Microprocessor

4.65V

1

WATCHDOG

TRANSITION DETECTOR

1.3V

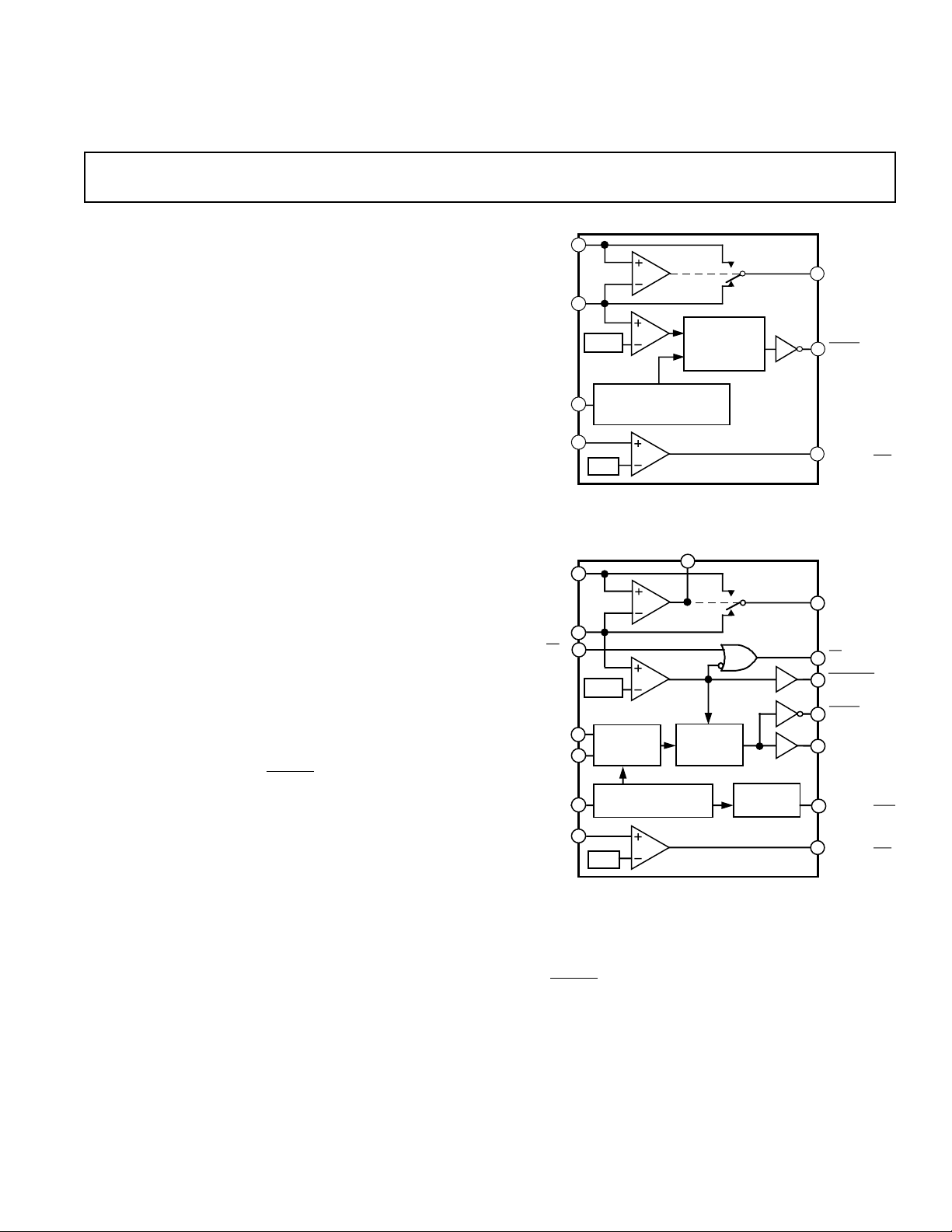

ADM691

ADM693

ADM695

V

OUT

V

BATT

V

CC

WATCHDOG

INPUT (WDI)

POWER FAIL

INPUT (PFI)

1

VOLTAGE DETECTOR = 4.65V (ADM691, ADM695)

4.40V (ADM693)

POWER FAIL

OUTPUT (PFO)

RESET

WATCHDOG

TIMER

RESET &

WATCHDOG

TIMEBASE

RESET

GENERATOR

BATT ON

OSC IN

OSC SEL

WATCHDOG

OUTPUT (WDO)

RESET

LOW LINE

CE

OUT

CE

IN

4.65V

1

RESET

GENERATOR

2

WATCHDOG

TRANSITION DETECTOR

(1.6s)

1.3V

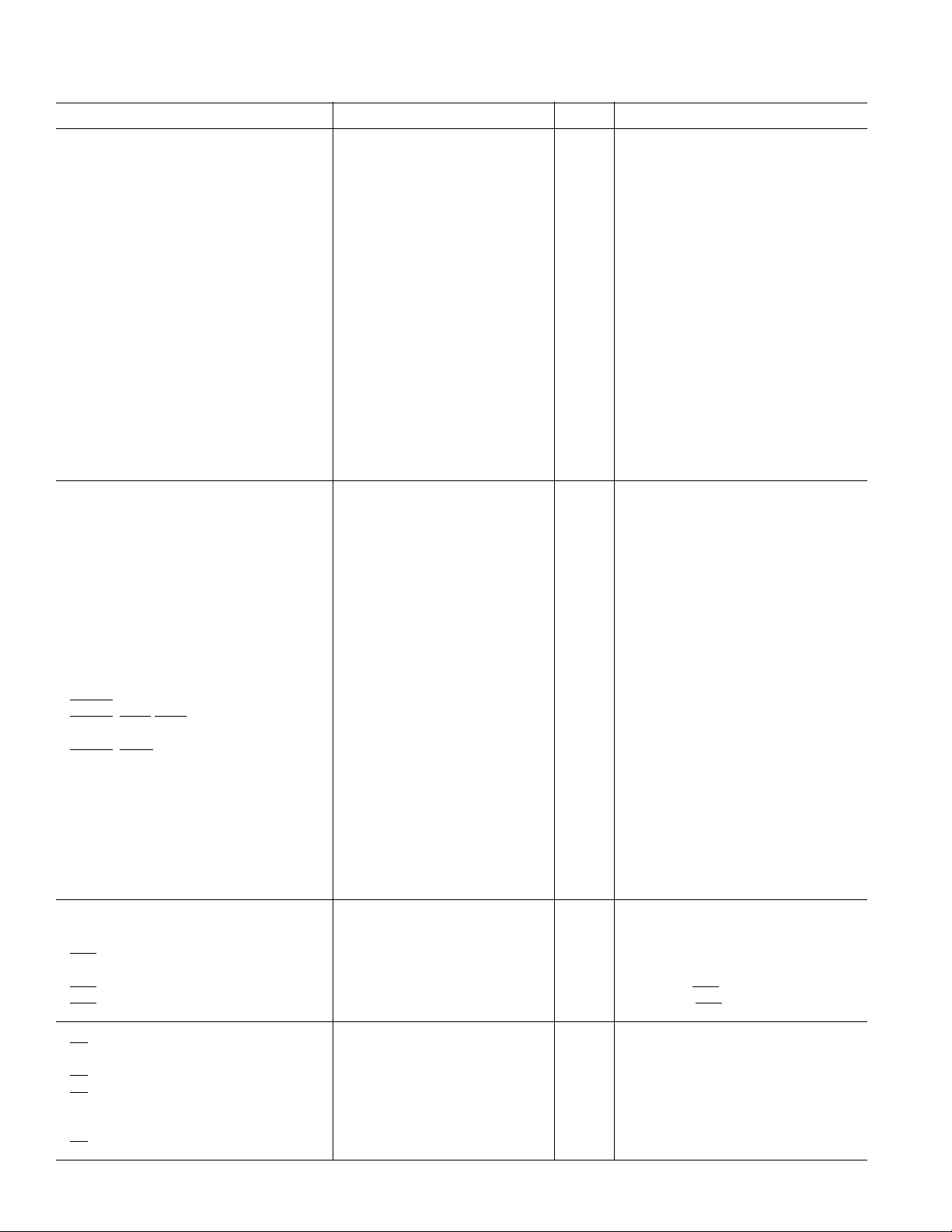

ADM690

ADM692

ADM694

V

OUT

V

BATT

V

CC

WATCHDOG

INPUT (WDI)

