with FFT Analysis and Storage

ADIS16228

Rev. B

Information furnished by Analog Devices is believed to be accurate and reliable. However, no

Trademarks and registered trademarks are the property of their respective owners.

Fax: 781.461.3113 ©2011–2012 Analog Devices, Inc. All rights reserved.

ADIS16228

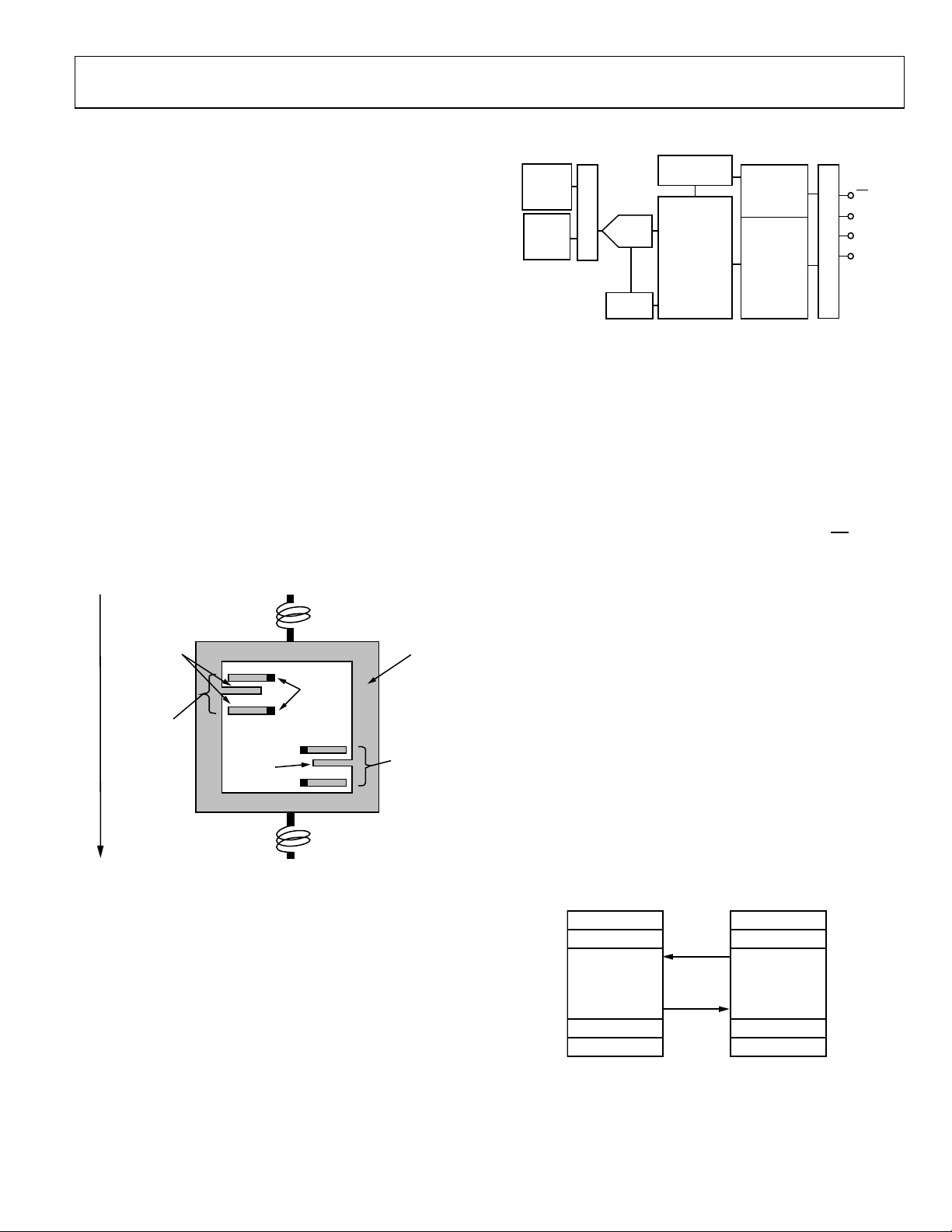

RECORD

STORAGE

ALARMS

INPUT/

OUTPUT

CONTROLLER

ADC

TRIAXIAL

MEMS

SENSOR

TEMP

SENSOR

SUPPLY

POWER

MANAGEMENT

CS

SCLK

DIN

DOUT

GND

VDDRSTDIO1

CONTROL

REGISTERS

SPI

PORT

OUTPUT

REGISTERS

FILTER

WINDOW

FFT

CAPTURE

BUFFER

10069-001

DIO2

Data Sheet

FEATURES

Frequency domain triaxial vibration sensor

Flat frequency response up to 5 kHz

Digital acceleration data, ±18 g measurement range

Digital range settings: 0 g to 1 g/5 g/10 g/20 g

Real-time sample mode: 20.48 kSPS, single-axis

Capture sample modes: 20.48 kSPS, three axes

Trigger modes: SPI, timer, external

Programmable decimation filter, 11 rate settings

Multirecord capture for selected filter settings

Manual capture mode for time domain data collection

FFT, 512-point, real valued, all three axes (x, y, z)

3 windowing options: rectangular, Hanning, flat top

Programmable FFT averaging: up to 255 averages

Storage: 14 FFT records on all three axes (x, y, z)

Programmable alarms, 6 spectral bands

2-level settings for warning and fault definition

Adjustable response delay to reduce false alarms

Internal self-test with status flags

Digital temperature and power supply measurements

2 auxiliary digital I/Os

SPI-compatible serial interface

Identification registers: serial number, device ID, user ID

Single-supply operation: 3.0 V to 3.6 V

Operating temperature range: −40°C to +125°C

15 mm × 24 mm × 15 mm aluminum package, flex connector

APPLICATIONS

Vibration analysis

Condition monitoring

Machine health

Instrumentation, diagnostics

Safety shutoff sensing

Digital Triaxial Vibration Sensor

GENERAL DESCRIPTION

The ADIS16228 iSensor® is a complete vibration sensing system

that combines triaxial acceleration sensing with advanced time

domain and frequency domain signal processing. Time domain

signal processing includes a programmable decimation filter

and selectable windowing function. Frequency domain processing

includes a 512-point, real-valued FFT for each axis, along with

FFT averaging, which reduces the noise floor variation for finer

resolution. The 14-record FFT storage system offers users the

ability to track changes over time and capture FFTs with multiple

decimation filter settings.

The 20.48 kSPS sample rate and 5 kHz flat frequency band

provide a frequency response that is suitable for many machine

health applications. The aluminum core provides excellent

mechanical coupling to the MEMS acceleration sensors. An

internal clock drives the data sampling and signal processing

system during all operations, which eliminates the need for an

external clock source. The data capture function has three modes

that offer several options to meet the needs of many different

applications. In addition, real-time mode provides direct access

to streaming data on one axis. The SPI and data buffer structure

provide convenient access to data output. The ADIS16228 also

offers a digital temperature sensor and digital power supply

measurements.

The ADIS16228 is available in a 15 mm × 24 mm × 15 mm module

with flanges, machine screw holes (M2 or 2-56), and a flexible

connector that enables simple user interface and installation. It

has an extended operating temperature range of −40°C to +125°C.

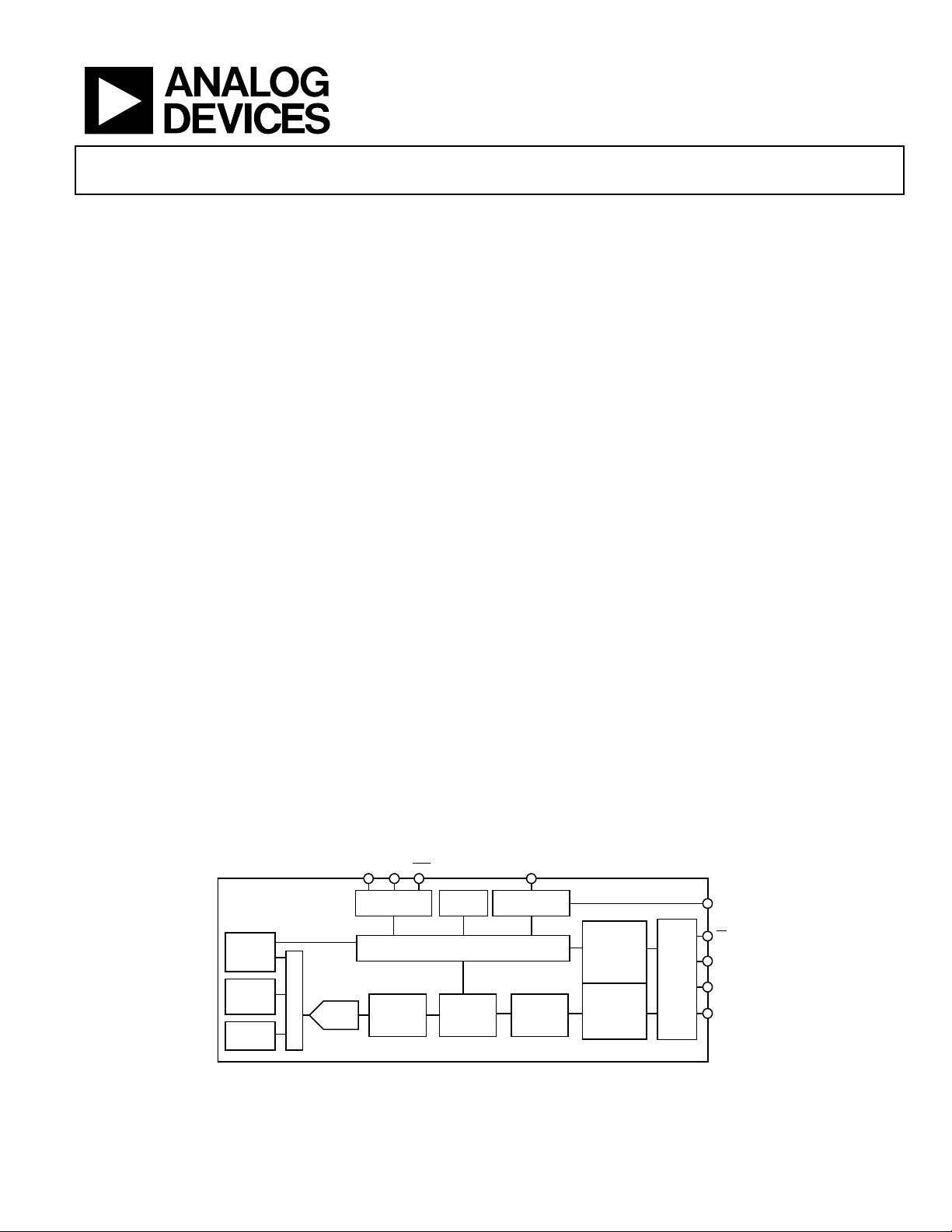

FUNCTIONAL BLOCK DIAGRAM

responsibility is assumed by Analog Devices for its use, nor for any infringements of patents or other

rights of third parties that may result from its use. Spe cifications subject to change without n otice. No

license is granted by implication or otherwise under any patent or patent rights of Analog Devices.

