Thermoelectric Cooler Controller

ADN8830

FEATURES

High Efficiency

Small Size: 5 mm 5 mm LFCSP

Low Noise: <0.5% TEC Current Ripple

Long-Term Temperature Stability: 0.01C

Temperature Lock Indication

Temperature Monitoring Output

Oscillator Synchronization with an External Signal

Clock Phase Adjustment for Multiple Controllers

Programmable Switching Frequency up to 1 MHz

Thermistor Failure Alarm

Maximum TEC Voltage Programmability

APPLICATIONS

Thermoelectric Cooler (TEC) Temperature Control

Resistive Heating Element Control

Temperature Stabilization Substrate (TSS) Control

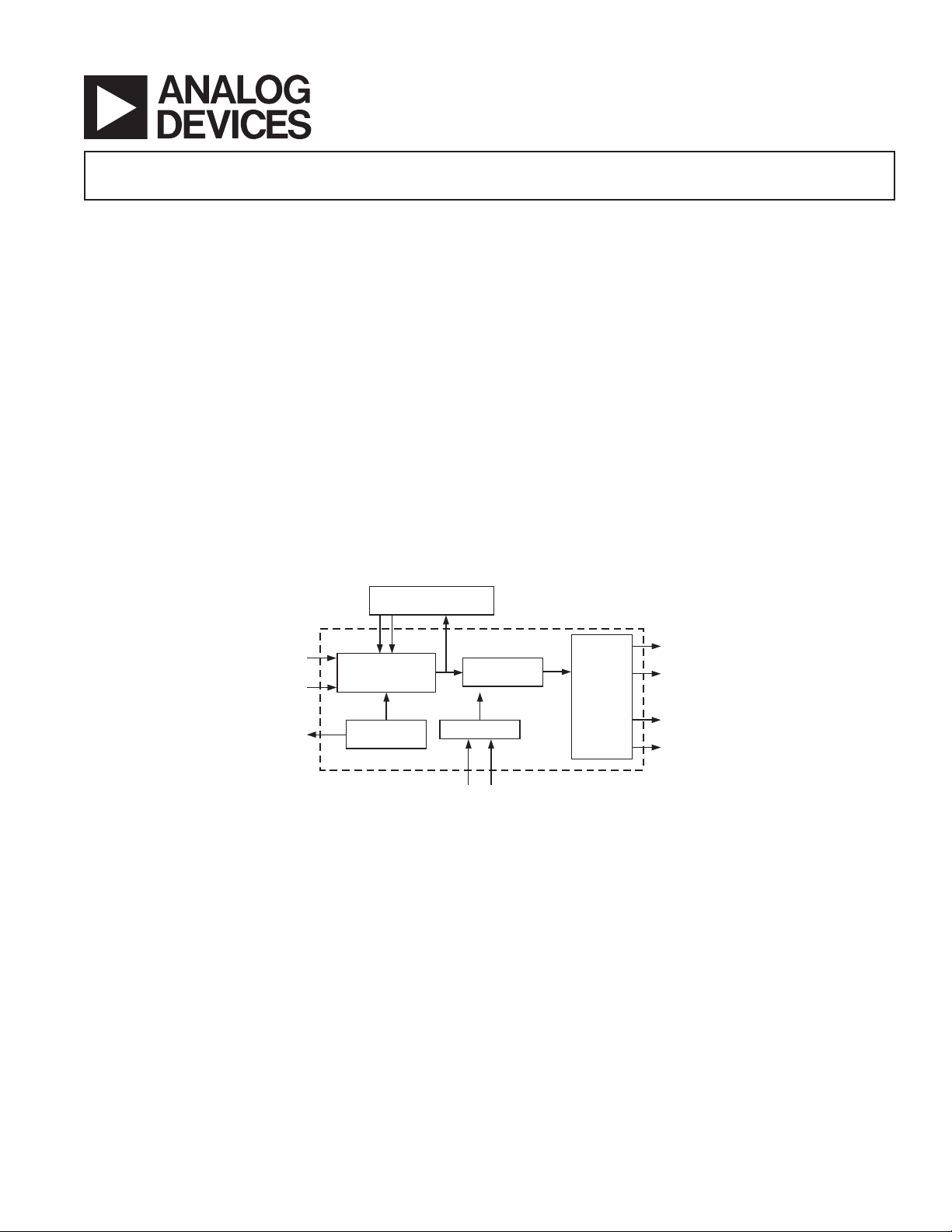

FUNCTIONAL BLOCK DIAGRAM

PID COMPENSATION

NETWORK

FROM

THERMISTOR

TEMPERATURE

SET

INPUT

V

REF

TEMPERATURE

MEASUREMENT

AMPLIFIER

VOLTA G E

REFERENCE

PWM

CONTROLLER

OSCILLATOR

GENERAL DESCRIPTION

The ADN8830 is a monolithic controller that drives a thermoelectric cooler (TEC) to stabilize the temperature of a laser diode

or a passive component used in telecommunications equipment.

This device relies on a negative temperature coefficient (NTC)

thermistor to sense the temperature of the object attached to the

TEC. The target temperature is set with an analog input voltage

either from a DAC or an external resistor divider.

The loop is stabilized by a PID compensation amplifier with

high stability and low noise. The compensation network can be

adjusted by the user to optimize temperature settling time. The

component values for this network can be calculated based on

the thermal transfer function of the laser diode or obtained

from the lookup table given in the Application Notes section.

Voltage outputs are provided to monitor both the temperature of

the object and the voltage across the TEC. A voltage reference

of 2.5 V is also provided.

P-CHANNEL

(UPPER MOSFET)

MOSFET

DRIVERS

N-CHANNEL

P-CHANNEL

(LOWER MOSFET)

N-CHANNEL

FREQUENCY/PHASE

CONTROL

REV. C

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties that

may result from its use. No license is granted by implication or otherwise

under any patent or patent rights of Analog Devices. Trademarks and

registered trademarks are the property of their respective owners.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 www.analog.com

Fax: 781/326-8703 © 2003 Analog Devices, Inc. All rights reserved.

ADN8830–SPECIFICATIONS

(@ VDD = 3.3 V to 5.0 V, V

configuration as shown in Figure 1, unless otherwise noted.)

= 0 V, TA = 25C, T

GND

= 25C, using typical application

SET

Parameter Symbol Conditions Min Typ Max Unit

TEMPERATURE STABILITY

Long-Term Stability Using 10 kΩ thermistor with

= –4.4% at 25°C 0.01 °C

PWM OUTPUT DRIVERS

Output Transition Time t

, t

R

F

CL = 3,300 pF 20 ns

Nonoverlapping Clock Delay 50 65 ns

Output Resistance R

Output Voltage Swing OUT A V

Output Voltage Ripple OUT A f

Output Current Ripple I

(N1, P1) IL = 50 mA 6 Ω

O

TEC

= 0 V 0 V

LIM

= 1 MHz 0.2 %

CLK

f

= 1 MHz 0.2 %

CLK

DD

V

LINEAR OUTPUT AMPLIFIER

I

Output Resistance R

R

O, P2

O, N2

Output Voltage Swing OUT B 0 V

= 2 mA 85 Ω

OUT

I

= 2 mA 178 Ω

OUT

DD

V

POWER SUPPLY

Power Supply Voltage V

DD

Power Supply Rejection Ratio PSRR V

Supply Current I

Shutdown Current I

Soft-Start Charging Current I

Undervoltage Lockout V

SY

SD

SS

OLOCK

= 3.3 V to 5 V, V

DD

–40°C ≤ T

≤ +85°C60 dB

A

= 0 V 80 92 dB

TEC

PWM not switching 8 12 mA

–40°C ≤ T

≤ +85°C15mA

A

Pin 10 = 0 V 5 µA

Low-to-high threshold 2.0 2.7 V

3.0 5.5 V

15 µA

ERROR AMPLIFIER

Input Offset Voltage V

Gain A

Input Voltage Range V

OS

V, IN

CM

Common-Mode Rejection Ratio CMRR 0.2 V < V

Open-Loop Input Impedance R

IN

VCM = 1.5 V 50 250 µV

20 V/V

0.2 2.0 V

< 2.0 V 58 68 dB

–40°C ≤ T

CM

≤ +85°C55 dB

A

1GΩ

Gain-Bandwidth Product GBW 2 MHz

REFERENCE VOLTAGE

Reference Voltage V

REF

I

< 2 mA 2.37 2.47 2.57 V

REF

OSCILLATOR

Synchronization Range f

Oscillator Frequency f

CLK

CLK

Pin 25 connected to external clock 200 1,000 kHz

Pin 24 = VDD; (R = 150 kΩ; 800 1,000 1,250 kHz

Pin 25 = GND)

LOGIC CONTROL*

Logic Low Input Threshold 0.2 V

Logic High Input Threshold 3 V

Logic Low Output Level 0.2 V

Logic High Output Threshold VDD – 0.2 V

*Logic inputs meet typical CMOS I/O conditions for source/sink current (~1 µA).

Specifications subject to change without notice.

