A

A

Six Degrees of Freedom Inertial Sensor

FEATURES

Tri-axis digital gyroscope with digital range scaling

±300°/sec, ±600°/sec, ±1200°/sec settings

Tight orthogonal alignment: 0.05°

Tri-axis digital accelerometer: ±18 g

Autonomous operation and data collection

No external configuration commands required

Start-up time: 180 ms

Sleep mode recovery time: 4 ms

Factory-calibrated sensitivity, bias, and axial alignment

Calibration temperature range: −40°C to +85°C

SPI-compatible serial interface

Wide bandwidth: 330 Hz

Embedded temperature sensor

Programmable operation and control

Automatic and manual bias correction controls

Bartlett window, FIR filter length, number of taps

Digital I/O: data ready, alarm indicator, general-purpose

Alarms for condition monitoring

Sleep mode for power management

DAC output voltage

Enable external sample clock input: up to 1.2 kHz

Single-command self-test

Single-supply operation: 4.75 V to 5.25 V

2000 g shock survivability

Operating temperature range: −40°C to +105°C

APPLICATIONS

Medical instrumentation

Robotics

Platform controls

Navigation

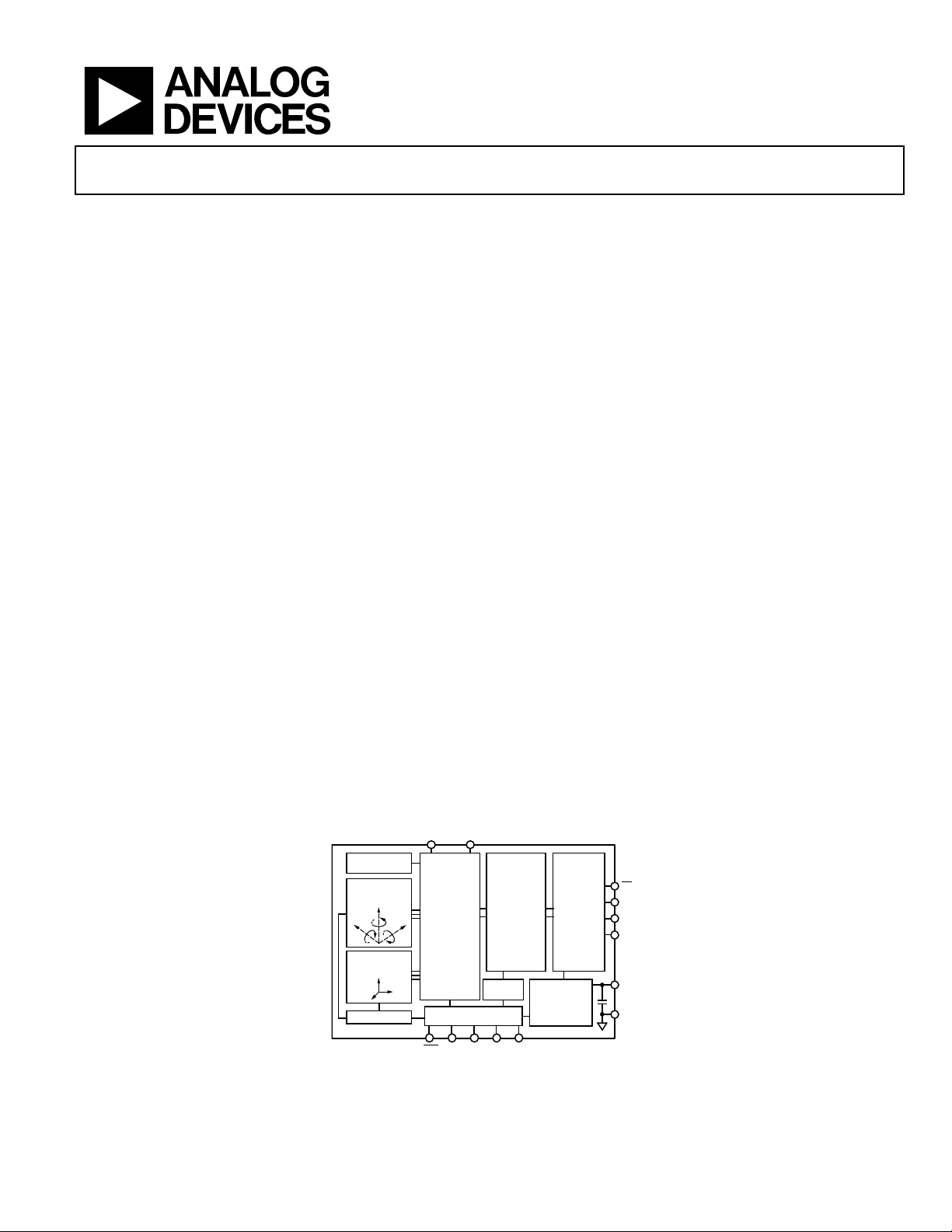

FUNCTIONAL BLOCK DIAGRAM

TEMPERATURE

SENSOR

MEMS

ANGULAR RATE

SENSOR

TRI-AXIS MEMS

ACCELERATIO N

SENSOR

SELF-TEST

ADIS16367

Rev. A

Information furnished by Analog Devices is believed to be accurate and reliable. However, no

responsibility is assumed by Anal og Devices for its use, nor for any infringements of patents or ot her

rights of third parties that may result from its use. Specifications subject to change without notice. No

license is granted by implication or otherwise under any patent or patent rights of Analog Devices.

Trademarks and registered trademarks are the property of their respective owners.

UX_

ADC

SIGNAL

CONDITIONI NG

AND

CONVERSIO N

CONTROL

RST

UX_

DAC

DIGI TAL

Figure 1.

ADIS16367

GENERAL DESCRIPTION

The ADIS16367 iSensor® is a complete inertial system that includes

a tri-axis gyroscope and tri-axis accelerometer. Each sensor in

the ADIS16367 combines industry-leading iMEMS® technology

with signal conditioning that optimizes dynamic performance.

The factory calibration characterizes each sensor for sensitivity,

bias, alignment, and linear acceleration (gyro bias). As a result, each

sensor has its own dynamic compensation formulas that provide

accurate sensor measurements over a temperature range of

−40°C to +85°C.

The ADIS16367 provides a simple, cost-effective method for

integrating accurate, multiaxis inertial sensing into industrial

systems, especially when compared with the complexity and

investment associated with discrete designs. All necessary motion

testing and calibration are part of the production process at the

factory, greatly reducing system integration time. Tight orthogonal

alignment simplifies inertial frame alignment in navigation

systems. An improved SPI interface and register structure provide

faster data collection and configuration control.

The ADIS16367 uses a compatible pinout and the same package

as the ADIS1635x family. Therefore, systems that currently use

the ADIS1635x family can upgrade their performance with minor

