Dual, 16-Bit, 1000 MSPS,

TxDAC+ Digital-to-Analog Converter

FEATURES

Flexible CMOS interface allows dual-word, word, or byte load

Single-carrier W-CDMA ACLR = 80 dBc at 122.88 MHz IF

Analog output: adjustable 8.7 mA to 31.7 mA, R

Novel 2×/4×/8× interpolator/complex modulator allows

carrier placement anywhere in the DAC bandwidth

Gain and phase adjustment for sideband suppression

Multichip synchronization interface

High performance, low noise PLL clock multiplier

Digital inverse sinc filter

Low power: 900 mW at 500 MSPS, full operating conditions

72-lead, exposed paddle LFCSP

APPLICATIONS

Wireless infrastructure

W-CDMA, CDMA2000, TD-SCDMA, WiMAX, GSM, LTE

Digital high or low IF synthesis

Transmit diversity

Wideband communications: LMDS/MMDS, point-to-point

Cable modem termination systems

= 25 Ω to 50 Ω

L

AD9125

GENERAL DESCRIPTION

The AD9125 is a dual, 16-bit, high dynamic range TxDAC+®

digital-to-analog converter (DAC) that provides a sample rate of

1000 MSPS, permitting a multicarrier generation up to the Nyquist

frequency. It includes features optimized for direct conversion

transmit applications, including complex digital modulation,

and gain and offset compensation. The DAC outputs are optimized

to interface seamlessly with analog quadrature modulators, such

as the ADL537x F-MOD series from Analog Devices, Inc. A 4-wire

serial port interface allows programming/readback of many internal parameters. Full-scale output current can be programmed

over a range of 8.7 mA to 31.7 mA. The AD9125 comes in a

72-lead LFCSP.

PRODUCT HIGHLIGHTS

1. Ultralow noise and intermodulation distortion (IMD)

enable high quality synthesis of wideband signals from

baseband to high intermediate frequencies.

2. A proprietary DAC output switching technique enhances

dynamic performance.

3. The current outputs are easily configured for various

single-ended or differential circuit topologies.

4. The flexible CMOS digital interface allows the standard

32-wire bus to be reduced to a 16-wire bus.

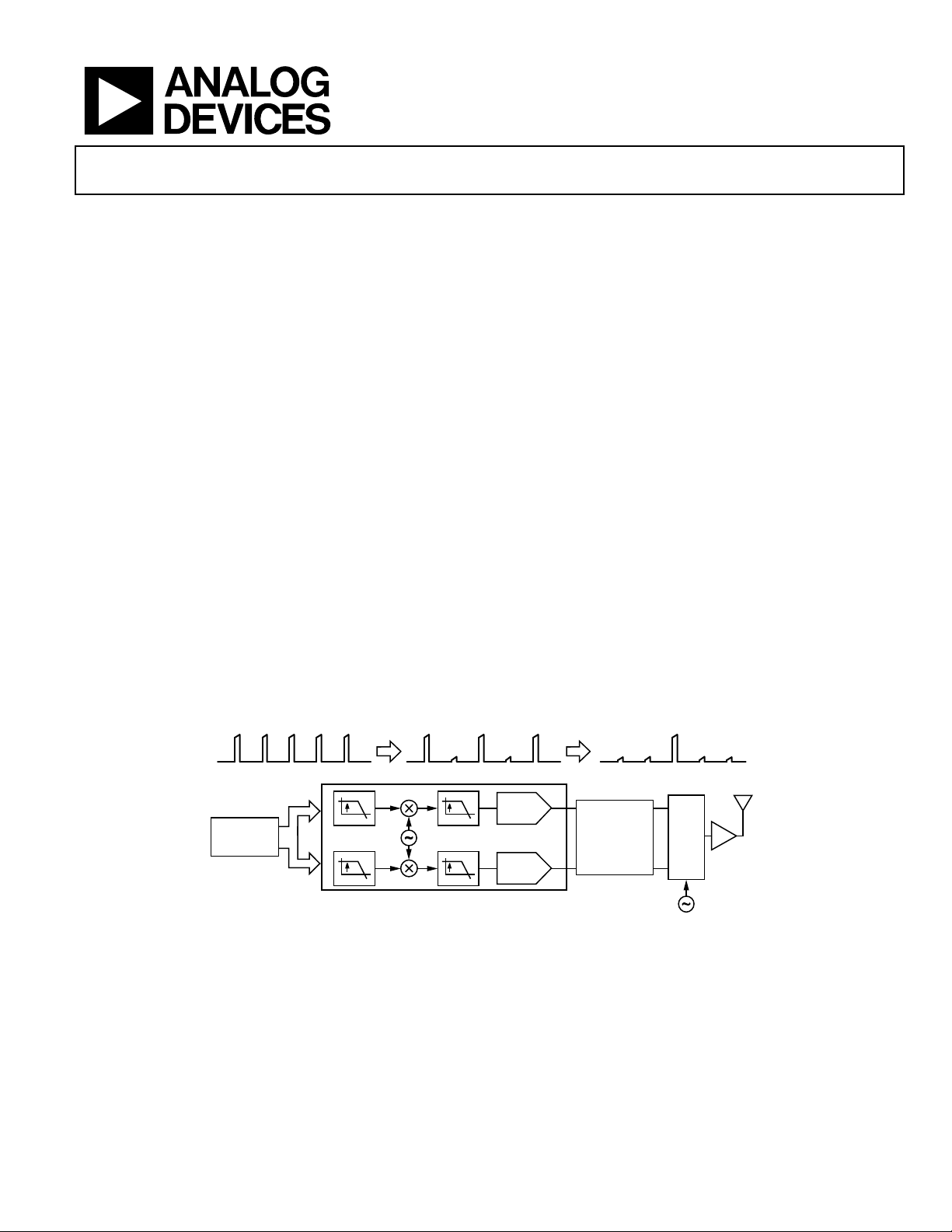

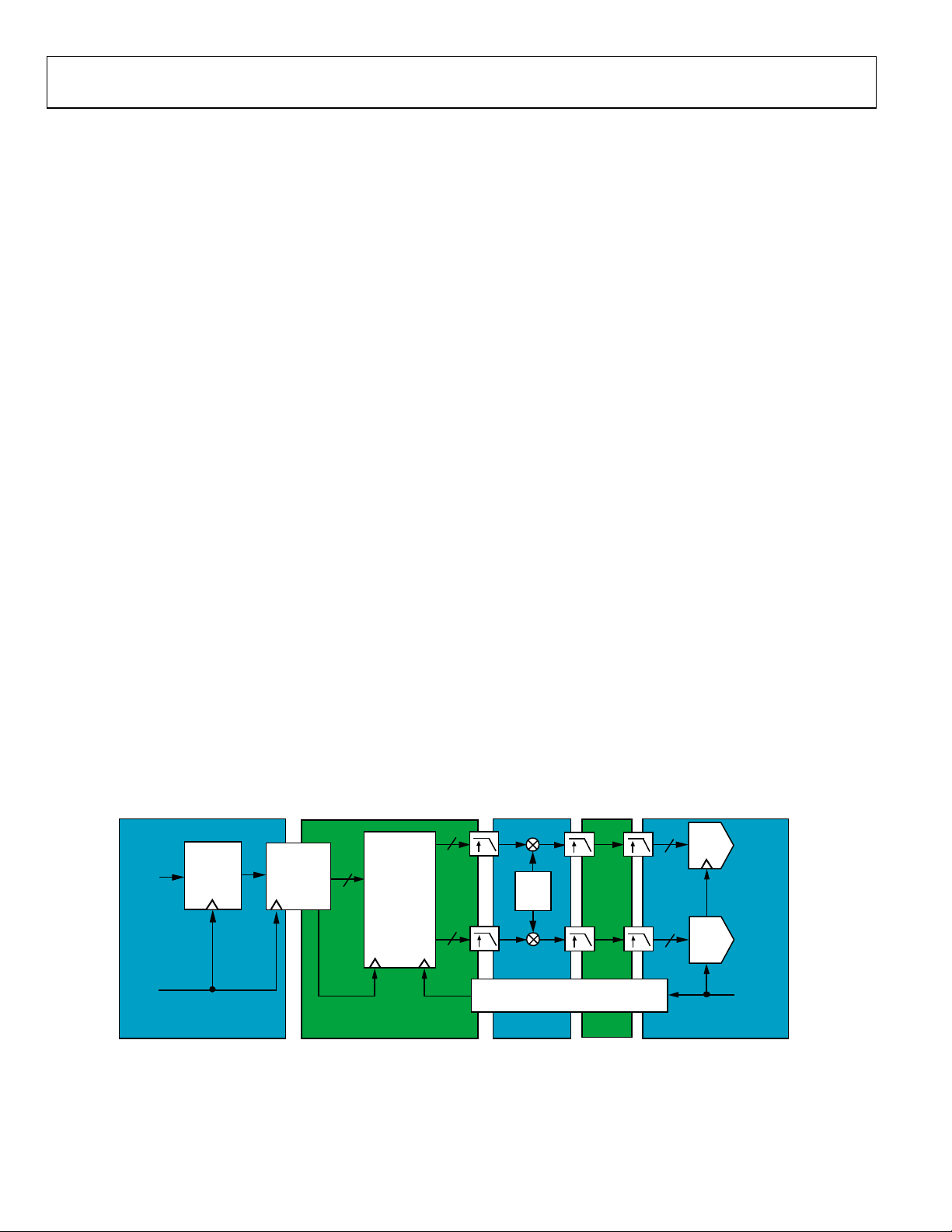

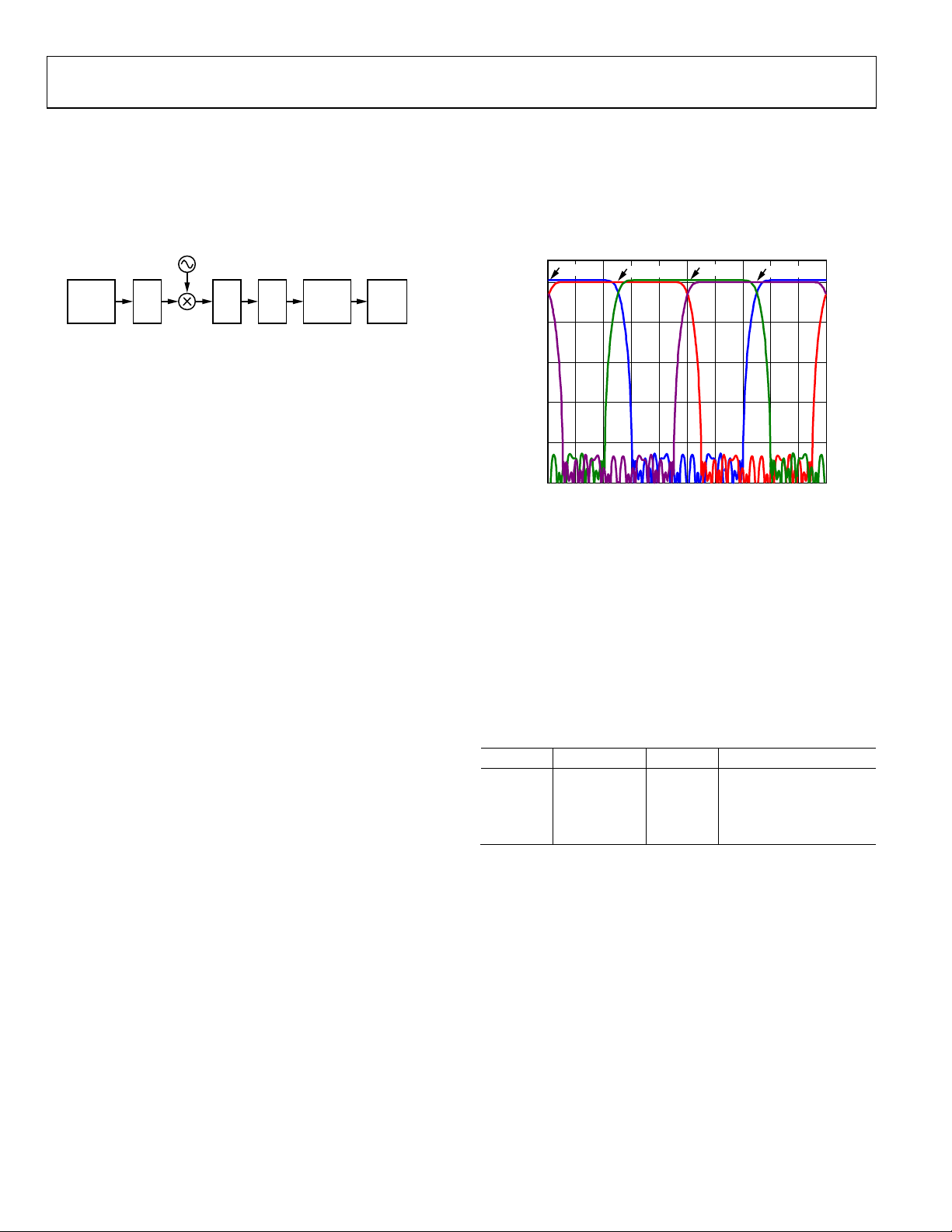

TYPICAL SIGNAL CHAIN

COMPLEX BAS EBAND

DC

2

DIGITAL

BASEBAND

PROCESSOR

NOTES

1. AQM = ANALOG QUADRATURE MODULATOR.

SIN

COS

2

Rev. 0

Information furnished by Analog Devices is believed to be accurate and reliable. However, no

responsibility is assumed by Analog Devices for its use, nor for any infringements of patents or other

rights of third parties that may result from its use. Specifications subject to change without notice. No

license is granted by implication or otherwise under any patent or patent rights of Analog Devices.

Trademarks and registered trademarks are the property of their respective owners.

COMPL E X I F

2/4

2/4

RF

f

IF

I DAC

ANTIALIASING

FILTER

Q DAC

Figure 1.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700 www.analog.com

Fax: 781.461.3113 ©2010 Analog Devices, Inc. All rights reserved.

LO – f

IF

AQM

LO

PA

09016-001

AD9125

TABLE OF CONTENTS

Features .............................................................................................. 1

Applications ....................................................................................... 1

General Description ......................................................................... 1

Product Highlights ........................................................................... 1

Typical Signal Chain ......................................................................... 1

Revision History ............................................................................... 2

Functional Block Diagram .............................................................. 3

Specifications ..................................................................................... 4

DC Specifications ......................................................................... 4

Digital Specifications ................................................................... 5

Latency and Power-Up Timing Specifications ......................... 5

AC Specifications .......................................................................... 6

Absolute Maximum Ratings ............................................................ 7

Thermal Resistance ...................................................................... 7

ESD Caution .................................................................................. 7

Pin Configuration and Function Descriptions ............................. 8

Typical Performance Characteristics ........................................... 10

Terminolog y .................................................................................... 16

Theory of Operation ...................................................................... 17

Serial Port Operation ................................................................. 17

Data Format ................................................................................ 17

Serial Port Pin Descriptions ...................................................... 17

Serial Port Options ..................................................................... 18

Device Configuration Register Map ............................................ 19

Device Configuration Register Descriptions .......................... 21

CMOS Input Data Ports ................................................................ 29

Dual-Word Mode ....................................................................... 29

Word Mode ................................................................................. 29

Byte Mode .................................................................................... 29

Interface Timing ......................................................................... 30

FIFO Operation .......................................................................... 30

Digital Datapath .............................................................................. 32

Premodulation ............................................................................ 32

Interpolation Filters ................................................................... 32

NCO Modulation ....................................................................... 35

Datapath Configuration ............................................................ 35

Determining Interpolation Filter Modes ................................ 36

Datapath Configuration Example ............................................ 37

Data Rates vs. Interpolation Modes ......................................... 38

Coarse Modulation Mixing Sequences .................................... 38

Quadrature Phase Correction ................................................... 39

DC Offset Correction ................................................................ 39

Inverse Sinc Filter ....................................................................... 39

DAC Input Clock Configurations ................................................ 40

DAC Input Clock Configurations ............................................ 40

Analog Outputs............................................................................... 42

Transmit DAC Operation .......................................................... 42

Auxiliary DAC Operation ......................................................... 43

Baseband Filter Implementation .............................................. 44

Driving the ADL5375-15 .......................................................... 44

Reducing LO Leakage and Unwanted Sidebands .................. 44

Device Power Dissipation .............................................................. 45

Temperature Sensor ................................................................... 46

Multichip Synchronization ............................................................ 47

Synchronization with Clock Multiplication ............................... 47

Synchronization with Direct Clocking .................................... 49

Data Rate Mode Synchronization ............................................ 49

FIFO Rate Mode Synchronization ........................................... 50

Additional Synchronization Features ...................................... 51

Interrupt Request Operation ........................................................ 52

Interrupt Service Routine .......................................................... 52

Interface Timing Validation .......................................................... 53

SED Operation ............................................................................ 53

SED Example .............................................................................. 53

Example Start-Up Routine ........................................................ 54

Outline Dimensions ....................................................................... 55

Ordering Guide .......................................................................... 55

