A1

V

IN

CLK CLK

A2

SWITCH

50V

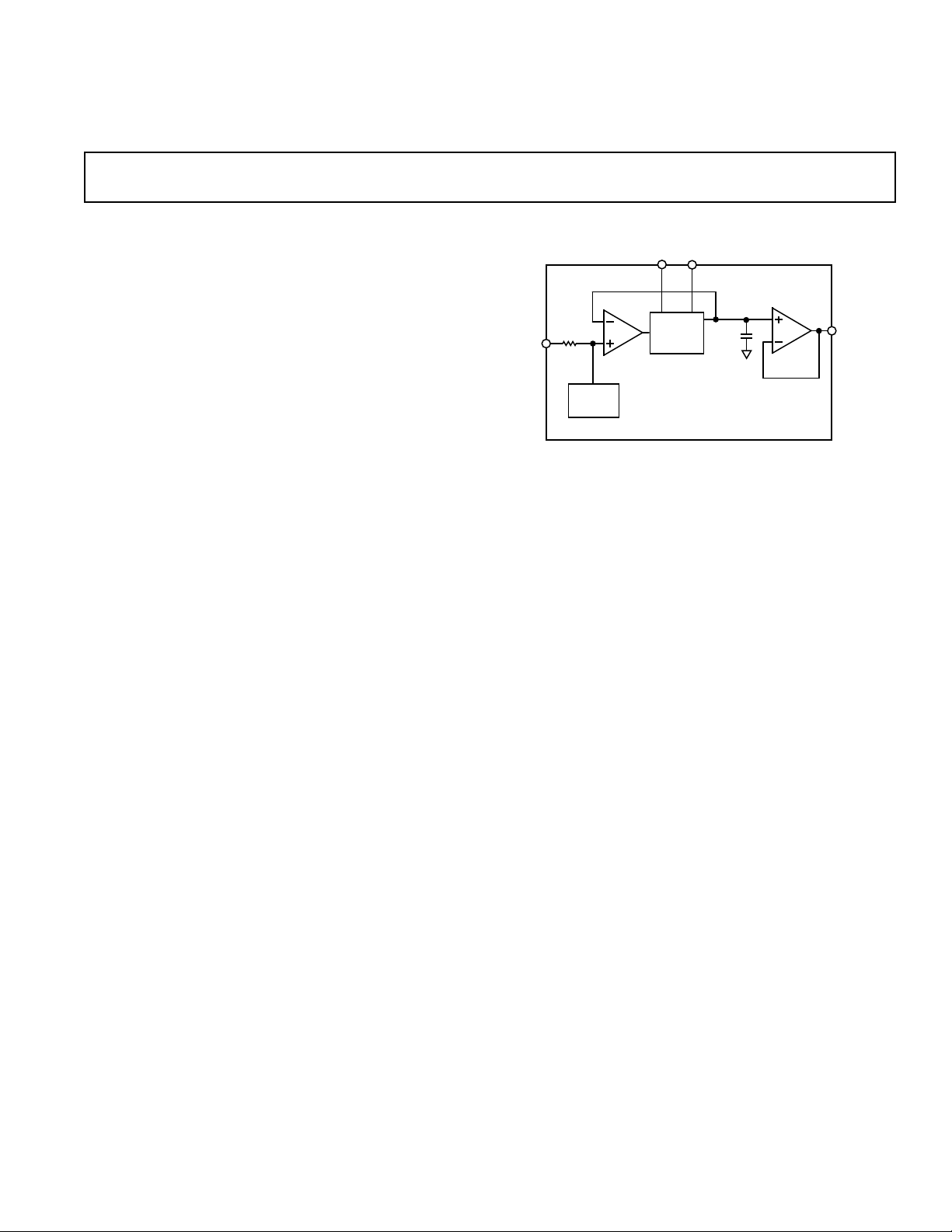

AD9100

62.3V

CLAMP

C

HOLD

22pF

V

OUT

Ultrahigh Speed

a

FEATURES

Excellent Hold Mode Distortion into 250 V

–88 dB @ 30 MSPS (2.3 MHz VIN)

–83 dB @ 30 MSPS (12.1 MHz V

–74 dB @ 30 MSPS (19.7 MHz V

16 ns Acquisition Time to 0.01%

<1 ps Aperture Jitter

250 MHz Tracking Bandwidth

83 dB Feedthrough Rejection @ 20 MHz

3.3 nV/√Hz Spectral Noise Density

MlL-STD-Compliant Versions Available

APPLICATIONS

A/D Conversion

Direct IF Sampling

Imaging/FLIR Systems

Peak Detectors

Radar/EW/ECM

Spectrum Analysis

CCD ATE

GENERAL DESCRIPTION

The AD9100 is a monolithic track-and-hold amplifier which

sets a new standard for high speed and high dynamic range

applications. It is fabricated in a mature high speed complementary bipolar process. In addition to innovative design topologies,

a custom package is utilized to minimize parasitics and optimize

dynamic performance.

Acquisition time (hold to track) is 13 ns to 0.1% accuracy, and

16 ns to 0.01%. The AD9100 boasts superlative hold-mode

frequency domain performance; when sampling at 30 MSPS

hold mode distortion is less than 83 dBfs for analog frequencies

up to 12 MHz; and –74 dBfs at 20 MHz. The AD9100 can also

drive capacitive loads up to 100 pF with little degradation in

acquisition time; it is therefore well suited to drive 8- and 10-bit

flash converters at clock speeds to 50 MSPS. With a spectral

noise density of 3.3 nV/√Hz and feedthrough rejection of 83 dB

at 20 MHz, the AD9100 is well suited to enhance the dynamic

range of many 8- to 16-bit systems.

)

IN

)

IN

Monolithic Track-and-Hold

AD9100*

FUNCTIONAL BLOCK DIAGRAM

The AD9100 is “user friendly” and easy to apply: (1) it requires

+5 V/–5.2 V power supplies; (2) the hold capacitor and switch

power supply decoupling capacitors are built into the DIP package; (3) the encode clock is differential ECL to minimize clock

jitter; (4) the input resistance is typically 800 kΩ; (5) the analog

input is internally clamped to prevent damage from voltage

transients.

The AD9100 is available in a 20-lead side-brazed “skinny DIP”

package. Commercial, industrial, and military temperature

grade parts are available. Consult the factory for information

about the availability of 883-qualified devices.

PRODUCT HIGHLIGHTS

1. Hold Mode Distortion is guaranteed.

2. Monolithic construction.

3. Analog input is internally clamped to protect against overvoltage transients and ensure fast recovery.

4. Output is short circuit protected.

5. Drives capacitive loads to 100 pF.

6. Differential ECL clock inputs.

*Patent pending.

