Ten Degrees of Freedom Inertial Sensor

ADIS16407

Rev. C

rights of third parties that may result from its use. Specifications subject to change without notice. No

Trademarks and registered trademarks are the prop erty of their respective owner s.

Fax: 781.461.3113 ©2011 Analog Devices, Inc. All rights reserved.

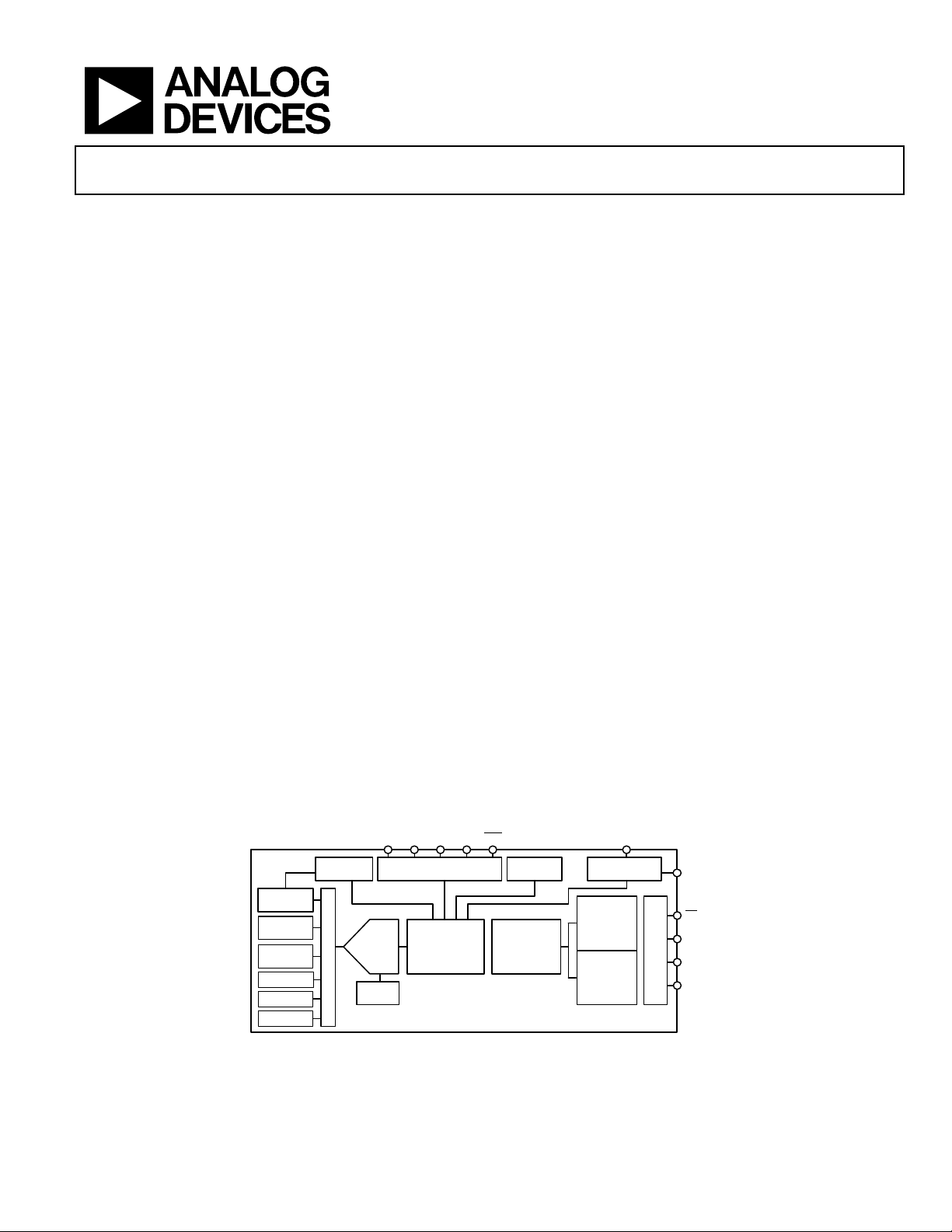

CONTROLLLER

CLOCK

TRIAXIAL

GYRO

TRIAXIAL

ACCEL

POWER

MANAGEMENT

CS

SCLK

DIN

DOUT

GND

VDD

TEMP

VDD

DIO1

DIO2

DIO3

DIO4

RST

SPI

TRIAXIAL

MAGN

PRESSURE

SELF TEST I/O ALARMS

OUTPUT

DATA

REGISTERS

USER

CONTROL

REGISTERS

CALIBRATION

AND

FILTERS

ADIS16407

09797-001

Data Sheet

FEATURES

Triaxial digital gyroscope with digital range scaling

±75°/sec, ±150°/sec, ±300°/sec settings

Axis-to-axis alignment, <0.05°

Triaxial digital accelerometer, ±18 g minimum

Triaxial digital magnetometer, ±2.5 gauss minimum

Digital barometer, 10 mbar to 1200 mbar

Calibrated pressure range: 300 mbar to 1100 mbar

Autonomous operation and data collection

No external configuration commands required

210 ms start-up time, 4 ms sleep mode recovery time

Factory calibrated sensitivity, bias, and axial alignment

Calibration temperature range: −40°C to +85°C

SPI-compatible serial interface

Embedded temperature sensor

Programmable operation and control

Automatic and manual bias correction controls

Bartlett window FIR length, number of taps

Digital I/O: data ready, alarm indicator, general-purpose

Alarms for condition monitoring

Sleep mode for power management

DAC output voltage

Enable external sample clock input up to 1.1 kHz

Single command self test

Single-supply operation: 4.75 V to 5.25 V

2000 g shock survivability

Operating temperature range: −40°C to +105°C

GENERAL DESCRIPTION

The ADIS16407 iSensor® device is a complete inertial system

that includes a triaxial gyroscope, a triaxial accelerometer, a

triaxial magnetometer, and pressure sensors. Each sensor in

the ADIS16407 combines industry-leading iMEMS® technology

with signal conditioning that optimizes dynamic performance.

The factory calibration characterizes each sensor for sensitivity,

bias, alignment, and linear acceleration (gyro bias). As a result,

each sensor has its own dynamic compensation formulas that

provide accurate sensor measurements.

The ADIS16407 provides a simple, cost-effective method for

integrating accurate, multiaxis inertial sensing into industrial

systems, especially when compared with the complexity and

investment associated with discrete designs. All necessary motion

testing and calibration are part of the production process at the

factory, greatly reducing system integration time. Tight orthogonal

alignment simplifies inertial frame alignment in navigation systems.

The SPI and register structure provide a simple interface for

data collection and configuration control.

The ADIS16407 has a compatible pinout for systems that currently

use ADIS1635x, ADIS1636x, and ADIS1640x IMU products.

The ADIS16407 is packaged in a module that is approximately

23 mm × 23 mm × 23 mm and has a standard connector interface.

APPLICATIONS

Platform stabilization and control

Navigation

Robotics

FUNCTIONAL BLOCK DIAGRAM

Information furnished by Analog Devices is believed to be accurate and reliable. However, no

responsibility is assumed by Analog Devices for its use, nor for any infringements of patents or other

license is granted by implication or otherwise under any patent or patent rights of Analog Devices.

Figure 1.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700 www.analog.com

ADIS16407 Data Sheet

TABLE OF CONTENTS

Features .............................................................................................. 1

Applications ....................................................................................... 1

General Description ......................................................................... 1

Functional Block Diagram .............................................................. 1

Revision History ............................................................................... 2

Specifications ..................................................................................... 3

Timing Specifications .................................................................. 6

Absolute Maximum Ratings ............................................................ 7

ESD Caution .................................................................................. 7

Pin Configuration and Function Descriptions ............................. 8

Typical Performance Characteristics ............................................. 9

Basic Operation ............................................................................... 10

Reading Sensor Data .................................................................. 10

Output Data Registers ................................................................ 11

Input ADC Channel ................................................................... 13

Device Configuration ................................................................ 13

User Registers .................................................................................. 14

System Functions ............................................................................ 15

Global Commands ..................................................................... 15

Power Management .................................................................... 15

Product Identification ................................................................ 15

Memory Management ............................................................... 15

Self Test Function ....................................................................... 16

Status/Error Flags ....................................................................... 16

Input/Output Configuration ......................................................... 17

Data Ready Indicator ................................................................. 17

General-Purpose Input/Output................................................ 17

Auxiliary DAC ............................................................................ 17

Digital Processing Configuration ................................................. 18

Sample Rate ................................................................................. 18

Input Clock Configuration ....................................................... 18

Digital Filtering........................................................................... 18

Dynamic Range .......................................................................... 18

Calibration ....................................................................................... 19

Gyroscopes .................................................................................. 19

Accelerometers ........................................................................... 20

Magnetometer Calibration ........................................................ 20

Flash Updates .............................................................................. 21

Restoring Factory Calibration .................................................. 21

Alarms .............................................................................................. 22

Static Alarm Use ......................................................................... 22

Dynamic Alarm Use .................................................................. 22

Alarm Reporting ........................................................................ 22

Applications Information .............................................................. 23

Installation/Handling................................................................. 23

Gyroscope Bias Optimization ................................................... 23

Interface Printed Circuit Board (PCB) .................................... 23

Outline Dimensions ....................................................................... 24

Ordering Guide .......................................................................... 24

REVISION HISTORY

10/11—Rev. B to Rev. C

Change to Burst Read Function Section and Figure 12 ............ 10

Changed .25 mg to 3.333 mg ........................................ Throughout

Changes to System Functions Section ......................................... 15

Change to Product Identification Section ................................... 15

Change to Table 36 ......................................................................... 15

Changes to Digital Filtering Section, Table 47, Caption for

Figure 18, and Figure 19 ................................................................ 18

Change to Table 67 ......................................................................... 22

7/11—Rev. A to Rev. B

Change to Table 1, Barometer, Sensitivity Parameter .................. 4

Rev. C | Page 2 of 24

Added Barometer Section; Changes to Table 40 ........................ 16

Changes to Table 55, Table 56, Table 57 ...................................... 20

Changes to Table 58, Table 59, Table 60 ...................................... 21

6/11—Rev. 0 to Rev. A

Changes to Device Configuration Section and Figure 16 ......... 13

Changes to Figure 19 ...................................................................... 18

Changes to Figure 25 Caption ...................................................... 24

Changes to Ordering Guide .......................................................... 24

