Page 1

Analog/DVI

FEATURES

Analog/DVI dual interface

Supports high bandwidth digital content protection

RGB-to-YCbCr 2-way color conversion

Automated clamping level adjustment

1.8 V/3.3 V power supply

100-lead, Pb-free LQFP

RGB and YCbCr output formats

Analog interface

8-bit triple ADC

150 MSPS maximum conversion rate

Macrovision® detection

2:1 input mux

Full sync processing

Sync detect for hot plugging

Midscale clamping

Digital video interface

DVI 1.0

150 MHz DVI receiver

Supports HDCP 1.1

APPLICATIONS

Advanced TVs

HDTVs

Projectors

LCD monitors

R/G/B OR YPbPr

R/G/B OR YPbPr

HSYNC 0

HSYNC 1

HSYNC 0

HSYNC 1

SOGIN 0

SOGIN 1

COAST

CKINV

CKEXT

RTERM

DDCSCL

DDCSDA

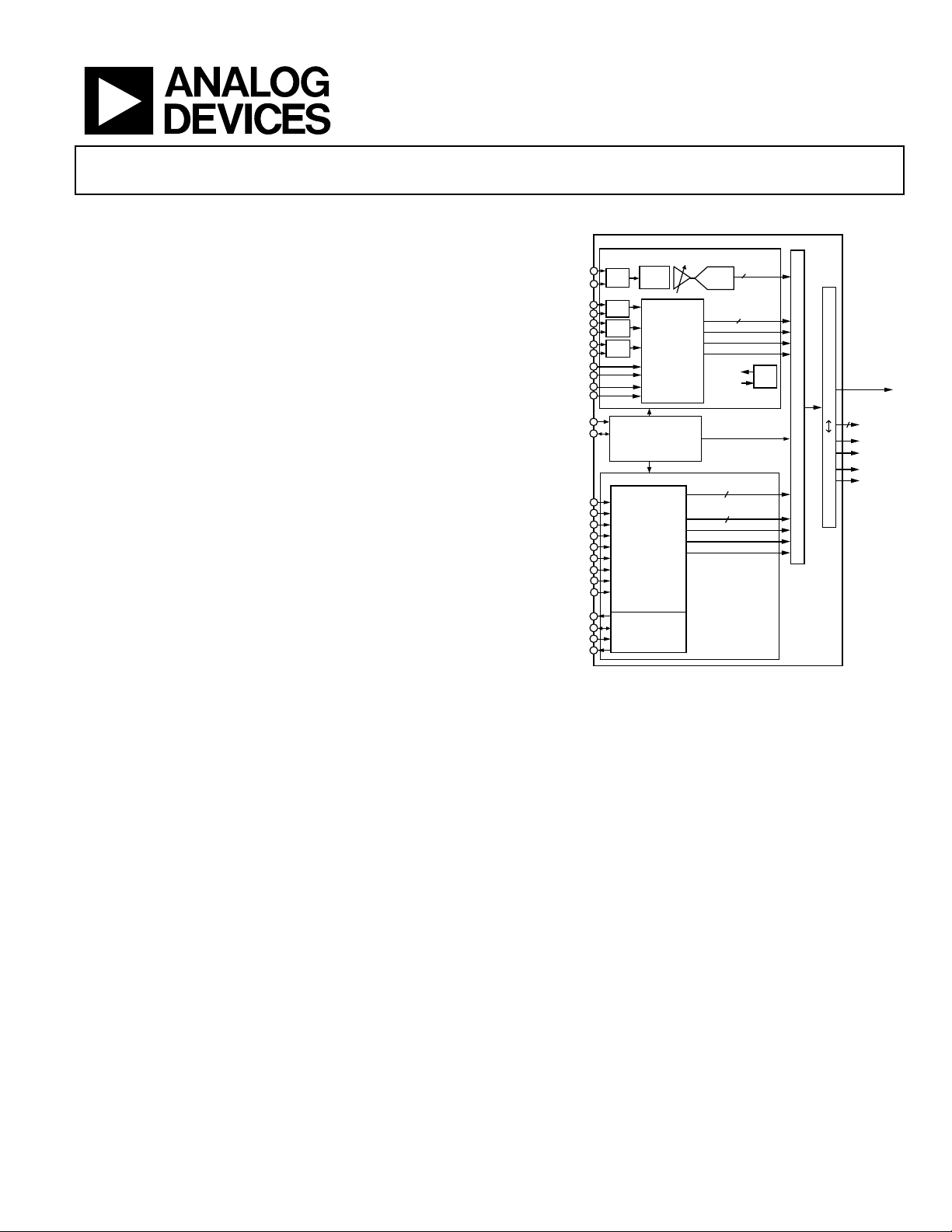

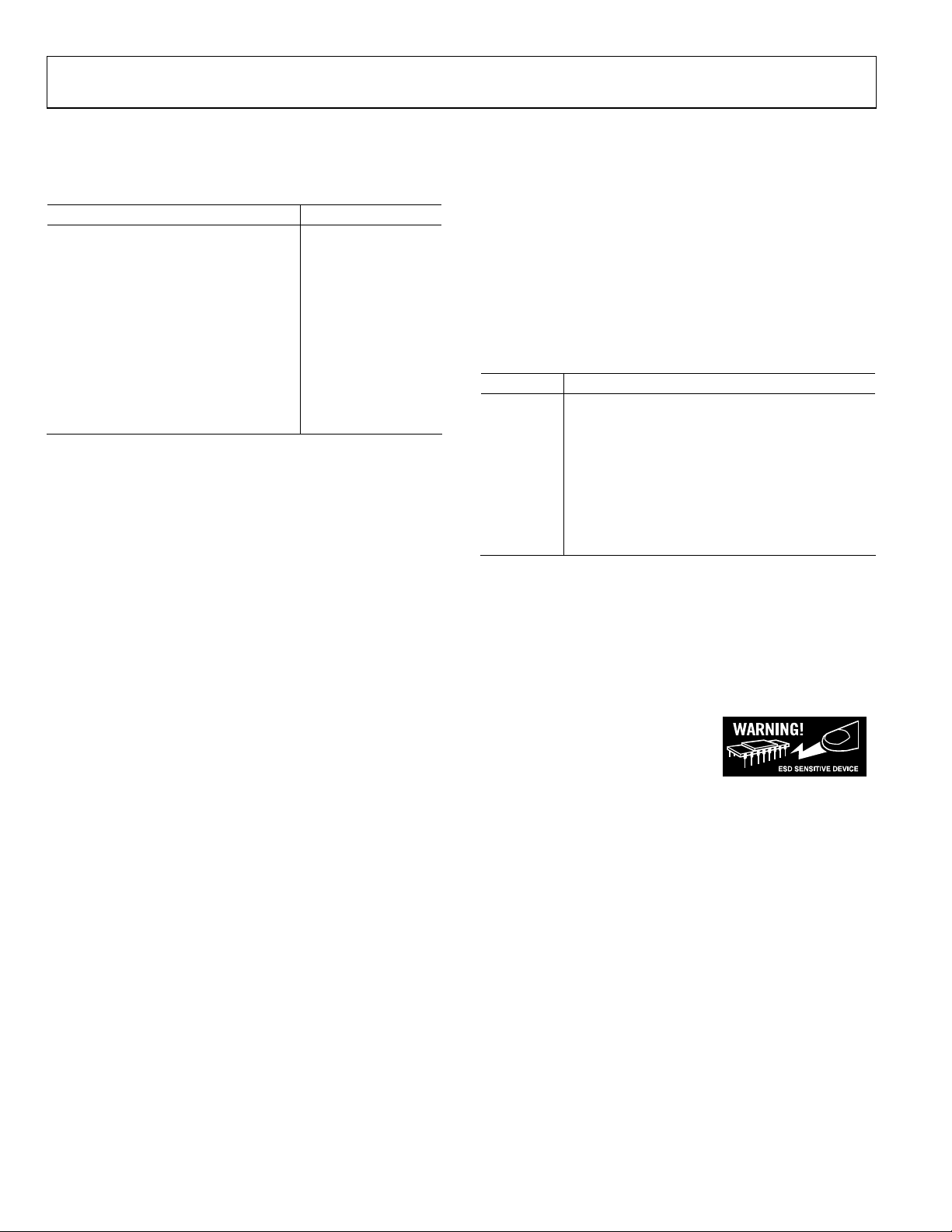

Dual-Display Interface

AD9396

FUNCTIONAL BLOCK DIAGRAM

FILT

SCL

SDA

Rx0+

Rx0–

Rx1+

Rx1–

Rx2+

Rx2–

RxC+

RxC–

MCL

MDA

IN0

IN1

ANALOG INTERFACE

2:1

CLAMP

MUX

2:1

MUX

2:1

MUX

2:1

MUX

POWER MANAGEMENT

DIGITAL INTERFACE

SYNC

PROCESSING

AND

CLOCK

GENERATION

SERIAL REGISTER

AND

DVI RECEIVER

HDCP

Figure 1.

A/D

REFOUT

REFIN

2

R/G/B 8 × 3

OR YCbCr

2

DATACK

HSOUT

VSOUT

SOGOUT

REF

R/G/B 8 × 3

OR YCbCr

DATACK

DE

HSYNC

VSYNC

AD9396

MUXES

R/G/B 8 × 3

YCbCr (4:2:2

OR 4:4:4)

2

DATACK

HSOUT

RGB YCbCr MATRIX

VSOUT

SOGOUT

DE

05690-001

GENERAL DESCRIPTION

The AD9396 offers designers the flexibility of an analog

interface and digital visual interface (DVI) receiver integrated

on a single chip. Also included is support for high bandwidth

digital content protection (HDCP).

The AD9396 is a complete 8-bit, 150 MSPS monolithic analog

interface optimized for capturing component video (YPbPr)

and RGB graphics signals. Its 150 MSPS encode rate capability

and full power analog bandwidth of 330 MHz supports all

HDTV formats (up to 1080p and 720p) and FPD resolutions up

to SXGA (1280 × 1024 @ 80 Hz).

The analog interface includes a 150 MHz triple ADC with

internal 1.25 V reference, a phase-locked loop (PLL), programmable gain, offset, and clamp control. The user provides only

1.8 V and 3.3 V power supply, analog input, and HSYNC.

Three-state CMOS outputs may be powered from 1.8 V to 3.3V.

The on-chip PLL generates a pixel clock from HSYNC. Pixel

Rev. 0

Information furnished by Analog Devices is believed to be accurate and reliable.

However, no responsibility is assumed by Analog Devices for its use, nor for any

infringements of patents or other rights of third parties that may result from its use.

Specifications subject to change without notice. No license is granted by implication

or otherwise under any patent or patent rights of Analog Devices. Trademarks and

registered trademarks are the property of their respective owners.

clock output frequencies range from 12 MHz to 150 MHz. PLL

clock jitter is typically less than 700 ps p-p at 150 MHz. The

AD9396 also offers full sync processing for composite sync and

sync-on-green (SOG) applications.

The AD9396 contains a DVI-compatible receiver and supports

all HDTV formats (up to 1080p and 720p) and display

resolutions up to SXGA (1280 × 1024 @ 80 Hz). The receiver

features an intrapair skew tolerance of up to one full clock cycle.

With the inclusion of HDCP, displays may now receive

encrypted video content. The AD9396 allows for authentication

of a video receiver, decryption of encoded data at the receiver,

and renewability of that authentication during transmission as

specified by the HDCP 1.1 protocol.

Fabricated in an advanced CMOS process, the AD9396 is provided in a space-saving, 100-lead, surface-mount, Pb-free plastic

LQFP and is specified over the 0ºC to 70ºC temperature range.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700 www.analog.com

Fax: 781.461.3113 © 2005 Analog Devices, Inc. All rights reserved.

