Analog Devices ADMCF340 a (2) Datasheet

A

a

DashDSP® 64-Lead Flash and ROM Memory

Mixed-Signal DSP with Enhanced Analog Front End

ADMC(F)340

TARGET APPLICATIONS

Refrigerator and Air Conditioner Compressors,

Washing Machines

Industrial Variable Speed Drives, HVAC

MOTOR TYPES

Permanent Magnet Synchronous Motors (PMSM),

Brushless DC Motors (BDCM), AC Induction Motors

(ACIM), Switched Reluctance Motors (SRM)

FEATURES

20 MHz Fixed-Point DSP Core

Single Cycle Instruction Execution (50 ns)

ADSP-21xx Family Code Compatibility

Independent Computational Units

ALU

Multiplier/Accumulator

Barrel Shifter

Multifunction Instructions

Single Cycle Context Switch

Powerful Program Sequencer

Zero Overhead Looping

Conditional Instruction Execution

2 Independent Data Address Generators

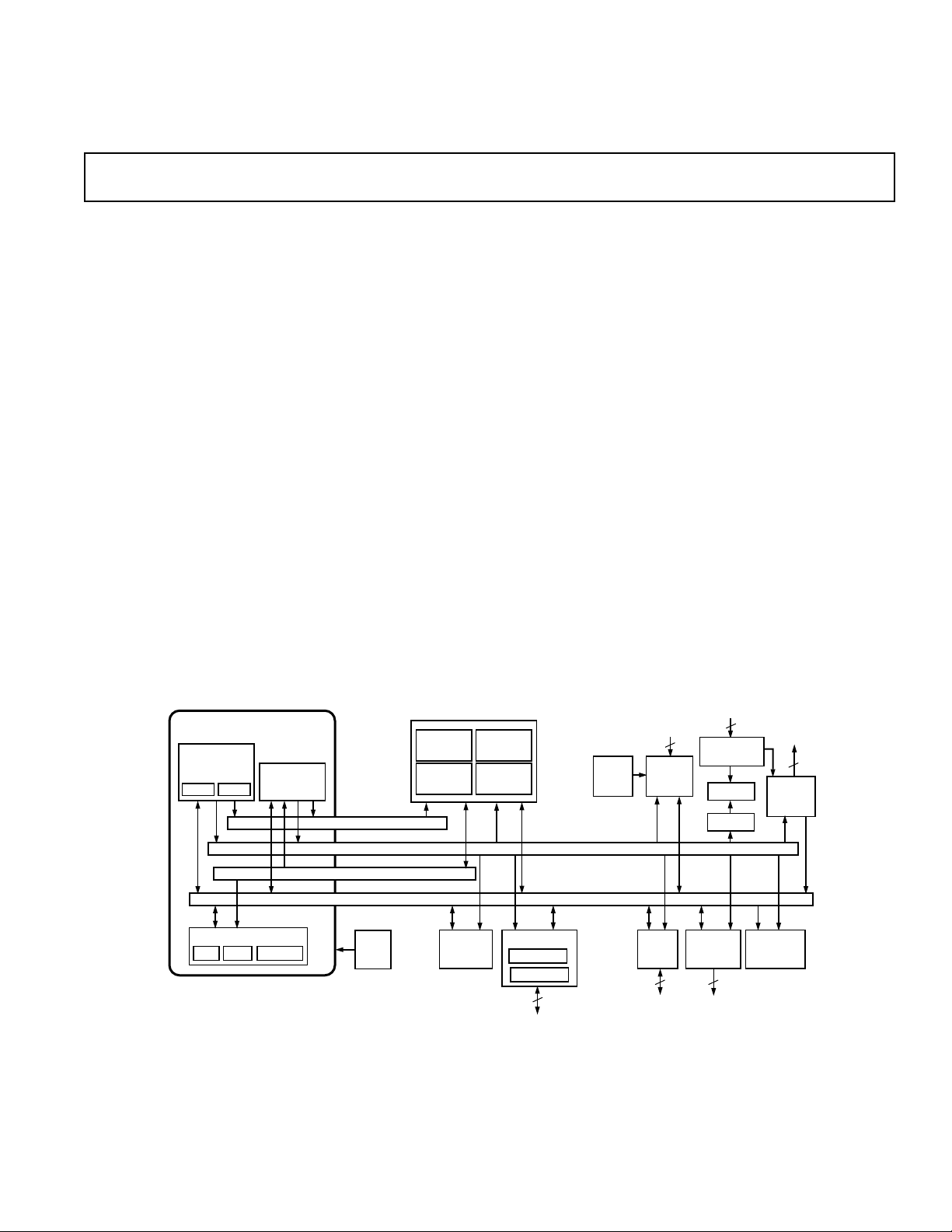

FUNCTIONAL BLOCK DIAGRAM

ADSP-21xx BASE

ARCHITECTURE

DATA

ADDRESS

GENERATORS

DAG 1 DAG 2

PROGRAM

SEQUENCER

PROGRAM MEMORY ADDRESS

DATA MEMORY ADDRESS

PROGRAM MEMORY DATA

DATA MEMORY DATA

MEMORY BLOCK

PROGRAM

ROM

4K 24

PROGRAM

RAM

512 24

Memory Configuration

512 16-Bit Data Memory RAM

512 24-Bit Program Memory RAM

4K 24-Bit Program Memory ROM

4K 24-Bit Total Program FLASH Memory

(ADMCF340 only)

3 Independent FLASH Memory Sectors

3584 24 Bit, 256 24 Bit, 256 24 Bit

Low Cost Pin Compatible ROM Option

16-Bit Watchdog Timer

Programmable 16-Bit Internal Timer with Prescaler

2 Double Buffered Serial Ports with SPI Mode

Support

Integrated Power-On Reset Function

3-Phase 16-Bit PWM Generation Unit

16-Bit Center-Based PWM Generator

Programmable PWM Pulsewidth

Edge Resolution of 50 ns

Programmable Narrow Pulse Deletion

153 Hz Minimum Switching Frequency

Double/Single Update Mode Control

Individual Enable and Disable for Each PWM

Output

High Frequency Chopping Mode for

Transformer-Coupled Gate Drives

(continued on page 8)

MOTOR CONTROL PERIPHERALS

PROGRAM

FLASH

4K 24

DATA

MEMORY

512 16

ADC SUBSYSTEM

V

ANALOG

REF

2.5V

INPUTS

10

I

SENSE

AND TRIP

SHA

TIMERS

3

AMP

16-BIT

THREE-

PHASE

PWM

6

ARITHMETIC UNITS

SHIFTER

MACALU

DashDSP is a registered trademark of Analog Devices, Inc.

POR

TIMER

REV. A

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties that

may result from its use. No license is granted by implication or otherwise

under any patent or patent rights of Analog Devices.

SERIAL PORT

SPORT 0

SPORT 1

7

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 www.analog.com

Fax: 781/326-8703 © Analog Devices, Inc., 2002

PIO

2 16-BIT

AUX

PWM

225

WATCH-

DOG

TIMER

ADMC(F)340

(VDD = 5%, GND = 0 V. For ADMCF340, TA = –40C to +85C.

