Dual Input Network Clock

www.BDTIC.com/ADI

FEATURES

Flexible reference inputs

Input frequencies: 8 kHz to 750 MHz

Two reference inputs

Loss of reference indicators

Auto and manual holdover modes

Auto and manual switchover modes

Smooth A-to-B phase transition on outputs

Excellent stability in holdover mode

Programmable 16 + 1-bit input divider, R

Differential HSTL clock output

Output frequencies to 750 MHz

Low jitter clock doubler for frequencies > 400 MHz

Single-ended CMOS output for frequencies < 150 MHz

Programmable digital loop filter (< 1 Hz to ~100 kHz)

High speed digitally controlled oscillator (DCO) core

DDS with integrated 14-bit DAC

Excellent dynamic performance

Programmable 16 + 1-bit feedback divider, S

Software controlled power-down

64-lead LFCSP package

Generator/Synchronizer

AD9549

APPLICATIONS

Network synchronization

Reference clock jitter cleanup

SONET/SDH clocks up to OC-192, including FEC

Stratum 3/3E reference clocks

Wireless base stations, controllers

Cable infrastructure

Data communications

GENERAL DESCRIPTION

The AD9549 provides synchronization for many systems,

including synchronous optical networks (SONET/SDH). The

AD9549 generates an output clock, synchronized to one of two

external input references. The external references may contain

significant time jitter, also specified as phase noise. Using a

digitally controlled loop and holdover circuitry, the AD9549

continues to generate a clean (low jitter), valid output clock

during a loss of reference condition, even when both references

have failed.

The AD9549 operates over an industrial temperature range of

−40°C t

o +85°C.

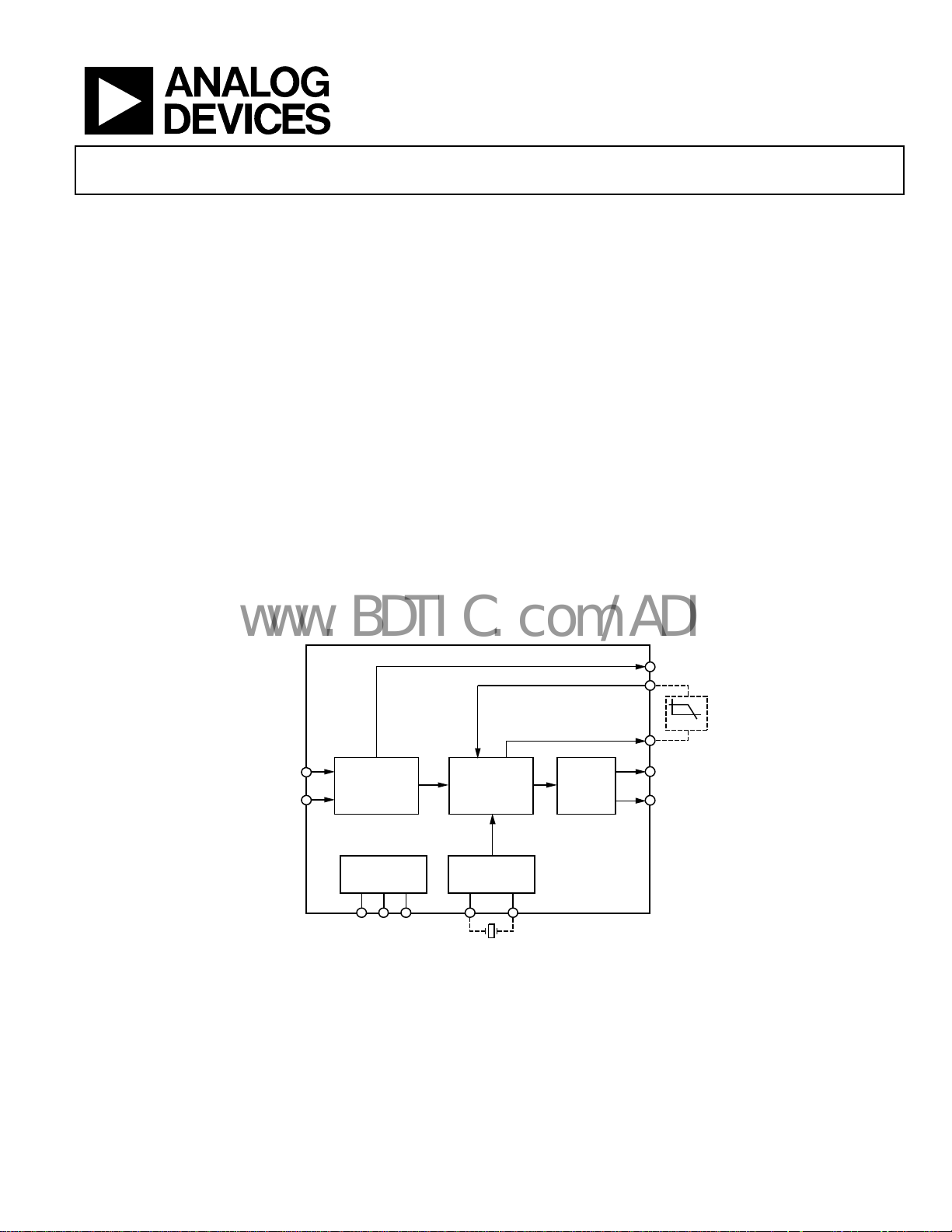

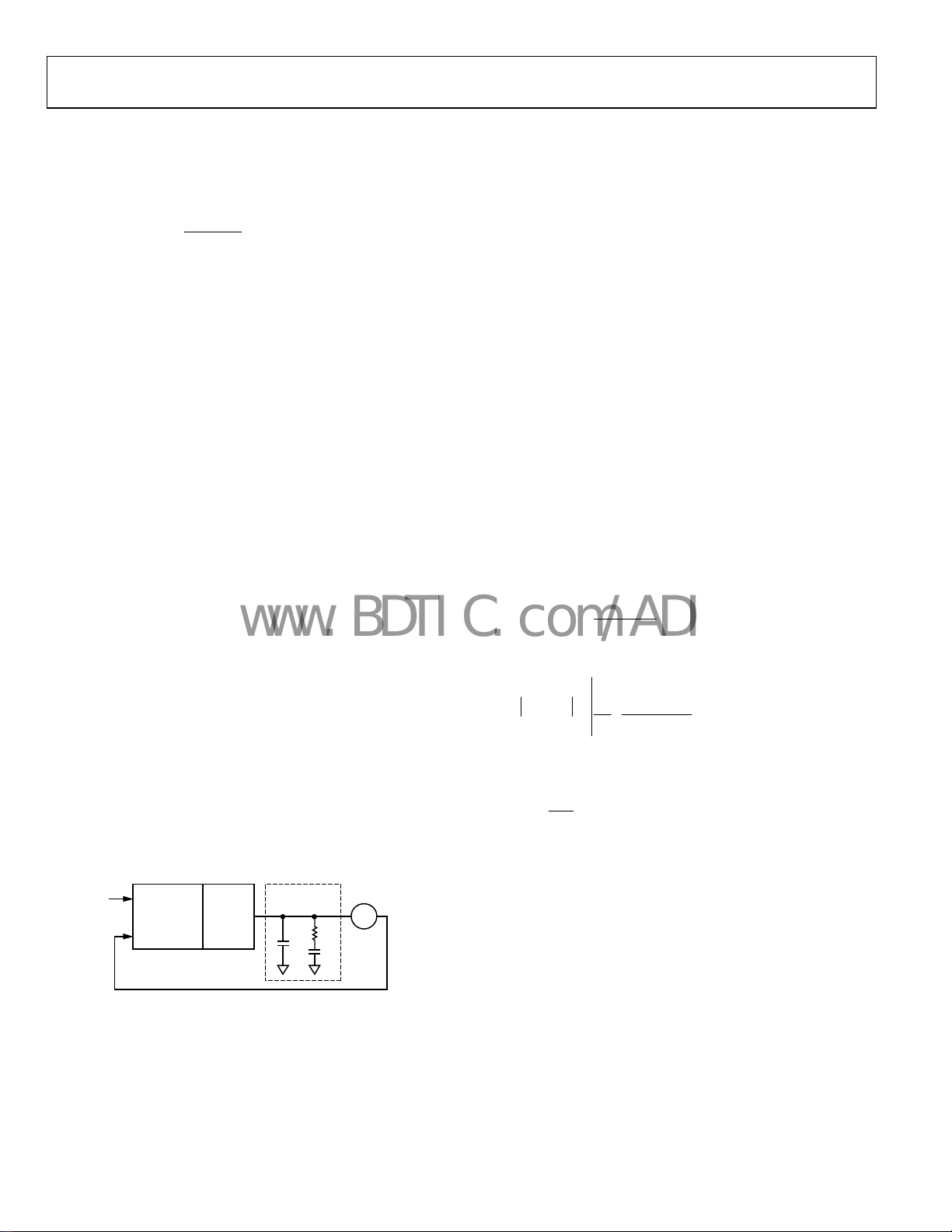

REFA_IN

REFB_IN

AD9549

REFERENCE

MONITORS

AND

SWITCHING

SERIAL PORT,

I/O LOGIC

DIGITAL INTERFACE

DIGITAL PLL

R

R, S DIVIDERS

HOLDOVER

SYSTEM CLOCK

MULTIPLIER

Figure 1. Basic Block Diagram

FDBK_IN

DAC_OUT

CLOCK

OUTPUT

DRIVERS

S1 TO S4

FILTER

OUT

OUT_CMOS

06744-001

Rev. 0

Information furnished by Analog Devices is believed to be accurate and reliable. However, no

responsibility is assumed by Anal og Devices for its use, nor for any infringements of patents or ot her

rights of third parties that may result from its use. Specifications subject to change without notice. No

license is granted by implication or otherwise under any patent or patent rights of Analog Devices.

Trademarks and registered trademarks are the property of their respective owners.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700 www.analog.com

Fax: 781.461.3113 ©2007 Analog Devices, Inc. All rights reserved.

AD9549

www.BDTIC.com/ADI

TABLE OF CONTENTS

Features .............................................................................................. 1

Applications....................................................................................... 1

General Description......................................................................... 1

Revision History ............................................................................... 2

Specifications..................................................................................... 3

DC Specifications ......................................................................... 3

AC Specifications.......................................................................... 5

Absolute Maximum Ratings............................................................ 8

ESD Caution.................................................................................. 8

Pin Configuration and Function Descriptions............................. 9

Typical Performance Characteristics ........................................... 12

Input/Output Termination Recommendations.......................... 15

Theory of Operation ...................................................................... 16

Overview...................................................................................... 16

PLL Core (DPLLC)..................................................................... 16

Phase Detector ............................................................................ 20

Digital Loop Filter Coefficients ................................................21

Closed-Loop Phase Offset......................................................... 22

Lock Detection............................................................................23

Reference Monitors.................................................................... 24

Reference Switchover................................................................. 25

Holdover ...................................................................................... 27

Output Frequency Range Control............................................ 30

Reconstruction Filter ................................................................. 30

FDBK Inputs ............................................................................... 30

Reference Inputs......................................................................... 31

SYSCLK Inputs ........................................................................... 31

Harmonic Spur Reduction........................................................ 33

Output Clock Drivers and 2× Frequency Multiplier............. 34

Frequency Slew Limiter............................................................. 35

Frequency Estimator.................................................................. 35

Status and Warnings .................................................................. 36

Thermal Performance.................................................................... 39

AD9549 Power-Up......................................................................... 40

Power-On Reset .......................................................................... 40

Programming Sequence ............................................................ 40

Power Supply Partitioning............................................................. 41

3.3 V Supplies.............................................................................. 41

1.8 V Supplies.............................................................................. 41

Serial Control Port ......................................................................... 42

Serial Control Port Pin Descriptions ....................................... 42

Operation of Serial Control Port.............................................. 42

The Instruction Word (16 Bits) ................................................ 43

MSB/LSB First Transfers ........................................................... 43

I/O Register Map............................................................................ 46

I/O Register Description ............................................................... 51

Serial Port Configuration (Reg 0000 to Reg 0005) ................ 51

Power-Down and Reset (Reg 0010 to Reg 0013) ................... 51

System Clock (Reg 0020 to Reg 0023)..................................... 52

Digital PLL Control and Dividers (Reg 0100 to Reg 0130).. 53

Free-Run (Single-Tone) Mode (Reg 01A0 to Reg 01AD)..... 55

Reference Selector/Holdover (Reg 01C0 to Reg 01C3)......... 56

Doubler and Output Drivers (Reg 0200 to Reg 0201)........... 57

Monitor (Reg 0300 to Reg 0335) .............................................. 57

Calibration (User-Accessible Trim) (Reg 0400 to Reg 0410) 61

Harmonic Spur Reduction (Reg 0500 to Reg 0509).............. 62

Sample Application Circuit........................................................... 64

Outline Dimensions ....................................................................... 65

Ordering Guide .......................................................................... 65

REVISION HISTORY

8/07—Revision 0: Initial Version

Rev. 0 | Page 2 of 68

AD9549

www.BDTIC.com/ADI

SPECIFICATIONS

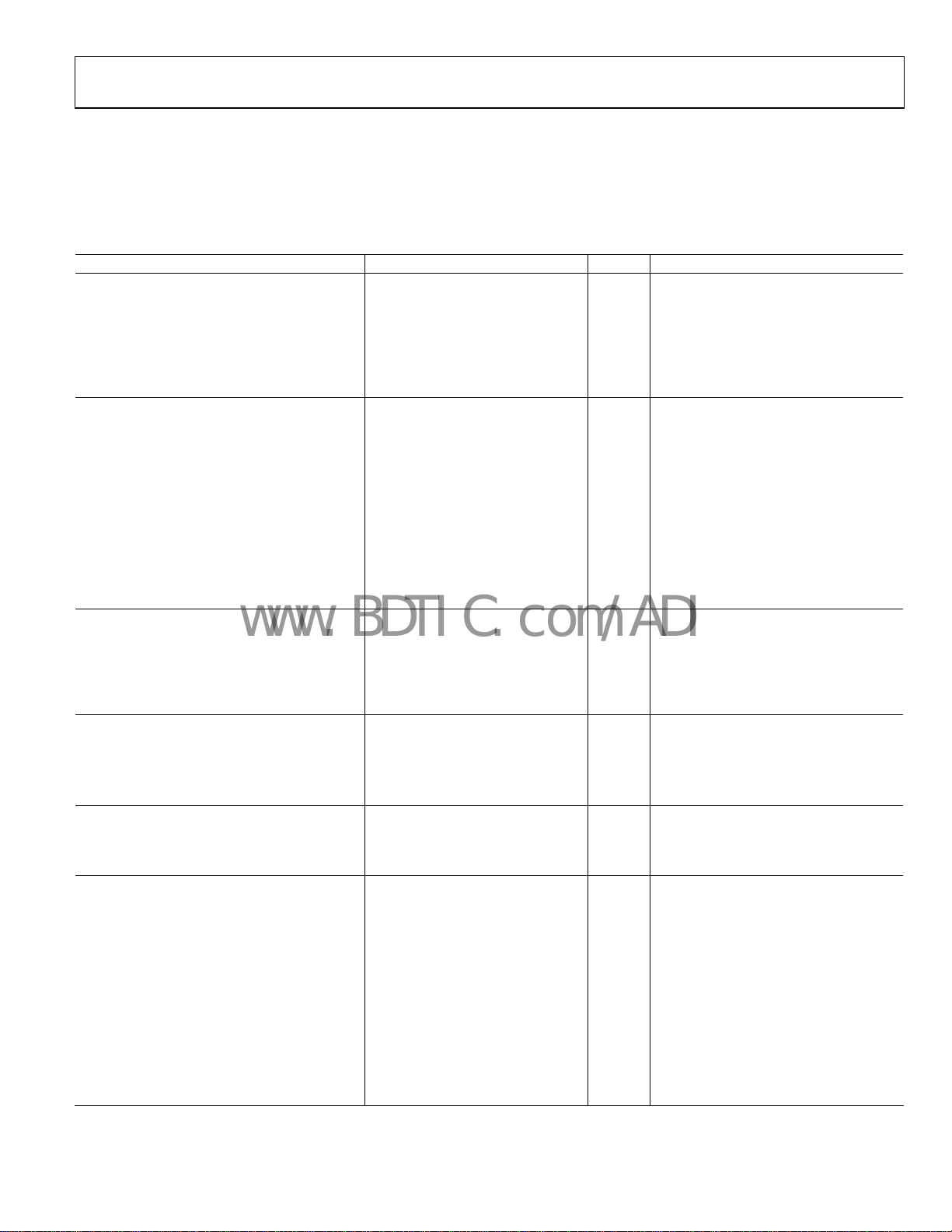

DC SPECIFICATIONS

Unless otherwise noted, AVDD = 1.8 V ± 5%, AVDD3 = 3.3 V ± 5%, DVDD = 1.8 V ± 5%, DVDD_I/O = 3.3 V ± 5%. AVSS = 0 V,

DVSS = 0 V.

