Digitally Programmable

a

FEATURES

Single +5 V Supply

TTL and CMOS Compatible

10 ps Delay Resolution

2.5 ns to 10 ms Full-Scale Range

Maximum Trigger Rate 50 MHz

MIL-STD-883-Compliant Versions Available

APPLICATIONS

Disk Drive Deskewing

Data Communications

Test Equipment

Radar I & Q Matching

GENERAL DESCRIPTION

The AD9501 is a digitally programmable delay generator which

provides programmed time delays of an input pulse. Operating

from a single +5 V supply, the AD9501 is TTL- or CMOScompatible, and is capable of providing accurate timing adjustments with resolutions as low as 10 ps. Its accuracy and

programmability make it ideal for use in data deskewing and

pulse delay applications, as well as clock timing adjustments.

Full-scale delay range is set by the combination of an external

resistor and capacitor, and can range from 2.5 ns to 10 µs for a

Delay Generator

AD9501

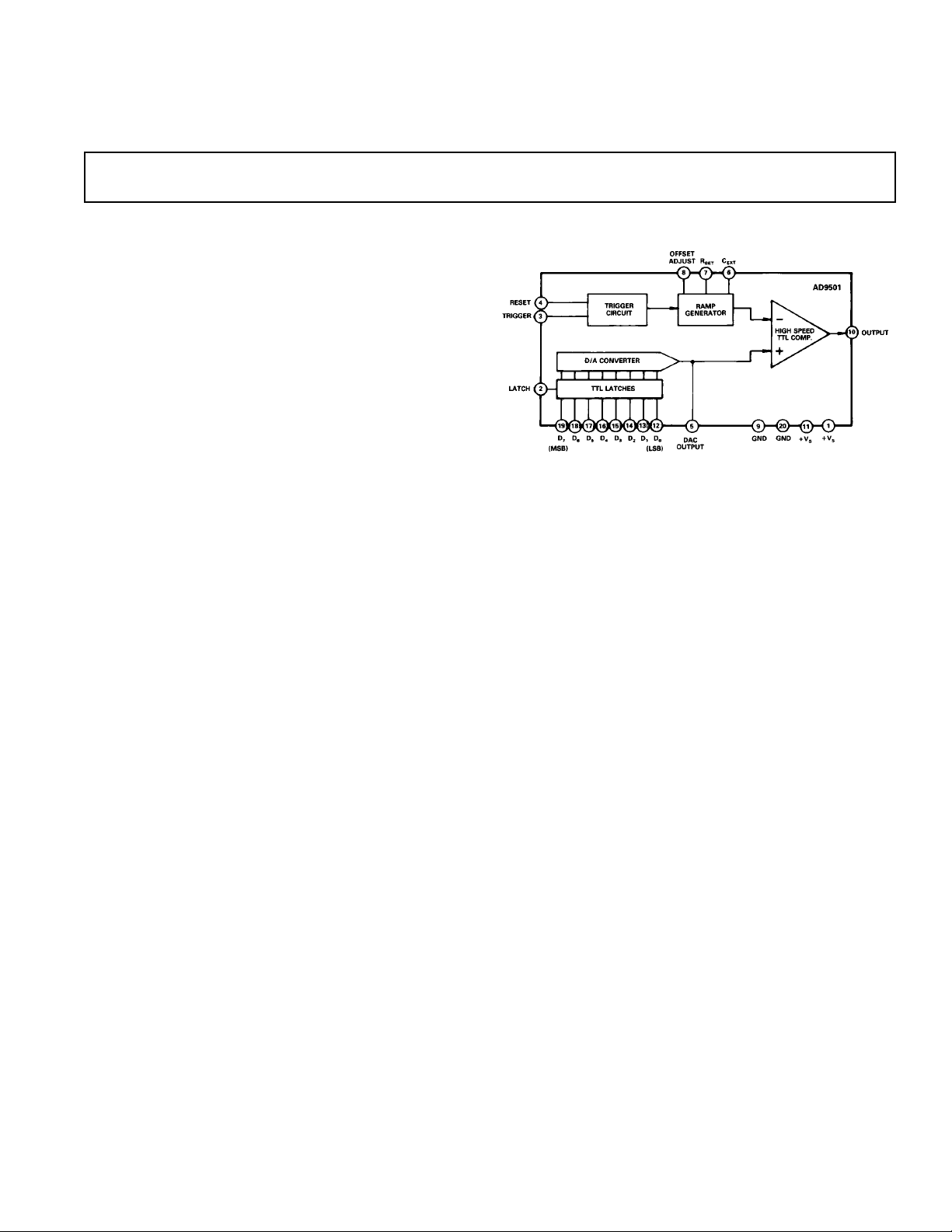

FUNCTIONAL BLOCK DIAGRAM

single AD9501. An eight-bit digital word selects a time delay

within the full-scale range. When triggered by the rising edge of

an input pulse, the output of the AD9501 will be delayed by an

amount equal to the selected time delay (t

propagation delay (t

The AD9501 is available for a commercial temperature range of

0°C to +70°C in a 20-pin plastic DIP, 20-pin ceramic DIP, and

a 20-lead plastic leaded chip carrier (PLCC). Devices fully

compliant to MIL-STD-883 are available in ceramic DIPs.

