Page 1

50 MHz, Precision, Low Distortion,

O

Data Sheet

FEATURES

Bandwidth: 50 MHz at 5 V

Low noise: 4.5 nV/√Hz

Offset voltage: 100 μV typical, specified over

entire common-mode range

Slew rate: 41 V/μs

Rail-to-rail input and output swing

Input bias current: 1 pA

Single-supply operation: 2.7 V to 5.5 V

Space-saving MSOP and SOIC_N packaging

APPLICATIONS

Optical communications

Laser source drivers/controllers

Broadband communications

High speed ADCs and DACs

Microwave link interface

Cell phone PA control

Video line drivers

Audio

Low Noise CMOS Amplifiers

AD8651/AD8652

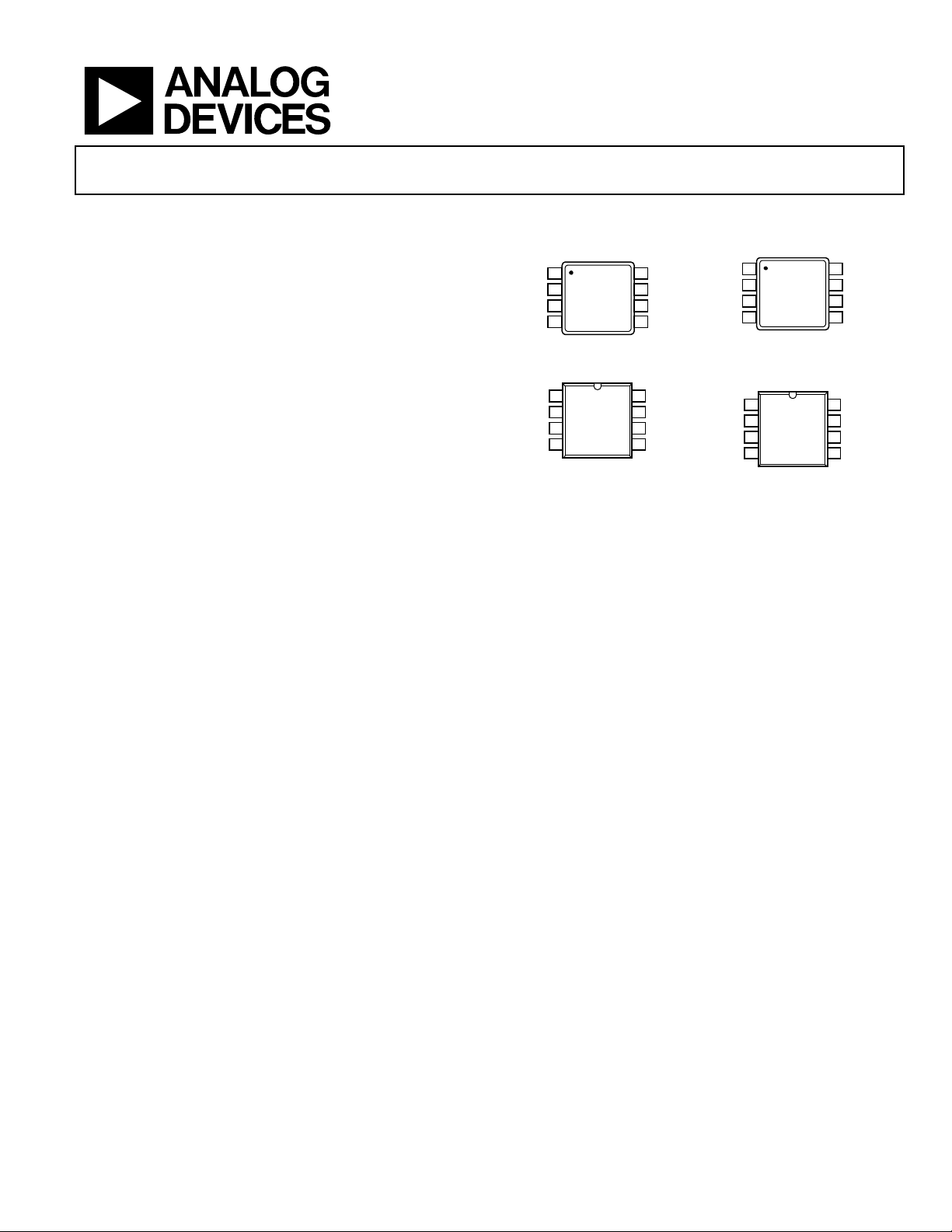

PIN CONFIGURATIONS

UT A

NC

1

AD8651

–IN

2

TOP VIEW

+IN

3

(Not to Scale)

–

4

V

NC = NO CONNECT

NC

8

+

7

V

OUT

6

NC

5

03301-001

Figure 1. 8-Lead MSOP (RM-8) Figure 2. 8-Lead MSOP (RM-8)

1

NC

AD8651

–IN

2

+IN

3

TOP VIEW

(Not to S cale)

–

4

V

NC = NO CONNECT

8

NC

+

7

V

OUT

6

NC

5

03301-002

Figure 3. 8-Lead SOIC_N (R-8) Figure 4. 8-Lead SOIC_N (R-8)

–IN A

+IN A

V

OUT A

–IN A

+IN A

–

–

V

1

AD8652

2

TOP VIEW

3

(Not to S cale)

4

1

AD8652

2

3

TOP VIEW

(Not to S cale)

4

8

7

6

5

8

7

6

5

+

V

OUT B

–IN B

+IN B

+

V

OUT B

–IN B

+IN B

03301-003

03301-004

GENERAL DESCRIPTION

The AD865x family consists of high precision, low noise, low

distortion, rail-to-rail CMOS operational amplifiers that run

from a single-supply voltage of 2.7 V to 5.5 V.

The AD865x family is made up of rail-to-rail input and output

amplifiers with a gain bandwidth of 50 MHz and a typical

voltage offset of 100 μV across common mode from a 5 V

supply. It also features low noise—4.5 nV/√Hz.

The AD865x family can be used in communications applications,

such as cell phone transmission power control, fiber optic

networking, wireless networking, and video line drivers.