4/11—Revision 0: Initial Version

Data Sheet ADIS16407

Misalignment

Axis to axis

±0.05

Degrees

3 dB Bandwidth

330 Hz

Dynamic Range

±18

g

Output Noise

No filtering

9

mg rms

Nonlinearity

Best fit straight line

0.5 % of FS

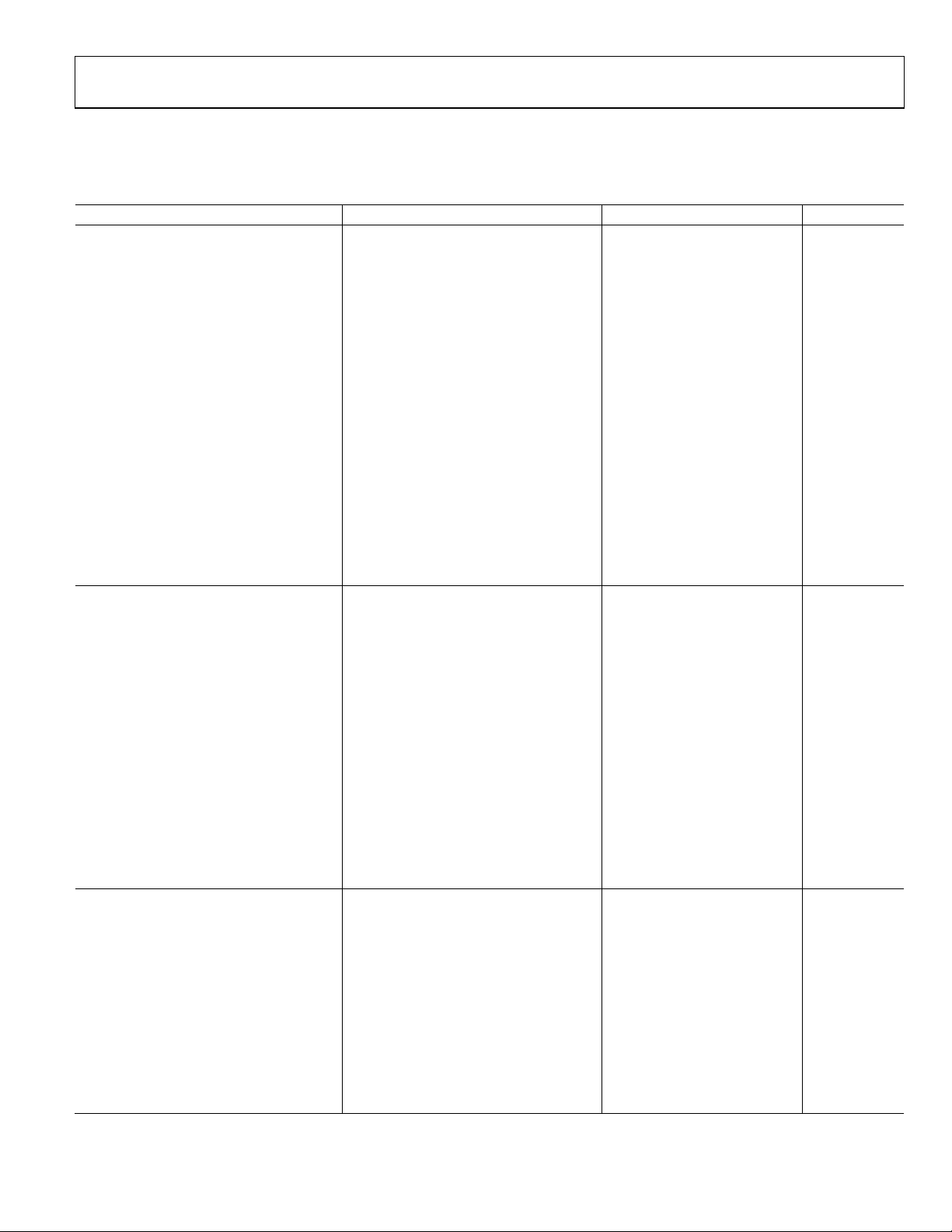

SPECIFICATIONS

TA = 25°C, VDD = 5 V, angular rate = 0°/sec, dynamic range = ±300°/sec ± 1 g, unless otherwise noted.

Table 1.

