Complete 12-Bit 40 MHz

REV. B

160

160

©2011 Analog Devices, Inc. All rights reserved.

CCD Signal Processor

AD9945

FEATURES

40 MSPS Correlated Double Sampler (CDS)

6 dB to 40 dB 10-Bit Variable Gain Amplifier (VGA)

Low Noise Optical Black Clamp Circuit

Preblanking Function

12-Bit 40 MSPS A/D Converter

No Missing Codes Guaranteed

3-Wire Serial Digital Interface

3 V Single-Supply Operation

Low Power: mW @ 3 V Supply

Space-Saving 32-Lead 5 mm

5 mm LFCSP

APPLICATIONS

Digital Still Cameras

Digital Video Camcorders

PC Cameras

Portable CCD Imaging Devices

CCTV Cameras

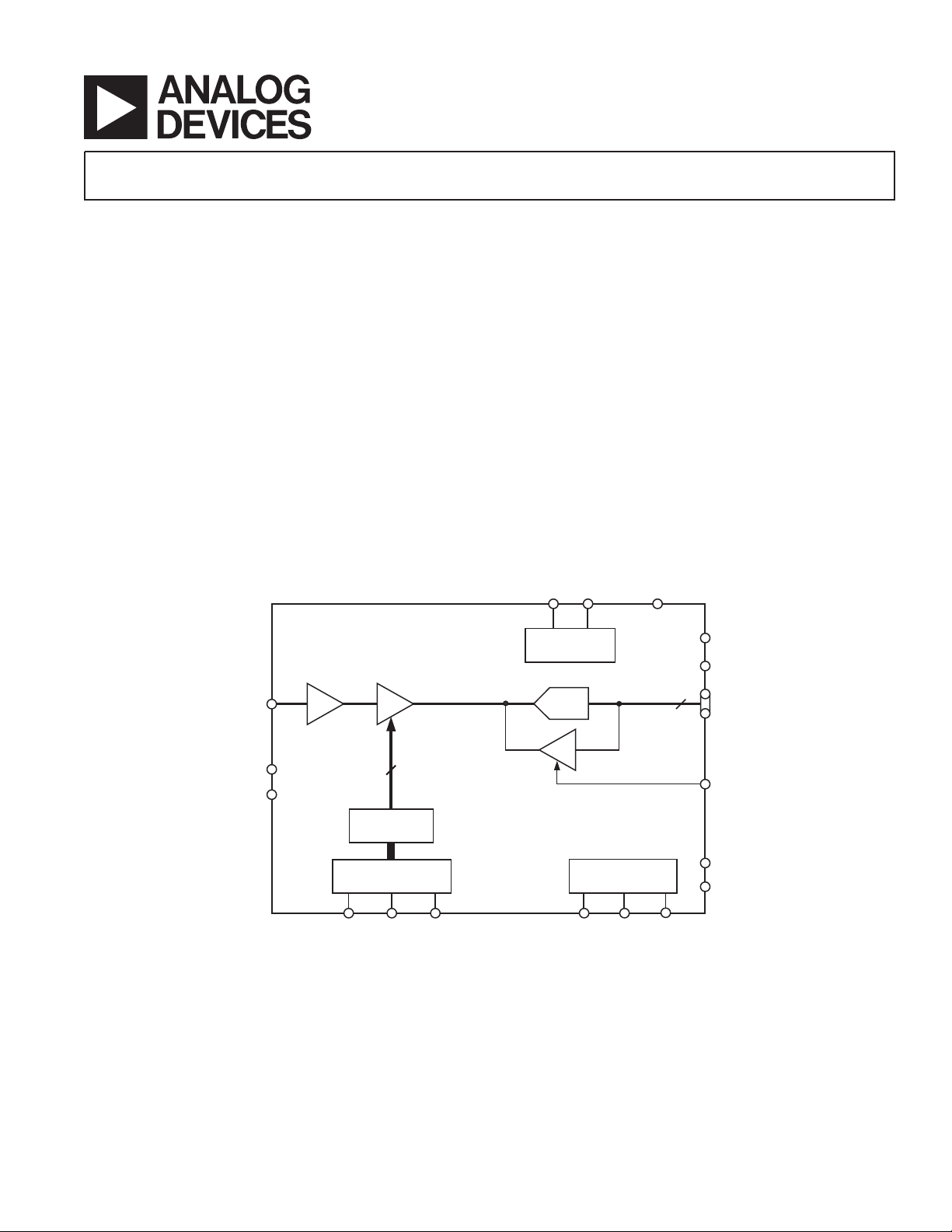

FUNCTIONAL BLOCK DIAGRAM

AD9945

6dB TO 40dB

CCDIN

VGACDS

GENERAL DESCRIPTION

The AD9945 is a complete analog signal processor for CCD

applications. It features a 40 MHz single-channel architecture

designed to sample and condition the outputs of interlaced and

progressive scan area CCD arrays. The AD9945’s signal chain

consists of a correlated double sampler (CDS), a digitally controlled variable gain amplifier (VGA), a black level clamp, and a

12-bit A/D converter.

The internal registers are programmed through a 3-wire serial digital

interface. Programmable features include gain adjustment, black

level adjustment, input clock polarity, and power-down modes.

The AD9945 operates from a single 3 V power supply, typically dissipates mW, and is packaged in a space-saving

32-lead LFCSP.

REFT

REFB

BAND GAP

REFERENCE

12-BIT

ADC

PBLK

DRVDD

DRVSS

12

DOUT

SL

10

CONTROL

REGISTERS

DIGITAL

INTERFACE

SDATASCK

AVDD

AVSS

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties that

may result from its use. No license is granted by implication or otherwise

under any patent or patent rights of Analog Devices. Trademarks and

