14/12/10-Bit, 1200 MSPS

D/A Converters

Preliminary Technical Data AD9736/AD9735/AD9734

FEATURES

• 1.8/3.3 V Dual Supply Operation

• AD9736 SFDR > 53 dBc to f

• AD9736 IMD > 65 dBc to f

= 600 MHz

OUT

= 600 MHz

OUT

• AD9736 DNL = ± 1.0 LSB

• AD9736 INL = ± 2.0 LSB

• Low power: 380 mW (I

= 20 mA; f

OUTFS

= 330 MHz)

OUT

• LVDS data interface with on-chip 100 Ω terminations

• Analog Output: Adjustable 10-30mA (RL=25 Ω to 50 Ω)

• On-Chip 1.2 V Reference

• 160 pin BGA Package

APPLICATIONS

• Instrumentation

• Automatic Test Equipment

• RADAR

• Avionics

• Wideband Communications Systems:

Point-to-Point Wireless

LMDS

PA Linearization

PRODUCT DESCRIPTION

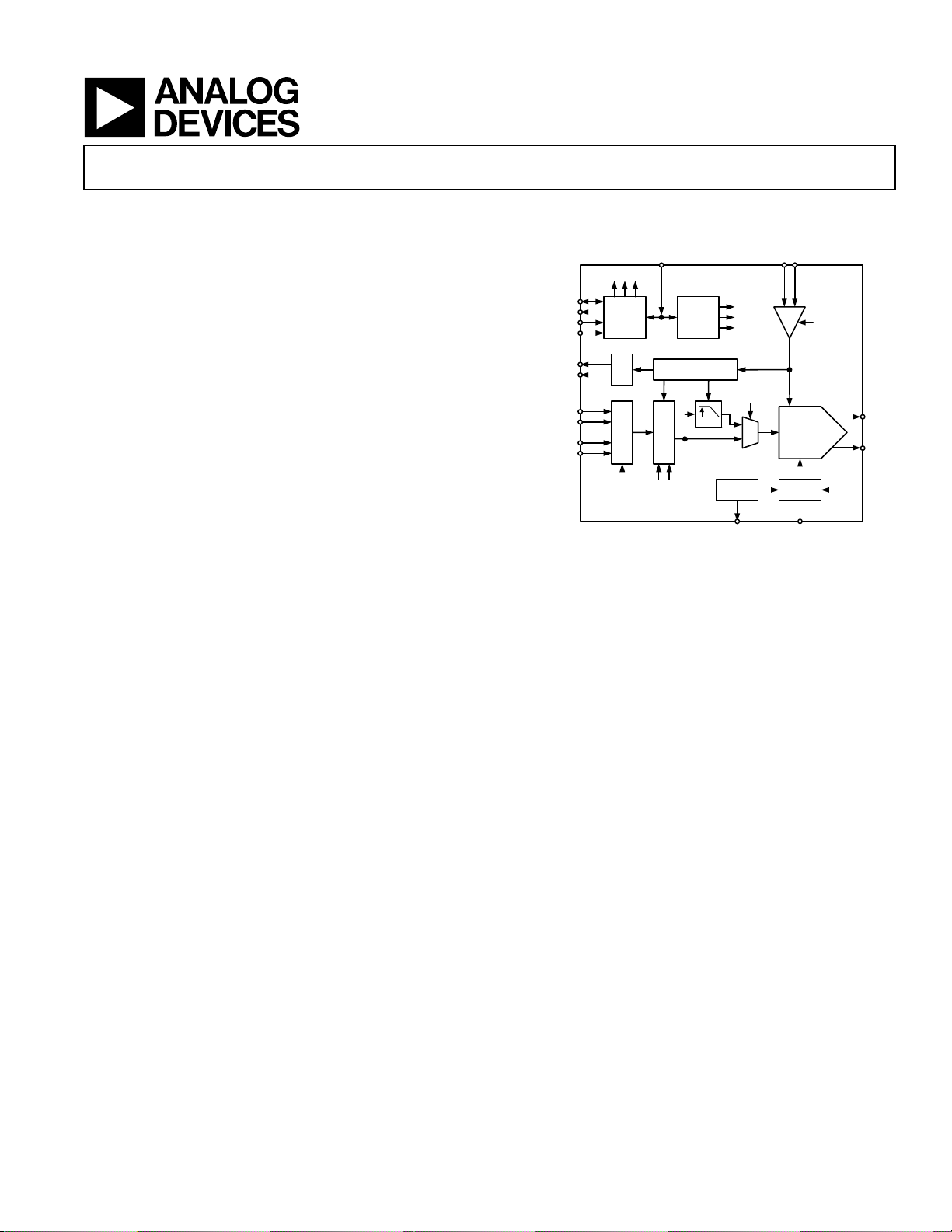

FUNCTIONAL BLOCK DIAGRAM

CLK-

CLK+

14,12,10-Bit

DAC

Reference

Current

RSET

C3

S2

SDO

CSB

SCLK

DATACLK_OUT+

DATACLK_OUT-

DATACLK_IN+

DATACLK_IN-

DB[13:0]+

DB[13:0]-

RESET

S1 S2 S3

SDI

SPI

LVDS

Driver

LVDSReceiver

C2 C1 S1

Controller

Clock Distribution

Synchronization

Figure 1. Functional Block Diagram

C1

C2

C3

S3

2X

Bandgap

VREF

PRODUCT HIGHLIGHTS

Ultra-low Noise and Intermodulation Distortion (IMD) enable

high quality synthesis of wideband signals at intermediate

frequencies up to 600 MHz.

IOUTA

IOUTB

The AD9736, AD9735, and AD9734 are high performance, high

frequency DACs that provide sample rates of up to 1200 MSPS,

permitting multi-carrier generation up to their Nyquist frequency.

The AD9736 is the 14 bit member of the family, while the AD9735

and the AD9734 are the 12 and 10 bit members, respectively. They

include a serial peripheral interface (SPI) port that provides for

programming many internal parameters and also enables read-back

of status registers. They use a reduced specification LVDS interface

to minimize data interface noise that may degrade performance.

The output current can be programmed over a range of 10mA to

30mA. The AD9736 family is manufactured on a 0.18µm CMOS

process and operates from 1.8V and 3.3V supplies for a total power

consumption of 380mW in bypass mode. It is supplied in a 160 pin

BGA package for reduced package parasitics.

Rev. PrJ 9/7/2004

Information furnished by Analog Devices is believed to be accurate and reliable.

However, no responsibility is assumed by Analog Devices for its use, nor for any

infringements of patents or other rights of third parties that may result from its

use. No license is granted by implication or otherwise under any patent or patent

rights of Analog Devices. Trademarks and registered trademarks are the property

of their respective companies.

Double Data Rate (DDR) LVDS data receivers support the

maximum conversion rate of 1200 MSPS.

Direct pin programmability of basic functions or SPI port access

for complete control of all AD9736 family functions.

Manufactured on a CMOS process, the AD9736 family uses a

proprietary switching technique that enhances dynamic

performance.

The current output(s) of the AD9736 family can be easily

configured for various single-ended or differential circuit

topologies.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700 www.analog.com

Fax: 781.326.8703 © 2004 Analog Devices, Inc. All rights reserved.

AD9736/AD9735/AD9734 Preliminary Technical Data

TABLE OF CONTENTS

AD9736/AD9735/AD9734—Specifications ........................................3

DC SPECIFICATIONS ......................................................................3

DIGITAL SPECIFICATIONS............................................................4

AC SPECIFICATIONS....................................................................... 5

EXPLANATION OF TEST LEVELS................................................ 5

PIN FUNCTION DESCRIPTIONS...................................................... 6

PIN CONFIGURATION........................................................................ 7

PACKAGE OUTLINE.............................................................................9

Ordering Guide ...................................................................................9

TYPICAL PERFORMANCE CHARACTERISTICS........................10

SPI REGISTER MAP ............................................................................14

SPI REGISTER DESCRIPTIONS........................................................15

General Description ..............................................................................19

Serial Peripheral Interface................................................................19

AD9736 Data Interface Controllers ....................................................22

AD9736 LVDS Sample Logic...........................................................23

AD9736 SYNC Logic and Controller.............................................25

AD9736 Digital Built-In Self Test........................................................27

AD9736 Analog Control Register .......................................................28

Voltage Reference...................................................................................29

Applications Information .....................................................................30

AD9736 Evaluation Board Schematics...............................................31

AD9736 Evaluation Board PCB Layout..............................................36

REVISION HISTORY

Revision PrA: Initial Version

Revision PrB: Updated data based on initial evaluation results

Revision PrC: Updated data for web display and ongoing evaluation results

Revision PrD: Added SPI port information

Revision PrE: Cleaned up SPI port tables, added AD9736 rev A evaluation board schematics

Revision PrF: Added BGA Package Outline Drawing

Revision PrG: Added Package Pinout

Revision PrH: Added SPI Port Description

Revision PrI: Edits for readability and clarity, Added Idd typical values and plots, Updated SPI register tables, Added LVDS and SYNC controller

sections, Added pin function table, Added BIST description, Added Analog control section, Added Vref section, Updated eval

board schematic and PCB layout

Revision PrJ: Update BIST information, Update SPI definition to include SCLK edge change for read operation, Add SPI timing, Annotate

schematic to show component values for output circuit, Update ACLR plots, Add PCB fabrication details.

Rev. PrJ | Page 2 of 42

Preliminary Technical Data AD9736/AD9735/AD9734

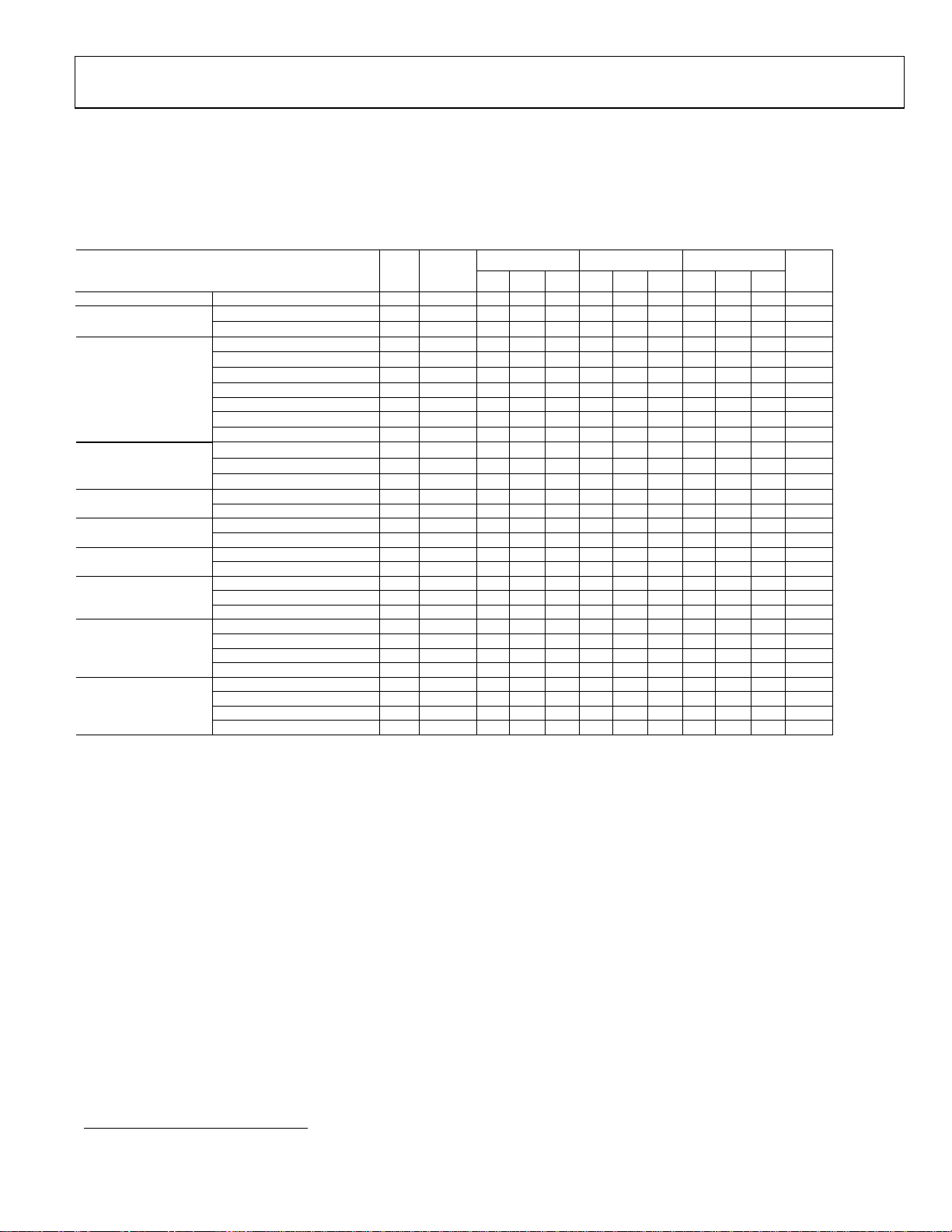

AD9736/AD9735/AD9734—SPECIFICATIONS1

DC SPECIFICATIONS

(VDDA33 = VDDD33 = 3.3 V, VDDA18 = VDDD18 = VDDCLK = 1.8 V, MAXIMUM SAMPLE RATE, FS = 20MA,

1X MODE, 25 OHM 1% BALANCED LOAD, UNLESS OTHERWISE NOTED)

AD9736 AD9735 AD9734

Parameter Temp Test Level

RESOLUTION 14 12 10 Bits

ACCURACY

ANALOG OUTPUTS

TEMPERATURE DRIFT

REFERENCE

ANALOG SUPPLY VOLTAGES

DIGITAL SUPPLY VOLTAGES

POWER CONSUMPTION

SUPPLY CURRENTS

1X Mode

SUPPLY CURRENTS

2x Mode, Interpoation Enabled

Integral Nonlinearity (INL)

Differential Nonlinearity (DNL)

Offset Error TBD TBD TBD % FSR

Gain Error (With Internal Reference)

Gain Error (Without Internal Reference)

