2.7 GHz DDS-Based

Agile

RFTM Synthesizer

FEATURES

400 MSPS internal DDS clock speed

48-bit frequency tuning word

14-bit programmable phase offset

Integrated 14-bit DAC

Excellent dynamic performance

Phase noise ≤ 135 dBc/Hz @ 1 KHz offset

−80 dB SFDR @ 160 MHz (±100 KHz offset I

25 Mb/s write-speed serial I/O control

200 MHz phase frequency detector inputs

655 MHz programmable input dividers for the phase

frequency detector (÷M, ÷N) {M, N = 1..16} (bypassable)

Programmable RF divider (÷R) {R = 1, 2, 4, 8} (bypassable)

8 phase/frequency profiles

1.8 V supply for device operation

DELTA

FREQUENCY

PLL_LOCK/SYNC_IN

I/O_UPDATE

SYNC_OUT

REFCLK

REFCLK

TUNING WORD

SYNC_CLK

CML CLOCK DRIVER

24

FREQUENCY

ACCUMULATOR

DELTA

FREQUENCY

RAMP RATE

RF-DIVIDER

÷R

)

OUT

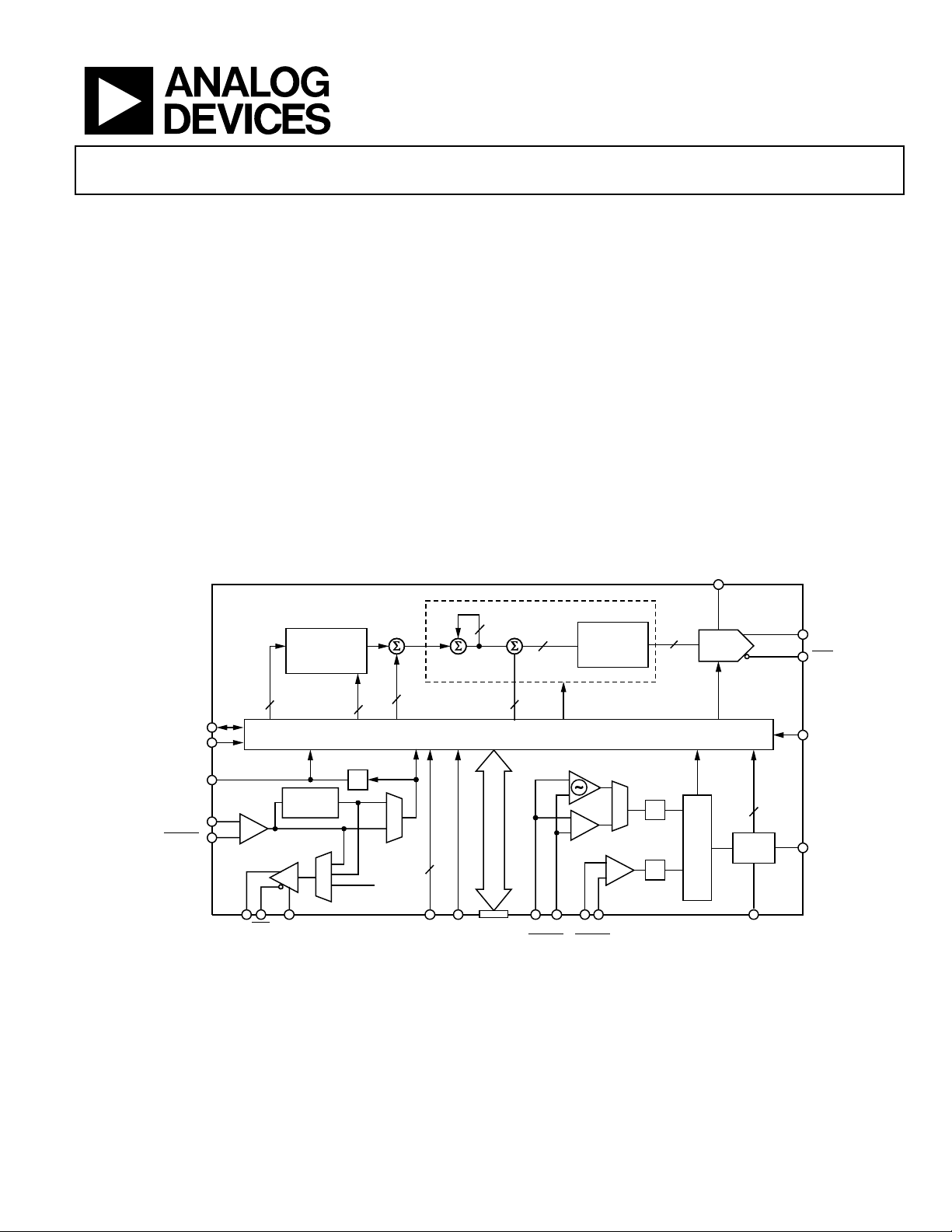

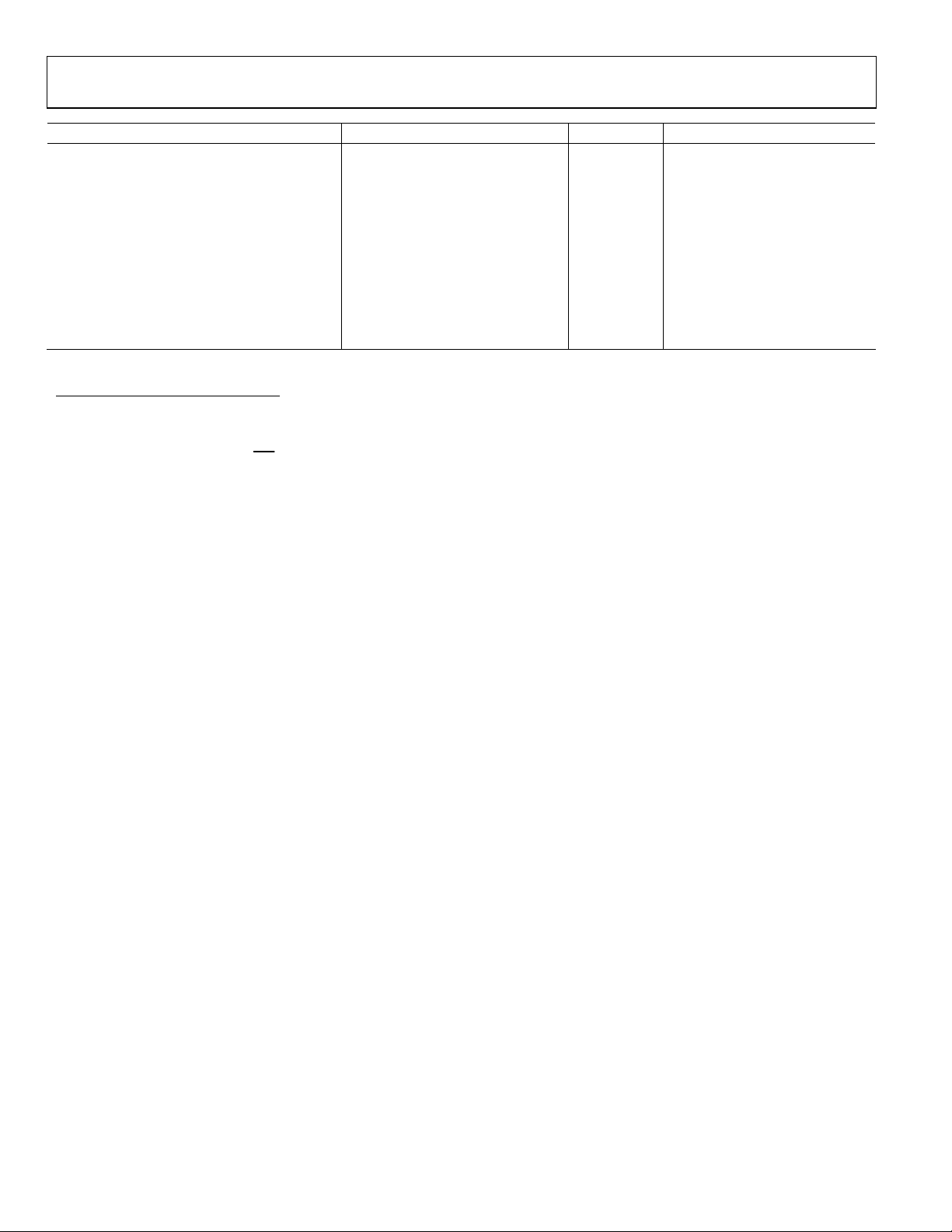

FUNCTIONAL BLOCK DIAGRAM

FTW

48

16

TIMING AND CONTRO LLOGIC

SYSCLK

÷4

3

FROM PLLOSC

48

PHASE

ACCUMULATOR

PHASE

OFFSET

WORD

AD9956

3.3 V supply for I/O and charge pump

Software controlled power-down

48-lead LFCSP package

Automatic linear frequency sweeping capability (in DDS)

Programmable charge pump current (up to 4 mA)

Phase modulation capability

Multichip synchronization

Dual-mode PLL lock detect

655 MHz CML-mode PECL-compliant driver

APPLICATIONS

Agile LO frequency synthesis

FM chirp source for radar and scanning systems

Automotive radars

Test and measurement equipment

Acousto-optic device drivers

DAC_RSET

PHASE

OFFSET

DDS CORE

19 14

14

PHASE TO

AMPLITUDE

CONVERSION

SYSCLK

OSCILLATOR

BUFFER

LOCK

DETECT

÷M

÷N

DAC

SYSCLK

CHARGE

PUMP

SCALER

3

ΦBUFFER

CHARGE

PUMP

IOUT

IOUT

I/O_RESET

CP_OUT

DRV DRV DRV_RSET

PS<2:0>

RESET I/O PORT

Rev. A

Information furnished by Analog Devices is believed to be accurate and reliable.

However, no responsibility is assumed by Analog Devices for its use, nor for any

infringements of patents or other rights of third parties that may result from its use.

Specifications subject to change without notice. No license is granted by implication

or otherwise under any patent or patent rights of Analog Devices. Trademarks and

registered trademarks are the property of their respective owners.

Figure 1.

PLLREF/

PLLREF

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700

Fax: 781.326.8703 © 2004 Analog Devices, Inc. All rights reserved.

