Single Chip DSP

a

TARGET APPLICATIONS

Washing Machines, Refrigerator Compressors, Fans,

Pumps, Industrial Variable Speed Drives

FEATURES

26 MIPS Fixed-Point DSP Core

Single Cycle Instruction Execution (38.5 ns)

ADSP-2100 Family Code Compatible

Independent Computational Units

ALU

Multiplier/Accumulator

Barrel Shifter

Multifunction Instructions

Single Cycle Context Switch

Powerful Program Sequencer

Zero Overhead Looping

Conditional Instruction Execution

Two Independent Data Address Generator

Memory Configuration

2K 24-Bit Program Memory RAM

2K 24-Bit Program Memory ROM

1K 16-Bit Data Memory RAM

Three-Phase 16-Bit PWM Generator

16-Bit Center-Based PWM Generator

Programmable Deadtime and Narrow Pulse Deletion

Motor Controller

ADMC331

Edge Resolution to 38.5 ns

198 Hz Minimum Switching Frequency

Double/Single Duty Cycle Update Mode Control

Programmable PWM Pulsewidth

Suitable for AC Induction and Synchronous Motors

Special Signal Generation for Switched Reluctance

Motors

Special Crossover Function for Brushless DC Motors

Individual Enable and Disable for all PWM Outputs

High Frequency Chopping Mode for Transformer

Coupled Gate Drives

Hardwired Polarity Control

External PWMTRIP Pin

Seven Analog Input Channels

Acquisition Synchronized to PWM Switching

Frequency

Conversion Speed Control

24 Bits of Digital I/O Port

Bit Configurable as Input or Output

Change of State Interrupt Support

Two 8-Bit Auxiliary PWM Timers

Synchronized Analog Output

Programmable Frequency

0% to 100% Duty Cycle

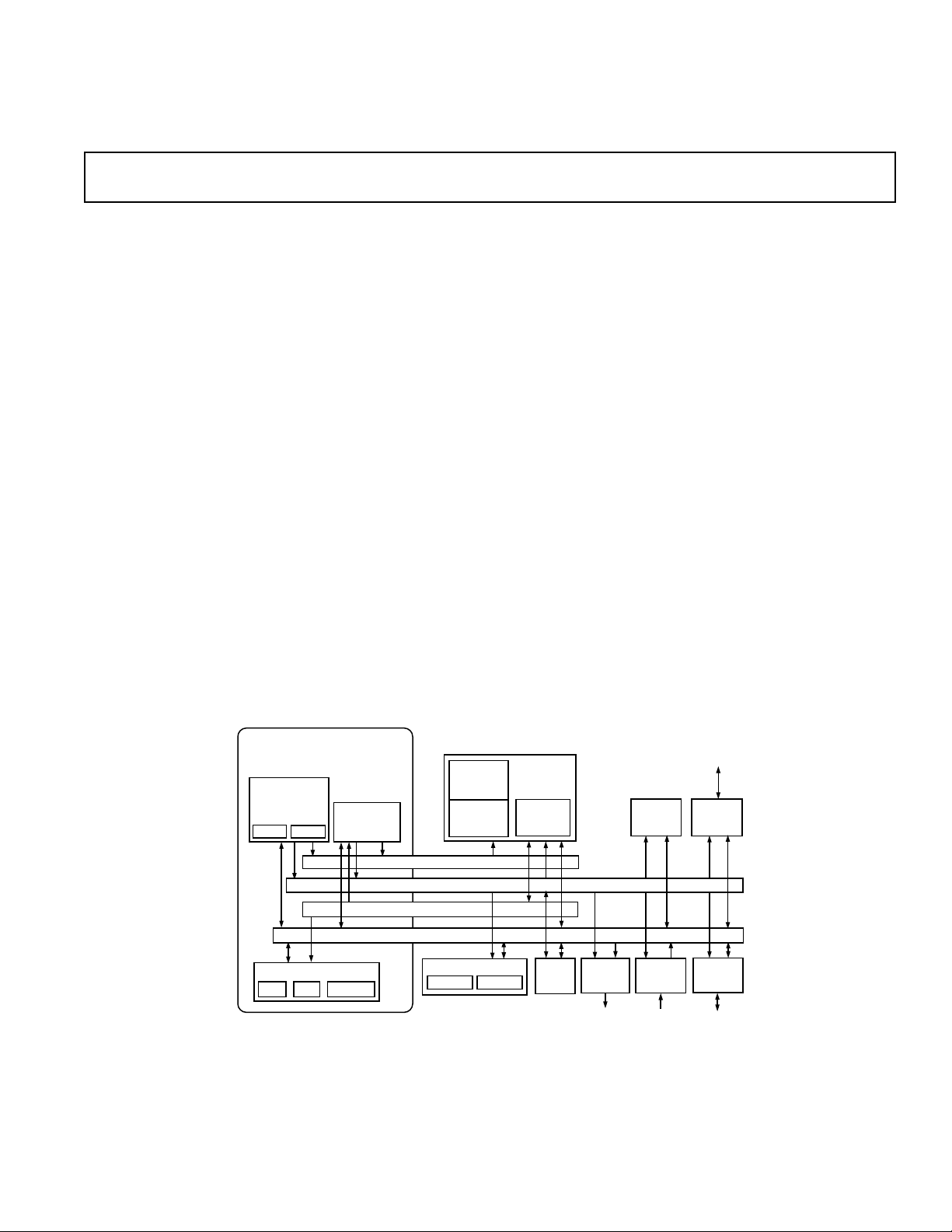

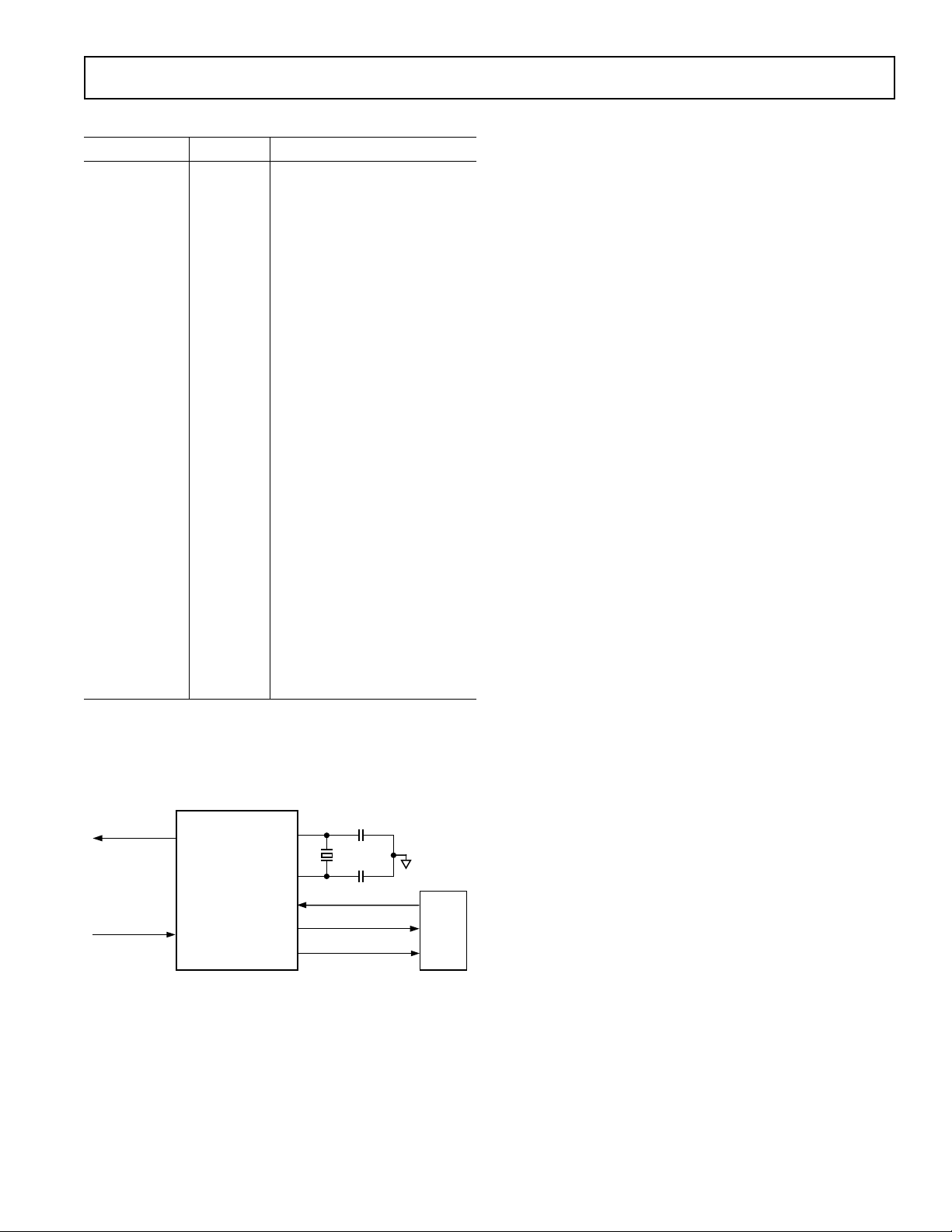

FUNCTIONAL BLOCK DIAGRAM

ADSP-2100 BASE

ARCHITECTURE

DATA

ADDRESS

GENERATORS

DAG 2

DAG 1

ARITHMETIC UNITS

MAC

ALU

PROGRAM

SEQUENCER

PROGRAM MEMORY ADDRESS

DATA MEMORY ADDRESS

PROGRAM MEMORY DATA

DATA MEMORY DATA

SHIFTER

PROGRAM

2K 24

PROGRAM

2K 24

SERIAL PORTS

SPORT 0

REV. B

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

(Continued on page 7)

ROM

RAM

MEMORY

AUX

PWM

WATCH-

DOG

TIMER

7

ANALOG

INPUTS

24-BIT

PIO

16-BIT

3-PHASE

PWM

DATA

RAM

1K 16

2 8 BIT

SPORT 1

TIMER

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 World Wide Web Site: http://www.analog.com

Fax: 781/326-8703 © Analog Devices, Inc., 2000

ADMC331–SPECIFICATIONS

(VDD = +5 V 10%, GND = SGND = 0 V, TA = –40C to +85C, unless otherwise noted)

Parameter Min Typ Max Units Conditions/Comments

ANALOG-TO-DIGITAL CONVERTER Charging Capacitor = 1000 pF

2.5 kHz Sample Frequency

Signal Input 0.3 3.3

Resolution 12

1

2

V

Bits No Missing Codes

Converter Linearity 2 12 LSBs

Zero Offset 5 50 mV

Channel-to-Channel Comparator Match 22 mV

Comparator Delay 600 ns

Current Source 10.16 12.7 15.24 µA

Current Source Linearity 2 %

ELECTRICAL CHARACTERISTICS

V

Logic Low 0.8 V

IL

Logic High 2 V

V

IH

V

Low Level Output Voltage 0.4 V IOL = 2 mA

OL

V

Low Level Output Voltage (XTAL) 0.5 V IOL = 2 mA

OL

High Level Output Voltage 4 V I

V

OH

I

Low Level Input Current –10 µAV

IL

I

High Level Input Current 10 µAV

IH

I

Hi-Level PWMTRIP, PIO0–PIO23 Current 100 µA@ V

IH

I

Hi-Level PWMPOL/PWMSR Current 10 µA@ V

IH

I

Lo-Level PWMTRIP, PIO0–PIO23 Current 10 µA@ V

IL

Lo-Level PWMPOL/PWMSR Current 100 µA@ V

I

IL

I

Supply Current (Dynamic) 120 mA 13 MHz DSP Clock

DD

I

Supply Current (Idle) 60 mA 13 MHz DSP Clock

DD

= 0.5 mA

OH

= 0 V

IN

= V

IN

DD

= max, VIN = VDD max

DD

= max, VIN = VDD max

DD

= max, VIN = 0 V

DD

= max, VIN = 0 V

DD

REFERENCE VOLTAGE OUTPUT

Voltage Level 2.2 2.55 2.9 V 100 µA Load

Output Voltage Change T

MIN

to T

MAX

20 mV

16-BIT PWM TIMER

Counter Resolution 16 Bits

Edge Resolution (Single Update Mode) 76.9 ns 13 MHz CLKIN

Edge Resolution (Double Update Mode) 38.5 ns 13 MHz CLKIN

Programmable Deadtime Range 0 78 µs 13 MHz CLKIN

Programmable Deadtime Increments 76.9 ns 13 MHz CLKIN

Programmable Pulse Deletion Range 0 78 µs 13 MHz CLKIN

Programmable Pulse Deletion Increments 76.9 ns 13 MHz CLKIN

PWM Frequency Range 0.198 kHz 13 MHz CLKIN

PWMSYNC Pulsewidth (T

) 0.077 9.8 µs 13 MHz CLKIN

CRST

Gate Drive Chop Frequency Range 0.02 6.5 MHz 13 MHz CLKIN

AUXILIARY PWM TIMERS

Resolution 8 Bits

PWM Frequency 0.051 6.5 MHz 13 MHz CLKIN

NOTES

1

Signal input max V = 3.5 V if VDD = 5 V ± 5%.