Full Scale Output Current 10 20 30 10 20 30 10 20 30 mA

Output Compliance Range 1.0 1.0 1.0 V

Output Resistance TBD TBD TBD

Output Capacitance TBD TBD TBD pF

Offset TBD TBD TBD

Gain TBD TBD TBD

Reference Voltage TBD TBD TBD

Internal Reference Voltage 1.2 1.2 1.2 V

Output Current 100 100 100 nA

VDDA33 3.13 3.3 3.47 3.13 3.3 3.47 3.13 3.3 3.47 V

VDDA18 1.70 1.8 1.90 1.70 1.8 1.90 1.70 1.8 1.90 V

VDDD33 3.13 3.3 3.47 3.13 3.3 3.47 3.13 3.3 3.47 V

VDDD18 1.70 1.8 1.90 1.70 1.8 1.90 1.70 1.8 1.90 V

Bypass Mode 380 380 380 mW

FIR Interpolation Filter Enabled 550 550 550 mW

Standby Power TBD TBD TBD mW

IDDA33 25 TBD TBD mA

IDDA18 47 TBD TBD mA

IDDD33 10 TBD TBD mA

IDDD18 122 TBD TBD mA

IDDA33 25 TBD TBD mA

IDDA18 47 TBD TBD mA

IDDD33 10 TBD TBD mA

IDDD18 234 TBD TBD mA

Min Typ Max Min Typ Max Min Typ Max

TBD TBD LSB

± 2.0

TBD TBD LSB

± 1.0

± 0.5

± 0.5

± 0.5

± 0.5

± 0.5

± 0.5

Table 1: DC Specifications

Unit

% FSR

% FSR

kΩ

ppm/°C

ppm/°C

ppm/°C

1

Specifications subject to change without notice

Rev. PrJ | Page 3 of 42

AD9736/AD9735/AD9734 Preliminary Technical Data

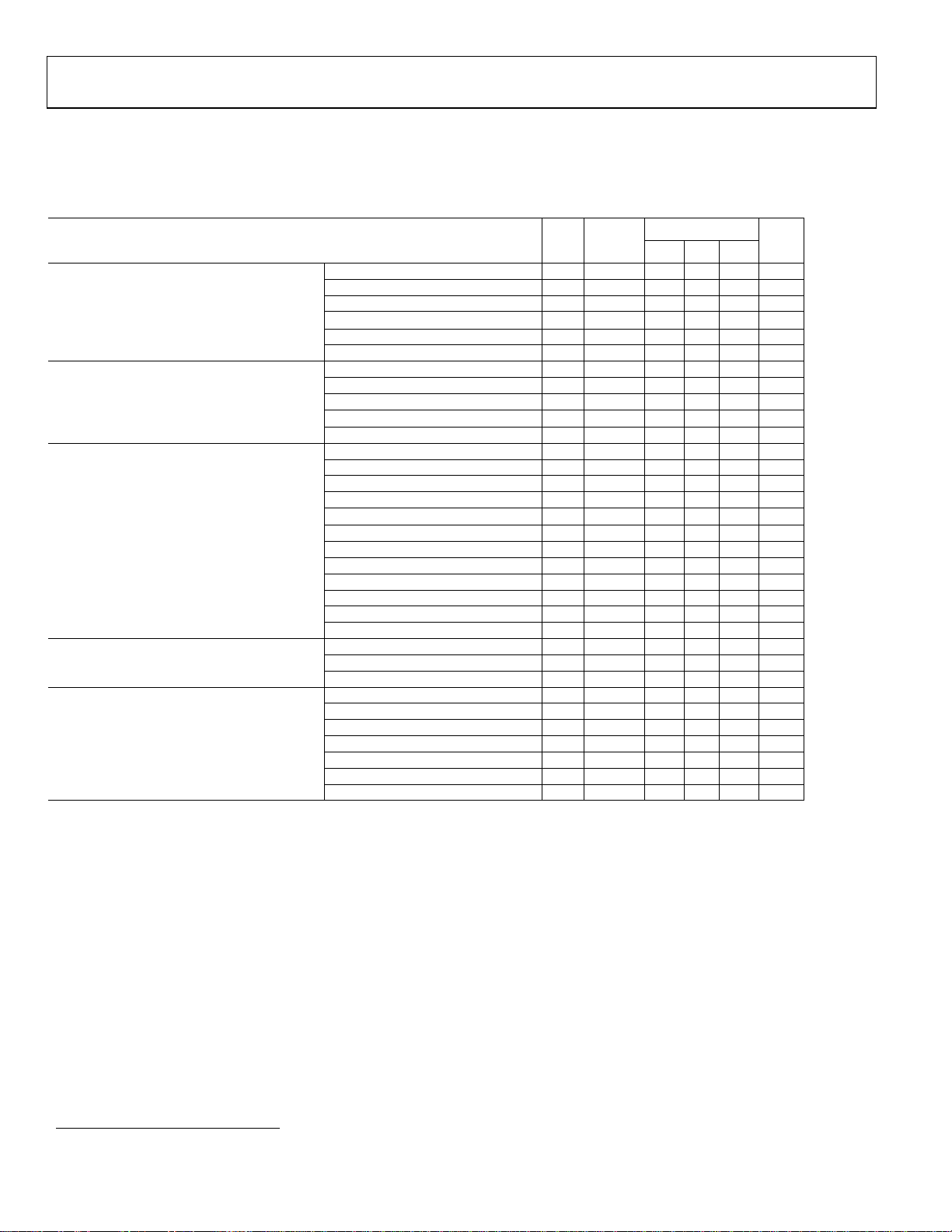

DIGITAL SPECIFICATIONS1

(VDDA33 = VDDD33 = 3.3 V, VDDA18 = VDDD18 = VDDCLK = 1.8 V, MAXIMUM SAMPLE RATE, FS = 20MA,

1X MODE, 25 OHM 1% BALANCED LOAD, UNLESS OTHERWISE NOTED)

LVDS DATA INPUTS (DB[13:0]+, DB[13:0]-)

DB+ = Via, DB- = Vib

LVDS CLOCK INPUT (DATACLK_IN+, DATACLK_IN-)

DATACLK+ = Via, DATACLK- = Vib

LVDS CLOCK OUTPUT (DATACLK_OUT+, DATACLK_ OUT-)

DATACLK_OUT+ = Voa, DATACLK_OUT- = Vob

100 ohm termination

DAC CLOCK INPUT (CLK+, CLK-)

SERIAL PERIPHERAL INTERFACE

AD9736,35,34 Parameter Temp Test Level

Min Typ Max

Input voltage range, Via or Vib 825 1575 mV

Input differential threshold -100 100 mV

Input differential hysteresis 20 mV

Receiver differential input impedance 80 120

LVDS input rate 1200 MSPS

LVDS data Bit Error Rate TBD Err/Bit

Input voltage range, Via or Vib 825 1575 mV

Input differential threshold -100 100 mV

Input differential hysteresis 20 mV

Receiver differential input impedance 80 120

Maximum Clock Rate 600 MHz

Output voltage high, Voa or Vob 1375 mV

Output voltage low, Voa or Vob 1025 mV

Output differential voltage 150 200 250 mV

Output offset voltage 1150 1250 mV

Output impedance, single ended 80 100 120

Ro mismatch between A & B 10 %

Change in |Vod| between ‘0’ and ‘1’ 25 mV

Change in Vos between ‘0’ and ‘1’ 25 mV

Output current – Driver shorted to ground 20 mA

Output current – Drivers shorted together 4 mA

Power-off output leakage TBD mA

Maximum Clock Rate 600 MHz

Differential peak-to-peak Voltage 800 mV

Common Mode Voltage 400 mV

Maximum Clock Rate 1200 MHz

Maximum Clock Rate (SCLK, 1/t

Minimum pulse width high, t

Minimum pulse width low, t

Minimum SDIO and CSB to SCLK setup, tDS 10 ns

Minimum SCLK to SDIO hold, tDH 5 ns

Maximum SCLK to valid SDIO and SDO, tDV 20 ns

Minimum SCLK to invalid SDIO and SDO, t

) 20 MHz

SCLK

20 ns

PWH

20 ns

PWL

5 ns

DNV

Table 2: Digital Specifications

Unit

Ω

Ω

Ω

1

LVDS Drivers and Receivers are compliant to the IEEE-1596 Reduced Range Link, unless otherwise noted

Rev. PrJ | Page 4 of 42

Preliminary Technical Data AD9736/AD9735/AD9734

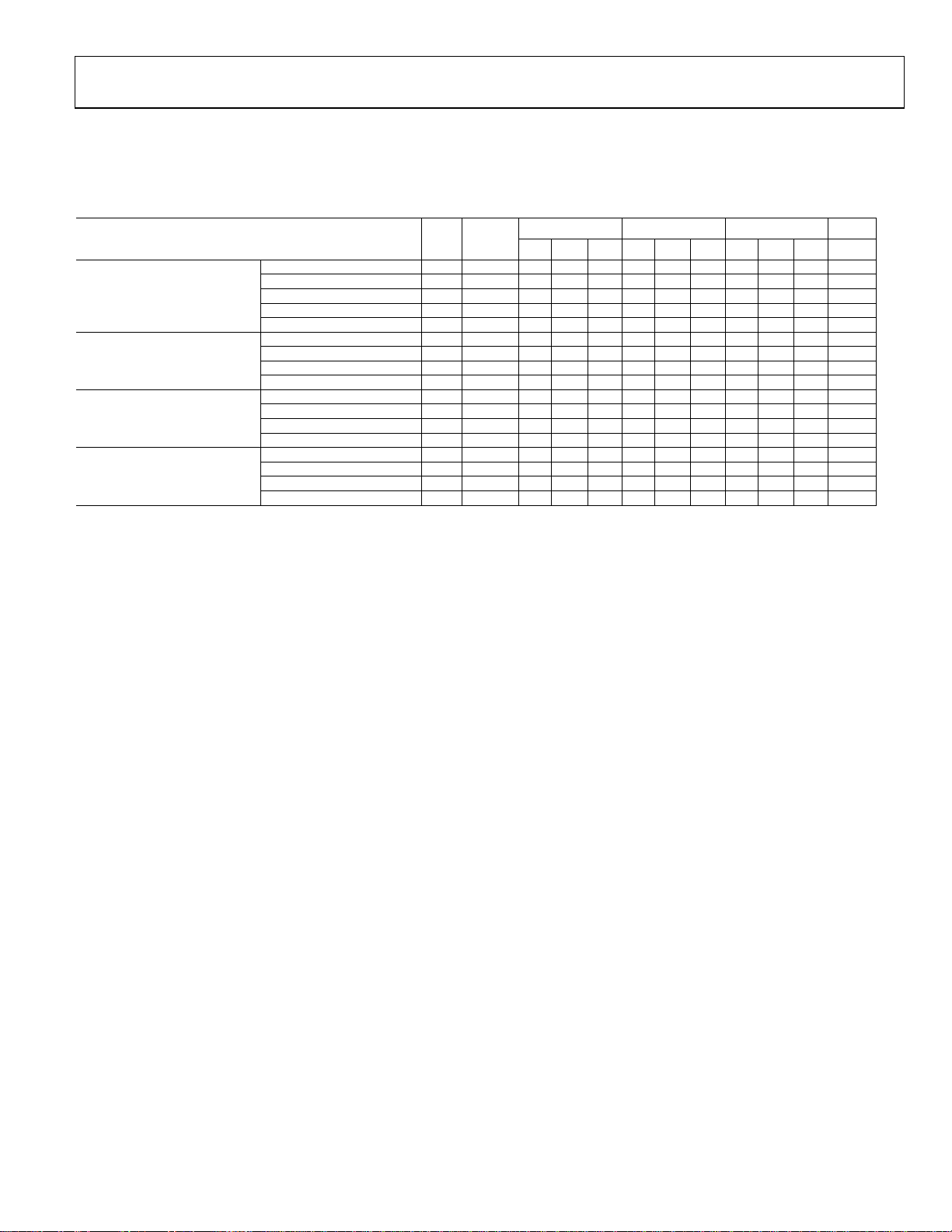

AC SPECIFICATIONS

(VDDA33 = VDDD33 = 3.3 V, VDDA18 = VDDD18 = VDDCLK = 1.8 V, MAXIMUM SAMPLE RATE, FS = 20MA,

1X MODE, 25 OHM 1% BALANCED LOAD, UNLESS OTHERWISE NOTED)

AD9736 AD9735 AD9734

Parameter Temp Test Level

DYNAMIC PERFORMANCE

SPURIOUS FREE DYNAMIC RANGE (SFDR)

Two Tone Intermodulation Distortion (IMD)

Noise Spectral Density (NSD)

Maximum Update Rate 1200 1200 1200 MSPS

Output Settling Time (tst) (to 0.025%) TBD TBD TBD ns

Output Rise Time (10% to 90%) TBD TBD TBD ns

Output Fall Time (90% to 10%) TBD TBD TBD ns

Output Noise (IoutFS=20mA) TBD TBD TBD pA/rtHz

f

= 1200 MSPS, f

DAC

f

= 1200 MSPS, f

DAC

f

= 1200 MSPS, f

DAC

f

= 1200 MSPS, f

DAC

f

= 1200 MSPS, f

DAC

f

= 1200 MSPS, f

DAC

f

= 1200 MSPS, f

DAC

f

= 1200 MSPS, f

DAC

f

= 1200 MSPS, f

DAC

f

= 1200 MSPS, f

DAC

f

= 1200 MSPS, f

DAC

f

= 1200 MSPS, f

DAC

= 50 MHz 80 dBc

OUT

= 100 MHz 77 dBc

OUT

= 316 MHz 63 dBc

OUT

= 550 MHz 55 dBc

OUT

= 50 MHz 85 dBc

OUT

= 100 MHz 84 dBc

OUT

= 316 MHz 74 dBc

OUT

= 550 MHz 65 dBc

OUT

= 50 MHz -165 dBm/Hz

OUT

= 100 MHz -164 dBm/Hz

OUT

= 316 MHz -158 dBm/Hz

OUT

= 550 MHz -155 dBm/Hz

OUT

Table 3: AC Specifications

Min Typ Max Min Typ Max Min Typ Max Unit

EXPLANATION OF TEST LEVELS

TEST LEVEL

I 100% production tested.

II 100% production tested at +25°C and guaranteed by design and characterization at specified temperatures.

III Sample Tested Only

IV Parameter is guaranteed by design and characterization testing.

V Parameter is a typical value only.

VI 100% production tested at +25°C and guaranteed by design and characterization for industrial temperature range.

