system starts up, the

controller constantly monitors the condition of the ac line (see

Figure 19).

VAC

VIN_OFF (REG 0x36)

TIMER

1/4

VIN_LOW FLAG

(REG 0x7C[3])

TIMER

1/4

Figure 19. AC Line Early Fault Detection

To provide early detection of ac line faults, the instantaneous

value of VAC is compared to the VIN_OFF value in Register

0x36. If VAC remains below the VIN_OFF threshold for a time

longer than the programmed period, the VIN_LOW flag is set

in Register 0x7C. The programmed period can be either a fraction of the detected ac line period (one-quarter or one-half) or

it can be an absolute time (2 ms or 4 ms); the value is set in

Register 0xFE2E.

The controller does not take any action, but the VIN_LOW

signal can be used to set the AC_OK signal and to trigger

immediate actions in the power system.

The VIN_OFF threshold is intended solely to provide early

warning of problems on the ac line; it is not used to shut down

the power supply. The VIN_UV_FAULT_LIMIT register

(Register 0x59) is used for that purpose.

09696-015

ADC INPUT RANGE = 1.6V

VIN_OV_FAULT_LI MIT = 270VAC (REG 0x55)

VAC

= 265V

HIGH LINE LIMIT (VAC

LOW LINE LIMIT (VAC

VIN_ON = 85V

VIN_UV_WARN_LIM IT = 80V

VIN_OFF = 70V

VIN_UV_FAULT_LIM IT = 70V

TH

TH

) = 180V (REG 0xFE35)

) = 150V (REG 0xFE36)

(REG 0x35)

AC

(REG 0x58)

AC

(REG 0x36)

AC

(REG 0x59)

AC

VAC

MAX

MIN

HYSTERESIS

= 90V

AC

AC

ZONE

09696-016

Figure 20. Input Voltage Limits

Rev. 0 | Page 21 of 84

ADP1047/ADP1048 Data Sheet

V

SOFT START PROCEDURE

The PSON signal is used to enable or disable the PFC stage.

After PSON is asserted, the ADP1047/ADP1048 start monitoring VAC and, if the ac line conditions are met, they initiate the

soft start procedure, as shown in Figure 21.

Startup is gated by the rms value of the ac line voltage measured

on one half period of the ac line frequency. When VAC is above

the VIN_ON value, the BROWN_OUT flag is reset and the soft

start sequence is initiated. At the same time, the inrush delay

time and soft start delay time timers begin. Both of these timers

can be programmed to count 0 to 7 line cycles (or 0 to 14 half

line cycles in steps of 2).

After the inrush delay time programmed in Register 0xFE2E,

Bits[2:0], the INRUSH flag is reset and the inrush signal (Pin 17)

is asserted, closing the inrush current relay. (Note that the INRUSH

flag is active low.) The inrush signal is set at the zero crossing of

the ac voltage, if this crossing is detected. This setting allows

zero voltage turn-on if a solid-state switch is used (zero voltage

turn-on is not relevant with mechanical relays).

After the soft start delay time (programmed in Register 0xFE2D,

Bits[5:3]), the output voltage is ramped up according to the soft

start time programmed in Register 0xFE2D, Bits[2:0].

Some of the flags can be blanked during soft start so that the

programmed action of the flag does not take place if the flag

is set during the soft start period (see Register 0xFE08 and

Register 0xFE09).

IN_ON (REG 0x35)

VIN_OFF (REG 0x36)

VAC

When output voltage regulation is reached and all flags are OK, the

POWER_GOOD# flag is reset and the PGOOD signal (Pin 16)

is set to Logic Level 1. (Note that the POWER_GOOD# flag is

active low.)

The soft start time can be programmed to one of eight values:

112 ms, 168 ms, 224 ms, 280 ms, 392 ms, 504 ms, 616 ms, or

728 ms (set in Register 0xFE2D, Bits[2:0]).

The soft start delay time (Register 0xFE2D, Bits[5:3]) can be

programmed from 0 to 7 full line cycles in increments of 1

(that is, two of the rectified half line cycles).

The inrush delay time (Register 0xFE2E, Bits[2:0]) can be programmed from 0 to 7 full line cycles in increments of 1 (that is,

two of the rectified half line cycles).

If no zero crossings are detected, the programmed maximum ac

line period, MAX_AC_PERIOD_SET (Register 0xFE28), is used.

LINE FAULT PROTECTIONS

Line faults occur when the ac line is not behaving correctly

and include anomalies such as a missing ac line cycle (can be

partial), brownout, or high distortion levels. When a line fault

occurs, the ADP1047/ADP1048 can be programmed to react

according to the situation.