The AD865x family features the newest generation of DigiTrim®

in-package trimming. This new generation measures and corrects

the offset over the entire input common-mode range, providing

less distortion from V

variation than is typical of other rail-to-

OS

rail amplifiers. Offset voltage and CMRR are both specified and

guaranteed over the entire common-mode range as well as over

the extended industrial temperature range.

The AD865x family is offered in the narrow 8-lead SOIC

package and the 8-lead MSOP package. The amplifiers are

specified over the extended industrial temperature range

(−40°C to +125°C).

Rev. D Document Feedback

Information furnished by Analog Devices is believed to be accurate and reliable. However, no

responsibility is assumed by Analog Devices for its use, nor for any infringements of patents or other

rights of third parties that may result from its use. Specifications subject to change without notice. No

license is granted by implication or otherwise under any patent or patent rights of Analog Devices.

Trademarks and registered trademarks are the property of their respective owners.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700 ©2006–2014 Analog Devices, Inc. All rights reserved.

Technical Support www.analog.com

Page 2

AD8651/AD8652 Data Sheet

TABLE OF CONTENTS

Features .............................................................................................. 1

Thermal Resistance .......................................................................5

Applications ....................................................................................... 1

Pin Configurations ........................................................................... 1

General Description ......................................................................... 1

Revision History ............................................................................... 2

Specifications ..................................................................................... 3

Electrical Characteristics ............................................................. 3

Absolute Maximum Ratings ............................................................ 5

ESD Caution .................................................................................. 5

REVISION HISTORY

2/14—Rev. C to Rev. D

Changes to Figure 21 ........................................................................ 8

Updated Outline Dimensions ....................................................... 18

Changes to Ordering Guide .......................................................... 19

8/06—Rev. B. to Rev. C

Changes to Figure 1 to Figure 4 ...................................................... 1

Changes to Figure 7 and Figure 9 ................................................... 6

Changes to Figure 23 ........................................................................ 9

Changes to Figure 53 ...................................................................... 14

Updated Outline Dimensions ....................................................... 18

Changes to Ordering Guide .......................................................... 19

9/04—Rev. A to Rev. B

Added AD8652 .................................................................... Universal

Change to General Description ....................................................... 1

Changes to Electrical Characteristics ............................................. 3

Changes to Absolute Maximum Ratings ........................................ 5

Change to Figure 23 .......................................................................... 9

Change to Figure 26 .......................................................................... 9

Change to Figure 36 ........................................................................ 11

Change to Figure 42 ........................................................................ 12

Change to Figure 49 ........................................................................ 13

Change to Figure 51 ........................................................................ 13

Inserted Figure 52 ............................................................................ 13

Change to Theory of Operation section ....................................... 14

Change to Input Protection section .............................................. 15

Changes to Ordering Guide ........................................................... 20

Typical Performance Characteristics ..............................................6

Applications ..................................................................................... 14

Theory of Operation .................................................................. 14

Layout, Grounding, and Bypassing Considerations .............. 15

Outline Dimensions ....................................................................... 18

Ordering Guide .......................................................................... 19

6/04—Rev. 0 to Rev. A

Change to Figure 18 ............................................................................. 8

Change to Figure 21 ............................................................................. 9

Change to Figure 29 ............................................................................. 10

Change to Figure 30 ............................................................................. 10

Change to Figure 43 ............................................................................. 12

Change to Figure 44 ............................................................................. 12

Change to Figure 47 ............................................................................. 13

Change to Figure 57 ............................................................................. 17

10/03 Revision 0: Initial Version

Rev. D | Page 2 of 20

Page 3

Data Sheet AD8651/AD8652

SPECIFICATIONS

ELECTRICAL CHARACTERISTICS

V+ = 2.7 V, V– = 0 V, VCM = V+/2, TA = 25°C, unless otherwise specified.

Table 1.

Parameter Symbol Conditions Min Typ Max Unit

INPUT CHARACTERISTICS

Offset Voltage VOS

AD8651 0 V ≤ VCM ≤ 2.7 V 100 350 μV

–40°C ≤ TA ≤ +85°C, 0 V ≤ VCM ≤ 2.7 V 1.4 mV

–40°C ≤ TA ≤ +125°C, 0 V ≤ VCM ≤ 2.7 V 1.6 mV

AD8652 0 V ≤ VCM ≤ 2.7 V 90 300 μV

–40°C ≤ TA ≤ +125°C, 0 V ≤ VCM ≤ 2.7 V 0.4 1.3 mV

Offset Voltage Drift TCVOS 4 μV/°C

Input Bias Current IB 1 10 pA

–40°C ≤ TA ≤ +125°C 600 pA

Input Offset Current IOS 1 10 pA

–40°C ≤ TA ≤ +85°C 30 pA

–40°C ≤ TA ≤ +125°C 600 pA

Input Voltage Range VCM –0.1 +2.8 V

Common-Mode Rejection Ratio CMRR

AD8651 V+ = 2.7 V, –0.1 V < VCM < +2.8 V 75 95 dB

–40°C ≤ TA ≤ +85°C, –0.1 V < VCM < +2.8 V 70 88 dB

–40°C ≤ TA ≤ +125°C, –0.1 V < VCM < +2.8 V 65 85 dB

AD8652 V+ = 2.7 V, –0.1 V < VCM < +2.8 V 77 95 dB

–40°C ≤ TA ≤ +125°C, –0.1 V < VCM < +2.8 V 73 90 dB

Large Signal Voltage Gain AVO RL = 1 kΩ, 200 mV < VO < 2.5 V 100 115 dB

RL = 1 kΩ, 200 mV < VO < 2.5 V, TA = 85°C 100 114 dB

RL = 1 kΩ, 200 mV < VO < 2.5 V, TA = 125°C 95 108 dB

OUTPUT CHARACTERISTICS

Output Voltage High VOH IL = 250 μA, –40°C ≤ TA ≤ +125°C 2.67 V

Output Voltage Low VOL IL = 250 μA, –40°C ≤ TA ≤ +125°C 30 mV

Short-Circuit Limit ISC Sourcing 80 mA

Sinking 80 mA

Output Current IO 40 mA

POWER SUPPLY

Power Supply Rejection Ratio PSRR VS = 2.7 V to 5.5 V, VCM = 0 V 76 94 dB

–40°C ≤ TA ≤ +125°C 74 93 dB

Supply Current ISY

AD8651 IO = 0 9 12 mA

–40°C ≤ TA ≤ +125°C 14.5 mA

AD8652 IO = 0 17.5 19.5 mA

–40°C ≤ TA ≤ +125°C 22.5 mA

INPUT CAPACITANCE C

Differential 6 pF

Common Mode 9 pF

DYNAMIC PERFORMANCE

Slew Rate SR G = 1, RL = 10 kΩ 41 V/μs

Gain Bandwidth Product GBP G = 1 50 MHz

Settling Time, 0.01% G = ±1, 2 V step 0.2 μs

Overload Recovery Time VIN × G = 1.48 V+ 0.1 μs

Total Harmonic Distortion + Noise THD + N G = 1, RL = 600 Ω, f = 1 kHz, VIN = 2 V p-p 0.0006 %