POWER FAIL

INPUT (PFI)

1

VOLTAGE DETECTOR = 4.65V (ADM690, ADM694)

4.40V (ADM692)

2

RESET PULSE WIDTH = 50ms (ADM690, ADM692)

200ms (ADM694)

POWER FAIL

OUTPUT (PFO)

RESET

a

FEATURES

Superior Upgrade for MAX690–MAX695

Specified Over Temperature

Low Power Consumption (5 mW)

Precision Voltage Monitor

Reset Assertion Down to 1 V V

Low Switch On-Resistance 1.5 V Normal,

20 V in Backup

High Current Drive (100 mA)

Watchdog Timer—100 ms, 1.6 s, or Adjustable

600 nA Standby Current

Automatic Battery Backup Power Switching

Extremely Fast Gating of Chip Enable Signals (5 ns)

Voltage Monitor for Power Fail

APPLICATIONS

Microprocessor Systems

Computers

Controllers

Intelligent Instruments

Automotive Systems

CC

Supervisory Circuits

ADM690–ADM695

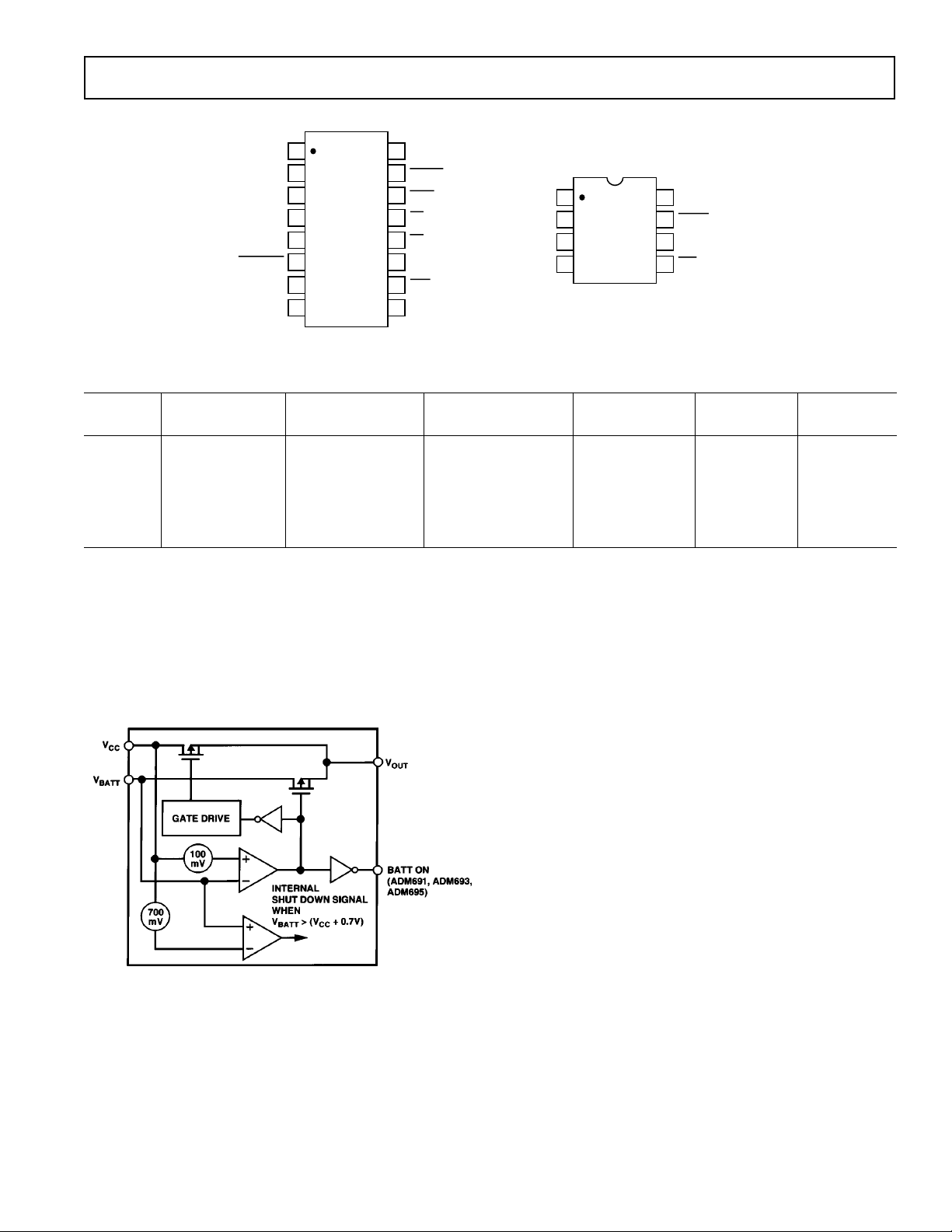

FUNCTIONAL BLOCK DIAGRAMS

GENERAL DESCRIPTION

The ADM690–ADM695 family of supervisory circuits offers

complete single chip solutions for power supply monitoring and

battery control functions in microprocessor systems. These

functions include µP reset, backup battery switchover, watchdog

timer, CMOS RAM write protection, and power failure warning. The complete family provides a variety of configurations to

satisfy most microprocessor system requirements.

The ADM690, ADM692 and ADM694 are available in 8-pin

DIP packages and provide:

1. Power-on reset output during power-up, power-down and

brownout conditions. The

tional with V

as low as 1 V.

CC

RESET output remains opera-

2. Battery backup switching for CMOS RAM, CMOS

microprocessor or other low power logic.

3. A reset pulse if the optional watchdog timer has not been

toggled within a specified time.

4. A 1.3 V threshold detector for power fail warning, low battery

detection, or to monitor a power supply other than +5 V.

The ADM691, ADM693 and ADM695 are available in 16-pin

DIP and small outline packages and provide three additional

functions.

1. Write protection of CMOS RAM or EEPROM.

2. Adjustable reset and watchdog timeout periods.

3. Separate watchdog timeout, backup battery switchover, and

low V

REV. A

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

status outputs.

CC

The ADM690–ADM695 family is fabricated using an advanced

epitaxial CMOS process combining low power consumption

(5 mW), extremely fast Chip Enable gating (5 ns) and high reliability.

RESET assertion is guaranteed with VCC as low as 1 V.

In addition, the power switching circuitry is designed for minimal voltage drop thereby permitting increased output current

drive of up to 100 mA without the need for an external pass

transistor.

© Analog Devices, Inc., 1996

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 617/329-4700 Fax: 617/326-8703

ADM690–ADM695–SPECIFICA TIONS

(VCC = Full Operating Range, V

T

unless otherwise noted)

