3.75 Gbps Quad Bidirectional

q

FEATURES

Optimized for dc to 3.75 Gbps data

Programmable input equalization

Up to 22 dB boost at 1.875 GHz

Compensates up to 30 meters of CX4 cable up to 3.75 Gbps

Compensates up to 40 inches of FR4 up to 3.75 Gbps

Programmable output pre-emphasis/de-emphasis

Up to 12 dB boost at 1.875 GHz (3.75 Gbps)

Compensates up to 15 meters of CX4 cable up to 3.75 Gbps

Compensates up to 40 inches of FR4 up to 3.75 Gbps

Flexible 1.8 V to 3.3 V core supply

Per lane P/N pair inversion for routing ease

Low power: 125 mW/channel up to 3.75 Gbps

DC- or ac-coupled differential CML inputs

Programmable CML output levels

50 Ω on-chip termination

Loss-of-signal detection

Temperature range operation: −40°C to +85°C

Supports 8b10b, scrambled, or uncoded NRZ data

2

I

C control interface

64-lead LFCSP (QFN) package

APPLICATIONS

10GBase-CX4

HiGig™

InfiniBand®

1×, 2× Fibre Channel

XAUI™

Gigabit Ethernet over backplane or cable

CPRI™

50 Ω cables

CX4 E

ualizer

ADN8102

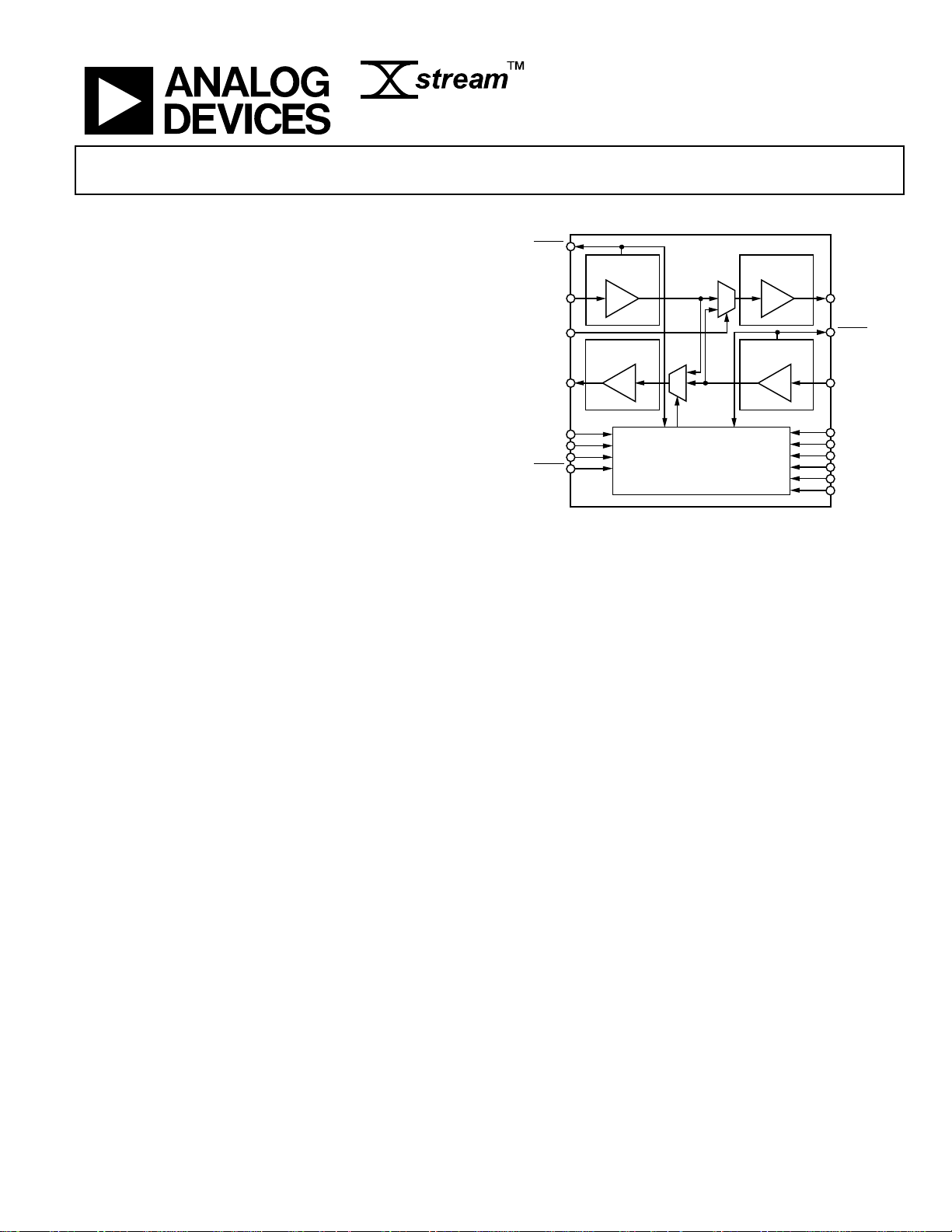

FUNCTIONAL BLOCK DIAGRAM

LOS_B

RECEIVE

EQUALIZ ATION

Ix_B[3:0]

Ox_A[3:0]

ADDR[1:0]

SCL

SDA

RESET

LB

EQ

TRANSMIT

PRE-EMPHASIS

PE

GENERAL DESCRIPTION

The ADN8102 is a quad, bidirectional, CX4 cable/backplane

equalizer with eight differential PECL-/CML-compatible inputs

with programmable equalization and eight differential CML

outputs with programmable output levels and pre-emphasis or

de-emphasis. The operation of this device is optimized for NRZ

data at rates up to 3.75 Gbps.

The receive inputs provide programmable equalization to

compensate for up to 30 meters of CX4 cable (24 AWG) or

40 inches of FR4, and programmable pre-emphasis to compensate

for up to 15 meters of CX4 cable (24 AWG) or 40 inches of FR4

at 3.75 Gbps. Each channel also provides programmable loss-ofsignal detection and loopback capability for system testing and

debugging.

The ADN8102 is controlled through toggle pins, an I

interface that provides more flexible control, or a combination of

both. Every channel implements an asynchronous path supporting

dc to 3.75 Gbps NRZ data, fully independent of other channels. The

ADN8102 has low latency and very low channel-to-channel skew.

The main application for the ADN8102 is to support switching

in chassis-to-chassis applications over CX4 or InfiniBand cables.

The ADN8102 is packaged in a 9 mm × 9 mm 64-lead LFCSP

(QFN) package and operates from −40°C to +85°C.

ADN8102

2:1

CONTROL LO GIC

Figure 1.

TRANSMIT

PRE-EMPHASIS

2:1

RECEIVE

EQUALIZ ATION

PE

EQ

Ox_B[3:0]

LOS_A

Ix_A[3:0]

EQ_A[1:0]

PE_A[1:0]

EQ_B[1:0]

PE_B[1:0]

ENA

ENB

2

C® control

07060-001

Rev. B

Information furnished by Analog Devices is believed to be accurate and reliable. However, no

responsibility is assumed by Analog Devices for its use, nor for any infringements of patents or other

rights of third parties that may result from its use. Specifications subject to change without notice. No

license is granted by implication or otherwise under any patent or patent rights of Analog Devices.

Trademarks and registered trademarks are the property of their respective owners.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700 www.analog.com

Fax: 781.461.3113 ©2008–2010 Analog Devices, Inc. All rights reserved.

ADN8102

TABLE OF CONTENTS

Features .............................................................................................. 1

Applications ....................................................................................... 1

Functional Block Diagram .............................................................. 1

General Description ......................................................................... 1

Revision History ............................................................................... 2

Specifications ..................................................................................... 3

Timing Specifications .................................................................. 5

Absolute Maximum Ratings ............................................................ 6

ESD Caution .................................................................................. 6

Pin Configuration and Function Descriptions ............................. 7

Typical Performance Characteristics ............................................. 9

Theory of Operation ...................................................................... 16

Introduction ................................................................................ 16

Receivers ...................................................................................... 17

Equalization Settings .................................................................. 17

Lane Inversion ............................................................................ 18

Loopback ..................................................................................... 20

Transmitters ................................................................................ 21

Selective Squelch and Disable ................................................... 24

I2C Control Interface ...................................................................... 25

Serial Interface General Functionality..................................... 25

I2C Interface Data Transfers—Data Write .............................. 25

I2C Interface Data Transfers—Data Read ............................... 26

Applications Information .............................................................. 27

Output Compliance ................................................................... 27

Printed Circuit Board (PCB) Layout Guidelines ................... 29

Register Map ................................................................................... 31

Outline Dimensions ....................................................................... 33

Ordering Guide .......................................................................... 33

REVISION HISTORY

10/10—Rev. A to Rev. B

Changes to Power Supply/Supply Current Parameter, Table 1 ... 4

Added t

Renumbered Sequentially ................................................................ 5

Added Junction Temperature Parameter, Table 3 ........................ 6

Changes to Introduction Section .................................................. 16

Added Table 5; Renumbered Sequentially .................................. 16

Changes to Equalization Settings Section ................................... 17

Added Table 7 and Advanced Equalization Settings Section ... 17

Changes to Table 8 .......................................................................... 18

Added Table 12 ............................................................................... 20

Changes to Loopback Section and Changes to Table 13 ........... 20

Added Table 14 ............................................................................... 21

Changes to Table 15 ........................................................................ 21

Changes to Table 17 ........................................................................ 22

Deleted High Current Setting and Output Level Shift

Section .............................................................................................. 23

Deleted Table 14; Renumbered Sequentially .............................. 24

Changes to Table 18 ........................................................................ 24

Added Table 19 ............................................................................... 24

Deleted Table 15 .............................................................................. 25

Added Applications Information Section and Output

Compliance Section ....................................................................... 27

Parameter and Note 1, Table 2 and Figure 3;

RESET

Moved TxHeadroom and Figure 44 ............................................. 27

Changes to TxHeadroom and Figure 44 ..................................... 27

Added Table 20 ............................................................................... 27

Added Table 21 ............................................................................... 28

Deleted Transmission Lines Section and Soldering Guidelines

for Chip Scale Package Section ..................................................... 28

Changes to Printed Circuit Board (PCB) Layout Guidelines

Section .............................................................................................. 29

Added Figure 45, Supply Sequencing Section, Thermal Paddle

Design Section, and Figure 46 ...................................................... 29

Added Stencil Design for the Thermal Paddle, Figure 47, and

Figure 48 .......................................................................................... 30

8/08—Rev. 0 to Rev. A

Changes to Features Section ............................................................ 1

Changes to Loss of Signal/Signal Detect Section ....................... 18

Added Recommended LOS Settings Section .............................. 18

Deleted Figure 39; Renumbered Sequentially ............................ 18

Exposed Paddle Notation Added to Outline Dimensions ........ 31

5/08—Revision 0: Initial Version

Rev. B | Page 2 of 36

ADN8102

SPECIFICATIONS

VCC = 1.8 V, VEE = 0 V, V

T

= 25°C, unless otherwise noted.

A

Table 1.

Parameter Test Conditions/Comments Min Typ Max Unit

DYNAMIC PERFORMANCE

Maximum Data Rate/Channel (NRZ) 3.75 Gbps

Deterministic Jitter Data rate < 3.75 Gbps; BER = 1 × 10

Random Jitter VCC = 1.8 V 1.5 ps rms

Residual Deterministic Jitter

With Input Equalization Data rate < 3.25 Gbps; 0 inches to 40 inches FR4 0.20 UI

Data rate < 3.25 Gbps; 0 meters to 30 meters CX4 0.19 UI

Data rate < 3.75 Gbps; 0 inches to 40 inches FR4 0.24 UI

Data rate < 3.75 Gbps; 0 meters to 30 meters CX4 0.21 UI

With Output Pre-Emphasis Data rate < 3.25 Gbps; 0 inches to 40 inches FR4 0.13 UI

Data rate < 3.25 Gbps; 0 meters to 15 meters CX4 0.37 UI

Data rate < 3.75 Gbps; 0 inches to 40 inches FR4 0.14 UI

Data rate < 3.75 Gbps; 0 meters to 15 meters CX4 0.41 UI

Output Rise/Fall Time 20% to 80% 75 ps

Propagation Delay 1 ns

Channel-to-Channel Skew 50 ps

OUTPUT PRE-EMPHASIS

Equalization Method 1-tap programmable pre-emphasis

Maximum Boost 800 mV p-p output swing 6 dB

200 mV p-p output swing 12 dB

Pre-Emphasis Tap Range Minimum 2 mA

Maximum 12 mA

INPUT EQUALIZATION

Minimum Boost EQBY = 1 1.5 dB

Maximum Boost Maximum boost occurs at 1.875 GHz 22 dB

Number of Equalization Settings 8

Gain Step Size 2.5 dB

INPUT CHARACTERISTICS

Input Voltage Swing Differential, V

Input Voltage Range Single-ended absolute voltage level, VL minimum VEE + 0.4 V p-p

Single-ended absolute voltage level, VH maximum VCC + 0.5 V p-p

Input Resistance Single-ended 45 50 55 Ω

Input Return Loss Measured at 2.5 GHz 5 dB

OUTPUT CHARACTERISTICS

Output Voltage Swing DC, differential, PE = 0, default, VCC = 1.8 V 635 740 870

DC, differential, PE = 0, default, VCC = 3.3 V 800

DC, differential, PE = 0, minimum output level,2 VCC = 1.8 V 100

DC, differential, PE = 0, minimum output level,2 VCC = 3.3 V 100

DC, differential, PE = 0, maximum output level,2 VCC = 1.8 V 1300

DC, differential, PE = 0, maximum output level,2 VCC = 3.3 V 1800

TTI

= V

= VCC, RL = 50 Ω, differential output swing = 800 mV p-p differential, 3.75 Gbps, PRBS 27 − 1,

