12-Channel Gamma Buffers

FEATURES

Programmable 12-Channel Gamma Reference Generator

Mask Programmable Adjustable V

Upper/Lower Outputs Swing to V

COM

/GND

DD

Buffer

Continuous Output Current: 10 mA

V

Peak Output Current: 250 mA

COM

Outputs with Fast Settling Time for Load Change

Output Pins Are Compatible with ADD8701

Single-Supply Operation: 7 V to 16 V

Supply Current: 15 mA Max

APPLICATIONS

TFT LCD Panels

GENERAL DESCRIPTION

The ADD8702 is a low cost, mask programmable, 12-channel

gamma reference generator, plus an adjustable V

driver. This

COM

part is designed to provide gamma correction for high resolution

TFT LCD panels. The 12 gamma reference levels and V

COM

are

mask programmable to 0.3% resolution using the on-chip 500

chain resistor string. This reduces component and board costs.

The ADD8702 provides a complete programmed set of gamma

voltage references for the LCD source drivers. These references

settle quickly to load change. The V

output is stable with

COM

high capacitive loads and can source or sink 250 mA peak current. The V

output level can be adjusted using an external

COM

trim-potentiometer or discrete resistors.

with V

Buffer

COM

ADD8702

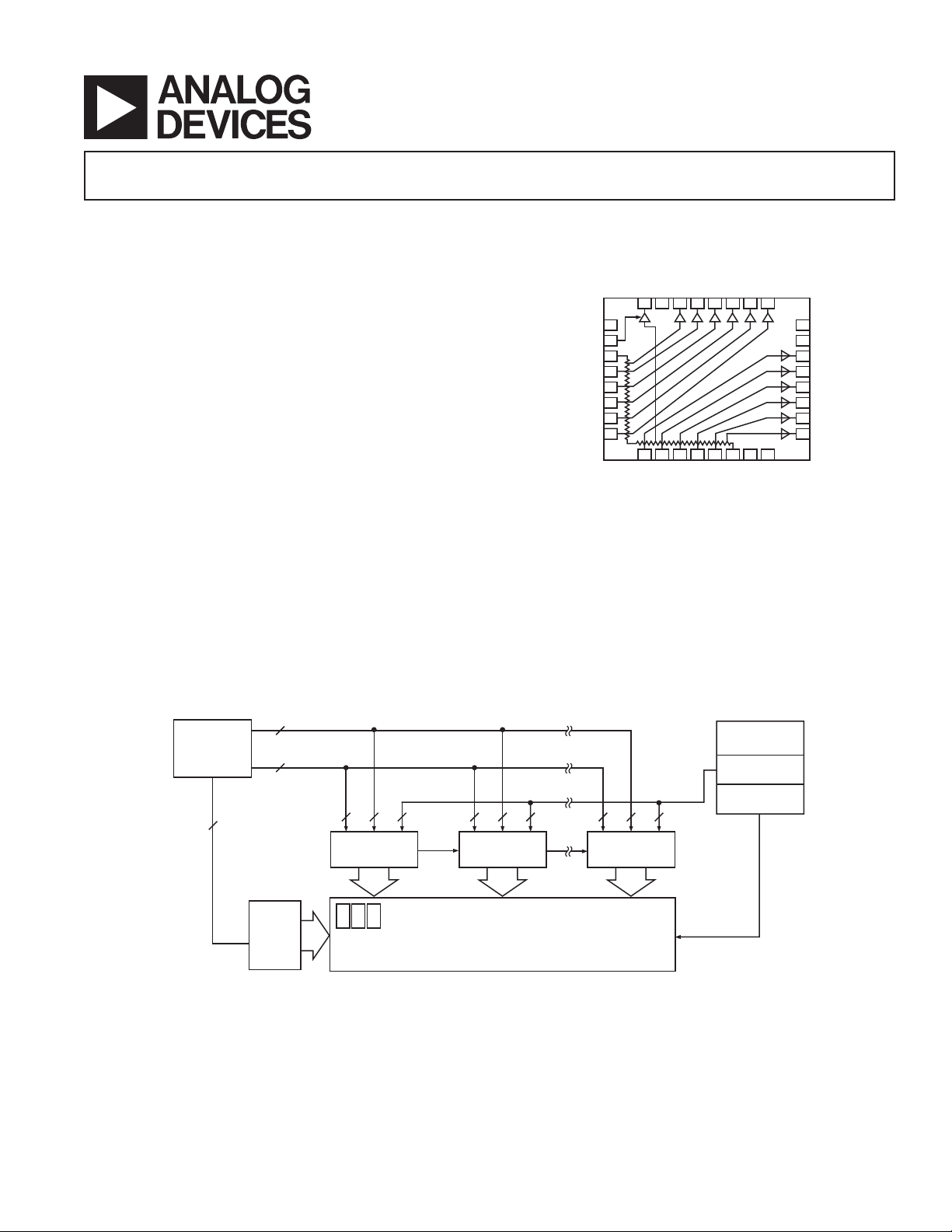

FUNCTIONAL BLOCK DIAGRAM

OUT

COM

V

GND

VGMA12

VGMA11

VGMA10

VGMA9

VGMA8

LOW

V

DD

V

VGMA7

GND

24

23

22

21

20

19

18

17

GND

V

DD

VGMA6

VGMA5

VGMA4

VGMA3

VGMA2

VGMA1

32 31 30 26 28 27 26 25

V

1

DD

V

ADJ

V

HIGH

VIN11

V

IN

V

V

V

2

3

4

10

5

6

9

IN

7

8

IN

7

8

IN

9 10 11 12 13 14 15 16

6

5

4

3

IN

IN

V

V

2

IN

IN

IN

V

V

V

COM

The output pins are compatible with the ADD8701. This allows

for single board design and fast turns for prototyping using the

initial ADD8701 board design.

The ADD8702 is specified over the temperature range of –40°C

to +85°C and comes in the 32-lead lead frame chip scale package (LFCSP) for compact board space.