registered trademarks are the property of their respective owners.

CLP

CLPOB

INTERNAL

TIMING

DATACLKSHDSHP

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 www.analog.com

Fax: 781/326-8703

DVDD

DVSS

AD9945–SPECIFICATIONS

(DRVDD = DVDD = 2.85 V, C = 20 pF, unless otherwise noted.)

L

160

2.85

(T

to T

GENERAL SPECIFICATIONS

MIN

, AVDD = DVDD = DRVDD= 3.0 V, f

MAX

Parameter Min Typ Max Unit

TEMPERATURE RANGE

Operating –20 +85 °C

Storage –65 +150 °C

POWER SUPPLY VOLTAGE

Analog, Digital, Digital Driver 3.6 V

POWER CONSUMPTION

Normal Operation (DRVDD Power not Included) mW

DRVDD Power Only (C

= 20 pF) 10 mW

LOAD

Power-Down Mode 1.5 mW

MAXIMUM CLOCK RATE 40 MHz

Specifications subject to change without notice.

DIGITAL SPECIFICATIONS

Parameter Symbol Min Typ Max Unit

LOGIC INPUTS

High Level Input Voltage V

Low Level Input Voltage V

High Level Input Current I

Low Level Input Current I

Input Capacitance C

LOGIC OUTPUTS

High Level Output Voltage, IOH = 2 mA V

Low Level Output Voltage, IOL = 2 mA V

Specifications subject to change without notice.

IH

IL

IH

IL

IN

OH

OL

2.1 V

2.2 V

= 40 MHz, unless otherwise noted.)

SAMP

0.6 V

10 µA

10 µA

10 pF

0.5 V

REV. A–2–

AD9945

REV. B

, AVDD = DVDD = DRVDD = 3.0 V, f = 40 MHz, Register 0xD = 0x838,

unless otherwise noted.)

MAX

MIN

(T to T

SAMP

See Variable Gain Amplifier section for VGA gain equation

Low Gain Mode

−1.5 0 +1.5

dB

See Table 1, Internal Register Map, for register information

See Figure 7 for VGA Gain Curve

SYSTEM SPECIFICATIONS

Parameter Min Typ Max Unit Notes

CDS

Maximum Input Range before Saturation* 1.0 Vp-p

Allowable CCD Reset Transient* 500 mV See Input Waveform in Footnote

Maximum CCD Black Pixel Amplitude* 100 mV

VARIABLE GAIN AMPLIFIER (VGA)