Table 1.

Parameter Min Typ Max Unit Test Conditions/Comments

SUPPLY VOLTAGE

DVDD_I/O (Pin 1) 3.135 3.30 3.465 V

DVDD (Pin 3, Pin 5, Pin 7) 1.71 1.80 1.89 V

AVDD3 (Pin 14, Pin 46, Pin 47, Pin 49) 3.135 3.30 3.465 V

AVDD3 (Pin 37) 1.71 3.30 3.465 V Pin 37 is typically 3.3 V, but can be set to 1.8 V

AVDD (Pin 11, Pin 19, Pin 23 to Pin 26, Pin 29,

Pin 30, Pin 36, Pin 42, Pin 44, Pin 45, Pin 53)

SUPPLY CURRENT

I

(Pin 14) 4.7 5.6 mA REFA, REFB buffers

AVDD3

I

(Pin 37) 3.8 4.5 mA CMOS output clock driver at 3.3 V

AVDD3

I

(Pin 46, Pin 47, Pin 49) 26 29 mA DAC output current source, fS = 1 GSPS

AVDD3

I

(Pin 36, Pin 42) 21 26 mA FDBK in, HSTL output clock driver (output

AVDD

I

(Pin 11) 12 15 mA REFA and REFB input buffer 1.8 V supply

AVDD

I

(Pin 19, Pin 23 to Pin 26, Pin 29,

AVDD

Pin 30, Pin 44, Pin 45)

I

(Pin 53) 41 49 mA DAC power supply

AVDD

I

(Pin 3, Pin 5, Pin 7) 254 265 mA Digital core

DVDD

I

(Pin 1) 4 6 mA Digital I/O (varies dynamically)

DVDD_I/O

LOGIC INPUTS (Except Pin 32) Pin 56 to Pin 61, Pin 64, Pin 9, Pin 10,

Input High Voltage (VIH) 2.0 DVDD_I/O V

Input Low Voltage (VIL) DVSS 0.8 V

Input Current (I

, I

) ±60 ±200 µA At VIN = 0 V and VIN = DVDD_I/O

INH

INL

Maximum Input Capacitance (CIN) 3 pF

CLKMODESEL (Pin 32) LOGIC INPUT Pin 32 only

Input High Voltage (VIH) 1.4 AVDD V

Input Low Voltage (VIL) AVSS 0.4 V

Input Current (I

, I

) −18 −50 µA At VIN = 0 V and VIN = AVDD

INH

INL

Maximum Input Capacitance (CIN) 3 pF

LOGIC OUTPUTS Pin 62 and bidirectional Pin 9, Pin 10,

Output High Voltage (VOH) 2.7 DVDD V IOH = 1 mA

Output Low Voltage (VOL) DVSS 0.4 V IOL = 1 mA

REFERENCE INPUTS Pin 12, Pin 13, Pin 15, Pin 16

Input Capacitance 3 pF

Input Resistance 8.5 11.5 14.5 kΩ Differential at Register 40F[1:0] = 00

Differential Operation

Common Mode Input Voltage1

(Applicable When DC-Coupled)

Differential Input Voltage Swing

1

Single-Ended Operation Register 040F[1:0] = 10

Input Voltage High (VIH) 2.0 AVDD3 V

Input Voltage Low (VIL) AVSS 0.8 V

Threshold Voltage AVDD3 −

Input Current 1 mA Single-ended operation

1.71 1.80 1.89 V

doubler turned on.)

194 255 mA Aggregate analog supply, including

system clock PLL

Pin 54, Pin 55, Pin 63

Pin 54, Pin 55, and Pin 63

1.5 AVDD3 −

0.2

V Differential operation; note that LVDS

signals must be ac-coupled

500 mV p-p Differential operation

0.66

AVDD3 −

0.82

AVDD3 −

0.98

V Register 040F[1:0] = 10 (other settings

possible)

Rev. 0 | Page 3 of 68

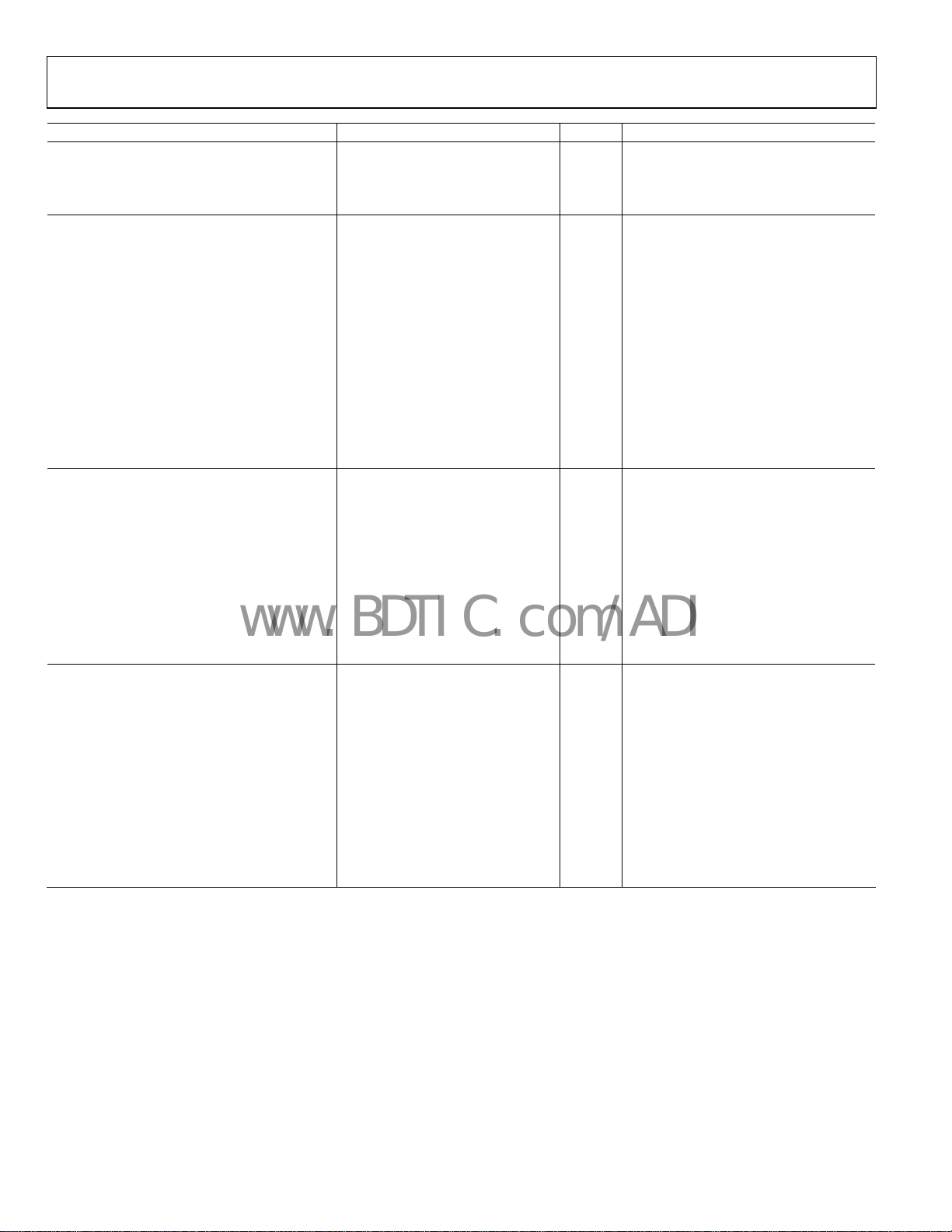

AD9549

www.BDTIC.com/ADI

Parameter Min Typ Max Unit Test Conditions/Comments

FDBK INPUT Pin 40, Pin 41

Input Capacitance 3 pF

Input Resistance 18 22 26 kΩ Differential

Differential Input Voltage Swing

SYSTEM CLOCK INPUT System clock inputs should always be ac-

SYSCLK PLL Bypassed

Input Capacitance 1.5 pF Single-ended, each pin

Input Resistance 2.4 2.6 2.8 kΩ Differential

Internally Generated DC Bias Voltage

Differential Input Voltage Swing

SYSCLK PLL Enabled

Input Capacitance 3 pF Single-ended, each pin

Input Resistance 2.4 2.6 2.8 kΩ Differential

Internally Generated DC Bias Voltage

Differential Input Voltage Swing

Crystal Resonator with SYSCLK PLL Enabled

Motional Resistance 9 100 Ω 25 MHz, 3.2 mm × 2.5 mm AT cut

CLOCK OUTPUT DRIVERS

HSTL Output Driver

Differential Output Voltage Swing

Common-Mode Output Voltage

CMOS Output Driver

Output Voltage High (VOH) AVDDX = 3.3 V 2.7 V IOH = 1 mA.

Output Voltage Low (VOL) AVDDX = 3.3 V 0.4 V IOL = 1 mA.

Output Voltage High (VOH) AVDDX = 1.8 V 1.4 V IOH = 1 mA.

Output Voltage Low (VOL) AVDDX = 1.8 V 0.4 V IOL = 1 mA.

TOTAL POWER DISSIPATION

All Blocks Running 1010 1250 mW Worst case over supply, temperature,

Power-Down Mode 24 mW Using either the Power-Down and Enable

Digital Power-Down Mode 515 650 mW

Default with SYSCLK PLL Enabled 905 1100 mW After reset or power up with fS = 1 GHz,

Default with SYSCLK PLL Disabled 895 1056 mW After reset or power up with fS = 1 GHz,

With REFA or REFB Power-Down 1046 mW One reference still powered up

With HSTL Clock Driver Power-Down 1036 mW

With CMOS Clock Driver Power-Down 1048 mW

1

Must be ≤ 0 V relative to AVDD3 (Pin 14) and ≥ 0 V relative to AVSS (Pin 33, Pin 43).

2

Relative to AVSS (Pin 33, Pin 43).

3

Must be ≤ 0 V relative to AVDD (Pin 36) and ≥ 0 V relative to AVSS (Pin 33, Pin 43).

2

225 mV p-p −12 dBm into 50 Ω; must be ac-coupled

coupled (both single-ended and differential)

2

3

2

3

0.93 1.17 1.38 V

632 mV p-p 0 dBm into 50 Ω

0.93 1.17 1.38 V

632 mV p-p 0 dBm into 50 Ω

1080 1280 1480 mV

Output driver static, see

Figure 12 for

output swing vs. frequency

2

0.7 0.88 1.06 V

Output driver static, see

Figure 14 for

output swing vs. frequency

process

register or PWRDOWN pin

S4 = 0, S1 to S3 = 1, f

SYSCLK

= 25MHz

S1 to S4 = 1

Rev. 0 | Page 4 of 68

AD9549

www.BDTIC.com/ADI

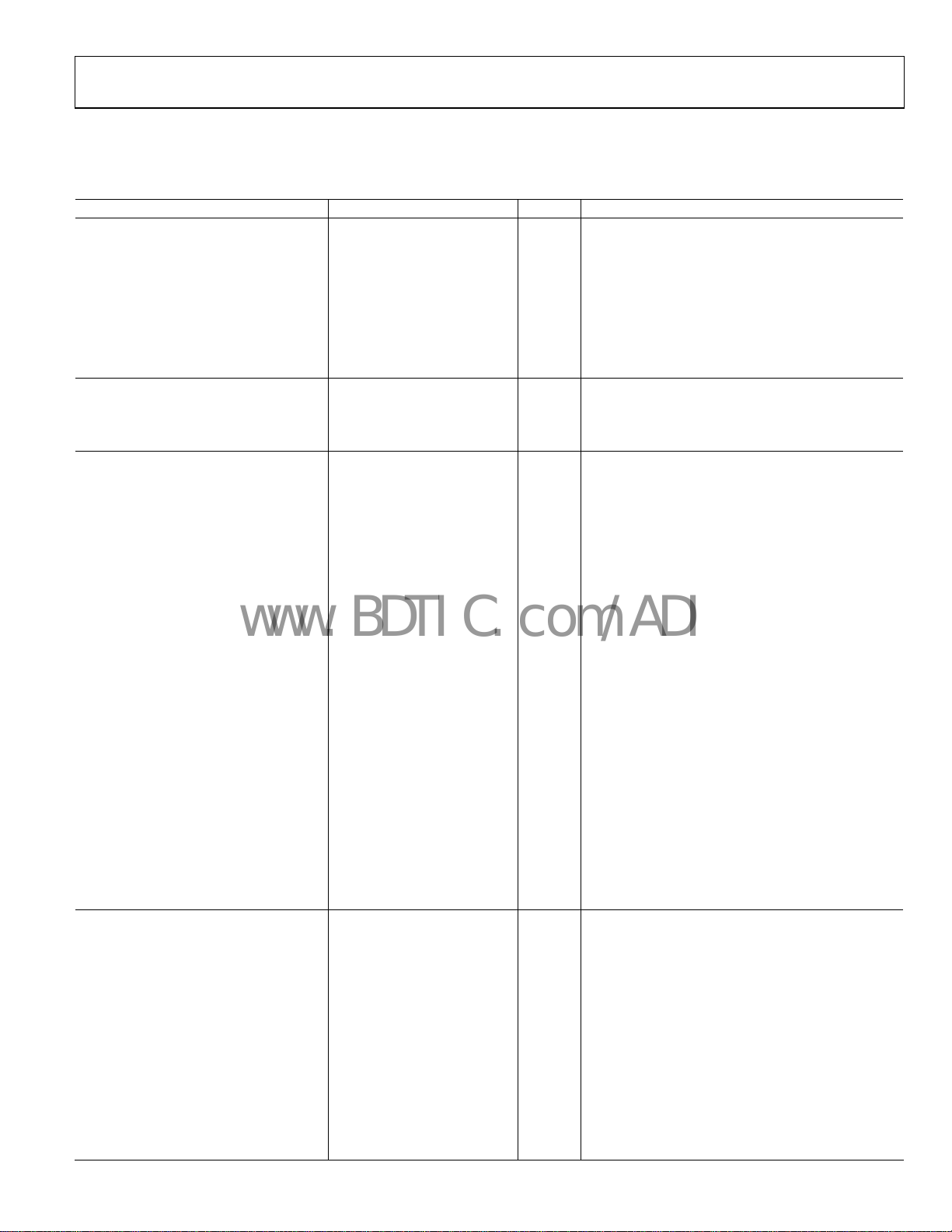

AC SPECIFICATIONS

Unless otherwise noted, fS = 1 GHz. DAC R

Table 2.