VIN_LOW FLAG

(REG 0x7C[3])

BROWN_OUT F LAG

(REG 0xFE8 0[2])

INRUSH PIN

VOUT

Figure 21. Soft Start and Inrush Current Control Timing

INRUSH

DELAY TIME = 2

(REG 0xFE 2E[2:0])

SOFT START

DELAY TIME = 3

(REG 0xFE2D[5:3])

SOFT START TIME

(REG 0xFE2D[2:0])

09696-017

Rev. 0 | Page 22 of 84

Data Sheet ADP1047/ADP1048

V

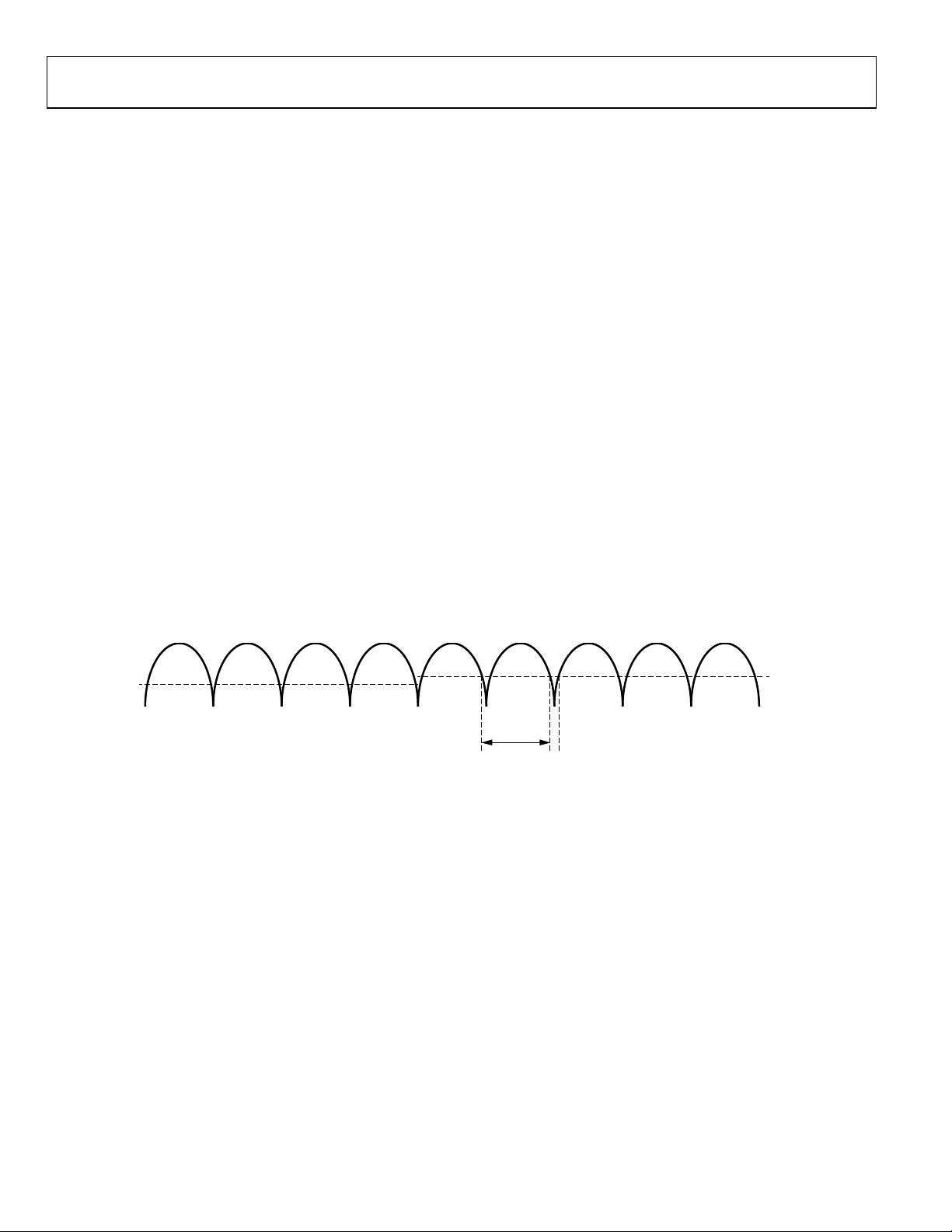

Missing AC Line Cycles

Figure 22 shows examples of the typical missing ac line cycles

fault. The VIN_LOW flag is set when the instantaneous voltage

is below VIN_OFF for more than a quarter or half line cycle

(depending on how it is programmed). This flag can be used as

an early warning to the system via the AC_OK pin when more

than a half cycle is missing. The BROWN_OUT flag is also set;

this flag does not cause a shutdown.

