Dual, 3 V, CMOS, LVDS

FEATURES

±15 kV ESD protection on output pins

600 Mbps (300 MHz) switching rates

Flow-through pinout simplifies PCB layout

300 ps typical differential skew

700 ps maximum differential skew

1.5 ns maximum propagation delay

3.3 V power supply

±355 mV differential signaling

Low power dissipation: 23 mW typical

Interoperable with existing 5 V LVDS receivers

Conforms to TIA/EIA-644 LVDS standard

Industrial operating temperature range (−40°C to +85°C)

Available in surface-mount (SOIC) package

APPLICATIONS

Backplane data transmission

Cable data transmission

Clock distribution

High Speed Differential Driver

ADN4663

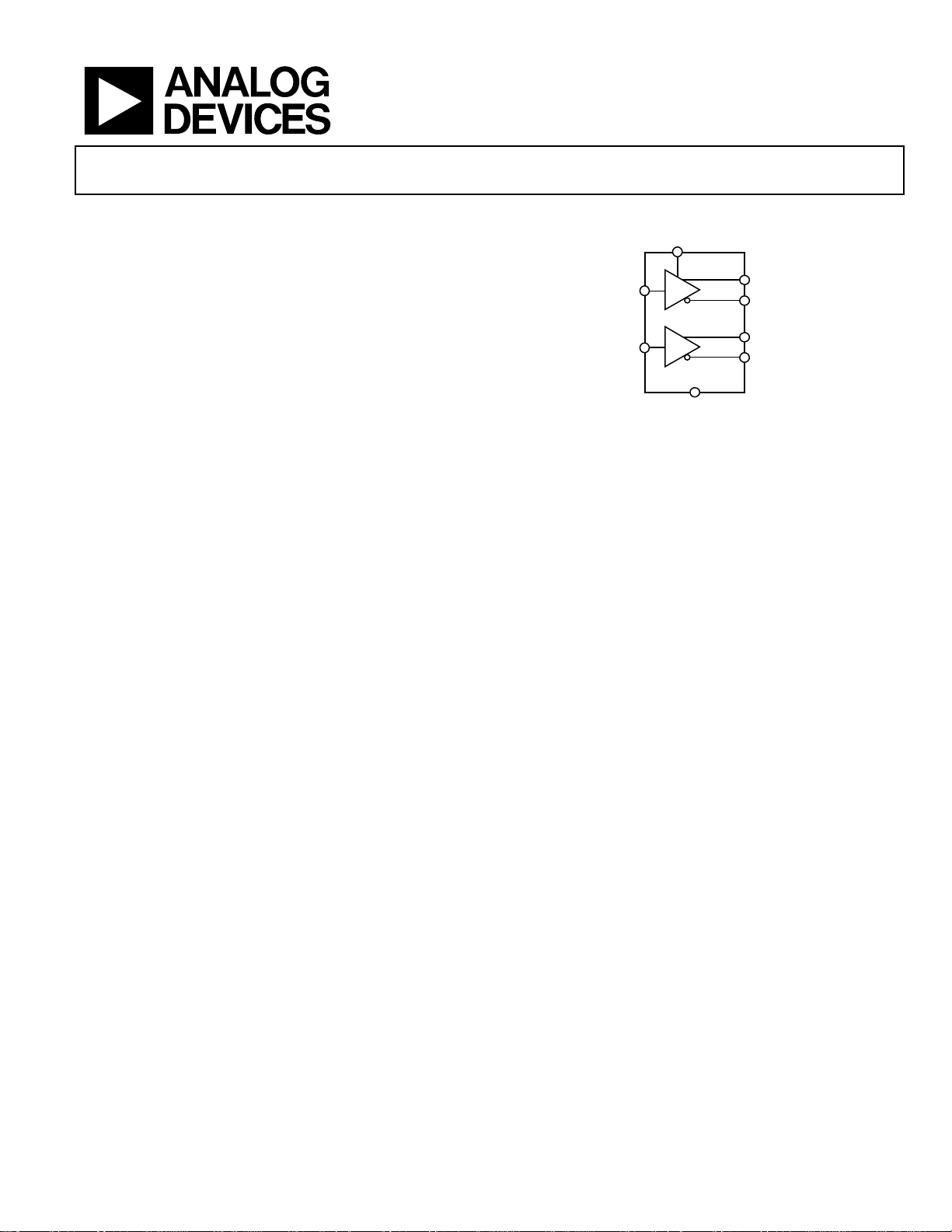

FUNCTIONAL BLOCK DIAGRAM

V

CC

ADN4663

D

IN1

D

IN2

GND

Figure 1.