Parameter Min Typ Max Unit Test Conditions/Comments

REFERENCE INPUTS Pin 12, Pin 13, Pin 15, Pin 16

Frequency Range (Sine Wave) 10 750 MHz Minimum recommended slew rate: 40 V/s

Frequency Range (CMOS) 0.008 50 MHz

Frequency Range (LVPECL) 0.008 725 MHz

Frequency Range (LVDS) 0.008 725 MHz LVDS must be ac-coupled; lower frequency bound may

Minimum Slew Rate 0.04 V/ns

Minimum Pulse Width High 620 ps

Minimum Pulse Width Low 620 ps

FDBK INPUT Pin 40, Pin 41

Input Frequency Range 10 400 MHz

Minimum Differential Input Level 225 mV p-p −12 dBm into 50 Ω; must be ac-coupled

Minimum Slew Rate 40 V/s

SYSTEM CLOCK INPUT Pin 27, Pin 28

SYSCLK PLL Bypassed

Input Frequency Range 250 1000 MHz Maximum f

Duty Cycle 45 55 %

Minimum Differential Input Level 632 mV p-p 0 dBm into 50 Ω

SYSCLK PLL Enabled

VCO Frequency Range, Low Band 700 810 MHz When in the range, use the low VCO band exclusively

VCO Frequency Range, Auto Band 810 900 MHz When in the range, use the VCO Auto band select

VCO Frequency Range, High Band 900 1000 MHz When in the range, use the high VCO band exclusively

Maximum Input Rate of System Clock

PFD

Without SYSCLK PLL Doubler

Input Frequency Range 11 200 MHz

Multiplication Range 4 66 Integer multiples of 2, maximum PFD rate and system

Minimum Differential Input Level 632 mV p-p 0 dBm into 50 Ω

With SYSCLK PLL Doubler

Input Frequency Range 6 100 MHz

Multiplication Range 8 132 Integer multiples of 8

Input Duty Cycle 50 % Deviating from 50% duty cycle may adversely affect

Minimum Differential Input Level 632 mV p-p 0 dBm into 50 Ω

Crystal Resonator with SYSCLK PLL

Enabled

Crystal Resonator Frequency Range 10 50 MHz AT cut, fundamental mode resonator

Maximum Crystal Motional Resistance 100 Ω

CLOCK DRIVERS

HSTL Output Driver

Frequency Range 20 725 MHz

Duty Cycle 48 52 %

Rise/Fall Time (20-80%) 115 165 ps 100 Ω termination across OUT/OUTB, 2 pF load

Jitter (12 kHz to 20 MHz) 1.0 ps fIN = 19.44 MHz, f

HSTL Output Driver with 2× Multiplier

Frequency Range 400 725 MHz

Duty Cycle 45 55 %

Rise/Fall Time (20% to 80%) 115 165 ps 100 Ω termination across OUT/OUTB, 2 pF load

Sub-harmonic Spur Level −35 dBc Without correction

Jitter (12 kHz to 20 MHz) 1.1 ps fIN = 19.44 MHz, f

= 10 k. Power supply pins within the range specified in the DC Specifications section.

SET

be higher depending on size of decoupling capacitor

is 0.4 × f

100 MHz

clock frequency must be met

spurious performance.

See the

SYSCLK Inputs section for recommendations

See

Figure 12 for maximum toggle rate

input (see

input (see

Rev. 0 | Page 5 of 68

Figure 3 to Figure 11 for test conditions)

Figure 3 to Figure 11 for test conditions)

OUT

SYSCLK

= 155.52 MHz. 50 MHz system clock

OUT

= 622.08 MHz, 50 MHz system clock

OUT

AD9549

www.BDTIC.com/ADI

Parameter Min Typ Max Unit Test Conditions/Comments

CMOS Output Driver

(AVDD3/Pin 37) @ 3.3 V

Frequency Range 0.008 150 MHz

Duty Cycle 45 55 65 % With 20 pF load and up to 150 MHz

Rise/Fall Time (20-80%) 3 4.6 ns With 20 pF load

CMOS Output Driver

(AVDD3/Pin 37) @ 1.8 V

Frequency Range 0.008 40 MHz

Duty Cycle 45 55 65 % With 20 pF load and up to 40 MHz

Rise/Fall Time (20% to 80%) 5 6.8 ns With 20 pF load

HOLDOVER

Frequency Accuracy

OUTPUT FREQUENCY SLEW LIMITER

Slew Rate Resolution 0.54 111 Hz/sec P = 216 for minimum; P = 25 for maximum

Slew Rate Range 0 3 × 10

REFERENCE MONITORS

Loss of Reference Monitor

Operating Frequency Range 7.63 × 103 167 × 106Hz

Minimum Frequency Error for

Continuous REF Present Indication

Minimum Frequency Error for

Continuous REF Present Indication

Maximum Frequency Error for

Continuous REF Lost Indication

Maximum Frequency Error for

Continuous REF Lost Indication

Reference Quality Monitor

Operating Frequency Range 0.008 150 MHz

Frequency Resolution (Normalized) 0.2 ppm f

Frequency Resolution (Normalized) 408 ppm f

Validation Timer

Timing Range 32 × 10

Timing Range 65 × 10

DAC OUTPUT CHARACTERISTICS

DCO Frequency Range (1st Nyquist Zone) 10 450 MHz DPLL loop bandwidth sets lower limit

Output Resistance 50 Ω Single-ended (each pin internally terminated to AVSS)

Output Capacitance 5 pF

Full-Scale Output Current 20 31.7 mA Range depends on DAC R

Gain Error −10 +10 %FS

Output Offset 0.6 A

Voltage Compliance Range AVSS −

DIGITAL PLL

Minimum Open-Loop Bandwidth 0.1 Hz Dependent on the frequency of REFA/REFB, the DAC

Maximum Open-Loop Bandwidth 100 kHz Dependent on the frequency of REFA/REFB, the DAC

Minimum Phase Margin 0 10 Degrees Dependent on the frequency of REFA/REFB, the DAC

Maximum Phase Margin 85 90 Degrees Dependent on the frequency of REFA/REFB, the DAC

PFD Input Frequency Range ~0.008 ~24.5 MHz

Feedforward Divider Ratio 1 131,070 1, 2, …,65,535 or 2, 4, …, 131,070

Feedback Divider Ratio 1 131,070 1, 2, …, 65,535 or 2, 4, …, 131,070

See

Figure 14 for maximum toggle rate

See

Figure 13 for maximum toggle rate

See the

Holdover section

16

Hz/sec P = 216 for minimum; P = 25 for maximum

−16 ppm f

−19 % f

−32 ppm f

−35 % f

= 8 kHz

REF

= 155 MHz

REF

= 8 kHz

REF

= 155 MHz

REF

= 8 kHz; OOL divider = 65,535 for minimum; OOL

REF

divider = 1 for max (see the

Monitor

section)

= 155 MHz; OOL divider = 65,535 for minimum; OOL

REF

divider = 1 for maximum

See the

Reference Validation Timers section

0.50

−9

137 s PIO = 5

−6

2.8 × 105s PIO = 16

+0.5 AVSS +

Outputs not dc-shorted to V

0.50

sample rate, and the P-, R-, and S-divider values

sample rate, and the P-, R-, and S-divider values

sample rate, and the P-, R-, and S-divider values

sample rate, and the P-, R-, and S-divider values

Reference Frequency

resistor

SET

SS

Rev. 0 | Page 6 of 68

AD9549

www.BDTIC.com/ADI

Parameter Min Typ Max Unit Test Conditions/Comments

LOCK DETECTION

Phase Lock Detector

Time Threshold Programming Range 0 2097 s FPFD_Gain = 200

Time Threshold Resolution 0.488 ps FPFD_Gain = 200

Lock Time Programming Range 32 × 10−9 275 s In power-of-2 steps

Unlock Time Programming Range 192 × 10−9 67 × 10−3s In power-of-2 steps

Frequency Lock Detector

Normalized Frequency Threshold

Programming Range

Normalized Frequency Threshold

Programming Resolution

Lock Time Programming Range 32 × 10−9 275 s In power-of-2 steps

Unlock Time Programming Range 192 × 10−9 67 × 10−3s In power-of-2 steps

DIGITAL TIMING SPECIFICATIONS

Time Required to Enter Power-Down 15 µs

Time Required to Leave Power-Down 18 µs

Reset Assert to High-Z Time

for S1 to S4 Configuration Pins

Reset Deassert to Low-Z Time

for S1 to S4 Configuration Pins

SERIAL PORT TIMING SPECIFICATIONS

SCLK Clock Rate (1/t

SCLK Pulse Width High, t

SCLK Pulse Width Low, t

SDO/SDIO to SCLK Setup Time, t

SDO/SDIO to SCLK Hold Time, t

) 25 50 MHz

CLK

HI

LO

DS

DH

SCLK Falling Edge to Valid Data on

SDIO/SDO, t

CSB to SCLK Setup Time, t

CSB to SCLK Hold Time, t

CSB Minimum Pulse Width High, t

DV

S

H

PWH

PROPAGATION DELAY

FDBK to HSTL Output Driver 2.8 ns

FDBK to HSTL Output Driver with 2×

Frequency Multiplier Enabled

FDBK to CMOS Output Driver 8.0 ns

FDBK Through S-Divider to CMOS

Output Driver

0 0.0021 FPFD_Gain = 200; normalized to (f

/R)2; see the

REF

Frequency Lock Detection section for details

5 ×

10

FPFD_Gain = 200; normalized to (f

−13

Frequency Lock Detection section for details

/R)2; see the

REF

60 ns Time from rising edge of RESET to high-Z on the S1, S2,

S3, S4 configuration pins

30 ns Time from falling edge of RESET to low-Z on the S1, S2,

S3, S4 configuration pins

Refer to

Figure 58 for all write-related serial port

parameters, maximum SCLK rate for readback is

governed by t

DV

8 ns

8 ns

1.93 ns

1.9 ns

11 ns

Refer to

Figure 56

1.34 ns

−0.4 ns

3 ns

7.3 ns

8.6 ns

Rev. 0 | Page 7 of 68

AD9549

www.BDTIC.com/ADI

ABSOLUTE MAXIMUM RATINGS

Table 3.

Parameter Rating

Analog Supply Voltage (AVDD) 2 V

Digital Supply Voltage (DVDD) 2 V

Digital I/O Supply Voltage

(DVDD_I/O)

DAC Supply Voltage (DAC_VDD) 3.6 V

Maximum Digital Input Voltage −0.5 V to DVDD_I/O + 0.5 V

Storage Temperature −65°C to +150°C

Operating Temperature Range −40°C to +85°C

Lead Temperature

(Soldering 10 sec)

Junction Temperature 150°C

Thermal Resistance1

θ

JA

θ

JB

θ

JC

1

The exposed pad on bottom of package must be soldered to ground in

order to achieve the specified thermal performance. See the Thermal

Performance section for more information.

3.6 V

300°C

25.2°C/W typical

13.9°C/W typical

1.7°C/W typical

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

ESD CAUTION

Rev. 0 | Page 8 of 68

AD9549

T

www.BDTIC.com/ADI

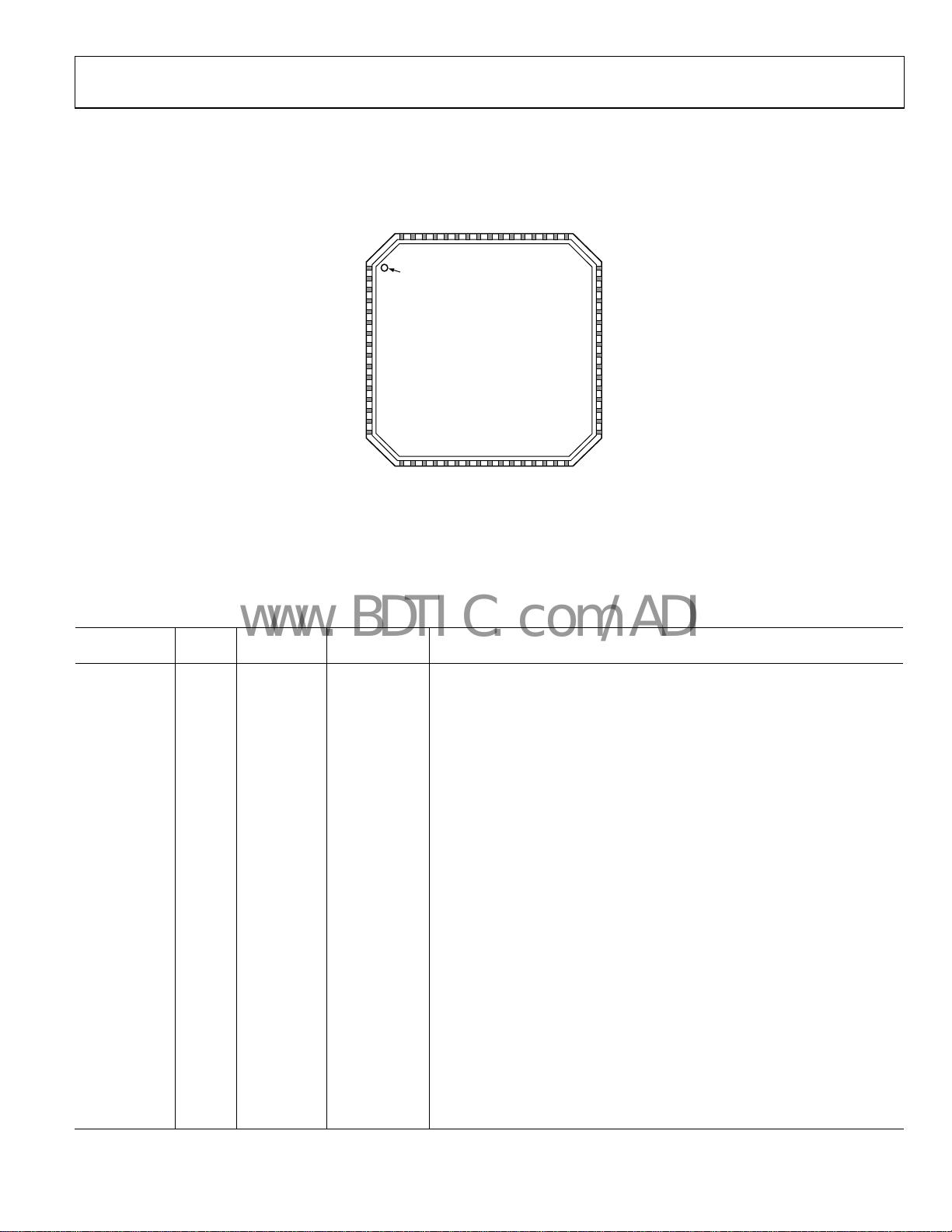

PIN CONFIGURATION AND FUNCTION DESCRIPTIONS

S4S3AVD D

AVSS

DAC_OUTB

DAC_OUT

AVDD3

49

DAC_RSET

48

AVDD3

47

AVDD3

46

AVD D

45

AVD D

44

AVSS

43

AVD D

42

FDBK_IN

41

FDBK_INB

40

AVSS

39

OUT_CMOS

38

AVDD3

37

AVD D

36

OUT

35

OUTB

34

AVSS

33

DVDD_I/O

DVSS

DVDD

DVSS

DVDD

DVSS

DVDD

DVSS

AVD D

REFA_IN

REFA_INB

AVD D3

REFB_IN

REFB_INB

SCLK

SDIO

SDO

CSB

IO_UPDATE

RESET

PWRDOWN

HOLDO VER

646362616059585756555453525150

PIN 1

1

INDICATOR

2

3

4

5

6

7

8

9

S1

10

S2

11

12

13

14

15

16

REFSELEC

AD9549

TOP VIEW

(Not to Scale)

NC = NO CONNECT

171819202122232425262728293031

NC

NC

AVD D

AVD D

AVD D

AVD D

AVD D

AVD D

AVD D

PFD_VRT

PFD_VRB

PFD_RSET

SYSCLK

SYSCLKB

32

LOOP_FILTER

CLKMODESEL

06744-002

Figure 2. 64-Lead LFCSP Pin Configuration

Table 4. Pin Function Descriptions

Input/

Ou

Pin No.

tput

Pin Type Mnemonic Description

1 I Power DVDD_I/O I/O Digital Supply.

2, 4, 6, 8 I Power DVSS Digital Ground. Connect to ground.

3, 5, 7 I Power DVDD Digital Supply.

