Page 1

A

A

16-Bit, 130 MSPS IF Sampling ADC

FEATURES

130 MSPS guaranteed sampling rate

78.7 dBFS SNR/90 dBc SFDR with 10 MHz input

(3.4 V p-p input, 130 MSPS)

77.7 dBFS SNR with 170.3 MHz input

(4.0 V p-p input, 130 MSPS)

77.0 dBFS SNR/84 dBc SFDR with 170 MHz input

(3.4 V p-p input, 130 MSPS)

76.3 dBFS SNR/86 dBc SFDR with 225 MHz input

(3.4 V p-p input, 125 MSPS)

89 dBFS two-tone SFDR with 169 MHz and 170 MHz

(130 MSPS)

60 fsec rms jitter

Excellent linearity

DNL = ±0.6 LSB typical

INL = ±5.0 LSB typical

2.0 V p-p to 4.0 V p-p differential full-scale input

Buffered analog inputs

LVDS outputs (ANSI-644 compatible) or CMOS outputs

Data format select (offset binary or twos complement)

Output clock available

APPLICATIONS

MRI receivers

Multicarrier, multimode, cellular receivers

Antenna array positioning

Power amplifier linearization

Broadband wireless

Radar

Infrared imaging

Communications instrumentation

GENERAL DESCRIPTION

The AD9461 is a 16-bit, monolithic, sampling, analog-to-digital

converter (ADC) with an on-chip track-and-hold circuit. It is

optimized for performance, small size, and ease of use. The

AD9461 operates up to 130 MSPS, providing a superior signalto-noise ratio (SNR) for instrumentation, medical imaging, and

radar receivers using baseband (<100 MHz) and IF frequencies.

The ADC requires 3.3 V and 5.0 V power supplies and a low

voltage differential input clock for full performance operation.

No external reference or driver components are required for

many applications. Data outputs are CMOS or LVDS compatible

(ANSI-644 compatible) and include the means to reduce the

overall current needed for short trace distances.

AD9461

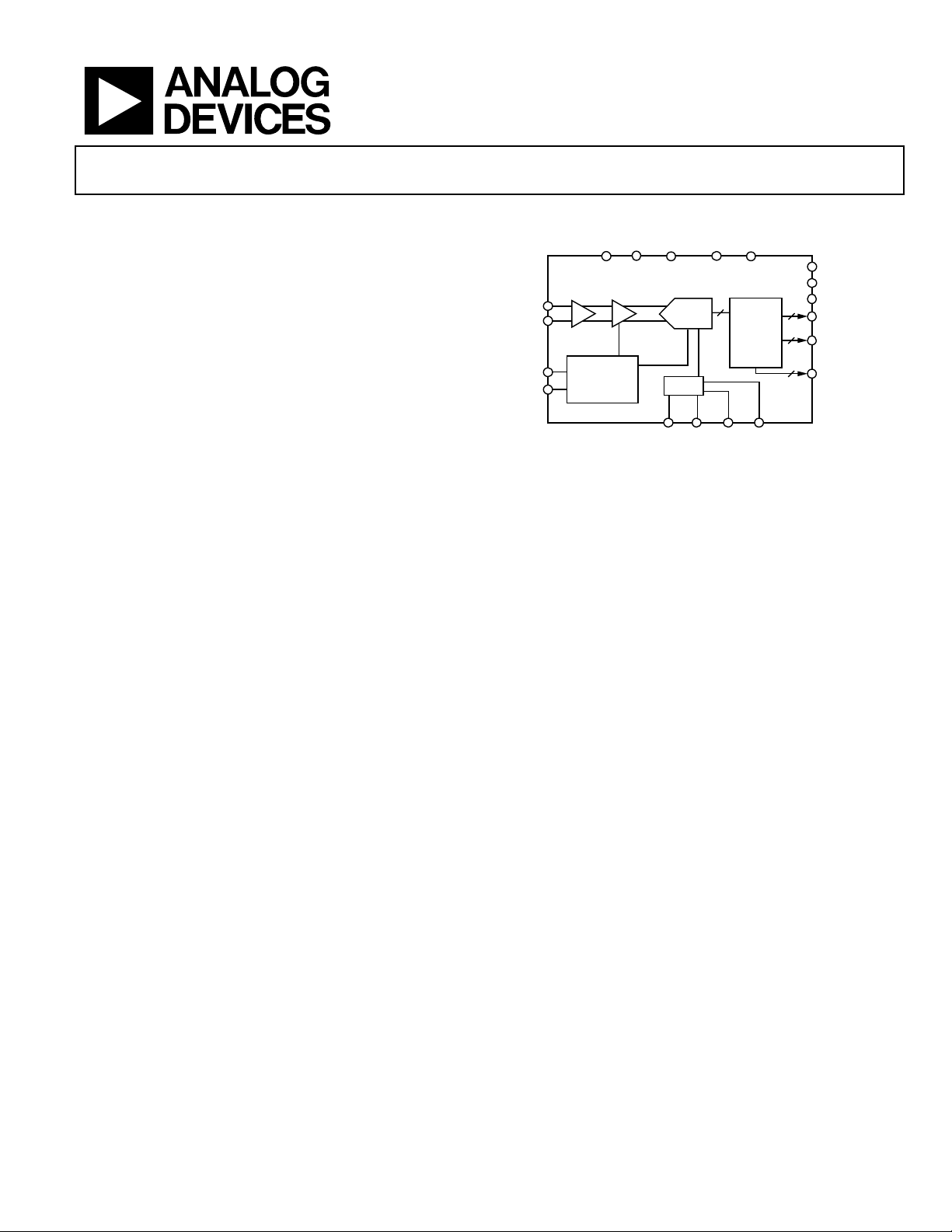

FUNCTIONAL BLOCK DIAGRAM

GND DRGND DRVDD

VDD1AVDD2

2

32

2

DFS

DCS MODE

OUTPUT MODE

OR

D15 TO D0

DCO

AD9461

VIN+

VIN–

CLK+

CLK–

BUFFER

CLOCK

AND TIMI NG

MANAGEMENT

T/H

VREF

PIPELINE

ADC

REF

Figure 1.

16

CMOS

OR

LVDS

OUTPUT

STAGING

REFBSENSE REFT

Optional features allow users to implement various selectable

operating conditions, including input range, data format select,

and output data mode.

The AD9461 is available in a Pb-free, 100-lead, surface-mount,

plastic package (100-lead TQFP_EP) specified over the industrial

temperature range −40°C to +85°C.

PRODUCT HIGHLIGHTS

1. True 16-bit linearity.

2. High performance: outstanding SNR performance for

baseband IFs in data acquisition, instrumentation,

magnetic resonance imaging, and radar receivers.

3. Ease of use: on-chip reference and high input impedance

track-and-hold with adjustable analog input range and an

output clock simplifies data capture.

4. Packaged in a Pb-free, 100-lead TQFP_EP.

5. Clock duty cycle stabilizer (DCS) maintains overall ADC

performance over a wide range of clock pulse widths.

6. Out-of-range (OR) outputs indicate when the signal is

beyond the selected input range.

06011-001

Rev. 0

Information furnished by Analog Devices is believed to be accurate and reliable. However, no

responsibility is assumed by Anal og Devices for its use, nor for any infringements of patents or ot her

rights of third parties that may result from its use. Specifications subject to change without notice. No

license is granted by implication or otherwise under any patent or patent rights of Analog Devices.

Trademarks and registered trademarks are the property of their respective owners.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700 www.analog.com

Fax: 781.461.3113 ©2006 Analog Devices, Inc. All rights reserved.

Page 2

AD9461

TABLE OF CONTENTS

Features.............................................................................................. 1

Pin Configurations and Function Descriptions............................8

Functional Block Diagram .............................................................. 1

Applications....................................................................................... 1

General Description ......................................................................... 1

Product Highlights ........................................................................... 1

Revision History ............................................................................... 2

Specifications..................................................................................... 3

DC Specifications ......................................................................... 3

AC Specifications.......................................................................... 4

Digital Specifications ................................................................... 5

Switching Specifications.............................................................. 5

Timing Diagrams.......................................................................... 6

Absolute Maximum Ratings............................................................ 7

Thermal Resistance ...................................................................... 7

ESD Caution.................................................................................. 7

Equivalent Circuits......................................................................... 12

Typical Performance Characteristics........................................... 13

Terminology.................................................................................... 16

Theory of Operation ...................................................................... 17

Analog Input and Reference Overview ................................... 17

Clock Input Considerations...................................................... 18

Power Considerations................................................................ 19

Digital Outputs........................................................................... 20

Timing ......................................................................................... 20

Operational Mode Selection ..................................................... 20

Evaluation Board............................................................................ 21

Outline Dimensions....................................................................... 28

Ordering Guide .......................................................................... 28

REVISION HISTORY

4/06—Revision 0: Initial Version

Rev. 0 | Page 2 of 28

Page 3

AD9461

SPECIFICATIONS

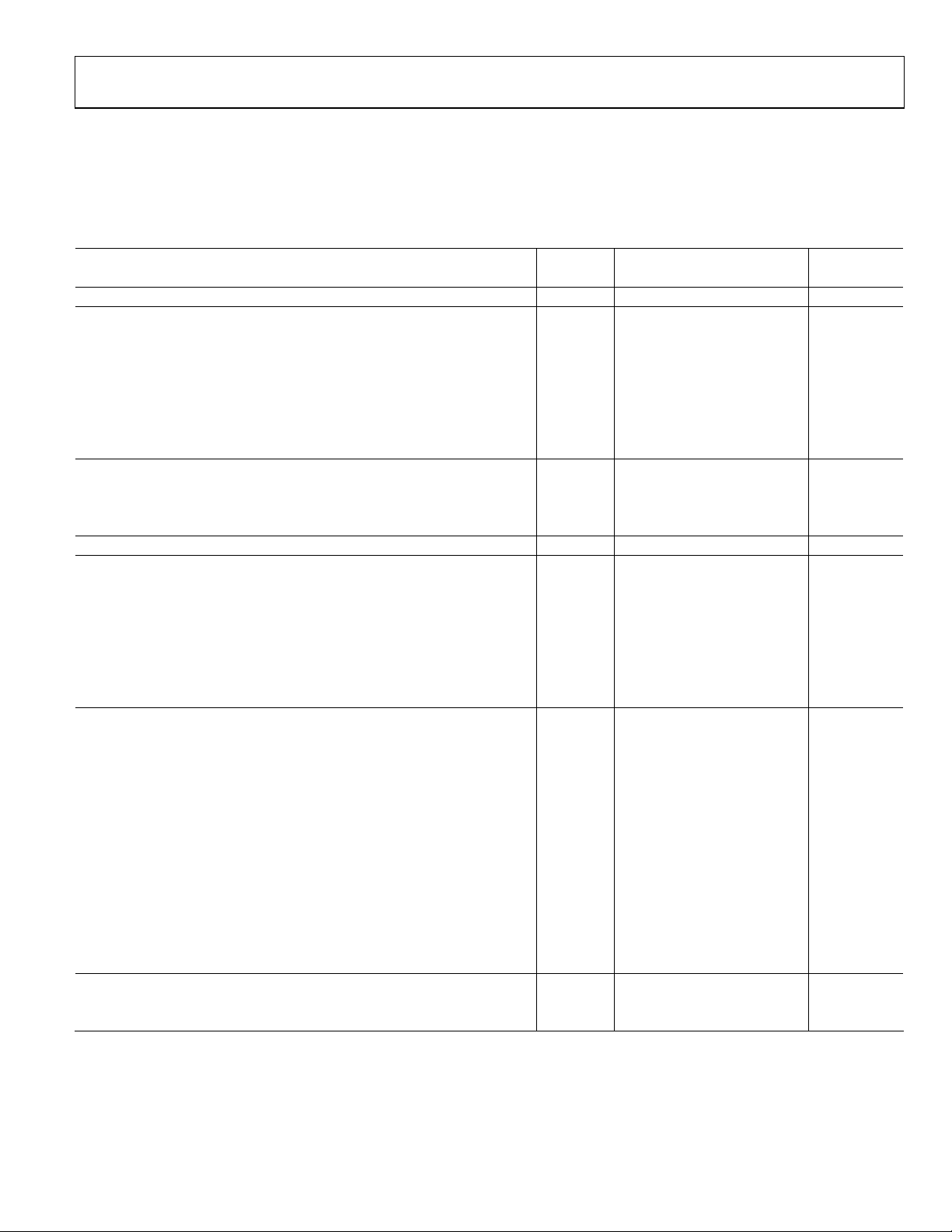

DC SPECIFICATIONS

AVDD1 = 3.3 V, AVDD2 = 5.0 V, DRVDD = 3.3 V, LVDS mode, specified minimum sampling rate, 3.4 V p-p differential input, internal

trimmed reference (1.0 V mode), A

Table 1.

