10.709 Gbps Laser Diode

a

FEATURES

Data Rates from 9.952 Gbps to 10.709 Gbps

Typical Rise/Fall Time 25 ps/23 ps

Bias Current Range 3 mA to 80 mA

Modulation Current Range 5 mA to 80 mA

Monitor Photodiode Current 50 A to 1200 A

Closed-Loop Control of Both Average Optical Power

and Extinction Ratio

Laser Fail and Laser Degrade Alarms

Automatic Laser Shutdown, ALS

Dual MPD Functionality for Wavelength Control

CML Data Inputs

50 Internal Data Terminations

3.3 V Single-Supply Operation

Driver Supplied in Dice Format

APPLICATIONS

SONET OC-192, SDH STM-64

Supports 10.667 Gbps and 10.709 Gbps FEC Rates

10 Gb Ethernet IEEE802.3ae

Driver Chipset

ADN2843

GENERAL DESCRIPTION

The ADN2943 chipset consists of two components, the ADN2845

and the ADN2844. The ADN2845 is a 10.709 Gbps laser diode

driver. The ADN2845 eliminates the need to ac couple since it

can deliver 80 mA of modulation while dc coupled to the laser

diode. It is intended to be copackaged with the laser to minimize

bond lengths, which improves performance of the optical

transmitter. For transmission line applications, contact HSN

Application Group at fiberoptic.ic@analog.com.

The ADN2844 offers a unique control loop algorithm and provides dual loop control of both average power and extinction ratio.

Programmable alarms are provided for laser fail (end of life) and

laser degrade (impending fail).

Both the ADN2844 and the ADN2845 are available as bare die.

The ADN2844 is also available in 5 mm ¥ 5 mm 32-lead LFCSP.

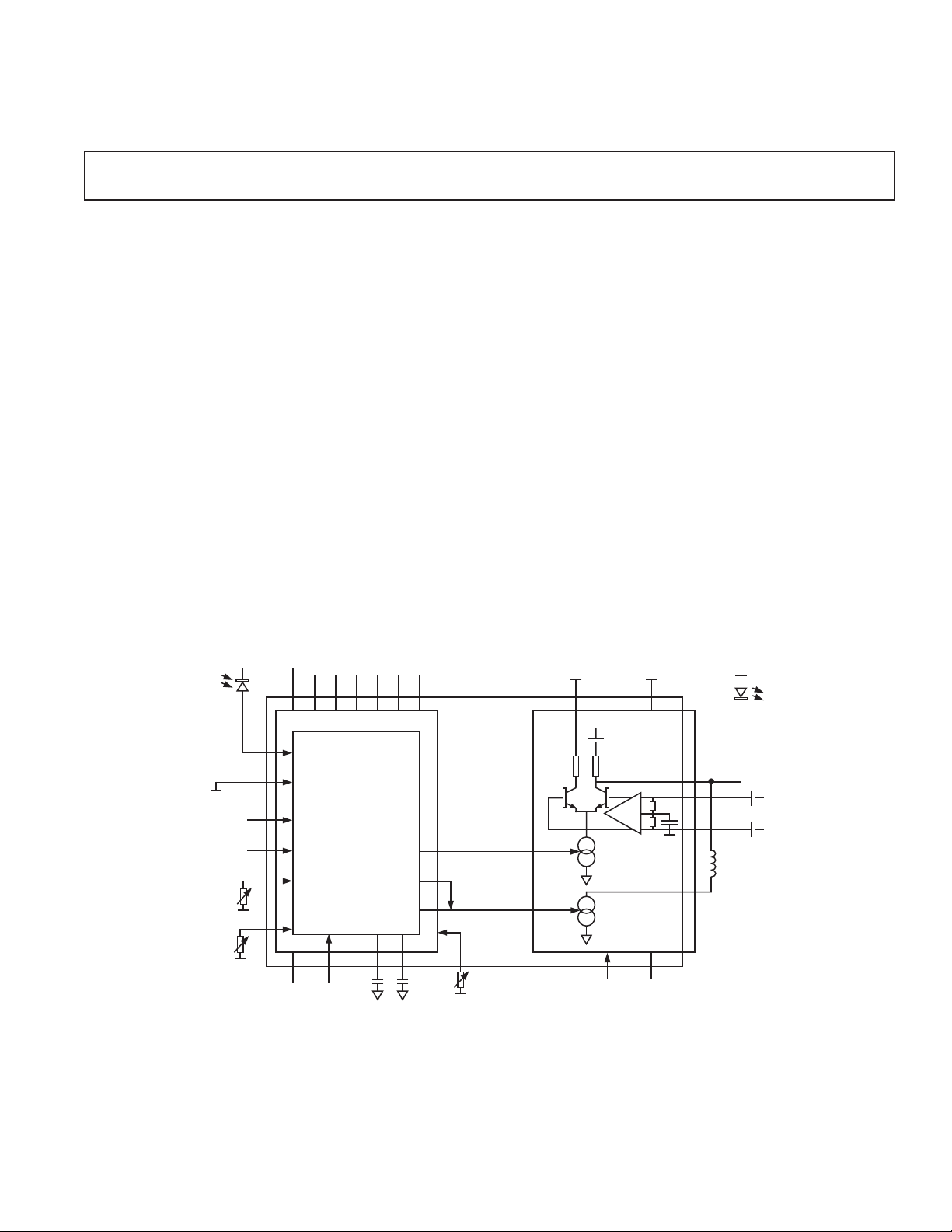

FUNCTIONAL BLOCK DIAGRAM

CC

IMPD

*

*

V

CC

GND

IMPDMON2

IMMON

IMPDMON

CONTROL

ERCAP PAVCAP

IDTONE

IBMON

V

MPD

IMPD2

GND

MODE

ALS

PSET

GND

ERSET

GND

*ADN2850 OR ADN2860 OPTICAL SUPERVISOR

FAIL

ADN2844

DEGRADE

ADN2843

D_IMOD

GND

IMOD_CTRL

IBIAS_CTRL

ASET

IMODN

V

V

CC

ALS

V

CC

ADN2845

GND

GND

CC

LD

IMODP

DATAP

DATAN

IBIAS

REV. 0

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties that

may result from its use. No license is granted by implication or otherwise

under any patent or patent rights of Analog Devices. Trademarks and

registered trademarks are the property of their respective companies.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 www.analog.com

Fax: 781/326-8703 © 2003 Analog Devices, Inc. All rights reserved.

