155/622 Mb/s Clock and Data Recovery IC

www.BDTIC.com/ADI

FEATURES

Meets SONET requirements for jitter transfer/

generation/tolerance

Quantizer sensitivity: 4 mV typical

Adjustable slice level: ±100 mV

Patented clock recovery architecture

Loss-of-signal detect range: 3 mV to 15 mV

Single-reference clock frequency for all rates, including

15/14 (7%) wrapper rate

Choice of 19.44 MHz, 38.88 MHz, 77.76 MHz, or

155.52 MHz REFCLK

REFCLK inputs: LVPECL/LVDS/LVCMOS/LVTTL compatible

(LVPECL/LVDS only at 155.52 MHz)

Optional 19.44 MHz on-chip oscillator to be used with

external crystal

Loss-of-lock indicator

Loopback mode for high speed test data

Output squelch and bypass features

Single-supply operation: 3.3 V

Low power: 540 mW typical

7 mm × 7 mm, 48-lead LFCSP

APPLICATIONS

SONET OC-3/-12, SDH STM-1/-4 and, 15/14 FEC rates

WDM transponders

Regenerators/repeaters

Test equipment

Passive optical networks

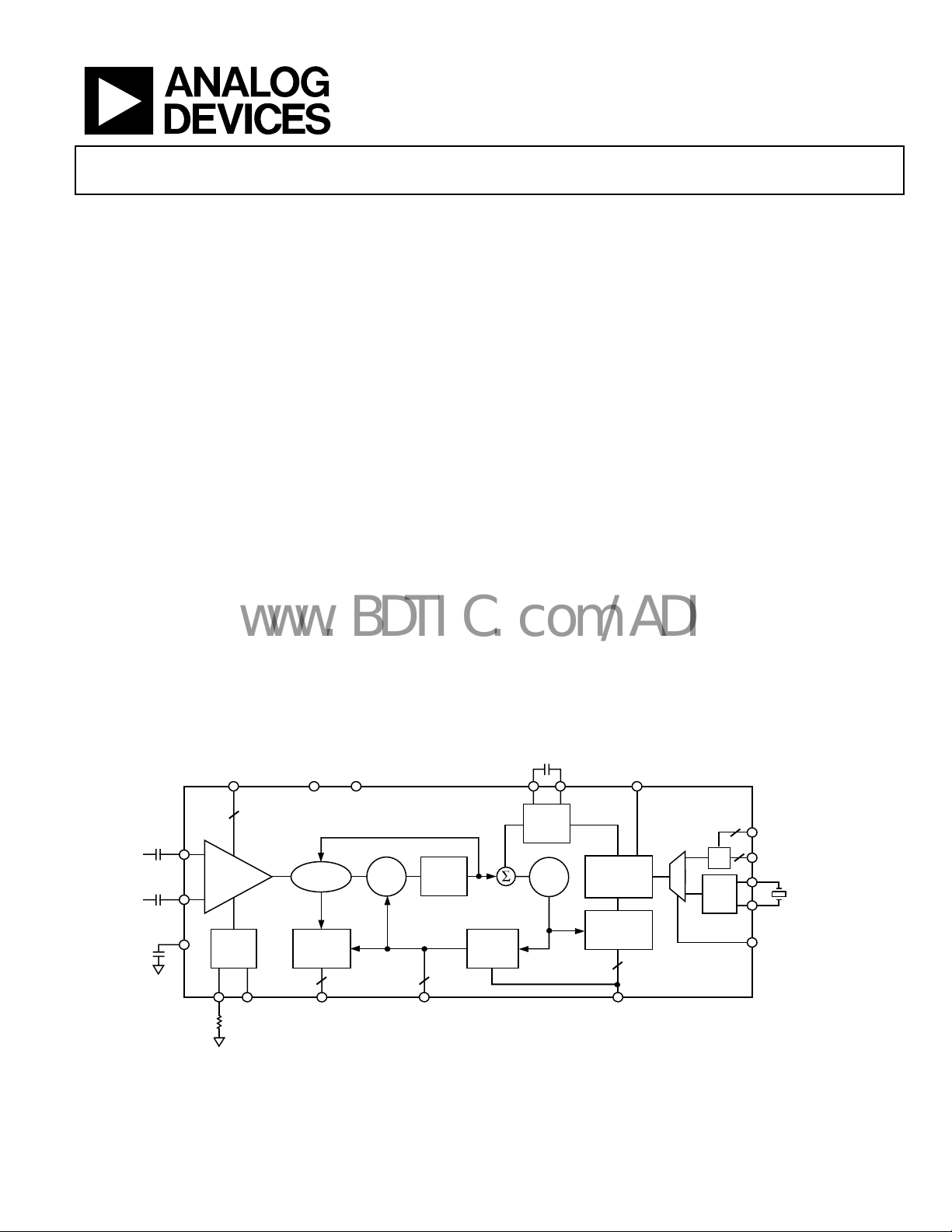

FUNCTIONAL BLOCK DIAGRAM

SLICEP/N VCC VEE

with Integrated Limiting Amp

ADN2807

GENERAL DESCRIPTION

The ADN2807 provides the receiver functions of quantization,

signal level detect, and clock and data recovery at rates of OC-3,

OC-12, and 15/14 FEC. All SONET jitter requirements are met,

including jitter transfer, jitter generation, and jitter tolerance. All

specifications are quoted for –40°C to +85°C ambient

temperature, unless otherwise noted.

The device is intended for WDM system applications and can

be used with either an external reference clock or an on-chip

oscillator with external crystal. Both native rates and 15/14 rate

digital wrappers are supported by the ADN2807, without any

change of reference clock.

This device, together with a PIN diode and a TIA preamplifier,

can implement a highly integrated, low cost, low power, fiber

optic receiver.

The receiver front end signal detect circuit indicates when the

input signal level has fallen below a user adjustable threshold.

The signal detect circuit has hysteresis to prevent chatter at the

output.

The ADN2807 is available in a compact 7 mm × 7 mm 48-lead

chip-scale package (LFCSP).

CF1 CF2

LOL

ADN2807

2

PIN

QUANTIZER

NIN

VREF

Rev. A

Information furnished by Analog Devices is believed to be accurate and reliable.

However, no responsibility is assumed by Analog Devices for its use, nor for any

infringements of patents or other rights of third parties that may result from its use.

Specifications subject to change without notice. No license is granted by implication

or otherwise under any patent or patent rights of Analog Devices. Trademarks and

registered trademarks are the property of their respective owners.

THRADJ

LEVEL

DETECT

PHASE

SHIFTER

DATA

RETIMING

PHASE

DET.

LOOP

FILTER

22

DIVIDER

1/2/4/16

Figure 1.

LOOP

FILTER

FREQUENCY

VCO

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700 www.analog.com

Fax: 781.326.8703 © 2004 Analog Devices, Inc. All rights reserved.

