1.8 V, 12-LVDS/24-CMOS Output,

FEATURES

2 selectable differential inputs

Selectable LVDS/CMOS outputs

Up to 12 LVDS (1.2 GHz) or 24 CMOS (250 MHz) outputs

<12 mW per channel (100 MHz operation)

54 fs rms integrated jitter (12 kHz to 20 MHz)

100 fs rms additive broadband jitter

2.0 ns propagation delay (LVDS)

135 ps output rise/fall (LVDS)

70 ps output-to-output skew (LVDS)

Sleep mode

Pin programmable control

1.8 V power supply

APPLICATIONS

Low jitter clock distribution

Clock and data signal restoration

Level translation

Wireless communications

Wired communications

Medical and industrial imaging

ATE and high performance instrumentation

Low Power Clock Fanout Buffer

ADCLK854

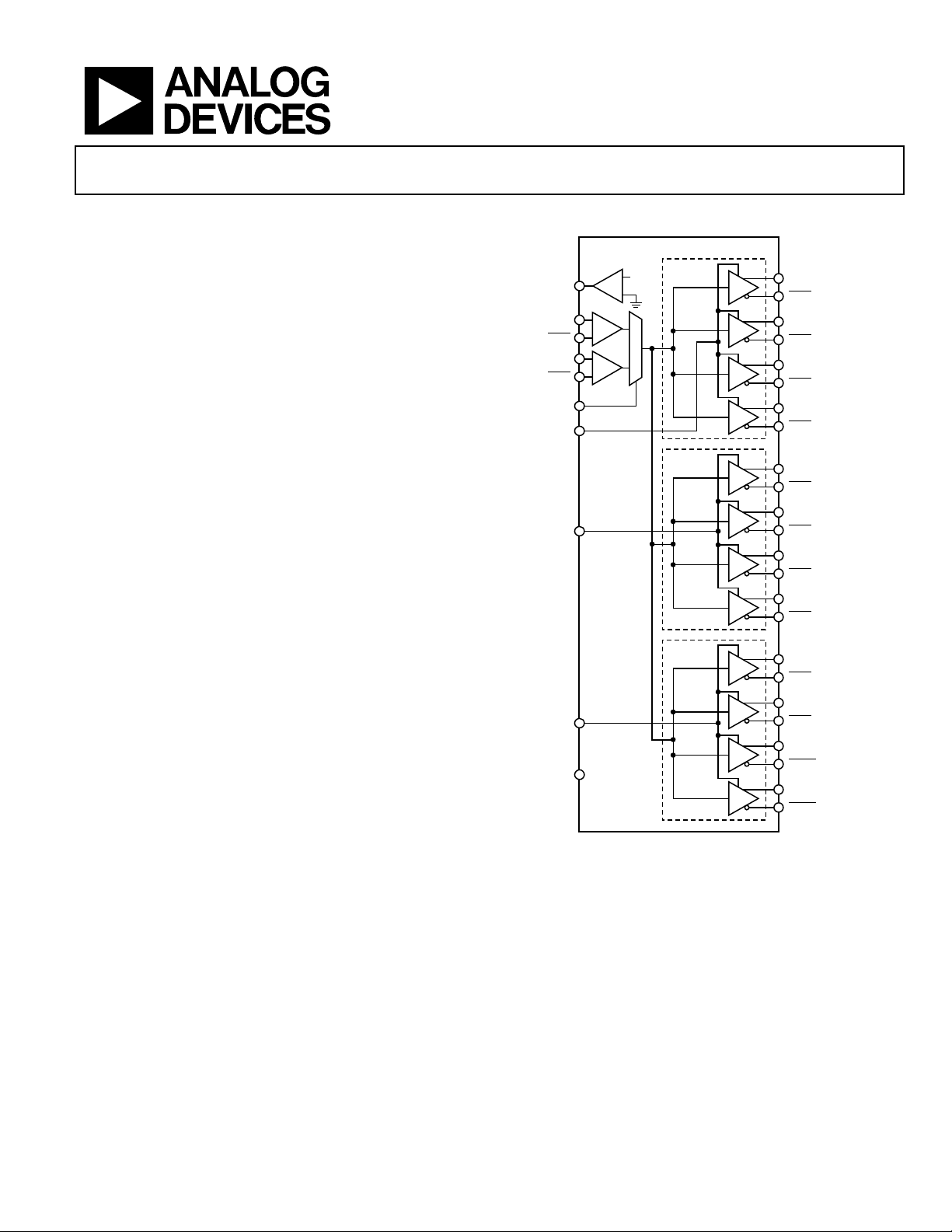

FUNCTIONAL BLOCK DIAGRAM

ADCLK854

LVDS/

VS/2

V

REF

CLK0

CLK0

CLK1

CLK1

IN_SEL

CTRL_A

CTRL_B

CMOS

LVDS/

CMOS

OUT0 (OUT0A)

OUT0 (OUT0B)

OUT1 (OUT1A)

OUT1 (OUT1B)

OUT2 (OUT2A)

OUT2 (OUT2B)

OUT3 (OUT3A)

OUT3 (OUT3B)

OUT4 (OUT4A)

OUT4 (OUT4B)

OUT5 (OUT5A)

OUT5 (OUT5B)

OUT6 (OUT6A)

OUT6 (OUT6B)

OUT7 (OUT7A)

OUT7 (OUT7B)

GENERAL DESCRIPTION

The ADCLK854 is a 1.2 GHz/250 MHz LVDS/CMOS fanout

buffer optimized for low jitter and low power operation. Possible

configurations range from 12 LVDS to 24 CMOS outputs,

including combinations of LVDS and CMOS outputs. Three

control lines are used to determine whether fixed blocks of

outputs (three banks of four) are LVDS or CMOS outputs.

