Page 1

Octal LNA/VGA/AAF/ADC

Preliminary Technical Data

FEATURES

8 channels of LNA, VGA, AAF, and ADC

Low noise preamplifier (LNA)

Input-referred noise = 1.2 nV/√Hz @ 7.5 MHz typical

SPI-programmable gain = 14 dB/15.6 dB/18 dB

Single-ended input; V

333 mV p-p/250 mV p-p

Dual mode, active input impedance match

Bandwidth (BW) > 70 MHz

Full-scale (FS) output = 2 V p-p diff

Variable gain amplifier (VGA)

Gain range = −6 dB to +24 dB

Linear-in-dB gain control

Antialiasing filter (AAF)

rd

-order Butterworth cutoff

3

Programmable from 8 MHz to 18 MHz

Analog-to-digital converter (ADC)

12 bits at 10 MSPS to 50 MSPS

SNR = 70 dB

SFDR = 80 dB

Serial LVDS (ANSI-644, IEEE 1596.3 reduced range link)

Data and frame clock outputs

Includes crosspoint switch to support

continuous wave (CW) Doppler

Low power, 150 mW/channel at 12 bits/40 MSPS (TGC)

60 mW/channel in CW Doppler

Single 1.8 V supply (3.3 V supply for CW Doppler output bias)

Flexible power-down modes

Overload recovery in <10 ns

Fast recovery from low power standby mode, <2 μs

100-pin TQFP

APPLICATIONS

Medical imaging/ultrasound

Automotive radar

GENERAL DESCRIPTION

The AD9271 is designed for low cost, low power, small size, and

ease of use. It contains eight channels of a variable gain amplifier

(VGA) with low noise preamplifier (LNA); an antialiasing filter

(AAF); and a 12-bit, 10 MSPS to 50 MSPS analog-to-digital

converter (ADC).

maximum = 400 mV p-p/

IN

and Crosspoint Switch

AD9271

The LNA has a single-ended-to-differential gain that is selectable

through the SPI. The LNA input noise is typically 1.2 nV/√Hz,

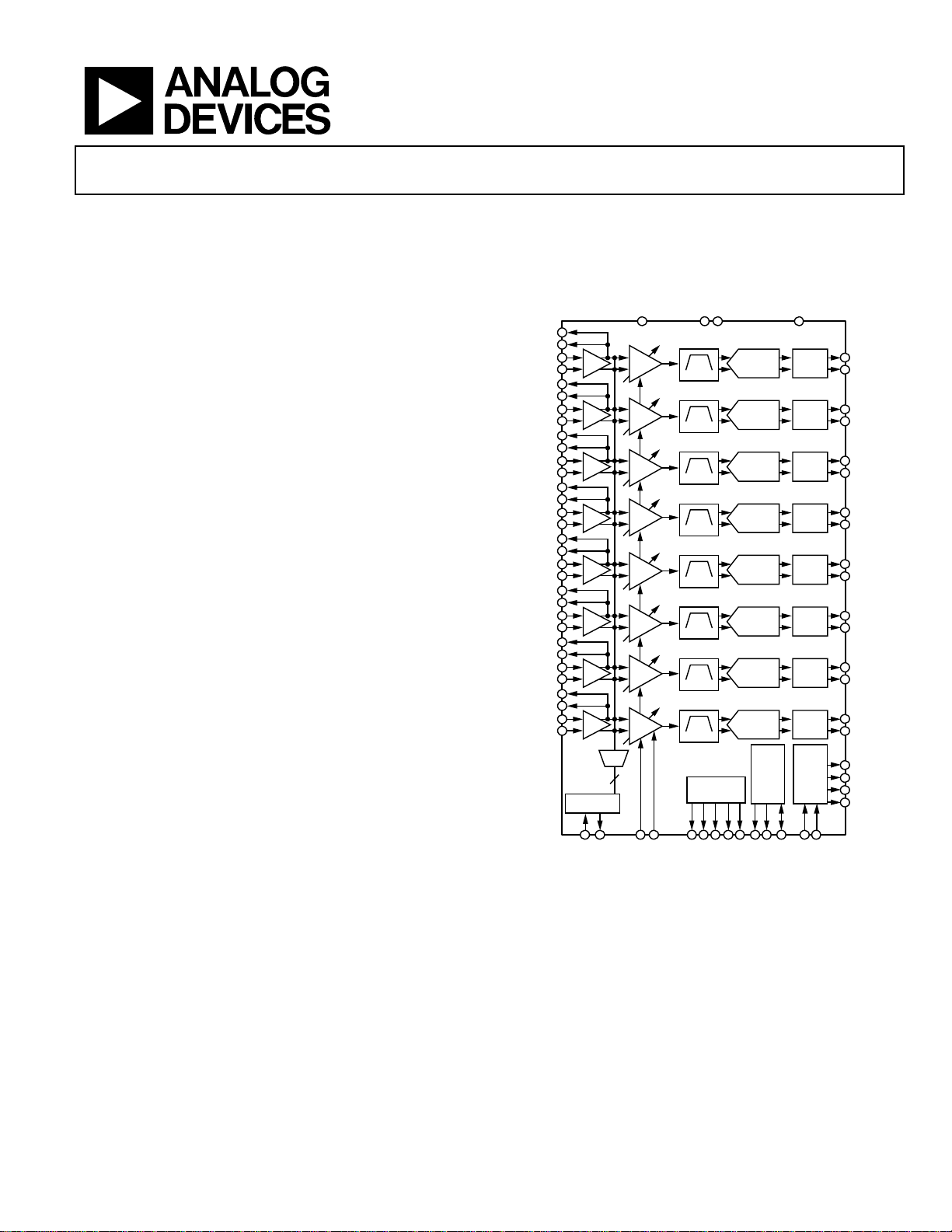

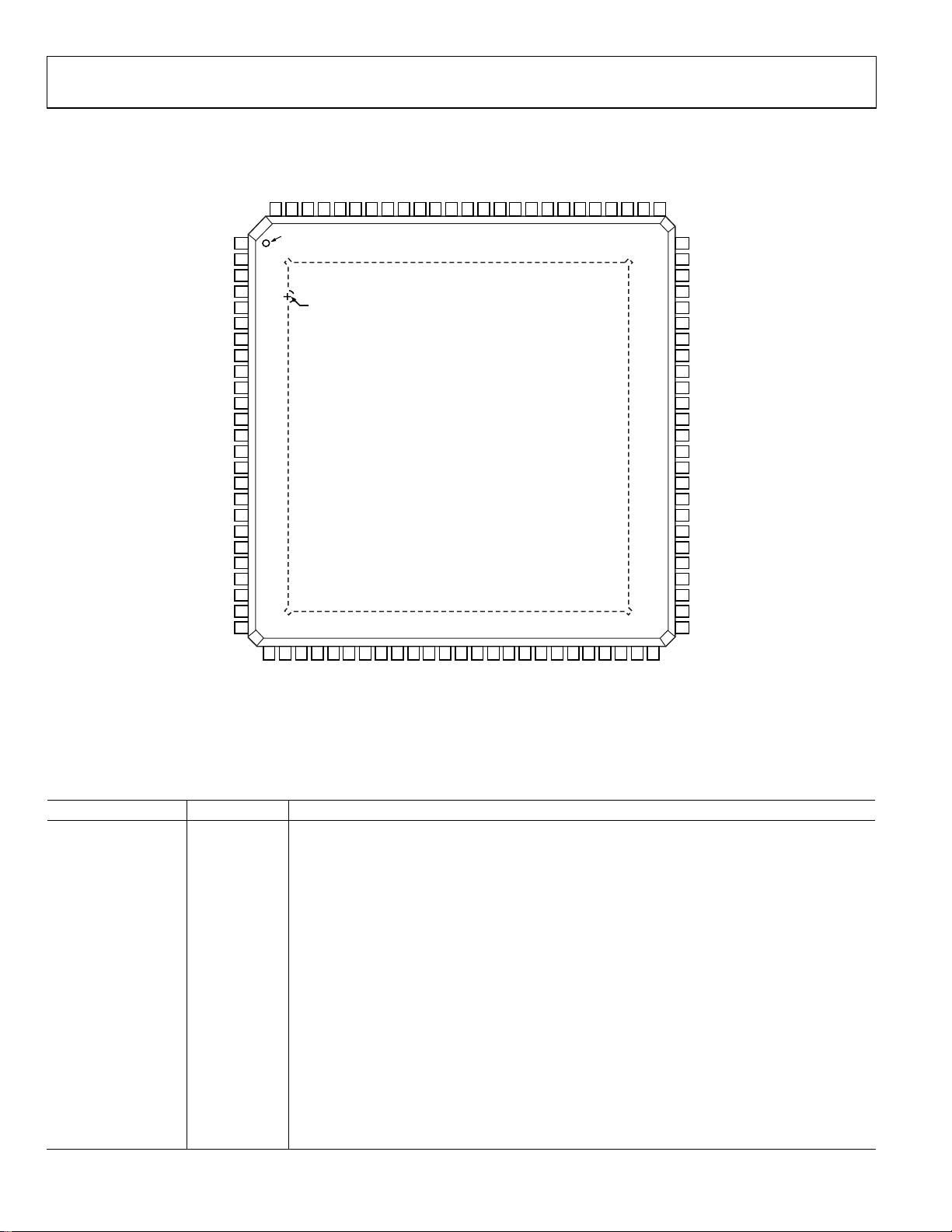

FUNCTIONAL BLOCK DIAGRAM

LOSW-A

LO-A

LI-A

LG-A

LOSW-B

LO-B

LI-B

LG-B

LOSW-C

LO-C

LI-C

LG-C

LOSW-D

LO-D

LI-D

LG-D

LOSW-E

LO-E

LI-E

LG-E

LOSW-F

LO-F

LI-F

LG-F

LOSW-G

LO-G

LI-G

LG-G

LO-H

LOSW-H

LI-H

LG-H

LNA

LNA

LNA

LNA

LNA

LNA

LNA

LNA

SWITCH

ARRAY

CWVDD

AVDD

VGA

VGA

VGA

VGA

VGA

VGA

VGA

VGA

g

m

6

GAIN–

GAIN+

CWD+/–[5:0]

Figure 1.Block Diagram

STDBY

PWDN

AAF

AAF

AAF

AAF

AAF

AAF

AAF

AAF

REFERENCE

VREF

REFB

SENSE

AD9271

12-BIT

PIPELINE

ADC

12-BIT

PIPELINE

ADC

12-BIT

PIPELINE

ADC

12-BIT

PIPELINE

ADC

12-BIT

PIPELINE

ADC

12-BIT

PIPELINE

ADC

12-BIT

PIPELINE

ADC

12-BIT

PIPELINE

ADC

REFT

RBIAS

DRVDD

CLK +

DOUT + A

DOUT – A

DOUT + B

DOUT – B

DOUT + C

DOUT – C

DOUT + D

DOUT – D

DOUT + E

DOUT – E

DOUT + F

DOUT – F

DOUT + G

DOUT – G

DOUT + H

DOUT – H

FCO+

FCO–

RATE

DCO+

MULTIPLIER

DCO–

CLK –

06304-001

SERIAL

LVDS

SERIAL

LVDS

SERIAL

LVDS

SERIAL

LVDS

SERIAL

LVDS

SERIAL

LVDS

SERIAL

LVDS

SERIAL

LVDS

DATA

PORT

SERIAL

INTERFACE

CSB

SDIO

SCLK

Each channel features a variable gain range of 30 dB, a fully

differential signal path, an active input preamplifier termination, a

maximum gain of up to 40 dB, and an ADC with a conversion

rate of up to 50 MSPS. The channel is optimized for dynamic

performance and low power in applications where a small

package size is critical.

Rev. PrA

Information furnished by Analog Devices is believed to be accurate and reliable. However, no

responsibility is assumed by Anal og Devices for its use, nor for any infringements of patents or ot her

rights of third parties that may result from its use. Specifications subject to change without notice. No

license is granted by implication or otherwise under any patent or patent rights of Analog Devices.

Trademarks and registered trademarks are the property of their respective owners.

and the combined input-referred noise of the entire channel

is 1.4 nV/√Hz at maximum gain. Assuming a 15 MHz noise

bandwidth (NBW) and a 15.6 dB LNA gain, the input SNR is

roughly 86 dB. In CW Doppler mode, the LNA output drives a

transconductance amp that is switched through an 8 × 6,

differential crosspoint switch. The switch is programmable

through the SPI.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700 www.analog.com

Fax: 781.461.3113 ©2007 Analog Devices, Inc. All rights reserved.

Page 2

AD9271 Preliminary Technical Data

TABLE OF CONTENTS

Features.............................................................................................. 1

Input Overdrive.......................................................................... 23

Applications....................................................................................... 1

General Description......................................................................... 1

Functional Block Diagram ..............................................................1

Revision History ...............................................................................2

Product Highlights........................................................................... 3

Specifications..................................................................................... 4

AC Specifications.......................................................................... 4

Digital Specifications ................................................................... 8

Switching Specifications.............................................................. 9

ADC Timing Diagrams .................................................................10

Absolute Maximum Ratings.......................................................... 11

Thermal Impedance................................................................... 11

ESD Caution................................................................................ 11

Pin Configuration and Function Descriptions........................... 12

Equivalent Circuits......................................................................... 15

CW Doppler Operation............................................................. 23

TGC Operation........................................................................... 25

A/D Converter............................................................................ 28

Clock Input Considerations...................................................... 28

Serial Port Interface (SPI).............................................................. 35

Hardware Interface..................................................................... 35

Memory Map .................................................................................. 37

Reading the Memory Map Table.............................................. 37

Reserved Locations .................................................................... 37

Default Values............................................................................. 37

Logic Levels................................................................................. 37

Evaluation Board............................................................................ 42

Power Supplies............................................................................ 42

Input Signals................................................................................ 42

Output Signals ............................................................................42

Typical Performance Characteristics........................................... 17

Theory of Operation ......................................................................20

Ultrasound................................................................................... 20

Channel Overview...................................................................... 21

REVISION HISTORY

x/07—Revision 0: Initial Version

Default Operation and Jumper Selection Settings................. 43

Outline Dimensions....................................................................... 56

Ordering Guide .......................................................................... 56

Rev. PrA | Page 2 of 58

Page 3

Preliminary Technical Data AD9271

The AD9271 requires a LVPECL-/CMOS-/LVDS-compatible

sample rate clock for full performance operation. No external

reference or driver components are required for many

applications.