REV. C–2–

ADN8830

ABSOLUTE MAXIMUM RATINGS*

Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 V

Input Voltage . . . . . . . . . . . . . . . . . . . . . . . GND to V

+ 0.3 V

S

Storage Temperature Range . . . . . . . . . . . . . –65°C to +150°C

Operating Temperature Range . . . . . . . . . . . . –40°C to +85°C

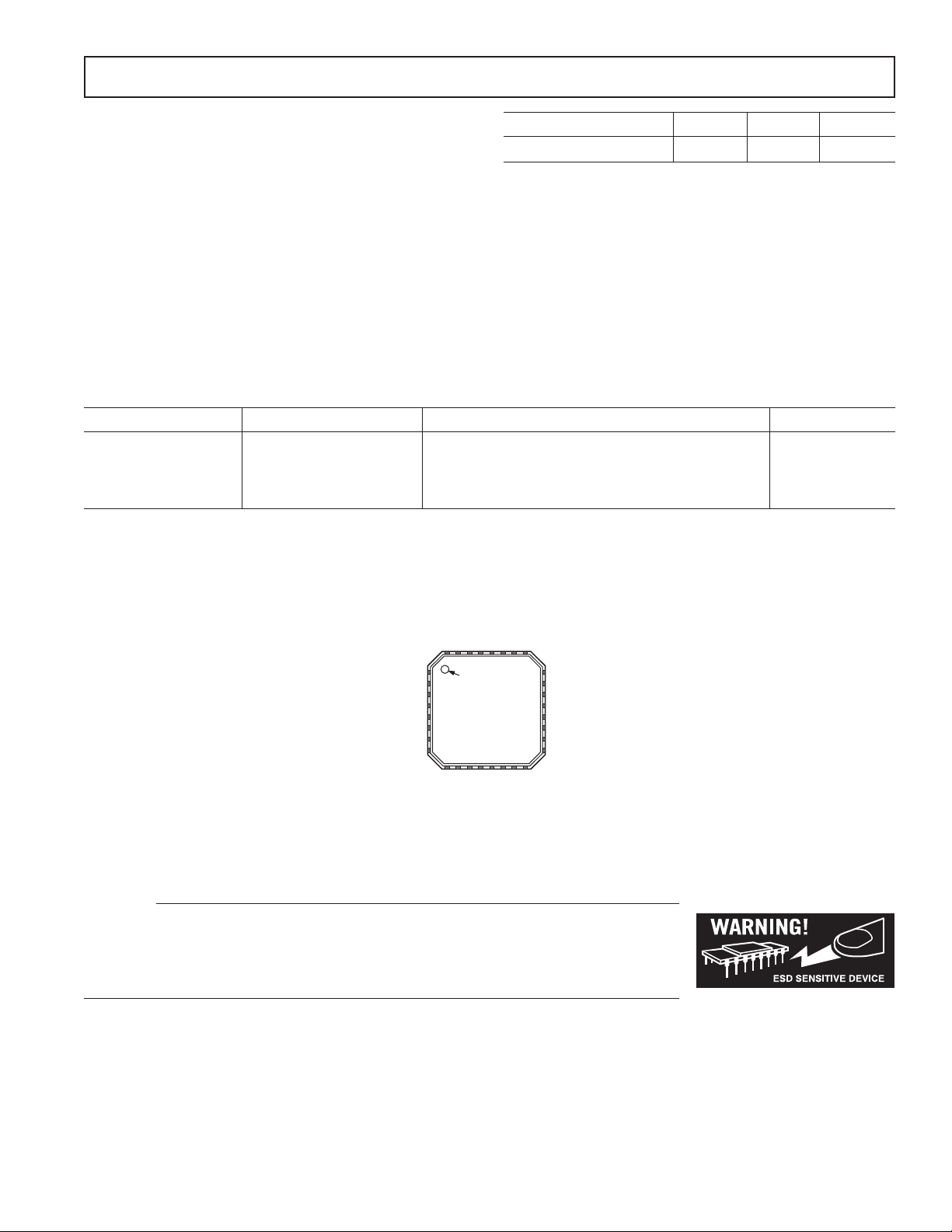

Package Type JA*

JC

Unit

32-Lead LFCSP (ACP) 35 10 °C/W

*JA is specified for worst-case conditions, i.e., JA is specified for a device

soldered in a 4-layer circuit board for surface-mount packages.

Operating Junction Temperature . . . . . . . . . . . . . . . . . . 125°C

Lead Temperature Range (Soldering, 10 sec) . . . . . . . . 300°C

ESD RATINGS

883 (Human Body) Model . . . . . . . . . . . . . . . . . . . . . . 1.0 kV

*Stresses above those listed under Absolute Maximum Ratings may cause perma-

nent damage to the device. This is a stress rating only; functional operation of the

device at these or any other conditions above those listed in the operational

sections of this specification is not implied. Exposure to absolute maximum rating

conditions for extended periods may affect device reliability.

ORDERING GUIDE

Model Temperature Range Package Description Package Option

ADN8830ACP –40°C to +85°C 32-Lead Lead Frame Chip Scale Package (LFCSP) CP-32-1

ADN8830ACP-REEL –40°C to +85°C 32-Lead Lead Frame Chip Scale Package (LFCSP) CP-32-1

ADN8830ACP-REEL7 –40°C to +85°C 32-Lead Lead Frame Chip Scale Package (LFCSP) CP-32-1

ADN8830-EVAL Evaluation Board

PIN CONFIGURATION

32 NC

31 TEMPOUT

30 AGND

29 PHASE

28 SYNCOUT

27 SOFTSTART

26 FREQ

25 SYNCIN

THERMFAULT 1

THERMIN 2

SD 3

TEMPSET 4

TEMPLOCK 5

NC 6

VREF 7

AVDD 8

PIN 1

INDICATOR

ADN8830

TOP VIEW

P2 11

N2 10

OUT B 9

COMPFB 13

TEMPCTL 12

NC = NO CONNECT

15

VLIM

COMPOUT 14

24 COMPOSC

23 PGND

22 N1

21 P1

20 PVDD

19 OUT A

18 COMPSWIN

17 COMPSWOUT

VTEC 16

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection. Although the

ADN8830 features proprietary ESD protection circuitry, permanent damage may occur on devices

subjected to high energy electrostatic discharges. Therefore, proper ESD precautions are recommended

to avoid performance degradation or loss of functionality.

REV. C

–3–

ADN8830

PIN FUNCTION DESCRIPTIONS

Pin No. Mnemonic Type Description

1 THERMFAULT Digital Output Indicates an Open or Short-Circuit Condition from Thermistor.

2 THERMIN Analog Input Thermistor Feedback Input.

3 SD Digital Input Puts Device into Low Current Shutdown Mode. Active low.

4 TEMPSET Analog Input Target Temperature Input.

5 TEMPLOCK Digital Output Indicates when Thermistor Temperature is within ±0.1°C of Target Tem-

perature as Set by TEMPSET Voltage.

6NCNo Connection, except as Noted in the Application Notes Section.

7 VREF Analog Output 2.5 V Reference Voltage.

8 AVDD Power Power for Nondriver Sections. 3.0 V min; 5.5 V max.

9 OUT B Analog Input Linear Output Feedback. Will typically connect to TEC+ pin of TEC.

10 N2 Analog Output Drives Linear Output External NMOS Gate.

11 P2 Analog Output Drives Linear Output External PMOS Gate.

12 TEMPCTL Analog Output Output of Error Amplifier. Connects to COMPFB through feedforward

section of compensation network.

13 COMPFB Analog Input Feedback Summing Node of Compensation Amplifier. Connects to

TEMPCTL and COMPOUT through compensation network.

14 COMPOUT Analog Output Output of Compensation Amplifier. Connects to COMPFB through feed-

back section of compensation network.

15 VLIM Analog Input Sets Maximum Voltage across TEC.

16 VTEC Analog Output Indicates Relative Voltage across the TEC. The 1.5 V corresponds to 0 V

across TEC. The 3.0 V indicates maximum output voltage, maximum heat

transfer through TEC.

17 COMPSWOUT Analog Output Compensation for Switching Amplifier.

18 COMPSWIN Analog Input Compensation for Switching Amplifier. Capacitor connected between

COMPSWIN and COMPSWOUT.

19 OUT A Analog Input PWM Output Feedback. Will typically connect to TEC– pin of TEC.

20 PVDD Power Power for Output Driver Sections. 3.0 V min; 5.5 V max.

21 P1 Digital Output Drives PWM Output External PMOS Gate.

22 N1 Digital Output Drives PWM Output External NMOS Gate.

23 PGND Ground Power Ground. External NMOS devices connect to PGND. Can be

connected to digital ground as noise sensitivity at this node is not critical.

24 COMPOSC Analog Input Connect as Indicated in the Application Notes Section.

25 SYNCIN Digital Input Optional Clock Input. If not connected, clock frequency set by FREQ pin.

26 FREQ Analog Input Sets Switching Frequency.

27 SOFTSTART Analog Input Controls Initialization Time for ADN8830 with Capacitor to Ground.

28 SYNCOUT Digital Output Phase Adjusted Clock Output. Phase set from PHASE pin. Can be used to

drive SYNCIN of other ADN8830 devices.

29 PHASE Analog Input Sets Switching and SYNCOUT Clock Phase Relative to SYNCIN Clock.

30 AGND Ground Analog Ground. Should be low noise for highest accuracy.

31 TEMPOUT Analog Output Indication of Thermistor Temperature.

32 NC No Connection.

REV. C–4–

VDD = 5V

R

FREQ

(k)

1,000

800

0

01,500250 500 750 1,000 1,250

600

400

200

VDD = 5V

T

A

= 25C

SWITCHING FREQUENCY (kHz)

TA = 25C

VOLTA GE (1V/DIV)

0

000

VOLTA GE (1V/DIV)

P1

N1

00000000

TIME (20ns/DIV)

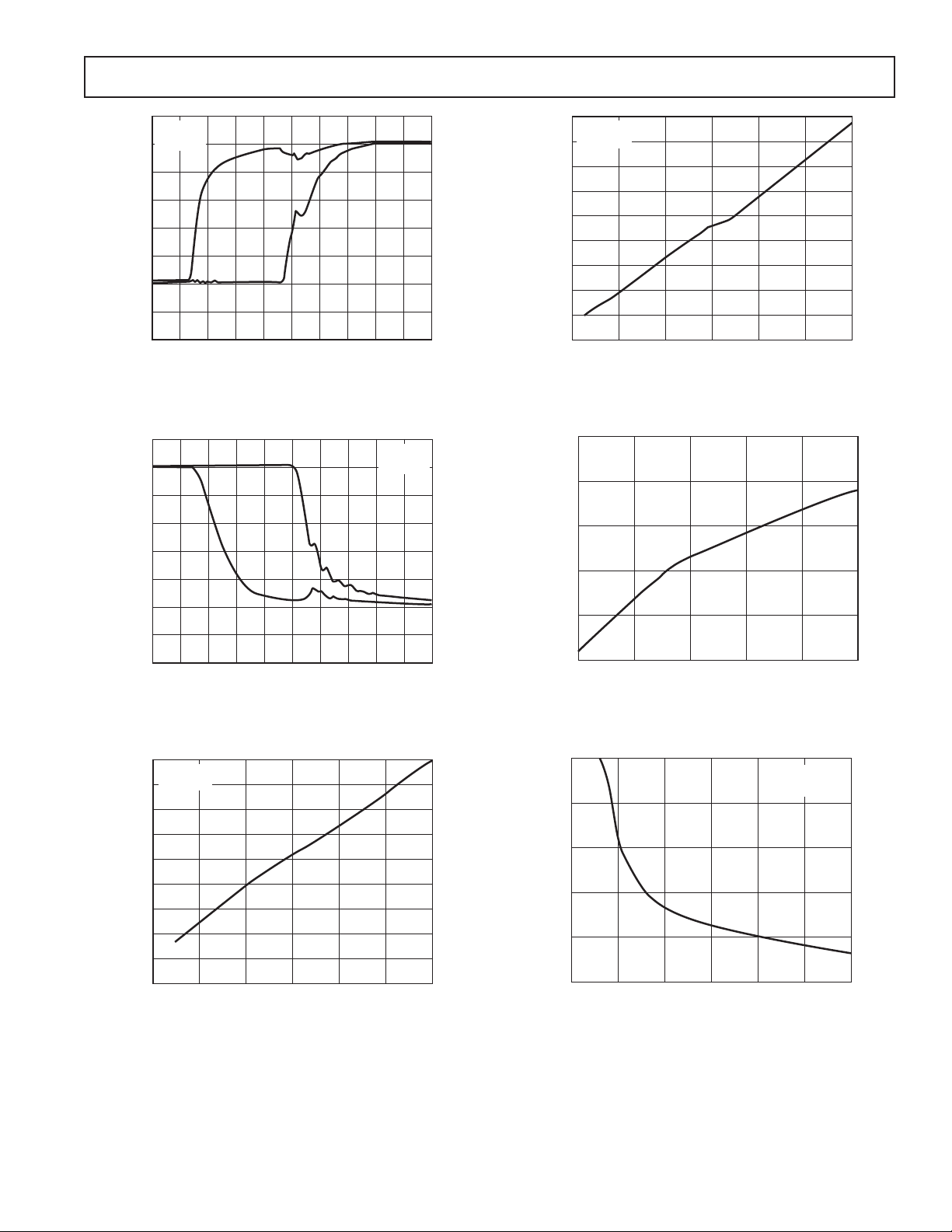

TPC 1. N1 and P1 Rise Time

P1

N1

Typical Performance Characteristics–ADN8830

360

SYNC IN = 200kHz

T

= 25C

A

320

280

240

200

160

120

PHASE SHIFT (Degrees)