The ADCLK854 offers two selectable inputs and a sleep mode

feature. The IN_SEL pin state determines which input is fanned

out to all the outputs. The SLEEP pin enables a sleep mode to

power down the device.

The inputs accept various types of single-ended and differential

logic levels including LVPECL, LVDS, HSTL, CML, and CMOS.

Tabl e 8 provides interface options for each type of connection.

This device is available in a 48-pin LFCSP package. It is specified

for operation over the standard industrial temperature range of

−40°C to +85°C.

CTRL_C

SLEEP

LVDS/

CMOS

Figure 1.

OUT8 (OUT8A)

OUT8 (OUT8B)

OUT9 (OUT9A)

OUT9 (OUT9B)

OUT10 (OUT10A)

OUT10 (OUT10B)

OUT11 (OUT11A)

OUT11 (OUT11B)

07218-001

Rev. 0

Information furnished by Analog Devices is believed to be accurate and reliable. However, no

responsibility is assumed by Analog Devices for its use, nor for any infrin gements of patents or other

rights of third parties that may result from its use. Specifications subject to change without notice. No

license is granted by implication or otherwise under any patent or patent rights of Analog Devices.

Trademarks and registered trademarks are the property of their respective owners.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700 www.analog.com

Fax: 781.461.3113 ©2009 Analog Devices, Inc. All rights reserved.

ADCLK854

TABLE OF CONTENTS

Features .............................................................................................. 1

Applications ....................................................................................... 1

General Description ......................................................................... 1

Functional Block Diagram .............................................................. 1

Revision History ............................................................................... 2

Specifications ..................................................................................... 3

Electrical Characteristics ............................................................. 3

Timing Characteristics ................................................................ 4

Clock Characteristics ................................................................... 5

Logic and Power Characteristics ................................................ 5

Absolute Maximum Ratings ............................................................ 6

Determining Junction Temperature .......................................... 6

ESD Caution .................................................................................. 6

Thermal Performance .................................................................. 6

Pin Configuration and Function Descriptions ............................. 7

Typical Performance Characteristics ..............................................9

Functional Description .................................................................. 12

Clock Inputs ................................................................................ 12

AC-Coupled Input Applications ............................................... 12

Clock Outputs ............................................................................. 12

Control and Function Pins ........................................................ 13

Power Supply ............................................................................... 13

Applications Information .............................................................. 14

Using the ADCLK854 Outputs for ADC Clock Applications

....................................................................................................... 14

LVDS Clock Distribution .......................................................... 14

CMOS Clock Distribution ........................................................ 14

Input Termination Options ....................................................... 15

Outline Dimensions ....................................................................... 16

Ordering Guide .......................................................................... 16

REVISION HISTORY

4/09—Revision 0: Initial Version

Rev. 0 | Page 2 of 16

ADCLK854

SPECIFICATIONS

ELECTRICAL CHARACTERISTICS

Typical (Typ) values are given for VS = 1.8 V and TA = 25°C, unless otherwise noted. Minimum (Min) and maximum (Max) values are given over

the full V

Table 1. Clock Inputs and Outputs

Parameter Symbol Min Typ Max Unit Conditions

CLOCK INPUTS Differential input

Input Sensitivity, Single-Ended 150 mV p-p

LVDS CLOCK OUTPUTS

CMOS CLOCK OUTPUTS Single-ended; termination = open; OUTx and

= 1.8 V ± 5% and TA = −40°C to +85°C variation, unless otherwise noted. Input slew rate > 1 V/ns, unless otherwise noted.

S

Input Frequency 0 1200 MHz

Input Sensitivity, Differential 150 mV p-p Jitter performance improves with higher slew

rates (greater voltage swing)

Input Level 1.8 V p-p Larger voltage swings can turn on the protection

diodes and degrade jitter performance

Input Common-Mode Voltage VCM V

Input Common-Mode Range V

0.4 VS − 0.4 V Inputs dc-coupled with 200 mV p-p signal applied

CMR

/2 − 0.1 VS/2 + 0.5 V Inputs are self-biased; enables ac coupling

S

Input Voltage Offset 30 mV

CLKx ac-coupled;

ac bypassed to ground

CLKx

Input Resistance (Differential) 7 kΩ

Input Capacitance CIN 2 pF

Input Bias Current (Each Pin) −350 +350 µA Full input swing

Termination = 100 Ω; differential (OUTx,

OUTx

)

Output Frequency 1200 MHz See Figure 9 for swing vs. frequency

Output Voltage Differential VOD 247 344 454 mV

Delta VOD VOD 50 mV

Offset Voltage VOS 1.125 1.25 1.375 V

Delta VOS VOS 50 mV

Short-Circuit Current ISA, ISB 3 6 mA Each pin (output shorted to GND)

