现货库存、技术资料、百科信息、热点资讯,精彩尽在鼎好!

2.3MHz Typical at Nominal Conditions, 2VFS Int Ref

Rev. PrJ

6/25/2004

Quad 8-Bit, 65 MSPS

Serial LVDS 3V A/D Converter

Preliminary Technical Data AD9289

FEATURES

• Four ADCs in one package

• Serial LVDS digital output data rates up to 520 Mbps (ANSI-

644)

• Data clock output provided

• SNR = 47 dB (to Nyquist)

• Excellent Linearity:

DNL = ±0.25 LSB (Typical)

INL = ±0.5 LSB (Typical)

• 400 MHz full power analog bandwidth

• Power dissipation = 112 mW Core ADC Power

per channel at 65 MSPS

• 1 Vpp – 2 Vpp input voltage range

• +3.0 V supply operation

• Power down mode

APPLICATIONS

• Tape drives

• Medical imaging

PRODUCT DESCRIPTION

The AD9289 is a quad 8-bit, 65 MSPS analog–to–digital converter

with an on–chip track–and–hold circuit and is designed for low

cost, low power, small size and ease of use. The product operates

up to 65 MSPS conversion rate and is optimized for outstanding

dynamic performance where a small package size is critical.

The ADC requires a single+3V power supply and an LVDS

compatible sample rate clock for full performance operation. No

external reference or driver components are required for many

applications. A separate output power supply pin supports LVDS

compatible serial digital output levels.

The ADC automatically multiplies up the sample rate clock for the

appropriate LVDS serial data rate. An FCO trigger is provided to

signal a new output byte. Power down is supported, and the ADC

consumes less than 10mW when enabled.

Fabricated on an advanced CMOS process, the AD9289 is

available in a 64-ball mini-BGA package (64 CSP_BGA)

specified over the industrial temperature range (–40°C to +85°C).

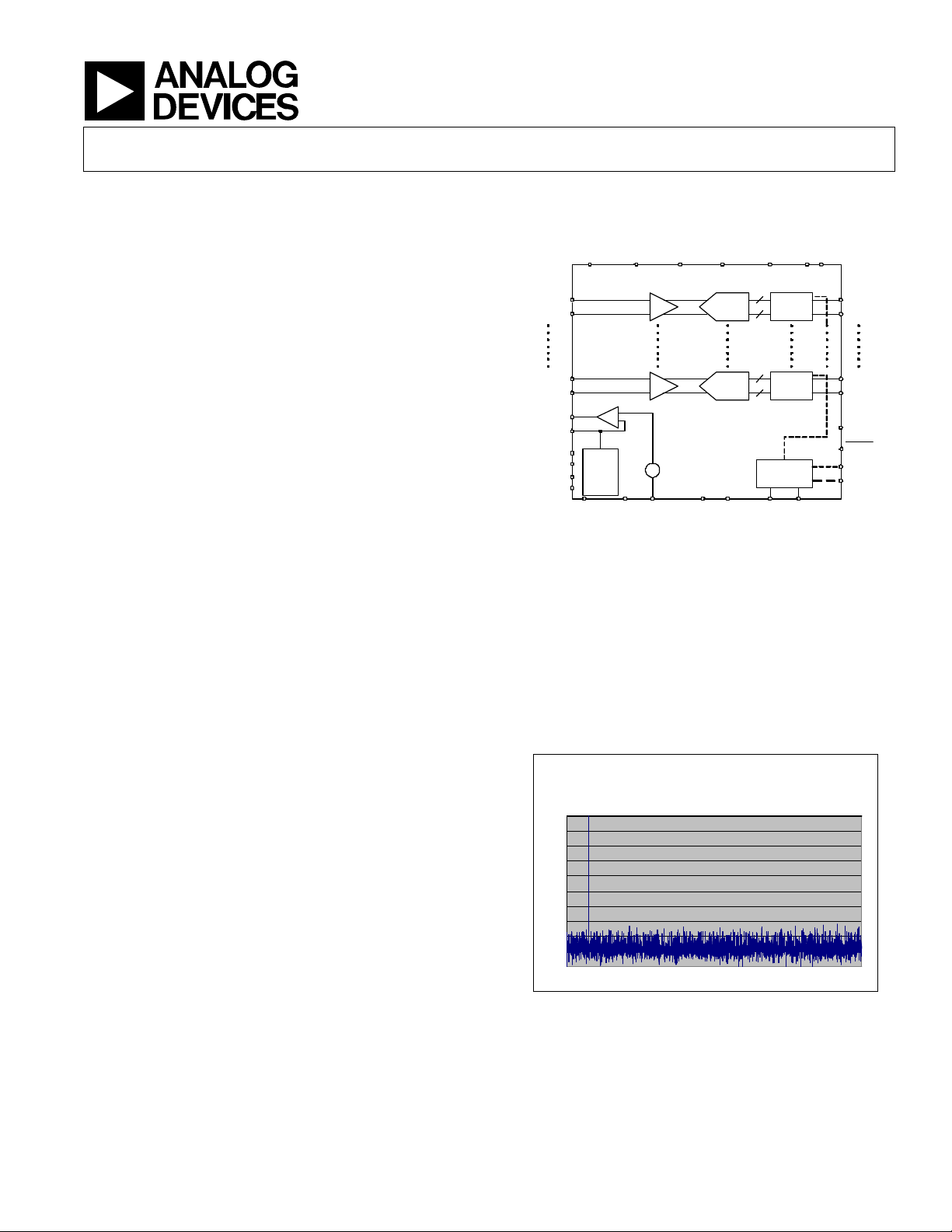

FUNCTIONAL BLOCK DIAGRAM

VIN+A

VIN-A

VIN+D

VIN-D

VREF

SENSE

REFT_A

REFB_A

REFT_B

REFB_B

SHARED_REF CML

AVDD DRVDD

DRGND

Ref

Select

Figure 1. Functional Block Diagram

PDWN

AD9289

SHA

SHA

+

0.5 V

-

Pipeline

ADC

Pipeline

ADC

FCO+ FCO-

8

8

Data Rate

Multiplier

CLK+ CLK-AGND

Serial

LVDS

Serial

LVDS

OR+ OR-S1

PRODUCT HIGHLIGHTS

1. Four analog-to-digital converters are contained in one small,

space saving package.