D

D

D

D

OUT1+

OUT1–

OUT2+

OUT2–

07927-001

GENERAL DESCRIPTION

The ADN4663 is a dual, CMOS, low voltage differential

signaling (LVDS) line driver offering data rates of over

600 Mbps (300 MHz), and ultralow power consumption.

It features a flow-through pinout for easy PCB layout and

separation of input and output signals.

The device accepts low voltage TTL/CMOS logic signals and

converts them to a differential current output of typically

±3.1 mA for driving a transmission medium such as a

twisted-pair cable. The transmitted signal develops a differential

voltage of typically ±355 mV across a termination resistor at the

receiving end, and this is converted back to a TTL/CMOS logic

level by a line receiver.

The ADN4663 and a companion receiver offer a new solution

to high speed point-to-point data transmission, and a low

power alternative to emitter-coupled logic (ECL) or positive

emitter-coupled logic (PECL).

Rev. 0

Information furnished by Analog Devices is believed to be accurate and reliable. However, no

responsibility is assumed by Analog Devices for its use, nor for any infringements of patents or other

rights of third parties that may result from its use. Specifications subject to change without notice. No

license is granted by implication or otherwise under any patent or patent rights of Analog Devices.

Trademarks and registered trademarks are the property of their respective owners.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700 www.analog.com

Fax: 781.461.3113 ©2009 Analog Devices, Inc. All rights reserved.

ADN4663

TABLE OF CONTENTS

Features .............................................................................................. 1

Applications ....................................................................................... 1

Functional Block Diagram .............................................................. 1

General Description ......................................................................... 1

Revision History ............................................................................... 2

Specifications ..................................................................................... 3

AC Characteristics ........................................................................ 4

Absolute Maximum Ratings ............................................................ 6

REVISION HISTORY

1/09—Revision 0: Initial Version

ESD Caution...................................................................................6

Pin Configuration and Function Descriptions ..............................7

Typical Performance Characteristics ..............................................8

Theory of Operation ...................................................................... 11

Applications Information .......................................................... 11

Outline Dimensions ....................................................................... 12

Ordering Guide .......................................................................... 12

