28-Lead ROM-Based

a

TARGET APPLICATIONS

Washing Machines, Refrigerator Compressors, Fans,

Pumps, Industrial Variable Speed Drives, Automotive

MOTOR TYPES

AC Induction Motors

Permanent Magnet Synchronous Motors (PMSM)

Brushless DC Motors (BDCM)

FEATURES

20 MIPS Fixed-Point DSP Core

Single Cycle Instruction Execution (50 ns)

ADSP-21xx Family Code Compatible

Independent Computational Units

ALU

Multiplier/Accumulator

Barrel Shifter

Multifunction Instructions

Single Cycle Context Switch

Powerful Program Sequencer

Zero Overhead Looping

Conditional Instruction Execution

Two Independent Data Address Generators

Memory Configuration

512 ⴛ 24-Bit Program Memory RAM

4K ⴛ 24-Bit Program Memory ROM

512 ⴛ 16-Bit Data Memory RAM

Three-Phase 16-Bit PWM Generator

16-Bit Center-Based PWM Generator

Programmable Dead Time and Narrow Pulse Deletion

DSP Motor Controller

ADMC326

Edge Resolution to 50 ns

150 Hz Minimum Switching Frequency

Double/Single Duty Cycle Update Mode Control

Programmable PWM Pulsewidth

Special Crossover Function for Brushless DC Motors

Individual Enable and Disable for Each PWM Output

High Frequency Chopping Mode for Transformer

Coupled Gate Drives

External PWMTRIP Pin

Integrated ADC Subsystem

Six Analog Inputs

Acquisition Synchronized to PWM Switching Frequency

Internal Voltage Reference

9-Pin Digital I/O Port

Bit Configurable as Input or Output

Change of State Interrupt Support

Two 8-Bit Auxiliary PWM Timers

Synthesized Analog Output

Programmable Frequency

0% to 100% Duty Cycle

Two Programmable Operational Modes

Independent Mode/Offset Mode

16-Bit Watchdog Timer

Programmable 16-Bit Internal Timer with Prescaler

Double Buffered Synchronous Serial Port

Hardware Support for UART Emulation

Integrated Power-On Reset Function

28-Lead SOIC or PDIP Package Options

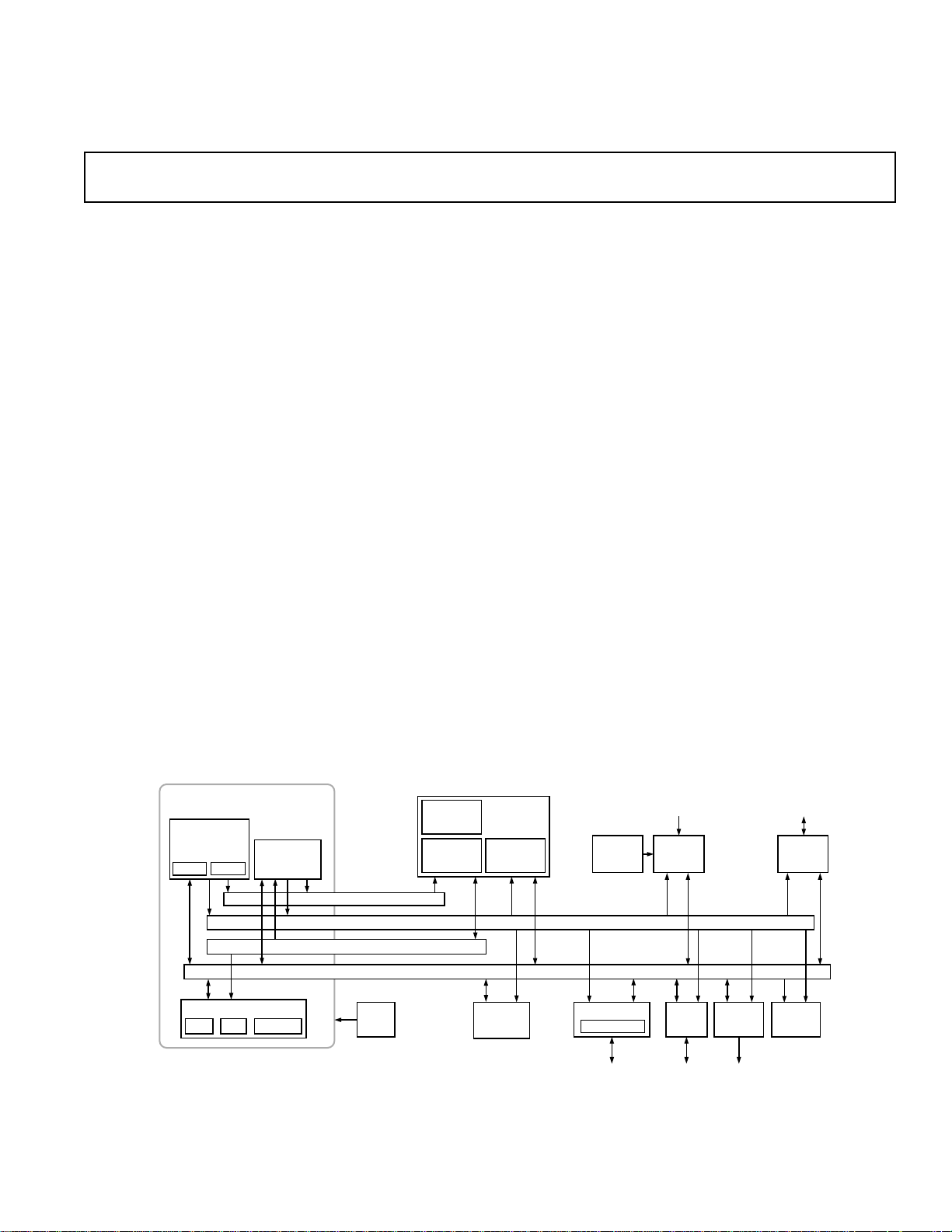

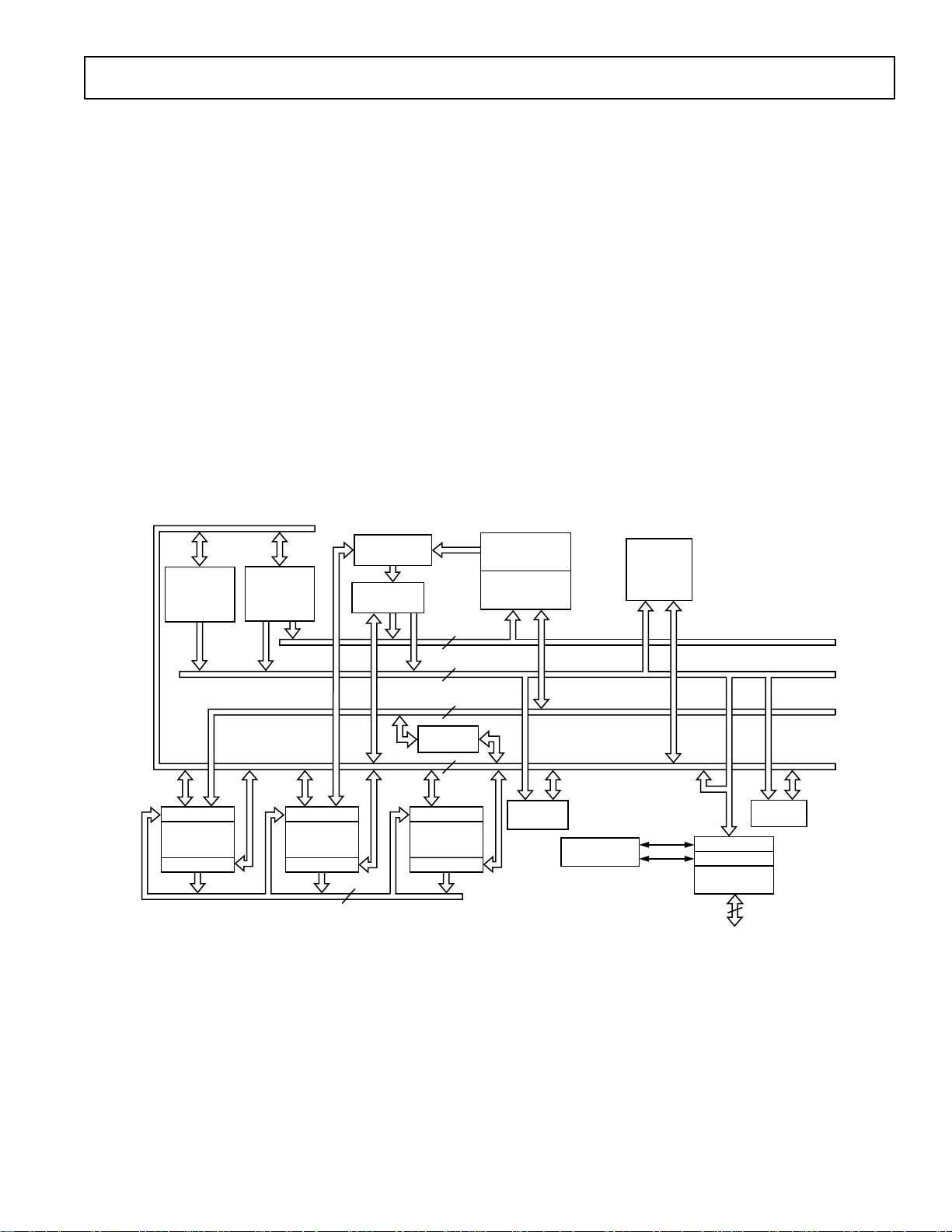

FUNCTIONAL BLOCK DIAGRAM

ADSP-2100 BASE

ARCHITECTURE

DATA

ADDRESS

GENERATORS

DAG 1

DAG 2

ARITHMETIC UNITS

PROGRAM

SEQUENCER

PROGRAM MEMORY ADDRESS

DATA MEMORY ADDRESS

PROGRAM MEMORY DATA

DATA MEMORY DATA

SHIFTERMACALU

POR

PROGRAM

ROM

4K 3 24

PROGRAM

RAM

512 3 24

REV. A

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

MEMORY

BLOCK

DATA

MEMORY

512 3 16

TIMER

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 World Wide Web Site: http://www.analog.com

Fax: 781/326-8703 © Analog Devices, Inc., 2000

VREF

SERIAL PORT

SPORT1

6

ANALOG

INPUTS

9-BIT

PIO

2 3 8-BIT

AUX

PWM

16-BIT

3-PHASE

PWM

WATCH-

DOG

TIMER

(VDD = +5 V ⴞ 5%, GND = 0 V, TA = –40ⴗC to +105ⴗC for ADMC326Y, TA = –40ⴗC to

ADMC326–SPECIFICATIONS

+125ⴗC for ADMC326T, CLKIN = 10 MHz, unless otherwise noted)

ANALOG-TO-DIGITAL CONVERTER

Parameter Min Typ Max Unit Conditions/Comments

Signal Input 0.3 3.5 V V1, V2, V3, VAUX0, VAUX1, VAUX2

Resolution

Linearity Error

Zero Offset

Channel-to-Channel Comparator Match

Comparator Delay 600 ns

ADC Hi-Level Input Current

ADC Lo-Level Input Current

NOTES

1

Resolution varies with PWM switching frequency (double update mode) 78.1 kHz = 8 bits, 4.9 kHz = 12 bits.

2

2.44 kHz sample frequency, V1, V2, VAUX0, VAUX1, VAUX2.

Specifications subject to change without notice.

1

2

2

2

2

2

–20 0 +20 mV

–10 µAV

2 4 Bits

12 Bits

20 mV

10 µAV

= 3.5 V

IN

= 0.0 V

IN

ELECTRICAL CHARACTERISTICS

Parameter Min Typ Max Unit Conditions/Comments

V

V

V

V

V

I

I

I

I

I

I

I

I

I

NOTES

1

Output pins PIO0–PIO8, AH, AL, BH, BL, CH, CL.

2

XTAL Pin.

3

Internal Pull-Up, RESET.

4

Internal Pull-Down, PWMTRIP, PIO0–PIO8.

5

Three-stateable pins DT1, RFS1, TFS1, SCLK1.

6

Outputs not Switching.

Specifications subject to change without notice.