firmware adjustments in their processor designs.

This compact module is approximately 23 mm × 23 mm × 23 mm

and provides a flexible connector interface that enables multiple

mounting orientation options.

CALIBRATI ON

AND

DIGI TAL

PROCESSING

ALARMS

DIO4/

DIO3DIO2DIO1

CLKIN

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700 www.analog.com

Fax: 781.461.3113 ©2010–2011 Analog Devices, Inc. All rights reserved.

OUTPUT

REGISTERS

AND SPI

INTERFACE

POWER

MANAGEMENT

CS

SCLK

DIN

DOUT

VCC

GND

08398-001

ADIS16367

TABLE OF CONTENTS

Features.............................................................................................. 1

Applications....................................................................................... 1

General Description ......................................................................... 1

Functional Block Diagram .............................................................. 1

Revision History ............................................................................... 2

Specifications..................................................................................... 3

Timing Specifications .................................................................. 5

Timing Diagrams.......................................................................... 5

Absolute Maximum Ratings............................................................ 6

ESD Caution.................................................................................. 6

Pin Configuration and Function Descriptions............................. 7

Typical Performance Characteristics ............................................. 8

Theory of Operation ........................................................................ 9

Basic Operation ............................................................................ 9

Reading Sensor Data.................................................................... 9

Device Configuration .................................................................. 9

Memory Map .............................................................................. 10

Burst Read Data Collection ...................................................... 11

Output Data Registers ............................................................... 11

Calibration................................................................................... 12

Operational Control................................................................... 12

Input/Output Functions............................................................ 14

Diagnostics.................................................................................. 15

Product Identification................................................................ 16

Applications Information.............................................................. 17

Installation/Handling................................................................. 17

Gyroscope Bias Optimization................................................... 17

Input ADC Channel................................................................... 17

