Page 1

查询ADM1025供应商查询ADM1025供应商

Low-Cost PC

a

FEATURES

Up to Eight Measurement Channels

Five Inputs to Measure Supply Voltages

Monitored Internally

V

CC

External Temperature Measurement with Remote Diode

On-Chip Temperature Sensor

Five Digital Inputs for VID Bits

Integrated 100 k⍀ Pull-Ups on VID Pins (ADM1025 Only)

LDCM Support

2C®

-Compatible System Management Bus (SMBus)

I

Programmable RESET Output Pin

Programmable INT Output Pin

Configurable Offset for Internal/External Channel

Shutdown Mode to Minimize Power Consumption

Limit Comparison of all Monitored Values

APPLICATIONS

Network Servers and Personal Computers

Microprocessor-Based Office Equipment

Test Equipment and Measuring Instruments

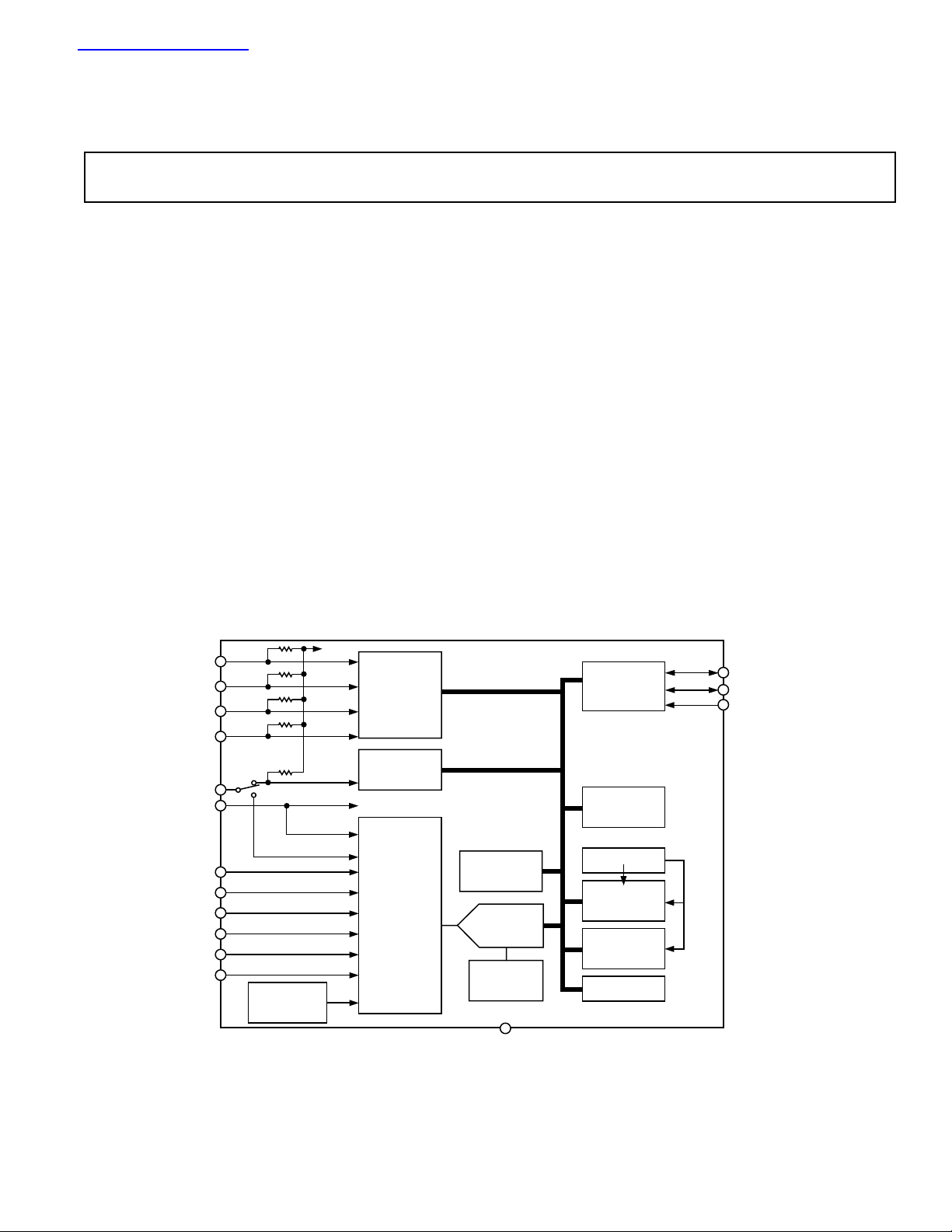

FUNCTIONAL BLOCK DIAGRAM

Hardware Monitor ASIC

ADM1025/ADM1025A*

PRODUCT DESCRIPTION

The ADM1025/ADM1025A is a complete system hardware

monitor for microprocessor-based systems, providing measurement and limit comparison of various system parameters. Five

voltage measurement inputs are provided, for monitoring 2.5 V,

3.3 V, 5 V and 12 V power supplies and the processor core

voltage. The ADM1025/ADM1025A can monitor a sixth power

supply voltage by measuring its own V

dedicated to a remote temperature-sensing diode, and an on-chip

temperature sensor allows ambient temperature to be monitored. The ADM1025A has open-drain VID inputs while the

ADM1025 has on-chip 100 kΩ pull-ups on the VID inputs.

Measured values and in/out of limit status can be read out via

2

an I

C-compatible serial System Management Bus. The device

can be controlled and configured over the same serial bus. The

device also has a programmable INT output to indicate undervoltage, overvoltage and over-temperature conditions.

The ADM1025/ADM1025A’s 3.0 V to 5.5 V supply voltage

range, low supply current, and I

it ideal for a wide range of applications. These include hardware

monitoring and protection applications in personal computers,

electronic test equipment, and office electronics.

. One input (two pins) is

CC

2

C-compatible interface make

V

VID0

VID1

VID2

VID3

300k⍀

/VID4

12V

IN

V

CC

V

CCPIN

2.5V

IN

3.3V

IN

5V

IN

D+

D–/NTI

BANDGAP

TEMPERATURE

SENSOR

*Patent Pending.

I2C is a registered trademark of Philips Corporation.

DD

100k⍀

PULLUPS

VID0–3

REGISTER

VID4

REGISTER

POWER TO CHIP

INPUT

ATTENUATORS

AND

ANALOG

MULTIPLEXER

REV. A

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

SERIAL BUS

INTERFACE

ADD/RST/INT/NTO

SDA

SCL

ADM1025/

ADM1025A

VALUE AND

LIMIT

REGISTERS

ADDRESS

POINTER

REGISTER

ADC

2.5V

BANDGAP

REFERENCE

GND

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 World Wide Web Site: http://www.analog.com

Fax: 781/326-8703 © Analog Devices, Inc., 2000

LIMIT

COMPARATORS

MEASUREMENT

STATUS

REGISTERS

OFFSET

REGISTER

CONFIGURATION

REGISTER

Page 2

ADM1025/ADM1025A–SPECIFICATIONS

P

arameter Min Typ Max Unit Test Conditions/Comments

(TA = T

MIN

to T

, VCC = V

MAX

MIN

to V

, unless otherwise noted.)

MAX

POWER SUPPLY

Supply Voltage, V

Supply Current, I

CC

CC

3.0 3.30 5.5 V (Note 1)

1.4 2.5 mA Interface Inactive, ADC Active

32 500 µA Standby Mode (Note 2)

TEMPERATURE-TO-DIGITAL CONVERTER

Internal Sensor Accuracy ± 3 °C

Resolution 1 °C

External Diode Sensor Accuracy ± 5 °C

± 3 °C60°C ≤ T

≤ 100°C; VCC = 3.3 V

A

Resolution 1 °C

Remote Sensor Source Current 180 µA High Level

11 µA Low Level

ANALOG-TO-DIGITAL CONVERTER

(INCLUDING MUX AND ATTENUATORS)

Total Unadjusted Error, TUE ±2 % (Note 3)

Differential Nonlinearity, DNL ± 1 LSB

Power Supply Sensitivity ± 1 %/V

Conversion Time (Analog Input or Internal Temperature) 11.6 ms (Note 4)

Conversion Time (External Temperature) 34.8 ms (Note 4)

Input Resistance (2.5 V, 3.3 V, 5 V, 12 V, V

) 100 140 250 kΩ

CCPIN

OPEN-DRAIN DIGITAL OUTPUT ADD/RST/INT/NTO

Output Low Voltage, V

High Level Output Leakage Current, I

OL

OH

0.1 1 µAV

0.4 V I

= –6.0 mA; V

OUT

= VCC; V

OUT

CC

= 3 V

CC

= 3 V

RST Pulsewidth 20 45 ms

OPEN-DRAIN SERIAL DATA BUS OUTPUT (SDA)

Output Low Voltage, V

High Level Output Leakage Current, I

OL

OH

0.1 1 µAV

0.4 V I

= –6.0 mA; VCC = 3 V

OUT

= V

OUT

CC

SERIAL BUS DIGITAL INPUTS (SCL, SDA)