Lo-Level Input Voltage 0.8 V

IL

Hi-Level Input Voltage 2 V

IH

Low Level Output Voltage

OL

Low Level Output Voltage

OL

High Level Output Voltage 4 V I

OH

Low Level Input Current

IL

Low Level Input Current –10 µAV

IL

High Level Input Current

IH

High Level Input Current 10 µAV

IH

Hi-Level Three-State Leakage Current

OZH

Lo-Level Three-State Leakage Current

OZL

Lo-Level PWMTRIP Current –10 µA@ V

IL

Supply Current (Idle)

DD

Supply Current (Dynamic)

DD

1

2

3

4

5

5

6

6

–120 µAV

–10 µAV

0.4 V IOL = 2 mA

0.8 V IOL = 2 mA

90 µAV

90 µAV

32 mA

55 mA

= –0.5 mA

OH

= 0 V

IN

= 0 V

IN

= V

IN

DD

= V

IN

DD

= V

IN

DD

= 0

IN

= Max, VIN = 0 V

DD

CURRENT SOURCE

1

Parameter Min Typ Max Unit Conditions/Comments

Programming Resolution 3 Bits

Default Current

2

70 83 95 µA ICONST_TRIM = 0x00

Tuned Current 95 100 105 µA

NOTES

1

For ADC Calibration.

2

0.3 V to 3.5 V ICONST Voltage.

Specifications subject to change without notice.

–2–

REV. A

VOLTAGE REFERENCE

Parameter Min Typ Max Unit Conditions/Comments

Voltage Level (V

) 2.40 2.50 2.60 V

REF

2.45 2.50 2.55 V T

= +25°C to +125°C SOIC

A

Output Voltage Drift 35 ppm/°C

NOTES

1

This specification for voltage level (V

Specifications subject to change without notice.

) is for SOIC package only, at specified temperature range.

REF

POWER-ON RESET

Parameter Min Typ Max Unit Conditions/Comments

Reset Threshold (V

Hysteresis (V

HYST

Reset Active Timeout Period (t

NOTES

1216

CLKOUT Cycles.

Specifications subject to change without notice.

) 3.2 3.7 4.2 V

RST

) 100 mV

)3.21ms

RST

ADMC326

1

REV. A

–3–

ADMC326

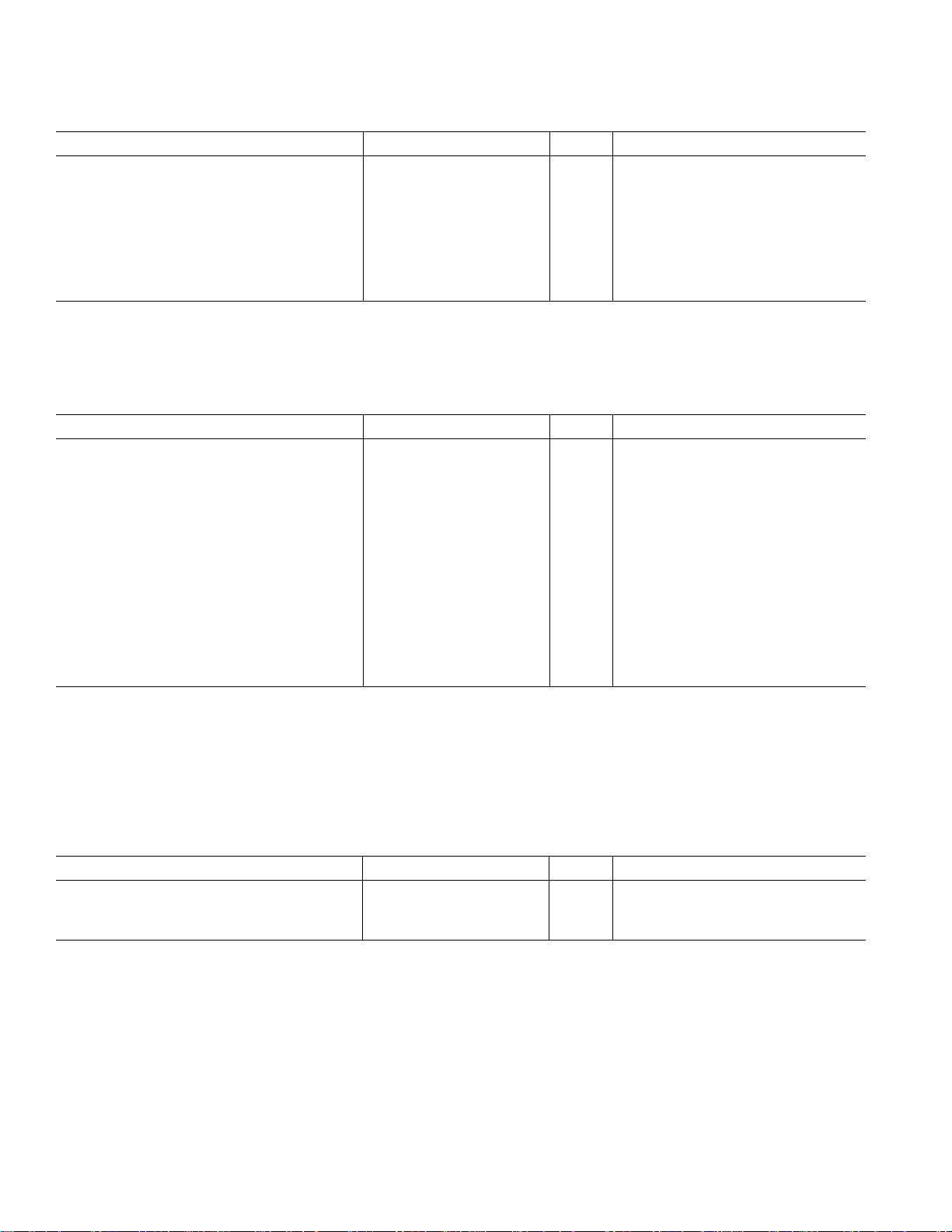

TIMING PARAMETERS

Parameter Min Max Unit

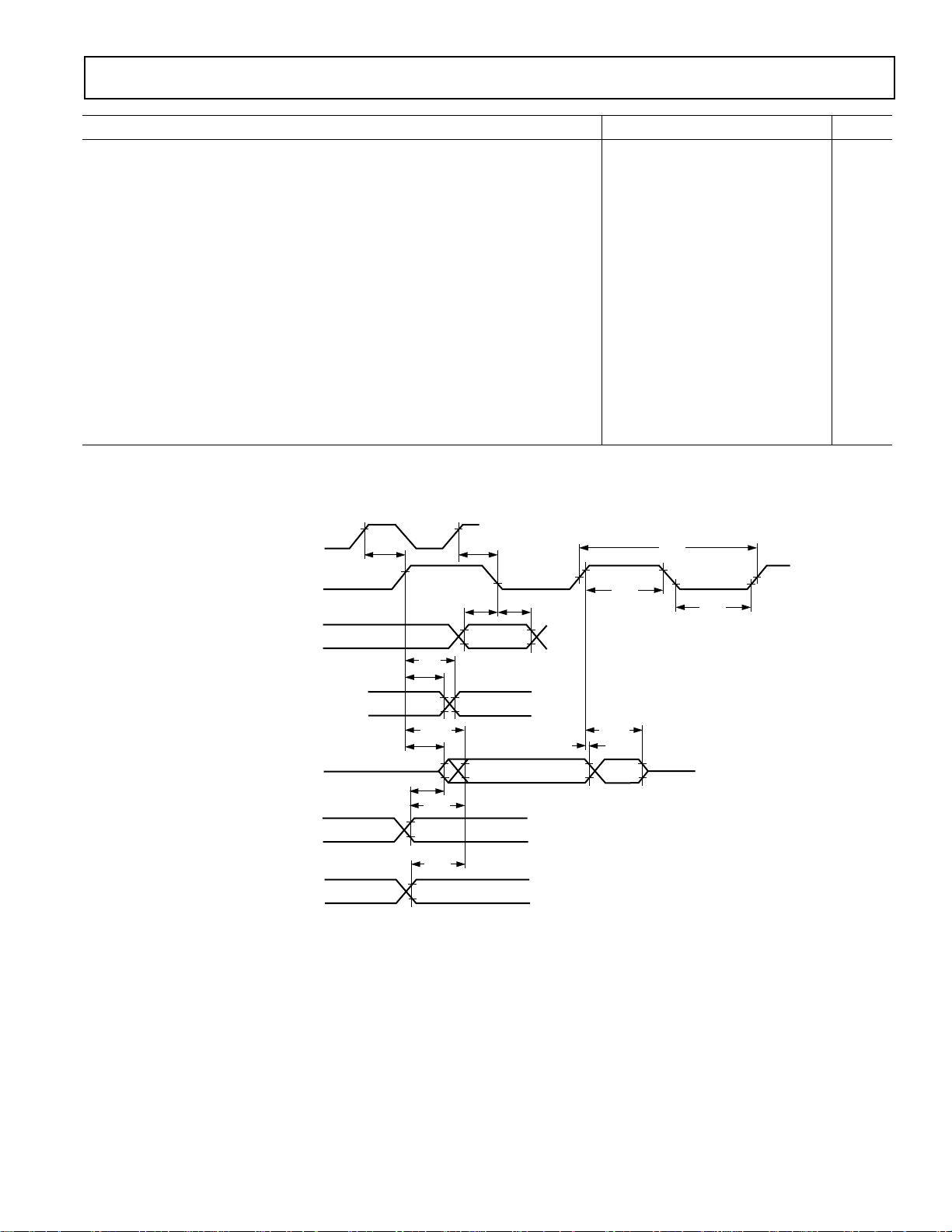

Clock Signals

Signal t

frequency equal to half the instruction rate; a 10 MHz input clock (which is

equivalent to 100 ns) yields a 50 ns processor cycle (equivalent to 20 MHz). When

t

CK

all relevant timing parameters to obtain specification value.

Example: t

Timing Requirements:

t

CKIN

t

CKIL

t

CKIH

Switching Characteristics:

t

CKL

t

CKH

t

CKOH

Control Signals

Timing Requirement:

t

RSP

PWM Shutdown Signals

Timing Requirement:

t

PWMTPW

NOTES

1

Applies after power-up sequence is complete.

Specifications subject to change without notice.

is defined as 0.5 t

CK

values are within the range of 0.5 t

= 0.5 tCK – 10 ns = 0.5 (50 ns) – 10 ns = 15 ns.