NOISE PERFORMANCE

Voltage Noise Density en f = 10 kHz 5 nV/√Hz

f = 100 kHz 4.5 nV/√Hz

Current Noise Density in f = 10 kHz 4 fA/√Hz

IN

Rev. D | Page 3 of 20

Page 4

AD8651/AD8652 Data Sheet

V+ = 5 V, V– = 0 V, VCM = V+/2, TA = 25°C, unless otherwise specified.

Table 2.

Parameter Symbol Conditions Min Typ Max Unit

INPUT CHARACTERISTICS

Offset Voltage VOS

AD8651 0 V ≤ VCM ≤ 5 V 100 350 μV

–40°C ≤ TA ≤ +85°C, 0 V ≤ VCM ≤ 5 V 1.4 mV

–40°C ≤ TA ≤ +125°C, 0 V ≤ VCM ≤ 5 V 1.7 mV

AD8652 0 V ≤ VCM ≤ 5 V 90 300 μV

–40°C ≤ TA ≤ +125°C, 0 V ≤ VCM ≤ 5 V 0.4 1.4 mV

Offset Voltage Drift TCVOS 4 μV/°C

Input Bias Current IB 1 10 pA

–40°C ≤ TA ≤ +85°C 30 pA

–40°C ≤ TA ≤ +125°C 600 pA

Input Offset Current IOS 1 10 pA

–40°C ≤ TA ≤ +85°C 30 pA

–40°C ≤ TA ≤ +125°C 600 pA

Input Voltage Range VCM –0.1 +5.1 V

Common-Mode Rejection Ratio CMRR

AD8651 0.1 V < VCM < 5.1 V 80 95 dB

–40°C ≤ TA ≤ +85°C, 0.1 V < VCM < 5.1 V 75 94 dB

–40°C ≤ TA ≤ +125°C, 0.1 V < VCM < 5.1 V 70 90 dB

AD8652 0.1 V < VCM < 5.1 V 84 100 dB

–40°C ≤ TA ≤ +125°C, 0.1 V < VCM < 5.1 V 76 95 dB

Large Signal Voltage Gain AVO RL = 1 kΩ, 200 mV < VO < 4.8 V 100 115 dB

RL = 1 kΩ, 200 mV < VO < 4.8 V, TA = 85°C 98 114 dB

RL = 1 kΩ, 200 mV < VO < 4.8 V, TA = 125°C 95 111 dB

OUTPUT CHARACTERISTICS

Output Voltage High VOH IL = 250 µA, –40°C ≤ TA ≤ +125°C 4.97 V

Output Voltage Low VOL IL = 250 µA, –40°C ≤ TA ≤ +125°C 30 mV

Short-Circuit Limit ISC Sourcing 80 mA

Sinking 80 mA

Output Current IO 40 mA

POWER SUPPLY

Power Supply Rejection Ratio PSRR VS = 2.7 V to 5.5 V, V

–40°C ≤ TA ≤ +125°C 74 93 dB

Supply Current ISY

AD8651 IO = 0 9.5 14.0 mA

–40°C ≤ TA ≤ +125°C 15 mA

AD8652 IO = 0 17.5 20.0 mA

–40°C ≤ TA ≤ +125°C 23.5 mA

INPUT CAPACITANCE C

Differential 6 pF

Common Mode 9 pF

DYNAMIC PERFORMANCE

Slew Rate SR G = 1, RL = 10 kΩ 41 V/µs

Gain Bandwidth Product GBP G = 1 50 MHz

Settling Time, 0.01% G = ±1, 2 V step 0.2 μs

Overload Recovery Time VIN × G = 1.2 V+ 0.1 μs

Total Harmonic Distortion + Noise THD + N G = 1, RL = 600 Ω, f = 1 kHz, VIN = 2 V p-p 0.0006 %

NOISE PERFORMANCE

Voltage Noise Density en f = 10 kHz 5 nV/√Hz

f = 100 kHz 4.5 nV/√Hz

Current Noise Density in f = 10 kHz 4 fA/√Hz

IN

= 0 V 76 94 dB

CM

Rev. D | Page 4 of 20

Page 5

Data Sheet AD8651/AD8652

ABSOLUTE MAXIMUM RATINGS

Absolute maximum ratings apply at 25°C, unless otherwise noted.

Table 3.

Parameter Rating

Supply Voltage 6.0 V

Input Voltage GND to VS + 0.3 V

Differential Input Voltage ±6.0 V

Output Short-Circuit Duration to GND Indefinite

Electrostatic Discharge (HBM) 4000 V

Storage Temperature Range

RM, R Package −65°C to +150°C

Operating Temperature Range −40°C to +125°C

Junction Temperature Range

RM, R Package −65°C to +150°C

Lead Temperature (Soldering, 10 sec) 300°C

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

ESD CAUTION

THERMAL RESISTANCE

θJA is specified for the worst-case conditions, that is, a device

soldered in a circuit board for surface-mount packages.