Gain Control Resolution 1024 Steps

Gain Monotonicity Guaranteed

Gain Range

Minimum Gain 5.3 dB

Maximum Gain 40.0 41.5 dB

BLACK LEVEL CLAMP

Clamp Level Resolution 256 Steps

Clamp Level Measured at ADC Output

Minimum Clamp Level 0 LSB

Maximum Clamp Level 255 LSB

A/D CONVERTER

Resolution 12 Bits

Differential Nonlinearity (DNL) ± 0.5 LSB

No Missing Codes Guaranteed

Data Output Coding Straight Binary

Full-Scale Input Voltage 2.0 V

VOLTAGE REFERENCE

Reference Top Voltage (REFT) 2.0 V

Reference Bottom Voltage (REFB) 1.0 V

SYSTEM PERFORMANCE Specifications Include Entire Signal Chain

Gain Range

Low Gain (VGA Code = 0) 5.3 dB

Maximum Gain (VGA Code = 1023) 40.0 41.5 dB

Gain Accuracy 1.0 dB

Peak Nonlinearity, 500 mV Input Signal 0.1 % 12 dB Gain Applied

Total Output Noise 1.2 LSB rms AC Grounded Input, 6 dB Gain Applied

Power Supply Rejection (PSR) 40 dB

*Input Signal Characteristics defined as follows:

500mV TYP

RESET TRANSIENT

Specifications subject to change without notice.

100mV TYP

OPTICAL BLACK PIXEL

1V TYP

INPUT SIGNAL RANGE

–3–

AD9945

REV. B

TIMING SPECIFICATIONS

(CL = 20 pF, f

= 40 MHz, CCD Mode Timing in Figures 8 and 9, Serial Timing in Figures 4 and 5.)

SAMP

Parameter Symbol Min Typ Max Unit

SAMPLE CLOCKS

DATACLK, SHP, SHD Clock Period t

DATACLK High/Low Pulse Width t

SHP Pulse Width t

SHD Pulse Width t

CLPOB Pulse Width* t

SHP Rising Edge to SHD Falling Edge t

SHP Rising Edge to SHD Rising Edge t

Internal Clock Delay t

CONV

ADC

SHP

SHD

COB

S1

S2

ID

25 ns

10 12.5 ns

6.25 ns

6.25 ns

220 Pixels

6.25 ns

11.25 12.5 ns

3ns

DATA OUTPUTS

Output Delay t

OD

9.5 ns

Pipeline Delay 10 Cycles

SERIAL INTERFACE

Maximum SCK Frequency f

SL to SCK Setup Time t

SCK to SL Hold Time t

SDATA Valid to SCK Rising Edge Setup t

SCK Falling Edge to SDATA Valid Hold t

*Minimum CLPOB pulse width is for functional operation only. Wider typical pulses are recommended to achieve low noise clamp performance.

Specifications subject to change without notice.

SCLK

LS

LH

DS

DH

10 MHz

10 ns

10 ns

10 ns

10 ns

ABSOLUTE MAXIMUM RATINGS*

With

Respect

Parameter To Min Max Unit

AVDD AVSS –0.3 +3.9 V

DVDD DVSS –0.3 +3.9 V

DRVDD DRVSS –0.3 +3.9 V

Digital Outputs DRVSS –0.3 DRVDD + 0.3 V

SHP, SHD, DATACLK DVSS –0.3 DVDD + 0.3 V

CLPOB, PBLK DVSS –0.3 DVDD + 0.3 V

SCK, SL, SDATA DVSS –0.3 DVDD + 0.3 V

REFT, REFB, CCDIN AVSS –0.3 AVDD + 0.3 V

Junction Temperature 150 °C

Lead Temperature 300 °C

(10 sec)

*Stresses above those listed under Absolute Maximum Ratings may cause perma-

nent damage to the device. This is a stress rating only; functional operation of the

device at these or any other conditions outside of those indicated in the operational

sections of this specification is not implied. Exposure to absolute maximum ratings

for extended periods may affect device reliability.

