Low Phase Noise, Fast Settling, 6 GHz

PLL Frequency Synthesizer

ADF4196

Rev. B

Trademarks and registered trademarks are the prop erty of their respective owner s.

Fax: 781.461.3113 ©2011 Analog Devices, Inc. All rights reserved.

09450-001

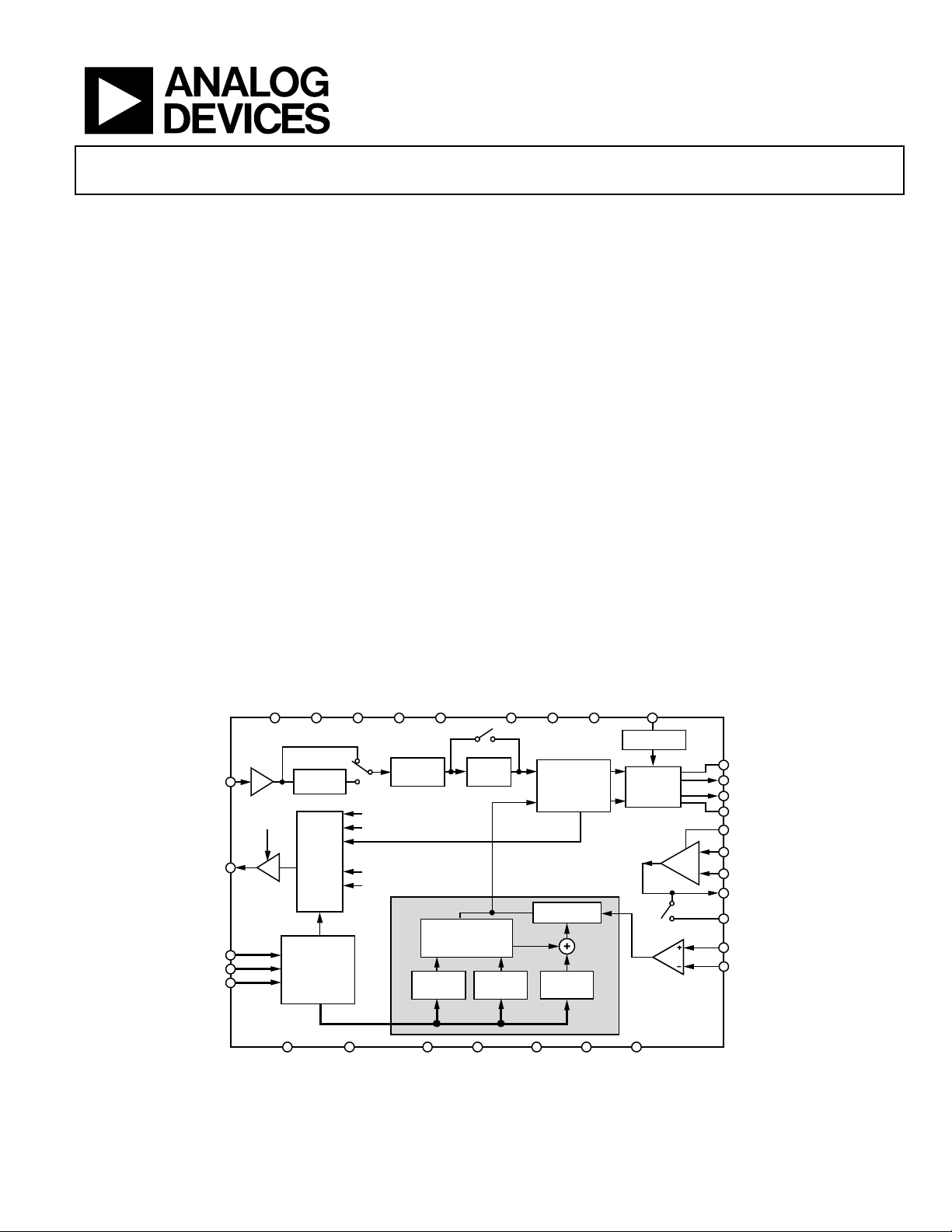

N COUNTER

SW1

CP

OUT+

CP

OUT–

SW2

REFERENCE

DATA

LE

24-BIT

DATA

REGISTER

CLK

REF

IN

A

GND

1

A

GND

2 D

GND

1 D

GND

2 D

GND

3

SD

GND

SW

GND

V

DD

DGND

LOCK DETE CT

R

DIV

N

DIV

SDV

DDDVDD

1 DVDD2 DVDD3

AV

DD

VP1 VP2

VP3 R

SET

OUTPUT

MUX

MUX

OUT

–

+

HIGH-Z

PHASE

FREQUENCY

DETECTOR

ADF4196

FRACTIONAL

INTERPOLATOR

MODULUS

REG

FRACTION

REG

INTEGER

REG

RF

IN+

RF

IN–

×2

DOUBLER

4-BIT R

COUNTER

/2

DIVIDER

CHARGE

PUMP

–

+

+

–

DIFFERENTIAL

AMPLIFIER

CMR

AIN–

AIN+

A

OUT

SW3

Data Sheet

FEATURES

Fast settling, fractional-N PLL architecture

Single PLL replaces ping-pong synthesizers

Frequency hop across GSM band in 5 μs with phase settled

within 20 μs

1 degree rms phase error at 4 GHz RF output

Digitally programmable output phase

RF input range up to 6 GHz

3-wire serial interface

On-chip, low noise differential amplifier

Phase noise figure of merit: −216 dBc/Hz

APPLICATIONS

GSM/EDGE base stations

PHS base stations

Pulse Doppler radar

Instrumentation and test equipment

Beam-forming/phased array systems

GENERAL DESCRIPTION

The ADF4196 frequency synthesizer can be used to implement

local oscillators (LO) in the upconversion and downconversion

sections of wireless receivers and transmitters. Its architecture is

specifically designed to meet the GSM/EDGE lock time requirements for base stations, and the fast settling feature makes the

ADF4196 suitable for pulse Doppler radar applications.

The ADF4196 consists of a low noise, digital phase frequency

detector (PFD) and a precision differential charge pump.

A differential amplifier converts the differential charge pump

output to a single-ended voltage for the external voltage controlled

oscillator (VCO). The sigma-delta (Σ-Δ) based fractional interpolator, working with the N divider, allows programmable modulus

fractional-N division. Additionally, the 4-bit reference (R) counter

and on-chip frequency doubler allow selectable reference signal

(REF

) frequencies at the PFD input.

IN

A complete phase-locked loop (PLL) can be implemented if the

synthesizer is used with an external loop filter and a VCO. The

switching architecture ensures that the PLL settles within the

GSM time slot guard period, removing the need for a second

PLL and associated isolation switches. This decreases the cost,

complexity, PCB area, shielding, and characterization found on

previous ping-pong GSM PLL architectures.

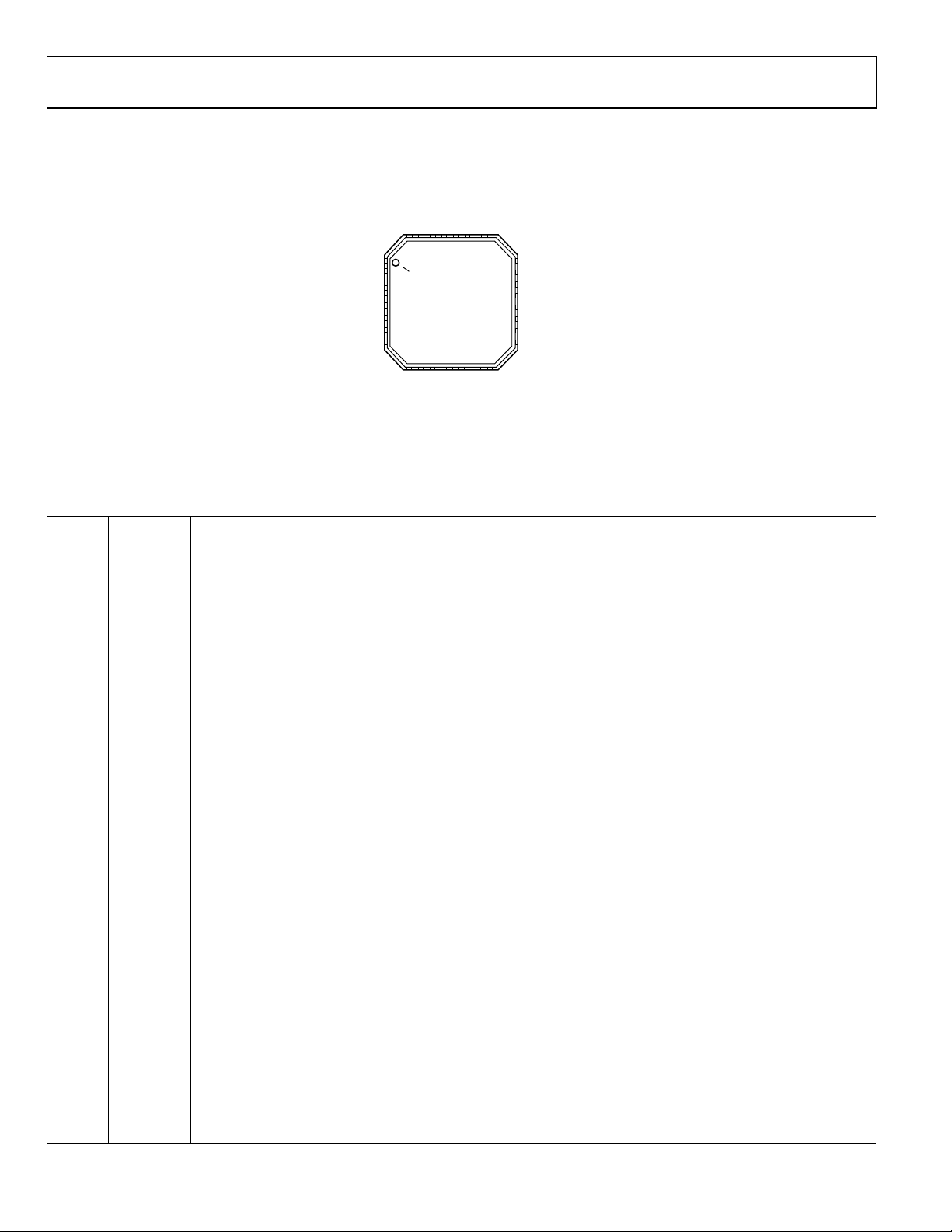

FUNCTIONAL BLOCK DIAGRAM

Information furnished by Analog Devices is believed to be accurate and reliable. However, no

responsibility is assumed by Analog Devices for its use, nor for any infringements of patents or other

rights of third parties that may result from its use. Specifications subject to change without notice. No

license is granted by implication or otherwise under any patent or patent rights of Analog Devices.