Figure 1.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700

www.analog.com

ADIS16228 Data Sheet

TABLE OF CONTENTS

Features .............................................................................................. 1

Applications ....................................................................................... 1

General Description ......................................................................... 1

Functional Block Diagram .............................................................. 1

Revision History ............................................................................... 2

Specifications ..................................................................................... 3

Timing Specifications .................................................................. 4

Absolute Maximum Ratings ............................................................ 5

ESD Caution .................................................................................. 5

Pin Configuration and Function Descriptions ............................. 6

Theory of Operation ........................................................................ 7

Sensing Element ........................................................................... 7

Signal Processing .......................................................................... 7

User Interface ................................................................................ 7

Basic Operation................................................................................. 8

SPI Write Commands .................................................................. 8

SPI Read Commands ................................................................... 8

Data Recording and Signal Processing ........................................ 11

Recording Mode ......................................................................... 11

Spectral Record Production ...................................................... 12

Sample Rate/Filtering ................................................................. 12

Dynamic Range/Sensitivity ....................................................... 14

Pre-FFT Windowing .................................................................. 15

FFT ............................................................................................... 16

Recording Times ......................................................................... 16

Data Records ............................................................................... 16

FFT Record Flash Endurance ................................................... 16

Spectral Alarms ............................................................................... 17

Alarm Definition ........................................................................ 17

Alarm Indicator Signals ............................................................. 18

Alarm Flags and Conditions ..................................................... 18

Alarm Status ................................................................................ 19

Worst -Case Condition Monitoring.......................................... 19

Reading Output Data ..................................................................... 20

Reading Data from the Data Buffer ......................................... 20

Accessing FFT Record Data ...................................................... 20

Data Format ................................................................................ 21

Real-Time Data Collection ....................................................... 21

Power Supply/Temperature ....................................................... 21

FFT Event Header ...................................................................... 22

System Tools .................................................................................... 23

Global Commands ..................................................................... 23

Status/Error Flags ....................................................................... 23

Power-Down ............................................................................... 23

Operation Managment .............................................................. 24

Input/Output Functions ............................................................ 24

Self-Tes t ....................................................................................... 25

Flash Memory Management ..................................................... 25

Device Identification .................................................................. 25

Applications Information .............................................................. 26

Interface Board ........................................................................... 26

Mating Connector ...................................................................... 26

Outline Dimensions ....................................................................... 27

Ordering Guide .......................................................................... 27

REVISION HISTORY

3/12—Rev. A to Rev. B

Changes to Recording Times Section and Table 21 ................... 16

Changes to Interface Board Section ............................................. 26

8/11—Rev. 0 to Rev. A

Changes to General Description .................................................... 1

Changes to Output Noise and Bandwidth Parameters, Table 1 .... 3

Added CAL_ENABLE Register to Table 8 .................................. 10

Changes to Real-Time Mode Section; Changes to Table 11;

Change to Figure 14 ....................................................................... 12

Changes to Figure 15 ...................................................................... 13

Added Dynamic Range/Sensitivity Section; Added Table 13,

Renumbered Sequentially; Added Figure 16, Figure 17, and

Figure 18, Renumbered Sequentially ........................................... 14

Rev. B | Page 2 of 28

Change to Dynamic Range Settings Section............................... 15

Changes to Recording Times Section .......................................... 16

Changes to Figure 20 and Figure 21 ............................................ 20

Changes to Table 49, Table 50, and Table 51; Change to

Real-Time Data Collection Section ............................................. 21

Change to Power-Down Section .................................................. 23

7/11—Revision 0: Initial Version

Data Sheet ADIS16228

Bandwidth

±5% flatness,2 CAL_ENABLE[4] = 0, see Figure 17

840 Hz

FLASH MEMORY

SPECIFICATIONS

TA = −40°C to +125°C, VDD = 3.3 V, unless otherwise noted.

Table 1.

Parameter Test Conditions/Comments Min Typ Max Unit

ACCELEROMETERS

Measurement Range1 TA = 25°C ±18

Sensitivity, FFT TA = 25°C, 0 g to 20 g range setting 0.3052 mg/LSB

Sensitivity, Time Domain TA = 25°C 0.6104 mg/LSB

Sensitivity Error TA = 25°C ±6 %

Nonlinearity With respect to full scale ±0.2 ±1.25 %

Cross-Axis Sensitivity 2.6 %

Alignment Error With respect to package 1.5 Degrees

Offset Error TA = 25°C ±1

Offset Temperature Coefficient 1 mg/°C

Output Noise TA = 25°C, 20.48 kHz sample rate, time domain 12 mg rms

Output Noise Density TA = 25°C, 10 Hz to 1 kHz 0.248 mg/√Hz

±5% flatness,2 CAL_ENABLE[4] = 1, see Figure 18 5000 Hz

Sensor Resonant Frequency 5.5 kHz

LOGIC INPUTS3

Input High Voltage, V

Input Low Voltage, V

Logic 1 Input Current, I

Logic 0 Input Current, I

All Except

RST

RST

−1 mA

2.0 V

INH

0.8 V

INL

VIH = 3.3 V ±0.2 ±1 µA

INH

VIL = 0 V

INL

−40 −60 µA

Input Capacitance, CIN 10 pF

DIGITAL OUTPUTS3

Output High Voltage, VOH I

Output Low Voltage, VOL I

= 1.6 mA 2.4 V

SOURCE

= 1.6 mA 0.4 V

SINK

g

g

Endurance4 10,000 Cycles

Data Retention5 TJ = 85°C, see Figure 23 20 Years

START-UP TIME6

Initial Startup 202 ms

Reset Recovery7

pulse low or GLOB_CMD[7] = 1 54 ms

RST

Sleep Mode Recovery 2.3 ms

CONVERSION RATE REC_CTRL1[11:8] = 0x1 (SR0 sample rate selection) 20.48 kSPS

Clock Accuracy 3 %

POWER SUPPLY Operating voltage range, VDD 3.0 3.3 3.6 V

Power Supply Current Record mode, TA = 25°C 40 48 mA

Sleep mode, TA = 25°C 230 µA

1

The maximum range depends on the frequency of vibration.

2

Assumes that frequency flatness calibration is enabled.

3

The digital I/O signals are 5 V tolerant.

4

Endurance is qualified as per JEDEC Standard 22, Method A117 and measured at −40°C, +25°C, +85°C, and +125°C.

5

Retention lifetime equivalent at junction temperature (TJ) = 85°C as per JEDEC Standard 22, Method A117. Retention lifetime depends on junction temperature.

6

The start-up times presented reflect the time it takes for data collection to begin.

7

RST

The

pin must be held low for at least 15 ns.

Rev. B | Page 3 of 28

ADIS16228 Data Sheet

CS

SCLK

DOUT

DIN

1 2 3 4 5 6 15 16

R/W A5A6 A4 A3 A2

D2

MSB DB14

D1 LSB

DB13 DB12 DB10DB11 DB2 LSBDB1

t

CS

t

SFS

t

DAV

t

SR

t

SF

t

DHD

t

DSU

10069-002

CS

SCLK

t

STALL

10069-003

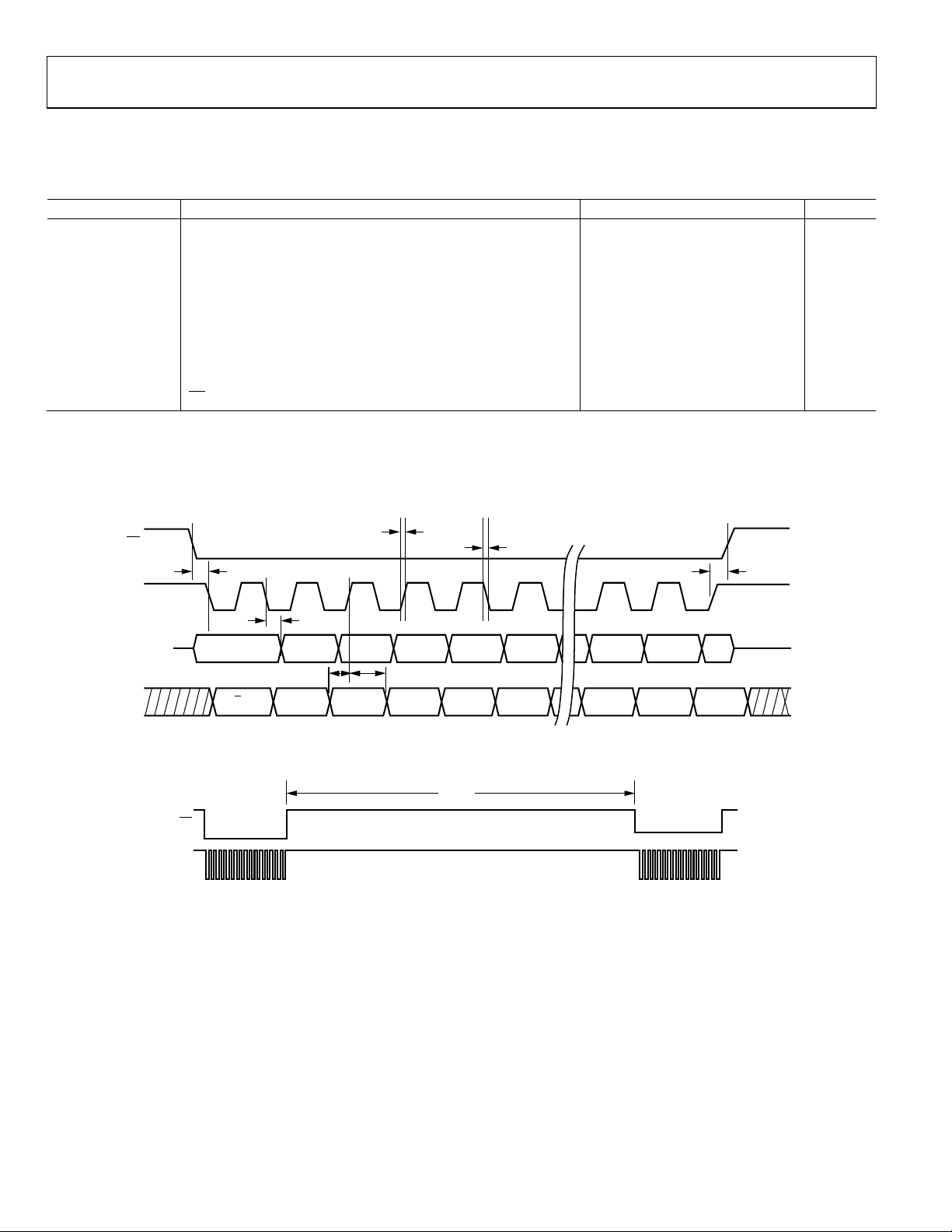

TIMING SPECIFICATIONS

TA = 25°C, VDD = 3.3 V, unless otherwise noted.

Table 2.

Parameter Description Min1 Typ Max Unit

f

SCLK frequency 0.01 2.5 MHz

SCLK

t

Stall period between data, between 16th and 17th SCLK 16.5 µs

STAL L

tCS Chip select to SCLK edge 48.8 ns

t

DOUT valid after SCLK edge 100 ns

DAV

t

DIN setup time before SCLK rising edge 24.4 ns

DSU

t

DIN hold time after SCLK rising edge 48.8 ns

DHD

tSR SCLK rise time 12.5 ns

tSF SCLK fall time 12.5 ns

tDF, tDR DOUT rise/fall times 5 12.5 ns

t

SFS

1

Guaranteed by design, not tested.