Input High Voltage, V

Input Low Voltage, V

IL

IH

2.1 V

0.8 V

Hysteresis 500 mV

DIGITAL INPUT LOGIC LEVELS

(ADD, VID0–VID4, NTI)

5

VID0–3 Input Resistance 100 kΩ ADM1025 Only

VID4 Input Resistance 300 kΩ ADM1025 Only

100 kΩ ADM1025A

2.1 V

0.8 V

Input High Voltage, V

Input Low Voltage, V

6

IH

6

IL

DIGITAL INPUT LEAKAGE CURRENT

Input High Current, I

Input Low Current, I

IL

Input Capacitance, C

IH

IN

–1 µAV

1 µAV

IN

IN

= V

= 0

CC

5pF

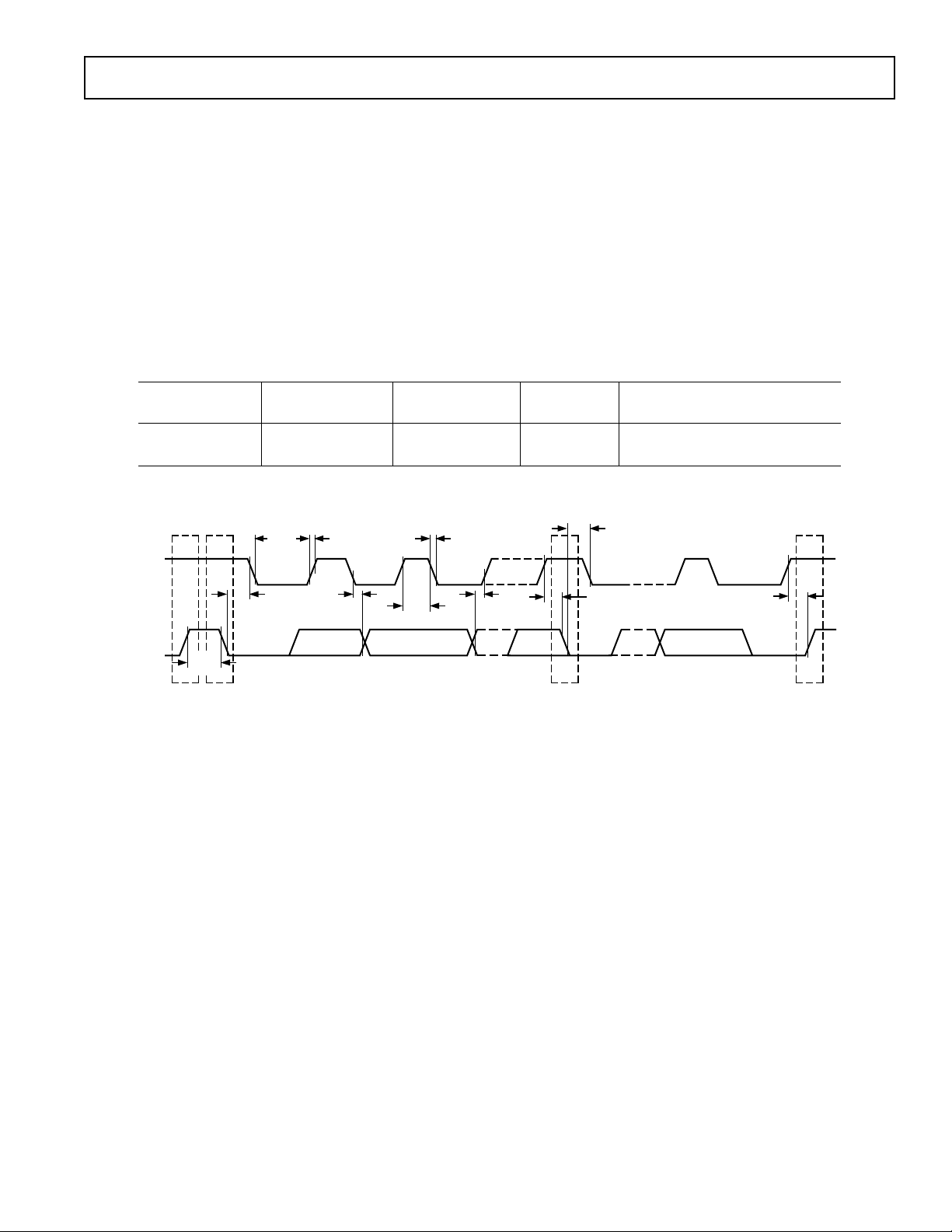

SERIAL BUS TIMING

Clock Frequency, f

Glitch Immunity, t

Bus Free Time, t

Start Setup Time, t

Start Hold Time, t

Stop Condition Setup Time t

SCL Low Time, t

SCL High Time, t

SCL, SDA Rise Time, t

SCL, SDA Fall Time, t

Data Setup Time, t

Data Hold Time, t

NOTES

1

All voltages are measured with respect to GND, unless otherwise specified.

2

Typicals are at TA = 25°C and represent most likely parametric norm. Shutdown current typ is measured with VCC = 3.3 V.

3

TUE (Total Unadjusted Error) includes Offset, Gain and Linearity errors of the ADC, multiplexer and on-chip input attenuators, including an external series input

protection resistor value between zero and 1 kΩ.

4

Total monitoring cycle time is nominally 114.4 ms. Monitoring Cycle consists of 6 Voltage + 1 Internal Temperature + 1 External Temperature readings.

5

ADD is a three-state input that may be pulled high, low or left open-circuit.

6

Timing specifications are tested at logic levels of V

Specifications subject to change without notice.

SCLK

SW

BUF

SU:STA

HD:STA

LOW

HIGH

SU:DAT

HD:DAT

50 ns See Figure 1

1.3 µs See Figure 1

600 ns See Figure 1

600 ns See Figure 1

SU:STO

600 ns See Figure 1

1.3 µs See Figure 1

0.6 µs See Figure 1

R

F

100 ns See Figure 1

300 ns See Figure 1

= 0.8 V for a falling edge and V

IL

= 2.2 V for a rising edge.