Figure 1.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700 www.analog.com

ADF4196 Data Sheet

TABLE OF CONTENTS

Features .............................................................................................. 1

Applications ....................................................................................... 1

General Description ......................................................................... 1

Functional Block Diagram .............................................................. 1

Revision History ............................................................................... 2

Specifications ..................................................................................... 3

Timing Characteristics ................................................................ 4

Absolute Maximum Ratings ............................................................ 5

Thermal Resistance ...................................................................... 5

Transistor Count ........................................................................... 5

ESD Caution .................................................................................. 5

Pin Configuration and Function Descriptions ............................. 6

Typical Performance Characteristics ............................................. 8

Theory of Operation ...................................................................... 11

General Description ................................................................... 11

Reference Input ........................................................................... 11

RF Input Stage ............................................................................. 11

PFD and Charge Pump .............................................................. 12

Differential Charge Pump ......................................................... 12

Fast Lock Timeout Counters ..................................................... 12

Differential Amplifier ................................................................ 13

MUX

and Lock Detect ......................................................... 13

OUT

REVISION HISTORY

12/11—Rev. A t o R e v. B

Changes to Figure 10, Figure 11, Figure 13, and

Figure 14 ............................................................................................ 9

Change to Figure 31 ....................................................................... 17

10/11—Revision A: Initial Version

Input Shift Register .................................................................... 13

Register Map ................................................................................... 14

FRAC/INT Register (R0) Latch Map ....................................... 15

MOD/R Register (R1) Latch Map ............................................ 16

Phase Register (R2) Bit Latch Map .......................................... 17

Function Register (R3) Latch Map ........................................... 18

Charge Pump Register (R4) Latch Map .................................. 19

Power-Down Register (R5) Bit Map ........................................ 20

Mux Register (R6) Latch Map and Truth Table ..................... 21

Programming the ADF4196 .......................................................... 22

Worked Example ........................................................................ 22

Spur Mechanisms ....................................................................... 22

Power-Up Initialization ............................................................. 23

Changing the Frequency of the PLL and the Phase Lookup

Tabl e ............................................................................................. 23

Applications Information .............................................................. 25

Local Oscillator for a GSM Base Station ................................. 25

Interfacing ................................................................................... 27

PCB Design Guidelines ............................................................. 27

Outline Dimensions ....................................................................... 28

Ordering Guide .......................................................................... 28

Rev. B | Page 2 of 28

Data Sheet ADF4196

RF CHARACTERISTICS

CHARGE PUMP

Output Noise

7

nV/√Hz

At 20 kHz offset

Input Low Voltage, VIL

0.7 V

22

27

mA

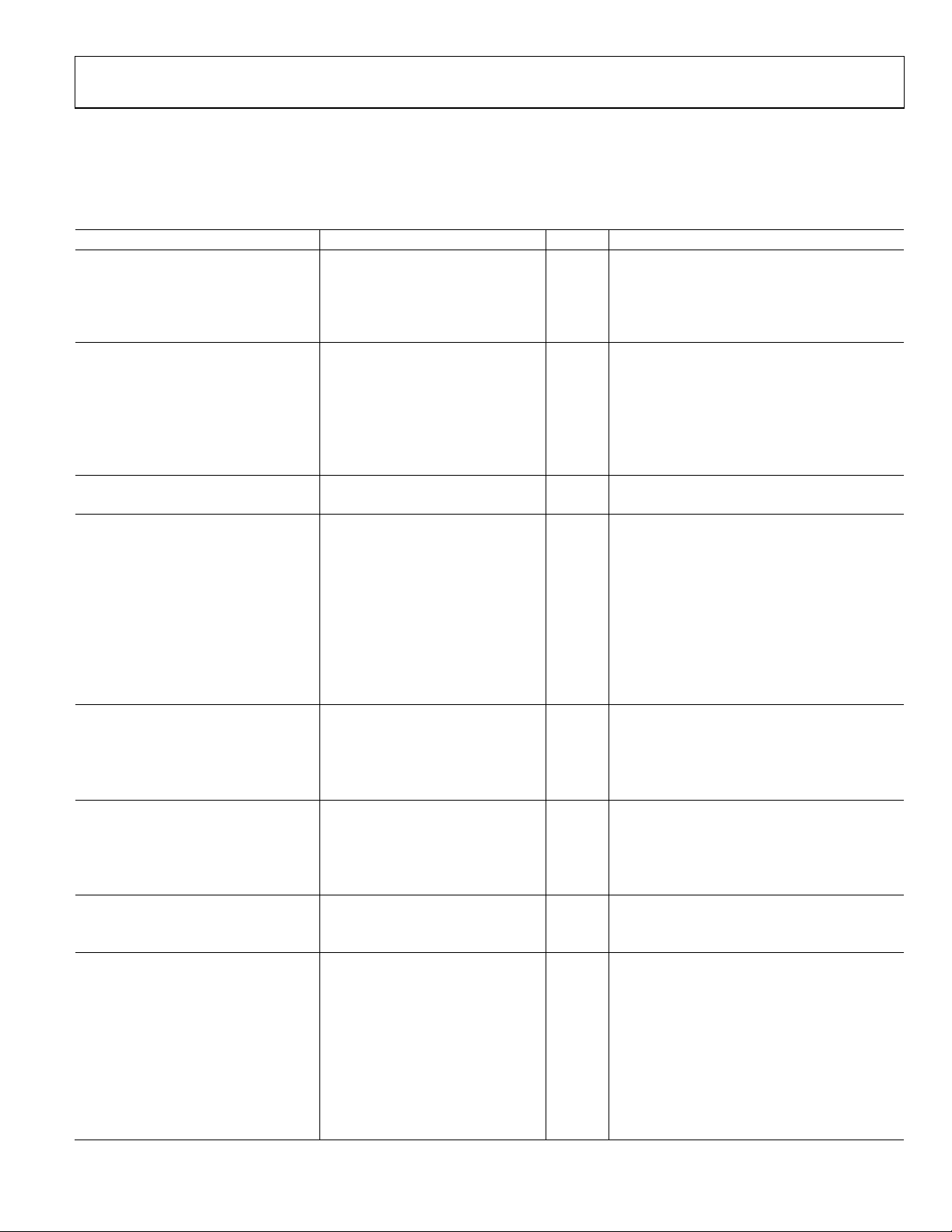

SPECIFICATIONS

AVDD = DVDD1, DVDD2, DVDD3 = SDVDD = 3 V ± 10%; VP1, VP2 = 5 V ± 10%; VP3 = 5.35 V ± 5%; A

R

= 2.4 kΩ; dBm referred to 50 Ω; TA = T

SET

MIN

to T

, unless otherwise noted. Operating temperature range = −40°C to +85°C.

MAX

Table 1.

Parameter Min Typ Max Unit Test Conditions/Comments

GND

1, A

GND

2 = D

GND

1, D

GND

2, D

GND

3 = 0 V;

RF Input Frequency (RF

) 0.4 6 GHz See Figure 21 for input circuit

IN±

RF Input Sensitivity −10 0 dBm

Maximum Allowable Prescaler Output

Frequency

1

750 MHz

REFIN CHARACTERISTICS

REFIN Input Frequency 300 MHz For f > 120 MHz, set REF/2 bit = 1 (Register R1)

REFIN Edge Slew Rate 300 V/µs

REFIN Input Sensitivity 0.7 VDD V p-p AC-coupled

0 to VDD V CMOS compatible

REFIN Input Capacitance 10 pF

REFIN Input Current ±100 µA

PHASE DETECTOR

Phase Detector Frequency 26 MHz

ICP Up/Down

High Value 6.6 mA R

Low Value 104 µA R

= 2.4 kΩ

SET

= 2.4 kΩ

SET

Absolute Accuracy 5 %

R

Range 1 4 kΩ Nominally R

SET

= 2.4 kΩ

SET

ICP Three-State Leakage 1 nA

ICP Up vs. Down Matching 0.1 % 0.75 V ≤ VCP ≤ VP1, VP2, VP3 − 1.5 V

ICP vs. VCP 1 % 0.75 V ≤ VCP ≤ VP1, VP2, VP3 − 1.5 V

ICP vs. Temperature 1 % 0.75 V ≤ VCP ≤ VP1, VP2, VP3 − 1.5 V

DIFFERENTIAL AMPLIFIER

Input Current 1 nA

Output Voltage Range 1.4 VP3 − 0.3 V

VCO Tuning Range 1.8 VP3 − 0.8 V

LOGIC INPUTS

Input High Voltage, VIH 1.4 V

Input Current, I

Input Capacitance, CIN 10 pF

LOGIC OUTPUTS

Output High Voltage, VOH VDD − 0.4 V IOH = 500 µA

Output Low Voltage, VOL 0.4 V IOL = 500 µA

POWER SUPPLIES

AVDD 2.7 3.3 V

DVDD1, DVDD2, DVDD3 AVDD V

VP1, VP2 4.5 5.5 V AVDD ≤ VP1, VP2 ≤ 5.5 V

VP3 5.0 5.65 V VP1, VP2 ≤ VP3 ≤ 5.65 V

IDD (AVDD + DVDD1, DVDD2, DVDD3 +

SDV

IDD (VP1 + VP2) 22 27 mA

IDD (VP3) 24 30 mA

IDD Power-Down 10 µA

, I

±1 µA

INH

INL

)

DD

Rev. B | Page 3 of 28

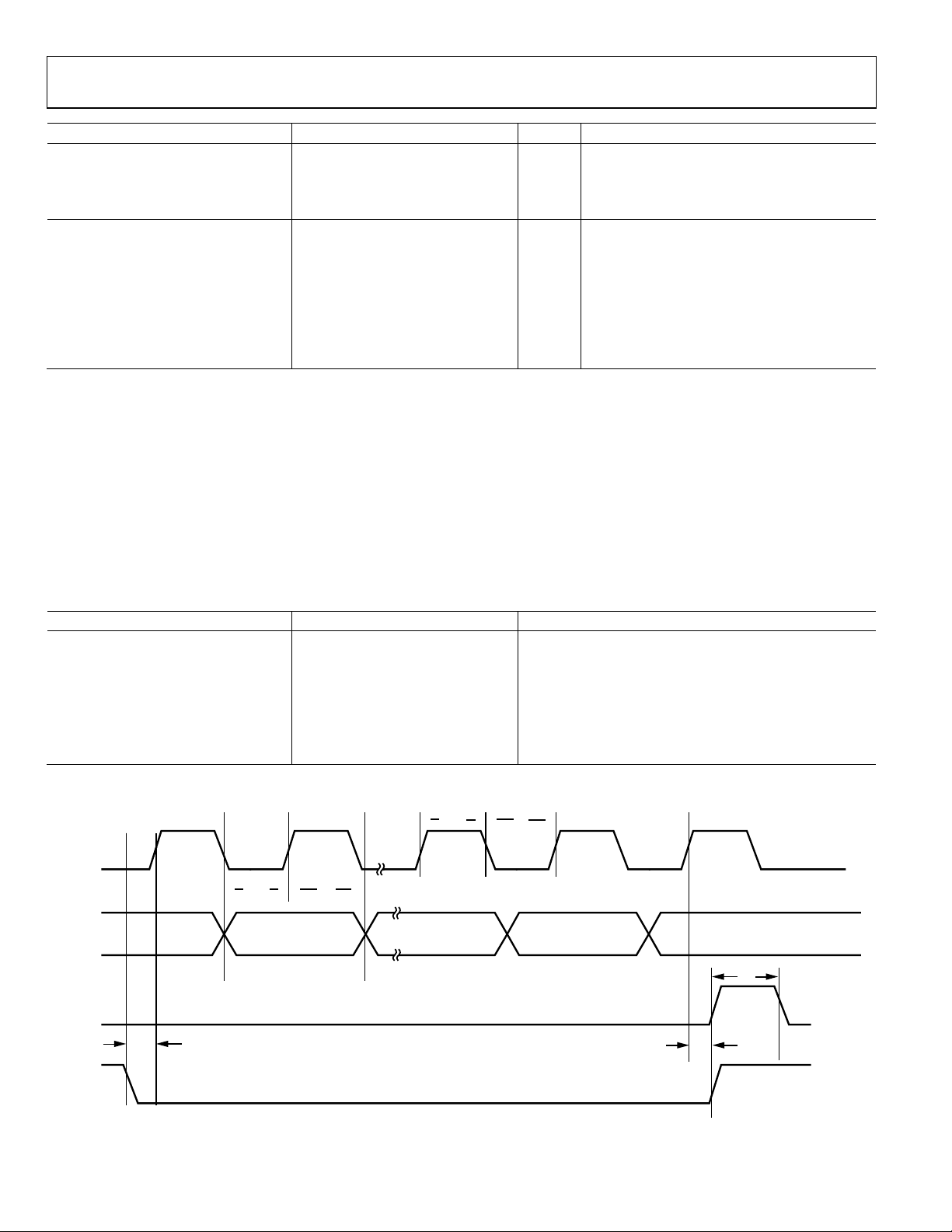

ADF4196 Data Sheet

1800 MHz3

−102

dBc/Hz

At 5 kHz offset and 13 MHz PFD frequency

t6

10 ns min

CLK to LE setup time

09450-002

CLK

DATA

DB23

(MSB)

DB22

DB1 (LSB)

(CONTRO L BIT C2)

DB2 (LSB)

(CONTRO L BIT C3)

DB0 (LSB)

(CONTRO L BIT C1)

LE

LE

t

2

t

4

t

5

t

3

t

7

t

6

t

1

Parameter Min Typ Max Unit Test Conditions/Comments

SW1, SW2, AND SW3

On Resistance

SW1 and SW2 65 Ω

SW3 75 Ω

NOISE CHARACTERISTICS

Output

900 MHz2 −108 dBc/Hz At 5 kHz offset and 26 MHz PFD frequency

Phase Noise

Normalized Phase Noise Floor

)4

(PN

SYNTH

Normalized 1/f Noise (PN

1

Choose a prescaler value that ensures that the frequency on the RF input is less than the maximum allowable prescaler frequency (750 MHz).

2

f

= 26 MHz; f

REF

IN

3

f

= 13 MHz; f

REF

IN

4

The synthesizer phase noise floor is estimated by measuring the in-band phase noise at the output of the VCO and subtracting 20 log(N) (where N is the N divider

value) and 10 log(f

5

The PLL phase noise is composed of 1/f (flicker) noise plus the normalized PLL noise floor. The formula for calculating the 1/f noise contribution at an RF frequency,

fRF, and at an offset frequency, f, is given by PN = P1_f + 10 log(10 kHz/f) + 20 log(fRF/1 GHz). Both the normalized phase noise floor and flicker noise are modeled in

ADIsimPLL™.

