Dual-Channel, 14-Bit, CCD Signal

A

A

Processor with Precision Timing Core

FEATURES

1.8 V analog and digital core supply voltage

Correlated double sampler (CDS) with

−3 dB, 0 dB, +3 dB, and +6 dB gain

6 dB to 42 dB, 10-bit variable gain amplifier (VGA)

14-bit, 65 MHz analog-to-digital converter (ADC)

Black level clamp with variable level control

Complete on-chip timing generator

Precision Timing core with 240 ps resolution @ 65 MHz

On-chip 3 V horizontal and RG drivers

100-lead, 9 mm × 9 mm, 0.8 mm pitch, CSP_BGA package

Internal low dropout (LDO) regulator circuitry

APPLICATIONS

Professional HDTV camcorders

Professional/high end digital cameras

Broadcast cameras

Industrial high speed cameras

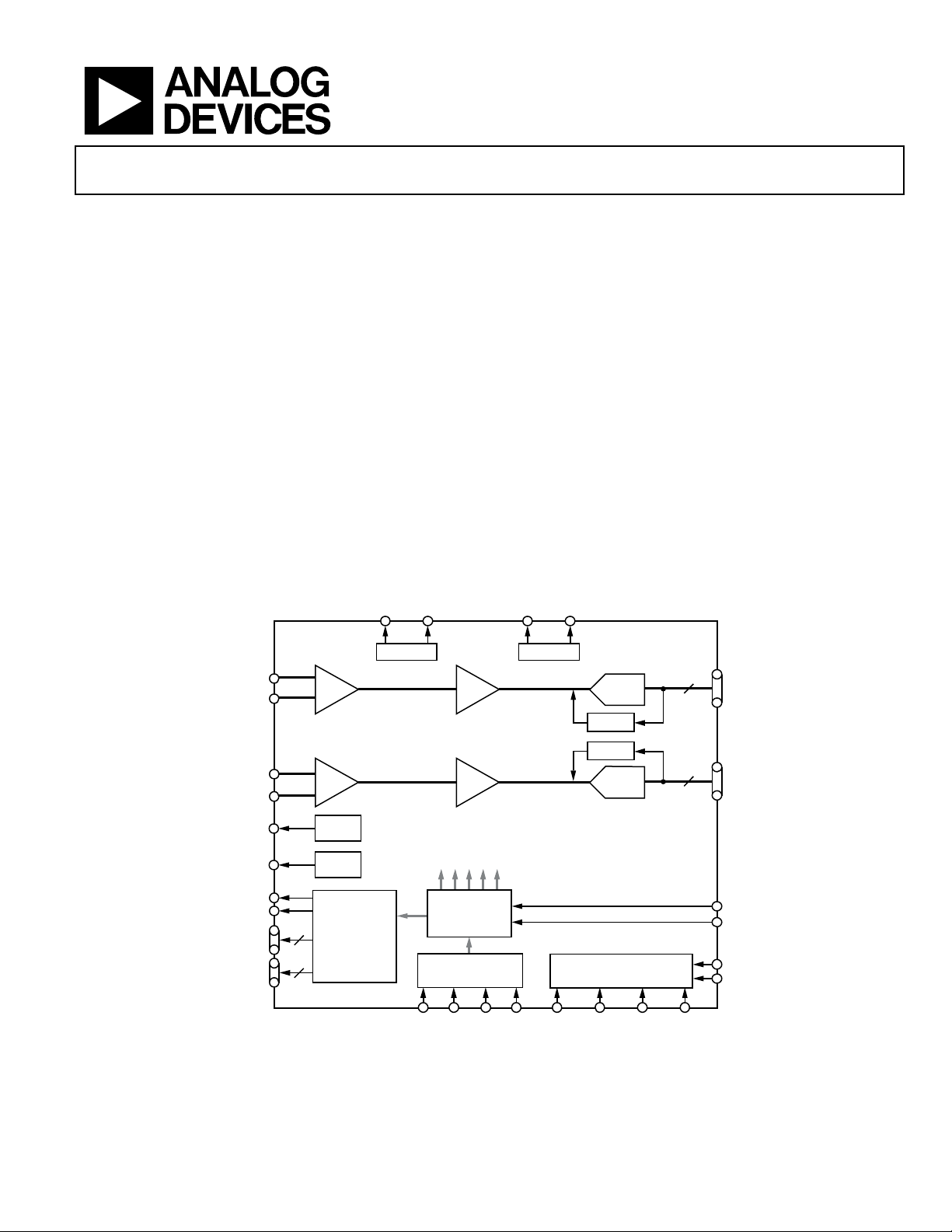

AD9974

GENERAL DESCRIPTION

The AD9974 is a highly integrated, dual-channel, chargecoupled device (CCD) signal processor for high speed digital

video camera applications. Each channel is specified at pixel

rates of up to 65 MHz. The AD9974 consists of a complete

analog front end (AFE) with analog-to-digital conversion,

combined with a programmable timing driver. The Precision

Timi ng™ core allows adjustment of high speed clocks with

approximately 240 ps resolution at 65 MHz operation.

Each AFE includes black level clamping, CDS, VGA, and

a 65 MSPS, 14-bit ADC. The timing driver provides the high

speed CCD clock drivers for the RG_A, RG_B, H1_A to H4_A,

and H1_B to H4_B outputs. A 3-wire serial interface is used to

program each channel of the AD9974.

Available in a space-saving, 9 mm × 9 mm, CSP_BGA package,

the AD9974 is specified over an operating temperature range of

−25°C to +85°C.

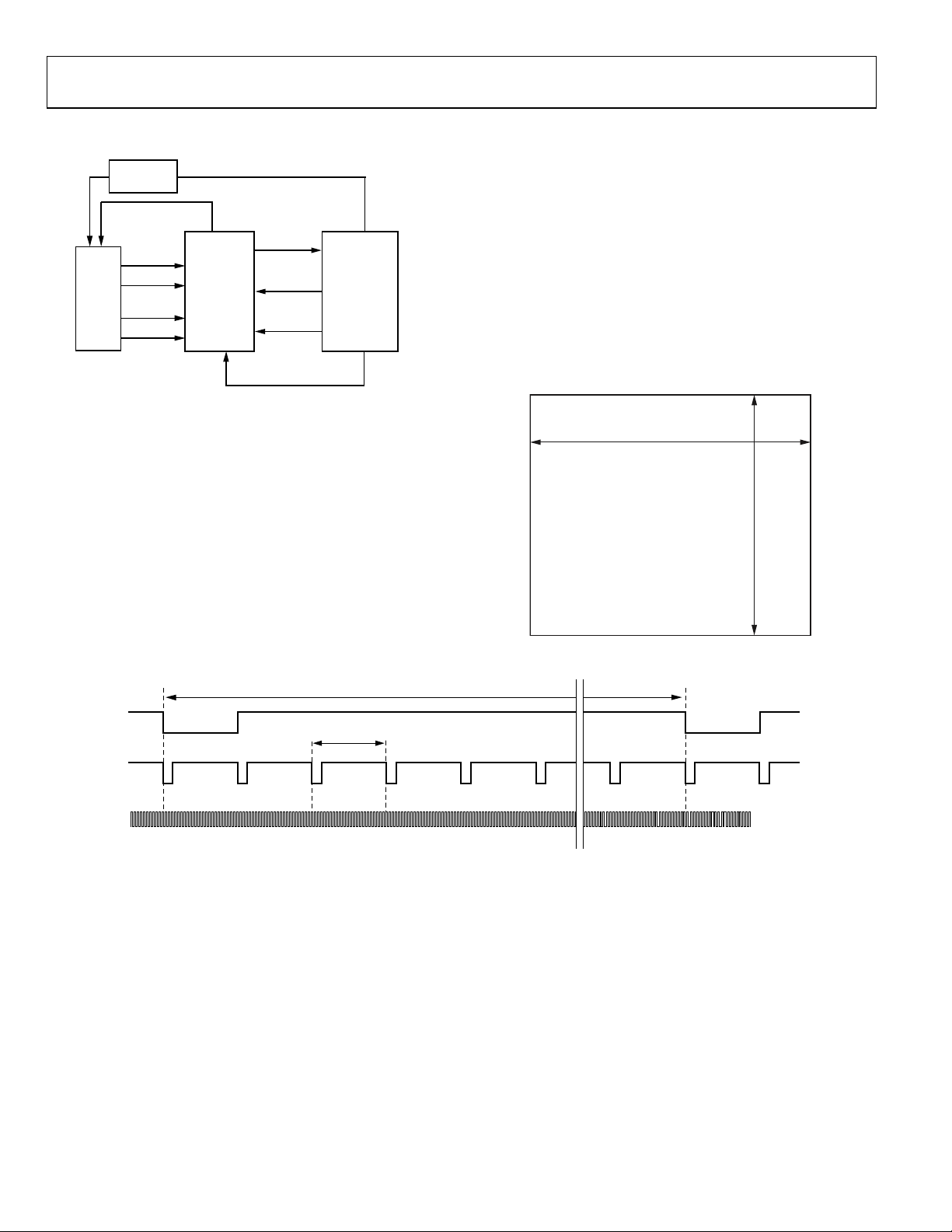

AD9974

CCDINP_A

CCDINM_A

CCDINP_B

CCDINM_B

1.8V OUTP UT LDO A

1.8V OUTP UT LDO B

RG_A

RG_B

H1_A TO H4_

H1_B TO H4_B

4

4

CDS

CDS

HORIZONTAL

FUNCTIONAL BLOCK DIAGRAM

REFT_AREFB_

–3, 0, +3, +6dB

–3, 0, +3, +6dB

DRIVERS

VREF_A

VGA

VGA

INTERNAL CL OCKS

PRECISION

TIMING

CORE

SYNC

GENERATOR

HD_A VD_A HD_B VD_B

REFT_B REFB_B

6dB TO 42d B

6dB TO 42d B

Figure 1.

VREF_B

SL_A

CLAMP

CLAMP

INTERNAL

REGISTERS

SDATA_A

ADC

ADC

SL_B

14

14

SDATA_B

DOUT_A

DOUT_B

CLI_A

CLI_B

SCK_A

SCK_B

5955-001

Rev. A

Information furnished by Analog Devices is believed to be accurate and reliable. However, no

responsibility is assumed by Analog Devices for its use, nor for any infringements of patents or other

rights of third parties that may result from its use. Specifications subject to change without notice. No

license is granted by implication or otherwise under any patent or patent rights of Analog Devices.

Trademarks and registered trademarks are the property of their respective owners.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700 www.analog.com

Fax: 781.461.3113 ©2009 Analog Devices, Inc. All rights reserved.

AD9974

TABLE OF CONTENTS

Features .............................................................................................. 1

Applications ....................................................................................... 1

General Description ......................................................................... 1

Functional Block Diagram .............................................................. 1

Revision History ............................................................................... 2

Specifications ..................................................................................... 3

Channel-to-Channel Specifications ........................................... 3

Timing Specifications .................................................................. 4

Digital Specifications ................................................................... 5

Analog Specifications ................................................................... 6

Absolute Maximum Ratings ............................................................ 8

Thermal Characteristics .............................................................. 8

ESD Caution .................................................................................. 8

Pin Configuration and Function Descriptions ............................. 9

Typical Performance Characteristics ........................................... 11

Equivalent Input/Output Circuits ................................................ 12

Terminolog y .................................................................................... 13

Theory of Operation ...................................................................... 14

Programmable Timing Generation .............................................. 15

Precision Timing High Speed Timing Core ............................. 15

Horizontal Clamping and Blanking ......................................... 18

Complete Field—Combining H-Patterns ............................... 25

Mode Registers ........................................................................... 26

Horizontal Timing Sequence Example .................................... 28

Analog Front End Description and Operation ...................... 29

Applications Information .............................................................. 33

Recommended Power-Up Sequence ....................................... 33

Standby Mode Operation .......................................................... 36

CLI Frequency Change .............................................................. 36

Circuit Configuration ................................................................ 37

Grounding and Decoupling Recommendations .................... 37

3-Wire Serial Interface Timing ..................................................... 39

Layout of Internal Registers ...................................................... 40

Updating of Register Values ...................................................... 41

Complete Register Listing ............................................................. 42

Outline Dimensions ....................................................................... 50

Ordering Guide .......................................................................... 50

REVISION HISTORY

10/09—Revision A: Initial Version

Changes to Table 1 ............................................................................ 3

Changes to Table 3 ............................................................................ 4

Changes to Pin Function Descriptions Table ............................... 9

Changes to Figure 11 ...................................................................... 12

Changes to Individual HBLK Pattern Section ............................ 20

Changes to Table 14 ........................................................................ 25

Added Example Register Setting for Power-Up Section ........... 34

Added Additional Restrictions Section ....................................... 35

Changes to Table 2 .......................................................................... 36

Changes to 3 V System Compatibility Section ........................... 37

Changes to Grounding and Decoupling

Recommendations Section ............................................................ 37

Changes to Table 30 ........................................................................ 48

Changes to Table 31 ........................................................................ 49

Changes to Ordering Guide .......................................................... 50

Rev. A | Page 2 of 52

AD9974

SPECIFICATIONS

X = A = B, unless otherwise noted.

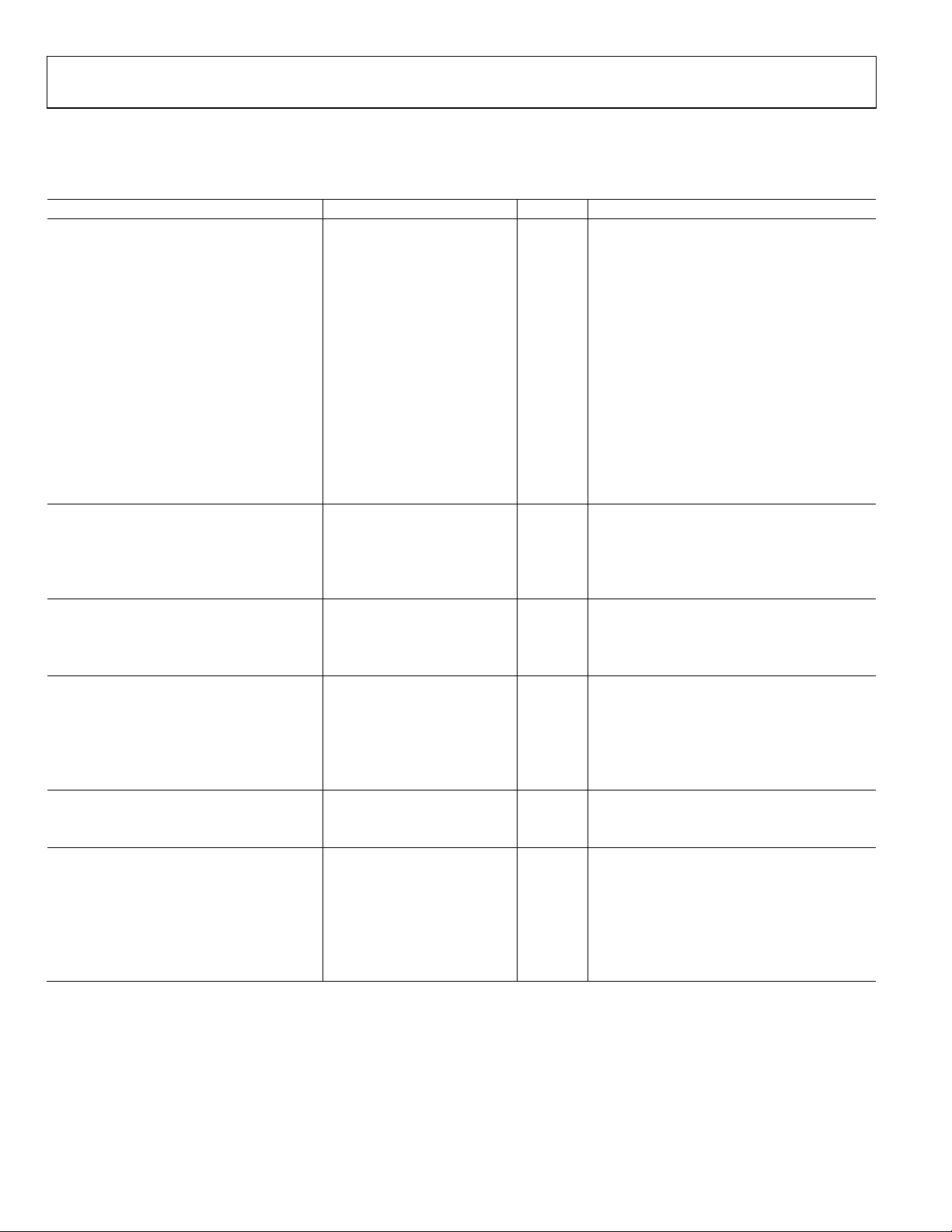

Table 1.

