Dual PWM Fan Controller and Temperature

a

FEATURES

Software Programmable and Automatic Fan Speed

Control

Automatic Fan Speed Control Allows Control

Independent of CPU Intervention after Initial Setup

Control Loop Minimizes Acoustic Noise and Power

Consumption

Remote and Local Temperature Monitoring

Dual Fan Speed Measurement

Supports Backup and Redundant Fans

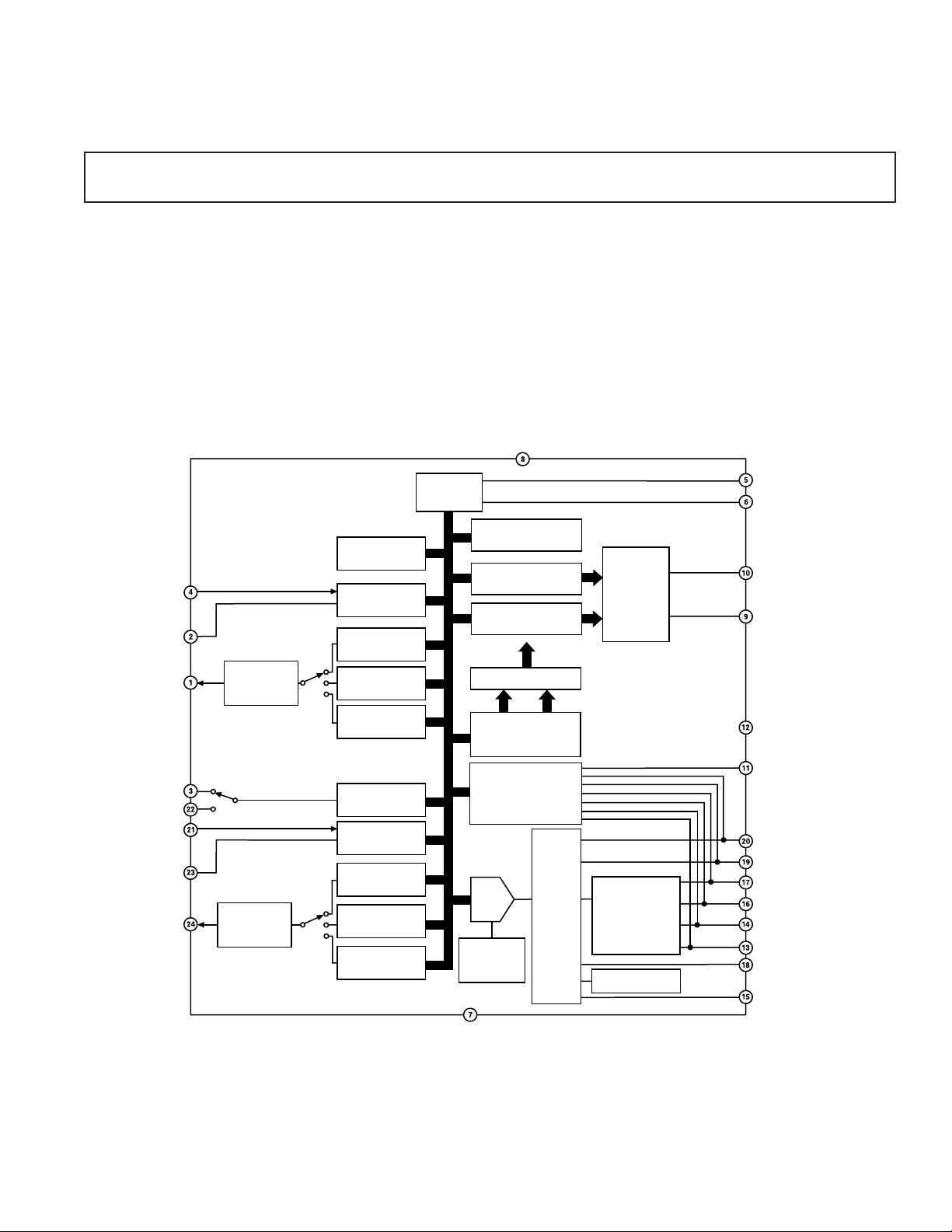

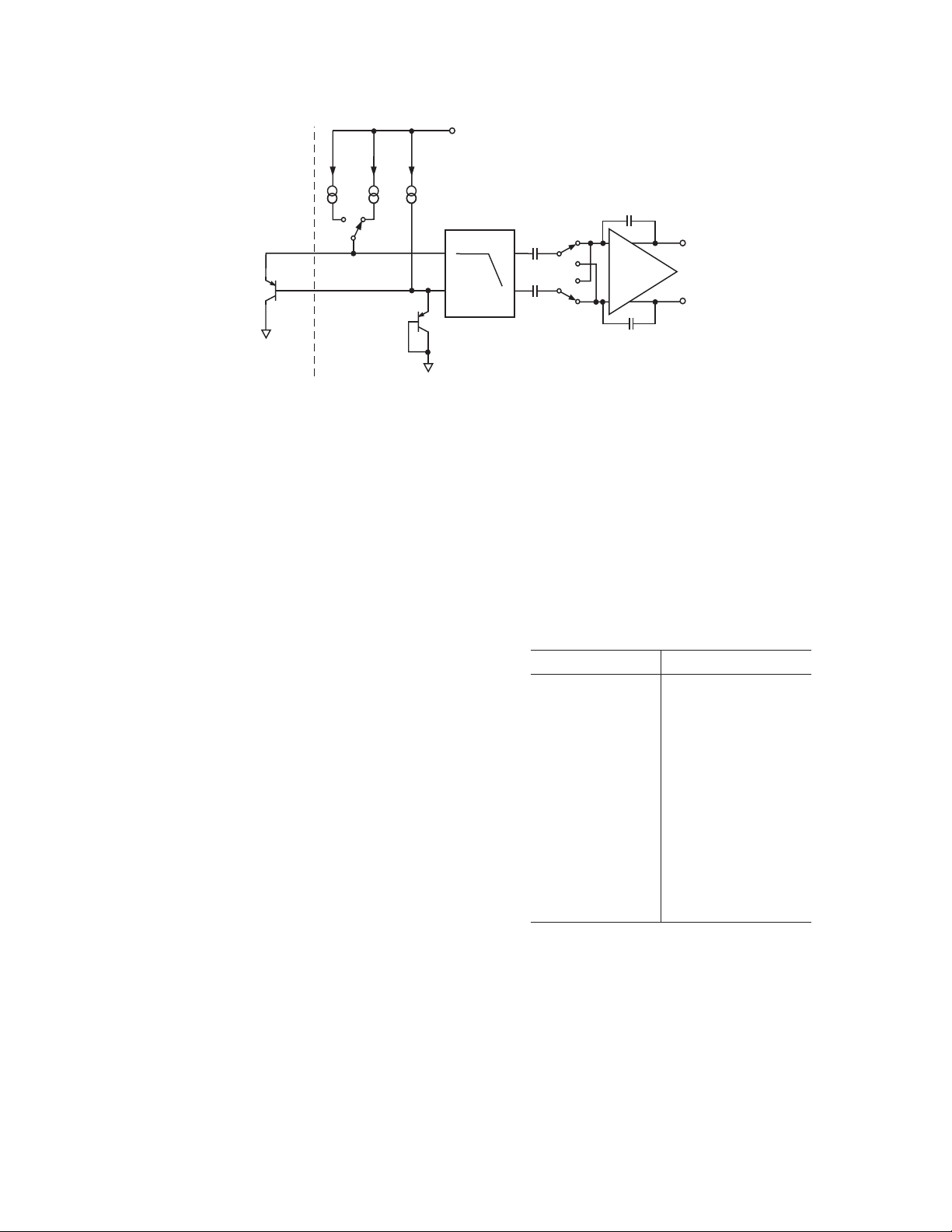

FUNCTIONAL BLOCK DIAGRAM

ADM1029

SLAVE ADDRESS

REGISTER

PRESENT1

FAULT1

FAN 1 STATUS

REGISTER

FAN 1 MIN

SPEED REGISTER

Monitor for High Availability Systems

ADM1029*

Supports Hot Swapping of Fans

Cascadable Fault Output Allows Fault Signaling

between Multiple ADM1029s

Address Pin Allows Up to Eight ADM1029s in A System

Small 24-Lead QSOP Package

APPLICATIONS

Network Servers and Personal Computers

Microprocessor-Based Office Equipment

High Availability Telecommunications Equipment

V

CC

SERIAL BUS

INTERFACE

ADDRESS POINTER

REGISTER

INTERRUPT MASK

REGISTERS

INTERRUPT STATUS

REGISTERS

INTERRUPT

MASKING

SCL

SDA

INT

CFAULT

DRIVE1

TACH1

TACH2

PRESENT2

FAULT2

DRIVE2

*Protected by U.S. Patent Numbers 6,255,973 and 6,188,189

PWM

CONTROLLER

PWM

CONTROLLER

FAN 1 ALARM

SPEED REGISTER

FAN 1 HOT-PLUG

SPEED REGISTER

FAN SPEED

COUNTER

FAN 2 STATUS

REGISTER

FAN 2 MIN

SPEED REGISTER

FAN 2 ALARM

SPEED REGISTER

FAN 2 HOT-PLUG

SPEED REGISTER

REFERENCE

GND

REV. A

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties that

may result from its use. No license is granted by implication or otherwise

under any patent or patent rights of Analog Devices. Trademarks and

registered trademarks are the property of their respective companies.

LIMIT COMPARATOR

VALUE AND LIMIT

REGISTERS

G.P. I/O REGISTER

ADC

ANALOG

MUX

BANDGAP

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 www.analog.com

Fax: 781/326-8703 © 2003 Analog Devices, Inc. All rights reserved.

REMOTE SENSOR

SIGNAL

CONDITIONING

BANDGAP

TEMP SENSOR

RESET

GPIO2

AIN1/GPIO1

AIN0/GPIO0

D2+/GPIO6

D2–/GPIO5

D1+/GPIO4

D1–/GPIO3

TMIN/INSTALL

ADD

1, 2

ADM1029–SPECIFICATIONS

(TA = T

Parameter Min Typ Max Unit Test Conditions/Comments

POWER SUPPLY

Supply Voltage, V

Supply Current, I

CC

CC

3.0 3.30 5.5 V

TEMPERATURE-TO-DIGITAL CONVERTER

Internal Sensor Accuracy ± 1 ± 3 °C

Resolution 1 °C

External Diode Sensor Accuracy ± 3 ± 5 °C0°C ≤ T

Resolution 1 °C

Remote Sensor Source Current 90 µA High Level

ANALOG-TO-DIGITAL CONVERTER

Total Unadjusted Error, TUE ± 1%Note 3

Differential Nonlinearity, DNL ± 1 LSB

Power Supply Sensitivity ± 1 %/ V

Conversion Time

Analog Input or Internal Temperature 11.6 ms

External Temperature 185.6 ms

FAN RPM-TO-DIGITAL CONVERTER

Accuracy ± 6%60°C ≤ TA ≤ 100°C: VCC = 3.3 V

Full-Scale Count 255

FAN 1 and FAN 2 Nominal Input RPM

4

Internal Clock Frequency 56.4 60.0 63.6 kHz

OPEN-DRAIN DIGITAL OUTPUTS (INT, CFAULT)

Output Low Voltage, V

High Level Output Current, I

OL

OH

OPEN-DRAIN SERIAL DATA BUS OUTPUT (SDA)

Output Low Voltage, V

High Level Output Leakage Current, I

OL

OH

SERIAL BUS DIGITAL INPUTS (SCL, SDA)

Input High Voltage, V

Input Low Voltage, V

IL

IH

2.1 V

Hysteresis 500 mV

DIGITAL INPUT LOGIC LEVELS RESET,

GPIO1-6, FAULT1/2, TACH1/2, PRESENT1/2

Input High Voltage, V

Input Low Voltage, V

IL

IH

2.1 V

DIGITAL INPUT CURRENT

Input High Current, I

Input Low Current, I

Input Capacitance, C

SERIAL BUS TIMING

Clock Frequency, f

Glitch Immunity, t

Bus Free Time, t

Start Setup Time, t

Start Hold Time, t

IH

IL

IN

5

SCLK

SW

BUF

SU:STA

HD:STA

Stop Condition Setup Time, t

SU:STO

–1 µAV

10 100 kHz See Figure 1

4.7 µs See Figure 1

4.7 µs See Figure 1

4 µs See Figure 1

4 µs See Figure 1

to T

MIN

, VCC = V

MAX

MIN

to V

, unless otherwise noted.)

MAX

1.7 3.0 mA Interface Inactive, ADC Active

1.5 mA ADC Inactive, DAC Active

10 60 µA Shutdown Mode

≤ 100°C

A

5.5 µA Low Level

8800 rpm Divisor = 1, Fan Count = 153

4400 rpm Divisor = 2, Fan Count = 153

2200 rpm Divisor = 4, Fan Count = 153

1100 rpm Divisor = 8, Fan Count = 153

0.4 V I

0.1 1 µAV

0.4 V I

0.1 1 µAV

= –6.0 mA, VCC = 3 V

OUT

= V

OUT

OUT

OUT

CC

= –6.0 mA, VCC = 3 V

= V

CC

0.8 V

0.8 V

= V

IN

+1 µAV

IN

CC

= 0

20 pF

50 ns See Figure 1

–2–

REV. A

ADM1029

Parameter Min Typ Max Unit Test Conditions/Comments

5

SERIAL BUS TIMING

SCL Low Time, t

SCL High Time, t

SCL, SDA Rise Time, t

SCL, SDA Fall Time, t

Data Setup Time, t

Data Hold Time, t

NOTES

1

All voltages are measured with respect to GND, unless otherwise specified.

2

Typicals are at TA = 25°C and represent most likely parametric norm. Shutdown current typ is measured with VCC = 3.3 V.

3

TUE (Total Unadjusted Error) includes Offset, Gain, and Linearity errors of the ADC, multiplexer.

4

The total fan count is based on two pulses per revolution of the fan tachometer output.

5

Timing specifications are tested at logic levels of VIL = 0.8 V for a falling edge and VIH = 2.1 V for a rising edge.