Refer to the Analog Devices Military Products Databook or current

AD9501/883B data sheet for detailed specifications.

PD

).

) plus an inherent

D

REV. A

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 617/329-4700 Fax: 617/326-8703

AD9501–SPECIFICA TIONS

ABSOLUTE MAXIMUM RATINGS

Positive Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . +7 V

Digital Input Voltage Range . . . . . . . . . . . . . . . –0.5 V to +V

Trigger/Reset Input Volt. Range . . . . . . . . . . . . –0.5 V to +V

Minimum R

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30 Ω

SET

Digital Output Current (Sourcing) . . . . . . . . . . . . . . . 10 mA

1

Operating Temperature Range

AD9501JN/JP/JQ . . . . . . . . . . . . . . . . . . . . . . 0°C to +70°C

S

S

AD9501SQ . . . . . . . . . . . . . . . . . . . . . . . –55°C to +125°C

Storage Temperature Range . . . . . . . . . . . . –65°C to +150°C

Junction Temperature

2

. . . . . . . . . . . . . . . . . . . . . . . +175°C

Lead Soldering Temperature (10 sec) . . . . . . . . . . . . +300°C

Digital Output Current (Sinking) . . . . . . . . . . . . . . . . 50 mA

ELECTRICAL CHARACTERISTICS

[+VS = +5 V; C

device output connected to Pin 4 RESET input unless otherwise noted]

= Open; R

EXT

= 3090 Ω (Full-Scale Range =100 ns); Pin 8 grounded; and

SET

08C to +708C –558C to +1258C

Test AD9501JN/JP/JQ AD9501SQ

Parameter Temp Level Min Typ Max Min Typ Max Units

RESOLUTION 8 8 Bits

ACCURACY

Differential Nonlinearity +25°C I 0.5 0.5 LSB

Integral Nonlinearity +25°C I 1 1 LSB

Monotonicity +25°C I Guaranteed Guaranteed

DIGITAL INPUTS

Latch Input “1” Voltage Full VI 2.0 2.3 V

Latch Input “0” Voltage Full VI 0.8 0.8 V

Logic “1” Voltage Full VI 2.0 2.0 V

Logic “0” Voltage Full VI 0.8 0.8 V

Logic “1” Current Full VI 60 60 µA

Logic “0” Current Full VI 3 3 µA

Digital Input Capacitance +25°C IV 5.5 5.5 pF

Data Setup Time (t

Data Hold Time (t

Latch Pulse Width (t

3

)

S

4

)

H

) +25°C V 3.5 3.5 ns

L

+25°C V 2.5 2.5 ns

+25°C V 2.5 2.5 ns

Reset/Trigger Pulse Width (tR, tT) +25°CV 2 2 ns

DYNAMIC PERFORMANCE

Maximum Trigger Rate

Minimum Propagation Delay (t

Propagation Delay Tempco

5

PD

7

+25°CIV 1822 1822 MHz

6

)

+25°C I 25 30 25 30 ns

Full V 25 25 ps/°C

Full-Scale Range Tempco Full V 36 36 ps/°C

Delay Uncertainty +25°C V 53 53 ps

Reset Propagation Delay (t

Reset-to-Trigger Holdoff (t

Trigger-to-Reset Holdoff (t

Minimum Output Pulse Width

Output Rise Time

Output Fall Time

DAC Settling Time (t

12

12

LD

Linear Ramp Settling Time (t

8

RD

THO

RHO

)

9

)

10

)

11

+25°C I 14.5 17.5 14.5 17.5 ns

+25°C V 4.5 4.5 ns

+25°C V 19 19 ns

+25°C V 7.5 7.5 ns

+25°C I 2.3 3.5 2.3 3.5 ns

13

)

LRS

+25°C I 1.0 2.0 1.0 2.0 ns

+25°C V 30 30 ns

14

)