Timing Diagrams

high after SCLK edge 5 ns

CS

Figure 2. SPI Timing and Sequence

Figure 3. DIN Bit Sequence

Rev. B | Page 4 of 28

Data Sheet ADIS16228

Any Axis, Unpowered

2000 g

ABSOLUTE MAXIMUM RATINGS

Table 3.

Parameter Rating

Acceleration

Any Axis, Powered 2000 g

VDD to GND −0.3 V to +6.0 V

Digital Input Voltage to GND −0.3 V to +5.3 V

Digital Output Voltage to GND −0.3 V to +3.6 V

Analog Inputs to GND −0.3 V to +3.6 V

Temperature

Operating Temperature Range −40°C to +125°C

Storage Temperature Range −65°C to +150°C

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

Table 4. Package Characteristics

Package Type θJA θJC Device Weight

15-Lead Module 31°C/W 11°C/W 6.5 grams

ESD CAUTION

Rev. B | Page 5 of 28

ADIS16228 Data Sheet

10069-004

TOP VIEW

BOTTOM VIEW

PIN 15

PIN 15

PIN 1

PIN 1

NOTES

1. LEADS ARE E X P OSED COPPER P ADS THAT ARE LOCATED ON

THE BOTTOM SIDE OF THE FLEXIBLE INTERFACE CABLE.

2. PACKAGE IS NOT SUITABLE FOR SOLDER REFLOW ASSEMBLY PROCESSES.

3. EXAMPLE MATING CONNECTOR:AVX CORPORATION

FLAT FLEXIBLE CONNECTOR (FFC)

P/N: 04-6288-015-000- 846.

3, 4, 5, 8

GND S Ground.

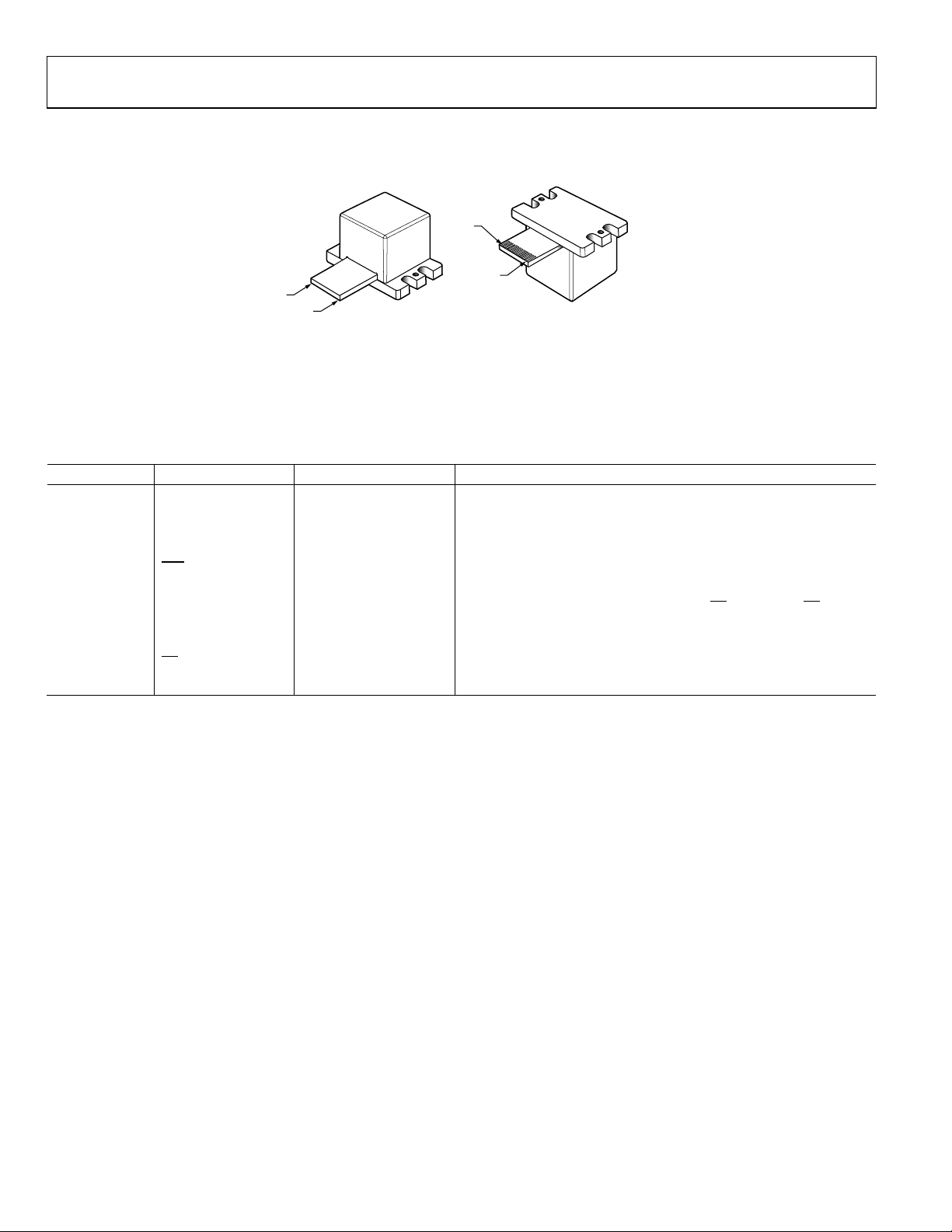

PIN CONFIGURATION AND FUNCTION DESCRIPTIONS

Figure 4. Pin Configuration

Table 5. Pin Function Descriptions

Pin No. Mnemonic Type1 Description

1, 2 VDD S Power Supply, 3.3 V.

6, 9 DNC N/A No Connect. Do not connect to these pins.

7 DIO2 I/O Digital Input/Output Line 2.

10

I Reset, Active Low.

RST

11 DIN I SPI, Data Input.

12 DOUT O SPI, Data Output. DOUT is an output when CS is low. When CS is high,

DOUT is in a three-state, high impedance mode.

13 SCLK I SPI, Serial Clock.

14

I SPI, Chip Select.

CS

15 DIO1 I/O Digital Input/Output Line 1.

1

S is supply, O is output, I is input, and I/O is input/output.

Rev. B | Page 6 of 28

Data Sheet ADIS16228

MOVABLE

FRAME

ACCELERATION

UNIT

FORCING

CELL

UNIT SENSING

CELL

MOVING

PLATE

FIXED

PLATES

PLATE

CAPACITORS

ANCHOR

ANCHOR

10069-005

TRIAXIAL

MEMS

SENSOR

CLOCK

CONTROLLER

CAPTURE

BUFFER

CONTROL

REGISTERS

SPI

SIGNALS

SPI PORT

OUTPUT

REGISTERS

TEMP

SENSOR

ADC

10069-006

CS

SCLK

DIN

DOUT

NONVOLATILE

FLASH MEMORY

(NO SPI ACCESS)

MANUAL

FLASH

BACKUP

START-UP

RESET

VOLATILE

SRAM

SPI ACCESS

10069-007

THEORY OF OPERATION

The ADIS16228 is a vibration sensing system that combines a

triaxial MEMS accelerometer with advanced signal processing.

The SPI-compatible port and user register structure provide

convenient access to frequency domain vibration data and many

user controls.

SENSING ELEMENT

Digital vibration sensing in the ADIS16228 starts with a MEMS

accelerometer core on each axis. Accelerometers translate linear

changes in velocity into a representative electrical signal, using

a micromechanical system like the one shown in Figure 5. The

mechanical part of this system includes two different frames

(one fixed, one moving) that have a series of plates to form

a variable, differential capacitive network. When experiencing

the force associated with gravity or acceleration, the moving

frame changes its physical position with respect to the fixed

frame, which results in a change in capacitance. Tiny springs

tether the moving frame to the fixed frame and govern the

relationship between acceleration and physical displacement.

A modulation signal on the moving plate feeds through each

capacitive path into the fixed frame plates and into a demodulation

circuit, which produces the electrical signal that is proportional

to the acceleration acting on the device.

SIGNAL PROCESSING

Figure 6 offers a simplified block diagram for the ADIS16228.

The signal processing stage includes time domain data capture,

digital decimation/filtering, windowing, FFT analysis, FFT

averaging, and record storage. See Figure 14 for more details

on the signal processing operation.

Figure 5. MEMS Sensor Diagram

Figure 6. Simplified Sensor Signal Processing Block Diagram

USER INTERFACE

SPI Interface

The user registers (which include both the output registers and

the control registers, as shown in Figure 6) manage user access

to both sensor data and configuration inputs. Each 16-bit register

has its own unique bit assignment and two addresses: one for its

upper byte and one for its lower byte. Table 8 provides a memory

map for each register, along with its function and lower byte

address. The data collection and configuration command uses

the SPI, which consists of four wires. The chip select (

activates the SPI interface, and the serial clock (SCLK)

synchronizes the serial data lines. Input commands clock into

the DIN pin, one bit at a time, on the SCLK rising edge. Output

data clocks out of the DOUT pin on the SCLK falling edge.

When the SPI is used as a slave device, the DOUT contents

reflect the information requested using a DIN command.

Dual-Memory Structure

The user registers provide addressing for all input/output operations

in the SPI interface. The control registers use a dual-memory

structure. The controller uses SRAM registers for normal

operation, including user-configuration commands. The flash

memory provides nonvolatile storage for control registers that

have flash backup (see Table 8). Storing configuration data

in the flash memory requires a manual flash update command

(GLOB_CMD[6] = 1, DIN = 0xBE40). When the device powers

on or resets, the flash memory contents load into the SRAM, and

the device starts producing data according to the configuration

in the control registers.

CS

) signal

Rev. B | Page 7 of 28

Figure 7. SRAM and Flash Memory Diagram

ADIS16228 Data Sheet

SYSTEM

PROCESSOR

SPI MASTER

ADIS16228

SCLK

CS

DIN

DOUT

SCLK

SS

MOSI

MISO

3.3V

IRQ2

IRQ1

DIO2

VDD

I/O LINES ARE COMPATIBLE WITH

3.3V OR 5V LOGIC LEVELS

14

13

11

12

7

DIO1

15

1 2

3 4 5 8

10069-008

UPPER BYTE

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

LOWER BYTE

10069-009

CS

DIN

SCLK

10069-010

DOUT = 0011 1111 0110 0100 = 0x3F64 = 16,228 = P ROD_ID

SCLK

CS

DIN

DOUT

10069-011

R/W

R/W

A6 A5 A4 A3 A2 A1 A0 D7 D6 D5 D4 D3 D2 D1 D0

DB0DB1DB2DB3DB4DB5DB6DB7DB8DB9DB10DB11DB12DB13DB14DB15

NOTES

1. DOUT BITS ARE BASED ON THE PREVIOUS 16-BIT SEQUENCE (R/W = 0).

CS

SCLK

DIN

DOUT

A6 A5

DB13DB14

DB15

10069-012

BASIC OPERATION

The ADIS16228 uses a SPI for communication, which enables

a simple connection with a compatible, embedded processor

platform, as shown in Figure 8. The factory default configuration

for DIO1 provides a busy indicator signal that transitions low

when an event completes and data is available for user access.

Use the DIO_CTRL register (see Table 66) to reconfigure DIO1

and DIO2, if necessary.