Specifications subject to change without notice.

(continued)

LOW

HIGH

SU:DAT

HD:DAT

1.3 µs See Figure 1

450µs See Figure 1

R

F

1000 ns See Figure 1

300 ns See Figure 1

250 ns See Figure 1

300 ns See Figure 1

ABSOLUTE MAXIMUM RATINGS*

Positive Supply Voltage (VCC) . . . . . . . . . . . . . . . . . . . . . 6.5 V

Voltage on Pins 13–18 . . . . . . . . . . . . –0.3 V to (V

+ 0.3 V)

CC

Voltage on Any Other Input or Output Pin . . . . –0.3 V to +6.5 V

Input Current at Any Pin . . . . . . . . . . . . . . . . . . . . . . . ± 5 mA

Package Input Current . . . . . . . . . . . . . . . . . . . . . . . ± 20 mA

Maximum Junction Temperature (T

max) . . . . . . . . . . 150°C

J

Storage Temperature Range . . . . . . . . . . . . –65°C to +150°C

Lead Temperature

Vapor Phase (60 sec) . . . . . . . . . . . . . . . . . . . . . . . . . 215°C

Infrared (15 sec) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200°C

ESD Rating All Pins . . . . . . . . . . . . . . . . . . . . . . . . . . . 2000 V

*Stresses above those listed under Absolute Maximum Ratings may cause perma-

nent damage to the device. This is a stress rating only; functional operation of the

device at these or any other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute maximum rating

conditions for extended periods may affect device reliability.

THERMAL CHARACTERISTICS

24-Lead QSOP Package:

θ

= 105°C/W, θJC = 39°C/W

JA

ORDERING GUIDE

Temperature Package Package

Model Range Description Option

ADM1029ARQ 0°C to 100°C Shrink Small Outline RQ-24

Package (QSOP)

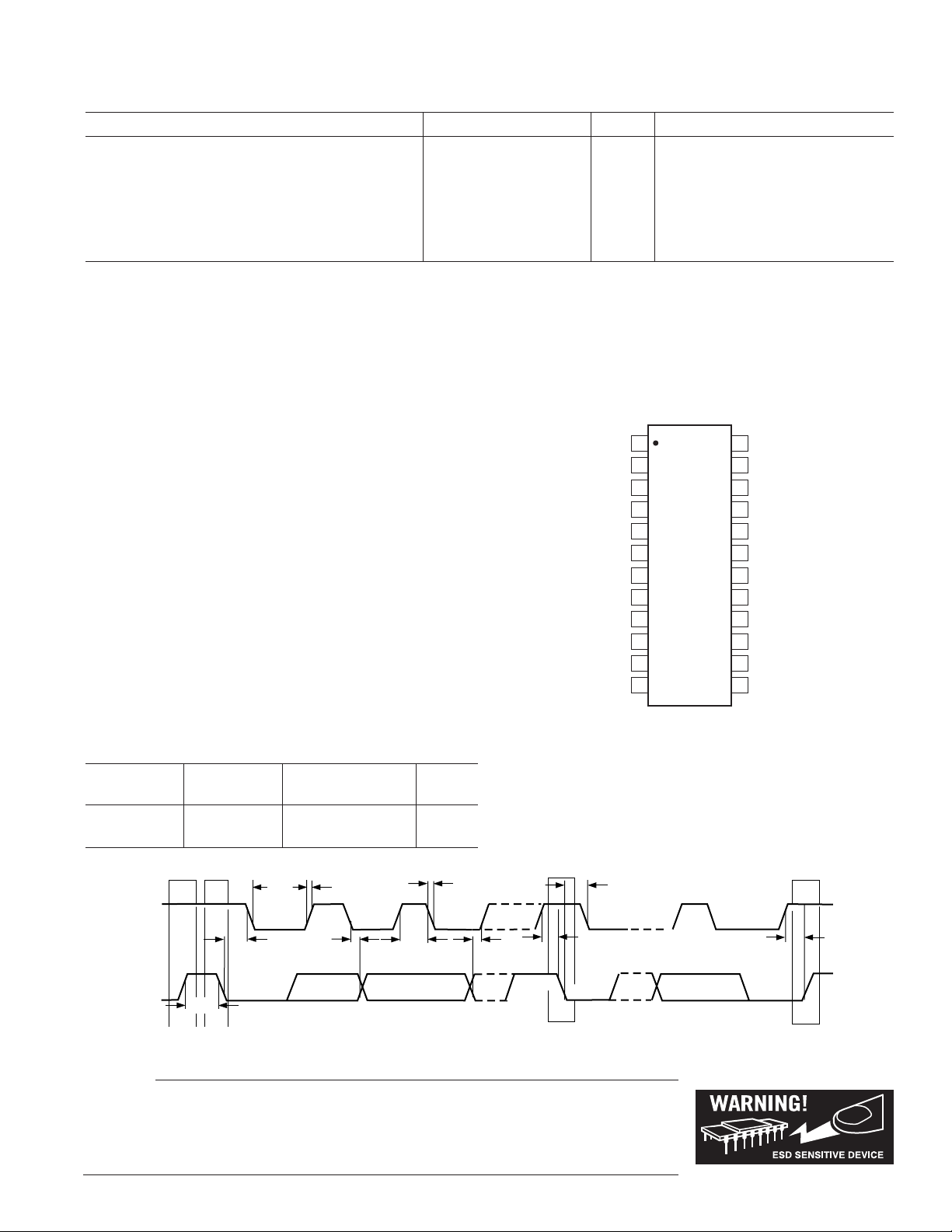

PIN CONFIGURATION

1

DRIVE1

2

FAULT1

3

TACH1

SCL

SDA

GND

V

INT

GPIO2

RESET

CC

4

5

6

7

(Not To Scale)

8

9

10

11

12

ADM1029

TOP VIEW

PRESENT1

CFAULT

24

DRIVE2

23

FAULT2

22

TACH2

21

PRESENT2

20

AIN1/GPIO1

19

AIN0/GPIO0

18

TMIN/INSTALL

17

D2+/GPIO6

16

D2–/GPIO5

15

ADD

14

D1+/GPIO4

13

D2–/GPIO3

SCL

SDA

t

R

t

LOW

t

HD;STA

t

BUF

S

P

t

HD;DAT

t

HIGH

t

F

t

SU;DAT

t

HD;STA

t

SU;STA

S

Figure 1. Diagram for Serial Bus Timing

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection. Although the

ADM1029 features proprietary ESD protection circuitry, permanent damage may occur on devices

subjected to high energy electrostatic discharges. Therefore, proper ESD precautions are recommended

to avoid performance degradation or loss of functionality.

REV. A

–3–

t

SU;STO

P

ADM1029

PIN FUNCTION DESCRIPTIONS

Pin No. Mnemonic Description

1 DRIVE1 Open Drain Digital Output. Pulsewidth Modulated (PWM) output to control the speed of

Fan 1. Requires 10 kΩ typical pull-up resistor.

2 FAULT1 Open Drain Digital I/O. When used with a fan having a fault output, a Logic 0 input to this pin

signals a fault on Fan 1. Also used as a fault output.

3 TACH1 Open Drain Digital Input. Digital fan tachometer input for Fan 1. Will accept logic signals up

to 5 V even when V

4 PRESENT1

Open Drain Digital Input. A shorting link in the fan connector holds this pin low when

Fan 1 is connected.

5 SCL Open Drain Digital Input. Serial Bus Clock. Requires 2.2 kΩ pull-up typical.

6 SDA Digital I/O. Serial Bus bidirectional data. Open-drain output requires 2.2 kΩ pull-up.

7GND System Ground

8V

CC

Power (3.0 V to 5.5 V). Typically powered from 3.3 V power rail. Bypass with the parallel

combination of 10 µF (electrolytic or tantalum) and 0.1 µF (ceramic) bypass capacitors.

9 CFAULT

Open Drain Digital I/O. Cascade fault input/output used for fault signaling between

multiple ADM1029s.

10 INT Digital Output. Interrupt Request (Open Drain). The output is enabled when Bit 1 of the

Configuration Register is set to 0. The default state is enabled.

11 GPIO2 Open Drain Digital I/O. General-purpose logic I/O pin.

12 RESET Open Drain Digital Input. Active low reset input.

13 D1–/GPIO3 Analog Input/Open Drain Digital I/O. Connected to cathode of external temperature-sensing

diode, or may be reconfigured as a general-purpose logic input/output.

14 D1+/GPIO4 Analog Input/Open Drain Digital I/O. Connected to anode of external temperature-sensing

diode, or may be reconfigured as a general-purpose logic input/output.

15 ADD Eight-Level Analog Input. Used to set the three LSBs of the serial bus address.

16 D2–/GPIO5 Analog Input/Open Drain Digital I/O. Connected to cathode of external temperature-sensing

diode, or may be reconfigured as a general-purpose logic input/output.

17 D2+/GPIO6 Analog Input/Open Drain Digital I/O. Connected to anode of external temperature-sensing

diode, or may be reconfigured as a general-purpose logic input/output.

18 TMIN/INSTALL Eight-Level Analog Input. The voltage on this pin defines whether automatic fan speed control

is enabled, the minimum temperature at which the fan(s) will turn on in automatic speed con-

trol mode, and the number of fans that should be installed.

19 AIN0/GPIO0 Analog Input/Open Drain Digital I/O. May be configured as a 0 V to 2.5 V analog input or as a

general-purpose digital I/O pin.

20 AIN1/GPIO1 Analog Input/Open Drain Digital I/O. May be configured as a 0 V to 2.5 V analog input or as a

general-purpose digital I/O pin.

21 PRESENT2 Open Drain Digital Input. A shorting link in the fan connector holds this pin low when Fan 2

is connected.

22 TACH2 Open Drain Digital Input. Digital fan tachometer input for Fan 2. Will accept logic signals up

to 5 V even when V

23 FAULT2 Open Drain Digital I/O. When used with a fan having a fault output, a Logic 0 input to this pin

signals a fault on Fan 2. Also used as a fault output.

24 DRIVE2 Open Drain Digital Output. Pulsewidth Modulated (PWM) output to control the speed of

Fan 2. Requires 10 kΩ typical pull-up resistor.

is lower than 5 V.

CC

is lower than 5 V.

CC

–4–

REV. A

Typical Performance Characteristics–ADM1029

110

100

90

80

70

60

50

40

30

20

10

0

0 10 20 30 40 50 60 70 80 90 100 110

READING

MEASURED TEMPERATURE

1

0

–1

–2

–3

–4

–5

–6

–7

–8

–9

–10

–11

–12

–13

–14

–15

–16

1.0 2.2 3.3 4.7 10.0 22.0 47.0

REMOTE TEMPERATURE ERROR – ⴗC

DXP – DXN CAPACITANCE – nF

15

10

5

0

–5

–10

–15

REMOTE TEMPERATURE ERROR – ⴗC

–20

0 3.3 10 30 100

LEAKAGE RESISTANCE – M⍀

DXP TO GND

DXP TO VCC(3.3V)

TPC 1. Remote Temperature Error vs. PC Board Track

Resistance

4.5

4.0

3.5

3.0

2.5

2.0

1.5

1.0

0.5

0

REMOTE TEMPERATURE ERROR – ⴗC

V

IN

–0.5

–1.0

01481216 20 50 100 200 300

VIN = 250mV p-p

= 100mV p-p

FREQUENCY – MHz

400

500

600

TPC 2. Remote Temperature Error vs. Power Supply

Noise Frequency

TPC 4. Pentium® III Temperature Measurement vs.

ADM1029 Reading

TPC 5. Remote Temperature Error vs. Capacitance

Between D+ and D–

10

9

8

7

6

5

4

3

REV. A

2

1

REMOTE TEMPERATURE ERROR – ⴗC

0

–1

00.40.810 600150 40050 250 500100 200 350 450 550300

FREQUENCY – MHz

TPC 3. Remote Temperature Error vs. Common-Mode

Noise Frequency

V

= 100mV p-p

IN

V

= 60mV p-p

IN

VIN = 40mV p-p

–5–

80

70

60

50

40

30

SUPPLY CURRENT – A

20

10

0

0 1 5 10 25 50 75 100 250 500 750 1000

SCLK FREQUENCY – kHz

VCC = 5V

VCC = 3.3V

TPC 6. Standby Current vs. Clock Frequency

ADM1029

13

12

11

10

9

8

7

6

5

4

3

2

1

REMOTE TEMPERATURE ERROR – ⴗC

0

–1

0

12 40020 300100 500148 16 50 200

VIN = 40mV p-p

VIN = 30mV p-p

V

IN

FREQUENCY – MHz

= 20mV p-p

600

TPC 7. Remote Temperature Error vs. Differential-Mode

Noise Frequency

32

30

28

26

24

22

20

18

16

14

12

10

SUPPLY CURRENT – A

8

6

4

2

0

1.0 1.4 1.8 2.2 2.6 3.0 3.4 3.8 4.2 4.6

SUPPLY VOLTAGE – V

TPC 8. Standby Supply Current vs. Supply Voltage

10

9

8

7

6

5

4

3

2

1

LOCAL TEMPERATURE ERROR – ⴗC

0

–1

0 1 4 8 12 16 20 50 100 200 300 400 500 600

FREQUENCY – MHz

VIN = 250mV p-p

VIN = 100mV p-p

TPC 10. Local Sensor Temperature Error vs. Power Supply

Noise Frequency

120

110

100

90

80

70

60

50

40

TEMPERATURE – ⴗC

30

20

10

0

0 1 2 3 4 5 6 7 8 9 10

TIME – Seconds

TPC 11. ADM1029 Response to Thermal Shock

1.80

1.75

1.70

1.65

1.60

1.55

1.50

1.45

1.40

1.35

1.30

1.25

SUPPLY CURRENT – mA

1.20

1.15

1.10

1.05

1.00

2.0 2.2 2.4 2.6 2.8 3.0 3.2 3.4 3.6 3.8 4.0 4.2 4.4 4.6 4.8 5.0

SUPPLY VOLTAGE – V

TPC 9. Supply Current vs. Supply Voltage

–6–

0.10

0.00

–0.10

–0.20

–0.30

–0.40

–0.50

–0.60

ERROR – ⴗC

–0.70

–0.80

–0.90

–1.00

–1.10

–1.20

02040608085100 105 120

TEMPERATURE – ⴗC

TPC 12. Remote Temperature Error

REV. A

ADM1029

0.05

0.00

–0.05

–0.10

–0.15

–0.20

–0.25

–0.30

ERROR – ⴗC

–0.35

–0.40

–0.45

–0.50

–0.55

–0.60

02040608085100 105 120

TEMPERATURE – ⴗC

TPC 13. Local Temperature Error

PRODUCT DESCRIPTION

The ADM1029 is a versatile fan controller and monitor for use

in personal computers, servers, telecommunications equipment,

or any high-availability system where reliable control and monitoring of multiple cooling fans is required. Each ADM1029 can

control the speed of one or two fans and can measure the speed

of fans that have a tachometer output. The ADM1029 can also

measure the temperature of one or two external sensing diodes

or an internal temperature sensor, allowing fan speed to be

adjusted to keep system temperature within acceptable limits. The

ADM1029 has FAULT inputs for use with fans that can signal

failure conditions, and inputs to detect whether or not fans are

connected.