If any other flag that is programmed for shut down is set (in this

example, VOUT_UV_FAULT), the power supply shuts down,

the INRUSH pin is asserted, and the controller prepares for the

next soft start cycle.

If the BROWN_OUT flag is cleared before VOUT drops below

the VOUT_UV_FAULT_LIMIT value (Register 0x44), operation resumes in normal mode (or fast loop mode if enabled);

otherwise, if VOUT drops below VOUT_UV_FAULT_LIMIT,

the INRUSH pin is reset and a new soft start cycle is started.

VAC

PSON Delay

The PSON start delay is programmable using Register 0xFE06,

Bits[3:2]. Four options are available: 0 ms, 50 ms, 250 ms, and

1000 ms.

Brownout Conditions

Brownout is another typical line fault condition in which the

line drops below the minimum specified operating level. This

level can be set with VIN_UV_FAULT_LIMIT (Register 0x59).

This flag can be programmed according to the standard PMBus

flag response. For example, it can be programmed to shut down

and restart after a certain delay.

During brownout, there are other conditions that can occur,

such as input overcurrent or output undervoltage. Each of these

faults can be programmed to shut down or disable the output,

based on the response action.

VIN_ON (REG 0x35)

VIN_OFF (REG 0x36)

VIN_LOW FLAG

(REG 0x7C[3])

BROWN_OUT F LAG

(REG 0xFE80[ 2])

INRUSH DELAY TIME

INRUSH PIN

VOUT

VOUT_UV_FAULT_LIMIT

Figure 22. Line Fault (Missing Cycles) Timing Diagram

(REG 0x44)

(REG 0xFE2E [2:0])

SOFT START TIME

(REG 0xFE2D[2:0])

09696-018

AC

VIN_ON (REG 0x35)

VIN_UV_FAULT_LIM IT

(1 CYCLE DEBOUNCE)

Figure 23. Brownout Timing Diagram (VIN_UV_FAULT_RESPONSE Register Programmed to Shut Down After a One-Cycle Debounce)

(REG 0x59)

BROWN_OUT F LAG

(REG 0xFE80 [2])