Table 4. Thermal Resistance

Package Type θJA θ

8-Lead MSOP (RM) 210 45 °C/W

8-Lead SOIC_N (R) 158 43 °C/W

Unit

JC

Rev. D | Page 5 of 20

Page 6

AD8651/AD8652 Data Sheet

TYPICAL PERFORMANCE CHARACTERISTICS

60

50

VS = ±2.5V

V

= 0V

CM

100

VS = 5V

80

NUMBER OF AMPLI F IERS

(µV)

OS

V

300

200

100

–100

–200

40

30

20

10

0

–200

–160

–120

–80

–40

VOS (µV)

0

Figure 5. Input Offset Voltage Distribution

VS = ±2.5V

V

= 0V

CM

0

60

40

(µV)

OS

V

20

0

–20

40

80

120

160

200

03301-005

0123456

COMMON-MODE VOLTAGE (V)

3301-008

Figure 8. Input Offset Voltage vs. Common-Mode Voltage

500

VS = ±2.5V

400

300

200

INPUT BIAS CURRENT (pA)

100

–300

–50 0 50 100 150

TEMPERATURE (°C)

Figure 6. Input Offset Voltage vs. Temperature

60

50

40

30

20

NUMBER OF AMPLI F IERS

10

0

01234567891011

TCVOS(µV/°C)

VS= ±2.5V

=0V

V

CM

: –40°C TO +125°C

T

A

Figure 7. TCVOS Distribution

0

3301-006

040 140120100806020

TEMPERATURE (°C)

3301-009

Figure 9. Input Bias Current vs. Temperature

10

8

6

4

SUPPLY CURRENT (mA)

2

0

02 65431

3301-007

SUPPLY VOLTAGE (V)

3301-010

Figure 10. Supply Current vs. Supply Voltage

Rev. D | Page 6 of 20

Page 7

Data Sheet AD8651/AD8652

V

V

12

VS = ±2.5V

11

2.50

2.00

VS = 5V

I

= 250µA

L

10

9

8

SUPPLY CURRENT (mA)

7

6

–50 0 50 100 150

TEMPERATURE (°C)

Figure 11. Supply Current vs. Temperature

500

400

300

) (mV)

OUT

–

200

SY

(

100

V

OH

V

OL

VS=±2.5V

1.50

1.00

OUTPUT SWING LOW (mV)

0.50

0

3301-011

–50 0 50 100 150

TEMPERATURE (°C)

03301-014

Figure 14. Output Voltage Swing Low vs. Temperature

100

80

60

40

CMRR (dB)

20

VS = ±2.5V

0

0204060 10080

CURRENT LOAD (mA)

Figure 12. Output Voltage to Supply Rail vs. Load Current

4.997

4.996

4.995

4.994

4.993

4.992

OUTPUT SWING HIGH (V)

4.991

4.990

–50 0 50 100 150

TEMPERATURE (°C)

VS = 5V

I

L

Figure 13. Output Voltage Swing High vs. Temperature

= 250µA

0

3301-012

10 1k 10M1M100k10k100

FREQUENCY (Hz)

3301-015

Figure 15. CMRR vs. Frequency

110

105

100

CMRR (dB)

95

90

3301-013

–50 0 50 100 150

TEMPERATURE (°C)

VS = ±2.5V

3301-016

Figure 16. CMRR vs. Temperature

Rev. D | Page 7 of 20

Page 8

AD8651/AD8652 Data Sheet

CMRR (dB)

82

85

100

97

91

88

94

TEMPERA

TURE (°C)

–50

0

50

100

150

03301-017

PSRR (dB)

0

100

80

60

40

20

FREQUENCY (Hz)

1 10 100 1k

10k 100k 1M

10M 100M

VS = ±2.5V

+PSRR

–PSRR

03301-018

PSRR (dB)

80

85

100

95

90

TEMPERA

TURE (°C)

–50 0 50

100 150

V

S

= ±2.5V

03301-019

VOLTAGE NOISE DENSIT

Y (nV/√Hz)

1

100

10

FREQUENC

Y (Hz)

10

1k 100k10k

100

V

S

= ±2.5V

03301-020

CURRENT NOIS E DE NS ITY

(fA/√Hz)

0

40

30

20

10

FREQUENCY (Hz)

100

1k 100k10k

V

S

= ±2.5V

03301-021

VS = ±2.5V

V

IN

= 6.4V

V

OUT

V

IN

VOLTAGE (1V/DIV)

TIME (200µ s/DIV)

0

03301-022

Figure 17. CMRR vs. Temperature

Figure 18. PSRR vs. Frequency

Figure 20. Voltage Noise Density vs. Frequency

Figure 21. Current Noise Density vs. Frequency

Figure 19. PSRR vs. Temperature

Figure 22. No Phase Reversal

Rev. D | Page 8 of 20

Page 9

Data Sheet AD8651/AD8652

140

120

100

80

60

40

OPEN-LOOP GAIN (dB)

20

0

–20

10 100 1k 10k 100k 1M 10M 100M

FREQUENCY ( Hz)

Figure 23. Open-Loop Gain and Phase vs. Frequency

117

116

115

114

OPEN-LOOP GAIN (dB)

113

VS = ±2.5V

VS = ±2.5V

R

= 1kΩ

L

0

–45

–90

–135

–180

PHASE (Degrees)

03301-023

60

40

G = 100

20

G = 10

0

G = 1

CLOSED-LOOP GAIN (dB)

–20

–40

5k

50k 5M500k 50M 300M

FREQUENCY ( Hz)

VS = ±2.5V

R

= 1MΩ

L

C

= 47pF

L

3301-026

Figure 26. Closed-Loop Gain vs. Frequency

6

5

4

3

2

MAXIMUM OUTPUT SWING (V)

1

VS = 5V

VS = 2.7V

112

–50 0 50 100 150

TEMPERATURE (°C)

Figure 24. Open-Loop Gain vs. Temperature

140

=250µA

I

130

120

110

100

90

OPEN-LOOP GAIN (dB)

80

70

60

0 100 150 250200

50

OUTPUT VOLTAGE SWING FROM THE RAILS (mV)

L

IL=2.5mA

IL=4.2mA

V

S

Figure 25. Open-Loop Gain vs. Output Voltage Swing

=±2.5V

0

100k 100M10M1M

03301-024

FREQUENCY ( Hz)

3301-027

Figure 27. Maximum Output Swing vs. Frequency

VS = ±2.5V

= 47pF

C

L

= 1

A

V

VOLTAGE (1V/DIV)

03301-025

TIME (100µ s/DIV)