ADN2843–SPECIFICATIONS

(VCC = 3.0 V to 3.6 V, All specifications T

values as specified at 25C.)

MIN

to T

, unless otherwise noted. Typical

MAX

Parameter Min Typ Max Unit Conditions

LASER BIAS (BIAS)

Output Current I

Compliance Voltage 1.2 V

I

during ALS 10 A See Note 1

BIAS

ALS Shutdown Response Time 10 s

BIAS

380mA

– 1.0 V

CC

MODULATION CURRENT (IMODP, IMODN) See Note 2

Output Current I

Compliance Voltage 1.2 V

I

during ALS 10 A

MOD

Rise Time 25 ps

MOD

580mA

CC

V

Fall Time 23 ps

Random Jitter 170 fs rms See Note 3

Total Jitter 7.41 ps p-p See Note 4

POWER SET INPUT (PSET)

External Capacitance 80 pF See Note 5

Voltage 1.15 1.35 V

EXTINCTION RATIO SET INPUT (ERSET)

Allowable Resistance Range 1.5 25 k

Voltage 1.15 1.35 V

ALARM SET (ASET)

Allowable Resistance Range 1.2 13.2 k

Voltage 1.15 1.35 V

Hysteresis 5 %

CONTROL LOOP

Time Constant 0.22 s

DATA INPUTS (DATAP, DATAN)

V p-p (Single-Ended Peak-to-Peak) 300 800 mV

Input Impedance

(Single-Ended)

50

LOGIC INPUTS (ALS, MODE)

V

IH

V

IL

2.4 V

0.8 V

ALARM OUTPUTS (Internal 30 k to VCC)

V

OH

V

OL

2.4 V

0.4 V

IDTONE

f

IN

Input Current Range 50 4000 A

10 1000 kHz

Voltage on IDTONE VCC – 2 V

MONITOR PD (MPD, MPD2)

Current 50 1200 A

Input Voltage 1.65 V

IBMON, IMMON, IMPDMON, IMPDMON2

IBMON, IMMON Division Ratio 100 A/A

IMPDMON, IMPDMON2 1 A/A

IMPDMON to IMPDMON2 Matching 2 %

Measured at 1200 A

Compliance Voltage 0 VCC – 1.5 V

SUPPLY

V

CC

I

(ADN2844) 36 mA See Note 6

CC

I

(ADN2845) 75 mA See Note 6

CC

NOTES

1

In ALS mode current is sourced to the laser from the I

2

The ADN2845 high speed specifications are measured into a 5 load.

3

RMS jitter measured with a 0000 0000 1111 1111 repeating pattern at 10.7 Gbps rate.

4

Peak-to-peak total jitter measured with a 213 – 1 PRBS with 80 CIDs pattern at 10.7 Gbps rate.

5

Max capacitance refers to capacitance of photodiode and other parasitic capacitance.

6

I

= 0, I

BIAS

Specifications subject to change without notice.

= 0 (when ALS is asserted). See Power Dissipation section on page 7 for calculation of complete power dissipation.

MOD

pin, which reverse biases the laser.

BIAS

3.0 3.3 3.6 V

REV. 0–2–

ADN2843

ABSOLUTE MAXIMUM RATINGS*

(TA = 25°C, unless otherwise noted.)

VCC to GND . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.2 V

Digital Inputs (ALS, MODE) . . . . . . . . –0.5 V to V

IMODN, IMODP . . . . . . . . . . . . . . . . . . . . . . . . . V

+ 0.3 V

CC

+ 1.2 V

CC

MOD_CONTROL to GND . . . . . . . . . . . . . . –0.5 V to 4.2 V

IBIAS_CONTROL to GND . . . . . . . . . . . . . . –0.5 V to 4.2 V

D_MOD to GND . . . . . . . . . . . . . . . . . . . . . . –0.5 V to 4.2 V

DATAP to GND . . . . . . . . . . . . . . . . . . . . . . . –0.5 V to 4.2 V

DATAN to GND . . . . . . . . . . . . . . . . . . . . . . –0.5 V to 4.2 V

Operating Temperature Range

Industrial . . . . . . . . . . . . . . . . . . . . . . . . . . .–40°C to +85°C

Storage Temperature Range . . . . . . . . . . . . . –65°C to +150°C

Junction Temperature (T

*Stresses above those listed under Absolute Maximum Ratings may cause perma-

nent damage to the device. This is a stress rating only; functional operation of the

device at these or any other conditions above those listed in the operational

sections of this specification is not implied. Exposure to absolute maximum rating

conditions for extended periods may affect device reliability.

