V

查询ADM1178供应商查询ADM1178供应商

Hot Swap Controller and

Digital Power Monitor with ALERTB Output

FEATURES

Allows safe board insertion and removal from a live

backplane

Controls supply voltages from 3.15 V to 16.5 V

Precision current sense amplifier

Precision voltage input

12-bit ADC for current and voltage readback

Charge pumped gate drive for external N-channel FET

Adjustable analog current limit with circuit breaker

±3% accurate hot swap current limit level

Fast response limits peak fault current

Automatic retry or latch-off on current fault

Programmable hot swap timing via TIMER pin

Active-high ON pin

ALERTB output for overcurrent interrupt

2

C® fast mode-compliant interface (400 kHz maximum)

I

10-lead MSOP

APPLICATIONS

Power monitoring/power budgeting

Central office equipment

Telecommunication and data communication equipment

PCs/servers

GENERAL DESCRIPTION

The ADM1178 is an integrated hot swap controller and current

sense amplifier that offers digital current and voltage monitoring

via an on-chip, 12-bit analog-to-digital converter (ADC),

communicated through an I

An internal current sense amplifier senses voltage across the sense

resistor in the power path via the VCC pin and the SENSE pin.

2

C interface.

VCC

SENSE

ON

3.15V TO 16.5

ADM1178

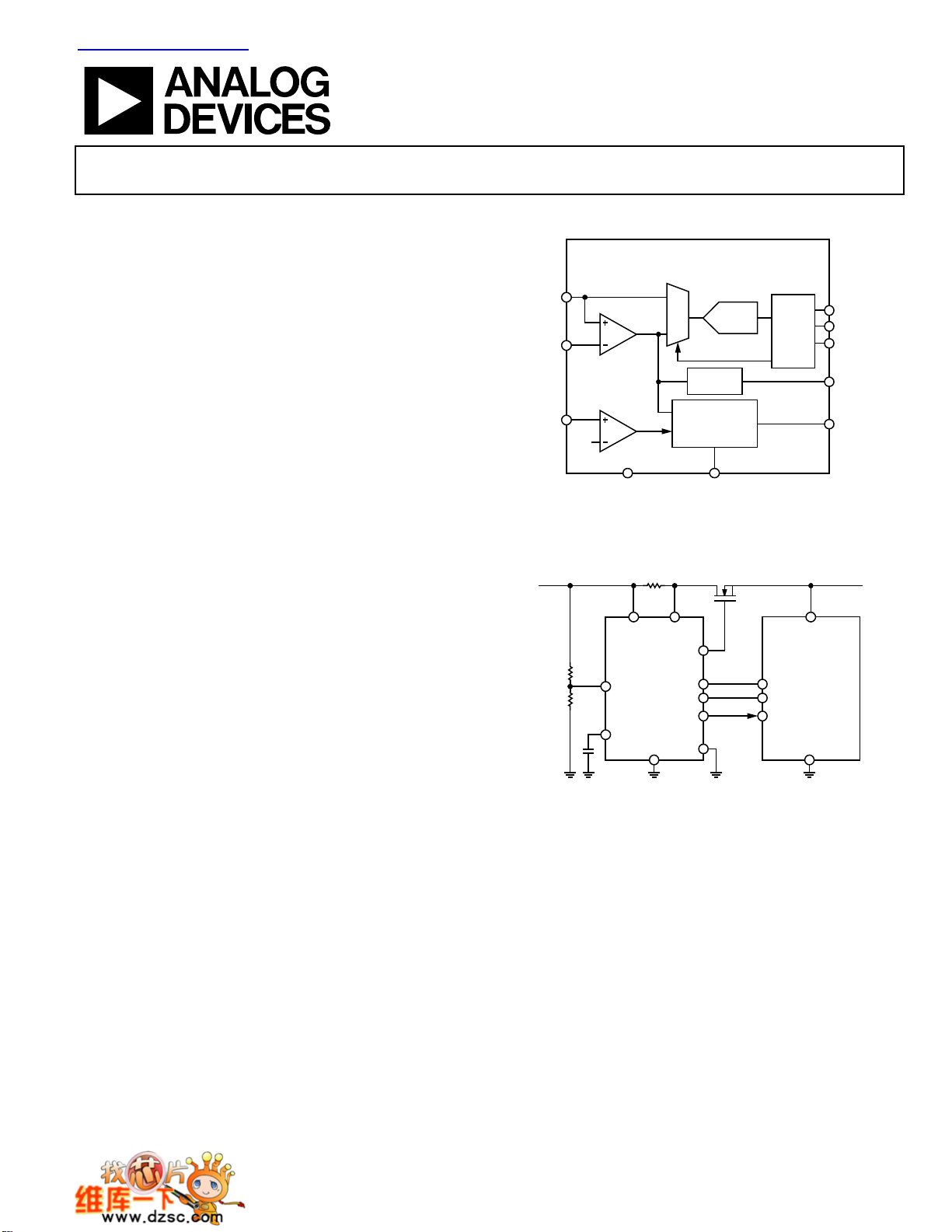

FUNCTIONAL BLOCK DIAGRAM

ADM1178

MUX

V

A

CURRENT

SENSE

AMPLIFIER

1.3V

UV COMPARATOR

GND

R

ADM1178

ON

TIMER

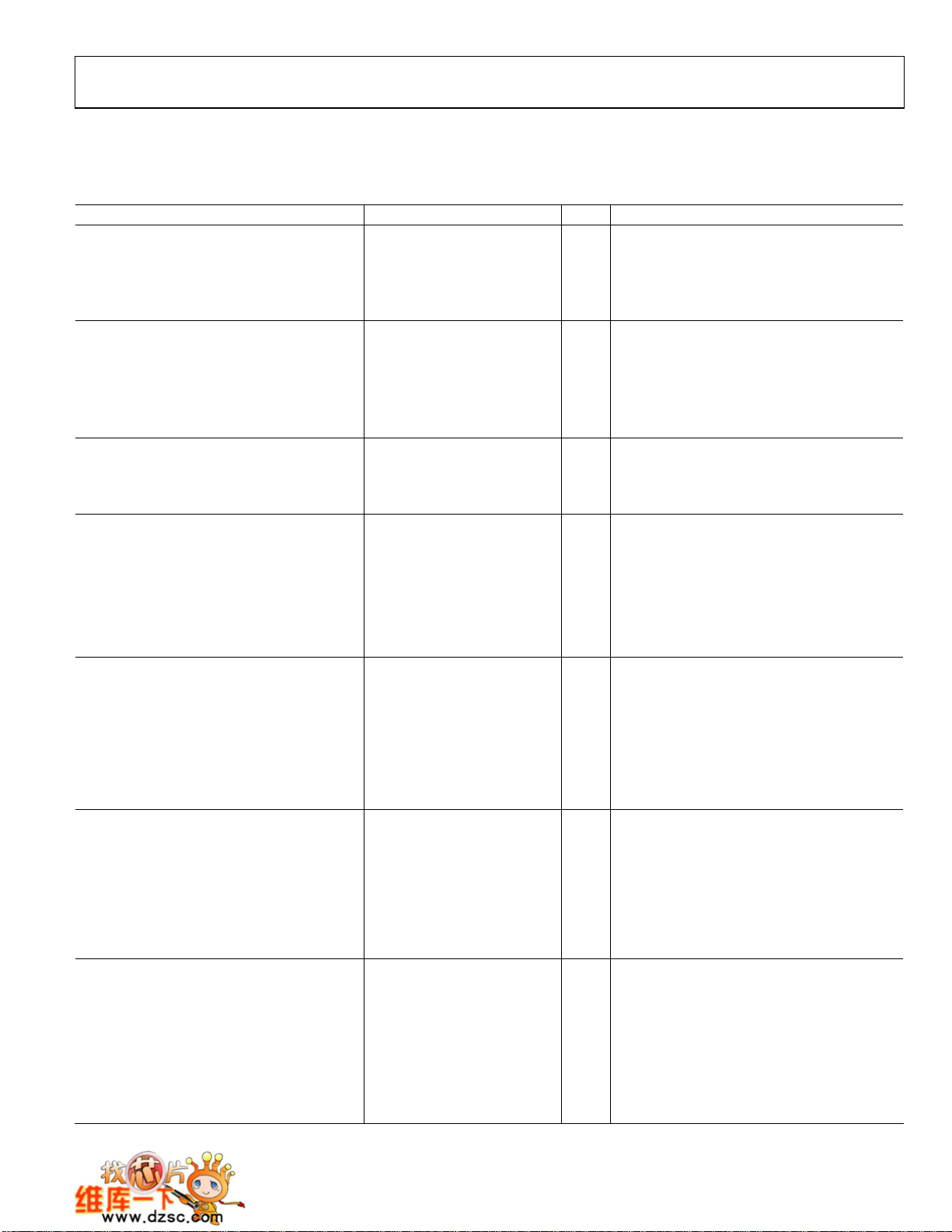

Figure 2. Applications Diagram

SENSE

GND

0

I

1

SENSEVCC

GATE

ALERTB

12-BIT

ADC

ALERT

FET DRIVE

CONTROLLER

TIMER

Figure 1.

N-CHANNEL FET

SDA

SCL

ADR

CONTROLLER

SDA

SCL

INTERRUPT

2

C

I

P = VI

SDA

SCL

ADR

ALERTB

GATE

06048-001

06048-002

The ADM1178 limits the current through this resistor by controlling the gate voltage of an external N-channel FET in the power

path, via the GATE pin. The sense voltage (and, therefore, the

inrush current) is kept below a preset maximum.

The ADM1178 protects the external FET by limiting the time

that it spends with the maximum current running in it. This

current limit period is set by the choice of capacitor attached

to the TIMER pin. Additionally, the device provides protection

from overcurrent events that may occur after the hot swap event

is complete. In case of a short-circuit event, the current in the

sense resistor exceeds an overcurrent trip threshold, and the

FET is switched off immediately by pulling down the GATE pin.

