Continuous Rate 10 Mbps to 2.7 Gbps Clock

www.BDTIC.com/ADI

FEATURES

Serial data input: 10 Mbps to 2.7 Gbps

Exceeds ITU-T jitter specifications

Integrated limiting amplifier

5 mV sensitivity (ADN2817 only)

Adjustable slice level: ±100 mV (ADN2817 only)

Patented dual-loop clock recovery architecture

Programmable LOS detect (ADN2817 only)

Integrated PRBS generator and detector

No reference clock required

Loss of lock indicator

Supports double data rate

Bit error rate monitor (BERMON) or sample phase adjust options

Rate selectivity without the use of a reference clock

2

I

C interface to access optional features

Single-supply operation: 3.3 V

Low power

650 mW (ADN2817)

600 mW (ADN2818)

5 mm × 5 mm 32-lead LFCSP

APPLICATIONS

SONET OC-1, OC-3, OC-12, OC-48, and all associated FEC rates

Fibre Channel, 2× Fibre Channel, GbE, HDTV, and others

WDM transponders

Regenerators/repeaters

Test equipment

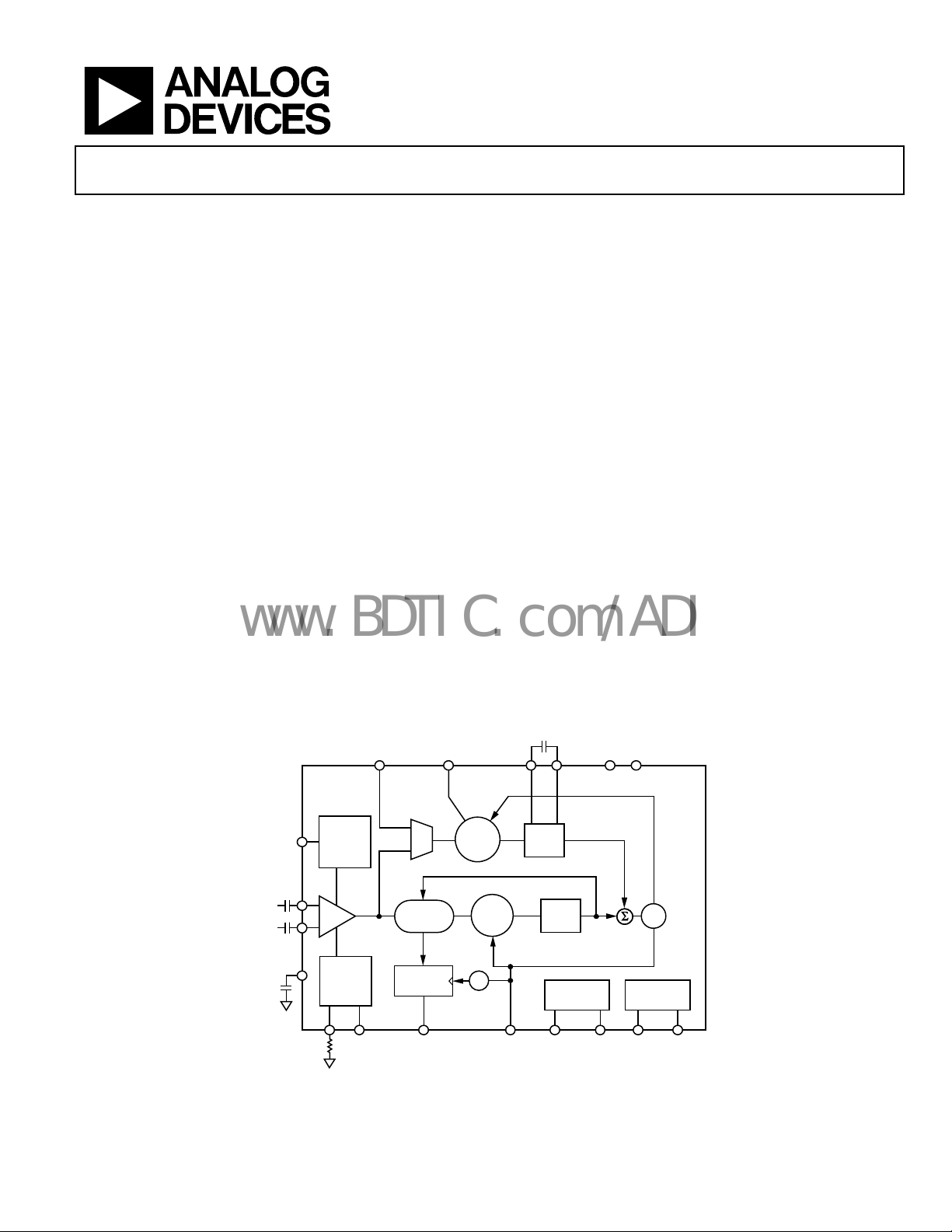

FUNCTIONAL BLOCK DIAGRAM

REFCLKP/REFCLKN

(OPTIO NAL)

LOL

and Data Recovery ICs

ADN2817/ADN2818

GENERAL DESCRIPTION

The ADN2817/ADN2818 provide the receiver functions of

quantization, signal level detect, and clock and data recovery for

continuous data rates from 10 Mbps to 2.7 Gbps. The ADN2817/

ADN2818 automatically lock to all data rates without the need for

an external reference clock or programming. All SONET jitter

requirements are exceeded, including jitter transfer, jitter generation,

and jitter tolerance. All specifications are quoted for −40°C to

+85°C ambient temperature, unless otherwise noted.

This device, together with a PIN diode and a TIA preamplifier,

can implement a highly integrated, low cost, and low power

fiber optic receiver.

The ADN2817/ADN2818 have many optional features available

through an I

the data rate onto which the ADN2817 or ADN2818 is locked,

or the user can set the device to lock only to one particular data

rate if provisioning of data rates is required. A BERMON circuit

provides an estimate of the received bit error rate (BER) without

interruption of the data. Alternatively, the user can adjust the

data sampling phase to optimize the received BER.

The ADN2817/ADN2818 are available in a compact 5 mm ×

5 mm, 32-lead, lead frame chip scale package.

CF1 CF2

2

C® interface. For example, the user can read back

VCC VEE

SLICE

THRADJ

ADJUST

(ADN2817

ONLY)

LOS

DETECT

(ADN2817

ONLY)

LOS DATAOUTP/

PHASE

SHIFTER

DATA

RETIMING

DATAOUTN

SLICEP/

SLICEN

PIN

NIN

VREF

Rev. A

Information furnished by Analog Devices is believed to be accurate and reliable. However, no

responsibility is assumed by Analog Devices for its use, nor for any infringements of patents or other

rights of third parties that may result from its use. Specifications subject to change without notice. No

license is granted by implication or otherwise under any patent or patent rights of Analog Devices.

Trademarks and registered trademarks are the property of their respective owners.

FREQ/

LOCK

DET

PHASE

DET

ΔФ

CLKOUTP/

CLKOUTN

Figure 1.

ADN2817/ADN2818

LOOP

FILTER

LOOP

FILTER

BERMON

VBER BERMODE

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700 www.analog.com

Fax: 781.461.3113 ©2007–2008 Analog Devices, Inc. All rights reserved.

VCO

I2C

REGISTERS

SCK SDA

06001-001

ADN2817/ADN2818

www.BDTIC.com/ADI

TABLE OF CONTENTS

Features .............................................................................................. 1

Applications ....................................................................................... 1

General Description ......................................................................... 1

Functional Block Diagram .............................................................. 1

Revision History ............................................................................... 2

Specifications ..................................................................................... 3

Jitter Specifications ....................................................................... 4

Output and Timing Specifications ............................................. 5

Bit Error Rate Monitor Specifications ....................................... 7

Timing Characteristics ................................................................ 8

Absolute Maximum Ratings ............................................................ 9

Thermal Characteristics .............................................................. 9

ESD Caution .................................................................................. 9

Pin Configuration and Function Descriptions ........................... 10

Typical Performance Characteristics ........................................... 11

I2C Interface Timing and Internal Register Description ........... 13

Terminology .................................................................................... 17

Input Sensitivity and Input Overdrive ..................................... 17

Single-Ended vs. Differential .................................................... 17

LOS Response Time ................................................................... 17

Jitter Specifications ......................................................................... 18

Jitter Generation ......................................................................... 18

Jitter Transfer ............................................................................... 18

Jitter Tolerance ............................................................................ 18

Theory of Operation ...................................................................... 19

Functional Description .................................................................. 21

Frequency Acquisition ............................................................... 21

Lock Detector Operation .......................................................... 21

Harmonic Detector .................................................................... 22

Limiting Amplifier (ADN2817 Only) ..................................... 22

Slice Level Adjust (ADN2817 Only) ........................................ 22

Loss of Signal (LOS) Detector (ADN2817 Only) .................. 22

Sample Phase Adjust .................................................................. 23

Bit Error Rate (BER) Monitor ................................................... 23

Squelch Mode ............................................................................. 24

I2C Interface ................................................................................ 24

Reference Clock (Optional) ...................................................... 25

Additional Features Available via the I2C Interface ............... 27

Applications Information .............................................................. 29

PCB Design Guidelines ............................................................. 29

DC-Coupled Application .......................................................... 31

Coarse Data Rate Readback Look-Up Table ............................... 32

HI_CODE and LO_CODE Look-Up Table ................................ 34

Outline Dimensions ....................................................................... 37

Ordering Guide .......................................................................... 37

REVISION HISTORY

8/08—Rev. 0 to Rev. A

Changes to Features Section, General Description Section, and

Figure 1 .............................................................................................. 1

Added Bit Rate Monitor Specifications Section and Table 4;

Renumbered Sequentially ................................................................ 7

Changes to Figure 5 and Table 6 ................................................... 10

Changes to Table 7 and Table 8 ..................................................... 14

Changes to Table 14 ........................................................................ 15

Added Table 15 ............................................................................... 15

Added Table 16 ............................................................................... 16

Added Sample Phase Adjust Section and Bit Error Rate (BER)

Monitor Section .............................................................................. 23

Added Figure 32; Renumbered Sequentially .............................. 24

Changes to Figure 36 ...................................................................... 29

Added Exposed Pad Notation to Outline Dimensions ............. 37

7/07—Revision 0: Initial Version

Rev. A | Page 2 of 40

ADN2817/ADN2818

www.BDTIC.com/ADI

SPECIFICATIONS

TA = T

unless otherwise noted.

Table 1.

Parameter Conditions Min Typ Max Unit

QUANTIZER—DC CHARACTERISTICS

QUANTIZER—AC CHARACTERISTICS

QUANTIZER—SLICE ADJUSTMENT ADN2817 only

LOSS OF SIGNAL DETECT (LOS) ADN2817 only

R

R

R

LOSS OF LOCK DETECT (LOL)

ACQUISITION TIME

DATA RATE READBACK ACCURACY

MIN

to T

, VCC = V

MAX

MIN

to V

, VEE = 0 V, CF = 0.47 µF, SLICEP = SLICEN = VEE, input data pattern: PRBS 223 − 1,

MAX

Input Voltage Range @ PIN or NIN, dc-coupled 1.8 2.8 V

Peak-to-Peak Differential Input PIN − NIN 2.0 V

Input Common-Mode Level DC-coupled (see Figure 40, Figure 41, and Figure 42) 2.3 2.5 2.8 V

Differential Input Sensitivity 223 − 1 PRBS, ac-coupled,1 BER = 1 × 10

−10

ADN2817 10 5 mV p-p

ADN2818 200 mV p-p

Data Rate 10 2700 Mbps

S11 @ 2.5 GHz −15 dB

Input Resistance Differential 100 Ω

Input Capacitance 0.65 pF

Gain SLICEP − SLICEN = ±0.5 V 0.10 0.11 0.13 V/V

Differential Control Voltage Input SLICEP − SLICEN −0.95 +0.95 V

Control Voltage Range DC level @ SLICEP or SLICEN VEE 0.95 V

Slice Threshold Offset ±1 mV

Loss of Signal Detect Range (See Figure 6) R

= 0 Ω 14.2 20.0 mV

Thresh

= 100 kΩ 2.1 5.0 mV

Thresh

Hysteresis (Electrical)

OC-48 R

OC-1 R

LOS Assert Time DC-coupled

LOS Deassert Time DC-coupled

= 0 Ω 6.2 8.2 dB

Thresh

= 100 kΩ 4.7 7.7 dB

Thresh

= 0 Ω 4.9 7.5 dB

Thresh

= 10 kΩ 3.0 7.3 dB

Thresh

2

2

500 ns

450 ns

VCO Frequency Error for LOL Assert With respect to nominal 1000 ppm

VCO Frequency Error for LOL Deassert With respect to nominal 250 ppm

LOL Response Time

OC-48 1.0 μs

OC-12 1.0 μs

10 Mbps 500 μs

Lock to Data Mode

OC-48 1.3 ms

OC-12 2.0 ms

OC-3 3.4 ms

OC-1 9.8 ms

10 Mbps 40.0 ms

Optional Lock to REFCLK Mode 10.0 ms

Coarse Readback See Tab le 19 10 %

Fine Readback In addition to REFCLK accuracy 100 ppm

Rev. A | Page 3 of 40

ADN2817/ADN2818

www.BDTIC.com/ADI

Parameter Conditions Min Typ Max Unit

POWER SUPPLY

Voltage 3.0 3.3 3.6 V

Current

ADN2817 210 247 mA

ADN2818 180 217 mA

OPERATING TEMPERATURE RANGE −40 +85 °C

1

PIN and NIN should be differentially driven and ac-coupled for optimum sensitivity.