in phase

OUTx

Output Frequency 250 MHz With 10 pF load per output; see Figure 16 for

swing vs. frequency

Output Voltage High VOH V

− 0.1 V @ 1 mA load

S

Output Voltage Low VOL 0.1 V @ 1 mA load

Output Voltage High VOH V

− 0.35 V @ 10 mA load

S

Output Voltage Low VOL 0.35 V @ 10 mA load

Reference Voltage V

REF

Output Voltage VS/2 − 0.1 VS/2 VS/2 + 0.1 V ±500 µA

Output Resistance 60 Ω

Output Current 500 µA

Rev. 0 | Page 3 of 16

ADCLK854

TIMING CHARACTERISTICS

Table 2. Timing Characteristics

Parameter Symbol Min Typ Max Unit Conditions

LVDS OUTPUTS Termination = 100 differential; 3.5 mA

Output Rise/Fall Time tR , tF 135 235 ps 20% to 80% measured differentially

Propagation Delay, Clock-to-LVDS Output tPD 1.5 2.0 2.7 ns V

Temperature Coefficient 2.0 ps/°C

Output Skew

1

LVDS Outputs in the Same Bank 50 ps

All LVDS Outputs

On the Same Part 65 ps

Across Multiple Parts 390 ps

Additive Time Jitter

Integrated Random Jitter 54 fs rms BW = 12 kHz to 20 MHz; clock = 1000 MHz

74 fs rms BW = 50 kHz to 80 MHz; clock = 1000 MHz

86 fs rms BW = 10Hz to 100 MHz; clock = 1000 MHz

Broadband Random Jitter

2

150 fs rms Input slew = 1 V/ns, see Figure 11

Crosstalk Induced Jitter 260 fs rms Calculated from spur energy with an

CMOS OUTPUTS

Output Rise/Fall Time tR, tF 525 950 ps 20% to 80%; C

Propagation Delay, Clock-to-CMOS Output tPD 2.5 3.2 4.2 ns 10 pF load

Temperature Coefficient 2.2 ps/°C

Output Skew

1

CMOS Outputs in the Same Bank 155 ps

All CMOS Outputs

On the Same Part 175 ps

Across Multiple Parts 640 ps

Additive Time Jitter

Integrated Random Jitter 56 fs rms BW = 12 kHz to 20 MHz; clock = 200 MHz

Broadband Random Jitter

2

100 fs rms Input slew = 2 V/ns, see Figure 11

Crosstalk Induced Jitter 260 fs rms Calculated from spur energy with an

LVDS-TO-CMOS OUTPUT SKEW

LVDS Output(s) and CMOS Output(s) on the

3

0.8 1.6 ns CMOS load = 10 pF and LVDS load = 100 Ω

Same Part

1

This is the difference between any two similar delay paths while operating at the same voltage and temperature.

2

Calculated from the SNR of the ADC method.

3

Measured at the rising edge of the clock signal.

= V

ICM

, VID = 0.5 V

REF

interferer 10 MHz offset from the carrier

= 10 pF

LOAD

interferer 10 MHz offset from the carrier

Rev. 0 | Page 4 of 16

ADCLK854

CLOCK CHARACTERISTICS

Table 3. Clock Output Phase Noise

Parameter Min Typ Max Unit Conditions

CLOCK-TO-LVDS ABSOLUTE PHASE NOISE Input slew rate > 1 V/ns

1000 MHz −90 dBc/Hz @ 10 Hz offset

−108 dBc/Hz @ 100 Hz offset

−117 dBc/Hz @ 1 kHz offset

−126 dBc/Hz @ 10 kHz offset

−135 dBc/Hz @ 100 kHz offset

−141 dBc/Hz @ 1 MHz offset

−146 dBc/Hz @ 10 MHz offset

CLOCK-TO-CMOS ABSOLUTE PHASE NOISE Input slew rate > 1 V/ns

200 MHz −101 dBc/Hz @ 10 Hz offset

−119 dBc/Hz @ 100 Hz offset

−127 dBc/Hz @ 1 kHz offset

−138 dBc/Hz @ 10 kHz offset

−147 dBc/Hz @ 100 kHz offset

−153 dBc/Hz @ 1 MHz offset

−156 dBc/Hz @ 10 MHz offset

LOGIC AND POWER CHARACTERISTICS

Table 4. Control Pin Characteristics

Parameter Symbol Min Typ Max Unit Conditions

CONTROL PINS (IN_SEL, CTRL_x, SLEEP)1

Logic 1 Voltage VIH V

Logic 0 Voltage VIL 0.4 V

Logic 1 Current IIH 5 8 20 A

Logic 0 Current IIL −5 +5 A

Capacitance 2 pF

POWER

Supply Voltage Requirement VS 1.71 1.8 1.89 V VS = 1.8 V ± 5%

LVDS Outputs Full operation

LVDS @ 100 MHz 84 100 mA All outputs enabled as LVDS and loaded, RL = 100

LVDS @ 1200 MHz 175 215 mA All outputs enabled as LVDS and loaded, RL = 100

CMOS Outputs

Full operation

CMOS @ 100 MHz 115 140 mA All outputs enabled as CMOS and loaded, CL = 10 pF

CMOS @ 250 MHz 265 325 mA All outputs enabled as CMOS and loaded, CL = 10 pF

SLEEP

Power Supply Rejection

2

LVDS

CMOS

1

These pins each have a 200 kΩ internal pull-down resistor.

2

Change in t

per change in VS.

PD

3 mA SLEEP pin pulled high; does not include power dissipated

PSR

PSR

− 0.4 V

S

0.9 ps/mV

t

PD

1.2 ps/mV

t

PD

in the external resistors

Rev. 0 | Page 5 of 16

ADCLK854

ABSOLUTE MAXIMUM RATINGS

Table 5.