IH

400 kHz See Figure 1

300 ns See Figure 1

300 ns See Figure 1

–2–

REV. A

Page 3

ADM1025/ADM1025A

ABSOLUTE MAXIMUM RATINGS*

Positive Supply Voltage (VCC) . . . . . . . . . . . . . . . . . . . . .6.5 V

Voltage on 12 V V

Pin . . . . . . . . . . . . . . . . . . . . . . . . . 20 V

IN

Voltage on Any Input or Output Pin . . . . . . . . . –0.3 V to +6.5 V

Input Current at Any Pin . . . . . . . . . . . . . . . . . . . . . . . ± 5 mA

Package Input Current . . . . . . . . . . . . . . . . . . . . . . . ± 20 mA

Maximum Junction Temperature (TJ max) . . . . . . . . . . 150°C

Storage Temperature Range . . . . . . . . . . . . –65°C to +150°C

Lead Temperature, Soldering

Vapor Phase 60 sec . . . . . . . . . . . . . . . . . . . . . . . . . . . 215°C

Infrared 15 sec . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200°C

ESD Rating All Pins . . . . . . . . . . . . . . . . . . . . . . . . . . 2000 V

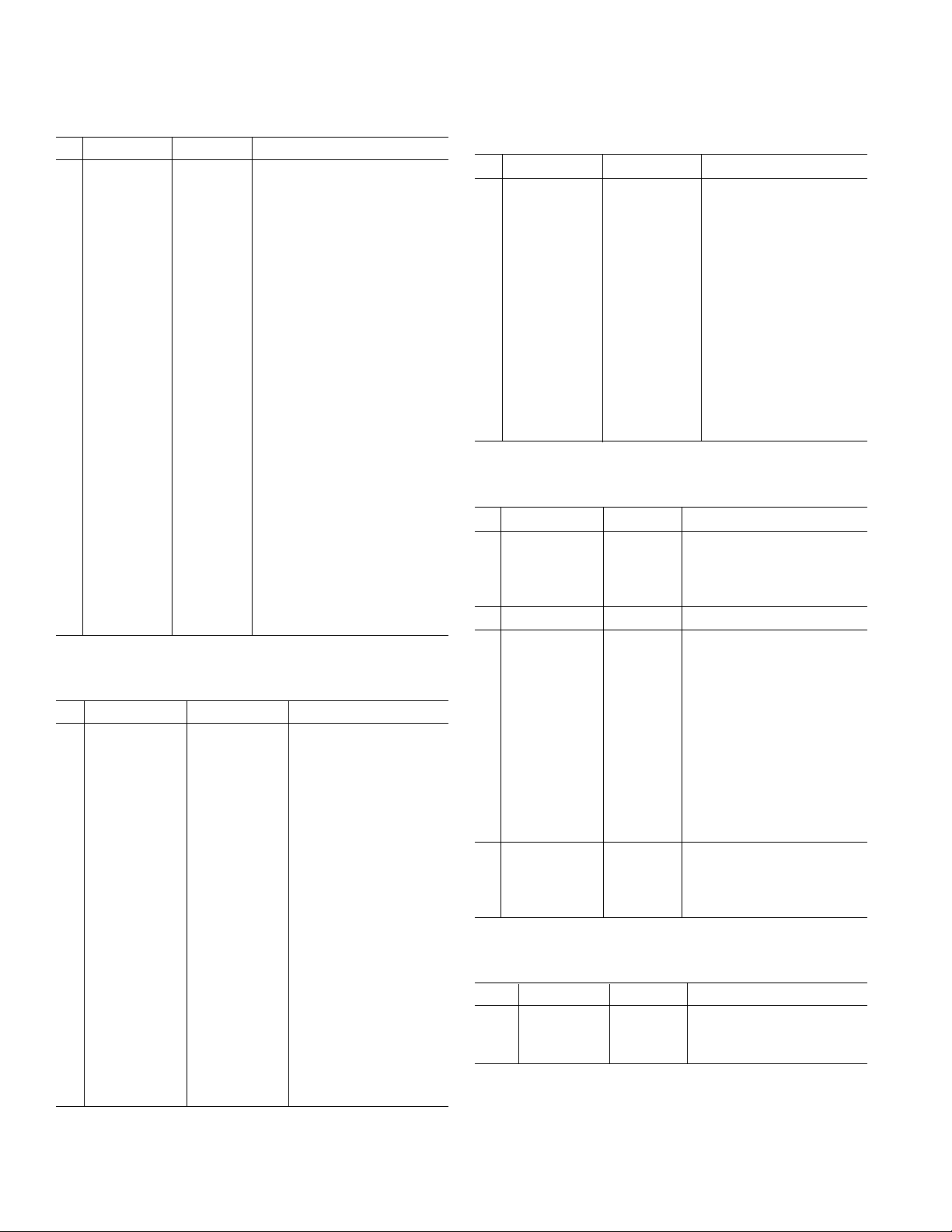

ORDERING GUIDE

Temperature Package Package

Model Range Description Option Option

ADM1025ARQ 0°C to 100°C 16-Lead QSOP RQ-16 Integrated 100

ADM1025AARQ 0°C to 100°C 16-Lead QSOP RQ-16 Open-Drain VID Inputs

t

LOW

t

R

t

F

*Stresses above those listed under Absolute Maximum Ratings may cause perma-

nent damage to the device. This is a stress rating only; functional operation of the

device at these or any other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute maximum rating

conditions for extended periods may affect device reliability.

THERMAL CHARACTERISTICS

16-Lead QSOP Package:

θ

= 105°C/W

JA

= 39°C/W

θ

JC

kΩ

VID Pull-Ups

t

HD:STA

SCL

SDA

t

t

HD:STA

t

BUF

S

HD:DAT

t

HIGH

t

SU:DAT

t

SU:STA

t

HD:STO

PSP

Figure 1. Diagram for Serial Bus Timing

REV. A

–3–

Page 4

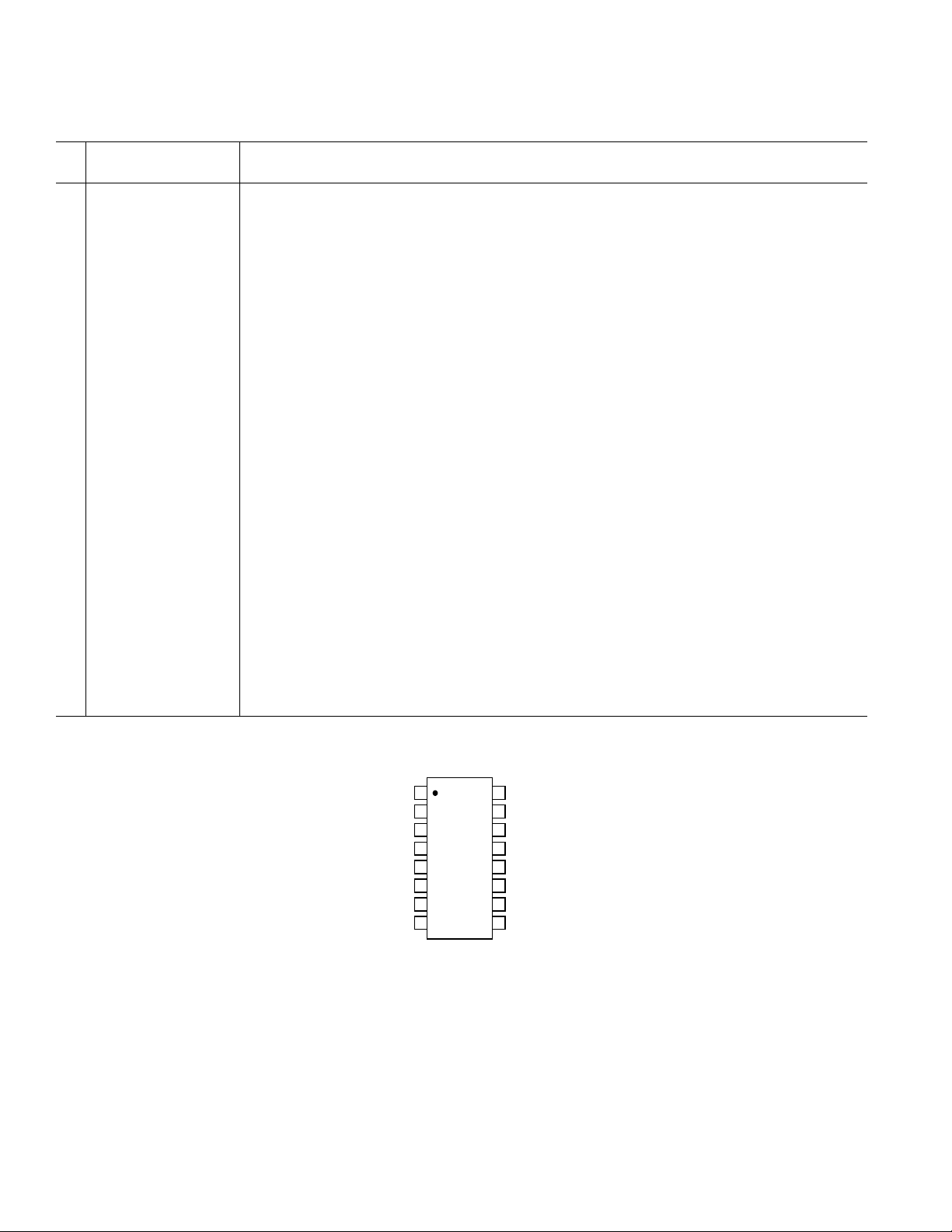

ADM1025/ADM1025A

PIN FUNCTION DESCRIPTIONS

Pin

No. Mnemonic Description

1 SDA Digital I/O. Serial bus bidirectional data. Open-drain output.

2 SCL Digital Input. Serial bus clock.

3 GND System Ground.

4V

CC

5 VID0 Digital Input. Core voltage ID readouts from the processor. This value is read into the VID0–VID3

6 VID1 Digital Input. Core voltage ID readouts from the processor. This value is read into the VID0–VID3

7 VID2 Digital Input. Core voltage ID readouts from the processor. This value is read into the VID0–VID3

8 VID3 Digital Input. Core voltage ID readouts from the processor. This value is read into the VID0–VID3

9 D–/NTI Analog/Digital Input. Connected to cathode of external temperature sensing diode. If held high at

10 D+ Analog Input. Connected to anode of external temperature sensing diode.

11 12 V

12 5 V

13 3.3 V

14 2.5 V

15 V

/VID4 Programmable Analog/Digital Input. Defaults to 12 VIN analog input at power-up, but may be pro-

IN

IN

IN

IN

CCPIN

16 ADD/RST/INT/NTO Programmable Digital I/O. The lowest order programmable bit of the SMBus Address, sampled on

Power. Can be powered by +3.3 V standby power if monitoring in low power states is required.

This pin also serves as the analog input to monitor V

CC

.

Status Register. It has an on-chip 100 kΩ pull-up resistor (ADM1025 only).

Status Register. It has an on-chip 100 kΩ pull-up resistor (ADM1025 only).

Status Register. It has an on-chip 100 kΩ pull-up resistor (ADM1025 only).

Status Register. It has an on-chip 100 kΩ pull-up resistor (ADM1025 only).

power-up, initiates NAND tree test mode.

grammed as VID4 Core Voltage ID readout from the processor. This value is read into the VID4

Status Register. In analog 12 V

mode it has an on-chip voltage attenuator. In VID4 mode it has an

IN

on-chip 300 kΩ pull-up resistor.

Analog Input. Monitors 5 V supply.

Analog Input. Monitors 3.3 V supply.

Analog Input. Monitors 2.5 V supply.

Analog Input. Monitors processor core voltage (0 V to 3.0 V).

SMB activity as a three-state input. Can also be configured to give a minimum 20 ms low reset

output pulse. Alternatively, can be programmed as an interrupt output for temperature/voltage

interrupts. Functions as the output of the NAND tree in NAND tree test mode.

