10.7 Gbps Active Back-Termination,

FEATURES

Up to 10.7 Gbps operation

Very low power: 670 mW (IBIAS = 40 mA, IMOD = 40 mA)

Typical 24 ps rise/fall times

Full back-termination of output transmission lines

Drives TOSAs with resistances ranging from 5 Ω to 50 Ω

PECL-/CML-compatible data inputs

Bias current range: 10 mA to 100 mA

Differential modulation current range: 10 mA to 80 mA

Automatic laser shutdown (ALS)

3.3 V operation

Compact 3 mm × 3 mm LFCSP package

Voltage input control for bias and modulation currents

XFP-compliant bias current monitor

Optical evaluation board available

APPLICATIONS

SONET OC-192 optical transceivers

SDH STM-64 optical transceivers

10 Gb Ethernet optical transceivers

XFP/X2/XENPAK/XPAK/MSA 300 optical modules

SR and VSR optical links

Differential Laser Diode Driver

ADN2525

GENERAL DESCRIPTION

The ADN2525 laser diode driver is designed for direct modulation of packaged laser diodes having a differential resistance

ranging from 5 Ω to 50 Ω. The active back-termination technique

provides excellent matching with the output transmission lines

while reducing the power dissipation in the output stage. The

back-termination in the ADN2525 absorbs signal reflections

from the TOSA end of the output transmission lines, enabling

excellent optical eye quality to be achieved even when the

TOSA end of the output transmission lines is significantly misterminated. The small package provides the optimum solution

for compact modules where laser diodes are packaged in low

pin-count optical subassemblies.

The modulation and bias currents are programmable via the

MSET and BSET control pins. By driving these pins with

control voltages, the user has the flexibility to implement

various average power and extinction ratio control schemes,

including closed-loop control and look-up tables. The automatic

laser shutdown feature allows the user to turn on/off the bias

and modulation currents by driving the ALS pin with the

proper logic levels.

The product is available in a space-saving 3 mm × 3 mm LFCSP

package specified from −40°C to +85°C.