Page 2

AD9396

TABLE OF CONTENTS

Features .............................................................................................. 1

Applications....................................................................................... 1

Functional Block Diagram .............................................................. 1

General Description ......................................................................... 1

Specifications..................................................................................... 3

Analog Interface Electrical Characteristics............................... 3

Digital Interface Electrical Characteristics ............................... 4

Absolute Maximum Ratings............................................................ 6

Explanation of Test Levels........................................................... 6

ESD Caution.................................................................................. 6

Pin Configuration and Function Descriptions............................. 7

Design Guide................................................................................... 11

General Description................................................................... 11

Digital Inputs ..............................................................................11

Analog Input Signal Handling.................................................. 11

2-Wire Serial Register Map ........................................................... 21

2-Wire Serial Control Register Details ........................................ 29

Chip Identification..................................................................... 29

PLL Divider Control.................................................................. 29

Clock Generator Control .......................................................... 29

Input Gain ................................................................................... 30

Input Offset ................................................................................. 30

Sync .............................................................................................. 30

Coast and Clamp Controls........................................................ 31

Status of Detected Signals ......................................................... 31

Polarity Status ............................................................................. 32

BT656 Generation...................................................................... 36

Macrovision................................................................................. 36

Color Space Conversion............................................................ 37

2-Wire Serial Control Port ............................................................ 39

HSYNC and VSYNC Inputs...................................................... 11

Serial Control Port ..................................................................... 11

Output Signal Handling............................................................. 11

Clamping ..................................................................................... 11

Timing.......................................................................................... 15

DVI Receiver ............................................................................... 19

DE Generator ..............................................................................19

4:4:4 to 4:2:2 Filter...................................................................... 19

Timing Diagrams........................................................................ 20

REVISION HISTORY

10/05—Revision 0: Initial Version

PCB Layout Recommendations.................................................... 41

Analog Interface Inputs............................................................. 41

Power Supply Bypassing ............................................................ 41

PLL ............................................................................................... 41

Outputs (Both Data and Clocks).............................................. 42

Digital Inputs .............................................................................. 42

Color Space Converter (CSC) Common Settings...................... 43

Outline Dimensions ....................................................................... 45

Ordering Guide .......................................................................... 45

Rev. 0 | Page 2 of 48

Page 3

AD9396

SPECIFICATIONS

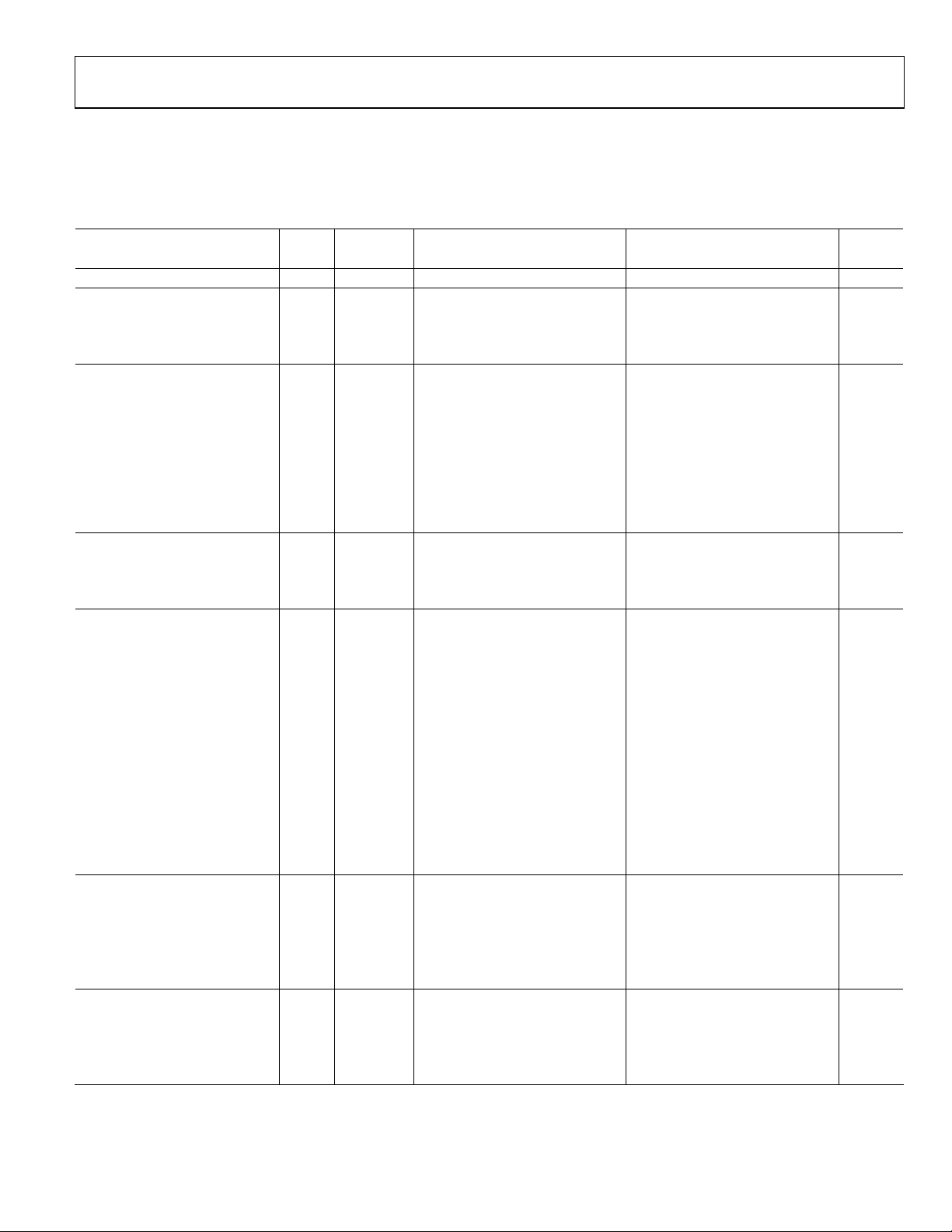

ANALOG INTERFACE ELECTRICAL CHARACTERISTICS

V

= 3.3 V, DVDD = PVDD = 1.8 V, ADC clock = maximum.

DD, VD

Table 1.

AD9396KSTZ-100 AD9396KSTZ-150

Parameter Temp Test Level Min Typ Max Min Typ Max Unit

RESOLUTION 8 8 Bits

DC ACCURACY

Differential Nonlinearity 25°C I –0.6 +1.6/–1.0 ±0.7 +1.8/–1.0 LSB

Integral Nonlinearity 25°C I ±1.0 ±2.1 ±1.1 ±2.25 LSB

No Missing Codes Full Guaranteed Guaranteed

ANALOG INPUT

Input Voltage Range

Minimum Full VI 0.5 0.5 V p–p

Maximum Full VI 1.0 1.0 V p–p

Gain Tempco 25°C V 100 220 ppm/°C

Input Bias Current 25°C V 0.2 1 μA

Input Full-Scale Matching

25C

Full

VI

VI

Offset Adjustment Range Full V 50 50 %FS

SWITCHING PERFORMANCE

1

Maximum Conversion Rate Full VI 100 150 MSPS

Minimum Conversion Rate Full VI 10 10 MSPS

Data to Clock Skew Full IV −0.5 +2.0 −0.5 +2.0 ns

SERIAL PORT TIMING

t

BUFF

t

STAH

t

DHO

t

DAL

t

DAH

t

DSU

t

STASU

t

STOSU

Full VI 4.7 4.7 μs

Full VI 4.0 4.0 μs

Full VI 0 0 μs

Full VI 4.7 4.7 μs

Full VI 4.0 4.0 μs

Full VI 250 250 ns

Full VI 4.7 4.7 μs

Full VI 4.0 4.0 μs

HSYNC Input Frequency Full VI 15 110 15 110 KHz

Maximum PLL Clock Rate Full VI 100 150 MHz

Minimum PLL Clock Rate Full IV 12 12 MHz

PLL Jitter 25°C IV 700 700 ps p-p

Sampling Phase Tempco Full IV 15 15 ps/°C

DIGITAL INPUTS (5 V Tolerant)

Input Voltage, High (VIH) Full VI 2.6 2.6 V

Input Voltage, Low (VIL) Full VI 0.8 0.8 V

Input Current, High (IIH) Full V −82 −82 μA

Input Current, Low (IIL) Full V 82 82 μA

Input Capacitance 25°C V 3 3 pF

DIGITAL OUTPUTS

Output Voltage, High (VOH) Full VI VDD − 0.1 VDD − 0.1 V

Output Voltage, Low (VOL) Full VI 0.4 0.4 V

Duty Cycle, DATACK Full V 45 50 55 45 50 55 %

Output Coding Binary Binary

1.25

1.50

5

7

1.25

1.50

5

7

%FS

%FS

Rev. 0 | Page 3 of 48

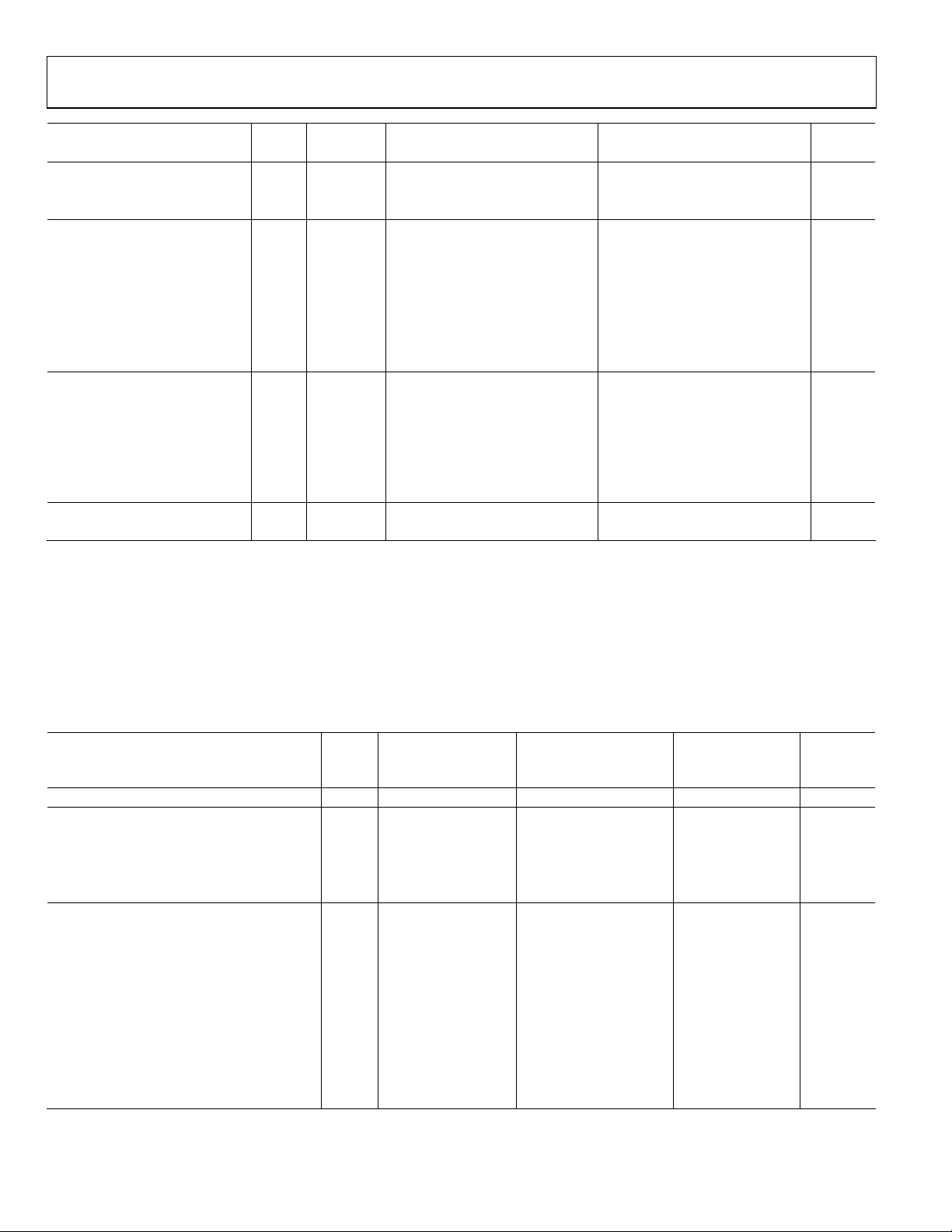

Page 4

AD9396

AD9396KSTZ-100 AD9396KSTZ-150

Parameter Temp Test Level Min Typ Max Min Typ Max Unit

POWER SUPPLY

VD Supply Voltage Full IV 3.15 3.3 3.47 3.15 3.3 3.47 V

DVDD Supply Voltage Full IV 1.7 1.8 1.9 1.7 1.8 1.9 V

VDD Supply Voltage Full IV 1.7 3.3 3.47 1.7 3.3 3.47 V

PVDD Supply Voltage Full IV 1.7 1.8 1.9 1.7 1.8 1.9 V

ID Supply Current (VD) 25°C VI 260 300 330 mA

I

Supply Current (DVDD) 25°C VI 45 60 85 mA

DVDD

IDD Supply Current (VDD)

IP

Supply Current (P

VDD

Total Power Full VI 1.1 1.4 1.15 1.4 W

Power-Down Dissipation Full VI 130 130 mW

DYNAMIC PERFORMANCE

Analog Bandwidth, Full

Power

Signal-to-Noise Ratio (SNR) 25°C I 46 46 dB

Without Harmonics

fIN = 40.7 MHz Full V 45 45 dB

Crosstalk Full V 60 60 dBc

THERMAL CHARACTERISTICS

θJA Junction-to-Ambient V 35 35 °C/W

1

Drive strength = high.

2

DATACK load = 15 pF, data load = 5 pF.

3

Specified current and power values with a worst-case pattern (on/off).

2

VDD

25°C VI 37 100

) 25°C VI 10 15 20 mA

3

130

3

mA

25°C V 330 330 MHz

DIGITAL INTERFACE ELECTRICAL CHARACTERISTICS

VDD = VD = 3.3 V, DVDD = PVDD = 1.8 V, ADC clock = maximum.

Table 2.