PIN CONFIGURATION

SDA

SCL

GND

V

VID0

VID1

VID2

VID3

1

2

3

4

CC

5

6

7

8

ADM1025/

ADM1025A

TOP VIEW

(Not to Scale)

16

ADD/RST/INT/NTO

V

15

CCPIN

2.5V

14

IN

3.3V

13

IN

5V

12

IN

12V

/VID4

11

IN

10

D+

D–/NTI

9

–4–

REV. A

Page 5

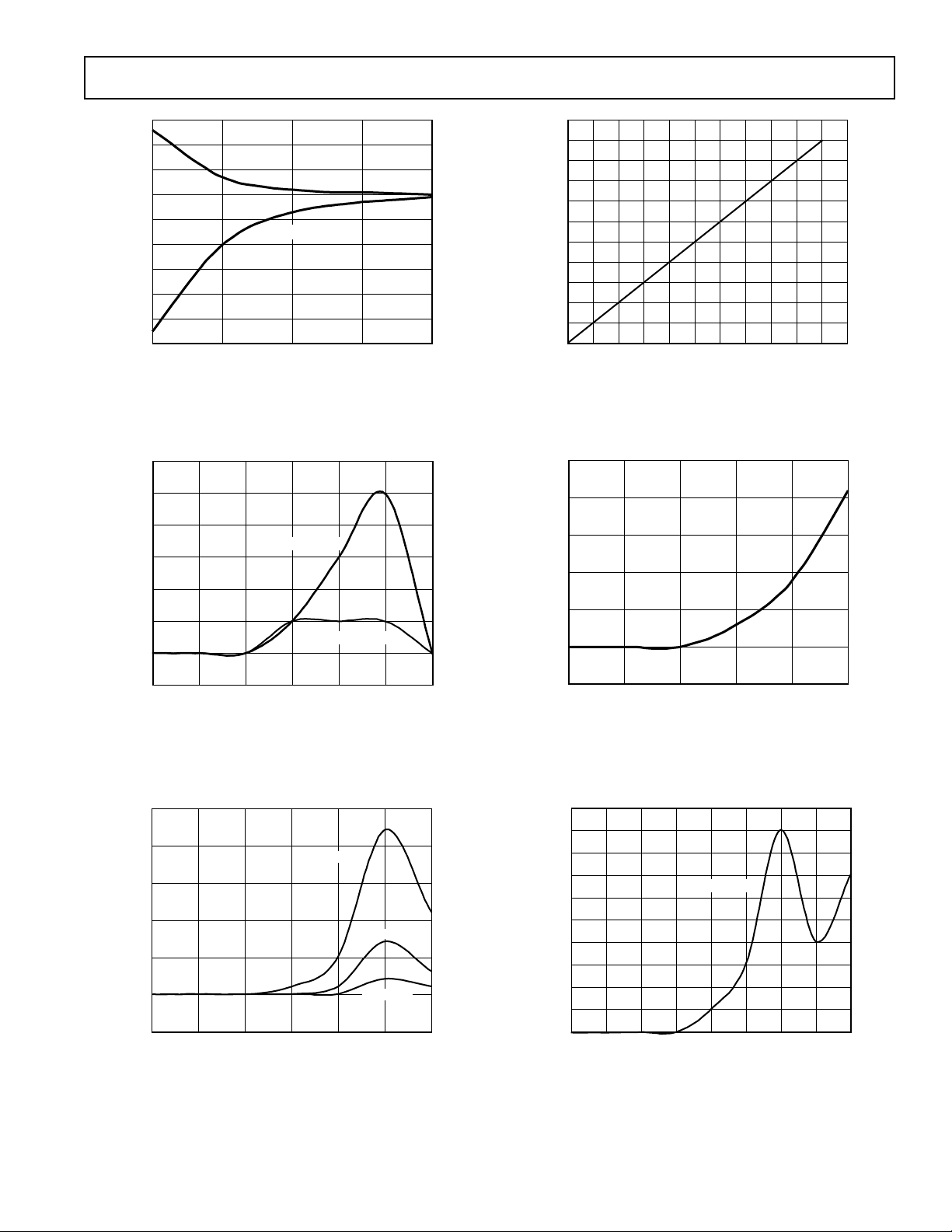

Typical Performance Characteristics–

ADM1025/ADM1025A

30

20

10

0

–10

–20

–30

TEMPERATURE ERROR – ⴗC

–40

–50

–60

1 1003.3

LEAKAGE RESISTANCE – M⍀

DXP TO GND

DXP TO VCC (5V)

10 30

Figure 2. Temperature Error vs. PC Board Track Resistance

6

5

4

250mV p-p REMOTE

3

2

1

TEMPERATURE ERROR – ⴗC

0

100mV p-p REMOTE

120

100

90

80

70

60

50

READING

40

30

20

10

0

0 11010

20 30 40 50

MEASURED TEMPERATURE

60 70 80 90 100

Figure 5. Pentium II® Temperature Measurement vs.

ADM1025/ADM1025A Reading

25

20

15

10

5

TEMPERATURE ERROR – ⴗC

0

–1

50 50M500

5k

50k

FREQUENCY – Hz

500k 5M

Figure 3. Temperature Error vs. Power Supply Noise

Frequency

25

20

15

10

5

TEMPERATURE ERROR – ⴗC

0

–5

50 50M500

5k 50k 500k 5M

FREQUENCY – Hz

100mV p-p

50mV p-p

25mV p-p

Figure 4. Temperature Error vs. Common-Mode Noise

Frequency

–5

1102.2

3.2 4.7 7

DXP-DXN CAPACITANCE – nF

Figure 6. Temperature Error vs. Capacitance Between D+

and D–

10

9

8

TEMPERATURE ERROR – ⴗC

7

6

5

4

3

2

1

0

50 50M500

5k 50k 500k 5M

10mV SQ. WAVE

100k 25M

FREQUENCY – Hz

Figure 7. Temperature Error vs. Differential-Mode Noise

Frequency

Pentium II is a registered trademark of Intel Corporation.

REV. A

–5–

Page 6

ADM1025/ADM1025A

26.5

26.0

SHUTDOWN CURRENT – A

25.5

25.0

24.5

24.0

23.5

23.0

22.5

–40 –20

VDD = 3.3V

0 20 40 60 80 100 120

TEMPERATURE – C

Figure 8. Standby Current vs. Temperature

GENERAL DESCRIPTION

The ADM1025/ADM1025A is a complete system hardware

monitor for microprocessor-based systems. The device communicates with the system via a serial System Management Bus.

The serial bus controller has a hardwired address line for device

selection (Pin 16), a serial data line for reading and writing

addresses and data (Pin 1), and an input line for the serial clock

(Pin 2). All control and programming functions of the ADM1025/

ADM1025A are performed over the serial bus.

MEASUREMENT INPUTS

The device has six measurement inputs, five for voltage and one

for temperature. It can also measure its own supply voltage and

can measure ambient temperature with its on-chip temperature

sensor.

Pins 11 through 15 are analog inputs with on-chip attenuators,

configured to monitor 12 V, 5 V, 3.3 V, 2.5 V and the processor

core voltage, respectively. Pin 11 may alternatively be programmed

as a digital input for Bit 4 of the processor voltage ID code.

Power is supplied to the chip via Pin 4 and the system also

monitors the voltage on this pin.

Remote temperature sensing is provided by the D+ and D–

inputs, to which a diode-connected, external temperaturesensing transistor may be connected.

An on-chip bandgap temperature sensor monitors system ambient temperature.

SEQUENTIAL MEASUREMENT

When the ADM1025/ADM1025A monitoring sequence is started,

it cycles sequentially through the measurement of analog inputs

and the temperature sensors. Measured values from these inputs

are stored in Value Registers. These can be read out over the

serial bus, or can be compared with programmed limits stored

in the Limit Registers. The results of out-of-limit comparisons

are stored in the Status Registers, which can be read over the

serial bus to flag out of limit conditions.

PROCESSOR VOLTAGE ID

Five digital inputs (VID4 to VID0—Pins 5 to 8 and 11) read the

processor voltage ID code and store it in the VID registers, from

which it can be read out by the management system over the

serial bus. If Pin 11 is configured as a 12 V analog input (powerup default), the VID4 bit in the VID4 register will default to 0.

The VID pins have internal 100 kΩ pull-up resistors (ADM1025

only).

ADD/RST/INT/NTO

Pin 16 is a programmable digital I/O pin. After power-up, at the

first sign of SMBus activity, it is sampled to set the lowest two

bits of the serial bus address. During board-level, NAND tree

connectivity testing, this pin functions as the output of the NAND

tree. During normal operation Pin 16 may be programmed as a

reset output to provide a low going 20 ms reset pulse when

enabled, or it may be programmed as an interrupt output for

out-of-limit temperature and/or voltage events. These functions

are described in more detail later.

INTERNAL REGISTERS OF THE ADM1025/ADM1025A

A brief description of the ADM1025/ADM1025A’s principal

internal registers is given below. More detailed information on

the function of each register is given in Tables V to XV.

Configuration Register: Provides control and configuration.

Address Pointer Register: This register contains the address that

selects one of the other internal registers. When writing to the

ADM1025/ADM1025A, the first byte of data is always a register

address, which is written to the Address Pointer Register.

Status Registers: Two registers to provide status of each limit

comparison.

VID Registers: The status of the VID0 to VID4 pins of the

processor can read from these registers.

Value and Limit Registers: The results of analog voltage

inputs and temperature measurements are stored in these registers, along with their limit values.