REVISION HISTORY

6/10—Revision 0: Initial Version

Rev. 0 | Page 2 of 56

AD9125

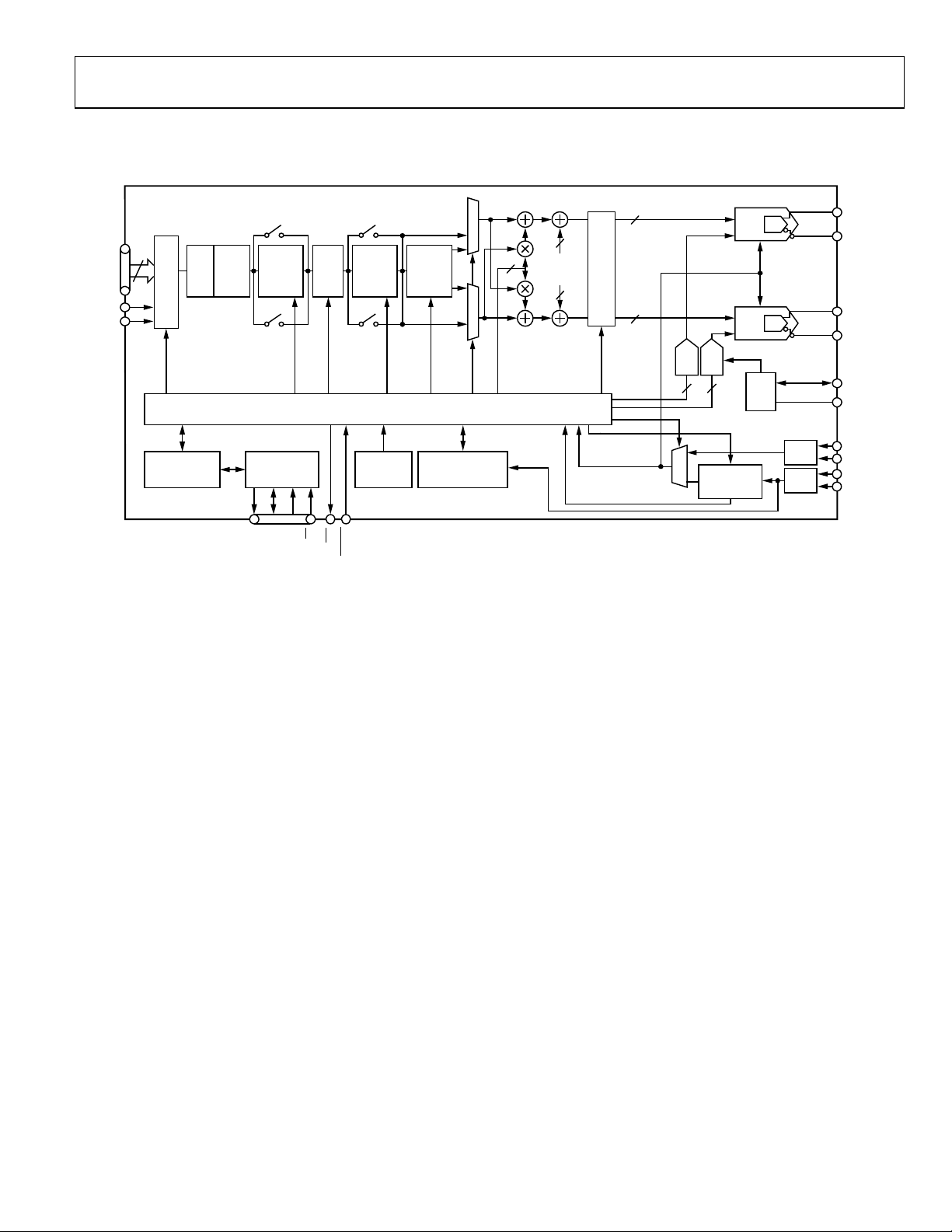

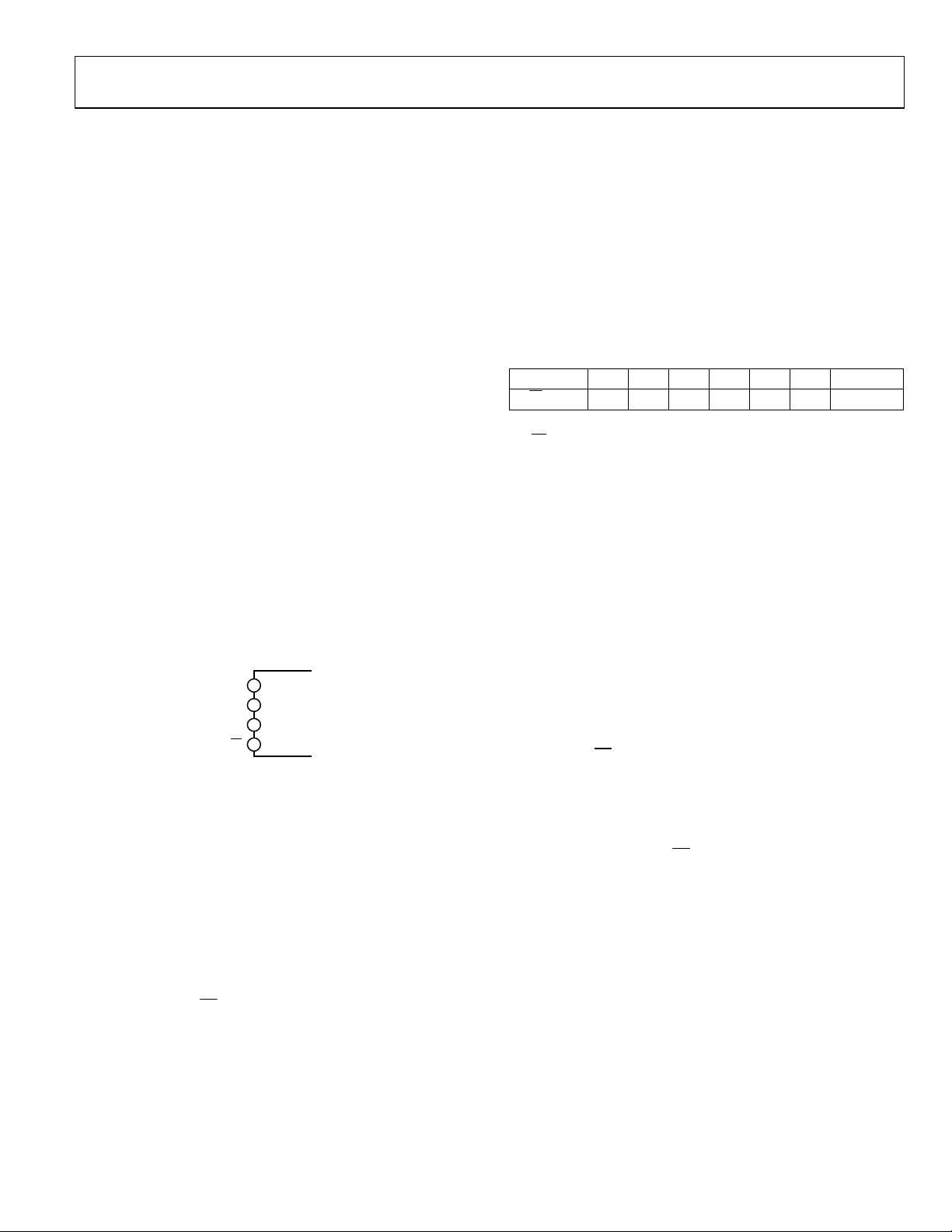

FUNCTIONAL BLOCK DIAGRAM

D[31:0]

DCI

FRAME

f

/2

DATA

PRE

FIFO HB1 HB2 HB3

DATA

RECEIVER

MODE

PROGRAMMING

REGISTERS

MOD

SERIAL

INPUT/OUTPUT

PORT

SDO

NCO

AND

MOD

HB1_CLK

INTERNAL CL OCK TIMING AND CONT ROL LOGIC

CS

SDIO

IRQ

SCLK

10

HB2_CLK

HB3_CLK

INTP

FACTOR

PHASE

CORRECTION

POWER-ON

RESET

RESET

MULTICHIP

SYNCHRONIZATION

SYNC

Figure 2. AD9125 Functional Block Diagram

16

I OFFSET

Q OFFSET

16

16

INV

SINC

16

INVSINC_CLK

PLL CONTROL

DACCLK

PLL_LOCK

GAIN 110GAIN 2

10

DAC CLK_SEL

0

1

MULTIPLIER

(2× TO 16×)

DACCLK

CLOCK

1.2G

DAC 1

16-BIT

1.2G

DAC 1

16-BIT

REF

AND

BIAS

AUX

AUX

CLK

RCVR

CLK

RCVR

IOUT1P

IOUT1N

IOUT2P

IOUT2N

REFIO

FSADJ

DACCLKP

DACCLKN

REFCLKP

REFCLKN

09016-002

Rev. 0 | Page 3 of 56

AD9125

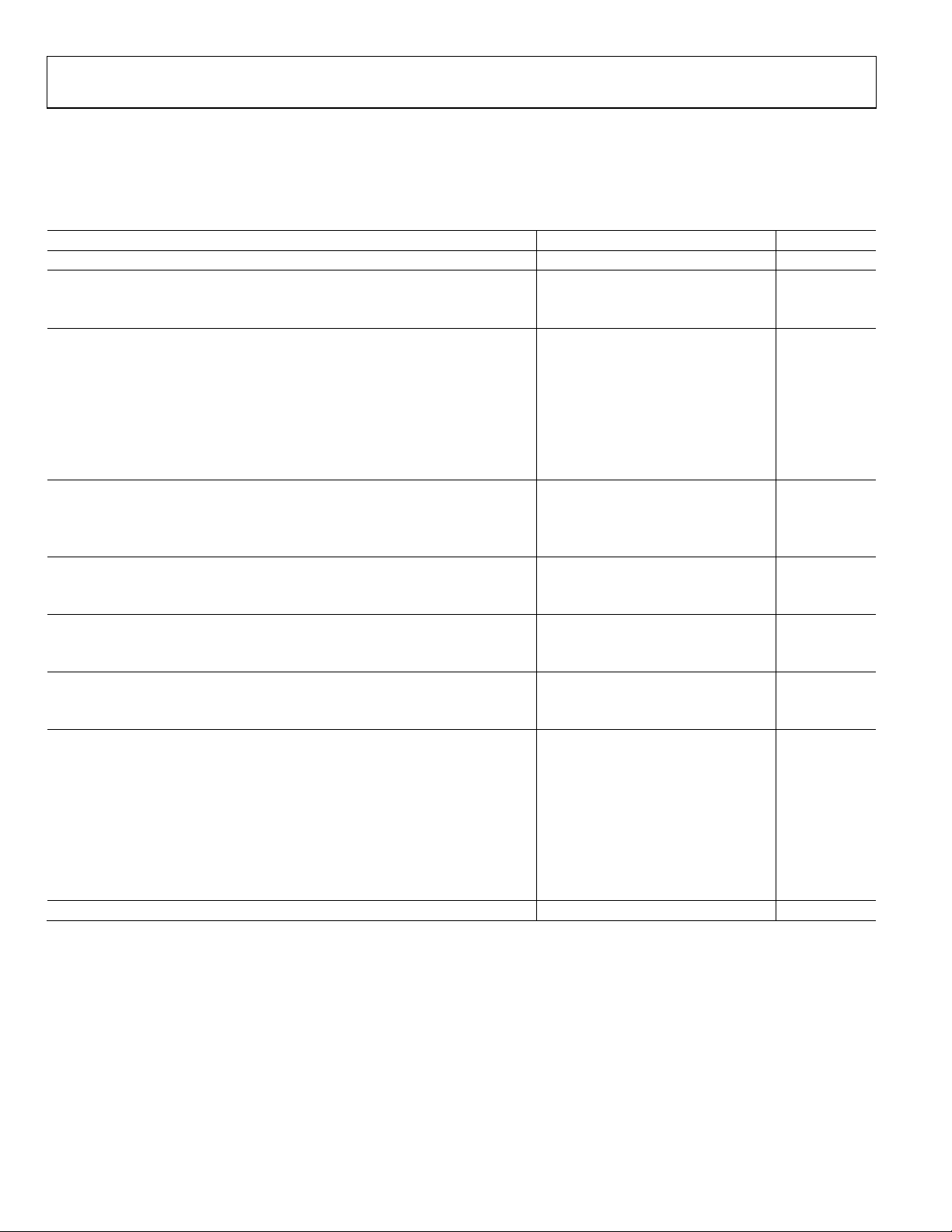

SPECIFICATIONS

DC SPECIFICATIONS

T

to T

MIN

Table 1.

Parameter Min Typ Max Unit

RESOLUTION 16 Bits

ACCURACY

Differential Nonlinearity (DNL) ±2.1 LSB

Integral Nonlinearity (INL) ±3.7 LSB

MAIN DAC OUTPUTS

Offset Error −0.001 0 +0.001 % FSR

Gain Error (with Internal Reference) −3.6 ±2 +3.6 % FSR

Full-Scale Output Current1 8.66 19.6 31.66 mA

Output Compliance Range −1.0 +1.0 V

Output Resistance 10 MΩ

Gain DAC Monotonicity Guaranteed

Settling Time to Within ±0.5 LSB 20 ns

MAIN DAC TEMPERATURE DRIFT

Offset 0.04 ppm/°C

Gain 100 ppm/°C

Reference Voltage 30 ppm/°C

REFERENCE

Internal Reference Voltage 1.2 V

Output Resistance 5 kΩ

ANALOG SUPPLY VOLTAGES

AVDD33 3.13 3.3 3.47 V

CVDD18 1.71 1.8 1.89 V

DIGITAL SUPPLY VOLTAGES

DVDD18 1.71 1.8 1.89 V

IOVDD 1.71 1.8/3.3 3.47 V

POWER CONSUMPTION

2× Mode, f

2× Mode, f

8× Mode, f

AVDD33 55 58 mA

CVDD18 78 85 mA

DVDD18 440 490 mA

Power-Down Mode 1.5 2.7 mW

Power Supply Rejection Ratio, AVDD33 −0.3 +0.3 % FSR/V

OPERATING RANGE −40 +25 +85 °C

1

Based on a 10 kΩ external resistor.

, AVDD33 = 3.3 V, DVDD18 = 1.8 V, CVDD18 = 1.8 V, I

MAX

= 491.52 MSPS, IF = 10 MHz, PLL Off 834 mW

DAC

= 491.52 MSPS, IF = 10 MHz, PLL On 913 mW

DAC

= 800 MSPS, IF = 10 MHz, PLL Off 1114 1227 mW

DAC

= 20 mA, maximum sample rate, unless otherwise noted.

OUTFS

Rev. 0 | Page 4 of 56

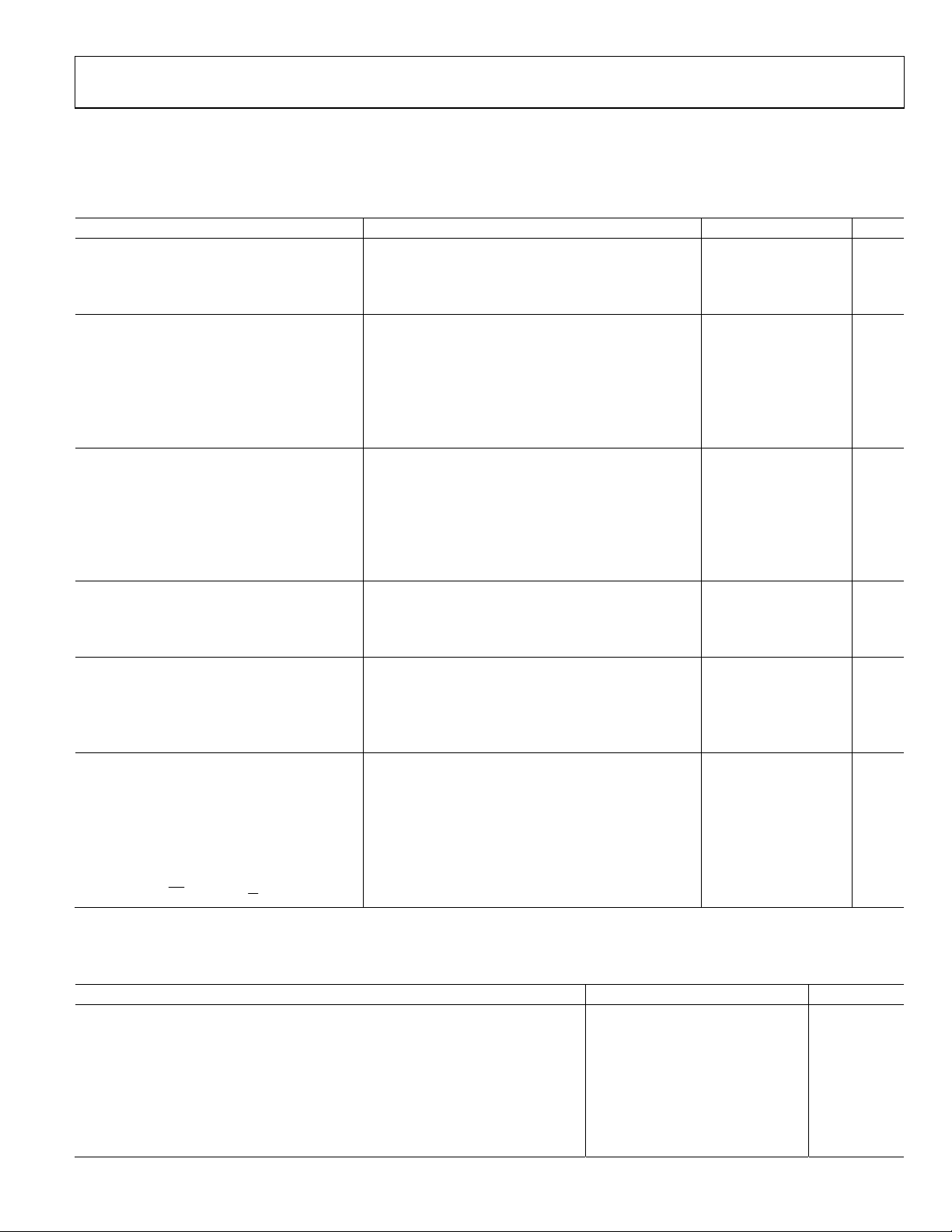

AD9125

DIGITAL SPECIFICATIONS

T

to T

MIN

otherwise noted.