PLLOSC/

PLLOSC

www.analog.com

CP_RSET

04806-0-001

AD9956

TABLE OF CONTENTS

Product Overview............................................................................. 3

CML Driver................................................................................. 19

Specifications..................................................................................... 4

Loop Measurement Conditions.................................................. 9

Absolute Maximum Ratings.......................................................... 10

ESD Caution................................................................................ 10

Pin Configuration and Function Descriptions........................... 11

Typical Performance Characteristics........................................... 13

Typical Application Circuits .......................................................... 16

Application Circuit Explanations ............................................. 17

General Description....................................................................... 18

DDS Core..................................................................................... 18

PLL Circuitry .............................................................................. 18

REVISION HISTORY

9/04—Data Sheet Changed from Rev. 0 to Rev. A

Changes to the Pin Configuration................................................ 11

Changes to the Pin Function Descriptions ................................. 12

Changes to Table 5.......................................................................... 24

Changes to CFR2<15:12> PLLREF Divider

Control Bits (÷N)............................................................................ 31

Changes to CFR2<11:8> PLLREF Divider

Control Bits (÷M)........................................................................... 31

Changes to Ordering Guide.......................................................... 32

Modes of Operation ....................................................................... 20

DDS Modes of Operation ......................................................... 20

Synchronization Modes for Multiple Devices .............................. 20

Serial Port Operation..................................................................... 22

Instruction Byte .......................................................................... 23

Serial Interface Port Pin Description....................................... 23

MSB/LSB Transfers .................................................................... 23

Register Map and Description ...................................................... 24

Control Function Register Descriptions ................................. 27

Outline Dimensions....................................................................... 32

Ordering Guide .......................................................................... 32

7/04—Revision: Initial Version

Rev. A | Page 2 of 32

AD9956

PRODUCT OVERVIEW

The AD9956 is Analog Devices’ newest AgileRF synthesizer.

The device is comprised of DDS and PLL circuitry. The DDS

features a 14-bit DAC operating at up to 400 MSPS and a 48-bit

frequency tuning word (FTW). The PLL circuitry includes a

phase frequency detector with scaleable 200 MHz inputs

(divider inputs operate up to 655 MHz) and digital control over

the charge pump current. The device also includes a 655 MHz

CML-mode PECL-compliant driver with programmable slew

rates. The AD9956 uses advanced DDS technology, an internal

high speed, high performance DAC, and an advanced phase

frequency detector/charge pump combination, which, when

used with an external VCO, enables the synthesis of digitally

programmable, frequency-agile analog output sinusoidal waveforms up to 2.7 GHz. The AD9956 is designed to provide fast

frequency hopping and fine tuning resolution (48-bit frequency

tuning word). Information is loaded into the AD9956 via a

serial I/O port that has a device write-speed of 25 Mb/s. The

AD9956 DDS block also supports a user-defined linear sweep

mode of operation.

The AD9956 is specified to operate over the extended

automotive range of −40°C to +125°C.

Rev. A | Page 3 of 32

AD9956

SPECIFICATIONS

AVDD = DVDD = 1.8 V ± 5%; DVDD_I/O = CP_VDD = 3.3 V ± 5% (@ TA = 25°C) DAC_R

DRV_R

= 4.02 kΩ, unless otherwise noted.

SET

Table 1.

Parameter Min Typ Max Unit Test Conditions/Comments

RF DIVIDER (REFCLK ) INPUT SECTION (÷R)

RF Divider Input Range 1 2700 MHz

Input Capacitance (DC) 3 pF

Input Impedance (DC) 1500 Ω

Input Duty Cycle 42 50 58 %

Input Power/Sensitivity −10 +4 dBm Single-ended, into a 50 Ω load

Input Voltage Level 350 1000 mV p-p

PHASE FREQUENCY DETECTOR/CHARGE PUMP

PLLREF Input

Input Frequency

2

÷M Set to Divide by at Least 4 655 MHz

÷M Bypassed 200 MHz

Input Voltage Levels 200 450 600 mV p-p

Input Capacitance 10 pF

Input Resistance 1500 Ω

PLLOSC Input

Input Frequency

÷N Set to Divide by at Least 4 655 MHz

÷N Bypassed 200 MHz

Input Voltage Levels 200 450 600 mV p-p

Input Capacitance 10 pF

Input Resistance 1500 Ω

Charge Pump Source/Sink Maximum Current 4 mA

Charge Pump Source/Sink Accuracy −15 +5 %

Charge Pump Source/Sink Matching −5 +5 %

Charge Pump Output Compliance Range

3

0.5 CP_VDD − 0.5 V

PLL_LOCK Drive Strength 2 mA

PHASE FREQUENCY DETECTOR NOISE FLOOR

@ 50 kHz PFD Frequency 149 dBc/Hz

@ 2 MHz PFD Frequency 133 dBc/Hz

@ 100 MHz PFD Frequency 116 dBc/Hz

@ 200 MHz PFD Frequency 113 dBc/Hz

CML OUTPUT DRIVER (DRV)

Differential Output Voltage Swing

4

720 mV 50 Ω load to supply, both lines

Maximum Toggle Rate 655 MHz

Common-Mode Output Voltage 1.75 V

Output Duty Cycle 42 50 58 %

Output Current

Continuous

5

7.2 mA

Rising Edge Surge 20.9 mA

Falling Edge Surge 13.5 mA

Output Rise Time 250 ps 100 Ω terminated, 5 pF load

= 3.92 kΩ, CP_R

SET

DDS SYSCLK not to exceed

400 MSPS

= 3.09 kΩ,

SET

1

Rev. A | Page 4 of 32

AD9956

Parameter Min Typ Max Unit Test Conditions/Comments

LOGIC INPUTS (SDI/O, I/O_RESET, RESET,

I/O_UPDATE, PS0 to PS2, SYNC_IN)

VIH, Input High Voltage 2.0 V

VIL, Input Low Voltage 0.8 V

I

, I

Input Current ±1 ±5 µA

INH

INL

CIN, Maximum Input Capacitance 3 pF

LOGIC OUTPUTS (SDO, SYNC_OUT, PLL_LOCK)6

VOH, Output High Voltage 2.7 V

VOH, Output Low Voltage 0.4 V

I

OH

I

OL

POWER CONSUMPTION

Total Power Consumed, All Functions On 400 mW

IAVDD 85 mA

IDVDD 45 mA

IDVDD_I/O 20 mA

ICP_VDD 15 mA

Power-Down Mode 80 mW

WAKE-UP TIME (from Power-Down Mode)

Digital Power-Down (CFR1<7>) 12 ns

DAC Power-Down (CFR2<39>) 7 µs

RF Divider Power-Down (CFR2<23>) 400 ns

Clock Driver Power-Down (CFR2<20>) 6 µs

Charge Pump Full Power-Down (CFR2<4>) 10 µs

Charge Pump Quick Power-Down (CFR2<3>) 150 ns

DAC OUTPUT CHARACTERISTICS

Resolution 14 Bits

Full-Scale Output Current 10 15 mA

Gain Error −10 +10 % FS

Output Offset 0.6 µA

Output Capacitance 5 pF

Voltage Compliance Range AVDD − 0.50 AVDD + 0.50 V

Wideband SFDR (DC to Nyquist)

10 MHz Analog Out −64 dBc

40 MHz Analog Out −62 dBc

80 MHz Analog Out −60 dBc

120 MHz Analog Out −55 dBc

160 MHz Analog Out −55 dBc

Narrowband SFDR

10 MHz Analog Out (±1 MHz) −89 dBc

10 MHz Analog Out (±250 kHz) −91 dBc

10 MHz Analog Out (±50 kHz) −93 dBc

40 MHz Analog Out (±1 MHz) −87 dBc

40 MHz Analog Out (±250 kHz) −89 dBc

40 MHz Analog Out (±50 kHz) −91 dBc

80 MHz Analog Out (±1 MHz) −85 dBc

80 MHz Analog Out (±250 kHz) −87 dBc

80 MHz Analog Out (±50 kHz) −89 dBc

120 MHz Analog Out (±1 MHz) −83 dBc

120 MHz Analog Out (±250 kHz) −85 dBc

120 MHz Analog Out (±50 kHz) −87 dBc

100 µA

100 µA

Rev. A | Page 5 of 32

AD9956

Parameter Min Typ Max Unit Test Conditions/Comments

160 MHz Analog Out (±1 MHz) −81 dBc

160 MHz Analog Out (±250 kHz) −83 dBc

160 MHz Analog Out (±50 kHz) −85 dBc

DAC Residual Phase Noise

19.7 MHz F

OUT

@ 10 Hz Offset 125 dBc/Hz

@ 100 Hz Offset 135 dBc/Hz

@ 1 kHz Offset 143 dBc/Hz

@ 10 kHz Offset 152 dBc/Hz

@ 100 kHz Offset 158 dBc/Hz

>1 MHz Offset 163 dBc/Hz

51.84 MHz F

OUT

@ 10 Hz Offset 119 dBc/Hz

@ 100 Hz Offset 125 dBc/Hz

@ 1 kHz Offset 132 dBc/Hz

@ 10 kHz Offset 142 dBc/Hz

@ 100 kHz Offset 150 dBc/Hz

>1 MHz Offset 155 dBc/Hz

105.3 MHz Analog Out

@ 10 Hz Offset 105 dBc/Hz

@ 100 Hz Offset 115 dBc/Hz

@ 1 kHz Offset 122 dBc/Hz

@ 10 kHz Offset 131 dBc/Hz

@ 100 kHz Offset 139 dBc/Hz

>1 MHz Offset 142 dBc/Hz

155.52 MHz Analog Out

@ 10 Hz Offset 105 dBc/Hz

@ 100 Hz Offset 110 dBc/Hz

@ 1 kHz Offset 119 dBc/Hz

@ 10 kHz Offset 127 dBc/Hz

@ 100 kHz Offset 135 dBc/Hz

>1 MHz Offset 142 dBc/Hz

CRYSTAL OSCILLATOR (ON PLLREF INPUT)

Operating Range 20 25 30 MHz

Residual Phase Noise (@ 25 MHz)