Offset Register: Allows either an internal or external temperature channel reading to be offset by a two’s complement value

written to this register.

SERIAL BUS INTERFACE

Control of the ADM1025/ADM1025A is carried out via the

serial bus. The ADM1025/ADM1025A is connected to this

bus as a slave device, under the control of a master device or

master controller.

The ADM1025/ADM1025A has a 7-bit serial bus address. When

the device is powered up, it will do so with a default serial bus

address. The five MSBs of the address are set to 01011, the two

LSBs are determined by the logical states of Pin 16 at power-up.

This is a three-state input that can be grounded, connected to

V

or left open-circuit to give three different addresses:

CC

Table I. Address Selection

–6–

ADD Pin A1 A0

GND 0 0

No Connect 1 0

V

CC

01

REV. A

Page 7

ADM1025/ADM1025A

If ADD is left open-circuit the default address will be 0101110.

ADD is sampled only after power-up, so any changes made will

have no effect, unless power is cycled.

The facility to make hardwired changes to A1 and A0 allows the

user to avoid conflicts with other devices sharing the same serial

bus if, for example, more than one ADM1025/ADM1025A is

used in a system. However, as previously mentioned, the ADD

pin may also function as a reset output or interrupt output. Use

of these functions may restrict the addresses that can be set. See

the sections on RST and INT for further information.

The serial bus protocol operates as follows:

1. The master initiates data transfer by establishing a START

condition, defined as a high-to-low transition on the serial

data line SDA while the serial clock line SCL remains high.

This indicates that an address/data stream will follow. All

slave peripherals connected to the serial bus respond to the

START condition, and shift in the next eight bits, consisting

of a 7-bit address (MSB first) plus an R/W bit, which determines the direction of the data transfer, i.e., whether data

will be written to or read from the slave device.

The peripheral whose address corresponds to the transmitted

address responds by pulling the data line low during the low

period before the ninth clock pulse, known as the Acknowledge Bit. All other devices on the bus now remain idle while

the selected device waits for data to be read from or written

to it. If the R/W bit is a 0, the master will write to the slave

device. If the R/W bit is a 1, the master will read from the

slave device.

2. Data is sent over the serial bus in sequences of nine clock

pulses, eight bits of data followed by an Acknowledge Bit

from the slave device. Transitions on the data line must

occur during the low period of the clock signal and remain

stable during the high period, as a low-to-high transition

when the clock is high may be interpreted as a STOP signal.

The number of data bytes that can be transmitted over the

serial bus in a single READ or WRITE operation is limited

only by what the master and slave devices can handle.

3. When all data bytes have been read or written, stop conditions are established. In WRITE mode, the master will pull

the data line high during the 10th clock pulse to assert a

STOP condition. In READ mode, the master device will

override the acknowledge bit by pulling the data line high

during the low period before the 9th clock pulse. This is

known as No Acknowledge. The master will then take the

data line low during the low period before the 10th clock

pulse, then high during the 10th clock pulse to assert a

STOP condition.

Any number of bytes of data may be transferred over the serial

bus in one operation, but it is not possible to mix read and write

in one operation, because the type of operation is determined at

the beginning and cannot subsequently be changed without

starting a new operation.

In the case of the ADM1025/ADM1025A, write operations

contain either one or two bytes, and read operations contain one

byte, and perform the following functions:

To write data to one of the device data registers or read data

from it, the Address Pointer Register must be set so that the

correct data register is addressed, data can then be written into

that register or read from it. The first byte of a write operation

always contains an address that is stored in the Address Pointer

Register. If data is to be written to the device, the write operation contains a second data byte that is written to the register

selected by the address pointer register.

This is illustrated in Figure 9a. The device address is sent over

the bus followed by R/W set to 0. This is followed by two data

bytes. The first data byte is the address of the internal data

register to be written to, which is stored in the Address Pointer

Register. The second data byte is the data to be written to the

internal data register.

SCL

SDA

START BY

MASTER

19

1 0 1 1 A1 A0 D7

FRAME 1

SERIAL BUS ADDRESS BYTE

SCL (CONTINUED)

SDA (CONTINUED)

R/W0

ADM1025

ACK. BY

1

D7 D6

1

D6

D5 D4 D3

D2

D2

D1 D0

D1

D5 D4 D3

ADDRESS POINTER REGISTER BYTE

FRAME 2

FRAME 3

DATA BYTE

ACK. BY

ADM1025

D0

9

9

ACK. BY

ADM1025

STOP BY

MASTER

Figure 9a. Writing a Register Address to the Address Pointer Register, then Writing Data to the Selected Register

REV. A

–7–

Page 8

ADM1025/ADM1025A

191

SCL

SDA 1 0 1 1 A1 A0 D7

START BY

MASTER

0

FRAME 1

SERIAL BUS ADDRESS BYTE

R/W

ACK. BY

ADM1025

Figure 9b. Writing to the Address Pointer Register Only

19

SCL

0

SDA

START BY

MASTER

1 0 1 1 A1 A0 D7

FRAME 1

SERIAL BUS ADDRESS BYTE

R/W

ACK. BY

ADM1025

Figure 9c. Reading Data from a Previously Selected Register

When reading data from a register there are two possibilities:

1. If the ADM1025/ADM1025A’s Address Pointer Register

value is unknown or not the desired value, it is first necessary

to set it to the correct value before data can be read from the

desired data register. This is done by performing a write to

the ADM1025/ADM1025A as before, but only the data byte

containing the register address is sent, as data is not to be

written to the register. This is shown in Figure 9b.

A read operation is then performed consisting of the serial bus

address, R/W bit set to 1, followed by the data byte read from

the data register. This is shown in Figure 9c.

2. If the Address Pointer Register is known to be already at the

desired address, data can be read from the corresponding

data register without first writing to the Address Pointer

Register, so Figure 9b can be omitted.

NOTES

1. Although it is possible to read a data byte from a data register

without first writing to the Address Pointer Register, if the

Address Pointer Register is already at the correct value, it is

not possible to write data to a register without writing to the

Address Pointer Register, because the first data byte of a

write is always written to the Address Pointer Register.

2. In Figures 9a to 9c, the serial bus address is shown as the

default value 01011(A1)(A0), where A1 and A0 are set by

the three-state ADD pin.

3. In addition to supporting the Send Byte and Receive Byte

protocols, the ADM1025/ADM1025A also supports the

Read Byte protocol (see System Management Bus specifications Rev. 1.1 for more information).

4. If Reset or Interrupt functionality is required, address pin

cannot be strapped to GND, as this would keep the ADD/

RST/INT/NTO pin permanently low.

MEASUREMENT INPUTS

The ADM1025/ADM1025A has six external measurement

inputs, five for voltage and one (two pins) for temperature.

Internal measurements are also carried out on V

and the

CC

on-chip temperature sensor.

–8–

9

D6

ADDRESS POINTER REGISTER BYTE

1

D6

D4

D5

FRAME 2

D5 D4 D3

FRAME 2

DATA BYTE FROM ADM1025

D3

D2

D2

D1

D1

D0

ACK. BY

ADM1025

D0

NO ACK.

BY MASTER

STOP BY

MASTER

9

STOP BY

MASTER

A-TO-D CONVERTER

These inputs are multiplexed into the on-chip, successive approximation, analog-to-digital converter. This has a resolution

of eight bits. The basic input range is zero to 2.5 V, but the

inputs have built-in attenuators to allow measurement of 2.5 V,

3.3 V, 5 V, 12 V and the processor core voltage V

, without

CCP

any external components. To allow for the tolerance of these

supply voltages, the A-to-D converter produces an output of

3/4 full scale (decimal 192) for the nominal input voltage, and

so has adequate headroom to cope with overvoltages. Table II

shows the input ranges of the analog inputs and output codes of

the A-to-D converter.

When the ADC is running, it samples and converts an input

every 11.6 ms, except for the external temperature (D+ and D–)

input. This has special input signal conditioning and is averaged

over 16 conversions to reduce noise; a measurement on this

input takes nominally 34.8 ms.

INPUT CIRCUITS

The internal structure for the analog inputs are shown in Figure

10. Each input circuit consists of an input protection diode, an

attenuator, plus a capacitor to form a first-order low-pass filter

which gives the input immunity to high frequency noise.

