ESD Protected, EMC Compliant, 3.3 V,

a

FEATURES

Operates with +3.3 V Supply

ESD Protection: 8 kV Meets IEC1000-4-2

EFT Protection: 2 kV Meets IEC1000-4-4

EIA RS-422 and RS-485 Compliant Over Full CM Range

19 k Input Impedance

Up to 50 Transceivers on Bus

20 Mbps Data Rate

Short Circuit Protection

Specified Over Full Temperature Range

Thermal Shutdown

Interoperable with 5 V Logic

1 mA Supply Current

2 nA Shutdown Current

8 ns Skew

APPLICATIONS

Telecommunications

DTE-DCE Interface

Packet Switching

Local Area Networks

Data Concentration

Data Multiplexers

Integrated Services Digital Network (ISDN)

AppleTalk

Industrial Controls

20 Mbps, EIA RS-485 Transceiver

ADM3485E

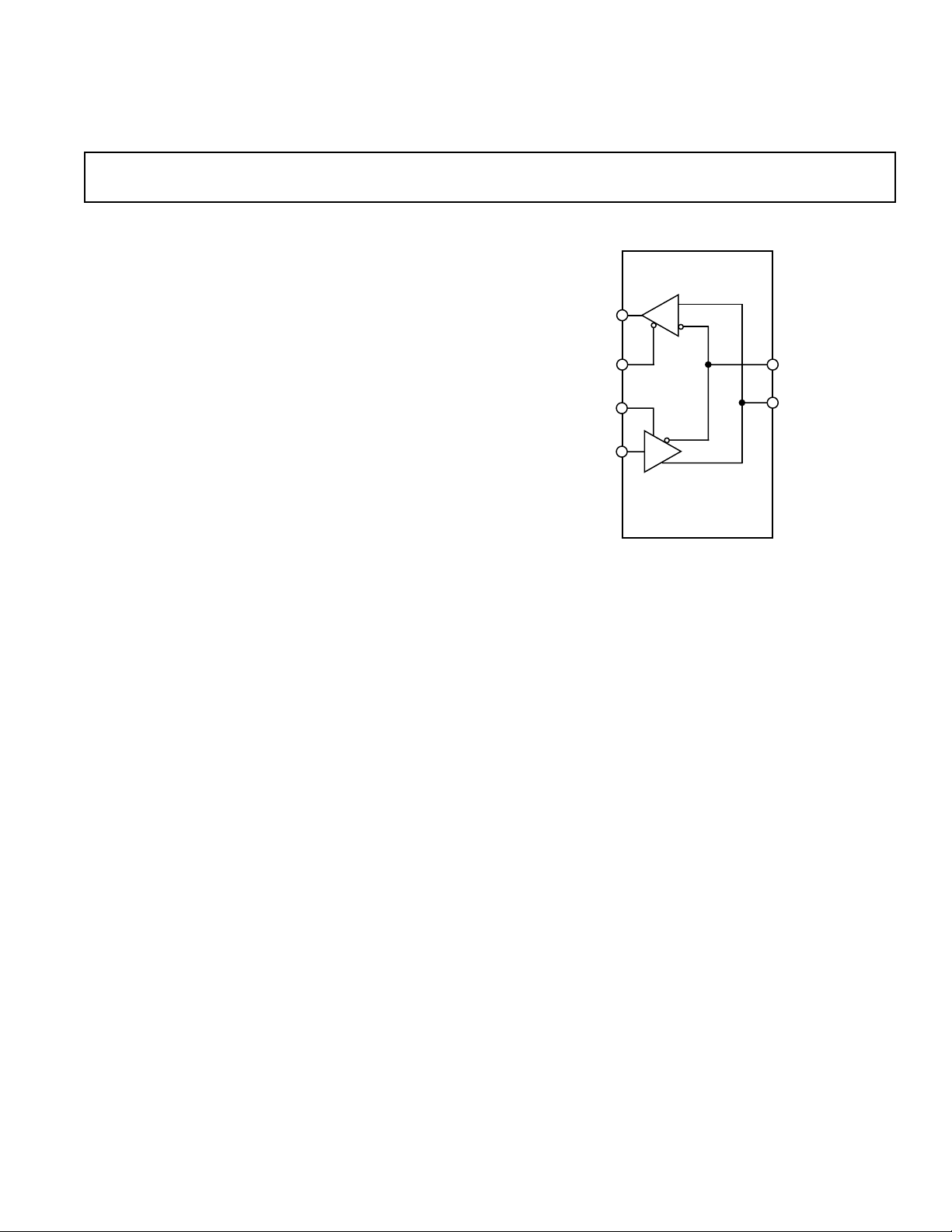

FUNCTIONAL BLOCK DIAGRAM

ADM3485E

RO

RE

DE

DI

R

B

A

D

GENERAL DESCRIPTION

The ADM3485E is a low power differential line transceiver

designed to operate using a single +3.3 V power supply. Low

power consumption makes it ideal for power sensitive applications. It is suitable for communication on multipoint bus transmission lines. Internal protection against electrostatic discharge

(ESD) and electrical fast transient (EFT) allows operation in

electrically harsh environments.

It is intended for balanced data transmission and complies with

both EIA Standards RS-485 and RS-422. It contains a differential line driver and a differential line receiver, and is suitable for

half duplex data transfer.

The input impedance is 19 kΩ allowing up to 50 transceivers to

be connected on the bus.

REV. A

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

Excessive power dissipation caused by bus contention or by

output shorting is prevented by a thermal shutdown circuit.

This feature forces the driver output into a high impedance

state if, during fault conditions, a significant temperature

increase is detected in the internal driver circuitry.

The receiver contains a fail-safe feature that results in a

logic high output state if the inputs are unconnected

(floating).

The ADM3485E is fabricated on BiCMOS, an advanced

mixed technology process combining low power CMOS

with fast switching bipolar technology.

The ADM3485E is fully specified over the industrial temperature range and is available in 8-lead DIP and SOIC

packages.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 World Wide Web Site: http://www.analog.com

Fax: 781/326-8703 © Analog Devices, Inc., 2000

ADM3485E–SPECIFICATIONS

(VCC = +3.3 V 0.3 V. All specifications T

MIN

to T

unless otherwise noted.)