= 200 kHz; fRF = 900 MHz; loop bandwidth = 40 kHz.

STEP

= 200 kHz; fRF = 1800 MHz; loop bandwidth = 60 kHz.

STEP

). PN

PFD

SYNTH

)5 −110 dBc/Hz Measured at 10 kHz offset, normalized to 1 GHz

1_f

= PN

− 10 log(f

TOT

TIMING CHARACTERISTICS

AVDD = DVDD1, DVDD2, DVDD3 = 3 V ± 10%; VP1, VP2 = 5 V ± 10%; VP3 = 5.35 V ± 5%; A

R

= 2.4 kΩ; dBm referred to 50 Ω; TA = T

SET

−216 dBc/Hz

) − 20 log(N).

PFD

to T

MIN

, unless otherwise noted. Operating temperature = −40°C to +85°C.

MAX

At VCO output with dither off, PLL loop

bandwidth = 500 kHz

1, A

GND

GND

2 = D

GND

1, D

GND

2, D

3 = 0 V;

GND

Table 2.

Parameter Limit Description

t1 10 ns min LE setup time

t2 10 ns min DATA to CLK setup time

t3 10 ns min DATA to CLK hold time

t4 15 ns min CLK high duration

t5 15 ns min CLK low duration

t7 15 ns min LE pulse width

Timing Diagram

Figure 2. Timing Diagram

Rev. B | Page 4 of 28

Data Sheet ADF4196

Peak Temperature

260°C

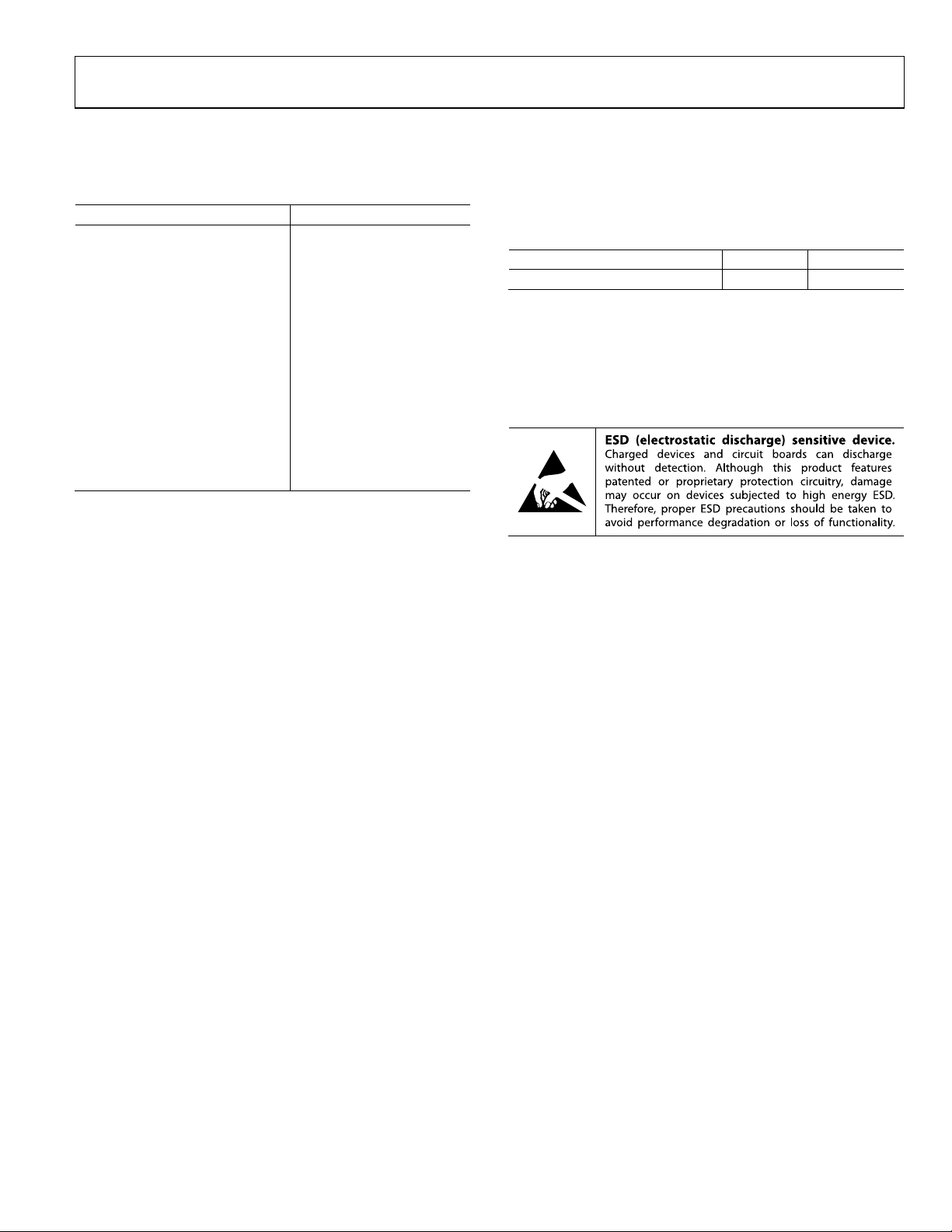

ABSOLUTE MAXIMUM RATINGS

TA = 25°C, unless otherwise noted.

Table 3.

Parameter Rating

AVDD to Ground −0.3 V to +3.6 V

AVDD to DVDD1, DVDD2, DVDD3, SDVDD −0.3 V to +0.3 V

VP1, VP2, VP3 to Ground −0.3 V to +5.8 V

VP1, VP2, VP3 to AVDD −0.3 V to +5.8 V

Digital I/O Voltage to Ground −0.3 V to VDD + 0.3 V

Analog I/O Voltage to Ground −0.3 V to VP1, VP2, VP3 + 0.3 V

REFIN, RF

Operating Temperature Range

Industrial −40°C to +85°C

Storage Temperature Range −65°C to +125°C

Maximum Junction Temperature 150°C

Reflow Soldering

Time at Peak Temperature 40 sec

, RF

to Ground −0.3 V to VDD + 0.3 V

IN+

IN−

THERMAL RESISTANCE

θJA is specified for the worst-case conditions, that is, a device

soldered in a circuit board for surface-mount packages.

Table 4. Thermal Resistance

Package Type θJA Unit

32-Lead LFCSP (Paddle Soldered) 27.3 °C/W

TRANSISTOR COUNT

This device includes 75,800 metal oxide semiconductors (MOS)

and 545 bipolar junction transistors (BJT).

ESD CAUTION

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

This device is a high performance RF integrated circuit with

an ESD rating of <2 kV, and it is ESD sensitive. Take proper

precautions for handling and assembly.

Rev. B | Page 5 of 28

ADF4196 Data Sheet

09450-003

1CMR

2A

OUT

3SW3

4A

GND

1

5RF

IN–

6RF

IN+

7AV

DD

24 V

P

2

23 R

SET

22 A

GND

2

21

D

GND

3

20 V

P

1

19 LE

18 DATA

17 CLK

8DV

DD

1

ADF4196

TOP VIEW

(Not to Scale)

9D

GND

1

10DV

DD

2

11

REF

IN

12

D

GND

2

13DV

DD

3

14

SD

GND

15

SDV

DD

16

MUX

OUT

32 V

P

3

31 AIN+

30 CP

OUT+

29

SW1

28 SW

GND

27

SW2

26 CP

OUT–

25

AIN–

PIN 1

INDICATOR

NOTES

1. THE EXPOSED PADDLE MUST BE CONNECTED

TO THE G ROUND PLANE.

5

RF

8

DVDD1

Power Supply Pin for the N Divider. DVDD1 should be at the same voltage as AVDD. Place a 0.1 µF decoupling

PIN CONFIGURATION AND FUNCTION DESCRIPTIONS

Figure 3. Pin Configuration

Table 5. Pin Function Descriptions

Pin No. Mnemonic Description

1 CMR

2 A

OUT

Differential Amplifier Output. This pin is the differential amplifier output to tune the external VCO.

Common-Mode Reference Voltage for the Output Voltage Swing of the Differential Amplifier. Internally biased to

three-fifths of V

3. Requires a 0.1 µF capacitor to the ground plane.

P

3 SW3 Fast Lock Switch 3. This switch is closed when the SW3 timeout counter is active.

4 A

1 Analog Ground. This is the ground return pin for the differential amplifier and the RF section.

GND

IN−

Complementary Input to the RF Prescaler. This pin must be decoupled to the ground plane with a small bypass

capacitor, typically 100 pF.

6 RF

7 AVDD

Input to the RF Prescaler. This small-signal input is ac-coupled to the external VCO.

IN+

Power Supply Pin for the RF Section. Nominally 3 V. Place a 100 pF decoupling capacitor to the ground plane as

close as possible to this pin.

capacitor to the ground plane as close as possible to this pin.

9 D

10 DVDD2

1 Ground Return Pin for DVDD1.

GND

Power Supply Pin for the REF

Buffer and R Divider. Nominally 3 V. Place a 0.1 µF decoupling capacitor to the

IN

ground plane as close as possible to this pin.

11 REFIN

Reference Input. This CMOS input has a nominal threshold of V

/2 and a dc equivalent input resistance of 100 kΩ.

DD

This input can be driven from a TTL or CMOS crystal oscillator, or it can be ac-coupled.

12 D

2 Ground Return Pin for DVDD2 and DVDD3.

GND

13 DVDD3 Power Supply Pin for the Serial Interface Logic. Nominally 3 V.

14 SD

15 SDVDD

Ground Return Pin for the Digital Σ-Δ Modulator.

GND

Power Supply Pin for the Digital Σ-Δ Modulator. Nominally 3 V. Place a 0.1 µF decoupling capacitor to the ground

plane as close as possible to this pin.

16 MUX

17 CLK

18 DATA

19 LE

20 VP1

21 D

22 A

Multiplexer Output. This multiplexer output allows the lock detect, the scaled RF, or the scaled reference frequency

to be accessed externally (see Figure 35 for details).

Serial Clock Input. Data is clocked into the 24-bit shift register on the CLK rising edge. This input is a high

impedance CMOS input.

OUT

Serial Data Input. The serial data is loaded MSB first with the three LSBs as the control bits. This input is a high

impedance CMOS input.

Load Enable, CMOS Input. When LE goes high, the data stored in the shift register is loaded into the register that is

selected by the three LSBs.

Power Supply Pin for the Phase Frequency Detector (PFD). Nominally 5 V, V

Place a 0.1 µF decoupling capacitor to the ground plane as close as possible to this pin.

3 Ground Return Pin for VP1.

GND

2 Ground Return Pin for VP2.

GND

Rev. B | Page 6 of 28

1 should be at the same voltage as VP2.

P

Data Sheet ADF4196

25.0

30

CP

Differential Charge Pump Positive Output Pin. Connect this pin to AIN+ and the loop filter.

Pin No. Mnemonic Description

23 R

24 VP2

25 AIN− Negative Input Pin for the Differential Amplifier.

26 CP

27 SW2 Fast Lock Switch 2. This switch is closed to SW

28 SW

29 SW1 Fast Lock Switch 1. This switch is closed to SW

31 AIN+ Positive Input Pin for the Differential Amplifier.

32 VP3

EP Exposed Paddle. The exposed paddle must be connected to the ground plane.

SET

Connecting a resistor between this pin and GND sets the charge pump output current. The nominal voltage bias at

pin is 0.55 V. The relationship between ICP and R

the R

SET

=

I

CP

R

SET

Therefore, with R

= 2.4 kΩ, ICP = 104 µA.

SET

Power Supply Pin for the Charge Pump. Nominally 5 V, V

is

SET

2 should be at the same voltage as VP1. Place a 0.1 µF

P

decoupling capacitor to the ground plane as close as possible to this pin.

Differential Charge Pump Negative Output Pin. Connect this pin to AIN− and the loop filter.

OUT−

when the SW1/SW2 timeout counter is active.

GND

Ground for SW1 and SW2 Switches. Connect this pin to the ground plane.

GND

when the SW1/SW2 timeout counter is active.

GND

OUT+

Power Supply Pin for the Differential Amplifier. Ranges from 5.0 V to 5.5 V. Place a 0.1 µF decoupling capacitor to

the ground plane as close as possible to this pin. V

3 also requires a 10 µF decoupling capacitor to the ground plane.

