Page 1

a Boot loading the ADMC300 from a Motorola M68HC11 SCI Port

INTRODUCTION

In addition to its ability to boot load from a serial ROM or

EEPROM, the ADMC300 DSP Motor Controller can be boot

loaded from an external device configured as a standard

Universal Asynchronous Receiver Transmitter (UART). This

document describes how to boot load the ADMC300 from a

Motorola M68HC11 microcontroller using its Serial

Communications Interface (SCI).

UART Boot Load Requirements

To download code and data to the ADMC300 the external

device’s transmit line (TxD) must be connected to the

ADMC300’s SPORT1 receive line (DR1B pin). Similarly its

receive line (RxD) must be connected to the ADMC300’s

SPORT1 transmit line (DT1 pin). RS-232 line drivers can be

used to convert from the data receive and transmit TTL signals

to the RS-232 standard. The protocol used for asynchronous

communication is 1 start bit, 8 data bits, 1 stop bit, and no

parity.

UART Boot Load Operation

At reset the ADMC300 ROM monitor program initializes and

first tries to boot load from an SROM/EEPROM on its DR1A

pin. If no device is present on DR1A, or an invalid program is

detected, the monitor will fail this interface and switch its input

to the DR1B pin. It takes approximately 1250 DSP cycles

following reset for this to happen (50us @ 25 MHz

CLKOUT). Next the monitor waits to receive 2 bytes of

information on DR1B. For the monitor to recognize an

external UART boot loading device these 2 bytes must be

0x70, 0x71 respectively.

The first byte received (0x70) is called the autobaud byte. It is

used to calculate the baud rate at which the data is coming in.

This is known as the autobaud feature. The ADMC300 will

lock onto the baud rate of the external device automatically up

to a maximum baud rate of 300 kHz for a 25 MHz CLKOUT.

The second byte received (0x71) is called the header byte. It

tells the monitor what type of interface it is connected to. For

the UART boot loader the header byte is 0x71.