MAX

Parameter Min Typ Max Units Test Conditions/Comments

DRIVER

Differential Output Voltage, V

∆|V

| for Complementary Output States 0.2 V R = 54 Ω or 100 Ω, Figure 1

OD

Common-Mode Output Voltage V

∆|V

| for Complementary Output States 0.2 V R = 54 Ω or 100 Ω, Figure 1

OC

OD

OC

CMOS Input Logic Threshold Low, V

CMOS Input Logic Threshold High, V

2.0 V RL = 100 Ω, Figure 1, VCC > 3.1 V

1.5 V R

1.5 V R

= 54 Ω, Figure 1

L

= 60 Ω, Figure 2, –7 V < V

L

3 V R = 54 Ω or 100 Ω, Figure 1

INL

2.0 V

INH

0.8 V

< +12 V

TST

Logic Input Current (DE, DI, RE) ± 1.0 µA

Output Short Circuit Current ± 250 mA VO = –7 V or +12 V

RECEIVER

Differential Input Threshold Voltage, V

Input Voltage Hysteresis, ∆V

TH

Input Resistance 12 19 kΩ –7 V < V

Input Current (A, B) +1 mA V

–0.2 +0.2 V –7 V < VCM < +12 V

TH

50 mV VCM = 0 V

= +12 V

IN

–0.8 mA V

= –7 V

IN

< +12 V

CM

Logic Enable Input Current (RE) ± 1 µA

Output Voltage Low, V

Output Voltage High, V

OL

OH

VCC – 0.4 V V I

Short Circuit Output Current ± 60 mA V

Three-State Output Leakage Current ± 1.0 µAV

0.4 V I

= +2.5 mA

OUT

= –1.5 mA

OUT

= GND or V

OUT

= 3.6 V, 0 V < V

CC

CC

OUT

< V

CC

POWER SUPPLY CURRENT

I

CC

1 1.2 mA DE = V

Outputs Unloaded,

, RE = 0 V

CC

1 1.2 mA DE = 0 V, RE = 0 V

Supply Current in Shutdown 0.002 1 µA DE = 0 V, RE = V

CC

ESD/EFT IMMUNITY

ESD Protection ± 8 kV IEC1000-4-2 A, B Pins Contact Discharge

EFT Protection ± 2 kV IEC1000-4-4, A, B Pins

Specifications subject to change without notice.

–2–

REV. A

ADM3485E

TIMING SPECIFICATIONS

(VCC = +3.3 V, TA = +25C)

Parameter Min Typ Max Units Test Conditions/ Comments

DRIVER

Differential Output Delay T

DD

Differential Output Transition Time 1 8 15 ns R

Propagation Delay Input to Output T

Driver O/P to O/P T

SKEW

PLH

, T

PHL

135nsR

72235nsR

8nsR

= 60 Ω, CL1 = CL2 = 15 pF, Figure 3

L

= 60 Ω, CL1 = CL2 = 15 pF, Figure 3

L

= 27 Ω, CL1 = CL2 = 15 pF, Figure 7

L

= 54 Ω, CL1 = CL2 = 15 pF, Figure 3

L

ENABLE/DISABLE

Driver Enable to Output Valid 45 90 ns R

Driver Disable Timing 40 80 ns R

= 110 Ω, CL = 50 pF, Figure 2

L

= 110 Ω, CL = 50 pF, Figure 2

L

Driver Enable from Shutdown 650 110 ns RL = 110 Ω, CL = 15 pF, Figure 2

RECEIVER

Time to Shutdown 80 190 300 ns

Propagation Delay Input to Output T

Skew T

Receiver Enable T

Receiver Disable T

PLH–TPHL

EN

DEN

PLH

, T

PHL

25 65 90 ns CL = 15 pF, Figure 8

10 ns CL = 15 pF, Figure 8

25 50 ns CL = 15 pF, Figure 6

25 45 ns CL = 15 pF, Figure 6

Receiver Enable from Shutdown 500 ns CL = 15 pF, Figure 6

Specifications subject to change without notice.

TIMING SPECIFICATIONS

(VCC = +3.3 V 0.3 V, TA = T

MIN

to T

MAX

)

Parameter Min Typ Max Units Test Conditions/ Comments

DRIVER

Differential Output Delay T

DD

Differential Output Transition Time 2 8 15 ns R

Propagation Delay Input to Output T

Driver O/P to O/P T

SKEW

PLH

, T

PHL

170nsR

72270nsR

= 60 Ω, CL1 = CL2 = 15 pF, Figure 3

L

= 60 Ω, CL1 = CL2 = 15 pF, Figure 3

L

= 27 Ω, CL1 = CL2 = 15 pF, Figure 7

L

10 ns RL = 54 Ω, CL1 = CL2 = 15 pF, Figure 3

ENABLE/DISABLE

Driver Enable to Output Valid 45 110 ns R

Driver Disable Timing 40 110 ns R

= 110 Ω, CL = 50 pF, Figure 2

L

= 110 Ω, CL = 50 pF, Figure 2

L

Driver Enable from Shutdown 650 110 ns RL = 110 Ω, CL = 15 pF, Figure 2

RECEIVER

Time to Shutdown 50 190 500 ns

Propagation Delay Input to Output T

Skew T

Receiver Enable T

Receiver Disable T

PLH–TPHL

EN

DEN

PLH

, T

PHL

25 65 115 ns CL = 15 pF, Figure 8

20 ns CL = 15 pF, Figure 8

25 50 ns CL = 15 pF, Figure 6

25 50 ns CL = 15 pF, Figure 6

Receiver Enable from Shutdown 600 ns CL = 15 pF, Figure 6

Specifications subject to change without notice.

–3–REV. A

ADM3485E

ABSOLUTE MAXIMUM RATINGS*

(TA = +25°C unless otherwise noted)

VCC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +7 V

Inputs

Driver Input (DI) . . . . . . . . . . . . . . . . –0.3 V to V

Control Inputs (DE, RE) . . . . . . . . . . –0.3 V to V

+ 0.3 V

CC

+ 0.3 V

CC

Receiver Inputs (A, B) . . . . . . . . . . . . . . . –7.5 V to +12.5 V

Outputs

Driver Outputs . . . . . . . . . . . . . . . . . . . . . –7.5 V to +12.5 V

Receiver Output . . . . . . . . . . . . . . . . . –0.5 V to V

+ 0.5 V

CC

Power Dissipation 8-Lead DIP . . . . . . . . . . . . . . . . . 800 mW

, Thermal Impedance . . . . . . . . . . . . . . . . . . . . 140°C/W

θ

JA

Power Dissipation 8-Lead SOIC . . . . . . . . . . . . . . . . 650 mW

, Thermal Impedance . . . . . . . . . . . . . . . . . . . . 115°C/W

θ

JA

Operating Temperature Range

Industrial (A Version) . . . . . . . . . . . . . . . . –40°C to +85°C

Storage Temperature Range . . . . . . . . . . . . –65°C to +150°C

Lead Temperature (Soldering, 10 sec) . . . . . . . . . . . . +300°C

Vapor Phase (60 sec) . . . . . . . . . . . . . . . . . . . . . . . . +215°C

Infrared (15 sec) . . . . . . . . . . . . . . . . . . . . . . . . . . . +220°C

ESD Rating: Air (Human Body Model, All Pins) . . . . . >4 kV

ESD Rating: IEC1000-4-2 Contact (A, B Pins) . . . . . . >8 kV

EFT Rating: IEC1000-4-4 (A, B Pins) . . . . . . . . . . . . . >2 kV

*Stresses above those listed under Absolute Maximum Ratings may cause perma-

nent damage to the device. This is a stress rating only; functional operation of the

device at these or any other conditions above those listed in the operational sections

of this specification is not implied. Exposure to absolute maximum ratings for

extended periods of time may affect device reliability.