Parameter Min Typ Max Unit

TEMPERATURE RANGE

Operating −25 +85 °C

Storage −65 +150 °C

POWER SUPPLY VOLTAGE

AVDD_X (AFE, Timing Core) 1.6 1.8 2.0 V

RGVDD_X (RG_X Driver) 2.7 3.3 3.6 V

HVDD_X (H1_X to H4_X Drivers) 2.7 3.3 3.6 V

DVDD_X (All Other Digital) 1.6 1.8 2.0 V

DRVDD_X (Parallel Data Output Drivers) 1.6 3.0 3.6 V

IOVDD_X (I/O Supply Without the Use of LDO) 1.6 1.8 3.6 V

POWER SUPPLY CURRENTS—65 MHz OPERATION

AVDD_X (1.8 V) 55 mA

RGVDD_X (3.3 V, 20 pF RG Load) 5 mA

HVDD_X1 (3.3 V, 200 pF Total Load on H1 to H4) 40 mA

DVDD_X (1.8 V) 15 mA

DRVDD_X (3.0 V) 3 mA

IOVDD_X (1.8 V) 2 mA

POWER SUPPLY CURRENTS—STANDBY MODE OPERATION

Reference Standby 10 mA

Total Shutdown 0.5 mA

2

LDO

IOVDD_X (I/O Supply When Using LDO) 3.0 V

Output Voltage 1.85 V

Output Current 60 100 mA

CLOCK RATE (CLI) 8 65 MHz

1

The total power dissipated by the HVDD (or RGVDD) supply can be approximated as follows: Total HVDD Power = [C

Reducing the capacitive load and/or reducing the HVDD supply reduces the power dissipation. C

2

LDO should be used to supply only AVDD and DVDD.

is the total capacitance seen by all H-outputs.

LOAD

× HVDD × Pixel Frequency] × HVDD.

LOAD

CHANNEL-TO-CHANNEL SPECIFICATIONS

X = A = B, T

Table 2.

Parameter Min Typ Max Unit Test Conditions/Comments

LINEARITY MISMATCH

CROSSTALK ERROR CDS = 0 dB

Channel A to Channel B −82 dB Full-scale step applied to Channel A while measuring response on Channel B

Channel B to Channel A −82 dB Full-scale step applied to Channel B while measuring response on Channel A

1

See the section for further measurement explanation. Terminology

MIN

to T

, AVDD_X = DVDD_X = 1.8 V, f

MAX

1

<0.5 % Absolute value above 1⁄16 of maximum output code

= 65 MHz, typical timing specifications, unless otherwise noted.

CLI

Rev. A | Page 3 of 52

AD9974

TIMING SPECIFICATIONS

X = A = B, CL = 20 pF, AVDD_X = DVDD_X = 1.8 V, f

Table 3.

Parameter Min Typ Max Unit Comments

MASTER CLOCK (CLI) See Figure 17

CLI Clock Period (t

CLI High/Low Pulse Width (t

) 15.38 ns

CONV

) 6.9 7.7 8.9 ns

ADC

Delay from CLI Rising Edge to Internal Pixel Position 0 (t

AFE

SHP Rising Edge to SHD Rising Edge (tS1) 6.9 7.7 8.5 ns See Figure 21

AFE Pipeline Delay 16 Cycles See Figure 22

CLPOB Pulse Width (Programmable) (t

1

)

2 20 Pixels

COB

HD Pulse Width t

VD Pulse Width 1 HD period ns

SERIAL INTERFACE See Figure 52

Maximum SCK Frequency (f

) 40 MHz

SCLK

SL to SCK Setup Time (tLS) 10 ns

SCK to SL Hold Time (tLH) 10 ns

SDATA Valid to SCK Rising Edge Setup (tDS) 10 ns

SCK Rising Edge to SDATA Valid Hold (tDH) 10 ns

H-COUNTER RESET SPECIFICATIONS See Figure 49

HD Pulse Width t

VD Pulse Width 1 HD period ns

VD Falling Edge to HD Falling Edge(t

HD Falling Edge to CLI Rising Edge(t

) 0 VD period − t

VDHD

) 3 t

HDCLI

CLI Rising Edge to SHPLOC (Internal Sample Edge) (t

TIMING CORE SETTING RESTRICTIONS

Inhibited Region for SHP Edge Location (t

Inhibited Region for SHP or SHD with Respect to H-Clocks

(See Figure 21)

RETIME = 0, MASK = 0 (t

RETIME = 0, MASK = 1 (t

RETIME = 1, MASK = 0 (t

RETIME = 1, MASK = 1 (t

3, 4, 5, 6

) H × NEGLOC − 15 H × NEGLOC − 0 Edge location

SHDINH

) H × POSLOC − 15 H × POSLOC − 0 Edge location

SHDINH

) H × NEGLOC − 15 H × NEGLOC − 0 Edge location

SHPINH

) H × POSLOC − 15 H × POSLOC − 0 Edge location

SHPINH

) (See Figure 21)250 64/0 Edge location

SHPINH

Inhibited Region for DOUTPHASE Edge Location (t

(See Figure 21)

1

Minimum CLPOB pulse width is for functional operation only. Wider typical pulses are recommended to achieve good clamp performance.

2

Only applies to slave mode operation. The inhibited area for SHP is needed to meet the timing requirements for t

3

When 0x34[2:0] HxBLKRETIME bits are enabled, the inhibit region for SHD location changes to inhibit region for SHP location.

4

When sequence register 0x09[23:21] HBLK masking registers are set to 0, the H-edge reference becomes H × NEGLOC.

5

The H-clock signals that have SHP/SHD inhibit regions depend on the HCLK mode: Mode 1 = H1, Mode 2 = H1, H2, and Mode 3 = H1, H3.

6

These specifications apply when H1POL, H2POL, RGPOL, and HLPOL are all set to 1 (default setting).

= 65 MHz, unless otherwise noted.

CLI

) 5 ns

CLIDLY

ns

CONV

ns

CONV

) 3 t

CLISHP

DOUTINH

)

SHDLOC + 0 SHDLOC + 15 Edge location

ns

CONV

− 2 ns

CONV

− 2 ns

CONV

for proper H-counter reset operation.

CLISHP

Rev. A | Page 4 of 52

AD9974

DIGITAL SPECIFICATIONS

X = A = B, IOVDD_X = 1.6 V to 3.6 V, RGVDD_X = HVDD_X = 2.7 V to 3.6 V, CL = 20 pF, T

Table 4.

Parameter Min Typ Max Unit Test Conditions/Comments

LOGIC INPUTS

High Level Input Voltage (VIH) IOVDD − 0.6 V

Low Level Input Voltage (VIL) 0.6 V

High Level Input Current (IIH) 10 μA

Low Level Input Current (IIL) 10 μA

Input Capacitance (CIN) 10 pF

LOGIC OUTPUTS

High Level Output Voltage (VOH) IOVDD − 0.5 V IOH = 2 mA

Low Level Output Voltage (VOL) 0.5 V IOL = 2 mA

CLI INPUT (CLI_BIAS = 0)

High Level Input Voltage (V

Low Level Input Voltage (V

) IOVDD/2 + 0.5 V

IHCLI

) IOVDD/2 − 0.5 V

ILCLI

H-DRIVER OUTPUTS

High Level Output Voltage at Maximum Current (VOH) HVDD − 0.5 V

Low Level Output Voltage at Maximum Current 0.5 V

Maximum Output Current (Programmable) (VOL) 30 mA

Maximum Load Capacitance 100 pF

MIN

to T

, unless otherwise noted.

MAX

Rev. A | Page 5 of 52

AD9974

ANALOG SPECIFICATIONS

X = A = B, AVDD_X = 1.8 V, f

Table 5.

Parameter Min Typ Max Unit Test Conditions/Comments

CDS1

Allowable CCD Reset Transient 0.5 0.8 V

CDS Gain Accuracy

−3 dB CDS Gain −3.3 −2.8 −2.3

0 dB CDS Gain (Default) −0.7 −0.2 +0.3

3 dB CDS Gain 2.3 2.8 3.3

6 dB CDS Gain 4.9 5.4 5.9

Maximum Input Voltage VGA gain = 5.6 dB (Code 15, default value)

−3 dB CDS Gain 1.4 V p-p

0 dB CDS Gain (Default) 1.0 V p-p

3 dB CDS Gain 0.7 V p-p

6 dB CDS Gain 0.5 V p-p

Allowable OB Pixel Amplitude

0 dB CDS Gain (Default) −100 +200 mV

6 dB CDS Gain −50 +100 mV

VARIABLE GAIN AMPLIFIER (VGA_X)

Gain Control Resolution 1024 Steps

Gain Monotonicity Guaranteed

Low Gain Setting (VGA Code 15, Default) 6 dB

Maximum Gain Setting (VGA Code 1023) 42 dB

BLACK LEVEL CLAMP

Clamp Level Resolution 1024 Steps

Minimum Clamp Level (Code 0) 0 LSB Measured at ADC output

Maximum Clamp Level (Code 1023) 1023 LSB Measured at ADC output

ADC (CHN_A and CHN_B)

Resolution 14 Bits

Differential Nonlinearity (DNL) −1.0 ±0.5 +1.2 LSB

No Missing Codes Guaranteed

Integral Nonlinearity (INL) 5 15 LSB

Full-Scale Input Voltage 2.0 V

VOLTAGE REFERENCE

Reference Top Voltage (REFT_X) 1.4 V

Reference Bottom Voltage (REFB_X) 0.4 V

SYSTEM PERFORMANCE Specifications include entire signal chain

VGA Gain Accuracy 0 dB CDS gain (default)

Low Gain (Code 15) 5.1 5.6 6.1 dB Gain = (0.0359 × code) + 5.1 dB

Maximum Gain (Code 1023) 41.3 41.8 42.3 dB

Peak Nonlinearity, 500 mV Input Signal 0.1 0.4 % 12 dB total gain applied

Total Output Noise 2 LSB rms AC-grounded input, 6 dB gain applied

Power Supply Rejection (PSR) 48 dB Measured with step change on supply

1

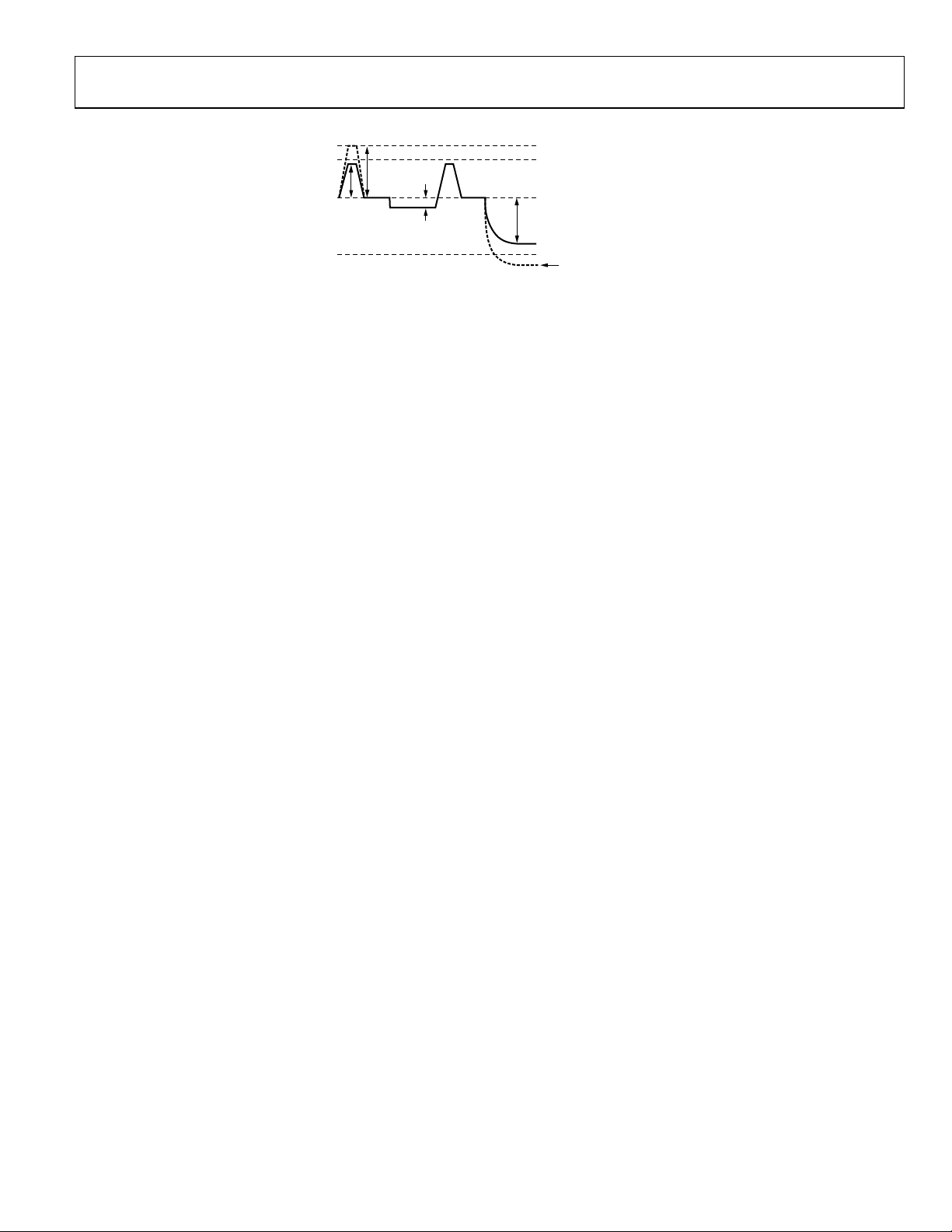

Input signal characteristics are defined as shown in . Figure 2

= 65 MHz, typical timing specifications, T

CLI

MIN

to T

, unless otherwise noted.