AD9396KSTZ-100

AD9396KSTZ-150

Te st

Parameter

Level

Conditions Min Typ Max Min Typ Max Unit

RESOLUTION 8 8 Bit

DC DIGITAL I/O Specifications

High Level Input Voltage, (VIH) VI 2.5 2.5 V

Low Level Input Voltage, (VIL) VI 0.8 0.8 V

High Level Output Voltage, (VOH) VI VDD − 0.1 V

Low Level Output Voltage, (VOL) VI VDD − 0.1 0.1 0.1 V

DC SPECIFICATIONS

Output High Level IV Output drive = high 36 36 mA

(I

) (V

OHD

= VOH) IV Output drive = low 24 24 mA

OUT

Output Low Level IV Output drive = high 12 12 mA

I

, (V

OLD

= VOL) IV Output drive = low 8 8 mA

OUT

DATACK High Level IV Output drive = high 40 40 mA

V

, (V

OHC

= VOH) IV Output drive = low 20 20 mA

OUT

DATACK Low Level IV Output drive = high 30 30 mA

V

, (V

OLC

Differential Input Voltage, Single-

= VOL) IV Output drive = low 15 15 mA

OUT

IV 75 700 75 700 mV

Ended Amplitude

Rev. 0 | Page 4 of 48

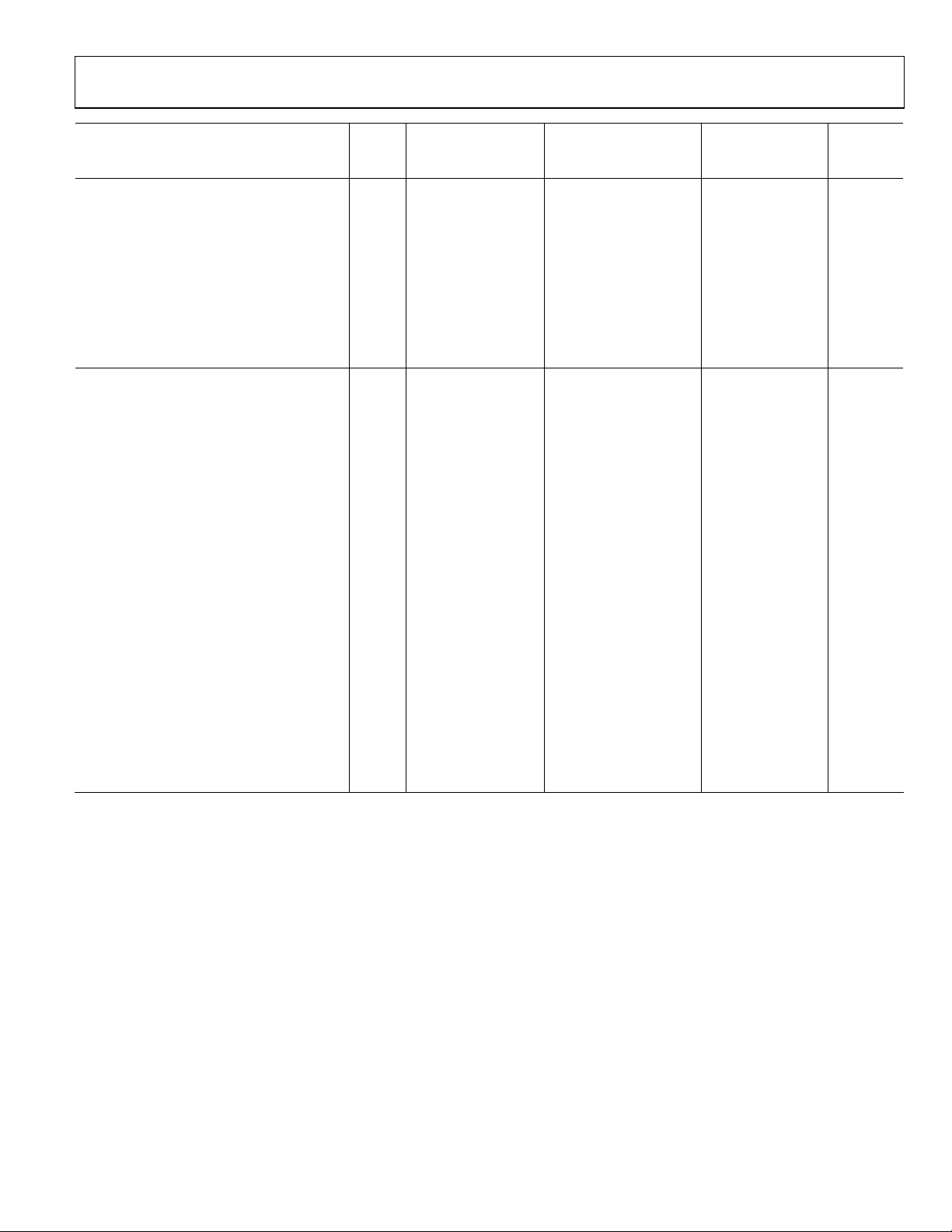

Page 5

AD9396

AD9396KSTZ-100

AD9396KSTZ-150

Te st

Parameter

Level

Conditions Min Typ Max Min Typ Max Unit

POWER SUPPLY

VD Supply Voltage IV 3.15 3.3 3.47 3.15 3.3 3.47 V

VDD Supply Voltage IV 1.7 3.3 347 1.7 3.3 347 V

DVDD Supply Voltage IV 1.7 1.8 1.9 1.7 1.8 1.9 V

PVDD Supply Voltage IV 1.7 1.8 1.9 1.7 1.8 1.9 V

IVD Supply Current (Typical Pattern)

I

Supply Current (Typical Pattern)

VDD

I

Supply Current (Typical Pattern)

DVDD

I

Supply Current (Typical Pattern)

PVDD

1

V 80 100 80 110 mA

2

V 40 1003 55 1753mA

1, 4

V 88 110 110 145 mA

1

V 26 35 30 40 mA

Power-Down Supply Current (IPD) VI 130 130 mA

AC SPECIFICATIONS

Intrapair (+ to −) Differential Input Skew

(T

)

DPS

Channel-to-Channel Differential Input

CCS

)

Skew (T

Low-to-High Transition Time for Data and

Controls (D

LHT

)

IV

Low-to-High Transition Time for

DATACK (D

LHT

)

IV

High-to-Low Transition Time for Data and

Controls (D

HLT

)

IV

High-to-Low Transition Time for

DATACK (D

HLT

)

IV

Clock to Data Skew5 (T

Duty Cycle, DATACK

DATACK Frequency (F

1

The typical pattern contains a gray scale area, output drive = high. Worst-case pattern is alternating black and white pixels.

2

The typical pattern contains a gray scale area, output drive = high.

3

Specified current and power values with a worst-case pattern (on/off).

4

DATACK load = 10 pF, data load = 5 pF.

5

Drive strength = high.

) IV –0.5 +2.0 –0.5 2.0 ns

SKEW

5

) VI 20 150 MHz

CIP

IV 360 ps

IV 6

IV

IV

IV

IV

Output drive = high;

= 10 pF

C

L

Output drive = low;

C

= 5 pF

L

Output drive = high;

= 10 pF

C

L

Output drive = low;

= 5 pF

C

L

Output drive = high;

C

= 10 pF

L

Output drive = low;

= 5 pF

C

L

Output drive = high;

C

= 10 pF

L

Output drive = low;

= 5 pF

C

L

900 ps

1300 ps

650 ps

1200 ps

850 ps

1250 ps

800 ps

1200 ps

IV 45 50 55 %

Clock

Period

Rev. 0 | Page 5 of 48

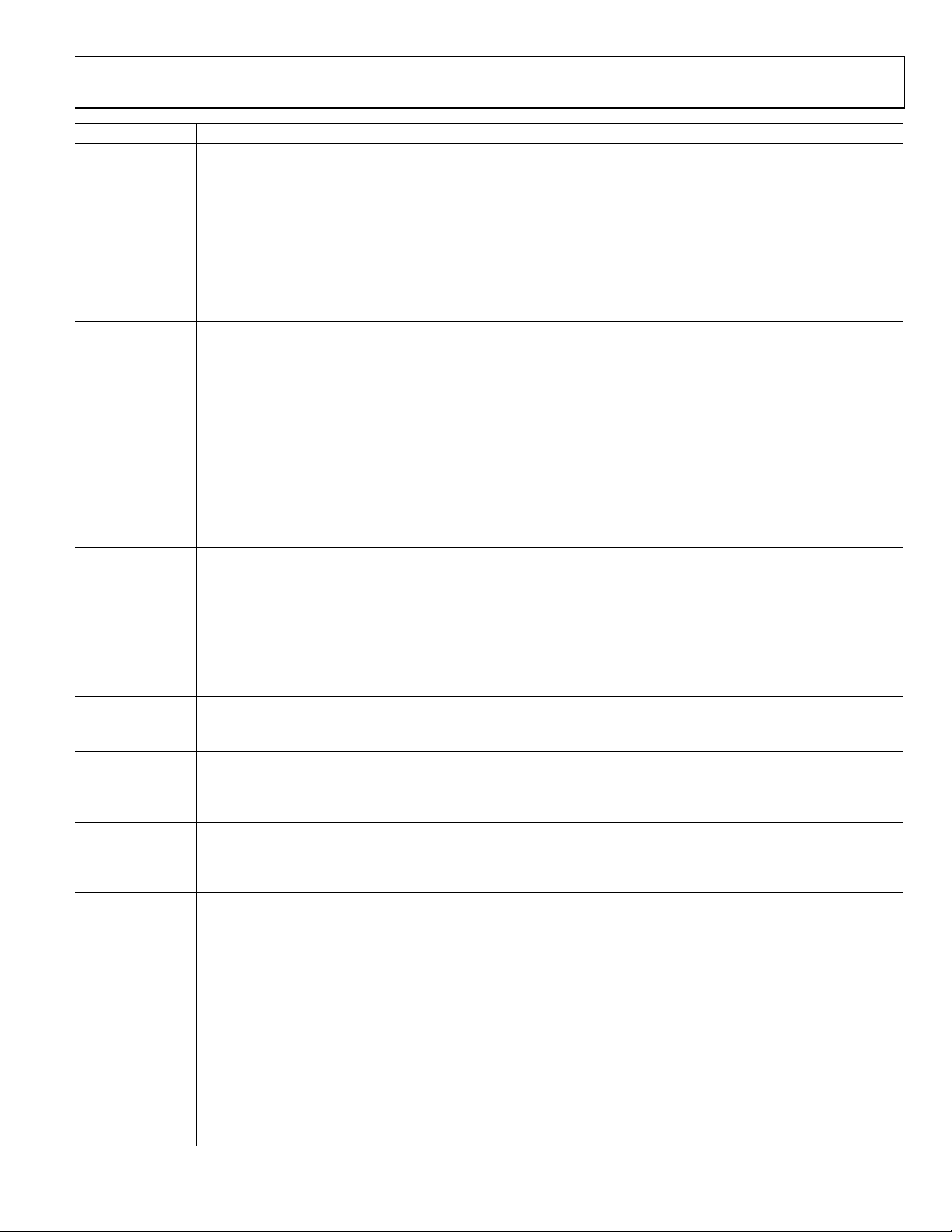

Page 6

AD9396

ABSOLUTE MAXIMUM RATINGS

Table 3.

Parameter Rating

V

D

VDD 3.6 V

DV

DD

PV

DD

Analog Inputs VD to 0.0 V

Digital Inputs 5 V to 0.0 V

Digital Output Current 20 mA

Operating Temperature Range −25°C to +85°C

Storage Temperature Range −65°C to +150°C

Maximum Junction Temperature 150°C

Maximum Case Temperature 150°C

3.6 V

1.98 V

1.98 V

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

EXPLANATION OF TEST LEVELS

Table 4.

Level Test

I 100% production tested.

II

III Sample tested only.

IV

V Parameter is a typical value only.

VI

100% production tested at 25°C and sample

tested at specified temperatures.

Parameter is guaranteed by design and

characterization testing.

100% production tested at 25°C; guaranteed by

design and characterization testing.

ESD CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily accumulate on

the human body and test equipment and can discharge without detection. Although this product features

proprietary ESD protection circuitry, permanent damage may occur on devices subjected to high energy

electrostatic discharges. Therefore, proper ESD precautions are recommended to avoid performance

degradation or loss of functionality.