3301-028

Figure 28. Large Signal Response

Rev. D | Page 9 of 20

Page 10

AD8651/AD8652 Data Sheet

A

2

V

VS = ±2.5V

V

= 200mV

IN

A

= 1

V

0V

–2.5V

OUTPUT

VS = ±2.5V

= 200mV

V

IN

GAIN = –15

VOLTAGE (100mV/DIV)

TIME (10µ s/DIV)

Figure 29. Small Signal Response

30

VS = ±2.5V

V

= 200mV

IN

A

= 1

25

V

L OVERSHOOT (%)

SMALL SIGN

20

15

10

5

0

020 706050403010

CAPACITANCE (pF)

–OS

Figure 30. Small Signal Overshoot vs. Load Capacitance

2.5V

+OS

VS = ±2.5V

V

IN

GAIN = –15

= 200mV

00m

0V

3301-029

TIME (200ns/DIV)

INPUT

3301-032

Figure 32. Positive Overload Recovery Time

40

VS = ±2.5V

30

20

GAIN = 10

10

OUTPUT IMPEDANCE (Ω)

GAIN = 100

0

3301-030

10 1k 100k10k100

FREQUENCY ( Hz)

GAIN = 1

3301-033

Figure 33. Output Impedance vs. Frequency

60

50

VS = ±1.35V

V

= 0V

CM

–200mV

0V

0V

TIME (200n s/DIV)

Figure 31. Negative Overload Recovery Time

3301-031

NUMBER OF AMPLIF IERS

40

30

20

10

0

–200

–160

–120

–80

–40

VOS (µV)

0

Figure 34. Input Offset Voltage Distribution

40

80

120

160

200

03301-034

Rev. D | Page 10 of 20

Page 11

Data Sheet AD8651/AD8652

V

V

300

VS = ±1.35V

V

= 0V

CM

200

100

0

(µV)

OS

V

–100

–200

–300

–50 0 50 100 150

TEMPERATURE (°C)

Figure 35. Input Offset Voltage vs. Temperature

80

60

40

VS = 2.7V

3301-035

500

400

300

) (mV)

OUT

–

200

SY

(

100

0

0204060 10080

V

OH

CURRENT LOAD (mA)

V

OL

Figure 38. Output Voltage to Supply Rail vs. Load Current

2.697

2.696

2.695

2.694

VS= ±1.35V

VS = 2.7V

I

= 250µA

L

3301-038

20

0

INPUT OFFSET VOLTAGE (µV)

–20

0123

INPUT COMMO N- MO DE V OLTAGE (V)

Figure 36. Input Offset Voltage vs. Common-Mode Voltage

11

VS = ±1.35V

10

9

8

SUPPLY CURRENT (mA)

7

6

–50 0 50 100 150

TEMPERATURE (°C)

2.693

2.692

OUTPUT SWING HIGH (V)

2.691

2.690

3301-036

–50 0 50 100 150

TEMPERATURE (°C)

3301-039

Figure 39. Output Voltage Swing High vs. Temperature

3.00

2.50

2.00

1.50

1.00

OUTPUT SWING LOW (mV)

0.50

0

3301-037

–50 0 50 100 150

TEMPERATURE (°C)

VS = 2.7V

I

= 250µA

L

3301-040

Figure 37. Supply Current vs. Temperature

Figure 40. Output Voltage Swing Low vs. Temperature

Rev. D | Page 11 of 20

Page 12

AD8651/AD8652 Data Sheet

V

S

= ±1.35V

A

V

= 1

VOLTAGE (1V/DIV)

TIME (200µ s/DIV)

03301-041

V

S

= ±1.35V

CL= 47pF

AV = 1

VOLTAGE (500mV/DI V )

TIME (100µ s/DIV)

03301-042

VS = ±1.35V

V

IN

= 200mV

C

L

= 47pF

A

V

= 1

VOLTAGE (100mV/DI V )

TIME (10µ s/DIV)

03301-043

SMALL SIGNAL OVERSHOOT (%)

0

30

25

20

15

10

5

CAP

ACIT

ANCE (pF)

0

20 70

60504030

10

+OS

V

S

= ±1.35V

VIN = 200mV

–OS

03301-044

VS = ±1.35V

V

IN

= 200mV

GAIN = –10

TIME (200ns/DIV)

–200mV

1.35V

0V

0V

03301-045

V

S

= ±1.35V

VIN= 200mV

GAIN = –10

TIME (200ns/DIV)

0V

0V

200mV

–1.35V

03301-046

Figure 41. No Phase Reversal

Figure 42. Large Signal Response

Figure 44. Small Signal Overshoot vs. Load Capacitance

Figure 45. Negative Overload Recovery Time

Figure 43. Small Signal Response

Figure 46. Positive Overload Recovery Time

Rev. D | Page 12 of 20

Page 13

Data Sheet AD8651/AD8652

CMRR (dB)

0

100

80

60

40

20

FREQUENCY (Hz)

10

1k

10M

1M

100k

10k

100

V

S

= ±1.35V

03301-047

PSRR (dB)

0

100

80

60

40

20

FREQUENC

Y

(Hz)

1 10 100

1k 10k

100k

1M 10M

V

S

= ±1.35V

+PSRR

–PSRR

03301-048

OPEN-LOOP GAIN (dB)

–20

0

20

40

60

80

100

120

140

PHA

SE (

De

grees)

–180

–135

–90

–45

0

FREQUENCY ( Hz )

10 100 1k 10k 100k

1M 10M 100M

VS = ±1.35V

03301-049

A

VO

(dB)

108

1

10

120

1

18

1

16

114

1

12

TEMPERA

TURE (°C)

–50

0

50

100

150

V

S

= ±1.35V

R

L

= 1kΩ

03301-050

G = 100

G = 10

G = 1

VS = ±1.35V

RL = 1MΩ

CL = 47pF

FREQUENCY (Hz)

CLOSED-LOO

P

GAIN (dB)

5k

–40

–20

20

0

60

40

50k

5M500k 50M

300M

03301-051

FREQUENCY (Hz)

10M100 1k 10k 100k

1M

CHANNEL SEPARATION (dB)