Rev. PrJ | Page 5 of 42

AD9736/AD9735/AD9734 Preliminary Technical Data

PIN FUNCTION DESCRIPTIONS

Pin No. Name Description

A1, A2, A3, B1, B2, B3, C1, C2, C3, D2, D3 VDDC 1.8V, Clock supply

A4, A5, A6, A9, A10, A11, B4, B5, B6, B9,

B10, B11, C4, C5, C6, C9, C10, C11, D4, D5,

D6, D9, D10, D11

A7, B7, C7, D7 IOUTB DAC negative output, 10mA to 30mA full scale output current

A8, B8, C8, D8 IOUTA DAC positive output, 10mA to 30mA full scale output current

A12, A13, B12, B13, C12, C13, D12, D13 VDDA 3.3V Analog supply

A14, K1 DNC Do Not Connect

B14 I120

C14 VREF

D1, E2, E3, E4, F2, F3, F4, G1, G2, G3, G4 VSSC Clock supply ground

D14 IPTAT

E1, F1 CLK-, CLK+ Negative, Positive DAC clock input (DACCLK)

E11, E12, F11, F12, G11, G12 VSSA Analog supply ground shield

E13 IRQ / UNSIGNED

E14 RESET / PD

F13 CSB / 2x See SPI and PIN Mode sections for pin description

F14 SDIO / FIFO See SPI and PIN Mode sections for pin description

G13 SCLK / FSC0 See SPI and PIN Mode sections for pin description

G14 SDO / FSC1 See SPI and PIN Mode sections for pin description

H1, H2, H3, H4, H11, H12, H13, H14, J1, J2,

J3, J4, J11, J12, J13, J14

K2, K3, K4, K11, K12, L2, L3, L4, L5, L6, L9,

L10, L11, L12, M3, M4, M5, M6, M9, M10,

M11, M12

K13, K14 DB<13> -, + Negative, Positive data input bit 13 (MSB), reduced swing LVDS

L1 PIN_MODE

L7, L8, M7, M8, N7, N8, P7, P8 VDD33 3.3V Digital supply

L13, L14 DB<12> -, + Negative, Positive data input bit 12, reduced swing LVDS

M2, M1 DB<0> -, + Negative, Positive data input bit 0 (LSB), reduced swing LVDS

M13, M14 DB<11> -, + Negative, Positive data input bit 11, reduced swing LVDS

N1, P1 DB<1> -, + Negative, Positive data input bit 1, reduced swing LVDS

N2, P2 DB<2> -, + Negative, Positive data input bit 2, reduced swing LVDS

N3, P3 DB<3> -, + Negative, Positive data input bit 3, reduced swing LVDS

N4, P4 DB<4> -, + Negative, Positive data input bit 4, reduced swing LVDS

N5, P5 DB<5> -, + Negative, Positive data input bit 5, reduced swing LVDS

N6, P6 DATACLK_OUT -, + Negative, Positive output clock, reduced swing LVDS

N9, P9 DATACLK_IN -, + Negative, Positive data input clock, reduced swing LVDS

N10, P10 DB<6> -, + Negative, Positive data input bit 6, reduced swing LVDS

N11, P11 DB<7> -, + Negative, Positive data input bit 7, reduced swing LVDS

N12, P12 DB<8> -, + Negative, Positive data input bit 8, reduced swing LVDS

N13, P13 DB<9> -, + Negative, Positive data input bit 9, reduced swing LVDS

N14, P14 DB<10> -, + Negative, Positive data input bit 10, reduced swing LVDS

VSSA Analog supply ground

Nominal 1.2V reference tied to analog ground via 10kohm resistor to generate a

120uA reference current

Bandgap voltage reference I/O, tie to analog ground via 1nF capacitor, output

impedance approximately 5kohms

Factory test, output current proportional to absolute temperature, approximately

10uA at 25C with approximately 20nA/C slope

If PIN_MODE = 0, IRQ: Active low open-drain interrupt request output, pull up to

VDD3.3 with 10kohm resistor

If PIN_MODE = 1, UNSIGNED: Digital input pin where 0 = two’s complement input

data format, 1 = unsigned

If PIN_MODE = 0, RESET: 1 resets the AD9736

If PIN_MODE = 1, PD: 1 puts the AD9736 in the power down state

VDD 1.8V Digital supply

VSS Digital supply ground

0, SPI Mode, SPI enabled

1, PIN Mode, SPI disabled, direct pin control

Rev. PrJ | Page 6 of 42

Preliminary Technical Data AD9736/AD9735/AD9734

S

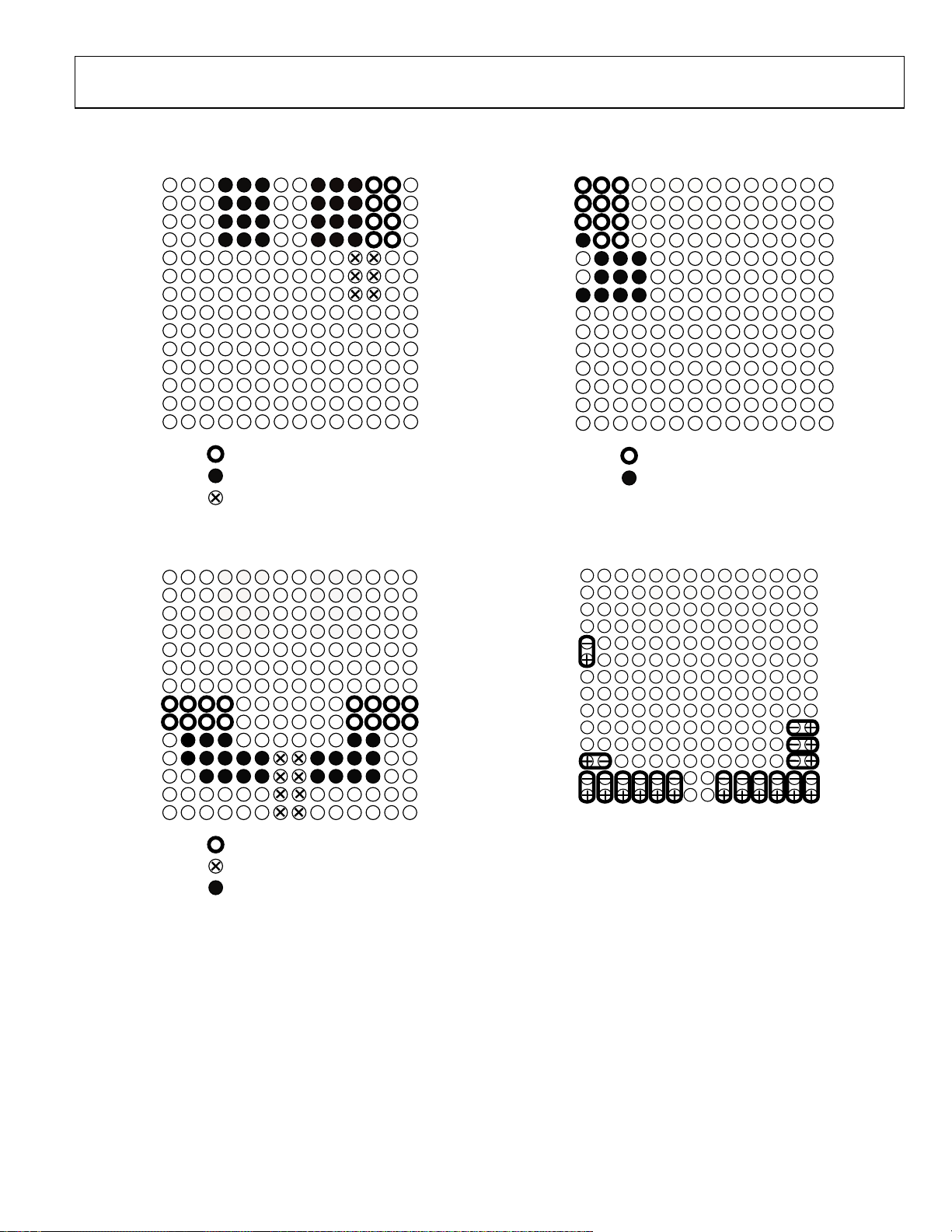

PIN CONFIGURATION

1234567891011121314

A

B

C

D

E

F

G

H

J

K

L

M

N

P

1 2 3 4 5 6 7 8 9 10 11 12 13 14

A

B

C

D

E

F

G

H

J

K

L

M

N

P

VDDA, 3.3V, Analog Supply

VSSA, Analog Supply Ground

VSSA, Analog Supply Ground Shield

Figure 2. AD9736 Analog Supply Pins ( TOP view)

1234567891011121314

A

B

C

D

E

F

G

H

J

K

L

M

N

P

VDD, 1.8V Digital Supply

VDD33, 3.3V Digital Supply

VSS Digital Supply Ground

Figure 4. AD9736 Digital Supply Pins ( TOP view)

VDDC, 1.8V, Clock Supply

VSSC, Clock Supply Ground

CLKN

LVDS0 (LSB)

Figure 3. AD9736 Clock Supply Pins ( TOP view)

1 2 3 4 5 6 7 8 9 10 11 12 13 14

A

B

C

D

E

F

CLKP

G

H

J

K

L

M

N

P

LVDS

LVDS1

LVDS3

LVDS4

LVDS5

LVDSCLKP,N OUT

DCLKP,N IN

LVDS6

LVDS7

LVDS8

LVDS9

LVDS10

LVDS13 (M

LVDS12

LVDS11

Figure 5. AD9736 Digital LVDS Inputs, Clock I/O (TOP view)

Rev. PrJ | Page 7 of 42

AD9736/AD9735/AD9734 Preliminary Technical Data

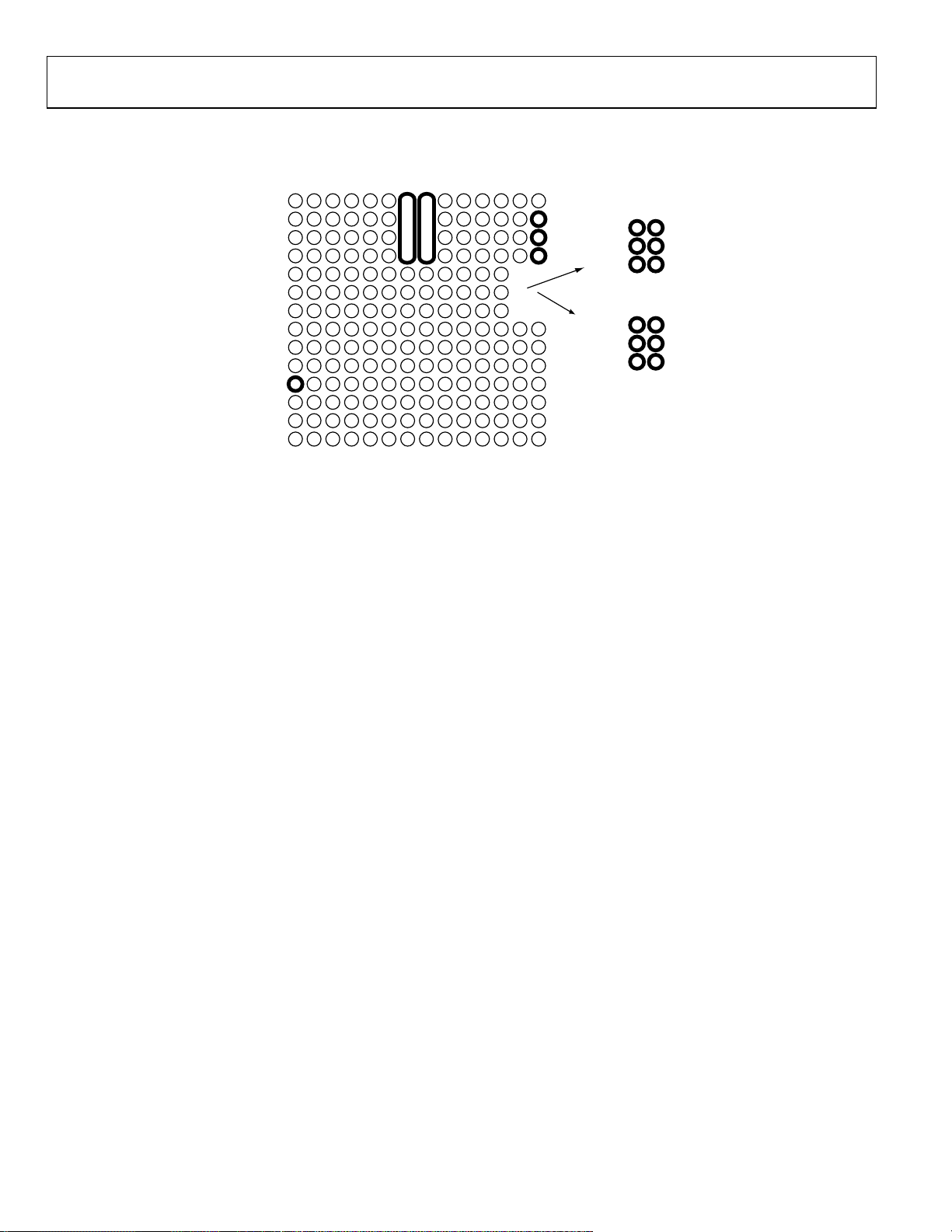

IOUTN

IOUTP

PIN_MODE=0,

I120

VREF

IPTAT

UNSIGNED

SPI ENABLED

IRQ

CSB

SCLK

PIN_MODE=1,

SPI DISABLED

2x

FSCO

RESET

SDIO

SDO

PD

FIFO

FSC1

PIN_MODE

1 2 3 4 5 6 7 8 9 1011121314

A

B

C

D

E

F

G

H

J

K

L

M

N

P

Figure 6. AD9736 Analog I/O and SPI Control Pins ( TOP view)

Rev. PrJ | Page 8 of 42

Preliminary Technical Data AD9736/AD9735/AD9734

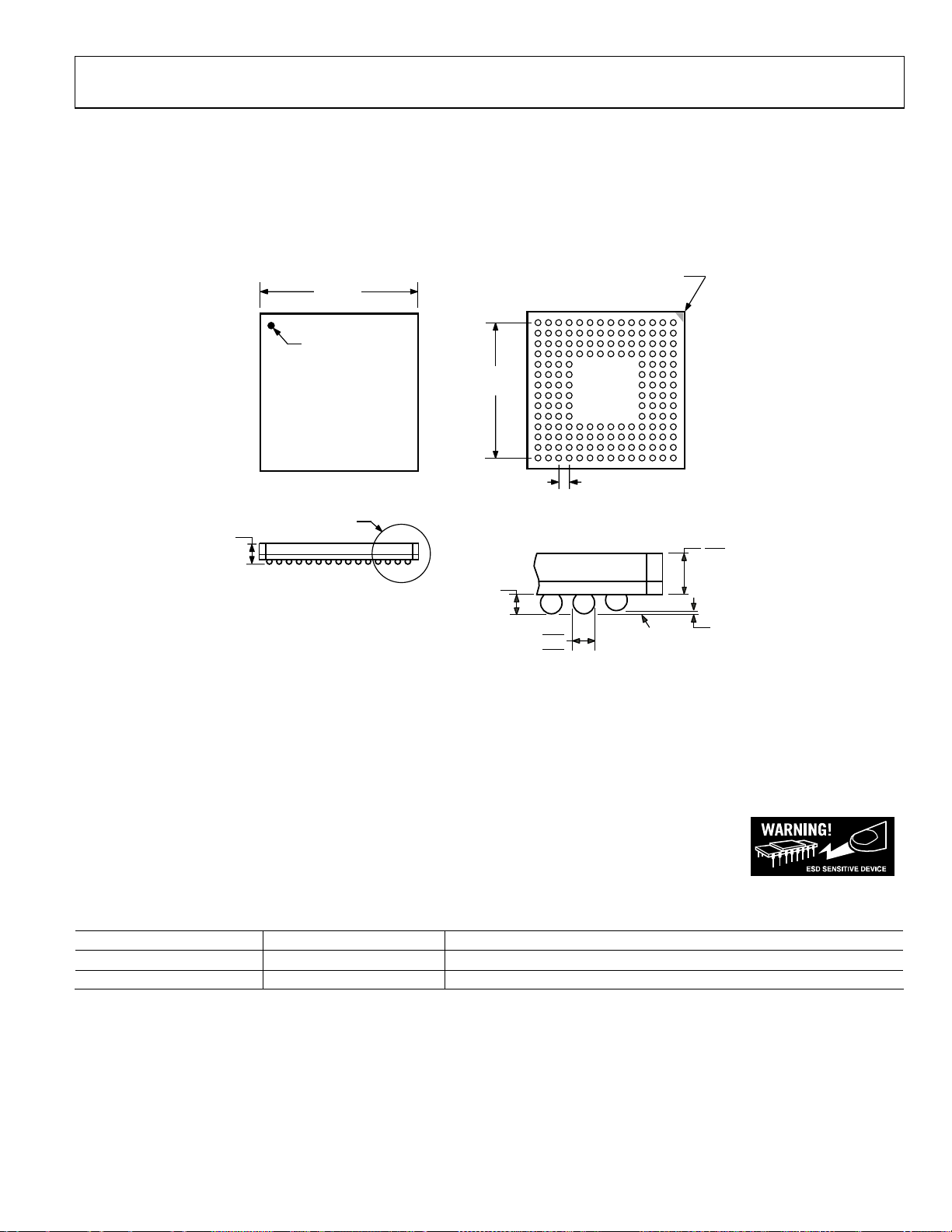

a

PACKAGE OUTLINE

160-Lead Chip Scale Ball Grid Array [CSPBGA]

(BC-160)

Dimensions shown in millimeters

A1 CORNER

INDEX AREA

95

BOTTOM

VIEW

0.80 BSC

DETAIL A

4

321

A

B

C

D

E

F

G

H

J

K

L

M

N

P

1.00

0.85

1.40 MAX

12.00

BSC SQ

BALL A1

INDICATOR

TOP VIEW

DETAIL A

10.40

BSC

1413121110 876

0.25 MIN

0.55

0.50

0.45

BALL DIAMETER

COMPLIANT WITH JEDEC STANDARDS MO-205-AE.