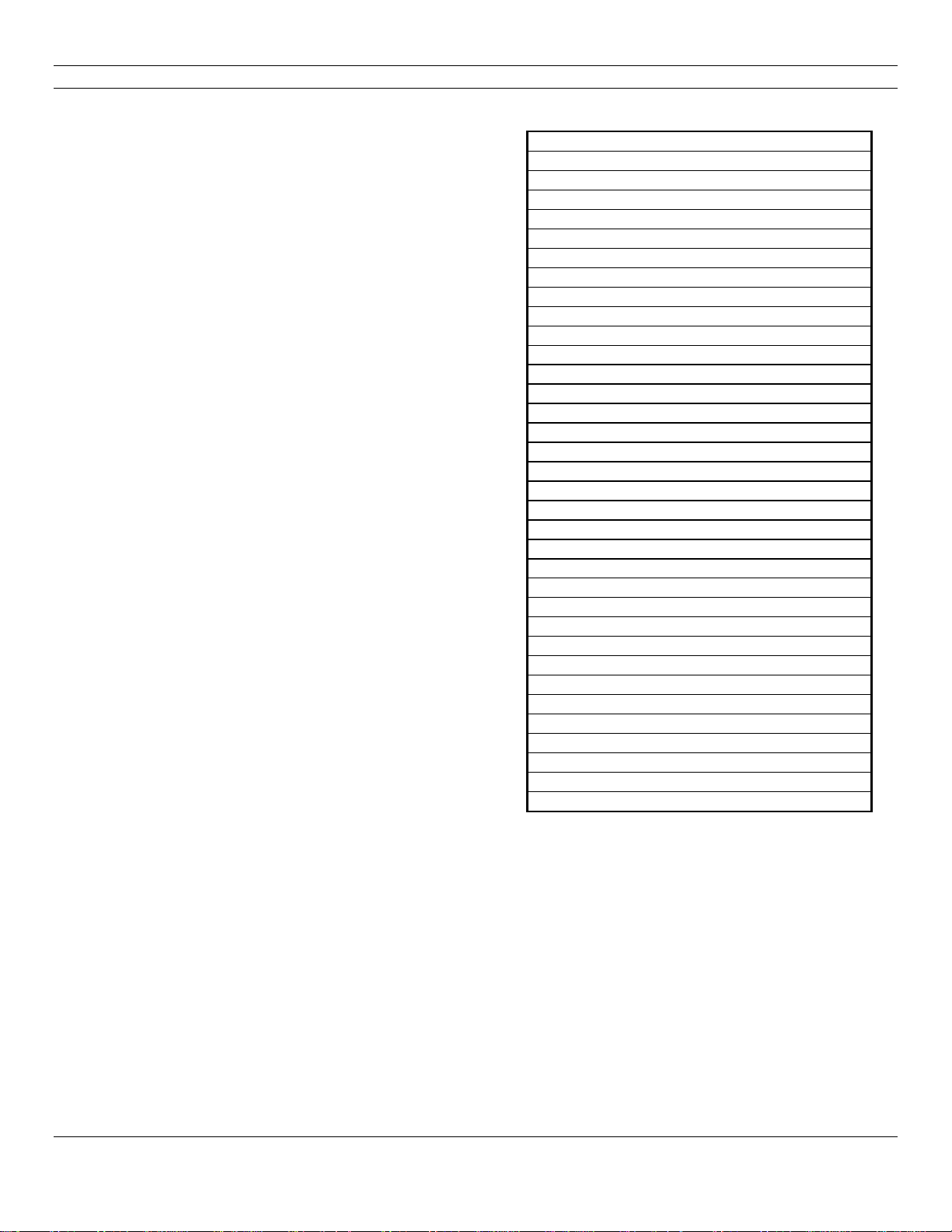

Following these first two bytes the monitor then receives the

code and data to be loaded into the ADMC300 program and

data memory. The required syntax for the file being loaded is

shown in Table 1. Each row of the table represents 1 byte in

the file.

Both the program and data memory portions of the boot load

file contain checksums that are used by the monitor to verify

correct loading operation. The PM checksum is calculated by

accumulating, in the MR0 register, the upper 16 bits of each

PM location received. The lower 8 bits are accumulated in the

MR1 register. When all locations have been received, the

MR1 register is masked with 0xFF, removing any overflow out

of the 8 bits. The MR0 register is then compared to the upper

16 bits of the received checksum and the MR1 register is

compared to the lower 8 bits of the received checksum. The

DM checksum is calculated in the same way as the upper 16

bits of the PM checksum. You can use the MAKEPROM tool

(included in the evaluation kit software) to calculate these

expected checksums for you. Use the -c option and

MAKEPROM will print out the expected checksums that you

can then enter into your boot load file.

Each byte received by the ADMC300, including the header

byte, is echoed back over DT1. The autobaud byte is not

echoed back. The external device may use this echo as a

means of synchronization and verification that the data has

been received correctly. As the monitor receives the boot load

file it extracts the program and data memory blocks, stores

them in memory, and calculates the checksums. The monitor

compares the checksums against the expected checksums that

it receives. If the monitor detects a checksum miscompare it

will fail the boot load and restart itself.

If the monitor successfully loads the program and data

memories without error then it starts execution of the loaded

program at location 0x0060.

Boot Loading Example 1 from the M68HC11

The program listed in Appendix A boot loads the program

example1.dsp (included in the evaluation kit software) from

the M68HC11 SCI port to the ADMC300. The data array

“TESTFILE” was created by extracting the bytes from the

example1.exe file. The checksums were calculated by running

the MAKEPROM tool with the -c option on the example1.exe

file.

As can be seen in the program the autobaud and header bytes

seem different from the required 0x70, 0x71 as stated earlier.

REV. A Motion Control Group, Analog Devices, 1997

Page 2

Analog Devices, Inc., 1997 Boot loading the ADMC300 from a Motorola M68HC11 SCI Port

This is because a UART sends and receives LSB first, while

the SPORT on the ADMC300 sends and receives MSB first.

Also the UART sends a start bit (0) first and a stop bit (1) last.

Therefore a 0x87 written to the SCDAT register on the

M68HC11 will be received by the ADMC300 as a 0x70.

Likewise a 0xC7 sent by the M68HC11 will be received as a

0x71 by the ADMC300.