Rev. 0

Information furnished by Analog Devices is believed to be accurate and reliable. However, no

responsibility is assumed by Anal og Devices for its use, nor for any infringements of p atents or other

rights of third parties that may result from its use. Specifications subject to change without notice. No

license is granted by implication or otherwise under any patent or patent rights of Analog Devices.

Trademarks and registered trademarks are the property of their respective owners.

A 12-bit ADC can measure the current seen in the sense

resistor, as well as the supply voltage on the VCC pin. An alert

output can be set to trigger when the ADC current reading

exceeds a programmed overcurrent limit threshold.

2

An industry-standard I

C interface allows a controller to read

current and voltage data from the ADC. Measurements can be

initiated by an I

2

C command. Alternatively, the ADC can run

continuously, and the user can read the latest conversion data

whenever it is required. Up to four unique I

2

C addresses can be

created, depending on the way the ADR pin is connected.

The ADM1178 is packaged in a 10-lead MSOP.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700 www.analog.com

Fax: 781.461.3113 ©2006 Analog Devices, Inc. All rights reserved.

ADM1178

TABLE OF CONTENTS

Features .............................................................................................. 1

Initial Timing Cycle ................................................................... 14

Applications....................................................................................... 1

General Description......................................................................... 1

Functional Block Diagram .............................................................. 1

Revision History ............................................................................... 2

Specifications..................................................................................... 3

Absolute Maximum Ratings............................................................ 6

ESD Caution.................................................................................. 6

Pin Configuration and Function Descriptions............................. 7

Typical Performance Characteristics ............................................. 8

Overview of the Hot Swap Function............................................ 13

Undervoltage Lockout ............................................................... 13

ON Function ............................................................................... 13

TIMER Function ........................................................................ 13

GATE and TIMER Functions During a Hot Swap ............... 14

Calculating Current Limits and Fault Current Limit Time.. 14

Hot Swap Retry Cycle on the ADM1178-1............................. 15

Voltage and Current Readback..................................................... 16

Serial Bus Interface..................................................................... 16

Identifying the ADM1178 on the I

General I

Write and Read Operations ...................................................... 18

Quick Command........................................................................ 18

Write Command Byte................................................................ 18

Write Extended Byte .................................................................. 19

Read Voltage and/or Current Data Bytes................................ 20

Applications Waveforms................................................................ 22

ALERTB Output......................................................................... 23

Kelvin Sense Resistor Connection ........................................... 23

Outline Dimensions ....................................................................... 24

Ordering Guide .......................................................................... 24

2

C Timing.................................................................... 16

2

C Bus............................... 16

REVISION HISTORY

9/06—Revision 0: Initial Version

Rev. 0 | Page 2 of 24

ADM1178

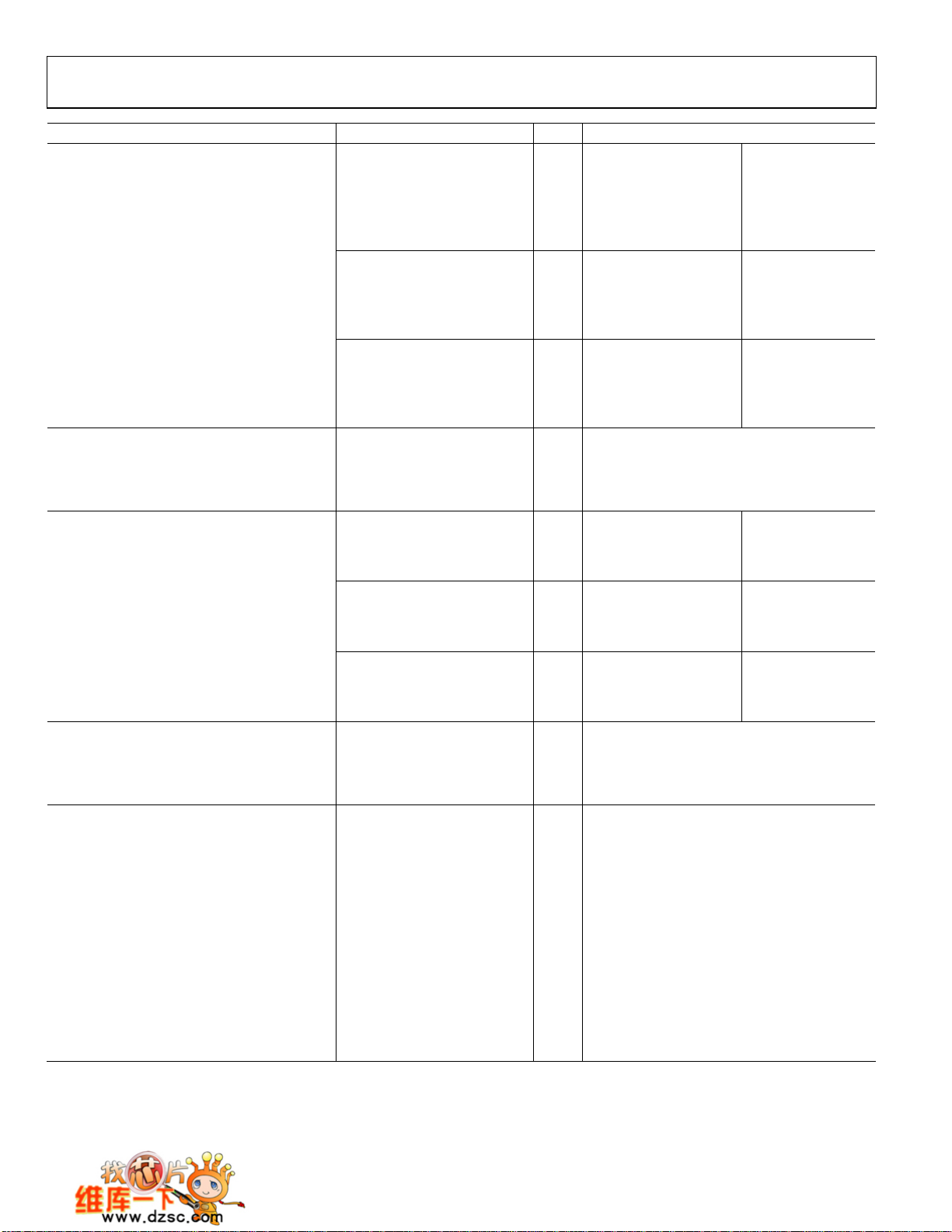

SPECIFICATIONS

VCC = 3.15 V to 16.5 V; TA = −40°C to +85°C; typical values at TA = 25°C, unless otherwise noted.

Table 1.