Rev. 0 | Page 6 of 48

Page 7

AD9396

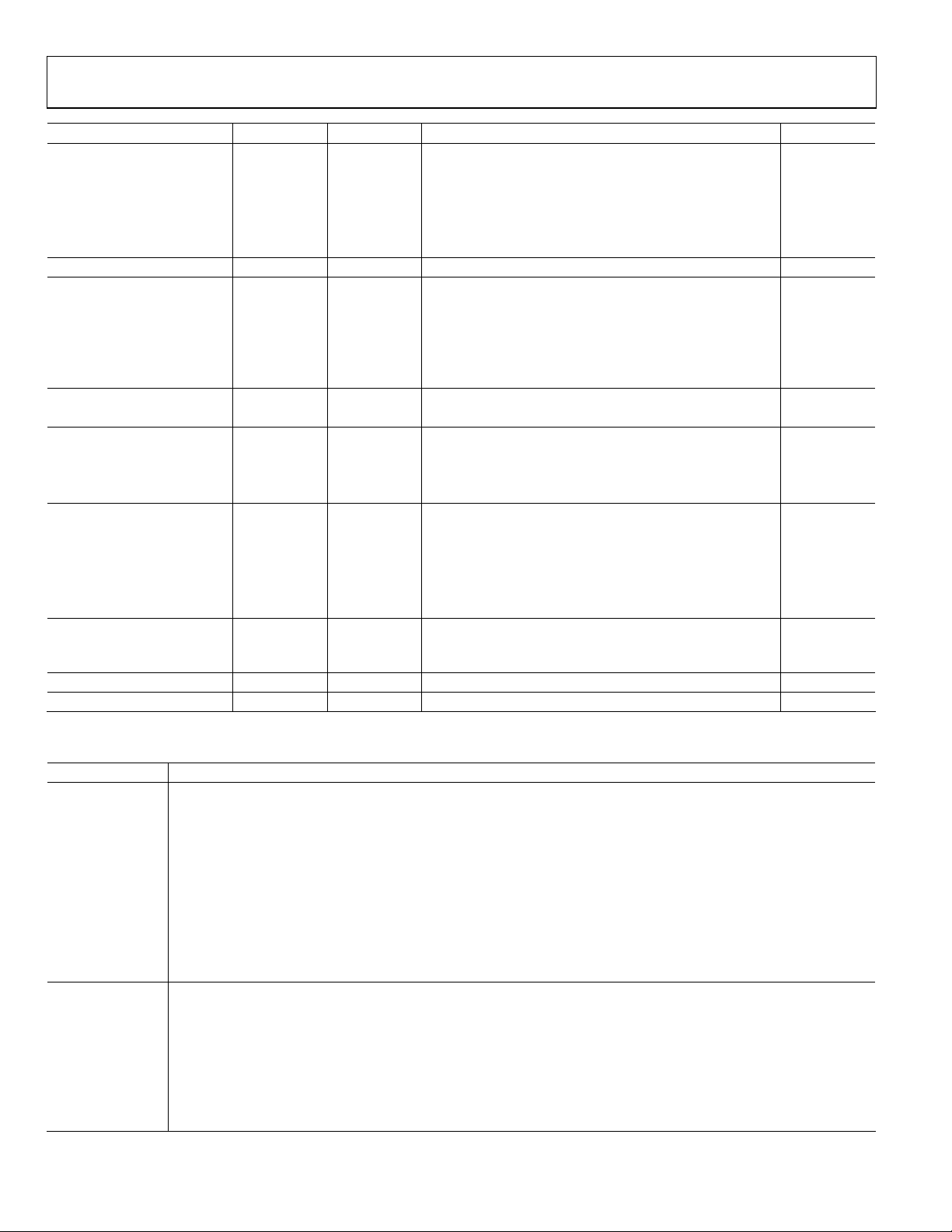

PIN CONFIGURATION AND FUNCTION DESCRIPTIONS

AIN0

AIN1

VDDRED 0

99

100

RED 1

98

RED 2

97

RED 3

96

RED 4

95

RED 5

94

RED 6

93

92

RED 7

GND

91

VDDDATACKDEHSOUT

898887

90

SOGOUT

VSOUT

86

85

O/E FIELD

SDA

SCL

84

82

83

PWRDN

81

VDR

80

79

GND

R

787776

D

V

1

GND

V

GND

NC

NC

NC

NC

CTL3

CTL2

2

3

4

5

6

7

8

9

10

DD

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

GREEN 7

GREEN 6

GREEN 5

GREEN 4

GREEN 3

GREEN 2

GREEN 1

GREEN 0

BLUE 7

BLUE 6

BLUE 5

BLUE 4

BLUE 3

BLUE 2

BLUE 1

BLUE 0

NC = NO CONNECT

PIN 1

26

CTL127CTL0

28

NC

29

GND

30

DV

AD9396

TOP VIEW

(Not to Scale)

31

33

34

32

D

DD

DD

V

GND

Rx0–

DV

35

Rx0+

36

GND

37

Rx1–

38

Rx1+

39

GND

40

Rx2–

41

Rx2+

42

GND

44

45

43

V

RxC–

RxC+

48

46

47

D

DD

GND

DV

RTERM

75

GND

74

G

AIN0

73

SOGIN 0

72

V

D

71

G

AIN1

70

SOGIN 1

69

GND

68

B

AIN0

67

V

D

66

B

AIN1

65

GND

64

HSYNC 0

63

HSYNC 1

62

EXTCLK/COAST

61

VSYNC 0

60

VSYNC 1

59

PV

DD

58

PGND

57

FILT

56

PV

DD

55

PGND

54

PV

DD

53

GND

52

MDA

51

MCL

49

50

DDCSCL

DDCSDA

05690-002

Figure 2. Pin Configuration

Table 5. Complete Pinout List

Pin Type Pin No. Mnemonic Function Value

INPUTS 79 R

77 R

74 G

71 G

68 BB

66 BB

AIN0

AIN1

AIN0

AIN1

AIN0

AIN1

Analog Input for Converter R Channel 0 0.0 V to 1.0 V

Analog Input for Converter R Channel 1 0.0 V to 1.0 V

Analog Input for Converter G Channel 0 0.0 V to 1.0 V

Analog Input for Converter G Channel 1 0.0 V to 1.0 V

Analog Input for Converter B Channel 0 0.0 V to 1.0 V

Analog Input for Converter B Channel 1 0.0 V to 1.0 V

64 HSYNC 0 Horizontal SYNC Input for Channel 0 3.3 V CMOS

63 HSYNC 1 Horizontal SYNC Input for Channel 1 3.3 V CMOS

61 VSYNC 0 Vertical SYNC Input for Channel 0 3.3 V CMOS

60 VSYNC 1 Vertical SYNC Input for Channel 1 3.3 V CMOS

73 SOGIN 0 Input for Sync-on-Green Channel 0 0.0 V to 1.0 V

70 SOGIN 1 Input for Sync-on-Green Channel 1 0.0 V to 1.0 V

62 EXTCLK External Clock Input—Shares Pin with COAST 3.3 V CMOS

62 COAST PLL COAST Signal Input—Shares Pin with EXTCLK 3.3 V CMOS

81 PWRDN Power-Down Control 3.3 V CMOS

OUTPUTS 92 to 99 RED [7:0] Outputs of Red Converter, Bit 7 is MSB V

2 to 9 GREEN [7:0] Outputs of Green Converter, Bit 7 is MSB V

12 to 19 BLUE [7:0] Outputs of Blue Converter, Bit 7 is MSB V

Rev. 0 | Page 7 of 48

DD

DD

DD

Page 8

AD9396

Pin Type Pin No. Mnemonic Function Value

OUTPUTS 89 DATACK Data Output Clock V

87 HSOUT HSYNC Output Clock (Phase-Aligned with DATACK) V

85 VSOUT VSYNC Output Clock (Phase-Aligned with DATACK) V

86 SOGOUT SOG Slicer Output V

84 O/E FIELD Odd/Even Field Output V

24, 25, 26, 27 CTL(3-0) Control 3, 2, 1, and 0. V

REFERENCES 57 FILT Connection for External Filter Components for PLL

POWER SUPPLY

80, 76, 72,

V

D

Analog Power Supply and DVI Terminators 3.3 V

67, 45, 33

100, 90, 10 V

59, 56, 54 PV

48, 32, 30 DV

DD

DD

DD

Output Power Supply 1.8 V to 3.3 V

PLL Power Supply 1.8 V

Digital Logic Power Supply 1.8 V

GND Ground 0 V

CONTROL 83 SDA Serial Port Data I/O 3.3 V CMOS

82 SCL Serial Port Data Clock 3.3 V CMOS

HDCP 49 DDCSCL HDCP Slave Serial Port Data Clock 3.3 V CMOS

50 DDCSDA HDCP Slave Serial Port Data I/O 3.3 V CMOS

51 MCL HDCP Master Serial Port Data Clock 3.3 V CMOS

52 MDA HDCP Master Serial Port Data I/O 3.3 V CMOS

DIGITAL VIDEO DATA 35 Rx0+ Digital Input Channel 0 True TMDS

34 Rx0− Digital Input Channel 0 Complement TMDS

38 Rx1+ Digital Input Channel 1 True TMDS

37 Rx1− Digital Input Channel 1 Complement TMDS

41 Rx2+ Digital Input Channel 2 True TMDS

40 Rx2− Digital Input Channel 2 Complement TMDS

DIGITAL VIDEO CLOCK

43 RxC+ Digital Data Clock True TMDS

INPUTS

44 RxC− Digital Data Clock Complement TMDS

DATA ENABLE 88 DE Data Enable 3.3 V CMOS

RTERM 46 RTERM Sets Internal Termination Resistance 500 Ω

Table 6. Pin Function Descriptions

Mnemonic Description

INPUTS

R

AIN0

G

AIN0

BB

AIN0

R

AIN1

G

AIN1

BB

AIN1

Analog Input for the Red Channel 0.

Analog Input for the Green Channel 0.

Analog Input for the Blue Channel 0.

Analog Input for the Red Channel 1.

Analog Input for the Green Channel 1.

Analog Input for Blue Channel 1.

High impedance inputs that accept the red, green, and blue channel graphics signals, respectively. The three channels

are identical and can be used for any colors, but colors are assigned for convenient reference. They accommodate input

signals ranging from 0.5 V to 1.0 V full scale. Signals should be ac-coupled to these pins to support clamp operation

(see Figure 3 for an input reference circuit).

Rx0+ Digital Input Channel 0 True.

Rx0− Digital Input Channel 0 Complement.

Rx1+ Digital Input Channel 1 True.

Rx1− Digital Input Channel 1 Complement.

Rx2+ Digital Input Channel 2 True.

Rx2− Digital input Channel 2 Complement.

These six pins receive three pairs of transition minimized differential signaling (TMDS) pixel data (at 10× the pixel rate)

from a digital graphics transmitter.

DD

DD

DD

DD

DD

DD

Rev. 0 | Page 8 of 48

Page 9

AD9396

Mnemonic Description

RxC+ Digital Data Clock True.

RxC− Digital Data Clock Complement.

This clock pair receives a TMDS clock at 1× pixel data rate.

HSYNC 0 Horizontal Sync Input Channel 0.

HSYNC 1 Horizontal Sync Input Channel 1.

These inputs receive a logic signal that establishes the horizontal timing reference and provides the frequency

reference for pixel clock generation. The logic sense of this pin is controlled by Serial Register 0x12, Bits 5:4 (HSYNC

polarity). Only the leading edge of HSYNC is active; the trailing edge is ignored. When HSYNC polarity = 0, the falling

edge of HSYNC is used. When HSYNC polarity = 1, the rising edge is active. The input includes a Schmitt trigger for

noise immunity.

VSYNC 0 Vertical Sync Input Channel 0.

VSYNC 1 Vertical Sync Input Channel 1.

These are the inputs for vertical sync.

SOGIN 0 Sync-on-Green Input Channel 0.

SOGIN 1 Sync-on-Green Input Channel 1.

These inputs are provided to assist with processing signals with embedded sync, typically on the green channel. The

pin is connected to a high speed comparator with an internally generated threshold. The threshold level can be

programmed in 10 mV steps to any voltage between 10 mV and 330 mV above the negative peak of the input signal.

The default voltage threshold is 150 mV. When connected to an ac-coupled graphics signal with embedded sync, it

produces a noninverting digital output on SOGOUT. (This is usually a composite sync signal, containing both vertical

and horizontal sync (HSYNC) information that must be separated before passing the horizontal sync signal to HSYNC.)

When not used, this input should be left unconnected. For more details on this function and how it should be

configured, refer to the

EXTCLK/COAST Coast Input to Clock Generator (Optional).

This input may be used to cause the pixel clock generator to stop synchronizing with HSYNC and continue producing a

clock at its current frequency and phase. This is useful when processing signals from sources that fail to produce

horizontal sync pulses during the vertical interval. The coast signal is generally not required for PC-generated signals.

The logic sense of this pin is controlled by coast polarity (Register 0x18, Bits 6:5). When not used, this pin may be

grounded and input coast polarity programmed to 1 (Register 0x18, Pin 5), or tied high (to VD through a 10 kΩ resistor)

and input coast polarity programmed to 0. Input coast polarity defaults to 1 at power-up. This pin is shared with the

EXTCLK function, which does not affect coast functionality. For more details on coast, see the description in the Clock

Generation

EXTCLK/COAST External Clock.

RTERM

PWRDN

FILT External Filter Connection.

OUTPUTS

HSOUT

VSOUT

SOGOUT

O/E FIELD

This allows the insertion of an external clock source rather than the internally generated PLL-locked clock. This pin is

shared with the coast function, does not affect EXTCLK functionality.

RTERM is the termination resistor used to drive the AD9396 internally to a precise 50 Ω termination for TMDS lines. This

should be a 500 Ω 1% tolerance resistor.

Power-Down Control/Three-State Control.

The function of this pin is programmable via Register 0x26 [2:1].

For proper operation, the pixel clock generator PLL requires an external filter. Connect the filter shown in

this pin. For optimal performance, minimize noise and parasitics on this node. For more information see the section on

PCB Layout Recommendations.

Horizontal Sync Output.

A reconstructed and phase-aligned version of the HSYNC input. Both the polarity and duration of this output can be

programmed via the serial bus registers. By maintaining alignment with DATACK and Data, data timing with respect to

horizontal sync can always be determined.

Vertical Sync Output.

The separated VSYNC from a composite signal or a direct passthrough of the VSYNC signal. The polarity of this output

can be controlled via serial bus bit (Register 0x24 [6]).

Sync-on-Green Slicer Output.

This pin outputs one of four possible signals (controlled by Register 0x24 [2:1]): raw SOG, raw HSYNC, regenerated

HSYNC from the filter, or the filtered HSYNC. See

connected. (Note: besides slicing off SOG, the output from this pin is not processed on the AD9396. VSYNC separation

is performed via the sync separator.

Odd/Even Field Bit for Interlaced Video. This output identifies whether the current field (in an interlaced signal) is odd

or even. The polarity of this signal is programmable via Register 0x24 [4].

section.

HSYNC and VSYNC Inputs section.