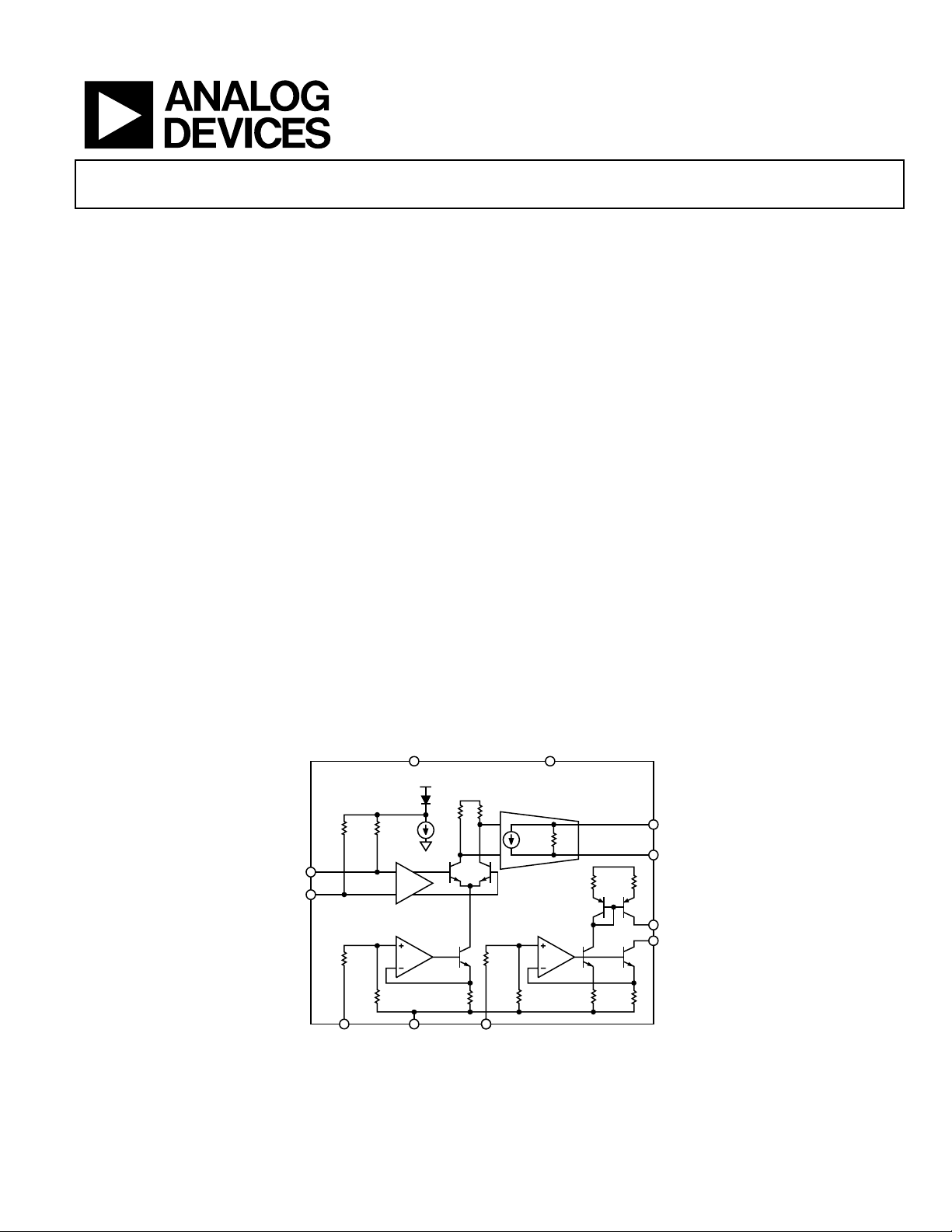

FUNCTIONAL BLOCK DIAGRAM

VCC ALS

VCC

50Ω 50Ω

GND

DATAP

DATAN

800Ω

200Ω

MSET GND BSET

Rev. 0

Information furnished by Analog Devices is believed to be accurate and reliable.

However, no responsibility is assumed by Analog Devices for its use, nor for any

infringements of patents or other rights of third parties that may result from its use.

Specifications subject to change without notice. No license is granted by implication

or otherwise under any patent or patent rights of Analog Devices. Trademarks and

registered trademarks are the property of their respective owners.

VCC

Figure 1.

ADN2525

50ΩIMOD

VCC

800Ω

200Ω

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700

Fax: 781.461.3113 © 2005 Analog Devices, Inc. All rights reserved.

200Ω 2Ω

www.analog.com

IMODP

IMODN

IBMON

IBIAS

02461-001

ADN2525

TABLE OF CONTENTS

Specifications..................................................................................... 3

Thermal Specifications ................................................................ 4

Absolute Maximum Ratings............................................................ 5

ESD Caution.................................................................................. 5

Pin Configuration and Function Descriptions............................. 6

Typical Performance Characteristics ............................................. 7

Theory of Operation ........................................................................ 9

Input Stage ..................................................................................... 9

Bias Current .................................................................................. 9

Automatic Laser Shutdown (ALS) ........................................... 10

Modulation Current ................................................................... 10

REVISION HISTORY

3/05—Revision 0: Initial Version

Load Mis-termination ............................................................... 12

Power Consumption .................................................................. 12

Applications Information .............................................................. 13

Typical Application Ci rc u it ....................................................... 13

Layout Guidelines....................................................................... 13

Design Example.......................................................................... 14

Headroom Calculations ........................................................ 14

BSET and MSET Pin Voltage Calculation .......................... 14

Outline Dimensions ....................................................................... 15

Ordering Guide .......................................................................... 15

Rev. 0 | Page 2 of 16

ADN2525

SPECIFICATIONS

VCC = VCC

Typical values are specified at 25°C, IMOD = 40 mA.

Table 1.

Parameter Min Typ Max Unit Test Conditions/Comments

BIAS CURRENT (IBIAS)

Bias Current Range 10 100 mA

Bias Current while ALS Asserted 100 µA ALS = high

Compliance Voltage1 0.6 VCC – 1.2 V IBIAS = 100 mA

0.6 VCC – 0.8 V IBIAS = 10 mA

MODULATION CURRENT (IMODP, IMODN)

Modulation Current Range 10 80 mA diff R

Modulation Current while ALS Asserted 0.5 mA diff ALS = high

Rise Time (20% to 80%)

Fall Time (20% to 80%)

Random Jitter

Deterministic Jitter3,

Differential |S22| −10 dB 5 GHz < F < 10 GHz, Z0 = 50 Ω differential

−14 dB F < 5 GHz, Z0 = 50 Ω differential

Compliance Voltage1 VCC − 1.1 VCC + 1.1 V

DATA INPUTS (DATAP, DATAN)

Input Data Rate 10.7 Gbps NRZ

Differential Input Swing 0.4 1.6 V p-p diff Differential ac-coupled

Differential |S11| −16.8 dB F < 10 GHz, Z0 = 100 Ω differential

Input Termination Resistance 85 100 115 Ω Differential

BIAS CONTROL INPUT (BSET)

BSET Voltage to IBIAS Gain 75 100 120 mA/V

BSET Input Resistance 800 1000 1200 Ω

MODULATION CONTROL INPUT (MSET)

MSET Voltage to IMOD Gain 70 88 110 mA/V See Figure 29

MSET Input Resistance 800 1000 1200 Ω

BIAS MONITOR (IBMON)

IBMON to IBIAS Ratio 10 µA/mA

Accuracy of IBIAS to IBMON Ratio −5.0 +5.0 %

−4.0 +4.0 %

−2.5 +2.5 %

−2 +2 %

AUTOMATIC LASER SHUTDOWN (ALS)

V

IH

V

IL

I

IL

I

IH

ALS Assert Time 10 µs Rising edge of ALS to fall of IBIAS and IMOD below

ALS Negate Time 10 µs Falling edge of ALS to rise of IBIAS and IMOD above

POWER SUPPLY

V

CC

I

CC5

I

SUPPLY6

1

Refers to the voltage between the pin for which the compliance voltage is specified and GND.

2

The pattern used is composed by a repetitive sequence of eight 1s followed by eight 0s at 10.7 Gbps.