Rev. 0 | Page 2 of 12

ADN4663

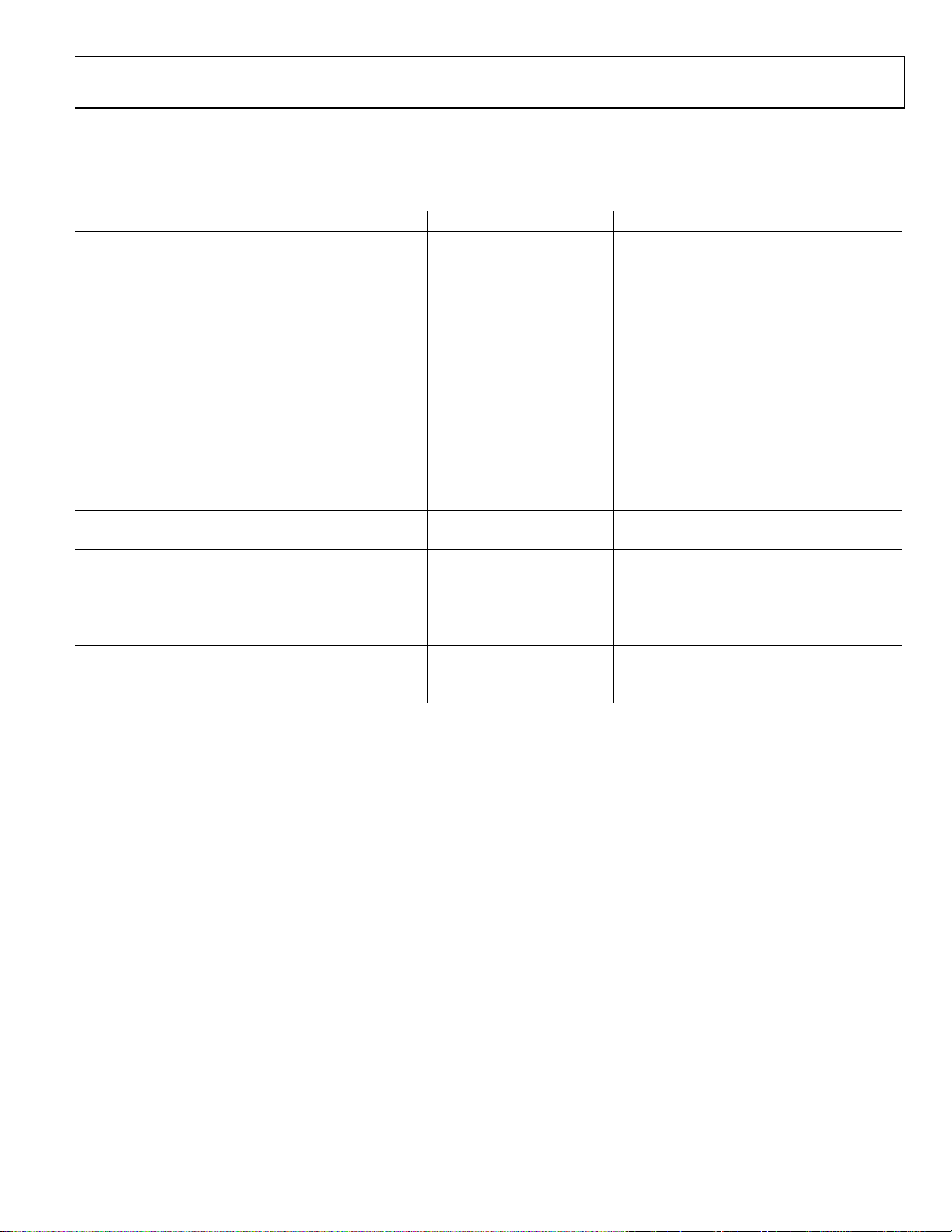

SPECIFICATIONS

VCC = 3.0 V to 3.6 V; RL = 100 Ω; CL = 15 pF to GND; all specifications T

Table 1.

Parameter

LVDS OUT PUTS (D

1, 2

OUTx+

Symbol Min Typ Max Unit Test Conditions

, D

)

OUTx−

Differential Output Voltage VOD 250 355 450 mV See Figure 2 and Figure 4

ΔV

Change in Magnitude of VOD for

1 35 |mV| See Figure 2 and Figure 4

OD

Complementary Output States

Offset Voltage VOS 1.125 1.2 1.375 V See Figure 2 and Figure 4

3 25 |mV| See Figure 2 and Figure 4

Change in Magnitude of VOS for

ΔV

OS

Complementary Output States

Output High Voltage VOH 1.4 1.6 V See Figure 2 and Figure 4

Output Low Voltage V

INPUTS (D

, D

)

IN1

IN2

0.90 1.1 V See Figure 2 and Figure 4

OL

Input High Voltage VIH 2.0 VCC V

Input Low Voltage VIL GND 0.8 V

Input High Current IIH −10 ±2 +10 μA VIN = 3.3 V or 2.4 V

Input Low Current IIL −10 ±1 +10 μA VIN = GND or 0.5 V

Input Clamp Voltage VCL −1.5 −0.6 V ICL = −18 mA

LVDS OUTPUT PROTECTION (D

Output Short-Circuit Current3 I

LVDS OUTPUT LEAKAGE (D

Power-Off Leakage I

OUTx+

, D

OUTx+

, D

)

OUTx−

−5.7 −8.0 mA D

OS

)

OUTx−

−10 ±1 +10 μA V

OFF

POWER SUPPLY

Supply Current, Unloaded ICC 8 14 mA No load, D

Supply Current, Loaded I

10 20 mA D

CCL

ESD PROTECTION

D

, D

OUTx+

All Pins Except D

1

Current into device pins is defined as positive. Current out of device pins is defined as negative. All voltages are referenced to ground except VOD, ΔVOD, and ΔVOS.

2

The ADN4663 is a current mode device and functions within data sheet specifications only when a resistive load is applied to the driver outputs. Typical range is

90 Ω to 110 Ω.

3

Output short-circuit current (IOS) is specified as magnitude only; minus sign indicates direction only.