Parameter Min Typ Max Unit Conditions

VCC PIN

Operating Voltage Range, V

Supply Current, I

CC

Undervoltage Lockout, V

Undervoltage Lockout Hysteresis, V

VCC

UVLO

UVLOHYST

ON PIN

Input Current, I

INON

−2 +2 μA

Rising Threshold, V

Trip Threshold Hysteresis, V

ONTH

ONHYST

Glitch Filter Time 3 μs

ALERTB PIN

Output Low Voltage, V

ALERTOL

1 1.5 mA I

Input Current, I

ALERT

SENSE PIN

Input Leakage, I

Overcurrent Fault Timing Threshold, V

Overcurrent Limit Threshold, V

Fast Overcurrent Trip Threshold, V

SENSE

OCTIM

LIM

OCFAST

GATE PIN

Drive Voltage, V

GATE

Pull-Up Current 8 12.5 17 μA V

Pull-Down Current 1.5 mA V

5 mA V

7 mA V

TIMER PIN

Pull-Up Current (Power On Reset), I

Pull-Up Current (Fault Mode), I

Pull-Down Current (Retry Mode), I

Pull-Down Current, I

Trip Threshold H igh, V

Trip Threshold Low, V

100 μA Normal operation, V

TIMERDN

TIMERH

TIMERL

TIMERUPPOR

TIMERUPFAULT

TIMERDNRETRY

ADR PIN

Set Address to 00, V

Set Address to 01, R

Set Address to 10, I

Set Address to 11, V

Input Current for 11 Decode, I

Input Current for 00 Decode, I

ADRLOWV

ADRLOWZ

ADRHIGHZ

ADRHIGHV

ADRLOW

ADRHIGH

3.15 16.5 V

1.7 2.5 mA

2.8 V VCC rising

80 mV

−100

+100 nA ON < 1.5 V

1.26 1.3 1.34 V ON rising

35 50 65 mV

0.05 0.1 V I

−1 +1 μA V

−1 +1 μA V

92 mV

= −100 μA

ALERT

= −2 mA

ALERT

= VCC; ALERTB not asserted

ALERT

= V

SENSE

VCC

V

= (V

OCTRIM

VCC

− V

SENSE

TIMER pin

97 100 103 mV

V

= (V

− V

LIM

VCC

), closed-loop regulation to a

SENSE

current limit

115 mV

V

OCFAST

= (V

VCC

− V

SENSE

turned on

3 6 9 V V

9 11 13 V V

7 10 13 V V

−3.5 −5 −6.5 μA Initial cycle, V

GATE

GATE

GATE

GATE

GATE

GATE

GATE

− V

VCC

− V

VCC

− V

VCC

= 0 V

= 3 V, V

= 3 V, V

= 3 V, V

, V

, V

, V

VCC

VCC

VCC

VCC

VCC

VCC

TIMER

= 3.15 V

= 5 V

= 16.5 V

= 3.15 V

= 5 V

= 16.5 V

= 1 V

−40 −60 −80 μA During current fault, V

2 3 μA

After current fault and during a cool-down

period on a retry device, V

1.26 1.3 1.34 V TIMER rising

0.175 0.2 0.225 V TIMER falling

0 0.8 V Low state

135 150 165 kΩ

Resistor to ground state, load pin with specified

resistance for 01 decode

−1 +1 μA

Open state, maximum load allowed on ADR pin

for 10 decode

2 5.5 V High state

3 10 μA V

−40 −22 μA V

= 2.0 V to 5.5 V

ADR

= 0 V to 0.8 V

ADR

), fault timing starts on the

), gate pull-down current

= 1 V

TIMER

= 1 V

TIMER

= 1 V

TIMER

Rev. 0 | Page 3 of 24

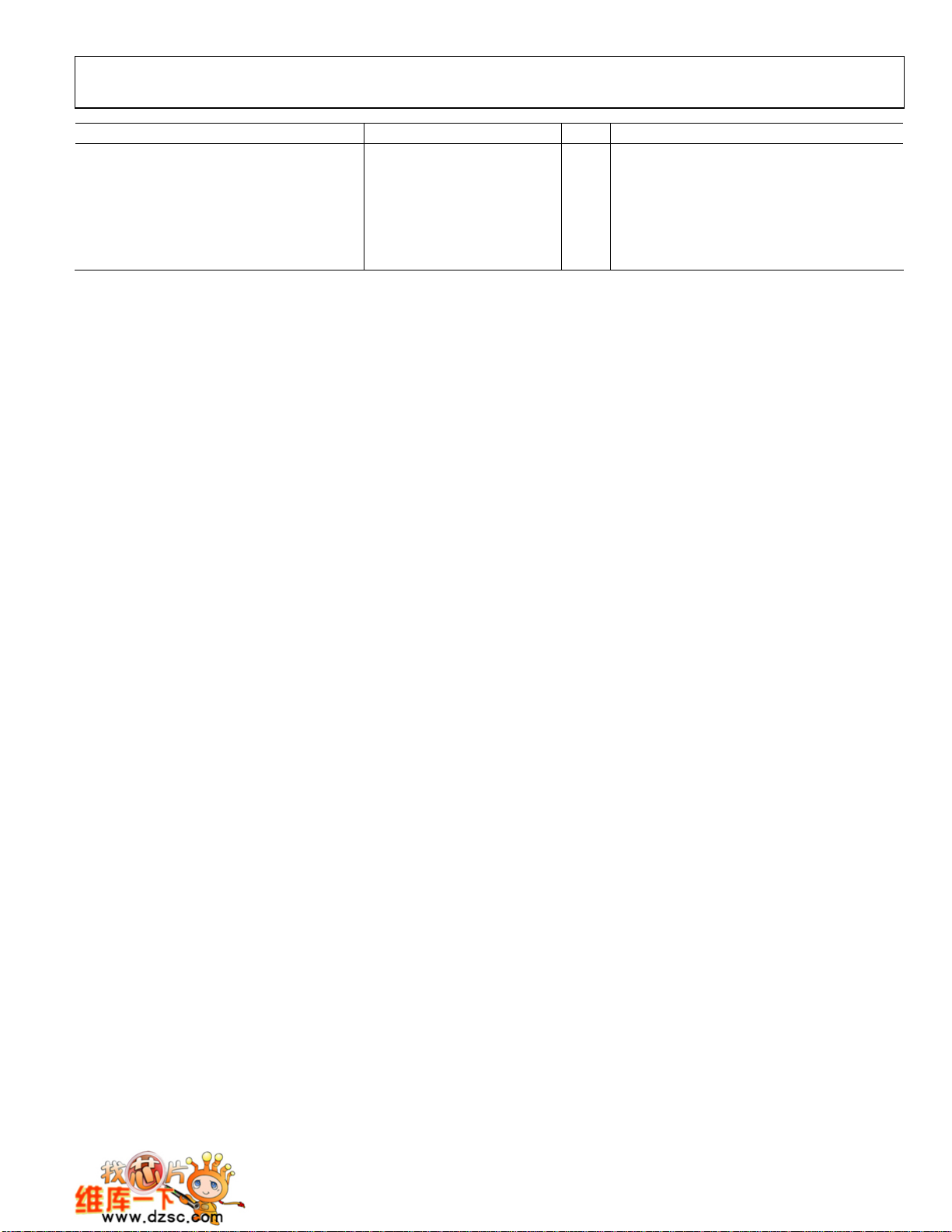

ADM1178

Parameter Min Typ Max Unit Conditions

MONITORING ACCURACY1

Current Sense Absolute Accuracy −1.45

−1.8

−2.8

−5.7

−1.5

−1.8

−2.95

−6.1

−1.95

−2.45

−3.85

−6.7

V

for ADC Full Scale 105.84 mV

SENSE

Voltage Sense Accuracy −0.85

−0.9 +0.9 %

−0.85

−0.9 +0.9 %

−0.9

−1.15 +1.15 %

VCC for ADC Full Scale,

6.65 V

Low Range (VRANGE = 1)

VCC for ADC Full Scale,

26.35 V

High Range (VRANGE = 0)

I2C TIMING

Low Level Input Voltage, V

High Level Input Voltage, V

Low Level Output Voltage on SDA, V

Output Fall Time on SDA from V

Maximum Width of Spikes Suppressed by

Input Filtering on SDA and SCL Pins

Input Current, II, on SDA/SCL When Not

Driving Out a Logic Low

0.3 V

IL

0.7 V

IH

0.4 V I

OL

to V

IHMIN

ILMAX

V

BUS

20 +

0.1 C

250 ns CB = bus capacitance from SDA to GND

B

50 250 ns

−10 +10 μA

Input Capacitance on SDA/SCL 5 pF

SCL Clock Frequency, f

400 kHz

SCL

Low Period of the SCL Clock 600 ns

High Period of the SCL Clock 1300 ns

+1.45 % V

+1.8 % V

+2.8 % V

+5.7 % V

+1.5 % V

+1.8 % V

+2.95 % V

+6.1 % V

+1.95 % V

+2.45 % V

+3.85 % V

+6.7 % V

+0.85 %

+0.85 %

+0.9 %

V

BUS

= 75 mV 0°C to +70°C

SENSE

= 50 mV 0°C to +70°C

SENSE

= 25 mV 0°C to +70°C

SENSE

= 12.5 mV 0°C to +70°C

SENSE

= 75 mV 0°C to +85°C

SENSE

= 50 mV 0°C to +85°C

SENSE

= 25 mV 0°C to +85°C

SENSE

= 12.5 mV 0°C to +85°C

SENSE

= 75 mV −40°C to +85°C

SENSE

= 50 mV −40°C to +85°C

SENSE

= 25 mV −40°C to +85°C

SENSE

= 12.5 mV −40°C to +85°C

SENSE

This is an absolute value to be used when

converting ADC codes to current readings;

any inaccuracy in this value is factored into

absolute current accuracy values (see specs

for Current Sense Absolute Accuracy)

VCC = 3 V minimum

0°C to +70°C

(low range)

= 6 V minimum

V

CC

0°C to +70°C

(high range)

VCC = 3 V minimum

0°C to +85°C

(low range)

= 6 V minimum

V

CC

0°C to +85°C

(high range)

VCC = 3 V minimum

−40°C to +85°C

(low range)

= 6 V minimum

V

CC

−40°C to +85°C

(high range)

These are absolute values to be used when

converting ADC codes to voltage readings;

any inaccuracy in these values is factored into

voltage accuracy values (see specs for Voltage

Accuracy)

= 3 mA

OL

Rev. 0 | Page 4 of 24

ADM1178

Parameter Min Typ Max Unit Conditions

Setup Time for a Repeated Start Condition,

t

SU;STA

SDA Output Data Hold Time, t

Setup Time for a Stop Condition, t

HD;DAT

SU;STO

Bus Free Time Between a Stop and a Start

Condition, t

BUF

Capacitive Load for Each Bus Line 400 pF

1

Monitoring accuracy is a measure of the error in a code that is read back for a particular voltage/current. This is a combination of amplifier error, reference error, ADC

error, and error in ADC full-scale code conversion factor.

600 ns

100 900 ns

600 ns

1300 ns

Rev. 0 | Page 5 of 24

ADM1178

ABSOLUTE MAXIMUM RATINGS

Table 2.