2

Resolution varies with PWM switching frequency (13 MHz Clock in Double Update mode), 50.7 kHz = 9 bits, 6.3 kHz = 12 bits.

Specifications subject to change without notice.

–2–

REV. B

ADMC331

CLKIN

CLKOUT

t

CKOH

t

CKI

t

CKIH

t

CKH

t

CKL

t

CKIL

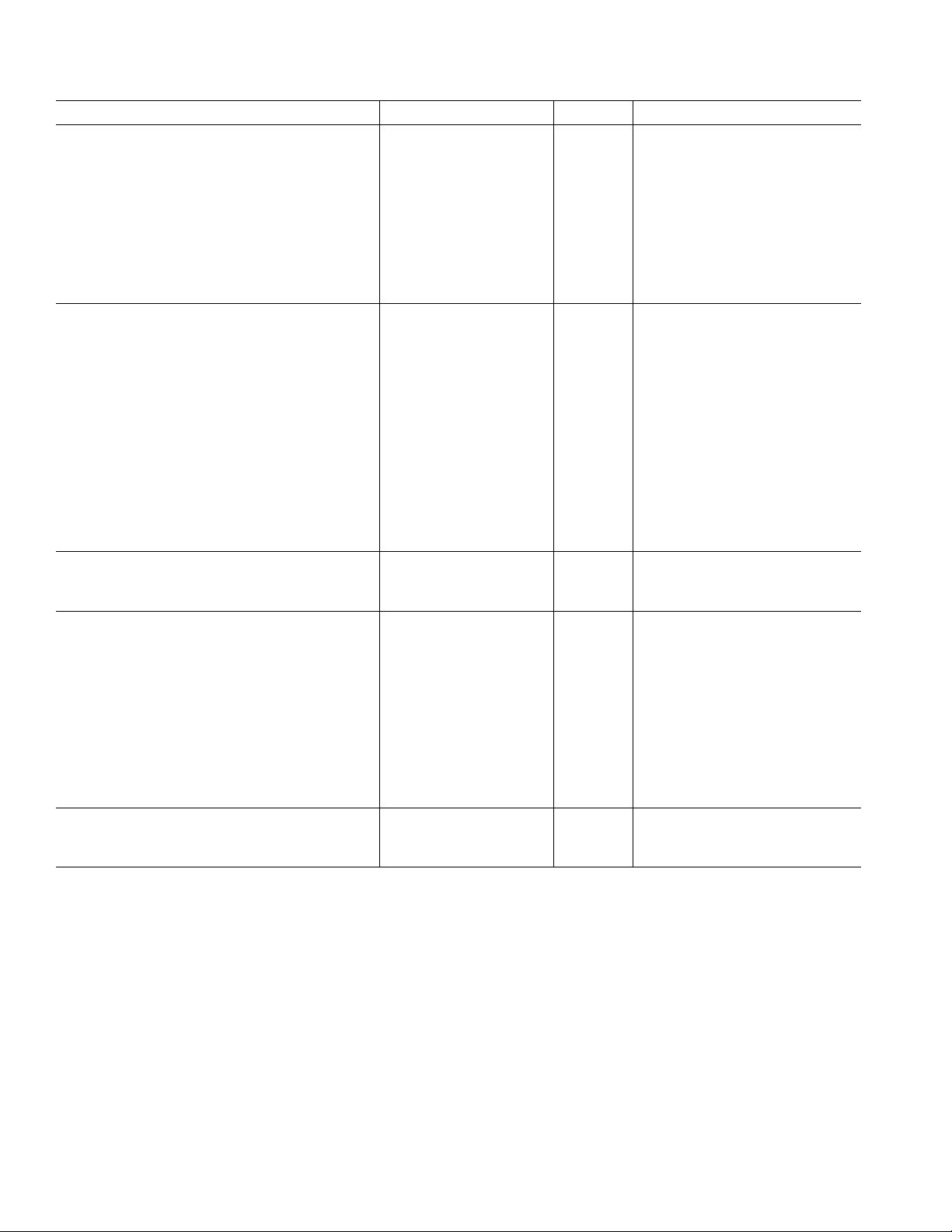

TIMING PARAMETERS

Parameter Min Max Unit

Clock Signals

tCK is defined as 0.5 t

to half the instruction rate; a 13 MHz input clock (which is equivalent to 76.9 ns)

yields a 38.5 ns processor cycle (equivalent to 26 MHz). t

of 0.5 t

period should be substituted for all relevant timing parameters to obtain

CKI

specification value.

Example: t

= 0.5 tCK – 10 ns = 0.5 (38.5 ns) – 10 ns = 9.25 ns.

CKH

Timing Requirements:

t

CKI

t

CKIL

t

CKIH

Switching Characteristics:

t

CKL

t

CKH

t

CKOH

Control Signals

Timing Requirement:

t

RSP

PWM Shutdown Signals

Timing Requirement:

t

PWMTPW

NOTE

1

Applies after power-up sequence is complete. Internal phase lock loop requires no more than 2000 CLKIN cycles assuming stable CLKIN (not including crystal

oscillator start-up time).

. The ADMC331 uses an input clock with a frequency equal

CKI

values within the range

CK

CLKIN Period 76.9 150 ns

CLKIN Width Low 20 ns

CLKIN Width High 20 ns

CLKOUT Width Low 0.5 tCK – 10 ns

CLKOUT Width High 0.5 tCK – 10 ns

CLKIN High to CLKOUT High 0 20 ns

RESET Width Low 5 t

PWMTRIP Width Low 2 t

CK

CK

1

ns

ns

Figure 1. Clock Signals

–3–REV. B

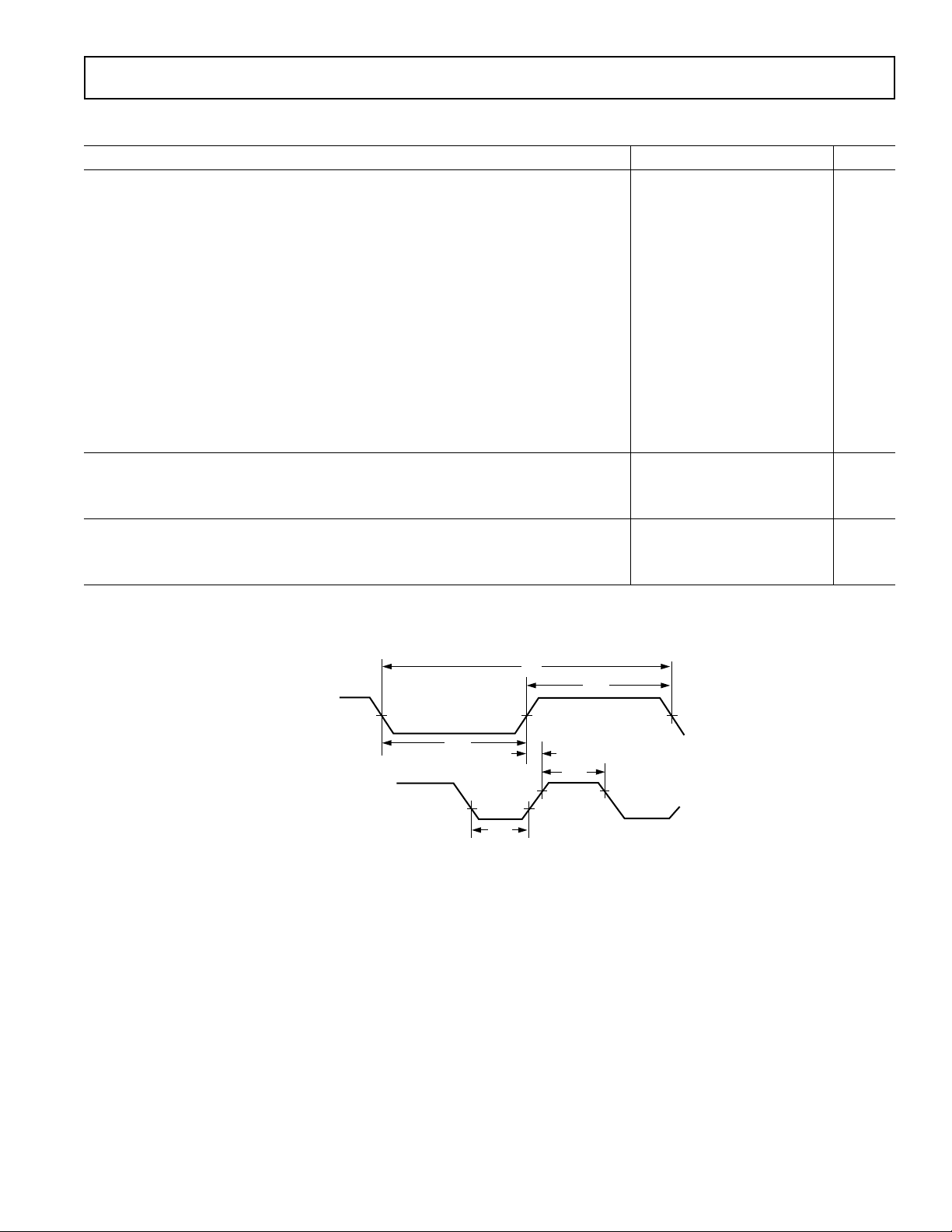

ADMC331

Parameter Min Max Unit

Serial Ports

Timing Requirements:

t

SCK

t

SCS

t

SCH

t

SCP

Switching Characteristics:

t

CC

t

SCDE

t

SCDV

t

RH

t

RD

t

SCDH

t

SCDD

t

TDE

t

TDV

t

RDV

SCLK Period 100 ns

DR/TFS/RFS Setup before SCLK Low 15 ns

DR/TFS/RFS Hold after SCLK Low 20 ns

SCLKIN Width 40 ns

CLKOUT High to SCLK

OUT

0.25 t

CK

0.25 tCK + 20 ns

SCLK High to DT Enable 0 ns

SCLK High to DT Valid 30 ns

TFS/RFS

TFS/RFS

Hold after SCLK High 0 ns

OUT

Delay from SCLK High 30 ns

OUT

DT Hold after SCLK High 0 ns

SCLK High to DT Disable 30 ns

TFS (Alt) to DT Enable 0 ns

TFS (Alt) to DT Valid 25 ns

RFS (Multichannel, Frame Delay Zero) to DT Valid 30 ns

CLKOUT

SCLK

DR

RFS

TFS

RFS

OUT

TFS

OUT

DT

TFS

(ALTERNATE

FRAME MODE)

(MULTICHANNEL MODE,

FRAME DELAY 0 [MFD = 0])

RFS

t

CC

IN

IN

t

t

RH

SCDE

t

t

TDE

t

RD

SCDV

t

t

TDV

RDV

t

CC

t

t

SCDD

t

t

SCH

SCS

t

SCDH

SCP

t

SCK

t

SCP

Figure 2. Serial Ports

–4–

REV. B

ADMC331

WARNING!

ESD SENSITIVE DEVICE

ABSOLUTE MAXIMUM RATINGS*

Supply Voltage (VDD) . . . . . . . . . . . . . . . . . . –0.3 V to +7.0 V

Supply Voltage (AV

Input Voltage . . . . . . . . . . . . . . . . . . . . –0.3 V to V

Output Voltage Swing . . . . . . . . . . . . . .–0.3 V to V

) . . . . . . . . . . . . . . . . .–0.3 V to +7.0 V

DD

+ 0.3 V

DD

+ 0.3 V

DD

*Stresses greater than those listed above may cause permanent damage to the

device. These are stress ratings only; functional operation of the device at these

or any other conditions greater than those indicated in the operational sections of

this specification is not implied. Exposure to absolute maximum rating conditions

for extended periods may affect device reliability.