2

When ac-coupled, the LOS assert and deassert time is dominated by the RC time constant of the ac coupling capacitor and the 50 Ω input termination of the ADN2817

input stage.

JITTER SPECIFICATIONS

TA = T

unless otherwise noted.

Table 2.

Parameter Conditions Min Typ Max Unit

PHASE-LOCKED LOOP CHARACTERISTICS

1

Jitter tolerance of the ADN2817/ADN2818 at these jitter frequencies is better than what the test equipment is able to measure.

MIN

to T

, VCC = V

MAX

MIN

to V

, VEE = 0 V, CF = 0.47 F, SLICEP = SLICEN = VEE, input data pattern: PRBS 223 − 1,

MAX

Jitter Transfer Bandwidth

OC-48 548 839 kHz

OC-12 93 137 kHz

OC-3 30 40 kHz

Jitter Peaking

OC-48 0 0.03 dB

OC-12 0 0.03 dB

OC-3 0 0.03 dB

Jitter Generation

OC-48 12 kHz to 20 MHz 0.001 0.003 UI rms

0.02 0.046 UI p-p

OC-12 12 kHz to 5 MHz 0.001 0.004 UI rms

0.01 0.036 UI p-p

OC-3 12 kHz to 1.3 MHz 0.001 0.004 UI rms

0.01 0.023 UI p-p

Jitter Tolerance 223 − 1 PRBS

OC-48 600 Hz

6 kHz

1

1

20.0 UI p-p

92.0 UI p-p

100 kHz 7.0 UI p-p

1 MHz

1

1.00 UI p-p

20 MHz 0.53 UI p-p

OC-12 30 Hz

300 Hz

1

100.0 UI p-p

1

44.0 UI p-p

25 kHz 7.35 UI p-p

250 kHz

1

1.00 UI p-p

5 MHz 0.52 UI p-p

OC-3 30 Hz

300 Hz

1

50.0 UI p-p

1

23.5 UI p-p

6500 Hz 6.71 UI p-p

65 kHz

1

1.00 UI p-p

130 kHz 0.54 UI p-p

Rev. A | Page 4 of 40

ADN2817/ADN2818

www.BDTIC.com/ADI

OUTPUT AND TIMING SPECIFICATIONS

Table 3.

Parameter Conditions Min Typ Max Unit

CML OUPUT CHARACTERISTICS (CLKOUTP/CLKOUTN,

DATAOUTP/DATAOUTN)

Single-Ended Output Swing, VSE See Figure 3 300 350 600 mV

Differential Output Swing, V

See Figure 3 600 700 1200 mV

DIFF

Output Voltage

High, VOH VCC V

Low, VOL VCC − 0.6 VCC − 0.35 VCC − 0.3 V

CML Outputs Timing

Rise Time 20% to 80% 80 112 ps

Fall Time 80% to 20% 80 123 ps

Setup Time, tS See Figure 2, OC-48 150 200 250 ps

Hold Time, tH See Figure 2, OC-48 150 200 250 ps

Setup Time, t

Hold Time, t

See Figure 4, OC-48 140 170 200 ps

DDRS

See Figure 4, OC-48 200 230 260 ps

DDRH

I2C INTERFACE DC CHARACTERISTICS LVCMOS

Input Voltage

High, VIH 0.7 VCC V

Low, VIL 0.3 VCC V

Input Current VIN = 0.1 VCC or VIN = 0.9 VCC −10.0 +10.0 μA

Output Low Voltage VOL, IOL = 3.0 mA 0.4 V

I2C INTERFACE TIMING See Figure 22

SCK Clock Frequency 400 kHz

SCK Pulse Width High

High, t

Low, t

600 ns

HIGH

1300 ns

LOW

Start Condition

Hold Time, t

Setup Time, t

600 ns

HD;STA

600 ns

SU;STA

Data

Setup Time, t

Hold Time, t

100 ns

SU;DAT

300 ns

HD;DAT

SCK/SDA Rise/Fall Time, tR/tF 20 + 0.1 Cb 300 ns

Stop Condition Setup Time, t

Bus Free Time Between a Stop and a Start, t

600 ns

SU;STO

1300 ns

BUF

REFCLK CHARACTERISTICS Optional lock to REFCLK mode

Input Voltage Range @ REFCLKP or REFCLKN

VIL 0 V

VIH VCC V

Minimum Differential Input Drive 100 mV p-p

Reference Frequency 10 200 MHz

Required Accuracy 100 ppm

Rev. A | Page 5 of 40

ADN2817/ADN2818

www.BDTIC.com/ADI

Parameter Conditions Min Typ Max Unit

LVTTL DC INPUT CHARACTERISTICS

Input Voltage

High, VIH 2.0 V

Low, VIL 0.8 V

Input Current

High IIH, VIN = 2.4 V +5 μA

Low IIL, VIN = 0.4 V −5 μA

LVTTL DC OUTPUT CHARACTERISTICS

Output Voltage

High VOH, IOH = −2.0 mA 2.4 V

Low VOL, IOL = +2.0 mA 0.4 V

Rev. A | Page 6 of 40

ADN2817/ADN2818

www.BDTIC.com/ADI

BIT ERROR RATE MONITOR SPECIFICATIONS

TA = T

unless otherwise noted.

Table 4.

Parameter Conditions Min Typ Max Unit

BERMON Extrapolation Mode I2C controlled eye profiling

BERMON Voltage Output Mode Analog voltage output

Sample Phase Adjust Mode

to T

MIN

Final Computed BER Accuracy

, VCC = V

MAX

MIN

to V

, VEE = 0 V, CF = 0.47 µF, SLICEP = SLICEN = VEE, input data pattern: PRBS 223 − 1,

MAX

Input BER range 1 × 10

−3

to 1 × 10

−12

,

±1 Decades

input deterministic jitter (DJ) < 0.4 UI,

DJ ceiling > 1 × 10−2; asymmetry < 0.1 UI;

requires external data processing algorithms

to implement Q factor extrapolation

18

Number of Bits (NUMBITS)

Number of data bits to collect pseudo errors;

user programmable in increment factors of

3

over the range 218 to 239

2

PBER Measurement Time

2

239 UI

Numbits/

sec

data rate

BER Range 5 × 10−2 BER

Sample Phase Adjust Resolution 6 Degrees

Sample Phase Adjust Accuracy <6 Degrees

Sample Phase Adjust Range With respect to normal sampling instant −0.5 +0.5 UI

Minimum Input Signal Level Differential peak to peak 4 mV

Power Increase BER enabled 160 mW

BER standby 77 mW

BER Accuracy

Input BER range 1 × 10

input DJ = 0 UI, DJ ceiling > 1 × 10

−3

to 1 × 10−9,

−2

;

±1 Decades

asymmetry = 0 UI; BER is read as a voltage on

the VBER pin, when the BER mode pin = VEE

−3

Input BER range 1 × 10

to 1 × 10−9,

input DJ = 0.2 UI, DJ ceiling > 1 × 10

−2

;