Max) . . . . . . . . . . . . . . . . . . 150°C

J

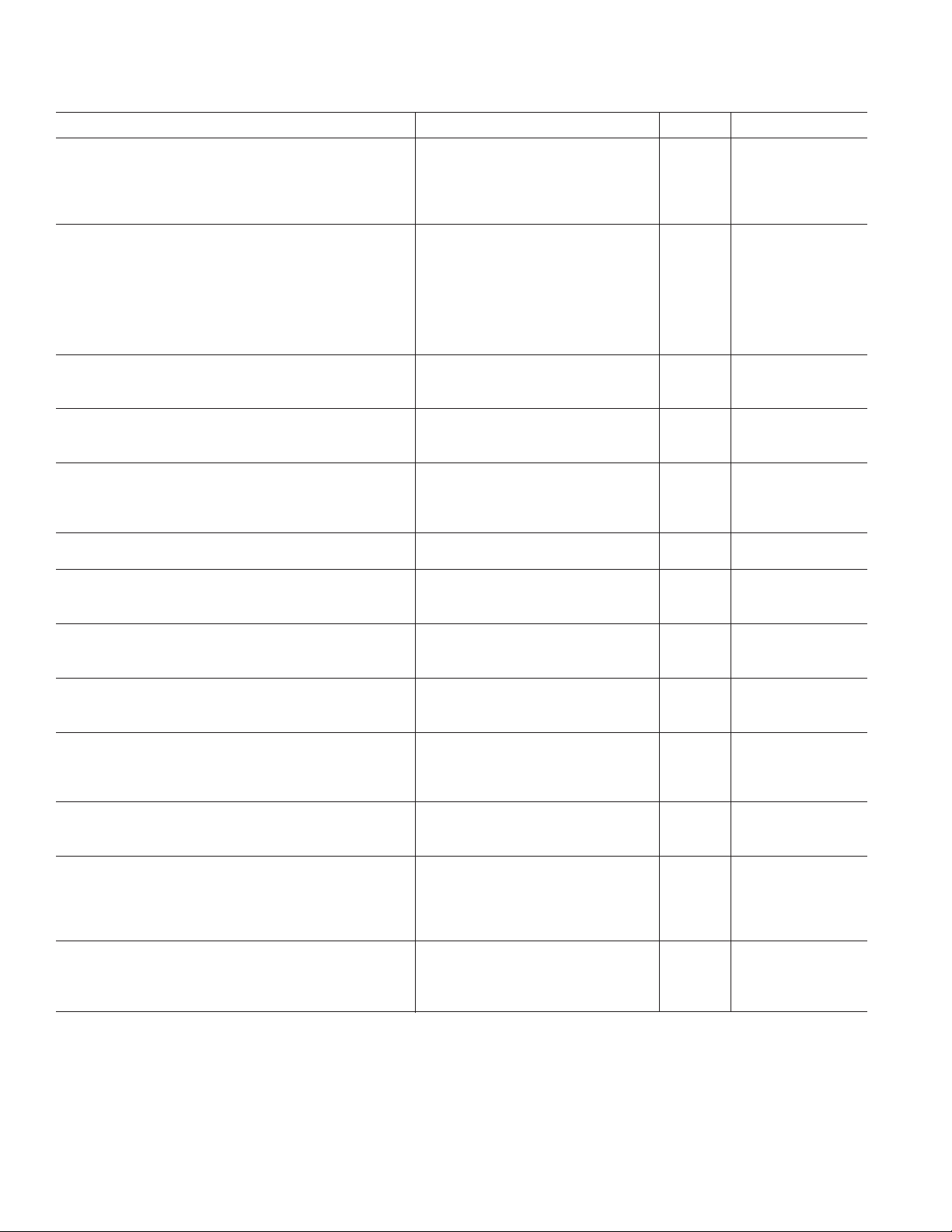

ADN2844 METALLIZATION PHOTOGRAPH

IBMON

IMMON

ALS

IDTONE

GND

ORDERING GUIDE

Temperature Package

Model Range Option

ADN2843CHIPSET –40°C to +85°C ADN2844 Control

Loop: 32-Lead LFCSP

ADN2845 Data

Switch: Dice

ADN2843CHIPSET-B –40°C to +85°C ADN2844 Control

Loop: Dice

ADN2845 Data

Switch: Dice

EVAL-ADN2843 Evaluation Board

GND

DEGRADE

GND

FAIL

V

IBIAS_CTRL

GND

IMOD_CTRL

D_IMOD

GND

GND

CC

ASET

ERSET

PSET

GND

3000m

IMPD

IMPDMON

IMPD2

IMPDMON2

GND

GND

GND

MODE

PAV CAP

ERCAP

V

CC

GND

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection. Although the

ADN2843 features proprietary ESD protection circuitry, permanent damage may occur on devices

subjected to high energy electrostatic discharges. Therefore, proper ESD precautions are recommended

to avoid performance degradation or loss of functionality.