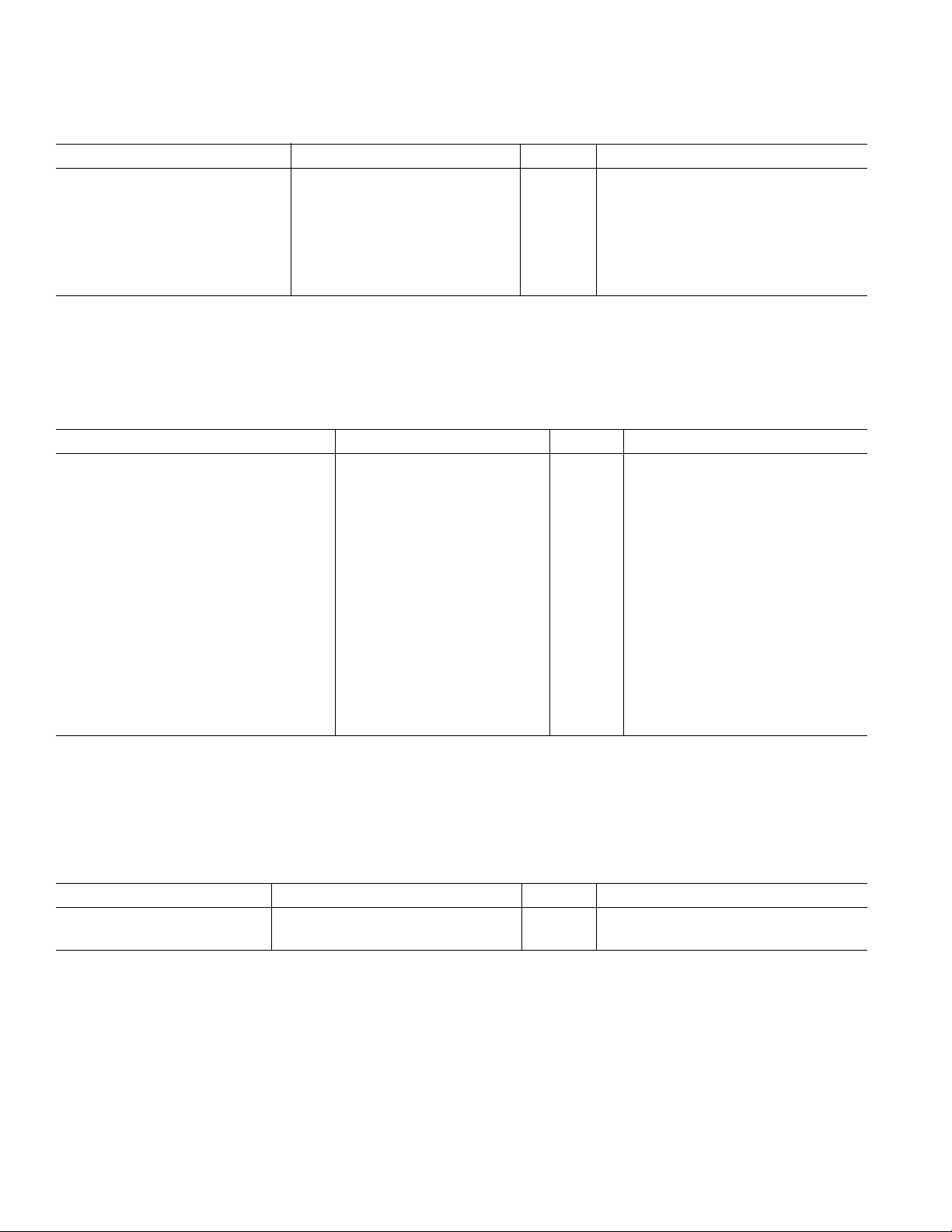

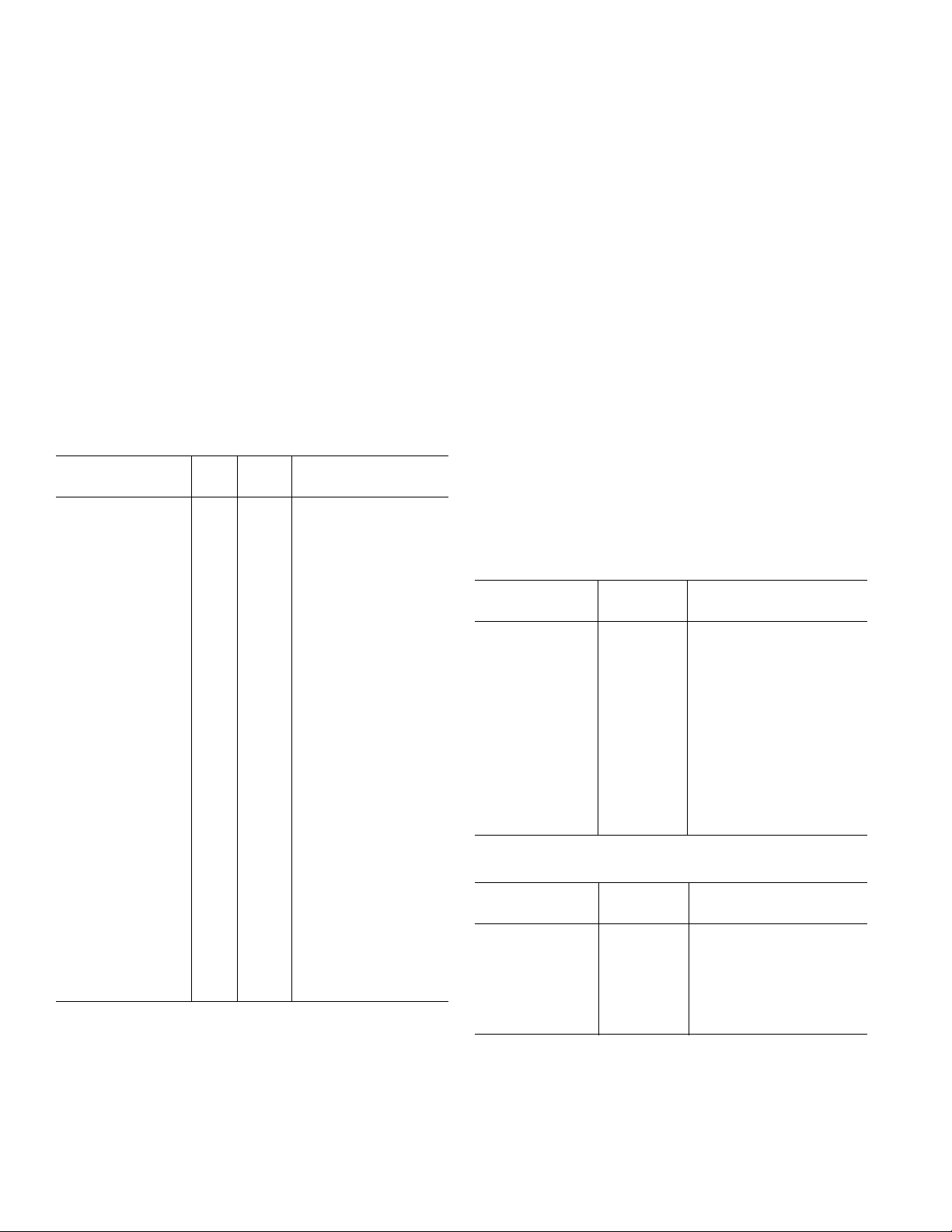

ANALOG-TO-DIGITAL CONVERTER

Parameter Min Typ Max Unit Conditions/Comments

Signal Input 0.3 3.5 V VAUX0, VAUX1, VAUX2

Resolution

Linearity Error

Zero Offset

Comparator Delay 600 ns

ADC High Level Input Current

ADC Low Level Input Current

NOTES

1

Resolution varies with PWM switching frequency (double update mode) 78.1 kHz = 8 bits, 4.9 kHz = 12 bits.

2

2.44 kHz sample frequency, VAUX0, VAUX1, VAUX2.

3

Extrapolated point outside of operating range. 2.44 kHz sample frequency.

Specifications subject to change without notice.

1

2

3

2

2

–32 0 +7 mV

–10 µAV

For ADMC340, TA = –40C to +125C. CLKIN = 10 MHz, unless otherwise noted.)

12 Bits

3 4 Bits

10 µAV

= 3.5 V

IN

= 0.0 V

IN

I

AMPLIFIER–TRIP

SENSE

Parameter Min Typ Max Unit Conditions/Comments

Signal Operating Range –400 +400 mV

I

SENSE

I

Gain –2.6 –2.51 –2.34 % VIN = –400 mV to +400 mV

SENSE

Gain Channel Matching 5.5 % VIN = –400 mV to +400 mV

I

SENSE

I

Gain Stability

SENSE

I

Linearity

SENSE

Internal Offset Voltage

I

SENSE

I

Internal Offset Stability

SENSE

I

Signal-to-Noise Ratio (SNR)

SENSE

Signal-to-Noise Ratio Less Distortion 54 dB

I

SENSE

3

(SNR)

I

Total Harmonic Distortion

SENSE

Input Current –200 +10 µAV

I

SENSE

I

Input Resistance 11.5 kΩ

SENSE

1

2

2

2

3

3

89 Bits

1.68 1.87 2.1 V

0.8 % VIN = –400 mV to +400 mV

2.1 %

51 dB

–40 dB

–53 dB

= –400 mV to +400 mV

IN

TRIP Threshold Low –690 –430 mV

TRIP Threshold High +430 +690 mV

TRIP Minimum Pulsewidth

NOTES

1

Variation of gain with VDD and temperature.

2

VIN = –400 mV to +400 mV.

3

fIN = 1 kHz sine wave, VIN = –400 mV to +400 mV, fS = 4 kHz.

4

High or low TRIP threshold.

Specifications subject to change without notice.

CURRENT SOURCE

4

5 µs

1

Parameter Min Typ Max Unit Conditions/Comments

Programming Resolution 3 Bits

Tuned Current

NOTES

1

For ADC calibration.

2

0.3 V to 3.5 V I

Specifications subject to change without notice.

2

CONST

91 100 109 µA

voltage.