+1/−2 Decades

asymmetry = 0 UI; BER is read as a voltage on

the VBER pin, when the BER mode pin = VEE

Numbits Number of data bits to collect pseudo errors 227 UI

Measurement Time 2.5 Gbps 0.054 sec

1 Gbps 0.134 sec

155 Mbps 0.865 sec

10 Mbps 1.34 sec

VBER Voltage Range Via 3 kΩ resistor to VEE 0.1 0.9 V

Minimum Input Signal Level Differential peak to peak 4 mV

Power Increase BER voltage mode 160 mW

Sample Phase Adjust Step Size Monotonic 6 Degrees

Sample Phase Adjust Accuracy <6 Degrees

Sample Phase Adjust Range With respect to normal sampling instant −0.5 +0.5 UI

Power Increase 160 mW

Rev. A | Page 7 of 40

ADN2817/ADN2818

www.BDTIC.com/ADI

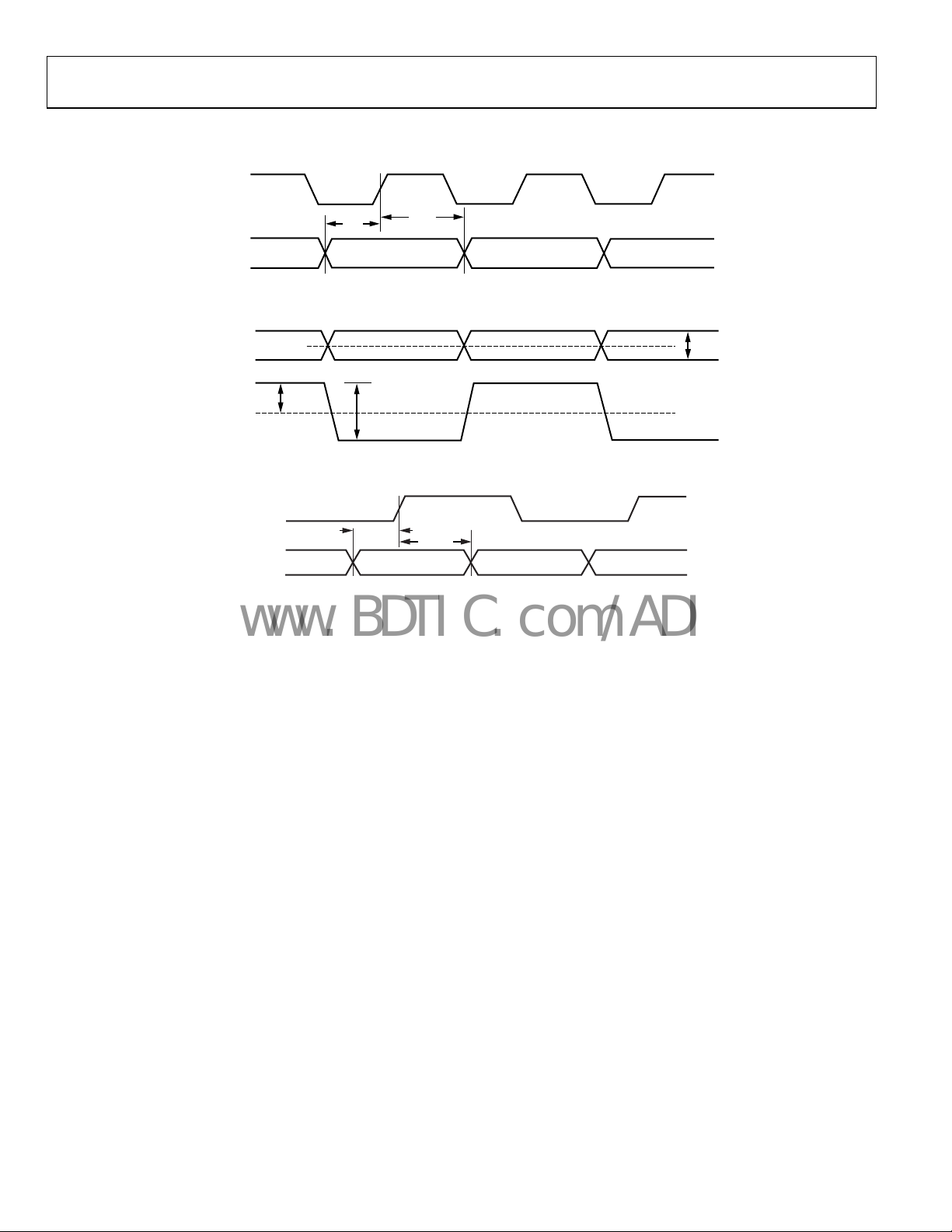

TIMING CHARACTERISTICS

CLKOUTP

t

t

S

DATAOUTP/

DATAOUTN

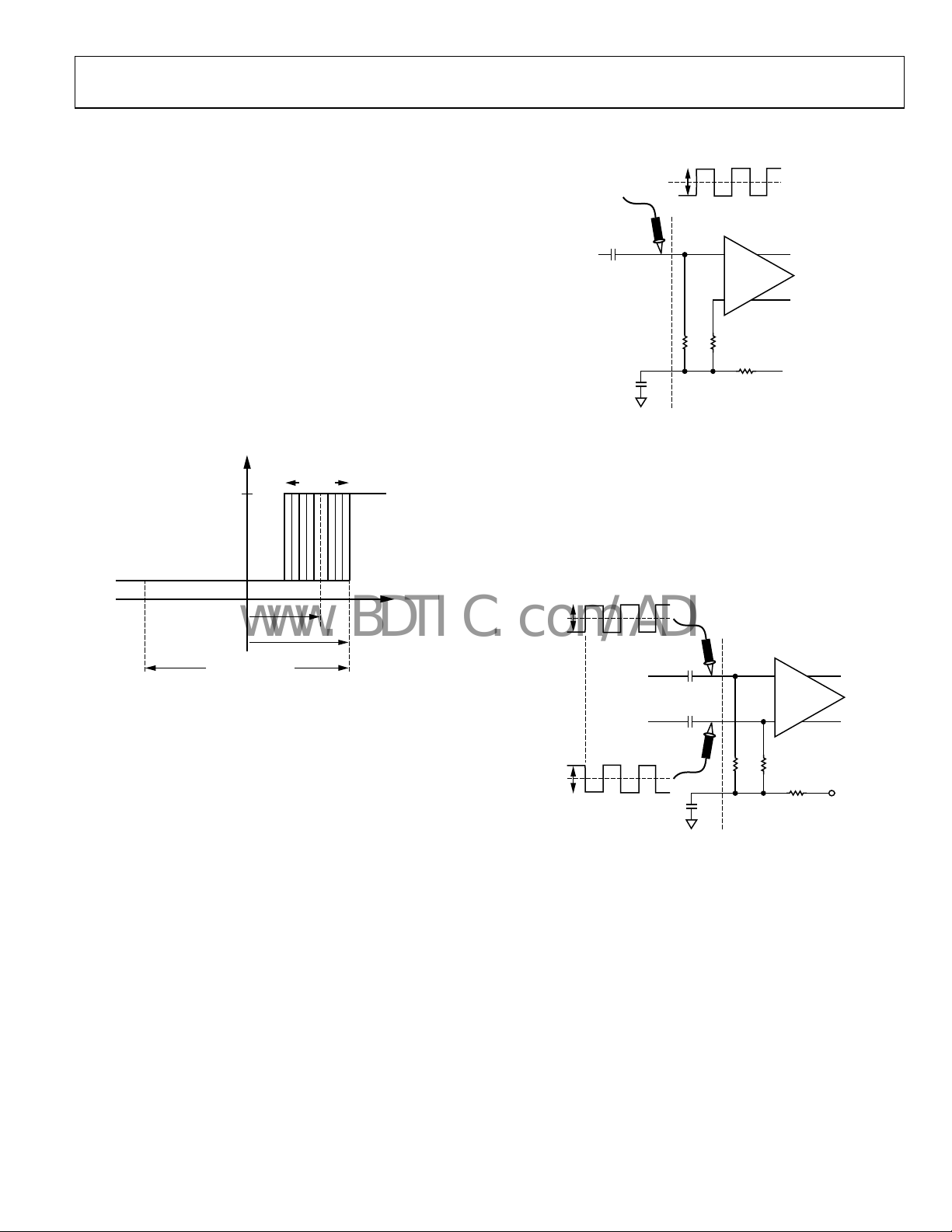

Figure 2. Default Mode Output Timing

OUTP

OUTN

OUTP – OUTN

V

CML

V

0V

SE

V

DIFF

Figure 3. Single-Ended vs. Differential Output Specifications

CLKOUTP/

CLKOUTN

DATAOUT P/

CLKOUTN

t

DDRS

Figure 4. Double Data Rate Mode Output Timing

H

t

DDRH

06001-002

V

SE

06001-003

06001-042

Rev. A | Page 8 of 40

ADN2817/ADN2818

www.BDTIC.com/ADI

ABSOLUTE MAXIMUM RATINGS

TA = T

C

F

Table 5.

Parameter Rating

Supply Voltage (VCC) 4.2 V

Input Voltage (All Inputs)

Junction Temperature, Maximum 125°C

Storage Temperature Range −65°C to +150°C

Lead Temperature (Soldering 10 sec) 300°C

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

to T

MIN

= 0.47 µF, SLICEP = SLICEN = VEE, unless otherwise noted.

Minimum VEE − 0.4 V

Maximum VCC + 0.4 V

, VCC = V

MAX

MIN

to V

, VEE = 0 V,

MAX

THERMAL CHARACTERISTICS

Thermal Resistance

32-lead LFCSP, 4-layer board with exposed paddle soldered to

VEE: θ

= 28°C/W.

JA

ESD CAUTION

Rev. A | Page 9 of 40

ADN2817/ADN2818

www.BDTIC.com/ADI

PIN CONFIGURATION AND FUNCTION DESCRIPTIONS

VBER

VCC

VEE

DATAOUTP

DATAOUTN

SQUELCH

CLKOUTP

CLKOUTN

25

26

27

28

29

31

30

32

VCC

VREF

NIN

PIN

SLICEP

SLICEN

VEE

1

2

3

4

5

6

7

8

PIN 1

INDICATOR

ADN2817/

ADN2818

TOP VIEW

(Not to Scale)

9

11

12

10

VCC

THRADJ

REFCLKP

REFCLKN

13

VEE

BERMODE

NOTES

1. EXPOSE D PADDLE ON THE BOTTOM OF THE PACKAGE

MUST BE CONNECT ED TO VEE.

24

VCC

23

VEE

22

LOS

21

SDA

20

SCK

19

SADDR5

18

VCC

17

VEE

16

15

14

CF2

CF1

LOL

06001-004

Figure 5. Pin Configuration

Table 6. Pin Function Descriptions

Pin No. Mnemonic Type1 Description

1 BERMODE DI Set this pin to logic low to enable analog voltage output mode for BER monitor.

2 VCC P Power for Input Stage, LOS.

3 VREF AO Internal VREF Voltage. Decouple to GND with a 0.1 μF capacitor.

4 NIN AI Differential Data Input. CML.

5 PIN AI Differential Data Input. CML.

6 SLICEP AI Differential Slice Level Adjust Input.

7 SLICEN AI Differential Slice Level Adjust Input.

8 VEE P GND for the Limiting Amplifier (Lim Amp), LOS.

9 THRADJ AI LOS Threshold Setting Resistor.

10 REFCLKP DI Differential REFCLK Input. 10 MHz to 200 MHz.

11 REFCLKN DI Differential REFCLK Input. 10 MHz to 200 MHz.

12 VCC P VCO Power.

13 VEE P VCO GND.

14 CF2 AO Frequency Loop Capacitor.

15 CF1 AO Frequency Loop Capacitor.

16 LOL DO Loss of Lock Indicator. Active high, LVTTL.

17 VEE P FLL Detector GND.

18 VCC P FLL Detector Power.

19 SADDR5 DI Slave Address Bit 5.

20 SCK DI I2C Clock Input.

21 SDA DI I2C Data Input.

22 LOS DO Loss of Signal Detect Output. Active high, LVTTL.

23 VEE P Output Buffer, I2C GND.

24 VCC P Output Buffer, I2C Power.

25 CLKOUTN DO Differential Recovered Clock Output. CML.

26 CLKOUTP DO Differential Recovered Clock Output. CML.

27 SQUELCH DI Disable Clock and Data Outputs. Active high, LVTLL.

28 DATAOUTN DO Differential Recovered Data Output. CML.

29 DATAOUTP DO Differential Recovered Data Output. CML.

30 VEE P Phase Detector, Phase Shifter GND.

31 VCC P Phase Detector, Phase Shifter Power.

32 VBER AO This pin represents BER when analog BERMON is enabled with 3 kΩ to VEE.

EP EPAD P Connect exposed pad to VEE. Note that the exposed pad must be connected to VEE.

1

P = power, AI = analog input, AO = analog output, DI = digital input, DO = digital output.

Rev. A | Page 10 of 40

ADN2817/ADN2818

V

www.BDTIC.com/ADI

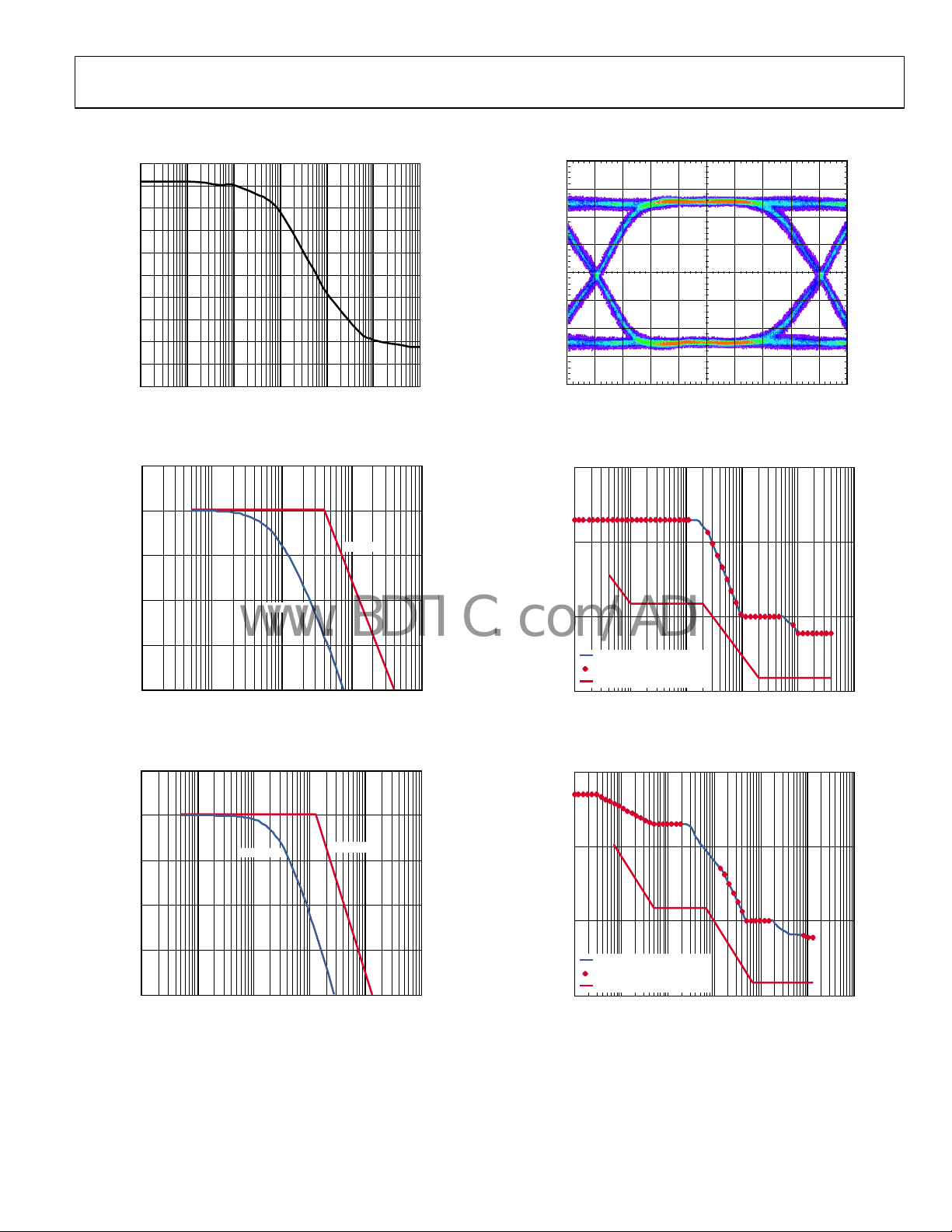

TYPICAL PERFORMANCE CHARACTERISTICS

0.020

0.018

0.016

0.014

0.012

0.010

0.008

TRIP POINT (mV p-p)