Table 2.

Parameter Conditions Min Typ Max Unit

CMOS DATA INPUTS

Input VIN Logic High 1.2 V

Input VIN Logic Low 0.6 V

Maximum Bus Speed 250 MHz

SERIAL PORT OUTPUT LOGIC LEVELS

Output V

IOVDD = 2.5 V 1.8 V

IOVDD = 3.3 V 2.0 V

Output V

IOVDD = 2.5 V 0.4 V

IOVDD = 3.3 V 0.4 V

SERIAL PORT INPUT LOGIC LEVELS

Input VIN Logic High IOVDD = 1.8 V 1.2 V

IOVDD = 2.5 V 1.6 V

IOVDD = 3.3 V 2.4 V

Input VIN Logic Low IOVDD = 1.8 V 0.6 V

IOVDD = 2.5 V 0.8 V

IOVDD = 3.3V 0.8 V

DACCLK INPUT (DACCLKP, DACCLKN)

Differential Peak-to-Peak Voltage 100 500 2000 mV

Common-Mode Voltage Self biased input, ac couple 1.25 V

Maximum Clock Rate 1000 MHz

REFCLK INPUT (REFCLKP, REFCLKN)

Differential Peak-to-Peak Voltage 100 500 2000 mV

Common-Mode Voltage 1.25 V

REFCLKx Frequency, PLL Mode 1 GHz ≤ f

REFCLKx Frequency, SYNC Mode See the Multichip Synchronization section for conditions 0 600 MHz

SERIAL PERIPHERAL INTERFACE

Maximum Clock Rate (SCLK) 40 MHz

Minimum Pulse Width High (t

Minimum Pulse Width Low (t

Setup Time, SDI to SCLK (tDS) 1.9 ns

Hold Time, SDI to SCLK (tDH) 0.2 ns

Data Valid, SDO to SCLK (tDV) 2.3 ns

Setup Time, CS to SCLK (t

, AVDD33 = 3.3 V, IOVDD = 3.3 V, DVDD18 = 1.8 V, CVDD18 = 1.8 V, I

MAX

Logic High IOVDD = 1.8 V 1.4 V

OUT

Logic Low IOVDD = 1.8 V 0.4

OUT

≤ 2.1 GHz 15.625 600 MHz

VCO

) 12.5 ns

PWH

) 12.5 ns

PWOL

) 1.4 ns

D

CS

= 20 mA, maximum sample rate, unless

OUTFS

LATENCY AND POWER-UP TIMING SPECIFICATIONS

Table 3.

Parameter Min Typ Max Unit

LATENCY (DACCLK Cycles)

1× Interpolation (with or Without Modulation) 64 Cycles

2× Interpolation (with or Without Modulation) 135 Cycles

4× Interpolation (with or Without Modulation) 292 Cycles

8× Interpolation (with or Without Modulation) 608 Cycles

Inverse Sinc 20 Cycles

Fine Modulation 8 Cycles

Power-Up Time 260 ms

Rev. 0 | Page 5 of 56

AD9125

AC SPECIFICATIONS

T

to T

MIN

Table 4.

Parameter Min Typ Max Unit

SPURIOUS-FREE DYNAMIC RANGE (SFDR)

f

DAC

f

DAC

f

DAC

f

DAC

TWO-TONE INTERMODULATION DISTORTION (IMD)

f

DAC

f

DAC

f

DAC

f

DAC

NOISE SPECTRAL DENSITY (NSD) EIGHT-TONE, 500 kHz TONE SPACING

f

DAC

f

DAC

f

DAC

W-CDMA ADJACENT CHANNEL LEAKAGE RATIO (ACLR), SINGLE CARRIER

f

DAC

f

DAC

f

DAC

W-CDMA SECOND ACLR, SINGLE CARRIER

f

DAC

f

DAC

f

DAC

, AVDD33 = 3.3 V, DVDD18 = 1.8 V, CVDD18 = 1.8 V, I

MAX

= 100 MSPS, f

= 200 MSPS, f

= 400 MSPS, f

= 800 MSPS, f

= 200 MSPS, f

= 400 MSPS, f

= 400 MSPS, f

= 800 MSPS, f

= 200 MSPS, f

= 400 MSPS, f

= 800 MSPS, f

= 491.52 MSPS, f

= 491.52 MSPS, f

= 983.04 MSPS, f

= 491.52 MSPS, f

= 491.52 MSPS, f

= 983.04 MSPS, f

= 20 MHz 78 dBc

OUT

= 50 MHz 80 dBc

OUT

= 70 MHz 69 dBc

OUT

= 70 MHz 72 dBc

OUT

= 50 MHz 84 dBc

OUT

= 60 MHz 86 dBc

OUT

= 80 MHz 84 dBc

OUT

= 100 MHz 81 dBc

OUT

= 80 MHz −162 dBm/Hz

OUT

= 80 MHz −163 dBm/Hz

OUT

= 80 MHz −164 dBm/Hz

OUT

= 10 MHz 82 dBc

OUT

= 122.88 MHz 80 dBc

OUT

= 122.88 MHz 81 dBc

OUT

= 10 MHz 88 dBc

OUT

= 122.88 MHz 86 dBc

OUT

= 122.88 MHz 88 dBc

OUT

= 20 mA, maximum sample rate, unless otherwise noted.

OUTFS

Table 5. Interface Speeds

Mode Interpolation f

f

BUS

f

DATA

DAC

Byte Mode 1× 250 62.5 62.5

2× (HB1) 250 62.5 125

2× (HB2) 250 62.5 125

4× 250 62.5 250

8× 250 62.5 500

Word Mode 1× 250 125 125

2× (HB1) 250 125 250

2× (HB2) 250 125 250

4× 250 125 500

8× 250 125 1000

Dual-Word Mode 1× 250 250 250

2× (HB1) 250 250 500

2× (HB2) 250 250 500

4× 250 250 1000

8× 125 125 1000

Rev. 0 | Page 6 of 56

AD9125

ABSOLUTE MAXIMUM RATINGS

Table 6.

With

Parameter

AVDD33

IOVDD

DVDD18, CVDD18

AVS S

EPAD

CVSS

DVSS

FSADJ, REFIO,

IOUT1P/IOUT1N,

IOUT2P/IOUT2N

D[31:0], FRAME, DCI EPAD, DVSS −0.3 V to DVDD18 + 0.3 V

DACCLKP/DACCLKN,

REFCLKP/REFCLKN

RESET, IRQ, CS, SCLK,

SDIO, SDO

Junction Temperature 125°C

Storage Temperature

Range

Respect To Rating

AVSS, EPAD,

CVSS, DVSS

AVSS, EPAD,

CVSS, DVSS

AVSS, EPAD,

CVSS, DVSS

EPAD, CVSS,

DVSS

AVSS, CVSS,

DVSS

AVSS, EPAD,

DVSS

AVSS, EPAD,

CVSS

AVSS −0.3 V to AVDD33 + 0.3 V

DVSS −0.3 V to CVDD18 + 0.3 V

EPAD, DVSS −0.3 V to IOVDD + 0.3 V

−65°C to +150°C

−0.3 V to +3.6 V

−0.3 V to +3.6 V

−0.3 V to +2.1 V

−0.3 V to +0.3 V

−0.3 V to +0.3 V

−0.3 V to +0.3 V

−0.3 V to +0.3 V

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

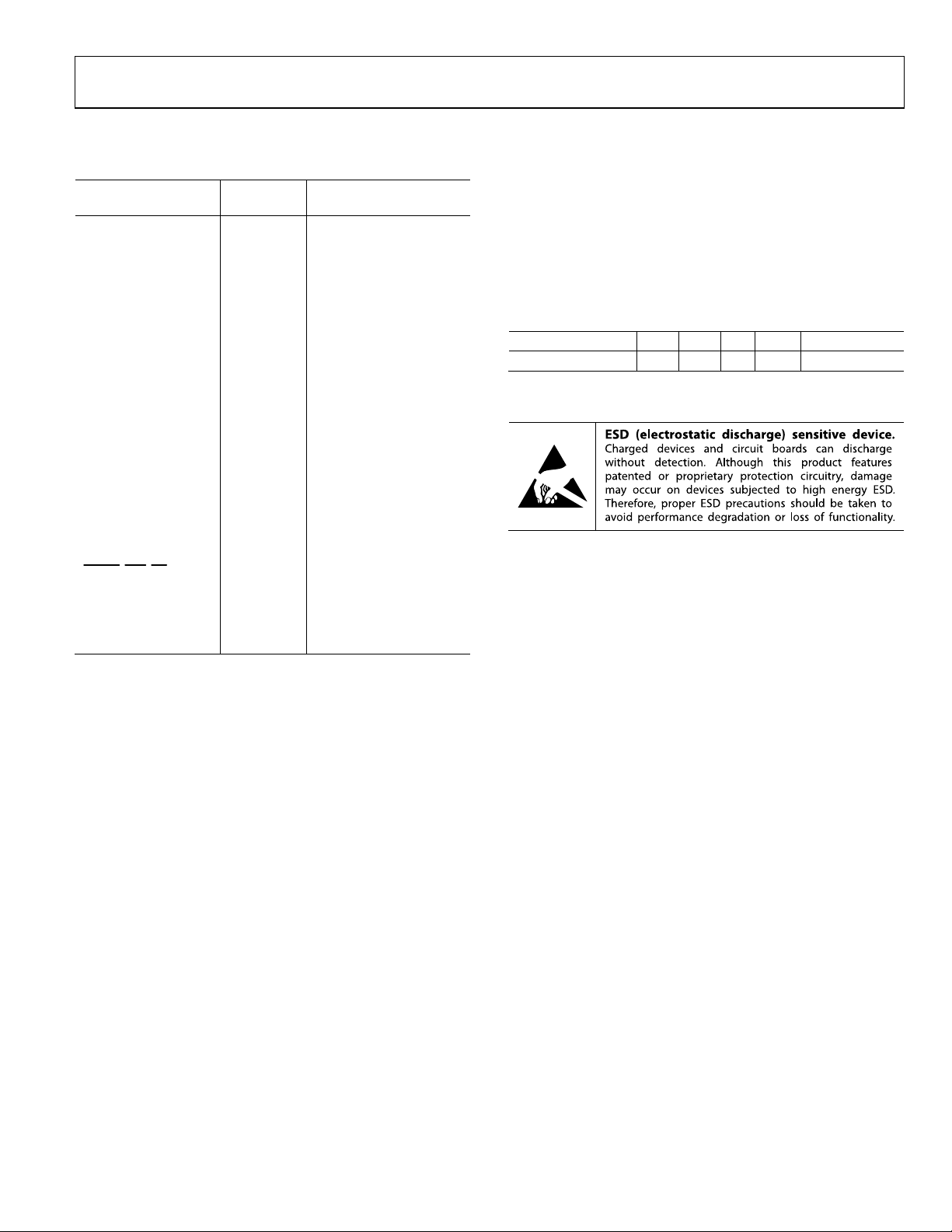

THERMAL RESISTANCE

The exposed paddle (EPAD) must be soldered to the ground

plane for the 72-lead LFCSP. The EPAD performs as an

electrical and thermal connection to the board.

Typical θ

, θJB, and θJC values are specified for a 4-layer board in

JA

still air. Airflow increases heat dissipation, effectively reducing

θ

and θJB.

JA

Table 7. Thermal Resistance

Package θJA θJB θJC Unit Conditions

72-Lead LFCSP 20.7 10.9 1.1 °C/W EPAD soldered

ESD CAUTION

Rev. 0 | Page 7 of 56

AD9125

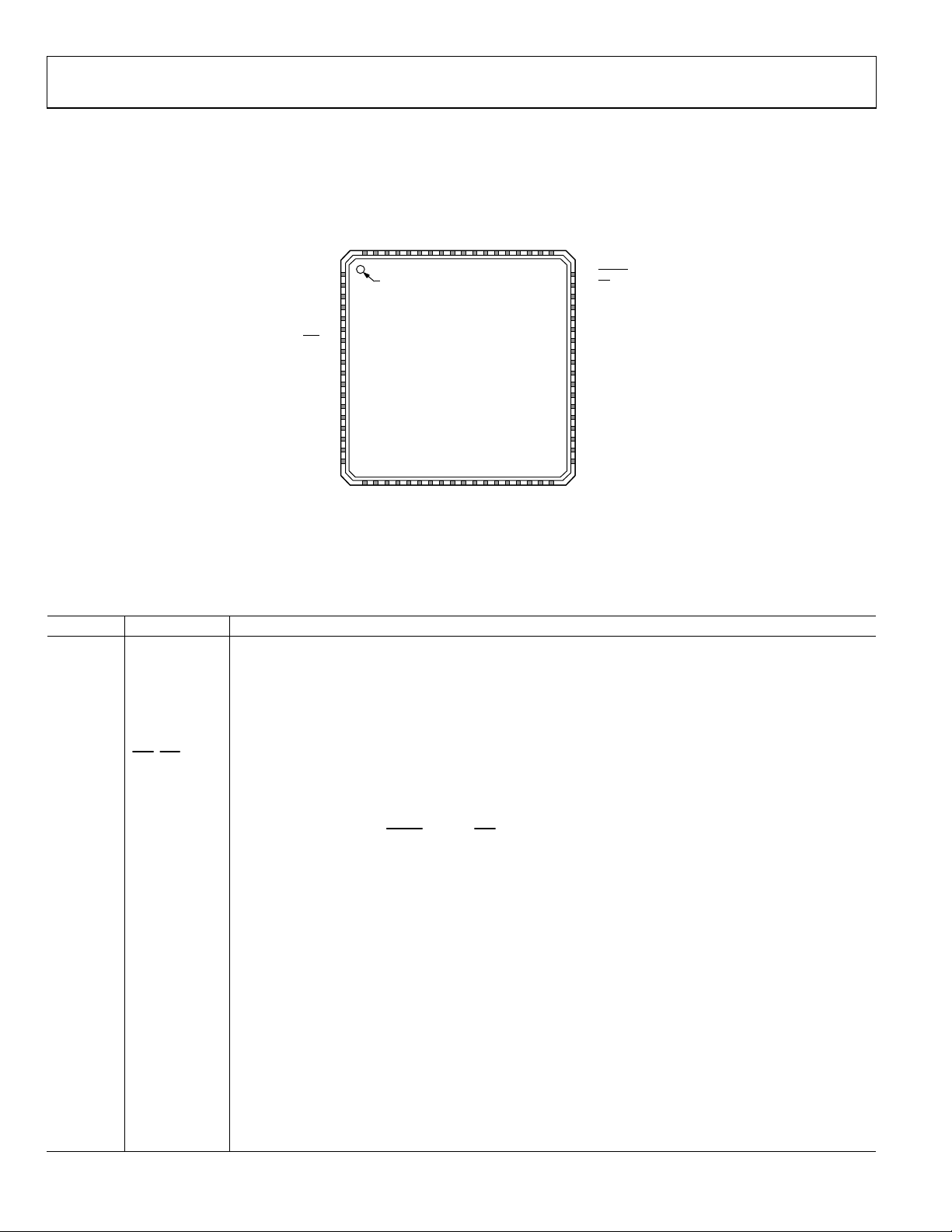

PIN CONFIGURATION AND FUNCTION DESCRIPTIONS

CVDD18

CVDD18

REFCLKP

REFCLKN

AVDD33

IOUT1P

IOUT1N

AVDD33

AVSS

FSADJ

REFIO

AVSS

AVDD33

IOUT2N

IOUT2P

AVDD33

AVSS

NC

7271706968676665646362616059585756

55

CVDD18

DACCLKP

DACCLKN

DVDD18

NOTES

1. NC = NO CONNECT.

2. EXPOSED PAD MUST BE CONNECTED TO AVSS.

CVSS

FRAME

NC

IRQ

D31

D30

NC

IOVDD

D29

D28

D27

D26

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17D25

18D24

PIN 1

INDICATOR

(Not to S cale)

192021222324252627282930313233

D23

D22

D21

D20

D19

D18

D17

AD9125

TOP VIEW

NC

DCI

D16

DVSS

DVDD18

D15

D14

D13

34

D12

35D11

36D10

54

53

52

51

50

49

48

47

46

45

44

43

42

41

40

39

38

37

RESET

CS

SCLK

SDIO

SDO

DVDD18

D0

D1

D2

D3

DVSS

DVDD18

D4

D5

D6

D7

D8

D9

09016-003

Figure 3. Pin Configuration

Table 8. Pin Function Descriptions

Pin No. Mnemonic Description

1 CVDD18 1.8 V Clock Supply. Supplies clock receivers, clock distribution, and PLL circuitry.

2 DACCLKP DAC Clock Input, Positive.

3 DACCLKN DAC Clock Input, Negative.

4 CVSS Clock Supply Common.

5 FRAME Frame Input.

6 NC No Connect

7

IRQ

(INT)

Interrupt Request. Open Drain, Active Low Output. Connect external pull-up to IOVDD.

8 D31 Data Bit 31.

9 D30 Data Bit 30.

10 NC No Connect.

11 IOVDD

Supply for Serial Port Pin, RESET

Pin, and IRQ Pin. 1.8 V to 3.3 V can be applied to this pin.