Figure 6 to

Figure 8, the Sync Processing Block Diagram, to view how this pin is

Rev. 0 | Page 9 of 48

Page 10

AD9396

Mnemonic Description

DATA ENABLE Data Enable that defines valid video. Can be received in the signal or generated by the AD9396.

CTL(3 to 0)

SERIAL PORT

SDA Serial Port Data I/O for Programming AD9396 Registers—I2C® Address is 0x98.

SCL Serial Port Data Clock for Programming AD9396 Registers.

DDCSDA Serial Port Data I/O for HDCP Communications to Transmitter—I2C Address is 0x74 or 0x76.

DDCSCL Serial Port Data Clock for HDCP Communications to Transmitter.

MDA Serial Port Data I/O to EEPROM with HDCP Keys—I2C Address is 0xA0.

MCL Serial Port Data Clock to EEPROM with HDCP Keys.

DATA OUTPUTS

Red [7:0] Data Output, Red Channel.

Green [7:0] Data Output, Green Channel.

Blue [7:0] Data Output, Blue Channel.

DATA CLOCK

OUTPUT

DATACK

POWER SUPPLY1

VD (3.3 V)

VDD

(1.8 V to 3.3 V)

PVDD (1.8 V)

DVDD (1.8 V)

GND

1

The supplies should be sequenced such that VD and VDD are never less than 300 mV below DVDD. At no time should DVDD be more than 300 mV greater than VD or VDD.

Control 3, Control 2, Control 1, and Control 0 are output from the DVI stream. Refer to the DVI 1.0 specification for

explanation.

The main data outputs. Bit 7 is the MSB. The delay from pixel sampling time to output is fixed, but is different if the

color space converter is used. When the sampling time is changed by adjusting the phase register, the output timing is

shifted as well. The DATACK and HSOUT outputs are also moved, so the timing relationship among the signals is

maintained.

Data Clock Output.

This is the main clock output signal used to strobe the output data and HSOUT into external logic. Four possible output

clocks can be selected with Register 0x25 [7:6]. These are related to the pixel clock (1/2× pixel clock, 1× pixel clock, 2×

frequency pixel clock and a 90° phase shifted pixel clock) and they are produced either by the internal PLL clock

generator or EXTCLK and are synchronous with the pixel sampling clock. The polarity of DATACK can also be inverted

via Register 0x24 [0]. The sampling time of the internal pixel clock can be changed by adjusting the phase register.

When this is changed, the pixel-related DATACK timing is shifted as well. The DATA, DATACK, and HSOUT outputs are all

moved, so the timing relationship among the signals is maintained.

Analog Power Supply.

These pins supply power to the ADCs and terminators. They should be as quiet and filtered as possible.

Digital Output Power Supply.

A large number of output pins (up to 27) switching at high speed (up to 150 MHz) generates many power supply

transients (noise). These supply pins are identified separately from the VD pins, so take care to minimize output noise

transferred into the sensitive analog circuitry. If the AD9396 is interfacing with lower voltage logic, V

may be

DD

connected to a lower supply voltage (as low as 1.8 V) for compatibility.

Clock Generator Power Supply.

The most sensitive portion of the AD9396 is the clock generation circuitry. These pins provide power to the clock PLL

and help the user design for optimal performance. The designer should provide quiet, noise-free power to these pins.

Digital Input Power Supply.

This supplies power to the digital logic.

Ground.

The ground return for all circuitry on-chip. It is recommended that the AD9396 be assembled on a single solid ground

plane, with careful attention to ground current paths.

Rev. 0 | Page 10 of 48

Page 11

AD9396

DESIGN GUIDE

GENERAL DESCRIPTION

The AD9396 is a fully integrated solution for capturing analog

RGB or YUV signals and digitizing them for display on flat

panel monitors, projectors, or PDPs. In addition, the AD9396

has a digital interface for receiving DVI signals and is capable of

decoding HDCP-encrypted signals through connections to an

external EEPROM. The circuit is ideal for providing an

interface for HDTV monitors or as the front end to high

performance video scan converters.

Implemented in a high performance CMOS process, the

interface can capture signals with pixel rates of up to 150 MHz.

The AD9396 includes all necessary input buffering, signal dc

restoration (clamping), offset and gain (brightness and contrast)

adjustment, pixel clock generation, sampling phase control, and

output data formatting. Included in the output formatting is a

color space converter (CSC), which accommodates any input

color space and can output any color space. All controls are

programmable via a 2-wire serial interface. Full integration of

these sensitive analog functions makes system design straightforward and less sensitive to the physical and electrical

environment.

DIGITAL INPUTS

All digital control inputs (HSYNC, VSYNC, I2C) on the

AD9396 operate to 3.3 V CMOS levels. In addition, all digital

inputs except the TMDS (HDMI/DVI) inputs are 5 V tolerant.

(Applying 5 V to them does not cause any damage.) TMDS

inputs (Rx0+/Rx0−, Rx1+/Rx1−, Rx2+/Rx2−, and RxC+/RxC−)

must maintain a 100 Ω differential impedance (through proper

PCB layout) from the connector to the input where they are

internally terminated (50 Ω to 3.3 V). If additional ESD

protection is desired, use of a California Micro Devices (CMD)

CM1213 (among others) series low capacitance ESD protection

offers 8 kV of protection to the HDMI TMDS lines.

ANALOG INPUT SIGNAL HANDLING

The AD9396 has six high impedance analog input pins for the

red, green, and blue channels. They accommodate signals

ranging from 0.5 V p-p to 1.0 V p-p.

Signals are typically brought onto the interface board via a

DVI-I connector, a 15-pin D connector, or RCA-type connectors. The AD9396 should be located as close as practical to

the input connector. Signals should be routed via 75 matched

impedance traces to the IC input pins.

At the input pins, the signal should be resistively terminated

(75 to the signal ground return) and capacitively coupled to

the AD9396 inputs through 47 nF capacitors. These capacitors

form part of the dc restoration circuit.

In an ideal world of perfectly matched impedances, the best

performance can be obtained with the widest possible signal

bandwidth. The ultrawide bandwidth inputs of the AD9396

(330 MHz) can track the input signal continuously as it moves

from one pixel level to the next, and digitizes the pixel during a

long, flat pixel time. In many systems, however, there are

mismatches, reflections, and noise, which can result in excessive

ringing and distortion of the input waveform. This makes it

more difficult to establish a sampling phase that provides good

image quality. It has been shown that a small inductor in series

with the input is effective in rolling off the input bandwidth

slightly, and providing a high quality signal over a wider range

of conditions. Using a Fair-Rite #2508051217Z0 HIGH SPEED

SIGNAL CHIP BEAD inductor in the circuit, as shown in

Figure 3, gives good results in most applications.

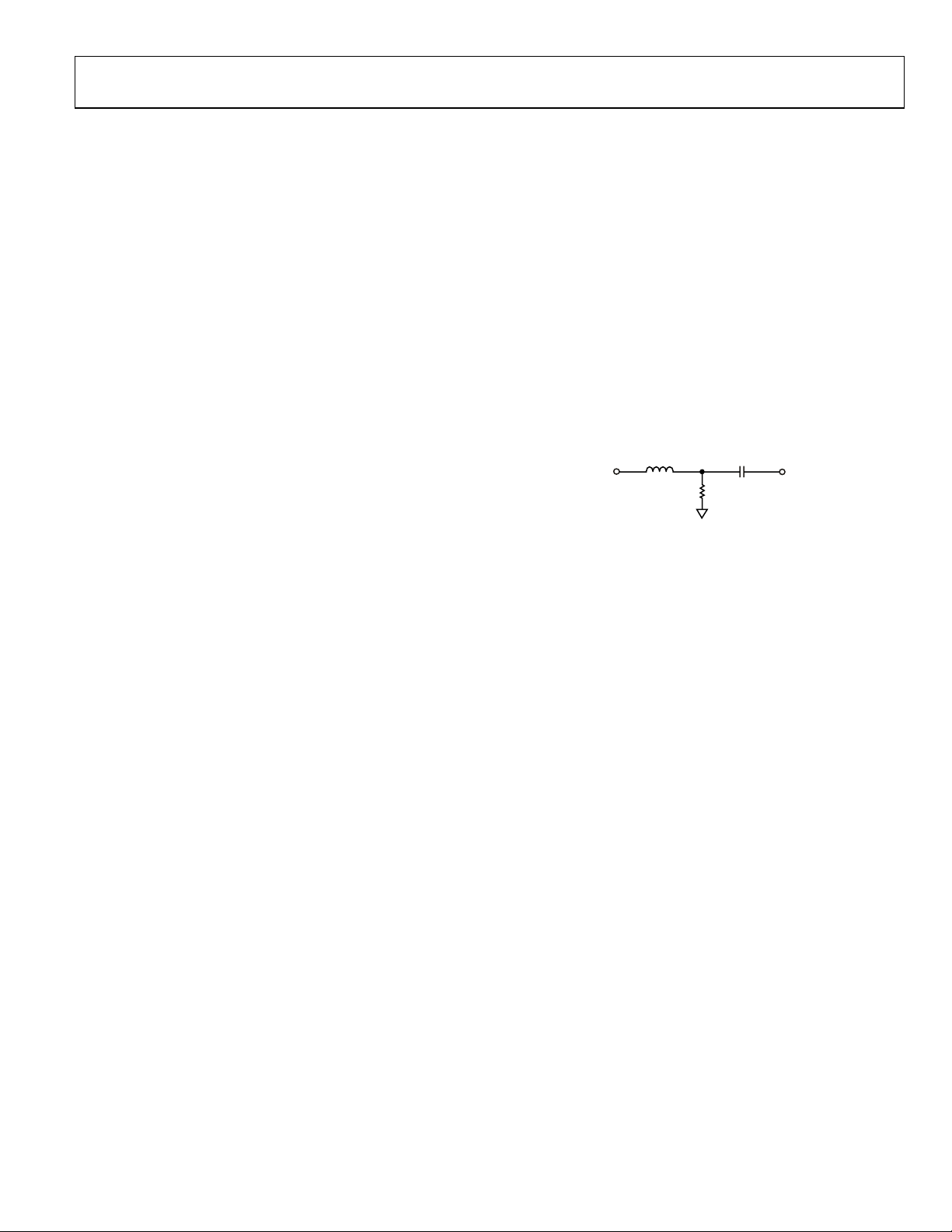

RGB

INPUT

Figure 3. Analog Input Interface Circuit

47nF

75Ω

R

AIN

G

AIN

B

AIN

05690-003

HSYNC AND VSYNC INPUTS

The interface also takes a horizontal sync signal, which is used

to generate the pixel clock and clamp timing. This can be either

a sync signal directly from the graphics source, or a preprocessed TTL or CMOS level signal.

The HSYNC input includes a Schmitt trigger buffer for

immunity to noise and signals with long rise times. In typical

PC-based graphic systems, the sync signals are TTL-level

drivers feeding unshielded wires in the monitor cable. As such,

no termination is required.

SERIAL CONTROL PORT

The serial control port is designed for 3.3 V logic. However, it is

tolerant of 5 V logic signals.

OUTPUT SIGNAL HANDLING

The digital outputs are designed to operate from 1.8 V to 3.3 V

(V

).

DD

CLAMPING

RGB Clamping

To properly digitize the incoming signal, the dc offset of the

input must be adjusted to fit the range of the on-board ADC.

Most graphics systems produce RGB signals with black at

ground and white at approximately 0.75 V. However, if sync

signals are embedded in the graphics, the sync tip is often at

ground and black is at 300 mV. Then white is at approximately

1.0 V. Some common RGB line amplifier boxes use emitterfollower buffers to split signals and increase drive capability.

Rev. 0 | Page 11 of 48

Page 12

AD9396

This introduces a 700 mV dc offset to the signal, which must be

removed for proper capture by the AD9396.

to within ½ LSB in 10 lines with a clamp duration of 20 pixel

periods on a 75 Hz SXGA signal.

The key to clamping is to identify a portion (time) of the signal

when the graphic system is known to be producing black. An

offset is then introduced which results in the ADCs producing a

black output (Code 0x00) when the known black input is

present. The offset then remains in place when other signal

levels are processed, and the entire signal is shifted to eliminate

offset errors.

In most PC graphics systems, black is transmitted between

active video lines. With CRT displays, when the electron beam

has completed writing a horizontal line on the screen (at the

right side), the beam is deflected quickly to the left side of the

screen (called horizontal retrace) and a black signal is provided

to prevent the beam from disturbing the image.

In systems with embedded sync, a blacker-than-black signal

(HSYNC) is produced briefly to signal the CRT that it is time to

begin a retrace. For obvious reasons, it is important to avoid

clamping on the tip of HSYNC. Fortunately, there is virtually

always a period following HSYNC, called the back porch, where

a good black reference is provided. This is the time when

clamping should be done.

Clamp timing employs the AD9396 internal clamp timing

generator. The clamp placement register is programmed with

the number of pixel periods that should pass after the trailing

edge of HSYNC before clamping starts. A second register

(clamp duration) sets the duration of the clamp. These are both

8-bit values, providing considerable flexibility in clamp

generation. The clamp timing is referenced to the trailing edge

of HSYNC because, though HSYNC duration can vary widely,

the back porch (black reference) always follows HSYNC. A

good starting point for establishing clamping is to set the clamp

placement to 0x08 (providing 8 pixel periods for the graphics

signal to stabilize after sync) and set the clamp duration to 0x14

(giving the clamp 20 pixel periods to re-establish the black

reference). For three-level syncs embedded on the green

channel, it is necessary to increase the clamp placement to

beyond the positive portion of the sync. For example, a good

clamp placement (Register 0x19) for a 720p input is 0x26. This

delays the start of clamp by 38 pixel clock cycles after the rising

edge of the three-level sync, allowing plenty of time for the

signal to return to a black reference.

