Digital Controller for Isolated

T

Data Sheet

FEATURES

Integrates all typical PWM controller functions

7 PWM control signals

Digital control loop

Integrated programmable loop filters

Programmable voltage line feedforward

Dedicated soft start filter

Programmable dead time for improved efficiency

Remote and local voltage sense

Primary and secondary side current sense

Synchronous rectifier control

Current sharing

OrFET control

2

I

C interface

Extensive fault detection and protection

Extensive programming and telemetry

Fast digital calibration

User accessible EEPROM

APPLICATIONS

AC-to-DC power supplies

Isolated dc-to-dc power supplies

Redundant power supply systems

Server, storage, network, and communications

infrastructure

DC

INPU

Power Supply Applications

GENERAL DESCRIPTION

The ADP1046 is a flexible, digital secondary side controller

designed for ac-to-dc and isolated dc-to-dc secondary side

applications. The ADP1046 is pin-compatible with the

ADP1043A and offers several enhancements and new features,

including voltage feedforward, improved loop response, and

programmable dead time control to maximize efficiency.

The ADP1046 is optimized for minimal component count,

maximum flexibility, and minimum design time. Features

include local and remote voltage sense, primary and secondary

side current sense, digital pulse-width modulation (PWM)

generation, current sharing, and redundant OrFET control. The

control loop digital filter and compensation terms are integrated

and can be programmed over the I

protection features include overcurrent protection (OCP), overvoltage protection (OVP), undervoltage lockout (UVLO), and

overtemperature protection (OTP).

The built-in EEPROM provides extensive programming of the

integrated loop filter, PWM signal timing, inrush current, and

soft start timing and sequencing. Reliability is improved through

a built-in checksum and programmable protection circuits.

A comprehensive GUI is provided for easy design of loop

filter characteristics and programming of the safety features.

The industry-standard I

monitoring and system test functions.

The ADP1046 is available in a 32-lead LFCSP and operates

from a single 3.3 V supply.

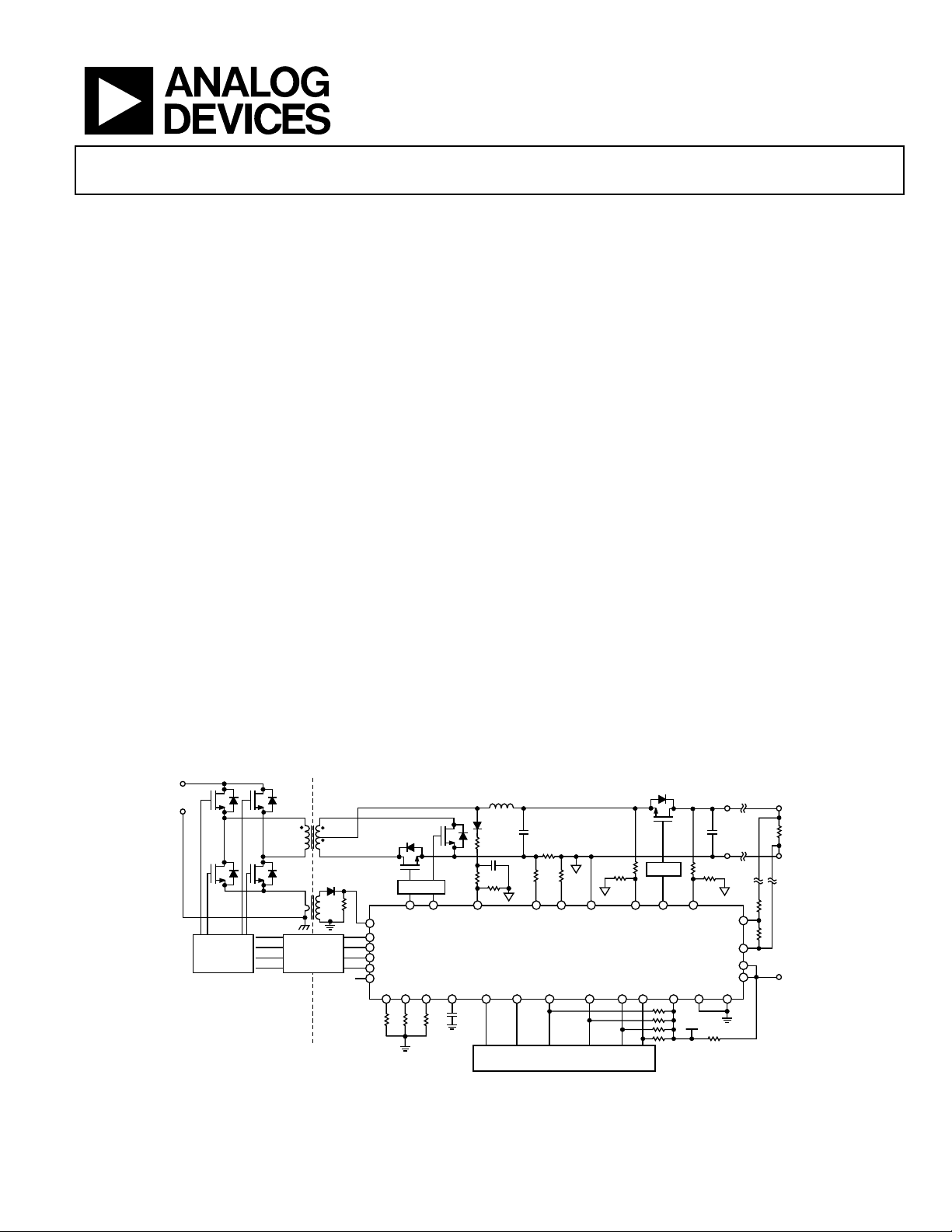

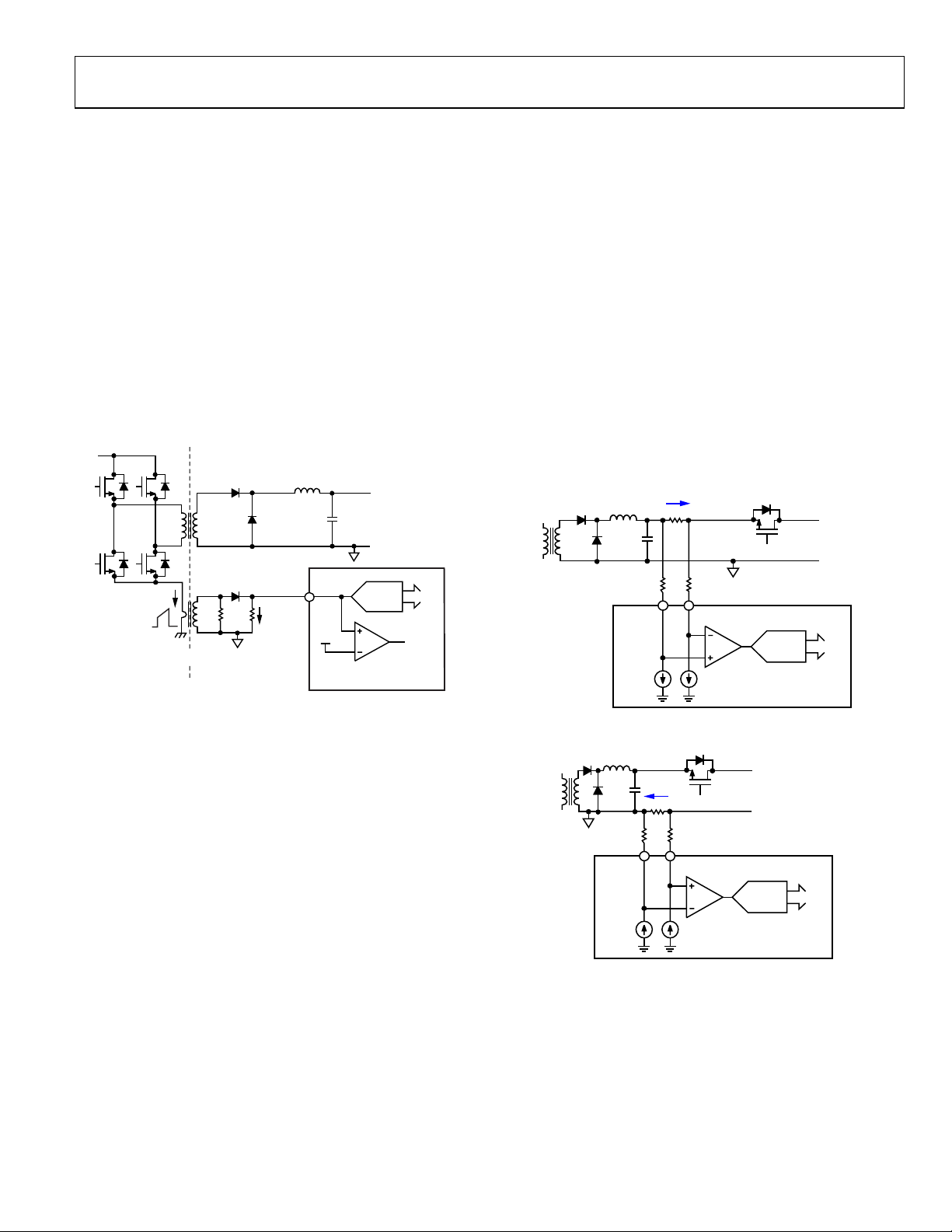

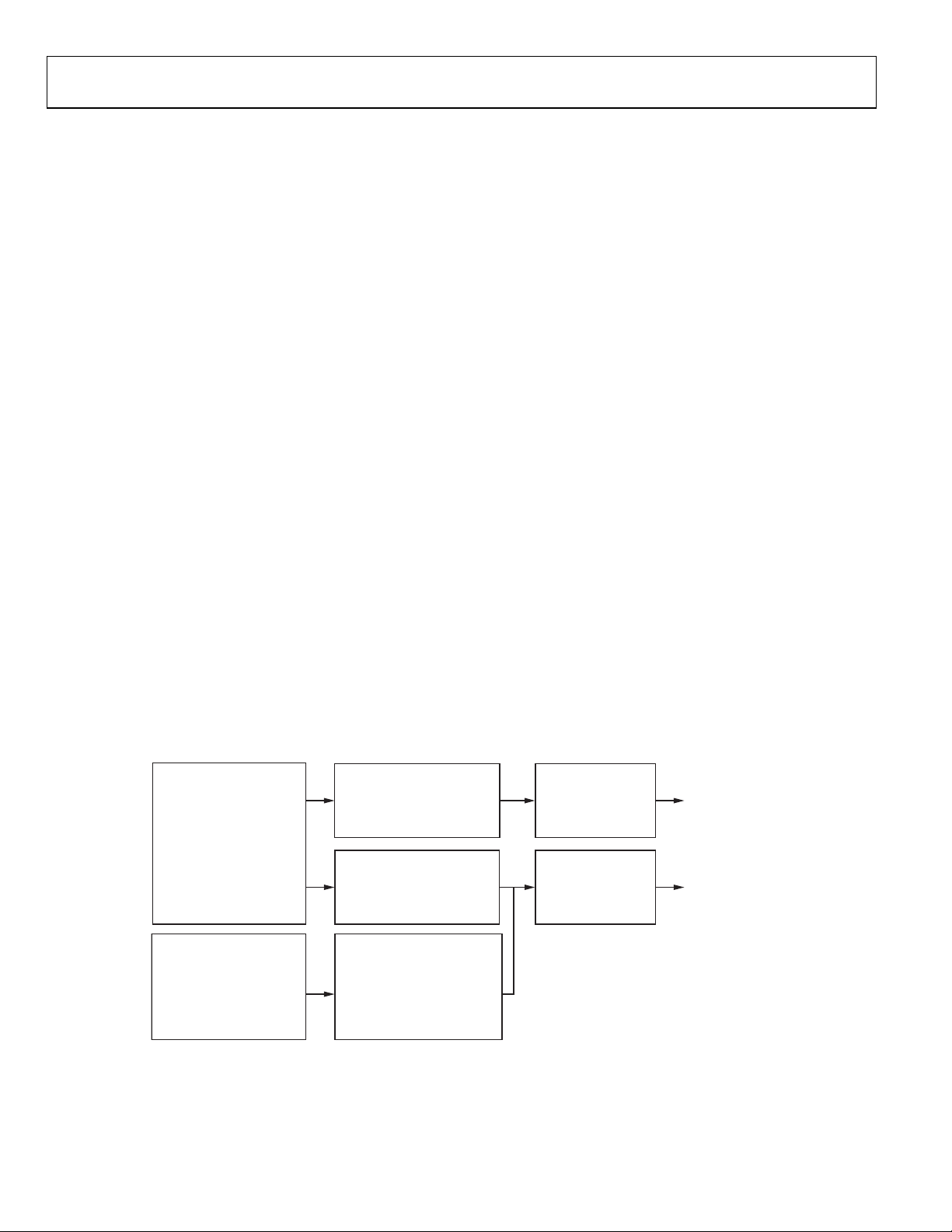

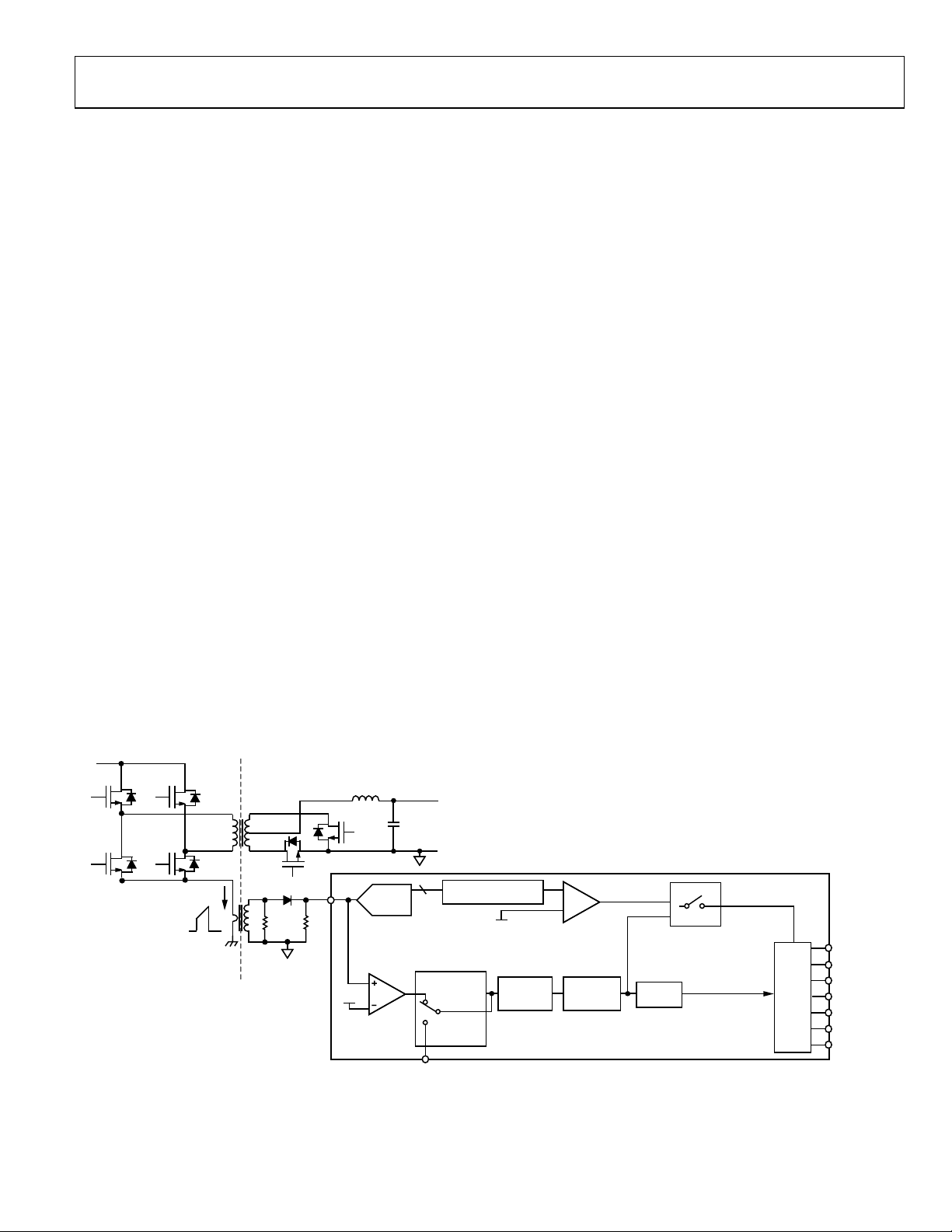

TYPICAL APPLICATION CIRCUIT

ADP1046

2

C interface. Programmable

2

C bus provides access to the many

LOAD

DRIVER

DRIVER

SR1 SR2 ACSNS VS1 GATE

CS1

OUTA

DRIVER

Rev. A

Information furnished by Analog Devices is believed to be accurate and reliable. However, no

responsibility is assumed by Analog Devices for its use, nor for any infringements of patents or other

rights of third parties that may result from its use. Specifications subject to change without notice. No

license is granted by implication or otherwise under any patent or patent rights of Analog Devices.

Trademarks and registered trademarks are the property of their respective owners.

iCoupler

OUTB

OUTC

OUTD

OUTAUX

RES RTDADD VCORE FLAGIN PSON PGOOD2 PGOOD1 SDA SCL VDD DGND AGND

Figure 1.

CS2– CS2+ PGND

ADP1046

MICROCONTROLLER

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700 www.analog.com

Fax: 781.461.3113 ©2012 Analog Devices, Inc. All rights reserved.