THERMAL CHARACTERISTICS

Thermal Resistance

32-Lead LFCSP Package

= 27.7 °C/W

θ

JA

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection. Although the

AD9945 features proprietary ESD protection circuitry, permanent damage may occur on devices

subjected to high energy electrostatic discharges. Therefore, proper ESD precautions are recommended

to avoid performance degradation or loss of functionality.

–4–

PIN CONFIGURATION

REV. B

NOTES

1. IT IS RECOMMENDED THAT THE EXPOSED PAD BE

SOLDERED TO THE GROUND PLANE OF THE PCB.

32 D1

31 D0

30 NC

29 NC

28 NC

27 SCK

26 SDATA

25 SL

AD9945

D2 1

D3 2

D4 3

D5 4

D6 5

D7 6

D8 7

D9 8

PIN 1

INDICATOR

AD9945

TOP VIEW

D11 10

D10 9

DRVDD 11

DVDD 13

DRVSS 12

DVSS 15

DATACLK 14

PBLK 16

24 REFB

23 REFT

22 CCDIN

21 AVSS

20 AVDD

19 SHD

18 SHP

17 CLPOB

PIN FUNCTION DESCRIPTIONS

Pin Number Mnemonic Type Description

1 to 10, 31, 32 D2 to D11, D0, D1 DO Digital Data Outputs

11 DRVDD P Digital Output Driver Supply

12 DRVSS P Digital Output Driver Ground

13 DVDD P Digital Supply

14 DATACLK DI Digital Data Output Latch Clock

15 DVSS P Digital Supply Ground

16 PBLK DI Preblanking Clock Input

17 CLPOB DI Black Level Clamp Clock Input

18 SHP DI CDS Sampling Clock for CCD’s Reference Level

19 SHD DI CDS Sampling Clock for CCD’s Data Level

20 AVDD P Analog Supply

21 AVSS P Analog Ground

22 CCDIN AI Analog Input for CCD Signal

23 REFT AO A/D Converter Top Reference Voltage Decoupling

24 REFB AO A/D Converter Bottom Reference Voltage Decoupling

25 SL DI Serial Digital Interface Load Pulse

26 SDATA DI Serial Digital Interface Data Input

27 SCK DI Serial Digital Interface Clock Input

28 to 30 NC NC Internally Pulled Down. Float or connect to GND.

TYPE: AI = Analog Input, AO = Analog Output, DI = Digital Input, DO = Digital Output, P = Power.

–5–

AD9945

REV. B

DEFINITIONS OF SPECIFICATIONS

Differential Nonlinearity (DNL)

An ideal ADC exhibits code transitions that are exactly 1 LSB

apart. DNL is the deviation from this ideal value. Thus, every

code must have a finite width. No missing codes guaranteed to

12-bit resolution indicates that all 4096 codes must be present

over all operating conditions.

Peak Nonlinearity

Peak nonlinearity, a full signal chain specification, refers to the

peak deviation of the output of the AD9945 from a true straight

line. The point used as zero scale occurs 1/2 LSB before the first

code transition. Positive full scale is defined as a level 1 1/2 LSB

beyond the last code transition. The deviation is measured from

the middle of each particular output code to the true straight line.

The error is then expressed as a percentage of the 2 V ADC fullscale signal. The input signal is always appropriately gained up to

fill the ADC’s full-scale range.

Total Output Noise

The rms output noise is measured using histogram techniques.

The standard deviation of the ADC output codes is calculated in

LSB and represents the rms noise level of the total signal chain

EQUIVALENT INPUT CIRCUITS

DVDD

at the specified gain setting. The output noise can be converted

to an equivalent voltage, using the relationship

N

1 LSB = (ADC Full Scale/2

codes)

where N is the bit resolution of the ADC. For the AD9945,

1 LSB is 0.5 mV.

Power Supply Rejection (PSR)

The PSR is measured with a step change applied to the supply

pins. This represents a very high frequency disturbance on the

AD9945’s power supply. The PSR specification is calculated

from the change in the data outputs for a given step change in

the supply voltage.

Internal Delay for SHP/SHD

The internal delay (also called aperture delay) is the delay that

occurs from the time when a sampling edge is applied to the

AD9945 until the actual sample of the input signal is held. Both

SHP and SHD sample the input signal during the transition from

low to high, so the internal delay is measured from each clock’s

rising edge to the instant the actual internal sample is taken.