80

40

0

VDD = 5V

= 25C

T

A

0

TPC 4. Clock Phase Shift vs. Phase Voltage

2.480

2.475

2.470

( V)

REF

V

2.465

2.460

VPHASE (V)

2.40.4 0.8 1.2 1.6 2.0

0

000

00000000

TIME (20ns/DIV)

TPC 2. N1 and P1 Fall Time

360

SYNC IN = 1MHz

= 25C

T

A

320

280

240

200

160

120

PHASE SHIFT (Degrees)

80

40

0

0

VPHASE (V)

TPC 3. Clock Phase Shift vs. Phase Voltage

2.455

–40 85–15

TPC 5. V

2.40.4 0.8 1.2 1.6 2.0

TPC 6. Switching Frequency vs. R

10 35 60

TEMPERATURE (C)

vs. Temperature

REF

FREQ

REV. C

–5–

ADN8830

1,000

VDD = 5V

= 150k

R

990

FREQ

980

970

960

950

940

SWITCHING FREQUENCY (kHz)

930

920

–40 85–15

10 35 60

TEMPERATURE (C)

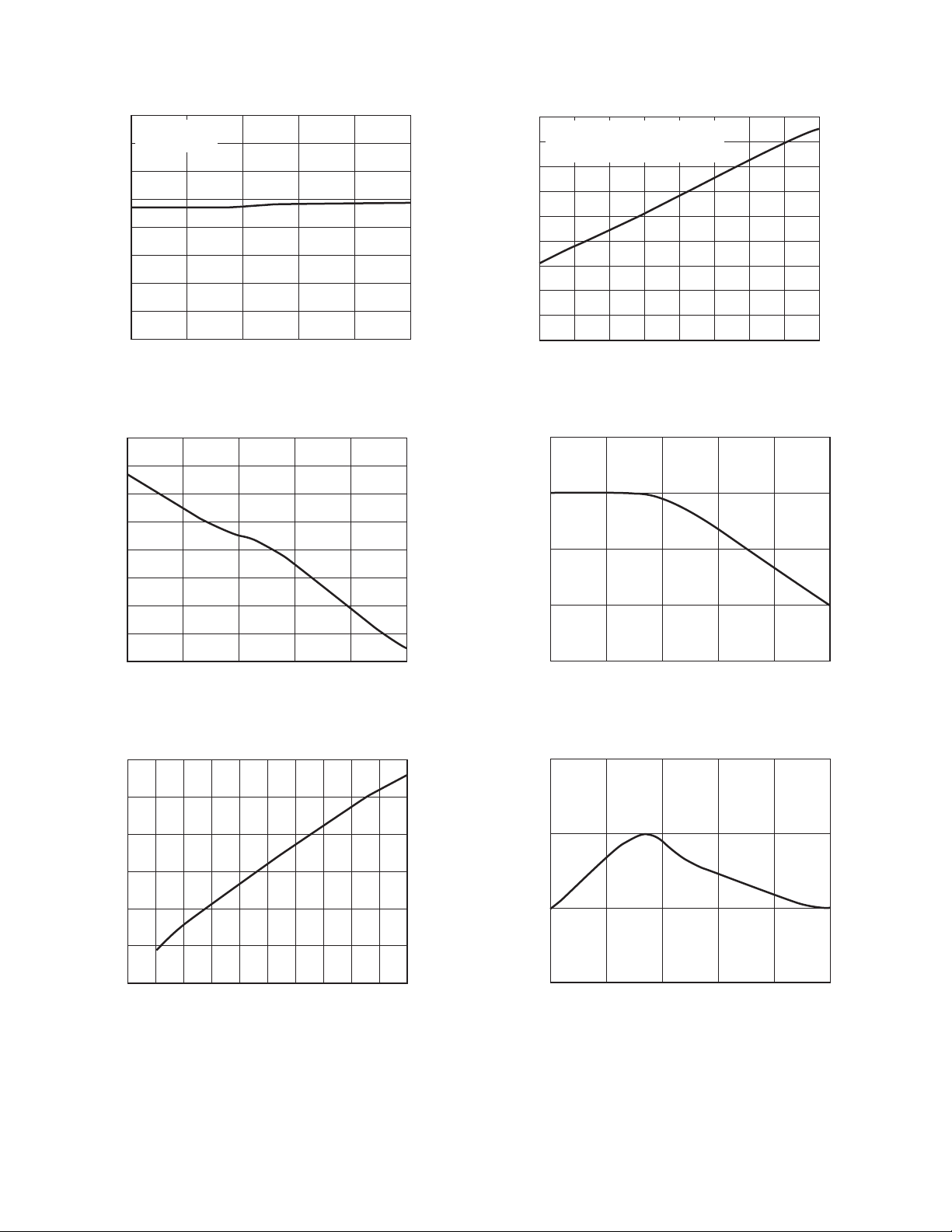

TPC 7. Switching Frequency vs. Temperature

70

65

60

55

50

45

VDD = 5V

= 25C

T

40

A

USING CIRCUIT SHOWN IN FIGURE 1

35

30

25

20

15

SUPPLY CURRENT (mA)

10

5

0

200 1,000300 400 500 600 700 800 900

SWITCHING FREQUENCY (kHz)

TPC 10. Supply Current vs. Switching Frequency

2.06

2.05

2.04

45

OFFSET VOLTAGE (V)

40

35

30

–40 85–15

10 35 60

TEMPERATURE (C)

TPC 8. Offset Voltage vs. Temperature

200

100

0

–100

–200

OFFSET VOLTAGE (V)

–300

–400

02.00.2

0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8

COMMON-MODE VOLTAGE (V)

TPC 9. Offset Voltage vs. Common-Mode Voltage

2.03

THERM FAULT UPPER THRESHOLD (V)

2.02

–40 85–15

10 35 60

TEMPERATURE (C)

TPC 11. Open Thermistor Fault Threshold vs. Temperature

0.26

0.25

0.24

THERM FAULT LOWER THRESHOLD (V)

0.23

–40 85–15

10 35 60

TEMPERATURE (C)

TPC 12. Short Thermistor Fault Threshold vs.

Temperature

REV. C–6–

ADN8830

APPLICATION NOTES

Principle of Operation

The ADN8830 is a controller for a TEC and is used to set and

stabilize the temperature of the TEC. A voltage applied to the

input of the ADN8830 corresponds to a target temperature

setpoint. The appropriate current is then applied to the TEC

to pump heat either to or away from the object whose temperature is being regulated. The temperature of the object is

measured by a thermistor and is fed back to the ADN8830 to

correct the loop and settle the TEC to the appropriate final

temperature. For best stability, the thermistor should be mounted

in close proximity to the object. In most laser diode modules,

the TEC and thermistor are already mounted in the unit and

are used to regulate the temperature of the laser diode.

A complete TEC controller solution requires:

• A precision input amplifier stage to accurately measure the

difference between the target and object temperatures.

• A compensation amplifier to optimize the stability and

temperature settling time.

• A high output current stage. Because of the high output

currents involved, a TEC controller should operate with

high efficiency to minimize the heat generated from

power dissipation.

In addition, an effective controller should operate down to 3.3 V

and have an indication of when the target temperature has been

reached. The ADN8830 accomplishes all of these requirements

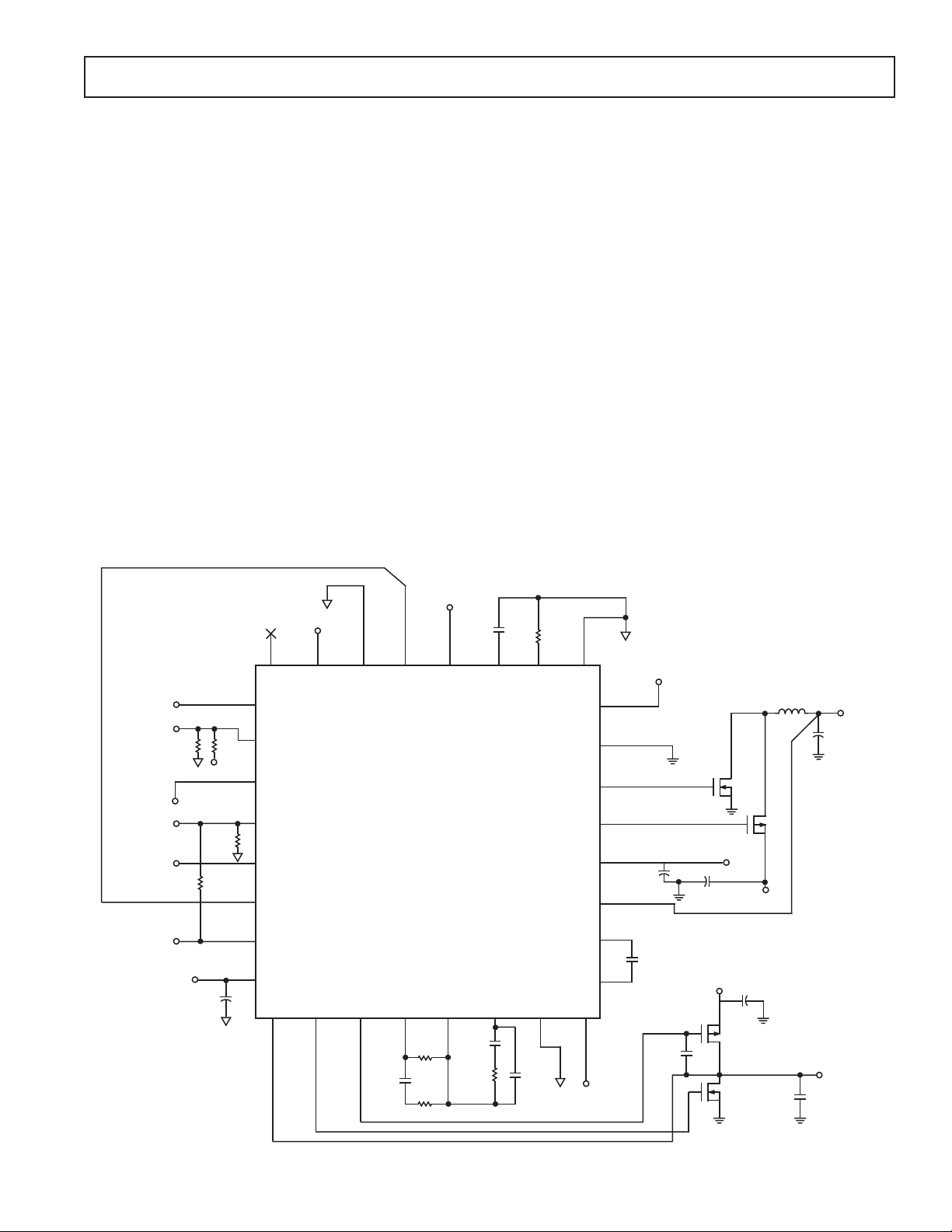

with a minimum of external components. Figure 1 shows a

reference design for a typical application.