VS2

V

DD

VS3+

VS3–

SHAREo

SHAREi

10045-001

ADP1046 Data Sheet

TABLE OF CONTENTS

Features .............................................................................................. 1

Applications ....................................................................................... 1

General Description ......................................................................... 1

Typical Application Circuit ............................................................. 1

Revision History ............................................................................... 3

Functional Block Diagram .............................................................. 4

Specifications ..................................................................................... 5

Absolute Maximum Ratings .......................................................... 10

Thermal Resistance .................................................................... 10

Soldering ...................................................................................... 10

ESD Caution ................................................................................ 10

Pin Configuration and Function Descriptions ........................... 11

Typical Performance Characteristics ........................................... 13

Theory of Operation ...................................................................... 15

Current Sense .............................................................................. 15

Voltage Sense and Control Loop .............................................. 16

ADCs ............................................................................................ 16

VS1 Operation (VS1) ................................................................. 16

VS2 Operation (VS2) ................................................................. 17

VS3 Operation (VS3+, VS3−) ................................................... 17

Voltage Line Feedforward and ACSNS.................................... 17

Digital Filter ................................................................................ 17

PWM and Sync Rect Outputs (OUTA, OUTB, OUTC,

OUTD, OUTAUX, SR1, SR2) ................................................... 18

Synchronous Rectification ........................................................ 19

SR (Synchronous Rectifier) Delay ............................................ 19

Adaptive Dead Time Control.................................................... 19

Light Load Mode ........................................................................ 19

Modulation Limit ....................................................................... 19

Soft Start ...................................................................................... 20

OrFET Control (GATE) ............................................................ 22

VDD ............................................................................................. 24

VDD/VCORE OVLO ................................................................ 24

Power Good ................................................................................. 24

Current Sharing (Share) ............................................................ 25

Power Supply System and Fault Monitoring ............................... 27

Flags .............................................................................................. 27

Monitoring Functions ................................................................ 27

Voltage Readings ........................................................................ 27

Current Readings ........................................................................ 27

Rev. A | Page 2 of 96

Power Readings .......................................................................... 28

Power Monitoring Accuracy ..................................................... 28

First Flag Fault ID and Value Registers ................................... 28

External Flag Input (FLAGIN Pin) .......................................... 28

Temperature Readings (RTD Pin) ........................................... 28

Overtemperature Protection (OTP) ........................................ 29

Overcurrent Protection (OCP) ................................................ 29

Constant Current Mode ............................................................ 30

Overvoltage Protection (OVP) ................................................. 30

Undervoltage Protection (UVP) .............................................. 31

AC Sense (ACSNS)..................................................................... 31

Volt-Second Balance .................................................................. 32

Digital Load Line and Slew Rate .............................................. 32

Power Supply Calibration and Trim ............................................ 33

CS1 Tri m ...................................................................................... 33

CS2 Tri m ...................................................................................... 33

Voltage Calibration and Trim ................................................... 34

Output Voltage Setting (VS3+, VS3− Trim) ........................... 34

VS1 Trim ...................................................................................... 34

VS2 Trim ...................................................................................... 34

RTD/OTP Trim .......................................................................... 34

ACSNS Calibration and Trim ................................................... 35

Layout Guidelines ........................................................................... 36

CS2+ and CS2− ........................................................................... 36

VS3+ and VS3−........................................................................... 36

VDD ............................................................................................. 36

SDA and SCL .............................................................................. 36

CS1 ............................................................................................... 36

Exposed Pad ................................................................................ 36

VCORE ........................................................................................ 36

RES ............................................................................................... 36

RTD .............................................................................................. 36

AGND, DGND, and PGND ...................................................... 36

I2C Interface Communication ...................................................... 37

Features ........................................................................................ 37

Overview ..................................................................................... 37

I2C Address .................................................................................. 37

Data Transfer............................................................................... 37

General Call Support ................................................................. 39

10-Bit Addressing ....................................................................... 39

Data Sheet ADP1046

Fast Mode ..................................................................................... 39

Repeated Start Condition ........................................................... 39

Electrical Specifications .............................................................. 39

Fault Conditions .......................................................................... 39

Timeout Condition ..................................................................... 39

Data Transmission Faults ........................................................... 39

Data Content Faults .................................................................... 39

EEPROM .......................................................................................... 41

Overview ...................................................................................... 41

Page Erase Operation ................................................................. 41

Read Operation (Byte Read and Block Read) ......................... 41

Write Operation (Byte Write and Block Write) ...................... 42

EEPROM Password..................................................................... 42

Downloading EEPROM Settings to Internal Registers .......... 42

Saving Register Settings to the EEPROM ................................ 43

EEPROM CRC Checksum ......................................................... 43

Software GUI ................................................................................... 44

Register Listing ................................................................................ 45

Detailed Register Descriptions ...................................................... 49

Fault Registers .............................................................................. 49

Value Registers ............................................................................. 52

Current Sense and Current Limit Registers ............................ 55

Voltage Sense Registers............................................................... 60

REVISION HISTORY

6/12—Rev. 0 to Rev. A

Changes to Table 1 ............................................................................ 6

Change to Table 2 ............................................................................ 10

Change to Read from Main Block, Page 2 to Page 15 Section .. 41

Change to Write to Main Block, Page 4 to Page 15 Section ...... 42

Change to Table 49 .......................................................................... 60

3/12—Revision 0: Initial Version

ID Registers .................................................................................. 63

PWM and Synchronous Rectifier Timing Registers .............. 64

Digital Filter Programming Registers ...................................... 74

Adaptive Dead Time Registers .................................................. 76

Soft Start Filter Programming Registers .................................. 80

Extended Functions Registers ................................................... 81

EEPROM Registers ..................................................................... 84

Resonant Mode Operation ............................................................. 87

Resonant Mode Enable ............................................................... 87

PWM Timing in Resonant Mode ............................................. 87

Synchronous Rectification in Resonant Mode ........................ 87

Adjusting the Timing of the PWM Outputs ........................... 88

Frequency Limit Setting ............................................................. 88

Feedback Control in Resonant Mode ....................................... 88

Soft Start in Resonant Mode ...................................................... 88

Light Load Operation (Burst Mode) ........................................ 88

OUTAUX in Resonant Mode .................................................... 88

Protections in Resonant Mode .................................................. 88

Resonant Mode Register Descriptions ..................................... 89

Outline Dimensions ........................................................................ 93

Ordering Guide ........................................................................... 93