+25°C V 20 20 ns

DIGITAL OUTPUT

Logic “1” Voltage (Source 1 mA) Full VI 2.4 2.4 V

Logic “0” Voltage (Sink 4 mA) Full VI 0.24 0.4 0.24 0.5 V

POWER SUPPLY

15

Positive Supply Current (+5.0 V) Full VI 69.5 83 69.5 83 mA

Power Dissipation Full VI 415 415 mW

Power Supply Rejection Ratio

16

Full-Scale Range Sensitivity +25°C I 0.7 2.0 0.7 2.0 ns/V

Minimum Prop Delay Sensitivity +25°C I 0.45 1.7 0.45 1.7 ns/V

–2–

REV. A

AD9501

NOTES

1

Absolute maximum ratings are limiting values, to be applied individually, and beyond which the serviceability of the circuit may be impaired. Functional operability

is not necessarily implied. Exposure to absolute maximum rating conditions for an extended period of time may affect device reliability.

2

Typical thermal impedances: 20-lead plastic leaded chip carrier θJA= 73°C/W; θJC= 29°C/W. 20-pin ceramic DIP θJA= 65°C/W; θJC= 20°C/W. 20-pin plastic DIP

θJA= 65°C/W; θJC= 26°C/W.

3

Digital data inputs must remain stable for the specified time prior to the positive transition of the LATCH signal.

4

Digital data inputs must remain stable for the specified time after the positive transition of the LATCH signal.

5

Programmed delay (tD) = 0 ns. Maximum self-resetting trigger rate is limited to 6.9 MHz with 100 ns programmed delay. If tD= 0 ns and external RESET signal is

used, maximum trigger rate is 23 MHz.

6

Programmed delay (tD) = 0 ns. In operation, any programmed delays are in addition to the minimum propagation delay (tPD).

7

Programmed delay (tD) = 0 ns. [Minimum propagation delay (tPD)].

8

Measured from 50% transition point of the RESET signal input to the 50% transition point of the falling edge of the output.

9

Minimum time from the falling edge of RESET to the triggering input to insure valid output pulse, using external RESET pulse.

10

Minimum time from triggering event to rising edge of RESET to insure valid output event, using external RESET pulse. Extends to 125 ns when programmed delay

is 100 ns.

11

When self-resetting with a full-scale programmed delay.

12

Measured from +0.4 V to +2.4 V; source = 1 mA; sink = 4 mA.

13

Measured from the data input to the time when the AD9501 becomes 8-bit accurate, after a full-scale change in the program delay data word.

14

Measured from the RESET input to the time when the AD9501 becomes 8-bit accurate, after a full-scale programmed delay.

15

Supply voltage should remain stable within ±5% for normal operation.

16

Measured at +VS = +5.0 V ± 5%; specification shown is for worst case.

Specifications subject to change without notice.

EXPLANATION OF TEST LEVELS

Test Level

I – 100% production tested.

II – 100% production tested at +25°C, and sample tested at specified

temperatures.

III – Sample tested only.

IV – Parameter is guaranteed by design and characterization testing.

V – Parameter is a typical value only.

VI – All devices are 100% production tested at +25°C. 100% production

tested at temperature extremes for extended temperature devices;

sample tested at temperature extremes for commercial/industrial

devices.

ORDERING GUIDE

Device Temperature Description Option*

AD9501JN 0°C to +70°C 20-Pin Plastic DIP N-20

AD9501JP 0°C to +70°C 20-Lead PLCC P-20A

AD9501JQ 0°C to +70°C 20-Pin Ceramic DIP Q-20

AD9501SQ –55°C to +125°C 20-Pin Ceramic DIP Q-20

*N = Plastic DIP; P = Plastic Leaded Chip Carrier; Q = Cerdip.