Parameter Rating

Supply Voltage

VS to GND 2 V

Inputs

CLKx and

CLKx

−0.3 V to +2 V

CMOS Inputs −0.3 V to +2 V

Outputs

Maximum Voltage −0.3 V to +2 V

Voltage Reference Voltage (V

) −0.3 to +2 V

REF

Operating Temperature

Ambient Range −40°C to +85°C

Junction 150°C

Storage Temperature Range −65°C to +150°C

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

DETERMINING JUNCTION TEMPERATURE

To determine the junction temperature on the application

printed circuit board (PCB), use the following equation:

where:

T

is the junction temperature (°C).

J

T

CASE

top center of the package.

Ψ

is from Tabl e 6.

JT

P

is the power dissipation.

D

Val u es of

design considerations.

mation of T

where

Values of

and PCB design considerations.

ESD CAUTION

T

= T

J

+ (ΨJT × PD)

CASE

is the case temperature (°C) measured by the user at the

θ

are provided for package comparison and PCB

JA

θ

can be used for a first-order approxi-

JA

by the equation

J

T

= TA + (

J

T

θ

× PD)

JA

is the ambient temperature (°C).

A

θ

are provided in Table 6 for package comparison

JB

THERMAL PERFORMANCE

Table 6.

Parameter Symbol Description (Using a 2S2P Test Board) Value

Junction-to-Ambient Thermal Resistance

θ

JA

Still Air Per JEDEC JESD51-2

0.0 m/sec Air Flow 42 °C/W

Moving Air

θ

JMA

Per JEDEC JESD51-6

1.0 m/sec Air Flow 37 °C/W

2.5 m/sec Air Flow 33 °C/W

Junction-to-Board Thermal Resistance

θ

JB

Moving Air Per JEDEC JESD51-8

1.0 m/sec Air Flow 26 °C/W

Junction-to-Case Thermal Resistance

θ

JC

Moving Air Per MIL-STD 883, Method 1012.1

Die-to-Heat Sink 2 °C/W

Junction-to-Top-of-Package Characterization Parameter

Ψ

JT

Still Air Per JEDEC JESD51-2

0 m/sec Air Flow 0.5 °C/W

1

Results are from simulations. The PCB is a JEDEC multilayer type. Thermal performance for actual applications requires careful inspection of the conditions in the

application to determine if they are similar to those assumed in these calculations.

1

Unit

Rev. 0 | Page 6 of 16

ADCLK854

)

PIN CONFIGURATION AND FUNCTION DESCRIPTIONS

S

V

37

NC36

35

NC

34

OUT4 (OUT4A)

33

OUT4 (OUT4B)

32

OUT5 (OUT5A)

31

OUT5 (OUT5B)

30

V

S

29

GND

28

OUT6 (OUT6A)

27

OUT6 (OUT6B)

26

OUT7 (OUT7A)

25

OUT7 (OUT7B)

S

V

GND

OUT8 (OUT8B)

OUT8 (OUT8A)

07218-002

V

REF

CLK0

CLK0

GND

CLK1

CLK1

OUT11 (OUT11B)

OUT11 (OUT11A)

IN_SEL

CTRL_A

CTRL_B

OUT0 (OUT0B)OUT1 (OUT1A)OUT1 (OUT1B)GND

OUT0 (OUT0A

4847464544434241403938

1

2

3

4

5

6

7

V

S

8

9

10

11

12

NOTES:

1. NC = NO CONNECT .

2. EXPOSE D PADDLE MUST BE CONNECTED TO GND.

PIN 1

INDICAT OR

13141516171819

SLEEP

CTRL_C

VSOUT2 (OUT2A)OUT2 (OUT2B)OUT3 (OUT3A)OUT3 (OUT3B)GND

ADCLK854

TOP VIEW

(Not to Scale)

V

GND

OUT10 (OUT 10B)

OUT10 (OUT 10A)

2021222324

S

OUT9 (OUT9B)

OUT9 (OUT9A)

Figure 2. Pin Configuration

Table 7. Pin Function Descriptions

Pin No. Mnemonic Description

1 V

2

Reference Voltage.

REF

CLK0

Input (Negative) 0.

3 CLK0 Input (Positive) 0.

7, 18, 24, 30,

VS Supply Voltage.

37, 43

5

CLK1

Input (Negative) 1.

6 CLK1 Input (Positive) 1.

8

OUT11

(OUT11B)

Complementary Side of Differential LVDS Output 11, or CMOS Output 11 on Channel B.

9 OUT11 (OUT11A) True Side of Differential LVDS Output 11, or CMOS Output 11 on Channel A.

10 IN_SEL

Input Select. (0 = CLK0,

CLK0

; 1 = CLK1,

). CMOS logic input with 200 kΩ pull-down resistor.

CLK1

11 CTRL_A Control for Output 3 to Output 0 (0 = LVDS, 1 = CMOS). CMOS logic input with 200 kΩ pull-down resistor.

12 CTRL_B Control for Output 7 to Output 4 (0 = LVDS, 1 = CMOS). CMOS logic input with 200 kΩ pull-down resistor.

13 CTRL_C Control for Output 11 to Output 8 (0 = LVDS, 1 = CMOS). CMOS logic input with 200 kΩ pull-down resistor.

14 SLEEP Sleep Mode Control (0 = normal operation, 1 = sleep). CMOS logic input with 200 kΩ pull down resistor.

15

OUT10

(OUT10B)

Complementary Side of Differential LVDS Output 10, or CMOS Output 10 on Channel B.

16 OUT10 (OUT10A) True Side of Differential LVDS Output 10, or CMOS Output 10 on Channel A.

4, 17, 23, 29,

GND Ground Pin.