TTO

−12

33 ps p-p

1

= VCC − 0.6 V 300 2000

ICM

mV pp

mV pp

mV pp

mV pp

mV pp

mV pp

mV pp

Rev. B | Page 3 of 36

ADN8102

Parameter Test Conditions/Comments Min Typ Max Unit

Output Voltage Range

Single-ended absolute voltage level, TxHeadroom = 0;

minimum

V

L

Single-ended absolute voltage level, TxHeadroom = 0;

V

V

VH maximum

Single-ended absolute voltage level, TxHeadroom = 1;

minimum

V

L

Single-ended absolute voltage level, TxHeadroom = 1;

maximum

V

H

V

V

Output Current Minimum output current per channel 2 mA

Maximum output current per channel, VCC = 1.8 V 21 mA

Output Resistance Single-ended 43 50 57 Ω

Output Return Loss Measured at 2.5 GHz 5 dB

LOS CHARACTERISTICS

Assert Level IN_A/IN_B LOS threshold = 0x0C 20 mV diff

Deassert Level IN_A/IN_B LOS hysteresis = 0x0D 225 mV diff

POWER SUPPLY

Operating Range

VCC V

DVCC V

V

(VEE + 0.4 V + 0.5 × VID) < V

TTI

V

(VCC − 1.1 V + 0.5 × VOD) < V

TTO

= 0 V 1.7 1.8 3.6 V

EE

= 0 V, DVCC ≤ (VCC + 1.3 V) 3.0 3.3 3.6 V

EE

< (VCC + 0.5 V) VEE + 0.4 1.8 3.6 V

TTI

< (VCC + 0.5 V) VCC − 1.1 1.8 3.6 V

TTO

Supply Current

I

V

TTO

= 1.8 V, all outputs enabled 63 69 mA

TTO

ICC VCC = 1.8 V, all outputs enabled 460 565 mA

LOGIC CHARACTERISTICS

Input High, VIH DVCC = 3.3 V 2.5 V

Input Low, VIL 1.0 V

Output High, VOH 2.5 V

Output Low, VOL 1.0 V

THERMAL CHARACTERISTICS

Operating Temperature Range −40 +85 °C

θJA 22 °C/W

1

V

is the input common-mode voltage.

ICM

2

Programmable via I2C.

− 1.1 V

CC

+ 0.6 V

CC

− 1.2 V

CC

+ 0.6 V

CC

Rev. B | Page 4 of 36

ADN8102

TIMING SPECIFICATIONS

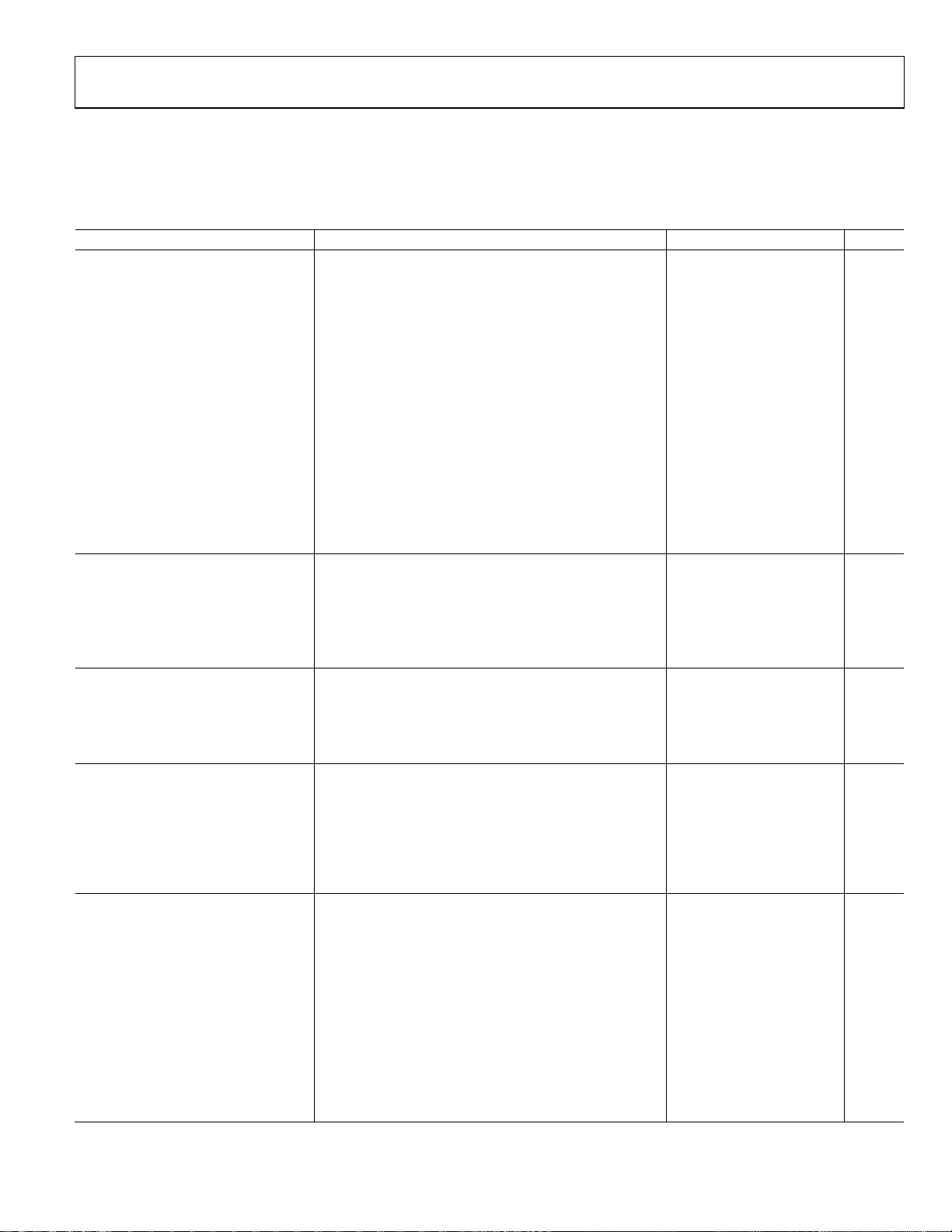

Table 2. I2C Timing Parameters

Parameter Min Max Unit Description

f

0 400 kHz SCL clock frequency

SCL

t

0.6 Not applicable μs Hold time for a start condition

HD:STA

t

0.6 Not applicable μs Setup time for a repeated start condition

SU:STA

t

1.3 Not applicable μs Low period of the SCL clock

LOW

t

0.6 Not applicable μs High period of the SCL clock

HIGH

t

0 Not applicable μs Data hold time

HD:DAT

t

10 Not applicable ns Data setup time

SU:DAT

tR 1 300 ns Rise time for both SDA and SCL

tF 1 300 ns Fall time for both SDA and SCL

t

0.6 Not applicable μs Setup time for a stop condition

SU:STO

t

1 Not applicable ns Bus free time between a stop and a start condition

BUF

CIO 5 7 pF Capacitance for each I/O pin

t

10 Not applicable ns Reset pulse width1

RESET

1

Reset pulse width is defined as the time

SDA

RESET

is held below the logic low threshold (VIL) listed in Table 1 while the DVCC supply is within the operating range in Table 1.

t

t

HD:DAT

SU:DAT

t

R

t

HIGH

t

F

Figure 2. I

t

SU:STA

2

C Timing Diagram

t

HD:STA

t

SU:STO

t

R

t

BUF

SPSrS

07060-010

SCL

t

F

t

LOW

t

HD:STA

4.0

DVCC MAX LIMIT

3.5

DVCC MIN LIMIT

3.0

2.5

DVCC (V)

2.0

VOLTAGE (V)

1.5

1.0

0.5

0

0 5 10 15 20 25 30 35 40 45 50

Figure 3. Reset Timing Diagram

RESET

TIME (ns)

t

RESET

07060-103

Rev. B | Page 5 of 36

ADN8102

ABSOLUTE MAXIMUM RATINGS

Table 3.

Parameter Rating

VCC to VEE 3.7 V

V

V

TTI

V

V

TTO

Internal Power Dissipation 4.26 W

Differential Input Voltage 2.0 V

Logic Input Voltage VEE − 0.3 V < VIN < VCC + 0.6 V

Storage Temperature Range −65°C to +125°C

Lead Temperature 300°C

Junction Temperature 125°C

+ 0.6 V

CC

+ 0.6 V

CC

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress rating

only; functional operation of the device at these or any other

conditions above those indicated in the operational section of

this specification is not implied. Exposure to absolute maximum

rating conditions for extended periods may affect device reliability.

ESD CAUTION

Rev. B | Page 6 of 36

ADN8102

A

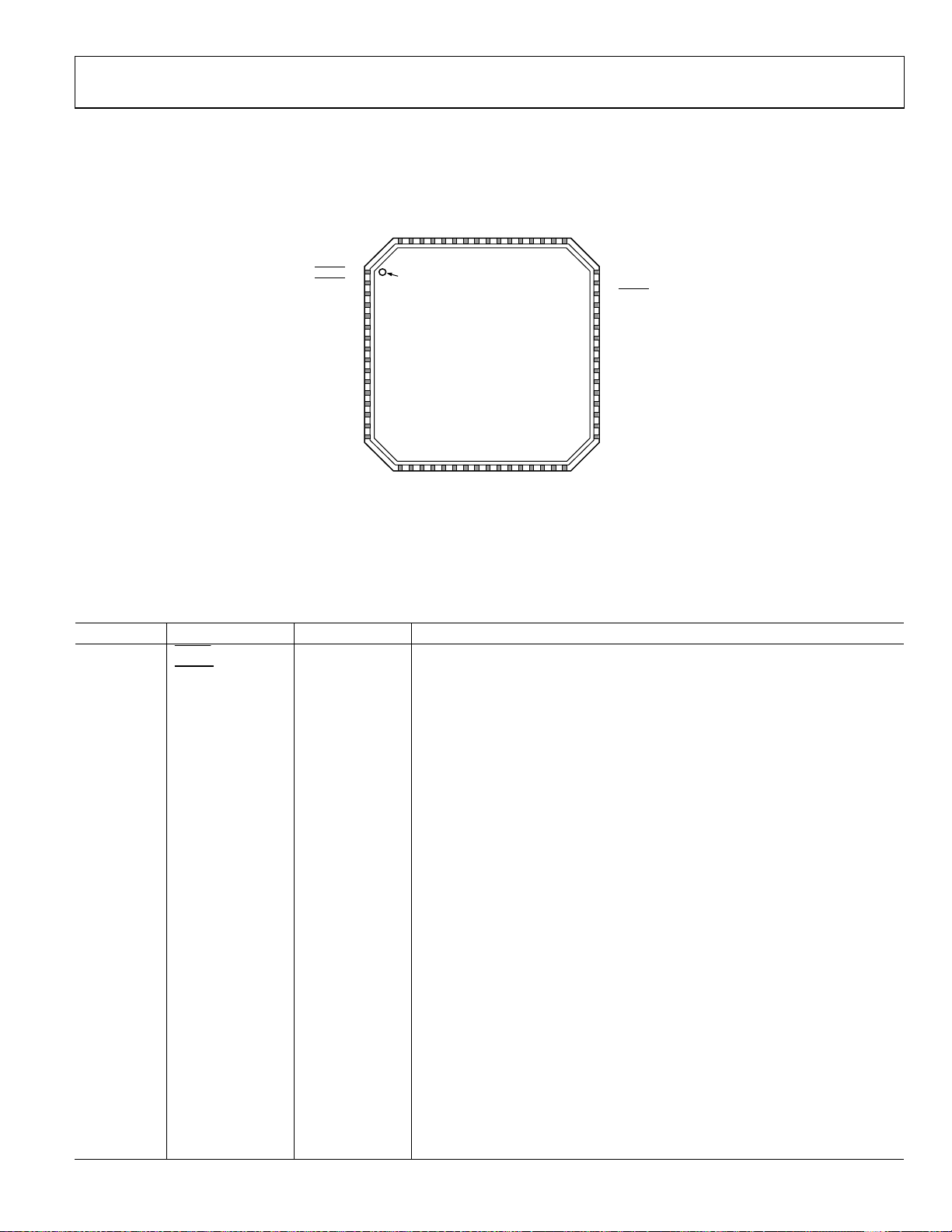

PIN CONFIGURATION AND FUNCTION DESCRIPTIONS

PE_A1

PE_A0

ENA

OP_A0

ON_A0

VCC

OP_A1

ON_A1

VTTO

OP_A2

ON_A2

VEE

OP_A3

ON_A3

ADDR1

646362616059585756555453525150

ADDR0

49

RESET

LOS_

IN_A0

IP_A0

VCC

IN_A1

IP_A1

VTTI

IN_A2

IP_A2

VEE

IN_A3

IP_A3

DVCC

EQ_A1

EQ_A0

PIN 1

1

INDICATO R

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

171819202122232425262728293031

VEE

NOTES

1. EXPOSE D PAD MUST BE CONNECT ED TO VEE.

LB

OP_B0

ON_B0

ADN8102

TOP VIEW

(Not to Scale)