–2–

REV. A

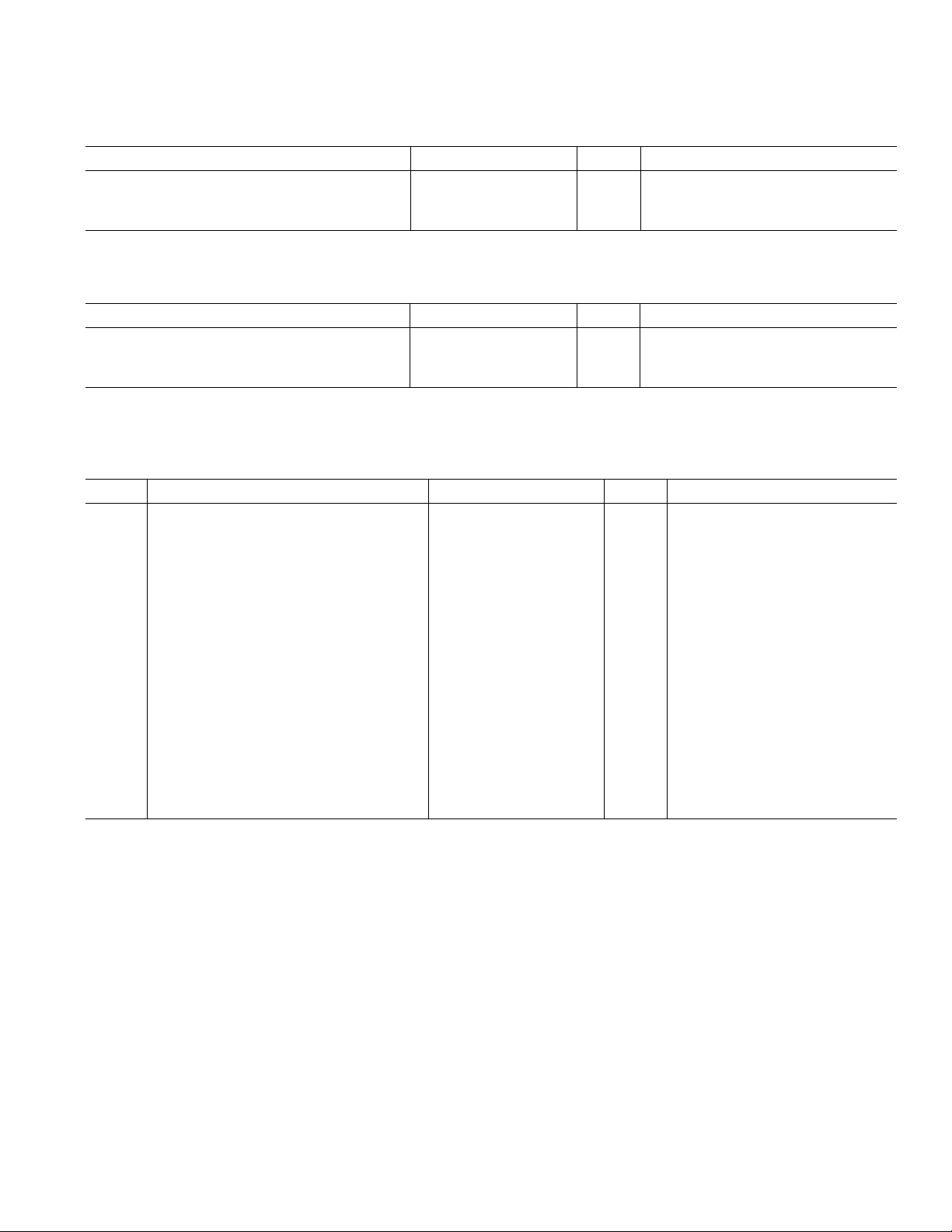

ADMC(F)340

VOLTAGE REFERENCE

Parameter Min Typ Max Unit Conditions/Comments

Voltage Level (V

)2.44 2.50 2.55 V –40°C to +85°C (ADMCF340 only)

REF

2.44 2.50 2.55 V –40°C to +125°C (ADMC340 ROM only)

Drift 110 ppm/°C

Specifications subject to change without notice.

POWER-ON RESET

Parameter Min Typ Max Unit Conditions/Comments

Reset Threshold 3.20 3.65 4.10 V

Hysteresis 100 mV

Reset Active Timeout Period 3.2

*216 CLKOUT cycles.

Specifications subject to change without notice.

*

ms

ELECTRICAL CHARACTERISTICS

Symbol Parameter Min Typ Max Unit Conditions/Comments

V

IL

V

IH

V

IL

V

IH

V

OL

V

OL

V

OH

I

IL

I

IL

I

IH

I

IH

I

IH

I

OZH

I

OZL

I

DD

I

DD

I

DD

I

DD

NOTES

1

PWMPOL and PWMSR pins only.

2

Output pins PORTA0–PORTA8, PORTB0–PORTB15, AH, AL, BH, BL, CH, CL.

3

XTAL pin.

4

Internal pull-up, RESET.

5

Internal pull-down, PWMTRIP, PORTA0–PORTA8, PORTB0–PORTB15.

6

Three-stateable pins, DT1, RFS0, TFS0, SCLK1.

7

Outputs not switching.

Specifications subject to change without notice.

Low Level Input Voltage 0.8 V

High Level Input Voltage 2 V

Low Level Input Voltage

High Level Input Voltage 2.60 V

Low Level Output Voltage

Low Level Output Voltage

High Level Output Voltage 4 V I

Low Level Input Current RESET Pin

Low Level Input Current –10 µAV

High Level Input Current RESET Pin

High Level Input Current

High Level Input Current 10 µAV

High Level Three-State Leakage Current

Low Level Three-State Leakage Current6–10 µAV

Supply Current (Idle)

Supply Current (Dynamic)

Supply Current (Idle)

Supply Current (Dynamic)

1

2

3

4

4

5

7

7

7

7

–100 µAV

6

1.75 V

0.4 V I

0.8 V I

30 µAV

100 µAV

100 µAV

2 mA

OL =

= 2 mA

OL

= 0.5 mA

OH

= 0 V

IN

= 0 V

IN

= V

IN

= V

IN

= V

IN

= V

IN

= 0 V

IN

DD

DD

DD

DD

35 mA VDD = 5.25 V (ADMC340 only)

60 mA VDD = 5.25 V (ADMC340 only)

55 mA VDD = 5.25 V (ADMCF340 only)

135 mA VDD = 5.25 V (ADMCF340 only)