122.2k

12V

3.3V

2.5V

V

5V

CCPIN

IN

IN

IN

IN

22.7k

91.6k

55.2k

62.6k

82.4k

36.7k

111.2k

19.6k

105k⍀

⍀

⍀

⍀

⍀

⍀

⍀

⍀

⍀

⍀

35pF

25pF

25pF

25pF

10pF

MUX

Figure 10. Structure of Analog Inputs

REV. A

Page 9

ADM1025/ADM1025A

Table II. A/D Output Code vs. V

IN

Input Voltage A/D Output

12 V

IN

5 V

IN

VCC/3.3 V

IN

2.5 V

IN

V

CCPIN

Decimal Binary

<0.062 <0.026 <0.0172 <0.013 <0.012 0 0000 0000

0.062–0.125 0.026–0.052 0.017–0.034 0.013–0.026 0.012–0.023 1 0000 0001

0.125–0.188 0.052–0.078 0.034–0.052 0.026–0.039 0.023–0.035 2 0000 0010

0.188–0.250 0.078–0.104 0.052–0.069 0.039–0.052 0.035–0.047 3 0000 0011

0.250–0.313 0.104–0.130 0.069–0.086 0.052–0.065 0.047–0.058 4 0000 0100

0.313–0.375 0.130–0.156 0.086–0.103 0.065–0.078 0.058–0.070 5 0000 0101

0.375–0.438 0.156–0.182 0.103–0.120 0.078–0.091 0.070–0.082 6 0000 0110

0.438–0.500 0.182–0.208 0.120–0.138 0.091–0.104 0.082–0.093 7 0000 0111

0.500–0.563 0.208–0.234 0.138–0.155 0.104–0.117 0.093–0.105 8 0000 1000

•

•

•

4.000–4.063 1.666–1.692 1.100–1.117 0.833–0.846 0.749–0.761 64 (1/4 Scale) 0100 0000

•

•

•

8.000–8.063 3.330–3.560 2.200–2.217 1.667–1.680 1.499–1.511 128 (1/2 Scale) 1000 0000

•

•

•

12.000–12.063 5.000–5.026 3.300–3.317 2.500–2.513 2.249–2.261 192 (3/4 Scale) 1100 0000

•

•

•

15.312–15.375 6.380–6.406 4.210–4.230 3.190–3.203 2.869–2.881 245 1111 0101

15.375–15.437 6.406–6.432 4.230–4.245 3.203–3.216 2.881–2.893 246 1111 0110

15.437–15.500 6.432–6.458 4.245–4.263 3.216–3.229 2.893–2.905 247 1111 0111

15.500–15.563 6.458–6.484 4.263–4.280 3.229–3.242 2.905–2.916 248 1111 1000

15.625–15.625 6.484–6.510 4.280–4.300 3.242–3.255 2.916–2.928 249 1111 1001

15.625–15.688 6.510–6.536 4.300–4.314 3.255–3.268 2.928–2.940 250 1111 1010

15.688–15.750 6.536–6.562 4.314–4.330 3.268–3.281 2.940–2.951 251 1111 1011

15.750–15.812 6.562–6.588 4.331–4.348 3.281–3.294 2.951–2.964 252 1111 1100

15.812–15.875 6.588–6.615 4.348–4.366 3.294–3.307 2.964–2.975 253 1111 1101

15.875–15.938 6.615–6.640 4.366–4.383 3.307–3.320 2.975–2.987 254 1111 1110

>15.938 >6.640 >4.383 >3.320 >2.988 255 1111 1111

REV. A

–9–

Page 10

ADM1025/ADM1025A

TEMPERATURE MEASUREMENT SYSTEM

Internal Temperature Measurement

The ADM1025/ADM1025A contains an on-chip bandgap temperature sensor, whose output is digitized by the on-chip ADC.

The temperature data is stored in the Local Temperature Value

Register (address 27h). As both positive and negative temperatures can be measured, the temperature data is stored in two’s

complement format, as shown in Table III. Theoretically, the

temperature sensor and ADC can measure temperatures from

–128°C to +127°C with a resolution of 1°C, although temperatures below 0°C and above 100°C are outside the operating

temperature range of the device.

External Temperature Measurement

The ADM1025/ADM1025A can measure temperature using an

external diode sensor or diode-connected transistor, connected to

Pins 9 and 10.

The forward voltage of a diode or diode-connected transistor,

operated at a constant current, exhibits a negative temperature

coefficient of about –2 mV/°C. Unfortunately, the absolute

value of V

, varies from device to device, and individual calibra-

BE

tion is required to null this out, so the technique is unsuitable

for mass production.

The technique used in the ADM1025/ADM1025A is to measure

the change in V

when the device is operated at two differ-

BE

ent currents.

This is given by:

= KT/q × ln(N)

∆V

BE

where:

K is Boltzmann’s constant

q is charge on the carrier

T is absolute temperature in Kelvins

N is ratio of the two currents

Figure 11 shows the input signal conditioning used to measure

the output of an external temperature sensor. This figure shows

the external sensor as a substrate transistor, provided for temperature monitoring on some microprocessors, but it could

equally well be a discrete transistor.

If a discrete transistor is used, the collector will not be grounded,

and should be linked to the base. If a PNP transistor is used,

the base is connected to the D– input and the emitter to the D+

input. If an NPN transistor is used, the emitter is connected to

the D– input and the base to the D+ input.

Bit 6 of Status Register 2 (42h) is set if a remote diode fault is

detected. The ADM1025/ADM1025A detects shorts from D+

to GND or supply, as well as shorts/opens between D+/D–.

V

DD

IN ⴛ II

BIAS

Table III. Temperature Data Format

Temperature Digital Output

–128°C 1000 0000

–125°C 1000 0011

–100°C 1001 1100

–75°C 1011 0101

–50°C 1100 1110

–25°C 1110 0111

0°C 0000 0000

+10°C 0000 1010

+25°C 0001 1001

+50°C 0011 0010

+75°C 0100 1011

+100°C 0110 0100

+125°C 0111 1101

+127°C 0111 1111

To prevent ground noise interfering with the measurement, the

more negative terminal of the sensor is not referenced to ground,

but is biased above ground by an internal diode at the D– input.

If the sensor is used in a very noisy environment, a capacitor of

value up to 1 nF may be placed between the D+ and D– inputs

to filter the noise.

To measure ∆V

, the sensor is switched between operating

BE

currents of I and N × I. The resulting waveform is passed through

a 65 kHz low-pass filter to remove noise, then to a chopperstabilized amplifier that performs the functions of amplification

and rectification of the waveform to produce a dc voltage proportional to ∆V

. This voltage is measured by the ADC to give

BE

a temperature output in 8-bit two’s complement format. To

further reduce the effects of noise, digital filtering is performed

by averaging the results of sixteen measurement cycles. An

external temperature measurement takes nominally 34.8 ms.

LAYOUT CONSIDERATIONS

Digital boards can be electrically noisy environments and care

must be taken to protect the analog inputs from noise, particularly when measuring the very small voltages from a remote

diode sensor. The following precautions should be taken:

1. Place the ADM1025/ADM1025A as close as possible to the

remote sensing diode. Provided that the worst noise sources

such as clock generators, data/address buses and CRTs are

avoided, this distance can be four to eight inches.

2. Route the D+ and D– tracks close together, in parallel, with

grounded guard tracks on each side. Provide a ground plane

under the tracks if possible.

3. Use wide tracks to minimize inductance and reduce noise

pickup. 10 mil track minimum width and spacing is

recommended.

D+

REMOTE

SENSING

TRANSISTOR

D–

BIAS

DIODE

LOW-PASS

FILTER

= 65kHz

f

C

Figure 11. Signal Conditioning for External Diode

Temperature Sensors

V

V

OUT+

OUT–

TO

ADC

–10–

GND

D+

D–

GND

10MIL

10MIL

10MIL

10MIL

10MIL

10MIL

10MIL

Figure 12. Arrangement of Signal Tracks

REV. A

Page 11

ADM1025/ADM1025A

4. Try to minimize the number of copper/solder joints, which

can cause thermocouple effects. Where copper/solder joints

are used, make sure that they are in both the D+ and D–

path and at the same temperature.

Thermocouple effects should not be a major problem as 1°C

corresponds to about 240 µV, and thermocouple voltages are

about 3 µV/

thermocouples with a big temperature differential between

them, thermocouple voltages should be much less than 200 µV.

5. Place 0.1 µF bypass and 1 nF input filter capacitors close to

the ADM1025/ADM1025A.

6. If the distance to the remote sensor is more than 8 inches, the

use of twisted pair cable is recommended. This will work up

to about 6 to 12 feet.

7. For really long distances (up to 100 feet) use shielded twisted

pair such as Belden #8451 microphone cable. Connect the

twisted pair to D+ and D– and the shield to GND close to

the ADM1025/ADM1025A. Leave the remote end of the

shield unconnected to avoid ground loops.

Because the measurement technique uses switched current

sources, excessive cable and/or filter capacitance can affect the

measurement. When using long cables, the filter capacitor may

be reduced or removed.

Cable resistance can also introduce errors. 1 Ω series resistance

introduces about 0.5°C error.

LIMIT VALUES

High and low limit values for each measurement channel are

stored in the appropriate limit registers. As each channel is

measured, the measured value is stored and compared with the

programmed limit.

STATUS REGISTERS

The results of limit comparisons are stored in Status Registers 1

and 2. The Status Register bit for a particular measurement

channel reflects the status of the last measurement and limit

comparison on that channel. If a measurement is within limits

the corresponding Status Register bit will be cleared to “0.” If

the measurement is out of limits the corresponding status register bit will be set to “1.”

The state of the various measurement channels may be polled

by reading the Status Registers over the serial bus. Reading the

Status Registers does not affect their contents. Out-of-limit

temperature/voltage events may also be used to generate an

interrupt, so that remedial action such as turning on a cooling

fan may be taken immediately. This is described in the section

on RST and INT.