9, 10, 54, 55 I/O 3.3 V CMOS S1, S2, S3, S4

Configurable I/O Pins. These pins are configured under program control (see

the Status and Warnings section) and do not have internal pull-up/pull-down

esistors.

r

11, 19, 23 to

I Power AVDD Analog Supply. Connect to a nominal 1.8 V supply.

26, 29, 30, 36,

42, 44, 45, 53

12 I

Differential

nput

I

REFA_IN

Frequency/Phase Reference A Input. This inter

nally biased input is typically accoupled and, when configured as such, can accept any differential signal with

single-ended swing between 0.4 V and 3.3 V. If dc-coupled, LVPECL or CMOS

input is preferred.

13 I

Differential

nput

I

REFA_INB

Complementary Frequency/Phase Reference A Input. Complementary signal

to the input pr

ovided on Pin 12. If using a single-ended, dc-coupled CMOS

signal into REFA_IN, bypass this pin to ground with a 0.01 F capacitor.

14, 46, 47, 49 I Power AVDD3 Analog Supply. Connect to a nominal 3.3 V supply.

15 I

Differential

nput

I

REFB_IN

Frequency/Phase Reference B Input. This internally biased input is typically accoupled and, when configured as such, can accept any differential signal with

single-ended swing between 0.4 V and 3.3 V. If dc-coupled, LVPECL or CMOS

input is preferred.

16 I

Differential

nput

I

REFB_INB

Complementary Frequency/Phase Reference B Input. Complementary signal to

the input provided on Pin 15. If using a single-ended, dc-coupled CMOS signal

into REFB_IN, bypass this pin to ground with a 0.01 F capacitor.

17, 18 NC No Connect. These are excess, unused pins that can be left floating.

20, 21 O

PFD_VRB,

T

PFD_VR

These pins must be capacitively decoupled. See the Phase Detector Pin

onnections section for details.

C

Rev. 0 | Page 9 of 68

AD9549

www.BDTIC.com/ADI

Input/

Pin No.

22 O

27 I

28 I

31 O LOOP_FILTER

32 I 1.8 V CMOS CLKMODESEL

33, 39, 43, 52 O GND AVSS Analog Ground. Connect to ground.

34 O 1.8 V HSTL OUTB

35 O 1.8 V HSTL OUT

37 I Power AVDD3

38 O 3.3 V CMOS OUT_CMOS

40 I

41 I

48 O

50 O

51 O

56 I/O 3.3 V CMOS REFSELECT

57 I/O 3.3 V CMOS HOLDOVER

58 I 3.3 V CMOS PWRDOWN

59 I 3.3 V CMOS RESET

60 I 3.3 V CMOS IO_UPDATE

Output Pin Type Mnemonic Description

Current Set

esistor

R

Differential

nput

I

Differential

nput

I

Differential

nput

I

Differential

nput

I

Current Set

esistor

R

Differential

utput

O

Differential

utput

O

PFD_RSET

SYSCLK

SYSCLKB

FDBK_INB

FDBK_IN

DAC_RSET

DAC_OUT

DAC_OUTB

Connect a 5 kΩ resistor from this pin to ground (see the Phase Detector Pin

onnections section).

C

System Clock Input. The system clock input has internal dc biasing and should

alwa

ys be ac-coupled, except when using a crystal. Single-ended 1.8 V CMOS

can also be used but can introduce a spur caused by an input duty cycle that is

not 50%. When using a crystal, tie the CLKMODESEL pin to AVSS, and connect

crystal directly to this pin and Pin 28.

Complementary System Clock. Complementary signal to the input provided

on P

in 27. Use a 0.01 F capacitor to ground on this pin if the signal provided

on Pin 27 is single-ended.

System Clock Multiplier Loop Filter. When using the fr

drive the system clock, an external loop filter must be constructed and

attached to this pin. This pin is pulled high when the system clock PLL is

bypassed and can be left floating in this mode. See Figure 44 for a diagram of

the system cloc

Clock Mode Select. Set to GND when connecting a crystal to the system clock

in 27 and Pin 28). Pull up to 1.8 V when using either an oscillator or an

input (P

external clock source. This pin can be left floating when the system clock PLL is

bypassed. (See the SYSCLK Inputs section for details on the use of this pin.)

Complementary HSTL Output. See the Specifications and Primary 1.8 V

erential HSTL Driver sections for details.

Diff

HSTL Output. See the Specifications and Primary 1.8 V Differential HSTL Driver

tions for details.

sec

Analog Supply for CMOS Output Driver: This pin

1.8 V. This pin should be powered even if the CMOS driver is not used. See the

Power Supply Partitioning section for power supply partitioning.

CMOS Output. See the Specifications section and the Output Clock Drivers and

requency Multiplier section. This pin is 1.8 V CMOS if Pin 37 is set to 1.8 V.

2× F

Complementary Feedback Input. In standard operating mode, this pin is

c

onnected to the filtered DAC_OUTB output. This internally biased input is

typically ac-coupled, and when configured as such, can accept any differential

signal whose single-ended swing is at least 400 mV.

Feedback Input. In standard operating mode

filtered DAC_OUT output

DAC Output Current Setting Resistor. Connect a resistor (usually 10 kΩ) from

this pin to GND

DAC Output. This signal should be filtered and sent back on chip through

FDBK_IN input. This pin has an internal 50 Ω pull-down resistor.

Complimentary DAC Output. This signal should be filtered and sent back on

chip thr

ough FDBK_INB input. This pin has an internal 50 Ω pull-down resistor.

Reference Select Input. In manual mode, the REFSELECT pin operates as a high

impedanc

output pin. Logic 0 (low) indicates/selects REFA. Logic 1 (high) indicates/selects

REFB. There is no internal pull-up/pull-down resistor on this pin.

Holdover (Active High). In manual holdover mode, this pin is used to force the

AD9549 in

holdover status. There is no internal pull-up/pull-down resistor on this pin.

Power-Down. When this active high pin is asserted, the device becomes

inac

pull-down resistor.

Chip Reset. When this active high pin is a

that on power-up, a 10 s reset pulse is internally generated when the power

supplies reach a threshold and stabilize. This pin has an internal 50 kΩ pulldown resistor.

I/O Update. A logic transition from 0 to 1 on this pin transf

port registers to the control registers (see the Write section). This pin has an

ternal 50 kΩ pull-down resistor.

in

e input pin, while in automatic mode, it operates as a low impedance

to holdover mode. In automatic holdover mode, it indicates

tive and enters the full power-down state. This pin has an internal 50 kΩ

equency multiplier to

k PLL loop filter.

is normally 3.3 V but can be

, this pin is connected to the

. See the DAC Output section.

sserted, the chip goes into reset. Note

ers data from the I/O

Rev. 0 | Page 10 of 68

AD9549

www.BDTIC.com/ADI

Input/

Pin No.

61 I 3.3 V CMOS CSB

62 O 3.3 V CMOS SDO

63 I/O 3.3 V CMOS SDIO

64 I 3.3 V CMOS SCLK

Exposed Die

Pad

Output Pin Type Mnemonic Description

Chip Select. Active low. When programming a device, this pin must be held

w. In systems where more than one AD9549 is present, this pin enables

lo

individual programming of each AD9549. This pin has an internal 100 kΩ pullup resistor.

Serial Data Output. When the device is in 3-wire mode, data is r

There is no internal pull-up/pull-down resistor on this pin.

Serial Data Input/Output. When

this pin. In 2-wire mode, data reads and writes both occur on this pin. There is

no internal pull-up/pull-down resistor on this pin.

Serial Programming Clock. Data clock for serial programming. This pin has an

ternal 50 kΩ pull-down resistor.

in

O GND AVSS Analog Ground. Connect to ground.

the device is in 3-wire mode, data is written via

ead on this pin.

Rev. 0 | Page 11 of 68

AD9549

–

–

–

–

–

–

www.BDTIC.com/ADI

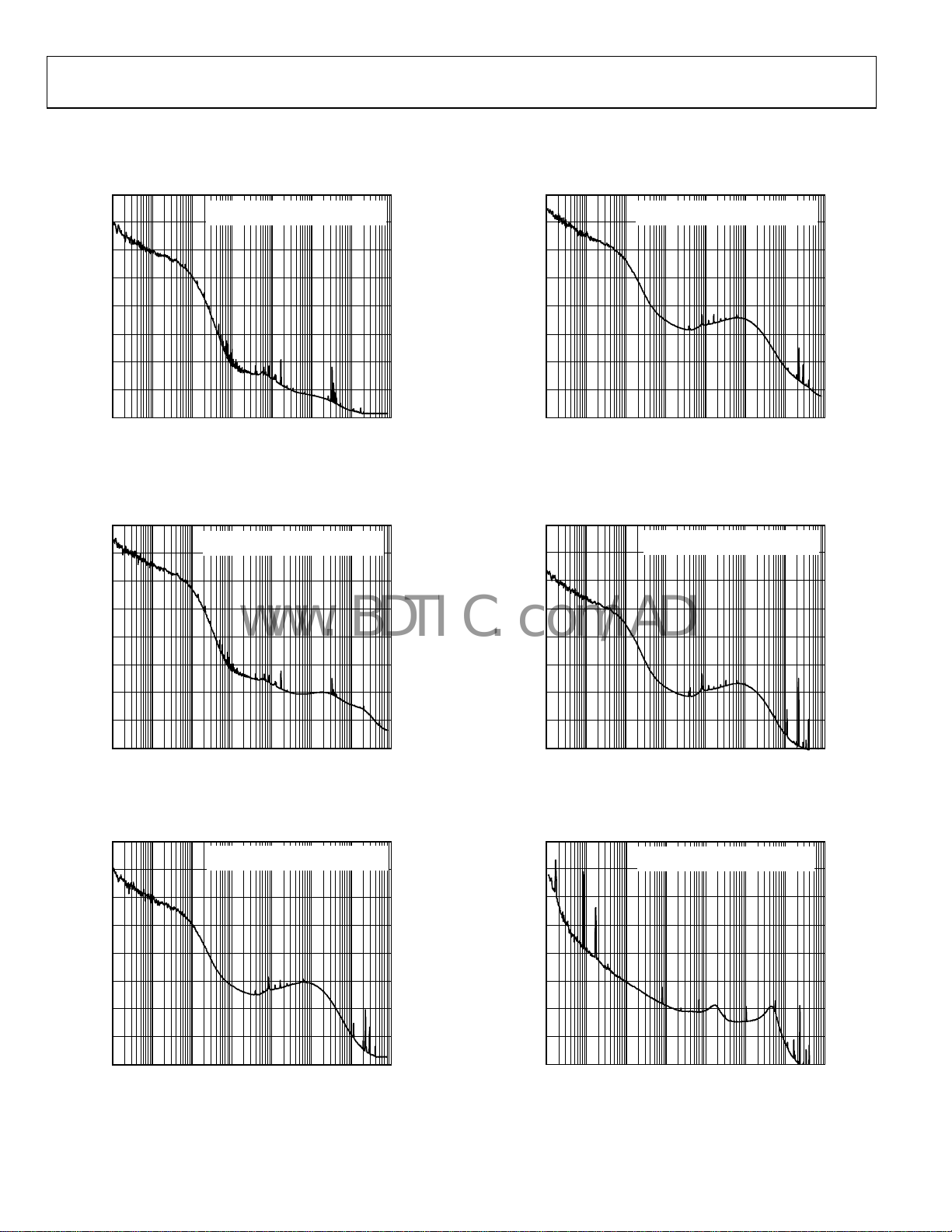

TYPICAL PERFORMANCE CHARACTERISTICS

Unless otherwise noted, AVDD, AVDD3, and DVDD at nominal supply voltage; fS = 1 GHz, DAC R

–80

70

RMS JITTER (12kHz TO 20MHz): 0.18p s

RMS JITTER (50kHz TO 80MHz): 0.24p s

70

–80

= 10 k.

SET

RMS JITTER (12kHz TO 20MHz): 1.09p s

RMS JITTER (50kHz TO 80MHz): 1.14p s

–90

–100

–110

–120

PHASE NOISE (dBc/Hz)

–130

–140

–150

10 100 1k 10k 100k 1M 10M 100M

FREQUENCY OF FSET (Hz)

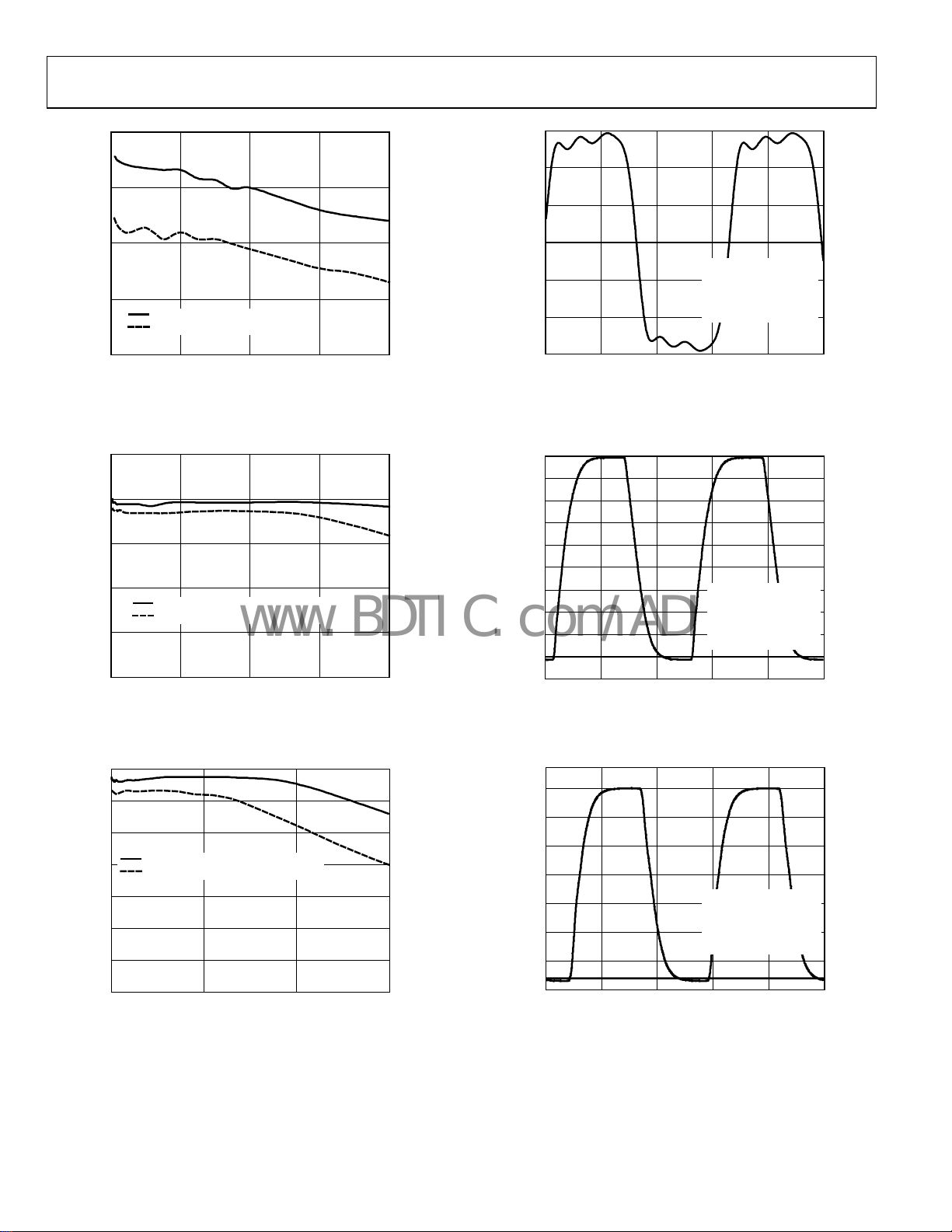

Figure 3. Additive Phase Noise at HSTL Output Driver, SYSCLK = 1 GHz

PLL Bypassed), f

(SYSCLK

= 311.04 MHz, DPLL Loop BW = 1 kHz

f

OUT

70

–80

–90

–100

–110

–120

PHASE NOISE (dBc/Hz)