0

–20

–40

–60

–80

–100

–120

–140

V

IN

28mV p-p

V+

V–

V–

V+

–2.5V

+2.5V

V

OUT

R1

10kΩ

R2

100Ω

VS = ±2.5V

03301-052

Figure 47. CMRR vs. Frequency

Figure 48. PSRR vs. Frequency

Figure 50. Open-Loop Gain vs. Temperature

Figure 51. Closed-Loop Gain vs. Frequency

Figure 49. Open-Loop Gain and Phase vs. Frequency

Rev. D | Page 13 of 20

Figure 52. Channel Separation vs. Frequency

Page 14

AD8651/AD8652 Data Sheet

COMMON-MODE VOLTAGE (V)

V

OS

(µV)

0

–600

–200

200

600

400

0

–400

21 43 5 6

03301-053

COMMON-MODE VOLTAGE (V)

V

OS

(µV)

0

–600

–200

200

600

400

0

–400

21 43 5 6

03301-061

APPLICATIONS

THEORY OF OPERATION

The AD865x family consists of voltage feedback, rail-to-rail

input and output precision CMOS amplifiers that operate from

2.7 V to 5.5 V of power supply voltage. These amplifiers use

Analog Devices, Inc. DigiTrim technology to achieve a higher

degree of precision than is available from most CMOS

amplifiers. DigiTrim technology, used in a number of Analog

Devices amplifiers, is a method of trimming the offset voltage of

the amplifier after it has been assembled. The advantage of

post-package trimming is that it corrects any offset voltages

caused by the mechanical stresses of assembly.

The AD865x family is available in standard op amp pinouts,

making DigiTrim completely transparent to the user. The input

stage of the amplifiers is a true rail-to-rail architecture, allowing

the input common-mode voltage range of the op amp to extend

to both positive and negative supply rails. The open-loop gain

of the AD865x with a load of 1 kΩ is typically 115 dB.

The AD865x can be used in any precision op amp application.

The amplifiers do not exhibit phase reversal for common-mode

voltages within the power supply. With voltage noise of

4.5 nV/√Hz and –105 dB distortion for 10 kHz, 2 V p-p signals,

the AD865x is a great choice for high resolution data

acquisition systems. Their low noise, sub-pA input bias current,

precision offset, and high speed make them superb preamps for

fast photodiode applications. The speed and output drive

capabilities of the AD865x also make the amplifiers useful in

video applications.

Rail-to-Rail Output Stage

The voltage swing of the output stage is rail-to-rail and is

achieved by using an NMOS and PMOS transistor pair connected in a common source configuration. The maximum

output voltage swing is proportional to the output current, and

larger currents will limit how close the output voltage can get to

the proximity of the output voltage to the supply rail. This is a

characteristic of all rail-to-rail output amplifiers. With 40 mA of

output current, the output voltage can reach within 5 mV of the

positive and negative rails. At light loads of >100 kΩ, the output

swings within ~1 mV of the supplies.

The NMOS and PMOS input stages are separately trimmed

using DigiTrim to minimize the offset voltage in both differential pairs. Both NMOS and PMOS input differential pairs are

active in a 500 mV transition region when the input commonmode voltage is approximately 1.5 V below the positive supply

voltage. A special design technique improves the input offset

voltage in the transition region that traditionally exhibits a

slight V

variation. As a result, the common-mode rejection

OS

ratio is improved within this transition band. Compared to the

Burr Brown OPA350 amplifier, shown in Figure 53, the

AD865x, shown in Figure 54, exhibits much lower offset voltage

shift across the entire input common-mode range, including the

transition region.

Figure 53. Input Offset Distribution over Common-Mode

Voltage for the OPA350

Rail-to-Rail Input Stage

The input common-mode voltage range of the AD865x extends

to both positive and negative supply voltages. This maximizes

the usable voltage range of the amplifier, an important feature

for single-supply and low voltage applications. This rail-to-rail

input range is achieved by using two input differential pairs, one

NMOS and one PMOS, placed in parallel. The NMOS pair is active

at the upper end of the common-mode voltage range, and the

PMOS pair is active at the lower end of the common-mode range.

Figure 54. Input Offset Distribution over Common-Mode

Input Protection for the AD865x

Rev. D | Page 14 of 20

Page 15

Data Sheet AD8651/AD8652

(| V

CC

–

V

E

E

| – 0

.7V)

30m

A

F

OR

L

ARG

E |

V

CC

– V

E

E

|

FO

R

V

IN

BEY

OND

SUPPLYVOLTAG

ES

R

I

>

R

I

–

V

I

N

+

+

V

O

30mA

(VIN–

V

EE

+ 0.

7V)

RI>

30mA

(V

IN

– V

E

E

– 0.

7V)

RI>

+

–

AD865x

03301-054

Input Protection

As with any semiconductor device, if a condition exists for the

input voltage to exceed the power supply, the device input

overvoltage characteristic must be considered. The inputs of the

AD865x family are protected with ESD diodes to either power

supply. Excess input voltage energizes internal PN junctions in

the AD865x, allowing current to flow from the input to the

supplies. This results in an input stage with picoamps of input

current that can withstand up to 4000 V ESD events (human

body model) with no degradation.

Excessive power dissipation through the protection devices

destroys or degrades the performance of any amplifier. Differential

voltages greater than 7 V result in an input current of approximately

(| V

– V

CC

| – 0.7 V)/RI, where RI is the resistance in series with

EE

the inputs. For input voltages beyond the positive supply, the

input current is approximately (V

– VCC – 0.7)/RI. For input

IN

voltages beyond the negative supply, the input current is about

(V

– VEE + 0.7)/RI. If the inputs of the amplifier sustain

IN

differential voltages greater than 7 V or input voltages beyond

the amplifier power supply, limit the input current to 10 mA by

using an appropriately sized input resistor (R

), as shown in

I

Figure 55.

Bypassing schemes are designed to minimize the supply

impedance at all frequencies with a parallel combination of

capacitors of 0.1 µF and 4.7 µF. Chip capacitors of 0.1 µF (X7R

or NPO) are critical and should be as close as possible to the

amplifier package. The 4.7 µF tantalum capacitor is less critical

for high frequency bypassing, and, in most cases, only one is

needed per board at the supply inputs.