Pins ±15 kV Human body model

OUTx−

, D

OUTx+

±4 kV Human body model

OUTx−

MIN

to T

, unless otherwise noted.

MAX

= VCC, D

INx

= VCC or GND, VCC = 0 V

OUT

= VCC or GND

INx

= 0 V or D

OUTx+

= VCC or GND

INx

= GND, D

INx

OUTx−

= 0 V

Rev. 0 | Page 3 of 12

ADN4663

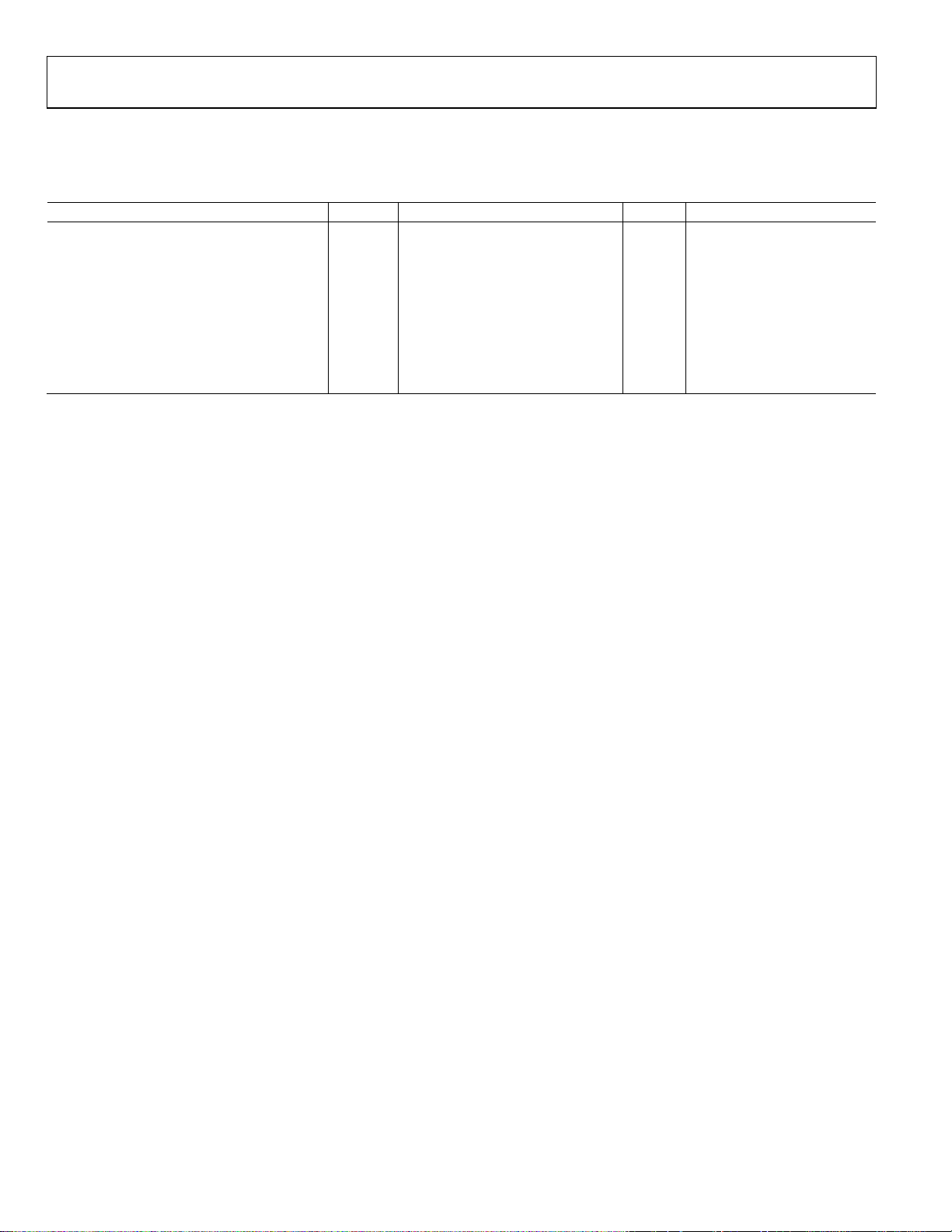

AC CHARACTERISTICS

VCC = 3.0 V to 3.6 V; RL = 100 Ω; C

1

= 15 pF to GND; all specifications T

L

MIN

to T

, unless otherwise noted.