38, 44

19

OUT9

(OUT9B)

Complementary Side of Differential LVDS Output 9, or CMOS Output 9 on Channel B.

20 OUT9 (OUT9A) True Side of Differential LVDS Output 9, or CMOS Output 9 on Channel A.

21

OUT8

(OUT8B)

Complementary Side of Differential LVDS Output 8, or CMOS Output 8 on Channel B.

22 OUT8 (OUT8A) True Side of Differential LVDS Output 8, or CMOS Output 8 on Channel A.

25

OUT7

(OUT7B)

Complementary Side of Differential LVDS Output 7, or CMOS Output 7 on Channel B.

Rev. 0 | Page 7 of 16

ADCLK854

Pin No. Mnemonic Description

26 OUT7 (OUT7A) True Side of Differential LVDS Output 7, or CMOS Output 7 on Channel A.

27

28 OUT6 (OUT6A) True Side of Differential LVDS Output 6, or CMOS Output 6 on Channel A.

31

32 OUT5 (OUT5A) True Side of Differential LVDS Output 5, or CMOS Output 5 on Channel A.

33

34 OUT4 (OUT4A) True Side of Differential LVDS Output 4, or CMOS Output 4 on Channel A.

35 NC No Connect.

36 NC No Connect.

39

40 OUT3 (OUT3A) True Side of Differential LVDS Output 3, or CMOS Output 3 on Channel A.

41

42 OUT2 (OUT2A) True Side of Differential LVDS Output 2, or CMOS Output 2 on Channel A.

45

46 OUT1 (OUT1A) True Side of Differential LVDS Output 1, or CMOS Output 1 on Channel A.

47

48 OUT0 (OUT0A) True Side of Differential LVDS Output 0, or CMOS Output 0 on Channel A.

(49) EPAD Exposed Paddle. The exposed paddle must be connected to GND.

OUT6

OUT5

OUT4

OUT3

OUT2

OUT1

OUT0

(OUT6B)

(OUT5B)

(OUT4B)

(OUT3B)

(OUT2B)

(OUT1B)

(OUT0B)

Complementary Side of Differential LVDS Output 6, or CMOS Output 6 on Channel B.

Complementary Side of Differential LVDS Output 5, or CMOS Output 5 on Channel B.

Complementary Side of Differential LVDS Output 4, or CMOS Output 4 on Channel B.

Complementary Side of Differential LVDS Output 3, or CMOS Output 3 on Channel B.

Complementary Side of Differential LVDS Output 2, or CMOS Output 2 on Channel B.

Complementary Side of Differential LVDS Output 1, or CMOS Output 1 on Channel B.

Complementary Side of Differential LVDS Output 0, or CMOS Output 0 on Channel B.

Rev. 0 | Page 8 of 16

ADCLK854

TYPICAL PERFORMANCE CHARACTERISTICS

VS = +1.8 V, TA = 25°C, unless otherwise noted.

2

CH2 100mV M 200ps 10.0G S/s CH1 –36.0mV

Figure 3. LVDS Output Waveform @ 1200 MHz Figure 6. LVDS Output Waveform @ 200 MHz

2.3

2.2

2.1

2.0

1.9

PROPATATI ON DELAY (ns)

1.8

1.7

0.1 1.71.51.31.10.90.70.50.3

INPUT DIFFERENTIAL (V p-p)

Figure 4. LVDS Propagation Delay vs. Input Differential Voltage (VID)

2

7218-003

07218-004

CH2 100mV M 1.0n s 10.0GS/ s CH1 –36.0mV

2.4

2.3

2.2

2.1

2.0

1.9

1.8

1.7

PROPAGATION DELAY (ns)

1.6

1.5

1.4

200 1600140012001000800600400

INPUT COMMON-MODE (mV)

Figure 7. LVDS Propagation Delay vs. V

7218-006

07218-007

ICM

55

54

53

52

51

50

49

DUTY CYCLE (%)

48

47

46

45

0 200 400 600 800 1000 1200

FREQUENCY (MHz)

Figure 5. LVDS Output Duty Cycle vs. Frequency Figure 8. LVDS Differential Output Swing vs. Power Supply Voltage

07218-005

Rev. 0 | Page 9 of 16

715

705

695

685

DIFFERENTIAL OUTPUT SWING (mV p-p)

675

1.62 1.921.821.72

POWER SUPPLY (V)

07218-008

ADCLK854

–

900

800

700

600

500

DIFFERENTIAL OUTPUT SWING (mV p-p)

400

100

200

300

400

500

600

700

800

900

1000

INPUT FREQ UENCY (MHz)

Figure 9. LVDS Differential Output Swing vs. Input Frequency

1100

1200

1300

1400

1500

1600

1700

80

–90

–100

–110

–120

–130

–140

–150

PHASE NOISE (d Bc/Hz)

–160

–170

–180

07218-009

ABSOLUTE PHASE NOISE ME ASURED @ 1GHz WI TH AGILENT

E5052 USING WENZEL CLOCK SOURCE CONSISTING OF A

WENZEL 100MHz CRYSTAL OSCILLATOR (P/N 500-06672),

WENZEL 5× MULTIPLIER (P/N LNOM-100-5-13-14-F-A), AND A

WENZEL 2× MULTIPLIER (P/N LNDD-500-14-14-1-D).