2. A Data Clock Out (DCO) is provided which operates up to

260 MHz.

3. The outputs of each ADC are serialized and provided on the

rising and falling edge of DCO). Output data rates up to 520

Mbps (8 bits x 65 MSPS) are available.

4. The AD9289 operates from a single 3V power supply.

5. The clock duty cycle stabilizer maintains performance over a

wide range of input clock duty cycles

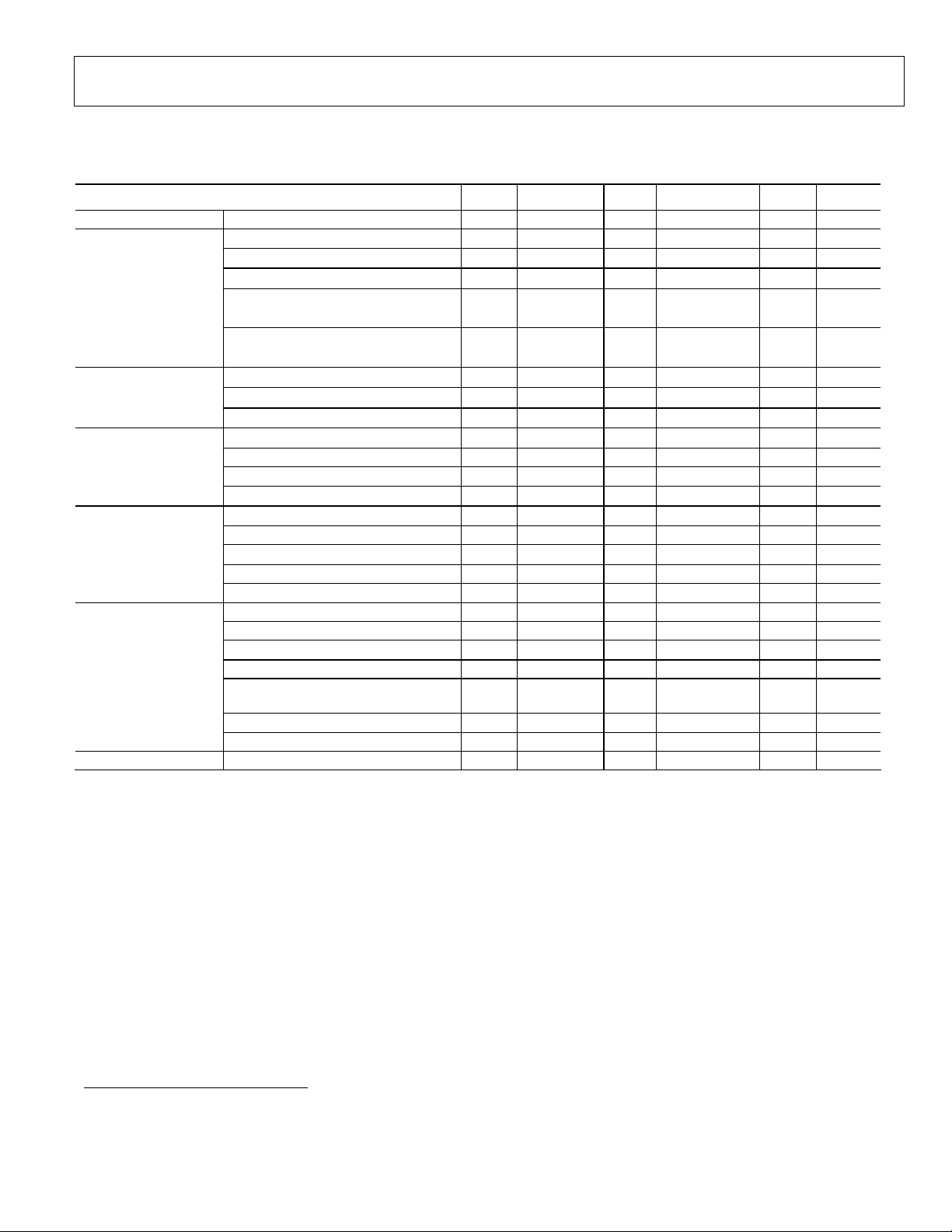

AD9289 R1

SNR = 49.1dB, SFDR = 71.9dB

0

-10

-20

-30

-40

-50

-60

-70

-80

-90

-100

0 5 10 15 20 25 30

D1+A

D1-A

D1+D

D1-D

LVDSBIAS

LOCK

DCO+

DCO-

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

that may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices. Trademarks

and registered trademarks are the property of their respective companies.

Figure 2. Measured FFT

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106,

U.S.A.

Tel: 781.329.4700 www.analog.com

Fax: 781.326.8703 © 2004 Analog Devices, Inc. All rights reserved.

AD9289 Preliminary Technical Data

TABLE OF CONTENTS

AD9289—Specifications ............................................................ 3

DIGITAL SPECIFICATIONS ................................................. 4

AC SPECIFICATIONS........................................................... 4

SWITCHING SPECIFICATIONS........................................... 5

EXPLANATION OF TEST LEVELS...................................... 5

Absolute Maximum Ratings........................................................ 6

Definitions .................................................................................7

Theory of Operation ...................................................................9

Clock Input............................................................................. 9

Analog Inputs......................................................................... 9

Voltage Reference....................................................................9

Internal Reference Connection ...............................................10

External Reference Operation ................................................10

Digital Outputs......................................................................11

Timing..................................................................................11

PLL

CML Pin ............................................................................... 11

Overange............................................................................... 11

Pin Configurations ....................................................................13

Timing Diagram........................................................................14

Ordering Guide .....................................................................16

Output ................................................................ 11

LOCK

REVISION HISTORY

Revision PrA: Initial Version

Revision PrB: Updated specifications

Revision PrC: Added application section

Revision PrD: Revised block diagram, added LOCK/ output to timing diagram, added offset and gain matching definitions, updated Theory of