P

Rev. B | Page 7 of 28

ADF4196 Data Sheet

–

–

–

–

TYPICAL PERFORMANCE CHARACTERISTICS

FREQ. UNIT GHz KEYWORD R

PARAM TYPE S IMPEDANCE 50

DATA FORMAT MA

FREQ. MAGS11 ANGS11

0.5 0.8897 –16.6691

0.6 0.87693 –19.9279

0.7 0.85834 –23.561

0.8 0.85044 –26.9578

0.9 0.83494 –30.8201

1.0 0.81718 –34.9499

1.1 0.80229 –39.0436

1.2 0.78917 –42.3623

1.3 0.77598 –46.322

1.4 0.75578 –50.3484

1.5 0.74437 –54.3545

1.6 0.73821 –57.3785

1.7 0.7253 –60.695

1.8 0.71365 –63.9152

1.9 0.70699 –66.4365

2.0 0.7038 –68.4453

2.1 0.69284 –70.7986

2.2 0.67717 –73.7038

Figure 4. S-Parameter Data for the RF Input

FREQ. MAGS11 ANGS11

2.3 0.67107 –75.8206

2.4 0.66556 –77.6851

2.5 0.6564 –80.3101

2.6 0.6333 –82.5082

2.7 0.61406 –85.5623

2.8 0.5977 –87.3513

2.9 0.5655 –89.7605

3.0 0.5428 –93.0239

3.1 0.51733 –95.9754

3.2 0.49909 –99.1291

3.3 0.47309 –102.208

3.4 0.45694 –106.794

3.5 0.44698 –111.659

3.6 0.43589 –117.986

3.7 0.42472 –125.62

3.8 0.41175 –133.291

3.9 0.41055 –140.585

4.0 0.40983 –147.97

09450-038

10

5

0

–5

–10

–15

RF SENSITIVITY (d Bm)

–20

–25

–30

01234

4/5 PRESCALER 8/9 PRESCALER

FREQUENCY (GHz)

Figure 7. RF Input (RF

) Sensitivity

IN

09450-005

765

30

–40

–50

–60

–70

–80

–90

–100

–110

–120

–130

PHASE NOISE (dBc/Hz)

–140

–150

–160

–170

1k 10k 100k 1M 10M

GSM900 Rx SETUP, 40kHz LOOP BW, DITHER OFF

RF = 1092.8M Hz ,

N = 42 4/130

INTEG ER BOUNDARY S PUR: –103dBc @ 80 0 kHz

f

= 26MHz, MOD = 130

REF

FREQUENC Y (Hz)

100M

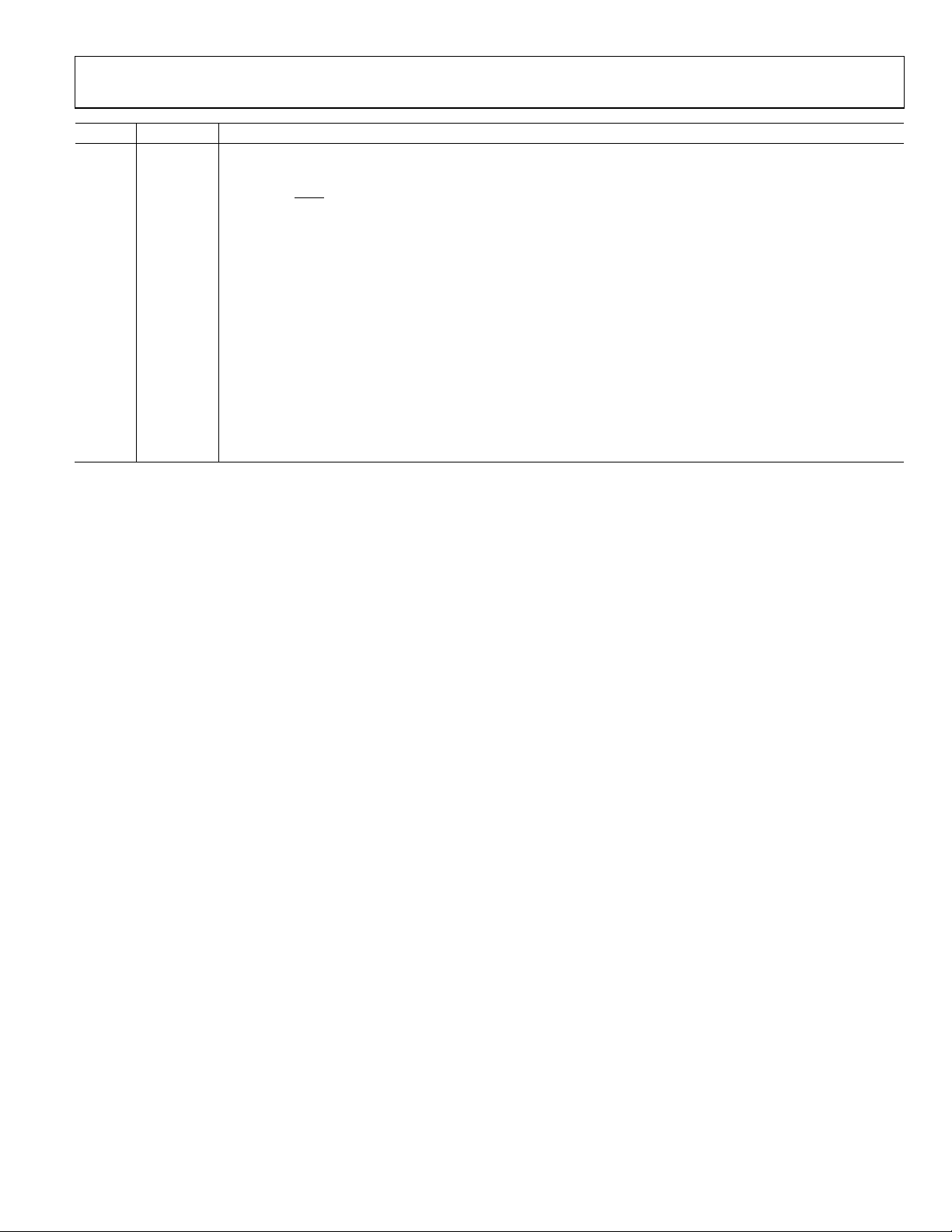

Figure 5. Single-Sideband (SSB) Phase Noise Plot at 1092.8 MHz

(GSM900 Rx Setup) vs. Free Running VCO Noise

60

DCS1800 Tx SETUP WITH DITHER OFF,

60kHz LOOP BW, 13 MHz PFD.

MEASURED ON EVAL-ADF4193EBZ1 BOARD

–70

–80

–90

400kHz SPURS @ 2 5°C

30

–40

–50

–60

–70

–80

–90

–100

–110

–120

–130

PHASE NOISE (dBc/Hz)

–140

–150

09450-006

–160

–170

1k 10k 100k 1M 10M

DCS1800 Tx SETUP, 60kHz LOOP BW, DITHER OFF

RF = 1842.6M Hz ,

DSB INTE GRATED PHASE ERROR = 0 .46° RMS

SIRENZA 184 3T V CO

f

= 13MHz, MOD = 65

REF

FREQUENC Y (Hz)

09450-007

100M

Figure 8. Single-Sideband (SSB) Phase Noise Plot at 1842.6 MHz

(DCS1800 Tx Setup)

60

DCS1800 Tx SETUP WITH DITHER OFF,

60kHz LOOP BW, 13MHz PFD.

MEASURED ON EVAL-ADF4193E BZ 1 BOARD

–70

–80

–90

600kHz SPURS @ 25°C

–100

SPUR LEVEL (dBc)

–110

–120

1846 1859

FREQUENC Y (MHz)

400kHz SPURS @ 85°C

09450-010

1872

Figure 6. 400 kHz Fractional Spur Levels Across All DCS1800 Tx Channels

over Two Integer Multiples of the PFD Reference

–100

SPUR LEVEL (dBc)

–110

–120

1846 1859

FREQUENCY (MHz)

600kHz SPURS @ 85°C

1872

09450-011

Figure 9. 600 kHz Fractional Spur Levels Across All DCS1800 Tx Channels over

Two Integer Multiples of the PFD Reference

Rev. B | Page 8 of 28

Data Sheet ADF4196

09450-040

TIME (µs)

CONTROL VOLTAGE (V)

–1

0

1

2

3

4

5

9876543210

V

TUNE

CP

OUT+

CP

OUT–

DCS1800 Tx SETUP, 60kHz LOO P BW.

MEASURED ON EVAL-ADF4193EBZ1

EVALUATION BOARD.

TIMERS: I

CP

= 28, SW1/S W2, SW3 = 35.

FREQUENCY L OCK IN WIDE BW MODE @ 4µs.

09450-008

TIME (µs)

PHASE ERROR (Deg rees)

–5 0 5 10 15 20 25 30 35 40

–50

50

40

30

20

10

0

–10

–20

–30

–40

45

+25°C

+85°C

–40°C

DCS1800 Tx SETUP, 60kHz LOO P BW.

MEASURED ON EVAL-ADF4193EBZ1

EVALUATION BOARD WITH AD8302

PHASE DETECT OR.

TIMERS: I

CP

= 28, SW1/S W2, SW3 = 35.

PEAK PHASE ERROR < 5° @ 17.8µs

09450-012

CP

OUT

+ / CP

OUT

– VOLTAGE (V)

I

CP

(mA)

CHANGE PUMP MISMATCH (%)

0 0.5 1.0 1.5 2.0 2.5

3.0 3.5 4.0 4.5

–8

–6

–4

–2

0

2

4

6

8

–2.0

–1.5

–1.0

–0.5

0

0.5

1.0

1.5

2.0

5.0

ICP

OUT

+ P, ICP

OUT

– P

CHARGE PUMP MISMATCH (%)

NORMAL OP E RATING RANGE

ICP

OUT

+ N, ICP

OUT

– N

IUP= | ICP

OUT

+ P | + | ICP

OUT

– N |

I

DOWN

= | ICP

OUT

– P | + | ICP

OUT

+ N |

09450-041

TIME (µs)

CONTROL VOLTAGE (V)

–1

0

1

2

3

4

5

9876543210

V

TUNE

CP

OUT–

CP

OUT+

DCS1800 Tx SETUP, 60kHz LOO P BW.

MEASURED ON EVAL-ADF4193EBZ1

EVALUATION BOARD.

TIMERS: I

CP

= 28, SW1/S W2, SW3 = 35.

FREQUENCY L OCK IN WIDE BW MODE @ 5µs.

09450-009

TIME (µs)

PHASE ERROR (Deg rees)

–5 0 5 10 15 20 25 30 35 40

–50

50

40

30

20

10

0

–10

–20

–30

–40

45

+25°C

+85°C

–40°C

DCS1800 Tx SETUP, 60kHz LOO P BW.

MEASURED ON EVAL-ADF4193EBZ1

EVALUATION BOARD WITH AD8302

PHASE DETECT OR.

TIMERS: I

CP

= 28, SW1/S W2, SW3 = 35.