Rev. A | Page 3 of 96

ADP1046 Data Sheet

RES

VS3–

VS3+

PGOOD1

VDD

GATE

PGND

ACSNS

VS1

OUTA

OUTB

SR1

SR2

OUTC

OUTD

CS1

PSON

SCL

SDA

CS2–

CS2+

VS2

VCORE

AGND

OUTAUX

PGOOD2

SHAREi

FLAGIN

DGND

RTDADD

ADC

ADC ADC

ADC

ADC

UVLO

PWM

ENGINE

V

REF

LDO

ADC

ADC

8kB

EEPROM

DIGITAL

CORE

I

2

C

INTERFACE

PWM

OSC

1.2V

+ –

0.45V

+ –

V_OVP

SHAREo

10045-002

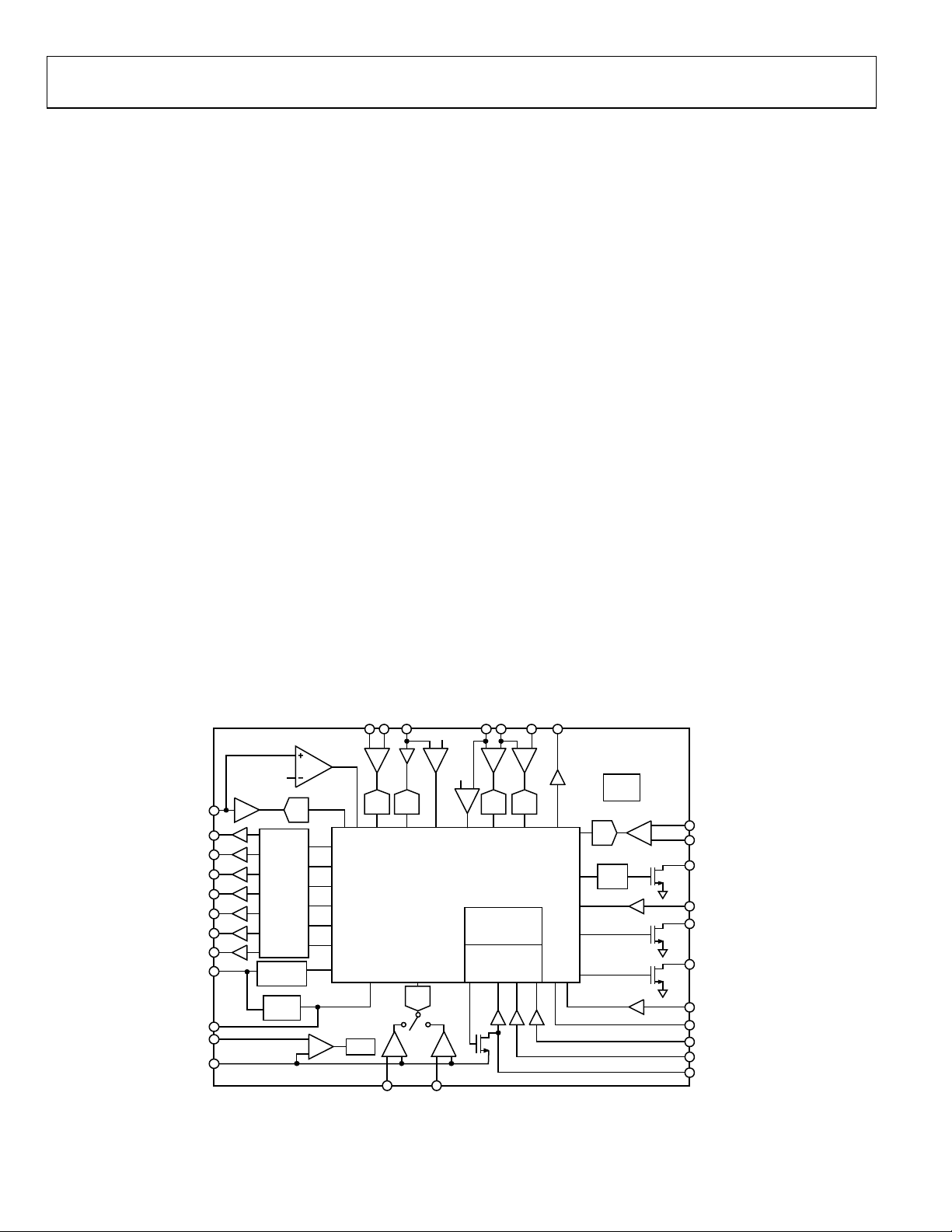

ADP1046

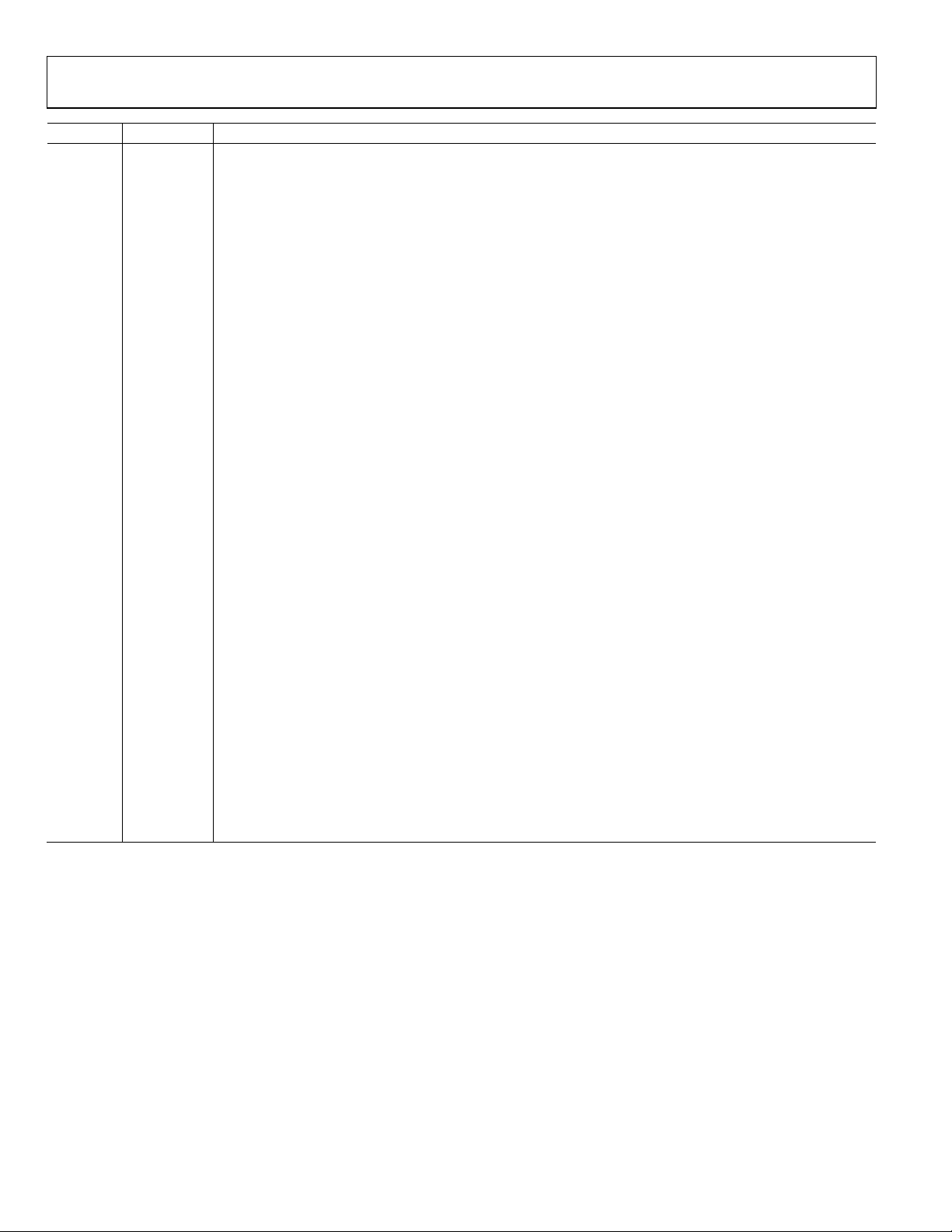

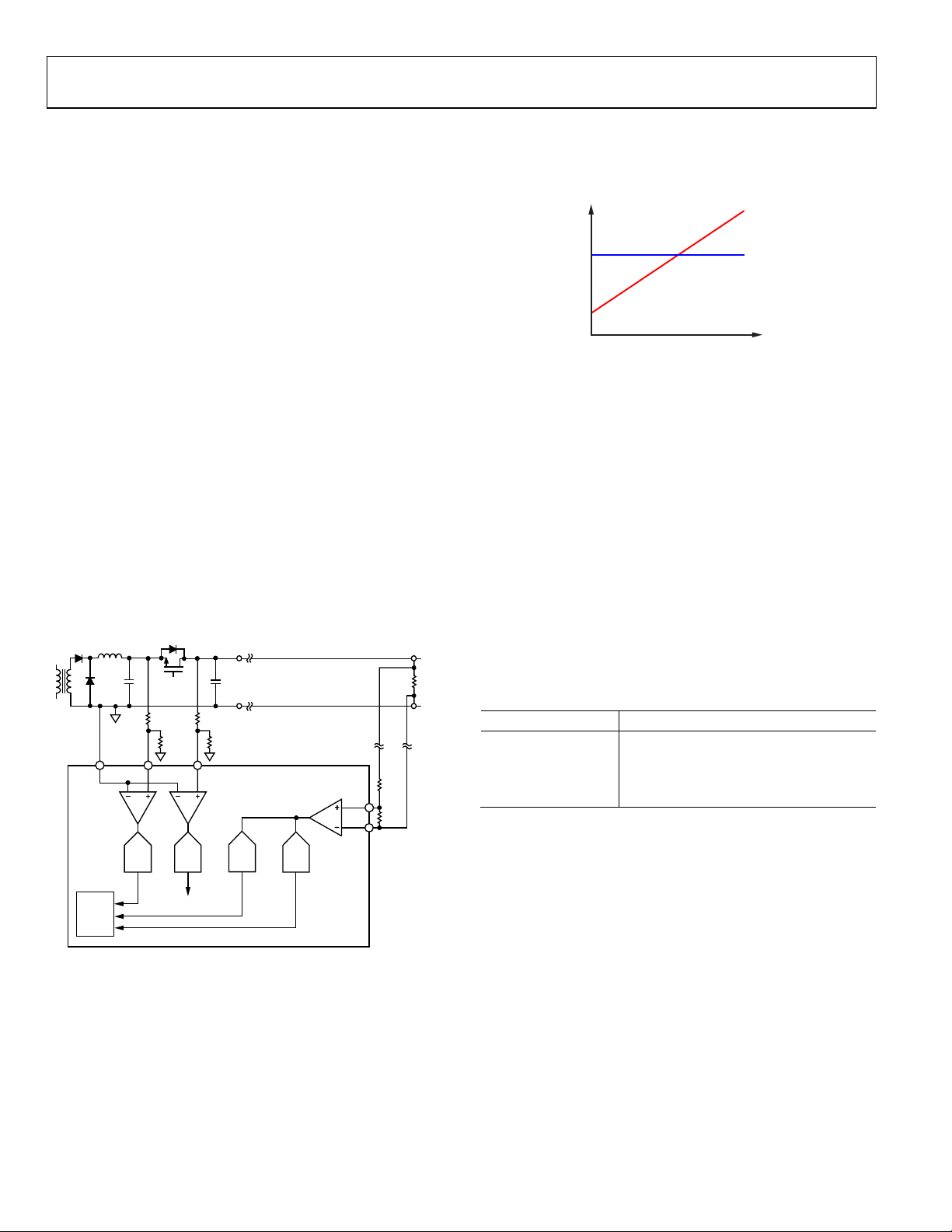

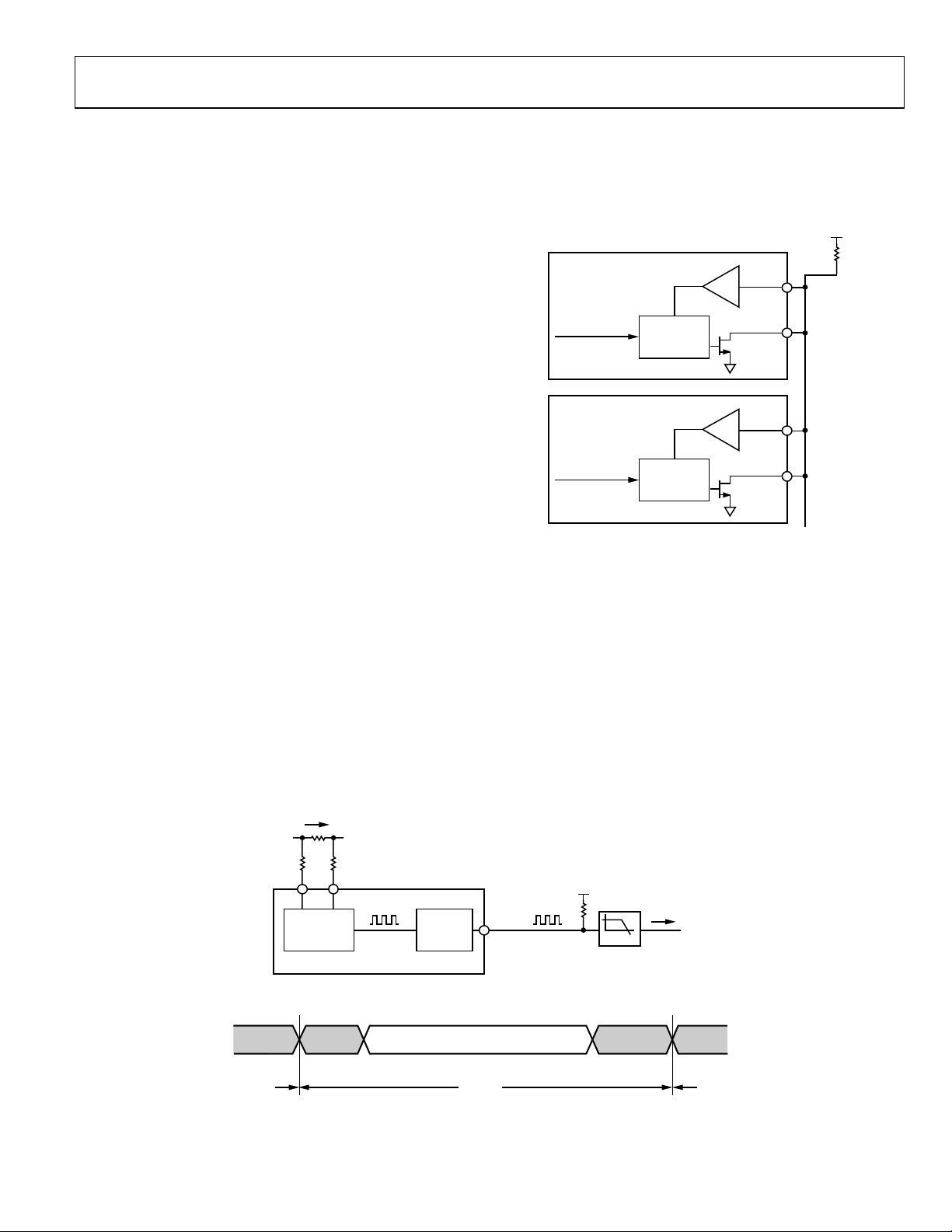

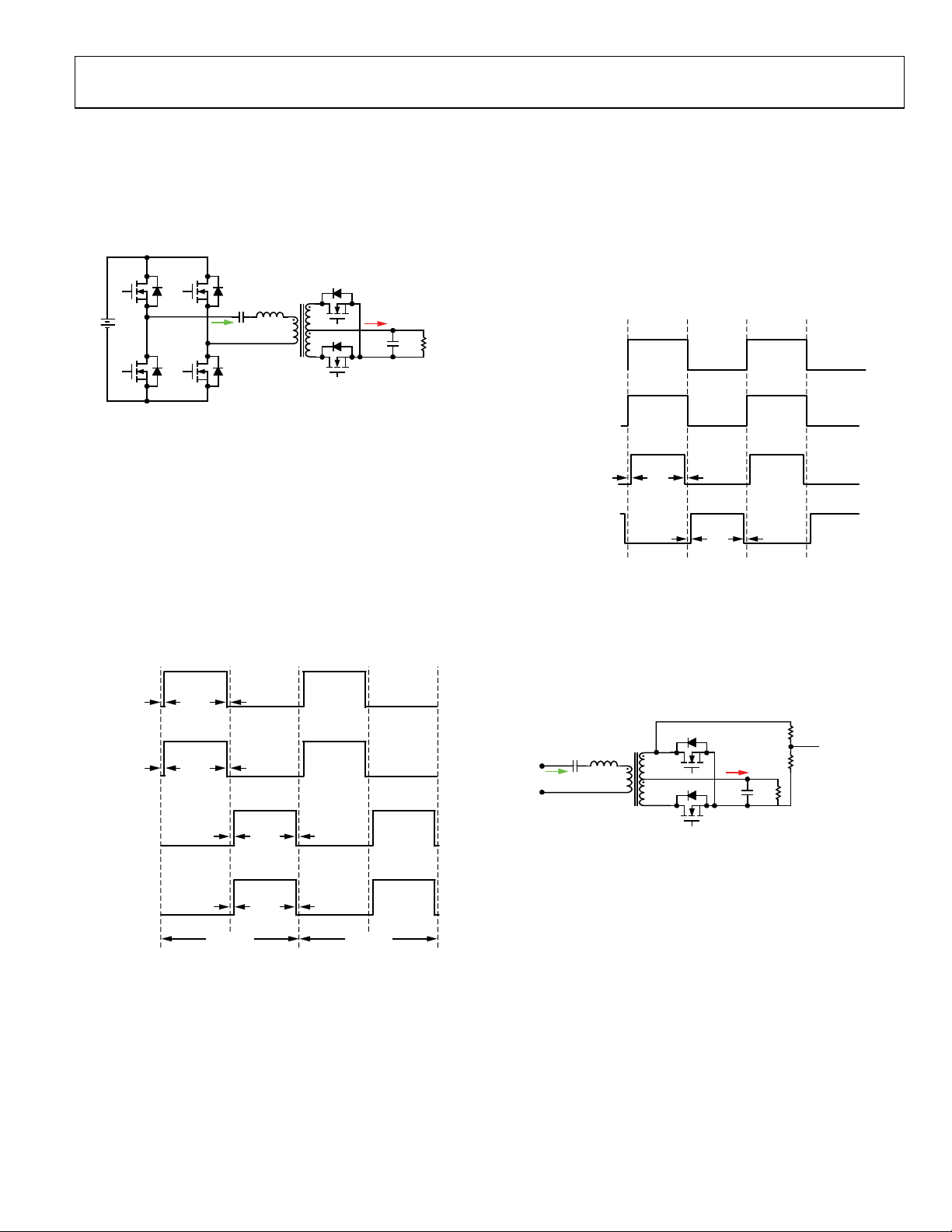

The ADP1046 is a secondary side controller for switch mode

power supplies (SMPS). It is designed for use in isolated redundant applications. The ADP1046 integrates the typical functions

that are needed to control a power supply, such as

• Output voltage sense and feedback

• Voltage line feedforward control

• Digital loop filter compensation

• PWM generation

• Current sharing

• Current, voltage, and temperature sense

• OrFET control

• Housekeeping and I

2

C interface

• Calibration and trimming

The main function of controlling the output voltage is performed

using the feedback ADCs, the digital loop filter, and the PWM

block.

The feedback ADCs use a multipath approach (patent pending).

The ADP1046 combines a high speed, low resolution (fast and

coarse) ADC with a low speed, high resolution (slow and accurate)

ADC. Loop compensation is implemented using the digital filter.

This proportional, integral, derivative (PID) filter is implemented

in the digital domain to allow easy programming of filter characteristics, which is of great value in customizing and debugging

designs.

FUNCTIONAL BLOCK DIAGRAM

The PWM block generates up to seven programmable PWM

outputs for control of FET drivers and synchronous rectification

FET drivers. This programmability allows many traditional and

unique switching topologies to be realized.

A current share bus interface is provided for paralleling multiple

power supplies. The ADP1046 also has hot-swap OrFET sense

and control for N + 1 redundant power supplies.

Conventional power supply housekeeping features, such as remote

and local voltage sense and primary and secondary side current

sense, are included. An extensive set of protections is offered,

including overvoltage protection (OVP), overcurrent protection

(OCP), overtemperature protection (OTP), undervoltage protection (UVP), ground continuity monitoring (voltage continuity),

and ac sense.

All these features are programmable through the I

2

C bus interface. This bus interface is also used to calibrate the power supply.

Other information that is useful for power monitoring, such as

input current, output current, and fault flags, is also available

through the I

2

C bus interface.

The internal EEPROM can store all programmed values and

allows standalone control without a microcontroller. A free,

downloadable GUI is available and provides all the necessary

software to program the ADP1046. To obtain the latest software

and a user guide, visit http://www.analog.com/digitalpower.

The ADP1046 operates from a single 3.3 V supply and is specified

from −40°C to +125°C.

Figure 2. ADP1046 Simplified Block Diagram

Rev. A | Page 4 of 96

Data Sheet ADP1046

OVLO

3.8

4.0

4.1

V

LOAD

LOAD

−48 +48

mV

Temperature Coefficient

65

ppm/°C

Leakage Current

1.0

µA

resolution is 7 bits

VS2 and VS3 OVP Threshold

Relative to nominal voltage (1 V) on VS2

−2.0 +2.0

% FSR

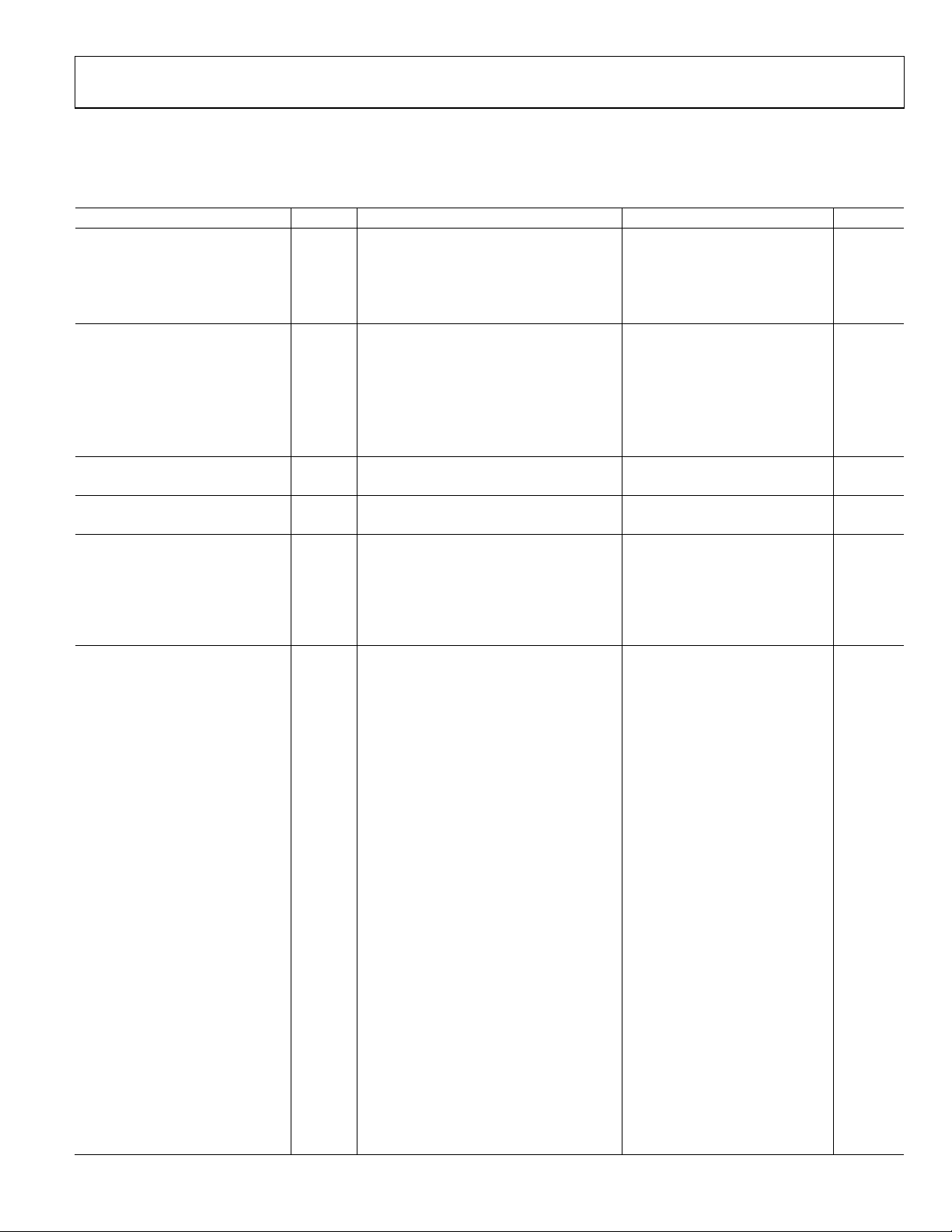

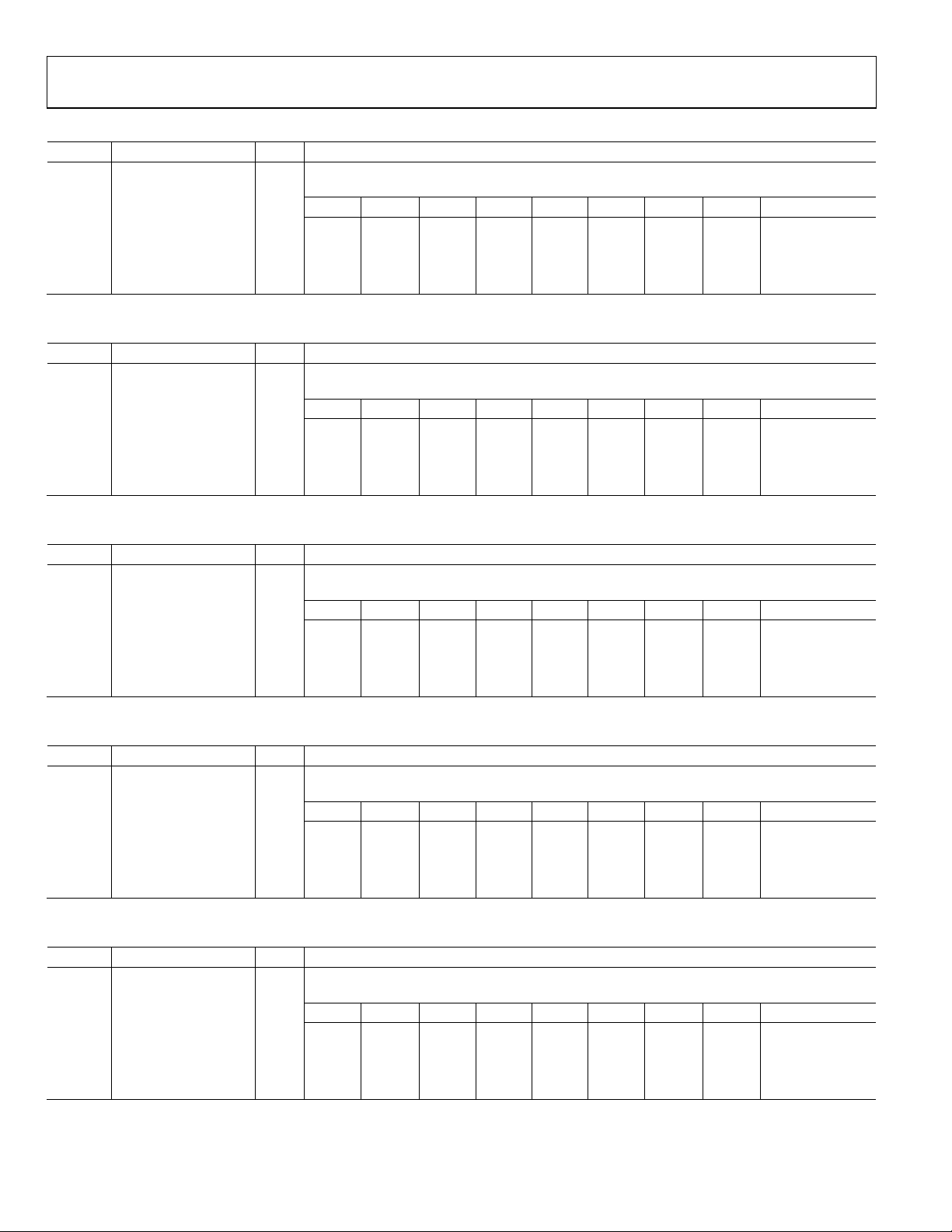

SPECIFICATIONS

VDD = 3.0 V to 3.6 V, TA = −40°C to +125°C, unless otherwise noted. FSR = full-scale range.

Table 1.

Parameter Symbol Test Conditions/Comments Min Typ Max Unit

SUPPLY

Supply Voltage VDD 4.7 µF capacitor connected to AGND 3.0 3.3 3.6 V

Supply Current IDD Normal operation (PSON is high or low) 20 mA

During EEPROM programming (40 ms) IDD + 8 mA

Shutdown (VDD below UVLO) 100 µA

POWER-ON RESET

Power-On Reset VDD rising 3.0 V

UVLO VDD falling 2.75 2.85 2.97 V

UVLO Hysteresis 40 mV

OVLO Debounce When set to 2 µs 2.0 µs

When set to 500 µs 500 µs

VCORE PIN 0.33 µF capacitor connected to DGND

Output Voltage TA = 25°C 2.4 2.5 2.7 V

OSCILLATOR AND PLL

PLL Frequency RES = 10 kΩ (±0.1%) 190 200 210 MHz

OUTA, OUTB, OUTC, OUTD,

OUTAUX, SR1, SR2, GATE PINS

Output Low Voltage VOL Source current = 10 mA 0.4 V

Output High Voltage VOH Source current = 10 mA VDD − 0.4 V

Rise Time C

Fall Time C

VS1, VS2, VS3 LOW SPEED ADCs

Input Voltage Range VIN Differential voltage from VS1, VS2 to

Usable Input Voltage Range 0 1.4 V

ADC Clock Frequency 1.56 MHz

Register Update Rate 10 ms

Voltage Sense Measurement

Accuracy

0% to 100% of usable input voltage range −3.0 +3.0 % FSR

= 50 pF 3.5 ns

= 50 pF 1.5 ns

0 1 1.6 V

PGND, and from VS3+ to VS3−

Factory trimmed at 1.0 V

10% to 90% of usable input voltage range −2.0 +2.0 % FSR

−32 +32 mV

900 mV to 1.1 V −1.0 +1.0 % FSR

−16 +16 mV

Voltage Sense Measurement

Resolution

Common-Mode Voltage Offset −0.25 +0.25 % FSR

Voltage Differential from VS3−

to PGND

VS1 Accurate OVP Speed Register 0x32[1:0] = 00; equivalent

VS1 OVP Threshold Accuracy Relative to nominal voltage (1 V) on VS1 −2.0 +2.0 % FSR