LOCK

DETECTOR

FRACTIONAL

DIVIDER

3

SEL[0..2]CLKOUTP/NDATAOUTP/NSDOUT

/n

XTAL

OSC

2

2

REFSEL[0..1]

REFCLKP/N

XO1

XO2

REFSEL

03877-0-001

ADN2807

www.BDTIC.com/ADI

TABLE OF CONTENTS

Specifications..................................................................................... 3

Absolute Maximum Ratings............................................................ 5

Thermal Characteristics .............................................................. 5

ESD Caution.................................................................................. 5

Pin Configuration and Function Descriptions............................. 6

Definition of Terms.......................................................................... 8

Maximum, Minimum, and Typical Specifications ................... 8

Input Sensitivity and Input Overdrive....................................... 8

Single-Ended vs. Differential ...................................................... 8

LOS Response Time ..................................................................... 9

Jitter Specifications....................................................................... 9

Theory of Operation ...................................................................... 10

Functional Description ..................................................................12

Multirate Clock and Data Recovery......................................... 12

Limiting Amplifier ..................................................................... 12

Slice Adjust.................................................................................. 12

Loss-of-Signal (LOS) Detector................................................. 12

Reference Clock.......................................................................... 12

Lock Detector Operation.......................................................... 13

Squelch Mode ............................................................................. 14

Test Modes—Bypass and Loop-back....................................... 14

Application Information................................................................ 15

PCB Design Guidelines ............................................................. 15

Choosing AC Coupling Capacitors.......................................... 17

DC-Coupled Application .......................................................... 17

LOL Toggling during Loss of Input Data ................................ 17

Outline Dimensions....................................................................... 19

Ordering Guide .......................................................................... 19

REVISION HISTORY

5/04—Data Sheet Changed from Rev. 0 to Rev. A

Changes to Specifications............................................................ 3

hange to Table 7 and Table 8 ..................................................13

C

1/04—Revision 0: Initial Version

Rev. A | Page 2 of 20

ADN2807

www.BDTIC.com/ADI

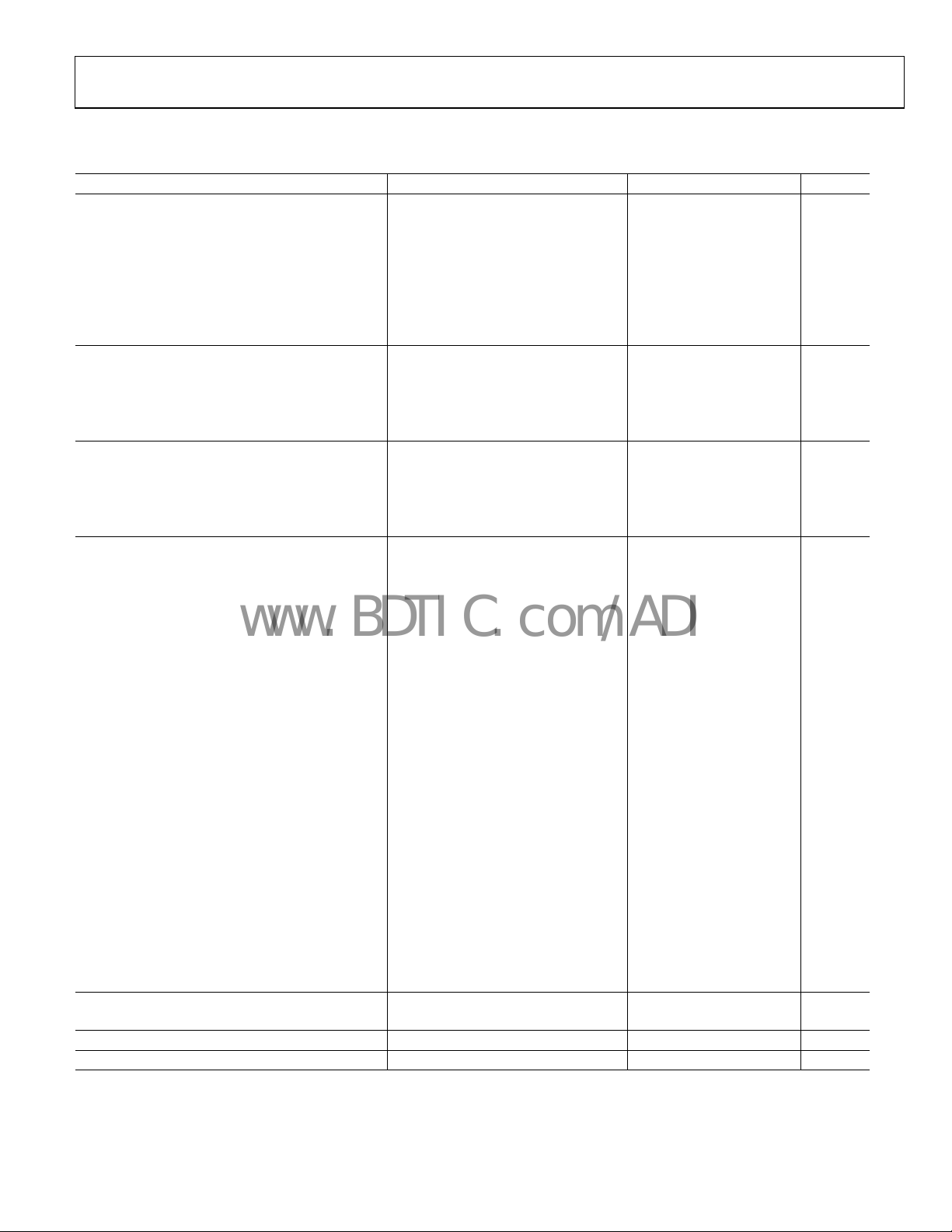

SPECIFICATIONS

Table 1. TA = T

Parameter Conditions Min Typ Max Unit

QUANTIZER–DC CHARACTERISTICS

Input Voltage Range @ PIN or NIN, dc-coupled 0

Peak-to-Peak Differential Input

Input Common-Mode Level DC-coupled (See Figure 26) 0.4

Differential Input Sensitivity PIN−NIN, ac-coupled1, BER = 1 × 10

Input Overdrive See Figure 8

Input Offset

Input RMS Noise BER = 1 × 10

QUANTIZER–AC CHARACTERISTICS

Small Signal Gain Differential

Input Resistance Differential

Input Capacitance

Pulse-Width Distortion

QUANTIZER SLICE ADJUSTMENT

Gain SliceP – SliceN = ±0.5 V 0.11 0.20 0.30 V/V

Control Voltage Range SliceP – SliceN –0.8

@ SliceP or SliceN 1.3

Slice Threshold Offset ±1.0 mV

LEVEL SIGNAL DETECT (SDOUT)

Level Detect Range (See Figure 4) R

Response Time DC-coupled 0.1 0.3 5 µs

Hysteresis (Electrical)

R

LOSS-OF-LOCK DETECTOR (LOL)