Interface Printed Circuit Board (PCB).................................... 17

Outline Dimensions....................................................................... 18

Ordering Guide .......................................................................... 18

REVISION HISTORY

2/11—Rev. 0 to Rev. A

Changes to Gyroscopes Misalignment and Accelerometers

Misalignment Test Conditions/Comments, Table 1 .................... 3

Changes to Table 30 and Table 31 ................................................ 16

1/10—Revision 0: Initial Version

Rev. A | Page 2 of 20

ADIS16367

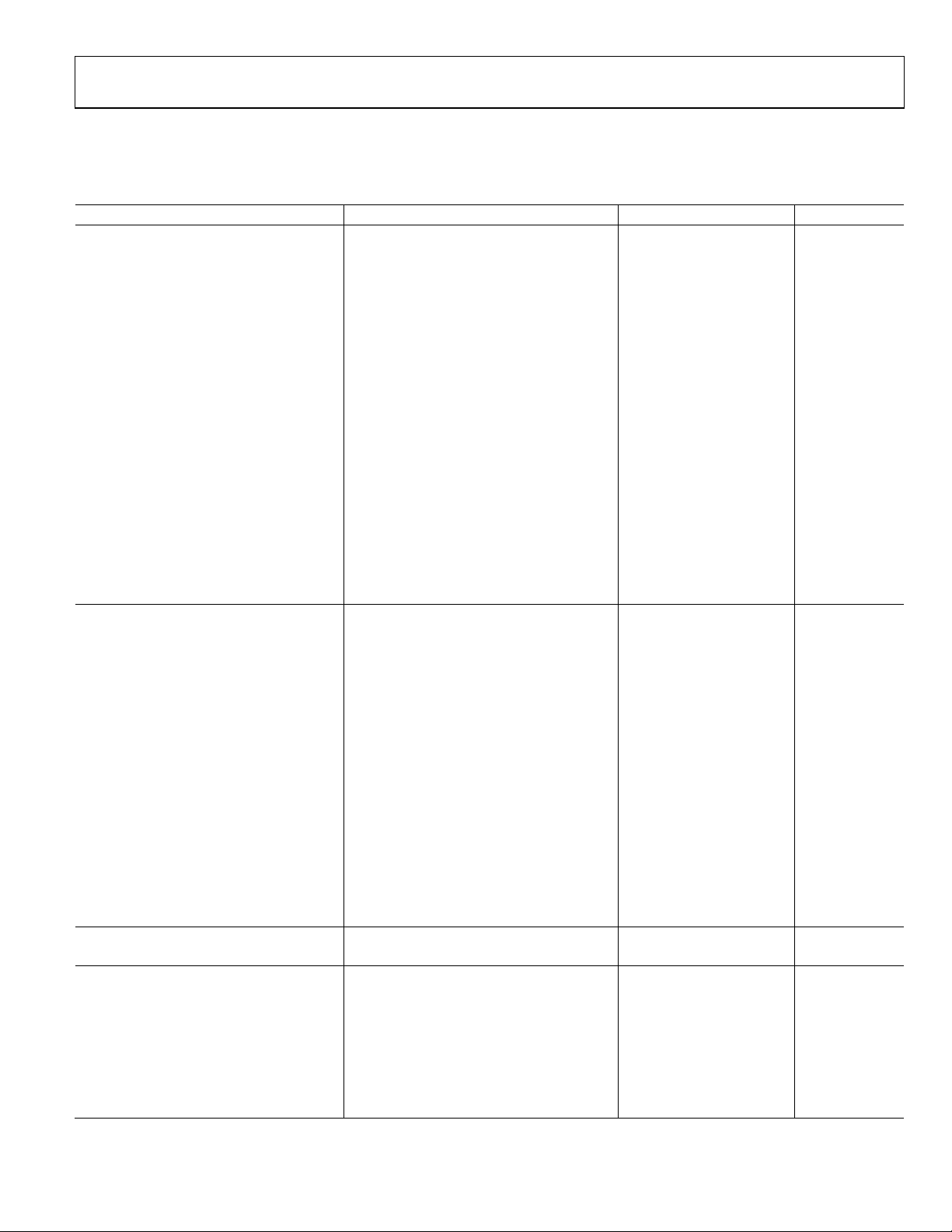

SPECIFICATIONS

TA = 25°C, VCC = 5.0 V, angular rate = 0°/sec, dynamic range = ±300°/sec ± 1 g, unless otherwise noted.