2390m

REV. 0

–3–

ADN2843

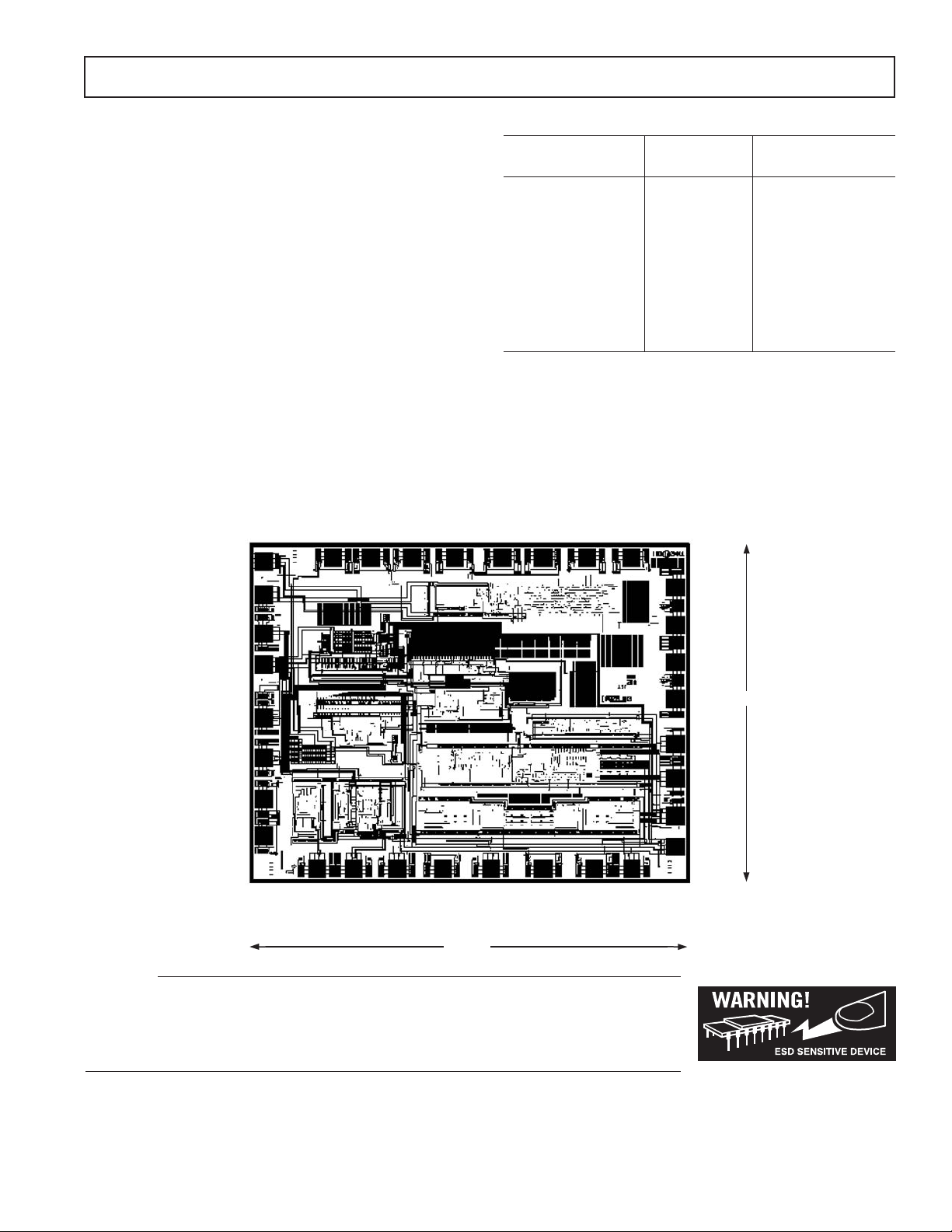

ADN2845 METALLIZATION PHOTOGRAPH

DATAN

1340m

(20m)

DATAP

GND

NC

GND

V

CC

V

CC

GNDV

CC

GNDIBIAS_CTRLALS IMOD_CTRL

1140m

(20m)

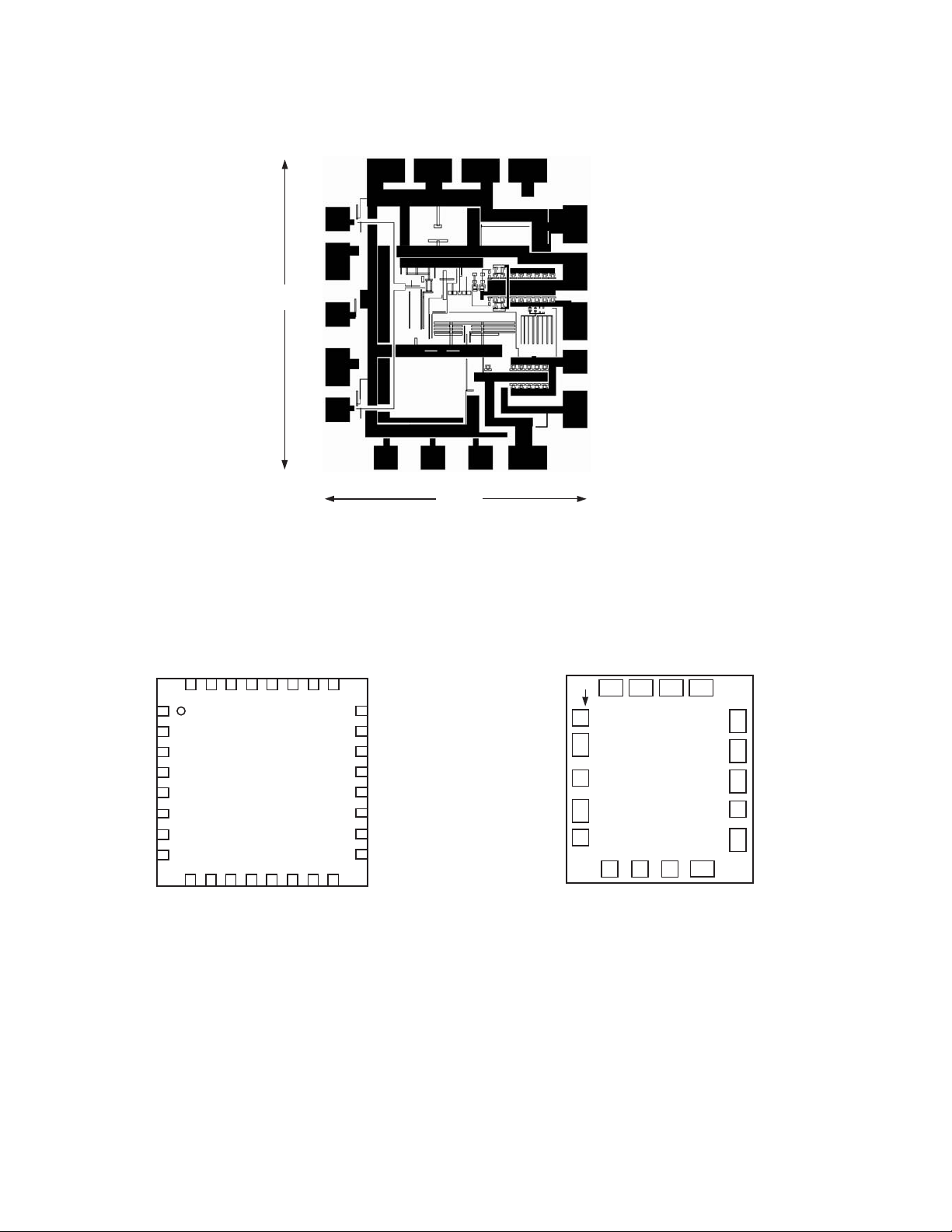

PIN CONFIGURATIONS

V

CC

(IMODN TERM)