SEATING

PLANE

0.12 MAX

COPLANARITY

Figure 7. AD9736 BGA Package Outline Drawing

ESD CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily accumulate on the

human body and test equipment and can discharge without detection. Although this product features proprietary

ESD protection circuitry, permanent damage may occur on devices subjected to high energy electrostatic discharges.

Therefore, proper ESD precautions are recommended to avoid performance degradation or loss of functionality.

Ordering Guide

Model Temperature Range Description

AD9736BBC

-40°C to +85°C (Ambient)

AD9736-EB 25°C (Ambient) Evaluation Board

160-Lead Chip Scale BGA

Table 4: Ordering Guide

Rev. PrJ | Page 9 of 42

AD9736/AD9735/AD9734 Preliminary Technical Data

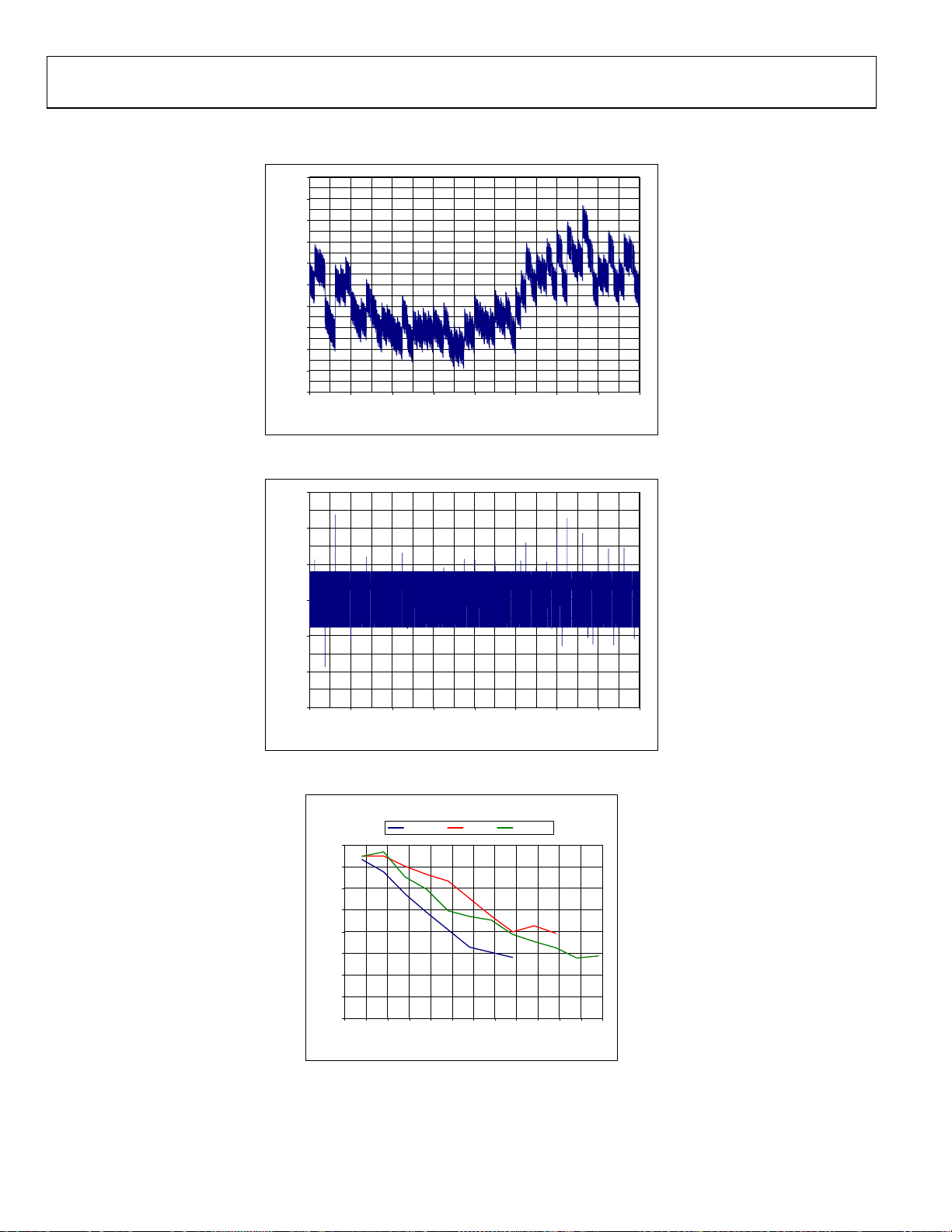

TYPICAL PERFORMANCE CHARACTERISTICS

1

0.8

0.6

0.4

0.2

0

Error - LSB

-0.2

-0.4

-0.6

-0.8

-1

0 2048 4096 6144 8192 10240 12288 14336 16384

Code

Figure 8. AD9736, Typical INL

0.5

0.3

0.1

-0.1

Error - LSB

-0.3

-0.5

-0.7

0 2048 4096 6144 8192 10240 12288 14336 16384

Code

Figure 9. AD9736, Typical DNL

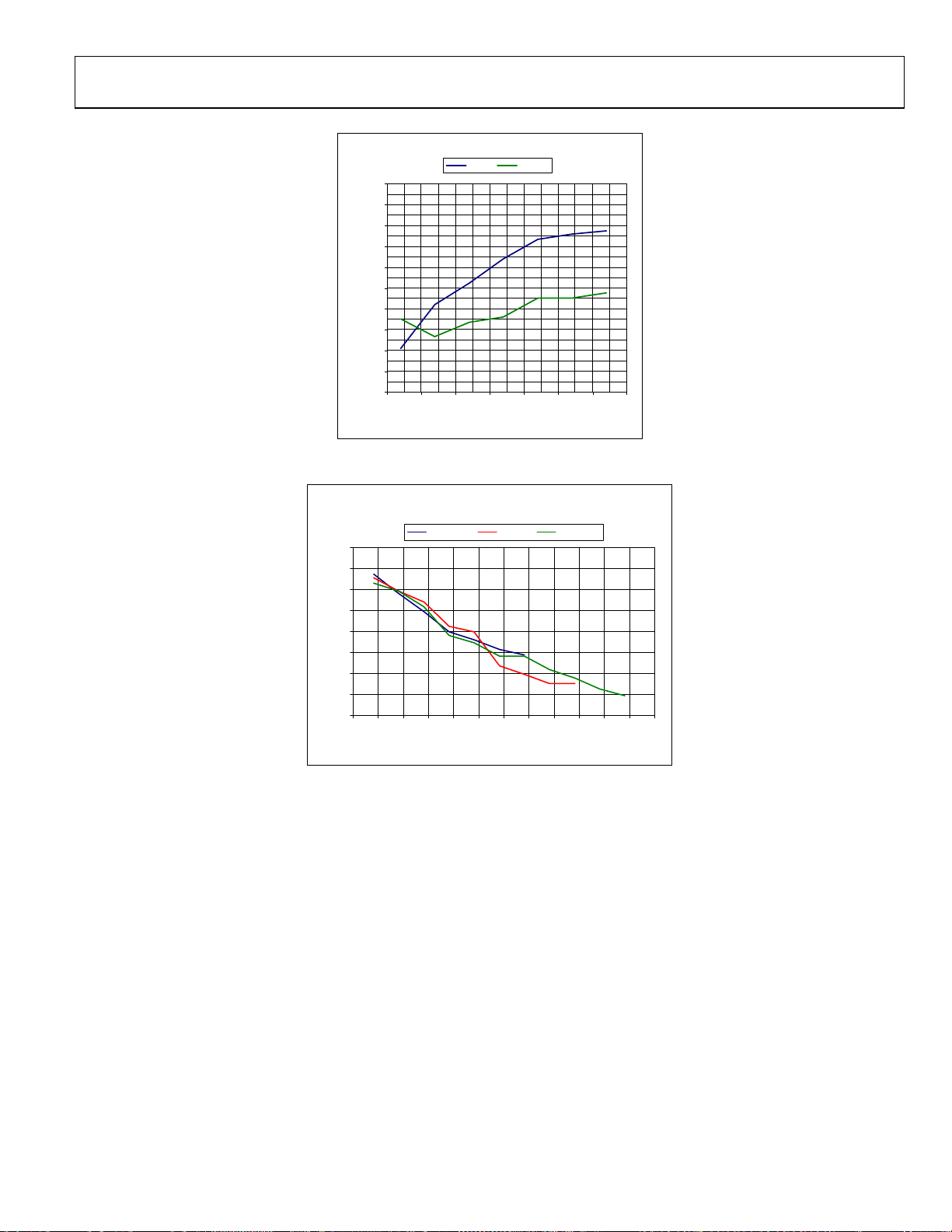

3rd Order IM D With Respect t o Fout ( 20 mA FS)

800MSPS 1GSPS 1.2GSPS

90

85

80

75

70

IMD - [dBc]

65

60

55

50

0 50 100 150 200 250 300 350 400 450 500 550 600

Fout - [ MHz ]

Figure 10. AD9736, 3rd Order IMD vs. Fout and Sample Rate

Rev. PrJ | Page 10 of 42

Preliminary Technical Data AD9736/AD9735/AD9734

NSD Comparison With 1-Tone and 8-Tones at 1.2GSPS

1 Tone 8 Tones

-150

-152

-154

-156

-158

-160

-162

NSD - dBm / Hz

-164

-166

-168

-170

0 100 200 300 400 500 600 700

Figure 11. AD9736, Noise Spectral Density (NSD) vs. Fout at 1.2GSPS

In- Band SFDR With Respect to Fout (2 0mA FS)

Fout - Mhz

90

85

80

75

70

65

SFDR - [dBc]

60

55

50

0 50 100 150 200 250 300 350 400 450 500 550 600

800MSPS 1GSPS 1.2GSPS

Fout - [MHz]