Parameter Test Conditions/Comments Min Typ Max Unit

GYROSCOPES

Dynamic Range ±300 ±350 °/sec

Initial Sensitivity Dynamic range = ±300°/sec 0.0495 0.05 0.0505 °/sec/LSB

Dynamic range = ±150°/sec 0.025 °/sec/LSB

Dynamic range = ±75°/sec 0.0125 °/sec/LSB

Sensitivity Temperature Coefficient −40°C ≤ TA ≤ +85°C ±40 ppm/°C

Axis to frame (package) ±0.5 Degrees

Nonlinearity Best fit straight line ±0.1 % of FS

Initial Bias Error ±1 σ ±3 °/sec

In-Run Bias Stability 1 σ, SMPL_PRD = 0x0001 0.007 °/sec

Angular Random Walk 1 σ, SMPL_PRD = 0x0001 1.9 °/√hr

Bias Temperature Coefficient −40°C ≤ TA ≤ +85°C ±0.01 °/sec/°C

Linear Acceleration Effect on Bias Any axis, 1 σ (MSC_CTRL[7] = 1) 0.05 °/sec/g

Bias Voltage Sensitivity VDD = 4.75 V to 5.25 V ±0.3 °/sec/V

Output Noise ±300°/sec range, no filtering 0.8 °/sec rms

Rate Noise Density f = 25 Hz, ±300°/sec range, no filtering 0.044 °/sec/√Hz rms

Sensor Resonant Frequency 14.5 kHz

ACCELEROMETERS Each axis

Initial Sensitivity 3.285 3.33 3.38 mg/LSB

Sensitivity Temperature Coefficient −40°C ≤ TA ≤ +85°C ±50 ppm/°C

Misalignment Axis to axis 0.2 Degrees

Axis to frame (package) ±0.5 Degrees

Nonlinearity Best fit straight line 0.1 % of FS

Initial Bias Error ±1 σ ±50 mg

In-Run Bias Stability 1 σ, SMPL_PRD = 0x0001 0.2 mg

Velocity Random Walk 1 σ, SMPL_PRD = 0x0001 0.2 m/sec/√hr

Bias Temperature Coefficient −40°C ≤ TA ≤ +85°C

Bias Voltage Sensitivity VDD = 4.75 V to 5.25 V 2.5 mg/V

Noise Density No filtering 0.5 mg/√Hz rms

3 dB Bandwidth 330 Hz

Sensor Resonant Frequency 5.5 kHz

MAGNETOMETER

Dynamic Range ±2.5 ±3.5 gauss

Initial Sensitivity 25°C 0.49 0.5 0.51 mgauss/LSB

Sensitivity Temperature Coefficient 25°C, 1 σ 600 ppm/°C

Misalignment Axis to axis 0.25 Degrees

Axis to frame (package) 0.5 Degrees

±0.3 mg/°C

Initial Bias Error 25°C, 0 gauss stimulus ±4 mgauss

Bias Temperature Coefficient −40°C ≤ TA ≤ +85°C 0.5 mgauss/°C

Output Noise

Noise Density

Bandwidth −3 dB 1540 Hz

25°C, no filtering, rms

25°C, no filtering, rms

Rev. C | Page 3 of 24

1.15 mgauss

0.06 mgauss/√Hz

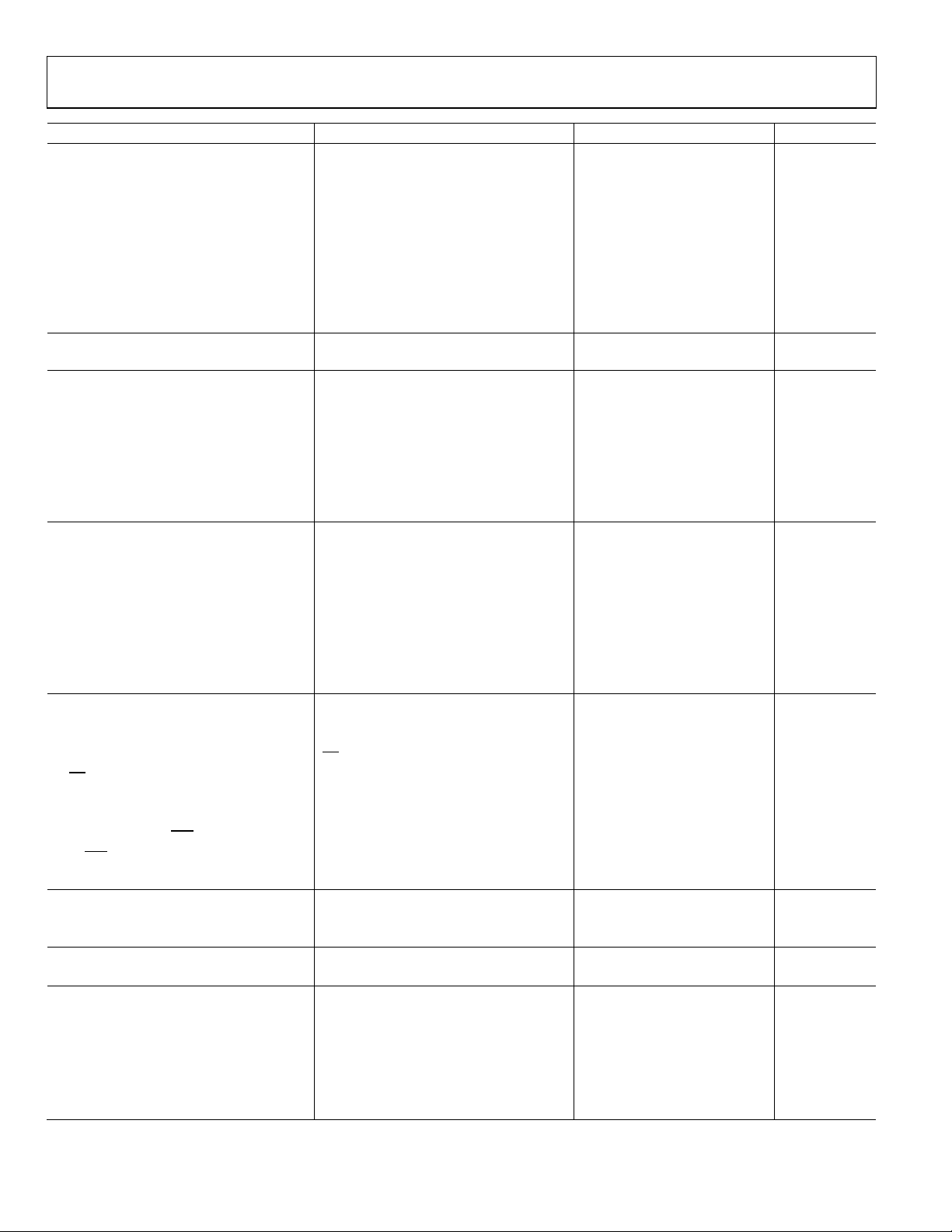

ADIS16407 Data Sheet

Sensitivity

0.3125

µbar/LSB

CS Wake-Up Pulse Width

20

μs

Sleep Mode Recovery Time

7 ms

Parameter Test Conditions/Comments Min Typ Max Unit

BAROMETER

Pressure Range

Operating 300 1100 mbar

Extended1 10 1200 mbar

Total Error 25°C, 300 mbar to 1100 mbar 1.5 mbar

Relative Error2 −40°C to +85°C, 300 mbar to 1100 mbar 2.5 mbar

Linearity3 25°C, 300 mbar to 1100 mbar 0.1 % of FS

−40°C to +85°C, 300 mbar to 1100 mbar 0.15 % of FS

Noise 0.027 mbar rms

TEMPERATURE SENSOR

Scale Factor 25°C, output = 0x0000 0.14 °C/LSB

ADC INPUT

Resolution 12 Bits

Integral Nonlinearity ±2 LSB

Differential Nonlinearity ±1 LSB

Offset Error ±4 LSB

Gain Error ±2 LSB

Input Range 0 3.3 V

Input Capacitance During acquisition 20 pF

DAC OUTPUT 5 kΩ/100 pF to GND

Resolution 12 Bits

Relative Accuracy 101 LSB ≤ input code ≤ 4095 LSB ±4 LSB

Differential Nonlinearity ±1 LSB

Offset Error ±5 mV

Gain Error ±0.5 %

Output Range 0 3.3 V

Output Impedance 2 Ω

Output Settling Time 10 µs

LOGIC INPUTS4

Input High Voltage, VIH 2.0 V

Input Low Voltage, VIL 0.8 V

CS signal to wake up from sleep mode

0.55 V

Logic 1 Input Current, IIH VIH = 3.3 V ±0.2 ±10 µA

Logic 0 Input Current, IIL VIL = 0 V

All Pins Except RST

RST Pin

Input Capacitance, CIN 10 pF

DIGITAL OUTPUTS4

Output High Voltage, VOH I

Output Low Voltage, VOL I

FLASH MEMORY Endurance5 10,000 Cycles

Data Retention6 TJ = 85°C 20 Years

FUNCTIONAL TIMES7 Time until new data is available

Power-On Start-Up Time 220 ms

Reset Recovery Time 105 ms

Flash Memory Update Time 75 ms

Flash Memory Test Time 30 ms

Automatic Self Test Time SMPL_PRD = 0x0001 52 ms

40 60 µA

1 mA

= 1.6 mA 2.4 V

SOURCE

= 1.6 mA 0.4 V

SINK

Rev. C | Page 4 of 24

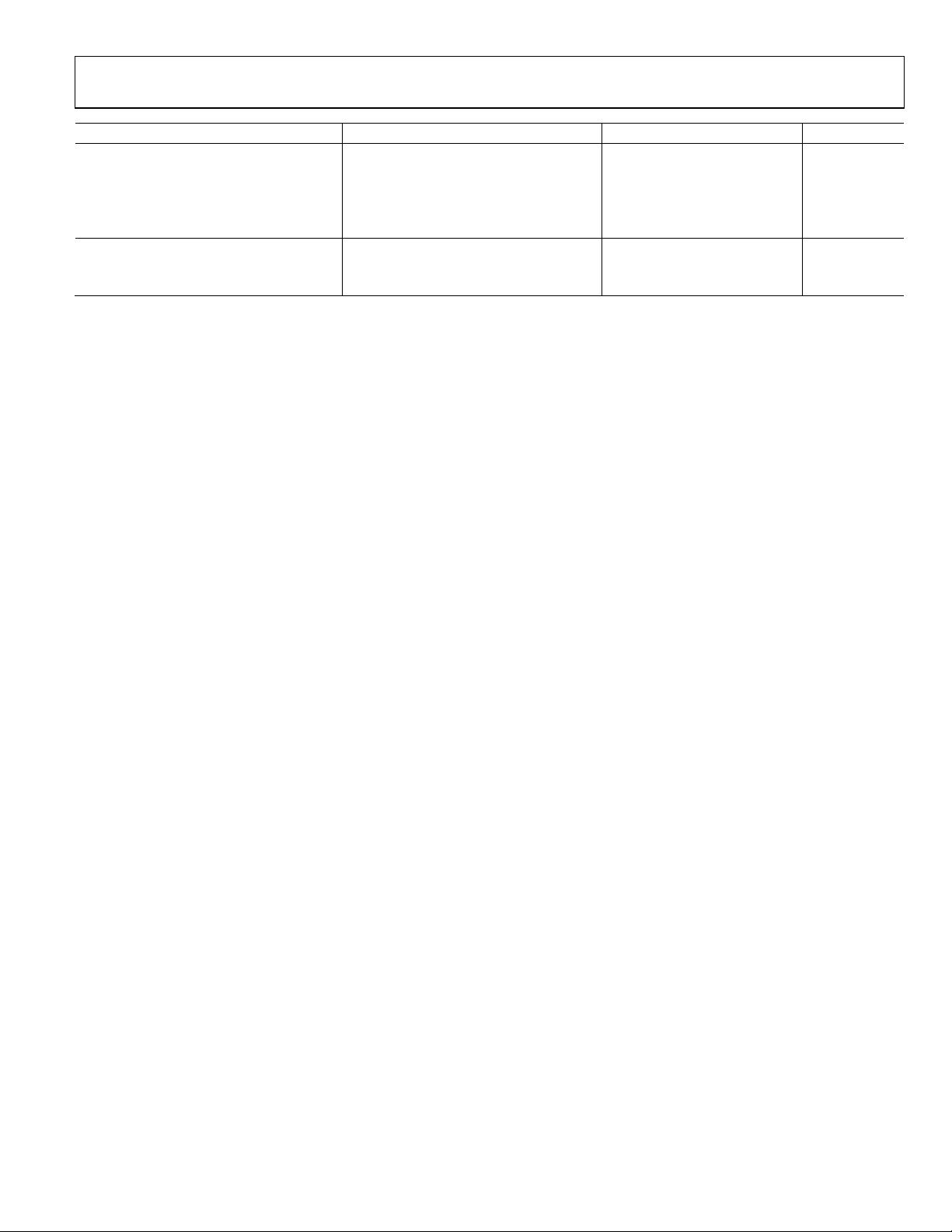

Data Sheet ADIS16407

Sync Input Clock9

0.8 1.1

kHz

Sleep mode

1.4 mA

Parameter Test Conditions/Comments Min Typ Max Unit

CONVERSION RATE SPS

xGYRO_OUT, xACCL_OUT, xMAGN_OUT SMPL_PRD = 0x0001 819.2 SPS

BAR_OUT, BARO_OUTL8 SMPL_PRD = 0x0001 51.2 SPS

Clock Accuracy ±3 %

POWER SUPPLY Operating voltage range, VDD 4.75 5.0 5.25 V

Power Supply Current 70 mA

1

The extended pressure range is guaranteed by design.

2

The relative error assumes that the initial error, at +25°C, is corrected in the end application.

3

Linearity errors assume a full scale (FS) of 1000 mbar.

4

The digital I/O signals are driven by an internal 3.3 V supply, and the inputs are 5 V tolerant.

5

Endurance is qualified as per JEDEC Standard 22, Method A117, and measured at −40°C, +25°C, +85°C, and +125°C.

6

The data retention lifetime equivalent is at a junction temperature (TJ) of 85°C as per JEDEC Standard 22, Method A117. Data retention lifetime decreases with junction

temperature.

7

These times do not include thermal settling and internal filter response times (330 Hz bandwidth), which may affect overall accuracy.

8

The BARO_OUT and BARO_OUTL registers sample at a rate that is 1/16th that of the other output registers.

9

The sync input clock functions below the specified minimum value, but at reduced performance levels.

Rev. C | Page 5 of 24

ADIS16407 Data Sheet

tCS

Chip select to SCLK edge

48.8

48.8

ns

t

5 5 ns

CS

SCLK

DOUT

DIN

1 2 3 4 5 6 15 16

R/W A5A6 A4 A3 A2

D2

MSB

DB14

D1 LSB

DB13 DB12 DB10DB11 DB2 LSBDB1

t

CS

t

SFS

t

DAV

t

DHD

t

DSU

09797-002

CS

SCLK

t

READRATE

t

STALL

09797-003

t

3

t

X

t

2

t

1

SYNC

CLOCK (DIO 4)

DATA

READY

07570-004

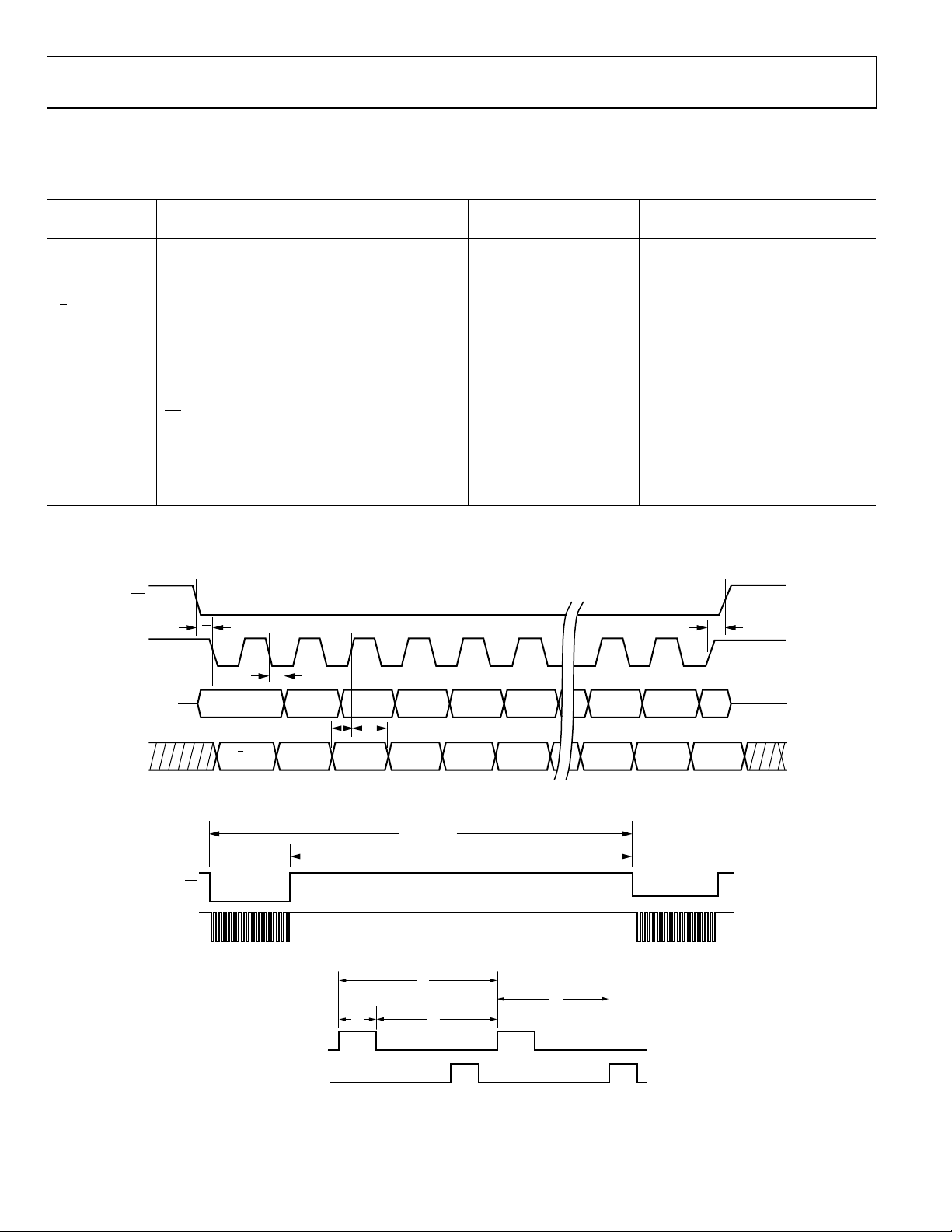

TIMING SPECIFICATIONS

TA = 25°C, VDD = 5 V, unless otherwise noted.

Table 2.

Normal Mode Burst Read

Parameter Description Min1 Typ Max Min1 Typ Max Unit

f

Serial clock 0.01 2.0 0.01 1.0 MHz

SCLK

t

Stall period between data 9 1/f

STA LL

t

Read rate 40 µs

READRATE

t

DOUT valid after SCLK edge 100 100 ns

DAV

t

DIN setup time before SCLK rising edge 24.4 24.4 ns

DSU

t

DIN hold time after SCLK rising edge 48.8 48.8 ns

DHD

t

, t

SCLKR

SCLK rise/fall times, not shown in Timing Diagrams 5 12.5 5 12.5 ns

SCLKF

tDR, tDF DOUT rise/fall times, not shown in Timing Diagrams 5 12.5 5 12.5 ns

SFS

t

1

CS high after SCLK edge

Input sync positive pulse width 5 5 µs

tx Input sync low time 100 100 µs

t

2

t

3

1

Guaranteed by design and characterization, but not tested in production.

Input sync to data ready output 600 600 µs

Input sync period 910 910 µs

Timing Diagrams

µs

SCLK

Figure 2. SPI Timing and Sequence

Figure 3. Stall Time and Data Rate

Figure 4. Input Clock Timing Diagram

Rev. C | Page 6 of 24

Data Sheet ADIS16407

Any Axis, Unpowered

2000 g

Temperature

ABSOLUTE MAXIMUM RATINGS

Table 3.

Parameter Rating

Acceleration

Any Axis, Powered 2000 g

VDD to GND −0.3 V to +6.0 V

Digital Input Voltage to GND −0.3 V to +5.3 V

Digital Output Voltage to GND −0.3 V to +3.6 V

Analog Input to GND −0.3 V to +3.6 V

Operating Range −40°C to +105°C

Storage Range −65°C to +125°C

Pressure 6 bar

1

Extended exposure to temperatures outside the specified temperature

range of −40°C to +105°C can adversely affect the accuracy of the factory

calibration. For best accuracy, store the parts within the specified operating

range of −40°C to +105°C.

2

Although the device is capable of withstanding short-term exposure to

150°C, long-term exposure threatens internal mechanical integrity.