VIN_UV_ FAULT FLAG

INRUSH PIN

SHUTDOWN

09696-019

Rev. 0 | Page 23 of 84

ADP1047/ADP1048 Data Sheet

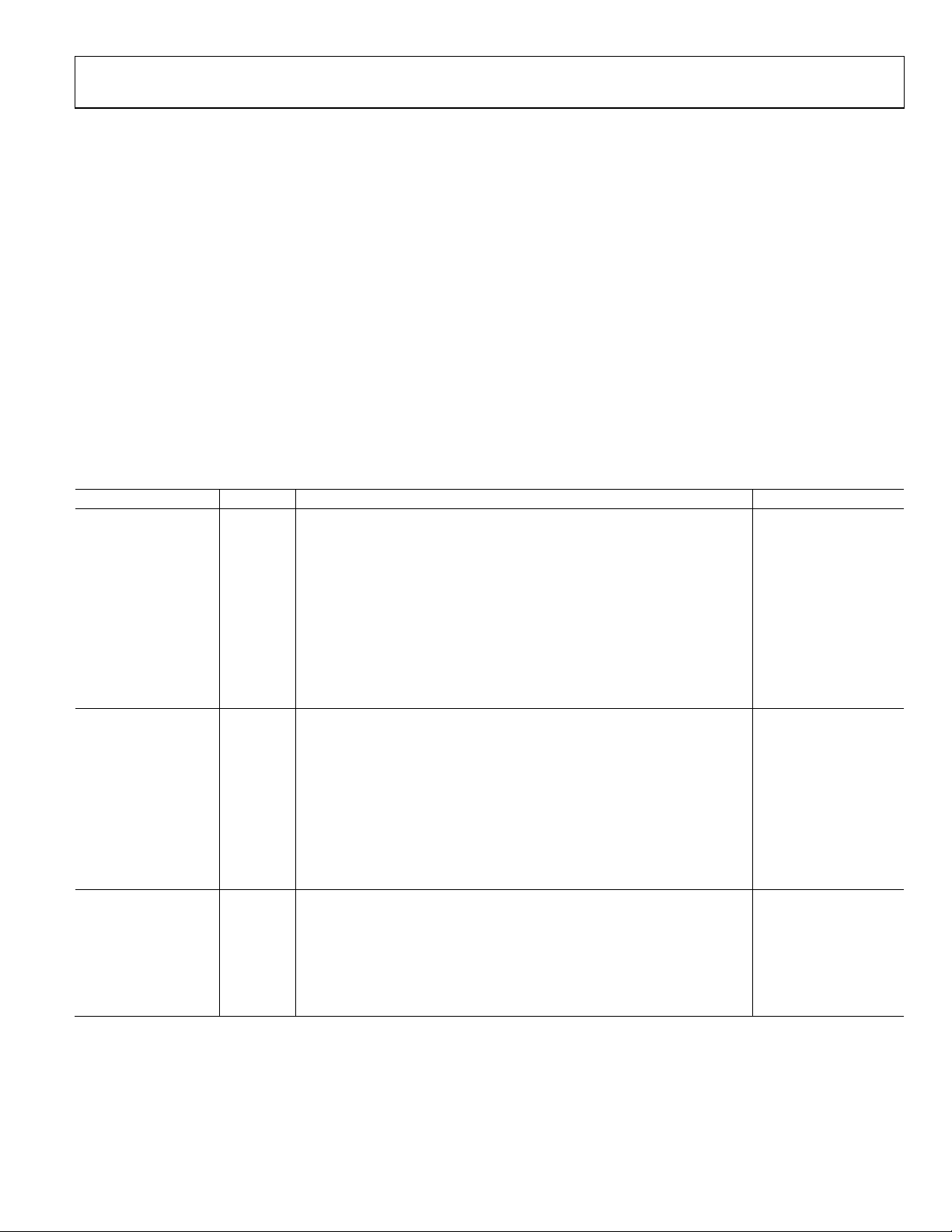

ADVANCED INPUT POWER METERING

The ADP1047/ADP1048 monitor and communicate critical

information, including input and output voltage, input and

output current, temperature, and efficiency. They also monitor

a n d c om mu ni c at e O VP, U V P, O CP, OT P, an d o p e n -l oo p pr ot ec tion functions. An I

2

C interface reads all these values and flags

and programs their thresholds. The on-chip EEPROM can be

used to store all of the settings for the thresholds.

True rms values are calculated at the end of each half ac line

cycle by integrating the instantaneous values across each line

cycle. These values have a resolution of 11 bits and are used to

calculate the average, but are not available to be read through

the PMBus interface.

The averaging window is programmable from zero full line

cycles to 4096 full line cycles using Register 0xFE3A. At the

end of each averaging period, the new value for average power

is written to the READ_PIN register (Register 0x97) and is

available to be read back through the interface until it is

overwritten by the next averaged value at the end of the next

averaging period.

For this reason, the polling frequency used to read average

power through the PMBus interface must be equal to or higher

than the averaging window to maintain data integrity. The

averaging window is programmable over a wide range of times

to accommodate different situations.

Input voltage, input current, output voltage, and input power

are reported in linear format in the following registers:

•

Input voltage: READ_VIN (Register 0x88)

Input current: READ_IIN (Register 0x89)

•

Output voltage: READ_VOUT (Register 0x8B)

•

Input power: READ_PIN (Register 0x97)

•

VAC

PGND

CS+

CS–

ADC AVG

ADC AVG

Figure 24. Block Diagram of Power Monitoring

RMS

RMS

RMS

1 2 3

AC

SYNC

AVG

0 LINE CYCLES

TO 4096

LINE CY CLES

V

IN

P

IN

I

IN

09696-022

Table 10. Data Format and Range for VIN, IIN, PIN, and V

OUT

Metering Data Mantissa (Bits) Exponent (N) Minimum Range Minimum LSB Maximum Range Maximum LSB

VIN 11 −3 to −1 256 V 0.125 V 1024 V 0.5 V

IIN 11 −10 to −5 2 A 0.976 mA 64 A 0.03125 A

PIN 11 −4 to +3 256 W 125 mW 32.8 kW 16 W

V

11 −3 to 0 256 V 0.125 V 2048 V 1 V

OUT

Rev. 0 | Page 24 of 84

Data Sheet ADP1047/ADP1048

POWER SUPPLY SYSTEM AND FAULT MONITORING

The ADP1047/ADP1048 have extensive system and fault monitoring capabilities. The system monitoring functions include

voltage, current, power, and temperature readings. The fault

conditions include out of limit for current, voltage, power, and

temperature. The limits for the fault conditions are programmable.

An extensive set of flags is set when certain thresholds or limits

are exceeded. These flags are described in Ta b l e 1 1 and Table 1 2.

FLAG CONVENTIONS

A flag indicates a fault condition; therefore, a flag is set (equal to

1, or high) when the fault or bad condition occurs. Good flags,

such as POWER_GOOD# and AC_OK, are active low flags. For