MAX

= +2.8 V, TA = T

BATT

Parameter Min Typ Max Units Test Conditions/Comments

BATTERY BACKUP SWITCHING

V

Operating Voltage Range

CC

ADM690, ADM691, ADM694, ADM695 4.75 5.5 V

ADM692, ADM693 4.5 5.5 V

V

Operating Voltage Range

BATT

ADM690, ADM691, ADM694, ADM695 2.0 4.25 V

ADM692, ADM693 2.0 4.0 V

V

Output Voltage VCC – 0.05 VCC – 0.025 V I

OUT

V

in Battery Backup Mode V

OUT

Supply Current (Excludes I

) 1 1.95 mA I

OUT

V

– 0.5 VCC – 0.25 V I

CC

BATT

– 0.05 V

– 0.02 V I

BATT

Supply Current in Battery Backup Mode 0.6 1 µAV

Battery Standby Current 5.5 V > V

(+ = Discharge, – = Charge) –0.1 +0.02 µAT

= 1 mA

OUT

≤ 100 mA

OUT

= 250 µA, VCC < V

OUT

= 100 mA

OUT

= 0 V, V

CC

= +25°C

A

CC

BATT

> V

= 2.8 V

+ 0.2 V

BATT

BATT

– 0.2 V

–1.0 +0.02 µA

Battery Switchover Threshold 70 mV Power Up

V

CC

– V

BATT

50 mV Power Down

Battery Switchover Hysteresis 20 mV

BATT ON Output Voltage 0.3 V I

BATT ON Output Short Circuit Current 35 mA BATT ON = V

= 3.2 mA

SINK

= 4.5 V Sink Current

OUT

0.5 1 25 µA BATT ON = 0 V Source Current

RESET AND WATCHDOG TIMER

Reset Voltage Threshold

ADM690, ADM691, ADM694, ADM695 4.5 4.65 4.73 V

ADM692, ADM693 4.25 4.4 4.48 V

Reset Threshold Hysteresis 40 mV

Reset Timeout Delay

ADM690, ADM691, ADM692, ADM693 35 50 70 ms OSC SEL = HIGH, V

ADM694, ADM695 140 200 280 ms OSC SEL = HIGH, V

Watchdog Timeout Period, Internal Oscillator 1.0 1.6 2.25 s Long Period, V

70 100 140 ms Short Period, V

CC

CC

= 5 V, TA = +25°C

CC

= 5 V, TA = +25°C

CC

= 5 V, TA = +25°C

= 5 V, TA = +25°C

Watchdog Timeout Period, External Clock 3840 4097 Cycles Long Period

768 1025 Cycles Short Period

Minimum WDI Input Pulse Width 50 ns V

RESET Output Voltage @ VCC = +1 V 4 200 mV I

RESET, LOW LINE Output Voltage 0.4 V I

3.5 V I

RESET, WDO Output Voltage 0.4 V I

3.5 V I

= 0.4, VIH = 3.5 V

IL

= 10 µA, VCC = 1 V

SINK

= 1.6 mA, VCC = 4.25 V

SINK

= 1 µA, VCC = 5 V

SOURCE

= 1.6 mA, VCC = 5 V

SINK

= 1 µA, VCC = 4.25 V

SOURCE

Output Short Circuit Source Current 1 3 25 µA

Output Short Circuit Sink Current 25 mA

WDI Input Threshold V

CC

= 5 V

1

Logic Low 0.8 V

Logic High 3.5 V

WDI Input Current 20 50 µA WDI = V

, TA = +25°C

OUT

–50 –15 µA WDI = 0 V, TA = +25°C

POWER FAIL DETECTOR

PFI Input Threshold 1.25 1.3 1.35 V V

= +5 V

CC

PFI Input Current –25 ±0.01 +25 nA

PFO Output Voltage 0.4 V I

3.5 V I

= 3.2 mA

SINK

SOURCE

= 1 µA

PFO Short Circuit Source Current 1 3 25 µA PFI = Low, PFO = 0 V

PFO Short Circuit Sink Current 25 mA PFI = High, PFO = V

OUT

CHIP ENABLE GATING

CE

Threshold 0.8 V V

IN

3.0 V V

CE

Pull-Up Current 3 µA

IN

CE

Output Voltage 0.4 V I

OUT

V

– 1.5 V I

OUT

V

– 0.05 V I

OUT

IL

IH

= 3.2 mA

SINK

= 3.0 mA

SOURCE

= 1 µA, VCC = 0 V

SOURCE

CE Propagation Delay 5 9 ns

MIN

to

–2–

REV. A

ADM690–ADM695

Parameter Min Typ Max Units Test Conditions/Comments

OSCILLATOR

OSC IN Input Current ±2 µA

OSC SEL Input Pull-Up Current 5 µA

OSC IN Frequency Range 0 250 kHz OSC SEL = 0 V

OSC IN Frequency with External Capacitor 4 kHz OSC SEL = 0 V, C

NOTE

1

WDI is a three level input which is internally biased to 38% of VCC and has an input impedance of approximately 125 kΩ.

Specifications subject to change without notice.

= 47 pF

OSC

ABSOLUTE MAXIMUM RATINGS*

(TA = +25°C unless otherwise noted)

VCC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . –0.3 V to +6 V

V

All Other Inputs . . . . . . . . . . . . . . . . . . –0.3 V to V

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . –0.3 V to +6 V

BATT

OUT

+ 0.5 V

Input Current

V

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200 mA

CC

V

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50 mA

BATT

GND . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 mA

Digital Output Current . . . . . . . . . . . . . . . . . . . . . . . . . 20 mA

Power Dissipation, N-8 DIP . . . . . . . . . . . . . . . . . . . .400 mW

θ

Thermal Impedance . . . . . . . . . . . . . . . . . . . . . 120°C/W

JA

Power Dissipation, Q-8 DIP . . . . . . . . . . . . . . . . . . . .500 mW

θ

Thermal Impedance . . . . . . . . . . . . . . . . . . . . . 125°C/W

JA

Power Dissipation, N-16 DIP . . . . . . . . . . . . . . . . . . .600 mW

θ

Thermal Impedance . . . . . . . . . . . . . . . . . . . . . 135°C/W

JA

Power Dissipation, Q-16 DIP . . . . . . . . . . . . . . . . . . . 600 mW

θ

Thermal Impedance . . . . . . . . . . . . . . . . . . . . . 100°C/W

JA

Power Dissipation, R-16 SOIC . . . . . . . . . . . . . . . . . .600 mW

θ

Thermal Impedance . . . . . . . . . . . . . . . . . . . . . 110°C/W

JA

Operating Temperature Range

Industrial (A Version) . . . . . . . . . . . . . . . . . –40°C to +85°C

Extended (S Version) . . . . . . . . . . . . . . . . .–55°C to +125°C

Lead Temperature (Soldering, 10 secs) . . . . . . . . . . . . +300°C

Vapor Phase (60 secs) . . . . . . . . . . . . . . . . . . . . . . . +215°C

Infrared (15 secs) . . . . . . . . . . . . . . . . . . . . . . . . . . . +220°C

Storage Temperature Range . . . . . . . . . . . . . –65°C to +150°C

ORDERING GUIDE

Model Temperature Range Package Option

ADM690AN –40°C to +85°C N-8

ADM690AQ –40°C to +85°C Q-8

ADM690SQ –55°C to +125°C Q-8

ADM691AN –40°C to +85°C N-16

ADM691AR –40°C to +85°C R-16

ADM691AQ –40°C to +85°C Q-16

ADM691SQ –55°C to +125°C Q-16

ADM692AN –40°C to +85°C N-8

ADM692AQ –40°C to +85°C Q-8

ADM692SQ –55°C to +125°C Q-8

ADM693AN –40°C to +85°C N-16

ADM693AR –40°C to +85°C R-16

ADM693AQ –40°C to +85°C Q-16

ADM693SQ –55°C to +125°C Q-16

ADM694AN –40°C to +85°C N-8

ADM694AQ –40°C to +85°C Q-8

ADM694SQ –55°C to +125°C Q-8

ADM695AN –40°C to +85°C N-16

ADM695AR –40°C to +85°C R-16

ADM695AQ –40°C to +85°C Q-16

ADM695SQ –55°C to +125°C Q-16

*Stresses above those listed under “Absolute Maximum Ratings” may cause

permanent damage to the device. This is a stress rating only and functional

operation of the device at these or any other conditions above those listed in the

operational sections of this specification is not implied. Exposure to absolute

maximum ratings for extended periods of time may affect device reliability.

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection.

Although the ADM690–ADM695 features proprietary ESD protection circuitry, permanent

damage may occur on devices subjected to high energy electrostatic discharges. Therefore,

proper ESD precautions are recommended to avoid performance degradation or loss of

functionality.

REV. A

–3–

WARNING!

ESD SENSITIVE DEVICE

ADM690–ADM695

Mnemonic Function

PIN FUNCTION DESCRIPTION

V

V

V

CC

BATT

OUT

Power Supply Input: +5 V Nominal.

Backup Battery Input. Connect to Ground if a backup battery is not used.

Output Voltage, VCC or V

can supply up to 100 mA to power CMOS RAM. Connect V

is internally switched to V

BATT

depending on which is at the highest potential. V

OUT

to VCC if V

OUT

OUT

and V

are not used.

BATT

OUT

GND 0 V. Ground reference for all signals.