1, 2

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

Table 4. Package Characteristics

Package Type θJA θJC Device Weight

24-Lead Module

39.8°C/W 14.2°C/W 16 grams

(ML-24-2)

ESD CAUTION

Rev. C | Page 7 of 24

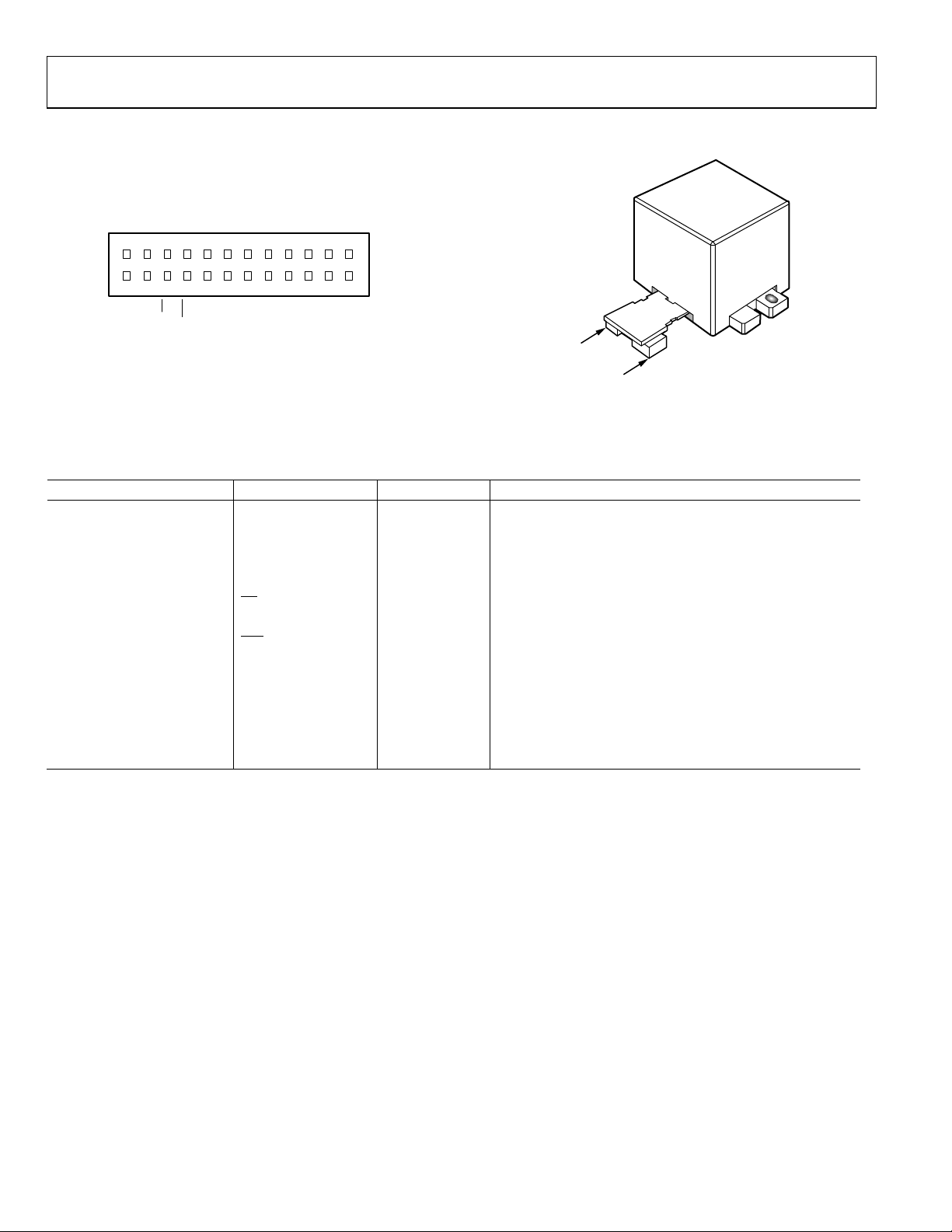

ADIS16407 Data Sheet

NOTES

1. THIS VIEW REPRESENTS THE TOP VIEW OF THE MATING CONNECTOR.

2. WHE N CONNECTED, THE PINS ARE NOT VISIBLE.

3. MAT ING CONNECT OR: SAMTEC CLM-112-02 OR EQUIVALENT .

4. DNC = DO NOT CONNECT.

1

DIO3

SCLK

DIN

DIO1

DIO2

VDD

GND

GND

DNC

DNC

AUX_ADC

DNC

DIO4/CLKIN

DOUT

CS

RST

VDD

VDD

GND

DNC

DNC

AUX_DAC

DNC

DNC

23456789101112131415161718192021222324

ADIS16407

TOP VIEW

(Not to S cale)

09797-005

PIN 1

PIN 23

09797-006

1

DIO3

I/O

Configurable Digital Input/Output.

PIN CONFIGURATION AND FUNCTION DESCRIPTIONS

Figure 5. Pin Configuration

Figure 6. Axial Orientation

Table 5. Pin Function Descriptions

Pin No. Mnemonic Type1 Description

2 DIO4/CLKIN I/O Configurable Digital Input/Output or Sync Clock Input.

3 SCLK I SPI Serial Clock.

4 DOUT O SPI Data Output. Clocks the output on the SCLK falling edge.

5 DIN I SPI Data Input. Clocks the input on the SCLK rising edge.

6

CS

I SPI Chip Select.

7 DIO1 I/O Configurable Digital Input/Output.

8

RST

I Reset.

9 DIO2 I/O Configurable Digital Input/Output.

10, 11, 12 VDD S Power Supply.

13, 14, 15 GND S Power Ground.

16, 17, 18, 19, 22, 23, 24 DNC N/A Do Not Connect. Do not connect to these pins.

20 AUX_DAC O Auxiliary, 12-Bit DAC Output.

21 AUX_ADC I Auxiliary, 12-Bit ADC Input.

1

S is supply, O is output, I is input, N/A is not applicable.

Rev. C | Page 8 of 24

Data Sheet ADIS16407

0.001

0.01

0.1

0.1 1 10 100 1k 10k

Tau (sec)

ROOT ALLAN VARIANCE (°/sec)

–1σ

MEAN

+1σ

09797-007

0.0001

0.001

0.01

0.1 1 10 100 1k 10k

Tau (sec)

ROOT ALLAN V

ARIANCE (g)

–1σ

MEAN

+1σ

09797-008

TYPICAL PERFORMANCE CHARACTERISTICS

Figure 7. Gyroscope Root Allan Variance

Figure 8. Accelerometer Root Allan Variance

Rev. C | Page 9 of 24

ADIS16407 Data Sheet

SYSTEM

PROCESSOR

SPI MASTER

ADIS16407

SCLK

CS

DIN

DOUT

SCLK

SS

MOSI

MISO

5V

IRQ

DIO1

VDD

I/O LINES ARE COMPATIBLE WITH

3.3V OR 5V LOGIC LEVELS

10

6

3

5

4

7

11

12

13

14

15

09797-009

XGYRO_OUT

DIN

DOUT

YGYRO_OUT

ZGYRO_OUT

0x0400 0x0600

0x0800

09797-010

DOUT = 1111 1001 1101 1010 = 0xF9DA = –1574 LSBs => –19.675°/ sec

DIN = 0000 0100 0000 0000 = 0x0400

SCLK

CS

DIN

DOUT

09797-011

0x4200

DON’T CARE

1 2 3 15

CS

SCLK

DIN

DOUT

XGYRO_OUTSUPPLY_OUT

AUX_ADC

09797-012

R/W

R/W

A6 A5 A4 A3 A2 A1 A0 DC7 DC6 DC5 DC4 DC3 DC2 DC1 DC0

D0D1D2D3D4D5D6D7D8D9D10D11D12D13D14D15

CS

SCLK

DIN

DOUT

A6 A5

D13D14D15

NOTES

1. THE DOUT BIT PATTERN REFLECTS THE ENTIRE CONTENTS OF THE REGISTER IDENTIFIED BY [A6:A0]

IN THE PREVIOUS 16-BIT DIN SEQUENCE W HE N R/W = 0.

2. IF R/W = 1 DURING THE P RE V IOUS SEQUE NCE , DOUT IS NOT DEFINE D.

09797-013

BASIC OPERATION

The ADIS16407 is an autonomous system that requires no user

initialization. When it has a valid power supply, it initializes itself

and starts sampling, processing, and loading sensor data into

the output registers at a sample rate of 819.2 SPS. DIO1 pulses

high after each sample cycle concludes. The SPI interface enables

simple integration with many embedded processor platforms,

as shown in Figure 9 (electrical connection) and Ta ble 6 (pin

functions).

READING SENSOR DATA

The ADIS16407 provides two different options for acquiring

sensor data: single register and burst register. A single register

read requires two 16-bit SPI cycles. The first cycle requests the

contents of a register using the bit assignments in Figure 13.

Bit DC7 to Bit DC0 are don’t care for a read, and then the output

register contents follow on DOUT during the second sequence.

Figure 10 includes three single register reads in succession. In

this example, the process starts with DIN = 0x0400 to request

the contents of XGYRO_OUT, then follows with 0x0600 to

request YGYRO_OUT and 0x0800 to request ZGYRO_OUT.

Full duplex operation enables processors to use the same 16-bit

SPI cycle to read data from DOUT while requesting the next set

of data on DIN. Figure 11 provides an example of the four SPI

signals when reading XGYRO_OUT in a repeating pattern.

Figure 9. Electrical Connection Diagram

Table 6. Generic Master Processor Pin Names and Functions

Pin Name Function

SS

Slave select

SCLK Serial clock

MOSI Master output, slave input

MISO Master input, slave output

IRQ Interrupt request

The ADIS16407 SPI interface supports full duplex serial communication (simultaneous transmit and receive) and uses the bit

sequence shown in Figure 13. Tabl e 7 provides a list of the most

common settings that require attention to initialize the serial

port of a processor for the ADIS16407 SPI interface.

Table 7. Generic Master Processor SPI Settings

Processor Setting Description

Master The ADIS16407 operates as a slave

SCLK Rate ≤ 2 MHz1 Maximum serial clock rate

SPI Mode 3 CPOL = 1 (polarity), CPHA = 1 (phase)

MSB-First Mode Bit sequence

16-Bit Mode Shift register/data length

1

For burst read, SCLK rate ≤ 1 MHz.

Figure 10. SPI Read Example

Figure 11. Example SPI Read, Second 16-Bit Sequence

Burst Read Function

The burst read function enables the user to read all output registers

using one command on the DIN line and shortens the stall time

between each 16-bit segment to one SCLK cycle (see Tabl e 2).

Figure 12 provides the burst read sequence of data on each SPI

signal. The sequence starts with writing 0x4200 to DIN, followed

by each output register clocking out on DOUT, in the order in

which they appear in Ta b le 8.

Figure 12. Burst Read Sequence

Figure 13. SPI Communication Bit Sequence

Rev. C | Page 10 of 24

Data Sheet ADIS16407

ZGYRO_OUT

0x08

Gyroscope, z-axis

Y-AXIS

a

Y

g

Y

g

X

X-AXIS

a

X

Z-AXIS

a

Z

g

Z

m

X

m

Y

m

Z

09797-014

[13:0]

[14]

Error/alarm, 1 = active, see DIAG_STAT for error flags

+300°/sec

+6000

0x1770

xx01 0111 0111 0000

[14]

Error/alarm, 1 = active, see DIAG_STAT for error flags

[15]

New data indicator (ND), 1 = new data in register

[13:0]

Z-axis acceleration data, twos complement format,

OUTPUT DATA REGISTERS

The output registers in Tab l e 8 provide the most recent sensor

data produced by the ADIS16407. Each output register has flags

for new data indication and error/alarm conditions, which

reduces the need to monitor DIAG_STAT.

Table 8. Output Data Register Formats

Register Address Measurement

SUPPLY_OUT 0x02 Power supply

XGYRO_OUT 0x04 Gyroscope, x-axis

YGYRO_OUT 0x06 Gyroscope, y-axis

XACCL_OUT 0x0A Accelerometer, x-axis

YACCL_OUT 0x0C Accelerometer, y-axis

ZACCL_OUT 0x0E Accelerometer, z-axis

XMAGN_OUT 0x10 Magnetometer, x-axis

YMAGN_OUT 0x12 Magnetometer, y-axis

ZMAGN_OUT 0x14 Magnetometer, z-axis

BARO_OUT 0x16 Barometer/pressure, higher

BARO_OUTL 0x18 Barometer/pressure, lower

TEMP_OUT1 0x1A Internal temperature

AUX_ADC 0x1C Auxiliary ADC

1

This is most useful for monitoring relative changes in the temperature.

[14] Error/alarm, 1 = active, see DIAG_STAT for error flags

Y-axis gyroscope data, twos complement format,

0.05°/sec per LSB, when SENS_AVG[15:8] = 0x04

Table 11. ZGYRO_OUT (Base Address = 0x08), Read Only

Bits Description

[15] New data indicator (ND), 1 = new data in register

[13:0]

Z-axis gyroscope data, twos complement format,

0.05°/sec per LSB, when SENS_AVG[15:8] = 0x04

Table 12. Rotation Rate, Twos Complement Format

Rotation Rate Decimal Hex Binary

+0.1°/sec +2 0x0002 xx00 0000 0000 0010

+0.05°/sec +1 0x0001 xx00 0000 0000 0001

0°/sec 0 0x0000 xx00 0000 0000 0000

−0.05°/sec −1 0x3FFF xx11 1111 1111 1111

−0.1°/sec −2 0x3FFE xx11 1111 1111 1110

−300°/sec −6000 0x2890 xx10 1000 1001 0000

Accelerometers

Figure 14 provides arrows (aX, aY, aZ) that indicate the direction

of acceleration, which produces a positive response in the

gyroscope output registers: XACCL_OUT (x-axis, Ta b le 13),

YACCL_OUT (y-axis, Tab l e 14), and ZACCL_OUT (z-axis,

Tabl e 15). Tab l e 16 illustrates the accelerometer data format.

Figure 14. Inertial Sensor Direction Reference

Gyroscopes

Figure 14 provides arrows (gX, gY, gZ) that indicate the direction

of rotation, which produces a positive response in the gyroscope

output registers: XGYRO_OUT (x-axis, Table 9), YGYRO_OUT

(y-axis, Tabl e 10), and ZGYRO_OUT (z-axis, Ta b le 11). Tab l e 12

illustrates the gyroscope data format.