–130

RMS JITT ER (12kHz TO 20MHz): 0.36p s

RMS JITT ER (50kHz TO 80MHz): 0.42p s

= 19.44 MHz,

REF

–90

–100

–110

–120

PHASE NOISE (dBc/Hz)

–130

–140

–150

06744-003

10 100 1k 10k 100k 1M 10M 100M

FREQUENCY OF FSET (Hz)

06744-006

Figure 6. Additive Phase Noise at HSTL Output Driver, SYSCLK = 1 GHz

(SYSCLK PLL

50 MHz), f

Enabled and Driven by R&S SMA100 Signal Generator at

= 19.44 MHz, f

REF

= 622.08 MHz, DPLL Loop BW = 1 kHz,

OUT

System Clock Doubler Enabled, HSTL Doubler Enabled

PHASE NOISE (dBc/Hz)

70

–80

–90

–100

–110

–120

–130

RMS JITT ER (12kHz TO 20MHz): 1.0p s

RMS JITT ER (50kHz TO 80MHz): 1.2p s

–140

–150

10 100 1k 10k 100k 1M 10M 100M

FREQUENCY OF FSET (Hz)

Figure 4. Additive Phase Noise at HSTL Output Driver, SYSCLK = 1 GHz

(SYSCLK

PLL Bypassed), f

= 19.44 MHz, f

REF

= 622.08 MHz,

OUT

DPLL Loop BW = 1 kHz, HSTL Output Doubler Enabled

70

–80

–90

–100

–110

–120

PHASE NOISE (dBc/Hz)

–130

–140

–150

10 100 1k 10k 100k 1M 10M 100M

RMS JITTER (12kHz TO 20MHz): 1.01p s

RMS JITTER (50kHz TO 80MHz): 1.04p s

FREQUENCY OF FSET (Hz)

Figure 5. Additive Phase Noise at HSTL Output Driver, SYSCLK = 1 GHz

(SYSCLK PLL

Enabled Driven by R&S SMA100 Signal Generator at 50 MHz),

= 19.44 MHz, f

f

REF

= 311.04 MHz, DPLL Loop BW = 1 kHz

OUT

06744-004

(SYSCLK PLL

06744-005

Rev. 0 | Page 12 of 68

–140

–150

10 100 1k 10k 100k 1M 10M 100M

FREQUENCY OF FSET (Hz)

Figure 7. Additive Phase Noise at HSTL Output Driver, SYSCLK = 1 GHz

Enabled and Driven by R&S SMA100 at 50 MHz), f

= 155.52 MHz, SYSCLK Doubler Enabled, DPLL Loop BW =1 kHz

f

OUT

70

–80

–90

–100

–110

–120

PHASE NOISE (dBc/Hz)

–130

–140

–150

10 100 1k 10k 100k 1M 10M 100M

RMS JITT ER (12kHz TO 20MHz): 1.07p s

RMS JITT ER (50kHz TO 80MHz): 1.16p s

FREQUENCY OF FSET (Hz)

= 19.44 MHz,

REF

Figure 8. Additive Phase Noise at HSTL Output Driver, SYSCLK = 1 GHz

(SYSCLK PLL

Enabled and Driven by R&S SMA100 Signal Generator at

50 MHz), f

= 8 kHz, f

REF

= 155.52 MHz, DPLL Loop BW = 10 Hz

OUT

06744-007

06744-008

AD9549

–

–

www.BDTIC.com/ADI

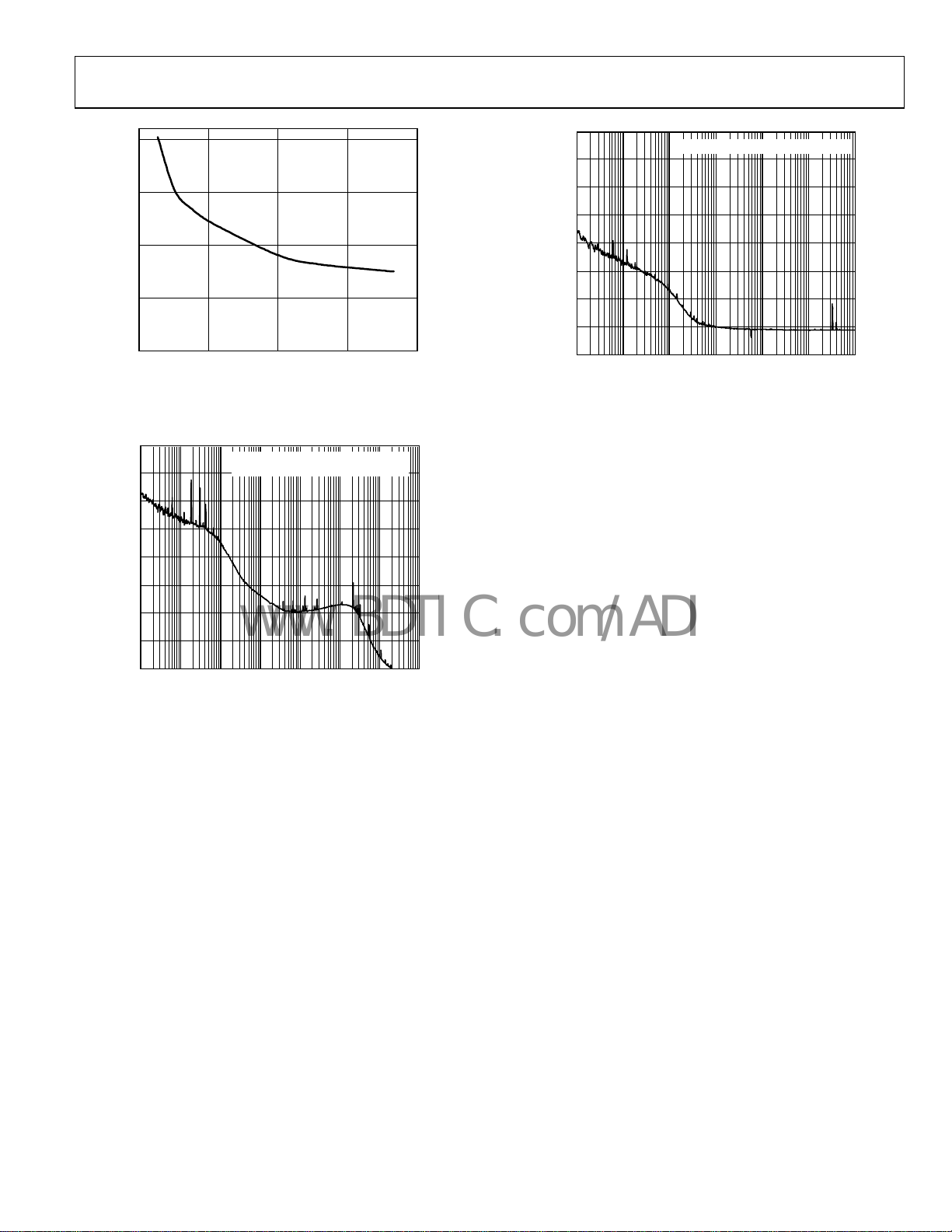

2.0

1.5

1.0

0.5

12kHz TO 20MHz RMS JITTER (ps)

0

10 30 50 70 90

SYSTEM CLOCK PLL INPUT FREQUENCY (MHz)

Figure 9. 12 kHz to 20 MHz RMS Jitter v

SYSCLK = 1 GHz, f

70

–80

–90

–100

–110

= 19.44 MHz, f

REF

RMS JITT ER (12kHz TO 20MHz): 1.26p s

RMS JITT ER (50kHz TO 80MHz): 1.30p s

06744-009

s. System Clock PLL Input Frequency,

= 155.52 MHz

OUT

70

–80

–90

–100

–110

–120

PHASE NOISE (dBc/Hz)

–130

–140

–150

10 100 1k 10k 100k 1M 10M

RMS JITTER (12kHz TO 20M Hz): 4.2ps

FREQUENCY OFFSET (Hz)

06744-011

Figure 11. Additive Phase Noise at HSTL Output Driver, SYSCLK = 500 MHz

(SYSCLK

PLL Disabled), f

= 10.24 MHz, f

REF

= 20.48 MHz,

OUT

DPLL Loop BW = 1 kHz

–120

PHASE NOISE (dBc/Hz)

–130

–140

–150

10 100 1k 10k 100k 1M 10M 100M

FREQUENCY OF FSET (Hz)

Figure 10. Additive Phase Noise at HSTL Output Driver, SYSCLK = 1 GHz

(SYSCLK PLL

Enabled and Driven by a 25 MHz Fox Crystal Oscillator),

f

= 19.44 MHz, f

REF

= 155.52 MHz, DPLL Loop BW = 1 kHz

OUT

06744-010

Rev. 0 | Page 13 of 68

AD9549

www.BDTIC.com/ADI

650

600

0.6

0.4

0.2

550

(mV)

500

NOM SKEW 25°C, 1.8V SUPPLY

SLOW SKEW 90°C, 1. 7V SUPPLY

450

0 200 400 600 800

(MHz)

06744-012

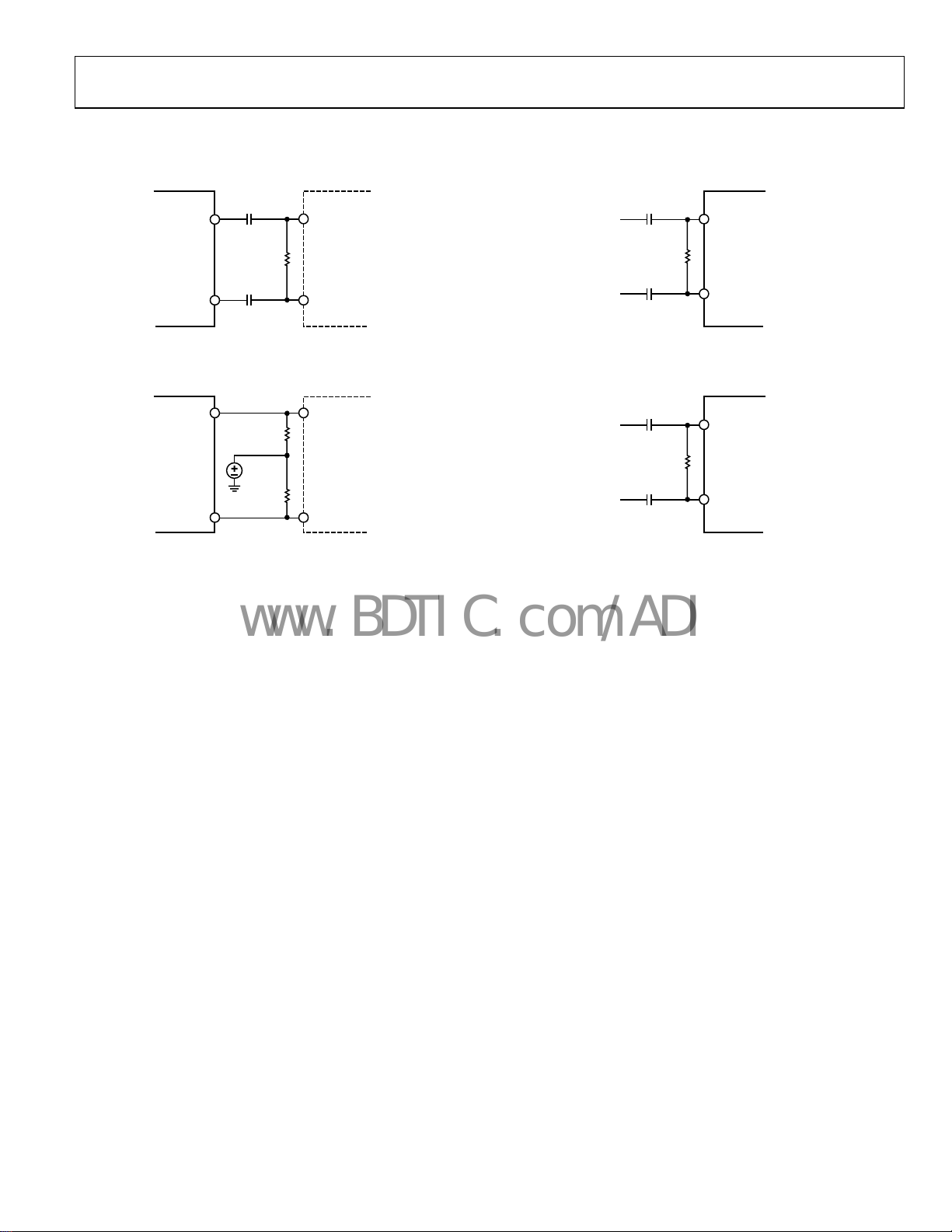

Figure 12. HSTL Output Driver Single-Ended Peak-to-Peak Amplitude vs.

Toggle Rate (100 Ω Across Differential Pair)

2.5

2.0

1.5

(V)

1.0

NOM SKEW 25° C, 1.8V SUPPLY (20pF)

0.5

0

0 1020304

SLOW S KEW 90°C, 1.7V SUPPL Y (20pF )

(MHz)

0

06744-013

Figure 13. CMOS Output Driver Peak-to-Peak Amplitude vs. Toggle Rate

VDD3 = 1.8 V) with 20 pF Load

(A

0

(V)

FREQUENCY= 600MHz

(20→80%) = 104ps

T

–0.2

–0.4

–0.6

0 0.5 1.0 1.5 2.0 2.5

RISE

T

FALL

V p-p = 1. 17V DIFF.

DUTY CYCLE = 50%

(ns)

(80→20%) = 107ps

Figure 15. Typical HSTL Output Waveform, Nominal Conditions,

DC-Coupl

1.8

1.6

1.4

1.2

1.0

0.8

(V)

0.6

0.4

0.2

0

–0.2

0 20 40 60 80 100

Figure 16. Typical CMOS Output Dr

ed, Differential Probe Across 100 Ω load

FREQUENCY= 20MHz

T

(20→80%) = 5.5ns

RISE

T

(80→20%) = 5.9ns

FALL

V p-p = 1.8V

DUTY CYCLE = 53%

(ns)

iver Waveform (@ 1.8 V),

Nominal Conditions, Estimated Capacitance: 5 pF

06744-015

06744-016

3.5

3.0

2.5

2.0

(V)

1.5

1.0

0.5

NOM SKEW 25°C, 3.3V SUPPLY (20pF)

SLOW SKEW 90°C, 3.0V SUPPLY (20pF)

0

0 50 100 150

(MHz)

06744-014

Figure 14. CMOS Output Driver Peak-to-Peak Amplitude vs. Toggle Rate

VDD3 = 3.3 V) with 20 pF Load

(A

Rev. 0 | Page 14 of 68

3.3

2.8

2.3

1.8

(V)

1.3

0.8

0.3

–0.2

0 102030405

FREQUENCY= 40MHz

T

(20→80%) = 2.25ns

RISE

T

FALL

V p-p = 3.3V

DUTY CYCLE = 52%

(ns)