The program sci_ex1.asm was tested on a Motorola

M68HC11EVB board connected to an ADMC300 evaluation

board. A serial cable was connected from the host port

connector on the M68HC11EVB to the UART connector on

the ADMC300 evaluation board. The test procedure was as

follows:

1. Reset the ADMC300 board.

2. Download the sci_ex1.s19 file to the

M68HC11EVB.

3. Execute “call c400” on the M68HC11EVB.

4. Observe the PWM signals come alive on the

ADMC300.

Number of PM Blocks

PM Start Address Block 1 (MSB)

PM Start Address Block 1 (LSB)

Number of PM Lines in Block 1 (MSB)

Number of PM Lines in Block 1 (LSB)

.

. Block 1 Code

.

PM Start Address Block N (MSB)

PM Start Address Block N (LSB)

Number of PM Lines in Block N (MSB)

Number of PM Lines in Block N (LSB)

.

. Block N Code

.

PM Checksum (Upper Byte)

PM Checksum (Middle Byte)

PM Checksum (Lower Byte)

Number of DM Blocks

DM Start Address Block 1 (MSB)

DM Start Address Block 1 (LSB)

Number of DM Lines in Block 1 (MSB)

Number of DM Lines in Block 1 (LSB)

.

. Block 1 Data

.

DM Start Address Block N (MSB)

DM Start Address Block N (LSB)

Number of DM Lines in Block N (MSB)

Number of DM Lines in Block N (LSB)

.

. Block N Data

.

DM Checksum (Upper Byte)

DM Checksum (Lower Byte)

Table 1. File Syntax For UART Boot Loading

REV. A Page 2

Page 3

Analog Devices, Inc., 1997 Boot loading the ADMC300 from a Motorola M68HC11 SCI Port

M68HC11 Program Listing (sci_ex1.asm)

* Download's the example1 program to the ADMC300

HOSTCO EQU $E330 * connect sci to host port

TARGCO EQU $E338

IODEV EQU $AA

SCSR EQU $102E

SCDAT EQU $102F

FILESIZE EQU 164

ORG $C400

* connect to ADMC300 over host I/O port

CLR IODEV * IODEV=SCI

JSR HOSTCO * connect SCI to host I/O port

LDAA #$87 * send autobaud character

JSR OUTBYTE

LDAA #$C7 * send header byte

JSR OUTBYTE

JSR INBYTE * receive echo of header byte

STAA HBYTE

* load the ADMC300 with the user program

LDX #TESTFILE

LDY #FILESIZE

LOADLP LDAA 0,X

JSR OUTBYTE * send 1 byte

JSR INBYTE * receive echo

STAA ECHO

INX

DEY

CPY #0

BNE LOADLP

* disconnect from ADMC300 and return to BUFFALO program

LDAA #$01

STAA IODEV * IODEV=ACIA

JSR TARGCO * connect SCI to target on evb board

RTS

**********

* INBYTE() - Read SCI. Returns a=char or 0.

* NOTE: Routine is identical to BUFFALO INPUT routine except

* no cop reset and only SCI portion of code is used.

**********

INBYTE EQU *

PSHX

PSHY

JSR INSCIBYT read sci

PULY

PULX

RTS

**********

* OUTBYTE() - Output character in A.

* NOTE: Routine is identical to BUFFALO OUTPUT routine except

* only SCI portion of code is used.

REV. A Page 3

Page 4

Analog Devices, Inc., 1997 Boot loading the ADMC300 from a Motorola M68HC11 SCI Port

**********

OUTBYTE EQU *

PSHA save registers

PSHB

PSHX

PSHY

JSR OUTSCIBYT write sci

PULY

PULX

PULB

PULA

RTS

**********

* INSCIBYT() - Read from SCI. Return a=char.

* NOTE: Routine identical to BUFFALO INSCI routine except don't mask

* parity so you get a full byte. Also changed branch so it

* waits here instead of INBYTE because it wasn't working if you

* received a byte = 0.

**********

INSCIBYT LDAA SCSR read status reg

ANDA #$20

BEQ INSCIBYT jump if rdrf=0

LDAA SCDAT read data register

INSCIBYT1 RTS

**********

* OUTSCIBYT() - Output A to sci.