YUV Clamping

YUV graphic signals are slightly different from RGB signals in

that the dc reference level (black level in RGB signals) can be

at the midpoint of the graphics signal rather than the bottom.

For these signals it can be necessary to clamp to the midscale

range of the ADC range (128) rather than the bottom of the

ADC range (0).

Clamping to midscale rather than ground can be accomplished

by setting the clamp select bits in the serial bus register. Each of

the three converters has its own selection bit so that they can be

clamped to either midscale or ground independently. These bits

are located in Register 0x1B [7:5]. The midscale reference

voltage is internally generated for each converter.

Auto-Offset

The auto-offset circuit works by calculating the required offset

setting to yield a given output code during clamp. When this

block is enabled, the offset setting in the I

clamp code rather than an actual offset. The circuit compares

the output code during clamp to the desired code and adjusts

the offset up or down to compensate.

The offset on the AD9396 can be adjusted automatically to a

specified target code. This option allows the user to set the

offset to any value and be assured that all channels with the

same value programmed into the target code will match. This

eliminates any need to adjust the offset at the factory. This

function is capable of running continuously any time the clamp

is asserted.

There is an offset adjust register for each channel, namely the

offset registers at the 0x08, 0x0A, and 0x0C addresses. The

offset adjustment is a signed (twos complement) number with

±64 LSB range. The offset adjustment is added to whatever

offset the auto-offset comes up with. For example: using ground

clamp, the target code is set to 4. To get this code, the autooffset generates an offset of 68. If the offset adjustment is set to

+10, the offset sent to the converter is 78. Likewise, if the offset

adjust is set to −10, the offset sent to the converter is 58. Refer

to application note AN-775, Implementing the Auto-Offset

Function of the AD9880, for a detailed description of how to use

this function.

2

C is seen as a desired

Clamping is accomplished by placing an appropriate charge on

the external input coupling capacitor. The value of this capacitor affects the performance of the clamp. If it is too small,

there is a significant amplitude change during a horizontal line

time (between clamping intervals). If the capacitor is too large,

then it takes excessively long for the clamp to recover from a

large change in the incoming signal offset. The recommended

value (47 nF) results in recovering from a step error of 100 mV

Rev. 0 | Page 12 of 48

Sync-on-Green (SOG)

The SOG input operates in two steps. First, it sets a baseline

clamp level from the incoming video signal with a negative peak

detector. Second, it sets the sync trigger level to a programmable level (typically 150 mV) above the negative peak. The

SOG input must be ac-coupled to the green analog input

through its own capacitor. The value of the capacitor must be

1 nF ± 20%. If SOG is not used, this connection is not required.

Page 13

AD9396

8

Note that the SOG signal is always negative polarity. For more

detail on setting the SOG threshold and other SOG-related

functions, see the

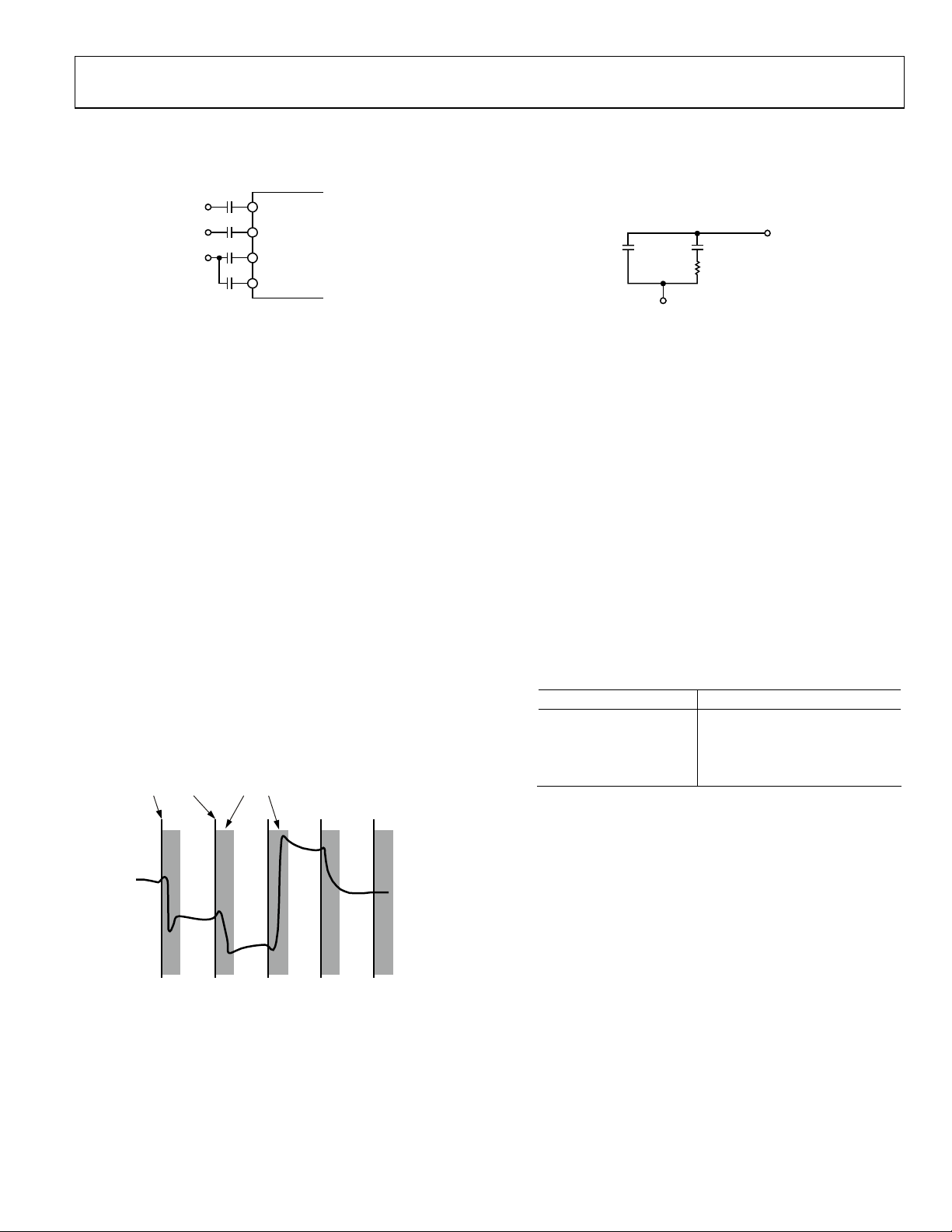

Figure 4. Typical Clamp Configuration for RGB/YUV Applications

Sync Processing section.

47nF

R

1nF

AIN

B

AIN

G

AIN

SOG

47nF

47nF

05690-004

Clock Generation

A PLL is employed to generate the pixel clock. In this PLL,

the HSYNC input provides a reference frequency. A voltage

controlled oscillator (VCO) generates a much higher pixel clock

frequency. This pixel clock is divided by the PLL divide value

(Register 0x01 and Register 0x02) and phase compared with the

HSYNC input. Any error is used to shift the VCO frequency

and to maintain the lock between the two signals.

The stability of this clock is a very important element in providing the clearest and most stable image. During each pixel time,

there is a period during which the signal slews from the old

pixel amplitude and settles at its new value. This is followed by a

time when the input voltage is stable before the signal must slew

to a new value. The ratio of the slewing time to the stable time is

a function of the bandwidth of the graphics DAC and the

bandwidth of the transmission system (cable and termination).

It is also a function of the overall pixel rate. Clearly, if the

dynamic characteristics of the system remain fixed, then the

slewing and settling time is likewise fixed. This time must be

subtracted from the total pixel period, leaving the stable period.

At higher pixel frequencies, the total cycle time is shorter and

the stable pixel time also becomes shorter.

PIXEL CLOCK INVALID SAMPLE TIMES

The PLL characteristics are determined by the loop filter design,

the PLL charge pump current, and the VCO range setting. The

loop filter design is shown in

Figure 6. Recommended settings

of the VCO range and charge pump current for VESA standard

display modes are listed in

C

P

nF

Table 9 .

C

Z

80nF

R

Z

1.5kΩ

FILT

Figure 6. PLL Loop Filter Detail

PV

D

05690-006

Four programmable registers are provided to optimize the

performance of the PLL. These registers are:

• The 12-bit divisor register (R0x01, R0x02). The input

HSYNC frequency range can be any frequency which,

combined with the PLL_Div, does not exceed the VCO

range. The PLL multiplies the frequency of the HSYNC

signal, producing pixel clock frequencies in the range of

10 MHz to 100 MHz. The divisor register controls the

exact multiplication factor.

• The 2-bit VCO range register (R0x03). To improve the

noise performance of the AD9396, the VCO operating

frequency range is divided into four overlapping regions.

The VCO range register sets this operating range. The

frequency ranges for the lowest and highest regions are

shown in

Tabl e 7.

Table 7.

VCORNGE Pixel Rate Range

00 12 to 30

01 30 to 60

10 60 to 120

11 120 to 150

• The 5-bit phase adjust register (R0x05). The phase of the

generated sampling clock can be shifted to locate an

optimum sampling point within a clock cycle. The phase

adjust register provides 32 phase-shift steps of 11.25° each.

The HSYNC signal with an identical phase shift is available

through the HSOUT pin.

The coast pin or the internal coast is used to allow the PLL to

continue to run at the same frequency, in the absence of the

05690-005

Figure 5. Pixel Sampling Times

Any jitter in the clock reduces the precision with which the

sampling time can be determined and must also be subtracted

from the stable pixel time. Considerable care has been taken in

the design of the AD9396 clock generation circuit to minimize

jitter. The clock jitter of the AD9396 is less than 13% of the total

pixel time in all operating modes, making the reduction in the

valid sampling time due to jitter negligible.

Rev. 0 | Page 13 of 48

incoming HSYNC signal or during disturbances in HSYNC

(such as equalization pulses). This can be used during the

vertical sync period or any other time that the HSYNC signal is

unavailable. The polarity of the coast signal can be set through

the coast polarity register. Also, the polarity of the HSYNC

signal can be set through the HSYNC polarity register. For both

HSYNC and coast, a value of 1 is active high. The internal coast

function is driven from the VSYNC signal, which is typically a

time when HSYNC signals can be disrupted with extra

equalization pulses.

Page 14

AD9396

Power Management

The AD9396 uses the activity detect circuits, the active interface

bits in the serial bus, the active interface override bits, the

power-down bit, and the power-down pin to determine the

correct power state. There are four power states: full-power,

seek mode, auto power-down, and power-down.

Tabl e 8 summarizes how the AD9396 determines the power

mode and the circuitry that is powered on/off in each of these

modes. The power-down command has priority and then the

automatic circuitry. The power-down pin (Pin 81—polarity set

Table 8. Power-Down Mode Descriptions

Inputs

Mode Power-Down

1

Sync Detect

2

Auto PD Enable

Full Power 1 1 X Everything

Seek Mode 1 0 0 Everything

Seek Mode 1 0 1

Power-Down 0 X

1

Power-down is controlled via Bit 0 in Serial Bus Register 0x26.

2

Sync detect is determined by OR’ing Bit 7 to Bit 2 in Serial Bus Register 0x15.

3

Auto power-down is controlled via Bit 7 in Serial Bus Register 0x27.

Table 9. Recommended VCO Range and Charge Pump Current Settings for Standard Display Formats

Standard

Resolution

Refresh Rate

(Hz)

Horizontal

Frequency (kHz) Pixel Rate (MHz) VCO Range

VGA 640 × 480 60 31.5 25.175 00 101

72 37.7 31.500 01 011

75 37.5 31.500 01 100

85 43.3 36.000 01 100

SVGA 800 × 600 56 35.1 36.000 01 100

60 37.9 40.000 01 101

72 48.1 50.000 01 110

75 46.9 49.500 01 110

85 53.7 56.250 01 110

XGA 1024 × 768 60 48.4 65.000 10 011

70 56.5 75.000 10 100

75 60.0 78.750 10 100

80 64.0 85.500 10 101

85 68.3 94.500 10 110

SXGA 1280 × 1024 60 64.0 108.000 10 110

1280 × 1024 75 80.0 135.000 11 110

TV 480i 60 15.75 13.51 00 010

480p 60 31.47 27 00 101

720p 60 45 74.25 10 100

1035i 60 33.75 74.25 10 100

1080i 60 33.75 74.25 10 100

1080p 60 67.5 148.5 11 110

1

These are preliminary recommendations for the analog PLL and are subject to change without notice.

by Register 0x26[3]) can drive the chip into four power-down

options. Bit 2 and Bit 1 of Register 0x26 control these four

options. Bit 0 controls whether the chip is powered down or the

outputs are placed in high impedance mode (with the exception

of SOG). Bit 7 to Bit 4 of Register 0x26 control whether the

outputs, SOG, Sony Philips digital interface (SPDIF ) or I

or Inter-IC sound bus) outputs are in high impedance mode or

not. See the

2-Wire Serial Control Register Detail section for

more detail.