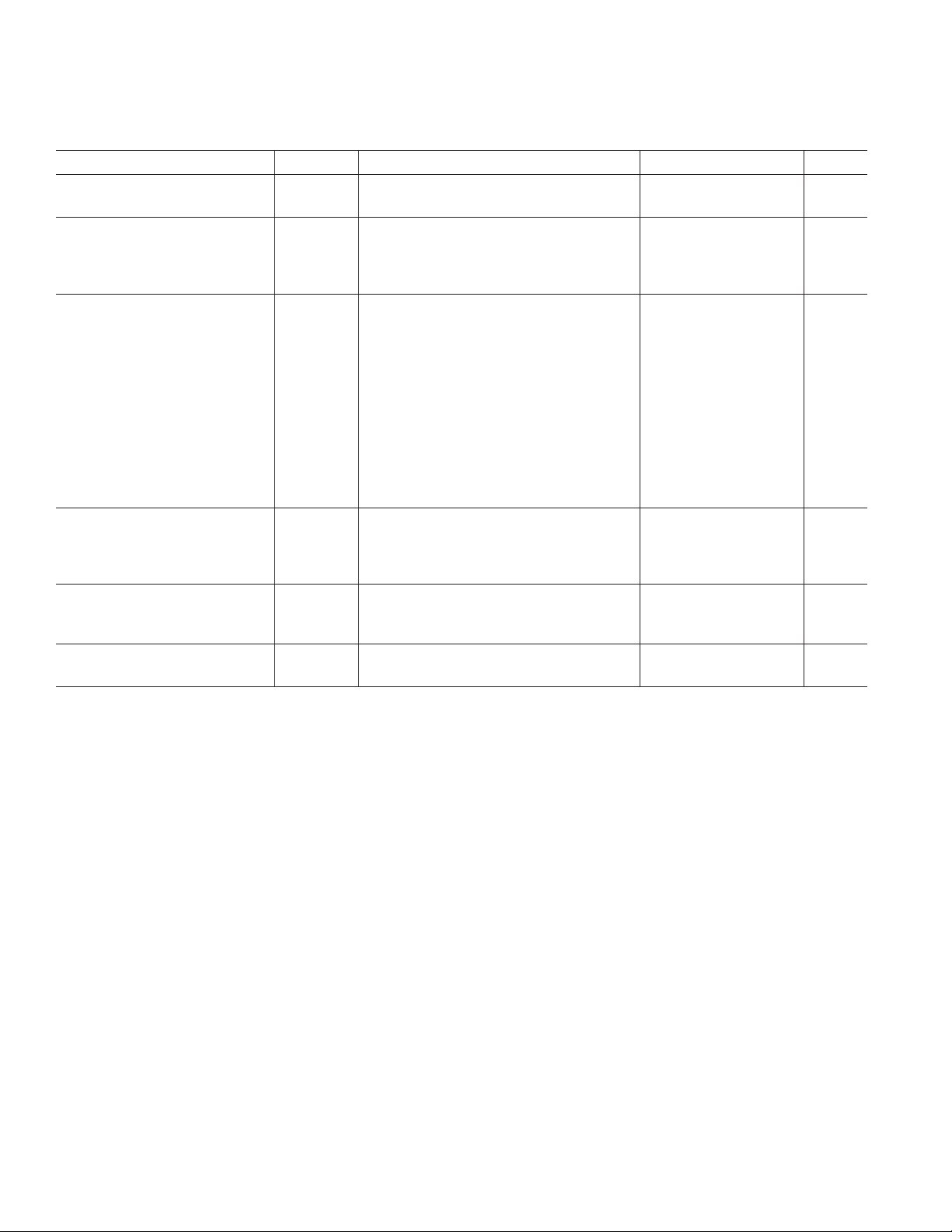

PAN E L

TIMING

CONTROLLER

TIMING AND CONTROL

SCAN DRIVER CONTROL

SCAN

DRIVERS

768

SOURCE DRIVER

NO. 1

384

R

G B

Figure 1. Typical SVGA TFT LCD Application

REV. 0

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties that

may result from its use. No license is granted by implication or otherwise

under any patent or patent rights of Analog Devices. Trademarks and

registered trademarks are the property of their respective companies.

ADD8702

SOURCE DRIVER

NO. 2

384

TFT COLOR PANEL

1024 768

GAMMA

REFERENCE

VOLTAG ES

SOURCE DRIVER

NO. 8

384

GAMMA

V

COM

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 www.analog.com

Fax: 781/326-8703 © 2003 Analog Devices, Inc. All rights reserved.

ADD8702–SPECIFICATIONS

ELECTRICAL CHARACTERISTICS

(VDD = 16 V, TA = 25ⴗC, unless otherwise specified.)

Parameter Symbol Conditions Min Typ Max Unit

OUTPUT ACCURACY

V

ERROR V

SYSTEM

SY ERROR

10 50 mV

MASK PROGRAMMABLE

RESISTOR STRING

Total Resistor String R

Resistor Matching R

TOTAL

MATCH

500 Elements V

LOW

to V

HIGH

22.5 kΩ

Any Two Segments 1 %

OUTPUT CHARACTERISTICS

Output Voltage High V

OUT

(VGMA11, VGMA12) I

Output Voltage Mid V

OUT

IL = 100 µA 15.995 V

= 5 mA 15.85 15.95 V

L

–40°C ≤ T

≤ +85°C 15.75 V

A

IL = 5 mA 14.6 V

(VGMA3 to VGMA10)

Output Voltage Low V

OUT

IL = 100 µA5mV

(VGMA1, VGMA2) IL = 5 mA 50 150 mV

Continuous Output Current I