3

Measured using the high speed characterization circuit shown in Figure 3.

4

The pattern used is K28.5 (00111110101100000101) at 10.7 Gbps rate.

5

Only includes current in the ADN2525 VCC pins.

6

Includes current in ADN2525 VCC pins and dc current in IMODP and IMODN pull-up inductors. See the section for total supply current calculation. Power Consumption

to VCC

MIN

2, 3

0.4 0.9 ps rms

, TA = −40°C to +85°C, 50 Ω differential load resistance, unless otherwise noted.

MAX

LOAD

2, 3

24 32.5 ps

2, 3

24 32.5 ps

4

7.2 12 ps p-p

10 mA ≤ IBIAS < 20 mA, R

20 mA ≤ IBIAS < 40 mA, R

40 mA ≤ IBIAS < 70 mA, R

70 mA ≤ IBIAS < 100 mA, R

2.4 V

0.8 V

−20 +20 µA

0 200 µA

10% of nominal; see Figure 2

90% of nominal; see Figure 2

3.07 3.3 3.53 V

39 45 mA V

157 176 mA V

BSET

BSET

= 5 Ω to 50 Ω differential

IBMON

IBMON

IBMON

IBMON

= V

= 0 V

MSET

= V

MSET

= 0 V. I

= ICC + IMODP + IMODN

SUPPLY

= 1 kΩ

= 1 kΩ

= 1 kΩ

= 1 kΩ

Rev. 0 | Page 3 of 16

ADN2525

VEEV

V

THERMAL SPECIFICATIONS

Table 2.

Parameter Min Typ Max Unit Conditions/Comments

θ

J-PAD

θ

J-TOP

IC Junction Temperature 125 °C

2.6 5.8 10.7 °C/W Thermal resistance from junction to bottom of exposed pad.

65 72.2 79.4 °C/W Thermal resistance from junction to top of package.

ALS

IBIAS

AND IMOD

90%

ALS

NEGATE TIME

t

= 50Ω

Z

0

J2

GND GND GND

J3

GND GND

10%

ALS

ASSERT TIME

Figure 2. ALS Timing Diagram

EE

TP1

VCC

DATAP

DATAN

VCC

VEE

1kΩ

TP2

ADN2525

J8 J5

VBSET

BSET IBMON IBIAS GND

GND

= 50Ω Z0 = 25Ω Z0 = 50Ω

Z

0

10nF

10nF

GND

MSET NC1 ALS GND

VMSET

GND

10Ω

IMODP

IMODN

VCC

VCC

VEE

EE

10nF

10nF

22µF

GND

GND

GND

Z

= 25Ω Z0 = 50ΩZ0 = 50ΩZ0 = 50Ω

0

GND

GND

t

02461-002

GND

BIAS TEE

35Ω

35Ω

GND

GND

BIAS TEE

GND

BIAS TEE: Picosecond Pulse Labs Model 5542-219

Adapter: Pasternack PE-9436 2.92mm female-to-female adapter

Attenuator: Pasternack PE-7046 2.92mm 20dB attenuator

70Ω

GNDGND

VEE

ADAPTER

ADAPTER

ATTENUATOR

ATTENUATOR

GND

50Ω

OSCILLOSCOPE

50Ω

GND

GND GND GND

02461-003

Figure 3. High Speed Characterization Circuit

Rev. 0 | Page 4 of 16

ADN2525

ABSOLUTE MAXIMUM RATINGS

Table 3.

Parameter Min Max Unit

Supply Voltage, VCC to GND −0.3 +4.2 V

IMODP, IMODN to GND VCC − 1 .5 4.75 V

DATAP, DATAN to GND VCC − 1.8 VCC − 0.4 V

All Other Pins −0.3 VCC + 0.3 V

Junction Temperature 150 °C

Storage Temperature −65 +150 °C

Soldering Temperature

(Less than 10 sec)

240 °C

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

ESD CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily accumulate on

the human body and test equipment and can discharge without detection. Although this product features

proprietary ESD protection circuitry, permanent damage may occur on devices subjected to high energy

electrostatic discharges. Therefore, proper ESD precautions are recommended to avoid performance

degradation or loss of functionality.

Rev. 0 | Page 5 of 16

ADN2525

PIN CONFIGURATION AND FUNCTION DESCRIPTIONS

VCC

DATAN

DATAP

VCC

161514

13

BSET

VCC

IMODP

12

11

10

9

IBMON

IBIAS

GND

02461-016

1

MSET

NC

ALS

GND

2

3

4

PIN 1

INDICATOR

ADN2525

TOP VIEW

5

678

VCC

IMODN

Figure 4. Pin Configuration

Note: The exposed pad on the bottom of the package must be connected to the VCC or GND plane.