Parameter Rating

VCC Pin 20 V

SENSE Pin 20 V

TIMER Pin −0.3 V to +6 V

ON Pin −0.3 V to +20 V

ALERTB Pin 30 V

GATE Pin 30 V

SDA Pin, SCL Pin −0.3 V to +6 V

ADR Pin −0.3 V to +7 V

Storage Temperature Range −65°C to +125°C

Operating Temperature Range −40°C to +85°C

Lead Temperature Range (Soldering, 10 sec) 300°C

Junction Temperature 150°C

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

Table 3. Thermal Resistance

Package Type θ

10-Lead MSOP 137.5 °C/W

JA

Unit

ESD CAUTION

Rev. 0 | Page 6 of 24

ADM1178

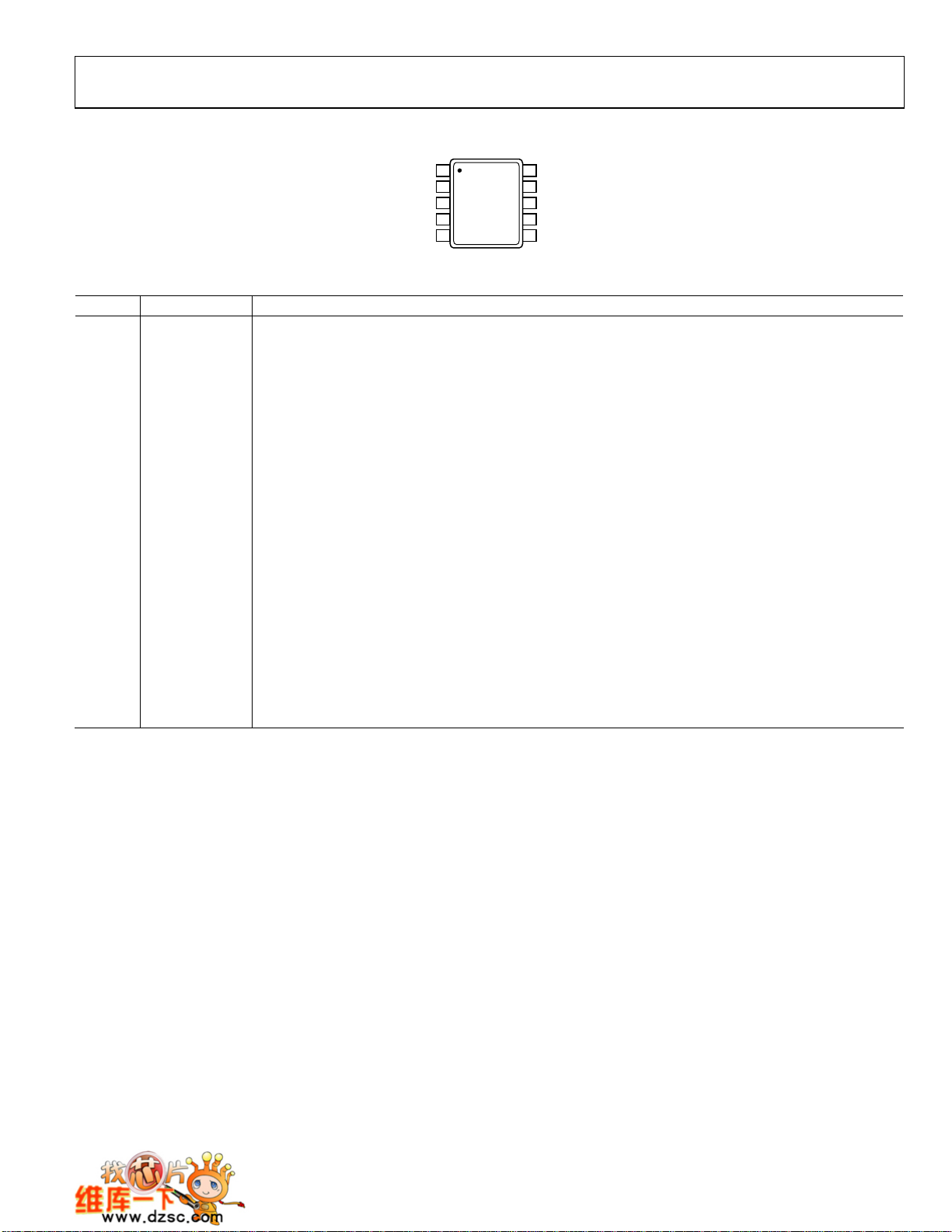

PIN CONFIGURATION AND FUNCTION DESCRIPTIONS

1

VCC

SENSE

2

ADM1178

ON

3

TOP VIEW

(Not to Scale)

GND

4

5

TIMER

Figure 3. Pin Configuration

Table 4. Pin Function Descriptions

Pin No. Mnemonic Description

1 VCC

Positive Supply Input Pin. The operating supply voltage range is from 3.15 V to 16.5 V. An undervoltage

lockout (UVLO) circuit resets the ADM1178 when a low supply voltage is detected.

2 SENSE

Current Sense Input Pin. A sense resistor between the VCC pin and the SENSE pin sets the analog current

limit. The hot swap operation of the ADM1178 controls the external FET gate to maintain the (V

voltage at 100 mV or below.

3 ON

Undervoltage Input Pin. Active high pin. An internal ON comparator has a trip threshold of 1.3 V, and the

output of this comparator is used as an enable for the hot swap operation. With an external resistor divider

from VCC to GND, this pin can be used to enable the hot swap operation on a specific voltage on VCC, giving

an undervoltage function.

4 GND Chip Ground Pin.

5 TIMER

Timer Pin. An external capacitor, C

TIMER

The GATE pin turns off when the TIMER pin is pulled beyond the upper threshold. An overvoltage detection

with an external Zener can be used to force this pin high.

6 SCL I2C Clock Pin. Open-drain input requires an external resistive pull-up.

7 SDA I2C Data I/O Pin. Open-drain input/output. Requires an external resistive pull-up.

8 ADR

9 GATE

2

C Address Pin. This pin can be tied low, tied high, left floating, or tied low through a resistor to set four

I

different I

2

C addresses.

GATE Output Pin. This pin is the high-side gate drive of an external N-channel FET. This pin is driven by the

FET drive controller, which utilizes a charge pump to provide a 12.5 μA pull-up current to charge the FET

GATE pin. The FET drive controller regulates to a maximum load current (100 mV through the sense resistor)

by modulating the GATE pin.

10 ALERTB

Alert Output Pin. Active-low, open-drain configuration. This pin asserts when an overcurrent condition is

present. The overcurrent level that causes an alert to be asserted is digitally programmable via the I

interface. This function can also be enable/disabled via I

10

ALERTB

GATE

9

ADR

8

SDA

7

6

SCL

06048-003

− V

SENSE

)

VCC

, sets a 270 ms/μF initial timing cycle delay and a 21.7 ms/μF fault delay.

2

2

C.

C

Rev. 0 | Page 7 of 24

ADM1178

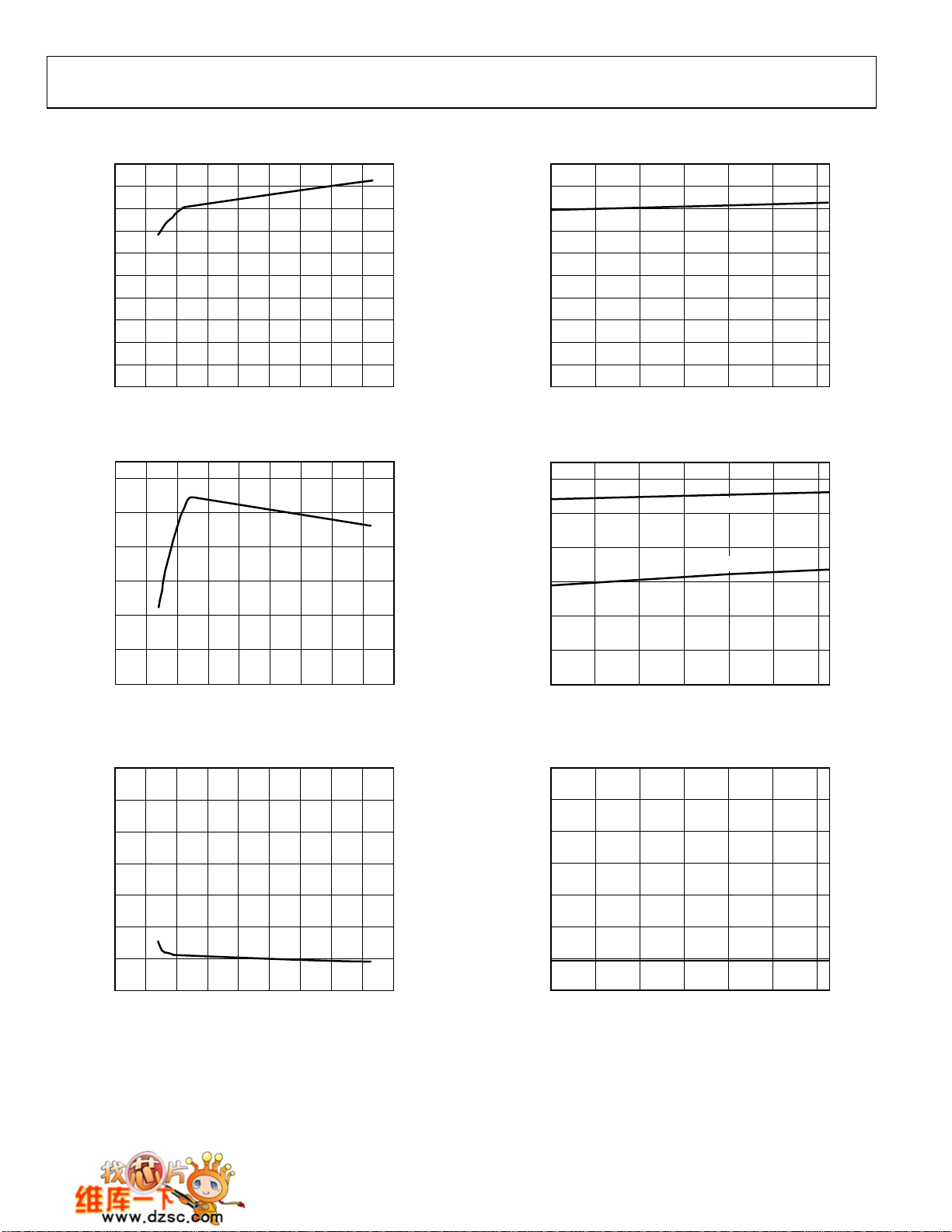

TYPICAL PERFORMANCE CHARACTERISTICS

2.0

1.8

1.6

1.4

1.2

1.0

(mA)

CC

I

0.8

0.6

0.4

0.2

0

024681014112 16

VCC (V)

Figure 4. Supply Current vs. Supply Voltage

8

06048-021

2.0

1.8

1.6

1.4

1.2

1.0

(mA)

CC

I

0.8

0.6

0.4

0.2

0

–40 806040200–20

TEMPERATURE (°C)

Figure 7. Supply Current vs. Temperature (Gate On)

06048-022

12

10

8

6

DRIVE VOLTAGE (V)

4

2

0

01

Figure 5. Drive Voltage (V

0

–2

–4

–6

(µA)

–8

GATE

I

–10

VCC (V)

− VCC) vs. Supply Voltage

GATE

8161412108642

06048-029

12

10

8

6

DRIVE VOLTAGE (V)

4

2

0

–40 806040200–20

Figure 8. Drive Voltage (V

0

–2

–4

–6

(µA)