Temperature is monitored by connecting the measurement

thermistor to a precision amplifier, called the error amplifier,

with a simple resistor divider. This voltage is compared against

the temperature set input voltage, creating an error voltage that

is proportional to their difference. To maintain accurate wavelength and power from the laser diode, this difference voltage

must be as accurate as possible. For this reason, self-correction

auto-zero amplifiers are used in the input stage of the ADN8830,

providing a maximum offset voltage of 250 µV over time and

temperature. This results in final temperature accuracy within

±0.01°C in typical applications, eliminating the ADN8830 as an

error source in the temperature control loop. A logic output is

provided at TEMPLOCK to indicate when the target temperature

has been reached.

The output of the error amplifier is then fed into a compensation amplifier. An external network consisting of a few resistors

and capacitors is connected around the compensation amplifier.

This network can be adjusted by the user to optimize the step

THERMFAULT

THERMIN

TEMPSET

TEMPLOCK

VREF

RTH

10k

@25C

3.3V

3.3V

VREF

10F

R2

7.68k

0.1%

R3

10k

0.1%

R4

7.68k

0.1%

C8

SYNCOUT

TEMPOUT

32 31 30 29 28 27 26 25

1

2

3

4

0.1F

C1

R1

150k

ADN8830

5

6

7

8

9

10 11

12 13 14 15 16

C9

10F

100k

R6

C10

330pF

C11

1F

R5

205k

R7

1M

VTEC

3.3V

24

23

22

21

20

19

18

17

10F

C5

10nF

C3

2.2nF

C6

Q1

FDW2520C-B

C4

22F

CDE ESRD

3.3V

3.3V

C7

10F

Q3

FDW2520C-A

Q4

FDW2520C-B

4.7H

COILCRAFT

DO3316-472

3.3V

L1

Q2

FDW2520C-A

C12

3.3nF

TEC–

C2

22F

CDE ESRD

TEC+

REV. C

Figure 1. Typical Application Schematic

–7–

ADN8830

response of the TEC’s temperature either in terms of settling time

or maximum current change. Details of how to adjust the compensation network are given in the Compensation Loop section.

The ADN8830 can be easily integrated with a wavelength locker

for fine-tune temperature adjustment of the laser diode for a

specific wavelength. This is a useful topology for tunable wavelength lasers. Details are highlighted in the Using the TEC

Controller ADN8830 with a Wave Locker section.

The TEC is driven differentially using an H-bridge configuration to maximize the output voltage swing. The ADN8830

drives external transistors that are used to provide current to the

TEC. These transistors can be selected by the user based on the

maximum output current required for the TEC. The maximum

voltage across the TEC can be set through use of the VLIM pin

on the ADN8830.

To further improve the power efficiency of the system, one side

of the H-bridge uses a switched output. Only one inductor and

one capacitor are required to filter out the switching frequency.

The output voltage ripple is a function of the output inductor

and capacitor and the switching frequency. For most applications, a 4.7 µH inductor, 22 µF capacitor, and switching frequency

of 1 MHz maintains less than ±0.5% worst-case output voltage

ripple across the TEC. The other side of the H-bridge does not

require any additional circuitry.

The oscillator section of the ADN8830 controls the switched

output section. A single resistor sets the switching frequency

from 100 kHz to 1 MHz. The clock output is available at the

SYNCOUT pin and can be used to drive another ADN8830

device by connecting to its SYNCIN pin. The phase of the

clock is adjusted by a voltage applied to the PHASE pin, which

can be set by a simple resistor divider. Phase adjustment allows

two or more ADN8830 devices to operate from the same clock

frequency and not have all outputs switch simultaneously, which

could create an excessive power supply ripple. Details of how to

adjust the clock frequency and phase are given in the Setting the

Switching Frequency section.

For effective indication of a catastrophic system failure, the

ADN8830 alerts to open-circuit or short-circuit conditions from the

thermistor, preventing an erroneous and potentially damaging

temperature correction from occurring. With some additional

external circuitry, output overcurrent detection can be implemented to provide warning in the event of a TEC short-circuit

failure. This circuit is highlighted in the Setting Maximum

Output Current and Short-Circuit Protection section.

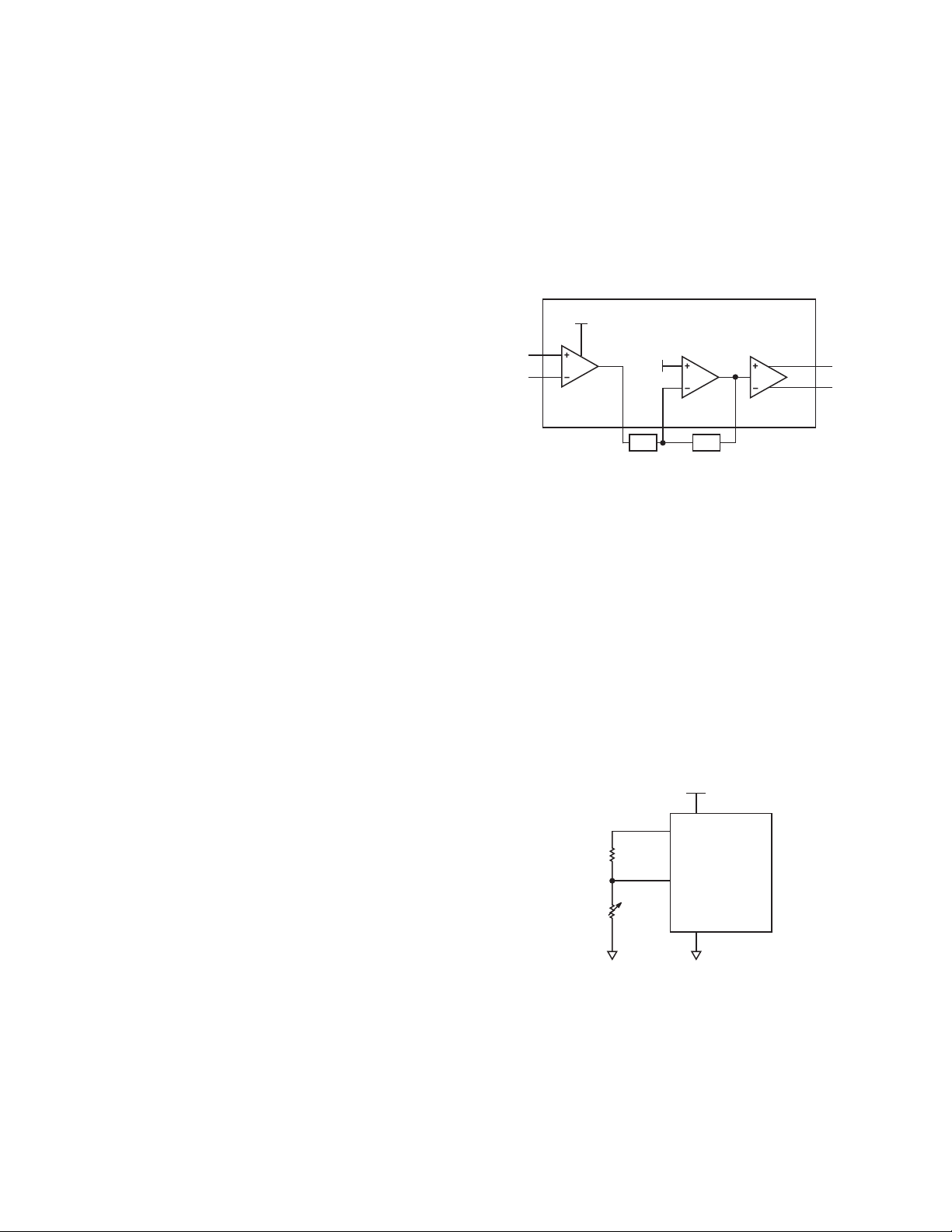

Signal Flow Diagram

Figure 2 shows the signal flow diagram through the ADN8830.

The input amplifier is fixed with a gain of 20. The voltage at

TEMPCTL can be expressed as

TEMPCTL TEMPSET THERMIN=×

()

+20 1 5– .

(1)

When the temperature is settled, the thermistor voltage will be

equal to the TEMPSET voltage, and the output of the input

amplifier will be 1.5 V.

The voltage at TEMPCTL is then fed into the compensation

amplifier whose frequency response is dictated by the compensation network. Details on the compensation amplifier can be

found in the Compensation Loop section. When configured as a

simple integrator or PID loop, the dc forward gain of the

compensation section is equal to the open-loop gain of the

compensation amplifier, which is over 80 dB or 10,000. The

output from the compensation loop at COMPOUT is then fed

to the linear amplifier. The output of the linear amplifier at

OUT B is fed with COMPOUT into the PWM amplifier whose

output is OUT A. These two outputs provide the voltage drive

directly to the TEC. Including the external transistors, the gain of

the differential output section is fixed at 4. Details on the output

amplifiers can be found in the Output Driver Amplifiers section.

1.5V

PWM/LINEAR

AMPLIFIERS

AV = 4

19

OUT A

OUT B

9

TEMPSET

THERMIN

4

2

INPUT

AMPLIFIER

AV = 20

12 13 14

TEMPCTL COMPOUT

COMPENSATION

AMPLIFIER

1.5V

Z1

COMPFB

A

V

= Z2/Z1

Z2

Figure 2. Signal Flow Block Diagram of the ADN8830

Thermistor Setup

The temperature of the thermal object, such as a laser diode, is

detected with a negative temperature coefficient (NTC) thermistor.

The thermistor’s resistance exhibits an exponential relationship to

the inverse of temperature, meaning the resistance decreases at

higher temperatures. Thus, by measuring the thermistor resistance,

temperature can be ascertained. Betatherm is a leading supplier

of NTC thermistors. Thermistor information and details can be

found at www.betatherm.com.

For this application, the resistance is measured using a voltage

divider. The thermistor is connected between THERMIN (Pin 2)

and AGND (Pin 30). Another resistor (R

) is connected between

X

VREF (Pin 7) and THERMIN (Pin 2), creating a voltage divider

for the VREF voltage. Figure 3 shows the schematic for this

configuration.

V

DD

8

7

R

X

2

ADN8830

R

THERM

30

Figure 3. Connecting a Thermistor to the ADN8830

With the thermistor connected from THERMIN to AGND, the

voltage at THERMIN will decrease as temperature increases.

To maintain the proper input-to-output polarity in this configuration, OUT A (Pin 19) should connect to the TEC– pin on the

TEC, and OUT B (Pin 9) should connect to the VTEC+ pin.

The thermistor can also be connected from VREF to THERMIN

with R

connecting to ground. In this case, OUT A must connect to

X

TEC+ with OUT B connected to TEC– for proper operation.