MAX

Rev. A | Page 6 of 52

AD9974

800mV

MAXIMUM

500mV TYP

RESET TRANSIENT

200mV MAX

OPTICAL BLACK PIXEL

MAXIMUM INPUT LIMIT =

LESSER OF 2.2V

OR (AVDD + 0.3V )

+1.8V TYP (AVDD)

+1.3V TYP (AVDD – 0.5V)

DC RESTORE VO LTAGE

1V MAXIMUM INPUT

SIGNAL RANGE

(0dB CDS GAIN)

0V (AVSS)

MINIMUM INPUT LIMIT

(AVSS – 0.3V)

05957-002

Figure 2. Input Signal Characteristics

Rev. A | Page 7 of 52

AD9974

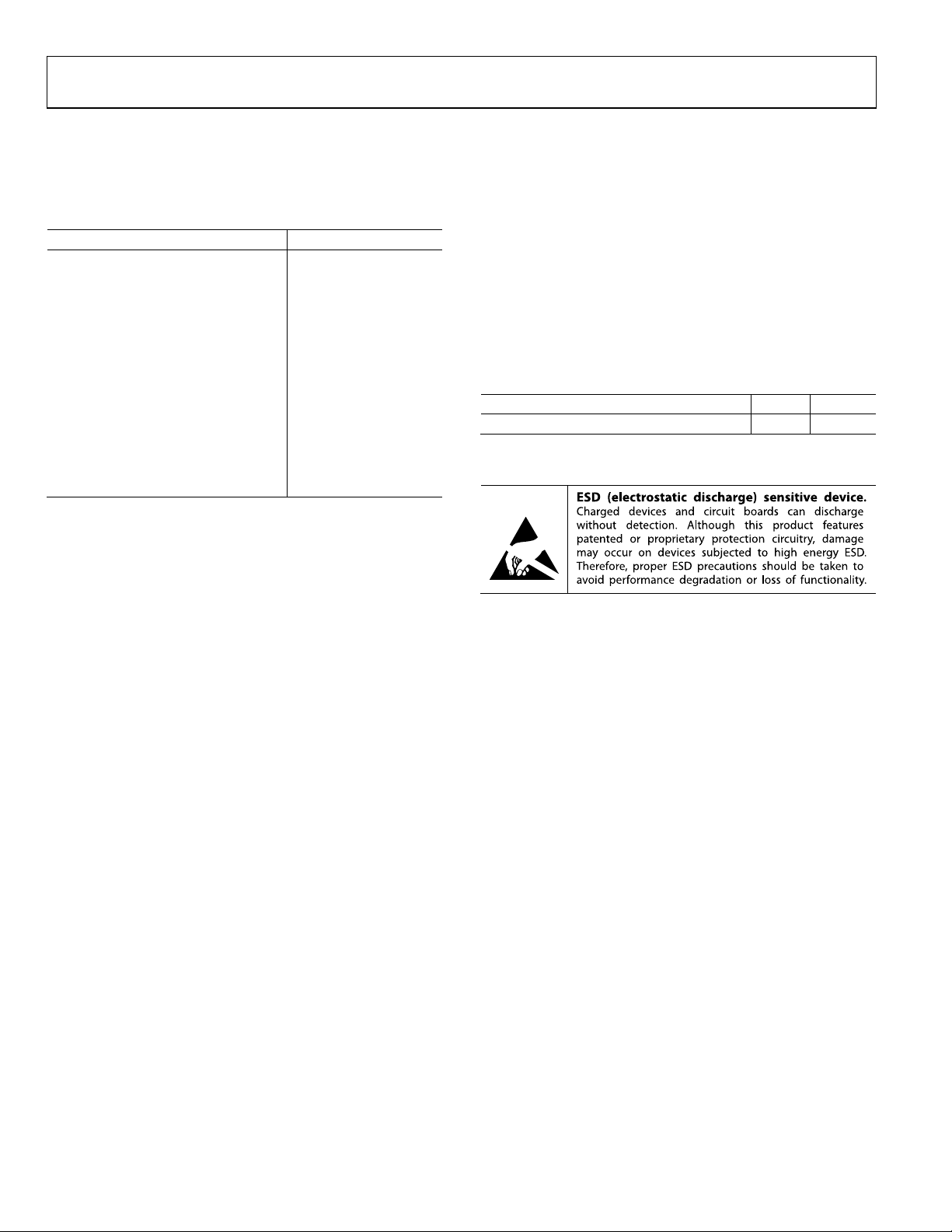

ABSOLUTE MAXIMUM RATINGS

Ratings apply to both Channel A and Channel B, unless

otherwise noted.

Table 6.

Parameter Rating

AVDD to AVSS −0.3 V to +2.2 V

DVDD to DVSS −0.3 V to +2.2 V

DRVDD to DRVSS −0.3 V to +3.9 V

IOVDD to DVSS −0.3 V to +3.9 V

HVDD to HVSS −0.3 V to +3.9 V

RGVDD to RGVSS −0.3 V to +3.9 V

Any VSS −0.3 V to +0.3 V

RG Output to RGVSS −0.3 V to RGVDD + 0.3 V

H1 to H4, HL Output to HVSS −0.3 V to HVDD + 0.3 V

SCK, SL, SDI to DVSS −0.3 V to IOVDD + 0.3 V

REFT, REFB, CCDINM, CCDINP to AVSS −0.2 V to AVDD + 0.2 V

Junction Temperature 150°C

Lead Temperature (10 sec) 350°C

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

THERMAL CHARACTERISTICS

θJA is measured using a 4-layer PCB with the exposed paddle

soldered to the board.

Table 7. Thermal Resistance

Package Type θJA Unit

100-Lead, 9 mm × 9 mm, CSP_BGA 38.3 °C/W

ESD CAUTION

Rev. A | Page 8 of 52

AD9974

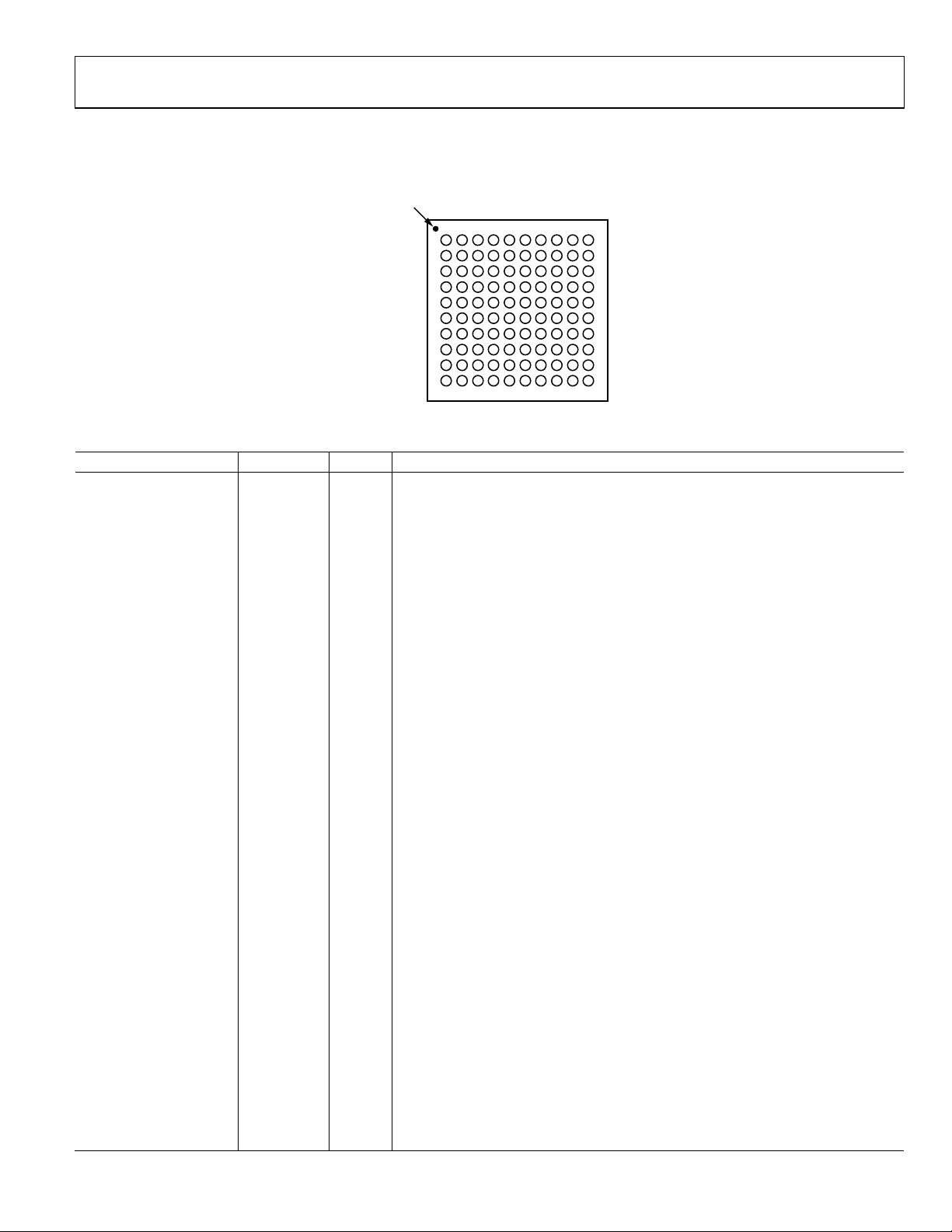

PIN CONFIGURATION AND FUNCTION DESCRIPTIONS

AD9974

TOP VIEW

A1 CORNER

INDEX AREA

A

B

C

D

E

F

G

H

J

K

Figure 3. Pin Configuration

(Not to S cale)

2345678910

1

05955-003

Table 8. Pin Function Descriptions

Ball Location Mnemonic Type

1

Description

B2 SL_A DI 3-Wire Serial Load for Channel A.

C2 SDATA_A DI 3-Wire Serial Data for Channel A.

D2 SCK_A DI 3-Wire Serial Clock for Channel A.

C1 REFT_A AO Reference with Top Decoupling for Channel A. Decouple with 0.1 μF to AVSS_A.

D1 REFB_A AO Reference with Bottom Decoupling for Channel A. Decouple with 0.1 μF to AVSS_A.

A1 CCDINM_A AI Analog Input for Channel A Image Sensor Signal.

F4 H1_A DO CCD Horizontal Clock 1 for Channel A.

F3 H2_A DO CCD Horizontal Clock 2 for Channel A.

D4 H3_A DO CCD Horizontal Clock 3 for Channel A.

D3 H4_A DO CCD Horizontal Clock 4 for Channel A.

B4 RG_A DO CCD Reset Gate Clock for Channel A.

J2 DRVSS_A P Digital Driver Ground for Channel A.

K3 DRVDD_A P Digital Driver Supply for Channel A: 1.8 V or 3.0 V.

E3 HVSS_A P H1_A to H4_A Driver Ground for Channel A.

E4 HVDD_A P H1_A to H4_A Driver Supply for Channel A: 3.0 V.

C3 RGVSS_A P RG_A Driver Ground for Channel A.

C4 RGVDD_A P RG_A Driver Supply for Channel A: 3.0 V.

B3 IOVDD_A P

Digital I/O Supply: 1.8 V or 3.0 V (HD, VD, SL, SCK, SDATA) and LDO Input (3.0 V Only)

When LDO Is Used.

A4 CLI_A DI Master Clock Input for Channel A.

B1 AVSS_A P Analog Ground for Channel A.

A2 CCDINP_A AI Analog Input for Channel A Image Sensor Signal.

F2 DVSS_A P Digital Ground for Channel A.

F1 DVDD_A P Digital Supply for Channel A: 1.8 V.

E2 VD_A DI Vertical Sync Pulse for Channel A.

E1 HD_A DI Horizontal Sync Pulse for Channel A.

B8 SL_B DI 3-Wire Serial Load for Channel B.

C8 SDATA_B DI 3-Wire Serial Data for Channel B.

A5 LDO_OUT_A P 1.8 V LDO Output from Channel A.

A6 CCDINM_B AI Analog Input for Channel B Image Sensor Signal.

D8 SCK_B DI 3-Wire Serial Clock for Channel B.

C7 REFT_B AO Reference with Top Decoupling for Channel B. Decouple with 0.1 μF to AVSS_B.

D7 REFB_B AO Reference with Bottom Decoupling for Channel B. Decouple with 0.1 μF to AVSS_B.

A7 CCDINP_B AI Analog Input for Channel B Image Sensor Signal.

F10 H1_B DO CCD Horizontal Clock 1 for Channel B.

F9 H2_B DO CCD Horizontal Clock 2 for Channel B.

Rev. A | Page 9 of 52

AD9974

Ball Location Mnemonic Type

1

Description

D10 H3_B DO CCD Horizontal Clock 3 for Channel B.

D9 H4_B DO CCD Horizontal Clock 4 for Channel B.

B10 RG_B DO CCD Reset Gate Clock for Channel B.

J8 DRVSS_B P Digital Driver Ground for Channel B.

K9 DRVDD_B P Digital Driver Supply for Channel B: 1.8 V or 3.0 V.

E9 HVSS_B P H1_B to H4_B Driver Ground for Channel B.

E10 HVDD_B P H1_B to H4_B Driver Supply for Channel B: 3.0 V.

C9 RGVSS_B P RG_B Driver Ground for Channel B.

C10 RGVDD_B P RG_B Driver Supply for Channel B: 3.0 V.

B9 IOVDD_B P

Digital I/O Supply: 1.8 V or 3.0 V (HD, VD, SL, SCK, SDATA) and LDO Input (3.0 V Only)

When LDO Is Used.

A10 LDO_OUT_B P 1.8 V LDO Output from Channel B.

B7 AVSS_B P Analog Ground for Channel B.

A8 AVDD_B P Analog Supply for Channel B: 1.8 V.

F8 DVSS_B P Digital Ground for Channel B.

F7 DVDD_B P Digital Supply for Channel B: 1.8 V.

E8 VD_B DI Vertical Sync Pulse for Channel B.

E7 HD_B DI Horizontal Sync Pulse for Channel B.

A3 AVDD_A P Analog Supply for Channel A: 1.8 V.

G1 D0_A DO Data Outputs Channel A.

H1 D1_A DO Data Outputs Channel A.

J1 D2_A DO Data Outputs Channel A.

K1 D3_A DO Data Outputs Channel A.

G2 D4_A DO Data Outputs Channel A.

H2 D5_A DO Data Outputs Channel A.

K2 D6_A DO Data Outputs Channel A.

G3 D7_A DO Data Outputs Channel A.

H3 D8_A DO Data Outputs Channel A.

J3 D9_A DO Data Outputs Channel A.

K4 D10_A DO Data Outputs Channel A.

J4 D11_A DO Data Outputs Channel A.

H4 D12_A DO Data Outputs Channel A.