ADCLK854

CLOCK SOURCE

10 100M10M1M100k10k1k100

FREQUENCY OFFSET (Hz)

07218-012

Figure 12. Absolute Phase Noise LVDS @ 1000 MHz

350

325

300

275

250

225

200

175

150

CURRENT (mA)

125

100

75

50

25

0

0 200 400 600 800 1000 1200 1400 1600 1800

FREQUENCY (MHz)

Figure 10. LVDS Current vs. Frequency; All Banks Set to LVDS

500

450

400

350

300

250

200

JITTER ( fs rms)

150

100

50

0

022.01.51.00.5

INPUT SLEW RATE (V/ns)

Figure 11. Additive Broadband Jitter vs. Input Slew Rate

300

250

200

150

CURRENT (mA)

100

50

0

25 50 75 100 125 150 175 225200 250

07218-110

ALL BANKS LVDS

FREQUENCY (MHz )

Figure 13. LVDS/CMOS Current vs. Frequency with Various Logic

Combinations

55

54

53

52

51

50

49

DUTY CYCLE (%)

48

47

46

.5

07218-011

45

0 50 100 150 200 250

FREQUENCY (MHz)

Figure 14. CMOS Output Duty Cycle vs. Frequency (10 pF Load)

ALL BANKS CMOS

2 BANKS CMOS

1 BANK LVDS

1 BANK CMOS

2 BANKS LVDS

07218-113

07218-014

Rev. 0 | Page 10 of 16

ADCLK854

1

CH1 300mV 1.25ns/DI V CH1 954mV

7218-015

1

CH1 300mV 5.0ns/DIV CH1 954mV

Figure 15. CMOS Output Waveform @ 200 MHz (10 pF Load) Figure 18. CMOS Output Waveform @ 50 MHz (10 pF Load)

1.9

1.8

1.7

1.6

1.5

1.4

OUTPUT SWING (V)

1.3

1.2

1.1

50 100 150 200 250

FREQUENCY (MHz)

25°C

85°C

07218-016

1.8

1.7

1.6

OUTPUT SWING (V)

1.5

1.4

0220015010050

= 750Ω

R

LOAD

= 500Ω

R

LOAD

R

FREQUENCY (MHz )

LOAD

= 300Ω

R

LOAD

= 1kΩ

Figure 16. CMOS Output Swing vs. Frequency by Temperature (10 pF Load) Figure 19. CMOS Output Swing vs. Frequency by Resistive Load

2.0

1.9

1.8

1.7

1.6

1.5

1.4

OUTPUT SWING (V)

1.3

1.2

1.1

1.0

0 50 100 150 200 250

FREQUENCY (MHz)

C

C

L

C

L

= 5pF

L

= 10pF

= 20pF

07218-017

Figure 17. CMOS Output Swing vs. Frequency by Capacitive Load

7218-018

50

07218-019

Rev. 0 | Page 11 of 16

ADCLK854

V

A

V

A

V

V

FUNCTIONAL DESCRIPTION

The ADCLK854 accepts a clock input from one of two inputs

and distributes the selected clock to all output channels. The

outputs are grouped into three banks of four and can be set to

either LVDS or CMOS levels. This allows the selection of multiple logic configurations ranging from 12 LVDS to 24 CMOS

outputs, along with other combinations using both types of logic.

CLOCK INPUTS

The ADCLK854 differential inputs are internally self-biased.

The clock inputs have a resistor divider that sets the commonmode level for the inputs. The complementary inputs are biased

about 30 mV lower than the true input to avoid oscillations if

the input signal stops. See Figure 20 for the equivalent input

circuit.

The inputs can be ac-coupled or dc-coupled. Table 8 displays a

guide for input logic compatibility. A single-ended input can be

accommodated by ac or dc coupling to one side of the differential

input; bypass the other input to ground with a capacitor.

Note that jitter performance degrades with low input slew rate,

as shown in Figure 11. See Figure 27 through Figure 32 for

different termination schemes.

S

9kΩ 9.5kΩ

CLKx

9kΩ

Figure 20. ADCLK854 Input Stage

10kΩ10kΩ

AC-COUPLED INPUT APPLICATIONS

The ADCLK854 offers two options for ac coupling. The first

option requires no external components (excluding the dc

blocking capacitor), it allows the user to simply couple the

reference signal onto the clock input pins. For more information, see Figure 29.

8.5kΩ

CLKx

GND

07218-020

The second option allows the use of the V

bias level for the ADCLK854. The V

CLKx

CLKx and

through resistors. This method allows lower

REF

pin to set the dc

REF

pin can be connected to

impedance termination of signals at the ADCLK854 (for more

information, see Figure 32). The internal bias resistors remain

in parallel with the external biasing. However, the relatively

high impedance of the internal resistors allows the external

termination to V

to dominate. This method is also useful

REF

when offsetting the inputs; using only the internal biasing, as

previously mentioned, is not desirable.

CLOCK OUTPUTS

Each driver consists of a differential LVDS output or two singleended CMOS outputs (always in phase). When the LVDS driver

is enabled, the corresponding CMOS driver is in tristate; when

the CMOS driver is enabled, the corresponding LVDS driver is

powered down and tristated. Figure 21 and Figure 22 display

the equivalent output stage.