NC

IMODP

IBIAS

NC

ASET

ERSET

PSET

GND

IMPD

IMPDMON

IMPDMON2

IMPD2

D_IMOD

GND

GND

32 31 30 29

1

2

3

4

5

6

7

8

ADN2844

BOND PAD SIZE: >115m

BOND PAD PITCH: >104m

DIE SIZE: 3000m 2390m

9101112

CC

V

GND

ERCAP

GND

IMOD_CTRL

28 27 26

13 14 15

GND

MODE

PAVCAP

VCCIBIAS_CTRL

GND

25

16

GND

GND

24

IDTONE

23

IBMON

22

IMMON

21

ALS

20

FAIL

19

DEGRADE

18

GND

17

GND

DATAN

GND

NC

GND

DATAP

CC

V

VCCV

1

ADN2845

PAD PITCH: 200m

MAXIMUM DIE SIZE: 1.16mm

1.36mm

DIE THICKNESS: 0.25mm

SINGLE PAD SIZE: 92m 92m

DOUBLE PAD SIZE: 151m 92m

ALS

IMOD_CTRL

CC

GND

GND

IBIAS_CTRL

V

CC

(IMODN TERM)

NC

IMODP

IBIAS

NC

REV. 0–4–

ADN2844 PIN FUNCTION DESCRIPTIONS

Pin No. Mnemonic Function

1 ASET Alarm Current Threshold Set (Should be Terminated with a 1.2 k

Resistor when Not Used)

2 ERSET Extinction Ratio Current Set

3 PSET Average Optical Power Set

4GND Negative Supply

5 IMPD Monitor Photodiode Current Input (Tie to GND when Not in Use)

6IMPDMON Mirrored Current from IMPD (Tie to V

7 IMPDMON2 Mirrored Current from IMPD2 (For Optional Use with Two MPDs, Tie to V

when Not in Use)

CC

when Not in Use)

CC

8IMPD2 Optional Second MPD Current Input (Tie to GND when Not in Use)

9GND Negative Supply

10 V

CC

Positive Supply

11 ERCAP Extinction Ratio Loop Capacitor

12 PAVCAP Average Power Loop Capacitor

13 MODE Control Loop Operating Mode Logic Input (Should Not Be Left Floating)

14, 15, 17 GND Negative Supply

18, 31, 32 GND Negative Supply

16 GND Negative Supply

19 DEGRADE DEGRADE Alarm Output, Open Collector, Active High

20 FAIL FAIL Alarm Output, Open Collector, Active High

21 ALS Automatic Laser Shutdown Logic Input (Should Not Be Left Floating)

22 IMMON Modulation Current Mirror Output, Current Source from V

23 IBMON Bias Current Mirror Output, Current Source from V

CC

CC

24 IDTONE ID Tone Input Current (Tie to VCC when Not in Use)

25 GND Negative Supply

26 V

CC

Positive Supply

27 IBIAS_CTRL Control Output Current Sink

28 GND Negative Supply

29 IMOD_CTRL Control Output Current Sink

30 D_IMOD Control Output Current Sink

ADN2843

ADN2845 PIN FUNCTION DESCRIPTIONS

Pin No. Mnemonic Function

1 DATAN AC-Coupled CML Data, Negative Differential Terminal

2GND Negative Supply

3, 13 NC No Connect, Leave Floating

4GND Negative Supply

5 DATAP AC-Coupled CML Data, Positive Differential Terminal

6 ALS Automatic Laser Shutdown Logic Input

7 IMOD_CTRL Modulation Current Control Input (Control Circuit Sinks IMOD/10 from Pin to GND)

8IBIAS_CTRL BIAS Current Control Input (Control Circuit Sinks IBIAS/10 from Pin to GND)

9GND Negative Supply

10 NC No Connect, Leave Floating

11 IBIAS BIAS Current

12 IMODP Modulation Current

14 V

CC

VCC Connection for IMODN Termination Resistor

15 GND Negative Supply

16–18 V

CC

Positive Supply

REV. 0

–5–

ADN2843

GENERAL

Laser diodes have current-in to light-out transfer functions as

shown in Figure 1. Two key characteristics of this transfer function

are the threshold current, I

, and slope in the linear region

TH

beyond the threshold current, referred to as the slope efficiency, LI.

ER = P1

P0

= P1 + P0

P

P1

P

AV

OPTICAL POWER

P0

AV

2

P

P

LI =

I

I

ITHCURRENT

Figure 1. Laser Transfer Function

CONTROL

A monitor photodiode, MPD, is required to control the LD. The

MPD current is fed into the ADN2843 to control the power

and extinction ratio, continuously adjusting the bias current and

modulation current in response to the laser’s changing threshold

current and light-to-current slope efficiency.

The ADN2843 uses automatic power control, APC, to maintain

a constant average power over time and temperature.

The ADN2843 uses closed-loop extinction ratio control to allow

optimum setting of the extinction ratio for every device. Thus,

SONET/SDH interface standards can be met over device variation,

temperature, and laser aging. Closed-loop modulation control

eliminates the need to either overmodulate the LD or include

external components for temperature compensation, thus reducing

research and development time and second sourcing issues.

The ADN2843 dual-loop control has two modes of operation.

Each mode is given by the configuration of the MODE and

D_IMOD pins as shown below.

Operation MODE D_IMOD

Mode Pin Setting Pin Connected to

AHIGH IBIAS

B LOW IBIAS_CTRL

Configuring the ADN2843 in Mode A or Mode B (see Figures 3

and 4) enables users to achieve accurate control of the extinction ratio. Mode B is suitable for applications where an IBIAS

pin is not available to the TOSA, or where there is no space

on the TOSA for an IBIAS inductor. Experimental data and

simulation for typical lasers has shown ER to be 0.3 dB to 0.5 dB

better in Mode A, at a 5 dB extinction ratio. Care should be

taken to ensure that the extra capacitance on the I

BIAS

pin

due to the D_IMOD connection does not degrade the eye

quality. When physical constraints do not allow a low capacitance interconnect between D_IMOD and I

, the ADN2843

BIAS

should be configured in Mode B (see Figure 4).