@ 10 Hz Offset 95 dBc/Hz

@ 100 Hz Offset 120 dBc/Hz

@ 1 kHz Offset 137 dBc/Hz

@ 10 kHz Offset 156 dBc/Hz

@ 100 kHz Offset 164 dBc/Hz

>1 MHz Offset 170 dBc/Hz

DIGITAL TIMING SPECIFICATIONS

CS

to SCLK Setup Time TPRE

Period of SCLK (Write Speed) TSCLKW 40 ns

Period of SCLK (Read Speed) TSCLKR 400 ns

Serial Data Setup Time TDSU 6.5 ns

Serial Data Hold Time TDHLD 0 ns

TDV Data Valid Time TDV 40 ns

I/O Update to SYNC_CLK Setup Time TUD 7 ns

PS<2:0> to SYNC_CLK Setup Time TPS 7 ns

6 ns

Rev. A | Page 6 of 32

AD9956

Parameter Min Typ Max Unit Test Conditions/Comments

Latencies/Pipeline Delays

I/O Update to DAC Frequency Change 33 SYSCLK Cycles

I/O Update to DAC Phase Change 33 SYSCLK Cycles

PS<2:0> to DAC Frequency Change 29 SYSCLK Cycles

PS<2:0> to DAC Phase Change 29 SYSCLK Cycles

I/O Update to CP_OUT Scaler Change 4 SYSCLK Cycles

I/O Update to Frequency Accumulator

Step Size Change

I/O Update to Frequency Accumulator

Ramp Rate Change

RF DIVIDER/CML DRIVER EQUIVALENT

INTRINSIC TIME JITTER

FIN = 414.72 MHz, F

BW = 12 kHz −> 400 kHz 136 fS rms OC1, RF Divider R = 8

FIN = 1244.16 MHz, F

BW = 12 kHz −> 1.3 MHz 101 fS rms OC3, RF Divider R = 8

FIN = 2488.32 MHz, F

BW = 12 kHz −> 5 MHz 108 fS rms OC12, RF Divider R = 4

RF DIVIDER/CML DRIVER RESIDUAL PHASE NOISE

FIN = 157.6 MHz, F

@ 10 Hz −115 dBc/Hz

@ 100 Hz −126 dBc/Hz

@ 1 kHz −134 dBc/Hz

@ 10 kHz −143 dBc/Hz

@ 100 kHz −150 dBc/Hz

> 1 MHz −151 dBc/Hz

FIN = 1240 MHz, F

OUT

@ 10 Hz −111 dBc/Hz

@ 100 Hz −122 dBc/Hz

@ 1 kHz −129 dBc/Hz

@ 10 kHz −138 dBc/Hz

@ 100 kHz −146 dBc/Hz

@ 1 MHz −150 dBc/Hz

>3 MHz −153 dBc/Hz

FIN = 2488MHz, F

OUT

@ 10 Hz −97 dBc/Hz

@ 100 Hz −110 dBc/Hz

@ 1 kHz −120 dBc/Hz

@ 10 kHz −126 dBc/Hz

@ 100 kHz −136 dBc/Hz

@ 1 MHz −141 dBc/Hz

>3 MHz −144 dBc/Hz

TOTAL SYSTEM TIME JITTER FOR 622 MHz CLOCK

12 kHz to 5 MHz Bandwidth 0.7 ps rms

7

4 SYSCLK Cycles

4 SYSCLK Cycles

= 51.84 MHz

OUT

= 155.52 MHz

OUT

= 622.08 MHz

OUT

= 19.7 MHz RF Divider R = 8

OUT

= 155 MHz RF Divider R = 8

= 622 MHz RF Divider R = 4

See the Loop Measurement Conditions section

Rev. A | Page 7 of 32

AD9956

Parameter Min Typ Max Unit Test Conditions/Comments

TOTAL SYSTEM JITTER AND PHASE NOISE FOR

105.33 MHz ADC CLOCK GENERATION CIRCUIT

Converter Limiting Jitter 0.53 ps rms

Resultant SNR 67 dB

Phase Noise of Fundamental

@ 10 Hz Offset −75 dBc/Hz

@ 100 Hz Offset −87 dBc/Hz

@ 1 kHz Offset −93 dBc/Hz

@ 10 kHz Offset −105 dBc/Hz

@ 100 kHz Offset −145 dBc/Hz

@ ≥1 MHz Offset −152 dBc/Hz

See the Loop Measurement Conditions section

DRV

.

1

The input impedance of the REFCLK input is 1500 Ω. However, in order to provide matching on the clock line, an external 50 Ω load is used.

2

Driving the PLLREF input buffer, the crystal oscillator section of this input stage performs up to only 30 MHz.

3

The charge pump output compliance range is functionally 0.2 V to (CP_VDD − 0.2 V). The value listed here is the compliance range for 5% matching.

4

Measured as peak-to-peak from DRV to

5

For a 4.02 kΩ resistor from DRV_RSET to GND.

6

Assumes a 1 mA load.

7

I/O_UPDATE/PS<2:0> are detected by the AD9956 synchronous to the rising edge of SYNC_CLK. Each latency measurement is from the first SYNC_CLK rising edge

after the I/O_UPDATE/PS<2:0> state change.

Rev. A | Page 8 of 32

AD9956

LOOP MEASUREMENT CONDITIONS

622 MHz OC-12 Clock

VCO = Sirenza 190-640T

105 MHz Converter Clock

VCO = Sirenza 190-845T

Reference = Wenzel 500-10116 (30.3 MHz)

Loop Filter = 10 kHz BW, 60° Phase Margin

C1 = 170 nF, R1 = 14.4 Ω, C2 = 5.11 µF, R2 = 89.3 Ω,

C3 Omitted

CP_OUT = 4 mA (Scaler = ×8)

÷R = 2, ÷M = 1, ÷N = 1

Reference = Wenzel 500-10116 (30.3 MHz)

Loop Filter = 10 kHz BW, 45° Phase Margin

C1 = 117 nF, R1 = 28 Ω, C2 = 1.6 µF, R2 = 57.1 Ω, C3 = 53.4 nF

CP_OUT = 4 mA (Scaler = ×8)

÷R = 8, ÷M = 1, ÷N = 1

INPUT OUTPUT

C1

Figure 2. Generic Loop Filter

R2

R1

C2

C3

04806-0-033

Rev. A | Page 9 of 32

AD9956

ABSOLUTE MAXIMUM RATINGS

Table 2.

Parameter Rating

Analog Supply Voltage (AVDD) 2 V

Digital Supply Voltage (DVDD) 2 V

Digital I/O Supply Voltage

(DVDD_I/0)

Charge Pump Supply Voltage

(CPVDD)

Maximum Digital Input Voltage −0.5 V to DVDD_I/O + 0.5 V

Storage Temperature −65°C to +150°C

Operating Temperature Range −40°C to +125°C

Lead Temperature Range

(Soldering 10 sec)

Junction Temperature 150°C

Thermal Resistance (θJA) 26°C/W

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

3.6 V

3.6 V

300°C

ESD CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily accumulate

on the human body and test equipment and can discharge without detection. Although this product features

proprietary ESD protection circuitry, permanent damage may occur on devices subjected to high energy electrostatic discharges. Therefore, proper ESD precautions are recommended to avoid performance degradation

or loss of functionality.

Rev. A | Page 10 of 32

AD9956

T

PIN CONFIGURATION AND FUNCTION DESCRIPTIONS

AVDD

DAC_RSE

DRV_RSET

CP_RSET

AVDD

AGND

PLLOSC

PLLOSC

PLLREF

PLLREF

AVDD

4847464544434241403938

AGND

37

DGND

35

34

33

32

31

30

29

28

27

26

25

CP_OUT36

CP_VDD

AGND

DRV

DRV

CP_VDD

AGND

REFCLK

REFCLK

AVDD

AGND

DVDD

04806-0-008

1

AGND

2

AVDD

3

AGND

4

AVDD

5

IOUT

6

IOUT

7

AVDD

8

AGND

RESET

DVDD

DGND

9

10

11

12

I/O_RESET

NC = NO CONNECT

PIN 1

INDICATOR

AD9956

TOP VIEW

(Not to Scale)

13141516171819

CS

SDO

SDI/O

SCLK

DVDD_I/O

SYNC_OUT

2021222324

PS0

I/O_UPDATE

PLL_LOCK/SYNC_IN

PS1

PS2

Figure 3. 48-Lead LFCSP Pin Configuration

Note that the exposed paddle on this package is an electrical connection (Pin 49) as well as a thermal enhancement. For the device to

function properly, the paddle MUST be attached to analog ground.

Rev. A | Page 11 of 32

AD9956

Table 3. 48-Lead LFCSP Pin Function Description

Pin No. Mnemonic Description

1, 3, 8, 26, 30,

34, 37, 43, 49

2, 4, 7, 27, 38,

44, 48

5 IOUT DAC Analog Output.

6

9 I/O_RESET

10 RESET

11, 25 DVDD Digital Core Supply (1.8 V).

12, 24 DGND Digital Ground.

13 SDO Serial Data Output. Used only when device is programmed for 3-wire serial data mode.

14 SDI/O

15 SCLK Serial Data Clock. Provides the clock signal for the serial data port.

16

17 DVDD_I/O Digital Interface Supply (3.3 V).

18 SYNC_OUT Synchronization Clock Output.

19 PLL_LOCK/SYNC_IN

20 I/O_UPDATE

21 to 23 PS0 to PS2

28

29 REFCLK RF Divider and DDS REFCLK Input.

32

33 DRV CML Driver Output.

31, 35 CP_VDD

36 CP_OUT Charge Pump Output.

39 PLLREF Phase Frequency Detector Reference Input.

40

41

42 PLLOSC Phase Frequency Detector Oscillator (Feedback) Input.

45 CP_RSET Charge Pump Current Set (Program Charge Pump Current with a Resistor to AGND).

46 DRV_RSET CML Driver Output Current Set (Program CML Output Current with a Resistor to AGND).

47 DAC_RSET DAC Output Current Set (Program DAC Output Current with a Resistor to AGND).

AGND Analog Ground.

AVDD Analog Core Supply (1.8 V).

IOUT

CS Active Low Signal That Enables Shared Serial Busses. When brought high, the serial port ignores

REFCLK

DRV

PLLREF

PLLOSC

DAC Analog Complementary Output.

Resets the serial port when synchronization is lost in communications but does not reset the de-

vice itself (ACTIVE HIGH). When not being used, this pin should be forced low, because it floats to

the threshold value.

Master RESET. Clears all accumulators and returns all registers to their default values (ACTIVE

HIGH).

Serial Data I/O. When the part is programmed for 3-wire serial data mode, this is input only; in

2-wire mode, it serves as both the input and output.

the serial data clocks.

Bidirectional Dual Function Pin. Depending on device programming, it is either the DDS’ synchronization input (allows alignment of multiple subclocks) or the PLL lock detect output signal.

This input pin, when set high, transfers the data from the I/O buffers to the internal registers on the

rising edge of the internal SYNC_CLK, which can be observed on SYNC_OUT.