CKH

. The ADMC326 uses an input clock with a

CKIN

CKIN

CLKIN Period 100 150 ns

CLKIN Width Low 20 ns

CLKIN Width High 20 ns

CLKOUT Width Low 0.5 tCK – 10 ns

CLKOUT Width High 0.5 tCK – 10 ns

CLKIN High to CLKOUT High 0 20 ns

RESET Width Low 5 t

PWMTRIP Width Low t

period, they should be substituted for

CK

CK

1

ns

ns

CLKIN

CLKOUT

t

CKIN

t

CKIL

t

CKL

Figure 1. Clock Signals

t

t

CKOH

CKH

t

CKIH

–4–

REV. A

ADMC326

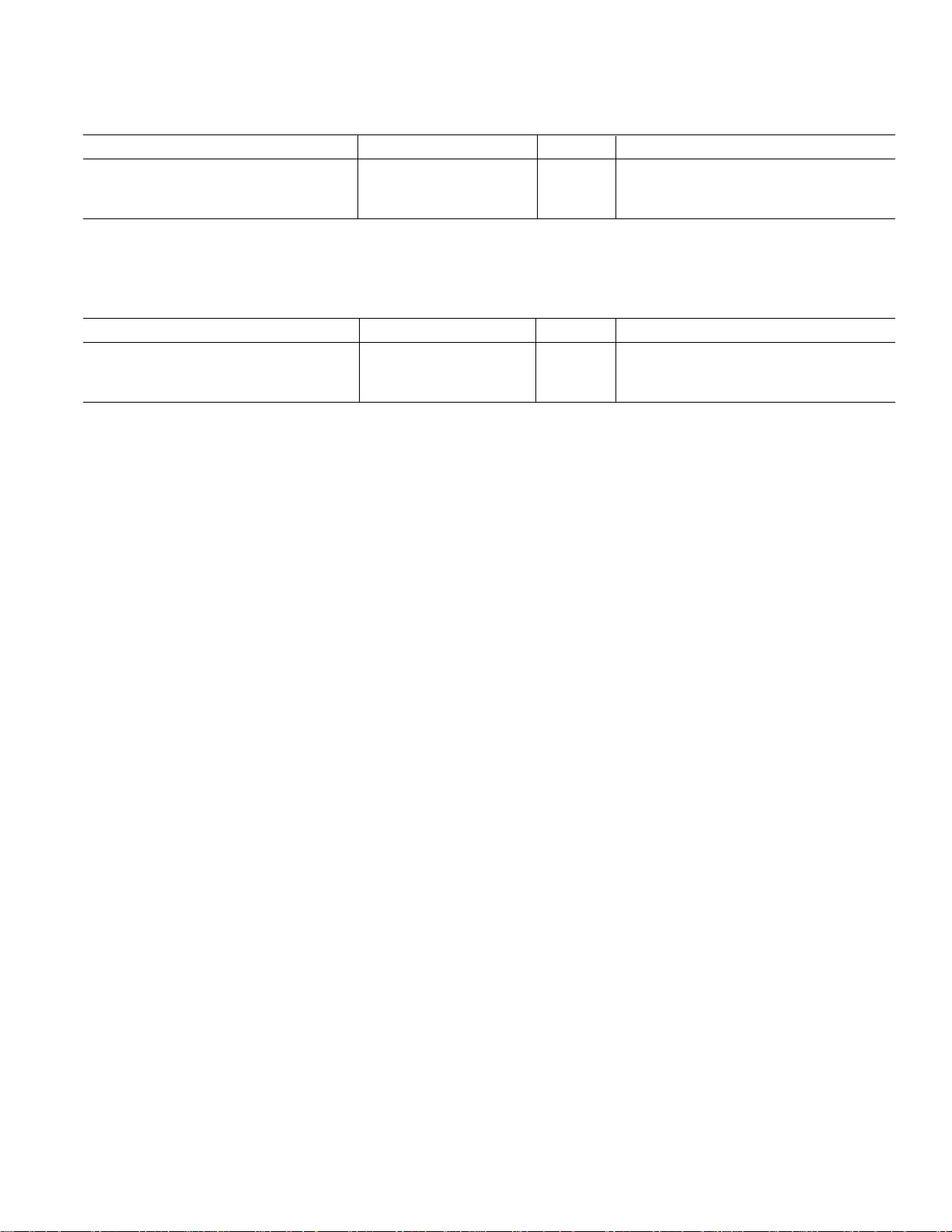

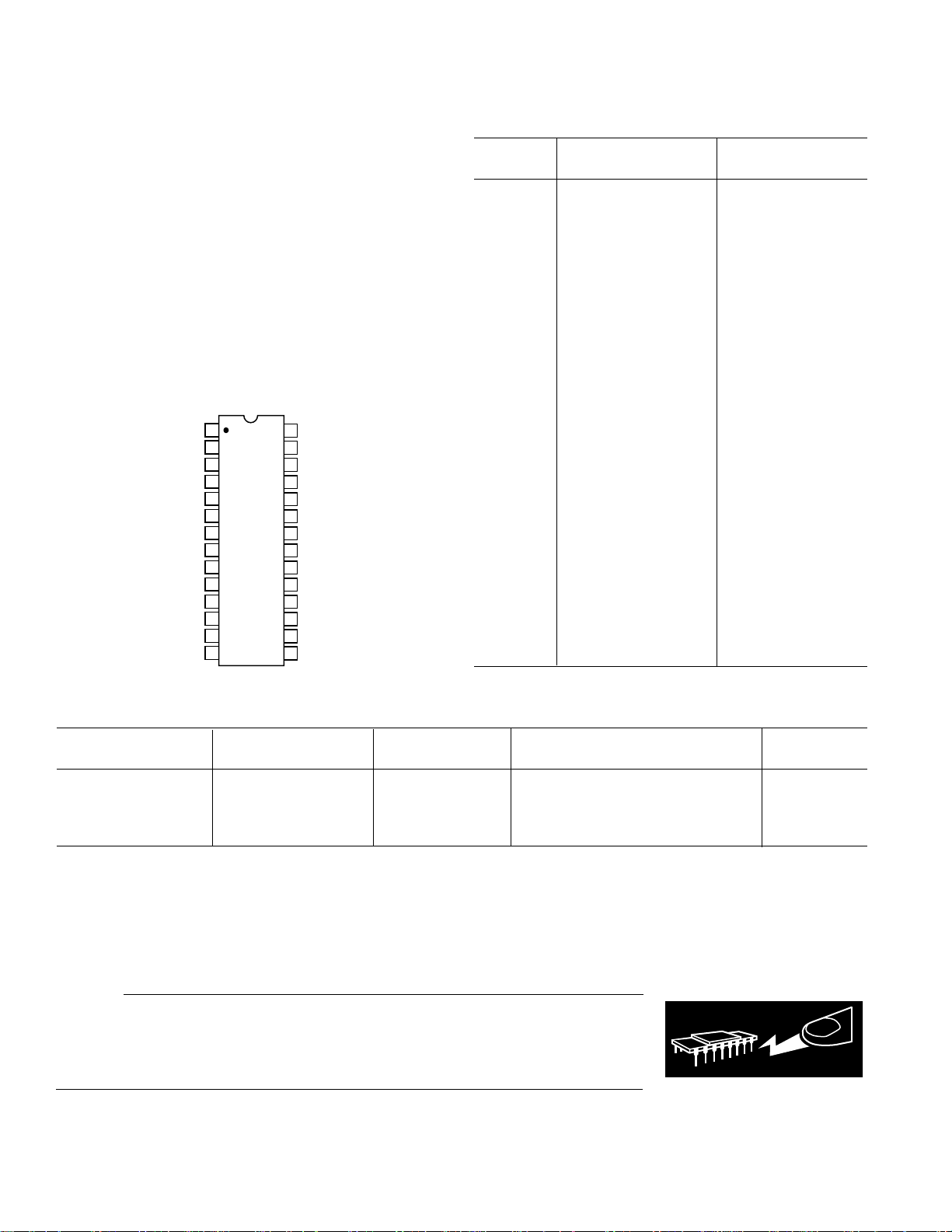

Parameter Min Max Unit

Serial Ports

Timing Requirements:

t

SCK

t

SCS

t

SCH

t

SCP

Switching Characteristics:

t

CC

t

SCDE

t

SCDV

t

RH

t

RD

t

SCDH

t

SCDD

t

TDE

t

TDV

t

RDV

Specifications subject to change without notice.

SCLK Period 100 ns

DR/TFS/RFS Setup before SCLK Low 15 ns

DR/TFS/RFS Hold after SCLK Low 20 ns

SCLKIN Width 40 ns

CLKOUT High to SCLK

OUT

0.25 t

0.25 tCK + 20 ns

CK

SCLK High to DT Enable 0 ns

SCLK High to DT Valid 30 ns

TFS/RFS

TFS/RFS

Hold after SCLK High 0 ns

OUT

Delay from SCLK High 30 ns

OUT

DT Hold after SCLK High 0 ns

SCLK High to DT Disable 30 ns

TFS (Alt) to DT Enable 0 ns

TFS (Alt) to DT Valid 25 ns

RFS (Multichannel, Frame Delay Zero) to DT Valid 30 ns

CLKOUT

SCLK

RFS

TFS

RFS

OUT

TFS

OUT

TFS

(ALTERNATE

FRAME MODE)

(MULTICHANNEL MODE,

FRAME DELAY 0 [MFD = 0])

RFS

DT

DR

t

CC

IN

IN

t

t

SCDE

t

t

RH

t

TDE

RD

SCDV

t

t

RDV

TDV

t

CC

t

t

SCS

SCH

t

t

SCDH

SCDD

t

SCK

t

SCP

t

SCP

Figure 2. Serial Port Timing

REV. A

–5–

ADMC326

WARNING!

ESD SENSITIVE DEVICE

ABSOLUTE MAXIMUM RATINGS*

Supply Voltage (VDD) . . . . . . . . . . . . . . . . . . –0.3 V to +7.0 V

Input Voltage . . . . . . . . . . . . . . . . . . . . . –0.3 V to V

Output Voltage Swing . . . . . . . . . . . . . . –0.3 V to V

+ 0.3 V

DD

+ 0.3 V

DD

Operating Temperature Range (Ambient)

ADMC326Y . . . . . . . . . . . . . . . . . . . . . . –40°C to +105°C

ADMC326T . . . . . . . . . . . . . . . . . . . . . . –40°C to +125°C

Storage Temperature Range . . . . . . . . . . . . –65°C to +150°C

Lead Temperature (5 sec) . . . . . . . . . . . . . . . . . . . . . . . 280°C

*Stresses greater than those listed may cause permanent damage to the device.

These are stress ratings only; functional operation of the device at these or any

other conditions greater than those indicated in the operational sections of this

specification is not implied. Exposure to absolute maximum rating conditions for

extended periods may affect device reliability.

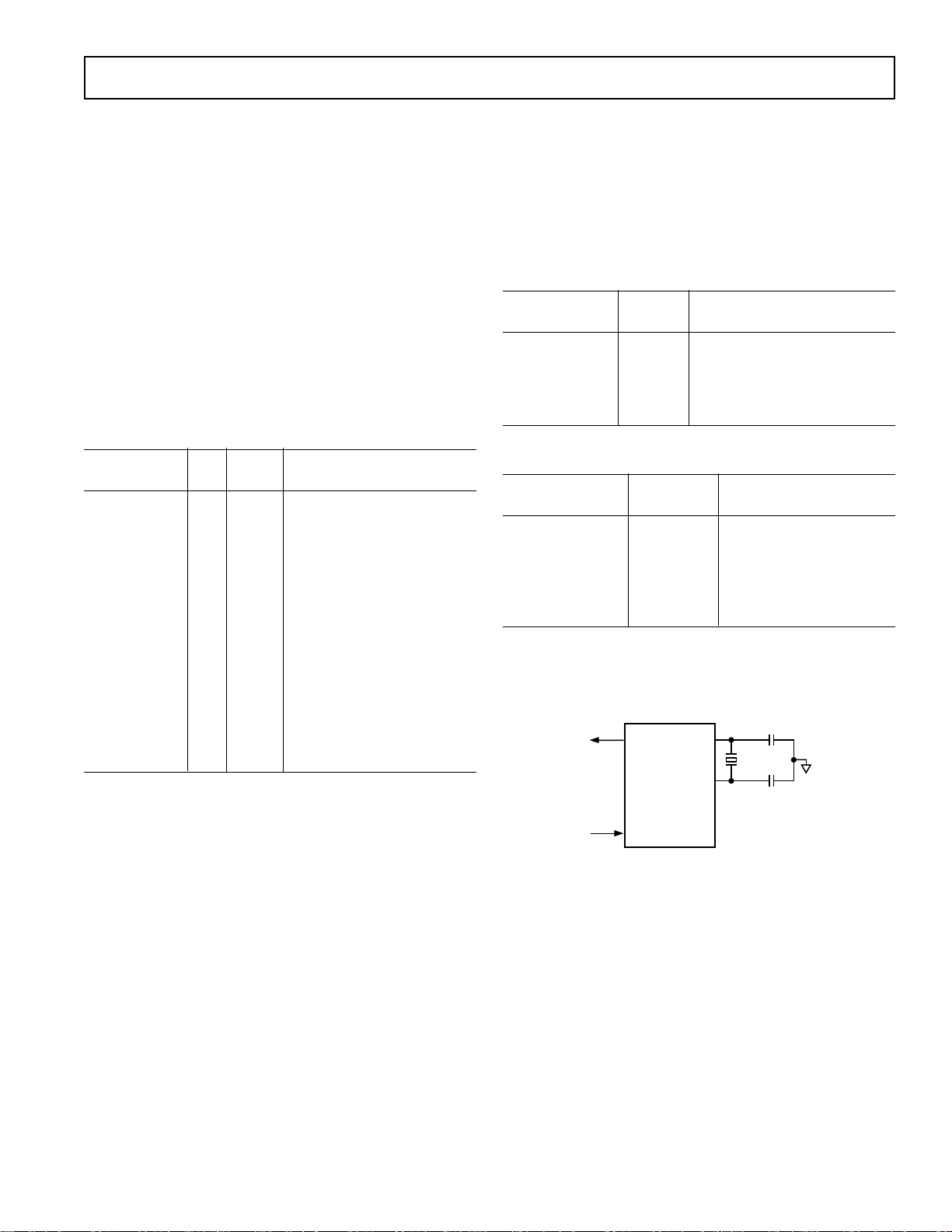

PIN CONFIGURATION

PIO6/CLKOUT

PIO5/RFS1

PIO4/DR1A

PIO3/SCLK1

PIO2/DR1B

PIO1/DT1

PIO0/TFS1

CLKIN

XTAL

V

PWMTRIP

10

DD

11

12

V3

13

V2

14

V1

1

2

3

4

5

6

ADMC326

7

TOP VIEW

(Not to Scale)

8

9

28

PIO7/AUX1

27

PIO8/AUX0

AL

26

25

AH

BL

24

BH

23

CL

22

CH

21

20

RESET

GND

19

ICONST

18

VAUX2

17

16

VAUX1

15

VAUX0

PIN FUNCTION DESCRIPTIONS

Pin Pin Pin

No. Name Type

1 PIO6/CLKOUT I/O

2 PIO5/RFS1 I/O

3 PIO4/DR1A I/O

4 PIO3/SCLK1 I/O

5 PIO2/DR1B I/O

6 PIO1/DT1 I/O

7 PIO0/TFS1 I/O

8 CLKIN I

9 XTAL O

10 V

DD

SUP

11 PWMTRIP I

12 V3 I

13 V2 I

14 V1 I

15 VAUX0 I

16 VAUX1 I

17 VAUX2 I

18 ICONST O

19 GND GND

20 RESET I

21 CH O

22 CL O

23 BH O

24 BL O

25 AH O

26 AL O

27 PIO8/AUX0 I/O

28 PIO7/AUX1 I/O

ORDERING GUIDE

Temperature Instruction Package Package

Model Range Rate Description Option

ADMC326YR-xxx-yy –40°C to +105°C 20 MHz 28-Lead Wide Body (SOIC) R-28

ADMC326TR-xxx-yy –40°C to +125°C 20 MHz 28-Lead Wide Body (SOIC) R-28

ADMC326YN-xxx-yy –40°C to +105°C 20 MHz 28-Lead Wide Body (PDIP) N-28

ADMC326TN-xxx-yy –40°C to +125°C 20 MHz 28-Lead Wide Body (PDIP) N-28

NOTES

xxx = customer identification code.

yy = ROM identification code.