Operation

Revision PrE: Updated timing diagram and PLL description

Revision PrF: Updated Timing Specs, Pin Function Description (Added DNC pins), Added Pin Configuration Diagram and Package Outline

Revision PrG: Added DCR pin info, updated lvdsbias resistor value,

Revision H: Updated reference description, Removed S3, Added scope plot, Added FFT, Updated Tpd, Tcpd, Tmsb, Power, Updated

LVDSBIAS Resistor value, Min Encodeà 20MSPS

Revision I: Updated Power Supply Range, Added thermal impedance number,

Revision J: Added CML description, Modified Timing Diagram, Changed MSB naming to FCO,Removed S2, Modified Tpd,

Rev. PrJ | Page 2 of 16 6/25/2004

Preliminary Technical Data AD9289

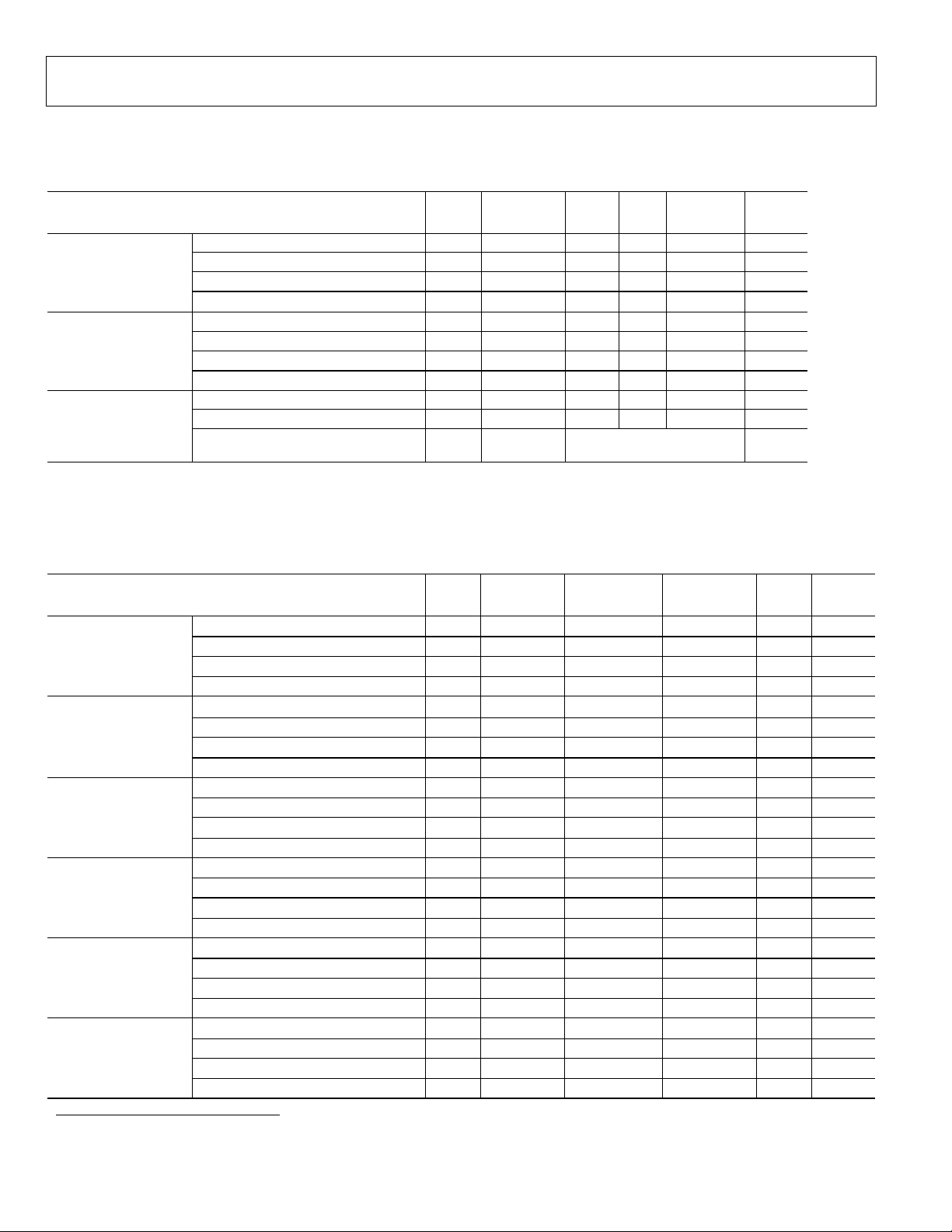

AD9289—SPECIFICATIONS

AVDD = 3.0V, DRVDD = 3.0V; INT REF; DIFFERENTIAL ANALOG AND CLOCK INPUTS

Parameter Temp Test Level Min Typ Max Unit

RESOLUTION 8 Bits

No Missing Codes Full VI Guaranteed

Offset Matching

Gain Matching2

ACCURACY

TEMPERATURE

DRIFT

REFERENCE

ANALOG INPUTS

POWER SUPPLY

CROSSTALK Crosstalk Full V 70 dB

Differential Nonlinearity (DNL)

Full VI LSB

Integral Nonlinearity (INL)

Full VI LSB

Offset Error Full V

Gain Error2 Full V

Reference Full V

Internal Reference Voltage

Output Current Full V uA

Input Current Full V uA

Input Resistance Full V 7

Differential Input Voltage Range 1 –2 Vpp

Common Mode Voltage Full V 1.5 V

Input Resistance Full V tbd

Input Capacitance Full V 5 pF

Analog Bandwidth, Full Power Full V 400 MHz

AVDD Full IV 2.85 3.0 3.15 V

DRVDD Full IV 2.85 3.0 3.15 V

Power Dissipation3 Full VI 558 mW

Power Down Dissipation Full VI <10 mW

Power Supply Rejection Ratio

(PSRR)

IAVDD3 Full VI 150 mA

DRVDD3 Full VI 36 mA

1

25°C

25°C

25°C

25°C

25°C

25°C

Table 1

I

I

I

I

± 25

± 2

± 0.25

± 0.5

± 16

± 150

I 0.5 V

I mV/V

mV

% FS

LSB

LSB

ppm/°C

ppm/°C

ppm/°C

kΩ

kΩ

1

Specifications subject to change without notice

2

Gain error and gain temperature coefficients are based on the ADC only (with a fixed 0.5 V external reference and a 1 V p-p differential analog input).