Operating Temperature Range (Ambient) . . . –40°C to +85°C

Storage Temperature Range . . . . . . . . . . . . –65°C to +150°C

Lead Temperature (5 sec) . . . . . . . . . . . . . . . . . . . . . .+280°C

ORDERING GUIDE

Temperature Instruction Package Package

Model Range Rate Description Option

ADMC331BST –40°C to +85°C 26 MHz 80-Lead Plastic Thin Quad Flatpack (TQFP) ST-80

ADMC331-ADVEVALKIT Development Tool Kit

ADMC331-PB Evaluation/Processor Board

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection.

Although the ADMC331 features proprietary ESD protection circuitry, permanent damage may

occur on devices subjected to high-energy electrostatic discharges. Therefore, proper ESD

precautions are recommended to avoid performance degradation or loss of functionality.

–5–REV. B

ADMC331

PIN FUNCTION DESCRIPTIONS

Pin Pin Pin

No. Type Name

1 O/P VREF

2 SUP AV

DD

3 GND GND

4 BIDIR PIO9

5 BIDIR PIO8

6 BIDIR PIO7

7 BIDIR PIO6

8 BIDIR PIO5

9 BIDIR PIO4

10 BIDIR PIO3

11 BIDIR PIO2

12 BIDIR PIO1

13 BIDIR PIO0

14 O/P AUX1

15 O/P AUX0

16 BIDIR PIO10

17 BIDIR PIO11

18 SUP V

DD

19 I/P PWMTRIP

20 GND GND

Pin Pin Pin

No. Type Name

21 SUP V

DD

22 GND GND

23 BIDIR PIO12

24 BIDIR PIO13

25 O/P PWMSYNC

26 O/P CL

27 O/P CH

28 O/P BL

29 O/P BH

30 O/P AL

31 O/P AH

32 BIDIR PIO14

33 BIDIR PIO15

34 BIDIR PIO16

35 SUP V

DD

36 GND GND

37 BIDIR PIO17

38 GND GND

39 BIDIR PIO18

40 GND GND

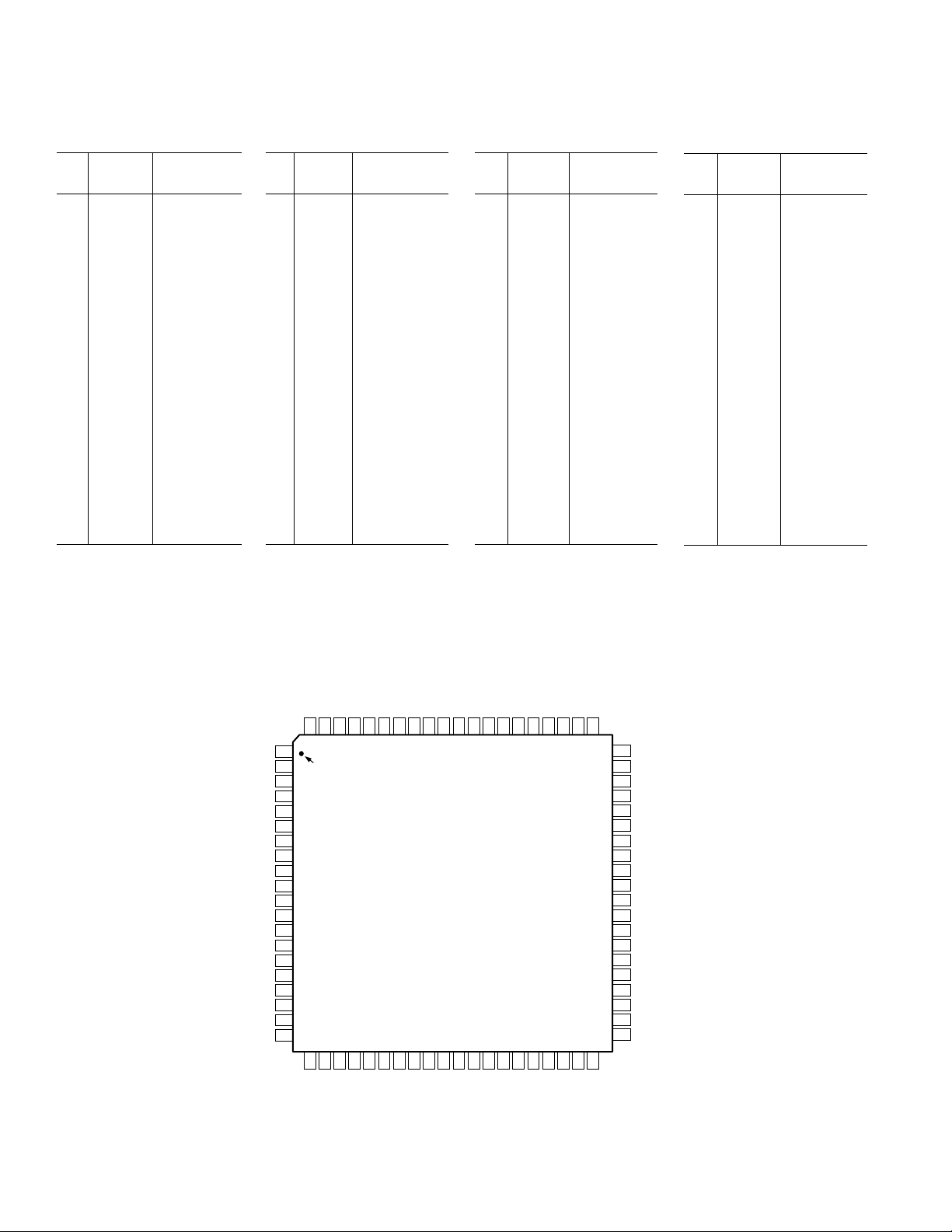

PIN CONFIGURATION

80-Lead Plastic Thin Quad Flatpack (TQFP)

Pin Pin Pin

No. Type Name

41 GND GND

42 GND GND

43 O/P XTAL

44 I/P CLKIN

45 I/P PWMPOL

46 I/P RESET

47 GND GND

48 SUP V

49 BIDIR PIO19

50 BIDIR PIO20

51 O/P CLKOUT

52 GND GND

53 O/P DT1

54 BIDIR TFS1

55 BIDIR RFS1/SROM

56 I/P DR1A

57 I/P DR1B

58 BIDIR SCLK1

59 O/P DT0

60 I/P PWMSR

(ST-80)

DD

Pin Pin Pin

No. Type Name

61 BIDIR TFS0

62 BIDIR RFS0

63 I/P DR0

64 BIDIR SCLK0

65 BIDIR PIO21

66 BIDIR PIO22

67 BIDIR PIO23

68 SUP V

DD

69 GND GND

70 GND AGND

71 I/P CAPIN

72 O/P ICONST

73 GND SGND

74 I/P V1

75 I/P V2

76 I/P V3

77 I/P VAUX0

78 I/P VAUX1

79 I/P VAUX2

80 I/P VAUX3

VREF

AV

GND

PIO9

PIO8

PIO7

PIO6

PIO5

PIO4

PIO3

PIO2

PIO1

PIO0

AUX1

AUX0

PIO10

PIO11

V

PWMTRIP

GND

VAUX3

80

7978777675

1

PIN 1

2

DD

DD

IDENTIFIER

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

DD

V

GND

PIO12

25

24

PIO13

PWMSYNC

V2

26

CL

V1

74

27

CH

CAPIN

ICONST

SGND

73

727170

ADMC331

TOP VIEW

(Not to Scale)

30

28

29

AL

BL

BH

V3

VAUX0

VAUX1

VAUX2

DD

V

GND

AGND

31

AH

PIO22

PIO23

69686766656463

32

35

33

34

DD

V

PIO16

PIO15

PIO14

PIO21

36

GND

SCLK0

37

38

GND

PIO17

DR0

RFS0

62

39

GND

PIO18

TFS0

61

40

60

PWMSR

DT0

59

SCLK1

58

DR1B

57

DR1A

56

55

RFS1/ SROM

TFS1

54

53

DT1

GND

52

51

CLKOUT

50

PIO20

PIO19

49

V

48

DD

GND

47

46

RESET

45

PWMPOL

CLKIN

44

XTAL

43

GND

42

GND

41

–6–

REV. B

ADMC331

(Continued from page 1)

Two Programmable Operational Modes

Independent Mode

Offset Mode

16-Bit Watchdog Timer

Programmable 16-Bit Internal Timer with Prescaler

Two Double Buffered Synchronous Serial Ports

Four Boot Load Protocols via SPORT1

2

PROM/SROM Booting

E

UART Booting (SCI Compatible) with Autobaud

Feature

Synchronous Master Booting with Autobaud Feature

Synchronous Slave Booting with Autobaud Feature

Debugger Interface via SPORT1 with Autobaud (UART

and Synchronous Supported)

ROM Utilities

Full Debugger for Program Development

Preprogrammed Math Functions

Preprogrammed Motor Control Functions—Vector

Transformations

80-Lead TQFP Package

Industrial Temperature Range –40C to +85C

GENERAL DESCRIPTION

The ADMC331 is a low cost, single-chip DSP-based controller,

suitable for ac induction motors, permanent magnet synchronous motors, brushless dc motors, and switched reluctance

motors. The ADMC331 integrates a 26 MIPS, fixed-point DSP

core with a complete set of motor control peripherals that permits fast, efficient development of motor controllers.

The DSP core of the ADMC331 is the ADSP-2171, which is

completely code compatible with the ADSP-2100 DSP family

and combines three computational units, data address generators and a program sequencer. The computational units comprise an ALU, a multiplier/accumulator (MAC) and a barrel

shifter. The ADSP-2171 adds new instructions for bit manipulation, multiplication (X squared), biased rounding and global

interrupt masking. In addition, two flexible, double-buffered,

bidirectional, synchronous serial ports are included in the

ADMC331.

The ADMC331 provides 2K × 24-bit program memory RAM,

2K × 24-bit program memory ROM and 1K × 16-bit data

memory RAM. The program and data memory RAM can be

boot loaded through the serial port from a Serial ROM (SROM),

E2PROM, asynchronous (UART) connection or synchronous

connection. The program memory ROM includes a monitor

that adds software debugging features through the serial port. In

addition, a number of preprogrammed mathematical and motor

control functions are included in the program memory ROM.

The motor control peripherals of the ADMC331 include a

16-bit center-based PWM generation unit that can be used to

produce high accuracy PWM signals with minimal processor

overhead and seven analog input channels. The device also

contains two auxiliary 8-bit PWM channels, a 16-bit watchdog timer and expanded capability through the serial ports

and 24-bit digital I/O ports.