Average power and extinction ratio for both modes are set using

the PSET and ERSET pins, respectively. Potentiometers are

connected between these pins and ground. The potentiometer

R

is used to set the average power. The potentiometer R

PSET

ERSET

is used to set the extinction ratio. The internal control loops

force the PSET and ERSET pins to 1.23 V above GND. For

initial setup, R

PSET

and R

may be calculated using the

ERSET

following formulas:

The PSET resistor is given by the following formulas:

123.

V

I

AV

W

()

where I

R

PSET

is average MPD current.

AV

=

The value of the ERSET resistor is a function of the operation

mode of the ADN2843 as follows:

For Mode A:

ER

RR

=¥

ERSET PSET

ER

+ 1

1–

For Mode B:

R

PSET

=¥

will change from laser diode to laser

and R

need to be adjusted for each

PSET

Note that I

ERSET

diode, therefore R

R

and I

ERSET

ERSET

PSET

laser diode. When tuning the laser diode, R

adjusted first with R

set, R

R

PSET

is adjusted to set the desired extinction ratio, and

ERSET

is again adjusted to re-establish the desired average power.

Once the values R

at 25 k. Once the average power is

ERSET

PSET

and R

have been adjusted to set the

ERSET

ER

ER

+21

1–

PSET

should be

desired average power and extinction ratio, the control loops

maintain these values of average power and extinction ratio over

environmental conditions and time.

PAVCAP AND ERCAP

The control loop constants are set by the PAVCAP and ERCAP

capacitors. The required value for the PAVCAP and ERCAP

capacitors is 22 nF.

The PAVCAP and ERCAP capacitors are connected between

the respective pins and GND. The capacitors should be low

leakage multilayer ceramic capacitors with an insulation resistance

>100 G

or an RC >1000 s, whichever is lowest.

ALARMS

The ADN2843 is designed to allow interface compliance to

ITU-T-G958 (11/94), Section 10.3.1.1.2 (Transmitter Fail),

and Section 10.3.1.1.3 (transmitter degrade). The ADN2843

has two alarms, DEGRADE and FAIL. These alarms are raised

when I

exceeds the respective DEGRADE and FAIL thresh-

BIAS

olds. These alarms are active high. A resistor between ground

and the ASET pin is used to set the current at which these

alarms are raised. The current through the ASET resistor is a

ratio of 1:100 to the FAIL alarm threshold. The DEGRADE

alarm will be raised at 90% of the FAIL threshold.

Example:

50 45

ImAsoI mA

==

FAIL DEGRADE

I

R

I

== =

ASET

100

123 123

== =

ASET

50

FAIL

..

I

ASET

mA

100

V

500

500

V

A

A

246

. W

k

The laser degrade alarm, DEGRADE, is provided to give a warning of imminent laser failure if the laser diode degrades further or

if environmental conditions continue to stress the LD, such as

increasing temperature.

REV. 0–6–

ADN2843

The laser fail alarm, FAIL, is activated when the transmitter can

no longer be guaranteed to be SONET/SDH compliant. This

occurs when one of the following conditions arise:

∑ The ASET threshold is reached.

∑ The ALS pin is set high. This shuts off the modulation and

bias currents to the LD, resulting in the MPD current

dropping to zero. This gives closed-loop feedback to the

system that ALS has been enabled.

DEGRADE is raised only when the bias current exceeds

90% of the alarm threshold.

ALARM INTERFACE

The alarm voltages are open collector outputs. An internal

pull-up resistor of 30k

value to V

. However, this can be overdriven with an external

CC

that is used to pull the logic high

resistor, allowing alarm interfacing to non-VCC levels. The

FAIL output may not be connected directly to the ALS pin to

shut down the bias and modulation currents. It can however

be latched using a flip-flop, and the output of the flip-flop can

then be used to activate ALS. Non-V

must be below the V

DATA INPUTS

used for the ADN2843.

CC

alarm output levels

CC

Figure 2 shows a simplified schematic of the ADN2845 data

inputs. The data inputs are terminated via the equivalent of a

internal resistor between DATAN and DATAP. This

100

provides 50

termination for single-ended signals. The actual

signal on the switching devices is attenuated by a factor of 2

internally. There is a high impedance circuit to set the commonmode voltage, which is designed to change over temperature. It

is recommended that ac coupling be used to eliminate the need

for matching between the common-mode voltages.

DATAN

DATAP

25

25

25

25

2k

ADN2845

INTERNAL

REFERENCE

Figure 2. Simplified Schematic of Data Inputs

MONITOR CURRENTS

IBMON, IMMON mirror the bias, modulation current at a ratio

of 1:100 for increased monitoring functionality. IMPDMON and

IMPDMON2 mirror the current in IMPD and IMPD2, respectively, with a ratio of 1. All monitors source current from V

CC

.

If the MPD monitoring function is not required, then the IMPD

pin should be tied to ground and the monitor photodiode cathode

should be connected directly to the PSET pin. When the MPD

monitor functions are not used, IMPDMON and IMPDMON2

should be tied to V

MPD CURRENT

CC

.

The maximum average MPD current is specified in the specifications section. This maximum current specified is limited by the

MPD monitoring circuitry. If the monitoring function is not

required, then IMPD and IMPD2 should be grounded, the moni-

REV. 0

–7–

tor photodiode cathode should be connected directly to the PSET

node, and IMPDMON and IMPDMON2 should be tied to V

CC

.

MPD currents as high as 3 mA can be used in this configuration.

Another way to increase the MPD current range without sacrificing the monitoring function is to use IMPD and IMPD2 in

parallel. This effectively doubles the current range but raises the

lower MPD current specification from 50 A to 100 A. If this

configuration is used, the IMPDMON and IMPDMON2 pins

should be tied together and terminated with a single resistor.

The mirror ratio of 1 is maintained in this configuration.