Table 1.

Parameter Test Conditions/Comments Min Typ Max Unit

GYROSCOPES

Dynamic Range ±1200 ±1400 °/sec

Initial Sensitivity Dynamic range = ±1200°/sec 0.198 0.2 0.202 °/sec/LSB

Dynamic range = ±600°/sec 0.1 °/sec/LSB

Dynamic range = ±300°/sec 0.05 °/sec/LSB

Sensitivity Temperature Coefficient −40°C ≤ TA ≤ +85°C ±40 ppm/°C

Misalignment Axis-to-axis ±0.05 Degrees

Axis-to-frame (package) ±0.5 Degrees

Nonlinearity Best-fit straight line ±0.1 % of FS

Initial Bias Error ±1 σ ±3 °/sec

In-Run Bias Stability 1 σ, SMPL_PRD = 0x0001 0.013 °/sec

Angular Random Walk 1 σ, SMPL_PRD = 0x0001 2.0 °/√hr

Bias Temperature Coefficient −40°C ≤ TA ≤ +85°C ±0.01 °/sec/°C

Linear Acceleration Effect on Bias Any axis, 1 σ (MSC_CTRL[7] = 1) 0.075 °/sec/g

Bias Voltage Sensitivity VCC = 4.75 V to 5.25 V ±0.3 °/sec/V

Output Noise ±1200°/sec range, no filtering 0.8 °/sec rms

Rate Noise Density f = 25 Hz, ±1200°/sec range, no filtering 0.044 °/sec/√Hz rms

3 dB Bandwidth 330 Hz

Sensor Resonant Frequency 14.5 kHz

Self-Test Change in Output Response ±1200°/sec range setting ±170 ±350 ±625 LSB

ACCELEROMETERS Each axis

Dynamic Range ±18

Initial Sensitivity 3.285 3.33 3.38 mg/LSB

Sensitivity Temperature Coefficient −40°C ≤ TA ≤ +85°C ±50 ppm/°C

Misalignment Axis-to-axis 0.2 Degrees

Axis-to-frame (package) ±0.5 Degrees

Nonlinearity Best-fit straight line 0.1 % of FS

Initial Bias Error ±1 σ ±50 mg

In-Run Bias Stability 1 σ 0.2 mg

Velocity Random Walk 1 σ 0.2 m/sec/√hr

Bias Temperature Coefficient −40°C ≤ TA ≤ +85°C ±0.3 mg/°C

Bias Voltage Sensitivity VCC = 4.75 V to 5.25 V 2.5 mg/V

Output Noise No filtering 9 mg rms

Noise Density No filtering 0.5 mg/√Hz rms

3 dB Bandwidth 330 Hz

Sensor Resonant Frequency 5.5 kHz

Self-Test Change in Output Response X-axis and y-axis 59 151 LSB

TEMPERATURE SENSOR

Scale Factor Output = 0x0000 at 25°C (±5°C) 0.136 °C/LSB

ADC INPUT

Resolution 12 Bits

Integral Nonlinearity ±2 LSB

Differential Nonlinearity ±1 LSB

Offset Error ±4 LSB

Gain Error ±2 LSB

Input Range 0 3.3 V

Input Capacitance During acquisition 20 pF

g

Rev. A | Page 3 of 20

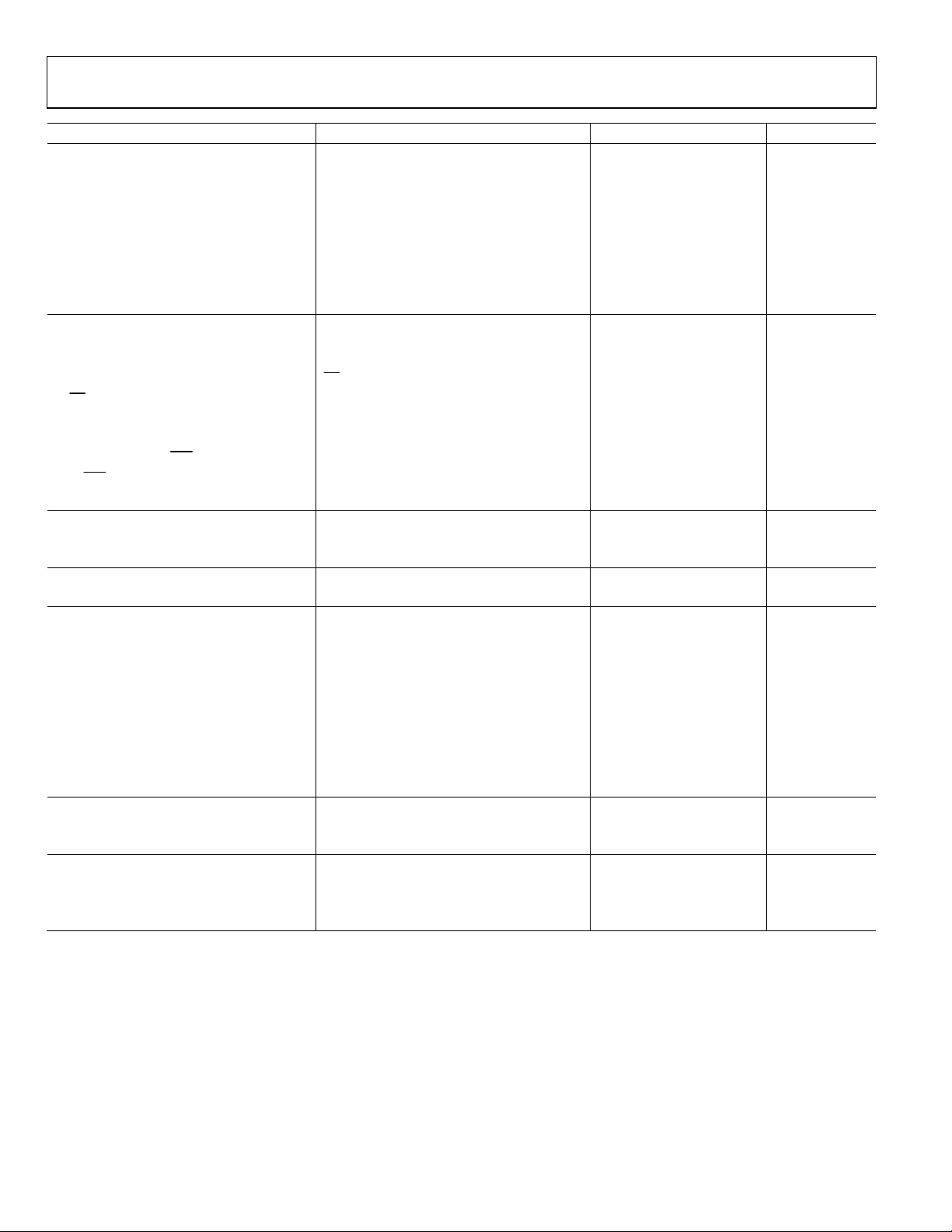

ADIS16367