REV. B

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

Information furnished by Analog Devices is believed to be accurate and

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 World Wide Web Site: http://www.analog.com

Fax: 781/326-8703 © Analog Devices, Inc., 1998

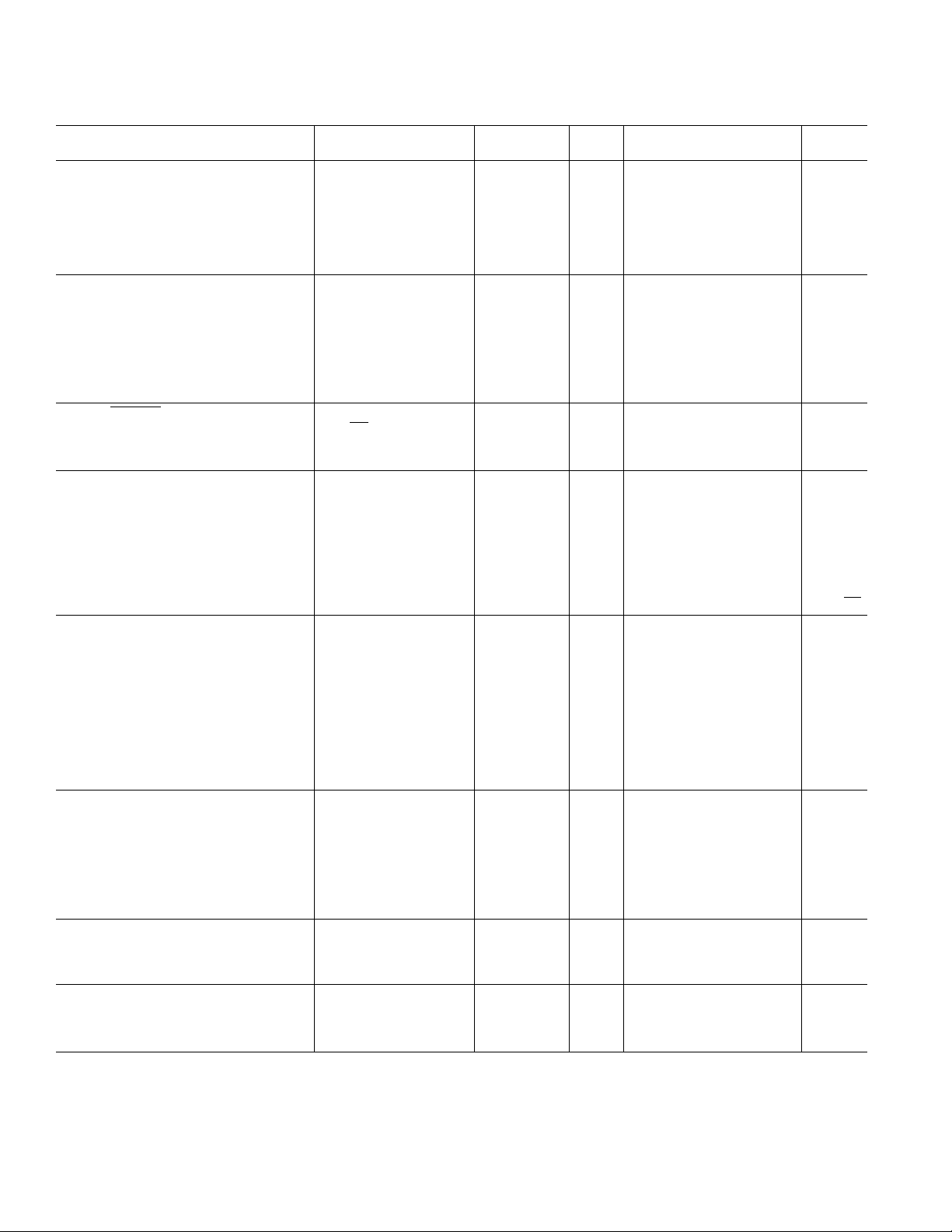

AD9100–SPECIFICATIONS

ELECTRICAL CHARACTERISTICS

(unless otherwise noted, +VS = +5 V; –VS = –5.2 V; R

Test AD9100JD/AD/SD

= 100 V; RIN = 50 V)