The ADC automatically multiplies the sample rate clock for

the appropriate LVDS serial data rate. A data clock (DCO) for

capturing data on the output and a frame clock (FCO) trigger

for signaling a new output byte are provided.

Powering down individual channel is supported to increase battery

life for portable applications. There is also a standby mode option

that allows quick power-up for power cycling. In CW Doppler

operation, the VGA, AAF, and ADC are powered down. The

power of the TGC path scales with selectable speed grades.

The ADC contains several features designed to maximize flexibility

and minimize system cost, such as a programmable clock, data

alignment, and programmable digital test pattern generation. The

digital test patterns include built-in fixed patterns, built-in

pseudorandom pattern, and custom user-defined test patterns

entered via the serial port interface.

Fabricated in an advanced CMOS process, the AD9271 is

available in a 14 mm × 14 mm, Pb-free, 100-lead TQFP. It is

specified over the industrial temperature range of –40°C to +85°C.

PRODUCT HIGHLIGHTS

1. Small Footprint. Eight channels are contained in a small,

space-saving package. Full TGC path, ADC, and crosspoint

switch contained within a 100-lead, 16 mm × 16 mm, TQFP.

2. Low power of 150 mW/channel at 40 MSPS.

3. Integrated Crosspoint Switch. This switch allows numerous

multichannel configuration options to enable the CW

Doppler mode.

4. Ease of Use. A data clock output (DCO) operates up to

300 MHz and supports double data rate operation (DDR).

5. User Flexibility. Serial port interface (SPI) control offers a wide

range of flexible features to meet specific system requirements.

6. Integrated Third-Order Antialiasing Filter. This filter is

placed between TGC path and ADC and is programmable

from 8 MHz to 18 MHz.

Rev. PrA | Page 3 of 58

Page 4

AD9271 Preliminary Technical Data

SPECIFICATIONS

AC SPECIFICATIONS

AVDD = 1.8 V, DRVDD = 1.8 V, CWVDD = 3.3 V, 1.0 V internal ADC reference, AIN = 5 MHz, RS = 50 Ω, LNA gain = 15.6 dB (6),

unless otherwise noted.

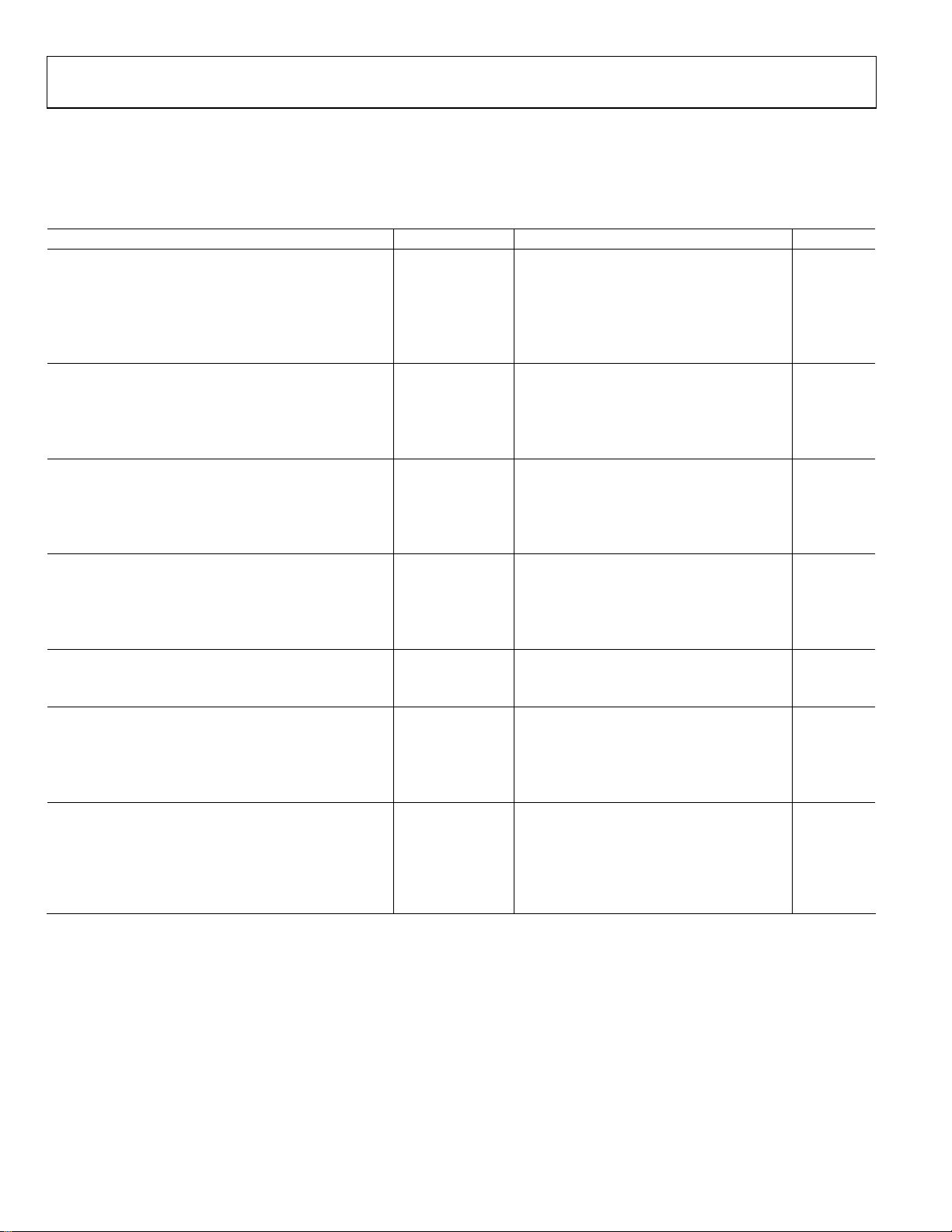

Table 1.

AD9271-25 AD9271-40 AD9271-50

Parameter1 Conditions Min Typ Max Min Typ Max Min Typ Max Unit

LNA

CHARACTERISTICS

Gain = 5/6/8 Single-ended

Single-ended

Input Voltage

Range, Gain =

5/6/8

Input Common

Mode

Input Resistance RFB = 200 Ω, 50 50 50 Ω

RFB = 400 Ω, 100 100 100 Ω

RFB = ∞ 15 15 15 kΩ

Input Capacitance LI-x 15 15 15 pF

−3 dB Bandwidth 40 60 70 MHz

Input Noise

Voltage,

Gain = 5/6/8

1 dB Input

Compression

Point

Gain = 5/6/8

Active

Termination

Match

Unterminated RFB = ∞ 4.9 4.4 4.2 dB

FULL-CHANNEL (TGC)

CHARACTERISTICS

AAF High-Pass

Cutoff

AAF Low-Pass

Cutoff

Group Delay

Variation

Bandwidth

Tolerance

Input-Referred

Noise Voltage,

LNA Gain =

5/6/8

Correlated Noise No signal −30 −30 −30 dB

Output Offset AAF high-pass

Signal-to-Noise

Ratio (SNR)

FIN = 5 MHz at −7

dBFS

input to

differential

output

input to

single-ended

output

LNA output

limited to

2 V p-p

differential

output

1.4 1.4 1.4 V

R

= 0 Ω, RFB = ∞ 1.4/1.4/1.3 1.3/1.2/1.1 1.3/1.2/1.1 nV/√Hz

S

V

= 0 V 782.6/649.1/508.8 782.6/649.1/508.8 782.6/649.1/508.8 mV p-p

GAIN

Ω, RFB = 200 Ω 6.7 6.7 6.7 dB

−3 dB DC/350/700 DC/350/700 DC/350/700 kHz

−3 dB,

programmable

f = 1 MHz to

10 MHz, gain =

0 V to 1 V

±15 ±15 ±15 %

RFB = ∞ 1.7/1.6/1.5 1.6/1.4/1.3 1.6/1.4/1.2 nV/√Hz

= 700 kHz

GAIN pin = 0 V 65 65 65 dBFS

14/15.6/18 14/15.6/18 14/15.6/18 dB

8/9.6/12 8/9.6/12 8/9.6/12 dB

400/333/250 400/333/250 400/333/250 mV p-p

1/3 × f

(8 to 18)

±1 ±1 ±1 ns

TBD TBD TBD LSB

SAMPLE

1/3 × f

(8 to 18)

SAMPLE

1/3 × f

(8 to 18)

SAMPLE

MHz

2

SE

Rev. PrA | Page 4 of 58

Page 5

Preliminary Technical Data AD9271

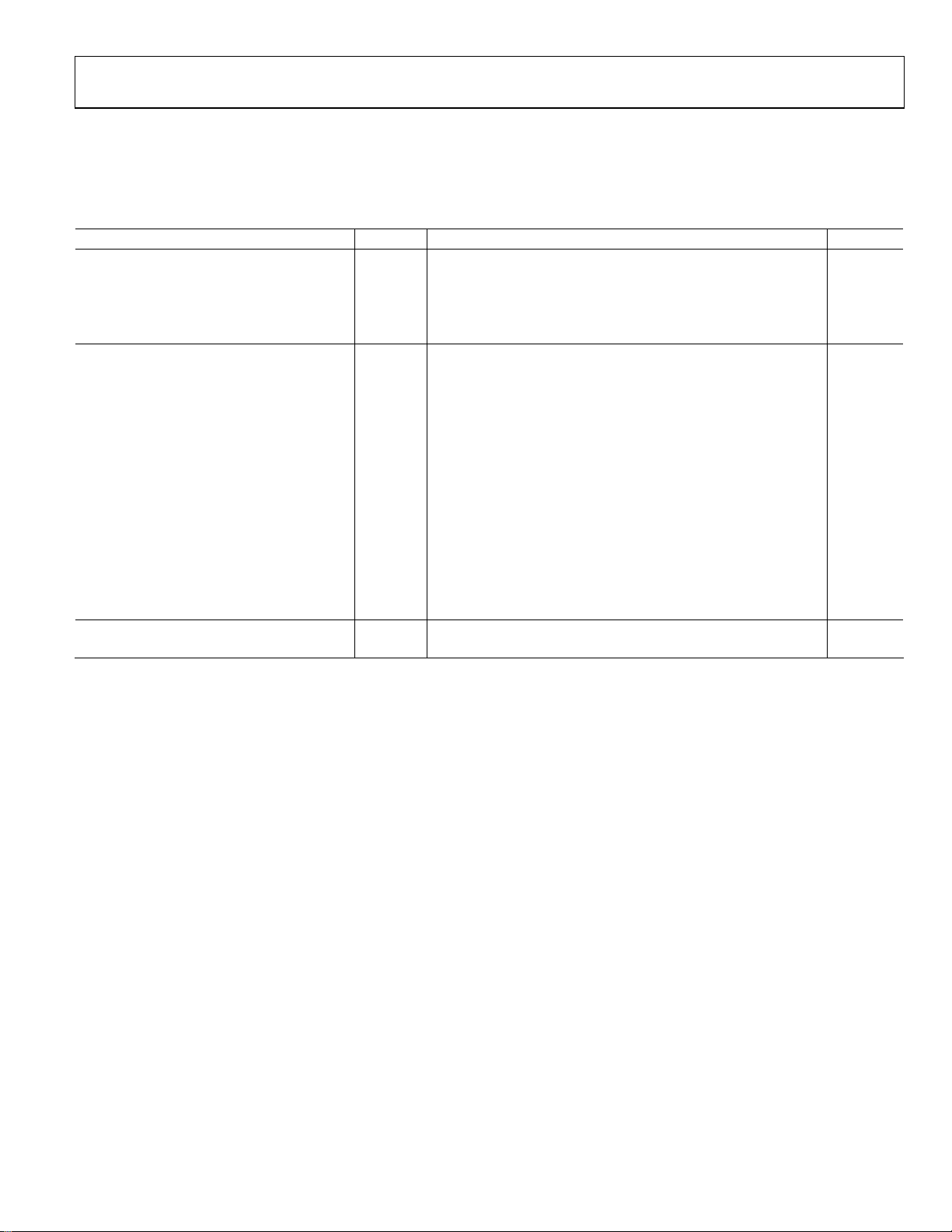

AD9271-25 AD9271-40 AD9271-50

Parameter1 Conditions Min Typ Max Min Typ Max Min Typ Max Unit

FIN = 5 MHz at −1

dBFS

Harmonic

Distortion

Second Harmonic,

= 5 MHz at

F

IN

−7 dBFS

Second Harmonic,

= 5 MHz at

F

IN

−1 dBFS

Third Harmonic,

F

= 5 MHz at

IN

−7 dBFS

Third Harmonic,

F

= 5 MHz at

IN

−1 dBFS

Two-Tone IMD3

(2 × F1 − F2)

Distortion

F

= 5.0 MHz at

IN1

−1 dBFS

= 5.1 MHz at

F

IN2

−26 dBFS

Channel-to-

Channel

Crosstalk

Channel-to-

Channel

Crosstalk

(Overrange

Condition)