To place an order for a custom ROM-coded ADMC326 processor, please request a copy of the ADMC ROM ordering package, available from your Analog Devices

Sales representative.

Analog Devices assesses a charge for each ROM mask generated in addition to a minimum order quantity. Please consult your sales representative for details.

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection.

Although the ADMC326 features proprietary ESD protection circuitry, permanent damage may

occur on devices subjected to high energy electrostatic discharges. Therefore, proper ESD

precautions are recommended to avoid performance degradation or loss of functionality.

–6–

REV. A

ADMC326

GENERAL DESCRIPTION

The ADMC326 is a low cost, single-chip DSP-based controller,

suitable for permanent magnet synchronous motors, AC induction

motors and brushless dc motors. The ADMC326 integrates a

20 MIPS, fixed-point DSP core with a complete set of motor

control and system peripherals that permits fast, efficient

development of motor controllers.

The DSP core of the ADMC326 is the ADSP-2171, which is

completely code compatible with the ADSP-21xx DSP family

and combines three computational units, data address generators

and a program sequencer. The computational units comprise an

ALU, a multiplier/accumulator (MAC) and a barrel shifter. The

ADSP-2171 adds new instructions for bit manipulation, multipli-

cation (× squared), biased rounding and global interrupt masking.

The system peripherals are the power-on reset circuit (POR),

the watchdog timer and a synchronous serial port. The serial

port is configurable and double buffered, with hardware support

for UART and SCI port emulation.

INSTRUCTION

REGISTER

DATA

ADDRESS

GENERATOR

#1

DATA

ADDRESS

GENERATOR

#2

PROGRAM

SEQUENCER

14

The ADMC326 provides 512 × 24-bit program memory RAM,

4K × 24-bit program memory ROM and 512 × 16-bit data

memory RAM. The program memory ROM contains the userspecified program code and is defined using a single metal layer

mask. The program and data memory RAM can be used for

dynamic data storage.

The motor control peripherals of the ADMC326 comprise a

12-bit analog data acquisition system with six analog input

channels and an internal voltage reference. In addition, a threephase, 16-bit, center-based PWM generation unit can be used to

produce high accuracy PWM signals with minimal processor

overhead. The ADMC326 also contains two auxiliary PWM

outputs, and nine lines of digital I/O.

Because the ADMC326 has a limited number of pins, a number

of functions such as the auxiliary PWM and the serial communication port are multiplexed with the nine programmable input/

output (PIO) pins. The pin functions can be independently

selected to allow maximum flexibility for different applications.

PM ROM

4K 3 24

PM RAM

512 3 24

PMA BUS

DM RAM

512 3 16

INPUT REGS

ALU

OUTPUT REGS

INPUT REGS

MAC

OUTPUT REGS

16

14

24

BUS

EXCHANGE

16

INPUT REGS

SHIFTER

OUTPUT REGS

R BUS

CONTROL

LOGIC

Figure 3. DSP Core Block Diagram

DMA BUS

PMD BUS

DMD BUS

COMPANDING

CIRCUITRY

TRANSMIT REG

RECEIVE REG

SERIAL

PORT

6

TIMER

REV. A

–7–

ADMC326

DSP CORE ARCHITECTURE OVERVIEW

Figure 3 is an overall block diagram of the DSP core of the

ADMC326, which is based on the fixed-point ADSP-2171. The

flexible architecture and comprehensive instruction set of the

ADSP-2171 allow the processor to perform multiple operations

in parallel. In one processor cycle (50 ns with a 10 MHz CLKIN)

the DSP core can:

• Generate the next program address.

• Fetch the next instruction.

• Perform one or two data moves.

• Update one or two data address pointers.

• Perform a computational operation.

This all takes place while the processor continues to:

• Receive and transmit through the serial port.

• Decrement the interval timer.

• Generate three-phase PWM waveforms for a power inverter.

• Generate two signals using the 8-bit auxiliary PWM timers.

• Acquire four analog signals.

• Decrement the watchdog timer.

The processor contains three independent computational units:

the arithmetic and logic unit (ALU), the multiplier/accumulator

(MAC) and the shifter. The computational units process 16-bit

data directly and have provisions to support multiprecision computations. The ALU performs a standard set of arithmetic and

logic operations as well as providing support for division primitives. The MAC performs single-cycle multiply, multiply/add,

and multiply/subtract operations with 40 bits of accumulation.

The shifter performs logical and arithmetic shifts, normalization,

denormalization and derive-exponent operations. The shifter

can be used to efficiently implement numeric format control, including floating-point representations.

The internal result (R) bus directly connects the computational

units so that the output of any unit may be the input of any unit

on the next cycle.

A powerful program sequencer and two dedicated data address

generators ensure efficient delivery of operands to these computational units. The sequencer supports conditional jumps and

subroutine calls and returns in a single cycle. With internal loop

counters and loop stacks, the ADMC326 executes looped code

with zero overhead; no explicit jump instructions are required to

maintain the loop.

Two data address generators (DAGs) provide addresses for

simultaneous dual operand fetches from data memory and program memory. Each DAG maintains and updates four address

pointers (I registers). Whenever the pointer is used to access

data (indirect addressing), it is post-modified by the value in

one of four modify (M registers). A length value may be associated with each pointer (L registers) to implement automatic

modulo addressing for circular buffers. The circular buffering

feature is also used by the serial ports for automatic data transfers to and from on-chip memory. DAG1 generates only data

memory address and provides an optional bit-reversal capability.

DAG2 may generate either program or data memory addresses

but has no bit-reversal capability.

Efficient data transfer is achieved with the use of five internal

buses:

• Program memory address (PMA) bus.

• Program memory data (PMD) bus.

• Data memory address (DMA) bus.

• Data memory data (DMD) bus.

• Result (R) bus.

Program memory can store both instructions and data, permitting the ADMC326 to fetch two operands in a single cycle—

one from program memory and one from data memory. The

ADMC326 can fetch an operand from on-chip program memory

and the next instruction in the same cycle.

The ADMC326 writes data from its 16-bit registers to the 24-bit

program memory using the PX register to provide the lower

eight bits. When it reads data (not instructions) from 24-bit program memory to a 16-bit data register, the lower eight bits are

placed in the PX register.

The ADMC326 can respond to a number of distinct DSP core

and peripheral interrupts. The DSP interrupts comprise a serial

port receive interrupt, a serial port transmit interrupt, a timer

interrupt, and two software interrupts. Additionally, the motor

control peripherals include two PWM interrupts and a PIO

interrupt.

The serial port (SPORT1) provides a complete synchronous

serial interface with optional companding in hardware and a

wide variety of framed and unframed data transmit and receive

modes of operation. SPORT1 can generate an internal programmable serial clock or accept an external serial clock.

A programmable interval counter is also included in the DSP

core and can be used to generate periodic interrupts. A 16-bit

count register (TCOUNT) is decremented every n processor

cycles, where n–1 is a scaling value stored in the 8-bit TSCALE

register. When the value of the counter reaches zero, an interrupt

is generated, and the count register is reloaded from a 16-bit

period register (TPERIOD).

The ADMC326 instruction set provides flexible data moves

and multifunction (one or two data moves with a computation)

instructions. Each instruction is executed in a single 50 ns processor cycle (for a 10 MHz CLKIN). The ADMC326 assembly

language uses an algebraic syntax for ease of coding and readability. A comprehensive set of development tools supports

program development. For further information on the DSP

core, refer to the ADSP-2100 Family User’s Manual, Third Edition,

with particular reference to the ADSP-2171.

Serial Port

The ADMC326 incorporates a complete synchronous serial

port (SPORT1) for serial communication and multiprocessor

communication. The following is a brief list of capabilities of the

ADMC326 SPORT1. Refer to the ADSP-2100 Family User’s

Manual, Third Edition, for further details.

• SPORT1 is bidirectional and has a separate, double-buffered

transmit and receive section.

• SPORT1 can use an external serial clock or generate its own

serial clock internally.

• SPORT1 has independent framing for the receive and transmit sections. Sections run in a frameless mode or with frame

synchronization signals internally or externally generated.

Frame synchronization signals are active high or inverted,

with either of two pulsewidths and timings.

• SPORT1 supports serial data word lengths from 3 bits to 16

bits and provides optional A-law and µ-law companding ac-

cording to ITU (formerly CCITT) recommendation G.711.

–8–

REV. A

ADMC326

• SPORT1 receive and transmit sections can generate unique

interrupts on completing a data word transfer.

• SPORT1 can receive and transmit an entire circular buffer of

data with only one overhead cycle per data word. An interrupt

is generated after a data buffer transfer.

• SPORT1 can be configured to have two external interrupts

(IRQ0 and IRQ1), and the Flag In and Flag Out signals.

The internally generated serial clock may still be used in this

configuration.

• SPORT1 has two data receive pins (DR1A and DR1B), which

are internally multiplexed onto the one DR1 port of the

SPORT1. The particular data receive pin selected is determined by a bit in the MODECTRL register.

PIN FUNCTION DESCRIPTION

The ADMC326 is available in a 28-lead SOIC package and a

28-lead PDIP package. Table I describes the pins.

Table I. Pin List

Group # of Input/

Name Pins Output Function

RESET 1 I Processor Reset Input

SPORT1

CLKOUT

CLKIN, XTAL 2 I, O External Clock or Quartz

PIO0–PIO8

AUX0–AUX1

AH–CL 6 O PWM Outputs

PWMTRIP 1 I PWM Trip Signal

V1, V2, V3 3 I Analog Inputs

VAUX0–VAUX2 3 I Auxiliary Analog Input

ICONST 1 O ADC Constant Current Source

V

GND 1 Ground

NOTE

1

Multiplexed pins, selectable individually through the PIOSELECT and

PIODATA1 registers.

INTERRUPT OVERVIEW

DD

1

1

6 I/O Serial Port 1 Pins (TFS1,

RFS1, DT1, DR1A, DR1B,

SCLK1)

1 O Processor Clock Output

1

9 I/O Digital I/O Port Pins

1

2 O Auxiliary PWM Outputs

1 Power Supply

Crystal Connection Point

The ADMC326 can respond to 16 different interrupt sources

with minimal overhead, five of which are internal DSP core

interrupts and 11 are from the motor control peripherals. The five

DSP core interrupts are SPORT1 receive (or IRQ0) and trans-

mit (or IRQ1), the internal timer, and two software interrupts.

The motor control peripheral interrupts are the nine programmable I/Os and two from the PWM (PWMSYNC pulse and

PWMTRIP). All motor control interrupts are multiplexed into the

DSP core through the peripheral IRQ2 interrupt. The interrupts

are internally prioritized and individually maskable. A detailed

description of the entire interrupt system of the ADMC326 is

presented later, following a more detailed description of each

peripheral block.

Memory Map

The ADMC326 has two distinct memory types: program memory

and data memory. In general, program memory contains user

code and coefficients, while the data memory is used to store

variables and data during program execution. Both program

REV. A

–9–

memory RAM and ROM are provided on the ADMC326. Pro-

gram memory RAM is arranged as one contiguous 512 × 24-bit

block, starting at address 0x0000. Program memory ROM is a

4K × 24-bit block located at address 0x0800. Data memory is

arranged as a 512 × 16-bit block starting at address 0x3800. The

motor control peripherals are memory mapped into a region of

the data memory space starting at 0x2000. The complete program

and data memory maps are given in Tables II and III, respectively.

Table II. Program Memory Map

Memory

Address Range Type Function

0x0000–0x002F RAM Interrupt Vector Table

0x0030–0x01FF RAM User Program Memory

0x0200–0x07FF Reserved

0x0800–0x17FF ROM User Program Memory

0x1800–0x3FFF Reserved

Table III. Data Memory Map

Memory

Address Range Type Function

0x0000–0x1FFF Reserved

0x2000–0x20FF Memory Mapped Registers

0x2100–0x37FF Reserved

0x3800–0x39FF RAM User Data Memory

0x3A00–0x3BFF RAM Reserved

0x3C00–0x3FFF Memory Mapped Registers

SYSTEM INTERFACE

Figure 4 shows a basic system configuration for the ADMC326

with an external crystal.