Profile Select Pins. Specify one of eight frequency tuning word/phase offset word profiles. In linear

sweep mode, PS0 determines the state of the sweep. In linear sweep no dwell mode, PS0 is a trigger that initiates the sweep. PS1 and PS2 have no function during linear sweep mode or linear

sweep no dwell mode.

RF Divider and DDS REFCLK Complementary Input.

CML Driver Complementary Output.

Charge Pump Supply Pin (3.3 V). To minimize noise on the charge pump, isolate this supply from

DVDD_I/O.

Phase Frequency Detector Reference Complementary Input.

Phase Frequency Detector Oscillator (Feedback) Complementary Input.

Note that the exposed paddle on this package is an electrical connection (Pin 49) as well as a thermal enhancement. In order for the

device to function properly, the paddle MUST be attached to analog ground.

Rev. A | Page 12 of 32

AD9956

TYPICAL PERFORMANCE CHARACTERISTICS

RF ATT

500Hz

DELTA 1 [T1]

REF LVL

0dBm

0

–10

–20

–30

–40

–50

–60

–70

–80

1

–90

–100

CENTER 10.1MHz 100kHz/ SPAN 1MHz

–84.82dB

–404.80961924kHz

RBW

500Hz

VBW

20s

SWT

1

Figure 4. AD9956 DAC Performance: 400 MSPS Clock,

–78.67dB

1

, 1 MHz Span

OUT

RBW

VBW

SWT

1

500Hz

500Hz

20s

10 MHz F

REF LVL

0dBm

0

–10

–20

–30

–40

–50

–60

–70

–80

–90

–100

CENTER 40.1MHz 100kHz/ SPAN 1MHz

DELTA 1 [T1]

–100.20040080kHz

Figure 5. AD9956 DAC Performance: 400 MSPS Clock,

–57.74dB

, 1 MHz Span

OUT

RBW

VBW

SWT

1

500Hz

500Hz

20s

40 MHz F

REF LVL

0dBm

0

–10

–20

–30

–40

–50

–60

1

–70

–80

–90

–100

CENTER 100.1MHz 100kHz/ SPAN 1MHz

DELTA 1 [T1]

–400.80160321kHz

Figure 6. AD9956 DAC Performance: 400 MSPS Clock,

100 MHz F

, 1 MHz Span

OUT

UNIT

RF ATT

UNIT

RF ATT

UNIT

20dB

20dB

20dB

DELTA 1 [T1]

REF LVL

dB

A

1 AP

04806-0-015

0dBm

0

1

–10

–20

–30

–40

–50

–60

–70

–80

–90

–100

START 0Hz 16.9MHz/ STOP 169MHz

–67.45dB

74.50901804MHz

RBW

VBW

SWT

1

Figure 7. AD9956 DAC Performance: 400 MSPS Clock,

OUT

–62.65dB

, 200 MHz Span

RBW

VBW

SWT

10 MHz F

REF LVL

dB

A

1 AP

04806-0-016

0dBm

0

–10

–20

–30

–40

–50

–60

–70

–80

–90

–100

START 0Hz 20MHz/ STOP 200MHz

DELTA 1 [T1]

100.20040080MHz

1

Figure 8. AD9956 DAC Performance: 400 MSPS Clock,

OUT

–48.78dB

, 200 MHz Span

RBW

VBW

SWT

1

1

40 MHz F

REF LVL

dB

A

1 AP

04806-0-017

0dBm

0

–10

–20

–30

–40

–50

–60

–70

–80

–90

–100

START 0Hz 20MHz/ STOP 200MHz

DELTA 1 [T1]

–400.80160321kHz

Figure 9. AD9956 DAC Performance: 400 MSPS Clock,

100 MHz F

, 200 MHz Span

OUT

10kHz

10kHz

4.3s

10kHz

10kHz

1

10kHz

10kHz

RF ATT

20dB

UNIT

dB

A

1 AP

04806-0-018

RF ATT

20dB

5s

UNIT

dB

A

1 AP

04806-0-019

RF ATT

20dB

5s

UNIT

dB

A

1 AP

04806-0-020

Rev. A | Page 13 of 32

AD9956

REF LVL

0dBm

0

–10

–20

–30

–40

–50

–60

–70

–80

–90

–100

CENTER 159.5MHz 100kHz/ SPAN 1MHz

Figure 10. AD9956 DAC Performance: 400 MSPS Clock,

0

–10

–20

–30

–40

–50

–60

–70

–80

–90

–100

L(f) (dBc/Hz)

–110

–120

–130

–140

–150

–160

–170

10 1k100 10k 100k 1M

0

–10

–20

–30

–40

–50

–60

–70

–80

–90

–100

L(f) (dBc/Hz)

–110

–120

–130

–140

–150

–160

–170

10 1k100 10k 100k 1M

DELTA 1 [T1]

–78.13dB

–100.20040080kHz

160 MHz F

RBW

VBW

SWT

1

1

, 1 MHz Span

OUT

FREQUENCY (Hz)

500kHz

20s

UNIT

RF ATT

500kHz

Figure 11. AD9956 DDS/DAC Residual Phase Noise

400 MHz Clock, 10 MHz Output

FREQUENCY (Hz)

Figure 12. AD9956 DDS/DAC Residual Phase Noise

400 MHz Clock, 40 MHz Output

20dB

DELTA 1 [T1]

REF LVL

dB

A

1 AP

04806-0-021

0dBm

0

–10

–20

–30

–40

–50

–60

–70

–80

–90

–100

START 0Hz 20MHz/ STOP 200MHz

–56.33dB

–80.96192385MHz

RBW

10kHz

VBW

5s

SWT

1

UNIT

1

20dB

dB

A

1 AP

04806-0-022

RF ATT

10kHz

Figure 13. AD9956 DAC Performance: 400 MSPS Clock,

, 200 MHz Span

OUT

FREQUENCY (Hz)

04806-0-025

04806-0-023

160 MHz F

0

–10

–20

–30

–40

–50

–60

–70

–80

–90

–100

L(f) (dBc/Hz)

–110

–120

–130

–140

–150

–160

–170

10 1k100 10k 100k 10M1M

Figure 14. AD9956 DDS/DAC Residual Phase Noise

400 MHz Clock, 103 MHz Output

0

–10

–20

–30

–40

–50

–60

–70

–80

–90

–100

L(f) (dBc/Hz)

–110

–120

–130

–140

–150

04806-0-024

–160

–170

10 1k100 10k 100k 10M1M

FREQUENCY (Hz)

04806-0-026

Figure 15. AD9956 DDS/DAC Residual Phase Noise

400 MHz Clock, 159 MHz Output

Rev. A | Page 14 of 32

AD9956

0

–10

–20

–30

–40

–50

–60

–70

–80

–90

–100

L(f) (dBc/Hz)

–110

–120

–130

–140

–150

–160

–170

10 1k100 10k 100k 10M1M

FREQUENCY (Hz)

Figure 16. RF Divider and CML Driver Residual

Phase Noise (840 MHz In, 105 MHz Out)

0

–10

–20

–30

–40

–50

–60

–70

–80

–90

–100

L(f) (dBc/Hz)

–110

–120

–130

–140

–150

–160

–170

10 1k100 10k 100k 10M1M

FREQUENCY (Hz)

Figure 17. RF Divider and CML Driver Residual

Phase Noise (1240 MHz In, 155 MHz Out)

0

–10

–20

–30

–40

–50

–60

–70

–80

–90

–100

L(f) (dBc/Hz)

–110

–120

–130

–140

–150

–160

–170

10 1k100 10k 100k 10M1M

FREQUENCY (Hz)

Figure 18. RF Divider and CML Driver Residual

Phase Noise (1680 MHz In, 210 MHz Out)

04806-0-027

04806-0-028

04806-0-029

0

–10

–20

–30

–40

–50

–60

–70

–80

–90

–100

L(f) (dBc/Hz)

–110

–120

–130

–140

–150

–160

–170

10 1k100 10k 100k 100M10M1M

FREQUENCY (Hz)

Figure 19. RF Divider and CML Driver Residual

Phase Noise (2488 MHz In, 622 MHz Out)

0

–10

–20

–30

–40

–50

–60

–70

–80

–90

–100

L(f) (dBc/Hz)

–110

–120

–130

–140

–150

–160

–170

–180

10 1k100 10k 100k 10M1M

FREQUENCY (Hz)

Figure 20. Total System Phase Noise for 105 MHz Converter Clock

0

–10

–20

–30

–40

–50

–60

–70

–80

–90

–100

L(f) (dBc/Hz)

–110

–120

–130

–140

–150

–160

–170

–180

10 1k100 10k 100k 10M1M

FREQUENCY (Hz)

Figure 21. Total System Phase Noise for 622 MHz OC-12 Clock

04806-0-030

04806-0-031

04806-0-032

Rev. A | Page 15 of 32

AD9956

L

TYPICAL APPLICATION CIRCUITS

25MHz

CRYSTAL

PHASE FREQUENCY

DETECTOR/CHARGE PUMP

÷M

PLLREF

CP_OUT

PLLOSC

÷N

AD9956

Figure 22. Dual-Clock Configuration

LPF

Figure 23. Fractional-Divider Loop

LPF

DDS

PLLREF

CP_OUT

PLLOSC

DAC

400MHz

VCO

DAC

DDS

LPF

÷R

CML

DRIVER

VCO

÷R

AD9956

LPF

04806-0-011

CLOCK1

CLOCK1′

04806-0-010

25MHz

CRYSTA

8-LEVEL FSK

CML

DRIVER

÷R

DDS

DAC

(FC = 100MHz)

BPF

AD9956

PLLREF

CP_OUT

PLLOSC

÷N

LPF

VCO

2.5GHz

TONE

Figure 24. LO and Baseband Modulation Generation

BPF

04806-0-012

Rev. A | Page 16 of 32

AD9956

PHASE FREQUENCY

÷M

÷N

DETECTOR

REF

OSC

CHARGE

PUMP

LPF

÷R

622MHz

VCO

CML

DRIVER

CLOCK1

EXTERNAL

REFERENCE

AD9956

Figure 25. Optical Networking Clock

FREQUENCY

DDS

DAC

LPF

÷N

Figure 26. Direct Upconversion

APPLICATION CIRCUIT EXPLANATIONS

Dual-Clock Configuration

In this loop, M = 1, N = 16, and R = 4. The DDS tuning word is

also equal to ¼ so that the frequency of CLOCK 1’ equals the

frequency of CLOCK 1. Phase adjustments in the DDS provide

a 14-bit programmable rising edge skew capability of CLOCK 1’

with respect to CLOCK 1 (see Figure 22).