VCC

VTTO

OP_B1

ON_B1

VEE

OP_B2

OP_B3

ON_B2

ON_B3

ENB

48

SCL

47

SDA

46

LOS_B

45

IP_B0

44

IN_B0

43

VCC

42

IP_B1

41

IN_B1

40

VTTI

39

IP_B2

38

IN_B2

37

VEE

36

IP_B3

35

IN_B3

34

EQ_B1

33

EQ_B0

32

PE_B1

PE_B0

Figure 4. Pin Configuration

Table 4. Pin Function Descriptions

Pin No. Mnemonic Type Description

1

2

RESET

LOS_A

Control Reset Input, Active Low

Digital I/O Port A Loss of Signal Status, Active Low

3 IN_A0 I/O High Speed Input Complement

4 IP_A0 I/O High Speed Input

5 VCC Power Positive Supply

6 IN_A1 I/O High Speed Input Complement

7 IP_A1 I/O High Speed Input

8 VTTI Power Input Termination Supply

9 IN_A2 I/O High Speed Input Complement

10 IP_A2 I/O High Speed Input

11 VEE Power Negative Supply

12 IN_A3 I/O High Speed Input Complement

13 IP_A3 I/O High Speed Input

14 DVCC Power Digital Power Supply

15 EQ_A1 Control Port A Input Equalization MSB

16 EQ_A0 Control Port A Input Equalization LSB

17 VEE Power Negative Supply

18 LB Control Loopback Control

19 ON_B0 I/O High Speed Output Complement

20 OP_B0 I/O High Speed Output

21 VCC Power Positive Supply

22 ON_B1 I/O High Speed Output Complement

23 OP_B1 I/O High Speed Output

24 VTTO Power Output Termination Supply

25 ON_B2 I/O High Speed Output Complement

26 OP_B2 I/O High Speed Output

27 VEE Power Negative Supply

Rev. B | Page 7 of 36

7060-002

ADN8102

Pin No. Mnemonic Type Description

28 ON_B3 I/O High Speed Output Complement

29 OP_B3 I/O High Speed Output

30 ENB Control Port B Enable

31 PE_B1 Control Port B Output Pre-Emphasis MSB

32 PE_B0 Control Port B Output Pre-Emphasis LSB

33 EQ_B0 Control Port B Input Equalization LSB

34 EQ_B1 Control Port B Input Equalization MSB

35 IN_B3 I/O High Speed Input Complement

36 IP_B3 I/O High Speed Input

37 VEE Power Negative Supply

38 IN_B2 I/O High Speed Input Complement

39 IP_B2 I/O High Speed Input

40 VTTI Power Input Termination Supply

41 IN_B1 I/O High Speed Input Complement

42 IP_B1 I/O High Speed Input

43 VCC Power Positive Supply

44 IN_B0 I/O High Speed Input Complement

45 IP_B0 I/O High Speed Input

46

47 SDA Control I2C Control Interface Data Input/Output

48 SCL Control I2C Control Interface Clock Input

49 ADDR0 Control I2C Control Interface Address LSB

50 ADDR1 Control I2C Control Interface Address MSB

51 ON_A3 I/O High Speed Output Complement

52 OP_A3 I/O High Speed Output

53 VEE Power Negative Supply

54 ON_A2 I/O High Speed Output Complement

55 OP_A2 I/O High Speed Output

56 VTTO Power Output Termination Supply

57 ON_A1 I/O High Speed Output Complement

58 OP_A1 I/O High Speed Output

59 VCC Power Positive Supply

60 ON_A0 I/O High Speed Output Complement

61 OP_A0 I/O High Speed Output

62 ENA Control Port A Enable

63 PE_A0 Control Port A Output Pre-Emphasis LSB

64 PE_A1 Control Port A Output Pre-Emphasis MSB

EP EPAD Power EPAD Must Be Connected to VEE

LOS_B

Digital I/O Port B Loss of Signal Status, Active Low

Rev. B | Page 8 of 36

ADN8102

V

V

V

V

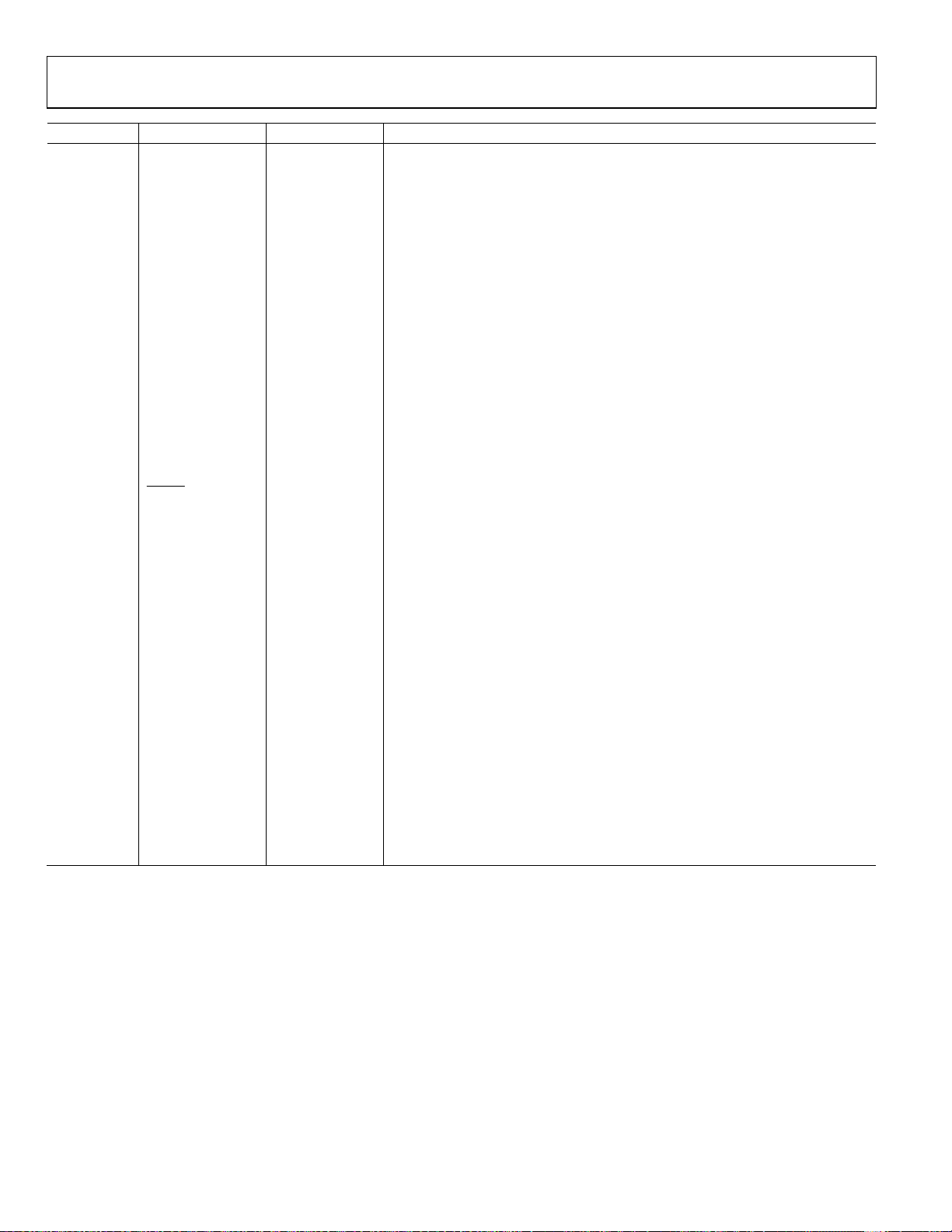

TYPICAL PERFORMANCE CHARACTERISTICS

DATA OUT

PATTERN

GENERATOR

2 2

INPUT

PIN

ADN8102

AC-COUPL ED

EVALUATION

OUTPUT

BOARD

50Ω CABLES

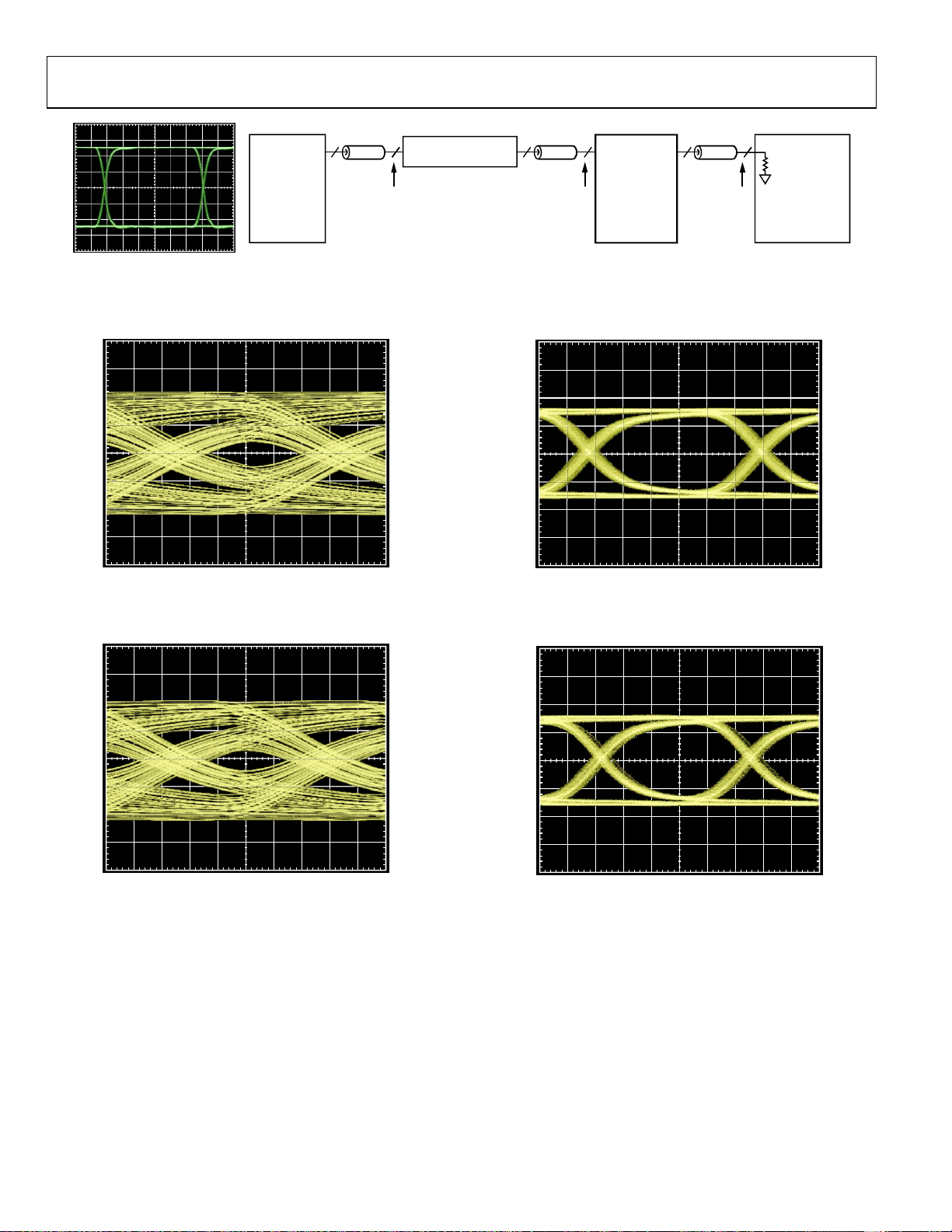

Figure 5. Standard Test Circuit (No Channel)

50Ω CABLES

2 2

PIN

50Ω

TP2TP1

OSCILLOSCOPE

HIGH SPEED

SAMPLING

07060-011

200mV/DI

50ps/DIV

07060-012

200mV/DI

50ps/DIV

Figure 6. 3.25 Gbps Input Eye (TP1 from Figure 5) Figure 8. 3.25 Gbps Output Eye, No Channel (TP2 from Figure 5)

200mV/DI

50ps/DIV

07060-013

200mV/DI

50ps/DIV

Figure 7. 3.75 Gbps Input Eye (TP1 from Figure 5) Figure 9. 3.75 Gbps Output Eye, No Channel (TP2 from Figure 5)