Peak Output Current I

Settling Time—Voltage t

CHARACTERISTICS

V

COM

Continuous Output Current I

Peak Output Current I

Settling Time—Voltage t

OUT

PK

S

OUT

PK

S

–40°C ≤ T

1 V Step 0.1%, RL = 10 kΩ, CL = 200 pF 1 µs

1 V Step 0.1%, RL = 10 kΩ, CL = 200 pF 0.8 µs

≤ +85°C 250 mV

A

10 mA

150 mA

35 mA

250 mA

SUPPLY CHARACTERISTICS

Supply Voltage V

DD

716V

Power Supply Rejection Ratio PSRR VS = 6 V to 17 V, –40°C ≤ TA ≤ +85°C6875 dB

SUPPLY CURRENT I

SYS

No Load 11 15 mA

–40°C ≤ TA ≤ +85°C16mA

Specifications subject to change without notice.

REV. 0–2–

ADD8702

ABSOLUTE MAXIMUM RATINGS*

Supply Voltage (VS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18 V

Storage Temperature Range . . . . . . . . . . . . . –65°C to +150°C

Operating Temperature Range . . . . . . . . . . . .–40°C to +85°C

Junction Temperature Range . . . . . . . . . . . . . –65°C to +150°C

Lead Temperature Range (Soldering, 60 sec.) . . . . . . . . 300°C

ESD Tolerance (HBM) . . . . . . . . . . . . . . . . . . . . . . . ± 1,000 V

*Stresses above those listed under Absolute Maximum Ratings may cause perma-

nent damage to the device. This is a stress rating only; functional operation of the

device at these or any other conditions above those indicated in the operational

sections of this specification is not implied. Exposure to absolute maximum rating

conditions for extended periods may affect device reliability.