REV. C–8–

ADN8830

Although the thermistor has a nonlinear relationship to temperature, near optimal linearity over a specified temperature

range can be achieved with the proper value of R

. First, the

X

resistance of the thermistor must be known, where

RRTT

T

and T

LOW

T

is the average. These resistances can be found in most

MID

==

THERM T LOW

@

1

RTT

==

@

TMID

2

RTT

==

@

T HIGH

3

are the endpoints of the temperature range and

HIGH

(2)

thermistor data sheets. In some cases, only the coefficients

corresponding to the Steinhart-Hart equation are given. The

Steinhart-Hart equation is

1

abnR cnR=+

11

T

()+()

3

[]

(3)

where T is the absolute temperature of the thermistor in Kelvin

(K = °C + 273.15), and R is the resistance of the thermistor at

that temperature. Based on the coefficients a, b, and c, R

THERM

can be calculated for a given T, albeit somewhat tediously, by

solving the cubic roots of this equation

1

1

3

3

2

(4)

ψ

R

χχ

=++

THERM

exp –––

2427 2427

1

1

3

2

3

ψ

2

++

2

χχ

where

1

a

–

T

X

=

and

c

ψ=

b

c

RX is then found as

RR R R RR

+

TT T T TT

R

12 23 13

=

X

RR R

+

TT T

13 2

22–

–

(5)

For the best accuracy as well as the widest selection range for

resistances, R

should be 0.1% tolerance. Naturally, the smaller

X

the temperature range required for control, the more linear

the voltage divider will be with respect to temperature. The

voltage at THERMIN is

R

V VREF

=

X

THERM

RR

+

THERM X

(6)

where VREF has a typical value of 2.47 V.

The ADN8830 control loop will adjust the temperature of the

TEC until V

we define as V

VmTT V

equals the voltage at TEMPSET (Pin 4), which

X

. Target temperature can be set by

SET

=

SET MID XMID

()

+–

(7)

where T equals the target temperature, and

VV

X HIGH X LOW

m

=

–

,,

–

TT

HIGH LOW

(8)

VX for high, mid, and low are found by using Equation 6 and

substituting R

variable m is the change in V

, RT2, and RT1, respectively, for R

T3

with respect to temperature and

X

THERM

. The

is expressed in V/°C.

The setpoint voltage can be driven from a DAC or another

voltage source, as shown in Figure 4. The reference voltage

for the DAC should be connected to VREF (Pin 7) on the

ADN8830 to ensure best accuracy from device to device.

For a fixed target temperature, a voltage divider network can be

used as shown in Figure 5. R1 is set equal to R

equal to the value of R

3.3V

1–4

AD7390

C

at the target temperature.

THERM

7

6

85

4

7

, and R2 is

X

3.3V

8

ADN8830

30

Figure 4. Using a DAC to Control the Temperature

Setpoint

3.3V

8

7

R1

4

ADN8830

R2

30

Figure 5. Using a Voltage Divider to Set a Fixed

Temperature Setpoint

Design Example 1

A laser module requires a constant temperature of 25°C. From

the manufacturer’s data sheet, we find the thermistor in the laser

module has a value of 10 kΩ at 25°C. Because the laser is not

required to operate at a range of temperatures, the value of R

X

can be set to 10 kΩ. TEMPSET can be set by a simple resistor

divider as shown in Figure 5, with R1 and R2 both equal to 10 kΩ.

Design Example 2

A laser module requires a continuous temperature control from

5°C to 45°C. The manufacturer’s data sheet shows the thermistor

has a value of 10 kΩ at 25°C, 25.4 kΩ at 5°C, and 4.37 kΩ at

45°C. Using Equation 5, R

is calculated to be 7.68 kΩ to yield

X

the most linear temperature-to-voltage conversion. A DAC

will be used to set the TEMPSET voltage.

DAC Resolution for TEMPSET

The temperature setpoint voltage to THERMIN can be set from

a DAC. The DAC must have a sufficient number of bits to achieve

adequate temperature resolution from the system. The voltage

range for THERMIN is found by multiplying the variable m

from Equation 8 by the temperature range.

THERMIN Voltage Range m T T

=×

–

()

MAX MIN

(9)

From Design Example 2, 40°C of the control temperature range

is achieved with a voltage range of only 1 V.

REV. C

–9–

ADN8830

To eliminate the resolution of the DAC as the principal source

of system error, the step size of each bit, V

, should be lower

STEP

than the desired system resolution. A practical value for absolute

DAC resolution is the equivalent of 0.05°C. The value of V

STEP

should be less than the value of m from Equation 8 multiplied

by the desired temperature resolution, or

VCm

<°×005.

STEP

(10)

where m is the slope of the voltage-to-temperature conversion

line, as found from Equation 8. From Design Example 2, where

m = 25 mV/°C, we see the DAC should have resolution better

than 1.25 mV per step.

The minimum number of bits required is then given as

log – log

VV

() ( )

Number of Bits

=

FS STEP

log 2

()

(11)

where VFS is the full-scale output voltage from the DAC, which

should be equal to the reference voltage from the ADN8830,

VREF = 2.47 V as given in the Specifications table for the

Reference Voltage. In this example, the minimum resolution is

11 bits. A 12-bit DAC, such as the AD7390, can be readily

found.

It is important that the full-scale voltage input to the DAC is tied

to the ADN8830 reference voltage, as shown in Figure 4. This

eliminates errors from slight variances of VREF.

Thermistor Fault and Temperature Lock Indications

Both the THERMFAULT (Pin 1) and TEMPLOCK (Pin 5)

outputs are CMOS compatible outputs that are active high.

THERMFAULT will be a logic low while the thermistor is

operating normally and will go to a logic high if a short or

open is detected at THERMIN (Pin 2). The trip voltage for

THERMFAULT is when THERMIN falls below 0.2 V or

exceeds 2.0 V. THERMFAULT provides only an indication of

a fault condition and does not activate any shutdown or protection circuitry on the ADN8830. To shut down the ADN8830, a

logic low voltage must be asserted on Pin 3, as described in the

Shutdown Mode section.

TEMPLOCK will output a logic high when the voltage at

THERMIN is within 2.5 mV of TEMPSET. This voltage can

be related to temperature by solving for m from Equation 8. For

most laser diode applications, 2.5 mV is equivalent to ±0.1°C.

If the voltage difference between THERMIN and TEMPSET is

greater than 2.5 mV, then TEMPLOCK will output a logic low.

The input offset voltage of the ADN8830 is guaranteed to within

250 µV, which for most applications is within ±0.01°C.

Setting the Switching Frequency

The ADN8830 has an internal oscillator to generate the switching frequency for the output stage. This oscillator can be either

set in free-run mode or synchronized to an external clock

signal. For free-run operation, SYNCIN (Pin 25) should be

connected to ground and COMPOSC (Pin 24) should be

connected to AVDD. The switching frequency is then set by a

single resistor connected from FREQ (Pin 26) to ground.

Table I shows R

for some common switching frequencies.

FREQ

Table I. Switching Frequencies vs. R

f

SWITCH

R

FREQ

FREQ

100 kHz 1.5 MΩ

250 kHz 600 kΩ

500 kHz 300 kΩ

750 kHz 200 kΩ

1 MHz 150 kΩ

For other frequencies, the value for this resistor, R

FREQ

, should

be set to

9

×150 10

=

f

SWITCH

is the switching frequency in Hz.

(12)

where f

R

FREQ

SWITCH

Higher switching frequencies reduce the voltage ripple across

the TEC. However, high switch frequencies will create more

power dissipation in the external transistors. This is due to the

more frequent charging and discharging of the transistors’ gate

capacitances. If large transistors are needed for a high output

current application, faster switching frequencies could reduce

the overall power efficiency of the circuit. This is covered in

detail in the Calculating Power Dissipation and Efficiency section.

The switching frequency of the ADN8830 can be synchronized

with an external clock by connecting the clock signal to SYNCIN

(Pin 25). Pin 24 should also be connected to an R-C network, as

shown in Figure 6. This network is simply used to compensate a

PLL to lock on to the external clock. To ensure the quickest

synchronization lock-in time, R

ADN8830

COMPOSC

should be set to 1.5 MΩ.

FREQ

1nF

24

1k

0.1F

FREQ

26

1.5M

Figure 6. Using an R-C Network on Pin 24 with

an External Clock

The relative phase of the ADN8830 internal oscillator compared

to the external clock signal can be adjusted. This is accomplished

by adjusting the voltage to PHASE (Pin 29) according to TPCs 3

and 4. The phase shift versus voltage can be approximated as

V

Phase Shift

where V

°= °×360

is the voltage at Pin 29, and VREF has a typical

PHASE

PHASE

VREF

(13)

value of 2.47 V.

To ensure the oscillator operates correctly, V

should remain

PHASE

higher than 100 mV and lower than 2.3 V. This is required for

either internal clock or external synchronization operation. A

resistor divider from VREF to ground can establish this voltage

easily, although any voltage source, such as a DAC, could be used

as well. If phase is not a consideration, for example with a single

ADN8830 being used, Pin 29 can be tied to Pin 6, which provides a 1.5 V reference voltage.

REV. C–10–

ADN8830

The phase adjusted output from the ADN8830 is available at

SYNCOUT (Pin 28). This pin can be used as a master clock

signal for driving other ADN8830 devices. Multiple ADN8830

devices can be either driven from a single master ADN8830

device by connecting its SYNCOUT pin to each slave’s SYNCIN

pin or daisy-chained by connecting each device’s SYNCOUT to

the next device’s SYNCIN pin.

Phase shifting is useful in systems that use more than one

ADN8830 TEC controller. It ensures the ADN8830 devices

will not switch at the same time, which could create excessive

ripple on the power supply voltage. By adjusting the phase of

each device, the switching transients can be spaced equally over

the clock period, reducing potential supply ripple and easing the

instantaneous current demand from the supply.

Using a single master clock, each slave ADN8830 should have a

different value phase shift. For example, with four TEC controllers, one slave device should be set for 90° of phase shift,

another for 180°, and the last for 270°. In a daisy-chain configuration, each slave device would be set with equal phase. Using

the previous example, each slave would be set to 90° with its

SYNCOUT pin connected to the next device’s SYNCIN pin.

Examples are shown in Figures 7 and 8.

25

6

V

ADN8830

MASTER

29 26

DD

24

R

FREQ

28

150k

50k

150k

25

7

100k

100k

25

7

50k

ADN8830

29 26

25

7

ADN8830

29 26

SLAVE

ADN8830

29

SLAVE

SLAVE

26

1.5M

1.5M

28

24

28

24

1k

0.1F

28

24

0.1F

1k

0.1F

NC

1k

NC

1nF

NC

1nF

1nF

Figure 7. Multiple ADN8830 Devices Driven from

a Master Clock

Soft Start on Power-Up

The ADN8830 can be programmed to ramp up for a specified

time after the power supply is applied or after shutdown is

de-asserted. This feature, known as soft start, is useful for

gradually increasing the duty cycle of the PWM amplifier. The

soft start time is set with a single capacitor connected from Pin 27

to ground according to Equation 14.

τ

SS SS

C=×150

where CSS is the value of the capacitor in microfarads, and

(14)

SS

is

the soft start time in milliseconds. To set a soft start time of 15 ms,

should equal 0.1 µF. A minimum soft start time of 10 ms is

C

SS

recommended to ensure proper initialization of the ADN8830

on power-up.

Shutdown Mode

The ADN8830 has a shutdown mode that deactivates the output

stage and puts the device into a low current standby state. The

current draw for the ADN8830 in shutdown is less than 100 µA.

The shutdown input, Pin 3, is active low. To shut down the

device, Pin 3 should be driven to logic low. Once a logic high is

applied, the ADN8830 will reactivate after the delay set by the

soft start circuitry. Refer to the Soft Start on Power-Up section

for more details on this feature.