PEAK PHASE ERROR < 5° @ 19.2µs

09450-013

FREQUENCY (MHz)

CONTROL VOLTAGE (V)

1780 1800 1820 1840 1860 1880 1900 1920 1940

0

2

1

3

4

5

VP1 = V

P

2 = 5V

V

P

3 = 5.5V

V

CMR

= 3.3V

CP

OUT–

(= AIN–)

A

OUT

(= V

TUNE

)

CP

OUT+

(= AIN+)

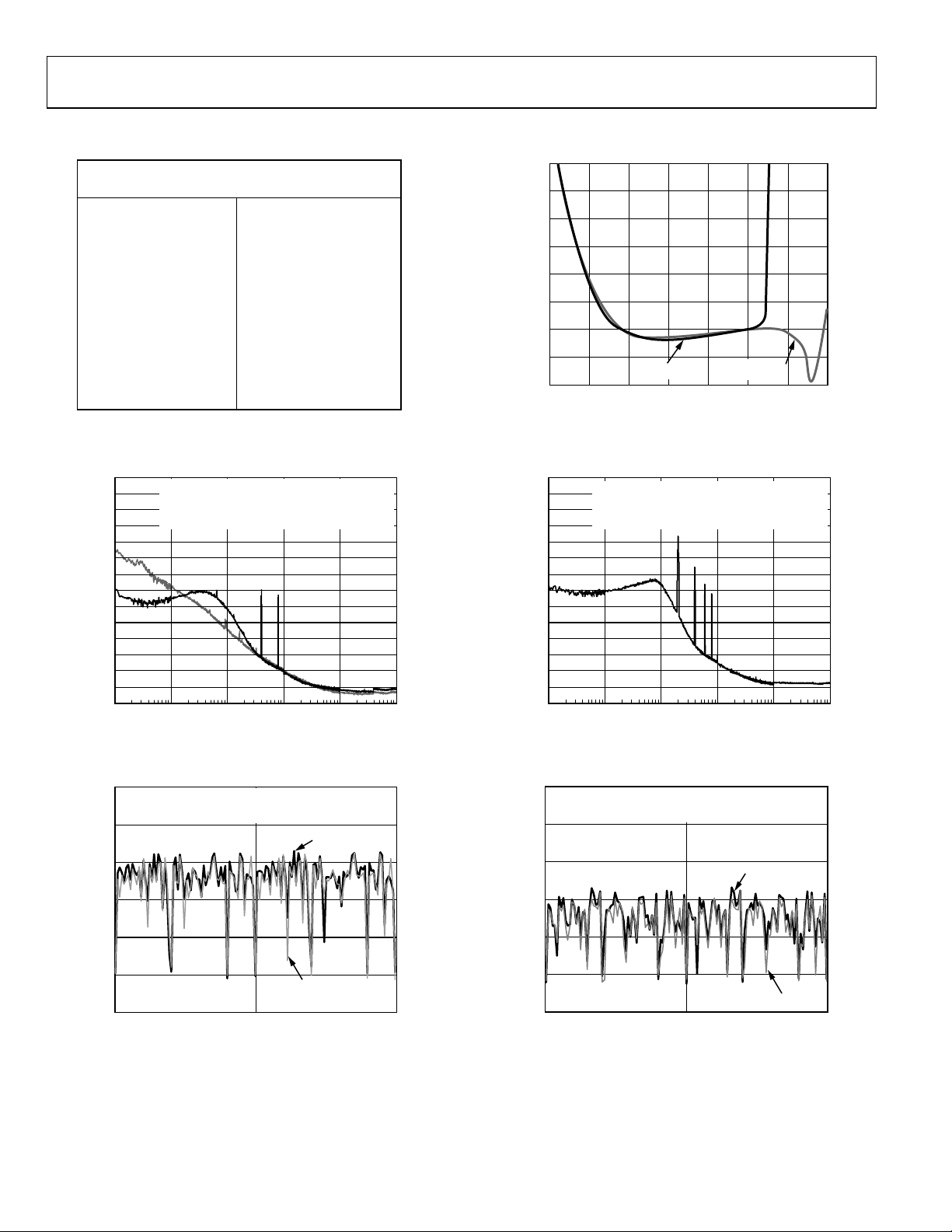

Figure 10. V

Settling Transient for a 75 MHz Jump from 1818 MHz to

TUNE

1893 MHz with Sirenza 1843T VCO

Figure 11. Phase Settling Transient for a 75 MHz Jump from 1818 MHz to

1893 MHz (V

= 1.8 V to 3.7 V with Sirenza 1843T VCO)

TUNE

Figure 13. V

Settling Transient for a 75 MHz Jump Down from 1893 MHz

TUNE

to 1818 MHz (Bottom of Allowed Tuning Range) with Sirenza 1843T VCO

Figure 14. Phase Settling Transient for a 75 MHz Jump Down from 1893 MHz

to 1818 MHz (V

= 3.7 V to 1.8 V with Sirenza 1843T VCO)

TUNE

Figure 12. Differential Charge Pump Output Compliance Range and

Charge Pump Mismatch with V

1 = VP2 = 5 V

P

Figure 15. Tuning Range with a Sirenza 1843T VCO and a 5.5 V Differential

Amplifier Power Supply Voltage

Rev. B | Page 9 of 28

ADF4196 Data Sheet

09450-042

FREQUENCY ( Hz )

NOISE (nV/ Hz)

1k 10k 100k 1M

1

10

100

1000

10M

7nV/ Hz @ 20kHz

09450-014

DRAIN VOLTAGE (V)

R

ON

(Ω)

0 1 2 3 4

0

100

70

90

80

60

50

40

30

20

10

5

+85°C

SW3

–40°C

+25°C

–40°C

+25°C

+85°C

SW1,

SW2

TUNING VOLTAGE RANGE

09450-044

PHASE CODE

PHASE DETECTOR OUTPUT (V)

0

0

1.8

1.5

1.2

0.9

0.6

0.3

13011710491786552392613

MEASURED USING AD8 3 02 PHAS E DETE CTOR

Y-AXIS SCALE: 10m V/DEGREE

RF = 1880MHz, PFD = 26MHz, MOD = 130

X-AXIS SCALE: 2. 7 7° /STEP

09450-045

INTERVAL BETWEEN R0 WRITES SHOULD BE A MULTIPLE OF MOD

REFERENCE CYCLES (5µs) FOR COHERENT PHASE MEASUREMENTS

SIGNAL

GENERATOR

OSCILLOSCOPE

ADF4193

EVAL BOARD

104MHz

5dBm

10MHz

EXT REF

1880MHz

1805MHz 1880MHz

RF

OUT

REF

IN

SIGNAL

GENERATOR

INPA

AD8302

EVB

VPHS

INPB

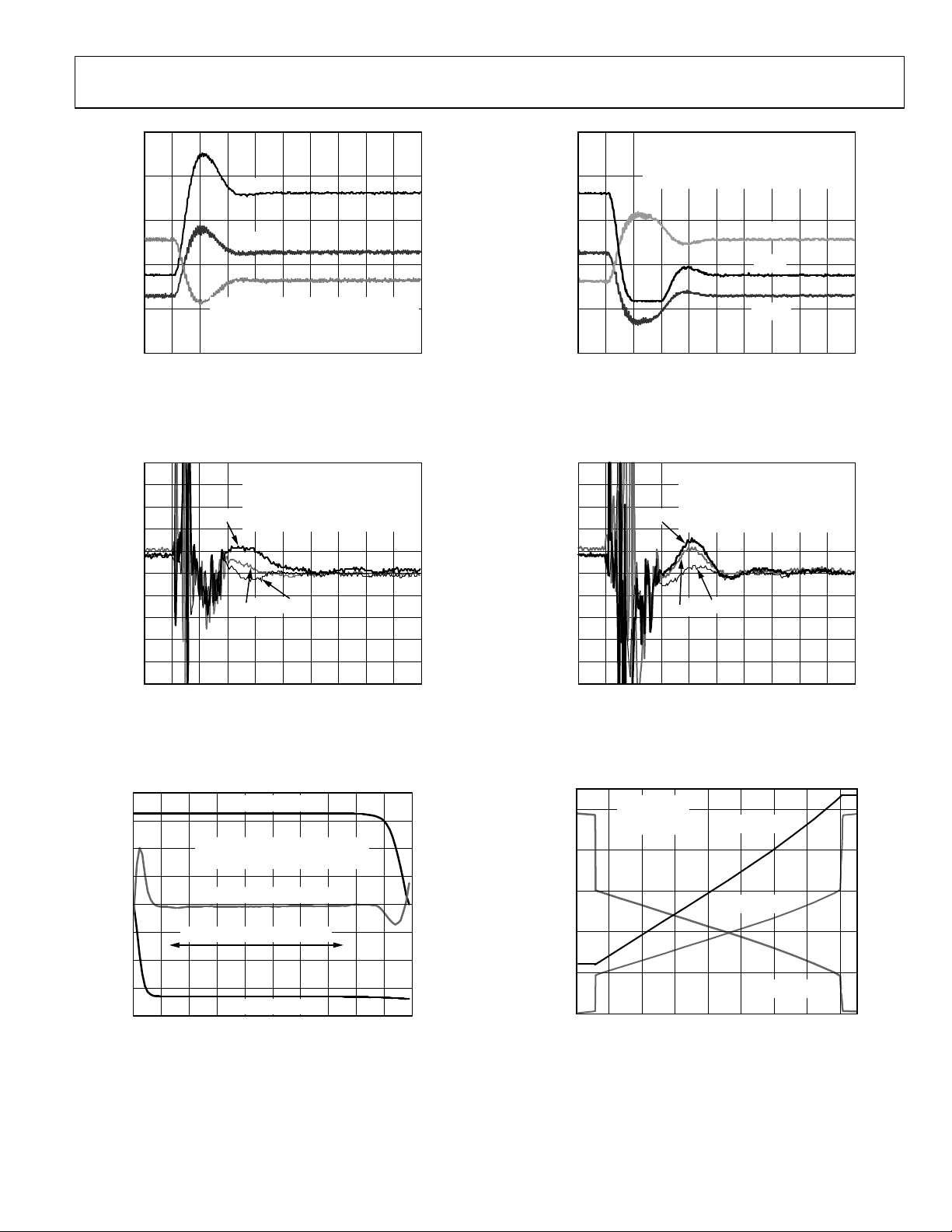

Figure 16. Voltage Noise Density Measured at the

Differential Amplifier Output

Figure 17. On Resistance of the SW1, SW2, and SW3 Loop Filter Switches

Figure 18. Detected RF Output Phase for Phase Code Sweep from 0 to MOD

Figure 19. Test Setup for Phase Lock Time Measurements

Rev. B | Page 10 of 28

Data Sheet ADF4196

09450-016

BUFFER

TO R COUNT E R

REF

IN

100kΩ

NC

SW2

SW3

NO

NC

SW1

POWER-DOWN

CONTROL

09450-017

BIAS

GENERATOR

1.6V

AGND

AV

DD

500Ω 500Ω

RF

IN–

RF

IN+

09450-018

THIRD-ORDER

FRACTIONAL

INTERPOLATOR

FRAC

VALUE

MOD

VALUE

INT

VALUE

RF N DIVIDE R N = INT + FRAC/ M OD

FROM RF

INPUT STAGE

TO PFD

N COUNTER

THEORY OF OPERATION

GENERAL DESCRIPTION

The ADF4196 is targeted at GSM base station requirements,

specifically to eliminate the need for ping-pong solutions.

It can also be used in pulse Doppler radar applications. The

ADF4196 works on the basis of fast lock, using a wide loop

bandwidth during a frequency change and narrowing the loop

bandwidth when frequency lock is achieved.

Widening the loop bandwidth is achieved by increasing the

charge pump current. To maintain stability with the changing

charge pump current, the ADF4196 includes switches that

change the loop filter component values.

The narrow loop bandwidth ensures that phase noise and spur

specifications are met. A differential charge pump and loop filter

topology ensure that the fast lock time benefit obtained from

widening the loop bandwidth is maintained when the loop is

restored to narrow bandwidth mode for normal operation.

REFERENCE INPUT

The reference input stage is shown in Figure 20. Switch SW1

and Switch SW2 are normally closed, and Switch SW3 is

normally open. During power-down, SW3 is closed, and SW1

and SW2 are opened to ensure that there is no loading of the

REF

pin. The falling edge of REFIN is the active edge at the

IN

positive edge triggered PFD.

RF INPUT STAGE

The RF input stage is shown in Figure 21. It is followed by a

two-stage limiting amplifier to generate the CML clock levels

needed for the prescaler. Two prescaler options are available:

4/5 and 8/9. Select the 8/9 prescaler for N divider values that

are greater than 80.

Figure 21. RF Input Stage

RF N Divider

The RF N divider allows a fractional division ratio in the PLL

feedback path. The integer and fractional parts of the division

are programmed using separate registers, as shown in Figure 22

and described in the INT, FRAC, and MOD Relationship section.

Integer division ratios from 26 to 511 are allowed, and a thirdorder Σ-Δ modulator interpolates the fractional value between

the integer steps.

Figure 20. Reference Input Stage

R Counter and Doubler

The 4-bit R counter allows the input reference frequency to

be divided down to produce the reference clock to the PFD.

A toggle flip-flop can be inserted after the R counter to provide

an additional divide-by-2. Using this option has the added

advantage of ensuring that the PFD reference clock has a 50/50

mark-to-space ratio. This ratio gives the maximum separation

between the fast lock timer clock, which is generated off the

falling edge of the PFD reference, and the rising edge, which is

the active edge in the PFD. It is recommended that this toggle

flip-flop be enabled for all even R divide values that are greater

than 2. The flip-flop must be enabled if dividing down a REF

frequency that is greater than 120 MHz.

An optional doubler before the 4-bit R counter can be used for

low REF

options, reference division ratios from 0.5 to 30 between REF

and the PFD are possible.

frequencies, up to 20 MHz. With these programmable

IN

IN

IN

Rev. B | Page 11 of 28

Figure 22. Fractional-N RF Divider

INT, FRAC, and MOD Relationship

The INT, FRAC, and MOD values, programmed through the

serial interface, make it possible to generate RF output frequencies

that are spaced by fractions of the PFD reference frequency.

The N divider value, shown inside the brackets of the following

equation for the RF VCO frequency (RF

), is composed of an

OUT

integer part (INT) and a fractional part (FRAC/MOD).