Fractional-Divider Loop

This loop offers the precise frequency division (48-bit) of the

DDS in the feedback path as well as the frequency sweeping

capability of the DDS. Programming the DDS to sweep from

24 MHz to 25 MHz sweeps the output of the VCO from

2.7 GHz to 2.6 GHz. The reference in this case is a simple

crystal (see Figure 23).

DDS

PHASE

DETECTOR

PLLREF

PLLOSC

DAC

CHARGE

PUMP

LPF

VCO

CLOCK2

≤650MHz

04806-0-013

04806-0-014

LO and Baseband Modulation Generation

Using the AD9956’s PLL section to generate an LO and the

DDS portion to generate a modulated baseband, this circuit

uses an external mixer to perform some simple modulation at

RF frequencies (see Figure 24).

Optical Networking Clock

This is the AD9956 configured as an optical networking clock.

The loop can be used to generate a 622 MHz clock for OC12.

The DDS can be programmed to output 8 kHz to serve as a base

reference for other circuits in the subsystem (see Figure 25).

Direct Upconversion

The AD9956 is configured to use the DDS as a precision reference to the PLL loop. Since the VCO is < 655 MHz, it can be fed

straight into the phase frequency detector feedback input (with

the divider enabled), as seen in Figure 26.

Rev. A | Page 17 of 32

AD9956

GENERAL DESCRIPTION

DDS CORE

The DDS can create digital phase relationships by clocking a

48-bit accumulator. The incremental value loaded into the

accumulator, known as the frequency tuning word, controls the

overflow rate of the accumulator. Similar to a sine wave completing a 2π radian revolution, the overflow of the accumulator

is cyclical in nature and generates a base frequency according to

the following equation.

fFTWf×

)(

=

o

s

48

2

The instantaneous phase of the sine wave is, therefore, the output of the phase accumulator block. This signal can be phaseoffset by programming an additive digital phase added to each

and every phase sample coming out of the accumulator.

These instantaneous phase values are then piped through a

phase-to-amplitude conversion (sometimes called an angleto-amplitude conversion or AAC) block. This algorithm follows

a COS(x) relationship where x is the phase coming out of the

phase offset block, normalized to 2π.

Finally, the amplitude words are piped to a 14-bit DAC. Because

the DAC is a sampled data system, the output is a reconstructed

sine wave that needs to be filtered to take high frequency

images out of the spectrum. The DAC is a current-steering

DAC that is AVDD referenced. To get a measurable voltage

output, the DAC outputs must terminate through a load resistor

to AVDD, typically 50 Ω. At positive full scale, IOUT sinks no

current and the voltage drop across the load resistor is zero.

However, the

IOUT

output sinks the DAC’s programmed fullscale output current, causing the maximum output voltage to

drop across the load resistor. At negative full-scale, the situation

is reversed and IOUT sinks the full-scale current (and generates

the maximum drop across the load resistor). At the same time,

IOUT

sinks no current (and generates no voltage drop). At

midscale, the outputs sink equal amounts of current, generating

equal voltage drops.

PLL CIRCUITRY

The AD9956 includes an RF divider (divide-by-R), a phase

frequency detector, and a programmable output current charge

pump. Incorporating these blocks together, users can generate

many useful circuits for frequency synthesis. A few simple

examples are shown in the Typical Application Circuits.

47

}20{

≤≤ FTW

The RF divider accepts differential or single-ended signals up to

2.7 GHz. The RF divider also supplies the SYSCLK input to the

DDS. Because the DDS operates up to only 400 MSPS, device

function requires that for any RF input signal > 400 MHz, the

RF divider be engaged. The RF divider can be programmed to

take values of 1, 2, 4, or 8. The ratio for the divider is programmed in the control register. The output of the divider can

be routed to the input of the on-chip CML driver. For lower

frequency input signals, it is possible to use the divider to divide

the input signal to the CML driver and use the undivided input

of the divider as the SYSCLK input to the DDS, or vice versa. In

all cases, the clock to the DDS should not exceed 400 MSPS.

The on-chip phase frequency detector has two differential

inputs, PLLREF (the reference input) and PLLOSC (the feedback or oscillator input). These differential inputs can be driven

by single-ended signals; however, when doing so, tie the unused

input through a 100 pF capacitor to the analog supply (AVDD).

The maximum speed of the phase frequency detector inputs is

200 MHz. Each of the inputs has a buffer and a divider (÷M on

PLLREF and ÷N on PLLOSC) that operates at up to 655 MHz.

If the signal exceeds 200 MHz, however, the divider must be

used. The dividers are programmed through the control registers

and take any integer value between 1 and 16.

The PLLREF input also has the option of engaging an in-line

oscillator circuit. Engaging this circuit means that the PLLREF

input can be driven with a crystal in the of 20 MHz ≤ PLLREF ≤

30 MHz range.

The charge pump outputs a current in response to an error

signal generated in the phase frequency detector. The output

current is programmed through by placing a resistor (CP_R

SET

)

from the CP_RSET pin to ground. The value is dictated by the

following equation:

1.55

CP_OUT

=

CP_R

SET

This sets the charge pump’s reference output current. Also, a

programmable scaler multiplies this base value by any integer

from 1 to 8, programmable through the CP current scale bits in

the Control Function Register 2, CFR2<2:0>.

Rev. A | Page 18 of 32

AD9956

CML DRIVER

For clocking applications, an on-chip current mode logic

(CML) driver is included. This CML driver generates very low

jitter clock edges. The outputs of the CML driver are current

outputs and drives PECL levels when terminated into a 100 Ω

load. The base output current of the driver is programmed by

attaching a resistor from the DRV_RSET pin to ground (nominally 4.02 kΩ for a continuous current of 7.2 mA). An optional

on-chip current programming resistor is enabled by setting a bit

in the control register. The rising edge and falling edge slew

rates are independently programmable to help control overshoot and ringing through the application of surge current

during rising edge transitions and falling edge transitions (see

Figure 27). There is a default surge current of 7.6 mA on the

rising edge and 4.05 mA on the falling edge. Bits in the control

register enable additional rising edge and falling edge surge

current, as well disable the default surge current (see the

Control Function Register Descriptions section for details). The

CML driver can be driven by the

• RF divider input

• RF divider output

• PLLOSC input

I(t)

Figure 27. Rising Edge and Falling Edge Surge Current Output of the

CML Clock Driver, as Opposed to the Steady State Continuous Current

RISING EDGE SURGE

CONTINUOUS

~250ps~250ps

FALLING EDGE SURGE

t

CONTINUOUS

04806-0-002

Rev. A | Page 19 of 32

AD9956

MODES OF OPERATION

DDS MODES OF OPERATION

Single-Tone Mode

This is the default mode of operation for the DDS core. The

phase accumulator runs at a fixed frequency, as per the active

profile’s tuning word. Likewise, any phase offset applied to the

signal is a static value, which comes from the phase offset word

of the active profile. The device has eight different phase/frequency profiles, each with its own 48-bit frequency tuning word

and 14-bit phase offset word. Profiles are selected by applying

their digital value on the profile-select pins (PS2, PS1, and PS0).

It is impossible to use the phase offset of one profile and the

frequency tuning word of another.

Linear Sweep Mode

This mode is entered by setting the linear sweep enable bit in

the control register (CFR1<17> = 1) but leaving the linear

sweep no dwell bit clear (CFR1<16> = 0). When the part is in

linear sweep mode, the frequency accumulator ramps the

output frequency of the device from a programmed lower

frequency to a programmed upper frequency or from the upper

frequency to the lower frequency. The lower frequency is set by the

frequency tuning word stored in Profile 0, and the upper frequency

is set by the frequency tuning word stored in Profile 1.

The combinational logic within the frequency accumulator

requires that the value stored at FTW0 must always be less than

the value stored in FTW. The direction of the sweep (sweep up

to FTW1, sweep down to FTW0) is controlled by the PS0 pin. A

high state on this pin tells the part to sweep up to FTW1. A low

state on this pin tells the part to sweep down to FTW0. The

frequency accumulator requires four values, which are stored in

the register map. First, it requires an incremental frequency

value that tells the frequency accumulator how big of a frequency step to take each time it takes a step when ramping up.

This value is stored in the rising delta frequency tuning word

(RDFTW). The second value required is the rate at which the

frequency accumulator should increment, that is, how often it

should take a step. This value is stored in the rising sweep ramp

rate word (RSRR). The RSRR value specifies the number of

SYNC_CLK cycles the frequency accumulator should count

between steps. The third and fourth values are the falling ramp

equivalents, the falling delta frequency tuning word (FDFTW)

and the falling sweep ramp rate (FSRR).

When operating in the linear sweep default mode, combinational logic ensures that the part never ramps up past FTW1,

even if the next RDFTW increments the frequency past FTW1.

Once it reaches FTW1, as long as the PS0 pin stays high, the

frequenc y remains at FT W1. Li kewise, t he internal log ic ensures

that the part never ramps down past FTW0, even if the next

RDFTW increments the frequency past FTW0. During a sweep

down (PS0 = 0), once the part reaches FTW0, as long as the PS0

pin stays low, the frequency remains at FTW0.

If a sweep is interrupted and the state of the PS0 pin is changed

during the midst of a sweep, the part begins sweeping in the

new direction at the rate dictated by the relevant delta frequency tuning word and sweep ramp rate word. For example, if

the part is programmed to sweep from 100 MHz to 140 MHz

and to take 1 kHz steps every 1000 sync clock cycles (rising and

falling sweep words are the same), it would take four seconds to

complete a sweep. If the PS0 has been low for a very long time

(more than four seconds), changing the PS0 pin to high starts a

sweep up to 140 MHz. If after two seconds (not enough time for

a full sweep in this example) the PS0 pin is brought low again,

the part begins sweeping down from the current value, roughly

120 MHz.

Linear Sweep No Dwell Mode

This mode is entered by setting the linear sweep enable bit and

the linear sweep no dwell bit in the control register

(CFR<17:16> =1). When the part is in linear sweep no dwell

mode, the frequency accumulator ramps the output frequency

of the device from a programmed lower frequency to a programmed upper frequency. Upon reaching the upper frequency,

the accumulator returns to the lower frequency directly, without

ramping back down. Unlike the default mode of the linear

sweep, this mode uses only the rising delta frequency tuning

word (RDFTW) and the rising sweep ramp rate (RSRR). The

operation is still controlled by the PS0 pin. In this mode, however, it acts as a trigger for the sweep, not a direction bit. Once a

PS0 low-to-high transition is detected, the part completes the

entire sweep, regardless of whether or not the PS0 pin is

changed back to low during the sweep. After the sweep is completed, another sweep may be initiated by applying another

rising edge on the PS0 pin. This means that the PS0 pin needs to

be brought low prior to the next sweep.