DATA

THREE-

STATE

330

DVSS

Figure 1. Digital Inputs—SHP, SHD,

DATACLK, CLPOB, PBLK, SCK, SL, SDATA

DVDD

DRVDD

DOUT

AVDD

60

AVSS

AVSS

Figure 3. CCDIN (Pin 22)

DVSS

Figure 2. Data Outputs—D0 to D11

DRVSS

–6–

Typical Performance Characteristics–AD9945

REV. B

180

165

V

= 3.3 V

150

135

120

POWER DISSIPATION (mV)

105

90

25

DD

V

= 3.0 V

DD

SAMPLE RATE (MHz)

TPC 1. Power vs. Sampling Rate

1.0

0.5

0

DNL (LSB)

– 0.5

4032

– 1.0

0

800 2400 3200

1600

CODE

4000

TPC 2. Typical DNL Performance

–7–

AD9945

REV. B

A3 A2 A1 A0

0 0 0 0

0 0 0 1

0 0 1 0

0 0 1 1

Startup

1 1 0 1

D11 to D0

Required start-up write must be set to 0x838.

NOTE: All register values default to 0x0000 at power-up except clamp level, which defaults to 128 decimal (128 LSB clamp level).

Low Gain Mode. Normally set to 00. To enable low gain mode, set to 11. When low gain mode

is enabled, VGA Gain register must be set to all zeroes.

Test Mode. Should always be set to 000.

D8, D7

D11 to D9

INTERNAL REGISTER DESCRIPTION

Table I. Internal Register Map

Register Address Bits

Name Data Bits Function

Operation D0 Software Reset (0 = Normal Operation, 1 = Reset all registers to default)

D2, D1 Power-Down Modes (00 = Normal Power, 01 = Standby, 10 = Total Shutdown)

D3 OB Clamp Disable (0 = Clamp ON, 1 = Clamp OFF)

D5, D4 Test Mode. Should always be set to 00.

D6 PBLK Blanking Level (0 = Blank Output to Zero, 1 = Blank to OB Clamp Level)

Control D0 SHP/SHD Input Polarity (0 = Active Low, 1 = Active High)

D1 DATACLK Input Polarity (0 = Active Low, 1 = Active High)

D2 CLPOB Input Polarity (0 = Active Low, 1 = Active High)

D3 PBLK Input Polarity (0 = Active Low, 1 = Active High)

D4 Three-State Data Outputs (0 = Outputs Active, 1 = Outputs Three-Stated)

D5 Data Output Latching (0 = Latched by DATACLK, 1 = Latch is Transparent)

D6 Data Output Coding (0 = Binary Output, 1 = Gray Code Output)

D11 to D7 Test Mode. Should always be set to 00000.

Clamp Level D7 to D0 OB Clamp Level (0 = 0 LSB, 255 = 255 LSB)

VGA Gain D9 to D0 VGA Gain (0 = 6 dB, 1023 = 40 dB)

–8–

SERIAL INTERFACE

REV. B

A3

A3

AD9945

SDATA

SCK

t

DS

t

SL

NOTES

1. SDATA BITS ARE INTERNALLY LATCHED ON THE RISING EDGES OF SCK.

2. SYSTEM UPDATE OF LOADED REGISTERS OCCURS ON SL RISING EDGE.

3. ALL 12 DATA BITS D0 TO D11 MUST BE WRITTEN. IF THE REGISTER CONTAINS FEWER THAN 12 BITS, ZEROS SHOULD BE

USED FOR THE UNDEFINED BITS.