–7–REV. B

ADMC331

DATA

ADDRESS

GENERATOR

#1

INPUT REGS

ALU

OUTPUT REGS

DATA

ADDRESS

GENERATOR

#2

INPUT REGS

OUTPUT REGS

MAC

INSTRUCTION

PROGRAM

SEQUENCER

16

R BUS

REGISTER

OUTPUT REGS

14

14

24

BUS

EXCHANGE

16

INPUT REGS

SHIFTER

PM ROM

2K 24

PM RAM

2K 24

CONTROL

LOGIC

PMA BUS

DMA BUS

PMD BUS

DMD BUS

TRANSMIT REG

RECEIVE REG

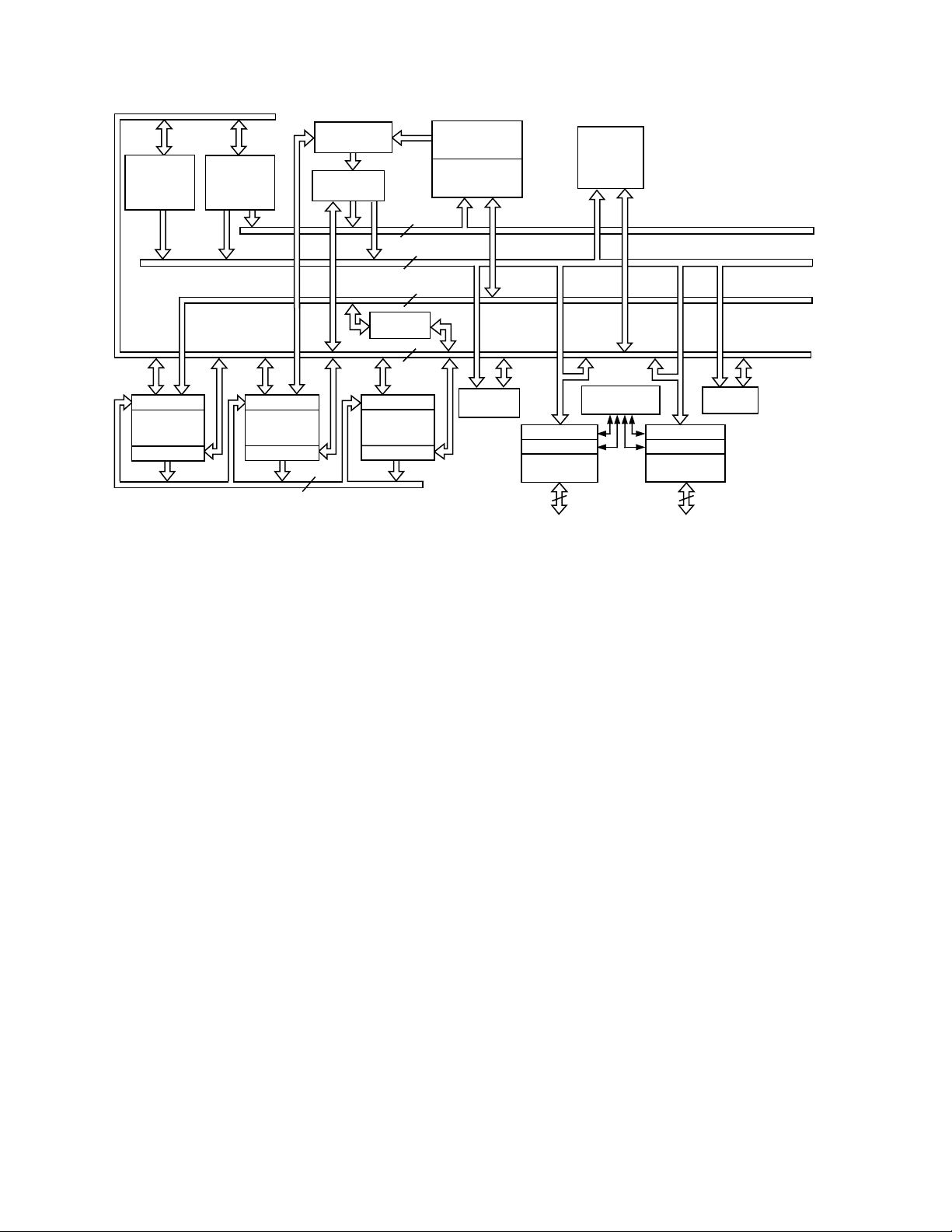

Figure 3. DSP Core Block Diagram

SERIAL

PORT 0

5

DM RAM

1K 16

COMPANDING

CIRCUITRY

TRANSMIT REG

RECEIVE REG

SERIAL

PORT 1

6

TIMER

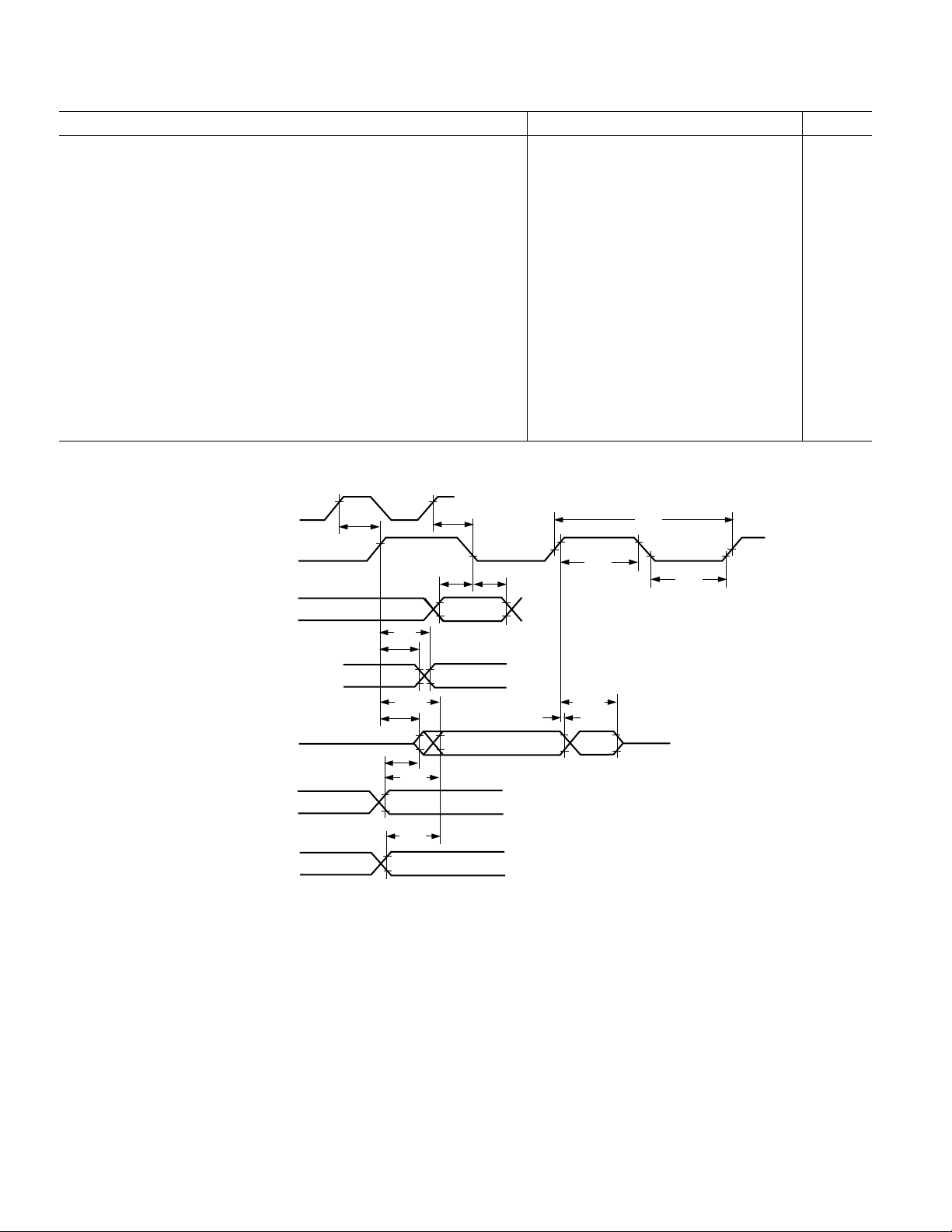

DSP CORE ARCHITECTURE OVERVIEW

Figure 3 is an overall block diagram of the DSP core of the

ADMC331, which is based on the fixed-point ADSP-2171. The

flexible architecture and comprehensive instruction set of the

ADSP-2171 allows the processor to perform multiple operations

in parallel. In one processor cycle (38.5 ns with a 13 MHz

CLKIN) the DSP core can:

• Generate the next program address.

• Fetch the next instruction.

• Perform one or two data moves.

• Update one or two data address pointers.

• Perform a computational operation.

This all takes place while the processor continues to:

• Receive and transmit through the serial ports.

• Decrement the interval timer.

• Generate three-phase PWM waveforms for a power inverter.

• Generate two signals using the 8-bit auxiliary PWM timers.

• Acquire four analog signals.

• Decrement the watchdog timer.

The processor contains three independent computational units:

the arithmetic and logic unit (ALU), the multiplier/accumulator

(MAC) and the shifter. The computational units process 16-bit

data directly and have provisions to support multiprecision computations. The ALU performs a standard set of arithmetic and

logic operations; division primitives are also supported. The

MAC performs single-cycle multiply, multiply/add, multiply/

subtract operations with 40 bits of accumulation. The shifter

performs logical and arithmetic shifts, normalization, denormalization

and derive exponent operations. The shifter can be used to efficiently implement numeric format control including floatingpoint representations.

The internal result (R) bus directly connects the computational

units so that the output of any unit may be the input of any unit

on the next cycle.

A powerful program sequencer and two dedicated data address

generators ensure efficient delivery of operands to these computational units. The sequencer supports conditional jumps and

subroutine calls and returns in a single cycle. With internal loop

counters and loop stacks, the ADMC331 executes looped code

with zero overhead; no explicit jump instructions are required

to maintain the loop.

Two data address generators (DAGs) provide addresses for

simultaneous dual operand fetches from data memory and

program memory. Each DAG maintains and updates four address pointers (I registers). Whenever the pointer is used to

access data (indirect addressing), it is post-modified by the

value in one of four modify (M registers). A length value may

be associated with each pointer (L registers) to implement automatic modulo addressing for circular buffers. The circular buffering feature is also used by the serial ports for automatic data

transfers to and from on-chip memory. DAG1 generates only

data memory address but provides an optional bit-reversal

capability. DAG2 may generate either program or data memory

addresses, but has no bit-reversal capability.

Efficient data transfer is achieved with the use of five internal

buses:

• Program Memory Address (PMA) Bus

• Program Memory Data (PMD) Bus

• Data Memory Address (DMA) Bus

• Data Memory Data (DMD) Bus

• Result (R) Bus

–8–

REV. B

ADMC331

Program memory can store both instructions and data, permitting the ADMC331 to fetch two operands in a single cycle—

one from program memory and one from data memory. The

ADMC331 can fetch an operand from on-chip program memory

and the next instruction in the same cycle.

The ADMC331 writes data from its 16-bit registers to the 24-bit

program memory using the PX register to provide the lower

eight bits. When it reads data (not instructions) from 24-bit

program memory to a 16-bit data register, the lower eight bits

are placed in the PX register.

The ADMC331 can respond to a number of distinct DSP core

and peripheral interrupts. The DSP core interrupts include

serial port receive and transmit interrupts, timer interrupts,

software interrupts and external interrupts. The motor control

peripherals also produce interrupts to the DSP core.

The two serial ports (SPORTs) provide a complete synchronous

serial interface with optional companding in hardware and a

wide variety of framed and unframed data transmit and receive

modes of operation. Each SPORT can generate an internal

programmable serial clock or accept an external serial clock.

Boot loading of both the program and data memory RAM of the

ADMC331 is through the serial port SPORT1.

A programmable interval counter is also included in the DSP

core and can be used to generate periodic interrupts. A 16-bit

count register (TCOUNT) is decremented every n processor

cycle, where n–1 is a scaling value stored in the 8-bit TSCALE

register. When the value of the counter reaches zero, an interrupt is

generated and the count register is reloaded from a 16-bit period register (TPERIOD).

The ADMC331 instruction set provides flexible data moves and

multifunction (one or two data moves with a computation) instructions. Each instruction is executed in a single 38.5 ns processor

cycle (for a 13 MHz CLKIN). The ADMC331 assembly language uses an algebraic syntax for ease of coding and readability. A comprehensive set of development tools support program

development. For further information on the DSP core, refer to

the ADSP-2100 Family User’s Manual, Third Edition, with par-

ticular reference to the ADSP-2171.

Serial Ports

The ADMC331 incorporates two complete synchronous serial

ports (SPORT0 and SPORT1) for serial communication and

multiprocessor communication. Following is a brief list of capabilities of the ADMC331 SPORTs. Refer to the ADSP-2100

Family User’s Manual, Third Edition, for further details.

• SPORTs are bidirectional and have a separate, double-buffered

transmit and receive section.

• SPORTs can use an external serial clock or generate their

own serial clock internally.

• SPORTs have independent framing for the receive and transmit sections. Sections run in a frameless mode or with frame

synchronization signals internally or externally generated. Frame

synchronization signals are active high or inverted, with either of

two pulsewidths and timings.

• SPORTs support serial data word lengths from 3 bits to 16

bits and provide optional A-law and µ-law companding ac-

cording to ITU (formerly CCITT) recommendation G.711.

• SPORT receive and transmit sections can generate unique

interrupts on completing a data word transfer.

• SPORTs can receive and transmit an entire circular buffer of

data with only one overhead cycle per data word. An interrupt

is generated after a data buffer transfer.

• SPORT0 has a multichannel interface to selectively receive

and transmit a 24-word or 32-word, time-division multiplexed, serial bitstream.

• SPORT1 can be configured to have two external interrupts

(IRQ0 and IRQ1), and the Flag In and Flag Out signals. The

internally generated serial clock may still be used in this configuration.