AD9461BSVZ

Parameter Te mp Min Typ Max Unit

RESOLUTION Full 16 Bits

ACCURACY

No Missing Codes Full Guaranteed

Offset Error Full −4.2 ±0.1 +4.2 mV

Gain Error 25°C −3 ±0.5 +3 % FSR

Full −3.4 +3.4 % FSR

Differential Nonlinearity (DNL)

Full −1.0 +1.3 LSB

Integral Nonlinearity (INL)1 25°C −7 ±5.0 +7 LSB

VOLTAGE REFERENCE

Output Voltage VREF = 1.7 V Full +1.7 V

Load Regulation @ 1.0 mA Full ±2 mV

Reference Input Current (External VREF = 1.7 V) Full 350 µA

INPUT REFERRED NOISE 25°C 2.6 LSB rms

ANALOG INPUT

Input Span

VREF = 1.7 V Full 3.4 V p-p

VREF = 1.0 V Full 2.0 V p-p

Internal Input Common-Mode Voltage Full 3.5 V

External Input Common-Mode Voltage Full 3.2 3.9 V

Input Resistance

Input Capacitance

2

2

POWER SUPPLIES

Supply Voltage

AVDD1 Full 3.14 3.3 3.46 V

AVDD2 Full 4.75 5.0 5.25 V

DRVDD—LVDS Outputs Full 3.0

DRVDD—CMOS Outputs Full 3.0 3.3 3.6 V

Supply Current

1

AVDD1 Full 405 426 mA

1, 3

AVDD2

1

I

—LVDS Outputs Full 72 81 mA

DRVDD

1

I

—CMOS Outputs Full 14 mA

DRVDD

PSRR

Offset Full 1 mV/V

Gain Full 0.2 %/V

POWER CONSUMPTION

LVDS Outputs Full 2.2 2.4 W

CMOS Outputs (DC Input) Full 2.0 W

1

Measured at the maximum clock rate, fIN = 15 MHz, full-scale sine wave, with a 100 Ω differential termination on each pair of output bits for LVDS output mode and

approximately 5 pF loading on each output bit for CMOS output mode.

2

Input capacitance or resistance refers to the effective impedance between one differential input pin and AGND. Refer to Figure 6 for the equivalent analog input structure.

3

For SFDR = AVDD1, I

decreases by ~8 mA, decreasing power dissipation.

AVDD2

= −1.0 dBFS, DCS on, SFDR = AGND, unless otherwise noted.

IN

1

25°C −1.0 ±0.6 +1.0 LSB

Full 1 kΩ

Full 6 pF

Full 131 143 mA

3.6 V

Rev. 0 | Page 3 of 28

Page 4

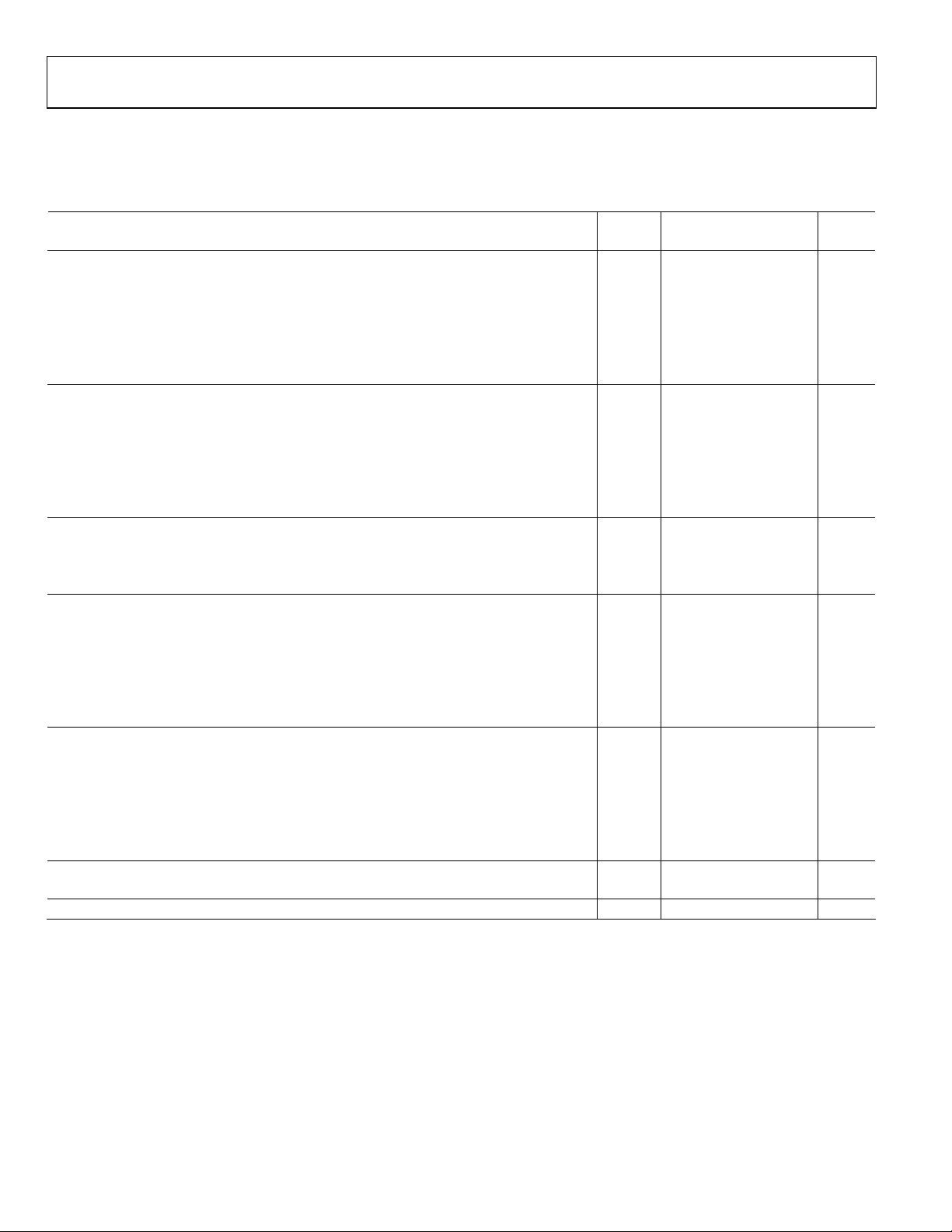

AD9461

AC SPECIFICATIONS

AVDD1 = 3.3 V, AVDD2 = 5.0 V, DRVDD = 3.3 V, LVDS mode, specified minimum sample rate, 3.4 V p-p differential input, internal

trimmed reference (1.7 V mode), A

Table 2.

Parameter Temp

SIGNAL-TO-NOISE RATIO (SNR)

fIN = 10 MHz 25°C 76.3 77.7 dB

Full 76.0 dB

fIN = 170 MHz

1

Full 73.8 dB

fIN = 225 MHz 25°C 74.4 dB

fIN = 225 MHz @125 MSPS 25°C 75.3 dB

SIGNAL-TO-NOISE AND DISTORTION (SINAD)

fIN = 10 MHz 25°C 74.0 76.7 dB

Full 74.0 dB

fIN = 170 MHz

1

Full 68.3 dB

fIN = 225 MHz 25°C 73.5 dB

fIN = 225 MHz @125 MSPS 25°C 74.6 dB

EFFECTIVE NUMBER OF BITS (ENOB)

fIN = 10 MHz 25°C 12.5 Bits

fIN = 170 MHz

1

fIN = 225 MHz 25°C 11.9 Bits

SPURIOUS-FREE DYNAMIC RANGE (SFDR, SECOND OR THIRD HARMONIC)

fIN = 10 MHz 25°C 82 90 dBc

Full 80 dBc

fIN = 170 MHz

1

Full 71 dBc

fIN = 225 MHz 25°C 82 dBc

fIN = 225 MHz @125 MSPS 25°C 86 dBc

WORST SPUR EXCLUDING SECOND OR THIRD HARMONICS

fIN = 10 MHz 25°C 88 96 dBc

Full 86 dBc

fIN = 170 MHz

1

Full 85 dBc

fIN = 225 MHz 25°C 91 dBc

fIN = 225 MHz @ 125 MSPS 25°C 93 dBc

TWO-TONE SFDR

fIN = 169.6 MHz @ −7 dBFS, 170.6 MHz @ −7 dBFS 25°C 89 dBFS

ANALOG BANDWIDTH Full 615 MHz

1

SFDR = high (AVDD1). See the Operational Mode Selection section.

= −1.0 dBFS, DCS on, SFDR = AGND, unless otherwise noted.

IN

25°C 74.2 76.0 dB

25°C 71.9 75.1 dB

25°C 12.2 Bits

25°C 77 84 dBc

25°C 89 95 dBc

AD9461BSVZ

Min Typ Max Unit

Rev. 0 | Page 4 of 28

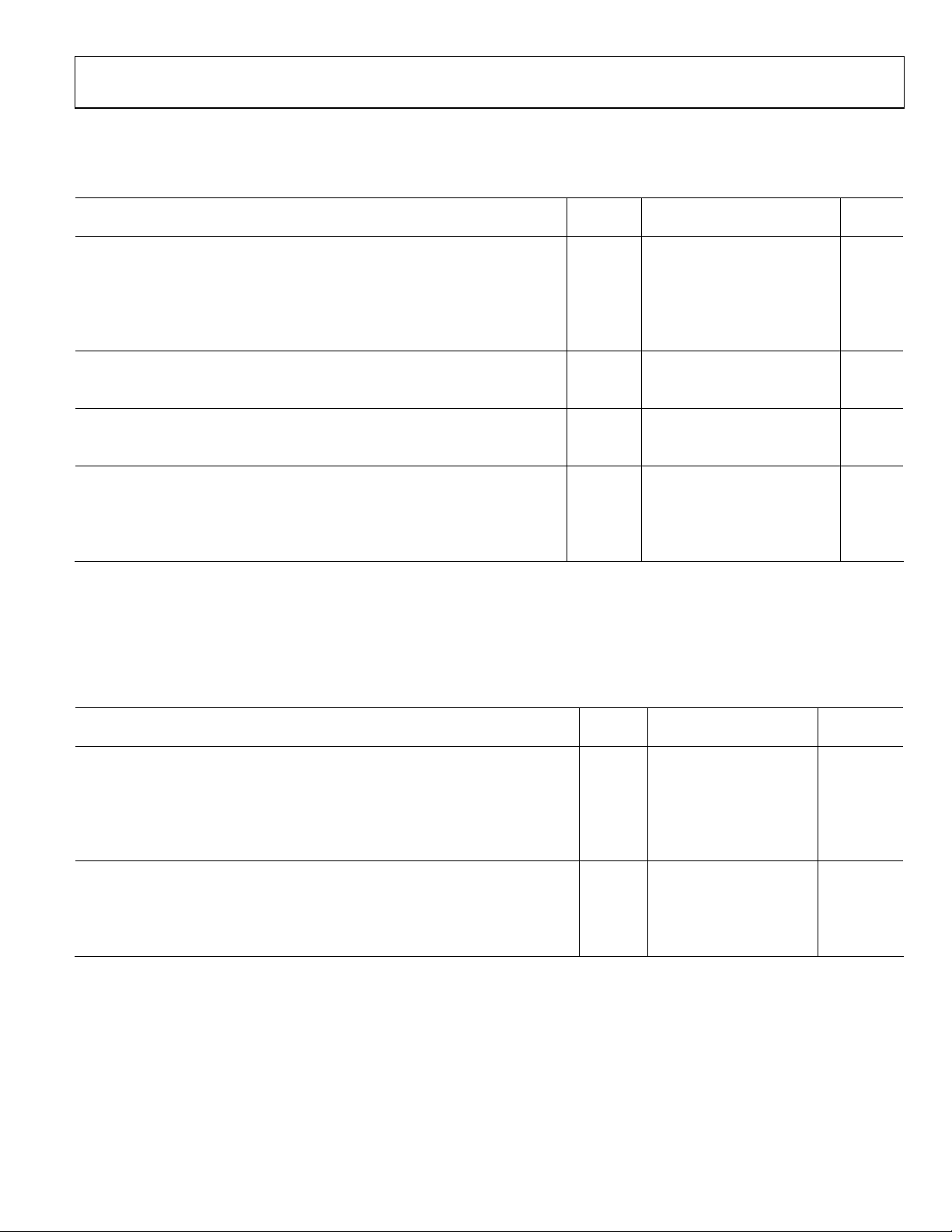

Page 5

AD9461

DIGITAL SPECIFICATIONS

AVDD1 = 3.3 V, AVDD2 = 5.0 V, DRVDD = 3.3 V, R

Table 3.