–8

GATE

I

–10

5V VIN

3.15V VIN

TEMPERATURE (°C)

− VCC) vs. Temperature

GATE

06048-030

–12

–14

01

VCC (V)

10 12 16148642

8

06048-027

Figure 6. Gate Pull-Up Current vs. Supply Voltage

–12

–14

–40 806040200–20

Figure 9. Gate Pull-Up Current vs. Temperature

Rev. 0 | Page 8 of 24

TEMPERATURE (°C)

06048-028

ADM1178

12

10

8

(mA)

6

GATE

I

4

2

0

01

Figure 10. Gate Pull-Down Current vs. V

VCC (V)

CC

at V

GATE

161412108642

8

06048-031

= 5 V

2.0

1.8

1.6

1.4

1.2

1.0

0.8

0.6

TIMER THRES HO LD (V)

0.4

0.2

0

01810 12 16148642

HIGH

LOW

VCC (V)

06048-038

Figure 13. Timer Threshold vs. Supply Voltage

2

0

–2

–4

(µA)

–6

GATE

I

–8

–10

–12

–14

01

V

GATE

(V)

Figure 11. Gate Pull-Up Current vs. Gate Voltage at V

20

15

(mA)

10

GATE

I

5

VCC = 3V

0

02

V

V

CC

GATE

V

CC

= 5V

(V)

= 12V

1412108642

6

06048-040

= 5 V

CC

2015105

5

06048-043

Figure 12. Gate Pull-Down Current vs. Gate Voltage

2.0

1.8

1.6

1.4

1.2

1.0

0.8

0.6

TIMER HIG H THRESHOLD (V)

0.4

0.2

0

–40 80

Figure 14. Timer Threshold vs. Temperature

100

90

80

70

60

50

40

GATE ON TIME (ms)

30

20

10

0

05.04.54.03.53.02.52.01.51.00.5

Figure 15. Current Limit On Time vs. Timer Capacitance

HIGH

LOW

TEMPERATURE (°C)

C

(µF)

TIMER

6040200–20

06048-039

06048-050

Rev. 0 | Page 9 of 24

ADM1178

0

0

–1

–2

(µA)

–3

TIMER

I

–4

–5

–6

018

VCC (V)

10 12 16148642

06048-032

Figure 16.Timer Pull-Up Current (Initial Cycle) vs. Supply Voltage

0

–10

–20

–30

(µA)

–40

TIMER

I

–50

–60

–1

–2

(µA)

–3

TIMER

I

–4

–5

–6

–40 806040200–20

Figure 19. Timer Pull-Up Current (Initial Cycle) vs. Temperature

0

–10

–20

–30

(µA)

–40

TIMER

I

–50

–60

TEMPERATURE (°C)

06048-033

–70

–80

018

VCC (V)

10 12 16148642

06048-034

Figure 17. Timer Pull-Up Current (C. B. Delay) vs. Supply Voltage

3.0

2.5

2.0

(µA)

1.5

TIMER

I

1.0

0.5

0

01810 12 16148642

VCC (V)

06048-036

Figure 18. Timer Pull-Down Current (Cool-Off Cycle) vs. Supply Voltage

–70

–80

–40 806040200–20

Figure 20. Timer Pull-Up Current (C. B. Delay) vs. Temperature

3.0

2.5

2.0

(µA)

1.5

TIMER

I

1.0

0.5

0

–40 806040200–20

Figure 21. Timer Pull-Down Current (Cool-Off Cycle) vs. Temperature

TEMPERATURE (°C)

TEMPERATURE (°C)

06048-035

06048-037

Rev. 0 | Page 10 of 24

ADM1178

120

115

110

105

(mV)

100

LIM

V

95

90

85

80

21

VCC (V)

8

16141210864

06048-041

Figure 22. Circuit Breaker Limit Voltage vs. Supply Voltage

110

108

106

104

102

100

V (mV)

98

96

94

92

90

–40 806040200–20

Figure 23. V

V

OCFAST

V

LIM

V

OCTIM

TEMPERATURE (°C)

, V

, V

OCTIM

LIM

OCFAST

vs. Temperature

06048-042

1000

900

800

700

600

500

400

300

HITS PER CO DE (1000 RE ADS)

200

100

0

2047 2048 2049 20502046

CODE

Figure 25. ADC Noise, Current Channel, Midcode Input, 1000 Reads

1000

900

800

700

600

500

400

300

HITS PER CO DE (1000 RE ADS)

200

100

0

780 781 782 783779

CODE

Figure 26. ADC Noise, 14:1 Voltage Channel, 5 V Input, 1000 Reads

06048-060

06048-061

11 DECODE 10 DECODE 01 DECODE 00 DECODE

3.2

3.0

2.8

2.6

2.4

2.2

2.0

1.8

1.6

ADR

V

1.4

1.2

1.0

0.8

0.6

0.4

0.2

0

–35 –30 –25 –20 –15 –10 –5 0 5 10

I

ADR

(µA)

Figure 24. Address Pin Voltage vs. Address Pin Current

for Four Addressing Options

06048-026

Rev. 0 | Page 11 of 24

1000

900

800

700

600

500

400

300

HITS PER CO DE ( 1000 RE ADS)

200

100

0

3079 3080 3081 30823078

CODE

Figure 27. ADC Noise, 7:1 Voltage Channel, 5 V Input, 1000 Reads

06048-062

ADM1178

4

3

2

1.0

0.8

INL (LSB)

DNL (LSB)

1

0

–1

–2

–3

–4

0 40002500 3000 3500200015001000500

4

3

2

1

0

–1

–2

–3

–4

0 40002500 3000 3500200015001000500

CODE

Figure 28. INL for ADC

CODE

Figure 29. DNL for ADC

0.6

0.4

OUTPUT LOW (V)

0.2

0

211514131211109876543

06048-023

VCC (V)

6

06048-048

Figure 31. Output Low Voltage vs. Supply @ 1 mA

2.0

1.8

1.6

1.4

1.2

1.0

0.8

OUTPUT LOW (V)

0.6

0.4

0.2

0

032.82.62.42.22.01.81.61.41.21.00.80.60.40.2

06048-024

LOAD CURRENT (mA)

.0

06048-049

Figure 32. Output Low Voltage vs. Load Current

0.60

0.55

0.50

0.45

0.40

0.35

0.30

0.25

ALERTB LO W ( V)

0.20

0.15

0.10

0.05

0

–40 806040200–20

TEMPERATURE (°C)

06048-047

Figure 30. Output Low Voltage vs. Temperature @ 1 mA

Rev. 0 | Page 12 of 24

ADM1178

OVERVIEW OF THE HOT SWAP FUNCTION

When circuit boards are inserted into a live backplane, discharged

supply bypass capacitors draw large transient currents from the

backplane power bus as they charge. Such transient currents can

cause permanent damage to connector pins, as well as dips on

the backplane supply that can reset other boards in the system.

The ADM1178 is designed to turn a circuit board supply

voltage on and off in a controlled manner, allowing the circuit

board to be safely inserted into or removed from a live backplane.

The ADM1178 can reside either on the backplane or on the

circuit board itself.

The ADM1178 controls the inrush current to a fixed maximum

level by modulating the gate of an external N-channel FET placed

between the live supply rail and the load. This hot swap function

protects the card connectors and the FET itself from damage

and limits any problems that may be caused by the high current

loads on the live supply rail.

The ADM1178 holds the GATE pin down (and, thus, the FET is

held off) until a number of conditions are met. An undervoltage

lockout circuit ensures that the device is provided with an adequate

input supply voltage. Once this has been successfully detected,

the device goes through an initial timing cycle to provide a delay

before it attempts to hot swap. This delay ensures that the board is

fully seated in the backplane before the board is powered up.

Once the initial timing cycle is complete, the hot swap function

is switched on under control of the ON pin. When the ON pin

is asserted high, the hot swap operation starts.

The ADM1178 charges up the gate of the FET to turn on the

load. It continues to charge up the GATE pin until the linear

current limit (set to 100 mV/R

) is reached. For some

SENSE

combinations of low load capacitance and high current limit,

this limit may not be reached before the load is fully charged up.

If current limit is reached, the ADM1178 regulates the GATE

pin to keep the current at this limit. For currents above the

overcurrent fault timing threshold, nominally 100 mV/R

SENSE

,

the current fault is timed by sourcing a current out to the

TIMER pin. If the load becomes fully charged before the fault

current limit time is reached (when the TIMER pin reaches

1.3 V), the current drops below the overcurrent fault timing

threshold. The ADM1178 then charges the GATE pin higher

to fully enhance the FET for lowest R

, and the TIMER pin

ON

is pulled down again.

The ADM1178-1 retries the hot swap operation indefinitely,

keeping the FET in its safe operating area (SOA) by using the

TIMER pin to time a cool-down period between hot swap

attempts. The current and voltage threshold combinations

on the TIMER pin set the retry duty cycle to 3.8%.

The ADM1178 is designed to operate over a range of supplies

from 3.15 V to 16.5 V.

UNDERVOLTAGE LOCKOUT

An internal undervoltage lockout (UVLO) circuit resets the

ADM1178 if the VCC

supply is too low for normal operation.

The UVLO has a low-to-high threshold of 2.8 V, with 80 mV

hysteresis. Above 2.8 V supply voltage, the ADM1178 starts the

initial timing cycle.

ON FUNCTION

The ADM1178 has an active-high ON pin. The ON pin is the

input to a comparator that has a low-to-high threshold of 1.3 V,

an 50 mV hysteresis, and a glitch filter of 3 s. A low input on

the ON pin turns off the hot swap operation by pulling the

GATE pin to ground, turning off the external FET. The TIMER

pin is also reset by turning on a pull-down current on this pin.

A low-to-high transition on the ON pin starts the hot swap

operation. A 10 k pull-up resistor connecting the ON pin to

the supply is recommended.