Pin 3 should not be left floating as there are no internal pull-up

or pull-down resistors. If the shutdown function is not required,

Pin 3 should be tied to VDD to ensure the device is always active.

Compensation Loop

The ADN8830 TEC controller has a built-in amplifier dedicated

for loop compensation. The exact compensation network is set

by the user and can vary from a simple integrator to PI, PID, or

any other type of network. The type of compensation and component values should be determined by the user since it will

depend on the thermal response of the object and the TEC. One

method for determining these values empirically is to input a step

function to TEMPSET, thus changing the target temperature,

and adjusting the compensation network to minimize the settling time of the object’s temperature.

A typical compensation network used for temperature control

of a laser module is a PID loop, which consists of a very low

frequency pole and two separate zeros at higher frequencies.

Figure 9 shows a simple network for implementing PID compensation. An additional pole is added at a higher frequency

than the zeros to reduce the noise sensitivity of the control loop.

The bode plot of the magnitude is shown in Figure 10.

REV. C

NC

25

6

V

ADN8830

MASTER

29

1nF

DD

24

28

150k

26

R

FREQ

0.1F

25

7

50k

1k

ADN8830

SLAVE

29 26

28

150k

1.5M

0.1F

25

7

50k

1nF

1k

ADN8830

SLAVE

29 26

1.5M

Figure 8. Multiple ADN8830 Devices Using a Daisy Chain

–11–

28

150k

0.1F

25

7

50k

1nF

1k

ADN8830

SLAVE

29 26

242424

1.5M

28

NC

ADN8830

The unity-gain crossover frequency of the feedforward amplifier

is given as

f

dB0

To ensure stability, the unity-gain crossover frequency should be

lower than the thermal time constant of the TEC and thermistor.

However, this thermal time constant may not be specified and

can be difficult to characterize.

There are many texts written on loop stabilization, and it is beyond

the scope of this data sheet to discuss all methods and trade-offs

in optimizing compensation networks. A simple method that

can be used to empirically determine a PID compensation loop

as shown in Figure 9 involves the following procedure:

1. Connect thermistor and TEC to the ADN8830 application

circuit. Power does not need to be applied to the laser diode

for this procedure. Monitor output voltage across the TEC

with an oscilloscope.

2. Short C1 and open C2, leaving just R1 and R3 as a simple

proportional-only compensation loop.

3. While maintaining a constant TEMPSET voltage, increase

the ratio of R1/R3, thus increasing the gain until loop oscillation starts to occur. Decrease this ratio by a factor of 2 from

the point of oscillation. The R1/R3 ratio will likely be less

than unity for most laser modules.

4. Add C1 capacitor and decrease value until oscillation starts,

then increase by a factor of 2. A good initial starting value for

C1 is to create a unity-gain crossover of 0.1 Hz based on

Equation 15.

5. Short R2 and increase C2 until oscillation starts. At this point,

either C2 can be decreased or R2 can be added to regain

stability. Generally speaking, R2 will be greater than R3 and

C2 will be one or more orders of magnitude less than C1.

6. TEMPSET should be adjusted with a step change while

observing the output voltage settling time. A step change of

100 mV should suffice. From here, C2, R2, and even C1 can

be decreased to minimize settling time at the expense of

additional output voltage overshoot.

7. An additional feedback capacitor, CF, in parallel with R1

and C1, can be added to add another high frequency pole. In

many cases, this improves the stability of the system without

increasing the settling time as out-of-band noise is filtered

out of the control signal. A 330 pF to 1 nF capacitor should

suffice, if required.

The typical values shown in the typical application circuit in

Figure 1 have R1 = 100 kΩ, R2 = 1 MΩ, R3 = 205 kΩ, C1 = 10 µF

C2 = 1 µF, and an additional feedback capacitor of 330 pF. For

most pump laser modules, this results in a 10°C TEMPSET step

settling time to within 0.1°C in less than 5 seconds.

1

12

80=××

REFERENCE

R3

RC

231

π

ADN8830

TEMPCTL COMPFB

TEC GAIN

VOLTA G E

13

COMPOUT

R1

(15)

,

14

C1

0dB

R1

R2||R3

R1

R3

MAGNITUDE (LOG SCALE)

1

2R3C1

1

2R1C1

FREQUENCY (Hz LOG SCALE)

1

2C2(R2+R3)12R2C2

Figure 10. Bode Plot for PID Compensation

Using the TEC Controller ADN8830 with a Wave Locker

Many optical applications require precision control of laser

wavelength. The wavelength of the laser diode can be adjusted

by changing its temperature, which is done through temperature

control of the TEC. Wavelength control can be done by feeding

a wave locker or etalon output back to the microprocessor and

using the microprocessor to calculate and reinstruct the TEC

controller with a new target temperature. However, this method

is computationally expensive and has time delays before the

adjustment is done. A faster responding and simpler method is

to feed the wave locker signal back to the TEC controller for

direct temperature control.

The ADN8830 is designed to be compatible with a wave locker

controller. Figure 11 shows the basic schematic. The TEMPCTL

output from ADN8830 is proportional to the object’s actual

temperature. This voltage is fed to the wave locker controller.

Also fed to the wave locker controller are the photodiode outputs from the wave locker, as well as the laser diode power and

a digital signal indicating a functional laser diode, both of which

come from the CW controller. The output of the wave locker

controller is then connected to the input of the compensation

network. This allows the wave locker controller to adjust the

TEC temperature based on the current temperature of the

object, the current wavelength of the laser diode, and the target

wavelength. Once the target wavelength is reached, the wave

locker controller sends a signal to the microcontroller indicating

that the laser signal is good.

LOCKER

PD1

LOCKER

PD2

WAVE LOCKER

GOOD

LASER DIODE

POWER

LASER DIODE

GOOD

TEC

CONTROL

TEMP IN

TO

MICROPROCESSOR

ADN8830

COMPFB

13

TEMPCTL

COMPOUT

14

COMPENSATION

NETWORK

FROM

LOCKER

FROM CW

CONTROLLER

12

R2

C2

CF

Figure 9. Implementing a PID Compensation Loop

Figure 11. Using the ADN8830 with a Wave Locker

REV. C–12–

ADN8830

Using TEMPOUT to Measure Temperature

The TEMPOUT pin is a voltage that is proportional to the

difference between the target temperature and the measured

thermistor temperature. The full equation for the voltage at

TEMPOUT is

TEMPOUT THERMIN TEMPSET=+×

15 3. –

()

(16)

The voltage range of TEMPOUT is 0 V to 3.0 V and is independent of power supply voltage.

Setting the Maximum TEC Voltage and Current

The ADN8830 can be programmed for a maximum output voltage to protect the TEC. A voltage from 0 V to 1.5 V applied to

the VLIM (Pin 15) input to the ADN8830 sets the maximum

TEC voltage, V

TEC, MAX

. This voltage can be set with either a

resistor divider or from a DAC. Because the output of the

ADN8830 is bidirectional, this voltage sets both the upper

and lower limits of the TEC voltage. The equation governing

V

TEC, MAX

is given in Equation 17 and the graph of this equation

is shown in Figure 12.

VVVLIM

TEC MAX,

5

4

3

(V)

TEC, MAX

2

V

1

0

02.00.5

Figure 12. VLIM Voltage vs. Maximum TEC Voltage

If the supply voltage is lower than V

. –=

()

×15 4

1.0 1.5

VLIM (V)

TEC, MAX

(17)

, the maximum TEC

voltage will obviously be equal to the supply voltage. The voltage

to VLIM should not exceed 1.5 V since this causes improper

operation of the output voltage limiting circuitry. Setting VLIM to

1.5 V can be used to deactivate the TEC current without

shutting down the ADN8830 in the event of a system failure. If a

maximum TEC voltage is not required, VLIM should be connected to ground. It is not advisable to leave VLIM floating as

this would cause unpredictable output behavior.

This feature should be used to limit the maximum output current

to the TEC as specified in the TEC data sheet. For example, if

the maximum TEC voltage is specified at 2 V, VLIM should be

set to 1 V. The maximum output voltage is then set to ±2V.

Output Driver Amplifiers

The output voltage across the TEC as measured from Pin 19 to

Pin 9 can be monitored at Pin 16. This is labeled as VTEC in

the typical application schematic in Figure 1. The voltage at

VTEC can vary from 0 V to 3 V independent of the power

supply voltage. Its equation is given as

where V

OUT A

and V

are the voltages at Pins 19 and 9, respec-

OUT B

tively. The ripple voltage at Pin 19 is filtered out internally and

does not appear at VTEC, leaving it as an accurate dc output of

the TEC voltage.

The TEC is driven with a differential voltage, allowing current

to flow in either direction through the TEC. This can provide

heat transfer either to or from the object being regulated without

the use of a negative voltage rail. The maximum output voltage

across the TEC is set by the voltage at VLIM (Pin 15). Refer to

the Setting the Maximum TEC Voltage and Current section for

details on this operation. With VLIM set to ground, the maximum

output voltage is the power supply voltage, V

DD

.

To achieve a differential output, the ADN8830 has two separate

output stages. OUT A is a switched output or pulse-width

modulated (PWM) amplifier, and OUT B is a high gain linear

amplifier. Although they achieve the same result, to provide

constant voltage and high current, their operation is different.

The exact equations for the two outputs are

OUT A COMPOUT OUT B=×

OUT B COMPOUT=×

()

()

+415– .

+––..14 1 5 15

(19)

(20)

where COMPOUT is the voltage at Pin 13. The voltage at

COMPOUT is determined by the compensation network that is

fed by the input amplifier, which receives its input voltage from

TEMPSET and THERMIN. Equation 20 is valid only in the

linear region of the linear amplifier. OUT B has a lower limit of

0 V and an upper limit of the power supply.

Because the COMPOUT voltage is not readily known, Equation 20 can be rewritten in terms of the TEC voltage, VTEC,

which is defined as OUT B – OUT A.

OUT B VTEC=× +415.

(21)

In Figure 1, Pins 10 and 11 provide the gate drive for Q3 and Q4,

which complete the linear output amplifier. This output voltage

is fed back to Pin 9 (OUT B) to close its loop. The gate-to-drain

capacitance of Q3 and Q4 provide the compensation for the

linear amplifier. If using the recommended FDW2520C transistors,

it will be necessary to add an additional 2.2 nF of capacitance

from the gate to the drain of the PMOS transistor to maintain

stability. A 3.3 nF capacitor should also be connected from the

drain to ground to prevent small oscillations when there is very

little or no current through the TEC.

These extra capacitors are specified only when using FDW2520C

transistors in the linear amplifier. If other transistors are used,

these values may need to be adjusted. To ensure the linear

amplifier is stable, the total gate-to-source capacitance for both

Q3 and Q4 should be at least 2.5 nF. Refer to the transistor’s

data sheet for its typical gate-to-drain capacitance values.

The output of the linear amplifier is proportional to the voltage

at Pin 13 (COMPOUT). Because the linear amplifier operates

with a gain of 14, its output will typically be at either ground or

V

if there is more than about 100 mA of current flowing

DD

through the TEC. This ensures Q3 and Q4 will not be a dominant source of power dissipation at high output currents.