SYNCHRONIZATION MODES FOR MULTIPLE DEVICES

In a DDS system, the SYNC_CLK is derived internally off the

master system clock, SYSCLK, with a ÷4 divider. Because the

divider does not power up to a known state, it is possible for

multiple devices in a system to have staggered clock-phase

relationships. This is because each device could potentially generate the SYNC_CLK rising edge from any one of four rising

edges of SYSCLK. This ambiguity can be resolved by employing

digital synchronization logic to control the phase relationships

of the derived clocks among different devices in the system. It is

important to note that the synchronization functions included

on the AD9956 control only the timing relationships among

different digital clocks. They do not compensate for the analog

timing skew on the system clock due to mismatched phase

relationships on the input clock, REFCLK. Figure 28 illustrates

this concept.

Rev. A | Page 20 of 32

AD9956

Automatic Synchronization

In automatic synchronization mode, the device is placed into

slave mode and automatically aligns the internal SYNC_CLK to

a master SYNC_CLK signal, supplied on the SYNC_IN input.

When this bit is enabled, the PLL_LOCK is not available as an

output, however, an out-of-lock condition can be detected by

reading Control Function Register 1 and checking the status of

the PLL_LOCK_ERROR bit, CFR1<24>. The automatic

synchronization function is enabled by setting the Control

Function Register 1 automatic synchronization bit, CFR1<3>.

To employ this function at higher clock rates (SYNC_CLK >

62.5 MHz and SYSCLK > 250 MHz), the high speed sync

enable bit (CFR1<0>) should be set as well.

Manual Synchronization, Hardware Controlled

In this mode, the user controls the timing relationship of the

SYNC_CLK with respect to SYSCLK. When hardware manual

synchronization is enabled, the PLL_LOCK/ SYNC_IN pin

becomes a digital input. For each and every rising edge detected

on the SYNC_IN input, the device advances the SYNC_IN

rising edge by one SYSCLK period. When this bit is enabled, the

PLL_LOCK is not available as an output. However, an out-oflock condition can be detected by reading Control Function

Register 1 and checking the status of the PLL Lock Error bit,

CFR1<24>. This synchronization function is enabled by setting

the hardware manual synchronization enable bit, CFR1<1>.

Manual Synchronization, Software Controlled

In this mode, the user controls the timing relationship between

SYNC_CLK and SYSCLK through software programming.

When the software manual synchronization bit (CFR1<2>) is

set high, the SYNC_CLK is advanced by one SYSCLK cycle.

Once this operation is complete, the bit is cleared. The user can

set this bit repeatedly to advance the SYNC_CLK rising edge

multiple times. Because the operation does not use the

PLL_LOCK/ SYNC_IN pin as a SYNC_IN input, the

PLL_LOCK signal can be monitored on the PLL_LOCK pin

during this operation.

SYNCHRONIZATION FUNCTIONS CAN ALIGN DIGITAL CLOCK

RELATIONSHIPS, THEY CANNOT DESKEW THE EDGES OF CLOCKS

SYSCLK DUT1

SYNC CLK

DUT1

SYSCLK DUT2

SYNC CLK DUT2 WITHOUT

SYNC_CLK ALIGNED

SYNC CLK DUT2 WITH

SYNC_CLK ALIGNED

Figure 28. Synchronization Functions: Capabilities and Limitations

01

3

2

30

012

3

04806-0-003

Rev. A | Page 21 of 32

AD9956

SCLK

S

SCLK

S

SCLK

S

SCLK

S

SERIAL PORT OPERATION

An AD9956 serial data-port communication cycle has two

phases. Phase 1 is the instruction cycle, which is the writing of

an instruction byte to the AD9956, coincident with the first

eight SCLK rising edges. The instruction byte provides the

AD9956 serial port controller with information regarding the

data transfer cycle, which is Phase 2 of the communication cycle.

The Phase 1 instruction byte defines whether the upcoming data

transfer is read or write and the serial address of the

register being accessed.

The first eight SCLK rising edges of each communication cycle

are used to write the instruction byte into the AD9956. The

remaining SCLK edges are for Phase 2 of the communication

cycle. Phase 2 is the actual data transfer between the AD9956

and the system controller. The number of bytes transferred

during Phase 2 of the communication cycle is a function of the

INSTRUCTION CYCLE

CS

register being accessed. For example, when accessing Control

Function Register 2, which is four bytes wide, Phase 2 requires that

four bytes be transferred. If accessing a frequency tuning word,

which is six bytes wide, Phase 2 requires that six bytes be

transferred. After transferring all data bytes per the instruction,

the communication cycle is completed.

At the completion of any communication cycle, the AD9956

serial port controller expects the next eight rising SCLK edges

to be the instruction byte of the next communication cycle. All

data input to the AD9956 is registered on the rising edge of

SCLK. All data is driven out of the AD9956 on the falling edge

of SCLK. Figure 29 through Figure 32 are useful in understanding the general operation of the AD9956 serial port.

DATA TRANSFER CYCLE

DI/O

DI/O

SDO

CS

DI/O

CS

CS

I6I5I4I3I2I

I

7

Figure 29. Serial Port Write Timing—Clock Stall Low

INSTRUCTION CYCLE

I6I5I4I3I2I1I

7

Figure 30. 3-Wire Serial Port Read Timing—Clock Stall Low

INSTRUCTION CYCLE

I6I5I4I3I2I

I

7

Figure 31. Serial Port Write Timing—Clock Stall High

INSTRUCTION CYCLE

I0D7D

1

1

D5D4D3D2D1D

6

0

04806-0-004

DATA TRANSFER CYCLE

0

D

O 7DO 6

DON'T CAREI

D

O 5DO 4DO 3DO 2DO 1DO 0

04806-0-005

DATA TRANSFER CYCLE

I

D7D

0

D5D4D3D2D1D

6

0

04806-0-006

DATA TRANSFER CYCLE

DI/O

I6I5I4I3I2I

I

7

Figure 32. 2-Wire Serial Port Read Timing—Clock Stall High

I

1

D

0

Rev. A | Page 22 of 32

O 7DO 6

D

O 5DO 4DO 3DO 2DO 1DO 0

04806-0-007

AD9956

K

INSTRUCTION BYTE

The instruction byte contains the following information:

Table 4.

D7 D6 D5 D4 D3 D2 D1 D0

R/Wb X X A4 A3 A2 A1 A0

R/Wb—Bit 7 of the instruction byte determines whether a read

or write data transfer occurs after the instruction byte write.

Logic 1 indicates a read operation. Logic 0 indicates a write

operation.

X, X—Bits 6 and 5 of the instruction byte are Don’t Care.

A4 to A0—Bits 4 to 0 of the instruction byte determine which

register is accessed during the data transfer portion of the

communications cycle.

SERIAL INTERFACE PORT PIN DESCRIPTION

SCLK—Serial Clock. The serial clock pin is used to synchronize

data to and from the AD9956 and to run the internal state

machines. The SCLK maximum frequency is 25 MHz.

CS

—Chip Select Bar. CS is an active low input that allows more

than one device on the same serial communications line. The

SDO and SDI/O pins go to a high impedance state when this

input is high. If driven high during any communications cycle,

that cycle is suspended until

can be tied low in systems that maintain control of SCLK.

SDI/O—Serial Data Input/Output. Data is always written to the

AD9956 on this pin. However, this pin can be used as a bidirectional data line. CFR1<7> controls the configuration of this pin.

The default value (0) configures the SDI/O pin as bidirectional.

SDO—Serial Data Out. Data is read from this pin for protocols

that use separate lines for transmitting and receiving data. When

the AD9956 operates in a single bidirectional I/O mode, this pin

does not output data and is set to a high impedance state.

I/O_RESET—A high signal on this pin resets the I/O port state

machines without affecting the addressable registers’ contents.

An active high input on the I/O_RESET pin causes the current

communication cycle to abort. After I/O_RESET returns low

(0), another communication cycle can begin, starting with the

instruction byte write. Note that when not in use, this pin

should be forced low, because it floats to the threshold value.

CS

is reactivated low. Chip select

MSB/LSB TRANSFERS

The AD9956 serial port can support both most significant bit

(MSB) first or least significant bit (LSB) first data formats. This

functionality is controlled by the LSB first bit in Control

Register 1 (CFR1<15>). The default value of this bit is low

(MSB first). When CFR1 <15> is set high, the AD9956 serial

port is in LSB first format. The instruction byte must be written

in the format indicated by CFR1 <15>. If the AD9956 is in LSB

first mode, the instruction byte must be written from least

significant bit to most significant bit. However, the instruction

byte phase of the communications cycle still precedes the data

transfer cycle.

For MSB first operation, all data written to (read from) the

AD9956 are in MSB first order. If the LSB mode is active, all

data written to (read from) the AD9956 are in LSB first order.

T

SCL

SDI/O

SCLK

SDI/O

SDO

PRE

CS

T

DSU

SYMBOL

T

PRE

T

SCLKW

T

DSU

T

DHLD

Figure 33. Timing Diagram for Data Write to AD9956

CS

DV

SCLKR

MAX

40ns

400ns

SYMBOL

T

T

Figure 34. Timing Diagram for Data Read to AD9956

T

SCLKW

T

DHLD

SECOND BITFIRST BIT

DEFINITION

MIN

CS SETUP TIME

6ns

PERIOD OF SERIAL DATA CLOCK (WRITE)

40ns

SERIAL DATA SETUP TIME

6.5ns

SERIAL DATA HOLD TIME

0ns

T

SCLKR

FIRST BIT SECOND BIT

T

DV

DEFINITION

DATA VALID TIME

PERIOD OF SERIAL DATA CLOCK (READ)

04806-0-034

04806-0-035

Rev. A | Page 23 of 32

AD9956

REGISTER MAP AND DESCRIPTION

Table 5.

Register

Name

(Serial

Address)

Control

Function

Register 1

(CFR1)

(0x00)

Control

Function

Register 2

(CFR2)

(0x01)

Rising Delta

Frequency

Tuning

Word

(RDFTW)

(0x02)

Falling Delta

Frequency

Tuning

Word

(FDFTW)

(0x03)

Rising

Sweep

Ramp Rate

(RSRR)

(0x04)

Falling

Sweep

Ramp Rate

(FSRR)

(0x05)

1

In all cases, open bits must be written to 0.