CLKOUT

ADMC326

RESET

XTAL

CLKIN

33pF

10MHz

33pF

Figure 4. Basic System Configuration

Clock Signals

The ADMC326 can be clocked either by a crystal or a TTLcompatible clock signal. For normal operation, the CLKIN

input cannot be halted, changed during operation, or operated

below the specified minimum frequency. If an external clock is

used, it should be a TTL-compatible signal running at half the

instruction rate. The signal is connected to the CLKIN pin of

the ADMC326. In this mode, with an external clock signal, the

XTAL pin must be left unconnected. The ADMC326 uses an

input clock with a frequency equal to half the instruction rate;

a 10 MHz input clock yields a 50 ns processor cycle (which is

equivalent to 20 MHz). Normally, instructions are executed in a

single processor cycle. All device timing is relative to the internal

instruction rate, which is indicated by the CLKOUT signal

when enabled.

Because the ADMC326 includes an on-chip oscillator feedback

circuit, an external crystal may be used instead of a clock source, as

ADMC326

shown in Figure 4. The crystal should be connected across the

CLKIN and XTAL pins, with two capacitors as shown in Figure 4.

A parallel-resonant, fundamental frequency, microprocessor-grade

crystal should be used. A clock output signal (CLKOUT) is

generated by the processor at the processor’s cycle rate of twice

the input frequency.

Reset

The ADMC326 DSP core and peripherals must be correctly reset when the device is powered up to assure proper initialization.

The ADMC326 contains an integrated power-on reset (POR)

circuit that provides a complete system reset on power-up and

power-down. The POR circuit monitors the voltage on the

ADMC326 V

reset while V

When this voltage is exceeded, the ADMC326 is held in reset

for an additional 2

power-down, when the voltage on the V

V

RST–VHYST

pin and holds the DSP core and peripherals in

DD

is less than the threshold voltage level, V

DD

16

DSP clock cycles (t

in Figure 5). On

RST

pin falls below

DD

RST

.

, the ADMC326 will be reset. Also, if the external

RESET pin is actively pulled low at any time after power-up, a

complete hardware reset of the ADMC326 is initiated.

V

RST

V

RESET

DD

t

RST

V

RST – VHYST

Figure 5. Power-On Reset Operation

The ADMC326 reset sets all internal stack pointers to the empty

stack condition, masks all interrupts, clears the MSTAT register

and performs a full reset of all of the motor control peripherals.

Following a power-up, it is possible to initiate a DSP core and

motor control peripheral reset by pulling the RESET pin low.

The RESET signal must meet the minimum pulsewidth specification, t

. Following the reset sequence, the DSP core starts

RSP

executing code from the internal PM ROM located at 0x0800.

DSP Control Registers

The DSP core has a system control register, SYSCNTL, memory

mapped at DM (0x3FFF). SPORT1 is configured as a serial

port when Bit 10 is set, or as flags and interrupt lines when this

bit is cleared. For proper operation of the ADMC326, all other

bits in this register must be cleared.

The DSP core has a wait state control register, MEMWAIT,

memory mapped at DM (0x3FFE). The default value of this

register is 0xFFFF. For proper operation of the ADMC326 this

register must be set to 0x8000.

The configuration of both the SYSCNTL and MEMWAIT

registers of the ADMC326 are shown at the end of this data sheet.

THREE-PHASE PWM CONTROLLER

Overview

The PWM generator block of the ADMC326 is a flexible, programmable, three-phase PWM waveform generator that can be

programmed to generate the required switching patterns to drive

a three-phase voltage source inverter for ac induction motors

(ACIM) or permanent magnet synchronous motors (PMSM).

In addition, the PWM block contains special functions that considerably simplify the generation of the required PWM switching

patterns for control of electronically commutated motors (ECM)

or brushless dc motors (BDCM).

The PWM generator produces three pairs of active high PWM

signals on the six PWM output pins (AH, AL, BH, BL, CH,

and CL). The six PWM output signals consist of three high side

drive signals (AH, BH, and CH) and three low side drive signals

(AL, BL, and CL). The switching frequency, dead time and

minimum pulsewidths of the generated PWM patterns are programmable using respectively the PWMTM, PWMDT, and

PWMPD registers. In addition, three registers (PWMCHA,

PWMCHB, and PWMCHC) control the duty cycles of the three

pairs of PWM signals.

Each of the six PWM output signals can be enabled or disabled

by separate output enable bits of the PWMSEG register. In

addition, three control bits of the PWMSEG register permit

crossover of the two signals of a PWM pair for easy control of

ECM or BDCM. In crossover mode, the PWM signal destined

for the high side switch is diverted to the complementary low

side output, and the signal destined for the low side switch is

diverted to the corresponding high side output signal.

In many applications, there is a need to provide an isolation

barrier in the gate-drive circuits that turn on the power devices

of the inverter. In general, there are two common isolation techniques: optical isolation using optocouplers, and transformer

isolation using pulse transformers. The PWM controller of the

ADMC326 permits mixing of the output PWM signals with a

high frequency chopping signal to permit an easy interface to

such pulse transformers. The features of this gate-drive chopping mode can be controlled by the PWMGATE register. There

is an 8-bit value within the PWMGATE register that directly

controls the chopping frequency. In addition, high frequency

chopping can be independently enabled for the high side and the

low side outputs using separate control bits in the PWMGATE

register.

The PWM generator is capable of operating in two distinct

modes: single update mode or double update mode. In single

update mode, the duty cycle values are programmable only once

per PWM period, so that the resultant PWM patterns are symmetrical about the midpoint of the PWM period. In the double

update mode, a second updating of the PWM duty cycle values

is implemented at the midpoint of the PWM period. In this mode,

it is possible to produce asymmetrical PWM patterns that produce lower harmonic distortion in three-phase PWM inverters.

This technique also permits the closed-loop controller to change

the average voltage applied to the machine winding at a faster

rate, allowing wider closed-loop bandwidths to be achieved. The

operating mode of the PWM block (single or double update mode)

is selected by a control bit in MODECTRL register.

The PWM generator of the ADMC326 also provides an internal

signal that synchronizes the PWM switching frequency to the

A/D operation. In single update mode, a PWMSYNC pulse is

produced at the start of each PWM period. In double update

mode, an additional PWMSYNC pulse is produced at the midpoint of each PWM period. The width of the PWMSYNC pulse

is programmable through the PWMSYNCWT register.

The PWM signals produced by the ADMC326 can be shut off

in a number of different ways. First, there is a dedicated asynchronous PWM shutdown pin, PWMTRIP, which, when brought

LO, instantaneously places all six PWM outputs in the OFF

–10–

REV. A

ADMC326

state. Because this hardware shutdown mechanism is asynchronous, and the associated PWM disable circuitry does not use

clocked logic, the PWM will shut down even if the DSP clock is

not running. The PWM system may also be shut down from

software by writing to the PWMSWT register.

Status information about the PWM system of the ADMC326 is

available to the user in the SYSSTAT register. In particular, the

state of PWMTRIP is available, as well as a status bit that indicates whether operation is in the first half or the second half of

the PWM period.

A functional block diagram of the PWM controller is shown in

Figure 6. The generation of the six output PWM signals on pins

AH to CL is controlled by four important blocks:

• The three-phase PWM timing unit, which is the core of the

PWM controller, generates three pairs of complemented and

dead-time-adjusted center-based PWM signals.

• The output control unit allows the redirection of the outputs

of the three-phase timing unit for each channel to either the

high side or the low side output. In addition, the output control unit allows individual enabling/disabling of each of the six

PWM output signals.

• The GATE drive unit provides the high chopping frequency

and its subsequent mixing with the PWM signals.

• The PWM shutdown controller manages the three PWM

shutdown modes (via the PWMTRIP pin, the analog block or

the PWMSWT register) and generates the correct RESET signal

for the Timing Unit.

• The PWM controller is driven by a clock at the same frequency

as the DSP instruction rate, CLKOUT, and is capable of

generating two interrupts to the DSP core. One interrupt is

generated on the occurrence of a PWMSYNC pulse, and the

other is generated on the occurrence of any PWM shutdown

action.

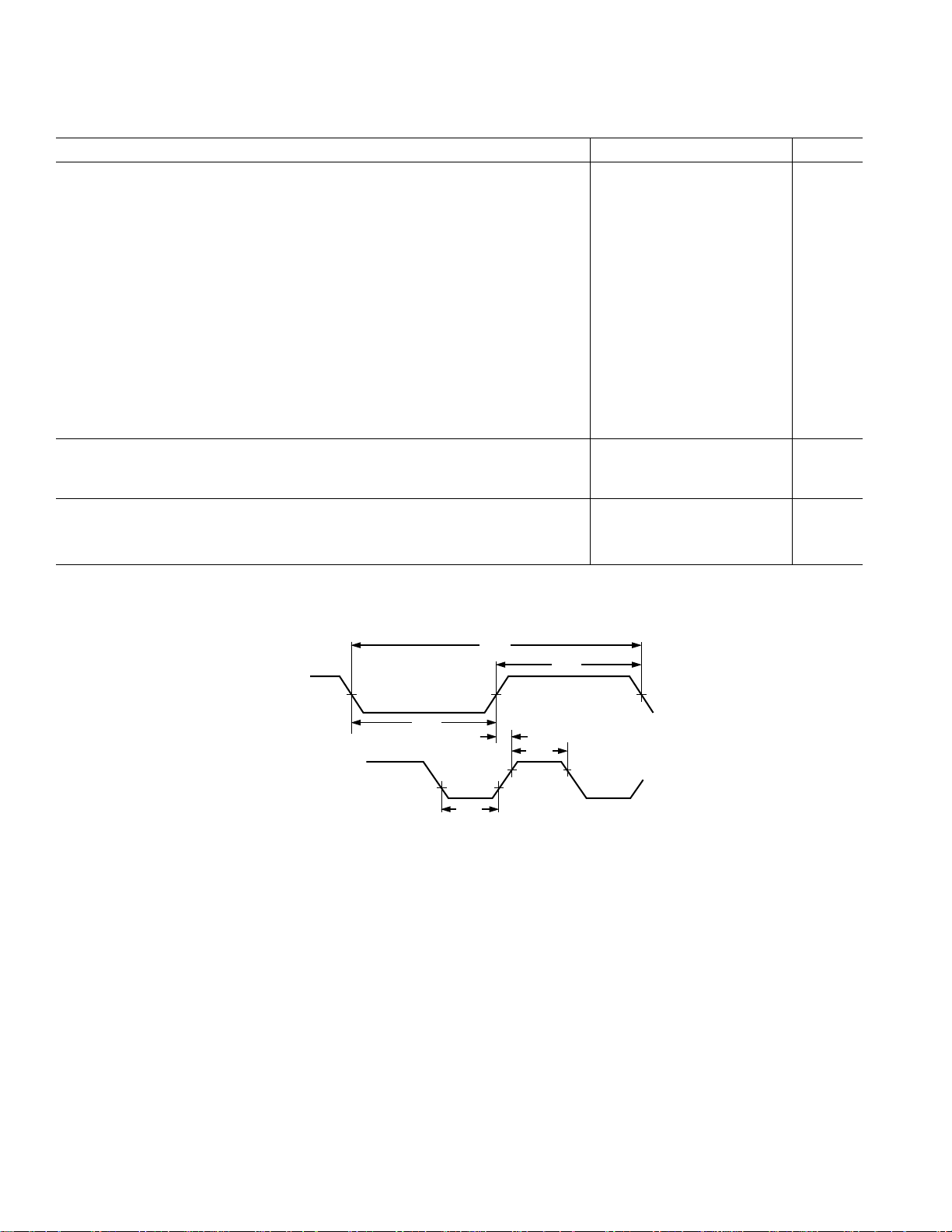

PWM CONFIGURATION

REGISTERS

PWMTM (15...0)

PWMDT (9...0)

PWMPD (15...0)

PWMSYNCWT (7...0)

MODECTRL (6)

PWM DUTY CYCLE

REGISTERS

PWMCHA (15...0)

PWMCHB (15...0)

PWMCHC (15...0)

Three-Phase Timing Unit

The 16-bit three-phase timing unit is the core of the PWM controller and produces three pairs of pulsewidth modulated signals

with high resolution and minimal processor overhead. There are

four main configuration registers (PWMTM, PWMDT, PWMPD

and PWMSYNCWT) that determine the fundamental characteristics of the PWM outputs. In addition, the operating mode

of the PWM (single or double update mode) is selected by Bit 6

of the MODECTRL register. These registers, in conjunction with

the three 16-bit duty cycle registers (PWMCHA, PWMCHB and

PWMCHC), control the output of the three-phase timing unit.