Figure 8. Electrical Hook-Up Diagram

Table 6. Generic Master Processor Pin Names and Functions

Pin Name Function

Slave select

SS

SCLK Serial clock

MOSI Master output, slave input

MISO Master input, slave output

IRQ1, IRQ2 Interrupt request inputs (optional)

The ADIS16228 SPI interface supports full duplex serial

communication (simultaneous transmit and receive) and uses

the bit sequence shown in Figure 12. Tab l e 7 provides a list of

the most common settings that require attention to initialize

a processor serial port for the ADIS16228 SPI interface.

Table 7. Generic Master Processor SPI Settings

Processor Setting Description

Master The ADIS16228 operates as a slave.

SCLK Rate ≤ 2.5 MHz Bit rate setting.

SPI Mode 3 Clock polarity/phase

(CPOL = 1, CPHA = 1).

MSB First Bit sequence.

16-Bit Shift register/data length.

Tabl e 8 provides a list of user registers with their lower byte

addresses. Each register consists of two bytes that each has its own

unique 7-bit address. Figure 9 relates the bits of each register to

their upper and lower addresses.

Figure 9. Generic Register Bit Definitions

SPI WRITE COMMANDS

User control registers govern many internal operations. The

DIN bit sequence in Figure 12 provides the ability to write to

these registers, one byte at a time. Some configuration changes

and functions require only one write cycle. For example, set

GLOB_CMD[11] = 1 (DIN = 0xBF08) to start a manual capture

sequence. The manual capture starts immediately after the last bit

clocks into DIN (16

th

SCLK rising edge). Other configurations may

require writing to both bytes.

Figure 10. SPI Sequence for Manual Capture Start (DIN = 0xBF08)

SPI READ COMMANDS

A single register read requires two 16-bit SPI cycles that also

use the bit assignments that are shown in Figure 12. The first

sequence sets

(Bits[A6:A0]). Bits[D7:D0] are don’t care bit s for a read DIN

sequence. DOUT clocks out the requested register contents

during the second sequence. The second sequence can also use

DIN to set up the next read. Figure 11 provides a signal diagram

for all four SPI signals while reading the PROD_ID. In this

diagram, DIN = 0x5600 and DOUT reflects the decimal

equivalent of 16,228.

R

/W = 0 and communicates the target address

Figure 11. Example SPI Read, PROD_ID, Second Sequence

Figure 12. Example SPI Read Sequence

Rev. B | Page 8 of 28

Data Sheet ADIS16228

Z_BUF

Read only

No

0x18

0x8000

Output, buffer for z-axis acceleration data

See Table 51

ALM_PNTR

Read/write

Yes

0x30

0x0000

Alarm, spectral alarm band pointer

See Table 27

LOT_ID1

Read only

Yes

0x52

N/A

Lot identification code

See Table 69

REC_FLSH_CNT

Read only

No

0x5E

N/A

Record flash write/erase counter

See Table 24

Table 8. User Register Memory Map

Register

Name

FLASH_CNT Read only Yes 0x00 N/A Status, flash memory write count See Table 68

X_SENS Read/write Yes 0x02 N/A X-axis accelerometer scale correction See Table 16

Y_SENS Read/write Ye s 0x04 N/A Y-axis accelerometer scale correction See Table 17

Z_SENS Read/write Ye s 0x06 N/A Z-axis accelerometer scale correction See Table 18

TEMP_OUT Read only No 0x08 0x8000 Output, temperature during capture See Table 56

SUPPLY_OUT Read only No 0x0A 0x8000 Output, power supply during capture See Table 54

FFT_AVG1 Read/write Yes 0x0C 0x0108 Control, FFT average size of 1, SR0 and SR1 See Table 19

FFT_AVG2 Read/write Yes 0x0E 0x0101 Control, FFT average size of 2, SR2 and SR3 See Table 20

BUF_PNTR Read/write No 0x10 0x0000 Control, buffer address pointer See Table 47

REC_PNTR Read/write No 0x12 0x0000 Control, record address pointer See Table 48

X_BUF Read only No 0x14 0x8000 Output, buffer for x-axis acceleration data See Table 49

Y_BUF Read only No 0x16 0x8000 Output, buffer for y-axis acceleration data See Table 50

REC_CTRL1 Read/write Yes 0x1A 0x1100 Control, Record Control Register 1 See Table 9

REC_CTRL2 Read/write Yes 0x1C 0x00FF Control, Record Control Register 2 See Table 14

REC_PRD Read/write Yes 0x1E 0x0000 Control, record period (automatic mode) See Table 10

ALM_F_LOW Read/write N/A 0x20 0x0000 Alarm, spectral band lower frequency limit See Table 28

ALM_F_HIGH Read/write N/A 0x22 0x0000 Alarm, spectral band upper frequency limit See Table 29

ALM_X_MAG1 Read/write N/A 0x24 0x0000 Alarm, x-axis, Alarm Trigger Level 1 (warning) See Table 30

ALM_Y_MAG1 Read/write N/A 0x26 0x0000 Alarm, y-axis, Alarm Trigger Level 1 (warning) See Table 31

ALM_Z_MAG1 Read/write N/A 0x28 0x0000 Alarm, z-axis, Alarm Trigger Level 1 (warning) See Table 32

ALM_X_MAG2 Read/write N/A 0x2A 0x0000 Alarm, x-axis, Alarm Trigger Level 2 (fault) See Table 33

ALM_Y_MAG2 Read/write N/A 0x2C 0x0000 Alarm, y-axis, Alarm Trigger Level 2 (fault) See Table 34

ALM_Z_MAG2 Read/write N/A 0x2E 0x0000 Alarm, z-axis, Alarm Trigger Level 2 (fault) See Table 35

Access

Flash

Backup

Address Default Function Reference

ALM_S_MAG Read/write Ye s 0x32 0x0000 Alarm, system alarm level See Table 36

ALM_CTRL Read/write Yes 0x34 0x0080 Alarm, configuration See Table 26

DIO_CTRL Read/write Yes 0x36 0x000F Control, functional I/O configuration See Table 66

GPIO_CTRL Read/write Yes 0x38 0x0000 Control, general-purpose I/O See Table 67

AVG_CNT Read/write Yes 0x3A 0x9630 Control, average count for sample rate options See Table 11

DIAG_STAT Read only No 0x3C 0x0000 Status, system error flags See Table 65

GLOB_CMD Write only No 0x3E N/A Control, global command register See Table 64

ALM_X_STAT Read only N/A 0x40 0x0000 Alarm, x-axis, status for spectral alarm bands See Table 37

ALM_Y_STAT Read only N/A 0x42 0x0000 Alarm, y-axis, status for spectral alarm bands See Table 38

ALM_Z_STAT Read only N/A 0x44 0x0000 Alarm, z-axis, status for spectral alarm bands See Table 39

ALM_X_PEAK Read only N/A 0x46 0x0000 Alarm, x-axis, peak value (most severe alarm) See Table 40

ALM_Y_PEAK Read only N/A 0x48 0x0000 Alarm, y-axis, peak value (most severe alarm) See Table 41

ALM_Z_PEAK Read only N/A 0x4A 0x0000 Alarm, z-axis, peak value (most severe alarm) See Table 42

TIME_STAMP_L Read only N/A 0x4C 0x0000 Record time stamp, lower word See Table 61

TIME_STAMP_H Read only N/A 0x4E 0x0000 Record time stamp, upper word See Table 62

Reserved N/A N/A 0x50 N/A N/A

LOT_ID2 Read only Yes 0x54 N/A Lot identification code See Table 70

PROD_ID Read only Ye s 0x56 0x3F64 Product identifier; convert to decimal = 16,228 See Table 71

SERIAL_NUM Read only Ye s 0x58 N/A Serial number See Table 72

USER_ID Read/write Ye s 0x5C 0x0000 User identification register See Table 73

Reserved N/A N/A 0x62 N/A N/A

Reserved N/A N/A 0x64 N/A N/A

Reserved N/A N/A 0x66 N/A N/A

Reserved N/A N/A 0x68 N/A N/A

Rev. B | Page 9 of 28

ADIS16228 Data Sheet

ALM_X_FREQ

Read only

N/A

0x70

0x0000

Alarm, x-axis, frequency of most severe alarm

See Table 43

CAL_ENABLE

Read/write

Yes

0x7A

0x0010

Control, frequency calibration enable

See Table 13

Reserved N/A N/A 0x6A N/A N/A

Reserved N/A N/A 0x6C N/A N/A

REC_INFO1 Read only N/A 0x6E N/A Record settings See Table 59

ALM_Y_FREQ Read only N/A 0x72 0x0000 Alarm, y-axis, frequency of most severe alarm See Table 44

ALM_Z_FREQ Read only N/A 0x74 0x0000 Alarm, z-axis, frequency of most severe alarm See Table 45

REC_INFO2 Read only N/A 0x76 N/A Record settings See Table 60

REC_CNTR Read only No 0x78 0x0000 Record counter See Table 22

Rev. B | Page 10 of 28

Data Sheet ADIS16228

DATA RECORDING AND SIGNAL PROCESSING

The ADIS16228 provides a complete sensing system for recording

and monitoring vibration data. Figure 13 provides a simplified

block diagram for the signal processing associated with spectral

record acquisition on all three axes (x, y, z). User registers

provide controls for data type (time or frequency), trigger mode

(manual or automatic), collection mode (real time or capture),

sample rates/filtering, windowing, FFT averaging, spectral alarms,

and I/O management.

RECORDING MODE

The recording mode selection establishes the data type (time or

frequency domain), trigger type (manual or automatic), and

data collection (captured or real time). The REC_CTRL1[1:0]

bits (S ee Table 9) provide four operating modes: manual FFT,

automatic FFT, manual time capture, and real time. After setting

REC_CTRL1, the manual FFT, automatic FFT, and manual time

capture modes require a start command to start acquiring a

spectral or time domain record. There are two start command

options in this mode: SPI and I/O. The SPI trigger involves setting

GLOB_CMD[11] = 1 (DIN = 0xBF08). The I/O trigger involves

using DIO_CTRL (see Table 66) to configure DIO1 or DIO2 as

an input trigger line.

Table 9. REC_CTRL1 (Base Address = 0x1A), Read/Write

Bits Description (Default = 0x1100)

[15:14] Not used (don’t care).

[13:12] Window setting.

00 = rectangular, 01 = Hanning, 10 = flat top, 11 = N/A.

11 SR3, 1 = enabled for FFT, 0 = disable.

Sample rate = 20,480 ÷ 2

10 SR2, 1 = enabled for FFT, 0 = disable.

Sample rate = 20,480 ÷ 2

9 SR1, 1 = enabled for FFT, 0 = disable.

Sample rate = 20,480 ÷ 2

8 SR0, 1 = enabled for FFT, 0 = disable.

Sample rate = 20,480 ÷ 2

7 Power-down between each recording. 1 = enabled.

[6:4] Not used (don’t care).

[3:2] Storage method.

00 = none, 01 = alarm trigger, 10 = all, 11 = N/A.

[1:0] Recording mode.

00 = manual FFT, 01 = automatic FFT,

10 = manual time capture, 11 = real-time sampling/data

access.

AVG_CNT[15:12]

AVG_ CN T[1 1:8 ]

AVG_ CN T[7 :4]

AVG_ CN T[3 :0]

(see Table 11).

(see Table 11).

(see Table 11).

(see Table 11).