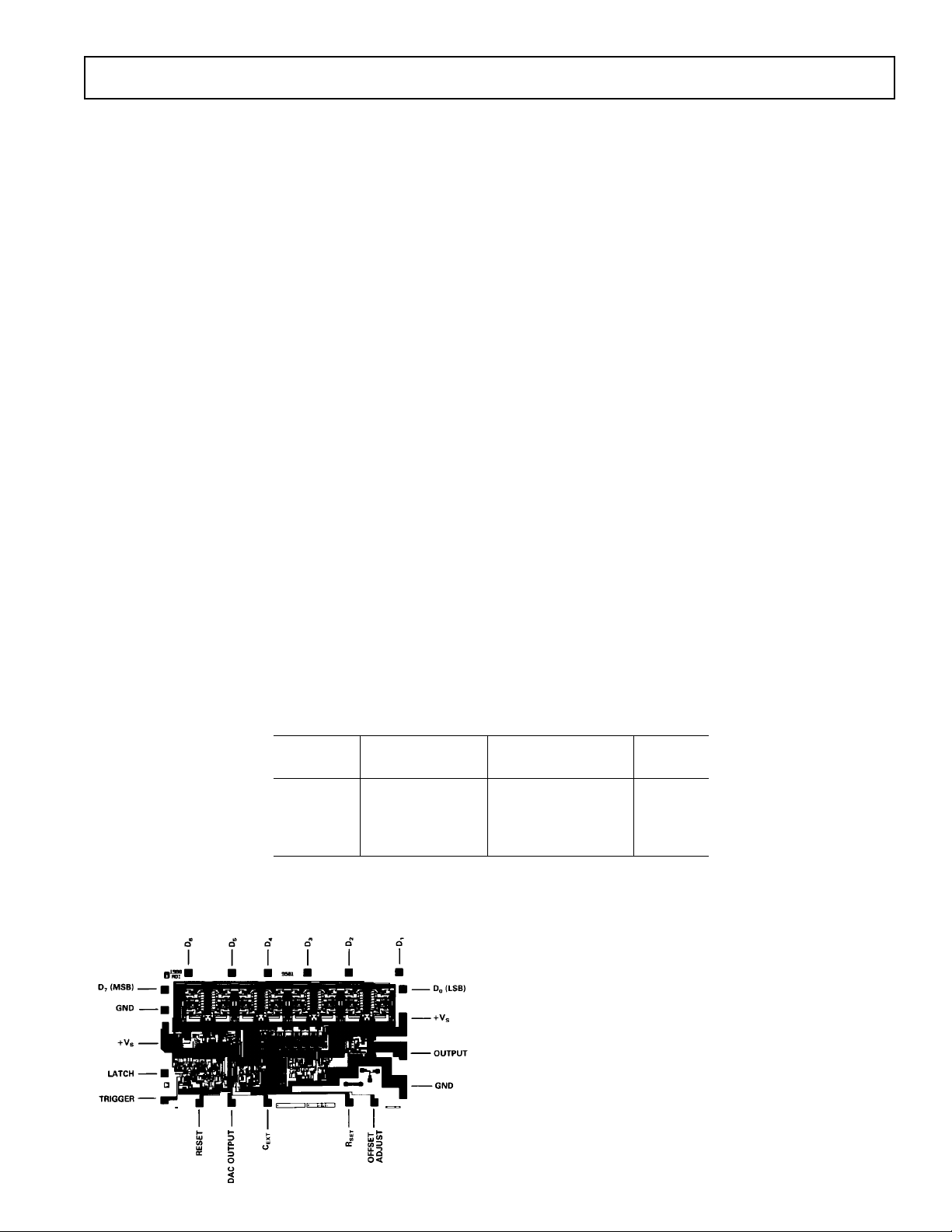

DIE LAYOUT AND MECHANICAL INFORMATION

Package

MECHANICAL INFORMATION

Die Dimensions . . . . . . . . . . . . . . . . . . 89 × 153 × 15 (±2) mils

Pad Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 × 4 mils

Metalization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Aluminum

Backing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . None

Substrate Potential . . . . . . . . . . . . . . . . . . . . . . . . . . . . Ground

Passivation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Oxynitride

Die Attach . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Gold Eutectic

Bond Wire . . . . . . . . 1.25 mil, Aluminum; Ultrasonic Bonding

or 1 mil, Gold; Gold Ball Bonding

REV. A

–3–

AD9501

WARNING!