RF

= f

OUT

× [INT + (FRAC/MOD)] (1)

PFD

where:

is the output frequency of the external VCO.

RF

OUT

f

is the PFD reference frequency.

PFD

The value of MOD is chosen to give the desired channel step

with the available reference frequenc y. Then, program the INT

and FRAC words for the desired RF output frequency. See the

Worked Example section for more information.

ADF4196 Data Sheet

09450-019

CLR

QD

R DIVIDER

N DIVIDER

CHARGE

PUMP

ARRAY

[64:1]

CMFB

EN[64:1]

CLR

QD

CP

OUT+

CP

OUT–

09450-035

V

BIAS

P

P P

N N

UP DOWN

DOWN UP

V

BIAS

N

CP

OUT+

C

POUT–

09450-036

SW1/SW2

TIMEOUT

COUNTER

SW3

TIMEOUT

COUNTER

I

CP

TIMEOUT

COUNTER

EN[64:1]

÷4

START

f

PFD

SW3

A

OUT

SW2

SW

GND

SW1

WRITE

TO R0

CHARGE PUMP

ENABLE LOGIC

PFD AND CHARGE PUMP

The PFD takes inputs from the R divider and N divider and

produces up and down outputs with a pulse width difference

that is proportional to the phase difference between the inputs.

The charge pump outputs a net up or down current pulse of

a width that is equal to this difference, to pump up or pump down

the voltage that is integrated into the loop filter, which in turn

increases or decreases the VCO output frequency. If the N divider

phase lags the R divider phase, a net up-current pulse is produced

that increases the VCO frequency (and, thus, the phase). If the

N divider phase leads the R divider edge, a net down-current

pulse is produced to reduce the VCO frequency and phase.

Figure 23 is a simplified schematic of the PFD and charge pump.

The charge pump is made up of an array of 64 identical cells,

each of which is fully differential. All 64 cells are active during

fast lock, and only one cell is active during normal operation.

Because a single-ended control voltage is required to tune the VCO,

an on-chip differential-to-single-ended amplifier is provided for

this purpose. In addition, because the phase-locked loop controls

only the differential voltage generated across the charge pump

outputs, an internal common-mode feedback (CMFB) loop

biases the charge pump outputs at a common-mode voltage of

approximately 2 V.

Figure 23. PFD and Differential Charge Pump Simplified Schematic

DIFFERENTIAL CHARGE PUMP

The charge pump cell has a fully differential design for best upto-down current matching (see Figure 24). Good matching is

essential to minimize the phase offset created when switching

the charge pump current from its high value (in fast lock mode)

to its nominal value (in normal mode).

To pump up, the up switches are on, and the PMOS current sources

out through CP

loop filter capacitors that are connected to CP

NMOS current sink on CP

external loop filter capacitors that are connected to CP

Therefore, the differential voltage between CP

increases.

To pump down, PMOS current sources out through CP

NMOS current sinks in through CP

(CP

, CP

OUT+

OUT−

, which increases the voltage on the external

OUT+

) differential voltage. The charge pump up/down

OUT+

decreases the voltage on the

OUT−

OUT+

, which decreases the

OUT+

. Similarly, the

.

OUT−

and CP

OUT−

and

OUT−

Rev. B | Page 12 of 28

matching is improved by an order of magnitude over the

conventional single-ended charge pump that depends on the

matching of two different device types. The up/down matching

in this structure depends on how a PMOS matches a PMOS,

and how an NMOS matches an NMOS.

Figure 24. Differential Charge Pump Cell

with External Loop Filter Components

FAST LOCK TIMEOUT COUNTERS

Timeout counters, clocked at one-quarter of the PFD reference

frequency, are provided to precisely control the fast locking

operation (see Figure 25). When a new frequency is programmed,

the fast lock timers start and the PLL locks into wide bandwidth

mode with the 64 identical 100 µA charge pump cells active (for a

total of 6.4 mA).

When the I

reduced to 1× by deselecting cells in binary steps over the next

six timer clock cycles, until only one 100 µA cell is active. The

switching of the charge pump current, from 6.4 mA to 100 µA,

equates to an 8-to-1 change in loop bandwidth; when this happens,

the loop filter must be changed to ensure stability. The SW1,

SW2, and SW3 switches change the loop filter.

The applications circuit shown in Figure 37 shows how the

switches can be used to reconfigure the loop filter time constants.

They close to short out external loop filter resistors during fast lock

and open when their counters time out to restore the filter time

constants to their normal values for the 100 µA charge pump

current. Because it takes six timer clock cycles to reduce the

charge pump current to 1×, it is recommended that both switch

timers be pro-grammed to the value of the I

counter times out, the charge pump current is

CP

timer plus 7.

CP

Figure 25. Fast Lock Timeout Counters

Data Sheet ADF4196

09450-020

AIN–

A

OUT

AIN+

CMR

V

P

3

C EXT =

0.1µF

20kΩ

30kΩ

500Ω 500Ω

500Ω 500Ω

09450-021

R DIVIDER OUTPUT

N DIVIDER OUTPUT

SERIAL DATA OUTPUT

D

GND

DV

DD

CONTROLMUX

MUX

OUT

LOGIC LOW

THREE-STATE OUTPUT

TIMER OUTPUTS

DIGITAL LOCK DETECT

LOGIC HIGH

NOTE:

1. NOT ALL MUX

OUT

MODES THAT ARE S HOWN REFER TO THE

MUX REGISTER.

0 1 1

Function

R3

DIFFERENTIAL AMPLIFIER

The internal, low noise, differential-to-single-ended amplifier

converts the differential charge pump output to a single-ended

control voltage for the tuning port of the VCO. Figure 26 shows

a simplified schematic of the differential amplifier. The output

voltage is equal to the differential voltage, offset by the voltage

on the CMR pin, according to the following equation:

V

= (V

AOUT

The CMR offset voltage is internally biased to three-fifths of

V

3, the differential amplifier power supply voltage, as shown in

P

Figure 26. Connect a 0.1 µF capacitor to the ground plane from

the CMR pin to roll off the thermal noise of the biasing resistors.

As shown in Figure 15, the differential amplifier output voltage

behaves according to Equation 2 over a 4 V range from ~1.2 V

minimum up to V

is guaranteed over a tuning voltage range from 1.8 V up to

V

3 − 0.8 V only. This range allows sufficient room for overshoot

P

in the PLL frequency settling transient.

Noise from the differential amplifier is suppressed inside the

PLL loop bandwidth. For loop bandwidths of >20 kHz, the 1/f

noise has a negligible effect on the PLL output phase noise.

Outside the loop bandwidth, the FM noise of the differential

amplifier modulates the VCO. The passive filter network following

the differential amplifier (see Figure 37) suppresses this noise

contribution to below the VCO noise from offsets of 400 kHz

and greater. This network has a negligible effect on lock time

because it is bypassed when SW3 is closed while the loop is

locking.

− V

AIN+

Figure 26. Differential Amplifier Block Diagram

P

) + V

AIN−

3 − 0.3 V maximum. However, fast settling

(2)

CMR

Figure 27. MUX

OUT

Circuit

Lock Detect

MUX

can be programmed to provide a digital lock detect

OUT

signal. Digital lock detect is active high. Its output goes high if

there are 40 successive PFD cycles with an input error of <3 ns.

For reliable lock detect operation with RF frequencies of <2 GHz,

it is recommended that this threshold be increased to 10 ns by

programming Register R6. The digital lock detect goes low again

when a new channel is programmed or when the error at the

PFD input exceeds 30 ns for one or more cycles.

INPUT SHIFT REGISTER

The ADF4196 serial interface includes a 24-bit input shift register.

Data is clocked in, MSB first, on each rising edge of CLK. Data

from the shift register is latched into one of eight control registers,

R0 to R7, on the rising edge of load enable (LE) The destination

register is determined by the state of the three control bits: C3

(DB2), C2 (DB1), and C1 (DB0) in the shift register. DB2, DB1,

and DB0 are the three LSBs, as shown in the timing diagram

in Figure 2. The truth table for these bits is shown in Tabl e 6.

Figure 28 shows a summary of how the registers are programmed.

Table 6. C3, C2, and C1 Truth Table

Control Bits

C3 (DB2) C2 (DB1) C1 (DB0) Register Name Register

0 0 0 FRAC/INT R0

0 0 1 MOD/R R1

0 1 0 Phase R2

MUX

MUX

The output multiplexer on the ADF4196 allows the user to

access various internal points on the chip. The state of MUX

is controlled by Bits[M4:M1] in the mux register. Figure 35

shows the full truth table; see Figure 27 for a block diagram

of the MUX

AND LOCK DETECT

OUT

Control

OUT

circuit.

OUT

1 0 0 Charge pump R4

1 0 1 Power-down R5

1 1 0 Mux R6

OUT

1 1 1 Test mode R7

Rev. B | Page 13 of 28

ADF4196 Data Sheet

09450-022

DB23F5DB22

F4

DB210DB20

F2

DB19

F1

DB18R4DB17

R3

DB16R2DB15R1DB14

M12

DB13

M11

DB12

M10

DB11M9DB10M8DB9M7DB8

M6

DB7M5DB6

M4

DB5M3DB4

M2

DB3M1DB2

C3 (0)

DB1

C2 (0)

DB0

C1 (1)

DBB DBB DBB DBB DBB

4-BIT RF R

COUNTER

CP ADJ

REF/2

RESERVED

PRESCALER

DOUBLER

ENABLE

12-BIT MODULUS

CONTROL

BITS

MOD/R REGISTER (R1)

DB150DB14

P12

DB13

P11

DB12

P10

DB11P9DB10P8DB9P7DB8P6DB7P5DB6

P4

DB5P3DB4P2DB3P1DB2

C3 (0)

DB1

C2 (1)

DB0

C1 (0)

DBB

RESERVED

12-BIT PHASE

CONTROL

BITS

PHASE REGISTER (R2)

DB150DB140DB13

0

DB120DB110DB100DB90DB8

0

DB70DB61DB5

F3

DB41DB3F1DB2

C3 (0)

DB1

C2 (1)

DB0

C1 (1)

PFD

POLARITY

RESERVED

CPO GND

RESERVED

CONTROL

BITS

FUNCTION REGISTER (R3)

DB15

M13

DB14

M12

DB13

M11

DB12

M10

DB110DB100DB90DB80DB71DB6

M4

DB5M3DB4M2DB3M1DB2

C3 (1)

DB1

C2 (1)

DB0

C1 (0)

RESERVED MUX

OUT

CONTROL

BITS

SIGMA-DELTA

AND

LOCK DETECT MODES

MUX REGISTER (R6)

DB150DB140DB130DB120DB110DB100DB90DB80DB70DB60DB50DB40DB30DB2

C3 (1)

DB1

C2 (1)

DB0

C1 (1)

RESERVED

CONTROL

BITS

TEST MO DE REGISTER (R7)

DB7F5DB6F4DB5F3DB4F2DB3

F1

DB2

C3 (1)

DB1

C2 (0)

DB0

C1 (1)

COUNTER

RESET

CP

3-STATE

PD

CHARGE

PUMP

PD

DIFF AMP

CONTROL

BITS

POWER-DOWN REGISTER (R5)

DB230DB220DB21

0

DB20

0

DB190DB180DB17

0

DB160DB150DB141DB13

C9

DB12C8DB11

C7

DB10C6DB9

C5

DB8C4DB7C3DB6C2DB5

C1

DB4F2DB3

F1

DB2

C3 (1)

DB1

C2 (0)

DB0

C1 (0)

9-BIT TIMEOUT COUNTERRESERVED

CONTROL

BITS

TIMER

SELECT

CHARGE PUMP REGISTER (R4)

DBB = DOUBLE BUFFERED BIT( S )

DB23N9DB22

N8

DB21N7DB20

N6

DB19N5DB18N4DB17N3DB16

N2

DB15N1DB14

F12

DB13

F11

DB12

F10

DB11F9DB10

F8

DB9F7DB8F6DB7

F5

DB6F4DB5

F3

DB4

F2

DB3F1DB2

C3 (0)

DB1

C2 (0)

DB0

C1 (0)

9-BIT RF I NT VALUE

12-BIT RF F RAC V ALUE

CONTROL

BITS

FRAC/INT REGISTER (R0)

REGISTER MAP

Figure 28. Bit Maps for Register R0 to Register R7

Rev. B | Page 14 of 28

Data Sheet ADF4196

09450-023

DB23N9DB22N8DB21N7DB20N6DB19N5DB18N4DB17N3DB16N2DB15N1DB14

F12

DB13

F11

DB12

F10

DB11F9DB10F8DB9F7DB8F6DB7F5DB6F4DB5F3DB4F2DB3F1DB2

C3 (0)

DB1

C2 (0)

DB0

C1 (0)

9-BIT RF INT VALUE 12-BIT RF FRAC VALUE

CONTROL

BITS

F12

0

0

0

0

.

