18-Channel Gamma Buffer

FEATURES

18 precision gamma reference outputs

Mask-programmable gamma resistors:

0.2% resolution and 0.1% accuracy

Mask-programmable voltage regulator: 0.4% accuracy

Upper 9 buffers swing to V

Lower 9 buffers swing to GND

Single-supply operation: 7.5 V to 16.5 V

Gamma current drive: 15 mA per channel

Peak output current: 150 mA

Output voltage stable under load conditions

Pin-to-pin compatible with ADD8709

48-lead, Pb-free LQFP and LFCSP

APPLICATIONS

LCD TV panels

LCD monitor panels

GENERAL DESCRIPTION

The ADD8708 is an 18-channel integrated gamma reference for

use in high resolution LCD TV and monitors panels. The output buffers feature high current drive and low offset voltage to

provide an accurate and stable gamma curve. The top nine

channels swing to V

Integrating the gamma setup resistors drastically reduces the

external component count while increasing the gamma curve

accuracy. To accommodate multiple column drivers and panel

architectures, the ADD8708 is mask programmable to a 0.2%

resolution using the on-chip 500 resistor string. An on-board

voltage regulator provides a fixed input for the resistor string,

isolating the gamma curve from the supply ripple.

The ADD8708 is specified over the temperature range of

–40°C to +105°C and comes in both a 48-lead, Pb-free,

lead-frame chip-scale package and a Pb-free, low-profile,

quad flat package.

DD

; the lower nine channels swing to GND.

DD

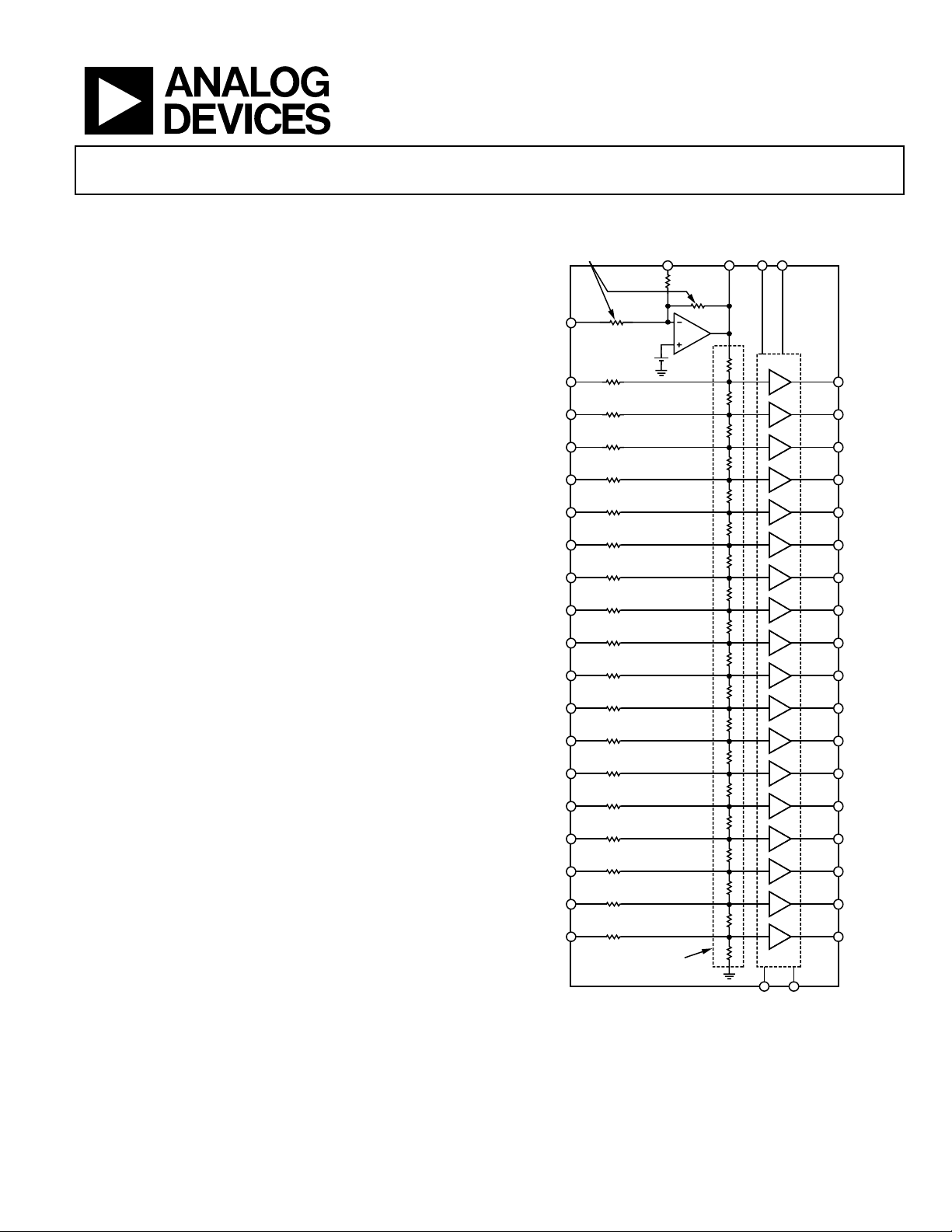

FUNCTIONAL BLOCK DIAGRAM

MASK-PROGRAMMABLE

REGULATOR RESISTORS

GND

1.2V

18

V

IN

V

17

IN

V

16

IN

V

15

IN

V

14

IN

V

13

IN

V

12

IN

V

11

IN

V

10

IN

V

IN

V

IN

V

IN

V

IN

V

IN

V

IN

V

IN

V

IN

V

IN

700Ω*

700Ω*

700Ω*

700Ω*

700Ω*

700Ω*

700Ω*

700Ω*

700Ω*

700Ω*

9

700Ω*

8

700Ω*

7

700Ω*

6

700Ω*

5

700Ω*

4

700Ω*

3

700Ω*

2

700Ω*

1

MASK-PROGRAMMABLE

RESISTOR STRING

*ESD PROTECTION RESISTORS

Figure 1. 48-Lead LQFP or LFCSP

FB V

700Ω*

+

–

with Regulator

ADD8708

VDDV

REG OUT

DD

GAMMA

BUFFERS

GND GND

V

18

OUT

V

17

OUT

V

16

OUT

V

15

OUT

V

14

OUT

V

13

OUT

V

12

OUT

V

11

OUT

V

10

OUT

V

9

OUT

V

8

OUT

V

7

OUT

V

6

OUT

V

5

OUT

V

4

OUT

V

3

OUT

V

2

OUT

V

1

OUT

04614-001

Rev. 0

Information furnished by Analog Devices is believed to be accurate and reliable.