G4 D13_A DO Data Outputs Channel A.

B5, C5, D5, E5, F5, G5, H5,

GND P Ground Connection.

J5, K5, B6, C6, D6, E6, F6,

G6, H6, J6, K6

A9 CLI_B DI Master Clock Input for Channel B.

G7 D0_B DO Data Outputs Channel B.

H7 D1_B DO Data Outputs Channel B.

J7 D2_B DO Data Outputs Channel B.

K7 D3_B DO Data Outputs Channel B.

G8 D4_B DO Data Outputs Channel B.

H8 D5_B DO Data Outputs Channel B.

K8 D6_B DO Data Outputs Channel B.

G9 D7_B DO Data Outputs Channel B.

H9 D8_B DO Data Outputs Channel B.

J9 D9_B DO Data Outputs Channel B.

K10 D10_B DO Data Outputs Channel B.

J10 D11_B DO Data Outputs Channel B.

H10 D12_B DO Data Outputs Channel B.

G10 D13_B DO Data Outputs Channel B.

1

AI = analog input, AO = analog output, DI = digital input, DO = digital output, P = power.

Rev. A | Page 10 of 52

AD9974

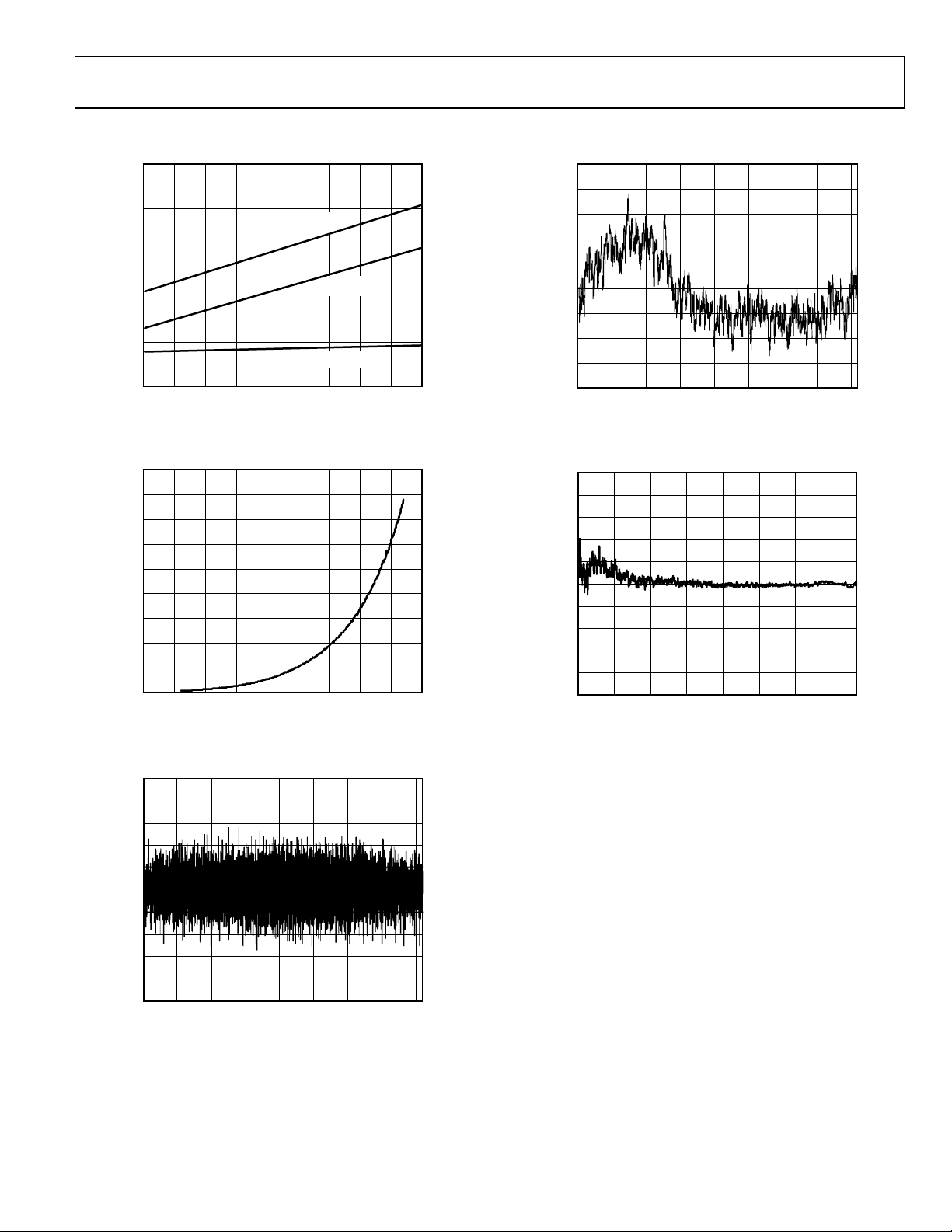

TYPICAL PERFORMANCE CHARACTERISTICS

250

200

150

100

POWER (mW)

50

0

20 25 30 35 40 45 50 55 60 65

TOTAL POWER

3.3V SUPPLIES

1.8V SUPPLIES

SAMPLE RATE (MHz)

Figure 4. Power vs. Sample Rate

05955-005

10

8

6

4

2

LSB

0

–2

–4

–6

–8

0

2k 4k 6k 8k 10k 12k 14k 16k

ADC OUTPUT CODE

05955-008

Figure 7. Integral Nonlinearity

180

160

140

120

100

80

60

RMS OUTPUT NOISE (LSB)

40

20

0

0 5 10 15 20 25 30 35 40 45

VGA GAIN (dB)

Figure 5. RMS Output Noise vs. VGA Gain

1.0

0.8

0.6

0.4

0.2

0

LSB

–0.2

–0.4

–0.6

–0.8

–1.0

0

2k 4k 6k 8k 10k 12k 14k 16k

ADC OUTPUT CODE

Figure 6. Differential Nonlinearity

1.0

0.8

0.6

0.4

0.2

0

–0.2

INL MISMATCH (%)

–0.4

–0.6

–0.8

–1.0

1k

3k 5k 7k 9k 11k 13k 15k

05955-006

ADC OUTPUT CODE

05955-009

Figure 8. Linearity Mismatch vs. ADC Output Code

05955-007

Rev. A | Page 11 of 52

AD9974

A

V

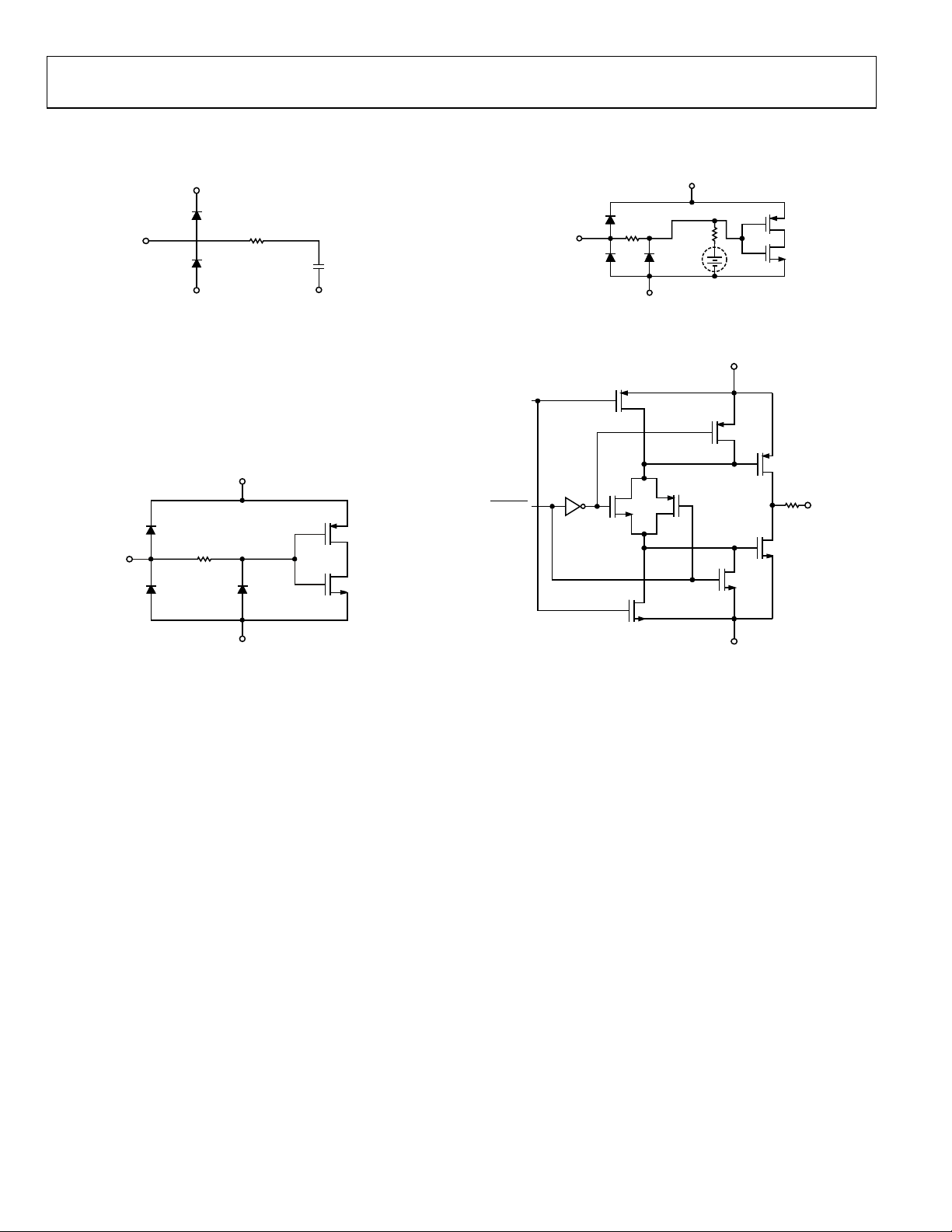

EQUIVALENT INPUT/OUTPUT CIRCUITS

DD

R

AVSS AVSS

Figure 9. CCDIN Input

IOVDD

330Ω

IOVDD

CLI

05955-010

330Ω

AVSS

100kΩ

+

05955-011

Figure 11. CLI Input, Register 0x15[0] = 1 Enables the Bias Circuit

HVDD OR RGVDD

DATA

ENABLE

OUTPUT

DVSS

Figure 10. Digital Inputs

05955-012

HVSS OR RGVSS

5955-013

Figure 12. H1 to H4 and RG Outputs

Rev. A | Page 12 of 52

AD9974

TERMINOLOGY

Differential Nonlinearity (DNL)

An ideal ADC exhibits code transitions that are exactly 1 LSB

apart. DNL is the deviation from this ideal value. Therefore,

every code must have a finite width. No missing codes guaranteed

to 14-bit resolution indicates that all 16,384 codes, each for its

respective input, must be present over all operating conditions.

Peak Nonlinearity

Peak nonlinearity, a full signal chain specification, refers to the

peak deviation of the output of the AD9974 from a true straight

line. The point used as zero scale occurs 0.5 LSB before the first

code transition. Positive full scale is defined as a level 1 LSB

and 0.5 LSB beyond the last code transition. The deviation is

measured from the middle of each particular output code to the

true straight line. The error is then expressed as a percentage

of the 2 V ADC full-scale signal. The input signal is always

appropriately gained up to fill the ADC full-scale range.

Tot a l O ut p ut Noi se

The rms output noise is measured using histogram techniques.

The standard deviation of the ADC output codes is calculated

in LSB and represents the rms noise level of the total signal

chain at the specified gain setting. The output noise can be

converted to an equivalent voltage using the relationship

1 LSB = (ADC Full Scale/2

where n is the bit resolution of the ADC. For the AD9974,

1 LSB is approximately 122.0 μV.

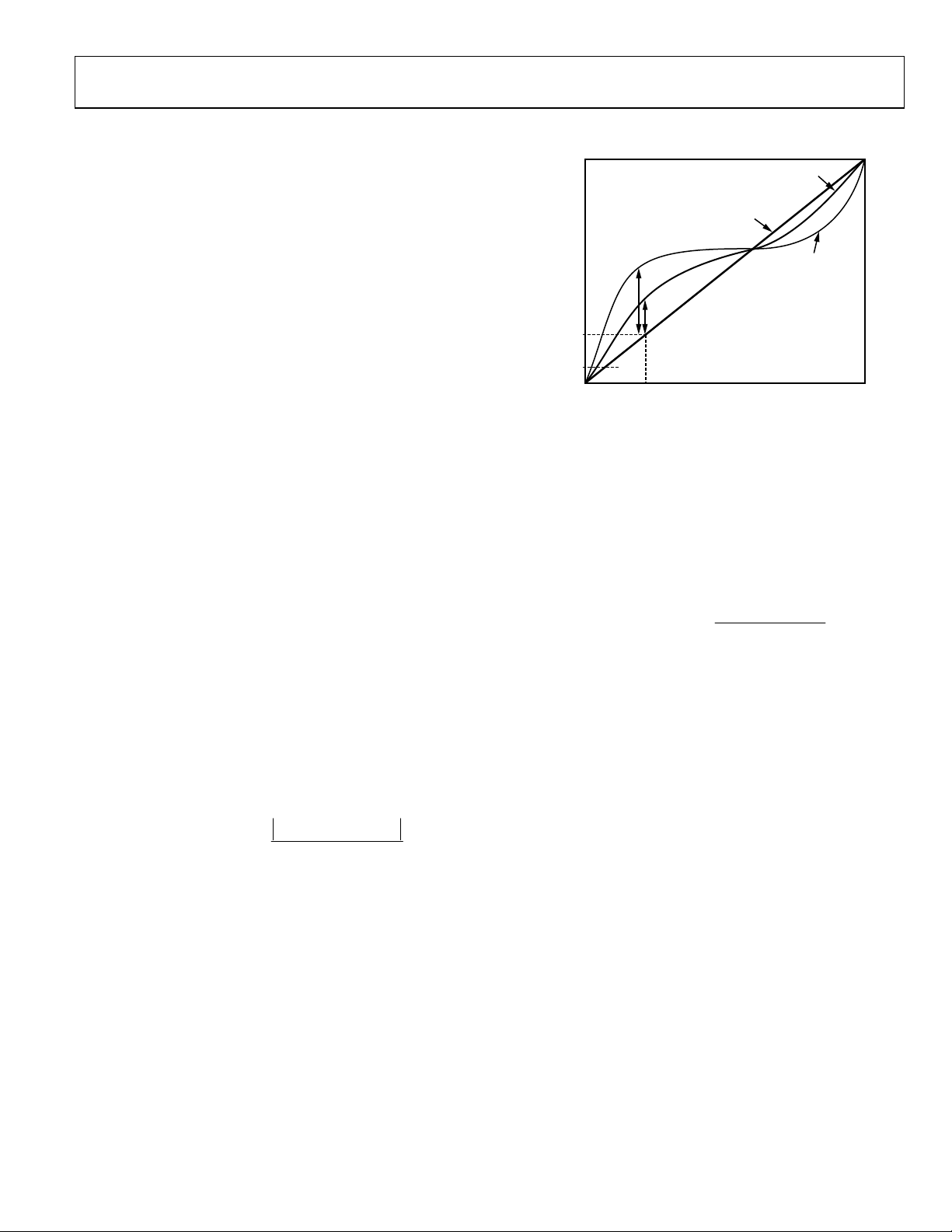

Linearity Mismatch

The linearity mismatch is calculated by taking the difference in

INL of the two channels at Input X, and then expressing the

difference as a percentage of the output code at X. The values

given in Tab le 2 are obtained over the range of 1⁄16 and

maximum of the output code. The general trend is for the

linearity mismatch to decrease as the output approaches the

maximum code, as shown in Figure 8.

n

Codes)

MAX

OUTPUT CODE (LSB)

OUTPUT (X)

MAX/16

INL A(X)

INL B(X)

0

0

XFS

INPUT VOLTAGE

Figure 13. Linearity Mismatch Definition

CHANNEL B

IDEAL

CHANNEL A

Power Supply Rejection (PSR)

The PSR is measured with a step change applied to the supply

pins. The PSR specification is calculated from the change in the

data outputs for a given step change in the supply voltage.