The ADM1029 communicates with the host processor over an

System Management (SMBus) serial bus. It supports eight

different serial bus addresses, so that up to eight devices can

be connected to a common bus, controlling up to sixteen fans.

This makes software support and hardware design scalable.

The ADM1029 has an interrupt output (INT) that allows it

to signal fault conditions to the host processor. It also has a

separate, cascadable fault output (CFAULT) that allows the

ADM1029 to signal a fault condition to other ADM1029s.

The ADM1029 has a number of useful features including an

automatic fan speed control option implemented in hardware

with no software requirement, automatic use of backup fans in

the event of fan failure, and supports hot-swapping of failed fans.

Table I. Resistor Ratios for Setting Serial Bus Address

FUNCTIONAL DESCRIPTION

SERIAL BUS INTERFACE

Control of the ADM1029 is carried out via the serial bus. The

ADM1029 is connected to this bus as a slave device, under the

control of a master device.

The ADM1029 has a 7-bit serial bus address. The four MSBs of

the address are set to 0101. The three LSBs can be set by the

user to give a total of eight different addresses, allowing up to

eight ADM1029s to be connected to a single serial bus segment.

To minimize device pin count and size, the three LSBs are set

using a single pin (ADD, Pin 15). This is an 8-level input whose

input voltage is set by a potential divider. The voltage on ADD

is sampled immediately after power-up and digitized by the

on-chip ADC to determine the value of the 3 LSBs. Since ADD

is sampled only at power-up, any changes made while power is

on will have no effect.

V

CC

R1

ADD

R2

GND

ADM1029

Figure 2. Setting the Serial Address

Table I shows resistor values for setting the 3 LSBs of the serial

bus address. The same principle is used to set the voltage on Pin

18 (TMIN/INSTALL), which controls the automatic fan speed

control function, and also tells the ADM1029 how many fans

should be installed, as described later.

If several ADM1029s are used in a system, their ADD inputs

can tap off a single potential divider, as shown in Figure 3.

V

CC

ADDRESS XXXX111

1.5k⍀

ADDRESS XXXX110

1k⍀

ADDRESS XXXX101

1k⍀

ADDRESS XXXX100

1k⍀

ADDRESS XXXX011

1k⍀

ADDRESS XXXX010

1k⍀

ADDRESS XXXX001

1.5k⍀

ADDRESS XXXX000

GND

ADD

ADD

ADD

ADD

ADD

ADD

ADD

ADD

ADM1029 #1

ADM1029 #2

ADM1029 #3

ADM1029 #4

ADM1029 #5

ADM1029 #6

ADM1029 #7

ADM1029 #8

Figure 3. Setting Address of up to Eight ADM1029s

3 MSBs Ideal Ratio R1 R2 Actual Error

of ADC R2/(R1 + R2) (k⍀)(k⍀) R2/(R1 + R2) % Address

111 N/A 0 ∞ 100101111

110 0.8125 18 82 0.82 +0.75 0101110

101 0.6875 22 47 0.6812 –0.63 0101101

100 0.5625 12 15 0.5556 –0.69 0101100

011 0.4375 15 12 0.4444 +0.69 0101011

010 0.3125 47 22 0.3188 +0.63 0101010

001 0.1875 82 18 0.18 –0.75 0101001

000 N/A ∞ 00 00101000

REV. A

–7–

ADM1029

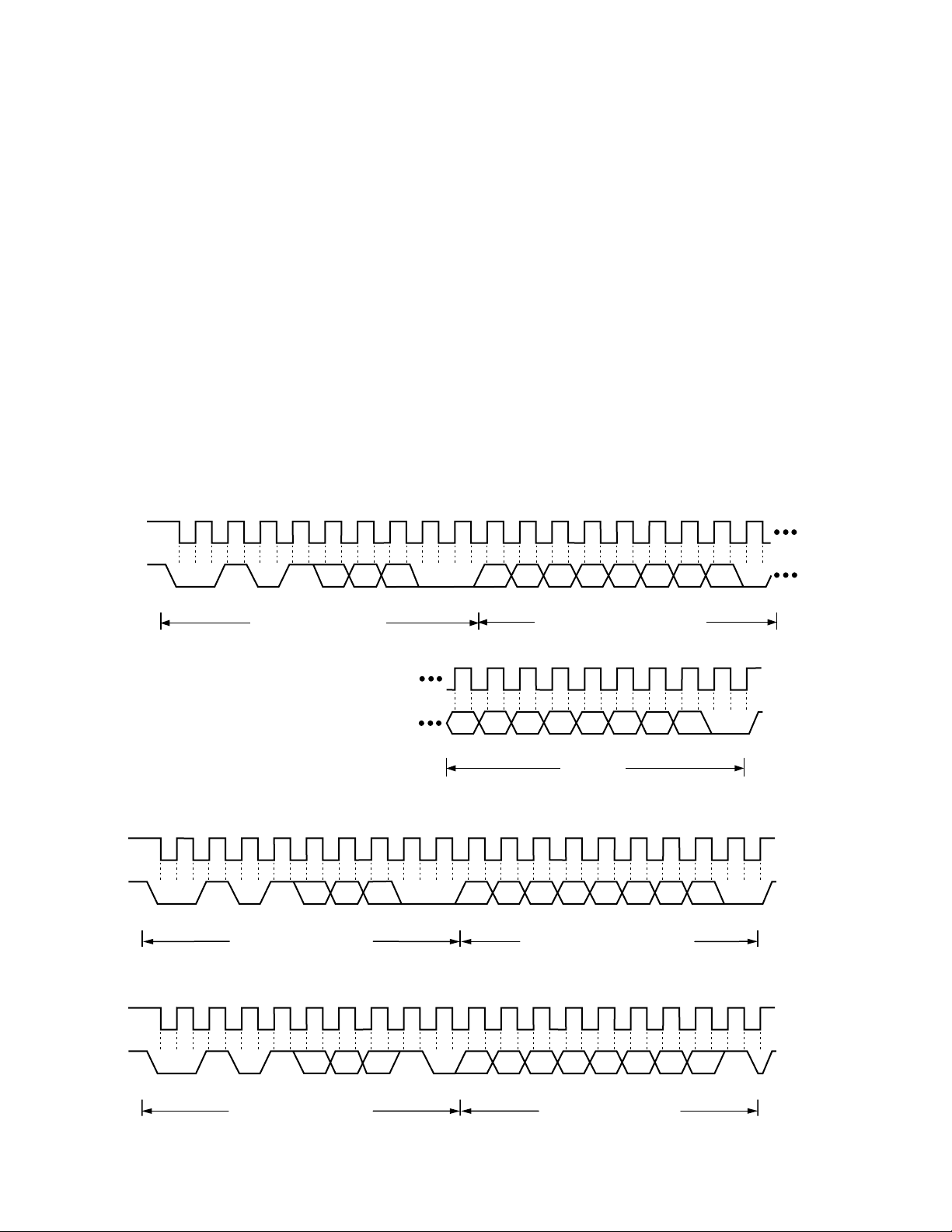

The serial bus protocol operates as follows:

1. The master initiates data transfer by establishing a START

condition, defined as a high-to-low transition on the serial

data line SDA, while the serial clock line SCL remains high.

This indicates that an address/data stream will follow. All

slave peripherals connected to the serial bus respond to the

START condition, and shift in the next eight bits, consisting

of a 7-bit address (MSB first) plus an R/W bit, which determines the direction of the data transfer, i.e., whether data

will be written to or read from the slave device.

The peripheral whose address corresponds to the transmitted

address responds by pulling the data line low during the low

period before the ninth clock pulse, known as the Acknowledge Bit. All other devices on the bus now remain idle while

the selected device waits for data to be read from or written

to it. If the R/W bit is a 0, the master will write to the slave

device. If the R/W bit is a 1 the master will read from the

slave device.

2. Data is sent over the serial bus in sequences of nine clock

pulses, eight bits of data followed by an acknowledge bit

from the slave device. Transitions on the data line must

191

SCL

occur during the low period of the clock signal and remain

stable during the high period, as a low-to-high transition

when the clock is high may be interpreted as a STOP signal.

The number of data bytes that can be transmitted over the

serial bus in a single READ or WRITE operation is limited

only by what the master and slave devices can handle.

3. When all data bytes have been read or written, stop conditions are established. In WRITE mode, the master will pull

the data line high during the tenth clock pulse to assert a

STOP condition. In READ mode, the master device will

override the acknowledge bit by pulling the data line high

during the low period before the ninth clock pulse. This is

known as No Acknowledge. The master will then take the

data line low during the low period before the tenth clock

pulse, high during the tenth clock pulse to assert a STOP

condition.

Any number of bytes of data may be transferred over the serial

bus in one operation, but it is not possible to mix read and write

in one operation, because the type of operation is determined at

the beginning and cannot subsequently be changed without

starting a new operation.

9

SDA

START BY

MASTER

101A2

0

SERIAL BUS ADDRESS BYTE

FRAME 1

SCL (CONTINUED)

SDA (CONTINUED)

A0

A1

W

R/

ACK. BY

ADM1029

1

D7 D6 D5

D6

D7

ADDRESS POINTER REGISTER BYTE

D4 D3 D2 D1

D5

FRAME 2

D4 D3 D2 D1

FRAME 3

DATA BYTE

D0

ACK. BY

ADM1029

D0

ACK. BY

ADM1029

9

STOP BY

MASTER

Figure 4a. Writing a Register Address to the Address Pointer Register, then Writing Data to the Selected Register

SCL

SDA

START BY

MASTER

191

101A2

0

SERIAL BUS ADDRESS BYTE

FRAME 1

A0 D7

A1

R/W

ACK. BY

ADM1029

D6

ADDRESS POINTER REGISTER BYTE

D4 D3 D2 D1

D5

FRAME 2

D0

ACK. BY

ADM1029

9

STOP BY

MASTER

Figure 4b. Writing to the Address Pointer Register Only

191

SCL

9

SDA

START BY

MASTER

101A2

0

SERIAL BUS ADDRESS BYTE

D6 D5

D4 D3 D2 D1

DATA BYTE FROM ADM1029

FRAME 2

FRAME 1

A0 D7

A1

R/W

ACK. BY

ADM1029

Figure 4c. Reading Data from a Previously Selected Register

–8–

D0

NO ACK.

BY MASTER

STOP BY

MASTER

REV. A

ADM1029

In the case of the ADM1029, write operations contain either

one or two bytes, and read operations contain one byte, and

perform the following functions:

To write data to one of the device data registers or read data

from it, the Address Pointer Register must be set so that the

correct data register is addressed, data can be written into that

register or read from it. The first byte of a write operation always

contains an address that is stored in the Address Pointer Register. If data is to be written to the device, the write operation

contains a second data byte that is written to the register

selected by the address pointer register.

This is illustrated in Figure 4a. The device address is sent over

the bus followed by R/W set to 0. This is followed by two data

bytes. The first data byte is the address of the internal data

register to be written to, which is stored in the Address Pointer

Register. The second data byte is the data to be written to the

internal data register.

When reading data from a register there are two possibilities:

1. If the ADM1029’s Address Pointer Register value is unknown

or not the desired value, it is first necessary to set it to the

correct value before data can be read from the desired data

register. This is done by performing a write to the ADM1029

as before, but only the data byte containing the register address

is sent, as data is not to be written to the register. This is

shown in Figure 4b.

A read operation is then performed consisting of the serial

bus address, R/W bit set to 1, followed by the data byte read

from the data register. This is shown in Figure 4c.

2. If the Address Pointer Register is known to be already at the

desired address, data can be read from the corresponding

data register without first writing to the Address Pointer

Register, so Figure 4b can be omitted.

Note: although it is possible to read a data byte from a data

register without first writing to the Address Pointer Register,

if the Address Pointer Register is already at the correct value,

it is not possible to write data to a register without writing to

the Address Pointer Register, because the first data byte of a

write is always written to the Address Pointer Register.

ALERT RESPONSE ADDRESS

The ADM1029 has an interrupt (INT) output that is asserted

low when a fault condition occurs. Several INT outputs can be

wire OR’d to a common interrupt line. When the host processor

receives an interrupt request, it would normally need to read the

interrupt status register of each device to identify which device

had made the interrupt request. However, the ADM1029 supports the optional Alert Response Address function of the SMBus

protocol. When the host processor receives an interrupt request

it can send a general call address (0001100) over the bus. The

device asserting INT will then send its own slave address back

to the host processor, so the device asserting INT can be identified immediately.

If more than one device is asserting INT, all devices will try to

respond with their slave address, but an arbitration process

ensures that only the lowest address will be received by the host.

After sending its slave address, the first device will then clear its

INT output. The host can then check if the INT is still low and

send the general call again if necessary until all devices asserting

INT have responded.

The ARA function can be disabled by setting Bit 2 of the Configuration Register (address 01h).