However, no responsibility is assumed by Analog Devices for its use, nor for any

infringements of patents or other rights of third parties that may result from its use.

Specifications subject to change without notice. No license is granted by implication

or otherwise under any patent or patent rights of Analog Devices. Trademarks and

registered trademarks are the property of their respective owners.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700

Fax: 781.326.8703 © 2004 Analog Devices, Inc. All rights reserved.

www.analog.com

ADD8708

TABLE OF CONTENTS

Electrical Characteristics................................................................. 3

Absolute Maximum Ratings............................................................ 4

ESD Caution.................................................................................. 4

Pin Configuration and Function Descriptions............................. 5

Typical Performance Characteristics ............................................. 7

Application Notes ........................................................................... 10

Tap Point Selection..................................................................... 10

Volt a ge R e gu l ator ....................................................................... 11

Maximum Power Dissipation ...................................................11

Land Pattern................................................................................ 11

Operating Temperature Range ................................................. 12

Typical Applications Ci r c u it ..........................................................14

Tap Point and Regulator Voltage Request Form......................... 15

Outline Dimensions ....................................................................... 16

Ordering Guide........................................................................... 16

REVISION HISTORY

10/04—Revision 0: Initial Version

Rev. 0 | Page 2 of 16

ADD8708

ELECTRICAL CHARACTERISTICS

VDD = 16 V, TA @ 25°C, unless otherwise noted.

Table 1.

Parameter Symbol Conditions Min Typ Max Unit

GAMMA CURVE CHARACTERISTICS

Accuracy R

Programming Resolution R

Total Resistor String R

BUFFER CHARACTERISTICS

OUTPUTS

Output Voltage Range (Ch18 to Ch10) V

Output Voltage Range (Ch9 to Ch1) V

Output vs. Load (Ch18, Ch17, Ch2, Ch1) ∆V

Output vs. Load (Ch16 to Ch3) ∆V

INPUTS

Offset Voltage V

Offset Voltage Drift ∆VOS/∆T

Input Bias Current I

Input Voltage Range (Ch18 to Ch10) V

Input Voltage Range (Ch9 to Ch1) V

DYNAMIC PERFORMANCE

Slew Rate SR RL = 10 kΩ, CL = 200 pF 4 6 V/µs

Bandwidth BW –3 dB, RL = 10 kΩ, CL = 200 pF 4.5 MHz

Settling Time to 0.1% t

Phase Margin Ф

Power Supply Rejection Ratio PSRR

VOLTAGE REGULATOR

Programmable Range V

Initial Regulator Accuracy V

Dropout Voltage V

I

Line Regulation REG

Load Regulation REG

Maximum Load Current I

Feedback Reference Voltage V

Feedback Input Bias Current I

SYSTEM ACCURACY

Total Error

3, 4

POWER SUPPLY

Supply Voltage V

Supply Current I

ACC

RES

TOTAL

OUT

OUT

OUT

OUT

OS

B

IN

IN

S

o

REG OUT

ACC

DO

O

REF

B FB

V

Total Error

DD

SY

1

2

2

LINE

LOADIO

0.1 0.4 %

500 segments 0.2 %

15 kΩ

IL = 100 µA 1.4 V

IL = 100 µA 0

DD

V

− 1.4

DD

V

V

IL = 20 mA 15 mV

IL = 5 mA 5 mV

5 15 mV

−40°C ≤ T

≤ +105°C

A

−40°C ≤ TA ≤ +105°C

1.4 V

0

20 µV/°C

0.5 1.5 µA

DD

V

− 1.4

DD

V

V

1 V, RL = 10 kΩ, CL = 200 pF 1.1 µs

RL = 10 kΩ, CL = 200 pF 55 Degrees

= 7 V to 17 V,

V

DD

−40°C ≤ T

≤ +105°C

A

5

No load; V

= 14.4V 0.4 1.5 %

REG OUT

68 90 dB

V

− 0.6

DD

V

IL = 100 µA 100 150 mV

= 5 mA 310 350 mV

L

VIN = 8.5 V to 16.5 V, V

= 8 V 0.01 0.20 %/V

OUT

= 100 µA to 10 mA 0.02 0.10 %/mA

−40°C ≤ TA ≤ +105°C

−40°C ≤ TA ≤ +105°C

−40°C ≤ TA ≤ +105°C

5 mA

1.2 V

-150 10 150 nA

0.5 3 %

7.5 16 V

No load; −40°C ≤ TA ≤ +105°C

9.5 16 mA

1

Gamma curve accuracy includes resistor matching and buffer errors, but excludes the regulator error.

2

∆V

is the shift from the desired output voltage under the specified current load.

OUT

3

Total error is the difference between the designed and actual output voltage divided by the actual regulator output voltage or full-scale voltage.

4

Total error includes regulator error, resistor string error, bias current effects, and buffer offset voltage.

Rev. 0 | Page 3 of 16

ADD8708

ABSOLUTE MAXIMUM RATINGS

Table 2.

Parameter Rating

Supply Voltage (VDD) 18 V

Input Voltage

Storage Temperature Range

Operating Temperature Range

1

−0.5 V to V

DD

−65°C to +150°C

−40°C to +105°C

Junction Temperature Range –65°C to +150°C

Lead Temperature Range (Soldering, 60 sec) 300°C

ESD Tolerance (HBM) ±1500 V

ESD Tolerance (MM) ±200 V

Table 3. Package Characteristics

Package Type θ

2

JA

3

θ

JA

Unit

LFCSP (CP) 28.3 47.7 °C/W

LQFP (ST) N/A 74.57 °C/W

1

See the section. Application Notes

2

θJA for exposed pad soldered to JEDEC 4-layer board.

3

θJA for exposed pad not soldered down.

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those indicated in the operational

sections of this specification is not implied. Exposure to

absolute maximum rating conditions for extended periods may

affect device reliability.

ESD CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily accumulate on

the human body and test equipment and can discharge without detection. Although this product features

proprietary ESD protection circuitry, permanent damage may occur on devices subjected to high energy

electrostatic discharges. Therefore, proper ESD precautions are recommended to avoid performance

degradation or loss of functionality.