REV. A

–3–

ADMC(F)340

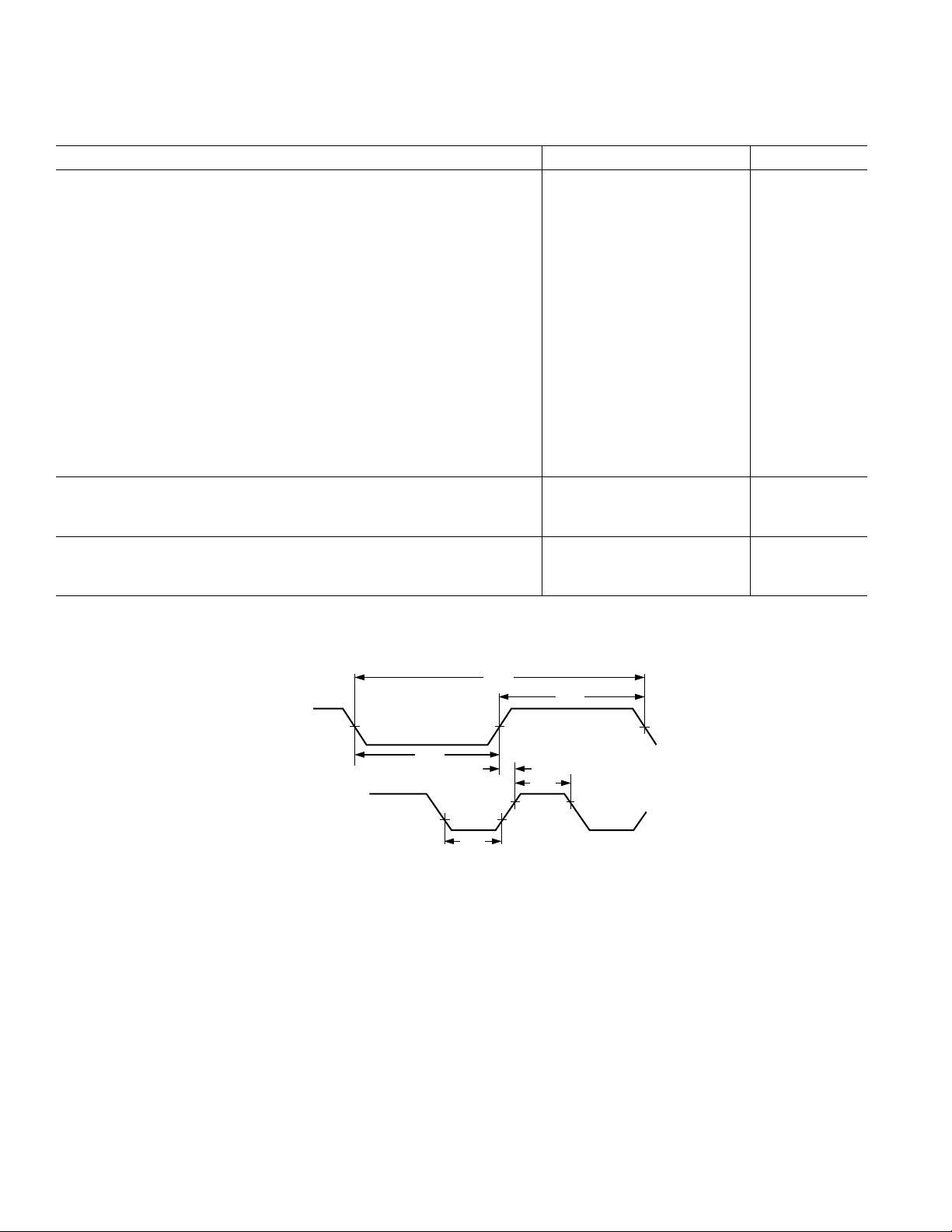

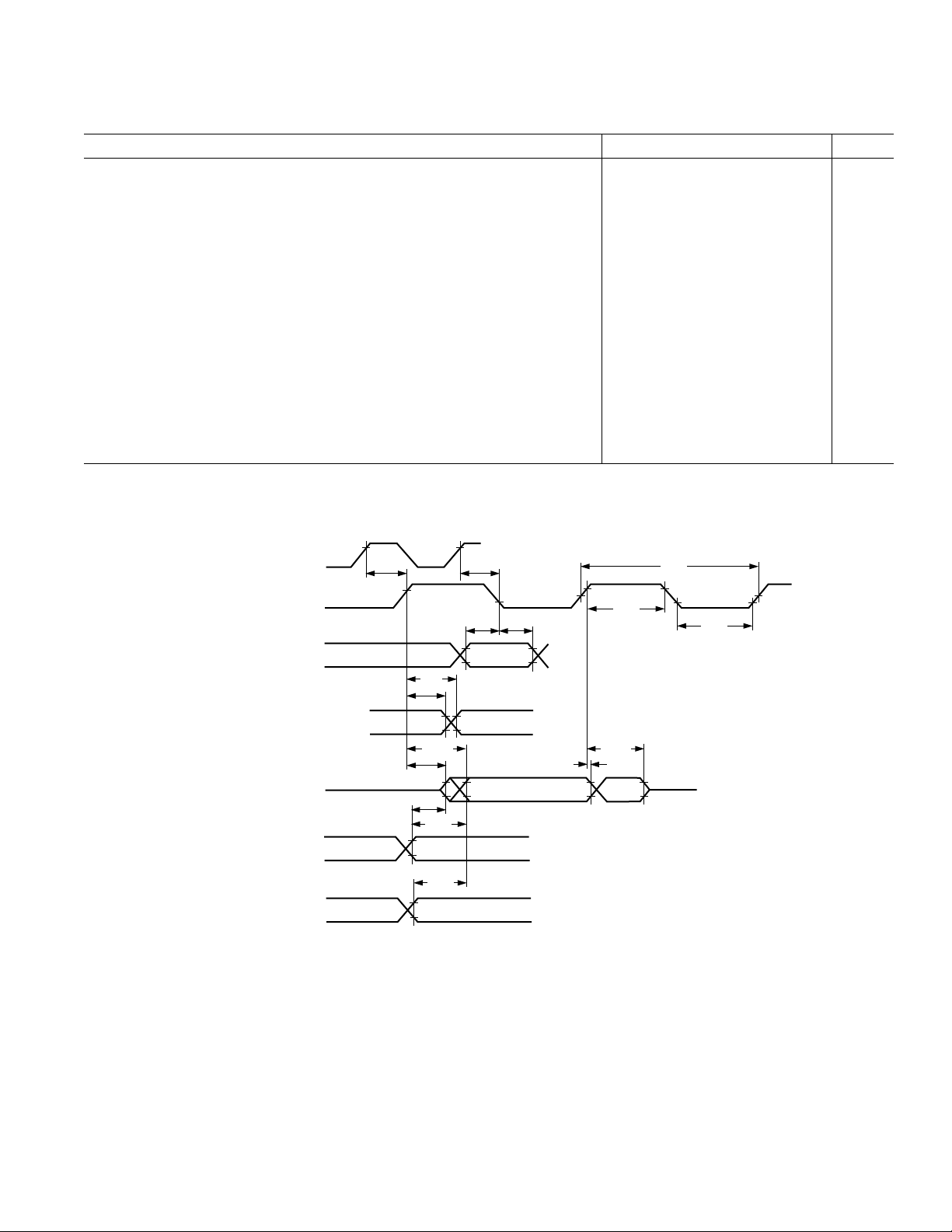

TIMING PARAMETERS

Parameter Min Max Unit

Clock Signals

Signal TCK is defined as 0.5 t

a frequency equal to half the instruction rate; a 10 MHz input clock (which is

equivalent to 100 ns) yields a 50 ns processor cycle (equivalent to 20 MHz).

When T

values are within the range of 0.5 t

CK

substituted for all relevant timing parameters to obtain specification value as

in the following example:

t T ns ns ns ns

=−=×−=05 10 05 50 10 15..

CKH CK

Timing Requirements:

t

CKIN

t

CKIL

t

CKIH

CLKIN Period 100 150 ns

CLKIN Width Low 20 ns

CLKIN Width High 20 ns

Switching Characteristics:

t

CKL

t

CKH

t

CKOH

CLKOUT Width Low 0.5 TCK – 10 ns

CLKOUT Width High 0.5 TCK – 10 ns

CLKIN High to CLKOUT High 0 20 ns

Control Signals

Timing Requirement:

t

RSP

RESET Width Low 5 TCK* ns

PWM Shutdown Signals

Timing Requirement:

t

PWMTPW

*Applies after power-up sequence is complete.

Specifications subject to change without notice.

PWMTRIP Width Low T

. The ADMC(F)340 uses an input clock with

CKIN

period, they should be

CKIN

CK

ns

CLKIN

CLKOUT

t

CKIN

t

CKIL

t

CKL

Figure 1. Clock Signals

t

t

CKOH

CKH

t

CKIH

–4–

REV. A

ADMC(F)340

TIMING PARAMETERS

Parameter Min Max Unit

Serial Ports

Timing Requirements:

t

SCK

t

SCS

t

SCH

t

SCP

Switching Characteristics:

t

CC

t

SCDE

t

SCDV

t

RH

t

RD

t

SCDH

t

SCDD

t

TDE

t

TDV

t

RDV

Specifications subject to change without notice.

SCLK Period 100 ns

DR/TFS/RFS Setup before SCLK Low 15 ns

DR/TFS/RFS Hold after SCLK Low 20 ns

SCLKIN Width 40 ns

CLKOUT High to SCLK

OUT

0.25 T

0.25 TCK + 20 ns

CK

SCLK High to DT Enable 0 ns

SCLK High to DT Valid 30 ns

TFS/RFS

TFS/RFS

Hold after SCLK High 0 ns

OUT

Delay from SCLK High 30 ns

OUT

DT Hold after SCLK High 0 ns

SCLK High to DT Disable 30 ns

TFS (Alt) to DT Enable 0 ns

TFS (Alt) to DT Valid 25 ns

RFS (Multichannel, Frame Delay Zero) to DT Valid 30 ns

CLKOUT

SCLK

DR

RFS

TFS

RFS

OUT

TFS

OUT

DT

TFS

(ALTERNATE

FRAME MODE)

(MULTICHANNEL MODE,

FRAME DELAY 0 [MFD = 0])

RFS

t

CC

IN

IN

t

t

SCDE

t

TDE

t

RH

t

RD

SCDV

t

TDV

t

RDV

t

CC

t

SCDD

t

t

t

SCS

SCH

t

SCDH

SCP

t

SCK

t

SCP

Figure 2. Serial Port Timing

REV. A

–5–

ADMC(F)340

WARNING!

ESD SENSITIVE DEVICE

ABSOLUTE MAXIMUM RATINGS*

Supply Voltage (VDD) . . . . . . . . . . . . . . . . . . –0.3 V to +7.0 V

Supply Voltage (AV

Input Voltage . . . . . . . . . . . . . . . . . . . . –0.3 V to V

Output Voltage Swing . . . . . . . . . . . . . –0.3 V to V

) . . . . . . . . . . . . . . . . . –0.3 V to +7.0 V

DD

+ 0.3 V

DD

+ 0.3 V

DD

ADMC340 Operating Temperature

Range (Ambient) . . . . . . . . . . . . . . . . . . . . –40°C to +85°C

ADMC340 Operating Temperature

Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . –40°C to +125°C

Storage Temperature Range . . . . . . . . . . . . –65°C to +150°C

Lead Temperature (5 sec) . . . . . . . . . . . . . . . . . . . . . . . 280°C

*Stresses greater than those listed may cause permanent damage to the device.

These are stress ratings only; functional operation of the device at these or any

other conditions greater than those indicated in the operational sections of this

specification is not implied. Exposure to absolute maximum rating conditions for

extended periods may affect device reliability.

1

AGND

2

DGND1

3

RESET

4

PB6

5

CH

6

PB7

7

PB8

8

CL

9

PB9

10

PB10

11

BH

12

PB11

13

PB12

14

BL

15

NC

16

NC

NC = NO CONNECT

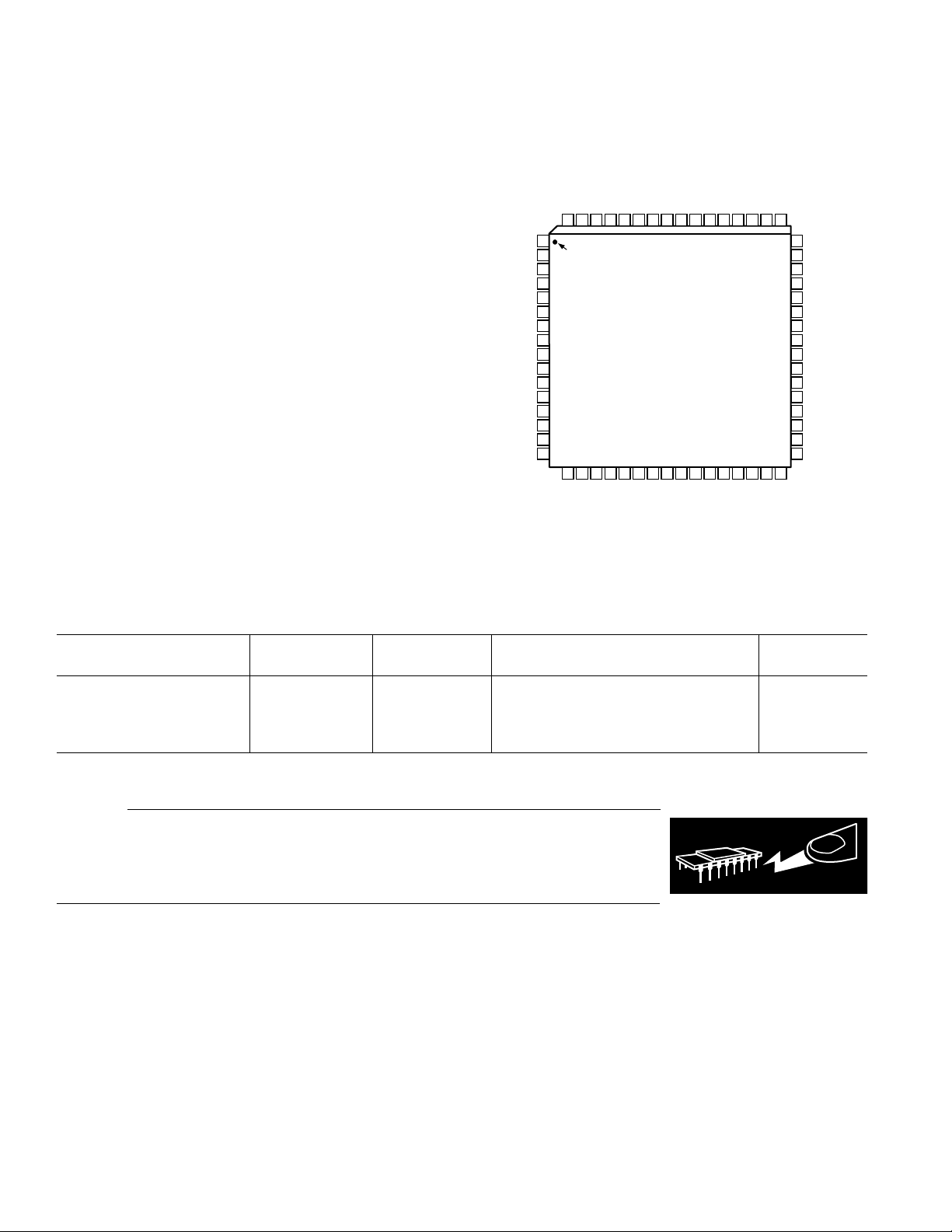

PIN CONFIGURATION

NC

ICONST

VAUX7

VAUX2

VAUX6

VAUX1

VAUX5

VAUX0

61

59

60

ADMC(F)340

20

22

21

PB14ALPB15

58

57

56

TOP VIEW

(Not to Scale)