3

Power-On or Comments

Serial bus, sync activity detect, SOG, band gap

reference

Serial bus, sync activity detect, SOG, band gap

reference

1

Current

1

2

S (IIS

Rev. 0 | Page 14 of 48

Page 15

AD9396

K

TIMING

The output data clock signal is created so that its rising edge

always occurs between data transitions and can be used to latch

the output data externally.

There is a pipeline in the AD9396, which must be flushed

before valid data becomes available. This means 23 data sets are

presented before valid data is available.

The timing diagram in

Figure 7 shows the operation of the

AD9396.

t

PER

t

DCYCLE

DATAC

Three things happen to HSYNC in the AD9396. First, the

polarity of HSYNC input is determined and thus has a known

output polarity. The known output polarity can be programmed

either active high or active low (Register 0x24, Bit 7). Second,

HSOUT is aligned with DATACK and data outputs. Third, the

duration of HSOUT (in pixel clocks) is set via Register 0x23.

HSOUT is the sync signal that should be used to drive the rest

of the display system.

Coast Timing

In most computer systems, the HSYNC signal is provided continuously on a dedicated wire. In these systems, the coast input

and function are unnecessary, and should not be used. The pin

should be permanently connected to the inactive state.

t

SKEW

DATA

HSOUT

Figure 7. Output Timing

HSYNC Timing

Horizontal sync (HSYNC) is processed in the AD9396 to

eliminate ambiguity in the timing of the leading edge with

respect to the phase-delayed pixel clock and data.

The HSYNC input is used as a reference to generate the pixel

sampling clock. The sampling phase can be adjusted, with

respect to HSYNC, through a full 360° in 32 steps via the phase

adjust register (to optimize the pixel sampling time). Display

systems use HSYNC to align memory and display write cycles,

so it is important to have a stable timing relationship between

the HSYNC output (HSOUT) and data clock (DATACK).

05690-009

In some systems, however, HSYNC is disturbed during the

vertical sync period (VSYNC). In some cases, HSYNC pulses

disappear. In other systems, such as those that employ

composite sync (Csync) signals or embedded SOG, HSYNC

includes equalization pulses or other distortions during

VSYNC. To avoid upsetting the clock generator during VSYNC,

it is important to ignore these distortions. If the pixel clock PLL

sees extraneous pulses, it attempts to lock to this new frequency,

and changes frequency by the end of the VSYNC period. It then

takes a few lines of correct HSYNC timing to recover at the

beginning of a new frame, tearing the image at the top of the

display.

The coast input is provided to eliminate this problem. It is an

asynchronous input that disables the PLL input and allows the

clock to free-run at its then-current frequency. The PLL can

free-run for several lines without significant frequency drift.

Coast can be generated internally by the AD9396 (see

Register 0x12[1]), can be driven directly from a VSYNC input,

or can be provided externally by the graphics controller.

Rev. 0 | Page 15 of 48

Page 16

AD9396

Sync Processing

The inputs of the sync processing section of the AD9396 are

combinations of digital HSYNCs and VSYNCs, analog sync-ongreen, or sync-on-Y signals, and an optional external coast

signal. From these signals, it generates a precise, jitter-free (9%

or less at 95 MHz) clock from its PLL; an odd/even field signal;

HSYNC and VSYNC out signals; a count of HSYNCs per

VSYNC; and a programmable SOG output. The main sync

processing blocks are the sync slicer, sync separator, HSYNC

filter, HSYNC regenerator, VSYNC filter, and coast generator.

The sync slicer extracts the sync signal from the green graphics

or luminance video signal that is connected to the SOGIN input

and outputs a digital composite sync. The sync separator’s task

is to extract VSYNC from the composite sync signal, which can

come from either the sync slicer or the HSYNC input. The

HSYNC filter is used to eliminate any extraneous pulses from

the HSYNC or SOGIN inputs, outputting a clean, low jitter

signal that is appropriate for mode detection and clock

generation. The HSYNC regenerator is used to re-create a clean,

although not low jitter, HSYNC signal that can be used for

mode detection and counting HSYNCs per VSYNC. The

VSYNC filter is used to eliminate spurious VSYNCs, maintain a

stable timing relationship between the VSYNC and HSYNC

output signals, and generate the odd/even field output. The

coast generator creates a robust coast signal that allows the PLL

to maintain its frequency in the absence of HSYNC pulses.

HSYNC 0

HSYNC 1

SOGIN 0

SOGIN 1

VSYNC 0

VSYNC 1

COAST

1

AD

1

AD

SYNC

SLICER

SYNC

SLICER

1

AD

1

AD

AD9396

1

ACTIVITY DETECT

2

POLARITY DETECT

3

REGENERATED HSYNC

4

FILTERED HSYNC

5

SET POLARITY

PD

PD

AD

AD

PD

PD

2

2

1

1

2

2

CHANNEL

SELECT

MUX

MUX

VSYNC

MUX

FILTER COAST VSYNC

0x12:0

Figure 8. Sync Processing Block Diagram

[0x11:3]

SYNC

PROCESSOR

AND

VSYNC FILTER

COAST SELECT

HSYNC

[0x11:7]

SELECT

MUX

SP SYNC FILTER EN

0x21:7

MUX

PLL SYNC FILTER EN

0x21:6

COAST

MUX

0x12:1

FH

MUX

HSYNC

PLL CLOCK

GENERATOR

HSYNC FILTER

AND

REGENERATOR

4

RH

SOGOUT SELECT

HSYNC/VSYNC

COUNTER

REG 26H, 27H

3

MUX

0x24:2,1

VSYNC

FILTERED

VSYNC

VSYNC FILTER EN

5

SP

MUX

0x21:5

SP

5

SP

5

SP

5

SOG OUT

VSYNC OUT

O/E

FIELD

HSYNC OUT

DATACK

05690-007

Rev. 0 | Page 16 of 48

Page 17

AD9396

S

Sync Slicer

The purpose of the sync slicer is to extract the sync signal from

the green graphics or luminance video signal that is connected

to the SOGIN input. The sync signal is extracted in a two-step

process. First, the SOG input (typically 0.3 V below the black

level) is detected and clamped to a known dc voltage. Next, the

signal is routed to a comparator with a variable trigger level (set

by Register 0x1D, Bits [7:3]), but nominally 0.128 V above the

clamped voltage. The sync slicer output is a digital composite

sync signal containing both HSYNC and VSYNC information

(see

Figure 9).

Sync Separator

As part of sync processing, the sync separator’s task is to extract

VSYNC from the composite sync signal. It works on the idea

that the VSYNC signal stays active for a much longer time than

the HSYNC signal. By using a digital low-pass filter and a

digital comparator, it rejects pulses with small durations (such

as HSYNCs and equalization pulses) and only passes pulses

with large durations, such as VSYNC (see

Figure 9).

The threshold of the digital comparator is programmable for

maximum flexibility. To program the threshold duration, write

a value (N) to Register 0x11. The resulting pulse width is

N × 200 ns. So if N = 5, the digital comparator threshold is 1 µs.

Any pulses less than 1 µs are rejected, while any pulse greater

than 1 µs passes through.

The sync separator on the AD9396 is simply an 8-bit digital

counter with a 6 MHz clock. It works independently of the

polarity of the composite sync signal. Polarities are determined

elsewhere on the chip. The basic idea is that the counter counts

up when HSYNC pulses are present. But because HSYNC

NEGATIVE PULSE WIDTH = 40 SAMPLE CLOCKS

700mV MAXIMUM

SOGIN

+300mV

0mV

–300mV

pulses are relatively short in width, the counter only reaches a

value of N before the pulse ends. It then starts counting down

until eventually reaching 0 before the next HSYNC pulse

arrives. The specific value of N varies for different video modes,

but is always less than 255. For example, with a 1 s width

HSYNC, the counter only reaches 5 (1 s/200 ns = 5). Now,

when VSYNC is present on the composite sync the counter also

counts up. However, because the VSYNC signal is much longer,

it counts to a higher number, M. For most video modes, M is at

least 255. So VSYNC can be detected on the composite sync

signal by detecting when the counter counts to higher than N.

The specific count that triggers detection, T, can be

programmed through the Serial Register 0x11.

Once VSYNC has been detected, there is a similar process to

detect when it goes inactive. At detection, the counter first

resets to 0, then starts counting up when VSYNC finishes. As in

the previous case, it detects the absence of VSYNC when the

counter reaches the threshold count, T. In this way, it rejects

noise and/or serration pulses. Once VSYNC is detected to be

absent, the counter resets to 0 and begins the cycle again.

There are two things to keep in mind when using the sync

separator. First, the resulting clean VSYNC output is delayed

from the original VSYNC by a duration equal to the digital

comparator threshold (N × 200 ns). Second, there is some

variability to the 200 ns multiplier value. The maximum variability over all operating conditions is ±20% (160 ns to 240 ns).

Because normal VSYNC and HSYNC pulse widths differ by a

factor of about 500 or more, 20% variability is not an issue.

OGOUT OUTPUT

CONNECTED TO

HSIN

COMPOSITE

SYNC

AT HSIN

VSOUT

FROM SYNC

SEPARATOR

Figure 9. Sync Slicer and Sync Separator Output

05690-008

Rev. 0 | Page 17 of 48

Page 18

AD9396

W

HSYNC Filter and Regenerator

The HSYNC filter is used to eliminate any extraneous pulses

from the HSYNC or SOGIN inputs, outputting a clean, low

jitter signal that is appropriate for mode detection and clock

generation. The HSYNC regenerator is used to re-create a clean,

although not low jitter, HSYNC signal that can be used for

mode detection and counting HSYNCs per VSYNC. The

HSYNC regenerator has a high degree of tolerance to

extraneous and missing pulses on the HSYNC input, but is not

appropriate for use by the PLL in creating the pixel clock

because of jitter.

The HSYNC regenerator runs automatically and requires no

setup to operate. The HSYNC filter requires setting up a filter

window. The filter window sets a periodic window of time

around the regenerated HSYNC leading edge where valid

HSYNCs are allowed to occur. The general idea is that

extraneous pulses on the sync input occur outside of this filter

window and thus are filtered out. To set the filter window

timing, program a value (x) into Register 0x20. The resulting

filter window time is ±x times 25 ns around the regenerated

HSYNC leading edge. Just as for the sync separator threshold

multiplier, allow a ±20% variance in the 25 ns multiplier to

account for all operating conditions (20 ns to 30 ns range).

A second output from the HSYNC filter is a status bit

(Register 0x16[0]) that tells whether extraneous pulses are

present on the incoming sync signal. Extraneous pulses are

often included for copy protection purposes; this status bit can

be used to detect that.

The filtered HSYNC (rather than the raw HSYNC/SOGIN

signal) for pixel clock generation by the PLL is controlled by

Register 0x21[6]. The regenerated HSYNC (rather than the

raw HSYNC/SOGIN signal) for sync processing is controlled by

Register 0x21[7]. Use of the filtered HSYNC and regenerated

HSYNC is recommended. See

Figure 10 for an illustration of a

filtered HSYNC.

HSIN

FILTER

INDOW

HSOUT

VSYNC

FILTER

WINDOW

EQUALIZATION

EXPECTED

EDGE

PULSES

05690-010

Figure 10. Sync Processing Filter

Rev. 0 | Page 18 of 48

Page 19

AD9396

T

T

VSYNC Filter and Odd/Even Fields

The VSYNC filter is used to eliminate spurious VSYNCs,

maintain a consistent timing relationship between the VSYNC

and HSYNC output signals, and generate the odd/even field

output.

The filter works by examining the placement of VSYNC with

respect to HSYNC and, if necessary, slightly shifting it in time at

the VSOUT output. The goal is to keep the VSYNC and

HSYNC leading edges from switching at the same time,

eliminating confusion as to when the first line of a frame

occurs. Enabling the VSYNC filter is done with Register

0x21[5]. Use of the VSYNC filter is recommended for all cases,

including interlaced video and is required when using the

HSYNC per VSYNC counter.

Figure 12 illustrates even/odd

field determination in two situations.

SYNC SEPARATOR THRESHOLD

FIELD 1 FIELD 0

QUADRAN

HSIN

VSIN

VSOUT

O/E FIELD

FIELD 1 FIELD 0

23 214431

EVEN FIELD

Figure 11.

SYNC SEPARATOR THRESHOLD

QUADRAN

HSIN

VSIN

VSOUT

O/E FIELD

FIELD 1 FIELD 0

23 21431

ODD FIELD

Figure 12. VSYNC Filter—Odd/Even

FIELD 1 FIELD 0

4

DVI RECEIVER

The DVI receiver section of the AD9396 allows the reception of

a digital video stream compatible with DVI 1.0. Embedded in

this data stream are HSYNCs, VSYNCs and display enable (DE)

signals. DVI restricts the received format to RGB, but the

inclusion of a programmable color space converter (CSC)

allows the output to be tailored to any format necessary. With

this, the scaler following the AD9396 can specify that it always

wishes to receive a particular format—for instance, 4:2:2

YCrCb—regardless of the transmitted mode. If RGB is sent, the

CSC can easily convert that to 4:2:2 YCrCb while relieving the

scaler of this task.

05690-011

05690-012

DE GENERATOR

The AD9396 has an on-board generator for DE, for start of

active video (SAV), and for end of active video (EAV), all of

which are necessary for describing the complete data stream for

a BT656-compatible output. In addition to this particular

output, it is possible to generate the DE for cases in which a

scaler is not used. This signal alerts the following circuitry as to

which are displayable video pixels.