AD9461BSVZ

Parameter Te mp Min Typ Max Unit

CMOS LOGIC INPUTS (DFS, DCS MODE, OUTPUT MODE)

High Level Input Voltage Full 2.0 V

Low Level Input Voltage Full 0.8 V

High Level Input Current Full 200 µA

Low Level Input Current Full −10 +10 µA

Input Capacitance Full 2 pF

DIGITAL OUTPUT BITS—CMOS MODE (D0 to D15, OTR)

High Level Output Voltage Full 3.25 V

Low Level Output Voltage Full 0.2 V

DIGITAL OUTPUT BITS—LVDS MODE (D0 to D15, OTR)

VOD Differential Output Voltage

2

VOS Output Offset Voltage Full 1.125 1.375 V

CLOCK INPUTS (CLK+, CLK−)

Differential Input Voltage Full 0.2 V

Common-Mode Voltage Full 1.3 1.5 1.6 V

Input Resistance Full 1.1 1.4 1.7 kΩ

Input Capacitance Full 2 pF

1

Output voltage levels measured with 5 pF load on each output.

2

LVDS R

= 100 Ω.

TERM

= 3.74 kΩ, unless otherwise noted.

LVD S_ BI AS

1

Full 247 545 mV

SWITCHING SPECIFICATIONS

AVDD1 = 3.3 V, AVDD2 = 5.0 V, DRVDD = 3.3 V, unless otherwise noted.

Table 4.

AD9461BSVZ

Parameter Te mp Min Typ Max Unit

CLOCK INPUT PARAMETERS

Maximum Conversion Rate Full 130 MSPS

Minimum Conversion Rate Full 1 MSPS

CLK Period Full 7.7 ns

CLK Pulse Width High1 (t

CLK Pulse Width Low1 (t

DATA OUTPUT PARAMETERS

Output Propagation Delay—CMOS (tPD)2 (Dx, DCO+) Full 3.35 ns

Output Propagation Delay—LVDS (tPD)3 (Dx+), (t

Pipeline Delay (Latency) Full 13 Cycles

Aperture Uncertainty (Jitter, tJ) Full 60 fsec rms

1

With duty cycle stabilizer (DCS) enabled.

2

Output propagation delay is measured from clock 50% transition to data 50% transition with 5 pF load.

3

LVDS R

= 100 Ω. Measured from the 50% point of the rising edge of CLK+ to the 50% point of the data transition.

TERM

) Full 3.1 ns

CLKH

) Full 3.1 ns

CLKL

)3 (DCO+) Full 2.3 3.6 4.8 ns

CPD

Rev. 0 | Page 5 of 28

Page 6

AD9461

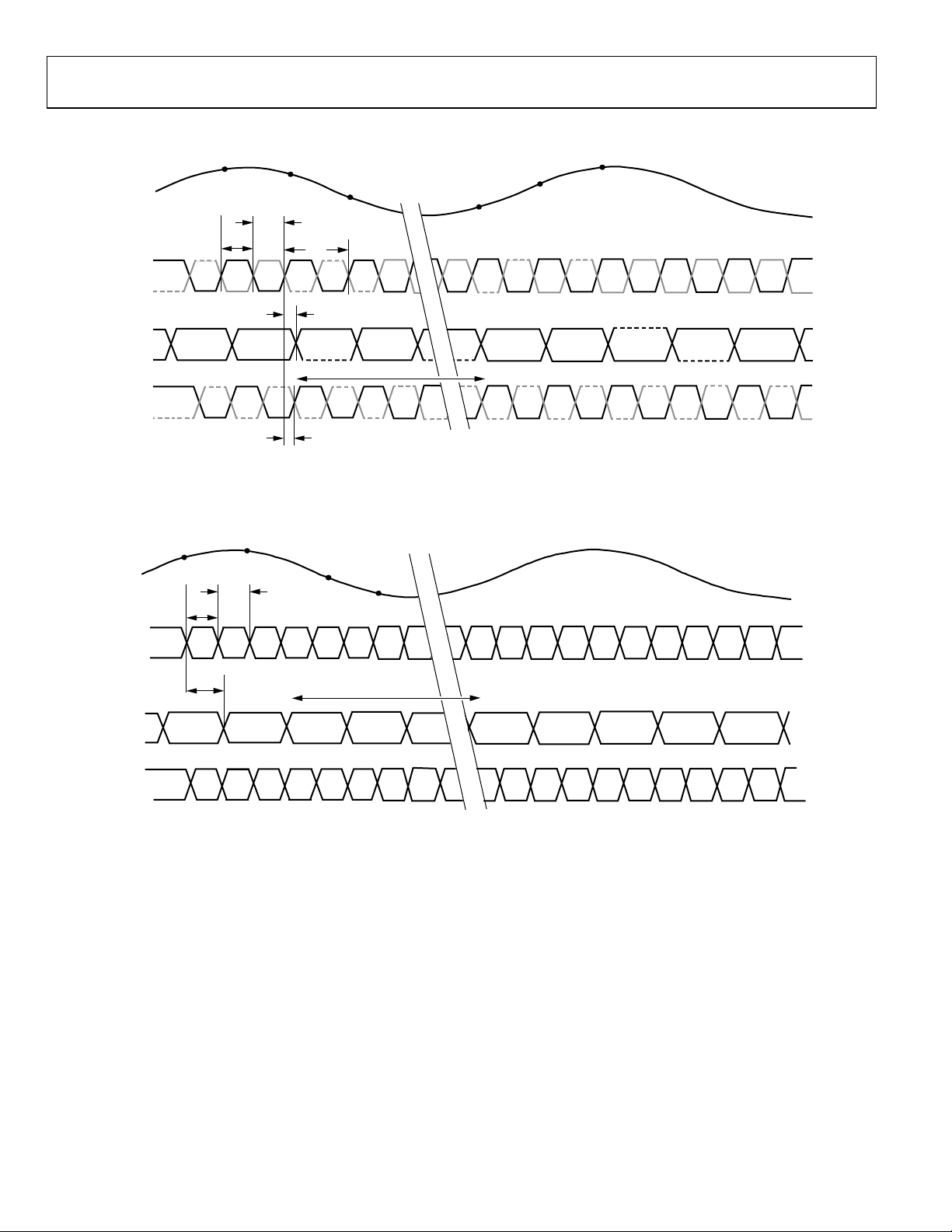

TIMING DIAGRAMS

A

IN

CLK+

CLK–

N – 1

t

CLKH

t

CLKL

N

N + 1

f

1/

S

t

PD

N + 13

N + 14

N + 15

DATA OUT

DCO+

DCO–

VIN

CLK–

CLK+

DX

DCO+

DCO–

N – 1

t

CLKH

N – 13

t

CPD

N – 12

13 CLOCK CYCLES

N

N + 1

06011-002

Figure 2. LVDS Mode Timing Diagram

N

N + 1

t

CLKL

t

PD

N – 13 N – 12 N – 1 N

N + 2

13 CLOCK CYCLES

06011-003

Figure 3. CMOS Timing Diagram

Rev. 0 | Page 6 of 28

Page 7

AD9461

ABSOLUTE MAXIMUM RATINGS

Table 5.

Parameter Rating

ELECTRICAL

AVDD1 to AGND −0.3 V to +4 V

AVDD2 to AGND −0.3 V to +6 V

DRVDD to DGND −0.3 V to +4 V

AGND to DGND −0.3 V to +0.3 V

AVDD1 to DRVDD −4 V to +4 V

AVDD2 to DRVDD −4 V to +6 V

AVDD2 to AVDD −4 V to +6 V

D0± through D15± to DGND −0.3 V to DRVDD + 0.3 V

CLK+/CLK− to AGND –0.3 V to AVDD1 + 0.3 V

OUTPUT MODE, DCS MODE, and

–0.3 V to AVDD1 + 0.3 V

DFS to AGND

VIN+, VIN− to AGND −0.3 V to AVDD2 + 0.3 V

VREF to AGND −0.3 V to AVDD1 + 0.3 V

SENSE to AGND −0.3 V to AVDD1 + 0.3 V

REFT, REFB to AGND −0.3 V to AVDD1 + 0.3 V

ENVIRONMENTAL

Storage Temperature Range −65°C to +125°C

Operating Temperature Range −40°C to +85°C

Lead Temperature (Soldering 10 sec) 300°C

Junction Temperature 150°C

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

THERMAL RESISTANCE

The heat sink of the AD9461 package must be soldered to

ground.

Airflow increases heat dissipation, effectively reducing θ

more metal directly in contact with the package leads from

metal traces through holes, ground, and power planes reduces

the θ

. It is required that the exposed heat sink be soldered to

JA

the ground plane.

Table 6.

Package Type θ

1

JA

2

θ

JB

3

θ

JC

100-Lead TQFP_EP 19.8 8.3 2 °C/W

1

Typical θJA = 19.8°C/W (heat sink soldered) for multilayer board in still air.

2

Typical θJB = 8.3°C/W (heat sink soldered) for multilayer board in still air.

3

Typical θJC = 2°C/W (junction to exposed heat sink) represents the thermal

resistance through heat sink path.

. Also,

JA

Unit

ESD CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily accumulate on

the human body and test equipment and can discharge without detection. Although this product features

proprietary ESD protection circuitry, permanent damage may occur on devices subjected to high energy

electrostatic discharges. Therefore, proper ESD precautions are recommended to avoid performance

degradation or loss of functionality.

Rev. 0 | Page 7 of 28

Page 8

AD9461

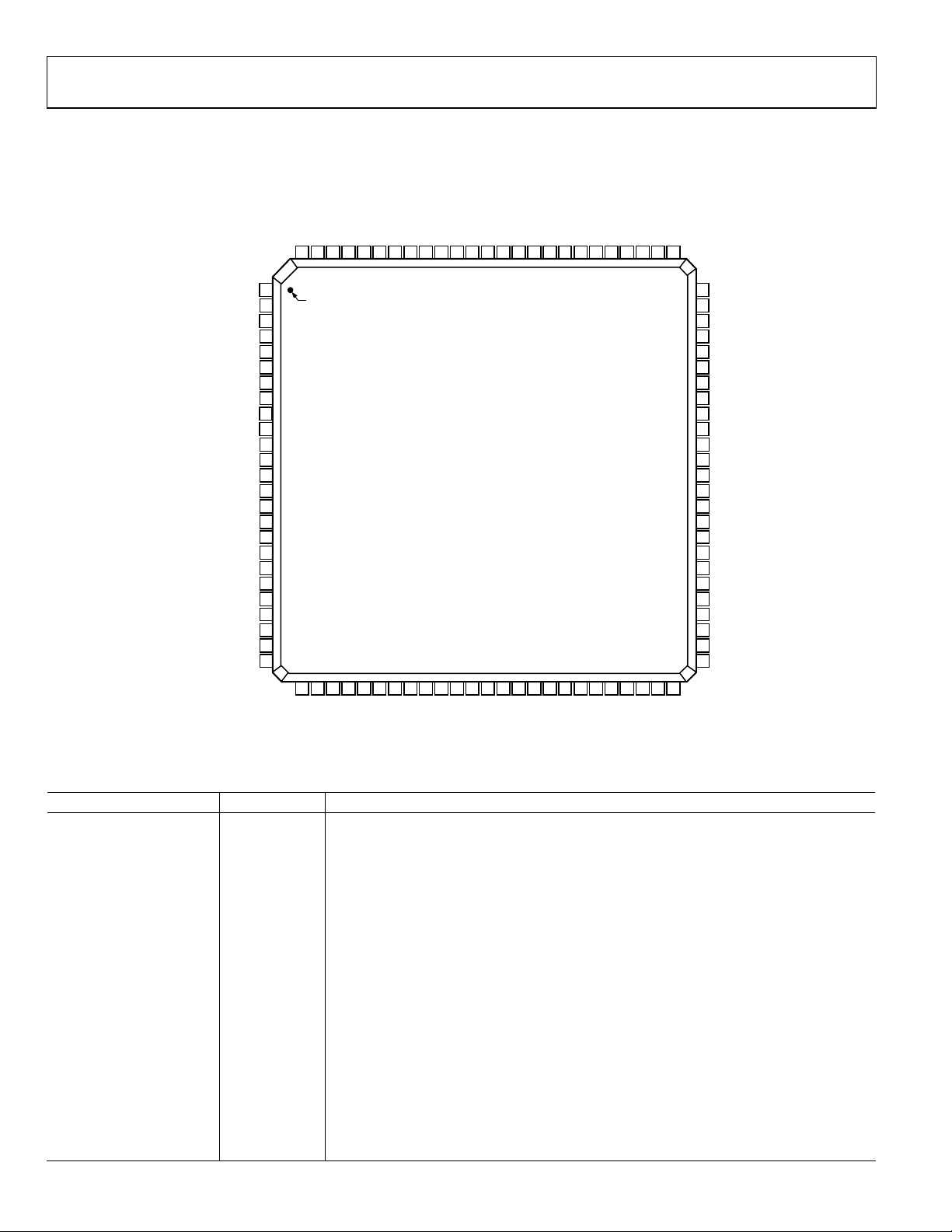

PIN CONFIGURATIONS AND FUNCTION DESCRIPTIONS

SFDR99AGND98AGND97AVDD196AVDD195AVDD194AVDD193AVDD192AVDD191AGND90OR+89OR–88DRVDD87DRGND86D15+ (MSB)85D15–84D14+83D14–82D13+81D13–80D12+79D12–78D11+77D11–76DRVDD