RESET Logic Output. RESET goes low if

1. V

falls below the Reset Threshold

CC

2. V

falls below V

CC

BATT

3. The watchdog timer is not serviced within its timeout period.

The reset threshold is typically 4.65 V for the ADM690/ADM691/ADM694/ADM695 and 4.4 V for the ADM692 and

ADM693.

after V

serviced within its timeout period. The

shown in Table I. The

RESET remains low for 50 ms (ADM690/ADM691/ADM692/ADM693) or 200 ms (ADM694/ADM695)

returns above the threshold. RESET also goes low for 50 (200) ms if the watchdog timer is enabled but not

CC

RESET pulse width can be adjusted on the ADM691/ADM693/ADM695 as

RESET output has an internal 3 µA pull up, and can either connect to an open collector

Reset bus or directly drive a CMOS gate without an external pull-up resistor.

WDI Watchdog Input. WDI is a three level input. If WDI remains either high or low for longer than the watchdog timeout

period,

RESET pulses low and WDO goes low. The timer resets with each transition on the WDI line. The watchdog

timer may be disabled if WDI is left floating or is driven to midsupply.

PFI Power Fail Input. PFI is the noninverting input to the Power Fail Comparator when PFI is less than 1.3 V,

goes low. Connect PFI to GND or V

when not used.

OUT

PFO

PFO Power Fail Output. PFO is the output of the Power Fail Comparator. It goes low when PFI is less than 1.3 V. The

comparator is turned off and

CE

CE

IN

OUT

Logic Input. The input to the CE gating circuit. Connect to GND or V

Logic Output. CE

threshold. If V

OUT

is below the reset threshold, CE

CC

BATT ON Logic Output. BATT ON goes high when V

PFO goes low when VCC is below V

is a gated version of the CEIN signal. CE

is forced high. See Figures 5 and 6.

OUT

is internally switched to the V

OUT

.

BATT

if not used.

OUT

tracks CEIN when VCC is above the reset

OUT

input. It goes low when V

BATT

OUT

is internally switched to VCC. The output typically sinks 35 mA and can directly drive the base of an external

PNP transistor to increase the output current above the 100 mA rating of V

OUT

.

LOW LINE Logic Output. LOW LINE goes low when VCC falls below the reset threshold. It returns high as soon as VCC rises

above the reset threshold.

RESET Logic Output. RESET is an active high output. It is the inverse of

RESET.

OSC SEL Logic Oscillator Select Input. When OSC SEL is unconnected (floating) or driven high, the internal oscillator sets

the reset active time and watchdog timeout period. When OSC SEL is low, the external oscillator input, OSC IN,

is enabled. OSC SEL has a 3 µA internal pull up, (see Table I).

OSC IN Oscillator Logic Input. With OSC SEL low, OSC IN can be driven by an external clock signal or an external

capacitor can be connected between OSC IN and GND. This sets both the reset active pulse timing and the watchdog timeout period (see Table I and Figure 4). With OSC SEL high or floating, the internal oscillator is enabled

and the reset active time is fixed at 50 ms typ. (ADM691/ADM693) or 200 ms typ (ADM695). In this mode the

OSC IN pin selects between fast (100 ms) and slow (1.6 s) watchdog timeout periods. In both modes, the timeout

period immediately after a reset is 1.6 s typical.

WDO Logic Output. The Watchdog Output, WDO, goes low if WDI remains either high or low for longer than the

watchdog timeout period.

WDO is set high by the next transition at WDI. If WDI is unconnected or at midsupply,

the watchdog timer is disabled and WDO remains high. WDO also goes high when LOW LINE goes low.

–4–

REV. A

PIN CONFIGURATIONS

ADM690–ADM695

V

BATT

V

OUT

V

GND

BATT ON

LOW LINE

OSC IN

OSC SEL

CC

1

2

3

4

5

(Not to Scale)

6

7

8

ADM691

ADM693

ADM695

TOP VIEW

16

15

14

13

12

11

10

9

RESET

RESET

WDO

CE

IN

CE

OUT

WDI

PFO

PFI

V

OUT

V

GND

PFI

CC

1

2

3

(Not to Scale)

4

ADM690

ADM692

ADM694

TOP VIEW

8

7

6

5

V

BATT

RESET

WDI

PFO

PRODUCT SELECTION GUIDE

Part Nominal Reset Nominal V

CC

Nominal Watchdog Battery Backup Base Drive Chip Enable

Number Time Reset Threshold Timeout Period Switching Ext PNP Signals

ADM690 50 ms 4.65 V 1.6 s Yes No No

ADM691 50 ms or ADJ 4.65 V 100 ms, 1.6 s, ADJ Yes Yes Yes

ADM692 50 ms 4.4 V 1.6 s Yes No No

ADM693 50 ms or ADJ 4.4 V 100 ms, 1.6 s, ADJ Yes Yes Yes

ADM694 200 ms 4.65 V 1.6 s Yes No No

ADM695 200 ms or ADJ 4.65 V 100 ms, 1.6 s, ADJ Yes Yes Yes

CIRCUIT INFORMATION

Battery Switchover Section

The battery switchover circuit compares VCC to the V

input, and connects V

occurs when V

when V

CC

is 50 mV higher than V

CC

is 70 mV greater than V

to whichever is higher. Switchover

OUT

BATT

as VCC falls, and

BATT

as VCC rises. This

20 mV of hysteresis prevents repeated rapid switching if V

BATT

CC

falls very slowly or remains nearly equal to the battery voltage.

If the continuous output current requirement at V

100 mA or if a lower V

CC–VOUT

voltage differential is desired,

OUT

exceeds

an external PNP pass transistor may be connected in parallel

with the internal transistor. The BATT ON output (ADM691/

ADM693/ADM695) can directly drive the base of the external

transistor.

A 20 Ω MOSFET switch connects the V

input to V

BATT

OUT

during battery backup. This MOSFET has very low input-tooutput differential (dropout voltage) at the low current levels

required for battery back up of CMOS RAM or other low

power CMOS circuitry. The supply current in battery back up

is typically 0.6 µA.

The ADM690/ADM691/ADM694/ADM695 operates with

battery voltages from 2.0 V to 4.25 V and the ADM692/ADM693

operates with battery voltages from 2.0 V to 4.0 V. High value

capacitors, either standard electrolytic or the farad size double

layer capacitors, can also be used for short-term memory back

up. A small charging current of typically 10 nA (0.1 µA max)

flows out of the V

terminal. This current is useful for

BATT

maintaining rechargeable batteries in a fully charged condition.

This extends the life of the back up battery by compensating

for its self discharge current. Also note that this current poses

no problem when lithium batteries are used for back up since

the maximum charging current (0.1 µA) is safe for even the

Figure 1. Battery Switchover Schematic

During normal operation with VCC higher than V

ternally switched to V

via an internal PMOS transistor

OUT

, VCC is in-

BATT

switch. This switch has a typical on-resistance of 1.5 Ω and can

supply up to 100 mA at the V

terminal. V

OUT

is normally

OUT

smallest lithium cells.

If the battery-switchover section is not used, V

connected to GND and V

should be connected to VCC.

OUT

should be

BATT

used to drive a RAM memory bank which may require instantaneous currents of greater than 100 mA. If this is the case then a

bypass capacitor should be connected to V

. The capacitor

OUT

will provide the peak current transients to the RAM. A capacitance value of 0.1 µF or greater may be used.

REV. A

–5–

ADM690–ADM695

POWER FAIL RESET OUTPUT

RESET is an active low output which provides a RESET signal

to the Microprocessor whenever V

V

falls below the reset threshold, the RESET output is forced

CC

is at an invalid level. When

CC

low. The nominal reset voltage threshold is 4.65 V (ADM690/

ADM691/ADM694/ADM695) or 4.4 V (ADM692/ADM693).

V

RESET

LOW LINE

CC

V2 V2

t

1

t

= RESET TIME.