LOAD

1

Parameter Conditions Temp Level Min Typ Max Units

DC ACCURACY

Gain ∆V

Offset V

= 2 V Full VI 0.989 0.994 V/V

IN

= 0 V Full VI –5 ±1+5mV

IN

Output Resistance 25°C V 0.4 Ω

Output Drive Capability Full VI ±40 ±60 mA

PSRR ∆V

= 0.5 V p-p Full VI 48 55 dB

S

Pedestal Sensitivity to Supply ∆VS = 0.5 V p-p Full VI 0.9 3 mV/V

ANALOG INPUT/OUTPUT

Output Voltage Range Full VI +2 ±2.2 –2 V

Input Bias Current 25°CVI–8±3+8µA

Input Overdrive Current

2

VIN = ±4 V; RIN = 50 Ω 25°CV ±22 mA

Full VI –16 +16 µA

Input Capacitance 25°C V 1.2 pF

Input Resistance 25°C, T

T

CLOCK/

CLOCK INPUTS

Input Bias Current CL/

Input Low Voltage (V

) Full VI –1.8 –1.5 V

IL

CL = –1.0 V Full VI 4 5 mA

MIN

VI 350 800 kΩ

MAX

VI 200 kΩ

Input High Voltage (VIH) Full VI –1.0 –0.8 V

TRACK MODE DYNAMICS

Bandwidth (–3 dB) V

≤ 0.4 V p-p Full IV 150 250 MHz

OUT

Slew Rate 4 V Step 25°C IV 550 850 V/µs

Overdrive Recovery Time

2

(to 0.1%) VIN = ±4 V to 0 V 25°CV 21 ns

4 V Step Full IV 500 V/µs

2nd Harm. Dist. (20 MHz, 2 V p-p) Full V –65 dBc

3rd Harm. Dist. (20 MHz, 2 V p-p) Full V –75 dBc

Integrated Output Noise (1-200 MHz) 25°CV 45 µV

RMS Spectral Noise @ 10 MHz 25°C V 3.3 nV/√Hz

HOLD MODE DYNAMICS

Worst Harmonic (2.3 MHz, 30 MSPS) V

Worst Harmonic (12.1 MHz, 30 MSPS) V

Worst Harmonic (12.1 MHz, 30 MSPS) V

Worst Harmonic (12.1 MHz, 30 MSPS) V

Worst Harmonic (19.7 MHz, 30 MSPS) V

Hold Noise

Droop Rate

3

4

= 2 V p-p 25°C V –83 dBfs

OUT

= 2 V p-p 25°C IV –80 –72 dBfs

OUT

= 2 V p-p T

OUT

= 2 V p-p T

OUT

= 2 V p-p 25°C V –74 dBfs

OUT

MAX

MIN

25°C V 300 3 t

IV –70 dBfs

IV –77 –68 dBfs

H

V/s rms

VIN = 0 V 25°CVI 110±mV/µs

T

T

MIN

MAX

VI 7 40 ±mV/µs

VI 5 30 ±mV/µs

Feedthrough Rejection (20 MHz) VIN = 2 V p-p Full V 83 dB

TRACK-TO-HOLD SWITCHING

Aperture Delay 25°C V +800 ps

Aperture Jitter 25°CV <1ps

Pedestal Offset V

= 0 V 25°CVI–8±1+8mV

IN

Full VI –10 +10 mV

Transient Amplitude VIN = 0 V Full V ±6mV

Settling Time to 1 mV Full IV 7 10 ns

Glitch Product VIN = 0 V 25°C V 15 pV-s

HOLD-TO-TRACK SWITCHING

Acquisition Time to 0.1% 2 V Step 25°CV 13 ns

Acquisition Time to 0.01% 2 V Step Full IV 16 23 ns

Acquisition Time to 0.01% 4 V Step 25°CV 20 ns

POWER SUPPLY

Power Dissipation Full VI 1.05 1.25 W

Current Full VI 96 118 mA

+V

S

–VS Current Full VI 116 132 mA

NOTES

1

AD9100JD: 0°C to +70°C. AD9100AD: –40°C to +85°C. AD9100SD: –55°C to +125°C. DIP θJA = 38°C/W; this is valid with the device mounted flush to a

grounded 2 oz. copper clad board with 16 sq. inches of surface area and no air flow.

2

The input to the AD9100 is internally clamped at ±2.3 V. The internal input series resistance is nominally 50 Ω.

3

Hold mode noise is proportional to the length of time a signal is held. For example, if the hold time (tH) is 20 ns, the accumulated noise is typically 6 µV (300 V/s 3

20 ns). This value must be combined with the track mode noise to obtain total noise.

4

Min and max droop rates are based on the military temperature range (–55°C to +125°C). Refer to the “Droop Rate vs Temperature” chart for min/max limits over

the commercial and industrial ranges.

Specifications subject to change without notice.

–2–

REV. B

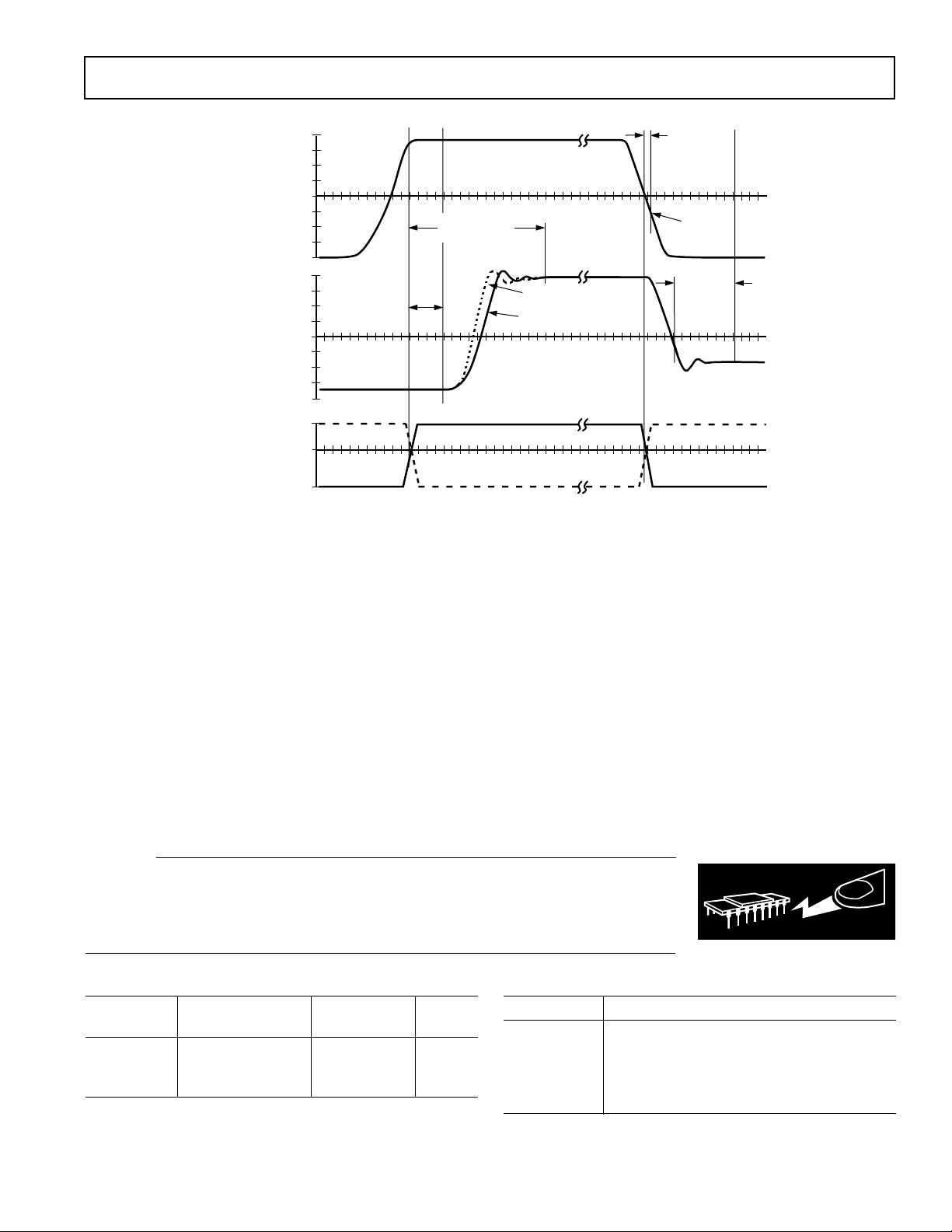

AD9100

WARNING!