07060-014

07060-015

Rev. B | Page 9 of 36

ADN8102

V

V

V

V

V

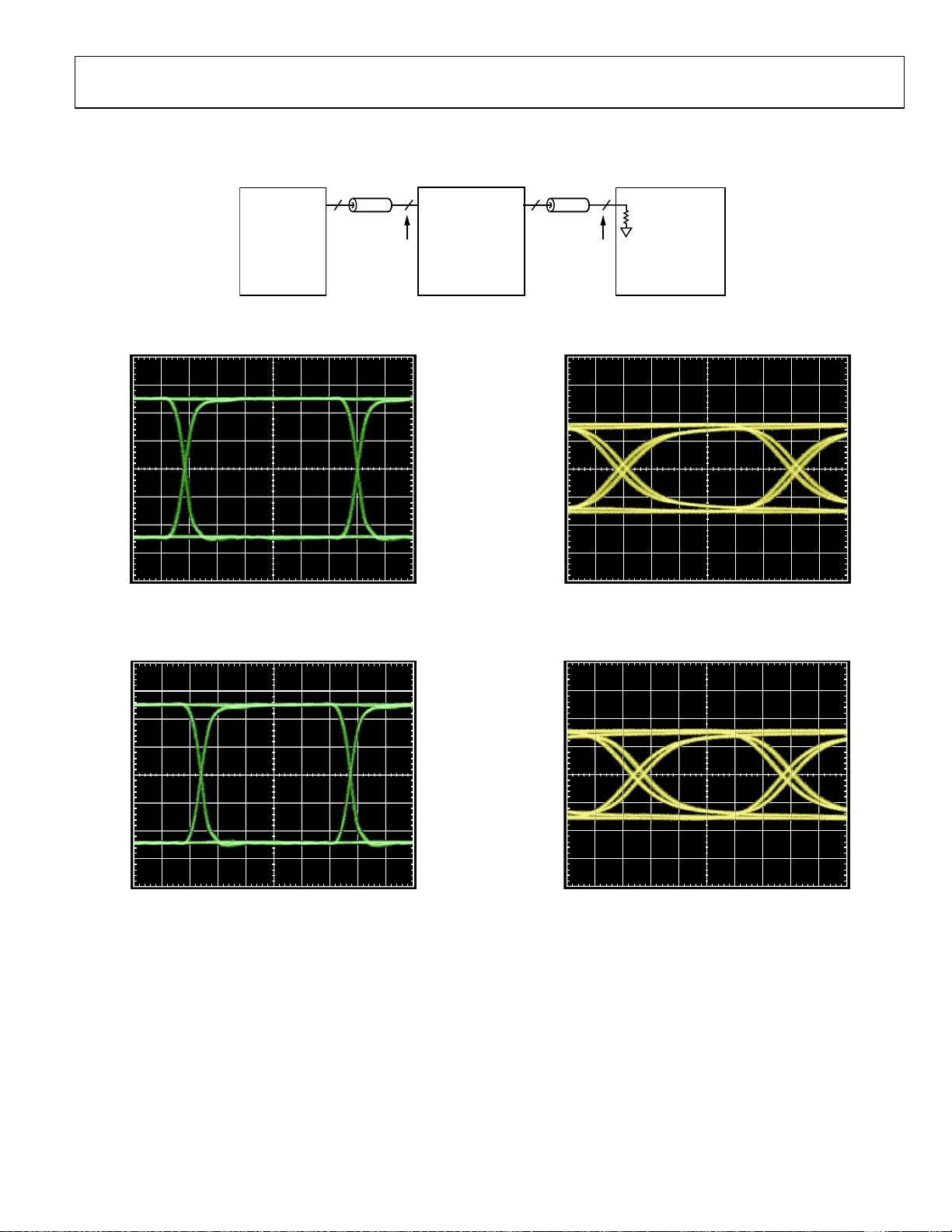

50Ω CABLES

DATA OUT

PATTERN

200mV/DI

GENERATOR

2 2

FR4 TEST BACKPLANE

DIFFERENTIAL

STRIPLINE TRACES

TP1

8mils WIDE, 8mils SPACE,

8mils DIELECTRIC HEIGHT

TRACE LENGT HS = 40''

50Ω CABLES

2 2

TP2

INPUT

OUTPUT

PIN

ADN8102

AC-COUPLED

EVALUATION

BOARD

2 2

PIN

50Ω CABLES

50Ω

HIGH SPEED

TP3

SAMPLING

OSCILLOSCOPE

REFERENCE EYE DI AGRAM AT TP1

50ps/DIV

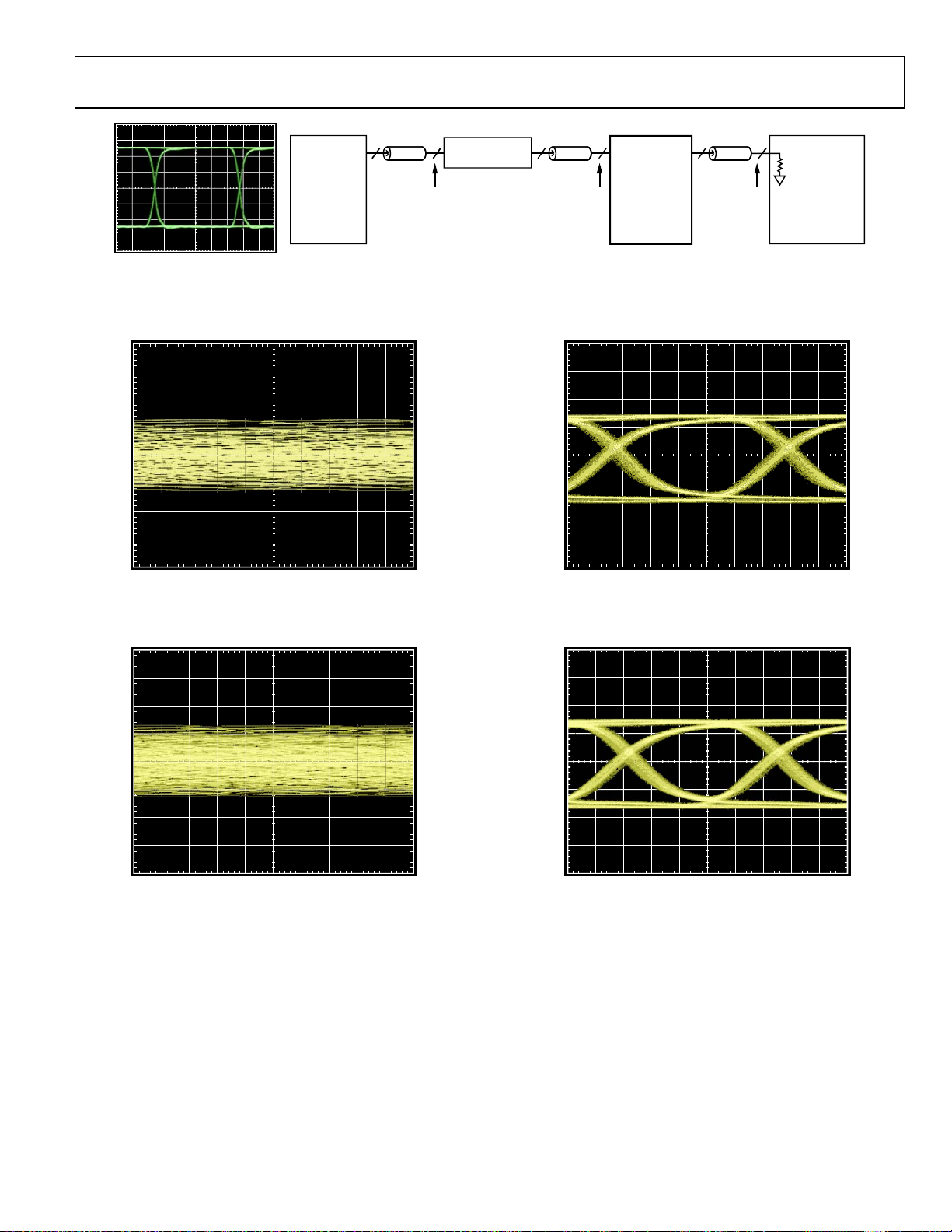

Figure 10. Input Equalization Test Circuit, FR4

200mV/DI

50ps/DIV

Figu re 11. 3. 25 Gbps I nput Eye, 40 Inch FR4 Input Channel (TP2 from Figure 10)

07060-017

200mV/DI

50ps/DIV

07060-019

Figure 13. 3.25 Gbps Output Eye, 40 Inch FR4 Input Channel, Best EQ Setting

(TP3 from Figure 10)

07060-016

200mV/DI

50ps/DIV

07060-018

Figu re 12. 3.75 Gb ps Input Eye, 40 Inch FR4 Input Channel (TP2 from Figure 10)

200mV/DI

50ps/DIV

07060-020

Figure 14. 3.75 Gbps Output Eye, 40 Inch FR4 Input Channel, Best EQ Setting

(TP3 from Figure 10)

Rev. B | Page 10 of 36

ADN8102

V

V

V

V

V

50Ω CABLES

DATA OUT

PATTERN

200mV/DI

GENERATOR

2 2

30m CX4 CABLE

TP1

50Ω CABLES

2 2

TP2

INPUT

OUTPUT

PIN

ADN8102

AC-COUPLED

EVALUATION

BOARD

2 2

PIN

50Ω CABLES

50Ω

HIGH SPEED

TP3

SAMPLING

OSCILLOSCOPE

REFERENCE EYE DI AGRAM AT TP1

50ps/DIV

Figure 15. Input Equalization Test Circuit, CX4

200mV/DI

50ps/DIV

Figure 16. 3.25 Gbps Input Eye, 30 Meters CX4 Cable (TP2 from Figure 15)

07060-021

200mV/DI

07060-022

50ps/DIV

07060-024

Figure 18. 3.25 Gbps Output Eye, 30 Meters CX4 Cable, Best EQ Setting

(TP3 from Figure 15)

200mV/DI

50ps/DIV

07060-023

Figure 17. 3.75 Gbps Input Eye, 30 Meters CX4 Cable (TP2 from Figure 15)

200mV/DI

50ps/DIV

07060-025

Figure 19. 3.75 Gbps Output Eye, 30 Meters CX4 Cable, Best EQ Setting

(TP3 from Figure 15)

Rev. B | Page 11 of 36

ADN8102

V

V

V

V

V

50Ω CABLES

DATA OUT

2 2

PATTERN

GENERATOR

200mV/DI

TP1

INPUT

OUTPUT

PIN

ADN8102

AC-COUPLED

EVALUATION

BOARD

50Ω CABLES

2 2

PIN

FR4 TEST BACKPL ANE

DIFFERENTIAL

STRIPLINE TRACES

TP2

8mils WIDE, 8mils SPACE,

8mils DIELECTRIC HEIGHT

TRACE LENGTHS = 40''

50Ω CABLES

2 2

TP3

50Ω

HIGH SPEED

SAMPLING

OSCILLOSCOPE

REFERENCE EYE DI AGRAM AT TP1

50ps/DIV

200mV/DI

50ps/DIV

Figure 21. 3.25 Gbps Output Eye, 40 Inch FR4 Output Channel,

PE = 0 (TP3 from Figure 20)

Figure 20. Output Pre-Emphasis Test Circuit, FR4

200mV/DI

07060-027

Figure 23. 3.25 Gbps Output Eye, 40 Inch FR4 Output Channel,

50ps/DIV

PE = Best Setting (TP3 from Figure 20)

07060-026

07060-029

200mV/DI

50ps/DIV

Figure 22. 3.75 Gbps Output Eye, 40 Inch FR4 Output Channel,

PE = 0 (TP3 from Figure 20)

07060-028

200mV/DI

50ps/DIV

Figure 24. 3.75 Gbps Output Eye, 40 Inch FR4 Output Channel,

PE = Best Setting (TP3 from Figure 20)

07060-030

Rev. B | Page 12 of 36

ADN8102

V

V

V

V

V

50Ω CABLES

DATA OUT

22

PATTERN

GENERATOR

200mV/DI

TP1

INPUT

OUTPUT

PIN

ADN8102

AC-COUPLED

EVALUATION

BOARD

50Ω CABLES

22

PIN

TP2

15m CX4 CABLE

50Ω CABLES

22

50Ω

HIGH SPEED

TP3

SAMPLING

OSCILLOSCOPE

REFERENCE EYE DI AGRAM AT TP1

50ps/DIV

50mV/DI

Figure 26. 3.25 Gbps Output Eye, 15 Meters CX4 Cable,

50ps/DIV

PE = 0 (TP3 from Figure 25)

Figure 25. Output Pre-Emphasis Test Circuit, CX4

50mV/DI

07060-032

Figure 28. 3.25 Gbps Output Eye, 15 Meters CX4 Cable,

50ps/DIV

PE = Best Setting (TP3 from Figure 25)

07060-031

07060-034

50mV/DI

50ps/DIV

Figure 27. 3.75 Gbps Output Eye, 15 Meters CX4 Cable,

PE = 0 (TP3 from Figure 25)

07060-033

50mV/DI

50ps/DIV

Figure 29. 3.75 Gbps Output Eye, 15 Meters CX4 Cable,

PE = Best Setting (TP3 from Figure 25)

07060-035

Rev. B | Page 13 of 36

ADN8102

80

70

60

100

80

50

40

30

20

DETERMINISTIC JITTER (ps)

10

0

02040

DATA RATE (Hz)

Figure 30. Deterministic Jitter vs. Data Rate

100

90

80

70

60

50

40

30

DETERMINISTIC JITTER (ps)

20

10

0

0 0.5 1.0 1.5 2.0 2.5

DIFFERENTIAL INPUT SWING (V)

Figure 31. Deterministic Jitter vs. Differential Input Swing

60

07060-036

07060-037

60

40

DETERMINI STIC JIT TER (ps)

20

0

1.0 1.5 2.0 2. 5 3.0 3.5 4.0

VCC = 1.8V

VCC = 3.3V

INPUT COMMON MODE (V)

Figure 33. Deterministic Jitter vs. Input Common Mode

100

80

60

40

DETERMINI STIC JIT TER (ps)

20

0

1.0 1.5 2.0 2. 5 3.0 3.5 4.0

(V)

V

CC

Figure 34. Deterministic Jitter vs. Supply Voltage (VCC)

07060-039

07060-040

100

80

60

40

DETERMINI STIC JIT TER (ps)

20

0

–60 –40 –20 0 20 40 60 80 100

TEMPERATURE ( °C)

Figure 32. Deterministic Jitter vs. Temperature

07060-038

Rev. B | Page 14 of 36

100

80

60

40

DETERMINI STIC JIT TER (ps)

20

0

1.0 1.5 2.0 2. 5 3.0 3.5 4.0

V

TTO

VCC = 1.8V

VCC = 3.3V

(V)

Figure 35. Deterministic Jitter vs. Output Termination Voltage (V

TTO

07060-041

)

ADN8102

450000

400000

350000

300000

250000

200000

150000

NUMBER OF SAMPLES

100000

50000

0

–8 –6 –4 –2 0 2 4 6 8 10

JITTER ( ps)

07060-042

Figure 36. Random Jitter Histogram

100

90

80

(ps)

F

/t

R

t

70

60

50

–60 –40 –20 0 20 40 60 80 100

Figure 37. Rise Time (t

tR/t

F

TEMPERATURE ( °C)

)/Fall Time (tF) vs. Temperature

R

07060-043

Rev. B | Page 15 of 36

ADN8102

A

THEORY OF OPERATION

INTRODUCTION

The ADN8102 is a quad, bidirectional cable and backplane

equalizer that provides both input equalization and output preemphasis on both the line card and cable sides of the device.