Manual FFT Mode

Set REC_CTRL1[1:0] = 00 to place the device in manual FFT

mode. Then use a start command to trigger the production of a

spectral record. When the device is acquiring a spectral record,

use the busy indicator (DIO1, per factory default) to drive an

interrupt service line on an external processor, which can start

data collection after the process completes. DIAG_STAT is the

only register that the SPI can read while the device is processing

a command. Reading this register returns a 0x00 while the device

is busy and 0x80 when the data is ready for external access. When

the spectral record is complete, the device waits for another start

command.

Automatic FFT Mode

Set REC_CTRL1[1:0] = 01 to place the device in automatic FFT

mode. Use the REC_PRD register (see Table 10) to program the

period between production of each spectral record. Then use a

start command to trigger periodic acquistion of a spectral record.

For example, set REC_PRD = 0x020A (DIN = 0x9E0A, 0x9F02)

to set the trigger period to 10 hours.

Table 10. REC_PRD (Base Address = 0x1E), Read/Write

Bits Description (Default = 0x0000)

[15:10] Not used (don’t care)

[9:8] Scale for data bits

00 = 1 second/LSB, 01 = 1 minute/LSB, 10 = 1 hour/LSB

[7:0] Data bits, binary format; range = 0 to 255

Manual Time Capture Mode

Set REC_CTRL1[1:0] = 10 to place the device into manual time

capture mode; then use a manual trigger to start a data collection

cycle. When the device is operating in this mode, 512 samples

of time domain data are loaded into the buffer for each axis.

This data goes through all time domain signal processing, except

the pre-FFT windowing, prior to loading into the data buffer for

user access. The manual trigger options are the same as in the

manual FFT mode (SPI, I/O).

MEMS ADC PROCESSING

Figure 13. Simplified Block Diagram

DATA

BUFFER

RECORDS

SPI AND

REGISTERS

10069-023

Rev. B | Page 11 of 28

ADIS16228 Data Sheet

[7:4]

Sample Rate Option 1, binary (0 to 10),

9

40

0.078

20

0.23

K = 1

x

K

N

A

N

a

1

÷N

A

TRIAXIS

MEMS

ACCEL

20.48kSPS

K

o

K

s

FFT

FFT

AVERAGE

(N

F

)

FREQUENCY

RESPONSE

CORRECTION

SAMPLE RATE SETTING

REC_CTRL1[11:8]

WINDOW SETTING

REC_CTRL1[13:12]

RANGE-SCALE S E TTING

K

s

= A

MAX

÷ 2

15

A

MAX

= PEAK FROM RE C_CTRL2[7:0]

N

F

= # OF AVERAGES

N

F

= FFT_AVGx[8:0]

WINDOW

FFT

RECORD

1

FFT

RECORD

m

FFT

RECORD

13

FFT

RECORD

0

FFT RECO RDS — NONVOLATILE FLASH MEMORY

m = REC_CNTR

REC_CTRL2[3:2]

10069-016

DATA

BUFFER

SPI

REGISTER

ACCESS

SENSITIVITY ADJUSTMENT

X_SENS, Y_SENS, Z_SENS

CAL_ENABLE[4]

Real-Time Mode

Set REC_CTRL1[1:0] = 11 to place the device into real-time mode.

In this mode, the device samples only one axis, at a rate of

20.48 kSPS, and provides data on its output register at the SR0

sample rate setting in AVG_CNT[3:0] (see Table 11). Select the

axis of measurement in this mode by reading its assigned register.

For example, select the x-axis by reading X_BUF, using DIN =

0x1400. See Table 49, Tabl e 50, or Table 51 for more information

on the x_BUF registers. Use DIO1 (Pin 15) to help manage external

access to real-time data. For example, this signal is suitable for

driving an interrupt line to initiate a service routine in an

external processor.

SPECTRAL RECORD PRODUCTION

The ADIS16228 produces a spectral record by taking a time

record of data on all three axes, then scaling, windowing, and

performing an FFT process on each time record. This process

repeats for a programmable number of FFT averages, with the FFT

result of each cycle accumulating in the data buffer. After completing the selected number of cycles, the FFT averaging process

completes by scaling the data buffer contents. Then the data

buffer contents are available to the SPI and output data registers.

more than one sample rate option is enabled while the device is in

the automatic FFT mode, the device produces a spectral record

for one SRx option, and then waits for the next automatic t rigger,

which occurs based on the time setting in the REC_PRD register

(see Tabl e 10). See Figure 15 for more details on how multiple

SRx options influence data collection and spectral record

production. When in real-time mode, the output data rate

reflects the SR0 setting.

Tabl e 12 provides a list of SRx settings available in the AVG _C N T

register (see Tab l e 11), along with the resulting sample rates, FFT

bin widths, bandwidth, and estimated total noise. Note that each

SRx setting also has associated range settings in the REC_CTRL2

register (see

Tabl e 14) and the FFT averaging settings that are

shown in the FFT_AVG1 and FFT_AVG2 registers (see Table 19

and Table 20, respectively).

Table 11. AVG_CNT (Base Address = 0x3A), Read/Write

Bits Description (Default = 0x9630)

[15:12] Sample Rate Option 3, binary (0 to 10),

SR3 option sample rate = 20,480 ÷ 2

AVG_CNT[15:12]

[11:8] Sample Rate Option 2, binary (0 to 10),

SR2 option sample rate = 20,480 ÷ 2

AVG_CNT[11:8]

SAMPLE RATE/FILTERING

The sample rate for each axis is 20.48 kSPS. The internal ADC

samples all three axes in a time-interleaving pattern (x1, y1, z1,

x2, y2…) that provides even distribution of data across the data

record. The averaging/decimating filter provides a control for

the final sample rate in the time record. By averaging and

decimating the time domain data, this filter provides the ability

to focus the spectral record on lower bandwidths, which produces

finer frequency resolution in each FFT frequency bin. AVG_CNT

(see Tabl e 11) provides the setting for the four dif-ferent sample

rate options in REC_CTRL1[11:8] (SRx, see Ta ble 9). All four

options are available when using the manual FFT, automatic

FFT, and manual time capture modes. When more than one

sample rate option is enabled while the device is in one of the

manual modes, the device produces a spectral record for one

SRx at a time, starting with the lowest number. After completing

the spectral record for one SRx option, the device waits for

another start command before producing a spectral record for

the next SRx option that is enabled in REC_CTRL1[11:8]. When

SR1 option sample rate = 20,480 ÷ 2

AVG_CNT[7:4]

[3:0] Sample Rate Option 0, binary (0 to 10),

SR0 option sample rate = 20,480 ÷ 2

AVG_CNT[3:0]

Table 12. Sample Rate Settings and Filter Performance

SRx

Option

Sample

Rate, f

(SPS)

Bin

Width

S

(Hz)

Bandwidth

(Hz)

Peak Noise

per Bin

(mg)

0 20,480 40 10,240 5.18

1 10,240 20 5120 3.66

2 5120 10 2560 2.59

3 2560 5 1280 1.83

4 1280 2.5 640 1.29

5 640 1.250 320 0.91

6 320 0.625 160 0.65

7 160 0.313 80 0.46

8 80 0.156 40 0.32

10 20 0.039 10 0.16

Figure 14. Signal Flow Diagram, REC_CTRL1[1:0] = 00 or 01, FFT Analysis Modes

Rev. B | Page 12 of 28

Data Sheet ADIS16228

X

1Y1

Y

2

Z

1

Z

2

PWR

2

TEMP

2

X

512Y512

Z

512

X

2

DATA CAPTURE

FFT RECORD

RECORDS

TRIGGER

SPI/DIO/TIMER

TRIGGER

SPI/DIO/TIMER

DATA RDY

TRIGGER

SPI/DIO/TIMER

DATA RDY

TRIGGER

SPI/DIO/TIMER

DATA RDY DATA RDY

RECORD 1

SR0

RECORD 1

SR1

RECORD 1

SR2

RECORD 1

SR3

512 SAMPLES 51 2 SAMPLES 512 SAMPLES

10069-021

FFT

1

FFT

2

FFT

N

FFT

AVG

TEMP

AVG

PWR

AVG

Figure 15. Spectral Record Production, with All SRx Settings Enabled

Rev. B | Page 13 of 28

ADIS16228 Data Sheet

1 = enable (see Figure 18)

20

0

2

4

6

8

10

12

14

16

18

1000 2000 4000 5000 6000

PEAK MAGNITUDE (g)

FREQUENCY ( Hz )

10069-116

2g PEAK RESPONSE

14g PEAK RESPONSE

16g PEAK RESPONSE

18g PEAK RESPONSE

100 1000 5000

MEAN

MAGNITUDE ( g)

FREQUENCY ( Hz )

10069-117

0.6

0.7

0.8

0.9

1.0

1.1

1.2

1.3

1.4

–3σ

+3σ

100 1000 5000

MEAN

MAGNITUDE ( g)

FREQUENCY ( Hz )

10069-118

0.9

1.0

1.1

–3σ

+3σ

DYNAMIC RANGE/SENSITIVITY

The range of the ADIS16228 accelerometers depends on the

frequency of the vibration. The accelerometers have a selfresonant frequency of 5.5 kHz, and the signal conditioning

circuit applies a single-pole, low-pass filter (2.5 kHz) to the

response. The self-resonant behavior of the accelerometer

influences the relationship between vibration frequency and

dynamic range, as shown in Figure 16, which displays the

response to peak input amplitudes, assuming a sinusoidal

vibration signature at each frequency. The accelerometer

resonance and low-pass filter also influence the magnitude

response, as shown in Figure 17.

Frequency Response Correction

The CAL_ENABLE register provides an on/off control bit for

a magnitude/frequency correction that extends the flatness

(5%) of this response up to 5 kHz. Set CAL_ENABLE[4] = 1

(DIN = 0xFA10) to enable this function, which produces a

magnitude/frequency response like the one that is shown in

Figure 18. Set CAL_ENABLE[4] = 0 to remove this correction,

and use a response that reflects the curve that is shown in

Figure 17. Note that this operation does not expand the dynamic

range of the sensor, but it can simplify the process of setting

spectral alarm limits and any other postprocessing routines.

Figure 17. Magnitude/Frequency Response (CAL_ENABLE[4] = 0)

Table 13. CAL_ENABLE (Base Address = 0x7A), Read/Write

Bits Description (Default = 0x00FF)

[15:5] Not used (don’t care)

4 Frequency/flatness calibration enable

0 = disable (see Figure 17)

[3:0] Not used (don’t care)

Figure 16. Peak Magnitude vs. Frequency

Rev. B | Page 14 of 28

Figure 18. Magnitude/Frequency Response (CAL_ENABLE[4] = 1)

Data Sheet ADIS16228

0 to 20

0.6104

0.3052

− 1

XM

XI

a

a

XI

a

XM

a

[15:0]

Z-axis scale correction factor (SCFz), twos complement

Dynamic Range Settings

REC_CTRL2 (see Table 14) provides four range settings that

are associated with each sample rate option, SRx. The range options

that are referenced in REC_CTRL2 reflect the maximum dynamic

range, which occurs at the lower part of the frequency range and

does not account for the decrease in range (see Figure 16). For

example, set REC_CTRL2[5:4] = 10 (DIN = 0x9C20) to set the

peak acceleration (A

) to 10 g on the SR2 sample rate option.