ORDERING GUIDE

Temperature Package Package

Model Range Description Option

ADD8702ACP-R2 –40°C to +85°C 32-Lead LFCSP CP-32

ADD8702ACP-REEL –40°C to +85°C 32-Lead LFCSP CP-32

ADD8702ACP-REEL7 –40°C to +85°C 32-Lead LFCSP CP-32

PIN CONFIGURATION

OUT

COM

32 V

31 GND

30 VGMA12

29 VGMA11

Package Type

1

JA

2

JB

Unit

32-Lead LFCSP (CP) 35 13 °C/W

NOTES

1

θJA is specified for worst-case conditions, i.e., θ

in circuit board for surface-mount packages.

2

ψJB is applied for calculating the junction temperature by reference to the board

temperature.

28 VGMA10

27 VGMA9

26 VGMA8

25 VGMA7

is specified for device soldered

JA

V

1

DD

ADJ 2

V

COM

V

HIGH

VIN11 4

V

10 5

IN

9 6

V

IN

V

8 7

IN

7 8

V

IN

PIN 1

INDICATOR

3

ADD8702

TOP VIEW

6 9

5 10

4 11

3 12

2 13

IN

IN

IN

IN

V

IN

V

V

V

V

14

LOW

V

15

V

DD

24 GND

23 V

22 VGMA6

21 VGMA5

20 VGMA4

19 VGMA3

18 VGMA2

17 VGMA1

GND 16

DD

PIN FUNCTION DESCRIPTIONS

Pin No. Mnemonic Description

1, 15, 23 V

2V

3V

4–13 V

14 V

DD

ADJ V

COM

HIGH

11–VIN2Gamma Buffer Inputs

IN

LOW

Power (+)

Adjust Input

COM

Highest Gamma Input Voltage

Lowest Gamma Input Voltage

16, 24, 31 GND Power (–)

17–22, 25–30 VGMA1–VGMA12 Gamma Buffer Outputs

32 V

OUT V

COM

Buffer Output

COM

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection. Although the

ADD8702 features proprietary ESD protection circuitry, permanent damage may occur on devices

subjected to high energy electrostatic discharges. Therefore, proper ESD precautions are recommended

to avoid performance degradation or loss of functionality.

REV. 0

–3–

ADD8702–Typical Performance Characteristics

)

)

CAPACITIVE LOAD (pF)

PHASE SHIFT (Degrees)

180

40

0 200 1,200400 600 800 1,000

160

140

120

80

60

100

VDD = 16V

GAMMA 1 TO 12

R

L

= 2k

GAMMA 12

GAMMA 1

12

TA = 25C

10

8

6

4

SUPPLY CURRENT (mA)

2

0

04 16

SUPPLY VOLTAGE (V)

812

TPC 1. Supply Current vs.

Supply Voltage

10

VDD = 16V

0

–10

GAIN (dB)

–20

–30

–40

GAMMA 10 TO 12

1M 10M

FREQUENCY (Hz)

2k, 10k

150

TPC 4. Frequency Response

vs. Resistive Loading

12

V

= 16V

DD

11

10

9

8

7

SUPPLY CURRENT (mA)

6

5

–40 85

25

TEMPERATURE (C)

TPC 2. Supply Current vs.

Temperature

10

VDD = 16V

V

COM

0

–10

–20

GAIN (dB)

–30

–40

30M100k

–50

1M 10M

FREQUENCY (Hz)

2k, 10k

150

30M100k

TPC 5. Frequency Response

vs. Resistive Loading

10

VDD = 16V

GAMMA 1 TO 9

0

–10

GAIN (dB)

–20

–30

–40

100k 30M

FREQUENCY (Hz)

2k, 10k

150

1M 10M

TPC 3. Frequency Response

vs. Resistive Loading

20

VDD = 16V

GAMMA 1 TO 9

10

0

GAIN (dB)

–10

–20

–30

340pF

540pF

1040pF

1M 10M

FREQUENCY (Hz

TPC 6. Frequency Response

vs. Capacitive Loading

50pF

100pF

30M100k

20

VDD = 16V

GAMMA 10 TO 12

10

0

GAIN (dB)