The device supports full loopback and through connectivity

of the two unidirectional half-links, each consisting of four

differential signal pairs.

The ADN8102 offers extensively programmable output levels

and pre-emphasis as well as the ability to disable the output

current. The receivers integrate a programmable, multizero

equalizer transfer function that is optimized to compensate

either typical backplane or typical cable losses.

The I/O on-chip termination resistors are terminated to usersettable supplies to support dc coupling in a wide range of logic

styles. The ADN8102 supports a wide core supply range; V

can be set from 1.8 V to 3.3 V. These features, together with

programmable output levels, allow for a wide range of dc- and

ac-coupled I/O configurations.

The ADN8102 supports several control and configuration

modes, as shown in Tabl e 5. The pin control mode offers access

to a subset of the total feature list but allows for a much

simplified control scheme. The primary advantage of using the

serial control interface is that it allows finer resolution in setting

receive equalization, transmitter preemphasis, loss-of-signal

(LOS) behavior, and output levels.

By default, the ADN8102 starts in pin control mode. Strobing

RESET

the

pin sets all on-chip registers to their default values

and uses pins to configure loopback, PE, and EQ levels. In

Table 5. Control Interface Mode Register

Address Default Register Name Bit Bit Name Functionality Description

0x0F 0x00 Control 7:2 Reserved Set to 0.

interface mode 1:0 MODE[1:0] 00 = toggle pin control. Asynchronous control through toggle pins only.

11 = serial control. Register-based control through the I2C serial interface.

CC

01 = Loopback control via toggle pins, equalization, and preemphasis via

register-based control through the I2C serial interface.

10 = Equalization and preemphasis via toggle pins and loopback control

via register-based control through the I

mixed mode, loopback is still controlled through the external

pin. The user can override PE and EQ settings in mixed mode.

In serial mode, all functions are accessed through registers, and

the control pin inputs are ignored, except

The ADN8102 register set is controlled through a 2-wire, I

interface. The ADN8102 acts only as an I

slave address for the ADN8102 I

2

C interface contains the static

RESET

.

2

2

C slave device. The 7-bit

C

value b10010 for the upper four bits. The lower two bits are

controlled by the input pins, ADDR[1:0]

LOS_B

Ix_B[3:0]

Ox_A[3:0]

DDR[1:0]

SCL

SDA

RESET

RECEIVE

EQUALIZATION

EQ

LB

TRANSMIT

PRE-EMPHASIS

PE

Figure 38. Simplified Functional Block Diagram

ADN8102

2:1

CONTROL LO GIC

TRANSMIT

PRE-EMPHASIS

2:1

RECEIVE

EQUALIZATION

PE

EQ

Ox_B[3:0]

LOS_A

Ix_A[3:0]

EQ_A[1:0]

PE_A[1:0]

EQ_B[1:0]

PE_B[1:0]

ENA

ENB

2

C serial interface.

07060-003

Rev. B | Page 16 of 36

ADN8102

V

RECEIVERS

Input Structure and Input Levels

The ADN8102 receiver inputs incorporate 50 Ω termination

resistors, ESD protection, and a multizero transfer function

equalizer that can be optimized for backplane or cable operation.

Each channel also provides a programmable LOS function that

provides an interrupt that can be used to squelch or disable the

associated output when the differential input voltage falls below the

programmed threshold value. Each receive channel also provides a

P/N inversion function that allows the user to swap the sign of

the input signal path to eliminate the need for board-level

crossovers in the receiver channel.

Tabl e 6 illustrates some, but not all, possible combinations of

input supply voltages.

Table 6. Common Input Voltage Levels

Configuration VCC (V) V

Low V

, ac-coupled input 1.8 1.6

TTI

(V)

TTI

Single 1.8 V supply 1.8 1.8

3.3 V core 3.3 1.8

Single 3.3 V supply 3.3 3.3

V

CC

TTI

IP

IN

V

EE

SIMPLI FIED REC EIVER INPUT CIRCUI T

R1

R2

RLN RLP

Q1

R3

1kΩ

RP

52Ω

Figure 39. Simplified Input Structure

RN

52Ω

750Ω

750Ω

Q2

I1

EQUALIZATION SETTINGS

The ADN8102 receiver incorporates a multizero transfer function,

continuous time equalizer that provides up to 22 dB of high

frequency boost at 1.875 GHz to compensate up to 30 meters

of CX4 cable or 40 inches of FR4 at 3.75 Gbps. The ADN8102

allows joint control of the equalizer transfer function of the

four equalizer channels in a single port through the I

interface. Port A and Port B equalizer transfer functions are

controlled via Register 0x80 and Register 0xA0, respectively.

The equalizer transfer function allows independent control of

the boost in two different frequency ranges for optimal matching

with the loss shape of the user’s channel (for example, skin-effect

loss dominated or dielectric loss dominated). By default, the

equalizer control is simplified to two independent look up

tables (LUT) of basic settings that provide nine settings, each

optimized for CX4 cable and FR4 to ease programming for

2

C control

07060-004

typical channels. The default state of the part selects the CX4

optimized equalization map for the IN_A[3:0] channels that

interface with the cable and the FR4 optimized equalization map

for the IN_B[3:0] channels that interface with the board. Full

control of the equalizer is available via the I

2

C control interface by

writing MODE[0] = 1 at Address 0x0F. Ta b l e 8 summarizes the

high frequency boost for each of the basic control settings and

the typical length of CX4 cable and FR4 trace that each setting

compensates. Setting the EQBY bit of the IN_A/IN_B configuration

registers high sets the equalization to 1.5 dB of boost, which

compensates 0 meters to 2 meters of CX4 or 0 inches to

5 inches of FR4.

Setting the LUT SELECT bit = 1 (Bit 1 in the IN_Ax/IN_Bx FR4

control registers) allows the default map selection (CX4 or FR4

optimized) to be overwritten via the LUT FR4/CX4 bit (Bit 0)

in the IN_Ax/IN_Bx FR4 control registers. Setting this bit high

selects the FR4 optimized map, and setting it low selects the CX4

optimized map. These settings are set on a per channel basis

(see Tabl e 9 and Ta b le 2 2 ).

Table 7.

LUT SELECT LUT FR4/CX4 Description

0 (default) X1

Port A eq optimized for CX4

cable

Port B eq optimized for FR4

PCB trace

1 0 Eq optimized for CX4 cable

1 1 Eq optimized for FR4 PCB trace

1

X = don’t care.

Advanced Equalization Settings

The user can also specify the boost in the midfrequency and high

frequency ranges independently. This is done by writing to the

IN_A/IN_B EQ1 control and IN_A/IN_B EQ2 control registers for

the channel of interest. Each of these registers provides 32 settings

of boost, with IN_A/IN_B EQ1 control setting the midfrequency

boost and IN_A/IN_B EQ2 control setting the high frequency

boost. The IN_A/IN_B EQx control registers are ordered such

that Bit 5 is a sign bit, and midlevel boost is centered on 0x00;

setting Bit 5 low and increasing the LSBs results in decreasing

boost, while setting Bit 5 high and increasing the LSBs results in

increasing boost. The EQ CTL SRC bit (Bit 6) in the IN_A/IN_B

EQ1 control registers determines whether the equalization

control for the channel of interest is selected from the optimized

map or directly from the IN_A/IN_B EQx control registers (per

port). Setting this bit high selects equalization control directly

from the IN_A/IN_B EQx control registers, and setting it low

selects equalization control from the selected optimized map.

Rev. B | Page 17 of 36

ADN8102

Table 8. Receive Equalizer Boost vs. Setting (CX4 and FR4 Optimized Maps)

IN_Ax/IN_Bx

EQ_A[1:0] and

EQ_B[1:0] Pins

X

0 0 0 10 2 to 6 3.5 5 to 10

1 0 12 8 to 10 3.9 10 to 15

1 2 0 14 12 to 14 4.25 15 to 20

3 0 17 16 to 18 4.5 20 to 25

4 0 19 20 to 22 4.75 25 to 30

2 5 0 20 24 to 26 5.0 30 to 35

6 0 21 28 to 30 5.3 35 to 40

3 7 0 22 30 to 32 5.5 35 to 40

1

X = Don’t care

Configuration,

EQ[2:0]

1

1 1.5 < 2 1.5 < 5

Table 9. Receive Configuration and Equalization Registers

Name Address Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0 Default

IN_A/IN_B

configuration

IN_A/IN_B

EQ1 control

IN_A/IN_B

EQ2 control

IN_Ax/IN_Bx

FR4 control

0x80, 0xA0 PNSWAP EQBY EN EQ[2] EQ[1] EQ[0] 0x30

0x83, 0xA3 EQ CTL SRC EQ1[5] EQ1[4] EQ1[3] EQ1[2] EQ1[1] EQ1[0] 0x00

0x84, 0xA4 EQ2[5] EQ2[4] EQ2[3] EQ2[2] EQ2[1] EQ2[0] 0x00

0x85, 0x8D, 0x95,

0x9D, 0xA5, 0xAD,

0xB5, 0xBD

Loss of Signal/Signal Detect

An independent signal detect output is provided for all eight

input ports of the device. The signal-detect function measures

the low frequency amplitude of the signal at the receiver input

and compares this measurement with a defined threshold level.

If the measurement indicates that the input signal swing is

smaller than the threshold for 250 μs, the channel indicates a

loss-of-signal event. Assertion and deassertion of the LOS signal

occurs within 100 μs of the event.

The LOS-assert and LOS-deassert levels are set on a per channel

basis through the I

2

C control interface, by writing to the IN_A/

IN_B LOS threshold and IN_A/IN_B LOS hysteresis registers,

respectively. The recommended settings are IN_A/IN_B LOS

threshold = 0x0C and IN_A/IN_B LOS hysteresis = 0x0D.

All ports are factory tested with these settings to ensure that an

LOS event is asserted for single-ended dc input swings less than

20 mV and is deasserted for single-ended dc input swings greater

than 225 mV.

The LOS status for each individual channel can be accessed

through the I

2

C control interface. The independent channel

LOS status can be read from the IN_A/IN_B LOS status registers

(Address 0x1F and Address 0x3F). The four LSBs of each register

represent the current LOS status of each channel, with high

representing an ongoing LOS event. The four MSBs of each

Cable Optimized FR4 Optimized

Typical CX4 Cable

EQBY Boost (dB)

LUT SELECT LUT FR4/CX4 0x00

Length (Meters) Boost (dB)

Typical FR4 Trace

Length (Inches)

register represent the historical LOS status of each channel,

with high representing a LOS event at any time on a specific

channel. The MSBs are sticky and remain high once asserted

until cleared by the user by overwriting the bits to 0.

Recommended LOS Settings

Recommended settings for LOS are as follows:

• Set IN_A/IN_B LOS threshold to 0x0C for an assert

voltage of 20 mV differential (40 mV p-p differential).

• Set IN_A/IN_B LOS hysteresis to 0x0D for a deassert voltage

of 225 mV differential (450 mV p-p differential).

LANE INVERSION

The input P/N inversion is a feature intended to allow the user

to implement the equivalent of a board-level crossover in a much

smaller area and without additional via impedance discontinuities

that degrade the high frequency integrity of the signal path. The

P/N inversion is available on a per port basis and is controlled

through the I

plished by writing to the PNSWAP bit (Bit 6) of the IN_A/IN_B

configuration register (see Tabl e 9) with low representing a

noninverting configuration and high representing an inverting

configuration. Note that using this feature to account for signal

inversions downstream of the receiver requires additional attention

when switching connectivity.

2

C control interface. The P/N inversion is accom-

Rev. B | Page 18 of 36

ADN8102

Table 10. LOS Threshold and Hysteresis Control Registers

Name Address Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0 Default

IN_A/IN_B

LOS threshold

IN_A/IN_B

LOS hysteresis

0x81,

0xA1

0x82,

0xA2

Table 11. LOS Status Registers

Name Address Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

IN_A/IN_B

LOS status

0x1F,

0x3F

THRESH[6] THRESH[5] THRESH[4] THRESH[3] THRESH[2] THRESH[1] THRESH[0] 0x04

HYST[6] HYST[5] HYST[4] HYST[3] HYST[2] HYST[1] HYST[0] 0x12

STICKY

LOS[3]

STICKY

LOS[2]

STICKY

LOS[1]

STICKY LOS[0]

REAL-TIME

LOS[3]

REAL-TIME

LOS[2]

REAL-TIME

LOS[1]

REAL-TIME

LOS[0]

Rev. B | Page 19 of 36

ADN8102

A

LOOPBACK

The ADN8102 provides loopback on both input ports (Port A:

cable interface input, and Port B: line card interface input). The

external loopback toggle pin, LB, controls the loopback of the Port

B input only (board side loopback). When loopback is asserted,

valid data continues to pass through the Port B link, but the

Port B input signals are also shunted to the Port A output to allow

testing and debugging without disrupting valid data. This

loopback, as well as loopback of the Port A input (cable side

loopback), can be programmed through the I

loopbacks are controlled through the I

Bit 0 and Bit 1 of the loopback control register (Register 0x02).