S

3.5m

OUTx

OUTx

3.5m

Figure 21. LVDS Output Simplified Equivalent Circuit

S

OUTA

Figure 22. CMOS Output Equivalent Circuit

07218-021

S

OUTB

7218-022

Table 8. Input Logic Compatibility

Supply (V) Logic Common Mode (V) Output Swing (V) AC-Coupled DC-Coupled

3.3 CML 2.9 0.8 Yes Not allowed

2.5 CML 2.1 0.8 Yes Not allowed

1.8 CML 1.4 0.8 Yes

Yes

3.3 CMOS 1.65 3.3 Not allowed Not allowed

2.5 CMOS 1.25 2.5 Not allowed

Not allowed

1.8 CMOS 0.9 1.8 Yes Yes

1.5 HSTL 0.75 0.75 Yes

LVDS 1.25 0.4 Yes

Yes

Yes

3.3 LVPECL 2.0 0.8 Yes Not allowed

2.5 LVPECL 1.2 0.8 Yes

Yes

1.8 LVPECL 0.5 0.8 Yes Yes

Rev. 0 | Page 12 of 16

ADCLK854

CONTROL AND FUNCTION PINS

CTRL_A—Logic Select

This pin selects either CMOS (high) or LVDS (low) logic for

Output 3, Output 2, Output 1, and Output 0. This pin has an

internal 200 kΩ pull-down resistor.

CTRL_B—Logic Select

This pin selects either CMOS (high) or LVDS (low) logic for

Output 7, Output 6, Output 5, and Output 4. This pin has an

internal 200 kΩ pull-down resistor.

CTRL_C—Logic Select

This pin selects either CMOS (high) or LVDS (low) logic for

Output 11, Output 10, Output 9, and Output 8. This pin has an

internal 200 kΩ pull-down resistor.

IN_SEL—Clock Input Select

A logic low selects CLK0 and

CLK1

CLK1 and

. This pin has an internal 200 kΩ pull-down

CLK0

whereas a logic high selects

resistor.

Sleep Mode

Sleep mode powers down the chip except for the internal band

gap. The input is active high, which puts the outputs into a

high-Z state. This pin has a 200 kΩ pull-down resistor.

POWER SUPPLY

The ADCLK854 requires a 1.8 V ± 5% power supply for VS. Best

practice recommends bypassing the power supply on the PCB

with adequate capacitance (>10 μF), and bypassing all power

pins with adequate capacitance (0.1 μF) as close to the part as

possible. The layout of the ADCLK854 evaluation board

(ADCLK854/PCBZ) provides a good layout example.

Exposed Metal Paddle

The exposed metal paddle on the ADCLK854 package is an

electrical connection as well as a thermal enhancement. For the

device to function properly, the paddle must be properly

attached to ground (GND). The ADCLK854 dissipates heat

through its exposed paddle. The PCB acts as a heat sink for the

ADCLK854. The PCB attachment must provide a good thermal

path to a larger heat dissipation area, such as the ground plane

on the PCB. This requires a grid of vias from the top layer down

to the ground plane. See Figure 23 for an example.

VIAS TO G ND PLANE

07218-023

Figure 23. PCB Land for Attaching Exposed Paddle

Rev. 0 | Page 13 of 16

ADCLK854

V

V

APPLICATIONS INFORMATION

USING THE ADCLK854 OUTPUTS FOR ADC CLOCK APPLICATIONS

Any high speed, analog-to-digital converter (ADC) is extremely

sensitive to the quality of the sampling clock provided by the

user. An ADC can be thought of as a sampling mixer, and any

noise, distortion, or timing jitter on the clock is combined with

the desired signal at the analog-to-digital output. Clock integrity

requirements scale with the analog input frequency and resolution, with higher analog input frequency applications at ≥14-bit

resolution being the most stringent. The theoretical SNR of an

ADC is limited by the ADC resolution and the jitter on the

sampling clock. Considering an ideal ADC of infinite resolution

where the step size and quantization error can be ignored, the

available SNR can be expressed approximately by

2π

⎤

1

⎥

Tf

⎥

J

A

⎦

SNR = 20log

T

J

=

1

0

2

0

0

f

S

4

0

0

f

S

1

p

s

2

p

s

1

0

p

s

1

2πf

0

f

S

ATJ

18

16

14

12

ENOB

10

8

6

⎡

SNR

where f

×=

log20

⎢

⎢

⎣

is the highest analog frequency being digitized and TJ

A

is the rms jitter on the sampling clock.

Figure 24 shows the required sampling clock jitter as a function

of the analog frequency and effective number of bits (ENOB).

For more information, see Application Note AN-756 and

Application Note AN-501 at www.analog.com.

110

100

90

80

70

SNR (dB)

60

50

40

30

10 1k100

f

FULL-SCAL E SINE WAVE ANALOG FREQUENCY (MHz)

A

Figure 24. SNR and ENOB vs. Analog Input Frequency

Many high performance ADCs feature differential clock inputs

to simplify the task of providing the required low jitter clock on

a noisy PCB. Distributing a single-ended clock on a noisy PCB

can result in coupled noise on the sample clock. Differential

distribution has inherent common-mode rejection that can

provide superior clock performance in a noisy environment.

Consider the input requirements of the ADC (differential or

single-ended, logic level, and termination) when selecting the

best clocking/converter solution.

LVDS CLOCK DISTRIBUTION

The ADCLK854 provides clock outputs that are selectable as

either CMOS or LVDS level outputs. LVDS is a differential

output option that uses a current-mode output stage. The

nominal current is 3.5 mA, which yields 350 mV output swing

across a 100 Ω resistor. The LVDS output meets or exceeds all

ANSI/TIA/EIA-644 specifications. A recommended termination

circuit for the LVDS outputs is shown in Figure 25.

If ac coupling is necessary, place decoupling capacitors either before

or after the 100 Ω termination resistor. See Application Note

AN-586 at www.analog.com for more information on LVDS.