Loss-of-Lock Response Time From f

POWER SUPPLY VOLTAGE 3.0 3.3 3.6 V

POWER SUPPLY CURRENT 150 164 215 mA

MIN

to T

, VCC = V

MAX

2

MIN

to V

, VEE = 0 V, CF = 4.7 µF, SLICEP = SLICEN = VCC, unless otherwise noted

MAX

–10

–10

244 µV rms

4 10 mV p-p

2 5 mV p-p

500

1.2 V

2.4 V

V

µV

54

100

0.65

dB

Ω

pF

10 ps

+0.8 V

VCC V

= 2 kΩ 9.4 13.3 18.0 mV

THRESH

R

= 20 kΩ 2.5 5.3 7.6 mV

THRESH

R

= 90 kΩ 0.7 3.0 5.2 mV

THRESH

OC-12, PRBS 2

R

THRESH

R

THRESH

R

THRESH

R

THRESH

OC-3, PRBS 2

R

THRESH

R

THRESH

R

THRESH

R

THRESH

OC-12, PRBS 2

R

THRESH

R

THRESH

R

THRESH

OC-3, PRBS 2

R

THRESH

R

THRESH

THRESH

23

= 2 kΩ 4.7 6.4 7.8 dB

= 20 kΩ 1.8 6.0 10.0 dB

= 90 kΩ

6.3

dB

= 90 kΩ @ 25°C 4.8 6.9 8.9 dB

23

= 2 kΩ 3.6 6.2 8.5 dB

= 20 kΩ

= 90 kΩ

5.6

5.6

dB

dB

= 90 k @ 25°C 3.4 6.6 9.9 dB

7

= 2 kΩ 5.7 6.6 7.8 dB

= 20 kΩ 3.9 6.2 8.5 dB

= 90 kΩ 3.2 6.7 9.9 dB

7

= 2 kΩ 5.4 6.6 7.7 dB

= 20 kΩ 4.6 6.4 8.2 dB

= 90 kΩ 3.9 6.8 9.7 dB

error > 1000 ppm 60 mV

VCO

Rev. A | Page 3 of 20

ADN2807

www.BDTIC.com/ADI

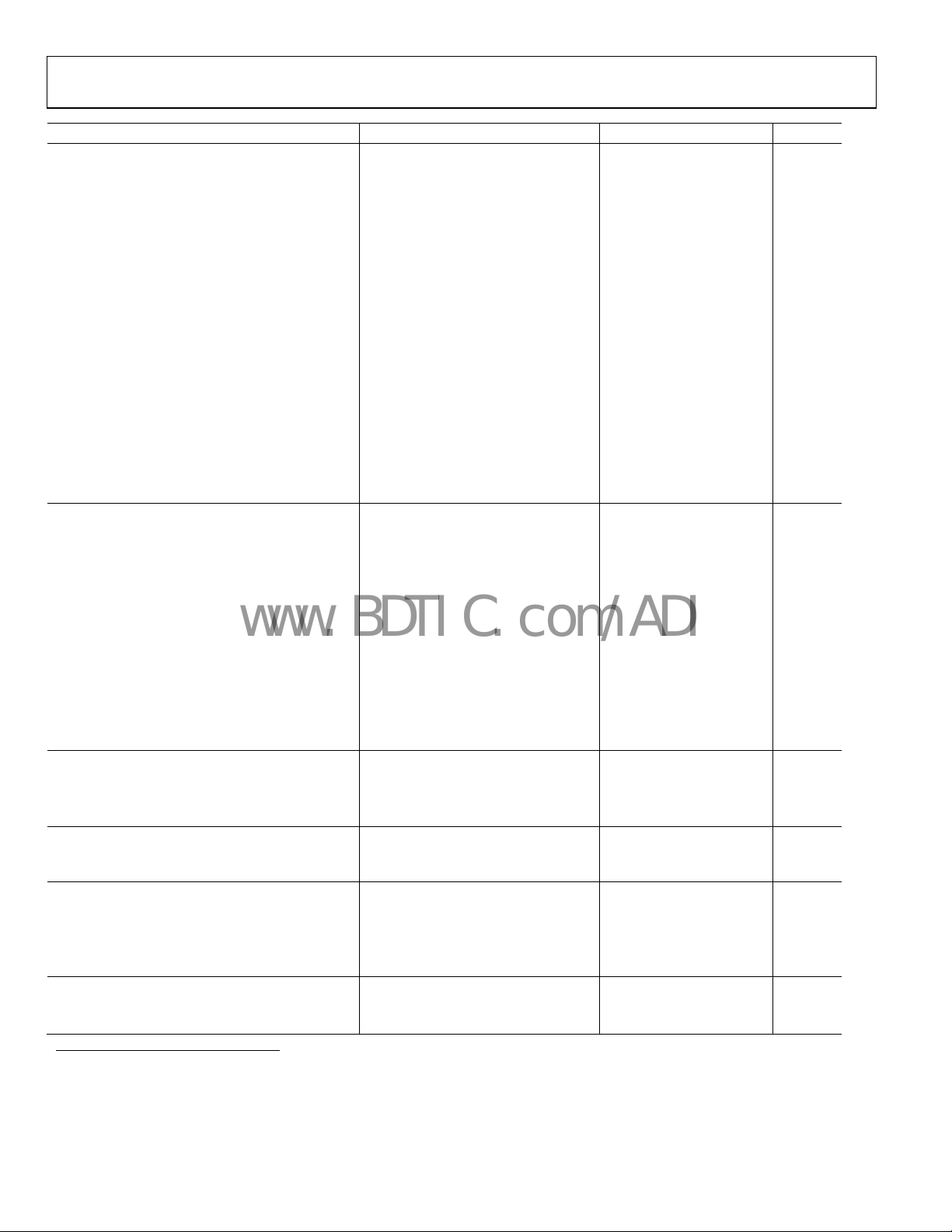

Parameter Conditions Min Typ Max Unit

PHASE-LOCKED LOOP CHARACTERISTICS PIN–NIN = 10 mV p-p

Jitter Transfer BW OC-12

OC-3

Jitter Peaking OC-12

OC-3

Jitter Generation OC-12, 12 kHz to 5 MHz

OC-3, 12 kHz to 1.3 MHz

Jitter Tolerance OC-12

3

30 Hz

300 Hz 44

25 kHz 5.8

3

250 kHz

1.0

OC-3

3

30 Hz

50

3

300 Hz

23.5

6500 Hz 6.0

65 kHz3 1.0 UI p-p

CML OUTPUTS (CLKOUTP/N, DATAOUTP/N)

Single-Ended Output Swing VSE (See Figure 7) 400 488 540 mV

Differential Output Swing V

Output High Voltage V

(See Figure 7) 850 975 1100 mV

DIFF

OH

Output Low Voltage VOL, referred to VCC –0.60

Rise Time 20% to 80%

Fall Time 80% to 20%

Setup Time TS (See Figure 3)

OC-12 750

OC-3 3145

Hold Time TH (See Figure 3)

OC-12 750

OC-3 3150 ps

REFCLK DC INPUT CHARACTERISTICS

Input Voltage Range @ REFCLKP or REFCLKN 0 VCC V

Peak-to-Peak Differential Input 100 mV

Common-Mode Level DC-coupled, single-ended VCC/2 V

TEST DATA DC INPUT CHARACTERISTICS4

CML inputs

(TDINP/N)

Peak-to-Peak Differential Input Voltage 0.8 V

LVTTL DC INPUT CHARACTERISTICS

Input High Voltage V

Input Low Voltage V

IH

IL

Input Current VIN = 0.4 V or VIN = 2.4 V –5 +5 µA

Input Current (SEL0 and SEL1 Only)

5

VIN = 0.4 V or VIN = 2.4 V –5 +50 µA

LVTTL DC OUTPUT CHARACTERISTICS

Output High Voltage VOH, IOH = –2.0 mA 2.4 V

Output Low Voltage VOL, IOL = +2.0 mA 0.4 V

1

PIN and NIN should be driven differentially, ac-coupled for optimum sensitivity.

2

PWD measurement made on quantizer outputs in BYPASS mode.

3

Jitter tolerance measurements are equipment limited.

4

TDINP/N are CML inputs. If the drivers to the TDINP/N inputs are anything other than CML, they must be ac-coupled.

5

SEL0 and SEL1 have internal pull-down resistors, causing higher IIH.

140 200 kHz

48 85 kHz

0.004

0.002

dB

dB

0.003 UI rms

0.02 0.04 UI p-p

0.002 UI rms

0.02 0.04 UI p-p

100

UI p-p

UI p-p

UI p-p

UI p-p

VCC

–0.30 V

150 ps

150 ps

UI p-p

UI p-p

UI p-p

V

ps

ps

ps

2.0 V

0.8 V

Rev. A | Page 4 of 20

ADN2807

www.BDTIC.com/ADI

ABSOLUTE MAXIMUM RATINGS

Table 2.