Rev. 0 | Page 4 of 16

ADD8708

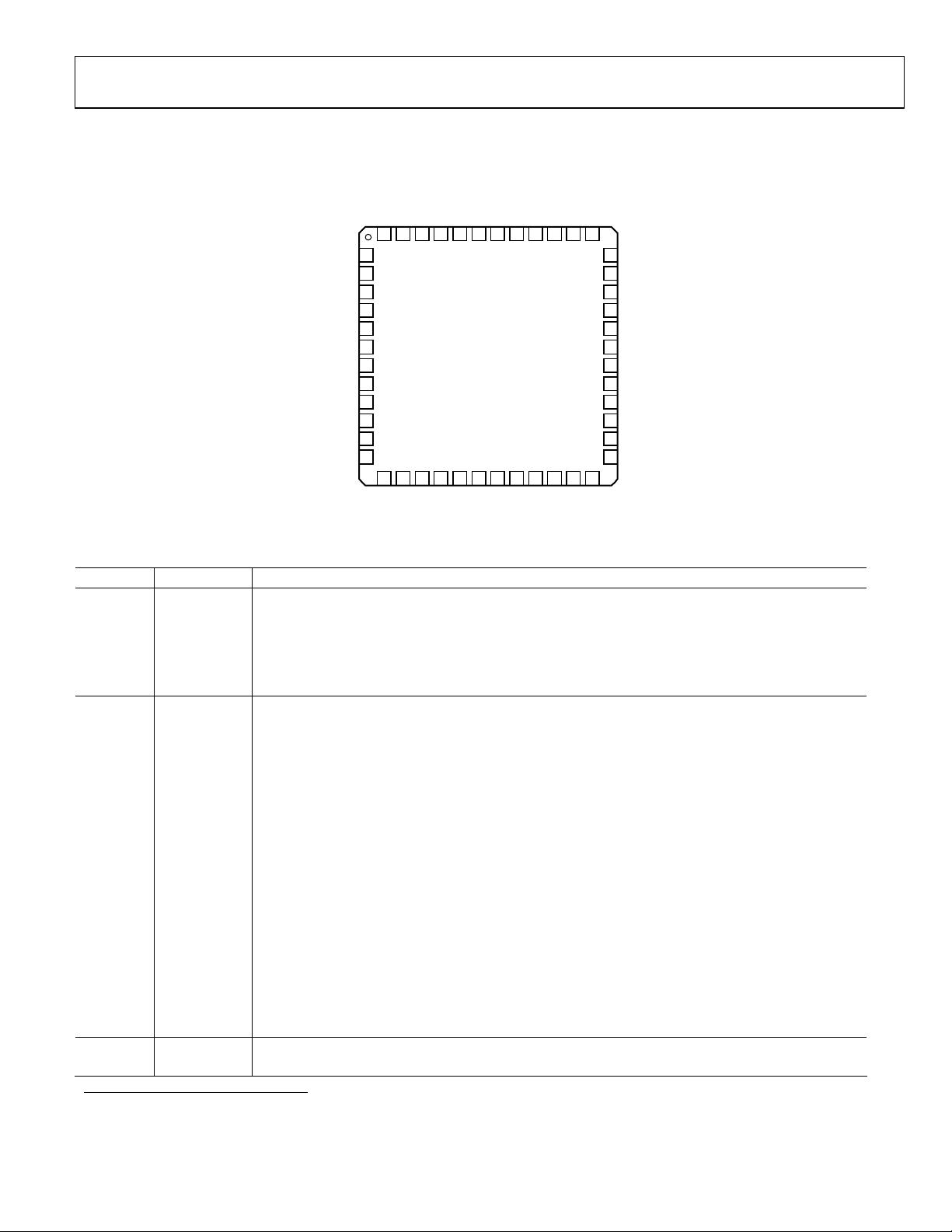

PIN CONFIGURATION AND FUNCTION DESCRIPTIONS

18

17

16

15

14

REG

V

REG OUT

GND

V

VIN18

V

IN

V

IN

V

IN

V

IN

V

IN

V

IN

V

IN

OUT

OUT

OUT

OUT

VDDGND

V

48 47 46 45 44 43 42 41 40 39 38 37

1

FB

2

3

DD

4

5

17

6

16

7

15

8

14

9

13

10

12

11

11

12

13 14 15 16 17 18 19 20 21 22 23 24

10

IN

V

9

8

7

IN

IN

IN

V

V

V

OUT

V

V

V

ADD8708

TOP VIEW

(Not to Scale)

6

5

4

IN

IN

IN

V

V

V

Figure 2. Pin Configuration

13

V

3

V

OUT

IN

12

11

DD

OUT

OUT

GND

V

V

2

IN

V

V

36

V

10

OUT

35

9

V

OUT

34

8

V

OUT

33

7

V

OUT

32

V

DD

GND

31

6

V

30

OUT

5

V

29

OUT

V

4

28

OUT

3

V

27

OUT

2

V

26

OUT

1

V

25

OUT

1

DD

IN

V

V

GND

04614-002

Table 4. Pin Function Descriptions

Pin No. Name Description

1 REG

FB

Regulator Feedback. Compares a percentage of the regulator output to the internal 1.2 V voltage

reference. Internal resistors are used to program the desired regulator output voltage.

2 GND Ground. Normally 0 V.

3 V

4 V

DD

REG OUT

Supply Voltage. Normally 16 V.

Regulator output voltage. Provides reference voltage to resistor string and is internally connected to

the top of the resistor string.

5 VIN18

6 VIN17

7 VIN16

8 VIN15

9 VIN14

10 VIN13

11 VIN12

12 VIN11

13 VIN10

14 VIN9

Buffer inputs. Normally floating.

1

15 VIN8

16 VIN7

17 VIN6

18 VIN5

19 VIN4

20 VIN3

21 VIN2

22 VIN1

23 GND Ground. Normally 0 V.

24 V

DD

Supply Voltage. Normally 16 V.

1

External resistors can be added to modify the internal resistor string to change the gamma voltage. An external resistor calculator is available upon request from your

local sales office.

Rev. 0 | Page 5 of 16

ADD8708

Pin No. Name Description

25 V

26 V

27 V

28 V

29 V

30 V

31 GND Ground. Normally 0 V.

32 V

33 V

34 V

35 V

36 V

37 V

38 V

39 GND Ground. Normally 0 V.

40 V

41 V

42 V

43 V

44 V

45 V

46 V

47 GND Ground. Normally 0 V.

48 V

OUT

OUT

OUT

OUT

OUT

OUT

DD

OUT

OUT

OUT

OUT

OUT

OUT

DD

OUT

OUT

OUT

OUT

OUT

OUT

DD

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

Buffer Outputs. These buffers can swing to ground.

Supply voltage. Normally 16 V.

Buffer Output. These buffers can swing to ground.

Buffer Output. These buffers can swing to VDD.

Normally 16 V.

Buffer Outputs. These buffers can swing to V

Supply voltage. Normally 16 V.

.