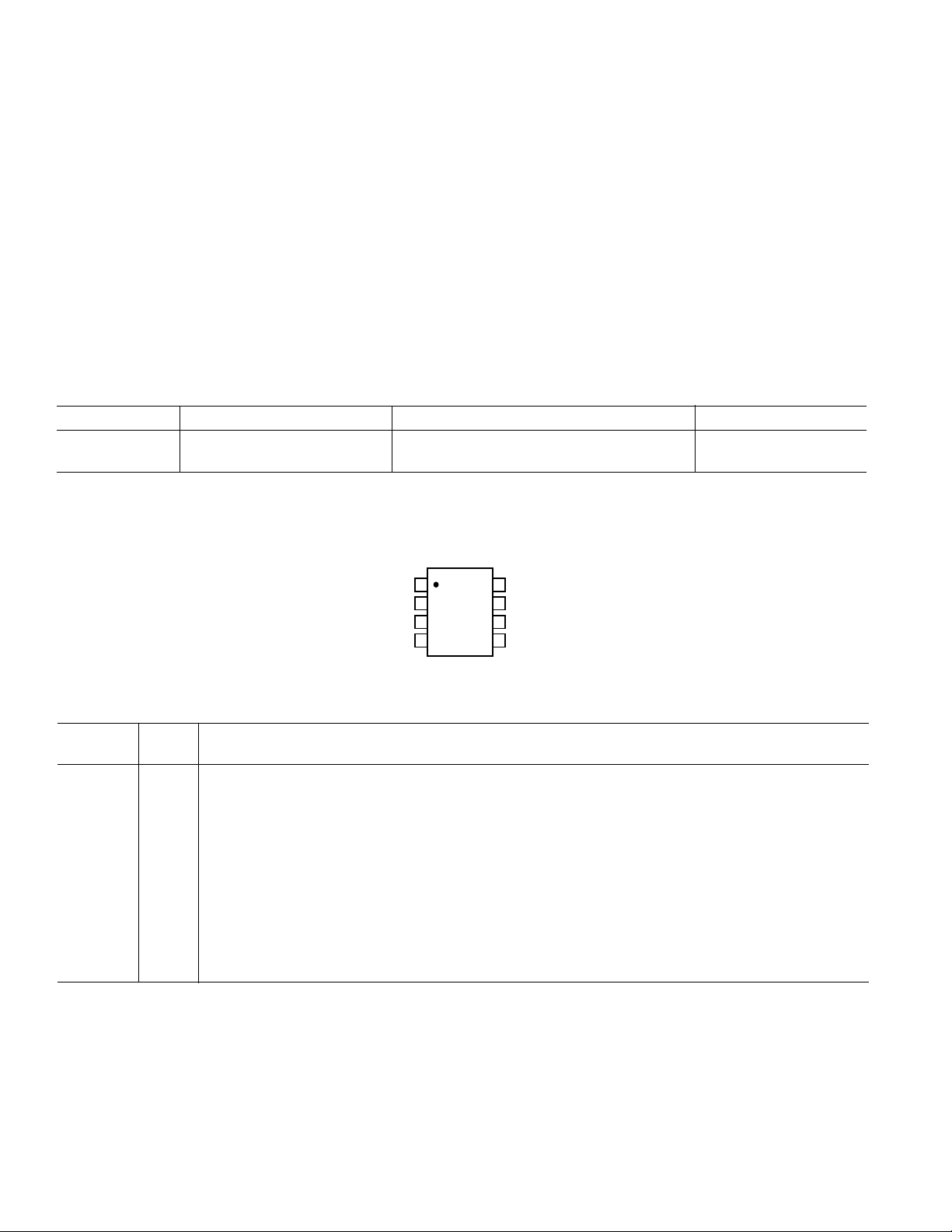

ORDERING GUIDE

Model Temperature Range Package Description Package Options

ADM3485EAN –40°C to +85°C Plastic DIP N-8

ADM3485EAR –40°C to +85°C Small Outline (SOIC) SO-8

PIN CONFIGURATION

DIP/SOIC

RO

RE

DE

DI

1

ADM3485E

2

3

TOP VIEW

(Not to Scale)

4

8

V

CC

7

B

6

A

5

GND

PIN FUNCTION DESCRIPTIONS

Mnemonic DIP/

Pin SOIC Function

RO 1 Receiver Output. High when A > B by 200 mV or low when A < B by 200 mV.

RE 2 Receiver Output Enable. With RE low, the receiver output RO is enabled. With RE high, the output goes

high impedance. If RE is high and DE low, the ADM3485E enters a shutdown state.

DE 3 Driver Output Enable. A high level enables the driver differential outputs, A and B. A low level places it in a

high impedance state.

DI 4 Driver Input. When the driver is enabled, a logic low on DI forces A low and B high, while a logic high on DI

forces A high and B low.

GND 5 Ground Connection, 0 V.

A 6 Noninverting Receiver Input A/Driver Output A.

B 7 Inverting Receiver Input B/Driver Output B.