Parameter Rating

Supply Voltage (VCC) 5.5 V

Minimum Input Voltage (All Inputs) VEE – 0.4 V

Maximum Input Voltage (All Inputs) VCC + 0.4 V

Maximum Junction Temperature 165°C

Storage Temperature –65°C to +150°C

Lead Temperature (Soldering 10 sec) 300°C

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

ESD CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily accumulate on

the human body and test equipment and can discharge without detection. Although this product features

proprietary ESD protection circuitry, permanent damage may occur on devices subjected to high energy

electrostatic discharges. Therefore, proper ESD precautions are recommended to avoid performance

degradation or loss of functionality.

THERMAL CHARACTERISTICS

Thermal Resistance

48-Lead LFCSP, 4-layer board with exposed paddle soldered

to VCC

θ

= 25°C/W

JA

Rev. A | Page 5 of 20

ADN2807

www.BDTIC.com/ADI

PIN CONFIGURATION AND FUNCTION DESCRIPTIONS

48 LOOPEN

47VCC

46VEE

45 SDOUT

44 BYPASS

43VEE

42VEE

41 CLKOUTP

40 CLKOUTN

39 SQUELCH

38 DATAOUTP

37 DATAOUTN

THRADJ 1

VCC 2

VEE 3

VREF 4

PIN 5

NIN 6

SLICEP 7

SLICEN 8

VEE 9

LOL 10

XO1 11

XO2 12

PIN 1

INDICATOR

ADN2807

TOPVIEW

VEE 16

REFSEL 15

REFCLKP 14

REFCLKN 13

VEE 19

TDINP 17

TDINN 18

CF1 21

VCC 20

VEE 22

REFSEL1 23

36VCC

35VCC

34VEE

33VEE

32 SEL0

31 NC

30 SEL1

29VEE

28VCC

27VEE

26VCC

25 CF2

REFSEL0 24

03877-0-002

Figure 2. Pin Configuration

Table 3. Pin Function Descriptions

Pin No. Mnemonic Type1Description

1 THRADJ AI LOS Threshold Setting Resistor.

2, 26, 28, Pad VCC P Analog Supply.

3, 9, 16, 19,

VEE P Ground.

22, 27, 29, 33,

34, 42, 43, 46

4 VREF AO Internal VREF Voltage. Decouple to GND with a 0.1 µF capacitor.

5 PIN AI Differential Data Input.

6 NIN AI Differential Data Input.

7 SLICEP AI Differential Slice Level Adjust Input.

8 SLICEN AI Differential Slice Level Adjust Input.

10 LOL DO Loss-of-Lock Indicator. LVTTL active high.

11 XO1 AO Crystal Oscillator.

12 XO2 AO Crystal Oscillator.

13 REFCLKN DI Differential REFCLK Input. LVTTL, LVCMOS, LVPECL, LVDS (LVPECL, LVDS only at 155.52 MHz).

14 REFCLKP DI Differential REFCLK Input. LVTTL, LVCMOS, LVPECL, LVDS (LVPECL, LVDS only at 155.52 MHz).

15 REFSEL DI Reference Source Select. 0 = on-chip oscillator with external crystal. 1 = external clock source, LVTTL.

17 TDINP AI Differential Test Data Input. CML.

18 TDINN AI Differential Test Data Input. CML.

20, 47 VCC P Digital Supply.

21 CF1 AO Frequency Loop Capacitor.

23 REFSEL1 DI Reference Frequency Select (See Table 6) LVTTL.

24 REFSEL0 DI Reference Frequency Select (See Table 6) LVTTL.

25 CF2 AO Frequency Loop Capacitor.

30 SEL1 DI Data Rate Select (See Table 5) LVTTL.

31 NC No Connect.

32 SEL0 DI Data Rate Select (See Table 5) LVTTL.

35, 36 VCC P Output Driver Supply.

37 DATAOUTN DO Differential Retimed Data Output. CML.

38 DATAOUTP DO Differential Retimed Data Output. CML.

39 SQUELCH DI Disable Clock and Data Outputs. Active high. LVTTL.

40 CLKOUTN DO Differential Recovered Clock Output. CML.

41 CLKOUTP DO Differential Recovered Clock Output. CML.

44 BYPASS DI Bypass CDR Mode. Active high. LVTTL.

45 SDOUT DO Loss-of-Signal Detect Output. Active high. LVTTL.

48 LOOPEN DI Enable Test Data Inputs. Active high. LVTTL.

1

Type: P = Power, AI = Analog Input, AO = Analog Output, DI = Digital Input, DO = Digital Output

Rev. A | Page 6 of 20

ADN2807

www.BDTIC.com/ADI

CLKOUTP

T

S

T

H

DATAOUTP/N

10

9

8

7

6

5

4

FREQUENCY

3

2

1

0

01123456789

Figure 5. LOS Hysteresis OC-3, −40°C, 3.6 V,

23

2

HYSTERESIS (dB)

–1 PRBS Input Pattern, RTH = 90 kΩ

OUTP

OUTN

OUTP–OUTN

V

CML

V

0V

SE

Figure 3. Output Timing

18

16

14

12

10

mV

8

6

4

2

0

0 100

THRADJ RESISTOR VS. LOSTRIP POINT

10 20 30 40 50 60 70 80 90

RESISTANCE (kΩ)

Figure 4. LOS Comparator Trip Point Programming

18

16

14

12

10

8

FREQUENCY

6

4

2

0

0

03877-0-005

01123456789 0

Figure 6. LOS Hysteresis OC-12, −40°C, 3.6 V,

V

DIFF

Figure 7. Single-Ended vs. Differential Output Specifications

03877-0-003

03877-0-004

HYSTERESIS (dB)

23

2

–1 PRBS Input Pattern, RTH = 90 kΩ

V

SE

03877-0-007

03877-0-006

Rev. A | Page 7 of 20

ADN2807

S

www.BDTIC.com/ADI

DEFINITION OF TERMS

MAXIMUM, MINIMUM, AND TYPICAL SPECIFICATIONS

Specifications for every parameter are derived from statistical

analyses of data taken on multiple devices from multiple wafer

lots. Typical specifications are the mean of the distribution of

the data for that parameter. If a parameter has a maximum (or a

minimum) value, that value is calculated by adding to (or

subtracting from) the mean six times the standard deviation of

the distribution. This procedure is intended to tolerate production variations. If the mean shifts by 1.5 standard deviations,

the remaining 4.5 standard deviations still provide a failure rate

of only 3.4 parts per million. For all tested parameters, the test

limits are guardbanded to account for tester variation, and

therefore guarantee that no device is shipped outside of data

sheet specifications.

SINGLE-ENDED VS. DIFFERENTIAL

AC coupling is typically used to drive the inputs to the

quantizer. The inputs are internally dc-biased to a commonmode potential of ~0.6 V. Driving the ADN2807 single-ended

and observing the quantizer input with an oscilloscope probe at

the point indicated in Figure 9 shows a binary signal with

average value equal to the common-mode potential and

instantaneous values both above and below the average value. It

is convenient to measure the peak-to-peak amplitude of this

signal and call the minimum required value the quantizer

sensitivity. Referring to Figure 8, since both positive and

negative offsets need to be accommodated, the sensitivity is

twice the overdrive.