0.006

0.004

0.002

0

110100

1k 100k10k 1M

R

(Ω)

TH

Figure 6. LOS Comparator Trip Point Programming

6001-005

200mV/DI

50ps/DIV

06001-040

Figure 9. Output Eye, OC-48

5

0

–5

GAIN (dB)

–10

–15

–20

100 1k 10k 100k 1M

ADN2817

JITTER F REQUENCY (Hz)

SONET

Figure 7. Jitter Transfer, OC-1

5

0

–5

GAIN (dB)

–10

–15

–20

100 1k 10k 100k 1M 10M

ADN2817

JITTER FREQUENCY (Hz)

SONET

Figure 8. Jitter Transfer, OC-3

100

10

1

JITTER AMPL ITUDE (UI)

ADN2817

EQUIPMENT LIMIT

SONET GR-253 CORE 004

0.1

10 100 1k 10k 100k 1M

6001-032

JITTER FREQUENCY (Hz)

06001-039

Figure 10. Jitter Tolerance, OC-1

100

10

1

JITTER AMPLITUDE (UI)

ADN2817

EQUIPMENT LIMIT

SONET GR-253 CORE 004

0.1

10 100 1k 10k 100k 10M1M

06001-034

JITTER FREQUENCY (Hz)

06001-038

Figure 11. Jitter Tolerance, OC-3

Rev. A | Page 11 of 40

ADN2817/ADN2818

www.BDTIC.com/ADI

5

0

SONET

–5

GAIN (dB)

–10

–15

–20

1k 10k 100k 1M 10M

ADN2817

JITTER F REQUENCY (Hz)

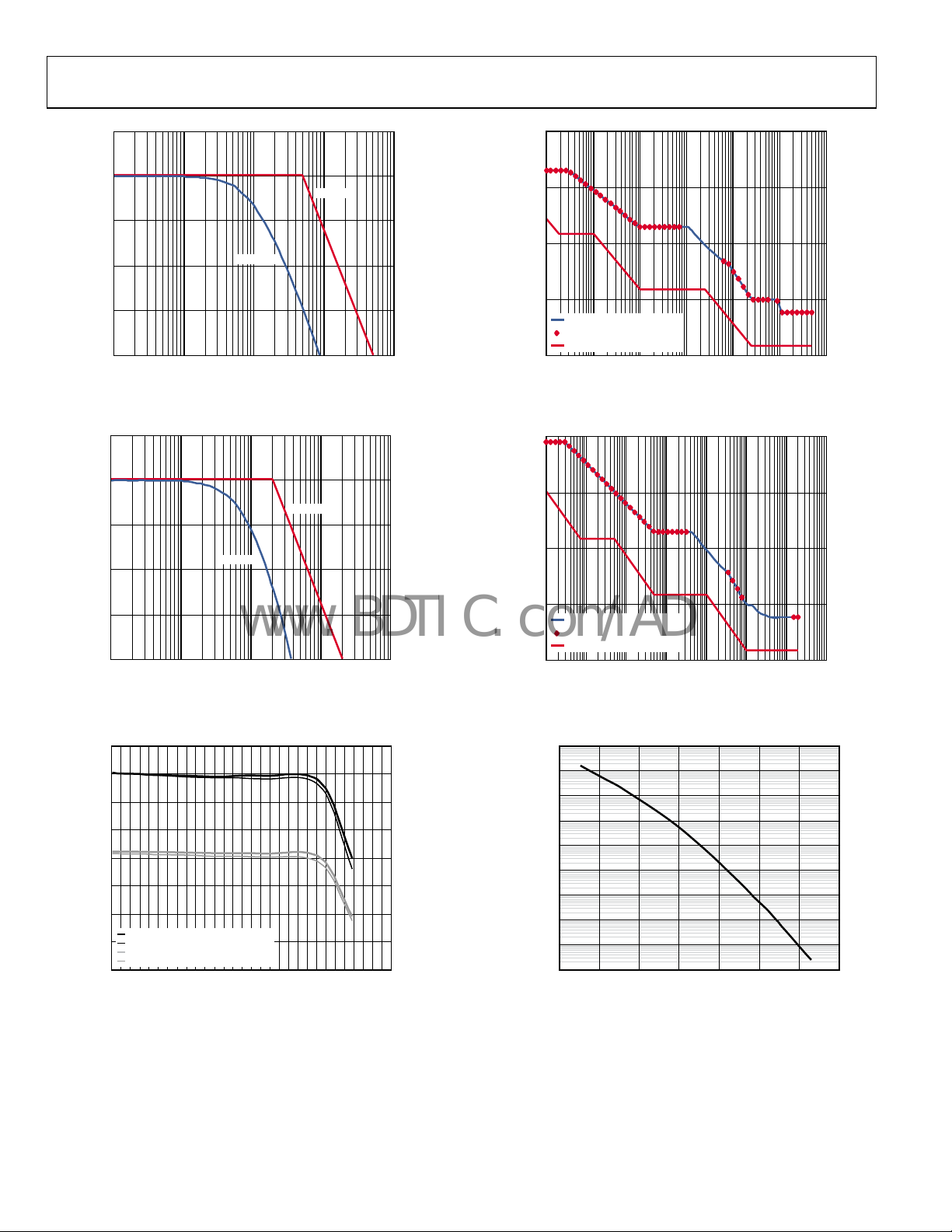

Figure 12. Jitter Transfer, OC-12

5

0

SONET

–5

GAIN (dB)

–10

ADN2817

06001-033

1000

100

10

JITTER AMP LITUDE (UI)

1

ADN2817

EQUIPMENT LIMIT

SONET GR- 253 CORE 004

0.1

10 100 1k 10k 100k 10M1M

JITTER F REQUENCY (Hz)

Figure 15. Jitter Tolerance, OC-12

1000

100

10

06001-037

–15

–20

10k 100k 1M 10M 100M

JITTER FRE QUENCY (Hz)

Figure 13. Jitter Transfer, OC-48

0.70

0.65

0.60

0.55

0.50

0.45

OUTPUT SWING (V)

0.40

CLKOUTP ADN2817 BOOST

0.35

CLKOUTN ADN2817 BOOS T

CLKOUTP ADN2817 NO BOOST

CLKOUTN ADN2817 NO BO OST

0.30

100M 600M 1.1G 1.6G 2.1G 2.6G 3.1G

DATA RATE (Hz)

Figure 14. Output Swing vs. Data Rate

JITTER AMPLITUDE (UI)

1

ADN2817

EQUIPMENT LIMIT

SONET GR- 253 CORE 004

0.1

10 100 1k 10k 100k 100M10M1M

06001-035

JITTER F REQUENCY (Hz)

06001-036

Figure 16. Jitter Tolerance, OC-48

1

0.1

0.01

0.001

0.0001

0.00001

0.000001

BIT ERROR RATE

0.0000001

0.00000001

0.000000001

06001-043

1.01.52.02.53.03.54.04.5

INPUT LEVEL (mV)

06001-041

Figure 17. Bit Error Rate vs. Input Level

Rev. A | Page 12 of 40

ADN2817/ADN2818

www.BDTIC.com/ADI

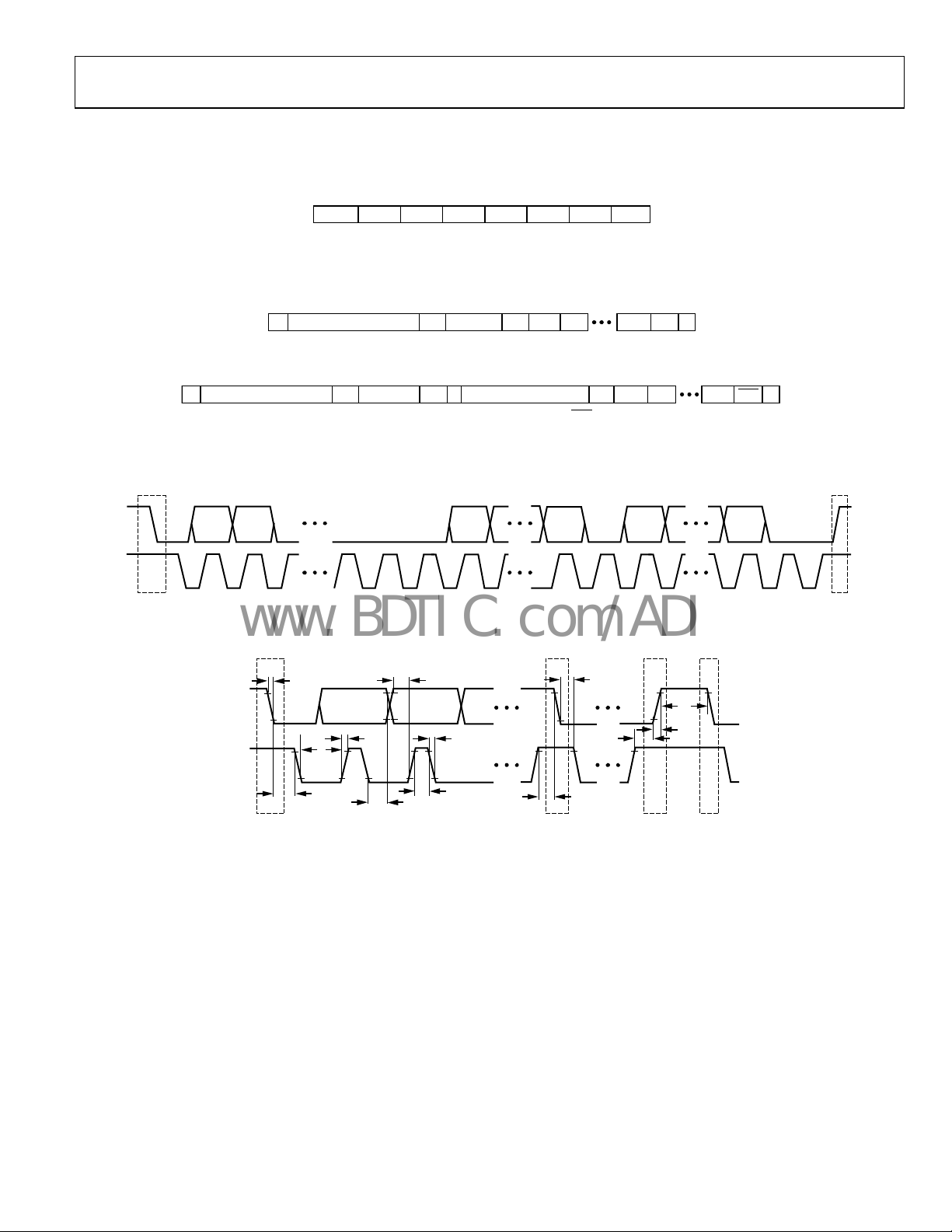

I2C INTERFACE TIMING AND INTERNAL REGISTER DESCRIPTION

SLAVE ADDRESS [6:0]

1A500000X

MSB = 1 SET BY

PIN 19

Figure 18. Slave Address Configuration

R/W

CTRL.