Crosstalk

The crosstalk is measured while applying a full-scale step to

one channel and measuring the interference on the opposite

channel.

)(

LSBceInterferen

⎛

⎜

×=

Crosstalk

log20)dB(

⎜

⎝

384,16

⎞

⎟

⎟

⎠

5955-004

MismatchLinearity

=

(%)

−

XBINLXAINL

)()(

XCodeOutput

)(

Rev. A | Page 13 of 52

AD9974

THEORY OF OPERATION

V DRIVER

H1_A TO H4_A, RG_A

H1_B TO H4_B, RG_B

CCDINP_A

CCDINM_A

CCD

CCDINP_B

CCDINM_B

V1 > Vx, VSG 1 > VS Gx, SUBCK

AD9974

INTEGRATED

AFE + TD

SERIAL

INTERFACE

DOUT_A

DOUT_B

HD_A, VD_A,

HD_B, VD_B

CLI_A, CLI _B

DIGITAL IMAGE

PROCESSING

ASIC

05955-014

Figure 14. Typical Application

Figure 14 shows the typical system block diagram for the AD9974.

The charge-coupled device (CCD) output is processed by the

analog front-end (AFE) circuitry of the AD9974, consisting of a

CDS, VGA, black level clamp, and ADC. The digitized pixel

information is sent to the digital image processor chip, which

performs the postprocessing and compression. To operate the

CCD, all CCD timing parameters are programmed into the

AD9974 from the system ASIC through the 3-wire serial

interface. From the system master clock, CLI_X, which is provided

by the image processor or external crystal, the AD9974 generates

the horizontal clocks of the CCD and all internal AFE clocks.

MAX VD LENG TH IS 8192 LINES

All AD9974 clocks are synchronized with VD and HD inputs.

All of the AD9974 horizontal pulses (CLPOB, PBLK, and

HBLK) are programmed and generated internally.

The H-drivers for H1 to H4 and RG are included in the

AD9974, allowing these clocks to be directly connected to the

CCD. An H-driver voltage of 3 V is supported in the AD9974.

Figure 15 and Figure 16 show the maximum horizontal and

vertical counter dimensions for the AD9974. All internal horizontal

and vertical clocking is controlled by these counters, which specify

line and pixel locations. Maximum HD length is 8191 pixels per

line, and maximum VD length is 8191 lines per field.

MAXIMUM COUNTE R DIM ENS I O NS

13-BIT HORIZONTAL = 8192 PIXELS MAX

13-BIT VERTICAL = 8192 L INES MAX

5955-015

Figure 15. Vertical and Horizontal Counters

CLI

VD

HD

MAX HD LENGTH IS 8192 PIXELS

Figure 16. Maximum VD/HD Dimensions

Rev. A | Page 14 of 52

05955-016

AD9974

S

PROGRAMMABLE TIMING GENERATION

PRECISION TIMING HIGH SPEED TIMING CORE

The AD9974 generates flexible high speed timing signals using

the Precision Timing core. This core, composed of the Reset

Gate RG, Horizontal Driver H1 to Horizontal Driver H4, and

SHP/SHD sample clocks, is the foundation for generating the

timing for both the CCD and the AFE. A unique architecture

makes it routine for the system designer to optimize image

quality by providing precise control over the horizontal CCD

readout and the AFE correlated double sampling.

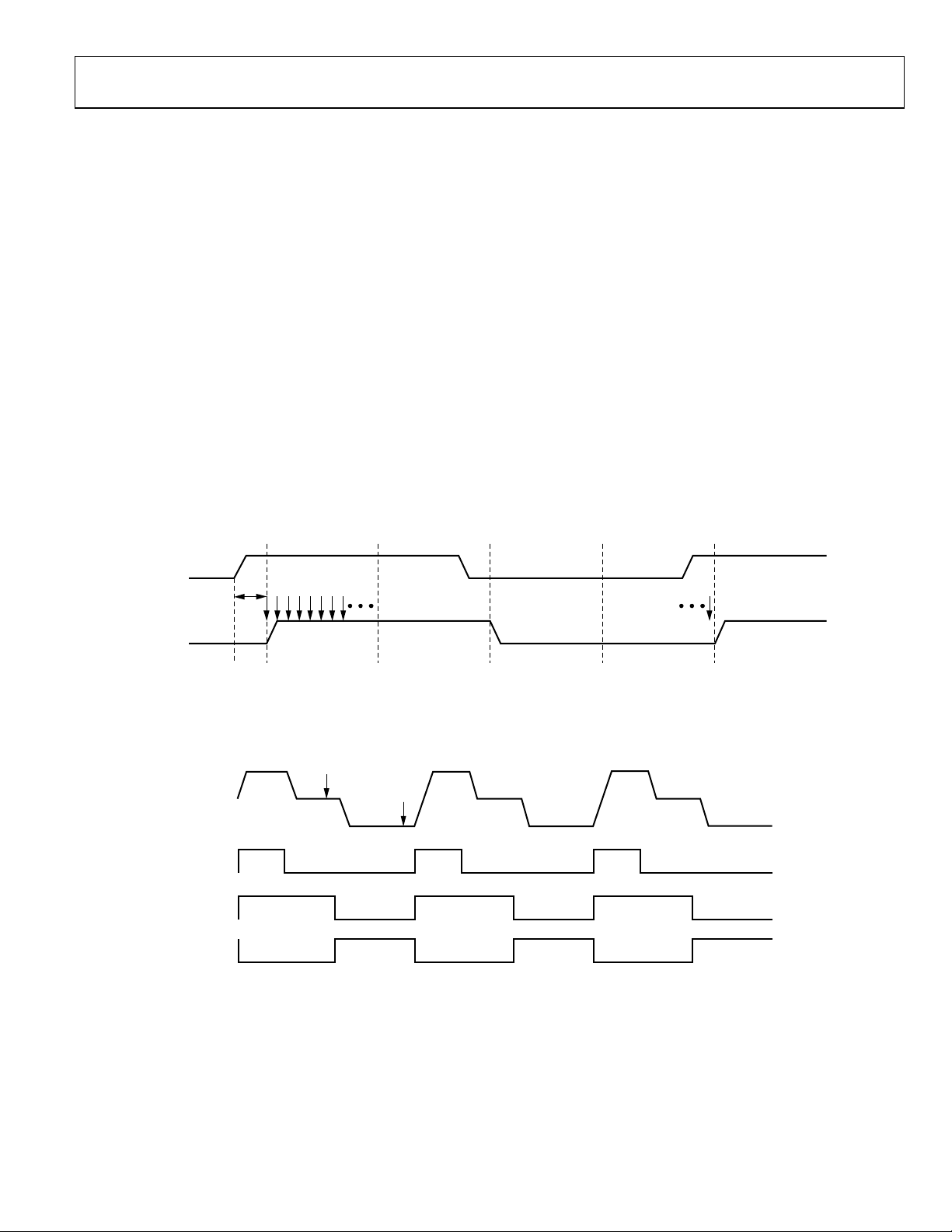

Timing Resolution

The Precision Timing core uses a master clock input (CLI_X)

as a reference. This clock input should be the same as the CCD

pixel clock frequency. Figure 17 illustrates how the internal timing

core divides the master clock period into 64 steps or edge positions;

therefore, the edge resolution of the Precision Timing core is

(t

/64). For more information on using the CLI input, refer to

CLI

the Applications Information section.

POSITION

P[0] P[64] = P[0]P[16] P[32] P[48]

Using a 65 MHz CLI frequency, the edge resolution of the

Precision Timing core is approximately 240 ps. If a 1× system

clock is not available, it is possible to use a 2× reference clock

by programming the CLIDIVIDE register (Address 0x0D). The

AD9974 then internally divides the CLI frequency by 2.

High Speed Clock Programmability

Figure 18 shows when the high speed clocks, RG, H1 to H4,

SHP, and SHD, are generated. The RG pulse has programmable

rising and falling edges and can be inverted using the polarity

control. The H1 and H2 horizontal clocks have separate programmable rising and falling edges, as well as separate polarity control.

The AD9974 provides additional HCLK-mode programmability,

as described in Ta bl e 9 .

The edge location registers are each six bits wide, allowing the

selection of all 64 edge locations. Figure 21 shows the default

timing locations for all of the high speed clock signals.

CLI

t

CLIDLY

1 PIXEL

PERIOD

NOTES

1. THE PIXEL CLOCK PERIOD IS DIVIDED INTO 64 POSITIONS, PROVIDING FINE EDGE RESOLUTION FOR HIGH SPEED CLOCKS.

2. THERE IS A F I XED DELAY FROM THE CLI INPUT TO THE INTERNAL PIXEL PERIOD POSITION (

t

CLIDLY

).

5955-017

Figure 17. High Speed Clock Resolution from CLI Master Clock Input

1

CCD

IGNAL

34

RG

56

H1, H3

H2, H4

PROGRAMMABLE CLOCK POSI T IONS:

1

SHP SAMPLE LOCATION.

2

SHD SAMPLE LO CAT I O N.

3

RG RISING EDGE.

4

RG FALLING EDGE.

5

H1 RISING EDGE.

6

H1 FALLING EDGE.

Figure 18. High Speed Clock Programmable Locations (HCLK Mode 1)

2

05955-018

Rev. A | Page 15 of 52

AD9974

12

H1, H3

43

H2, H4

H1 TO H4 P R OGRAMM A B LE LO CATI ONS:

1

H1 RISING EDGE.

2

H1 FALLING EDGE.

3

H2 RISING EDGE.

4

H2 FALLING EDGE.

5955-019

Figure 19. HCLK Mode 2 Operation

12

H1

H2

3

H3

H4

H1 TO H4 PROGRAMMABLE LOCATIONS:

1

H1 RISIN G EDGE .

2

H1 FALLING EDGE.

3

H3 RISIN G EDGE .

4

H3 FALLING EDGE.

4

05955-020

Figure 20. HCLK Mode 3 Operation

P[0]

P[32]P[16] P[48]POSITION

P[64] = P[0]

CLI

RGr[0] RGf[16]

RG

H1r[0] H1f[32]

H1

H2

t

CCD

SIGNAL

SHPLOC[32]

SHP

SHDLOC[0]

SHD

t

DOUTPHASEP

NOTES

1. ALL SIGNAL EDGES ARE FULLY PROGRAMMABLE TO ANY OF THE 64 POSITIONS WITHIN ONE PIXEL PERIOD.

TYPICAL P OSITI ONS FOR EACH SIGNAL ARE SHO WN. HCLK MODE 1 IS SHOWN.

2. CERTAIN POSITIONS SHOULD BE AVOIDED FO R EACH SIGNAL, S HOWN ABOVE AS INHIBIT REGIONS.

3. IF A SETTING I N THE INHIBIT REGION IS USED, AN UNSTABLE PIXEL S HIFT CAN OCCUR IN THE HBLK LOCATION OR AF E P IPELINE.

DOUTINH

DATAPHASEP[32]

S1

t

SHPINH

t

SHDINH

05955-021

Figure 21. High Speed Timing Default Locations

Rev. A | Page 16 of 52

AD9974

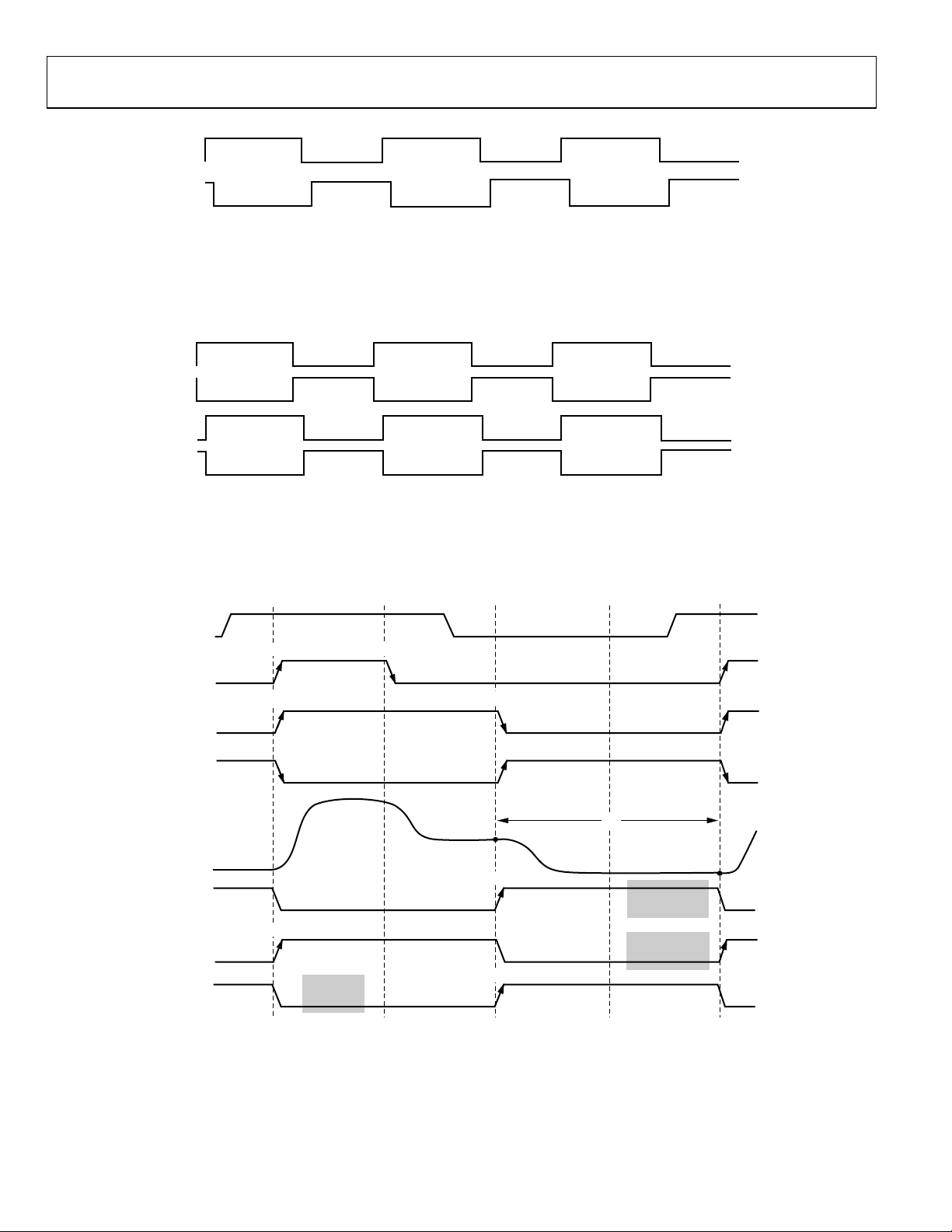

Table 9. HCLK Modes, Selected by HCLKMODE Register (Address 0x23[7:5])

HCLK Mode Register Value Description

Mode 1 001 H1 edges are programmable, with H3 = H1 and H2 = H4 = inverse of H1.