Table 9. XGYRO_OUT (Base Address = 0x04), Read Only

Bits Description

[15] New data indicator (ND), 1 = new data in register

[14] Error/alarm, 1 = active, see DIAG_STAT for error flags

[13:0]

X-axis gyroscope data, twos complement format,

0.05°/sec per LSB, when SENS_AVG[15:8] = 0x04

Table 13. XACCL_OUT (Base Address = 0x0A), Read Only

Bits Description

[15] New data indicator (ND), 1 = new data in register

[13:0]

X-axis acceleration data, twos complement format,

3.333 mg per LSB

Table 14. YACCL_OUT (Base Address = 0x0C), Read Only

Bits Description

[14] Error/alarm, 1 = active, see DIAG_STAT for error flags

[13:0]

Y-axis acceleration data, twos complement format,

3.333 mg per LSB

Table 15. ZACCL_OUT (Base Address = 0x0E), Read Only

Bits Description

[15] New data indicator (ND), 1 = new data in register

[14] Error/alarm, 1 = active, see DIAG_STAT for error flags

3.333 mg per LSB

Bits Description

[15] New data indicator (ND), 1 = new data in register

Table 10. YGYRO_OUT (Base Address = 0x06), Read Only

Rev. C | Page 11 of 24

ADIS16407 Data Sheet

Bits

Description

0 0 0x0000

xx00 0000 0000 0000

[11:0]

Internal temperature data, twos complement,

+25°C

0 LSB

0x000

xxxx 0000 0000 0000

Table 16. Acceleration, Twos Complement Format

Acceleration Decimal Hex Binary

+18 g +5401 0x1519 xx01 0101 0001 1001

+6.667 mg +2 0x0002 xx00 0000 0000 0010

+3.333 mg +1 0x0001 xx00 0000 0000 0001

0 g 0 0x0000 xx00 0000 0000 0000

−3.333 mg −1 0x3FFF xx11 1111 1111 1111

−6.667 mg −2 0x3FFE xx11 1111 1111 1110

−18 g −5401 0x2AE7 xx10 1010 1110 0111

Magnetometers

Figure 14 provides arrows (mX, mY, mZ) that indicate the direction

of the magnetic field, which produces a positive response in the

gyroscope output registers: XMAGN_OUT (x-axis, Ta b le 17),

YMAGN_OUT (y-axis, Tab l e 18), and ZAMAGN_OUT (z-axis,

Tabl e 19). Tab l e 20 illustrates the magnetic field intensity data

format.

Table 17. XMAGN_OUT (Base Address = 0x10), Read Only

Bits Description

[15] New data indicator (ND), 1 = new data in register

[14] Error/alarm, 1 = active, see DIAG_STAT for error flags

[13:0]

X-axis magnetic field intensity data, twos complement

format, 0.5 mgauss per LSB

Table 18. YMAGN_OUT (Base Address = 0x12), Read Only

Bits Description

[15] New data indicator (ND), 1 = new data in register

[14] Error/alarm, 1 = active, see DIAG_STAT for error flags

[13:0]

Y-axis magnetic field intensity data, twos complement

format, 0.5 mgauss per LSB

Table 19. ZMAGN_OUT (Base Address = 0x14), Read Only

Bits Description

[15] New data indicator (ND), 1 = new data in register

[14] Error/alarm, 1 = active, see DIAG_STAT for error flags

[13:0]

Z-axis magnetic field intensity data, twos complement

format, 0.5 mgauss per LSB

Table 20. Magnetometer, Twos Complement Format

Magnetic Field Decimal Hex Binary

+2.5 gauss +5000 0x1388 xx01 0011 1000 1000

+0.001 gauss +2 0x0002 xx00 0000 0000 0010

+0.0005 gauss +1 0x0001 xx00 0000 0000 0001

0 gauss 0 0x0000 xx00 0000 0000 0000

−0.0005 gauss −1 0x3FFF xx11 1111 1111 1111

−0.0005 gauss −2 0x3FFE xx11 1111 1111 1110

−2.5 gauss −5000 0x2C78 xx10 1100 0111 1000

Barometric Pressure

The barometric pressure measurements are contained in two

registers, BARO_OUT (Tab le 21) and BARO_OUTL (Ta b le 22)

registers. Tabl e 23 provides several numerical format examples

for BARO_OUT, which is sufficient for most applications.

Use BAR_OUTL and the following steps to increase the

numerical resolution by 8-bits for best performance:

1. Read BAR_OUT and multiply by 256 (shift 8 bits)

2. Read BAR_OUTL and max off upper 8 bits

3. Add results together for a 24-bit result,

where 1 LSB = 0.0003125 and 0x00000 = 0 mbar

Table 21. BARO_OUT (Base Address = 0x16), Read Only

Bits Description

[15] New data indicator (ND), 1 = new data in register

[14] Error/alarm, 1 = active, see DIAG_STAT for error flags

[13:0]

Barometric pressure data, binary data format,

0.08 mbar per LSB, 0x0000 = 0 mbar

Table 22. BARO_OUTL (Base Address = 0x18), Read Only

[15:8] Not used

[7:0]

Barometric pressure data, binary data format,

0.0003125 mbar per LSB, 0x0000 = 0 mbar

Table 23. Pressure, Binary, BARO_OUT Only

Pressure

(mbar)

1200 15,000 0x3A98 xx11 1010 1001 1000

1100 13,750 0x35B6 xx11 0101 1011 0110

1000 12,500 0x30D4 xx11 0000 1101 0100

0.16 2 0x0002 xx00 0000 0000 0010

0.08 1 0x0001 xx00 0000 0000 0001

Decimal Hex Binary

Internal Temperature

The internal temperature measurement data loads into the

TEMP_OUT (Tab l e 24) register. Tabl e 25 illustrates the

temperature data format.

Table 24. TEMP_OUT (Base Address = 0x1A), Read Only

Bits Description

[15] New data indicator (ND), 1 = new data in register

[14] Error/alarm, 1 = active, see DIAG_STAT for error flags

[13:12] Not used

0.136°C/LSB, 25°C = 0x000

Table 25. Temperature, Twos Complement Format

Temperature Decimal Hex Binary

+105°C +588 LSB 0x24C xxxx 0010 0100 1100

+85°C +441 LSB 0x1B9 xxxx 0001 1011 1001

+25.272°C +2 LSB 0x002 xxxx 0000 0000 0010

+25.136°C +1 LSB 0x001 xxxx 0000 0000 0001

+24.864°C −1 LSB 0xFFF xxxx 1111 1111 1111

+24.728°C −2 LSB 0xFFE xxxx 1111 1111 1110

−40°C −478 LSB 0xE22 xxxx 1110 0010 0010

Rev. C | Page 12 of 24

Data Sheet ADIS16407

1 V

414

0x19E

xxxx 0001 1001 1110

C2

C1

R1

VCC

D

D

09797-015

[11:0]

Analog input channel data, binary format,

SCLK

CS

DIN

DIN = 1011 1011 0000 0011 = 0xBB03, WRITE S 0x03 TO ADDRES S 0x3B.

09797-016

NONVOLATILE

FLASH MEMORY

(NO SPI ACCESS)

MANUAL

FLASH

BACKUP

START-UP

RESET

VOLATILE

SRAM

SPI ACCESS

09797-017

Power Supply

The SUPPLY_OUT register (Ta b l e 26) provides a measurement

of the voltage that is on the VDD pins of the device. Table 27

illustrates the power supply data format.

Table 26. SUPPLY_OUT (Base Address = 0x02), Read Only

Bits Description

[15] New data indicator (ND), 1 = new data in register

[14] Error/alarm, 1 = active, see DIAG_STAT for error flags

[13:12] Not used

[11:0]

Power supply measurement data, binary format,

2.418 mV/LSB, 0 V = 0x000

Table 27. Power Supply Data, Binary Format

Voltage Decimal Hex Binary

+5.25 V 2171 0x87B xxxx 1000 0111 1011

+5.0 V 2068 0x814 xxxx 1000 0001 0100

+4.75 V 1964 0x7AC xxxx 0111 1010 1100

4.836 mV 2 0x002 xxxx 0000 0000 0010

2.418 mV 1 0x001 xxxx 0000 0000 0001

0 V 0 0x000 xxxx 0000 0000 0000

INPUT ADC CHANNEL

The AUX_ADC register provides access to the auxiliary ADC

input channel. The ADC is a 12-bit successive approximation

converter that has an input circuit equivalent to the one shown

in Figure 15. The maximum input is 3.3 V. The ESD protection

diodes can handle 10 mA without causing irreversible damage.

The on resistance (R1) of the switch has a typical value of 100 Ω.

The sampling capacitor, C2, has a typical value of 16 pF.

Figure 15. Equivalent Analog Input Circuit

(Conversion Phase: Switch Open,

Track Phase: Switch Closed)

Table 29. Analog Input, Offset Binary Format

Input Voltage Decimal Hex Binary

3.3 V 4095 0xFFF xxxx 1111 1111 1111

1 V 1241 0x4D9 xxxx 0100 1101 1001

1.6118 mV 2 0x002 xxxx 0000 0000 0010

805.9 µV 1 0x001 xxxx 0000 0000 0001

0 V 0 0x000 xxxx 0000 0000 0000

DEVICE CONFIGURATION

The control registers in Tab l e 30 provide users with a variety of

configuration options. The SPI provides access to these registers,

one byte at a time, using the bit assignments in Figure 13. Each

register has 16 bits, where Bits[7:0] represent the lower address,

and Bits[15:8] represent the upper address. Figure 16 provides

an example of writing 0x03 to Address 0x3B (SMPL_PRD[15:8]),

using DIN = 0xBB03. This example reduces the sample rate by a

factor of eight (see Tab l e 46).

Figure 16. Example SPI Write Sequence

Dual Memory Structure

Writing configuration data to a control register updates its SRAM

contents, which are volatile. After optimizing each relevant control

register setting in a system, set GLOB_CMD[3] = 1 (DIN =

0xBE08) to backup these settings in nonvolatile flash memory.

The flash backup process requires a valid power supply level for

the entire 75 ms process time. Tabl e 30 provides a user register

memory map that includes a flash backup column. A “yes” in this

column indicates that a register has a mirror location in flash and,

when backed up properly, it automatically restores itself during

startup or after a reset. Figure 17 provides a diagram of the dual

memory structure used to manage operation and store critical user

settings.

Table 28. AUX_ADC (Base Address = 0x1C), Read Only

Bits Description

[15] New data indicator (ND), 1 = new data in register

[14] Error/alarm, 1 = active, see DIAG_STAT for error flags

[13:12] Not used

0.8059 mV/LSB, 0 V = 0x000

Figure 17. SRAM and Flash Memory Diagram

Rev. C | Page 13 of 24

ADIS16407 Data Sheet

Name

R/W

Flash Backup

Address2

Default

Function

Bit Assignments

ZACCL_OUT

R

No

0x0E

N/A

Z-axis accelerometer output

See Table 15

XACCL_OFF

R/W

Yes

0x24

0x0000

X-axis acceleration bias offset factor

See Table 52

XMAGN_SIC

R/W

Yes

0x30

0x0800

X-axis magnetometer, soft iron factor

See Table 58

SMPL_PRD

R/W

Yes

0x3A

0x0001

Internal sample period (rate) control

See Table 46

ALM_MAG2

R/W

Yes

0x46

0x0000

Alarm 2 amplitude threshold

See Table 63

USER REGISTERS

Table 30. User Register Memory Map1

FLASH_CNT R Yes 0x00 N/A Flash memory write count See Table 38

SUPPLY_OUT R No 0x02 N/A Power supply measurement See Table 26

XGYRO_OUT R No 0x04 N/A X-axis gyroscope output See Table 9

YGYRO_OUT R No 0x06 N/A Y-axis gyroscope output See Table 10

ZGYRO_OUT R No 0x08 N/A Z-axis gyroscope output See Table 11

XACCL_OUT R No 0x0A N/A X-axis accelerometer output See Table 13

YACCL_OUT R No 0x0C N/A Y-axis accelerometer output See Table 14

XMAGN_OUT R No 0x10 N/A X-axis magnetometer measurement See Table 17

YMAGN_OUT R No 0x12 N/A Y-axis magnetometer measurement See Table 18

ZMAGN_OUT R No 0x14 N/A Z-axis magnetometer measurement See Table 19

BARO_OUT R No 0x16 N/A Barometer pressure measurement, high word See Table 21

BARO_OUTL R No 0x18 N/A Barometer pressure measurement, low word See Table 22

TEMP_OUT R No 0x1A N/A Temperature output See Table 24

AUX_ADC R No 0x1C N/A Auxiliary ADC measurement See Table 28

XGYRO_OFF R/W Yes 0x1E 0x0000 X-axis gyroscope bias offset factor See Table 49

YGYRO_OFF R/W Yes 0x20 0x0000 Y-axis gyroscope bias offset factor See Table 50

ZGYRO_OFF R/W Ye s 0x22 0x0000 Z-axis gyroscope bias offset factor See Table 51

YACCL_OFF R/W Yes 0x26 0x0000 Y-axis acceleration bias offset factor See Table 53