(80→20%) = 2.6ns

0

Figure 17. CMOS Output Driver Waveform (@ 3.3 V), Nominal Conditions,

Esti

mated Capacitance: 5 pF, f

= 20 MHz

OUT

06744-017

AD9549

www.BDTIC.com/ADI

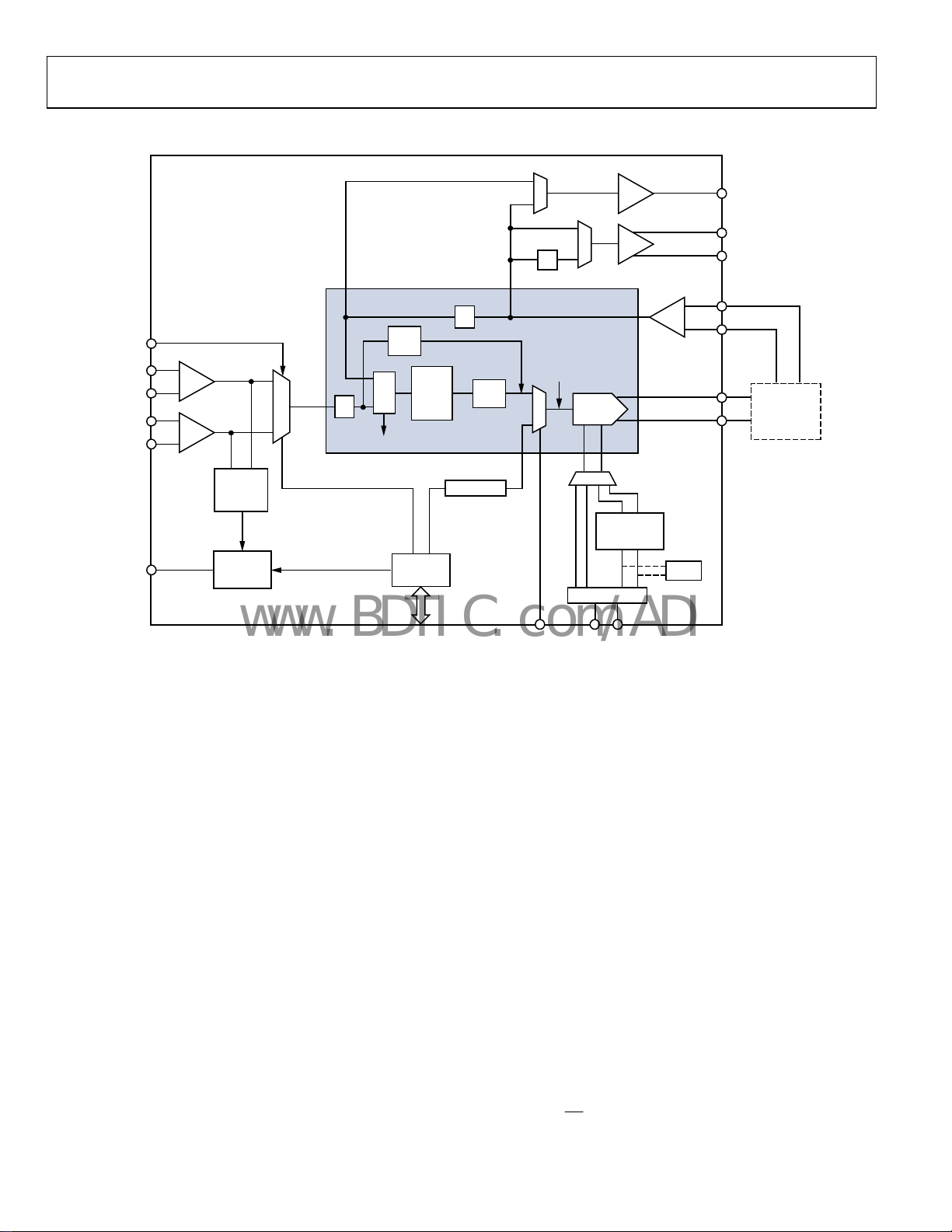

INPUT/OUTPUT TERMINATION RECOMMENDATIONS

0.01µF

AD9549

1.8V

HSTL

OUTPUT

100Ω

0.01µF

DOWNSTREAM

DEVICE

(HIGH-Z)

Figure 18. AC-Coupled HSTL Output Driver

AD9549

1.8V

HSTL

OUTPUT

50Ω

AVDD/2

50Ω

DOWNSTREAM

DEVICE

(HIGH-Z)

Figure 19. DC-Coupled HSTL Output Driver

0.01µF

100Ω

(OPTIONAL)

0.01µF

06744-018

AD9549

SELF-BIASING

REF INPUT

06744-020

Figure 20. Reference Input

0.1µF

100Ω

(OPTIONAL)

0.1µF

06744-019

AD9549

SELF-BIASING

FDBK INPUT

06744-021

Figure 21. FDBK Input

Rev. 0 | Page 15 of 68

AD9549

www.BDTIC.com/ADI

THEORY OF OPERATION

OUT_CMOS

REFSELECT

REFA_IN

REFB_IN

S1 TO S4

INPUT

MONITOR

OOL AND LO R

IRQ AND

STATUS

LOGIC

REF

÷R

REF_CNTRL

FREQ

EST.

PROG.

DIGITAL

PFD

LOOP

FILTER

LOCK DETECT

CONTROL

LOGIC

DIGITAL

INTERFACE

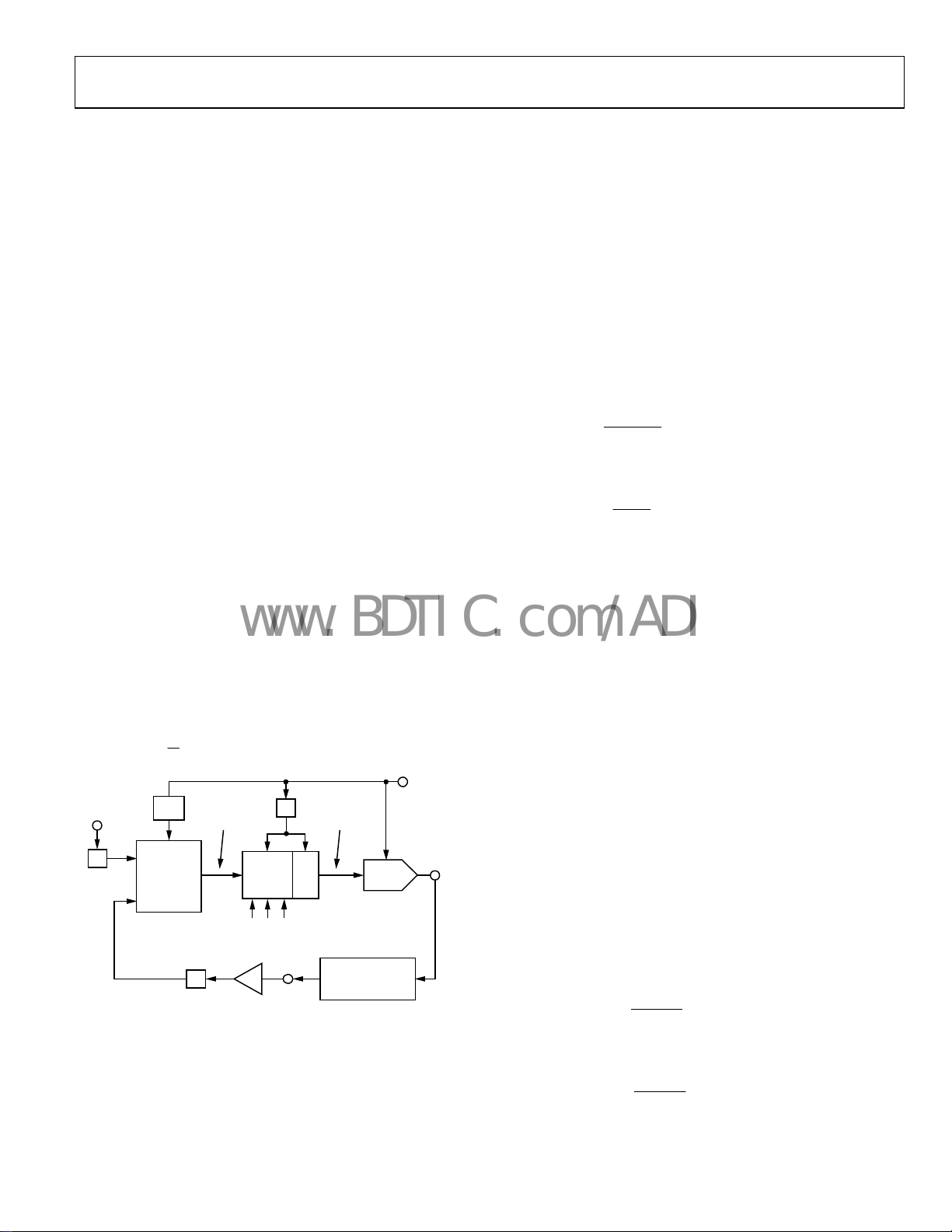

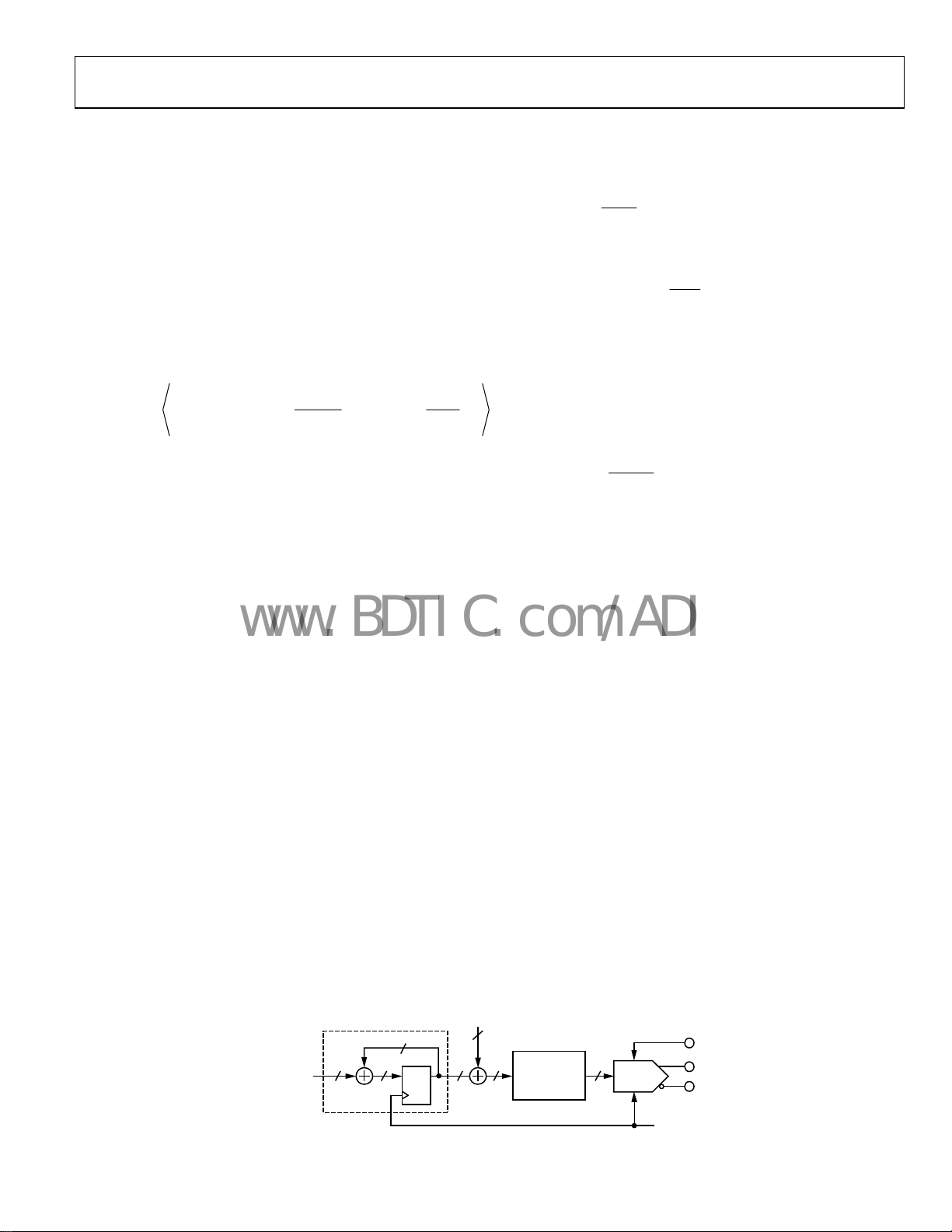

Figure 22. Detailed Block Diagram

OVERVIEW

The AD9549 provides a clocking output that is directly related

in phase and frequency to the selected (active) reference (REFA

or REFB) but has a phase noise spectrum primarily governed by

the system clock. A wide band of reference frequencies is supported. Jitter existing on the active reference is greatly reduced

by a programmable digital filter in the digital phase-locked loop

(PLL), which is the core of this product. The AD9549 supports

both manual and automatic holdover. While in holdover, the

AD9549 continues to provide an output as long as the system

clock is maintained. The frequency of the output during holdover is an average of the steady state output frequency prior to

holdover.

Also offered are manual and automatic switchover modes for

nging between the two references, should one become

cha

suspect or lost. A digitally controlled oscillator (DCO) is

implemented using a direct digital synthesizer (DDS) with an

integrated output DAC, clocked by the system clock. A bypassable PLL-based frequency multiplier is present enabling use of

an inexpensive, low frequency source for the system clock. For

best jitter performance, the system clock PLL should be bypassed,

and a low noise, high frequency system clock should be provided

directly. Sampling theory sets an upper bound for the DDS

output frequency at 50% of f

(where fS is the DAC sample rate),

S

2×

÷S

SLEW

HOLDOVER

DIGITAL PLL CORE

FREQUENCY

LIMIT

HOLDOVER SYSCLK

TUNING

WORD

DDS/DAC

LOW NOISE

MULTIPLIER

SYSCLK PORT

but a practical limitation of 40% of f

CLOCK

AMP

OUT

FDBK

EXTERNAL

ANALOG

LOW-PASS

FILTER

is generally recommended

S

to allow for the selectivity of the required off-chip

reconstruction filter. The output signal from the reconstruction

filter is fed back to the AD9549, both to complete the PLL and

to be processed through the output circuitry. The output

circuitry includes HSTL and CMOS output buffers, as well as a

frequency doubler for designs that need to provide frequencies

above the Nyquist level of the DDS.

The individual functional blocks are described in the following

secti

ons.

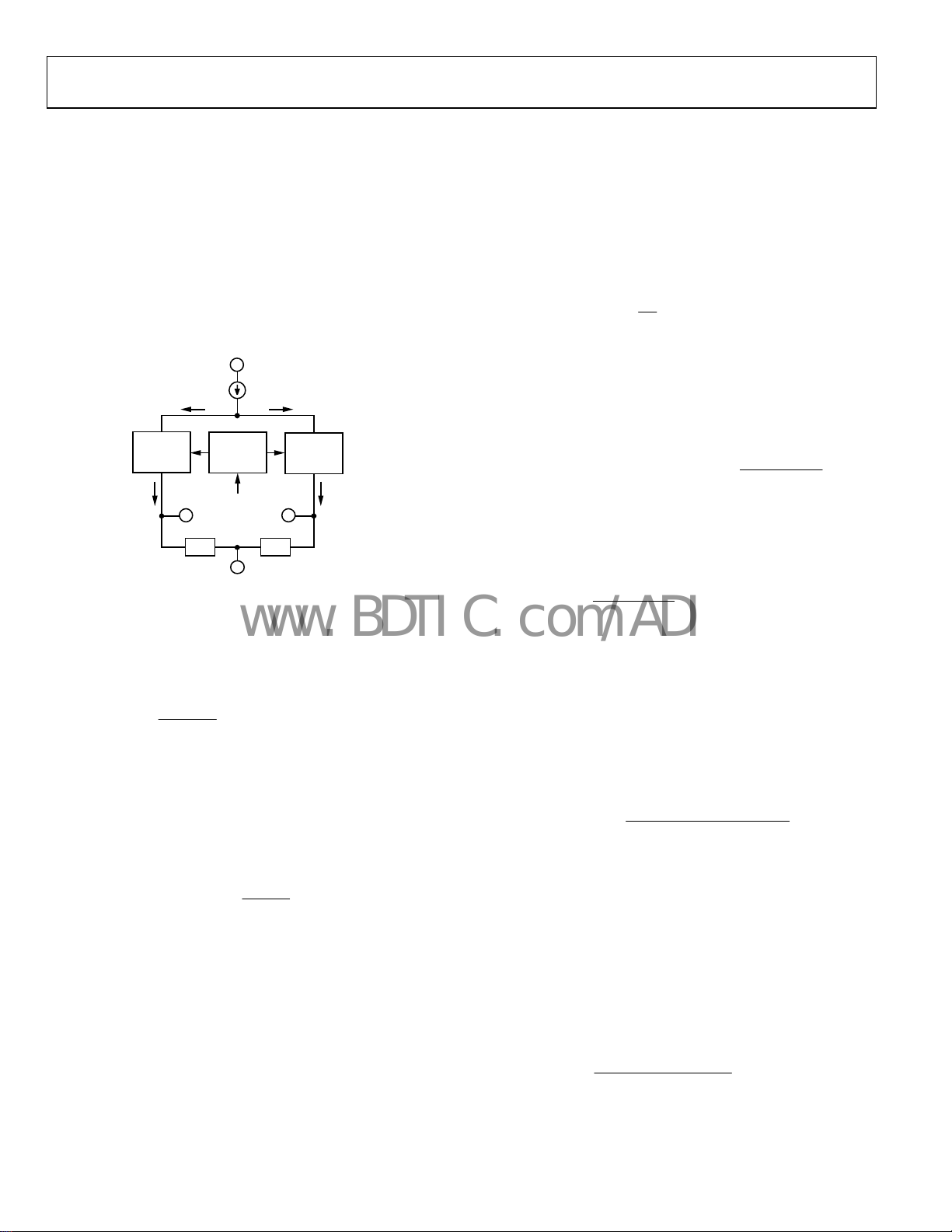

PLL CORE (DPLLC)

The digital phase-locked loop core (DPLLC) includes the

frequency estimation block and the digital phase lock control

block driving the DDS.