Figure 12. AD9736, In Band SFDR vs. Fout and Sample Rate

Rev. PrJ | Page 11 of 42

AD9736/AD9735/AD9734 Preliminary Technical Data

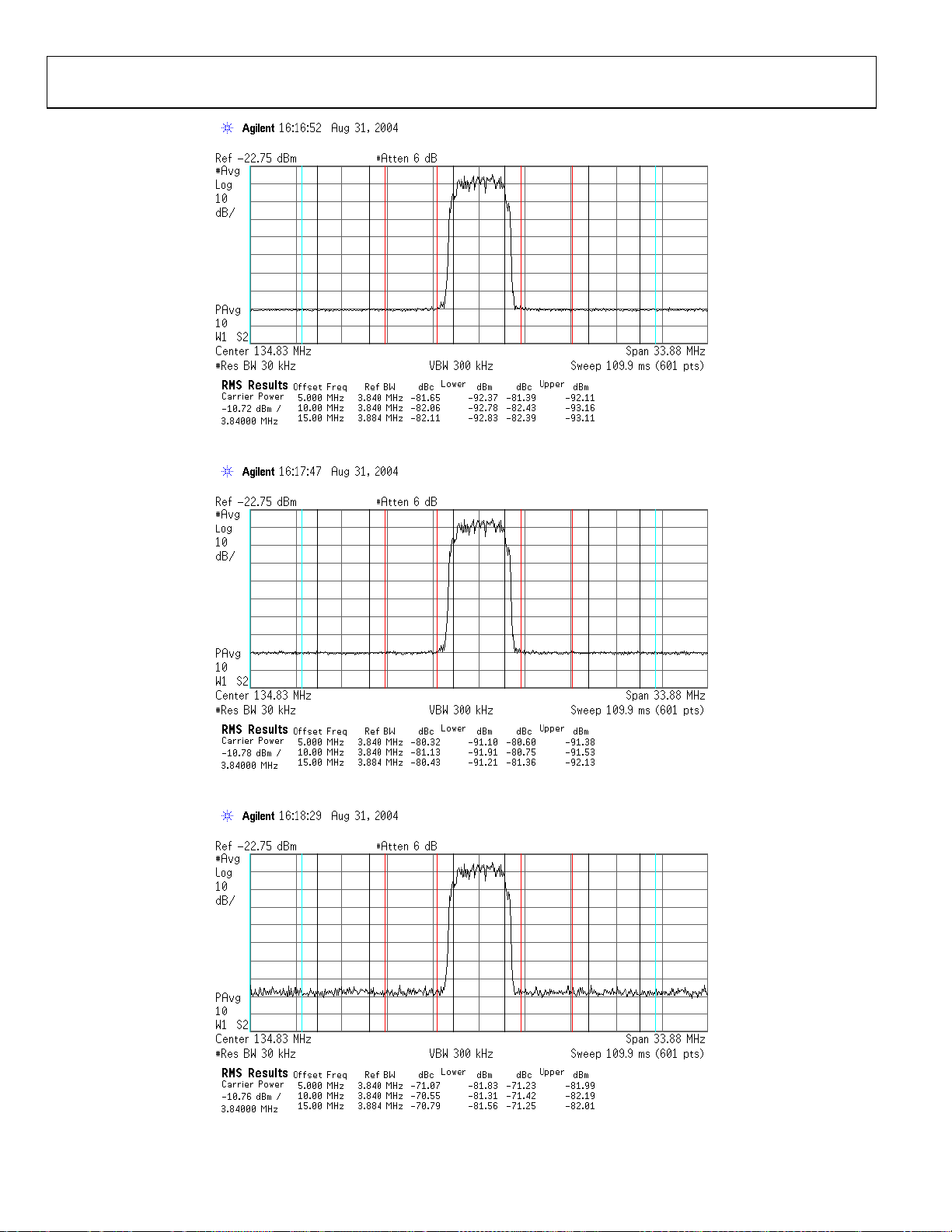

Figure 13. AD9736, WCDMA carrier at 134.83MHz, fdata=491.52MSPS

Figure 14. AD9735, WCDMA carrier at 134.83MHz, fdata=491.52MSPS

Figure 15. AD9734, WCDMA carrier at 134.83MHz, fdata=491.52MSPS

Rev. PrJ | Page 12 of 42

Preliminary Technical Data AD9736/AD9735/AD9734

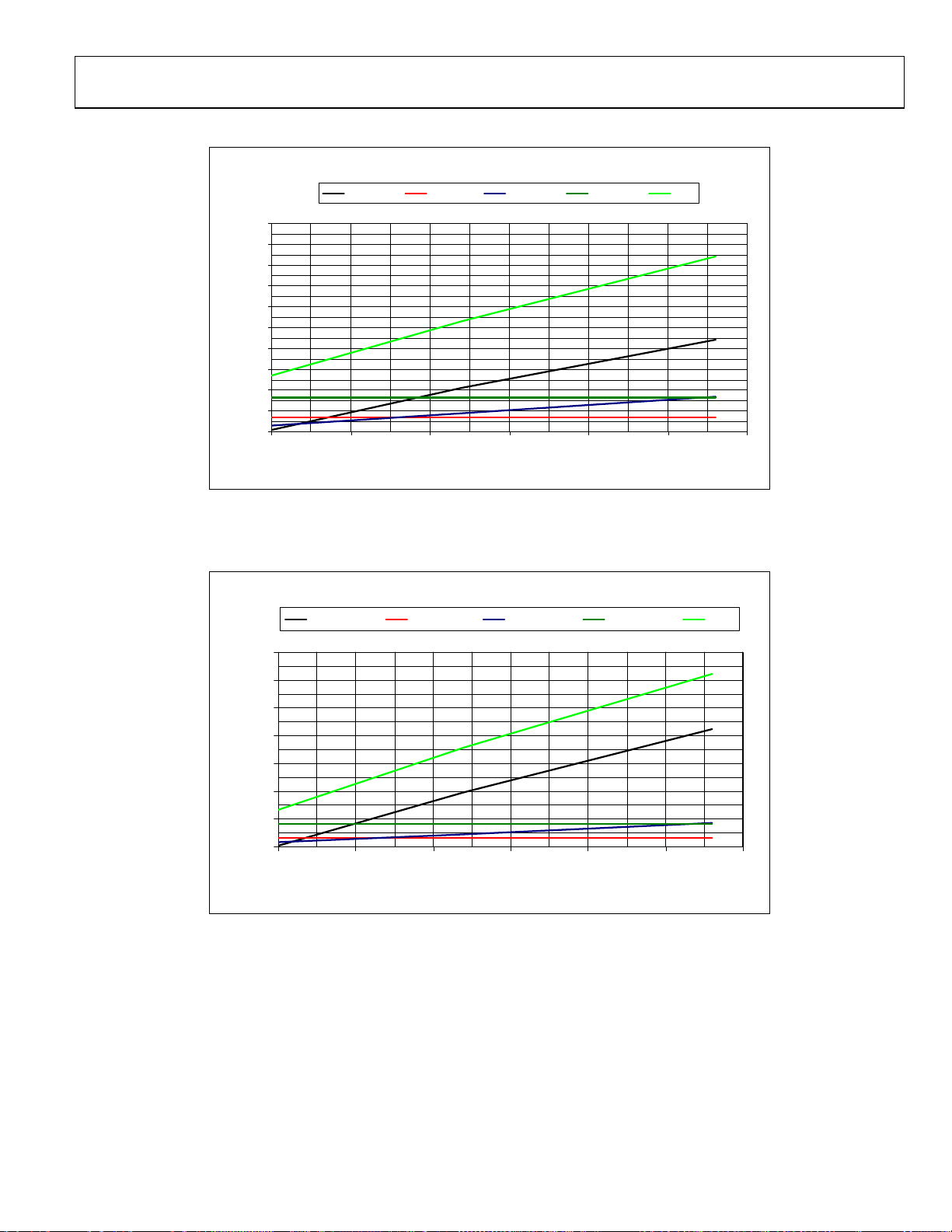

AD9736 Power Co nsu mpti o n 1x Mode Wi t h R espect to Clock Sp ee d

VDDD_1.8 VDDD_33 VDDA_1.8 VDDA_3.3 total

0.5

0.45

0.4

0.35

0.3

0.25

0.2

Power - W

0.15

0.1

0.05

0

0 250 500 750 1000 1250 1500

FCLK- MHz

Figure 16. AD9736 Power vs. Clock Frequency

AD9736 Power Co nsu mpti o n 2x Mode Wi t h R espect to Clock Sp ee d

VDDD_1.8 VDDD_33 VDDA_1.8 VDDA_3.3 total

0.7

0.6

0.5

0.4

0.3

Power - W

0.2

0.1

0

0 250 500 750 1000 1250 1500

FCLK- MHz

Figure 17. AD9736 Power vs. Clock Frequency in 2x Mode

Rev. PrJ | Page 13 of 42

AD9736/AD9735/AD9734 Preliminary Technical Data

SPI REGISTER MAP

ADR

ADR

DEC

HEX

0 00

1 01

2 02

3 03

4 04

5 05

6 06

7 07

8 08

9 09

10 0A

11 0B

Register

Name

MODE

IRQ

FSC_1

FSC_2

LVD S_ CN T1

LVD S_ CN T2

LVD S_ CN T3

SYNC_CNT1

SYNC_CNT2

RESERVED

RESERVED

RESERVED

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Default

SDIO_DIR LSBFIRST RESET LONG_INS 2X MODE FIFO MODE DATAFRMT PD 00 00

LVDS SYNC CROSS RESV’D IE_LVDS IE_SYNC IE_CROSS RESV’D 00 00

SLEEP FSC<9> FSC<8> 02 02

FSC<7> FSC<6> FSC<5> FSC<4> FSC<3> FSC<2> FSC<1> FSC<0> 00 00

MSD<3> MSD<2> MSD<1> MSD<0> MHD<3> MHD<2> MHD<1> MHD<0> 00 00

SD<3> SD<2> SD<1> SD<0> LCHANGE ERR_HI ERR_LO CHECK 00 00

LSURV LAUTO LFLT<3> LFLT<2> LFLT<1> LFLT<0> LTRH<1> LTRH<0> 00 00

FIFOSTAT3 FIFOSTAT2 FIFOSTAT1 FIFOSTAT0 VALID SCHANGE PHOF<1> PHOF<0> 00 00

SSURV SAUTO SFLT<3> SFLT<2> SFLT<1> SFLT<0> RESV’D STRH<0> 00 00

(HEX)

MODE

(HEX)

PIN

12 0C

13 0D

14 0E

15 0F

16 10

17 11

18 12

19 13

20 14

21 15

22 16

31 1F

RESERVED

RESERVED

ANA_CNT1

ANA_CNT2

RESERVED

BIST_CNT

BIST<7:0>

BIST<15:8>

BIST<23:16>

BIST<31:24>

CCLK _DIV

VERSION

MSEL<1> MSEL<0> TRMBG<2> TRMBG<1> TRMBG<0> C0 C0

HDRM<7> HDRM<6> HDRM<5> HDRM<4> HDRM<3> HDRM<2> HDRM<1> HDRM<0> CA CA

SEL<1> SEL<0> SIG_READ LVDS_EN SYNC_EN CLEAR 00 00

RESV’D RESV’D RESV’D RESV’D CCD<3> CCD<2> CCD<1> CCD<0> 00 00

VER<5> VER<4> VER<3> VER<2> VER<1> VER<0> RES10 RES12

Note: Write ‘0’ to unspecified or reserved bit locations. Reading these bits will return unknown values.

Tab le 5. SPI Re gi ste r M ap

Rev. PrJ | Page 14 of 42

Preliminary Technical Data AD9736/AD9735/AD9734

SPI REGISTER DESCRIPTIONS

REG 00 -> MODE

Reading REG 00 returns previously written values for all defined register bits unless otherwise noted. Reset value in bold text.

ADR Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0x00 MODE SDIO_DIR LSB/MSB RESET LONG_INS 2X MODE FIFO MODE DATAFRMT PD

SDIO_DIR : WRITE ->

LSBFIRST : WRITE ->

RESET : WRITE->

LONG_INS : WRITE ->

2X_MODE : WRITE ->

FIFO_MODE : WRITE ->

DATAFRMT : WRITE ->

PD : WRITE ->

REG 01 -> Interrupt Request (IRQ)

Reading REG 01 returns previously written values for all defined register bits unless otherwise noted. Reset value in bold text.

ADR Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0, Input only per SPI standard

1, Bidirectional per SPI standard

0, MSB first per SPI standard

1, LSB first per SPI standard

NOTE: Only change LSB/MSB order in single byte instructions to avoid erratic behavior due to bit order errors

0, Execute software reset of SPI and controllers, reload default register values EXCEPT registers 0x00 and 0x04

1, Set software reset prior to writing ‘0’ to execute the software reset

0, Short (single-byte) instruction word

1, Long (two-byte) instruction word, not necessary since the maximum internal address is REG31 (0x1F)

0, Disable 2x Interpolation Filter

1, Enable 2x Interpolation Filter

0, Disable FIFO synchronization

1, Enable FIFO synchronization

0, Signed input DATA with midscale = 0x0000

1, Unsigned input DATA with midscale = 0x2000

0, Enable LVDS Receiver, DAC and Clock Circuitry

1, Power down LVDS Receiver, DAC and Clock Circuitry

0x01 IRQ LVDS SYNC CROSS RESV’D IE_LVDS IE_SYNC IE_CROSS RESV’D

LVDS : WRITE -> Don’t Care

: READ ->

SYNC : WRITE -> Don’t Care

: READ ->

CROSS : WRITE -> Don’t Care

: READ ->

IE_LVDS : WRITE ->

IE_SYNC : WRITE ->

IE_CROSS : WRITE ->

0, No active LVDS receiver interrupt

1, Interrupt in LVDS receiver occurred

0, No active SYNC logic interrupt

1, Interrupt in SYNC logic occurred

0, No active CROSS logic interrupt

1, Interrupt in CROSS logic occurred

0, Reset LVDS receiver interrupt and disable future LVDS receiver interrupts

1, Enable LVDS receiver interrupt to activate IRQ pin

0, Reset SYNC logic interrupt and disable future SYNC logic interrupts

1, Enable SYNC logic interrupt to activate IRQ pin

0, Reset CROSS logic interrupt and disable future CROSS logic interrupts

1, Enable CROSS logic interrupt to activate IRQ pin

Rev. PrJ | Page 15 of 42

AD9736/AD9735/AD9734 Preliminary Technical Data

REG 02, 03 -> Full Scale Current (FSC)

Reading REG 02 & 03 return previously written values for all defined register bits unless otherwise noted. Reset value in bold text.

ADR Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0x02 FSC_1 SLEEP FSC<9> FSC<8>

0x03 FSC_2 FSC<7> FSC<6> FSC<5> FSC<4> FSC<3> FSC<2> FSC<1> FSC<0>

SLEEP : WRITE ->

FSC<9:0> : WRITE ->

REG 04, 05, 06 -> LVDS Controller (LVDS_CNT)

Reading REG 04, 05 & 06 return previously written values for all defined register bits unless otherwise noted. Reset value in bold text.

ADR Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0x04 LVDS_CNT1 MSD<3> MSD<2> MSD<1> MSD<0> MHD<3> MHD<2> MHD<1> MHD<0>

0x05 LVDS_CNT2 SD<3> SD<2> SD<1> SD<0> LCHANGE ERR_HI ERR_LO CHECK

0x06 LVDS_CNT3 LSURV LAUTO LFLT<3> LFLT<2> LFLT<1> LFLT<0> LTRH<1> LTRH<0>

MSD<3:0> : WRITE ->

: READ ->

MHD<3:0> : WRITE ->

: READ ->

0, Enable DAC output

1, Set DAC output current to 0mA

0x000, 10mA full scale output current

0x200, 20mA full scale output current NOTE: Iout = (72 + 192 * ( FSC<9:0> / 1024 ) ) * I120

0x3FF, 30mA full scale output current where I120 = Vref / R120u, for example 1.2V / 10k = 120uA

0x0, Set setup delay for the measurement system

If ( LAUTO == 1) the latest measured value for the setup delay

If ( LAUTO == 0) read back of the last SPI write to this bit

0x0, Set hold delay for the measurement system

If ( LAUTO == 1) the latest measured value for the hold delay

If ( LAUTO == 0) read back of the last SPI write to this bit

SD<3:0> : WRITE->

: READ ->

LCHA NGE : RE AD ->

ERR_HI : READ -> One of the 15 LVDS inputs is above the input voltage limits of the IEEE reduce link spec.

ERR_LO : READ -> One of the 15 LVDS inputs is below the input voltage limits of the IEEE reduced link spec.

CHECK : READ ->

LSURV : WRITE ->

LAUTO : WRITE ->

LFLT<3:0> : WRITE ->

0x0, Set sample delay

If ( LAUTO == 1) the result of a measurement cycle is stored in this register

If ( LAUTO == 0) read back of the last SPI write to this bit

0, No change from previous measurement

1, Change in value from the previous measurement

NOTE: The average filter and the threshold detection are not applied to this bit

0, Phase measurement – sampling in the previous or following DATA cycle

1, Phase measurement – sampling in the correct DATA cycle

0, The controller stops after completion of the current measurement cycle

1, Continuous measurements are taken and an interrupt is issued if the clock alignment drifts beyond the threshold value

0, Sample delay is not automatically updated

1, Continuously starts measurement cycles and updates the sample delay according to the measurement

NOTE: LSURV (REG06 Bit 7) must be set to 1 and the LVDS IRQ (REG01 Bit 3) must be set to 0 for AUTO mode

0x0, Average filter length, Delay = Delay + Delta Delay / 2^ LFLT<3:0>, values greater than 12 (0x0C) are clipped to 12

Rev. PrJ | Page 16 of 42

Preliminary Technical Data AD9736/AD9735/AD9734

LTRH<2:0> : : WRITE ->

REG 07, 08 -> SYNC Controller (SYNC_CNT)

Reading REG 07 & 08 return previously written values for all defined register bits unless otherwise noted. Reset value in bold text.