TEMPERATURE MEASUREMENT SYSTEM

LOCAL TEMPERATURE MEASUREMENT

The ADM1029 contains an on-chip bandgap temperature sensor,

whose output is digitized by the on-chip ADC. The temperature

data is stored in the Local Temp Value Register (address A0h).

As both positive and negative temperatures can be measured, the

temperature data is stored in two’s complement format, as shown

in Table II. Theoretically, the temperature sensor and ADC can

measure temperatures from –128°C to +127°C with a resolution

of 1°C, but temperatures outside the operating temperature

range of the device cannot be measured by the internal sensor.

REMOTE TEMPERATURE MEASUREMENT

The ADM1029 can measure the temperature of one or two

remote diode-connected transistors, connected to Pins 13 and

14 and/or 16 and 17. The data from the temperature measurements is stored in the Remote 1 and Remote 2 Temp Value

Registers (addresses A1h and A2h).

If two remote temperature measurements are not required, Pins

16 and 17 can be reconfigured as general-purpose logic I/O

pins, as explained later.

The forward voltage of a diode or diode-connected transistor,

operated at a constant current, exhibits a negative temperature

coefficient of about –2 mV/°C. The absolute value of V

varies

BE

from device to device and individual calibration is required to

null this out so, unfortunately, the technique is unsuitable for

mass production.

The technique used in the ADM1029 is to measure the change

in V

when the device is operated at two different currents.

BE

This is given by:

∆V

= KT/q × ln(N)

BE

where:

K is Boltzmann’s constant

q is charge on the carrier

T is absolute temperature in Kelvins

N is ratio of the two currents

Figure 5 shows the input signal conditioning used to measure

the output of a remote temperature sensor. This figure shows

the external sensor as a substrate transistor, provided for temperature monitoring on some microprocessors, but it could equally

well be a discrete transistor.

If a discrete transistor is used, the collector will not be grounded,

and should be linked to the base. If a PNP transistor is used, the

base is connected to the D– input and the emitter to the D+

input. If an NPN transistor is used, the emitter is connected to

the D– input and the base to the D+ input.

REV. A

–9–

ADM1029

V

DD

I

N ⴛ I

REMOTE

SENSING

TRANSISTOR

I

D+

D–

BIAS

DIODE

BIAS

LOW-PASS FILTER

f

C

= 65kHz

Figure 5. Signal Conditioning for Remote Diode Temperature Sensors

V

OUT

TO ADC

V

OUT

+

–

To prevent ground noise interfering with the measurement, the

more negative terminal of the sensor is not referenced to ground,

but biased above ground by an internal diode at the D– input. If

the sensor is used in a noisy environment, a capacitor of value

up to 1000 pF may be placed between the D+/D– pins.

To measure ∆V

, the sensor is switched between operating currents

BE

of I and N × I. The resulting waveform is passed through a 65 kHz

low-pass filter to remove noise, and to a chopper-stabilized amplifier

that performs the functions of amplification and rectification of

the waveform to produce a dc voltage proportional to ∆VBE. This

voltage is measured by the ADC to give a temperature output in

8-bit two’s complement format. To further reduce the effects of

noise, digital filtering is performed by averaging the results of 16

measurement cycles. An external temperature measurement takes

nominally 9.6 ms.

The results of external temperature measurements are stored in

8-bit, two’s complement format, as illustrated in Table II.

OFFSET REGISTERS

Digital noise and other error sources can cause offset errors in

the temperature measurement, particularly on the remote sensors. The ADM1029 offers a way to minimize these effects. The

offsets on the three temperature channels can be measured during

system characterization and stored as two’s complement values

in three offset registers at addresses 30h to 32h. The offset

values are automatically added to, or subtracted from, the temperature values, depending on whether the two’s complement

number corresponds to a positive or negative offset. Offset values from –15°C to +15°C are allowed.

The default value in the offset registers is zero, so if no offsets

are programmed, the temperature measurements are unaltered.

TEMPERATURE LIMITS

The contents of the Local and Remote Temperature Value Registers (addresses A0h to A2h) are compared to the contents of the

High and Low Limit Registers at addresses 90h to 92h and 98h

to 9Ah. How the ADM1029 responds to overtemperature/

undertemperature conditions depends on the status of the Temperature Fault Action Registers (addresses 40h to 42h). The

response of CFAULT, INT, and fan-speed-to-temperature events

depends on the setting of these registers, as explained later.

Table II. Temperature Data Format

Temperature Digital Output

–128°C 1000 0000

–125°C 1000 0011

–100°C 1001 1100

–75°C 1011 0101

–50°C 1100 1110

–25°C 1110 0111

0°C 0000 0000

+10°C 0000 1010

+25°C 0001 1001

+50°C 0011 0010

+75°C 0100 1011

+100°C 0110 0100

+125°C 0111 1101

+127°C 0111 1111

–10–

REV. A

ADM1029

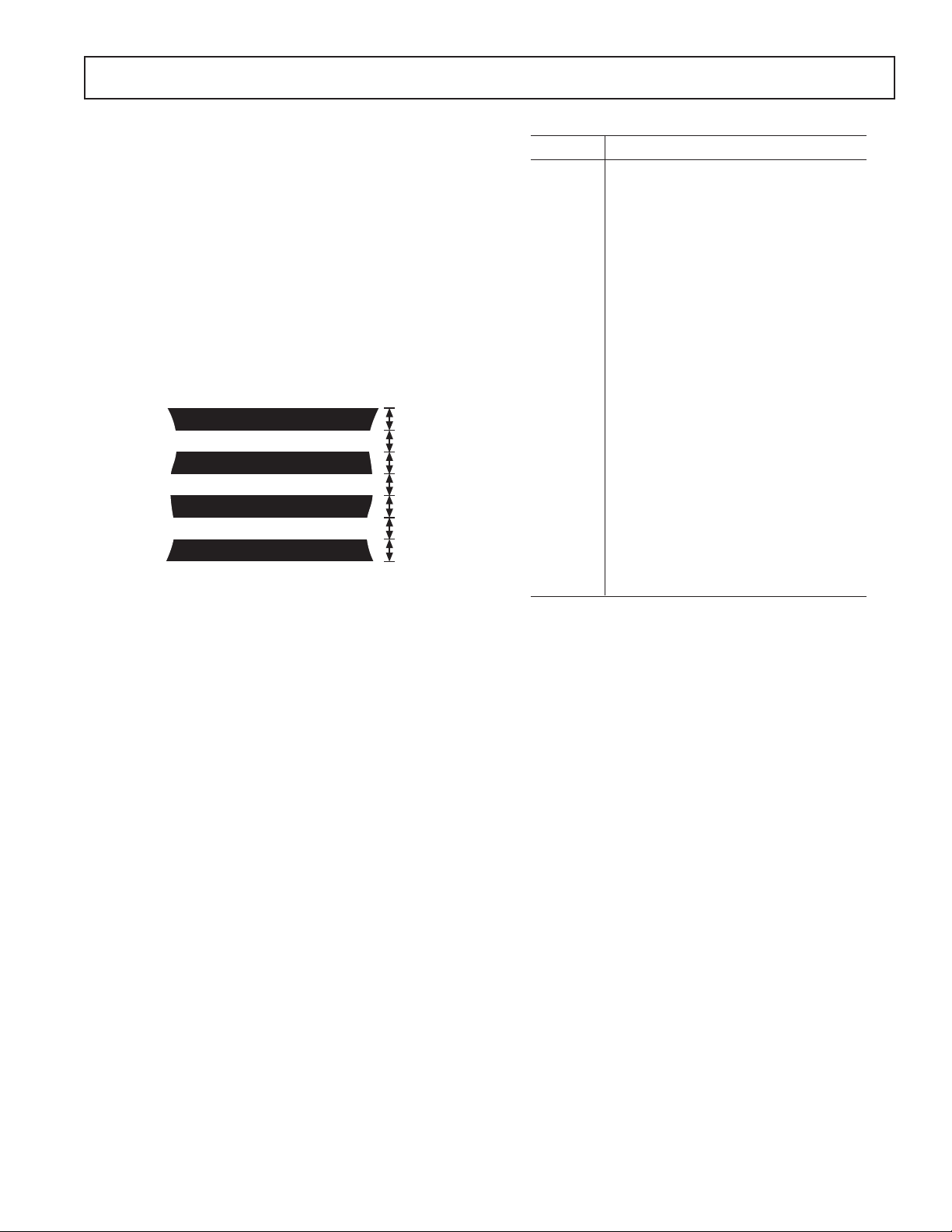

LAYOUT CONSIDERATIONS

Digital boards can be electrically noisy environments, and care

must be taken to protect the analog inputs from noise, particularly when measuring the very small voltages from a remote diode

sensor. The following precautions should be taken:

1. Place the ADM1029 as close as possible to the remote sens-

ing diode. Provided that the worst noise sources such as

clock generators, data/address buses, and CRTs are avoided,

this distance can be 4 to 8 inches.

2. Route the D+ and D– tracks close together, in parallel, with

grounded guard tracks on each side. Provide a ground plane

under the tracks if possible.

3. Use wide tracks to minimize inductance and reduce noise

pickup. Ten mil track minimum width and spacing is

recommended.

GND

D+

D–

GND

10MIL

10MIL

10MIL

10MIL

10MIL

10MIL

10MIL

Figure 6. Arrangement of Signal Tracks

4. Try to minimize the number of copper/solder joints, which

can cause thermocouple effects. Where copper/solder joints

are used, make sure that they are in both the D+ and D–

path and at the same temperature.

Thermocouple effects should not be a major problem as 1°C

corresponds to about 240 µV, and thermocouple voltages are

about 3 µV/

o

C of temperature difference. Unless there are two

thermocouples with a big temperature differential between

them, thermocouple voltages should be much less than 200 µV.

5. Place 0.1 µF bypass and 1000 pF input filter capacitors close

to the ADM1029.

6. If the distance to the remote sensor is more than 8 inches,

the use of twisted pair cable is recommended. This will work

up to about 6 to 12 feet.

7. For really long distances (up to 100 feet), use shielded

twisted pair such as Belden #8451 microphone cable. Connect the twisted pair to D+ and D– and the shield to GND

close to the ADM1029. Leave the remote end of the shield

unconnected to avoid ground loops.

Because the measurement technique uses switched current

sources, excessive cable and/or filter capacitance can affect the

measurement. When using long cables, the filter capacitor may

be reduced or removed.

Cable resistance can also introduce errors. 1 Ω series resistance

introduces about 0.5°C error.

TEMPERATURE-RELATED REGISTERS

Table III is a list of registers on the ADM1029 that are specific

to temperature measurement and control.

Table III. Temperature-Specific Registers

Address Description

0x06 Temp Devices Installed

0x30 Local Temp Offset

0x31 Remote 1 Temp Offset

0x32 Remote 2 Temp Offset

0x40 Local Temp Fault Action

0x41 Remote 1 Temp Fault Action

0x42 Remote 2 Temp Fault Action

0x48 Local Temp Cooling Action

0x49 Remote 1 Temp Cooling Action

0x4A Remote 2 Temp Cooling Action

0x80 Local Temp TMIN

0x81 Remote 1 Temp TMIN

0x82 Remote 2 Temp TMIN

0x88 Local Temp TRANGE/THYST

0x89 Remote 1 Temp TRANGE/THYST

0x8A Remote 2 Temp TRANGE/THYST

0x90 Local Temp High Limit

0x91 Remote 1 Temp High Limit

0x92 Remote 2 Temp High Limit

0x98 Local Temp Low Limit

0x99 Remote 1 Temp Low Limit

0x9A Remote 2 Temp Low Limit

0xA0 Local Temp Value

0xA1 Remote 1 Temp Value

0xA2 Remote 2 Temp Value

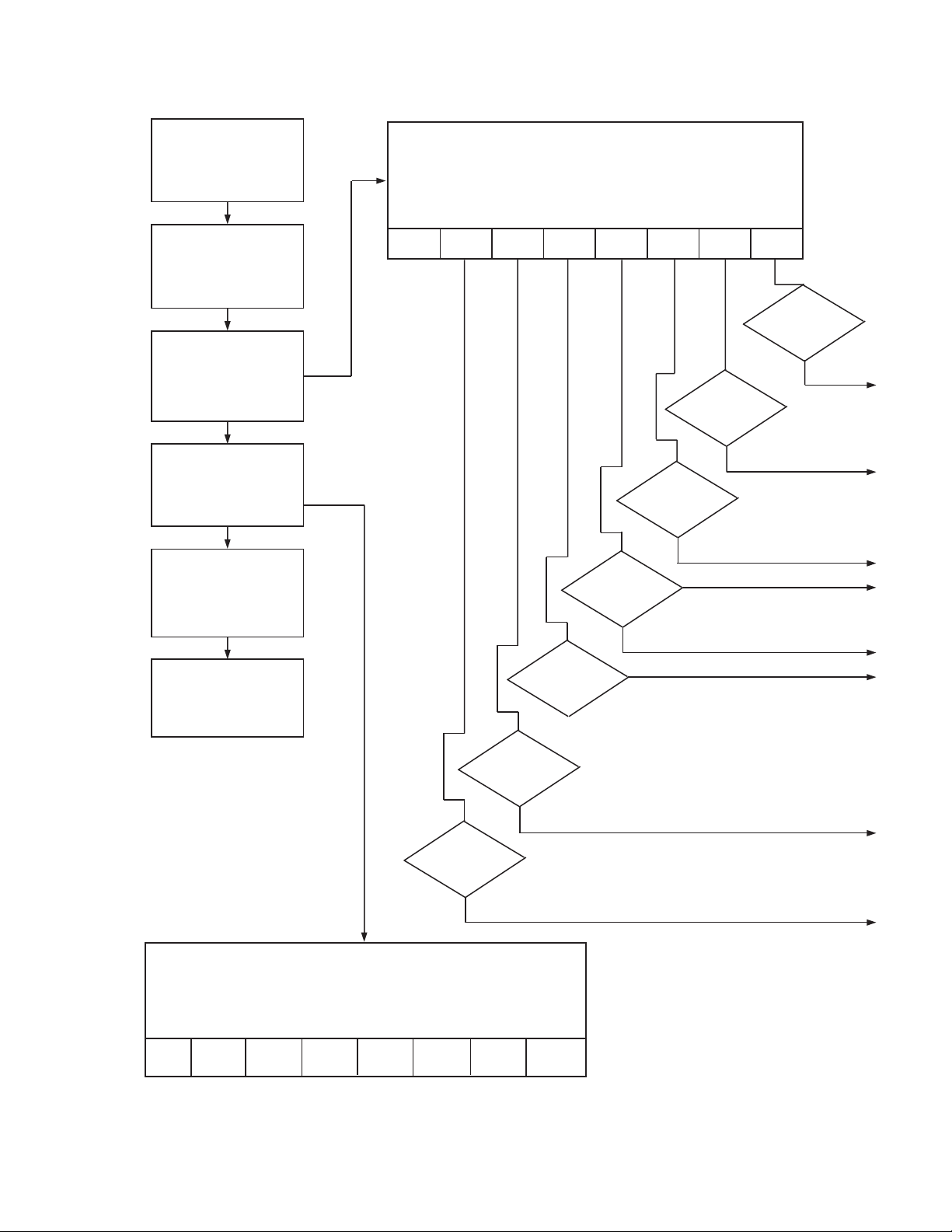

The flowchart in Figure 7 shows how to configure the ADM1029

to measure temperature. It also shows how to configure the

ADM1029’s behavior for out-of-limit temperature measurements.