Parameter Test Conditions/Comments Min Typ Max Unit

DAC OUTPUT 5 kΩ/100 pF to GND

Resolution 12 Bits

Relative Accuracy 101 LSB ≤ input code ≤ 4095 LSB ±4 LSB

Differential Nonlinearity ±1 LSB

Offset Error ±5 mV

Gain Error ±0.5 %

Output Range 0 3.3 V

Output Impedance 2 Ω

Output Settling Time 10 μs

LOGIC INPUTS1

Input High Voltage, VIH 2.0 V

Input Low Voltage, VIL 0.8 V

CS Wake-Up Pulse Width

Logic 1 Input Current, IIH V

Logic 0 Input Current, IIL V

All Pins Except RST

RST Pin

signal to wake up from sleep mode

CS

20 μs

= 3.3 V ±0.2 ±10 μA

IH

= 0 V

IL

40 60 μA

1 mA

Input Capacitance, CIN 10 pF

DIGITAL OUTPUTS1

Output High Voltage, VOH I

Output Low Voltage, VOL I

= 1.6 mA 2.4 V

SOURCE

= 1.6 mA 0.4 V

SINK

FLASH MEMORY Endurance2 10,000 Cycles

Data Retention3 T

= 85°C 20 Years

J

FUNCTIONAL TIMES4 Time until data is available

Power-On, Start-Up Time Normal mode, SMPL_PRD ≤ 0x09 180 ms

Low power mode, SMPL_PRD ≥ 0x0A 250 ms

Reset Recovery Time Normal mode, SMPL_PRD ≤ 0x09 60 ms

Low power mode, SMPL_PRD ≥ 0x0A 130 ms

Sleep Mode Recovery Time Normal mode, SMPL_PRD ≤ 0x09 4 ms

Low power mode, SMPL_PRD ≥ 0x0A 9 ms

Flash Memory Test Time Normal mode, SMPL_PRD ≤ 0x09 17 ms

Low power mode, SMPL_PRD ≥ 0x0A 90 ms

Automatic Self-Test Time SMPL_PRD = 0x0001 12 ms

CONVERSION RATE SMPL_PRD = 0x0001 to 0x00FF 0.413 819.2 SPS

Clock Accuracy ±3 %

Sync Input Clock5 0.8 1.2 kHz

POWER SUPPLY Operating voltage range, VCC 4.75 5.0 5.25 V

Power Supply Current Low power mode 24 mA

Normal mode 49 mA

Sleep mode 500 μA

1

The digital I/O signals are driven by an internal 3.3 V supply, and the inputs are 5 V tolerant.

2

Endurance is qualified as per JEDEC Standard 22, Method A117, and measured at −40°C, +25°C, +85°C, and +125°C.

3

The data retention lifetime equivalent is at a junction temperature (TJ) of 85°C as per JEDEC Standard 22, Method A117. Data retention lifetime decreases with junction

temperature.

4

These times do not include thermal settling and internal filter response times (330 Hz bandwidth), which may affect overall accuracy.

5

The sync input clock functions below the specified minimum value, at reduced performance levels.