The start of the DPLLC signal chain is the reference signal, f

which appears on REFA or REFB inputs. The frequency of this

signal can be divided by an integer factor of R via the feedforward divider. The output of the feedforward divider is routed to

the phase/frequency detector (PFD). Therefore, the frequency

at the input to the PFD is given by

f

R

=

f

PFD

R

06744-022

,

R

Rev. 0 | Page 16 of 68

AD9549

www.BDTIC.com/ADI

The PFD outputs a time series of digital words that are routed

to the digital loop filter. The digital filter implementation offers

many advantages: The filter response is determined by numeric

coefficients rather than discrete component values. There is no

aging of components and therefore, no drift of component value

over time. There is no thermal noise in the loop filter, and there

is no control node leakage current (which causes reference feedthrough in a traditional analog PLL).

The output of the loop filter is a time series of digital words.

T

hese words are applied to the frequency tuning input of a DDS

to steer the DCO frequency. The DDS provides an analog

output signal via an integrated DAC, effectively mimicking the

operation of an analog VCO.

The DPLLC can be programmed to operate in conjunction

ith an internal frequency estimator to help decrease the time

w

required to achieve lock. When the frequency estimator is

employed, frequency acquisition is accomplished in a two-step

process:

1. An es

timate is made of the frequency of f

. The phase

PFD

lock control loop is essentially inoperative during the

frequency estimation process. Once a frequency estimate is

made, it is delivered to the DDS so that its output frequency

is approximately equal to f

multiplied by S (the modulus

PFD

of the feedback divider).

2. The phas

e lock control loop becomes active and acts as a

servo to acquire and hold phase lock with the reference

signal.

As mentioned in Step 1, the DPLLC includes a feedback divider

hat allows the DCO to operate at an integer multiple (S) of f

t

This establishes a nominal DCO frequency (f

S

⎞

⎛

f

=

⎟

⎜

R

R

⎠

⎝

÷PFD

PHASE

DETECTO R

(TIME-TO-

DIGIT AL

SAMPLES

DELIVERED AT

DIV

THE CLK RAT E

LOOP

FILTER

αβ

FDBK_IN

÷S

Figure 23. AD9549 Digital PLL Block Diagram

÷P

CCI

ץ

PINS

SAMPLES

DELIVERED AT

SYSCLK RATE

EXTERNAL DAC

RECONSTRUCTION

REF

INPUT

÷R

f

CLK

DDS

CONVERTER)

), given by

DDS

DDS

FILTER

SYSCLK

DAC_OUT

PINS

PFD

Feedforward Divider (Divide-by-R)

The feedforward divider is an integer divider that allows

frequency prescaling of the REF source input signal while

maintaining the desired low jitter performance of the AD9549.

The feedforward divider is a programmable modulus divider

th very low jitter injection. The divider is capable of handling

wi

input frequencies as high as 750 MHz. The divider depth is 16-

Rev. 0 | Page 17 of 68

.

06744-023

bits cascaded with an additional divide-by-2. The divider

therefore is capable of integer division from 1 to 65,535 (index

of 1) or 2 to 131,070 (index of 2). The divider is programmed

via the I/O Register Map to trigger on either the rising (default)

or falling edge of the REF source input signal. Note that the

value stored in the R-divider register is one less than the actual

R-divider, so setting the R-divider register to zero results in an R

divider equal to one.

There is a lower bound on the value of R imposed by the phase

f

requency detector within the DPLLC, which has a maximum

operating frequency of f

, as explained in the Fine Phase

PFD[MAX]

Detector section. The R-Divider/2 bit must be set when REFA

r REFB is greater than 400 MHz. The user must also ensure

o

that R is chosen so that it satisfies the inequality

⎛

R

⎜

≥

ceil

⎜

f

⎝

⎞

f

R

⎟

⎟

][

MAXPFD

⎠

The upper bound is

f

⎛

⎞

≤

floor

R

R

⎜

⎟

kHz8

⎝

⎠

where the ceil(x) function yields the nearest integer ≥ x.

For example, if f

=155 MHz and f

R

= 24.5 MHz, then

PFD[MAX]

ceil (155/24.5) = 7, so R must be ≥ 7.

Feedback Divider (Divide-by-S)

The feedback divider is an integer divider allowing frequency

multiplication of the REF signal that appears at the input of the

phase detector. It is capable of handling frequencies well above

the Nyquist limit of the DDS. The divider depth is 16-bits cascaded with an additional divide-by-2. The divider is therefore

capable of integer division from 1 to 65,535 (index of 1) or 2 to

131,070 (index of 2). The divider is programmed via the I/O

Register Map to trigger on either the rising (default) or falling

edge of the feedback signal. Note that the value stored in the SDivider register is one less than the actual R-divider, so setting

the S-Divider register to zero results in an S-divider equal to one.

The feedback divider must be programmed within certain

b

oundaries. The S-Divider/2 bit must be set when FDBK_IN is

greater than 400 MHz. The upper boundary on the feedback

divider is the lesser of the maximum programmable value of

S and the maximum practical output frequency of the DDS

(~ 40% f

divider index of 1 and S

). Two equations are given—S

S

for an index of 2.

max2

⎛

%40

Rf

S

⎜

= 535,65,

MAX1

min

⎜

f

R

⎝

S

for a feedback

max1

⎞

⎟

⎟

⎠

or

⎛

%40

Rf

S

⎜

= 070,131,

S

where

sample rate, and

min

2

MAX

⎜

f

R

⎝

R is the modulus of the feedforward divider, f

f

is the input reference frequency.

R

⎞

⎟

⎟

⎠

is the DAC

S

AD9549

C

www.BDTIC.com/ADI

The DCO has a minimum frequency, f

DCO[MIN]

(see the DAC

Output Characteristics section of the AC Specifications table).

This i

mposes a lower bound, S

, on the feedback divider

MIN

value as well.

⎞

⎞

][RMINDCO

⎟

⎟

⎟

⎟

⎠

⎠

MIN

= 1,max

⎛

⎛

f

⎜

⎜

RS

⎜

⎜

f

⎝

⎝

Note that reduced DCO frequencies result in worse jitter

erformance (a consequence of the reduced slew rate of the

p

sinusoid generated by the DDS).

Forward and Reverse FEC Clock Scaling

The feedforward divider (divide-by-R) and feedback divider

(divide-by-S) enable FEC clock scaling. For instance, to

multiply the incoming signal by 255/237, set the S-divider to

255 and the R-divider to 237. One should be careful to abide by

the limitations on the R- and S-dividers, and make sure the

phase detector input frequency is within specified limits.

Phase Detector

The phase detector is composed of two detectors: a coarse phase

detector and a fine phase detector. The two detectors operate in

parallel. Both detectors measure the duration (t) of the pulses

generated by a conventional three-state phase/frequency detector.

Together, the fine and coarse phase detectors produce a digital

ord that is a time-to-digital conversion of the separation

w

between the edge transitions of the prescaled reference signal

and the feedback signal.

If the fine phase detector is able to produce a valid result, this

r

esult alone serves as the phase error measurement. If the fine

phase detector is either in an overflow or underflow condition,

the phase error measurement uses the coarse phase detector

instead.

Digital Loop Filter

The digital loop filter integrates and low-pass filters the digital

phase error values delivered by the phase detector. The loop

filter response mimics that of a 2

nd

order RC network used to

filter the output of a typical phase detector and charge pump

combination as shown in

LK

PHASE/

FREQUENCY

DETECTOR

Figure 24. Typical Analog PLL Block Diagram

Figure 24.

CHANGE

PUMP

LOOP FILTER

R2

C1

C2

VCO

6744-024

The building blocks implemented on the AD9549, however, are

digital. A time-to-digital converter that produces digital values

proportional to the edge timing error between the CLK and

feedback signals replaces the phase-frequency detector and

charge pump. A digital filter that processes the edge timing

error samples from the time-to-digital converter replaces the

loop filter. A DDS replaces the VCO, which produces a frequency

Rev. 0 | Page 18 of 68

that is linearly related to the digital value provided by the loop

filter. This is shown in

Figure 25 with some additional detail.

The samples provided by the time-to-digital converter are

de

livered to the loop filter at a sample rate equal to the CLK

frequency (that is, f

/R). The loop filter is intended to oversam-

R

ple the time-to-digital converter output at a rate determined by

the P-divider. The value of P is programmable via the I/O

Register Map. It is stored as a 5-bit number, P

. The value of PIO

IO

is related to P by the equation

PIO

P = 2

where 5 ≤ P

≤ 16.

IO

Hence, the P-divider can provide divide ratios between 32 and

65,536 in p

ower-of-2 steps. With a DAC sample rate of 1 GHz,

the loop filter sample rate can range from as low as 15.26 kHz to

a maximum of 31.25 MHz. Coupled to the loop filter is a

cascaded comb integrator (CCI) filter that provides a sample

rate translation between the loop filter sample rate (f

the DDS sample rate, f

.

S

/P) and

S

The choice of P is important because it controls both the

r

esponse of the CCI filter and the sample rate of the loop filter.

In order to understand the method for determining a useful

value for P, it is first necessary to examine the transfer function

of the CCI filter.

2

jω

P

⎡

)(

ωH

CCI

1

=

⎢

1(

⎣

⎤

e

−

−

⎥

− jω

eP

⎦

or

0,1

=

ω

CCI

⎛

)(

=

ωH

−

⎜

⎜

−

p

⎝

2

ωP

ω

⎞

)cos(11

,

⎟

⎟

)cos(1

⎠

0

>

ω

To evaluate the response in terms of absolute frequency, make

e substitution

th

π

2

f

=

ω

f

S

where f

H

is the DAC sample rate and f is the frequency at which

S

is to be evaluated.

CCI

Analysis of this function reveals that the CCI magnitude

r

esponse follows a low-pass characteristic that consists of a

series of P lobes. The lobes are bounded by null points occurring at frequency multiples of f

/P. The peak of each successive

S

lobe is lower that its predecessor over the frequency range

between dc and ½f

response is a reflection about the vertical at ½f

the first lobe (which appears between dc and f

. For frequencies greater than ½fS, the

S

. Furthermore,

S

/P) exhibits a

S

monotonically decreasing response. That is, the magnitude is

unity at dc, and it steadily decreases with frequency until it

vanishes at the first null point (f

/P).

S

The null points imply the existence of transmission zeros placed

a

t finite frequencies. While transmission zeros placed at infinity

yield minimal phase delay, zeros placed closer to dc result in

AD9549

www.BDTIC.com/ADI

increased phase delay. Hence, the position of the first null point

has a significant impact on the phase delay introduced by the

CCI filter. This is an important consideration because excessive

phase delay negatively impacts the overall closed-loop response.

As a rule of thumb, choose a value for P so that the frequency of

the first null point (f

loop bandwidth or 1.5 times the frequency of CLK (f

The value of P thus calculated (P

in practice. Because P is programmed as P

define P

in terms of PIO so that P

MAX

The condition P

/P) is the greater of 80 times the desired

S

) is the largest usable value

MAX

, it is necessary to

IO

can be determined.

IOMAX

IO

≤ P

ensures that the impact of the phase

IOMAX

/R).

R

delay of the CCI filter on the phase margin of the loop does not

exceed 5°. P

=

P

IOMAX

can be expressed as

IOMAX

⎧

⎪

⎨

⎪

⎩

⎡

⎛

⎜

⎢

logfloor,16min,5max

⎜

80

⎢

⎝

⎣

f

f

S

LOOP

⎤

⎡

⎞

⎟

⎥

⎟

⎥

⎠

⎦

⎛

f

2

S

⎜

⎢

logfloor,

22

⎜

f

3

⎢

⎣

REF

⎝

With a properly chosen value for P, the closed-loop response of

the digital PLL is primarily determined by the response of the

digital loop filter. Flexibility in controlling the loop filter

response translates directly into flexibility in the range of

applications satisfied by the architecture of the AD9549.

The AD9549 evaluation software automatically sets the value of

t

he P-divider based on the user’s input criteria. Therefore, the

formulas are provided here mainly to assist in understanding

how the part works.

Direct Digital Synthesizer

One of the primary building blocks of the digital PLL is a direct

digital synthesizer (DDS). The DDS behaves like a sinusoidal

signal generator. The frequency of the sinusoid generated by the

DDS is determined by a frequency tuning word (FTW), which

is a digital (that is, numeric) value. Unlike an analog sinusoidal

generator, a DDS uses digital building blocks and operates as a

sampled system. Thus, it requires a sampling clock (f

) that

S

serves as the DDS's fundamental timing source. The accumulator behaves as a modulo-2

48

counter with a programmable step

size (FTW). A block diagram of the DDS is shown in Figure 25.

The input to the DDS is a 48-bit FTW that provides the accum

ulator with a seed value. On each cycle of f

, the accumulator

S

adds the value of the FTW to the running total of its output.

For example, given an FTW = 5, the accumulator counts by 5s,

incrementing on each f

reaches the upper end of its capacity (2

cycle. Over time, the accumulator

S

48

in this case), at which

point, it rolls over, retaining the excess. The average rate at which

the accumulator rolls over establishes the frequency of the

48-BIT ACCUMULAT OR

48

FREQUENCY

TUNING WO RD

(FTW)

194848

QD

⎤

⎞

⎟

⎥

⎟

⎥

⎠

⎦

PHASE

OFFSET

output sinusoid. The average rollover rate of the accumulator is

given by the next equation and establishes the output frequency

(f

) of the DDS.

DDS

FTW

⎛

=

f

⎞

⎜

⎝

f

⎟

SDDS

48

2

⎠

Solving this equation for FTW yields

⎡

⎢

FTW

=

2round

⎢

⎣

For example, given that f

48

⎤

⎞

⎛

f

DDS

⎟

⎜

⎥

⎟

⎜

f

⎥

S

⎠

⎝

⎦

= 1 GHz and f

S

= 19.44 MHz, then

DDS

FTW = 5,471,873,547,255 (0x04FA05143BF7).

The relative phase of the sinusoid can be controlled numerically,

⎫

⎪

⎬

⎪

⎭

ell. This is accomplished using the phase offset input to the

as w

DDS (a programmable 16-bit value (phase); see the

Map section). The resulting phase offset, Φ (radians), is given by

phase

Δ

⎛

2

Φ

π=Δ

⎜

⎝

⎞

⎟

16

2

⎠

The DDS can be operated in either open-loop or closed-loop

m

ode, via the Close Loop bit in the DPLL Register.