PWM Switching Frequency: PWMTM Register

The PWM switching frequency is controlled by the PWM

period register, PWMTM. The fundamental timing unit of

the PWM controller is t

CK

= 1/f

CLKOUT

where f

CLKOUT

is the

CLKOUT frequency (DSP instruction rate). Therefore, for a

20 MHz CLKOUT, the fundamental time increment is 50 ns.

The value written to the PWMTM register is effectively the

number of t

clock increments in half a PWM period. The

CK

required PWMTM value is a function of the desired PWM

switching frequency (f

PWMTM

) and is given by:

PWM

f

CLKOUT

=

f

×

2

PWM

=

f

CLKIN

f

PWM

Therefore, the PWM switching period, TS, can be written as:

T PWMTM t

=× ×2

SCK

For example, for a 20 MHz CLKOUT and a desired PWM

switching frequency of 10 kHz (T

= 100 µs), the correct value

S

to load into the PWMTM register is:

6

×

PWMTM x E=

20 10

××

21010

3

=

1000 0 3 8

REV. A

CLK RESET

PWMSYNC

TO INTERRUPT

CONTROLLER

PWMTRIP

THREE-PHASE

PWM TIMING

UNIT

SYNC

Figure 6. Overview of the PWM Controller of the ADMC326

PWMSEG (8...0)

OUTPUT

CONTROL

UNIT

SYNC

OR

PWMSWT (0)

PWM SHUTDOWN CONTROLLER

–11–

PWMGATE (9...0)

GATE

DRIVE

UNIT

CLK

CLKOUT

AH

AL

BH

BL

CH

CL

PWMTRIP

ADMC326

The largest value that can be written to the 16-bit PWMTM

register is 0xFFFF = 65,535, which corresponds to a minimum

PWM switching frequency of:

6

×

20 10

fHz

PWM,min

=

×

2 65 535

=

153

,

for a CLKOUT frequency of 20 MHz.

PWM Switching Dead Time: PWMDT Register

The second important PWM block parameter that must be

initialized is the switching dead time. This is a short delay time

introduced between turning off one PWM signal (for example

AH) and turning on its complementary signal, AL. This short

time delay is introduced to permit the power switch being turned

off to completely recover its blocking capability before the

complementary switch is turned on. This time delay prevents a

potentially destructive short-circuit condition from developing

across the dc link capacitor of a typical voltage source inverter.

Dead time is controlled by the PWMDT register. The dead

time is inserted into the three pairs of PWM output signals. The

dead time, T

, is related to the value in the PWMDT register by:

D

T PWMDT t

=××=×22

DCK

PWMDT

f

CLKOUT

Therefore, a PWMDT value of 0x00A (= 10), introduces a 1 µs

delay between the turn-off of any PWM signal (for example AH)

and the turn-on of its complementary signal (AL). The amount

of the dead time can therefore be programmed in increments of

(or 100 ns for a 20 MHz CLKOUT). The PWMDT register

2 t

CK

is a 10-bit register. For a CLKOUT rate of 20 MHz its maximum

value of 0x3FF (= 1023) corresponds to a maximum programmed

dead time of:

T

= 1023 × 2 × t

Dmax

= 1023 × 2 × 50 × 10

CK

–9

sec

= 102 µs

The dead time can be programmed to zero by writing 0 to the

PWMDT register.

PWM Operating Mode: MODECTRL and SYSSTAT Registers

The PWM controller of the ADMCF326 can operate in two distinct modes: single update mode and double update mode. The

operating mode of the PWM controller is determined by the

state of Bit 6 of the MODECTRL register. If this bit is cleared, the

PWM operates in the single update mode. Setting Bit 6 places

the PWM in the double update mode. By default, following

either a peripheral reset or power-on, Bit 6 of the MODECTRL

register is cleared. This means that the default operating mode

is single update mode.

In single update mode, a single PWMSYNC pulse is produced

in each PWM period. The rising edge of this signal marks

the start of a new PWM cycle and is used to latch new values

from the PWM configuration registers (PWMTM, PWMDT,

PWMPD and PWMSYNCWT) and the PWM duty cycle

registers (PWMCHA, PWMCHB and PWMCHC) into the

three-phase timing unit. The PWMSEG register is also latched

into the output control unit on the rising edge of the PWMSYNC

pulse. In effect, this means that the parameters of the PWM

signals can be updated only once per PWM period at the start of

each cycle. Thus, the generated PWM patterns are symmetrical

about the midpoint of the switching period.

In double update mode, there is an additional PWMSYNC pulse

produced at the midpoint of each PWM period. The rising edge

of this new PWMSYNC pulse is again used to latch new values

of the PWM configuration registers, duty cycle registers and the

PWMSEG register. As a result, it is possible to alter both the

characteristics (switching frequency, dead time, minimum pulsewidth and PWMSYNC pulsewidth) and the output duty cycles

at the midpoint of each PWM cycle. Consequently, it is possible to produce PWM switching patterns that are no longer

symmetrical about the midpoint of the period (asymmetrical

PWM patterns).

In the double update mode, operation in the first half or the

second half of the PWM cycle is indicated by Bit 3 of the

SYSSTAT register. In double update mode, this bit is cleared

during operation in the first half of each PWM period (between

the rising edge of the original PWMSYNC pulse and the rising

edge of the new PWMSYNC pulse, which is introduced in

double update mode). Bit 3 of the SYSSTAT register is set

during the second half of each PWM period. If required, a user

may determine the status of this bit during a PWMSYNC interrupt service routine.

The advantages of the double update mode are that lower harmonic voltages can be produced by the PWM process and wider

control bandwidths are possible. However, for a given PWM

switching frequency, the PWMSYNC pulses occur at twice the

rate in the double update mode. Because new duty cycle values

must be computed in each PWMSYNC interrupt service routine,

there is a larger computational burden on the DSP in the double

update mode.

Width of the PWMSYNC Pulse: PWMSYNCWT Register

The PWM controller of the ADMCF326 produces an internal

PWM synchronization pulse at a rate equal to the PWM switching

frequency in single update mode and at twice the PWM frequency

in the double update mode. This PWMSYNC synchronizes

the operation of the PWM unit with the A/D converter system.

The width of this PWMSYNC pulse is programmable by the

PWMSYNCWT register. The width of the PWMSYNC pulse,

T

PWMSYNC

which means that the width of the pulse is programmable from t

to 256 t

, is given by:

T t PWMSYNCWT

PWMSYNC CK

(corresponding to 50 ns to 12.8 µs for a CLKOUT rate

CK

=× +

()

1

CK

of 20 MHz). Following a reset, the PWMSYNCWT register con-

tains 0x27 (= 39) so that the default PWMSYNC width is 2.0 µs.

PWM Duty Cycles: PWMCHA, PWMCHB, PWMCHC

Registers

The duty cycles of the six PWM output signals are controlled

by the three duty cycle registers, PWMCHA, PWMCHB, and

PWMCHC. The integer value in the register PWMCHA controls

the duty cycle of the signals on AH and AL. PWMCHB controls

the duty cycle of the signals on BH and BL, and PWMCHC

controls the duty cycle of the signals on CH and CL. The duty

cycle registers are programmed in integer counts of the fundamental time unit, t

, and define the desired on-time of the

CK

high-side PWM signal produced by the three-phase timing unit

over half the PWM period. The switching signals produced by

the three-phase timing unit are also adjusted to incorporate the

programmed dead time value in the PWMDT register.

–12–

REV. A

The PWM is center-based. This means that in single update mode

PWMCHA

2

PWMSYNCWT2 + 1

PWMCHA

1

PWMTM

1

PWMTM

2

PWMSYNCWT1 + 1

AH

AL

PWMSYNC

SYSSTAT (3)

2 3 PWMDT

1

2 3 PWMDT

2

the resulting output waveforms are symmetrical and centered in

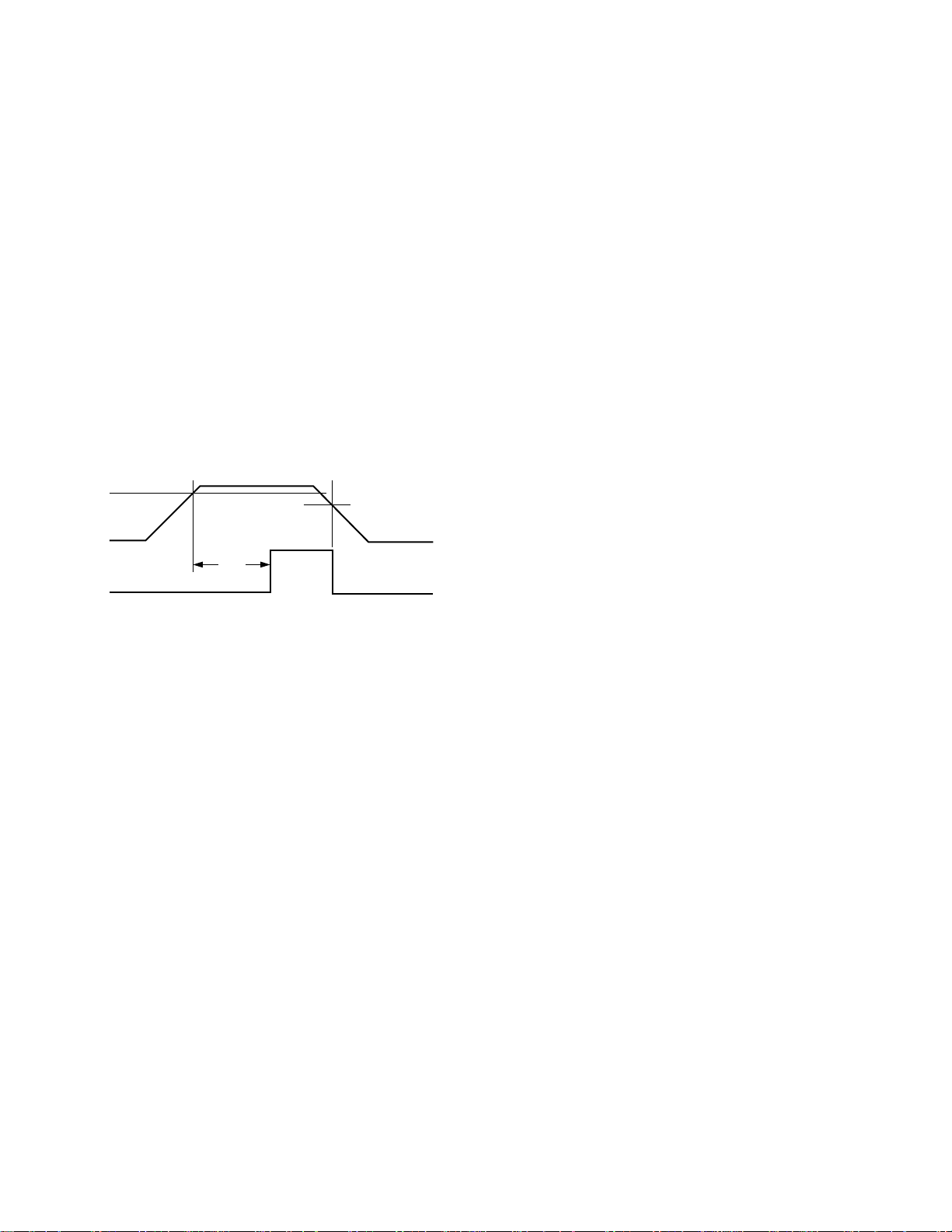

the PWMSYNC period. Figure 7 presents a typical PWM timing diagram illustrating the PWM-related registers’ (PWMCHA,

PWMTM, PWMDT, and PWMSYNCWT) control over the

waveform timing in both half cycles of the PWM period. The

magnitude of each parameter in the timing diagram is determined

by multiplying the integer value in each register by t

(typically

CK

50 ns). It may be seen in the timing diagram how dead time is

incorporated into the waveforms by moving the switching edges

away from the instants set by the PWMCHA register.

ADMC326

PWMCHA

AH

2 3 PWMDT

AL

PWMSYNC

SYSSTAT (3)

PWMTM

PWMCHA

2 3 PWMDT

PWMSYNCWT + 1

PWMTM

Figure 7. Typical PWM Outputs of Three-Phase Timing

Unit in Single Update Mode

Each switching edge is moved by an equal amount (PWMDT

) to preserve the symmetrical output patterns. The PWMSYNC

× t

CK

pulse, whose width is set by the PWMSYNCWT register, is also

shown. Bit 3 of the SYSSTAT register indicates which half cycle

is active. This can be useful in double update mode, as will be

discussed later.