3

Power dissipation measured with rated encode and a dc analog input (Outputs Static, I

0.5dBFS.

Rev. PrJ | Page 3 of 16 6/25/2004

VDD

= 0.). I

VCC

and I

measured with TBD MHz analog input @

VDD

AD9289 Preliminary Technical Data

DIGITAL SPECIFICATIONS

AVDD = 3.0V, DRVDD = 3.0V

Parameter Temp Test

Min Typ Max Unit

Level

Differential Input Voltage1 Full IV 247 mVpp

CLOCK INPUTS

(CLK+, CLK-)

LOGIC INPUTS

(LVDS Mode)

Input Common Mode Voltage Full IV 1.25 V

Input Resistance Full IV

Input Capacitance

Logic ‘1’ Voltage Full IV 2.0 V

Logic ‘0’ Voltage Full IV 0.8 V

Input Resistance Full IV 30

Input Capacitance Full IV 4 PF

Differential Output Voltage (VOD) Full IV 247 454 mV

Output Offset Voltage (VOS) Full IV 1.125 1.375 V DIGITAL OUTPUTS

Output Coding Full IV Twos Complement or

Table 2: Digital Specifications

25°C

IV pF

Binary

kΩ

kΩ

AC SPECIFICATIONS2

AVDD = 3.0 V, DRVDD = 3.0 V; INTERNAL REF; DIFFERENTIAL ANALOG AND CLOCK INPUT, LVDS OUTPUT

MODE

Parameter Temp Test

Level

SIGNAL TO NOISE

RATIO (SNR) –

Without Harmonics

SIGNAL TO NOISE

RATIO (SINAD) –

With Harmonics

EFFECTIVE

NUMBER OF BITS

(ENOB)

SPURIOUS FREE

DYNAMIC RANGE

(SFDR)

SECOND AND

THIRD HARMONIC

DISTORTION

TOTAL HARMONIC

DISTORTION (THD)

1

Clock Inputs are LVDS compatible .Clock Inputs require external DC bias and cannot be AC coupled.

2

SNR/harmonics based on an analog input voltage of –0.5 dBFS referenced to a 1 Vpp full-scale input range.

fIN= 10.3 MHz

fIN= 19.6 MHz

fIN= 32.5 MHz

fIN= 51 MHz

fIN= 10.3 MHz

fIN= 19.6 MHz

fIN= 32.5 MHz

fIN= 51 MHz

fIN= 10.3 MHz

fIN= 19.6 MHz

fIN= 32.5 MHz

fIN= 51 MHz

fIN= 10.3 MHz

fIN= 19.6 MHz

fIN= 32.5 MHz

fIN= 51 MHz

fIN= 10.3 MHz

fIN= 19.6 MHz

fIN= 32.5 MHz

fIN= 51 MHz

fIN= 10.3 MHz

fIN= 19.6 MHz

fIN= 32.5 MHz

fIN= 51 MHz

25°C

25°C

25°C

25°C

25°C

25°C

25°C

25°C

25°C

25°C

25°C

25°C

25°C

25°C

25°C

25°C

25°C

25°C

25°C

25°C

25°C

25°C

25°C

25°C

V 47.5 dB

V dB

I 47.5 dB

V dB

V 47 dB

V dB

I 47 dB

V dB

V 7.5 Bits

V Bits

I 7.5 Bits

V Bits

V 62 dB

V dB

I 59 dB

V dB

V 62 dBc

V dBc

I 59 dBc

V dBc

V 60 dBc

V dBc

I 58 dBc

V dBc

Min Typ Max Unit

Rev. PrJ | Page 4 of 16 6/25/2004

Preliminary Technical Data AD9289

Parameter Temp Test

Level

f

INTERMOD

DISTORTION (IMD)