MAX

Table 2.

Parameter2 Symbol Min Typ Max Unit Conditions/Comments

Differential Propagation Delay High to Low t

Differential Propagation Delay Low to High t

Differential Pulse Skew |t

PHLD

− t

|5 t

PLHD

Channel-to-Channel Skew6 t

Differential Part-to-Part Skew7 t

Differential Part-to-Part Skew8 t

Rise Time t

Fall Time t

Maximum Operating Frequency9 f

1

CL includes probe and jig capacitance.

2

AC parameters are guaranteed by design and characterization.

3

Generator waveform for all tests, unless otherwise specified: f = 50 MHz, ZO = 50 Ω, t

4

All input voltages are for one channel, unless otherwise specified. Other inputs are set to GND.

5

t

= |t

− t

SKD1

PHLD

same channel.

6

t

is the differential channel-to-channel skew of any event on the same device.

SKD2

7

t

, differential part-to-part skew, is defined as the difference between the minimum and maximum specified differential propagation delays. This specification

SKD3

applies to devices at the same VCC and within 5°C of each other within the operating temperature range.

8

t

, differential part-to-part skew, is the differential channel-to-channel skew of any event between devices. This specification applies to devices over recommended

SKD4

operating temperatures and voltage ranges, and across process distribution. t

9

f

generator input conditions: t

MAX

switching.

| is the magnitude difference in differential propagation delay time between the positive going edge and the negative going edge of the

PLHD

= t

< 1 ns (0% to 100%), 50% duty cycle, 0 V to 3 V. Output criteria: duty cycle = 45% to 55%, VOD > 250 mV, all channels

TLH

THL

0.3 0.8 1.5 ns See Figure 3 and Figure 4

PHLD

0.3 1.1 1.5 ns See Figure 3 and Figure 4

PLHD

0 0.3 0.7 ns See Figure 3 and Figure 4

SKD1

0 0.4 0.8 ns See Figure 3 and Figure 4

SKD2

0 1.0 ns See Figure 3 and Figure 4

SKD3

0 1.2 ns See Figure 3 and Figure 4

SKD4

0.2 0.5 1.0 ns See Figure 3 and Figure 4

TLH

0.2 0.5 1.0 ns See Figure 3 and Figure 4

THL

350 MHz See Figure 3

MAX

≤ 1 ns, and t

TLH

is defined as |maximum − minimum| differential propagation delay.

SKD4

≤ 1 ns.

THL

3, 4

Rev. 0 | Page 4 of 12

ADN4663

V

V

Test Circuits and Timing Diagrams

D

V

V

CC

CC

D

INx

Figure 2. Test Circuit for Driver V

D

SIGNAL

GENERATOR

C

INCLUDES LO AD AND TEST JIG CAPACITANCE.

L

INx

50Ω

Figure 3. Test Circuit for Driver Propagation Delay, Transition Time, and Maximum Operating Frequency

D

D

D

OUTx–

OUTx+

1.5V

INx

t

PLHD

0V (DIFFERENTIAL)

OUTx+

RL/2

VOSV

OD

OD

C

L

C

L

VV

and VOS

R

L

1.5V

t

PHLD

0V

D

D

07927-002

OUTx+

OUTx–

07927-003

3

0V

V

OH

V

OL

/2

R

L

D

OUTx–

CC

V

OD

80%

V

DIFF

20%

0V

t

THL

V

= D

DIFF

OUT+

– D

OUT–

80%

0V

20%

t

THL

07927-004

Figure 4. Driver Propagation Delay and Transition Time Waveforms

Rev. 0 | Page 5 of 12

ADN4663

ABSOLUTE MAXIMUM RATINGS

TA = 25°C, unless otherwise noted. All voltages are relative to

their respective ground.

Table 3.