23

24

25

PA8/(AUX0/CLKOUT)

PA7/(AUX1/PWMSYNC)

63

64

PIN 1

IDENTIFIER

18

17

NC

AH

62

19

PB13

SENSE1

VAUX4

I

55

26

2

DD

DV

PWMSR

V1

54

27

DGND2

53

28

SENSE2

SENSE3

I

V2

I

V3

50

52

51

31

29

30

PA6/DR1

PWMPOL

PA5/(FL1/DT1)

PA4(SCLK1/SCLK0)

PWMTRIP

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

PA3/TFS0

AV

DD

DVDD1

XTAL

NC

CLKIN

NC

PB5

PB4

PA0/DR0

PB3

PB2

PA1/DT0

PB1

PB0

PA2/RFS0

NC

ORDERING GUIDE

Temperature Instruction Package Package

Model Range Rate Description Option

ADMC(F)340BST –40°C to +85°C 20 MHz 64-Lead Thin Plastic Quad Flatpack ST-64

(LQFP)

ADMC(F)340-EVALKIT N/A N/A Development Tool Kit

ADMC340VST-XXX-XXXX –40°C to +125°C 20 MHz 64-Lead LQFP ST-64

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection. Although

the ADMC(F)340 features proprietary ESD protection circuitry, permanent damage may occur on

devices subjected to high energy electrostatic discharges. Therefore, proper ESD precautions are

recommended to avoid performance degradation or loss of functionality.

–6–

REV. A

PIN FUNCTION DESCRIPTIONS

ADMC(F)340

Pin Pin

No. Mnemonic Type

1 AGND GND

2 DGND1 GND

3 RESET D_IN

4 PB6 D_I/O

5CH D_OUT

6 PB7 D_I/O

7 PB8 D_I/O

8CL D_OUT

9 PB9 D_I/O

10 PB10 D_I/O

11 BH D_OUT

12 PB11 D_I/O

13 PB12 D_I/O

14 BL D_OUT

15 NC No Connect

16 NC No Connect

17 NC No Connect

18 AH D_OUT

19 PB13 D_I/O

20 PB14 D_I/O

21 AL D_OUT

22 PB15 D_I/O

23 PA8/(AUX0/CLKOUT) D_I/O

24 PA7/(AUX1/PWMSYNC) D_I/O

25 DV

2SUP

DD

26 PWMSR D_IN

27 DGND2 GND

28 PA6/DR1 D_I/O

29 PA5/(FL1/DT1) D_I/O

30 PA4/(SCLK1/SCLK0) D_I/O

31 PWMPOL D-IN

32 PA3/TFS0 D_I/O

Pin Pin

No. Mnemonic Type

33 NC No Connect

34 PA2/RFS0 D_I/O

35 PB0 D_I/O

36 PB1 D_I/O

37 PA1/DT0 D_I/O

38 PB2 D_I/O

39 PB3 D_I/O

40 PA0/DR0 D_I/O

41 PB4 D_I/O

42 PB5 D_I/O

43 NC No Connect

44 CLKIN D_I/O

45 NC No Connect

46 XTAL A_OUT

47 DV

48 AV

1SUP

DD

DD

SUP

49 PWMTRIP D_IN

50 V3 A_IN

51 I

SENSE3

A_IN

52 V2 A_IN

53 I

SENSE2

A_IN

54 V1 A_IN

55 I

SENSE1

A_IN

56 VAUX4 A_IN

57 VAUX0 A_IN

58 VAUX5 A_IN

59 VAUX1 A_IN

60 VAUX6 A_IN

61 VAUX2 A_IN

62 VAUX7 A-IN

63 ICONST A_OUT

64 NC No Connect

PA is the abbreviation of PORTA; PB is the abbreviation of PORTB.

REV. A

–7–

ADMC(F)340

(continued from page 1)

External PWMTRIP Pin

Switched Reluctance Motor Mode Selection Pin

PWM Polarity Selection Pin

Integrated 13-Channel ADC Subsystem

3 Bipolar I

Inputs with Programmable

SENSE

Sample-and-Hold Amplifier and Overcurrent

Protection (Usable as 3 Dedicated Analog Inputs)

3 Simultaneous Converting Voltage Inputs

7 Muxed Auxiliary Analog Inputs

Internal Voltage Reference (2.5 V)

Acquisition Synchronized to PWM Switching

Frequency

25-Lead Digital I/O Port

Bit Configurable as Input or Output

Change of State Interrupt Support

2 16-Bit Auxiliary PWM Timers

Synthesized Analog Output

Programmable Frequency

0% to 100% Duty Cycle

2 Programmable Operation Modes

Independent Mode/Offset Mode

GENERAL DESCRIPTION

The ADMC(F)340 is a low cost, single-chip DSP-based

controller suitable for permanent magnet synchronous, ac

induction, switched reluctance, and brushless dc motors. The

ADMC(F)340 integrates a 20 MHz, fixed-point DSP core with

a complete set of motor control and system peripherals for fast,

efficient development of motor controllers.

The DSP core of the ADMC(F)340 is completely code compatible

with the ADSP-21xx DSP family and combines three computational units, data address generators, and a program sequencer.

The computational units comprise an ALU, a multiplier/accumulator (MAC), and a barrel shifter. There are special instructions

for bit manipulation, multiplication (x squared), biased rounding,

and global interrupt masking. The system peripherals are the

power-on reset circuit (POR), the watchdog timer, and two

synchronous serial ports. The serial ports are configurable

and double buffered, with hardware support for UART, SCI,

and SPI port emulation. The ADMC(F)340 provides 512 × 24-bit

program memory RAM, 4K × 24-bit program memory ROM,

4K × 24-bit program FLASH memory, and 512 × 16-bit data

memory RAM. The user code will be stored and executed from

the flash memory. The program and data memory RAM can be

used for dynamic data storage or can be loaded through the

serial port from an external device as in other ADMCxx family

parts. The program memory ROM contains a monitor function

as well as useful routines for erasing, programming, and verifying

the flash memory.

The motor control peripherals of the ADMC(F)340 provide a 12-bit

analog data acquisition system with 13 analog input channels,

three dedicated I

functions (combining internal amplifi-

SENSE

cation, sampling, and overcurrent PWM shutdown features),

and an internal voltage reference. In addition, a three-phase,

16-bit, center-based PWM generation unit can be used to produce

high accuracy PWM signals with minimal processor overhead. The

ADMC(F)340 also contains two 16-bit auxiliary PWM timers

and 25 lines of programmable digital I/O.

Several functions, such as the auxiliary PWM and the serial

communication ports, are multiplexed with the nine PORTA

(9, PIO) programmable input/output (PIO) pins. The other 16

programmable digital I/O pins are dedicated. The pin functions

can be independently selected to allow maximum flexibility

for different applications.