Table 3. Pin Function Descriptions

Pin No. Mnemonic I/O Description

1 MSET Input Modulation Current Control Input

2 NC N/A No Connect—Leave Floating

3 ALS Input Automatic Laser Shutdown

4 GND Power Negative Power Supply

5 VCC Power Positive Power Supply

6 IMODN Output Modulation Current Negative Output

7 IMODP Output Modulation Current Positive Output

8 VCC Power Positive Power Supply

9 GND Power Negative Power Supply

10 IBIAS Output Bias Current Output

11 IBMON Output Bias Current Monitoring Output

12 BSET Input Bias Current Control Input

13 VCC Power Positive Power Supply

14 DATAP Input Data Signal Positive Input

15 DATAN Input Data Signal Negative Input

16 VCC Power Positive Power Supply

Exposed Pad Pad Power Connect to GND or VCC

Rev. 0 | Page 6 of 16

ADN2525

TYPICAL PERFORMANCE CHARACTERISTICS

TA = 25°C, VCC = 3.3 V, unless otherwise noted.

28.0

27.5

27.0

26.5

26.0

25.5

25.0

RISE TIME (ps)

24.5

24.0

23.5

23.0

27.5

27.0

26.5

26.0

25.5

25.0

FALL TIME (ps)

24.5

24.0

23.5

23.0

0.7

0.6

0.5

DIFFERENTIAL MODULATION CURRENT (mA)

Figure 5. Rise Time v s. IMOD

DIFFERENTIAL MODULATION CURRENT (mA)

Figure 6. Fall Time vs. IMOD

9

8

7

6

5

4

3

2

DETERMINISTIC JITTER (ps p-p)

1

1000 20406080

02461-004

0

DIFFERENTIAL MODULATION CURRENT (mA)

1000 20406080

02461-007

Figure 8. Deterministic Jitter vs. IMOD

350

300

250

200

150

100

TOTAL SUPPLY CURRENT (mA)

50

1000 20406080

02461-005

0

IBIAS = 100mA

IBIAS = 50mA

IBIAS = 10mA

DIFFERENTIAL MODULATION CURRENT (mA)

1000 20406080

02461-008

Figure 9. Total Supply Current vs. IMOD

0

–5

–10

DIFFERENTIAL |S11| (dB)

–15

–20

–25

–30

–35

–40

FREQUENCY (GHz)

Figure 10. Differential |S

1501234567891011121314

02461-009

|

11

0.4

0.3

0.2

RANDOM JITTER (ps RMS)

0.1

0

DIFFERENTIAL MODULATION CURRENT (mA)

1000 20406080

02461-006

Figure 7. Random Jitter vs. IMOD

Rev. 0 | Page 7 of 16

ADN2525

0

–5

–10

–15

–20

–25

–30

DIFFERENTIAL |S22| (dB)

–35

(ACQ LIMIT TEST) WAVEFORMS: 1000

–40

FREQUENCY (GHz)

Figure 11. Differential |S

16

14

12

10

8

6

% OCCURRENCE

4

2

0

RISE TIME (ps)

Figure 12. Worst-Case Rise Time Distribution

(VCC = 3.07 V, IBIAS = 100 mA, IMOD = 80 mA, T

16

1501234567891011121314

02461-010

|

22

Figure 14. Electrical Eye Diagram

(10.7 Gbps, PRBS31, IMOD = 80 mA)

02461-013

3023 24 25 26 27 28 29

02461-011

02461-014

Figure 15. Filtered SONET OC192 Optical Eye Diagram (for reference)

= 85°C)

A

(PRBS31 Pattern, Pav = −2 dBm, ER = 7 dB,

17% Mask Margin, NEC NX8341UJ TOSA)

14

12

10

8

6

% OCCURRENCE

4

2

0

FALL TIME (ps)

Figure 13. Worst-Case Fall Time Distribution

(VCC = 3.07 V, IBIAS = 100 mA, IMOD = 80 mA, T

= 85°C)

A

3023 24 25 26 27 28 29

02461-012

02461-015

Figure 16. Filtered 10G Ethernet Optical Eye

(PRBS31 Pattern, Pav = −2 dBm, ER = 5 dB,

41% Mask Margin, NEC NX8341UJ TOSA)

Rev. 0 | Page 8 of 16

ADN2525

THEORY OF OPERATION

As shown in Figure 1, the ADN2525 consists of an input stage

and two voltage controlled current sources for bias and modulation. The bias current is available at the IBIAS pin. It is controlled

by the voltage at the BSET pin, and can be monitored at the

IBMON pin. The differential modulation current is available at

the IMODP and IMODN pins. It is controlled by the voltage at

the MSET pin. The output stage implements the active backmatch circuitry for proper transmission line matching and

power consumption reduction. The ADN2525 can drive a load

having differential resistance ranging from 5 Ω to 50 Ω. The

excellent back-termination in the ADN2525 absorbs signal

reflections from the TOSA end of the output transmission lines,

enabling excellent optical eye quality to be achieved even when

the TOSA end of the output transmission lines is significantly

mis-terminated.

INPUT STAGE

The input stage of the ADN2525 converts the data signal applied

to the DATAP and DATAN pins to a level that ensures proper

operation of the high speed switch. The equivalent circuit of the

input stage is shown in Figure 17.

VCC

DATAP

VCC

DATAN

Figure 17. Equivalent Circuit of the Input Stage

The DATAP and DATAN pins are terminated internally with a

100 Ω differential termination resistor. This minimizes signal

reflections at the input, which could otherwise lead to degradation in the output eye diagram. It is not recommended to drive

the ADN2525 with single-ended data signal sources.