VS2 and VS3 OVP Speed Register 0x33[1:0] = 00; equivalent

Accuracy

12 Bits

−200 +200 mV

80 µs

resolution is 7 bits

80 µs

and VS3

Rev. A | Page 5 of 96

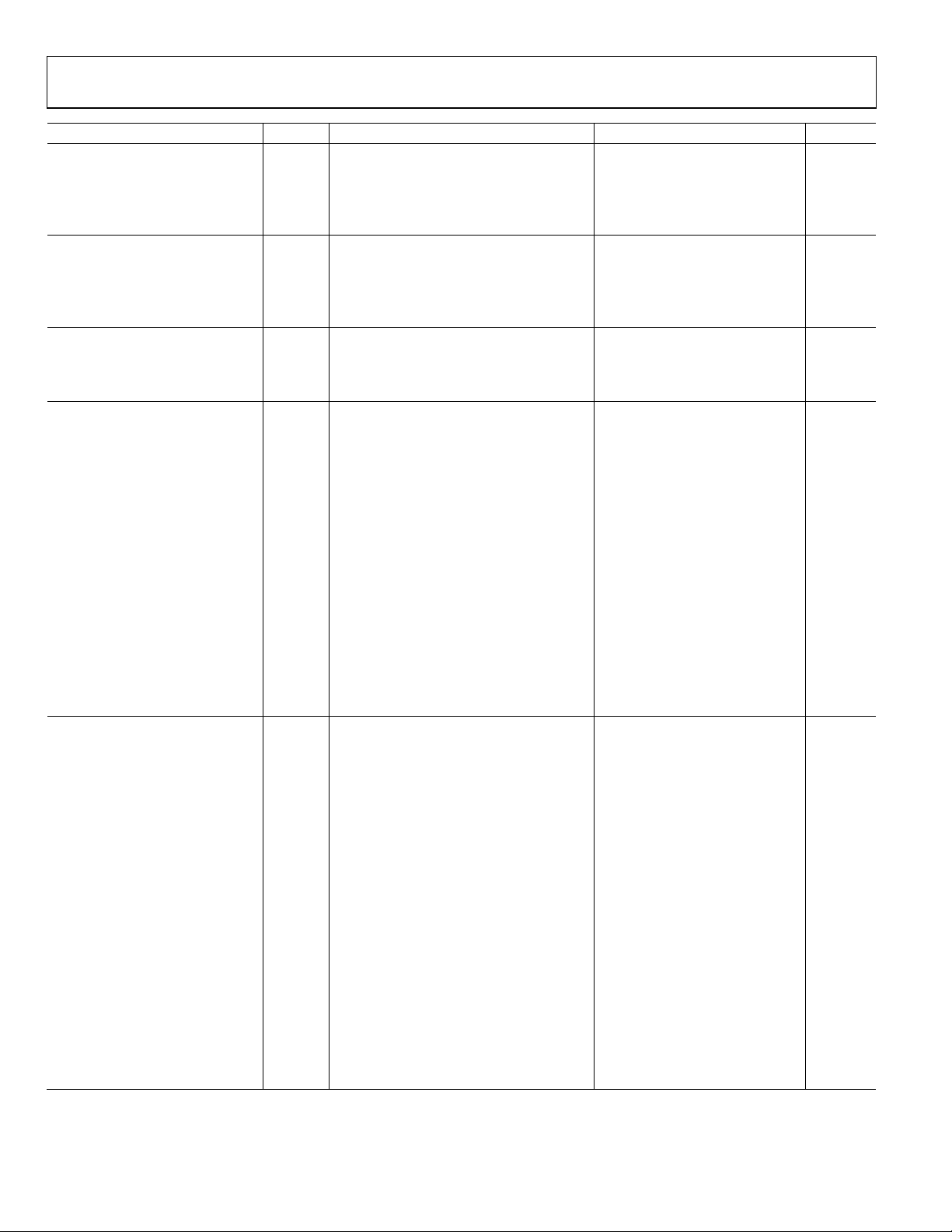

ADP1046 Data Sheet

At other thresholds (0.8 V to 1.6 V)

−2.06

+2.06

%

ADC Clock Frequency

1.56 MHz

ACSNS

Input Voltage Range

VIN 0 1 1.4

V

Parameter Symbol Test Conditions/Comments Min Typ Max Unit

VS3 HIGH SPEED ADC

Equivalent Sampling

Frequency

Equivalent Resolution fSW = 390.6 kHz 6 Bits

Dynamic Range ±30 mV

VS1 FAST OVP COMPARATOR

Threshold Accuracy At factory trim of 1.2 V 1 1.60 %

f

fSW kHz

SAMP

Propagation Delay Does not include debounce time

40 ns

(Register 0x0A[7] = 1)

VS1 UVP DIGITAL COMPARATOR

VS1 UVP Accuracy −2.0 +2.0 % FSR

Propagation Delay Does not include debounce time

80 µs

(Register 0x0B[3] = 1)

AC SENSE COMPARATOR PWM and resonant mode

Input Voltage Threshold 0.4 0.45 0.5 V

Propagation Delay

From ACSNS threshold to SRx rising edge

160 ns

(resonant mode only)

Input Voltage Range V

0 1 1.6 V

Usable Input Voltage Range 0 1.4 V

Sampling Frequency for I2C

100 Hz

Reporting

Sampling Period for

Equivalent resolution is 11 bits 10 µs

Feedforward

Measurement Accuracy Factory trimmed at 1.0 V

0% to 100% of usable input voltage range −5.0 +3.0 % FSR

10% to 90% of usable input voltage range −2.0 +2.0 % FSR

900 mV to 1.1 V −1.0 +1.0 % FSR

−16 +16 mV

Leakage Current 1.0 µA

CURRENT SENSE 1 (CS1 PIN)

Usable Input Voltage Range 0 1.3 V

ADC Clock Frequency 1.56 MHz

Register Update Rate 10 ms

Current Sense Measurement

Accuracy

Factory trimmed at 0.7 V; tested under dc

input conditions

10% to 50% of usable input voltage range −3.0 +3.0 % FSR

−41.4 +41.4 mV

0% to 100% of usable input voltage range −6.0 +3.0 % FSR

−84 +42 mV

40% to 60% of usable input voltage range −1.0 +1.0 % FSR

Current Sense Measurement

12 Bits

Resolution

CS1 Fast OCP Threshold 1.184 1.2 1.216 V

CS1 Fast OCP Speed 80 100 ns

CS1 Accurate OCP DC Accuracy 10% to 90% of usable input voltage range −2.0 +2.0 % FSR

−28 +28 mV

CS1 Accurate OCP Speed 2.62 5.24 ms

Leakage Current 1.0 μA

Rev. A | Page 6 of 96

Data Sheet ADP1046

Usable Input Voltage Range

0 110

mV

60 mV Setting

0 mV to 55 mV, VDD = 3.3 V

−1.8 +1.8

% FSR

−2.16

+2.16

mV

−18 mV setting

−12.22

−19.07

−25.92

mV

Current source set to 40 µA

38.45

40.3

41.95

µA

Parameter Symbol Test Conditions/Comments Min Typ Max Unit

CURRENT SENSE 2 (CS2+, CS2−

PINS)

Input Voltage Range VIN Differential voltage from CS2+ to CS2−,

ADC Clock Frequency 1.56 MHz

Temperature Coefficient

120 mV Range 0 mV to 100 mV 78 ppm/°C

0 mV to 50 mV 70 ppm/°C

60 mV Range 0 mV to 50 mV 156 ppm/°C

0 mV to 25 mV 140 ppm/°C

Current Sense Measurement

120 mV Setting 0 mV to 110 mV −2.1 +2.1 % FSR

−2.52 +2.52 mV

60 mV Setting 0 mV to 55 mV −4.2 +4.2 % FSR

−5.04 +5.04 mV

Current Sense Measurement

Accuracy

120 mV Setting 0 mV to 100 mV, VDD = 3.3 V −0.9 +0.9 % FSR

−1.08 +1.08 mV

0 120 mV

LSB = 29.297 μV

With 0.01% level shifting resistors

Current Sense Measurement

Resolution

CS2 Accurate OCP Speed 2.62 5.24 ms

Current Sink (High Side) 2 mA

Current Source (Low Side) 200 μA

Common-Mode Voltage at the

CS2+ and CS2− Pins

OrFET PROTECTION (CS2+, CS2−) Low-side and high-side current sensing

Fast OrFET Accuracy −3 mV setting +3.5 −3.00 −9.5 mV

−6 mV setting +0.29 −6.21 −12.71 mV

−9 mV setting −2.68 −9.43 −16.18 mV

−12 mV setting −5.89 −12.64 −19.39 mV

−15 mV setting −9.01 −15.86 −22.71 mV

−21 mV setting −15.29 −22.29 −29.29 mV

−24 mV setting −18.50 −25.50 −32.50 mV

Fast OrFET Speed Debounce = 40 ns 110 150 ns

RTD TEMPERATURE SENSE

ADC Clock Frequency 1.56 MHz

Input Voltage Range RTD to AGND 0 1.6 V

Usable Input Voltage Range 0 1.3 V

Source Current Factory trimmed to 46 μA (Register 0x11

Current source set to 10 µA 9.25 10.1 10.85 µA

Current source set to 20 µA 18.35 20.1 21.85 µA

Current source set to 30 µA 28.45 30.2 31.95 µA

12 Bits

To achieve CS2 measurement accuracy 0.8 1.0 1.4 V

44.35 46 47.65 µA

set to 0xE6)

Source Current Fine Setting See Register 0x11[5:0] 160 nA

RTD ADC

Register Update Rate 10 ms

Resolution 12 Bits

Rev. A | Page 7 of 96

ADP1046 Data Sheet

−42 +42

mV

EXT

SDA/SCL PINS

VDD = 3.3 V

BUF

SU;STA

SU;STO

SU ;D AT

SDA Hold Time

t

HD;DAT

For readback

125

ns

For write

300

ns

TIMEOUT

LOW

HIGH

LO;SEXT

Parameter Symbol Test Conditions/Comments Min Typ Max Unit

Measurement Accuracy Factory trimmed at 1 V

10 mV to 160 mV −0.5 +0.5 % FSR

−8 +8 mV

0% to 100% of usable input voltage range −3.0 +3.0 % FSR

Temperature Readings

According to Internal

Linearization Scheme

RTD source set to 46 µA (Register 0x11 set to

0xE6); NTC R0 = 100 kΩ, 1%, beta = 4250, 1%;

R

= 16.5 kΩ, 1%

25°C to 100°C 7 °C

100°C to 125°C 5 °C

OTP

Threshold Accuracy T = 85°C with 100 kΩ||16.5 kΩ −0.9 +0.25 % FSR

−14.4 +4 mV

T = 100°C with 100 kΩ||16.5 kΩ −0.5 +1.1 % FSR

−8 +17.6 mV

Comparator Speed 10.5 ms

OTP Threshold Hysteresis 16 mV

PGOOD1, PGOOD2, SHAREo PINS Open-drain outputs

Output Low Voltage VOL 0.4 V

PSON, SHAREi PINS Digital inputs

Input Low Voltage VIL 0.8 V

Input High Voltage VIH VDD − 0.8 V

Leakage Current 1.0 µA

FLAGIN PIN Digital input

Input Low Voltage VIL 0.4 V

Input High Voltage VIH VDD − 0.8 V

Propagation Delay Does not include debounce time (Register

200 ns

0x0A[3] = 1); flag action set to disable PSU

Leakage Current 1.0 µA

GATE PIN

Output Low Voltage VOL 0.4 V

Output High Voltage VOH VDD − 0.4 V

Input Low Voltage VIL 0.8 V

Input High Voltage VIH VDD − 0.8 V

Output Low Voltage VOL 0.4 V

Leakage Current 1.0 µA

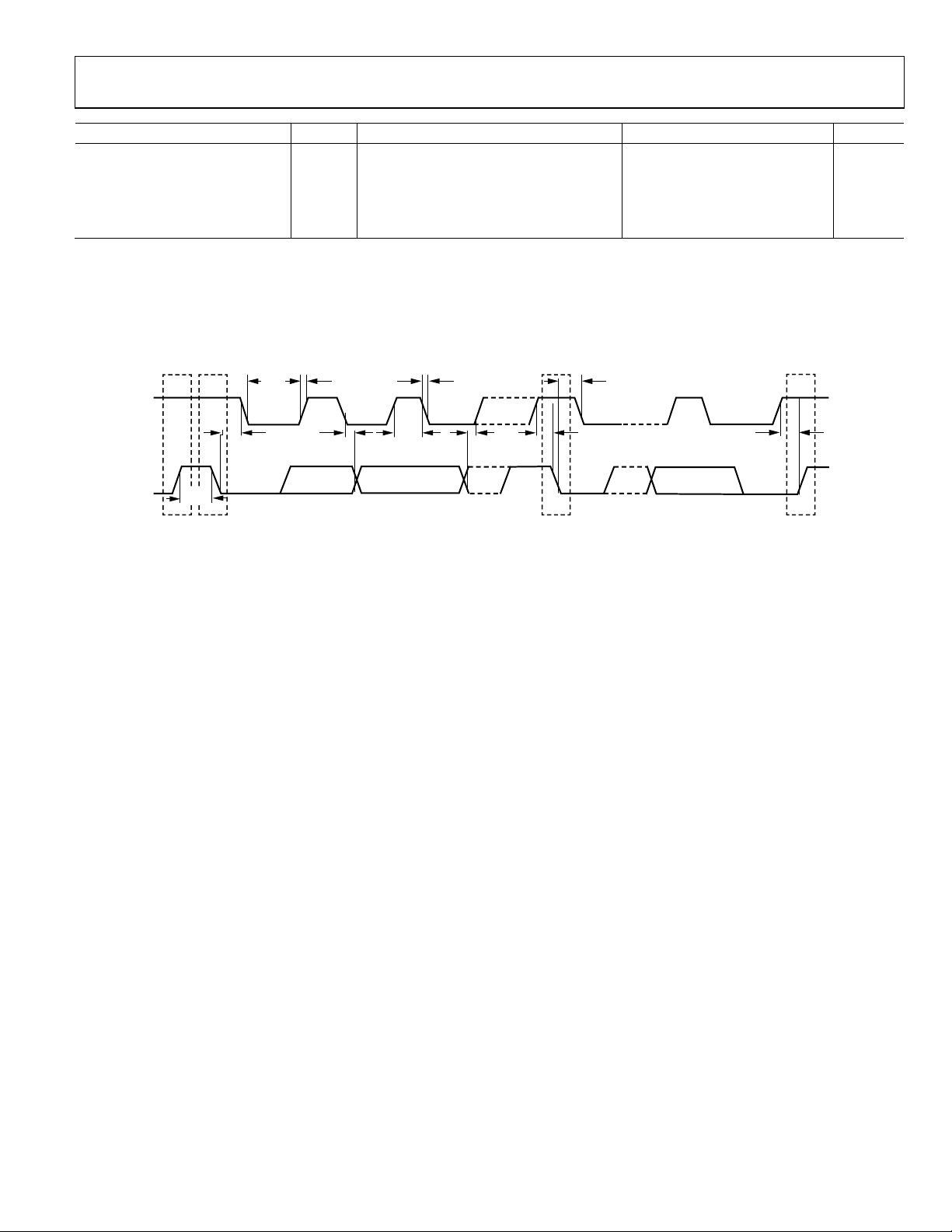

SERIAL BUS TIMING See Figure 3

Clock Operating Frequency 10 100 400 kHz

Bus-Free Time t

Start Hold Time t

Start Setup Time t

Stop Setup Time t

SDA Setup Time t

SCL Low Timeout t

SCL Low Period t

SCL High Period t

Clock Low Extend Time t

SCL, SDA Fall Time tF 20 300 ns

SCL, SDA Rise Time tR 20 300 ns

Between stop and start conditions 1.3 µs

HD;STA

Hold time after (repeated) start condition;

0.6 µs

after this period, the first clock is generated

Repeated start condition setup time 0.6 µs

0.6 µs

100 ns

25 35 ms

1.3 µs

0.6 µs

25 ms

Rev. A | Page 8 of 96

Data Sheet ADP1046

TJ = 125°C

10

Years

SCL

SDA

P S

t

BUF

t

HD;STA

t

HD;DAT

t

HIGH

t

SU;DAT

t

HD;STA

t

SU;STA

t

SU;STO

t

LOW

t

R

t

F

S P

10045-103

Parameter Symbol Test Conditions/Comments Min Typ Max Unit

EEPROM RELIABILITY

Endurance1 TJ = 85°C 10,000 Cycles

TJ = 125°C 1000 Cycles

Data Retention2 TJ = 85°C 20 Years

1

Endurance is qualified as per JEDEC Standard 22, Method A117, and is measured at −40°C, +25°C, +85°C, and +125°C. Endurance conditions are subject to change

pending EEPROM qualification.

2

Retention lifetime equivalent at junction temperature (TJ) = 85°C as per JEDEC Standard 22, Method A117. The derated retention lifetime equivalent at junction

temperature T

Timing Diagram

= 125°C is 2.87 years and is subject to change pending EEPROM qualification.

J

Figure 3. Serial Bus Timing Diagram

Rev. A | Page 9 of 96

ADP1046 Data Sheet

Digital Pins: OUTA, OUTB, OUTC, OUTD,

−0.3 V to VDD + 0.3 V

RTD, ADD

−0.3 V to VDD + 0.3 V

(20 sec to 40 sec)

ESD Charged Device Model

1.5 kV

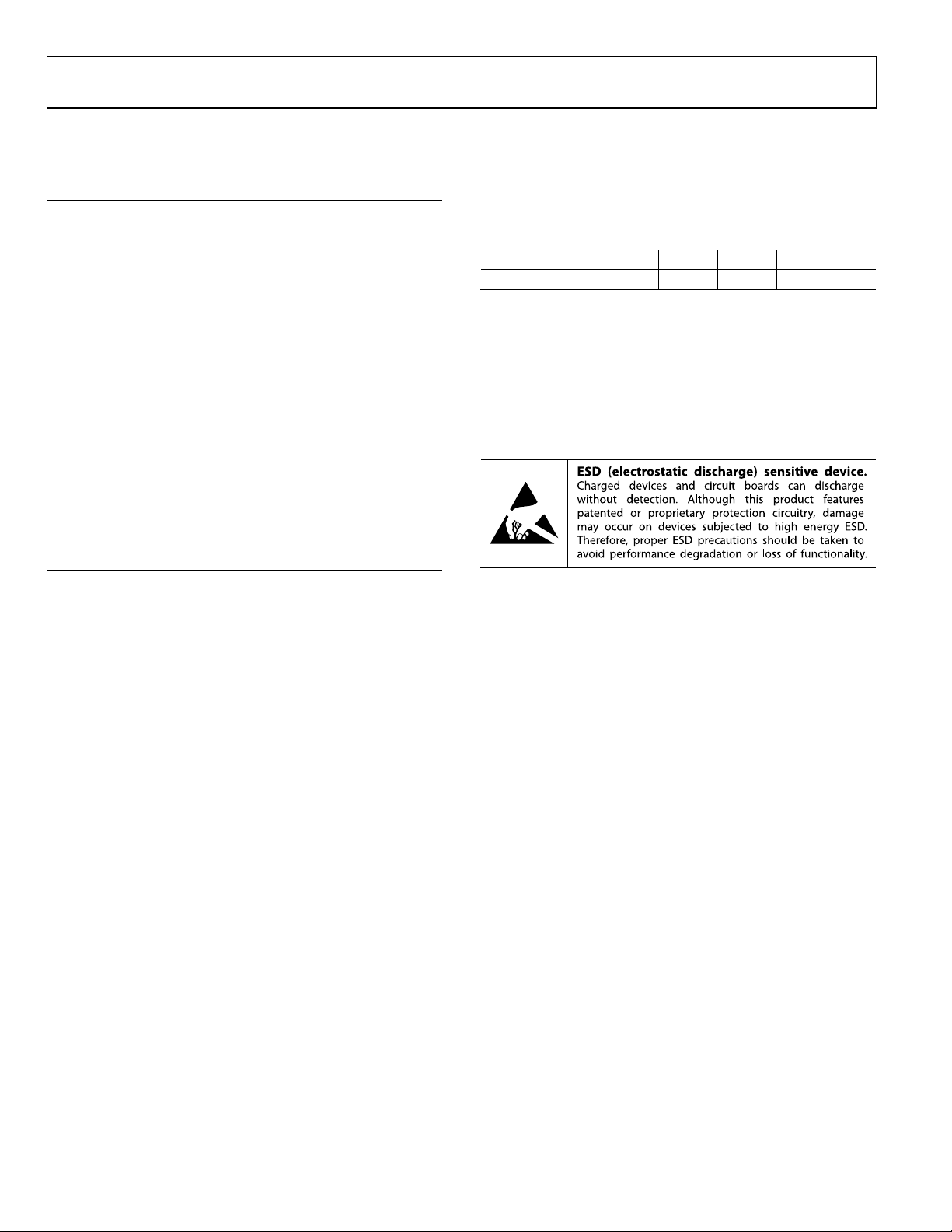

ABSOLUTE MAXIMUM RATINGS

Table 2.