ZACCL_OFF R/W Yes 0x28 0x0000 Z-axis acceleration bias offset factor See Table 54

XMAGN_HIC R/W Yes 0x2A 0x0000 X-axis magnetometer, hard iron factor See Table 55

YMAGN_HIC R/W Yes 0x2C 0x0000 Y-axis magnetometer, hard iron factor See Table 56

ZMAGN_HIC R/W Yes 0x2E 0x0000 Z-axis magnetometer, hard iron factor See Table 57

YMAGN_SIC R/W Yes 0x32 0x0800 Y-axis magnetometer, soft iron factor See Table 59

ZMAGN_SIC R/W Yes 0x34 0x0800 Z-axis magnetometer, soft iron factor See Table 60

GPIO_CTRL R/W No 0x36 0x0000 Auxiliary digital input/output control See Table 42

MSC_CTRL R/W Yes 0x38 0x0006 Miscellaneous control See Table 39

SENS_AVG R/W Yes 0x3C 0x0402 Dynamic range and digital filter control See Table 47

SLP_CTRL W No 0x3E N/A Sleep mode control See Table 33

DIAG_STAT R No 0x40 0x0000 System status See Table 40

GLOB_CMD W N/A 0x42 0x0000 System command See Table 32

ALM_MAG1 R/W Yes 0x44 0x0000 Alarm 1 amplitude threshold See Table 62

ALM_SMPL1 R/W Yes 0x48 0x0000 Alarm 1 sample size See Table 64

ALM_SMPL2 R/W Yes 0x4A 0x0000 Alarm 2 sample size See Table 65

ALM_CTRL R/W Yes 0x4C 0x0000 Alarm control See Table 66

AUX_DAC R/W No 0x4E 0x0000 Auxiliary DAC data See Table 43

Reserved N/A N/A 0x50 N/A Reserved

LOT_ID1 R Yes 0x52 N/A Lot identification number See Table 34

LOT_ID2 R Yes 0x54 N/A Lot identification number See Table 35

PROD_ID R Yes 0x56 0x4107 Product identifier See Table 36

SERIAL_NUM R Yes 0x58 N/A Serial number See Table 37

1

N/A means not applicable.

2

Each register contains two bytes. The address of the lower byte is displayed. The address of the upper byte is equal to the address of the lower byte plus 1.

Rev. C | Page 14 of 24

Data Sheet ADIS16407

MSC_CTRL

0x38

Self test, calibration, data ready

[15:12]

Reserved

SYSTEM FUNCTIONS

The ADIS16407 provides a number of system controls for

managing operation, using the registers in Tab l e 31.

Table 31. System Tool Registers

Register Name Address Description

SLP_CTRL 0x3E Sleep mode control

DIAG_STAT 0x40 Error flags

GLOB_CMD 0x42 Single command functions

LOT_ID1 0x52 Lot Identification Code 1

LOT_ID2 0x54 Lot Identification Code 2

PROD_ID 0x56 Product identifier

SERIAL_NUM 0x58 Serial number

GLOBAL COMMANDS

The GLOB_CMD register in Tabl e 32 provides trigger bits for

software reset, flash memory management, DAC control, and

calibration control. Start each of these functions by writing a 1 to

the assigned bit in GLOB_CMD. After completing the task, the bit

automatically returns to 0. For example, set GLOB_CMD[7] = 1

(DIN = 0xC280) to initiate a software reset, which stops the sensor

operation and runs the device through its start-up sequence. Set

GLOB_CMD[3] = 1 (DIN = 0xC208) to back up the user register

contents in nonvolatile flash. This sequence includes loading

the control registers with the data in their respective flash

memory locations prior to producing new data.

Table 32. GLOB_CMD (Base Address = 0x42), Write Only

Bits Description (Default = 0x0000)

[15:8] Not used

[7] Software reset

[6:4] Not used

[3] Flash update

[2] Auxiliary DAC data latch

[1] Factory calibration restore

[0] Gyroscope bias correction

PRODUCT IDENTIFICATION

The PROD_ID register in Tab l e 3 6 contains the binary equivalent

of the part number. It provides a product specific variable for

systems that need to track this in their system software. The

LOT_ID1 and LOT_ID2 registers in Tabl e 34 and Ta b le 35

combine to provide a unique, 32-bit lot identification code. The

SERIAL_NUM register in Tab l e 37 contains a binary number

that represents the serial number on the device label. The

assigned serial numbers in SERIAL_NUM are lot specific.

Table 34. LOT_ID1 (Base Address = 0x52), Read Only

Bits Description

[15:0] Lot identification, binary code

Table 35. LOT_ID2 (Base Address = 0x54), Read Only

Bits Description

[15:0] Lot identification, binary code

Table 36. PROD_ID Bit (Base Address = 0x56), Read Only

Bits Description (Default = 0x4017)

[15:0] Binary number, equivalent to part number

Contents = 16,407 = 0x4017

Table 37. SERIAL_NUM (Base Address = 0x58), Read Only

Bits Description

[11:0] Serial number, 1 to 4094 (0xFFE)

MEMORY MANAGEMENT

The FLASH_CNT register in Tabl e 38 provides a 16-bit counter

that helps track the number of write cycles to the nonvolatile flash

memory. The flash updates every time a manual flash update

occurs. A manual flash update is initiated by the GLOB_CMD[3]

bit and is also performed at the completion of the GLOB_CMD[1:0]

functions (see Ta b l e 32).

POWER MANAGEMENT

The SLP_CTRL register (see Ta b le 33) provides two sleep

modes for system level management: normal and timed. Set

SLP_CTRL[8] = 1 (DIN = 0xBF01) to start normal sleep mode.

When the device is in sleep mode, the following events can cause

it to wake up: asserting

high to low, or cycling the power. Use SLP_CTRL[7:0] to put the

device into sleep mode for a specified period. For example,

SLP_CNT[7:0] = 0x64 (DIN = 0xBE64) puts the

sleep for 50 seconds.

Table 33. SLP_CTRL (Base Address = 0x3E), Write Only

Bits Description

[15:9] Not used

[8] Normal sleep mode (1 = start sleep mode)

[7:0]

Timed sleep mode (write 0x01 to 0xFF to start)

Sleep mode duration, binary, 0.5 sec/LSB

CS

from high to low, asserting

ADIS16407 to

RST

from

Rev. C | Page 15 of 24

Table 38. FLASH_CNT (Base Address = 0x00), Read Only

Bits Description

[15:0] Binary counter

Checksum Test

Set MSC_CTRL[11] = 1 (DIN = 0xB908) to perform a checksum test of the internal program memory. This function takes a

summation of the internal program memory and compares it with

the original summation value for the same locations (from factory

configuration). Check the results in the DIAG_STAT register, which

is in Tabl e 4 0 . DIAG_STAT[6] equals 0 if the sum matches the

correct value, and 1 if it does not. Make sure that the power

supply is within specification for the entire 20 ms that this

function takes to complete.

ADIS16407 Data Sheet

Bits

Description (Default = 0x0006)

1 = enabled, 0 = disabled

[0]

Data ready line select

[12]

Z-axis gyroscope self test result

1 = fail, 0 = pass

[5]

Self test diagnostic result

1 = overrange, 0 = normal

1 = VDD > 5.25 V

1 = VDD < 4.75 V

SELF TEST FUNCTION

Gyroscopes/Accelerometers

The MSC_CTRL register in Tab l e 39 provides a self test function

for the gyroscopes and accelerometers. This function allows the

user to verify the mechanical integrity of each MEMS sensor.

When enabled, the self test applies an electrostatic force to each

internal sensor element, which causes them to move. The movement in each element simulates its response to actual rotation/

acceleration and generates a predictable electrical response in the

sensor outputs. The ADIS16407 exercises this function and

compares the response to an expected range of responses and reports

a pass/fail response to DIAG_STAT[5]. If this is high, the

DIAG_STAT[15:10] provide pass/fail flags for each inertial sensor.

Table 39. MSC_CTRL (Base Address = 0x38), Read/Write

[15:12] Not used

[11] Checksum memory test (cleared upon completion)1

1 = enabled, 0 = disabled

[10] Internal self test (cleared upon completion)1

1 = enabled, 0 = disabled

[9:8] Do not use, always set to 00

[7] Linear acceleration bias compensation for gyroscopes

[6] Point of percussion, see Figure 6

1 = enabled, 0 = disabled

[5:3] Not used

[2] Data ready enable

1 = enabled, 0 = disabled

[1] Data ready polarity

1 = active high, 0 = active low

1 = DIO2, 0 = DIO1

1

The bit is automatically reset to 0 after finishing the test.

Barometer

The barometer self test function is part of the power-on and

reset initialization processes. DIAG_STAT[7] (see Ta b le 40)

contains the result of this test after the device completes normal

operation. If DIAG_STAT[7] = 1, initiate a software reset by

setting GLOB_CMD[7] = 1 (DIN = 0xC280). If DIAG_STAT[7]

= 0 after the reset process completes, then the barometer is

functional. A persistent fail result in DIAG_STAT[7] indicates a

potential problem with the barometer.

STATUS/ERROR FLAGS

The DIAG_STAT register in Tabl e 40 provides error flags for

a number of functions. Each flag uses 1 to indicate an error condition and 0 to indicate a normal condition. Reading this register

provides access to the status of each flag and resets all of the bits

to 0 for monitoring future operation. If the error condition remains,

the error flag returns to 1 at the conclusion of the next sample

cycle. DIAG_STAT[0] does not require a read of this register to

return to 0. If the power supply voltage goes back into range, this

flag clears automatically. The SPI communication error flag in

DIAG_STAT[3] indicates that the number of SCLKs in a SPI

sequence did not equal a multiple of 16 SCLKs.

Table 40. DIAG_STAT (Base Address = 0x40), Read Only

Bits Description (Default = 0x0000)

[15] Z-axis accelerometer self test result

1 = fail, 0 = pass

[14] Y-axis accelerometer self test result

1 = fail, 0 = pass

[13] X-axis accelerometer self test result

1 = fail, 0 = pass

0 = pass

[11] Y-axis gyroscope self test result

[10] X-axis gyroscope self test result

1 = fail, 0 = pass

[9] Alarm 2 status

1 = active, 0 = inactive

[8] Alarm 1 status

1 = active, 0 = inactive

[7] Barometer self test

1 = fail (issue with sensor function), 0 = pass (no issue)

[6] Flash test (checksum) result

1 = fail, 0 = pass

1 = fail, 0 = pass

[4] Sensor overrange condition

[3] SPI communication

1 = fail (number of SCLKs not equal to a multiple of 16)

0 = pass (number of SCLKs is equal to a multiple of 16)

[2] Flash update verification

1 = fail (flash update was not successful)

0 = pass (flash update was successful)

[1] Power supply high

0 = VDD ≤ 5.25 V

[0] Power supply low

0 = VDD ≥ 4.75 V

Rev. C | Page 16 of 24

Data Sheet ADIS16407

GPIO_CTRL

0x36

General-purpose I/O control

[15:12]

Not used

[9]

General-Purpose I/O Line 2 (DIO2) data level

[3]

General-Purpose I/O Line 4 (DIO4) direction control

1 = output, 0 = input

INPUT/OUTPUT CONFIGURATION

Tabl e 41 provides a summary of registers that provide input/output

configuration and control.

Table 41. Input/Output Registers

Register Name Address Description

MSC_CTRL 0x38 Self test, calibration, data ready

AUX_DAC 0x4E Output voltage control, AUX_DAC

DATA READY INDICATOR

The factory default setting of MSC_CTRL[2:0] = 110 establishes

DIO1 as a positive polarity data ready signal. See Tabl e 39 for

additional data ready configuration options. For example, set

MSC_CTRL[2:0] = 100 (DIN = 0xB804) to change the polarity of

the data ready signal on DIO1 for interrupt inputs that require

negative logic inputs for activation. The pulse width is typically

between 60 µs and 150 µs, including jitter (±30 µs).