0 = WR

1 = RD

06001-007

S SLAVE ADDR, LSB = 0 (WR) A(S) A(S) A(S)DATASUB ADDR A(S) PDATA

Figure 19. I

2

C Write Data Transfer

06001-008

S

S = START BIT P = STOP BIT

A(S) = ACKNOWLEDG E BY SLAVE A(M) = ACKNOWLEDGE BY M ASTER

SSLAVE ADDR, LSB = 0 (WR) SLAVE ADDR, LSB = 1 (RD)A(S) A(S)SUB ADDR A(S ) DATA A(M) DATA PA(M)

A(M) = LACK OF ACKNOWLEDGE BY MASTER

Figure 20. I

2

C Read Data Transfer

6001-009

SDA

SCK

START BIT

S

SLAVE ADDRESS SUB ADDRESS DATA

SLADDR[4:0]

Figure 21. I

SUB ADDR[6:1] DATA[6:1]

2

C Data Transfer Timing

D0D7A0A7A5A6

STOP BIT

ACKACKWR ACK

P

06001-010

t

F

SDA

t

SCK

SSPS

LOW

t

HD;STA

t

R

t

HD;DAT

t

SU;DAT

Figure 22. I

t

F

t

HIGH

t

SU;STA

2

C Port Timing Diagram

t

HD;STA

t

SU;STO

t

BUF

t

R

06001-011

Rev. A | Page 13 of 40

ADN2817/ADN2818

www.BDTIC.com/ADI

Table 7. Internal Register Map

Reg Name R/W Addr D7 D6 D5 D4 D3 D2 D1 D0

FREQ0 R 0x00 MSB LSB

FREQ1 R 0x01 MSB LSB

FREQ2 R 0x02 0 MSB LSB

RATE R 0x03 COARSE_RD[8:1]

MISC R 0x04 x x LOS status Static

CTRLA W 0x08 f

CTRLA_RD R 0x05 Readback CTRLA

CTRLB W 0x09 Config

CTRLB_RD R 0x06 Readback CTRLB

CTRLC W 0x11 0 0 0 0 0 Config LOS Squelch mode 0

CTRLD W 0x22 CDR

CTRLE W 0x1F 0 0 0 0 0 PRBS/DDR enable

SEL_MODE W 0x34 0 0 0 0 0 0 CLK holdover

HI_CODE W 0x35 HI_CODE[8:1]

LO_CODE W 0x36 LO_CODE[8:1]

CODE_LSB W 0x39 0 0 0 0 0 0 HI_CODE[0] (LSB) LO_CODE[0] (LSB)

BERCTLA W 0x1E BER timer (NUMBITS) 0 BER start

BERCTLB W 0x1F 0 0 Enable

BERSTS R 0x20 x x x x x x x End of BER

BER_RES R 0x21 BER_RES[7:0], one byte of pseudo BER measurement result (NUMERRORS[39:0])

BER_DAC R 0x24 x x BER_DAC[5:0], input to BER DAC in analog BERMON mode

PHASE W 0x37 0 0 PHASE[5:0], twos compliment sample phase adjustment, PHASE code range is [−30, +30] decimal,

range Data rate/DIV_FREF ratio Measure

REF

LOL

bypass

Reset

MISC[4]

Disable

DATAOUT

buffer

Initiate freq

acquisition

Disable

CLKOUT

buffer

BERMON

which gives a sampling phase offset range of [−0.5, +0.5] UI; for example, PHASE = 111010 is

LOL

0 Reset

0 Initiate

BER

stdby

mode

−6 decimal, which gives a sampling phase offset of −6/+60 = −0.1 UI

LOL status Data rate

measurement

complete

0 0 0

MISC[2]

PRBS

sequence

Error count byte select, for example, 011 = Byte 3 of 5

pulse

0 Output mode

x COARSE_RD[0] (LSB)

Lock to REFCLK

data rate

PRBS mode

0

mode

measurement

(EOBM)

Table 8. Miscellaneous Register, MISC

LOS Status Static LOL LOL Status

D7 D6 D5 D4 D3 D2 D1 D0

x x 0 = no loss of signal 0 = waiting for next LOL 0 = locked 0 = measuring data rate x COARSE_RD[0]

1 = loss of signal 1 = static LOL until reset 1 = acquiring 1 = measurement complete

Table 9. Control Register, CTRLA

f

Range Data Rate/DIV_FREF Ratio Measure Data Rate Lock to REFCLK

REF

D7 D6 Range D5 D4 D3 D2 Ratio D1 D0

Set to 0 Set to 0 10 MHz to 25 MHz 0 0 0 0 1 Set to 1 to measure data rate 0 = lock to input data

Set to 0 Set to 1 25 MHz to 50 MHz 0 0 0 1 2 1 = lock to reference clock

Set to 1 Set to 0 50 MHz to 100 MHz 0 0 1 0 4

Set to 1 Set to 1 100 MHz to 200 MHz n 2n

1 0 0 0 256

Rev. A | Page 14 of 40

Data Rate Measurement

Complete

COAR SE_R D[0]

(LSB)

ADN2817/ADN2818

www.BDTIC.com/ADI

Table 10. Control Register, CTRLB

Config LOL Reset MISC[4] Initiate Frequency Acq Reset MISC[2]

D7 D6 D5 D4 D3 D2 D1 D0

0 = LOL pin normal operation

1 = LOL pin is static LOL

Table 11. Control Register, CTRLC

D7 D6 D5 D4 D3 D2 D1 D0

Set to 0 Set to 0 Set to 0 Set to 0 Set to 0 0 = active high LOS 0 = squelch CLK and DATA Set to 0

Table 12. Control Register, CTRLD

Disable

CDR Bypass

D7 D6 D5 D4 D3 D2 D1 D0 Function

0 = CDR enabled 0 = data buffer enabled 0 = CLK buffer enabled Set to 0

1 = CDR disabled 1 = data buffer disabled 1 = CLK buffer disabled 0 0 1 Generate mode

DATAOUT Buffer

Write a 1 followed

by 0 to reset MISC[4]

Disable

CLKOUT Buffer

Write a 1 followed

by 0 to initiate a

frequency acquisition

Configure LOS Squelch Mode

1 = active low LOS 1 = squelch CLK or DATA

Set

to 0

Initiate PRBS

Sequence PRBS Mode

Write a 1 followed

by 0 to initiate a

PRBS generate

sequence

Write a 1 followed

by 0 to reset MISC[2]

0 0 0 Power-down PRBS

1 0 0 Detect mode

Set

to 0

Set

to 0

Set

to 0

Table 13. Control Register, CTRLE

PRBS/DDR Enable

D7 D6 D5 D4 D3 D2 D1 D0 Function

Set to 0 Set to 0 Set to 0 Set to 0 Set to 0 0 1 0 Enable DDR mode (double data rate mode)

1 0 1 Enable PRBS detector/generator

All other combinations reserved

Table 14. SEL_MODE

CLK Holdover Mode

D7 D6 D5 D4 D5 D2 D1 D0

Set to 0 Set to 0 Set to 0 Set to 0 Set to 0 Set to 0 Set to 1 for clock holdover mode Set to 0

Table 15. BERCTLA

Error Count Byte Select

BER Timer (NUMBITS) BER Start Pulse

D7 D6 D5 No. of Bits D4 D3 D2 D1 D0 Byte Selection

0 0 0 218 bits Set to 0 Write a 1 followed by a 0 to initiate BER measurement 0 0 0 Byte 0

0 0 1 221 bits 0 0 1 Byte 1

0 1 0 224 bits 0 1 0 Byte 2

0 1 1 227 bits 0 1 1 Byte 3

1 0 0 230 bits 1 0 0 Byte 4

1 0 1 233 bits 1 0 1 Byte 5

1 1 0 236 bits

1 1 1 239 bits

(NUMERRORS[39:0])

Rev. A | Page 15 of 40

ADN2817/ADN2818

www.BDTIC.com/ADI

Table 16. BERCTLB

Enable BERMON BER Standby Mode Output Mode

D7 D6 D5 D4 D3 D2 D1 D0 Mode

Set to 0 Set to 0 0 = BER disabled 0 = BER measurement enabled Set to 0 0 0 0

1 = BER enabled 1 = BER measurement in standby mode

0 0 1

0 1 0

0 1 1

1

NDC = normal decision circuit data and clock, ODC = offset decision circuit data and clock, DIV0 = normal decision circuit data and half rate clock, DIV1 = offset

decision circuit data and half rate clock, → OB indicates that the referenced signals are routed to the data and clock chip output buffers.

NDC → OB

ODC → OB

DIV0 → OB

DIV1 → OB

1

1

1

1

Rev. A | Page 16 of 40

ADN2817/ADN2818

p

p

www.BDTIC.com/ADI

TERMINOLOGY

INPUT SENSITIVITY AND INPUT OVERDRIVE

Sensitivity and overdrive specifications for the quantizer involve

offset voltage, gain, and noise. The relationship between the logic

output of the quantizer and the analog voltage input is shown in

Figure 23. For sufficiently large positive input voltages, the output is

always Logic 1 and, similarly for negative inputs, the output is

always Logic 0. However, the transitions between Output Logic

Level 1 and Output Logic Level 0 are not at precisely defined

input voltage levels but occur over a range of input voltages. Within

this range of input voltages, the output might be either 1 or 0, or

it might even fail to attain a valid logic state. The width of this

zone is determined by the input voltage noise of the quantizer.

The center of the zone is the quantizer input offset voltage. Input

overdrive is the magnitude of signal required to guarantee the

correct logic level with 1 × 10

OUTPUT

−10

confidence level.

1

0

OFFSET

OVERDRIVE

NOISE

INPUT (V p-p)

10mV p-

SCOPE

PROBE

PIN

VREF

Figure 24. Single-Ended Sensitivity Measurement

+

QUANTIZER

–

50Ω50Ω

3kΩ

VREF

2.5V

06001-013

Differentially driving the ADN2817 (see Figure 25), sensitivity

seems to improve from observing the quantizer input with an

oscilloscope probe. This is an illusion caused by the use of a singleended probe. A 5 mV p-p signal appears to drive the ADN2817

quantizer. However, the single-ended probe measures only half

the signal. The true quantizer input signal is twice this value

because the other quantizer input is a complementary signal to

the signal being observed.

5mV p-

VREF

SCOPE

PROBE

SENSITIVITY

(2× OVERDRIVE )

Figure 23. Input Sensitivity and Input Overdrive

06001-012

SINGLE-ENDED vs. DIFFERENTIAL

AC coupling is typically used to drive the inputs to the quantizer.

The inputs are internally dc biased to a common-mode potential

of ~2.5 V. Driving the ADN2817/ADN2818 single-ended and

observing the quantizer input with an oscilloscope probe at the

point indicated in Figure 24 shows a binary signal with an average

value equal to the common-mode potential and instantaneous

values both above and below the average value. It is convenient

to measure the peak-to-peak amplitude of this signal and call

the minimum required value the quantizer sensitivity. Referring

to Figure 24, because both positive and negative offsets need to

be accommodated, the sensitivity is twice the overdrive. The

ADN2817 quantizer typically has 5 mV p-p sensitivity. The

ADN2818 does not have a limiting amplifier at its input. The

input sensitivity for the ADN2818 is 200 mV p-p.

VREF

PIN

NIN

VREF

5mV p-p

Figure 25. Differential Sensitivity Measurement

50Ω

+

QUANTIZER

–

50Ω

3kΩ

2.5V

06001-014

LOS RESPONSE TIME

The LOS response time is the delay between the removal of the

input signal and the indication of the loss of signal at the LOS

output, Pin 22. When the inputs are dc-coupled, the LOS assert

time of the ADN2817 is 450 ns typically and the deassert time is

500 ns typically. In practice, the time constant produced by the

ac coupling at the quantizer input and the 50 Ω on-chip input

termination determine the LOS response time.

Rev. A | Page 17 of 40

ADN2817/ADN2818

R

www.BDTIC.com/ADI

JITTER SPECIFICATIONS

The ADN2817/ADN2818 CDR is designed to achieve the best

bit error rate (BER) performance and exceeds the jitter transfer,

generation, and tolerance specifications proposed for SONET/SDH

equipment defined in the Telcordia® Technologies specification.

Jitter is the dynamic displacement of digital signal edges from

their long-term average positions, measured in unit intervals

(UI), where 1 UI = 1 bit period. Jitter on the input data can cause

dynamic phase errors on the recovered clock sampling edge. Jitter

on the recovered clock causes jitter on the retimed data.

The following sections briefly summarize the specifications

of jitter generation, transfer, and tolerance in accordance with

the Telcordia document (GR-253-CORE, Issue 3, September

2000) for the optical interface at the equipment level and the

ADN2817/ADN2818 performance with respect to those

specifications.

JITTER GENERATION

The jitter generation specification limits the amount of jitter

that can be generated by the device with no jitter and wander

applied at the input. For OC-48 devices, the band-pass filter

has a 12 kHz high-pass cutoff frequency with a roll-off of

20 dB/decade and a low-pass cutoff frequency of at least

20 MHz. The jitter generated must be less than 0.01 UI rms

and must be less than 0.1 UI p-p.