Overload Recovery LNA or VGA 10 10 10 ns

GAIN ACCURACY

Absolute Gain

Error

0.1 V < V

0.9 V < V

Channel-to-

Channel

Matching

GAIN CONTROL

INTERFACE

Normal Operating

Range

Gain Range 0 V to 1 V 10.6 40.6 10.6 40.6 10.6 40.6 dB

Scale Factor 32 32 32 dB/V

Response Time 30 dB change 350 350 350 ns

CW DOPPLER MODE

Transconductance,

LNA Gain =

5/6/8

Common Mode CW Doppler

Input-Referred

Noise Voltage,

LNA Gain =

5/6/8

Output DC Bias Per channel 2.4 2.4 2.4 mA

Maximum Output

Swing

POWER SUPPLY

AVDD 1.7 1.8 1.9 1.7 1.8 1.9 1.7 1.8 1.9 V

GAIN pin = 1 V 65 65 65 dBFS

GAIN pin = 0 V −65 −65 −65 dBFS

GAIN pin = 1 V −65 −65 −65 dBFS

GAIN pin = 0 V −70 −70 −70 dBFS

GAIN pin = 1 V −70 −70 −70 dBFS

GAIN pin = 1 V −65 −65 −65 dB

−70 −70 −70 dB

−70 −70 −70 dB

3

0 < V

< 0.1 V −1.0 +0.5 +2.0 −1.0 +0.5 +2.0 −1.0 +0.5 +2.0 dB

GAIN

<

GAIN

−1.0 +0.3 +1.0 −1.0 +0.3 +1.0 −1.0 +0.3 +1.0 dB

0.9 V, 1σ

<

GAIN

−2.0 -0.5 +1.0 −2.0 -0.5 +1.0 −2.0 -0.5 +1.0 dB

1 V

0.1 V < V

GAIN

<

1 1 1 dB

0.9 V

0 1 0 1 0 1 V

10/12/16 10/12/16 10/12/16 mA/V

1.5 3.6 1.5 3.6 1.5 3.6 V

output pins

R

= 0 Ω, RFB = ∞ 1.8 /1.7/1.5 1.7 /1.5/1.4 1.7 /1.5/1.3 nV/√Hz

S

Per channel ±2 ±2 ±2 mA p-

Rev. PrA | Page 5 of 58

p

Page 6

AD9271 Preliminary Technical Data

AD9271-25 AD9271-40 AD9271-50

Parameter1 Conditions Min Typ Max Min Typ Max Min Typ Max Unit

DRVDD 1.7 1.8 1.9 1.7 1.8 1.9 1.7 1.8 1.9 V

CWVDD 3.0 3.3 3.6 3.0 3.3 3.6 3.0 3.3 3.6

I

Full-channel

AVDD

CW Doppler

I

49 49 49 mA

DRVDD

Total Power

Dissipation

(Including

Output Drivers)

CW Doppler

Power-Down

Dissipation

Standby Power

Dissipation

Power Supply

Rejection Ratio

(PSRR)

ADC RESOLUTION 12 12 12 Bits

mode

mode with

four channels

enabled

Full-channel

mode

mode with

four channels

enabled

10 mW

65 65 65 mW

1 1 1 mV/V

500 622 746 mA

136 160 170 mA

984 1200 1400 mW

192 216 224 mW

Rev. PrA | Page 6 of 58

Page 7

Preliminary Technical Data AD9271

AD9271-25 AD9271-40 AD9271-50

Parameter1 Conditions Min Typ Max Min Typ Max Min Typ Max Unit

ADC REFERENCE

Output Voltage

Error (VREF = 1

V)

Load Regulation @

1.0 mA (VREF =

1 V)

Input Resistance 6 6 6 kΩ

1

See the AN-835 Application Note, Understanding High Speed ADC Testing and Evaluation, for a complete set of definitions and how these tests were completed.

2

SE = single ended.

3

The overrange condition is specified as being 6 dB more than the full-scale input range.

±2 ±2 ±2 mV

3 3 3 mV

Rev. PrA | Page 7 of 58

Page 8

AD9271 Preliminary Technical Data

DIGITAL SPECIFICATIONS

AVDD = 1.8 V, DRVDD = 1.8 V, CWVDD = 3.3 V, 400 m V p-p differential input, 1.0 V internal ADC reference, AIN = −0.5 dBFS, unless

otherwise noted.

Table 2.

Parameter1 Temperature Min Typ Max Unit

CLOCK INPUTS (CLK+, CLK−)

Logic Compliance CMOS/LVDS/LVPECL

Differential Input Voltage2 Full 250 mV p-p

Input Common-Mode Voltage Full 1.2 V

Input Resistance (Differential) 25°C 20 kΩ

Input Capacitance 25°C 1.5 pF

LOGIC INPUTS (PDWN, STBY, SCLK)

Logic 1 Voltage Full 1.2 3.6 V

Logic 0 Voltage Full 0.3 V

Input Resistance 25°C 30 kΩ

Input Capacitance 25°C 0.5 pF

LOGIC INPUT (CSB)

Logic 1 Voltage Full 1.2 3.6 V

Logic 0 Voltage Full 0.3 V

Input Resistance 25°C 70 kΩ

Input Capacitance 25°C 0.5 pF

LOGIC INPUT (SDIO)

Logic 1 Voltage Full 1.2 DRVDD + 0.3 V

Logic 0 Voltage Full 0 0.3 V

Input Resistance 25°C 30 kΩ

Input Capacitance 25°C 2 pF

LOGIC OUTPUT (SDIO)3

Logic 1 Voltage (IOH = 800 A) Full 1.79 V

Logic 0 Voltage (IOL = 50 A) Full 0.05 V

DIGITAL OUTPUTS (D+, D−), (ANSI-644)1

Logic Compliance LVDS

Differential Output Voltage (VOD) Full 247 454 mV

Output Offset Voltage (VOS) Full 1.125 1.375 V

Output Coding (Default) Offset binary

DIGITAL OUTPUTS (D+, D−),

(Low Power, Reduced Signal Option)

1

Logic Compliance LVDS

Differential Output Voltage (VOD) Full 150 250 mV

Output Offset Voltage (VOS) Full 1.10 1.30 V

Output Coding (Default) Offset binary

1

See the AN-835 Application Note, Understanding High Speed ADC Testing and Evaluation, for a complete set of definitions and how these tests were completed.

2

Specified for LVDS and LVPECL only.

3

Specified for 13 SDIO pins sharing the same connection.

Rev. PrA | Page 8 of 58

Page 9

Preliminary Technical Data AD9271

SWITCHING SPECIFICATIONS

AVDD = 1.8 V, DRVDD = 1.8 V, CWVDD = 3.3 V, 400 m V p-p differential input, 1.0 V internal ADC reference, AIN = −0.5 dBFS, unless

otherwise noted.

Table 3.

Parameter1 Temp Min Typ Max Unit

CLOCK2

Maximum Clock Rate Full 50 MSPS

Minimum Clock Rate Full 10 MSPS

Clock Pulse Width High (tEH) Full 10.0 ns

Clock Pulse Width Low (tEL) Full 10.0 ns

OUTPUT PARAMETERS

Propagation Delay (tPD) Full

Rise Time (tR) (20% to 80%) Full

Fall Time (tF) (20% to 80%) Full

FCO Propagation Delay (t

DCO Propagation Delay (t

DCO to Data Delay (t

DCO to FCO Delay (t

Data-to-Data Skew

DATA-MAX

− t

(t

Wake-Up Time (Standby) 25°C

Wake-Up Time (Power-Down) 25°C

Pipeline Latency Full

APERTURE

Aperture Uncertainty (Jitter) 25°C

1

See the AN-835 Application Note, Understanding High Speed ADC Testing and Evaluation, for a complete set of definitions and how these tests were completed.

2

Can be adjusted via the SPI interface.

3

Measurements were made using a part soldered to FR4 material.

4

t

/24 is based on the number of bits divided by 2, because the delays are based on half duty cycles.

SAMPLE

2, 3

DATA-MIN

) Full

FCO

)4 Full

CPD

)4 Full (t

DATA

)4 Full (t

FRAME

Full

)

1.5 2.3 3.1

300

300

1.5 2.3 3.1

+

t

FCO

/24)

(t

SAMPLE

/24) − 300 (t

SAMPLE

/24) − 300 (t

SAMPLE

±50 ±200

600

375

8

/24) (t

SAMPLE

/24) (t

SAMPLE

ns

/24) + 300 ps

SAMPLE

/24) + 300 ps

SAMPLE

ns

ps

ps

ns

ps

ns

s

CLK

cycles

<1

ps rms

Rev. PrA | Page 9 of 58

Page 10

AD9271 Preliminary Technical Data

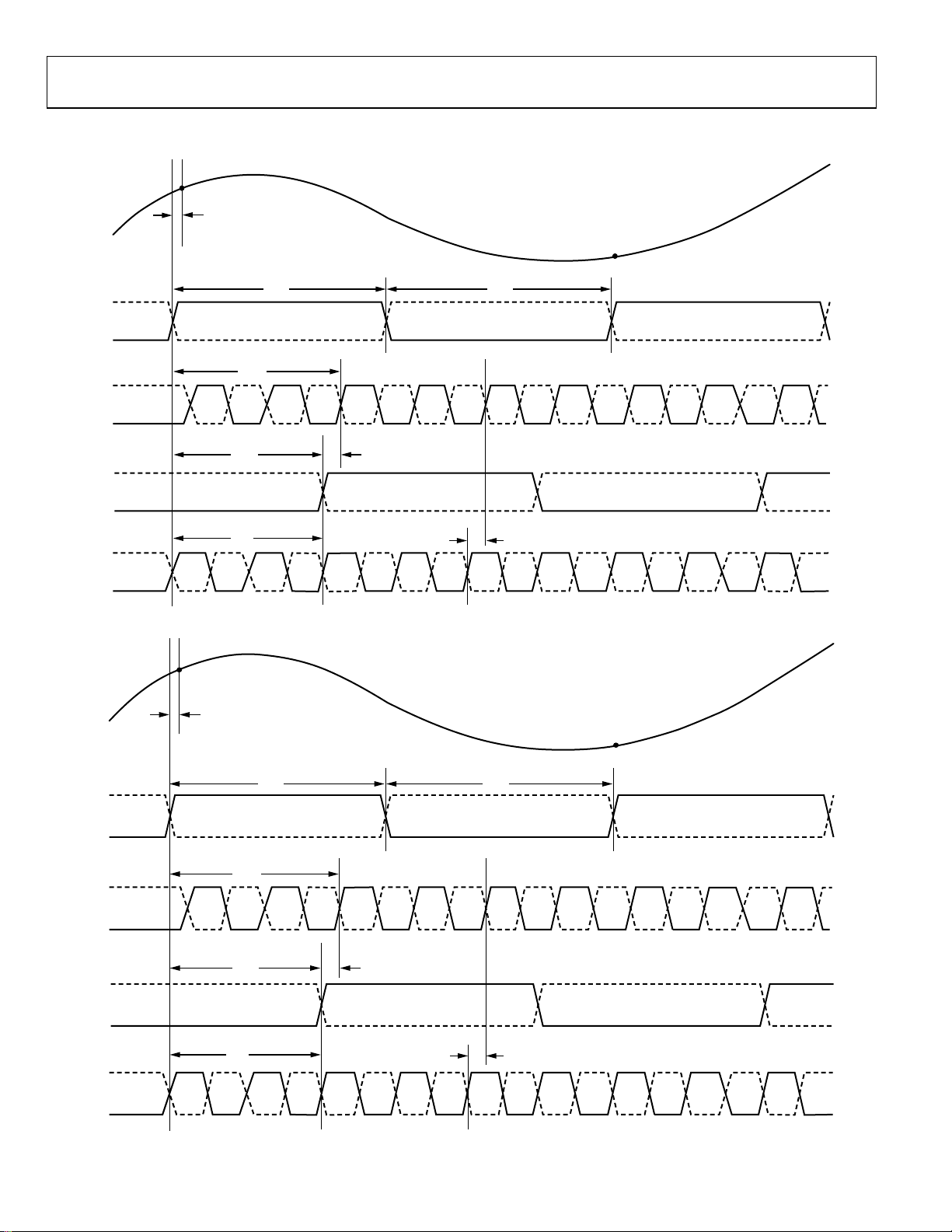

ADC TIMING DIAGRAMS

N – 1

AIN

CLK–

CLK+

DCO–

DCO+

FCO–

FCO+

DOUT–

DOUT+

N – 1

t

A

N

t

FCO

t

t

EH

t

CPD

t

FRAME

PD

MSB

D10

N – 8

N – 8D9N – 8D8N – 8D7N – 8D6N – 8D5N – 8D4N – 8D3N – 8D2N – 8D1N – 8D0N – 8

t

EL

t

DATA

D10

MSB

N – 7

N – 7

6304-002

Figure 2. 12-(Preliminary) Bit Data Serial Stream (Default)

AIN

CLK–

CLK+

DCO–

DCO+

FCO–

FCO+

DOUT–

DOUT+

t

A

N

t

EH

t

CPD

t

FCO

t

PD

t

FRAME

LSB

(N – 8)D0(N – 8)D1(N – 8)D2(N – 8)D3(N – 8)D4(N – 8)D5(N – 8)D6(N – 8)D7(N – 8)D8(N – 8)D9(N – 8)

t

EL

t

DATA

D10

(N – 8)

LSB

(N – 7)

D0

(N – 7)