= 19 MHz, f

IN1

f

= xx MHz, f

IN1

= 20 MHz

IN2

= xx MHz

IN2

25°C

25°C

Table 3: AC Specifications

V dBc TWO TONE

V dBc

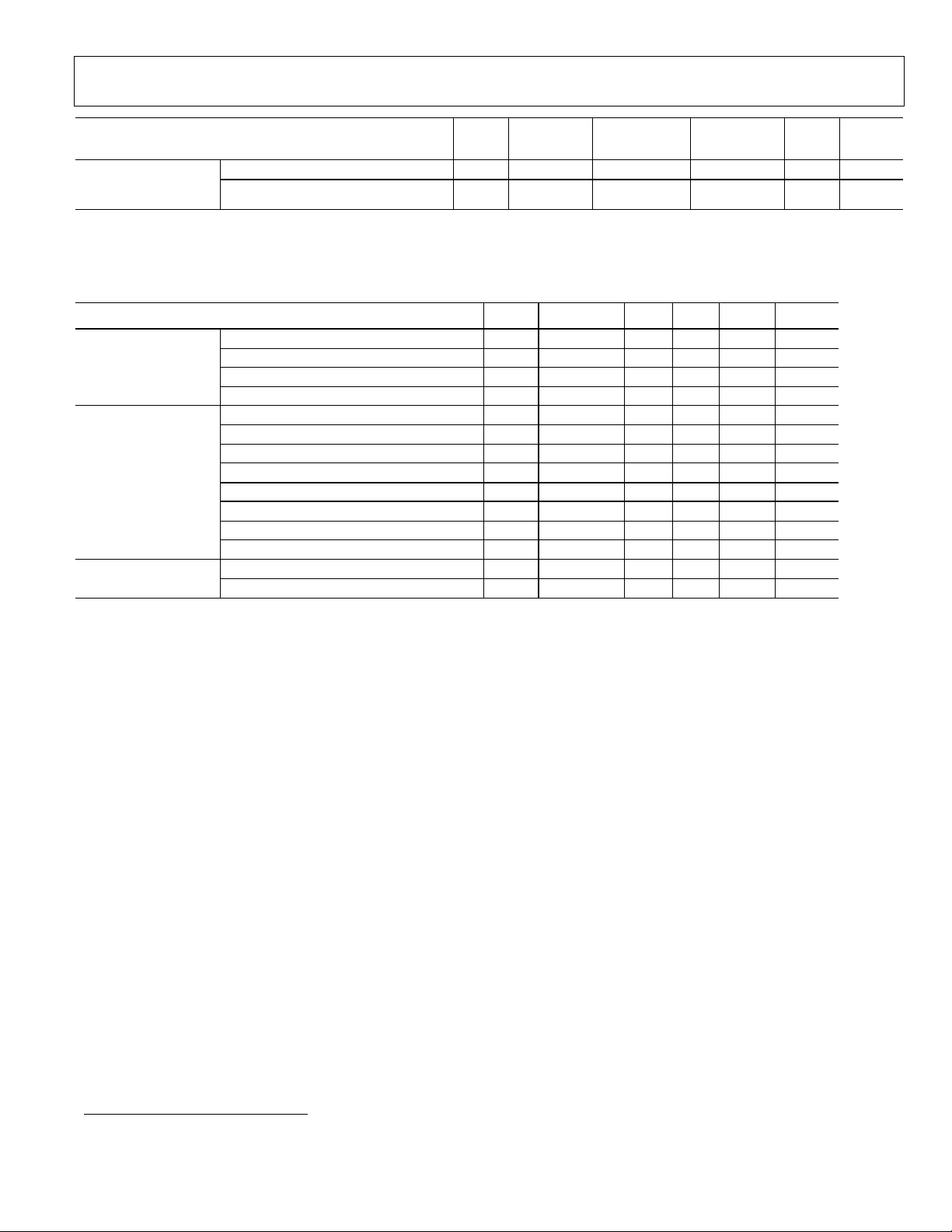

SWITCHING SPECIFICATIONS

AVDD = 3.0 V, DRVDD = 3.0 V; DIFFERENTIAL ENCODE INPUT

Parameter Temp Test Level Min Typ Max Unit

Maximum Clock Rate Full VI 65 MSPS

CLOCK

OUTPUT

PARAMETERS IN

LVDS MODE

APERTURE

Minimum Clock Rate Full VI 20 MSPS

Clock Pulse Width High (tEH) Full IV 6.9 ns

Clock Pulse Width Low (tEL) Full IV 6.9 ns

Valid Time (tV)1 Full VI ns

Propagation Delay (tPD) 1 Full VI 10 ns

MSB Propagation Delay (t

) 1 Full VI 10 ns

MSB

Rise Time (tR) (20% to 80%) Full V 0.5 ns

Fall Time (tF) (20% to 80%) Full V 0.5 ns

DCO Propagation Delay (t

Data to DCO Skew (tPD – t

) Full VI 10 ns

CPD

) Full IV

CPD

Pipeline Latency Full VI 6 cycles

Aperture Delay (tA)

Aperture Uncertainty (Jitter)

Table 4: Switching Specifications

25°C

25°C

Min Typ Max Unit

+/- 100

pS

V ps

V <1 ps rms

EXPLANATION OF TEST LEVELS

TEST LEVEL

I 100% production tested.

II 100% production tested at +25°C and guaranteed by design and characterization at specified temperatures.

III Sample Tested Only

IV Parameter is guaranteed by design and characterization testing.

V Parameter is a typical value only.

VI 100% production tested at +25°C and guaranteed by design and characterization for industrial temperature range.

1

tV and t

not to exceed an ac load of 5 pF or a dc current of ±40 µA. Rise and fall times measured from 20% to 80%.

are measured from the transition points of the CLK input to the 50%/50% levels of the digital outputs swing. The digital output load during test is

PD

Rev. PrJ | Page 5 of 16 6/25/2004

AD9289 Preliminary Technical Data

ABSOLUTE MAXIMUM RATINGS

Parameter Rating

AVDD Voltage

DRVDD Voltage

Analog Input Voltage

Electrical

Environmental

Thermal Impedance1

Stresses above those listed under the Absolute Maximum Ratings may cause permanent damage to the device. This is a stress rating only;

functional operation of the device at these or any other conditions above those indicated in the operational section of this specification is not

implied. Exposure to absolute maximum rating conditions for extended periods may affect device reliability.

Analog Input Current

Digital Input Voltage

Digital Output Current

VREF Input Voltage

Operating Temperature Range (Ambient)

Maximum Junction Temperature

Lead Temperature (Soldering, 10 sec)

Maximum Case Temperature

Storage Temperature Range (Ambient)

Table 5: Absolute Maximum Ratings

-40°C to +85°C

40°C/W

1

θ

for a 4 layer PCB with solid ground plane in still air.

ja

Rev. PrJ | Page 6 of 16 6/25/2004

Preliminary Technical Data AD9289

02.6

−

−

DEFINITIONS

pulse (CLK+) should be left in logic “1” state to achieve rated

ANALOG BANDWIDTH

The analog input frequency at which the spectral power of the

fundamental frequency (as determined by the FFT analysis) is

reduced by 3 dB.

performance; pulse width low is the minimum time the clock pulse

should be left in low state. See timing implications of changing t

in text. At a given clock rate, these specs define an acceptable

clock duty cycle.

clk

APERTURE DELAY

The delay between the 50% point of the rising edge of the

ENCODE command and the instant at which the analog input is

sampled.

APERTURE UNCERTAINTY (JITTER)

The sample-to-sample variation in aperture delay.

CROSSTALK

Coupling onto one channel being driven by a low level (-40 dBFS)

signal when the adjacent interfering channel is driven by a fullscale signal.

DIFFERENTIAL ANALOG INPUT RESISTANCE,

DIFFERENTIAL ANALOG INPUT CAPACITANCE,

AND DIFFERENTIAL ANALOG INPUT IMPEDANCE

The real and complex impedances measured at each analog input

port. The resistance is measured statically and the capacitance and

differential input impedances are measured with a network

analyzer.