ADR Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0x07 SYNC_CNT1 FIFOSTAT3 FIFOSTAT2 FIFOSTAT1 FIFOSTAT0 VALID SCHANGE PHOF<1> PHOF<0>

0x08 SYNC_CNT2 SSURV SAUTO SFLT<3> SFLT<2> SFLT<1> SFLT<0> RESV’D STRH<0>

FIFOSTAT<2:0> : READ -> Position of FIFO read counter, range from 0 to 7

000, Set auto update threshold values

FIFOSTAT<3> : READ ->

VALID : READ ->

SCHANGE : READ ->

PHOF<1:0> : WRITE ->

: READ ->

SSURV : WRITE ->

SAUTO : WRITE ->

SFLT<3:0> : WRITE ->

STRH<0> : WRITE ->

REG 14, 15 -> Analog Control (ANA_CNT)

Reading REG 14 & 15 return previously written values for all defined register bits unless otherwise noted. Reset value in bold text.

0, SYNC logic OK

1, Error in SYNC logic

0, FIFOSTAT<3:0> is not valid yet

1, FIFOSTAT<3:0> is valid after a reset

0, No change in FIFOSTAT<3:0>

1, FIFOSTAT<3:0> has changed since the previous measurement cycle when SSURV = 1 (surveillance mode active)

00, Change the readout counter

Current setting of the readout counter (PHOF<1:0>) in surveillance mode (SSURV = 1) after an interrupt

Current calculated optimal readout counter value in AUTO mode (SAUTO = 1)

0, The controller stops after completion of the current measurement cycle

1, Continuous measurements are taken and an interrupt is issued if the readout counter drifts beyond the threshold value

0, Readout counter (PHOF<3:0>) is not automatically updated

1, Continuously starts measurement cycles and updates the readout counter according to the measurement

NOTE: SSURV (REG08 Bit 7) must be set to 1 and the SYNC IRQ (REG01 Bit 2) must be set to 0 for AUTO mode

0x0, Average filter length, FIFOSTAT = FIFOSTAT + Delta FIFOSTAT / 2 ^ SFLT<3:0>, values greater than 12 (0x0C) are clipped to 12

0, If FIFOSTAT<2:0> = 0 | 7, generate a SYNC interrupt

1, If FIFOSTAT<2:0> = 0 | 1 | 6 | 7, generate a SYNC interrupt

ADR Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0x0E ANA_CNT1 MSEL<1> MSEL<0> TRMBG<2> TRMBG<1> TRMBG<0>

0x0F ANA_CNT2 HDRM<7> HDRM<6> HDRM<5> HDRM<4> HDRM<3> HDRM<2> HDRM<1> HDRM<0>

00, Mirror roll off frequency control = bypass

MSEL<1:0> : WRITE ->

TRMBG<2:0> : WRITE ->

HDRM<7:0> : WRITE ->

01, Mirror roll off frequency control = narrowest bandwidth

10, Mirror roll off frequency control = medium bandwidth

11, Mirror roll off frequency control = widest bandwidth

NOTE: See plot in the applications section

000, Bandgap temperature characteristic trim

NOTE: See plot in the applications section

0xCA, Output stack headroom control

HDRM<7:4> set reference offset from Vdd3v (vcas centering)

HDRM<3:0> set overdrive (current density) trim (temperature tracking)

Note: Set to 0xCA for optimum performance

Rev. PrJ | Page 17 of 42

AD9736/AD9735/AD9734 Preliminary Technical Data

REG 17, 18, 19, 20, 21 -> Built-in Self Test Control (BIST_CNT)

Reading REG17, 18, 19, 20 & 21 return previously written values for all defined register bits unless otherwise noted. Reset value in bold text.

ADR Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0x11 BIST_CNT SEL<1> SEL<0> SIG_READ LVDS_EN SYNC_EN CLEAR

0x12 BIST<7:0> BIST<7> BIST<6> BIST<5> BIST<4> BIST<3> BIST<2> BIST<1> BIST<0>

0x13 BIST<15:8> BIST<15> BIST<14> BIST<13> BIST<12> BIST<11> BIST<10> BIST<9> BIST<8>

0x14 BIST<23:16> BIST<23> BIST<22> BIST<21> BIST<20> BIST<19> BIST<18> BIST<17> BIST<16>

0x15 BIST<31:24> BIST<31> BIST<30> BIST<29> BIST<28> BIST<27> BIST<26> BIST<25> BIST<24>

00, Write result of the LVDS Phase 1 BIST to BIST<31:0>

SEL<1:0> : WRITE ->

01, Write result of the LVDS Phase 2 BIST to BIST<31:0>

10, Write result of the SYNC Phase 1 BIST to BIST<31:0>

11, Write result of the SYNC Phase 2 BIST to BIST<31:0>

SIG_READ : WRITE ->

LVDS_ EN : WRI TE- >

SYNC_EN : WRITE ->

CLEAR : WRITE ->

BIST<31:0> : READ -> Results of the Built-in Self Test

REG 22 -> Controller Clock Pre-divider (CCLK_DIV)

Reading REG 22 returns previously written values for all defined register bits unless otherwise noted. Reset value in bold text.

ADR Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0x16 CCLK_DIV RESV’D RESV’D RESV’D RESV’D CCD<3> CCD<2> CCD<1> CCD<0>

CCD<3:0> : WRITE ->

0, No action

1, Enable BIST signature readback

0, No action

1, Enable LVDS BIST

0, No Action

1, Enable SYNC BIST

0, No Action

1, Clear all BIST registers

0x0, Controller Clock = DACCLK / 16

0x1, Controller Clock = DACCLK / 32

0x2, Controller Clock = DACCLK / 64 …

0xF, Controller Clock = DACCLK / 524288

NOTE: The 100MHz to 1.2GHz DACCLK must be divided to less than 10MHz for correct operation. CCD<3:0> must be programmed to

divide the DACCLK so that this relationship is not violated. Controller Clock = DACCLK / ( 2 ^ ( CCD<3:0> + 4 ))

REG 31 -> VERSION

Reading REG 31 returns previously written values for all defined register bits unless otherwise noted. Reset value in bold text.

ADR Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0x1F VERSION VER<5> VER<4> VER<3> VER<2> VER<1> VER<0> RES10 RES12

VER<5:0> : READ -> Version number (part ID), 00001, Revision 1, initial release

RES10 (msb)

RES12 (lsb)

: READ ->

00, 14-bit DAC

01, 12-bit DAC

10, 10-bit DAC

Rev. PrJ | Page 18 of 42

Preliminary Technical Data AD9736/AD9735/AD9734

GENERAL DESCRIPTION

Serial Peripheral Interface

The AD9736/35/34 are 14/12/10-bit DACs which run at an update

rate up to 1.2GSPS. Input data can be accepted up to the full

1.2GSPS rate or a 2x interpolation filter may be enabled (2x mode)

allowing full-speed operation with a 600MSPS input data rate.

DATA and DATACLK_IN inputs are parallel LVDS meeting the

IEEE reduced swing LVDS specifications with the exception of

input hysteresis. The DATACLK_IN input runs at one half the

input DATA rate in a double data rate (DDR) format. Each edge of

DATACLK_IN is used to transfer DATA into the AD9736 as shown

in Figure 25.

The DACCLK (pins E1, F1) directly drives the DAC core to

minimize clock jitter. It is also divided by two (1x and 2x mode)

then output as the DATACLK_OUT. The DATACLK_OUT signal

is used to clock the data source. The DAC expects DDR LVDS data

(DB<13:0>) aligned with the DDR input clock (DATACLK_IN)

from a circuit similar to the one shown in Figure 35. Clock

relationships are shown in Table 6.

MODE DACCLK

1x 1.2GHz 600MHz 600MHz 1.2GSPS

2x 1.2GHz 600MHz 300MHz 600MSPS

Maintaining correct alignment of data and clock is a common

challenge with high-speed DACs, complicated by changes in

temperature and other operating conditions. The AD9736

simplifies this high-speed data capture problem with two adaptive

closed-loop timing controllers.

One timing controller manages the LVDS data and data clock

alignment (LVDS controller) and the other manages the LVDS data

and DACCLK alignment (SYNC controller). The LVDS controller

locates the data transitions and delays the DATACLK_IN so that its

transition is in the center of the valid data window. The SYNC

controller manages the FIFO that moves data from the LVDS

DATACLK_IN domain to the DACCLK domain. Both controllers

can be operated in manual mode under external processor control,

surveillance mode where error conditions generate external

interrupts or automatic mode where errors are automatically

corrected.

The LVDS and SYNC controllers include moving average filtering

for noise immunity and variable thresholds to control their activity.

Normally the controllers can be set to run in automatic mode and

they will make any necessary adjustments without dropping or

duplicating samples sent to the DAC. Both controllers require

initial calibration prior to entering automatic update mode.

DATACLK

OUT

Table 6. AD9736 Clock Relationships

DATACLK

IN

DATA

The AD9736 serial port is a flexible, synchronous serial

communications port allowing easy interface to many industrystandard microcontrollers and microprocessors. The serial I/O is

compatible with most synchronous transfer formats, including both

the Motorola SPI® and Intel® SSR protocols. The interface allows

read/write access to all registers that configure the AD9736. Single

or multiple byte transfers are supported, as well as MSB first or LSB

first transfer formats. The AD9736’s serial interface port can be

configured as a single pin I/O (SDIO) or two unidirectional pins for

in/out (SDIO/SDO).

SDO (Pin G14)

SDIO (Pin F14)

SCLK (Pin G13)

CSB (Pin F13)

Figure 18. AD9736 SPI Port

The AD9736 may optionally be configured via external pins rather

than the serial interface. When the PIN_MODE input (pin L1) is

high the serial interface is disabled and its pins are reassigned for

direct control of the DAC. Specific functionality is described in the

PIN Mode section.

AD9736

SPI Port

GENERAL OPERATION OF THE SERIAL INTERFACE

There are two phases to a communication cycle with the AD9736.

Phase 1 is the instruction cycle, which is the writing of an

instruction byte into the AD9736, coincident with the first eight

SCLK rising edges. The instruction byte provides the AD9736 serial

port controller with information regarding the data transfer cycle,

which is Phase 2 of the communication cycle. The Phase 1

instruction byte defines whether the upcoming data transfer is read

or write, the number of bytes in the data transfer, and the starting

register address for the first byte of the data transfer. The first eight

SCLK rising edges of each communication cycle are used to write

the instruction byte into the AD9736.

The remaining SCLK edges are for Phase 2 of the communication

cycle. Phase 2 is the actual data transfer between the AD9736 and

the system controller. Phase 2 of the communication cycle is a

transfer of 1, 2, 3, or 4 data bytes as determined by the instruction

byte. Using one multibyte transfer is the preferred method. Single

byte data transfers are useful to reduce CPU overhead when

register access requires one byte only. Registers change immediately

upon writing to the last bit of each transfer byte.

Control of the AD9736 functions is via the serially programmed

registers listed in Table 5.

CSB can be raised after each sequence of 8 bits (except the last byte)

to stall the bus. The serial transfer will resume when CSB is

lowered. Stalling on non-byte boundaries will reset the SPI.

Rev. PrJ | Page 19 of 42

AD9736/AD9735/AD9734 Preliminary Technical Data

SHORT INSTRUCTION MODE (8-BIT INSTRUCTION)

should stay low during the entire communication cycle.

The short instruction byte is shown in Table 7.

MSB LSB

I7 I6 I5 I4 I3 I2 I1 I0

R/W N1 N0 A4 A3 A2 A1 A0

Table 7. SPI Instruction Byte

R/W, Bit 7 of the instruction byte, determines whether a read or a

write data transfer will occur after the instruction byte write. Logic

high indicates read operation. Logic 0 indicates a write operation.

N1, N0, Bits 6 and 5 of the instruction byte, determine the number

of bytes to be transferred during the data transfer cycle. The bit

decodes are shown in Table 8.

A4, A3, A2, A1, A0, Bits 4, 3, 2, 1, 0 of the instruction byte,

determine which register is accessed during the data transfer

portion of the communications cycle. For multibyte transfers, this

address is the starting byte address. The remaining register

addresses are generated by the AD9736 based on the LSBFIRST bit

(REG00, bit 6).

N1 N2 Description

0 0 Transfer 1 Byte

0 1 Transfer 2 Bytes

1 0 Transfer 3 Bytes

1 1 Transfer 4 Bytes

Table 8. Byte Transfer Count

LONG INSTRUCTION MODE (16-BIT INSTRUCTION)

The long instruction bytes are shown in Table 7.

MSB LSB

I15 I14 I13 I12 I11 I10 I9 I8

R/W N1 N0 A12 A11 A10 A9 A8

I7 I6 I5 I4 I3 I2 I1 I0

A7 A6 A5 A4 A3 A2 A1 A0

Table 9. SPI Instruction Byte

If LONG_INS = 1 (REG00, bit 4) the instruction byte is extended to

two bytes where the second byte provides an additional 8 bits of

address information. Addresses 0x00 – 0x1F are equivalent in short

and long instruction modes. The AD9736 does not use any

addresses greater than 31 (0x1F) so always set LONG_INS = 0.

SERIAL INTERFACE PORT PIN DESCRIPTIONS

SCLK—Serial Clock. The serial clock pin is used to synchronize

data to and from the AD9736 and to run the internal state

machines. SCLK’s maximum frequency is 20 MHz. All data input

to the AD9736 is registered on the rising edge of SCLK. All data is

driven out of the AD9736 on the rising edge of SCLK.

CSB—Chip Select. Active low input starts and gates a

communication cycle. It allows more than one device to be used on

the same serial communications lines. The SDO and SDIO pins will

go to a high impedance state when this input is high. Chip select

SDIO—Serial Data I/O. Data is always written into the AD9736 on

this pin. However, this pin can be used as a bidirectional data line.

The configuration of this pin is controlled by SDIO_DIR at REG00,

bit 7. The default is Logic 0, which configures the SDIO pin as

unidirectional.

SDO—Serial Data Out. Data is read from this pin for protocols

that use separate lines for transmitting and receiving data. In the

case where the AD9736 operates in a single bidirectional I/O mode,

this pin does not output data and is set to a high impedance stat

e.

MSB/LSB TRANSFERS

The AD9736 serial port can support both most significant bit

(MSB) first or least significant bit (LSB) first data formats. This

functionality is controlled by LSBFIRST at REG00, bit 6. The

default is MSB first (LSBFIRST = 0).

When LSBFIRST = 0 (MSB first) the instruction and data bytes

must be written from most significant bit to least significant bit.

Multibyte data transfers in MSB first format start with an

instruction byte that includes the register address of the most

significant data byte. Subsequent data bytes should follow in order

from high address to low address. In MSB first mode, the serial

port internal byte address generator decrements for each data byte

of the multibyte communication cycle.

When LSBFIRST = 1 (LSB first) the instruction and data bytes

must be written from least significant bit to most significant bit.