FAN INTERFACING

The ADM1029 can be interfaced to many types of fan. It can be

used to control the speed of a simple two-wire fan. It can measure the speed of a fan with a tach output, and it can accept a

logic input from fans with a FAULT output. By means of a

shorting link in the fan connector it can also determine if a fan is

present or not and if fans have been hot-swapped.

The ADM1029 can control or monitor one or two fans. Bits 0

and 1 of the Fans Supported In System Register (03h) tell the

ADM1029 how many fans it should be controlling/monitoring.

In the following descriptions “installed” means that the corresponding bit of register 03h is set and the ADM1029 expects to

see a fan interfaced to it. It does not necessarily mean that the

fan is actually, physically, connected.

If a fan is installed, events such as a fault output and hot-swapping

of the fan can cause INT and CFAULT to be asserted, unless

they are masked for that particular event. If a fan is not installed,

but is still physically connected to the ADM1029, these events will

be ignored with respect to asserting INT or CFAULT, but will

still be reflected in the corresponding Fan Status Register.

Setting Bit 0 indicates that Fan 1 is installed and is set to 1

at power-up by default. Setting Bit 1 indicates that Fan 2 is

installed and depends on the state of Pin 18 (TMIN/INSTALL)

at power-up.

REV. A

–11–

ADM1029

DEFAULTS

LOCAL = 60ⴗC

REMOTE 1 = 70ⴗC

REMOTE 2 = 70ⴗC

DEFAULTS

LOCAL = 80ⴗC

REMOTE 1 = 100ⴗC

REMOTE 2 = 100ⴗC

DEFAULTS

LOCAL = 0ⴗC

REMOTE 1 = 0ⴗC

REMOTE 2 = 0ⴗC

CONFIGURE

TEMPERATURE LOW

LIMITS

LOCAL (REG 0x98)

REMOTE 1 (REG 0x99)

REMOTE 2 (REG 0x9A)

CONFIGURE

TEMPERATURE HIGH

LIMITS

LOCAL (REG 0x90)

REMOTE 1 (REG 0x91)

REMOTE 2 (REG 0x92)

CONFIGURE

TEMPERATURE FAULT

ACTION

LOCAL (REG 0x40)

REMOTE 1 (REG 0x41)

REMOTE 2 (REG 0x42)

CONFIGURE

TEMPERATURE COOLING

ACTION

LOCAL (REG 0x48)

REMOTE 1 (REG 0x49)

REMOTE 2 (REG 0x4A)

CONFIGURE

TEMPERATURE OFFSETS

LOCAL (REG 0x30)

REMOTE 1 (REG 0x31)

REMOTE 2 (REG 0x32)

BIT 0 = 1 ASSERT CFAULT ON OVER-TEMPERATURE

BIT 1 = 1 RUN FAN(S) ALARM SPEED ON OVER-TEMPERATURE

BIT 2 = 1 ASSERT INT ON OVER-TEMPERATURE

BIT 3 = 0 ALARM BELOW LOW TEMP LIMIT

BIT 3 = 1 ALARM ABOVE LOW TEMP LIMIT

BIT 4 = 1 ASSERT CFAULT WHEN LOW TEMP LIMIT CROSSED

BIT 5 = 1 RUN FAN ALARM SPEED ON UNDER-TEMPERATURE

BIT 6 = 1 ASSERT INT ON UNDER-TEMPERATURE

BIT 7 LATCHES A TEMPERATURE OUT-OF-LIMIT EVENT

7 6 5 4 3 2 1 0

IS

TEMPERATURE

>

HIGH LIMIT?

YES

IS

TEMPERATURE

>

HIGH LIMIT?

YES

ALARM ABOVE OR

BELOW LOW TEMP

LIMIT?

0 = ALARM BELOW TEMP LIMIT

IS

TEMPERATURE

>

HIGH LIMIT?

YES

CFAULT

FANS RUN

ALARM SPEED

INT

MEASURE

TEMPERATURE

LOCAL (REG 0xA0)

REMOTE 1 (REG 0xA1)

REMOTE 2 (REG 0xA2)

LOW TEMP LIMIT

LOW TEMP LIMIT

CROSSED?

YES

AUTOMATIC FAN SPEED CONTROL (SEE TABLE XI LATER)

BIT 0 = 1 FAN 1 RUNS AT ALARM SPEED FOR OUT-OF-LIMIT TEMPERATURE EVENTS;

BIT 1 = 1 FAN 2 RUNS AT ALARM SPEED FOR OUT-OF-LIMIT TEMPERATURE EVENTS;

XXXXXX10

OTHERWISE, FAN 1 RUNS AT SPEED DETERMINED BY AUTOMATIC FAN

CONTROL.

OTHERWISE, FAN 2 RUNS AT SPEED DETERMINED BY AUTOMATIC FAN

CONTROL.

LOW TEMP LIMIT

CROSSED?

YES

CROSSED?

1 = ALARM ABOVE TEMP LIMIT

CFAULT

YES

FANS RUN ALARM SPEED

INT

Figure 7. Temperature Sensing Flowchart

–12–

REV. A

ADM1029

If two fans are installed, Bit 0 would be 1 by default and Pin

18 would be tied high* to set Bit 1. If only one fan is installed, it

would normally be Fan 1 and Pin 18 would be tied low* to

clear Bit 1. However, both of these bits can be modified by

writing to the register, so it is possible to have Fan 2 installed

and not Fan 1, or even have no fans installed.

*Note that Pin 18 also sets TMIN for automatic fan speed control. If this function

is used, Pin 18 would be set to some other level according to Table IX.

FAULT INPUTS/OUTPUTS

The ADM1029 can be used with fans that have a fault output

which indicates if the fan has stalled or failed. If one or both of

the FAULT inputs (Pin 2 or Pin 23) goes low, both INT and

CFAULT will be asserted.

Events on the fault inputs are also reflected in Bits 2 and 3 of the

corresponding Fan Status Registers at addresses 10h and 11h.

Bit 2 reflects the inverse state of the FAULT pin (0 if FAULT is

high, 1 if FAULT is low), while Bit 3 is latched high if a FAULT

input goes low. It must be cleared by writing a zero to it.

If the fan(s) being used do not have a FAULT output, the FAULT

input(s) on the ADM1029 should be pulled high to V

CC

.

The FAULT pins can also be configured as open-drain outputs

by setting Bit 5 of the corresponding Fan Fault Action Register

(18h or 19h). If a FAULT pin is configured as an output, it will

still function as an input. This means that when a fault input

occurs it will be latched low by the fault output, even if the fault

input is removed. The fault output can be used to drive a fan

failure indicator such as an LED.

If the FAULT pin is used as an output, any input to the FAULT

pin should also be open-drain. This will avoid the fault input

trying to source a high current into the FAULT pin if the fault

input goes high while the fault output is low.

FAN PRESENT INPUTS

The fan PRESENT signal is implemented by a shorting link

to ground in the fan connector. When the fan is plugged in,

the corresponding PRESENT input (Pin 4 or Pin 21) on the

ADM1029 is pulled low. If the fan is unplugged, the PRESENT

input will be pulled high. INT and CFAULT will be asserted

(unless masked) and the event will be reflected in Bits 0 and

Bit 1 of the corresponding Fan Status Register.

Appearance or disappearance of a PRESENT input signal during normal operation signals to the ADM1029 that a fan has

been hot-plugged or unplugged. INT and CFAULT will be

asserted (unless masked). When a fan is hot-plugged, Bit 7 of

the corresponding Fan Status Register will be set and a Fan

Free Wheel Test commences automatically.

FAN SPEED MEASUREMENT

The fan counter does not count the fan tach output pulses

directly, because at low fan speeds it would take several seconds

to accumulate a reasonably large and accurate count. Instead,

the period of the fan revolution is measured by gating an onchip oscillator into the input of an 8-bit counter.

The fan speed measuring circuit is initialized on the first rising

edge of a fan tach pulse after monitoring is enabled by setting

Bit 4 of the Configuration Register. It then starts counting on

the rising edge of the second tach pulse and counts for four fan

tach periods, until the rising edge of the sixth tach pulse, or

until the counter overranges if the fan tach period is too long.

After the speed of the first fan has been measured, the speed of

the second fan (if installed) will be measured in the same way.

The measurement cycle will repeat until monitoring is disabled.

The fan speed measurements are stored in the Fan Tach Value

registers at addresses 70h and 71h.

If both fans are installed, Fan 1 will be measured first. If only

one fan is installed, the ADM1029 will still try to measure

both fans, starting with Fan 1, but the measurement on the

noninstalled fan will time out when the Fan Tach Value count

overranges.

The fan speed count is given by:

Count = f 4 60/R/N

where:

f is oscillator frequency in Hz

factor 4 is because 4 tach periods are counted

factor 60 is to convert minutes to seconds

R = fan speed in RPM

N is number of tach pulses per revolution

The frequency of the oscillator can be adjusted to suit the expected

frequency range of the fan tach pulses, which depends on the

fan speed and the number of tach pulses produced for each

revolution of the fan, which is either 1, 2, or 4. The oscillator

frequency is set by Bits 7 and 6 of the Fan Configuration Registers (68h for Fan 1 and 69h for Fan 2).

Table IV. Oscillator Frequencies

Bit 7 Bit 6 Oscillator Frequency (Hz)

00Measurement Disabled

01470

10940

111880

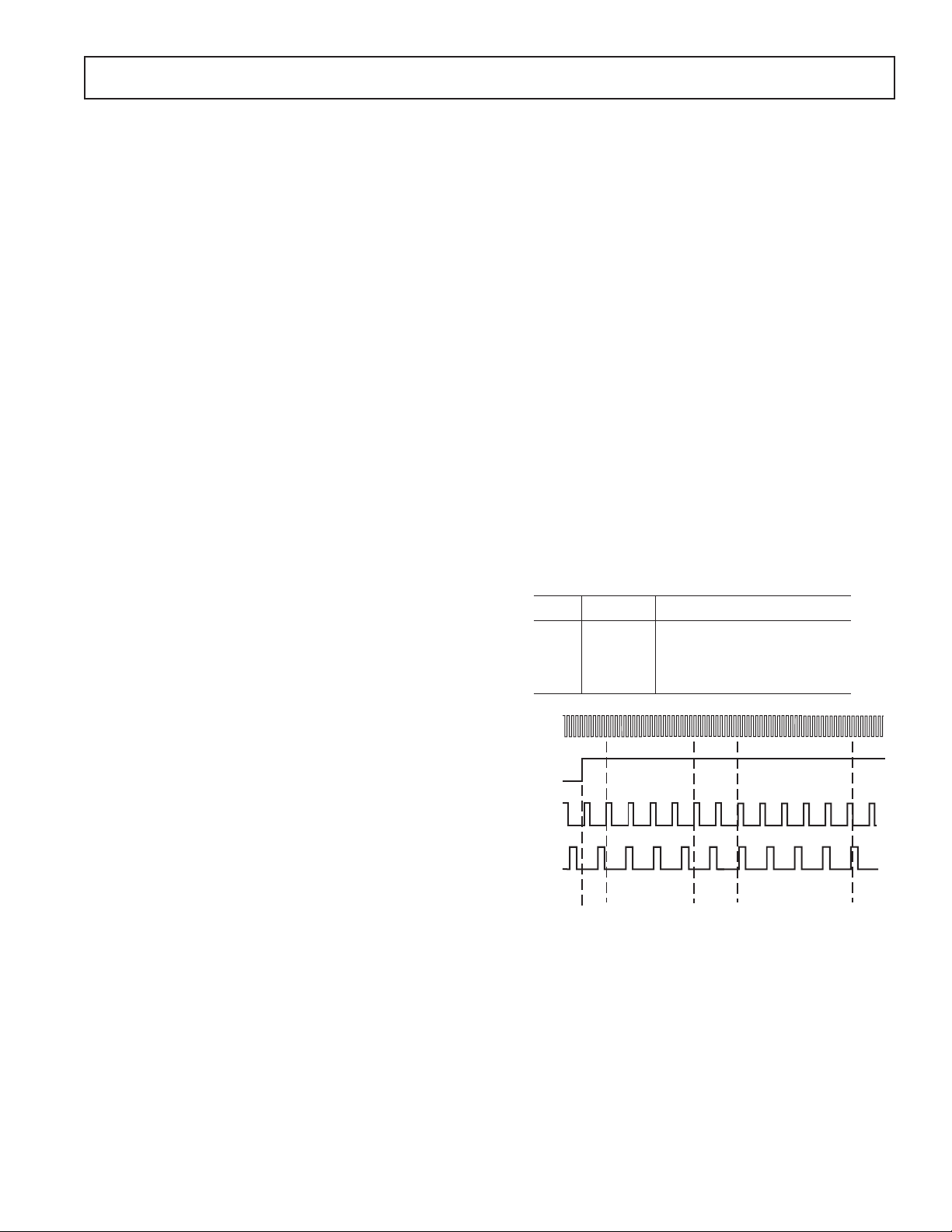

CLOCK

CONFIG

REG. BIT 4

FAN 1

TACH

FAN 2

TACH

START OF

MONITORING

CYCLE

FAN 1

MEASUREMENT

PERIOD

FAN 2

MEASUREMENT

PERIOD

Figure 8. Fan Speed Measurement

FAN SPEED LIMITS

Fans generally do not overspeed if run from the correct voltage,

so the failure condition of interest is under-speed due to electrical or mechanical failure. For this reason only low-speed limits

are programmed into the Tach Limit Registers for the fans.