1

V1 = RESET VOLTAGE THRESHOLD LOW

V2 = RESET VOLTAGE THRESHOLD HIGH

HYSTERESIS = V2–V1

V1 V1

t

1

Figure 2. Power Fail Reset Timing

On power-up RESET will remain low for 50 ms (200 ms for

ADM694 and ADM695) after V

rises above the appropriate

CC

reset threshold. This allows time for the power supply and microprocessor to stabilize. On power-down, the

remains low with V

as low as 1 V. This ensures that the

CC

RESET output

microprocessor is held in a stable shutdown condition.

This

RESET active time is adjustable on the ADM691/ADM693/

ADM695 by using an external oscillator or by connecting an

external capacitor to the OSC IN pin. Refer to Table I and

Figure 4.

The guaranteed minimum and maximum thresholds of the

ADM690/ADM691/ADM694/ADM695 are 4.5 V and 4.73 V,

while the guaranteed thresholds of the ADM692/ADM693 are

4.25 V and 4.48 V. The ADM690/ADM691/ADM694/ADM695

is, therefore, compatible with 5 V supplies with a +10%, –5%

tolerance while the ADM692/ADM693 is compatible with 5 V

± 10% supplies. The reset threshold comparator has approximately 50 mV of hysteresis. The response time of the reset voltage comparator is less than 1 µs. If glitches are present on the

V

line which could cause spurious reset pulses, then V

CC

CC

should be decoupled close to the device.

In addition to

tain an active high

RESET the ADM691/ADM693/ADM695 con-

RESET output. This is the complement of

RESET and is intended for processors requiring an active high

RESET signal.

Watchdog Timer RESET

The watchdog timer circuit monitors the activity of the microprocessor in order to check that it is not stalled in an indefinite

loop. An output line on the processor is used to toggle the

Watchdog Input (WDI) line. If this line is not toggled within the

selected timeout period, a

RESET pulse is generated. The

nominal watchdog timeout period is preset at 1.6 seconds on the

ADM690/ADM692/ADM694. The ADM691/ADM693/ADM695

may be configured for either a fixed “short” 100 ms or a “long”

1.6 second timeout period or for an adjustable timeout period.

If the “short” period is selected, some systems may be unable to

service the watchdog timer immediately after a reset, so the

ADM691/ADM693/ADM695 automatically selects the “long”

timeout period directly after a reset is issued. The watchdog

timer is restarted at the end of reset, whether the reset was

caused by lack of activity on WDI or by V

falling below the

CC

reset threshold.

The normal (short) timeout period becomes effective following

the first transition of WDI after

RESET has gone inactive. The

watchdog timeout period restarts with each transition on the

WDI pin. To ensure that the watchdog timer does not time out,

either a high-to-low or low-to-high transition on the WDI pin

must occur at or less than the minimum timeout period. If WDI

remains permanently either high or low, reset pulses will be

issued after each “long” timeout period (1.6 s). The watchdog

monitor can be deactivated by floating the Watchdog Input

(WDI) or by connecting it to midsupply.

WDI

WDO

t

2

RESET

t

1

t

= RESET TIME.

1

t

= NORMAL (SHORT) WATCHDOG TIMEOUT PERIOD.

2

t

= WATCHDOG TIMEOUT PERIOD IMMEDIATELY FOLLOWING A RESET.

3

t

1

t

3

t

1

Figure 3. Watchdog Timeout Period and Reset Active

Time

–6–

REV. A

ADM690–ADM695

OSC IN

OSC SEL

ADM691

ADM693

ADM695

8

7

C

OSC

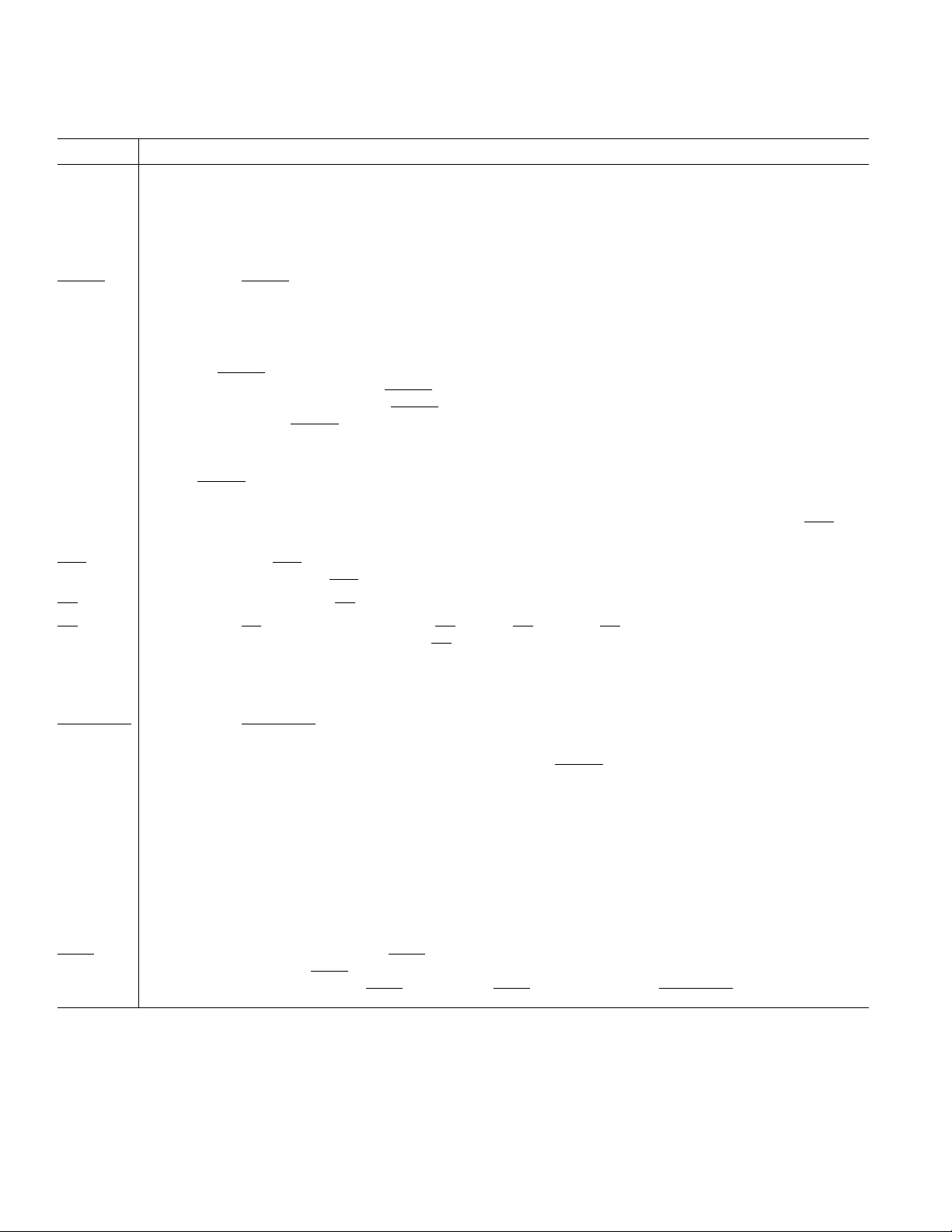

Table I. ADM691, ADM693, ADM695 Reset Pulse Width and Watchdog Timeout Selections

Watchdog Timeout Period Reset Active Period

Immediately

OSC SEL OSC IN Normal After Reset ADM691/ADM693 ADM695

Low External Clock Input 1024 CLKS 4096 CLKS 512 CLKS 2048 CLKS

Low External Capacitor 260 ms × C/47 pF 1.04 s × C/47 pF 130 ms × C/47 pF 520 ms × C/47 pF

Floating or High Low 100 ms 1.6 s 50 ms 200 ms

Floating or High Floating or High 1.6 s 1.6 s 50 ms 200 ms

NOTE

With the OSC SEL pin low, OSC IN can be driven by an external clock signal, or an external capacitor can be connected between OSC IN and GND. The nominal

internal oscillator frequency is 10.24 kHz. The nominal oscillator frequency with external capacitor is: F

The watchdog timeout period is fixed at 1.6 seconds, and the

reset pulse width is fixed at 50 ms on the ADM690/ADM692.