Parameter Rating

Supply Voltage (Continuous), VDD 4.2 V

THERMAL RESISTANCE

θJA is specified for the worst-case conditions, that is, a device

soldered in a circuit board for surface-mount packages.

OUTAUX, SR1, SR2, GATE, PGOOD1,

PGOOD2

VS3− to PGND, AGND, DGND −0.3 V to +0.3 V

VS1, VS2, VS3+, ACSNS −0.3 V to VDD + 0.3 V

CS1, CS2+, CS2− −0.3 V to VDD + 0.3 V

FLAGIN, PSON −0.3 V to VDD + 0.3 V

SDA, SCL −0.3 V to VDD + 0.3 V

SHAREo, SHAREi −0.3 V to VDD + 0.3 V

Operating Temperature Range −40°C to +125°C

Storage Temperature Range −65°C to +150°C

Junction Temperature 150°C

Peak Solder Reflow Temperature

SnPb Assemblies (10 sec to 30 sec) 240°C

RoHS-Compliant Assemblies

ESD Human Body Model 3.5 kV

260°C

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

Table 3. Thermal Resistance

Package Type θJA θJC Unit

32-Lead LFCSP 44.4 6.4 °C/W

SOLDERING

It is important to follow the correct guidelines when laying out

the PCB footprint for the ADP1046 and when soldering the

part onto the PCB. For detailed information about these guidelines, see the AN-772 Application Note.

ESD CAUTION

Rev. A | Page 10 of 96

Data Sheet ADP1046

PIN 1

INDICATOR

1VS2

2AGND

3VS1

4CS2–

5CS2+

6ACSNS

7CS1

8PGND

24 SHAREi

23 SHAREo

22 PGOOD1

21 PGOOD2

20 FLAGIN

19 PSON

18 SDA

17 SCL

9SR1

10SR2

11OUTA

12OUTB

13OUTC

14OUTD

15OUTAUX

16GATE

32

VS3+

31

VS3–

30

RES

29

ADD

28

RTD

27

VDD

26

VCORE

25

DGND

ADP1046

TOP VIEW

(Not to S cale)

NOTES

1. THE ADP1046 HAS AN EXPOSED THERMAL PAD ON THE UNDERSIDE

OF THEPACKAGE. FOR INCREASED RELIABILITY OF THE SOLDER

JOINTSAND MAXIM UM THERMAL CAPABILITY, IT IS RECOMMENDED

THAT THE PAD BE SOLDERED TO THE PCB AGND PLANE.

10045-003

4

CS2−

Inverting Differential Current Sense Input. Nominal voltage at this pin should be 1 V for best operation. When

9

SR1

Synchronous Rectifier Output. This PWM output connects to the input of a FET driver. This pin can be disabled

PIN CONFIGURATION AND FUNCTION DESCRIPTIONS

Figure 4. Pin Configuration

Table 4. Pin Function Descriptions

Pin No. Mnemonic Description

1 VS2 Power Supply Output Voltage Sense Input. This signal is referenced to PGND and is the input to a low frequency

Σ-Δ ADC. Nominal voltage at this pin should be 1 V. The resistor divider on this input must have a tolerance

specification of 0.5% or better to allow for trimming.

2 AGND Analog Ground. This pin is the ground for the analog circuitry and the return for the VDD pin of the ADP1046.

3 VS1 Local Output Voltage Sense Input. This signal is referenced to PGND. Nominal voltage at this pin should be 1 V.

The resistor divider on this input must have a tolerance specification of 0.5% or better to allow for trimming.

using low-side current sensing, place a 5 kΩ resistor between the sense resistor and this pin. When using high-

side current sensing in a 12 V application, place a 5.5 kΩ resistor between the sense resistor and this pin. When

using high-side current sensing with a voltage other than 12 V, use this formula to calculate the resistor value:

R = (V

− 1)/2 mA. A 0.1% resistor must be used to connect this circuit. If this pin is not used, connect it to PGND

OUT

and set CS2± to high-side current sense mode (set Bit 2 of Register 0x27). It is recommended that a 500 pF to

1000 pF capacitor be connected either across the resistor or from this pin to AGND.

5 CS2+ Noninverting Differential Current Sense Input. Nominal voltage at this pin should be 1 V for best operation.

When using low-side current sensing, place a 5 kΩ resistor between the sense resistor and this pin. When using

high-side current sensing in a 12 V application, place a 5.5 kΩ resistor between the sense resistor and this pin.

When using high-side current sensing with a voltage other than 12 V, use this formula to calculate the resistor

value: R = (V

− 1)/2 mA. A 0.1% resistor must be used to connect this circuit. If this pin is not used, connect it

OUT

to PGND and set CS2± to high-side current sense mode (set Bit 2 of Register 0x27). It is recommended that a

500 pF to 1000 pF capacitor be connected either across the resistor or from this pin to AGND.

6 ACSNS AC Sense Input. This input is connected upstream of the main output inductor through a resistor divider

network. The nominal voltage for this circuit is 0.45 V. This pin is also connected to the voltage feedforward

ADC (nominal voltage 1 V). This signal is referenced to PGND.

7 CS1 Primary Side Current Sense Input. This pin is connected to the primary side current sensing ADC and to the fast

OCP comparator. This signal is referenced to PGND. The resistors on this input must have a tolerance specification

8 PGND Power Ground. This pin is the ground connection for the main power rail of the power supply and is the

10 SR2 Synchronous Rectifier Output. This PWM output connects to the input of a FET driver. This pin can be disabled

11 OU TA PWM Output for Primary Side Switch. This pin can be disabled when not in use. This signal is referenced to AGND.

12 OUTB PWM Output for Primary Side Switch. This pin can be disabled when not in use. This signal is referenced to AGND.

of 0.5% or better to allow for trimming. If this pin is not used, connect it to PGND.

reference for all voltage and current sensing other than CS2± and VS3±. Star connect to AGND.

when not in use. This signal is referenced to AGND.

when not in use. This signal is referenced to AGND.

Rev. A | Page 11 of 96

ADP1046 Data Sheet

17

SCL

I2C Serial Clock Input. This signal is referenced to AGND.

this pin is 1 V. The resistor divider on this input must have a tolerance specification of 0.5% or better to allow for

Pin No. Mnemonic Description

13 OUTC PWM Output for Primary Side Switch. This pin can be disabled when not in use. This signal is referenced to AGND.

14 OUTD PWM Output for Primary Side Switch. This pin can be disabled when not in use. This signal is referenced to AGND.

15 OUTAUX Auxiliary PWM Output. This pin can be disabled when not in use. This signal is referenced to AGND.

16 GATE OrFET Gate Drive Output. This signal is referenced to AGND. If this pin is not used, leave it floating.

18 SDA I2C Serial Data Input and Output (Open Drain). This signal is referenced to AGND.

19 PSON Power Supply On Input. This signal is referenced to AGND. This pin is the hardware PSON control signal. It is

recommended that a 1 nF capacitor be connected from the PSON pin to AGND for noise debouncing and

decoupling.

20 FLAGIN Flag Input. An external signal can be input at this pin to generate a flag condition.

21 PGOOD2 Power-Good Output (Open Drain). This signal is referenced to AGND. This pin is controlled by the PGOOD2 flag.

This pin is set by a programmable combination of internal flags. If this pin is not used, connect it to AGND.

22 PGOOD1 Power-Good Output (Open Drain). This signal is referenced to AGND. This pin is controlled by the PGOOD1 flag.

This pin is set by a programmable combination of internal flags. If this pin is not used, connect it to AGND.

23 SHAREo Share Bus Output Voltage Pin. Connect this pin to 3.3 V through a pull-up resistor (typically 2.2 kΩ). When

configured for a digital share bus, this pin is a digital output. This signal is referenced to AGND. If this pin is

not used, connect it to AGND.

24 SHAREi Share Bus Feedback Pin. Connect this pin to the SHAREo pin. This signal is referenced to AGND. If this pin is not

used, connect it to AGND.

25 DGND Digital Ground. This pin is the ground reference for the digital circuitry of the ADP1046. Star connect to AGND.

26 VCORE Output of the 2.5 V Regulator. Connect a decoupling capacitor of at least 330 nF (1 µF maximum) from this pin

to DGND as close to the IC as possible to minimize PCB trace length. It is recommended that the VCORE pin not

be used as a reference or to generate other logic levels using resistive dividers.

27 VDD Positive Supply Input. This signal is referenced to AGND. Connect a 4.7 µF decoupling capacitor from this pin to

AGND as close to the IC as possible to minimize PCB trace length.

28 RTD Thermistor Input. Place a thermistor (100 kΩ, 1%, beta = 4250, 1%) in parallel with a 16.5 kΩ, 1% resistor. This

pin is referenced to AGND. If this pin is not used, connect it to AGND.

29 ADD Address Select Input. This pin is used to program the I2C address. Connect a resistor from ADD to AGND. This

signal is referenced to AGND.

30 RES Resistor Input. This pin sets up the internal voltage reference for the ADP1046. Connect a 10 kΩ, ±0.1% resistor

from RES to AGND. This signal is referenced to AGND.

31 VS3− Inverting Remote Voltage Sense Input. There should be a low ohmic connection to AGND. The resistor divider

on this input must have a tolerance specification of 0.5% or better to allow for trimming. Connect a 0.1 µF

capacitor from VS3− to AGND.

32 VS3+ Noninverting Remote Voltage Sense Input. This signal is referenced to VS3−, and the nominal input voltage at

trimming. This pin is the input to the high frequency Δ-Σ ADC.

EP Exposed Pad. The ADP1046 has an exposed thermal pad on the underside of the package. For increased

reliability of the solder joints and maximum thermal capability, it is recommended that the pad be soldered

to the PCB AGND plane.

Rev. A | Page 12 of 96

Data Sheet ADP1046

2.5

–2.5

–2.0

–1.5

–1.0

–0.5

0

0.5

1.0

1.5

2.0

–60 –40 –20 0 20 40 60 80 100 120 140

VS1 ADC ACCURACY (%FSR)

TEMPERATURE (°C)

10045-400

MAX SPEC

MIN SPEC

MIN MEAN

MAX

2.5

–2.5

–2.0

–1.5

–1.0

–0.5

0

0.5

1.0

1.5

2.0

–60 –40 –20 0 20 40 60 80 100 120 140

VS2 ADC ACCURACY (%FSR)

TEMPERATURE (°C)

10045-401

MAX SPEC

MIN SPEC

MIN MEAN

MAX

2.5

–2.5

–2.0

–1.5

–1.0

–0.5

0

0.5

1.0

1.5

2.0

–60 –40 –20 0 20 40 60 80 100 120 140

VS3 ADC ACCURACY (%FSR)

TEMPERATURE (°C)

10045-402

MAX SPEC

MIN SPEC

MIN MEAN

MAX

2.5

–2.5

–2.0

–1.5

–1.0

–0.5

0

1.0

0.5

1.5

2.0

–60 –40 –20 0 20 40 60 80 100 120 140

CS1 ADC ACCURACY (%FSR)

TEMPERATURE (°C)

10045-403

MAX SPEC

MIN SPEC

MIN

MEAN

MAX

2.5

–2.5

–2.0

–1.5

–1.0

–0.5

0

1.0

0.5

1.5

2.0

–60 –40 –20 0 20 40 60 80 100 120 140

CS2 ADC ACCURACY (%FSR)

TEMPERATURE (°C)

10045-404

MAX SPEC

MIN SPEC

MIN

MEAN

MAX

1.24

1.16

1.17

1.18

1.19

1.20

1.21

1.22

1.23

–60 –40 –20 0 20 40 60 80 100 120 140

CS1 FAST O CP THRESHOLD (V )

TEMPERATURE (°C)

10045-405

MIN

MAX

MAX SPEC

MIN SPEC

MEAN

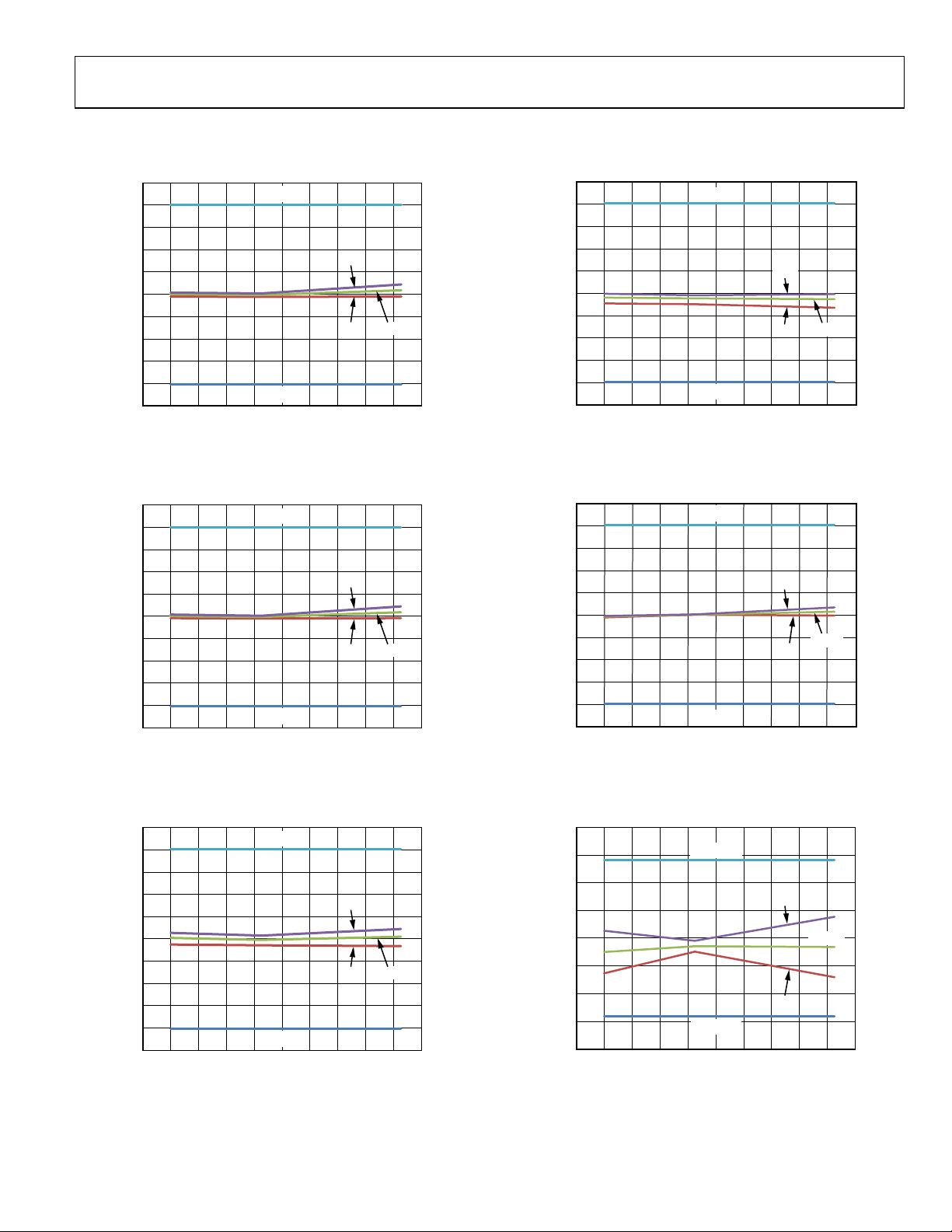

TYPICAL PERFORMANCE CHARACTERISTICS

Figure 5. VS1 ADC Accuracy vs. Temperature (from 10% to 90% of FSR)

Figure 8. CS1 ADC Accuracy vs. Temperature (from 10% to 90% of FSR)

Figure 6. VS2 ADC Accuracy vs. Temperature (from 10% to 90% of FSR)

Figure 7. VS3 ADC Accuracy vs. Temperature (from 10% to 90% of FSR)

Figure 9. CS2 ADC Accuracy vs. Temperature (from 10% to 90% of FSR)

Figure 10. CS1 Fast OCP Threshold vs. Temperature

Rev. A | Page 13 of 96

ADP1046 Data Sheet

2.5

–2.5

–2.0

–1.5

–1.0

–0.5

0

1.0

0.5

1.5

2.0

–60 –40 –20 0 20 40 60 80 100 120 140

ACSNS ADC ACCURACY (%FSR)

TEMPERATURE (°C)

10045-406

MIN

MAX SPEC

MIN SPEC

MEAN

MAX

4

–4

–3

–2

–1

0

1

2

3

–60 –40 –20 0 20 40 60 80 100 120 140

RTD ADC ACCURACY (%FSR)

TEMPERATURE (°C)

10045-408

MAX SPEC

MIN SPEC

MIN

MAX

MEAN

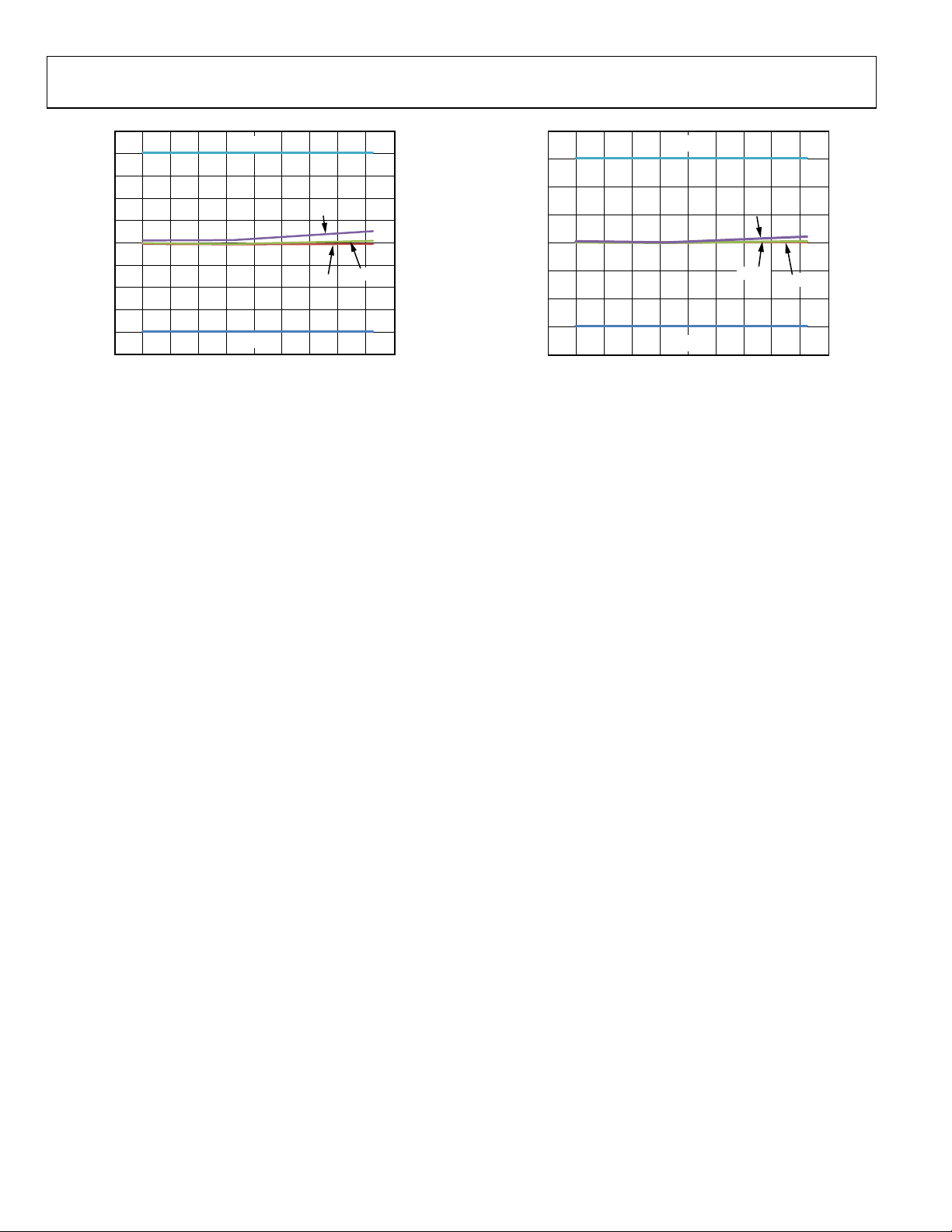

Figure 11. ACSNS ADC Accuracy vs. Temperature (from 10% to 90% of FSR)

Figure 12. RTD ADC Accuracy vs. Temperature (from 10% to 90% of FSR)

Rev. A | Page 14 of 96

Data Sheet ADP1046

CS1

1kΩ 10Ω

I = 100mA

I = 10A

V

IN

OUTA

OUTB

OUTC

OUTD

ADC

12 BITS

V

REF

FAST

OCP

1:100

1V

10045-010

CS2–CS2+

ADC

12 BITS

5.5kΩ 5.5kΩ

1V

I

12V

2mA 2mA

10045-011

CS2+CS2–

ADC

12 BITS

5kΩ 5kΩ

1V

I

200µA 200µA

10045-012

THEORY OF OPERATION

CURRENT SENSE

The ADP1046 has two current sense inputs: CS1 and CS2±.