Mode 2 010

Mode 3 100

Invalid Selection 000, 011, 101, 110, 111 Invalid register settings.

Table 10. H1, H2, RGCONTROL, DRVCONTROL, and SAMPCONTROL Register Parameters

Parameter Length (Bits) Range Description

Polarity 1 High/low

Positive Edge 6 0 to 63 edge location Positive edge location for H1/H3 and RG.

Negative Edge 6 0 to 63 edge location Negative edge location for H1/H3 and RG.

Sample Location 6 0 to 63 sample location Sampling location for SHP and SHD.

Drive Control 3 0 to 7 current steps Drive current for H1 to H4 and RG outputs, 0 to 7 steps of 4.3 mA each.

CLI

t

CLIDLY

CCDIN

NN+2N+1

N+3

N+4

H1 edges are programmable, with H3 = H1.

H2 edges are programmable, with H4 = H2.

H1 edges are programmable, with H2 = inverse of H1.

H3 edges are programmable, with H4 = inverse of H3.

Polarity control for H1/H3 and RG.

0 = no inversion.

1 = inversion.

N+13N+12N+11N+10N+9N+8N+7N+6N+5

N+14

N+16 N+17N+15

SHD

(INTERNAL)

ADC OUT

(INTERNAL)

DOUTPHASE

CLK

DOUT

NOTES

1. EXAMPLE SHOWN FOR SHDLO C = 0.

2. HIGHER VALUES OF SHD AND/ OR DOUTPHASE W ILL SHIFT DOUT TRANSITIO N TO THE RIGHT, WITH RESPECT TO CLI LOCATIO N.

SAMPLE PIXEL N

t

DOUTINH

N–14 N–4N–5N–6N–7N–8N–9N–10N–11N–12N–13 N–3 N–2 N–1 N N+1N–15N–16N–17

PIPELINE LATENCY = 16 CYCLES

N–14 N–4N–5N–6N–7N–8N–9N–10N–11N–12N–13 N–3 N–2 N–1 N N+1N–15N–16N–17

Figure 22. Pipeline Delay of AFE Data Outputs

H-Driver and RG Outputs Digital Data Outputs

In addition to the programmable timing positions, the AD9974

features on-chip output drivers for the RG and H1 to H4 outputs.

These drivers are powerful enough to drive the CCD inputs

directly. The H-driver and RG-driver current can be adjusted

for optimum rise/fall time into a particular load by using the

drive strength control registers (Address 0x35). Use the register

to adjust the drive strength in 4.3 mA increments. The minimum

setting of 0 is equal to off or three-state, and the maximum setting

of 7 is equal to 30.1 mA.

For maximum system flexibility, the AD9974 uses the

DOUTPHASE registers (Address 0x37[11:0]) to select the

location for the start of each new pixel data value. Any edge

location from 0 to 63 can be programmed. These registers

determine the start location of the data output and the DCLK

rising edge with respect to the master clock input, CLI_X.

The pipeline delay through the AD9974 is shown in Figure 22.

After the CCD input is sampled by SHD, there is a 16-cycle

delay until the data is available.

5955-022

Rev. A | Page 17 of 52

AD9974

C

HORIZONTAL CLAMPING AND BLANKING

The horizontal clamping and blanking pulses of the AD9974 are

fully programmable to suit a variety of applications. Individual

control is provided for CLPOB, PBLK, and HBLK during the

different regions of each field. This allows the dark pixel clamping

and blanking patterns to be changed at each stage of the readout

to accommodate different image transfer timing and high speed

line shifts.

Individual CLPOB and PBLK Patterns

The AFE horizontal timing consists of CLPOB and PBLK, as

shown in Figure 23. These two signals are programmed independently using the registers in Tab le 1 1 . The start polarity for

the CLPOB or PBLK signal is CLPOB_POL (PBLK_POL), and the

first and second toggle positions of the pulse are CLPOB_TOG1

(PBLK_TOG1) and CLPOB_TOG2 (PBLK_TOG2). Both signals

are active low and need to be programmed accordingly.

Two separate patterns for CLPOB and PBLK can be programmed

for each H-pattern, CLPOB0, CLPOB1, PBLK0, and PBLK1.

The CLPOB_PAT and PBLK_PAT field registers select which

of the two patterns is used in each field.

Figure 34 shows how the sequence change positions divide the

readout field into different regions. By assigning a different

H-pattern to each region, the CLPOB and PBLK signals can

change with each change in the vertical timing.

CLPOB and PBLK Masking Area

Additionally, the AD9974 allows the CLPOB and PBLK signals

to be disabled during certain lines in the field without changing

any of the existing pattern settings. There are three sets of start

and end registers for both CLPOB and PBLK that allow the

creation of up to three masking areas for each signal.

For example, to use the CLPOB masking, program the

CLPOBMASKSTART and CLPOBMASKEND registers to

specify the starting and ending lines in the field where the CLPOB

patterns are to be ignored. Figure 24 illustrates this feature.

The masking registers are not specific to a certain H-pattern;

they are always active for any existing field of timing. To disable

the CLPOB and PBLK masking feature, set these registers to the

maximum value of 0x1FFF.

Note that to disable CLPOB and PBLK masking during

power-up, it is recommended that CLPOBMASKSTART

(PBLKMASKSTART) be set to 8191 and CLPOBMASKEND

(PBLKMASKEND) be set to 0. This prevents any accidental

masking caused by different register update events.

HD

CLPOB

1

PBLK

PROGRAMMABLE SETTI NGS :

1

START POLARITY (CLAM P AND BLANK REGION ARE ACTIVE LO W).

2

FIRST TOGGLE POSITION.

3

SECOND TOGGLE POSITION.

ACTIVE

32

Figure 23. Clamp and Preblank Pulse Placement

ACTIVE

05955-023

VD

HD

LPOB

NO CLPOB SI GNAL

FOR LINE S 6 TO 8

0 1 2 597 598

CLPOBMASKSTART1 = 6 CL P OBMASKEND1 = 8

Figure 24. CLPOB Masking Example

CLPOBMASKSTART2 = CLPOBMASKEND2 = 600

NO CLPOB SI GNAL

FOR LINE 600

05957-024

Rev. A | Page 18 of 52

AD9974

Table 11. CLPOB and PBLK Pattern Registers

Parameter Length (Bits) Range Description

CLPOB0_TOG1 13 0 to 8191 pixel location First CLPOB0 toggle position within the line for each V-sequence.

CLPOB0_TOG2 13 0 to 8191 pixel location Second CLPOB0 toggle position within the line for each V-sequence.

CLPOB1_TOG1 13 0 to 8191 pixel location First CLPOB1 toggle position within the line for each V-sequence.

CLPOB1_TOG2 13 0 to 8191 pixel location Second CLPOB1 toggle position within the line for each V-sequence.

CLPOB_POL 9 High/low Starting polarity of CLPOB for each V-sequence [8:0] (in field registers).

CLPOB_PAT 9 0 to 9 settings CLPOB pattern selection for each V-sequence [8:0] (in field registers).

CLPOBMASKSTART 13 0 to 8191 pixel location CLPOB mask start position: three values available (in field registers).

CLPOBMASKEND 13 0 to 8191 pixel location CLPOB mask end position: three values available (in field registers).

PBLK0_TOG1 13 0 to 8191 pixel location First PBLK0 toggle position within the line for each V-sequence.

PBLK0_TOG2 13 0 to 8191 pixel location Second PBLK0 toggle position within the line for each V-sequence.

PBLK1_TOG1 13 0 to 8191 pixel location First PBLK1 toggle position within the line for each V-sequence.

PBLK1_TOG2 13 0 to 8191 pixel location Second toggle position within the line for each V-sequence.

PBLK_POL 9 High/low Starting polarity of PBLK for each V-sequence [8:0] (in field registers).

PBLK_PAT 9 0 to 9 settings PBLK pattern selection for each V-sequence [8:0] (in field registers).

PBLKMASKSTART 13 0 to 8191 pixel location PBLK mask start position: three values available (in field registers).

PBLKMASKEND 13 0 to 8191 pixel location PBLK mask end position: three values available (in field registers).

HD

HBLKTOGE1 HBLKTOGE2

HBLK

BLANK BLANK

BASIC HBLK PULSE IS GENERATED USING HBLKTOGE1 AND HBLKTOGE2 REGISTERS ( HBLKALT = 0).

Figure 25. Typical Horizontal Blanking Pulse Placement (HBLKMODE = 0)

05955-025

HD

HBLK

H1/H3

THE POLARITY OF H1/H3 DURING BLANKI NG IS PROG RAM M ABLE

(H2/H4 POLARITY IS SEPARATELY PROGRAMMABLE)

H1/H3

H2/H4

Figure 26. HBLK Masking Control

05955-026

Rev. A | Page 19 of 52

AD9974

Individual HBLK Patterns

The HBLK programmable timing shown in Figure 25 is similar

to CLPOB and PBLK; however, there is no start polarity control.

Only the toggle positions designate the start and the stop positions

of the blanking period. Additionally, as shown in Figure 26, there

is a polarity control, HBLKMASK, for H1/H3 and H2/H4 that

designates the polarity of the horizontal clock signals during the

blanking period. Setting HBLKMASK_H1 low sets H1 = H3 =

low and HBLKMASK_H2 high sets H2 = H4 = high during the

blanking. As with the CLPOB and PBLK signals, HBLK registers

are available in each H-pattern group, allowing unique blanking

signals to be used with different vertical timing sequences.

The AD9974 supports three modes of HBLK operation. HBLK

Mode 0 supports basic operation and provides some support for

special HBLK patterns. HBLK Mode 1 supports pixel mixing

HBLK operation. HBLK Mode 2 supports advanced HBLK operation. The following sections describe each mode. Register

parameters are detailed in Tab l e 1 2 .

HBLKTOGE2

HBLKTOGE1

HBLKTOGE3

HBLKTOGE4

HBLK Mode 0 Operation

There are six toggle positions available for HBLK. Normally,

only two of the toggle positions are used to generate the standard

HBLK interval. However, the additional toggle positions can be

used to generate special HBLK patterns, as shown in Figure 27.

The pattern in this example uses all six toggle positions to generate

two extra groups of pulses during the HBLK interval. By changing

the toggle positions, different patterns are created.

Separate toggle positions are available for even and odd lines.

If alternation is not needed, load the same values into the registers

for even (HBLKTOGE) and odd (HBLKTOGO) lines.

HBLKTOGE6

HBLKTOGE5

HBLK

H1/H3

H2/H4

SPECIAL H-BL ANK P ATTERN IS CREATED USING MUL TIPLE HBLK TOGGLE POSITIONS (HBL KALT = 0).

Figure 27. Generating Special HBLK Patterns

05955-027

Table 12. HBLK Pattern Registers

Register Length (Bits) Range Description

HBLK_MODE 2 0 to 2 HBLK modes Enables different HBLK toggle position operations.

0 = normal mode. Six toggle positions available for even and odd lines.

If even/odd alternation is not needed, set toggles for even/odd the same.

1 = pixel mixing mode. In addition to six toggle positions, the HBLKSTART,

HBLKEND, HBLKLEN, and HBLKREP registers can be used to generate HBLK

patterns. If even/odd alternation is not needed, set toggles for even/odd

the same.

2 = advanced HBLK mode. Divides HBLK interval into six different repeat

areas. Uses HBLKSTARTA/B/C and RA*H*REPA/B/C registers.

3 = test mode only. Do not access.

HBLKSTART 13 0 to 8191 pixel location Start location for HBLK in HBLK Mode 1 and HBLK Mode 2.

HBLKEND 13 0 to 8191 pixel location End location for HBLK in HBLK Mode 1 and HBLK Mode 2.

HBLKLEN 13 0 to 8191 pixels HBLK length in HBLK Mode 1 and HBLK Mode 2.

HBLKREP 13 0 to 8191 repetitions Number of HBLK repetitions in HBLK Mode 1 and HBLK Mode 2.

HBLKMASK_H1 1 High/low Masking polarity for H1 and H3 during HBLK.

HBLKMASK_H2 1 High/low Masking polarity for H2 and H4 during HBLK.

Rev. A | Page 20 of 52

AD9974

Register Length (Bits) Range Description

HBLKTOGO1 13 0 to 8191 pixel location First HBLK toggle position for odd lines in HBLK Mode 0 and HBLK Mode 1.

HBLKTOGO2 13 0 to 8191 pixel location Second HBLK toggle position for odd lines in HBLK Mode 0 and HBLK Mode 1.

HBLKTOGO3 13 0 to 8191 pixel location Third HBLK toggle position for odd lines in HBLK Mode 0 and HBLK Mode 1.

HBLKTOGO4 13 0 to 8191 pixel location Fourth HBLK toggle position for odd lines in HBLK Mode 0 and HBLK Mode 1.

HBLKTOGO5 13 0 to 8191 pixel location Fifth HBLK toggle position for odd lines in HBLK Mode 0 and HBLK Mode 1.

HBLKTOGO6 13 0 to 8191 pixel location Sixth HBLK toggle position for odd lines in HBLK Mode 0 and HBLK Mode 1.

HBLKTOGE1 13 0 to 8191 pixel location First HBLK toggle position for even lines in HBLK Mode 0 and HBLK Mode 1.

HBLKTOGE2 13 0 to 8191 pixel location Second HBLK toggle position for even lines in HBLK Mode 0 and HBLK Mode 1.

HBLKTOGE3 13 0 to 8191 pixel location Third HBLK toggle position for even lines in HBLK Mode 0 and HBLK Mode 1.

HBLKTOGE4 13 0 to 8191 pixel location Fourth HBLK toggle position for even lines in HBLK Mode 0 and HBLK Mode 1.

HBLKTOGE5 13 0 to 8191 pixel location Fifth HBLK toggle position for even lines in HBLK Mode 0 and HBLK Mode 1.

HBLKTOGE6 13 0 to 8191 pixel location Sixth HBLK toggle position for even lines in HBLK Mode 0 and HBLK Mode 1.

RA0H1REPA/B/C 12

[3:0] RA0H1REPA. Number of H1 pulses following HBLKSTARTA.

[7:4] RA0H1REPB. Number of H1 pulses following HBLKSTARTB.

[11:8] RA0H1REPC. Number of H1 pulses following HBLKSTARTC.