ESD SENSITIVE DEVICE

+2V

ANALOG

0V

INPUT

ACQUISITION TIME

(16ns)

TO

HOLD CAPACITOR/

ANALOG OUTPUT

CLOCK

INPUTS

–2V

+2V

0V

–2V

"1"

"0"

"HOLD"

CLOCK (PIN #19)

HOLD

TRACK

SWITCH

DELAY

TIME

(4ns)

Figure 1. Timing Diagram (1 ns/div)

ABSOLUTE MAXIMUM RATINGS

1

Supply Voltages (±VS) . . . . . . . . . . . . . . . . . . . . . . . . . . . ±6 V

Continuous Output Current . . . . . . . . . . . . . . . . . . . . . 70 mA

Analog Input Voltage

2

. . . . . . . . . . . . . . . . . . . . . . . . . . . ±5 V

Operating Temperature Range (Case)

AD9100JD . . . . . . . . . . . . . . . . . . . . . . . . . . . 0°C to +70°C

AD9100AD . . . . . . . . . . . . . . . . . . . . . . . . .–25°C to +85°C

AD9100SD . . . . . . . . . . . . . . . . . . . . . . . .–55°C to +125°C

Junction Temperature . . . . . . . . . . . . . . . . . . . . . . . . . +175°C

Storage Temperature . . . . . . . . . . . . . . . . . . .–65°C to +150°C

Lead Soldering Temperature (10 sec) . . . . . . . . . . . . . +300°C

NOTES

1

Absolute maximum ratings are limiting values to be applied individually, and

beyond which the serviceability of the circuit may be impaired. Functional

operability is not necessarily implied. Exposure to absolute maximum rating

conditions for an extended period of time may affect device reliability.

2

Analog input voltage should not exceed ±VS.

APERTURE

DELAY

(0.8ns)

VOLTAGE

LEVEL HELD

TRACK TO

OBSERVED AT

HOLD CAPACITOR

OBSERVED AT

ANALOG OUTPUT

"TRACK"

CLOCK

HOLD

SETTLING

(7ns)

"HOLD"

EXPLANATION OF TEST LEVELS

Test Level

I – 100% production tested.

II – 100% production tested at +25°C, and sample tested at

specified temperatures.

III – Periodically sample tested.

IV – Parameter is guaranteed by design and characterization

testing.

V – Parameter is a typical value only.

VI – All devices are 100% production tested at +25°C. 100%

production tested at temperature extremes for extended

temperature devices; sample tested at temperature

extremes for commercial/industrial devices.

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection.

Although the AD9100 features proprietary ESD protection circuitry, permanent damage may

occur on devices subjected to high energy electrostatic discharges. Therefore, proper ESD

precautions are recommended to avoid performance degradation or loss of functionality.

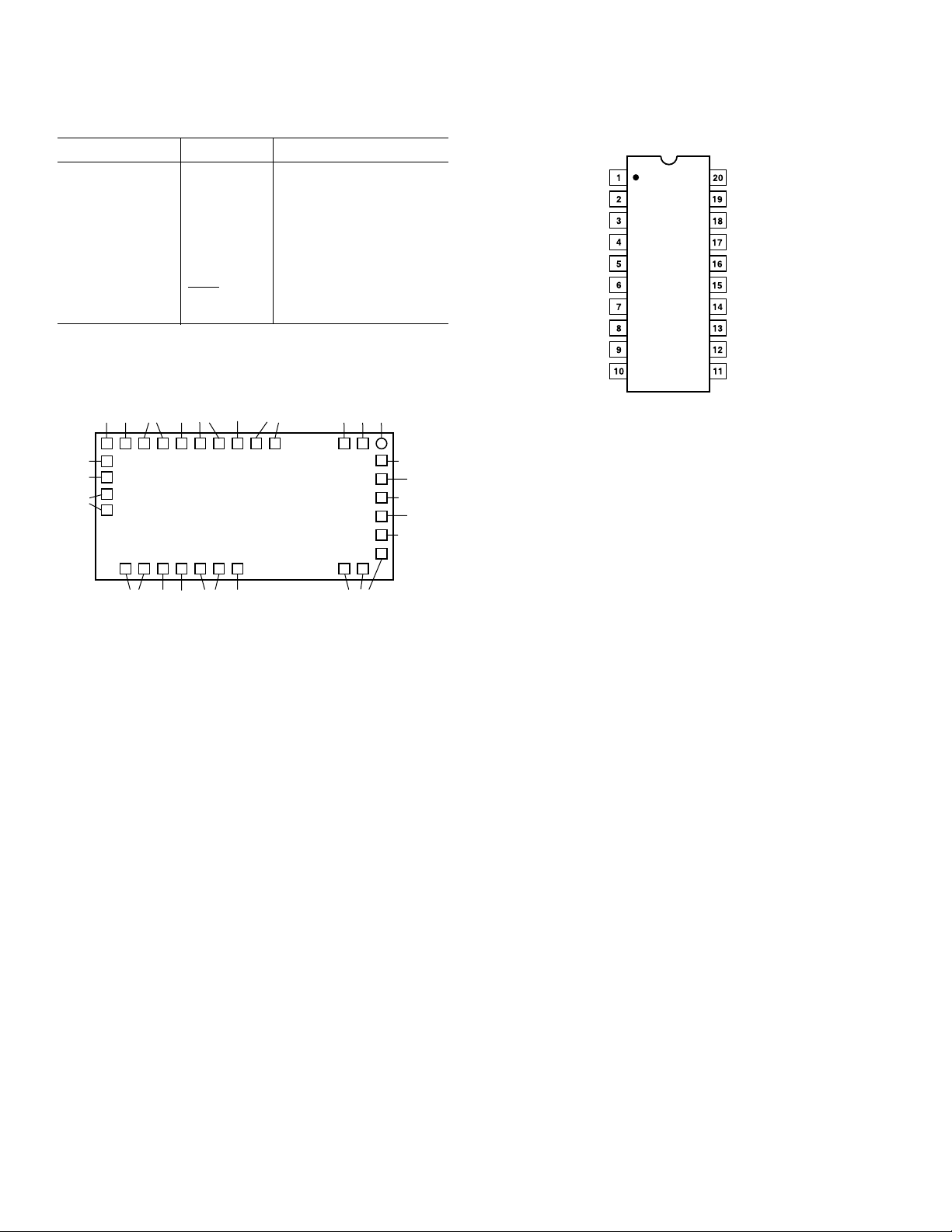

ORDERING GUIDE

Temperature Package Package

Model* Range Description Option

AD9100JD 0°C to +70°C Ceramic DIP D-20

AD9100AD –40°C to +85°C Ceramic DIP D-20

AD9100SD –55°C to +125°C Ceramic DIP D-20

*Consult factory about availability of parts screened to MIL-STD-883.