A2A0 A1 D0 D1 D2 D3 D4 D5 D6 D7 D8 D9 D10

t

DH

LS

Figure 4. Serial Write Operation

DATA FOR STARTING

REGISTER ADDRESS

SDATA

A0 A1 A2 D0 D1 D2 D3 D4 D5 D10 D11

SCK

SL

1162345678910

NOTES

1. MULTIPLE SEQUENTIAL REGISTERS MAY BE LOADED CONTINUOUSLY.

2. THE FIRST (LOWEST ADDRESS) REGISTER ADDRESS IS WRITTEN, FOLLOWED BY MULTIPLE 12-BIT DATA-WORDS.

3. THE ADDRESS WILL AUTOMATICALLY INCREMENT WITH EACH 12-BIT DATA-WORD (ALL 12 BITS MUST BE WRITTEN).

4. SL IS HELD LOW UNTIL THE LAST DESIRED REGISTER HAS BEEN LOADED.

5. NEW DATA IS UPDATED AT THE NEXT SL RISING EDGE.

...

...

...

15

DATA FOR NEXT

REGISTER ADDRESS

D0 D1 D10 D11

1817 2827

...

...

...

D11

t

LH

D0

D2D1

302931

...

...

...

Figure 5. Continuous Serial Write Operation to All Registers

–9–

AD9945

REV. B

DC RESTORE

0.1F

CCDIN

CDS

6dB TO 40dB

VGA

10

VGA GAIN

REGISTER

Figure 6. CCD Mode Block Diagram

CIRCUIT DESCRIPTION AND OPERATION

The AD9945 signal processing chain is shown in Figure 6. Each

processing step is essential in achieving a high quality image from

the raw CCD pixel data.

DC Restore

To reduce the large dc offset of the CCD output signal, a dc

restore circuit is used with an external 0.1 µF series coupling

capacitor. This restores the dc level of the CCD signal to

approximately 1.5 V to be compatible with the 3 V single supply

of the AD9945.

Correlated Double Sampler

The CDS circuit samples each CCD pixel twice to extract the

video information and reject low frequency noise. The timing

shown in Figure 8 illustrates how the two CDS clocks, SHP and

SHD, are used to sample the reference level and data level of

the CCD signal, respectively. The CCD signal is sampled on the

rising edges of SHP and SHD. Placement of these two clock

signals is critical in achieving the best performance from the CCD.

An internal SHP/SHD delay (t

) of 3 ns is caused by internal

ID

propagation delays.

Optical Black Clamp

The optical black clamp loop is used to remove residual offsets

in the signal chain and to track low frequency variations in the

CCD’s black level. During the optical black (shielded) pixel

interval on each line, the ADC output is compared with the

fixed black level reference, selected by the user in the clamp

level register. The resulting error signal is filtered to reduce

noise, and the correction value is applied to the ADC input

through a D/A converter. Normally, the optical black clamp

loop is turned on once per horizontal line, but this loop can be

updated more slowly to suit a particular application. If external

digital clamping is used during the postprocessing, the AD9945

optical black clamping may be disabled using Bit D3 in the

operation register (see the Serial Interface Timing and Internal

Register Description sections).

INTERNAL

V

REF

2V FULL SCALE

8

REGISTER

12

DOUT

CLPOB

8-BIT

DAC

12-BIT

ADC

OPTICAL BLACK

CLAMP

DIGITAL

FILTERING

CLAMP LEVEL

When the loop is disabled, the clamp level register may still be

used to provide programmable offset adjustment.

Horizontal timing is shown in Figure 9. The CLPOB pulse should

be placed during the CCD’s optical black pixels. It is recommended that the CLPOB pulse be used during valid CCD dark

pixels. The CLPOB pulse should be a minimum of 20 pixels wide

to minimize clamp noise. Shorter pulse widths may be used, but

clamp noise may increase and the loop’s ability to track low frequency variations in the black level will be reduced.

A/D Converter

The ADC uses a 2 V input range. Better noise performance results

from using a larger ADC full-scale range. The ADC uses a

pipelined architecture with a 2 V full-scale input for low noise

performance.

Variable Gain Amplifier

The VGA stage provides a gain range of 6 dB to 40 dB, programmable with 10-bit resolution through the serial digital interface.

The minimum gain of 6 dB is needed to match a 1 V input signal

with the ADC full-scale range of 2 V. A plot of the VGA gain curve

is shown in Figure 7.

VGA Gain dB VGA Code dB dB

42

36

30

24

VGA GAIN (dB)

18

12

6

0

=×

()

()

127 255 383 511 639 767 895 1023

VGA GAIN REGISTER CODE

+0 035 5 3..