DIFFERENTIAL ANALOG INPUT VOLTAGE RANGE

The peak to peak differential voltage that must be applied to the

converter to generate a full scale response. Peak differential

voltage is computed by observing the voltage on a single pin and

subtracting the voltage from the other pin, which is 180 degrees

out of phase. Peak to peak differential is computed by rotating the

inputs phase 180 degrees and taking the peak measurement again.

Then the difference is computed between both peak measurements.

DIFFERENTIAL NONLINEARITY

The deviation of any code width from an ideal 1 LSB step.

FULL SCALE INPUT POWER

Expressed in dBm. Computed using the following equation:

Power

Fullscale

2

V

Fullscale

=

log10

Z

001.

Input

rms

GAIN ERROR

Gain error is the difference between the measured and ideal full

scale input voltage range of the worst ADC.

GAIN MATCHING

Expressed in %FSR. Computed using the following equation:

minmax

=

ngGainMatchi

where FSR

FSR

min

is the most positive gain error of the ADCs and

max

is the most negative gain error of the ADCs.

+

2

FSRFSR

minmax

FSRFSR

%100*

HARMONIC DISTORTION, SECOND

The ratio of the rms signal amplitude to the rms value of the

second harmonic component, reported in dBc.

HARMONIC DISTORTION, THIRD

The ratio of the rms signal amplitude to the rms value of the third

harmonic component, reported in dBc.

EFFECTIVE NUMBER OF BITS

The effective number of bits (ENOB) is calculated from the

measured SNR based on the equation:

ENOB

=

MEASURED

76.1 dBSNR

INTEGRAL NONLINEARITY

The deviation of the transfer function from a reference line

measured in fractions of 1 LSB using a “best straight line”

determined by a least square curve fit.

MINIMUM CONVERSION RATE

The encode rate at which the SNR of the lowest analog signal

frequency drops by no more than 3 dB below the guaranteed limit.

CLOCK PULSE WIDTH/DUTY CYCLE

Pulse width high is the minimum amount of time that the Clock

Rev. PrJ | Page 7 of 16 6/25/2004

AD9289 Preliminary Technical Data

−

=

MAXIMUM CONVERSION RATE

The encode rate at which parametric testing is performed.

OFFSET ERROR

Offset error is the difference between the measured and ideal

voltage at the analog input that produces the midscale code at the

outputs. Offset error is given for the worst ADC.

OFFSET MATCHING

Expressed in mV. Computed using the following equation:

minmax OFFOFFhingOffsetMatc

where OFF

most negative offset error.

is the most positive offset error and OFF

max

min

is the

OUTPUT PROPAGATION DELAY

The delay between a differential crossing of CLK+ and CLK- and

the time when all output data bits are within valid logic levels.

NOISE (FOR ANY RANGE WITHIN THE ADC)

−−

noise

=

ZV

10*001.*

10

SignalSNRFS

dBFSdBcdBm

SIGNAL-TO-NOISE RATIO (WITHOUT

HARMONICS)

The ratio of the rms signal amplitude (set at 1 dB below full scale)

to the rms value of the sum of all other spectral components,

excluding the first five harmonics and dc.

SPURIOUS-FREE DYNAMIC RANGE (SFDR)

The ratio of the rms signal amplitude to the rms value of the peak

spurious spectral component. The peak spurious component may

or may not be a harmonic. It also may be reported in dBc (i.e.,

degrades as signal level is lowered) or dBFS (i.e., always related

back to converter full scale).

TWO-TONE INTERMODULATION DISTORTION

REJECTION

The ratio of the rms value of either input tone to the rms value of

the worst third order intermodulation product; reported in dBc.

TWO-TONE SFDR

The ratio of the rms value of either input tone to the rms value of

the peak spurious component. The peak spurious component may

or may not be an IMD product. It also may be reported in dBc (i.e.,

degrades as signal level is lowered) or in dBFS (i.e., always relates

back to converter full scale).

WORST OTHER SPUR

Where Z is the input impedance, FS is the full scale of the device

for the frequency in question, SNR is the value for the particular

input level and Signal is the signal level within the ADC reported

in dB below full scale. This value includes both thermal and

quantization noise.

POWER SUPPLY REJECTION RATIO

The ratio of a change in input offset voltage to a change in power

supply voltage.

SIGNAL-TO-NOISE-AND-DISTORTION (SINAD)

The ratio of the rms signal amplitude (set 1 dB below full scale) to

the rms value of the sum of all other spectral components,

including harmonics but excluding dc.

The ratio of the rms signal amplitude to the rms value of the worst

spurious component (excluding the second and third harmonic)

reported in dBc.

TRANSIENT RESPONSE TIME

Transient response time is defined as the time it takes for the ADC

to reacquire the analog input after a transient from 10% above

negative full scale to 10% below positive full scale.

OUT-OF-RANGE RECOVERY TIME

Out of range recovery time is the time it takes for the ADC to

reacquire the analog input after a transient from 10% above

positive full scale to 10% above negative full scale, or from 10%

below negative full scale to 10% below positive full scale.

Rev. PrJ | Page 8 of 16 6/25/2004

Preliminary Technical Data AD9289

THEORY OF OPERATION

Each A/D converter in the AD9289 architecture consists of a frontend sample and hold amplifier (SHA) followed by a pipelined

switched capacitor A/D converter. The pipelined A/D converter is

divided into two sections, consisting of six 1.5-bit stages and a

final 3-bit flash. Each stage provides sufficient overlap to correct

for flash errors in the preceding stages. The quantized outputs from

each stage are combined into a final 8-bit result in the digital

correction logic. The pipelined architecture permits the first stage

to operate on a new input sample while the remaining stages

operate on preceding samples. Sampling occurs on the rising edge

of the clock.

output driver supplies to avoid modulating the clock signal with

digital noise. Low jitter, crystal-controlled oscillators make the

best clock sources. If the clock is generated from another type of

source (by gating, dividing, or other methods), it should be retimed

by the original clock at the last step.

Analog Inputs

For best dynamic performance, the source impedances driving

VIN+ and VIN– should be matched such that common-mode

settling errors are symmetrical. These errors will be reduced by the

common-mode rejection of the A/D.