0.1

SLOPE = –20dB/DE CADE

JITTER GAIN (dB)

ACCEPTABLE

RANGE

JITTER FREQUENCY ( kHz)

Figure 26. Jitter Transfer Curve

f

C

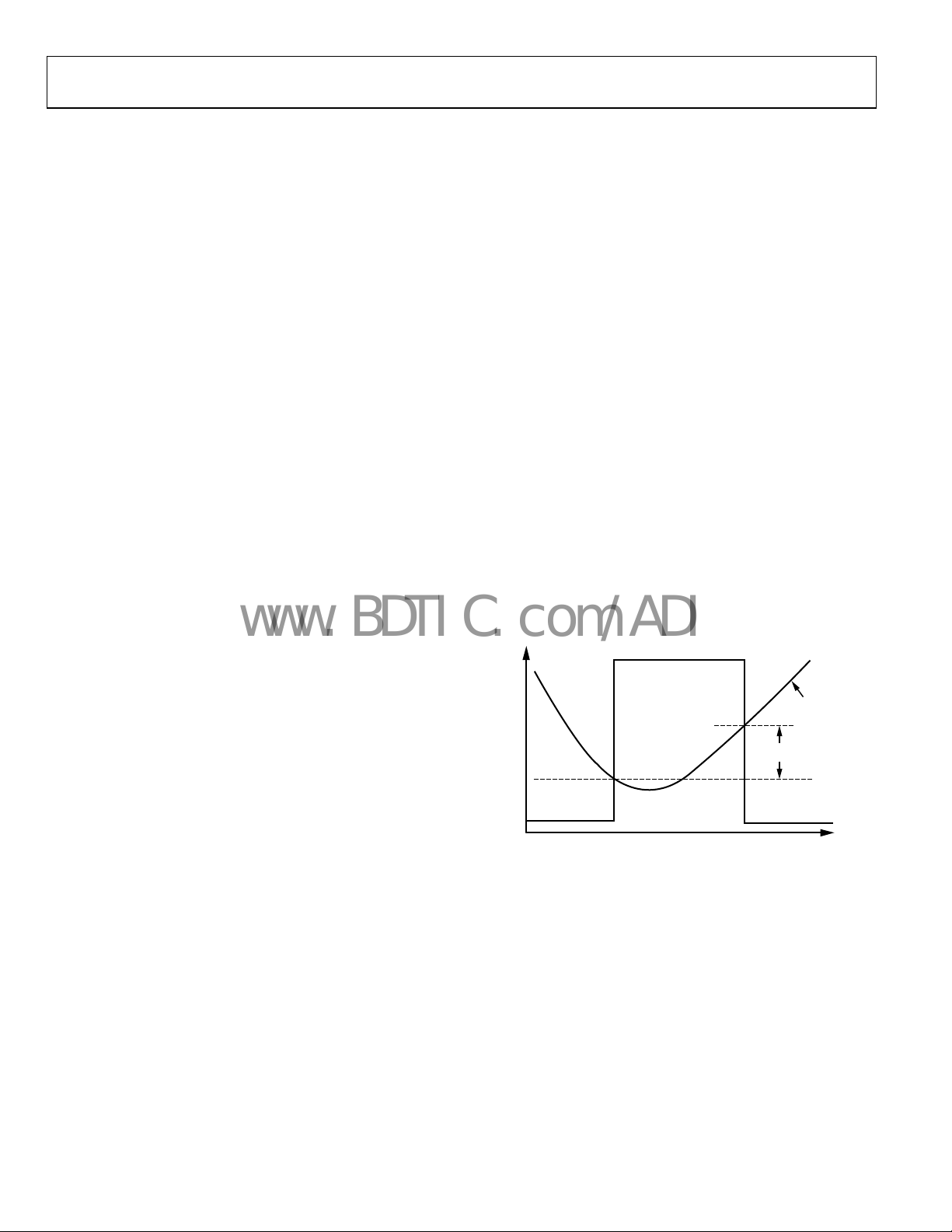

JITTER TOLERANCE

The jitter tolerance is defined as the peak-to-peak amplitude of

the sinusoidal jitter applied on the input signal, which causes a

1 dB power penalty. This is a stress test intended to ensure that

no additional penalty is incurred under the operating conditions

(see Figure 27).

15.00

SLOPE = –20d B/DECADE

6001-015

JITTER TRANSFER

The jitter transfer function is the ratio of the jitter on the output

signal to the jitter applied on the input signal vs. the frequency.

This parameter measures the limited amount of the jitter on

an input signal that can be transferred to the output signal

(see Figure 26).

1.50

AMPLITUDE (UI p-p)

0.15

INPUT JITTE

f

0

Figure 27. SONET Jitter Tolerance Mask

f

1

JITTER F REQUENCY (kHz)

f

2f3

f

4

06001-016

Rev. A | Page 18 of 40

ADN2817/ADN2818

p

G

www.BDTIC.com/ADI

THEORY OF OPERATION

The ADN2817/ADN2818 are delay- and phase-locked loop

circuits for clock recovery and data retiming from an NRZ

encoded data stream. The phase of the input data signal is tracked

by two separate feedback loops that share a common control

voltage. A high speed delay-locked loop path uses a voltage

controlled phase shifter to track the high frequency components

of input jitter. A separate phase control loop, comprised of the

VCO, tracks the low frequency components of input jitter. The

initial frequency of the VCO is set by a third loop, which

compares the VCO frequency with the input data frequency

and sets the coarse tuning voltage. The jitter tracking phaselocked loop controls the VCO by the fine-tuning control.

The delay- and phase-locked loops together track the phase of

the input data signal. For example, when the clock lags input

data, the phase detector drives the VCO to a higher frequency

and increases the delay through the phase shifter; both of these

actions serve to reduce the phase error between the clock and

data. The faster clock picks up phase, while, simultaneously, the

delayed data loses phase. Because the loop filter is an integrator,

the static phase error is driven to zero.

Another view of the circuit is that the phase shifter implements

the zero required for frequency compensation of a second-order

phase-locked loop, and this zero is placed in the feedback path

and, thus, does not appear in the closed-loop transfer function.

Jitter peaking in a conventional second-order phase-locked loop

is caused by the presence of this zero in the closed-loop transfer

function. Because this circuit has no zero in the closed-loop

transfer, jitter peaking is minimized.

The delay- and phase-locked loops together simultaneously

provide wideband jitter accommodation and narrow-band jitter

filtering. The linearized block diagram in

Figure 28 shows that

the jitter transfer function, Z(s)/X(s), is second-order low-pass,

providing excellent filtering. Note that the jitter transfer has no

zero, unlike an ordinary second-order phase-locked loop. This

means that the main PLL loop has virtually zero jitter peaking

(see Figure 29). This makes this circuit ideal for signal regenerator applications, where jitter peaking in a cascade of regenerators

can contribute to hazardous jitter accumulation.

The error transfer, e(s)/X(s), has the same high-pass form as an

ordinary phase-locked loop. This transfer function is free to be

optimized to give excellent wideband jitter accommodation,

because the jitter transfer function, Z(s)/X(s), provides the

narrow-band jitter filtering.

X(s)

INPUT

DATA

RECOVERED

CLOCK

d = PHASE DETECTOR GAIN

o = VCO GAIN

c = LOOP INTEGRATOR

sh = PHASE SHIF TER GAIN

n = DIVIDE RATIO

Figure 28. ADN2817/ADN2818 PLL/DLL Architecture

JITTER G AIN (dB)

Figure 29. ADN2817/ADN2818 Jitter Response vs. Conventional PLL

The delay- and phase-locked loops contribute to overall jitter

accommodation. At low frequencies of input jitter on the data

signal, the integrator in the loop filter provides high gain to track

large jitter amplitudes with small phase error. In this case, the

VCO is frequency modulated and jitter is tracked as in an ordinary

phase-locked loop. The amount of low frequency jitter that can

be tracked is a function of the VCO tuning range. A wider tuning

range gives larger accommodation of low frequency jitter. The

internal loop control voltage remains small for small phase

errors, so the phase shifter remains close to the center of its

range and thus contributes little to the low frequency jitter

accommodation.

Z(s)

n psh

psh

e(s)

d/sc

JITTER T RANSFER FUNCTI ON

Z(s)

=

X(s)

2

s

TRACKING ERROR T RANSFER FUNCTI ON

e(s)

=

X(s)

2

s

o

d psh

FREQUENCY ( kHz)

o/s

1/n

1

n psh

cn

s + 1

+

o

do

2

s

d psh

do

s++

c

cn

JITTER PEAKIN

IN ORDINARY PLL

c

ADN28xx

Z(s)

X(s)

06001-017

06001-018

Rev. A | Page 19 of 40

ADN2817/ADN2818

www.BDTIC.com/ADI

At medium jitter frequencies, the gain and tuning range of the

VCO are not large enough to track input jitter. In this case, the

VCO control voltage becomes large and saturates, and the VCO

frequency dwells at one extreme of its tuning range or the other.

The size of the VCO tuning range, therefore, has only a small

effect on the jitter accommodation. The delay-locked loop control

voltage is now larger, and so the phase shifter takes on the

burden of tracking the input jitter. The phase shifter range, in

UI, can be seen as a broad plateau on the jitter tolerance curve.

The phase shifter has a minimum range of 2 UI at all data rates.

The gain of the loop integrator is small for high jitter frequencies,

so that larger phase differences are needed to make the loop

control voltage big enough to tune the range of the phase shifter.

Large phase errors at high jitter frequencies cannot be tolerated.

In this region, the gain of the integrator determines the jitter

accommodation. Because the gain of the loop integrator declines

linearly with frequency, jitter accommodation is lower with higher

jitter frequency. At the highest frequencies, the loop gain is very

small, and little tuning of the phase shifter can be expected. In this

case, jitter accommodation is determined by the eye opening of the

input data, the static phase error, and the residual loop jitter

generation. The jitter accommodation is roughly 0.5 UI in this

region. The corner frequency between the declining slope and

the flat region is the closed-loop bandwidth of the delay-locked

loop, which is roughly 3 MHz at OC-48.

Rev. A | Page 20 of 40

ADN2817/ADN2818

www.BDTIC.com/ADI

FUNCTIONAL DESCRIPTION

FREQUENCY ACQUISITION

The ADN2817/ADN2818 acquire frequency from the data over

a range of data frequencies from 10 Mbps to 2.7 Gbps. The lock

detector circuit compares the frequency of the VCO and the

frequency of the incoming data. When these frequencies differ

by more than 1000 ppm, LOL is asserted. This initiates a frequency acquisition cycle. The VCO frequency is reset to the

bottom of its range, which is 10 MHz. The frequency detector

compares this VCO frequency and the incoming data frequency

and increments the VCO frequency, if necessary. Initially, the

VCO frequency is incremented in large steps to aid fast acquisition. As the VCO frequency approaches the data frequency, the

step size is reduced until the VCO frequency is within 250 ppm

of the data frequency, at which point LOL is deasserted.

Once LOL is deasserted, the frequency-locked loop is turned off.

The phase- and delay-locked loop (PLL/DLL) pulls in the VCO

frequency until the VCO frequency equals the data frequency.

The frequency loop requires a single external capacitor between

CF1 and CF2, Pin 14 and Pin 15. A 0.47 µF ± 20%, X7R ceramic

chip capacitor with <10 nA leakage current is recommended.

Leakage current of the capacitor can be calculated by dividing

the maximum voltage across the 0.47 µF capacitor, ~3 V, by the

insulation resistance of the capacitor. The insulation resistance

of the 0.47 F capacitor should be greater than 300 MΩ.

LOCK DETECTOR OPERATION

The lock detector on the ADN2817/ADN2818 has three modes

of operation: normal mode, REFCLK mode, and static LOL mode.

Normal Mode

In normal mode, the ADN2817/ADN2818 function as continuous

rate CDRs that lock onto any data rate from 10 Mbps to 2.7 Gbps

without the use of a reference clock as an acquisition aid. In this

mode, the lock detector monitors the frequency difference between

the VCO and the input data frequency, and deasserts the loss of

lock signal that appears on LOL (Pin 16) when the VCO is within

250 ppm of the data frequency. This enables the delay- and phaselocked loop (DLL/PLL), which pulls the VCO frequency in the

remaining amount and acquires phase lock. When locked, if the

input frequency error exceeds 1000 ppm (0.1%), the loss of lock

signal is reasserted and control returns to the frequency loop,

which begins a new frequency acquisition starting at the lowest

point in the VCO operating range, 10 MHz. The LOL pin remains

asserted until the VCO locks onto a valid input data stream to

within 250 ppm frequency error. This hysteresis is shown in

Figure 30.

–1000

Figure 30. Transfer Function of LOL

LOL Detector Operation Using a Reference Clock

In this mode, a reference clock is used as an acquisition aid to

lock the ADN2817/ADN2818 VCO. Lock to reference mode is

enabled by setting CTRLA[0] to 1. The user also needs to write

to the CTRLA[7:6] and CTRLA[5:2] bits to set the reference

frequency range and the divide ratio of the data rate with respect

to the reference frequency. For more details, see the Reference

Clock (Optional) section. In this mode, the lock detector monitors

the difference in frequency between the divided down VCO and

the divided down reference clock. The loss of lock signal, which

appears on the LOL (Pin 16), is deasserted when the VCO is

within 250 ppm of the desired frequency. This enables the DLL/

PLL, which pulls the VCO frequency in the remaining amount

with respect to the input data and acquires phase lock. Once

locked, if the input frequency error exceeds 1000 ppm (0.1%),

the loss of lock signal is reasserted and control returns to the

frequency loop, which reacquires with respect to the reference

clock. The LOL pin remains asserted until the VCO frequency is

within 250 ppm of the desired frequency. This hysteresis is shown

in Figure 30.