• SPORT1 is the default input for program and data memory

boot loading. The RFS1 pin can be configured internal to the

ADMC331 as an SROM/E

• SPORT1 has two data receive pins (DR1A and DR1B). The

DR1A pin is intended for synchronous boot loading from the

external SROM/E

data receive pin for boot loading from an external asynchronous (UART) connection (SCI compatible), an external

synchronous connection as the data receive pin for an external

device communicating over the debugger interface, or as the

data receive pin for a general purpose SPORT after booting.

These two pins are internally multiplexed onto the one DR1

port of the SPORT. The particular data receive pin selected is

determined by a bit in the MODECTRL register.

2

PROM. The DR1B pin can be used as the

2

PROM reset signal.

–9–REV. B

ADMC331

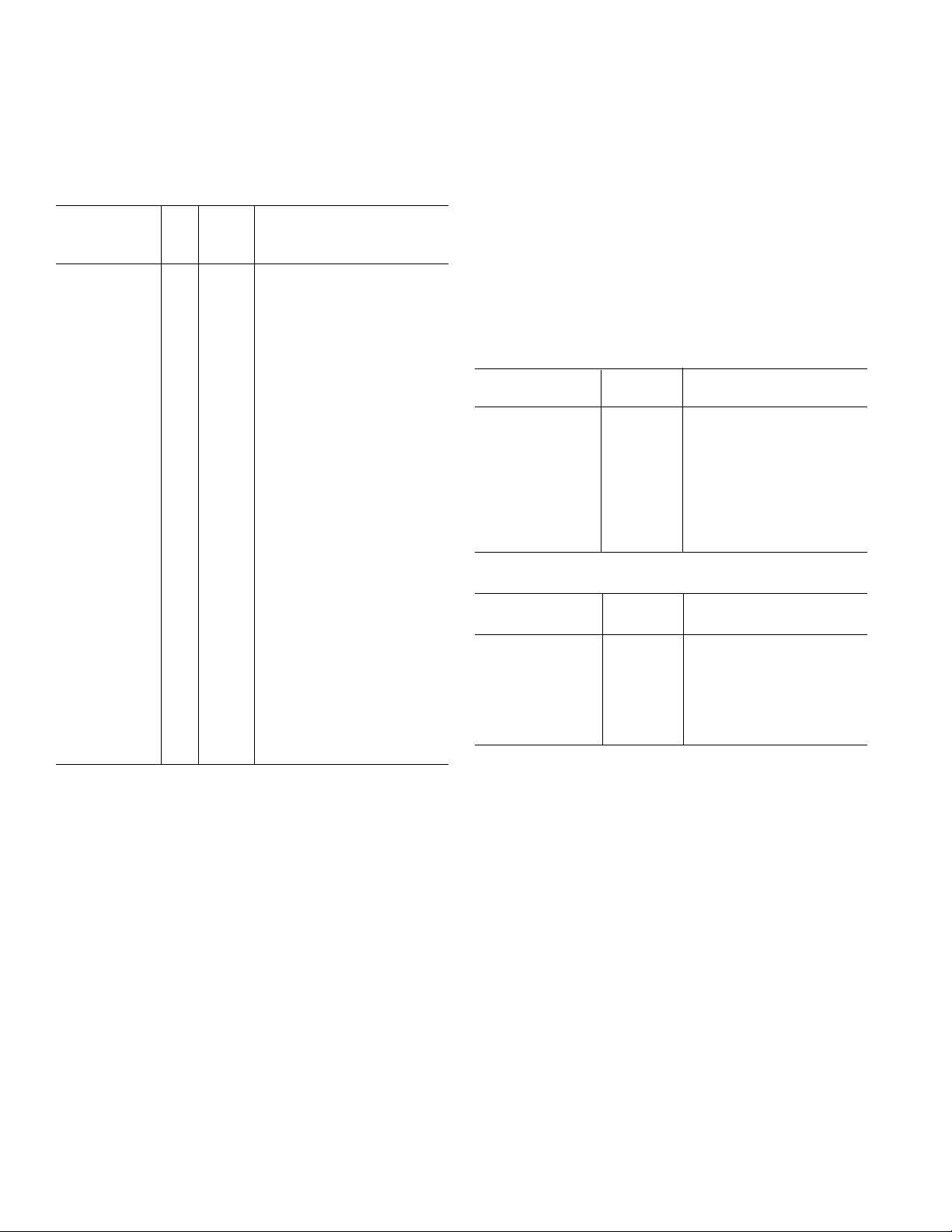

PIN FUNCTION DESCRIPTION

The ADMC331 is available in an 80-lead TQFP package. Table I

contains the pin descriptions.

Table I. Pin List

Pin #

Group of Input/

Name Pins Output Function

RESET 1 I/P Processor Reset Input.

SPORT0 5 I/P, O/P Serial Port 0 Pins (TFS0, RFS0,

DT0, DR0, SCLK0).

SPORT1 6 I/P, O/P Serial Port 1 Pins (TFS1, RFS1,

DT1, DR1A, DR1B, SCLK1).

CLKOUT 1 O/P Processor Clock Output.

CLKIN, XTAL 2 I/P, O/P External Clock or Quartz Crystal

Connection Point.

PIO0–PIO23 24 I/P, O/P Digital I/O Port Pins.

AUX0–AUX1 2 O/P Auxiliary PWM Outputs.

AH–CL 6 O/P PWM Outputs.

PWMTRIP 1 I/P PWM Trip Signal.

PWMPOL 1 I/P PWM Polarity Pin.

PWMSYNC 1 O/P PWM Synchronization Pin.

PWMSR 1 I/P Switch Reluctance Mode Pin.

V1–V3, 3 I/P Analog Inputs.

VAUX0–VAUX3 4 I/P Auxiliary Analog Input

CAPIN 1 I/P ADC Capacitor Input.

ICONST 1 O/P ADC Constant Current Source.

VREF 1 O/P Voltage Reference Output.

AV

DD

AGND 1 Analog Ground.

SGND 1 Analog Signal Ground

V

DD

GND 11

INTERRUPT OVERVIEW

1 Analog Power Supply.

5 Digital Power Supply.

Digital Ground.

The ADMC331 can respond to 34 different interrupt sources

with minimal overhead, 8 of which are internal DSP core

interrupts and 26 interrupts from the motor control peripherals.

The 8 DSP core interrupts are SPORT0 receive and transmit,

SPORT1 receive (or IRQ0) and transmit (or IRQ1), the internal

timer and two software interrupts. The motor control peripheral

interrupts are the 24 peripheral I/Os and two from the PWM

(PWMSYNC pulse and PWMTRIP). All motor control interrupts are multiplexed into the DSP core through the peripheral

IRQ2 interrupt. The interrupts are internally prioritized and individually maskable. A detailed description of the entire interrupt system of the ADMC331 is given later, following a more

detailed description of each peripheral block.

Memory Map

The ADMC331 has two distinct memory types: program

memory and data memory. In general, program memory contains

user code and coefficients, while the data memory is used to store

variables and data during program execution. Both program

memory RAM and ROM are provided on the ADMC331. Program memory RAM is arranged as one contiguous 2K × 24-bit

block, starting at address 0x0000. Program memory ROM is

located at address 0x0800. Data memory is arranged as a 1K ×

16-bit block starting at address 0x3800. The motor control

peripherals are memory mapped into a region of the data

memory space starting at 0x2000. The complete program and

data memory maps are given in Tables II and III, respectively.

Table II. Program Memory Map

Memory

Address Range Type Function

0x0000–0x002F RAM Interrupt Vector Table

0x0030–0x071F RAM User Program Space

0x0720–0x07EC RAM Reserved by Debugger

0x07ED–0x07FF RAM Reserved by Monitor

0x0800–0x0DEC ROM ROM Monitor

0x0DED–0x0FEA ROM ROM Math and Motor

Control Utilities

0x0FEB–0x0FFF ROM Reserved

Table III. Data Memory Map

Memory

Address Range Type Function

0x0000–0x1FFF Reserved

0x2000–0x20FF Memory Mapped Registers

0x2100–0x37FF Reserved

0x3800–0x3B5F RAM User Data Space

0x3B60–0x3BFF RAM Reserved by Monitor

0x3C00–0x3FFF Memory Mapped Registers

ROM Code

The 2K × 24-bit block of program memory ROM starting at address 0x0800 contains a monitor function that is used to download

and execute user programs via the serial port. In addition, the

monitor function supports an interactive mode in which commands

are received and processed from a host. An example of such a host

is the Windows

®

-based Motion Control Debugger, which is part of

the software development system for the ADMC331. In the interactive mode, the host can access both the internal DSP and peripheral motor control registers of the ADMC331, read and write to

both program and data memory, implement breakpoints and perform single-step and run/halt operation as part of the program

debugging cycle.

In addition to the monitor function, the program memory ROM

contains a number of useful mathematical and motor control utilities that can be called as subroutines from the user code. A complete list of these ROM functions is given in Table IV. The start

address of the function in the program memory ROM is also given.

Refer to the ADMC331 DSP Motor Controller Developer’s Reference

Manual for more details of the ROM functions.

Windows is a registered trademark of Microsoft Corporation.

–10–

REV. B

ADMC331

Table IV. ROM Utilities

Utility Address Function

PER_RST 0x07F1 Reset Peripherals.

UMASK 0x0DED Limits Unsigned Value to

Given Range.

PUT_VECTOR 0x0DF4 Facilitates User Setup of

Vector Table.

SMASK 0x0E06 Limits Signed Value to Given

Range.

ADMC_COS 0x0E26 Cosine Function.

ADMC_SIN 0x0E2D Sine Function.

ARCTAN 0x0E43 Arctangent Function.

RECIPROCAL 0x0E65 Reciprocal (1/×) Function.

SQRT 0x0E7B Square Root Function.

LN 0x0EB5 Natural Logarithm Function.

LOG 0x0EB8 Logarithm (Base 10) Function.

FLTONE 0x0ED4 Fixed Pt. to Float Conversion.

FIXONE 0x0ED9 Float to Fixed Pt. Conversion.

FPA 0x0EDD Floating Pt. Addition.

FPS 0x0EEC Floating Pt. Subtraction.

FPM 0x0EFC Floating Pt. Multiplication.

FPD 0x0F05 Floating Pt. Division.

FPMACC 0x0F26 Floating Pt. Multiply/Accumulate.

PARK 0x0F48 Forward/Reverse Park

Transformation.

REV_CLARK 0x0F5C Reverse Clark Transformation.

FOR_CLARK 0x0F72 Forward Clark Transformation.

COS64 0x0F80 64 Pt. COS Table.

ONE_BY_X 0x0FCO 16 Pt. 1/× Table.

SDIVQINT 0x0FD0 Unsigned Single Precision

Division (Integer).

SDIVQ 0x0FD9 Unsigned Single Precision

Division (Fractional).

SYSTEM INTERFACE

Figure 4 shows a basic system configuration for the ADMC331,

with an external crystal and serial E

2

PROM for boot loading of

program and data memory RAM.

CLKOUT

ADMC331

RESET

XTAL

CLKIN

DR1A

SCLK1

RFS1/ SROM

13 MHz

DATA

CLK

RESET

SERIAL

2

E

PROM

Figure 4. Basic System Configuration

Clock Signals

The ADMC331 can be clocked by either a crystal or a TTLcompatible clock signal. The CLKIN input cannot be halted,

changed during operation nor operated below the specified

minimum frequency during normal operation. If an external

clock is used, it should be a TTL-compatible signal running at

half the instruction rate. The signal is connected to the CLKIN

pin of the ADMC331. In this mode, with an external clock

signal, the XTAL pin must be left unconnected. The ADMC331

uses an input clock with a frequency equal to half the instruction rate; a 13 MHz input clock yields a 38.5 ns processor cycle

(which is equivalent to 26 MHz). Normally, instructions are

executed in a single processor cycle. All device timing is

relative to the internal instruction rate, which is indicated by

the CLKOUT signal.

Because the ADMC331 includes an on-chip oscillator feedback

circuit, an external crystal may be used instead of a clock

source, as shown in Figure 4. The crystal should be connected

across the CLKIN and XTAL pins, with two capacitors as

shown in Figure 4. A parallel-resonant, fundamental frequency,

microprocessor-grade crystal should be used. A clock output

signal (CLKOUT) is generated by the processor at the processor’s

cycle rate of twice the input frequency. This output can be

enabled and disabled by the CLKODIS bit of the SPORT0

Autobuffer Control Register, DM[0x3FF3]. However, extreme

care must be exercised when using this bit since disabling

CLKOUT effectively disables all motor control peripherals,

except the watchdog timer.