12 DVDD18 1.8 V Digital Supply. Supplies power to digital core and digital data ports.

13 D29 Data Bit 29.

14 D28 Data Bit 28.

15 D27 Data Bit 27.

16 D26 Data Bit 26.

17 D25 Data Bit 25.

18 D24 Data Bit 24.

19 D23 Data Bit 23.

20 D22 Data Bit 22.

21 D21 Data Bit 21.

22 D20 Data Bit 20.

23 D19 Data Bit 19.

24 D18 Data Bit 18.

25 D17 Data Bit 17.

26 D16 Data Bit 16.

27 DCI Data Clock Input.

Rev. 0 | Page 8 of 56

AD9125

Pin No. Mnemonic Description

28 NC No Connect.

29 DVDD18 1.8 V Digital Supply.

30 DVSS Digital Common.

31 D15 Data Bit 15.

32 D14 Data Bit 14.

33 D13 Data Bit 13.

34 D12 Data Bit 12.

35 D11 Data Bit 11.

36 D10 Data Bit 10.

37 D9 Data Bit 9.

38 D8 Data Bit 8.

39 D7 Data Bit 7.

40 D6 Data Bit 6.

41 D5 Data Bit 5.

42 D4 Data Bit 4.

43 DVDD18 1.8 V Digital Supply.

44 DVSS Digital Supply Common.

45 D3 Data Bit 3.

46 D2 Data Bit 2.

47 D1 Data Bit 1.

48 D0 Data Bit 0.

49 DVDD18 1.8 V Digital Supply.

50 SDO Serial Port Data Output (CMOS levels with respect to IOVDD).

51 SDIO Serial Port Data Input/Output (CMOS levels with respect to IOVDD).

52 SCLK Serial Port Clock Input (CMOS levels with respect to IOVDD).

53

54

55 NC No Connect.

56 AVSS Analog Supply Common.

57 AVDD33 3.3 V Analog Supply.

58 IOUT2P Q DAC Positive Current Output.

59 IOUT2N Q DAC Negative Current Output.

60 AVDD33 3.3 V Analog Supply.

61 AVSS Analog Supply Common.

62 REFIO Voltage Reference. Nominally 1.2 V output. Should be decoupled to analog common.

63 FSADJ Full-Scale Current Output Adjust. Place a 10 kΩ resistor on the analog common.

64 AVSS Analog Common.

65 AVDD33 3.3 V Analog Supply.

66 IOUT1N I DAC Negative Current Output.

67 IOUT1P I DAC Positive Current Output.

68 AVDD33 3.3 V Analog Supply.

69 REFCLKN PLL Reference Clock Input, Negative. This pin has a secondary function as the SYNC input.

70 REFCLKP PLL Reference Clock Input, Positive. This pin has a secondary function as the SYNC input.

71 CVDD18 1.8 V Clock Supply. Supplies clock receivers, clock distribution, and PLL circuitry.

72 CVDD18 1.8 V Clock Supply. Supplies clock receivers, clock distribution, and PLL circuitry.

EPAD

CS

RESET

Serial Port Chip Select. Active Low (CMOS levels with respect to IOVDD).

Reset. Active Low (CMOS levels with respect to IOVDD).

Exposed pad must be connected to AVSS. This provides an electrical, thermal, and mechanical connection

to the PCB.

Rev. 0 | Page 9 of 56

AD9125

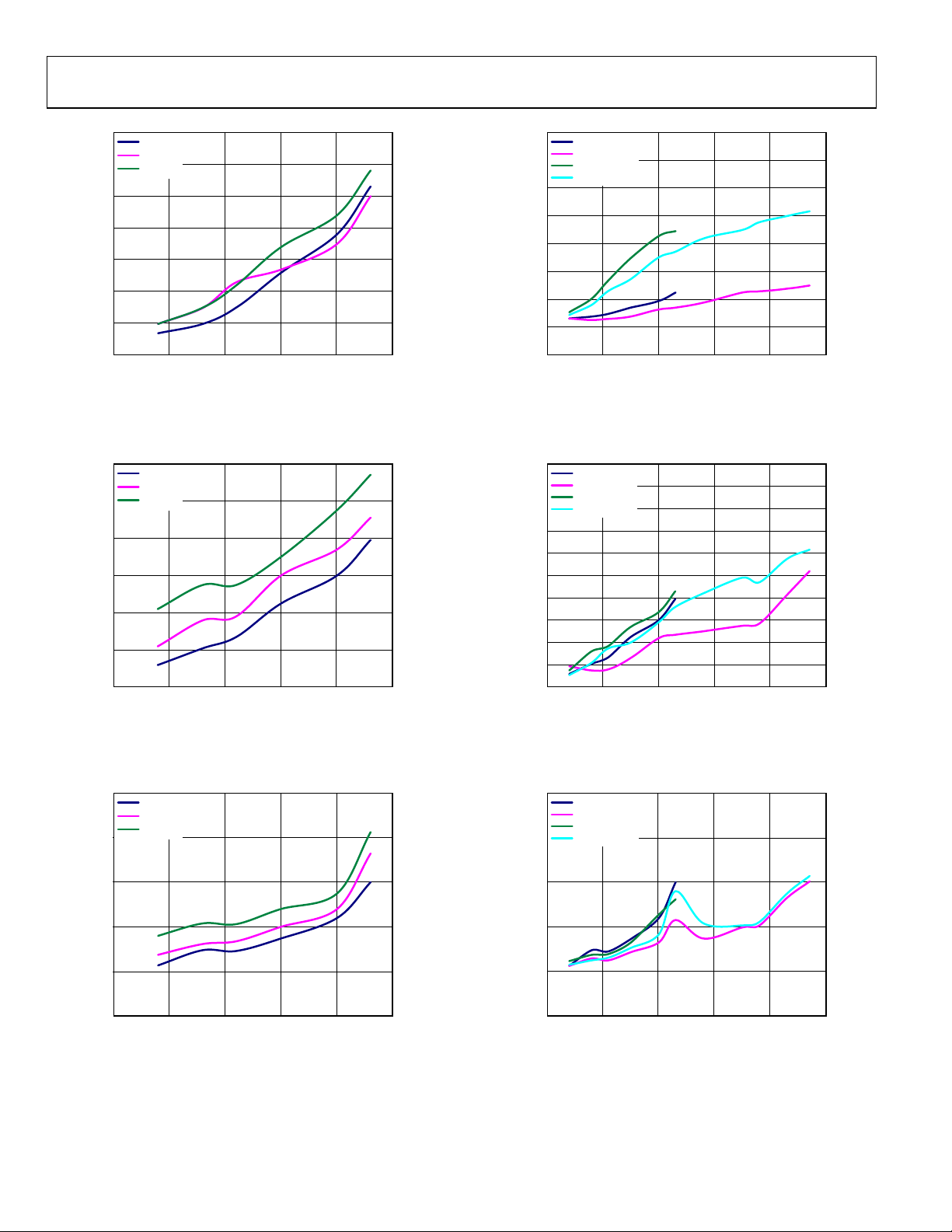

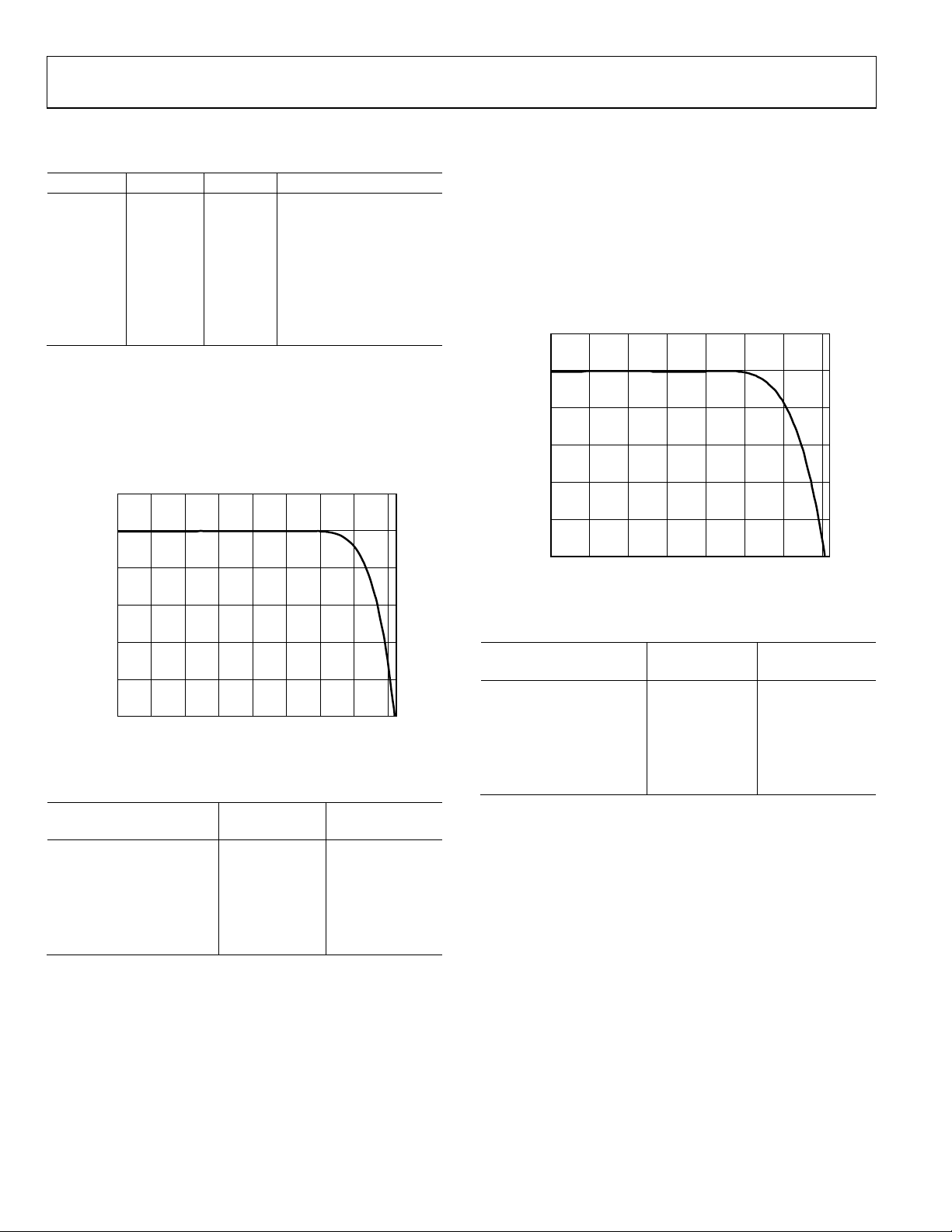

TYPICAL PERFORMANCE CHARACTERISTICS

0

f

= 125MSPS, S E COND HARMONIC

DATA

f

–10

–20

–30

–40

–50

–60

HARMONICS (dBc)

–70

–80

–90

–100

0 50 100 150 200 250 300

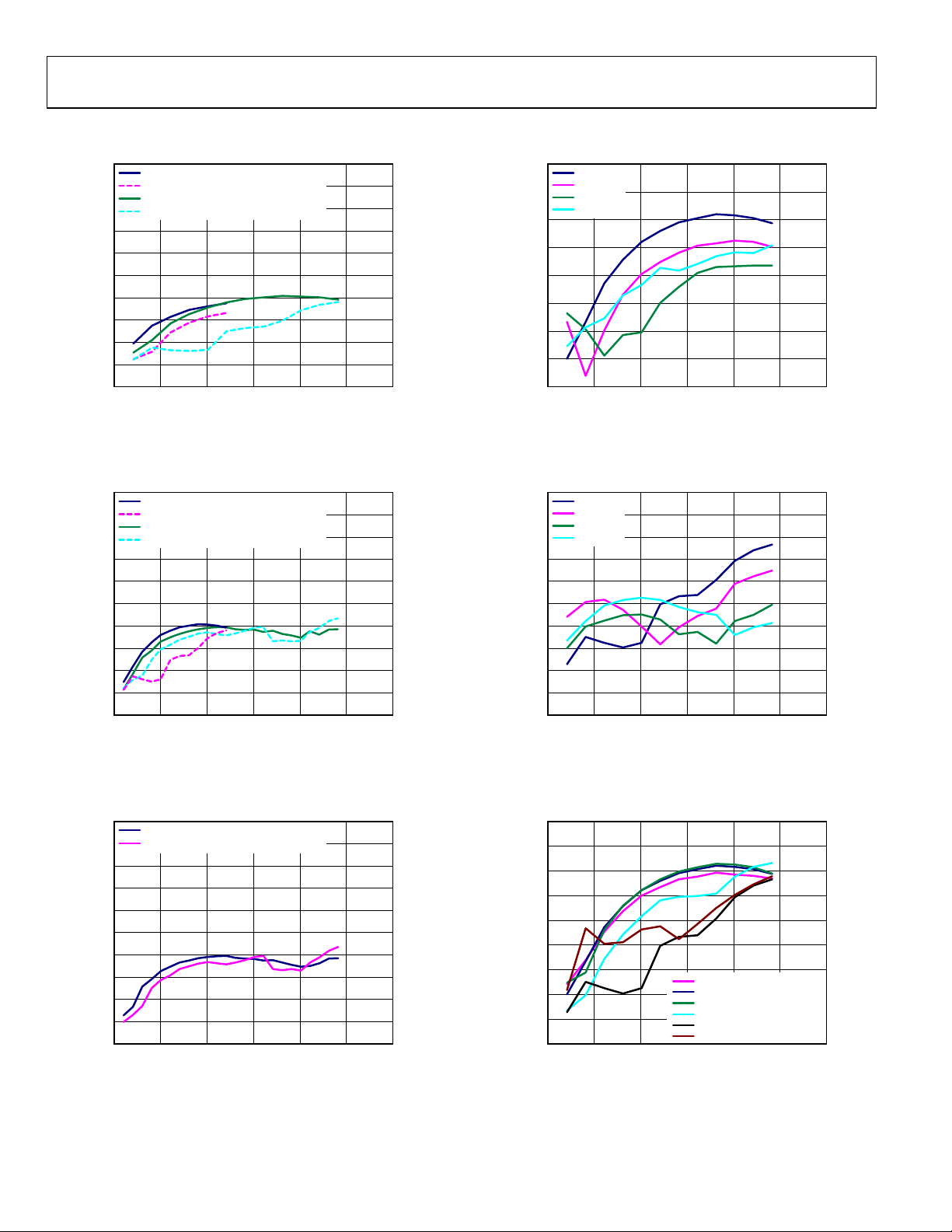

Figure 4. Harmonics vs. f

= 125MSPS, THIRD HARMONIC

DATA

f

= 250MSPS, S E COND HARMONIC

DATA

f

= 250MSPS, THIRD HARMONIC

DATA

f

(MHz)

OUT

over f

OUT

Digital Scale = 0 dBFS, f

, 2× Interpolation,

DATA

= 20 mA

SC

09016-101

–50

–55

–60

–65

–70

–75

HARMONICS (dBc)

–80

–85

–90

Figure 7. Second Harmonic vs. f

0dBFS

–6dBFS

–12dBFS

–18dBFS

0 50 100150200250300

f

(MHz)

OUT

over Digital Scale, 2× Interpolation,

OUT

= 250 MSPS, fSC = 20 mA

f

DATA

09016-104

0

f

= 125MSPS, S E COND HARMONIC

DATA

f

–10

–20

–30

–40

–50

–60

HARMONICS (d Bc)

–70

–80

–90

–100

0 100 200 300 400 500 600

Figure 5. Harmonics vs. f

0

–10

–20

–30

–40

–50

–60

HARMONICS (dBc)

–70

–80

–90

–100

0 100 200 300 400 500 600

Figure 6. Harmonics vs. f

= 125MSPS, THIRD HARMONIC

DATA

f

= 250MSPS, S E COND HARMONIC

DATA

f

= 250MSPS, THIRD HARMONIC

DATA

f

(MHz)

OUT

over f

OUT

Digital Scale = 0 dBFS, f

f

= 125MSPS, S E COND HARMONIC

DATA

f

= 125MSPS, THIRD HARMONIC

DATA

f

(MHz)

OUT

over f

OUT

Digital Scale = 0 dBFS, f

, 4× Interpolation,

DATA

= 20 mA

SC

, 8× Interpolation,

DATA

= 20 mA

SC

–50

–55

–60

–65

–70

–75

–80

HARMONICS (d Bc)

–85

–90

–95

–100

09016-102

Figure 8. Third Harmonic vs. f

–50

–55

–60

–65

–70

–75

–80

HARMONICS (dBc)

–85

–90

–95

09016-103

0dBFS

–6dBFS

–12dBFS

–18dBFS

0 50 100150200250300

f

(MHz)

OUT

over Digital Scale, 2× Interpolation,

OUT

= 250 MSPS, fSC = 20 mA

f

DATA

10mA, SECOND HARMONI C

20mA, SECOND HARMONI C

30mA, SECOND HARMONI C

10mA, THIRD HARMONIC

20mA, THIRD HARMONIC

30mA, THIRD HARMONIC

0 50 100150200250300

f

(MHz)

OUT

Figure 9. Harmonics vs. f

= 250 MSPS, Digital Scale = 0 dBFS

f

DATA

over fSC, 2× Interpolation,

OUT

09016-105

09016-106

Rev. 0 | Page 10 of 56

AD9125

–50

–55

–60

–65

–70

–75

–80

–85

HIGHEST DIGITAL S P UR ( dBc)