Grounding

A ground plane layer is important for densely packed PC

boards to spread the current-minimizing parasitic inductances.

However, an understanding of where the current flows in a

circuit is critical to implementing effective high speed circuit

design. The length of the current path is directly proportional to

the magnitude of parasitic inductances and, therefore, the high

frequency impedance of the path. High speed currents in an

inductive ground return create an unwanted voltage noise.

The length of the high frequency bypass capacitor leads is

critical. A parasitic inductance in the bypass grounding works

against the low impedance created by the bypass capacitor.

Place the ground leads of the bypass capacitors at the same

physical location. Because load currents also flow from the

supplies, the ground for the load impedance should be at the

same physical location as the bypass capacitor grounds. For the

larger value capacitors, intended to be effective at lower

frequencies, the current return path distance is less critical.

Leakage Currents

Poor PC board layout, contaminants, and the board insulator

Figure 55. Input Protection Method

Overdrive Recovery

Overdrive recovery is defined as the time it takes for the output

material can create leakage currents that are much larger than the

input bias current of the AD865x family. Any voltage differential

between the inputs and nearby traces sets up leakage currents

through the PC board insulator, for example 1 V/100 G = 10 pA.

Similarly, any contaminants on the board can create significant

leakage (skin oils are a common problem).

of an amplifier to come off the supply rail after an overload signal is

initiated. This is usually tested by placing the amplifier in a closedloop gain of 15 with an input square wave of 200 mV p-p while the

amplifier is powered from either 5 V or 3 V. Th e AD865x family

has excellent recovery time from overload conditions (see Figure 31

and Figure 32). The output recovers from the positive supply rail

within 200 ns at all supply voltages. Recovery from the negative rail

is within 100 ns at 5 V supply.

To significantly reduce leakages, put a guard ring (shield)

around the inputs and the input leads that are driven to the

same voltage potential as the inputs. This ensures that there is

no voltage potential between the inputs and the surrounding

area to set up any leakage currents. To be effective, the guard

ring must be driven by a relatively low impedance source and

should completely surround the input leads on all sides, above

and below, using a multilayer board.

LAYOUT, GROUNDING, AND BYPASSING CONSIDERATIONS

Power Supply Bypassing

Power supply pins can act as inputs for noise, so care must be

taken that a noise-free, stable dc voltage is applied. The purpose

of bypass capacitors is to create low impedances from the supply

to ground at all frequencies, thereby shunting or filtering most

of the noise.

Rev. D | Page 15 of 20

Another effect that can cause leakage currents is the charge

absorption of the insulator material itself. Minimizing the

amount of material between the input leads and the guard

ring helps to reduce the absorption. Also, low absorption

materials, such as Teflon® or ceramic, may be necessary in

some instances.

Page 16

AD8651/AD8652 Data Sheet

V

IN

0

0

0

3

2

U1

R

L

C

L

R

S

V

OUT

V

CC

03301-055

+

–

AD865x

V

+

V

–

200m

V

R

L

C

L

R

S

C

S

V

O

U

T

V

+

V

–

03301-056

+

–

AD

865

x

V

+

V

–

THD + NOISE (%)

0.0001

0.0002

0.0005

0.001

0.002

0.005

0.01

0.02

0.05

0.1

FREQUENCY (Hz)

V

SY

= +3.5V/–1. 5V

V

OUT

= 2.0V p-p

20 50 100 500 20k5k

2k1k

OPA350

AD8651

03301-057

Input Capacitance

Along with bypassing and grounding, high speed amplifiers can be

sensitive to parasitic capacitance between the inputs and ground. A

few picofarads of capacitance reduces the input impedance at high

frequencies, which in turn increases the amplifier gain, causing

peaking in the frequency response or oscillations. With the

AD865x, additional input damping is required for stability with

capacitive loads greater than 47 pF with direct input to output

feedback (see the Output Capacitance section).

Output Capacitance

When using high speed amplifiers, it is important to consider

the effects of the capacitive loading on amplifier stability.

Capacitive loading interacts with the output impedance of the

amplifier, causing reduction of the BW as well as peaking and

ringing of the frequency response. To reduce the effects of the

capacitive loading and allow higher capacitive loads, there are

two commonly used methods.

• As shown in Figure 56, place a small value resistor (R

) in

S

series with the output to isolate the load capacitor from the

amplifier output. Heavy capacitive loads can reduce the

phase margin of an amplifier and cause the amplifier

response to peak or become unstable. The AD865x is able

to drive up to 47 pF in a unity gain buffer configuration

without oscillation or external compensation. However, if

an application requires a higher capacitive load drive when

the AD865x is in unity gain, the use of external isolation

networks can be used. The effect produced by this resistor

is to isolate the op amp output from the capacitive load.

The required amount of series resistance has been

tabulated in Table 5 for different capacitive loads. While

this technique improves the overall capacitive load drive

for the amplifier, its biggest drawback is that it reduces the

output swing of the overall circuit.

• Another way to stabilize an op amp driving a large capacitive

load is to use a snubber network, as shown in Figure 57. Because

there is not any isolation resistor in the signal path, this method

has the significant advantage of not reducing the output swing.

The exact values of R

Figure 57, an optimum R

and CS are derived experimentally. In

S

and CS combination for a capacitive

S

load drive ranging from 50 pF to 1 nF was chosen. For this,

R

= 3 Ω and CS = 10 nF were chosen.

S

Figure 57. Snubber Network

Settling Time

The settling time of an amplifier is defined as the time it takes

for the output to respond to a step change of input and enter

and remain within a defined error band, as measured relative to

the 50% point of the input pulse. This parameter is especially

important in measurements and control circuits where amplifiers are used to buffer A/D inputs or DAC outputs. The design of

the AD865x family combines a high slew rate and a wide gain

bandwidth product to produce an amplifier with very fast

settling time. The AD865x is configured in the noninverting

gain of 1 with a 2 V p-p step applied to its input. The AD865x

family has a settling time of about 130 ns to 0.01% (2 mV). The

output is monitored with a 10×, 10 M, 11.2 pF scope probe.