Alternatively, an external resistor divider at the ON pin can be

used to program an undervoltage lockout value higher than the

internal UVLO circuit, thereby setting a voltage level at the

VCC supply, where the hot swap operation is to start. An RC

filter can be added at the ON pin to increase the delay time at

card insertion if the initial timing cycle delay is insufficient.

TIMER FUNCTION

The TIMER pin handles several timing functions with an

external capacitor, C

V

(0.2 V) and V

TIMERH

sources are a 5 µA pull-up, a 60 µA pull-up, a 2 µA pull-down,

and a 100 µA pull-down. The 100 µA pull-down is a non-ideal

current source, approximating a 7 k resistor below 0.4 V.

These current and voltage levels, together with the value of C

chosen by the user, determine the initial timing cycle time, the

fault current limit time, and the hot swap retry duty cycle.

. There are two comparator thresholds:

TIMER

(1.3 V). The four timing current

TIMERL

TIMER

If the fault current limit time is reached before the load drops

below the current limit, a fault has been detected, and the hot

swap operation is aborted by pulling down on the GATE pin to

turn off the FET. The ADM1178-2 is latched off at that point

and attempts to hot swap again only when the ON pin is deasserted

and then asserted again.

Rev. 0 | Page 13 of 24

ADM1178

GATE AND TIMER FUNCTIONS DURING

A HOT SWAP

During hot insertion of a board onto a live supply rail at VCC,

the abrupt application of supply voltage charges the external

FET drain/gate capacitance, which can cause an unwanted gate

voltage spike. An internal circuit holds GATE low before the

internal circuitry wakes up. This reduces the FET current surges

substantially at insertion. The GATE pin is also held low during

the initial timing cycle and until the ON pin has been taken

high to start the hot swap operation.

During hot swap operation, the GATE pin is first pulled up by

a 12 A current source. If the current through the sense resistor

reaches the overcurrent fault timing threshold, V

current of 60 µA on the TIMER pin, is turned on; and this pin

starts charging up. At a slightly higher voltage in the sense resistor, the error amplifier servos the GATE pin to maintain a constant

current to the load by controlling the voltage across the sense

resistor to the linear current limit, V

LIM

.

A normal hot swap is complete when the board supply capacitors

near full charge and the current through the sense resistor

drops to eventually reach the level of the board load current.

As soon as the current drops below the overcurrent fault timing

threshold, the current into the TIMER pin switches from being

a 60 A pull-up to being a 100 A pull-down. The ADM1178

then drives the GATE voltage as high as it can to fully enhance

the FET and reduce R

losses to a minimum.

ON

A hot swap fails if the load current does not drop below the

overcurrent fault timing threshold, V

, before the TIMER

OCTIM

pin has charged up to 1.3 V. In this case, the GATE pin is then

pulled down with a 2 mA current sink. The GATE pull-down

stays on until a hot swap retry starts, which can be forced by

deasserting and then re-asserting the ON pin. On the ADM1178-1,

the device retries automatically after a cool-down period.

The ADM1178 also features a method of protection from

sudden load current surges, such as a low impedance fault,

when the current seen across the sense resistor may go well

beyond the linear current limit. If the fast overcurrent trip

threshold, V

, is exceeded, the 2 mA GATE pull-down is

OCFAST

turned on immediately. This pulls the GATE voltage down

quickly to enable the ADM1178 to limit the length of the

current spike that gets through and also to bring the current

through the sense resistor back into linear regulation as quickly

as possible. This process protects the backplane supply from

sustained overcurrent conditions that may otherwise cause the

backplane supply to droop during the overcurrent event.

OCTIM

, a pull-up

CALCULATING CURRENT LIMITS AND FAULT

CURRENT LIMIT TIME

The nominal linear current limit is determined by a sense

resistor connected between the VCC pin and the SENSE pin,

as given by the Equation 1.

I

LIMIT(NOM)

= V

LIM(NOM)/RSENSE

= 100 mV/R

SENSE

(1)

The minimum linear fault current is given by Equation 2.

I

LIMIT(MIN)

= V

LIM(MIN)/RSENSE(MAX)

= 90 mV/R

SENSE(MAX)

(2)

The maximum linear fault current is given by Equation 3.

I

LIMIT(MAX)

= V

LIM(MAX)/RSENSE(MIN)

= 110 mV/R

SENSE(MIN)

(3)

The power rating of the sense resistor should be rated at the

maximum linear fault current level.

The minimum overcurrent fault timing threshold current is

given by Equation 4.

I

OCTIM(MIN)

= V

OCTIM(MIN)/RSENSE(MAX)

= 85 mV/R

SENSE(MAX)

(4)

The maximum fast overcurrent trip threshold current is given

by Equation 5.

I

OCFAST(MAX)

= V

OCFAST(MAX)/RSENSE(MIN)

= 115 mV/R

SENSE(MIN)

(5)

The fault current limit time is the time that a device spends

timing an overcurrent fault and is given by Equation 6.

t

FAULT

≈ 21.7 × C

ms/F (6)

TIMER

INITIAL TIMING CYCLE

When VCC is first connected to the backplane supply, the

internal supply (Time Point (1) in

must be charged up. A very short time later (significantly less

than 1 ms), the internal supply is fully up and, because the

undervoltage lockout voltage has been exceeded at VCC, the

device comes out of reset. During this first short reset period,

the GATE pin is held down with a 25 mA pull-down current,

and the TIMER pin is pulled down with a 100 A current sink.

The ADM1178 then goes through an initial timing cycle. At

Time Point (2), the TIMER pin is pulled high with 5 µA. At

Time Point (3), the TIMER reaches the V

the first portion of the initial cycle ends. The 100 µA current

source then pulls down the TIMER pin until it reaches 0.2 V at

Time Point (4). The initial cycle delay (Time Point (2) to Time

Point (4)) is related to C

≈ 270 × C

t

INITIAL

TIMER

ms/F (7)

TIMER

Figure 33) of the ADM1178

threshold, and

TIMERL

by Equation 7.

Rev. 0 | Page 14 of 24

ADM1178

When the initial timing cycle terminates, the device is ready to

start a hot swap operation (assuming the ON pin is asserted).

In the example shown in

Figure 33, the ON pin was asserted at

the same time as VCC was applied, so the hot swap operation

starts immediately after Time Point (4). At this point the FET

gate is charged up with a 12 A current source.

At Time Point (5), the threshold voltage of the FET is reached

and the load current begins to flow. The FET is controlled to

keep the sense voltage at 100 mV (this corresponds to a

maximum load current level defined by the value of R

At Time Point (6), V

GATE

and V

have reached their full

OUT

SENSE

).

potential, and the load current has settled to its nominal level.

Figure 34 illustrates the situation where the ON pin is asserted

after V

is applied.

CC

(1)

(2) (3)(4)(5) (6)

V

VCC

V

ON

V

TIMER

V

GATE

V

SENSE

V

OUT

INITIAL TIMING

CYCLE

Figure 33. Startup (ON Asserts as Power Is Applied)

06048-004

(1) (2) (3)(4) (5)(6) (7)

V

VCC

V

ON

V

TIMER

V

GATE

V

SENSE

V

OUT

INITIAL TIMING

CYCLE

06048-005

Figure 34. Startip (ON Asserts After Power Is Applied)

HOT SWAP RETRY CYCLE ON THE ADM1178-1

With the ADM1178-1, the device turns off the FET after an

overcurrent fault and then uses the TIMER pin to time a delay

before automatically retrying to hot swap.

As with all ADM1178 devices, on overcurrent fault is timed by

charging the TIMER cap with a 60 A pull-up current. When

the TIMER pin reaches 1.3 V, the fault current limit time has

been reached, and the GATE pin is pulled down. On the

ADM1178-1, the TIMER pin is then pulled down with a 2 A

current sink. When the TIMER pin reaches 0.2 V, it automatically restarts the hot swap operation.

The cool-down period is related to C

t

COOL

≈ 550 × C

ms/F (8)

TIMER

Thus, the retry duty cycle is given by Equation 9.

by Equation 8.

TIMER

Rev. 0 | Page 15 of 24

t

FAULT

/(t

COOL

+ t

) × 100% = 3.8% (9)

FAULT

ADM1178

VOLTAGE AND CURRENT READBACK

In addition to providing hot swap functionality, the ADM1178

also contains the components to allow voltage and current

readback over an Inter-IC (I

current sense amplifier and the voltage on the VCC pin are fed

into a 12-bit ADC via a multiplexer. The device can be instructed

to convert voltage and/or current at any time during operation

2

via an I

C command. When all conversions are complete, the

voltage and/or current values can be read out to 12-bit accuracy

in two or three bytes.

SERIAL BUS INTERFACE

Control of the ADM1178 is carried out via the I2C bus. This

interface is compatible with I

The ADM1178 is connected to this bus as a slave device, under

the control of a master device.

IDENTIFYING THE ADM1178 ON THE I2C BUS

The ADM1178 has a 7-bit serial bus slave address. When the

device powers up, it does so with a default serial bus address.

The three MSBs of the address are set to 111, and the two MSBs

are set to 10, giving an address of 111x10. Bit A2 and Bit A3 are

determined by the state of the ADR pin. There are four different

configurations available on the ADR pin that correspond to

four different I

2

C addresses for these bits (see Table 5 ). This

scheme allows four ADM1178 devices to operate on a single

2

I

C bus.

2

Table 5. Setting I

ADR Configuration Address

Low state 0xE4

Resistor to GND 0xEC

Floating (unconnected) 0xF4

High state 0xFC

C Addresses via the ADR Pin

GENERAL I2C TIMING

Figure 35 and Figure 36 show timing diagrams for general read

and write operations using the I

conditions for different types of read and write operations, which

are discussed later. The general I

1. The master initiates data transfer by establishing a start

condition, defined as a high-to-low transition on the serial

data line, SDA, while the serial clock line, SCL, remains

high. This indicates that a data stream follows.