ESD SENSITIVE DEVICE

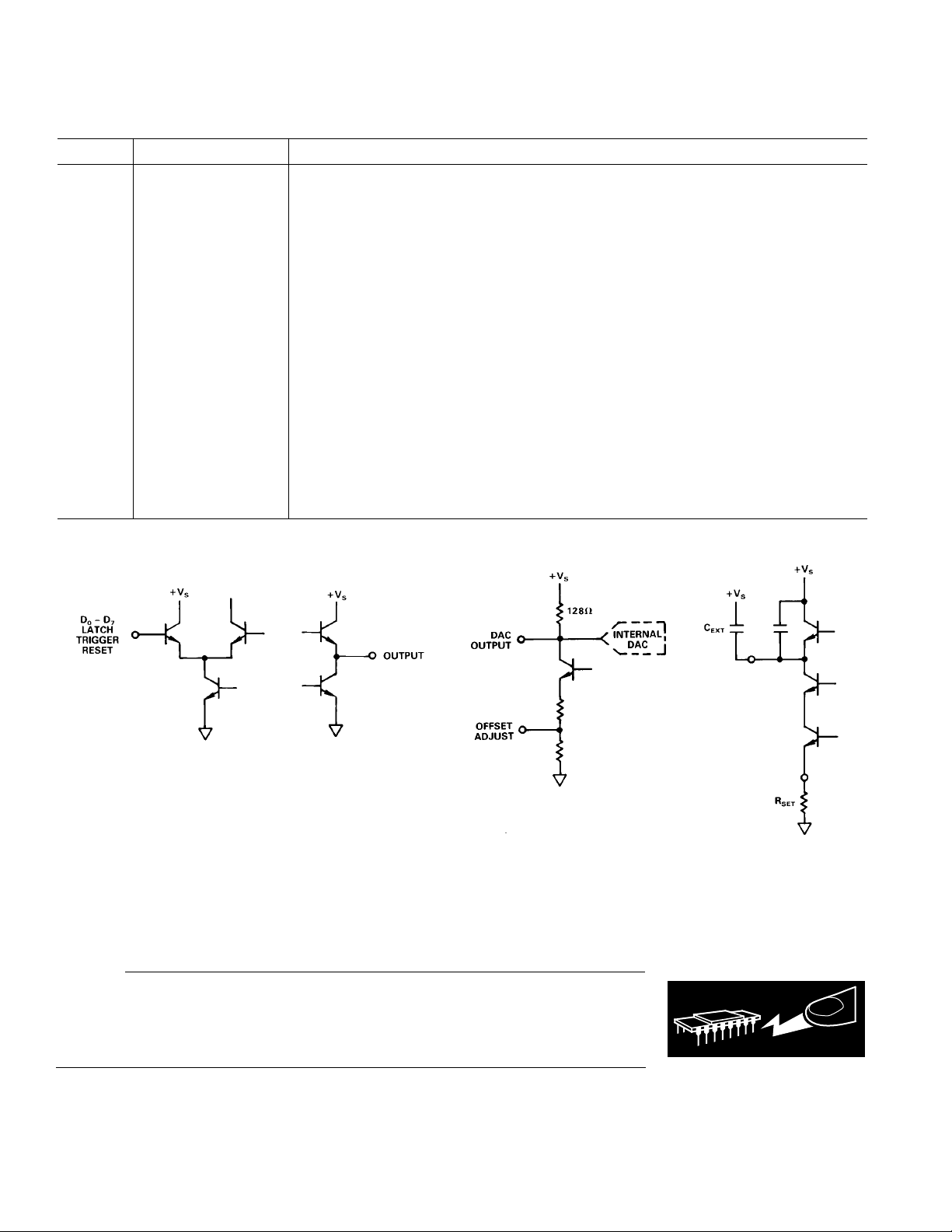

Pin No. Name Function

AD9501 PIN DESCRIPTIONS

1+V

S

2 LATCH TTL/CMOS register control line. Logic HIGH latches input data D

Positive voltage supply; nominally +5 V.

. Register is

0–D7

transparent for logic LOW.

3 TRIGGER TTL/CMOS-compatible input. Rising edge triggers the internal ramp generator, and begins

the delay cycle.

4 RESET TTL/CMOS-compatible input. Logic HIGH resets the ramp voltage and OUTPUT.

5 DAC OUTPUT Output voltage of the internal digital-to-analog converter.

6C

7R

EXT

SET

8 OFFSET ADJUST Normally connected to GROUND. Can be used to adjust minimum propagation delay (t

Optional external capacitor connected to +VS; used with R

to determine full-scale delay range (t

DFS

).

External resistor to ground, used to determine full-scale delay range (t

and 8.5 pF internal capacitor

SET

DFS

).

);

PD

see Theory of Operation text.

9 GROUND Circuit ground return.

10 OUTPUT TTL-compatible delayed output pulse.

11 +V

12-19 D

S

0–D7

Positive voltage supply; nominally +5 V.

TTL/CMOS-compatible inputs, used to set the programmed delay of the AD9501 delayed

output. D

is LSB and D7 is MSB.

0

20 GROUND Circuit ground return.

AD9501 Equivalent Circuits

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection.

Although the AD9501 features proprietary ESD protection circuitry, permanent damage may

occur on devices subjected to high energy electrostatic discharges. Therefore, proper ESD

precautions are recommended to avoid performance degradation or loss of functionality.