MAX

These settings help optimize FFT precision and sensitivity when

monitoring lower magnitude vibrations. For each range setting

in Tabl e 14, this stage scales the time domain data so that the

maximum value equates to 2

16

2

LSBs for frequency domain data.

15

LSBs for time domain data and

Note that the maximum range for each setting is 1 LSB smaller

than the listed maximum. For example, the maximum number

of codes in the frequency domain analysis is 2

16

− 1, or 65,535.

For example, when using a range setting of 1 g in one of the FFT

modes, the maximum measurement is equal to 1 g times 2

divided by 2

16

. See Table 15 for the resolution associated with

16

− 1,

each setting and Figure 14 for the location of this operation in

the signal flow diagram. The real-time mode automatically uses

the 20 g range setting.

Table 14. REC_CTRL2 (Base Address = 0x1C), Read/Write

Bits Description (Default = 0x00FF)

[15:8] Not used (don’t care)

[7:6] Measurement range, SR3

00 = 1 g, 01 = 5 g, 10 = 10 g, 11 = 20 g

[5:4] Measurement range, SR2

00 = 1 g, 01 = 5 g, 10 = 10 g, 11 = 20 g

[3:2] Measurement range, SR1

00 = 1 g, 01 = 5 g, 10 = 10 g, 11 = 20 g

[1:0] Measurement range, SR0

00 = 1 g, 01 = 5 g, 10 = 10 g, 11 = 20 g

Table 15. Range Settings and LSB Weights

Range Setting (g)

(REC_CTRL2[5:4])

0 to 1 0.0305 0.0153

0 to 5 0.1526 0.0763

0 to 10 0.3052 0.1526

Time Mode

(mg/LSB)

FFT Mode

(mg/LSB)

Scale Adjustment

The x_SENS registers (see Table 16, Table 17, and Table 18)

provide a fine-scale adjustment function for each axis. The

following equation describes how to use measured and ideal

values to calculate the scale factor for each register in LSBs:

SCFx =

× 218

where:

is the ideal x-axis value.

is the actual x-axis measurement.

These registers contain correction factors, which come from the

factory calibration process. The calibration process records

accelerometer output in four different orientations and

computes the correction factors for each register.

These registers also provide write access for in-system adjustment. Gravity provides a common stimulus for this type of

correction process. Use both +1 g and −1 g orientations to reduce

the effect of offset on this measurement. In this case, the ideal

measurement is 2 g, and the measured value is the difference of

the accelerometer measurements at +1 g and −1 g orientations.

The factory-programmed values are stored in flash memory and

are restored by setting GLOB_CMD[3] = 1 (DIN = 0xBE04)

(see Table 64).

Table 16. X_SENS (Base Address = 0x02), Read/Write

Bits Description (Default = N/A)

[15:0] X-axis scale correction factor (SCFx), twos complement

Table 17. Y_SENS (Base Address = 0x04), Read/Write

Bits Description (Default = N/A)

[15:0] Y-axis scale correction factor (SCFy), twos complement

Table 18. Z_SENS (Base Address = 0x06), Read/Write

Bits Description (Default = N/A)

PRE-FFT WINDOWING

REC_CTRL1[13:12] provide three options for pre-FFT windowing

of time data. For example, set REC_CTRL1[13:12] = 01 to use

the Hanning window, which offers the best amplitude resolution

of the peaks between frequency bins and minimal broadening

of peak amplitudes. The rectangular and flat top windows are

also available because they are common windowing options for

vibration monitoring. The flat top window provides accurate

amplitude resolution with a trade-off of broadening the peak

amplitudes.

Rev. B | Page 15 of 28

ADIS16228 Data Sheet

Function

Time (ms)

Processing Time, tPT

18.7

FFT Time, t

32.7

Number of Sample Rates Selected

Available Records

[15:0]

Flash write cycle count; record data only, binary

FFT

The FFT process converts each 512-sample time record into

a 256-point spectral record that provides magnitude vs.

frequency data.

FFT Averaging

The FFT averaging function combines multiple FFT records to

reduce the variation of the FFT noise floor, which enables detection

of lower vibration levels. Each SRx option in the REC_CTRL1

register has its own FFT average control, which establishes the

number of FFT records to average into the final FFT record.

To enable this function, write the number of averages for each

SRx option that is enabled in the REC_CTRL1 register to the

FFT_AVGx registers. For example, set FFT_AVG2[8:0] = 0x4A

(DIN = 0x9E4A) to set the number of FFT averages to 16 for the

SR2 sample rate option and 1024 for the SR3 sample rate option.

Table 19. FFT_AVG1 (Base Address = 0x0C), Read/Write

Bits Description (Default = 0x0108)

[15:8] FFT averages for a single record, SR1 sample rate,

N

in Figure 14; range = 1 to 255, binary

F

[7:0] FFT averages for a single record, SR0 sample rate,

N

in Figure 14; range = 1 to 255, binary

F

Table 20. FFT_AVG2 (Base Address = 0x0E), Read/Write

Bits Description (Default = 0x0101)

[15:8] FFT averages for a single record, SR3 sample rate,

N

in Figure 14; range = 1 to 255, binary

F

[7:0] FFT averages for a single record, SR2 sample rate,

N

in Figure 14; range = 1 to 255, binary

F

RECORDING TIMES

When using automatic FFT mode, the automatic recording period

(REC_PRD) must be greater than the total recording time. Use

the following equations to calculate the recording time:

Manual time mode

t

= tS + tPT + tST + t

R

tS = (512/20480) × 2

Note that the AVG _C NT variable in this relationship refers to

the decimal equivalent of the applicable nibble in the

AVG_CNT register (See Table 11).

FFT modes

t

= NF × (tS + tPT + t

R

Tabl e 21 provides a list of the processing times and settings that

are used in these equations.

Table 21. Typical Processing Times

FFT

Number of FFT Averages, NF Per FFT_AVG1, FFT_AVG2

Storage Time, tST 120.0

Alarm Scan Time, t

AST

AVG _C NT

) + tST + t

FFT

2.21

AST

AST

The storage time (tST) applies only when a storage method is

selected in REC_CTRL1[3:2] (see Tab l e 9 for more details about

the record storage settings). The alarm scan time (t

) applies

AST

only when the alarms are enabled in ALM_CTRL[4:0] (see

Tabl e 26 for more information). Understanding the recording

time helps predict when data is available, for systems that cannot

use DIO1 to monitor the status of these operations. Note that

when using automatic FFT mode, the automatic recording period

(REC_PRD) must be greater than the total recording time.

DATA RECORDS

After the ADIS16228 finishes processing FFT data, it stores the

data into the data buffer, where it is available for external access

using the SPI and x_BUF registers (see Tabl e 49 to Table 51).

REC_CTRL1[3:2] (see Table 9) provides programmable conditions

for writing buffer data into the FFT records, which are in

nonvolatile flash memory locations. Set REC_CTRL1[3:2] = 01

to store data buffer data into the flash memory records only

when an alarm condition is met. Set REC_CTRL1[3:2] = 10 to

store every set of FFT data into the flash memory locations. The

flash memory record provides space for a total of 14 records.

Each record stored in flash memory contains a header and

frequency domain (FFT) data from all three axes (x, y, and z).

When all 14 records are full, new records do not load into the

flash memory. The REC_CNTR register (see Tabl e 22) provides

a running count for the number of records that are stored. Set

GLOB_CMD[8] = 1 (DIN = 0xBF01) to clear all of the records in

flash memory.

Table 22. REC_CNTR (Base Address = 0x78), Read Only

Bits Description (Default = 0x0000)

[15:5] Not used

[4:0] Total number of records taken; range = 0 to 14, binary

When used in conjunction with automatic trigger mode and record

storage, FFT analysis for each sample rate option requires no additional inputs. Depending on the number of FFT averages, the time

between each sample rate selection may be quite large. Note that

selecting multiple sample rates reduces the number of records

available for each sample rate setting, as shown in Table 23.

Table 23. Available Records per Sample Rate Selected

1 14

2 7

3 4

4 3

FFT RECORD FLASH ENDURANCE

The REC_FLSH_CNT register (see Tab l e 24) increments when

all 14 records contain FFT data.

Table 24. REC_FLSH_CNT (Base Address = 0x5E), Read Only

Bits Description

Rev. B | Page 16 of 28

ALM_Y_MAG1

0x26

Y-Axis Alarm Trigger Level 1 (warning)

ALM_Z_FREQ

0x74

Z-axis alarm frequency of peak alarm

4

System alarm. 1 = temperature, 0 = power supply.

3

Alarm S enable (ALM_S_MAG). 1 = enabled, 0 = disabled.

MAGNITUDE

FREQUENCY

1 2 3 4 5 6

ALM_F_HIGH

ALM_F_LOW

ALM_x_MAG1

ALM_x_MAG2

10069-020

Data Sheet ADIS16228

SPECTRAL ALARMS

The alarm function offers six spectral bands for alarm detection.

Each spectral band has high and low frequency definitions,

along with two different trigger thresholds (Alarm 1 and Alarm 2)

for each accelerometer axis. Tab l e 25 provides a summary of

each register used to configure the alarm function.

Table 25. Alarm Function Register Summary

Register Address Description

ALM_F_LOW 0x20 Alarm frequency band, lower limit

ALM_F_HIGH 0x22 Alarm frequency band, upper limit

ALM_X_MAG1 0x24 X-Axis Alarm Trigger Level 1 (warning)

ALM_Z_MAG1 0x28 Z-Axis Alarm Trigger Level 1 (warning)

ALM_X_MAG2 0x2A X-Axis Alarm Trigger Level 2 (fault)

ALM_Y_MAG2 0x2C Y-Axis Alarm Trigger Level 2 (fault)

ALM_Z_MAG2 0x2E Z-Axis Alarm Trigger Level 2 (fault)

ALM_PNTR 0x30 Alarm pointer

ALM_S_MAG 0x32 System alarm trigger level

ALM_CTRL 0x34 Alarm configuration

DIAG_STAT 0x3C Alarm status

ALM_X_STAT 0x40 X-axis alarm status

ALM_Y_STAT 0x42 Y-axis alarm status

ALM_Z_STAT 0x44 Z-axis alarm status

ALM_X_PEAK 0x46 X-axis alarm peak

ALM_Y_PEAK 0x48 Y-axis alarm peak

ALM_Z_PEAK 0x4A Z-axis alarm peak

ALM_X_FREQ 0x70 X-axis alarm frequency of peak alarm

ALM_Y_FREQ 0x72 Y-axis alarm frequency of peak alarm

The ALM_CTRL register (see Table 26) provides control bits

that enable the spectral alarms of each axis, configures the system

alarm, sets the record delay for the spectral alarms, and configures

the clearing function for the DIAG_STAT error flags (see Table 65).

Table 26. ALM_CTRL (Base Address = 0x34), Read/Write

Bits Description (Default = 0x0080)

[15:12] Not used.

[11:8] Response delay; range = 0 to 15. Represents the number

of spectral records for each spectral alarm before a

spectral alarm flag is set high.

7 Latch DIAG_STAT error flags. Requires a clear status

command (GLOB_CMD[4]) to reset the flags to 0.

1 = enabled, 0 = disabled.

6 Enable DIO1 as an Alarm 1 output indicator and enable

5 System alarm comparison polarity.

1 = trigger when less than ALM_S_MAG[11:0].

0 = trigger when greater than ALM_S_MAG[11:0].