There are two open-loop modes: single tone and holdover. In

gle tone mode, the DDS behaves like a frequency synthesizer,

sin

and uses the value stored in the FTW0 register to determine its

ou tput frequenc y. A l te r n atively, the F T W and phase values

can be determined by the device itself using the frequency

estimator. Because single tone mode ignores the reference

inputs, it is very useful for generating test signals to aid in

debugging. Single tone mode must be activated manually via

register programming.

In holdover mode, the AD9549 uses past tuning words when

he loop is closed to determine its output frequency. Therefore,

t

the loop must have been successfully closed in order for holdover

mode to work. Switching in and out of holdover mode can be

either automatic or manual, depending on register settings.

Typically, the AD9549 operates in closed-loop mode. In closedl

oop mode, the FTW values come from the output of the digital

loop filter and vary with time. The DDS frequency is steered in

a manner similar to a conventional VCO-based PLL.

Note that in closed-loop mode, the DDS phase offset capability

is in

operative.

16

ANGLE TO

AMPLITUDE

CONVERSIO N

1419

DAC

(14-BIT)

I-SET

DAC+

DAC–

I/O Register

Figure 25. DDS Block Diagram

Rev. 0 | Page 19 of 68

f

S

06744-025

AD9549

www.BDTIC.com/ADI

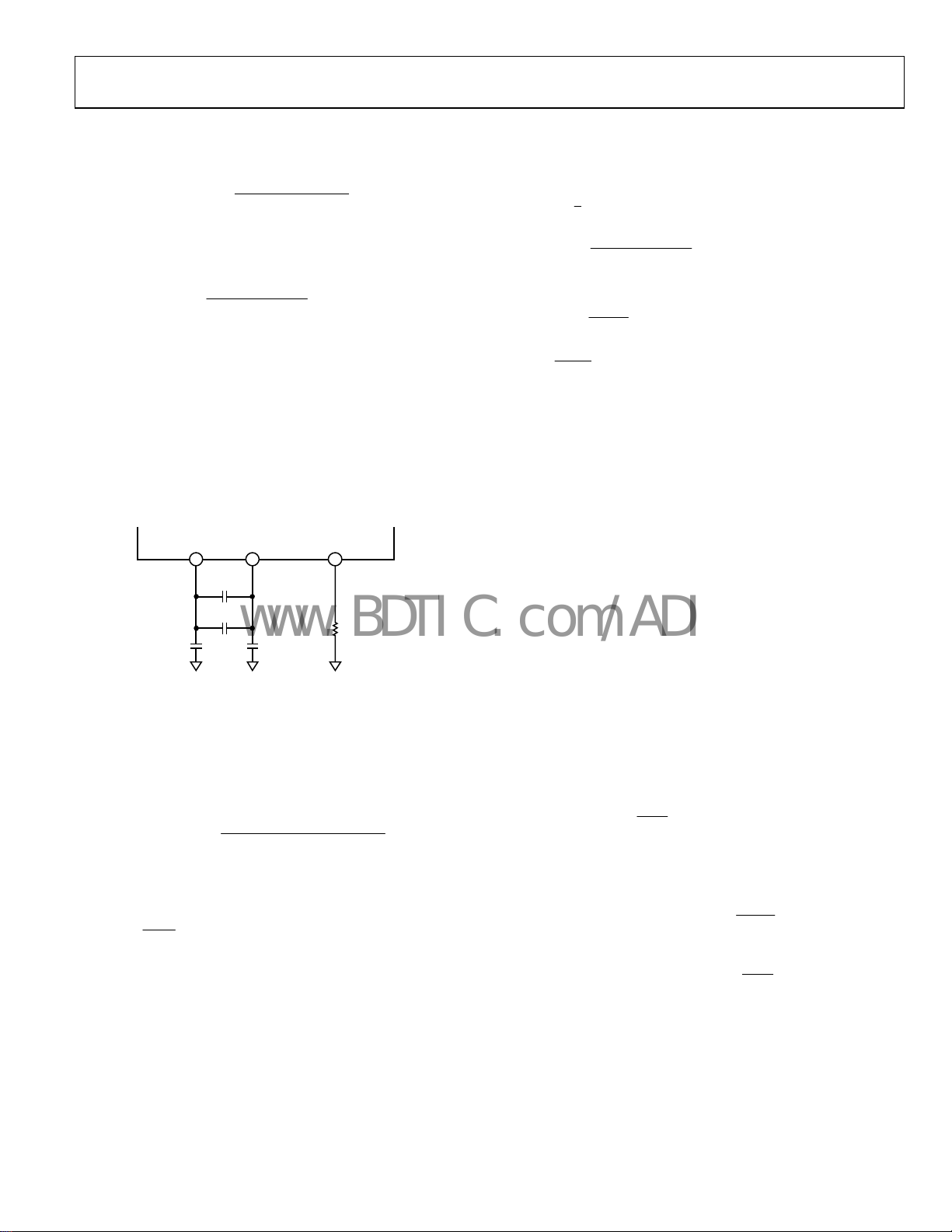

DAC Output

The output of the digital core of the DDS is a time series of

numbers representing a sinusoidal waveform. This series is

translated to an analog signal by means of a digital-to-analog

converter (DAC).

The DAC outputs its signal to two pins driven by a balanced

curr

ent source architecture (see theDAC output diagram in

Figure 26). The peak output current derives from the combinat

ion of two factors. The first is a reference current (I

DAC_REF

)

established at the DAC_RSET pin and the second is a scale

factor programmed into the I/O register map.

AVDD3

49

I

SWITCH

CONTROL

CODE

52

AVSS

FS

CURRENT

SWITCH

ARRAY

IFS/2 – I

CODE

5051

06744-026

)

DAC_REF

IFS/2 + I

The value of I

CURRENT

SWITCH

ARRAY

CODE

DAC_REF

IFS/2 IFS/2

IOUT IOUTB

50Ω 50Ω

Figure 26. DAC Output Pins

is set by connecting a resistor (R

between the DAC_RSET pin and ground. The DAC_RSET pin

is internally connected to a virtual voltage reference of 1.2 V

nominal, so the reference current can be calculated by

I

_

REFDAC

Note that the recommended value of I

leads to a recommended value for R

2.1

=

R

REFDAC

_

is 120 A, which

DAC_REF

of 10 k.

DAC_REF

The scale factor consists of a 10-bit binary number (FSC)

p

rogrammed into the DAC Full-Scale Current register in the

I/O register map. The full-scale DAC output current (I

DAC_FS

) is

given by

FSC

192

⎛

II

__

+=

72

⎜

REFDACFSDAC

⎝

Using the recommended value of R

1024

DAC_REF

⎞

⎟

⎠

, the full-scale DAC

output current can be set with 10-bit granularity over a range of

approximately 8.6 mA to 31.7 mA. 20 mA is the default value.

PHASE DETECTOR

Coarse Phase Detector

The coarse phase detector uses the DAC sample rate (fS) to

determine the edge timing deviation between the REF signal

and the feedback signal generated by the DDS. Hence, f

sets the

S

timing resolution of the coarse phase detector. At the recommended rate of f

= 1 GHz, the coarse phase detector spans a

S

range of over 131 s (sufficient to accommodate REF signal

frequencies as low as 8 kHz).

The phase gain of the coarse phase detector is controlled via the

I/O r

egisters by means of two numeric entries. The first is a 3bit power-of-2 scale factor, PDS. The second is a 6-bit linear

scale factor, PDG.

⎛

⎞

f

PDS

CPD

S

⎜

=

RPhaseGain

⎜

f

R

⎝

62+

⎟

()

PDG

⎟

⎠

Fine Phase Detector

The fine phase detector operates on a divided down version of fS

as its sampling time base. The sample rate of the fine phase

detector is set using a 4-bit word (PFD_Div) in the I/O register

map and is given by

f

S

RateSampleDetectorPhaseFine

=

)_(4 DivPFD

The default value of PFD_Div is 5, so for f

= 1 GHz, the default

S

sample rate of the fine phase detector is 50 MHz. The upper

bound on the maximum allowable input frequency to the phase

detector (f

f

Therefore, f

) is 49% of the sample rate, or

PFD[MAX]

f

MAXPFD

PFD[MAX]

=

][

S

)_(8

DivPFD

is 25 MHz in the preceding example.

The fine phase detector uses a proprietary technique to

det

ermine the phase deviation between the REF signal and

feedback signal.

The phase gain of the fine phase detector is controlled by an 8-

it scale factor (FPFD_Gain) in the I/O register map. The

b

nominal (default) value of FPFD_Gain is 200, and establishes

the phase gain as

710

=

DPhaseGain

FP

×

f

GainFPFDR

)_)(102(

R

Phase Detector Gain Matching

Although the fine and coarse phase detectors use different

means to make a timing measurement, it is essential that both

have equivalent phase gain. Without proper gain matching, the

closed-loop dynamics of the system cannot be properly controlled. Hence, the goal is to make PhaseGain

= PhaseGain

CPD

FPD

This leads to

PDS

+

S

7106

×=

GainFPFDPDGf

_)102()2(

which simplifies to

7

PDS

PDG

2

×

=

GainFPFD

_)1016(

f

S

.

Rev. 0 | Page 20 of 68

AD9549

π−=

{

[

(

(

)

www.BDTIC.com/ADI

Typically, FPFD_Gain is established first and then PDG and

PDS are calculated. The proper choice for PDS is given by

PDS

⎡

⎢

=

loground

⎢

⎣

7

⎛

×

⎜

2

⎜

⎝

_10

f

2

S

⎤

⎞

GainFPFD

⎟

⎥

⎟

⎥

⎠

⎦

The final value of PDS must satisfy 0 ≤ PDS ≤ 7. The proper

hoice for PDG is calculated using the following equation:

c

7

PDG

=

round

⎛

⎜

⎜

⎝

−SPDS

4

2

⎞

GainFPFD

_10

⎟

⎟

f

⎠

The final value of PDG must satisfy 0 ≤ PDG ≤ 63. For example,

let f

= 700 MHz and FPFD_Gain = 200, then PDS = 1 and

S

PDG = 23.

Note that the AD9549 evaluation software calculates register

val

ues that have the phase detector gains already matched.

Phase Detector Pin Connections

There are three pins associated with the phase detector that

must be connected to external components. Figure 27 shows the

ecommended component values and their connections.

r

AD9549

20 21 22

0.1µF

0.1µF

Figure 27. Phase Detector Pin Connections

10µF

PFD_VRT PFD_RSETPFD_VRB

0.1µF

4.99kΩ

06744-027

DIGITAL LOOP FILTER COEFFICIENTS

In order to provide the desired flexibility, the loop filter has

been designed with three programmable coefficients (α, β, and

γ). The coefficients along with P (where P = 2

define the response of the filter, which is given by

jω

2

)(

LoopFilter

⎛

⎜

=

αωH

⎜

⎝

To evaluate the response in terms of absolute frequency,

itute

subst

π

2

Pf

ω

where P

=

is the divide ratio of the P-divider, f

f

S

rate, and f is the frequency at which the function is to be

evaluated.

The loop filter coefficients are determined by the AD9549

valuation software according to three parameters:

e

• Φ is the desired closed-loop phase margin (0 < Φ < π/2 rad).

• f

• f

is the desired open-loop bandwidth (Hz).

LOOP

is the desired output frequency of the DDS (Hz). Note

DDS

that f

can also be expressed as f

DDS

PIO

) completely

−−+

)1(

γβe

jωωj

++−−+

γeγe

is the DAC sample

S

= fR(S/R).

DDS

⎞

⎟

⎟

)1()2(

⎠

Rev. 0 | Page 21 of 68

The three coefficients are calculated according to parameters

he following equations:

via t

)tan(4 ΦPfβ

C

1

=

α

βΦFγ )(

2

−=

⎛

⎜

⎜

⎝

38

π

2

7

⎞

⎟

⎟

GainFPFD

_10

⎠

βΦFff

)(

CDDS

where:

f

LOOP

1

1)(

)sin(

Φ

f

S

f

ΦF +=

C

=

FPFD_Gain is the value of the gain scale factor for the fine

phas

e detector as programmed into the I/O register map.

Note that the range of loop filter coefficients is limited as

fol

lows:

0 < α < 2

23

(~8.39 × 106)

−0.125 < β < 0

−0.125 < γ < 0

The preceding constraints on β and γ constrain the closed-loop

hase margin such that both β and γ assume negative values.

p

Even though β and γ are limited to negative quantities, the

values as programmed are positive. The negative sign is

assumed internally.

Note that the closed-loop phase margin is limited to the range

f 0° < Φ < 90° because β and γ are negative.

o

The three coefficients are implemented as digital elements,

n

ecessitating quantized values. Determination of the

programmed coefficient values in this context follows.

The quantized α coefficient is composed of three factors, where

α

, α1, and α2 are the programmed values for the α coefficient.

0

α

⎞

⎛

α

QUANTIZED

0

=

⎜

2048

⎝

⎟

⎠

The boundary values for each are 0 ≤ α

and 0 ≤ α

≤ 7. The optimal values of α0, α1, and α2 are

2

⎡

=

α

1

=

α

0

⎧

⎢

⎨

⎢

⎩

⎣

⎡

⎧

⎪

⎢

⎨

⎪

⎢

⎩

⎣

αα

−

()(

21

22

⎛

logceil,22min,0max

⎜

⎝

⎛

⎜

logfloor,7min,0max

⎜

⎝

()

)

≤ 4095, 0 ≤ α1 ≤ 22,

0

⎤

⎫

2048

α

⎞

⎟

⎥

4095

4095

×=

⎬

⎠

⎥

⎭

⎦

⎞

⎟

α

⎠

11

+−

αα

12

}

2round,4095min,0max

]

2

⎛

⎜

2 12

⎝

αα

⎤

⎫

⎞

⎪

⎟

−α+

11

⎥

⎬

⎟

⎪

⎥

⎠

⎭

⎦

The magnitude of the quantized β coefficient is composed of

o factors.

tw

)15(2+−

β

1

)

=

where β

ββ

QUANTIZED

and β 1 are the programmed values for the β

0

0

coefficient.

AD9549

[

]

(

)

K

(

www.BDTIC.com/ADI

The boundary values for each are 0 ≤ β0 ≤ 4095 and 0 ≤ β1 ≤ 7.

The optimal values of β

⎡

β

1

⎢

= 15

⎢

⎣

0

and β1 are

0

⎧

⎪

⎨

⎪

⎩

⎤

⎫

⎛

⎛

4095

⎜

⎜

logfloor,7min,0max

2

⎜

⎜

β

⎝

⎝

β

(){}

2round,4095min,0max

×=

ββ

⎞

⎞

⎪

⎟

⎟

⎟

⎠

+

1

⎥

−

15

⎬

⎟

⎥

⎪

⎠

⎭

⎦

The magnitude of the quantized γ coefficient is composed of

o factors.

tw

)15(2+−

γ

()

=

where γ

QUANTIZED

and γ1 are the programmed values for the γ coefficient;

0

the boundary values for each are 0 ≤ γ

The optimal values of γ

⎡

⎢

=γ 15

⎢

⎣

0

[]

1

γγ

0

and γ1 are

0

⎧

⎪

⎨

⎪

⎩

{}

≤ 4095 and 0 ≤ γ1 ≤ 7.

0

⎤

⎫

⎛

⎛

4095

⎜

⎜

logfloor,7min,0max

21

⎜

⎜

⎝

γ

⎝

()

2round,4095min,0max

⋅γ=γ

⎞

⎞

⎪

⎟

⎟

⎟

⎠

15

+γ

1

⎥

−

⎬

⎟

⎥

⎪

⎠

⎭

⎦

The min(), max(), floor(), ceil() and round() functions are

ined as follows:

def

The function min(x

•

, x2, … xn) chooses the smallest value

1

in the list of arguments.

The function max(x

•

, x2, … xn) chooses the largest value in

1

the list of arguments.

The function ceil(x) increases x to the next higher integer if

•

x is not an integer; otherwise, x is unchanged.

The function floor(x) reduces x to the next lower integer if

•

x is not an integer; otherwise, x is unchanged.

•

The function round(x) rounds x to the nearest integer.

To demonstrate the wide programmable range of the loop filter

b