RA1H1REPA/B/C 12 0 to 15 HCLK pulses HBLK Repeat Area 1. Number of H1 repetitions for HBLKSTARTA/B/C.

RA2H1REPA/B/C 12 0 to 15 HCLK pulses HBLK Repeat Area 2. Number of H1 repetitions for HBLKSTARTA/B/C.

RA3H1REPA/B/C 12 0 to 15 HCLK pulses HBLK Repeat Area 3. Number of H1 repetitions for HBLKSTARTA/B/C.

RA4H1REPA/B/C 12 0 to 15 HCLK pulses HBLK Repeat Area 4. Number of H1 repetitions for HBLKSTARTA/B/C.

RA5H1REPA/B/C 12 0 to 15 HCLK pulses HBLK Repeat Area 5. Number of H1 repetitions for HBLKSTARTA/B/C.

RA0H2REPA/B/C 12

[3:0] RA0H2REPA. Number of H2 pulses following HBLKSTARTA.

[7:4] RA0H2REPB. Number of H2 pulses following HBLKSTARTB.

[11:8] RA0H2REPC. Number of H2 pulses following HBLKSTARTC.

RA1H2REPA/B/C 12 0 to 15 HCLK pulses HBLK Repeat Area 1. Number of H2 repetitions for HBLKSTARTA/B/C.

RA2H2REPA/B/C 12 0 to 15 HCLK pulses HBLK Repeat Area 2. Number of H2 repetitions for HBLKSTARTA/B/C.

RA3H2REPA/B/C 12 0 to 15 HCLK pulses HBLK Repeat Area 3. Number of H2 repetitions for HBLKSTARTA/B/C.

RA4H2REPA/B/C 12 0 to 15 HCLK pulses HBLK Repeat Area 4. Number of H2 repetitions for HBLKSTARTA/B/C.

RA5H2REPA/B/C 12 0 to 15 HCLK pulses HBLK Repeat Area 5. Number of H2 repetitions for HBLKSTARTA/B/C.

HBLKSTARTA 13 0 to 8191 pixel location HBLK Repeat Area Start Position A for HBLK Mode 2.

HBLKSTARTB 13 0 to 8191 pixel location HBLK Repeat Area Start Position B for HBLK Mode 2.

HBLKSTARTC 13 0 to 8191 pixel location HBLK Repeat Area Start Position C for HBLK Mode 2.

HBLKALT_PAT1 3 0 to 5 even repeat area

HBLKALT_PAT2 3 0 to 5 even repeat area HBLK Mode 2, Odd Field Repeat Area 1 pattern.

HBLKALT_PAT3 3 0 to 5 even repeat area HBLK Mode 2, Odd Field Repeat Area 2 pattern.

HBLKALT_PAT4 3 0 to 5 even repeat area HBLK Mode 2, Odd Field Repeat Area 3 pattern.

HBLKALT_PAT5 3 0 to 5 even repeat area HBLK Mode 2, Odd Field Repeat Area 4 pattern.

HBLKALT_PAT6 3 0 to 5 even repeat area HBLK Mode 2, Odd Field Repeat Area 5 pattern.

0 to 15 HCLK pulses

for each A, B, and C

0 to 15 HCLK pulses

for each A, B, and C

HBLK Repeat Area 0. Number of H1 repetitions for HBLKSTARTA/B/C in

HBLK Mode 2 for even lines; odd lines are defined using HBLKALT_PAT.

HBLK Repeat Area 0. Number of H2 repetitions for HBLKSTARTA/B/C in

HBLK Mode 2 for even lines; odd lines are defined using HBLKALT_PAT.

HBLK Mode 2, Odd Field Repeat Area 0 pattern, selected from even field.

Repeat areas previously defined.

Rev. A | Page 21 of 52

AD9974

K

HBLK Mode 1 Operation

Enable multiple repeats of the HBLK signal by setting

HBLK_MODE to 1. In this mode, the HBLK pattern can be

generated using a different set of registers: HBLKSTART,

HBLKEND, HBLKLEN, and HBLKREP, along with the six

toggle positions (see Figure 28).

Separate toggle positions are available for even and odd lines.

If alternation is not needed, load the same values into the registers

for even (HBLKTOGE) and odd (HBLKTOGO) lines.

Generating HBLK Line Alternation

HBLK Mode 0 and HBLK Mode 1 provide the ability to

alternate different HBLK toggle positions on even and odd

lines. Separate toggle positions are available for even and odd

lines. If even/odd line alternation is not required, load the same

values into the registers for even (HBLKTOGE) and odd

(HBLKTOGO) lines.

Table 13. HCLK Width Register

Register Length (Bits) Description

HCLK_WIDTH 4 Controls H1 to H4 width during HBLK as a fraction of pixel rate.

0 = same frequency as pixel rate.

1 = 1/2 pixel frequency, that is, doubles the HCLK pulse width.

2 = 1/4 pixel frequency.

3 = 1/6 pixel frequency.

4 = 1/8 pixel frequency.

5 = 1/10 pixel frequency.

…

15 = 1/30 pixel frequency.

HBLKSTART HBLKTOGE1

HBLKTOGE2

HBL

TOGE4

Increasing H-Clock Width During HBLK

HBLK Mode 0 and HBLK Mode 1 allow the H1 to H4 pulse

width to be increased during the HBLK interval. As shown in

Figure 29, the H-clock frequency can be reduced by a factor of

1/2, 1/4, 1/6, 1/8, 1/10, 1/12, and so on, up to 1/30. To enable this

feature, the HCLK_WIDTH register (Address 0x34[7:4]) is set to

a value between 1 and 15. When this register is set to 0, the wide

HCLK feature is disabled. The reduced frequency occurs only for

H1 to H4 pulses that are located within the HBLK area.

The HCLK_WIDTH register is generally used in conjunction

with special HBLK patterns to generate vertical and horizontal

mixing in the CCD.

Note that the wide HCLK feature is available only in HBLK Mode 0

and HBLK Mode 1, not in HBLK Mode 2.

HBLKENDHBLKTOGE3

HBLK

HBLKLEN

HBLKREP = 3

H1/H3

H2/H4

HBLKREP NUMBER 1 HBLKREP NUMBER 2 HBLKREP NUMBER 3

H-BLANK REPE ATING PATTERN IS CREATED USING HBLKLEN AND HBLKRE P RE GISTERS.

Figure 28. HBLK Repeating Pattern Using HBLKMODE = 1

05955-028

HBLK

H1/H3

H2/H4

1/F

PIX

H-CLOCK FREQUENCY CAN BE REDUCED DURING HBLK BY 1/2 (AS SHO WN),

1/4, 1/6, 1/8, 1/10, 1/12, AND SO ON, UP TO 1/30 USI NG HBLKWI DTH REGISTER.

Figure 29. Generating Wide H-Clock Pulses During HBLK Interval

2 × (1/F

)

PIX

Rev. A | Page 22 of 52

5955-029

AD9974

HBLK Mode 2 Operation

HBLK Mode 2 allows more advanced HBLK pattern operation.

If unevenly spaced HCLK pulses in multiple areas are needed,

HBLK Mode 2 can be used. Using a separate set of registers,

HBLK Mode 2 can divide the HBLK region into up to six repeat

areas (see Tab l e 1 2 ). As shown in Figure 31, each repeat area

shares a common group of toggle positions, HBLKSTARTA,

HBLKSTARTB, and HBLKSTARTC. However, the number of

toggles following each start position can be unique in each

repeat area by using the RAH1REP and RAH2REP registers.

As shown in Figure 30, setting the RAH1REPA/RAH1REPB/

RAH1REPC or RAH2REPA/RAH2REPB/RAH2REPC registers

to 0 masks HCLK groups from appearing in a particular repeat

area. Figure 31 shows only two repeat areas being used, although

six are available. It is possible to program a separate number of

repeat area repetitions for H1 and H2, but generally the same

value is used for both H1 and H2.

HD

CREAT E UP TO 3 GROUPS OFTOGGLES

A, B, C COMMON IN ALL REPEAT AREAS

A

B

C

MASK A, B, C PULSES IN ANY REPEAT

AREA BY SETTING RA*H*REP* = 0

Figure 31 shows the following example:

RA0H1REPA/RA0H1REPB/RA0H1REPC =

RA0H2REPA/RA0H2REPB/RA0H2REPC =

RA1H1REPA/RA1H1REPB/RA1H1REPC =

RA1H2REPA/RA1H2REPB/RA1H2REPC = 2.

Furthermore, HBLK Mode 2 allows a different HBLK pattern

on even and odd lines. The HBLKSTARTA, HBLKSTARTB, and

HBLKSTARTC registers, as well as the RAH1REPA/RAH1REPB/

RAH1REPC and RAH2REPA/RAH2REPB/RAH2REPC registers,

define operation for the even lines. For separate control of the

odd lines, the HBLKALT_PAT registers specify up to six repeat

areas on the odd lines by reordering the repeat areas used for the

even lines. New patterns are not available, but the order of the

previously defined repeat areas on the even lines can be changed

for the odd lines to accommodate advanced CCD operation.

CHANGE NUMBER OF A, B, C PULSE S IN AN Y

REPEAT AREA USING RA*H*REP* REGI STERS

HD

HBLK

H1

H2

HBLKSTART

REPEATAREA 0

REPEATAREA 1 REPEAT AREA 2 REPEAT AREA 3 REPEAT AREA 4 REPEAT AREA 5

HBLKEND

5955-030

Figure 30. HBLK Mode 2 Operation

HBLKLEN

HBLKSTARTA

HBLKSTARTB

H1

RA0H1REPA

H2

HBLKSTART

RA0H2REPA

RA0H1REPB RA0H1REPC

RA0H2REPB RA0H2REPC

REPEAT AREA 0

HBLKSTARTC

HBLKREP = 2

TO CREATE 2 REPEAT AREAS

ALL RA*H*RE PA, B, C RE GISTERS = 2, TO CRE ATE 2 HCL K P ULSES

RA1H1REPA

RA1H2REPA

RA1H1REPB RA1H1REPC

RA1H2REPB RA1H2REPC

REPEATAREA 1

HBLKEND

05955-031

Figure 31. HBLK Mode 2 Registers

Rev. A | Page 23 of 52

AD9974

HBLK, PBLK, and CLPOB Toggle Positions

The AD9974 uses an internal horizontal pixel counter to position

the HBLK, PBLK, and CLPOB toggle positions. The horizontal

counter does not reset to 0 until 12 CLI periods after the falling

edge of HD. This 12-cycle pipeline delay must be considered

when determining the register toggle positions. For example, if

CLPOB_TOG1 is 100 and the pipeline delay is not considered,

the final toggle position is applied at 112. To obtain the correct

toggle positions, the toggle position registers must be set to the

desired toggle position minus 12.

PIXEL NO.

HD

For example, if the desired toggle position is 100, CLPOB_TOG

should be set to 88 (that is, 100 − 12). Figure 49 shows the 12-cycle

pipeline delay referenced to the falling edge of HD.

Caution

Toggle positions cannot be programmed during the 12-cycle

delay from the HD falling edge until the H-counter has reset.

See Figure 33 for an example of this restriction.

112103100600

(PIXEL COUNTER )

H1

CLPOB

H-COUNTER

12

DESIRED

TOGGLE

1. HBLKTOG1 60 (60 – 12) = 48

2. HBLKTOG2 100 ( 100 – 12) = 88

3. CLPOB_TOG1 103 (103 – 12) = 91

4. CLPOB_TOG2 112 (112 – 12) = 100

POSITION

ACTUAL

REGISTER

VALUE

Figure 32. Example of Register Setting to Obtain Desired Toggle Positions

VD

HD

NO TOGGLE POSITIONSALLOWED IN THISAREA

XXXX

NOTES

1. TOGGLE POSITIONS CANNOT BE PROGRAMMED W ITHIN 12 PI XELS OF P IXEL 0 LOCATION.

N-1 N 0 1 2N-2N-3N-4N-5N-6N-7N-8N-9N-10N-11N-12

Figure 33. Restriction for Toggle Position Placement

34

H-COUNTER

RESET

05955-032

05955-033

Rev. A | Page 24 of 52

AD9974

C

C

C

C

COMPLETE FIELD—COMBINING H-PATTERNS

After the H-patterns are created, they combine to create different

readout fields. A field consists of up to nine different regions

determined by the SCP registers. Within each region, a different

H-pattern group can be selected up to a maximum of 32 groups.

Registers to control the H-patterns are located in the field registers.

Tabl e 31 describes the field registers.

VD

HD

SCP 0

REGION 0

SCP 1 SCP 2

REGION 1 REGION 2 REGION 3 REGI ON 4 REGION 8

P3

S

H-Pattern Selection

The H-patterns are stored in the HPAT memory, as described in

Tabl e 20 . The user decides how many H-pattern groups are

required, up to a maximum of 32, and then uses the HPAT_SEL

registers to select which H-pattern group is output in each

region of the field. Figure 34 shows how to use the HPAT_SEL

and SCP registers. The SCP registers create the line boundaries

for each region.

P4

S

P5

S

P8

S

H-PATTERNS

HPAT_SEL0 HPAT_SEL1

FIELD SETTINGS:

1. SEQUENCE CHANG E POSIT IONS (SCP0-8) DE FINE EACH OF THE NINE AVAILABLE REGIONS IN THE FIE LD.

2. HPAT_SEL SELECTS THE DESIRED H-PATTERN FOR EACH REGIO N.

HPAT_SEL2

HPAT_SEL3

HPAT_SEL4

HPAT_SEL8

05955-034

Figure 34. Complete Field Divided into Regions

Table 14. Field Registers

Register Length (Bits) Range Description

SCPx 13 0 to 8191 line number Sequence change position for each region. Selects an individual line.

HPAT_SELx 5 0 to 31 H-patterns Selected H-pattern for each region of the field.

CLPOB_POL 9 High/low CLPOB start polarity settings for each region of the field.

CLPOB_PAT 9 0 to 9 patterns CLPOB pattern selector for each region of the field.

CLPOBMASKSTARTx,

13 Number of lines CLPOB mask positions for up to three masking configurations.

CLPOBMASKENDx

PBLK_POL 9 High/low PBLK start polarity settings for each region of the field.

PBLK_PAT 9 0 to 9 patterns PBLK pattern selector for each region of the field.

PBLKMASKSTARTx,

13 Number of lines PBLK mask positions for up to three masking configurations.

PBLKMASKENDx,

Rev. A | Page 25 of 52

AD9974

MODE REGISTERS

The mode registers contain registers to select the final field timing

of the AD9974. Typically, all of the field and H-pattern group

information is programmed into the AD9974 at startup. During

operation, the mode registers allow the user to select any combination of field timing to meet the current requirements of the

system. The advantage of using the mode registers in conjunction

with preprogrammed timing is that they greatly reduce the system

programming requirements during camera operation. Only a few

register writes are required when the camera operating mode is

changed, rather than having to write in all of the vertical timing

information with each camera mode change.

Table 15. Mode Registers

Register Length (Bits) Range Description

HPATNUM 5 0 to 31 H-pattern groups Total number of H-pattern groups, starting at Address 0x800.

FIELDNUM 3 0 to 7 fields Total number of applied fields. Set to 1 for single-field operation.