Static LOL Mode

The ADN2817/ADN2818 implement a static LOL feature, which

indicates if a loss of lock condition has ever occurred and remains

asserted, even if the ADN2817/ADN2818 regain lock, until the

static LOL bit is manually reset. I

static LOL bit. If there is ever an occurrence of a loss of lock

condition, this bit is internally asserted to logic high. The MISC[4]

bit remains high even after the ADN2817/ADN2818 reacquire

lock to a new data rate. This bit can be reset by writing a 1 followed

by 0 to I

2

C Register Bit CTRLB[6]. When reset, the MISC[4] bit

remains deasserted until another loss of lock condition occurs.

Writ i ng a 1 t o I

2

C Register Bit CTRLB[7] causes the LOL pin,

Pin 16, to become a static LOL indicator. In this mode, the LOL

pin mirrors the contents of the MISC[4] bit and has the functionality described in the previous paragraph. The CTRLB[7] bit

defaults to 0. In this mode, the LOL pin operates in the normal

operating mode, that is, it is asserted only when the ADN2817/

ADN2818 are in acquisition mode and deasserts when the

ADN2817/ADN2818 reacquire lock.

LOL

1

0–250 250 1000 f

2

C Register Bit MISC[4] is the

VCO

(ppm)

ERROR

06001-019

Rev. A | Page 21 of 40

ADN2817/ADN2818

www.BDTIC.com/ADI

HARMONIC DETECTOR

The ADN2817/ADN2818 provide a harmonic detector, which

detects whether the input data has changed to a lower harmonic

of the data rate onto which the VCO is currently locked. For

example, if the input data instantaneously changes from an OC-48,

2.488 Gbps to an OC-12, 622.080 Mbps bit stream, this could be

perceived as a valid OC-48 bit stream, because the OC-12 data

pattern is exactly 4× slower than the OC-48 pattern. Therefore,

if the change in data rate is instantaneous, a 101 pattern at OC-12 is

perceived by the ADN2817/ADN2818 as a 111100001111 pattern

at OC-48. If the change to a lower harmonic is instantaneous, a

typical CDR could remain locked at the higher data rate.

The ADN2817/ADN2818 implement a harmonic detector that

automatically identifies whether the input data has switched to a

lower harmonic of the data rate onto which the VCO is currently

locked. When a harmonic is identified, the LOL pin is asserted

and a new frequency acquisition is initiated. The ADN2817/

ADN2818 automatically lock onto the new data rate, and the

LOL pin is deasserted.

However, the harmonic detector does not detect higher harmonics of the data rate. If the input data rate switches to a

higher harmonic of the data rate onto which the VCO is currently

locked, the VCO loses lock, the LOL pin is asserted, and a new

frequency acquisition is initiated. The ADN2817/ ADN2818

automatically lock onto the new data rate.

The time to detect lock to harmonic is

16,384 × (T

d

/ρ)

where:

1/T

is the new data rate. For example, if the data rate is switched

d

from OC-48 to OC-12, then T

= 1/622 MHz.

d

ρ is the data transition density. Most coding schemes seek to

ensure that ρ = 0.5, for example, PRBS or 8b/10b encoding.

When the ADN2817/ADN2818 is placed in lock to reference

mode, the harmonic detector is disabled.

LIMITING AMPLIFIER (ADN2817 ONLY)

The limiting amplifier on the ADN2817 has differential inputs

(PIN/NIN) that internally terminate with 50 Ω to an on-chip

voltage reference (VREF = 2.5 V typically). The inputs are typically

ac-coupled externally, although dc coupling is possible as long

as the input common-mode voltage remains above 2.5 V (see

Figure 40, Figure 41, and Figure 42). Input offset is factory

trimmed to achieve better than 6 mV typical sensitivity with

minimal drift. The limiting amplifier can be driven differentially

or single-ended.

Rev. A | Page 22 of 40

SLICE LEVEL ADJUST (ADN2817 ONLY)

The quantizer slicing level can be offset by ±100 mV to mitigate

the effect of amplified spontaneous emission (ASE) noise or duty

cycle distortion by applying a differential voltage input of up to

±0.95 V to SLICEP/SLICEN inputs. If no adjustment of the slice

level is needed, SLICEP/SLICEN should be tied to VEE. The gain

of the slice adjustment is ~0.1 V/V.

LOSS OF SIGNAL (LOS) DETECTOR (ADN2817 ONLY)

The receiver front end LOS detector circuit detects when the input

signal level has fallen below a user-adjustable threshold. The

threshold is set with a single external resistor from Pin 9, THRADJ,

to VEE. The LOS comparator trip point vs. resistor value is shown

in Figure 6. If the input level to the ADN2817 drops below the

programmed LOS threshold, the output of the LOS detector, Pin 22

(LOS), is asserted to a Logic 1. The LOS detector response time is

450 ns by design but is dominated by the RC time constant in accoupled applications. The LOS pin defaults to active high.

However, by setting Bit CTRLC[2] to 1, the LOS pin is configured

as active low.

There is typically 6 dB of electrical hysteresis designed into the

LOS detector to prevent chatter on the LOS pin. This means that,

if the input level drops below the programmed LOS threshold

causing the LOS pin to assert, the LOS pin is not deasserted until

the input level has increased to 6 dB (2×) above the LOS threshold

(see Figure 31).

LOS OUTPUT

)

DIFF

INPUT VOLTAGE (V

Figure 31. ADN2817 LOS Detector Hysteresis

The LOS detector and the slice level adjust can be used simultaneously on the ADN2817. This means that any offset added to

the input signal by the slice adjust pins does not affect the LOS

detector measurement of the absolute input level.

INPUT LEVEL

HYSTERESIS

LOS THRESHOLD

06001-020

t

ADN2817/ADN2818

www.BDTIC.com/ADI

SAMPLE PHASE ADJUST

If the user is not using the BER monitoring function, sample

phase adjustment can be used to optimize the horizontal sampling point of the incoming data eye. The ADN2817 automatically

centers the sampling point to the best of its ability. However,

sample phase adjustment can be used to compensate for any

static phase offset of the CDR and data eye jitter profile asymmetry.

Sample phase adjustment is applied to the incoming eye via the

phase register. The sampling phase can be adjusted by ±0.5 UI,

in 6 degree steps, relative to the normal CDR data sampling

instant. Using the sample phase adjustment capability uses an

additional 160 mW of power. The AN-941 application note

gives additional information on the use of this feature.

BIT ERROR RATE (BER) MONITOR

The ADN2817 has a BER measurement feature that estimates

the actual bit error rate of the IC. This feature also allows data

eye jitter profiling and Q-factor estimation.

By knowing the BER at a sampling phase offset from the ideal

sampling phase (known as pseudo BER [PBER] values), it is

possible to extrapolate to obtain an estimate of the BER at the

actual sampling instant. This extrapolation relies on the assumption

that the input jitter is composed of deterministic and random

(Gaussian) components. The implementation requires off-chip

control and data processing to estimate the actual BER. A lower

accuracy voltage output mode is also supported that requires no

data processing or I

Brief Overview of Modes of Operation

The following two modes of operation are available for the BER

feature: the BER extrapolation mode and the voltage output mode.

Only one mode can be operational at a time. The BER extrapolation mode scans the input eye in the range of ±0.5 UI of the

data center and reads the measured PBER over the I

then applies a data processing algorithm to determine the BER.

Using the BER feature in this way provides for the greatest accuracy

in BER estimation as the magnitude of both random (Gaussian)

jitter and deterministic jitter can be estimated and used to predict

the actual BER.

In the voltage output mode, the part autonomously samples the

PBER at 0.1 UI offset and decodes this value to provide an estimate

of the input BER. This estimate is output via a DAC as an analog

current output. The AN-941 application note gives detailed

information on the use of the BER monitor features.

BER Extrapolation Mode

Power Saving

The following three power settings are available in BER

extrapolation mode: BER off, BER on, and BER standby.

In BER off mode (BERCTLB[5] = 0), the BER circuitry is

powered down with the ADN2817 providing normal CDR

operation.

2

C control.

2

C. The user

In BER on mode (BERCTLB[5] = 1), the internal BER circuitry

is powered up. The user can perform pseudo BER measurements

through the I

In BER standby mode (BERCTLB[5:4] = 11b), the BER is placed

into a lower power mode. This setting can only be set after

applying the BER on setting.

These modes are defined to allow optimal power saving

opportunities. It is not possible to switch between the BER

off setting and the BER on setting without losing lock. Switching

between the BER standby setting and the BER on setting is

achieved without interrupting data recovery. The incremental

power between the BER off setting and the BER standby setting

is 77 mW and between the BER off setting and the BER on setting

it is 160 mW.

2

C.

BER On Mode

The BER on mode allows the user to scan the incoming data eye

in the time dimension and build up a profile of the BER statistics.

The following is a brief overview of user protocol:

• The user powers up BER circuitry through I

• The user initiates the PBER measurement. Sample phase offset

and number of data bits to be counted (NUMBITS is a choice

between 2

through I

• The user initiates the pseudo BER measurement by writing a

1-to-0 transition on BERCTLA[3].

• BER logic indicates the end of the BER measurement with an

EOBM signal and updates the number of counted errors on

NUMERRORS[39:0]. The user must poll the I2C to determine

if the EOBM bit, BERSTS[0], has been asserted.

• The user reads back NUMERRORS[39:0] through the I

NUMERRORS[39:0] is read back through the 8-bit register

BER_RES at Address 0x21. The user sets BERCTLA[2:0] to

address one of the five NUMERRORS bytes and then reads the

selected byte from BER_RES.

• PBER for programmed sample phase is calculated as

numerrors/numbits.

• The user initiates another PBER measurement.

• The user sweeps the phase over −0.5 UI to +0.5 UI with respect

to the normal sampling instant to get the BER profile required.

The ADN2817 does not output the BER at the normal decision

instant. It outputs PBER measurements to the left and right of

the normal decision instants from which the user must calculate

what the BER is at the normal decision instant. A microprocessor is

required to parse the data and to use the remaining data for

BER estimation. Suitable algorithms are suggested in the BER

Monitor User Guide, AN-941.

18

, 221, 224, 227, 230, 233, 236, or 239) are supplied by user

2

C.

2

C.

2

C.

Rev. A | Page 23 of 40

ADN2817/ADN2818

www.BDTIC.com/ADI

Voltage Output Mode of Operation

A second mode of operation is the voltage output mode. This

mode is to give easy access to a coarse estimate of the BER. The

functionality is similar to that already described except that the

measurement is performed autonomously by the ADN2817,

and the result is output as a voltage on a pin from which the

actual BER can be inferred. Because this mode does not perform

scanning of the eye to separate out deterministic jitter from

random jitter effects, this method is less accurate under normal

applied jitter conditions.

The user merely has to bring the BERMODE pin low and read

the voltage on the VBER pin (see Figure 32). Alternatively, a 6bit value can be read over the I

0.9

0.7

0.5

0.3

0.1

VBER PIN VOLTAGE RELATIVE TO VEE (V)

0.001 0. 00001 0.0000001 0.000000001

Figure 32. VBER vs. Bit Error Rate

2

C

VBER VOLTAG E IS

GUARANTEED TO

SATURATE FOR

INPUT BERs LESS

THAN 0.000000001

VBER VOLTAGE IS

GUARANTEED TO

SATURATE FOR

INPUT BERs

GREATER THAN 0.001

LOG (BER)

06001-024

SQUELCH MODE

Two squelch modes are available with the ADN2817/ADN2818:

squelch DATAOUT and CLKOUT mode, and squelch DATAOUT

or CLKOUT mode.

Squelch DATAOUT and CLKOUT mode is selected when

CTRLC[1] = 0 (default mode). In this mode, when the squelch

input, Pin 27, is driven to a TTL high state, both the clock and

data outputs are set to the zero state to suppress downstream

processing. If the squelch function is not required, Pin 27 should

be tied to VEE.