06304-004

Figure 3. 12-(Preliminary) Bit Data Serial Stream, LSB First

Rev. PrA | Page 10 of 58

Page 11

Preliminary Technical Data AD9271

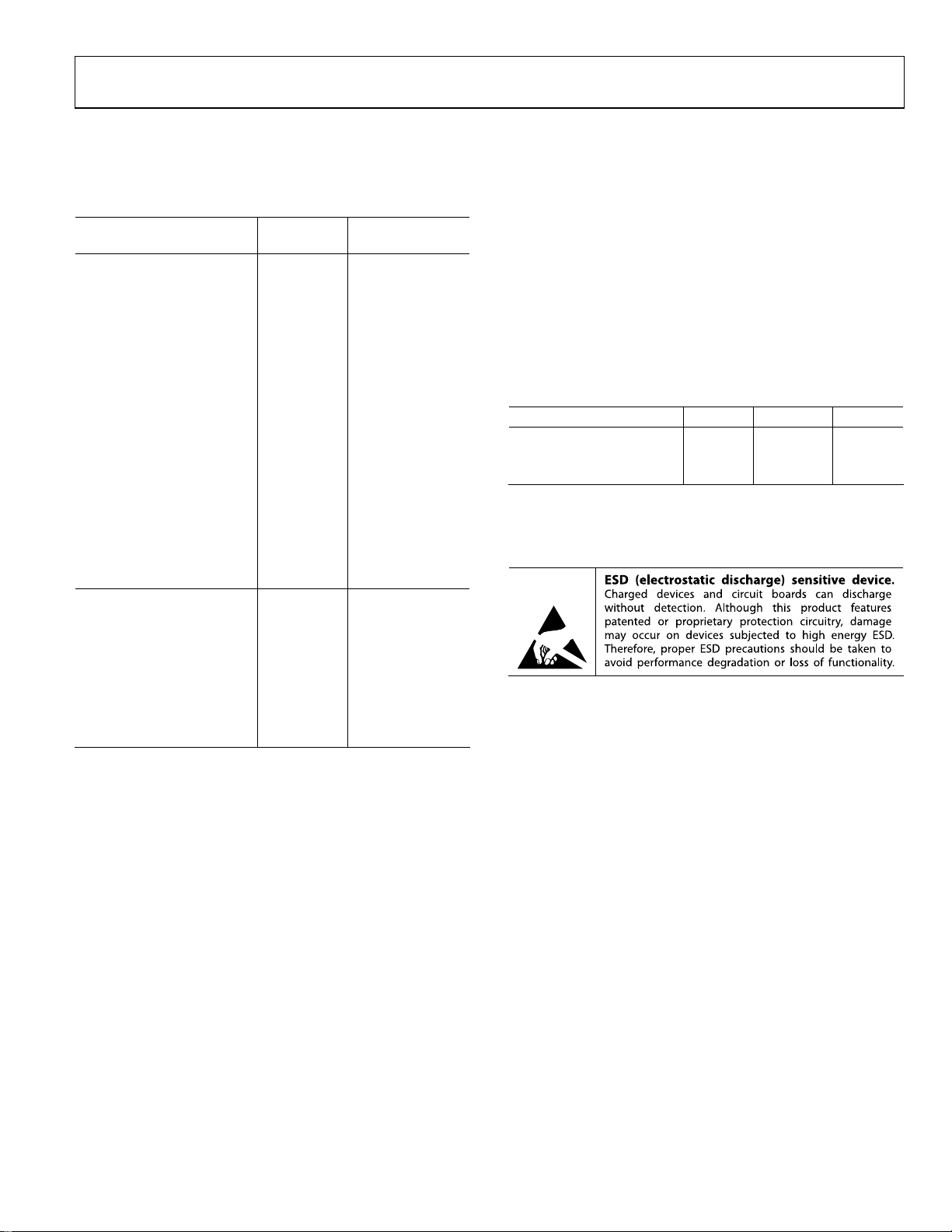

ABSOLUTE MAXIMUM RATINGS

Table 4.

With

Parameter

Respect To Rating

ELECTRICAL

AVDD GND −0.3 V to +2.0 V

DRVDD GND −0.3 V to +2.0 V

CWVDD GND −0.3 V to +3.9 V

GND GND −0.3 V to +0.3 V

AVDD DRVDD −2.0 V to +2.0 V

Digital Outputs

GND −0.3 V to +2.0 V

(DOUT+, DOUT−, DCO+,

DCO−, FCO+, FCO−)

CLK+, CLK− GND −0.3 V to +3.9 V

LI-x LG-x −0.3 V to +2.0 V

LO-x LG-x −0.3 V to +2.0 V

LOSW-x LG-x −0.3 V to +2.0 V

CWDx−, CWDx+ GND −0.3 V to +2.0 V

SDIO, GAIN+,GAIN− GND −0.3 V to +2.0 V

PDWN, STBY, SCLK, CSB GND −0.3 V to +3.9 V

REFT, REFB, RBIAS GND −0.3 V to +2.0 V

VREF, SENSE GND −0.3 V to +2.0 V

ENVIRONMENTAL

Operating Temperature

−40°C to +85°C

Range (Ambient)

Maximum Junction

150°C

Temperature

Lead Temperature

300°C

(Soldering, 10 sec)

Storage Temperature

−65°C to +150°C

Range (Ambient)

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

THERMAL IMPEDANCE

Table 5.

Air Flow Velocity (m/s) θ

0.0 20.3°C/W

1.0 14.4°C/W 7.6°C/W 4.7°C/W

2.5 12.9°C/W

1

θ

for a 4-layer PCB with solid ground plane (simulated). Exposed pad

JA

soldered to PCB.

1

θ

JA

JB

θJC

ESD CAUTION

Rev. PrA | Page 11 of 58

Page 12

AD9271 Preliminary Technical Data

G

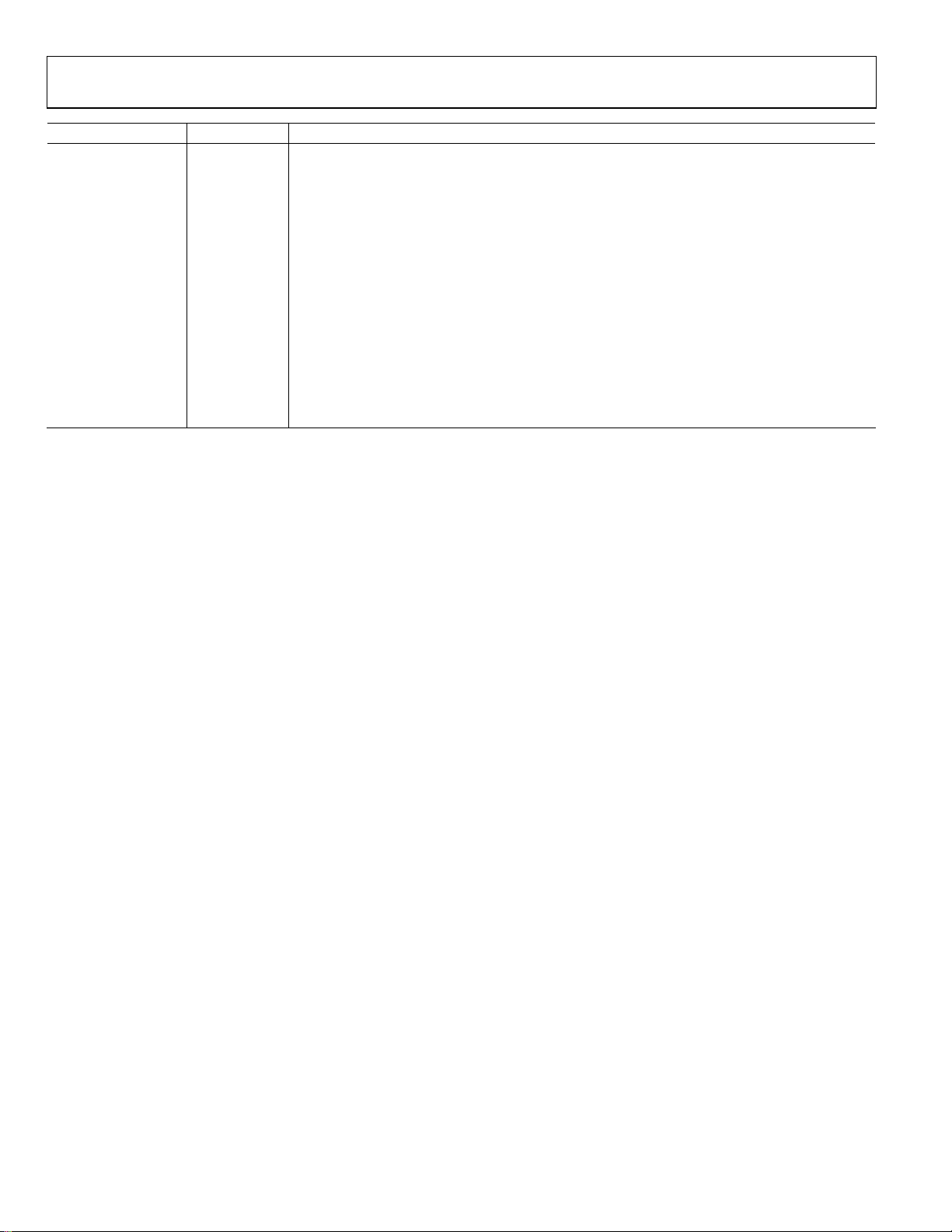

PIN CONFIGURATION AND FUNCTION DESCRIPTIONS

LOSW-D

LO–D

CWD0–

CWD0+

CWD1–

CWD1+

CWD2–

CWD2+

CWVD-D

GAIN–

GAIN+

RBIAS

SENSE

VREF

REFB

REFT

AVDD

CWD3–

CWD3+

CWD4–

CWD4+

CWD5–

CWD5+

LO–E

LOSW-E

LI-E

LG-E

AVDD

AVDD

LO-F

LOSW-F

LI-F

LG-F

AVDD

AVDD

LO-G

LOSW-

LI-G

LG-G

AVDD

AVDD

LO-H

LOSW-H

LI-H

LG-H

AVDD

AVDD

CLK–

CLK+

AVDD

9998979695949392919089888786858483828180797877

100

PIN 1

1

INDICATOR

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

EXPOSED PADDLE, PIN 0

(BOTTOM OF PACKAGE)

AD9271

TOP VIEW

(Not to Scale)