.

.

1

1

1

1

F11

0

0

0

0

.

.

.

1

1

1

1

F10

0

0

0

0

.

.

.

1

1

1

1

..........

..........

..........

..........

..........

..........

..........

..........

..........

..........

..........

F3

0

0

0

0

.

.

.

1

1

1

1

F2

0

0

1

1

.

.

.

0

0

1

1

F1

0

1

0

1

.

.

.

0

1

0

1

FRACTIO NAL VALUE (FRAC)

0

1

2

3

.

.

.

4092

4093

4094

4095

N8

0

.

.

.

1

N7

0

.

.

.

1

N9

0

.

.

.

1

N6

0

.

.

.

1

N5

1

.

.

.

1

N4

1

.

.

.

1

N3

0

.

.

.

1

N2

1

.

.

.

1

N1

0

.

.

.

1

INTEGER VALUE (INT)

26

.

.

.

511

0 ≤ FRAC < MOD

FRAC/INT REGISTER (R0) LATCH MAP

R0, the FRAC/INT register, is used to program the synthesizer

output frequency. On the PFD cycle following a write to R0,

the N divider section is updated with the new INT and FRAC

values, and the PLL automatically enters fast lock mode. The

charge pump current is increased to its maximum value and

remains at this value until the I

timeout counter times out;

CP

and the SW1, SW2, and SW3 switches close and remain closed

until the SW1/SW2 and SW3 timeout counters time out.

After all the registers are programmed during the initialization

sequence (see Tab l e 9), a new channel can be programmed

by performing a write to R0. However, as described in the

Programming the ADF4196 section, it may also be desirable

to program the R1 and R2 register settings on a channel-bychannel basis. These settings are double buffered by the write to

Register R0. This means that, although the data is loaded through

the serial interface on the respective R1 and R2 write cycles, the

synthesizer is not updated with their data until the next write to

Register R0.

Figure 29. Bit Map for Register R0

Control Bits

To select R0, the FRAC/INT register, the three LSBs (C3, C2,

and C1) should be set to 0, 0, 0.

9-Bit RF INT Value

Bits[DB23:DB15] set the INT value, which determines the

integer part of the feedback division factor. All integer values

from 26 to 511 are allowed (see the Worked Example section).

12-Bit RF FRAC Value

Bits[DB14:DB3] set the numerator of the fraction that is input

to the Σ-Δ modulator. This fraction, along with INT, specifies

the new frequency channel that the synthesizer locks to, as shown

in the Worked Example section. FRAC values from 0 to MOD − 1

cover channels over a frequency range that is equal to the PFD

reference frequency.

Rev. B | Page 15 of 28

ADF4196 Data Sheet

09450-024

DB23F5DB22F4DB210DB20F2DB19F1DB18R4DB17

R3

DB16R2DB15R1DB14

M12

DB13

M11

DB12

M10

DB11M9DB10M8DB9M7DB8M6DB7M5DB6M4DB5M3DB4M2DB3M1DB2

C3 (0)

DB1

C2 (0)

DB0

C1 (1)

4-BIT RF

R COUNTER

CP

ADJ

REF/2

RESERVED

PRESCALER

DOUBLER

ENABLE

12-BIT MO DULUS

CONTROL

BITS

01NOMINAL

ADJUSTED

CP ADJF5

01DISABLED

ENABLED

REF/2F4

0

1

F2

4/5

8/9

PRESCALER

0

1

F1

DOUBLER DIS ABLED

DOUBLER ENABL E D

DOUBLER ENABL E

M12

0

0

0

.

.

.

1

1

1

1

M11

0

0

0

.

.

.

1

1

1

1

M10

0

0

0

.

.

.

1

1

1

1

..........

..........

..........

..........

..........

..........

..........

..........

..........

..........

M3

1

1

1

.

.

.

1

1

1

1

M2

0

1

1

.

.

.

0

0

1

1

M1

1

0

1

.

.

.

0

1

0

1

INTERPO LATOR MODULUS VALUE (M OD)

13

14

15

.

.

.

4092

4093

4094

4095

R4

0

0

0

0

.

.

.

1

1

1

1

R3

0

0

0

1

.

.

.

1

1

1

1

R2

0

1

1

0

.

.

.

0

0

1

1

R1

1

0

1

0

.

.

.

0

1

0

1

RF R COUNTER DIVIDE RATI O

1

2

3

4

.

.

.

12

13

14

15

MOD/R REGISTER (R1) LATCH MAP

R1, the MOD/R register, sets the PFD reference frequency and

the channel step size, which is determined by the PFD frequency

divided by the fractional modulus. Note that the 12-bit modulus,

the 4-bit RF R counter, the doubler enable bits, REF/2, and

CP ADJ are double buffered. They do not take effect until the

next write to R0 (the FRAC/INT register) is complete.

Control Bits

Register R1 is selected with C3, C2, and C1 set to 0, 0, 1.

CP ADJ

When the CP ADJ bit is set to 1, the charge pump current is

scaled up 25% from its nominal value on the next write to R0.

When this bit is set to 0, the charge pump current remains at its

nominal value on the next write to R0. See the Programming

the ADF4196 section for more information on how this feature

can be used.

REF/2

Setting the REF/2 bit to 1 inserts a divide-by-2 toggle flip-flop

between the R counter and the PFD, which extends the maximum

REF

input rate.

IN

Reserved Bit

The reserved bit, DB21, must be set to 0.

Figure 30. Bit Map for Register R1

Prescaler (P/P + 1)

The dual-modulus prescaler (P/P + 1), along with INT, FRAC,

and MOD, determine the overall division ratio from RF

to the

IN

PFD input. Operating at CML levels, it takes the clock from the

RF input stage and divides it down for the counters. It is based on

a synchronous 4/5 core. When set to 4/5, the maximum RF

frequency allowed is 3 GHz. Therefore, when operating the

ADF4196 above 3 GHz, the prescaler must be set to 8/9. The

prescaler limits the INT value. If P = 4/5, then N

If P = 8/9, N

MIN

= 80.

Doubler Enable

MIN

= 26.

Setting the doubler enabler bit to 1 inserts a frequency doubler

between REF

and the 4-bit RF R counter. Setting this bit to 0

IN

bypasses the doubler.

4-Bit RF R Counter

The 4-bit RF R counter allows the REFIN frequency to be divided

down to produce the reference clock to the PFD. All integer

values from 1 to 15 are allowed (see the Worked Example section).

12-Bit Modulus

For a given PFD reference frequenc y, the fractional denominator

or modulus sets the channel step resolution at the RF output. All

Rev. B | Page 16 of 28

integer values from 13 to 4095 are allowed. See the Programming

the ADF4196 section for a Worked Example and guidelines for

selecting the value of MOD.

Data Sheet ADF4196

09450-025

DB15

0

DB14

P12

DB13

P11

DB12

P10

DB11

P9

DB10

P8

DB9

P7

DB8

P6

DB7

P5

DB6

P4

DB5

P3

DB4

P2

DB3

P1

DB2

C3 (0)

DB1

C2 (1)

DB0

C1 (0)

RESERVED

12-BIT PHASE

CONTROL

BITS

P12

0

0

0

.

.

.

1

1

1

1

P11

0

0

0

.

.

.

1

1

1

1

P10

0

0

0

.

.

.

1

1

1

1

..........

..........

..........

..........

..........

..........

..........

..........

..........

..........

P3

0

0

0

.

.

.

1

1

1

1

P2

0

0

1

.

.

.

0

0

1

1

P1

0

1

0

.

.

.

0

1

0

1

PHASE VALUE

1

0

1

2

.

.

.

4092

4093

4094

4095

1

0 ≤ PHASE VALUE < MOD

PHASE REGISTER (R2) BIT LATCH MAP

Figure 31. Bit Map for Register R2

R2, the phase register, is used to program the phase of the VCO

output signal.

Control Bits

Register R2 is selected with C3, C2, and C1 set to 0, 1, 0.

12-Bit Phase

The 12-bit phase word sets the seed value of the Σ-Δ modulator.

It can be programmed to any integer value from 0 to MOD, where

MOD is the modulus value that is programmed in Register R1,

Bits[DB14:DB3]. As the phase word is swept from 0 to MOD,

the phase of the VCO output sweeps over a 360° range in steps

of 360°/MOD.

Note that the phase bits are double buffered; they do not take

effect until the load enable of the next write to R0 (the FRAC/INT

register). Thus, to change the phase of the VCO output frequency,

it is necessary to rewrite the INT and FRAC values to Register R0

following the write to Register R2.

The output of a fractional-N PLL can settle to any one of the

MOD possible phase offsets with respect to the reference, where

MOD is the fractional modulus.

To keep the output at the same phase offset with respect to the

reference, each time that particular output frequency is programmed, the interval between writes to Register R0 must be an

integer multiple of MOD reference cycles.

To keep the outputs of two ADF4196-based synthesizers phase

coherent with each other (but not necessarily with the reference

they have in common), the write to Register R0 on both chips

must be performed during the same reference cycle. In this

case, the interval between the R0 writes does not need to be

an integer multiple of MOD cycles.

Reserved Bit

Set the reserved bit, DB15, to 0.

Rev. B | Page 17 of 28

ADF4196 Data Sheet

09450-026

DB150DB140DB13

0

DB12

0

DB110DB10

0

DB90DB80DB70DB6

1

DB5F3DB4

1

DB3F1DB2

C3 (0)

DB1

C2 (1)

DB0

C1 (1)

PFD

POLARITY

RESERVED

CPO GND

RESERVED

CONTROL

BITS

0

1

F1

NEGATIVE

POSITIVE

PFD POLARITY

0

1

F3

CPO/CPO GND

NORMAL

CPO GND

FUNCTION REGISTER (R3) LATCH MAP

Figure 32. Bit Map for Register R3

R3, the function register, needs to be programmed only during

the initialization sequence (see Tab l e 9).

Control Bits

Register R3 is selected with C3, C2, and C1 set to 0, 1, 1.

CPO GND

When the CPO GND bit is low, the charge pump outputs are

internally pulled to ground. This is invoked during the initialization sequence to discharge the loop filter capacitors. For

normal operation, this bit should be set to 1.

PFD Polarity

Set the PFD polarity bit to 1 for positive polarity, and set it to 0

for negative polarity.

Reserved Bits

Program the DB15 to DB6 reserved bits to a hexadecimal code of

0x001, and set the DB4 reserved bit to 1.

Rev. B | Page 18 of 28

09450-027

DB23

0

DB220DB210DB20

0

DB190DB180DB170DB160DB150DB141DB13C9DB12C8DB11C7DB10C6DB9C5DB8C4DB7C3DB6C2DB5C1DB4

F2

DB3F1DB2

C3 (1)

DB1

C2 (0)

DB0

C1 (0)

9-BIT TIMEOUT COUNTERRESERVED

CONTROL

BITS

TIMER

SELECT

0

0

1

1

F2

0

1

0

1

F1

SW1/SW2

SW3

I

CP

NOT USED

TIMER SELECT

C9

0

0

0

0

.

.

.

1

1

1

1

C8

0

0

0

0

.

.

.

1

1

1

1

C7

0

0

0

0

.

.

.

1

1

1

1

..........

..........

..........

..........

..........

..........

..........

..........

..........

..........

..........

C3

0

0

0

0

.

.

.

1

1

1

1

C2

0

0

1

1

.

.

.

0

0

1

1

C1

0

1

0

1

.

.

.

0

1

0

1

TIMEOUT COUNTER

0

1

2

3

.

.

.

508

509

510

511

xPFD CYCLES

0

4

8

12

.

.

.

2032

2036

2040

2044

DELAY µs

1

0

0.15

0.30

0.46

.

.

.

78.15

78.30

78.46

78.61

1

DELAY WITH 26MHz PFD

Data Sheet ADF4196

CHARGE PUMP REGISTER (R4) LATCH MAP

Figure 33. Bit Map for Register R4

R4, the charge pump register, is used for programming the timers

for loop filter switches. These switches help maintain the stability

of the loop filter after boosting the charge pump current.

Control Bits

Register R4 is selected with C3, C2, and C1 (Bits[DB2:DB0]) set

to 1, 0, 0.

Reserved Bits

For normal operation, set the DB23 to DB14 reserved bits to

a hexadecimal code of 0x001.

9-Bit Timeout Counter

These bits are used to program the fast lock timeout counters.