DATA

ADDRESS

GENERATOR

No. 1

INPUT REGS

ALU

OUTPUT REGS

DATA

ADDRESS

GENERATOR

No. 2

INPUT REGS

OUTPUT REGS

MAC

INSTRUCTION

REGISTER

PM ROM

4K 24

PROGRAM

SEQUENCER

16

R BUS

14

14

24

BUS

EXCHANGE

16

INPUT REGS

SHIFTER

OUTPUT REGS

PM RAM

512 24

CONTROL

LOGIC

Figure 3. DSP Core Block Diagram

–8–

PMA BUS

DMA BUS

PMD BUS

DMD BUS

COMPANDING

CIRCUITRY

FLASH

PROGRAM

MEMORY

4K 24

TRANSMIT REG

RECEIVE REG

SERIAL

PORT

6

DM RAM

512 16

TIMER

REV. A

ADMC(F)340

DSP CORE ARCHITECTURE OVERVIEW

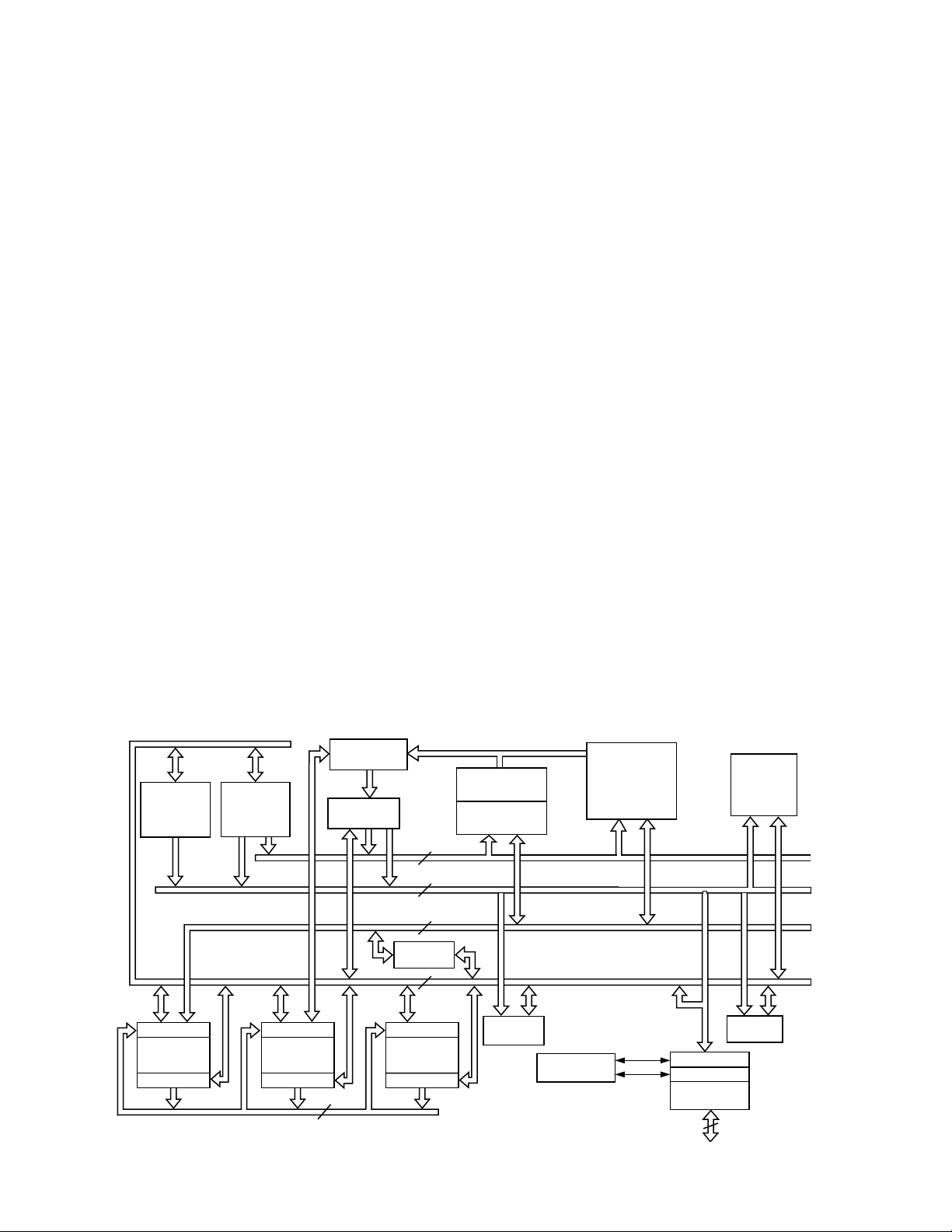

Figure 3 is an overall block diagram of the DSP core of the

ADMC(F)340. The flexible architecture and comprehensive

instruction set allow the processor to perform multiple operations

in parallel. In one processor cycle (50 ns with a 10 MHz CLKIN),

the DSP core can:

• Generate the next program address

• Fetch the next instruction

• Perform one or two data moves

• Update one or two data address pointers

• Perform a computational operation

This all takes place while the processor continues to:

•

Receive and transmit through the serial ports

•

Decrement the interval timer

•

Generate three-phase PWM waveforms for a power inverter

•

Generate two signals using the 16-bit auxiliary PWM timers

•

Acquire four analog signals

•

Decrement the watchdog timer

The processor contains three independent computational units:

the arithmetic and logic unit (ALU), the multiplier/accumulator

(MAC), and the shifter. The computational units process 16-bit

data directly and have provisions to support multiprecision com-

putations. The ALU performs a standard set of arithmetic and

logic operations as well as provides support for division primitives.

The MAC performs single-cycle multiply, multiply/add, and

multiply/subtract operations with 40 bits of accumulation. The

shifter performs logical and arithmetic shifts, normalization,

denormalization, and derive-exponent operations. The shifter

can be used to efficiently implement numeric format control,

including floating-point representations. The internal result (R)

bus directly connects the computational units so that the output

of any unit may be the input of any unit on the next cycle.

A powerful program sequencer and two dedicated data address

generators ensure efficient delivery of operands to these compu-

tational units. The sequencer supports conditional jumps and

subroutine calls and returns in a single cycle. With internal loop

counters and loop stacks, the ADMC(F)340 executes looped code

with zero overhead; no explicit jump instructions are required to

maintain the loop.

Two data address generators (DAGs) provide addresses for

simultaneous dual operand fetches from data memory and pro-

gram memory. Each DAG maintains and updates four address

pointers (I registers). Whenever the pointer is used to access

data (indirect addressing), it is post-modified by the value in

one of four modify (M) registers. A length value may be associated

with each pointer (L registers) to implement automatic modulo

addressing for circular buffers. The circular buffering feature is also

used by the serial ports for automatic data transfers to and from

on-chip memory. DAG1 generates only data memory addresses and

provides an optional bit-reversal capability. DAG2 may generate

either program or data memory addresses but has no bit-reversal

capability. Efficient data transfer is achieved with the use of five

internal buses:

• Program memory address (PMA) bus

• Program memory data (PMD) bus

• Data memory address (DMA) bus

• Data memory data (DMD) bus

• Result (R) bus

REV. A

–9–

Program memory can store both instructions and data, permitting

the ADMC(F)340 to fetch two operands in a single cycle—one from

program memory and one from data memory. The ADMC(F)340

can fetch both an operand from on-chip program memory and the

next instruction in the same cycle. The ADMC(F)340 writes

data from its 16-bit registers to the 24-bit program memory by

using the PX Register to provide the lower eight bits. When it reads

data (not instructions) from 24-bit program memory to a 16-bit

data register, the lower eight bits are placed into the PX Register.

The ADMC(F)340 can respond to a number of distinct DSP core

and peripheral interrupts. The DSP interrupts comprise a serial port

receive interrupt, a serial port transmit interrupt, a timer interrupt, and two software interrupts. Additionally, the motor control

peripherals include two PWM interrupts and a PIO interrupt.

The serial port (SPORT0) provides a complete synchronous

serial interface with optional companding in hardware and a wide

variety of framed and unframed data transmit and receive modes of

operation. SPORT0 and SPORT1 can generate an internal

programmable serial clock or accept an external serial clock.

A programmable interval counter is also included in the DSP core

and can be used to generate periodic interrupts. A 16-bit count

register (TCOUNT) is decremented every n processor cycle,

where n – 1 is a scaling value stored in the 8-bit TSCALE Register.

When the value of the counter reaches zero, an interrupt is

generated and the count register is reloaded from a 16-bit period

register (TPERIOD).

The ADMC(F)340 instruction set provides flexible data moves

and multifunction (one or two data moves with a computation)

instructions. Each instruction is executed in a single 50 ns

processor cycle (for a 10 MHz CLKIN). The ADMC(F)340

assembly language uses an algebraic syntax for ease of coding

and readability. A comprehensive set of development tools

supports program development. For further information on the

DSP core, refer to the ADSP-2100 Family User’s Manual, Third

Edition, with particular reference to the ADSP-2171.

SERIAL PORTS

The ADMC(F)340 incorporates two synchronous serial ports

(SPORT1 and SPORT0) for serial communication and multiprocessor communication. SPORT1 is primarily intended for

the interfacing of the debugging tools and/or code booting from

an external serial memory.

The following is a brief list of capabilities of the ADMC(F)340

SPORTs:

• SPORTs are bidirectional and have a separate, doublebuffered transmit and receive section.

• SPORTs can use an external serial clock or generate their

own serial clock internally.

• SPORTs have independent framing for the receive and

transmit sections. Sections run in a frameless mode or with

frame synchronization signals internally or externally

generated. Frame synchronization signals are active high or

inverted, with either of two pulsewidths and timings.

• SPORTs support serial data-word lengths from three bits to

16 bits and provide optional A-law and µ-law companding

according to ITU (formerly CCITT) recommendation G.711.

• SPORTs’ receive and transmit sections can generate unique

interrupts on completing a data-word transfer.

• SPORTs can receive and transmit an entire circular buffer

of data with only one overhead cycle per data-word. An

interrupt is generated after a data buffer transfer.

ADMC(F)340

• SPORT0 has one pin, SCLK0, shared with SPORT1.

During a boot phase (SPORT1 Boot Mode enabled by a bit

in the MODECTRL Register), the serial clock of SPORT1 is

externally available. The serial clock of SPORT0 is externally

available when the SPORT1 is configured in UART Mode.

• SPORT0 can be configured as a SPI Port (master mode only).

Refer to Table XI for more information. The clock phase and

polarity are programmable through the MODECTRL Register.

Refer to Table XI for pin configuration.

• SPORT0 has a multichannel interface to selectively receive

and transmit a 24-word or 32-word time division multiplexed

serial bit stream.

• SPORT1 is the default port for program/data memory boot

loading and for the development tools interface. The DT1/FL1

pin can be configured as the SROM/E

2

PROM reset signal.

The ADMC(F)340 is available in a 64-lead LQFP package.