CABLE SIDE LOO PBACK BOARD SIDE LOOPBACK FULL LO OPBACK

Ix_B[3:0]

Ox_A[3:0]

LB

RECEIVE

EQUALIZATION

EQ

TRANSMIT

PRE-EMPHASIS

PE

TRANSMIT

PRE-EMPHASIS

PE

RECEIVE

EQUALIZATION

EQ

Ox_B[3:0]

LOS_A

Ix_A[3:0]

2

C interface. The

2

C interface by writing to

RECEIVE

EQUALIZATION

Ix_B[3:0]

Ox_A[3:0]

LB

EQ

TRANSMIT

PRE-EMPHASIS

PE

Bit 0 represents loopback of the Port A inputs to the Port B

outputs (cable side loopback). Bit 1 represents loopback of the

Port B inputs to the Port A outputs (board side loopback), with

high representing loopback for both bits. Bit 1 can be overridden

by the LB pin if the pin mode register is set to enable loopback

via external pin as shown in Ta b le 5 . Both input ports can be

looped back simultaneously (full loopback) by writing high to

both Bit 0 and Bit 1, but in this case, valid data is disrupted on

each channel. Figure 40 illustrates the three loopback modes.

TRANSMIT

PRE-EMPHASIS

PE

RECEIVE

EQUA LIZATION

EQ

Ox_B[3:0 ]

LOS_A

Ix_A[3:0]

Ix_B[3:0]

Ox_A[3:0 ]

LB

RECEIVE

EQUALIZATION

EQ

TRANSMIT

PRE-EMPHASIS

PE

TRANSMIT

PRE-EMPHASIS

PE

RECEIVE

EQUALIZATION

EQ

Ox_B[3:0]

LOS_A

Ix_A[3:0]

DDR[1:0]

SCL

SDA

RESET

CONTROL LOGIC

EQ_A[1:0]

PE_A[1:0]

EQ_B[1:0]

PE_B[1:0]

ENA

ENB

ADDR[1:0]

SCL

SDA

RESET

CONTROL LOGIC

EQ_A[1:0]

PE_A [1:0]

EQ_B[1:0]

PE_B [1:0]

ENA

ENB

ADDR[1:0]

SCL

SDA

RESET

CONTROL LOGIC

EQ_A[1:0]

PE_A[1:0]

EQ_B[1:0]

PE_B[1:0]

ENA

ENB

07060-005

Figure 40. Loopback Modes of Operation

Table 12. Loopback Control Functionality

Control Mode1 LB Pin LB[1] LB[0] Description

Pin Control (00 or 01) 0 X2 X Loopback disabled

1 X X Board side loopback enabled

Serial Control X 0 0 Loopback disabled

(10 or 11) X 0 1 Cable side loopback enabled

X 1 0 Board side loopback enabled

X 1 1 Full loopback enabled

1

Refer to Table 5 for additional information regarding control mode settings.

2

X = don’t care.

Table 13. Loopback Control Register

Name Address Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0 Default

Loopback control 0x02 LB[1] LB[0] 0x00

Rev. B | Page 20 of 36

ADN8102

TRANSMITTERS

Output Structure and Output Levels

The ADN8102 transmitter outputs incorporate 50 Ω termination resistors, ESD protection, and an output current switch. Each

port provides control of both the absolute output level and the

pre-emphasis output level. It should be noted that the choice of

output level affects the output common-mode level. A 600 mV

peak-to-peak differential output level with full pre-emphasis

range requires an output termination voltage of 2.5 V or greater

(V

, VCC ≥ 2.5 V).

TTO

Tx SIMPLIFIED DIAGRAM

V3

VC

V2

VP

V1

VN

Figure 41. Simplified Output Structure

ON-CHIP

TERMINATION

RP

50Ω

Q1

+ I

I

DC

PE

ESD

RN

50Ω

Q2

I

TOT

Pre-Emphasis

The total output amplitude and pre-emphasis setting space is

reduced to a single map of basic settings that provide seven

settings of output equalization to ease programming for typical

channels. The PE_A/PE_B[1:0] pins provide selections 0, 2, 4,

and 6 of the seven pre-emphasis settings through toggle pin

control, covering the entire range of settings at lower resolution.

The full resolution of seven settings is available through the I

interface by writing to Bits[2:0] (PE[2:0] of the OUT_A/OUT_B

configuration registers) with I

2

C settings overriding the toggle

V

V

OP

ON

V

CC

TTO

EE

2

C

07060-006

pin control. Similar to the receiver settings, the ADN8102 allows

joint control of all four channels in a transmit port. Tab l e 15

summarizes the absolute output level, pre-emphasis level, and

high frequency boost for each of the basic control settings and

the typical length of the CX4 cable and FR4 trace that each

setting compensates.

Full control of the transmit output levels is available through the

2

I

C control interface. This full control is achieved by writing to

the OUT_A/OUT_B Output Level Control[1:0] registers for the

channel of interest. Tab le 1 7 shows the supported output level

settings of the OUT_A/OUT_B Output Level Control[1:0]

registers. Register settings not listed in Tab l e 1 7 are not

supported by the ADN8102.

The output equalization is optimized for less than 1.75 Gbps

operation but can be optimized for higher speed applications at

up to 3.75 Gbps through the I

2

C control interface by writing to

the DATA RATE bit (Bit 4) of the OUT_A/OUT_B configuration

registers, with high representing 3.75 Gbps and low representing

1.75 Gbps. The PE CTL SRC bit (Bit 7) in the OUT_A/OUT_B

Output Level Control 1 register determines whether the preemphasis and output current controls for the channel of interest

are selected from the optimized map or directly from the OUT_A/

OUT_B Output Level Control[1:0] registers (per channel). Setting

this bit high selects pre-emphasis control directly from the

OUT_A/OUT_B Output Level Control[1:0] registers, and setting

it low selects pre-emphasis control from the optimized map.

Table 14. Data Rate Select

OUT_A/OUT_B Configuration Bit 4 Supported Data Rates

0 (default) 0 Gbps to 1.75 Gbps

1 1.75 Gbps to 3.75 Gbps

Table 15. Transmit Pre-Emphasis Boost and Overshoot vs. Setting

PE[2:0] Register PE[1:0] Pins Boost (dB) Overshoot (%)

DC Swing

(mV p-p diff)

Typical CX4 Cable

Length (Meters)

Typical FR4 Trace

Length (Inches)

0 0 0 0 800 0 to 2.5 0 to 5

1 Not applicable 2 25 800 2.5 to 5 0 to 5

2 1 3.5 50 800 5 to 7.5 10 to 15

3 Not applicable 4.9 75 800 7.5 to 10 10 to 15

4 2 6 100 800 10 to 12.5 15 to 20

5 Not applicable 7.4 133 600 15 to 17.5 20 to 25

6 4 9.5 200 400 20 to 22.5 25 to 30

Table 16. Output Configuration Registers

Name Address Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0 Default

OUT_A/OUT_B configuration 0xC0, 0xE0 EN DATA RATE PE[2] PE[1] PE[0] 0x20

OUT_A/OUT_B Output Level Control 1 0xC1, 0xE1 PE CTL SRC OUTx_OLEV1[6:0] 0x40

OUT_A/OUT_B Output Level Control 0 0xC2, 0xE2 OUTx_OLEV0[6:0] 0x40

Rev. B | Page 21 of 36

ADN8102

Table 17. Output Level Settings

V

(mV) V

SW-DC

50 50 100 100 0.00 2 0x00 0x81

50 150 100 300 9.54 6 0x11 0x81

50 250 100 500 13.98 10 0x22 0x81

50 350 100 700 16.90 14 0x33 0x81

50 450 100 900 19.08 18 0x44 0x81

50 550 100 1100 20.83 22 0x55 0x81

50 650 100 1300 22.28 26 0x66 0x81

100 100 200 200 0.00 4 0x00 0x91

100 200 200 400 6.02 8 0x11 0x91

100 300 200 600 9.54 12 0x22 0x91

100 400 200 800 12.04 16 0x33 0x91

100 500 200 1000 13.98 20 0x44 0x91

100 600 200 1200 15.56 24 0x55 0x91

100 700 200 1400 16.90 28 0x66 0x91

150 150 300 300 0.00 6 0x00 0x92

150 250 300 500 4.44 10 0x11 0x92

150 350 300 700 7.36 14 0x22 0x92

150 450 300 900 9.54 18 0x33 0x92

150 550 300 1100 11.29 22 0x44 0x92

150 650 300 1300 12.74 26 0x55 0x92

150 750 300 1500 13.98 30 0x66 0x92

200 200 400 400 0.00 8 0x00 0xA2

200 300

200 400

200 500

200 600

200 700

200 800

250 250 500 500 0.00 10 0x00 0xA3

250 350 500 700 2.92 14 0x11 0xA3

250 450 500 900 5.11 18 0x22 0xA3

250 550 500 1100 6.85 22 0x33 0xA3

250 650 500 1300 8.30 26 0x44 0xA3

250 750 500 1500 9.54 30 0x55 0xA3

250 850 500 1700 10.63 34 0x66 0xA3

300 300 600 600 0.00 12 0x00 0xB3

300 400 600 800 2.50 16 0x11 0xB3

300 500 600 1000 4.44 20 0x22 0xB3

300 600 600 1200 6.02 24 0x33 0xB3

300 700 600 1400 7.36 28 0x44 0xB3

300 800 600 1600 8.52 32 0x55 0xB3

300 900 600 1800 9.54 36 0x66 0xB3

350 350 700 700 0.00 14 0x00 0xB4

350 450 700 900 2.18 18 0x11 0xB4

350 550 700 1100 3.93 22 0x22 0xB4

350 650 700 1300 5.38 26 0x33 0xB4

350 750 700 1400 6.62 30 0x44 0xB4

350 850 700 1700 7.71 34 0x55 0xB4

350 950 700 1900 8.67 38 0x66 0xB4

400 400 800 800 0.00 16 0x00 0xC4

400 500 800 1000 1.94 20 0x11 0xC4

400 600 800 1200 3.52 24 0x22 0xC4

400 700 800 1400 4.86 28 0x33 0xC4

400 800 800 1600 6.02 32 0x44 0xC4

400 900 800 1800 7.04 36 0x55 0xC4

400 1000 800 2000 7.96 40 0x66 0xC4

SW-PE

(mV) V

DPP-DC

400

400

400

400

400

400

(mV) V

(mV) PE (dB) I

DPP-PE

(mA) OUT_A/OUT_B OLEV 0 OUT_A/OUT_B OLEV 1

TOT

600 3.52 12 0x11 0xA2

800 6.02 16 0x22 0xA2

1000 7.96 20 0x33 0xA2

1200 9.54 24 0x44 0xA2

1400 10.88 28 0x55 0xA2

1600 12.04 32 0x66 0xA2

Rev. B | Page 22 of 36

ADN8102

V

(mV) V

SW-DC

450 450 900 900 0.00 18 0x00 0xC5

450 550 900 1100 1.74 22 0x11 0xC5

450 650 900 1300 3.19 26 0x22 0xC5

450 750 900 1500 4.44 30 0x33 0xC5

450 850 900 1700 5.52 34 0x44 0xC5

450 950 900 1900 6.49 38 0x55 0xC5

450 1050 900 2100 7.36 42 0x66 0xC5

500 500 1000 1000 0.00 20 0x00 0xD5

500 600 1000 1200 1.58 24 0x11 0xD5

500 700 1000 1400 2.92 28 0x22 0xD5

500 800 1000 1600 4.08 32 0x33 0xD5

500 900 1000 1800 5.11 36 0x44 0xD5

500 1000 1000 2000 6.02 40 0x55 0xD5

500 1100 1000 2200 6.85 44 0x66 0xD5

550 550 1100 1100 0.00 22 0x00 0xD6

550 650 1100 1300 1.45 26 0x11 0xD6

550 750 1100 1500 2.69 30 0x22 0xD6

550 850 1100 1700 3.78 34 0x33 0xD6

550 950 1100 1900 4.75 38 0x44 0xD6

550 1050 1100 2100 5.62 42 0x55 0xD6

550 1150 1100 2300 6.41 46 0x66 0xD6

600 600 1200 1200 0.00 24 0x00 0xE6

600 700 1200 1400 1.34 28 0x11 0xE6

600 800 1200 1600 2.50 32 0x22 0xE6

600 900 1200 1800 3.52 36 0x33 0xE6

600 1000 1200 2000 4.44 40 0x44 0xE6

600 1100 1200 2200 5.26 44 0x55 0xE6

600 1200 1200 2400 6.02 48 0x66 0xE6

650 650 1300 1300 0.00 26 0x01 0xE6

650 750 1300 1500 1.24 30 0x12 0xE6

650 850 1300 1700 2.33 34 0x23 0xE6

650 950 1300 1900 3.30 38 0x34 0xE6

650 1050 1300 2100 4.17 42 0x45 0xE6

650 1150 1300 2300 4.96 46 0x56 0xE6

700 700 1400 1400 0.00 28 0x02 0xE6

700 800 1400 1600 1.16 32 0x13 0xE6

700 900 1400 1800 2.18 36 0x24 0xE6

700 1000 1400 2000 3.10 40 0x35 0xE6

700 1100 1400 2300 3.93 44 0x46 0xE6

750 750 1500 1500 0.00 30 0x03 0xE6

750 850 1500 1700 1.09 34 0x14 0xE6

750 950 1500 1900 2.05 38 0x25 0xE6

750 1050 1500 2100 2.92 42 0x36 0xE6

800 800 1600 1600 0.00 32 0x04 0xE6

800 900 1600 1800 1.02 36 0x15 0xE6

800 1000 1600 2000 1.94 40 0x26 0xE6

850 850 1700 1700 0.00 34 0x05 0xE6

850 950 1700 1900 0.97 38 0x16 0xE6

900 900 1800 1800 0.00 36 0x06 0xE6

SW-PE

(mV) V

(mV) V

DPP-DC

(mV) PE (dB) I

DPP-PE

(mA) OUT_A/OUT_B OLEV 0 OUT_A/OUT_B OLEV 1

TOT

Rev. B | Page 23 of 36

ADN8102

SELECTIVE SQUELCH AND DISABLE

Each transmitter is equipped with output disable and output

squelch controls. Disable is a full power-down state: the transmitter current is reduced to zero, and the output pins pull up

to V

, but there is a delay of approximately 1 μs associated

TTO

with re-enabling the transmitter. The output disable control is

accessed through the EN bit (Bit 4) of the OUT_A/OUT_B

configuration registers through the I

Squelch is not a full power-down state but a state in which only

the output current is reduced to zero and the output pins pull

up to V

, and there is a much smaller delay to bring back the

TTO

output current. The output squelch and the output disable control

can both be accessed through the OUT_A/OUT_B squelch

control registers, with the top nibble representing the squelch

control for one entire output port, and the bottom nibble

representing the output disable for one entire output port. The

ports are disabled or squelched by writing 0s to the corresponding

nibbles. The ports are enabled by writing all 1s, which is the

2

C control interface.

default setting. For example, to squelch Port A, Register 0xC3

must be set to 0x0F. The entire nibble must be written to all 0s

for this functionality.