On the ADM694 the watchdog timeout period is also 1.6 seconds but the reset pulse width is fixed at 200 ms. The ADM691/

ADM693/ADM695 allow these times to be adjusted as shown

in Table I. Figure 4 shows the various oscillator configurations

which can be used to adjust the reset pulse width and watchdog

timeout period.

The internal oscillator is enabled when OSC SEL is high or

floating. In this mode, OSC IN selects between the 1.6 second

and 100 ms watchdog timeout periods. With OSC IN connected

high or floating, the 1.6 second timeout period is selected; while

with it connected low, the 100 ms timeout period is selected. In

either case, immediately after a reset, the timeout period is 1.6

seconds. This gives the microprocessor time to reinitialize the

system. If OSC IN is low, then the 100 ms watchdog period becomes effective after the first transition of WDI. The software

should be written such that the I/O port driving WDI is left in

its power-up reset state until the initialization routines are completed and the microprocessor is able to toggle WDI at the minimum watchdog timeout period of 70 ms.

Watchdog Output (WDO)

The Watchdog Output WDO (ADM691/ADM693/ADM695)

Figure 4c. Internal Oscillator (1.6 Second Watchdog)

provides a status output which goes low if the watchdog timer

“times out” and remains low until set high by the next transition

on the Watchdog Input.

WDO is also set high when VCC goes

below the reset threshold.

8

OSC SEL

ADM691

ADM693

CLOCK

0 TO 250kHz

7

OSC IN

ADM695

(Hz) = 184,000/C (pF).

OSC

Figure 4b. External Capacitor

NC

NC

NC

8

7

8

7

OSC SEL

ADM691

ADM693

ADM695

OSC IN

OSC SEL

ADM691

ADM693

ADM695

OSC IN

REV. A

Figure 4d. Internal Oscillator (100 ms Watchdog)

Figure 4a. External Clock Source

–7–

ADM690–ADM695

ADM69x

POWER

FAIL

INPUT

R

2

INPUT

POWER

1.3V

PFO

POWER

FAIL

OUTPUT

R

1

CE Gating and RAM Write Protection (ADM691/ADM693/

ADM695)

The ADM691/ADM693/ADM695 products include memory

protection circuitry which ensures the integrity of data in memory by preventing write operations when V

level. There are two additional pins,

CE

is at an invalid

CC

and CE

IN

OUT

, which

may be used to control the Chip Enable or Write inputs of

CMOS RAM. When V

of

CE

, with a 5 ns propagation delay. When VCC falls below

IN

the reset voltage threshold or V

CE

high, independent of CEIN.

OUT

CE

typically drives the CE, CS, or write input of battery

OUT

is present, CE

CC

BATT

is a buffered replica

OUT

, an internal gate forces

backed up CMOS RAM. This ensures the integrity of the data

in memory by preventing write operations when V

is at an in-

CC

valid level. Similar protection of EEPROMs can be achieved by

using the

If the 5 ns typical propagation delay of

nect

CE

to drive the store or write inputs.

OUT

CE

to GND and use the resulting CE

IN

CE

is excessive, con-

OUT

to control a

OUT

high speed external logic gate.

ADM69x

CE

IN

LOW = 0

V

CC

V

OK = 1

CC

CE

OUT

Power Fail Warning Comparator

An additional comparator is provided for early warning of failure

in the microprocessor’s power supply. The Power Fail Input

(PFI) is compared to an internal +1.3 V reference. The Power

Fail Output (

PFO) goes low when the voltage at PFI is less than

1.3 V. Typically PFI is driven by an external voltage divider

which senses either the unregulated dc input to the system’s 5 V

regulator or the regulated 5 V output. The voltage divider ratio

can be chosen such that the voltage at PFI falls below 1.3 V several milliseconds before the +5 V power supply falls below the

reset threshold.

PFO is normally used to interrupt the microprocessor so that data can be stored in RAM and the shut down

procedure executed before power is lost

Figure 7. Power Fail Comparator

Table II. Input and Output Status In Battery Backup Mode

Figure 5. Chip Enable Gating

V

CC

V2 V2

V1 V1

Signal Status

V

OUT

V

OUT

PMOS switch.

is connected to V

via an internal

BATT

RESET Logic low.

RESET

t

1

t

1

RESET Logic high. The open circuit output voltage is

equal to V

OUT

.

LOW LINE Logic low.

LOW LINE

BATT ON Logic high. The open circuit voltage is equal to

V

OUT.

WDI WDI is ignored. It is internally disconnected

from the internal pull-up resistor and does not

CE

IN

source or sink current as long as its input voltage

is between GND and V

. The input voltage

OUT

does not affect supply current.

WDO Logic high. The open circuit voltage is equal

CE

OUT

t

= RESET TIME.

1

V1 = RESET VOLTAGE THRESHOLD LOW

V2 = RESET VOLTAGE THRESHOLD HIGH

HYSTERESIS = V2–V1

Figure 6. Chip Enable Timing

to V

PFI The Power Fail Comparator is turned off and

has no effect on the Power Fail Output.

PFO Logic low.

CE

IN

CE

from its internal pull-up and does not source or

sink current as long as its input voltage is

between GND and V

.

OUT

is ignored. It is internally disconnected

IN

. The input voltage

OUT

does not affect supply current.

CE

OUT

OSC IN OSC IN is ignored.

OSC SEL OSC SEL is ignored.

–8–

Logic high. The open circuit voltage is equal to

V

.

OUT

REV. A

T ypical Performance Curves–ADM690–ADM695

10

90

100

0%

3.36 V

500ms

A4

1V1V

4.70

4.62

20 120

4.68

4.64

40

4.66

1008060

TEMPERATURE – °C

RESET VOLTAGE THRESHOLD – V

VCC = +5V

POWER-UP

POWER-DOWN

ADM690

ADM691

ADM694

ADM695

6

0

1.8

1.25

0

1.35

2

0

1

3

4

5

1.61.0 1.20.6 0.8 1.40.40.2

VCC = 5V

T

A

= +25°C

V

PFI

1.3V

30pF

PFO

+5V

10k

+5V

TIME – µs

5.00

VCC = 5V

TA = +25°C

4.95

– V

4.90

OUT

V

4.85

4.80

0 100

Figure 8. V

SLOPE = 1.5Ω

20

OUT

I

– mA

OUT

vs. I

OUT

Operation

1.303

1.302

1.301

1.300

PFI INPUT THRESHOLD – V

806040

Normal

2.80

VCC = 0V

V

BATT

T

I

OUT

vs. I

– µA

= +25°C

A

OUT

2.79

– V

2.78

OUT

V

2.77

2.76

0 1000

Figure 9. V

SLOPE = 20Ω

200

OUT

Backup

53

52

51

50

RESET ACTIVE TIME – ms

= +2.8V

800600400

Battery

VCC = +5V

ADM690

ADM691

ADM692

ADM693

Figure 10. Reset Output Voltage vs.

Supply Voltage

1.299

20 120

Figure 11. PFI Input Threshold vs.

Temperature

6

5

4

3

2

1

0

1.35

1.25

0

Figure 14. Power Fail Comparator

Response Time

REV. A

40

TEMPERATURE – °C

V

PFI

1.3V

TIME – µs

PFO

1008060

VCC = 5V

T

= +25°C

A

30pF

49

20 120

40

TEMPERATURE – °C

Figure 12. Reset Active Time vs.

Temperature

6

VCC = 5V

5

T

= +25°C

A

4

3

2

1

0

1.35

1.25

0.80.5 0.60.3 0.4 0.70.20.1

0

V

PFI

1.3V

TIME – µs

Figure 15. Power Fail Comparator

Response Time

PFO

1008060

30pF

Figure 13. Reset Voltage Threshold

vs. Temperature

90

8050 6030 40 702010

Figure 16. Power Fail Comparator

Response Time with Pull-Up Resistor

–9–

ADM690–ADM695

+APPLICATION INFORMATION

Increasing the Drive Current

If the continuous output current requirements at V

100 mA or if a lower V

CC–VOUT

voltage differential is desired,

OUT

exceed

an external PNP pass transistor may be connected in parallel

with the internal transistor. The BATT ON output (ADM691/

ADM693/ADM695) can directly drive the base of the external

transistor.