REV. B

–3–

EVALUATION BOARD ORDERING INFORMATION

Part Number Description

AD9100/PWB Printed Wiring Board (Only) of Evaluation

Circuit

AD9100/PCB Evaluation Board for AD9100T/H, Assembled

and Tested [Order AD9100T/H (DIP)

Separately]

AD9100

PIN FUNCTION DESCRIPTIONS/CONNECTIONS

Pin No. Description Connection

1–V

S

–5.2 V Power Supply

2, 3, 8, 10–13, 17 GND Common Ground Plane

4V

5, 7 –V

IN

S

Analog Input Signal

–5.2 V Power Supply

6, 15 BYPASS 0.1 µF to Ground

9V

14, 16, 20 +V

18

OUT

S

CLK Complement ECL Clock

Track-and-Hold Output

+5 V, Power Supply

19 CLK “True” ECL Clock

CHIP PAD ASSIGNMENTS

+VS CAP

(NOTE 1)

AD9100

TOP VIEW

(Not to scale)

–VS CAP

(NOTE 1)

HOLD CAP

(NOTE 3)

+VS+V

S

NC

23456789101112

113

32

+V

S

BYPASS

31

(NOTE 2)

+V

30

OUT

BYPASS

29

(NOTE 2)

28

+V

S

27

–V

S

+VS+V

NC

S

14

CLOCK

15

CLOCK

16

GND

17

18 19 20 21 22 23 24 25 26

–V

S

SIZE = 148 3 63 3 15 mils NC = NO CONNECT

NOTES:

1. SUPPLY BYPASS CAPACITOR; 0.01 TO 0.1mF CERAMIC

CONNECTED TO GROUND.

2. 0.01mF CERAMIC CONNECTED BETWEEN PAD 29 AND PAD 31.

3. HOLD CAPACITOR CONNECTED FROM PAD 4 AND PAD 5 TO

GROUND; 10–100pF, NOMINALLY 22pF. DIP PACKAGE DOES NOT

REQUIRE EXTERNAL HOLD CAPACITOR.

+V

GND

S

NC

–V

–V

S

IN

PIN CONFIGURATION

20-Lead Side-Brazed Ceramic DIP

–V

S

GND

GND

V

IN

S

S

AD9100

TOP VIEW

(Not to Scale)

–V

BYPASS

–V

GND GND

V

OUT

GND GND

+V

S

CLK

CLK

GND

+V

S

BYPASS

+V

S

GND

TERMINOLOGY

Analog Delay is the time required for an analog input signal to

propagate from the device input to output.

Aperture Delay tells when the input signal is actually sampled.

It is the time difference between the analog propagation delay of

the front-end buffer and the control switch delay time. (The

time from the hold command transition to when the switch is

opened.) For the AD9100, this is a positive value which means

that the switch delay is longer than the analog delay.

Aperture Jitter is the random variation in the aperture delay.

This is measured in ps-rms and results in phase noise on the

held signal.

Droop Rate is the change in output voltage as a function of

time (dV/dt). It is measured at the AD9100 output with the

device in hold mode and the input held at a specified dc value,

the measurement starts immediately after the T/H switches from

track to hold. Feedthrough Rejection is the ratio of the input

signal to the output signal when in hold mode. This is a measure of how well the switch isolates the input signal from feeding

through to the output.

Hold-to-Track Switch Delay is the time delay from the track

command to the point when the output starts to change and

acquire a new signal.

Pedestal Offset is the offset voltage step measured immediately

after the AD9100 is switched from track to hold with the input

held at zero volts. It manifests itself as an added offset during

the hold time.

Track-to-Hold Settling Time is the time necessary for the

track to hold switching transient to settle to within 1 mV of its

final value.

Track-to-Hold Switching Transient is the maximum peak

switch induced transient voltage which appears at the AD9100

output when it is switched from track to hold.

–4–

REV. B

50

0

100

30

10

20

20

0

40

806040

C – pF

LOAD

R

S

– V

NO RS NEEDED WHEN

C

L

IS LESS THAN 6pF

R

S

C

L

1kV

AD9100

0

–5

GAIN – dB

–10

INPUT FREQUENCY – MHz

30060DC 240180120

Figure 2. Gain vs. Frequency (Track

Mode)

–95

–90

VO = 2V p-p

ENCODE = 30 MSPS

RL = 250V

Typical Performance Characteristics–AD9100

60

50

40

30

PSRR – dB

20

10

Figure 3. Power Supply Rejection

Ratio vs. Frequency

60

DC

INPUT FREQUENCY – MHz

240180120

300

Figure 4. Recommended RS vs. C

for Optimal Settling Times

50

40

TRACK

LOAD

TRACK

HOLD

–85

dBc

–80

–75

–70

0

RL = 100V

4

INPUT FREQUENCY – MHz

20

16128

Figure 5. Worst Hold Mode Harmonic

vs. Analog Input Frequency

58

53

AD9060

48

AIN = 3.5V p-p

ENCODE = 40 MSPS

SNR, INCLUDING HARMONICS – dB

43

DC

AD9060 + AD9100

C

HOLD

C

HOLD

10 20 30

INPUT FREQUENCY – MHz

= 22pF

= 10pF

40

Figure 8. SNR vs. Analog Input

105

95

BEYOND

CAPABILITY

85

OF AVAILABLE

MEASUREMENT

dB

TOOLS

75

65

55

INPUT FREQUENCY – MHz

100212010

Figure 11. Feedthrough Rejection vs.

Input Frequency

REV. B

30

mV/ms

20

10

0

–50

TYPICAL

WORST CASE

+25

0

TEMPERATURE – 8C

+75

+125

Figure 6. Magnitude of Droop Rate

vs. Temperature

AD9100

10

FFT

PROC

CH*

27V

AD9060

A

IN

THE AD9060 IS A 10-BIT, 75MSPS MONOLITHIC

ADC FROM ANALOG DEVICES.

*

THE AD9100XD (DIP) HAS AN INTERNAL 22pF

HOLD CAPACITOR.

Figure 9.

1.0

V

= 2V STEP

OUT

0.1

0.01

% OF FULL SCALE

0.001

10

12 16 1814

ns

Figure 12. Settling Tolerance vs.