The counters are clocked at one-quarter the PFD reference

frequency; therefore, their time delay scales with the PFD

frequency according to the following equation:

Delay(s) = (Timeout Counter Value × 4)/(PFD Frequency)

For example, if 35 is loaded with timer select = 00, with

a 13 MHz PFD, SW1 and SW2 switch after the following:

(35 × 4)/13 MHz = 10.8 µs

Timer Select

The two timer select bits select the timeout counter that is to

be programmed. Note that setting up the ADF4196 for correct

operation requires setup of these three timeout counters: I

,

CP

SW1/SW2, and SW3. Therefore, three writes to this register

are required in the initialization sequence. Ta b le 7 shows

example values for a GSM Tx synthesizer with a 60 kHz final

loop bandwidth. See the Applications Information section for

more information.

Table 7. Recommended Values for a GSM Tx LO

Timer

Select

Timeout

Counter

Value

Time (µs) with

PFD = 13 MHz

10 ICP 28 8.6

01 SW3 35 10.8

00 SW1/SW2 35 10.8

On each write to R0, the timeout counters start. Switch SW3 closes

until the SW3 counter times out. Similarly, the SW1 and SW2

switches close until the SW1/SW2 counter times out. When the

I

counter times out, the charge pump current is ramped down

CP

from 64× to 1× in six binary steps. It is recommended that the

SW1/SW2 and SW3 timeout counter values be set equal to the

I

timeout counter value plus 7, as in the example shown in

CP

Tabl e 7.

Rev. B | Page 19 of 28

ADF4196 Data Sheet

09450-028

DB7F5DB6

F4

DB5

F3

DB4

F2

DB3

F1

DB2

C3 (1)

DB1

C2 (0)

DB0

C1 (1)

COUNTER

RESET

CP

3-STATE

PD

CHARGE

PUMP

CONTROL

BITS

PD

DIFF AMP

0

1

F4

0

1

F5

DISABLED

ENABLED

DIFF AMP

POWER-DOWN

0

1

F2

NORMAL OPERATION

3-STATE E NABLED

CHARGE PUMP

3-STATE

0

1

F1

NORMAL OPERATION

COUNTER RES E T

COUNTER RES E T

0

1

F3

DISABLED

ENABLED

CHARGE PUMP

POWER-DOWN

POWER-DOWN REGISTER (R5) BIT MAP

R5, the power-down register, can be used to power down the PLL

and differential amplifier sections. After power is initially applied,

Register R5 must be programmed to clear the power-down bits.

Then, before the ADF4196 comes out of power-down, the R2,

R1, and R0 registers must be programmed.

Control Bits

Register R5 is selected with C3, C2, and C1 set to 1, 0, 1.

Power-Down Differential Amplifier

When the DB7 and DB6 bits are set to 1, the differential

amplifier is put into power-down. When DB7 and DB6 are set

to 0, normal operation resumes.

Power-Down Charge Pump

Setting Bit DB5 to 1 activates a charge pump power-down, and

the following events occur:

• All active dc current paths are removed, except for the

differential amplifier.

• The R and N divider counters are forced to their load state

conditions.

Figure 34. Bit Map for Register R5

• The charge pump is powered down with its outputs in

three-state mode.

• The digital lock detect circuitry is reset.

• The RF

• The reference input buffer circuitry is disabled.

• The serial interface remains active and capable of loading

and latching data.

For normal operation, set Bit DB5 to 0, followed by a write to R0.

CP Three-State

When the CP three-state bit is set to 1, the charge pump outputs

enter three-state. Setting the CP three-state bit to 0 enables the

charge pump outputs.

Counter Reset

When the counter reset bit is set to 1, the counters are held in reset.

For normal operation, set this bit to 0, followed by a write to R0.

input is debiased.

IN

Rev. B | Page 20 of 28

Data Sheet ADF4196

09450-029

DB15

M13

DB14

M12

DB13

M11

DB12

M10

DB11

0

DB10

0

DB9

0

DB8

0

DB7

1

DB6

M4

DB5

M3

DB4

M2

DB3

M1

DB2

C3 (1)

DB1

C2 (1)

DB0

C1 (0)

RESERVED MUX

OUT

CONTROL

BITS

SIGMA-DELTA

AND

LOCK DETE CT MODES

0

1

1

M10

0

1

0

M11

0

0

0

ALL OTHER STATES

M12

0

0

1

M13

INIT STATE, DITHER OFF,

3ns LOCK DETECT THRESHOLD

DITHER ON

10ns LOCK DETECT THRESHOLD

RESERVED

SIGMA-DELTA MODES

0

0

0

0

0

0

0

0

1

1

1

1

1

1

1

1

M4

0

0

0

0

1

1

1

1

0

0

0

0

1

1

1

1

M3

0

0

1

1

0

0

1

1

0

0

1

1

0

0

1

1

M2

0

1

0

1

0

1

0

1

0

1

0

1

0

1

0

1

M1

3-STATE

DIGITAL LOCK DETECT

N DIVIDER O UTPUT

LOGIC HIGH

R DIVIDER O UTPUT

RESERVED

SERIAL DAT A OUTPUT

LOGIC LOW

R DIVIDER/ 2 OUTPUT

N DIVIDER/ 2 OUTPUT

RESERVED

RESERVED

I

CP

TIMEOUT SIGNAL

SW1/SW2 TIMEOUT SIGNAL

SW3 TIMEOUT SIGNAL

RESERVED

MUX

OUT

MUX REGISTER (R6) LATCH MAP AND TRUTH TABLE

R6, the mux register, is used to program MUX

Σ-Δ and lock detect modes.

Control Bits

Register R6 is selected with C3, C2, and C1 set to 1, 1, 0.

Σ-Δ and Lock Detect Modes

Bit DB15 to Bit DB12 are used to reconfigure certain PLL

operating modes. In the initialization sequence after power is

applied to the chip, the four bits must first be programmed to

all zeros. This initializes the PLL to a known state with dither

off in the Σ-Δ modulator and a 3 ns PFD error threshold in the

lock detect circuit.

To turn on dither in the Σ-Δ modulator, an additional write should

be made to Register R6 to program Bits[DB15:DB12] = 0011.

However, for lowest noise operation, it is best to leave dither off.

To change the lock detect threshold from 3 ns to 10 ns, perform

a separate write to R6 to program Bits[DB15:DB12] = 1001.

This separate write is needed for reliable lock detect operation

when the RF frequency is <2 GHz.

A write to R6 that programs Bits[DB15:DB12] = 0000 returns

operation to the default state with both dither off and a 3 ns

lock detect threshold.

Figure 35. Bit Map and MUX

, as well as

OUT

Truth Table for Register R6

OUT

Reserved Bits

For normal operation, the reserved bits (Bits[DB11:DB7]) must

be set to 00001.

MUX

Modes

OUT

These bits control the on-chip multiplexer, Pin 16 (see Figure 35

for the truth table). This pin is useful for diagnosis because it

allows the user to look at various internal points of the chip,

such as the R divider and the INT divider outputs.

In addition, it is possible to monitor the programmed timeout

counter intervals on MUX

. For example, if the ICP timeout

OUT

counter is programmed to 65 (with a 26 MHz PFD), then

following the next write to R0, a pulse width of 10 µs is

observed on the MUX

Digital lock detect is available via the MUX

OUT

pin.

OUT

pin.

Rev. B | Page 21 of 28

ADF4196 Data Sheet

PROGRAMMING THE ADF4196

The ADF4196 can synthesize output frequencies with a channel

step or resolution that is a fraction of the input reference frequency. For a given input reference frequency and a desired

output frequency step, the first choice to make is the PFD

reference frequency and the MOD value. After these are chosen,

the desired output frequency channels are set by programming

the INT and FRAC values.

WORKED EXAMPLE

In this example of a GSM900 Rx system, the RF output frequencies

must be generated with channel steps of 200 kHz. A reference

frequency input (REF

) of 104 MHz is available. The R divider

IN

setting that determines the PFD reference is shown in Equation 3.

f

= REFIN × [(1 + D)/(R × (1 + T))] (3)

PFD

where:

is the input reference frequency.

REF

IN

D is the doubler enable bit (0 or 1).

R is the 4-bit R counter code (1 to 15).

T is the REF/2 bit (0 or 1).

The maximum PFD reference frequency of 26 MHz is chosen,

and the following settings are programmed to give an R divider

value of 4:

• Doubler enable = 0

• R = 2

• REF/2 = 1

Next, the modulus is chosen to allow fractional steps of 200 kHz:

MOD = 26 MHz/200 kHz = 130 (4)

When the channel step is defined, Equation 5 shows how output

frequency channels are programmed.

RF

= [INT + (FRAC/MOD)] × f

OUT

(5)

PFD

where:

RF

is the desired RF output frequency.

OUT

INT is the integer part of the division.

FRAC is the numerator part of the fractional division.

MOD is the modulus or denominator part of the fractional

division.

Thus, the frequency channel at 962.4 MHz is synthesized by

programming the following values: INT = 37 and FRAC = 2.

SPUR MECHANISMS

The following sections describe the three different spur

mechanisms that arise with a fractional-N synthesizer and how

the ADF4196 can best be programmed to minimize them.

Fractional Spurs

The fractional interpolator in the ADF4196 is a third-order, Σ-Δ

modulator (SDM) with a modulus MOD that is programmable

to any integer value from 13 to 4095. If dither is enabled, the

minimum allowed value of MOD is 50. The SDM is clocked at

the PFD reference rate (f

to be synthesized at a channel step resolution of f

), which allows PLL output frequencies

PFD

/MOD.

PFD

With dither turned off, the quantization noise from the Σ-Δ

modulator appears as fractional spurs. The interval between spurs

is f

/L, where L is the repeat length of the code sequence in

PFD

the digital Σ-Δ modulator. For the third-order modulator used

in the ADF4196, the repeat length depends on the value of

MOD, as shown in

Tabl e 8.

Table 8. Fractional Spurs with Dither Off

Repeat

Condition (Dither Off)

MOD Is Divisible by 2 but Not by 3 2 × MOD Channel step/2

MOD Is Divisible by 3 but Not by 2 3 × MOD Channel step/3

MOD Is Divisible by 6 6 × MOD Channel step/6

All Other Divisors MOD Channel step

Length Spur Interval

With dither enabled, the repeat length is extended to 221 cycles,

regardless of the value of MOD, which makes the quantization

error spectrum look like broadband noise. This can degrade the

in-band phase noise at the PLL output by as much as 10 dB.

Therefore, for lowest noise, dither off is a better choice, particularly

when the final loop bandwidth is low enough to attenuate even

the lowest frequency fractional spur. The wide loop bandwidth

range that is available with the ADF4196 allows the use of dither

in most applications.

Integer Boundary Spurs

Another mechanism for fractional spur creation involves

interactions between the RF VCO frequency and the reference

frequency. When these frequencies are not integer related

(which is the purpose of a fractional-N synthesizer), spur

sidebands appear on the VCO output spectrum at an offset

frequency that corresponds to the beat note or difference

frequency between an integer multiple of the reference and

the VCO frequency.

These spurs are attenuated by the loop filter and are more

noticeable on channels that are close to integer multiples of the

reference, where the difference frequency can be inside the loop

bandwidth (thus, the name integer boundary spurs).

The 8:1 loop bandwidth switching ratio of the ADF4196 makes

it possible to attenuate all spurs to sufficiently low levels for most

applications. The final loop bandwidth can be chosen to ensure

that all spurs are far enough out of band and meet the lock time

requirements with the 8× bandwidth boost.

The programmable modulus and R divider of the ADF4196 can

also be used to avoid integer boundary channels. This option is

described in the Avoiding Integer Boundary Channels section.

Rev. B | Page 22 of 28

Data Sheet ADF4196

Reference Spurs

Reference spurs are generally not a problem in fractional-N

synthesizers because the reference offset is far outside the loop

bandwidth. However, any reference feedthrough mechanism

that bypasses the loop can cause a problem. One such mechanism

is feedthrough of low levels of on-chip reference switching noise

out of the RF

pins back to the VCO, resulting in reference

IN±

spur levels as high as −90 dBc. These spurs can be suppressed

below −110 dBc by inserting sufficient reverse isolation, for

example, through an RF buffer between the VCO and RF

IN±

pins.

Also, take care in the printed circuit board (PCB) layout to ensure

that the VCO is well separated from the input reference to avoid

a possible feedthrough path on the board.

POWER-UP INITIALIZATION

After applying power to the ADF4196 for the first time, a 14-2530

sequence is recommended, as described in Table 9.

The divider and timer settings used in the example in Table 9 are

for a DCS1800 Tx synthesizer with a 104 MHz REF