2 Alarm Z enable (ALM_Z_MAG). 1 = enabled, 0 = disabled.

1 Alarm Y enable (ALM_Y_MAG). 1 = enabled, 0 = disabled.

0 Alarm X enable (ALM_X_MAG). 1 = enabled, 0 = disabled.

DIO2 as an Alarm 2 output indicator. 1 = enabled.

ALARM DEFINITION

The alarm function provides six programmable spectral bands,

as shown in Figure 19. Each spectral alarm band has lower and

upper frequency definitions for all of the sample rate options

(SRx). It also has two independent trigger level settings, which

are useful for systems that value warning and fault condition

indicators.

Figure 19. Spectral Band Alarm Setting Example, ALM_PNTR = 0x03

Select the spectral band for configuration by writing its number

(1 to 6) to ALM_PNTR[2:0] (see Table 27). Then select the sample

rate option using ALM_PNTR[9:8]. This number represents a

binary number, which corresponds to the x in the SRx sample

rates option associated with REC_CTRL1[11:8] (see Table 9).

For example, set ALM_PNTR[7:0] = 0x05 (DIN = 0xB005) to

select Alarm Spectral Band 5, and set ALM_PNTR[15:8] = 0x02

(DIN = 0xB102) to select the SR2 sample rate option.

Table 27. ALM_PNTR (Base Address = 0x30), Read/Write

Bits Description (Default = 0x0000)

[15:10] Not used

[9:8] Sample rate option; range = 0 to 3 for SR0 to SR3

[7:3] Not used

[2:0] Spectral band number; range = 1 to 6

Alarm Band Frequency Definitions

After the spectral band and sample rate settings are set, program

the lower and upper frequency boundaries by writing their bin

numbers to the ALM_F_LOW register (see Table 28) and

ALM_F_HIGH register (see Tabl e 29). Use the bin width

definitions listed in Ta b l e 12 to convert a frequency into a bin

number for this definition. Calculate the bin number by dividing

the frequency by the bin width that is associated with the sample

rate setting. For example, if the sample rate is 5120 Hz and the

lower band frequency is 400 Hz, divide that number by the bin

width of 10 Hz to arrive at the 40

Then set ALM_F_LOW[7:0] = 0x28 (DIN = 0xA028) to establish

400 Hz as the lower frequency for the 5120 SPS sample rate setting.

th

bin as the lower band setting.

Rev. B | Page 17 of 28

ADIS16228 Data Sheet

[15:0]

Y-axis Alarm Trigger Level 1, 16-bit unsigned (see Table 14

Table 28. ALM_F_LOW (Base Address = 0x20), Read/Write

Bits Description (Default = 0x0000)

[15:8] Not used

[7:0] Lower frequency, bin number; range = 0 to 255

Table 33. ALM_X_MAG2 (Base Address = 0x2A), Read/Write

Bits Description (Default = 0x0000)

[15:0] X-axis Alarm Trigger Level 2, 16-bit unsigned (see Table 14

and Table 15 for the scale factor)

Table 29. ALM_F_HIGH (Base Address = 0x22), Read/Write

Bits Description (Default = 0x0000)

[15:8] Not used

[7:0] Upper frequency, bin number; range = 0 to 255

Alarm Trigger Settings

The ALM_x_MAG1 and ALM_x_MAG2 registers (see Tab l e 30

to Tabl e 35) provide two independent trigger settings for all three

axes of acceleration data. They use the data format established

by the range settings in the REC_CTRL2 register (see Tabl e 14)

and recording mode in REC_CTRL1[1:0] (see Table 9). For

example, when using the 0 g to 1 g mode for FFT analysis,

32,768 LSB is the closest setting to 500 mg. Therefore, set

ALM_Y_MAG2 = 0x8000 (DIN = 0xAD80, 0xAC00) to set the

critical alarm to 500 mg, when using the 0 g to 1 g range option

in REC_CTRL2 for FFT records. See Tab l e 14 and Tabl e 15 for

more information about formatting each trigger level. Note that

trigger settings that are associated with Alarm 2 should be

greater than the trigger settings for Alarm 1. In other words, the

alarm magnitude settings should meet the following criteria:

ALM_X_MAG2 > ALM_X_MAG1

ALM_Y_MAG2 > ALM_Y_MAG1

ALM_Z_MAG2 > ALM_Z_MAG1

Table 30. ALM_X_MAG1 (Base Address = 0x24), Read/Write

Bits Description (Default = 0x0000)

[15:0] X-axis Alarm Trigger Level 1, 16-bit unsigned (see Table 14

and Table 15 for the scale factor)

Table 31. ALM_Y_MAG1 (Base Address = 0x26), Read/Write

Bits Description (Default = 0x0000)

Table 34. ALM_Y_MAG2 (Base Address = 0x2C), Read/Write

Bits Description (Default = 0x0000)

[15:0] Y-axis Alarm Trigger Level 2, 16-bit unsigned (see Table 14

and Table 15 for the scale factor)

Table 35. ALM_Z_MAG2 (Base Address = 0x2E), Read/Write

Bits Description (Default = 0x0000)

[15:0] Z-axis Alarm Trigger Level 2, 16-bit unsigned (see Table 14

and Table 15 for the scale factor)

Table 36. ALM_S_MAG (Base Address = 0x32), Read/Write

Bits Description (Default = 0x0000)

[15:0] System alarm trigger level, data format matches target

from ALM_CTRL[4]

Enable Alarm Settings

Before configuring the spectral alarm registers, clear their

current contents by setting GLOB_CMD[9] = 1 (DIN = 0xBF02).

After completing the spectral alarm band definitions, save

the settings by setting GLOB_CMD[12] = 1 (DIN = 0xBF10).

The device ignores the save command if any of these locations

has already been written to.

ALARM INDICATOR SIGNALS

DIO_CTRL[5:2] (see Tab l e 66) and ALM_CTRL[6] (see

Tabl e 26) provide controls for establishing DIO1 and DIO2 as

dedicated alarm output indicator signals. Use DIO_CTRL[5:2]

to select the alarm function for DIO1 and/or DIO2; then set

ALM_CTRL[6] = 1 to enable DIO1 to serve as an Alarm 1 indicator and DIO2 as an Alarm 2 indicator. This setting establishes

DIO1 to indicate Alarm 1 (warning) conditions and DIO2 to

indicate Alarm 2 (critical) conditions.

and Table 15 for the scale factor)

Table 32. ALM_Z_MAG1 (Base Address = 0x28), Read/Write

Bits Description (Default = 0x0000)

[15:0] Z-axis Alarm Trigger Level 1, 16-bit unsigned (see Table 14

and Table 15 for the scale factor)

ALARM FLAGS AND CONDITIONS

The FFT header (see Table 58) contains both generic alarm flags

(DIAG_STAT[13:8]; see Tabl e 65) and spectral band-specific

alarm flags (ALM_x_STAT; see Table 37, Table 38, and Ta b l e 39).

The FFT header also contains magnitude (ALM_x_PEAK; see

Tabl e 40, Table 41, and Table 42) and frequency information

(ALM_x_FREQ; see Table 43, Table 44, and Table 45) associated

with the highest magnitude of vibration content in the record.

Rev. B | Page 18 of 28

Data Sheet ADIS16228

7

Alarm 2 on Band 2; 1 = alarm set, 0 = no alarm

Bits

Description (Default = 0x0000)

15

Alarm 2 on Band 6; 1 = alarm set, 0 = no alarm

14

Alarm 1 on Band 6; 1 = alarm set, 0 = no alarm

3

Not used

8

Alarm 1 on Band 3; 1 = alarm set, 0 = no alarm

3

Not used

[15:8]

Not used

ALARM STATUS

The ALM_x_STAT registers (see Ta b l e 37, Ta b l e 38, and Tabl e 39)

provide alarm bits for each spectral band on the current sample

rate option.

Table 37. ALM_X_STAT (Base Address = 0x40), Read Only

Bits Description (Default = 0x0000)

15 Alarm 2 on Band 6; 1 = alarm set, 0 = no alarm

14 Alarm 1 on Band 6; 1 = alarm set, 0 = no alarm

13 Alarm 2 on Band 5; 1 = alarm set, 0 = no alarm

12 Alarm 1 on Band 5; 1 = alarm set, 0 = no alarm

11 Alarm 2 on Band 4; 1 = alarm set, 0 = no alarm

10 Alarm 1 on Band 4; 1 = alarm set, 0 = no alarm

9 Alarm 2 on Band 3; 1 = alarm set, 0 = no alarm

8 Alarm 1 on Band 3; 1 = alarm set, 0 = no alarm

6 Alarm 1 on Band 2; 1 = alarm set, 0 = no alarm

5 Alarm 2 on Band 1; 1 = alarm set, 0 = no alarm

4 Alarm 1 on Band 1; 1 = alarm set, 0 = no alarm

3 Not used

[2:0] Most critical alarm condition, spectral band; range = 1 to 6

Table 38. ALM_Y_STAT (Base Address = 0x42), Read Only

WORST-CASE CONDITION MONITORING

The ALM_x_PEAK registers (see Table 40, Table 41, and

Tabl e 42) contain the peak magnitude for the worst-case alarm

condition in each axis. The ALM_x_FREQ registers (see Ta bl e 43,

Tabl e 44, and Ta ble 45) contain the frequency bin number for

the worst-case alarm condition.

Table 40. ALM_X_PEAK (Base Address = 0x46), Read Only

Bits Description (Default = 0x0000)

[15:0] Alarm peak, x-axis, accelerometer data format

Table 41. ALM_Y_PEAK (Base Address = 0x48), Read Only

Bits Description (Default = 0x0000)

[15:0] Alarm peak, y-axis, accelerometer data format

Table 42. ALM_Z_PEAK (Base Address = 0x4A), Read Only

Bits Description (Default = 0x0000)

[15:0] Alarm peak, z-axis, accelerometer data format

Table 43. ALM_X_FREQ (Base Address = 0x70), Read Only

Bits Description (Default = 0x0000)

[15:8] Not used

[7:0] Alarm frequency for x-axis peak alarm level,

FFT bin number; range = 0 to 255

13 Alarm 2 on Band 5; 1 = alarm set, 0 = no alarm

12 Alarm 1 on Band 5; 1 = alarm set, 0 = no alarm

11 Alarm 2 on Band 4; 1 = alarm set, 0 = no alarm

10 Alarm 1 on Band 4; 1 = alarm set, 0 = no alarm

9 Alarm 2 on Band 3; 1 = alarm set, 0 = no alarm

8 Alarm 1 on Band 3; 1 = alarm set, 0 = no alarm

7 Alarm 2 on Band 2; 1 = alarm set, 0 = no alarm

6 Alarm 1 on Band 2; 1 = alarm set, 0 = no alarm

5 Alarm 2 on Band 1; 1 = alarm set, 0 = no alarm

4 Alarm 1 on Band 1; 1 = alarm set, 0 = no alarm

[2:0] Most critical alarm condition, spectral band; range = 1 to 6

Table 39. ALM_Z_STAT (Base Address = 0x44), Read Only

Bits Description (Default = 0x0000)

15

14

13 Alarm 2 on Band 5; 1 = alarm set, 0 = no alarm

12 Alarm 1 on Band 5; 1 = alarm set, 0 = no alarm

11 Alarm 2 on Band 4; 1 = alarm set, 0 = no alarm

10 Alarm 1 on Band 4; 1 = alarm set, 0 = no alarm

9 Alarm 2 on Band 3; 1 = alarm set, 0 = no alarm

7 Alarm 2 on Band 2; 1 = alarm set, 0 = no alarm

6 Alarm 1 on Band 2; 1 = alarm set, 0 = no alarm

5 Alarm 2 on Band 1; 1 = alarm set, 0 = no alarm

4 Alarm 1 on Band 1; 1 = alarm set, 0 = no alarm

Alarm 2 on Band 6; 1 = alarm set, 0 = no alarm

Alarm 1 on Band 6; 1 = alarm set, 0 = no alarm

Table 44. ALM_Y_FREQ (Base Address = 0x72), Read Only

Bits Description (Default = 0x0000)

[15:8] Not used

[7:0] Alarm frequency for y-axis peak alarm level,

FFT bin number; range = 0 to 255

Table 45. ALM_Z_FREQ (Base Address = 0x74), Read Only

Bits Description (Default = 0x0000)

[7:0] Alarm frequency for z-axis peak alarm level,

FFT bin number; range = 0 to 255

[2:0] Most critical alarm condition, spectral band; range = 1 to 6

Rev. B | Page 19 of 28

ADIS16228 Data Sheet

READING OUTPUT DATA

The ADIS16228 samples, processes, and stores vibration data

from three axes (x, y, and z) into the data buffer and FFT

records (if selected). In manual time capture mode, the record

for each axis contains 512 samples. In manual and automatic FFT

mode, each record contains the 256-point FFT result for each

accelerometer axis. Table 46 provides a summary of registers that

provide access to processed sensor data.