Each stage of the pipeline, excluding the last, consists of a low

resolution flash A/D connected to a switched capacitor DAC and

interstage residue amplifier (MDAC). The residue amplifier

magnifies the difference between the reconstructed DAC output

and the flash input for the next stage in the pipeline. One bit of

redundancy is used in each one of the stages to facilitate digital

correction of flash errors. The last stage simply consists of a flash

A/D.

The input stage contains a differential SHA that can be configured

as ac- or dc-coupled in differential or single-ended modes. The

output-staging block aligns the data, carries out the error correction

and passes the data to the output buffers.During power-down the

output buffers go into a high-impedance state.

Clock Input

Typical high-speed A/D converters use both clock edges to

generate a variety of internal timing signals, and as a result may be

sensitive to clock duty cycle. Commonly a +/-5% tolerance is

required on the clock duty cycle to maintain dynamic performance

characteristics. The AD9289 contains a clock duty cycle stabilizer

that retimes the non-sampling edge, providing an internal clock

signal with a nominal 50% duty cycle. This allows a wide range of

clock input duty cycles without affecting the performance of the

AD9289. As shown in TPC XX, noise and distortion performance

are nearly flat over at least a +/-15% range of duty cycle. The

stabilizer circuit can be bypassed by grounding input pin DCR. (

There is an internal 22K ohm pull-up resistor)

The duty cycle stabilizer uses a delay-locked loop (DLL) to create

the non-sampling edge. As a result, any changes to the sampling

frequency will require approximately 100 clock cycles to allow the

DLL to acquire and lock to the new rate. High-speed, highresolution A/Ds are sensitive to the quality of the clock input. The

degradation in SNR at a given full-scale input frequency (fA) due

only to aperture jitter (tA) can be calculated with the following

equation:

SNR degradation = 20 × log10 [1/2 × pi × fA ×

tA]

In the equation, the rms aperture jitter, tA, represents the root sum

square of all jitter sources, which include the clock input, analog

input signal, and A/D aperture jitter specification. Undersampling

applications are particularly sensitive to jitter.

The clock input should be treated as an analog signal in cases

where aperture jitter may affect the dynamic range of the AD9289.

Power supplies for clock drivers should be separated from the A/D

Voltage Reference

A stable and accurate 0.5 V voltage reference is built into the

AD9289. The input range can be adjusted by varying the reference

voltage applied to the AD9289, using either the internal reference

or an externally applied reference voltage. The input span of the

A/D tracks reference voltage changes linearly. The Shared

Reference mode allows the user to connect the references from the

quad ADC together externally for superior gain and offset

matching performance. If the ADCs are to function independently,

the reference decoupling can be treated independently and can

provide superior isolation between the four channels. To enable

Shared Reference mode, the SHARED_REF pin must be tied high

and external differential references must be externally shorted.

(REFT_A must be externally shorted to REFT_B and REFB_A

must be shorted to REFB_B.) Note that channels A and B are

referenced to REFT_A and REFB_A and channels C and D are

referenced to REFT_B and REFB_B.

Figure 3. Shared Reference Mode

Rev. PrJ | Page 9 of 16 6/25/2004

AD9289 Preliminary Technical Data

Internal Reference Connection

A comparator within the AD9289 detects the potential at the

SENSE pin and configures the reference into four possible states,

which are summarized in Table I. If SENSE is grounded, the

reference amplifier switch is connected to the internal resistor

divider (see Figure 2), setting VREF to 1 V. Connecting the

SENSE pin to VREF switches the reference amplifier output to the

SENSE pin, completing the loop and providing a 0.5 V reference

output. If a resistor divider is connected as shown in Figure 3, the

switch will

again be set to the SENSE pin. This will put the reference

amplifier in a non-inverting mode with the VREF output defined as

follows:

VREF = .5 * (1 +R2/R1)

In all reference configurations, REFT and REFB drive the ADC

core and establish its input span. The input range of the ADC

always equals twice the voltage at the reference pin for either an

internal or an external reference.

Figure 5.Programmable Reference Connection

External Reference Operation

The use of an external reference may be necessary to enhance the

gain accuracy of the ADC or improve thermal drift characteristics.

When multiple ADCs track one another, a single reference

(internal or external) may be necessary to reduce gain matching

errors to an acceptable level. A high precision external reference

may also be selected to provide lower gain and offset temperature

drift. External reference mode is chosen by tying SENSE pin to

AVDD and driving VREF with external reference.

Figure 4.Internal Reference Connection

Rev. PrJ | Page 10 of 16 6/25/2004

Preliminary Technical Data AD9289

X

Selected Mode SENSE Voltage Internal Switch Position Resulting VREF (V) Resulting Differential

External Reference AVDD N/A N/A 2 × External Reference

Internal VREF SENSE 0.5 1.0

Programmable 0.2 V to VREF SENSE 0.5 × (1 + R2/R1) 2 × VREF

Internal AGND to 0.2 V Internal Divider 1.0 2.0

Table 1 Reference Settings

Digital Outputs

The AD9289’s differential outputs conform to the ANSI-644 LVDS

standard. To set the LVDS bias current, place a resistor (RSET is

nominally equal to 3.8 kΩ) to ground at the LVDSBIAS pin. The

RSET resistor current (~ 1.2/RSET) is ratioed on-chip setting the

output current at each output equal to a nominal 3.5 mA. A 100 Ω

differential termination resistor placed at the LVDS receiver inputs

results in a nominal 350 mV swing at the receiver.

The AD9289’s LVDS outputs facilitate interfacing with LVDS

receivers in custom ASICs and FPGAs that have LVDS capability

for superior switching performance in noisy environments. Single

point-to-point net topologies are recommended with a 100 Ω

termination resistor as close to the receiver as possible. It is

recommended to keep the trace length no longer than 3 inches and

to keep differential output trace lengths as equal as possible.

The format of the output data can be selected as offset binary or

twos complement. Pin S1 is used to set the format.

S1 Mode Data Format

AVDD Twos Complement

AGND Offset Binary

Table 6: S1 Configuration

Timing

Data from each A/D is serialized and provided on a separate

channel. The data rate for each serial stream is equal to 8-bits

times the sample clock rate, with a maximum of 520 MHz (8-bits x

65 MSPS = 520 MHz). The lowest typical conversion rate is 20

MSPS.