10mV p-p

VREF

INPUT SENSITIVITY AND INPUT OVERDRIVE

Sensitivity and overdrive specifications for the quantizer involve

offset voltage, gain, and noise. The relationship between the

logic output of the quantizer and the analog voltage input is

shown in Figure 8. For sufficiently large positive input voltage,

the output is always Logic 1; similarly for negative inputs, the

output is always Logic 0. However, the transitions between

output Logic Levels 1 and 0 are not at precisely defined input

voltage levels, but occur over a range of input voltages. Within

this zone of confusion, the output may be either 1 or 0, or it may

even fail to attain a valid logic state. The width of this zone is

determined by the input voltage noise of the quantizer. The

center of the zone of confusion is the quantizer input offset

voltage. Input overdrive is the magnitude of signal required to

guarantee a correct logic level with a 1 × 10

OUTPUT

1

0

OFFSET

OVERDRIVE

SENSITIVITY

(2× OVERDRIVE)

Figure 8. Input Sensitivity and Input Overdrive

NOISE

–10

confidence level.

INPUT (V p-p)

03877-0-008

SCOPE

PROBE

Figure 9. Single-Ended Sensitivity Measurement

COPE

PROBE

Figure 10. Differential Sensitivity Measurement

PIN

VREF

PIN

NIN

VREF

ADN2807

5mV p-p

ADN2807

50Ω 50Ω

50Ω 50Ω

+

QUANTIZER

+

QUANTIZER

VREF

03877-0-007

03877-0-010

Driving the ADN2807 differentially (Figure 10), sensitivity

seems to improve by observing the quantizer input with an

oscilloscope probe. This is an illusion caused by the use of a

single-ended probe. A 5 mV p-p signal appears to drive the

ADN2807 quantizer. However, the single-ended probe measures

only half the signal. The true quantizer input signal is twice this

value since the other quantizer input is complementary to the

signal being observed.

Rev. A | Page 8 of 20

ADN2807

www.BDTIC.com/ADI

LOS RESPONSE TIME

The LOS response time is the delay between the removal of the

input signal and indication of loss of signal (LOS) at SDOUT.

The ADN2807’s response time is 300 ns typ when the inputs are

dc-coupled. In practice, the time constant of ac coupling at the

quantizer input determines the LOS response time.

JITTER SPECIFICATIONS

The ADN2807 CDR is designed to achieve the best bit-errorrate (BER) performance, and has exceeded the jitter transfer,

generation, and tolerance specifications proposed for

SONET/SDH equipment defined in the Telcordia Technologies

specification. Jitter is the dynamic displacement of digital signal

edges from their long-term average positions measured in UI

(unit intervals), where 1 UI = 1 bit period. Jitter on the input

data can cause dynamic phase errors on the recovered clock

sampling edge. Jitter on the recovered clock causes jitter on the

retimed data. The following sections briefly summarize the

specifications of the jitter generation, transfer, and tolerance in

accordance with the Telcordia document (GR-253-CORE, Issue

3, September 2000) for the optical interface at the equipment

level, and the ADN2807 performance with respect to those

specifications.

Jitter Generation

The jitter generation specification limits the amount of jitter

that can be generated by the device with no jitter and wander

applied at the input.

Jitter Transfer

The jitter transfer function is the ratio of the jitter on the output

signal to the jitter applied on the input signal versus the

frequency. This parameter measures the limited amount of jitter

on an input signal that can be transferred to the output signal

(Figure 11).

0.1

SLOPE = –20dB/DECADE

JITTER GAIN (dB)

ACCEPTABLE

RANGE

f

C

JITTER FREQUENCY (kHz)

Figure 11. Jitter Transfer Curve

Jitter Tolerance

The jitter tolerance is defined as the peak-to-peak amplitude of

the sinusoidal jitter applied on the input signal that causes a

1 dB power penalty. This is a stress test intended to ensure that

no additional penalty is incurred under the operating

conditions (Figure 12).

15

SLOPE = –20dB/DECADE

1.5

0.15

INPUT JITTER AMPLITUDE (UI)

f

0

Figure 12. SONET Jitter Tolerance Mask

f

1

JITTER FREQUENCY (Hz)

f2f

3

f

4

03877-0-012

03877-0-011

Table 4. Jitter Transfer and Tolerance: SONET Specifications vs. ADN2807

Jitter Transfer Jitter Tolerance

Rate

SONET

Spec (fC)

ADN2807

(kHz)

Implementation

Margin

Mask Corner

Frequency (kHz) ADN2807

OC-12 500 kHz 140 3.6 250 kHz 4.8 MHz 0.15 1.0 6.67

OC-3 130 kHz 48 2.7 65 kHz 600 kHz 0.15 1.0 6.67

2

Jitter tolerance measurements are limited by test equipment capabilities.

Rev. A | Page 9 of 20

SONET Spec

(UI p-p)

ADN2807

(UI p-p)

Implementation

2

Margin

ADN2807

T

A

A

www.BDTIC.com/ADI

THEORY OF OPERATION

The ADN2807 is a delay-locked and phase-locked loop circuit

for clock recovery and data retiming from an NRZ encoded

data stream. The phase of the input data signal is tracked by two

separate feedback loops that share a common control voltage. A

high speed delay-locked loop path uses a voltage controlled

phase shifter to track the high frequency components of the

input jitter. A separate phase control loop, comprised of the

VCO, tracks the low frequency components of the input jitter.

The initial frequency of the VCO is set by a third loop, which

compares the VCO frequency with the reference frequency and

sets the coarse tuning voltage. The jitter tracking phase-locked

loop controls the VCO by the fine tuning control. The delayand phase-locked loops together track the phase of the input

data signal. For example, when the clock lags input data, the

phase detector drives the VCO to a higher frequency and also

increases the delay through the phase shifter. Both of these

actions serve to reduce the phase error between the clock and

data. The faster clock picks up phase while the delayed data

loses phase. Since the loop filter is an integrator, the static phase

error will be driven to zero.

Another view of the circuit is that the phase shifter implements

the zero required for the frequency compensation of a secondorder phase-locked loop. This zero is placed in the feedback

path and, therefore, does not appear in the closed-loop transfer

function. Jitter peaking in a conventional second-order phaselocked loop is caused by the presence of this zero in the closedloop transfer function. Since this circuit has no zero in the

closed-loop transfer, jitter peaking is minimized.

The delay- and phase-locked loops together simultaneously

provide wideband jitter accommodation and narrow-band jitter

filtering. The linearized block diagram in Figure 13 shows that

the jitter transfer function, Z(s)/X(s), is a second-order low-pass

providing excellent filtering. Note that the jitter transfer has no

zero, unlike an ordinary second-order phase-locked loop. This

means the main PLL loop has low jitter peaking (Figure 14),

which makes this circuit ideal for signal regenerator

applications where jitter peaking in a cascade of regenerators

can contribute to hazardous jitter accumulation.

psh

INPUT

DAT A

RECOVERED

d = PHASE DETEC

o = VCO GAIN

c = LOOP INTEGR

psh = PHASE SHIFTER GAIN

n = DIVIDE R

OR GAIN

TOR

TIO

Figure 13. PLL/DLL Architecture

CLOCK

e(s)X(s)

d/sc

Z(s)

JITTERTRANSFER FUNCTION

Z(s)

X(s)

TRACKING ERRORTRANSFER FUNCTION

e(s)

X(s)

o/s

1/n

=

cn

2

s

+ s +1

do

=

d psh

s2 + s +

1

2

s

c

n psh

o

do

cn

03877-0-013

The error transfer, e(s)/X(s), has the same high-pass form as an

ordinary phase-locked loop. This transfer function is free to be

optimized to give excellent wideband jitter accommodation

since the jitter transfer function, Z(s)/X(s), provides the narrowband jitter filtering. See Table 4 for error transfer bandwidths

and jitter transfer bandwidths at the various data rates. The

delay-locked and phase-locked loops contribute to overall jitter

accommodation. At low frequencies of input jitter on the data

signal, the integrator in the loop filter provides high gain to

track large jitter amplitudes with small phase error. In this case,

the VCO is frequency modulated, and jitter is tracked as in an

ordinary phase-locked loop. The amount of low frequency jitter

that can be tracked is a function of the VCO tuning range. A

wider tuning range gives larger accommodation of low

frequency jitter. The internal loop control voltage remains small

for small phase errors, so the phase shifter remains close to the

center of its range and thus contributes little to the low

frequency jitter accommodation.