+5V

INPUT

POWER

BATTERY

PNP TRANSISTOR

V

CC

V

BATT

ADM691

ADM693

ADM695

BATT

ON

0.1µF0.1µF

V

OUT

Figure 17. Increasing the Drive Current

Using a Rechargeable Battery for Back Up

If a capacitor or a rechargeable battery is used for back up then

the charging resistor should be connected to V

since this

OUT

eliminates the discharge path that would exist during power

down if the resistor is connected to V

+5V

INPUT

POWER

0.1µF

RECHARGEABLE

BATTERY

V

BATT

V

CC

CC

V

OUT

I =

R

ADM69x

.

– V

BATT

R

0.1µF

V

OUT

Figure 18. Rechargeable Battery

Adding Hysteresis to the Power Fail Comparator

For increased noise immunity, hysteresis may be added to the

power fail comparator. Since the comparator circuit is noninverting, hysteresis can be added simply by connecting a resistor between the

PFO output and the PFI input as shown in Figure 19.

PFO is low, resistor R3 sinks current from the summing

When

junction at the PFI pin. When

tion of R

and R4 source current into the PFI summing junc-

3

PFO is high, the series combina-

tion. This results in differing trip levels for the comparator.

+5V

+7V TO +15V

INPUT

POWER

7805

R

1

R

2

5V

PFO

0V

0V

VH = 1.3V (1+ ––– + –––

VL = 1.3V (1+ ––– – –––––––––––––

ASSUMING R

HYSTERESIS V

PFI

ADM69x

V

L

R

R

1

R

R

2

R1 (5V – 1.3V)

R

1

1.3V (R

R

2

R3 THEN

< <

4

– VL = 5V (–––

H

1

3

1.3V

V

IN

)

3 + R4

V

CC

R

3

V

H

)

)

R

1

)

R

2

PFO

R

4

TO

µP NMI

Figure 19. Adding Hysteresis to the Power Fail Comparator

Monitoring the Status of the Battery

The power fail comparator can be used to monitor the status of

the backup battery instead of the power supply if desired. This

is shown in Figure 20. The PFI input samples the battery voltage and generates an active low

PFO signal when the battery

voltage drops below a chosen threshold. It may be necessary to

apply a test load in order to determine the loaded battery voltage. This can be done under processor control using

Since CE

is forced high during the battery backup mode, the

OUT

CE

OUT.

test load will not be applied to the battery while it is in use, even

if the microprocessor is not powered.

–10–

REV. A

BATTERY

OPTIONAL

TEST LOAD

20kΩ

10MΩ

10MΩ

V

PFI

CE

BATT

OUT

+5V INPUT

POWER

V

CC

ADM69x

PFO

LOW BATTERY

CE

IN

APPLIES TEST LOAD

SIGNAL TO

µP I/O PIN

FROM µP I/O PIN

TO BATTERY

CONTROL

INPUT*

ADM690–ADM695

OSC SEL

D1

D2

OSC IN

*LOW = INTERNAL TIMEOUT

HIGH = EXTERNAL TIMEOUT

ADM69x

Figure 20. Monitoring the Battery Status

Alternate Watchdog Input Drive Circuits

The watchdog feature can be enabled and disabled under program control by driving WDI with a 3-state buffer (Figure 21a).

When three-stated, the WDI input will float thereby disabling

the watchdog timer.

WATCHDOG

STROBE

CONTROL

INPUT

WDI

ADM69x

Figure 21a. Programming the Watchdog Input

This circuit is not entirely foolproof, and it is possible that a

software fault could erroneously 3-state the buffer. This would

then prevent the ADM69x from detecting that the microprocessor is no longer operating correctly. In most cases a better

method is to extend the watchdog period rather than disabling

the watchdog. This may be done under program control using

the circuit shown in Figure 21b. When the control input is high,

the OSC SEL pin is low and the watchdog timeout is set by the

external capacitor. A 0.01 µF capacitor sets a watchdog timeout

delay of 100 seconds. When the control input is low, the OSC

SEL pin is driven high, selecting the internal oscillator. The

100 ms or the 1.6 s period is chosen, depending on which diode

in Figure 21b is used. With D1 inserted the internal timeout is

set at 100 ms, while with D2 inserted the timeout is set at 1.6 s.

Figure 21b. Programming the Watchdog Input

Replacing the Backup Battery

When changing the backup battery with system power on, spurious resets can occur when the battery is removed. This occurs

because the leakage current flowing out of the V

charge up the stray capacitance. If the voltage on V

within 50 mV of V

, a reset pulse is generated.

CC

BATT

pin will

reaches

BATT

If spurious resets during battery replacement are acceptable,

then no action is required. If not, then one of the following

solutions should be considered:

1. A capacitor from V

to GND. This gives time while the

BATT

capacitor is charging up to replace the battery. The leakage

current will charge up the external capacitor towards the V

CC

level. The time taken is related to the charging current, the

size of external capacitor and the voltage differential between

the capacitor and the charging voltage supply.

t = C

EXT

× V

DIFF

/I

The maximum leakage (charging) current is 1 µA over tem-

perature and V

= VCC–V

DIFF

. Therefore, the capacitor

BATT

size should be chosen such that sufficient time is available to

make the battery replacement.

C

EXT

= T

(1 µA/(VCC–V

REQD

BATT

))

If a replacement time of 5 seconds is allowed and assuming a

V

of 4.5 V and a V

CC

BATTERY

BATT

C

EXT

C

EXT

of 3 V

= 3.33 µF

V

BATT

ADM69x

REV. A

Figure 22a. Preventing Spurious RESETS During

Battery Replacement

2. A resistor from V

on V

BATT

replacement.

–11–

to GND. This will prevent the voltage

BATT

from rising to within 50 mV of VCC during battery

ADM690–ADM695

ADM690

ADM692

ADM694

R

2

R

1

PFO

+5V

V

CC

CMOS RAM

POWER

I/O LINE

µP NMI

µP RESET

µP SYSTEM

µP POWER

V

OUT

RESET

WDI

GND

PFI

V

BATT

BATTERY

+

0.1µF

ADM690

ADM692

ADM694

R

2

R

1

PFO

7805

INPUT

POWER

V > 8V

+5V

V

CC

CMOS RAM

POWER

I/O LINE

µP NMI

µP RESET

µP SYSTEM

µP POWER

V

OUT

RESET

WDI

GND

PFI

V

BATT

0.1µF

BATTERY

0.1µF

R =(V

– 50 mV)/1 µA

CC

Note that the resistor will discharge the battery slightly. With a

V

supply of 4.5 V, a suitable resistor is 4.3 MΩ. With a 3 V

CC

battery this will draw around 700 nA. This will be negligible in

most cases.

V

BATT

BATTERY

R

ADM69x

Figure 22b. Preventing Spurious RESETS During Battery

Replacement

TYPICAL APPLICATIONS

ADM690, ADM692 AND ADM694

Figure 23 shows the ADM690/ADM692/ADM694 in a typical

power monitoring, battery backup application. V

CMOS RAM. Under normal operating conditions with V

present, V

occurs, V

is internally connected to VCC. If a power failure

OUT

will decay and V

CC

will be switched to V

OUT

powers the

OUT

BATT

CC

thereby maintaining power for the CMOS RAM. A RESET

pulse is also generated when V

ADM690/ADM694 or 4.4 V for the ADM692.

remain low for 50 ms (200 ms for ADM694) after V

falls below 4.65 V for the

CC

RESET will

CC

returns

to 5 V.

The watchdog timer input (WDI) monitors an I/O line from the

µP system. This line must be toggled once every 1.6 seconds to

verify correct software execution. Failure to toggle the line indicates that the µP system is not correctly executing its program

and may be tied up in an endless loop. If this happens, a reset

pulse is generated to initialize the processor.

If the watchdog timer is not needed, the WDI input should be

left floating.

The Power Fail Input, PFI, monitors the input power supply via

a resistive divider network. The voltage on the PFI input is compared with a precision 1.3 V internal reference. If the input voltage drops below 1.3 V, a power fail output (

PFO) signal is

generated. This warns of an impending power failure and may

be used to interrupt the processor so that the system may be

shut down in an orderly fashion. The resistors in the sensing

network are ratioed to give the desired power fail threshold

voltage V

.