–4–

REV. A

AD9501

THEORY OF OPERATION

The AD9501 is a digitally programmable delay device. Its

function is to provide a precise incremental delay between input

and output, proportional to an 8-bit digital word applied to its

delay control port. Incremental delay resolution is 10 ps at the

minimum full-scale range of 2.5 ns. Digital delay data inputs,

latch, trigger and reset are all TTL/CMOS compatible. Output

is TTL-compatible.

Refer to the block diagram of the AD9501.

Inside the unit, there are three main subcircuits: a linear ramp

generator, an 8-bit digital-to-analog converter (DAC) and a

voltage comparator. The rising edge of the input (TRIGGER)

pulse initiates the delay cycle by triggering the ramp generator.

The voltage comparator monitors the ramp voltage and switches

the delayed output (Pin 10) HIGH when the ramp voltage

crosses the threshold set by the DAC output voltage. The DAC

threshold voltage is programmed by the user with digital inputs.

Figure 1, the AD9501 Internal Timing diagram, illustrates in

detail how the delay is determined. Minimum Delay (t

) is the

PD

sum of Trigger Circuit delay, Ramp Generator delay, and

Comparator delay.

The Trigger Circuit delay and Comparator delay are fixed;

Ramp Generator delay is a variable affected by the rate of

change of the linear ramp and (to a lesser degree) the value of

the offset voltage described below.

Maximum Delay is the sum of Minimum Delay (t

Scale Program Delay (t

DFS

).

) and Full-

PD

Ramp Generator delay is the time required for the ramp to slew

from its reset voltage to the most positive DAC reference

voltage (00

). The difference in these two voltages is nominally

H

18 mV (with OFFSET ADJUST open) or 34 mV (OFFSET

ADJUST grounded).

REV. A

Figure 1. AD9501 Internal Timing

–5–

AD9501

Offset between the two levels is necessary for three reasons.

First, offset allows the ramp to reset and settle without reentering the voltage range of the DAC. Second, the DAC may

overshoot as it switches to its most positive value (00

); this

H

could lead to false output pulses if there were no offset between

the ramp reset voltage and the upper reference. Overshoot on

the ramp could also lead to false outputs without the offset.

Finally, the ramp is slightly nonlinear for a short interval when it

is first started; the offset shifts the most positive DAC level

below this nonlinear region and maintains ramp linearity for

short programmed delay settings.

Pin 8 of the AD9501 is called OFFSET ADJUST (see block

diagram) and allows the user to control the amount of offset

separating the initial ramp voltage and the most positive DAC

reference. This, in turn, causes the Ramp Generator delay to

vary.

Figure 2 shows differences in timing which occur if OFFSET

ADJUST Pin 8 is grounded or open. The variable Ramp

Generator delay is the major component of the three

components which comprise Minimum Delay (t

PD

) and,

therefore, is affected by the connection to Pin 8.

It is preferable to ground Pin 8 because the smaller offset that

results from leaving it open increases the possibility of false output pulses. When grounding the pin, it should be grounded

directly or connected to ground through a resistor or potentiometer with a value of 10 kΩ or less.

Caution is urged when using resistance in series with Pin 8. The

possibility of false output pulses, as discussed above, is increased under these circumstances. Using resistance in series

with Pin 8 is recommended only when matching minimum delays between two or more AD9501 devices; it is not recommended if using a single AD9501. Changing the resistance

between Pin 8 and ground from zero to 10 kΩ varies the Ramp

Generator Delay by approximately 35%.

The Full-Scale Delay Range (t

) can be calculated from the

DFS

equation:

(t

)= R

DFS

Whenever Full-Scale Delay Range is 326 ns or less, C

be left open. Additional capacitance and/or larger values of R

SET

×(C

+8.5 pF)× 3.84

EXT

EXT

should

SET

increase the Linear Ramp Settling Time, which reduces the

maximum trigger rate. When delays longer than 326 ns are

required, up to 500 pF can be connected from C

R

should be selected in the range from 50 Ω to 10 kΩ. Graph

SET

EXT

to +VS.

1 shows typical Full-Scale Delay Ranges for various values of

R

SET

and C

EXT

.

Figure 2. AD9501 Minimum Delay (tPD) vs. Full-Scale Delay Range (t

–6–

DFS

)

REV. A

AD9501

Ramp charging current and DAC full-scale current are slaved

together in the AD9501 to minimize delay drift over temperature. To preserve the unit’s low drift performance, both R

and C

should have low temperature coefficients. Resistors

EXT

SET

which are used should be 1% metal film types.

The programmed delay (t

Graph 1. RC Values vs. Full-Scale Delay Range (t

) is set by the DAC inputs, D0–D7.