100

75

DRGND

74

D10+

73

D10–

72

D9+

71

D9–

70

D8+

69

D8–

68

DCO+

67

DCO–

66

D7+

65

D7–

64

DRVDD

63

DRGND

62

D6+

61

D6–

60

D5+

59

D5–

58

D4+

57

D4–

56

D3+

55

D3–

54

D2+

53

D2–

52

D1+

51

D1–

49

50

D0+

D0– (LSB)

06011-004

DNC

DFS

AVDD1

SENSE

VREF

AGND

REFT

REFB

AVDD2

AVDD2

AVDD2

AVDD2

AVDD2

AVDD2

AVDD1

AVDD1

AVDD1

AGND

VIN+

VIN–

AGND

AVDD2

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

DCS MODE

OUTPUT MODE

LVDS_BIAS

DNC = DO NOT CONNECT

PIN 1

AD9461

LVDS MODE

TOP VIEW

(Not to Scale)

26

AVDD227AVDD228AVDD229AVDD230AVDD231AVDD232AVDD133AVDD134AVDD135AVDD236AVDD137AVDD238AVDD1

39

40

41

42

43

46

47

48

CLK–

CLK+

AGND

AGND

AVDD144AVDD145AVDD1

AGND

DRVDD

DRGND

Figure 4. 100-Lead TQFP_EP Pin Configuration in LVDS Mode

Table 7. Pin Function Descriptions—100-Lead TQFP_EP in LVDS Mode

Pin No. Mnemonic Description

1 DCS MODE Clock Duty Cycle Stabilizer (DCS) Control Pin. CMOS compatible.

DCS = low (AGND) to enable DCS (recommended).

DCS = high (AVDD1) to disable DCS.

2 DNC Do Not Connect. This pin should float.

3 OUTPUT MODE CMOS-Compatible Output Logic Mode Control Pin.

OUTPUT MODE = 0 for CMOS mode.

OUTPUT MODE = 1 (AVDD1) for LVDS outputs.

4 DFS Data Format Select Pin. CMOS control pin that determines the format of the output data.

DFS = high (AVDD1) for twos complement.

DFS = low (ground) for offset binary format.

5 LVDS_BIAS Set Pin for LVDS Output Current. Place 3.7 kΩ resistor terminated to DRGND.

6, 18 to 20, 32 to 34, 36,

AVDD1 3.3 V (±5%) Analog Supply.

38, 43 to 45, 92 to 97

7 SENSE

Reference Mode Selection. Connect to AGND for internal 1.7 V reference (3.4 V p-p analog

input range); connect to AVDD1 for external reference.

8 VREF

1.7 V Reference I/O. The function is dependent on the SENSE pin and external programming

resistors. Decouple to ground with 0.1 µF and 10 µF capacitors.

9, 21, 24, 39, 42, 46, 91, 98,

99, Exposed Heat Sink

AGND

Analog Ground. The exposed heat sink on the bottom of the package must be connected to

AGND.

Rev. 0 | Page 8 of 28

Page 9

AD9461

Pin No. Mnemonic Description

10 REFT

11 REFB

12 to 17, 25 to 31, 35, 37 AVDD2 5.0 V Analog Supply (±5%).

22 VIN+ Analog Input—True.

23 VIN− Analog Input—Complement.

40 CLK+ Clock Input—True.

41 CLK− Clock Input—Complement.

47, 63, 75, 87 DRGND Digital Output Ground.

48, 64, 76, 88 DRVDD 3.3 V Digital Output Supply (3.0 V to 3.6 V).

49 D0− (LSB) D0 Complement Output Bit (LVDS Levels).

50 D0+ D0 True Output Bit.

51 D1− D1 Complement Output Bit.

52 D1+ D1 True Output Bit.

53 D2− D2 Complement Output Bit.

54 D2+ D2 True Output Bit.

55 D3− D3 Complement Output Bit.

56 D3+ D3 True Output Bit.

57 D4− D4 Complement Output Bit.

58 D4+ D4 True Output Bit.

59 D5− D5 Complement Output Bit.

60 D5+ D5 True Output Bit.

61 D6− D6 Complement Output Bit.

62 D6+ D6 True Output Bit.

65 D7− D7 Complement Output Bit.

66 D7+ D7 True Output Bit.

67 DCO− Data Clock Output—Complement.

68 DCO+ Data Clock Output—True.

69 D8− D8 Complement Output Bit.

70 D8+ D8 True Output Bit.

71 D9− D9 Complement Output Bit.

72 D9+ D9 True Output Bit.

73 D10− D10 Complement Output Bit.

74 D10+ D10 True Output Bit.

77 D11− D11 Complement Output Bit.

78 D11+ D11 True Output Bit.

79 D12− D12 Complement Output Bit.

80 D12+ D12 True Output Bit.

81 D13− D13 Complement Output Bit.

82 D13+ D13 True Output Bit.

83 D14− D14 Complement Output Bit.

84 D14+ D14 True Output Bit.

85 D15− D15 Complement Output Bit.

86 D15+ (MSB) D15 True Output Bit.

89 OR− Out-of-Range Complement Output Bit.

90 OR+ Out-of-Range True Output Bit.

100 SFDR

Differential Reference Output. Decoupled to ground with 0.1 µF capacitor and to REFB

(Pin 11) with 0.1 µF and 10 µF capacitors.

Differential Reference Output. Decoupled to ground with a 0.1 µF capacitor and to REFT

(Pin 10) with 0.1 µF and 10 µF capacitors.

SFDR Control Pin. CMOS-compatible control pin for optimizing the configuration of the

AD9461 analog front end. Connecting SFDR to AGND optimizes SFDR performance for

applications with analog input frequencies <40 MHz or >215 MHz. For applications with

analog inputs from 40 MHz to 215 MHz, connect this pin to AVDD1 for optimum SFDR

performance; power dissipation from AVDD2 decreases by ~40 mW.

Rev. 0 | Page 9 of 28

Page 10

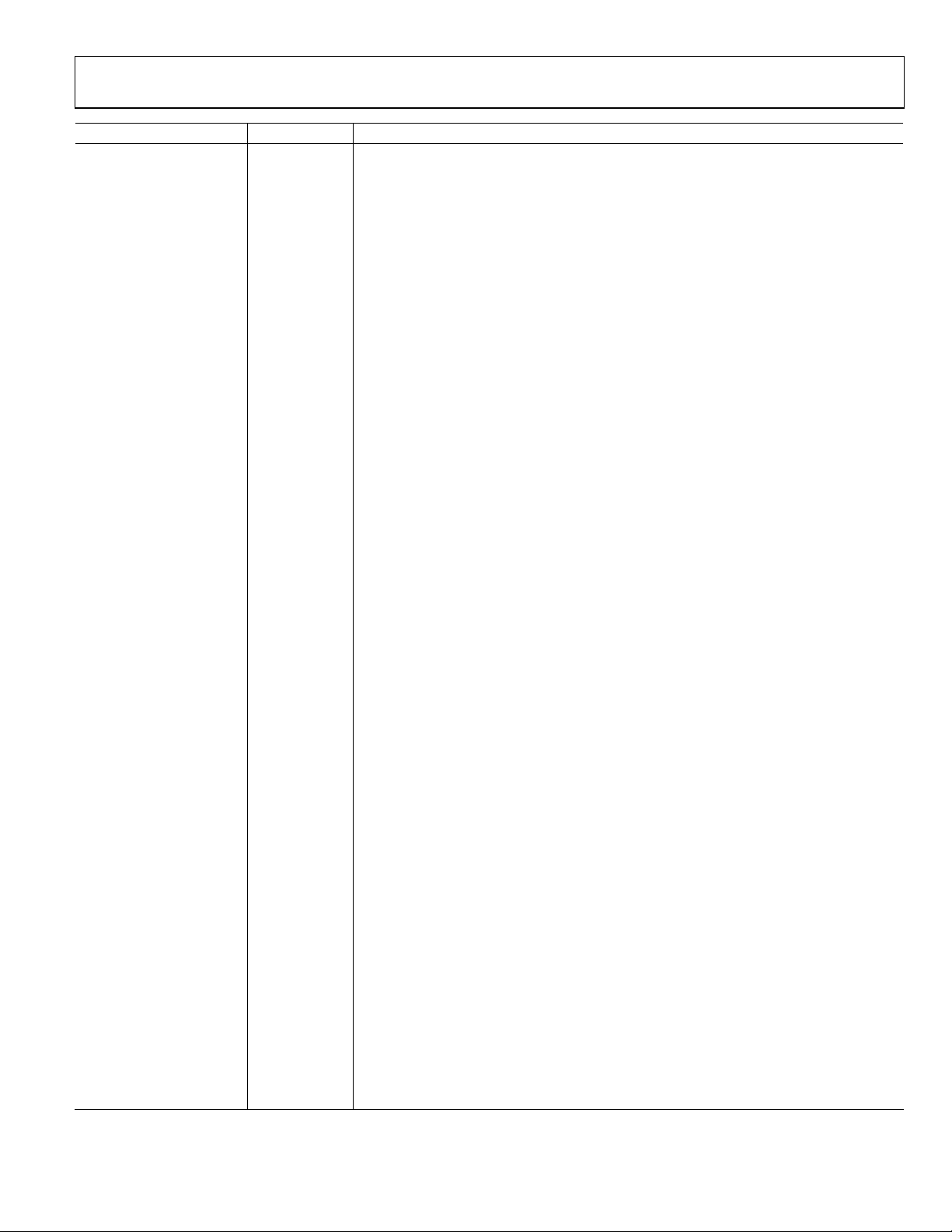

AD9461

SFDR99AGND98AGND97AVDD196AVDD195AVDD194AVDD193AVDD192AVDD191AGND90OR+89D15+ (MSB)88DRVDD87DRGND86D14+85D13+84D12+83D11+82D10+81D9+80D8+79D7+78D6+77D5+76DRVDD

100

DNC

DFS

AVDD1

SENSE

VREF

AGND

REFT

REFB

AVDD2

AVDD2

AVDD2

AVDD2

AVDD2

AVDD2

AVDD1

AVDD1

AVDD1

AGND

VIN+

VIN–

AGND

AVDD2

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

DCS MODE

OUTPUT MODE

LVDS_BIAS

DNC = DO NOT CONNE CT

PIN 1

AD9461

CMOS MODE

TOP VIEW

(Not to Scale)

26

AVDD227AVDD228AVDD229AVDD230AVDD231AVDD232AVDD133AVDD134AVDD135AVDD236AVDD137AVDD238AVDD1

39

40

41

42

43

CLK–

CLK+

AGND

AGND

AVDD144AVDD145AVDD1

Figure 5. 100-Lead TQFP_EP, Pin Configuration in CMOS Mode

75

DRGND

74

D4+

73

D3+

72

D2+

71

D1+

70

D0+ (LSB )

69

DNC

68

DCO+

67

DCO–

66

DNC

65

DNC

64

DRVDD

63

DRGND

62

DNC

61

DNC

60

DNC

59

DNC

58

DNC

57

DNC

56

DNC

55

DNC

54

DNC

53

DNC

52

DNC

51

DNC

46

47

48

49

DNC50DNC

AGND

DRVDD

DRGND

06011-005

Table 8. Pin Function Descriptions—100-Lead TQFP_EP in CMOS Mode

Pin No. Mnemonic Description

1 DCS MODE Clock Duty Cycle Stabilizer (DCS) Control Pin. CMOS compatible.

DCS = low (AGND) to enable DCS (recommended).