–10

–20

–30

TPC 7. Frequency Response

vs. Capacitive Loading

340pF

540pF

1040pF

1M 10M

FREQUENCY (Hz

50pF

100pF

20

VDD = 16V

V

COM

10

0

GAIN (dB)

–10

–20

30M100k

–30

TPC 8. Frequency Response

vs. Capacitive Loading

340pF

540pF

1040pF

1M 10M

FREQUENCY (Hz)

100pF

50pF

30M100k

TPC 9. Input and Output Phase

Shift vs. Capacitive Load

REV. 0–4–

ADD8702

V

= 16V

DD

= 10k

R

L

C

= 100pF

L

VOLTA GE (2V/DIV)

TIME (2s/DIV)

TPC 10. Large Signal Transient

Response

11

10

9

8

7

6

5

4

AMPLITUDE (V)

3

2

1

0

–200 1,800

120pF

320pF

520pF

200 600 1,000 1,400

TIME (ns)

VDD = 16V

GAMMA = 2

1F

TPC 13. Transient Load

Response vs. Capacitive Load

10F

16

VDD = 16V

= 33

R

14

NULL

= 100pF

C

L

12

10

8

6

SLEW RATE (V/s)

4

2

0

–40 85

V

SLEW RATE FALLING

COM

V

SLEW RATE RISING

COM

25

TEMPERATURE (C)

TPC 11. Slew Rate vs. Temperature

11

10

9

8

320pF

7

6

5

4

AMPLITUDE (V)

3

2

1

0

–200 1,800

120pF

520pF

200 600 1,000 1,400

TIME (ns)

VDD = 16V

GAMMA = 11

10F

1F

TPC 14. Transient Load

Response vs. Capacitive Load

VOLTA GE (20mV/DIV)

7V < VDD < 16V

= 33

R

NULL

= 0.1F

C

L

TIME (20s/DIV)

TPC 12. Small Signal Transient

Response

11

10

9

8

120pF

7

6

5

4

AMPLITUDE (V)

3

2

1

0

–200 1,800

320pF

520pF

200 600 1,000 1,400

TIME (ns)

VDD = 16V

V

1F10F

TPC 15. Transient Load

Response vs. Capacitive Load

COM

100

VDD = 16V

90

GAMMA 1 TO 9

80

70

60

50

40

30

20

OUTPUT VOLTAGE ERROR (mV)

10

0

0.001 0.01 1000.1 1 10

LOAD CURRENT (mA)

SOURCE

TPC 16. Output Voltage

Error vs. Load Current

SINK

1,400

VDD = 16V

GAMMA 10 TO 12

1,200

1,000

800

600

400

OUTPUT VOLTAGE ERROR (mV)

200

0

0.001 0.01 1000.1 1 10

LOAD CURRENT (mA)

TPC 17. Output Voltage

Error vs. Load Current

SINK

SOURCE

50

VDD = 16V

45

V

COM

40

35

30

25

20

15

10

OUTPUT VOLTAGE ERROR (mV)

5

0

0.001 0.01 1000.1 1 10

LOAD CURRENT (mA)

TPC 18. Output Voltage

Error vs. Load Current

SOURCE

SINK

REV. 0

–5–

ADD8702

)

)

6,000

VDD = 16V

= 25C

T

A

5,000

ALL CHANNELS

4,000

3,000

2,000

1,000

FREQUENCY (No. of Amplifiers)

0

–14 –6 2 10 182634

–22

OUTPUT VOLTAGE ERROR (mV)

TPC 19. Output Voltage Error

Distribution

70

VDD = 16V

60

50

40

30

20

10

VOLTA G E NOISE DENSITY (nV/ Hz)

–10

AND BUFFERS 1 TO 9

V

COM

MARKER SET @ 10kHz

MARKER READING = 25.7nV/ Hz

0

051015 20 25

FREQUENCY (Hz

TPC 22. Voltage Noise Density

vs. Frequency

80

ALL CHANNELS

= 8V

V

60

DD

= 25C

T

A

40

20

0

–20

–40

–60

–80

–100

POWER SUPPLY REJECTION RATIO (dB)

–120

100 1k 10M10k 100k 1M

FREQUENCY (Hz)

PSRR

TPC 20. Power Supply Rejection

Ratio vs. Frequency

70

VDD = 16V

60

BUFFERS 10 TO 12

MARKER SET @ 10kHz

MARKER READING = 36.6nV/ Hz

50

40

30

20

10

0

VOLTA G E NOISE DENSITY (nV/ Hz)

–10

051015 20 25

FREQUENCY (Hz

TPC 23. Voltage Noise Density

vs. Frequency

VOLTA GE (3V/DIV)

TIME (40s/DIV)

TPC 21. No Phase Reversal

REV. 0–6–

APPLICATIONS

Figure 1 is a block diagram of the configuration of an XGAcompatible (1024 ⫻ 768) TFT color panel with the ADD8702

providing gamma correction reference voltages to the source

drivers and an integrated V

16V

driver for LCD common node.