50Ω

50Ω

VCC

02461-017

The ADN2525 input stage must be ac-coupled to the signal

source to eliminate the need for matching between the commonmode voltages of the data signal source and the input stage of

the driver (see Figure 18). The ac-coupling capacitors should

have an impedance less than 50 Ω over the required frequency

range. Generally this is achieved using 10 nF to 100 nF capacitors.

50Ω 50Ω

DATA SIGNAL SOURCE

Figure 18. AC-Coupling the Data Source to the

ADN2525 Data Inputs

C

C

ADN2525

DATAP

DATAN

02461-018

BIAS CURRENT

The bias current is generated internally using a voltage-to-current

converter consisting of an internal operational amplifier and a

transistor as shown in Figure 19.

ADN2525

800Ω

200Ω

GND

Figure 19. Voltage-to-Current Converter Used to Generate IBIAS

The voltage-to-current conversion factor is set at 100 mA/V by

the internal resistors, and the bias current is monitored using a

current mirror with a gain equal to 1/100. By connecting a 1 kΩ

resistor between IBMON and GND, the bias current can be

monitored as a voltage across the resistor. A low temperature

coefficient precision resistor must be used for the IBMON

resistor (R

). Any error in the value of R

IBMON

ances, or drift in its value over temperature, contributes to the

overall error budget for the IBIAS monitor voltage. If the IBMON

voltage is being connected to an ADC for A/D conversion,

should be placed close to the ADC to minimize errors

R

IBMON

due to voltage drops on the ground plane.

VCC

RR

I

BMON

I

BIAS

200Ω

2Ω

IBMONBSET

IBIAS

due to toler-

IBMON

02461-019

Rev. 0 | Page 9 of 16

ADN2525

ALS

The equivalent circuits of the BSET, IBIAS, and IBMON pins

are shown in Figure 20, Figure 21, and Figure 22.

VCC

BSET

800Ω

200Ω

Figure 20. Equivalent Circuit of the BSET Pin

IBIAS

VCC

2Ω

Figure 21. Equivalent Circuit of the IBIAS Pin

VCC

100Ω

VCC

VCC

VCC

500Ω

2kΩ

02461-021

02461-020

two bias current levels (10 mA and 100 mA), but it can be

calculated for any bias current by using the following equation:

V

COMPLIANCE_MAX

(V) = VCC(V) − 0.75 − 4.4 × IBIAS(A)

See the Applications Information section for example headroom

calculations.

The function of the inductor L is to isolate the capacitance of

the IBIAS output from the high frequency signal path. For

recommended components, see Table 5.

AUTOMATIC LASER SHUTDOWN (ALS)

The ALS pin is a digital input that enables/disables both the bias

and modulation currents, depending on the logic state applied,

as shown in Table 4.

Table 4.

ALS Logic State IBIAS and IMOD

High Disabled

Low Enabled

Floating Enabled

The ALS pin is compatible with 3.3 V CMOS and TTL logic

levels. Its equivalent circuit is shown in Figure 24.

VCC

VCC

100Ω

VCC

IBMON

02461-022

Figure 22. Equivalent Circuit of the IBMON Pin

The recommended configuration for BSET, IBIAS, and IBMON

is shown in Figure 23.

TO LASER CATHODE

IBIAS

L

IBIAS

ADN2525

BSET

VBSET

GND

IBMON

R

1kΩ

IBMON

02461-023

Figure 23. Recommended Configuration for BSET, IBIAS, and IBMON Pins

The circuit used to drive the BSET voltage must be able to drive

the 1 kΩ input resistance of the BSET pin. For proper operation

of the bias current source, the voltage at the IBIAS pin must be

between the compliance voltage specifications for this pin over

supply, temperature, and bias current range. See the Specifications

table. The maximum compliance voltage is specified for only

100Ω

50kΩ

2kΩ

02461-024

Figure 24. Equivalent Circuit of the ALS Pin

MODULATION CURRENT

The modulation current can be controlled by applying a dc

voltage to the MSET pin. This voltage is converted into a dc

current by using a voltage-to-current converter using an

operational amplifier and a bipolar transistor as shown in

Figure 25.

VCC

IMODP

IMODN

FROM INPUT STAGE

MSET

800Ω

200Ω

GND

ADN2525

Figure 25. Generation of Modulation Current on the ADN2525

50ΩIMOD

02461-025

Rev. 0 | Page 10 of 16

ADN2525

V

V

This dc current is switched by the data signal applied to the

input stage (DATAP and DATAN pins) and gained up by the

output stage to generate the differential modulation current at

the IMODP and IMODN pins.

The output stage also generates the active back-termination,

which provides proper transmission line termination. Active

back-termination uses feedback around an active circuit to

synthesize a broadband termination resistance. This provides

excellent transmission line termination, while dissipating less

power than a traditional resistor passive back-termination. The

equivalent circuits for MSET, IMODP, and IMODN are shown

in Figure 26 and Figure 27.