0.55 V

Rev. A | Page 4 of 20

ADIS16367

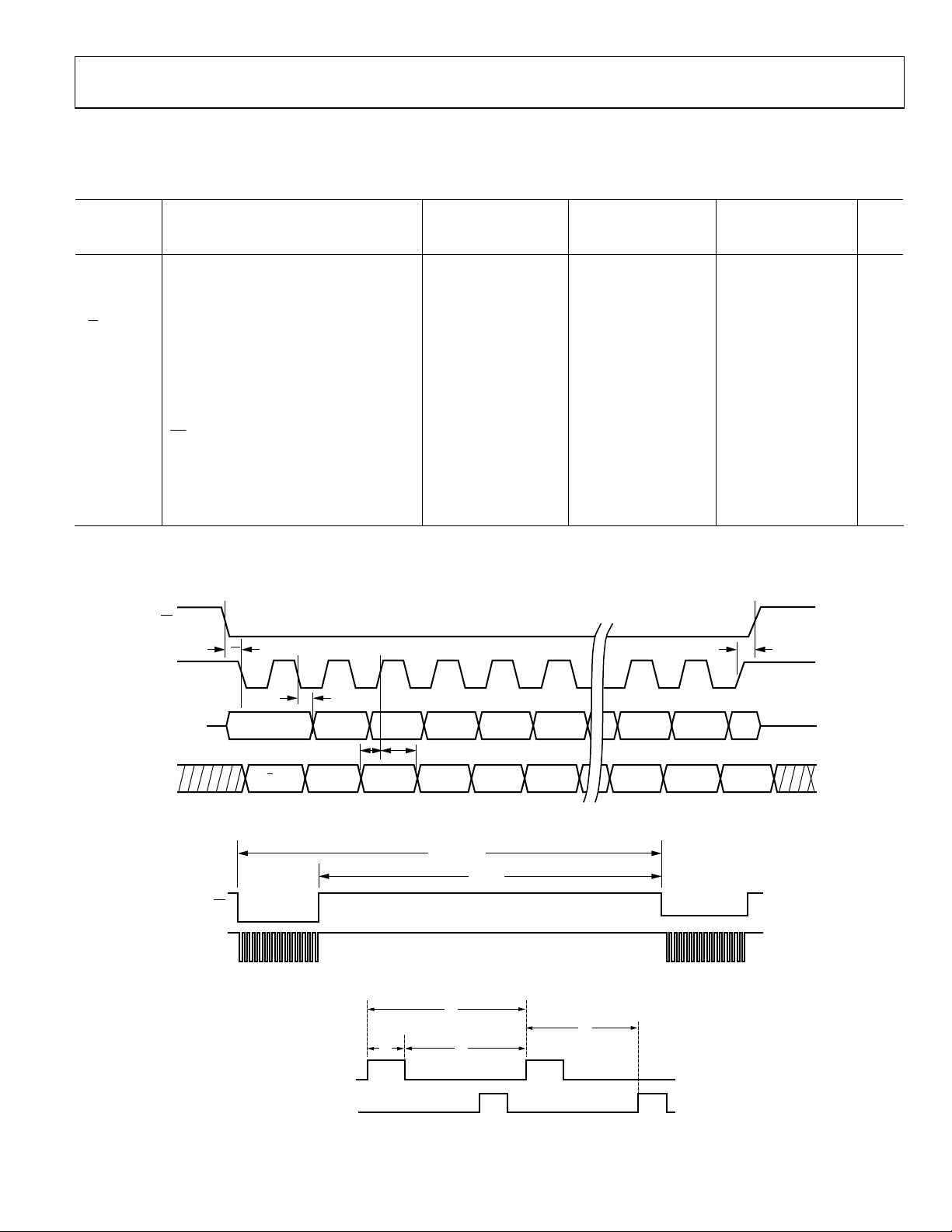

TIMING SPECIFICATIONS

TA = 25°C, VCC = 5 V, unless otherwise noted.

Table 2.

Normal Mode

(SMPL_PRD ≤ 0x09)

Parameter Description Min1 Typ Max Mi n1 Typ Max Min1 Typ Max Unit

f

Serial clock 0.01 2.0 0.01 0.3 0.01 1.0 MHz

SCLK

t

Stall period between data 9 75 1/f

STALL

t

Read rate 40 100 μs

READRATE

tCS Chip select to clock edge 48.8 48.8 48.8 ns

t

DOUT valid after SCLK edge 100 100 100 ns

DAV

t

DIN setup time before SCLK rising edge 24.4 24.4 24.4 ns

DSU

t

DIN hold time after SCLK rising edge 48.8 48.8 48.8 ns

DHD

t

, t

SCLKR

SCLK rise/fall times 5 12.5 5 12.5 5 12.5 ns

SCLKF

tDR, tDF DOUT rise/fall times 5 12.5 5 12.5 5 12.5 ns

t

SFS

t

1

high after SCLK edge

CS

Input sync positive pulse width 5 5 μs

5 5 5 ns

tx Input sync low time 100 100 μs

t

2

t

3

1

Guaranteed by design and characterization, but not tested in production.

Input sync to data-ready output 600 600 μs

Input sync period 833 833 μs

Low Power Mode

(SMPL_PRD ≥ 0x0A) Burst Read

μs

SCLK

TIMING DIAGRAMS

CS

SCLK

DOUT

DIN

CS

SCLK

t

CS

1 2 3 4 5 6 15 16

t

DAV

MSB DB14

R/W A5A6 A4 A3 A2

DB13 DB12 DB10DB11 DB2 L SBDB1

t

DSU

t

DHD

D2