S

LVDS

DIFFERENTIAL (COUPLED)

100Ω

100Ω

Figure 25. LVDS Output Termination

S

LVDS

07218-025

CMOS CLOCK DISTRIBUTION

The output drivers of the ADCLK854 can be configured as

CMOS drivers. When selected as a CMOS driver, each output

becomes a pair of CMOS outputs. These outputs are 1.8 V

CMOS compatible.

When single-ended CMOS clocking is used, some of the

following guidelines apply.

Design point-to-point connections such that each driver has only

one receiver, if possible. Connecting outputs in this manner allows

for simple termination schemes and minimizes ringing due to

possible mismatched impedances on the output trace. Series termination at the source is generally required to provide transmission

line matching and/or to reduce current transients at the driver.

The value of the resistor (typically 10 Ω to 100 Ω) is dependent

on the board design and timing requirements. CMOS outputs

are also limited in terms of the capacitive load or trace length

that they can drive. Typically, trace lengths less than 3 inches are

07218-024

recommended to preserve signal rise/fall times and signal integrity.

60.4Ω

1.0 INCH

CMOS CMOS

10Ω

MICROSTRIP

07218-026

Figure 26. Series Termination of CMOS Output

Termination at the far end of the PCB trace is a second option.

The CMOS outputs of the ADCLK854 do not supply enough

current to provide a full voltage swing with a low impedance

resistive, far end termination, as shown in Figure 27. The far end

termination network should match the PCB trace impedance and

provide the desired switching point. The reduced signal swing may

Rev. 0 | Page 14 of 16

ADCLK854

V

V

still meet receiver input requirements in some applications. This

can be useful when driving long trace lengths on less critical

networks.

S

10Ω

CMOS CM OS

50Ω

100Ω

100Ω

07218-027

Figure 27. CMOS Output with Far End Termination

Because of the limitations of single-ended CMOS clocking,

consider using differential outputs when driving high speed

signals over long traces. The ADCLK854 offers LVDS outputs

that are better suited for driving long traces wherein the inherent

noise immunity of differential signaling provides superior

performance for clocking converters.

Figure 30. Typical AC-Coupled or DC-Coupled PECL Configuration

CLK

CLK

CLK

50Ω 50Ω

– 2V

V

CC

CLK

CLK

50Ω 50Ω

– 2V

V

CC

07218-030

(See Table 8 for LVPECL DC-Coupling Limitations)

CLK

INPUT TERMINATION OPTIONS

For single-ended operation always bypass unused input to

GND, as shown in Figure 31.

Figure 32 illustrates the use of V

termination into V

/2. In addition, a way to negate the 30 mV

S

input offset is with external resistor values; for example, using a

1.8 V CMOS with long traces to provide far end termination.

CLK

100Ω

CLK

CLK

100Ω

CLK

Figure 28. Typical AC-Coupled or DC-Coupled LVDS or HSTL Configuration

(See Table 8 for More Information)

CLK

CLK

V

to provide low impedance

REF

CC

CC

7218-028

CLK

CLK

CLK

CLK

Figure 31. Typical 1.8 V CMOS Configurations for Short Trace Lengths

(See Table 8 for CMOS Compatibility)

V

REF

CLK

Figure 32. Use of V

CLK

to Provide Low Impedance Termination into VS/2

REF

07218-032

07218-031

CLK

CLK

7218-029

Figure 29. Typical AC-Coupled or DC-Coupled CML Configuration

(See Table 8 for CML Coupling Limitations)

Rev. 0 | Page 15 of 16

ADCLK854

OUTLINE DIMENSIONS

PIN 1

INDICATOR

7.00

BSC SQ

6.75

BSC SQ

0.60 MAX

0.50

BSC

0.60 MAX

36

37

EXPOSED

PAD

(BOTTOM VI EW)

0.30

0.23

0.18

48

PIN 1

1

INDICATOR

*

2.90

2.80 SQ

2.70

1.00

0.85

0.80

SEATING

PLANE

12° MAX

TOP VI EW

0.80 MAX

0.65 TYP

0.05 MAX

0.02 NOM

COPLANARITY

0.20 REF

*

COMPLIANT TO JEDEC STANDARDS MO-220-VKKD- 2

WITH EXCE PTION T O EXPOSED P AD DIMENSION.

0.08

0.50

0.40

0.30

25

24

5.50 REF

FOR PROPER CO NNECTION O F

THE EXPOSED PAD, REFER TO

THE PIN CONF IGURATIO N AND

FUNCTION DESCRI PTIONS

SECTION O F THIS DAT A SHEET.

12

13

0.20 MIN

080508-A

Figure 33. 48-Lead Lead Frame Chip Scale Package [LFCSP_VQ]

7 mm × 7 mm Body, Very Thin Quad

CP-48-6

Dimensions shown in millimeters

ORDERING GUIDE

Model Temperature Range Package Description Package Option

ADCLK854BCPZ

ADCLK854BCPZ-REEL7

ADCLK854/PCBZ

1

Z = RoHS Compliant Part.

1

1

−40°C to +85°C 48-Lead LFCSP_VQ CP-48-6

1

Evaluation Board

−40°C to +85°C 48-Lead LFCSP_VQ CP-48-6

©2009 Analog Devices, Inc. All rights reserved. Trademarks and

registered trademarks are the property of their respective owners.

D07218-0-4/09(0)

Rev. 0 | Page 16 of 16

Loading...

Loading...