Reset

The RESET signal initiates a master reset of the ADMC331.

The RESET signal must be asserted during the power-up sequence to assure proper initialization. RESET during initial

power-up must be held long enough to allow the internal clock

to stabilize. If RESET is activated any time after power-up, the

clock continues to run and does not require stabilization time.

The power-up sequence is defined as the total time required for

the crystal oscillator circuit to stabilize after a valid V

DD

is applied to the processor, and for the internal phase-locked loop

(PLL) to lock onto the specific crystal frequency. A minimum

of 2000 CLKIN cycles ensures that the PLL has locked, but

does not include the crystal oscillator start-up time. During this

power-up sequence, the RESET signal should be held low. On

any subsequent resets, the RESET signal must meet the minimum pulsewidth specification, t

RSP

.

If an RC circuit is used to generate the RESET signal, the use of

an external Schmitt trigger is recommended.

The master reset sets all internal stack pointers to the empty

stack condition, masks all interrupts, initializes DSP core registers and performs a full reset of all of the motor control peripherals. When the RESET line is released, the first instruction is

fetched from internal program memory ROM at location 0x0800.

The internal monitor code at this location then commences the

boot-loading sequence over the serial port, SPORT1. A software controlled full peripheral reset is achieved by toggling the

DSP FL2 flag from 1 to 0 to 1 again.

–11–REV. B

ADMC331

Boot Loading

On power-up or reset, the ADMC331 is configured so that

execution begins at the internal PM ROM at address 0x0800.

This starts execution of the internal monitor function that first

performs some initialization functions and copies a default interrupt vector table to addresses 0x0000–0x002F of program memory

RAM. The monitor next attempts to boot load from an external

SROM or E

2

PROM on SPORT1 using the three wire connec-

tion of Figure 4. The monitor program first toggles the RFS1/

SROM pin of the ADMC331 to reset the serial memory device.

If an SROM or E

2

PROM is connected to SPORT1, data is

clocked into the ADMC331 at a rate CLKOUT/20. Both program and data memory RAM can be loaded from the SROM or

2

PROM. After the boot load is complete, program execution

E

begins at address 0x0030. This is where the first instruction of

the user code should be placed.

If boot loading from an E

2

PROM is unsuccessful, the monitor

code reconfigures SPORT1 as a UART and attempts to receive

commands from an external device on this serial port. The

monitor then waits for a byte to be received over SPORT1,

locks onto the baud rate of the external device (autobaud feature) and takes in a header word that tells it with what type of

device it is communicating. There are six alternatives:

• A UART boot loader such as a Motorola 68HC11SCI port.

• A synchronous slave boot loader (the clock is external).

• A synchronous master boot loader (the ADMC331 provides the

clock).

• A UART debugger interface.

• A synchronous master debugger interface.

• A synchronous slave debugger interface.

With the debugger interface, the monitor enters an interactive

mode in which it processes commands received from the external device.

DSP Control Registers

The DSP core has a system control register, SYSCNTL, memory

mapped at DM (0x3FFF). SPORT0 is enabled when Bit 12 is

set, disabled when this bit is cleared. SPORT1 is enabled when

Bit 11 is set, disabled when this bit is cleared. SPORT1 is configured as a serial port when Bit 10 is set, or as flags and interrupt lines when this bit is cleared. For proper operation of the

ADMC331, all other bits in this register must be cleared (which

is their default).

The DSP core has a wait state control register, MEMWAIT,

memory mapped at DM (0x3FFE). For proper operation of the

ADMC331, this register must always contain the value 0x8000

(which is the default).

The configuration of both the SYSCNTL and MEMWAIT

registers of the ADMC331 is shown at the end of the data sheet.

THREE-PHASE PWM CONTROLLER

Overview

The PWM generator block of the ADMC331 is a flexible, programmable, three-phase PWM waveform generator that can be

programmed to generate the required switching patterns to drive

a three-phase voltage source inverter for ac induction (ACIM),

or permanent magnet synchronous (PMSM) or a switched or

variable reluctance (SRM) motor control. In addition, the

PWM block contains special functions that considerably simplify the generation of the required PWM switching patterns for

control of the electronically commutated motor (ECM) or

brushless dc motor (BDCM).

The PWM generator produces three pairs of PWM signals on

the six PWM output pins (AH, AL, BH, BL, CH and CL). The

six PWM output signals consist of three high side drive signals

(AH, BH and CH) and three low side drive signals (AL, BL and

CL). The polarity of the generated PWM signals may be

programmed by the PWMPOL pin, so that either active HI or

active LO PWM patterns can be produced by the ADMC331.

The switching frequency, dead time and minimum pulsewidths

of the generated PWM patterns are programmable using respectively the PWMTM, PWMDT and PWMPD registers. In addition, three duty cycle control registers (PWMCHA, PWMCHB

and PWMCHC) directly control the duty cycles of the three

pair of PWM signals.

When the PWMSR pin is pulled low, the PWM generator transforms the six PWM output signals into six waveforms for

switched reluctance gate drive signals. The low side PWM

signals from the three-phase timing unit assume permanently

ON states, independent of the value written to the duty-cycle

registers. The duty cycles of the high side PWM signals from the

timing unit are still determined by the three duty-cycle registers.

Each of the six PWM output signals can be enabled or disabled

by separate output enable bits of the PWMSEG register. In

addition, three control bits of the PWMSEG register permit

crossover of the two signals of a PWM pair for easy control of

ECM or BDCM. In crossover mode, the PWM signal destined

for the high side switch is diverted to the complementary low

side output and the signal destined for the low side switch is

diverted to the corresponding high side output signal.

In many applications, there is a need to provide an isolation

barrier in the gate-drive circuits that turn on the power devices

of the inverter. In general, there are two common isolation

techniques, optical isolation using opto-couplers, and transformer isolation using pulse transformers. The PWM controller

of the ADMC331 permits mixing of the output PWM signals

with a high frequency chopping signal to permit easy interface to

such pulse transformers. The features of this gate-drive chopping mode can be controlled by the PWMGATE register. There

is an 8-bit value within the PWMGATE register that directly controls the chopping frequency. In addition, high frequency chopping

can be independently enabled for the high side and the low side

outputs using separate control bits in the PWMGATE register.

The PWM generator is capable of operating in two distinct

modes, single update mode or double update mode. In single

update mode, the duty cycle values are programmable only once

per PWM period, so that the resultant PWM patterns are symmetrical about the midpoint of the PWM period. In the double

update mode, a second updating of the PWM duty cycle values

is implemented at the midpoint of the PWM period. In this

mode, it is possible to produce asymmetrical PWM patterns,

that produce lower harmonic distortion in three-phase PWM

inverters. This technique also permits the closed loop controller

to change the average voltage applied to the machine winding at

a faster rate and so permits fast closed loop bandwidths to be

achieved. The operating mode of the PWM block (single or

double update mode) is selected by a control bit in MODECTRL

register.

–12–

REV. B

ADMC331

PWM CONFIGURATION

REGISTERS

PWMTM (15 . . . 0)

PWMDT (9 . . . 0)

PWMPD (9 . . . 0)

PWMSYNCWT (7 . . . 0)

MODECTRL (6)

THREE-PHASE

PWM TIMING

CLK

PWMSYNC

TO INTERRUPT

CONTROLLER

PWMTRIP

PWM DUTY CYCLE

REGISTERS

PWMCHA (15 . . . 0)

PWMCHB (15 . . . 0)

PWMCHC (15 . . . 0)

PWMSEG PWMGATE

UNIT

SYNC

RESET

SWITCHED

RELUCTANCE

CONTROL

UNIT

SR

OR

OUTPUT

CONTROL

UNIT

SYNC

PWMSWT (0)

Figure 5. Overview of the PWM Controller of the ADMC331

CLK

GATE

DRIVE

UNIT

POL

AH

AL

BH

BL

CH

CL

CLKOUT

PWMSYNC

PWMPOL

PWMSR

PWMTRIP

The PWM generator of the ADMC331 also provides an output

pulse on the PWMSYNC pin that is synchronized to the PWM

switching frequency. In single update mode, a PWMSYNC

pulse is produced at the start of each PWM period. In double

update mode, an additional PWMSYNC pulse is produced at

the midpoint of each PWM period. The width of the PWMSYNC pulse is programmable through the PWMSYNCWT

register.

The PWM signals produced by the ADMC331 can be shut-off

in two different ways. Firstly there is a dedicated asynchronous

PWM shutdown pin, PWMTRIP, that when brought LO, instantaneously places all six PWM outputs in the OFF state (as

determined by the state of the PWMPOL pin). This hardware

shutdown mechanism is asynchronous so that the associated

PWM disable circuitry does not go through any clocked logic,

thereby ensuring correct PWM shutdown even in the event of a

loss of DSP clock. In addition to the hardware shutdown feature, the PWM system may be shutdown in software by writing

to the PWMSWT register.

Status information about the PWM system of the ADMC331 is

available to the user in the SYSSTAT register. In particular,

the state of the PWMTRIP, PWMPOL and PWMSR pins is

available, as well as a status bit that indicates whether operation

is in the first half or the second half of the PWM period.

A functional block diagram of the PWM controller is shown in

Figure 5. The generation of the six output PWM signals on

pins AH to CL is controlled by four important blocks:

• The Three-Phase PWM Timing Unit, which is the core of the

PWM controller, generates three pairs of complemented and

dead time adjusted center based PWM signals.

• The Switched Reluctance Control Unit transforms the threephase outputs into six PWM wave forms for switched reluctance gate drive signals.

• The Output Control Unit allows the redirection of the outputs of the Three-Phase Timing Unit for each channel to

either the high side or the low side output. In addition, the

Output Control Unit allows individual enabling/disabling of

each of the six PWM output signals.

• The GATE Drive Unit provides the correct polarity output

PWM signals based on the state of the PWMPOL pin. The

Gate Drive Unit also permits the generation of the high frequency chopping frequency and its subsequent mixing with

the PWM signals.

The PWM controller is driven by a clock at the same frequency

as the DSP instruction rate, CLKOUT, and is capable of generating two interrupts to the DSP core. One interrupt is generated on the occurrence of a PWMSYNC pulse and the other is

generated on the occurrence of any PWM shutdown action.

Three-Phase Timing Unit

The 16-bit three-phase timing unit is the core of the PWM

controller and produces three pair of pulsewidth modulated

signals with high resolution and minimal processor overhead.

The outputs of this timing unit are active LO such that a low

level is interpreted as a command to turn ON the associated

power device. There are four main configuration registers

(PWMTM, PWMDT, PWMPD and PWMSYNCWT) that

determine the fundamental characteristics of the PWM outputs.

In addition, the operating mode of the PWM (single or double

update mode) is selected by Bit 6 of the MODECTRL register.

–13–REV. B

ADMC331

These registers, in conjunction with the three 16-bit duty-cycle

registers (PWMCHA, PWMCHB and PWMCHC), control the

output of the three-phase timing unit.

PWM Switching Frequency, PWMTM Register

The PWM switching frequency is controlled by the 16-bit read/

write PWM period register, PWMTM. The fundamental timing

unit of the PWM controller is t

(DSP instruction rate).

CK

Therefore, for a 26 MHz CLKOUT, the fundamental time

increment is 38.5 ns. The value written to the PWMTM register is effectively the number of t

clock increments in half a

CK

PWM period. The required PWMTM value is a function of the

desired PWM switching frequency (f

f

PWMTM =

CLKOUT

2 × f

) and is given by:

PWM

f

CLKIN

=

f

PWM

PWM

Therefore, the PWM switching period, TS, can be written as:

TS= 2 × PWMTM × t

CK

For example, for a 26 MHz CLKOUT and a desired PWM

switching frequency of 10 kHz (TS = 100 µs), the correct value

to load into the PWMTM register is:

6

PWMTM =

26 ×10

2 ×10 ×10

= 1300

3

The largest value that can be written to the 16-bit PWMTM

register is 0xFFFF = 65,535 which corresponds to a minimum

PWM switching frequency of:

6

f

PWM,min

PWM Switching Dead Time, PWMDT Register

26 ×10

=

2 × 65,535

= 198.4 Hz

The second important parameter that must be set up in the

initial configuration of the PWM block is the switching dead

time. That is a short delay time introduced between turning off

one PWM signal (AH) and turning on the complementary signal, AL. This short time delay is introduced to permit the

power switch being turned off (AH in this case) to completely

recover its blocking capability before the complementary switch

is turned on. This time delay prevents a potentially destructive

short-circuit condition from developing across the dc link capacitor of a typical voltage source inverter.