Bit

Range

<31:24> Open

<23:16>

<15:8> LSB First

<7:0>

<39:32>

<31:24> Clock Driver Rising Edge <31:29>

<23:16>

<15:8> Divider N Control <15:12> Divider M Control <11:8> 0x00

<7:0> Open

<23:16> Rising Delta Frequency Tuning Word <23:16> 0x00

<15:8> Rising Delta Frequency Tuning Word <15:8> 0x00

<7:0> Rising Delta Frequency Tuning Word <7:0> 0x00

<23:16> Falling Delta Frequency Tuning Word <23:16> 0x00

<15:8> Falling Delta Frequency Tuning Word <15:8> 0x00

<7:0> Falling Delta Frequency Tuning Word <7:0> 0x00

<15:8> Rising Sweep Ramp Rate <15:8> 0x00

<7:0> Rising Sweep Ramp Rate <7:0> 0x00

<15:8> Rising Sweep Ramp Rate <15:8> 0x00

<7:0> Rising Sweep Ramp Rate <7:0> 0x00

(MSB) Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1

1

LOAD SRR @

I/O_UPDATE

Digital

PowerDown

DAC

PowerDown

RF Divider

PowerDown

1

Open1

Open1 Open1 Open1 Open1 Open1 Open1

Auto-Clr

Frequency

Accum.

SDI/O

Input

Only

PFD Input

PowerDown

Open1 Open1 Open1 Open1 Open1

RF Divider Ratio

<22:21>

Default

Bit 0

(LSB)

PLL Lock

Error

AutoClr

Phase

Accum.

Open1 Open1 Open1 Open1 Open1 Open1 0x00

PLLREF

Crystal

Enable

CP

Polarity

Enable

Sine

Output

SYNC_CLK

Disable

Clock Driver Falling Edge Control

<28:26>

Clock

Driver

PowerDown

CP

Full PD

Clear

Frequency

Accum.

Auto Sync

Multiple

AD9956s

Clock Driver Input

Select <19:18>

CP

Quick PD

Clear

Phase

Accum.

Software

Manual

Sync

Linear

Sweep

Enable

Hardware

Manual

Sync

Internal

Band Gap

PowerDown

PLL Lock

Detect

Enable

Slew Rate

Control

CP Current Scale <2:0> 0x07

Linear

Sweep

No Dwell

High

Speed

Sync

Enable

Internal

CML

Driver

DRV_RSET

PLL Lock

Detect

Mode

RF Div

REFCLK

Mux Bit

Value/

Profile

0x00

0x00

0x00

0x00

0x00

0x78

Rev. A | Page 24 of 32

AD9956

Register Name

(Serial Address)

Profile Control Register

No. 0 (PCR0) (0x06)

Bit Range (MSB) Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1

<63:56> Open

<55:48> Phase Offset Word 0 (POW0) <7:0> 0x00

<47:40> Frequency Tuning Word 0 (FTW0) <47:40> 0x00

<39:32> Frequency Tuning Word 0 (FTW0) <39:32> 0x00

<31:24> Frequency Tuning Word 0 (FTW0) <31:24> 0x00

<23:16> Frequency Tuning Word 0 (FTW0) <23:16> 0x00

<15:8> Frequency Tuning Word 0 (FTW0) <15:8> 0x00

<7:0> Frequency Tuning Word 0 (FTW0) <7:0> 0x00

Profile Control Register

No. 1 (PCR1) (0x07)

<63:56> Open1 Phase Offset Word 1 (POW1) <13:8> 0x00

<55:48> Phase Offset Word 1 (POW1) <7:0> 0x00

<47:40> Frequency Tuning Word 1 (FTW1) <47:40> 0x00

<39:32> Frequency Tuning Word 1 (FTW1) <39:32> 0x00

<31:24> Frequency Tuning Word 1 (FTW1) <31:24> 0x00

<23:16> Frequency Tuning Word 1 (FTW1) <23:16> 0x00

<15:8> Frequency Tuning Word 1 (FTW1) <15:8> 0x00

<7:0> Frequency Tuning Word 1 (FTW1) <7:0> 0x00

Profile Control Register

No. 2 (PCR2) (0x08)

<63:56> Open1 Phase Offset Word 2 (POW2) <13:8> 0x00

<55:48> Phase Offset Word 2 (POW2) <7:0> 0x00

<47:40> Frequency Tuning Word 2 (FTW1) <47:40> 0x00

<39:32> Frequency Tuning Word 2 (FTW2) <39:32> 0x00

<31:24> Frequency Tuning Word 2 (FTW2) <31:24> 0x00

<23:16> Frequency Tuning Word 2 (FTW2) <23:16> 0x00

<15:8> Frequency Tuning Word 2 (FTW2) <15:8> 0x00

<7:0> Frequency Tuning Word 2 (FTW2) <7:0> 0x00

Profile Control Register

No. 3 (PCR3) (0x09)

<63:56> Open1 Phase Offset Word 3 (POW3) <13:8> 0x00

<55:48> Phase Offset Word 3 (POW3) <7:0> 0x00

<47:40> Frequency Tuning Word 3 (FTW3) <47:40> 0x00

<39:32> Frequency Tuning Word 3 (FTW3) <39:32> 0x00

<31:24> Frequency Tuning Word 3 (FTW3) <31:24> 0x00

<23:16> Frequency Tuning Word. 3 (FTW3) <23:16> 0x00

<15:8> Frequency Tuning Word 3 (FTW3) <15:8> 0x00

<7:0> Frequency Tuning Word 3 (FTW3) <7:0> 0x00

1

In all cases, open bits must be written to 0.

1

Phase Offset Word 0 (POW0) <13:8> 0x00

Bit 0

(LSB)

Default Value/

Profile

Rev. A | Page 25 of 32

AD9956

Register Name

(Serial Address)

Profile Control

Register

No. 4 (PCR4) (0x0A)

Profile Control

Register

No. 5 (PCR5) (0x0B)

Profile Control

Register

No. 6 (PCR6) (0x0C)

Profile Control

Register

No. 7 (PCR7) (0x0D)

1

In all cases, open bits must be written to 0.

Bit

Range

(MSB)

Bit 7

<63:56> Open

<55:48> Phase Offset Word 4 (POW4) <7:0> 0x00

<47:40> Frequency Tuning Word 4 (FTW4) <47:40> 0x00

<39:32> Frequency Tuning Word 4 (FTW4) <39:32> 0x00

<31:24> Frequency Tuning Word 4 (FTW4) <31:24> 0x00

<23:16> Frequency Tuning Word 4 (FTW4) <23:16> 0x00

<15:8> Frequency Tuning Word 4 (FTW4) <15:8> 0x00

<7:0> Frequency Tuning Word 4 (FTW4) <7:0> 0x00

<63:56> Open1 Phase Offset Word 5 (POW5) <13:8> 0x00

<55:48> Phase Offset Word 5 (POW5) <7:0> 0x00

<47:40> Frequency Tuning Word 5 (FTW5) <47:40> 0x00

<39:32> Frequency Tuning Word 5 (FTW5) <39:32> 0x00

<31:24> Frequency Tuning Word 5 (FTW5) <31:24> 0x00

<23:16> Frequency Tuning Word 5 (FTW5) <23:16> 0x00

<15:8> Frequency Tuning Word 5 (FTW5) <15:8> 0x00

<7:0> Frequency Tuning Word 5 (FTW5) <7:0> 0x00

<63:56> Open1 Phase Offset Word 6 (POW6) <13:8> 0x00

<55:48> Phase Offset Word 6 (POW6) <7:0> 0x00

<47:40> Frequency Tuning Word 6 (FTW6) <47:40> 0x00

<39:32> Frequency Tuning Word 6 (FTW6) <39:32> 0x00

<31:24> Frequency Tuning Word 6 (FTW6) <31:24> 0x00

<23:16> Frequency Tuning Word 6 (FTW6) <23:16> 0x00

<15:8> Frequency Tuning Word 6 (FTW6) <15:8> 0x00

<7:0> Frequency Tuning Word 6 (FTW6) <7:0> 0x00

<63:56> Open1 Phase Offset Word 7 (POW7) <13:8> 0x00

<55:48> Phase Offset Word 7 (POW7) <7:0> 0x00

<47:40> Frequency Tuning Word 7 (FTW7) <47:40> 0x00

<39:32> Frequency Tuning Word 7 (FTW7) <39:32> 0x00

<31:24> Frequency Tuning Word 7 (FTW7) <31:24> 0x00

<23:16> Frequency Tuning Word 7 (FTW7) <23:16> 0x00

<15:8> Frequency Tuning Word 7 (FTW7) <15:8> 0x00

<7:0> Frequency Tuning Word 7 (FTW7) <7:0> 0x00

Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1

1

Phase Offset Word 4 (POW4) <13:8> 0x00

Bit 0

(LSB)

Default

Value/

Profile

Rev. A | Page 26 of 32

AD9956

CONTROL FUNCTION REGISTER DESCRIPTIONS

Control Function Register 1 (CFR1)

This control register is comprised of four bytes, all of which

must be written during a write operation involving CFR1. CFR1

is used to control various functions, features, and operating

modes of the AD9956. The functionality of each bit(s) is

described below. In general, the bit is named for the function it

serves when the bit is set.

CFR1<31:25> Open. Unused locations. Write a Logic 0

CFR1<24> PLL Lock Error (Read-Only)

When the device is operating in automatic synchronization

mode or hardware manual synchronization mode (see below),

the PLL_LOCK/ SYNC_IN pin behaves as the SYNC_IN. To

determine whether or not the PLL has become unlocked while

in synchronization mode, this bit serves as a flag to indicate that

an unlocked condition has occurred within the phase frequency

detector. Once set, the flag stays high until it is cleared by a

readback of the value even though the loop might have

relocked. Readback of the CFR1 register clears this bit.

CFR1<24> = 0 indicates that the loop has maintained lock since

the last readback.

CFR1<24> = 1 indicates that the loop became unlocked at some

point since the last readback of this bit.

CFR1<23> Load Sweep Ramp Rate at I/O_UPDATE, also

known as Load SRR @ I/O_UPDATE

The sweep ramp rate is set by entering a value to a down

counter that is clocked by the SYNC_CLK. Each time a new step

is taken in the linear sweep algorithm, the ramp rate value is

passed from the linear sweep ramp rate register to this down

counter. When set, CFR1<23>, enables the user to force the part

to restart the countdown sequence for the current linear sweep

step by toggling the I/O_UPDATE pin.