Rev. A | Page 10 of 20

ADN2807

www.BDTIC.com/ADI

At medium jitter frequencies, the gain and tuning range of the

VCO are not large enough to track the input jitter. In this case,

the VCO control voltage becomes large and saturates, and the

VCO frequency dwells at one or the other extreme of its tuning

range. The size of the VCO tuning range, therefore, has only a

small affect on the jitter accommodation. The delay-locked loop

control voltage is now larger; therefore, the phase shifter takes

on the burden of tracking the input jitter. The phase shifter

range, in UI, can be seen as a broad plateau on the jitter

tolerance curve. The phase shifter has a minimum range of 2 UI

at all data rates.

The gain of the loop integrator is small for high jitter

frequencies, so larger phase differences are needed to make the

loop control voltage big enough to tune the range of the phase

shifter. Large phase errors at high jitter frequencies cannot be

tolerated. In this region, the gain of the integrator determines

the jitter accommodation. Since the gain of the loop integrator

declines linearly with frequency, jitter accommodation is lower

with higher jitter frequency. At the highest frequencies, the loop

gain is very small, and little tuning of the phase shifter can be

expected. In this case, jitter accommodation is determined by

the eye opening of the input data, the static phase error, and the

residual loop jitter generation. The jitter accommodation is

roughly 0.5 UI in this region. The corner frequency between the

declining slope and the flat region is the closed loop bandwidth

of the delay-locked loop, which is roughly 5 MHz for OC-12

data rates and 600 kHz for OC-3 data rates.

JITTER PEAKING

IN ORDINARY PLL

JITTER

GAIN

(dB)

d psh

o

n psh

Figure 14. Jitter Response vs. Conventional PLL

c

ADN2807

Z(s)

X(s)

f

(kHz)

03877-0-014

Rev. A | Page 11 of 20

ADN2807

www.BDTIC.com/ADI

FUNCTIONAL DESCRIPTION

MULTIRATE CLOCK AND DATA RECOVERY

The ADN2807 recovers clock and data from serial bit streams at

OC-3, OC-12 data rates as well as the 15/14 FEC rates. The

output of the 2.5 GHz VCO is divided down in order to support

the lower data rates. The data rate is selected by the SEL[2..0]

inputs (Table 5).

Table 5. Data Rate Selection

SEL[1..0] Rate Frequency (MHz)

00 OC-12 622.08

01 OC-3 155.52

10 OC-12 FEC 666.51

11 OC-3 FEC 166.63

LIMITING AMPLIFIER

The limiting amplifier has differential inputs (PIN/NIN) that

are internally terminated with 50 Ω to an on-chip voltage

reference (VREF = 0.6 V typically). These inputs are normally

ac-coupled, although dc-coupling is possible as long as the input

common-mode voltage remains above 0.4 V (Figure 24 to

Figure 26 in the Applications Information section). Input offset

is factory trimmed to achieve better than 4 mV typical

sensitivity with minimal drift. The limiting amplifier can be

driven differentially or single-ended.

SLICE ADJUST

The quantizer slicing level can be offset by ±100 mV to mitigate

the effect of ASE (amplified spontaneous emission) noise by

applying a differential voltage input of ±0.8 V to SLICEP/N

inputs. If no adjustment of the slice level is needed, SLICEP/N

should be tied to VCC.

LOSS-OF-SIGNAL (LOS) DETECTOR

The receiver front end level signal detect circuit indicates when

the input signal level has fallen below a user adjustable

threshold. The threshold is set with a single external resistor

from THRADJ (Pin 1) to GND. The LOS comparator trip point

versus the resistor value is illustrated in Figure 4 (this is only

valid for SLICEP = SLICEN = VCC). If the input level to the

ADN2807 drops below the programmed LOS threshold,

SDOUT (Pin 45) will indicate the loss-of-signal condition with

a Logic 1. The LOS response time is ~300 ns by design but will

be dominated by the RC time constant in ac-coupled

applications. If the LOS detector is used, the quantizer slice

adjust pins must both be tied to VCC. This is to avoid

interaction with the LOS threshold level.

Note that it is not expected to use both LOS and slice adjust at

the same time. Systems with optical amplifiers need the slice

adjust to evade ASE. However, a loss-of-signal in an optical link

that uses optical amplifiers causes the optical amplifier output

to be full-scale noise. Under this condition, the LOS would not

detect the failure. In this case, the loss-of-lock signal indicates

the failure because the CDR circuitry is unable to lock onto a

signal that is full-scale noise.

REFERENCE CLOCK

There are three options for providing the reference frequency to

the ADN2807: differential clock, single-ended clock, or crystal

oscillator. See Figure 15 to Figure 17 for example configurations.

ADN2807

REFCLKP

BUFFER

REFCLKN

VCC

VCC

VCC

Figure 15. Differential REFCLK Configuration

VCC

CLK

OSC

REFCLKP

OUT

REFCLKN

NC

VCC

VCC

VCC

Figure 16. Single-Ended REFCLK Configuration

XO1

XO2

XO1

XO2

100kΩ 100kΩ

CRYSTAL

OSCILLATOR

REFSEL

ADN2807

100kΩ 100kΩ

CRYSTAL

OSCILLATOR

REFSEL

VCC/2

BUFFER

VCC/2

03877-0-015

03877-0-016

Rev. A | Page 12 of 20

ADN2807

www.BDTIC.com/ADI

Table 7. Required Crystal Specifications

Parameter Value

Mode Series Resonant

Frequency/Overall Stability 19.44 MHz ± 100 ppm

Frequency Accuracy ±100 ppm

Temperature Stability ±100 ppm

Aging ±100 ppm

ESR 50 Ω max

REFSEL must be tied to VCC when the REFCLKN/P inputs are

active or to VEE when the oscillator is used. No connection

between the XO pin and REFCLK input is necessary (Figure 15

to Figure 17). Note that the crystal should operate in series

resonant mode, which renders it insensitive to external

parasitics. No trimming capacitors are required.

LOCK DETECTOR OPERATION

The lock detector monitors the frequency difference between

the VCO and the reference clock and deasserts the loss-of-lock

signal when the VCO is within 500 ppm of center frequency.

This enables the phase loop, which then maintains phase lock,

unless the frequency error exceeds 0.1%. Should this occur, the

loss-of-lock signal is reasserted and control returns to the

frequency loop, which will reacquire and maintain a stable clock

signal at the output. The frequency loop requires a single

external capacitor between CF1 and CF2. The capacitor

specification is given in Table 8.

Table 8. Recommended CF Capacitor Specification

Parameter Value

Temperature Range –40°C to +85°C

Capacitance >3.0 µF

Leakage <80 nA

Rating >6.3 V

LOL

XO1

XO2

ADN2807

100kΩ 100kΩ

CRYSTAL

OSCILLATOR

REFSEL

BUFFER

VCC/2

03877-0-017

VCC

REFCLKP

NC

REFCLKN

19.44MHz

Figure 17. Crystal Oscillator Configuration

The ADN2807 can accept any of the following reference clock

frequencies: 19.44 MHz, 38.88 MHz, and 77.76 MHz at LVTTL/

LVCMOS/LVPECL/LVDS levels, or 155.52 MHz at LVPECL/

LVDS levels via the REFCLKN/P inputs, independent of data

rate. The input buffer accepts any differential signal with a

peak-to-peak differential amplitude of greater than 100 mV

(e.g., LVPECL or LVDS) or a standard single-ended low voltage

TTL input, providing maximum system flexibility. The

appropriate division ratio can be selected using the REFSEL0/1

pins according to Table 6. Phase noise and duty cycle of the

reference clock are not critical, and 100 ppm accuracy is

sufficient.