Figure 7. VGA Gain Curve

–10–

CCD MODE TIMING

REV. B

CCD

SIGNAL

DATACLK

OUTPUT

DATA

t

ID

SHP

t

SHD

NOTES

1. RECOMMENDED PLACEMENT FOR DATACLK RISING EDGE IS BETWEEN THE SHD RISING EDGE AND NEXT SHP FALLING EDGE.

2. CCD SIGNAL IS SAMPLED AT SHP AND SHD RISING EDGES.

EFFECTIVE PIXELS

NN+1N+2 N+9 N+10

t

ID

S1

t

OD

N–10 N– 9 N– 8 N–1 N

t

S2

t

CP

Figure 8. CCD Mode Timing

HORIZONTAL

OPTICAL BLACK PI XELS

BLANKIN G

DUMMY PIXELS EFFECTIVE PIXELS

AD9945

CCD

SIGNAL

CLPOB

PBLK

OUTPUT

DATA

EFFECTIVE PIXEL DATA

NOTES

1. CLPOB WILL OVERWRITE PBLK. PBLK WILL NOT AFFECT CLAMP OPERATION IF OVERLAPPING WITH CLPOB.

2. PBLK SIGNAL IS OPTIONAL.

3. DIGITAL OUTPUT DATA WILL BE ALL ZEROS DURING PBLK. OUTPUT DATA LATENCY IS NINE DATACLK CYCLES.

OB PIXEL DATA DUMMY BLACK EFFECTIVE DATA

Figure 9. Typical CCD Mode Line Clamp Timing

–11–

AD9945

REV. B

APPLICATIONS INFORMATION

The AD9945 is a complete analog front end (AFE) product for

digital still camera and camcorder applications. As shown in

Figure 10, the CCD image (pixel) data is buffered and sent to the

AD9945 analog input through a series input capacitor. The

AD9945 performs the dc restoration, CDS, gain adjustment, black

CCD

V-DRIVE

V

OUT

BUFFER

0.1F

TIMING

CCD

AD9945

CCDIN

GENERATOR

REGISTER-

TIMING

Figure 10. System Applications Diagram

level correction, and analog-to-digital conversion. The AD9945’s

digital output data is then processed by the image processing

ASIC. The internal registers of the AD9945—used to control

gain, offset level, and other functions—are programmed by the

ASIC or microprocessor through a 3-wire serial digital interface.

A system timing generator provides the clock signals for both the

CCD and the AFE.

DIGITAL

OUT

DATA

OUTPUTS

SERIAL

INTERFACE

DIGITAL IMAGE

PROCESSING

ASIC

ADC

CDS/CLAMP

TIMING

–12–

AD9945

REV. B

Internal Power-On Reset Circuitry

After power-on, the AD9945 will automatically reset all internal

registers and perform internal calibration procedures. This takes

approximately 1 ms to complete. During this time, normal clock

signals and serial write operations may occur. However, serial

register writes will be ignored until the internal reset operation

is completed.

Required Start-Up Write

During power-up of the AD9945, 0x838 must be written into

Register 0xD for proper start-up operation.

Grounding and Decoupling Recommendations

As shown in Figure 11, a single ground plane is recommended for

the AD9945. This ground plane should be as continuous as

possible. This will ensure that all analog decoupling capacitors

provide the lowest possible impedance path between the power

and bypass pins and their respective ground pins. All decoupling

capacitors should be located as close as possible to the package

pins. A single clean power supply is recommended for the AD9945,

but a separate digital driver supply may be used for DRVDD

(Pin 11). DRVDD should always be decoupled to DRVSS (Pin 12),

which should be connected to the analog ground plane. If the digital

outputs (Pins 1 to 10, 31, and 32) must drive a load larger than 20 pF,

buffering is recommended to reduce digital code transition noise.

Alternatively, placing series resistors close to the digital output pins

may also help reduce noise.