VTEC V V

=×

REV. C

()

OUT A OUT B

+025 15. – .

(18)

–13–

ADN8830

Inductor Selection

In addition to the external transistors, the PWM amplifier requires

an inductor and a capacitor at its output to filter the switched

output waveform. Proper inductor selection is important to

achieve the best efficiency. The duty cycle of the PWM sets the

OUT A output voltage and is

OUT A

D

=

V

DD

(22)

The average current through the inductor is equal to the TEC

current. The ripple current through the inductor, ⌬I

, varies

L

with the duty cycle and is equal to

VD D

××

1–

∆I

where f

DD

=

L

is the clock frequency as set by the resistor R

CLK

()

Lf

×

CLK

FREQ

(23)

at

Pin 26 or an external clock frequency. Refer to the Setting the

Switching Frequency section for more information. Selecting a

faster switching frequency or a larger value inductor will reduce

the ripple current through the inductor. The waveform of the

inductor current is shown in Figure 13.

I

TEC

INDUCTOR CURRENT (A)

T =

f

CLK

1

TIME

∆I

L

Figure 13. Current Waveform Through Inductor

It is important to select an inductor that can tolerate the maximum possible current that could pass through it. Most TECs

are specified with a maximum voltage and current for proper

and reliable operation. The maximum instantaneous inductor

current can be found as

II I

L MAX TEC MAX L,,

.=+×05 ∆

(24)

where ⌬IL can be found from Equation 23 with the appropriate

duty cycle calculated from Equation 22 with OUT A = V

TEC, MAX

.

Design Example 3

A TEC is specified with a maximum current of 1.5 A and maximum voltage of 2.5 V. The ADN8830 will be operating from a

3.3 V supply voltage with a 200 kHz clock and a 4.7 µH inductor.

The duty cycle of the PWM amplifier at 2.5 V is calculated to be

75.8%. Using Equation 23, the inductor ripple current is found

to be 664 mA. From Equation 24, the maximum inductor current

will be 1.82 A and should be considered when selecting the

inductor. Notice that increasing the clock frequency to 1 MHz would

reduce I

L, MAX

to 1.56 A.

Design Example 4

Using the same TEC as above, the ADN8830 will be powered

from 5.0 V instead. Here, the duty cycle is 50%, which happens

to be the worst-case duty cycle for inductor current ripple. Now

DIL equals 1.33 A with a 200 kHz clock, and I

L, MAX

is 2.83 A.

Reducing the inductor ripple current is another compelling

reason to operate the ADN8830 from a 3.3 V supply instead.

Table II lists some inductor manufacturers and part numbers

along with some key specifications. The column I

refers to the

MAX

maximum current at which the inductor is rated to remain linear.

Although higher currents can be pushed through the inductor,

efficiency and ripple voltage will be dramatically degraded.

This is by no means a complete list of manufacturers or inductors

that can be used in the application. More information on these

inductors is available at their websites. Note the trade-offs

between inductor height, maximum current, and series resistance.

Smaller inductors cannot handle as muèH current and therefore

require higher clock speeds to reduce their ripple current. They

also have higher series resistance, which can lower the overall

efficiency of the ADN8830.

PWM Output Filter Requirements

The switching of Q1 and Q2 creates a pulse width modulated

(PWM) square wave from 0 V to V

. This square wave must

DD

be filtered sufficiently to create a steady voltage that will drive

the TEC. The ripple voltage across the TEC is a function of the

inductor ripple current, the L-C filter cutoff frequency, and the

equivalent series resistance (ESR) of the filter capacitor. The

equivalent circuit for the PWM side is given in Figure 14.

Table II. Partial List of Inductors and Key Specifications

Inductance (H) I

(A) R

MAX

(m⍀)Height (mm) Part Number Manufacturer Website

S, TYP

4.7 1.1 200 1 LPO1704-472M Coilcraft www.coilcraft.com

4.7 1.59 55 2 A918CY-4R7M Toko www.toko.com

4.7 3.9 48 2.8 UP2.8B-4R7 Cooper www.cooperet.com

4.7 1.5 90 3 DO1608C-472 Coilcraft www.coilcraft.com

4.7 1.32 56 3 CDRH4D28 4R7 Sumida www.sumida.com

4.7 7.5 12 4.5 892NAS-4R7M Toko www.toko.com

4.7* 5.4 18 5.2 DO3316P-472 Coilcraft www.coilcraft.com

10 2.7 80 2.8 UP2.8B-100 Cooper www.cooperet.com

15 8 32 8 DO5022P-153HC Coilcraft www.coilcraft.com

47 4.5 86 7.1 DO5022P-473 Coilcraft www.coilcraft.com

*Recommend inductor in typical application circuit Figure 1.

REV. C–14–

ADN8830

PVDD

P1

N1

Q1

V

X

Q2

L1R2

R1

C1

OUT A

R

L

OUT B

DENOTES

PGND

Figure 14. Equivalent Circuit for PWM Amplifier and Filter

In this circuit, RL is the TEC resistance, R2 is the parasitic

resistance of the inductor combined with the equivalent r

DS, ON

of Q1 and Q2, and R1 is the ESR of C1. The voltage, VX, is the

pulse-width modulated waveform that switches between PVDD

and ground. This is a second-order low-pass filter with an exact

cutoff frequency of

RR

1

f

=

C

2

π

+

2

L

RRCL

+

111

()

L

(25)

Practically speaking, R1 and R2 are several tens of milliohms and

are much smaller than the TEC resistance, which can be a few

ohms. The cutoff frequency can be roughly approximated as

1

f

=

C

1

CL

2

11π

(26)

This cutoff frequency should be much lower than the clock

frequency to achieve adequate filtering of the switched output

waveform. Also of importance is the damping factor, , of the

L-C filter. Too low a damping factor will result in a longer

settling time and could potentially cause stability problems for

the temperature control loop. Neglecting R1 and R2 again, the

damping factor is simply

1

ζ

=

2

11RL

C

L

(27)

Using the recommended values of L1 = 4.7 µH and C1 = 22 µF

results in a cutoff frequency of 15.7 kHz. With a TEC resistance

of 2 Ω, the damping factor is 0.12. The cutoff frequency can be

decreased to lower the output voltage ripple with slower clock

frequencies by increasing L1 or C1. Increasing C1 may appear

to be a simpler approach as it would not increase the physical

size of the inductor, but there is a potential stability danger in

lowering the damping factor too far. It is recommended that ζ

remain greater than 0.05 to provide a reasonable settling time

for the TEC. Increasing ζ also makes finding the proper PID

compensation easier as there is less ringing in the L-C output

filter. To allow adequate phase and gain margin for the PWM

amplifier, Table III should be used to find the lower limit of

cutoff frequency for a given damping factor.

Table III. Minimum L-C Filter Cutoff

Frequency vs. Damping Factor

f

C, MIN

(kHz)

0.05 8

0.1 4

0.2 2

0.3 1.9

0.5 1.6

> 0.707 1.5

Calculating PWM Output Ripple Voltage

Although it may seem that fC can be arbitrarily lowered to reduce

output ripple, the ripple voltage is also dependent on the ESR of

C1, shown as R1 in Figure 14. This resistance creates a zero

that turns the second-order filter into a first-order filter at high

frequencies. The location of this zero is

1

=

Z

1

211

π

RC

(28)

With a clock frequency greater than Z1, and presumably greater

than fC, the output voltage ripple is

∆∆OUT A I R

∆OUT A

=×1

L

VD DR

DD

=

–

11

()

Lf

1

CLK

for f Z

()

CLK

1

>

(29)

(30)

The worst-case voltage ripple occurs when the duty cycle of the

PWM output is exactly 50%, or when OUT A = 0.5 V

DD

. As

shown in Equation 31

OUT A

DD

CLK

for f Z

()

CLK

≈>

MAX

41

fL

1

(31)

1

VR

Here it can be directly seen that increasing the inductor value or

clock frequency will reduce the ripple. Choosing a low ESR

capacitor will ensure R1 remains low. Operating from a lower

supply voltage will also help reduce the output ripple voltage

from the L-C filter. With a clock frequency equal to Z1 but

presumably greater than f

∆OUT A V

=

MAX DD

Which, if f

∆OUT A

< Z1, can be further simplified to

CLK

MAX

, the worst-case output voltage ripple is

C

CLK

CLK

CLK

2

2

+

for f Z

()

CLK

for f Z

()

CLK

1

(32)

=

1

(33)

22

RC f

16 1 1 1

()

LC f

32 1 1

V

=<

DD

LC f

32 1 1

A typical 100 µF surface-mount electrolytic capacitor can have

an ESR of over 100 mΩ, pulling this zero to below 16 kHz, and

resulting in an excess of ripple voltage across the TEC. Low ESR

capacitors, such as ceramic or polymer aluminum capacitors,

are recommended instead. Polymer aluminum capacitors can

provide more bulk capacitance per unit area over ceramic ones,

saving board space. Table IV shows a limited list of capacitors

with their equivalent series resistances.

This is by no means a complete list of all capacitor manufacturers

or capacitor types that can be used in the application. The 22 µF

capacitor recommended has a maximum ESR of 35 mΩ, which

puts Z1 at 207 kHz. Using a 3.3 V supply with the recommended

inductor and capacitor listed with a 1 MHz clock frequency will

yield a worst-case ripple voltage at OUT A of about 6 mV.

External FET Requirements

External FETs are required for both the PWM and linear amplifiers

that drive OUT A and OUT B from the ADN8830. Although it

is important to select FETs that can supply the maximum current

required to the TEC, they should also have a low enough resistance (r

) to prevent excessive power dissipation and improve

DS, ON

efficiency. Other key requirements from these FET pairs are

slightly different for the PWM and linear outputs.

REV. C

–15–

ADN8830

The gate drive outputs for the PWM amplifier at P1 (Pin 21)

and N1 (Pin 22) have a typical nonoverlap delay of 65 ns.

This is done to ensure that one FET is completely off before

the other FET is turned on, preventing current from shooting

through both simultaneously.

The input capacitance (C

) of the FET should not exceed 5 nF.

ISS

The P1 and N1 outputs from the ADN8830 have a typical output

impedance of 6 Ω. This creates a time constant in combination

with C

of the external FETs equal to 6 Ω C

ISS

. To ensure

ISS

shoot-through does not occur through these FETs, this time

constant should remain less than 30 ns.

The linear output from the ADN8830 uses N2 (Pin 10) and

P2 (Pin 11) to drive the gates of the linear side FETs, shown as

Q3 and Q4 in Figure 1. Local compensation for the linear amplifier is achieved through the gate-to-drain capacitances (C

GD

) of

Q3 and Q4. The value of CGD, which can be determined from

the data sheet, is usually referred to as C

capacitance. The exact C

value should be determined from a

RSS

, the reverse transfer

RSS

graph that shows capacitance versus drain-to-source voltage,

using the power supply voltage as the appropriate V

To ensure stability of the linear amplifier, the total C

DS

.

GD

of the

PMOS device, Q3, should be greater than 2.5 nF and the total

of the NMOS should be greater than 150 pF. External

C

GD

capacitance can be added around the FET to increase the effective

of the transistor. This is the function of C6 in the typical

C

GD

application schematic shown in Figure 1. If external capacitance

must be added, it will generally only be required around the

PMOS transistor.