V

CC

8 Power Supply, 3.3 V ± 0.3 V.

–4–

REV. A

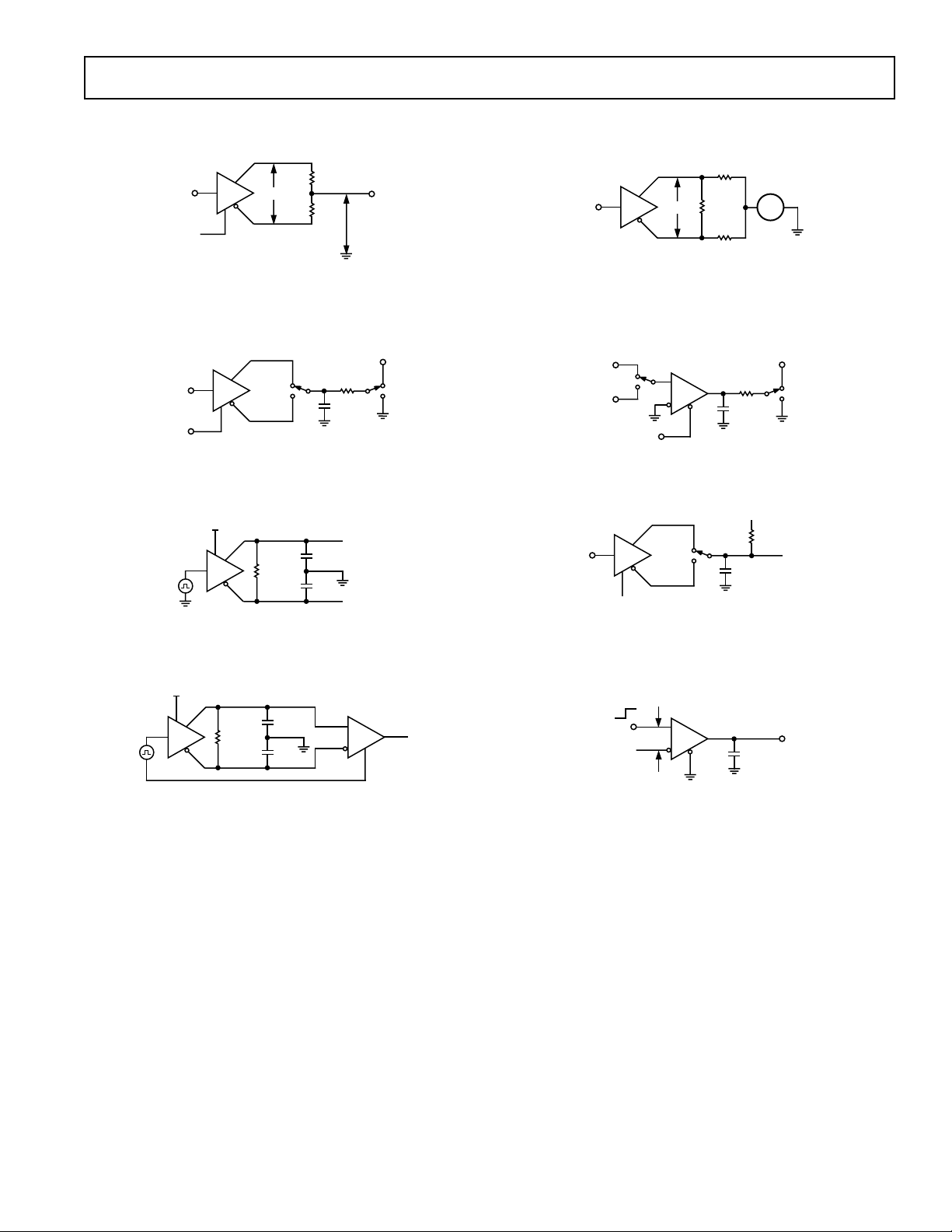

Test Circuits

ADM3485E

V

OD

V

CC

R/2

R/2

V

OC

Figure 1. Driver Voltage Measurement Test Circuit

V

CC

R

L

C

L

V

OUT

S20V OR 3V

DE IN

DE

S1

Figure 2. Driver Enable/Disable Test Circuit

C

DI

D

RL

DIFF

L1

V

OUT

C

L2

Figure 3. Driver Differential Output Delay Test Circuit

375

V

OD3

R

375

V

L

TST

Figure 5. Driver Voltage Measurement Test Circuit 2

V

R

L

OUT

CC

L

S2

+1.5V

–1.5V

S1

RE IN

RE

C

V

Figure 6. Receiver Enable/Disable Test Circuit

V

OM

R

L

V

DE

IN

V

CC

S1

C

L

OUT

Figure 7. Driver Propagation Delay Test Circuit

C

DI

D

RL

DIFF

L1

C

L2

A

B

RO

R

RE

Figure 4. Driver/Receiver Propagation Delay Test Circuit

3V

0V

V

ID

+1.5V

RE

V

OUT

C

L

Figure 8. Receiver Propagation Delay Test Circuit

–5–REV. A

ADM3485E

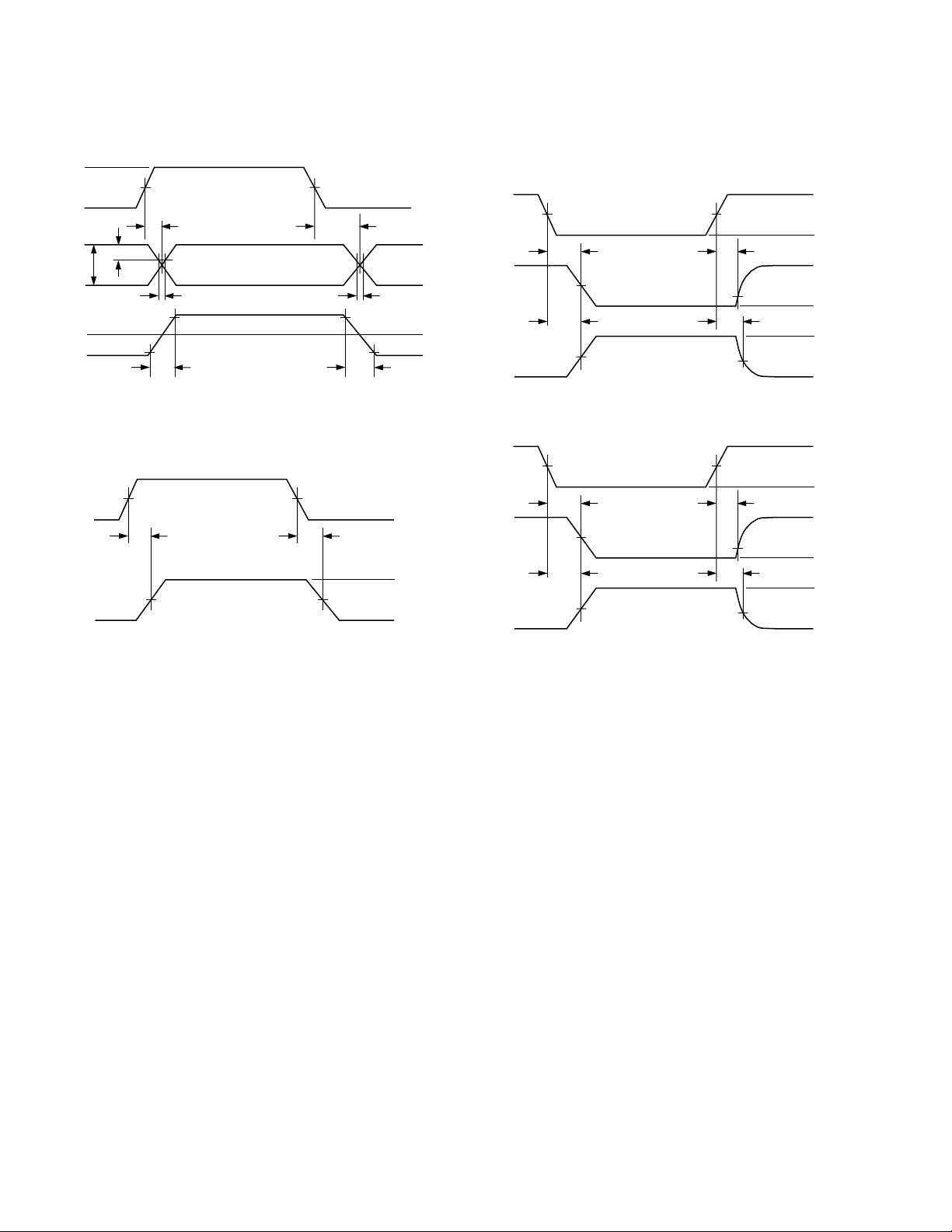

Switching Characteristics

3V

1.5V 1.5V

0V

B

A

0V

–VO

VO

VO

10% POINT

1/2 VO

90% POINT

t

PLH

t

SKEW

t

R

t

PLH

t

SKEW

90% POINT

10% POINT

t

F

DE

3V

1.5V

t

ZL

D

D

0V

1.5V

t

ZH

1.5V

O/P

LOW

O/P

HIGH

1.5V

t

LZ

t

0V

+ 0.25V

V

OL

HZ

V

OH

– 0.25V

V

OL

V

OH