These inputs sense, protect, and control the primary input

current, secondary output current, and the share bus

information. They can be calibrated to reduce errors due to

external components.

CS1 Operation (CS1)

CS1 is typically used for the monitoring and protection of

the primary side current, which is commonly sensed using a

current transformer (CT). The input signal at the CS1 pin is fed

into an ADC for current monitoring. The range of the ADC is

0 V to 1.4 V. The input signal is also fed into a comparator for

pulse-by-pulse OCP protection. The typical configuration for

the CS1 current sense is shown in Figure 13.

When using low-side current sensing, the current sources are

200 µA; therefore, the required resistor value is 1 V/200 µA = 5 kΩ.

When using high-side current sensing, the current sources are

2 mA; therefore, the resistor value required is (V

In the case of V

= 12 V, the required resistor value is 5.5 kΩ.

OUT

− 1 V)/2 mA.

OUT

Typical configurations are shown in Figure 14 and Figure 15.

Various thresholds and limits can be set for CS2±, such as OCP.

These thresholds and limits are described in the Current Sense

and Current Limit Registers section.

When not in use, the CS2+ and CS2− inputs should both be

connected directly to PGND, and CS2± should be set to highside current sense mode (Register 0x27[2] = 1).

The CS2 ADC is used to measure the CS2 current; the reading

is averaged every 2.62 ms in an asynchronous fashion. This

averaged reading is used to make fault decisions, such as the

CS2 OCP fault. The ADP1046 also writes the 12-bit CS2

reading every 10 ms to Register 0x18.

Figure 13. Current Sense 1 (CS1) Operation

The CS1 ADC is used to measure the average value of the

primary current; the reading is averaged every 2.62 ms in an

asynchronous fashion to make fault decisions. The ADP1046

also writes the 12-bit CS1 reading every 10 ms to Register 0x13.

The fast OCP comparator is used to limit the instantaneous

primary current within each switching cycle and has a nominal

threshold of 1.2 V.

Various thresholds and limits can be set for CS1, as described in

the Current Sense and Current Limit Registers section.

CS2 Operation (CS2+, CS2−)

CS2+ and CS2− are differential inputs used for the monitoring

and protection of the secondary side current. The full-scale

range of the CS2 ADC is programmable to 60 mV or 120 mV.

The differential inputs are fed into an ADC through a pair of

external resistors that provide the necessary level shifting. The

device pins, CS2+ and CS2−, are internally regulated to approximately 1 V by internal current sources.

Figure 14. High-Side Resistive Current Sense

Figure 15. Low-Side Resistive Current Sense (Recommended)

Rev. A | Page 15 of 96

ADP1046 Data Sheet

VS1

VS3+

VS3–

VS2

ADC

PGND

VS3VS2

12 BITS

VS1

12 BITS

DIGITAL

FILTER

1V 1V

12V 12V

11kΩ

1kΩ

1V

LOAD

11kΩ11kΩ

1kΩ 1kΩ

12V

HF

ADC

ADC

VS3

12 BITS

ADC

10045-013

MAGNITUDE

FREQUENCY

NYQUIST ADC

NOISE

Σ-Δ ADC

NOISE

10045-014

195.3

7 bits

VOLTAGE SENSE AND CONTROL LOOP

Multiple voltage sense inputs on the ADP1046 are used for the

monitoring, control, and protection of the power supply output.

This information is available through the I

sense points can be calibrated digitally to minimize errors due to

external components. This calibration can be performed in the

production environment, and the settings can be stored in the

EEPROM of the ADP1046 (see the Power Supply Calibration

and Tri m section for more information).

For voltage monitoring, the VS1, VS2, and VS3 voltage value

registers (Register 0x15, Register 0x16, and Register 0x17,

respectively) are updated every 10 ms. The ADP1046 stores every

ADC sample for 10 ms and then outputs the average value at the

end of the 10 ms period. Therefore, if these registers are read at

least every 10 ms, a true average value is read.

The ADP1046 uses two separate sensing points: VS1 and VS3±,

depending on the condition of the OrFET. When the OrFET is

turned off, the control loop is regulated via VS1; when the OrFET

is turned on, the control loop is regulated via the differential

sensing on VS3±. This sensing mechanism effectively performs

a local and remote voltage sense.

The control loop of the ADP1046 features a patented multipath

architecture. The output voltage is converted simultaneously by

two ADCs: a high accuracy ADC and a high speed ADC. The

complete signal is reconstructed and processed in the digital

filter to provide a high performance, cost competitive solution.

2

C interface. All voltage

Σ-Δ ADCs also differ from Nyquist rate ADCs in that the quantization noise is not uniform across the frequency spectrum. At

lower frequencies, the noise is lower, and at higher frequencies,

the noise is higher (see Figure 17).

Figure 17. Noise Performance for Nyquist Rate and Σ-Δ ADCs

The low frequency ADC runs at approximately 1.56 MHz. For a

specified bandwidth, the equivalent resolution can be calculated

as follows:

ln(1.56 MHz/BW)/ln2 = N bits

For example, at a bandwidth of 95 Hz, the equivalent

resolution/noise is

ln(1.5 MHz/95)/ln2 = 14 bits

At a bandwidth of 1.5 kHz, the equivalent resolution/noise is

ln(1.56 MHz/1.5 kHz)/ln2 = 10 bits

The high frequency ADC has a clock of 25 MHz. It is comb

filtered and outputs at the switching frequency (f

) into the

SW

digital filter. The equivalent resolution at some sample

frequencies is listed in Ta b l e 5.

Figure 16. Voltage Sense Configuration

ADCs

Two kinds of Σ-Δ ADCs are used in the feedback loop of the

ADP1046: a low frequency (LF) ADC that runs at 1.56 MHz

and a high frequency (HF) ADC that runs at 25 MHz.

Σ-Δ ADCs have a resolution of one bit and operate differently

from traditional flash ADCs. The equivalent resolution obtainable depends on how long the output bit stream of the Σ-Δ is

sampled.

Table 5. Equivalent Resolutions for High Frequency ADC

at Various Switching Frequencies

fSW (kHz) High Frequency ADC Resolution

48.8 9 bits

97.7 8 bits

390.6 6 bits

The HF ADC has a range of ±30 mV. Using a base switching

frequency (f

increases to 200 kHz (7-bit HF ADC resolution), the quantization

noise is 0.9375 mV (1 LSB). Increasing f

quantization noise to 3.75 mV (1 LSB = 2 × 30 mV/2

VS1 OPERATION (VS1)

Rev. A | Page 16 of 96

VS1 is used for the monitoring and protection of the power supply

voltage at the output of the LC stage, upstream of the OrFET. The

VS1 sense point on the power rail needs an external resistor

divider to bring the nominal input voltage to 1 V at the VS1 pin

(see Figure 16). The resistor divider is necessary because the VS1

ADC input range is 0 V to 1.6 V (12-bit reading). This divideddown signal is internally fed into a low speed Σ-Δ ADC. The output

of the VS1 ADC goes to the digital filter and is also updated in

Register 0x15 every 10 ms. The VS1 signal is referenced to PGND.

When the OrFET is turned off, the power supply is regulated

from the VS1 sense point instead of the VS3± sense point.

) of 100 kHz (8-bit HF ADC resolution), when fSW

SW

to 400 kHz increases the

SW

6

= 0.9375 mV).

Data Sheet ADP1046

ACSNS

ADC

0V TO 1.6V

ACSNS

FEEDFORWARD

ADC

0.6V TO 1. 6V

PROGRAMMABLE

ACTION (REG 0x0D[3:0])

FEEDFORWARD

GAIN

(REG 0x75[1:0])

DPWM

ENGINE

DIGITAL

FILTER

ACSNS GAIN TRIM

(REG 0x5E)

0.45V

1/x

Vx

R1

R2

FROM

SECONDARY

WINDING

10045-015

R

ACSNS

DIGITAL

FILTER

OUTPUT

OUTx

t

MODULATION

t

S

t

S

t

MODULATION

10045-016

−

−

×+

−

×

×

=

az

bz

c

z

z

m

d

H(z)

68.7124.202

VS2 OPERATION (VS2)

VS2 is used in conjunction with VS1 to control the OrFET gate

drive turn-on. The VS2 sense point on the power rail needs an

external resistor divider to bring the nominal common-mode

signal to 1 V at the VS2 pin (see Figure 16).

The resistor divider is necessary because the VS2 ADC input

range is 0 V to 1.6 V. This divided-down signal is internally fed

into the VS2 ADC. The output of the VS2 ADC goes to the VS2

voltage value register (Register 0x16). The VS2 signal is never

used for the control loop but is used to control the turn-on and

turn-off of the OrFET (see the OrFET Control (GATE) section)

as well as the voltage continuity flag. If the OrFET function of

the ADP1046 is not used, it is recommended that the VS2 input

be connected directly to PGND. The VS2 value is updated in

Register 0x16 every 10 ms.

VS3 OPERATION (VS3+, VS3−)

VS3± is used for the monitoring and protection of the remote

load voltage. VS3± is a fully differential input that is the main

feedback sense point for the power supply control loop. The

VS3± sense point on the power rail needs an external resistor

divider to bring the nominal common-mode signal to 1 V at

the VS3± pins (see Figure 16). The resistor divider is necessary

because the VS3 ADC input range is 0 V to 1.6 V. This divideddown signal is internally fed into a high frequency (HF) ADC.

The output of the VS3 ADC goes to the digital filter and is also

updated in Register 0x17 every 10 ms. The HF ADC is also the

high frequency feedback loop for the power supply.

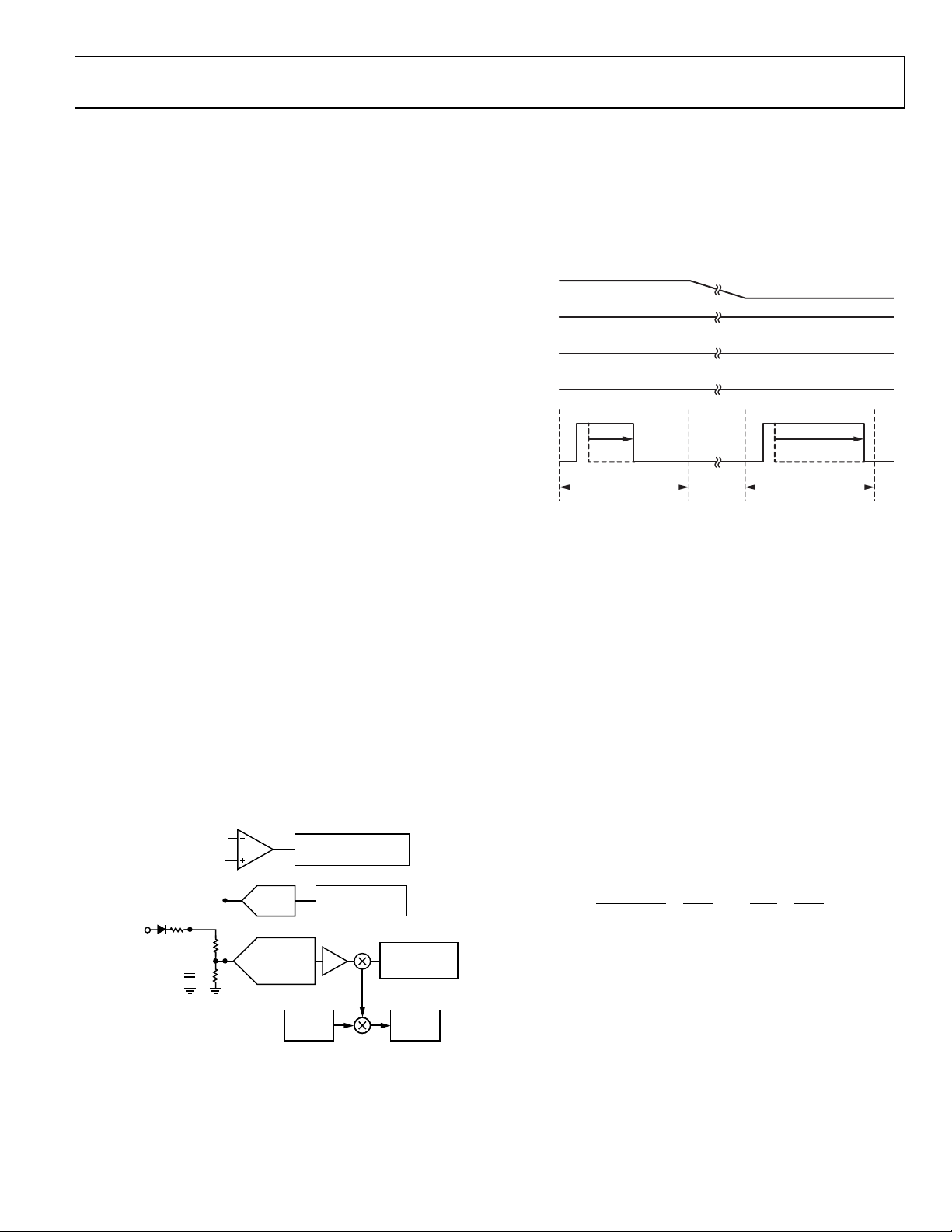

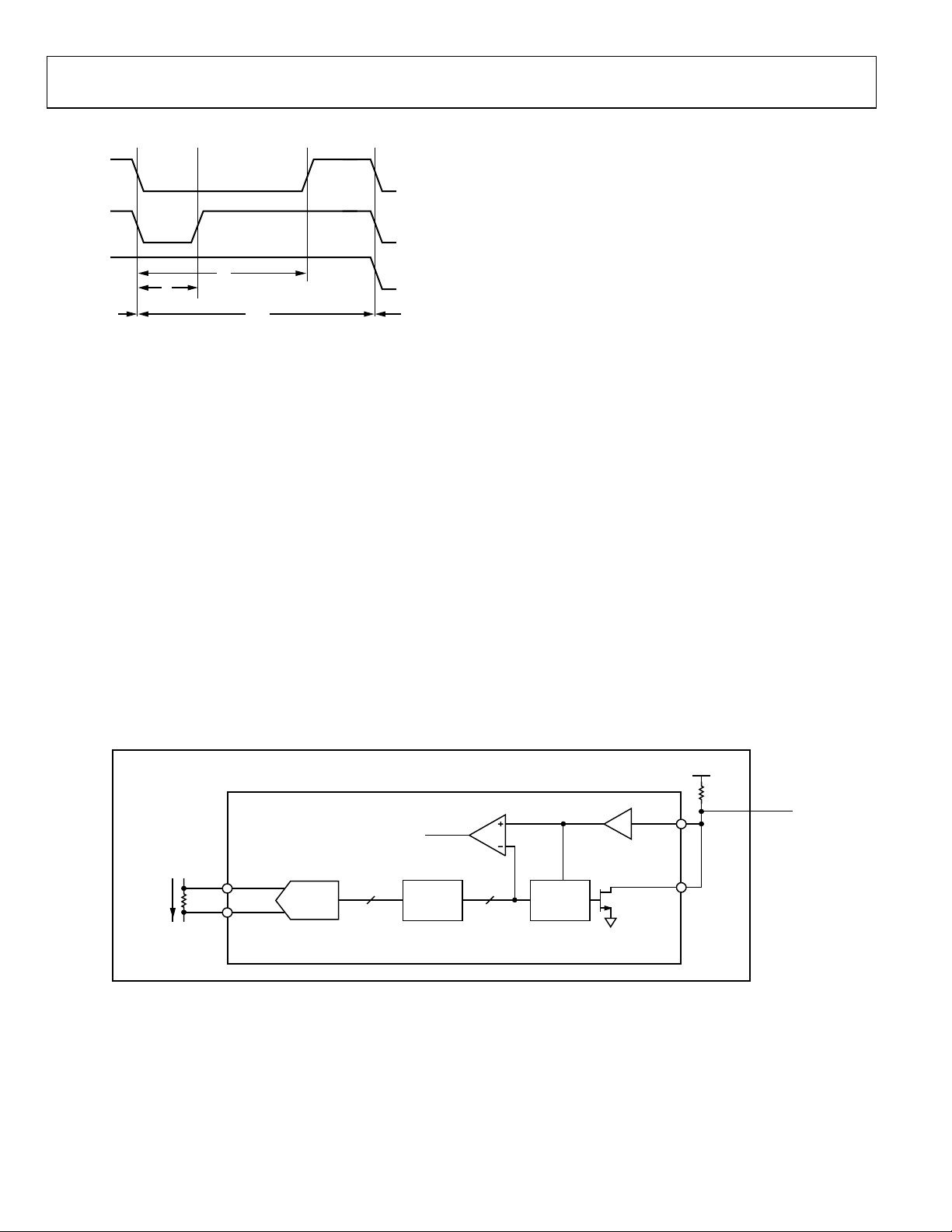

VOLTAGE LINE FEEDFORWARD AND ACSNS

The ADP1046 supports voltage line feedforward control to

improve line transient performance. The ACSNS value is used

to divide the output of the digital filter, and the result is fed into

the PWM engine. The input voltage signal can be sensed at the

secondary winding of the isolation transformer and must be

filtered by an RCD network to eliminate the voltage spike at the

switch node (see Figure 18).