The dead time is controlled by the 10-bit, read/write PWMDT

register. There is only one dead time register that controls the

dead time inserted into the three pairs of PWM output signals.

The dead time, T

, is related to the value in the PWMDT regis-

D

ter by:

TD= PWMTM × 2 × t

CK

Therefore, a PWMDT value of 0x00A (= 10), introduces a

769.2 ns delay between the turn-off on any PWM signal (AH)

and the turn-on of its complementary signal (AL). The amount

of the dead time can therefore be programmed in increments of

(or 76.92 ns for a 26 MHz CLKOUT). The PWMDT

2t

CK

register is a 10-bit register so that its maximum value is 0x3FF

(=1023) corresponding to a maximum programmed dead time

of:

T

= 1023 × 2 × tCK = 1023 × 2 × 38.46 × 10–9 = 78.69 µs

D,max

for a CLKOUT rate of 26 MHz. Obviously, the deadtime can

be programmed to be zero by writing 0 to the PWMDT register.

PWM Operating Mode, MODECTRL and SYSSTAT Registers

The PWM controller of the ADMC331 can operate in two

distinct modes: single update mode and double update mode.

The operating mode of the PWM controller is determined by

the state of Bit 6 of the MODECTRL register. If this bit is

cleared, the PWM operates in the single update mode. Setting

Bit 6 places the PWM in the double update mode. By default,

following either a peripheral reset or power on, Bit 6 of the

MODECTRL register is cleared so that the default operating

mode is in single update mode.

In single update mode, a single PWMSYNC pulse is produced

in each PWM period. The rising edge of this signal marks the

start of a new PWM cycle and is used to latch new values from

the PWM configuration registers (PWMTM, PWMDT, PWMPD

and PWMSYNCWT) and the PWM duty-cycle registers

(PWMCHA, PWMCHB and PWMCHC) into the three-phase

timing unit. In addition, the PWMSEG register is also latched

into the output control unit on the rising edge of the PWMSYNC

pulse. In effect, this means that the characteristics and resultant

duty cycles of the PWM signals can be updated only once per

PWM period at the start of each cycle. The result is that PWM

patterns that are symmetrical about the midpoint of the switching period are produced.

In double update mode, there is an additional PWMSYNC

pulse produced at the midpoint of each PWM period. The rising

edge of this new PWMSYNC pulse is again used to latch new

values of the PWM configuration registers, duty-cycle registers

and the PWMSEG register. As a result it is possible to alter

both the characteristics (switching frequency, dead time, minimum

pulsewidth and PWMSYNC pulsewidth) as well as the output

duty cycles at the midpoint of each PWM cycle. Consequently, it is

possible to produce PWM switching patterns that are no longer

symmetrical about the midpoint of the period (asymmetrical

PWM patterns).

In the double update mode, it may be necessary to know whether

operation at any point in time is in either the first half or the

second half of the PWM cycle. This information is provided by

Bit 3 of the SYSSTAT register, which is cleared during operation in the first half of each PWM period (between the rising

edge of the original PWMSYNC pulse and the rising edge of

the new PWMSYNC pulse introduced in double update mode).

Bit 3 of the SYSSTAT register is set during operation in the

second half of each PWM period. This status bit allows the user

to make a determination of the particular half-cycle during

implementation of the PWMSYNC interrupt service routine, if

required.

The advantage of the double update mode is that lower harmonic voltages can be produced by the PWM process and faster

control bandwidths are possible. However, for a given PWM

switching frequency, the PWMSYNC pulses occur at twice the

rate in the double update mode. Since new duty cycle values

must be computed in each PWMSYNC interrupt service routine, there is a larger computational burden on the DSP in the

double update mode.

–14–

REV. B

ADMC331

Width of the PWMSYNC Pulse, PWMSYNCWT Register

The PWM controller of the ADMC331 produces an output

PWM synchronization pulse at a rate equal to the PWM switching frequency in single update mode and at twice the PWM

frequency in the double update mode. This pulse is available

for external use at the PWMSYNC pin. The width of this

PWMSYNC pulse is programmable by the 8-bit read/write

PWMSYNCWT register. The width of the PWMSYNC pulse,

T

PWMSYNC

so that the width of the pulse is programmable from t

, is given by:

T

PWMSYNC

= tCK × (PWMSYNCWT + 1)

to 256 t

CK

CK

(corresponding to 38.5 ns to 9.84 µs for a CLKOUT rate of

26 MHz). Following a reset, the PWMSYNCWT register contains 0x27 (= 39) so that the default PWMSYNC width is

1.54 µs, again for a 26 MHz CLKOUT.

PWM Duty Cycles, PWMCHA, PWMCHB, PWMCHC

Registers

The duty cycles of the six PWM output signals on pins AH to

CL are controlled by the three 16-bit read/write duty-cycle

registers, PWMCHA, PWMCHB, and PWMCHC. The integer

value in the register PWMCHA controls the duty cycle of the

signals on AH and AL, in PWMCHB, controls the duty cycle of

the signals on BH and BL and in PWMCHC, controls the duty

cycle of the signals on CH and CL. The duty-cycle registers are

programmed in integer counts of the fundamental time unit,

, and define the desired on-time of the high side PWM signal

t

CK

produced by the three-phase timing unit over half the PWM

period. The switching signals produced by the three-phase

timing unit are also adjusted to incorporate the programmed

dead time value in the PWMDT register. The three-phase

timing unit produces active LO signals so that a LO level corresponds to a command to turn on the associated power device.

A typical pair of PWM outputs (in this case for AH and AL)

from the timing unit are shown in Figure 6 for operation in

single update mode. All illustrated time values indicate the

integer value in the associated register and can be converted to

time simply by multiplying by the fundamental time increment,

t

. Firstly, it is noted that the switching patterns are perfectly

CK

symmetrical about the midpoint of the switching period in

this single update mode since the same values of PWMCHA,

PWMTM and PWMDT are used to define the signals in both

half cycles of the period. It can be seen how the programmed

duty cycles are adjusted to incorporate the desired dead time

into the resultant pair of PWM signals. Clearly, the dead time is

incorporated by moving the switching instants of both PWM

signals (AH and AL) away from the instant set by the PWMCHA

register. Both switching edges are moved by an equal amount

(PWMDT × t

) to preserve the symmetrical output patterns.

CK

Also shown is the PWMSYNC pulse whose width is set by the

PWMSYNCWT register and Bit 3 of the SYSSTAT register,

which indicates whether operation is in the first or second half

cycle of the PWM period.

Obviously negative values of T

and TAL are not permitted and

AH

the minimum permissible value is zero, corresponding to a 0%

duty cycle. In a similar fashion, the maximum value is T

,

S

corresponding to a 100% duty cycle.

PWMCHA

AH

2 PWMDT

AL

PWMSYNC

SYSSTAT (3)

PWMTM PWMTM

PWMCHA

2 PWMDT

PWMSYNCWT + 1

Figure 6. Typical PWM Outputs of Three-Phase Timing

Unit in Single Update Mode (Active LO Waveforms)

The resultant on-times of the PWM signals in Figure 6 may be

written as:

T

= 2 × (PWMCHA – PWMDT) × t

AH

TAL = 2 × (PWMTM–PWMCHA–PWMDT) × t

CK

CK

and the corresponding duty cycles are:

T

PWMCHA – PWMDT

AH

=

T

S

T

PWMTM – PWMCHA – PWMDT

AL

=

T

S

PWMTM

PWMTM

dAL=

dAH=

The output signals from the timing unit for operation in double

update mode are shown in Figure 7. This illustrates a completely general case where the switching frequency, dead time

and duty cycle are all changed in the second half of the PWM

period. Of course, the same value for any or all of these quantities could be used in both halves of the PWM cycle. However,

it can be seen that there is no guarantee that symmetrical PWM

signal will be produced by the timing unit in this double update

mode. Additionally, it is seen that the dead time is inserted into

the PWM signals in the same way as in the single update mode.

AH

AL

PWMSYNC

SYSSTAT (3)

2 PWMDT

PWMSYNCWT1 + 1

PWMTM

PWMCHA

1

1

1

PWMCHA

2

2 PWMDT

PWMSYNCWT2 + 1

PWMTM

2

2

Figure 7. Typical PWM Outputs of Three-Phase Timing

Unit in Double Update Mode (Active LO Waveforms)

In general, the on-times of the PWM signals in double update

mode can be defined as:

TAH= PWMCHA1+ PWMCHA2− PWMDT1− PWMDT

()

TAL= ( PWMTM1+ PWMTM2– PWMCHA1– PWMCHA

– PWMDT1– PWMDT2) ×

t

CLK

× t

2

CK

2

–15–REV. B

ADMC331

where the subscript 1 refers to the value of that register during

the first half cycle and the subscript 2 refers to the value during

the second half cycle. The corresponding duty cycles are:

T

dAL=

dAL=

AH

T

S

T

AL

T

S

(PWMCHA

=

(PWMTM

=

+ PWMCHA2– PWMDT1– PWMDT2)

1

(PWMTM

+ PWMTM2– PWMCHA1– PWMCHA2– PWMDT1– PWMDT2)

1

+ PWMTM2)

1

(PWMTM

+ PWMTM2)

1

since for the completely general case in double update mode,

the switching period is given by:

TS= (PWMTM1+ PWMTM2)× t

CK

Again, the values of TAH and TAL are constrained to lie between

zero and T

.

S

Similar PWM signals to those illustrated in Figure 6 and Figure 7 can be produced on the BH, BL, CH and CL outputs by

programming the PWMCHB and PWMCHC registers in a manner identical to that described for PWMCHA.

The PWM controller does not produce any PWM outputs until

all of the PWMTM, PWMCHA, PWMCHB and PWMCHC

registers have been written to at least once. Once these registers

have been written, internal counting of the timers in the threephase timing unit is enabled.

Effective PWM Resolution

In single update mode, the same value of PWMCHA, PWMCHB and PWMCHC are used to define the on-times in both

half cycles of the PWM period. As a result, the effective resolution of the PWM generation process is 2 t

(or 76.9 ns for a

CK

26 MHz CLKOUT) since incrementing one of the duty-cycle

registers by 1 changes the resultant on-time of the associated

PWM signals by t

in each half period (or 2 tCK for the full

CK

period).

In double update mode, improved resolution is possible since

different values of the duty cycles registers are used to define the

on-times in both the first and second halves of the PWM period.

As a result, it is possible to adjust the on-time over the whole

period in increments of t

PWM resolution of t

. This corresponds to an effective

CK

in double update mode (or 38.5 ns for a

CK

26 MHz CLKOUT).

The achievable PWM switching frequency at a given PWM

resolution is tabulated in Table V.

Table V. Achievable PWM Resolution in Single and Double

Update Modes

Resolution Single Update Mode Double Update Mode

(Bit) PWM Frequency (kHz) PWM Frequency (kHz)

8 50.7 101.5

9 25.4 50.7

10 12.7 25.4

11 6.3 12.7

12 3.2 6.3

Minimum Pulsewidth, PWMPD Register

In many power converter switching applications, it is desirable

to eliminate PWM switching signals below a certain width. It

takes a certain finite time to both turn on and turn off modern

power semiconductor devices. Therefore, if the width of any of

the PWM signals goes below some minimum value, it may be

desirable to completely eliminate the PWM switching for that

particular cycle.

The allowable minimum on-time for any of the six PWM outputs over half a PWM period that can be produced by the PWM

controller may be programmed using the 10-bit read/write

PWMPD register. The minimum on-time is programmed in

increments of t

produced over any half PWM period, T

so that the minimum on-time that will be

CK

, is related to the

MIN

value in the PWMPD register by:

T

= PWMPD ×t

MIN

CK

so that a PWMPD value of 0x002 defines a permissible minimum on-time of 76.9 ns for a 26 MHz CLKOUT.

In each half cycle of the PWM, the timing unit checks the ontime of each of the six PWM signals. If any of the times are

found to be less than the value specified by the PWMPD register, the corresponding PWM signal is turned OFF for the entire

half period and its complementary signal is turned completely

ON.

Consider the example where PWMTM = 200, PWMCHA = 5,

PWMDT = 3, PWMPD = 10 with a CLKOUT of 26 MHz

and operation in single update mode. In this case, the PWM

switching frequency is 65 kHz and the dead time is 230 ns.