–90

–95

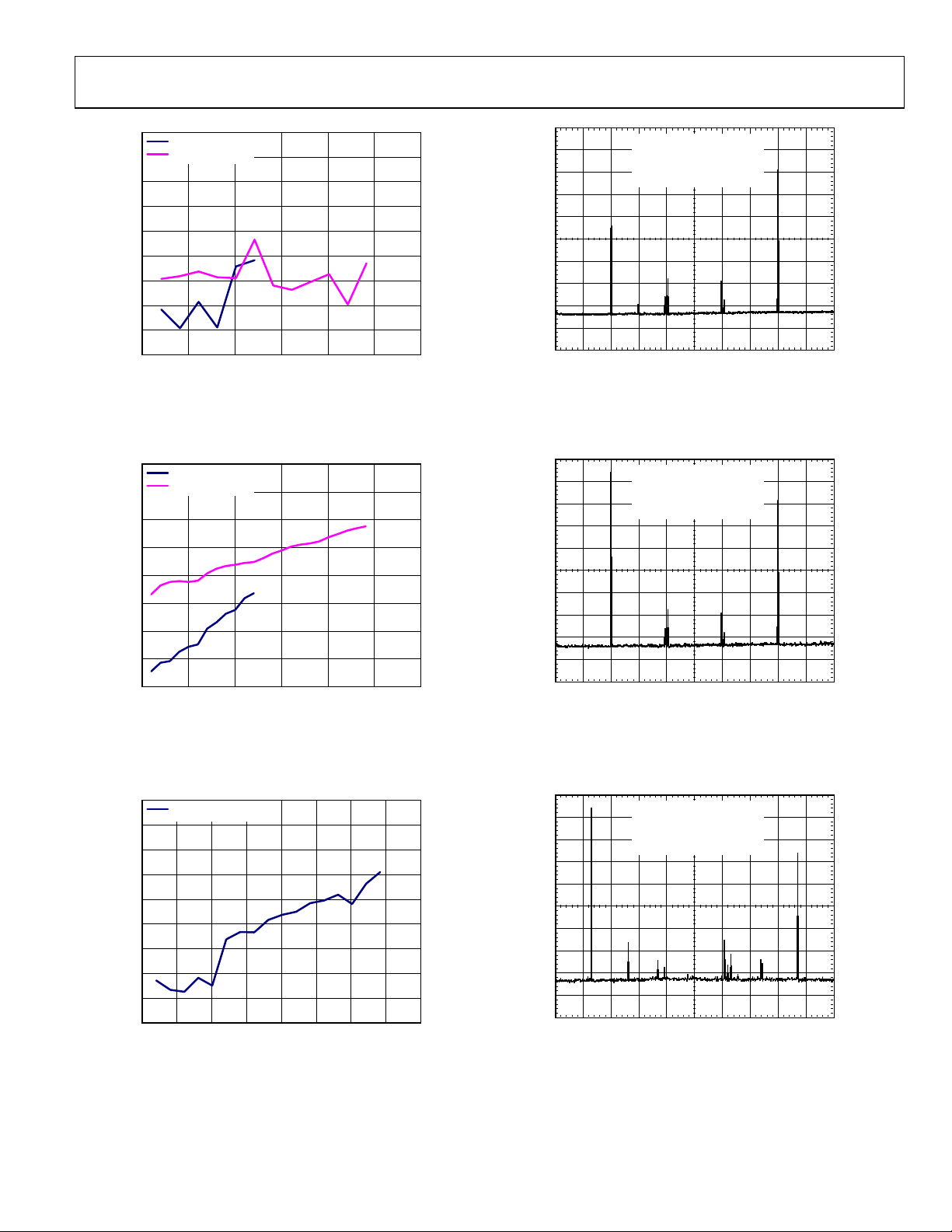

Figure 10. Highest Digital Spur vs. f

f

= 125MSPS

DATA

f

= 250MSPS

DATA

0 50 100 150 200 250 300

f

(MHz)

OUT

Digital Scale = 0 dBFS, f

OUT

over f

, 2× Interpolation,

DATA

= 20 mA

SC

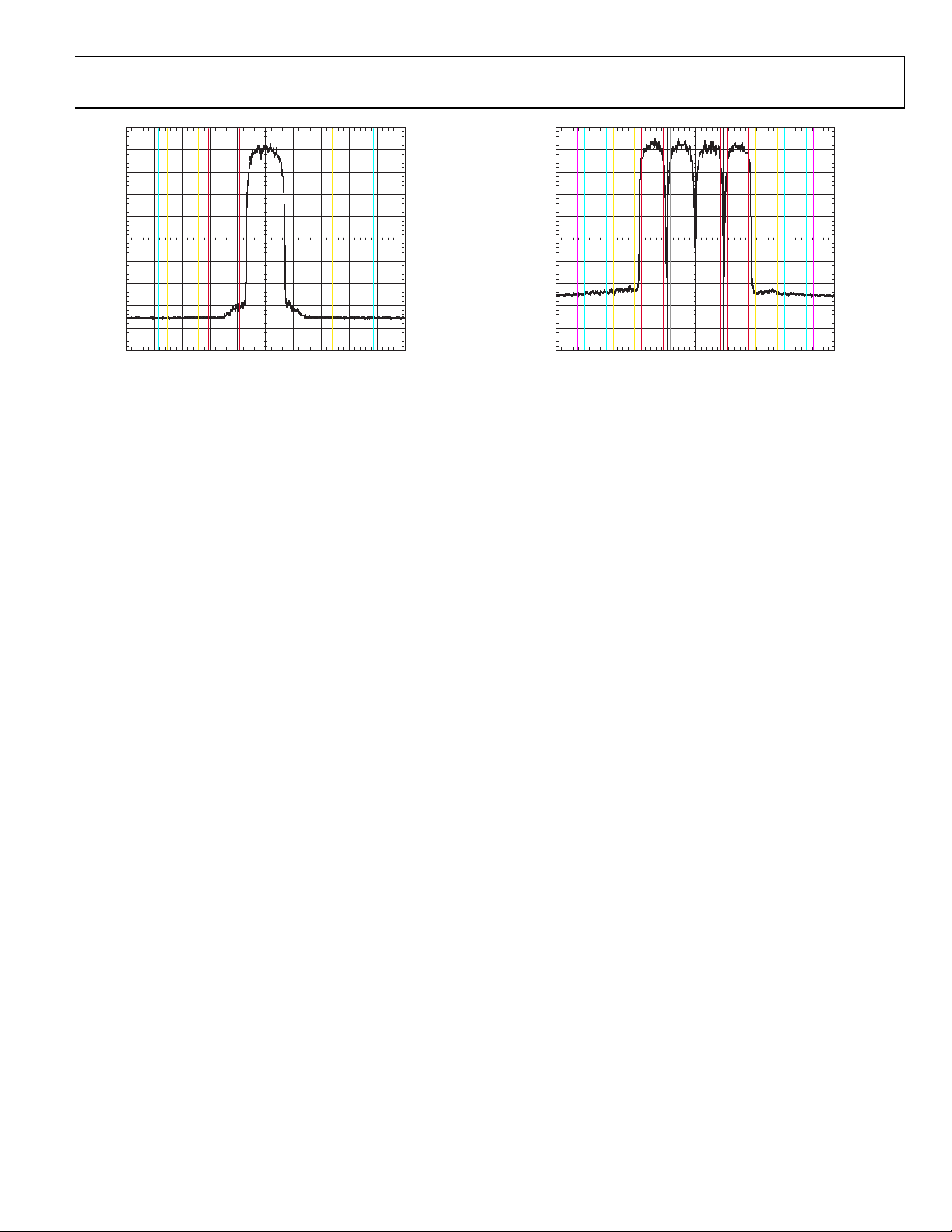

2× INTERPO LATION,

SINGLE-TONE SPECTRUM,

f

= 250MSPS,

DATA

f

= 101MHz

OUT

START 1.0 MHz

#RES BW 10kHz

09016-107

VBW 10kHz STOP 500.0M Hz

SWEEP 6.017s (601 PTS)

09016-110

Figure 13. 2× Interpolation, Single-Tone Spectrum

–50

–55

–60

–65

–70

–75

–80

HIGHEST DIGITAL S P UR ( dBc)

–85

–90

Figure 11. Highest Digital Spur vs. f

–50

–55

–60

–65

–70

–75

–80

–85

HIGHEST DIGITAL S P UR ( dBc)

–90

–95

Figure 12. Highest Digital Spur vs. f

f

= 125MSPS

DATA

f

= 250MSPS

DATA

0 100 200 300 400 500 600

f

(MHz)

OUT

040035030025020015010050

Digital Scale = 0 dBFS, f

f

= 125MSPS

DATA

Digital Scale = 0 dBFS, f

f

OUT

OUT

(MHz)

OUT

over f

over f

, 4× Interpolation,

DATA

= 20 mA

SC

, 8× Interpolation,

DATA

= 20 mA

SC

4× INTERPO LATION,

SINGLE-TONE SPECTRUM,

f

= 125MSPS,

DATA

f

= 101MHz

OUT

START 1.0 MHz

#RES BW 10kHz

09016-108

VBW 10kHz STOP 500.0M Hz

SWEEP 6.017s (601 PTS)

09016-111

Figure 14. 4× Interpolation, Single-Tone Spectrum

8× INTERPO LATION,

SINGLE-TONE SPECTRUM,

f

= 125MSPS,

DATA

f

= 131MHz

OUT

START 1.0 MHz

#RES BW 10kHz

09016-109

VBW 10kHz STOP 1.0G Hz

SWEEP 12.05s (601 PTS)

09016-112

Figure 15. 8× Interpolation, Single-Tone Spectrum

Rev. 0 | Page 11 of 56

AD9125

–50

–55

–60

f

DATA

f

DATA

= 125MSPS

= 250MSPS

–50

–55

–60

0dBFS

–6dBFS

–12dBFS

–18dBFS

–65

–70

IMD (dBc)

–75

–80

–85

–90

0 50 100 150 200 250 300

f

(MHz)

OUT

–50

–55

–60

–65

–70

IMD (dBc)

–75

–80

–85

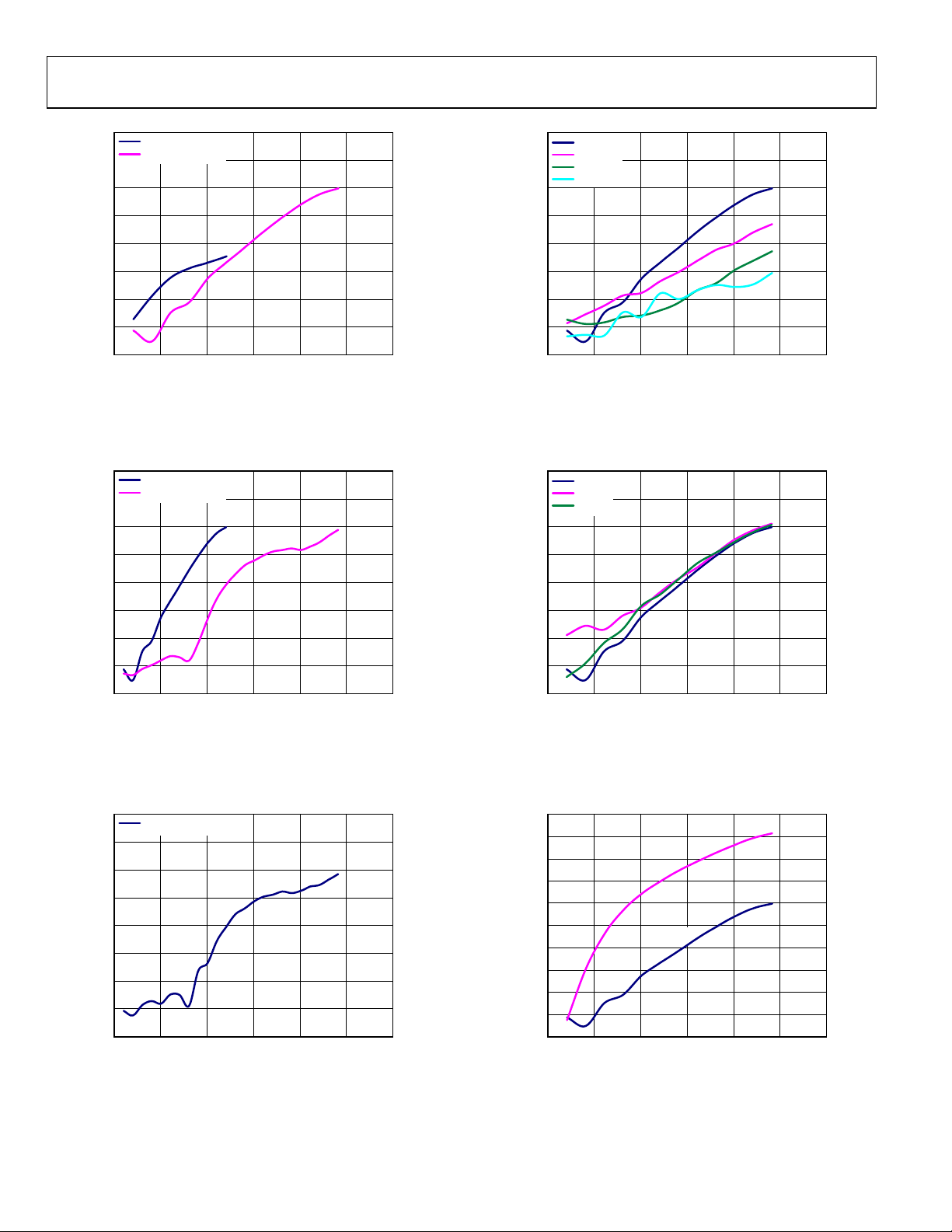

Figure 16. IMD vs. f

Digital Scale = 0 dBFS, f

f

= 125MSPS

DATA

f

= 250MSPS

DATA

OUT

over f

, 2× Interpolation,

DATA

= 20 mA

SC

–65

–70

IMD (dBc)

–75

–80

–85

–90

0 50 100 150 200 250 300

f

(MHz)

09016-113

Figure 19. IMD vs. f

f

DATA

–50

–55

–60

–65

–70

IMD (dBc)

–75

–80

–85

20mA

30mA

10mA

OUT

over Digital Scale, 2× Interpolation,

OUT

= 250 MSPS, fSC = 20 mA

09016-116

–90

0 100 200 300 400 500 600

f

(MHz)

OUT

Figure 17. IMD vs. f

Digital Scale = 0 dBFS, f

–50

–55

–60

–65

–70

IMD (dBc)

–75

–80

–85

–90

f

= 125MSPS

DATA

0 100 200 300 400 500 600

Figure 18. IMD vs. f

Digital Scale = 0 dBFS, f

OUT

OUT

over f

f

OUT

over f

, 4× Interpolation,

DATA

= 20 mA

SC

(MHz)

, 8× Interpolation,

DATA

= 20 mA

SC

–90

0 50 100 150 200 250 300

f

(MHz)

09016-114

Figure 20. IMD vs. f

OUT

OUT

over fSC, 2× Interpolation, f

= 250 MSPS,

DATA

09016-117

Digital Scale = 0 dBFS

–40

–45

–50

–55

–60

–65

IMD (dBc)

–70

–75

–80

–85

–90

0 50 100 150 200 250 300

09016-115

PLL ON

PLL OFF

Figure 21. IMD vs. f

f

(MHz)

OUT

, PLL On vs. PLL Off

OUT

09016-118

Rev. 0 | Page 12 of 56

AD9125

–154

–156

–158

–160

–162

NSD (dBm/Hz)

–164

–166

–168

0600500400300200100

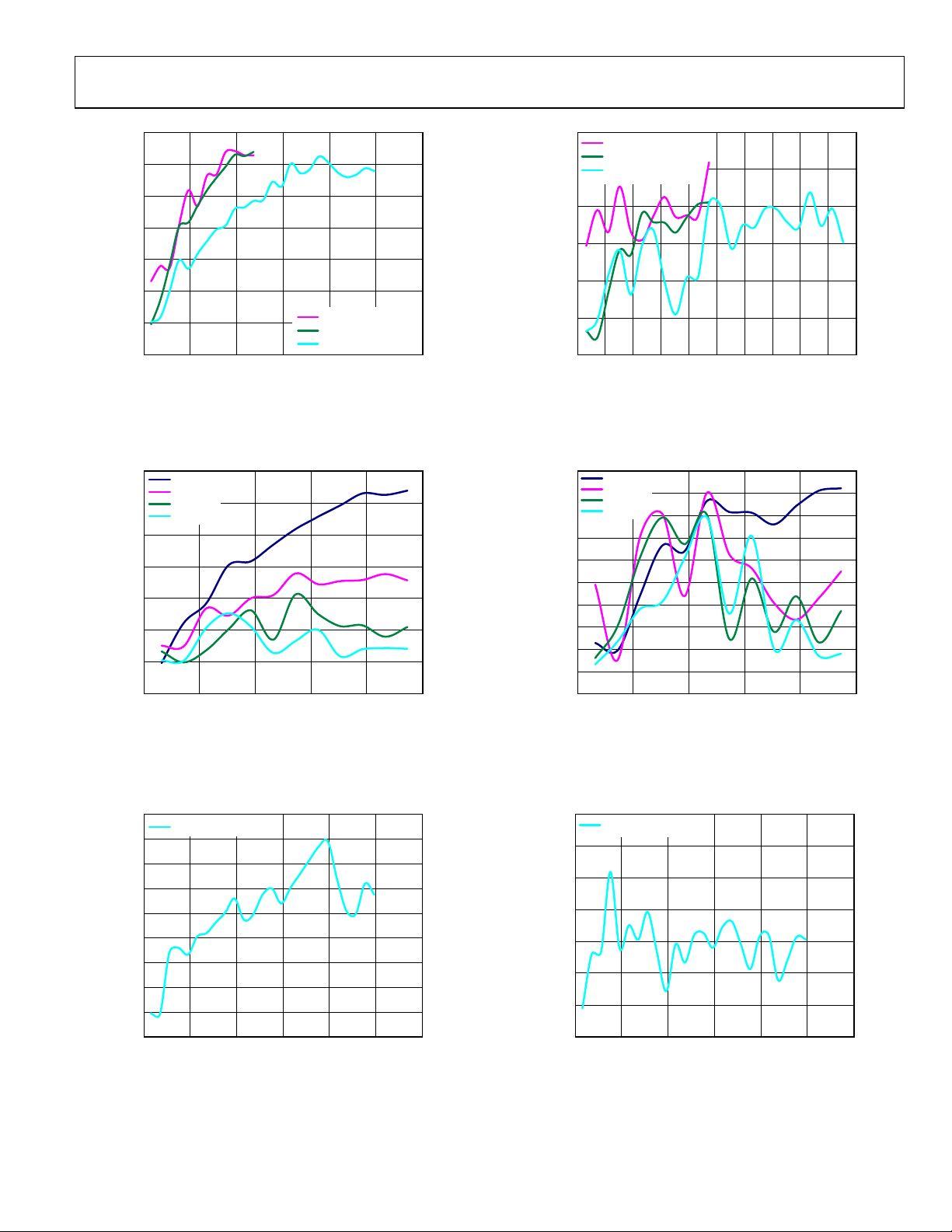

Figure 22. One-Tone NSD vs. f

Scale = 0 dBFS, f

2×,

f

DATA

4×,

f

DATA

8×,

f

DATA

f

(MHz)