The resultant on-times of the PWM signals shown in Figure 7

may be written as:

T PWMCHA PWMDT t

=× ×

22( –)

AH CK

T PWMTM PWMCHA PWMDT t

=× ×

AL CK

(– –)

The corresponding duty cycles are:

d

==

AH

T

d

==

AL

T

PWMCHA PWMDT

AH

T

S

PWMTM PWMCHA PWMDT

AL

T

S

–

PWMTM

––

PWMTM

Obviously, negative values of TAH and TAL are not permitted

because the minimum permissible value is zero, corresponding

to a 0% duty cycle. In a similar fashion, the maximum value is

, corresponding to a 100% duty cycle.

T

S

The output signals from the timing unit for operation in double

update mode are shown in Figure 8. This illustrates a completely

general case where the switching frequency, dead time and duty

cycle are all changed in the second half of the PWM period. Of

course, the same value for any or all of these quantities could be

used in both halves of the PWM cycle. However, it can be seen

that there is no guarantee that symmetrical PWM signals will be

produced by the timing unit in this double update mode. Additionally, it is seen that the dead time is inserted into the PWM

signals in the same way as in the single update mode.

Figure 8. Typical PWM Outputs of Three-Phase Timing

Unit in Double Update Mode

In general, the on-times of the PWM signals in double update

mode are defined by:

T

– PWMDT

TAL = (PWMTM1 + PWMTM2 – PWMCHA

– PWMCHA2 – PWMDT1 – PWMDT

= (PWMCHA1 + PWMCHA2 – PWMDT

AH

) × t

2

CK

1

) × t

2

1

CK

where the subscript 1 refers to the value of that register during

the first half cycle and the subscript 2 refers to the value during

the second half cycle. The corresponding duty cycles are:

T

d

d

AH

=

AH

T

S

PWMCHA PWMCHA

()

=

PWMTM PWMTM

()

PWMDT PWMDT

()

–

PWMTM PWMTM

()

T

AL

=

AL

T

S

PWMTM PWMTM PWMCHA

()

=

PWCHA PWMDT PWMDT

()

−

()

+

12

+

12

+

12

+

12

++

12 1

PWMTM PWMTM

()

++

212

PWMTM PWMTM

+

12

+

12

because for the completely general case in double update mode,

the switching period is given by:

T

= (PWMTM1 + PWMTM

S

) × t

2

CK

Again, the values of TAH and TAL are constrained to lie between

zero and T

.

S

PWM signals similar to those illustrated in Figure 7 and Figure

8 can be produced on the BH, BL, CH, and CL outputs by programming the PWMCHB and PWMCHC registers in a manner

identical to that described for PWMCHA.

The PWM controller does not produce any PWM outputs until

all of the PWMTM, PWMCHA, PWMCHB, and PWMCHC

registers have been written to at least once. After these registers

have been written, the counters in the three-phase timing unit

are enabled. Writing to these registers also starts the main PWM

timer. If during initialization, the PWMTM register is written

REV. A

–13–

ADMC326

after the PWMCHA, PWMCHB, and PWMCHC registers,

then the first PWMSYNC pulse (and interrupt if enabled) will

be generated (1.5 × t

× PWMTM) seconds after the initial

CK

write to the PWMTM register in single update mode. In double

update mode, the first PWMSYNC pulse will be generated

× PWMTM) seconds after the initial write to the PWMTM

(t

CK

register in single update mode.

Effective PWM Resolution

In single update mode, the same values of PWMCHA, PWMCHB

and PWMCHC are used to define the on-times in both half

cycles of the PWM period. As a result, the effective resolution of

the PWM generation process is 2 t

(or 100 ns for a 20 MHz

CK

CLKOUT) since incrementing one of the duty cycle registers by

one changes the resultant on-time of the associated PWM signals by t

in each half period (or 2 tCK for the full period).

CK

In double update mode, improved resolution is possible since

different values of the duty cycles registers are used to define the

on-times in both the first and second halves of the PWM period.

As a result, it is possible to adjust the on-time over the whole

period in increments of t

PWM resolution of t

. This corresponds to an effective

CK

in double update mode (or 50 ns for a

CK

20 MHz CLKOUT).

The achievable PWM switching frequency at a given PWM

resolution is tabulated in Table IV.

Table IV. Achievable PWM Resolution in Single and Double

Update Modes

Resolution Single Update Mode Double Update Mode

(Bit) PWM Frequency (kHz) PWM Frequency (kHz)

8 39.1 78.1

9 19.5 39.1

10 9.8 19.5

11 4.9 9.8

12 2.4 4.9

Minimum Pulsewidth: PWMPD Register

In many power converter switching applications, it is desirable

to eliminate PWM switching pulses shorter than a certain width.

It takes a finite time to both turn on and turn off modern power

semiconductor devices. Therefore, if the width of any of the PWM

pulses is shorter than some minimum value, it may be desirable to

completely eliminate the PWM switching for that particular cycle.

The allowable minimum on-time for any of the six PWM outputs for half a PWM period that can be produced by the PWM

controller may be programmed using the PWMPD register. The

minimum on-time is programmed in increments of t

so that

CK

the minimum on-time that will be produced for any half PWM

period, T

, is related to the value in the PWMPD register by:

MIN

T

= PWMPD × t

MIN

CK

A PWMPD value of 0x002 defines a permissible minimum

on-time of 100 ns for a 20 MHz CLKOUT.

In each half cycle of the PWM, the timing unit checks the ontime of each of the six PWM signals. If any of the times is found

to be less than the value specified by the PWMPD register, the

corresponding PWM signal is turned OFF for the entire half

period, and its complementary signal is turned completely ON.

Consider the example where PWMTM = 200, PWMCHA = 5,

PWMDT = 3, and PWMPD = 10 with a CLKOUT of 20 MHz

while operating in single update mode. For this case, the PWM

switching frequency is 50 kHz and the dead time is 300 ns. The

minimum permissible on-time of any PWM signal over one-half

of any period is 500 ns. Clearly, for this example, the dead-time

adjusted on-time of the AH signal for one-half a PWM period is

(5–3) × 50 ns = 100 ns. Because this is less than the minimum

permissible value, output AH of the timing unit will remain

OFF (0% duty cycle). Additionally, the AL signal will be turned

ON for the entire half period (100% duty cycle).

Output Control Unit: PWMSEG Register

The operation of the output control unit is managed by the 9-bit

read/write PWMSEG register. This register sets two distinct

features of the output control unit that are directly useful in the

control of ECM or BDCM.

The PWMSEG register contains three crossover bits, one for each

pair of PWM outputs. Setting Bit 8 of the PWMSEG register

enables the crossover mode for the AH/AL pair of PWM signals;

setting Bit 7 enables crossover on the BH/BL pair of PWM signals;

and setting Bit 6 enables crossover on the CH/CL pair of PWM

signals. If crossover mode is enabled for any pair of PWM signals,

the high-side PWM signal from the timing unit (for example

AH) is diverted to the associated low-side output of the output

control unit so that the signal will ultimately appear at the AL

pin. Of course, the corresponding low-side output of the timing

unit is also diverted to the complementary high-side output of

the output control unit so that the signal appears at Pin AH.

Following a reset, the three crossover bits are cleared so that the

crossover mode is disabled on all three pairs of PWM signals.

The PWMSEG register also contains six bits (Bits 0 to 5) that

can be used to individually enable or disable each of the six PWM

outputs. If the associated bit of the PWMSEG register is set,

the corresponding PWM output is disabled regardless of the

value of the corresponding duty cycle register. This PWM output

signal will remain in the OFF state as long as the corresponding

enable/disable bit of the PWMSEG register is set. The PWM

output enable function gates the crossover function. After a

reset, all six enable bits of the PWMSEG register are cleared,

thereby enabling all PWM outputs by default.

In a manner identical to the duty cycle registers, the PWMSEG is

latched on the rising edge of the PWMSYNC signal so that changes

to this register only become effective at the start of each PWM

cycle in single update mode. In double update mode, the PWMSEG register can also be updated at the midpoint of the PWM cycle.

In the control of an ECM, only two inverter legs are switched

at any time, and often the high-side device in one leg must be

switched ON at the same time as the low-side driver in a second

leg. Therefore, by programming identical duty cycles for two PWM

channels (for example, let PWMCHA = PWMCHB) and setting

Bit 7 of the PWMSEG register to crossover the BH/BL pair of

PWM signals, it is possible to turn ON the high-side switch of

Phase A and the low-side switch of Phase B at the same time. In

the control of an ECM, one inverter leg (Phase C in this example)

is disabled for a number of PWM cycles. This disable may be

implemented by disabling both the CH and CL PWM outputs

by setting Bits 0 and 1 of the PWMSEG register. This is illustrated in Figure 9 where it can be seen that both the AH and

BL signals are identical, because PWMCHA = PWMCHB, and

the crossover bit for Phase B is set. In addition, the other four

signals (AL, BH, CH, and CL) have been disabled by setting

the appropriate enable/disable bits of the PWMSEG register.

–14–

REV. A

For the situation illustrated in Figure 9, the appropriate value

PWMTM

PWMTM

[4 3 (GDCLK+1) 3

t

CK

]

2 3 PWMDT

2 3 PWMDT

PWMCHA

PWMCHA

for the PWMSEG register is 0x00A7. In ECM operation, because each inverter leg is disabled for certain periods of time,

the PWMSEG register is changed based upon the position of

the rotor shaft (motor commutation).

ADMC326

AH

AL

BH

BL

CH

CL

2 3 PWMDT

PWMTM

PWMCHA

= PWMCHB

PWMCHA

= PWMCHB

2 3 PWMDT

PWMTM

Figure 9. An example of PWM signals suitable for ECM

control. PWMCHA = PWMCHB, BH/BL are a crossover pair.

AL, BH, CH and CL outputs are disabled. Operation is in

single update mode.

Gate Drive Unit: PWMGATE Register

The gate drive unit of the PWM controller adds features that

simplify the design of isolated gate drive circuits for PWM

inverters. If a transformer-coupled power device gate drive

amplifier is used, the active PWM signal must be chopped at

a high frequency. The PWMGATE register allows the programming of this high frequency chopping mode. The chopped active

PWM signals may be required for the high-side drivers only, for

the low-side drivers only, or for both the high-side and low-side

switches. Therefore, independent control of this mode for both

high- and low-side switches is included with two separate control bits in the PWMGATE register.

Typical PWM output signals with high-frequency chopping

enabled on both high-side and low-side signals are shown in

Figure 10. Chopping of the high-side PWM outputs (AH, BH,

and CH) is enabled by setting Bit 8 of the PWMGATE register.

Chopping of the low-side PWM outputs (AL, BL, and CL) is

enabled by setting Bit 9 of the PWMGATE register. The high

chopping frequency is controlled by the 8-bit word (GDCLK)

written to Bits 0 to 7 of the PWMGATE register. The period

and the frequency of this high frequency carrier are:

T GDCLK t

=× +

41

CHOP CK

f

CHOP

()

[]

f

=

CLKOUT

GDCLK

×+

41

()

[]

×

The GDCLK value may range from 0 to 255, corresponding

to a programmable chopping frequency rate from 19.5 kHz to

5 MHz for a 20 MHz CLKOUT rate. The gate drive features

must be programmed before operation of the PWM controller

and typically are not changed during normal operation of the

PWM controller. Following a reset, by default, all bits of the

PWMGATE register are cleared so that high frequency chopping is disabled.

Figure 10. Typical PWM signals with high frequency gate

chopping enabled on both high-side and low-side switches

(GDCLK is the integer equivalent of the value in Bits 0 to 7

of the PWMGATE register.)

PWM Shutdown

In the event of external fault conditions, it is essential that the

PWM system be instantaneously shut down. Two methods of

sensing a fault condition are provided by the ADMC326. For

the first method, a low level on the PWMTRIP pin initiates an

instantaneous, asynchronous (independent of DSP clock) shutdown of the PWM controller. This places all six PWM outputs in

the OFF state, disables the PWMSYNC pulse and associated

interrupt signal and generates a PWMTRIP interrupt signal.

The PWMTRIP pin has an internal pull-down resistor so that

even if the pin becomes disconnected, the PWM outputs will be

disabled. The state of the PWMTRIP pin can be read from

Bit 0 of the SYSSTAT register.

The second method for detecting a fault condition is through

the I

pin in the analog block of the ADMC326. The I

SENSE

SENSE

pin monitors the feedback signals from a dc bus current sensing

resistor that represents the total current in the motor. When the

voltage of I

goes below I

SENSE

trip threshold, PWMTRIP

SENSE

will be internally pulled low. The negative edge of the internal

PWMTRIP will generate a shutdown in the same manner as a

negative edge on pin PWMTRIP.

It is possible through software to initiate a PWM shutdown by

writing to the 1-bit read/write PWMSWT register (0x2061).

Writing to this bit generates a PWM shutdown in a manner

identical to the PWMTRIP or I

pins. Following a PWM

SENSE

shutdown, it is possible to determine if the shutdown was generated from hardware or software by reading the same PWMSWT

register. Reading this register also clears it.