GENERAL-PURPOSE INPUT/OUTPUT

DIO1, DIO2, DIO3, and DIO4 are configurable, general-purpose

input/output lines that serve multiple purposes. The data ready

controls in MSC_CTRL[2:0] have the highest priority for

configuring DIO1 and DIO2. The alarm indicator controls in

ALM_CTRL[2:0] have the second highest priority for configuring

DIO1 and DIO2. The external clock control associated with

SMPL_PRD[0] has the highest priority for DIO4 configuration

(see Tab l e 46). GPIO_CTRL in Tab l e 42 has the lowest priority

for configuring DIO1, DIO2, and DIO4, and has absolute

control over DIO3.

Table 42. GPIO_CTRL (Base Address = 0x36), Read/Write

Bits Description (Default = 0x0000)

[11] General-Purpose I/O Line 4 (DIO4) data level

[10] General-Purpose I/O Line 3 (DIO3) data level

[8] General-Purpose I/O Line 1 (DIO1) data level

[7:4] Not used

Example Input/Output Configuration

For example, set GPIO_CTRL[3:0] = 0100 (DIN = 0xB604)

to set DIO3 as an output signal pin and DIO1, DIO2, and

DIO4 as input signal pins. Set the output on DIO3 to 1 by

setting GPIO_CTRL[10] = 1 (DIN = 0xB704). Then, read

GPIO_CTRL[7:0] (DIN = 0x3600) and mask off GPIO_CTRL[9:8]

and GPIO_CTRL[11] to monitor the digital signal levels on

DIO4, DIO2, and DIO1.

AUXILIARY DAC

The AUX_DAC register in Ta b le 43 provides user controls for

setting the output voltage on the AUX_DAC pin. The 12-bit

AUX_DAC line can drive its output to within 5 mV of the ground

reference when it is not sinking current. As the output approaches

0 V, the linearity begins to degrade (~100 LSB starting point). As

the sink current increases, the nonlinear range increases. The

DAC latch command in GLOB_CMD[2] (see Ta b l e 32) moves

the values of the AUX_DAC register into the DAC input register,

enabling both bytes to take effect at the same time. This prevents

undesirable output levels, which reflect single byte changes of

the AUX_DAC register.

Table 43. AUX_DAC (Base Address = 0x4E), Read/Write

Bits Description (Default = 0x0000)

[15:12] Not used

[11:0]

Table 44. Setting AUX_DAC = 1 V

DIN Description

0xCED9 AUX_DAC[7:0] = 0xD9 (217 LSB)

0xCF04 AUX_DAC[15:8] = 0x04 (1024 LSB)

0xC204

Data bits, scale factor = 0.8059 mV/LSB, offset binary

format, 0 V = 0 LSB

GLOB_CMD[2] = 1; move values into the DAC input

register, resulting in a 1 V output level

1 = output, 0 = input

[2] General-Purpose I/O Line 3 (DIO3) direction control

1 = output, 0 = input

[1] General-Purpose I/O Line 2 (DIO2) direction control

[0] General-Purpose I/O Line 1 (DIO1) direction control

1 = output, 0 = input

Rev. C | Page 17 of 24

ADIS16407 Data Sheet

A

V

DIGITAL PROCESSING CONFIGURATION

Table 45. Digital Processing Registers

Register Name Address Description

SMPL_PRD 0x3A Sample rate control

SENS_AVG 0x3C Digital filtering and range control

SAMPLE RATE

The internal sampling system produces new data in the output

data registers at a rate of 819.2 SPS. The SMPL_PRD register in

Table 46 provides two functional controls that affect sampling

and register update rates. SMPL_PRD[12:8] provides a control

for reducing the update rate, using an averaging filter with a decimated output. These bits provide a binomial control that divides

the data rate by a factor of 2 every time this number increases

by 1. For example, set SMPL_PRD[15:8] = 0x04 (DIN = 0xBB04)

to set the decimation factor to 16. This reduces the update rate

to 51 SPS and the bandwidth to 25 Hz.

Table 46. SMPL_PRD (Base Address = 0x3A), Read/Write

Bits Description (Default = 0x0001)

[15:13] Not used

[12:8] D, decimation rate setting, binomial, see Figure 19

[7:1] Not used

[0] Clock

1 = internal 819.2 SPS

0 = external

INPUT CLOCK CONFIGURATION

SMPL_PRD[0] provides a control for synchronizing the internal

sampling to an external clock source. Set SMPL_PRD[0] = 0

(DIN = 0xBA00) and GPIO_CTRL[3] = 0 (DIN = 0xB600) to

enable the external clock. See Table 2 and Figure 4 for timing

information.

DIGITAL FILTERING

The SENS_AVG register in Table 47 provides user controls for

the low-pass filter. This filter contains two cascaded averaging

filters that provide a Bartlett window, FIR filter response (see

Figure 19). For example, set SENS_AVG[2:0] = 100 (DIN = 0xBC04)

to select 33 taps. When used with the default sample rate of

819.2 SPS and zero decimation (SMPL_PRD[15:8] = 0x00), this

value reduces the sensor bandwidth to approximately 16 Hz.

MEMS

SENSOR

LOW-PASS

FILTER

330Hz

ADC

0

–20

–40

–60

–80

MAGNITUDE (dB)

–100

N = 2

N = 4

–120

N = 16

N = 64

–140

0.001 0.01 0.1 1

FREQUENCY (f/

f

)

S

Figure 18. Bartlett Window, FIR Filter Frequency Response

(Phase Delay = (2N

− 1)/2 Samples)

B

DYNAMIC RANGE

The SENS_AVG[10:8] bits provide three dynamic range settings

for this gyroscope. The lower dynamic range settings (±75°/sec

and ±150°/sec) limit the minimum filter tap sizes to maintain

resolution. For example, set SENS_AVG[10:8] = 010 (DIN =

0xBD02) for a measurement range of ±150°/sec. Because this

setting can influence the filter settings, program SENS_AVG[10:8]

before programming SENS_AVG[2:0] if more filtering is required.

Table 47. SENS_AVG (Base Address = 0x3C), Read/Write

Bits Description (Default = 0x0402)

[15:11] Not used

[10:8] Measurement range (sensitivity) selection

100 = ±300°/sec (default condition)

010 = ±150°/sec, filter taps ≥ 9 (Bits[2:0] ≥ 0x02)

001 = ±75°/sec, filter taps ≥ 33 (Bits[2:0] ≥ 0x04)

[7:3] Not used

[2:0] Filter Size Variable B

Total number of taps; NT = 2

See Figure 18 for filter response

BARTLET T WINDO W

FIR FILTER

N

B

1

x(n)

N

B

n = 1

N

B

1

x(n)

N

B

n = 1

ERAGE/

DECIMATION

FILTER

N

D

1

x(n)

N

D

n = 1

B + 1

− 1

÷N

D

09797-018

B = SENS_AVG[2:0]

B

= 2

LOW-PASS, TWO-POLE (404Hz, 757Hz)

GYROSCOPES

ACCELEROMETERS

LOW-PASS, SING LE-POL E (330H z)

Figure 19. Sampling and Frequency Response Block Diagram

EXTERNAL CLOCK ENAB LED

CLOCK

819.2SPS

BY SMPL_PRD[0] = 0

N

B

NT = 2NB - 1

D = SMPL_PRD[ 12: 8]

D

N

= 2

D

ND = NUMBER OF TAPS

09797-019

Rev. C | Page 18 of 24

Data Sheet ADIS16407

XMAGN_HIC

0x2A

Hard iron correction, x-axis

XGYRO_OFF

X-AXIS

MEMS

GYRO

ADC

FACTORY

CALIBRATION

AND

FILTERING

XGYRO_OUT

09797-020

CALIBRATION

The mechanical structure and assembly process of the ADIS16407

provide excellent position and alignment stability for each sensor,

even after subjected to temperature cycles, shock, vibration, and

other environmental conditions. The factory calibration includes a

dynamic characterization of each gyroscope and accelerometer over

temperature and generates sensor specific correction formulas.

Tabl e 48 provides a list of registers that can help optimize system

performance after installation. Figure 20 illustrates the summing

function for the offset correction register of each sensor.

Table 48. Registers for User Calibration

Register Address Description

XGYRO_OFF 0x1E Gyroscope bias, x-axis

YGYRO_OFF 0x20 Gyroscope bias, y-axis

ZGYRO_OFF 0x22 Gyroscope bias, z-axis

XACCL_OFF 0x24 Accelerometer bias, x-axis

YACCL_OFF 0x26 Accelerometer bias, y-axis

ZACCL_OFF 0x28 Accelerometer bias, z-axis

YMAGN_HIC 0x2C Hard iron correction, y-axis

ZMAGN_HIC 0x2E Hard iron correction, z-axis

XMAGN_SIC 0x30 Soft iron correction, x-axis

YMAGN_SIC 0x32 Soft iron correction, y-axis

ZMAGN_SIC 0x34 Soft iron correction, z-axis

MSC_CTRL 0x38 Miscellaneous calibration

GLOB_CMD 0x42 Automatic calibration

GYROSCOPES

The XGYRO_OFF (Table 49), YGYRO_ OFF (Tabl e 50), and

ZGYRO_ OFF (Tab l e 51) registers provide user-programmable

bias adjustment function for the x-, y-, and z-axis gyroscopes,

respectively. Figure 20 illustrates that they contain bias correction

factors that adjust to the sensor data immediately before it loads

into the output register.

Figure 20. User Calibration, XGYRO_OFF Example

Gyroscope Bias Error Estimation

Any system level calibration function must start with an estimate

of the bias errors, which typically comes from a sample of gyroscope output data, when the device is not in motion. The sample

size of data depends on the accuracy goals. Figure 7 provides a

trade-off relationship between averaging time and the expected

accuracy of a bias measurement. Vibration, thermal gradients,

and power supply instability can influence the accuracy of this

process.

Table 49. XGYRO_OFF (Base Address = 0x1E), Read/Write

Bits Description (Default = 0x0000)

[15:14] Not used

[13:0]

X-axis, gyroscope offset correction factor,

twos complement, 0.0125°/sec per LSB

Table 50. YGYRO_OFF (Base Address = 0x20), Read/Write

Bits Description (Default = 0x0000)

[15:14] Not used

[13:0]

Y-axis, gyroscope offset correction factor,

twos complement, 0.0125°/sec per LSB

Table 51. ZGYRO_OFF (Base Address = 0x22), Read/Write

Bits Description (Default = 0x0000)

[15:14] Not used

[13:0]

Z-axis, gyroscope offset correction factor,

twos complement, 0.0125°/sec per LSB

Gyroscope Bias Correction Factors

When the bias estimate is complete, multiply the estimate by −1

to change its polarity, convert it into digital format for the offset

correction registers (Ta b le 49), and write the correction factors

to the correction registers. For example, lower the x-axis bias by

10 LSB (0.125°/sec) by setting XGYRO_OFF = 0x1FF6 (DIN =

0x9F1F, 0x9EF6).

Single Command Bias Correction

GLOB_CMD[0] (Tabl e 32) loads the xGYRO_OFF registers

with the values that are the opposite of the values that are in

xGYRO_OUT, at the time of initiation. Use this command,

together with the decimation filter (SMPL_PRD[12:8], Tab l e 46),

to automatically average the gyroscope data and improve the

accuracy of this function, as follows:

1. Set SENS_AVG[10:8] = 001 (DIN = 0xBD01) to optimize

the xGYRO_OUT sensitivity to 0.0125°/sec/LSB.

2. Set SMPL_PRD[12:8] = 0x10 (DIN = 0xBB10) to set the

decimation rate to 65,536 (2

16

), which provides an averaging

time of 80 seconds (65,536 ÷ 819.2 SPS).

3. Wait for 80 seconds while keeping the device motionless.

4. Set GLOB_CMD[0] = 1 (DIN = 0xC201) and wait for the

time it takes to perform the flash memory backup (~75 ms).

Rev. C | Page 19 of 24

ADIS16407 Data Sheet

ORIGIN ALIGNMENT REFERENCE POINT

SEE MSC_CTRL[6].