DD

Rev. 0 | Page 6 of 16

ADD8708

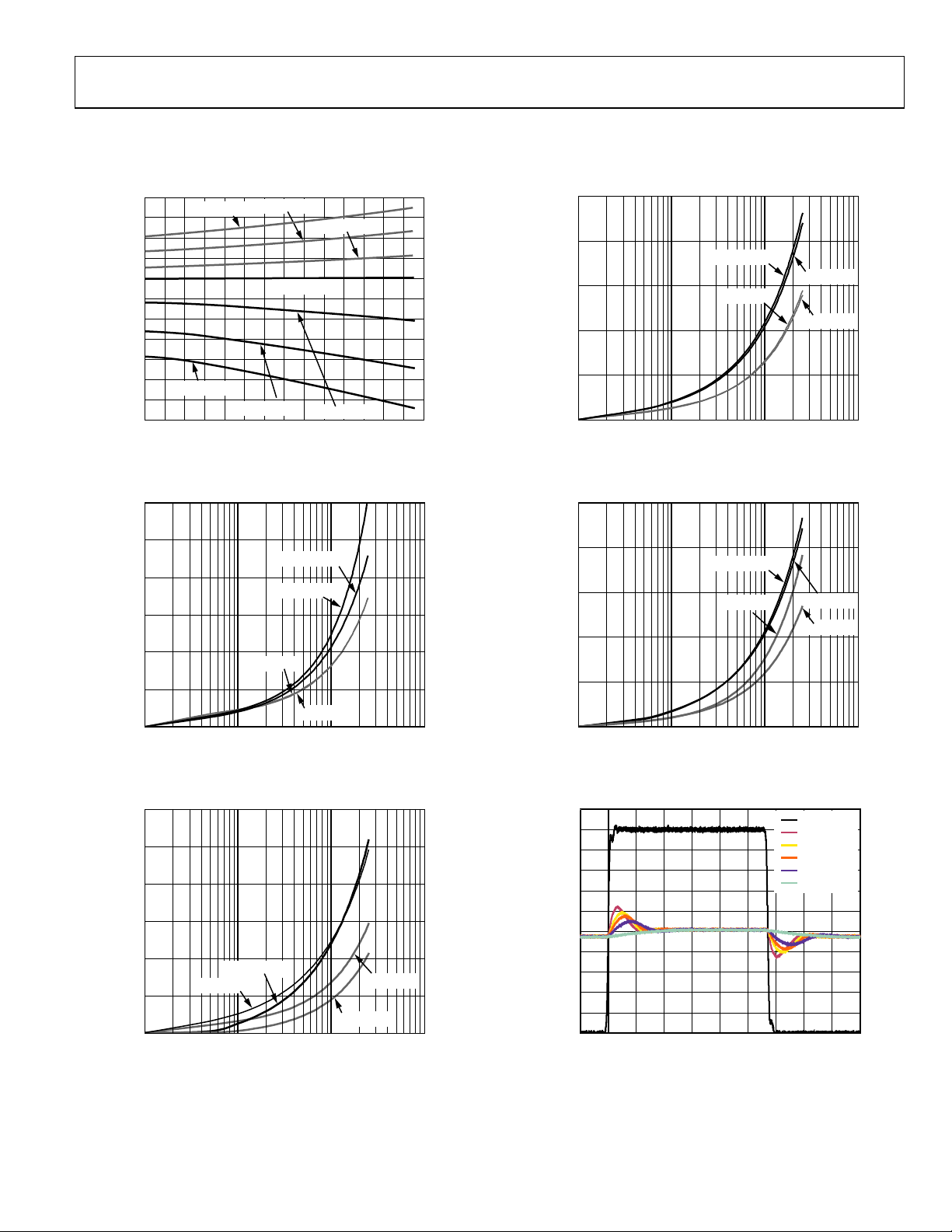

TYPICAL PERFORMANCE CHARACTERISTICS

20

15

10

5

0

–5

–10

–15

–20

–25

OUTPUT VOLTAGE ERROR (mV)

–30

–35

–20–100 102030405060708090100110120

I

SOURCE

I

SINK

= 25mA

I

= 25mA

SINK

I

= 15mA

SOURCE

TEMPERATURE (°C)

= 15mA

I

LOAD

I

= 0mA

I

SOURCE

SINK

= 5mA

= 5mA

Figure 3. Output Voltage Error vs. Temperature

30

04614-003

25

20

CH3 SOURCE

15

10

5

OUTPUT VOLTAGE ERROR (mV)

0

0.1 1 10 100

LOAD CURRENT (mA)

CH3 SINK

CH9 SOURCE

CH9 SINK

Figure 6. Output Voltage Error vs. Load Current (Channels 3 and 9)

25

04614-006

25

CH17 SOURCE

20

15

10

OUTPUT VOLTAGE ERROR (mV)

5

0

0.1 1 10 100

CH18 SOURCE

CH18 SINK

CH17 SINK

LOAD CURRENT (mA)

Figure 4. Output Voltage Error vs. Load Current (Channels 17 and 18)

30

25

20

15

10

OUTPUT VOLTAGE ERROR (mV)

5

0

0.1 1 10 100

CH10 SOURCE

CH16 SOURCE

LOAD CURRENT (mA)

CH10 SINK

CH16 SINK

Figure 5. Output Voltage Error vs. Load Current (Channels 10 and 16)

04614-004

04614-005

20

CH1 SOURCE

15

10

5

OUTPUT VOLTAGE ERROR (mV)

0

0.1 1 10 100

LOAD CURRENT (mA)

CH1 SINK

CH2 SOURCE

CH2 SINK

04614-007

Figure 7. Output Voltage Error vs. Load Current (Channels 1 and 2)

AMPLITUDE (V)

11

10

9

8

7

6

5

4

3

2

1

0

–200 180016001400120010008006004002000

TIME (ns)

10V PULSE

120pF

320pF

520pF

1nF

10nF

04614-008

Figure 8. Gamma Buffers Transient Load Response vs. Capacitive Loading

Rev. 0 | Page 7 of 16

ADD8708

1000

900

800

700

600

500

400

300

NUMBER OF AMPLIFIERS

200

100

0

–0.30 –0.18 –0.10 –0.02 0.06 0.14 0.22 0.30

0.3

MAX ERROR EACH STEP

0.2

0.1

0

ERROR (%)