76

LI-D

75

LG-D

74

AVDD

73

AVDD

72

LO-C

71

LOSW-C

70

LI-C

69

LG-C

68

AVDD

67

AVDD

66

LO-B

65

64

LOSW-B

LI-B

63

LG-B

62

AVDD

61

AVDD

60

59

LO-A

58

LOSW-A

57

LI-A

LG-A

56

AVDD

55

54

AVDD

53

CSB

52

SDIO

SCLK

51

2627282930313233343536373839404142434445464748

FCO–

DRVDD

DCO–

DOUT + F

DOUT – H

DOUT + H

DOUT – G

DOUT + G

DOUT – F

DOUT – E

DOUT + E

FCO+

DCO+

DOUT – B

DOUT – C

DOUT – D

DOUT + D

DOUT + B

DOUT + C

DRVDD

DOUT – A

DOUT + A

50

49

STBY

AVDD

PWDN

Figure 4. 100-Lead TQFP

Table 6. Pin Function Descriptions

Pin No. Name Description

0 GND Ground (Exposed paddle should be tied to a quiet analog ground)

3, 4, 9, 10, 15,

AVDD 1.8 V Analog Supply

16, 21, 22, 25,

50, 54, 55, 60,

61, 66, 67, 72,

73,92

26, 47 DRVDD 1.8 V Digital Output Driver Supply

84 CWVDD 3.3 V Analog Supply

1 LI-E LNA Analog Input for Channel E

2 LG-E LNA Ground for Channel E

5 LO-F LNA Analog Output for Channel F

6 LOSW-F LNA Analog Output Complement for Channel F

7 LI-F LNA Analog Input for Channel F

8 LG-F LNA Ground for Channel F

11 LO-G LNA Analog Output for Channel G

12 LOSW-G LNA Analog Output Complement for Channel G

13 LI-G LNA Analog Input for Channel G

14 LG-G LNA Ground for Channel G

06304-005

Rev. PrA | Page 12 of 58

Page 13

Preliminary Technical Data AD9271

Pin No. Name Description

17 LO-H LNA Analog Output for Channel H

18 LOSW-H LNA Analog Output Complement for Channel H

19 LI-H LNA Analog Input for Channel H

20 LG-H LNA Ground for Channel H

23 CLK− Clock Input Complement

24 CLK+ Clock Input True

27 DOUT − H ADC H Digital Output Complement

28 DOUT + H ADC H True Digital Output True

29 DOUT − G ADC C Digital Output Complement

30 DOUT + G ADC C True Digital Output

31 DOUT − F ADC B Digital Output Complement

32 DOUT + F ADC B True Digital Output True

33 DOUT − E ADC A Digital Output Complement

34 DOUT + E ADC A True Digital Output True

35 DCO− Frame Clock Digital Output Complement

36 DCO+ Frame Clock Digital Output True

37 FCO− Frame Clock Digital Output Complement

38 FCO+ Frame Clock Digital Output True

39 DOUT − D ADC H Digital Output Complement

40 DOUT + D ADC H True Digital Output True

41 DOUT − C ADC C Digital Output Complement

42 DOUT + C ADC C True Digital Output

43 DOUT − B ADC B Digital Output Complement

44 DOUT + B ADC B True Digital Output True

45 DOUT − A ADC A Digital Output Complement

46 DOUT + A ADC A True Digital Output True

48 STDBY Standby Power Down

49 PDWN Full Power Down

51 SCLK Serial Clock

52 SDIO Serial Data Input/Output

53 CSB Chip Select Bar

56 LG-A LNA Ground for Channel A

57 LI-A LNA Analog Input for Channel A

58 LOSW-A LNA Analog Output Complement for Channel A

59 LO-A LNA Analog Output for Channel A

62 LG-B LNA Ground for Channel B

63 LI-B LNA Analog Input for Channel B

64 LOSW-B LNA Analog Output Complement for Channel B

65 LO-B LNA Analog Output for Channel B

68 LG-C LNA Ground for Channel C

69 LI-C LNA Analog Input for Channel C

70 LOSW-C LNA Analog Output Complement for Channel C

71 LO-C LNA Analog Output for Channel C

74 LG-D LNA Ground for Channel D

75 LI-D LNA Analog Input for Channel D

76 LOSW-D LNA Analog Output Complement for Channel D

77 LO-D LNA Analog Output for Channel D

78 CWD0− CW Doppler Output Complement for Channel 0

79 CWD0+ CW Doppler Output True for Channel 0

80 CWD1− CW Doppler Output Complement for Channel 1

81 CWD1+ CW Doppler Output True for Channel 1

82 CWD2− CW Doppler Output Complement for Channel 2

83 CWD2+ CW Doppler Output True for Channel 2

Rev. PrA | Page 13 of 58

Page 14

AD9271 Preliminary Technical Data

Pin No. Name Description

85 GAIN− GAIN Control Voltage Input Complement

86 GAIN+ GAIN Control Voltage Input True

87 RBIAS External resistor sets the internal ADC core bias current

88 SENSE Reference Mode Selection

89 VREF Voltage Reference Input/Output

90 REFB Differential Reference (Negative)

91 REFT Differential Reference (Positive)

93 CWD3− CW Doppler Output Complement for Channel 3

93 CWD3+ CW Doppler Output True for Channel 3

95 CWD4− CW Doppler Output Complement for Channel 4

96 CWD4+ CW Doppler Output True for Channel 4

97 CWD5− CW Doppler Output Complement for Channel 5

98 CWD5+ CW Doppler Output True for Channel 5

99 LO-E LNA Analog Output for Channel E

100 LOSW-E LNA Analog Output Complement for Channel E

Rev. PrA | Page 14 of 58

Page 15

Preliminary Technical Data AD9271

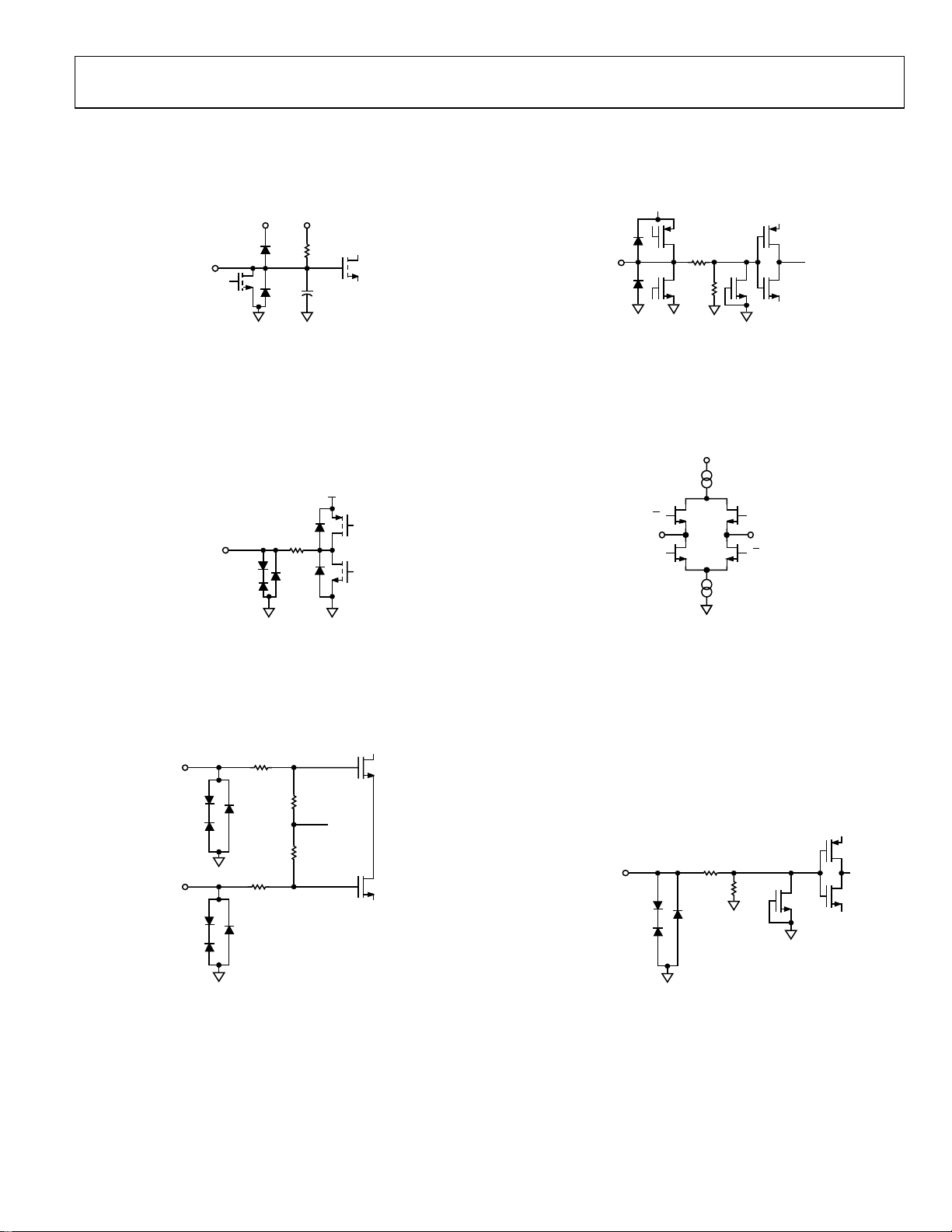

V

Ω

A

S

EQUIVALENT CIRCUITS

CM

15kΩ

06304-073

LI-x,

LG-x

AVDD

Figure 5. Equivalent LNA Input Circuit

AVDD

LO-x,

LOSW-x

10Ω

Figure 6. Equivalent LNA Output Circuit

VDD

SDIO

350Ω

30kΩ

06304-008

Figure 8. Equivalent SDIO Input Circuit

DRVDD

V

DOUT– DOUT+

V

06304-075

DRGND

V

V

6304-009

Figure 9. Equivalent Digital Output Circuit

CLK+

CLK–

10

10kΩ

10kΩ

10Ω

Figure 7. Equivalent Clock Input Circuit

1.25V

06304-007

Rev. PrA | Page 15 of 58

CLK OR PDWN

OR STBY

1kΩ

30kΩ

Figure 10. Equivalent SCLK Input Circuit

06304-010

Page 16

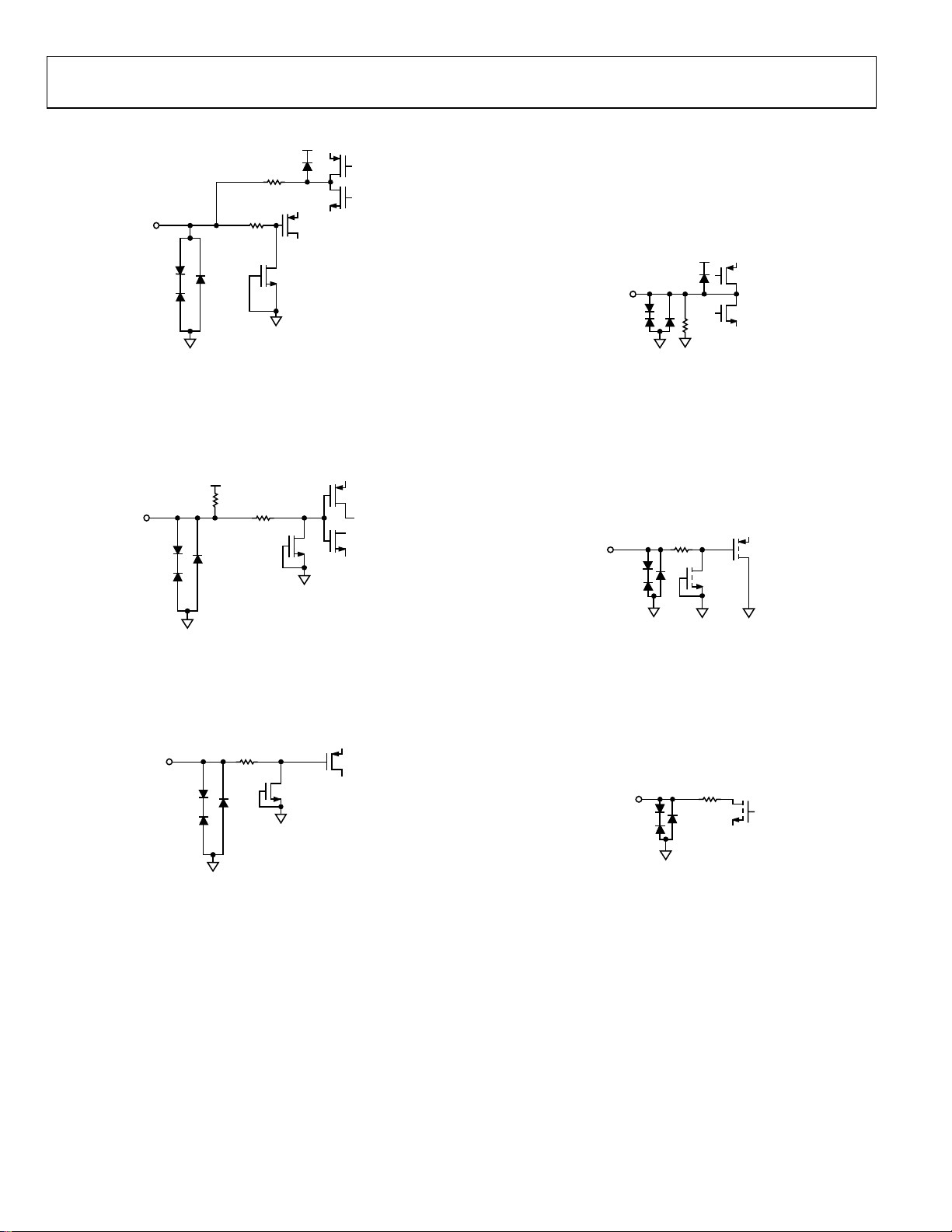

AD9271 Preliminary Technical Data

A

V

C

Ω

AVDD

RBIAS

100Ω

Figure 11. Equivalent RBIAS Circuit

DD

70kΩ

CSB

1kΩ

Figure 12. Equivalent CSB Input Circuit

AVDD

VREF

6kΩ

06304-011

6304-014

Figure 14. Equivalent VREF Circuit

GAIN

06304-012

50Ω

06304-074

Figure 15. Equivalent GAIN Input Circuit

SENSE

Figure 13. Equivalent SENSE Circuit

1kΩ

WDx+,

CWDx–

06304-013

10

06304-076

Figure 16. Equivalent CWD Output Circuit

Rev. PrA | Page 16 of 58

Page 17

Preliminary Technical Data AD9271

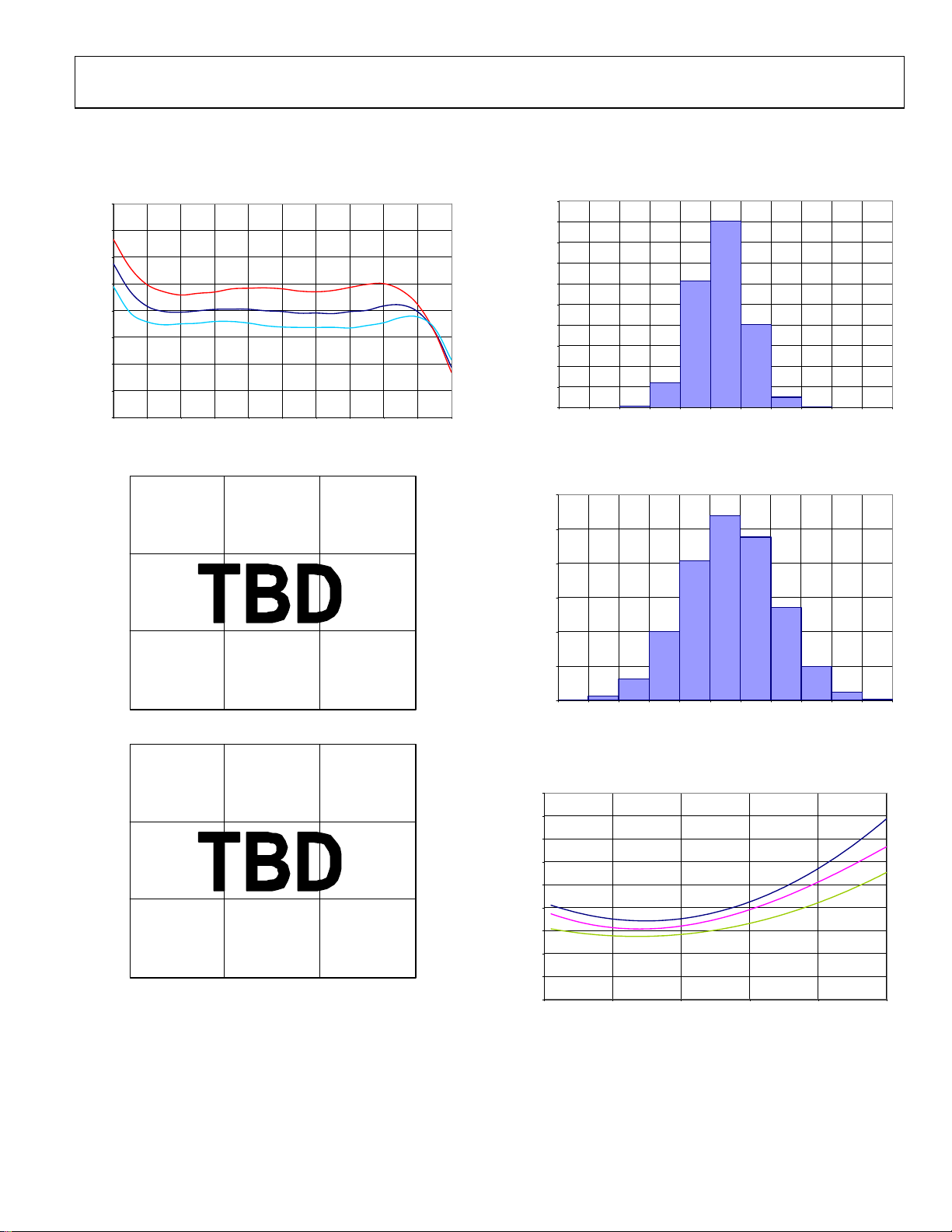

TYPICAL PERFORMANCE CHARACTERISTICS

(f

= 50 MSPS, AIN = 5 MHz, LPF = 1/3 × f

SAMPLE

, LNA gain = 6×)

SAMPLE

2.00

1.50

1.00

0.50

0.00

Absolute Error (dB)

-0.50

-1.00

-1.50

-2.00

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1

Figure 17. Absolute Gain Error vs. V

85C

25C

-40C

Vgain (V)

at Three Temperatures

GAIN

2000000

1800000

1600000

1400000

1200000

1000000

Number of Hits

800000

600000

400000

200000

0

-5-4-3-2-1012345

Figure 20. Output-Referred Noise Histogram with Gain Pin at 0.0V, AD9271-

Codes

50

1200000

1000000

800000

600000

Number of Hits

400000

Figure 18. Gain Error Histogram

Figure 19. Gain Match Histogram for V

= 0.2 V and 0.7 V

GAIN

200000

0

-5-4-3-2-1012345

Codes

Figure 21. Output-Referred Noise Histogram with Gain Pin at 1.0V, AD9271-

50

4.5

4

3.5

3

2.5

2

Input-referred Noise (nV/sqrt-Hz )

1.5

1

0.5

0

0 5 10 15 20 25

LNA Gain = 5x

LNA Gain = 6x

LNA Gain = 8x

Frequency (MHz)