CC

MSET

Figure 26. Equivalent Circuit of the MSET Pin

VCC VCC

25Ω

3.3Ω 3.3Ω

Figure 27. Equivalent Circuit of the IMODP and IMODN Pins

800Ω

200Ω

CC

02461-026

IMODPIMODN

25Ω

02461-027

The recommended configuration of the MSET, IMODP, and

IMODN pins is shown in Figure 28. See Table 5 for recommended components.

IBIAS

ADN2525

IMODP

VCC

LCL

Z0 = 25Ω Z0 = 25Ω

C

The ratio between the voltage applied to the MSET pin and the

differential modulation current available at the IMODP and

IMODN pins is a function of the load resistance value as shown

in Figure 29.

210

200

190

180

170

mA/V

160

150

140

130

120

110

100

MINIMUM

90

80

70

60

DIFFERENTIAL LOAD RESISTANCE

TYPICAL

MAXIMUM

550 5 10 15 20 25 30 35 40 45 50

02461-029

Figure 29. MSET Voltage to Modulation Current Ratio vs.

Differential Load Resistance

Using the resistance of the TOSA, the user can calculate the

voltage range that should be applied to the MSET pin to generate

the required modulation current range (see the example in the

Applications Information section).

The circuit used to drive the MSET voltage must be able to

drive the 1 kΩ resistance of the MSET pin. To be able to drive

80 mA modulation currents through the differential load, the

output stage of the ADN2525 (IMODP, IMODN pins) must be

ac-coupled to the load. The voltages at these pins have a dc

component equal to VCC, and an ac component with singleended peak-to-peak amplitude of IMOD × 25 Ω. This is the

case even if the load impedance is less than 50 Ω differential,

since the transmission line characteristic impedance sets the

peak-to-peak amplitude. For proper operation of the output stage,

the voltages at the IMODP and IMODN pins must be between

the compliance voltage specifications for this pin over supply,

temperature, and modulation current range as shown in

Figure 30. See the Applications Information section for

example headroom calculations.

VIMODP, IMODN

TOSA

= 25Ω Z0 = 25Ω

VMSET

Z

MSET

IMODN

GND

0

L

L

VCC

VCC

Figure 28. Recommended Configuration for the

02461-028

VCC + 1.1V

NORMAL OPERATION REGION

VCC

VCC – 1.1V

MSET, IMODP, and IMODN Pins

02461-030

Figure 30. Allowable Range for the Voltage at

IMODP and IMODN

Rev. 0 | Page 11 of 16

ADN2525

E

(

)

θ×+

θ×θ

×

LOAD MIS-TERMINATION

Due to its excellent S22 performance, the ADN2525 can drive

differential loads that range from 5 Ω to 50 Ω. In practice, many

TOSAs have differential resistance less than 50 Ω. In this case,

with 50 Ω differential transmission lines connecting the

ADN2525 to the load, the load end of the transmission lines are

mis-terminated. This mis-termination leads to signal reflections

back to the driver. The excellent back-termination in the

ADN2525 absorbs these reflections, preventing their reflection

back to the load. This enables excellent optical eye quality to be

achieved, even when the load end of the transmission lines is

significantly mis-terminated. The connection between the load

and the ADN2525 must be made with 50 Ω differential (25 Ω

single-ended) transmission lines so that the driver end of the

transmission lines is properly terminated.

POWER CONSUMPTION

The power dissipated by the ADN2525 is given by

V

⎛

VCCP

MSET

⎜

⎝

+×=

5.13

where:

VCC is the power supply voltage.

IBIAS is the bias current generated by the ADN2525.

is the voltage applied to the MSET pin.

V

MSET

I

is the sum of the current that flows into the VCC,

SUPPLY

IMODP, and IMODN pins of the ADN2525 when

IBIAS = IMOD = 0 expressed in amps (see Table 1).

is the average voltage on the IBIAS pin.

V

IBIAS

Considering V

to IBIAS, the dissipated power becomes

V

BSET

VCCP ×+

/IBIAS = 10 as the conversion factor from

BSET

V

⎛

MSET

⎜

⎝

+×=

To ensure long-term reliable operation, the junction temperature of the ADN2525 must not exceed 125°C, as specified in

Table 2. For improved heat dissipation, the module’s case can be

used as heat sink as shown in Figure 31. A compact optical

module is a complex thermal environment, and calculations of

device junction temperature using the package θ

ambient thermal resistance) do not yield accurate results.

I

SUPPLY

⎞

⎟

⎠

⎞

⎟

⎠

V

IBIASSUPPLY

BSET

105.13

×+

IBIASVI

V

IBIAS

(junction-to-

JA

THERMAL COMPOUND

DIE

PACKAG

PCB

COPPER PLANE

Figure 31. Typical Optical Module Structure

VIAS

MODULE CASE

T

TOP

T

J

T

PAD

THERMO-COUPLE

The following procedure can be used to estimate the IC

junction temperature:

= Temperature at top of package in °C.

T

TOP

= Temperature at package exposed paddle in °C.

T

PAD

= IC junction temperature in °C.

T

J

P = Power dissipation in W.

= Thermal resistance from IC junction to package top.

θ

J-TOP

θ

= Thermal resistance from IC junction to package exposed

J-PAD

pad.