09797-021

ADC

+

XMAGN_OUT

×

MAGNETIC

SENSOR

FACTORY

CALIBRATION

AND FILTE RING

XMAGN_SIC

XMAGN_HIC

09797-022

Bits

Description (Default = 0x0800)

Bits

Description (Default = 0x0800)

Bits

Description (Default = 0x0800)

ACCELEROMETERS

The XACCL_ OFF (Tab l e 52), YACCL_ OFF (Tabl e 53), and

ZACCL_ OFF (Tab l e 54) registers provide user programmable

bias adjustment function for the x-, y-, and z-axis accelerometers,

respectively. These registers adjust the accelerometer data in the

same manner as XGYRO_OFF functions in Figure 20.

Table 52. XACCL_OFF (Base Address = 0x24), Read/Write

Bits Description (Default = 0x0000)

[15:14] Not used

[13:0]

Table 53. YACCL_OFF (Base Address = 0x26), Read/Write

Bits Description (Default = 0x0000)

[15:14] Not used

[13:0]

Table 54. ZACCL_OFF (Base Address = 0x28), Read/Write

Bits Description (Default = 0x0000)

[15:14] Not used

[13:0]

Accelerometer Bias Error Estimation

Under static conditions, orient each accelerometer in positions

where the response to gravity is predictable. A common approach

to this is to measure the response of each accelerometer when

they are oriented in peak response positions, that is, where ±1 g

is the ideal measurement position. Next, average the +1 g and

−1 g accelerometer measurements together to estimate the

residual bias error. Using more points in the rotation can

improve the accuracy of the response.

Accelerometer Bias Correction Factors

When the bias estimate is complete, multiply the estimate by

−1 to change its polarity, convert it to the digital format for the

offset correction registers (Tab l e 52), and write the correction

factors to the correction registers. For example, lower the x-axis

bias by 10 LSB (33.3 mg) by setting XACCL_OFF = 0x1FF6

(DIN = 0xA51F, 0xA4F6).

Point of Percussion Alignment

Set MSC_CTRL[6] = 1 (DIN = 0xB846) to enable this feature

and maintain the factory default settings for DIO1. This feature

performs a point of percussion translation to the point identified

in Figure 21. See Tab le 3 9 for more information on MSC_CTRL.

X-axis, accelerometer offset correction factor,

twos complement, 3.333 mg/LSB

Y-axis, accelerometer offset correction factor,

twos complement, 3.333 mg/LSB

Z-axis, accelerometer offset correction factor,

twos complement, 3.333 mg/LSB

Figure 21. Point of Percussion Physical Reference

MAGNETOMETER CALIBRATION

The ADIS16407 provides registers that contribute to both hard

iron and soft iron correction factors, as shown in Figure 22

Figure 22. Hard Iron and Soft Iron Factor Correction

Hard Iron Correction

The XMAGN_HIC (Tab l e 55), YMAGN_HIC (Tab l e 56), and

ZMAGN_HIC (Tab le 5 7) registers provide the user programmable

bias adjustment function for the x-, y-, and z-axis magnetometers,

respectively. Hard iron effects result in an offset of the magnetometer response.

Table 55. XMAGN_HIC (Base Address = 0x2A), Read/Write

[15:14] Not used

[13:0]

Table 56. YMAGN_HIC (Base Address = 0x2C), Read/Write

[15:14] Not used

[13:0]

Table 57. ZMAGN_HIC (Base Address = 0x2E), Read/Write

[15:14] Not used

[13:0]

X-axis hard iron correction factor,

twos complement, 0.5 mgauss/LSB, 0x0000 = 0

Y-axis hard iron correction factor,

twos complement, 0.5 mgauss/LSB, 0x0000 = 0

Z-axis hard iron correction factor,

twos complement, 0.5 mgauss/LSB, 0x0000 = 0

Rev. C | Page 20 of 24

Data Sheet ADIS16407

Hard Iron Factors

When the hard iron error estimation is complete, take the

following steps:

1. Multiply the estimate by −1 to change its polarity.

2. Convert it into digital format for the hard iron correction

registers (Tab le 55).

3. Write the correction factors to the correction registers. For

example, lower the x-axis bias by 10 LSB (5 mgauss) by

setting XMAGN_HIC = 0x1FF6 (DIN = 0xAB1F, 0xAAF6).

Soft Iron Effects

The XMAGN_SIC (Tab l e 58), YMAGN_SIC (Tabl e 59), and

ZMAGN_SIC (Ta bl e 60) registers provide an adjustment

variable for the magnetometer sensitivity adjustment in each

magnetometer response to simplify the process of performing a

system level soft iron correction.

Table 58. XMAGN_SIC (Base Address = 0x30), Read/Write

Bits Description (Default = 0x0800)

[15:12] Not used

[11:0] X-axis soft iron correction factor, binary format,

Scale factor = 100%/2048LSB, 0x000 = 0

Example: 0x800 = 100% (factory scale unchanged)

Maximum = 0xFFF = 200% − 100%/2048

Table 59. YMAGN_SIC (Base Address = 0x32), Read/Write

Bits Description (Default = 0x0800)

[15:12] Not used

[11:0] Y-axis soft iron correction factor, binary format,

Scale factor = 100%/2048LSB, 0x000 = 0

Example: 0x800 = 100% (factory scale unchanged)

Maximum = 0xFFF = 200% − 100%/2048

Soft Iron Factors

When the soft iron error estimation is complete, convert the

sensitivity into the digital format for the soft iron correction

registers (Tab le 58) and write the correction factors to the

correction registers. A simple method for converting the

correction factor is to divide it by 2 and multiply it by 4095. For

example, increasing the default soft iron factor to approximately

1.15 uses a binary code for 2355, or 0x933. Increase the soft iron

correction factor for the y-axis to approximately 1.15 by setting

YMAGN_SIC = 0x0933 (DIN = 0xB309, 0xB233).

FLASH UPDATES

When using the user calibration registers to optimize system

level accuracy, keep in mind that the register values are volatile

until their contents are saved in the nonvolatile flash memory.

After writing all of the correction factors into the user correction

registers, set GLOB_CMD[3] = 1 (DIN = 0xC204) to save these

settings in nonvolatile flash memory. Be sure to consider the

endurance rating of the flash memory when determining how

often to update the user correction factors in the flash memory.

RESTORING FACTORY CALIBRATION

Set GLOB_CMD[1] = 1 (DIN = 0xC202) to execute the factory

calibration restore function. This is a single command function,

which resets the gyroscope and accelerometer offset registers to

0x0000 and all sensor data to 0. Then, it automatically updates the

flash memory within 75 ms and restarts sampling and processing

data. See Tab l e 32 for more information on GLOB_CMD.

Table 60. ZMAGN_SIC (Base Address = 0x34), Read/Write

Bits Description (Default = 0x0800)

[15:12] Not used

[11:0] Z-axis soft iron correction factor, binary format,

Scale factor = 100%/2048LSB, 0x000 = 0

Example: 0x800 = 100% (factory scale unchanged)

Maximum = 0xFFF = 200% − 100%/2048

Rev. C | Page 21 of 24

ADIS16407 Data Sheet

ALM_CTRL

0x4C

Alarm configuration

Bits

Description (Default = 0x0000)

0110 = YACCL_OUT

[6]

Alarm 1, dynamic/static (1 = dynamic, 0 = static)

[3]

Not used

[0]

Alarm output line select (1 = DIO2, 0 = DIO1)

ALM_MAG2 = 0x03E8 = 1,000 LSB = 50°/sec

ALARMS

Alarm 1 and Alarm 2 provide two independent alarms. Ta ble 61

lists the alarm control registers, including ALM_CTRL (Tab l e 66),

which provides control bits for data source selection, static/

dynamic comparison, filtering, and alarm indicator.

Table 61. Registers for Alarm Configuration

Register Address Description

ALM_MAG1 0x44 Alarm 1 trigger setting

ALM_MAG2 0x46 Alarm 2 trigger setting

ALM_SMPL1 0x48 Alarm 1 sample period

ALM_SMPL2 0x4A Alarm 2 sample period

STATIC ALARM USE

The static alarms setting compares the data source selection

(ALM_CTRL[15:8]) with the values in the ALM_MAGx registers

listed in Ta b l e 62 and Tab l e 63, using ALM_MAGx[15] to determine the trigger polarity. The data format in these registers

matches the format of the data selection in ALM_CTRL[15:8].

See Tabl e 67, Alarm 1, for a static alarm configuration example.

Table 62. ALM_MAG1 (Base Address = 0x44), Read/Write

Bits Description (Default = 0x0000)

[15] Trigger polarity

1 = greater than, 0 = less than

[14] Not used

[13:0]

Threshold setting; matches for format of

ALM_CTRL[11:8] output register selection

Table 63. ALM_MAG2 (Base Address = 0x46), Read/Write

Bits Description (Default = 0x0000)

[15] Trigger polarity

1 = greater than, 0 = less than

[14] Not used

[13:0]

Threshold setting; matches for format of

ALM_CTRL[15:12] output register selection

DYNAMIC ALARM USE

The dynamic alarm setting monitors the data selection for a

rate-of-change comparison. The rate-of-change comparison is

represented by the magnitude in the ALM_MAGx registers over

the time represented by the number-of-samples setting in the

ALM_SMPLx registers, located in Tabl e 64 . See Tabl e 6 7 , Alarm 2,

for a dynamic alarm configuration example.

Table 64. ALM_SMPL1 (Base Address = 0x48), Read/Write

Bits Description (Default = 0x0000)

[15:8] Not used

[7:0] Binary, number of samples (both 0x00 and 0x01 = 1)

Table 65. ALM_SMPL2 (Base Address = 0x4A), Read/Write

Bits Description (Default = 0x0000)

[15:8] Not used

[7:0] Binary, number of samples (both 0x00 and 0x01 = 1)

Rev. C | Page 22 of 24

ALARM REPORTING

The DIAG_STAT [ 9:8] bits provide error flags that indicate an

alarm condition. The ALM_CTRL[2:0] bits provide controls for

a hardware indicator using DIO1 or DIO2.

Table 66. ALM_CTRL (Base Address = 0x4C), Read/Write

[15:12] Alarm 2 data source selection

0000 = disable

0001 = SUPPLY_OUT

0010 = XGYRO_OUT

0011 = YGYRO_OUT

0100 = ZGYRO_OUT

0101 = XACCL_OUT

0111 = ZACCL_OUT

1001 =XMAGN_OUT

1010 = YMAGN_OUT

1011 = ZMAGN_OUT

1100 = AUX_ADC

[11:8] Alarm 1 data source selection (same as Alarm 2)

[7] Alarm 2, dynamic/static (1 = dynamic, 0 = static)

[5] Not used

[4] Data source filtering (1 = filtered, 0 = unfiltered)

[2] Alarm indicator (1 = enabled, 0 = disabled)

[1] Alarm indicator active polarity (1 = high, 0 = low)

Alarm Example

Tabl e 67 offers an example that configures Alarm 1 to trigger when

filtered ZACCL_OUT data drops below 0.7 g, and Alarm 2 to

trigger when filtered ZGYRO_OUT data changes by more than

50°/sec over a 100 ms period, or 500°/sec

helps reduce false triggers from noise and refine the accuracy

of the trigger points. The ALM_SMPL2 setting of 82 samples

provides a comparison period that is approximately equal to

100 ms for an internal sample rate of 819.2 SPS.

Table 67. Alarm Configuration Example

DIN Description

0xCD47, ALM_CTRL = 0x4797

0xCC97

0xC703,

0xC6E8

0xC500,

0xC4D2

0xCA52

Alarm 2: dynamic, Δ-ZGYRO_OUT

(Δ-time, ALM_SMPL2) > ALM_MAG2

Alarm 1: static, ZACCL_OUT < ALM_MAG1, filtered data

DIO2 output indicator, positive polarity

ALM_MAG1 = 0x00D2 = 210 LSB = +0.7 g

ALM_SMPL2[7:0] = 0x52 = 82 samples

82 samples ÷ 819.2 SPS = ~100 ms

2

. The filter setting

Data Sheet ADIS16407

11 12

2

1

21

11 12

J2

J1

23.75

21.24

30.10

27.70

1.20

NOTES

1. DIMENSIONS IN MILLIMETERS.

09797-023

1 2

3 4

5 6

7

8

9 10

11

12

AUX_ADC

AUX_DAC

DNC

DNC

DIO2

DNC

DNC

DIO1

DIO4

DIO3

GND

J2

GND

2

4

6

8

10

1

3

5

7

9

11

12

RST

CS

GND

GND

VCC

GND

VCC

VCC

DIN

DOUT

SCLK

J1

DNC

09797-024

APPLICATIONS INFORMATION

INSTALLATION/HANDLING