Figure 2. SPI Timing and Sequence

t

READRATE

t

STALL

Figure 3. Stall Time and Data Rate

t

3

t

2

t

X

SYNC

CLOCK (DIO 4)

DATA

READY

t

1

Figure 4. Input Clock Timing Diagram

Rev. A | Page 5 of 20

D1 LSB

08398-004

t

SFS

08398-002

08398-003

ADIS16367

ABSOLUTE MAXIMUM RATINGS

Table 3.

Parameter Rating

Acceleration

Any Axis, Unpowered 2000 g

Any Axis, Powered 2000 g

VCC to GND −0.3 V to +6.0 V

Digital Input Voltage to GND −0.3 V to +5.3 V

Digital Output Voltage to GND −0.3 V to VCC + 0.3 V

Analog Input to GND −0.3 V to +3.6 V

Operating Temperature Range −40°C to +105°C

Storage Temperature Range −65°C to +125°C

1

Extended exposure to temperatures outside the specified temperature

range of −40°C to +105°C can adversely affect the accuracy of the factory

calibration. For best accuracy, store the parts within the specified operating

range of −40°C to +105°C.

2

Although the device is capable of withstanding short-term exposure to

150°C, long-term exposure threatens internal mechanical integrity.

1, 2

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

Table 4. Package Characteristics

Package Type θJA θ

24-Lead Module (ML-24-2) 39.8°C/W 14.2°C/W 16 grams

ESD CAUTION

Device

JC

Weight

Rev. A | Page 6 of 20

Loading...

Loading...