Restarting the PWM after a fault condition is detected requires

clearing the fault and reinitializing the PWM. Clearing the fault

requires that PWMTRIP returns to a HI state and I

to a voltage greater than the I

trip threshold. After the fault

SENSE

SENSE

returns

has been cleared, the PWM can be restarted by writing to registers

PWMTM, PWMCHA, PWMCHB and PWMCHC. After the fault

is cleared and the PWM registers are initialized, internal timing

of the three-phase timing unit will resume, and the new duty cycle

values will be latched on the next rising edge of PWMSYNC.

PWM Registers

The configuration of the PWM registers is described at the end

of the data sheet. The parameters of the 16-bit PWM Timer is

tabulated in Table V.

ADC OVERVIEW

The ADC of the ADMC326 is based upon the single slope

conversion technique. This approach offers an inherently

monotonic conversion process and, to within the noise and stability of its components, there will be no missing codes.

REV. A

–15–

ADMC326

Table V. Fundamental Characteristics of PWM Generation Unit of ADMC326

16-BIT PWM TIMER

Parameter Min Typ Max Unit

Counter Resolution 16 Bits

Edge Resolution (Single Update Mode) 100 ns

Edge Resolution (Double Update Mode) 50 ns

Programmable Dead Time Range 0 100 µs

Programmable Dead Time Increments 100 ns

Programmable Pulse Deletion Range 0 100 µs

Programmable Pulse Deletion Increments 100 ns

PWM Frequency Range 150 Hz

PWMSYNC Pulsewidth (T

Gate Drive Chop Frequency Range 0.02 5 MHz

) 0.05 12.5 µs

CRST

Table VI. ADC Auxiliary Channel Selection

MODECTRL (1) MODECTRL (0)

Select ADCMUX1 ADCMUX0

VAUX0 0 0

VAUX1 0 1

VAUX2 1 0

Calibration (V

)1 1

REF

The single slope technique has been adapted on the ADMC326

for four channels that are simultaneously converted. Refer to

Figure 11 for the functional schematic of the ADC. Three of the

main inputs (V1, V2, and V3) are directly connected as high

impedance voltage inputs. The fourth channel has been configured with a serially-connected 4-to-1 multiplexer. Table VI

shows the multiplexer input selection codes. One of these auxiliary

multiplexed channels is used to calibrate the ramp against the

internal voltage reference (V

C

GND

ICONST

EXTERNAL

CHARGING

CAP

VAUX0

VAUX1

VAUX2

V

C

V1

V2

V3

4 -1

MUX

).

REF

ICONST_TRIM<2:0>

(CAP RESET)

COMP

COMP

COMP

COMP

V1L

V2L

V3L

VAUXL

PWMSYNC (CONVST)

ADC

REGISTERS

12-BIT

ADC

TIMER

BLOCK

V

REF

CLK MODECTRL<7>

ADC REGISTERS

ADC1

ADC2

ADC3

ADCAUX

MODECTRL<0..1>

Figure 11. ADC Overview

Comparing each ADC input to a reference ramp voltage, and timing the comparison of the two signals, performs the conversion

process. The actual conversion point is the time point intersection of the input voltage and the ramp voltage (V

) as shown in

C

Figure 12. This time is converted to counts by the 12-bit ADC

Timer Block and is stored in the ADC registers. The ramp voltage used to perform the conversion is generated by driving a

fixed current into an off-chip capacitor, where the capacitor

voltage is

V

= (I/C) × t

C

Following reset, V

= 0 at t = 0. This reset and the start of the

C

conversion process are initiated by the PWMSYNC pulse, as

shown in Figure 12. The width of the PWMSYNC pulse is

controlled by the PWMSYNCWT register and should be

pr ogrammed according to Figure 13 to ensure complete resetting.

In order to compensate for IC process manufacturing tolerances

(and to adjust for capacitor tolerances), the current source of the

ADMC326 is software programmable. The software setting of the

magnitude of the ICONST current generator is accomplished by

selecting one of eight steps over an approximately 20% current range.

V

VIL

PWMSYNC

COMPARATOR

OUTPUT

t

VIL

T

PWM –TCRST

V

C

V

T

CMAX

CRST

V1

t

Figure 12. Analog Input Block Operation

The ADC system consists of four comparators and a single timer,

which may be clocked at either the DSP rate or half the DSP

rate depending on the setting of the ADCCNT bit (Bit 7) of the

MODECTRL register. When this bit is cleared, the timers count

at a slower rate of CLKIN. When this bit is set, they count at

CLKOUT or twice the rate of CLKIN. ADC1, ADC2, ADC3,

and ADCAUX are the registers that capture the conversion times,

which are effectively the timer value when the associated comparator trips.

–16–

REV. A

ADMC326

200

150

100

DECIMAL COUNTS

50

0

2

468100

CHARGING CAPACITOR – nF

Figure 13. PWMSYNCWT Program Value

ADC Resolution

The ADC is intrinsically linked to the PWM block through the

PWMSYNC pulse controlling the ADC conversion process.

Because of this link, the effective resolution of the ADC is a

function of both the PWM switching frequency and the rate at

which the ADC counter timer is clocked. For a CLKOUT period

and a PWM period of T

of t

CK

, the maximum count of the

PWM

ADC is given by:

Max Count = min (4095, (T

PWM

– T

CRST

)/2 tCK)

for MODECTRL Bit 7 = 0

Max Count = min (4095, (T

PWM

– T

CRST

)/tCK)

for MODECTRL Bit 7 = 1

Where T

is equal to the PWM period if operating in single

PWM

update mode, or it is equal to half that period if operating in

double update mode. For an assumed CLKOUT frequency of

20 MHz and PWMSYNC pulsewidth of 2.0 µs, the effective

resolution of the ADC block is tabulated for various PWM

switching frequencies in Table VII.

Table VII. ADC Resolution Examples

PWM MODECTRL[7] = 0 MODECTRL[7] = 1

Freq. Max Effective Max Effective

(kHz) Count Resolution Count Resolution

2.4 4095 12 4095 12

4 2480 >11 4095 12

8 1230 >10 2460 >11

18 535 >9 1070 >10

25 380 >8 760 >9

Charging Capacitor Selection

The charging capacitor value is selected based on the sample

(PWM) frequency desired. A selected capacitor value that is

too small will reduce the available resolution of the ADC by

having the ramp voltage rise rapidly and convert too quickly,

not utilizing all possible counts available in the PWM cycle. Too

large a capacitor may not convert in the available PWM cycle,

returning 0xFFF. To select a charging capacitor use Figure 14,

select the sampling frequency desired, then determine if the cur-

rent source is to be tuned to a nominal 100 µA or left in the

default (0x0 code) trim state, then determine the proper charge

capacitor from the appropriate curve.

100

– nF

10

NOM

C

DEFAULT ICONST

1

1 10010

TUNED ICONST

PWM FREQUENCY – kHz

Figure 14. Timing Capacitor Selection

Programmable Current Source

The ADMC326 has an internal current source that is used to

charge an external capacitor, generating the voltage ramp used

for conversion. The magnitude of the output of the current source

circuit is subject to manufacturing variations and can vary from

one device to the next. Therefore, the ADMC326 incudes a programmable current source whose output can always be tuned to

within 5% of the target 100 µA. A 3-bit register, ICONST_TRIM,

allows the user to make this adjustment. The output current is

proportional to the value written to the register: 0x0 produces

the minimum output, and 0x7 produces the maximum output.

The default value of ICONST_TRIM after reset is 0x0.

ADC Reference Ramp Calibration

The peak of the ADC ramp voltage should be as close as possible to 3.5 V to achieve the optimum ADC resolution and

signal range. When the current source is in the Default State,

the peak of the ADC ramp slope will be lower than this “3.5 V”

target ramp. When the current source value is increased, the

ADC ramp slope will become closer to the target value. The

“tuned” ramp slope is the one closest to the target ramp.

A simple calibration procedure using the internal 2.5 V reference

voltage allows the selection of the ICONST_TRIM register

value to reach this “tuned” ramp slope:

1. A high quality linear ADC capacitor is selected using Figure

14 for a tuned ICONST.

2. Program PWMSYNCWT to proper count as in Figure 13.

3. The ADC Max Count is calculated, as described in the ADC

Resolution section.

4. The target reference conversion count is calculated as TAR-

GET = (Max Count) × (2.5 V/3.5 V).

5. Reset or software sets the ICONST_TRIM register to zero.

6. Select the calibration V

in software on ADC multiplexer

REF

and wait one PWM cycle for updated ADC value.

7. The calibration channel value is compared with the target

reference conversion.

8. If this value is greater than the TARGET, the ICONST_TRIM

value is incremented by one, and Step 7 is repeated.

9. If the calibration channel value is less than the TARGET, the

calibration is completed.

REV. A

–17–

ADMC326

AUX0

AUX1

2 3 (AUXTM1 + 1)

2 3 (AUXTM0 + 1)

2 3 AUXCH0

2 3 (AUXTM0 + 1)

2 3 AUXCH1

ADC Registers

The configuration of all registers of the ADC System is shown

at the end of the data sheet.

AUXILIARY PWM TIMERS

Overview

The ADMC326 provides two variable frequency, variable duty

cycle, 8-bit, auxiliary PWM outputs that are available at the

AUX1 and AUX0 pins when enabled. These auxiliary PWM

outputs can be used to provide switching signals to other circuits in a typical motor control system such as power factor

corrected front-end converters or other switching power converters. Alternatively, by addition of a suitable filter network,

the auxiliary PWM output signals can be used as simple singlebit digital-to-analog converters.

The auxiliary PWM system of the ADMC326 can operate in

two different modes: independent mode, or offset mode. The

operating mode of the auxiliary PWM system is controlled by Bit 8

of the MODECTRL register. Setting Bit 8 of the MODECTRL

register places the auxiliary PWM system in the independent

mode. In this mode, the two auxiliary PWM generators are

completely independent and separate switching frequencies and

duty cycles may be programmed for each auxiliary PWM output.

In this mode, the 8-bit AUXTM0 register sets the switching frequency of the signal at the AUX0 output pin. Similarly, the

8-bit AUXTM1 register sets the switching frequency of the signal at the AUX1 pin. The fundamental time increment for the

auxiliary PWM outputs is twice the DSP instruction rate (or

2 t

Since the values in both AUXTM0 and AUXTM1 can range

from 0 to 0xFF, the achievable switching frequency of the auxiliary PWM signals may range from 39.1 kHz to 10 MHz for a

CLKOUT frequency of 20 MHz.

The on-time of the two auxiliary PWM signals is programmed

by the two 8-bit AUXCH0 and AUXCH1 registers, according to:

so that output duty cycles from 0% to 100% are possible. Duty

cycles of 100% are produced if the on-time value exceeds the

period value. Typical auxiliary PWM waveforms in independent

mode are shown in Figure 16(a).

3.5V

TARGET

RAMP

V

REF

MINIMUM

RAMP

0.3V

Figure 15. Current Ramp

) and the corresponding switching periods are given by:

CK

T

= 2 × (AUXTM0 + 1) × t

AUX0

T

= 2 × (AUXTM1 + 1) × t

AUX1

T

ON, AUX0

TON,

= 2 × (AUXCH0) × t

= 2 × (AUXCH1) × t

AUX1

CK

CK

CK

CK

When Bit 8 of the MODECTRL register is cleared, the auxiliary

PWM channels are placed in offset mode. In offset mode, the

switching frequency of the two signals on the AUX0 and AUX1

pins are identical and controlled by AUXTM0 in a manner

similar to that previously described for independent mode. In

addition, the on times of both the AUX0 and AUX1 signals are

controlled by the AUXCH0 and AUXCH1 registers as before.

However, in this mode the AUXTM1 register defines the offset

time from the rising edge of the signal on the AUX0 pin to that

on the AUX1 pin according to:

T

= 2 × (AUXTM1 + 1) × t

OFFSET

CK

For correct operation in this mode, the value written to the

AUXTM1 register must be less than the value written to the

AUXTM0 register. Typical auxiliary PWM waveforms in offset

mode are shown in Figure 16(b). Again, duty cycles from 0% to

100% are possible in this mode.

In both operating modes, the resolution of the auxiliary PWM

system is eight bits only at the minimum switching frequency

(AUXTM0 = AUXTM1 = 255 in independent mode, AUXTM0

= 255 in offset mode). Obviously, as the switching frequency is

increased, the resolution is reduced.

Values can be written to the auxiliary PWM registers at any time.

However, new duty cycle values written to the AUXCH0 and

AUXCH1 registers only become effective at the start of the next

cycle. Writing to the AUXTM0 or AUXTM1 registers causes the

internal timers to be reset to 0 and new PWM cycles to begin.