T

TOP

J-TOP

PAD

T

TOP

02461-032

θ

P

Figure 32. Electrical Model for Thermal Calculations

T

TOP

and T

can be determined by measuring the temperature

PAD

θ

J-PAD

T

PAD

T

at points inside the module as shown in Figure 31. The thermocouples should be positioned to obtain an accurate measurement

of the package top and paddle temperatures. Using the model

shown in Figure 32, the junction temperature can be calculated

using the following formula:

PADJ

=

T

J

−

−

PADJ

−

θ×+

TOPTOPJ

θ+θ

TOPJ

−

TTP

−

PADPADJ

TOPJ

−

where θ

J-TOP

and θ

are given in Table 2 and P is the power

J-PAD

dissipated by the ADN2525.

02461-031

Rev. 0 | Page 12 of 16

ADN2525

N

APPLICATIONS INFORMATION

TYPICAL APPLICATION CIRCUIT

Figure 33 shows the typical application circuit for the ADN2525.

The dc voltages applied to the BSET and MSET pins control the

bias and modulation currents. The bias current can be monitored

as a voltage drop across the 1 kΩ resistor connected between

the IBMON pin and GND. The ALS pin allows the user to turn

on/off the bias and modulation currents, depending on the logic

level applied to the pin. The data signal source must be connected

to the DATAP and DATAN pins of the ADN2525 using 50 Ω

transmission lines. The modulation current outputs, IMODP

and IMODN, must be connected to the load (TOSA) using 50 Ω

differential (25 Ω single-ended) transmission lines. Table 5

shows recommended components for the ac-coupling interface

between the ADN2525 and TOSA. For up-to-date component

recommendations, contact your sales representative.

Table 5.

Component Value Description

R1, R2 36 Ω 0603 size resistor

R3, R4 200 Ω 0603 size resistor

C3, C4 100 nF

L2, L3, L6, L7 82 nH

L1, L4, L5, L8 10 µH

0603 size capacitor,

Phycomp 223878615649

0402 size inductor,

Murata LQW15AN82NJ0

0603 size inductor,

Murata LQM21FN100M70L

LAYOUT GUIDELINES

Due to the high frequencies at which the ADN2525 operates,

care should be taken when designing the PCB layout to obtain

optimum performance. Controlled impedance transmission

lines must be used for the high speed signal paths. The length

of the transmission lines must be kept to a minimum to reduce

losses and pattern-dependent jitter. The PCB layout must be

symmetrical, both on the DATAP, DATAN inputs, and on the

IMODP, IMODN outputs, to ensure a balance between the

differential signals. All VCC and GND pins must be connected

to solid copper planes by using low inductance connections.

When the connections are made through vias, multiple vias can

be connected in parallel to reduce the parasitic inductance.

Each GND pin must be locally decoupled with high quality

capacitors. If proper decoupling cannot be achieved using a

single capacitor, the user can use multiple capacitors in parallel

for each GND pin. A 20 µF tantalum capacitor must be used as

general decoupling capacitor for the entire module. For

guidelines on the surface-mount assembly of the ADN2525,

consult the Amkor Technology® application note “Application

Notes for Surface Mount Assembly of Amkor’s

MicroLeadFrame® (MLF) Packages.”

BSET

DATAP

DATA

MSET

+3.3V

VCC

VCC

L1

L2

GND

GND

L3

L4 R2

VCC

L8

R1

L7

C4

C3

L6

L5 R3

R4

VCC

GND

VCC VCC

Z0 = 50Ω Z0 = 25Ω Z0 = 25Ω

Z

= 50Ω

0

VCC

BSET IBMON IBIAS GND

VCC

DATAP

C1

DATAN

C2

VCC

MSET NC1 ALS GND

VCC

C7

20µF

GND

R5

1kΩ

TP1

ADN2525

ALS

C5

10nF

VCC

IMODP

IMODN

VCC

C6

10nF

GND

GND

VCC

Z0 = 25Ω Z0 = 25Ω

VCC

Figure 33. Typical ADN2525 Application Circuit

TOSA

02461-033

Rev. 0 | Page 13 of 16

ADN2525

DESIGN EXAMPLE

This design example covers

• Headroom calculations for IBIAS, IMODP, and IMODN pins.

• Calculation of the typical voltage required at the BSET and

MSET pins in order to produce the desired bias and

modulation currents.

This design example assumes that the resistance of the TOSA is

25 Ω, the forward voltage of the laser at low current is V

IBIAS = 40 mA, IMOD = 60 mA, and VCC = 3.3 V.

Headroom Calculations

To ensure proper device operation, the voltages on the IBIAS,

IMODP, and IMODN pins must meet the compliance voltage

specifications in Table 1.

Considering the typical application circuit shown in Figure 33,

the voltage at the IBIAS pin can be written as

= VCC − VF − (IBIAS × R

V

IBIAS

TOSA

) − V

LA

where:

VCC is the supply voltage.

V

is the forward voltage across the laser at low current.

F

is the resistance of the TOSA.

R

TOSA

V

is the dc voltage drop across L5, L6, L7, and L8.

LA

is the dc voltage drop across L1, L2, L3, and L4.