Two output clocks are provided to assist in capturing data from the

AD9289. The data clock out (DCO) is used to clock the output

data and is equal to four times the sampling clock (CLK) rate.

Data is clocked out of the AD9289 on the rising and falling edges

Span (V p-p)

of DCO. The FCO clock is used to signal the start of a new output

byte and is equal to the sampling clock rate. See the Timing

Diagram for more information.

PLL

LOCK

The AD9289 contains an internal PLL that is used to generate the

data clock out (DCO). When the PLL is locked, the LOCK/ signal

will be low, indicating valid data on the outputs.

If for any reason the PLL loses lock, the LOCK/ signal will go

high as soon as the lock circuitry detects an unlocked condition.

While the PLL is unlocked, the data outputs and DCO will remain

in the last known state. If the LOCK/ signal goes high in the

middle of a byte, no data or DCO signals will be available for the

rest of the byte. It will take at least 1 µs to regain lock if lock is

lost.

Once the PLL regains lock, the DCO will start. The first valid data

byte will be indicated by the FCO signal. See the Timing Diagram

for more information.

Output

CML Pin

A common mode level output is available at F3. This output selfbiases to AVDD/2. This is a relatively high impedance output (two

5K resistors in series between AVDD and ground) with an output

impedance of 2.5K which may need to be considered when using

as a reference.

Overange

The AD9289 has an Overange output available that indicates when

the ADC is driven out of range. OR+ is driven high in overrange

condition, with the digital outputs are clamped to all zeroes or all

ones.Pin Function Descriptions

Rev. PrJ | Page 11 of 16 6/25/2004

AD9289 Preliminary Technical Data

Pin No. Name Description Pin No. Name Description

C8 CLK+ Input Clock – True

D8 CLK- Input Clock – Complement G8 VIN+D ADC D Analog Input – True

F2, E4,

F7

G2, E5,

D7,E7,G7

C3, C6 DRVDD 3 V Digital Output Supply C4 DCO+ Data Clock Output – True

D3, D6 DRGND Digital Ground C1 FCO+ Frame Clock Output (MSB Indicator)

H5 VREF Voltage Reference Input/Output C2 FCO- Frame Clock Output (MSB Indicator)

H4 SENSE Reference Mode Selection B1 D1+A ADC A True Digital Output

F4 REFT_A Differential Reference (Positive) A1 D1-A ADC A Complement Digital Output

G4 REFB_A Differential Reference (Negative) B3 D1+B ADC B True Digital Output

F5 REFT_B Differential Reference (Positive) A3 D1-B ADC B Complement Digital Output

G5 REFB_B Differential Reference (Negative) B5 D1+C ADC C True Digital Output

E8 PDWN Power Down Selection (set pin to

C7 S1* Data Format B7 D1+D ADC D True Digital Output

G1 VIN+A ADC A Analog Input – True D1 OR+ Over Range True

F1 VIN-A ADC A Analog Input – Complement D2 OR- Over Range Complement

H2 VIN+B ADC B Analog Input – True H1 LVDSBIAS LVDS Bias Resistor Pin (3.8K to gnd)

H3 VIN-B ADC B Analog Input – Complement G3 SHARED_REF Shared Reference Control Bit

H7 VIN+C ADC C Analog Input – True F3 CML Common Mode Level Output ( = AVDD/2)

H6 VIN-C ADC C Analog Input – Complement D4 LOCK/ PLL Lock Output

A2,A4,A6,

A8,B2,B4,

B6,B8,D5,

E1,E2,E3,

F6,G6,H8

• S1 has an internal on-chip pulldown resistor

AVDD 3 V Analog Supply F8 VIN-D ADC D Analog Input – Complement

AGND Analog Ground C5 DCO- Data Clock Output – Complement

True Output

Complement Output

A5 D1-C ADC C Complement Digital Output

Logic Hi enables duty cycle control circuit

Logic Lo disables duty cycle control circuit

DNC

(Do Not

Connect)

AVDD for power down)

E6 DCR Duty Cycle Control Enable Input

Table 7: Pin Function Descriptions

Rev. PrJ | Page 12 of 16 6/25/2004

Preliminary Technical Data AD9289

PIN CONFIGURATIONS

1 2 3 4 5 6 7 8

A

B

C

D

E

F

G

H

Figure 6: BGA Top View

Rev. PrJ | Page 13 of 16 6/25/2004

AD9289 Preliminary Technical Data

TIMING DIAGRAM

Figure 7: Timing Diagram

Measured Timing Encode = 65MHz (DCO = 260MHz)

Rev. PrJ | Page 14 of 16 6/25/2004

Preliminary Technical Data AD9289

Dim Min. Nom. Max

Dim Min. Nom. Max A 1.35 1.55 1.70

b 0.45 0.50 0.55 A1 0.25 0.34 e

A2 1.10 1.21 1.31

aaa

D 7.90 8.00 8.10

bbb

D1 5.60 BSC

ddd

E 7.90 8.00 8.10

eee

E1 5.60 BSC

fff

OUTLINE DIMENSIONS

Figure 8: BGA Package Outline

0.80 BSC

0.10

0.10

0.12

0.15

0.08

Rev. PrJ | Page 15 of 16 6/25/2004

AD9289 Preliminary Technical Data

© 2004 Analog Devices, Inc. All rights reserved. Trademarks and

ESD CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily accumulate on

the human body and test equipment and can discharge without detection. Although this product features

proprietary ESD protection circuitry, permanent damage may occur on devices subjected to high energy

electrostatic discharges. Therefore, proper ESD precautions are recommended to avoid performance

degradation or loss of functionality.

Ordering Guide

Model Temperature Range Description

AD9289BBC-65

AD9289BBC-65EB 25°C (Ambient) Evaluation Board

-40°C to +85°C (Ambient)

64 CSP_BGA

Table 8: Ordering Guide

registered trademarks are the property of their respective

companies.

Printed in the U.S.A. PR03682-0-6/04(PrJ)

Rev. PrJ | Page 16 of 16 6/25/2004

Loading...

Loading...