T

= (1.3 R1/R2) + 1.3 V

V

T

= (VT/1.3) – 1

R

1/R2

Figure 23a. ADM690/ADM692/ADM694 Typical Application

Circuit A

Figure 23b shows a similar application but in this case the PFI

input monitors the unregulated input to the 7805 voltage regulator. This gives an earlier warning of an impending power failure. It is useful with processors operating at low speeds or

where there are a significant number of housekeeping tasks to be

completed before the power is lost.

Figure 23b. A DM690/ADM692/ADM694 Typical Application

Circuit B

ADM691, ADM693, ADM695

A typical connection for the ADM691/ADM693/ADM695 is

shown in Figure 24. CMOS RAM is powered from V

5 V power is present this is routed to V

V

is routed to V

BATT

V

, but if more current is required, an external PNP transistor

CC

can be added. When V

. V

OUT

CC

can supply up to 100 mA from

OUT

is higher than V

. If VCC fails then

OUT

, the BATT ON

BATT

OUT

. When

output goes low, providing up to 25 mA of base drive for the

external transistor. A 0.1 µF capacitor is connected to V

supply the transient currents for CMOS RAM. When V

lower than V

backup battery to V

, an internal 20 Ω MOSFET connects the

BATT

OUT

.

OUT

CC

to

is

–12–

REV. A

ADM690–ADM695

INPUT POWER

+5V

0.1µF

RESET

CMOS

RAM

ADDRESS

DECODE

0.1µF

A0–A15

I/O LINE

NMI

RESET

µP

R

R

1

2

3V

BATTERY

NC

0.1µF

V

CC

V

BATT

PFI

GND

OSC IN

OSC SEL

LOW LINE WDO

SYSTEM STATUS

INDICATORS

BATT

ON

ADM691

ADM693

ADM695

V

OUT

CE

OUT

CE

WDI

PFO

RESET

IN

Figure 24. ADM691/ADM693/ADM695 Typical Application

Reset Output

The internal voltage detector monitors VCC and generates a

RESET output to hold the microprocessor’s Reset line low

when V

timer holds

after V

repeated toggling of

is below 4.65 V (4.4 V for ADM693). An internal

CC

RESET low for 50 ms (200 ms for the ADM695)

rises above 4.65 V (4.4 V for ADM693). This prevents

CC

RESET even if the 5 V power drops out

and recovers with each power line cycle.

The crystal oscillator normally used to generate the clock for mi-

croprocessors can take several milliseconds to stabilize. Since

most microprocessors need several clock cycles to reset,

RESET

must be held low until the microprocessor clock oscillator has

started. The power-up

RESET pulse lasts 50 ms (200 ms for the

ADM695) to allow for this oscillator start-up time. If a different

reset pulse width is required, then a capacitor should be connected to OSC IN or an external clock may be used. Please refer

to Table I and Figure 4. The manual reset switch and the 0.1 µF

capacitor connected to the reset line can be omitted if a manual

reset is not needed. An inverted, active high, RESET output is

also available.

Power Fail Detector

The +5 V V

power line is monitored via a resistive potential

CC

divider connected to the Power Fail Input (PFI). When the

voltage at PFI falls below 1.3 V, the Power Fail Output (

PFO)

drives the processor’s NMI input low. If for example a Power

Fail threshold of 4.8 V is set with resistors R

processor will have the time when V

CC

and R2, the micro-

1

falls from 4.8 V to 4.65 V

to save data into RAM. An earlier power fail warning can be

generated if the unregulated dc input to the 5 V regulator is

available for monitoring. This will allow more time for microprocessor housekeeping tasks to be completed before power is

lost.

RAM Write Protection

The ADM691/ADM693/ADM695 CE

Select inputs of the CMOS RAM.

as V

is above the 4.65 V (4.4 V for ADM693) reset threshold.

CC

falls below the reset threshold, CE

If V

CC

pendent of the logic level at

CE

CE

. This prevents the micropro-

IN

line drives the Chip

OUT

follows CEIN as long

OUT

goes high, inde-

OUT

cessor from writing erroneous data into RAM during power-up,

power-down, brownouts and momentary power interruptions.

Watchdog Timer

The microprocessor drives the Watchdog Input (WDI) with an

I/O line. When OSC IN and OSC SEL are unconnected, the

microprocessor must toggle the WDI pin once every 1.6 seconds to verify proper software execution. If a hardware or software failure occurs such that WDI not toggled, the ADM691/

ADM693 will issue a 50 ms (200 ms for ADM695)

RESET

pulse after 1.6 seconds. This typically restarts the microprocessor’s power-up routine. A new

RESET pulse is issued

every 1.6 seconds until WDI is again strobed. If a different

watchdog timeout period is required, then a capacitor should be

connected to OSC IN or an external clock may be used. Please

refer to Table I and Figure 4.

The WATCHDOG OUTPUT (

dog timer is not serviced within its timeout period. Once

WDO) goes low if the watch-

WDO

goes low, it remains low until a transition occurs at WDI. The

watchdog timer feature can be disabled by leaving WDI

unconnected.

The

RESET output has an internal 3 µA pull-up, and can either

connect to an open collector reset bus or directly drive a CMOS

gate without an external pull-up resistor.

REV. A

–13–

ADM690–ADM695

PIN 1

0.210

(5.33)

MAX

0.160 (4.06)

0.115 (2.93)

0.022 (0.558)

0.014 (0.356)

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

8-Pin Plastic DIP (N-8)

58

0.280 (7.11)

0.240 (6.10)

0.100

(2.54)

BSC

4

0.070 (1.77)

0.045 (1.15)

0.060 (1.52)

0.015 (0.38)

0.150

(3.81)

MIN

SEATING

PLANE

0.325 (8.25)

0.300 (7.62)

0.015 (0.381)

0.008 (0.204)

1

0.430 (10.92)

0.348 (8.84)

16-Lead Plastic DIP (N-16)

0.195 (4.95)

0.115 (2.93)

PIN 1

0.210

(5.33)

0.200 (5.05)

0.125 (3.18)

16

1

0.022 (0.558)

0.014 (0.356)

SEATING

0.022 (0.558)

0.014 (0.356)

PIN 1

PLANE

0.200

(5.08)

MAX

0.840 (21.33)

0.745 (18.93)

0.100

(2.54)

BSC

0.070 (1.77)

0.045 (1.15)

8-Pin Cerdip (Q-8)

MAX

BSC

5

4

0.070 (1.78)

0.30 (0.76)

8

1

0.420 (10.67)

0.100 (2.54)

9

8

0.310 (7.87)

0.220 (5.59)

0.060 (1.52)

0.015 (0.38)

0.150

(3.81)

MIN

0.280 (7.11)

0.240 (6.10)

0.060 (1.52)

0.015 (0.38)

0.150

(3.81)

SEATING

PLANE

0.325 (8.25)

0.300 (7.62)

0.015 (0.381)

0.008 (0.204)

0.320 (8.13)

0.290 (7.37)

0.015 (0.381)

0.008 (0.204)

0.195 (4.95)

0.115 (2.93)

–14–

REV. A

16-Lead Cerdip (Q-16)

ADM690–ADM695

SEATING

PLANE

0.299

(7.60)

0.012

(0.3)

PIN 1

0.200

(5.08)

MAX

16

0.022 (0.558)

0.014 (0.356)

1

0.05 (1.27)

1

0.840 (21.34) MAX

0.100 (2.54)

BSC

16-Lead SOIC (R-16)

916

8

0.413 (10.50)

0.019 (0.49)

REF

0.070 (1.78)

0.30 (0.76)

0.419

(10.65)

0.104

(2.65)

9

8

0.030

(0.75)

0.013

(0.32)

0.310 (7.87)

0.220 (5.59)

0.060 (1.52)

0.015 (0.38)

0.150

(3.81)

MIN

0.320 (8.13)

0.290 (7.37)

0.015 (0.381)

0.008 (0.204)

0.042

(1.07)

REV. A

–15–

C1782a–2–6/96

–16–

PRINTED IN U.S.A.

Loading...

Loading...