2

C) bus. The voltage output of the

2

C fast mode (400 kHz maximum).

2

C. The I2C specification defines

2

C protocol operates as follows:

All slave peripherals connected to the serial bus respond to

the start condition and shift in the next eight bits, consisting

of a 7-bit slave address (MSB first), plus an R/

W

bit that

determines the direction of the data transfer; that is,

whether data is written to or read from the slave device (0

= write, 1 = read).

The peripheral whose address corresponds to the transmitted

address responds by pulling the data line low during the

low period before the ninth clock pulse, known as the

acknowledge bit, and holding it low during the high period

of this clock pulse. All other devices on the bus remain

idle, while the selected device waits for data to be read

from it or written to it. If the R/

writes to the slave device. If the R/

W

bit is 0, the master

W

bit is 1, the master

reads from the slave device.

2. Data is sent over the serial bus in sequences of nine clock

pulses: eight bits of data followed by an acknowledge bit

from the slave device. Data transitions on the data line

must occur during the low period of the clock signal and

remain stable during the high period because a low-tohigh transition when the clock is high can be interpreted as

a stop signal.

If the operation is a write operation, the first data byte after

the slave address is a command byte. This tells the slave

device what to expect next. It can be an instruction, such

as telling the slave device to expect a block write; or it can

be a register address that tells the slave where subsequent

data is to be written.

Because data can flow in only one direction, as defined by

W

the R/

bit, it is not possible to send a command to a slave

device during a read operation. Before doing a read operation,

it may first be necessary to do a write operation to tell the

slave what sort of read operation to expect and/or the

address from which data is to be read.

3. When all data bytes have been read or written, stop

conditions are established. In write mode, the master pulls

the data line high during the 10th clock pulse to assert

a stop condition. In read mode, the master device releases

the SDA line during the low period before the ninth clock

pulse, but the slave device does not pull it low. This is known as

a no acknowledge. The master then takes the data line low

during the low period before the 10th clock pulse, then high

during the 10th clock pulse to assert a stop condition.

Rev. 0 | Page 16 of 24

ADM1178

SCL

SDA

START BY MAST E R

SCL

(CONTINUED)

SDA

(CONTINUED)

SCL

SDA

START BY MAST E R

SCL

(CONTINUED)

SDA

(CONTINUED)

9

SLAVE

SLAVE

9

SLAVE

MASTER

1

D6

D7

9

2

C Write Timing Diagram

1

D7

9

2

C Read Timing Diagram

D5

1

D6

D5

1

D4

COMMAND CODE

D4

DATA BYTE

D3

FRAME 2

D3

FRAME 2

D2 D1

D2 D1

ACKNOWLEDGE BY

FRAME N

DATA BYTE

ACKNOWLEDGE BY

FRAME N

DATA BYTE

D0

SLAVE

D0

MASTER

1

0

0

11

FRAME 1

SLAVE ADDRESS

1

D7 D6 D5 D4 D3 D2 D1 D0 D7 D6 D5 D4 D3 D2 D1 D0

A1 A0 R/W

1

FRAME 3

DATA BYTE

ACKNOWLEDG E BY

ACKNOWLEDGE BY

Figure 35. General I

1

0

0

11

FRAME 1

SLAVE ADDRESS

1

D7 D6 D5 D4 D3 D2 D1 D0 D7 D6 D5 D4 D3 D2 D1 D0

A1 A0 R/W

1

FRAME 3

DATA BYTE

ACKNOWLEDG E BY

ACKNOWLEDGE BY

Figure 36. General I

9

9

ACKNOWLEDG E BY

SLAVE

9

9

NO ACKNOWLEDGE

STOP

BY

MASTER

STOP

BY

MASTER

06048-006

06048-007

t

SU;STA

t

HD;STA

t

SU;STO

P

06048-008

SCLSCL

SDA

t

LOW

t

HD;STA

t

BUF

S

P

t

t

HD;DAT

HIGH

t

F

t

SU;DAT

S

R

t

Figure 37. Serial Bus Timing Diagram

Rev. 0 | Page 17 of 24

ADM1178

WRITE AND READ OPERATIONS

The I2C specification defines several protocols for different

types of read and write operations. The operations used in the

ADM1178 are discussed in the sections that follow.

Tabl e 6

shows the abbreviations used in the command diagrams.

Table 6. I

2

C Abbreviations

Abbreviation Condition

S Start

P Stop

R Read

W Write

A Acknowledge

N No acknowledge

QUICK COMMAND

The quick command operation allows the master to check if the

slave is present on the bus, as follows:

1. The master device asserts a start condition on SDA.

2. The master sends the 7-bit slave address, followed by the

write bit (low).

3. The addressed slave device asserts an acknowledge on SDA.

12 3

SLAVE

S

ADDRESS

Figure 38. Quick Command

WA

06048-009

WRITE COMMAND BYTE

In the write command byte operation, the master device sends

a command byte to the slave device, as follows:

1. The master device asserts a start condition on SDA.

2. The master sends the 7-bit slave address, followed by the

write bit (low).

3. The addressed slave device asserts an acknowledge on SDA.

4. The master sends the command byte. The command byte

is identified by an MSB =0. An MSB =1 indicates an

extended register write (see the

section.)

5. The slave asserts an acknowledge on SDA.

6. The master asserts a stop condition on SDA to end the

transaction.

12 3 456

SLAVE

S

ADDRESS

Figure 39. Write Command Byte

WA

The seven LSBs of the command byte are used to configure and

control the ADM1178.

Tabl e 7 provides details of the function

of each bit.

Write Extended Byte

COMMAND

BYTE

AP

06048-010

Table 7. Command Byte Operations

Bit Default Name Function

C0 0 V_CONT

Set to convert voltage continuously. If readback is attempted before the first conversion is complete, the

ADM1178 asserts an acknowledge and returns all 0s in the returned data.

C1 0 V_ONCE

Set to convert voltage once. Self-clears. I2C asserts a no acknowledge on attempted reads until the ADC

conversion is complete.

C2 0 I_CONT

Set to convert voltage continuously. If readback is attempted before the first conversion is complete, the

ADM1178 asserts an acknowledge and returns all 0s in the returned data.

C3 0 I_ONCE

Set to convert current once. Self-clears. I2C asserts a no acknowledge on attempted reads until the ADC

conversion is complete.

C4 0 VRANGE

Selects different internal attenuation resistor networks for voltage readback. A 0 in C4 selects a 14:1 voltage

divider. A 1 in C4 selects a 7:2 voltage divider. With an ADC full scale of 1.902 V, the voltage at the VCC pin for

an ADC full-scale result is 26.35 V for VRANGE = 0 and 6.65 V for VRANGE = 1.

C5 0 N/A Unused.

C6 0 STATUS_RD

Status read. When this bit is set, the data byte read back from the ADM1178 is the STATUS byte. This contains

the status of the device alerts. See

Table 15 for full details of the STATUS byte.

Rev. 0 | Page 18 of 24

ADM1178

WRITE EXTENDED BYTE

In the write extended byte operation, the master device writes

to one of the three extended registers of the slave device, as follows:

1. The master device asserts a start condition on SDA.

2. The master sends the 7-bit slave address, followed by the

write bit (low).

3. The addressed slave device asserts an acknowledge on SDA.

7. The slave asserts an acknowledge on SDA.

8. The master asserts a stop condition on SDA to end the

transaction.

12 345678

S

ADDRESS

SLAVE

REGISTER

WA

ADDRESS

Figure 40. Write Extended Byte

REGISTER

A

DATA

AP

06048-011

4. The master sends the register address byte. The MSB of

this byte is set to 1 to indicate an extended register write.

Tabl e 9, Ta b le 1 0, and Tab l e 1 1 give details of each extended

register.

The two LSBs indicate which of the three extended registers

are written to (see

Tabl e 8). All other bits should be set to 0.

Table 8. Extended Register Addresses

A6 A5 A4 A3 A2 A1 A0 Extended Register

5. The slave asserts an acknowledge on SDA.

6. The master sends the command byte. The command byte

is identified by an MSB = 0. An MSB = 1 indicates an

0 0 0 0 0 0 1 ALERT_EN

0 0 0 0 0 1 0 ALERT_TH

0 0 0 0 0 1 1 CONTROL

extended register write.

Table 9. ALERT_EN Register Operations

Bit Default Name Function

0 0 EN_ADC_OC1

Enabled if a single ADC conversion on the I channel has exceeded the threshold set in the ALERT_TH

register.

1 0 EN_ADC_OC4

Enabled if four consecutive ADC conversions on the I channel have exceeded the threshold set in the

ALERT_TH register.

2 1 EN_HS_ALERT

Enabled if the hot swap has either latched off or entered a cool-down cycle because of an overcurrent

event.

3 0 EN_OFF_ALERT

Enables an alert if the HS operation is turned off by a transition that deasserts the ON pin or by an

operation that writes the SWOFF bit high.

4 0 CLEAR

Clears the ON_ALERT, HS_ALERT, and ADC_ALERT status bits in the STATUS register. These may

immediately reset if the source of the alert has not been cleared or disabled with the other bits in this

register. This bit self-clears to 0 after the STATUS register bits have been cleared.

Table 10. ALERT_TH Register Operations

Bit Default Function

7:0 FF

The ALERT_TH register sets the current level at which an alert occurs. Defaults to ADC full scale. The ALERT_TH 8-bit

number corresponds to the top eight bits of the current channel data.

Table 11. CONTROL Register Operations

Bit Default Name Function

0 0 SWOFF Forces hot swap off. Equivalent to deasserting the ON pin.

Rev. 0 | Page 19 of 24

ADM1178

READ VOLTAGE AND/OR CURRENT DATA BYTES

The ADM1178 can be set up to provide information in three

different ways (see the

on how the device is configured, the following data can be read

out of the device after a conversion (or conversions).