DUAL MPD DWDM FUNCTION

The MPD function mirrors the current in MPD to the PSET pin

and to the IMPDMON pin with a ratio of 1. A second monitor

photodiode can be connected to the IMPD2 pin. Its current is

mirrored to IMPDMON2 and also to the PSET pin, where it is

summed with the current mirrored from IMPD. The two MPD

monitor currents can be used as inputs to a DWDM wavelength

control function when used in combination with various optical

filtering techniques. If the IMPD monitor function is not required,

the monitor photodiode can be directly connected to the PSET

pin, and the IMPD pin must be tied to GND. If the IMPD2 pin

is not being used, it should be tied to GND.

IDTONE

The IDTONE pin is supplied for fiber identification/supervisory

channels or for control purposes. This pin modulates the optical

one level by adding a current to IMOD over a possible range of

2% of minimum I

to 10% of maximum I

MOD

. The IDTONE

MOD

current is set by an external current sink connected to the

IDTONE pin. There is a gain of 2 between the IDTONE pin

and the I

current. To ratio the IDTONE current to I

MOD

MOD

, the

input current can be derived from the IMMON output current.

If the IDTONE function is not being used, this pin must be tied

to V

to properly disable it.

CC

Note that using IDTONE during transmission may cause optical

eye degradation.

AUTOMATIC LASER SHUTDOWN (ALS)

The ADN2843 ALS allows compliance to ITU-T-G958 (11/94),

Section 9.7. When ALS is asserted, both bias and modulation

currents are turned off. In ALS mode, current is sourced to the

laser from the I

pin, which reverse biases the laser and ensures

BIAS

that it is turned off. Correct operation of ALS can be confirmed

by the FAIL alarm being raised when ALS is asserted. Note this

is the only time that DEGRADE will be low while FAIL is high.

Note that for correct ALS operation, the ALS pin on the

ADN2845 and ADN2844 should be connected and terminated with a 10 kW resistor. The ADN2843 ALS should be

driven with correct logic levels (see Specifications section). ALS

should never be left floating.

POWER DISSIPATION

The power dissipation of the ADN2845 can be calculated using

the following expressions:

ImA ImA ImA

=+¥

75 1 75 0 3

CC MOD BIAS

=¥

PV I A V I A V I A

CC CC IMOD MOD IBIAS BIAS

where V

V

IMOD

is the average voltage on the I

IBIAS

..

+¥

()

is the average voltage on the IMOD pin, and

+¥

()

/

()

pin.

BIAS

()

+¥

2

()

ADN2843

**

1k

CC

10nF

1518

CC

NC

IMODP

IBIAS

NC

IBIAS_CTRL

96

IBIAS_CTRL

V

CC

100F TANTALUM

GND

14

10nF

10

GND

V

CC

10nF

CC

V

GND

IDTONE

IBMON

IMMON

ALS

FAIL

DEGRADE

GND

V

CC

V

24

V

CC

MPD

CC

**

1k

1k

**

10k

V

V

V

CC

CC

10nF

V

CC

10nF

10nF

32 25

GND

GND

1

ASET

ERSET

PSET

1

5

ALS

D_IMOD

DATAN

GND

NC

GND

DATAP

VCCV

IMODNTERM

ADN2845

IMOD_CTRL

GND

IMOD_CTRL

ADN2844

GND

IMPD

IMPDMON

**

V

CC

IMPDMON2

IMPD2

8

CC

ERCAP

PAVCAP

MODE

GND

V

9 16

22nF

10nF

NOTES

*FOR DIGITAL PROGRAMMING, THE ADN2850 OR ADN2860 OPTICAL SUPERVISOR CAN BE USED.

**OPTIONAL MONITORING OF CURRENTS.

22nF

V

CC

GND

V

CC

GND

GND

17

GND

Figure 3. ADN2843 Application Circuit (Mode A)

•Best high frequency board layout techniques including power and ground planes should be used.

• To minimize inductance, keep the connections between the ADN2845 and the laser diode as short as possible. Inductances <0.3 nH

are recommended for best performance. Critical bonds are IMODP and V

(Pin 14). Ribbon bonding can be used to reduce

CC

bond inductance. Minimize bond lengths for ADN2845 pads to achieve low inductance.

•Place bypass capacitor on laser anode as close to laser as possible.

•Bypass capacitors should be placed as close as possible to V

CC

pads.

• 50 controlled impedance interconnects should be used on the DATA inputs.

•Parasitic capacitance on IBIAS_CTRL and IMOD_CTRL interconnects should be less than 100 pF. If decoupling caps are used

on IBIAS_CTRL and IMOD_CTRL, they should be tied to V

rather than GND.

CC

• An inductor should be used in the bias current path. A Microwave Components coil 30-1847-GCCAS-01 (48 mil 24 mil) should

be used.

•The recommended substrate connection is to GND. However, the performance is not affected by connecting the substrate to V

CC.

REV. 0–8–

ADN2843

10nF

10nF

V

CC

V

V

CC

10nF 10nF

V

CC

VCCV

CC

1

DATAN

GND

IMODNTERM

ADN2845

NC

GND

5

DATAP

ALS GND

IMOD_CTRL

CC

1518

NC

IMODP

IBIAS

GND

IBIAS_CTRL

96

V

CC

100F TANTALUM

GND

14

10nF

10

V

CC

V

CC

V

CC

MPD

10nF

32 25

CC

V

IDTONE

IBMON

IMMON

ALS

FAIL

DEGRADE

GND

GND

GND

GND

GND

V

CC

24

17

GND

LBWSET

1

ASET

D_IMOD

GND

IMOD_CTRL

IBIAS_CTRL

ERSET

PSET

**

ADN2844

GND

IMPD

IMPDMON

1k

**

IMPDMON2

V

CC

IMPD2

8

CC

ERCAP

PAVCAP

MODE

GND

V

9 16

10nF

NOTES

*FOR DIGITAL PROGRAMMING, THE ADN2850 OR ADN2860 OPTICAL SUPERVISOR CAN BE USED.