PIN FUNCTION DESCRIPTION

Table I. Pin List

Pin Group No. of Input/

Name Pins Output Function

PWMPOL 1 I PWM Polarity

PWMSR 1I PWM Switched

Reluctance Mode

RESET 1I Processor Reset Input

SPORT1

SPORT0

1

1

2 I/O Serial Port 1 Pins

(DT1/FL1, DR1)

5 I/O Serial Port 0 Pins

(DT0, DR0, RFS0,

CLKOUT

TFS0, SCLK1/

1

1

1

I/O Processor Clock

SCLK0

2

)

Output

CLKIN, XTAL 2 I/O External Clock or

Quartz Crystal

1

PORTA0–PORTA8

PORTB0–PORTB15 16 I/O Digital I/O Port Pins

AUX0–AUX1

1

9 I/O Digital I/O Port Pins

2O Auxiliary PWM

Connection Point

Outputs

AH-CL 6 O PWM Outputs

PWMTRIP 1I PWM Trip Signal

V1 to V3 3 I I

I

SENSE1 to ISENSE3

3I Analog Inputs

SENSE

Inputs

VAUX0-VAUX7 7 I Auxiliary Analog Inputs

ICONST 1 O ADC Constant

Current Source

DV

AV

DD

DD

3I Power Supply

3I Power Supply

GND 3 I Ground

NOTES

1

Multiplexed pins, individually selectable through PORTA_SELECT and

PORTA_DATA Registers.

2

SCLK1/SCLK0 multiplexed signals, selectable through MODECTRL

Register Bit 4.

INTERRUPT OVERVIEW

The ADMC(F)340 can respond to 34 different interrupt sources

with minimal overhead, seven of which are internal DSP core

interrupts and 27 of which are from the motor control peripherals.

The seven DSP core interrupts are SPORT1 receive (or IRQ0)

and transmit (or IRQ1), SPORT0 receive and transmit, the

internal timer, and two software interrupts. The motor control

peripheral interrupts are the 25 programmable I/Os and two from

the PWM (PWMSYNC pulse and PWMTRIP). All motor control

interrupts are multiplexed into the DSP core through the peripheral IRQ2 interrupt. The interrupts are internally prioritized and

individually maskable. A detailed description of the entire interrupt

system of the ADMC(F)340 is presented in the Interrupt

Control section, which follows the detailed descriptions of each

peripheral block.

MEMORY MAP

The ADMC(F)340 has two distinct memory types: program

and data. In general, program memory contains user code and

coefficients, while the data memory is used to store variables and

data during program execution. Three kinds of program memory are

provided on the ADMC(F)340: RAM, ROM, and FLASH. The

motor control peripherals are memory mapped into a region of the

data memory space starting at 0x2000. The complete program and

data memory maps are given in Tables II and III, respectively.

Table II. Program Memory Map

Memory

Address Range Type Function

0x0000–0x002F RAM Internal Vector Table

0x0030–0x01FF RAM User Program Memory

0x0200–0x07FF Reserved

0x0800–0x17FF ROM Reserved Program Memory

0x1800–0x1FFF Reserved

0x2000–0x20FF FLASH User Program Memory

Sector 0

0x2100–0x21FF FLASH User Program Memory

Sector 1

0x2200–0x2FFF FLASH User Program Memory

Sector 2

0x3000–0x3FFF Reserved

Table III. Data Memory Map

Memory

Address Range Type Function

0x0000–0x1FFF Reserved

0x2000–0x20FF Memory Mapped Registers

0x2100–0x37FF Reserved

0x3800–0x39FF RAM User Data Memory

0x3A00–0x3BFF RAM Reserved

0x3C00–0x3FFF Memory Mapped Registers

–10–

REV. A

ADMC(F)340

FLASH MEMORY SUBSYSTEM

The ADMC(F)340 has 4K × 24-bit user-programmable, nonvolatile flash memory. A flash programming utility is provided with the

development tools and performs the basic device programming

operations: erase, program, and verify.

The flash memory array is portioned into three asymmetrically

sized sectors of 256 words, 256 words, and 3,584 words, labeled

Sector 0, Sector 1, and Sector 2, respectively. These sectors are

mapped into external program memory address space.

Four flash memory interface registers are connected to the DSP.

These 16-bit registers are mapped into the register area of data

memory space. They are named Flash Memory Control Register

(FMCR), Flash Memory Address Register (FMAR), Flash

Memory Data Register Low (FMDRL), and Flash Memory Data

Register High (FMDRH). These registers are diagrammed

beginning with Figure 21. They are used by the flash memory

programming utility. The user program may read these registers

but should not modify them directly. The flash programming

utility provides a complete interface to the flash memory.

Note that from the point of view of 2171 core, the flash memory

is placed externally. It means the core accesses them through an

external memory interface that multiplexes the program memory

and data memory buses into a single external bus. Therefore, if

more than one external transfer must be made in the same

instruction, there will be at least one overhead cycle required.

Special Flash Registers

The flash module has four nonvolatile 8-bit registers called Special

Flash Registers (SFRs) that are accessible independently of

the main flash array via the flash programming utility. These

registers are for general-purpose, nonvolatile storage. When

erased, the Special Flash Registers contain all 0s. To read

Special Flash Registers from the user program, call the read_reg

routine contained in the ROM. Refer to the ADMCF34x DSP

Motor Controller Developers’ Reference Manual for an example.

Boot-from-Flash Code

A security feature is available in the form of a code that when set

causes the processor to execute the program in flash memory at

power-up or reset. In this mode, the flash programming utility and

debugger are unable to communicate with the ADMC(F)340.

Consequently, the contents of the flash memory can be neither

programmed nor read.

The boot-from-flash code may be set via the flash programming

utility when the user’s program is thoroughly tested and loaded

into flash program memory at Address 0x2200. The user’s program must contain a mechanism for clearing the boot-from-flash

code if reprogramming the flash memory is desired. The only

way to clear boot-from-flash is from within the user program, by

calling the flash_init or auto_erase_reg routines that are included

in the ROM. The user program must be signaled in some way to

call the necessary routine to clear the boot-from-flash code. An

example would be to detect a high level on a PIO pin during

startup initialization and then call the flash_init or auto-erase-reg

routine. The flash_init routine will erase the entire user program

in flash memory before clearing the boot-from-flash code, thus

ensuring the security of the user program. If security is not a

concern, the auto_erase_reg routine can be used to clear the

boot-from-flash code while leaving the user program intact.

Refer to the ADMCF34x DSP Motor Controller Developers’

Reference Manual for further instructions and an example of

using the boot-from-flash code.

FLASH PROGRAM BOOT SEQUENCE

On power-up or reset, the processor begins instruction execution

at Address 0x0800 of internal program ROM. The ROM monitor

program that is located there checks the boot-from-flash code. If

that code is set, the processor jumps to location 0x2200 in external

flash program memory, where it expects to find the user’s

application program.

If the boot-from-flash code is not set, the monitor attempts to

boot from an external device as described in the ADMCF34x

DSP Motor Controller Developers’ Reference Manual.

SYSTEM INTERFACE

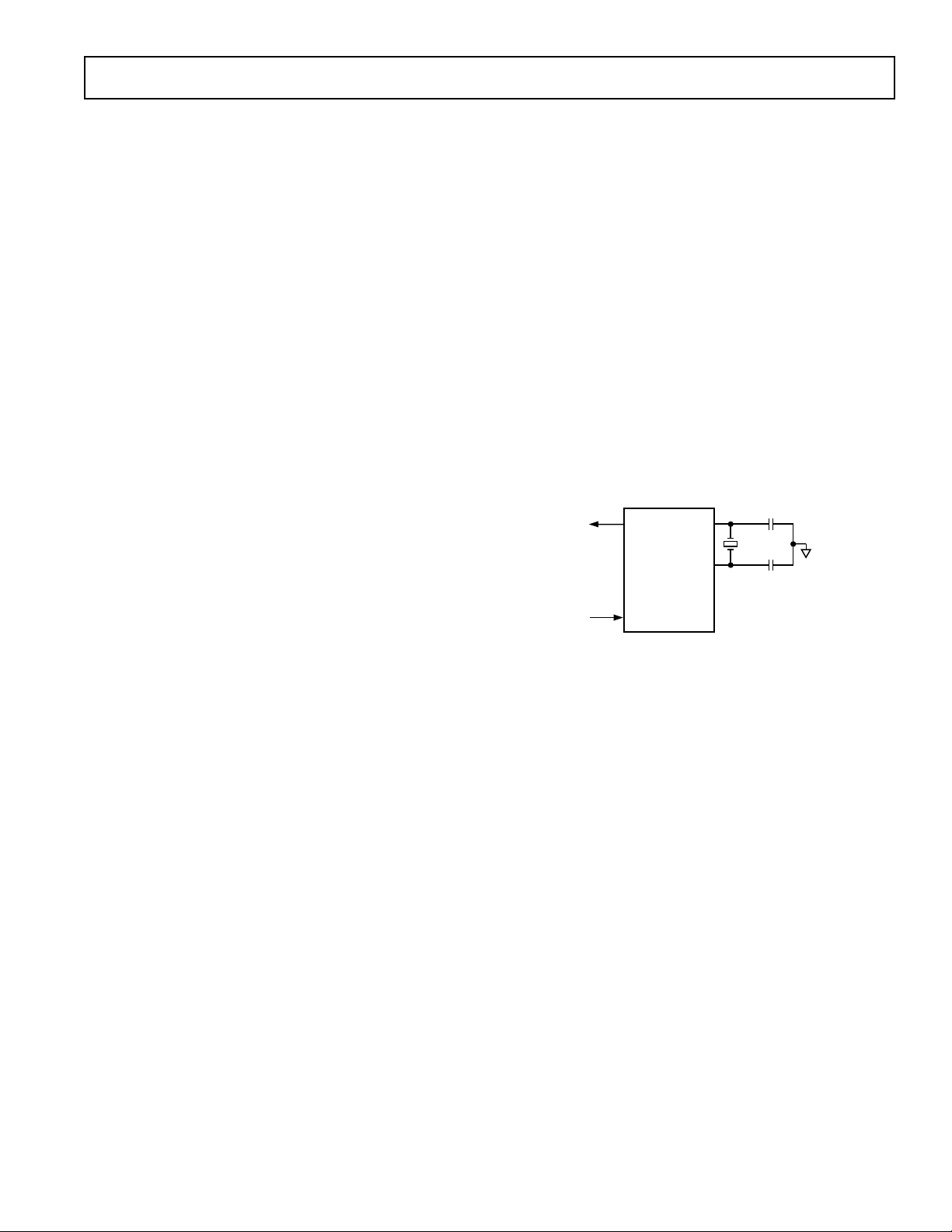

Figure 4 shows a basic system configuration for the ADMC(F)340

with an external crystal.