Table 46. Output Data Registers

Register Address Description

TEMP_OUT 0x08 Internal temperature

SUPPLY_OUT 0x0A Internal power supply

BUF_PNTR 0x10 Data buffer index pointer

REC_PNTR 0x12 FFT record index pointer

X_BUF 0x14 X-axis accelerometer buffer

Y_BUF 0x16 Y- axis accelerometer buffer

Z_BUF 0x18 Z- axis accelerometer buffer

GLOB_CMD 0x3E FFT record retrieve command

TIME_STAMP_L 0x4C Time stamp, lower word

TIME_STAMP_H 0x4E Time stamp, upper word

REC_INFO1 0x6E FFT record header information

REC_INFO2 0x76 FFT record header information

READING DATA FROM THE DATA BUFFER

After completing a spectral record and updating each data

buffer, the ADIS16228 loads the first data sample from each

data buffer into the x_BUF registers (see Table 49, Table 50, and

Table 51) and sets the buffer index pointer in the BUF_PNTR

register (see Table 47) to 0x0000. The index pointer determines

which data samples load into the x_BUF registers. For example,

writing 0x009F to the BUF_PNTR register (DIN = 0x9100,

DIN = 0x909F) causes the 160th sample in each data buffer

location to load into the x_BUF registers. The index pointer

increments with every x_BUF read command, which causes the

next set of capture data to load into each capture buffer register

automatically. This enables an efficient method for reading all

256 samples in a record, using sequential read commands,

without having to manipulate the BUF_PNTR register.

DATAIN BUFFERS LOAD INTO

USER OUTPUT REGISTERS

X_BUF

Y_BUF

Z_BUF

SUPPLY_OUT

TEMP_OUT

BUF_PNTR

256/512

0

X-AXIS

ACCELEROMETER

DATA

BUFFER

INTERNAL SAMPLING SYSTEM SAMPLES, PROCESSES, AND

ST O RES DATA IN DATA BUFFE RS.

Y-AXIS

ACCELEROMETER

DATA

BUFFER

FFT ANALYSIS

Z-AXIS

ACCELEROMETER

DATA

BUFFER

Figure 20. Data Buffer Structure and Operation

Table 47. BUF_PNTR (Base Address = 0x10), Read/Write

Bits Description (Default = 0x0000)

[15:9] Not used

[8:0] Data bits; range = 0 to 255 (FFT), 0 to 511 (time)

ACCESSING FFT RECORD DATA

The FFT records can be stored in flash memory. The REC_PNTR

register (see Table 48) and GLOB_CMD[13] (see Table 64)

provide access to the FFT records, as shown in Figure 21. For

example, set REC_PNTR[7:0] = 0x0A (DIN = 0x920A) and

GLOB_CMD[13] = 1 (DIN = 0xBF20) to load FFT Record 10 in

the FFT buffer for SPI/register access.

Table 48. REC_PNTR (Base Address = 0x12), Read/Write

Bits Description (Default = 0x0000)

[15:4] Not used

[3:0] Data bits

FFT

RECORD

X Y Z

FFT

HEADER

FFT

RECORD

0

0

1

X Y Z

FFT

HEADER

1

FFT

RECORD

m

X Y Z

FFT

HEADER

m

FFT

RECORD

15

X Y Z

FFT

HEADER

15

10069-013

Rev. B | Page 20 of 28

m = REC_PNTR

GLOB_CMD[13] = 1

REGISTERS

Figure 21. FFT Record Access

DATA

BUFFER

X, Y, Z

FFT

HEADER

SPI

REGISTERS

10069-119

Data Sheet ADIS16228

Acceleration (mg)

LSB

Hex

Binary

100 × 5 ÷ 65,536

100

0x0064

0000 0000 0110 0100

~1000

+6,554

0x199A

0001 0001 10011010

3.3 + 0.0012207

2704

0xA90

1010 1001 0000

DATA FORMAT

Tabl e 49, Table 50, and Table 51 list the bit assignments for

the x_BUF registers. The acceleration data format depends

on the range scale setting in REC_CTRL2 (see Ta b l e 14) and the

recording mode settings in REC_CTRL1 (see Table 9). Tabl e 52

provides some data formatting examples for the FFT mode, and

Tabl e 53 offers some data formatting examples for the16-bit,

twos complement format used in manual time mode.

Table 49. X_BUF (Base Address = 0x14), Read Only

Bits Description (Default = 0x8000)

[15:0] X-acceleration data buffer register.

Format = twos complement (time), binary (FFT).

Table 50. Y_BUF (Base Address = 0x16), Read Only

Bits Description (Default = 0x8000)

[15:0] Y-acceleration data buffer register.

See Table 15 for scale sensitivity.

Format = twos complement (time), binary (FFT).

Table 51. Z_BUF (Base Address = 0x18), Read Only

Bits Description (Default = 0x8000)

[15:0] Z-acceleration data buffer register.

See Table 15 for scale sensitivity.

Format = twos complement (time), binary (FFT).

See Table 15 for scale sensitivity.

REAL-TIME DATA COLLECTION

When using real-time mode, select the output channel by

reading the associated x_BUF register. For example, set DIN =

0x1600 to select the y-axis sensor for sampling. After selecting

the channel, use the data-ready signal to trigger subsequent data

reading of the Y_BUF register. In this mode, use the time domain

data formatting for a range setting of 20 g, as shown in Ta b l e 15.

POWER SUPPLY/TEMPERATURE

At the end of each spectral record, the ADIS16228 also measures

power supply and internal temperature. It accumulates a 5.12 ms

record of power supply measurements at a sample rate of 50 kHz

and takes 64 samples of internal temperature data over a period

of 1.7 ms. The average of the power supply and internal temperature loads into the SUPPLY_OUT register (see Tab l e 54) and the

TEMP_OUT register (see Table 56), respectively. When using

real-time mode, these registers update only when this mode starts.

Table 54. SUPPLY_OUT (Base Address = 0x0A), Read Only

Bits Description (Default = 0x8000)

[15:12] Not used

[11:0] Power supply, binary, 3.3 V = 0xA8F, 1.22 mV/LSB

Table 55. Power Supply Data Format Examples

Supply Level (V) LSB Hex Binary

3.6 2949 0xB85 1011 1000 0101

Table 52. FFT Mode, 5 g Range, Data Format Examples

4,999.9237 65,535 0xFFFF 1111 1111 1111 1111

2 × 5 ÷ 65,536 2 0x0002 0000 0000 0000 0010

1 × 5 ÷ 65,536 1 0x0001 0000 0000 0000 0001

0 0 0x0000 0000 0000 0000 0000

Table 53. Manual Time Mode, 5 g Range, Data Format

Examples

Acceleration (mg) LSB Hex Binary

+4999.847 +32,767 0x7FFF 1111 1111 1111 1111

+2 × 5 ÷ 32,768 +2 0x0002 0000 0000 0000 0010

+1 × 5 ÷ 32,768 +1 0x0001 0000 0000 0000 0001

0 0 0x0000 0000 0000 0000 0000

−1 × 5 ÷ 32,768 −1 0xFFFF 1111 1111 1111 1111

−2 × 5 ÷ 32,768 −2 0xFFFE 1111 1111 1111 1110

~−1000 −6554 0xE666 1110 0110 0110 0110

−5000 −32,768 0x8000 1000 0000 0000 0000

3.3 2703 0xA8F 1010 1000 1111

3.3 − 0.0012207 2702 0xA8E 1010 1000 1110

3.15 2580 0xA14 1010 0001 0100

Table 56. TEMP_OUT (Base Address = 0x08), Read Only

Bits Description (Default = 0x8000)

[15:12] Not used

[11:0] Temperature data, offset binary, 1278 LSB = +25°C,

−0.47°C/LSB

Table 57. Internal Temperature Data Format Examples

Temperature (°C) LSB Hex Binary

125 1065 0x429 0100 0010 1001

25 + 0.47 1277 0x4FD 0100 1111 1101

25 1278 0x4FE 0100 1111 1110

25 − 0.47 1279 0x4FF 0100 1111 1111

0 1331 0x533 0101 0011 0011

−40 1416 0x588 0101 1000 1000

Rev. B | Page 21 of 28

ADIS16228 Data Sheet

ALM_X_FREQ

0x70

X-axis alarm frequency of peak alarm

ALM_Y_FREQ

0x72

Y-axis alarm frequency of peak alarm

[15:0]

Record time stamp, high integer, binary, seconds

FFT EVENT HEADER

Each FFT record has an FFT header that contains information

that fills all of the registers listed in Tab l e 58. The information

in these registers contains recording time, record configuration

settings, status/error flags, and several alarm outputs. The registers

listed in Table 58 update with every record event and also update

with record-specific information when using GLOB_CMD[13]

(see Tabl e 64) to retrieve a data set from the FFT record in flash

memory.

Table 58. FFT Header Register Information

Register Address Description

DIAG_STAT 0x3C Alarm status

ALM_X_STAT 0x40 X-axis alarm status

ALM_Y_STAT 0x42 Y-axis alarm status

ALM_Z_STAT 0x44 Z-axis alarm status

ALM_X_PEAK 0x46 X-axis alarm peak

ALM_Y_PEAK 0x48 Y-axis alarm peak

ALM_Z_PEAK 0x4A Z-axis alarm peak

TIME_STMP_L 0x4C Time stamp, lower word

TIME_STMP_H 0x4E Time stamp, upper word

REC_INFO1 0x6E FFT record header information

ALM_Z_FREQ 0x74 Z-axis alarm frequency of peak alarm

REC_INFO2 0x76 FFT record header information

The REC_INFO1 register (see Tab l e 59) and the REC_INFO2

register (see Table 60) capture the settings associated with the

current FFT record.