These registers are at address 78h for Fan 1 and 79h for

Fan 2. It should be noted that, since fan period rather than

speed is being measured, the fan speed count will be larger

the slower the fan speed. Therefore a fan failure fault will occur

when the measurement exceeds the limit value.

REV. A

–13–

ADM1029

For the most accurate fan failure indication, the oscillator

frequency should be chosen to give as large a limit value as

possible without the counter overranging. A count close to 3/4

full-scale or 191 is the optimum value.

For example, if a fan produces two tach pulses per revolution

and the fan failure speed is to be 600 rpm, the oscillator frequency should be set to 940 Hz. This will give a count at the fail

speed of:

940 4 60/600/2 = 188

If the oscillator frequency were only 470 Hz, the count would

be 94, while an oscillator frequency of 1880 Hz cannot be used

because the count would be 376 and the counter would overrange.

FAN MONITORING CYCLE TIME

Five complete tach periods are required to carry out a fan speed

measurement Therefore, if the start of a fan measurement just

misses a rising edge, the measurement can take almost six tach

periods for each fan.

The worst-case monitoring cycle time is when both fans are

under speed and the fan speed counter counts up to its maximum value. The actual count takes 256 oscillator pulses over

four tach periods, plus a further two tach periods or 128 oscillator pulses before the count starts. The total monitoring cycle

time is therefore:

t

MEAS

= 384/f

OSC(FAN 1)

+ 384/f

OSC(FAN 2)

In order to read a valid result from the Fan Tach Value Registers,

the total monitoring time allowed after starting the monitoring

cycle should be greater than this.

TACH SIGNAL CONDITIONING

Signal conditioning in the ADM1029 accommodates the slow

rise and fall times typical of fan tachometer outputs. The maximum input signal range is 0 V to 5 V, even if V

is less than

CC

5 V. In the event that these inputs are supplied from fan outputs

that exceed 0 V to 5 V, either resistive attenuation of the fan

signal or diode clamping must be included to keep inputs within

an acceptable range.

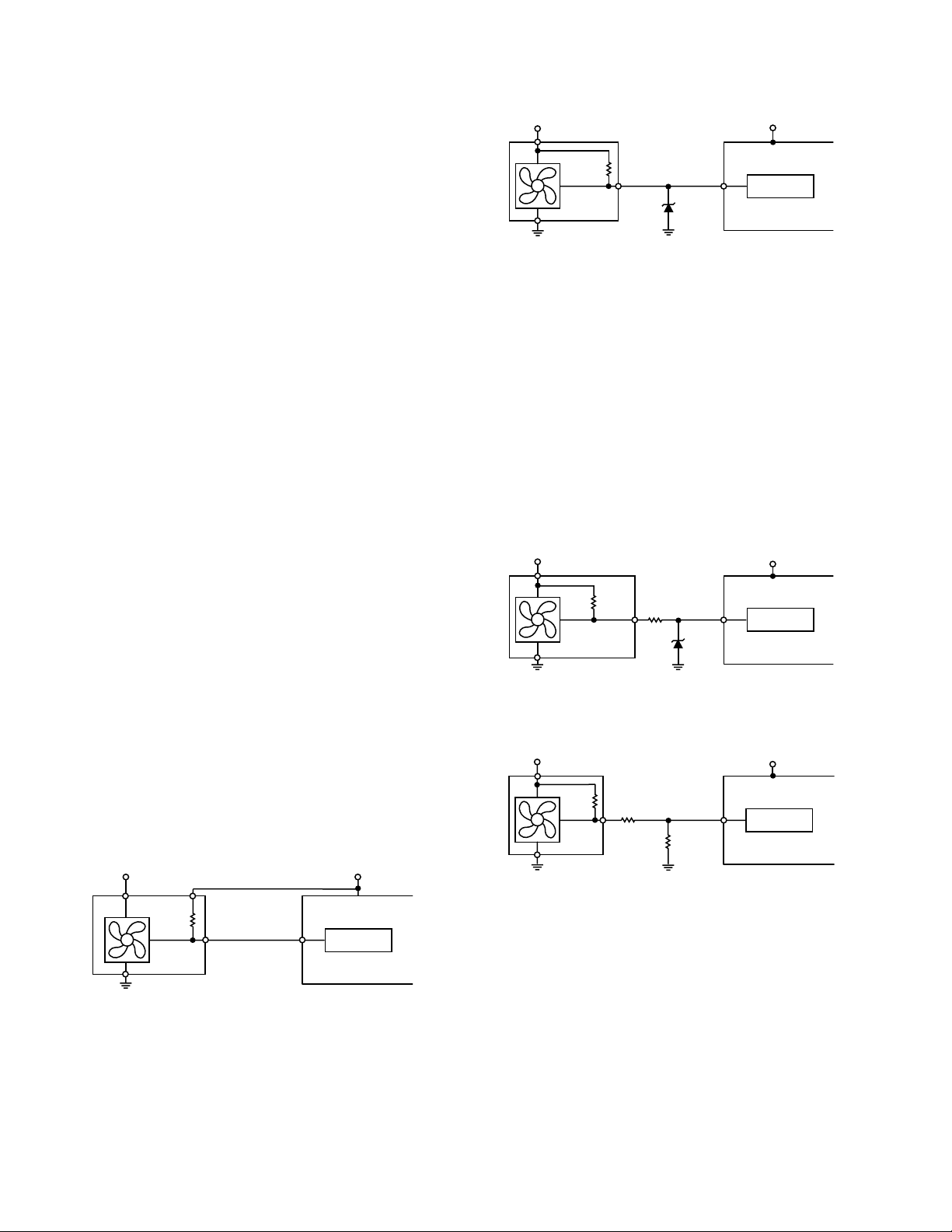

Figures 9a to 9d show circuits for most common fan tach outputs.

If the fan tach output has a resistive pull-up to V

, it can be

CC

connected directly to the fan input, as shown in Figure 9a.

12V

PULL-UP

4.7k

TYP

⍀

TACH

OUTPUT

TACH1

OR TACH2

Figure 9a. Fan with Tach Pull-Up to +V

V

CC

FAN SPEED

COUNTER

CC

If the fan output has a resistive pull-up to 12 V (or other voltage

greater than 6.5 V), the fan output can be clamped with a Zener

diode, as shown in Figure 9b. The Zener voltage should be

chosen so that it is greater than V

but less than 6.5 V, allowing

IH

for the voltage tolerance of the Zener. A value of between 3 V

and 5 V is suitable.

12V

PULL-UP

4.7k⍀

*CHOOSE ZD1 VOLTAGE APPROX. 0.8 ⴛ V

TYP

TACH

OUTPUT

OR TACH2

TACH1

ZD1*

ZENER

V

CC

FAN SPEED

COUNTER

CC

Figure 9b. Fan with Tach. Pull-Up to Voltage >6.5 V (e.g.,

12 V) Clamped with Zener Diode

If the fan has a strong pull-up (less than 1 kΩ) to 12 V, or a

totem-pole output, a series resistor can be added to limit the

Zener current, as shown in Figure 9c. Alternatively, a resistive

attenuator may be used, as shown in Figure 9d.

R1 and R2 should be chosen such that:

2 V < V

PULLUP

× R2/(R

+ R1 + R2) < 5 V

PULLUP

The fan inputs have an input resistance of nominally 160 kΩ to

ground, so this should be taken into account when calculating

resistor values.

With a pull-up voltage of 12 V and pull-up resistor less than

1 kΩ, suitable values for R1 and R2 would be 100 kΩ and 47 kΩ.

This will give a high input voltage of 3.83 V.

12V

TACH

O/P

PULL-UP

TYP <1k⍀

OR TOTEM-POLE

*CHOOSE ZD1 VOLTAGE APPROX. 0.8 ⴛ V

R1

10k⍀

TACH1

OR TACH2

ZD1

ZENER*

V

CC

FAN SPEED

COUNTER

CC

Figure 9c. Fan with Strong Tach. Pull-Up to >VCC or

Totem-Pole Output, Clamped with Zener and Resistor

12V

<1k⍀

R1*

TACH

OUTPUT

OR TACH2

R2*

*SEE TEXT

TACH1

V

CC

FAN SPEED

COUNTER

Figure 9d. Fan with Strong Tach. Pull-Up to >VCC or

Totem-Pole Output, Attenuated with R1/R2

FAN SPEED CONTROL

Fan speed is controlled using pulsewidth modulation (PWM).

The PWM outputs (Pins 1 and 24) give a pulse output with a

programmable frequency (default 250 Hz) and a duty-cycle

defined by the contents of the relevant fan speed register, or by

the automatic fan speed control when this mode is enabled. The

speed at which a fan runs is determined by fault conditions and

the settings of various control and mask registers.

A fan can only be driven if it is defined as being supported by

the controller in register 02h. The ADM1029 supports up to

two fans, so Bits 0 and 1 of this register are permanently set.

This register is read-only.

–14–

REV. A

ADM1029

A fan will only be driven if it is defined as being supported by

the system in register 03h. If Bit 0 of this register is set, it indicates that Fan 1 is installed. This is the power-on default. If

Bit 1 is set, it indicates that Fan 2 is installed. This bit is set by

the state of Pin 18 at power-up. This register is read/write and

the default/power-on setting can be overwritten. If a fan is not

supported in register 03h it will not be driven, even if it is physically installed.

The PWM outputs are open-drain outputs. They require pull-up

resistors and must be amplified and buffered to drive the fans.

Minimum Speed

The normal operating fan speed is set by the four LSBs of the

Fan 1 and Fan 2 Minimum/Alarm Speed Registers (addresses

60h, 61h). These bits also set the minimum speed at which a fan

will run in automatic control mode. These bits should be set to

05h. This corresponds to 33% PWM duty-cycle, which is the

lowest speed at which most fans will run reliably.

Fan(s) will run at minimum speed if there is no fault condition,

automatic fan speed is disabled, and there are no other overriding conditions.

Alarm Speed

Alarm speed is set by the four MSBs of the Fan 1 and Fan 2

Minimum/Alarm Speed Registers (addresses 60h, 61h). Fan(s)

will run at alarm speed if any of the following conditions occurs,

assuming the condition has not been masked out using the Fan

Event Mask Registers:

•

Setting Bit 0 of register 07h forces Fan 1 to run at alarm speed

(Set Fan x Alarm Speed Register).

•

Setting Bit 1 of register 07h forces Fan 2 to run at alarm speed

(Set Fan x Alarm Speed Register).

If monitoring is disabled by clearing Bit 4 of the Configuration Register, all fans controlled by the ADM1029

will run at alarm speed.

•

When a GPIO pin is configured as an input by setting Bit 0 of

the corresponding GPIO Behavior Register, and Bit 4 of the

GPIO Behavior Register is also set, all fans controlled by the

ADM1029 will go to alarm speed when the logic input is

asserted (high or low, depending on the polarity bit, Bit 1 of

the corresponding GPIO Behavior Register).

•

If Bit 7 of a Fan Fault Action Register is set (18h—Fan 1, 19h

—Fan 2) the corresponding fan will go to alarm speed when

CFAULT is pulled low by an external source.

•

If a tach measurement exceeds the set limit, all fans controlled

by the ADM1029 will run at alarm speed.

•

If a fan fault input pin is asserted (low), all fans controlled by

the ADM1029 will run at alarm speed.

•

If Bit 1 of a Temp. Fault Action Register is set (40h—Local

Sensor, 41h—Remote 1, 42h—Remote 2), all fans controlled

by the ADM1029 will go to alarm speed if the corresponding

temperature high limit is exceeded.

•

If Bit 5 of a Temp. Fault Action Register is set, all fans controlled by the ADM1029 will go to alarm speed if a temperature

input crosses the corresponding temperature low limit, the

direction depending on the setting of Bit 3 of the Temp. Control register. (0 = alarm when input goes below low limit, 1 =

alarm when input goes above low limit).

•

If Bit 1 of an AIN Behavior Register is set (50h—AIN0,

51h—AIN1), all fans controlled by the ADM1029 will go to

alarm speed if the corresponding AIN high limit is exceeded.

•

If Bit 5 of an AIN Behavior Register is set, all fans controlled

by the ADM1029 will go to alarm speed if an analog input

crosses the corresponding AIN low limit, the direction depending on the setting of Bit 3 of the AIN control register. (0 =

alarm when input goes below low limit, 1 = alarm when input

goes above low limit).

•

If a thermal override occurs while the ADM1029 is in sleep

mode, all fans controlled by the ADM1029 will run at

alarm speed.

Hot-Plug Speed

Hot-plug speed is set by the four LSBs of the Fan 1 and Fan 2

Configuration Registers (addresses 68h and 69h). The PWM

frequency is set by Bits 4 and 5 of these registers, while Bits 6

and 7 set the number of pulses per revolution for fan speed

measurement.

Fan(s) will run at hot-plug speed if any of the following conditions occur, assuming the condition has not been masked using

the Fan Event Mask Registers:

•

If a fan is unplugged, the other fan (if any) controlled by the

ADM1029 will run at hot-plug speed.

•

Setting Bit 0 of register 08h forces Fan 1 to run at hot-plug

speed (Set Fan x Hot-Plug Speed).

•

Setting Bit 1 of register 08h forces Fan 2 to run at hot-plug

speed (Set Fan x Hot-Plug Speed).