THD Readings vs. Common-Mode Voltage

Total harmonic distortion of the AD865x family is well below

0.0004% with any load down to 600 Ω. The distortion is a

function of the circuit configuration, the voltage applied, and

the layout, in addition to other factors. The AD865x family

outperforms its competitor for distortion, especially at

frequencies below 20 kHz, as shown in Figure 58.

Figure 56. Driving Large Capacitive Loads

Table 5. Optimum Values for Driving Large Capacitive Loads

CL RS

100 pF 50 Ω

500 pF 35 Ω

1.0 nF 25 Ω

Figure 58. Total Harmonic Distortion

Rev. D | Page 16 of 20

Page 17

Data Sheet AD8651/AD8652

V

IN

2V p-p

47pF

600Ω

V

OUT

+3.5V

–1.5V

03301-058

+

–

AD865x

f

SAMPLE

= 250kSPS

fIN = 45kHz

INPUT RANGE = 0V

TO 5V

FREQUENC

Y (kHz)

AMPLITUDE (dB of Full Scale)

0

–160

–100

–120

–140

–80

–60

–40

–20

0

10 20 30

40 50 60 70 80

90 100 110 120

03301-059

1

µ

F

3

2

U1

I

N

2.7nF

33Ω

V

CC

5V

1kΩ

10kΩ

10k

Ω

1kΩ

AD7685

V

I

N

0V TO

5

V

f

I

N

=

45kH

z

03301-060

+

–

AD865x

V

+

V

–

Figure 59. THD + N Test Circuit

Driving a 16-Bit ADC

The AD865x family is an excellent choice for driving high

speed, high precision ADCs. The driver amplifier for this type

of application needs low THD + N as well as quick settling time.

Figure 61 shows a complete single-supply data acquisition

solution. The AD865x family drives the AD7685, a 250 kSPS,

16-bit data converter.

1

The AD865x is configured in an inverting gain of 1 with a 5 V

single supply. Input of 45 kHz is applied, and the ADC samples

at 250 kSPS. The results of this solution are listed in Tab le 6.

The advantage of this circuit is that the amplifier and ADC can

be powered with the same power supply. For the case of

a noninverting gain of 1, the input common-mode voltage

encompasses both supplies.

1

For more information about the AD7685 data converter, go to

http://www.analog.com/Analog_Root/productPage/productHome/0%2C21

21%2CAD7685%2C00.html

Figure 61. AD865x Driving a 16-Bit ADC

Table 6. Data Acquisition Solution of Figure 60

Parameter Reading (dB)

THD + N 105.2

SFDR 106.6

2nd Harmonics 107.7

3rd Harmonics 113.6

Figure 60. Frequency Response of AD865x Driving a 16-Bit ADC

Rev. D | Page 17 of 20

Page 18

AD8651/AD8652 Data Sheet

COMPLI ANT TO JEDEC STANDARDS MO-187-AA

6°

0°

0.80

0.55

0.40

4

8

1

5

0.65 BSC

0.40

0.25

1.10 MAX

3.20

3.00

2.80

COPLANARITY

0.10

0.23

0.09

3.20

3.00

2.80

5.15

4.90

4.65

PIN 1

IDENTIFIER

15° MAX

0.95

0.85

0.75

0.15

0.05

10-07-2009-B

CON

TROLLING DIMENSIONS ARE IN MILLIME

TER

S; I

NCH

DIME

NSIONS

(IN PARENTHESES)AR

E RO

UND

ED-O

FF MILLIMETER EQUIVALENTS FOR

REF

ERE

NCE

ONLY

AND ARE NOT APPROPRIATEFOR USE I

N DE

SIGN

.

COMPLIANT TO JEDEC ST

AND

ARDS

MS-

012

-AA

0

1

2

40

7

-

A

0.25 (0.0098)

0.

17 (

0.00

67)

1.27 (0

.0

500

)

0.40 (0.0157)

0

.50

(0.

0196

)

0.25 (0.00

99)

4

5°

8°

0

°

1.75 (0.0688)

1.3

5 (0.0532)

SE

ATIN

G

PLANE

0.25 (0.0098)

0.

10 (

0.0

040)

4

1

8 5

5.0

0(0

.196

8)

4.80(0

.18

90)

4.00 (0.1574)

3.

80 (

0.14

97)

1.27 (0.0500)

BSC

6.2

0 (0.2441)

5.8

0 (0

.228

4)

0.51 (0.0201)

0

.31 (

0.0122)

CO

PLA

NAR

ITY

0.10

OUTLINE DIMENSIONS

Figure 62. 8-Lead Mini Small Outline Package [MSOP]

Dimensions shown in millimeters

(RM-8)

Figure 63. 8-Lead Standard Small Outline Package [SOIC_N]

Narrow Body

(R-8)

Dimensions shown in millimeters and (inches)

Rev. D | Page 18 of 20

Page 19

Data Sheet AD8651/AD8652

Model1

Temperature Range

Package Description

Package Option

Branding

AD8651ARMZ

–40°C to +125°C

8-Lead MSOP

RM-8

BEA#

ORDERING GUIDE

AD8651ARMZ-REEL –40°C to +125°C 8-Lead MSOP RM-8 BEA#

AD8651ARZ –40°C to +125°C 8-Lead SOIC_N R-8

AD8651ARZ-REEL –40°C to +125°C 8-Lead SOIC_N R-8

AD8651ARZ-REEL7 –40°C to +125°C 8-Lead SOIC_N R-8

AD8652ARMZ –40°C to +125°C 8-Lead MSOP RM-8 A05

AD8652ARMZ-REEL –40°C to +125°C 8-Lead MSOP RM-8 A05

AD8652ARZ –40°C to +125°C 8-Lead SOIC_N R-8

AD8652ARZ-REEL –40°C to +125°C 8-Lead SOIC_N R-8

AD8652ARZ-REEL7 –40°C to +125°C 8-Lead SOIC_N R-8

1

Z = RoHS compliant part; # denotes lead-free product may be top or bottom marked.

Rev. D | Page 19 of 20

Page 20

AD8651/AD8652 Data Sheet

©2006–2014 Analog Devices, Inc. All rights reserved. Trademarks and

NOTES

registered trademarks are the property of their respective owners.

C03301-0-2/14(D)

Rev. D | Page 20 of 20

Loading...

Loading...