An on-chip oscillator to be used with an external crystal is also

provided as an alternative to using the REFCLKN/P inputs.

Details of the recommended crystal are given in Table 7.

Table 6. Reference Frequency Selection

Applied Reference

REFSEL REFSEL[1..0]

Frequency (MHz)

1 00 19.44

1 01 38.88

1 10 77.76

1 11 155.52

0 XX

REFCLKP/N Inactive. Use 19.44 MHz

XTAL on Pins XO1, XO2 (Pull REFCLKP

to VCC)

1

1000 500 0 500 1000 f

Figure 18. Transfer Function of LOL

Rev. A | Page 13 of 20

ERROR

VCO

(ppm)

03877-0-018

ADN2807

www.BDTIC.com/ADI

ADN2807

PIN

NIN

VREF

+

QUANTIZER

50Ω 50Ω

50Ω 50Ω

VCC

TDINP/N LOOPEN BYPASS

Figure 19. Test Modes

SQUELCH MODE

When the squelch input is driven to a TTL high state, both the

clock and data outputs are set to the zero state to suppress

downstream processing. If desired, this pin can be directly

driven by the LOS (loss-of-signal) detector output (SDOUT). If

the squelch function is not required, the pin should be tied to

VEE.

TEST MODES—BYPASS AND LOOP-BACK

When the bypass input is driven to a TTL high state, the

quantizer output is connected directly to the buffers driving the

data out pins, thus bypassing the clock recovery circuit

(Figure 19). This feature can help the system to deal with

nonstandard bit rates.

0

CDR

FROM

QUANTIZER

1

OUTPUT

RETIMED

DATA CLK

10

DATAOUTP/N CLKOUTP/N SQUELCH

03877-0-019

The loopback mode can be invoked by driving the LOOPEN

pin to a TTL high state, which facilitates system diagnostic

testing. This will connect the test inputs (TDINP/N) to the

clock and data recovery circuit (per Figure 19). The test inputs

have internal 50 Ω terminations and can be left floating when

not in use. TDINP/N are CML inputs and can be dc-coupled

only when being driven by CML outputs. The TDINP/N inputs

must be ac-coupled if driven by anything other than CML

outputs. Bypass and loop-back modes are mutually exclusive;

only one of these modes can be used at any given time. The

ADN2807 is put into an indeterminate state if both BYPASS

and LOOPEN pins are set to Logic 1 at the same time.

Rev. A | Page 14 of 20

ADN2807

www.BDTIC.com/ADI

APPLICATION INFORMATION

PCB DESIGN GUIDELINES

Proper RF PCB design techniques must be used for optimal

performance.

Power Supply Connections and Ground Planes

Use of one low impedance ground plane to both analog and

digital grounds is recommended. The VEE pins should be

soldered directly to the ground plane to reduce series

inductance. If the ground plane is an internal plane and

connections to the ground plane are made through vias,

multiple vias may be used in parallel to reduce the series

inductance, especially on Pins 33 and 34, which are the ground

returns for the output buffers.

Use of a 10 µF electrolytic capacitor between VCC and GND is

r

ecommended at the location where the 3.3 V supply enters the

PCB. Use of 0.1 µF and 1 nF ceramic chip capacitors should be

placed between IC power supply VCC and GND as close as

possible to the ADN2807’s VCC pins. Again, if connections to

the supply and ground are made through vias, the use of

multiple vias in parallel will help to reduce series inductance,

especially on Pins 35 and 36, which supply power to the high

speed CLKOUTP/N and DATAOUTP/N output buffers. Refer

to the schematic in Figure 20 for recommended connections.

Transmission Lines

Use of 50 Ω transmission lines are required for all high

frequency input and output signals to minimize reflections,

including PIN, NIN, CLKOUTP, CLKOUTN, DATAOUTP, and

DATAOUTN (also REFCLKP/N for a 155.52 MHz REFCLK). It

is also recommended that the PIN/NIN input traces are

matched in length and that the CLKOUTP/N and

DATAOUTP/N traces are matched in length. All high speed

CML outputs, CLKOUTP/N and DATAOUTP/N, also require

100 Ω back termination chip resistors connected between the

output pin and VCC. These resistors should be placed as close

as possible to the output pins. These 100 Ω resistors are in

parallel with on-chip 100 Ω termination resistors to create a

50 Ω back termination (Figure 21).

The high speed inputs, PIN and NIN, are internally terminated

wi

th 50 Ω to an internal reference voltage (Figure 22). A 0.1 µF

capacitor is recommended between VREF (Pin 4) and GND to

provide an ac ground for the inputs.

As with any high speed mixed-signal design, care should be

t

aken to keep all high speed digital traces away from sensitive

analog nodes.

Soldering Guidelines for Chip Scale Package

The leads on the 48-lead LFCSP are rectangular. The printed

circuit board pad for these should be 0.1 mm longer than the

package lead length and 0.05 mm wider than the package lead

width. The land should be centered on the pad. This ensures

that solder joint size is maximized. The bottom of the LFCSP

has a central exposed pad. The pad on the printed circuit board

should be at least as large as this exposed pad. The user must

connect the exposed pad to analog VCC. If vias are used, they

should be incorporated into the pad at 1.2 mm pitch grid. The

via diameter should be between 0.3 mm and 0.33 mm, and the

via barrel should be plated with 1 oz. copper to plug the via.

Rev. A | Page 15 of 20

ADN2807

www.BDTIC.com/ADI

VCC

TRANSMISSION

LINES

VCC

36

VCC

35

VEE

34

VEE

33

SEL0

32

NC

31

SEL1

30

VEE

29

VCC

28

VEE

27

VCC

26

CF2

25

µC

50Ω

CLKOUTP

CLKOUTN

DATAOUTP

DATAOUTN

1nF

µC

NC

µC

1nF

4.7µF

(SEETABLE8 FOR SPECS)