Acquisition Time

–5–

CLK

2mV/DIV

10ns

CLK

100ns/DIV

Figure 7. Track-to-Hold-to-Track Switch

Transients

58

56

54

52

AIN = 3.5V p-p

SNR, INCLUDING HARMONICS – dB

ENCODE = 20 MSPS

50

DC 20

AD9060 + AD9100

C

AD9060

5

INPUT FREQUENCY – MHz

Figure 10. SNR vs. Analog Input

20

10ns

HOLD

C

HOLD

= 10pF

= 22pF

1510

AD9100

THEORY OF OPERATION

The AD9100 utilizes a new track and hold architecture. Previous commercially available high speed track and holds used an

open loop input buffer, followed by a diode bridge, hold capacitor, and output buffer (closed or open loop) with a FET device

connected to the hold capacitor. This architecture required

mixed device technology and, usually, hybrid construction. The

sampling rate of these hybrids has been limited to 20 MSPS for

12-bit accuracy. Distortion generated in the front-end amplifier/

bridge limited the dynamic range performance to the “mid-70

dBfs” for analog input signals of less than 10 MHz. Broadband

and switch-generated noise limited the SNR of previous track

and holds to about 70 dB.

The AD9100 is a monolithic device using a high frequency

complementary bipolar process to achieve new levels of high

speed precision. Its patent pending architecture breaks from the

traditional architecture described above. (See the block diagram

on the first page.) The switching type bridge has been integrated

into the first stage closed loop input amplifier. This innovation

provides error (distortion) correction for both the switch and

amplifier, while still achieving slew rates representative of an

open-loop design. In addition, acquisition slew current for the

hold capacitor is higher than standard diode bridge and switch

configurations, removing a main contributor to the limits of

maximum sampling rate and input frequency.

Switching circuits in the device use current steering (versus

voltage switching) to provide improved isolation between the

switch and analog sections. This results in low aperture time

sensitivity to the analog input signal, and reduced power supply

and analog switching noise. Track to hold peak switching transient is typically only 6 mV and settles to less than 1 mV in 7 ns.

In addition, pedestal sensitivity to analog input voltage is very

low (0.6 mV/V) and being first order linear does not significantly

affect distortion.

The closed-loop output buffer includes zero voltage bias current

cancellation, which results in high-temperature droop rates

equivalent to those found in FET type inputs. The buffer also

provides first order quasistatic bias correction resulting in an

extremely high input resistance and very low droop sensitivity vs.

input voltage level (typically less than 1.5 mV/V–µs.) This

closed-loop architecture inherently provides high speed loop

correction and results in low distortion under heavy loads.

The extremely fast time constant linearity (7 ns to 0.01% for a

2 V step) ensures that the output buffer does not limit the

AD9100 sampling rate or analog input frequency. (The acquisition and settling time are primarily limited only by the input

amplifier and switch.) The output is transparent to the overall

AD9100 hold mode distortion levels for loads as low as 250 Ω.

Full-scale track and acquisition slew rates achieved by the

AD9100 are 800 and 1000 V/µs, respectively. When combined

with excellent phase margin (typically 5% overshoot), wide

bandwidth, and dc gain accuracy, acquisition time to 0.01% is

only 16 ns. Though not production tested, settling to 14-bit

accuracy (–86 dB distortion @ 2.3 MHz) can be inferred to be

20 ns.

Acquisition Time

Acquisition time is the amount of time it takes the AD9100 to

reacquire the analog input when switching from hold to track

mode. The interval starts at the 50% clock transition point and

ends when the input signal is reacquired to within a specified

error band at the hold capacitor.

The hold to track switch delay (t

t) cannot be subtracted

DH

from this acquisition time because it is a charging time delay

that occurs when moving from hold to track; this is typically

4 ns to 6 ns and is the longest delay. Therefore, the track time

required for the AD9100 is the acquisition time minus the aperture delay time. Note that the acquisition time is defined as the

settled voltage at the hold capacitor and does not include the

delay and settling time of the output buffer. The example below

illustrates why the output buffer amplifier does not contribute to

the overall AD9100 acquisition time.

V

IN

INPUT

BUFFER

V

CH

V

OUT

t

DHT

6ns

TRACK

TIME

V

CH

OUTPUT

C

H

ACQUISITION TIME AT

TO X%

C

H

BUFFER

t

S

HOLD

V

OUT

PEAK TRANSIENT

SEEN BY OUTPUT

BUFFER

Figure 13. Acquisition Time Diagram

The exaggerated illustration in Figure 13 shows that VCH has

settled to within x% of its final value, but V

(due to slew rate

OUT

limitations, finite BW, power supply ringing, etc.) has not

settled during the track time. However, since the output buffer

always “tracks” the front end circuitry, it “catches up” during

the hold time and directly superimposes itself (less about 600 ps

of analog delay) to V

. Since the small-signal settling time of

CH

the output buffer is about 1.8 ns to ± 1 mV and is significantly

less than the specified hold time, acquisition time should be

referenced to the hold capacitor.

Note that most of the hold settling time and output acquisition

time are due to the input buffer and the switch network. For

track time, the output buffer contributes only about 5 ns of the

total; in hold mode, it contributes only 1.8 ns (as stated above).

A stricter definition of acquisition time would total the acquisition and hold times to a defined accuracy. To obtain 12 bit +

distortion levels and 30 MSPS operation, the recommended

track and hold times are 20 ns and 13.5 ns, respectively. To

drive an 8-bit flash converter with a 2 V p-p full-scale input,

hold time to 1 LSB accuracy will be limited primarily by the

encoder, rather than by the AD9100. This makes it possible to

reduce track time to approximately 13 ns, with hold time chosen

to optimize the encoder’s performance.

–6–

REV. B

AD9100

Hold vs. Track Mode Distortion

In many traditional high speed, open loop track-and-holds,

track mode distortion is often much better than hold mode

distortion. Track mode distortion does not include nonlinearities due to the switch network, and does not correlate to the

relevant hold mode distortion. But since hold mode distortion

has traditionally been omitted from manufacturer’s specification

tables, users have had to discover for themselves the effective

overall hold mode distortion of the combined T/H and encoder.

The architecture of the AD9100 minimizes hold mode distortion

over its specified frequency range. As an example, in track mode

the worst harmonic generated for a 20 MHz input tone is typically –65 dBfs. In hold mode, under the same conditions

and sampling at 30 MSPS, the worst harmonic generated is

–74 dBfs. The reason is the output buffer in hold mode has only

dc distortion relevancy. With its inherent linearity (7 ns settling

to 0.01%), the output buffer has essentially settled to its dc

distortion level even for track plus hold times as short as 30 ns.

For a traditional open-loop output buffer, the ac (track mode)

and dc (hold mode) distortion levels are often the same.