Figure 9. Driver Propagation Delay, Rise/Fall Timing

A–B

RO

0V

t

PLH

1.5V

0V

t

PLH

V

OH

1.5V

V

OL

Figure 10. Receiver Propagation Delay

Figure 11. Driver Enable/Disable Timing

RE

1.5V

t

ZL

R

R

0V

1.5V

t

ZH

1.5V

O/P

LOW

O/P

HIGH

1.5V

t

LZ

t

HZ

Figure 12. Receiver Enable/Disable Timing

V

V

OL

OH

+ 0.25V

– 0.25V

3V

0V

V

OL

V

OH

–6–

REV. A

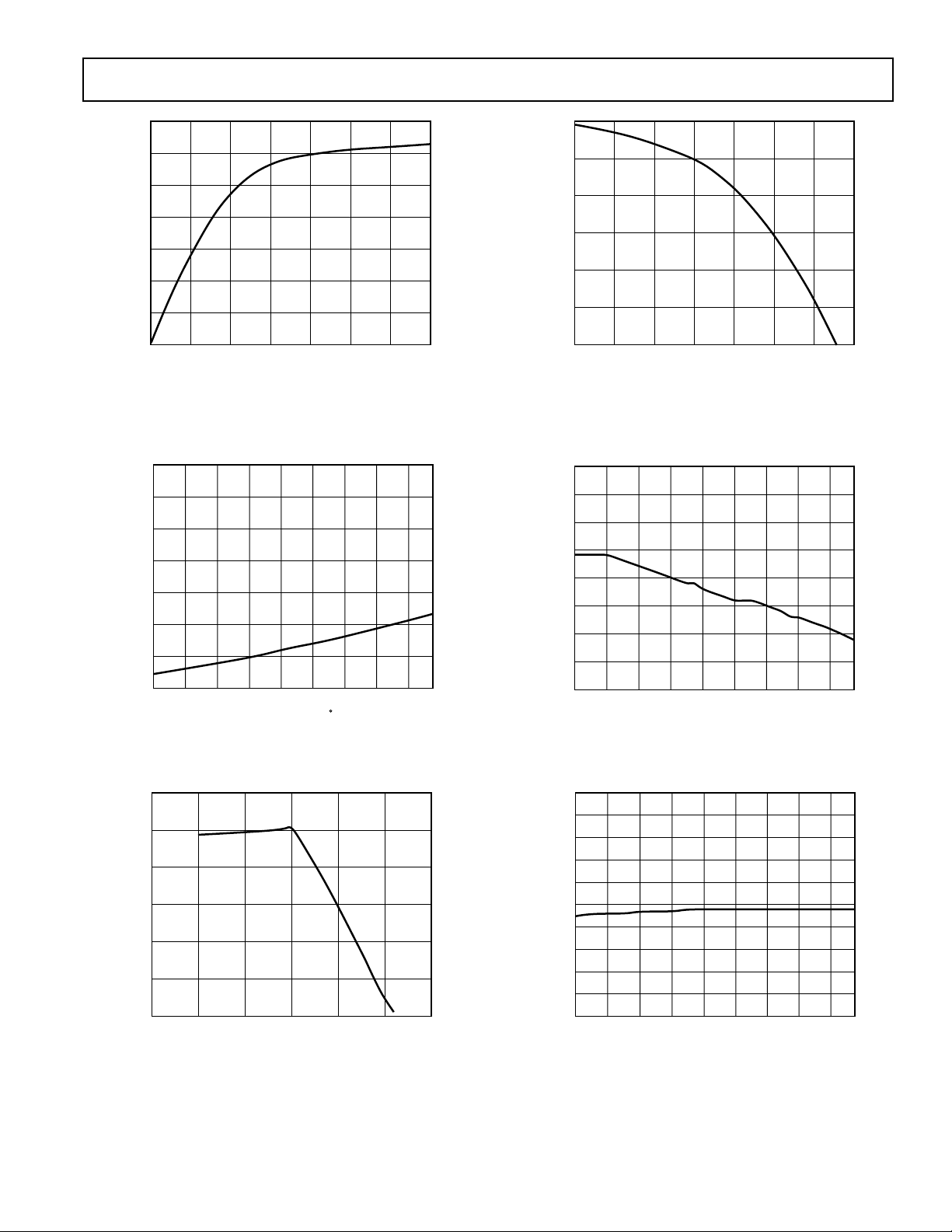

Typical Performance Characteristics–A

TEMPERATURE – C

3.30

–50 70

–30

RECEIVER O/P HIGH VOLTAGE – V

–10 10 30 50

3.25

3.15

3.10

3.05

2.90

3.20

3.00

2.95

90 110

DM3485E

14

12

10

8

6

4

OUTPUT CURRENT – mA

2

0

0

1.5

1.0

OUTPUT LOW VOLTAGE – V

2.0

2.5

3.0

3.50.5

Figure 13. Output Current vs. Receiver Output Low

Voltage

0.8

0.7

0.6

0.5

12

10

8

6

4

OUTPUT CURRENT – mA

2

0

0

0.5

1.5

1.0

OUTPUT HIGH VOLTAGE – V

2.0

2.5

3.0

3.5

Figure 16. Output Current vs. Receiver Output High

Voltage

0.4

0.3

0.2

RECEIVER OUTPUT LOW VOLTAGE – V

0.1

–30

–50 90

–10 10 30 50 70

TEMPERATURE – C

110

Figure 14. Receiver Output Low Voltage vs. Temperature

120

100

80

60

40

DRIVER OUTPUT CURRENT – mA

20

0

0.5

0

DIFFERENTIAL OUTPUT VOLTAGE – V

1.0

1.5

2.0

2.5

3.0