DCS = high (AVDD1) to disable DCS.

2, 49 to 62, 65 to 66, 69 DNC Do Not Connect. These pins should float.

3 OUTPUT MODE CMOS-Compatible Output Logic Mode Control Pin.

OUTPUT MODE = 0 for CMOS mode.

OUTPUT MODE = 1 (AVDD1) for LVDS outputs.

4 DFS Data Format Select Pin. CMOS control pin that determines the format of the output data.

DFS = high (AVDD1) for twos complement.

DFS = low (ground) for offset binary format.

5 LVDS_BIAS Set Pin for LVDS Output Current. Place 3.7 kΩ resistor terminated to DRGND.

6, 18 to 20, 32 to 34, 36,

AVDD1 3.3 V (±5%) Analog Supply.

38, 43 to 45, 92 to 97

7 SENSE

Reference Mode Selection. Connect to AGND for internal 1.7 V reference (3.4 V p-p analog

input range); connect to AVDD1 for external reference.

8 VREF

1.7 V Reference I/O. The function is dependent on the SENSE pin and external programming

resistors. Decouple to ground with 0.1 µF and 10 µF capacitors.

9, 21, 24, 39, 42, 46, 91, 98,

99, Exposed Heat Sink

10 REFT

AGND

Analog Ground. The exposed heat sink on the bottom of the package must be connected to

AGND.

Differential Reference Output. Decoupled to ground with 0.1 µF capacitor and to REFB

(Pin 11) with 0.1 µF and 10 µF capacitors.

Rev. 0 | Page 10 of 28

Page 11

AD9461

Pin No. Mnemonic Description

11 REFB

12 to 17, 25 to 31, 35, 37 AVDD2 5.0 V Analog Supply (±5%).

22 VIN+ Analog Input—True.

23 VIN− Analog Input—Complement.

40 CLK+ Clock Input—True.

41 CLK− Clock Input—Complement.

47, 63, 75, 87 DRGND Digital Output Ground.

48, 64, 76, 88 DRVDD 3.3 V Digital Output Supply (3.0 V to 3.6 V).

67 DCO− Data Clock Output—Complement.

68 DCO+ Data Clock Output—True.

70 D0+ (LSB) D0 True Output Bit (CMOS Levels).

71 D1+ D1 True Output Bit.

72 D2+ D2 True Output Bit.

73 D3+ D3 True Output Bit.

74 D4+ D4 True Output Bit.

77 D5+ D5 True Output Bit.

78 D6+ D6 True Output Bit.

79 D7+ D7 True Output Bit.

80 D8+ D8 True Output Bit.

81 D9+ D9 True Output Bit.

82 D10+ D10 True Output Bit.

83 D11+ D11 True Output Bit.

84 D12+ D12 True Output Bit.

85 D13+ D13 True Output Bit.

86 D14+ D14 True Output Bit.

89 D15+ (MSB) D15 True Output Bit.

90 OR+ Out-of-Range True Output Bit.

100 SFDR

Differential Reference Output. Decoupled to ground with a 0.1 µF capacitor and to REFT

(Pin 10) with 0.1 µF and 10 µF capacitors.

SFDR Control Pin. CMOS-compatible control pin for optimizing the configuration of the

AD9461 analog front end. Connecting SFDR to AGND optimizes SFDR performance for

applications with analog input frequencies <40 MHz or >215 MHz. For applications with

analog inputs from 40 MHz to 215 MHz, connect this pin to AVDD1 for optimum SFDR

performance; power dissipation from AVDD2 decreases by ~40 mW.

Rev. 0 | Page 11 of 28

Page 12

AD9461

V

A

EQUIVALENT CIRCUITS

AVDD2

VIN+

VIN–

3.5V

6pF

6pF

X1

AVDD2

1kΩ

1kΩ

Figure 6. Equivalent Analog Input Circuit

DRVDD DRVDD

1.2V

LVDSBI AS

3.74kΩ

Figure 7. Equivalent LVDS_BIAS Circuit

T/H

I

LVDSOUT

DRVDD

DX

06011-006

06011-009

Figure 9. Equivalent CMOS Digital Output Circuit

DD

K

06011-007

DCS MODE,

OUTPUT MODE,

DFS

30kΩ

06011-010

Figure 10. Equivalent Digital Input Circuit,

DFS, DCS MODE, OUTPUT MODE

VDD1

DRVDD

3kΩ3kΩ

V

DX– DX+

V

V

V

06011-008

Figure 8. Equivalent LVDS Digital Output Circuit

CLK+

Ω

2.5k

Figure 11. Equivalent Sample Clock Input Circuit

2.5kΩ

CLK–

06011-011

Rev. 0 | Page 12 of 28

Page 13

AD9461

TYPICAL PERFORMANCE CHARACTERISTICS

AVDD1 = 3.3 V, AVDD2 = 5.0 V, DRVDD = 3.3 V, rated sample rate, LVDS mode, DCS enabled, TA = 25°C, 3.4 V p-p differential

input, A

= −1 dBFS, internal trimmed reference (nominal VREF = 1.7 V), unless otherwise noted.

IN

0

–10

–20

–30

–40

–50

–60

–70

–80

AMPLITUDE (dBFS)

–90

–100

–110

–120

–130

0 16.25 32.50 48.75 65.00

FREQUENCY (MHz)

130MSPS

10.3MHz @ –1.0dBFS

SNR = 77.7dB

ENOB = 12.6 BI TS

SFDR = 90dBc

Figure 12. 130 MSPS, 64k Point Single-Tone FFT, 10.3 MHz

06011-012

5

4

3

2

1

0

INL (LSB)

–1

–2

–3

–4

–5

0 655365734449152409603276824576163848192

Figure 15. 130 MSPS, INL Error vs. Output Code, 10.3 MHz

OUTPUT CODE

06011-017

0

130MSPS

–10

170.3MHz @ –1.0d BFS

SNR = 75.4dB

–20

ENOB = 12.3 BI TS

–30

SFDR = 86dBc

–40

–50

–60

–70

–80

AMPLITUDE (dBFS)

–90

–100

–110

–120

–130

0 16.25 32.50 48.75 65.00

FREQUENCY (MHz)

Figure 13. 130 MSPS, 64k Point Single-Tone FFT,170.3 MHz

0.6

0.4

0.2

0

DNL (LS B)

–0.2

95

90

85

(dB)

80

75

06011-015

70

SFDR = +85°C

SFDR = +25°C

SFDR = –40°C

SNR = –40°C

SNR = +25°C

0 50 100 150 200

ANALOG INPUT FREQUENCY (MHz)

SNR = +85°C

06011-018

Figure 16. 130 MSPS, SNR/SFDR vs. Analog Input Frequency, 3.4 V p-p

95

90

85

(dB)

80

SFDR = +85°C

SFDR = +25°C

SFDR = –40°C

SNR = –40°C

–0.4

–0.6

0 655365734449152409603276824576163848192

OUTPUT CODE

Figure 14. 130 MSPS, DNL Error vs. Output Code, 10.3 MHz

06011-016

Rev. 0 | Page 13 of 28

75

70

0 50 100 150 200

ANALOG INPUT FREQUENCY (MHz)

SNR = +85°C

SNR = +25°C

Figure 17. 130 MSPS, SNR/SFDR vs. Analog Input Frequency,

3.4 V p-p, CMOS Output Mode

06011-019

Page 14

AD9461

120

SFDR dBFS

100

80

60

(dB)

40

20

0

SNR dBFS

–90 –80 –70 –60 –50 –40 –30 –20 –10 0

Figure 18. 130 MSPS,170.3 MHz SNR/SFDR vs. Analog Input Amplitude

95

SFDR dBc

SNR dB

ANALOG INPUT AMPLIT UDE (dB)

0

–10

–20

–30

–40

–50

WORST IMD3 dBc

–60

–70

–80

–90

SFDR AND IMD3 (d B)

–100

–110

06011-020

–120

–130

–100 –90 –80 –70 –60 –50 –40 –30 –20 –10 0

SFDR dBFS

WORST IMD3 dBFS

ANALOG INPUT AMPLIT UDE (dB)

SFDR dBc

06011-025

Figure 21. 130 MSPS, Two-Tone SFDR vs. Analog Input Amplitude,

169.6 MHz, 170.6 MHz

6000

90

85

SFDR = –40°C

(dB)

80

75

70

0 50 100 150 200

SFDR = +25°C

SFDR = +85°C

SNR = –40°C

SNR = +85°C

ANALOG INPUT FREQUENCY ( M Hz )

SNR = +25°C

Figure 19. 125 MSPS, SNR/SFDR vs. Analog Input Frequency, 3.4 V p-p

120

100

80

60

(dB)

40

SFDR dBc

SFDR dBFS

SNR dBFS

5000

4000

3000

FREQUENCY

2000

1000

06011-021

0

N–9

N–8

N–7

N–6

N–5

N–4

N–3

N–2

N–1

N+0

N+1

N+2

N+3

N+4

N+5

N+6

N+7

N–11

N–10

BIN

N+8

06011-028

N+9

N+10

N+11

Figure 22. 130 MSPS, Grounded Input Histogram

0

105MSPS

170.6MHz @ –7.0dBFS

–20

169.6MHz @ –7.0dBFS

SFDR = 89dBF S

–40

–60

–80

AMPLITUDE ( d BF S)

–100

20

SNR dB

0

–90 –80 –70 –60 –50 –40 –30 –20 –10 0

ANALOG INPUT AMPLIT UDE (dB)

06011-023

Figure 20. 130 MSPS, 170.3 MHz SNR/SFDR vs. Analog Input Amplitude,

CMOS Output Mode

Rev. 0 | Page 14 of 28

–120

–140

0 15.625 31.250 46.875 62.500

FREQUENCY (MHz)

Figure 23. 130 MSPS, 64k Point Two-Tone FFT, 169.6 MHz, 170.6 MHz

06011-029

Page 15

AD9461

0.6

0.5

0.4

90

SFDR dBc

85

0.3

0.2

0.1

GAIN ERROR (%FS )

0

–0.1

–0.2

–40 –20 0 20 806040

TEMPERATURE (° C)

Figure 24. 130 MSPS, Gain vs. Temperature

97

170.3MHz SFDR dBc

92

87

(dBc)

82

77

72

1.82.02.22.42.62.83.03.23.43.63.84.0 4.2

ANALOG INPUT RANGE (V p- p)

170.3MHz SNR dBF S

Figure 25. 130 MSPS, SNR, SFDR vs. Analog Input Range

80

(dB)

75

70

06011-030

65

2.9 3.1 3.3 3.5 4.13.7 3. 9

ANALOG INPUT COMMON-MO DE VOLTAG E (V)

SNR dB

06011-046

Figure 27. 130 MSPS, SNR/SFDR vs. Analog Input Common Mode

90

SFDR dBc

85

80

(dB)

75

70

06011-047

65

45 65 85 105 145125

SNR dB

SAMPLE RATE (MSPS)

06011-035

Figure 28. Single-Tone SNR/SFDR vs. Sample Rate 170.3 MHz

1.734

1.732

1.730

1.728

1.726

1.724

VREF (V)

1.722

1.720

1.718

1.716

–40 –20 0 20 806040

TEMPERATURE (° C)

06011-032

Figure 26. 130 MSPS, VREF vs. Temperature

Rev. 0 | Page 15 of 28

Page 16

AD9461

(

TERMINOLOGY

Analog Bandwidth (Full Power Bandwidth)

The analog input frequency at which the spectral power of the

fundamental frequency (as determined by the FFT analysis) is

reduced by 3 dB.

Two -Tone SFDR

The ratio of the rms value of either input tone to the rms value

of the peak spurious component. The peak spurious component

may or may not be an IMD product.

Aperture Delay (t

)

A

The delay between the 50% point of the rising edge of the clock

and the instant at which the analog input is sampled.

Aperture Uncertainty (Jitter, t

)

J

The sample-to-sample variation in aperture delay.

Clock Pulse Width and Duty Cycle

Pulse width high is the minimum amount of time that the

clock pulse should be left in the Logic 1 state to achieve rated

performance. Pulse width low is the minimum time the clock

pulse should be left in the low state. At a given clock rate, these

specifications define an acceptable clock duty cycle.

Differential Nonlinearity (DNL, No Missing Codes)

An ideal ADC exhibits code transitions that are exactly 1 LSB

apart. DNL is the deviation from this ideal value. Guaranteed

no missing codes to 16-bit resolution indicates that all 65,536

codes must be present over all operating ranges.