MONITORING CYCLE TIME

The monitoring cycle begins when a one is written to the Start

Bit (Bit 0) of the Configuration Register. The ADC measures

each analog input in turn and as each measurement is completed the result is automatically stored in the appropriate value

register. This “round-robin” monitoring cycle continues until it

is disabled by writing a 0 to Bit 0 of the Configuration Register.

o

C of temperature difference. Unless there are two

As the ADC will normally be left to free-run in this manner, the

time taken to monitor all the analog inputs will normally not be

of interest, as the most recently measured value of any input can

be read out at any time.

INPUT SAFETY

Scaling of the analog inputs is performed on-chip, so external

attenuators are normally not required. However, since the power

supply voltages will appear directly at the pins, its is advisable to

add small external resistors in series with the supply traces to the

chip to prevent damaging the traces or power supplies should

an accidental short such as a probe connect two power supplies together.

As the resistors will form part of the input attenuators, they will

affect the accuracy of the analog measurement if their value is

too high. The analog input channels are calibrated assuming an

external series resistor of 500 Ω, and the accuracy will remain

within specification for any value from zero to 1 kΩ, so a standard 510 Ω resistor is suitable.

The worst such accident would be connecting 0 V to 12 V—a

total of 12 V difference, with the series resistors this would draw

a maximum current of approximately 12 mA.

LAYOUT AND GROUNDING

Analog inputs will provide best accuracy when referred to a

clean ground. A separate, low impedance ground plane for

analog ground, which provides a ground point for the voltage

dividers and analog components, will provide best performance

but is not mandatory.

The power supply bypass, the parallel combination of 10 µF

(electrolytic or tantalum) and 0.1 µF (ceramic) bypass capacitors

connected between Pin 9 and ground, should also be located as

close as possible to the ADM1025/ADM1025A.

RST/INT OUTPUT

As previously mentioned, Pin 16 is a multifunction pin. Its state

after power-on is latched to set the lowest two bits of the serial

bus address. During NAND tree board-level connectivity testing

it functions as the output of the NAND tree. It may also be used

as a reset output, or as an interrupt output for out-of-limit temperature/voltage events.

Pin 16 is programmed as a reset output by clearing bit 0 of the

Test Register and setting Bit 7 of the VID Register. A low going,

20 ms, reset output pulse can then be generated by setting Bit 4

of the Configuration Register.

If Bit 7 of the VID Register is cleared, Pin 16 can be programmed

as an interrupt output for out-of-limit temperature/voltage events

(INT). Desired interrupt operation is achieved by changing the

values of Bits 1 and 0 of the Test Register as shown in Table IV.

Note, however, that Bits 2 to 7 of the Test Register must be

zeros (not don’t cares). If, for example, INT is programmed for

thermal and voltage interrupts, then if any temperature or voltage measurement goes outside its respective high or low limit,

the INT output will go low. It will remain low until Status Register 1 is read, when it will be cleared. If the temperature or

voltage remains out of limit, INT will be reasserted on the next

monitoring cycle. INT can also be cleared by issuing an Alert

Response Address Call.

REV. A

–11–

Page 12

ADM1025/ADM1025A

Table IV. Controlling the Operation of INT

Test Register

Bit 1 Bit 0 Function

0 0 Interrupts Disabled

0 1 Thermal Interrupt Only

1 0 Voltage Interrupt Only

1 1 Voltage and Thermal Interrupts

Note that Bit 7 of VID register should be zero, and that Bits 2 to 7 of Test

Register must be zeros.

When Pin 16 is used as a RST or INT output, it is open-drain and

requires an external pull-up resistor. This will restrict the address

function on Pin 16 to being high at power-up. If the RST or INT

function is required and two ADM1025/ADM1025As are to be

used on the same serial bus, A1/A0 can be set to 10 by using a

high value pull-up on Pin 16 (100 kΩ or greater). This will not

override the “floating” condition of ADD during power-up.

Note, however, that the RST/INT outputs of two or more

devices cannot be wire-OR’d, as the devices would then have

the same address. If the RST/INT outputs need to be connected

to a common interrupt line, they can be OR’d together using the

circuit of Figure 13.

If the RST or INT functionality is not required, a third address

may be used by setting A1/A0 to 00 by using a 1 kΩ pull-down

resistor on Pin 16. Note that this address should not be used if

RST or INT is required, since using this address will cause the

device to appear to be generating resets or interrupts, since Pin

16 will be permanently tied low.

V

CC

R1

V

CC

1k⍀

R2

470k⍀

V

CC

R5

4.7k⍀

OPEN-COLLECTOR

AND GATE

RST OR INT

A1/A0 = 01

ADD/RST/INT/NTO

ADM1025/

ADM1025A

#1

A1/A0 = 10

ADD/RST/INT/NTO

ADM1025/

ADM1025A

#2

SDA

SCL

SDA

SCL

Figure 13. Using Two ADM1025/ADM1025As on the

Same Bus with a Common Interrupt

GENERATING AN SMBALERT

The INT output can be used as an interrupt output or can be

used as an SMBALERT. One or more INT outputs can be connected to a common SMBALERT line connected to the master.

If a device’s INT line goes low, the following procedure occurs:

1. SMBALERT pulled low.

2. Master initiates a read operation and sends the Alert

Response Address (ARA = 0001 100). This is a general call

address that must not be used as a specific device address.

3. The device whose INT output is low responds to the Alert

Response Address, and the master reads its device address.

The address of the device is now known and it can be interrogated in the usual way.

4. If more than one device’s INT output is low, the one with

the lowest device address will have priority, in accordance

with normal SMBus arbitration.

5. Once the ADM1025/ADM1025A has responded to the Alert

Response Address, it will reset its INT output; however, if

the error condition that caused the interrupt persists, INT

will be reasserted on the next monitoring cycle.

NAND TREE TESTS

A NAND tree is provided in the ADM1025/ADM1025A for

Automated Test Equipment (ATE) board level connectivity

testing. The device is placed into NAND Test Mode by powering up with Pin 9 (D-/NTI) held high. This pin is automatically

sampled after power-up and if it is connected high, the NAND

test mode is invoked.

In NAND test mode, all digital inputs may be tested as illustrated below. ADD/RST/INT/NTO will become the NAND test

output pin.

To perform a NAND tree test, all pins are initially driven low.

The test vectors set all inputs low, then one-by-one toggle them

high (keeping them high). Exercising the test circuit with this

“walking one” pattern, starting with the input closest to the output of the tree, cycling toward the farthest, causes the output of

the tree to toggle with each input change. Allow for a typical

propagation delay of 500 ns. The structure of the NAND tree is

shown in Figure 14.

SDA

SCL

VID0

VID1

VID2

VID3

ADD/RST/INT/NTO

Figure 14. NAND Tree

Note: If any of the inputs shown in Figure 14 are unused, they

should not be connected directly to ground, but via a resistor

such as 10 kΩ. This will allow the ATE (Automatic Test Equipment) to drive every input high so that the NAND tree test can

be properly carried out. Refer to Table XVI for Test Vectors.

–12–

REV. A

Page 13

ADM1025/ADM1025A

USING THE ADM1025/ADM1025A

Power-On RESET

When power is first applied, the ADM1025/ADM1025A performs a “power- on reset” on several of its registers. Registers

whose power-on values are not shown have power-on conditions

that are indeterminate. Value and limit registers are reset to 00h

on power-up. The ADC is inactive. In most applications, usually the first action after power-on would be to write limits into

the Limit Registers.

Power-on reset clears or initializes the following registers (the

initialized values are shown in Table VI):

– Configuration Register

– Status Registers #1 and #2

– VID0-3 Register

– VID4 Register

– Test Register

INITIALIZATION

Configuration Register Initialization performs a similar, but not

identical, function to power-on reset.

Configuration Register Initialization is accomplished by setting

Bit 7 of the Configuration Register high. This bit automatically

clears after being set.

USING THE CONFIGURATION REGISTER

Control of the ADM1025/ADM1025A is provided through the

configuration register. The Configuration Register is used to

start and stop the ADM1025/ADM1025A, programming the

operating modes of Pins 11 and 16, and provide the initialization function described above.

Bit 0 of the Configuration Register controls the monitoring loop

of the ADM1025/ADM1025A. Setting Bit 0 low stops the monitoring loop and puts the ADM1025/ADM1025A into a low power

mode thereby reducing power consumption. Serial bus communication is still possible with any register in the ADM1025/

ADM1025A while in low power mode. Setting Bit 0 high starts

the monitoring loop.

Bit 4 of the Configuration Register causes a low going 20 ms (typ)

pulse at the RST pin (Pin 16) when set. This bit is self-clearing.

Bit 5 of the Configuration Register selects the operating mode of

pin 11 between the default of 12 V analog input (Bit 5 = 0) and

VID4 (Bit 5 = 1).

Bit 7 of the Configuration Register is used to start a Configuration Register Initialization when it is set to 1.

USING THE OFFSET REGISTER

This register contains a two’s complement value that is added

(or subtracted if the number is negative) to either the internal or

external temperature reading. Note that the default value in the

offset register is zero, so zero is always added to the temperature

reading. The offset register is configured for the external temperature channel by default. It may be switched to the internal

channel by setting Bit 0 of the Test Register to 1, setting Bit 6 of

the VID Register to 1, and clearing Bit 7 of the VID Register.

before starting the ADC to avoid spurious out-of-limit conditions. The time taken to complete the analog measurements

depends on how they are configured, as described elsewhere.