* NOTE: Routine is identical to BUFFALO OUTSCI routine except no crlf code

* and don't mask parity so you output a full byte

**********

OUTSCIBYT LDAB SCSR read status

BITB #$80

BEQ OUTSCIBYT loop until tdre=1

STAA SCDAT send byte

RTS

ORG $C000

* user variables

HBYTE RMB 1

ECHO RMB 1

* file to load over UART (164 bytes)

TESTFILE FCB $01 * # of PM blocks

FCB $00 * PM start address MSB

FCB $60 * PM start address LSB

FCB $00 * # of lines MSB

FCB $2D * # of lines LSB

FCB $1C * code for this block

FCB $06

FCB $AF

FCB $3C

FCB $08

FCB $0C

FCB $3C

FCB $00

FCB $04

FCB $40

FCB $20

FCB $04

REV. A Page 4

Page 5

Analog Devices, Inc., 1997 Boot loading the ADMC300 from a Motorola M68HC11 SCI Port

FCB $0D

FCB $03

FCB $A3

FCB $23

FCB $A2

FCB $0F

FCB $0D

FCB $0C

FCB $3A

FCB $00

FCB $00

FCB $00

FCB $00

FCB $00

FCB $00

FCB $18

FCB $06

FCB $7F

FCB $40

FCB $00

FCB $0A

FCB $92

FCB $04

FCB $2A

FCB $40

FCB $4B

FCB $0A

FCB $92

FCB $00

FCB $8A

FCB $40

FCB $00

FCB $CA

FCB $92

FCB $00

FCB $9A

FCB $40

FCB $01

FCB $2A

FCB $92

FCB $00

FCB $AA

FCB $40

FCB $00

FCB $0A

FCB $92

FCB $00

FCB $FA

FCB $40

FCB $20

FCB $5A

FCB $92

FCB $00

FCB $BA

FCB $38

FCB $03

FCB $50

FCB $40

FCB $08

FCB $1B

FCB $1C

REV. A Page 5

Page 6

Analog Devices, Inc., 1997 Boot loading the ADMC300 from a Motorola M68HC11 SCI Port

FCB $DD

FCB $EF

FCB $38

FCB $05

FCB $90

FCB $40

FCB $08

FCB $AB

FCB $1C

FCB $DD

FCB $EF

FCB $40

FCB $40

FCB $24

FCB $82

FCB $01

FCB $DA

FCB $23

FCB $A2

FCB $0F

FCB $92

FCB $01

FCB $DA

FCB $0A

FCB $00

FCB $0F

FCB $00

FCB $00

FCB $00

FCB $00

FCB $00

FCB $00

FCB $83

FCB $80

FCB $00

FCB $92

FCB $00

FCB $C0

FCB $83

FCB $80

FCB $10

FCB $92

FCB $00

FCB $D0

FCB $83

FCB $80

FCB $20

FCB $92

FCB $00

FCB $E0

FCB $0A

FCB $00

FCB $1F

FCB $00

FCB $00

FCB $00

FCB $00

FCB $00

FCB $00

FCB $0A

FCB $00

REV. A Page 6

Page 7

Analog Devices, Inc., 1997 Boot loading the ADMC300 from a Motorola M68HC11 SCI Port

FCB $1F

FCB $16 * PM checksum USB

FCB $8B * PM checksum MSB

FCB $9E * PM checksum LSB

FCB $03 * # of DM blocks

FCB $38 * DM start address MSB 1st block

FCB $00 * DM start address LSB

FCB $00 * # of lines MSB

FCB $01 * # of lines LSB

FCB $01 * data for 1st block

FCB $38

FCB $38 * DM start address MSB 2nd block

FCB $01 * DM start address LSB

FCB $00 * # of lines MSB

FCB $01 * # of lines LSB

FCB $02 * data for 2nd block

FCB $64

FCB $38 * DM start address MSB 3rd block

FCB $02 * DM start address LSB

FCB $00 * # of lines MSB

FCB $01 * # of lines LSB

FCB $03 * data for 3rd block

FCB $90

FCB $07 * DM checksum MSB

FCB $2C * DM checksum LSB

REV. A Page 7

Loading...

Loading...