–0.1

–0.2

–0.3

0123456789101112

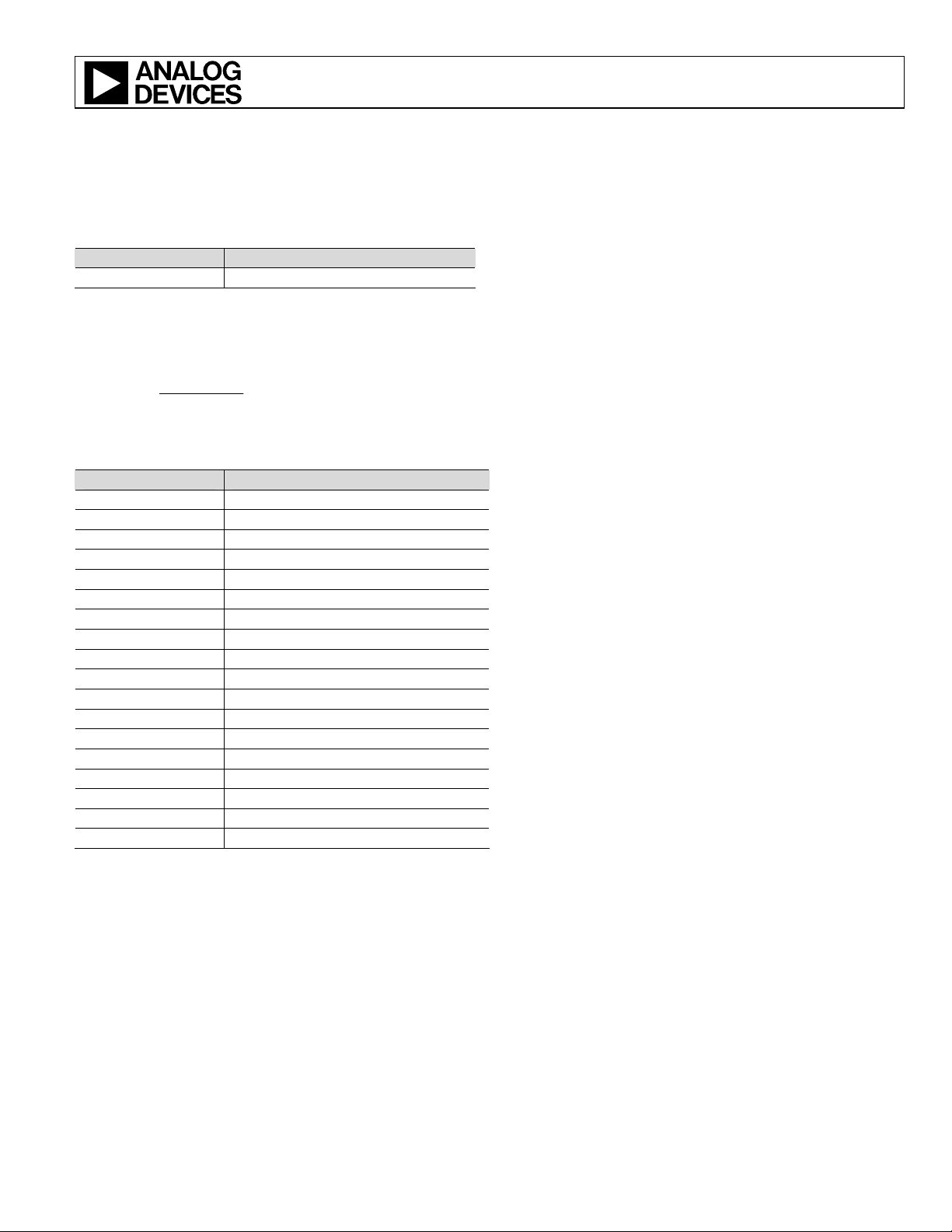

Figure 10. Gamma Output Error per Channel (920 Parts)

15

14

13

12

11

10

9

8

7

6

5

OUTPUT VOLTAGE (V)

4

3

2

1

0

17 012345678910111213141516

GAMMA OUTPUT ERROR DUE TO OFFSET AND

RESISTOR MATCHING (% OF FS)

Figure 9. Gamma Output Voltage Error

TYPICAL UNIT B

TYPICAL UNIT A

OUTPUT CHANNEL

TYPICAL UNIT C

MIN ERROR EACH STEP

I

= 0mA

LOAD

I

= 5mA

LOAD

= 10mA

I

LOAD

INPUT VOLTAGE (V)

04614-009

04614-010

04614-011

0

100

200

300

400

500

600

700

DROPOUT VOLTAGE (mV)

800

900

1000

01234567891011121314151617181920

OUTPUT CURRENT (mA)

Figure 12. Dropout Voltage vs. Output Current

800

750

700

650

600

550

500

450

400

350

300

250

200

DROPOUT VOLTAGE (mV)

150

100

50

0

–25–15–55 152535455565758595105115

TEMPERATURE (°C)

10mA

5mA

0mA

Figure 13. Dropout Voltage vs. Temperature

14.5

14.4

14.3

14.2

14.1

14.0

13.9

REGULATOR OUTPUT (V)

13.8

13.7

13.6

0 2 4 6 8 101214161820

+25°C

°

C

+55

+85

LOAD CURRENT (mA)

°

C

+95

°

C

+105

–20°C

°

C

04614-012

04614-013

0

°

C

04614-014

Figure 11. Dropout Characteristics

Rev. 0 | Page 8 of 16

Figure 14. Regulator Output vs. I

over Temperature

LOAD

ADD8708

14.45

0mA

14.40

14.35

14.30

REGULATOR OUTPUT (V)

14.25

14.20

–20–100 102030405060708090100110

TEMPERATURE (°C)

5mA

Figure 15. Regulator Output vs. Temperature

18

17

C

LOAD

= 1µF

10mA

04712-0-021

400

200

12

11

10

9

8

7

6

5

4

SUPPLY CURRENT (mA)

3

2

1

0

024681012141618

SUPPLY VOLTAGE (V)

Figure 18. Supply Current vs. Supply Voltage

11.0

10.9

10.8

04614-018

16

INPUT VOLTAGE (V)

15

14

0.1

LOAD CURRENT (mA)

5

TIME (100µs/DIV)

Figure 16. Regulator Line Transient Response

C

= 1µF

LOAD

TIME (100µs/DIV)

0

–200

–400

40

20

0

–20

–40

OUTPUT VOLTAGE CHANGE (mV)

OUTPUT VOLTAGE CHANGE (mV)

04614-016

04614-017

10.7

10.6

SUPPLY CURRENT (mA)

10.5

10.4

–20 120100806040200

TEMPERATURE (°C)

Figure 19. Supply Current vs. Temperature

04614-019

Figure 17. Regulator Load Transient Response

Rev. 0 | Page 9 of 16

ADD8708

V

APPLICATION NOTES

The ADD8708 is a mask-programmable gamma reference

generator that allows source drivers to be optimized for the

different combinations of liquid crystals, glass sizes, etc. in

large LCD panels. It generates 18 gamma reference outputs

that can be mask-programmed in 0.2% increments using the

500 matched internal resistors (see Figure 20), so that every

point on the curve can be targeted within 0.1% of the desired

value.