VCC

0.1µF

0.1µF

VCC

VCC

VCC

TIA

0.1µF

50Ω

50Ω

10µF

C

IN

VCC

µC

19.44MHz

R

1nF

0.1µF

TH

THRADJ

VCC

VEE

VREF

PIN

NIN

SLICEP

SLICEN

VEE

LOL

XO1

XO2

4 × 100Ω

µC

1nF0.1µF

LOOPEN

VCC

VEE

SDOUT

BYPASS

VEE

VEE

CLKOUTP

CLKOUTN

48 47 46 45 44 43 42 41 40 39 38 37

1

2

3

4

5

6

7

8

9

10

11

ADN2807

12

13 14 15 16 17 18 19

REFCLKN

NC

REFSEL

REFCLKP

VCC

EXPOSED PAD

TIED OFFTO

VCC PLANE

WITH VIAS

1nF

VEE

TDINP

TDINN

NC

NC

0.1µ F

20 21 22 23 24

CF1

VEE

VCC

DATAOUTP

SQUELCH

VEE

REFSEL1

µC

DATAOUTN

REFSEL0

100Ω

VCC

100Ω

VCC

100Ω 100Ω

0.1µ F

0.1µ F

50Ω

50Ω

ADN2807

Figure 21. AC-Coupled Output Configuration

1nF

Figure 20. Typical Application Circuit

V

TERM

50Ω

50Ω

V

TERM

03877-0-021

VCC

0.1µF

VCC

C

0.1µ F

IN

C

IN

TIA

50Ω

50Ω

Figure 22. AC-Coupled Input Configuration

ADN2807

PIN

NIN

50Ω 50Ω

VREF

03877-0-020

03877-0-022

Rev. A | Page 16 of 20

ADN2807

www.BDTIC.com/ADI

CHOOSING AC COUPLING CAPACITORS

The ac coupling capacitors at the input (PIN, NIN) and output

(DATAOUTP, DATAOUTN) of the ADN2807 must be chosen

so that the device works properly at both OC-3 and OC-12 data

rates. When choosing the capacitors, the time constant formed

with the two 50 Ω resistors in the signal path must be

considered. When a large number of consecutive identical digits

(CIDs) are applied, the capacitor voltage can drop due to

baseline wander (Figure 23), causing pattern dependent jitter

(PDJ). For the ADN2807 to work robustly at both OC-3 and

OC-12, a minimum capacitor of 0.1 µF to PIN/NIN and 0.1 µF

on DATAOUTP/DATAOUTN should be used. This is based on

the assumption that 1000 CIDs must be tolerated, and that the

PDJ should be limited to 0.01 UI p-p.

DC-COUPLED APPLICATION

The inputs to the ADN2807 can also be dc-coupled. This may

be necessary in burst mode applications where there are long

periods of CIDs, and where baseline wander cannot be

tolerated. If the inputs to the ADN2807 are dc-coupled, care

must be taken not to violate the input range and common-mode

level requirements of the ADN2807 (Figure 24 to Figure 26). If

dc coupling is required and the output levels of the TIA do not

adhere to the levels shown in Figure 25 and Figure 26, there

must be level shifting and/or an attenuator between the TIA

outputs and the ADN2807 inputs.

LOL TOGGLING DURING LOSS OF INPUT DATA

If the input data stream is lost due to a break in the optical link

(or for any reason), the clock output from the ADN2807 stays

within 1000 ppm of the VCO center frequency as long as there

is a valid reference clock. The LOL pin will toggle at a rate of

several kHz. This is because the LOL pin will toggle between a

Logic 1 and Logic 0 while the frequency loop and phase loop

swap control of the VCO. The chain of events is as follows:

• The ADN2807 is locked to the input data stream; LOL = 0.

• The input data stream is lost due to a break in the link. The

VCO frequency drifts until the frequency error is greater

than 1000 ppm. LOL is asserted to a Logic 1 as control of

the VCO is passed back to the frequency loop.

• The frequency loop pulls the VCO to within 500 ppm of its

center frequency. Control of the VCO is passed back to the

phase loop and LOL is deasserted to Logic 0.

• The phase loop tries to acquire, but there is no input data

present so the VCO frequency drifts.

• The VCO frequency drifts until the frequency error is

greater than 1000 ppm. LOL is asserted to a Logic 1 as

control of the VCO is passed back to the frequency loop.

This process is repeated until a valid input data stream is

re-established.

C

IN

V2V1

PIN

TIA

1

V1

V1b

V2

V2b

V

DIFF

V

= V2–V2b

DIFF

VTH = ADN2807 QUANTIZERTHRESHOLD

NOTES

1. DURING DATA PATTERNS WITH HIGH TRANSITION DENSITY, DIFFERENTIAL DC VOLTAGE AT V1 AND V2 IS 0.

2. WHENTHE OUTPUT OFTHE TIA GOESTO CID, V1 AND V1b ARE DRIVEN TO DIFFERENT DC LEVELS. V2 AND V2b

DISCHARGETOTHE V

3. WHENTHE BURST OF DATA STARTS AGAIN,THE DIFFERENTIAL DC OFFSET ACROSSTHE AC COUPLING CAPACITORS IS APPLIEDTOTHE INPUT LEVELS,

CAUSING A DC SHIFT INTHE DIFFERENTIAL INPUT. THIS SHIFT IS LARGE ENOUGH SUCHTHAT ONE OFTHE STATES, EITHER HIGH OR LOW DEPENDING ON

THE LEVELS OF V1 AND V1bWHENTHE TIA WENT TO CID, IS CANCELLED OUT. THE QUANTIZERWILL NOT RECOGNIZETHIS AS A VALID STATE.

4. THE DC OFFSET SLOWLY DISCHARGES UNTILTHE DIFFERENTIAL INPUT VOLTAGE EXCEEDSTHE SENSITIVITY OF THE ADN2807. THE QUANTIZERWILL BE

ABLETO RECOGNIZE BOTH HIGH AND LOW STATES ATTHIS POINT.

LEVEL,WHICH EFFECTIVELY INTRODUCES A DIFFERENTIAL DC OFFSETACROSSTHE AC COUPLING CAPACITORS.

REF

C

V2bV1b

IN

50Ω

50Ω

NIN

Figure 23. Example of Baseline Wander

ADN2807

+

V

LIMAMP CDR

REF

C

OUT

DATAOUTP

C

OUT

DATAOUTN

432

V

REF

VTH

03877-0-023

Rev. A | Page 17 of 20

ADN2807

www.BDTIC.com/ADI

INPUT (V)

VCC

TIA

50Ω

50Ω

0.1µ F

ADN2807

PIN

NIN

50Ω 50Ω

VREF

Figure 24. ADN2807 with DC-Coupled Inputs

V p-p = PIN – NIN = 2 × V

PIN

NIN

= 10mV AT SENSITIVITY

SE

V

= 5mV MIN

SE

Figure 25. Minimum Allowed DC-Coupled Input Levels

03877-0-024

VCM= 0.4V MIN

(DC-COUPLED)

03877-0-025

INPUT (V)

V p-p = PIN – NIN = 2 × V

PIN

NIN

= 2.4V MAX

SE

V

= 1.2V MAX

SE

Figure 26. Maximum Allowed DC-Coupled Input Levels

V

= 0.6V

CM

(DC-COUPLED)

03877-0-026

Rev. A | Page 18 of 20

ADN2807

www.BDTIC.com/ADI

OUTLINE DIMENSIONS

0.30

0.23

0.18

PIN 1

48

INDICATOR

1

BSC SQ

PIN 1

INDICATOR

7.00

0.60 MAX

37

36

0.60 MAX

5.25

5.10 SQ

4.95

12

13

0.25 MIN

1.00

0.85

0.80

12° MAX

SEATING

PLANE

TOP

VIEW

0.80 MAX

0.65 TYP

0.50 BSC

COMPLIANT TO JEDEC STANDARDS MO-220-VKKD-2

6.75

BSC SQ

0.20 REF

0.50

0.40

0.30

0.05 MAX

0.02 NOM

COPLANARITY

25

0.08

BOTTOM

VIEW

24

5.50

REF

Figure 27. 48-Lead Lead Frame Chip Scale Package [LFCSP]

7 mm × 7 mm Body (CP-48)

Dimensions shown in millimeters

ORDERING GUIDE

Model Temperature Range Package Description Package Option

ADN2807ACP –40°C to +85°C 48-Lead LFCSP CP-48

ADN2807ACP-RL –40°C to +85°C 48-Lead LFCSP CP-48

Rev. A | Page 19 of 20

ADN2807

www.BDTIC.com/ADI

NOTES

© 2004 Analog Devices, Inc. All rights reserved. Trademarks and

registered trademarks are the property of their respective owners.

D03877–0–5/04(A)

Rev. A | Page 20 of 20

Loading...

Loading...