Figure 22. Short-Circuit, Input-Referred Noise vs. Frequency

Rev. PrA | Page 17 of 58

Page 18

AD9271 Preliminary Technical Data

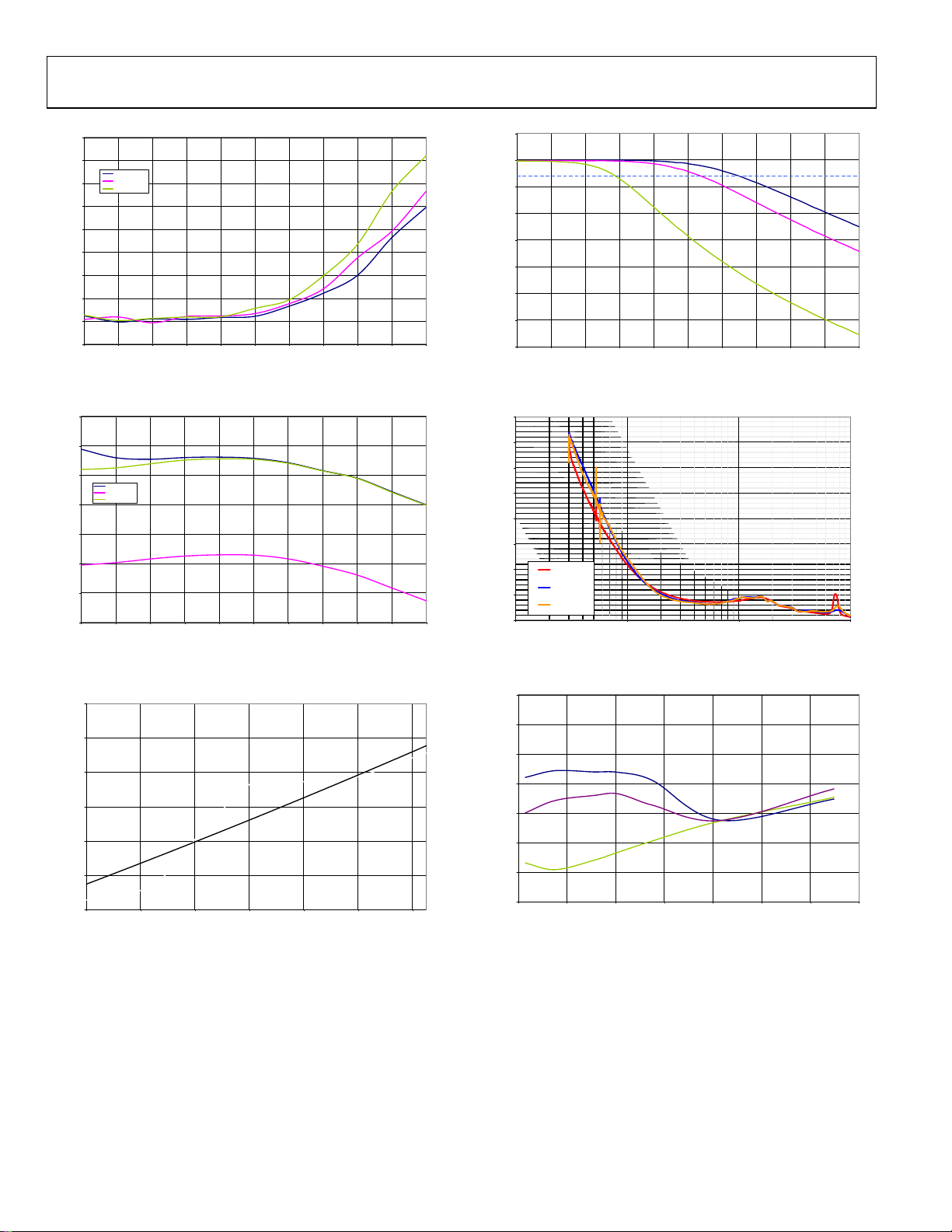

-99

-100

LNA Gain = 5x

LNA Gain = 6x

-101

LNA Gain = 8x

-102

-103

-104

-105

Output-referred Noise (d BFS/rt-Hz)

-106

-107

-108

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1

Figure 23. Short-Circuit, Output-Referred Noise vs. V

66

64

62

SNR (dBFS)

SINAD (dB)

SINAD (dBFS)

60

SNR/SINAD

58

56

54

52

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1

Vgain (V)

GAIN

Vgain (V)

Figure 24. SNR/SINAD vs. Gain

1.7

1.65

1.6

1.55

0

-5

-3dB line

-10

-15

-20

Fundamental (dBFS)

-25

-30

-35

-40

0 2.5 5 7.5 10 12.5 15 17.5 20 22.5 25

Figure 26. Antialiasing Filter (AAF) Pass-Band Response

400

350

300

250

200

Group Delay (ns)

150

100

Vgain = 0.0 V

Vgain = 0.5 V

50

Vgain = 1.0 V

0

0.1 1 10 100

Frequency (MHz)

Analog Input Frequency (MHz)

(1/3)*25MHz

(1/3)*50MHz

(1/3)*40MHz

Figure 27. Antialiasing Filter (AAF) Group Delay Response

-50

-55

-60

-65

H2 (dBFS)

-70

Vgain=0.2V

Vgain=1V

1.5

Input-referred noise (nV/rt-Hz)

1.45

1.4

-40-200 20406080

Temperature (C)

Figure 25. Short-Circuit, Input-Referred Noise vs. Temperature

Rev. PrA | Page 18 of 58

-75

-80

-85

2 4 6 8 10 12 14 16

Vgain=0.5V

Fin (MHz)

Figure 28. Second-Order Harmonic Distortion vs. Frequency

Page 19

Preliminary Technical Data AD9271

-50

-40

-55

-60

-65

Vgain=1V

H3 (dBFS)

-70

-75

Vgain=0.2V

-80

-85

2 4 6 8 10121416

Figure 29. Third-Order Harmonic Distortion vs. Frequency

-40

-50

-60

Vgain=0V

Vgain=0.5V

Vgain=1V

-70

-80

Second Harmonic (dBFS)

-90

-100

-110

-40 -35 -30 -25 -20 -15 -10 -5 0

Vgain=0.5V

Fin (MHz)

ADC Output Level (dBFS)

Figure 30. Second-Order Harmonic Distortion vs. ADC Output Level

-50

-60

Vgain=0V

Vgain=0.5V

Vgain=1V

-70

-80

Third Harmonic (dBFS)

-90

-100

-110

-40 -35 -30 -25 -20 -15 -10 -5 0

ADC Output Level (dBFS)

Figure 31. Third-Order Harmonic Distortion vs. ADC Output Level

Rev. PrA | Page 19 of 58

Page 20

AD9271 Preliminary Technical Data

THEORY OF OPERATION

ULTRASOUND

The primary application for the AD9271 is medical ultrasound.

Figure 32 shows a simplified block diagram of an ultrasound

system. A critical function of an ultrasound system is the time

gain control (TGC) compensation for physiological signal

attenuation. Because the attenuation of ultrasound signals is

exponential with respect to distance (time), a linear-in-dB VGA

is the optimal solution.

Key requirements in an ultrasound signal chain are very low

noise, active input termination, fast overload recovery, low

power, and differential drive to an ADC. Because ultrasound

machines use beam-forming techniques requiring large binaryweighted numbers (for example, 32 to 512) of channels, the

lowest power at the lowest possible noise is of key importance.

TX HV AMPs

Most modern machines use digital beam forming. In this

technique, the signal is converted to digital format immediately

following the TGC amplifier; beam forming is done digitally.

The ADC resolution of 12 bits with up to 50 MSPS sampling

satisfies the requirements of both general-purpose and highend systems.

Power consumption and low cost are of primary importance in

low-end and portable ultrasound machines, and the AD9271 is

designed for these criteria.

For additional information regarding ultrasound systems, refer

to “How Ultrasound System Considerations Influence Front-End

Component Choice,” Analog Dialogue, Volume 36, Number 3,

May–July 2002.

TX BEAMFORMER

BEAMFORMER

CENTRAL CONT ROL

MULTICHANNEL

TGC USES MANY VG As

AD9271

TRANSDUCER

ARRAY

128, 256 ETC.

ELEMENTS

HV

MUX/

DEMUX

BIDIRECTIO NAL

CABLE

T/R

SWITCHES

TIME GAIN COMPENSATION

TGC

VGALNA

CW

CW (ANALOG)

BEAMFORMER

AUDIO

OUTPUT

Figure 32. Simplified Ultrasound System Block Diagram

AAF

ADC

SPECTRAL

DOPPLER

PROCESSING

MODE

Rx BEAMFORMER

(B AND F MODES)

IMAGE AND

MOTION

PROCESSING

(B MODE)

DISPLAY

COLOR

DOPPLER (PW )

PROCESSING

(F MODE)

06304-077

Rev. PrA | Page 20 of 58

Page 21

Preliminary Technical Data AD9271

RFB1

CFB

RFB2

LO-X

LOSW-X

g

m

TO

SWITCH

ARRAY

CDW+

CDW–

CS

CSH

RS

CLG

LI-X

LG-X

LNA

ATTENUATOR

–30dB TO 0d B

GAIN

INTERPOL ATOR

Figure 33. Simplified Block Diagram of Single Channel

CHANNEL OVERVIEW

Each channel contains both a TGC and CW Doppler signal

path. Common to both signal paths, the LNA provides useradjustable input impedance termination. The CW Doppler path

includes a transconductance amplifier and crosspoint switch.

The TGC path includes a differential X-AMP® VGA, an

antialiasing filter, and an ADC. Figure 33 shows a simplified

block diagram with external components.

The signal path is fully differential throughout to maximize

signal swing and reduce even-order distortion; however, the

LNA is designed to be driven from a single-ended signal source.

Low Noise Amplifier (LNA)

Good noise performance relies on a proprietary ultralow noise

LNA at the beginning of the signal chain, which minimizes the

noise contribution in the following VGA. Active impedance

control optimizes noise performance for applications that benefit

from input impedance matching.

A simplified schematic of the LNA is shown in Figure 34. LI-x is

capacitively coupled to the source. An on-chip bias generator

establishes dc input bias voltages of around 1.4 V and centers

the output common-mode levels at 0.9 V (VDD/2). A capacitor,

C

, of the same value as the input coupling capacitor, CS, is

LG

connected from the LG-x pin to ground.

CFB

RFB1

RFB2

LOSW

LO-X

CS

RS

CSH

LI-X

LG-X

CLG

+24dB

GAIN–

GAIN+

AAF

SERIAL PORT

INTERFACE

CSB

12-BIT

PIPELINE

ADC

SDIO

SCLK

SERIAL

LVDS

AD9271

DOUT + X

DOUT – X

06304-071

The LNA supports differential output voltages as high as 2 V p-p

with positive and negative excursions of ±0.5 V from a

common-mode voltage of 0.9 V. The LNA differential gain sets

the maximum input signal before saturation. One of three gains

is set through the SPI. The corresponding input full-scale for

the gain settings of 5, 6, or 8 is 400 mV p-p, 333 mV p-p, and

250 mV p-p, respectively. Overload protection ensures quick

recovery time from large input voltages. Because the inputs are

capacitively coupled to a bias voltage near midsupply, very large

inputs can be handled without interacting with the ESD protection.

Low value feedback resistors and the current-driving capability

of the output stage allow the LNA to achieve a low input-referred

noise voltage of 1.2 nV/√Hz. This is achieved with a current

consumption of only 16 mA per channel (30 mW). On-chip

resistor matching results in precise single-ended gains critical

for accurate impedance control. The use of a fully differential

topology and negative feedback minimizes distortion. Low HD2

is particularly important in second harmonic ultrasound imaging

applications. Differential signaling enables smaller swings at

each output, further reducing third-order distortion.

Active Impedance Matching

The LNA consists of a single-ended voltage gain amplifier with

differential outputs and the negative output externally available.

For example, with a fixed gain of 6 (15.6 dB), an active input

termination is synthesized by connecting a feedback resistor

between the negative output pin, LO-x, and the positive input

pin, LI-x. This technique is well known and results in the input

resistance shown in Equation 2, where A/2 is the single-ended

gain or the gain from the LI-x inputs to the LO-x outputs.

R

FB

R

=

IN

1(

(2)

A

)

+

2

Figure 34. Simplified LNA Schematic

06304-101

Rev. PrA | Page 21 of 58

Page 22

AD9271 Preliminary Technical Data

is needed in series with RFB because the dc levels at Pin LO-x

C

Because the amplifier has a gain of 6× from its input to its

differential output, it is important to note that the gain A/2 is

the gain from Pin LI-x to Pin LO-x, and is 6 dB less than the

gain of the amplifier, or 9.6 dB (3×). The input resistance is

reduced by an internal bias resistor of 15 kΩ in parallel with the

source resistance connected to Pin LI-x, with Pin LG-x ac

IN

, the

FB

grounded. Equation 3 can be used to calculate the needed R

for a desired R

R

IN

For example, to set R

, even for higher values of RIN.

IN

R

FB

= k15||

+

)31(

(3)

Ω

to 200 Ω, the value of RFB is 845 Ω. If the

IN

simplified equation, Equation 2, is used to calculate R

resulting value is 190 Ω, resulting in a less than 0.1 dB gain

error. Factors such as a dynamic source resistance might

influence the absolute gain accuracy more significantly. At

higher frequencies, the input capacitance of the LNA needs to

be considered. The user must determine the level of matching

accuracy and adjust R

accordingly.

FB

The bandwidth (BW) of the LNA is about 70 MHz. Ultimately

the BW of the LNA limits the accuracy of the synthesized R

= RS up to about 200 Ω, the best match is between

For R

IN

.

IN

100 kHz and 10 MHz, where the lower frequency limit is

determined by the size of the ac-coupling capacitors, and the

upper limit, by the LNA BW. Furthermore, the input

capacitance and R

1k

RIN = 500Ω, RFB = 2.5kΩ

RIN = 200Ω, RFB = 1kΩ

100

RIN = 100Ω, RFB = 499Ω

limit the BW at higher frequencies.

S

RSH = ∞, CSH = 0 pF

RSH = 50Ω, CSH = 22 pF

FB

and Pin LI-x are unequal.