Parameter Rating

VCC to GND −0.3 V to +4 V

Input Voltage (D

Output Voltage (D

Short-Circuit Duration (D

Operating Temperature Range

Industrial −40°C to +85°C

Storage Temperature Range −65°C to +150°C

Junction Temperature (TJ max) 150°C

Power Dissipation (TJ max − TA)/θJA

SOIC Package

θJA Thermal Impedance 149.5°C/W

Reflow Soldering Peak Temperature

Pb-Free 260°C ± 5°C

) to GND −0.3 V to VCC + 0.3 V

INx

, D

OUTx+

) to GND −0.3 V to VCC + 0.3 V

OUTx−

, D

OUTx+

) to GND Continuous

OUTx−

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

ESD CAUTION

Rev. 0 | Page 6 of 12

ADN4663

PIN CONFIGURATION AND FUNCTION DESCRIPTIONS

8

V

1

CC

IN1

IN2

ADN4663

2

TOP VIEW

3

(Not to Scale)

4

D

D

GND

Figure 5. Pin Configuration

Table 4. Pin Function Descriptions

Pin No. Mnemonic Description

1 VCC

Power Supply Input. The part can be operated from 3.0 V to 3.6 V, and the supply should be decoupled with a

10 μF solid tantalum capacitor in parallel with a 0.1 μF capacitor to GND.

2 D

3 D

Driver Channel 1 Logic Input.

IN1

Driver Channel 2 Logic Input.

IN2

4 GND Ground reference point for all circuitry on the part.

5 D

6 D

7 D

8 D

OUT2−

OUT2+

OUT1+

OUT1−

Channel 2 Inverting Output Current Driver. When D

flows out of D

OUT2−

.

Channel 2 Noninverting Output Current Driver. When D

current flows into D

OUT2+

.

Channel 1 Noninverting Output Current Driver. When D

current flows into D

OUT1+

.

Channel 1 Inverting Output Current Driver. When D

flows out of D

OUT1−

.

D

OUT1–

D

7

OUT1+

D

6

OUT2+

5

D

OUT2–

7927-005

is high, current flows into D

IN2

is high, current flows out of D

IN2

is high, current flows out of D

IN1

is high, current flows into D

IN1

OUT2−

OUT1−

. When D

. When D

OUT2+

. When D

OUT1+

. When D

is low, current

IN2

is low,

IN2

is low,

IN1

is low, current

IN1

Rev. 0 | Page 7 of 12

ADN4663

(

(

–

TYPICAL PERFORMANCE CHARACTERISTICS

1.415

TA = 25°C

R

= 100Ω

L

V)

OH

1.414

1.413

OUTPUT HIGH VOLTAGE, V

1.412

3.0 3.1 3.2 3.3 3.4 3.5 3.6

POWER SUPPLY VOLTAGE, VCC (V)

Figure 6. Output High Voltage vs. Power Supply Voltage

1.090

TA = 25°C

R

= 100Ω

L

V)

OL

1.089

1.088

325.0

TA = 25°C

= 100Ω

R

(mV)

OD

DIFFERENTIAL OUTP UT VOLTAGE, V

07927-006

L

324.8

324.6

324.4

324.2

324.0

3.0 3.1 3.2 3.3 3.4 3.5 3.6

POWER SUPPLY VOLTAGE, VCC (V)

07927-009

Figure 9. Differential Output Voltage vs. Power Supply Voltage

500

TA = 25°C

V

= 3.3V

(mV)

OD

CC

450

400

350

OUTPUT LOW VOLTAGE, V

1.087

3.03.13.23.33.43.53.6

POWER SUPPLY VOLTAGE, VCC (V)

Figure 7. Output Low Voltage vs. Power Supply Voltage

3.9

(mA)

OS

–4.0

–4.1

SHORT-CIRCUIT CURRENT, I

–4.2

3.0 3.1 3.2 3.3 3.4 3.5 3. 6

POWER SUPPLY VOLTAGE, VCC (V)

= GND OR V

V

IN

TA = 25°C

V

= 0V

OUT

Figure 8. Output Short-Circuit Current vs. Power Supply Voltage

300

DIFFERENTIAL OUTPUT VOLTAGE, V

250

90 100 110 120 130 140 150

07927-007

LOAD RESIST OR, RL (Ω)

07927-010

Figure 10. Differential Output Voltage vs. Load Resistor

1.252

TA = 25°C

R

= 100Ω

CC

(mV)

OS

OFFSET VOLTAGE, V

07927-008

L

1.251

1.250

1.249

3.0 3.1 3.2 3.3 3.4 3.5 3.6

POWER SUPPLY VOLTAGE, VCC (V)