CFR1 <22> = 0 (default). Issuing an I/O_UPDATE has no effect

on the current state of the frequency accumulator.

CFR1 <22> = 1. Issuing an I/O_UPDATE signal to the part

clears the current contents of the frequency accumulator for

one sync-clock period.

CFR1 <21> Auto-Clear Phase Accumulator

This bit enables the auto-clear function for the phase accumulator. The auto-clear function serves as a reset function for the

phase accumulator, which then begins accumulating from a

known phase value of 0.

CFR1<21> = 0 (default). Issuing an I/O_UPDATE has no effect

on the current state of the phase accumulator.

CFR1<21> = 1. Issuing an I/O_UPDATE clears the current contents of the phase accumulator for one SYNC_CLK period.

CFR1 <20> Enable Sine Output

Two different trigonometric functions can be used to convert

the phase angle to an amplitude value, cosine or sine. This bit

selects the function used.

CFR1<20> = 0 (default). The phase-to-amplitude conversion

block uses a cosine function.

CFR1<20> = 1. The phase-to-amplitude conversion block uses a

sine function.

CFR1 <19> Clear Frequency Accumulator

This bit serves as a static-clear or a clear-and-hold bit for the

frequency accumulator. It prevents the frequency accumulator

from incrementing the value as long as it is set.

CFR1 <19> = 0 (default). The frequency accumulator operates

normally.

CFR1<23> = 0 (default). The linear sweep ramp rate countdown

value is loaded only upon completion of a countdown sequence.

CFR1<23> = 1. The linear sweep ramp rate countdown value is

reloaded, if an I/O_UPDATE signal is sent to the part during a

sweep.

CFR1<22> Auto-Clear Frequency Accumulator

This bit enables the auto-clear function for the frequency accumulator. The auto-clear function serves as a clear and release function for the frequency accumulator (which performs the linear

sweep operation), which then begins sweeping from a known value

of FTW0.

Rev. A | Page 27 of 32

CFR1 <19> = 1. The frequency accumulator is cleared and held

at a value of 0.

CFR1 <18> Clear Phase Accumulator

This bit serves as a static-clear or a clear-and-hold it for the

phase accumulator. It prevents the phase accumulator from

incrementing the value as long as it is set.

CFR1 <18> = 0 (default). The phase accumulator operates

normally.

CFR1 <18> = 1. The phase accumulator is cleared and held at a

value of 0.

AD9956

CFR1 <17> Linear Sweep Enable

This bit turns on the frequency accumulator, which enables the

DDS to perform linear sweeping.

CFR1<7> Digital Power-Down

This bit powers down the digital circuitry not directly related to

the I/O port. The I/O port functionality is not suspended, regardless of the state of this bit.

CFR1<17> = 0 (default). The DDS generates frequencies in

single-tone mode.

CFR1<17> = 1. The DDS uses the frequency accumulator to

sweep the frequency tuning word being sent to the phase

accumulator according to the values set in the delta frequency

tuning word and delta frequency ramp rate registers. For a

detailed explanation of this mode, see the linear sweep mode of

operation section.

CFR1 <16> Linear Sweep No Dwell

This bit dictates the behavior of the DDS core upon completion

of a linear sweep.

CFR1<16> = 0 (default). Upon reaching the upper value of the

sweep (FTW1), the DDS holds at the frequency value stored in

FTW1.

CFR1<16> = 1. Upon reaching the upper value of the sweep

(FTW1), the DDS returns to the initial value in the sweep

(FTW0) and continues to output that frequency until a new

sweep is initiated (by bringing PS0 low and then high).

CFR1 <15> LSB First Serial Data Mode

The serial data transfer to the device can be either MSB first or

LSB first. This bit controls that operation.

CFR1<15> = 0 (default). Serial data transfer to the device is in

MSB first mode.

CFR1<15> = 1. Serial data transfer to the device is in LSB first

mode.

CFR1<14> SDI/O Input Only (3-Wire Serial Data Mode)

The serial port on the AD9956 can act in 2-wire mode (SCLK

and SDI/O) or 3-wire mode (SCLK, SDI/O, and SDO). This bit

toggles the serial port between these two modes.

CFR1<7> = 0 (default). Digital logic operating as normal.

CFR1<7> = 1. All digital logic not directly related to the I/O

port is powered down. Internal digital clocks are suspended.

CFR1<6> Phase Frequency Detector Input Power-Down

This bit controls the input buffers on the phase frequency detector. It provides a way to gate external signals from the phase

frequency detector itself.

CFR1<6> = 0 (default). Phase frequency detector input buffers

are functioning normally.

CFR1<6> = 1. Phase frequency detector input buffers are powered down, isolating the phase frequency detector from the

outside world.

CFR1<5> PLLREF Crystal Enable

The AD9956 phase frequency detector has an on-chip oscillator

circuit. When enabled, the reference input to the phase frequency detector (PLLREF/

CFR1<5> = 0 (default). Phase frequency detector reference

input operates as a standard analog input.

CFR1<5> = 1. Reference input oscillator circuit is enabled,

allowing the use of a crystal for the reference of the phase

frequency detector.

CFR1<4> SYNC_CLK Disable

If synchronization of multiple devices is not required, the spectral energy resulting from this signal can be reduced by gating

the output buffer off. This function gates the internal clock reference SYNC_CLK (SYSCLK/4) off of the SYNC_OUT pin.

CFR1<4> = 0 (default). SYNC_CLK signal is present on the

SYNC_OUT pin and is ready to be ported to other devices.

PLLREF

) can be driven by a crystal.

CFR1<14> = 0 (default). Serial data transfer to the device is in

2-wire mode. The SDI/O pin is bidirectional.

CFR1<14> = 1. Serial data transfer to the device is in 3-wire

mode. The SDI/O pin is input only.

CFR1<13:8> Open

Unused locations. Write a Logic 0.

Rev. A | Page 28 of 32

CFR1<4> = 1. SYNC_CLK signal is gated off, putting the

SYNC_OUT pin into a high impedance state.

CFR1<3> Automatic Synchronization

One of the synchronization modes of the AD9956 forces the

DDS core to derive the internal reference from an external reference supplied on the SYNC_IN pin. For details on synchronization modes for the DDS core, see the Synchronization Modes

for Multiple Devices section.

AD9956

CFR1<3> = 0 (default). The automatic synchronization function

of the DDS core is disabled.

CFR1<3> = 1. The automatic synchronization function is on.

The device is slaved to an external reference and adjusts the

internal SYNC_CLK to match the external reference, which is

supplied on the SYNC_IN input.

CFR1<2> Software Manual Synchronization

Rather than relying on the part to automatically synchronize the

internal clocks, the user can program the part to advance the

internal SYNC_CLK one system clock cycle. This bit is self

clearing and can be set multiple times.

CFR1<2> = 0 (default). The SYNC_CLK stays in the current

timing relationship to SYSCLK.

CFR1<2> = 1. The SYNC_CLK advances the rising and falling

edges by one SYSCLK cycle. This bit is then self-cleared.

CFR1<1> Hardware Manual Synchronization

Similar to the software manual synchronization (CFR1<2>),

this function enables the user to advance the SYNC_CLK rising

edge by one system clock period. This bit enables the

PLL_LOCK/SYNC_IN pin as a digital input. Once enabled,

every rising edge on the SYNC_IN input advances the

SYNC_CLK by one SYSCLK period. While enabled, the

PLL_LOCK signal is not available on an external pin. However,

loop out-of-lock events trigger a flag in the control register

(CFR1<24>).

CFR1<1> = 0 (default). The hardware manual synchronization

function is disabled. Either the part is outputting the

PLL_LOCK (CFR1<3> = 0), or it is using the SYNC_IN to slave

the SYNC_CLK signal to an external reference provided on

SYNC_IN (CFR1<3> = 1).

CFR1<1> = 1. PLL_LOCK/SYNC_IN is set as a digital input.

Each subsequent rising edge on this pin advances the

SYNC_CLK rising edge by one SYSCLK period.

CFR1<0> High Speed Synchronization Enable Bit

This bit enables extra functionality in the auto synchronization

algorithm, which enables the device to synchronize high speed

clocks (SYNC_CLK > 62.5 MHz).

CFR1<0> = 0 (default). High speed synchronization is disabled.

CFR1<0> = 1. High speed synchronization is enabled.

Control Function Register 2 (CFR2)

This control register is comprised of five bytes, which must be

written during a write operation involving CFR2. With some

minor exceptions, the CFR2 primarily controls analog and timing functions on the AD9956.

CFR2<39> DAC Power-Down Bit

This bit powers down the DAC portion of the AD9956 and puts

it into the lowest power dissipation state.

CFR2<39> = 0 (default). DAC is powered on and operating.

CFR2<39> = 1. DAC is powered down and the output is in a

high impedance state.

CFR2<38> to CFR2<34> Open

Unused locations. Write a Logic 0.

CFR2<33> Internal Band Gap Power-Down

To shut off all internal quiescent current, the band gap needs to

be powered down. This is normally not done because it takes a

long time (~10 ms) for the band gap to power up and settle to

its final value.

CFR2<33> = 0. Even when all other sections are powered down,

the band gap is powered up and is providing a regulated voltage.

CFR2<33> = 1. The band gap is powered down.

CFR2<32> Internal CML Driver DRV_RSET

To program the CML driver’s output current, a resistor

must be placed between the DRV_RSET pin and ground. This

bit enables an internal resistor to program the output current of

the driver.

CFR2<32> = 0 (default). The DRV_RSET pin is enabled,

and an external resistor must be attached to the CP_RSET pin

to program the output current.

CFR2<32> = 1. The CML current is programmed by the internal resistor and ignores the resistor on the DRV_REST pin.

CFR2<31:29> Clock Driver Rising Edge

These bits control the slew rate of the CML clock driver output’s

rising edge. When these bits are on, additional current is sent to

the output driver to increase the rising edge slew rate capability;

the contributions of each bit are cumulative. Table 6 describes

how the bits increase the current. Note that the additional current is on only during the rising edge of the waveform for approximately 250 ps, but not on during the entire transition.

Table 6. CML Clock Driver Rising Edge Slew Rate

Control Bits and Associated Surge Current

CFR2<31> = 1 7.6 mA

CFR2<30> = 1 3.8 mA

CFR2<29> = 1 1.9 mA

Rev. A | Page 29 of 32

AD9956

CFR2<28:26> Clock Driver Falling Edge Control

These bits control the slew rate of the CML clock driver output’s

falling edge. When these bits are on, additional current is sent to

the output driver to increase the rising edge slew rate capability.