Multibyte data transfers in LSB first format start with an

instruction byte that includes the register address of the least

significant data byte followed by multiple data bytes. The serial port

internal byte address generator increments for each byte of the

multibyte communication cycle.

The AD9736 serial port controller data address will decrement

from the data address written toward 0x00 for multibyte I/O

operations if the MSB first mode is active. The serial port controller

address will increment from the data address written toward 0x1F

for multibyte I/O operations if the LSB first mode is active.

NOTES ON SERIAL PORT OPERATION

The AD9736 serial port configuration is controlled by REG00, bits

4, 5, 6 and 7. It is important to note that the configuration changes

immediately upon writing to the last bit of the register. For

multibyte transfers, writing to this register may occur during the

middle of communication cycle. Care must be taken to compensate

for this new configuration for the remaining bytes of the current

communication cycle. The same considerations apply to setting the

software reset, RESET (REG00, bit 5). All registers are set to their

default values EXCEPT REG00 and REG04 which remain

unchanged.

Use of only single byte transfers when changing serial port

Rev. PrJ | Page 20 of 42

Preliminary Technical Data AD9736/AD9735/AD9734

configurations or initiating a software reset is highly

recommended. In the event of unexpected programming sequences

the AD9736 SPI may become inaccessible. For example, if user

code inadvertently changes the LONG_INS bit or LSBFIRST bit the

following bits may have unexpected results. The SPI can be

returned to a known state by writing an incomplete byte (1-7 bits)

of all zeroes followed by three bytes of 0x00. This will return to

MSB first short instructions (REG00 = 0x00) so the device may be

reinitialized.

INSTRUCTION CYCLE DATA TRANSFER CYCLE

CSB

SCLK

SDIO

SDO

CSB

SCLK

SDIO

SDO

CSB

SCLK

SDIO

CSB

R/WN0N1A0A1 A2A3A4D7D6ND5

D7 D6ND5

N

N

Figure 19. Serial Register Interface Timing MSB First

INSTRUCTION CYCLE DATA TRANSFER CYCLE

A0 A1 A2 A3 A4 N1 N0 R/W D0D10D2

D0D10D2

0

0

Figure 20. Serial Register Interface Timing LSB First

t

DS

t

DS

t

PWH

t

t

SCLK

t

PWL

DH

INSTRUCTION BIT 6INSTRUCTION BIT 7

Figure 21. Timing Diagram for SPI Register Write

D00D10D20D3

0

D00D10D20D3

0

D7ND6ND5ND4

N

D7ND6ND5ND4

N

03152-PrD-006

PIN MODE OPERATION

When the PIN_MODE input (pin L1) is set high, the SPI port is

disabled. The SPI port pins are remapped as shown in Table 10. The

function of these pins is described in Table 11. The remaining

PIN_MODE register settings are shown in Table 5, the SPI register

map.

Pin Number PIN_MODE = 0 PIN_MODE = 1

E13 IRQ UNSIGNED

F13 CSB 2X

G13 SCLK FSC0

E14 RESET PD

F14 SDIO FIFO

G14 SDO FSC1

Table 10. SPI_MODE vs. PIN_MODE Inputs

Pin Function

UNSIGNED

2X

0, Two’s complement input data format

1, Unsigned input data format

0, Interpolation disabled

1, Interpolation = 2x enabled

00, Sleep mode

FSC1, FSC0

01, 10mA full scale output current

10, 20mA full scale output current

11, 30mA full scale output current

PD

FIFO

0, Chip enabled

1, Chip in power down state

0, Input FIFO disabled

1, Input FIFO enabled

Table 11. PIN_MODE Input Functions

Care must be taken when using PIN_MODE since only the control

bits shown in Table 11 can be changed. If the remaining register

default values are not suitable for the desired operation

PIN_MODE cannot be used.

SCLK

t

DNV

I1 I0 D7 D6 D5

SDIO

t

DV

Figure 22. Timing Diagram for SPI Register Read

After the last instruction bit is written to the SDIO pin the driving

signal must be set to a high impedance in time for the bus to turn

around. The serial output data from the AD9736 will be enabled by

the falling edge of SCLK. This causes the first output data bit to be

shorter than the remaining data bits as shown in Figure 22.

Rev. PrJ | Page 21 of 42

AD9736/AD9735/AD9734 Preliminary Technical Data

AD9736 DATA INTERFACE CONTROLLERS

There are 2 internal controllers that can be utilized in the operation

of the AD9736. The first controller helps maintain optimum LVDS

data sampling and the second controller helps maintain optimum

synchronization between the DACCLK and the incoming data. The

LVDS controller is responsible for optimizing the sampling of the

data from the LVDS bus (DB13:0) while the SYNC controller

resolves timing problems between the DAC_CLK (CLK+, CLK-)

and the DATACLK. A block diagram of these controllers is shown

in Figure 23.

The controllers are clocked with a divided down version of the

DAC_CLK. The divide ratio is set utilizing the controller clock

predivider bits (CCD<3:0>) located at REG22 bits 3:0 to generate

the controller clock as follows:

Controller Clock = DAC_CLK / ( 2 ^ ( CCD<3 :0> + 4 ))

NOTE: The controller clock may not exceed 10MHz for correct

operation. Until CCD<3:0> has been properly programmed to

meet this requirement the DAC output may not be stable.

The LVDS and SYNC controllers can be independently operated in

3 different modes via SPI port REG06 and REG08.

1. Manual Mode

2. Surveillance Mode

3. Auto Mode

In manual mode all of the timing measurements and updates are

externally controlled via the SPI.

In surveillance mode each controller takes measurements and

calculates a new “optimal” value continuously. The result of the

measurement can be passed through an averaging filter before

evaluating the results for increased noise immunity. The filtered

result is compared to a threshold value set via REG06 and REG08

of the SPI port. If the error is greater then the threshold, an

interrupt is triggered and the controller stops. REG01 of the SPI

port controls the interrupts with bits 3 and 2 enabling the

respective interrupts and bits 7 and 6 indicating the respective

controller’s interrupt. If an interrupt is enabled it will also activate

the AD9736’s IRQ pin. In order to clear an interrupt the interrupt

enable bit of the respective controller must be set to a zero for at

least one controller clock cycle (controller clock < 10MHz).

Auto mode is almost identical to surveillance mode. Instead of

triggering an interrupt and stopping the controller, the controller

automatically updates its settings to the newly calculated “optimal”

value and continues to run.

DACCLK

DACCLK

DATACLK_OUT

DATACLK_OUT

CLK Control

CLK Control

LVDS

LVDS

Data Source

Data Source

i.e. FPGA

i.e. FPGA

DATACLK_IN

DATACLK_IN

DB<13:0>

DB<13:0>

Figure 23.AD9736 Internal Synchronization Engine

Controller

Controller

LVDS

LVDS

SAMPLE

SAMPLE

LOGIC

LOGIC

SYNC

SYNC

Controller

Controller

SYNC

SYNC

LOGIC

LOGIC

FIFO

FIFO

DAC

DAC

Rev. PrJ | Page 22 of 42

Preliminary Technical Data AD9736/AD9735/AD9734

K

AD9736 LVDS Sample Logic

SAMPLING SIGNAL (CSS) is controlled by MHD3:0 (REG04, bits

3:0).

A simplified diagram of the AD9736 LVDS data sampling engine is

shown in Figure 24, with the timing relationships shown in Figure

25.

The incoming LVDS data is latched by the DATA SAMPLING

SIGNAL (DSS) which is derived from DATACLK_IN. The LVDS

controller delays DATACLK_IN to create the DATA SAMPLING

SIGNAL (DSS) which is adjusted to sample the LVDS data in the

center of the valid data window. The skew between the

DATACLK_IN and the LVDS data bits (DB<13:0>) must be

minimal (t1 and t2 in Figure 25) for proper operation. Therefore, it

is recommended that the DATACLK_IN be generated in the same

manner as the LVDS data bits (DB<13:0>) with the same driver and

data lines (i.e. it should just be another LVDS data bit running a

constant 01010101… sequence, as shown in Figure 35).

DB<13:0>

DATA SAMPLING

DATACLK

IN

Figure 24. AD9736 Internal LVDS Data Sampling Logic

LVD S

RX

SIGNAL

SD<3:0>

Sample Delay

LVD S

RX

MSD<3:0>

Delay

MHD<3:0>

Delay

FF

FF

DELAYED

CLOCK

SIGNAL

FF

D1

D2

CHEC

CLOCK

SAMPLING

SIGNAL

LVDS SAMPLE LOGIC CALIBRATION

DATACLK_IN transitions must be time aligned with the LVDS

data (DB<13:0>) transitions. This allows the CLOCK SAMPLING

SIGNAL (CSS, derived from the DATACLK_IN), to find the valid

data window of DB<13:0> by locating the DATACLK_IN edges.

The latching (rising) edge of CSS is initially placed using bits

SD<3:0> and can then be shifted to the left using MSD<3:0> and to

the right using MHD<3:0>. When CSS samples the DELAYED

CLOCK SIGNAL (DCS) and the result is a 1, (which can be read

back via the CHECK bit at REG05, bit 0) then the sampling is

occurring in the correct data cycle. In order to find the leading

edge of the data cycle, increment MSD (Measured Set-up Delay)

until CHECK goes low. In order to find the trailing edge, increment

MHD (Measured Hold Delay) until CHECK goes low. Always set

MHD = 0 when incrementing MSD and vice-versa.

Note: The incremental units of SD, MSD, and MHD are in units of

real time, not fractions of a clock cycle. At this time, the delay from

each increment of these bits has not been fully characterized. Over

process, voltage, and temperature, each increment may introduce

between 25 and 100ps of delay with a nominal target of 80ps.

OPERATING THE LVDS CONTROLLER IN MANUAL

MODE VIA THE SPI PORT

The manual operation of the LVDS controller allows the user to

step through both the set-up and hold delays to calculate the

optimal sampling delay (i.e. center of the data eye).

With SD<3:0> and MHD<3:0> set to zero, increment the set-up

time delay (MSD<3:0>, REG04, bits 7:4) until the check bit

(REG05, bit 0) goes low and record this value. This locates the

leading DATACLK_IN (and DATA) transition as shown in Figure

26.

With SD<3:0> and MSD<3:0> set to zero, increment the hold time

delay (MHD<3:0>, REG04, bits 3:0) until the check bit (REG05 bit

0) goes low and record this value. This locates the trailing

DATACLK_IN (and DATA) transition as shown in Figure 27.

The internal DATA SAMPLING SIGNAL delay must be calibrated

to optimize the data sample timing. Once calibrated, the AD9736

can generate an IRQ or automatically correct its timing if

temperature or voltage variations change the timing too much. This

calibration is done by using the delayed CLOCK SAMPLING

SIGNAL (CSS) to sample the DELAYED CLOCK SIGNAL (DCS).

The LVDS sampling logic can find the edges of the DATACLK_IN

signal and from this measurement the center of the valid data

window can be located.

The internal delay line which derives the delayed DATA

SAMPLING SIGNAL (DSS) from DATACLK_IN is controlled by

SD3:0 (REG05, bits 7:4) while the DELAYED CLOCK SIGNAL

(DCS) is controlled by MSD3:0 (REG04, bits 7:4) and the CLOCK

Rev. PrJ | Page 23 of 42

Once both DATACLK_IN edges are located the Sample Delay

(SD<3:0>, REG05, bits 7:4) must be updated according to the

following equation:

Sample Delay = ( MHD – MSD ) / 2

After updating SD<3:0>, verify that the sampling signal is in the

middle of the valid data window by adjusting both MHD then

MSD with the new sample delay until the CHECK bit goes low. The

new MHD and MSD values should be equal or within one unit

delay if SD<3:0> was set correctly.

NOTE: The Sample Delay calibration just described should be

performed prior to enabling Surveillance mode or Auto mode.

AD9736/AD9735/AD9734 Preliminary Technical Data

SAMPLE

DELAY

PROP DELAY

TO LATCH

PROP DELAY

TO LATCH

Figure 25. AD9736 Internal LVDS Data Sampling Logic Timing

set up time (ts)

MSD<3:0> = 0 1 2 3 4 5

hold time (th)

Sample Delay , SD<3:0>

t1

CSS Samples DCS

t2

DB13:0

DATACLK_IN

DATA SAMPLING

SIGNAL

D1

D2

DB<13:0>

DATACLK_IN

CSS with

MHD<3:0> = 0

DCS, delayed

by MSD<3:0>

CHECK = 1 1 1 1 1 0

CHECK = 1

Figure 26. Set-Up Delay Measurement

set up time (ts)

MHD<3:0> = 0 1 2 3 4 5

CHECK = 1 1 1 1 1 0

hold time (th)

Sample Delay, SD<3:0>

CHECK = 1

CSS Samples DCS

DB<13:0>

DATACLK_IN

CSS, delayed

by MHD<3:0>

DCS with

MSD<3:0> = 0

Figure 27. Hold Delay Measurement

Rev. PrJ | Page 24 of 42

Preliminary Technical Data AD9736/AD9735/AD9734

OPERATING THE LVDS CONTROLLER IN SURVEILLANCE AND AUTO MODE

In surveillance mode, the controller searches for the edges of the

data eye in the same manner as above in the manual mode of

operation and triggers an interrupt if the CLOCK SAMPLING

SIGNAL (CSS) has moved more than the threshold value set by

LTHR<1:0> (REG06, bits 1:0).

There is an internal filter which averages the set-up and hold time

measurements to filter out noise and glitches on the clock lines.

between the DACCLK and the DATACLK_IN clock domains. The

SYNC Controller writes data from DB<13:0> into an eight word

memory based on a cyclic write counter clocked by the CLOCK

SAMPLING SIGNAL (CSS) which is a delayed version of

DACCLK_IN. The data is read out of the memory based on a

second cyclic read counter clocked by DACCLK. The eight word

deep FIFO shown in Figure 28 provides sufficient margin to

maintain proper timing under most conditions. The SYNC logic is

designed to prevent the read and write pointers from crossing. If

the timing drifts far enough to require an update of the phase offset

(PHOF<1:0>) two samples will be duplicated or dropped. Figure 29

shows the timing diagram for the SYNC logic.

Average Value = ( MHD – MSD ) / 2

New Average = Average Value + ( Delta Average / 2 ^ LFLT<3:0> )

If an accumulating error in the Average Value causes it to exceed

the Threshold value (LTHR<1:0>) an interrupt will be issued.

The maximum allowable value for LFLT<3:0> is 12.

In surveillance mode, the ideal sampling point should first be

found using manual mode and applied to the sample delay

registers. The user should then set the threshold and filter values

depending on how far the CSS signal is allowed to drift before an

interrupt occurs. Then set the surveillance bit high (REG06, bit 7)

and monitor the interrupt signal either via the SPI port read back

(REG01, bit 3) or the IRQ pin.