The feedforward scheme modifies the modulation value based

on the ACSNS voltage. When the ACSNS input is 1 V, the line

feedforward has no effect. For example, if the digital filter output

remains unchanged and the ACSNS voltage changes to 50% of

its original value (still higher than 0.5 V), the modulation of the

falling edge of OUTx doubles and vice versa (see Figure 19). The

voltage line feedforward function is optional and is programmable

using Register 0x75.

Figure 19. Feedforward Control on Modulation

The ACSNS level comparator is also connected on the same pin

and flags an ACSNS fault when the voltage on the pin is below

0.45 V within each switching period. The ACSNS level comparator

is used to detect whether the node is switching.

DIGITAL FILTER

The loop response of the power supply can be changed using the

internal programmable digital filter. A Type 3 filter architecture

has been implemented. To tailor the loop response to the specific

application, the low frequency gain, zero location, pole location,

and high frequency gain can all be set individually (see the Digital

Filter Programming Registers section). It is recommended that

the Analog Devices, Inc., software GUI be used to program the

filter. The software GUI displays the filter response in Bode plot

format and can be used to calculate all stability criteria for the

power supply.

From the sensed voltage to the duty cycle, the transfer function

of the filter in z-domain is as follows:

Figure 18. Feedforward Configuration

The ACSNS voltage must be set to 1 V when the nominal input

voltage is applied. The ACSNS ADC sampling period is 10 µs;

therefore, the decision to modify the PWM outputs based on

input voltage is performed at this rate.

where:

a = filter_pole_register_value/256.

b = filter_zero_register_value/256.

c = high_frequency_gain_register_value.

d = low_frequency_gain_register_value.

m = 1 when 48.8 kHz ≤ f

m = 2 when 97.7 kHz ≤ f

m = 4 when 195.3 kHz ≤ f

m = 8 when 390.6 kHz ≤ f

where f

Rev. A | Page 17 of 96

< 97.7 kHz.

SW

< 195.3 kHz.

SW

< 390.6 kHz.

SW

.

SW

is the switching frequency.

SW

ADP1046 Data Sheet

sf

sf

z(s)

SW

SW

−

+

=

2

2

ISOLATORDRIVER

DRIVER

OUTA

OUTB

OUTC

OUTD

SR1 SR2

V

IN

OUTA

OUTD

OUTC

OUTB

SR1

SR2

10045-117

To transfer the z-domain value to the s-domain, plug the following bilinear transformation equation into the H(z) equation:

The digital filter introduces an extra phase delay element into

the control loop. The digital filter circuit sends the duty cycle

information to the PWM circuit at the beginning of each switching cycle (unlike an analog controller, which makes decisions on

the duty cycle information continuously). Therefore, the extra

phase delay for phase margin, Φ, introduced by the filter block is

Φ = 360 × (f

C/fSW

)

where:

f

is the crossover frequency.

C

f

is the switching frequency.

SW

At one-tenth the switching frequency, the phase delay is 36°.

The GUI incorporates this phase delay into its calculations.

Note that the GUI does not account for other delays such as

gate driver and propagation delays.

Two sets of registers allow for two distinct filter responses.

The main filter, called the normal mode filter, is controlled by

programming Register 0x60 to Register 0x63. The light load

mode filter is controlled by programming Register 0x64 to

Register 0x67. The ADP1046 uses the light load mode filter

only when the output current measured on CS2± is below the

load current threshold (programmed using Register 0x3B[2:0]).

The Analog Devices software GUI allows the user to program the

light load mode filter in the same manner as the normal mode

filter. It is recommended that the GUI be used for this purpose.

In addition, during the soft start process, a soft start filter can

be used in combination with the normal mode filter and the

light load mode filter. The soft start filter is programmed using

Register 0x71 to Register 0x74. For more information, see the

Soft Start section.

Filter Transitions

To avoid output voltage glitches and provide a seamless

transition from one filter to another, the ADP1046 supports

programmable filter transitions. This feature allows a gradual

transition from one filter to another. Filter transitions are

programmed using Register 0x7A[2:0].

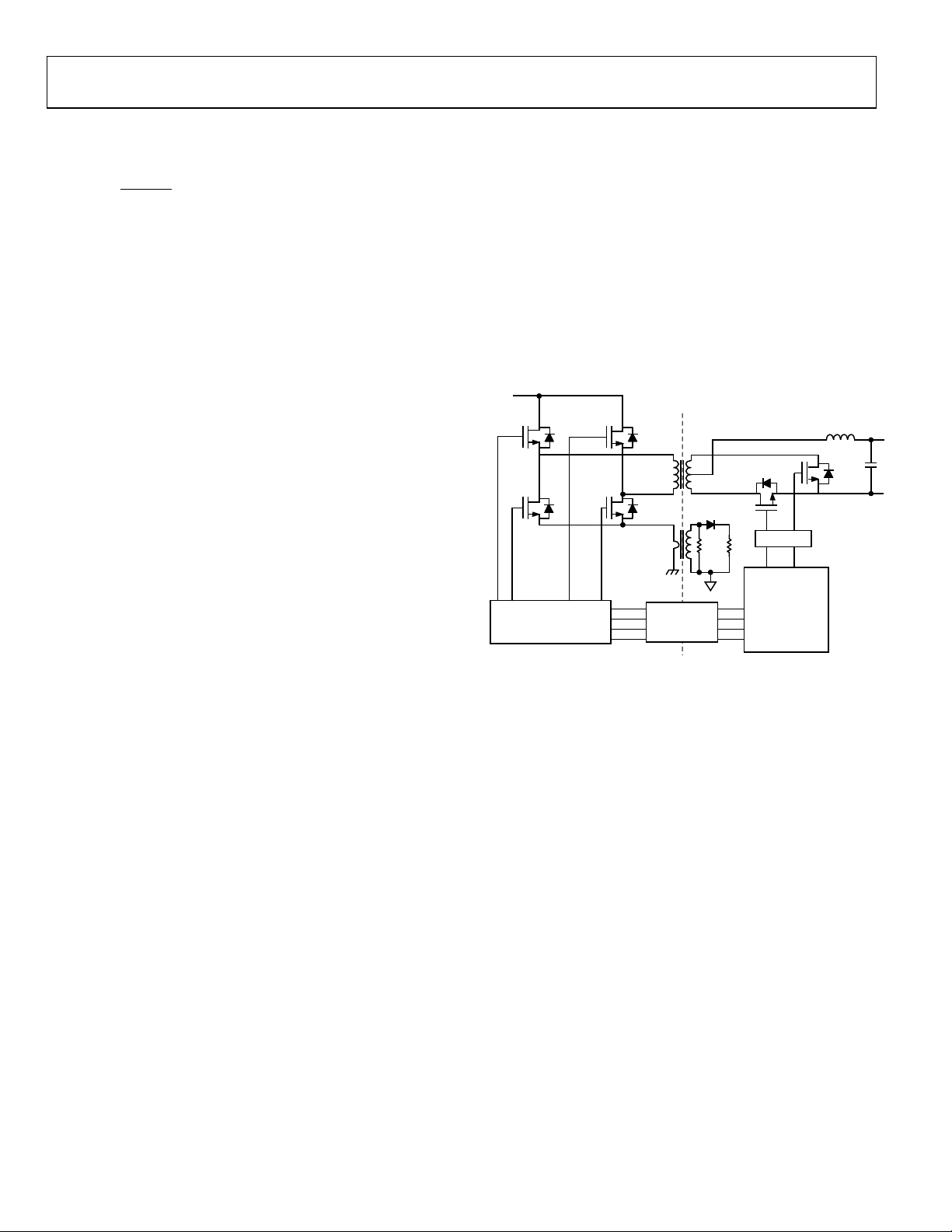

PWM AND SYNC RECT OUTPUTS (OUTA, OUTB, OUTC, OUTD, OUTAUX, SR1, SR2)

The PWM and SR outputs are used for control of the primary

side drivers and the synchronous rectifier drivers. These outputs

can be used for several control topologies such as full-bridge,

phase-shifted ZVS configurations and interleaved, two switch

forward converter configurations. Delays between rising and

falling edges can be individually programmed. Special care

must be taken to avoid shootthrough and cross-conduction.

It is recommended that the Analog Devices software GUI be

used to program these outputs. Figure 20 shows an example

configuration to drive a full-bridge, phase-shifted topology

with synchronous rectification.

Figure 20. PWM Pin Assignment for Full-Bridge, Phase-Shifted Topology

with Synchronous Rectification

The PWM and SR outputs are all synchronized with each

other. Therefore, when reprogramming more than one of these

outputs, it is important to first update all the registers and then

latch the information into the ADP1046 at the same time. During

reprogramming, the outputs are temporarily disabled. A special

instruction is sent to the ADP1046 to ensure that new timing

information is programmed simultaneously. This is done by

setting Bit 1 in Register 0x7F. It is recommended that PWM

outputs be disabled when not in use.

OUTAUX is an additional PWM output pin. OUTAUX allows

an extra PWM signal to be generated at a different frequency

from the other six PWM outputs. This signal can be used to

drive an extra power converter stage, such as a buck controller

located in front of a full-bridge converter. OUTAUX can also

be used as a clock reference signal.

For more information about the various programmable switching

frequencies and PWM timings, see the PWM and Synchronous

Rectifier Timing Registers section (Register 0x3F to Register 0x5C).

Rev. A | Page 18 of 96

OUTx

t

MODULATION_LIMIT

t

RX

t

FX

10045-118

Data Sheet ADP1046

SYNCHRONOUS RECTIFICATION

SR1 and SR2 are recommended for use as the PWM control

signals when using synchronous rectification. These PWM

signals can be configured much like the other PWM outputs.

An optional soft start can be applied to the synchronous

rectifier PWM outputs. The SR soft start can be programmed

using Register 0x54[1:0].

• When SR soft start is disabled (Register 0x54[0] = 0),

the SR signals are turned on to their full PWM duty cycle

values immediately.

• When SR soft start is enabled (Register 0x54[0] = 1), the

SR signals ramp up from zero duty cycle to the desired

duty cycle in steps of 40 ns per switching cycle.

The advantage of ramping the SR signals is to minimize the

output voltage step that occurs when the SR FETs are turned

on without a soft start. The advantage of turning the SR signals

completely on immediately is that they can help to minimize

the voltage transient caused by a load step.

Using Register 0x54[1], the SR soft start can be programmed to

occur only once (the first time that the SR signals are enabled)

or every time that the SR signals are enabled, for example, when

the system enters or exits light load mode.

When programming the ADP1046 to use SR soft start, ensure

correct operation of this function by setting the falling edge of

SR1 (t

) to a lower value than the rising edge of SR1 (t9) and by

10

setting the falling edge of SR2 (t

edge of SR2 (t

). SR soft start can also be disabled by setting

11

) to a lower value than the rising

12

Register 0x0F[7] = 1.

SR (SYNCHRONOUS RECTIFIER) DELAY

The ADP1046 is well suited for dc-to-dc converters in isolated

topologies. Every time a PWM signal crosses the isolation barrier

an additional propagation delay is added due to the isolating

components. The ADP1046 allows programming of an adjustable

delay (0 ns to 315 ns in steps of 5 ns) using Register 0x79[5:0]. This

delay moves both SR1 and SR2 later in time to compensate for the

added delay due to the isolating components (see Figure 56). In

this way, the edges of all PWM outputs can be aligned, and the

SR delay can be applied separately as a constant dead time.

ADAPTIVE DEAD TIME CONTROL

A set of registers called the adaptive dead time (ADT) registers

(Register 0x68 to Register 0x70) allows the dead time between

PWM edges to be adapted on the fly. The ADP1046 uses the ADT

only when the modulation is below the dead time (primary

current) threshold programmed in Register 0x68. The Analog

Devices software GUI allows the user to easily program the dead

time values, and it is recommended that the GUI be used for

this purpose.

Before ADT is configured, the primary current threshold must

be programmed. Each individual PWM rising and falling edge

(t

to t14) can then be programmed to have a specific dead time

1

offset at no load (zero current).

Rev. A | Page 19 of 96

This offset can be positive or negative and is relative to the nominal

edge position. When the CS1 current is between zero and the

current threshold, the amount of dead time is linearly adjusted

in steps of 5 ns. The averaging period of the CS1 current and

the speed of the dead time adjustment can also be programmed

in Register 0x70 to accommodate faster or slower adjustment.

For example, if the CS1 threshold is set to 2 A, t

rising edge of 100 ns. If the ADT setting for t

t

moves to 140 ns when the current is 0 A and to 120 ns when

1

has a nominal

1

is 40 ns at no load,

1

the current is 1 A. Similarly, ADT can be applied in the negative

direction.

LIGHT LOAD MODE

The ADP1046 can be configured to disable PWM outputs under

light load conditions based on the value of CS2. Register 0x3B

and Register 0x7D are used to program the light load mode

thresholds for turn-off and turn-on of SR1, SR2, and other

PWM outputs. Below the light load threshold programmed in

Register 0x3B, the SR outputs are disabled; the user can also

program any of the other PWM outputs to shut down below

this threshold. Light load mode allows the ADP1046 to be used

with interleaved topologies that incorporate automatic phase

shedding at light load.

To prevent the system from oscillating between light load

and normal modes due to the thresholds being programmed

too close to each other, a programmable debounce is provided

in Register 0x7D[5:4]. This debounce prevents the part from

changing state within the programmed interval.

The speed of the SR enable is programmable from 37.5 µs to 300 µs

in four discrete steps using Register 0x7D[3:2]. This ensures that,

in case of a load step, the SR signals (and any other PWM outputs

that are temporarily disabled) can be turned on quickly enough to

prevent damage to the FETs that they are controlling.

The light load mode digital filter is also used during light

load mode.

MODULATION LIMIT

The modulation limit register (Register 0x2E) can be

programmed to apply a maximum duty cycle modulation limit

to any PWM signal, thus limiting the modulation range of any

PWM output. When modulation is enabled, the maximum

modulation limit is applied to all PWM outputs collectively. As

shown in Figure 21, this limit is the maximum time variation

for the modulated edges from the default timing, following the

configured modulation direction. There is no minimum duty

cycle limit setting. Therefore, the user must set the rising edges

and falling edges based on the case with the least modulation.

Figure 21. Modulation Limit Settings

ADP1046 Data Sheet

10045-119

Each LSB in Register 0x2E corresponds to a different time step

size, depending on the switching frequency (see Tab l e 46). The

modulated edges cannot extend beyond one switching cycle.

The GUI provided with the ADP1046 is recommended for

programming this feature (see Figure 22).

Figure 22. Setting Modulation Limits (Modulation Range Shown by Arrows)

SOFT START

The turning on and off of the ADP1046 is controlled by the

hardware PSON pin and/or the software PSON register,

depending on the configured settings in Register 0x2C.

When the user turns on the power supply (enables PSON),

the following soft start procedure occurs (see Figure 23).

1. The PSON signal is enabled at Time t

programmed to be always on (Register 0x2C[7:6] = 00),

PSON is enabled as soon as VCORE is above UVLO.

2. The ADP1046 waits for the programmed PS_ON delay

(set in Register 0x2C[4:3]).

3. The soft start begins to ramp up the internal digital refer-

ence. The total duration of the soft start ramp is programmable from 5 ms to 100 ms using Register 0x5F[7:5].

4. If the soft start from precharge function is enabled

(Register 0x5F[4] = 1), the soft start ramp starts from

the value of the output voltage sensed on VS1 or VS3±

(depending on the OrFET status), and the soft start ramp

time is reduced proportionally. If the soft start from precharge function is disabled, the soft start ramp time is the

programmed value in Register 0x5F[7:5].

5. When the power supply voltage exceeds the VS1 under-

voltage protection (UVP) limit (set in Register 0x34[6:0]),

the UVP flag is reset.

6. The OrFET is turned on as soon as the OrFET enable thresh-

old is met. (The OrFET enable threshold is programmed in

Register 0x30[6:5].) The regulation point is switched from

VS1 to VS3±.

7. If no other fault conditions are present, the PGOODx

signals wait for the programmed debounce time (set in

Register 0x2D[7:4]) and are then enabled. The soft start

flag must be unmasked in Register 0x7B and Register 0x7C

(Bit 7 must be set to 0).

8. If no OrFET is used, the power supply must be configured

to regulate using VS3 at all times (Register 0x33[2] = 1).

VS2 can be used as a secondary OVP mechanism.

. If the part is

0

Fault Condition During Soft Start

If a fault condition occurs during soft start, the controller responds

as programmed unless the flag is blanked. Flag blanking during

soft start is programmed in Register 0x0F. The UVP and ACSNS

flags are always blanked during soft start. The OTP, FLAGIN,

OVP, and OCP fault flags can be blanked during soft start by

setting the appropriate bits in Register 0x0F.

Digital Compensation Filters During Soft Start

The ADP1046 has a dedicated soft start filter (SSF) that can be

used to fine-tune and optimize the dynamic response during

the output voltage ramp-up.

Before it ramps up the internal reference after the PSON signal

is enabled, the ADP1046 evaluates whether the OrFET should

be turned on or off by looking at the difference between VS1

and VS2. This step is done to determine whether the regulation

point should be VS1 or VS3± (see Figure 23).

• If the regulation point is VS1, the soft start filter is used

by default during the ramp-up. At the end of the soft start

ramp, the part switches to the normal mode filter (NMF).

• If the regulation point is VS3±, the part starts the ramp

using the normal mode filter (NMF).

In both cases, after the voltage reaches 12.5% of the nominal

output voltage value, the load current is evaluated.

• If the load current is below the light load mode threshold,

the part switches to the light load mode filter (LLF).

• If the load current is above the light load mode threshold,

the normal mode filter is used until the end of the soft start

ramp, even if the system subsequently enters light load

mode based on a change to the load current.

Register 0x2C can be programmed to configure the use of the

different filters during soft start as follows:

• Force soft start filter (Bit 0). This option forces the part to

use the soft start filter even when the regulation point is

VS3. In some cases, this option allows better fine-tuning of

the ramp-up voltage. This option can also be selected when

an OrFET is not used.

• Disable light load mode during soft start (Bit 1). This

option prevents the use of the light load mode filter during

soft start, even if the light load condition is met. The light

load mode filter is available for use after the end of the soft

start ramp.