OUT

over Interpolation Rate and f

OUT

= 20 mA, PLL Off

SC

= 250MSPS

= 125MSPS

= 125MSPS

DATA

09016-119

, Digital

–160

–161

–162

–163

NSD (dBm/Hz)

–164

–165

–166

Figure 25. Eight-Tone NSD vs. f

2×,

f

= 250MSPS

DATA

4×,

f

= 125MSPS

DATA

8×,

f

= 125MSPS

DATA

0 50 100 150 200 250 300 350 400 500450

f

(MHz)

OUT

over Interpolation Rate and f

OUT

Digital Scale = 0 dBFS, f

= 20 mA, PLL Off

SC

DATA

09016-122

,

–154

–156

–158

–160

–162

NSD (dBm/Hz)

–164

–166

–168

0dBFS

–6dBFS

–12dBFS

–18dBFS

025020015010050

Figure 23. One-Tone NSD vs. f

4× Interpolation, f

–158

–159

–160

–161

–162

–163

NSD (dBm/Hz)

–164

–165

–166

–167

8×,

0600500400300200100

f

DATA

= 125MSPS

Figure 24. One-Tone NSD vs. f

Digital Scale = 0 dBFS, f

f

(MHz)

OUT

over Digital Scale, f

OUT

= 20 mA, PLL Off

SC

f

(MHz)

OUT

over Interpolation Rate and f

OUT

= 20 mA, PLL On

SC

DATA

= 200 MSPS,

,

DATA

–161.5

–162.0

–162.5

–163.0

–163.5

–164.0

–164.5

NSD (dBm/Hz)

–165.0

–165.5

–166.0

–166.5

09016-120

Figure 26. Eight-Tone NSD vs. f

–160

–161

–162

–163

–164

NSD (dBm/Hz)

–165

–166

–167

09016-121

Figure 27. Eight-Tone NSD vs. f

0dBFS

–6dBFS

–12dBFS

–18dBFS

0 50 100 150 200 250

f

(MHz)

OUT

over Digital Scale, f

OUT

4× Interpolation, f

8×,

f

= 125MSPS

DATA

0 100 200 300 500400 600

Digital Scale = 0 dBFS, f

= 20 mA, PLL Off

SC

f

(MHz)

OUT

over Interpolation Rate and f

OUT

= 20 mA, PLL On

SC

= 200 MSPS,

DATA

DATA

09016-123

09016-124

,

Rev. 0 | Page 13 of 56

AD9125

ACLR (dBc)

–77

–78

–79

–80

–81

–82

–83

0dBFS

–3dBFS

–6dBFS

ACLR (dBc)

–50

–55

–60

–65

–70

–75

–80

–85

2×, PLL OFF

4×, PLL OFF

2×, PLL ON

4×, PLL ON

–84

0 50 100 150 200 250

f

(MHz)

OUT

Figure 28. One-Carrier W-CDMA ACLR vs. f

over Digital Cutback,

OUT

Adjacent Channel, PLL Off

–78

–80

–82

–84

ACLR (dBc)

–86

–88

–90

0dBFS

–3dBFS

–6dBFS

0 50 100 150 200 250

f

(MHz)

OUT

Figure 29. One-Carrier W-CDMA ACLR vs. f

OUT

Alternate Channel, PLL Off

–70

–75

0dBFS

–3dBFS

–6dBFS

over f

DAC

–90

0 100 200 300 400 500

f

(MHz)

09016-125

Figure 31. One-Carrier W-CDMA ACLR vs. f

OUT

over Interpolation Rate,

OUT

09016-128

Adjacent Channel, PLL On vs. PLL Off

–70

–72

–74

–76

–78

–80

–82

ACLR (dBc)

–84

–86

–88

–90

09016-126

,

Figure 32. One-Carrier W-CDMA ACLR vs. f

2×, PLL OFF

4×, PLL OFF

2×, PLL ON

4×, PLL ON

0 100 200 300 400 500

f

(MHz)

OUT

over Interpolation Rate,

OUT

09016-129

Alternate Channel, PLL On vs. PLL Off

–70

–75

2×, PLL OFF

4×, PLL OFF

2×, PLL ON

4×, PLL ON

–80

–85

ACLR (dBc)

–90

–95

0 50 100 150 200 250

f

(MHz)

OUT

Figure 30. One-Carrier W-CDMA ACLR vs. f

OUT

Second Alternate Channel, PLL Off

over f

DAC

09016-127

,

Rev. 0 | Page 14 of 56

–80

ACLR (dBc)

–85

–90

–95

0 100 200 300 400 500

f

(MHz)

OUT

Figure 33. One-Carrier W-CDMA ACLR vs. f

over Interpolation Rate,

OUT

Second Alternate Channel, PLL On vs. PLL Off

09016-130

AD9125

START 133.06M Hz

#RES BW 30kHz

RMS RESULTS FREQ LOWER UPPER

CARRIER POWER 5.00MHz 3.840MHz –75.96 –85.96 –77.13 –87.13

–10.00dBm/ 10.00MHz 3.840MHz –85.33 –95.33 –85.24 –95.25

3.840MHz 15.00MHz 2.888MHz –95.81 –95.81 –85.43 –95.43

OFFSET REF BW dBc dBm dBc dBm

VBW 30kHz STOP 166.94MHz

SWEEP 143.6ms (601 PTS)

Figure 34. Four-Carrier W-CDMA ACLR Performance, IF ≈150 MHz

START 125.88MHz

#RES BW 30kHz

TOTAL CARRIER POWER: –11.19dBm/15.3600MHz

RRC FILTER: OFF FILTER ALPHA 0.22

REF CARRIER POWER: –16.89dBm/3.84000MHz

09016-131

1 –16.92dBm 5.000MHz 3.840MHz –65.88 –82.76 –67.52 –84.40

2 –16.89dBm 10.00MHz 3.840MHz –68.17 –85.05 –69.91 –86.79

3 –17.43dBm 15.00MHz 3.840MHz –70.42 –87.31 –71.40 –88.28

4 –17.64dBm

OFFSET FREQ INTEG BW dBc dBm dBc dBm

VBW 30kHz S TOP 174.42M Hz

SWEEP 206.9ms (601 PTS)

LOWER UPPER

09016-132

Figure 35. One-Carrier W-CDMA ACLR Performance, IF ≈150 MHz

Rev. 0 | Page 15 of 56

AD9125

TERMINOLOGY

Integral Nonlinearity (INL)

INL is defined as the maximum deviation of the actual analog

output from the ideal output, determined by a straight line drawn

from zero scale to full scale.

Differential Nonlinearity (DNL)

DNL is the measure of the variation in analog value, normalized

to full scale, associated with a 1 LSB change in digital input code.

Offset Error

The deviation of the output current from the ideal of zero is

called offset error. For IOUT1P, 0 mA output is expected when

the inputs are all 0s. For IOUT1N, 0 mA output is expected

when all inputs are set to 1.

Gain Error

The difference between the actual and ideal output span. The

actual span is determined by the difference between the outputs

when all inputs are set to 1 vs. when all inputs are set to 0.

Output Compliance Range

The range of allowable voltage at the output of a current output

DAC. Operation beyond the maximum compliance limits can

cause either output stage saturation or breakdown, resulting in

nonlinear performance.

Temp er at u re D ri ft

Temperature drift is specified as the maximum change from

the ambient (25°C) value to the value at either T

MIN

or T

MAX

.

For offset and gain drift, the drift is reported in ppm of fullscale range (FSR) per degree Celsius. For reference drift, the

drift is reported in ppm per degree Celsius.

Power Supply Rejection (PSR)

The maximum change in the full-scale output as the supplies

are varied from minimum to maximum specified voltages.

Settling Time

The time required for the output to reach and remain within a

specified error band around its final value, measured from

the start of the output transition.

Spurious-Free Dynamic Range (SFDR)

The difference in decibels between the peak amplitude of the

output signal and the peak spurious signal within the dc to the

Nyquist frequency of the DAC. Typically, energy in this band is

rejected by the interpolation filters. This specification, therefore,

defines how well the interpolation filters work and the effect of

other parasitic coupling paths to the DAC output.

Signal-to-Noise Ratio (SNR)

SNR is the ratio of the rms value of the measured output signal

to the rms sum of all other spectral components below the Nyquist

frequency, excluding the first six harmonics and dc. The value

for SNR is expressed in decibels.

Interpolation Filter

If the digital inputs to the DAC are sampled at a multiple rate of

f

(interpolation rate), a digital filter can be constructed that

DATA

has a sharp transition band near f

appear around f

(output data rate) can be greatly suppressed.

DAC

/2. Images that typically

DATA

Adjacent Channel Leakage Ratio (ACLR)

The ratio in decibels relative to the carrier (dBc) between the

measured power within a channel and that of its adjacent channel.

Complex Image Rejection

In a traditional two-part upconversion, two images are created

around the second IF frequency. These images have the effect

of wasting transmitter power and system bandwidth. By placing

the real part of a second complex modulator in series with the

first complex modulator, either the upper or lower frequency

image near the second IF can be rejected.

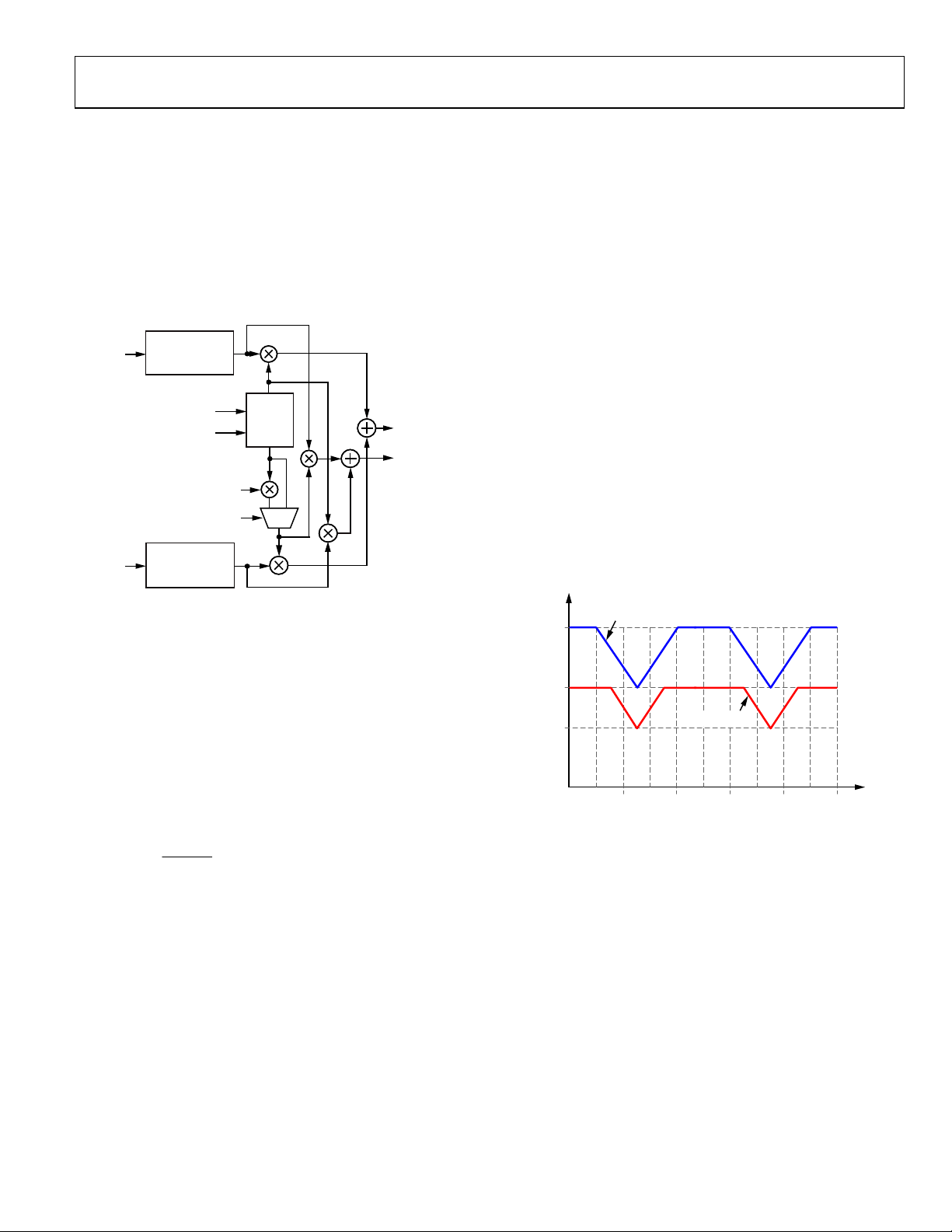

DATA

DCI

LATCH

INPUT

f

INTERFACE

DATA

FORMAT

32

WRITE

POINTER

16

2

FIFO

16

2

READ

POINTER

f

/

f

DATA

HB1

Figure 36. Defining Data Rates

Rev. 0 | Page 16 of 56

f

SIN

NCO

COS

CLOCK GENERATOR

AND DISTRIBUTOR

/

f

NCO

HB2

16

22

22

f

HB3

I DAC

16

Q DAC

DACCLK

f

DAC

09016-136

AD9125

THEORY OF OPERATION

The AD9125 combines many features that make it a very attractive

DAC for wired and wireless communications systems. The dual

digital signal path and dual DAC structure allow an easy interface

to common quadrature modulators when designing single

sideband transmitters. The speed and performance of the AD9125

allows wider bandwidths and more carriers to be synthesized than

in previously available DACs. In addition, these devices include an

innovative low power, 32-bit, complex NCO that greatly increases

the ease of frequency placement.

The AD9125 offers features that allow simplified synchronization

with incoming data and between multiple devices. Auxiliary

DACs are also provided on chip for output dc offset compensation

(for local oscillator [LO] compensation in single sideband [SSB]

transmitters) and for gain matching (for image rejection

optimization in SSB transmitters).

SERIAL PORT OPERATION

The serial port is a flexible, synchronous serial communication

port, allowing easy interface to many industry-standard microcontrollers and microprocessors. The serial I/O is compatible

with most synchronous transfer formats, including both the

Motorola SPI® and Intel® SSR protocols. The interface allows

read/write access to all registers that configure the AD9125.

Single- or multiple-byte transfers are supported, as well as MSBfirst or LSB-first transfer formats. The serial interface ports can

be configured as a single-pin I/O (SDIO) or two unidirectional

pins for input/output (SDIO/SDO).

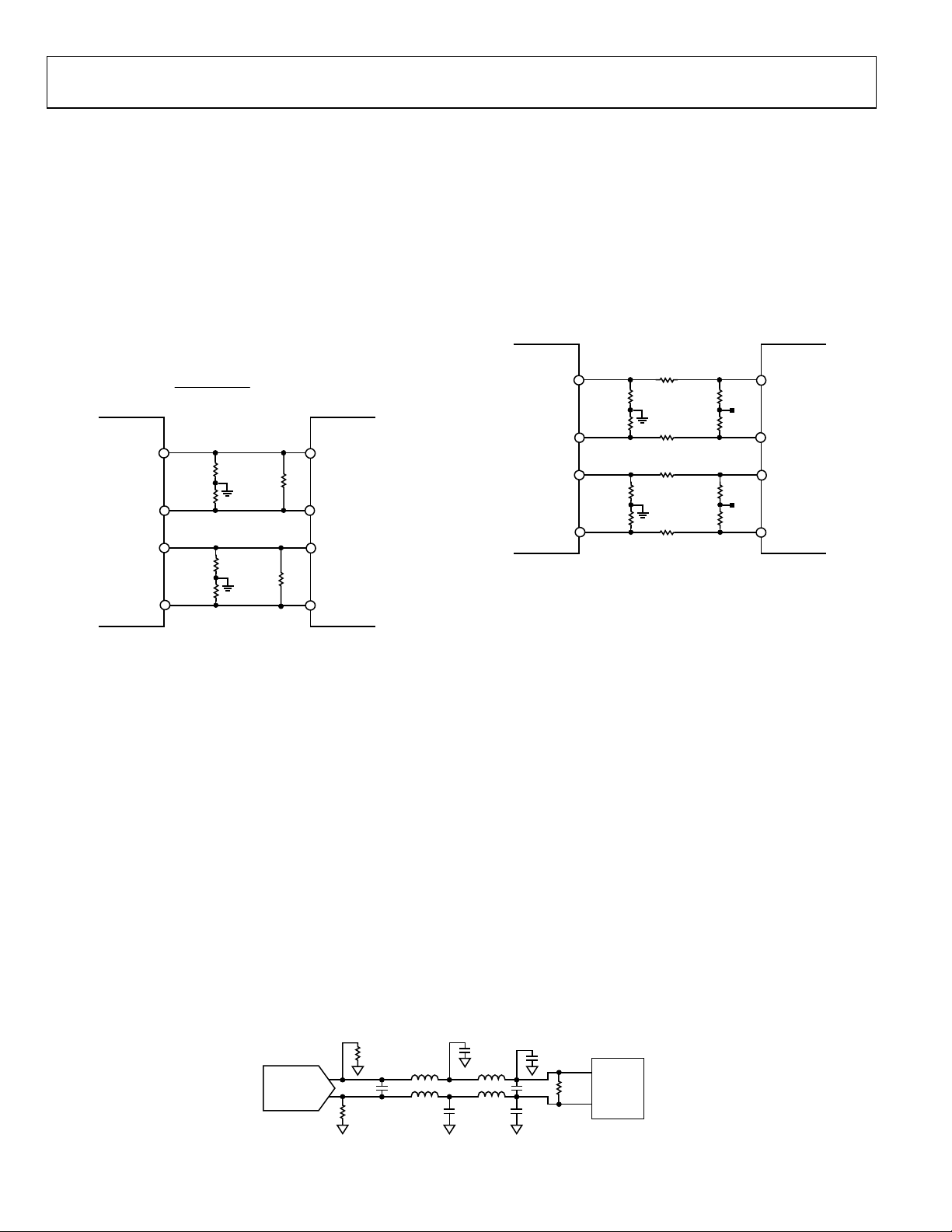

50

SDO

51

SDIO

SCLK

Figure 37. Serial Port Interface Pins

There are two phases of a communication cycle with the

AD9125. Phase 1 is the instruction cycle (the writing of an

instruction byte into the device), which is coincident with the

first eight SCLK rising edges. The instruction byte provides the

serial port controller with information regarding the data

transfer cycle, which is Phase 2 of the communication cycle.