COM

BUFFER

R

NULL

V

HIGH

VIN11

V

IN

ADD8702

A12

A11

10

A10

GMA 12

GMA 11

GMA 10

C

R

T

L

Figure 2. Bandwidth Measurement Information

Panel size and resolution determine the number of gamma

reference voltages required. For a 256-grayscale level, 8-bit color

scheme, 6 ⫻ 2 external reference nodes should be sufficient to

match the characteristics of the LCD driver to the characteristics

of the actual LCD panel for improved picture quality. External

reference gamma correction voltages are often generated using

a simple resistor ladder. Using the ADD8702, the resistor

ladder is incorporated in the IC for reduced cost and number

of components.

16V

5V

BUFFER

33 1k

V

TH

0.1s

V

TH

10V

5V

0V

Figure 3. Transient Load Regulation Test Circuit

The ADD8702 is designed to meet the rail-to-rail capability

needed by the application, yet offers the lowest cost per channel

solution. The ADD8702 gamma buffers offer 10 mA continuous

drive current capability. To be more competitive, the design

maximizes the die area by allowing specific channels to swing to

the positive rail and negative rail. So it is imperative that the

channels swinging close to the supply rail be used for the positive gamma references and the channels swinging close to GND

be used for the negative gamma references. The V

buffer can

COM

handle up to 35 mA continuous output current and can drive up

to 1,000 pF pure capacitive load. Provision is available to adjust

the V

voltage to a desired level. Refer to Figure 4 for an

COM

example of an application circuit for adjusting the output of the

buffer.

V

COM

GMA 9

GMA 8

GMA 7

GMA 6

GMA 5

GMA 4

GMA 3

GMA 2

GMA 1

V

COM

V

IN

V

IN

V

IN

V

IN

VIN5

V

IN

V

IN

V

IN

V

LOW

V

DD

GND

ADJUST

V

2k

COM

A9

A8

A7

A6

A5

A4

A3

A2

A1

AMP

LCD SOURCE DRIVER

LCD COMMON PLANE

9

8

7

6

4

3

2

32k

ADD8702

Figure 4. Application Circuit

Table I. ADD8702 – 000 Mask Option, Resistor Tap Points

(0 ≤ ≤ 500) VDD = 12.5 V, V

= 12.5 V, and V

HIGH

LOW

= GND

POSITIVE GAMMA REFERENCES

NEGATIVE GAMMA REFERENCES

REV. 0

Tap Point () Voltage Unit

VGMA1 8 0.2 V

VGMA2 57 1.43 V

VGMA3 84 2.11 V

VGMA4 115 2.89 V

VGMA5 139 3.48 V

VGMA6 194 4.86 V

VGMA7 218 5.45 V

VGMA8 298 7.45 V

VGMA9 371 9.29 V

VGMA10 418 10.45 V

VGMA11 442 11.04 V

VGMA12 488 12.2 V

V

COM

200 5 V

–7–

ADD8702

OUTLINE DIMENSIONS

32-Lead Lead Frame Chip Scale Package [LFCSP]

(CP-32)

Dimensions shown in millimeters

PIN 1

INDICATOR

1.00

0.90

0.80

12 MAX

SEATING

PLANE

5.00

BSC SQ

TOP

VIEW

0.80 MAX

0.65 NOM

0.30

0.23

0.18

COMPLIANT TO JEDEC STANDARDS MO-220-VHHD-2

4.75

BSC SQ

0.20 REF

0.05 MAX

0.02 NOM

0.60 MAX

0.50

BSC

0.50

0.40

0.30

COPLANARITY

0.08

0.60 MAX

25

24

17

16

BOTTOM

VIEW

3.50

REF

PIN 1

32

9

INDICATOR

1

3.25

3.10

SQ

2.95

8

C03820–0–6/03(0)

–8–

REV. 0

Loading...

Loading...