Integral Nonlinearity (INL)

INL is the deviation of each individual code from a line drawn

from negative full scale through positive full scale. The point

used as negative full scale occurs ½ LSB before the first code

transition. Positive full scale is defined as a level 1½ LSB beyond

the last code transition. The deviation is measured from the

middle of each particular code to the true straight line.

Signal-to-Noise and Distortion (SINAD)

SINAD is the ratio of the rms input signal amplitude to the rms

value of the sum of all other spectral components below the

Nyquist frequency, including harmonics but excluding dc.

Signal-to-Noise Ratio (SNR)

SNR is the ratio of the rms input signal amplitude to the rms

value of the sum of all other spectral components below the

Nyquist frequency, excluding the first six harmonics and dc.

Spurious-Free Dynamic Range (SFDR)

SFDR is the ratio of the rms signal amplitude to the rms value

of the peak spurious spectral component. The peak spurious

component may be a harmonic. SFDR can be reported in dBc (that

is, degrades as signal level is lowered) or dBFS (always related back

to converter full scale).

Total Harmonic Distortion (THD)

The ratio of the rms input signal amplitude to the rms value of

the sum of the first six harmonic components.

Effective Number of Bits (ENOB)

The effective number of bits for a sine wave input at a given

input frequency can be calculated directly from its measured

SINAD using the following formula:

)

ENOB

=

SINAD

6.02

1.76−

Gain Error

The first code transition should occur at an analog value of

½ LSB above negative full scale. The last transition should occur

at an analog value of 1½ LSB below the positive full scale. Gain

error is the deviation of the actual difference between first and

last code transitions and the ideal difference between first and

last code transitions.

Maximum Conversion Rate

The clock rate at which parametric testing is performed.

Minimum Conversion Rate

The clock rate at which the SNR of the lowest analog signal

frequency drops by no more than 3 dB below the guaranteed

limit.

Offset Error

The major carry transition should occur for an analog value of

½ LSB below VIN+ = VIN−. Offset error is defined as the

deviation of the actual transition from that point.

Out-of-Range Recovery Time

The time it takes for the ADC to reacquire the analog input

after a transition from 10% above positive full scale to 10%

above negative full scale, or from 10% below negative full scale

to 10% below positive full scale.

Output Propagation Delay (t

)

PD

The delay between the clock rising edge and the time when all

bits are within valid logic levels.

Power-Supply Rejection Ratio

The change in full scale from the value with the supply at the

minimum limit to the value with the supply at the maximum

limit.

Tem p er at u re Dr i ft

The temperature drift for offset error and gain error specifies

the maximum change from the initial (25°C) value to the value

at T

MIN

or T

MAX

.

Rev. 0 | Page 16 of 28

Page 17

AD9461

F

F

THEORY OF OPERATION

The AD9461 architecture is optimized for high speed and ease

of use. The analog inputs drive an integrated, high bandwidth

track-and-hold circuit that samples the signal prior to quantization

by the 16-bit pipeline ADC core. The device includes an on-board

reference and input logic that accepts TTL, CMOS, or LVPECL

levels. The digital output logic levels are user selectable as standard

3 V CMOS or LVDS (ANSI-644 compatible) via the OUTPUT

MODE pin.

ANALOG INPUT AND REFERENCE OVERVIEW

A stable and accurate 0.5 V band gap voltage reference is built

into the AD9461. The input range can be adjusted by varying

the reference voltage applied to the AD9461, using either the

internal reference or an externally applied reference voltage.

The input span of the ADC tracks reference voltage changes

linearly.

Internal Reference Connection

A comparator within the AD9461 detects the potential at the

SENSE pin and configures the reference into three possible states,

summarized in

amplifier switch is connected to the internal resistor divider (see

Figure 29), setting VREF to ~1.7 V. If a resistor divider is

connected as shown in

SENSE pin. This puts the reference amplifier in a noninverting

mode with the VREF output defined as

In all reference configurations, REFT and REFB drive the

analog-to-digital conversion core and establish its input span.

The input range of the ADC always equals twice the voltage at

the reference pin for either an internal or an external reference.

Internal Reference Trim

The internal reference voltage is trimmed during the production

test; therefore, there is little advantage to the user supplying an

external voltage reference to the AD9461. The gain trim is

performed with the AD9461 input range set to 3.4 V p-p

nominal (SENSE connected to AGND). Because of this trim,

and the maximum ac performance provided by the 3.4 V p-p

analog input range, there is little benefit to using analog input

Tabl e 9 . If SENSE is grounded, the reference

Figure 30, the switch again sets to the

R2

⎛

VVREF 15.0

⎜

⎝

⎞

+×=

⎟

R1

⎠

ranges <2 V p-p. However, reducing the range can improve SFDR

performance in some applications. Likewise, increasing the

range up to 3.4 V p-p can improve SNR. Users are cautioned

that the differential nonlinearity of the ADC varies with the

reference voltage. Configurations that use <2.0 V p-p can

exhibit missing codes and, therefore, degraded noise and

distortion performance.

VIN+

10µ

10µ

VIN–

CORE

VREF

+

0.1µF

SENSE

Figure 29. Internal Reference Configuration

+

0.1µF

R2

SENSE

R1

Figure 30. Programmable Reference Configuration

VIN+

VIN–

VREF

SELECT

LOGIC

AD9461

SELECT

LOGIC

0.5V

AD9461

ADC

0.5V

ADC

CORE

REFT

0.1µF

0.1µF 10µF

REFB

0.1µF

REFT

0.1µF

0.1µF 10µF

REFB

0.1µF

+

+

06011-036

06011-037

Rev. 0 | Page 17 of 28

Page 18

AD9461

A

Table 9. Reference Configuration Summary

Selected Mode SENSE Voltage Resulting VREF (V) Resulting Differential Span (V p-p)

External Reference AVDD N/A 2 × external reference

Programmable Reference 0.2 V to VREF

Programmable Reference

0.2 V to VREF

(Set for 2 V p-p)

Internal Fixed Reference AGND to 0.2 V 1.7 3.4

R2

⎞

⎛

10.5

⎜

⎝

⎛

10.5

⎜

⎝

, (See Figure 30)

+×

⎟

R1

⎠

R2

⎞

, R1 = R2 = 1 kΩ

+×

⎟

R1

⎠

2 × VREF

2.0

External Reference Operation

When the SENSE pin is tied to AVDD, the internal reference is

disabled, allowing the use of an external reference. An internal

reference buffer loads the external reference with an equivalent

7 kΩ load. The internal buffer continues to generate the positive

and negative full-scale references, REFT and REFB, for the

ADC core. The input span is always twice the value of the

reference voltage; therefore, the external reference must be

limited to a maximum of 2.0 V. See Figure 24 for gain variation vs.

temperature.

Analog Inputs

As with most new high speed, high dynamic range ADCs, the

analog input to the AD9461 is differential. Differential inputs

improve on-chip performance because signals are processed

through attenuation and gain stages. Most of the improvement

is a result of differential analog stages having high rejection of

even-order harmonics. There are also benefits at the PCB level.

First, differential inputs have high common-mode rejection of

stray signals, such as ground and power noise. Second, they

provide good rejection of common-mode signals, such as local

oscillator feedthrough. The specified noise and distortion of the

AD9461 cannot be realized with a single-ended analog input;

therefore, such configurations are discouraged. Contact sales for

recommendations of other 16-bit ADCs that support singleended analog input configurations.

The AD9461 analog input voltage range is offset from ground

by 3.5 V. Each analog input connects through a 1 kΩ resistor to

the 3.5 V bias voltage and to the input of a differential buffer. The

internal bias network on the input properly biases the buffer for

maximum linearity and range (see the Equivalent Circuits section).

Therefore, the analog source driving the AD9461 should be accoupled to the input pins. The recommended method for driving

the analog input of the AD9461 is to use an RF transformer to

convert single-ended signals to differential (see Figure 32). Series

resistors between the output of the transformer and the AD9461

analog inputs help isolate the analog input source from switching

transients caused by the internal sample-and-hold circuit. The

series resistors, along with the 1 kΩ resisters connected to the

internal 3.5 V bias, must be considered in impedance matching

the transformer input. For example, if R

is set to 51 Ω, RS is set

T

to 33 Ω and there is a 1:1 impedance ratio transformer, the input

matches a 50 Ω source with a full-scale drive of 16.0 dBm. The

50 Ω impedance matching can also be incorporated on the

secondary side of the transformer, as shown in the evaluation

board schematic (see Figure 35).

0.1µF

R

S

VIN+

AD9461

R

S

VIN–

06011-039

ANALOG

INPUT

SIGNAL

Figure 32. Transformer-Coupled Analog Input Circuit

DT1–1WT

R

T

With the 1.7 V reference, which is the nominal value (see the

Internal Reference Trim section), the differential input range of

the AD9461 analog input is nominally 3.4 V p-p or 1.7 V p-p on

each input (VIN+ or VIN−).

CLOCK INPUT CONSIDERATIONS

Any high speed ADC is extremely sensitive to the quality of the

sampling clock provided by the user. A track-and-hold circuit is

essentially a mixer, and any noise, distortion, or timing jitter on

the clock combines with the desired signal at the analog-todigital output. For that reason, considerable care was taken in

the design of the clock inputs of the AD9461, and the user is

VIN+

advised to give careful thought to the clock source.

Typical high speed ADCs use both clock edges to generate a

1.7V p-p

3.5V

variety of internal timing signals and, as a result, can be sensitive

to the clock duty cycle. Commonly a 5% tolerance is required on

VIN–

DIGITAL OUT = ALL 1s DIGITAL OUT = ALL 0s

06011-038

Figure 31. Differential Analog Input Range for VREF = 1.7 V

Rev. 0 | Page 18 of 28

the clock duty cycle to maintain dynamic performance characteristics. The AD9461 contains a clock duty cycle stabilizer (DCS)

that retimes the nonsampling edge, providing an internal clock

signal with a nominal ~50% duty cycle. Noise and distortion performance are nearly flat for a 30% to 70% duty cycle with the DCS

Page 19

AD9461

V

formance are nearly flat for a 30% to 70% duty cycle with the DCS

enabled. The DCS circuit locks to the rising edge of CLK+ and

optimizes timing internally. This allows for a wide range of input

duty cycles at the input without degrading performance. Jitter in

the rising edge of the input is still of paramount concern and is

not reduced by the internal stabilization circuit. The duty cycle

control loop does not function for clock rates of less than 30 MHz

nominally. The loop is associated with a time constant that

should be considered in applications where the clock rate can

change dynamically, requiring a wait time of 1.5 μs to 5 μs after a

dynamic clock frequency increase or decrease before the DCS

loop is relocked to the input signal. During the time that the

loop is not locked, the DCS loop is bypassed, and the internal

device timing is dependent on the duty cycle of the input clock

signal. In such an application, it can be appropriate to disable the

duty cycle stabilizer. In all other applications, enabling the DCS

circuit is recommended to maximize ac performance.

The DCS circuit is controlled by the DCS MODE pin; a CMOS

logic low (AGND) on DCS MODE enables the duty cycle stabilizer,

and logic high (AVDD1 = 3.3 V) disables the controller.

The AD9461 input sample clock signal must be a high quality,

extremely low phase noise source to prevent degradation of performance. Maintaining 16-bit accuracy places a premium on the

encode clock phase noise. SNR performance can easily degrade

by 3 dB to 4 dB with 70 MHz analog input signals when using a

high jitter clock source. (See the

AN-501 Application Note,

Aperture Uncertainty and ADC System Performance for more

information.) For optimum performance, the AD9461 must be

clocked differentially. The sample clock inputs are internally

biased to ~1.5 V, and the input signal is usually ac-coupled into

the CLK+ and CLK− pins via a transformer or capacitors.

Figure 33 shows one preferred method for clocking the

AD9461. The clock source (low jitter) is converted from singleended to differential using an RF transformer. The back-to-back

Schottky diodes across the secondary of the transformer limit

clock excursions into the AD9461 to approximately 0.8 V p-p

differential. This helps prevent the large voltage swings of the

clock from feeding through to other portions of the AD9461 and

limits the noise presented to the sample clock inputs.

If a low jitter clock is available, it helps to band-pass filter the

clock reference before driving the ADC clock inputs. Another

option is to ac couple a differential ECL/PECL signal to the encode

input pins, as shown in

CRYSTAL

SINE

SOURCE

Figure 33. Crystal Clock Oscillator, Differential Encode

Figure 34.