D

DFS

)

The minimum delay through the AD9501 corresponds to an

input code of 00

, and FFH gives the full-scale delay. Any

H

programmed delay can be approximated by:

tD=(DAC code/256) ×t

DFS

Total delay through the AD9501 for any given DAC code is

equal to:

t

TOTAL=tD+tPD

As shown on the block diagram, TTL/CMOS latches are

included to store the digital delay data. Data is latched when

LATCH is HIGH. When LATCH is LOW, the latches are

transparent, and the DAC will attempt to follow any changes on

inputs D

0–D7

.

The System Timing Diagram, Figure 3, shows the timing

relationship between the input data and the latch. The DAC

settling time (t

) is approximately 30 ns. After the digital

LD

(Programmed Delay) data is updated, a minimum 30 ns must

elapse between the time LATCH goes high and the arrival of a

TRIGGER pulse to assure rated pulse delay accuracy.

When RESET goes HIGH, the ramp timing capacitor (C

EXT

+

8.5 pF) is discharged. The RESET input is level-sensitive, and

overrides the TRIGGER input. Therefore, any trigger pulse

which occurs when RESET is HIGH will not produce an output

pulse. As shown on the system timing diagram, Figure 3, the

next trigger pulse should not occur before the Linear Ramp

Settling Time (t

) interval is completed to assure rated pulse

LRS

delay accuracy.

REV. A

Figure 3. AD9501 System Timing

–7–

AD9501

For most applications, OUTPUT can be tied to RESET. This

causes the output pulse to be narrow (equal to the Reset

Propagation Delay t

applied to RESET. To assure a valid output pulse, however, the

delay between TRIGGER and RESET should be equal to or

greater than the total delay of t

timing diagram Figure 1.

As shown in that figure, the capacitor voltage discharges very

rapidly and includes a small amount of overshoot and ringing.

Rated timing delay will not be realized unless subsequent trigger

events are delayed until after the linear ramp settles to its reset

voltage value.

The values for the various delay increments in the specification

table are based on a Full-Scale Delay Range of 100 ns with

OUTPUT tied to RESET (self-resetting operation).

When Full-Scale Delay Range is set for intervals shorter than

100 ns, the rate of change of the linear ramp is increased. This

faster rate means the Maximum Trigger Rate shown in the

specification table is increased because the Ramp Generator

Delay and, consequently, Minimum Propagation Delay t

become smaller.

Linear Ramp Settling Time t

Scale Delay Range is decreased. Minimum Delays for various

Full-Scale Delay Range values are shown in Figure 2.

APPLICATIONS

The AD9501 is useful in a wide variety of precision timing

applications because of its ability to delay TTL/ CMOS pulse

edges by increments as small as 10 ps.

). Alternatively, an external pulse can be

RD

+ tD illustrated in the internal

PD

PD

also becomes shorter as Full-

LRS

Figure 4. AD9501 Typical Circuit Configuration

In Figure 4, the AD9501 typical circuit configuration, the

delayed output is tied back to the RESET input. This will produce a narrow output pulse whose leading edge is delayed by an

amount proportional to the 8-bit digital word stored in the onboard latches. For the configuration shown, the output pulse

width will be equal to the Reset Propagation Delay (t

RD

). If

wider pulses are required, a delay can be inserted between

OUTPUT and RESET. If preferred, an external pulse can be

used as a reset input to control the timing of the falling edge

(and consequently, the width) of the delayed output.

Multiple Signal Path Deskewing

High speed electronic systems with parallel signal paths require

that close delay matching be maintained. If delay mismatch

(time skew) occurs, errors can occur during data transfer. For

these situations, the matching of delays is generally accomplished by carefully matching lead lengths.

Figure 5. Multiple Signal Path Deskewing

–8–

REV. A

AD9501

This delay matching is often difficult when using high speed,

high-pin-count testers because lead length and circuit

impedance can change when the tester setup is changed for

different types of devices. The skew which might result from

these changes can be compensated by using AD9501 units as

shown in Figure 5.

When deskewing multiple signal paths, a single stimulus pulse is

applied to all inputs of the AD9501s which are used. The delay

for each signal path is then measured by the tester’s delay

measurement circuit. Using a closed loop technique, all delays

are equalized by changing the digital value held in the register of

each AD9501. Once all delays have been matched to the desired

tolerance, the calibration loop is opened; and the tester is ready

to test the new type of device.

Digitally Programmable Oscillator

Two AD9501s can be configured as an stable oscillator, as

shown in Figure 6.

triggered from a common clock signal. Their outputs go to the

inputs of an RS flip-flop. A digital delay value is applied as an

input to each with AD9501 #2 typically having a larger value

than AD9501 #1.