TAP POINT 4

TAP POINT 3

TAP POINT 2

TAP POINT 1

EACH R = 30Ω

TYPICALLY

Figure 20. 500 Mask-Programmable Resistor String

In a typical panel application, the selected source drivers have

an internal gamma curve that is not ideal for the specific panel

(see Figure 21). The ADD8708 allows the gamma curve in the

source drivers to be adjusted appropriately, and also ensures

that all the source drivers have the same gamma curve.

16

14

12

10

8

6

PANEL GAMMA CURVE

CORRECTED BY ADD8708

GAMMA VOLTAGE (V)

4

2

0

ORIGINAL GAMMA CURVE

IN SOURCE DRIVERS

GAMMA REFERENCE INPUT POINTS

Figure 21. Original and Corrected Gamma Cur ves

The matching and tracking accuracy of the internal resistors is

typically 0.1% with worst-case deviation from the desired curve

within 0.4% of the ideal gamma curve, over temperature.

The ADD8708 also includes a low-dropout linear regulator to

provide a stable reference level for the gamma curve for

optimum panel performance.

TAP POINT 500

TAP POINT 499

TAP POINT 498

TAP POINT 497

04614-020

04614-021

TAP POINT SELECTION

The ADD8708 uses a single resistor string consisting of 500

individual elements. The tap points are mask programmable

and completely independent of each other. See the Tap Point

and Regulator Voltage Request Form in this data sheet.

V

REG OUT

500–TP

X

IN

X

TP

X

Figure 22. Gamma Buffers Tap Point Circuit

Tap point voltages can be derived from the following equation:

OUT

500

TP

X

XV ×=

where TP

is the desired tap point for the Xth channel.

X

Table 5. Typical Mask Implementation

VDD = 16 V, V

= 14.4 V, 0 ≤ X ≤ 500

REG OUT

Tap Point (X) Voltage Units

V

18 500 14.400 V

OUT

V

17 396 11.405 V

OUT

V

16 369 10.627 V

OUT

V

15 361 10.397 V

OUT

V

14 354 10.195 V

OUT

V

13 350 10.080 V

OUT

V

12 341 9.821 V

OUT

V

11 317 9.130 V

OUT

V

10 299 8.611 V

OUT

V

9 225 6.480 V

OUT

V

8 211 6.077 V

OUT

V

7 177 5.098 V

OUT

V

6 167 4.810 V

OUT

V

5 163 4.694 V

OUT

V

4 154 4.435 V

OUT

V

3 146 4.205 V

OUT

V

2 118 3.398 V

OUT

V

1 7 0.202 V

OUT

_______________________________

1

ADD8708 release samples do not have these typical values. The values on the

samples are nonmonotonic and can be provided upon request.

V

X

OUT

04614-022

V

OUTREG

1

Rev. 0 | Page 10 of 16

ADD8708

VOLTAGE REGULATOR

The on-board voltage regulator provides a regulated voltage to

the resistor chain to provide stable gamma voltages.

The two mask-programmable internal resistors, R

and R2,

1

and a reference voltage set the output of the regulator. The

typical values of these parts are shown in Figure 23. In addition,

see the Tap Point and Regulator Voltage Request Form in this

data sheet.

R

2

R

5kΩ

V

REF

1.2V

Figure 23. Voltage Regulator

55kΩ

1

V

REG OUT

+

–

04614-023

The internal resistors have a typical accuracy of 0.1%. External

resistors can be used to adjust the regulator voltage; however, it

is not recommended. Please contact your local sales office for

further details.

MAXIMUM POWER DISSIPATION

The maximum safe power dissipation in the ADD8708 package

is limited by the associated rise in junction temperature (T

the die. At approximately 150°C, the glass transition temperature, the properties of the plastic change. Even temporarily

exceeding this temperature limit may change the stresses that

the package exerts on the die, permanently shifting the parametric performance of the ADD8708. Exceeding a junction

temperature of 175°C for an extended period can result in

changes in the silicon devices, potentially causing failure.

) on

J

LAND PATTERN

The LFCSP package comes with a thermal pad. Soldering down

this thermal pad dramatically improves the heat dissipation of

the package. It is necessary to attach vias that connect the

soldered thermal pad to another layer on the board. This

provides an avenue to dissipate the heat away from the part.

Without vias, the heat is isolated directly under the part.

Subdivide the solder paste, or stencil layer, for the thermal pad

to reduce solder balling and splatter. It is not critical how the

subdivisions are arranged, as long as the total coverage of the

solder paste for the thermal pad is greater than 50%. The land

pattern is critical to heat dissipation. A suggested land pattern is

shown in Figure 22.

The thermal pad is attached to the substrate. In the ADD8708,

the substrate is connected to V

. To be electrically safe, the

DD

thermal pad should be soldered to an area on the board that is

electrically isolated or connected to V

. Attaching the thermal

DD

pad to ground adversely affects the performance of the part.

Rev. 0 | Page 11 of 16

ADD8708

OPERATING TEMPERATURE RANGE

The junction temperature is as follows:

= T

T

J

where:

T

AMB

= junction-to-ambient thermal resistance, in °C/watt.

θ

JA

P

= power dissipated in the device, in watts.

DIS

For the ADD8708, P

P

DIS

where:

V

I

OUT X(+)

power dissipation (current comes from V

−I

dissipation (current goes to GND).

(V

In this example, T

values in Table 6.

Table 6.

V

V

OUT

V

OUT

V

OUT

V

OUT

V

OUT

V

OUT

V

OUT

V

OUT

V

OUT

V

OUT

V

OUT

V

OUT

V

OUT

V

OUT

V

OUT

V

OUT

V

OUT

V

OUT

Σ(I

+ θJA × P

AMB

DIS

= ambient temperature.

can be calculated by this equation:

DIS

= VDD × IDQ + Σ(I

Σ(−I

OUT X(−)

× I

DD

= nominal system power requirements.

DQ

× (VDD − V

× V

OUT X(−)

– V

DD

OUT X

REG OUT

OUT X

) × I

AMB

× V

OUT X

= negative-current amplifier load power

LOAD

= 95°C. To calculate P

(V) I

OUT X(+)

OUT X

× (VDD − V

) + (VDD – V

OUT X

REG OUT

)) +

) × I

LOAD

)= positive-current amplifier load

).

DD

= regulator load power dissipation.