4:4:4 TO 4:2:2 FILTER

The AD9396 contains a filter that allows it to convert a signal

from YCrCb 4:4:4 to YCrCb 4:2:2 while maintaining the

maximum accuracy and fidelity of the original signal.

Input Color Space to Output Color space

The AD9396 can support a wide variety of output formats, such

as the following:

• RGB 24-bit

• 4:4:4 YCrCb 8-bit

• 4:2:2 YCrCb 8-bit, 10-bit, and 12-bit

• Dual 4:2:2 YCrCb 8-bit

Color Space Conversion (CSC) Matrix

The color space conversion (CSC) matrix in the AD9396

consists of three identical processing channels. In each channel,

three input values are multiplied by three separate coefficients.

Also included are an offset value for each row of the matrix and

a scaling multiple for all values. Each value has a 13-bit, twos

complement resolution to ensure the signal integrity is maintained. The CSC is designed to run at speeds up to 150 MHz

supporting resolutions up to 1080p at 60 Hz. With any-to-any

color space support, formats such as RGB, YUV, YCbCr, and

others are supported by the CSC.

The main inputs, R

inputs from each channel. These inputs are based on the input

format detailed in

CSC inputs is shown in

Table 10. CSC Port Mapping

Input Channel CSC Input Channel

R/CR R

Gr/Y G

B/CB BB

One of the three channels is represented in Figure 13. In each

processing channel the three inputs are multiplied by three

separate coefficients marked a1, a2, and a3. These coefficients

are divided by 4096 to obtain nominal values ranging from

−0.9998 to +0.9998. The variable labeled ‘a4’ is used as an offset

control. The CSC_Mode setting is the same for all three

processing channels. This multiplies all coefficients and offsets

by a factor of 2

, GIN, and BIN come from the 8-bit to 12-bit

IN

Tabl e 11 . The mapping of these inputs to the

Tabl e 10 .

IN

IN

IN

CSC_Mode

.

Rev. 0 | Page 19 of 48

Page 20

AD9396

The functional diagram for a single channel of the CSC, as

shown in

channels. The coefficients for these channels are b1, b2, b3, b4,

c1, c2, c3, and c4.

A programming example and register settings for several

common conversions are listed in the

(CSC) Common Settings

For a detailed functional description and more programming

examples, refer to the application note AN-795, AD9880 Color

Space Converter User's Guide.

TIMING DIAGRAMS

The following timing diagrams show the operation of the

AD9396.The output data clock signal is created so that its rising

edge always occurs between data transitions and can be used to

Figure 13, is repeated for the remaining G and B

Color Space Converter

.

DATAIN

HSIN

P0 P1 P2 P5P3 P4 P9P6 P8 P10 P11P7

latch the output data externally. There is a pipeline in the

AD9396, which must be flushed before valid data becomes

available. This means six data sets are presented before valid

data is available.

CSC_Mode[1:0]

a1[12:0]

[11:0]

R

IN

[11:0]

B

IN

G

[11:0]

IN

×

a2[12:0]

×

a3[12:0]

×

×

×

×

4096

4096

1

4096

1

+

1

Figure 13. Single CSC Channel

a4[12:0]

×4

+

+

×2

2

R

[11:0]

OUT

1

0

05690-013

DATACK

8 CLOCK CYCLE DELAYS

DATAOUT

2 CLOCK CYCLE DELAYS

HSOUT

Figure 14. RGB ADC Timing

P0 P1 P2 P3

05690-014

DATAIN

HSIN

DATACK

YOUT

CB/CROUT

HSOUT

P0 P1 P2 P5P3 P4 P9P6 P8 P10 P11P7

2 CLOCK CYCLE DELAYS

NOTES:

1. PIXEL AFTER HSOUT CORRESPONDS TO BLUE INPUT.

2. EVEN NUMBER OF PIXEL DELAYS BETWEEN HSOUT AND DATAOUT.

Figure 15. YCrCb ADC Timing

8 CLOCK CYCLE DELAYS

Y0 Y1 Y2 Y3

B0 R0 B2 R2

05690-015

Table 11.

Port Red Green Blue

Bit 7 6 5 4 3 2 1 0 7 6 5 4 3 2 1 0 7 6 5 4 3 2 1 0

4:4:4 Red/Cr [7:0] Green/Y [7:0] Blue/Cb [7:0]

4:2:2 CbCr [7:0] Y [7:0]

4:4:4 DDR

DDR ↑ 1 G [3:0] DDR ↑ B [7:4] DDR ↑ B [3:0] DDR 4:2:2 ↑ CbCr [11:0]

DDR

↓ R [7:0]

DDR ↓ G [7:4] DDR 4:2:2 ↓ Y,Y [11:0]

DDR 4:2:2

↑ CbCr ↓ Y, Y

4:2:2 to 12 CbCr [11:0] Y [11:0]

1

Arrows in the table indicate clock edge. Rising edge of clock = ↑, falling edge = ↓.

Rev. 0 | Page 20 of 48

Page 21

AD9396

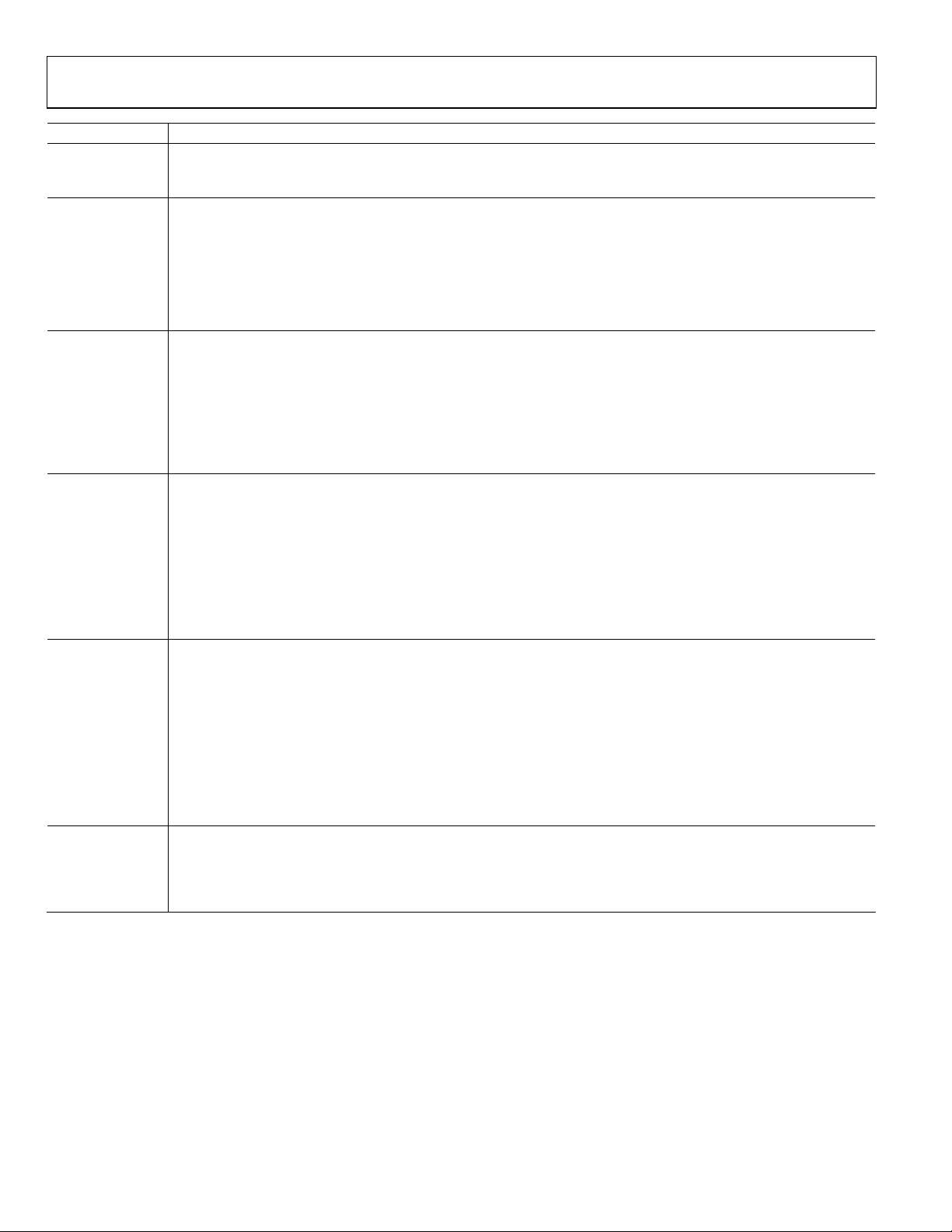

2-WIRE SERIAL REGISTER MAP

The AD9396 is initialized and controlled by a set of registers that determines the operating modes. An external controller is employed to

write and read the control registers through the 2-wire serial interface port.

Table 12. Control Register Map

Hex

Address

0x00 Read [7:0] 00000000 Chip Revision Chip revision ID.

0x01 Read/Write [7:0] 01101001 PLL Divider MSB PLL feedback divider value MSB.

0x02 Read/Write [7:4] 1101**** PLL Divider PLL feedback divider value.

0x03 Read/Write [7:6] 01****** VCO Range VCO range.

[5:3] **001*** Charge Pump Charge pump current control for PLL.

[2]

0x04 Read/Write [7:3] 10000*** Phase Adjust Selects the clock phase to use for the ADC clock.

0x05 Read/Write [7:0] 10000000 Red Gain

0x06 Read/Write [7:0] 10000000 Green Gain

0x07 Read/Write [7:0] 10000000 Blue Gain

0x08 Read/Write [7:0] 00000000 Red Offset Adjust User adjustment of auto-offset. Allows user control of brightness.

0x09 Read/Write [7:0] 10000000 Red Offset Red offset/target code. 0 = small offset, 255 = large offset.

0x0A Read/Write [7:0] 00000000

0x0B Read/Write [7:0] 10000000 Green Offset Green offset/target code. 0 = small offset, 255 = large offset.

0x0C Read/Write [7:0] 00000000 Blue Offset Adjust User adjustment of auto-offset. Allows user control of brightness.

0x0D Read/Write [7:0] 10000000 Blue Offset Blue offset/target code. 0 = small offset, 255 = large offset.

0x0E Read/Write [7:0] 00100000

0x0F Read/Write [7:2] 010000**

0x10 Read/Write [7:2] 010000**

0x11 Read/Write [7] 0******* HSYNC Source 0 = HSYNC.

1 = SOG.

[6] *0******

1 = manual HSYNC source.

[5] **0***** VSYNC Source 0 = VSYNC.

1 = VSYNC from SOG.

[4] ***0****

1 = manual HSYNC source.

[3] ****0*** Channel Select 0 = Channel 0.

1 = Channel 1.

[2] *****0**

1 = manual channel select.

[1] ******0* Interface Select 0 = analog interface.

1 = digital interface.

[0] *******0 Interface Override 0 = auto-interface select.

1 = manual interface select.

Read/Write

or Read Only

Bits

Default

Value

*****0**

Register Name Description

External Clock

Enable

Green Offset

Adjust

Sync Separator

Threshold

SOG Comparator

Threshold Enter

SOG Comparator

Threshold Exit

HSYNC Source

Override

VSYNC Source

Override

Channel Select

Override

Selects the external clock input rather than the internal PLL clock.

Controls the gain of the red channel PGA. 0 = low gain,

255 = high gain.

Controls the gain of the green channel PGA. 0 = low gain,

255 = high gain.

Controls the gain of the blue channel PGA. 0 = low gain,

255 = high gain.

User adjustment of auto-offset. Allows user control of brightness.

Selects the maximum HSYNC pulse width for composite sync

separation.

The enter level for the SOG slicer. Must be less than or equal to the

exit level.

The exit level for the SOG slicer. Must be greater than or equal to

the enter level.

0 = auto HSYNC source.

0 = auto HSYNC source.

0 = autochannel select.

Rev. 0 | Page 21 of 48

Page 22

AD9396

Hex

Address

0x12 Read/Write [7] 1*******

1 = active high.

[6] *0******

1 = manual HSYNC polarity.

[5] **1*****

1 = active high.

[4] ***0****

1 = manual VSYNC polarity.

[3] ****1***

1 = active high.

[2] *****0**

1 = manual coast polarity.

[1] ******0* Coast Source 0 = internal coast.

1 = external coast.

[0] *******1 Filter Coast VSYNC 0 = Use raw VSYNC for coast generation.

1 = Use filtered VSYNC for coast generation.

0x13 Read/Write [7:0] 00000000 Precoast Number of HSYNC periods before VSYNC to coast.

0x14 Read/Write [7:0] 00000000 Postcoast Number of HSYNC periods after VSYNC to coast.

0x15 Read [7] 0*******

1 = detected.

[6] *0******

1 = detected.

[5] **0***** VSYNC 0 Detected 0 = not detected.

1 = detected.

[4] ***0**** VSYNC 1 Detected 0 = not detected.

1 = detected.

[3] ****0*** SOG 0 Detected 0 = not detected.

1 = detected.

[2] *****0** SOG1 Detected 0 = not detected.

1 = detected.

[1] ******0* Coast Detected 0 = not detected.

1 = detected.

0x16 Read [7] 0******* HSYNC 0 Polarity 0 = active low.

1 = active high.

[6] *0****** HSYNC 1 Polarity 0 = active low.

1 = active high.

[5] **0***** VSYNC 0 Polarity 0 = active low.

1 = active high.