In auto mode, the same steps should be taken to set up the sample

delay, threshold and filter length. In order to run the controller in

auto mode both the LAUTO (REG06, bit 6) and LSURV (REG06,

bit 7) bits need to be set to 1. In AUTO mode the LVDS interrupt

should be set low (REG01, bit 7) to allow the Sample Delay to be

automatically updated if the threshold value is exceeded.

AD9736 SYNC Logic and Controller

A FIFO structure is utilized to synchronize the data transfer

SYNC LOGIC AND CONTROLLER OPERATION

The relationship between the readout pointer and the write pointer

will initially be unknown since the startup relationship between

DACCLK and DATACLK_IN is unknown. The SYNC logic

measures the relative phase between the two counters with the zero

detect block and the Flip Flop in Figure 5 above. The relative phase

is returned in FIFOSTAT<2:0> (REG07, bits 6:4) and SYNC logic

errors are indicated by FIFOSTAT<3> (REG07, bit 7). If

FIFOSTAT<2:0> returns a value of zero or seven it signifies that the

memory is sampling in a critical state (read and write pointers are

close to crossing). If the FIFOSTAT<2:0> returns a value of 3 or 4 it

signifies the memory is sampling at the optimal state (read and

write pointers are farthest apart). If FIFOSTAT<2:0> returns a

critical value the pointer can be adjusted with the phase offset

PHOF<1:0> (REG07, bits 1:0). Due to the architecture of the FIFO

the phase offset can only adjust the read pointer in steps of two.

OPERATING IN MANUAL MODE

Allow DACCLK and DATACLK_IN to stabilize then enable FIFO

mode (REG00, bit 2). Read FIFOSTAT<2:0> (REG07, bits 6:4) to

determine if adjustment is needed. For example if FIFOSTAT<2:0>

= 6 the timing is not yet critical but it is not optimal. To return to

an optimal state (FIFOSTAT<2:0> = 4) the PHOF<1:0> (REG07,

bits 1:0) needs to be set to 1. Setting PHOF<1:0> = 1 effectively

increments the read pointer by 2. This causes the write pointer

value to be captured two clocks later decreasing FIFOSTAT<2:0>

from 6 to 4.

DB<13:0>

DB<13:0>

CSS

CSS

M0

8 Word

8 Word

Memory

Memory

Write

Write

Counter

Counter

M0

M7

M7

Figure 28. SYNC Logic Block Diagram

Rev. PrJ | Page 25 of 42

Adder

Adder

Read

Read

Counter

Counter

DAC<13:0>

DAC<13:0>

ZD

ZD

FFFF

FFFF

PHOF<1:0>

PHOF<1:0>

DACCLK

DACCLK

FIFOSTAT<2:0>

FIFOSTAT<2:0>

AD9736/AD9735/AD9734 Preliminary Technical Data

1

OPERATION IN SURVEILLANCE AND AUTO MODES

Once FIFOSTAT<2:0> has been manually placed in an optimal

state the AD9736 SYNC logic can be run in Surveillance or Auto

mode. To start, turn on Surveillance mode by setting SSURV = 1

(REG08, bit 7) then enable the sync interrupt (REG01, bit 2). If

STRH<0> = 0 (REG08, bit 0) an interrupt will occur if

FIFOSTAT<2:0> = 0 or 7. If STRH<0> = 1 (REG08, bit 0) an

interrupt will occur if FIFOSTAT<2:0> = 0, 1, 6 or 7. The interrupt

can be read at REG01, bit 6 at the AD9736 IRQ pin.

To enter Auto mode, complete the preceding steps then set SAUTO

DACCLK

IN TERN AL_D ELA Y

DATACLK_OUT

EXTERNAL_DELAY

DATACLK_IN

= 1 (REG09, bit 6). Next set the SYNC interrupt = 0 (REG01, bit 2),

to allow the phase offset (PHOF<1:0>) to be automatically updated

if FIFOSTAT<2:0> violates the threshold value.

The FIFOSTAT signal is filtered to improve noise immunity and

reduce unnecessary phase offset updates. The filter operates with

the following algorithm:

FIFOSTAT = FIFOSTAT + Delta FIFOSTAT / 2 ^ SFLT<3:0>

Where 0 <= SFLT<3:0> <= 12. Values greater than 12 are set to 12.

DATA_IN

CSS1

D1

CSS2

D2

WRITE _PTR1

M0

M1

M2

M3

M4

M5

M6

B C D E F G H I J K M OL N P RQA

SAMPLE_HOLD

SAMPLE_SETUP

SAMPLE_DELAY

A

0 1 2 3 4 5 6 7 0 1 2 3

C

B

E

D

G

F

I

H

J

Safe Zone Error Zone

A

B

C

Data ‘A’ can be

D

safely read from

the FIFO in the

E

Safe Zone. In

the Error Zone,

the pointers

F

may briefly

overlap due to

K

M

L

5 6 7 0

I

O

N

J

K

Q

P

FIFOSTAT is set

equal to the

write pointer

L

each time the

read pointer

M

changes from 7

to 0.

G

M7

READ_PTR1

FIFOSTAT

DAC_DATA

4 5 6 7 0 1 2 3 4 5 6 740

44 4

A B C D E F G H I J K L M

H

1 2 3 4

Figure 29. SYNC Logic Timing Diagram

Rev. PrJ | Page 26 of 42

Preliminary Technical Data AD9736/AD9735/AD9734

AD9736 DIGITAL BUILT-IN SELF TEST

BIST may be used to validate data transfer to the AD9736 in

addition to final ATE device verification. There are 4 BIST

signatures that can be read back using Registers 18-21 based on the

setting of the BIST selection bits (REG17, bits 7:6) as shown in

Table 12.

1 - LVDS Phase 1 0 0

2 - LVDS Phase 2 0 1

3 - SYNC Phase 1 1 0

4 - SYNC Phase 2 1 1

Table 12. BIST Selection Bits

The BIST signature returned from the AD9736 will depend on the

input DATA during the test. Since the filters in the DAC have

SEL<1> SEL<0>

D1

memory, it is important to put the correct idle value on the DATA

inputs to flush the memory prior to reading the BIST signature.

Placing the idle value on the data inputs also allows the BIST to be

setup while the DAC clock is running. The idle value should be all

zeroes in unsigned mode (0x0000) and all zeroes except for the

MSB in two’s complement mode (0x2000).

The BIST consists of two stages; the first stage is after the LVDS

receiver and the second stage is after the FIFO stage. The first BIST

stage verifies correct sampling of the data from the LVDS bus while

the second BIST stage verifies correct synchronization between the

DAC_CLK domain and the DATA_CLK domain. The BIST vector

is generated using 32 bit LFSR signature logic. Since the internal

architecture is a two bus parallel system there are two 32-bit LFSR

signature logic blocks on the both the LVDS and SYNC blocks.

Figure 30 shows where the LVDS and SYNC phases are located.

SYNC Logic

DB<13:0>

DATACLK_IN

LVD S

RX

Figure 24

LVD S

BIST

PH1

D2

LVD S

BIST

PH2

Figure 30. Block Diagram Showing LVDS and SYNC Phase 1 and Phase 2

BIST OPERATION

The internal signature generator processes the input data to create

the BIST signatures. An external program which implements the

same algorithm may be used to generate the expected signature for

comparison. A Matlab routine can be provided upon request to

perform this function.

Clock the test vector in as described below and compare the

signature register values to the expected value to verify correct

operation and input data capture.

With all clocks running:

1. Apply the idle vector to the data inputs (0x0000 if

unsigned, 0x2000 if two's complement) for 1024 clocks,

2. Set LVDS_EN (REG17, bit 2) and SYNC_EN (REG17, bit

1) high,

SYNC

FIFO 2x

SPI Port

3. Set CLEAR (REG17, bit 0) high,

4. Set CLEAR low to clear the BIST signature register,

5. Clock the BIST vector into the LVDS data inputs,

6. After the BIST vector is complete, return the inputs to the

idle vector value,

7. Set LVDS_EN (REG17, bit 2) and SYNC_EN (REG17, bit

1) low,

8. Set the desired SEL<1:0> bits and read back the four

BIST signature registers (REG18, 19, 20 and 21).

When the DAC is in 1x mode, the signature at SYNC BIST, Phase 1

should equal the signature at LVDS BIST, Phase 1. The same is

true for Phase 2. BIST does not support 2x mode.

BIST

PH1

SYNC

BIST

PH2

DAC

Rev. PrJ | Page 27 of 42

AD9736/AD9735/AD9734 Preliminary Technical Data

AD9736 ANALOG CONTROL REGISTER

The AD9736 includes some registers for optimizing its analog

performance. These registers include temperature trim for the

bandgap, noise reduction in the output current mirror and output

current mirror headroom adjustments.

BANDGAP TEMPERATURE CHARACTERISTIC TRIM BITS

Using TRMBG<2:0> (REG14, bits 2:0) the temperature

characteristic of the internal bandgap can be trimmed to minimize

the drift over temperature as shown in Figure 31.

MIRROR ROLL OFF FREQUENCY CONTROL

With MSEL<1:0> (REG14, bits 7:6) the user can adjust the noise

contribution of the internal current mirror to optimize the 1/F

noise. Figure 32 shows MSEL vs. the 1/F noise with 20mA FullScale current into a 50ohm resistor.

Figure 32. 1/F Noise With Respect to MSEL Bits

Figure 31. BANDGAP Temperature Characteristic for Various TRMBG Values

It is important to note that the temperature changes are sensitive to

process variations and the above plot may not be representative of

all fabrication lots. Optimum adjustment requires measurement of

the device operation at two temperatures and development of a

trim algorithm to program the correct TRMBG<2:0> values in

external non-volatile memory.

HEADROOM BITS

HDRM<7:0> (REG15, bits 7:0) is for internal evaluation and it is

not recommended to change them from their default reset values.

Rev. PrJ | Page 28 of 42

Preliminary Technical Data AD9736/AD9735/AD9734

VOLTAGE REFERENCE

The AD9736 output current is set by a combination of digital

control bits and the I120 reference current as shown in Figure 33.

AD9736

Vbg

1.2V

Vref

I120

1nF

10kΩ

The reference current is obtained by forcing the bandgap voltage

across an external 10kohm resistor from I120 (pin B14) to ground.

The 1.2V nominal bandgap voltage (Vref) will generate a 120uA

reference current in the 10k resistor. This current is adjusted

digitally by FSC<9:0> (REG02, REG03) to set the output full scale

current I

FS

:

FS

Vref

R

I120

Figure 33. Voltage Reference Circuit

⎛

⎜

27

⎜

⎝

192

⎛

⎜

1024

⎝

FSC<9:0>

Current

Scaling

FSCI

DAC

Ifull-scale

⎞

⎞

⎟

><×+×= 0:9

⎟

⎟

⎠

⎠

The full scale output current range is 10mA to 30mA for register

values from 0x000 to 0x3FF. The default value of 0x200 generates

20mA full scale. The typical range is shown in

35

30

25

20

(ma)

FS

I

15

10

5

0

0 200 400 600 800 1000

Figure 34. IFS vs. DAC Gain Code

VREF (pin C14) must be bypassed to ground with a 1nF capacitor.

The bandgap voltage is present on this pin and may be buffered for

use in external circuitry. The typical output impedance is near

5kohms. If desired, an external reference may be used to overdrive

the internal reference by connecting it to the VREF pin.

IPTAT (pin D14) is used for factory testing. It may be left floating

(preferred) or tied to analog ground. It will output a current which

is proportional to absolute temperature. The nominal output is

approximately 10uA at 25C. The slope is approximately 20nA per

degree C.

DAC gain code

Figure 34.

Rev. PrJ | Page 29 of 42

AD9736/AD9735/AD9734 Preliminary Technical Data

B

APPLICATIONS INFORMATION

FPGA/ASIC DAC DRIVER REQUIREMENTS

To achieve data synchronization using the high speed capability of

the AD9736, ADI recommends the configuration in Figure 35 for

the FPGA/ASIC driving the digital inputs. Using the Double Data

Rate DATACLK_OUT, this configuration will generate the LVDS

DATACLK_IN to drive the AD9736 at the DDR rate. The circuit

also synchronizes the DATACLK_IN and the digital input data

(DB<13:0>) as required by the AD9736. The synchronization

engine in the AD9736 then uses DATACLK_IN to generate the

internal CLOCK SAMPLING SIGNAL to capture the incoming

data via the Manual, Surveillance or Auto mode.

To operate in 2x mode, the circuit in Figure 35 must be modified to

include a divide-by-two block in the DATACLK_OUT path.

Without this additional divider the DATA and DATACLK_IN will

be running 2x too fast. DATACLK_OUT is always DACCLK/2.

Figure 35. Recommended FPGA/ASIC Configuration for Driving AD9736

Digital Inputs, 1x Mode

DATA1

DATA2

D1

D2

DB

A C E

B D

Figure 36. FPGA/ASIC Timing for Driving AD9736 Digital Inputs, 1x Mode

DATACLK_OUT+

DATACLK_IN+

TIMING ERROR BUDGET

The following components make up the timing error budget for the

AD9736:

1. AD9736 DATACLK_OUT jitter

2. AD9736 DATACLK_IN jitter

A

A

B C

C

D

3. DB13:0 jitter

4. DB13:0 skew from data source

5. DB13:0 receiver skew margin (board + AD9736 internal

delays)

6. DB13:0 to DATACLK_IN skew from data source

Rev. PrJ | Page 30 of 42

Preliminary Technical Data AD9736/AD9735/AD9734

AD9736 EVALUATION BOARD SCHEMATICS

D

DEVORPPAETAD

MRJ

82.8030.bveragbcadagigmorfatadecruoSA

1

SNOISIVER

NOITPIRCSEDVER

C

B

A

VERREBMUNGNIWARDONMCSFEZIS

C

5

F0

1

TEEHS

91.5040=ETADELIF

1234

ELACSTONODELACS

ENON

B NEGORDYH

GNIRUTCAFUNAM

78810AM,NOTGNIMLIW

TEERTSNRUBOW408

NOTGNIMLIW

234

ASSV

SRETLIFTUPNIREWOP

:YBDEVORPPA:YBNWARD

TUDREDNU

1PJ

SSV

33DDV

4PT

DER

ETI

RREF6L

0121CL

11BT

GID33

SSV

KLB

FU01

V3.6

41C

ESACA

21BT

SSV

B81DDV

5PT

FU01

V3.6

22C

7PT

ESACA

DER

ETIRREF7L

0121CL

D

A81DDV

SSV

31PT

KLB

6PT

D

E

R

ETIRREF5L

0121CL

31BT

GID81

SSV

41PT

KLB

FU01

V3.6

81C

ES

A

CA

41BT

SSV

C

33ADDV

DER

1PT

ETIRREF1L

0121CL

ANA33

12BT

B

ASSV

CDDV

DER

9PT

KLB

FU01

1C

ESACA

3PT

V3.6

ETIRREF3L

0121CL

ANA81

32BT

22BT

ASSV

ASSV

KLB

FU01

01C

ESACA