Voltage and Current Readback

The ADM1178 digitizes both voltage and current. Three bytes

are read out of the device in the format shown in

Table 12. Voltage and Current Readback Format

Byte Contents B7 B6 B5 B4 B3 B2 B1 B0

1

Voltage

MSBs

2

Current

MSBs

3

Voltage

LSBs

Voltage Readback

The ADM1178 digitizes voltage only. Two bytes are read out of

the device in the format shown in

Table 13. Voltage Only Readback Format

Byte Contents B7 B6 B5 B4 B3 B2 B1 B0

1 Voltage MSBs V11 V10 V9 V8 V7 V6 V5 V4

2 Voltage LSBs V3 V2 V1 V0 0 0 0 0

Current Readback

The ADM1178 digitizes current only. Two bytes are read out of

the device in the format shown in

Table 14. Current Only Readback Format

Byte Contents B7 B6 B5 B4 B3 B2 B1 B0

1 Current MSBs I11 I10 I9 I8 I7 I6 I5 I4

2 Current LSBs I3 I2 I1 I0 0 0 0 0

The following series of events occurs when the master receives

three bytes (voltage and current data) from the slave device:

Write Command Byte section). Depending

Tabl e 12 .

V11 V10 V9 V8 V7 V6 V5 V4

I11 I10 I9 I8 I7 I6 I5 I4

V3 V2 V1 V0 I3 I2 I1 I0

Tabl e 13 .

Tabl e 14 .

For cases where the master is reading voltage only or current

only, only two data bytes are read. Step 7 and Step 8 are not

required.

12 345678910

SLAVE

S

ADDRESS

12 345678

S

RA

DATA 1 DATA 2 NPDATA 3AA

Figure 41. Three-Byte Read from ADM1178

SLAVE

ADDRESS

Figure 42. Two-Byte Read from ADM1178

RA

REGISTER

ADDRESS

REGISTER

A

DATA

NP

06048-012

06048-013

Converting ADC Codes to Voltage and Current Readings

The following equations can be used to convert ADC codes

representing voltage and current from the ADM1175 12-bit

ADC into actual voltage and current values.

Voltage = (V

FULLSCALE

/4096) × Code

where:

V

= 6.65 (7:2 range) or 26.35 (14:1 range).

FULLSCALE

Code is the ADC voltage code read from the device (Bit V0

to

Bit V11).

Current = ((I

/4096) × Code)/Sense Resistor

FULLSCALE

where:

FULLSCALE

= 105.84 mV.

I

Code is the ADC current code read from the device (Bit I0 to

Bit I11).

Read Status Register

A single register of status data can also be read from the

ADM1178.

1. The master device asserts a start condition on SDA.

1. The master device asserts a start condition on SDA.

2. The master sends the 7-bit slave address, followed by the

read bit (high).

3. The addressed slave device asserts an acknowledge on SDA.

4. The master receives the first data byte.

5. The master asserts an acknowledge on SDA.

6. The master receives the second data byte.

7. The master asserts an acknowledge on SDA.

8. The master receives the third data byte.

9. The master asserts a no acknowledge on SDA.

10. The master asserts a stop condition on SDA, and the

transaction ends.

2. The master sends the 7-bit slave address, followed by the

3. The addressed slave device asserts an acknowledge on SDA.

4. The master receives the status byte.

5. The master asserts an acknowledge on SDA.

Tabl e 15 shows the ADM1178 status registers in detail. Note

that Bit 1, Bit 3, and Bit 5 are cleared by writing to Bit 4 of the

ALERT_EN register (CLEAR).

Rev. 0 | Page 20 of 24

read bit (high).

Figure 43. Status Read from ADM1178

12 345

SLAVE

S

ADDRESS

RA

DATA 1 A

06048-014

ADM1178

Table 15. Status Byte Operations

Bit Name Function

0 ADC_OC An ADC-based overcurrent comparison has been detected on the last three conversions.

1 ADC_ALERT

2 HS_OC

3 HS_ALERT The hot swap has failed since the last time this was reset. Cleared by writing to Bit 4 of the ALERT_EN register.

4 OFF_STATUS

5 OFF_ALERT An alert has been caused by either the ON pin or the SWOFF bit. Cleared by writing to Bit 4 of the ALERT_EN register.

An ADC-based overcurrent trip has happened, which has caused the alert. Cleared by writing to Bit 4 of the ALERT_EN

register.

The hot swap is off due to an analog overcurrent event. On parts that latch off, this is the same as the HS_ALERT status

bit (if EN_HS_ALERT = 1). On the retry parts, this indicates the current state: a 0 can indicate that the data was read

during a period when the device was retrying or that it has successfully hot swapped by retrying after at least one

overcurrent timeout.

The state of the ON pin. Set to 1 if the input pin is deasserted. Can also be set to 1 by writing to the SWOFF bit of the

CONTROL register.

Rev. 0 | Page 21 of 24

ADM1178

APPLICATIONS WAVEFORMS

1

2

3

4

CH1 1.5A CH2 1.00V

CH3 20.0V CH4 10.0V

M40.0ms

Figure 44. Inrush Current Control into 220 μF Load

LOAD

, CH2 = V

(CH1 = I

1

2

3

4

TIMER

, CH3 = V

GATE

, CH4 = V

OUT

1

2

3

4

CH1 1.5A CH2 1.00V

06048-070

CH3 20.0V CH4 10.0V

M10.0ms

06048-073

Figure 47. Overcurrent Condition During Operation (ADM1178-1 Model)

)

(CH1 = I

1

2

3

4

LOAD

, CH2 = V

TIMER

, CH3 = V

GATE

, CH4 = V

OUT

)

CH1 1.5A CH2 1.00V

CH3 20.0V CH4 10.0V

M10.0ms

Figure 45. Overcurrent Condition at Startup (ADM1178-1 Model)

(CH1 = I

LOAD

1

2

3

4

CH1 1.5A CH2 1.00V

CH3 20.0V CH4 10.0V

, CH2 = V

TIMER

, CH3 = V

M20.0ms

GATE

, CH4 = V

Figure 46. Overcurrent Condition at Startup (ADM1178-2 Model)

(CH1 = I

LOAD

, CH2 = V

TIMER

, CH3 = V

GATE

, CH4 = V

OUT

OUT

CH1 1.5A CH2 1.00V

06048-071

CH3 20.0V CH4 10.0V

M20.0ms

06048-074

Figure 48. Overcurrent Condition During Operation (ADM1178-2 Model)

LOAD

, CH2 = V

)

(CH1 = I

TIMER

, CH3 = V

GATE

, CH4 = V

OUT

)

06048-072

)

Rev. 0 | Page 22 of 24

ADM1178

V

ALERTB OUTPUT

The ALERTB output is an open-drain pin with 30 V tolerance.

This output can be used as an overcurrent flag by connecting it

to the general-purpose logic input of a controller. Under normal

operation, this output is pulled high. (An external pull-up resistor

should be used because this is an open-drain pin.) When an overcurrent condition occurs, the ADM1178 pulls this output low.

If any of the enabled latched alerts in the status byte (ADC_ALERT,

HS_ALERT, and OFF_ALERT) are triggered, the ALERTB output

asserts. For a programmable ADC-based overcurrent limit level

point, the ADC_ALERT latch must be enabled. The overcurrent

threshold that triggers an alert is then programmed via the

ALERT_TH register.

3.15V TO 16.5

R

SENSE

N-CHANNEL FET

KELVIN SENSE RESISTOR CONNECTION

When using a low value sense resistor for high current measurement, the problem of parasitic series resistance may arise.

The lead resistance can be a substantial fraction of the rated

resistance, making the total resistance a function of lead length.

This problem can be avoided by using a Kelvin sense connection.

This type of connection separates the current path through the

resistor and the voltage drop across the resistor.

the correct way to connect the sense resistor between the VCC

pin and the SENSE pin of the ADM1178.

SENSE RESISTOR

CURRENT

FLOW FROM

SUPPLY

Figure 50 shows

CURRENT

FLOW TO

LOAD

ADM1178

ON

TIMER

GND

SENSEVCC

GATE

SDA

SCL

ALERTB

ADR

CONTROLLER

P = VI

SDA

SCL

INTERRUPT

KELVIN SENSE TRACES

VCC SENSE

ADM1178

06048-100

Figure 50. Kelvin Sense Connections

06048-015

Figure 49. Using the ALERTB Output as an Interrupt

Rev. 0 | Page 23 of 24

ADM1178

OUTLINE DIMENSIONS

3.10

3.00

2.90

6

10

3.10

3.00

2.90

1

PIN 1

0.50 BSC

0.95

0.85

0.75

0.15

0.05

0.33

0.17

COPLANARITY

0.10

COMPLIANT TO JEDEC STANDARDS MO-187-BA

Figure 51. 10-Lead Mini Small Outline Package [MSOP]

5.15

4.90

4.65

5

1.10 MAX

SEATING

PLANE

0.23

0.08

8°

0°

(RM-10)

Dimensions shown in millimeters

0.80

0.60

0.40

ORDERING GUIDE

Model Hot Swap Retry Option Temperature Range Package Description Package Option Branding

ADM1178-1ARMZ-R71Automatic Retry Version −40°C to +85°C 10-Lead MSOP RM-10 M62

ADM1178-2ARMZ-R71Latched Off Version −40°C to +85°C 10-Lead MSOP RM-10 M64

EVAL-ADM1178EBZ

1

Z = Pb-free part.

1

Evaluation Board

Purchase of licensed I2C components of Analog Devices or one of its sublicensed Associated Companies conveys a license for the purchaser under the Philips I2C Patent

Rights to use these components in an I2C system, provided that the system conforms to the I2C Standard Specification as defined by Philips.

©2006 Analog Devices, Inc. All rights reserved. Trademarks and

registered trademarks are the property of their respective owners.

D06048-0-9/06(0)

T

Rev. 0 | Page 24 of 24

TTT

Loading...

Loading...