Table 7. Active Termination External Component Values

Minimum

LNA Gain RIN (Ω) RFB (Ω)

CSH (pF) BW (MHz)

5× 50 175 90 49

6× 50 200 70 59

8× 50 250 50 73

5× 100 350 30 49

6× 100 400 20 59

8× 100 500 10 73

5× 200 700 na 49

6× 200 800 na 49

8× 200 1000 na 49

LNA Noise

The short-circuit noise voltage (input-referred noise) is an

important limit on system performance. The short-circuit noise

voltage for the LNA is 1.2 nV/√Hz or 1.4 nV/√Hz (at maximum

gain), including the VGA noise. These measurements, which

are taken without a feedback resistor, provide the basis for

calculating the input noise and noise figure performance of the

configurations shown in Figure 43. Figure 43 and Figure 44 are

simulations of noise figure vs. R

results using these

S

configurations and an input-referred noise voltage for the VGA

of 4 nV/√Hz. Unterminated (R

= ∞) operation exhibits the

FB

lowest equivalent input noise and noise figure. Figure 44 shows

the noise figure vs. source resistance rising at low R

—where the

S

LNA voltage noise is large compared with the source noise—

and at high R

due to current noise.

S

UNTERMINATED

R

IN

R

S

+

V

IN

–

V

OUT

INPUT IMPEDANCE (Ω)

10

RIN = 50Ω, RFB = 249Ω

1M100k 50M10M

FREQUENCY (Hz)

RSH = ∞, CSH = 0 pF

RSH = 50Ω, CSH = 22 pF

Figure 35. RIN vs. Frequency for Various Values of RFB

(Effects of R

and CSH are Also Shown

SH

Figure 35 shows RIN vs. frequency for various values of RFB. Note

that at the lowest value, 50 Ω, R

peaks at frequencies greater

IN

than 10 MHz. This is due to the BW roll-off of the LNA as

mentioned earlier.

However, as can be seen for larger R

values, parasitic capacitance

IN

starts rolling off the signal BW before the LNA can produce

peaking. C

not be used for values of R

lists the recommended values for R

further degrades the match; therefore, CSH should

SH

that are greater than 100 Ω. Table 7

IN

and CSH in terms of RIN.

FB

Rev. PrA | Page 22 of 58

RESISTIVE TERMINAT ION

R

IN

R

S

+

V

IN

–

ACTIVE IMPEDANCE MATCH

R

S

+

V

IN

–

RIN=

R

IN

1 + A/2

R

S

R

FB

Figure 36. Input Configurations

V

OUT

R

FB

V

OUT

03199-079

Page 23

Preliminary Technical Data AD9271

V

7

INCLUDES NOISE OF VGA

6

5

4

3

NOISE FI GURE (dB)

2

1

SIMULATION

0

50 100 1k

RESISTIVE TERMINAT ION

Figure 37. Noise Figure vs. R

= RIN)

(R

S

ACTIVE IM PEDANCE MATCH

UNTERMINATED

RS (Ω)

for Resistive,

S

03199-076

Active Matched and Unterminated Inputs, Gain = 1 V

7

INCLUDES NOISE OF VGA

6

5

4

3

NOISE FI GURE (dB)

2

1

SIMULATION

0

50 100 1k

Figure 38. Noise Figure vs. R

R

R

R

= 50Ω

IN

R

= 75Ω

IN

= 100Ω

IN

= 200Ω

IN

R

=

∞

FB

RS (Ω)

for Various Fixed Values of RIN,

S

03199-077

Actively Matched, Gain = 1 V.

The primary purpose of input impedance matching is to

improve the system transient response. With resistive termination,

the input noise increases due to the thermal noise of the

matching resistor and the increased contribution of the LNA’s

input voltage noise generator. With active impedance matching,

however, the contributions of both are smaller than they would

be for resistive termination by a factor of 1/(1 + LNA Gain).

Figure 37 shows the relative noise figure (NF) performance. In

this graph, the input impedance was swept with R

to preserve

S

the match at each point. The noise figures for a source impedance

of 50 are 7.1 dB, 4.1 dB, and 2.5 dB for the resistive, active,

and unterminated configurations, respectively. The noise

figures for 200 are 4.6 dB, 2.0 dB, and 1.0 dB, respectively.

Figure 38 shows the NF vs. R

for various values of RIN, which is

S

helpful for design purposes. The plateau in the NF for actively

matched inputs mitigates source impedance variations. For

comparison purposes, a preamp with a gain of 15.6 dB and

noise spectral density of 1.2 nV/√Hz, combined with a VGA

with 4 nV/√Hz, yields a noise figure degradation of

approximately 1.5 dB (for most input impedances), which is

significantly worse than the AD9271 performance.

Rev. PrA | Page 23 of 58

INPUT OVERDRIVE

Excellent overload behavior is of primary importance in ultrasound. Both the LNA and VGA have built-in overdrive

protection and quickly recover after an overload event.

Input Overload Protection

As with any amplifier, voltage clamping prior to the inputs is

highly recommended if the application is subject to high

transient voltages.

A block diagram of a simplified ultrasound transducer interface

is shown in Figure 39. A common transducer element serves the

dual functions of transmitting and receiving ultrasound energy.

During the transmitting phase, high voltage pulses are applied

to the ceramic elements. A typical transmit/receive (T/R) switch

may consist of four high voltage diodes in a bridge configuration.

Although the diodes ideally block transmit pulses from the

sensitive receiver input, diode characteristics are not ideal, and

resulting leakage transients imposed on the LI-x inputs can be

problematic.

Because ultrasound is a pulse system and time-of-flight is used

to determine depth, quick recovery from input overloads is

essential. Overload can occur in the preamp and the VGA.

Immediately following a transmit pulse, the typical VGA gains

are low, and the LNA is subject to overload from T/R switch

leakage. With increasing gain, the VGA can become overloaded

due to strong echoes that occur near field echoes and

acoustically dense materials, such as bone.

Figure 39 illustrates an external overload protection scheme. A

pair of back-to-back Schottky diodes is installed prior to

installing the ac-coupling capacitors. Although the BAS40

diodes are shown, any diode is prone to exhibiting some amount

of shot noise. Many types of diodes are available for achieving the

desired noise performance. The configuration shown in Figure

39 tends to add 2 nV√Hz of input-referred noise. Decreasing the

5 kΩ resistor and increasing the 2 kΩ resistor may improve noise

contribution, depending on the application. With the diodes

shown in Figure 39, clamping levels of ±0.5 V or less

significantly enhances the system overload performance.

+5

Tx

DRIVER

TRANSDUCER

5kΩ

5kΩ

HV

BAS40-04

2kΩ

–5V

10nF

10nF

Figure 39. Input Overload Protection

AD9271

LNA

6304-100

CW DOPPLER OPERATION

Modern ultrasound machines used for medical applications

employ a 2

n

binary array of receivers for beam forming, with

Page 24

AD9271 Preliminary Technical Data

typical array sizes of 16 or 32 receiver channels phase-shifted

and summed together to extract coherent information. When

used in multiples, the desired signals from each of the channels

can be summed to yield a larger signal (increased by a factor N,

where N is the number of channels), and the noise is increased by

the square root of the number of channels. This technique

enhances the signal-to-noise performance of the machine. The

critical elements in a beam-former design are the means to

align the incoming signals in the time domain and the means to

sum the individual signals into a composite whole.

Beam forming, as applied to medical ultrasound, is defined as the

phase alignment and summation of signals that are generated

from a common source but received at different times by a

multielement ultrasound transducer. Beam forming has two

functions: It imparts directivity to the transducer, enhancing its

gain, and it defines a focal point within the body from which the

location of the returning echo is derived.

AD9271

g

LNA

LNA

m

g

m

The AD9271 includes the front-end components needed to

implement analog beam forming for CW Doppler operation.

These components allow CW channels with similar phases to be

coherently combined before phase alignment and down mixing,

thus reducing the number of delay lines or adjustable phase

shifters/down mixers (AD8333 or AD8339) required. Next, if

delay lines are used, the phase alignment is performed and then

the channels are coherently summed and down converted by a

dynamic range I/Q demodulator. Alternatively, if phase shifters/

down mixers, such as the AD8333 and AD8339, are used, phase

alignment and down conversion are done before coherently

summing all channels into I/Q signals. In either case, the resultant I

and Q signals are filtered and sampled by two high resolution

ADCs, and the sampled signals are processed to extract the

relevant Doppler information.

8 × CHANNEL

LNA

LNA

8 × AD9271

LNA

LNA

8 × CHANNEL

LNA

LNA

g

m

g

m

AD9271

g

m

g

m

g

m

g

m

ARRAY

SWITCH

ARRAY

2.5V

2.5V

2.5V

2.5V

600nH

600nH

600nH

600nH

600nH

600nH

600nH

600nH

700Ω

700Ω

700Ω

700Ω

3 × AD8333

AD8333

AD8333

I

OPA

Q

OPA

16-BIT

ADC

16-BIT

ADC

06304-096

SWITCH

Figure 40. Typical CW Doppler System Using the AD9271 and AD8339

Rev. PrA | Page 24 of 58

Page 25

Preliminary Technical Data AD9271

A

A

Crosspoint Switch

Each LNA is followed by a transconductance amp for V/I conversion. Currents can be routed to one of six pairs of differential

outputs or to 12 single-ended outputs for summing. Each CWD

output pin sinks 2.4 mA dc current, and the signal has a full-scale

of ±2 mA for each channel selected by the cross-point switch.

For example, if four channels were to be summed on one CWD

output, the output would sink 9.6 mA dc and have a full-scale

current output of ±8 mA. The maximum number of channels

combined must be considered in setting the load impedance for

I/V conversion to ensure that the full-scale swing and commonmode voltage are within the operating limits of the AD9271.

When interfacing to the AD8339, a common-mode voltage of

2.5 V and a full-scale swing of 2.8 V p-p are desired This can be

accomplished by connecting an inductor between each CWD

output and a 2.5 V supply, and then connecting either a singleended or differential load resistance to the CWD outputs. The

value of resistance should be calculated based on the maximum

number of channels that can be combined.

CWD outputs are required under full-scale swing to be within

1.5 V and CWVDD (3.3 V supply).

Table 9. ADC Specifications

ADC Parameters Specifications

FS/FSrms (Vpp/mV) 2/707

SNR (dB) 70

ENOB (Bits) 11.3

SFDR (dB) −82

Noise (rms uV/nV/rt(Hz)) 194/50

In summary, the maximum gain required is determined by

(ADC Noise Floor/VGA Input Noise Floor) + Margin =

20 log(194/4.7) + 10 dB = 42.3 dB

The minimum gain required is determined by

(ADC Input FS/VGA Input FS) + Margin =

20 log(2/0.333) – 6 dB = 9.6 dB

Therefore, a 12-bit, 40 MSPS ADC with 15 MHz of bandwidth

should suffice in achieving the dynamic range required for most

ultrasound systems today.

The system gain is distributed as listed in Table 7.

TGC OPERATION

The signal path is fully differential throughout to maximize

signal swing and reduce even-order distortion; however, the

LNAs are designed to be driven from a single-ended signal

source. Gain values are referenced from the single-ended LNA

input to the differential output of the LNA. A simple exercise in

understanding the maximum and minimum gain requirements

is shown in Figure 41.

Table 8. LNA Specifications

LNA Parameters Specifications

BW (MHz) 15

FS/FSrms (mVpp/mV) 333/118

SNR (dB) 88.1

ENOB (Bits) 14.3

Noise (rms uV/nV/rt(Hz)) 4.65/1.2

MINIMUM GAIN

LNA FS

(0.333V p-p SE)

DC EQUIVALENT

DC EQUIVALENT

DYNAMIC RA NGE

VGA NOI SE FL OOR

(4.7µV rms)

Figure 41. Gain Requirements of TGC for a 12-Bit, 40 MSPS ADC

88dB

MAXIMUM GAIN

ADC FS (2V p-p)

70dB

ADC NOISE FL OOR

(194µV rms)

Table 10. Channel Gain Distribution

Section Nominal Gain (dB)

LNA 14/15.6/18

Attenuator 0 to −30

VGA Amp 25

Filter 0

ADC 0

Total 9 to 39/10.6 to 40.6/13 to 43

The linear-in-dB gain range of the TGC path is 30 dB, extending

from 9.6 dB to 39.6 dB. The slope of the gain control interface is

30 dB/V, and the gain control range is 0 V to 1 V. Equation 1 is

the expression for gain.

dB

30)(

GAIN

V

(1)

ICPTVdBGain

+=

where ICPT is the intercept point of the LNA gain.

In its default condition, the LNA has a gain of 15.6 dB (6×) and

the VGA gain is −6 dB if the voltage on the V

pin is 0 V.

GAIN

This gives rise to a total gain (or ICPT) of 9.6 dB through the

TGC path if the LNA input is unmatched, or of 3.6 dB if the

LNA is matched to 50 Ω (R

V

pin is 1 V, however, the VGA gain is 24 dB. This gives rise

GAIN

= 200 Ω). If the voltage on the

FB

to a total gain of 39.6 dB through the TGC path if the LNA

06304-097

input is unmatched, or of 33.5 dB if the LNA input is matched.

Each of the LNA outputs is dc-coupled to a VGA input. The

VGA consists of an attenuator with a range of 30 dB followed by

an amplifier with 24 dB of gain for a net gain range of −5 dB to

+25 dB. The X-AMP gain-interpolation technique results in low

Rev. PrA | Page 25 of 58

Page 26

AD9271 Preliminary Technical Data

Ω

gain error and uniform bandwidth, and differential signal paths

minimize distortion.

At low gain the VGA should limit the system noise performance

(SNR), whereas at high gains the noise is defined by the source

and LNA. The maximum voltage swing is bounded by the fullscale peak-to-peak ADC input voltage (2 V p-p).

Variable Gain Amplifier

The differential X-AMP VGA provides precise input

attenuation and interpolation. It has a low input-referred noise

of 4 nV/√Hz and excellent gain linearity. A simplified block

diagram is shown in Figure 42.

GAIN

VIP

VIN

g

m

3dB

GAIN INTERPOLATOR

POSTAMP

+

Gain Control

The gain control interface, GAIN+, is a differential input. V

GAIN

varies the gain of all VGAs through the interpolator by selecting

the appropriate input stages connected to the input attenuator.