Droop Rate

Droop rate does not necessarily affect a track and hold’s distortion characteristics. If the droop rate is constant versus the input

voltage for a given hold time, it manifests itself as a dc offset to

the encoder. For the AD9100, the droop rate is typically

±1 mV/µs. If a signal is held for 1 µs, a subsequent encoder

would see a 1 mV offset voltage. If there is no droop sensitivity

to the held voltage value, the 1 mV offset would be constant

and “ride” on the input signal and introduce no hold-mode

nonlinearities .

In instances in which droop rate varies proportionately to the

magnitude of the held voltage signal level, a gain error only is

introduced to the A/D encoder. The AD9100 has a droop sensitivity to the input level of 1.5 mV/ V–µs. For a 2 V p-p input

signal, this translates to a 0.15%/µs gain error and does not

cause additional distortion errors.

For the AD9100, droop sensitivity to input level is insignificant.

However, hold times longer than about 2 µs can cause distortion due

to the R 3 C

time constant at the hold capacitor. In addition,

H

hold mode noise will increase linearly vs. hold time and thus

degrade SNR performance.

Layout Considerations

For best performance results, good high speed design techniques must be applied. The component (top) side ground

plane should be as large as possible; two-ounce copper cladding

is preferable. All runs should be as short as possible, and decoupling capacitors must be used.

Figure 14 is the schematic of a recommended AD9100 evaluation board. (Contact factory concerning availability of assembled

boards.) All 0.01 µF decoupling capacitors should be low induc-

tance surface mount devices (P/N 05085C103MT050 from

AVX) and connected on the component side within 30 mils of

the designated pins; with the other sides soldered directly to the

top ground plane.

J6J5

J7

C10

C9

+V

S

+

C13

10mF

C5

TP3

C6

C7

C8

R4

Q

Q

510V

R5

510V

–5.2V

–V

S

C14

10mF

C1

TP1

J1

V

IN

50V

J2

V

OUT

J3

V

BUFF

AD9620

CLOCK

IN

+5V

NOTE:

CONNECT TO W1 FOR TTL CLOCK SIGNALS;

CONNECT TO W2 FOR GROUND-REFERENCED SIGNALS.

C2

R

IN

C3

C4

R

5V

R

L

2kV

R1

100V

R2

W1

6V

W2

R3

4V

AD9100

DUT

(DIP)

S

+V

S–VS

AD96685

LE

Figure 14. AD9100/PCB Evaluation Board Diagram

The 10 µF low frequency power supply tantalum decoupling

capacitors should be located within 1.5 inches of the AD9100.

The common 0.01 µF supply capacitors can be wired together.

The common power supply bus (connected to the 10 µF capaci-

tor and power supply source) can be routed to the underside of

the board to the daisy chain wired 0.01 µF supply capacitors.

For remote input and/or output drive applications, controlled

impedances are required to minimize line reflections which will

reduce signal fidelity. When capacitive and/or high impedance

levels are present, the load and/or source should be physically

located within approximately one inch of the AD9100. Note

that a series resistance, R

6 pF. (The Recommended R

Performance Section” shows values of R

, is required if the load is greater than

S

vs. CL chart in the “Typical

S

for various capacitive

S

loads which result in no more than a 20% increase in settling

time for loads up to 80 pF.) As much of the ground plane as

possible should be removed from around the V

and V

IN

OUT

pins

to minimize coupling onto the analog signal path.

While a single ground plane is recommended, the analog signal

and differential ECL clock ground currents follow a narrow path

directly under their common voltage signal line. To reduce

reflections, especially when terminations are used for transmission

line efficiency, the clock, V

, and V

IN

signals and respective

OUT

ground paths should not cross each other; if they do, unwanted

coupling can result.

High current ground transients via the high frequency decoupling capacitors can also cause unwanted coupling to the V

and V

current loops. Therefore, these analog terminations

OUT

IN

should be kept as far as possible from the power supply decoupling capacitors to minimize feedthrough.

REV. B

–7–

AD9100

Using Sockets

Pin sockets (P/N 6-330808-3 from AMP) should be used if the

device can not be soldered directly to the PCB. High profile or

wire wrap type sockets will dramatically reduce the dynamic

performance of the device in addition to increasing the case-toambient thermal resistance.

Driving the Encode Clock

The AD9100 requires a differential ECL clock command. Due

to the high gain bandwidth of the AD9100 internal switch, the

input clock should have a slew rate of at least 100 V/µs.

To obtain maximum signal to noise performance, especially at

high analog input frequencies, a low jitter clock source is required. The AD9100 clock can be driven by an AD96685, an

ultrahigh speed ECL comparator with very low jitter.

ANALOG

INPUT

AD9100

AD9620

INTO LOW

RESISTIVE

LOAD

Figure 16. Using AD9620 as Isolation Amplifier

Direct IF Conversion

The AD9100 can be used to sample super-Nyquist signals,

making wide dynamic range direct IF to digital conversion practical. By reducing the analog input level to the track and hold,

distortion due to the AD9100 can be minimized. As the input

level is reduced, the gain in the output amplifier (see Figure 17)

must be increased to match the full scale level of the subsequent

analog-to-digital converter.

POST-AMP

CLK

Figure 15. Clock/

1kV

–5.2V

Clock

150V150V

1kV

–5.2V

Input Stage

CLK

Driving the Analog Input

Special care must be taken to ensure that the analog input signal

is not compromised before it reaches the AD9100. To obtain

maximum signal to noise performance, a very low phase noise

analog source is required. In addition, input filtering and/or a

low harmonic signal source is necessary to maximize the spurious free dynamic range. Any required filtering should be done

close to the AD9100 and away from any digital lines.

Overdriving the Analog Input

The AD9100 has input clamps that prevent hard saturation of

the output buffer, thereby providing fast overvoltage recovery

when the analog input transitions to the linear region (±2 V).

The clamps are set internally at ±2.3 V and cannot be altered by

the user. The output settles to 0.1% of its value 21 ns after the

overvoltage condition is alleviated. When the analog input is

outside the linear region, the analog output will be at either

+2.2 V or –2.2 V.

Matching the AD9100 to A/D Encoders

The AD9100’s analog output level may have to be offset or

amplified to match the full-scale range of a given A/D converter.

This can generally be accomplished by inserting an amplifier

after the AD9100. For example, the AD671 is a 12-bit 500 ns

monolithic ADC encoder that requires a 0 to +5 V full-scale

analog input. An AD84X series amplifier could be used to condition the AD9100 output to match the full-scale range of the

AD671.