DATA

OUTPUTS

SERIAL

INTERFACE

D0

D1

32

31

D2 1

D3 2

D4 3

D5 4

D6 5

D7 6

D8 7

D9 8

12

DRIVER

SUPPLY

3V

PIN 1

IDENTIFIER

9

10

D11

D10

0.1F

3

30 NC

29 NC

28 NC

AD9945

TOP VIEW

(Not to Scale)

11

1213141516

DVDD

DRVSS

DRVDD

27 SCK

26 SDATA

DVSS

DATACLK

0.1F

25 SL

PBLK

3V

ANALOG

SUPPLY

24 REFB

23 REFT

22 CCDIN

21 AVSS

20 AVDD

19 SHD

18 SHP

17 CLPOB

1.0F

1.0F

0.1F

0.1F

5

CLOCK

INPUTS

CCDIN

3V

ANALOG

SUPPLY

NOTE

THE EXPOSED PAD ON THE BOTTOM OF THE AD9945 SHOULD BE

SOLDERED TO THE GND PLANE OF THE PRINTED CIRCUIT BOARD

Figure 11. Recommended Circuit Configuration for CCD Mode

NC = NO CONNECT

–13–

AD9945

OUTLINE DIMENSIONS

0.08

0.60 MAX

25

24

EXPOSED

PAD

(BOTTOM VIEW)

17

16

3.50 REF

PIN 1

32

9

FOR PROPER CONNECTION OF

THE EXPOSED PAD, REFER TO

THE PIN CONFIGURATION AND

FUNCTION DESCRIPTIONS

SECTION OF THIS DATA SHEET.

INDICATOR

1

3.25

3.10 SQ

2.95

8

0.25 MIN

011708-A

5.00

PIN 1

INDICATOR

1.00

0.85

0.80

12° MAX

SEATING

PLANE

BSC SQ

TOP

VIEW

0.80 MAX

0.65 TYP

0.30

0.23

0.18

COMPLIANT TO JEDEC STANDARDS MO-220-VHHD-2

4.75

BSC SQ

0.20 REF

0.05 MAX

0.02 NOM

0.60 MAX

0.50

BSC

0.50

0.40

0.30

COPLANARITY

Figure 1. 32-Lead Lead Frame Chip Scale Package [LFCSP_VQ]

5 mm × 5 mm Body, Very Thin Quad

(CP-32-2)

Dimensions shown in millimeters

ORDERING GUIDE

Model1 Temperature Range Package Description Package Option

AD9945KCPZ −20°C to +85°C 32-Lead Lead Frame Chip Scale Package [LFCSP_VQ] CP-32-2

AD9945KCPZRL7 −20°C to +85°C 32-Lead Lead Frame Chip Scale Package [LFCSP_VQ] CP-32-2

1

Z = RoHS Compliant Part.

REVISION HISTORY

1/11—Rev. A to Rev. B

Changed 140 mW to 160 mW Throughout .................................. 1

Changes to Power Supply Voltage Parameter and Power

Consumption, Normal Operation (DRVDD Power not

Included) Parameter in General Specifications Table .................. 2

Changed 2.7 V to 2.85 V in Digital Specifications Table

Summary ............................................................................................ 2

Changes to System Specifications Table Summary ....................... 3

Added Low Gain Mode Parameter in System Specifications

Table .................................................................................................... 3

Added Exposed Pad Notation to Pin Configuration .................... 5

Changes to TPC 1 .............................................................................. 7

Changes to Table 1 ............................................................................ 8

Changes to Figure 4 and Figure 5 ................................................... 9

Added Required Start-Up Write Section ..................................... 13

Changes to Grounding and Decoupling Recommendations

Section .............................................................................................. 13

Moved Ordering Guide .................................................................. 14

Changes to Ordering Guide ........................................................... 14

11/03—Rev. 0 to Rev. A

Changes to Timing Specifications................................................... 4

Changes to Ordering Guide ............................................................. 4

Changes to Figure 11 ...................................................................... 13

Updated Outline Dimensions ........................................................ 14

©2011 Analog Devices, Inc. All rights reserved. Trademarks and

registered trademarks are the property of their respective owners.

D03636-0-1/11(B)

Rev. B | Page 14 of 14

Loading...

Loading...