•

When a GPIO pin is configured as an input by setting Bit 0 of

the corresponding GPIO Behavior Register, and Bit 5 of the

GPIO Behavior Register is also set, all fans controlled by the

ADM1029 will go to hot-plug speed when the logic input is

asserted (high or low, depending on the polarity bit, Bit 1 of

the corresponding GPIO Behavior Register).

•

If Bit 6 of a Fan Fault Action Register is set (18h for Fan 1,

19h for Fan 2) the corresponding fan will go to hot-plug speed

when CFAULT is pulled low by an external source.

Note: If operating conditions and register settings are such that

both alarm speed and hot-plug speed would be triggered, which

one takes priority is determined by Bit 5 of the Fan 1 and Fan 2

Status Registers (addresses 10h and 11h). If this bit is set, hot-plug

speed takes priority. If it is cleared, alarm speed takes priority.

Full Speed

Fans will run at full speed if the corresponding bits in the Set

Fan x Full Speed Register (address 09h) are set: Bit 0 for Fan 1

and Bit 1 for Fan 2.

Fan Mask Registers

The effect of various conditions on fan speed can be enabled or

disabled by mask registers. In all these registers, setting Bit 0 of

the register enables Fan 1 to go to alarm speed or hot-plug speed if

the corresponding event occurs, while setting Bit 1 enables Fan

2. Clearing these bits masks the effect of the corresponding

event on fan speed.

Registers 20h and 21h are Fan Event Mask Registers. Bits 0 and

1 of register 20h enable (bit set) or mask (bit clear) the effect of

a Fan 1 fault (underspeed or fault input) on Fan 1 and Fan 2

speed. Similarly, Bits 0 and 1 of register 21h enable (bit set)

REV. A

–15–

ADM1029

or mask (bit clear) the effect of a Fan 2 Fault on Fan 1 and

Fan 2 speed.

Registers 38h to 3Eh are GPIO X Event Mask Registers. Bits 0

and 1 of these registers enable or mask the effect of a GPIO

assertion on Fan 1 and Fan 2 speed.

Note: Registers 48h to 4Ah are Temp. Cooling Action Registers. Bits 0 and 1 of these registers enable or mask the effect of

Local, Remote 1, and Remote 2 temperature faults on Fan 1

and Fan 2 speed. These registers also determine which temperature channel controls each fan in automatic fan speed control

mode, as described later.

Registers 58h and 59h are AIN Event Mask Registers. Bits 0

and 1 of these registers enable or mask the effect of an AIN outof-limit event on Fan 1 and Fan 2 speed.

MODES OF OPERATION

The ADM1029 has three different modes of operation. These

modes determine the behavior of the system.

1. PWM Duty Cycle Select Mode (directly sets fan speed under

software control).

2. Thermal Trip Mode

3. Automatic Fan Speed Control Mode

PWM DUTY CYCLE SELECT MODE

The ADM1029 may be operated under software control by

clearing bits <1:0> of the three Temp Cooling Action Registers

(Reg 0x48, 0x49, 0x4A). Once under Software Control, each

fan speed may be controlled by programming values of PWM

Duty Cycle in to the device. Values of PWM Duty Cycle between

0% to 100% may be written to the four LSBs of the Fan 1 and

Fan 2 Minimum/Alarm Speed Registers (addresses 60h, 61h).

to control the speed of each fan. Table V shows the relationship

between hex values written to the Minimum/Alarm Speed Registers and PWM duty cycle obtained.

Table V. PWM Duty Cycle Select Mode

Hex Value PWM Duty Cycle

00 0%

01 7%

02 14%

03 20%

04 27%

05 33% Recommended

06 40%

07 47%

08 53%

09 60%

0A 67%

0B 73%

0C 80%

0D 87%

0E 93%

0F 100% (Default)

It is recommended that the minimum PWM duty cycle be set to

33% (0x05). This has been determined to be the lowest PWM

*Bits <3:0> set the Minimum PWM duty cycle, bits <7:4> set the Alarm Speed

PWM duty cycle for each fan.

duty cycle that most fans will run reliably at. Note that the PWM

duty cycle values programmed in to these registers also define

the PWM duty cycle that the fans will turn on at, in Automatic

Fan Speed Control Mode. It is recommended that after powerup, the PWM duty cycle is set to 33% before enabling Automatic

Fan Speed Control.

THERMAL TRIP MODE

The ADM1029 can thermally trip the fan(s) for simple on/off

fan control, or 2-speed fan control. For example, a fan can be

programmed to run at 33% duty cycle. If the temperature exceeds

the high temperature limit set for that temperature channel, the

fan can automatically trip and run at Alarm Speed. The fan will

continue to run at Alarm Speed even if the temperature error

condition subsides, until the Latch Temp Fault bit (Bit 7 of the

Temp x Fault Action Reg) is cleared in software by writing a 0

to it. To configure Fan 1 normally, run at 33% but to thermally

trip to Alarm Speed for a Remote 2 measured temperature of

70°C, set up the following registers:

1. Configure the normal PWM duty cycle for Fan 1 to 33%.

Fan 1 Minimum/Alarm Speed Reg (0x60) = 0xF5

2. Set the Remote 2 High Temperature Limit = 70°C.

Remote 2 Temp High Limit Reg (0x92) = 0x46

3. Configure Alarm Speed on Overtemperature function for

Remote 2 Temperature channel.

Set Bit 1 of Temp 2 Fault Action Reg (0x42)

4. Enable Fan 1 to be controlled by Remote 2 Temperature.

Set Bit 0 of Temp 2 Cooling Action Reg (0x4A)

Once the fan thermally trips to Alarm Speed, it will continue to

run at Alarm Speed until the temperature drops below the High

Temperature Limit and the Latch Temp Fault bit (Bit 7 of the

Temp 2 Fault Action Reg) is cleared to 0.

EVENT LATCH BITS

Certain events that occur will cause latch bits to be set in various registers on the ADM1029. Once a latch bit is set, it will

need to be cleared by software for the system to return to normal operation. To detect if a latch bit has been set, the INT pin

can be used to signal a latch event to the system supervisor.

Alternatively, the Status Registers can be polled periodically,

and any latch bits that are set can be cleared. The events that

cause latch bits to be set are:

1. Thermal Events. If the fan is run at Alarm Speed on Overtemperature or Undertemperature, this will set the Latch

Temp Fault bit (Bit 7 of the Temp x Fault Action Registers

0x40–0x42).

2. Missing Fan. If a fan is missing, i.e., has been unplugged, the

Missing Latch bit (Bit 1 of Fan x Status Registers) is set.

3. Hotplugged Fan. If a new fan is inserted into the system, Bit

7 (Hotplug Latch bit) of the Fan x Status Register is set.

4. FAULT Asserted. If the fan becomes stuck and its FAULT

output asserts low, Bit 2 (Fault Latch bit) of the Fan x

Status register is set.

5. TACH Failure. If the fan runs underspeed or becomes stuck,

then Bit 6 (Tach Fault Latch Bit) of the Fan x Status Register is set.

–16–

REV. A

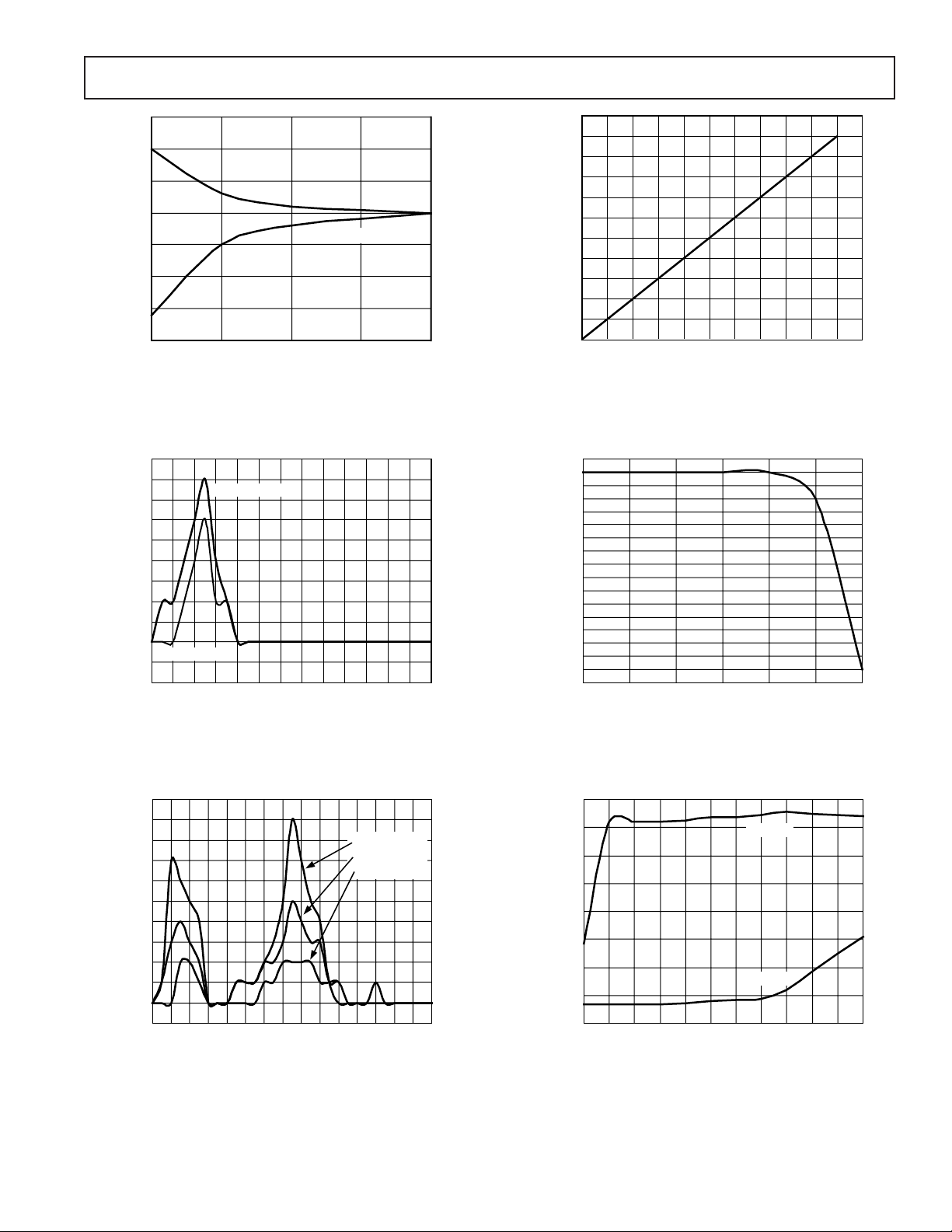

AUTOMATIC FAN SPEED CONTROL

PWM DUTY CYCLE – %

100

53

66

73

87

33

40

47

60

80

93

TEMPERATURE – ⴗC

T

MIN

T

MAX

= T

MIN

+ T

RANGE

0

5

10

20

40

80

60

T

RANGE

= 80ⴗC

T

RANGE

= 40ⴗC

T

RANGE

= 20ⴗC

T

RANGE

= 10ⴗC

T

RANGE

= 5ⴗC

PWM DUTY CYCLE – %

TEMPERATURE – ⴗC

T

MIN

T

MAX

= T

MIN

+ T

RANGE

0

20

40

80

60

T

RANGE

= 40ⴗC

T

RANGE

= 40ⴗC

T

RANGE

= 40ⴗC

100

53

66

87

40

73

33

47

60

80

93

The ADM1029 has a local temperature channel and two remote

temperature channels, which may be connected to an on-chip

diode-connected transistor on a CPU or a general-purpose

discrete transistor. These three temperature channels may be

used as the basis for an automatic fan speed control loop to

drive fans using Pulsewidth Modulation (PWM).

HOW DOES THE CONTROL LOOP WORK?

The Automatic Fan Speed Control Loop is shown in Figure 10.

ADM1029

In order for the fan speed control loop to work, certain loop

parameters need to be programmed in to the device:

1. T

2. T

3. T

4. Programmable hysteresis is included in the control loop to

REV. A

MAX

FAN SPEED

MIN

SPIN UP FOR 2 SECONDS

T

MIN

TEMPERATURE

T

MAX

= T

MIN

+ T

RANGE

Figure 10. Automatic Fan Speed Control

. This is the temperature at which a fan should switch

MIN

on and run at minimum speed. The fan will only turn on

once the temperature being measured rises above the T

MIN

value programmed. The fan will spin up for a predetermined time (default = 2 secs). See Fan Spin-Up section

for more details.

. This will be the temperature range over which the

RANGE

ADM1029 will automatically adjust fan speed. As the temperature increases beyond T

increased accordingly. The T

, the PWM duty cycle will be

MIN

parameter actually defines

RANGE

the fan speed versus temperature slope of the control loop.

. This is defined as the temperature at which a fan

MAX

will be at its maximum speed. At this temperature, the PWM

duty cycle driving the fan will be 100%. T

T

MIN

and T

+ T

RANGE

. Since this parameter is the sum of the T

RANGE

parameters, it does not need to be programmed

is given by

MAX

MIN

into a register on-chip.

prevent the fans continuously switching on and off if the

temperature is close to T

until such time as the temperature drops below T

The four MSBs of the T

0x88, 0x89, 0x8A) contain a temperature hysteresis value

that can be programmed from 0001 to 1111. This allows a

temperature hysteresis range from 1°C to 15°C for each

temperature measurement channel.

. The fans will continue to run

MIN

RANGE/THYST

registers (Registers

MIN–THYST

.

–17–

Figure 11. PWM Duty Cycle vs. Temperature Slopes

(T

)

RANGE

Figure 11 shows the different control slopes determined by the

value chosen, and programmed in to the ADM1029.

T

RANGE

T

was set to 0°C to start all slopes from the same point. It

MIN

can be seen how changing the T

value affects the PWM

RANGE

Duty Cycle vs. Temperature Slope.

Figure 12 shows how for a given T

value affects the loop. Increasing the T

the T

since T

(temperature at which the fan runs full speed) value,

MAX

MAX

= T

MIN

+ T

. Note, however, that the PWM

RANGE

, changing the T

RANGE

value will increase

MIN

MIN

Duty Cycle versus Temperature slope remains exactly the same.