Figure 15. Driver Output Current vs. Differential

Output Voltage

Figure 17. Receiver Output High Voltage vs. Temperature

2.6

2.5

2.4

2.3

2.2

– V

2.1

OD

V

2.0

1.9

1.8

1.7

1.6

–30

–50 70

–10 10 30 50

TEMPERATURE – C

90 110

Figure 18. Driver Differential Output Voltage vs. Temperature

REV. A

–7–

ADM3485E

1.20

1.15

1.10

1.05

1.00

0.95

– mA

CC

I

0.90

0.85

0.80

0.75

0.70

–50 70

ICC (mA) DE = VCC, RE = X

ICC (mA) RE = LO, DE = LO

–30

–10 10 30 50

TEMPERATURE – C

90 110

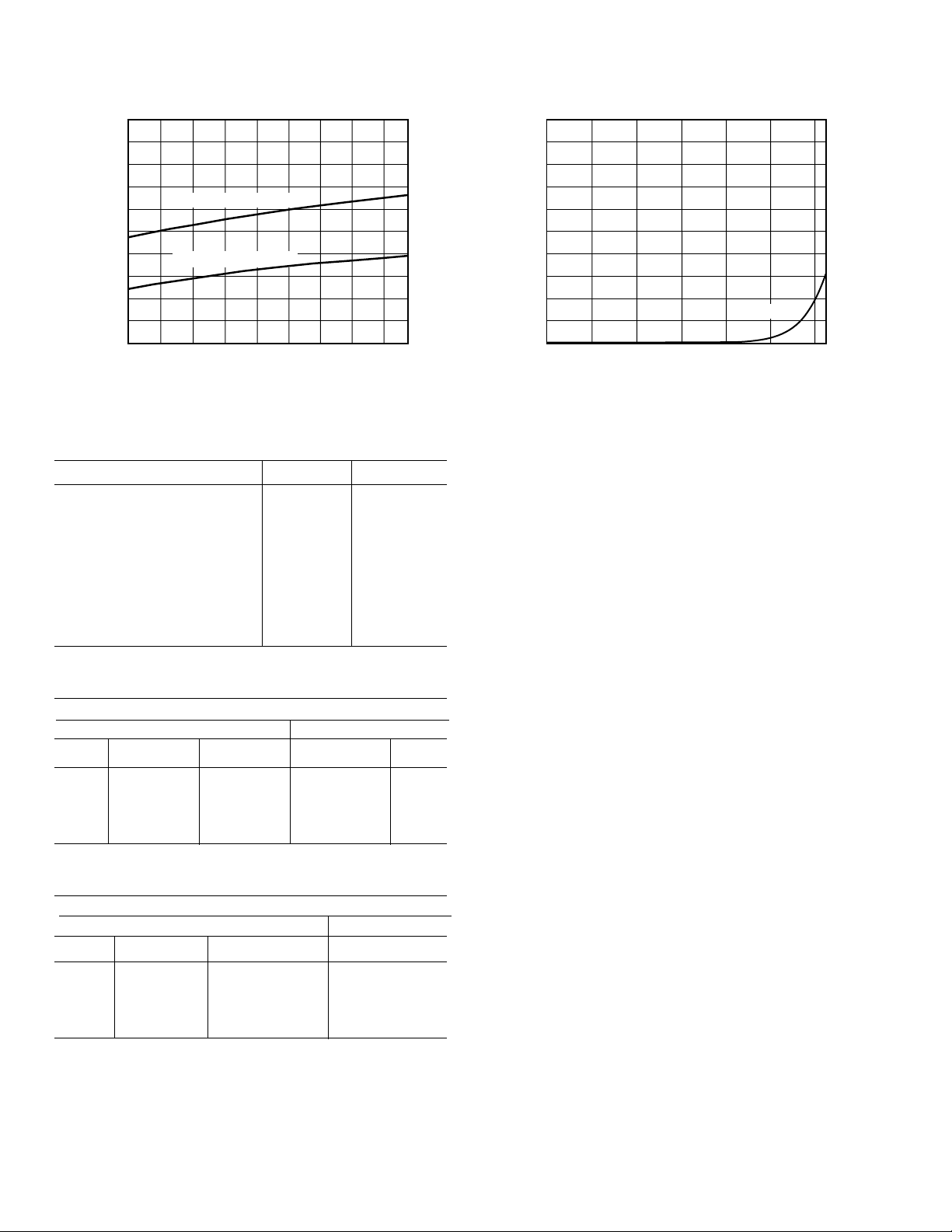

Figure 19. Supply Current vs. Temperature

Table I. Comparison of RS-422 and RS-485 Interface Standards

Specification RS-422 RS-485

Transmission Type Differential Differential

Maximum Data Rate 10 MB/s 10 MB/s

Maximum Cable Length 4000 ft. 4000 ft.

Minimum Driver Output Voltage ±2 V ± 1.5 V

Driver Load Impedance 100 Ω 54 Ω

ESD/EFT TRANSIENT PROTECTION SCHEME

The ADM3485E uses protective clamping structures on its

inputs and outputs that clamp the voltage to a safe level and

dissipate the energy present in ESD (Electrostatic) and EFT

(Electrical Fast Transients) discharges.

The protection structure achieves ESD protection up to ±8 kV

according to IEC1000-4-2, and EFT protection up to ± 2 kV on

all I-O lines.