Ultralow Distortion/Low Resistive Load Applications

When driving low resistive loads or when the widest possible

spurious free dynamic range is required, system performance

can be improved by isolating the load from the AD9100. (See

Figure 16.) The AD9620 low distortion closed-loop buffer

amplifier has an input resistance of 800 kΩ and generates harmonics that are less than those generated by the AD9100. Other

buffers should not be considered if their harmonics are not

lower than those of the AD9100.

IF INPUT

6100 mV

T/H CLOCK

ADC CLOCK

AD9100

GAIN ADJ TO

20ns

UTILIZE MAX

ADC RANGE

5ns

T/H CLOCK ADC CLOCK

TRACK

HOLD

"1"

"0"

ADCAD9618

Figure 17. IF Sampling with Track-and-Hold

This technique is not confined to processing Nyquist signals.

Figure 18 illustrates the spurious free dynamic range of the

AD9100 as a function of analog input signal level and frequency.

Without the output amplifier (2 V p-p input), 70 dB+ dynamic

range is observed only to about 24 MHz. By reducing the

analog input to 200 mV p-p, >70 dB SFDR can be maintained

to 70 MHz IFs.

The optimum T/H input level for a particular IF can be determined by examining the T/H spurious and noise performance.

The highest input signal level which will provide the required

SFDR gives the lowest noise performance. When sampling

super Nyquist signals, the IF will be aliased to baseband and

can be observed by using FFT analysis.

90

80

70

2V p-p INPUT

60

SPURIOUS-FREE DYNAMIC RANGE – dBc

50

10

INPUT FREQUENCY – MHz

500mV p-p INPUT

200mV p-p INPUT

50 604030200

70

Figure 18. SFDR vs. Input Frequency at 10 MSPS

–8–

REV. B

AD9100

AD9618

LOW

LEVEL

SOURCE

TO

ENCODER

AD9100

In the FFT spectrum below (see Figure 19), the 71.4 MHz IF is

observed at 1.4 MHz. Note that the highest frequency observed

(FS/2) is determined by the sample rate of the T/H.

0

–20

–40

–60

–80

–100

78 68 25 3

DC

FREQUENCY – MHz

4

4.03.02.01.0

5.0

Figure 19. 71.4 MHz Signal Sampled at 10 MSPS with

200 mV p-p Input

Low Noise Applications

When processing low level single event signals in which noise

performance is the primary concern, amplification ahead of the

AD9100 can increase overall system signal to noise ratio. Frontend amplification often results in an increase in hold mode

distortion levels because of the track mode limitations of the

amplifier which is used. Depending on the signal levels and

bandwidth, the AD9618 low noise high gain amplifier is a possible candidate for this application. See Figure 20.

As a general rule, if the goal is maximize SNR (minimize noise),

pre-AD9100 amplification is recommended. When the system

goal is to maximize the spurious free dynamic range (minimize

distortion), post-AD9100 amplification is recommended.

Figure 20. Using AD9618 as Pre-Amp for AD9100

REV. B

–9–

AD9100

0.1%

0.025%

0.025%

0.1%

0.1%

0.025%

0.025%

0.1%

TRACK COMMAND

(NOT TO SCALE)

C

VOLTAGE

HOLD

REFERENCE

MEASUREMENT

POINT

+1V

–1V

V

2V INPUT STEP

100V LOAD

100403020

IN

TIME – ns

INPUT

BUFFER

C

HOLD

Figure 21. Acquisition Time

TRACK COMMAND

(NOT TO SCALE)

V

OUT

REFERENCE

MEASUREMENT

POINT

+1V

–1V

2V INPUT STEP

100V LOAD

100403020

C

HOLD

TIME – ns

OUTPUT

BUFFER

R

Figure 22. Output Acquisition Time

V

OUT

HOLD

0

V

= 2V p-p

OUT

R

= 250V

LOAD

20

40

60

dB BELOW FULL SCALE

80

100

120

ENCODE = 30 MSPS

t

= 20ns

TRACK

t

= 13.5ns

TRACK

97658432

Figure 23. Frequency (500 kHz/Division) Analog Input =

540 kHz

0

V

= 2V p-p

OUT

= 250V

R

LOAD

20

40

60

958476

dB BELOW FULL SCALE

80

100

120

ENCODE = 30 MSPS

t

= 20ns

TRACK

t

= 13.5ns

HOLD

ALL HARMONICS

ARE ALIASED

3

2

Figure 24. Frequency (500 kHz/Division) Analog Input =

2.3 MHz

–10–

REV. B

AD9100

0

20

40

60

dB BELOW FULL SCALE

80

100

120

9

5

4

V

= 2V p-p

OUT

R

= 100V

LOAD

ENCODE = 30 MSPS

t

= 20ns

TRACK

t

= 13.5ns

HOLD

ALL HARMONICS

ARE ALIASED

6

7

28

3

Figure 25. Frequency (500 kHz/Division) Analog Input =

12.1 MHz

4 PLACES

0.25 (6.35)

2.5 (63.5)

0.25 (6.35)

0

V

= 2V p-p

OUT

= 100V

R

LOAD

20

40

60

dB BELOW FULL SCALE

80

100

120

ENCODE = 30 MSPS

t

= 20ns

TRACK

t

= 13.5ns

HOLD

ALL HARMONICS

ARE ALIASED

Figure 27. Frequency (500 kHz/Division) Analog Input =

19.8 MHz

+VS GND –VS

J7 J6 J5

a

34809 (A)

3.4

(86.36)

Figure 26. Bottom of AD9100/PCB Evaluation Board Viewed

from Above

J3 VBUFF

AD9100

EVALUATION

BOARD

C13

J4 CLOCK IN

W1

W3

R2

C12

U2

DUT

U1

R3

R1

RS

RL

RIN

J2 VOUT

J1 VIN

W2

R4

R5

TP3

TP1

Figure 28. Top of AD9100/PCB Evaluation Board Viewed

from Above

REV. B

–11–

AD9100

0.175 (4.45)

MAX

SEATING

PLANE

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

20-Lead Side-Brazed Ceramic DIP

(D-20)

1.052 6 0.011

(26.721 6 0.279)

20

1

0.020 (0.51)

0.016 (0.41)

PIN 1 IDENTIFIER

0.100 (2.54)

TYP

11

0.290 6 0.010

(7.366 6 0.254)

10

0.020 6 0.005

(0.508 6 0.127)

0.05 (1.27)

TYP

0.150

(3.81)

MIN

0.300 (7.62)

REF

0.010 6 0.002

(0.254 6 0.051)

C1513a–0–6/98

–12–

PRINTED IN U.S.A.

REV. B

Loading...

Loading...