The Phase 1 instruction byte defines whether the upcoming

data transfer is a read or write and the starting register address

for the first byte of the data transfer. The first eight SCLK rising

edges of each communication cycle are used to write the

instruction byte into the device.

A logic high on the

CS

pin followed by a logic low resets the

serial port timing to the initial state of the instruction cycle.

From this state, the next eight rising SCLK edges represent the

instruction bits of the current I/O operation.

CS

SPI

PORT

52

53

09016-010

The remaining SCLK edges are for Phase 2 of the communication

cycle. Phase 2 is the actual data transfer between the device and

the system controller. Phase 2 of the communication cycle is a

transfer of one or more data bytes. Registers change immediately

upon writing to the last bit of each transfer byte, except for the

frequency tuning word and NCO phase offsets, which only change

when the frequency update bit (Register 0x36, Bit 0) is set.

DATA FORMAT

The instruction byte contains the information shown in Tab l e 9 .

Table 9. Serial Port Instruction Byte

I7 (MSB) I6 I5 I4 I3 I2 I1 I0 (LSB)

R/W

A6 A5 A4 A3 A2 A1 A0

R/W, Bit 7 of the instruction byte, determines whether a read or

write data transfer occurs after the instruction byte write. Logic 1

indicates a read operation, and Logic 0 indicates a write

operation.

A6 to A0, Bit 6 to Bit 0 of the instruction byte, determine the

register that is accessed during the data transfer portion of the

communication cycle. For multibyte transfers, A6 is the starting

byte address. The remaining register addresses are generated by

the device based on the LSB_FIRST bit (Register 0x00, Bit 6).

SERIAL PORT PIN DESCRIPTIONS

Serial Clock (SCLK)

The serial clock pin synchronizes data to and from the device

and runs the internal state machines. The maximum frequency

of SCLK is 40 MHz. All data input is registered on the rising

edge of SCLK. All data is driven out on the falling edge of SCLK.

Chip Select (

An active low input starts and gates a communication cycle.

It allows more than one device to be used on the same serial

communication lines. The SDO and SDIO pins go to a high

impedance state when this input is high. During the

communication cycle, the

Serial Data I/O (SDIO)

Data is always written into the device on this pin. However, this

pin can be used as a bidirectional data line. The configuration

of this pin is controlled by Register 0x00, Bit 7. The default is

Logic 0, configuring the SDIO pin as unidirectional.

Serial Data Out (SDO)

Data is read from this pin for protocols that use separate lines

for transmitting and receiving data. In the case where the device

operates in a single bidirectional I/O mode, this pin does not

output data and is set to a high impedance state.

CS

)

CS

pin should stay low.

Rev. 0 | Page 17 of 56

AD9125

SERIAL PORT OPTIONS

The serial port can support both MSB-first and LSB-first data

formats. This functionality is controlled by the LSB_FIRST bit

(Register 0x00, Bit 6). The default is MSB-first (LSB_FIRST = 0).

When LSB_FIRST = 0 (MSB-first), the instruction and data bit

must be written from MSB to LSB. Multibyte data transfers in

MSB-first format start with an instruction byte that includes the

register address of the most significant data byte. Subsequent data

bytes should follow from the high address to the low address. In

MSB-first mode, the serial port internal byte address generator

decrements for each data byte of the multibyte communication cycle.

When LSB_FIRST = 1 (LSB-first), the instruction and data bit

must be written from LSB to MSB. Multibyte data transfers in

LSB-first format start with an instruction byte that includes the

register address of the least significant data byte followed by

multiple data bytes. The serial port internal byte address generator

increments for each byte of the multibyte communication cycle.

The serial port controller data address decrements from the

data address written toward 0x00 for multibyte I/O operations

if the MSB-first mode is active. The serial port controller address

increments from the data address written toward 0x7F for

multibyte I/O operations if the LSB-first mode is active.

INSTRUCTION CYCLE DATA TRANSFER CYCLE

CS

SCLK

SDIO

SDO

R/W A6 A5 A4 A3 A2 A1 A0 D7 D6ND5

D7 D6ND5

Figure 38. Serial Register Interface Timing, MSB First

INSTRUCTION CYCLE DATA TRANSFER CYCLE

CS

SCLK

SDIO

SDO

A0 A1 A2 A3 A4 N0 N1 R/W D00D10D2

D00D10D2

Figure 39. Serial Register Interface Timing, LSB First

t

CS

SCLK

SDIO

DS

t

DS

t

PWH

t

t

SCLK

t

PWL

DH

INSTRUCTION BIT 6INSTRUCTION BIT 7

Figure 40. Timing Diagram for Serial Port Register Write (t

CS

N

N

0

0

D00D10D20D3

0

D00D10D20D3

0

N

N

to t

DS

09016-011

D7ND6ND5ND4

D7ND6ND5ND4

09016-012

09016-013

)

CS

D

SCLK

t

DV

SDIO,

SDO

DATA BIT n – 1DATA BIT n

09016-014

Figure 41. Timing Diagram for Serial Port Register Read

Rev. 0 | Page 18 of 56

AD9125

DEVICE CONFIGURATION REGISTER MAP

Table 10. Device Configuration Register Map

Register Name

Comm 0x00 SDIO LSB_FIRST Reset 0x00

Power Control 0x01 Power-

Data Format 0x03 Binary

Interrupt Enable 1 0x04 Enable

Interrupt Enable 2 0x05 0 0 0 Enable

Event Flag 1 0x06 PLL

Event Flag 2 0x07 AED

Clock Receiver

Control

PLL Control 1 0x0A PLL

PLL Control 2 0x0C PLL loop bandwidth[2:0] PLL charge pump current[4:0] 0xD1

PLL Control 3 0x0D N2[1:0] PLL cross

PLL Status 1 0x0E PLL lock VCO control voltage[3:0] 0x00

PLL Status 2 0x0F VCO band readback[5:0] 0x00

Sync Control 1 0x10 Sync

Sync Control 2 0x11 Sync phase request[5:0] 0x00

Sync Status 1 0x12 Sync lost Sync

Sync Status 2 0x13 Sync phase readback[7:0] (6.2 format) N/A

FIFO Control 0x17 FIFO phase offset[2:0] 0x04

FIFO Status 1 0x18 FIFO

FIFO Status 2 0x19 FIFO level[7:0] N/A

Datapath Control 0x1B Bypass

HB1 Control 0x1C HB1[1:0] Bypass HB1 0x00

HB2 Control 0x1D HB2[5:0] Bypass HB2 0x00

HB3 Control 0x1E HB3[5:0] Bypass HB3 0x00

Chip ID 0x1F Chip ID[7:0] 0x08

Addr

(Hex)

0x08 DACCLK

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0 Default

down

DAC I

data

format

PLL lock

lost

lock

lost

duty

correction

enable

enable

Warning 1

premod

Powerdown

DAC Q

Q data

first

Enable

PLL

lock

PLL

locked

REFCLK

duty

correction

PLL

manual

enable

Data/FIFO

rate toggle

locked

FIFO

Warning 2

Bypass

−1

sinc

Powerdown data

receiver

MSB swap Data bus width[1:0] 0x00

Enable

sync

signal

lost

Sync

signal

lost

DACCLK

cross-

correction

Rising

N/A

FIFO soft

Bypass

NCO

Powerdown

aux ADC

Enable

sync

signal

lock

AED

compare

pass

Sync

signal

locked

compare

pass

REFCLK

cross-

correction

control

enable

NCO gain Bypass

PLL lock

Enable

sync

phase

lock

Enable

AED

compare

fail

Sync

phase

locked

AED

compare

fail

1 1 1 1 0x3F

Manual VCO band[5:0] 0x40

edge sync

Enable

soft

FIFO

sync

Enable

SED

compare

fail

Soft

FIFO

sync

SED

compare

fail

N0[1:0] N1[1:0] 0xD9

align ack

phase

compensation and

dc offset

Enable

FIFO

Warning 1

0 0 0x00

FIFO

Warning 1

N/A

Sync Averaging[2:0] 0x48

FIFO soft

align

request

Select

sideband

status

Enable

FIFO

Warning 2

FIFO

Warning 2

FIFO reset

aligned

Send I data

to Q data

0x10

0x00

N/A

N/A

0xE4

Rev. 0 | Page 19 of 56

AD9125

Register Name

FTW 1 (LSB) 0x30 FTW[7:0] 0x00

FTW 2 0x31 FTW[15:8] 0x00

FTW 3 0x32 FTW[23:16] 0x00

FTW 4 (MSB) 0x33 FTW[31:24] 0x00

NCO Phase Offset

LSB

NCO Phase Offset

MSB

NCO FTW Update 0x36 Frame

I Phase Adj LSB 0x38 I phase adjust[7:0] 0x00

I Phase Adj MSB 0x39 I phase adjust[9:8] 0x00

Q Phase Adj LSB 0x3A Q phase adjust[7:0] 0x00

Q Phase Adj MSB 0x3B Q phase adjust[9:8] 0x00

I DAC Offset LSB 0x3C I DAC offset[7:0] 0x00

I DAC Offset MSB 0x3D I DAC offset[15:8] 0x00

Q DAC Offset LSB 0x3E Q DAC offset[7:0] 0x00

Q DAC Offset MSB 0x3F Q DAC offset[15:8] 0x00

I DAC FS Adjust 0x40 I DAC FS adjust[7:0] 0xF9

I DAC Control 0x41 I DAC

Aux DAC I Data 0x42 I aux DAC[7:0] 0x00

I Aux DAC

Control

Q DAC FS Adjust 0x44 Q DAC FS adjust[7:0] 0xF9

Q DAC Control 0x45 Q DAC

Aux DAC Q Data 0x46 Q aux DAC[7:0] 0x00

Q Aux DAC

Control

Die Temperature

Range Control

Die Temperature

LSB

Die Temperature

MSB

SED Control 0x67 SED

Compare I0 LSBs 0x68 Compare Value I0[7:0] 0xB6

Compare

I0 MSBs

Compare

Q0 LSBs

Compare

Q0 MSBs

Compare I1 LSBs 0x6C Compare Value I1[7:0] 0x16

Compare I1 MSBs 0x6D Compare Value I1[15:8] 0x1A

Compare

Q1 LSBs

Addr

(Hex) Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0 Default

0x34 NCO phase offset[7:0] 0x00

0x35 NCO phase offset[15:8] 0x00

FTW ack

sleep

0x43 I Aux

DAC sign

sleep

0x47 Q Aux

DAC sign

0x48 FS current[2:0] Reference current[2:0] Capacitor

0x49 Die temperature[7:0] N/A

0x4A Die temperature[15:8] N/A

compare

enable

0x69 Compare Value I0[15:8] 0x7A

0x6A Compare Value Q0[7:0] 0x45

0x6B Compare Value Q0[15:8] 0xEA

0x6E Compare Value Q1[7:0] 0xC6

I DAC FS adjust[9:8] 0x01

I Aux DAC

current

direction

Q DAC FS adjust[9:8] 0x01

Q Aux DAC

current

direction

Sample

I aux DAC

sleep

Q aux

DAC

sleep

error

detected

Frame FTW

request

I aux DAC[9:8] 0x00

Q aux DAC[9:8] 0x00

Auto-

Update

Compare

clear

enable

FTW ack

fail

Update

FTW

request

value

Compare

pass

0x00

0x02

0x00

Rev. 0 | Page 20 of 56

AD9125

Register Name

Compare

Q1 MSBs

SED I LSBs 0x70 Errors detected I_BITS[7:0] 0x00

SED I MSBs 0x71 Errors detected I_BITS[15:8] 0x00

SED Q LSBs 0x72 Errors detected Q_BITS[7:0] 0x00

SED Q MSBs 0x73 Errors detected Q_BITS[15:8] 0x00

Die Revsion 0x7F Revision[3:0] 0x0C

DEVICE CONFIGURATION REGISTER DESCRIPTIONS

Table 11. Device Configuration Register Descriptions

Register

Name

Comm 0x00 7 SDIO SDIO operation. 0

0 = SDIO operates as an input only.

1 = SDIO operates as a bidirectional input/output.

6 LSB_FIRST Serial port communication LSB or MSB first. 0

0 = MSB first.

1 = LSB first.

5 Reset

Power Control 0x01 7 Power-down DAC I 1 = powers down DAC I. 0

6 Power-down DAC Q 1 = powers down DAC Q. 0

5

4

0 PLL lock status 1 = PLL is locked. 0

Data Format 0x03 7 Binary data format 0 = input data is in twos complement format. 0

1 = input data is in binary format.

6 Q data first Indicates I/Q data pairing on data input. 0

0 = I data sent to data receiver first.

1 = Q data sent to data receiver first.

5 MSB swap Swaps the bit order of the data input port. 0

[1:0] Data bus width Data receiver interface mode. 0

00 = dual-word mode; 32-bit interface bus width.

01 = word mode; 16-bit interleaved interface bus width.

10 = byte mode; 8-bit interleaved interface bus width.

11 = invalid.

Interrupt Enable 1 0x04 7 Enable PLL lock lost 1 = enables interrupt for PLL lock lost. 0

6 Enable PLL lock 1 = enables interrupt for PLL lock. 0

5 Enable sync signal lost 1 = enables interrupt for sync signal lock lost. 0

4 Enable sync signal lock 1 = enables interrupt for sync signal lock. 0

3

2 Enable soft FIFO sync 1 = enables interrupt for soft FIFO reset. 0

Addr

(Hex) Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0 Default

0x6F Compare Value Q1[15:8] 0xAA

Address

(Hex) Bits Name Description Default

0

0

Power-down data

receiver

Power-down auxiliary

ADC

Enable sync phase

locked

1 = device is held in reset when this bit is written high

and is held there until the bit is written low.

1 = powers down the input data receiver. 0

1 = powers down the auxiliary ADC for temperature

sensor.

0 = order of the data bits corresponds to the pin

descriptions.

1 = bit designations are swapped; most significant bits

become the least significant bits.

See the CMOS Input Data Ports section for details on

the operation of the different interface modes.

1 = enables interrupt for clock generation ready. 0

Rev. 0 | Page 21 of 56

AD9125

Register

Name

1 Enable FIFO Warning 1 1 = enables interrupt for FIFO Warning 1. 0

0 Enable FIFO Warning 2 1 = enables interrupt for FIFO Warning 2. 0

Interrupt Enable 2 0x05 7 Set to 0 Set this bit to 0. 0

Event Flag 11 0x06 7 PLL lock lost

6 PLL locked

5 Sync signal lost

4 Sync signal locked

3 Sync phase locked

2 Soft FIFO sync

1 FIFO Warning 1

0 FIFO Warning 2

Event Flag 21 0x07 4 AED comparison pass

3 AED comparison fail

2 SED comparison fail

Clock Receiver

Control

4 REFCLK cross-correction

Address

(Hex) Bits Name Description Default

6 Set to 0 Set this bit to 0. 0

5 Set to 0 Set this bit to 0. 0

4

3

2

1 Set to 0 Set this bit to 0. 0

0 Set to 0 Set this bit to 0. 0

0x08 7 DACCLK duty correction 1 = enables duty-cycle correction on the DACCLK input. 0

6 REFCLK duty correction 1 = enables duty-cycle correction on the REFCLK input. 0

5 DACCLK cross-correction

Enable AED comparison

pass

Enable AED comparison

fail

Enable SED comparison

fail

1 = enables interrupt for AED comparison pass. 0

1 = enables interrupt for AED comparison fail. 0

1 = enables interrupt for SED comparison fail. 0

1 = indicates that the PLL, which had been previously

locked, has unlocked from the reference signal. This is a

latched signal.

1 = indicates that the PLL has locked to the reference

clock input.

1 = indicates that the sync logic, which had been

previously locked, has lost alignment. This is a latched

signal.

1 = indicates that the sync logic did achieve sync

alignment. This is indicated when no phase changes

were requested for at least a few full averaging cycles.

1 = indicates that the internal digital clock generation logic

is ready. This occurs when internal clocks are present and

stable.

1 = indicates that a FIFO reset originating from a serial

port-based request has successfully completed. This is a

latched signal.

1 = indicates that the difference between the FIFO read

and write pointers is 1.