Receiver Input Resistance 4 kΩ min 12 kΩ min

Receiver Input Sensitivity ± 200 mV ± 200 mV

Receiver Input Voltage Range –7 V to +7 V –7 V to +12 V

No. of Drivers/Receivers Per Line 1/10 32/32

ESD TESTING

Two coupling methods are used for ESD testing, contact discharge and air-gap discharge. Contact discharge calls for a direct connection to the unit being tested. Air-gap discharge uses

a higher test voltage but does not make direct contact with the

Table II. Transmitting Truth Table

Transmitting

Inputs Outputs

RE DE DI B A

X11 01

X10 10

0 0 X Hi-Z Hi-Z

1 0 X Hi-Z Hi-Z

unit under test. With air discharge, the discharge gun is moved

toward the unit under test, developing an arc across the air gap,

hence the term air-discharge. This method is influenced by humidity, temperature, barometric pressure, distance and rate of

closure of the discharge gun. The contact-discharge method,

while less realistic, is more repeatable and is gaining acceptance

and preference over the air-gap method.

Although very little energy is contained within an ESD pulse,

the extremely fast rise time, coupled with high voltages, can

cause failures in unprotected semiconductors. Catastrophic

destruction can occur immediately as a result of arcing or heat-

Table III. Receiving Truth Table

ing. Even if catastrophic failure does not occur immediately, the

device may suffer from parametric degradation, which may

Receiving

Inputs Outputs

RE DE A–B RO

0 X > +0.2 V 1

0 X < –0.2 V 0

0 X Inputs O/C 1

1XX Hi-Z

result in degraded performance. The cumulative effects of continuous exposure can eventually lead to complete failure.

I-O lines are particularly vulnerable to ESD damage. Simply

touching or plugging in an I-O cable can result in a static discharge that can damage or completely destroy the interface

product connected to the I-O port.

It is extremely important, therefore, to have high levels of ESD

protection on the I-O lines.

It is possible that the ESD discharge could induce latchup in the

device under test, so it is important that ESD testing on the I-O

pins be carried out while device power is applied. This type of

testing is more representative of a real-world I-O discharge

where the equipment is operating normally when the discharge

occurs.

100

90

80

70

60

50

– nA

CC

I

40

30

20

10

0

–20

–40 80

0 204060

TEMPERATURE – C

ICC (mA)

Figure 20. Shutdown Current vs. Temperature

–8–

REV. A

ADM3485E

100%

90%

PEAK

I

36.8%

10%

t

RL

t

DL

Figure 21. Human Body Model Current Waveform

Table IV. ESD Test Results

ESD Test Method I-O Pins

IEC1000-4-2: Contact ±8 kV

100%

90%

TIME t

Four severity levels are defined in terms of an open-circuit voltage as a function of installation environment. The installation

environments are defined as

1. Well-Protected

2. Protected

3. Typical Industrial

4. Severe Industrial

V

t

300ms 16ms

V

5ns

50ns

t

0.2/0.4ms

Figure 23. IEC1000-4-4 Fast Transient Waveform

Table V shows the peak voltages for each of the environments.

PEAK

I

10%

0.1 TO 1ns

30ns

60ns

TIME

t

Figure 22. IEC1000-4-2 ESD Current Waveform

FAST TRANSIENT BURST IMMUNITY (IEC1000-4-4)

IEC1000-4-4 (previously 801-4) covers electrical fast-transient/

burst (EFT) immunity. Electrical fast transients occur as a

result of arcing contacts in switches and relays. The tests simulate the interference generated when, for example, a power relay

disconnects an inductive load. A spark is generated due to the

well known back EMF effect. In fact, the spark consists of a

burst of sparks as the relay contacts separate. The voltage appearing on the line, therefore, consists of a burst of extremely

fast transient impulses. A similar effect occurs when switching

on fluorescent lights.

The fast transient burst test, defined in IEC1000-4-4, simulates

this arcing and its waveform is illustrated in Figure 23. It consists of a burst of 2.5 kHz to 5 kHz transients repeating at

300 ms intervals. It is specified for both power and data lines.

Table V. Peak Voltages

Level V

(kV) PSU V

PEAK

PEAK

(kV) I-O

1 0.5 0.25

2 1 0.5

32 1

44 2

A simplified circuit diagram of the actual EFT generator is

illustrated in Figure 24.

C

D

HIGH

VOLTAGE

SOURCE

R

C

C

C

R

L

M

Z

S

50

OUTPUT

Figure 24. EFT Generator

These transients are coupled onto the signal lines using an EFT

coupling clamp. The clamp is 1 m long and completely surrounds the cable, providing maximum coupling capacitance

(50 pF to 200 pF typ) between the clamp and the cable. High

energy transients are capacitively coupled onto the signal lines.

Fast rise times (5 ns) as specified by the standard result in very

effective coupling. This test is very severe since high voltages are

coupled onto the signal lines. The repetitive transients can often

cause problems, where single pulses do not. Destructive latchup

may be induced due to the high energy content of the transients.

Note that this stress is applied while the interface products are

powered up and are transmitting data. The EFT test applies

hundreds of pulses with higher energy than ESD. Worst case

transient current on an I-O line can be as high as 40 A.

–9–REV. A

ADM3485E

Test results are classified according to the following

1. Normal performance within specification limits.

2. Temporary degradation or loss of performance that is selfrecoverable.

3. Temporary degradation or loss of function or performance

that requires operator intervention or system reset.

4. Degradation or loss of function that is not recoverable due to

damage.

APPLICATIONS INFORMATION

Differential Data Transmission

Differential data transmission is used to reliably transmit data at

high rates over long distances and through noisy environments.

Differential transmission nullifies the effects of ground shifts

and noise signals that appear as common-mode voltages on the

line.

Two main standards are approved by the Electronics Industries

Association (EIA) which specify the electrical characteristics of

transceivers used in differential data transmission. The RS-422

standard specifies data rates up to 10 MBaud and line lengths

up to 4000 ft. A single driver can drive a transmission line with

up to 10 receivers.

The RS-485 standard was defined to cater to true multipoint

communications. This standard meets or exceeds all the requirements of RS-422, but also allows multiple drivers and

receivers to be connected to a single bus. An extended commonmode range of –7 V to +12 V is defined.

The most significant difference between RS-422 and RS-485 is

the fact that the drivers may be disabled thereby allowing more

than one to be connected to a single line. Only one driver should

be enabled at a time, but the RS-485 standard contains additional specifications to guarantee device safety in the event of

line contention.