The nominal V

range for 30 dB/V is 0 V to 1 V, with the best

GAIN

gain-linearity from about 0.1 V to 0.9 V, where the error is

typically less than ±0.2 dB. For V

and less than 0.1 V, the error increases. The value of the V

voltages greater than 0.9 V

GAIN

GAIN

voltage can be increased to that of the supply voltage without

gain foldover.

Gain control response time is less than 750 ns to settle within 10%

of the final value for a change from minimum to maximum gain.

There are two ways in which the GAIN pins can be interfaced.

Using a single-ended method, a Kelvin type of connection to

ground should be used as shown in Figure 43. For driving multiple

devices, it is preferred to use a differential method as shown in

Figure 44. In either method, the GAIN pins should be dc-coupled

and driven to accommodate a 1 V full-scale input.

–

POSTAMP

Figure 42. Simplified VGA Schematic

06304-078

The input of the VGA is a 12-stage differential resistor ladder with

3.01 dB per tap. The resulting total gain range is 30 dB, which

allows for range loss at the endpoints. The effective input resistance

per side is 180

Ω nominally for a total differential resistance of

360 Ω. The ladder is driven by a fully differential input signal from

the LNA. LNA outputs are dc-coupled to avoid external decoupling

capacitors. The common-mode voltage of the attenuator and the

VGA is controlled by an amplifier that uses the same midsupply

voltage derived in the LNA, permitting dc coupling of the LNA

to the VGA without introducing large offsets due to commonmode differences. However, any offset from the LNA will be

amplified as the gain is increased, producing an exponentially

increasing VGA output offset.

The input stages of the X-AMP are distributed along the ladder,

and a biasing interpolator, controlled by the gain interface,

determines the input tap point. With overlapping bias currents,

signals from successive taps merge to provide a smooth

attenuation range from 0 dB to −30 dB. This circuit technique

results in linear-in-dB gain law conformance and low distortion

levels—only deviating ±0.2 dB or less from the ideal. The gain

slope is monotonic with respect to the control voltage and is

stable with variations in process, temperature, and supply.

The X-AMP inputs are part of a 25 dB gain feedback amplifier

that completes the VGA. Its bandwidth is about 80 MHz. The

input stage is designed to reduce feedthrough to the output and

to ensure excellent frequency response uniformity across the

gain setting.

Rev. PrA | Page 26 of 58

Figure 43. Single-Ended Gain Pin Configuration

AD9271

GAIN+

GAIN–

499

±0.25DC AT

100Ω

0.5V CM

0.01µF

100Ω

0.01µF

Figure 44. Differential Gain Pin Configuration

±0.25DC AT

0.5V CM

AD8318

499Ω

499Ω

0.5V CM

523Ω

AVDD

26kΩ

10kΩ

50Ω

±0.5V DC

VGA Noise

In a typical application, a VGA compresses a wide dynamic

range input signal to within the input span of an ADC. The

input-referred noise of the LNA limits the minimum resolvable

input signal, whereas the output-referred noise, which depends

primarily on the VGA, limits the maximum instantaneous

dynamic range that can be processed at any one particular gain

control voltage. This limit is set in accordance with the

quantization noise floor of the ADC.

Output- and input-referred noise as a function of V

GAIN

are

shown in Figure TBD and Figure TBD for the short-circuited

input conditions. The input noise voltage is simply equal to the

output noise divided by the measured gain at each point in the

control range.

The output-referred noise is a flat 65 nV/√Hz over most of the

gain range, because it is dominated by the fixed output-referred

noise of the VGA. At the high end of the gain control range, the

6304-098

Page 27

Preliminary Technical Data AD9271

noise of the LNA and source prevail. The input-referred noise

reaches its minimum value near the maximum gain control

voltage, where the input-referred contribution of the VGA is

miniscule.

At lower gains, the input-referred noise, and therefore the noise

figure, increases as the gain decreases. The instantaneous

dynamic range of the system is not lost, however, because the

input capacity increases as the input-referred noise increases.

The contribution of the ADC noise floor has the same

dependence. The important relationship is the magnitude of the

VGA output noise floor relative to that of the ADC.

Gain control noise is a concern in very low noise applications.

Thermal noise in the gain control interface can modulate the

channel gain. The resultant noise is proportional to the output

signal level and usually only evident when a large signal is present.

The gain interface includes an on-chip noise filter, which reduces

this effect significantly at frequencies above 5 MHz. Care should be

taken to minimize noise impinging at the GAIN input. An external

RC filter can be used to remove V

source noise. The filter band-

GAIN

width should be sufficient to accommodate the desired control

bandwidth.

Tuning is normally off to avoid changing the capacitor settings

during critical times. The tuning circuit is enabled and disabled

through the SPI. Tuning should be done after initial power-up

and after reprogramming the filter cutoff scaling or ADC

sample rate. Occasional retuning during an idle time is

recommended.

Antialiasing Filter

The filter that the signal reaches prior to the ADC is used to

reject dc signals and to bandlimit the signal for antialiasing.

Figure 45 shows the architecture of the filter.

4kΩ

1C*

56/112pF

56/112pF

*C = 0.5 TO 3.1pF

2kΩ 2kΩ 2kΩ

6.5C*7.5C*

2kΩ 2kΩ 2kΩ

1C*

4kΩ

Figure 45. Simplified Filter Schematic

The filter can be configured for dc coupling or to have a single

pole for high-pass filtering at either 700 kHz or 350 kHz

(programmed through the SPI). The high-pass pole, however, is

not tuned and can vary by ±30%.

A third-order Butterworth low-pass filter is used to reduce

noise bandwidth and provide antialiasing for the ADC. The

filter uses on-chip tuning to trim the capacitors to set the

desired cutoff and reduce variation. The default −3dB cutoff is

1/3 the ADC sample clock rate. The cutoff can be scaled to 0.7,

0.8, 0.9, 1, 1.1, 1.2, or 1.3 times this frequency through the SPI.

The cutoff can be set from 8 MHz to 18 MHz.

06304-099

Rev. PrA | Page 27 of 58

Page 28

AD9271 Preliminary Technical Data

V

V

A/D CONVERTER

The AD9271 architecture consists of a pipelined ADC that is

divided into three sections: a 4-bit first stage followed by eight

1.5-bit stages and a 3-bit flash. Each stage provides sufficient

overlap to correct for flash errors in the preceding stages. The

quantized outputs from each stage are combined into a 12-bit

result in the digital correction logic. The pipelined architecture

permits the first stage to operate on a new input sample and the

remaining stages to operate on preceding samples. Sampling

occurs on the rising edge of the clock.

Each stage except for the last of the pipeline consists of a low

resolution flash ADC connected to a switched-capacitor DAC

and interstage residue amplifier (MDAC). The residue amplifier

magnifies the difference between the reconstructed DAC output

and the flash input for the next stage in the pipeline. One bit of

redundancy is used in each stage to facilitate digital correction

of flash errors. The last stage consists of a flash ADC.

The output staging block aligns the data, carries out the error

correction, and passes the data to the output buffers. The data is

then serialized and aligned to the frame and output clock.

CLOCK INPUT CONSIDERATIONS

For optimum performance, the AD9271 sample clock inputs

(CLK+ and CLK−) should be clocked with a differential signal.

This signal is typically ac-coupled into the CLK+ and CLK− pins

via a transformer or capacitors. These pins are biased internally

and require no additional bias.

Figure 46 shows the preferred method for clocking the AD9271.

The low jitter clock source, such as the Valpey Fisher oscillator

VFAC3-BHL-50MHz, is converted from single-ended to

differential using an RF transformer. The back-to-back Schottky

diodes across the secondary transformer limit clock excursions

into the AD9271 to approximately 0.8 V p-p differential. This

helps prevent the large voltage swings of the clock from feeding

through to other portions of the AD9271 and preserves the fast

rise and fall times of the signal, which are critical to low jitter

performance.

3.3V

OUT

EN

VFAC3

Figure 46. Transformer-Coupled Differential Clock

If a low jitter clock is available, another option is to ac-couple a

differential PECL signal to the sample clock input pins as shown

in Figure 47. The AD951x family of clock drivers offers excellent

jitter performance.

0.1µF

50Ω

MINI-CIRCUI TS

ADT1–1WT, 1:1Z

XFMR

100Ω

0.1µF

0.1µF

0.1µF

SCHOTTKY

DIODES:

HSM2812

CLK+

ADC

AD9271

CLK–

3.3V

VFAC3

OUT

EN

*

50Ω

*

50Ω RESISTOR IS OPTIONAL.

0.1µF

0.1µF

AD951x FAMILY

CLK

PECL DRIVER

CLK

0.1µF

CLK+

100Ω

0.1µF

240Ω240Ω

ADC

AD9271

CLK–

06304-051

Figure 47. Differential PECL Sample Clock

3.3V

AD951x FAMILY

OUT

50Ω

0.1µF

CLK

LVDS DRIVER

0.1µF

CLK

*

VFAC3

EN

*

50Ω RESISTOR IS OPTIONAL.

0.1µF

100Ω

0.1µF

CLK+

ADC

AD9271

CLK–

06304-052

Figure 48. Differential LVDS Sample Clock

In some applications, it is acceptable to drive the sample clock

inputs with a single-ended CMOS signal. In such applications,

CLK+ should be driven directly from a CMOS gate, and the

CLK− pin should be bypassed to ground with a 0.1 F capacitor

in parallel with a 39 kΩ resistor (see Figure 48). Although the

CLK+ input circuit supply is AVDD (1.8 V), this input is

designed to withstand input voltages up to 3.3 V, making the

selection of the drive logic voltage very flexible.

3.3

AD951x FAMILY

CLK

CMOS DRIVER

CLK

0.1µF

OPTIONA L

100Ω

39kΩ

0.1µF

CLK+

ADC

AD9271

CLK–

06304-053

50Ω

0.1µF

0.1µF

*

VFAC3

OUT

EN

*

50Ω RESISTOR IS OPTIONAL.

Figure 49. Single-Ended 1.8 V CMOS Sample Clock

3.3

OUT

EN

VFAC3

*

50Ω RESISTOR IS OPTIONAL.

06304-050

0.1µF

*

50Ω

0.1µF

Figure 50. Single-Ended 3.3 V CMOS Sample Clock

AD951x FAMILY

CLK

CMOS DRIVER

CLK

OPTION AL

100Ω

0.1µF

0.1µF

CLK+

ADC

AD9271

CLK–

06304-054

Clock Duty Cycle Considerations

Typical high speed ADCs use both clock edges to generate a

variety of internal timing signals. As a result, these ADCs may

be sensitive to the clock duty cycle. Commonly, a 5% tolerance

is required on the clock duty cycle to maintain dynamic

performance characteristics. The AD9271 contains a duty cycle

Rev. PrA | Page 28 of 58

Page 29

Preliminary Technical Data AD9271

stabilizer (DCS) that retimes the nonsampling edge, providing

an internal clock signal with a nominal 50% duty cycle. This

allows a wide range of clock input duty cycles without affecting

the performance of the AD9271. When the DCS is on, noise

and distortion performance are nearly flat for a wide range of

duty cycles. However, some applications may require the DCS

function to be off. If so, keep in mind that the dynamic range

performance can be affected when operated in this mode. See the

Memory Map section for more details on using this feature.

The duty cycle stabilizer uses a delay-locked loop (DLL) to

create the nonsampling edge. As a result, any changes to the

sampling frequency require approximately eight clock cycles

to allow the DLL to acquire and lock to the new rate.

Clock Jitter Considerations

High speed, high resolution ADCs are sensitive to the quality of the

clock input. The degradation in SNR at a given input frequency

) due only to aperture jitter (tJ) can be calculated by

(f

A

SNR Degradation = 20 × log 10[1/2 × π × f

In this equation, the rms aperture jitter represents the root mean

square of all jitter sources, including the clock input, analog input

signal, and ADC aperture jitter. IF undersampling applications

are particularly sensitive to jitter (see Figure 51).

× tJ]

A

The clock input should be treated as an analog signal in cases

where aperture jitter may affect the dynamic range of the AD9271.

Power supplies for clock drivers should be separated from the

ADC output driver supplies to avoid modulating the clock signal

with digital noise. Low jitter, crystal-controlled oscillators make

the best clock sources, such as the Valpey Fisher VFAC3 series.

If the clock is generated from another type of source (by gating,

dividing, or other methods), it should be retimed by the

original clock at the last step.

Refer to the AN-501 Application Note and the AN-756

Application Note for more in-depth information about jitter

performance as it relates to ADCs (visit www.analog.com).

130

RMS CLOCK JIT TER REQUI REMENT

120

110

100

90

80

SNR (dB)

70

10 BITS

60

8 BITS

50

40

30

1 10 100 1000

Figure 51. Ideal SNR vs. Input Frequency and Jitter

ANALOG INPUT FREQUENCY (MHz)

0.125ps

0.25ps

0.5ps

1.0ps

2.0ps

16 BITS

14 BITS

12 BITS

06304-038

Rev. PrA | Page 29 of 58

Page 30

AD9271 Preliminary Technical Data

Power Dissipation and Power-Down Mode

As shown in Figure 52, the power dissipated by the AD9271 is

proportional to its sample rate. The digital power dissipation

does not vary much because it is determined primarily by the

DRVDD supply and bias current of the LVDS output drivers.

800

700

600

500

400

Currents (mA)

25MSPS Speed Grade

300

40MSPS Speed Grade

50MSPS Speed Grade

IDRVDD

200

100

0

0 102030405060

Figure 52. Supply Current vs. f

190

180

170

160

150

140

Power/channel (mW)

130

120

110

100

0 102030405060

Figure 53. Power per Channel vs. f

Sampling Frequency (MSPS)

SAMPLE

Sampling Frequency (MSPS)

SAMPLE

for fIN = 7.5 MHz

25MSPS Speed Grade

40MSPS Speed Grade

50MSPS Speed Grade

for fIN = 7.5 MHz

By asserting the PDWN pin high, the AD9271 is placed in

power-down mode. In this state, the ADC typically dissipates

xx mW. During power-down, the LVDS output drivers are placed

in a high impedance state. The AD9271 returns to normal

operating mode when the PDWN pin is pulled low. This pin is

both 1.8 V and 3.3 V tolerant.

In power-down mode, low power dissipation is achieved by