FIELD_SEL1 5 0 to 31 field groups Selected first field.

FIELD_SEL2 5 0 to 31 field groups Selected second field.

FIELD_SEL3 5 0 to 31 field groups Selected third field.

FIELD_SEL4 5 0 to 31 field groups Selected fourth field.

FIELD_SEL5 5 0 to 31 field groups Selected fifth field.

FIELD_SEL6 5 0 to 31 field groups Selected sixth field.

FIELD_SEL7 5 0 to 31 field groups Selected seventh field.

A basic still camera application can require five fields of horizontal timing: one for draft mode operation, one for autofocusing,

and three for still image readout. With the AD9974, all of the

register timing information for the five fields is loaded at startup.

Then, during camera operation, the mode registers select

which field timing to activate, depending on how the camera

is being used.

The AD9974 supports up to seven field sequences selected from

up to 31 preprogrammed field groups using the FIELD_SEL

registers. When FIELDNUM is greater than 1, the AD9974 starts

with Field 1 and increments to each Field n at the start of each VD.

Figure 35 provides examples of mode configuration settings.

This example assumes to have four field groups, Field Group 0

to Field Group 3, stored in memory.

Rev. A | Page 26 of 52

AD9974

H-PATTERN MEMORY

FIELD 0

FIELD 1

FIELD 2

FIELD 3

EXAMPLE 1:

TOTAL FIELDS = 3, F IRST FI E LD = FIELD 0, SECOND F IELD = FI E LD 1, THIRD F IELD = FIELD 2

FIELD_SEL1 = 0 FIELD_SEL2 = 1 FIELD_SEL3 = 2

FIELD 0

FIELD 1 FIELD 2

EXAMPLE 2:

TOTAL FIELDS = 1, FIRST FIELD = FIELD 3

FIELD_SEL1 = 3

FIELD 3

EXAMPLE 3:

TOTAL FIELDS = 4, FIRST FIELD = FIELD 5, SECOND FIELD = FIELD 1, THIRD FI ELD = FIE LD 4, FOURTH FIELD = FIELD 2

FIELD_SEL1 = 5 FIELD_SEL2 = 1 FIELD_SEL3 = 4 FIELD_SEL4 = 2

FIELD 5

FIELD 1 FIELD 4

FIELD 2

05955-035

Figure 35. Example of Mode Configurations

Rev. A | Page 27 of 52

AD9974

HORIZONTAL TIMING SEQUENCE EXAMPLE

Figure 36 shows an example of a CCD layout. The horizontal

register contains 28 dummy pixels that occur on each line

clocked from the CCD. In the vertical direction, there are

10 optical black (OB) lines at the front of the readout and two

at the back of the readout. The horizontal direction has four

OB pixels in the front and 48 in the back.

Figure 37 shows the basic sequence layout to use during the

effective pixel readout. The 48 OB pixels at the end of each line

are used for the CLPOB signals. PBLK is optional and is often

used to blank the digital outputs during the HBLK time. HBLK

is used during the vertical shift interval.

Because PBLK is used to isolate the CDS input (see the Analog

Front End Description and Operation section), do not use the

PBLK signal during CLPOB operation. The change in the offset

behavior that occurs during PBLK impacts the accuracy of the

CLPOB circuitry.

The HBLK, CLPOB, and PBLK parameters are programmed

in the V-sequence registers. More elaborate clamping schemes,

such as adding a separate sequence to clamp all the shielded

OB lines, can be used. This requires configuring a separate

V-sequence for clocking out the OB lines.

The CLPOBMASK registers are also useful for disabling the

CLPOB on a few lines without affecting the setup of the

clamping sequences. It is important to use CLPOB only during

valid OB pixels. During other portions on the frame timing,

such as vertical blanking or SG line timing, the CCD does not

output valid OB pixels. Any CLPOB pulse that occurs during

this time causes errors in clamping operation and, therefore,

changes in the black level of the image.

2 VERTICAL

OB LINES

V

4 OB PIXELS

EFFECTIVE IMAGE AREA

H

HORIZONTAL CCD REGISTE R

48 OB PIXELS

10 VERTICAL

OB LINES

CCD OUTPUT

OPTICAL BLACK

HD

VERTICAL SHIFT VERT. SHIFT

SHP

SHD

H1/H3

H2/H4

HBLK

PBLK

CLPOB

NOTES

1. PBLK ACTIVE (LOW) S HOULD NOT BE US E D DURING CLPOB ACTIVE (L OW).

OB

DUMMY EFFECTIVE PIXELS

Figure 37. Horizontal Sequence Example

28 DUMMY PIXELS

Figure 36. Example CCD Configuration

OPTICAL BLACK

05955-036

5955-037

Rev. A | Page 28 of 52

AD9974

ANALOG FRONT END DESCRIPTION AND OPERATION

0.1µF 0.1µF

REFTREFB

DC RESTORE

0.4V 1.4V

AD9974

SHP

PBLK (WHEN DCBYP = 1)

SHP

SHD

CDS

–3dB, 0dB,

+3dB, +6dB

CDS GAIN

REGISTER

SHP

GENERATION

DOUT

SHD

PHASE

PRECISION

TIMING

Figure 38. Channel A and Channel B Analog Front End Functional Block Diagram

6dB ~ 42dB

VGA

VGA GAIN

REGISTER

CLPOB PBLK

GENERATION

TIMING

0.1µF

CCDIN

CLI

1.2V

1

S1

2

S2

PBLK

1

S1 IS NORMALLY CLOS ED.

2

S2 IS NORMAL LY OPEN.

The AD9974 signal processing chain is shown in Figure 38.

Each processing step is essential for achieving a high quality

image from the raw CCD pixel data.

DC Restore

To reduce the large dc offset of the CCD output signal, a dc

restore circuit is used with an external 0.1 μF series coupling

capacitor. This restores the dc level of the CCD signal to approximately 1.2 V, making it compatible with the 1.8 V core supply

voltage of the AD9974. The dc restore switch is active during

the SHP sample pulse time.

The dc restore circuit can be disabled when the optional PBLK

signal is used to isolate large-signal swings from the CCD input

(see the Analog Preblanking section). Bit 6 of Address 0x00

controls whether the dc restore is active during the PBLK interval.

Analog Preblanking

During certain CCD blanking or substrate clocking intervals,

the CCD input signal to the AD9974 may increase in amplitude

beyond the recommended input range. The PBLK signal can be

used to isolate the CDS input from large-signal swings. As shown

in Figure 38, when PBLK is active (low), the CDS input is isolated

from the CCDIN pin (S1 open) and is internally shorted to

ground (S2 closed).

Rev. A | Page 29 of 52

V-H

DOUT PHASE

OUTPUT

DATA

LATCH

PBLK

CLPOB

14

BLANK TO

ZERO OR

CLAMP LEVEL

DAC

INTERNAL

V

REF

14-BIT

ADC

OPTICAL BLACK

CLAMP

DIGITAL

FILTER

2V FULL SCALE

CLAMP LEVEL

REGISTER

During the PBLK active time, the ADC outputs can be

programmed to output all 0s or the programmed clamp level.

Note that because the CDS input is shorted during PBLK, the

CLPOB pulse should not be used during the same active time as

the PBLK pulse.

Correlated Double Sampler (CDS)

The CDS circuit samples each CCD pixel twice to extract the

video information and to reject low frequency noise. The timing

shown in Figure 21 illustrates how the two internally generated

CDS clocks, SHP and SHD, are used to sample the reference

level and data level of the CCD signal, respectively. The placement

of the SHP and SHD sampling edges is determined by the setting

of the SHPLOC and SHDLOC register located at Address 0x36.

Placement of these two clock signals is critical for achieving the

best performance from the CCD. The CDS gain is variable in

four steps by using the AFE Register Address 0x04: −3 dB, 0 dB

(default), +3 dB, and +6 dB. Improved noise performance results

from using the +3 dB and +6 dB settings, but the input range is

reduced (see Tabl e 5).

DOUT

VD

HD

5955-038

AD9974

E

Input Configurations

The CDS circuit samples each CCD pixel twice to extract the video

information and reject low frequency noise (see Figure 39). There

are three possible configurations for the CDS: inverting CDS mode,

noninverting CDS mode, and SHA mode. The CDSMODE

register (Address 0x00[9:8]) selects which configuration is used.

SHP

CCDINP

CCDINM

SHA1

SHA2

SHD

DIFF

AMP

CDS_OUT

05955-039

Figure 39. CDS Block Diagram (Conceptual)

Inverting CDS Mode

For this configuration, the signal from the CCD is applied to the

positive input of the (CCDINP) CDS system with the minus

side (CCDINM) grounded (see Figure 40). The CDSMODE

register setting for this configuration is 0x00. Traditional CCD

applications use this configuration with the reset level established

below the AVDD supply level by the AD9974 dc restore circuit,

at approximately 1.5 V. The maximum saturation level is 1.0 V

below the reset level, as shown in Figure 41 and Ta b le 16 . A maximum saturation voltage of 1.4 V is also possible when using the

minimum CDS gain setting.

AD9974

CCDINP

IMAGE

SENSOR

CCDINM

SHA/

CDS

(N) SIGNAL SAMPL

SIGNAL LEVEL

(V

)

FS

(N + 1) RESET SAMPLE

5955-041

V

RESET LEVEL

(V

)

RST

(N) RESET SAMPLE

DD

Figure 41. Traditional Inverting CDS Signal

Table 16. Inverting Voltage Levels

Signal Level Symbol Min (mV) Typ (mV) Max (mV)

Saturation VFS 1000 1400

Reset V

VDD − 500 VDD − 300 VDD

RST

Supply Voltage VDD 1600 1800 2000

Noninverting Input

If the noninverting input is desired, the reset (or black) level

signal is established at a voltage above ground potential.

Saturation (or white) level is approximately 1 V. Samples are

taken at each signal level. See Figure 42 and Ta ble 1 7.

SIGNAL LEVEL

(V

)

FS

(N) SIGNAL SAMPLE

(N + 1) RESET SAMPLE

05955-042

RESET LEVEL

(V

)

RST

GND

(N) RESET SAMPLE

Figure 42. Noninverting CDS Signal

NOTES

1. COUPLING CAPACITOR IS NOT REQ UIRED FOR CERT AIN

BLACK LEVEL RE FERENCE VOL TAGES.

Figure 40. Single Input CDS Configuration

5955-040

Rev. A | Page 30 of 52

Table 17. Noninverting Voltage Levels

Signal Level Symbol Min (mV) Typ (mV) Max (mV)

Saturation VFS 1000 1400

Reset V

0 250 500

RST

AD9974

SHA Mode—Differential Input Configuration

This configuration uses a differential input sample/hold

amplifier (SHA) (see Figure 43).

AD9974

CCDINP

IMAGE

SENSOR

CCDINM

Figure 43. SHA Mode—Differential Input Configuration

SHA/

CDS

05955-043

Referring to Figure 46 and Tab l e 1 9 , the CCDINM signal is a

constant dc voltage set at a level above ground potential. The

sensor signal is applied to the other input, and samples are taken

at the signal minimum and at a point of signal maximum. The

resulting differential signal is the difference between the signal

and the reference voltage.

(N + 1) SIGNAL SAMPLE

(N) SIGNAL SAMPLE

In this configuration, a signal is applied to the CCDINP input

and, simultaneously, an inverse signal is applied to the CCDINM

input. Sampling occurs on both signals at the same time. This

creates the differential output for amplification and the ADC

(see Figure 44 and Ta b le 1 8 ).

(N + 1) SIGNAL SAMPLE

(N) SIGNAL SAMPLE

INPUT_POS

BLACK SIGNAL LEVEL (V

MINIMUM SIGNAL LEVEL (V

GND

BLK

)

PEAK SIGNAL

LEVEL (V

FS

)

MIN

)

INPUT_NEG

Figure 44. SHA Mode—Differential Input Signal

Table 18. SHA Mode—Differential Voltage Levels

Signal Level Symbol Min (mV) Typ (mV) Max (mV)

Black V

0

BLK

Saturation VFS 1000 VDD − 300 1400

Minimum V

0 1800

MIN

INPUT_POS

INPUT_NEG

5955-046

BLACK SIGNAL LEVEL (V

MINIMUM SIGNAL LEVEL (V

GND

BLK

PEAK SIGNAL

LEVEL (V

)

MIN

)

FS

)

Figure 46. SHA Mode—Single–Ended Input Signal (DC-Coupled)

Table 19. SHA Mode—Single-Ended Input Voltages

Signal Level Symbol Min (mV) Typ (mV) Max (mV)

Black V

0

BLK

Saturation VFS 1000 1400

Minimum V

0

MIN

CDS Timing Control

The timing shown in Figure 21 illustrates how the two internally

generated CDS clocks, SHP and SHD, are used to sample the

reference level and data level of the CCD signal, respectively. The

placement of the SHP and SHD sampling edges is determined by

05955-044

the setting of the SHPLOC and SHDLOC register located at

Address 0x36. Placement of these two clock signals is critical in

achieving the best performance from the CCD.

SHA Timing Control

When SHA mode is selected, only the SHPLOC setting is used

to sample the input signal, but the SHDLOC signal should still

be programmed to an edge setting of SHPLOC + 32.

SHA Mode—DC-Coupled, Single–Ended Input

The SHA mode can also be used in a single-ended fashion, with

the signal from the image sensor applied to the CDS/SHA using

a single input, CCDINP. This is similar to the differential configuration, except in this case, the CCDINM line is held at a constant

dc voltage, establishing a reference level that matches the image

sensor reference voltage (see Figure 45).

AD9974

CCDINP

IMAGE

SENSOR

CCDINM

NOTES

1. DC VOLT AGE ABOVE GROUND MAYBE USED TO

MATCH THE SENSOR REFERENCE L E V E L.

Figure 45. SHA Mode—Single–Ended Input Configuration, DC-Coupled

SHA/

CDS

05955-045

Rev. A | Page 31 of 52

AD9974

G

A

Variable Gain Amplifier

The VGA stage provides a gain range of approximately 6 dB to

42 dB, programmable with 10-bit resolution through the serial

digital interface. A gain of 6 dB is needed to match a 1 V input

signal with the ADC full-scale range of 2 V. When compared to

1 V full-scale systems, the equivalent gain range is 0 dB to 36 dB.

The VGA gain curve follows a linear-in-dB characteristic. The

exact VGA gain is calculated for any gain register value by

Gain (dB) = (0.0359 × Code) + 5.1 dB

where Code is the range of 0 to 1023.

42

36

30

24

GAIN (dB)

V

18

12

6

0 127 255 383 511 639 767 895 1023

VGA GAIN REGISTER CODE

Figure 47. VGA Gain Curve

05955-047

ADC

The AD9974 uses a high performance ADC architecture optimized for high speed and low power. Differential nonlinearity

(DNL) performance is typically better than 0.5 LSB. The ADC

uses a 2 V input range. See Figure 5, Figure 6, and Figure 7 for

typical noise performance and linearity plots for the AD9974.

Optical Black Clamp

The optical black clamp loop is used to remove residual offsets

in the signal chain and track low frequency variations in the

CCD black level. During the optical black (shielded) pixel interval

on each line, the ADC output is compared with a fixed black