ADT1–1WT

0.1µF

HSMS2812

DIODES

CLK+

AD9461

CLK–

6011-040

T

0.1µF

ECL/

PECL

VT

Figure 34. Differential ECL for Encode

0.1µF

ENCODE

AD9461

ENCODE

06011-041

Jitter Considerations

High speed, high resolution ADCs are sensitive to the quality

of the clock input. The degradation in SNR at a given input

f

frequency (

(

t

) can be calculated using the following equation:

J

SNR = −20 log[2πf

) and rms amplitude due only to aperture jitter

INPUT

× tJ]

INPUT

In the equation, the rms aperture jitter represents the root-meansquare of all jitter sources including the clock input, analog input

signal, and ADC aperture jitter specification. IF undersampling

applications are particularly sensitive to jitter

The clock input should be treated as an analog signal in cases

where aperture jitter can affect the dynamic range of the AD9461.

Power supplies for clock drivers should be separated from the

ADC output driver supplies to avoid modulating the clock signal

with digital noise. Low jitter crystal-controlled oscillators make

the best clock sources. If the clock is generated from another type

of source (by gating, dividing, or another method), it should be

synchronized by the original clock during the last step.

POWER CONSIDERATIONS

Care should be taken when selecting a power source. The use of

linear dc supplies is highly recommended. Switching supplies

tend to have radiated components that can be received by the

AD9461. Each of the power supply pins should be decoupled as

closely to the package as possible using 0.1 μF chip capacitors.

The AD9461 has separate digital and analog power supply pins.

The analog supplies are denoted AVDD1 (3.3 V) and AVDD2

(5 V), and the digital supply pins are denoted DRVDD. Although

the AVDD1 and DRVDD supplies can be tied together, best performance is achieved when the supplies are separate. This is

because the fast digital output swings can couple switching

current back into the analog supplies. Note that both AVDD1

and AVDD2 must be held within 5% of the specified voltage.

The DRVDD supply of the AD9461 is a dedicated supply for the

digital outputs in either LVDS or CMOS output mode. When in

LVDS mode, the DRVDD should be set to 3.3 V. In CMOS mode,

the DRVDD supply can be connected from 2.5 V to 3.6 V for

compatibility with the receiving logic.

Rev. 0 | Page 19 of 28

Page 20

AD9461

DIGITAL OUTPUTS

LVDS Mode

The off-chip drivers on the chip can be configured to provide

LVDS-compatible output levels via Pin 3 (OUTPUT MODE).

LVDS outputs are available when OUTPUT MODE is CMOS

logic high (or AVDD1 for convenience) and a 3.74 kΩ R

resistor is placed at Pin 5 (LVDS_BIAS) to ground. Dynamic

performance, including both SFDR and SNR, maximizes when

using the AD9461 in LVDS mode; designers are encouraged to

take advantage of this mode. The AD9461 outputs include

complementary LVDS outputs for each data bit (Dx+/Dx−), the

overrange output (OR+/OR−), and the output data clock output

(DCO+/DCO−). The R

resistor current is multiplied on-chip,

SET

setting the output current at each output equal to a nominal

3.5 mA (11 × I

). A 100 Ω differential termination resistor

R

SET

placed at the LVDS receiver inputs results in a nominal 350 mV

swing at the receiver. LVDS mode facilitates interfacing with

LVDS receivers in custom ASICs and FPGAs that have LVDS

capability for superior switching performance in noisy

environments. Single point-to-point net topologies are

recommended, with a 100 Ω termination resistor located as

close to the receiver as possible. It is recommended to keep the

trace length less than two inches and to keep differential output

trace lengths as equal as possible.

CMOS Mode

In applications that can tolerate a slight degradation in dynamic

performance, the AD9461 output drivers can be configured to

interface with 2.5 V or 3.3 V logic families by matching

DRVDD to the digital supply of the interfaced logic. CMOS

outputs are available when OUTPUT MODE is CMOS logic

low (or AGND for convenience). In this mode, the output data

bits, Dx, are single-ended CMOS, as is the overrange output,

OR+. The output clock is provided as a differential CMOS

signal, DCO+/DCO−. Lower supply voltages are recommended

to avoid coupling switching transients back to the sensitive

analog sections of the ADC. The capacitive load to the CMOS

outputs should be minimized, and each output should be

connected to a single gate through a series resistor (220 Ω) to

minimize switching transients caused by the capacitive loading.

Table 10. Digital Output Coding

VIN+ − VIN−

Code

65,536 +1.700 +1.000 1111 1111 1111 1111 0111 1111 1111 1111

32,768 0 0 1000 0000 0000 0000 0000 0000 0000 0000

32,767 −0.000058 −0.0000305 0111 1111 1111 1111 1111 1111 1111 1111

0 −1.70 −1.00 0000 0000 0000 0000 1000 0000 0000 0000

Input Span = 3.4 V p-p (V)

VIN+ − VIN−

Input Span = 2 V p-p (V)

SET

TIMING

The AD9461 provides latched data outputs with a pipeline delay

of 13 clock cycles. Data outputs are available one propagation

delay (t

) after the rising edge of CLK+. Refer to Figure 2 and

PD

Figure 3 for detailed timing diagrams.

OPERATIONAL MODE SELECTION

Data Format Select

The data format select (DFS) pin of the AD9461 determines

the coding format of the output data. This pin is 3.3 V CMOS

compatible, with logic high (or AVDD1, 3.3 V) selecting twos

complement and DFS logic low (AGND) selecting offset binary

format.

Output Mode Select

The OUPUT MODE pin controls the logic compatibility,

as well as the pinout of the digital outputs. This pin is a CMOScompatible input. With OUTPUT MODE = 0 (AGND), the

AD9461 outputs are CMOS compatible, and the pin assignment

for the device is as defined in

(AVDD1, 3.3 V), the AD9461 outputs are LVDS compatible, and

the pin assignment for the device is as defined in

Duty Cycle Stabilizer

The DCS circuit is controlled by the DCS MODE pin; a CMOS

logic low (AGND) on DCS MODE enables the DCS, and logic

high (AVDD1, 3.3 V) disables the controller.

SFDR Enhancement

Under certain conditions, the SFDR performance of the AD9461

improves by decreasing the power of the core of the ADC. The

SFDR control pin (Pin 100) is a CMOS-compatible control pin

to optimize the configuration of the AD9461 analog front end.

Connecting SFDR to AGND optimizes SFDR performance for

applications with analog input frequencies <40 MHz or >215 MHz.

For applications with analog inputs from 40 MHz to 215 MHz,

connect this to AVDD1 for optimum SFDR performance; power

dissipation from AVDD2 decreases by ~40 mW.

Digital Output

Offset Binary (D15•••D0)

Tabl e 1 0 summarizes the output coding.

Tabl e 8 . With OUTPUT MODE = 1

Digital Output

Twos Complement (D15•••D0)

Tabl e 7 .

Rev. 0 | Page 20 of 28

Page 21

AD9461

EVALUATION BOARD

Evaluation boards are offered to configure the AD9461 in either

CMOS mode or LVDS mode only. This design represents a

recommended configuration for using the device over a wide

range of sampling rates and analog input frequencies. These

evaluation boards provide all the support circuitry required to

operate the ADC in its various modes and configurations.

Complete schematics are shown in

Gerber files are available from engineering applications

demonstrating the proper routing and grounding techniques

that should be applied at the system level.

Figure 35 through Figure 38.

The LVDS mode evaluation boards include an LVDS-to-CMOS

translator, making them compatible with the high speed ADC

FIFO evaluation kit (HSC-ADC-EVALA-SC). The kit includes a

high speed data capture board that provides a hardware solution

for capturing up to 32 kB samples of high speed ADC output

data in a FIFO memory chip (user upgradeable to 256 kB

samples). Software is provided to enable the user to download

the captured data to a PC via the USB port. This software also

includes a behavioral model of the AD9461 and many other

high speed ADCs.

It is critical that signal sources with very low phase noise

(<60 fsec rms jitter) are used to realize the ultimate

performance of the converter. Proper filtering of the input

signal to remove harmonics and lower the integrated noise at

the input is also necessary to achieve the specified noise

performance.

The evaluation boards are shipped with a 115 V ac to 6 V dc

power supply. The evaluation boards include low dropout

regulators to generate the various dc supplies required by the

AD9461 and its support circuitry. Separate power supplies are

provided to isolate the DUT from the support circuitry. Each

input configuration can be selected by proper connection of

various jumpers (see

Figure 35).

Behavioral modeling of the AD9461 is also available at

www.analog.com/ADIsimADC. The ADIsimADC™ software

supports virtual ADC evaluation using ADI proprietary behavioral

modeling technology. This allows rapid comparison between the

AD9461 and other high speed ADCs with or without hardware

evaluation boards.

The user can choose to remove the translator and terminations

to access the LVDS outputs directly.

Rev. 0 | Page 21 of 28

Page 22

AD9461

P21

PTMICRO4

P22

PTMICRO4

GND

P1

1

P2

2

P3

3

P4

4

P1

1

P2

2

P3

3

P4

4

DRGND

XTALPWR

EXTREF

DRGND

DRVDD

GND

VCC

GND

5V

DRVDD

MTHOLE6

H4

MTHOLE6

H3

MTHOLE6

H1

MTHOLE6

H2

D11_C/D6_Y

D11_T/D7_Y

D12_C/D8_Y

D12_T/D9_Y

D13_C/D10_Y

D13_T/D11_Y

D14_C/D12_Y

D14_T/D13_Y

D15_C/D14_Y

(MSB) D15_T/D15_Y

DRGND

DRVDD

DOR_C

DOR_T/DOR_Y

GND

VCC

VCC

VCC

VCC

VCC

VCC

GND

DRVDD

76

D11_C

77

D11_T

78

D12_C

79

D12_T

80

D13_C

81

D13_T

82

D14_C

83

D14_T

84

D15_C

85

D15_T

86

DRGND

87

DRVDD

88

OR_C

89

OR_T

90

AGND

91

AVDD1

92

AVDD1

93

AVDD1

94

AVDD1

95

AVDD1

96

AVDD1

97

AGND

98

AGND

99

SFDR

100

EPAD

101

D9_T/D3_Y

D10_C/D4_Y

DRGND

D10_T/D5_Y

72

73

74

75

D9_T

D10_T

D10_C

DRGND

71

D9_C/D2_Y

D9_C

70

D8_T/D1_Y

69

D8_T

D8_C/D0_Y

68

D8_C

DR

DRB

67

DCO

DCOB

66

D7_T

D7_T

D7_C

65

D7_C

64

AD9461

DRGND

DRVDD

63

DRVDD

DRGND

D6_T

62

D6_T

61

D6_C

D6_C

D5_T

60

D5_T

59

D5_C

58

D5_C

D4_T

57

D4_T

D4_C

D4_C

D3_T

56

D3_T

D3_C

55

D3_C

54

D2_T

53

D2_T

D2_C

52

D2_C

D1_T

D1_T

D1_C

51

D1_C

D0_T

50

D0_C

49

DRVDD

48

DRGND

47

AGND

46

AVDD1

45

AVDD1

44

AVDD1

43

AGND

42

ENCB

41

ENC

40

AGND

39

AVDD1

38

AVDD2

37

AVDD1

36

AVDD2

35

AVDD1

34

AVDD1

33

AVDD1

32

AVDD2

31

AVDD2

30

AVDD2

29

AVDD2

28

AVDD2

27

AVDD2

26

D0_T

D0_C (LSB)