Table 18. Squelch and Disable Control Registers

Name Address Data Default

OUT_A/

OUT_B

squelch

control

0xC3,

0xE3

SQUELCH[3:0] DISABLE[3:0]

0xFF

Table 19. Squelch and Disable Functionality

SQUELCH[3:0]

1111 1111 Enabled (default)

xxxx1 0000 Disabled

0000 1111 Squelched

1

xxxx = don’t care

DISABLE[3:0]

Output State

Rev. B | Page 24 of 36

ADN8102

G

I2C CONTROL INTERFACE

SERIAL INTERFACE GENERAL FUNCTIONALITY

The ADN8102 register set is controlled through a 2-wire

2

C interface. The ADN8102 acts only as an I2C slave device.

I

Therefore, the I

master to configure the ADN8102 and other I

2

C bus in the system needs to include an I2C

2

C devices that

may be on the bus. Data transfers are controlled using the two

2

I

C wires: the SCL input clock pin and the SDA bidirectional

data pin.

The ADN8102 I

2

C interface can be run in the standard (100 kHz)

and fast (400 kHz) modes. The SDA line only changes value

when the SCL pin is low with two exceptions. To indicate the

beginning or continuation of a transfer, the SDA pin is driven

low while the SCL pin is high, and to indicate the end of a

transfer, the SDA line is driven high while the SCL line is high.

Therefore, it is important to control the SCL clock to toggle

only when the SDA line is stable, unless indicating a start,

repeated start, or stop condition.

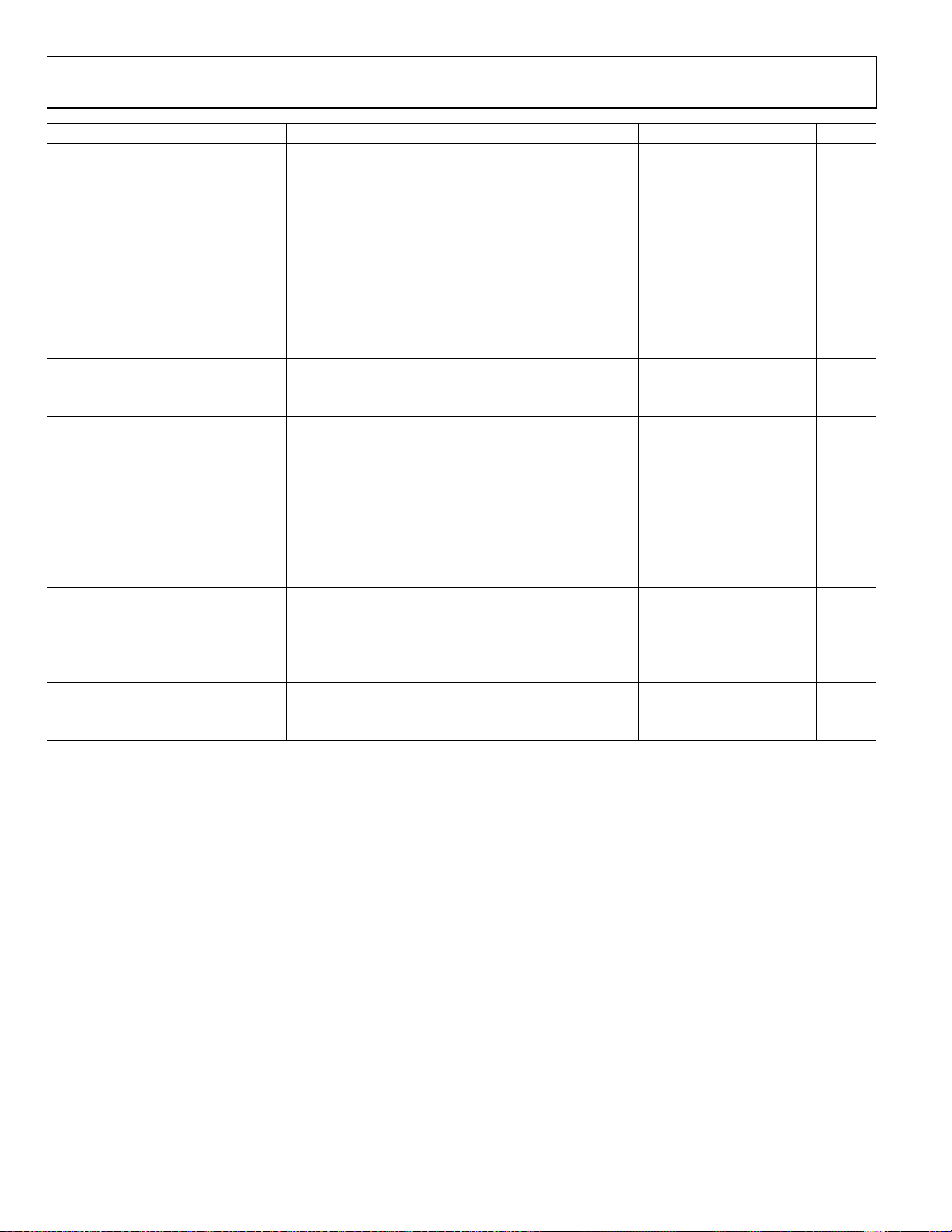

I2C INTERFACE DATA TRANSFERS—DATA WRITE

To write data to the ADN8102 register set, a microcontroller, or

any other I

to the ADN8102 slave device. The steps that need to be completed

are listed as follows, where the signals are controlled by the I

master, unless otherwise specified. A diagram of the procedure

can be seen in Figure 42.

1. Send a start condition (while holding the SCL line high,

2. Send the ADN8102 part address (seven bits) whose upper

3. Send the write indicator bit (0).

4. Wait for the ADN8102 to acknowledge the request.

5. Send the register address (eight bits) to which data is to be

6. Wait for the ADN8102 to acknowledge the request.

2

C master, needs to send the appropriate control signals

2

C

pull the SDA line low).

five bits are the static value 10010b and whose lower two

bits are controlled by the ADDR[1:0] input pins. This transfer

should be MSB first.

written. This transfer should be MSB first.

7. Send the data (eight bits) to be written to the register whose

address was set in Step 5. This transfer should be MSB first.

8. Wait for the ADN8102 to acknowledge the request.

9a. Send a stop condition (while holding the SCL line high,

pull the SDA line high) and release control of the bus.

9b. Send a repeated start condition (while holding the SCL line

high, pull the SDA line low) and continue with Step 2 in

this procedure to perform another write.

9c. Send a repeated start condition (while holding the SCL line

high, pull the SDA line low) and continue with Step 2 of

the read procedure (in the I2C Interface Data Transfers—

Data Read section) to perform a read from another address.

9d. Send a repeated start condition (while holding the SCL line

high, pull the SDA line low) and continue with Step 8 of

the read procedure (in the I2C Interface Data Transfers—

Data Read section) to perform a read from the same

address set in Step 5.

Figure 42 shows the ADN8102 write process. The SCL signal is

shown along with a general write operation and a specific example.

In the example, Data 0x92 is written to Address 0x6D of an

ADN8102 part with a part address of 0x4B. The part address is

seven bits wide. The upper five bits of the ADN8102 are internally

set to 10010b. The lower two bits are controlled by the ADDR[1:0]

pins. In this example, the bits controlled by the ADDR[1:0] pins

are set to 11b. In Figure 42, the corresponding step number is

visible in the circle under the waveform. The SCL line is driven by

2

the I

C master and never by the ADN8102 slave. As for the SDA

line, the data in the shaded polygons is driven by the ADN8102,

whereas the data in the nonshaded polygons is driven by the I

2

C

master. The end phase case shown is that of Step 9a.

Note that the SDA line only changes when the SCL line is low,

except for the case of sending a start, stop, or repeated start

condition, Step 1 and Step 9 in this case.

SCL

ENERAL CASE

SDA

EXAMPLE

SDA

START REGISTER ADDR

FIXED PART ADDR

1

2 2 3 4 5 6 7 8 9a

ADDR

[1:0]

ACK ACK ACK

R/W

Figure 42. I

2

C Write Diagram

STOPDATA

7060-008

Rev. B | Page 25 of 36

ADN8102

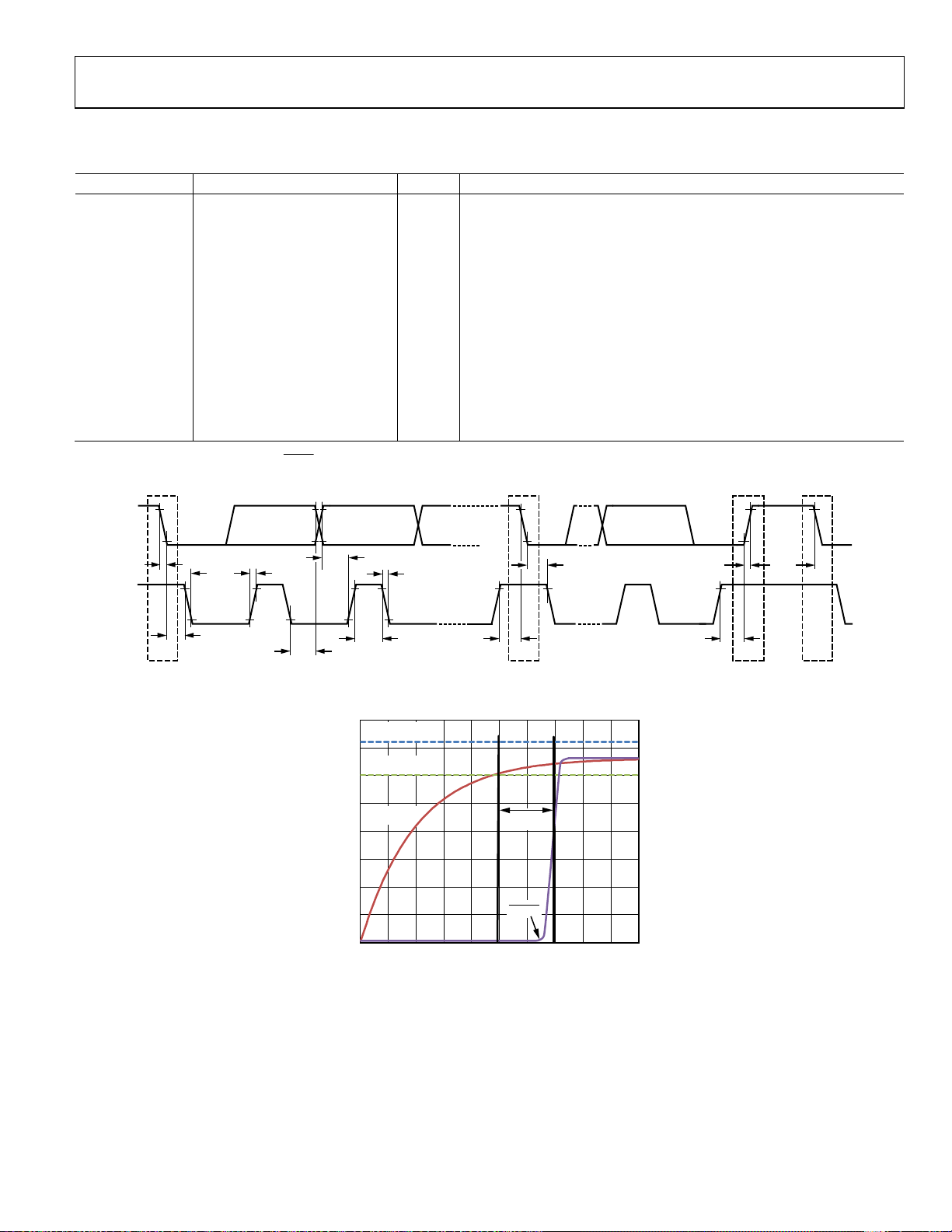

I2C INTERFACE DATA TRANSFERS—DATA READ

To read data from the ADN8102 register set, a microcontroller,

or any other I

signals to the ADN8102 slave device. The steps that need to be

completed are listed as follows, where the signals are controlled

by the I

procedure can be seen in Figure 43.