07927-011

Figure 11. Offset Voltage vs. Power Supply Voltage

Rev. 0 | Page 8 of 12

ADN4663

TA = 25°C

19

C

= 15pF

L

V

= 3.3V

CC

V

= 0V TO 3. 3V

IN

17

(mA)

R

= 100Ω PER DRIVER

L

CC

15

BOTH CHANNELS SW ITCHING

13

11

ONE CHANNEL SWITCHING

9

POWER SUPPL Y CURRENT, I

7

5

0.01 0.1 1 10 100 1k

SWITCHING FREQUENCY (MHz)

Figure 12. Power Supply Current vs. Switching Frequency

12.5

TA = 25°C

f = 1MHz

C

= 15pF

L

V

= 0V TO 3. 3V

IN

12.0

(mA)

R

= 100Ω PER DRIVER

CC

L

11.5

11.0

1200

1100

t

PLHD

t

PHLD

R

= 100Ω PER DRIVER

L

TA = 25°C

f = 1MHz

C

= 15pF

L

1000

DIFFERENT IAL PROPAGATION DELAY (ns)

900

3.0 3.1 3.2 3. 3 3.4 3.5 3. 6

07927-012

POWER SUPPLY VOLTAGE, VCC (V)

07927-015

Figure 15. Differential Propagation Delay vs. Power Supply Voltage

1200

VCC = 3.3V

f = 1MHz

C

= 15pF

L

R

= 100Ω PER DRIVER

L

1100

1000

t

PHLD

t

PLHD

10.5

POWER SUPPL Y CURRENT, I

10.0

3.0 3.1 3.2 3.3 3.4 3. 5 3.6

POWER SUPPLY VOLTAGE, VCC (V)

Figure 13. Power Supply Current vs. Power Supply Voltage

15

VCC = 3.3V

f = 1MHz

= 15pF

C

L

= 0V TO 3V

V

14

(mA)

CC

IN

= 100Ω PER DRIVER

R

L

13

12

11

POWER SUPPL Y CURRENT, I

10

–40 –15 10 35 60 85

TEMPERATURE (°C)

Figure 14. Power Supply Current vs. Ambient Temperature

DIFFERENT IAL PROPAGATION DELAY (ns)

900

–40–200 20406080100

07927-013

AMBIENT TEMPERATURE, TA (°C)

07927-016

Figure 16. Differential Propagation Delay vs. Ambient Temperature

100

TA = 25°C

f = 1MHz

C

= 15pF

L

R

= 100Ω PER DRIVER

80

(ps)

L

SKD1

60

40

20

DIFFERENTIAL SKEW , t

0

3.03.13.23.33.43.53.6

07927-014

POWER SUPPLY VOLTAGE, VCC (V)

07927-017

Figure 17. Differential Skew vs. Power Supply Voltage

Rev. 0 | Page 9 of 12

ADN4663

50

VCC = 3.3V

f = 1MHz

C

= 15pF

L

R

= 100Ω PER DRIVER

L

40

(ps)

SKD1

30

20

10

DIFFERENTIAL SKEW, t

0

–40 –20 0 20 40 60 80 100

AMBIENT TEMPERATURE, TA (°C)

Figure 18. Differential Skew vs. Ambient Temperature

400

R

= 100Ω PER DRIVER

380

360

t

TLH

t

THL

L

TA = 25°C

f = 1MHz

C

= 15pF

L

400

VCC = 3.3V

f = 1MHz

C

= 15pF

L

R

= 100Ω PER DRIVER

L

380

t

TLH

360

TRANSITION TIME (ps)

340

320

–40 –20 0 20 40 60 80 100

07927-018

AMBIENT TEMPERATURE, TA (°C)

t

THL

07927-020

Figure 20. Transition Time vs. Ambient Temperature

TRANSITION TIME (ps)

340

320

3.0 3.1 3.2 3.3 3.4 3.5 3.6

POWER SUPPLY VOLTAGE, VCC (V)

07927-019

Figure 19. Transition Time vs. Power Supply Voltage

Rev. 0 | Page 10 of 12

ADN4663

V

V

THEORY OF OPERATION

The ADN4663 is a dual line driver for low voltage differential

signaling. It takes a single-ended 3 V logic signal and converts

it to a differential current output. The data can then be transmitted

for considerable distances, over media such as a twisted-pair cable

or PCB backplane, to an LVDS receiver, where it develops a voltage

across a terminating resistor, R

. This resistor is chosen to match

T

the characteristic impedance of the medium, typically around

100 . The differential voltage is detected by the receiver and

converted back into a single-ended logic signal.