DRVDD

DRGND

GND

VCC

VCC

VCC

GND

ENCB

ENC

GND

VCC

5V

VCC

5V

VCC

VCC

VCC

5V

DCS MODE

DNC

OUTPUT MODE

DFS

LVDSBIAS

AVDD1

SENSE

VREF

AGND

REFT

REFB

AVDD2

AVDD2

AVDD2

AVDD2

AVDD2

AVDD2

AVDD1

AVDD1

AVDD1

AGND

VIN+

VIN–

AGND

7

6

VCC

GND

9

8

10

GND

C86

0.1µF

E25

E27

E24

E26

E41

VCC

GND

R1

GND

EXTREF

DNP

R3

14

13

15

12

11

C3

0.1µF

+

GND

3.74kΩ

16

5V

5V

5V

5V

C2

0.1µF

C51

10µF

C9

0.1µF

GND

C40

0.1µF

C39

10µF

GND

R2

DNP

GND

20

21

19

18

17

5V

5V

C98

GND

DNP

GND

VCC

VCC

VCC

T1

ETC1-1-13

R5

DNP

GND

234

1

GND

E19

VCC

E4

E18

E36

VCC

GND

E10

E5

E6

E1

VCC

GND

GND

SCLK

E3

E9

VCC

5

GND

R11

1kΩ

VCC

E2

E14

GND

23

22

24

25

GND

R28

33Ω

C7

0.1µF

R4

GND

GND

TOUT

C12

0.1µF

CT

2

15

34

TINB

GND

C5

L1

10nH

J4

SMBMST

AVDD2

5V

25Ω

125

T2

3

PRISEC

TOUTB

PRI SEC

0.1µF

ANALOG

C13

DNP

OPTIONAL

R35

GND

TOUT

624

153

GND

33Ω

C8

GND

0.1µF

CT

PRI SEC

NC

TINB TO UTB

06011-042

DNP = DO NOT PO PULATE

R9

DNP

0.1µF

C91

R6

25Ω

ETC1-1-13

4

E15

T5

ADT1-1WT

Figure 35. Evaluation Board Schematic

Rev. 0 | Page 22 of 28

Page 23

AD9461

VIN

DRVDDX

DRGND

1

C41

0.1µF

DNP

C1

10µF

DNP

+

VXTAL

OPTIONAL ENCODE CIRCUITS

GND

5V

XTALPWR

C44

10µF

DNP

+

E30

E31

E20

VXTAL

ENC

CR1

2

1

XTALINPUT

8

1

OUTVCC

U2

ECLOSC

VEE ~OUT

7

14

GND

GND

VXTAL

ENCB

3

DRGNDGND

L2

0Ω

GND

OUT1

U3

3.3V

ADP3338-3.3

U7

ADP3338-3.3

OUT

DRVDDX

VCCX

GND

1

GND

OUT1

3.3V

OUT

VCCX

C4

10µF

+

342

IN

VIN

C6

10µF

+

342

IN

C88

+

C87

+

DRGND

10µF

DRGND

GND

10µF

GND

VIN

5VX

GND

GND

OUT1

OUT

5VX

GND

3

3

2

C34

10µF

+

342

IN

VIN

C33

10µF

+

1

1

C89

+

GND

10µF

GND

GND

DNP = DO NOT PO PULATE

06011-043

ENCODE

GND

GND

CR2

6

123

DNP

DNP

J1

5

NC

1

2

GND

C42

0.1µF

4

SEC

PRI

C26

R8

SMBMST

L5

0.1µF

GND

50Ω

VCCXVCC

DRVDDXDRVDD

L4

FERRITE

5VX5V

1

L3

FERRITE

FERRITE

U14

5V

ADP3338-5

XTALINPUT

POWER OPTIONS

2

P4

PJ-002A

3

LOADING SYMMETRICAL

CR2 TO MAKE LAYOUT AND PARASIT IC

T3

ADT1-1WT

0Ω

R39

C36

R7

DNP

J5

SMBMST

Figure 36. Evaluation Board Schematic, Encode, Optional Encode, and Power Options

Rev. 0 | Page 23 of 28

Page 24

AD9461

BYPASS CAPACITORS

VCC

+

C64

GND

VCC

GND

DRVDD

DRGND

GND

GND

GND

C43

10µF

0.1µF

+

C65

C47

10µF

0.1µF

5V

+

C56

10µF

5V

5V

C11

0.1µF

C85

0.1µF

C23

0.1µF

C35

0.1µF

C14

DNP

C53

0.1µF

C72

DNP

C94

0.1µF

C32

0.1µF

C17

DNP

C52

0.1µF

C73

DNP

C95

0.1µF

C21

0.1µF

C30

0.01µF

C16

DNP

C58

0.01µF

C22

0.1µF

C20

0.1µF

C15

0.1µF

C108

DNP

C59

0.1µF

C28

0.1µF

C27

0.1µF

C31

DNP

DRVDD

DRGND

C109

DNP

C93

DNP

C110

DNP

C96

0.1µF

C90

0.1µF

C38

0.1µF

C69

DNP

C37

DNP

C97

0.1µF

C50

0.1µF

C60

0.1µF

C29

DNP

C70

DNP

C48

0.1µF

C84

0.1µF

C10

0.1µF

C19

DNP

C45

DNP

C18

0.1µF

C46

0.1µF

C61

DNP

C49

DNP

EXTREF

GND

+

C75

DNP

C55

10µF

DNP

DNP = DO NOT POPULATE

06011-044

Figure 37. Evaluation Board Schematic, Bypass Capacitors

Rev. 0 | Page 24 of 28

Page 25

AD9461

DRO

DRVDD

R190ΩR10

DRVDD

DRGND

D15O

D13O

D11O

D9O

D8O

GND

35

P35

P36

36

D14O

R3R1R2

33

P33

P34

34

D13O

312

R4

31

32

D12O

4

D14O

P31

P32

R5

5

DRVDD

29

P29

P30

30

D11O

R6

27

P27

28

D10O

6

23

25

P23

P25

P24

P26

P28

24

26

D8O

D9O

9

R8

R7

8

7

DRGND

DRVDD

DRO

DRGND

37

39

P37

P39

P38

P40

38

40

ORO

DRGND

D15O

16151413121110

220

RSO16ISO

RZ5

ORO

0Ω

DRVDD

DRVDD

DRVDD

DRGND

DRGND

DRVDD

D10O

D12O

D7O

17

19

21

P17

P19

P21

P18

P20

P22

18

20

22

D7O

16151413121110

220

RSO16ISO

DRVDD

DRGND

15

16

D6O

P15

P16

D6O

D4O

D3O

D5O

9

11

13

P9

P11

P13

P10

P12

P14

10

12

14

D4O

D5O

D3O

R6

R5

R4

R3R1R2

5

4

312

DRVDD

D0O

D2O

D1O

DRGND

1

3

5

7

P1

P3

P5

P7

P7

C40MS

P2

P4

P6

P8

8

D2O

6

DRVDD

2

4

6

DRGND

D1O

D0O

9

R8

R7

RZ4

8

7

DRGND

DRVDD

DRVDD

DRGND

91011

12

13

14

15

16

4Y

3Y

2Y

1Y

VCC

GND

EN_1_2

U15

2A

1B

1A

SN75LVDT390

1

DR

DRB

EN_3_4

4B

4A

3B

3A

2B

8765432

DOR_C

DRO_T/DOR_Y

64

D4Y

D3Y

D2Y

D1Y

C4Y

C3Y

C2Y

A1Y

VCC2

VCC1

A2A

A1B

D14_T/D13_Y

D15_C/D14_Y

DRGND

39

P39

P40

40

DRGND

ENA

GND1

A3A

A2B

D13_T/D11_Y

D14_C/D12_Y

DOR_C

37

P37

P38

38

DOR_T/DOR_Y

A3B

D13_C/D10_Y

35

36

GND

U8

A1A

SN75LVDT386

D15_T/D14_Y

D12_T/D9_Y

D15_C/D14_Y

P35

P36

D15_T/D15_Y

A4A

33

34

A4B

987654321

D12_C/D8_Y

D14_C/D12_Y

P33

P34

D14_T/D13_Y

B1A

10

D11_T/D7_Y

D13_C/D10_Y

31

P31

P32

32

D13_T/D11_Y

ENB

B1B

11

D11_C/D6_Y

29

30

B2A

12

D10_T/D5_Y

D12_C/D8_Y

P29

P30

D12_T/D9_Y

B2B

D10_C/D4_Y

27

28

D11_C/D6_Y

P27

D11_T/D7_Y

13

P28

B3A

D9_T/D3_Y

14

25

26

B3B

15

D9_C/D2_Y

D10_C/D4_Y

P25

P26

D10_T/D5_Y

GND2

B4A

D8_T/D1_Y

B4Y

B3Y

B2Y

B1Y

A4Y

A3Y

A2Y

C1Y

VCC4

VCC3

GND3

C2A

C1B

C1A

B4B

19

18

17

16

D7_T

D6_T

D7_C

D8_C/D0_Y

D8_C/DO_Y

DRB

D9_C/D2_Y

19

21

23

P19

P21

P23

P20

P22

P24

20

22

24

DR

D9_T/D3_Y

D8_T/D1_Y

20

C2B

D6_C

D7_C

17

P17

18

D7_T

21

P18

C3A

22

D5_T

15

16

C3B

23

D5_C

D6_C

P15

P16

D6_T

ENC

C4A

24

D4_T

D5_C

13

P13

P14

14

D5_T

D4_C

C4B

25

D1A

D3_T

D4_C

11

P11

12

D4_T

END

VCC6

VCC5

GND5

GND4

D4B

D4A

D3B

D3A

D2B

D2A

D1B

32

31

30

29

28

27

26

D2_T

D1_T

D2_C

7

P7

8

D2_C

P8

D2_T

D1_C

5

P5

6

D1_T

D0_T

D1_C

D0_C

D0_C

DRGND

1

3

P1

P3

P2

P4

P6

2

4

D0_T

DRGND

D3_C

D3_C

9

P9

P10

P12

10

D3_T

C78

0.1µF

C77

0.1µF

C82

0.1µF

C76

0.1µF

GND

GND

P6

C40MS

06011-045

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

Figure 38. Evaluation Board Schematic

Rev. 0 | Page 25 of 28

Page 26

AD9461

Table 11. AD9461 Customer Evaluation Board Bill of Material

Item Qty. Reference Designator Description Package Value1Manufacturer Mfg. Part No.

1 7 C4, C6, C33, C34, C87, C88, C89 Capacitor TAJD 10 F

2 44

3 2 C30, C58 Capacitor 201 0.01 F

4 4 C39, C56, C64, C65 Capacitor TAJD 10 F

5 1 C51 Capacitor 805 10 F

6 1 CR1 Diode SOT23M5

7 1 CR2

8 20

9 2 J1, J4 SMA SMA

10 1 L1 Inductor 0603A 10 nH Coilcraft, Inc.

11 3 L3, L4, L5

12 1 P4 Power jack PJ-002A

13 1 P7 Header C40MS Samtec, Inc.

14 1 R3 Resistor 402 3.74 kΩ

15 1 R8 Resistor 402 50 Ω

16 4 R10, R19, R39, L2 Resistor 402 0 Ω

17 1 R11 BRES402 402 1 kΩ

18 2 R28, R35 Resistor 402 33 Ω

19 2 RZ4, RZ5 Resistor array 16-pin 22 Ω

20 1 T3 Transformer ADT1-1WT Mini-Circuits ADT1-1WT

21 1 U1 AD9461BSVZ-105/130 SV-100-3

22 1 U14 ADP3338-5 SOT-223HS

23 2 U3, U7 ADP3338-3.3 SOT-223HS

24 1 U8 SN75LVDT386 TSSOP64

25 1 U15 SN75LVDT390 SOIC16PW

26 2 R4, R6 Resistor 402 25 Ω

C2, C3, C5, C7, C8, C9, C10, C11, C12,

C15, C20, C21, C22, C23, C26, C27,

C28, C32, C35, C38, C40, C42, C43,

C46, C47, C48, C50, C52, C53, C59,

C60, C76, C77, C78, C82, C84, C85,

C86, C90, C91, C94, C95, C96, C97

1

E1, E2, E3, E4, E5, E6, E9, E10, E14, E18,

E19, E20, E24, E25, E26, E27, E30, E31,

E36, E41

Capacitor 402 0.1 F

Diode SOT23M5 DNP

Header EHOLE

EMIFIL®

BLM31PG500SN1L

Rev. 0 | Page 26 of 28

1206MIL

Digi-Key

Corporation

Digi-Key

Corporation

Digi-Key

Corporation

Digi-Key

Corporation

Digi-Key

Corporation

Digi-Key

Corporation

Digi-Key

Corporation

Mouser

Electronics

Digi-Key

Corporation

Mouser

Electronics

Digi-Key

Corporation

Digi-Key

Corporation

Digi-Key

Corporation

Digi-Key

Corporation

Digi-Key

Corporation

Digi-Key

Corporation

Digi-Key

Corporation

Analog

Devices, Inc.

Analog

Devices, Inc.

Analog

Devices, Inc.

Arrow

Electronics,

Inc.

Arrow

Electronics,

Inc.

Digi-Key

Corporation

478-1699-2

PCC2146CT-ND

445-1796-1-ND

478-1699-2

490-1717-1-ND

MA3X71600LCTND

MA3X71600LCTND

517-6111TG

ARFX1231-ND

0603CS10NXGBU

81-BLM31P500S

CP-002A-ND

TSW-120-08-LD-RA

P3.74KLCT-ND

P49.9LCT-ND

P0.0JCT-ND

P1.0KLCT-ND

P33JCT-ND

742C163220JCTND