Once the measurements have been completed, the results can be

read from the Value Registers at any time.

REDUCED POWER AND SHUTDOWN MODE

The ADM1025/ADM1025A can be placed in a low power

mode by setting Bit 0 of the Configuration Register to 0. This

disables the internal ADC. Full shutdown mode may then be

achieved by setting Bit 7 of the VID Register to 1 AND Bit 0 of

the Test Register to 1. This turns off power to all analog circuits

and stops the monitoring cycle, if running, but it does not affect

the condition of any of the registers. The device will return to its

previous state when these bits are reset to zero.

5 V OPERATION

The ADM1025/ADM1025A may be operated with V

CC

connected to any supply voltage between 3.0 V and 5.5 V, but it

should be noted that the device has been optimized for 3.3 V

operation. In particular, the internal voltage divider used to

measure the supply voltage is optimized for 3.3 V. Powering the

device from 5 V will cause the V

Reading Register (Register

CC

25h) to overrange. In this case, the 5 V measurement should be

read from the 5 V Reading Register (Register 23h), instead of

the V

Reading Register. Note also that when 12 VIN/VID4 pin

CC

is programmed to read VID4, due to its internal voltage divider,

it will only read V

= 2.1 V on 12 VIN/VID4 pin as logic high if

IH

device is being powered from 3.3 V supply.

REGISTERS

Table V. Address POINTER Register

Bit Name R/W Description

7–0 Address Pointer Write Address of ADM1025/

ADM1025A Registers. See

the tables below for detail.

Table VI. List of Registers

Address Power On

Register A7–A0 Value of

Name in Hex Registers: <7:0>

Configuration Register 40h 0000 1000

Status Register 1 41h 0000 0000

Status Register 2 42h 0000 0000

VID Register 47h <7:4> = 0000, <3:0> =

VID3–VID0

VID4 Register 49h <0> = VID4; Default =

1000 000 (VID4)

Value and Limit

Registers 15–3Dh

Company ID 3Eh 0100 0001

Stepping 3Fh 0010 (Bits 3:0 Version

Number)

STARTING CONVERSION

The monitoring function of the ADM1025/ADM1025A is started

by writing to the Configuration Register and setting Start (Bit 0),

high. Limit values should be written into the Limit Registers

REV. A

–13–

Page 14

ADM1025/ADM1025A

Table VII. Register 40H – Configuration Register

Bit Name R/W Description

0 START Read/Write Logic 1 enables start-up of

monitor ASIC, Logic 0 places

the ASIC in standby mode. At

start-up, limit checking functions and scanning begins. Note,

all HIGH and LOW LIMITS

should be set into the ADM1025/

ADM1025A prior to turning on

this bit. (Power-up Default = 0)

1 Reserved Read

2 Reserved Read

3 Reserved Read

4 RESET Read/Write Setting this bit generates a

minimum 20 ms low pulse on

Pin 16, if the function is

enabled.

5 +12/VID4 Read/Write Selects whether Pin 11 acts

Select as a 12 V Analog Input monitor-

ing pin, or as a VID[4] input.

This pin defaults to the 12 V

Analog Input. (Default = 0)

6 Reserved Read

7 Initialization Read/Write Logic 1 restores power-up

default values to the Configu-

ration Register and Status

Registers. This bit automati-

cally clears itself and the power-

on default is zero.

Table VIII. Register 41H – STATUS Register 1 (Power-On

Default <7:0> = 00h)

Bit Name R/W Description

0 +2.5 V_Error Read Only A one indicates a High

or Low limit has been

exceeded.

1V

_Error Read Only A one indicates a High

CCP

or Low limit has been

exceeded.

2 +3.3 V_Error Read Only A one indicates a High

or Low limit has been

exceeded.

3 +5 V_Error Read Only A one indicates a High

or Low limit has been

exceeded.

4 Local Temp Read Only A one indicates that a

Error High or a Low Tem-

perature limit has been

exceeded.

5 Remote Temp Read Only A one indicates a High

Error or Low Remote Tem-

perature Limit has been

exceeded.

6 Reserved

7 Reserved

Table IX. Register 42H – Status Register 2 (Power-On Default

<7:0> = 00h)

Bit Name R/W Description

0 +12 V_Error Read Only A one indicates a High

or Low limit has been

exceeded.

1V

_Error Read Only A one indicates a High

CC

or Low limit has been

exceeded.

2 Reserved Read Only Undefined

3 Reserved Read Only Undefined

4 Reserved Read Only Undefined

5 Reserved Read Only Undefined

6 Remote Diode Read Only A one indicates either a

Fault short or open circuited

fault on the remote ther-

mal diode inputs.

7 Reserved Read Only Undefined

Table X. Register 47h – VID REGISTER (Power-On Default

= 0000 (VID[3:0]))

Bit Name R/W Description

0–3 VID[3:0] Read Only The VID[3:0] inputs from

Pentium/PRO power supplies

to indicate the operating

voltage (e.g., 1.3 V to 2.9 V).

4–5 Reserved Read Only Undefined

6 Offset Config Read/Write Configures offset register to

be used with internal or

external channel. If Bit 0 of

Test Register = 1, and Bit 7

of VID Register = 0, then

setting this bit to 1 configures the Offset Register to the

internal temperature channel. Clearing this bit configures the Offset Register to the

external temperature channel. (Default = 0)

7 RST ENABLE Read/Write When set to 1, enables the

RST output function on Pin

16. This bit defaults to 0 on

power-up. (RST Disabled.)

Table XI. Register 49h – VID4 Register (Power-On Default =

1000 000(VID4))

Bit Name R/W Description

0 VID4 Read VID4 Input (If Selected)

(Defaults to 0)

1–7 Reserved Read

–14–

REV. A

Page 15

ADM1025/ADM1025A

Table XII. Registers 15h–3Dh – Value and Limit Registers

Address R/W Description

15h Read/Write Manufacturers Test Register

1Fh Read/Write Offset Register

20h Read Only 2.5 V Reading

21h Read Only V

Reading

CCP

22h Read Only 3.3 V Reading

23h Read Only 5 V Reading

24h Read Only 12 V Reading

25h Read Only V

Reading

CC

26h Read Only Remote Diode Temperature Reading

27h Read Only Local Temperature Reading

2Bh Read/Write 2.5 V High Limit

2Ch Read/Write 2.5 V Low Limit

2Dh Read/Write V

2Eh Read/Write V

High Limit

CCP

Low Limit

CCP

2Fh Read/Write 3.3 V High Limit

30h Read/Write 3.3 V Low Limit

31h Read/Write 5 V High Limit

32h Read/Write 5 V Low Limit

33h Read/Write 12 V High Limit

34h Read/Write 12 V Low Limit

35h Read/Write V

36h Read/Write V

High Limit

CC

Low Limit

CC

37h Read/Write Remote Temperature High Limit

38h Read/Write Remote Temperature Low Limit

39h Read/Write Local Temperature High Limit

3Ah Read/Write Local Temperature Low Limit

NOTE

For the high limits of the voltages, the device is doing a greater-than comparison. For the low limits, however, it is doing a less-than or equal comparison.

Table XIV. Register 3Eh – Company ID

Value (Bits 7:0) R/W Description

0100 0001 Read Only This location contains the

company identification

number which may be used

by software to determine

the manufacturer’s device.

This register is read only.

Table XV. Register 3Fh – Stepping

Value (Bits 7:0) R/W Description

0010 [Version] Read Only Stepping ID Number and

Version

Table XVI. NAND Tree Test Vectors

Vector ADD/RST/

No. SDA SCL VID0 VID1 VID2 VID3 INT/NTO

10000001

20000010

30000111

40001110

50011111

60111110

71111111

Table XIII. Register 15h – Manufacturers Test Register

Bit Name R/W Description

0 Read/Write Used to select RST or INT

functions. Refer to RST/INT

Input section.

1 Read/Write Used to select RST or INT

functions. Refer to RST/INT

Input section.

2–7 Reserved Read/Write Reserved. Only values written

to these bits should be zeros.

REV. A

–15–

Page 16

ADM1025/ADM1025A

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

16-Lead QSOP

(RQ-16)

0.197 (5.00)

0.189 (4.80)

16

0.157 (3.99)

0.150 (3.81)

0.010 (0.25)

0.004 (0.10)

REF: JEDEC 0.150" SSOP – DRAWING NUMBER MO-137

0.059 (1.50)

MAX

1

PIN 1

0.025

(0.64)

BSC

9

8

0.069 (1.75)

0.053 (1.35)

0.012 (0.30)

0.008 (0.20)

0.244 (6.20)

0.228 (5.79)

SEATING

PLANE

0.010 (0.20)

0.007 (0.18)

C00060a–2.5–7/00 (rev. A)

8ⴗ

0ⴗ

0.050 (1.27)

0.016 (0.41)

–16–

PRINTED IN U.S.A.

REV. A

Loading...

Loading...