V

LB

= 1 V,

F

Assuming V

= 0 V and IMOD = 60 mA, the minimum voltage

LB

at the modulation output pins is equal to

VCC − (IMOD × 25)/2 = VCC − 0.75

VCC − 0.75 > VCC − 1.1 V, which satisfies the requirement.

The maximum voltage at the modulation output pins is equal to

VCC + (IMOD × 25)/2 = VCC + 0.75

VCC + 0.75 < VCC + 1.1 V, which satisfies the requirement.

Headroom calculations must be repeated for the minimum and

maximum values of the required IBIAS and IMOD ranges to

ensure proper device operation over all operating conditions.

BSET and MSET Pin Voltage Calculation

To set the desired bias and modulation currents, the BSET and

MSET pins of the ADN2525 must be driven with the appropriate

dc voltage. The voltage range required at the BSET pin to generate

the required IBIAS range can be calculated using the BSET

voltage to IBIAS gain specified in Table 1. Assuming that IBIAS

= 40 mA and the typical IBIAS/V

ratio of 100 mA/V, the

BSET

BSET voltage is given by

V

BSET

IBIAS

(mA)

mA/V100

40

100

V4.0

===

For proper operation, the minimum voltage at the IBIAS pin

should be greater than 0.6 V, as specified by the minimum

IBIAS compliance specification in Table 1.

Assuming that the voltage drop across the 25 Ω transmission

lines is negligible and that V

V

= 3.3 − 1 − (0.04 × 25) = 1.3 V

IBIAS

= 1.3 V > 0.6 V, which satisfies the requirement.

V

IBIAS

=0 V, VF = 1 V, IBIAS = 40 mA,

LA

The maximum voltage at the IBIAS pin must be less than the

maximum IBIAS compliance specification as described by the

following equation:

V

COMPLIANCE_MAX

= VCC − 0.75 − 4.4 × IBIAS(A)

For this example:

V

COMPLIANCE_MAX

V

= 1.3 V < 2.53 V, which satisfies the requirement.

IBIAS

= VCC – 0.75 − 4.4 × 0.04 = 2.53 V

To calculate the headroom at the modulation current pins

(IMODP, IMODN), the voltage has a dc component equal to

VCC due to the ac-coupled configuration and a swing equal to

IMOD × 25 Ω. For proper operation of the ADN2525, the

voltage at each modulation output pin should be within the

normal operation region shown in Figure 30.

The BSET voltage range can be calculated using the required

IBIAS range and the minimum and maximum BSET voltage to

IBIAS gain values specified in Table 1.

The voltage required at the MSET pin to produce the desired

modulation current can be calculated using

IMOD

V

MSET

=

K

where K is the MSET voltage to IMOD ratio.

The value of K depends on the actual resistance of the TOSA.

It can be read using the plot shown in Figure 29. For a TOSA

resistance of 25 Ω, the typical value of K = 120 mA/V. Assuming

that IMOD = 60 mA and using the preceding equation, the

MSET voltage is given by

MSET

IMOD

mA/V120

V

60

120

V5.0

===

(mA)

The MSET voltage range can be calculated using the required

IMOD range and the minimum and maximum K values. These

can be obtained from the minimum and maximum curves in

Figure 29.

Rev. 0 | Page 14 of 16

ADN2525

R

OUTLINE DIMENSIONS

0.50

0.40

PIN 1

INDICATO

1.00

0.85

0.80

SEATING

PLANE

12° MAX

3.00

BSC SQ

VIEW

0.30

0.23

0.18

TOP

*

2.75

BSC SQ

0.80 MAX

0.65 TYP

0.05 MAX

0.02 NOM

0.20 REF

COMPLIANT TO JEDEC STANDARDS MO-220-VEED-2

EXCEPT FOR EXPOSED PAD DIMENSION

0.45

0.50

BSC

1.50 REF

0.60 MAX

Figure 34. 16-Lead Lead Frame Chip Scale Package [LFCSP]

3 mm × 3 mm Body

(CP-16-3)

Dimensions shown in millimeters

13

12

(BOTTOM VIEW)

9

8

EXPOSED

PA D

0.30

16

1

4

5

PIN 1 INDICATOR

1.65

*

1.50 SQ

1.35

0.25 MIN

ORDERING GUIDE

Model Temperature Range Package Description Package Option Branding

ADN2525ACPZ-WP

ADN2525ACPZ-R2

ADN2525ACPZ-REEL7

1

Z = Pb-free part.

1

−40°C to +85°C

16-Lead Lead Frame Chip Scale Package,

CP-16-3 F06

50-Piece Waffle Pack

1

−40°C to +85°C

16-Lead Lead Frame Chip Scale Package,

CP-16-3 F06

500-Piece Reel

1

−40°C to +85°C

16-Lead Lead Frame Chip Scale Package,

CP-16-3 F06

7” 1500-Piece Reel

Rev. 0 | Page 15 of 16

ADN2525

NOTES

© 2005 Analog Devices, Inc. All rights reserved. Trademarks and

registered trademarks are the property of their respective owners.

D05077–0–3/05 (0)

Rev. 0 | Page 16 of 16

Loading...

Loading...