1. Send a start condition (while holding the SCL line high,

2. Send the ADN8102 part address (seven bits) whose

3. Send the write indicator bit (0).

4. Wait for the ADN8102 to acknowledge the request.

5. Send the register address (eight bits) from which data is

6. Wait for the ADN8102 to acknowledge the request.

7. Send a repeated start condition (while holding the SCL

8. Send the ADN8102 part address (seven bits) whose

9. Send the read indicator bit (1).

10. Wait for the ADN8102 to acknowledge the request.

11. The ADN8102 then serially transfers the data (eight bits)

12. Acknowledge the data.

2

C master, needs to send the appropriate control

2

C master, unless otherwise specified. A diagram of the

pull the SDA line low).

upper five bits are the static value 10010b and whose

lower two bits are controlled by the input pins ADDR[1:0].

This transfer should be MSB first.

to be read. This transfer should be MSB first. The register

address is kept in memory in the ADN8102 until the

part is reset or the register address is written over with

the same procedure (Step 1 to Step 6).

line high, pull the SDA line low).

upper five bits are the static value 10010b and whose

lower two bits are controlled by the input pins ADDR[1:0].

This transfer should be MSB first.

held in the register indicated by the address set in Step 5.

13a. Send a stop condition (while holding the SCL line high,

pull the SDA line high) and release control of the bus.

13b. Send a repeated start condition (while holding the SCL

line high, pull the SDA line low) and continue with Step 2

of the write procedure (in the I2C Interface Data

Transfers—Data Write section) to perform a write.

13c. Send a repeated start condition (while holding the SCL

line high, pull the SDA line low) and continue with Step 2 of

this procedure to perform a read from a another address.

13d. Send a repeated start condition (while holding the SCL

line high, pull the SDA line low) and continue with Step 8 of

this procedure to perform a read from the same address.

Figure 43 shows the ADN8102 read process. The SCL signal is

shown along with a general read operation and a specific example.

In the example, Data 0x49 is read from Address 0x6D of an

ADN8102 part with a part address of 0x4B. The part address is

seven bits wide. The upper five bits of the ADN8102 are internally

set to 10010b. The lower two bits are controlled by the ADDR[1:0]

pins. In this example, the bits controlled by the ADDR[1:0] pins

are set to 11b. In Figure 43, the corresponding step number is

visible in the circle under the waveform. The SCL line is driven

2

by the I

C master and never by the ADN8102 slave. As for the SDA

line, the data in the shaded polygons is driven by the ADN8102,

whereas the data in the nonshaded polygons is driven by the I

2

C

master. The end phase case shown is that of Step 13a.

Note that the SDA line changes only when the SCL line is low,

except for the case of sending a start, stop, or repeated start

condition, as in Step 1, Step 7, and Step 13. In Figure 43, A is the

same as ACK in Figure 42. Equally, Sr represents a repeated

start where the SDA line is brought high before SCL is raised.

SDA is then dropped while SCL is still high.

SCL

GENERAL CASE

START REGISTER ADDR

SDA

EXAMPLE

SDA

FIXED PART

ADDR

ADDR

[1:0]

R/

AAASr A

W

3221

4 5 6 7 8 1098 11 12 13a

Figure 43. I

2

C Read Diagram

Rev. B | Page 26 of 36

FIXED PART

ADDR

ADDR

[1:0]

R/

W

STOPDATA

07060-009

ADN8102

APPLICATIONS INFORMATION

OUTPUT COMPLIANCE

In low voltage applications, users must pay careful attention

to both the differential and common-mode signal levels. The

choice of output voltage swing, preemphasis setting, supply

voltages (V

peak and settled single-ended voltage swings and the commonmode shift measured across the output termination resistors.

These choices also affect output current and, consequently,

power consumption. For ac-coupled applications, certain

combinations of supply voltage, output voltage swing, and

preemphasis settings may violate the single-ended absolute output

low voltage, as specified in Tabl e 1. Under these conditions,

the performance is degraded; therefore, these settings are not

recommended. Tabl e 21 includes annotations that identify these

settings. In dc-coupled applications, the far-end termination voltage

should be equal to V

preemphasis settings listed in Tab le 17 .

and V

CC

), and output coupling (ac or dc) affect

TTO

to allow the full list of output swing and

TTO

TxHeadroom

The TxHeadroom register (Register 0x23) allows configuration

of the individual transmitters for extra headroom at the output

for high current applications. The bits in this register are active

high (default) and are one per output (see Tab l e 22 ). Setting a

bit high puts the respective transmitter in a configuration for

extra headroom, and setting a bit low does not provide extra

headroom. The TxHeadroom bits should only be set high when

required for a given output swing as listed in Tab l e 21. Note that

TxHeadroom is not available for V

V

TTO

V

OCM

t

PE

Figure 44. Simplified Output Voltage Levels Diagram

< 2.5 V.

CC

V

SW-DC

V

V

H-DC

L-DC

V

V

H-PE

SW-PE

V

L-PE

07060-140

Table 20. Symbol Definitions

Symbol Formula Definition

IDC Programmable Output current that sets output level

IPE Programmable Output current for PE delayed tap

I

I

TTO

V

25 Ω × I

DPP-DC

+ IPE Total transmitter output current

DC

× 2

DC

Peak-to-peak differential voltage swing of

nonpreemphasized waveform

V

25 Ω × I

DPP-PE

TTO

× 2

Peak-to-peak differential voltage swing of preemphasized

waveform

V

V

SW-DC

V

V

SW-PE

∆V

OCM_DC-COUPLED

∆V

OCM_AC-COUPLED

V

V

OCM

V

V

H-DC

V

V

L-DC

V

V

H-PE

V

V

L-PE

25 Ω × I

50 Ω × I

DPP-DC

DPP-PE

− ∆V

TTO

− ∆V

TTO

− ∆V

TTO

− ∆V

TTO

− ∆V

TTO

/2 = V

/2 = V

– V

H-DC

H-PE

/2 Output common-mode shift, dc-coupled outputs

TTO

/2 Output common-mode shift, ac-coupled outputs

TTO

= ( V

OCM

+ V

OCM

− V

OCM

+ V

OCM

− V

OCM

DC single-ended voltage swing

L-DC

– V

Preemphasized single-ended voltage swing

L-PE

+ V

H-DC

DPP-DC

DPP-DC

DPP-PE

DPP-PE

)/2 Output common-mode voltage

L-DC

/2 DC single-ended output high voltage

/2 DC single-ended output low voltage

/2 Maximum single-ended output voltage

/2 Minimum single-ended output voltage

Rev. B | Page 27 of 36

ADN8102

Table 21. Output Compliance for AC-Coupled Outputs

V

(mV) V

SW-DC

200 200 0.00 8 0x00 0xA2 Supported Supported Supported

200 300 3.52 12 0x11 0xA2 Supported Supported Supported

200 400 6.02 16 0x22 0xA2 Supported Supported Supported

200 500 7.96 20 0x33 0xA2 Supported Supported Supported

200 600 9.54 24 0x44 0xA2 Supported Supported Supported

200 700 10.88 28 0x55 0xA2 Supported Supported Not Supported

200 800 12.04 32 0x66 0xA2 Use TX_HDRM = 1 Use TX_HDRM = 1 Not Supported

300 300 0.00 12 0x00 0xB3 Supported Supported Supported

300 400 2.50 16 0x11 0xB3 Supported Supported Supported

300 500 4.44 20 0x22 0xB3 Supported Supported Supported

300 600 6.02 24 0x33 0xB3 Supported Supported Supported

300 700 7.36 28 0x44 0xB3 Supported Supported Supported

300 800 8.52 32 0x55 0xB3 Use TX_HDRM = 1 Use TX_HDRM = 1 Not Supported

300 900 9.54 36 0x66 0xB3 Not Supported Not Supported Not Supported

400 400 0.00 16 0x00 0xC4 Supported Supported Supported

400 500 1.94 20 0x11 0xC4 Supported Supported Supported

400 600 3.52 24 0x22 0xC4 Supported Supported Supported

400 700 4.86 28 0x33 0xC4 Supported Supported Supported

400 800 6.02 32 0x44 0xC4 Use TX_HDRM = 1 Use TX_HDRM = 1 Not Supported

400 900 7.04 36 0x55 0xC4 Not Supported Not Supported Not Supported

400 1000 7.96 40 0x66 0xC4 Not Supported Not Supported Not Supported

600 600 0.00 24 0x00 0xE6 Supported Supported Supported

600 700 1.34 28 0x11 0xE6 Supported Supported Supported

600 800 2.50 32 0x22 0xE6 Use TX_HDRM = 1 Use TX_HDRM = 1 Not Supported

600 900 3.52 36 0x33 0xE6 Not Supported Not Supported Not Supported

600 1000 4.44 40 0x44 0xE6 Not Supported Not Supported Not Supported

600 1100 5.26 44 0x55 0xE6 Not Supported Not Supported Not Supported

600 1200 6.02 48 0x66 0xE6 Not Supported Not Supported Not Supported

(mV) PE (dB) I

SW-PE

(mA) OLEV 0 OLEV1 VCC=V

TOT

=3.3V VCC=V

TTO

=2.5V VCC=V

TTO

TTO

=1.8V

Rev. B | Page 28 of 36

ADN8102

PRINTED CIRCUIT BOARD (PCB) LAYOUT GUIDELINES

The high speed differential inputs and outputs should be routed

with 100 Ω controlled impedance, differential transmission

lines. The transmission lines, either microstrip or stripline,

should be referenced to a solid low impedance reference plane.

An example of a PCB cross-section is shown in Figure 45. The

trace width (W), differential spacing (S), height above reference

plane (H), and dielectric constant of the PCB material determine

the characteristic impedance. Adjacent channels should be kept

apart by a distance greater than 3 W to minimize crosstalk.

WSW

SOLDERMASK

SIGNAL (MICROSTRIP )

PCB DIEL ECTRI C

REFERENCE PLANE

PCB DIEL ECTRI C

SIGNAL (ST RIPLINE )

PCB DIEL ECTRI C

REFERENCE PLANE

PCB DIEL ECTRI C

WSW

Figure 45. Example of a PCB Cross-Section

Power Supply Connections and Ground Planes

Use of one low impedance ground plane is recommended.

The VEE pins should be soldered directly to the ground plane

to reduce series inductance. If the ground plane is an internal

plane and connections to the ground plane are made through

vias, multiple vias can be used in parallel to reduce the series

inductance. The exposed pad should be connected to the VEE

plane using plugged vias so that solder does not leak through

the vias during reflow.

Use of a 10 μF electrolytic capacitor between VCC and VEE is

recommended at the location where the 3.3 V supply enters the

printed circuit board (PCB). It is recommended that 0.1 μF and

1 nF ceramic chip capacitors be placed in parallel at each supply

pin for high frequency, power supply decoupling. When using

0.1 μF and 1 nF ceramic chip capacitors, they should be placed

between the IC power supply pins (VCC, VTTI, and VTTO)

and VEE, as close as possible to the supply pins.

By using adjacent power supply and GND planes, excellent high

frequency decoupling can be realized by using close spacing

between the planes. This capacitance is given by

C

= 0.88εr × A/d (pF)

PLANE

where:

ε

is the dielectric constant of the PCB material.

r

A is the area of the overlap of power and GND planes (cm

d is the separation between planes (mm).

For FR4, ε

= 4.4 and 0.25 mm spacing, C ≈ 15 pF/cm2.

r

H

7060-149

2

).

Rev. B | Page 29 of 36

Supply Sequencing

Ideally, all power supplies should be brought up to the appropriate levels simultaneously (power supply requirements are set by

the supply limits in Tab l e 1 and the absolute maximum ratings

listed in Table 3 ). In the event that the power supplies to the

ADN8102 are brought up separately, the supply power-up

sequence is as follows: DV

and lastly V

with V

V

and V

TTI

and V

TTI

and V

TTI

being powered off first.

TTO

contain ESD protection diodes to the VCC power

TTO

is powered first, followed by VCC,

CC

. The power-down sequence is reversed,

TTO

domain (see Figure 39 and Figure 41). To avoid a sustained high

current condition in these devices (I

and V

be powered off before V

supplies should be powered on after VCC and should

TTO

.

CC

SUSTAINED

< 64 mA), the V

TTI

If the system power supplies have a high impedance in the

powered off state, then supply sequencing is not required

provided the following limits are observed:

or V

• Peak current from V

TTI

• Sustained current from V

to VCC < 200 mA.

TTO

or V

TTI

to VCC < 64 mA.

TTO

Thermal Paddle Design

The LFCSP is designed with an exposed thermal paddle to

conduct heat away from the package and into the PCB. By

incorporating thermal vias into the PCB thermal paddle,

heat is dissipated more effectively into the inner metal layers

of the PCB. To ensure device performance at elevated

temperatures, it is important to have a sufficient number of

thermal vias incorporated into the design. An insufficient

number of thermal vias results in a θ

value larger than

JA

specified in Tabl e 1. Additional PCB footprint and assembly

guidelines are described in the AN-772 Application Note, A

Design and Manufacturing Guide for the Lead Frame Chip Scale

Package (LFCSP).

It is recommended that a via array of 4 × 4 or 5 × 5 with a

diameter of 0.3 mm to 0.33 mm be used to set a pitch between

1.0 mm and 1.2 mm. A representative of these arrays is shown in

Figure 46.

THERMAL

VIA

THERMAL

PADDLE

07060-150

Figure 46. PCB Thermal Paddle and Via

ADN8102

R

Stencil Design for the Thermal Paddle

To effectively remove heat from the package and to enhance

electrical performance, the thermal paddle must be soldered

(bonded) to the PCB thermal paddle, preferably with minimum