Rev. A | Page 20 of 96

Data Sheet ADP1046

OrFET E NABLE

UVP

t

0

PSON

VS3

VS1

(VS1 – VS2)

VOLTAGE

OrFET GATE

LOOP CONTROLLED

FROM VS1

LOOP CONTROLLED

FROM VS3

UVP FLAG

PGOOD1

PS_ON DELAY

(REG 0x2C[4:3])

RAMP TIME

(REG 0x5F[7: 5] )

PGOOD DE BOUNCE

(REG 0x2D)

10045-120

PSON

V

OUT

RAMP TIME

(REG 0x5F[7: 5] )

12.5% REF

LIGHT LOAD

FILTER (LLF)

NORMAL MODE FILTER (NMF)

OR SOFT START FILTER (SSF)

NORMAL MODE FILTER (NMF)

OR SOFT START FILTER (SSF)

NORMAL MODE FILTER (NMF)

OR SOFT START FILTER (SSF)

LLF OR NMF

BASED ON

LOAD

LLF OR NMF

BASED ON

LOAD

10045-121

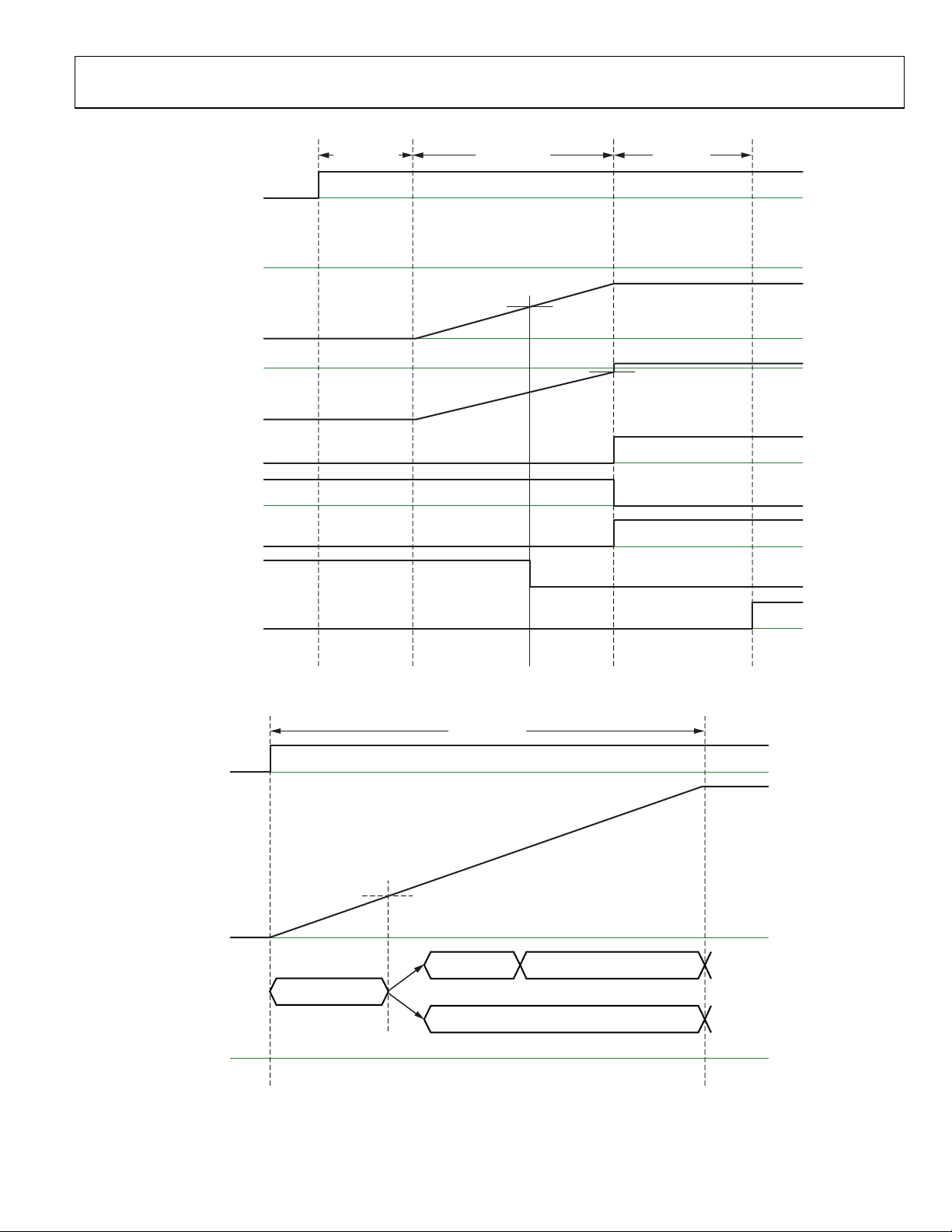

Figure 23. Soft Start Timing Diagram

Figure 24. Filter Sequencing at Startup

Rev. A | Page 21 of 96

ADP1046 Data Sheet

FAST OrFET

COMPARATOR

FAST OrFET

THRESHOLD

OrFET

DISABLE

CS2– CS2+

12V

11kΩ

11kΩ

1kΩ

1kΩ

V

OUT

VS2VS1

R

SENSE

GATE

FAST OrFET

BYPASS

FAST OrFET

DEBOUNCE

S

R

Q

OrFET

ENABLE

OrFET

ENABLE THRES HOLD

FLAGS

DRIVER

DEBOUNCE

GATE

DISABLE

10045-122

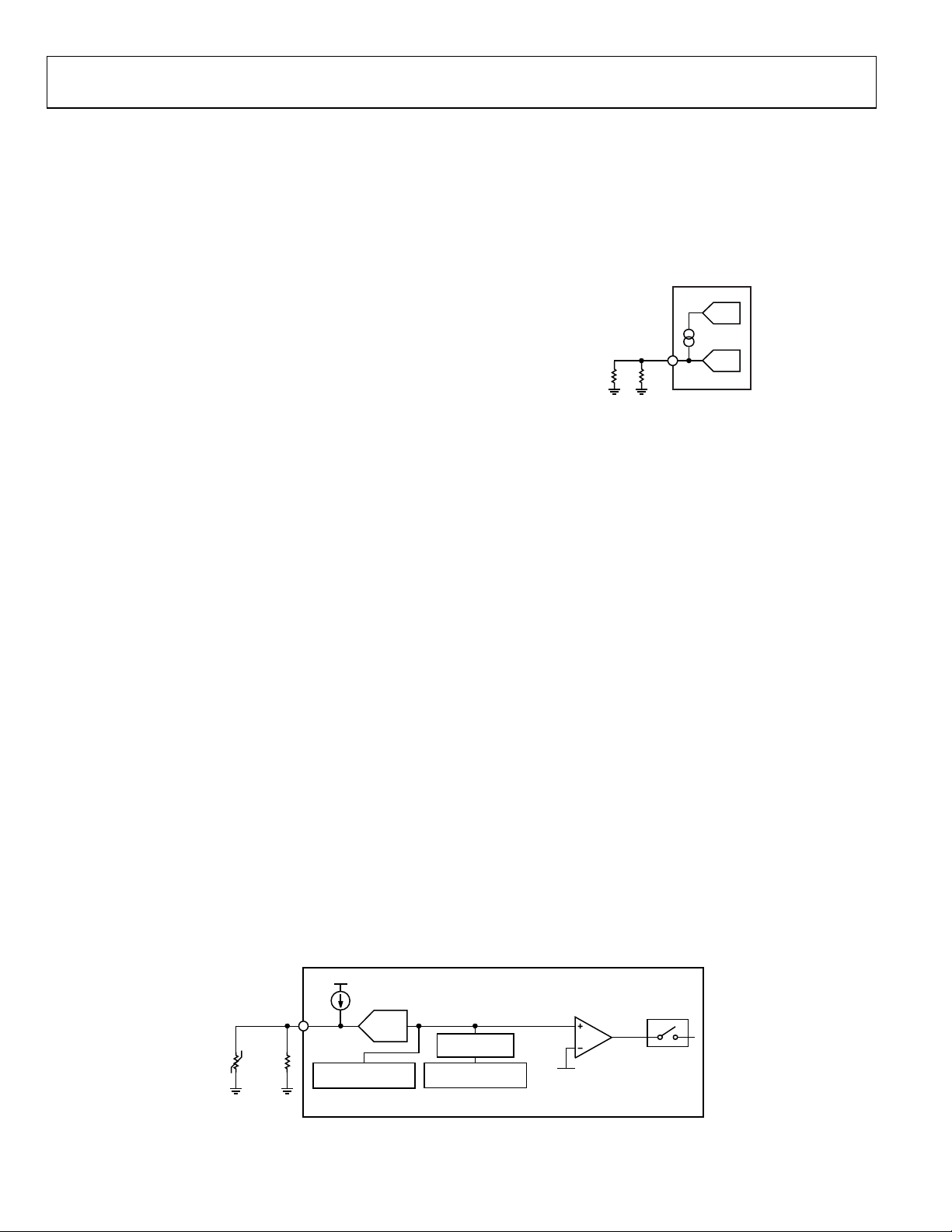

ORFET CONTROL (GATE)

The GATE control signal drives an external OrFET. The OrFET

is used in redundant systems to protect against power flow into

the power supply from another supply’s output terminals. This

ensures that power flows only out of the power supply and that

the unit can be hot-swapped.

The GATE pin is a totem-pole output and does not require a

pull-up resistor. The GATE pin polarity can be programmed via

Register 0x2D[1] to be active high or active low. The GATE output is CMOS level (0 V to 3.3 V). An external driver is required

to turn the OrFET on or off.

OrFET Turn-On

The turn-on process for the OrFET is controlled by the voltage

difference between VS1 and VS2. For this reason, the VS1 and

VS2 readings must be correctly calibrated for the OrFET function to perform properly.

The OrFET turn-on circuit detects the voltage difference between

VS1 and VS2 (see Figure 25). When the forward voltage drop from

VS1 to VS2 is greater than the programmable OrFET enable

threshold set in Register 0x30[6:5], the OrFET is enabled. The

OrFET enable threshold can be set to 0%, −0.5%, −1%, or −2%

of the nominal output voltage.

OrFET Turn-Off

The OrFET can be turned off by three methods:

• Fault flag. Any flag in a fault configuration register

(Register 0x08 to Register 0x0D) can be programmed with

an action to turn off the OrFET. The OrFET is kept off for

as long as the flag is set.

• OrFET programmable comparator. If the reverse voltage

present on CS2± exceeds the analog comparator threshold

programmed in Register 0x30[4:2], the OrFET is turned off.

This comparator can be disabled using Register 0x30[0].

• GATE signal disable. When Register 0x5D[0] = 1, the

GATE signal is disabled and has no effect on the VSx

feedback point.

OrFET GATE Control and Regulation Points

The GATE signal is enabled when the threshold configured

in Register 0x30[6:5]) is met. The GATE signal controls a very

important function of output voltage regulation: the control

loop sensing point.

• When the GATE signal is disabled, the OrFET is turned off

and the voltage regulation sensing point is VS1.

• When the GATE signal is enabled, the OrFET is turned on

and the voltage regulation sensing point is VS3±.

Recommended Setup for a 12 V Application

In normal operating mode, follow this procedure:

• When 12 V < V

< OVP, use the fast OrFET control

OUT

circuit to turn off the Or FE T.

• When V

> OVP, use load OVP to turn off the OrFET.

OUT

In light load mode, follow this procedure:

• When 12 V < V

< OVP, use ACSNS to turn off the

OUT

OrF ET.

• When V

> OVP, use load OVP to turn off the OrFET.

OUT

In a 12 V application, when an internal short circuit occurs, use

CS1 OCP or VS1 UVP to shut down the unit and restart it.

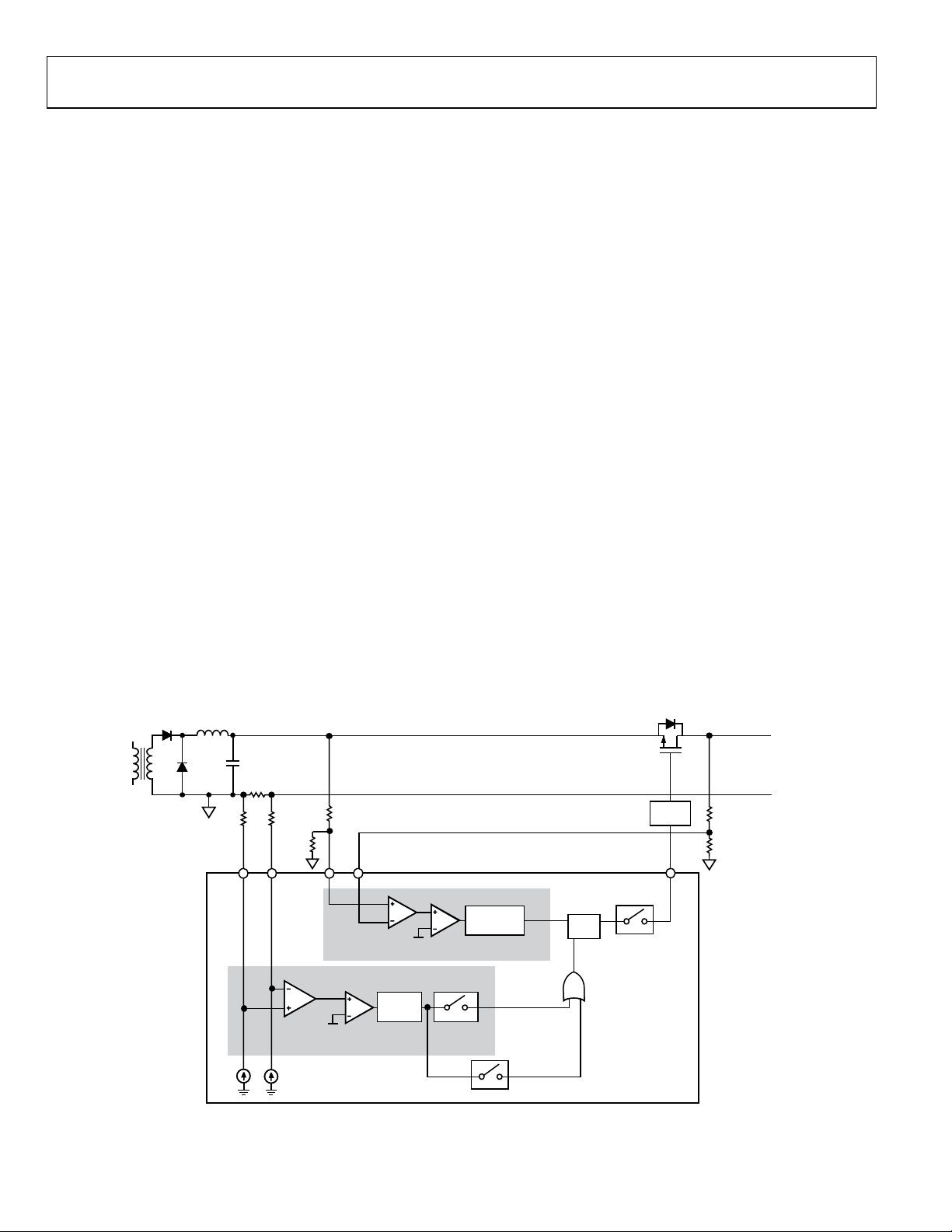

Figure 25. OrFET Control Circuit Internal Detailed Diagram

Rev. A | Page 22 of 96

Data Sheet ADP1046

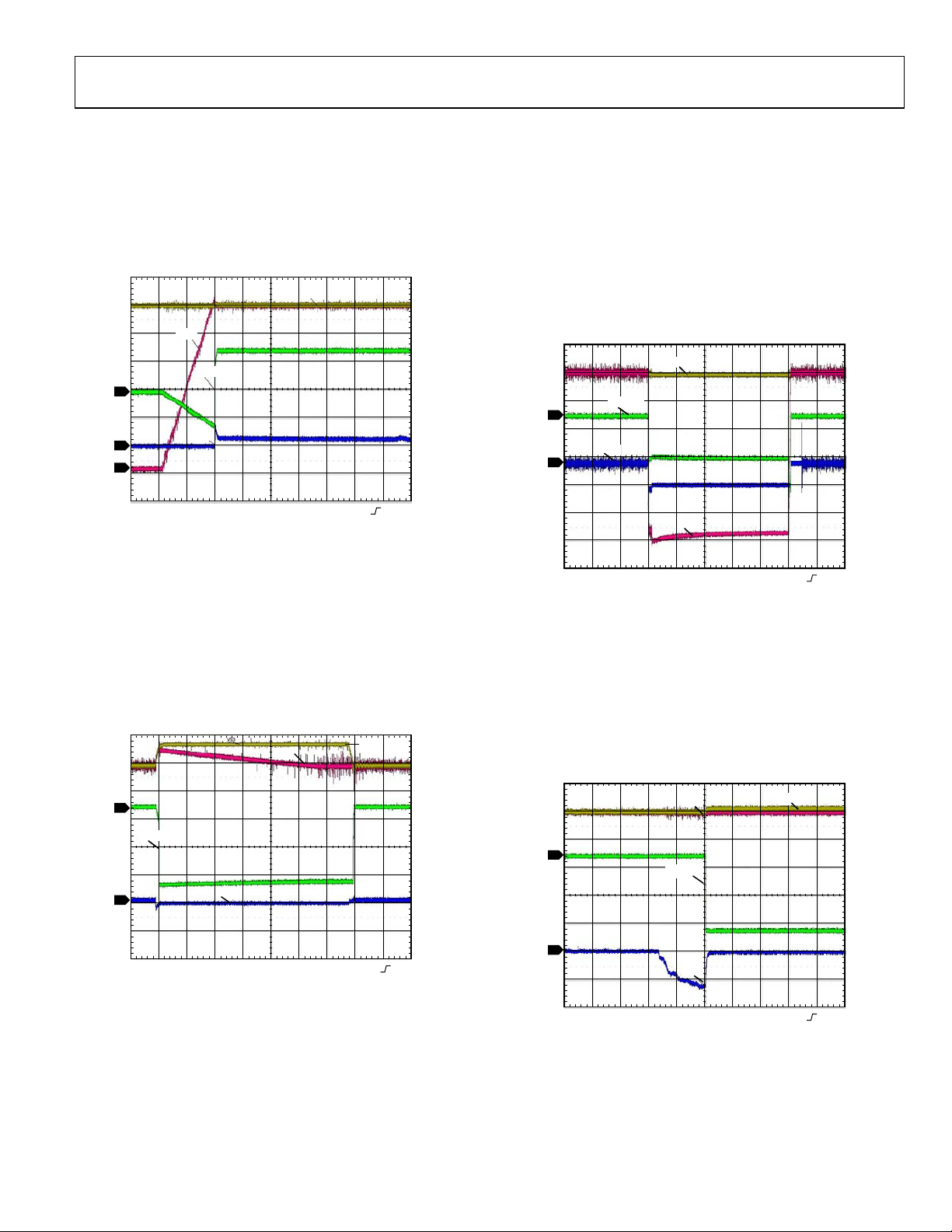

CH2 2.00V

CH4 10.0V

CH1 2.00V

CH3 2.00A

M10.0ms A CH4 100mV

2

3

4

CS2

VS3

VS1

OrFET

10045-017

CH2 2.00V

CH4 10.0V

CH1 2.00V

CH3 2.00A

M50.0ms A CH4 0mV

3

4

CS2

VS3

VS1