As shown by the timing portion of the diagram, changing the

delay value from one clock cycle to the next generates a pseudorandom pulse whose leading and trailing edge delays are controlled relative to Clock In. The dashed lines illustrate how the

programmed delays of the AD9501 components control both

the timing and width of the generator output.

The frequency (f) and pulse width (t

) of the pulse generator

pw

can be determined as follows:

f = f

CLOCK IN

and:

tpw=t

TOT2–tTOT1

Figure 6. Digitally Programmable Oscillator

Delay through each side of the oscillator is determined by the

programmed delay (t

propagation delay (t

) of each AD9501 plus the minimum

D

) of each. Increasing the digital value

PD

applied to either AD9501 decreases frequency, just as

increasing RC decreases frequency in an analog ring oscillator.

Using a pair of AD9501 Delay Generators as shown allows the

user great flexibility because both the frequency and the duty

cycle of the oscillator are easily controlled.

Frequency of the oscillator output can be established with the

equation:

f =1/(2tPD+tD1+tD2)

when tD1 and tD2 are the programmed delays of AD9501 #1 and

AD9502 #2, respectively.

Programmable Pulse Generator

In this application, shown in Figure 7, two AD9501 units are

REV. A

–9–

with T

delay (t

being equal to each AD9501’s minimum propagation

TOT

) plus programmed delay (tD). If both AD9501s are

PD

set for the same full-scale delay range, their minimum

propagation delays will be approximately the same, and the

pulse width will be approximately equal to the difference in

programmed delays.

Digital Delay Detector

An unknown digital delay can be measured by applying a

repetitive clock to the circuit shown in Figure 8.

The pictured delay detector works in a manner similar to a

successive approximation ADC; in this circuit, however, a

D-type flip-flop replaces the ADC’s voltage comparator.

To calibrate the circuit, short out the unknown delay and apply

the clock input to both AD9501 units.

AD9501

Figure 7. Programmable Pulse Delay Generator

AD9501 #1 should be programmed so its delay is greater than

the zero-set programmed delay of AD9501 #2. To accomplish

this, continue to apply clock pulses and increment the digital

data into AD9501 #1 until the output of the successive approximation register (SAR) is 02H (00000010) or greater. At this

point, the delay through AD9501 #1 is slightly longer than the

delay through AD9501 #2, making it possible to use the SAR

output as the zero reference point for measuring the unknown

delay when it is reinserted into the circuit.

This calibration procedure compensates for the setup time of

the flip-flop, stray circuit delays and other nonideal characteristics

which are an inherent part of any circuit.

Eight cycles of the clock input are required to determine the

value of the unknown delay.

Figure 8. Digital Delay Detector

–10–

REV. A

AD9501

Analog Settling Time Measurement

This circuit, shown in Figure 9, functions in a manner similar to

the digital delay detector; for this application, too, the clock

must be repetitive. As in the delay detector, AD9501 #1 is used

to cancel the propagation delay of AD9501 #2, propagation

delay of the comparators, stray delays, etc. To accomplish this,

use the calibration procedure described earlier for the digital

delay generator.

The difference between the two circuits is in the detection

method. The register of the digital delay is replaced by a window comparator for the analog settling measurement.

Threshold voltages V1 and V2 are set for the desired tolerance

around the final value of the DUT output signal. As shown in

the lower portion of the diagram, the output of the detector is

high when the analog output signal of the converter is within the

limits set by V

Therefore, the settling time can be measured by starting the

delay of AD9501 #2 at its maximum setting and decrementing

it until the window comparator goes low. The difference

between the DAC codes applied to AD9501 #2 and AD9501

#1 is a measure of the settling time of the D/A converter being

tested.

and V2.

1

Figure 9. Analog Settling Time Measurement

Layout Considerations

Although the inputs and output of the AD9501 are digital, the

delay is determined by analog circuits. This makes it critical to

use high speed analog circuit layout techniques to achieve rated

performance.

The ground plane should be on the component side of the

board and extend under the AD9501 to shield it from digital

REV. A

–11–

switching signals. Most socket assemblies add significant

inter-lead capacitance, and should be avoided whenever possible. If sockets must be used, individual pin sockets such as

AMP part number 6330808-0 (closed knock-out end) or

6-330808-3 (open end) should be used.

Power supply decoupling is also critical for high speed design; a

0.1 µF capacitor should be connected as close as possible to

each supply pin.

AD9501

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

Suffixes JQ and SQ

C1295a–21–2/91

Suffix JN

Suffix JP

PRINTED IN U.S.A.

–12–

REV. A

Loading...

Loading...