In the event of zero output current through the TEC, there will

be no current flowing through Q3 and Q4. In this condition,

these FETs will not provide any small signal gain and thus no

negative feedback for the linear amplifier. This leaves only a

feedforward signal path through C

, which could cause a

GD

settling problem at OUT B. This is often seen as a small signal

oscillation at OUT B, but only when the TEC is at or very near

zero current.

The remedy for this potential minor instability is to add

capacitance from OUT B to ground. This may need to be determined empirically, but a good starting point is 1.5 times the

total C

while adding more C

. This is the function of C12 in Figure 1. Note that

GD

around Q3 and Q4 will help to ensure

GD

stability, it could potentially increase instability in the zero current

dead band region, requiring additional capacitance from

OUT B to ground.

Bear in mind that the addition of these capacitors is only

for local stabilization. The stability of the entire TEC application may need adjustment, which should be done around the

compensation amplifier. This is covered in the Compensation

Loop section.

There is one additional consideration for selecting both the

linear output FETs; they must have a minimum threshold

voltage (V

) of 0.6 V. Lower threshold voltages could cause

T

shoot-through current in the linear output transistors.

Table V shows the recommended FETs that can be used for the

linear output in the ADN8830 application. Table V includes the

appropriate external gate-to-drain capacitance (external C

and snubber capacitor value (C

) connected from OUT B to

SNUB

GD

)

ground that should be added to ensure local stability. Table VI

shows the recommended PWM output FETs. Although other

transistors can be used, these combinations have been tested

and are proved stable and reliable for typical applications.

Data sheets for these devices can be found at their respective

websites:

Fairchild – www.fairchildsemi.com

Vishay Siliconix – www.vishay.com

International Rectifier – www.irf.com

Calculating Power Dissipation and Efficiency

The total efficiency of the ADN8830 application circuit is simply

the ratio of the output power to the TEC divided by the total

power delivered from the supply. The idea in minimizing power

dissipation is to avoid both drawing additional power and reducing heat generated from the circuit. The dominant sources

of power dissipation will include resistive losses, gate charge

loss, core loss from the inductor, and the current used by the

ADN8830 itself.

The on-channel resistance of both the linear and PWM output

FETs will affect efficiency primarily at high output currents.

Because the linear amplifier operates in a high gain configuration,

it will be at either ground or V

when significant current is

DD

flowing through the TEC. In this condition, the power dissipation

through the linear output FET will be

PrI

FET LIN DS ON TEC,,

using either the r

=×

for the NMOS or the PMOS depending

DS, ON

2

(34)

on the direction of the current flow. In the typical application

setup in Figure 2, if the TEC is cooling the target object, the

PMOS is sourcing the current. If the TEC is heating the

object, the NMOS will be sinking current.

Table IV. Partial List of Capacitors and Key Specifications

Value (F) ESR (m)Voltage Rating (V) Part Number Manufacturer Website

10 60 6.3 NSP100M6.3D2TR NIC Components www.niccomp.com

22* 35 8 ESRD220M08B Cornell Dubilier www.cornell-dubilier.com

22 35 8 NSP220M8D5TR NIC Components www.niccomp.com

22 35 8 EEFFD0K220R Panasonic www.maco.panasonic.co.jp

47 25 6.3 NSP470M6.3D2TR NIC Components www.niccomp.com

68 18 8 ESRD680M08B Cornell Dubilier www.cornell-dubilier.com

100 95 10 594D107X_010C2T Vishay www.vishay.com

*Recommend capacitor in typical application circuit Figure 1.

REV. C–16–

ADN8830

Although the FETs that drive OUT A alternate between Q1 and

Q2 being on, they have an equivalent series resistance that is

equal to a weighted average of their r

RDr Dr

=× +

EQIV DS P DS N

,,

11

×

–

1

()

DS, ON

values.

(35)

The resistive power loss from the PWM transistors is then

PRI

FET PWM EQIV TEC,

=×

2

(36)

There is also a power loss from the continuing charging and

discharging of the gate capacitances on Q1 and Q2. The power

dissipated due to gate charge loss (P

PCVf

1

=

GCL ISS DD CLK

2

2

using the appropriate input capacitance (C

and PMOS. Both transistors are switching, so P

GCL

) is

) for the NMOS

ISS

should be

GCL

(37)

calculated for each one and will be added to find the total power

dissipated from the circuit.

The series resistance of the inductor, R2 from Figure 14, will

also exhibit a power dissipation equal to

PRI

2=×

R TEC2

2

(38)

Core loss from the inductor arises as a result of nonidealities of

the inductor. Although this is difficult to calculate explicitly, it

can be estimated as 80% of P

cies and 50% of P

PP

=×08.

LOSS RL

at 100 kHz. Judging conservatively

RL

at 1 MHz switching frequen-

RLS

(39)

Finally, the power dissipated by the ADN8830 is equal to the

current used by the device multiplied by the supply voltage.

Again, this exact equation is difficult to determine as we have

already taken into account some of the current while finding the

gate charge loss. A reasonable estimate is to use 40 mA as the

total current used by the ADN8830. The power dissipated from

the device itself is

PVmA

ADN DD8830

10=×

(40)

There are certainly other minor mechanisms for power dissipation in the circuit. However, a rough estimate of the total power

dissipated can be found by summing the preceding power dissipation equations. Efficiency is then found by comparing the

power dissipated with the required output power to the load.

P

Efficiency

=

LOAD

PP

+

LOAD DISS TOT

,

(41)

where

PIV

=×

LOAD LOAD LOAD

The measured efficiency of the system will likely be less than the

calculated efficiency. Measuring the efficiency of the application

circuit is fairly simple but must be done in an exact manner to

ensure the correct numbers are being measured. Using two high

current, low impedance ammeters and two voltmeters, the circuit should be set up as shown in Figure 15.

POWER SUPPLY

V

DD

A

V

ADN8830

GND

A

V

TEC

LOAD

Figure 15. Measuring Efficiency of the ADN8830 Circuit

Table V. Recommended FETs for Linear Output Amplifier

Part Number Type CGD (nF) Ext. CGD (nF) C

SNUB

(nF) r

(m)I

DS, ON

(A) Manufacturer

MAX

FDW2520C* NMOS 0.17 18 6.0 Fairchild

PMOS 0.15 2.2 3.3 35 4.5 Fairchild

IRF7401 NMOS 0.5 22 8.7 International Rectifier

IRF7233 PMOS 2.2 1.0 3.3 20 9.5 International Rectifier

FDR6674A NMOS 0.23 9.5 11.5 Fairchild

FDR840P PMOS 0.6 1.0 3.3 12 10 Fairchild

*Recommend transistors in typical application circuit Figure 1.

Table VI. Recommended FETs for PWM Output Amplifier

Part Number Type C

(nF) r

ISS

(m)Continuous I

DS,ON

(A) Manufacturer

MAX

FDW2520C* NMOS 1.33 18 6.0 Fairchild

PMOS 1.33 35 4.5 Fairchild

Si7904DN NMOS 1.0 30 5.3 Vishay Siliconix

Si7401DN PMOS 3.5 17 7.3 Vishay Siliconix

IRF7401 NMOS 1.6 22 8.7 International Rectifier

IRF7404 PMOS 1.5 40 6.7 International Rectifier

*Recommend transistors in typical application circuit Figure 1.

REV. C

–17–

ADN8830

The voltmeter to the TEC or output load should include the series

ammeter since the power delivered to the ammeter is considered part

of the total output power. However, the voltmeter measuring the

voltage delivered to the ADN8830 circuit should not include the

series ammeter from the power supply. This prevents a false supply

voltage power measurement since we are interested only in the

supply voltage power delivered to the ADN8830 circuit. Figures 16

and 17 show some efficiency measurements using the typical application circuit shown in Figure 1.

100

= 3V

V

SY

80

60

40

EFFICIENCY (%)

20

0

0 2,000500

Figure 16. Efficiency with f

100

= 3V

V

SY

80

60

VSY = 5V

1,000 1,500

I

(mA)

TEC

= 1 MHz

CLK

= 5V

V

SY

POWER SUPPLY

V

NOISE

SENSITIVE

SECTION

GND

DD

PGND PVDDAGNDAVD D

OUTPUT

SECTION

TEC

OR

LOAD

Figure 18. Using Star Connections to Minimize

Noise Pickup from Switched Output

The low noise power and ground are referred to as AVDD and

AGND, with the output supply and ground paths labeled PVDD

and PGND. These pins are labeled on the ADN8830 and should

be connected appropriately. Both sets of external FETs should be

connected to PVDD and PGND. All output filtering and PVDD

supply bypass capacitors should be connected to PGND.

All remaining connections to ground and power supply should be

done through AVDD and AGND. A 4-layer board layout is recommended for best performance with split power and ground

planes between the top and bottom layers. This provides the

lowest impedance for both supply and ground points. Setting the

ADN8830 above the AGND plane will reduce the potential noise

injection into the device. Figure 19 shows the top layer of the

layout used for the ADN8830 evaluation boards, highlighting the

power and ground split planes.

40

EFFICIENCY (%)

20

0

0 2,000500

Figure 17. Efficiency with f

1,000 1,500

I

(mA)

TEC

CLK

= 200 kHz

Note that higher efficiency can be achieved using a lower supply

voltage or a slower clock frequency. This is due to the fact that the

dominant source of power dissipation at high clock frequencies is the

gate charge loss on the PWM transistors.

Layout Considerations

The two key considerations for laying out the board for the

ADN8830 are to minimize both the series resistance in the output

and the potential noise pickup in the precision input section. The

best way to accomplish both of these objectives is to divide the

layout into two sections, one for the output components and the

other for the remainder of the circuit. These sections should have

independent power supply and ground current paths that are each

connected together at a single point near the power supply. This is

used to minimize power supply and ground voltage bounce on the

more sensitive input stages to the ADN8830 caused by the switching of the PWM output. Such a layout technique is referred to as a

“star” ground and supply connection. Figure 18 shows a block diagram of the concept.

Figure 19. Top Layer Reference Layout for ADN8830

Proper supply voltage bypassing should also be taken into consideration to minimize the ripple voltage on the power supply. A

minimum bypass capacitance of 10 µF should be placed in close

proximity to each component connected to the power supply. This

includes Pins 8 and 20 on the ADN8830 and both external PMOS

transistors. An additional 0.1 µF capacitor should be placed in

parallel to each 10 µF capacitor to provide bypass for high fre-

quency noise. Using a large bulk capacitor, 100 µF or greater, in

parallel with a low ESR capacitor where AVDD and PVDD connect will further improve voltage supply ripple. This is covered in

more detail in the Power Supply Ripple section.

REV. C–18–

ADN8830

SD

ON

CR

CR

=×

=×

11

11

Power Supply Ripple

Minimizing ripple on the power supply voltage can be an important consideration, particularly in signal source laser applications.

If the laser diode is operated from the same supply rail as the TEC

controller, ripple on the supply voltage could cause inadvertent

modulation of the laser frequency. As most laser diodes are driven

from a 5 V supply, it is recommended the ADN8830 be operated

from a separate 3.3 V regulated supply unless higher TEC voltages

are required. Operation from 3.3 V also improves efficiency, thus

minimizing power dissipation.