The permissible on-time of any PWM signal over one half of

any period is 384.6 ns. Clearly, for this example, the dead

time adjusted on-time of the AH signal over half a PWM

period is (5–3) × 38.5 ns = 77 ns. This is less than the permissible value, so the timing unit will output a completely OFF

(0% duty cycle) signal on AH. Additionally, the AL signal will

be turned ON for the entire half period (100% duty cycle).

Switched Reluctance Mode

The PWM block of the ADMC331 contains a switched reluctance mode that is controlled by the state of the PWMSR pin.

The switched reluctance (SR) mode is enabled by connecting

the PWMSR pin to GND. In this SR mode, the low side PWM

signals from the three-phase timing unit assume permanently

ON states, independent of the value written to the duty-cycle

registers. The duty cycles of the high side PWM signals from

the timing unit are still determined by the three duty-cycle registers. Using the crossover feature of the output control unit, it is

possible to divert the permanently ON PWM signals to either

the high side or the low side outputs. This mode is necessary

because in the typical power converter configuration for switched

or variable reluctance motors, the motor winding is connected

between the two power switches of a given inverter leg. Therefore, in order to build up current in the motor winding, it is

necessary to turn on both switches at the same time. Typical

active LO PWM signals during operation in SR mode are shown

in Figure 8 for operation in double update mode. It is clear that

the three low side signals (AL, BL and CL) are permanently ON

and the three high side signals are modulated so that the corresponding high side power switches are switched between the ON

and OFF states.

–16–

REV. B

ADMC331

AH

AL

BH

BL

CH

CL

PWMTM

PWMTM

PWMCHA

= PWMCHB

PWMCHA

= PWMCHB

2 PWMDT

2 PWMDT

PWMCHA

1

PWMCHA

2

2

PWMTM

2

2

AH

BH

CH

AL

BL

CL

PWMCHB

PWMCHC

PWMTM

1

1

1

PWMCHB

PWMCHC

Figure 8. Active LO PWM signals in SR Mode (PWMPOL =

PWMSR

= GND) for ADMC331 in double update mode.

The signals from the three-phase unit are not crossed over

(PWMSEG = 0) and the dead time is zero (PWMDT = 0).

The SR mode can only be enabled by connecting the PWMSR

pin to GND. There is no software means by which this mode

can be enabled. There is an internal pull-up resistor on the

PWMSR pin so that if this pin is left unconnected or becomes

disconnected the SR mode is disabled. Of course, the SR mode

is disabled when the PWMSR pin is tied to V

. The state of

DD

the PWMSR pin may be read from Bit 4 of the SYSSTAT

register.

Output Control Unit, PWMSEG Register

The operation of the Output Control Unit is controlled by the

9-bit read/write PWMSEG register that controls two distinct

features that are directly useful in the control of ECM or BDCM.

The PWMSEG register contains three crossover bits, one for

each pair of PWM outputs. Setting Bit 8 of the PWMSEG

register enables the crossover mode for the AH/AL pair of PWM

signals; setting Bit 7 enables crossover on the BH/BL pair of

PWM signals; setting Bit 6 enables crossover on the CH/CL

pair of PWM signals. If crossover mode is enabled for any pair

of PWM signals, the high side PWM signal from the timing unit

(i.e. AH) is diverted to the associated low side output of the

Output Control Unit so that the signal will ultimately appear at

the AL pin. Of course, the corresponding low side output of the

Timing Unit is also diverted to the complementary high side

output of the Output Control Unit so that the signal appears at

the AH pin. Following a reset, the three crossover bits are

cleared so that the crossover mode is disabled on all three pairs

of PWM signals.

The PWMSEG register also contains six bits (Bits 0 to 5) that

can be used to individually enable or disable each of the six

PWM outputs. The PWM signal of the AL pin is enabled by

setting Bit 5 of the PWMSEG register while Bit 4 controls AH,

Bit 3 controls BL, Bit 2 controls BH, Bit 1 controls CL and

Bit 0 controls the CH output. If the associated bit of the

PWMSEG register is set, then the corresponding PWM output

is disabled irrespective of the value of the corresponding duty

cycle register. This PWM output signal will remain in the OFF

state as long as the corresponding enable/disable bit of the

PWMSEG register is set. The implementation of this output

enable function is implemented after the crossover function.

Following a reset, all six enable bits of the PWMSEG register

are cleared so that all PWM outputs are enabled by default.

In a manner identical to the duty-cycle registers, the PWMSEG

is latched on the rising edge of the PWMSYNC signal so that

the changes to this register only become effective at the start of

each PWM cycle in single update mode. In double update mode,

the PWMSEG register can also be updated at the midpoint of

the PWM cycle.

In the control of an ECM, only two inverter legs are switched

at any time and often the high side device in one leg must be

switched ON at the same time as the low side driver in a second

leg. Therefore, by programming identical duty cycles values for

two PWM channels (i.e., PWMCHA = PWMCHB) and setting

Bit 7 of the PWMSEG register to crossover the BH/BL pair if

PWM signals, it is possible to turn ON the high side switch of

phase A and the low side switch of Phase B at the same time.

In the control of ECM, it is usual that the third inverter leg

(Phase C in this example) be permanently disabled for a number

of PWM cycles. This function is implemented by disabling both

the CH and CL PWM outputs by setting Bits 0 and 1 of the

PWMSEG register. This situation is illustrated in Figure 9

where it can be seen that both the AH and BL signals are identical, since PWMCHA = PWMCHB and the crossover bit for

Phase B is set. In addition, the other four signals (AL, BH, CH

and CL) have been disabled by setting the appropriate enable/

disable bits of the PWMSEG register. For the situation illustrated in Figure 9, the appropriate value for the PWMSEG

register is 0x00A7. In normal ECM operation, each inverter leg

is disabled for certain periods of time, so that the PWMSEG

register is changed based on the position of the rotor shaft

(motor commutation).

Figure 9. Example active LO PWM signals suitable for

ECM control, PWMCHA = PWMCHB, crossover BH/BL pair

and disable AL, BH, CH and CL outputs. Operation is in

single update mode.

Gate Drive Unit, PWMGATE Register

The Gate Drive Unit of the PWM controller adds features

that simplify the design of isolated gate drive circuits for

PWM inverters. If a transformer-coupled power device gate

driver amplifier is used, the active PWM signals must be

chopped at a high frequency. The 10-bit read/write PWMGATE

register allows the programming of this high frequency chopping

mode. The chopped active PWM signals may be required for

the high side drivers only, for the low side drivers only or for

both the high side and low side switches. Therefore, independent control of this mode for both high and low side switches is

–17–REV. B

ADMC331

included with two separate control bits in the PWMGATE

register.

Typical PWM output signals with high frequency chopping

enabled on both high side and low side signals are shown in

Figure 10. Chopping of the high side PWM outputs (AH, BH

and CH) is enabled by setting Bit 8 of the PWMGATE register.

Chopping of the low side PWM outputs (AL, BL and CL) is

enabled by setting Bit 9 of the PWMGATE register. The high

frequency chopping frequency is controlled by the 8-bit word

(GDCLK) placed in Bits 0 to 7 of the PWMGATE register.

The period of this high frequency carrier is:

T

= [4 × (GDCLK +1) ] ×t

CHOP

f

=

CHOP

[4 ×(GDCLK +1) ]

f

CLKOUT

CK

The GDCLK value may range from 0 to 255, corresponding to

a programmable chopping frequency rate from 25.39 kHz to

6.5 MHz for a 26 MHz CLKOUT rate. The gate drive features

must be programmed before operation of the PWM controller

and typically are not changed during normal operation of the

PWM controller. Following a reset, all bits of the PWMGATE

register are cleared so that high frequency chopping is disabled,

by default.

PWMCHA PWMCHA

2 PWMDT

[4 (GDCLK+1) tCK]

PWMTM

Figure 10. Typical Active LO PWM Signals with High Frequency Gate Chopping Enabled on Both High Side and

Low Side Switches

PWM Polarity Control, PWMPOL Pin

2 PWMDT

PWMTM

The polarity of the PWM signals produced at the output pins

AH to CL may be selected in hardware by the PWMPOL pin.

Connecting the PWMPOL pin to GND selects active LO PWM

outputs, such that a LO level is interpreted as a command to

turn on the associated power device. Conversely, connecting

to PWMPOL pin selects active HI PWM and the associ-

V

DD

ated power devices are turned ON by a HI level at the PWM

outputs. There is an internal pull-up on the PWMPOL pin, so

that if this pin becomes disconnected (or is not connected),

active HI PWM will be produced. The level on the PWMPOL

pin may be read from Bit 2 of the SYSSTAT register, where a

zero indicated a measure LO level at the PWMPOL pin.

PWM Shutdown

In the event of external fault conditions, it is essential that the

PWM system be instantaneously shut down in a safe fashion. A

falling edge on the PWMTRIP pin provides an instantaneous,

asynchronous (independent of the DSP clock) shutdown of the

PWM controller. All six PWM outputs are placed in the OFF

state (as defined by the PWMPOL pin). In addition, the PWMSYNC pulse is disabled and the associated interrupt is stopped.

The PWMTRIP pin has an internal pull-down resistor so that

if the pin becomes disconnected the PWM will be disabled.

The state of the PWMTRIP pin can be read from Bit 0 of the

SYSSTAT register.

In addition, it is possible to initiate a PWM shutdown in software by writing to the 1-bit read/write PWMSWT register. The

act of writing to this register generates a PWM shutdown command in a manner identical to the PWMTRIP pin. It does not

matter which value is written to the PWMSWT register. However, following a PWM shutdown, it is possible to read the

PWMSWT register to determine if the shutdown was generated

by hardware or software. Reading the PWMSWT register automatically clears its contents.

On the occurrence of a PWM shutdown command (either from

the PWMTRIP pin or the PWMSWT register), a PWMTRIP

interrupt will be generated. In addition, internal timing of the

three-phase timing unit of the PWM controller is stopped. Following a PWM shutdown, the PWM can only be re-enabled (in

a PWMTRIP interrupt service routine, for example) by writing

to all of the PWMTM, PWMCHA, PWMCHB and PWMCHC

registers. Provided the external fault has been cleared and the

PWMTRIP has returned to a HI level, internal timing of the

three-phase timing unit resumes and new duty cycle values are

latched on the next PWMSYNC boundary.

PWM Registers

The configuration of the PWM registers is described at the end

of the data sheet.

ADC OVERVIEW

The Analog Input Block of the ADMC331 is a 7-channel single

slope Analog Data Acquisition System with 12-bit resolution.

Data Conversion is performed by timing the crossover between

the Analog Input and Sawtooth Reference Ramp. A simple

voltage comparator detects the crossover and latches the timed

counter value into a channel-specific output register

The ADC system is comprised of seven input channels to the ADC

of which three (V1, V2, V3) have dedicated comparators. The

remaining four channels (VAUX0, VAUX1, VAUX2, VAUX3)

are multiplexed into the fourth comparator and are selected using

the ADCMUX0 and ADCMUX1 bits of the MODECTRL register (Table VI). This allows four conversions to be performed by the

ADC between successive PWMSYNC pulses.

Table VI. ADC Auxiliary Channel Selection

MODECTRL (1) MODECTRL (0)

Select ADCMUX1 ADCMUX0

VAUX0 0 0

VAUX1 0 1

VAUX2 1 0

VAUX3 1 1

Analog Block

The operation of the ADC block may be explained by reference

to Figures 11 and 12. The reference ramp is tied to one input of

each of the four comparators. This reference ramp is generated

by charging an external timing capacitor with a constant current

source. The timing capacitor is connected between pins CAPIN

and SGND. The capacitor voltage is reset at the start of each

PWMSYNC pulse, which by default is held high for 40 CLKOUT

cycles (T

= 1.54 µs for a 26 MHz CLKOUT). On the fall-

CRST

ing edge of PWMSYNC, the capacitor begins to charge at a rate

–18–

REV. B

determined by the capacitor and the current source values. An

internal current source is made available for connection to the

external timing capacitor on the ICONST pin. An external

current source could also be used, if required. The four input

comparators of the ADC block continuously compare the values

of the four analog inputs with the capacitor voltage. Each comparator output will go high when the capacitor voltage exceeds

the respective analog input voltage.

ADC Timer Block

The ADC timer block consists of a 12-bit counter clocked at a

rate determined by the ADCCNT bit in the MODECTRL

register. If ADCCNT is 0, the counter is clocked at twice the