, assume the

DIS

(mA) P (W)

OUT X

18 14.400 4.3 0.00688

17 11.405 5.2 0.0239

16 10.627

−4.4

0.0468

15 10.397 7.3 0.0409

14 10.195 7.6 0.0441

13 10.080

−3.9

0.0393

12 9.821 8.3 0.0513

11 9.130 7.9 0.0543

10 8.611

9 6.480

−4.5

−4.2

0.0389

0.0272

8 6.077 5.6 0.0556

7 5.098

6 4.810

−3.3

−6.9

0.0168

0.0332

5 4.694 5.7 0.0644

4 4.435 3.5 0.0405

3 4.205 9.6 0.113

2 3.398

1 0.202

OUT X(+)

× (VDD − V

OUT X

)) + Σ(−I

−9.5

−7.2

OUT X(−)

× V

OUT X

0.0323

0.00145

0.731

)

× IDQ = 16 V × 15 mA = 0.240 W

V

DD

– V

(V

DD

P

= 0.240 W + 0.731 W + 0.008 W =0.979 W

DIS

REG OUT

) × I

= (16 V – 14.4 V) × 5 mA = 0.008 W

LOAD

Example 1

Exposed pad soldered down with via θJA = 28.3°C/W:

T

= 95°C + (28.3°C/W) × (0.979 W) = 122.7°C

J

where 150°C is the maximum junction temperature that is

guaranteed before the part breaks down. The maximum process

limit is 125°C. Because T

is < 150°C and < 125°C, this example

J

demonstrates a condition where the part should perform within

process limits.

Example 2

Exposed pad not soldered down θJA = 47.7°C/W:

= 95°C + (47.7°C/W) × (0.979 W) = 141.7°C

T

J

In this example, T

is < 150°C but > 125°C. Although the part

J

should not exhibit any damage in this situation, the process

limits have been exceeded. The part may no longer operate

as intended.

These examples show that soldering down the exposed pad is

important for proper heat dissipation. Under the same powerup and loading conditions, the unsoldered part has a higher

temperature than the soldered part. Therefore, it is strongly

advised that the exposed pad be soldered to V

to maintain

DD

part integrity.

Rev. 0 | Page 12 of 16

ADD8708

7.31mm

SOLDER PASTE AREA

HEAT SINK

1.90mm

5.93mm

1.60mm

5.40mm

0.5mm

0.33mm DIAMETER

THERMAL VIA

0.075mm

0.075mm

0.28mm

1.60mm

0.69mm

5.78mm

04614-024

Figure 24. 48-Pin LFCSP (CP-48) Land Pattern—Dimensions Shown in Millimeters

Notes:

1. Areas in black represent the board metallization.

2. Areas in white represent the solder mask and vias.

3. Hatched area is for the heat sink solder paste.

4. The thermal pad is electrically active. The solder mask opening should be 0.150 mm larger than the pad size, resulting in 0.075 mm

of clearance between the copper pad and solder mask.

Rev. 0 | Page 13 of 16

ADD8708

V

TYPICAL APPLICATIONS CIRCUIT

NORMALLY

OPEN

ESD PROTECTION

RESISTOR

18

V

IN

17

V

IN

16

V

IN

15

V

IN

14

V

IN

13

V

IN

12

V

IN

11

V

IN

10

V

IN

9

V

IN

OPEN

NORMALLY

8

V

IN

7

V

IN

6

V

IN

5

V

IN

4

V

IN

3

V

IN

V

2

IN

1

V

IN

ESD PROTECTION

FB

5k

Ω

1.2V

700

Ω

700

Ω

700

Ω

700

Ω

700

Ω

700

Ω

700

Ω

700

Ω

700

Ω

700

Ω

700

Ω

700

Ω

700

Ω

700

Ω

700

Ω

700

Ω

700

Ω

700

Ω

RESISTORS

700

Ω

+

VOLTAGE

–

REGULATOR

TP18 = 500

TP17 = 396

TP16 = 369

TP15 = 361

TP14 = 354

TP13 = 350

TP12 = 341

TP11 = 317

TP10 = 299

TP9 = 225

TP8 = 211

TP7 = 177

TP6 = 167

TP5 = 163

TP4 = 154

TP3 = 146

TP2 = 118

TP1 = 7

REG OUT

V

0.1µF

55k

DD

Ω

Ω

0

3.12k

Ω

810

Ω

240

Ω

210

Ω

120

Ω

270

Ω

720

Ω

540

Ω

2.22k

Ω

420

Ω

1.02k

Ω

300

Ω

120

Ω

270

Ω

240

Ω

840

Ω

3.33k

Ω

210

Ω

GAMMA

BUFFERS

V

OUT

V

OUT

V

OUT

V

OUT

V

OUT

V

OUT

V

OUT

V

OUT

V

OUT

V

OUT

V

OUT

V

OUT

V

OUT

V

OUT

V

OUT

V

OUT

V

OUT

V

OUT

16V

GND GND

Figure 25. Typical Application Circuit

0.1µF

GAMMA 18

GAMMA 17

GAMMA 16

GAMMA 15

GAMMA 14

GAMMA 13

GAMMA 12

GAMMA 11

GAMMA 10

GAMMA 9

GAMMA 8

GAMMA 7

GAMMA 6

GAMMA 5

GAMMA 4

18

14.400V

17

11.405V

16

10.627V

15

10.397V

14

10.195V

13

10.080V

12

9.821V

11

9.130V

10

8.611V

9

6.480V

8

6.077V

7

5.098V

6

4.810V

5

4.694V

4

4.435V

3

4.205V

2

3.398V

1

0.202V

GAMMA 3

GAMMA 2

GAMMA 1

GAMMA 18

GAMMA 17

GAMMA 16

GAMMA 15

GAMMA 14

GAMMA 13

GAMMA 12

GAMMA 11

GAMMA 10

GAMMA 9

GAMMA 8

GAMMA 7

GAMMA 6

GAMMA 5

GAMMA 4

GAMMA 3

GAMMA 2

GAMMA 1

GAMMA 18

GAMMA 17

GAMMA 16

GAMMA 15

GAMMA 14

GAMMA 13

GAMMA 12

GAMMA 11

GAMMA 10

GAMMA 9

GAMMA 8

GAMMA 7

GAMMA 6

GAMMA 5

GAMMA 4

GAMMA 3

GAMMA 2

GAMMA 1

04614-025

Rev. 0 | Page 14 of 16

TAP POINT AND REGULATOR VOLTAGE REQUEST FORM

REGULATOR SECTION—V

To ensure correct regulator operation VDD must exceed V

= 15.0 V.

V

DD

Parameter Value (6.9 V – 15.4 V)

V

REG OUT

TAP POINT SECTION

Gamma output voltages are calculated using the following formula:

VTP

×

V

=

OUT

OUTREG

500

REG OUT

by 600 mV minimum—that is, a V

REG

= 14.4 V requires a minimum

REG

ADD8708

A Microsoft® Excel spreadsheet is available which automatically calculates the best tap point based on V

voltages for each gamma output.