Squelch DATAOUT or CLKOUT mode is selected when

CTRLC[1] is 1. In this mode, when the squelch input is driven

to a high state, the DATAOUT pins are squelched. When the

squelch input is driven to a low state, the CLKOUT pins are

squelched. This is especially useful in repeater applications,

where the recovered clock may not be needed.

I2C INTERFACE

The ADN2817/ADN2818 supports a 2-wire, I2C-compatible

serial bus driving multiple peripherals. Two inputs, serial data

(SDA) and serial clock (SCK), carry information between any

devices connected to the bus. Each slave device is recognized by

a unique address. The ADN2817/ADN2818 have two possible

7-bit slave addresses for both read and write operations. The

MSB of the 7-bit slave address is factory programmed to 1. Bit 5

of the slave address is set by Pin 19, SADDR5. Slave Address

Bits[4:0] are defaulted to all 0s. The slave address consists of the

7 MSBs of an 8-bit word. The LSB of the word either sets a read

or write operation (see Figure 18). Logic 1 corresponds to a read

operation and Logic 0 corresponds to a write operation.

To control the device on the bus, the following protocol must be

followed. First, the master initiates a data transfer by establishing

a start condition, defined by a high-to-low transition on SDA

while SCK remains high. This indicates that an address/data

stream follows. All peripherals respond to the start condition

and shift the next eight bits (the 7-bit address and the R/

The bits are transferred from MSB to LSB. The peripheral that

recognizes the transmitted address responds by pulling the

data line low during the ninth clock pulse. This is known as an

acknowledge bit. All other devices withdraw from the bus at

this point and maintain an idle condition. The idle condition is

where the device monitors the SDA and SCK lines waiting for

the start condition and correct transmitted address. The R/

bit determines the direction of the data. Logic 0 on the LSB of

the first byte means that the master writes information to the

peripheral. Logic 1 on the LSB of the first byte means that the

master reads information from the peripheral.

The ADN2817/ADN2818 act as standard slave devices on the

bus. The data on the SDA pin is eight bits long, supporting the

7-bit addresses plus the R/

W

bit. The ADN2817/ADN2818 have

eight subaddresses to enable the user-accessible internal registers

Tabl e 1 Tab l e 8

(see through ). It, therefore, interprets the first

byte as the device address and the second byte as the starting

subaddress. Auto-increment mode is supported, allowing data

to be read from, or written to, the starting subaddress and each

subsequent address without manually addressing the subsequent

subaddress. A data transfer is always terminated by a stop

condition. The user can also access any unique subaddress

register on a one-by-one basis without updating all registers.

Stop and start conditions can be detected at any stage of the

data transfer. If these conditions are asserted out of sequence

with normal read and write operations, they cause an immediate

jump to the idle condition. During a given SCK high period, the

user should issue one start condition, one stop condition, or a

single stop condition followed by a single start condition. If an

invalid subaddress is issued by the user, the ADN2817/ADN2818

do not issue an acknowledge and return to the idle condition.

W

bit).

W

Rev. A | Page 24 of 40

ADN2817/ADN2818

V

www.BDTIC.com/ADI

If the user exceeds the highest subaddress while reading back in

auto-increment mode, the highest subaddress register contents

continue to be output until the master device issues a no

acknowledge. This indicates the end of a read. In a no acknowledge

condition, the SDATA line is not pulled low on the ninth pulse.

See Figure 19 and Figure 20 for sample read and write data

transfers and Figure 21 for a more detailed timing diagram.

REFERENCE CLOCK (OPTIONAL)

A reference clock is not required to perform clock and data

recovery with the ADN2817/ADN2818. However, support for

an optional reference clock is provided. The reference clock can

be driven differentially or single-ended. If the reference clock is not

used, tie REFCLKP to VCC, and either leave REFCLKN floating or

tie it to VEE (the inputs are internally terminated to VCC/2). See

Figure 33 through Figure 35 for sample configurations.

The REFCLK input buffer accepts any differential signal with a

peak-to-peak differential amplitude of greater than 100 mV (for

example, LVPECL or LVDS) or a standard single-ended low

voltage TTL input, providing maximum system flexibility. Phase

noise and duty cycle of the reference clock are not critical and

100 ppm accuracy is sufficient.

ADN2817/ADN2818

REFCLKP

10

11

REFCLKN

Figure 33. Differential REFCLK Configuration

VCC

OUT

REFCLKP

10

REFCLKN

11

CLK

OSC

Figure 34. Single-Ended REFCLK Configuration

BUFFER

100kΩ100kΩ

VCC/2

ADN2817/ADN2818

BUFFER

100kΩ100kΩ

VCC/2

06001-021

06001-022

Rev. A | Page 25 of 40

ADN2817/ADN2818

CC

REFCLKP

10

REFCLKN

11

Figure 35. No REFCLK Configuration

BUFFER

100kΩ100kΩ

VCC/2

06001-023

The two uses of the reference clock are mutually exclusive. The

reference clock can be used either as an acquisition aid for the

ADN2817/ADN2818 to lock onto data, or to measure the frequency of the incoming data to within 0.01%. (There is the

capability to measure the data rate to approximately ±10%

without the use of a reference clock.) The modes are mutually

exclusive because, in the first use, the user knows exactly what

the data rate is and wants to force the part to lock onto only that

data rate; in the second use, the user does not know what the

data rate is and wants to measure it.

Lock to reference mode is enabled by writing 1 to I

2

C Register

Bit CTRLA[0]. Fine data rate readback mode is enabled by

writing 1 to I

2

C Register Bit CTRLA[1]. Writing a 1 to both

of these bits at the same time causes an indeterminate state

and is not supported.

Using the Reference Clock to Lock onto Data

Writing CTRLA[0] = 1 puts the ADN2817/ADN2818 into lock

to REFCLK (LTR) mode. In this mode, the ADN2817/ADN2818

lock onto a frequency derived from the reference clock according

to the following equation:

Data Rate/2

CTRLA[5:2]

= REFCLK/2

CTRLA[7:6]

The user must know exactly what the data rate is and provide

a reference clock that is a function of this rate. The ADN2817/

ADN2818 can still be used as continuous rate devices in this

configuration if a reference clock with a variable frequency is

provided (see Application Note AN-632).

The reference clock can be anywhere between 10 MHz and

200 MHz. By default, the ADN2817/ADN2818 expect a reference

clock of between 10 MHz and 25 MHz. If it is between 25 MHz

and 50 MHz, 50 MHz and 100 MHz, or 100 MHz and 200 MHz,

the user needs to configure the ADN2817/ADN2818 to use the

correct reference frequency range by setting two bits of the

CTRLA register, CTRLA[7:6].

Table 17. CTRLA[7:6] (f

Ratio) Settings

(f

REF

Range) with CTRLA[5:2]

REF

CTRLA[7:6] Range (MHz) CTRLA[5:2] Ratio

00 10 to 25 0000 1

01 25 to 50 0001 2

10 50 to 100 n

2n

11 100 to 200 1000 256

ADN2817/ADN2818

www.BDTIC.com/ADI

The user can specify a fixed integer multiple of the reference

clock to lock onto using CTRLA[5:2], where CTRLA should be

set to the data rate/DIV_FREF and DIV_FREF represents the

divided-down reference referred to the 10 MHz to 25 MHz band.

For example, if the reference clock frequency is 38.88 MHz and

the input data rate is 622.08 Mbps, then CTRLA[7:6] is set to

[01] to give a divided-down reference clock of 19.44 MHz.

CTRLA[5:2] is set to [0101], that is, 5, because

622.08 Mbps/19.44 MHz = 2

5

When the CTRLA[7:2] value is correct and CTRLA[0] has been

written to a Logic 1, it is recommended that a 1-to-0 transition

be written to CTRLB[5] to initiate a new frequency acquisition

with respect to the reference clock.

In this mode, if the ADN2817/ADN2818 lose lock for any

reason, they relock onto the reference clock and continue to

output a stable clock.

Though the ADN2817/ADN2818 operate in LTR mode, if

the user ever changes the reference frequency, the f

(CTRLA[7:6]), or the f

ratio (CTRLA[5:2]), this must be

REF

REF

range

followed by writing a 1-to-0 transition into the CTRLB[5] bit

to initiate a new frequency acquisition.

A frequency acquisition can also be initiated in LTR mode by

writing a 0-to-1 transition into CTRLA[0]; however, it is recommended that a frequency acquisition be initiated by writing

a 1-to-0 transition into CTRLB[5], as explained previously.

Using the Reference Clock to Measure Data Frequency

The user can also provide a reference clock to measure the

recovered data frequency. In this case, the user provides a

reference clock, and the ADN2817/ADN2818 compare the

frequency of the incoming data to the incoming reference clock

and return a ratio of the two frequencies to 0.01% (100 ppm).

The accuracy error of the reference clock is added to the accuracy

of the ADN2817/ADN2818 data rate measurement. For example, if

a 100 ppm accuracy reference clock is used, the total accuracy

of the measurement is within 200 ppm.

The reference clock can range from 10 MHz to 200 MHz. The

ADN2817/ADN2818 expects a reference clock between 10 MHz

and 25 MHz by default. If it is between 25 MHz and 50 MHz,

50 MHz and 100 MHz, or 100 MHz and 200 MHz, the user

needs to configure the ADN2817/ADN2818 to use the correct

reference frequency range by setting two bits of the CTRLA

register, CTRLA[7:6]. Using the reference clock to determine

the frequency of the incoming data does not affect the manner

in which the part locks onto data. In this mode, the reference

clock is used only to determine the frequency of the data. For

this reason, the user does not need to know the data rate to use

the reference clock in this manner.

Rev. A | Page 26 of 40

Prior to reading back the data rate using the reference clock, the

CTRLA[7:6] bits must be set to the appropriate frequency range

with respect to the reference clock being used. A fine data rate

readback is then executed as follows:

1. Write a 1 to CTRLA[1]. This enables the fine data rate

measurement capability of the ADN2817/ADN2818.

This bit is level sensitive and does not need to be reset

to perform subsequent frequency measurements.

2. Reset MISC[2] by writing a 1 followed by a 0 to CTRLB[3].

This initiates a new data rate measurement.

3. Readback MISC[2]. If it is 0, the measurement is not

complete. If it is 1, the measurement is complete and

the data rate can be read back on FREQ[22:0]. The time

for a data rate measurement is typically 80 ms.

4. Read back the data rate from the FREQ2[6:0], FREQ1[7:0],

and FREQ0[7:0] registers.

Use the following equation to determine the data rate:

f

DATARATE

= (FREQ[22..0] × f

REFCLK

(14 + SEL_RATE)

)/2

where:

FREQ[22:0] is the reading from FREQ2[6:0] (most significant

byte), FREQ1[7:0], and FREQ0[7:0] (least significant byte). See

Tabl e 18 .

is the data rate (Mbps).

f

DATAR ATE

f

is the REFCLK frequency (MHz).

REFCLK

SEL_RATE is the setting from CTRLA[7:6].

Table 18.

D21...

D22

D17 D16 D15 D14...D9 D8 D7 D6...D1 D0

FREQ2[6:0] FREQ1[7:0] FREQ0[7:0]

For example, if the reference clock frequency is 32 MHz, it falls

within the 25 MHz to 50 MHz range; therefore, the CTRLA[7:6]

setting is [01] resulting in SEL_RATE = 1. For this example, the

input data rate is 2.488 Gbps (OC-48). After following Step 1

through Step 4, the value that is read back on FREQ[22:0] =

0x26E010, which is equal to 2.5477 × 10

6

. Plugging this value

into the equation yields

((2.5477 × 10

6

) × (32 × 106))/(2

(14 + 1)

) = 2.488 Gbps

If subsequent frequency measurements are required, CTRLA[1]

should remain set to 1. It does not need to be reset. The

measurement process is reset by writing a 1 followed by a 0 to

CTRLB[3]. This initiates a new data rate measurement. Follow

Step 2 through Step 4 to read back the new data rate.

Note that a data rate readback is valid only if LOL is low. If LOL

is high, the data rate readback is invalid.

ADN2817/ADN2818

www.BDTIC.com/ADI

ADDITIONAL FEATURES AVAILABLE VIA THE I2C INTERFACE

Coarse Data Rate Readback

The data rate can be read back over the I2C interface to

approximately ±10% without needing an external reference

clock. A 9-bit register, COARSE_RD[8:0], can be read back

when LOL is deasserted. The 8 MSBs of this register are the

contents of the RATE[7:0] register. The LSB of the COARSE_RD

register is Bit MISC[0].