1 = indicates that the difference between the FIFO read

and write pointers is 2.

1 = indicates that the SED logic detected a valid input

data pattern compared with the preprogrammed

expected values. This is a latched signal.

1 = indicates that the SED logic detected an invalid

input data pattern compared with the preprogrammed

expected values. This is a latched signal that automatically clears when eight valid I/Q data pairs are

received.

1 = indicates that the SED logic detected an invalid

input data pattern compared with the preprogrammed

expected values. This is a latched signal.

1 = enables differential crossing correction on the DACCLK

input.

1 = enables differential crossing correction on the

REFCLK input.

0

0

0

0

0

0

0

0

0

0

1

1

Rev. 0 | Page 22 of 56

AD9125

Register

Name

PLL Control 1 0x0A 7 PLL enable

6 PLL manual enable Enables the manual selection of the VCO band. 1

[5:0] Manual VCO band Selects the VCO band to be used. 0

PLL Control 2 0x0C [7:5]

PLL Control 3 0x0D [7:6] N2[1:0]

00 = f

01 = f

10 = f

11 = f

4 PLL cross control enable Enables PLL cross-point controller. 1

[3:2] N0[1:0]

00 = f

01 = f

10 = f

11 = f

[1:0] N1[1:0]

00 = f

01 = f

10 = f

11 = f

PLL Status 1 0x0E 7 PLL lock

PLL Status 2 0x0F [5:0]

Sync Control 1 0x10 7 Sync enable 1 = enables the synchronization logic. 0

6 Data/FIFO rate toggle 0 = operates the synchronization at the FIFO reset rate. 1

1 = operates the synchronization at the data rate.

3 Rising edge sync 0 = sync is initiated on the falling edge of the sync input. 1

1 = sync is initiated on the rising edge of the sync input.

[2:0] Sync averaging[2:0]

000 = 1.

001 = 2.

010 = 4.

011 = 8.

100 = 16.

101 = 32.

Address

(Hex) Bits Name Description Default

1 = enables the PLL clock multiplier. REFCLK input is

0

used as the PLL reference clock signal.

1 = manual mode; the correct VCO band must be

determined by the user.

PLL loop

000 = loop bandwidth is nominally 200 kHz

bandwidth[2:0]

Selects the PLL loop filter bandwidth. 110

010 = loop bandwidth is nominally 450 kHz

100 = loop bandwidth is nominally 950 kHz

110 = loop bandwidth is nominally 2 MHz

[4:0]

00000 = lowest current setting.

PLL charge pump

current[4:0]

Sets the nominal PLL charge-pump current. 10001

11111 = highest current setting.

PLL control clock divider. These bits determine the ratio

3

of the DACCLK rate to the PLL controller clock rate.

must always be less than 80 MHz.

f

PC_CLK

DACCLK/fPC_CLK

DACCLK/fPC_CLK

DACCLK/fPC_CLK

DACCLK/fPC_CLK

PLL VCO divider. These bits determine the ratio of the

= 2.

= 4.

= 8.

= 16.

10

VCO output to the DACCLK frequencies.

VCO/fDACCLK

VCO/fDACCLK

VCO/fDACCLK

VCO/fDACCLK

PLL loop divider. These bits determine the ratio of the

= 1.

= 2.

= 4.

= 4.

01

DACCLK to the REFCLK frequencies.

DACCLK/fREFCLK

DACCLK/fREFCLK

DACCLK/fREFCLK

DACCLK/fREFCLK

The PLL generated clock is tracking the REFCLK input

= 2.

= 4.

= 8.

= 16.

R

signal.

[3:0]

VCO control

VCO control voltage readback (see Table 25). R

voltage[3:0]

VCO band

Indicates the VCO band currently selected. R

readback[5:0]

Sets the number of input samples that are averaged for

0

determining the sync phase.

Rev. 0 | Page 23 of 56

AD9125

Register

Name

110 = 64.

111 = 128.

Sync Control 2 0x11 5:0 Sync phase request[5:0]

000000 = 0 DACCLK cycles.

000001 = 1 DACCLK cycle.

…

111111 = 63 DACCLK cycles.

Sync Status 1 0x12 7 Sync lost

Sync Status 2 0x13 [7:0] Sync phase readback[7:0]

00000000 = 0.0.

00000001 = 0.25.

…

11111110 = 63.50.

11111111 = 63.75.

FIFO Control 0x17 [2:0] FIFO phase offset[2:0]

000 = 0.

001 = 1.

…

111 = 7.

FIFO Status 1 0x18 7 FIFO Warning 1 FIFO read and write pointers within ±1. 0

6 FIFO Warning 2 FIFO read and write pointers within ±2. 0

2

1 FIFO soft align request

0 FIFO reset aligned

FIFO Status 2 0x19 [7:0] FIFO level[7:0] Thermometer encoded measure of the FIFO level. 0

Datapath Control 0x1B 7 Bypass premod 1 = bypasses fS/2 premodulator. 1

6 Bypass sinc−1 1 = bypasses inverse sinc filter. 1

5 Bypass NCO 1 = bypasses NCO. 1

3 NCO gain

2

Address

(Hex) Bits Name Description Default

This sets the requested clock phase offset after sync.

The offset unit is in DACCLK cycles. This enables

repositioning of the DAC output with respect to the

sync input. The offset can also be used to skew the DAC

outputs between the synchronized DACs.

1 = indicates that synchronization had been attained

but was subsequently lost.

6 Sync locked 1 = indicates that synchronization has been attained. R

Indicates the averaged sync phase offset (6.2 format). If

the value differs from the requested sync phase value,

this indicates sync timing errors.

FIFO write pointer phase offset following FIFO reset.

This is the difference between the read pointer and the

write pointer values upon FIFO reset. The optimal value

is nominally 4.

FIFO soft align

acknowledge

Bypass phase compensation and dc offset

FIFO read and write pointers are aligned after a serial

port initiated FIFO reset.

Request FIFO read and write pointers alignment via the

serial port.

FIFO read and write pointers aligned after a hardware

reset.

0 = default. No gain scaling is applied to the NCO input

to the internal digital modulator.

1 = gain scaling of 0.5 is applied to the NCO input to the

internal digital modulator. This can eliminate saturation

of the modulator output for some combinations of data

inputs and NCO signals.

1 = bypasses phase compensation and dc offset. 1

0

R

R

4

0

0

0

Rev. 0 | Page 24 of 56

AD9125

Register

Name

1 Select sideband 0 = the modulator outputs high-side image. 0

0 Send I data to Q data

HB1 Control 0x1C [2:1] HB1[1:0]

HB2 Control 0x1D [6:1] HB2[5:0] Modulation mode for I Side Half-Band Filter 2. 0

HB3 Control 0x1E [6:1] HB3[5:0] Modulation mode for I Side Half-Band Filter 3. 0

0 Bypass HB3 1 = bypasses third-stage interpolation filter. 0

Chip ID 0x1F [7:0] Chip ID[7:0] This register identifies the device as an AD9125. 8

Address

(Hex) Bits Name Description Default

1 = the modulator outputs low-side image. The image is

spectrally inverted compared with the input data.

1 = ignores Q data from the interface and disables the

0

clocks to the Q datapath. Sends I data to both the I and

Q DACs.

0

00 = input signal is not modulated; filter pass band is

from −0.4 to +0.4 of f

.

IN1

01 = input signal is not modulated; filter pass band is

from 0.1 to 0.9 of f

10 = input signal is modulated by f

from 0.6 to 1.4 of f

11 = input signal is modulated by f

from 1.1 to 1.9 of f

.

IN1

; filter pass band is

.

IN1

.

IN1

IN1

; filter pass band is

IN1

0 Bypass HB1 1 = bypasses first-stage interpolation filter. 0

000000 = input signal is not modulated; filter pass band

is from −0.25 to +0.25 of f

.

IN2

001001 = input signal is not modulated; filter pass band

is from 0.0 to 0.5 of f

.

IN2

010010 = input signal is not modulated; filter pass band

is from 0.25 to 0.75 of f

.

IN2

011011 = input signal is not modulated; filter pass band

is from 0.5 to 1.0 of f

100100 = input signal is modulated by f

band is from 0.75 to 1.25 of f

101101 = input signal is modulated by f

band is from 1.0 to 1.5 of f

110110 = input signal is modulated by f

band is from 1.25 to 1.75 of f

111111 = input signal is modulated by f

band is from 1.5 to 2.0 of f

.

IN2

; filter pass

.

IN2

.

IN2

.

IN2

.

IN2

IN2

; filter pass

IN2

; filter pass

IN2

; filter pass

IN2

0 Bypass HB2 1 = bypasses second stage interpolation filter. 0

000000 = input signal is not modulated; filter pass band

is from −0.2 to +0.2 of f

.

IN3

001001 = input signal is not modulated; filter pass band

is from 0.05 to 0.45 of f

.

IN3

010010 = input signal is not modulated; filter pass band

is from 0.3 to 0.7 of f

.

IN3

011011 = input signal is not modulated; filter pass band

is from 0.55 to 0.95 of f

100100 = input signal is modulated by f

band is from 0.8 to 1.2 of f

101101 = input signal is modulated by f

band is from 1.05 to 1.45 of f

110110 = input signal is modulated by f

band is from 1.3 to 1.7 of f

111111 = input signal is modulated by f

band is from 1.55 to 1.95 of f

.

IN3

; filter pass

.

IN3

.

IN3

.

IN3

.

IN3

IN3

; filter pass

IN3

; filter pass

IN3

; filter pass

IN3

Rev. 0 | Page 25 of 56

AD9125

Register

Name

FTW 1 (LSB) 0x30 [7:0] FTW[7:0]

FTW 2 0x31 [7:0] FTW[15:8] See Register 0x30. 0

FTW 3 0x32 [7:0] FTW[23:16] See Register 0x30. 0

FTW 4 (MSB) 0x33 [7:0] FTW[31:24] See Register 0x30. 0

NCO Phase Offset

LSB

NCO Phase Offset

MSB

NCO FTW Update 0x36 5

I Phase Adj LSB 0x38 [7:0] I phase adjust[7:0]

I Phase Adj MSB 0x39 [1:0] I phase adjust[9:8] Register 0x38. 0

Q Phase Adj LSB 0x3A [7:0] Q phase adjust[7:0]

Q Phase Adj MSB 0x3B [1:0] Q phase adjust[9:8] See Register 0x3A. 0

I DAC Offset LSB 0x3C [7:0] I DAC offset[7:0]

I DAC Offset MSB 0x3D [7:0] I DAC offset[15:8] See Register 0x3C. 0

Q DAC Offset LSB 0x3E [7:0] Q DAC offset[7:0]

Q DAC Offset MSB 0x3F [7:0] Q DAC offset[15:8] See Register 0x3E. 0

I DAC FS Adjust 0x40 [7:0] I DAC FS adjust[7:0]

0x000 = 8.64 mA.

…

0x200 = 20.14 mA.

…

0x3FF = 31.66 mA.

I DAC Control 0x41 7 I DAC sleep

Aux DAC I Data 0x42 [7:0] I aux DAC[7:0]

0x000 = 0.000 mA.

0x001 = 0.002 mA.

…

0x3FF = 2.046 mA.

Address

(Hex) Bits Name Description Default

FTW[31:0] is the 32-bit frequency tuning word that

determines the frequency of the complex carrier

generated by the on-chip NCO. The frequency is not

updated when the FTW registers are written. The values

are only updated when Bit 0 of Register 0x36 transitions

from 0 to 1.

0x34 [7:0] NCO phase offset[7:0]

0x35 [7:0] NCO phase offset[15:8] See Register 0x34. 0

FRAME FTW

acknowledge

4 FRAME FTW request

1

0 Update FTW request

[1:0] I DAC FS adjust[9:8] See Register 0x40. 1

Update FTW

acknowledge

Rev. 0 | Page 26 of 56

NCO phase offset[15:0] sets the phase of the complex

carrier signal when the NCO is reset. The phase offset

spans between 0° and 360°. Each bit represents an offset of

0.0055°. The value is in twos complement format.

1 = indicates that the NCO has been reset due to an

extended FRAME pulse signal.

0 → 1 = the NCO is reset on the first extended FRAME

pulse after this bit transitions from 0 to 1.

1 = indicates that the FTW has been updated. 0

0 → 1 = the FTW is updated on 0-to-1 transition of this bit.

I phase adjust[9:0] is used to insert a phase offset

between the I and Q datapaths. This can be used to

correct for phase imbalance in a quadrature modulator.

See the Quadrature Phase Correction section for details.

Q phase adjust[9:0] is used to insert a phase offset

between the I and Q datapaths. This can be used to

correct for phase imbalance in a quadrature modulator.

See the Quadrature Phase Correction section for details.

I DAC offset[15:0] is a value added directly to the

samples written to the I DAC.

Q DAC offset[15:0] is a value added directly to the

samples written to the Q DAC.

I DAC FS adjust[9:0] sets the full-scale current of the

I DAC. The full-scale current can be adjusted from 8.64 mA

to 31.6 mA in step sizes of approximately 22.5 μA.

1 = puts the I-channel DAC into sleep mode (fast wakeup mode).

I aux DAC[9:0] sets the magnitude of the auxiliary DAC

current. The range is 0 mA to 2 mA, and the step size is 2 μA.

0

0

0

0

0

0

0

0

0

F9

0

0

AD9125

Register

Name

I Aux DAC Control 0x43 7 I aux DAC sign

Q DAC FS Adjust 0x44 [7:0] Q DAC FS adjust[7:0]

0x000 = 8.64 mA.

…

0x200 = 20.14 mA.

…

0x3FF = 31.66 mA.

Q DAC Control 0x45 7 Q DAC sleep

Aux DAC Q Data 0x46 [7:0]

0x000 = 0.000 mA.

0x001 = 0.002 mA.

…

0x3FF = 2.046 mA.

Q Aux DAC Control 0x47 7 Q aux DAC sign

6

1 = the auxiliary DAC Q sinks current.

5 Q aux DAC sleep Q-channel auxiliary DAC sleep 0

[1:0] Q aux DAC[9:8] See Register 0x46. 0

Die Temp Range

Control

…

111 = highest current.

[3:1] Reference current[2:0] Auxiliary ADC reference current. 1

000 = lowest current.

111 = highest current.

0 Capacitor value Auxiliary ADC internal capacitor value. 0

0 = 5 pF.

1 = 10 pF.

Die Temp LSB 0x49 [7:0] Die temp[7:0]

0xC422 = 25.1°C.

…

Die Temp MSB 0x4A [7:0] Die temp[15:8] See Register 0x49. R

Address

(Hex) Bits Name Description Default

0 = the auxiliary DAC I sign is positive, and the current is

directed to the IOUT1P pin (Pin 67).

6

1 = the auxiliary DAC I sinks current.

5 I aux DAC sleep I channel auxiliary DAC sleep. 0

[1:0] I Aux DAC[9:8] See Register 0x42. 0

[1:0] Q DAC FS adjust[9:8] See Register 0x44. 1

0x48 [6:4] FS current[2:0] Auxiliary ADC full-scale current. 0

000 = lowest current.

0xADCC = −39.9°C.

I aux DAC current

direction

Q aux DAC[7:0]

Q aux DAC current

direction

1 = the auxiliary DAC I sign is negative, and the current

is directed to the IOUT1N pin (Pin 66).

0 = the auxiliary DAC I sources current. 0

Q DAC FS adjust[9:0] sets the full-scale current of the

I DAC. The full-scale current can be adjusted from 8.64 mA

to 31.6 mA in step sizes of approximately 22.5 μA.

1 = puts the Q-channel DAC into sleep mode (fast wakeup mode).

Q aux DAC[9:0] sets the magnitude of the aux DAC current.

The range is 0 mA to 2 mA, and the step size is 2 μA.

0 = the auxiliary DAC Q sign is positive, and the current

is directed to the IOUT2P pin (Pin 58).

1 = the auxiliary DAC Q sign is negative, and the current

is directed to the IOUT2N pin (Pin 59).

0 = the auxiliary DAC Q sources current. 0

Die Temp[15:0] indicates the approximate die

temperature.

0xD8A8 = 84.8°C (see the Temperature Sensor section for

details).

0

F9

0

0

0

R

Rev. 0 | Page 27 of 56

AD9125

Register

Name

SED Control 0x67 7 SED compare enable

Compare I0 LSBs 0x68 [7:0] Compare Value I0[7:0]

Compare I0 MSBs 0x69 [7:0] Compare Value I0[15:8] See Register 0x68. 7A

Compare Q0 LSBs 0x6A [7:0] Compare Value Q0[7:0]

Compare Q0 MSBs 0x6B [7:0]

Compare I1 LSBs 0x6C [7:0] Compare Value I1[7:0]

Compare I1 MSBs 0x6D [7:0] Compare Value I1[15:8] See Register 0x6C. 1A

Compare Q1 LSBs 0x6E [7:0] Compare Value Q1[7:0]

Compare Q1 MSBs 0x6F [7:0]

SED I LSBs 0x70 [7:0]

SED I MSBs 0x71 [7:0]

SED Q LSBs 0x72 [7:0]

SED Q MSBs 0x73 [7:0]

Die Revision 0x7F [5:2] Revision[3:0] Corresponds to device die revision. 3

1

All bit event flags are cleared by writing the respective bit high.

Address

(Hex) Bits Name Description Default

1 = enables the SED circuitry. None of the flags in this

0

register or the values in Register 0x70 through

Register 0x73 are significant if the SED is not enabled.

5 Sample error detected

1 = indicates an error is detected. The bit remains set

0

until cleared. Any write to this register clears this bit to 0.

3 Autoclear enable

1 = enables autoclear mode. This activates Bit 1 and Bit

0

0 of this register and causes Register 0x70 through

Register 0x73 to be autocleared whenever eight