Cable and Data Rate

The transmission line of choice for RS-485 communications is a

twisted pair. Twisted pair cable tends to cancel common-mode

noise and also causes cancellation of the magnetic fields generated by the current flowing through each wire, thereby reducing

the effective inductance of the pair.

The ADM3485E is designed for bidirectional data communications on multipoint transmission lines. A typical application

showing a multipoint transmission network is illustrated in

Figure 23. Only one driver can transmit at a particular time, but

multiple receivers may be enabled simultaneously.

As with any transmission line, it is important that reflections are

minimized. This may be achieved by terminating the extreme

ends of the line using resistors equal to the characteristic impedance of the line. Stub lengths of the main line should also be

kept as short as possible. A properly terminated transmission

line appears purely resistive to the driver.

Receiver Open-Circuit Fail-Safe

The receiver input includes a fail-safe feature that guarantees a

logic high on the receiver when the inputs are open circuit or

floating.

Table VI. Comparison of RS-422 and RS-485 Interface

Standards

Specification RS-422 RS-485

Transmission Type Differential Differential

Maximum Cable Length 4000 ft. 4000 ft.

Minimum Driver Output Voltage ± 2 V ± 1.5 V

Driver Load Impedance 100 Ω 54 Ω

Receiver Input Resistance 4 kΩ min 12 kΩ min

Receiver Input Sensitivity ± 200 mV ± 200 mV

Receiver Input Voltage Range –7 V to +7 V –7 V to +12 V

–10–

REV. A

0.210 (5.33)

0.0098 (0.25)

0.0075 (0.19)

0.0500 (1.27)

0.0160 (0.41)

8

0

0.0196 (0.50)

0.0099 (0.25)

45

85

41

0.1968 (5.00)

0.1890 (4.80)

0.2440 (6.20)

0.2284 (5.80)

PIN 1

0.1574 (4.00)

0.1497 (3.80)

0.0500 (1.27)

BSC

0.0688 (1.75)

0.0532 (1.35)

SEATING

PLANE

0.0098 (0.25)

0.0040 (0.10)

0.0192 (0.49)

0.0138 (0.35)

MAX

0.160 (4.06)

0.115 (2.93)

0.022 (0.558)

0.014 (0.356)

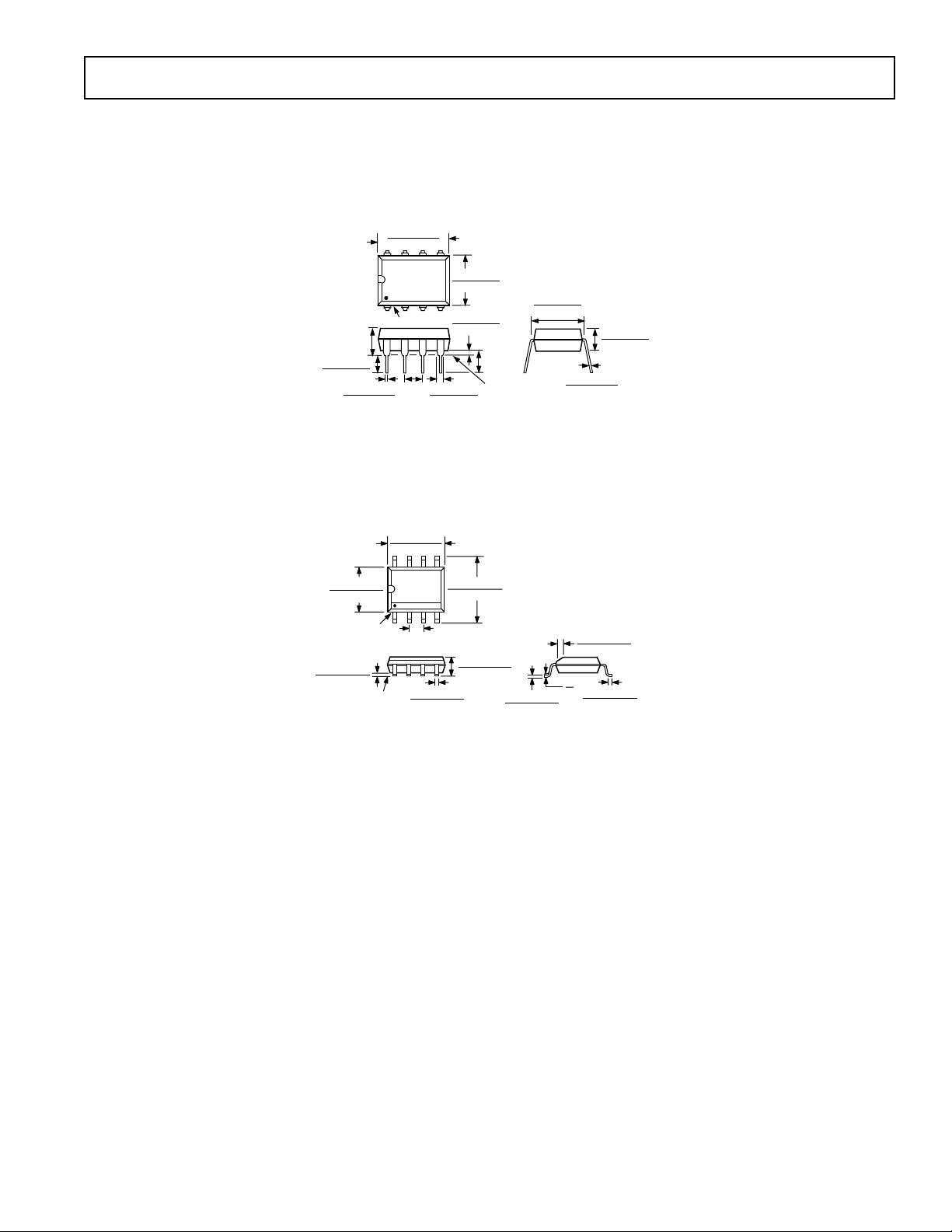

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

8-Lead Plastic DIP

(N-8)

0.430 (10.92)

0.348 (8.84)

8

14

PIN 1

0.100

(2.54)

BSC

5

0.280 (7.11)

0.240 (6.10)

0.060 (1.52)

0.015 (0.38)

0.070 (1.77)

0.045 (1.15)

0.130

(3.30)

MIN

SEATING

PLANE

0.325 (8.25)

0.300 (7.62)

0.015 (0.381)

0.008 (0.204)

8-Lead SOIC

(SO-8)

ADM3485E

0.195 (4.95)

0.115 (2.93)

C3338–0–5/00 (rev. A) 00075

PRINTED IN U.S.A.

–11–REV. A

Loading...

Loading...