Output Tap Point

V

18

OUT

V

17

OUT

V

16

OUT

V

15

OUT

V

14

OUT

V

13

OUT

V

12

OUT

V

11

OUT

V

10

OUT

V

9

OUT

V

8

OUT

V

7

OUT

V

6

OUT

V

5

OUT

V

4

OUT

V

3

OUT

V

2

OUT

V

1

OUT

and the desired output

REG OUT

CUSTOMER INFORMATION

Name: ____________________________________________

Company: ____________________________________________

Address: ____________________________________________

____________________________________________

Date: ____________________________________________

Please return this form to your local sales office.

Rev. 0 | Page 15 of 16

ADD8708

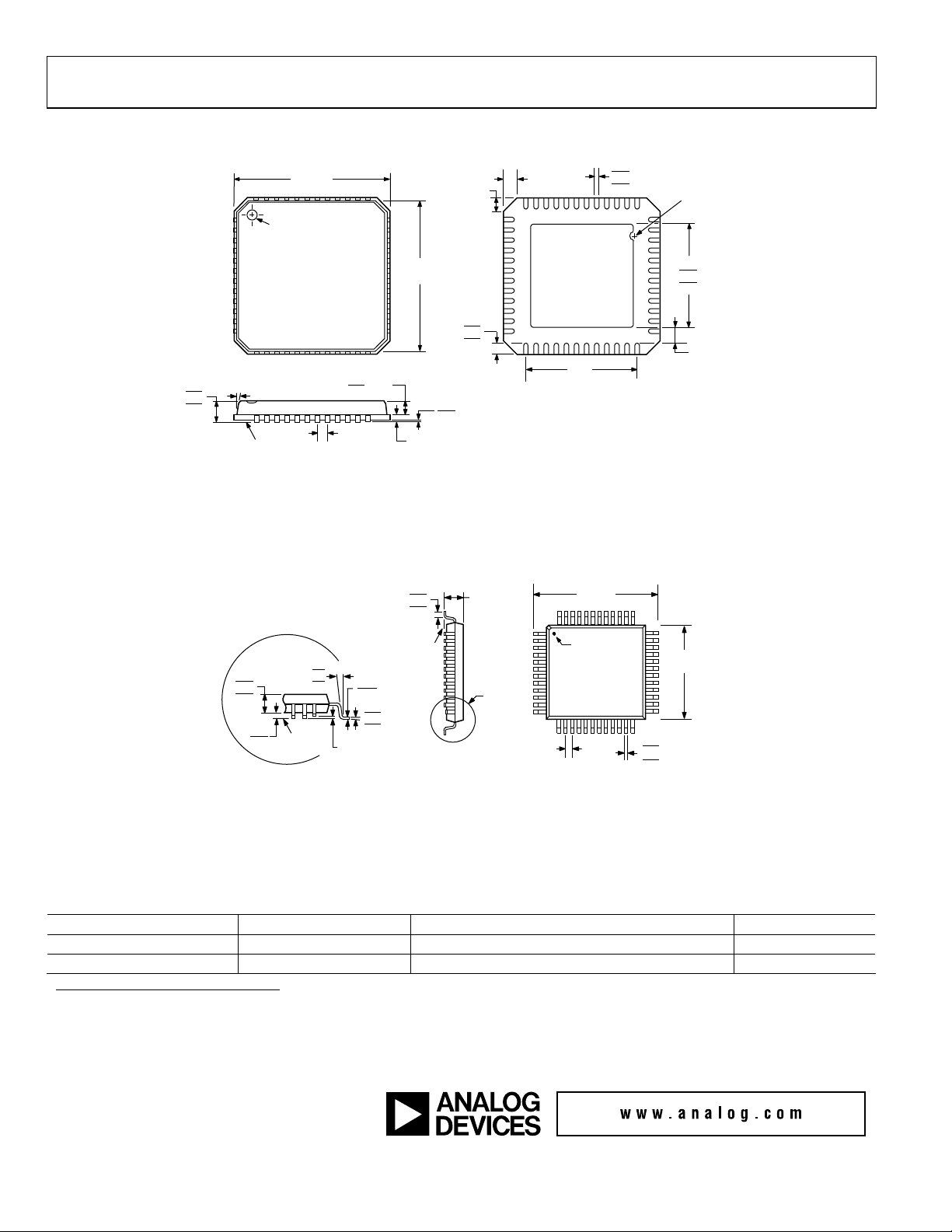

OUTLINE DIMENSIONS

0.30

0.23

0.18

PIN 1

48

INDICATOR

1

BSC SQ

PIN 1

INDICATOR

7.00

0.60 MAX

37

36

0.60 MAX

1.00

0.85

0.80

12° MAX

SEATING

PLANE

1.45

1.40

1.35

0.15

0.05

VIEW A

ROTATED 90° CCW

TOP

VIEW

0.80 MAX

0.65 TYP

0.50 BSC

COMPLIANT TO JEDEC STANDARDS MO-220-VKKD-2

6.75

BSC SQ

0.20REF

0.50

0.40

0.30

0.05 MAX

0.02 NOM

25

24

COPLANARITY

0.08

Figure 26. 48-Lead Lead Frame Chip Scale Package [LFCSP]

7 mm × 7 mm Body

(CP-48)

Dimensions shown in millimeters

10°

SEATING

PLANE

0.75

0.60

0.45

SEATING

PLANE

6°

0.20

2°

0.09

7°

3.5°

0°

0.08 MAX

COPLANARITY

COMPLIANT TO JEDEC STANDARDS MS-026BBC

1.60

MAX

VIEW A

Figure 27. 48-Lead Low Profile Quad Flat Package [LQFP]

(ST-48)

Dimensions shown in millimeters

EXPOSED

PAD

(BOTTOM VIEW)

5.50

REF

BSC SQ

48

1

PIN 1

TOP VIEW

(PINS DOWN)

12

13

0.50

BSC

9.00

5.25

5.10 SQ

4.95

12

13

0.25 MIN

37

36

7.00

BSC SQ

25

24

0.27

0.22

0.17

ORDERING GUIDE

1

Model

ADD8708WCPZ-REEL7

2

ADD8708WSTZ-REEL2 –40°C to +105°C 48-Lead Low Profile Quad Flat Package ST-48

1

Available in reels only.

2

Z = Pb-free part.

© 2004 Analog Devices, Inc. All rights reserved. Trademarks and

registered trademarks are the property of their respective owners.

D04614–0–10/04(0)

Temperature Range Package Description Package Option

–40°C to +105°C 48-Lead Lead Frame Chip Scale Package CP-48

Rev. 0 | Page 16 of 16

Loading...

Loading...