**OPTIONAL MONITORING OF CURRENTS.

22nF

22nF

V

CC

GND

V

CC

Figure 4. ADN2843 Application Circuit (Mode B)

10k

**

1k

1k

**

REV. 0

–9–

ADN2843

PARALLEL PLATE

DECOUPLING

CAPACITOR

GROUND PLANE

MPD

50 TRANSMISSION LINE

GROUND PLANE

18 15

V

V

CC

CC

DATAN

1

AGN D

ADN2845

AGN D

DATAP

5

AGN DV

CC

IMODNTERM

BACK FACET LIGHT

14

V

CC

IMODP

IBIAS

10

AGN DALS IMOD_CTRL IBIAS_CTRL

96

IBIAS OUTPUT INDUCTOR

PARALLEL PLATE

DECOUPLING

CAPACITORS

CERAMIC WITH GOLD

SURFACE THAT CONTACTS

THE LASER’S ANODE

LASER LIGHT

LASER

NOTES

• FOR OPTIMUM PERFORMANCE, RIBBON BONDS ARE RECOMMENDED ON PADS 1, 5, 12, AND 14. WIRES ARE 3 MIL OR 5 MIL RIBBONS <400m

• LONG. ALL OTHER PINS CAN BE ROUND WIRE <1mm.

• LASER’S ANODE IS CONNECTED TO V

• 12 AND PAD 14 RIBBONS.

• PARALLEL PLATE DECOUPLING CAPACITORS SHOULD BE >100pF AND BE OF MICROWAVE AVX TYPE, PART NO. GB0159391KA6N (390pF).

• THE RECOMMENDED SUBSTRATE CONNECTION IS TO GND. HOWEVER, PERFORMANCE IS NOT AFFECTED BY CONNECTING THE

• SUBSTRATE TO VCC.

• AN INDUCTOR SHOULD BE USED IN THE BIAS CURRENT PATH. A MICROWAVE COMPONENTS COIL 30-1847-GCCAS-01 (48 MIL 24 MIL)

SHOULD BE USED.

• THE EXTERNAL POWER SUPPLY IS CONNECTED AT THE PARALLEL PLATE DECOUPLING CAPACITOR.

THROUGH GOLD LAYER ON TOP OF CERAMIC STANDOFF. STANDOFF MINIMIZES LENGTH OF PAD

CC

Figure 5. Recommended Layout

Figure 6. 10 Gbps Optical Diagram Provided Courtesy of NEL.

= 0 dBm, ER = 5 dB, PRBS 31 Pattern.

P

AV

REV. 0–10–

ADN2844

ADN2843

DIE PAD COORDINATES

(With Origin in the Center of the Die)

ADN2845

Pad Number Pad Name X (m) Y (m)

1 ASET 1014.00 –1019.00

2 ERSET 769.00 –1019.00

3 PSET 486.00 –1019.00

4 GND 186.00 –1019.00

5IMPD –132.00 –1019.00

6 IMPDMON –479.00 –1019.00

7 IMPDMON2 –811.00 –1019.00

8 IMPD2 –1056.00 –1019.00

9 GND –1339.00 –877.00

10 V

11 ERCAP –1339.00 –429.00

CC

–1339.00 –672.00

12 PAVCAP –1339.00 –204.00

13 MODE –1339.00 91.00

14 GND –1339.00 335.00

15 GND –1339.00 580.00

16 GND –1339.00 824.00

17 GND –1051.00 1019.00

18 GND –761.00 1019.00

19 DEGRADE –476.00 1019.00

20 FAIL –207.00 1019.00

21 ALS 102.00 1019.00

22 IMMON 387.00 1019.00

23 IBMON 653.00 1019.00

24 IDTONE 904.00 1019.00

25 GND 1359.00 995.00

26 V

CC

1359.00 781.00

27 IBIAS_CNTRL 1359.00 523.00

28 GND 1359.00 317.00

29 IMOD_CTRL 1359.00 –29.00

30 D_IMOD 1359.00 –294.00

31 GND 1359.00 –562.00

32 GND 1359.00 –807.00

Pad Number Pad Name X (m) Y (m)

1 DATAN –500.00 400.00

2 GND* –500.00 222.00

3NC–500.00 0.00

4 GND* –500.00 –222.00

5 DATAP –500.00 –400.00

6 ALS –300.00 –600.00

7IMOD_CTRL –100.00 –600.00

8 IBIAS_CTRL 100.00 –600.00

9 GND* 300.00 –600.00

10 NC* 500.00 –400.00

11 IBIAS 500.00 –200.00

12 IMODP* 500.00 –30.00

13 NC* 500.00 178.00

14 V

15 GND* 300.00 600.00

(IMODN)* 500.00 378.00

CC

16 VCC* 100.00 600.00

17 V

* –100.00 600.00

CC

18 VCC* –300.00 600.00

*

Denotes double bond pad.

REV. 0

–11–

ADN2843

OUTLINE DIMENSIONS

32-Lead Lead Frame Chip Scale Package [LFCSP]

5 mm 5 mm

(CP-32)

Dimensions shown in millimeters

PIN 1

INDICATOR

1.00

0.90

0.80

12 MAX

SEATING

PLANE

5.00

BSC SQ

TOP

VIEW

0.80 MAX

0.65 NOM

0.30

0.23

0.18

COMPLIANT TO JEDEC STANDARDS MO-220-VHHD-2

4.75

BSC SQ

0.20 REF

0.05 MAX

0.02 NOM

0.60 MAX

0.50

BSC

0.50

0.40

0.30

COPLANARITY

0.08

25

24

17

16

0.60 MAX

BOTTOM

VIEW

3.50

REF

PIN 1

32

9

INDICATOR

1

3.25

3.10

SQ

2.95

8

Exposed paddle should be soldered to the most negative supply of the ADN284

(ADN2844 also available as bare die)

C02764–0–4/03(0)

–12–

REV. 0

Loading...

Loading...