Changing the T

Figure 12. Effect of Increasing T

value merely shifts the control slope.

MIN

Value on Control Loop

MIN

FAN SPIN-UP

As previously mentioned, once the temperature being measured

exceeds the T

value programmed, the fan will turn on at

MIN

minimum speed (default = 33% duty cycle). However, the problem with fans being driven by PWM is that 33% duty cycle is

not enough to reliably start the fan spinning. The solution is to

ADM1029

spin the fan up for a predetermined time, and once the fan has

spun up, its running speed may be reduced in line with the

temperature being measured.

The ADM1029 allows fan spin-up times between 1/64 second

and 16 seconds. The Fan Spin-Up Register (Register 0x0C)

allows the spin-up time for the fans to be programmed. Bit 3

of this register, when set, disables fan spin-up for both fans.

Table VI. Fan Spin-Up Times

Spin-Up Times

Bits 2:0 (Fan Spin-Up Register)

000 16 Seconds

001 8 Seconds

010 4 Seconds

011 2 Seconds (Default)

100 1 Second

101 1/4 Second

110 1/16 Second

111 1/64 Second

Once the Automatic Fan Speed Control Loop parameters have

been chosen, the ADM1029 device may be programmed. The

ADM1029 is placed into Automatic Fan Speed Control Mode

by writing to the three Temperature Cooling Action Registers

(Registers 0x48, 0x49, 0x4A). The device powers up in Automatic Fan Speed Control Mode by default, as long as the T

MIN

/

Install pin (Pin 18) does not have the disable option selected

/Install pin tied low or high). The default setting is that

(T

MIN

both fans will run at the fastest speed calculated by all three

temperature channels. The control mode offers flexibility in that

the user can decide which temperature channel/channels control

each fan (five options).

Table VII. Automatic Mode Fan Behavior

Option Temperature Cooling Action

1Bit 0 Register 0x49 and/or Bit 1 Reg 0x4A =

Remote Temp 1 Controls Fan 1, Remote Temp 2

Controls Fan 2

2Bit 0 Register 0x48 and Bit 1 Register 0x48 = 1

Local Temp Controls Fan 1 and/or Fan 2

3Bit 0 Register 0x49 and Bit 1 Register 0x49 =

Remote Temp 1 Controls Fan 1 and/or Fan 2

4Bit 0 Register 0x4A and Bit 1 Register 0x4A =

Remote Temp 2 Controls Fan 1 and/or Fan 2

5Bits 0, 1 Reg 0x48, 0x49, 0x4A = 1 Max Speed

Calculated by Local and Remote Temperature

Channels Controls Fans 1 and/or 2

When Option 5 is chosen, this offers increased flexibility. The

Local and Remote temperature channels can have independently

programmed control loops with different control parameters.

Whichever control loop calculates the fastest fan speed based on

the temperature being measured, drives both fans.

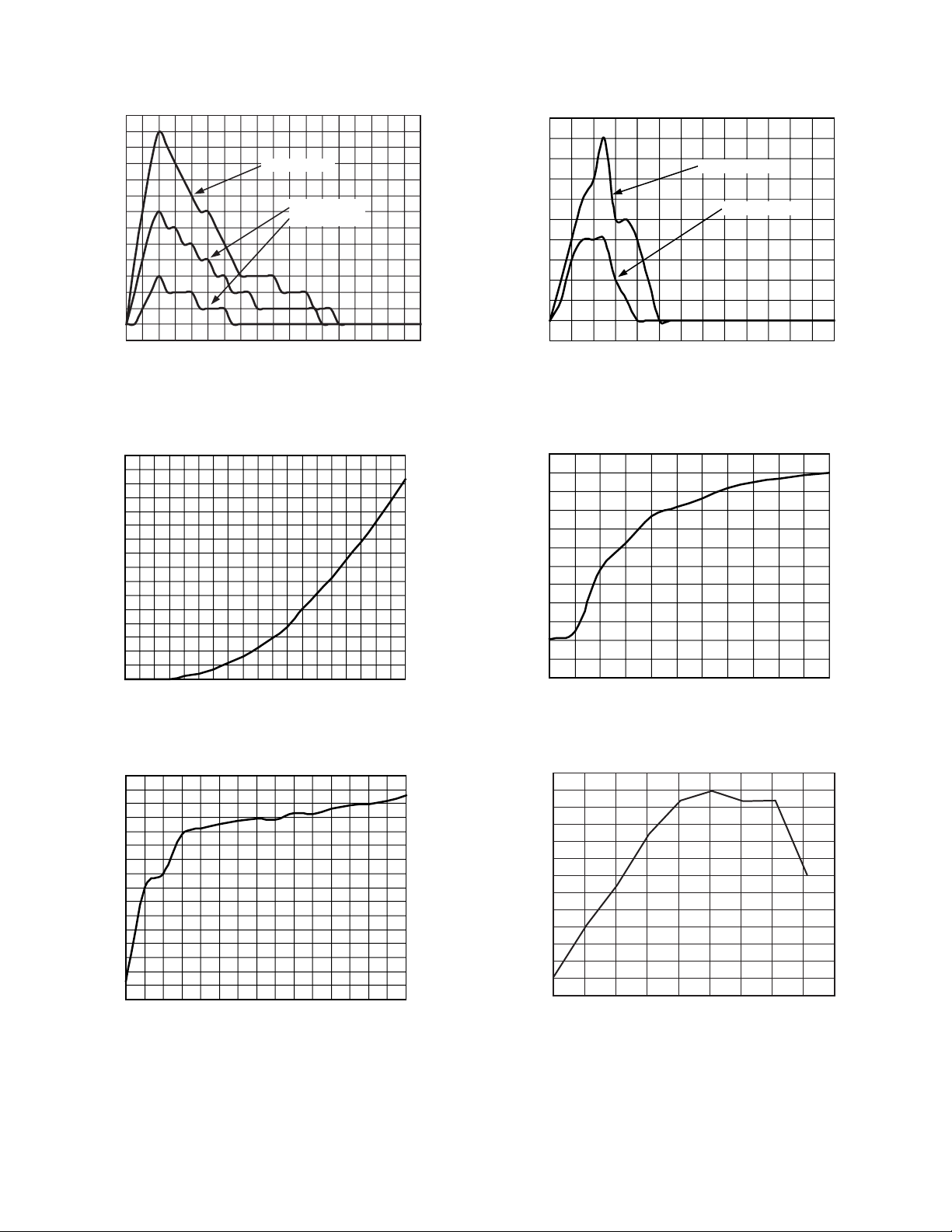

Figure 13 shows how the fan’s PWM duty cycle is determined

by two independent control loops. This is the type of Automode

Fan Behavior seen when Bits 0 and 1 of all three Temperature

Cooling Action Registers = 11. Figure 13a shows the control

loop for the Local Temperature channel. Its T

°

been programmed to 20

C, and its T

value is 40°C.

RANGE

value has

MIN

100

93

87

80

73

66

60

53

PWM DUTY CYCLE – %PWM DUTY CYCLE – %

47

40

33

02040 60

T

MIN

LOCAL TEMPERATURE – ⴗC

RANGE

T

= 40ⴗC

T

MAX

+ T

= T

MIN

RANGE

a.

100

93

87

80

73

66

60

53

47

40

33

02040 7080

T

MIN

REMOTE TEMPERATURE – ⴗC

RANGE

T

= 80ⴗC

= T

T

MAX

+ T

MIN

RANGE

b.

Figure 13. Max Speed Calculated by Local and Remote

Temperature Control Loops Drives Fans

The local temperature’s T

will thus be 60°C. Figure 13b

MAX

shows the control loop for the Remote 1 Temperature channel. Its

value has been set to 0°C, while its T

T

MIN

fore, the Remote 1 Temperature’s T

MAX

If both temperature channels measure 40

= 80°C. There-

RANGE

value will be 80°C.

°

C, both control

loops will calculate a PWM duty cycle of 66%. Therefore, the

fans will be driven at 66% duty cycle.

If both temperature channels measure 20

°

C, the local channel

will calculate 33% PWM duty cycle, while the Remote 1

channel will calculate 50% PWM duty cycle. Thus, the fans will

be driven at 50% PWM duty cycle. Consider the local temperature

°

measuring 60

°

C. The PWM duty cycle calculated by the local temperature

70

control loop will be 100% (since the temperature = T

C, while the Remote 1 temperature is measuring

). The

MAX

PWM duty cycle calculated by the Remote 1 temperature

°

control loop at 70

C will be approximately 90%. So the fans will

run full speed (100% duty cycle). Remember that the fan speed

will be based on the fastest speed calculated, and is not necessarily

based on the highest temperature measured. Depending on the

control loop parameters programmed, a lower temperature on one

channel may actually calculate a faster speed than a higher

temperature on another channel.

–18–

REV. A

ADM1029

PROGRAMMING THE AUTOMATIC FAN SPEED CONTROL LOOP

1. Program a value for T

2. Program a value for the slope T

3. T

MAX

= T

MIN

+ T

MIN

RANGE

.

.

RANGE

.

4. Program a value for Fan Spin-up Time.

5. Program the desired Automatic Fan Speed Control Mode

Behavior, i.e., which temperature channel controls each fan.

OTHER CONTROL LOOP PARAMETERS?

Having programmed all the above loop parameters, are there

any other parameters to worry about?

T

was defined as being the temperature at which a fan

MIN

switched on and ran at minimum speed. This minimum speed

should be set to 33%. If the minimum PWM duty cycle is

programmed to 33%, the fan control loops will operate as previously described.

It should be noted, however, that changing the minimum PWM

duty cycle affects the control loop behavior.

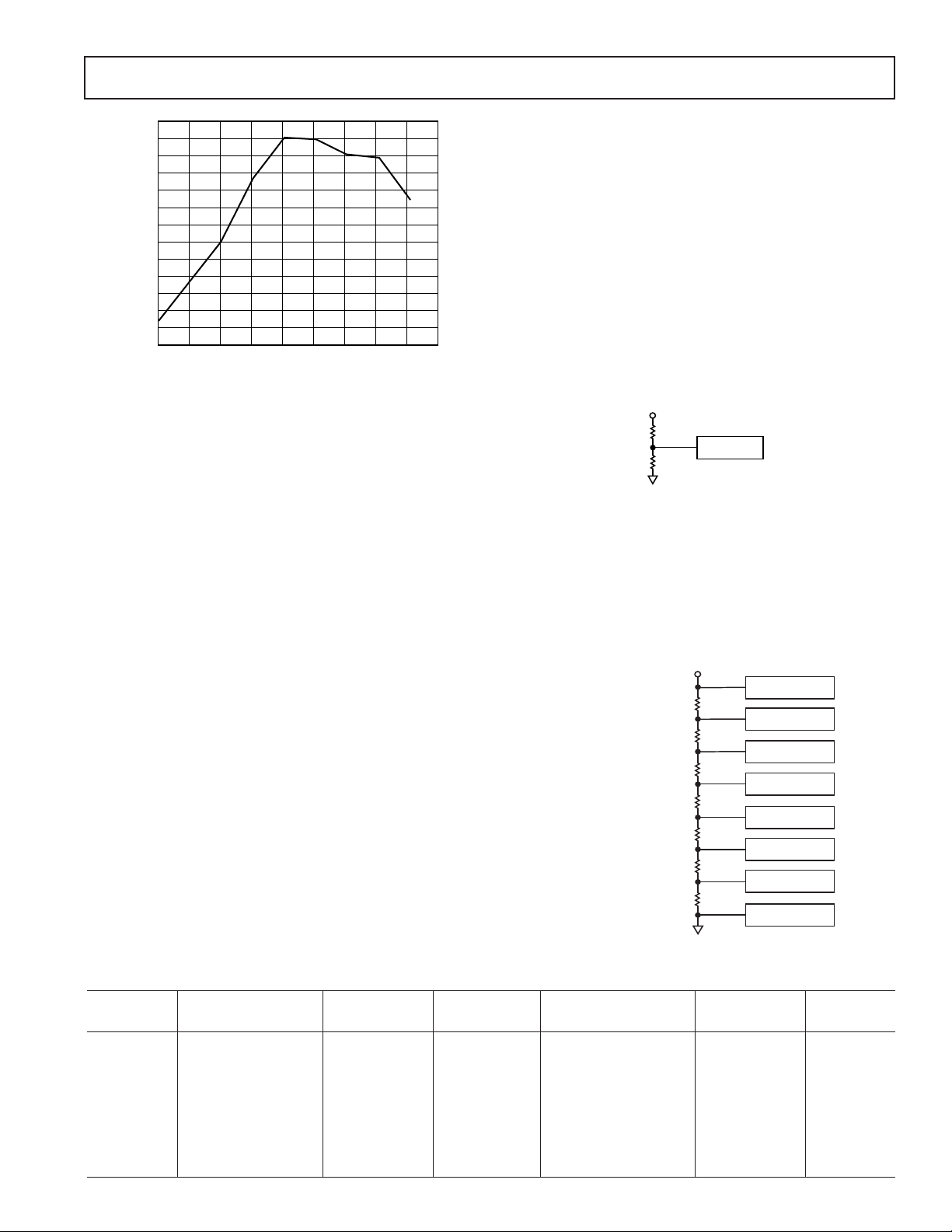

100

93

87

80

3

73

66

60

PWM DUTY CYCLE – %

53

47

40

33

0162840 60

T

MIN

2

1

= 40ⴗC

RANGE

T

TEMPERATURE – ⴗC

Figure 14. Effect of Changing Minimum Duty Cycle on

Control Loop with Fixed T

Slope 1 of Figure 14 shows T

MIN

and T

MIN

set to 0°C and the T

RANGE

Values

RANGE

chosen is 40°C. In this case, the fan’s PWM duty cycle will vary

over the range 33% to 100%. The fan will run full speed at

40°C. If the minimum PWM duty cycle at which the fan runs at

is changed, its effect can be seen on Slopes 2 and 3. Take

T

MIN

Case 2, where the minimum PWM duty cycle is reprogrammed

from 33% (default) to 53%. The fan will actually reach full speed

at a much lower temperature, 28°C. Case 3 shows that when