22pF

10MHz

22pF

Figure 4. Basic System Configuration

Clock Signals

CLKOUT

CLKIN

ADMC(F)340

RESET

XTAL

The ADMC(F)340 can be clocked either by a crystal or a TTL

compatible clock signal. For normal operation, the CLKIN

input cannot be halted, changed during operation, or operated

below the specified minimum frequency. If an external clock is

used, it should be a TTL compatible signal running at half the

instruction rate. The signal is connected to the CLKIN pin of

the ADMC(F)340. In this mode, with an external clock signal,

the XTAL pin must be left unconnected. The ADMC(F)340

uses an input clock with a frequency equal to half the instruction rate; a 10 MHz input clock yields a 50 ns processor cycle

(which is equivalent to 20 MHz). Normally, instructions are

executed in a single processor cycle. All device timing is relative to the internal instruction rate that is indicated by the

CLKOUT signal when enabled.

Because the ADMC(F)340 includes an on-chip oscillator feedback

circuit, an external crystal may be used instead of a clock source,

as shown in Figure 2. The crystal should be connected across the

CLKIN and XTAL pins with two capacitors (see Figure 2). A

parallel-resonant, fundamental frequency, microprocessor-grade

crystal should be used. A clock output signal (CLKOUT) is

generated by the processor at the processor’s cycle rate of twice

the input frequency.

REV. A

–11–

ADMC(F)340

Reset

The ADMC(F)340 DSP core and peripherals must be correctly

reset when the device is powered up to ensure proper unitization.

The ADMC(F)340 contains an integrated power-on-reset (POR)

circuit that provides a complete system reset on power-up and

power-down. The POR circuit monitors the voltage on the

ADMC(F)340 V

in reset while V

When this voltage is exceeded, the ADMC(F)340 is held in reset

for an additional 2

this time (T

RST

pin and holds the DSP core and peripherals

DD

is less than the threshold voltage level, V

DD

16

DSP clock cycles (T

in Figure 5). During

RST

RST

.

), the supply voltage must reach the recommended

operating condition. On power-down, when the voltage on the

pin falls below V

V

DD

RST

–V

, the ADMC(F)340 will be

HYST

reset. Also, if the external RESET pin is actively pulled low

at any time after power-up, a complete hardware reset of the

ADMC(F)340 is initiated.

V

RST

V

RESET

DD

T

RST

V

V

RST

HYST

–

Figure 5. Power-On Reset Operation

The ADMC(F)340 sets all internal stack pointers to the empty

stack condition, masks all interrupts, clears the MSTAT Register,

and performs a full reset of all the motor control peripherals.

Following a power-up, it is possible to initiate a DSP core and

motor control peripheral reset by pulling the RESET pin low.

The RESET signal must be the minimum pulsewidth specification,

. Following the reset sequence, the DSP core starts executing

t

RSP

code from the internal PM ROM located at 0x0800.

DSP Control Registers

The DSP core has a system control register, SYSCNTL, memorymapped at DM (0x3FFF). SPORT1 must be configured as a

serial port by setting Bit 10. SPORT0 and SPORT1 are enabled

by setting Bit 11 and Bit 12.

The DSP core has a wait state control register, MEMWAIT,

memory-mapped at DM (0x3FFE). The default value of this

register is 0xFFFF. For proper operation of the ADMC(F)340,

this register must always contain the value 0x8000. This value

sets the minimum access time to the program memory.

The configurations of both the SYSCNTL and MEMWAIT

Registers of the ADMC(F)340 are shown in Figure 30.

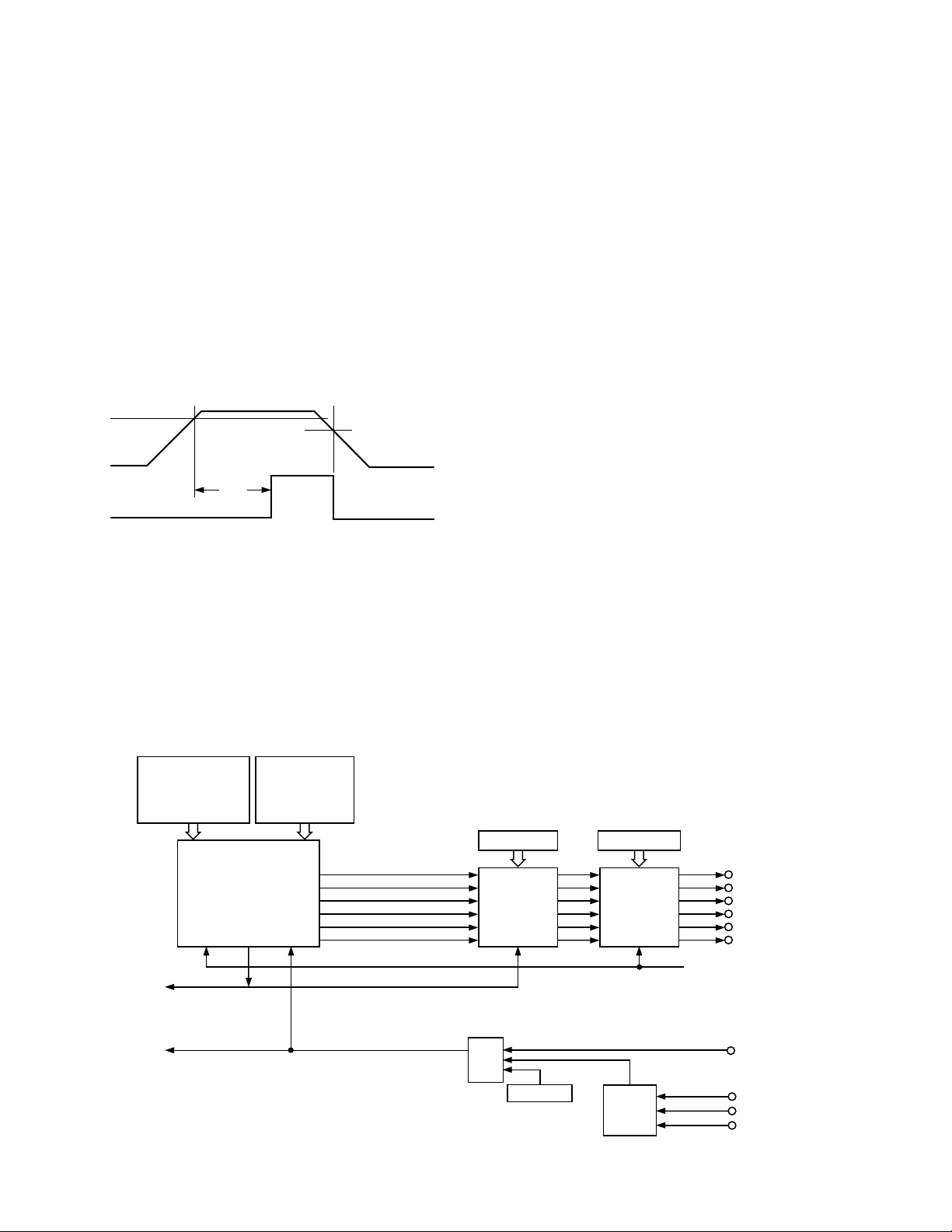

THREE-PHASE PWM CONTROLLER

Overview

The PWM generator block of the ADMC(F)340 is a flexible,

programmable, three-phase PWM waveform generator that can

be programmed to generate the required switching patterns to

drive a three-phase voltage source inverter for ac induction motors

(ACIM) or permanent magnet synchronous motors (PMSM).

In addition, the PWM block contains special functions that

considerably simplify the generation of the required PWM

switching patterns for control of electronically commutated

motors (ECM), brushless dc motors (BDCM), or switched

reluctance motors (SRM).

The six PWM output signals consist of three high side drive

signals (AH, BH, and CH) and three low side drive signals (AL,

BL, and CL). The switching frequency, dead time, and minimum

pulsewidths of the generated PWM patterns are programmable

using, respectively, the PWMTM, PWMDT, and PWMPD

Registers. In addition, three registers (PWMCHA, PWMCHB,

and PWMCHC) control the duty cycles of the three pairs of

PWM signals.

PWM CONFIGURATION

REGISTERS

PWMTM (15...0)

PWMDT (9...0)

PWMPD (9...0)

PWMSYNCWT (7...0)

MODECTRL (6)

THREE-PHASE

PWM TIMING

CLK RESETSYNC

PWMSYNC

TO INTERRUPT

CONTROLLER

PWMTRIP

PWM DUTY CYCLE

REGISTERS

PWMCHA (15...0)

PWMCHB (15...0)

PWMCHC (15...0)

UNIT

PWMSEG (8...0)

OUTPUT

CONTROL

UNIT

SYNC

OR

PWMSWT (0)

PWM SHUTDOWN CONTROLLER

PWMGATE (9...0)

DRIVE

OVER

CURRENT

TRIP

Figure 6. Overview of the PWM Controller of the ADMC(F)340

GATE

UNIT

CLK

CLKOUT

ANALOG BLOCK

AH

AL

BH

BL

CH

CL

PWMTRIP

I

SENSE1

I

SENSE2

I

SENSE3

–12–

REV. A

Loading...

Loading...