When D

(current source) through R

is high (Logic 1), current flows out of the D

INx

and back into the D

T

OUTx−

pin

OUTx+

pin (current

sink). At the receiver, this current develops a positive differential

voltage across R

in a Logic 1 at the receiver output. When D

sinks current and D

voltage across R

(with respect to the inverting input) and results

T

is low, D

INx

sources current; a negative differential

OUTx−

results in a Logic 0 at the receiver output.

T

OUTx+

The output drive current is between ±2.5 mA and ±4.5 mA

(typically ±3.55 mA), developing between ±250 mV and ±450 mV

across a 100 termination resistor. The received voltage is centered

around the receiver offset of 1.2 V. Therefore, the noninverting

receiver input is typically (1.2 V + [355 mV/2]) = 1.377 V, and

the inverting receiver input is (1.2 V − [355 mV/2]) = 1.023 V

for Logic 1. For Logic 0, the inverting and noninverting output

voltages are reversed. Note that because the differential voltage

reverses polarity, the peak-to-peak voltage swing across R

is

T

twice the differential voltage.

Current mode drivers offer considerable advantages over

voltage mode drivers such as RS-422 drivers. The operating

current remains fairly constant with increased switching

frequency, whereas that of voltage mode drivers increase

exponentially in most cases. This is caused by the overlap

as internal gates switch between high and low, which causes

currents to flow from the device power supply to ground.

A current mode device simply reverses a constant current

between its two outputs, with no significant overlap currents.

This is similar to emitter-coupled logic (ECL) and positive

emitter-coupled logic (PECL), but without the high quiescent

current of ECL and PECL.

APPLICATIONS INFORMATION

Figure 21 shows a typical application for point-to-point data

transmission using the ADN4663 as the driver and a LVDS

receiver.

+3.3

+

GND

10µF

TANTALUM

D

OUTx+

R

T

100Ω

D

OUTx–

LVDS RECEIVER

D

IN+

D

IN–

V

CC

0.1µF

V

CC

ADN4663

D

INx

Figure 21. Typical Application Circuit

GND

+3.3

+

D

OUT

07927-021

Rev. 0 | Page 11 of 12

ADN4663

OUTLINE DIMENSIONS

5.00 (0.1968)

4.80 (0.1890)

4.00 (0.1574)

3.80 (0.1497)

0.25 (0.0098)

0.10 (0.0040)

COPLANARITY

0.10

SEATING

CONTROLLING DIMENSIONS ARE IN MILLIMETERS; INCH DIMENSIONS

(IN PARENTHESES) ARE ROUNDED-OFF MILLIMETER EQUIVALENTS FOR

REFERENCE ONLY AND ARE NOT APPROPRIATE FOR USE IN DESIG N.

85

1

1.27 (0.0500)

BSC

PLANE

COMPLIANT TO JEDEC STANDARDS MS-012-A A

6.20 (0.2441)

5.80 (0.2284)

4

1.75 (0.0688)

1.35 (0.0532)

0.51 (0.0201)

0.31 (0.0122)

8°

0°

0.25 (0.0098)

0.17 (0.0067)

0.50 (0.0196)

0.25 (0.0099)

1.27 (0.0500)

0.40 (0.0157)

45°

012407-A

Figure 22. 8-Lead Standard Small Outline Package [SOIC(N)]

(R-8)

Dimensions shown in millimeters and (inches)

ORDERING GUIDE

Model Temperature Range Package Description Package Option

ADN4663BRZ1 −40°C to +85°C 8-Lead Standard Small Outline Package [SOIC-N] R-8

ADN4663BRZ-REEL71 −40°C to +85°C 8-Lead Standard Small Outline Package [SOIC-N] R-8

1

Z = RoHS Compliant Part.

©2009 Analog Devices, Inc. All rights reserved. Trademarks and

registered trademarks are the property of their respective owners.

D07927-0-1/09(0)

Rev. 0 | Page 12 of 12

Loading...

Loading...